Patents

Literature

966results about "Emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

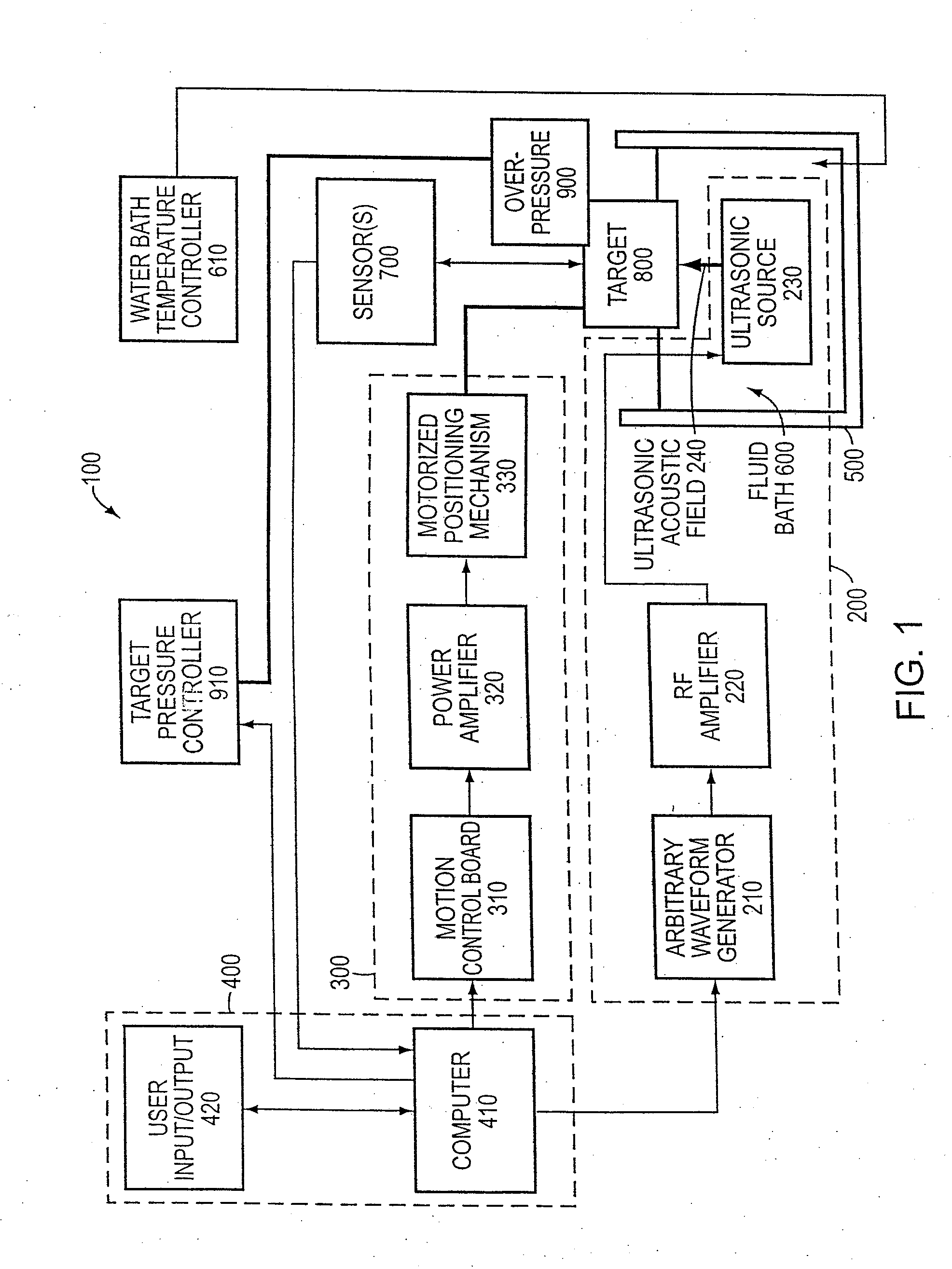

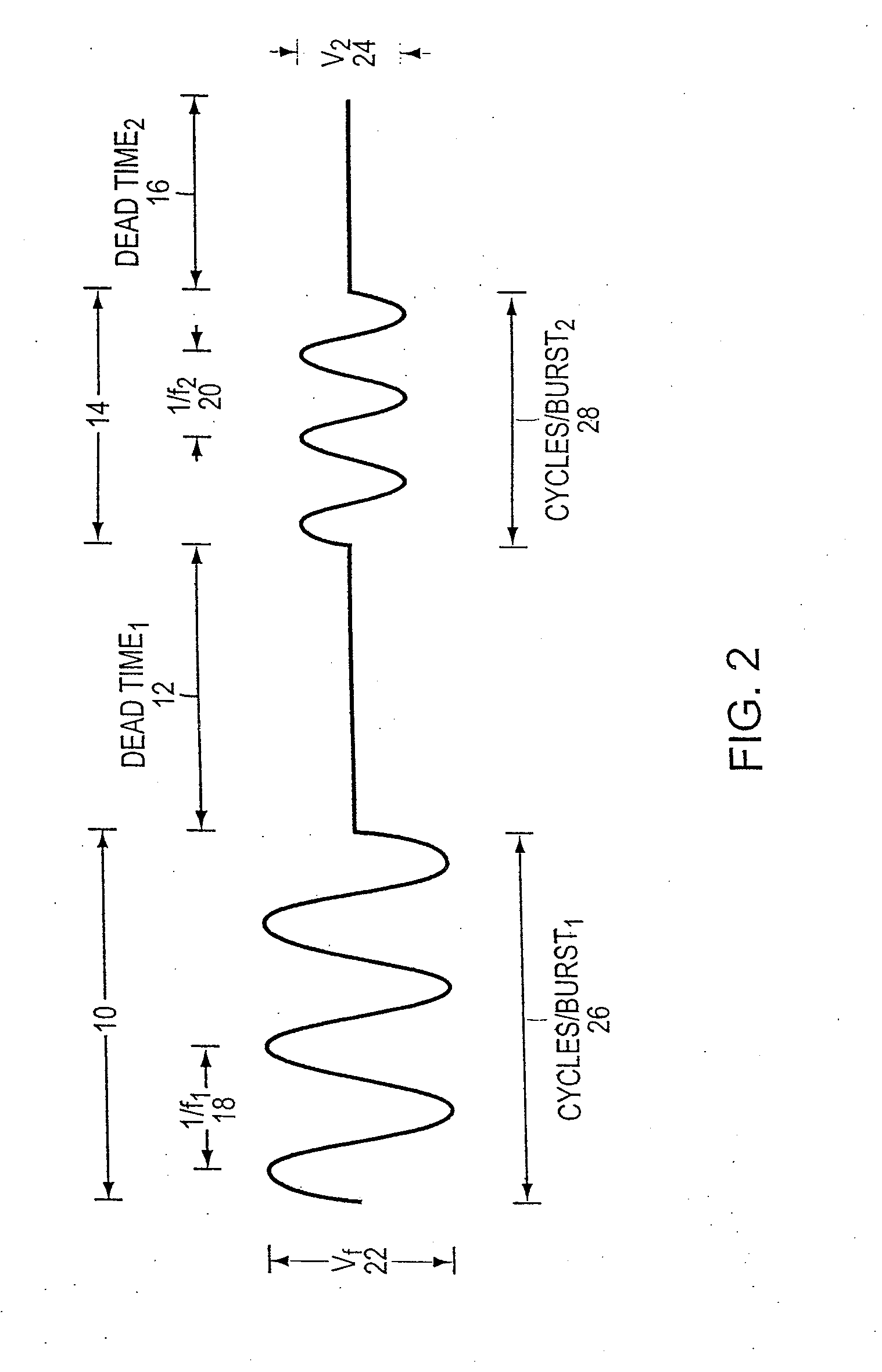

