Patents

Literature

523results about "Iron halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

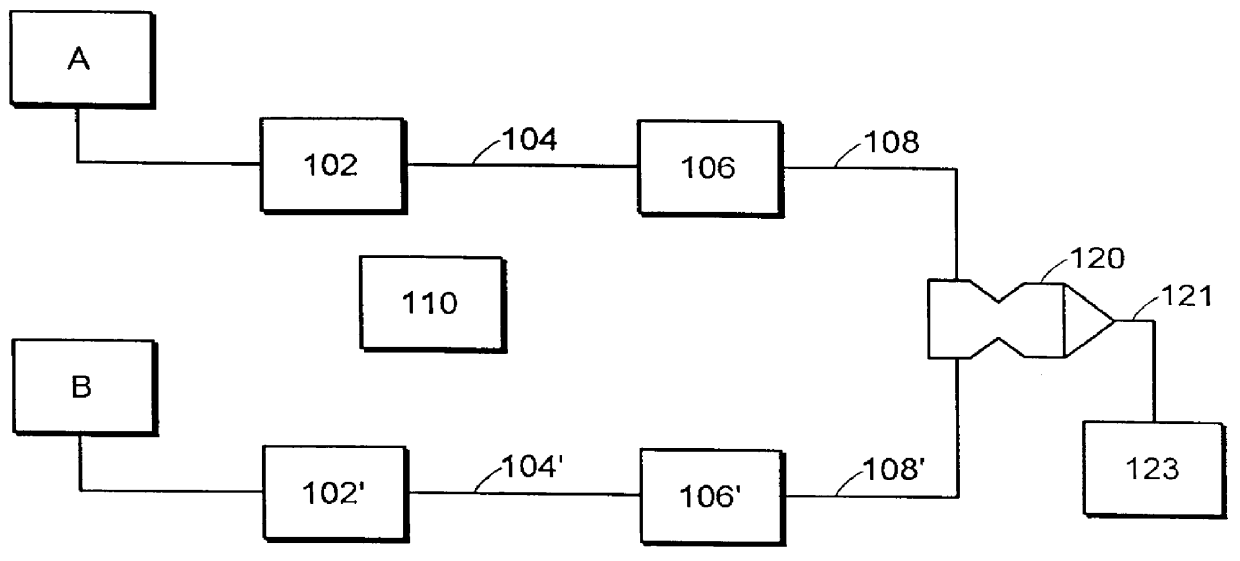

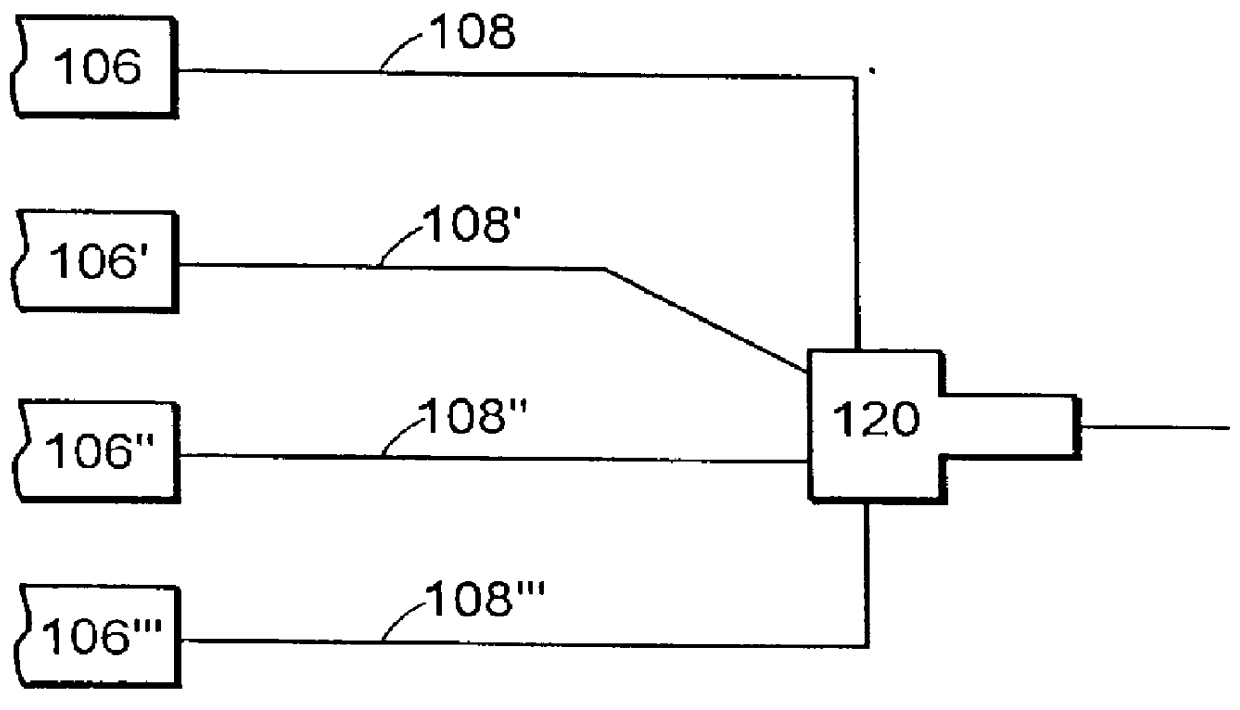

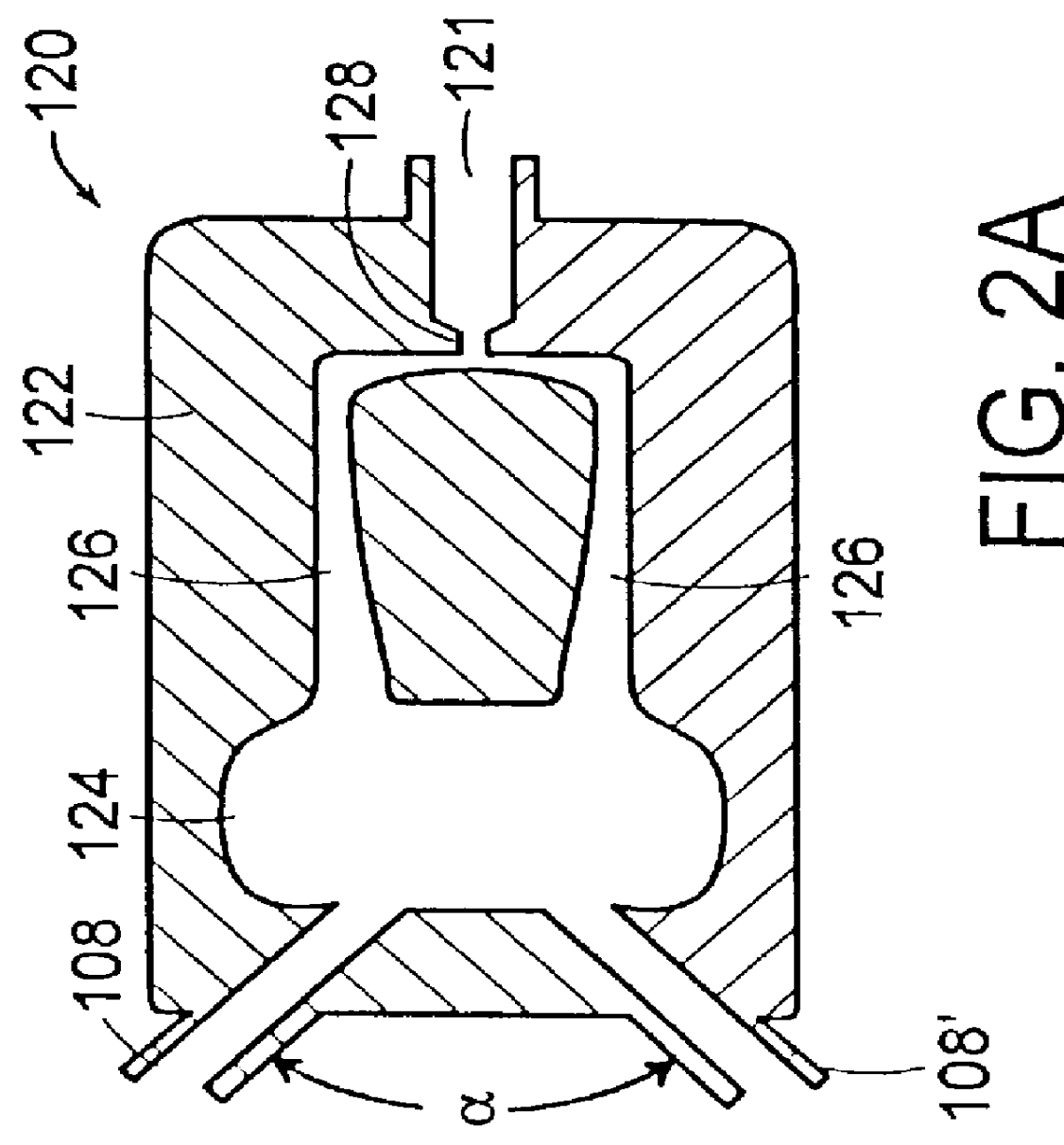

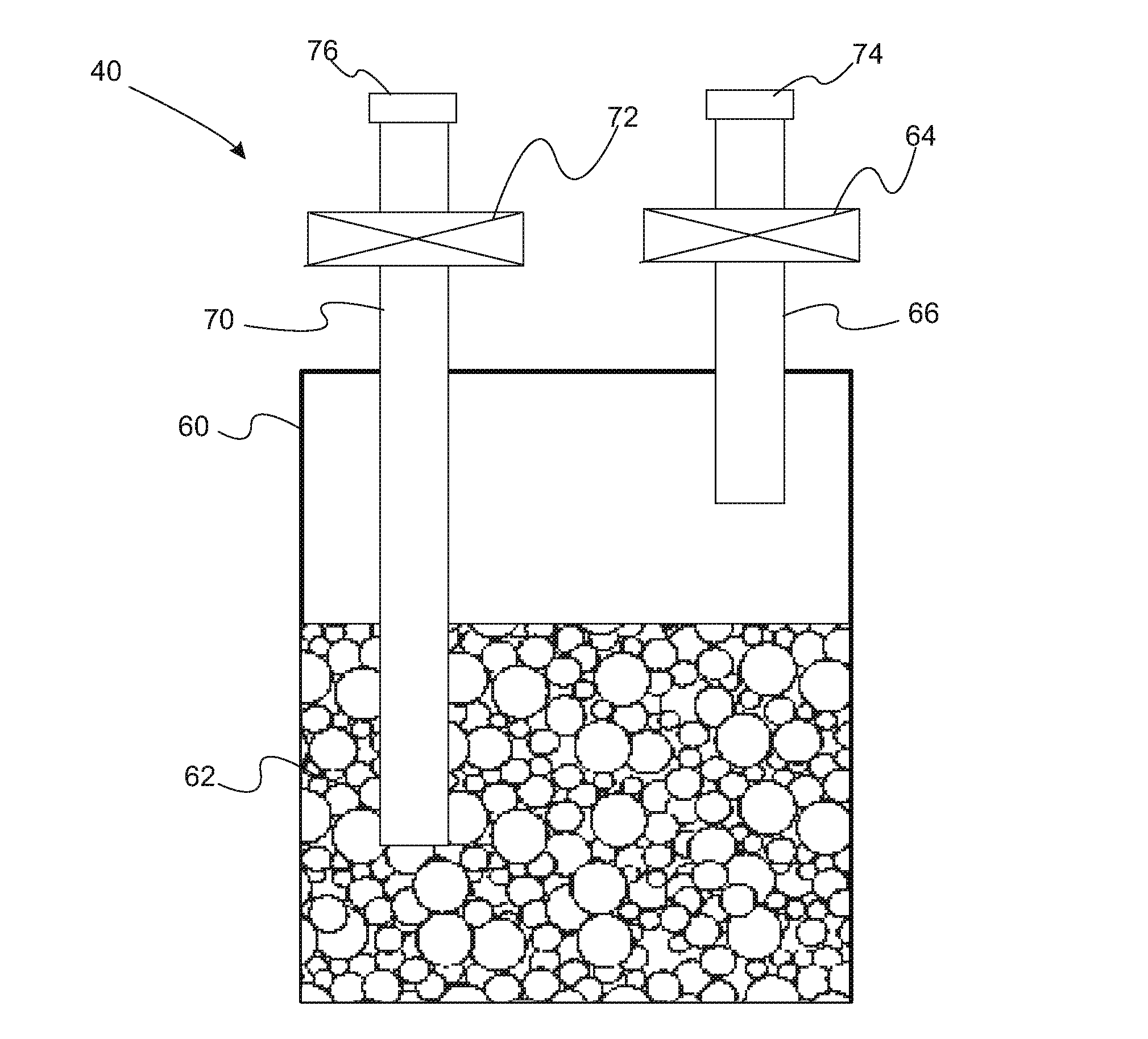

Use of multiple stream high pressure mixer/reactor

InactiveUS6159442AHigh strengthMaintain good propertiesCalcium/strontium/barium carbonatesPressurized chemical processStream flowHigh pressure

Owner:MICROFLUIDICS INT

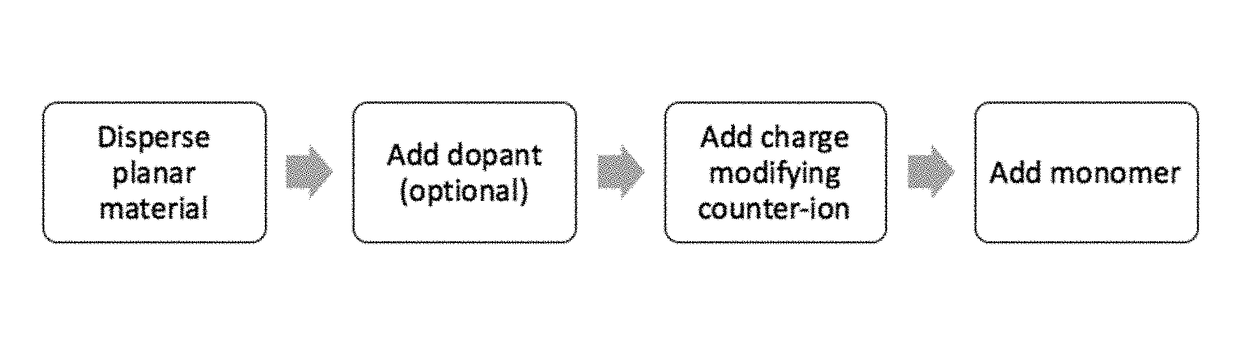

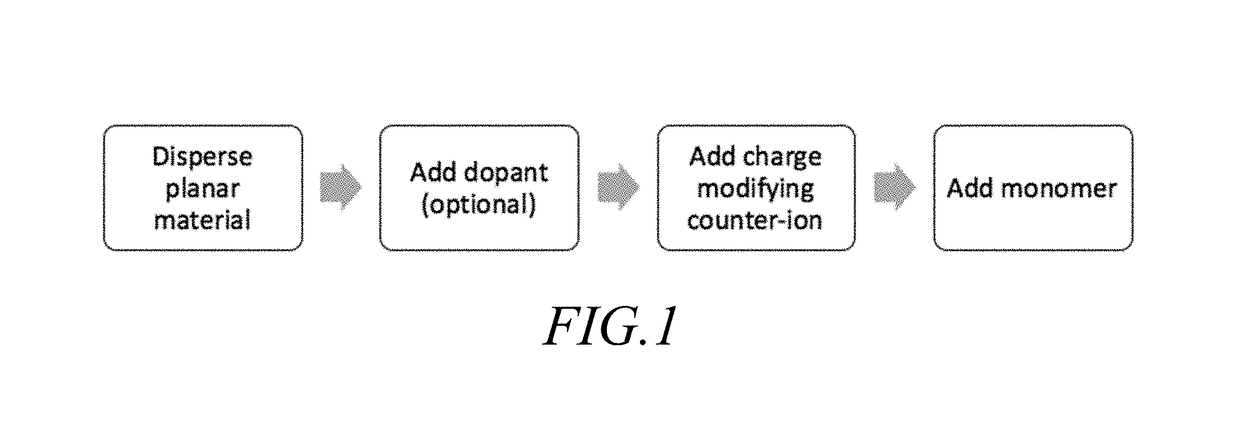

Conductive polymer-matrix compositions and uses thereof

A rubber composition comprising a plurality of composite particles and an elastomer is provided. A composite comprising a conductive polymer and a clay particle are also provided. Use of each in various applications and methods of preparing each are also provided.

Owner:POLYDROP LLC

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

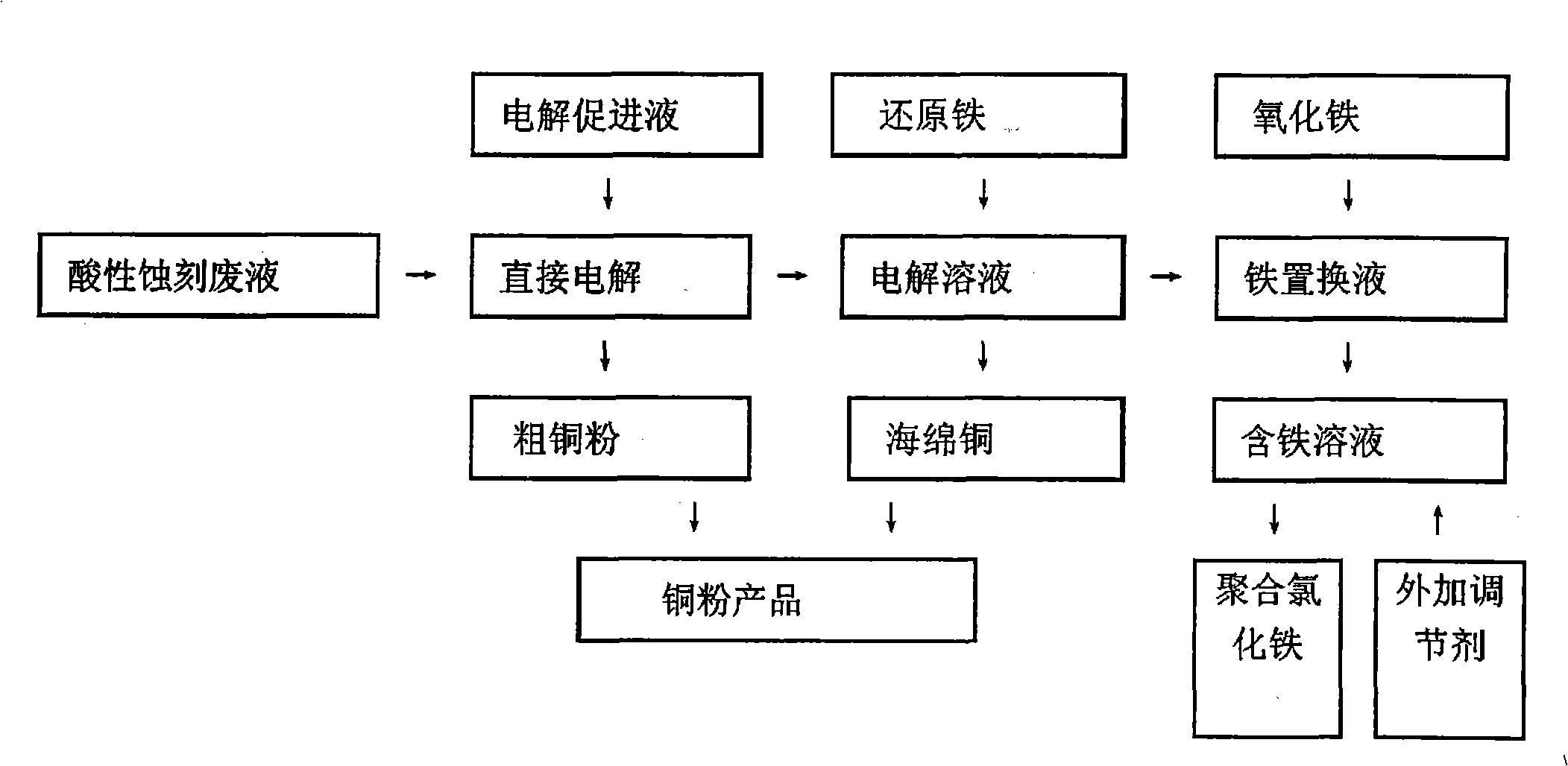

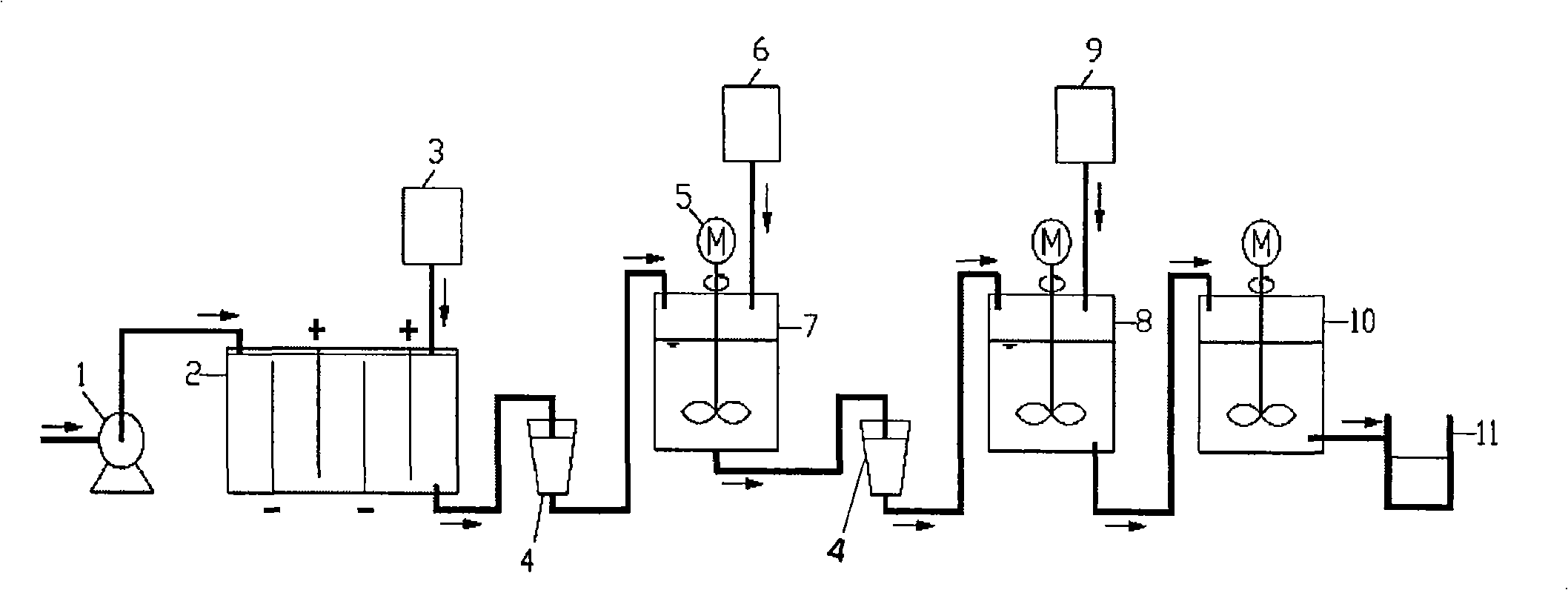

Method for extracting copper from printed circuit board acidic spent etching solution and preparing poly ferric chloride

InactiveCN101353795ASolve the rare problem of recyclingPromote resource recyclingPhotography auxillary processesProcess efficiency improvementAcid etchingElectrolysis

The invention relates to a method for extracting copper of a PCB acid etching waste liquid and preparing polyferric chloride, which comprises the following steps: the PCB acid etching waste liquid is electrolyzed directly and copper powder precipitated by electrolysis is reclaimed; reduced iron is added into a mixed solution after the electrolysis and copper sponge precipitated by replacement reaction is reclaimed; claimed crude copper is purified and prepared into copper powder products; the mixed solution after replacement reaction is added with ferric oxide or a substance containing Fe irons; the mixed solution mingled with the Fe irons is added respectively with a polymeric antioxidant and a stabilizer and simultaneously, the pH value of which is regulated with acid or alkali; and finally, the PFC is prepared. The method of the invention completely realizes reclamation and recycling of wastes and water environment treatment and finally 'zero' emission and has good environmental protection, simple preparation process, high economic benefit and wide application scope.

