Patents

Literature

89results about How to "Meet mass production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

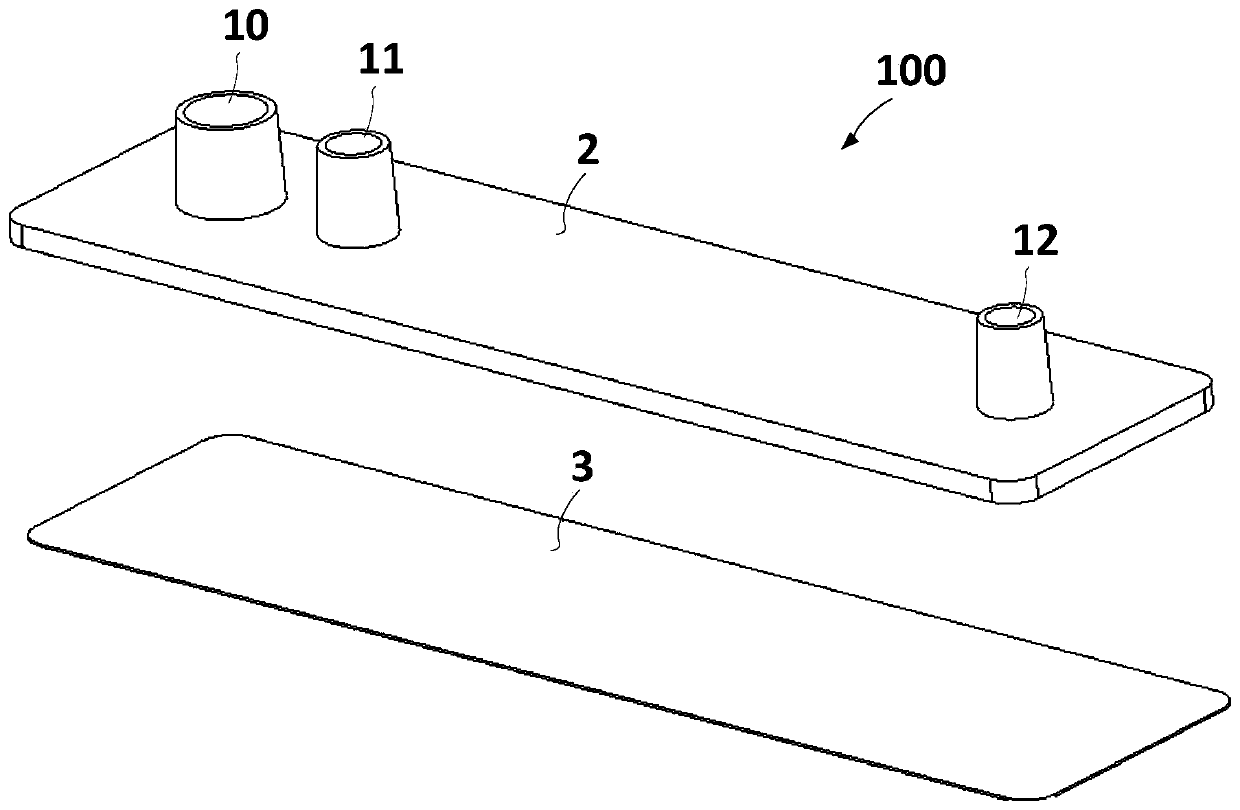

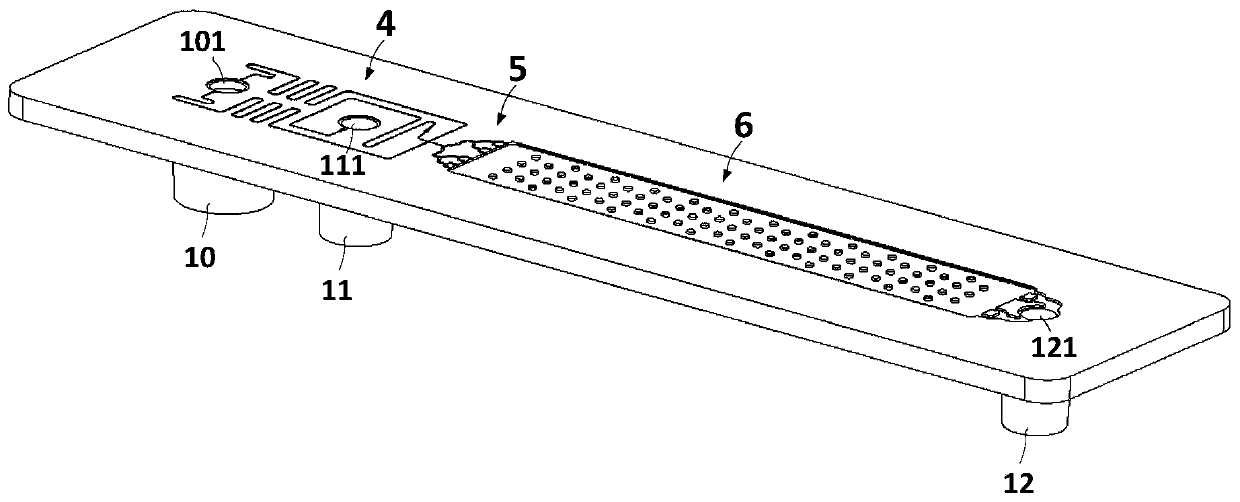

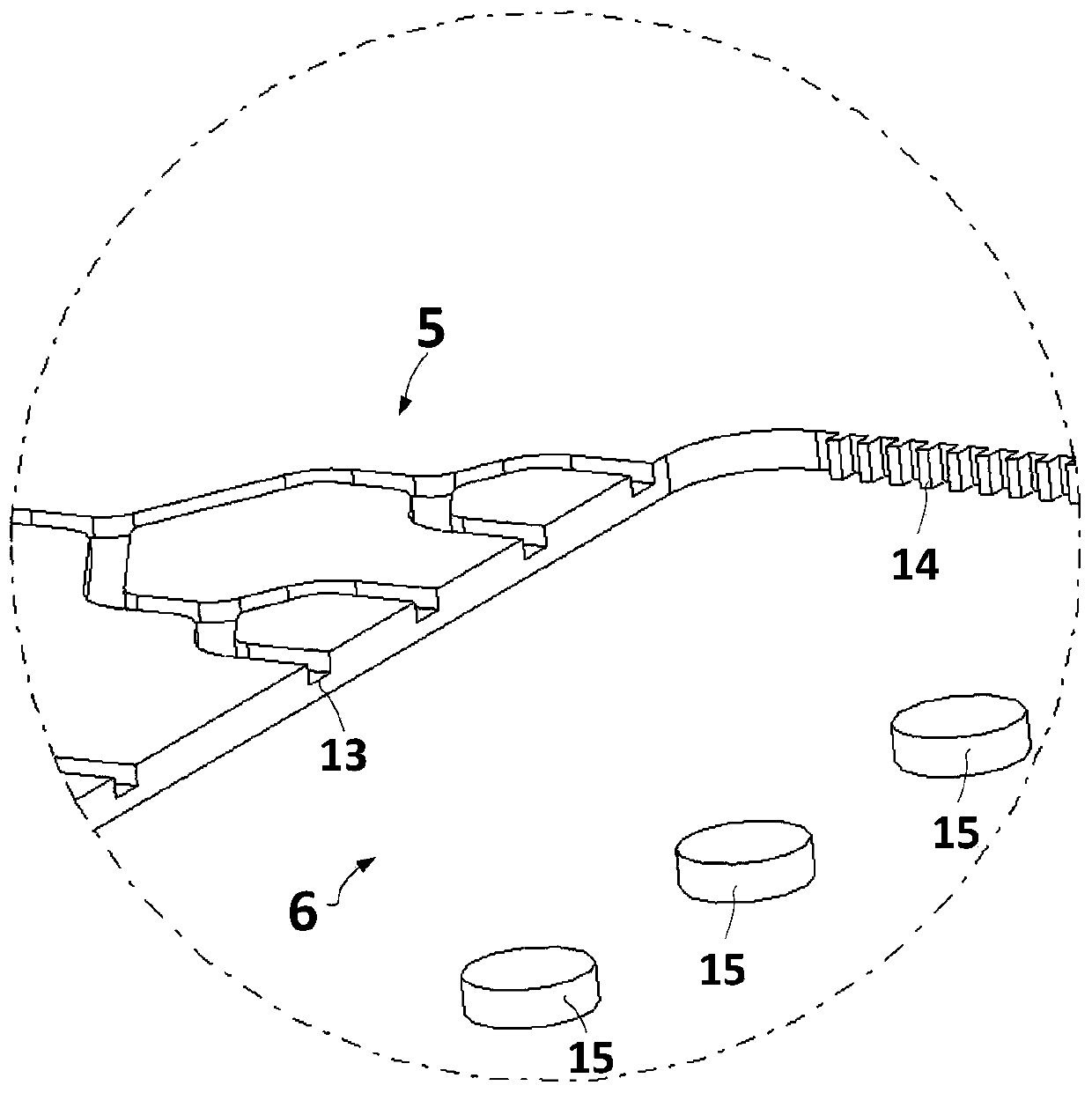

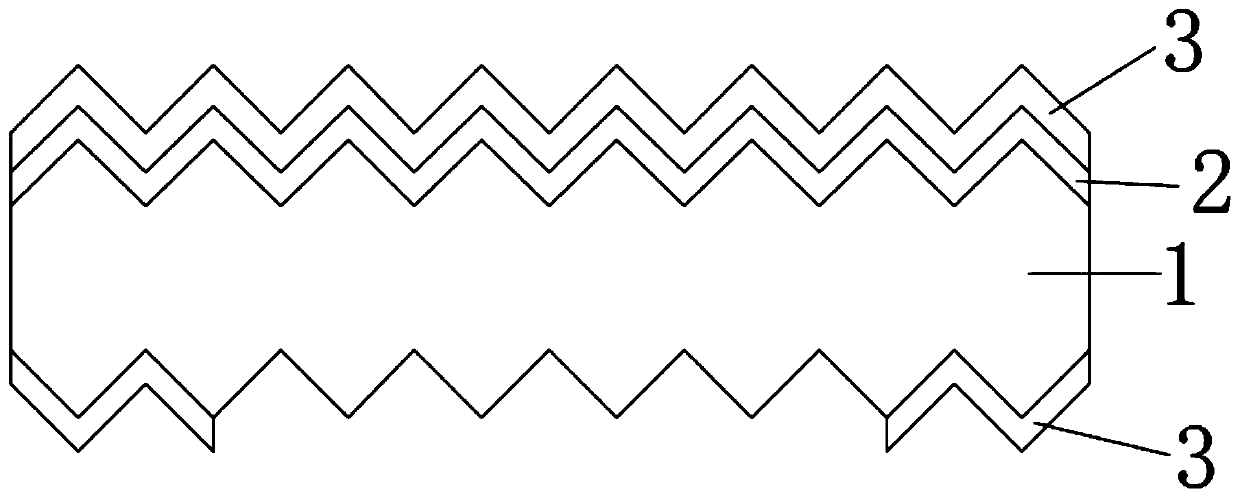

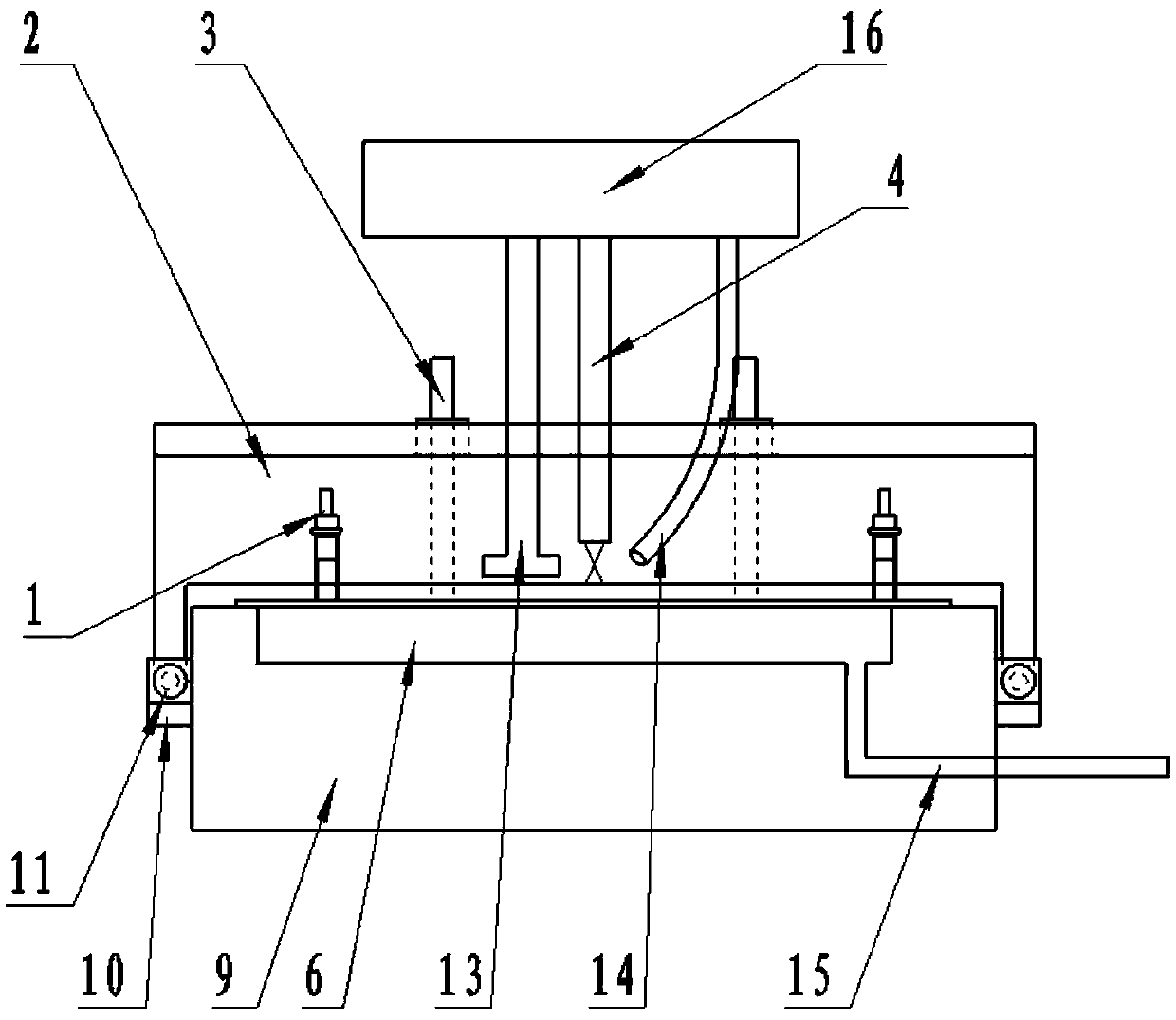

Integrated droplet microfluidic chip structure, preparation method and microfluidic chip assembly

PendingCN109825426AHighly integratedHigh degree of automationBioreactor/fermenter combinationsBiological substance pretreatmentsPositive pressureFluorescence

The invention provides an integrated droplet microfluidic chip structure. All functional modules of droplet generation, amplification and detection are integrated on the same microfluidic chip to achieve the whole enclosed process from the droplet generation to fluorescence detection. The invention also relates to an integrated droplet microfluidic chip structure preparation method and a microfluidic chip assembly. The structure is compatible with the positive pressure or negative pressure drive mode, the pressure response time is short, the rapid droplet generation can be achieved, and the sample preparation time is greatly reduced. Droplet generation oil is not required to be filled in advance, the operation is simple, and popularization and application in the technical field of digitalPCR are facilitated.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

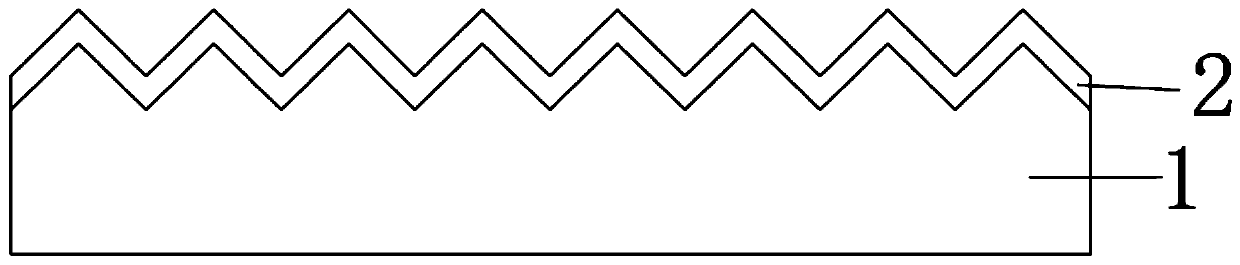

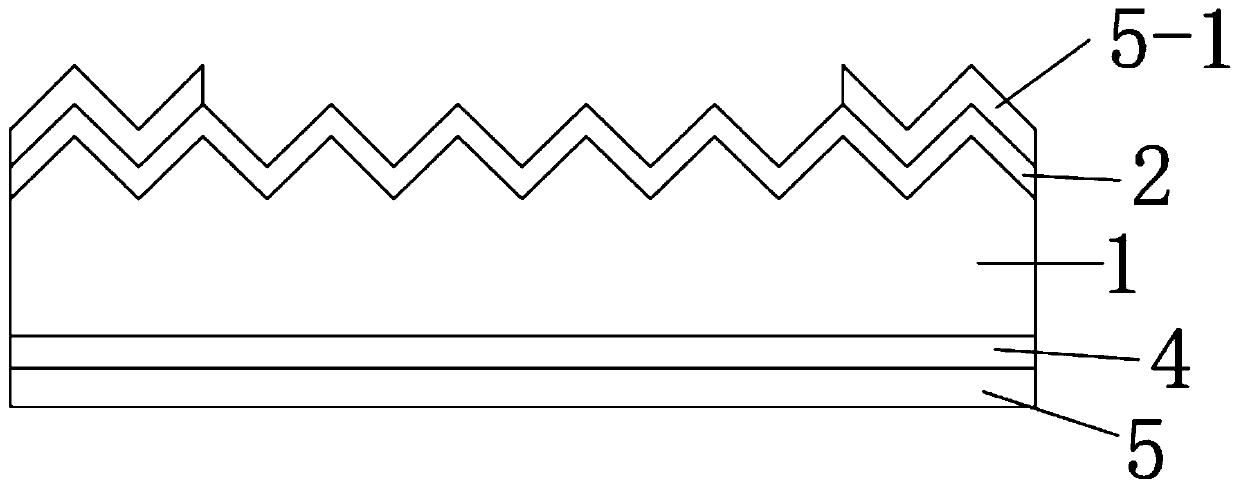

Method for removing front polycrystalline silicon winding plating

ActiveCN111341881AControl reaction rateMeet mass production needsFinal product manufacturePhotovoltaic energy generationAmorphous siliconSingle crystal

The invention relates to a method for removing front polycrystalline silicon winding plating. The method comprises the following steps: (1) performing boron diffusion on the front surface of a siliconwafer to form a p + emitter and a front borosilicate glass layer; (2) etching the back surface of the silicon wafer, etching the back surface into a plane, removing the boron-doped layer and the borosilicate glass layer on the back surface and the periphery, and removing the front borosilicate glass layer; (3) growing a tunneling oxide layer and an intrinsic amorphous silicon layer on the back surface of the silicon wafer, and forming a front winding polycrystalline silicon layer on the edge region of the front surface of the silicon wafer; (4) carrying out ion implantation on the intrinsic amorphous silicon layer to form a phosphorosilicate glass layer, and performing annealing to form a phosphorus-doped polycrystalline silicon layer; (5) plating a silicon nitride layer on the phosphorus-doped polycrystalline silicon layer; (6) placing the silicon wafer in a mixed solution of alkali and a single crystal additive to remove the front winding polycrystalline silicon layer; and (7) plating aluminum oxide layers on the two sides of the silicon wafer, and plating a passivation antireflection film layer on the aluminum oxide layer on the front side. According to the method, the reactionrate of the alkali liquor in the alkali winding plating solution and the winding plating polycrystalline silicon can be well controlled, and reaction windows can be increased.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