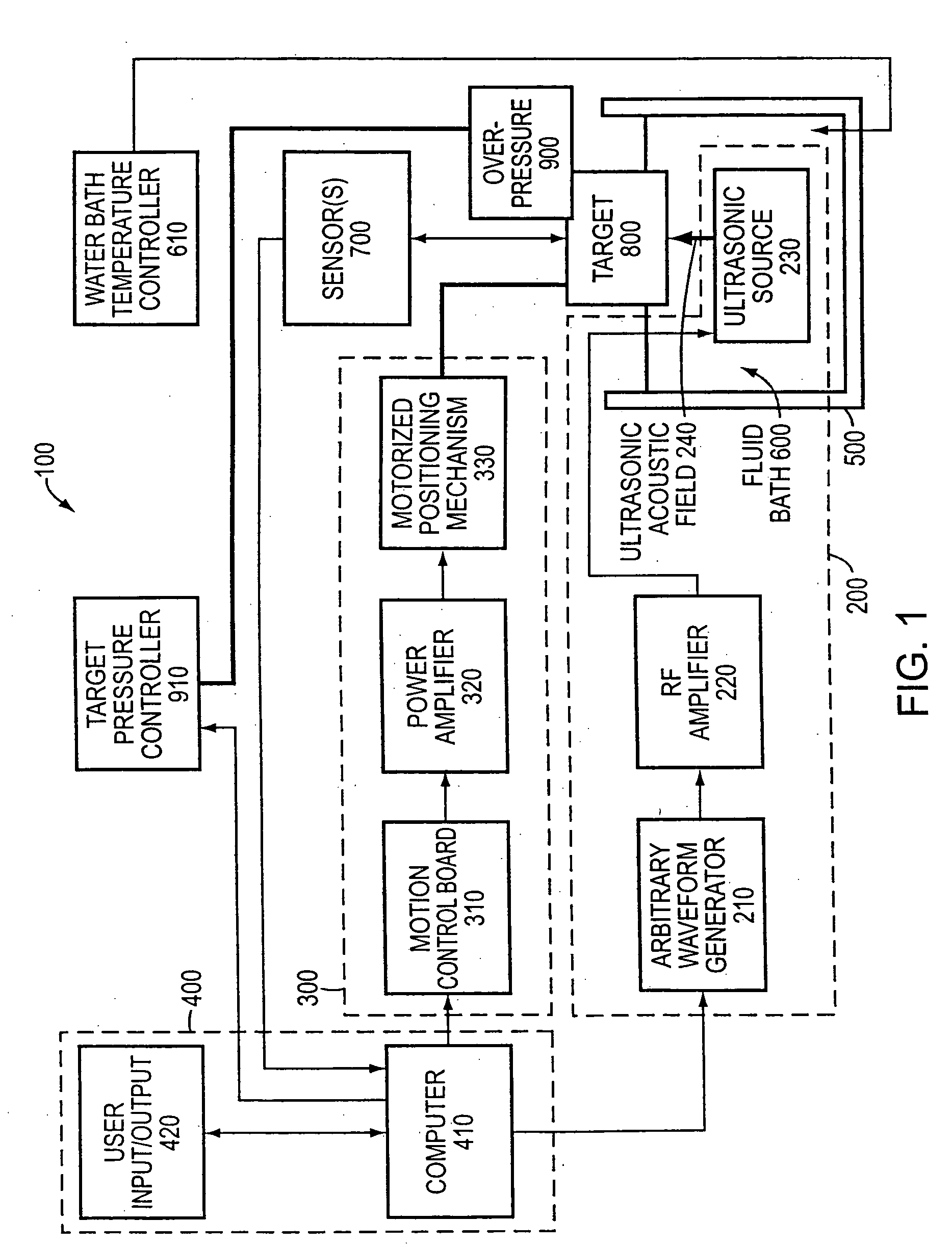

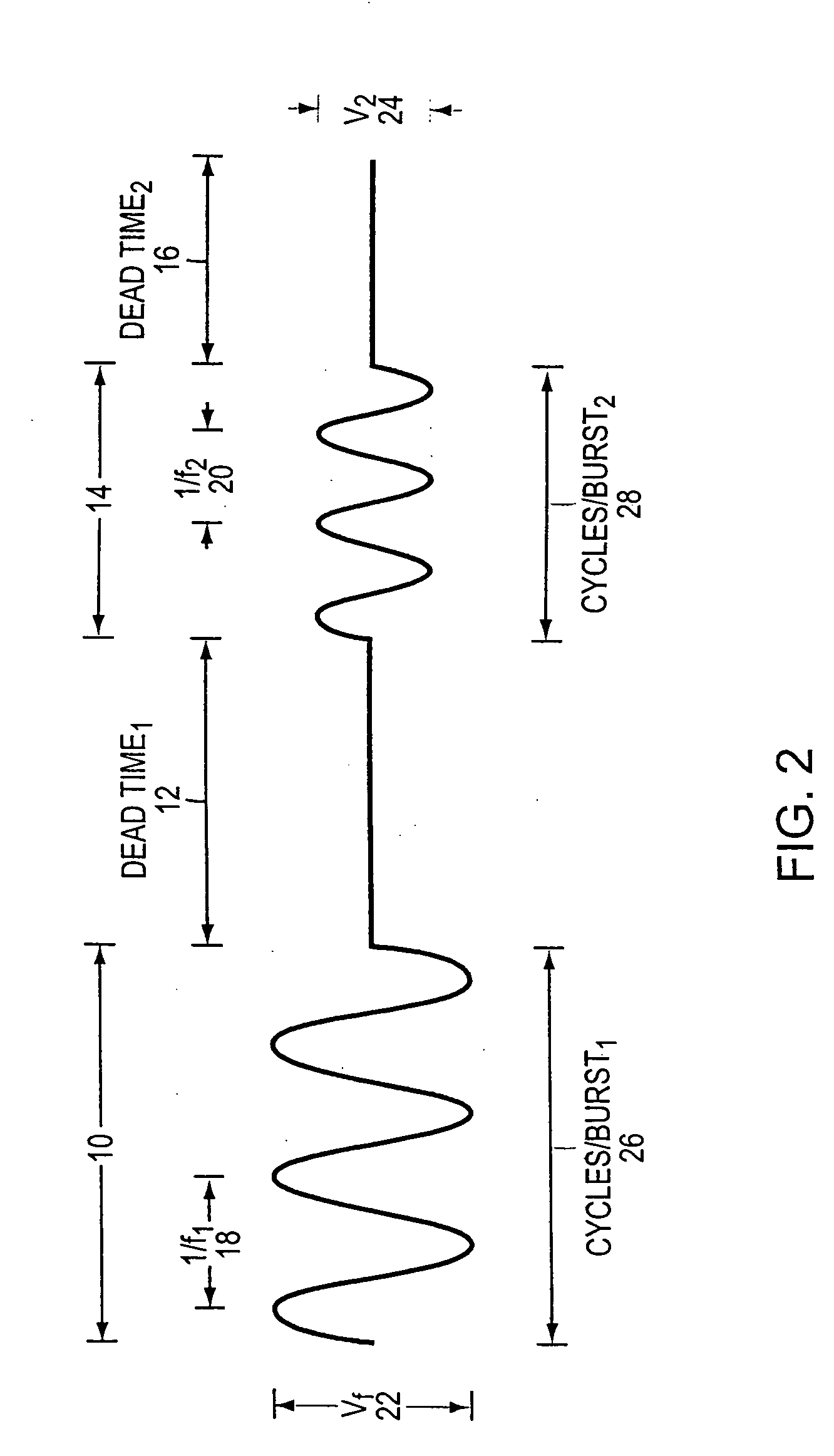