Owner:HUNAN VARY TECH

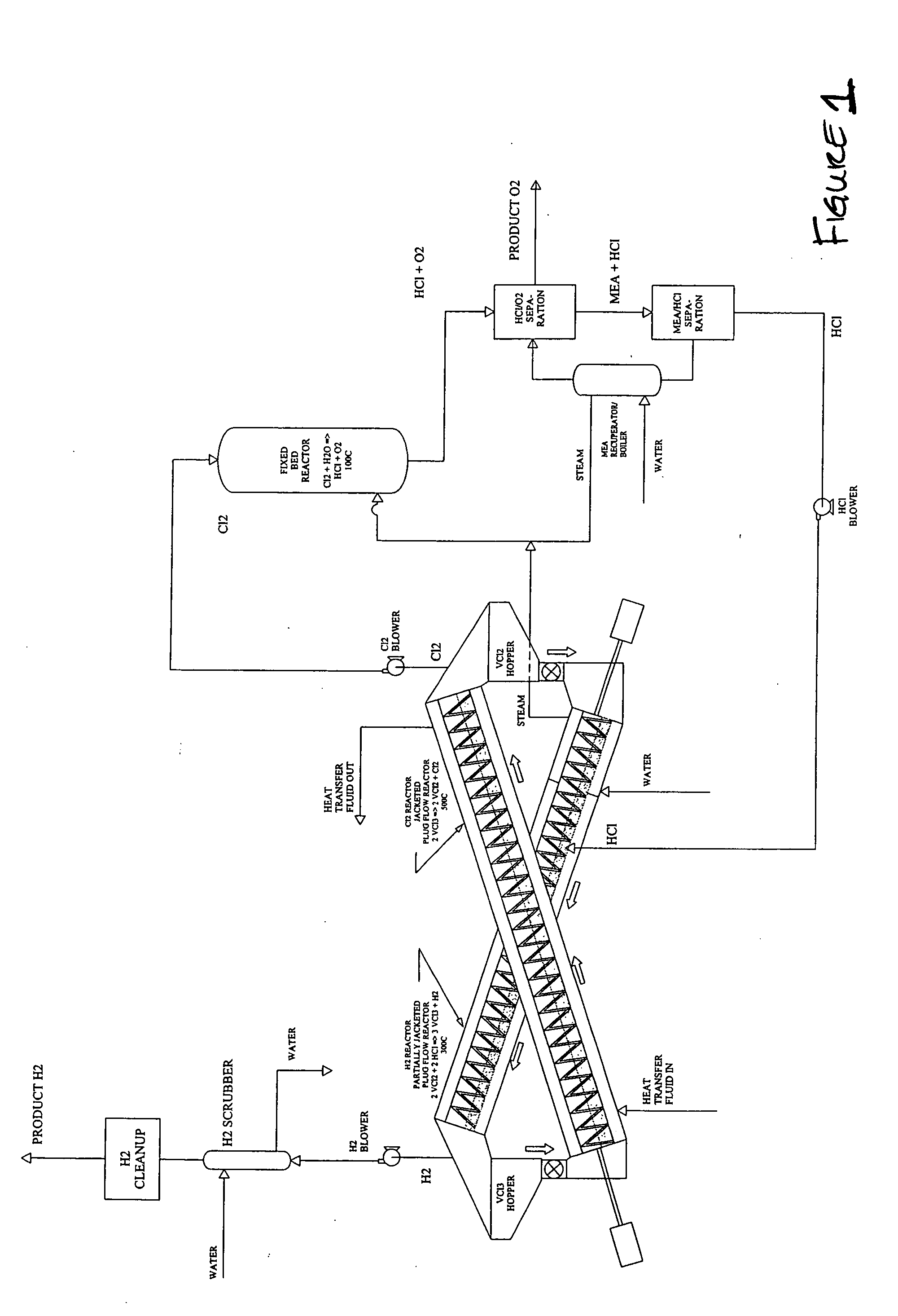

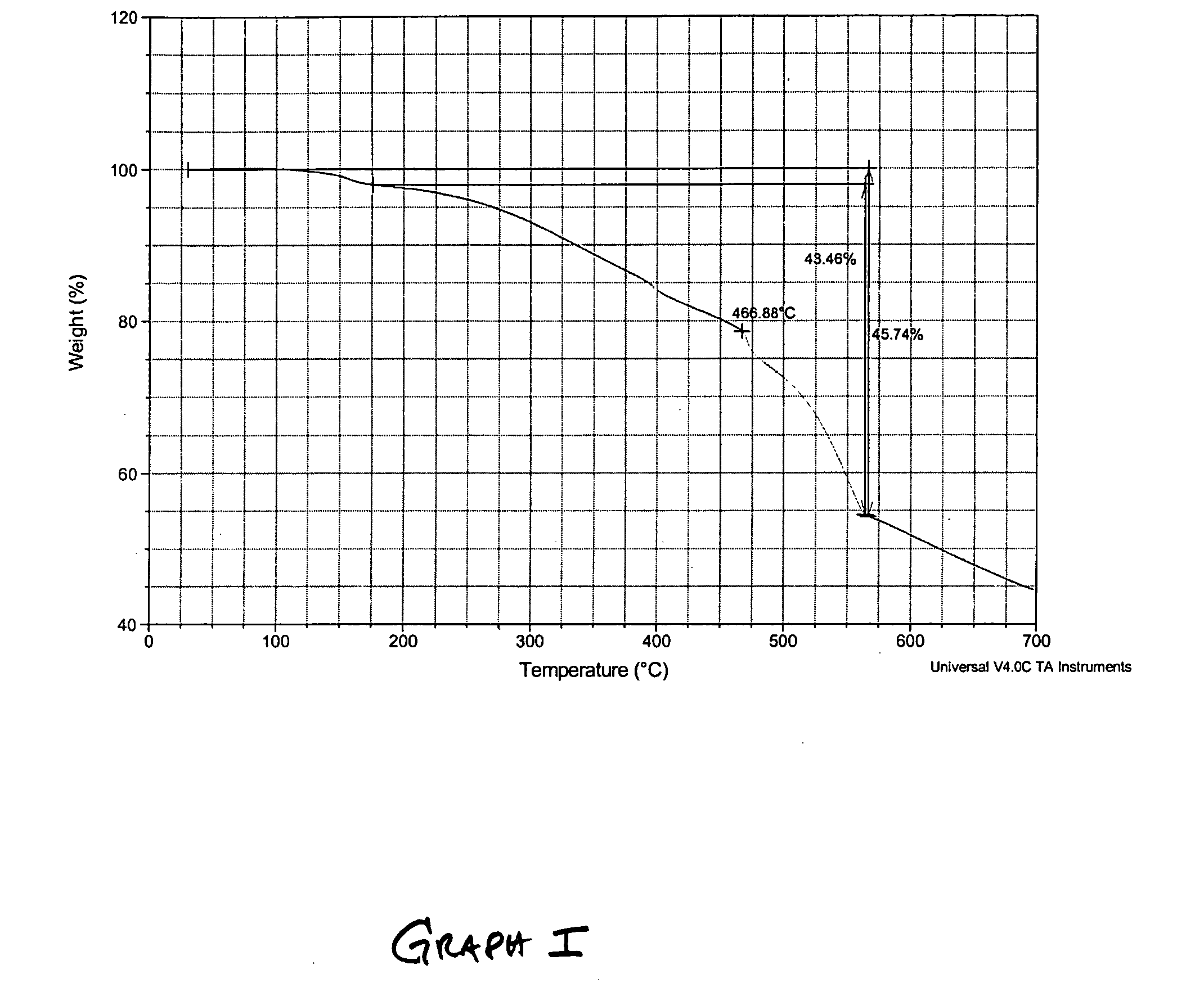

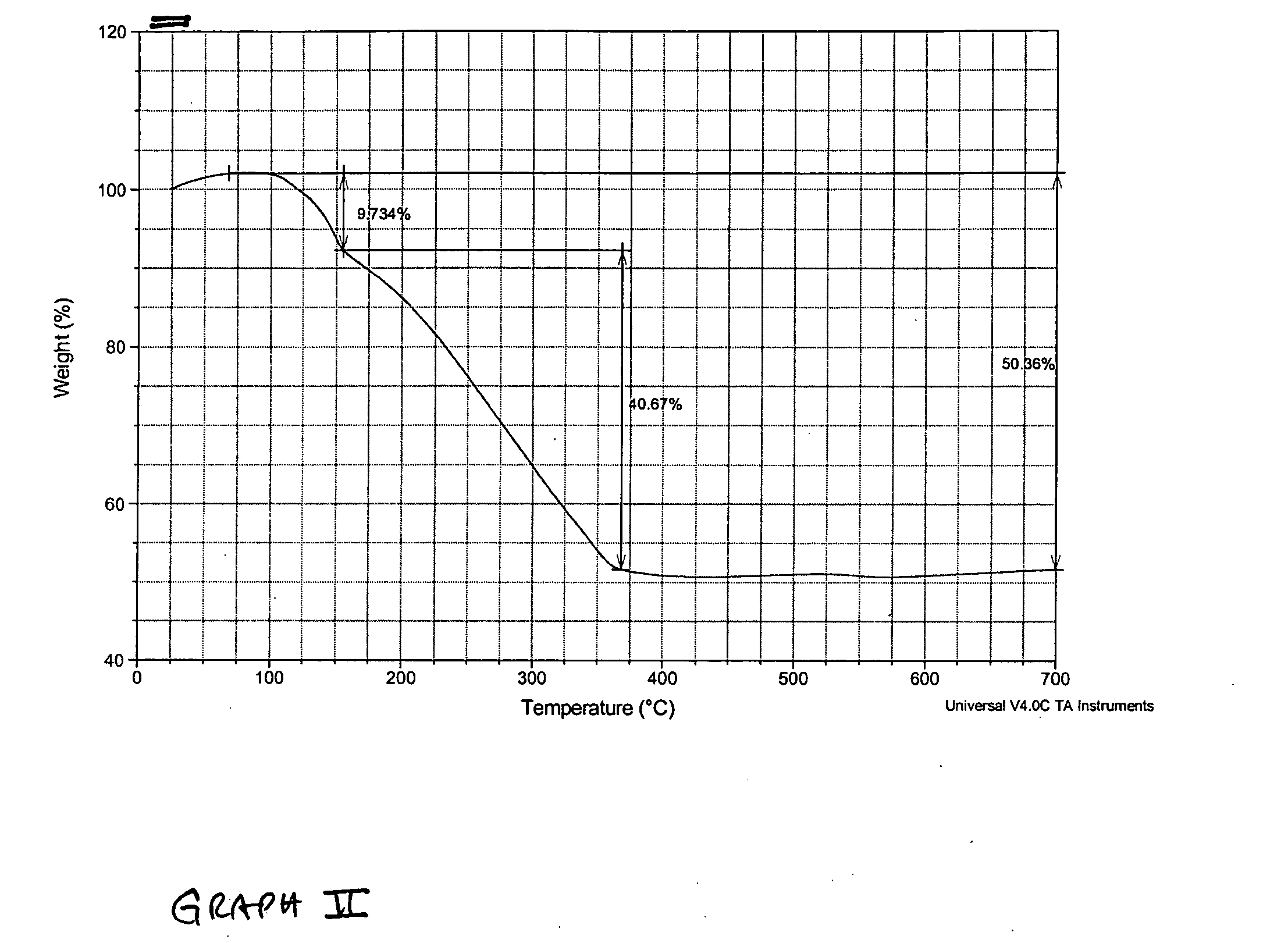

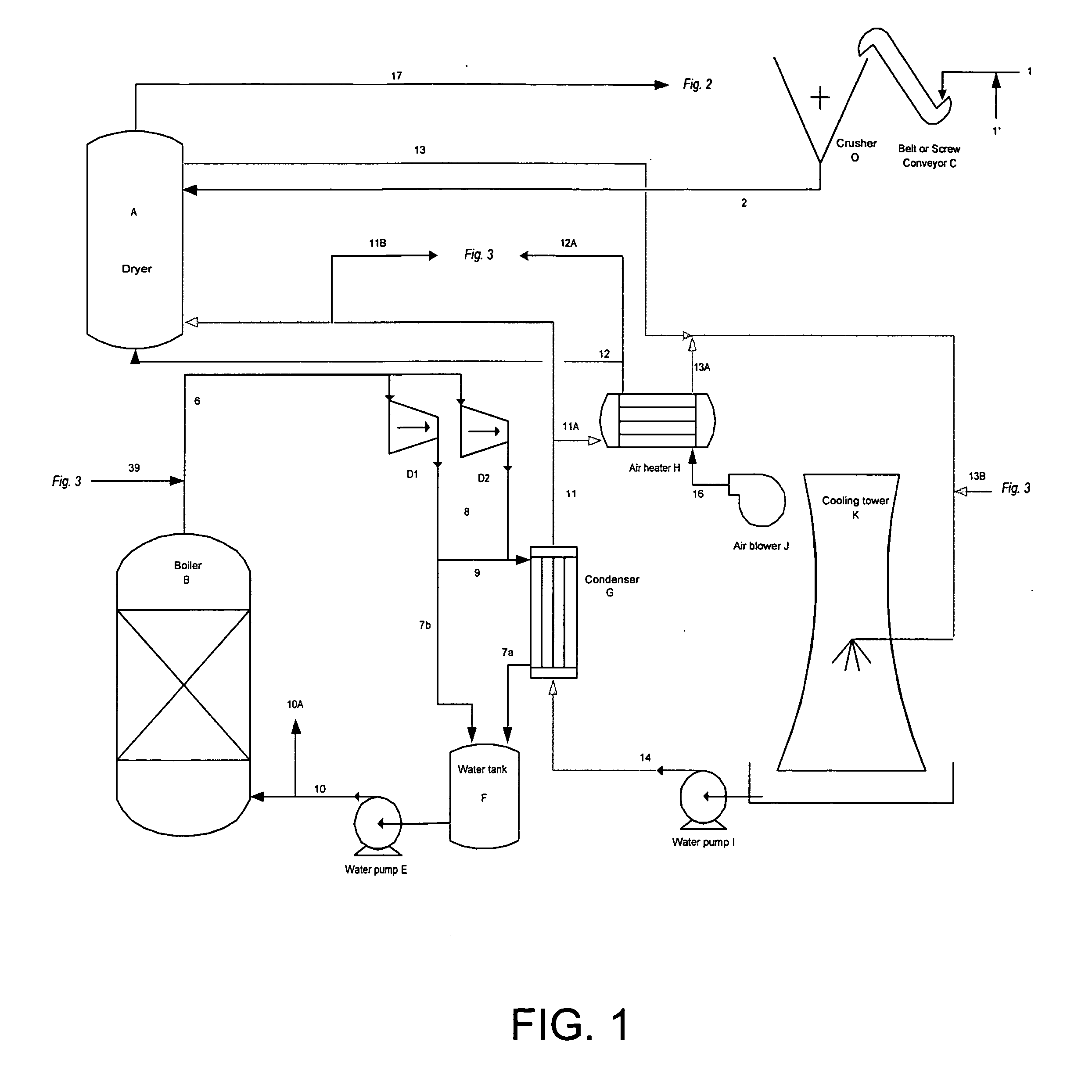

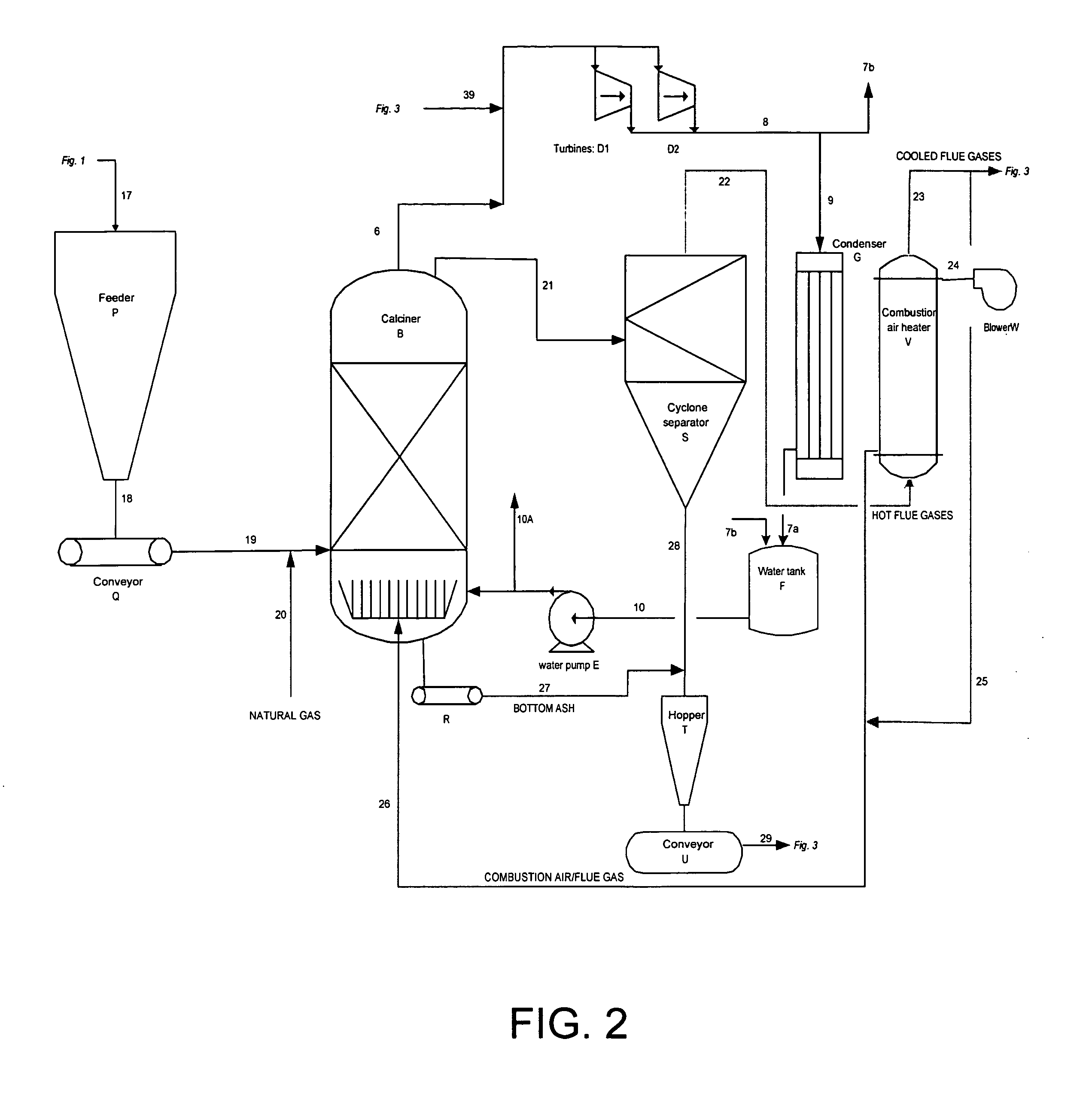

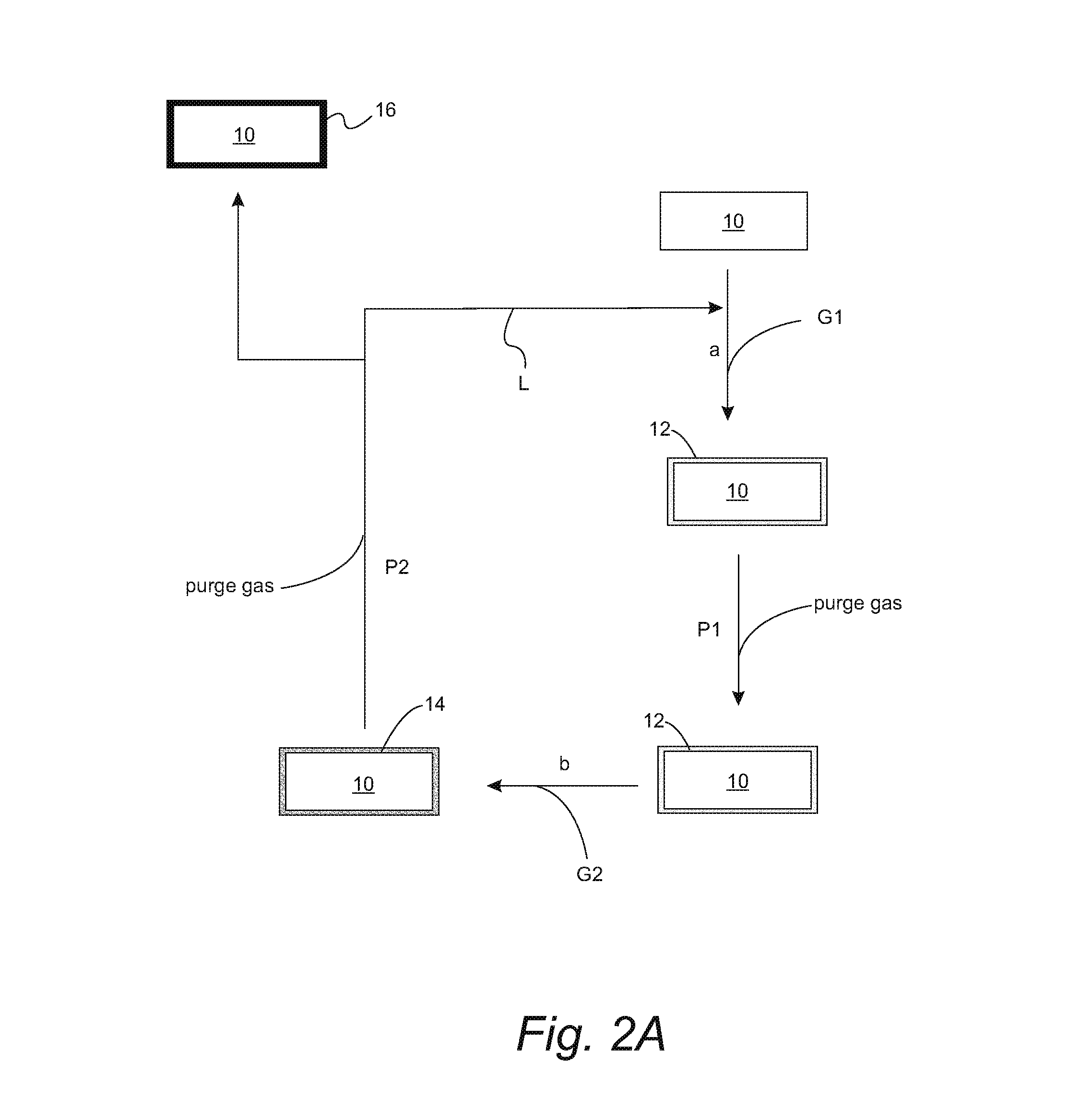

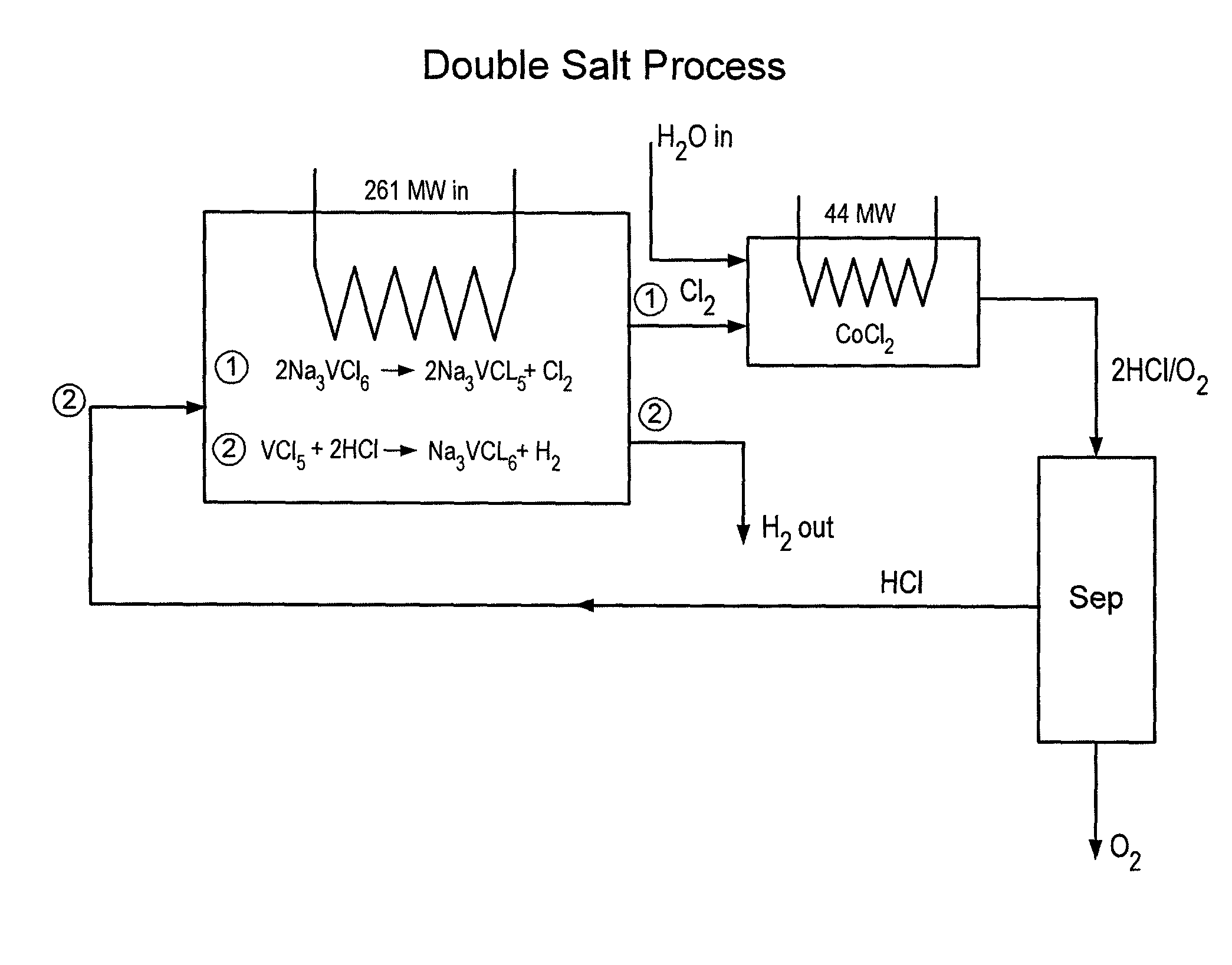

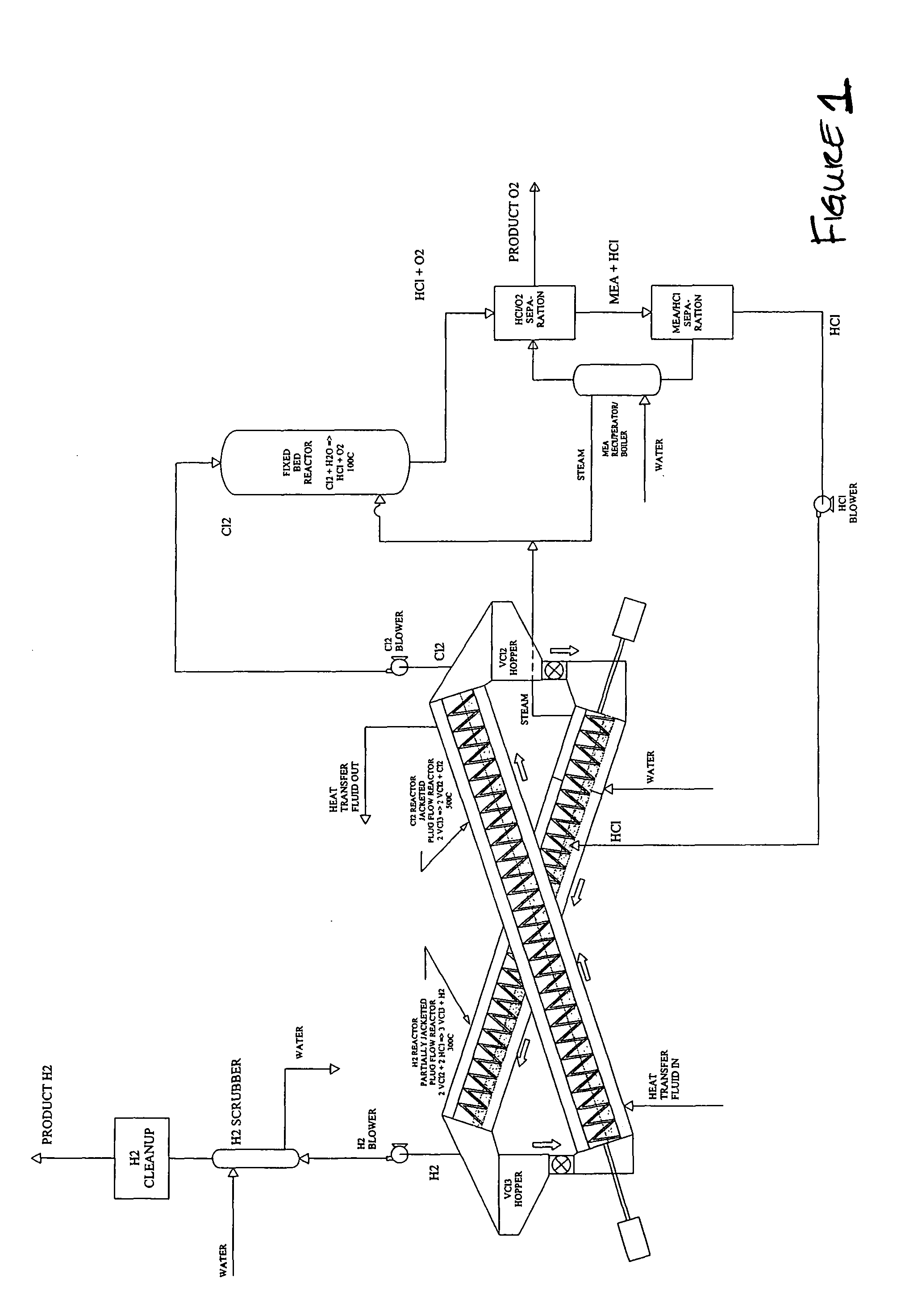

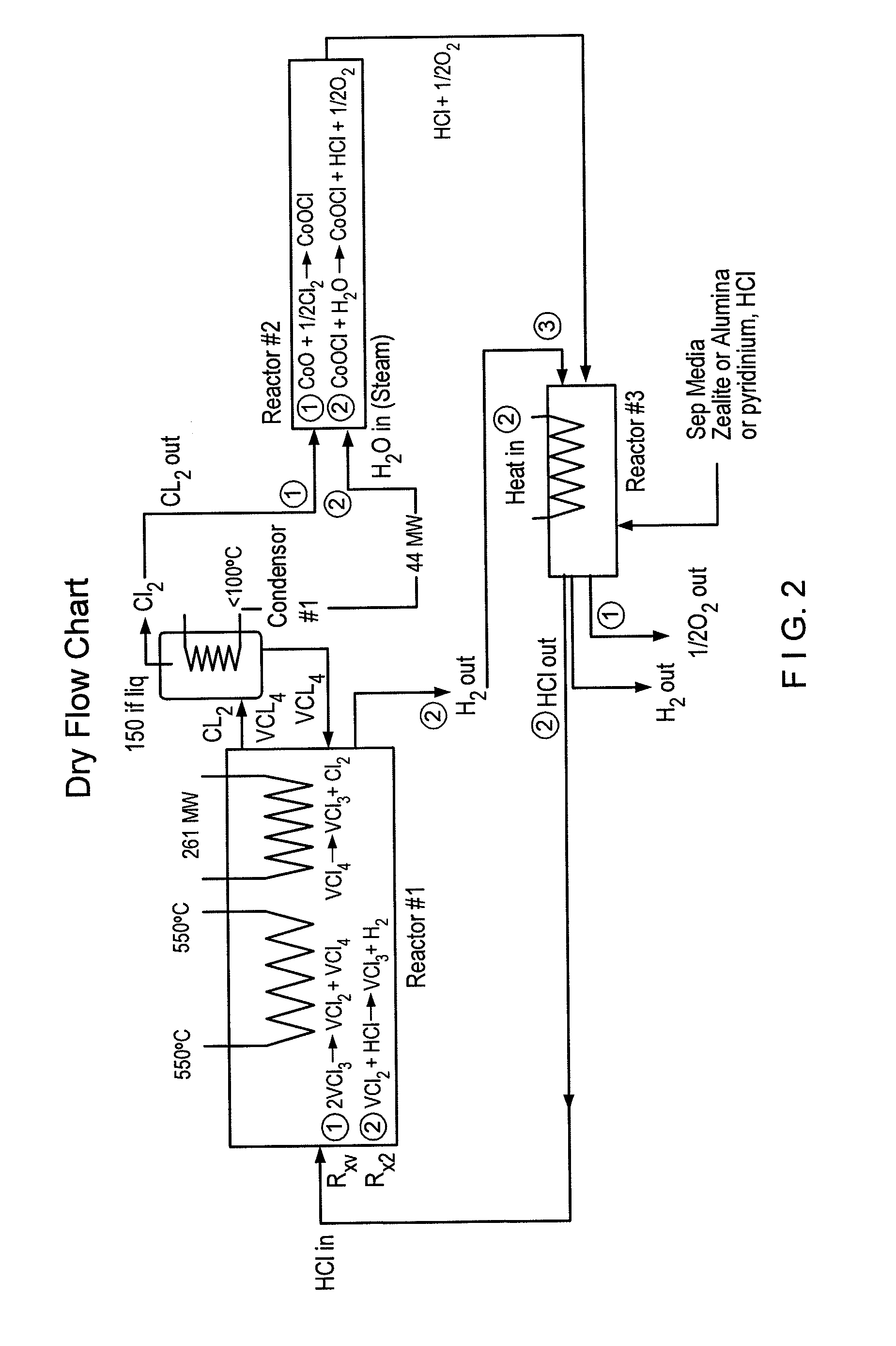

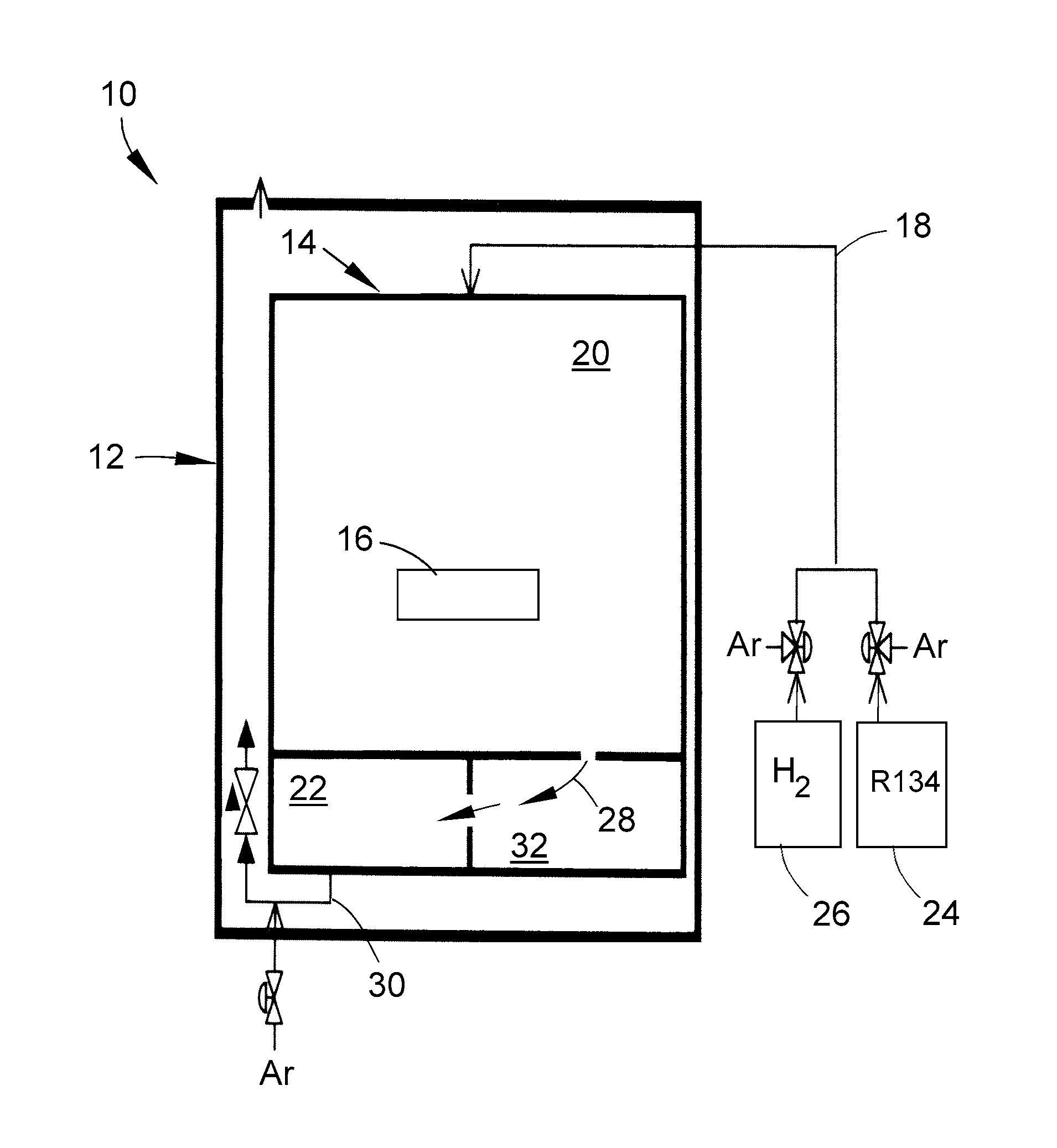

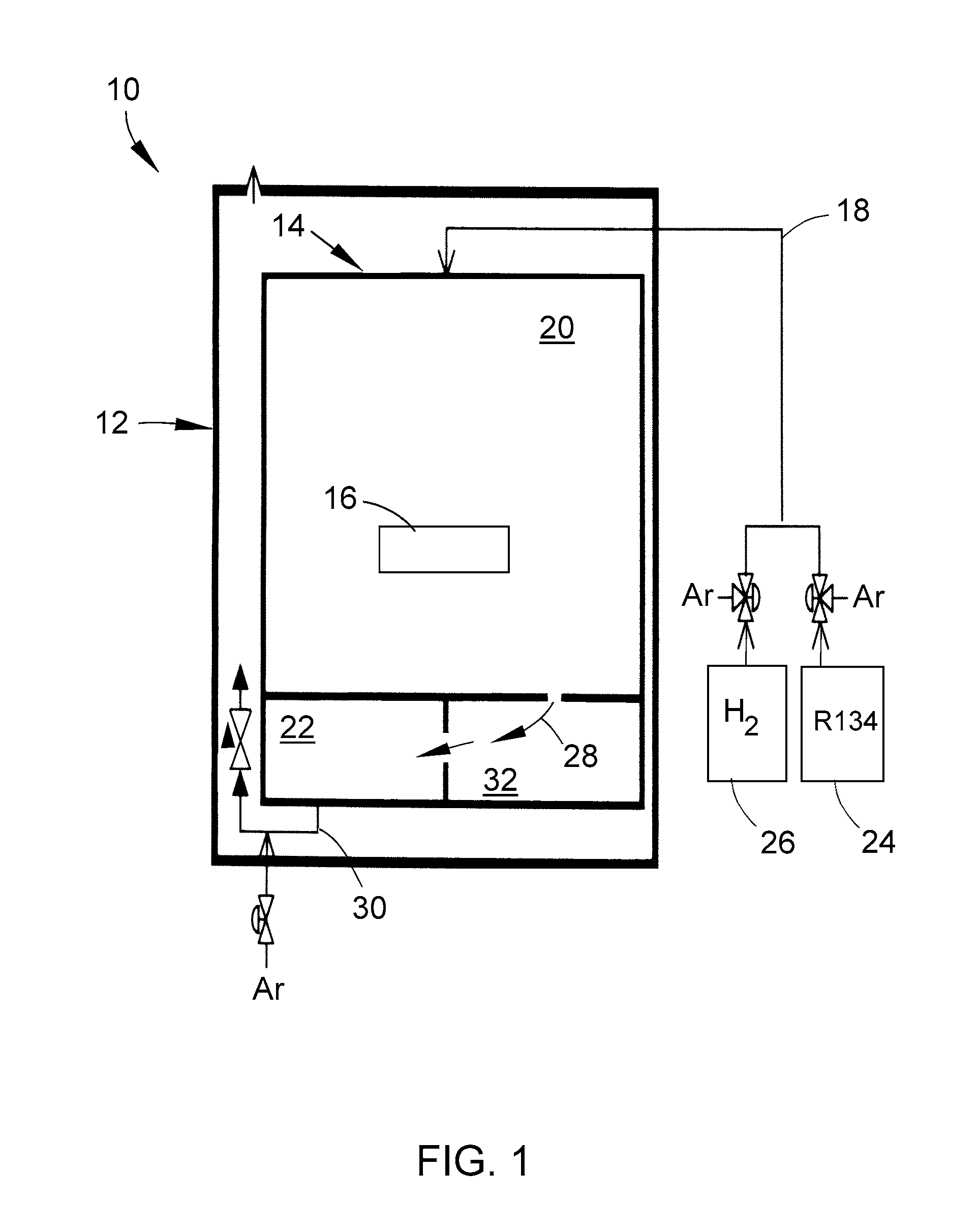

Thermochemical hydrogen produced from a vanadium decomposition cycle

InactiveUS20050013771A1Improve reliabilityHydrogen separation using liquid contactEnergy inputHydrogenDecomposition

A thermochemical water-splitting process all reactions of which operate at relatively low temperatures and high efficiencies, and in which relatively inexpensive materials and processing methods are made possible. This invention involves the decomposition of a metal halide compound, i.e., one which is capable of being reduced from a higher oxidation state to lower oxidation state, e.g. vanadium chloride III→vanadium dichloride. The process is cyclic and regenerative, and the only net inputs are water and heat; and the only net outputs are hydrogen and oxygen. The process makes it possible to utilize a wide variety of available heat, including solar, sources for the energy input.

Owner:AMENDOLA STEVEN

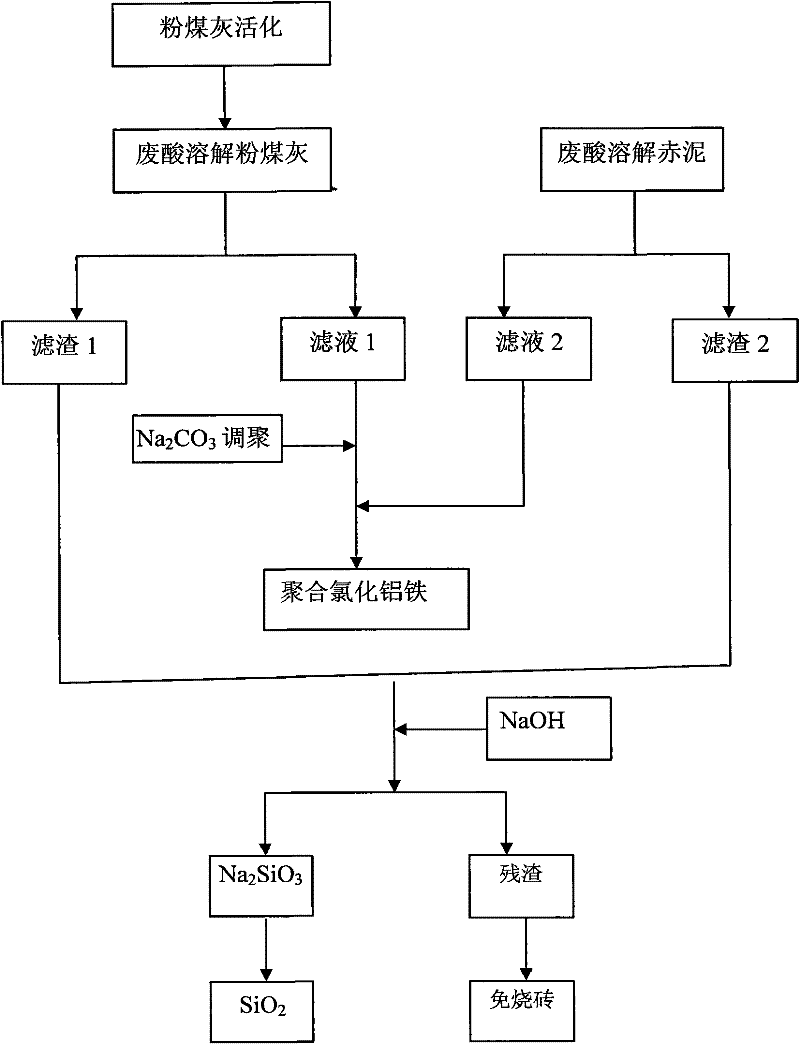

New method for resource comprehensive utilization of red mud and fly ash

InactiveCN102344171AAchieve recyclingAchieve near-zero emissionsSilicaSolid waste disposalAluminium chlorideRed mud

The invention discloses a new method for resource comprehensive utilization of red mud and fly ash, and relates to a comprehensive utilization of industrial waste, specifically to a preparation method for a flocculating agent of aluminum ferric chloride and white carbon black. The method comprises the following steps: (1) acid leaching: the red mud and the activated fly ash are adopted as raw materials, and react with HCl, wherein the leaching temperature is 70-90 DEG C, a solid-liquid ratio is 10:1-10:3, the HCl concentration is 3-6 mol.L<-1>, the leaching time is 4-10 hours; (2) polymerization: Na2CO3 is added to a dissolution solution 1 to carry