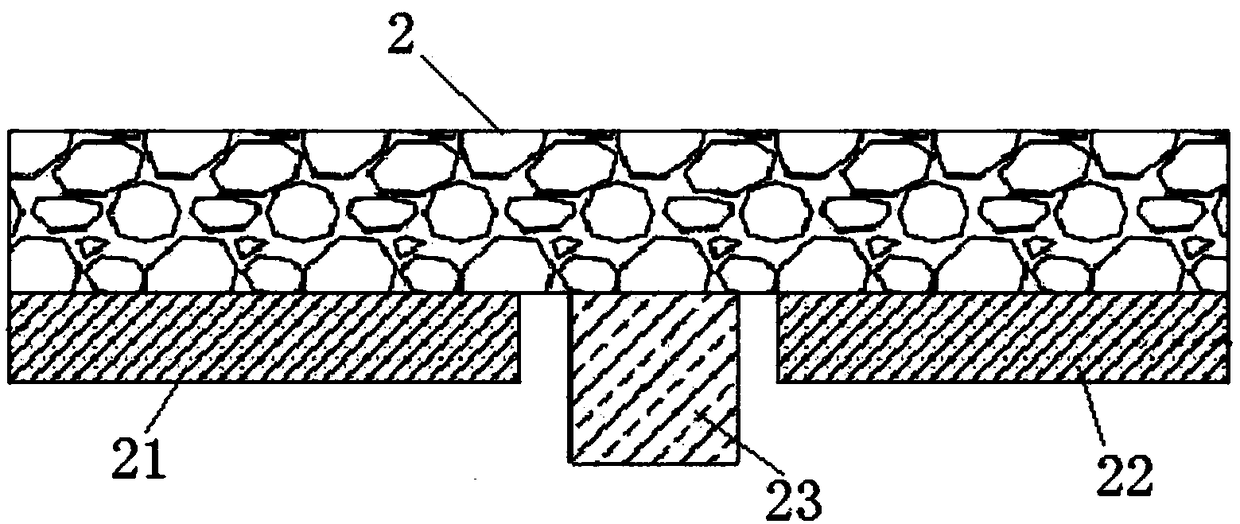

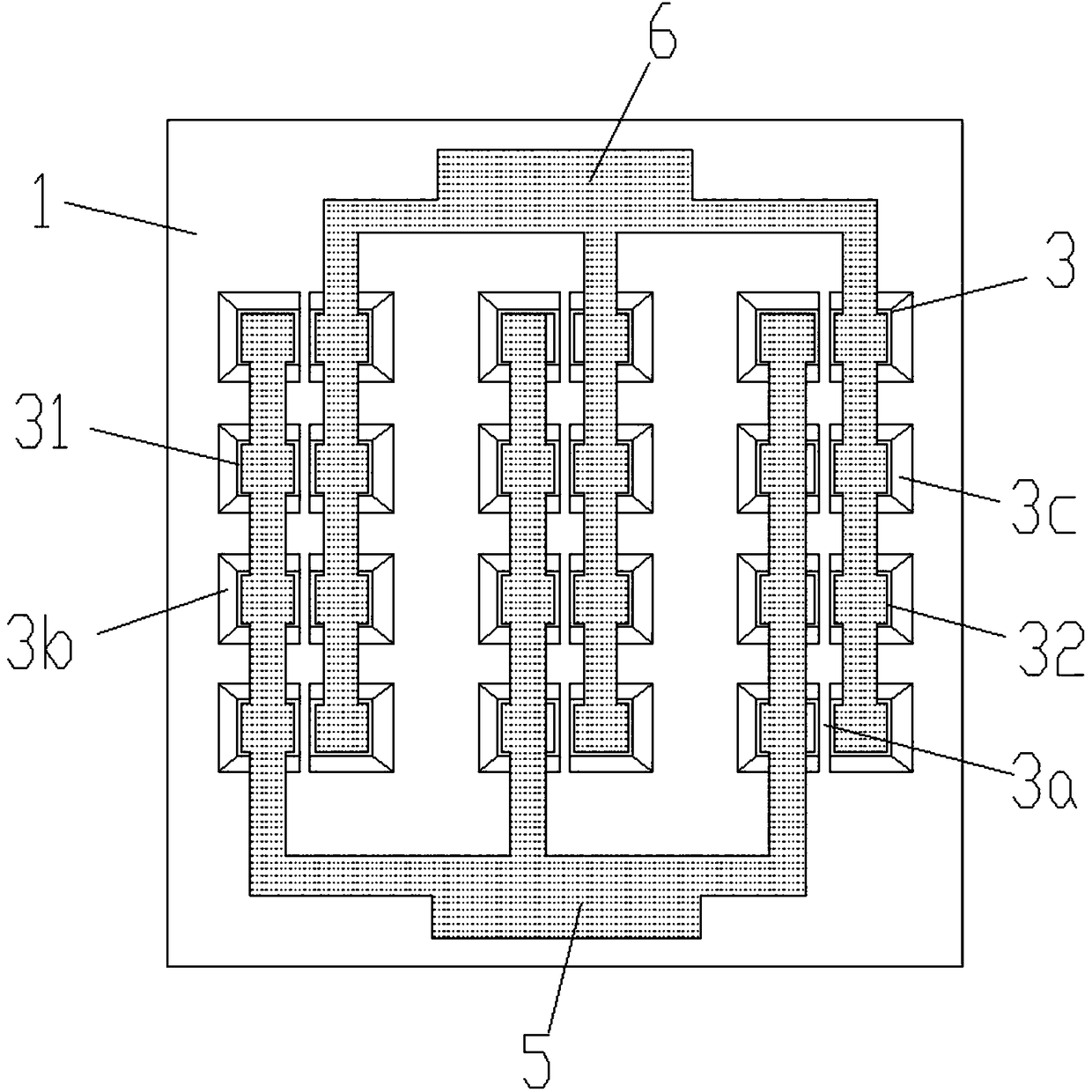

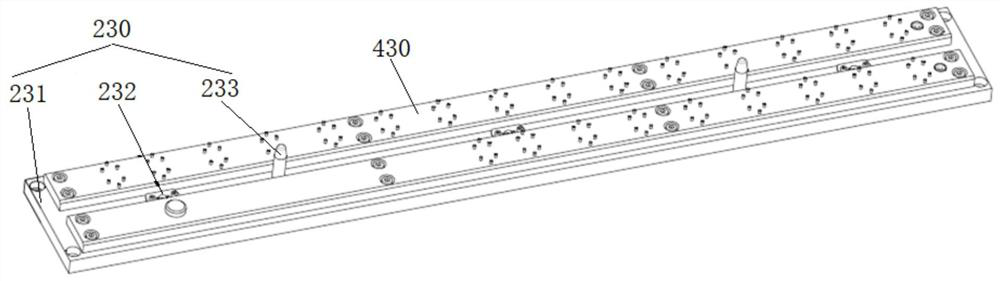

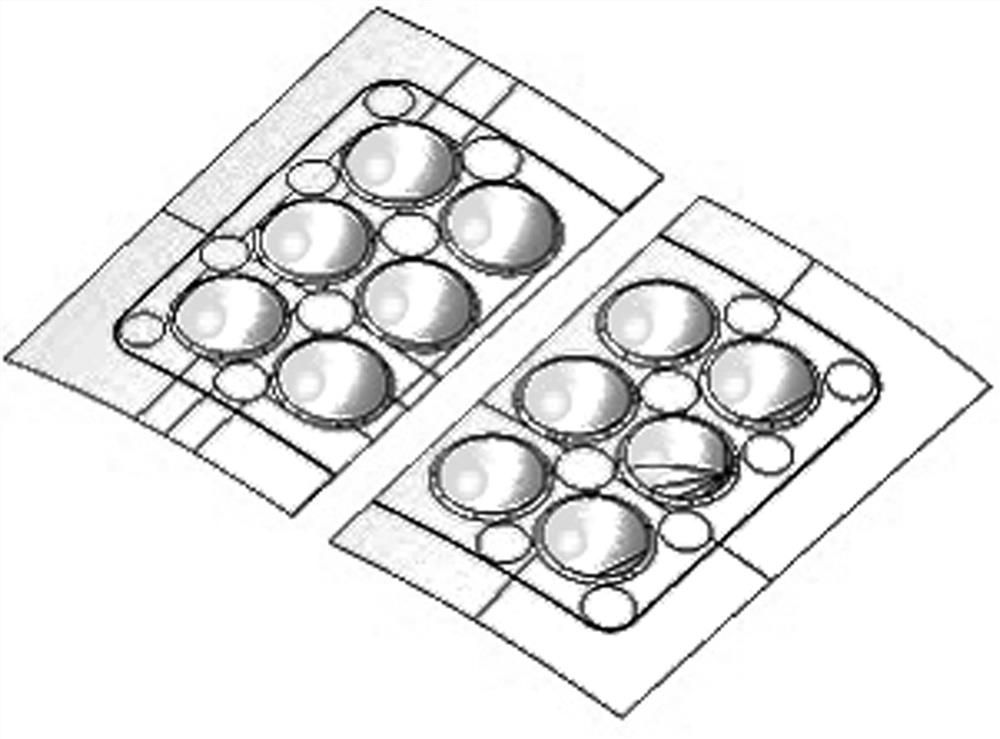

Light source component

ActiveCN108091753AImprove welding pass rateAvoid short circuit problemsSolid-state devicesSemiconductor devicesHeat conductingEngineering

The invention discloses a light source component, which comprises a substrate body and an LED chip, wherein an electrode surface of the LED chip faces the substrate body and comprises an N electrode and a P electrode; a plurality of mounting blocks for arranging the LED chip in a welding manner are formed on the substrate body; each mounting block is a mounting boss which protrudes above a board of the substrate body; a heat-conducting insulating layer covers the substrate body and the surfaces of the mounting blocks; each mounting boss is partitioned into a negative electrode area and a positive electrode area through an isolation groove; a negative electrode lead and a positive electrode lead are printed on the heat-conducting insulating layer; the LED chip is provided with an insulatingwall between the N electrode and the P electrode; and the lower end surface of the insulating wall is laminated with the upper surface of the heat-conducting insulating layer in the isolation grooves. According to the light source component, the welding yield of the LED chip in a relatively small GAP can be ensured, the heat dissipation capability of the component is improved, the stability of the welding process of the LED chip is improved, a short-circuit failure risk caused by mutual overflow infiltration of solder is avoided and the mass production requirements of a high-brightness and high-heat-dissipation light-emitting component can be met.

Owner:YANGZHOU UNIV

Method for preventing electrostatic dust collection explosion venting in converter double-slag smelting process

InactiveCN107805683AAvoid explosive conditionsPrevent explosion ventingManufacturing convertersSmelting processNitrogen

The invention discloses a method for preventing electrostatic dust collection explosion venting in the converter double-slag smelting process. The method includes the steps that when lance carrying deslagging is carried out for the first time in the converter smelting process, an oxygen lance is carried to a fire hole for nitrogen flushing, and as for the volume contents of gases in a dust remover, nitrogen flushing is stopped after O2 is smaller than or equal to 6% and CO is smaller than or equal to 9%. According to the method, by optimizing the primary slagging gas supply system, the converter oxygen lance is used for nitrogen flushing, the volume content of O2 entering the electrostatic field dust remover after converting is stopped is controlled to be 6% or below, the explosion conditions of a gas mixture of CO and O2 are effectively evaded, and therefore explosion venting of the electrostatic field dust remover in converter double-slag operation can be avoided, and the effects ofstabilizing the converter production rhythm, reducing the damage to dust removing equipment and prolonging the service life are achieved. Meanwhile, the double-slag operation is adopted in a converter, P controllability of the converter is improved and the volume production needs of high-end branded steel are met.

Owner:HEBEI IRON AND STEEL

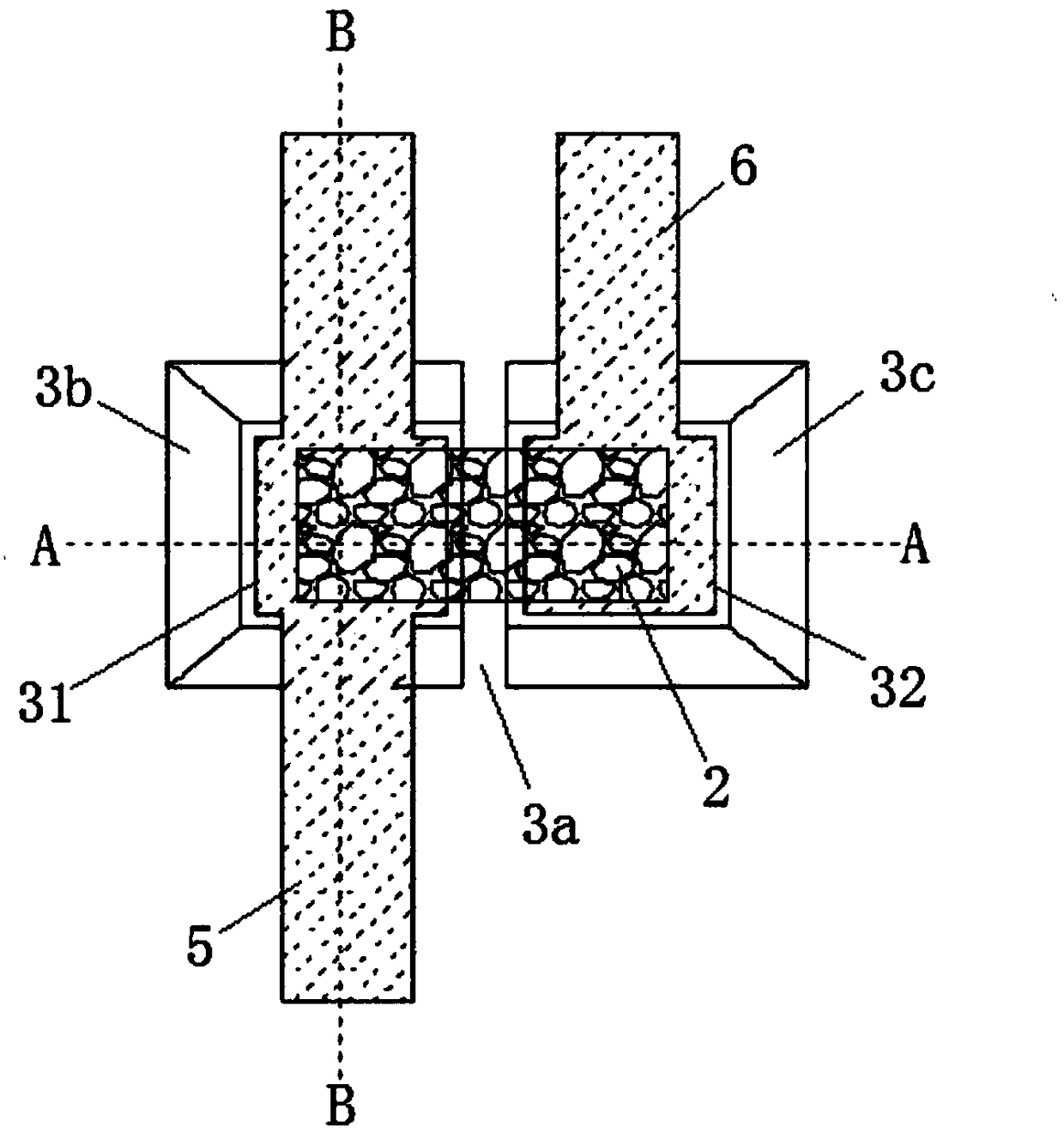

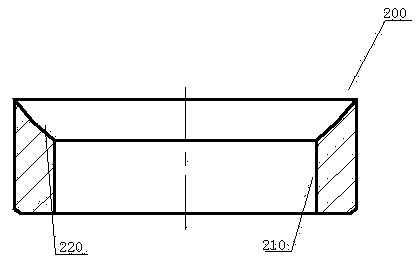

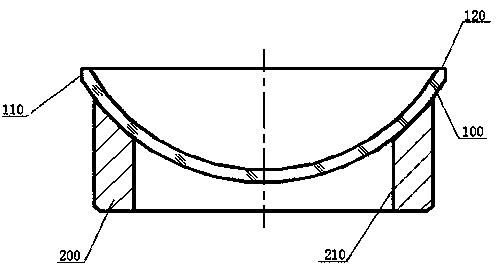

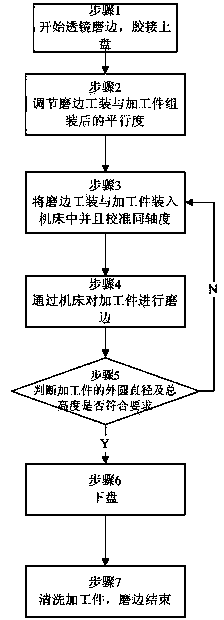

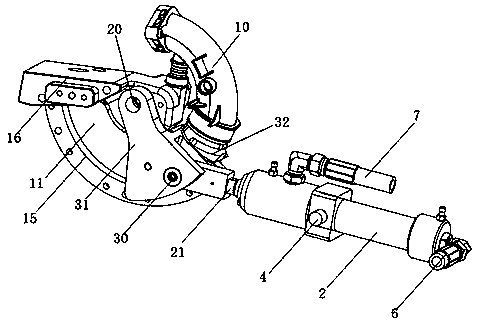

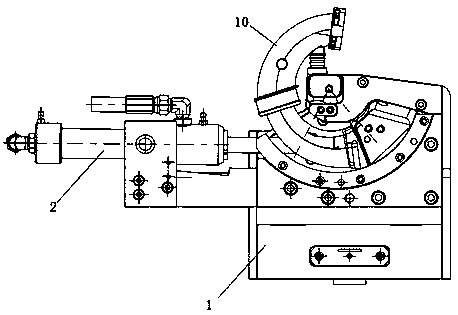

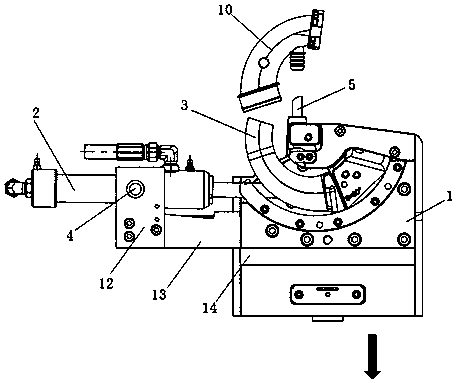

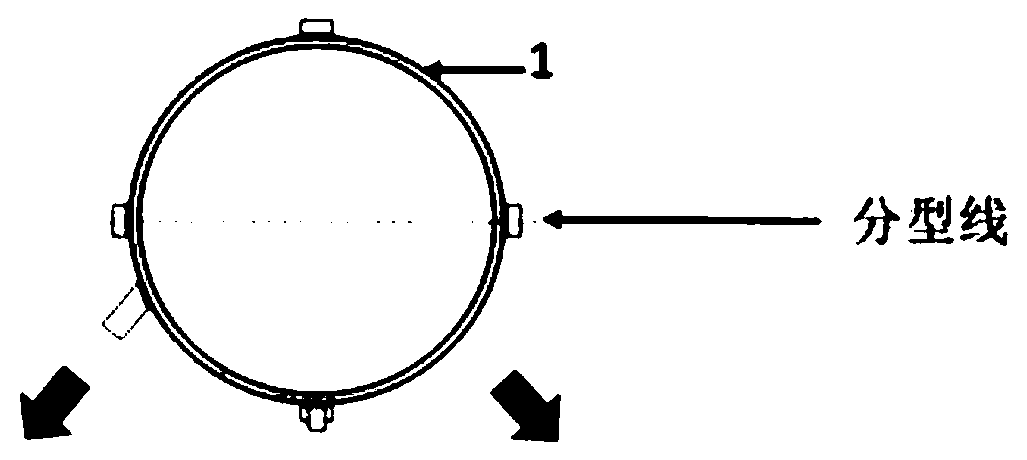

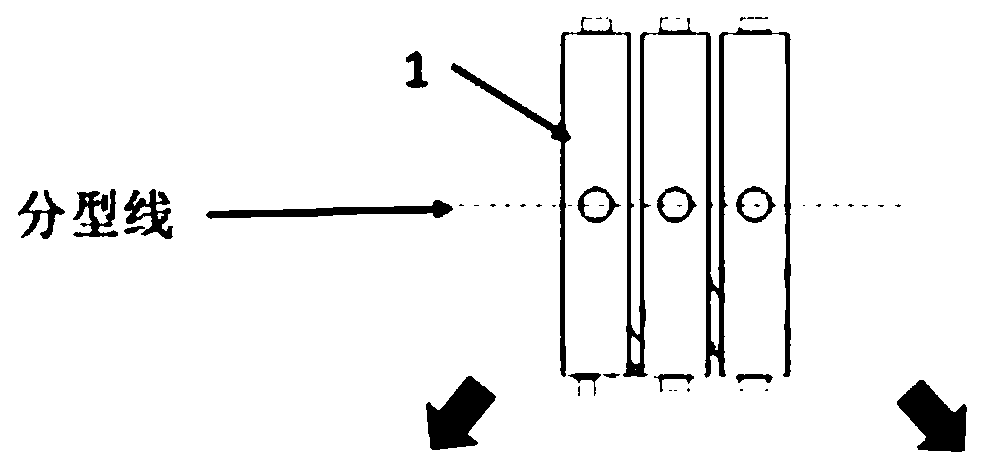

Edging device for meniscus lens centering and edging method thereof

ActiveCN103659516AImprove edging efficiencyMeet mass production needsEdge grinding machinesGrinding feed controlGrinding wheelMachine tool

The invention discloses an edging device for meniscus lens centering and an edging method thereof. The edging device is cylindrical. The top end of the edging device is provided with an arc-shaped lens cementing face. A through hole is formed in the edging device and communicated with the edging device. The edging method comprises the following steps of starting lens edging, cementing and loading a plate, splicing a meniscus lens work-piece and the lens cementing face of the edging device through bonding glue, adjusting the parallelism between the bottom edge of the edging device and the end face of the work-piece after cementing, installing the edging device and the work-piece which are integrally bonded in a machine tool, calibrating the coaxiality of the edging device and a main shaft of the machine tool, carrying out edging on the work-piece through a machine tool grinding wheel, polishing the work-piece until the diameter of the outer circle and the total height reach the specified numerical range, unloading the plate, separating the edging device and the work-piece which are integrally bonded, cleaning the work-piece, and finishing the edging process of a meniscus lens.

Owner:SHANGHAI XINYUE METER FACTORY

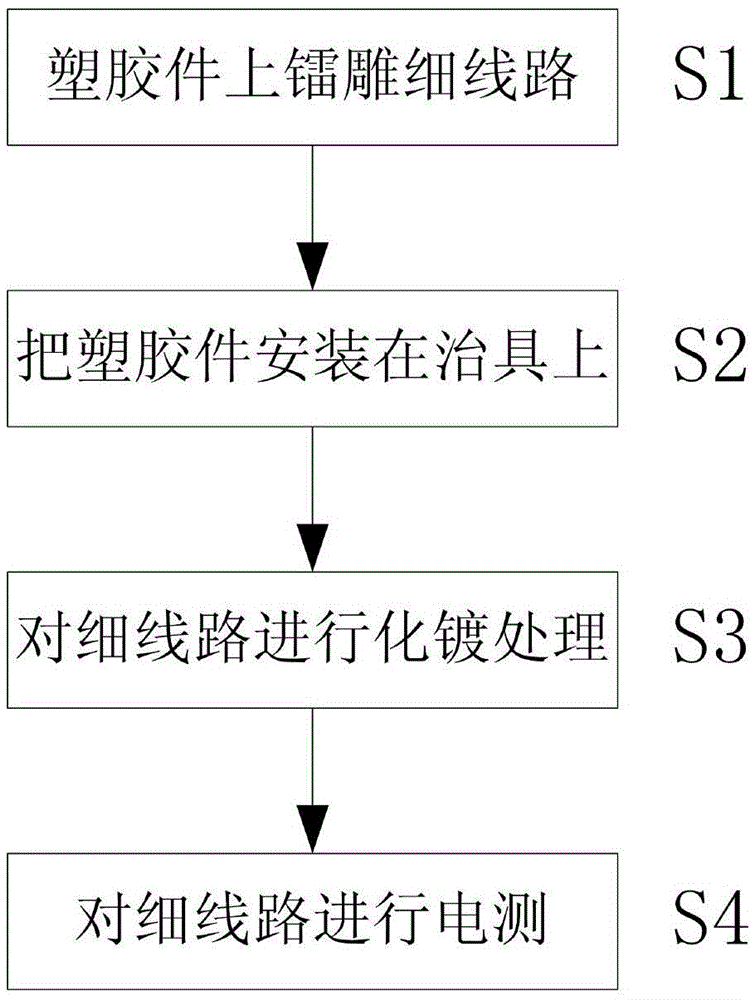

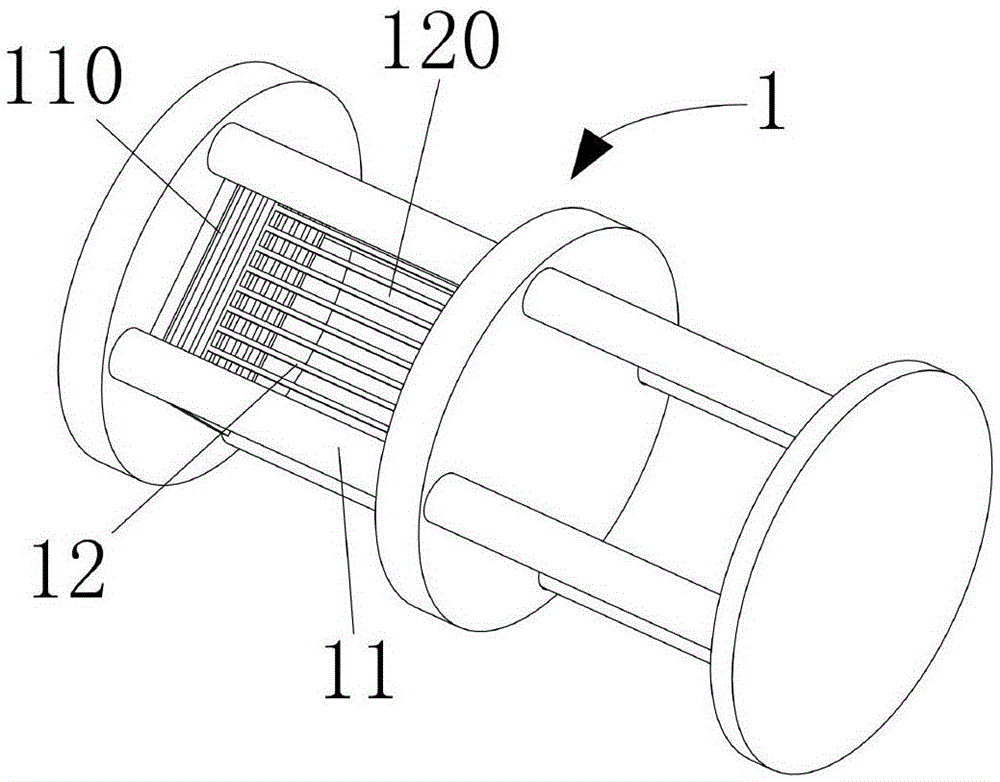

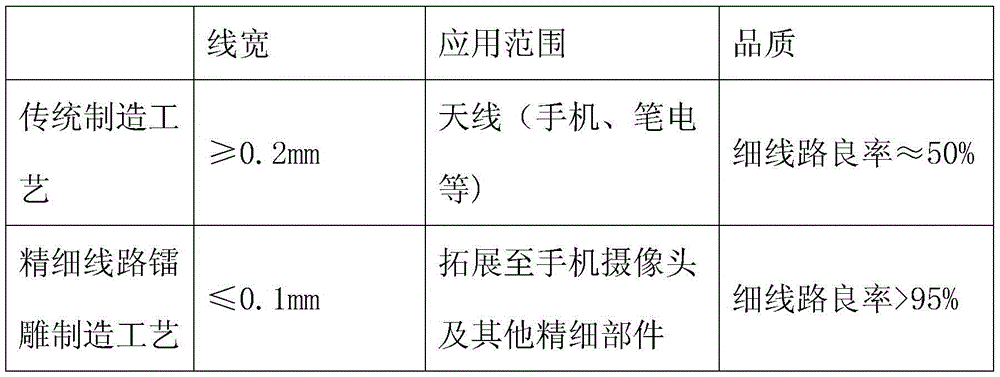

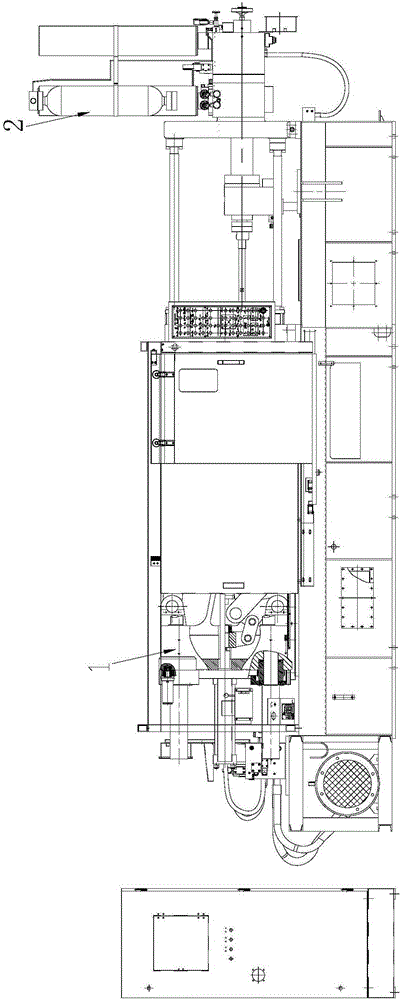

Laser engraving manufacturing process for fine circuit

InactiveCN105472901APrevent floodingAvoid disconnectionPrinted circuit manufactureChemical platingLaser engraving

The invention relates to a laser engraving manufacturing process for a fine circuit. The manufacturing process comprises the following steps: step 1, preparing a thin circuit with a width of less than or equal to 0.1 mm through a laser engraving manner in an LDS plastic part by utilizing an LDS laser; step 2, mounting the laser engraved plastic part on a jig that combines a roller and a suspension frame; step 3, performing chemical plating treatment on the laser engraved plastic part to obtain a required metal layer on the circuit; and step 4, performing electrical logging on the circuit after the metal layer is obtained. By adoption of the laser engraving manufacturing process for the fine circuit, large-scale production of the fine circuit with the thickness of less than or equal to 0.1 mm can be realized, and the applied range of the LDS process is expanded.

