Patents

Literature

86 results about "Copper reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(II) oxide can be reduced by hydrogen and its formula determined. Natural gas (mainly methane) can also be used as a reducing agent, but the reaction is much slower.

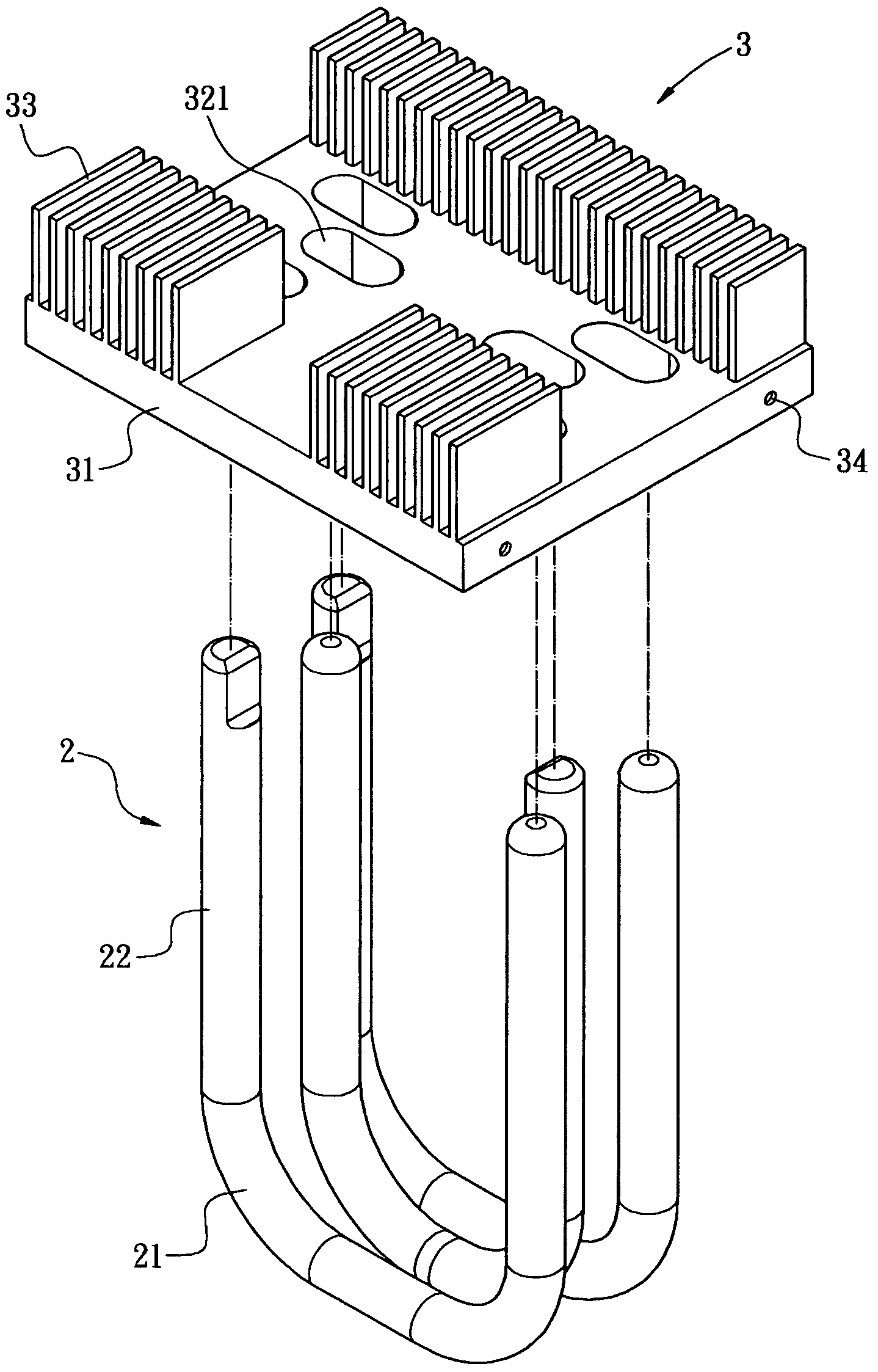

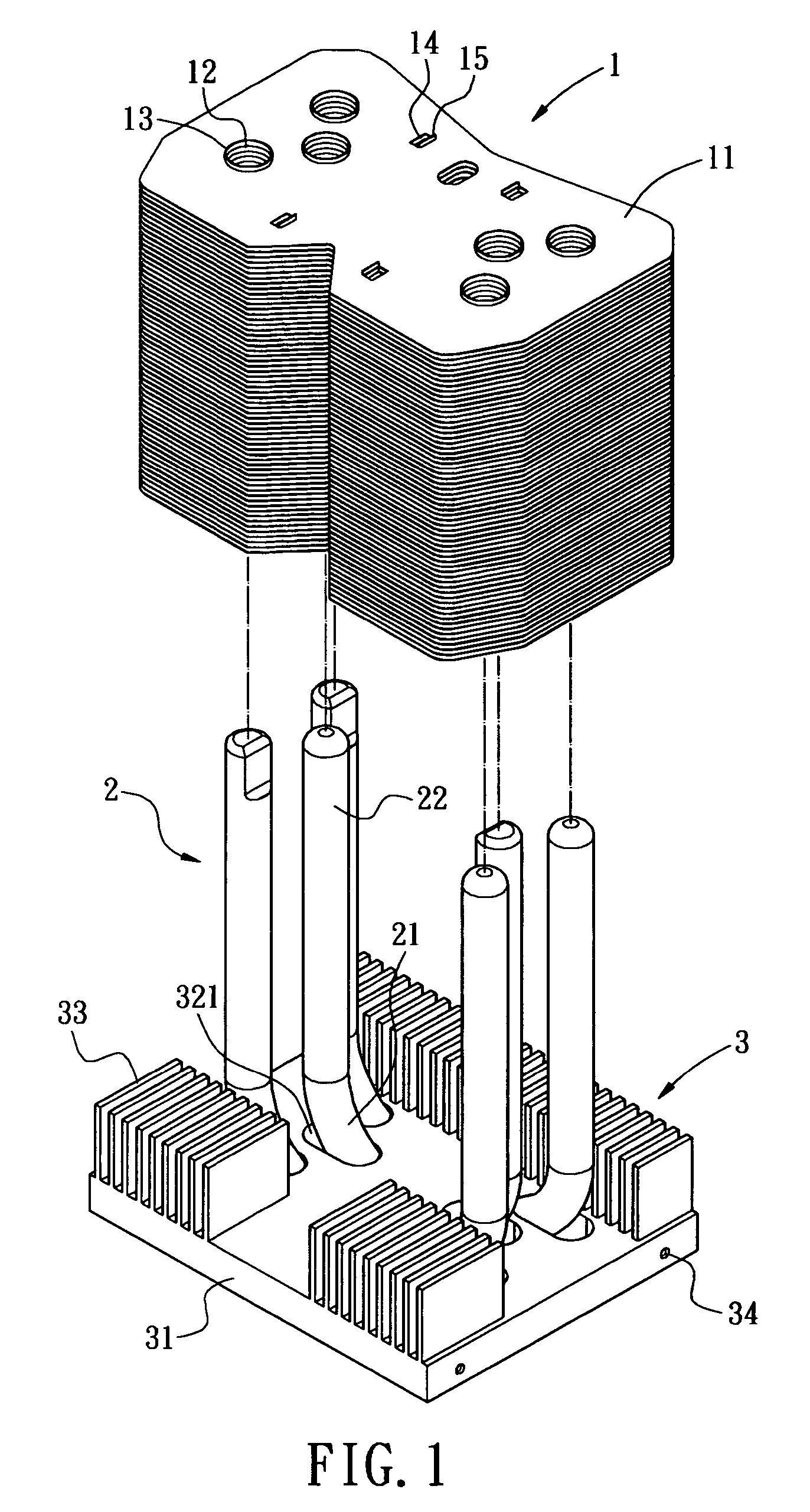

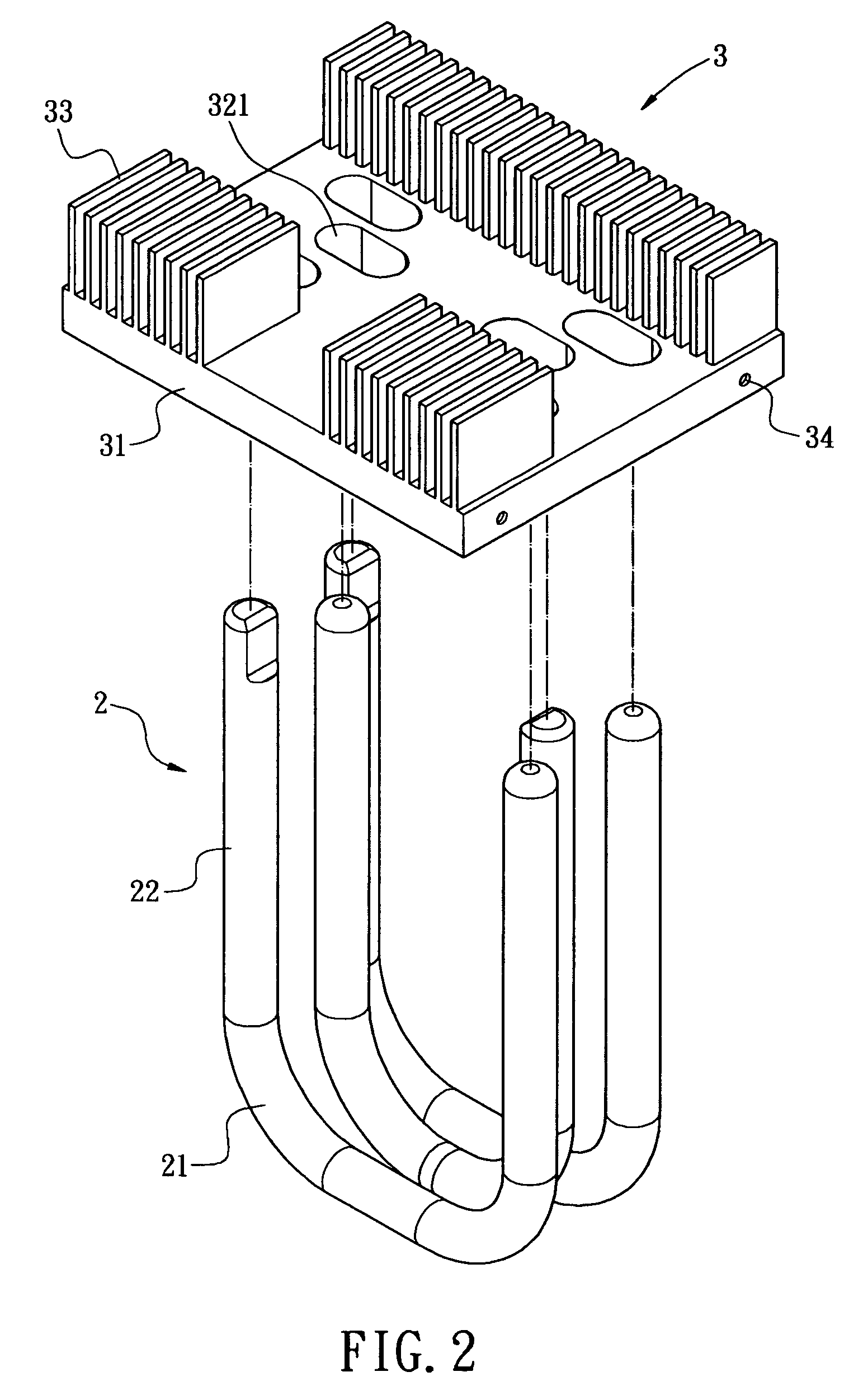

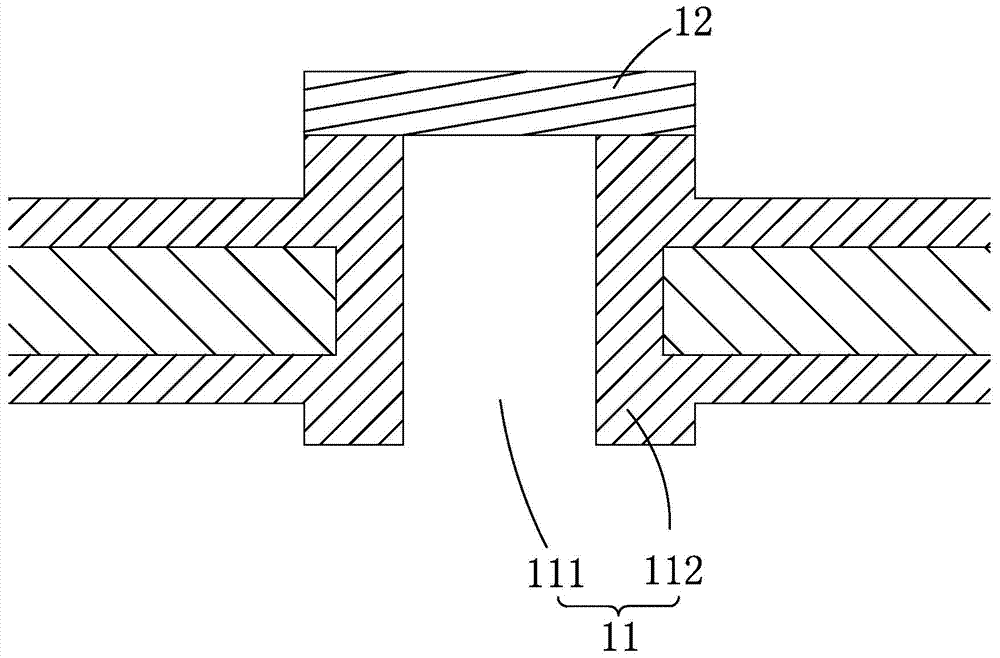

Thermal structure for electric devices

InactiveUS7245494B2Digital data processing detailsSemiconductor/solid-state device detailsThermal breakElectrical devices

A thermal module includes a thermal body, at least one thermal tube, and a holding part. The thermal tube includes a heat receiving portion and condenser terminals connecting with the thermal body, wherein the heat receiving portion has a plane. The holding part includes a plate body with trenches therein, wherein the trenches has through holes and a connecting part formed between the through holes. The through holes are used for receiving and holding the heat receiving portion of the thermal tube. The connecting part are connected with a top surface of the heat receiving portion. Thus, thermal transfer is speed up, and the thermal module is assembled without a thermal treatment which causing a copper reduction reaction, resulting in improvement of thermal conduction, reduction of cost, and manufacturing time saving.