out telomerization, a dissolution solution 2 is added to the dissolution solution 1 until the dissolution solution 1 is stable, then the polymerization reaction is performed to obtain the polyaluminum ferric chloride, wherein the temperature is 60-70 DEG C, the pH value is 2.5-3.0, the aging time is 12-24 hours; (3) white carbon black preparing: a NaOH solution is adopted to carry out alkali dissolution to dissolve the filter residue, then treatments of acidification and calcination are performed to obtain the powder SiO2, wherein the alkali dissolution temperature is 80-100 DEG C, the time is 4-8 hours.

Owner:孙建之

Method for treating ferric trichloride etching waste liquor

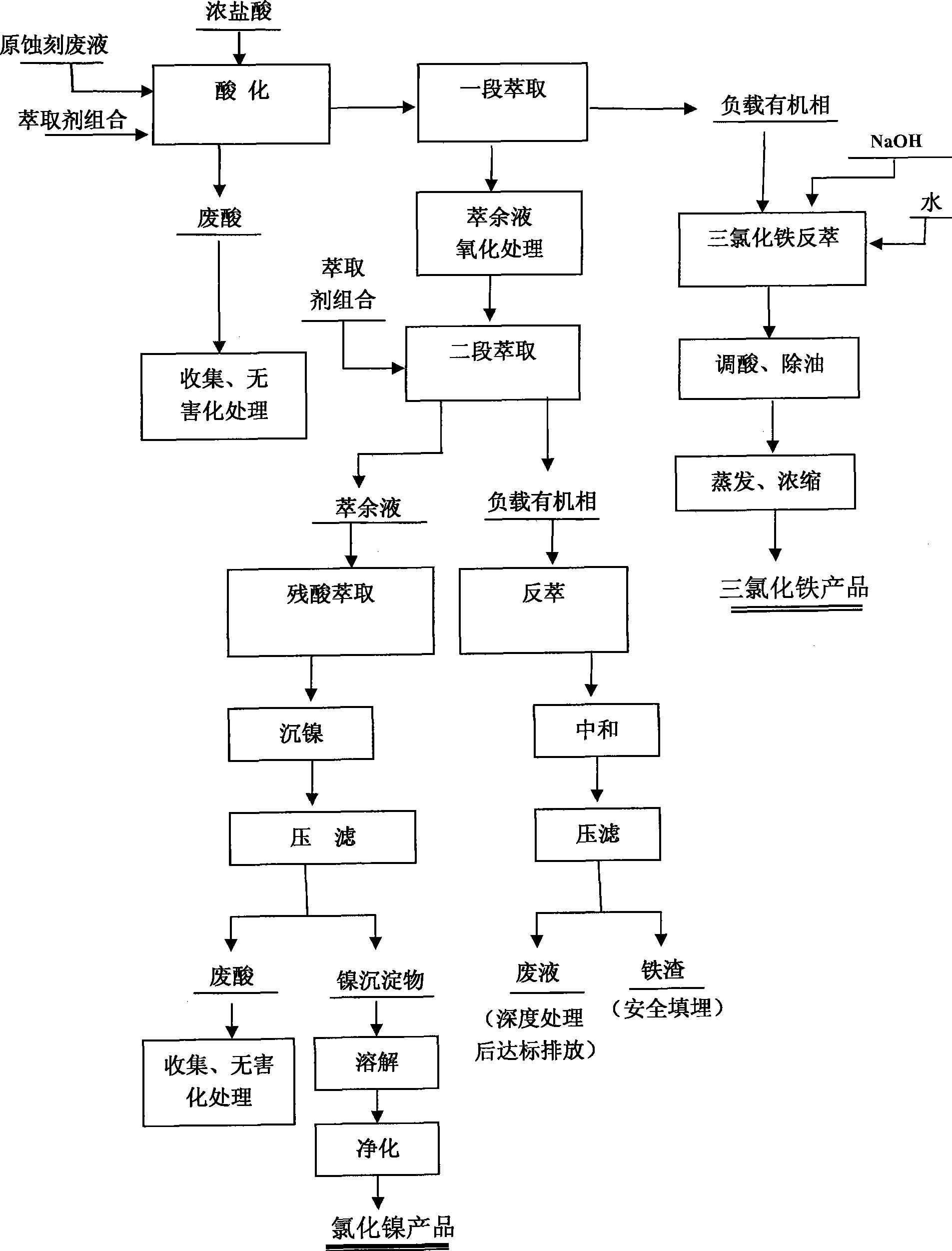

ActiveCN101497484AEasy to separateImprove efficiencyMultistage water/sewage treatmentNickel halidesLiquid wasteLiquid state

The invention relates to a method for treating ferric trichloride etching waste liquor, in particular to a method for treating the ferric trichloride etching waste liquor containing nickel, which mainly adopts a two-stage extraction method to remove iron so as to achieve the complete separation of the nickel and the iron, wherein a first stage extraction organic phase combination comprises 15 to 40 percent of extractant, 10 to 20 percent of synergist and 40 to 75 percent of diluent agent according to the volume ratio; a second stage extraction organic phase combination comprises 20 to 50 percent of extractant, 5 to 10 percent of synergist and 40 to 75 percent of diluent agent according to the volume ratio; the extractants and the synergists used in the two stages have various selections; and under the condition that the technological parameters are controlled strictly, with the two stages of extractions, the iron contained in the etching waste liquor is regenerated into a liquid state ferric trichloride product, and the nickel is regenerated into a nickel chloride product. The method overcomes various defects of the prior art, has good iron and nickel separation effect, high efficiency and low cost, achieves the resource recycling of valuable metals to the utmost extent while achieving the decontamination of the ferric trichloride etching waste liquor, and has board technique application prospect.