Owner:东莞光韵达光电科技有限公司

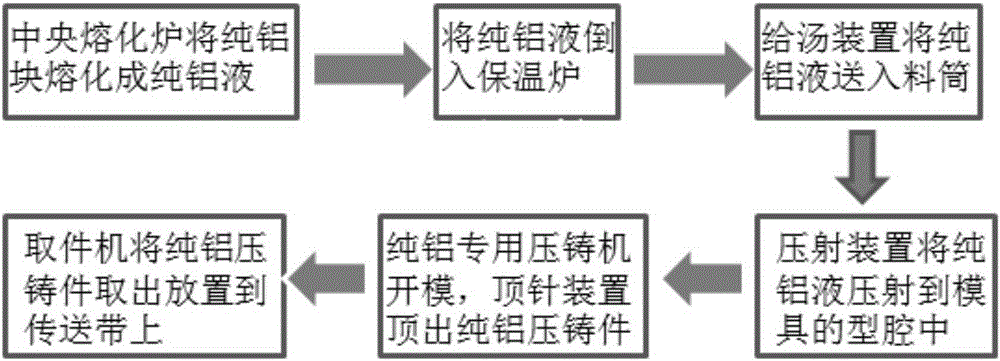

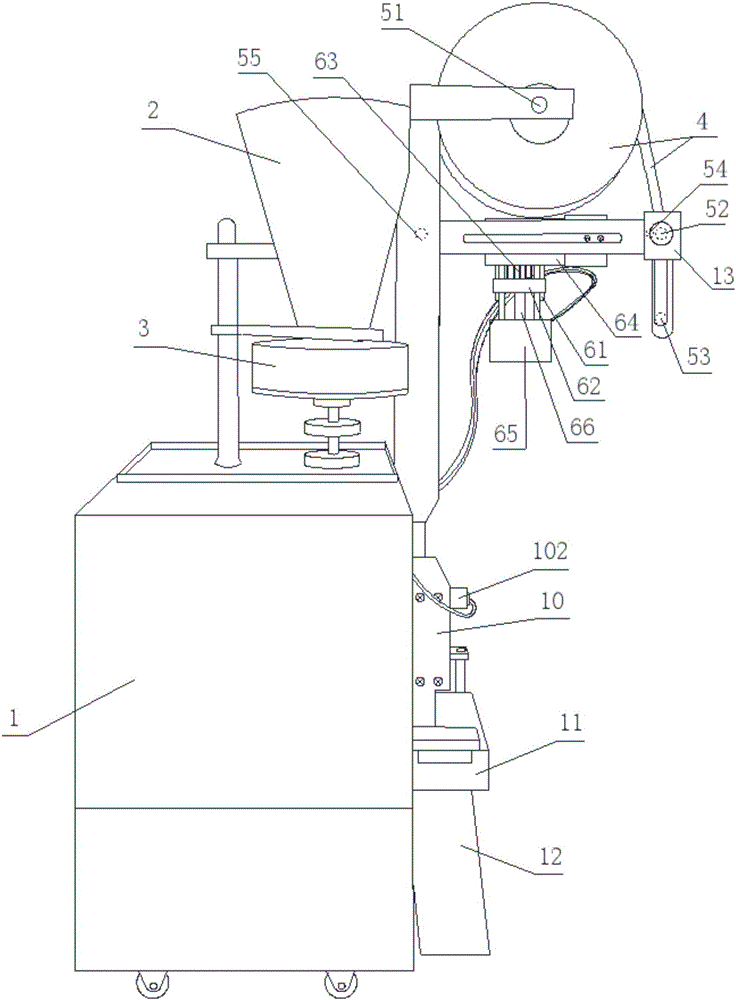

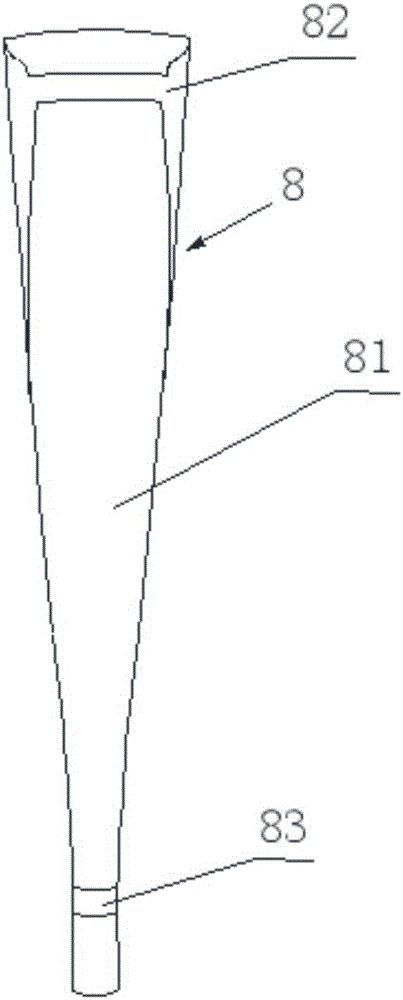

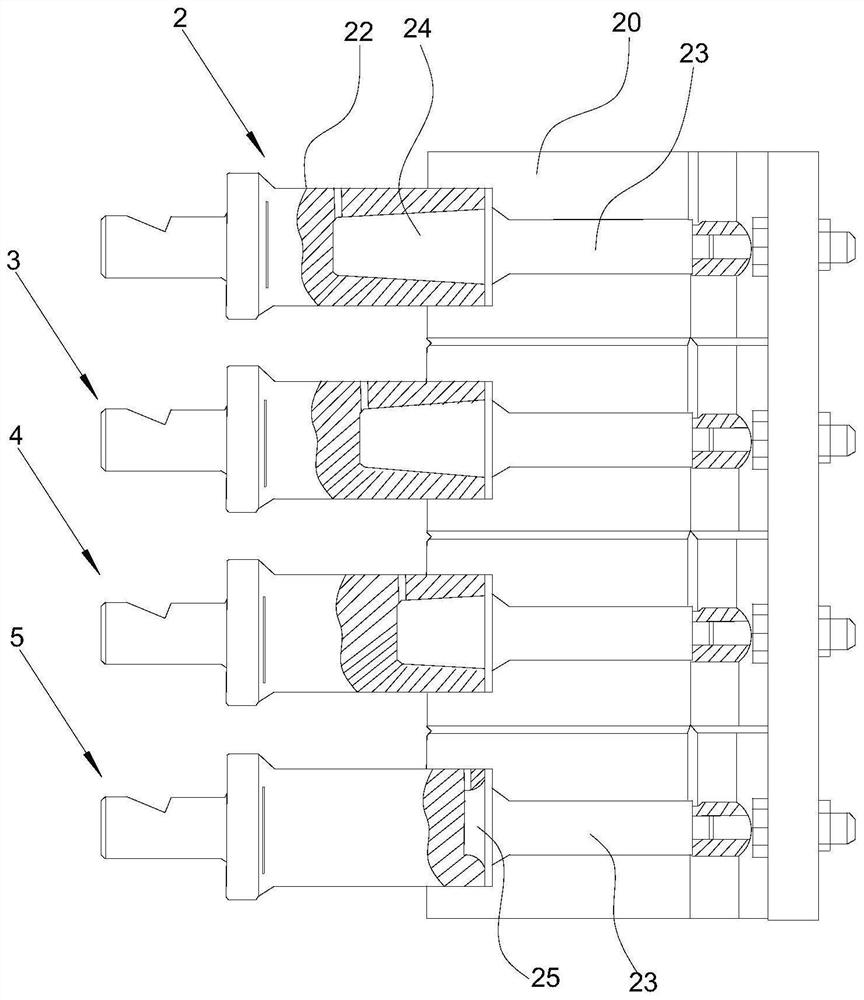

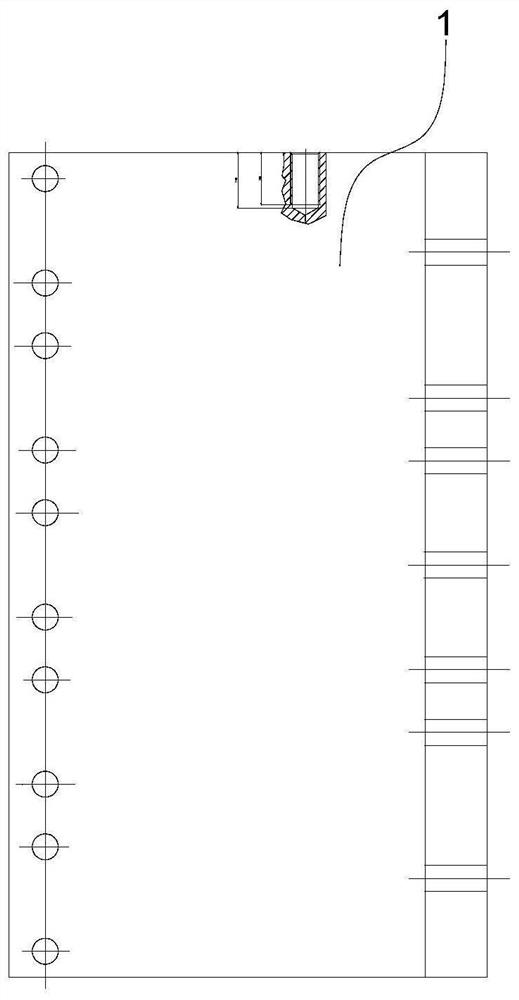

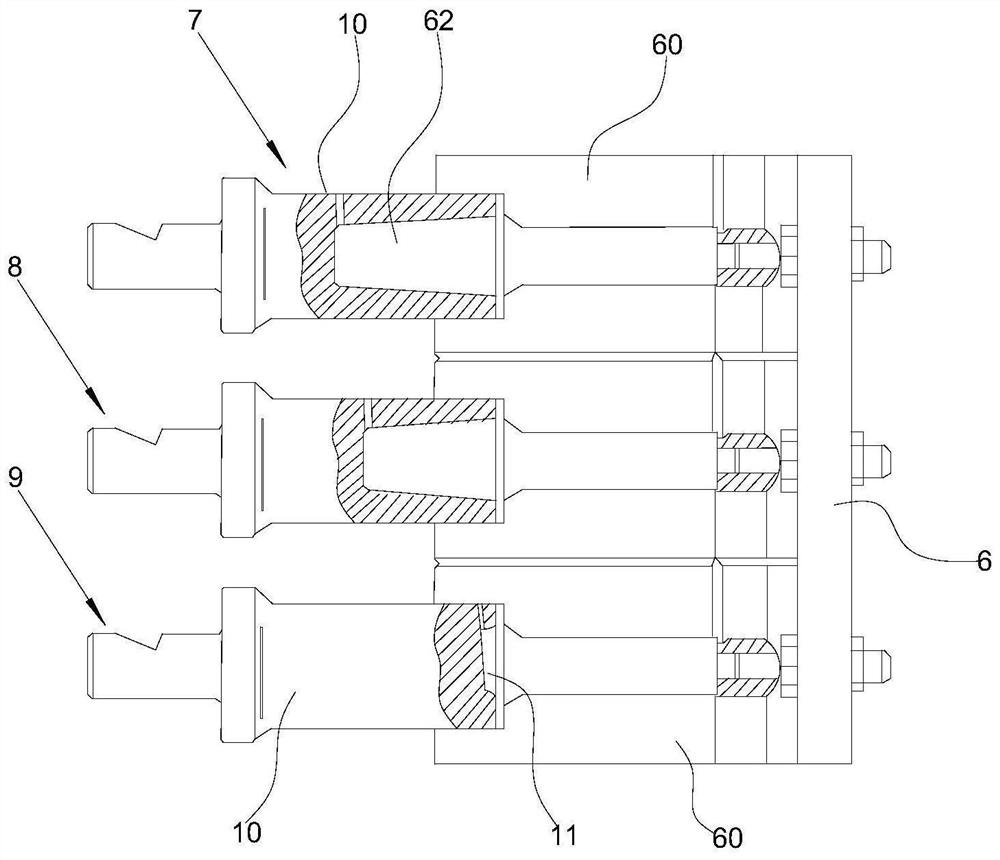

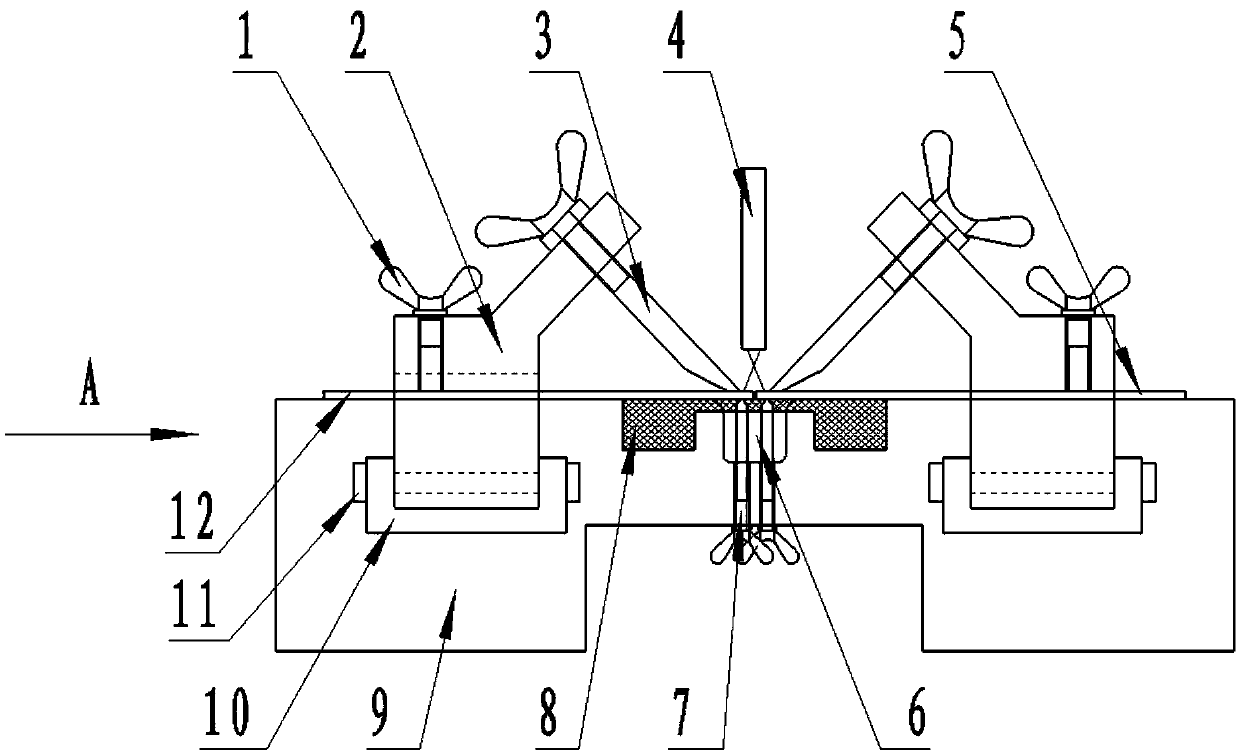

Pure-aluminium die casting equipment and pure-aluminium die casting technology

InactiveCN105234368AOvercome the problem of high resistance caused by poor liquidityImprove performanceDie castingElectro hydraulic

The invention is applicable to the technical field of pure-aluminium die casting, and discloses pure-aluminium die casting equipment and a pure-aluminium die casting technology. The pure-aluminium die casting equipment comprises a die-casting machine connected with a die-casting die; the die-casting machine comprises a material feeding barrel; the pure-aluminium die casting equipment further comprises a central melting furnace used for heating and melting an aluminium block, a heat preserving furnace used for performing heat preservation on molten aluminium, a molten aluminium feeding device used for conveying the molten aluminium into the material feeding barrel and a press-shooting device used for press-shooting the molten aluminium from the material feeding barrel to the die cavity of the die casting die; an ejecting device used for ejecting a formed product from the die cavity is arranged on one side of the die casting die; and the press-shooting device is provided with an electro-hydraulic proportional throttle valve with valve core position feedback. The above pure-aluminium die casting equipment is adopted in the pure-aluminium die casting technology. By adopting the pure-aluminium die casting equipment and the pure-aluminium die casting technology provided by the invention, the production qualification rate is high; the cost is low; and the requirement of markets on volume production of pure-aluminium parts is met.

Owner:SHENZHEN LEADWELL TECH CO LTD

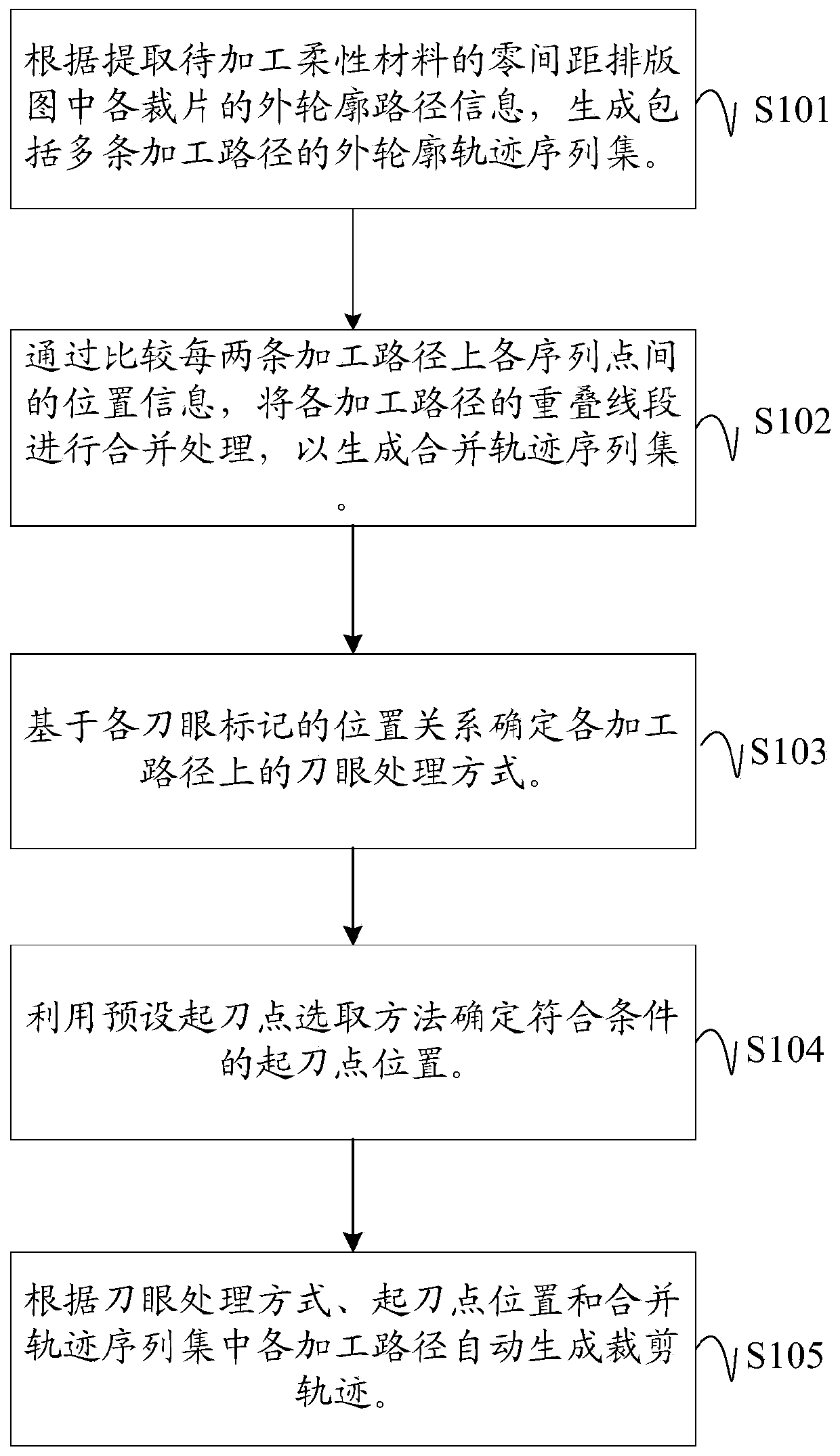

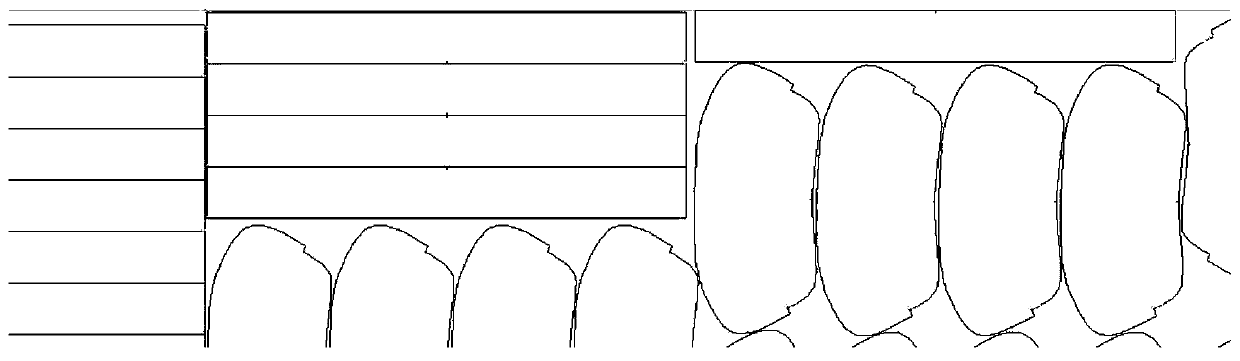

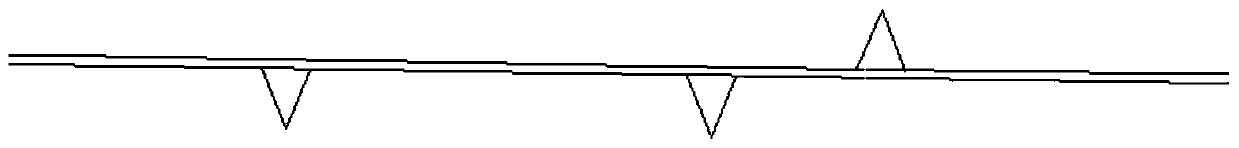

Automatic cutting track generation method and device for flexible material zero-interval layout graph

ActiveCN110989491AIncrease profitEfficient processingNumerical controlKnife bladesBatch manufacturing

The application discloses an automatic blade cutting track generation method and device for a flexible material zero-interval layout graph and a computer readable storage medium. The method applied toa cutting bed comprises the following steps: extracting outermost layer path information of each cutting piece in a zero-interval layout graph of a to-be-processed flexible material to obtain an outer contour track sequence set comprising a plurality of processing paths; combining overlapped line segments of all processing path by comparing position information of all sequence points on each twoprocessing paths; determining a cutter eye processing mode on each processing path based on the position relationship of each cutter eye mark, and determining a cutter starting point position of an adjacent cutting piece by utilizing a preset cutter starting point selection method; and automatically generating a cutting track according to the cutter eye processing mode, the cutter starting point position and the track sequence set after combining processing. On the basis of not sacrificing the utilization rate of the fabric, the zero-interval layout cutting pieces of the flexible material areefficiently processed with high quality, so that the batch production requirements of flexible materials such as clothing and vehicle decorations are met.