Owner:CPUMATE INC +1

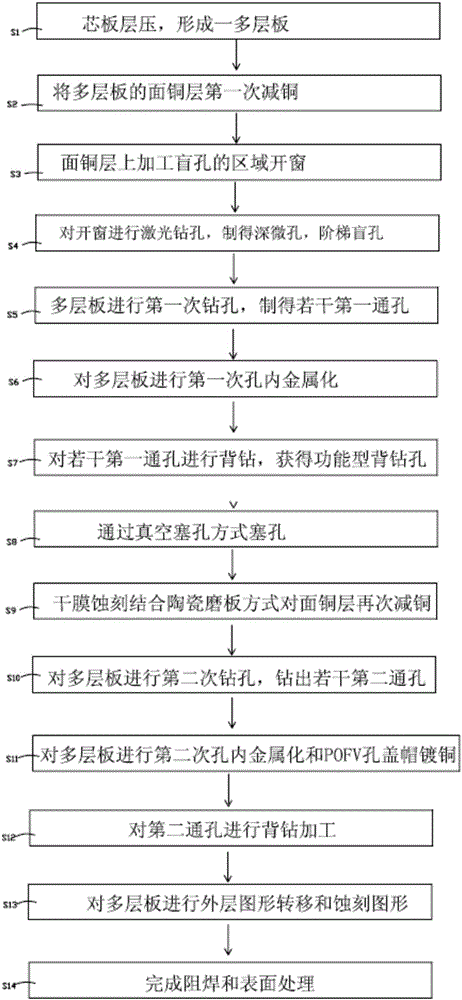

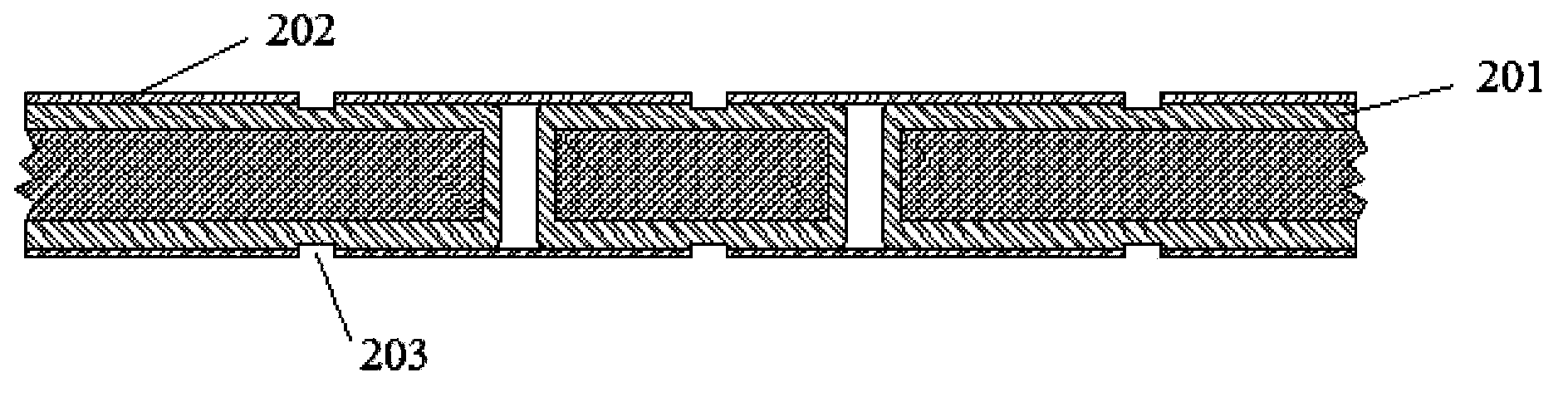

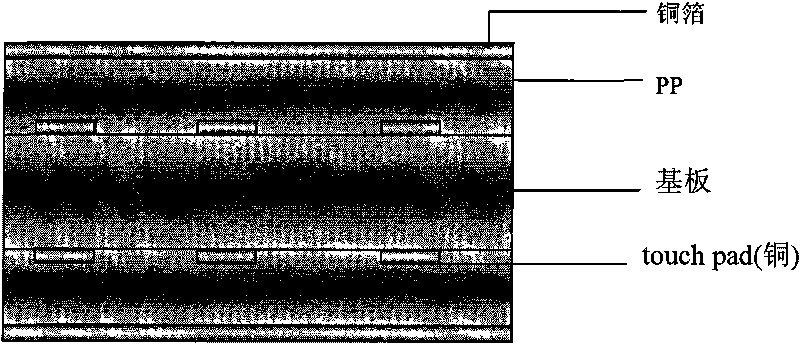

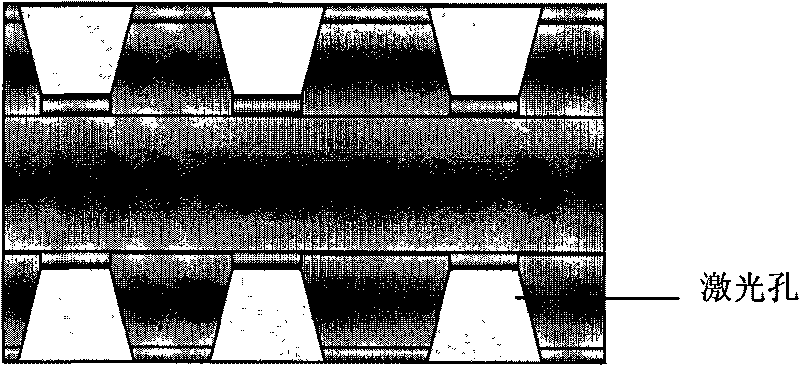

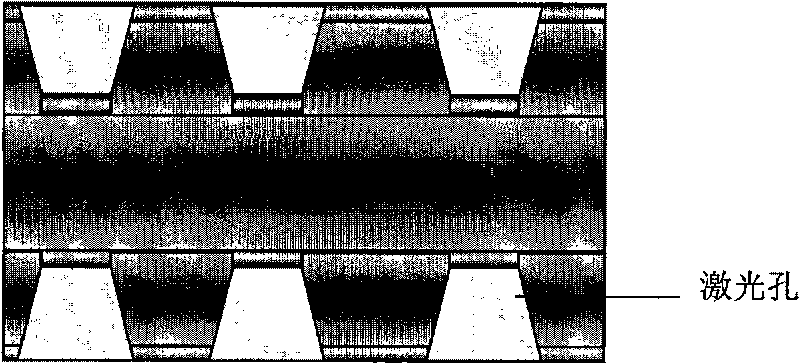

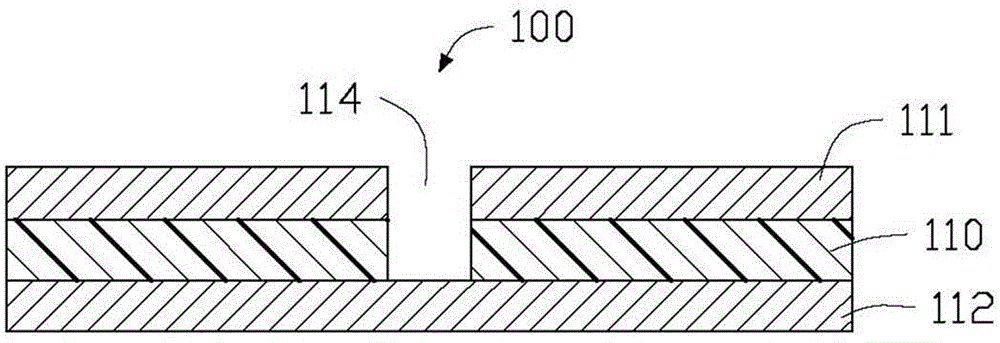

Manufacturing method of high-speed PCB and PCB

ActiveCN106793577AShort preparation cycleLow costPrinted circuit aspectsMultilayer circuit manufactureFine lineConnection type

The invention provides a manufacturing method of a high-speed PCB and the PCB. The manufacturing method includes the following steps that 1, lamination is carried out after a normal inner layer graph is manufactured; 2, copper reduction is carried out to achieve the size of 6 micrometers to 8 micrometers after lamination is completed; 3, +4.5 mil copper etching windowing is carried out on a deep micropore region and a first-order blind hole region overall; 4, laser drilling is carried out to complete deep micropore and first-order blind hole machining; 5, through holes needing resin hole plugging are mechanically drilled for the first time; 6, the interiors of the holes are metalized for the first time; 7, the through holes are back-drilled for the first time; 8, vacuum hole plugging is carried out; 9, the holes are covered with dry films, single side +5 mil dry film covering is carried out on deep micropores, first-order blind holes and the first through holes; 10, chemical copper reduction and ceramic grinding plate copper reduction are carried out to achieve the size of 20 micrometers to 25 micrometers; 11, second through holes are mechanically drilled; 12, the interiors of the holes are metalized for the second time, and POFV blocking is carried out; 13, the second through holes are back-drilled, and connection type functional holes are machined; 14, an outer layer graph is transferred, and a fine line graph is etched; 15, solder resisting and surface treatment are completed. The high-complexity high-speed PCB can be manufactured, the manufacturing period is short, and the cost is low.

Owner:DONGGUAN SHENGYI ELECTRONICS

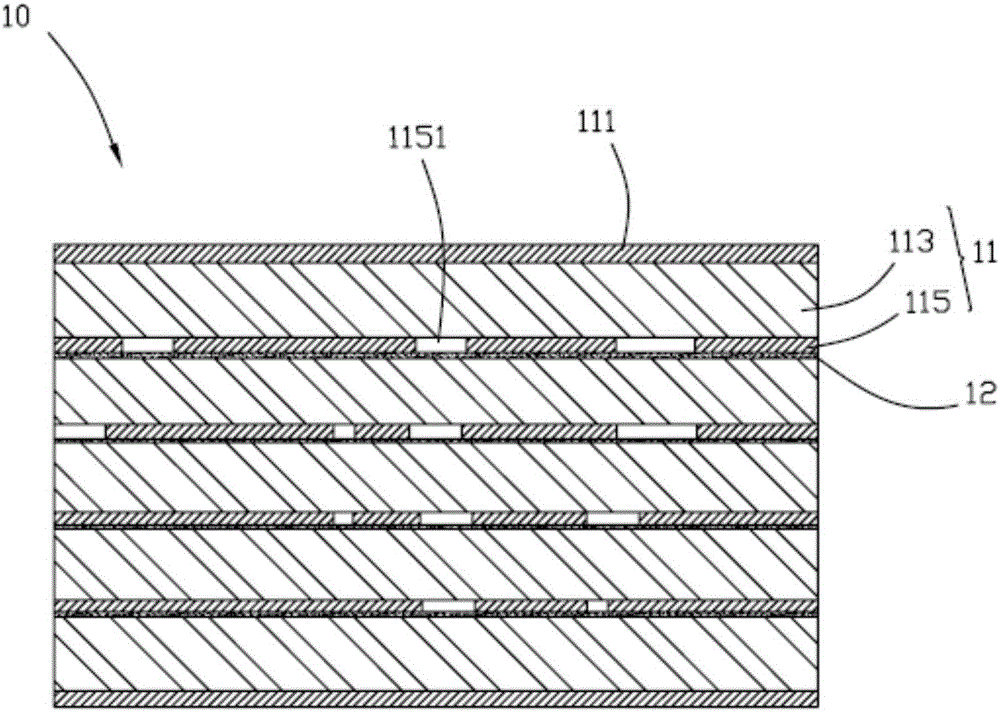

Manufacture method of high density interconnection board

InactiveCN105263274AImprove manufacturing qualityReduce productionMultilayer circuit manufactureCopper platingSurface layer

The present invention discloses a manufacture method of a high density interconnection board. The method comprises the steps of (S1) inner layer core plate cutting, first time inner layer core plate line graphic manufacture, and inner layer core plate lamination, (S2) inner layer core plate browning, drilling a surface layer blind hole by laser, and removing a browned layer, (S3) making an inner layer blind hole at a surface layer to a layer to be conducted, and carrying out metal processing on the surface layer blind hole and the inner layer blind hole, (S4) entire plate hole filling and plating, filling the blind hole and plating copper at the inner wall of the inner layer blind hole, and then carrying out inner layer hole plating such that surface layer blind hole and inner layer blind hole copper thickness satisfies a product requirement, (S5) inner layer blind hole filling by resin, grinding plate by an inner layer abrasive belt, and making a secondary inner layer circuit, and (S6) carrying out lamination and outer layer processing. According to the method, the processes of drilling a laser positioning hole, blind hole window opening, and copper reduction ara saved, at the same time the full plate plating mechanism can be realized by the surface layer blind hole and the inner layer blind hole, the manufacture processes are simplified, and the production quality of the blind holes are improved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

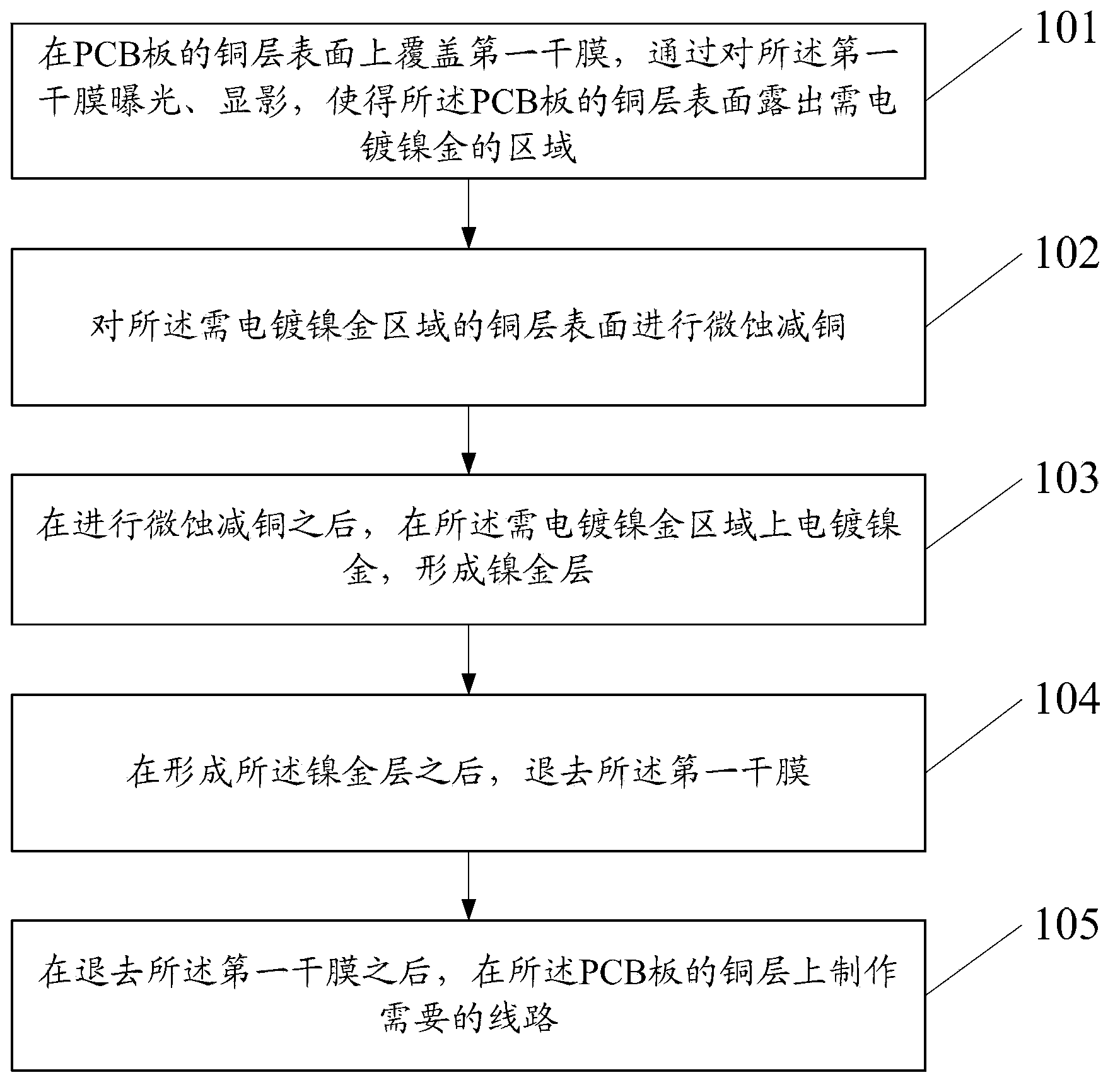

Selective nickel and gold plating method, PCB and device

ActiveCN104105350AReduce height differenceImprove bindingConductive material chemical/electrolytical removalConductive pattern reinforcementEtchingHeight difference

The invention discloses a selective nickel and gold plating method comprising the steps that a first dry film is covered on the surface of a copper layer of a PCB, and a area requiring nickel and gold plating is exposed out of the surface of the copper layer of the PBC via exposure and development; micro-etching and copper reduction are performed on the copper layer of the area requiring nickel and gold plating; and then nickel and gold are plated on the copper layer of the area requiring nickel and gold plating, then the first dry film is removed, and a required line is manufactured on the copper layer of the PCB. According to the method, nickel and gold are firstly plated on the surface of the copper layer of the PCB, and then the line is manufactured so that a lead wire for plating does not need to be manufactured in the overall implement process, and a problem of difficulty in nickel and gold plating on the PCB caused by the fact that the lead wire for plating cannot be manufactured on the PCB is solved. Besides, micro-etching and copper reduction are performed on the copper layer of the area requiring nickel and gold plating so that height difference between the nickel and gold surface of the nickel and gold area and the surface of the line without nickel and gold plating is reduced, and thus combination force of the dry film and the surface of the PCB in the subsequent dry film covering technology is enhanced.

Owner:SHENNAN CIRCUITS

Direct laser pore-forming method

InactiveCN101745744AShort production processLaser beam welding apparatusCopper foilManufacturing enterprises

The invention discloses a direct laser pore-forming method. In order to control the thickness of copper foil in the range of requirements, a plurality of HDI manufacturing enterprises adopt a process technology of copper reduction but can not overcome the defect of the process technology for the processing thickness capability of the copper foil. The direct laser pore-forming method comprises the following steps: designing and manufacturing optical alignment points for processing circuit board blind holes; using the copper foil for layering press fit; adopting melanism for surface treatment; using target holes for positioning, carrying out laser-drilling, and processing optical alignment points for positioning; carrying out laser-drilling again, positioning by the processed optical alignment points, and positioning and processing the blind holes in a board. After press fit, the method carries out two procedures of film rubbing and melanism and enters the procedure of laser-drilling, so the production procedures are reduced by a half. Furthermore, the method can process the copper foil with the thickness of 9-12 Mum.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Circuit board manufacturing method adopting resin plugging

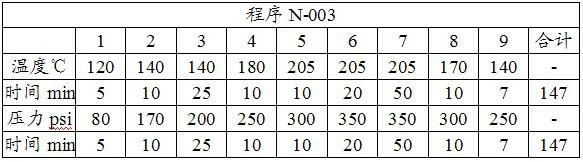

InactiveCN106341950AQuick removalPrinted circuit aspectsPrinted element electric connection formationCooking & bakingChemical solution

The invention relates to a circuit board manufacturing method adopting resin plugging. The method includes the following steps of: step one, rough shape cutting; step two, brownification and copper reduction; step three, hole drilling; and step 4, electroless plating copper / board plating: hole walls are metallized by using chemical deposition, and hole copper and a copper layer on a copper clad layer are thickened by 2 to 3 microns through adopting a whole-board electroplating method; step five, hole plating and dry film attachment: a photosensitive dry film is attached onto a board processed in the step four; step six, hole plating: copper electroplating thickening is performed on the board which has been subjected to hole plating and dry film attachment through adopting an electroplating method; step seven, resin plugging; step eight, board baking: resin is baked optimally and cured through high temperature; and step nine, adhesive residue removing: the resin and the dry film are eroded by using chemical solutions, while, the chemical solutions do not react with the copper. According to the circuit board manufacturing method adopting resin plugging of the invention, the resin is applied to the hole plated board, and hole plugging and curing can be carried out, and then, the resin on the surface of the board can be removed through a chemical adhesive removing method, and polishing is not required, and the copper thickness of the surface of the board is only 10 microns. With the circuit board manufacturing method adopting resin plugging of the invention adopted, a fine circuit board of which the minimum line width and line spacing can be 2.5mil can be produced.