Owner:DONGJIANG ENVIRONMENTAL

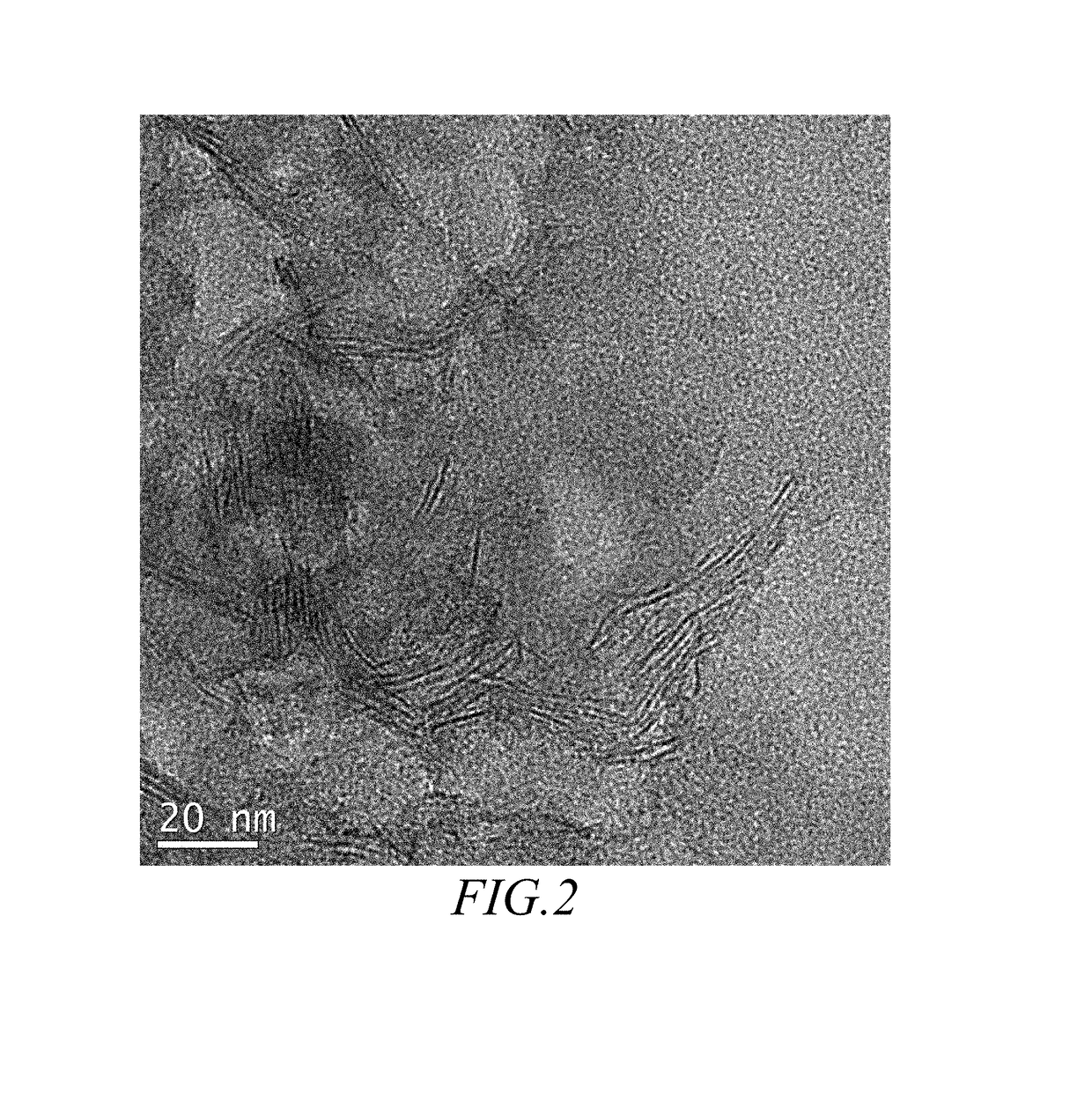

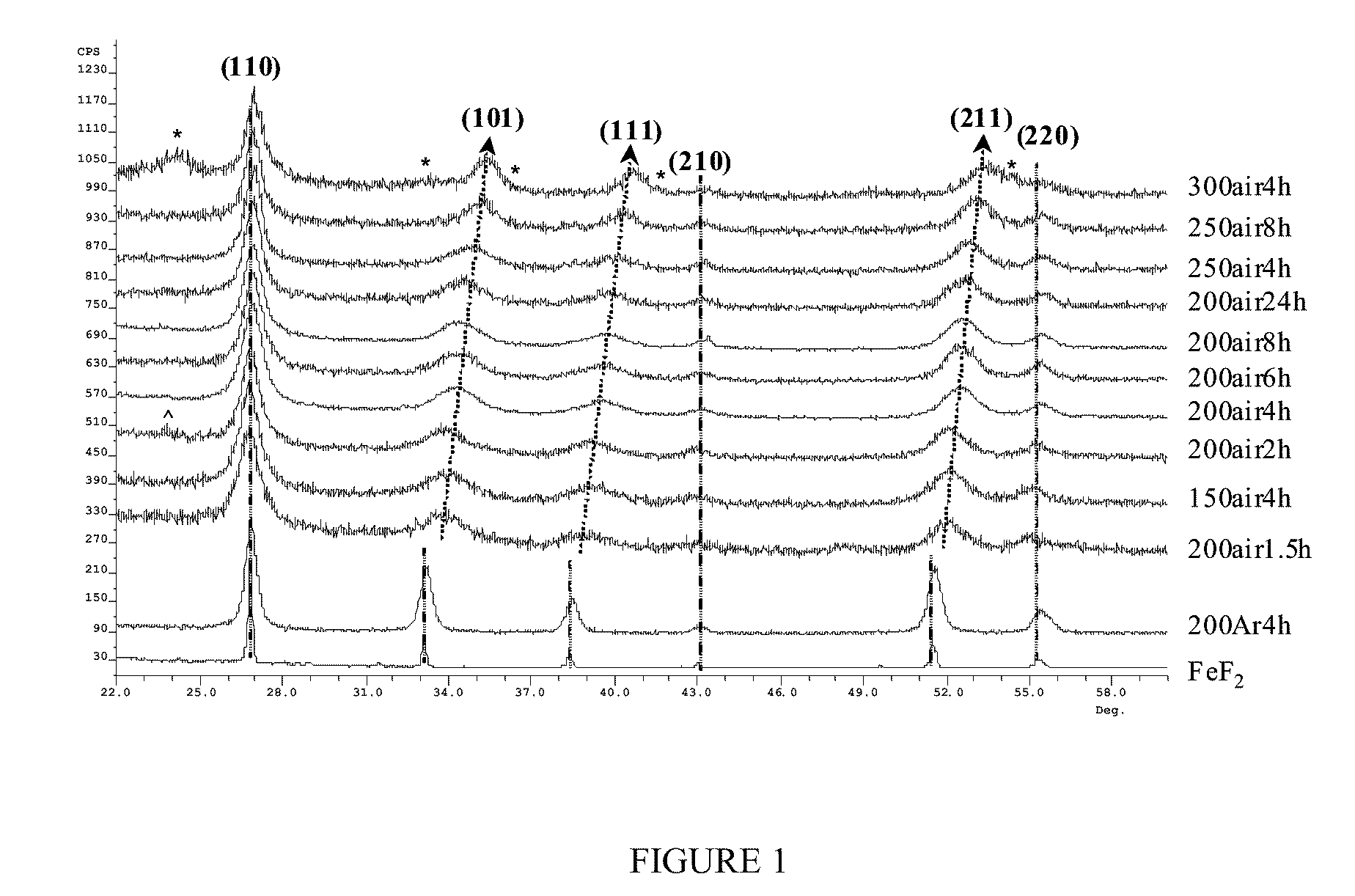

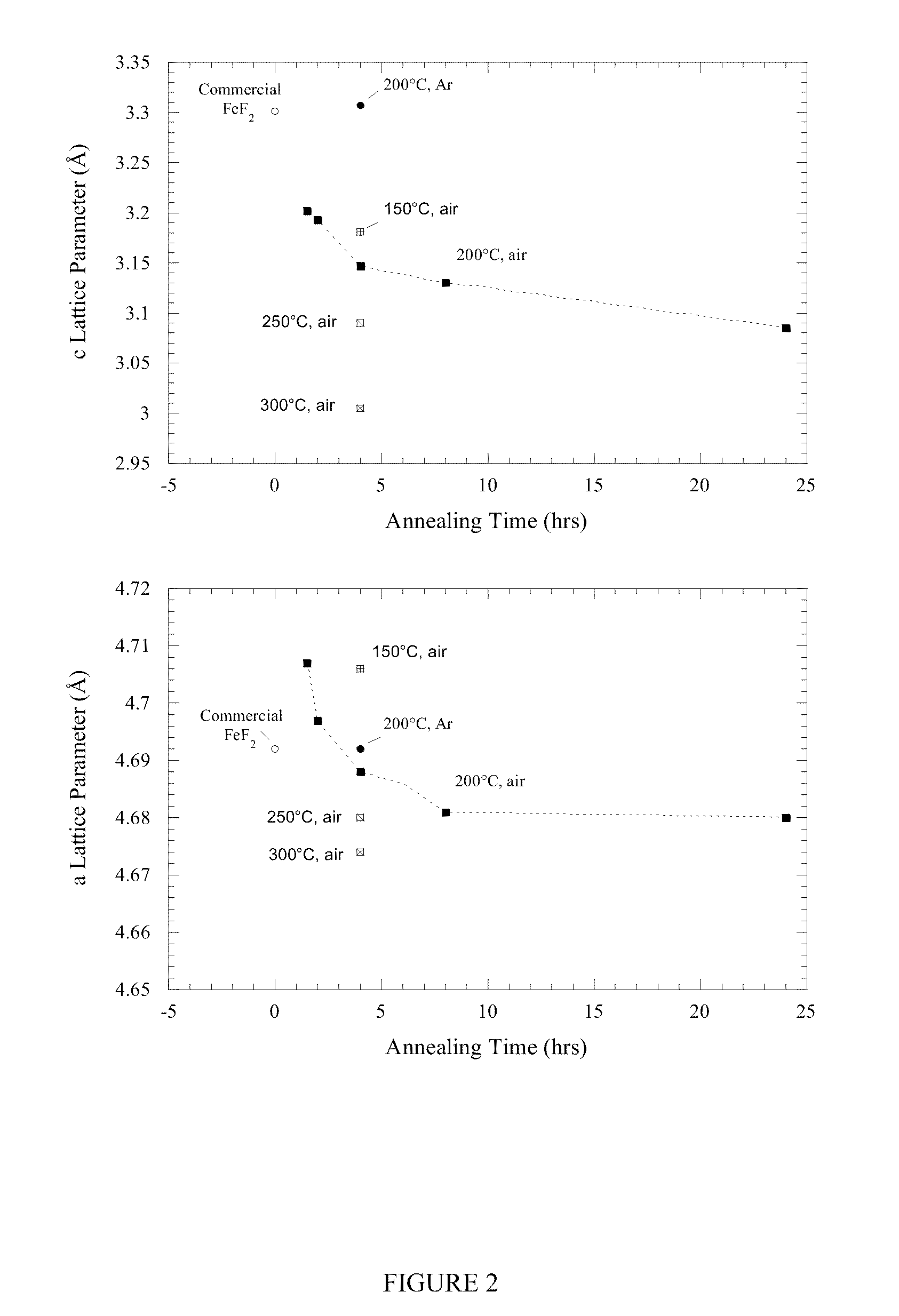

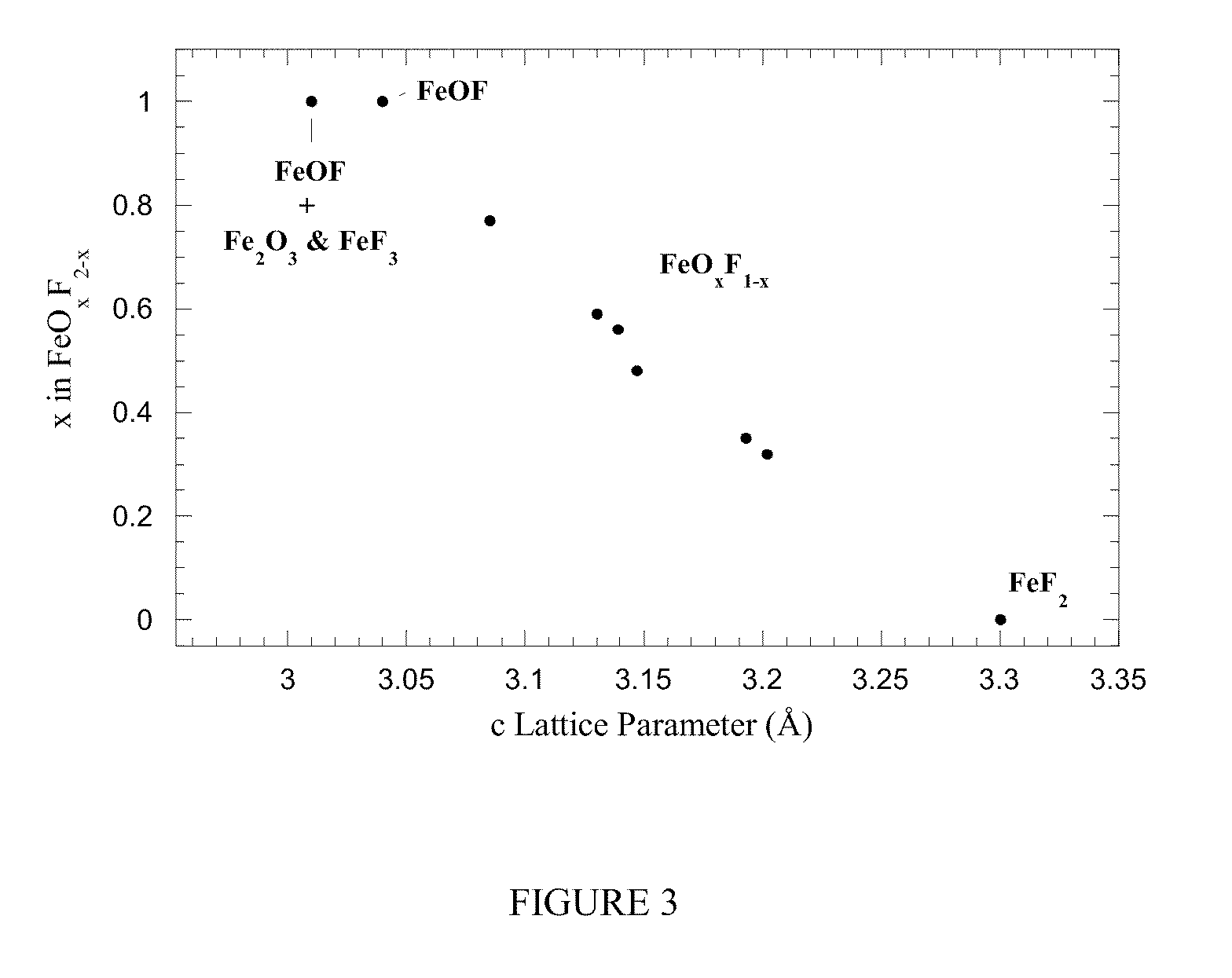

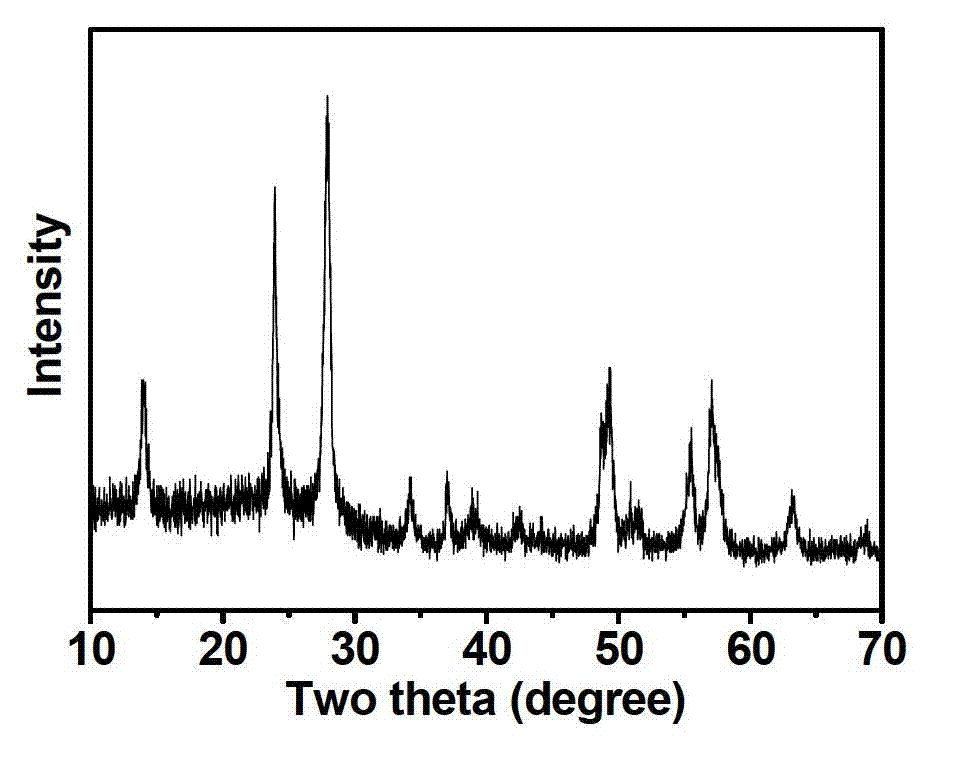

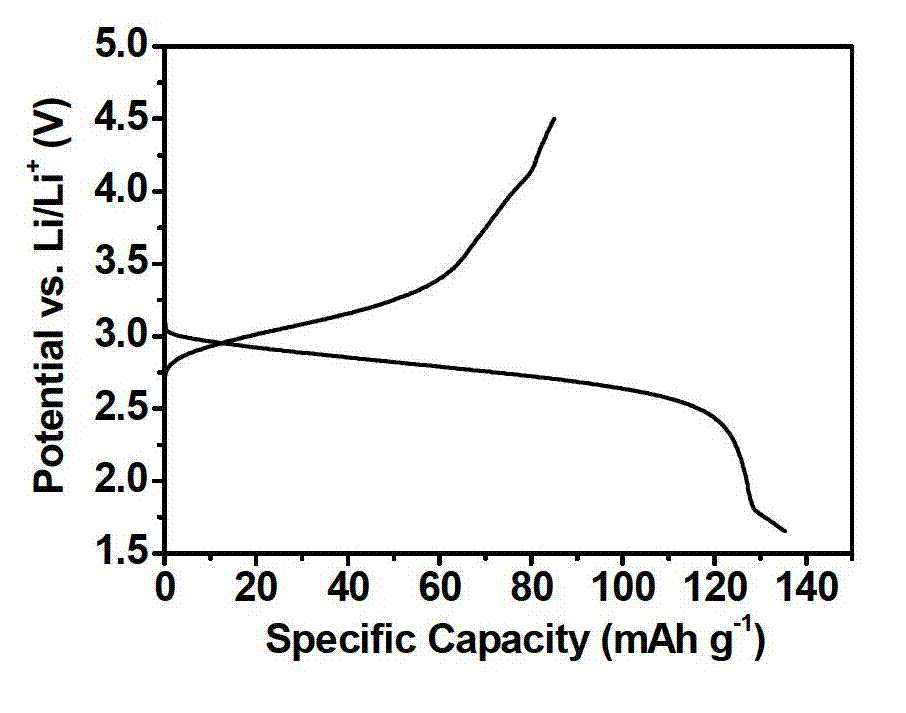

Iron Oxyfluoride Electrodes for Electrochemical Energy Storage

The present invention provides electrochemical energy storage systems comprising metallolyte composites, iron fluoride composites and iron oxyfluoride composites. The present invention further provides methods for fabricating metallolyte composites.