Owner:HANGZHOU ECHO SCI TECH

Steel ladle powder injection desulfuration refining process for low-sulfur steel production

The invention relates to a steel ladle powder injection desulfuration refining process for low-sulfur steel production. The process is characterized in that: 3.0 to 6.5kg / t of aluminum iron for strong deoxidation is adopted in converter tapping; 0.4 to 0.6kg / t of aluminum for slag surface deoxidation is added on the steel ladle slag surface after tapping is finished; the oxidation property (FeO%+Mn%) of station reaching top slag of steel ladles is less than or equal to 3.5 percent; the temperature of the molten steel reaching a powder injection desulfuration station is 1,610 to 1,640 DEG C, and Alt in the steel is 0.040 to 0.090 percent; the working pressure of steel ladle powder injection desulfuration delivery carrier gas is 3.0 to 4.0bar, and the flow is 40 to 60m<3> / h; and the powder injection velocity of steel ladle powder injection desulfuration is 40 to 60kg / min, and the consumption of the injection powder is 4.0 to 6.0 kg / t of steel. After the steel ladle powder injection desulfuration process is adopted, the sulfur content of the steel can be reduced from 50-80ppm to within 12ppm, and the desulfuration rate can reach 78.0 to 85.0 percent.

Owner:SHOUGANG CORPORATION

Construction reinforcement machining device and application method thereof

The invention provides a construction reinforcement machining device and an application method thereof. The construction reinforcement machining device comprises a first bracket, a straightening machine and a shearing machine; the straightening machine is arranged at one end of the first bracket; the straightening machine comprises a traction wheel, a feed port, a pressing wheel, a second bracket,a hydraulic cylinder, a first motor, a driving chain wheel, a bracket, a chain, a fourth shaft and a driven chain wheel; and the shearing machine is arranged at the middle part of the first bracket.The construction reinforcement machining device adopts integral design of straightening and shearing; after reinforcements are straightened by the straightening machine, the reinforcements enter a receiving frame of the shearing machine through a positioning hole; and the position of a travel switch is set according to a needed length, so that the straightened reinforcements are shorn off according to the needed length, the repeated carrying operation in reinforcement machining is reduced, the production time and the labor amount are saved, the production efficiency is improved, and the production cost is reduced.

Owner:浙江聚光交通设施有限公司

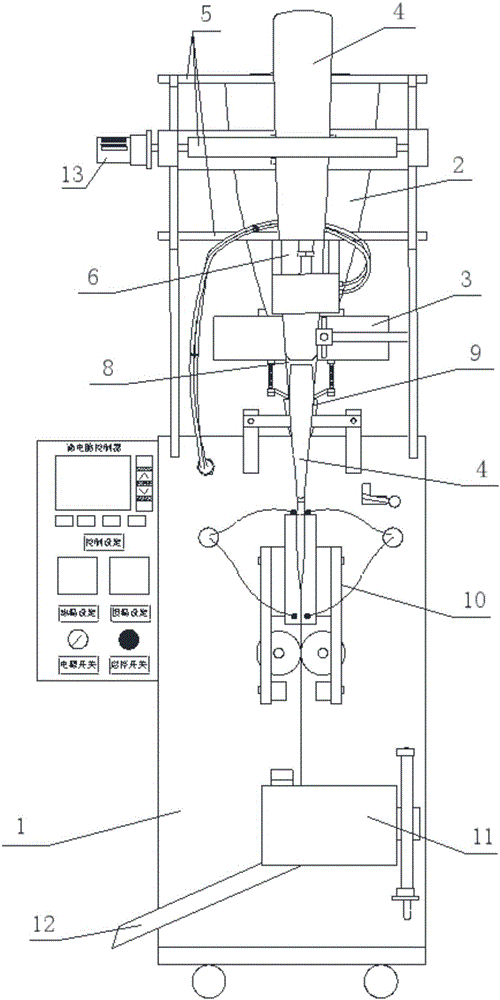

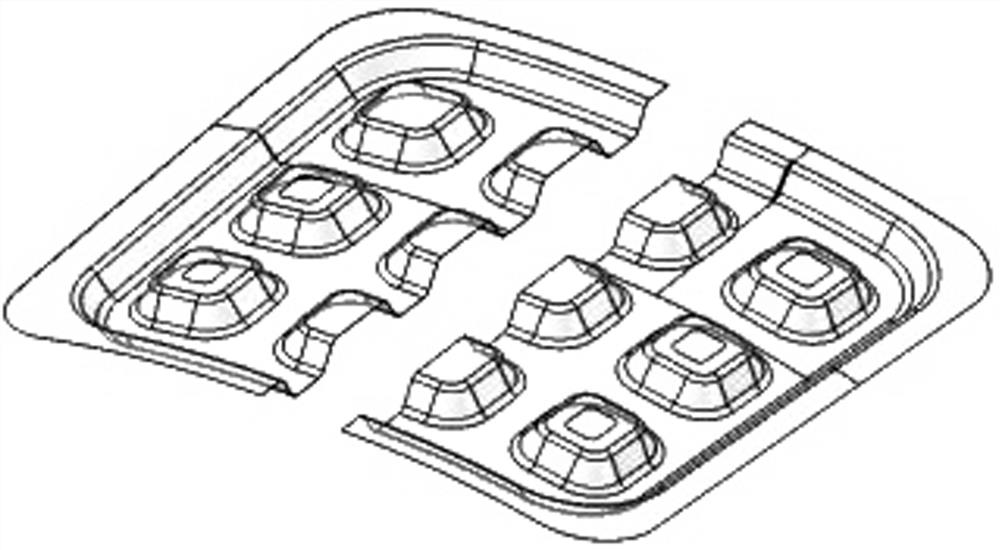

Automatic living-body subpackage-bag-type trichogramma releasing device and preparation method thereof

The invention discloses an automatic living-body subpackage-bag-type trichogramma releasing device and a preparation method thereof. The automatic living-body subpackage-bag-type trichogramma releasing device comprises a machine body. The machine body comprises a bracket mechanism and a cabinet mechanism. One side of the bracket mechanism is provided with a plurality of transmission shafts. The transmission shafts are wound by packaging paper. The packaging paper is locked in a forming machine through a hole puncher by the transmission shafts. The hole puncher is communicated with an external air pump. The other side of the bracket mechanism is provided with a discharging device, and the discharging device is communicated with a disc screening machine. The disc screening machine is communicated with a funnel device, and a joining port of the funnel device is extended to the side face of the forming machine and a packaging bag of which the bottom is sealed. The forming machine is stretched into a heat sealing machine. The lower end of the heat sealing machine is provided with an automatic cutting machine. The automatic cutting machine is connected with a chute. The heat sealing machine, the transmission shafts, the hole puncher and the disc screening machine are controlled by a circuit and program control device. According to the provided automatic living-body subpackage-bag-type trichogramma releasing device and the preparation method thereof, the operation is convenient, and the industrial large-scale efficient production is easy.

Owner:HUNAN ACAD OF FORESTRY +2

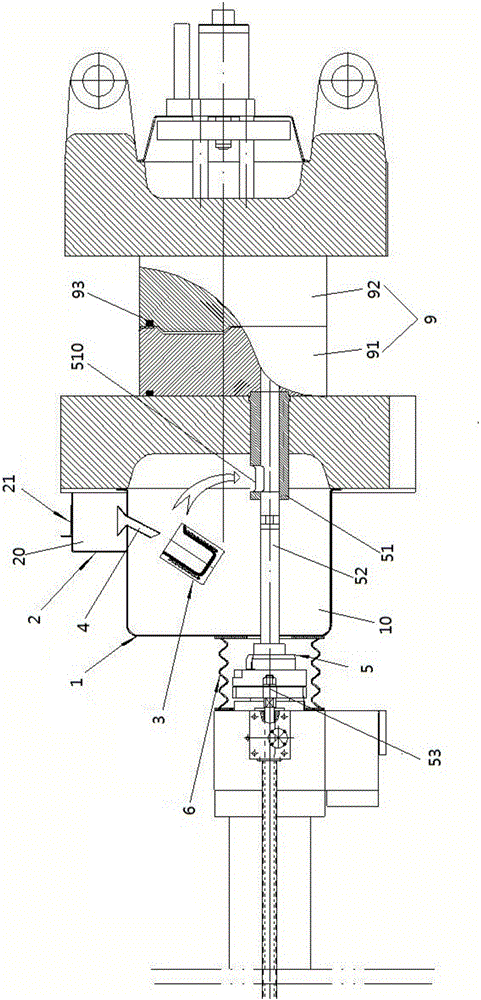

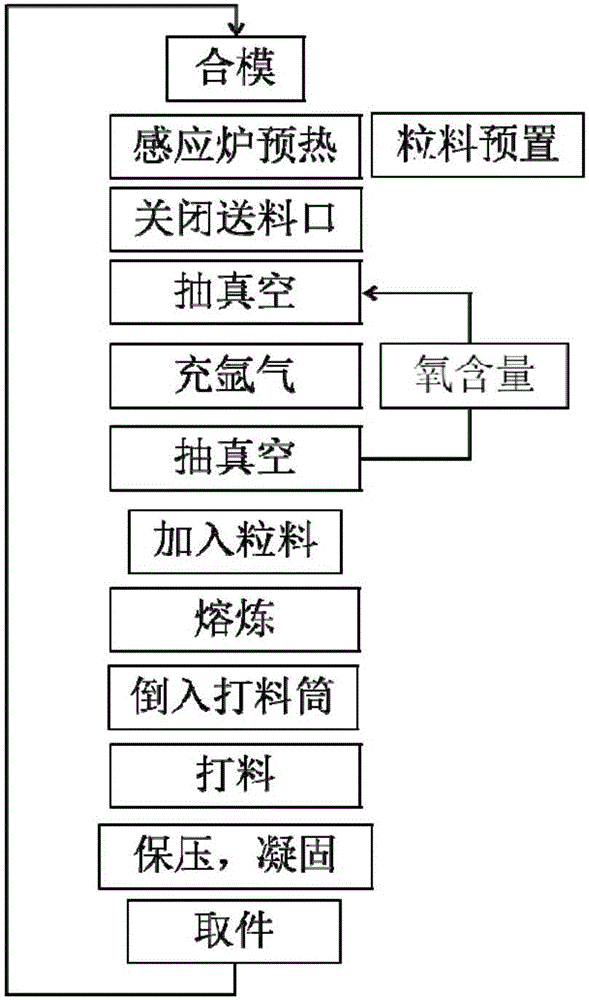

Liquid metal die-casting machine and die-casting method

The invention is applicable to the technical field of vacuum melting die-casting of amorphous alloy and discloses a liquid metal die-casting machine and a die-casting method. The liquid metal die-casting machine comprises a die-casting machine body, a vacuum chamber and a feeding chamber connected onto the vacuum chamber, wherein the vacuum chamber is provided with a vacuum cavity; a heating cup is arranged in the vacuum cavity; the feeding chamber is connected with a feeding door; a heating component is arranged in the feeding door; the vacuum chamber is connected with a vacuumizing device; the liquid metal die-casting machine further comprises a knockout device; the knockout device is used for injecting liquid metal heated by the heating cup into a die-casting die and comprises a knockout cylinder communicating the vacuum chamber and the die-casting die; and one end of the knockout cylinder stretches into the vacuum chamber, and the other end of the knockout cylinder is connected onto the die-casting die. The die-casting method is applicable to the liquid metal die-casting machine. According to the liquid metal die-casting machine and the die-casting method, the product quality and the production efficiency are high, and the production cost is low.

Owner:SHENZHEN LEADWELL TECH CO LTD

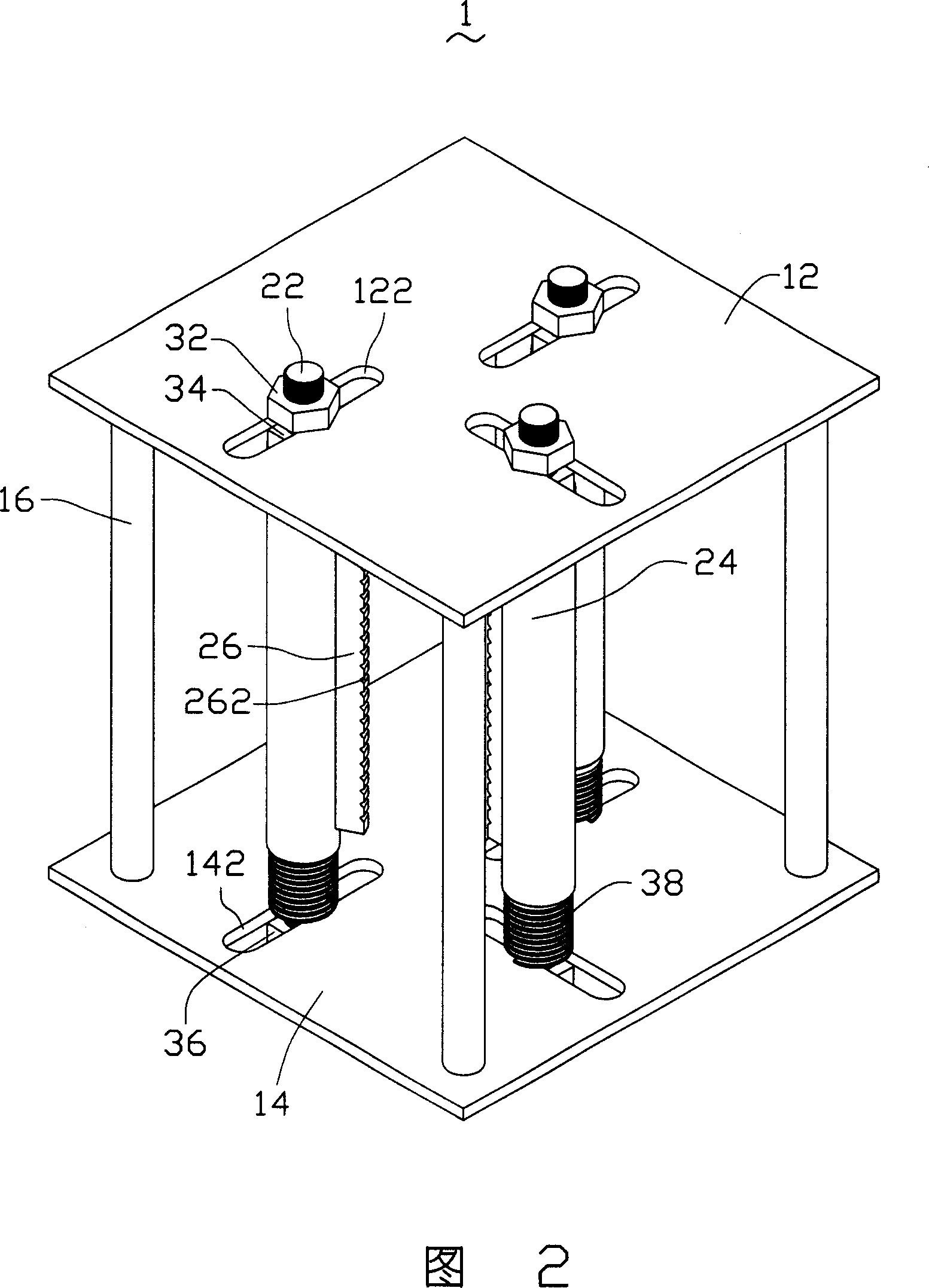

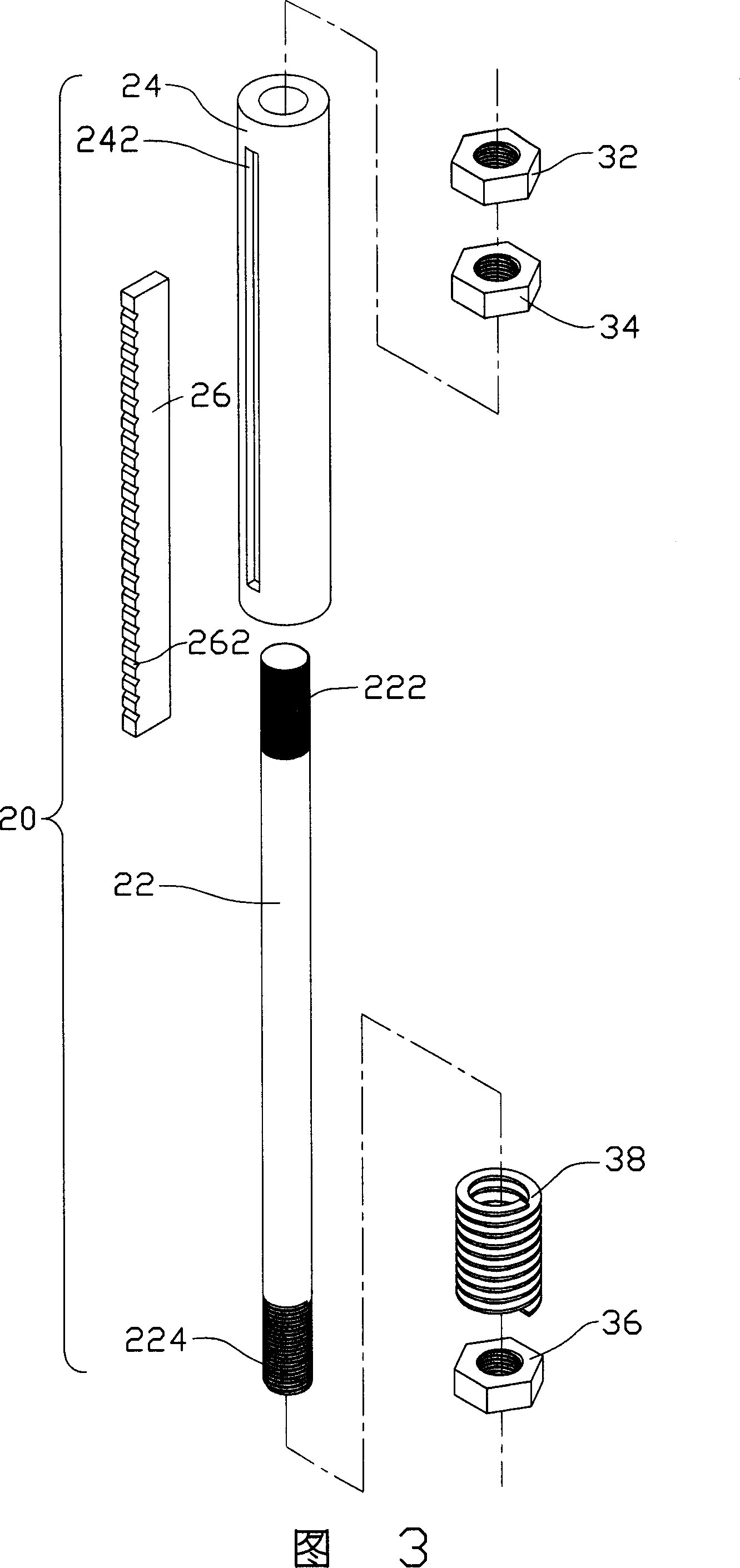

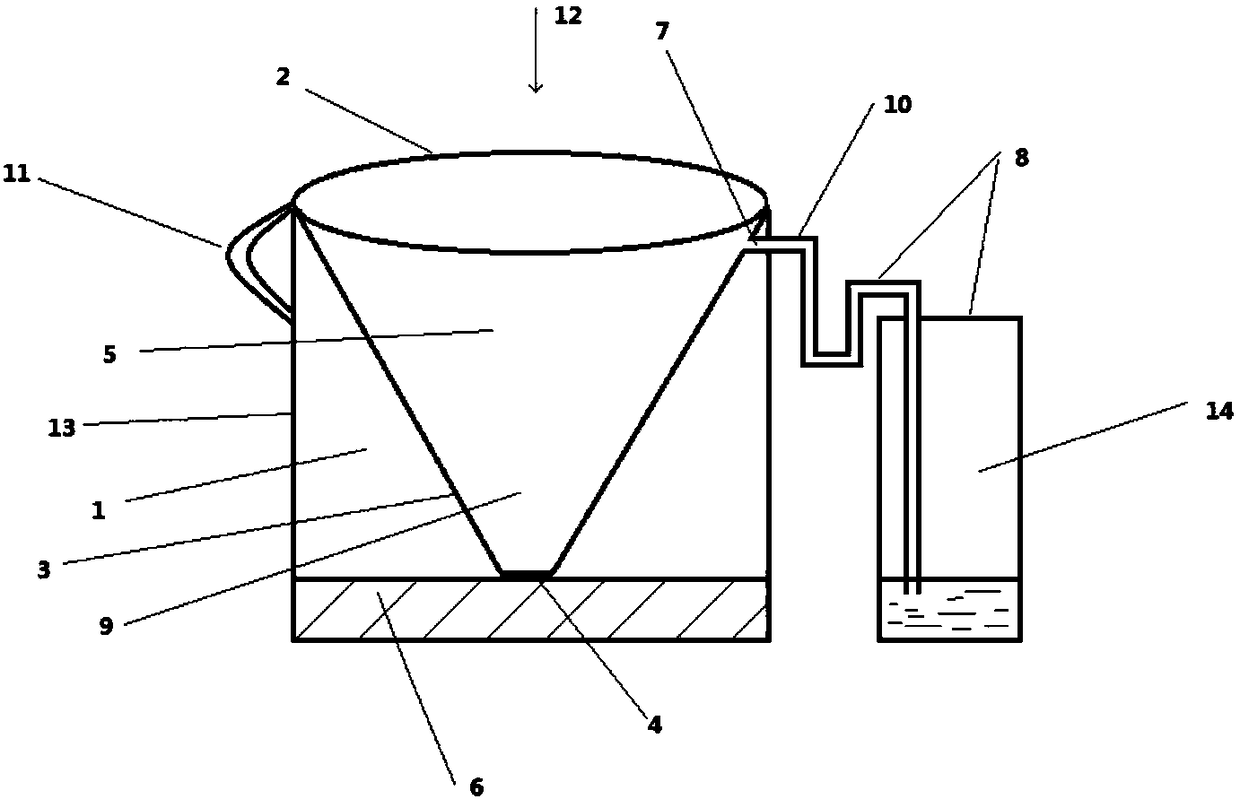

Optical-element washing structure

InactiveCN1936649AImprove cleaning efficiencyMeet mass production needsSpectales/gogglesEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