Owner:SHENZHEN XUNJIEXING TECH CORP LTD

Copper reduction process for printed circuit board

InactiveCN104135825AGuaranteed reliabilityCopper reduction is ingeniousPrinted circuit secondary treatmentAcid etchingChemical reaction

The invention provides a copper reduction process for a printed circuit board. The copper reduction process comprises: a dry film pressing step in which the processing of dry film pressing is performed on an integrally copper-plated substrate, and dry films are pressed on upper and lower surfaces of the substrate, wherein and a pore ring on the substrate is covered with the dry films; an exposing step in which the dry films on the two surfaces of the substrate are exposed, a part of the dry film not to be needed is irradiated by the light with a present wavelength; a developing step in which the exposed dry films are developed, and the part of the dry film not to be needed is removed; a copper reducing step in which unneeded surface copper on the developed substrate is removed, wherein as the pore ring is covered with the dry films, and a chemical reaction does not occur between copper reducing solution and the dry films, pore copper is not reduced; a film removing step in which the dry films on the substrate subjected to the copper reducing are completely removed; and a board grinding step in which grinding is performed so that the height of a copper layer at the pore ring and the height of the surface copper are consistent. In the copper reduction process for the printed circuit board, since the dry films cover the pore ring before the copper reducing step, an acid etching solution cannot chemically react with the dry films in the copper reducing step, so that pore copper is protected, reliability of the thickness of the pore copper is further guaranteed, and copper is ingeniously reduced.

Owner:东莞市五株电子科技有限公司

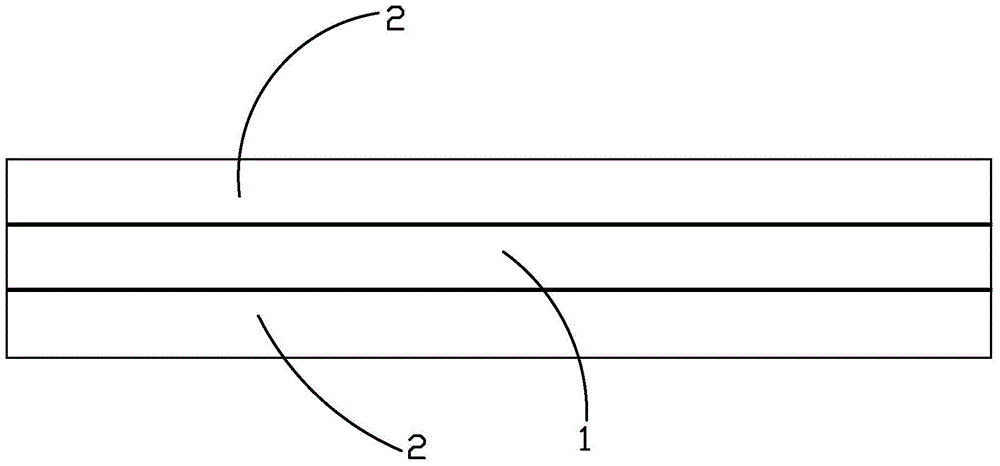

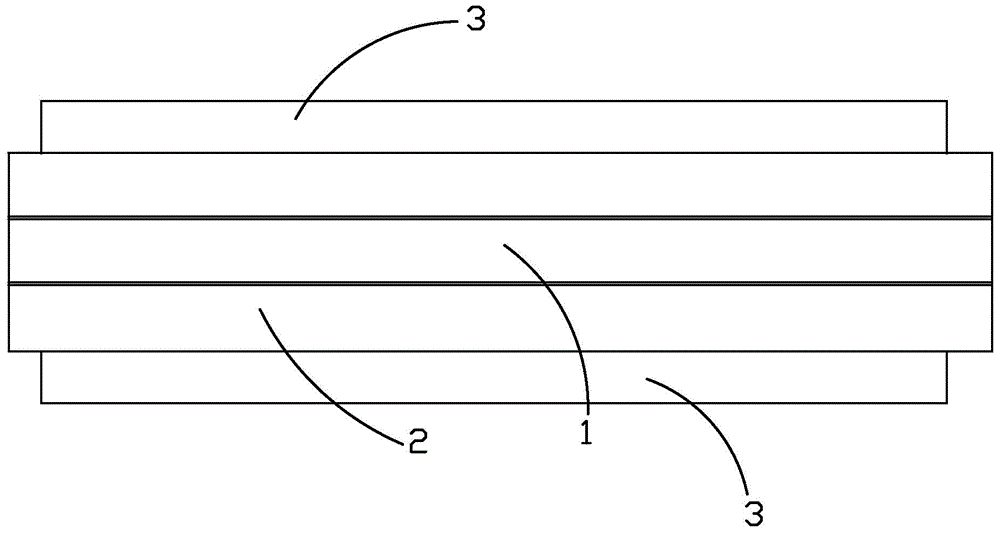

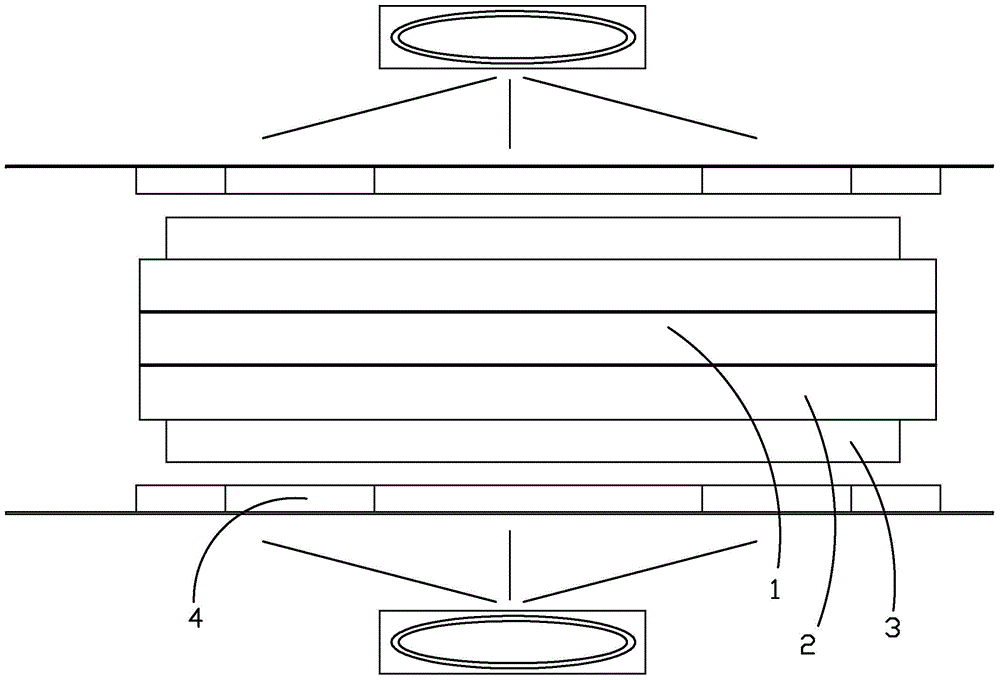

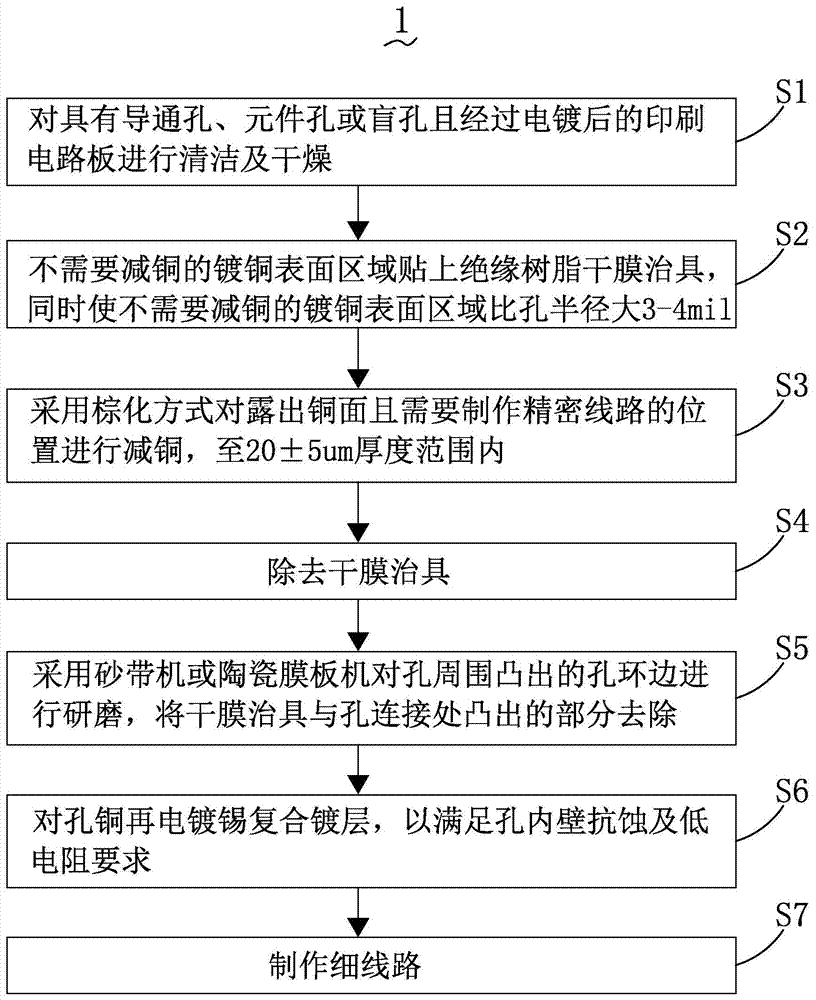

Technique for local copper thinning and precision circuit making of printed circuit boards

InactiveCN104519667AAvoid the problem of dirty etchingSimple processing methodProcessing steps orderCopper platingEngineering

The invention provides a technique for local copper thinning and precision circuit making of printed circuit boards. The technique includes the following steps: adhering a dry film to a coppering surface region, with on need for copper reduction, of one printed circuit board with holes and subjected to electroplating; by adopting a brownification mode, subjecting the position exposing the copper surface and needing precision circuit making to copper thinning to the thickness range of 20+ / -5um; removing the dry film; removing the protruding parts of the joints of the dry film and the holes. According to the technique, the method of dry film isolating copper thinning is adopted, the thickness after copper plating of the holes is guaranteed, and the problem of under etching of the made precision circuit due to too thick surface copper is avoided.