Owner:RUTGERS THE STATE UNIV

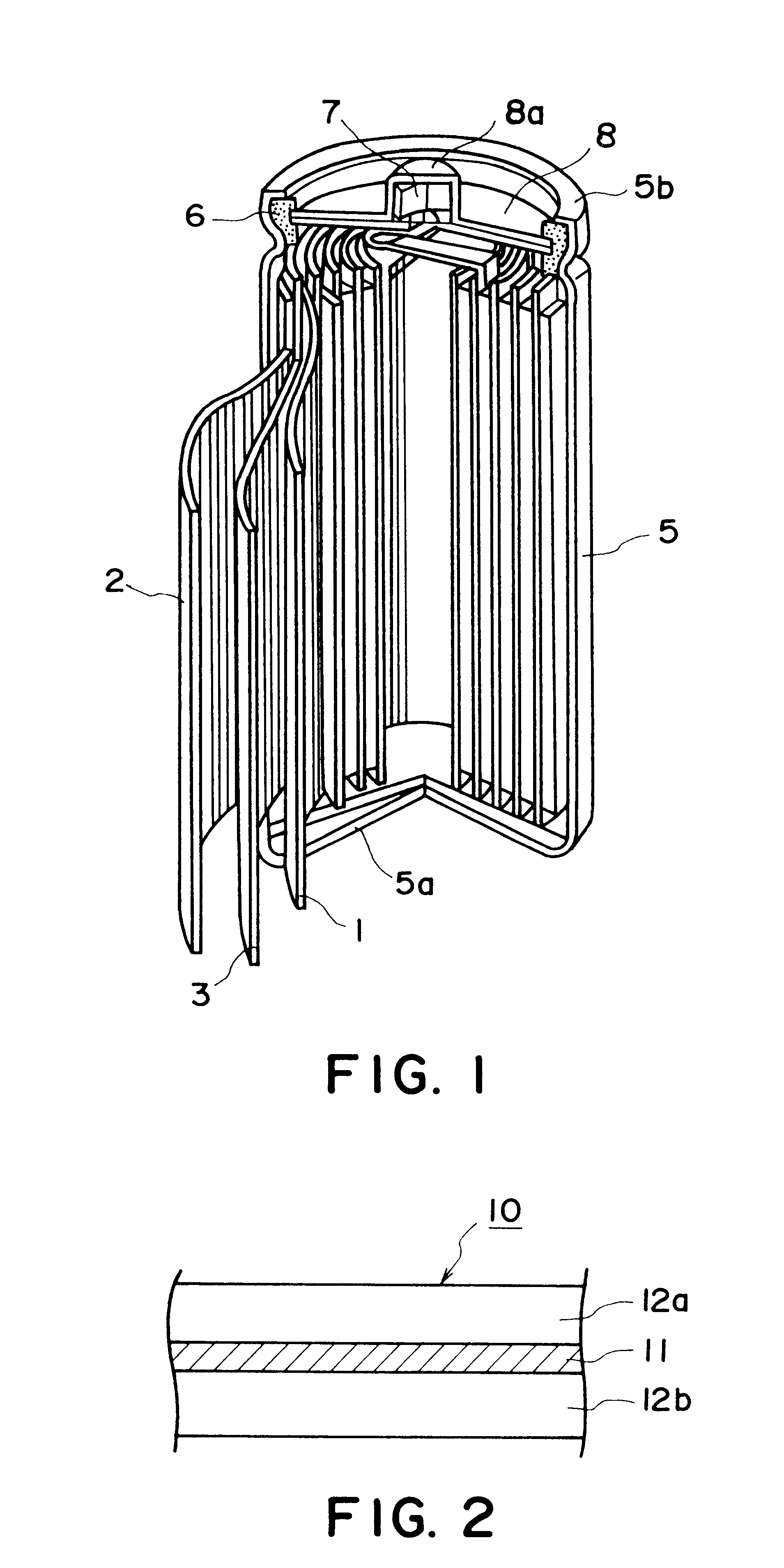

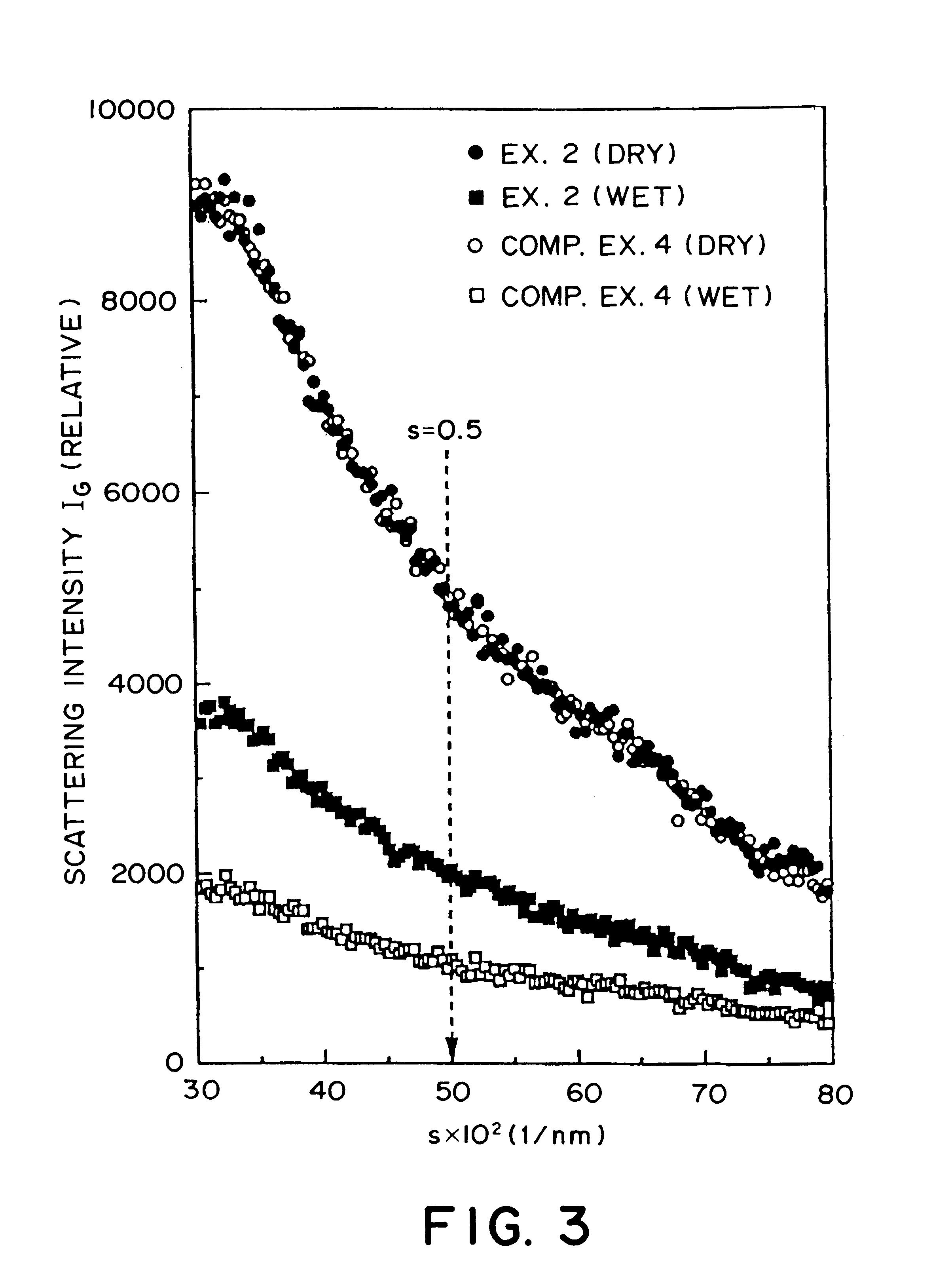

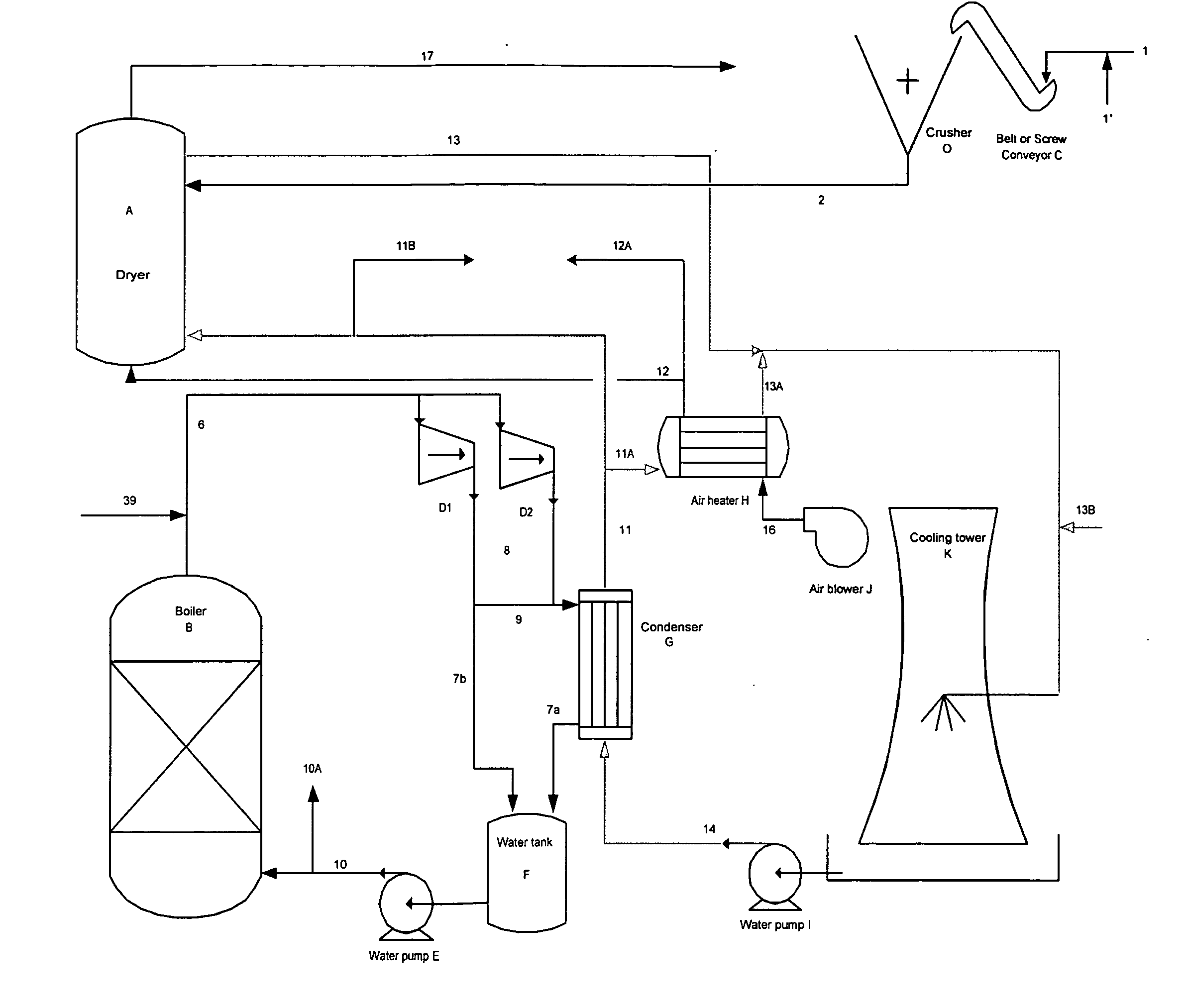

Carbonaceous electrode material for secondary battery

InactiveUS6569570B2Efficient use ofLarge capacityConductive materialCarbon preparation/purificationX-rayPhotochemistry

A carbonaceous electrode having improved capacities for doping and dedoping of a cell active substance, such as lithium, and suitable for a non-aqueous secondary battery, is constituted by a carbonaceous material obtained by carbonizing an aromatic condensation polymer formed by condensation of an aromatic compound having a phenolic hydroxy group and an aldehyde. The carbonaceous material is characterized by an atomic ratio H / C between hydrogen atoms and carbon atoms of below 0.1, a carbon dioxide adsorption capacity of at least 10 ml / g, and an X-ray scattering intensity ratio IW / ID of at least 0.25, wherein IW and ID represent scattering intensities as measured in a wet state and a dry state, respectively, at a parameter s=2.sin theta / lambd of 0.5 nm-1, wherein theta denotes a scattering angle and lambd denotes a wavelength of X-rays in X-ray small-angle scattering measurement.

Owner:KUREHA KAGAKU KOGYO KK

Process for producing polymeric aluminum ferric chloride coagulating agent by using pickling waste water containing iron

ActiveCN102372308AReduce manufacturing costImprove performanceIron halidesWater/sewage treatment by flocculation/precipitationLiquid wasteWater treatment

The invention relates to a process for producing a polymeric aluminum ferric chloride coagulating agent by using pickling waste water containing iron, wherein the pickling waste water and the raw material containing aluminum are adopted to produce the product. The preparation method is characterized by: adding the raw material containing the aluminum, industrial hydrochloric acid and the pickling waste water to a reactor according to a certain ratio; carrying out a reaction for 4 hours under pressure of 0.24-0.26 Mpa; evacuating the liquid inside the reactor; after settling for 4 hours, injecting the supernatant back to the reactor; adding an oxidant at a temperature of 50-60 DEG C; after reacting for 1 hour, heating to the temperature of about 80 DEG C; adding an aluminate, and continuously stirring for 2 hours; discharging the resulting liquid into a sedimentation tank, and settling for 1 hour, wherein the resulting supernatant is the polymeric aluminum ferric chloride finished product. The product of the present invention concurrently has the advantages of the iron-based coagulating agent and the aluminum-based coagulating agent, and is a widely applicable high quality coagulating agent for drinking water treatment and sewage treatment. The process of the present invention provides a feasible approach for the comprehensive utilization of the pickling waste water, and provides good economic benefits, social benefits and environmental benefits.

Owner:北京万水净水剂有限公司 +1

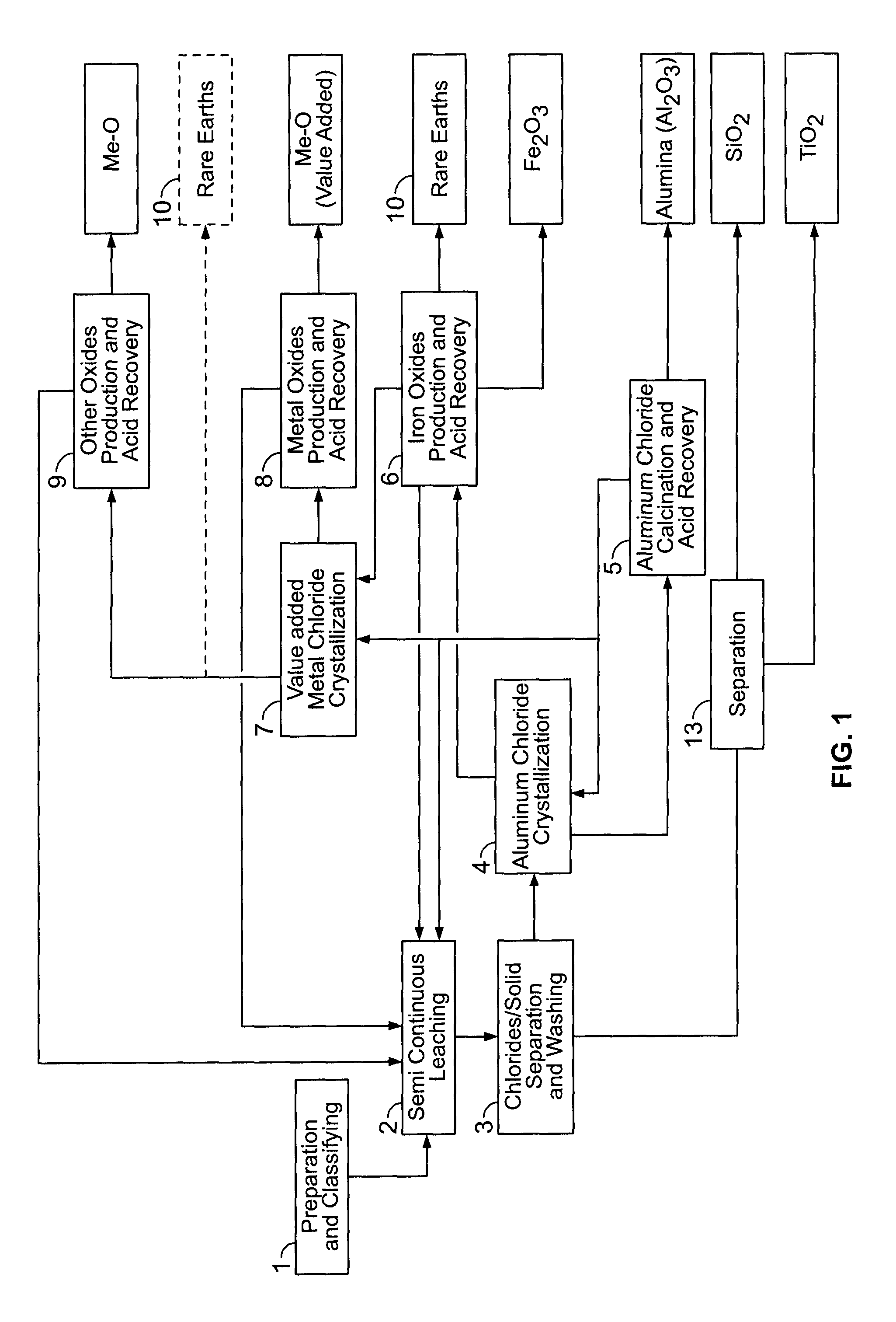

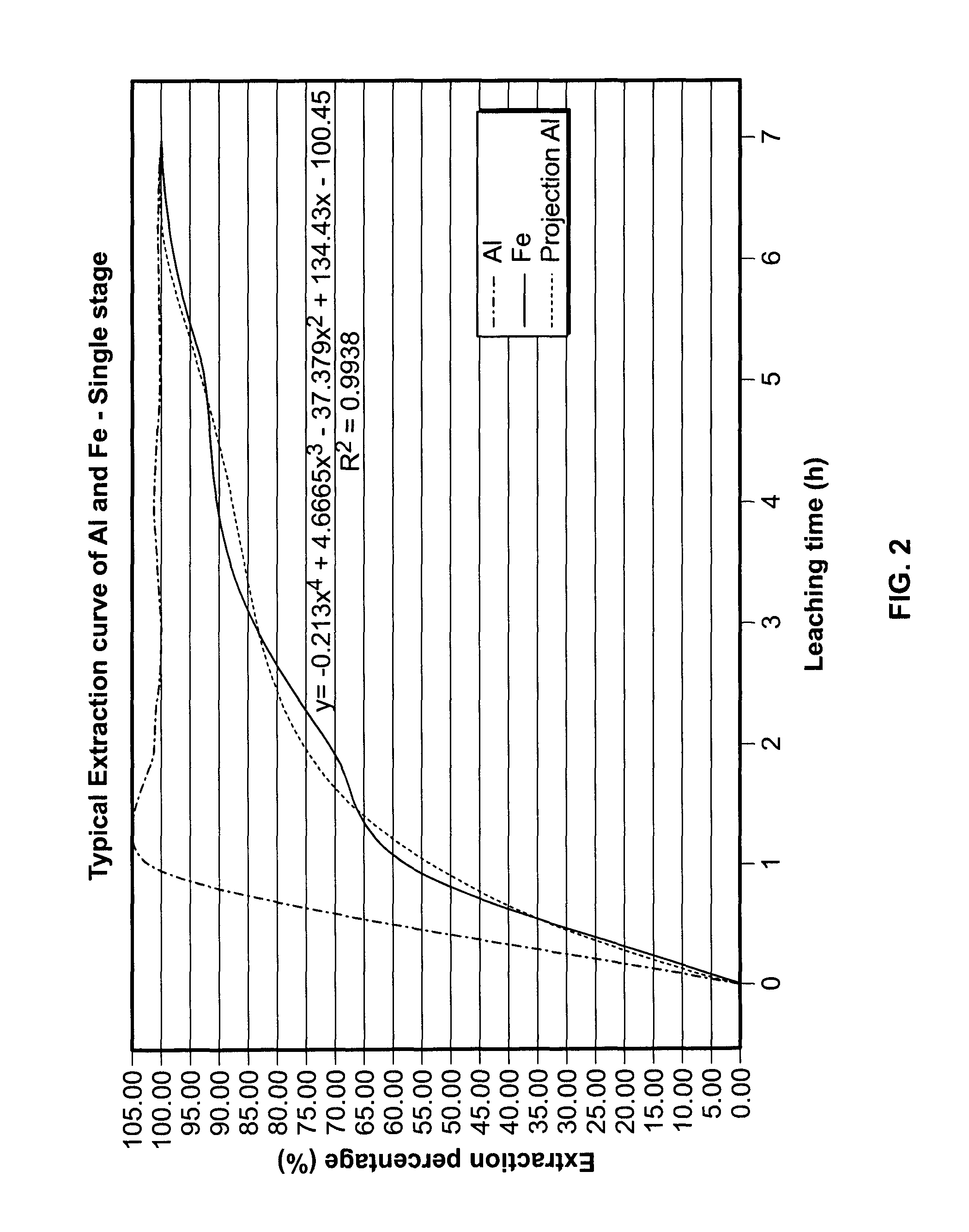

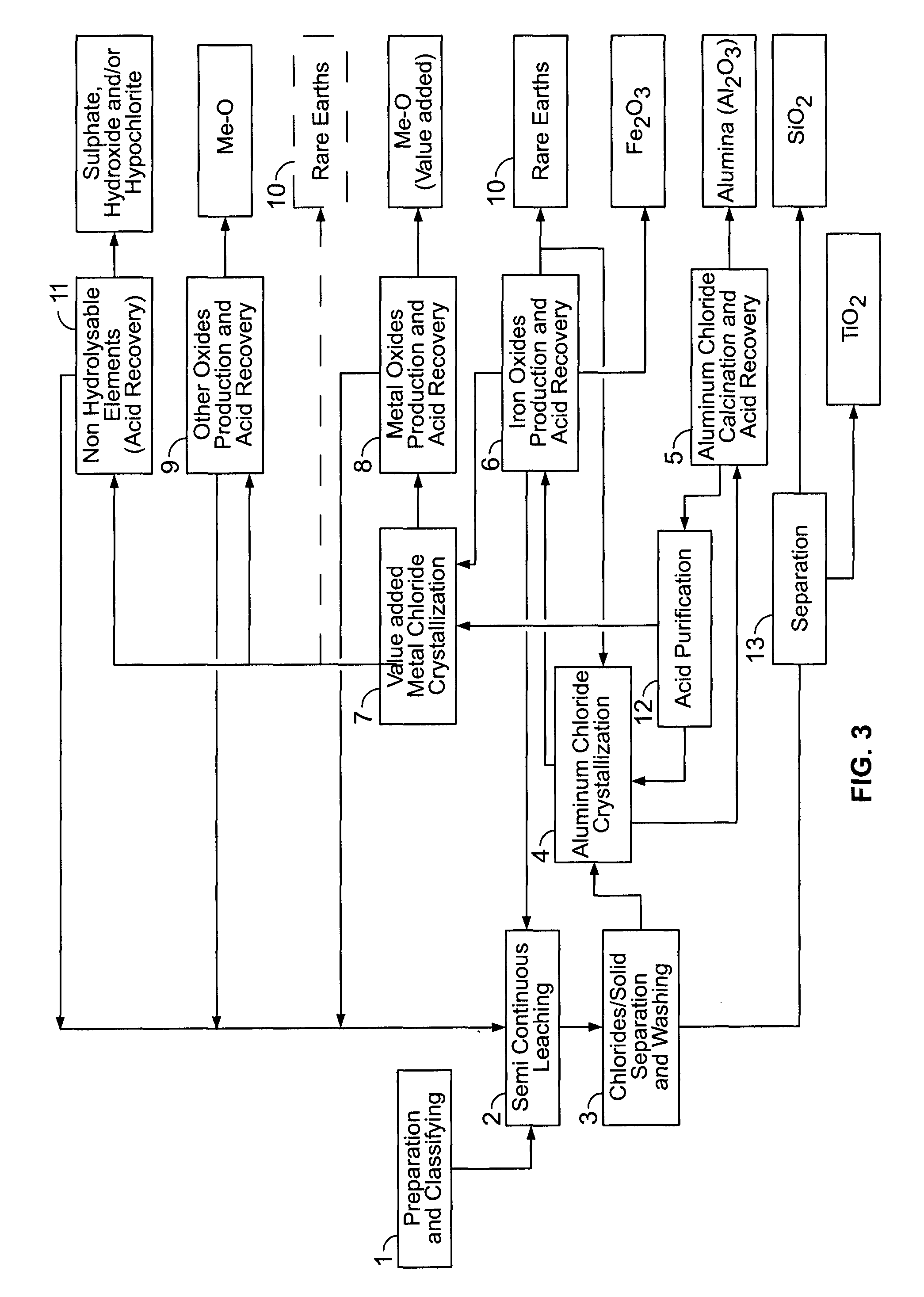

Metal chlorides and metals obtained from metal oxide containing materials

Method and apparatus for preparing at least one metal chloride from metal oxide containing material comprising calcining the metal oxide containing material under temperature conditions sufficient to obtain a calcined product comprising at least one metal oxide; and selectively chlorinating the calcined product to form at least one metal chloride.