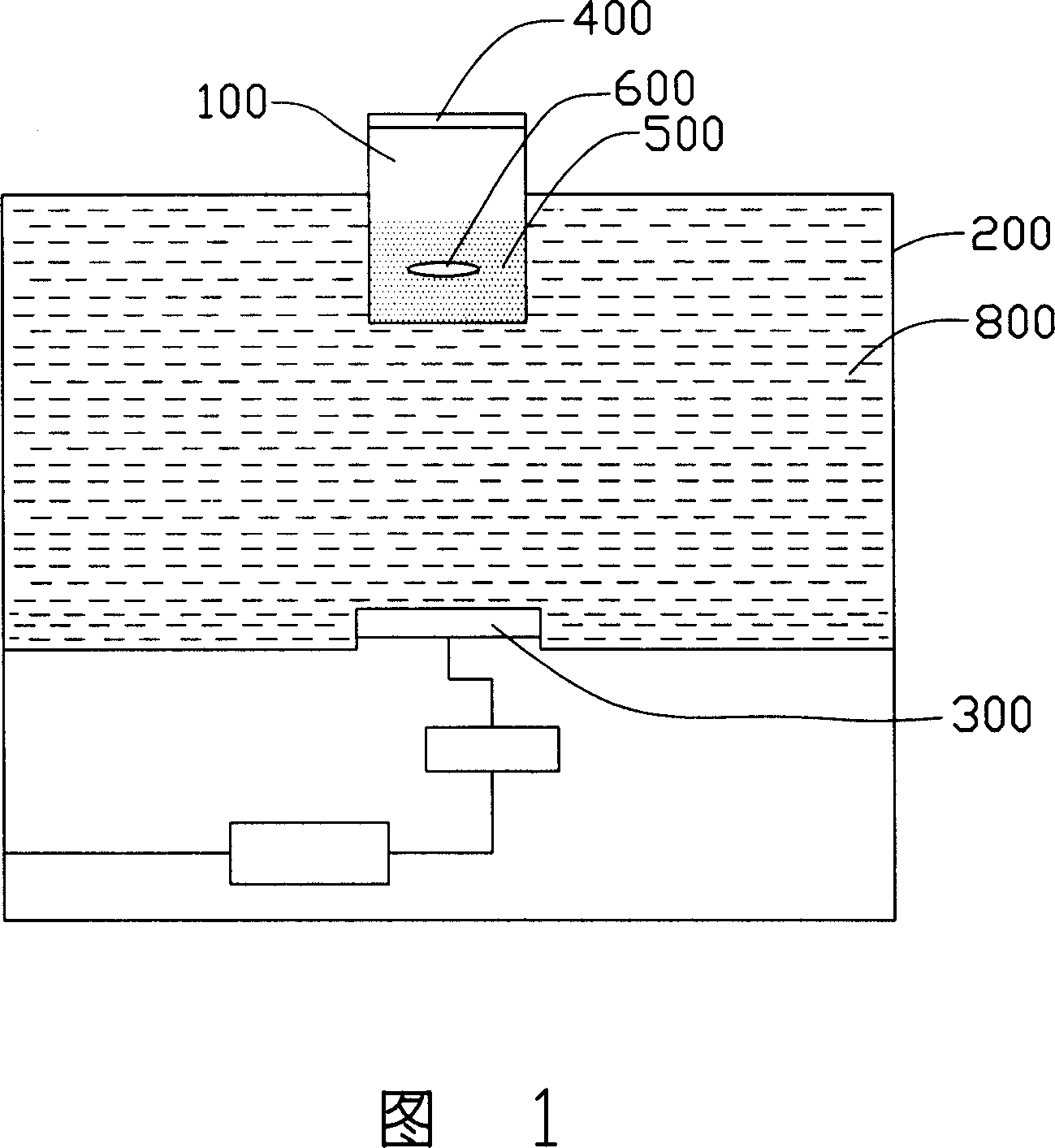

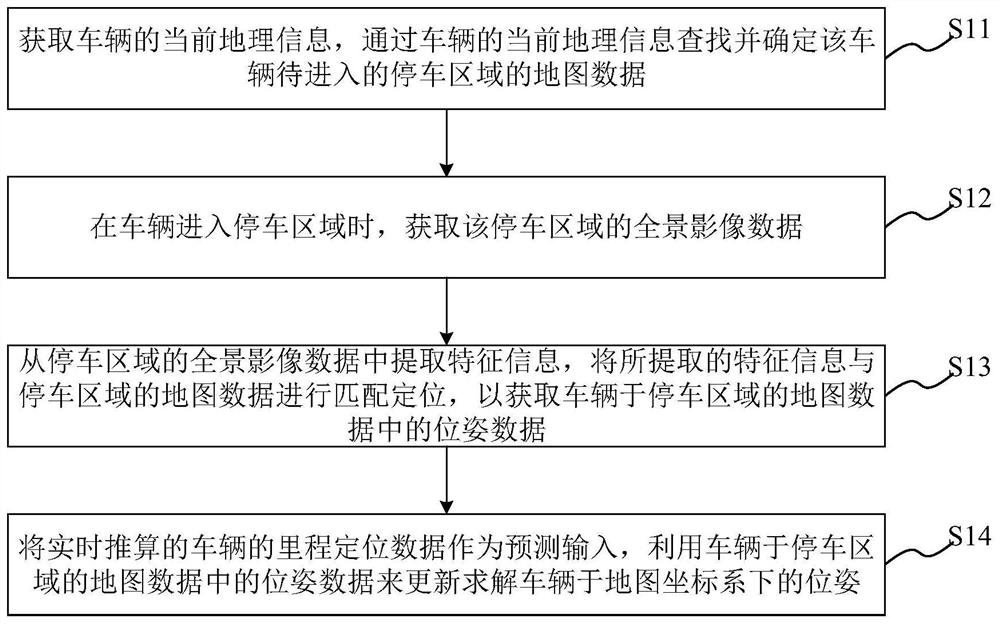

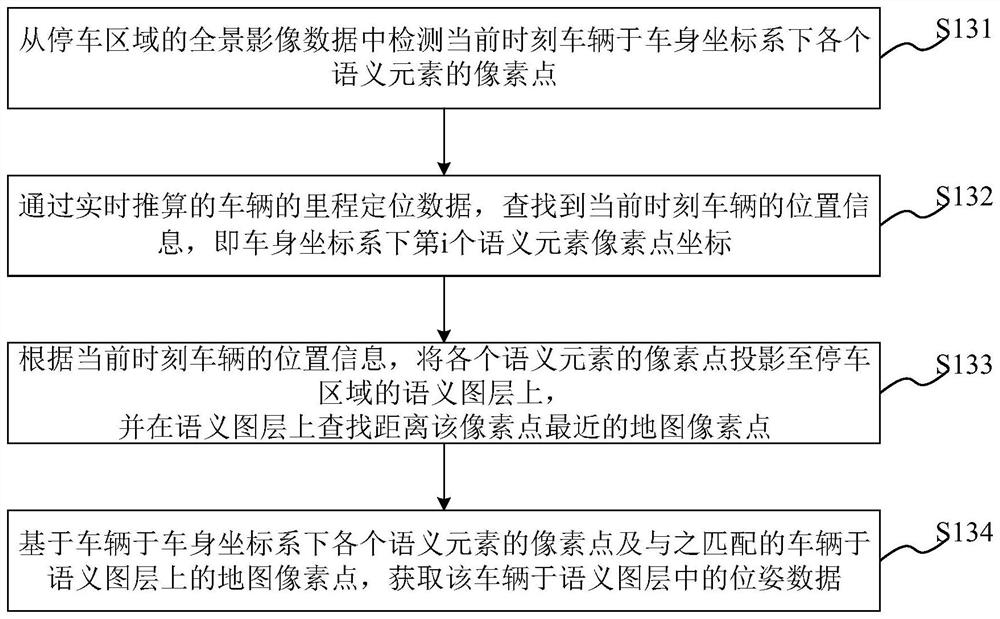

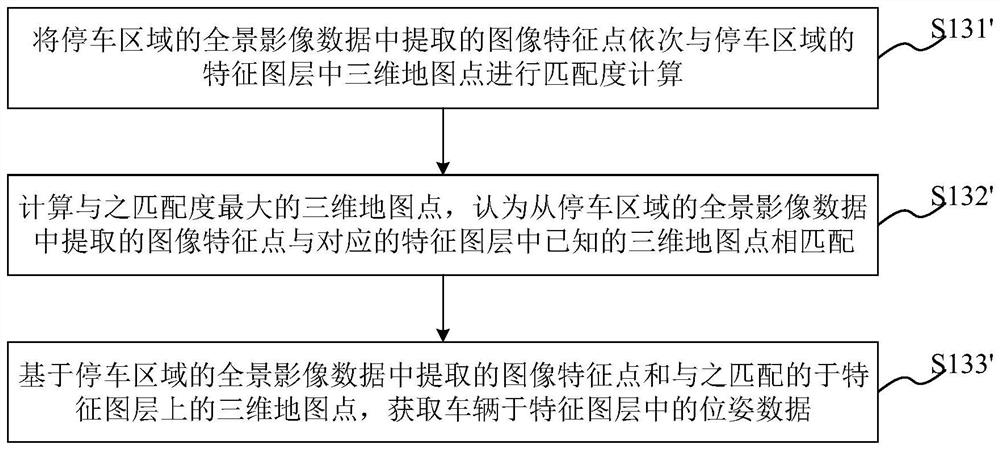

Vehicle positioning method, system and device and computer readable storage medium

PendingCN114111774AExpensive to fixPerformance constraintsInstruments for road network navigationNavigational calculation instrumentsParking areaComputer vision

The invention provides a vehicle positioning method, system and device and a computer readable storage medium, and the method comprises the steps: obtaining the current geographic information of a vehicle, and searching and determining the map data of a parking area where the vehicle is to enter through the current geographic information of the vehicle; when the vehicle enters the parking area, acquiring panoramic image data of the parking area; extracting feature information from the panoramic image data of the parking area, and matching and positioning the extracted feature information with map data of the parking area to obtain pose data of the vehicle in the map data of the parking area; the mileage positioning data, calculated in real time, of the vehicle is used as prediction input, and the pose data of the vehicle in the map data of the parking area are used for updating and solving the pose of the vehicle in the map coordinate system. The method is high in scene adaptability, the positioning precision meets the precision requirement of unmanned valet parking of the passenger car in the parking lot, and the mass production requirement of an autonomous valet parking system of the passenger car is met.

Owner:ZONGMU TECH SHANGHAI CO LTD

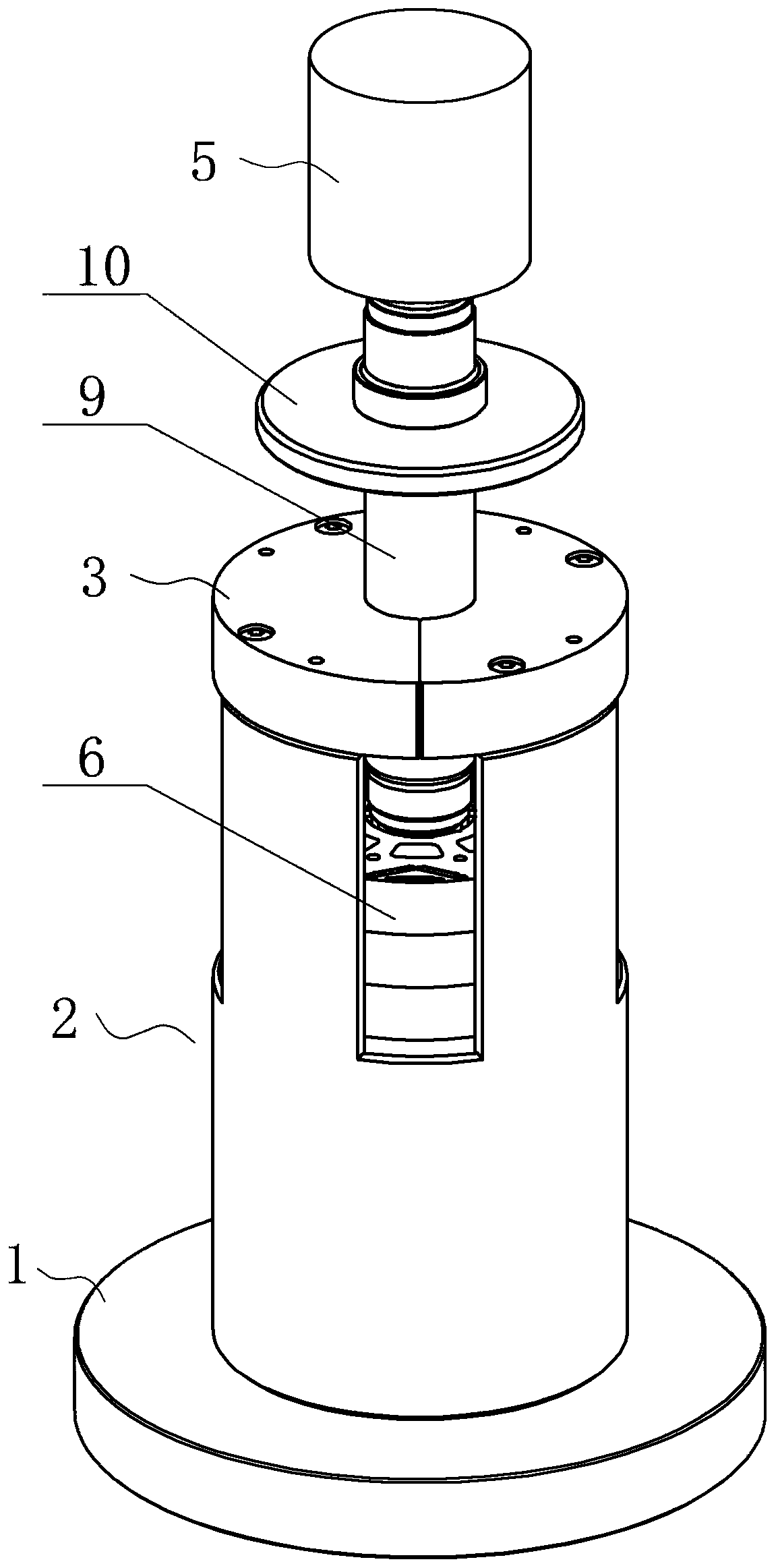

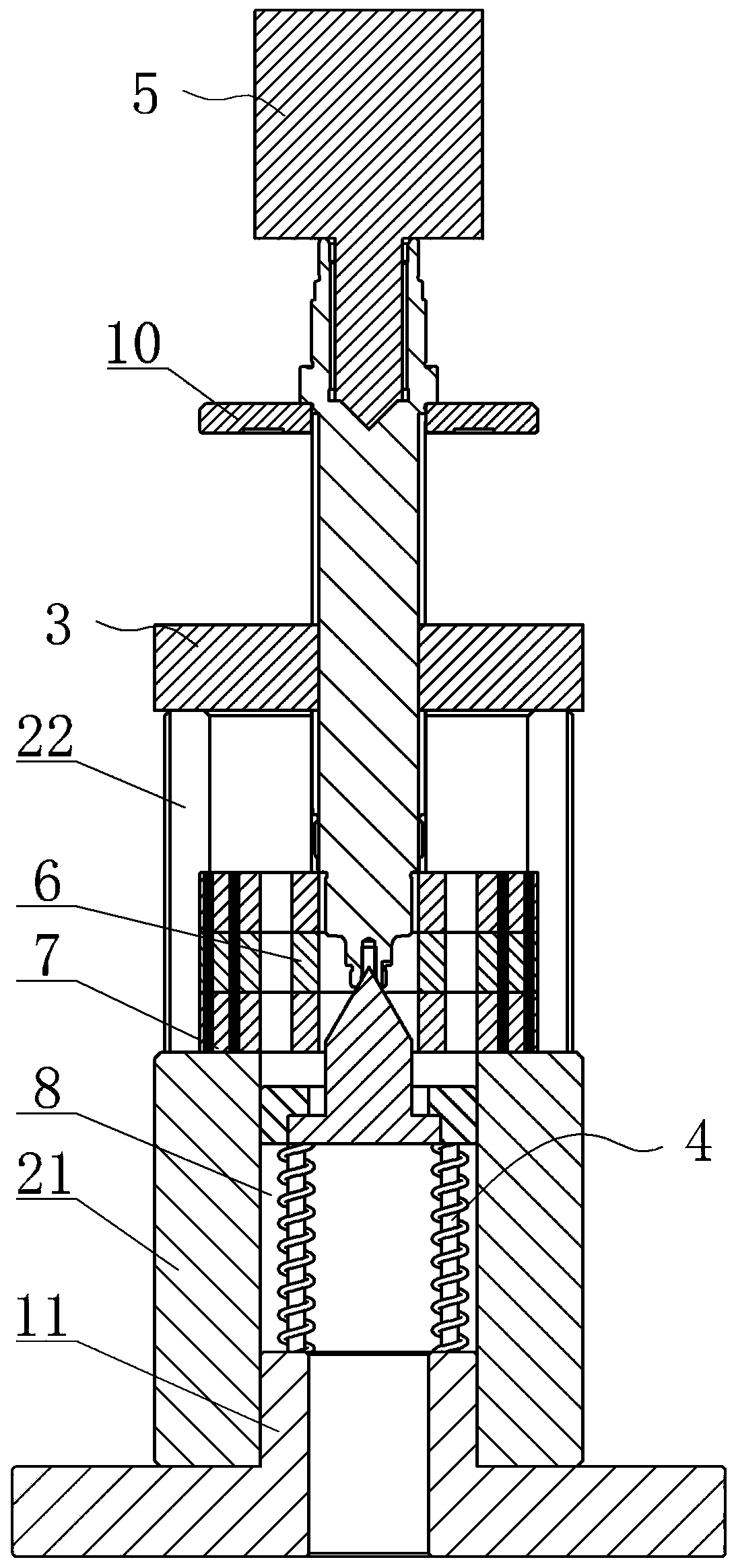

Motor rotor press-fitting tool and corresponding mounting method

PendingCN111313625ALow costSmall footprintManufacturing stator/rotor bodiesElectric machineEngineering

The invention provides a motor rotor press-fitting tool which is low in cost, small in occupied area, rapid in assembly and positioning and high in assembly efficiency and meets the mass production requirement. An upward convex positioning ring sleeve is arranged in the center of the base, and a plurality of inwards-concave receding grooves are annularly distributed in the upper end face of the positioning ring sleeve. A positioning threaded hole is formed in the center of each avoiding groove, a positioning support comprises a lower guide sleeve and an upper positioning sleeve, the diameter of the inner ring cavity of the lower guide sleeve is smaller than that of the guide cavity of the upper positioning sleeve, the inner ring part of the upper end surface of the lower guide sleeve is provided with a concave positioning pin hole corresponding to the rivet hole of the rotor core, the motor rotor press-fitting tool further comprises a matched positioning pin, the positioning pin is inserted into the inwards-concave positioning pin hole and then protrudes upwards, the upwards-protruding positioning pin is used for circumferential positioning of the rotor iron core, the positioning ring sleeve is sleeved with the lower guide sleeve, a guide cavity is formed between an inner ring cavity of the lower guide sleeve and the upper end face of the positioning ring sleeve, and a guide ejector pin assembly is arranged in the guide cavity.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

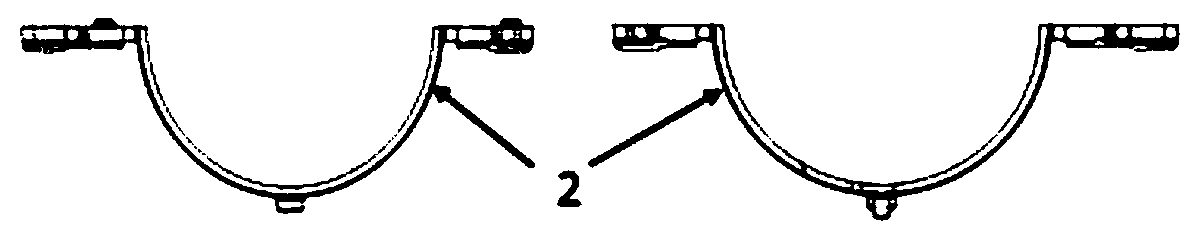

Arc-shaped core-pulling structure for mold

The invention relates to an arc-shaped core-pulling structure for a mold. The arc-shaped core-pulling structure comprises a large sliding block, a self-rotation cylinder and a rotary insert, wherein the self-rotation cylinder is arranged on the large sliding block and is connected with the large sliding block by a rotary shaft; the large sliding block is provided with an arc-shaped containing chamber; the rotary insert is arranged in the arc-shaped containing chamber and is connected with the large sliding block by a pivot; the self-rotation cylinder is provided with a telescopic shaft which is connected with the rotary insert by a pivot. The arc-shaped core-pulling structure has the beneficial effects that the transferring step of force between the components can be greatly reduced, and the self-rotation cylinder directly acts on the rotary core-pulling insert, so that the loss of the force can be reduced; the self-rotation cylinder can rotate by self and is omni-directional without the clamping phenomenon, so that the stability of the mechanism can be improved and further high-speed, high-quality and stable operation of the mold can be achieved; in addition, unstable structure factors in the production process of the mold can be controlled, the mold can be ensured to meet the mass-production requirement, and the quality of the mold and the stable movement of all the mechanisms can be improved.