Owner:SHENZHEN WUZHU TECH

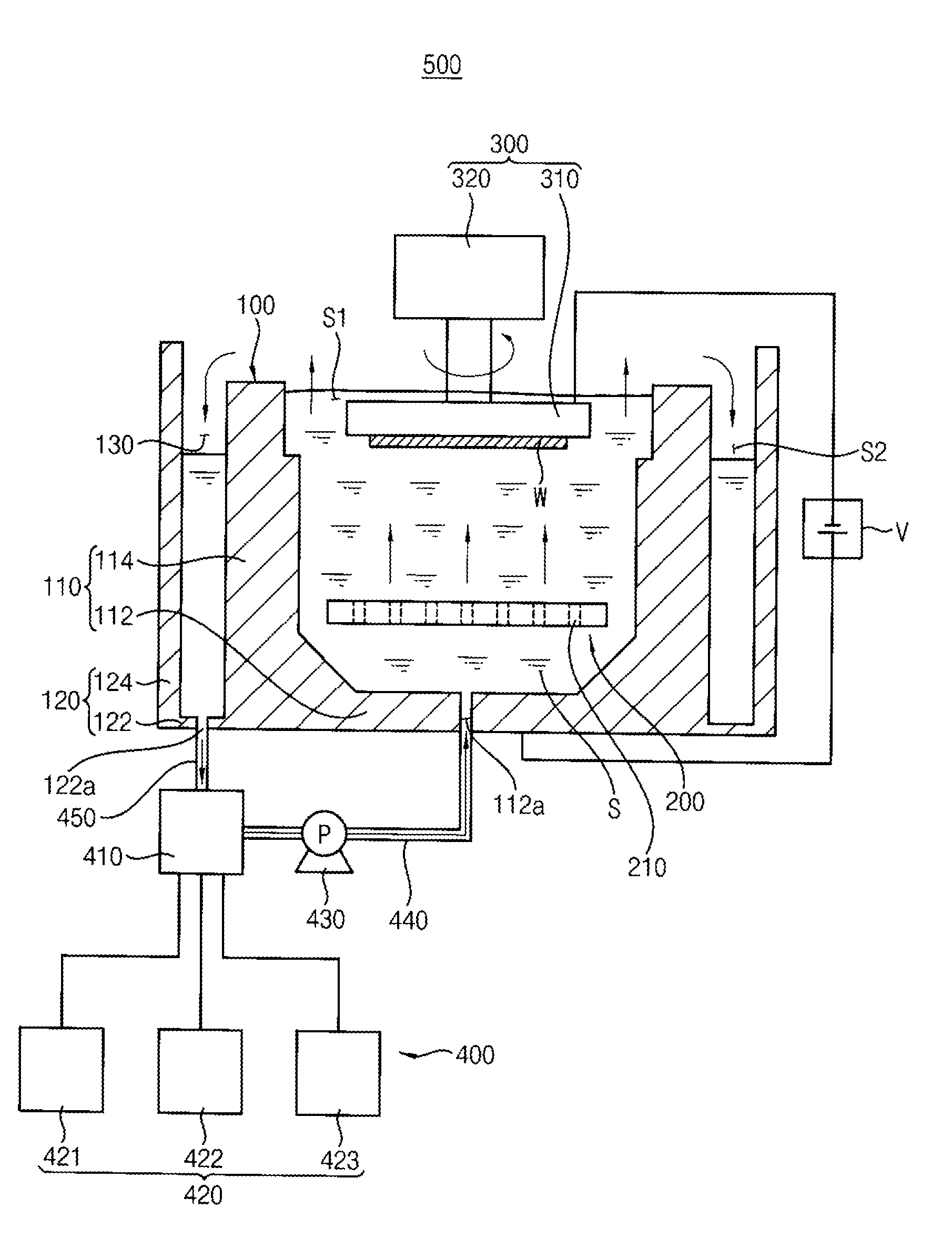

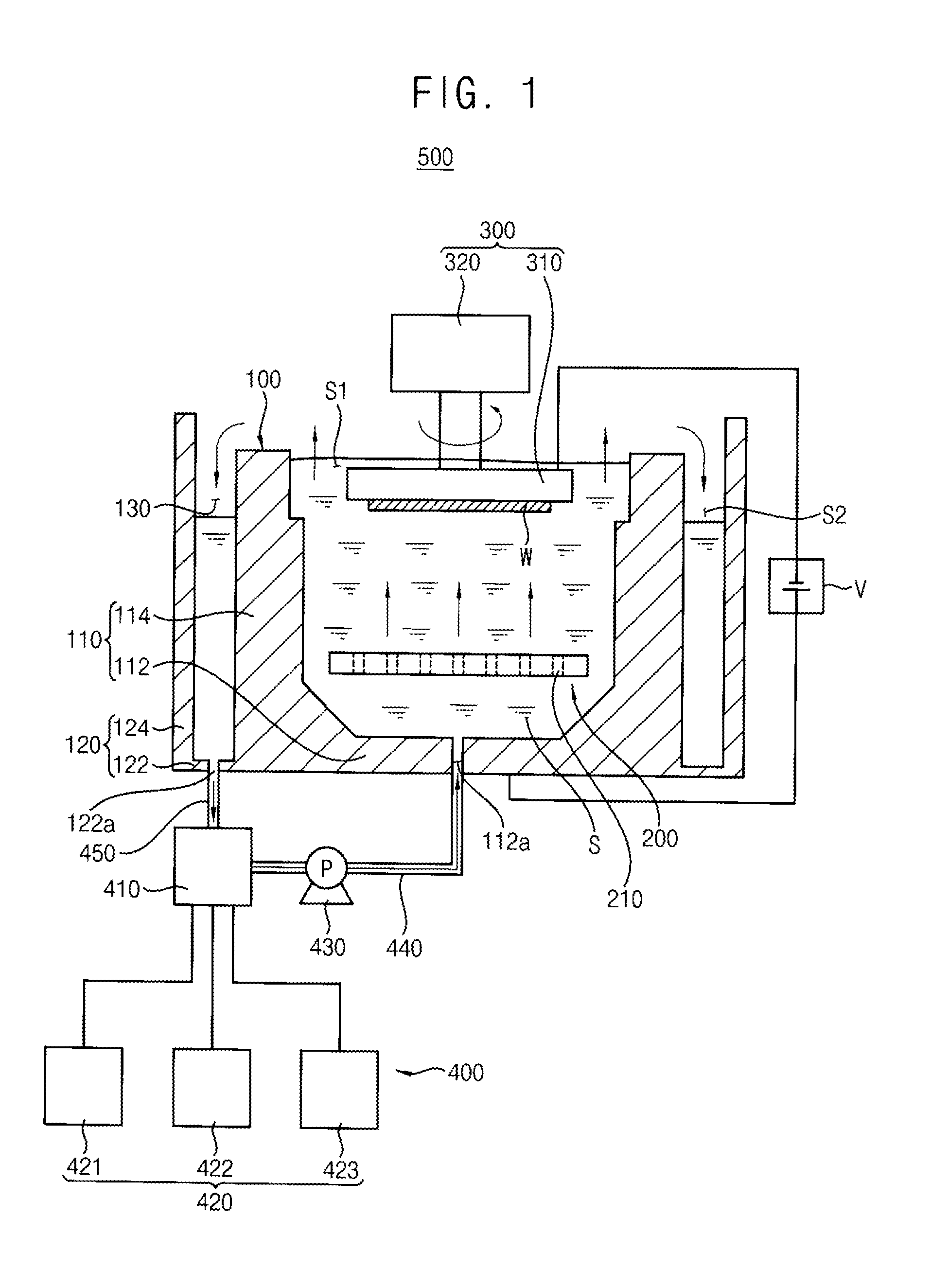

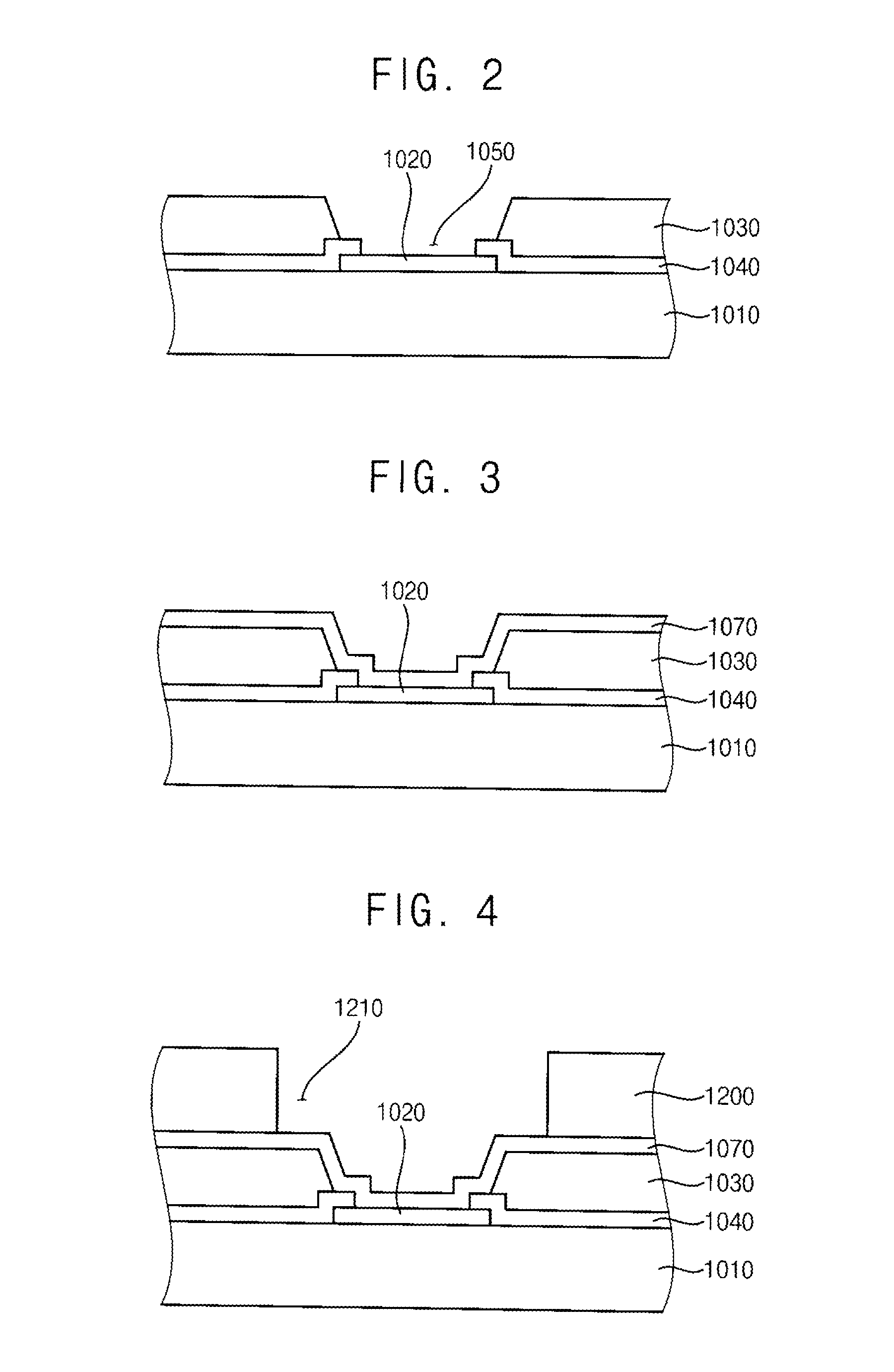

Copper electroplating solution and copper electroplating apparatus

ActiveUS20140197038A1Increasing overall electroplating processImprove processing efficiencyCellsSemiconductor devicesNitrogenAqueous electrolyte

An electroplating solution includes an aqueous electrolyte solution including water soluble copper salts, sulfide ions and chloride ions, an accelerator including an organic material having sulfur (S), the accelerator accelerating copper (Cu) reduction, a suppressor including a polyether compound, the suppressor selectively suppressing the copper reduction, and a leveler including a water soluble polymer having nitrogen that is dissolved into positive ions in the aqueous electrolyte solution.

Owner:SAMSUNG ELECTRONICS CO LTD

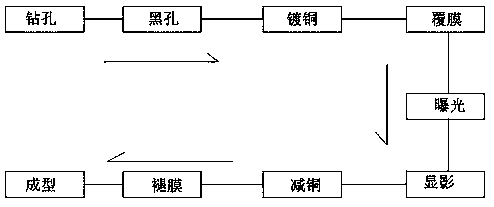

Manufacturing method for large-flexure high-density flexible printed circuit board

ActiveCN108521724ASolving "A/B/C" problemsImprove craftsmanshipPrinted element electric connection formationHigh densityCopper plating

The invention discloses a manufacturing method for a large-flexure high-density flexible printed circuit board, and the printed circuit board is produced according to the following sequence: drilling;hole blackening; copper plating; film coating; exposure; development; copper reduction; stripping; molding. According to the invention, the copper plating is executed completely, and then the copperreduction is performed locally, thereby reducing the problems in a scheme of the prior art. Moreover, the technical scheme employed in the invention greatly improves the whole technological capability.

Owner:深圳市合力泰光电有限公司

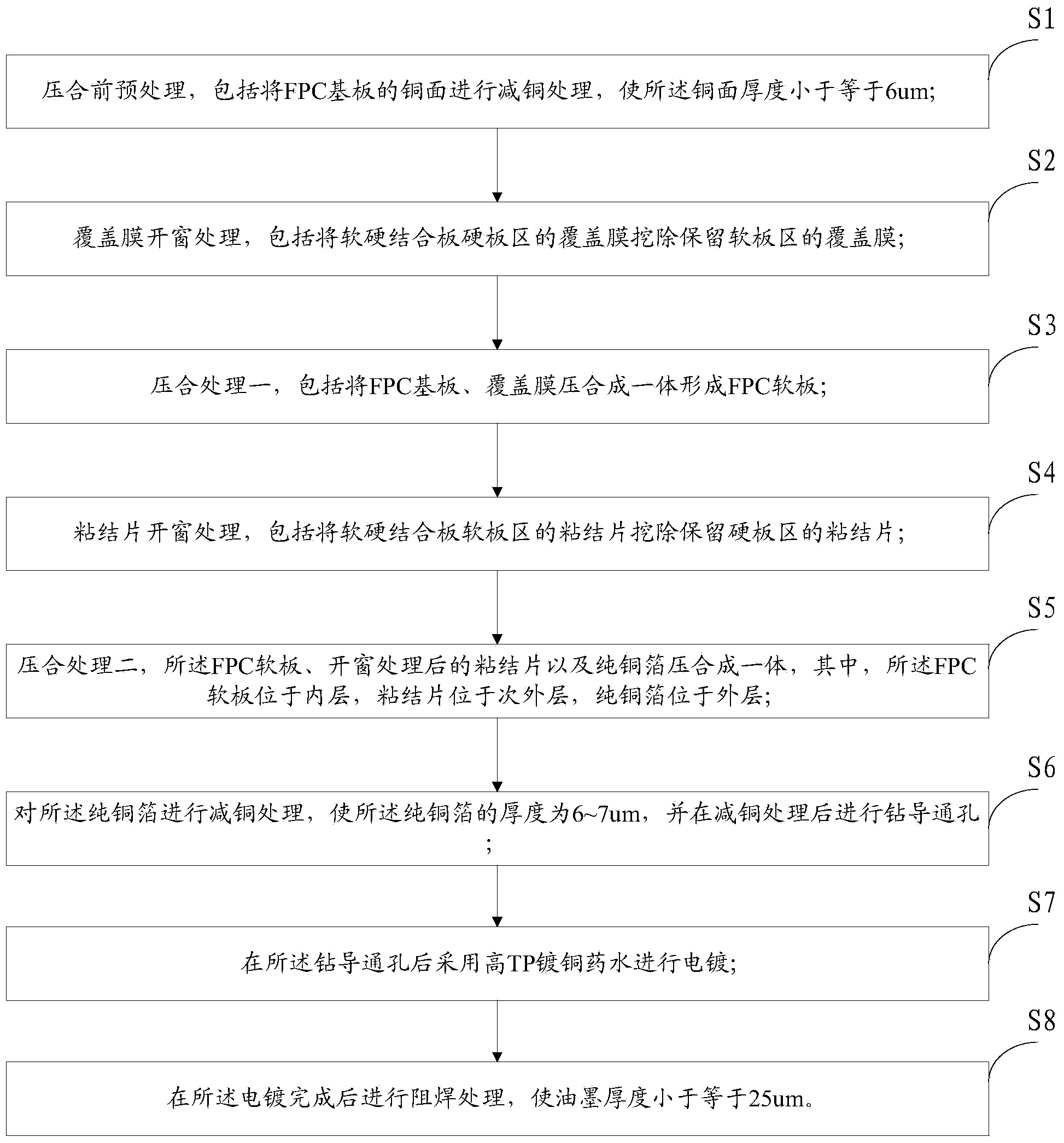

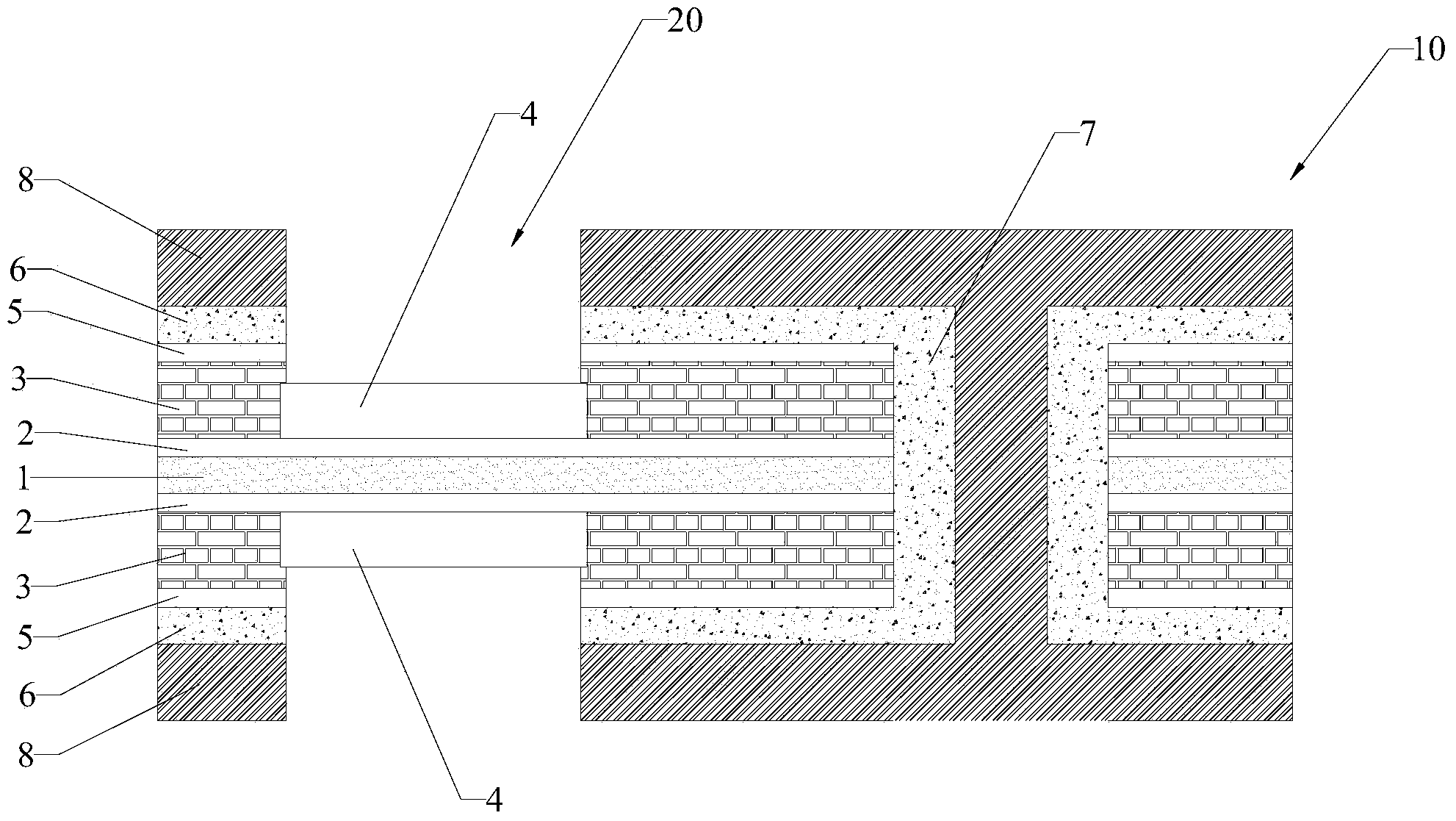

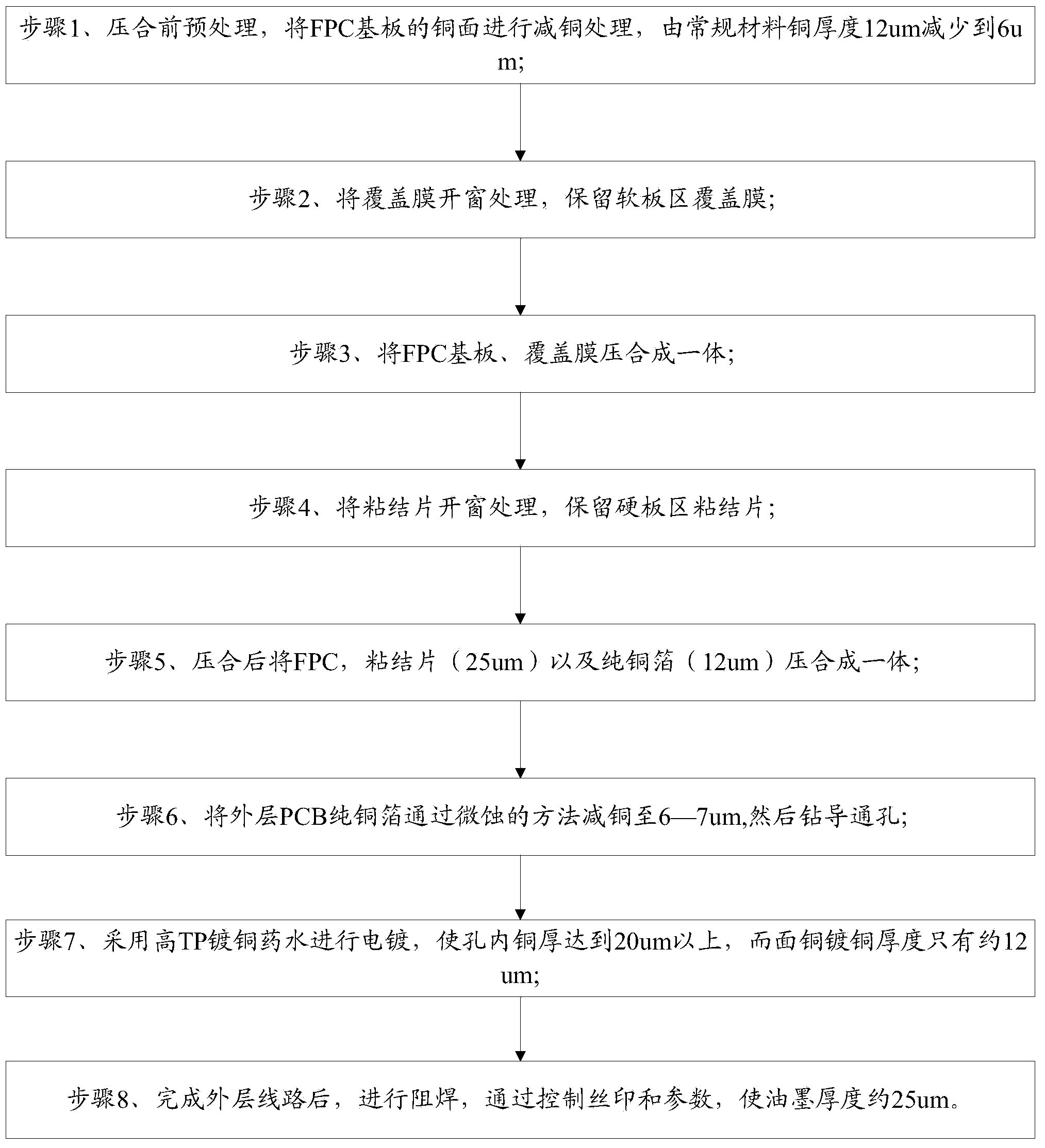

Camera soft and hard combination board manufacturing method

ActiveCN104302109AReduce thicknessControl thicknessPrinted circuit assemblingCopper platingCopper foil

The invention discloses a camera soft and hard combination board manufacturing method. The method includes the steps that preprocessing before press fit is performed, wherein copper reduction processing is performed on the copper surface of an FPC substrate; covering film windowing is performed, wherein a covering film on a hard board area is removed in an excavation mode and a covering film in a soft board area is reserved; the FPC substrate and the covering film are integrated through press fit to form a soft FPC board; bonding sheet windowing is performed, wherein bonding sheets in the soft board area of a soft and hard combination board are moved in an excavation mode and bonding sheets in the hard board area of the soft and hard combination board are reserved; second press fit processing is performed, wherein the soft FPC board, the bonding sheets subjected to windowing and pure copper foil are integrated through press fit; copper reduction processing is performed on the pure copper foil, the thickness of the pure copper foil is made to range from 6 microns to 7 microns, and through holes are drilled after copper reduction processing; after the through holes are drilled, a high-TP copper-plating solution is adopted for electroplating; after the electroplating, solder resisting is performed, and the thickness of printing ink is made to be smaller than or equal to 25 microns. Through the method, the thickness of the soft and hard combination board can be effectively reduced.