Owner:KEYSTONE METALS RECOVERY

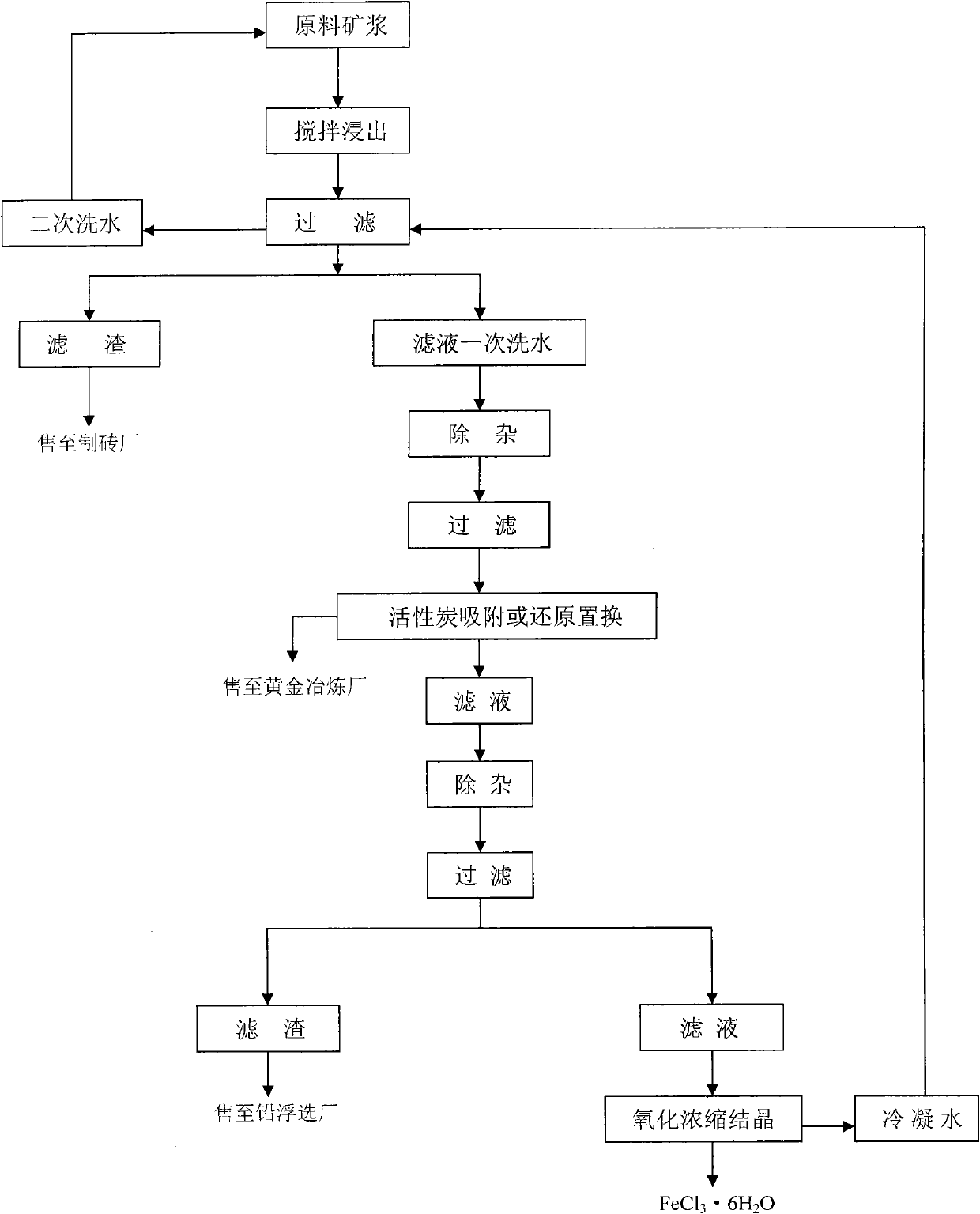

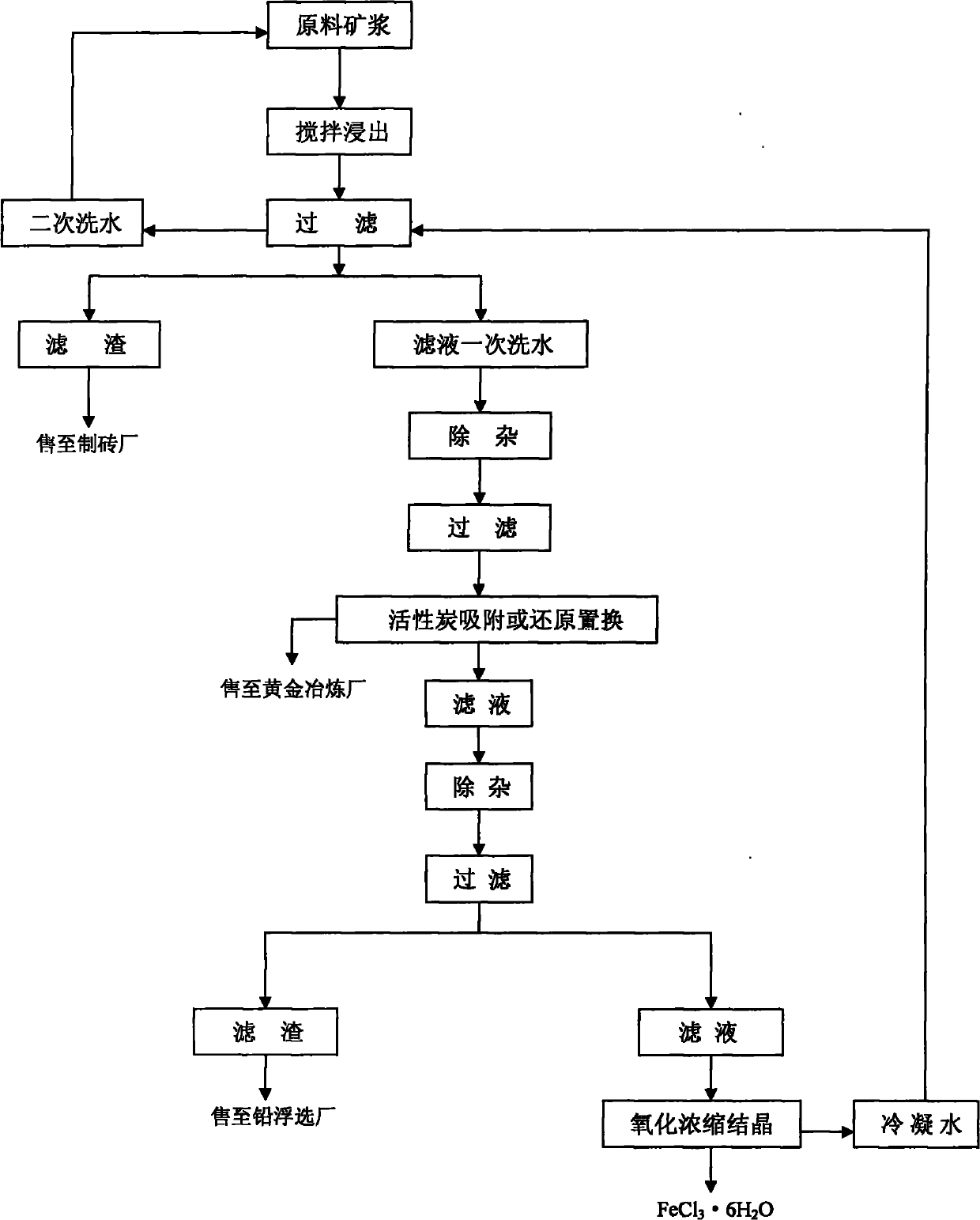

Comprehensive recycling process for valuable metal roasting-cyaniding gold-containing tailing

InactiveCN102168176AShort processWill not cause secondary pollutionProcess efficiency improvementIron halidesImpurityPollution

The invention discloses a comprehensive recycling process for valuable metal roasting-cyaniding gold-containing tailing, belonging to comprehensive recycling and utilization of industrial solid waste. The process comprises the following steps: selecting hydrochloric acid, chlorine and sodium hypochlorite as a leaching agent to leach gold, silver, iron, lead and arsenic to the maximum extent; adsorbing gold and silver with activated carbon, removing and recycling arsenic and lead through a series of solid-liquid separation and conversion, evaporating and crystallizing a ferric chloride solution subjected to impurity removal, thus finally producing a ferric chloride hexahydrate product, and realizing the comprehensive recycling process for valuable metal in the tailing. For the process, the available raw material sources are wide, the processing cost is low, the step-by-step impurity removal is thorough, all the impurities are recycled, no secondary pollution is generated, and the comprehensive recycling process can be used for fully realizing clean production, is environment-friendly and convenient for industrial production and has good promotion and application values.

Owner:田文学 +2

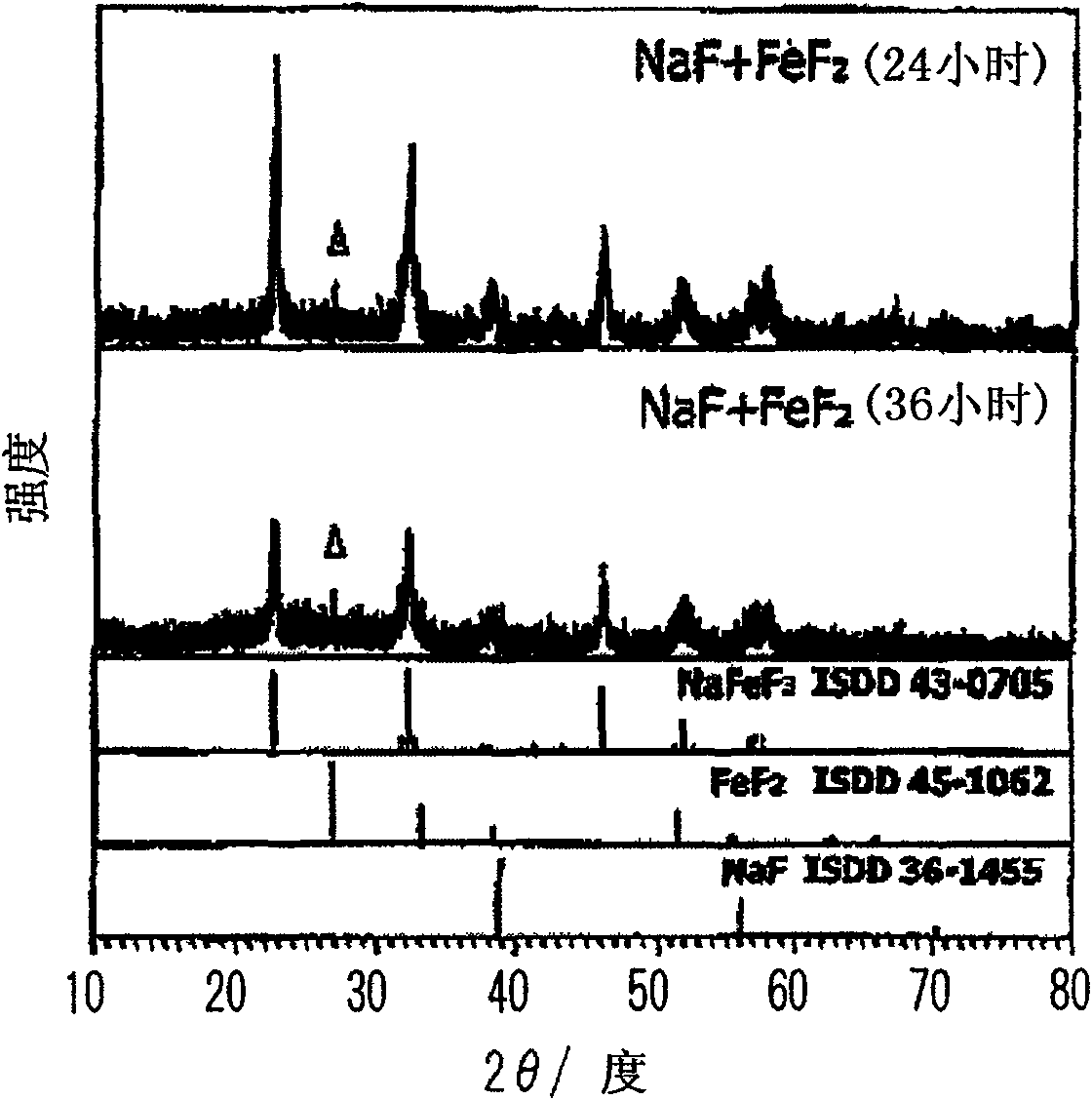

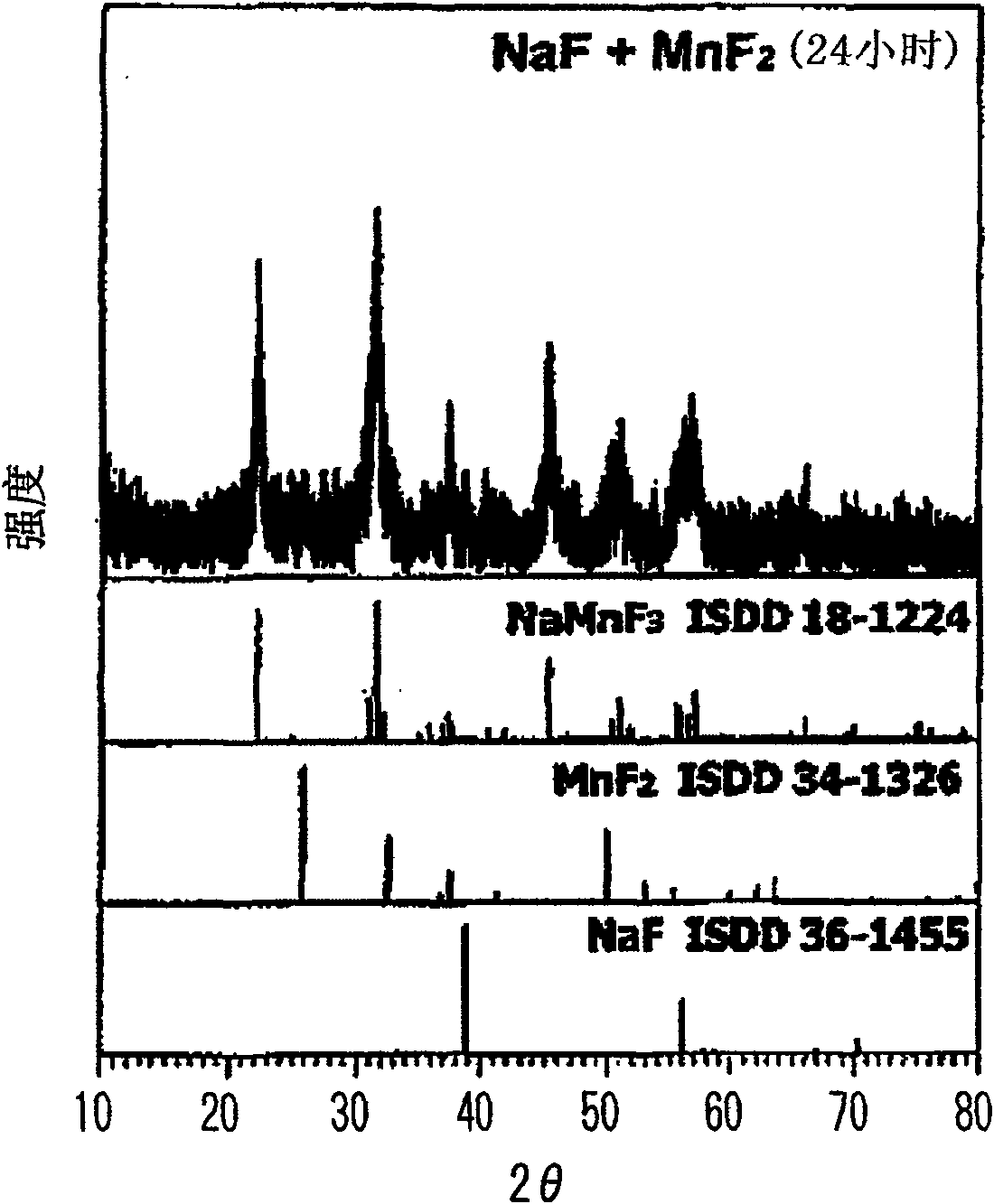

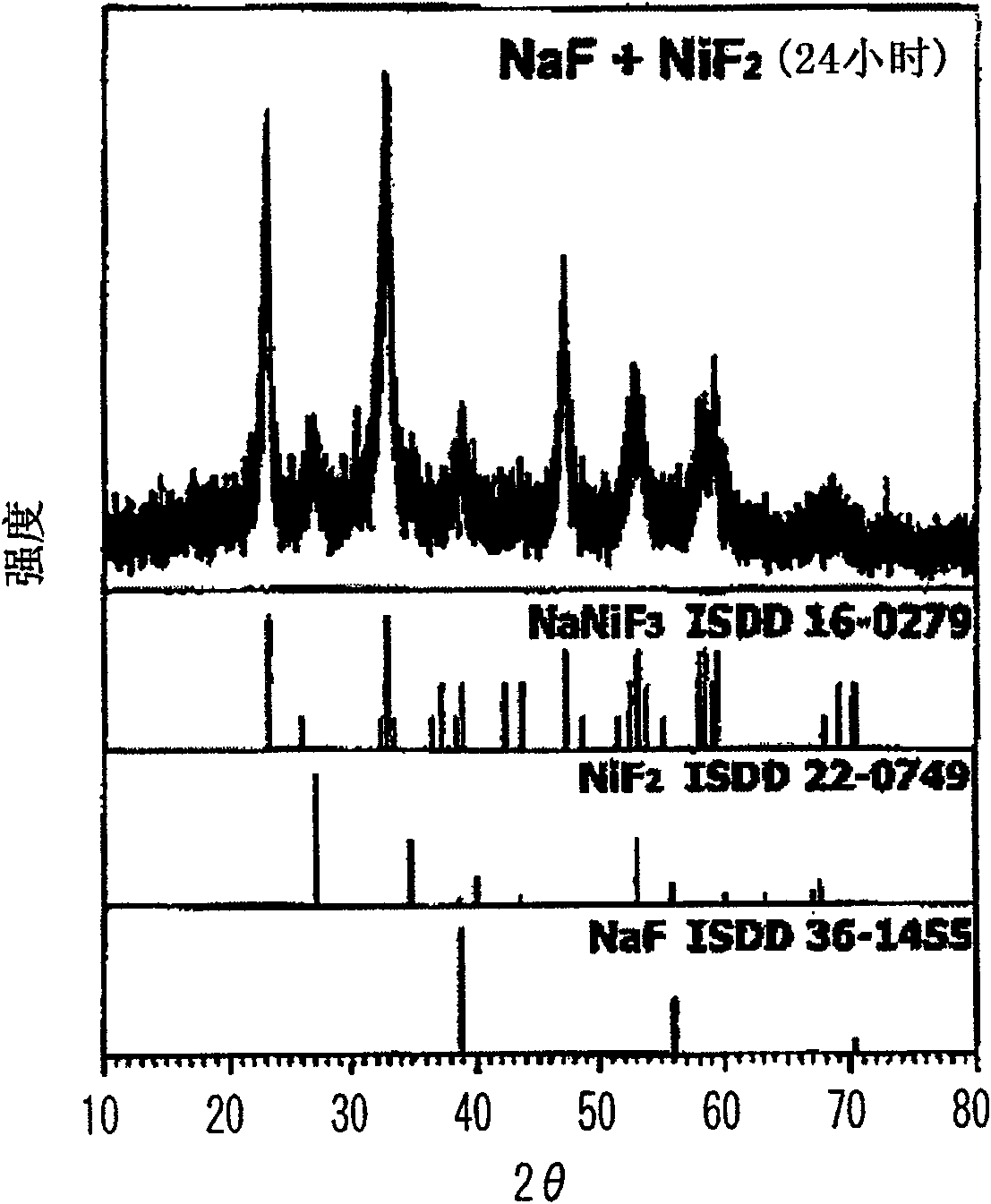

Cathode active material for nonaqueous electrolyte secondary battery and method of producing cathode active material for nonaqueous electrolyte secondary battery

To prepare a fluorinated cathode active material having a guest cation comprising sodium or lithium included therein in a nonaqueous electrolyte secondary battery, an alkali metal fluoride represented by the formula AF and a transition metal fluoride represented by the formula M'F2 are treated by chemical milling to thereby give a fluoride AM'F3. A satellite ball mill is preferably employed in the chemical milling treatment.

Owner:MITSUBISHI HEAVY IND LTD +1

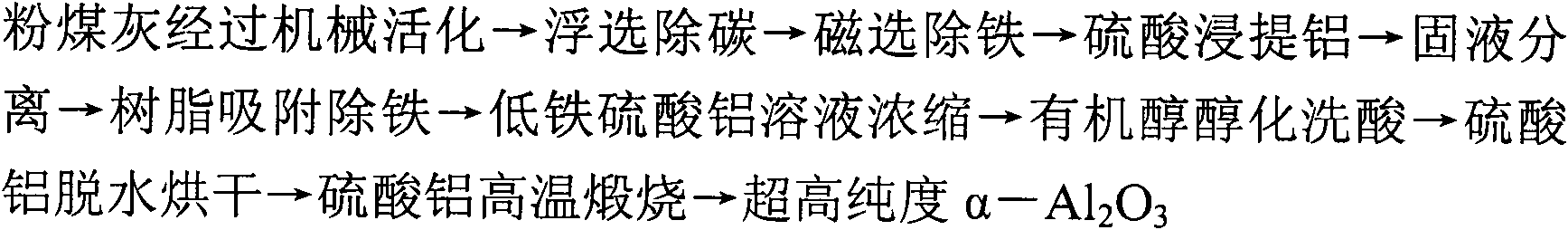

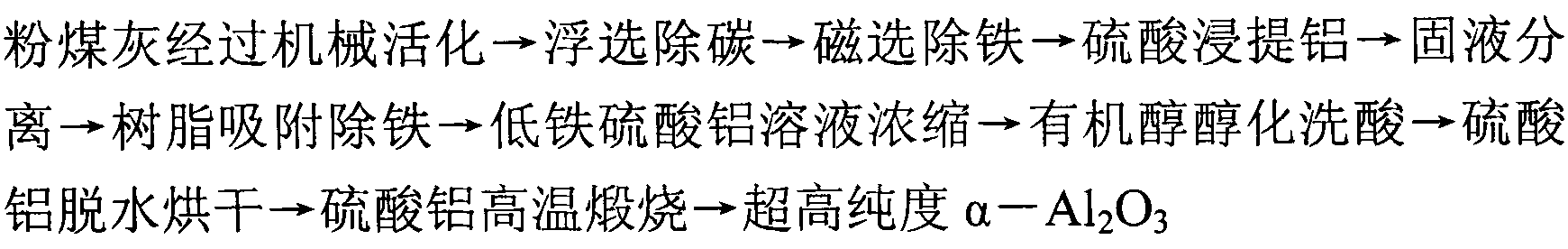

Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

InactiveCN102101686AReduce energy consumptionEasy to operatePigmenting treatmentSolid waste disposalAcid washingBiological activation

The invention discloses a process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina. In the process method, mechanical activation, flotation decarbonization, magnetic separation iron removal sulfuric acid aluminum lixiviation, solid-liquid separation, resin absorption iron removal, low-iron aluminum sulfate concentration, organic alcohol alcoholization acid washing, aluminum sulfate dehydration drying and aluminum sulfate high-temperature calcination are carried out on the coal ash so as to obtain ultra-high purity alpha-Al2O3, wherein the content of the Fe2O3 in the ultra-high purity alpha-Al2O3 is less than 2 ppm. By using the process method, the complicated purification problem that intermediate aluminum sulfate in the process of coal ash reclamation is necessarily subjected to a called Bayer circulation process is avoided, thereby simplifying the process flow, reducing the energy consumption, reducing the resource consumption and solving the technical problem of over-large secondary residue quantity accumulation. The process method has the advantages that the extraction efficiency is high, and the circulation recovery of organic alcohol and sulfuric acid and comprehensive utilization of byproducts such as resin and the like are achieved. In the invention, the process is simple, the process flow is short, the production process is easy to control, the content of the impurity in the product is low, and the quality of the product is stable.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

Ferric fluoride nano material and preparation method thereof

The invention discloses a ferric fluoride nano material and a preparation method thereof. The preparation method comprises the following steps of: dissolving inorganic ferric salt in an alcohol solvent to obtain alcohol solution containing iron; dispersing an inorganic fluorine source into the alcohol solution containing iron and adding the solution into a hydrothermal reaction kettle; carrying out the hydrothermal reaction kettle solution for 1 hour to 7 days at a temperature of 40 to 140 DEG C, naturally cooling, carrying out centrifugal separation, washing by ethanol and carrying out vacuum drying to obtain the ferric fluoride nano material. According to the preparation method of ferric fluoride, a volatile hydrofluoric acid fluorine source does not need to be used as a raw material, low-toxicity fluoride is used as the fluorine source, common ferric salt is used as a ferric source, the FeF3.0.33H2O nano material containing trace moisture is obtained by the simple solvent heat treatment, the preparation process is simple, the yield is high and the obtained material has high crystallinity. The method disclosed by the invention is a novel and practical process route for preparing the ferric fluoride nano material and has high actual application value.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

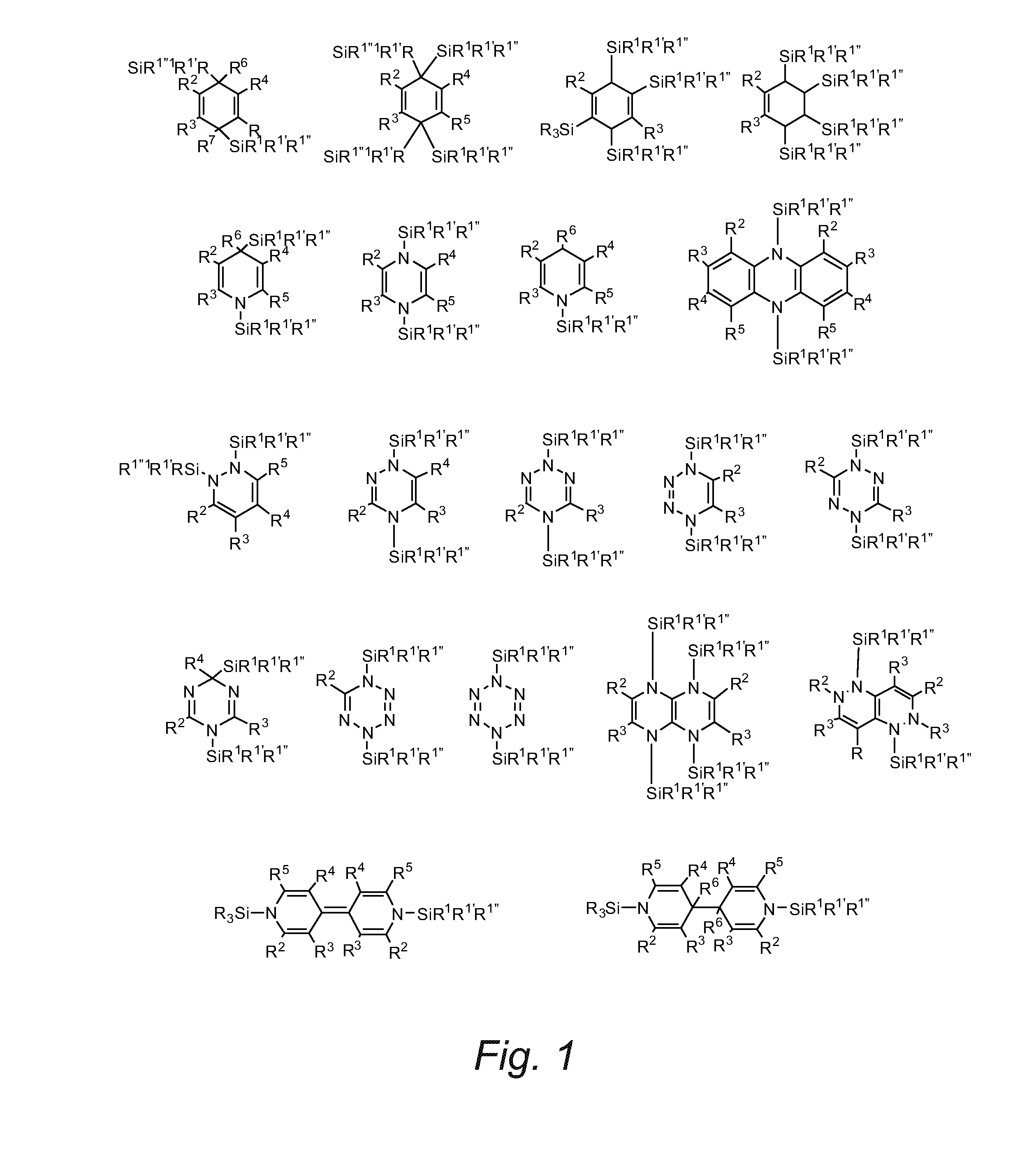

Bis(trimethylsilyl) six-membered ring systems and related compounds as reducing agents for forming layers on a substrate

ActiveUS20150004314A1Solve problemsGroup 4/14 element organic compoundsPipe supportsTrimethylsilylChemical compound

A first compound having an atom in an oxidized state is reacted with a bis(trimethylsilyl) six-membered ring system or related compound to form a second compound having the atom in a reduced state relative to the first compound. The atom in an oxidized state is selected from the group consisting of Groups 2-12 of the Periodic Table, the lanthanides, As, Sb, Bi, Te, Si, Ge, Sn, and Al.