Owner:JUNYI PRECISION MOLD SUZHOU CO LTD

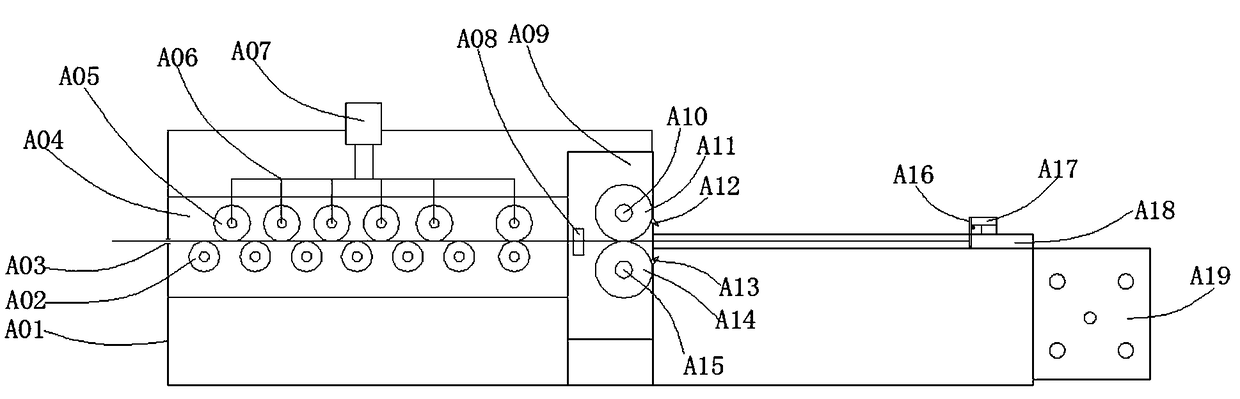

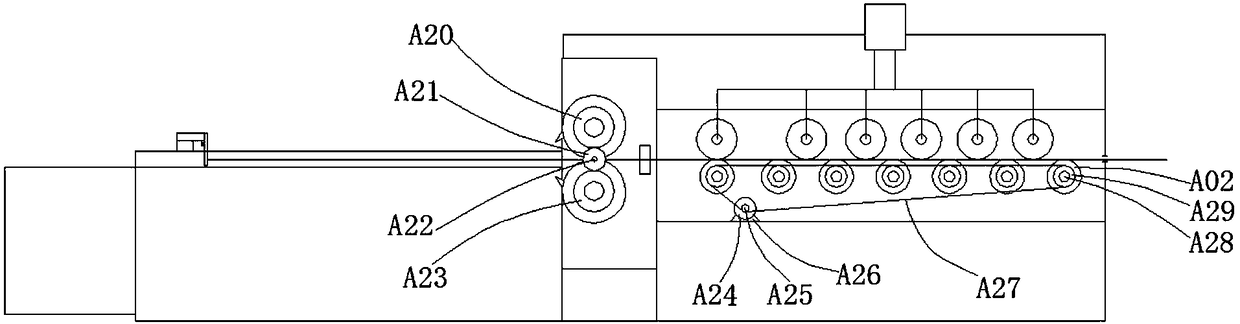

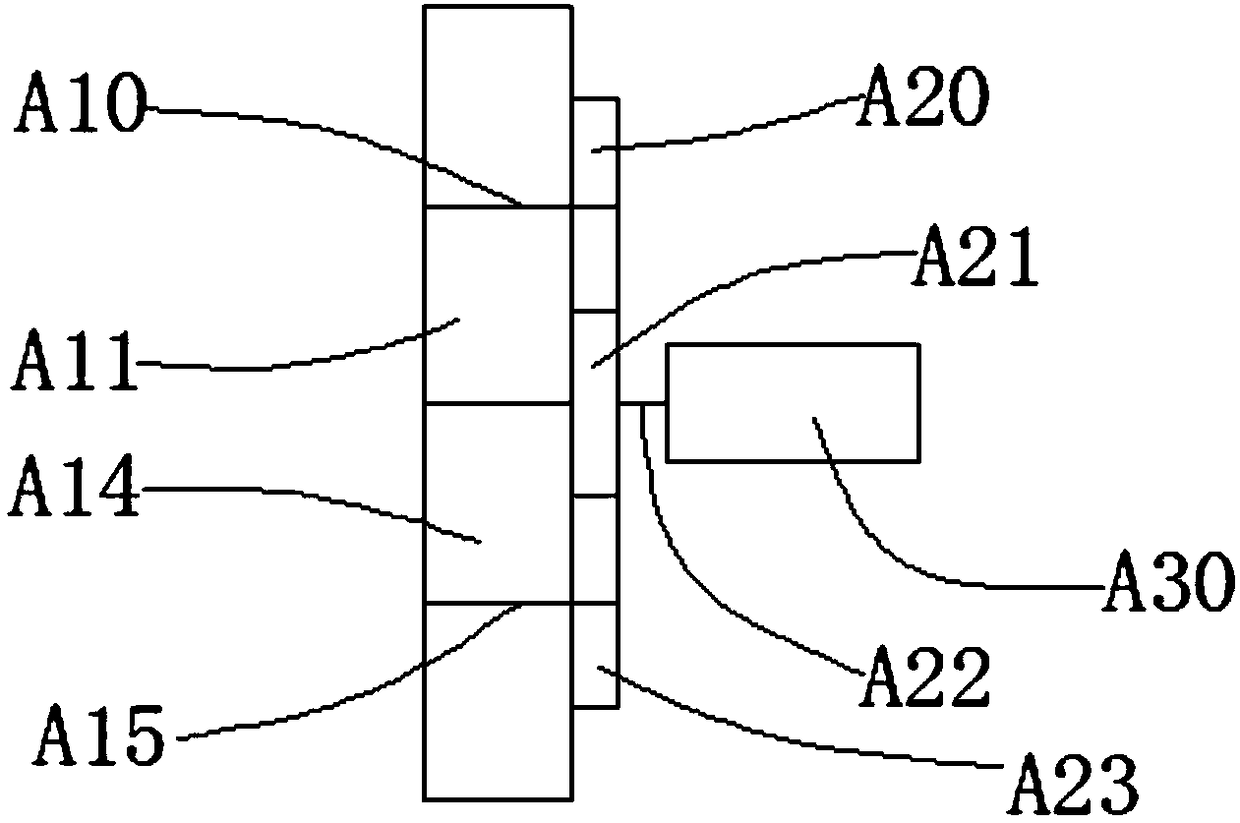

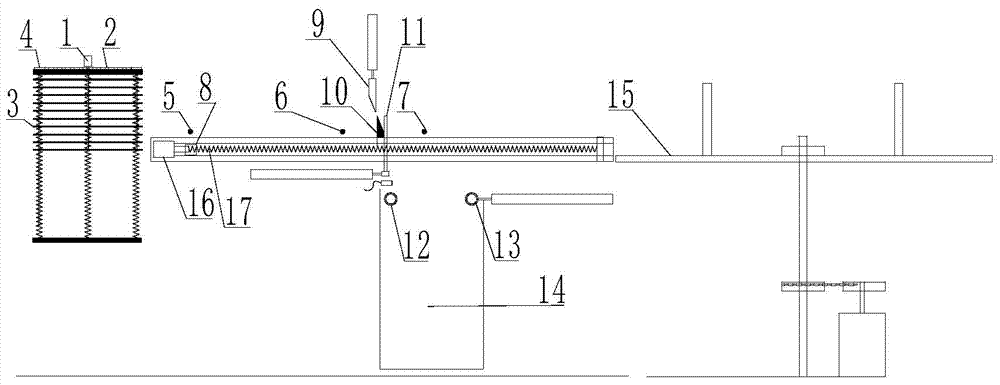

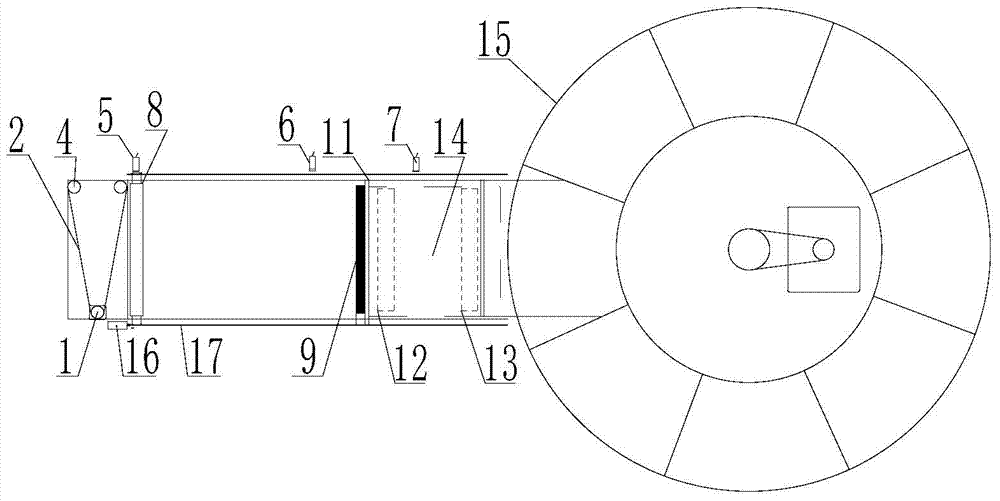

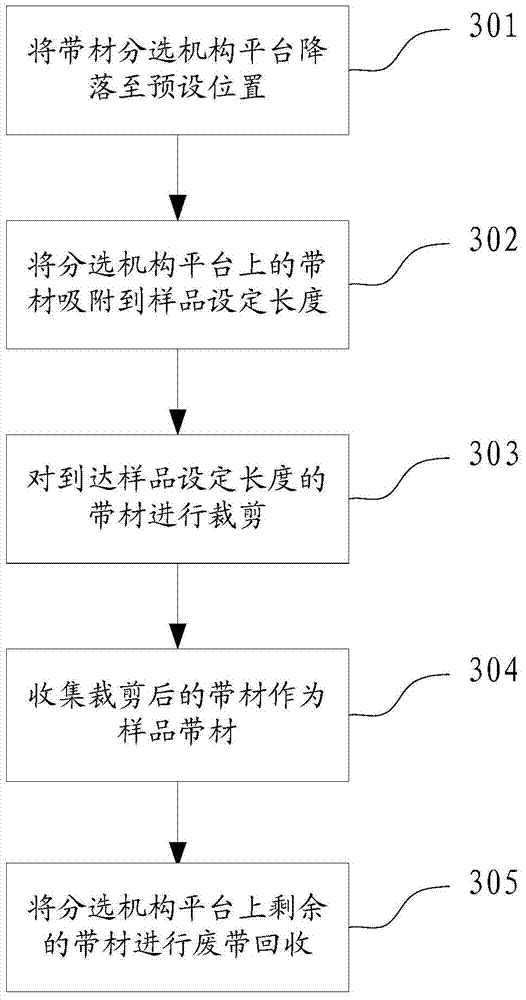

Physical model test and sample preparation method and device for amorphous strips

ActiveCN103616271ARealize continuous productionMeet mass production needsPreparing sample for investigationPhysical modelEngineering

The invention relates to a physical model test and sample preparation method for amorphous strips and a device thereof. The method comprises the steps of dropping a strip sorting mechanism platform to a preset position; adsorbing a strip on the sorting mechanism platform dropped to the preset position until a sample set length is reached; cutting the strip with the sample set length through a roll-in knife; collecting cut strips serving as sample strips after the number of the strips to be cut reaches a sample set number; recycling waste strips retained on the sorting mechanism platform. The device disclosed by the invention can fully automatically prepare a sample and realize continuous production of the sample strips, so that the accuracy and the efficiency of detecting a physical model of the amorphous strip are improved, and a requirement on the quantity production of the amorphous strip can be met.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

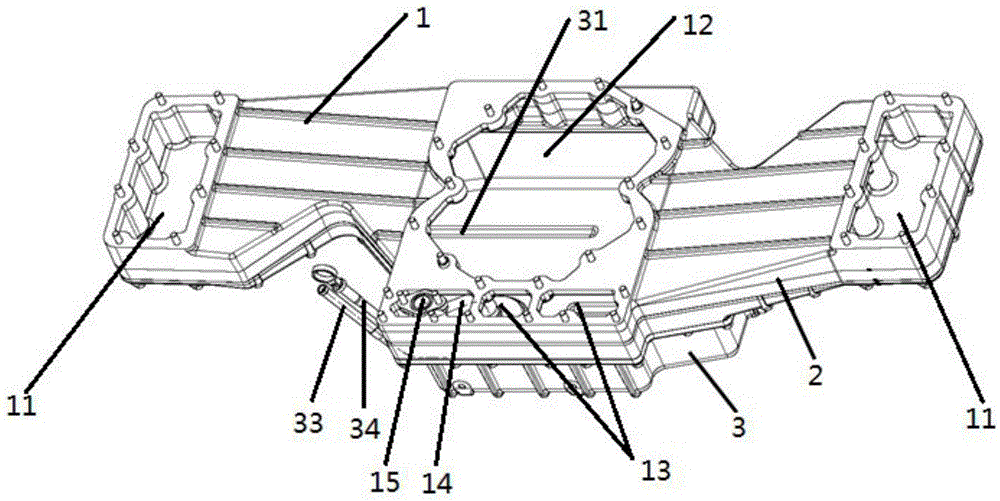

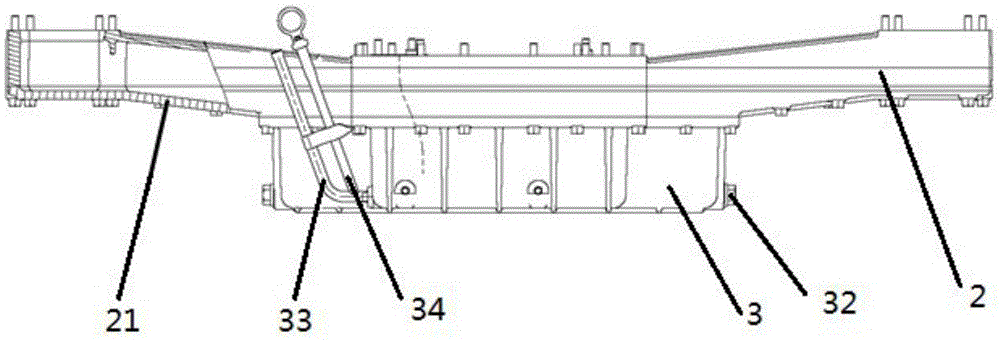

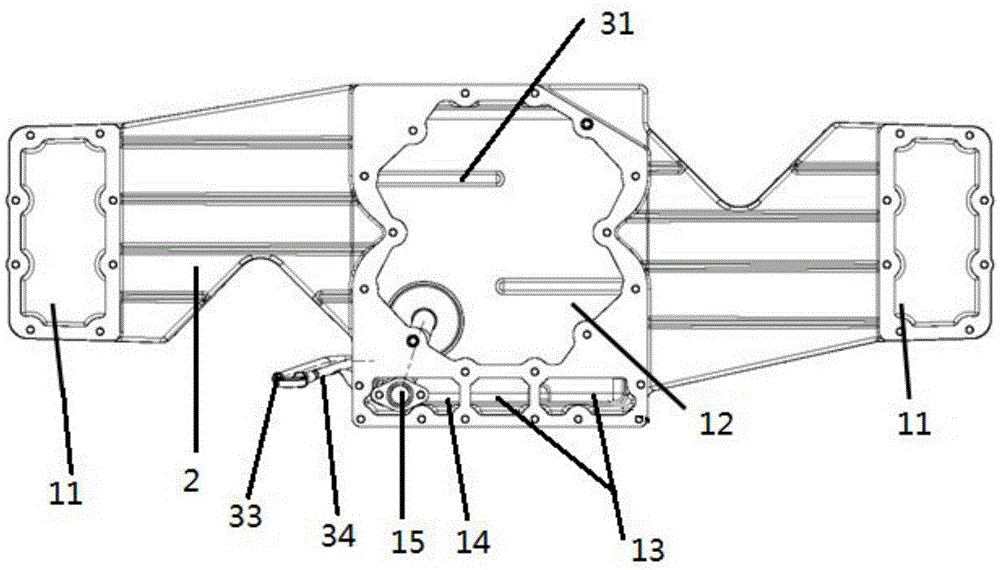

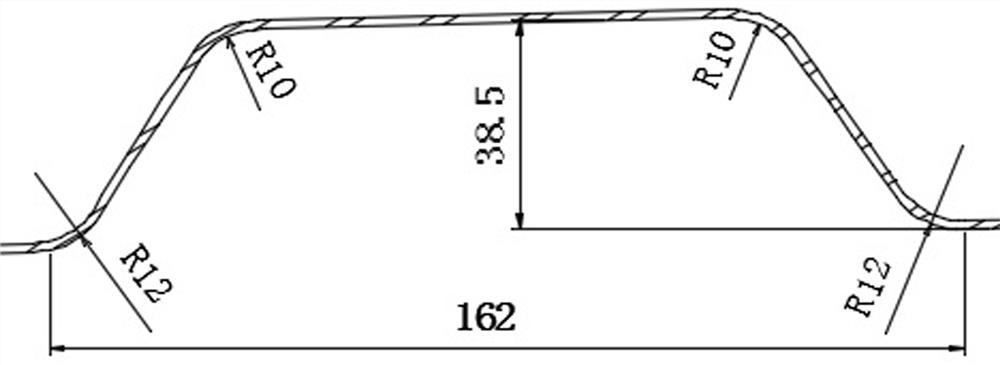

Oil pan assembly for two-stroke horizontally-opposed-piston and opposed-cylinder engine

ActiveCN105545405ABalance breathing exhaust working pressureBalance work pressureOilsumpsMachines/enginesWorking pressurePiston

The invention discloses an oil pan assembly for a two-stroke horizontally-opposed-piston and opposed-cylinder engine. The oil pan assembly comprises an upper oil pan body, a middle oil pan body and a lower oil pan body. The upper oil pan body is of a strip-shaped platelike structure. The two ends of the upper oil pan body are flush with each other, and the middle of the upper oil pan body is sunk. The upper oil pan body is provided with an oil return opening set and an oil pump oil inlet. The middle oil pan body is arranged below the upper oil pan body and matched with the upper oil pan body in structure. The middle portion of the middle oil pan body is hollowed out. Oil ways are arranged in the middle oil pan body. The lower oil pan body is arranged on the lower portion of the middle oil pan body. An oil discharging opening is formed in the lower oil pan body. According to the oil pan assembly, a cavity structure is formed jointly through the upper oil pan body, the middle oil pan body and the lower oil pan body, the waste gas sucking and exhausting working pressure of engine pistons on the two sides can be balanced effectively, and meanwhile the requirement for batch production is met.

Owner:ANHUI ZHONGDING SEALING PARTS

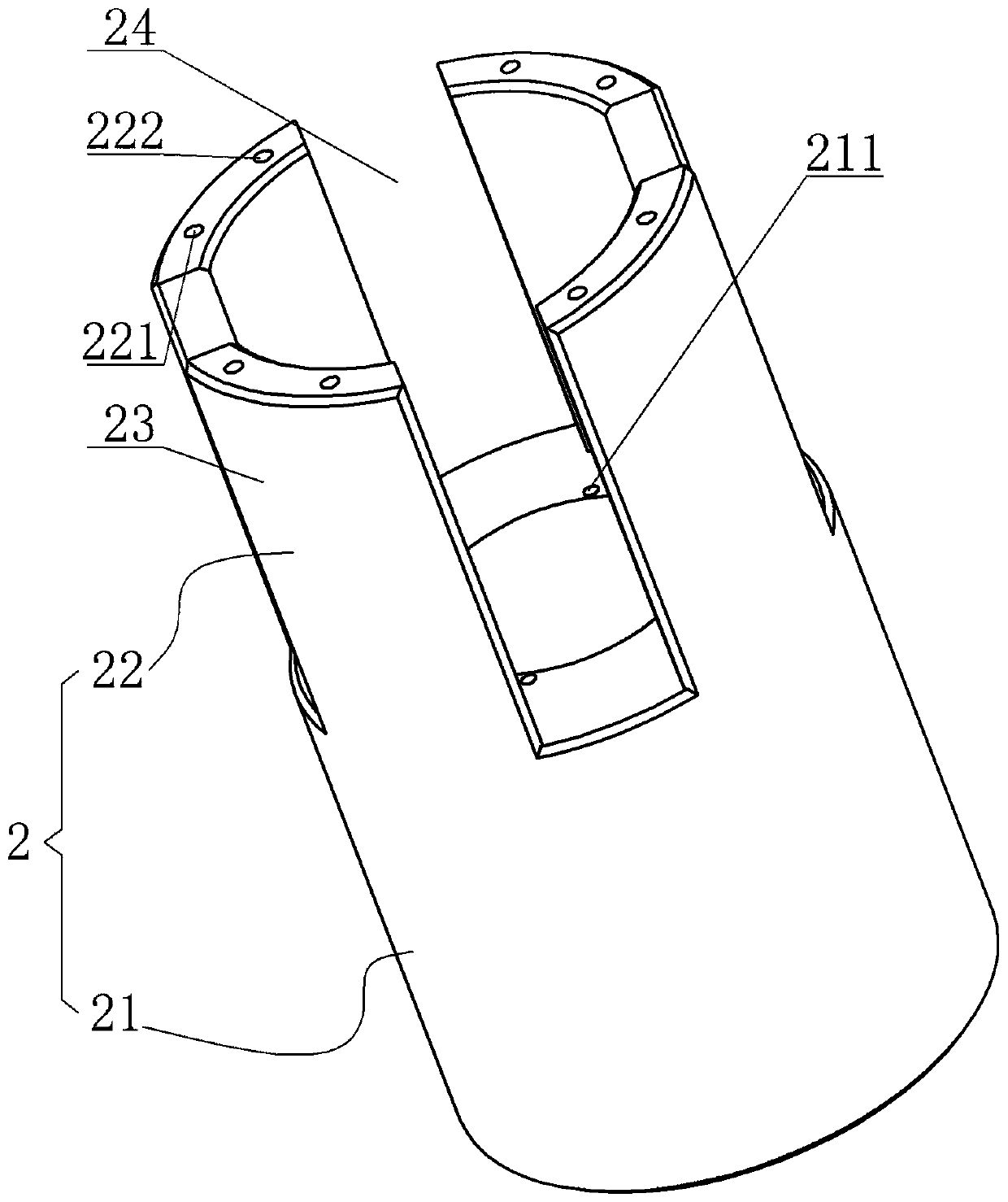

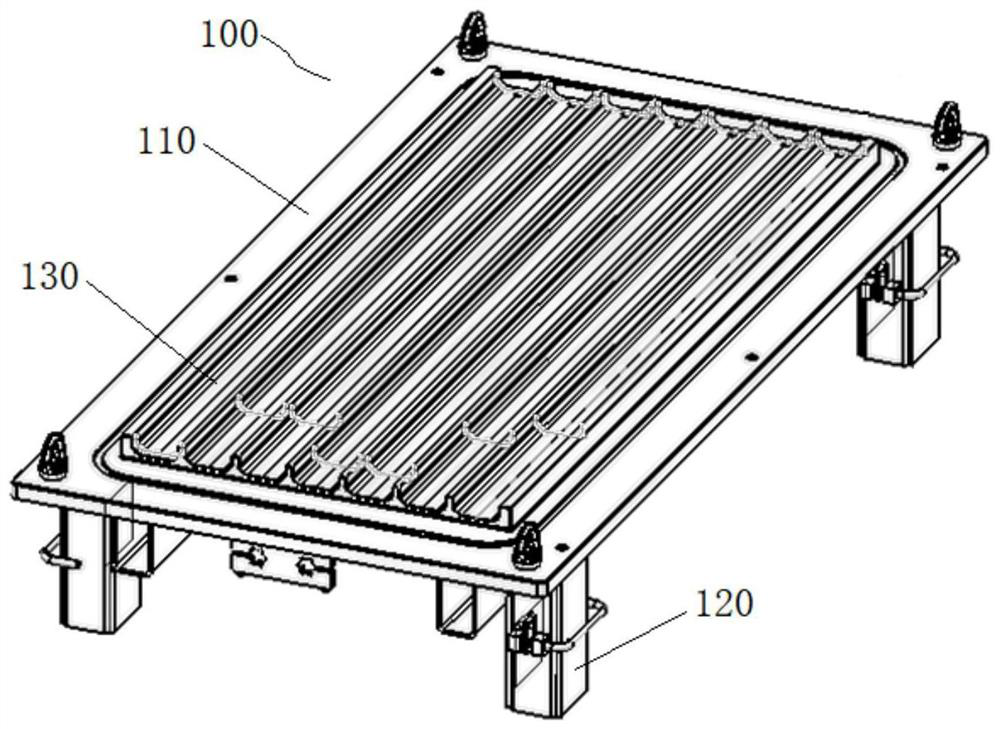

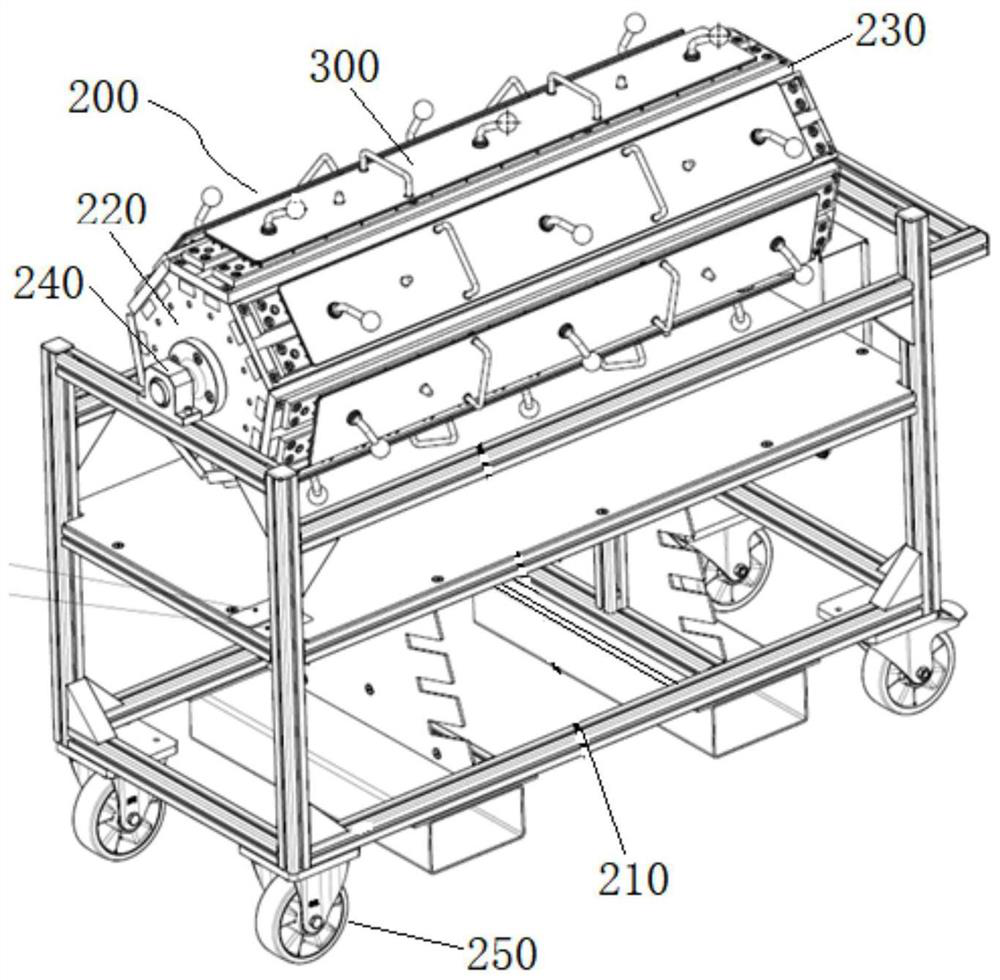

Composite material cap-shaped part preparation device with stop blocks and operation method of composite material cap-shaped part preparation device

ActiveCN113246500AMeet mass production needsReduce space consumptionDomestic articlesStructural engineeringAnnular array

The invention discloses a composite material cap-shaped part preparation device with stop blocks and an operation method of the composite material cap-shaped part preparation device and relates to the technical field of composite material manufacturing processes. The composite material cap-shaped part preparation device comprises a laying tool, a gluing tool and a press-fit tool, and the laying tool is used for forming a plurality of U-shaped skins at a time. The gluing tool comprises a frame, a rotatable multi-face cylindrical rotating cylinder is arranged at the top of the frame, a plurality of long-strip-shaped positioning grooves are formed in the multi-face cylindrical rotating cylinder and distributed around the axis of the multi-face cylindrical rotating cylinder in an annular array mode, and positioning mechanisms are arranged in the positioning grooves and used for positioning and installing the stop blocks. The press-fit tool comprises a press-fit plate, a plurality of bolt pressing mechanisms are arranged on the press-fit plate, the press-fit plate can press the U-shaped skins on the stop blocks through the bolt pressing mechanisms, during operation, composite material cap-shaped parts can be formed on a roller in batches, and the composite cap-shaped part preparation device has the advantages that the curing frequency is greatly reduced, the production efficiency is improved, and the production cost is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Nori-wrapped energy bar

The invention relates to a nori-wrapped energy bar and a preparation method thereof. The energy bar comprises a puffing bar body and a nori slice tightly wrapping the puffing bar body, the turn numberof the nori slice winding the pulling bar body is (1+1 / 8)-(1+1 / 3), and the portion between the nori slice and the puffing bar body and the lamination portions of the nori slice are bonded through bonding carriers respectively. The method comprises the steps that the nori slice and the puffing bar body are prepared separately; within two seconds after the nori slice is completely roasted, the norislice winds the processed puffing bar body, and after shape setting is conducted, cooling formation is conducted at 10-15 DEG C. According to the nori-wrapped energy bar, the nori slice and the puffing bar body are effectively and firmly combined to form a new product, the nutrient value of the energy bar and nori can be well combined, the product flavor is enriched, the taste is crispy, particularly by adopting the bonding carriers formed by compounding syrup and bonding powder, the bonding strength and stability are improved, in addition, the crispy degree of the nori slice and the puffingbar body can also be well improved, the modern consumption demand is met, and the large-batch production demand is also met.