Owner:台山市精诚达电路有限公司

Tin bronze smelting slagging constituent and application method thereof

ActiveCN103981388AImprove slag gathering effectSolve the problem of high copper contentSlagEconomic benefits

A tin bronze smelting slagging constituent includes a copper reduction slagging constituent and a slag conglomeration agent. The copper reduction slagging constituent is composed of 3-10 wt.% of charcoal powder and 90-97 wt.% of glass powder, and slag conglomeration agent consists of crushed crude pearlite. The application method is as below: in the melting process of tin bronze alloy, after qualification test of copper alloy melt composition, controlling the temperature of copper liquid at 1150-1250 DEG C, first adding glass powder containing charcoal powder and as reducing the slagging agent, adding 0.01-0.1% of the weight of the copper alloy melt, the copper alloy melt stirring after the addition of perlite powder, slag conglomeration agent, adding 0.01-0.2% of the weight of the copper alloy melt, then slightly and evenly stirring, so as to quickly conglomerate dross on the copper alloy melt in bulk, and fishing out the bulk by using a slag spoon. The smelting slagging constituent reduces the content of copper oxide and cuprous oxide in slag, and improves the slag conglomeration effect of perlite powder. Compared with the existing technology, the method reduces the copper content in the slag by more than 40%, greatly increase the copper rate in tin bronze smelting, and has good economic benefit.

Owner:JINTIAN COPPER GROUP CORP NINGBO

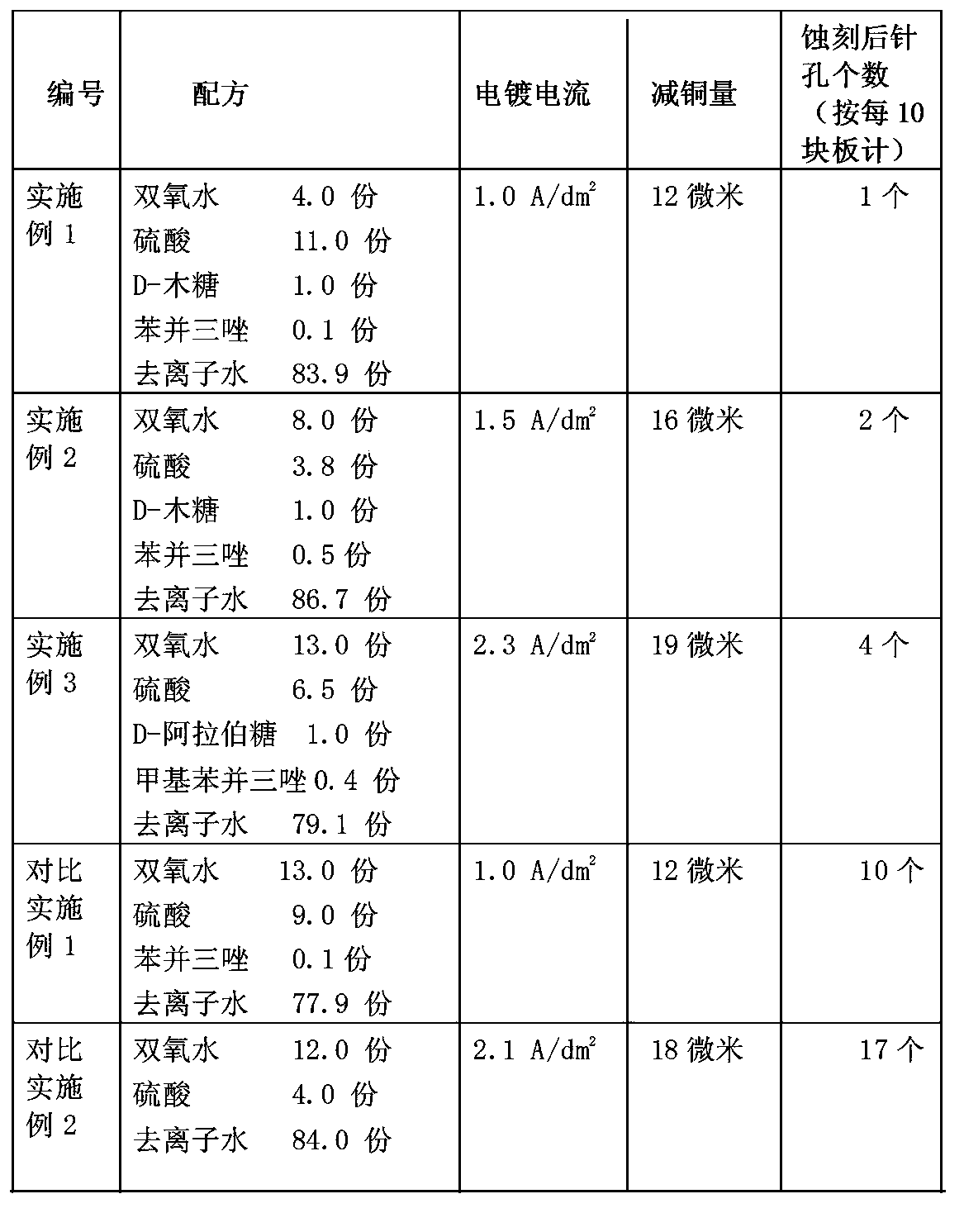

Copper reduction etching liquid for printed circuit boards

The invention discloses copper reduction etching liquid for printed circuit boards. The copper reduction etching liquid comprises the following raw materials by weight parts: 3.0-15.0 parts of hydrogen peroxide, 3.5-12.0 parts of sulfuric acid, 1.0-5.0 parts of D-pentose, 0.1-1.0 part of a copper corrosion inhibitor and 68.0-86.7 parts of de-ionized water. According to the copper reduction etching liquid, hydrogen peroxide and sulfuric acid react with copper to form water-soluble copper sulfate so as to thin a copper layer; D-pentose can be used for increasing the etching speed in the horizontal direction of the copper surface and inhibiting the etching speed in the vertical direction of the copper surface, so that etching is carried out in the horizontal direction of the copper surface as far as possible and the influence on the etching rate caused by different crystals on the copper surface is reduced; the copper corrosion inhibitor can be used for protecting the copper surface, so that the etched copper surface is kept bright; the manufacturing time of the printed circuit boards is effectively shortened, and the manufacturing cost is reduced.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY +1

Manufacturing method of fine circuit board free of corrosion resistant layer

InactiveCN106852003AAvoid the impact of side erosionImprove manufacturing qualityConductive pattern formationCopper foilElectroplating

The invention discloses a manufacturing method of a fine circuit board free of a corrosion resistant layer. The method comprises the processes of laminating, base copper reduction, drilling, depositing copper preplating, pattern electroplating, stripping and flash rusting and subsequent processes. According to the manufacturing method, the fine circuit board is manufactured by combining a thin copper foil with a flash rusting technology; the manufacturing method can be used for manufacturing an ultrafine circuit; and the manufacturing accuracy of the circuit is improved.

Owner:YIXING SILICON VALLEY ELECTRONICS TECH

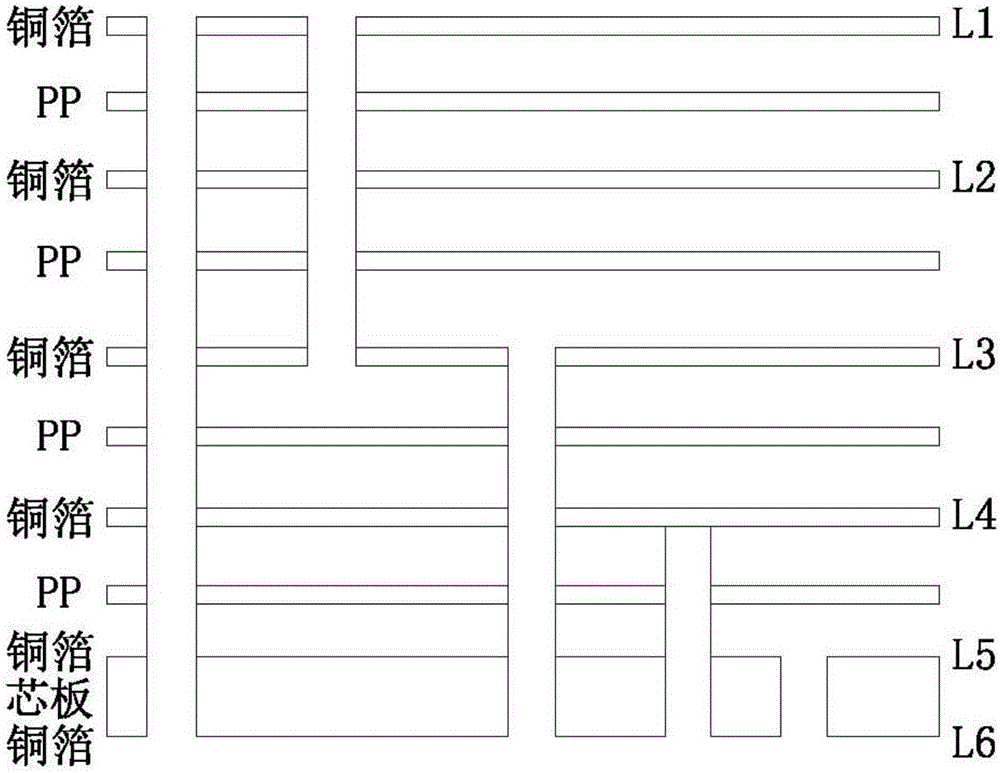

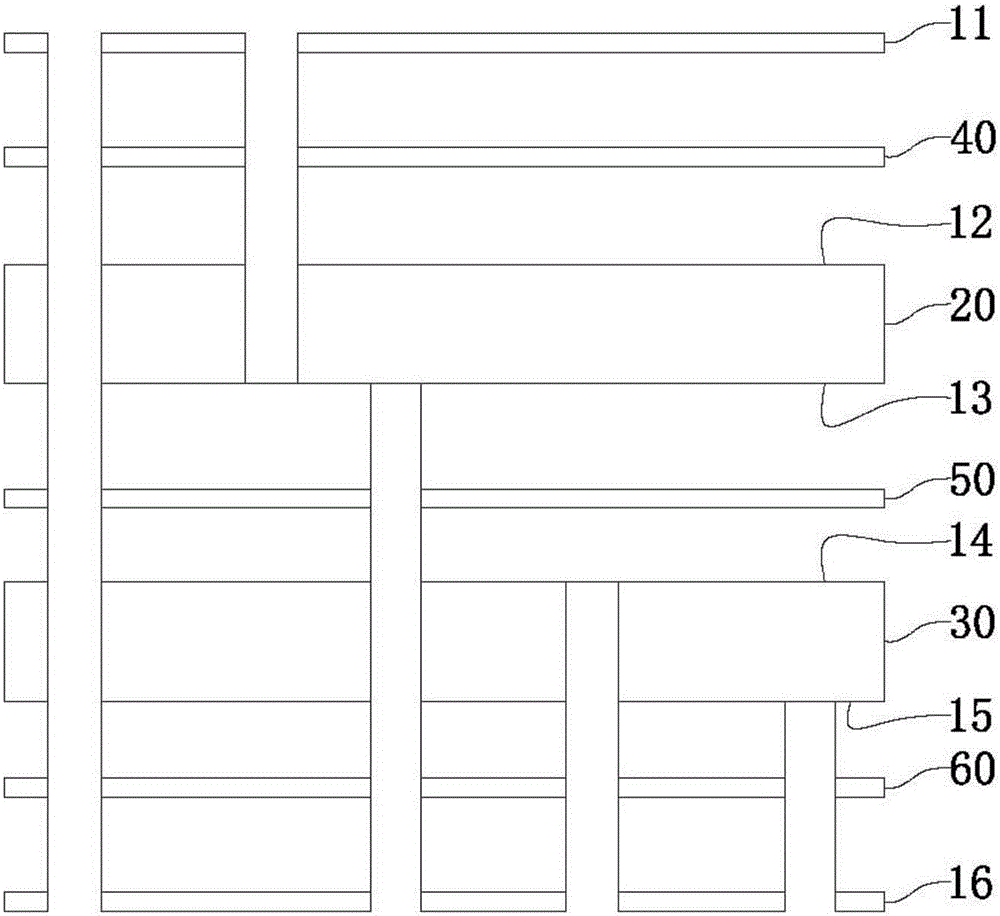

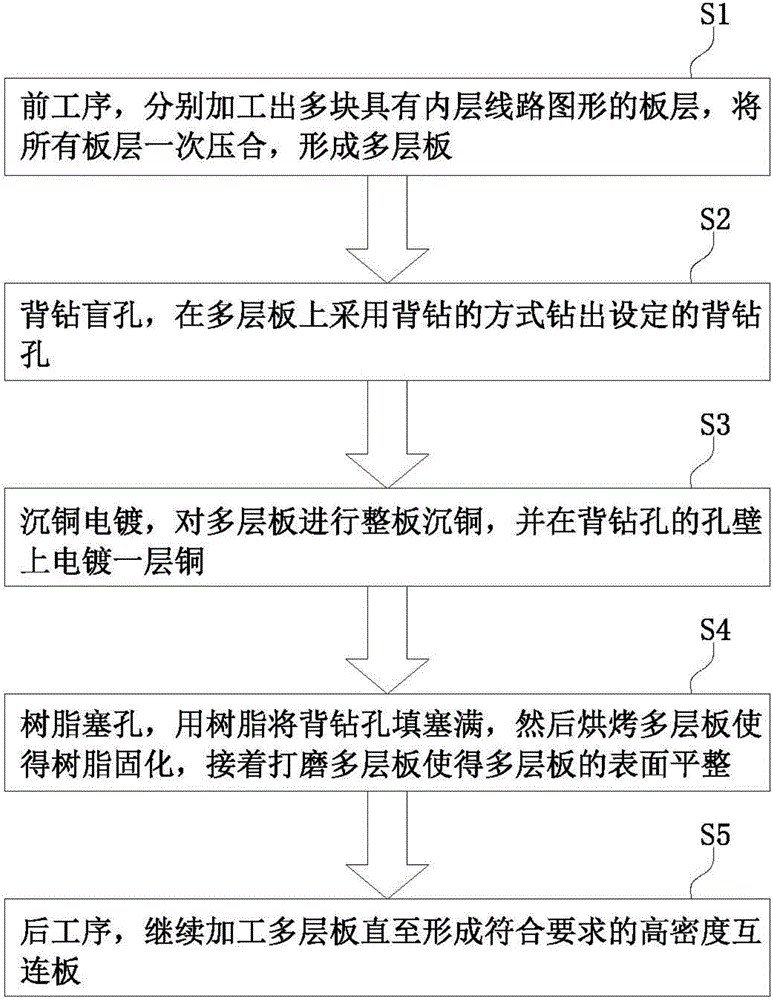

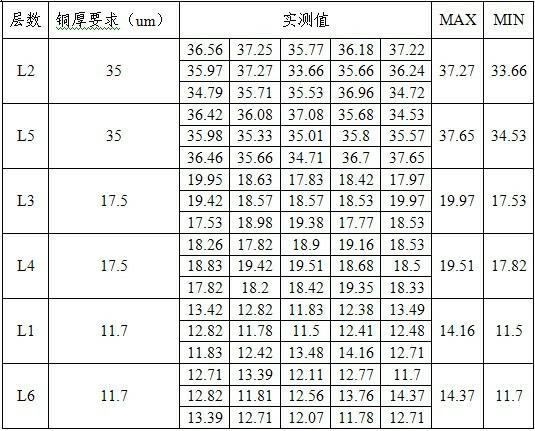

Preparation method for high-density interconnection board

InactiveCN106211640AQuality improvementAvoid expansion and contractionMultilayer circuit manufactureManufacturing technologyHigh density

The invention relates to the technical field of printed circuit board production and especially relates to a preparation method for a high-density interconnection board. The preparation method for the high-density interconnection board comprises the steps of carrying out a front process of processing multiple board layers with inner circuit patterns and laminating all board layers once, thereby forming a multilayer board; carrying out a blind hole back drill step of drilling a set back drill hole in a back drill mode; carrying out an electroless plating copper electroplating step of carrying out whole board electroless plating copper on the multilayer board and electroplating a layer of copper on the hole wall of the back drill hole; carrying out a resin hole plugging step of plugging the back drill hole by employing resin, baking the multilayer board, thereby enabling the resin to be cured, and then polishing the multilayer board, thereby enabling the surface of the multilayer board to be flat; and carrying out a post process of continuously processing the multilayer board until the high-density interconnection board satisfying a demand is formed. According to the method, multiple times of electroplating and copper reduction processes can be avoided, the copper thickness uniformity can be ensured, the electroplating and board polishing times can be reduced and the quality of the produced high-density interconnection board can be improved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