Owner:WAYNE STATE UNIV

Method for separating, purifying and recycling waste hydrochloric acid containing iron

ActiveCN101643288AAchieve recyclingHigh mechanical strengthCellsWater/sewage treatment by ion-exchangeWater useHigh concentration

The invention discloses a method for separating, purifying and recycling waste hydrochloric acid containing iron, belonging to the field of wastewater treatment. The method comprises the following steps: (A) filtrating with sands to remove suspended matter in iron casting waste hydrochloric acid flushing fluid, dropwise adding oxidant, ensuring the oxidized flushing fluid through a absorption tower filled with strongly alkaline anion exchange resin, adding industrial concentrated hydrochloric acid to increase the concentration of HCl in the treated effluent liquid and returning the obtained solution which is used as iron casting hydrochloric acid flushing fluid to recycle, to the production flow; (B) ensuring distilled water or deionized water used as regenerant through a resin bed to elute the exchanged iron complex genitive ions on the strongly alkaline anion exchange resin and forming high concentration ferric chloride water solution which can be used as purifying agent and is sentback to the production flow to use. In the invention, strongly alkaline anion exchange resin is used for the treatment and resource recovery of iron casting waste hydrochloric acid flushing fluid in the fields such as electroplating, iron and steel and the like so as to realize the complete recycling of hydrochloric acid; water is used as resin regenerant to regenerate resin and generate ferric chloride water solution simultaneously so that water can be used to prepare purifying agent.

Owner:NANJING UNIV

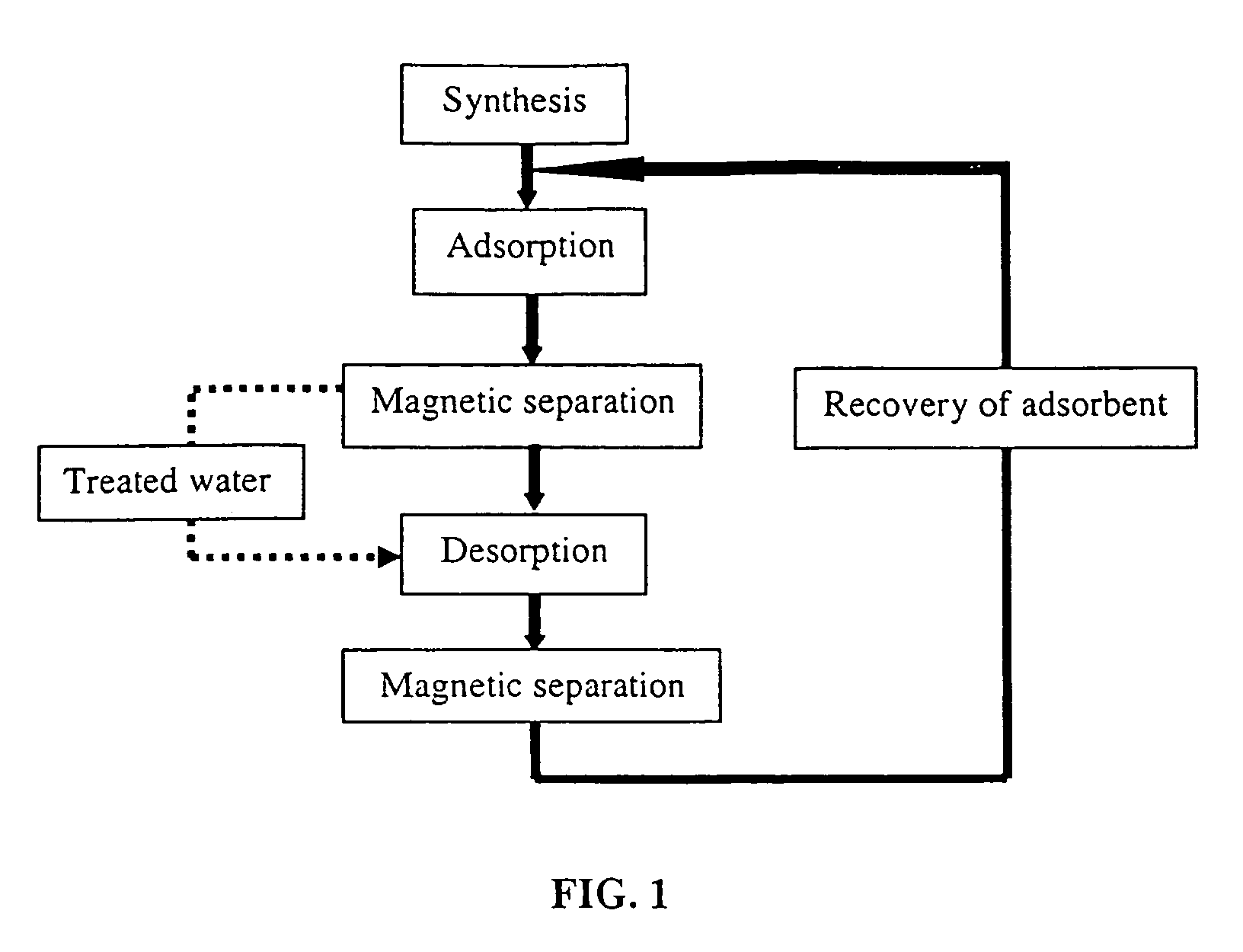

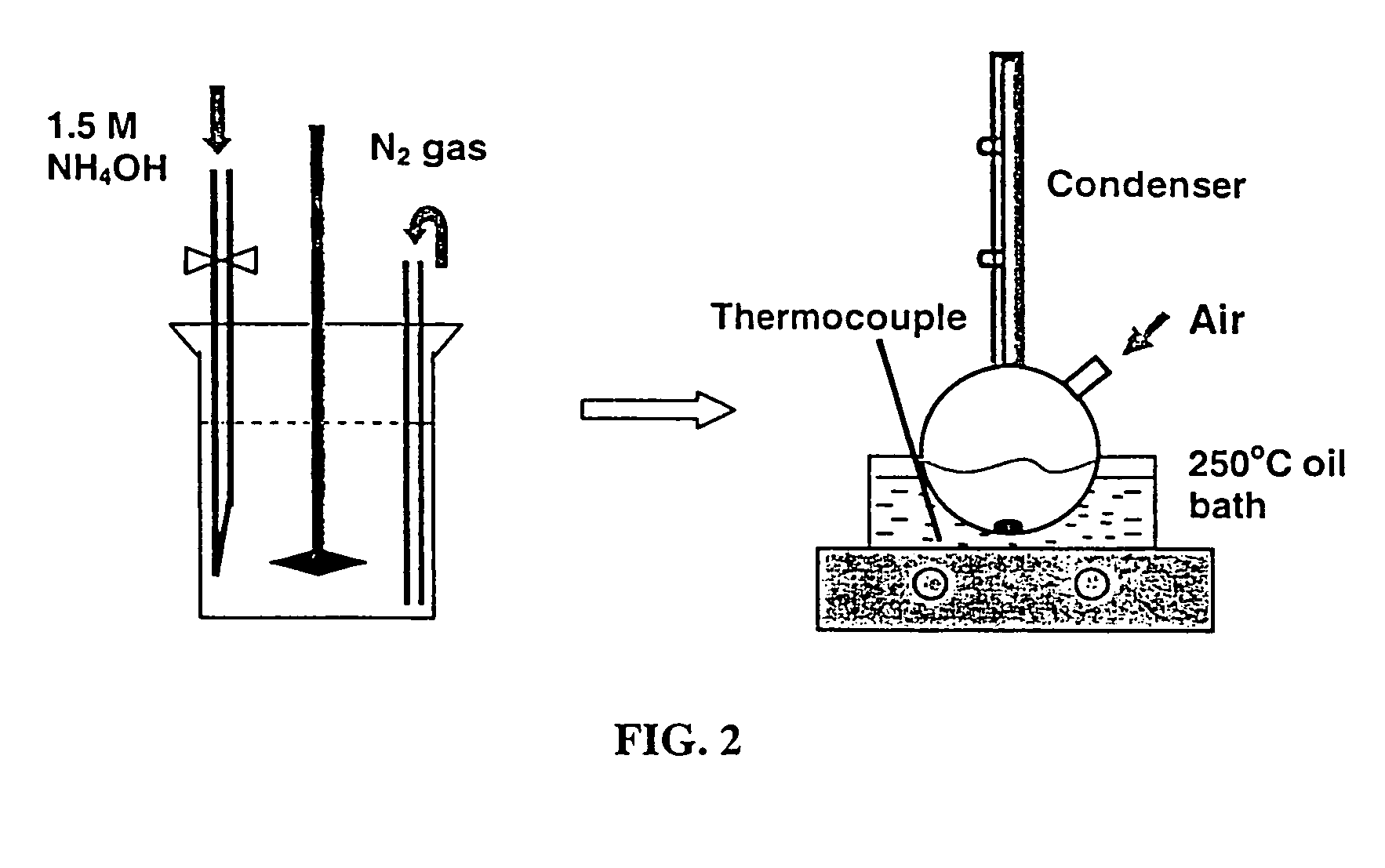

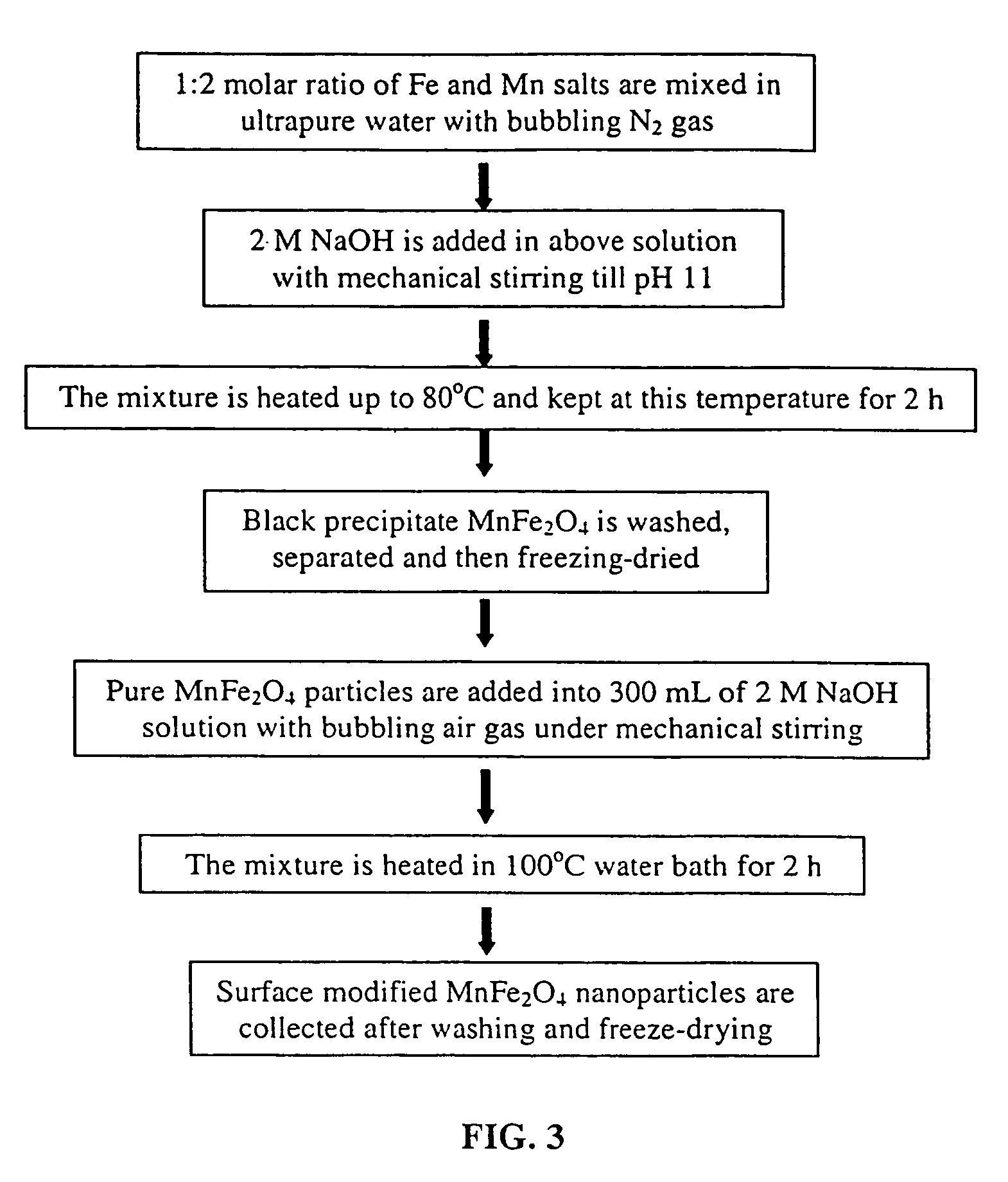

Synthesis of modified maghemite and jacobsite nanoparticles

ActiveUS7622423B1Good removal effectEfficient removalMaterial nanotechnologyOther chemical processesMaghemiteMagnetite Nanoparticles

The present invention provides a method for making modified jacobsite, Al-doped maghemite or modified maghemite nanoparticles that can be used to adsorb heavy metals, such as Cr(VI), found in wastewater. The magnetic nanoparticles can be separated using a magnetic field after adsorbing heavy metals from wastewater, and processed for reused.