Owner:苏迪(福建)生物科技有限公司

Manufacturing method for spiral cooling water jacket sand mold

InactiveCN110918881AImprove compactnessHigh strengthFoundry mouldsMoulding machinesWater jacketUltimate tensile strength

The invention belongs to the technical field of casting, and particularly relates to a manufacturing method for a spiral cooling water jacket sand mold. The method comprises the following steps that step 1, a cylindrical sand core is divided into two 180-degree semicircular sand cores for sand shooting molding respectively; step 2, reinforcing ribs are added at the two ends of each core head, so that each whole core head part is changed to be of a square frame structure, and the core head parts are bonded and fixed by using a simple special clamping fixture; and step 3, and the reinforcing ribs are sawed off to obtain the needed spiral water jacket sand core. The novel sand core manufacturing method is provided in the invention, the molding rate, and the density and the strength of the sand core can be well improved. Meanwhile, the mold structure can be greatly optimized, the mold structure is simple and is matched with equipment more easily, and the working efficiency is higher. The large-scale production requirement is met, and the problems that an existing mold is complex in structure and the sand core molding efficiency is low are solved.

Owner:CHINA FIRST AUTOMOBILE +1

Sheet metal forming method of multi-deep-cavity thin-wall part of aircraft

ActiveCN111922171ADoes not affect molding qualityAvoid wrinkling and crackingMetal formingMachine parts

The invention discloses a sheet metal forming method of a multi-deep-cavity thin-wall part of an aircraft. The method is characterized by comprising steps as follows: 1) according to a part forming technical scheme, a three-dimensional digital model of the part is obtained, so that the type of deep cavities of the part and the size of a standard deep cavity are determined; 2) according to the sizeof the deep cavities of the part, a spherical surface drawing die, a deep drawing die and a shaping deep drawing die are manufactured respectively; 3) a to-be-machined part is drawn into a semi-spherical shape by the spherical surface drawing die, and a part with a spherical surface deep cavity is obtained; 4) the semi-spherical deep cavity is subjected to deep drawing by the deep drawing die continuously and enabled to reach depth of the standard deep cavity, and a part with a transition size deep cavity is obtained; and 5) the part with the transition size deep cavity is drawn by the shaping drawing die, a part with the standard deep cavity is formed finally, meanwhile, pressure maintaining is carried out, and degree of film sticking is ensured. According to the method, machining efficiency, qualification rate and forming quality can be increased, and high-quality, high-efficiency and low-cost deep cavity manufacture of the part is realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

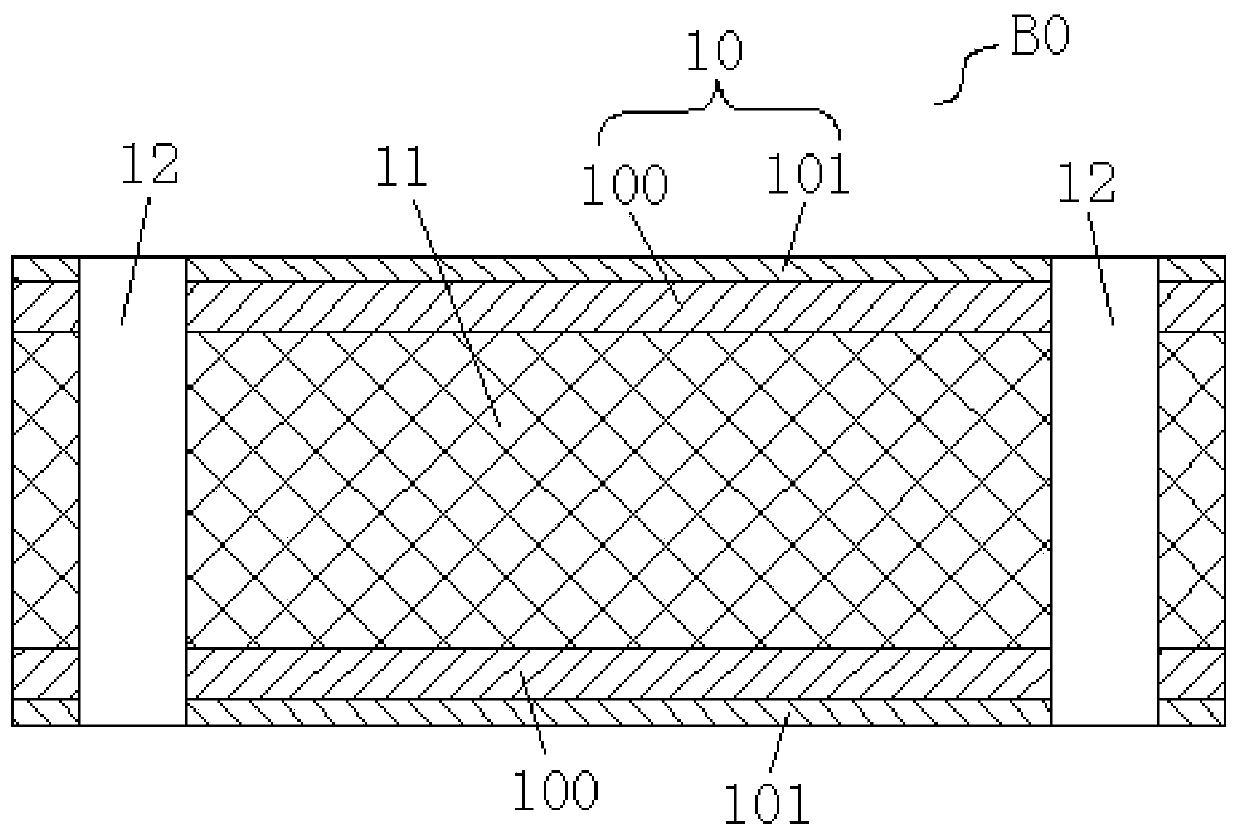

Manufacturing method of packaging substrate based on radio frequency filter

ActiveCN111465221AEasy to manufactureFunctionalInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilRadio frequency

The invention discloses a manufacturing method of a packaging substrate based on a radio frequency filter. The manufacturing method comprises the following steps of preparing a double-sided copper-clad substrate, and an ultrathin carrier copper foil on the double-sided copper-clad substrate being provided with a carrier copper foil and an ultrathin copper foil detachably arranged on the carrier copper foil; laminating a first prepreg and the first copper foil to obtain a first substrate; performing primary targeting and edge milling operation, and then manufacturing a first layer of circuit pattern to obtain a second substrate; laminating a second prepreg and the second copper foil to obtain a third substrate; performing secondary targeting and edge milling operation to obtain a fourth substrate; performing three times of edge milling operation after copper reduction to obtain a fifth substrate; dividing the fifth substrate to obtain a processing plate containing three layers of copperfoils; and carrying out conventional subsequent processing of the processing board to complete manufacturing of the packaging substrate based on the radio frequency filter. The manufacturing method is advantaged in that the manufacturing method is reasonable and easy to operate, and the radio frequency filter packaging substrate manufactured through the manufacturing method is strong in function,good in quality, good in design flexibility, low in manufacturing cost and the like, and can well replace a ceramic substrate.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

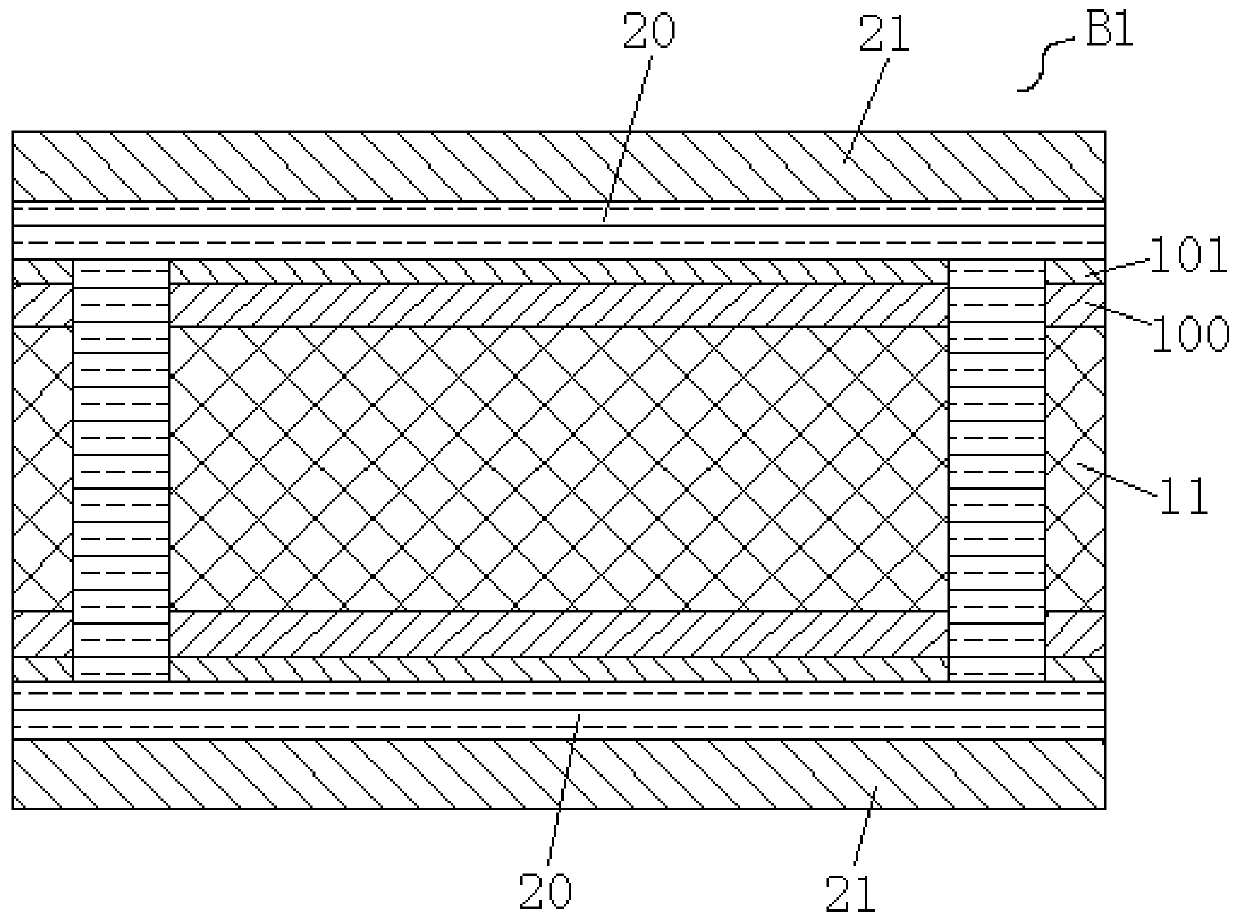

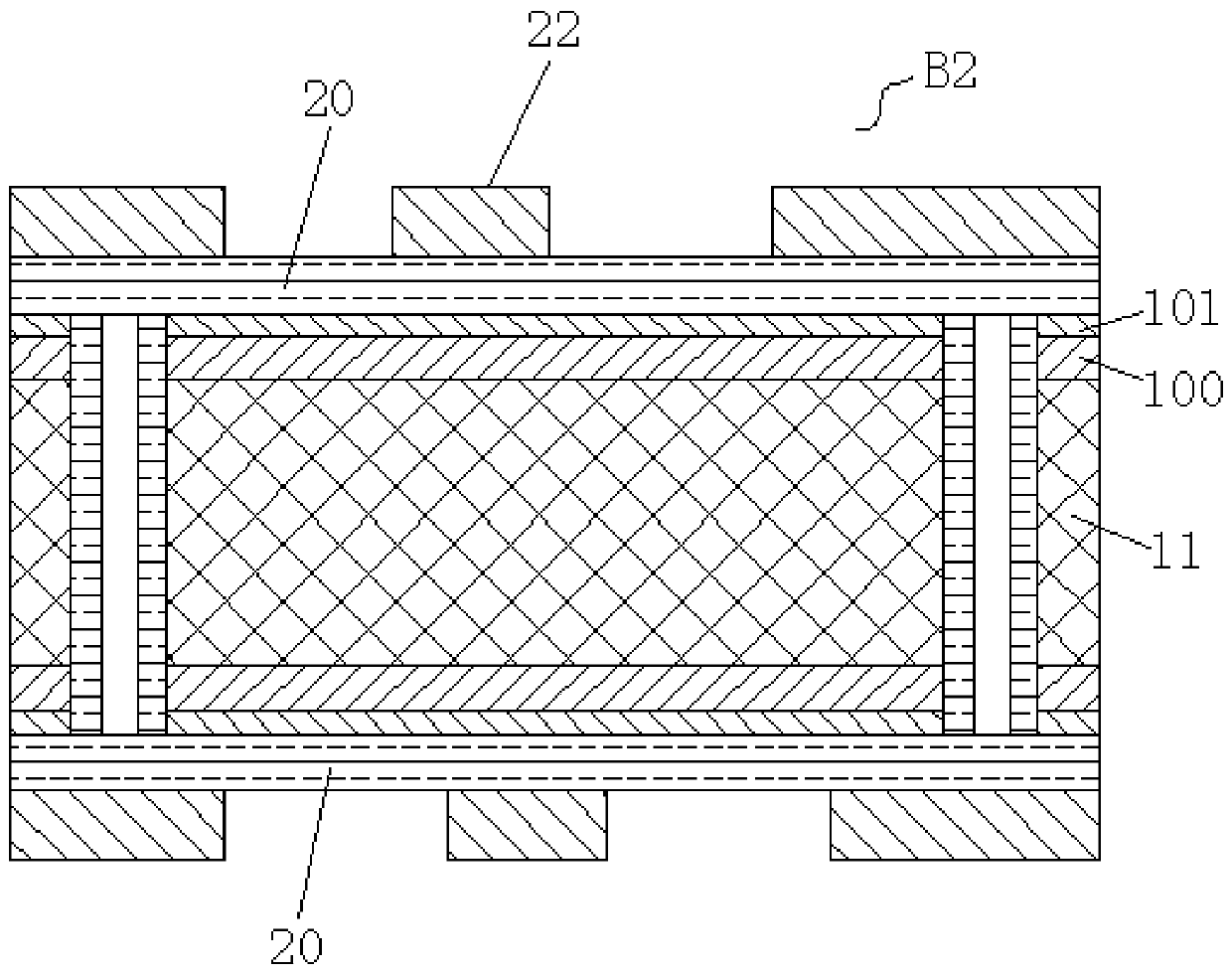

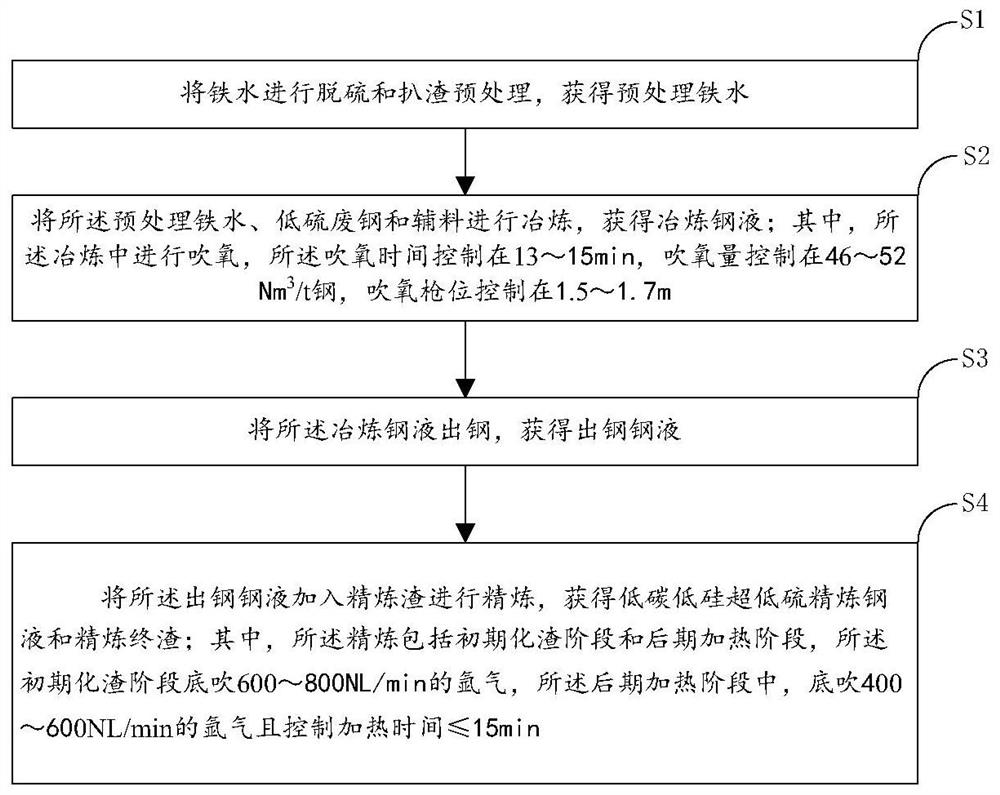

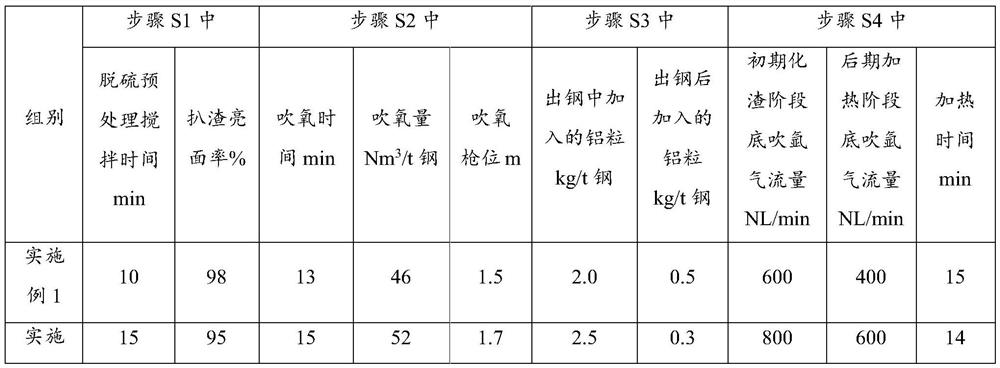

Method for producing low-carbon low-silicon ultralow-sulfur steel by adopting LF single-link process

ActiveCN113025781ASmelting to achieveMeet the needs of industrializationProcess efficiency improvementSteelmakingSmelting process

The invention discloses a method for producing low-carbon low-silicon ultralow-sulfur steel by adopting an LF single-link process. The method comprises the following steps of carrying out desulfurization and slagging-off pretreatment on molten iron to obtain pretreated molten iron; smelting the pretreated molten iron, low-sulfur waste steel and auxiliary materials, and obtaining smelted molten steel, wherein in the smelting process, the oxygen blowing time is controlled to be 13-15 min, the oxygen blowing amount is controlled to be 46-52 Nm<3> / ton of steel, and the oxygen blowing lance position is controlled to be 1.5-1.7 m; tapping the smelted molten steel, and obtaining tapped molten steel; adding refining slag into the tapped molten steel for refining, and obtaining low-carbon low-silicon ultralow-sulfur refined molten steel and refining final slag, wherein bottom blowing with 600-800 NL / min of argon is carried out in the initial slagging stage of refining, and bottom blowing with 400-600 NL / min of argon is carried out in the later heating stage of refining, and the heating time is controlled to be shorter than or equal to 15 min; and enabling the content of carbon in the steel to be 0.030%-0.050%, the content of silicon to be less than or equal to 0.050% and the content of sulfur to be less than or equal to 0.0020%.