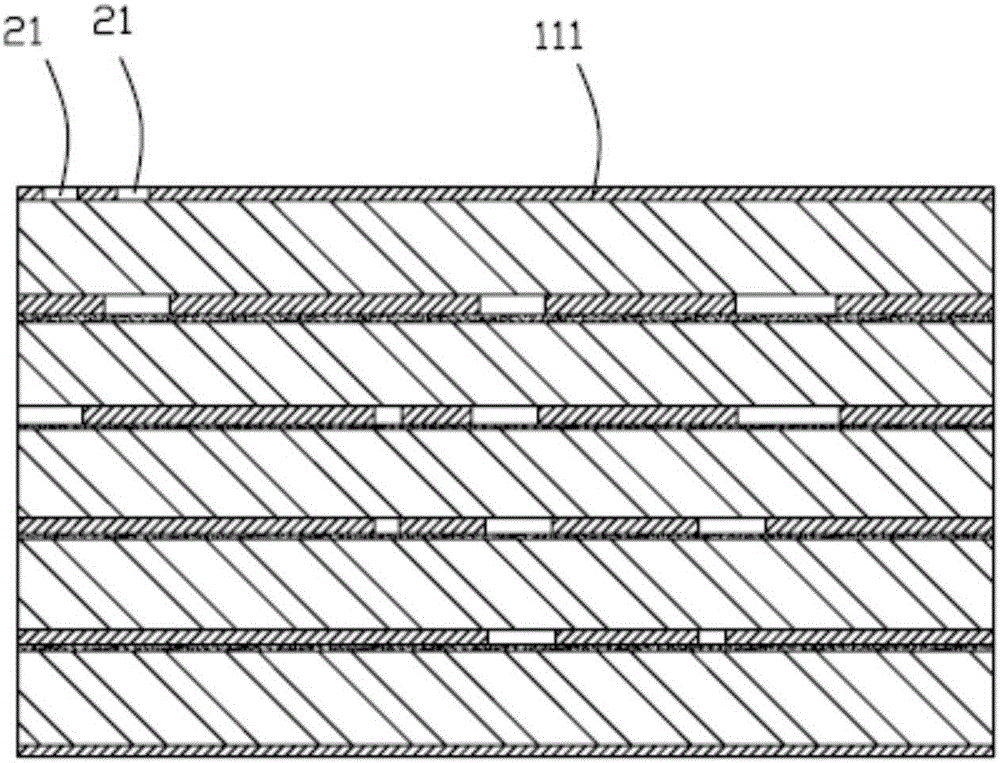

The preparation method of multi-layer pcb board

InactiveCN102291952ASmooth inner layer productionReduce scrap rateMultilayer circuit manufactureEngineeringCopper foil

The invention relates to a method for preparing a multi-layer PCB (printed circuit board). The method comprises the following steps: providing a plurality of core boards according to the number of layers of the multi-layer PCB, wherein the initial copper thickness of the outward surfaces of the outward core boards is more than the target copper thickness; carrying out film stripping treatment on the plurality of core boards; carrying out oxidation treatment on the plurality of core boards subjected to film stripping treatment; using copper foils to carry out lamination treatment on the plurality of core boards subjected to oxidation treatment; and using etching solution to carry out micro-etching copper thinning treatment on the plurality of core boards subjected to lamination to ensure the copper thickness of the outward surfaces of the outward core boards to be equal to the target copper thickness. The formula of the etching solution comprises divalent copper ions (140-160g / l) and hydrogen chloride (3.65-10.95g / l); and the specific weight of the etching solution is 1200-1400g / l. The method has the following beneficial effects: by optimally adjusting the parameters of the micro-etching copper thinning process, the final copper reduction of the product can be very accurate, the inner layer is produced smoothly, the scrappage is reduced and the production cost is saved.

Owner:奥士康精密电路(惠州)有限公司

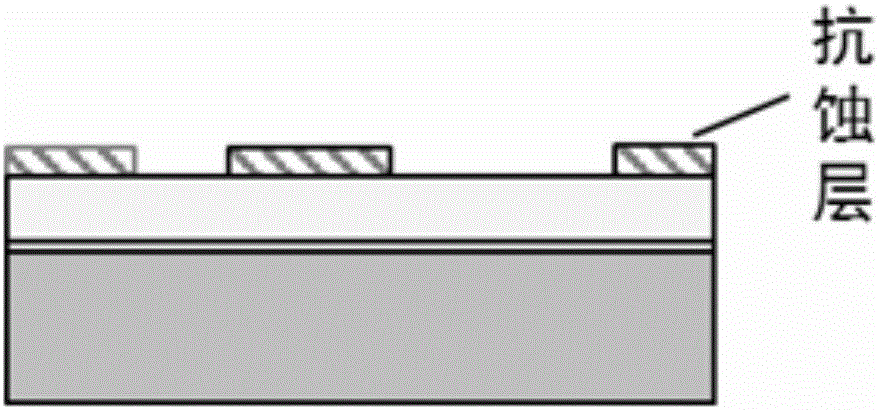

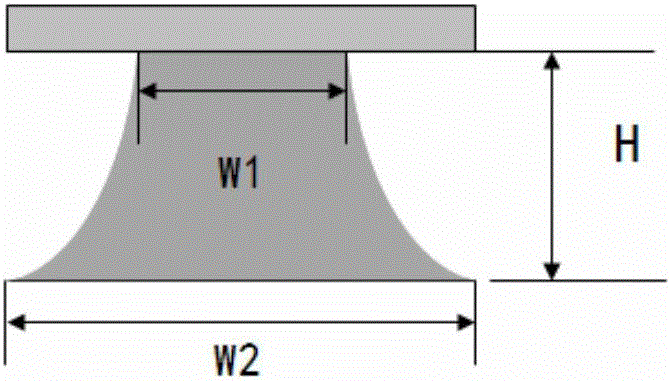

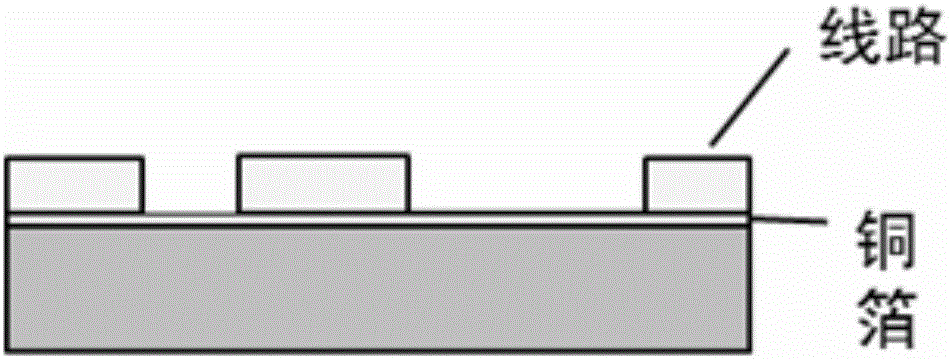

Method for improving uniformity of PCB copper reduction

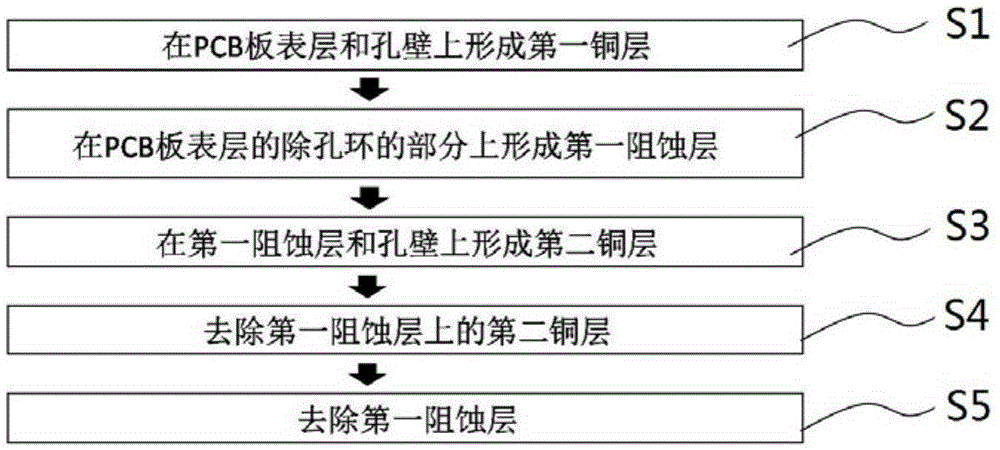

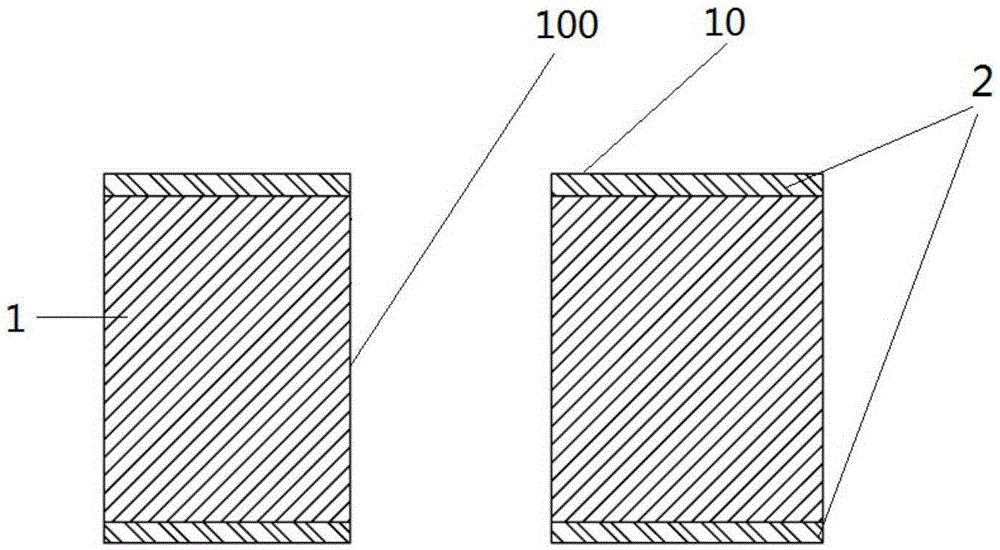

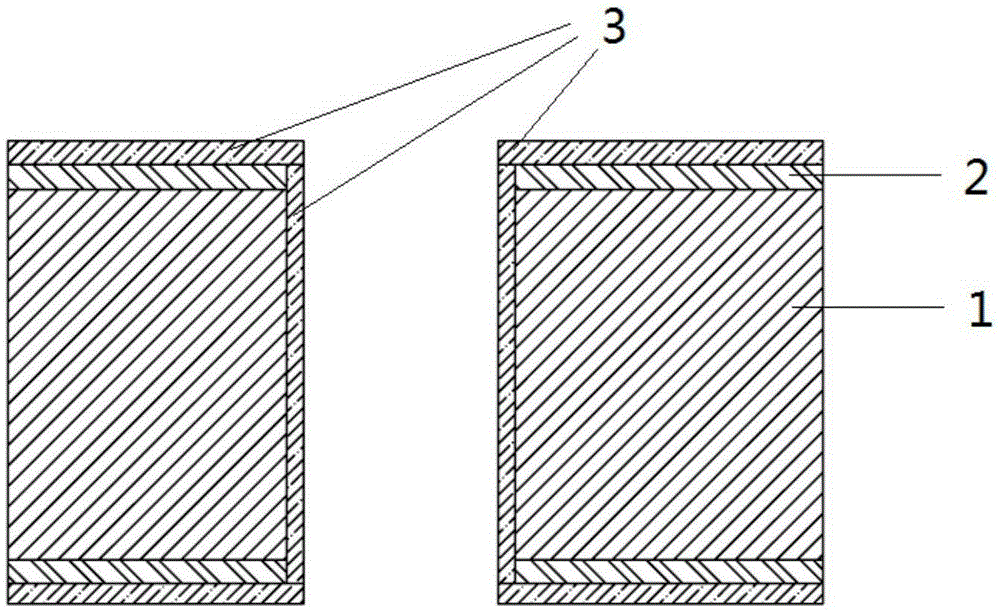

ActiveCN105392299AGuaranteed thicknessGuaranteed uniformityPrinted element electric connection formationSurface layerEtching

The invention discloses a method of improving the uniformity of PCB copper reduction. The method comprises the steps of forming a first copper layer on a surface layer of a PCB and a pore wall; forming an anti-corrosion layer on a portion, other than a pore ring, of the surface layer of the PCB; forming a second copper layer on the first anti-corrosion layer and the pore wall; removing the second copper layer on the first anti-corrosion layer; and removing the first anti-corrosion layer. In this way, the amount of copper reduction can be controlled by forming surface copper at a time, forming pore copper for a plurality of times, and forming the first anti-corrosion layer; the uniformity of the copper reduction is controlled by the etching of the first anti-corrosion layer; the thickness and uniformity of the surface copper are effectively ensured; and the method is convenient to operate and easy to implement.

Owner:NEW FOUNDER HLDG DEV LLC +1

Copper-reducing micro-etching agent and preparation method thereof

PendingCN110913596AImprove isotropyShorten speedConductive material chemical/electrolytical removalHigh current densityNanotechnology

The invention relates to the technical field of metal etching, in particular to a copper-reducing micro-etching agent with excellent isotropic etching performance and a preparation method of the copper-reducing micro-etching agent. According to the invention, a proper amount of the corrosion inhibitor and the N-containing heterocyclic compound are added into a sulfuric acid-hydrogen peroxide etchant system, the copper etching speed of the copper reduction micro-etching agent can be reduced, isotropy of etching is increased. Effective adsorption is carried out at a place with high current density through an N-containing heterocyclic compound. The copper-reducing micro-etching agent is good for deposition of metal ions in places with lower current density, so that the concave parts of the plate surface are leveled, the copper-reducing micro-etching agent has the comprehensive effect of reducing gaps between resin and hole walls at hole openings, the complete morphology is basically maintained, and the smooth proceeding of subsequent processes in the circuit board production is guaranteed.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

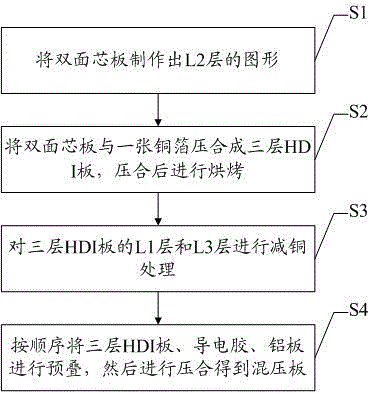

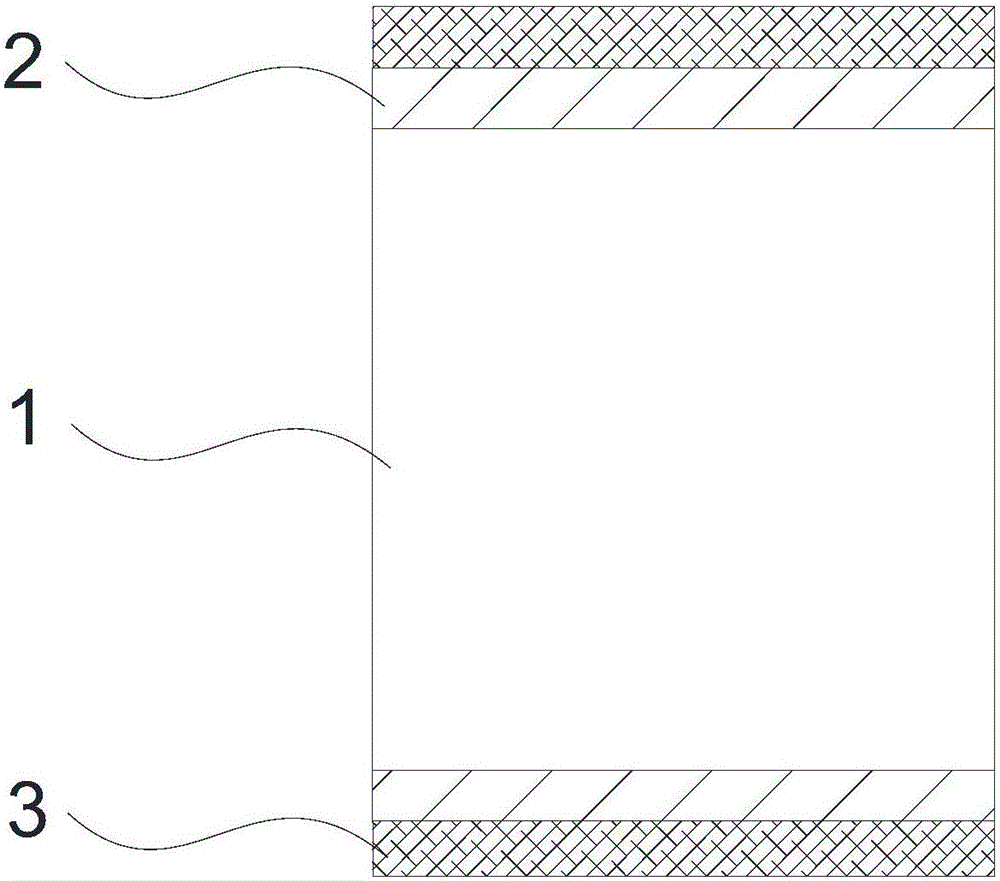

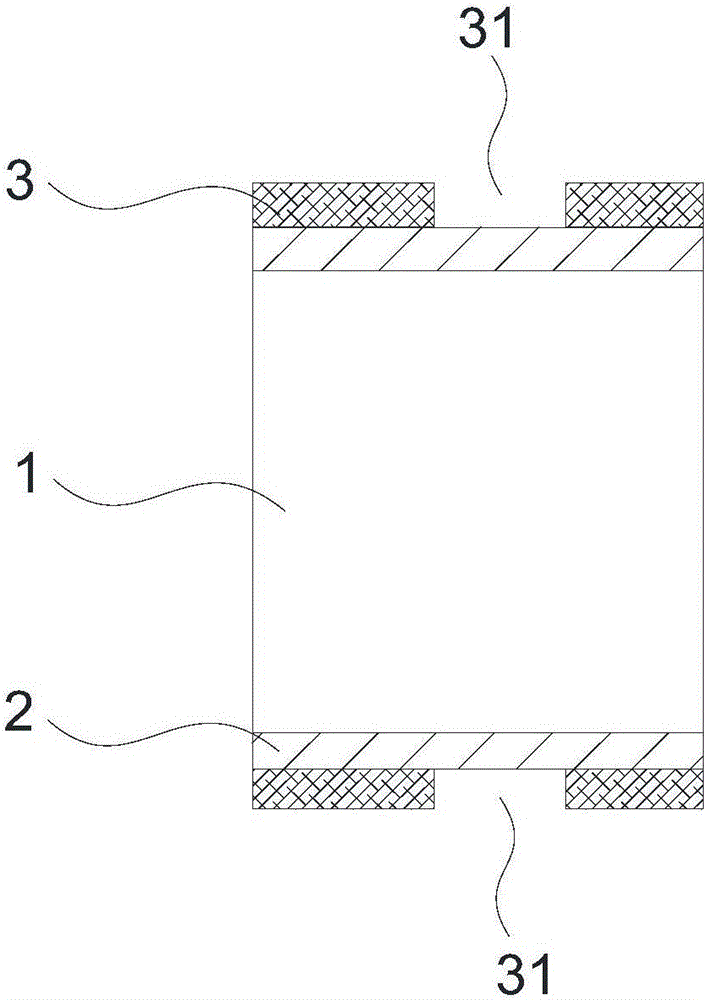

Mixed laminating board with three-layer HDI (high density interconnect) board and aluminum substrate and manufacturing method thereof