Owner:THE HONG KONG UNIV OF SCI & TECH

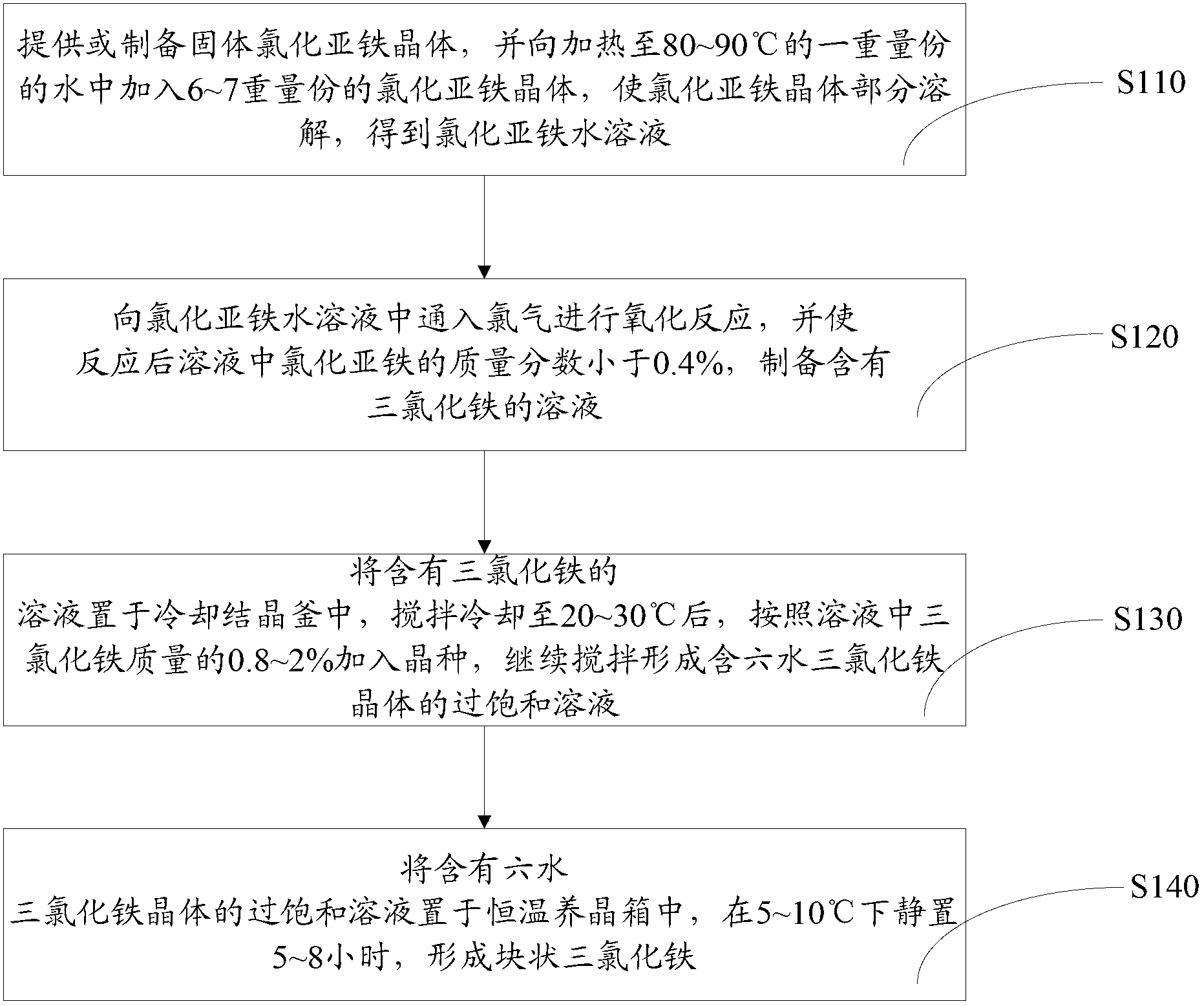

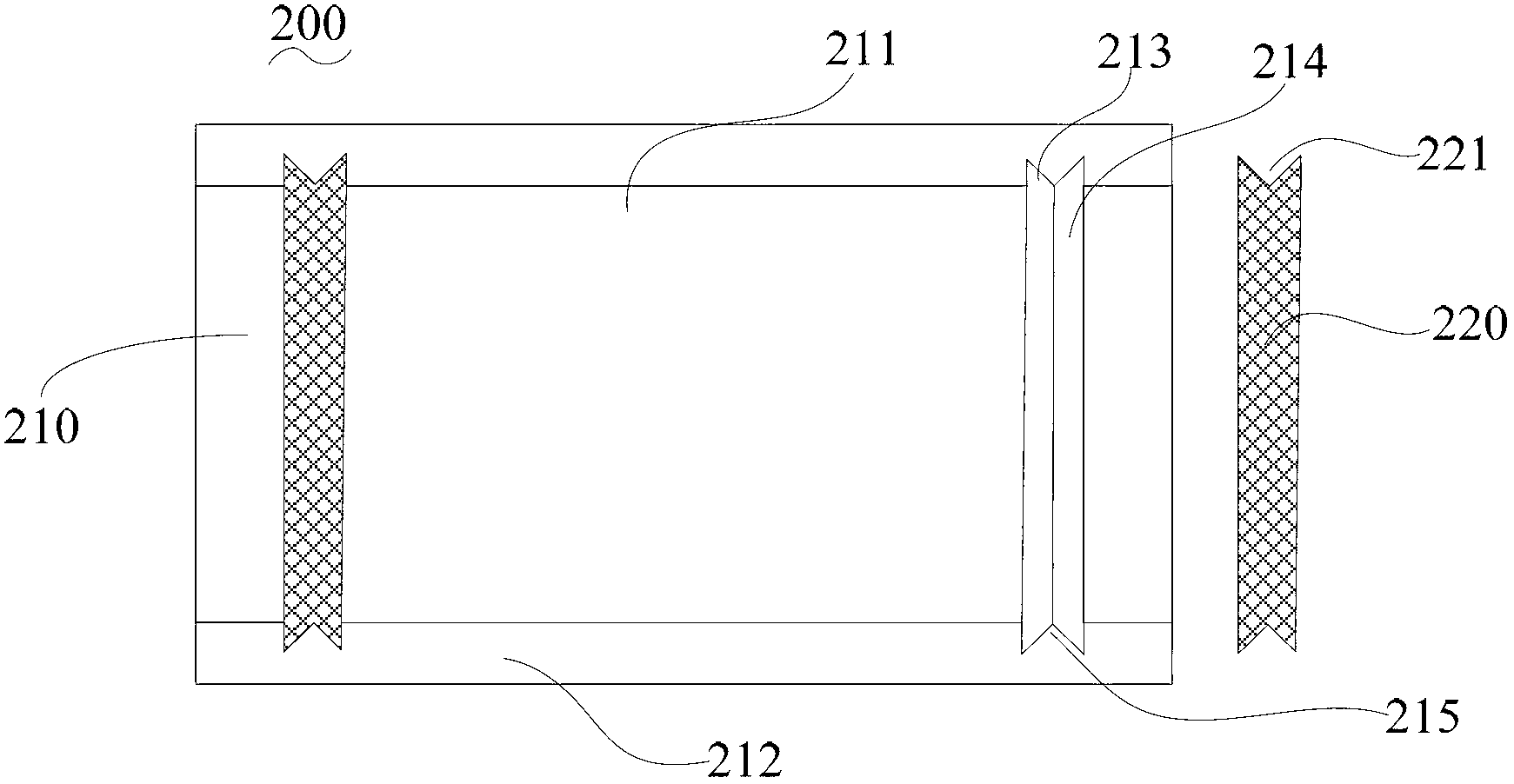

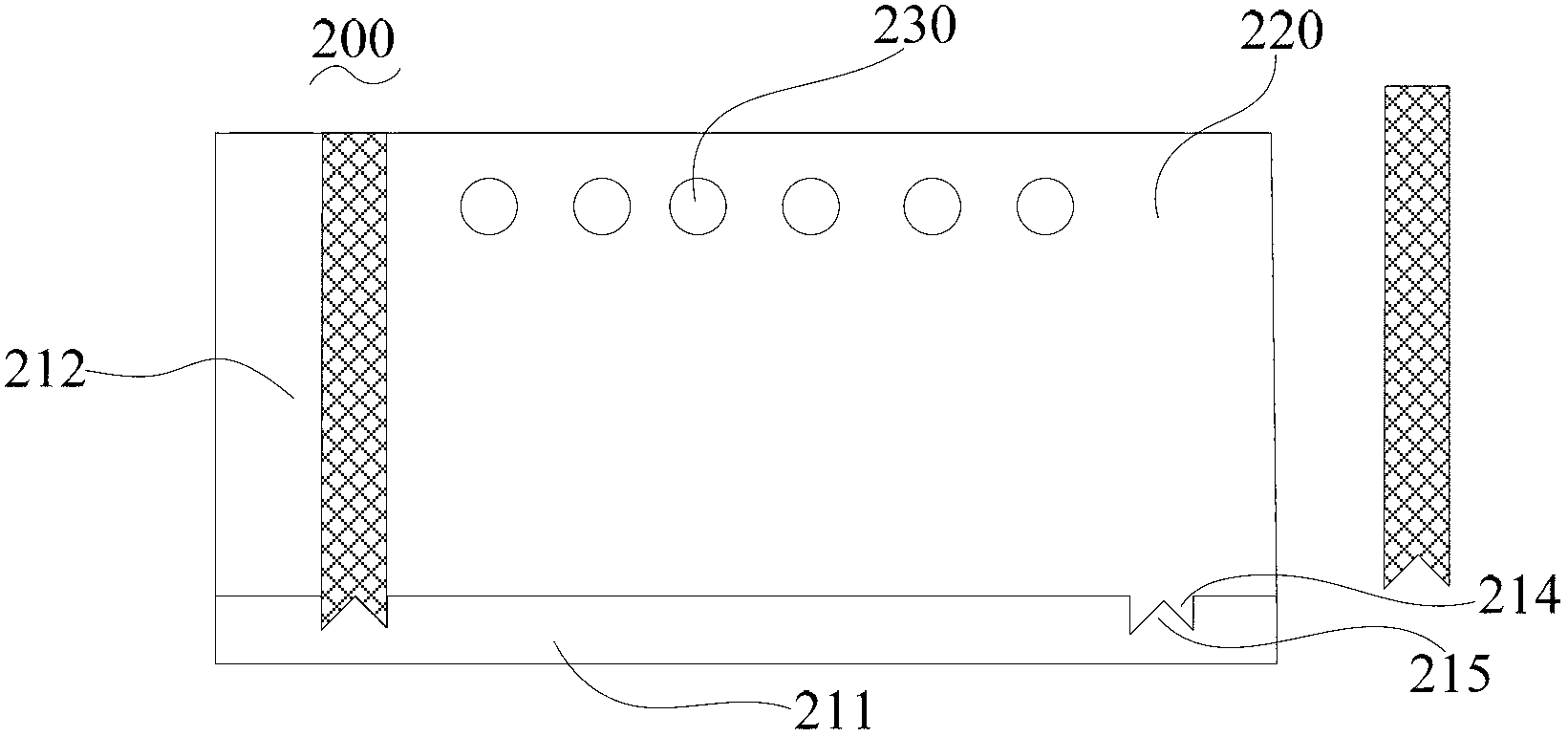

Method for preparing blocky ferric trichloride

The invention relates to a method for preparing blocky ferric trichloride. Blocky ferric trichloride can be produced both under constant-temperature crystal growing condition at 5-10 DEG C and at high-temperature environment temperature by adjusting the parameters of crystal cooling and crystal growing. In addition, solid ferric trichloride is used as a raw material, and impurities in the traditional pickling waste liquid are prevented from being mixed into a product; and chlorine gas is used as an oxidizing agent and does not contain any impurity. Finally, the blocky ferric trichloride can be directly obtained through crystal growing, the area of blocky ferric trichloride in direct contact with the air is small, the problem that ferric trichloride absorbs moisture easily can be effectively solved, the quality guarantee period of the product is prolonged, and the blocky ferric trichloride is easy to store and transport.

Owner:3R ENVIRONMENTAL TECH CO LTD

Method for preparing flocculant of ferric chloride of polysilicon acid

InactiveCN101003390AImprove stabilityUniform qualityIron halidesWater/sewage treatment by flocculation/precipitationSilicic acidAcid washing

This invention discloses a method for preparing a stable inorganic polymer flocculant, polyferric silicate chloride, from industrial acid-washing wastewater and iron scale by high-speed shearing, and its application in tap water purification. The method comprises: adding certain amounts of HCl and iron scale according to the contents of free acid and iron in industrial acid-washing wastewater, adding oxidant and stabilizer, oxidizing and polymerizing, adjusting the alkalinity with CaO (or MgO, or mixed slurry of Mg(OH)2 and Ca(OH)2) to obtain stable polyferric chloride, adding poly(silicic acid), and polymerizing under high speed shearing to obtain stable polyferric silicate chloride flocculant. The method has such advantages as simple process, mild reaction conditions and low investment, and is environmentally friendly. The prepared polyferric silicate chloride has better effect on tap water purification than polyferric chloride, ferric chloride and other iron-containing flocculant.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

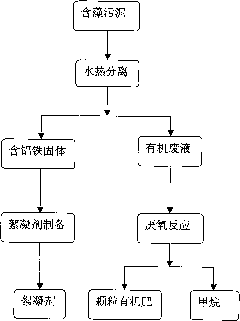

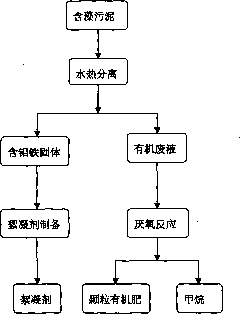

Method for preparing flocculant, fertilizer and methane with algae-containing sludge

InactiveCN101823768ATo achieve resourceRealize multi-channel resource utilizationSludge treatment by oxidationGas production bioreactorsLiquid productLiquid waste

The invention relates to a method for preparing flocculant, fertilizer and methane with sludge containing algae, which relates to a process for turning the sludge containing algae into resources. First, a hydrothermal oxidation technology is adopted to separate organic matter and inorganic matter in the sludge containing algae under the conditions of 150 to 180DEG C of temperature and 0.8 to 1MPa of pressure to obtain brown organic residual waste liquid and solid sludge containing aluminum and iron inorganic matter; and then the solid sludge is dried, ground and screened; hydrochloric acid is added into screen underflow to react for 1 to 2h at 90 to 100DEG C, and stays still; the pH value of a supernatant is regulated to 2.5 to 4, and the supernatant is cured for 12h at 50 to 60DEG C to obtain a PAC iron liquid product; the PAC iron liquid product is dried, and a PAC iron solid product is obtained; and the pH value of the organic residual waste liquid is regulated to 8 to 9, and the organic residual waste liquid enters an upflow anaerobic sludge bed reactor to react for 24h at 35DEG C to obtain granular organic fertilizer and combustible gas with 65 percent of methane content. The method for preparing flocculant, fertilizer and methane with algae-containing sludge has the advantages of simple process, low cost and high economic and social benefit, and can be widely applicable to the zero algae-containing sludge discharge and the clean production of sewage plants which treat lake sewage polluted by algae.

Owner:TONGJI UNIV

Preparation method of polyaluminum ferric chloride

ActiveCN104261525AImprove protectionSave resourcesIron halidesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateFiltration

The invention relates to a preparation method of polyaluminum ferric chloride, belonging to the technical field of preparation of inorganic high-polymer coagulating agents. The method comprises the following steps: adding dilute hydrochloric acid into a 10-14% iron-containing spent acid solution until the concentration of the iron-containing spent acid solution is enhanced to 15-18%, thereby obtaining an iron-containing spent acid solution; adding the iron-containing spent acid solution into a reaction vessel in batches, adding aluminum ash to obtain a stock solution, and carrying out polymerization reaction on the stock solution while continuously stirring, thereby obtaining a polyaluminum ferric chloride initial product; and discharging the initial product out of the reaction vessel, introducing into a precipitation tank, adding a back blending solution into the precipitation tank, adding a precipitant and PAM (polyacrylamide) into the precipitation tank, stirring uniformly, standing to stratify, introducing the supernatant into a finished product tank to obtain the polyaluminum ferric chloride, introducing the precipitate in the precipitation tank into a pressure filter to perform pressure filtration, and using the pressure filtrate as the back blending solution. The method saves the resources, and is beneficial to environmental protection; the processing steps are short and easy to operate; and the method has ideal energy-saving effect.

Owner:CHANGSHU CITY FOR THE YU ENVIRONMENT TECH

Method for preparing polyferric chloride flocculant by using steel wire rope sludge and waste salt

ActiveCN105271436AExcellent purificationReduce turbidityIron halidesWater/sewage treatment by flocculation/precipitationSludgeSulfide

The invention discloses a method for preparing a polyferric chloride flocculant by using steel wire rope sludge and waste salt. According to the method, the steel wire rope pickling sludge is dissolved in waste hydrochloric acid, lead ions in the dissolved solution are removed with a sulfide precipitation method, and the polyferric chloride flocculant is obtained; produced hydrogen sulfide gas meets the national odor pollutant emission standard after being subjected to falling-film absorption, packed tower absorption and activated carbon adsorption treatment, and meanwhile, whole-process sulfur element recycling is realized; cement is added to sludge residues for curing, and heavy metals are cured and stabilized. With the adoption of the method, the recovery rate of iron in the sludge is higher than 90%, the produced polyferric chloride flocculant has excellent performance in purification of domestic sewage, and produced lead sulfide meets the industrial purity requirement and can be used as an industrial raw material. With the adoption of the method, harmless disposal and resource utilization of the steel wire rope pickling sludge and the waste hydrochloric acid are realized simultaneously.

Owner:刘阳生

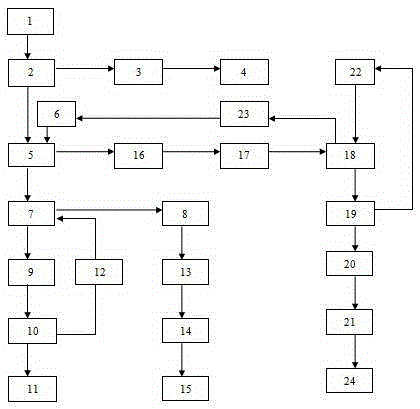

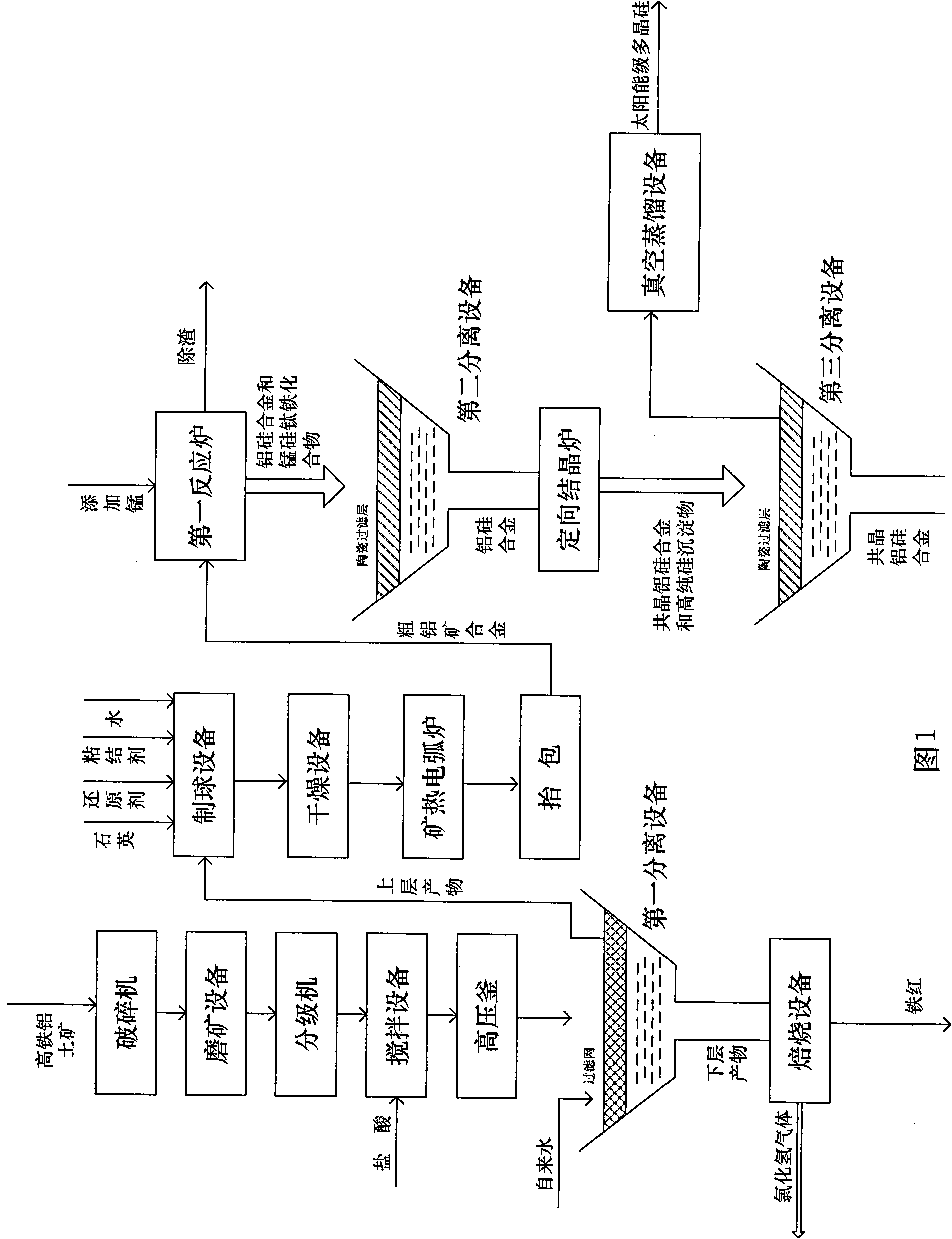

Combination production method for obtaining multi-products using high iron bauxite as raw material

The invention discloses a combination production method for industrially producing a plurality of products by using high-iron alumyte as a material. The combination production method comprises the steps of performing pressure-leaching the high-iron alumyte by using hydrochloric acid as a leaching medium, iron enters the hydrochloric acid in the form of ion to form the chloride of iron, aluminum is left in solid alumyte, thereby separating iron from aluminum; roasting a hydrochloric acid leaching fluid to obtain iron oxide red and a chlorine hydride gas, wherein the chloride hydride gas is absorbed by washing water and becomes hydrochloric acid, which can be recycled; and melting the upper layer of products, conducting directional crystallization to prepare a cocrystallized Al-Si alloy with silica content below 14wt%. Therefore, the high-iron alumyte which cannot be utilized currently, can be comprehensively utilized.

Owner:辽宁建元投资发展有限公司 +1

Thermochemical hydrogen produced from a vanadium decomposition cycle

InactiveUS7799315B2Improve reliabilityHigh thermal efficiencyHydrogen separation using liquid contactEnergy inputHydrogenDecomposition

A thermochemical water-splitting process all reactions of which operate at relatively low temperatures and high efficiencies, and in which relatively inexpensive materials and processing methods are made possible. This invention involves the decomposition of a metal halide compound, i.e., one which is capable of being reduced from a higher oxidation state to lower oxidation state, e.g. vanadium chloride III→vanadium dichloride. The process is cyclic and regenerative, and the only net inputs are water and heat; and the only net outputs are hydrogen and oxygen. The process makes it possible to utilize a wide variety of available heat, including solar, sources for the energy input.

Owner:AMENDOLA STEVEN

Method for preparing ferric chloride by quickly oxidizing iron dichloride

InactiveCN101514034AImprove economyIron halidesWater/sewage treatment by flocculation/precipitationRoom temperatureChloride

The invention belongs to the chemical engineering technical field, in particular to a method for preparing ferric chloride by quickly oxidizing iron dichloride, the specific steps of which are as follows: the mixed liquor of iron dichloride solution crystal and hydrochloric acid or steely hydrochloric acid pickling solution is well stirred in a reactor in the room temperature, an injector and a circulating pump are used for causing the liquid to be in recurrent state, and then in the normal atmosphere condition, oxygen, sodium nitrite or nitric acid are added so as to realize the oxidation reaction of the iron dichloride solution and obtain liquid ferric chloride solution. If the liquid ferric chloride solution is further concentrated, the solid ferric chloride crystal can be obtained. The preparation method is simple, does not need chlorine to serve as the oxidant and is characterized by safety and high effective; meanwhile, raw materials are easy to be gotten, has low cost, extensive development valve and application prospect.

Owner:TONGJI UNIV

PROCESSES FOR PREPARING ALUMINA AND MAGNESIUM CHLORIDE BY HCl LEACHING OF VARIOUS MATERIALS

The disclosed processes can be effective for treating various materials comprising several different metals. These materials can be leached with HCl for obtaining a leachate and a solid. Then, they can be separated from one another and a first metal can be isolated from the leachate. Then, a second metal can further be isolated from the leachate. The first and second metals can each be substantially selectively isolated from the leachate. This can be done by controlling the temperature of the leachate, adjusting pH, further reacting the leachate with HCl, etc. The metals that can be recovered in the form of metal chlorides can eventually be converted into the corresponding metal oxides, thereby allowing for recovering HCl. The various metals can be chosen from aluminum, iron, zinc, copper, gold, silver, molybdenum, cobalt, magnesium, lithium, manganese, nickel, palladium, platinum, thorium, phosphorus, uranium, titanium, rare earth element and rare metals.

Owner:ORBITE ALUMINAE INC

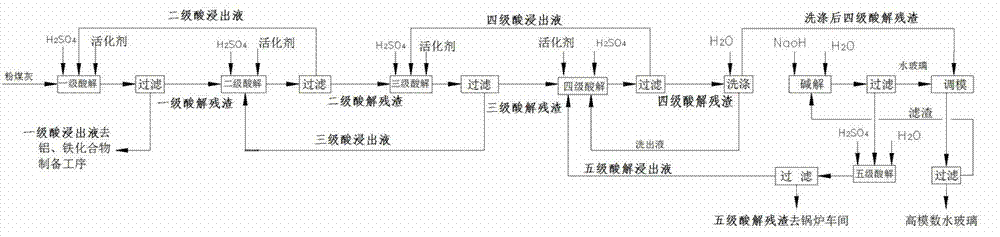

Fly ash decomposition method

The invention discloses a fly ash decomposition method. The method comprises the following steps: sending fly ash powder to an acidolysis process, adding sulfuric acid or hydrochloric acid or nitric acid to carry out a multistage acidolysis reaction with fluorite or industrial calcium fluoride as an activator in order to convert aluminum and iron elements in the fly ash powder into corresponding soluble salts entering a liquid phase, filtering, and separating to obtain an acid leachate containing aluminum salt and iron salt; washing acidolysis residues, mixing the acidolysis residues with water, adding sodium hydroxide to carry out an alkaline hydrolysis reaction, and filtering to prepare high modulus water glass; and washing alkaline hydrolysis residues, filtering, and sending the obtained acid leachate to a fore acidolysis process in order to be used for burdening. The decomposition rates of alumina and iron oxide in the fly ash reach above 90% and above 85% respectively; the modulus of the water glass is controlled between 3.2 and 3.8, the device investment is reduced, and the energy consumption and the raw material cost are reduced; and the method realizes recycling of decomposition residues, eliminates influences of secondary waste residues on environment, and lays a foundation for the preparation of aluminum, iron and silicon compounds.

Owner:NANYANG ORIENTAL APPL CHEM RES INST

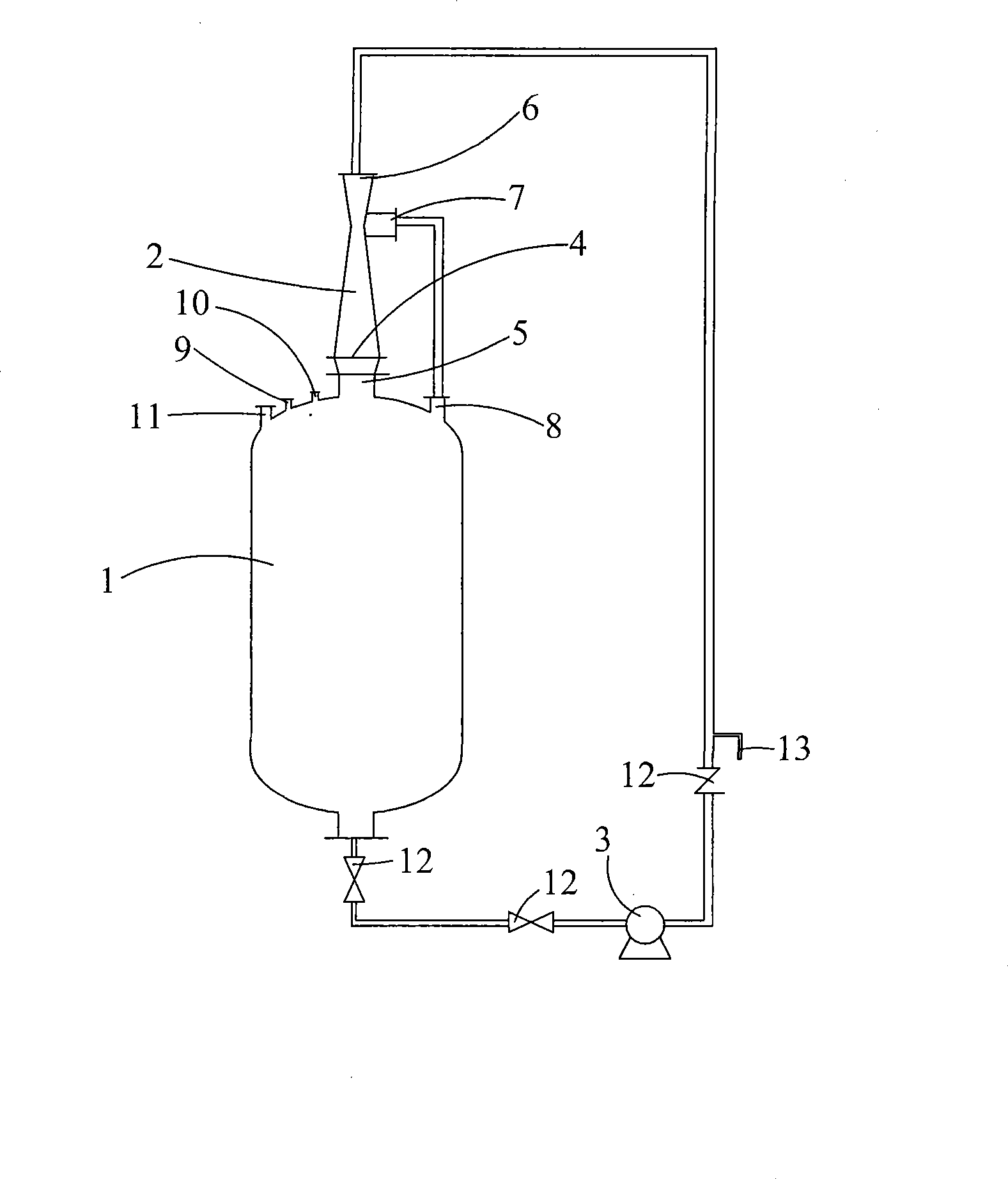

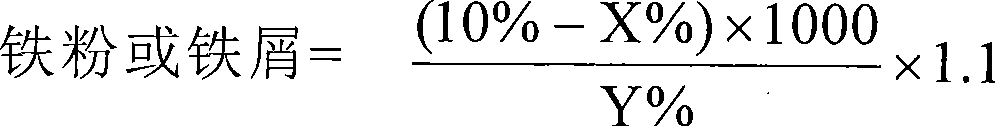

Process for preparing poly ferric chloride

InactiveCN101462776AReduce concentrationRealize comprehensive utilizationIron halidesChemical recyclingPtru catalystIron chloride

The invention relates to a method for preparing polyferric chloride. The method comprises: placing a pickling solution containing iron or hydrochloric acid pickle into a reaction kettle device and adding iron powder or iron slag into the reaction kettle device at the same time to heat materials with the heat generated in the exothermic reaction of the acid and the iron; and then adding a catalyst in and passing oxygen through the reaction kettle and then starting a circulating pump to circulating the reaction liquid for 3 to 5 hours till the polymerization finishes completely; and transferring the reaction liquid to a precipitation tank for precipitation or separation and enrich of products by filtering. The method for producing polyferric chloride by using the pickling solution and the hydrochloric acid pickle reduces production cost and realizes resource comprehensive use of waste.

Owner:金月祥

Fluoride ion cleaning method

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com