Owner:SHOUGANG CORPORATION

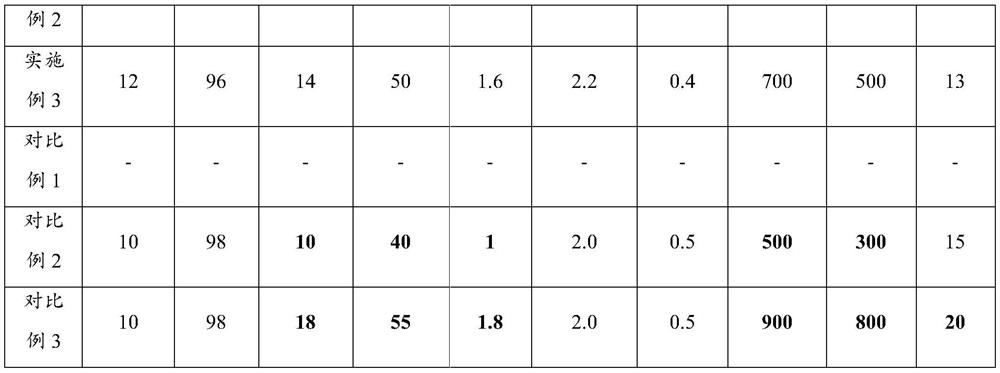

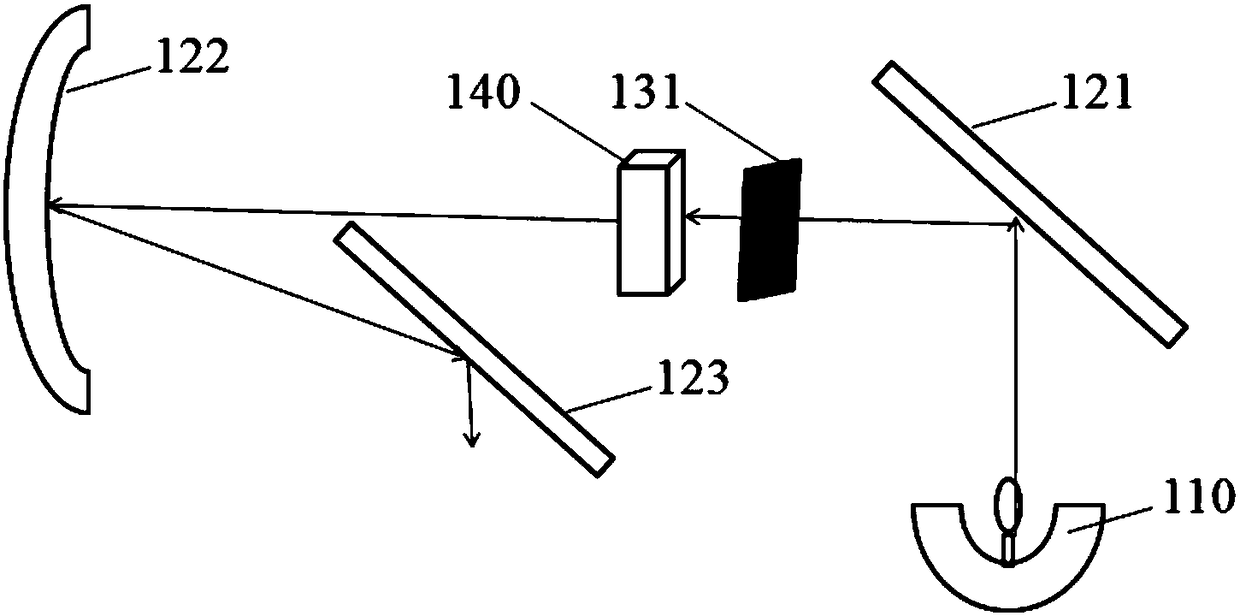

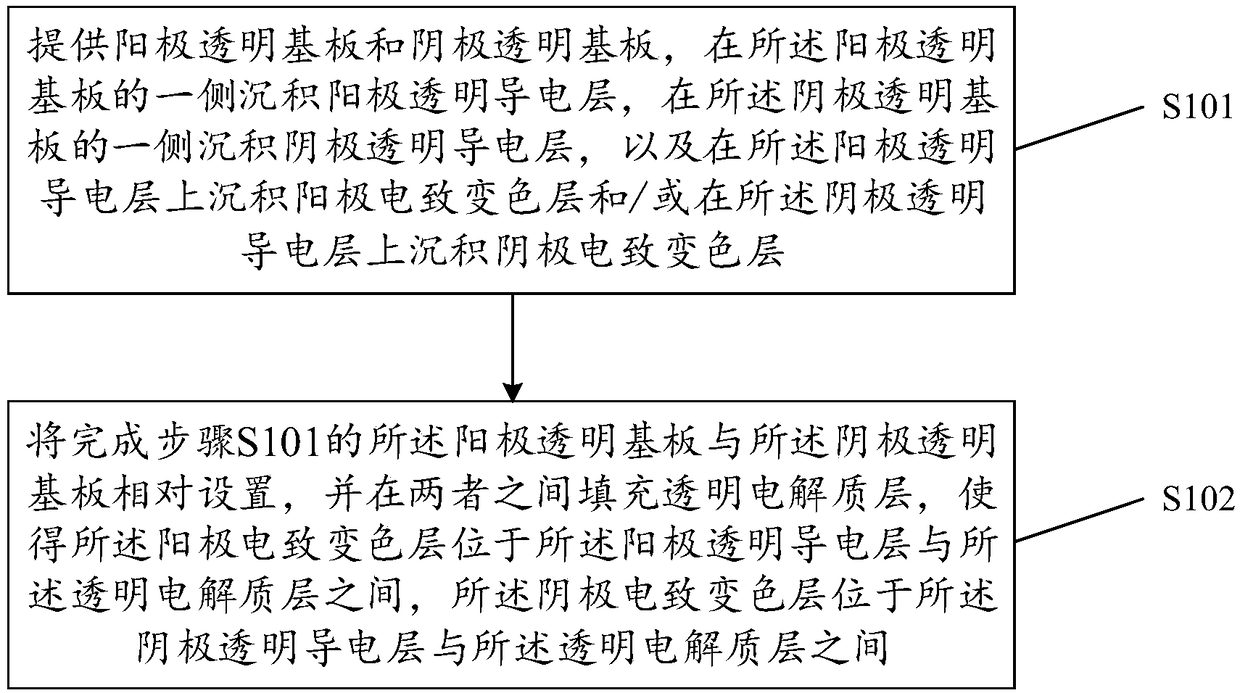

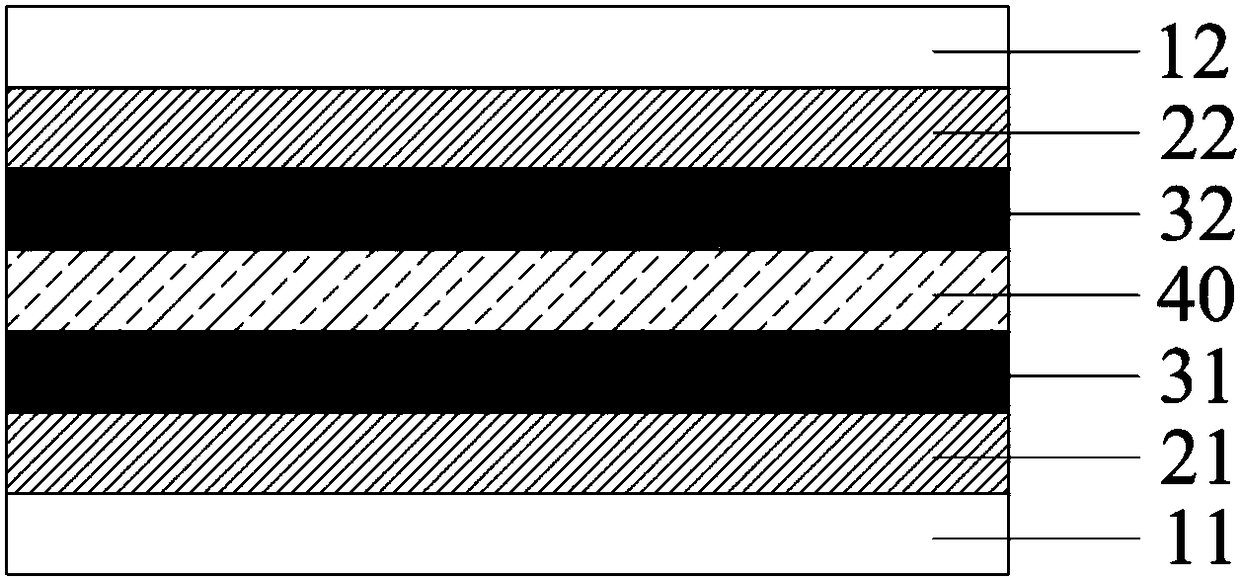

Light shielding plate and preparation method and application thereof

ActiveCN108535968AControl transmittanceConsistent transmittancePhotomechanical exposure apparatusMicrolithography exposure apparatusUltraviolet lightsTransmittance

The present invention provides a light shielding plate, the light shielding plate comprises an anode transparent substrate and a cathode transparent substrate which are oppositely disposed, the lightshielding plate also comprises a transparent electrolyte layer and an electrochromic layer between the anode transparent substrate and the cathode transparent substrate, the electrochromic layer comprises an anode electrochromic layer and a cathode electrochromic layer, the anode electrochromic layer is located between the anode transparent substrate and the transparent electrolyte layer, and thecathode electrochromic layer is located between the cathode transparent substrate and the transparent electrolyte layer. The light shielding plate is provided with the anode electrochromic layer and / or the cathode electrochromic layer. The ultraviolet light transmittance can be controlled by control of the color of the light shielding plate by an electric field, the uniform ultraviolet light transmittance in a same exposure range can be ensured, precise exposure can be achieved, and product quality and exposure process stability can be improved. At the same time, compared with a traditional mechanical light shielding plate, the opening and closing time is avoided, and the response time is short. The invention also provides a preparation method and application of the light shielding plate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Large titanium alloy blade upsetting blank manufacture mold with heads on two ends, and blank manufacture method thereof

ActiveCN111673027AAchieve precise positioningComplete fillingForging/hammering/pressing machinesEngine componentsMolding machineTitanium alloy

The invention discloses a large titanium alloy blade upsetting blank manufacture mold with heads on two ends. The mold comprises a large head gathering and shaping mechanism and a small head gatheringand shaping mechanism, wherein the large head gathering and shaping mechanism comprises a large head backward blocking base as well as a first large head gathering module, a second large head gathering module, a third large head gathering module and a large head shaping module which are successively disposed on the large head backward blocking base from top to bottom; and the small head gatheringand sharing mechanism comprises a small head backward blocking base as well as a first small head gather module, a second small head gathering module and a small head shaping module which are successively disposed on the small head backward blocking base from top to bottom. Through design of a specific three gatherings + one integration processing structure for a blank large head end, and designof a specific two gatherings + one shaping processing structure for a small head end, blade end shaping blank manufacture is realized. With the more exquisite gathering processing structure, occurrence of defects such as gathering instability and burr folding caused by excessive deformation can be avoided effectively, and batched production demands can be satisfied reliably.

Owner:AECC AERO SCI & TECH CO LTD

Automatic laser welding device and method

InactiveCN110877152AAvoid Duplicate PositioningMeet mass production needsWelding/cutting auxillary devicesAuxillary welding devicesPhysicsLaser soldering

The invention discloses an automatic laser welding device. The device comprises a butterfly-shaped process screw rod I, a clamping mechanism, a butterfly-shaped process screw rod II, a laser welding head, a back gas protection cavity, a butterfly-shaped process screw rod III, a compressible sealing gasket, a welding table, clamping grooves, process pins, a delay protection gas spray head, a side blowing protection gas spray head, a gas inlet pipe and a laser welding machine head, the clamping grooves are located in the two sides of the welding table and fixed to the welding table to form a whole, the clamping mechanism and the clamping grooves are provided with holes for assembly and positioning of the process pins, and the clamping mechanism and the clamping grooves can be connected to the side surface of the welding table surface through the process pins, and the butterfly-shaped process screw I and the butterfly-shaped process screw II are mounted on the clamping mechanism and are screwed with threaded holes in the clamping mechanism to fasten a part I to be welded and a part II to be welded. The automatic laser welding device can effectively avoid the problem of repeated positioning of parts in the batch production process, and can avoid the problems that the positioning precision is not high and the gas protection effect of the weld joint position is poor during welding.

Owner:AVIC GUIZHOU AIRPLANE

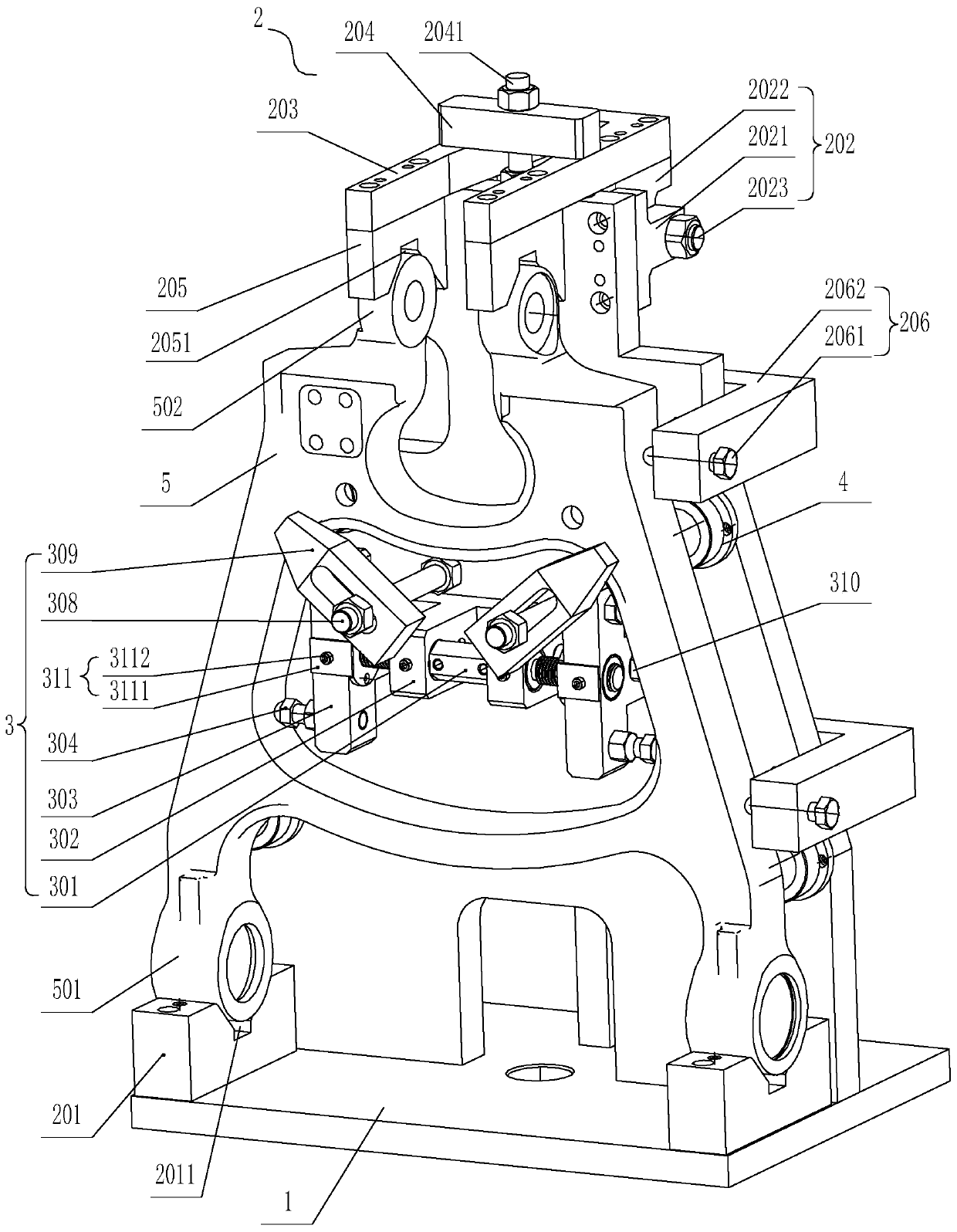

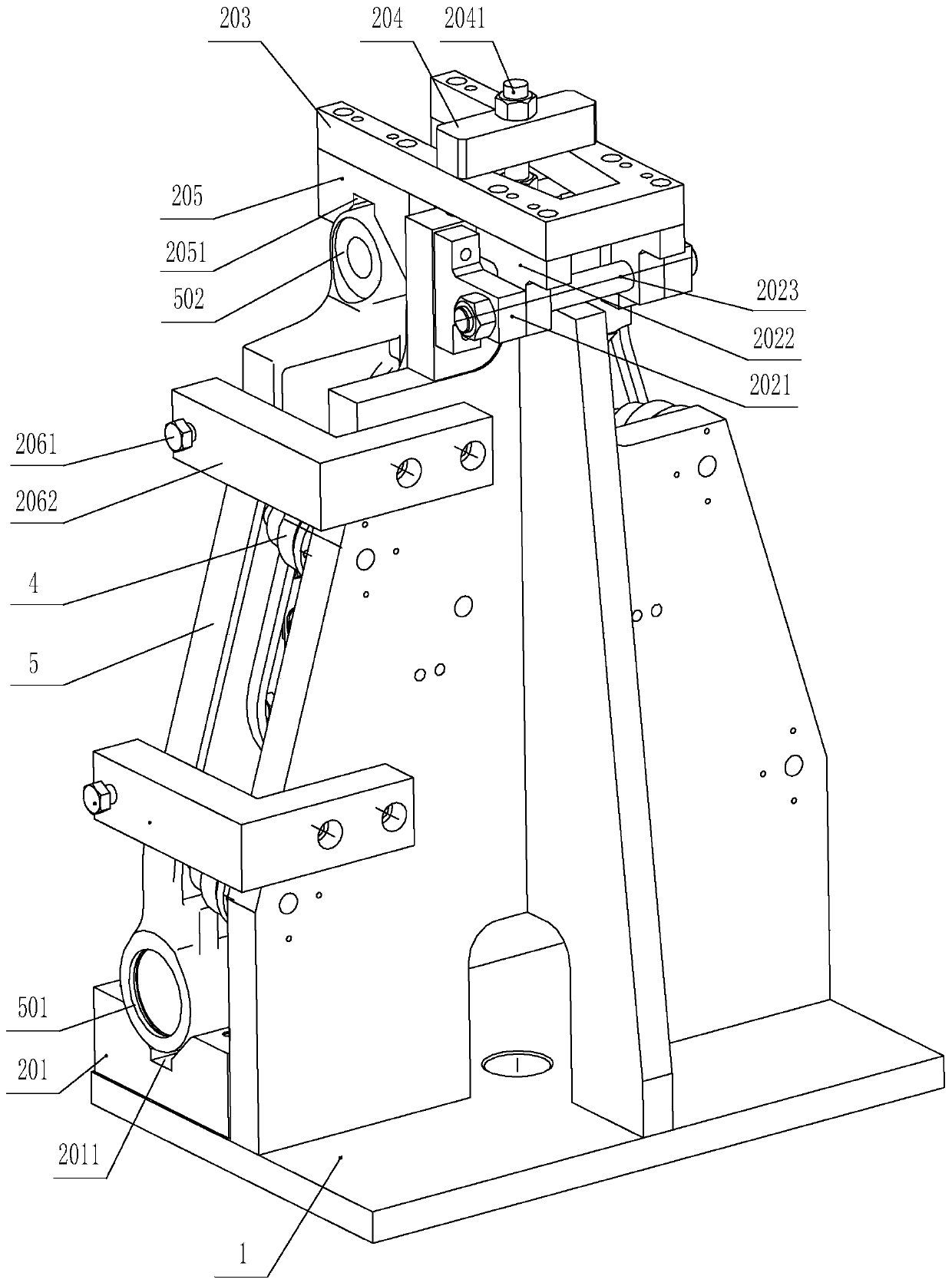

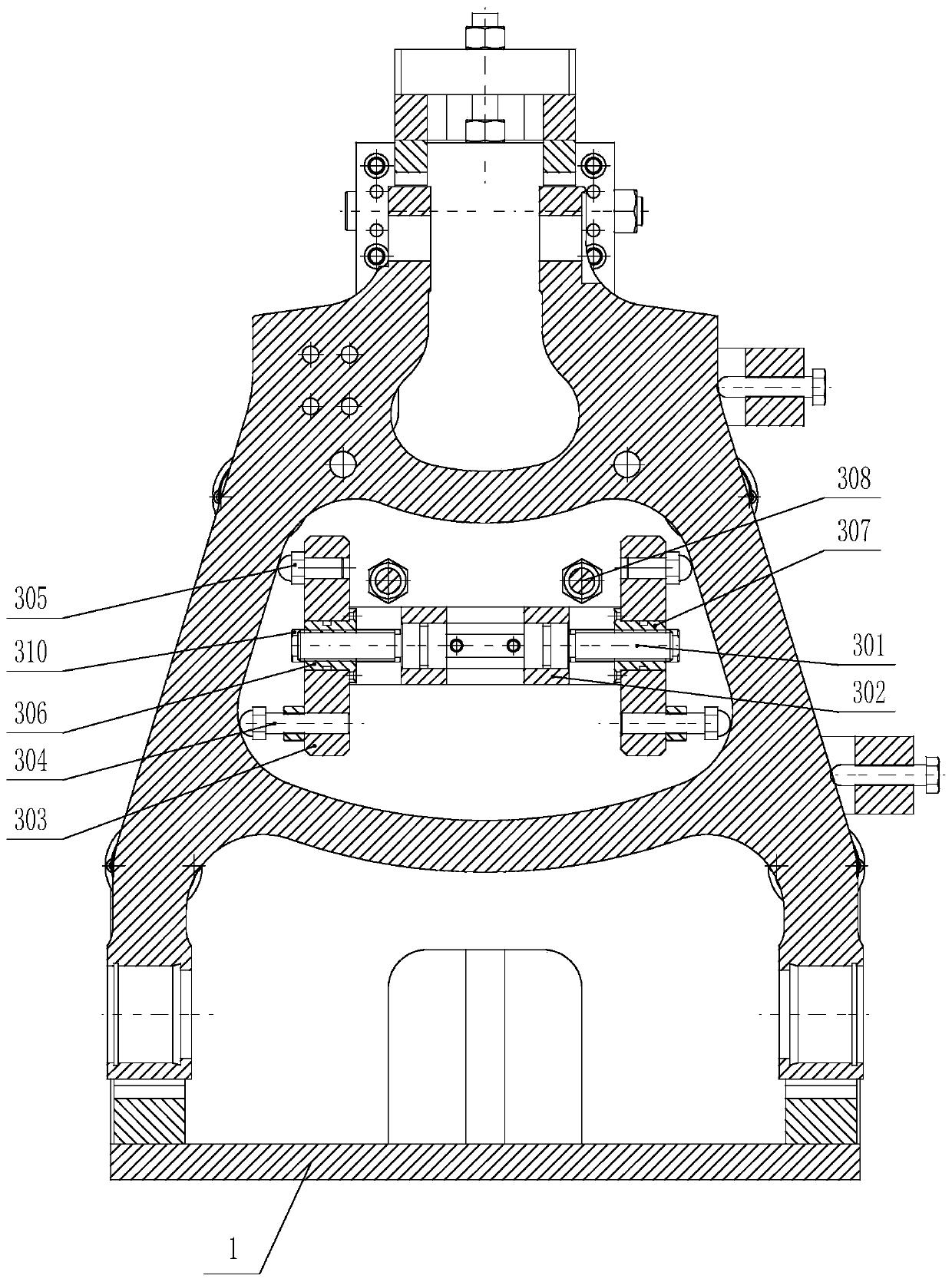

New energy vehicle axle swing arm machining tool

ActiveCN111546259ARealize one-time clamping and processingConstrain 6 degrees of freedomWork holdersNew energyControl theory

The invention discloses a new energy vehicle axle swing arm machining tool, and relates to a vehicle axle spare part machining tool. The new energy vehicle axle swing arm machining tool comprises a pedestal, a swing arm outer contour positioning device, a swing arm inner contour positioning device and an elastic auxiliary supporting assembly, wherein the swing arm outer contour positioning device,the swing arm inner contour positioning device and the elastic auxiliary supporting assembly are installed on the pedestal. The swing arm outer contour positioning device and the outer contour of a swing arm workpiece are in positioning connection, and the swing arm inner contour positioning device and the inner contour of the swing arm workpiece are in positioning connection. According to the new energy vehicle axle swing arm machining tool disclosed in the invention, the pedestal is used as a main body supporting frame, the swing arm outer contour positioning device is used for positioningand pressing the outer contour of a swing arm, the swing arm inner contour positioning device is used for positioning and pressing the inner contour of the swing arm, and therefore the six degrees offreedom of the swing arm workpiece can be restrained, the whole set of tool can achieve one-time clamping machining, the inner and outer contour positioning error clearance of the swing arm can be adjusted and compensated for through the elastic auxiliary supporting assembly, and the machining precision is high; and meanwhile, the advantages of being high in machining efficiency and reliable in structure are achieved, and the new energy vehicle axle swing arm machining tool can be applied and popularized easily.

Owner:FANGSHENG AXLE LIUZHOU

Solar-energy-based seawater desalination or sewage purification apparatus and solar-energy-based seawater desalination or sewage purification method

PendingCN108623061AMeet mass production needsTake advantage ofSeawater treatmentTreatment involving filtrationWater desalinationPurification methods

The invention provides a solar-energy-based seawater desalination or sewage purification apparatus and a solar-energy-based seawater desalination or sewage purification method. According to the apparatus, the apparatus contains a graphene filtration membrane; to-be-treated seawater or sewage passes through a ceramic filtration layer so as to achieve the first purification treatment of the water body; the first filtration water passes through the graphene filtration membrane so as to be filtered again to obtain the second filtration water, and the graphene filtration membrane has effects of heat absorption and heat transfer, and can evaporate the water passing through the membrane so as to achieve the third purification to prepare the purified water; the apparatus can completely use solar energy so as to achieve advantages of energy saving and environmental protection, and can purify sewage to obtain the purified water; the apparatus can further be used in the technical fields of seawater desalination and the like; and the apparatus has advantages of simple structure, complete purification, easy operation, short purification cycle and the like, and can meet small-scale production requirements and large-scale production requirements.

Owner:钟多琳 +1

Selenium-enriched food additive and preparation method thereof

InactiveCN108093746AIncrease selenium contentFast processGrowth substratesCulture mediaFood additiveCalcium biphosphate

The invention discloses a selenium-enriched food additive which comprises the following raw materials: corn seeds, wheat seeds, soybean seeds, garlic seeds and a selenium-containing culture solution.The selenium-containing culture solution comprises the following raw materials in parts by weight: 10-15 parts of an inorganic selenium powder, 4-6 parts of sodium chloride, 5-8 parts of potassium sulfate, 5-8 parts of calcium phosphate, 10-15 parts of urea and 400-500 parts of water, wherein the inorganic selenium powder is sodium selenite. The preparation method of the selenium-enriched food additive comprises the following steps: (1) preparing the selenium-containing culture solution; (2) soaking; (3) sprouting; (4) drying and crushing; (5) mixing and bagging. The selenium-enriched food additive and the preparation method thereof, disclosed by the invention, have the benefits that according to the preparation method, the content of selenium in the food additive can be greatly improved,and inorganic selenium is effectively converted into organic selenium; the preparation method is simple, short in preparation time period, low in production cost, suitable for various crop seeds and capable of meeting the needs of rapid and batch production.

Owner:合肥中科启奥生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com