ActiveCN106852031AAvoid warpingAvoid bendingMultilayer circuit manufactureConductive pattern layout detailsCooking & bakingHigh density

The invention discloses a mixed laminating board with a three-layer HDI (high density interconnect) board and an aluminum substrate and a manufacturing method thereof. The manufacturing method comprises the following steps of A, manufacturing a pattern of an L2 layer on a double-surface core board; B, laminating the pattern surface of the double-surface core board and a copper foil into the three-layer HDI board, and baking; C, performing copper reduction treatment on an L1 layer and an L3 layer of the three-layer HDI board; D, sequentially pre-overlapping the three-layer HDI board, a conductive adhesive and the aluminum substrate, and laminating, so as to obtain the mixed laminating board. The manufacturing method has the advantages that the phenomena of warping, bending and breaking of the HDI board in laminating are effectively avoided; the thickness of each copper layer of the HDI board is greater than or equal to 35mu m; the tolerance after laminating is controlled within + / -0.1mm, the precision of a finished product is improved, and the difficulty in manufacturing is decreased.

Owner:SHENZHEN KINWONG ELECTRONICS

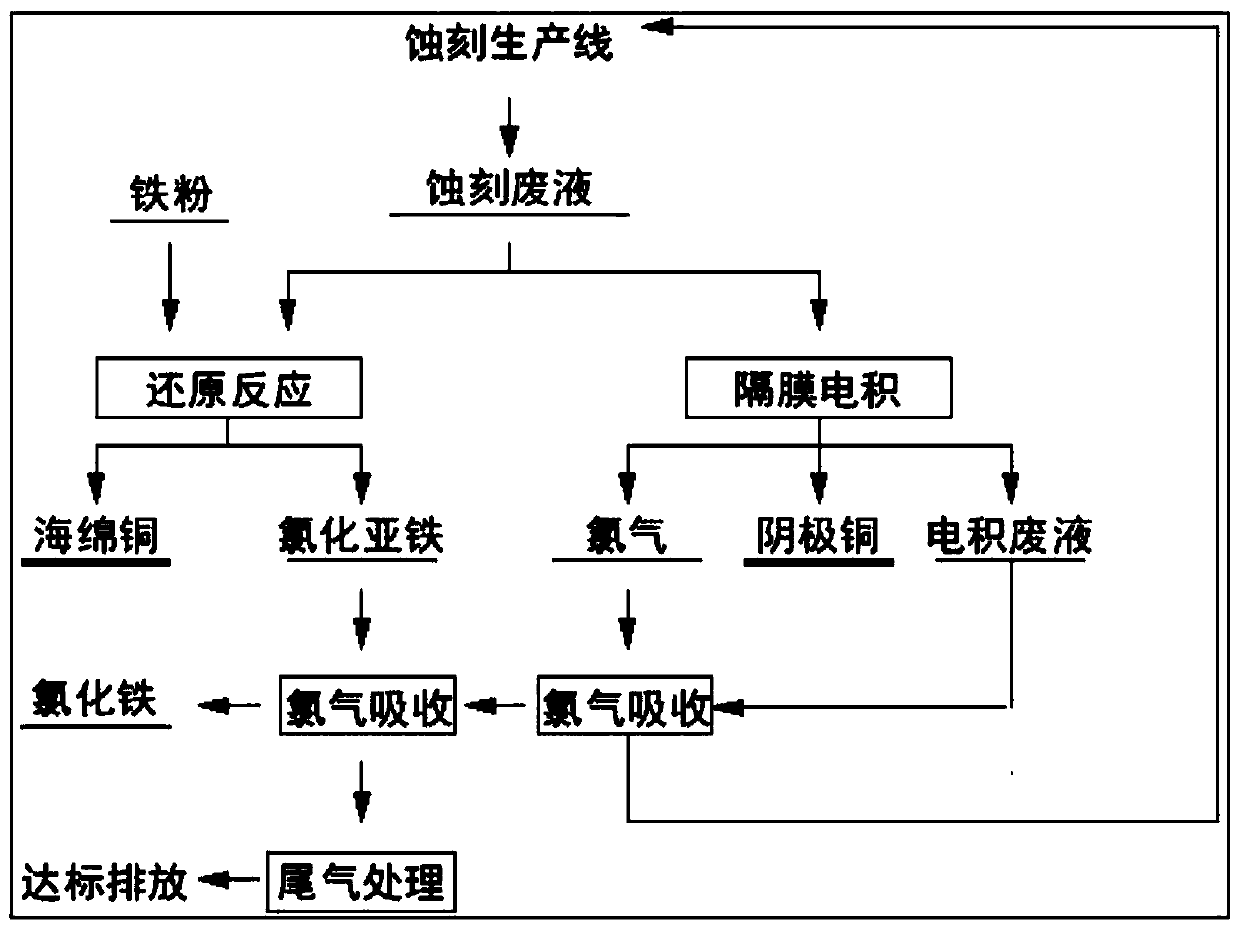

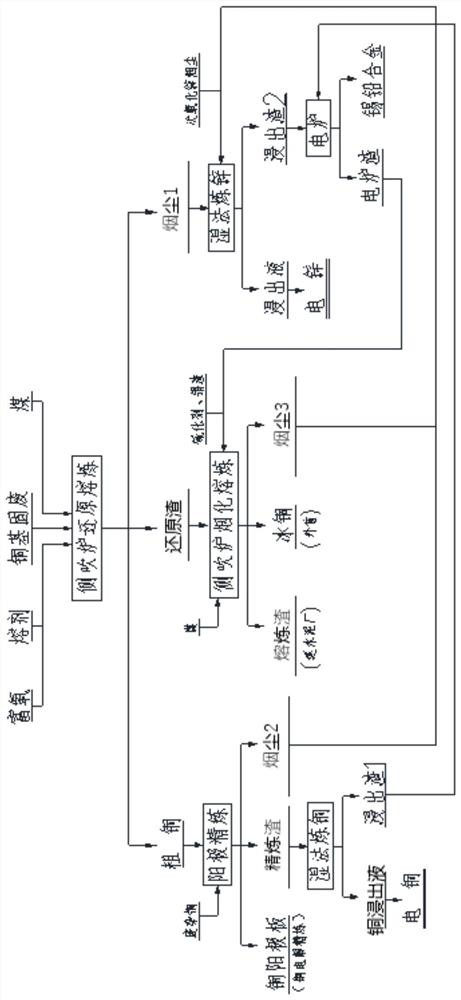

Method for online recovery of copper and chlorine from acidic waste etching liquid and regeneration of etching liquid

ActiveCN111560615AHigh recovery rateAvoid incrementalPhotography auxillary processesIron halidesElectrolysisCu2 ions

The invention provides a method for online recovery of copper and chlorine from acidic waste etching liquid and regeneration of the etching liquid. The method comprises the following steps of electrolysis of the waste etching liquid, regeneration of the etching liquid, recovery of cathode copper, copper reduction, solid-liquid separation, chlorine absorption and tail gas treatment. A part of the acidic etching waste liquid is conveyed into a reaction kettle for copper reduction, that is, an iron powder reduction method is added on the basis of a diaphragm electrodeposition method, copper ionsin the acidic etching waste liquid are reduced into copper powder by adding iron powder, the solution is converted into a ferrous chloride solution, the ferrous chloride solution is used for absorbingresidual chlorine or serving as a product, an open circuit is provided for a closed circulation system of an electrolysis module and an etching process solution, the problems that the system salt istoo high, impurities are accumulated and the etching rate is reduced are solved, the increment of the etching process solution is avoided, and the recovery rate of copper is increased.

Owner:KANFORT JIANGMEN ENVIRONMENTAL TECH CO LTD

Manufacturing method for printed circuit board covered with coating copper layers

InactiveCN105050327AControl depthIncrease contact areaCircuit precursor manufactureManufacturing technologyCopper coating

The invention discloses a manufacturing method for a printed circuit board coveried with coating copper layers, and relates to the circuit board production and manufacturing technology field. The manufacturing method comprises the following steps: firstly, a circuit board with a surface covered with copper foil is provided, part of copper is etched in a position, corresponding to a position of the circuit board needing drilling of a through hole, of the copper foil surface, thus a recess groove is formed in the copper foil surface, and the size of the recess groove is more than the hole diameter of through hole; secondly, the through hole in the first step is drilled; thirdly, full plate electroplating is carried out, and thus the surface of the circuit board and the inner wall of the through hole are covered with copper layersl fourthly, the through hole is subjected to resin filling, the resin for filling is subjected to flatting processing, and thus the outer surface of the covering copper layer is flat. The manufacturing method facilitates to remove the filling resin at the dense hole, manufacturing of copper coating is carried out after part of the recess groove is subjected to electrocoppering, and electrocoppering in the recess groove leaves copper reduction allowance for board wearing, and facilities flatting processing of the hole position. In addition, the contact area of the covered copper layer and the surface copper foil of the circuit board are increased, and the bonding strength is high.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

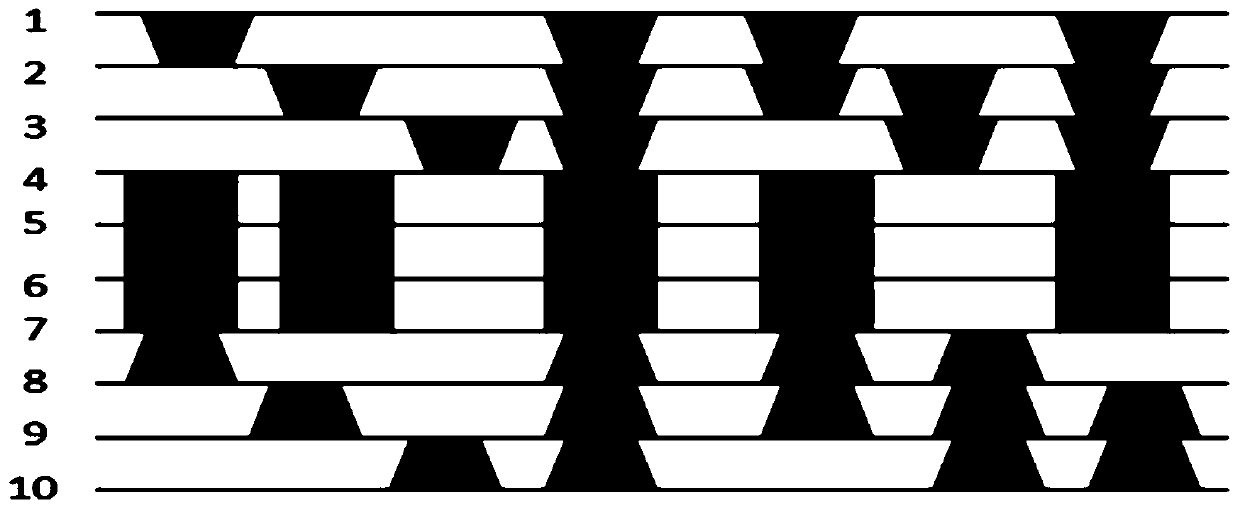

HDI printed circuit board manufacturing method and HDI printed circuit board

InactiveCN110572966AIncrease wiring areaIncrease copper reduction processMultilayer circuit manufactureConductive pattern layout detailsEngineeringPre treatment

The invention provides an HDI printed circuit board manufacturing method and an HDI printed circuit board. The HDI printed circuit board manufacturing method comprises the steps of core board pretreatment, pressing and pattern transfer, pattern plating and post process. According to the invention, a blind hole and a mechanical buried hole are combined through four lamination steps; the wiring areais maximized; the problems of delamination and poor blistering in the existing manufacturing process are solved; a copper reduction process is added after each lamination step; all holes are plated through spot plating, which ensures that the copper thickness of an etched circuit does not exceed 12 microns; and the method improves the production yield, reduces the production cycle, and reduces the cost.

Owner:深圳明阳电路科技股份有限公司

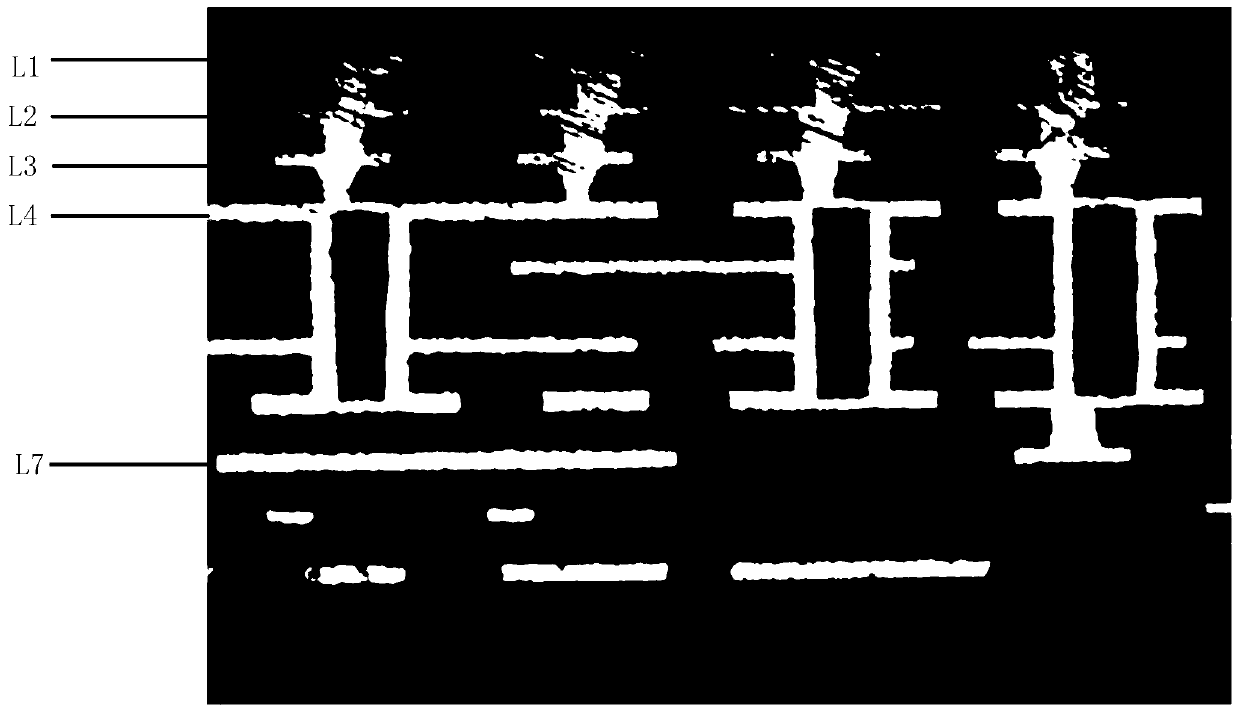

Manufacturing method of high-frequency mixed pressure printed circuit board

PendingCN110337200AReduce the amount of microetchImprove Hoz, the problem of piercing the bottom PAD of the blind holeMultilayer circuit manufacturePrinted element electric connection formationResistCopper plating

The invention provides a manufacturing method of a high-frequency mixed pressure printed circuit board. The method is characterized in that the method comprises the following steps: cutting-inner layer processing-etching-inspection-browning-pressing-copper reduction-laser drilling-gum residue removal-copper plating-porefilling-copper reduction-porefilling-copper reduction-drilling-degumming-boardplating-outer pattern transfer-etching-AOI detection-solder resist printing-text printing-moulding-flying probe test-silver plating- appearance inspection-packaging. The method solves the problem of not full hole filling of a high-frequency mixed pressure HDI board, optimizes hole filling and surface copper proportion hole filling parameters of the high-frequency mixed pressure HDI board, improvesthe quality problems of thick surface copper and poor uniformity in the prior art and reduces input of labor and material cost.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

Method for compensating copper thickness of PCB (printed circuit board)

ActiveCN104640360AReduce the problem of high edge and low centerEasy to controlPrinted circuit manufactureAcid etchingPrinted circuit board

The invention provides a method for compensating copper thickness of a PCB (printed circuit board). Forward and reverse pulse plating technology is adopted, so that the phenomenon that the edge of a copper surface of the PCB is high and the middle of the copper surface is low is effectively reduced. After copper reduction operation on the PCB for the first time, the PCB is turned upside down to be subjected to copper reduction, the defect of uneven copper reduction caused by time difference when the PCB enters acid etching liquid or micro etching liquid is effectively overcome. A milder micro etching liquid system is adopted and is organically combined with the acid etching technology, so that the processing efficiency on the copper thickness of the PCB is effectively improved.

Owner:SHENZHEN XINGDA PCB

Manufacturing method of substrate-like PCB

ActiveCN107809855AMeet packaging technical requirementsGood dimensional stabilityConductive material chemical/electrolytical removalCircuit susbtrate materialsSurface cleaningElectroplating

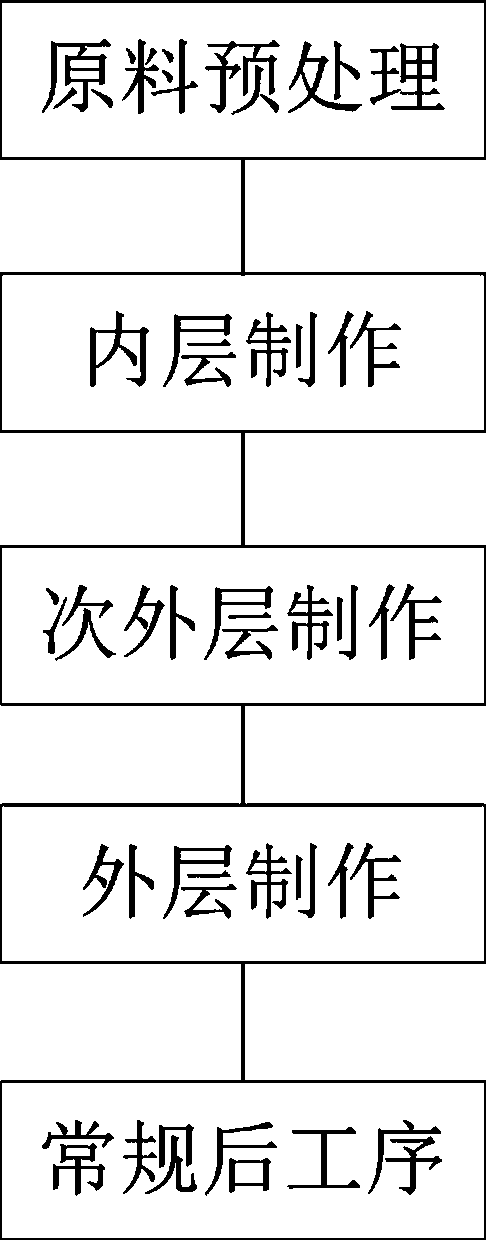

The invention discloses a manufacturing method of a substrate-like PCB. The manufacturing method comprises the following steps of raw material pretreatment: firstly a core board is manufactured by using BT material, a copper layer is coated on the upper and lower surfaces of the core board and the core board is enabled to form a copper-clad BT core board, then the copper-clad BT core board is cutaccording to the required side and board surface cleaning treatment is performed on the cut copper-clad BT core board; internal layer manufacturing, second external layer manufacturing and external layer manufacturing: concretely, internal layer manufacturing includes the process of performing copper reduction, brownification, blind hole lasering, adhesive dispensing, hole metallization, hole filling and electroplating, line manufacturing and pressing on the pretreated BT core plate; and routine post-treatment which is performed after completion of internal and external layer manufacturing. The manufacturing method of the substrate-like PCB has the advantages of being narrow in linewidth so as to further meet the SIP packaging technical requirements.

Owner:通元科技(惠州)有限公司

Method for comprehensive recovery of valuable metal from copper-based solid waste

ActiveCN111733325AEasy to recycleSuitable for industrial applicationsPhotography auxillary processesProcess efficiency improvementSlagZinc

The invention discloses a method for comprehensive recovery of valuable metal from copper-based solid waste. The method comprises the following steps of performing reduction smelting after uniform mixing and proportioning of the copper-based solid waste, coal and flux, and producing blister copper, reducing slag and dust 1; performing anode refining for the produced blister copper to obtain a copper anode plate, refining slag and dust 2, wherein the fuel rate is 5%-15%, and the slagging rate is 3%-30%; and acid leaching the produced refining slag to obtain cathode copper and leaching residues1. According to the method, not only can copper in the copper-based solid waste be separated effectively, but also scrap copper, secondary zinc oxide dust, tin slag 1 and additional metal solid wastecan be handled; and the purpose of cascade comprehensive and efficient recovery of copper, zinc, lead and tin in the whole process is achieved.

Owner:CHINA ALUMINUM INT ENG CORP +1

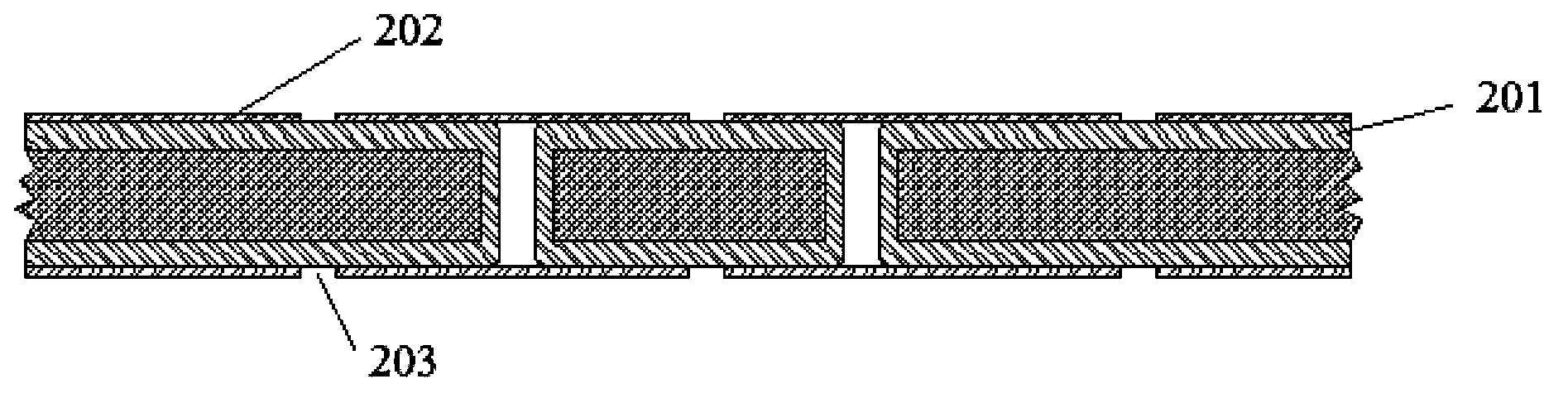

Flexible circuit board and manufacturing method thereof

ActiveCN105657988AReduce height differenceEasy to manufacturePrinted circuit aspectsHigh frequency circuit adaptationsCopper platingMetallurgy

The invention provides a manufacturing method for a flexible circuit board. The manufacturing method comprises: a substrate is provided, wherein the substrate consists of a base layer, a first bottom copper layer, and a second bottom copper layer; hole opening is carried out to obtain a first hole passing through the base layer and the first bottom copper layer; a dry film is pasted on the first bottom copper layer and the second bottom copper layer; the part of dry film is removed to expose the part of first bottom copper layer, wherein the exposed first bottom copper layer encircles the first hole in an annular mode; copper reduction processing is carried out on the exposed first bottom copper layer, so that a second hole communicated with the first hole is formed in the first bottom copper layer; local copper plating is carried out on the first hole and the second hole to form copper-plated hole rings are formed on the walls of the first hole and the second hole and a conducive hole is obtained; and the dry film is removed and the first bottom copper layer is processed to form a circuit layer, thereby obtaining a flexible circuit board. In addition, the invention also relates to a multi-layer flexible circuit board formed by using the manufacturing method.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

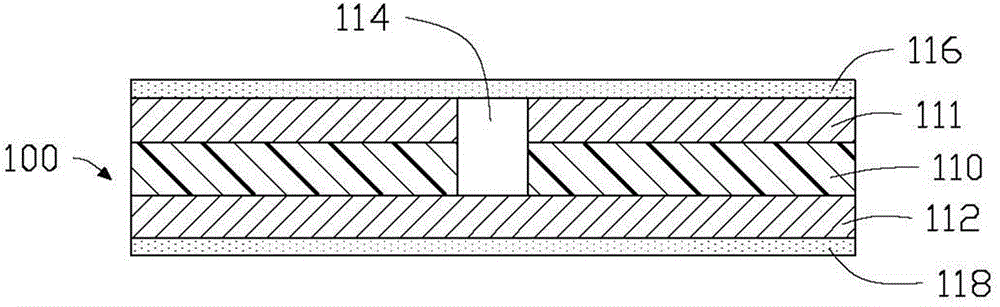

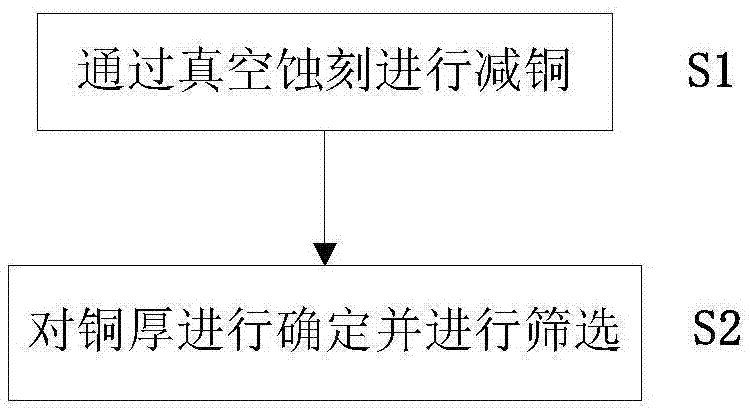

Copper foil substrate preparation method and metamaterial processing method using same

The invention relates to the field of material processing and particularly relates to a copper foil substrate preparation method and a metamaterial processing method using the same. The method comprises steps of uniformly reducing the copper thickness by vacuum etching of a plurality of copper foil substrates of the ordinary thickness; determining the thicknesses of the plurality of copper foil substrates after reducing the copper thickness; and selecting a copper foil substrate having a copper thickness conforming to a copper thickness specification and a copper thickness uniformity to a preset threshold as a substrate for subsequent microstructure processing. The copper foil substrate preparation method applies the vacuum etching only used in the PCB production process to the uniform reduction of the copper thickness, through the vacuum etching, the copper foil substrate of the ordinary thickness is processed into the thin copper foil substrate used in the microstructure processing, the processed thin copper foil substrate has the same properties as the thin copper foil substrate supplied on the market, and the cost of the thin copper foil substrate obtained by the copper reduction process is reduced by more than half compared with the thin copper foil substrate of 3-9 um which is directly purchased from the market, so that the problems the existing thin copper foil substrate is high in cost, difficult to process and the like are solved.

Owner:KUANG CHI INST OF ADVANCED TECH

HDI board manufacturing technology capable of improving blind hole cushion release

ActiveCN105101681AGrinding volume controllableImprove grinding efficiencyPrinted element electric connection formationManufacturing technologyEngineering

The invention belongs to the field of circuit board processing, and particularly relates to an HDI board manufacturing technology capable of improving blind hole cushion release. Controllability of belt sanding amount is realized by optimizing belt sanding parameters, the blind hole bottom is avoided from being combined with an electroplated layer critical interface, and the belt sanding efficiency after an electroplating process is improved; the copper thickness of a blind hole orifice is thinned through chemical copper reduction, the tensile stress for the blind hole bottom during sanding is reduced, and the risk of cushion release caused by microcracks formed at the blind hole bottom is reduced; the controllability of belt sanding amount is realized, the copper is reduced in a chemical copper reduction manner firstly before film withdrawl, the tensile stress for the blind hole bottom during sanding can be reduced, the formation of the microcracks at the blind hole bottom is avoided, and the risks of blind hole microcracks and cushion release can be reduced; the problems of microcracks and cushion release for an HDI board blind hole are solved; the cost is reduced, the success rate is improved, the consumption of materials is reduced, the ideas of energy conservation and environmental protection are met, and the HDI board manufacturing technology has great economic value and market prospect.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

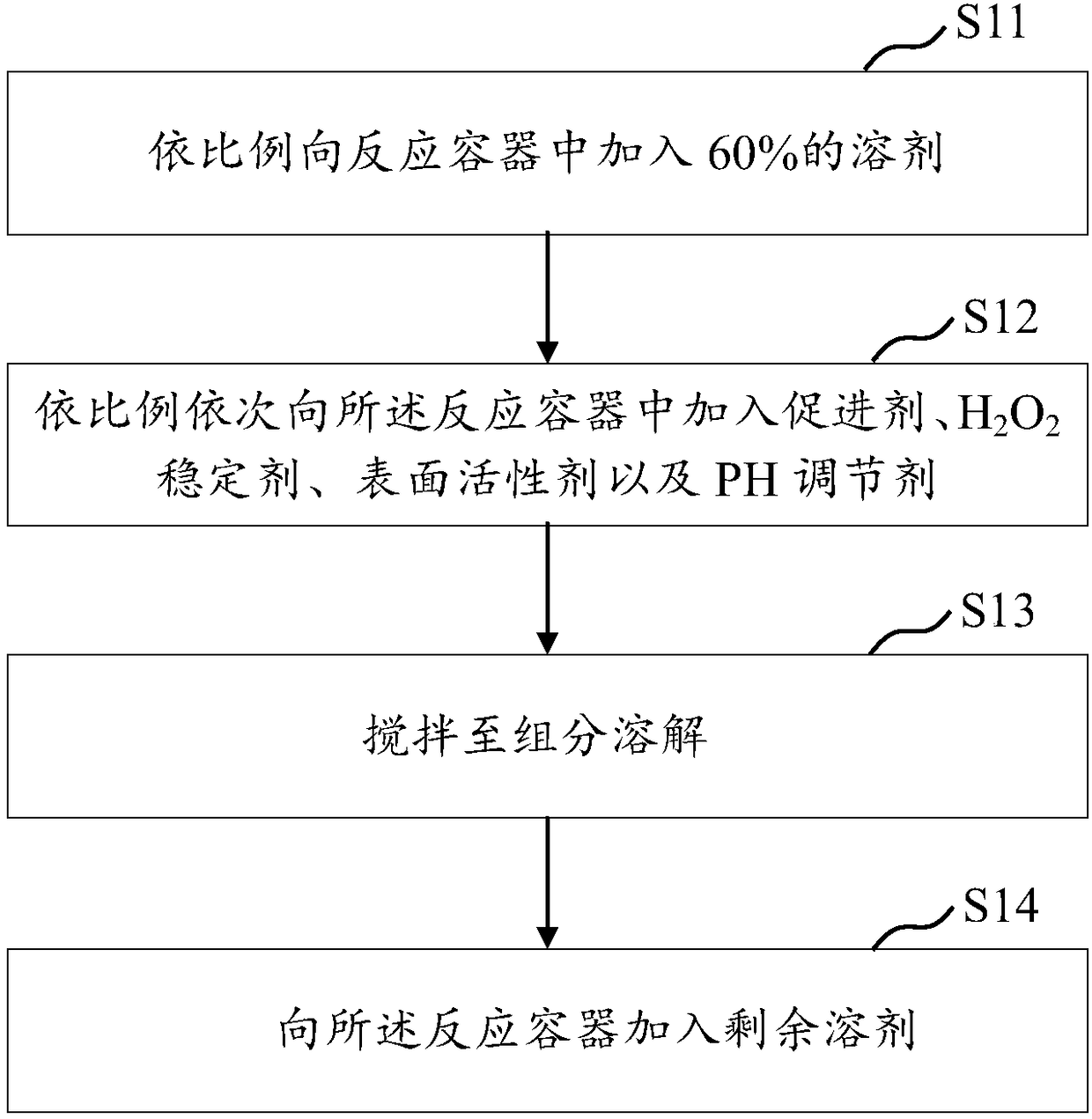

High-speed reduction copper liquid for PCB and preparation method

The invention discloses high-speed reduction copper liquid for a PCB and a preparation method. The high-speed reduction copper liquid is applied to copper reduction etching treatment. Etching medicineliquid comprises an accelerant, a surfactant, a PH modifier, a H2O2 stabilizing agent and a solvent; in per liter of the medicine liquid, the content of the accelerant is 30-36 g, the content of thesurfactant is 12-18 g, the PH modifier is 100-140 ml 50% sulfuric acid solution, the solvent is 700-740 ml water, the H2O2 stabilizing agent comprises three components, wherein the first component is35-45 ml, the second component is 15-21 ml, and the third component is 50-54 g. The H2O2 stabilizing agent is used for reducing the decomposition rate of H2O2, and improving the copper ion tolerance of the high-speed reduction copper liquid.

Owner:深圳市百诣良科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com