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS6948843B2Improve reaction speedAccelerating molecular interactionSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

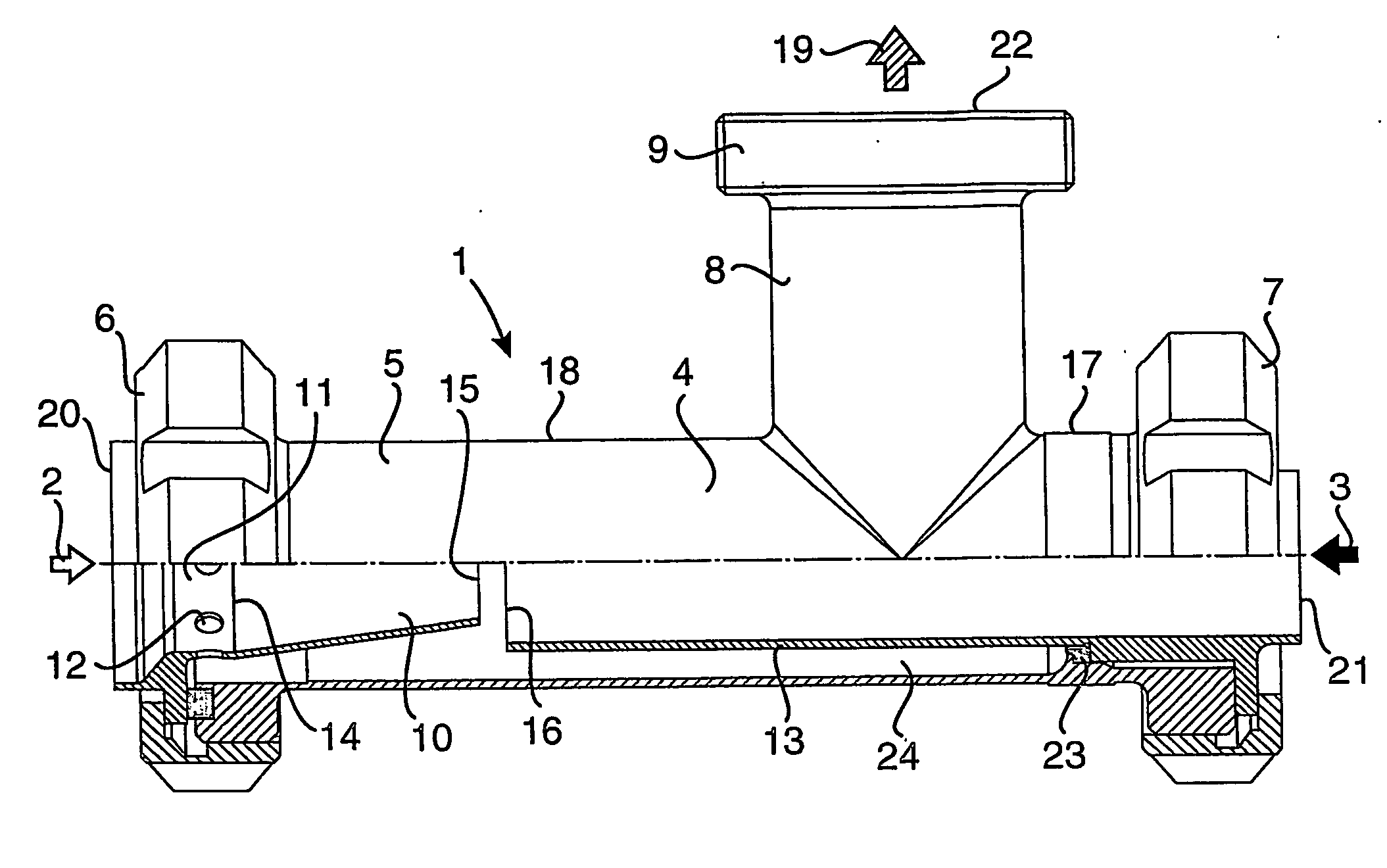

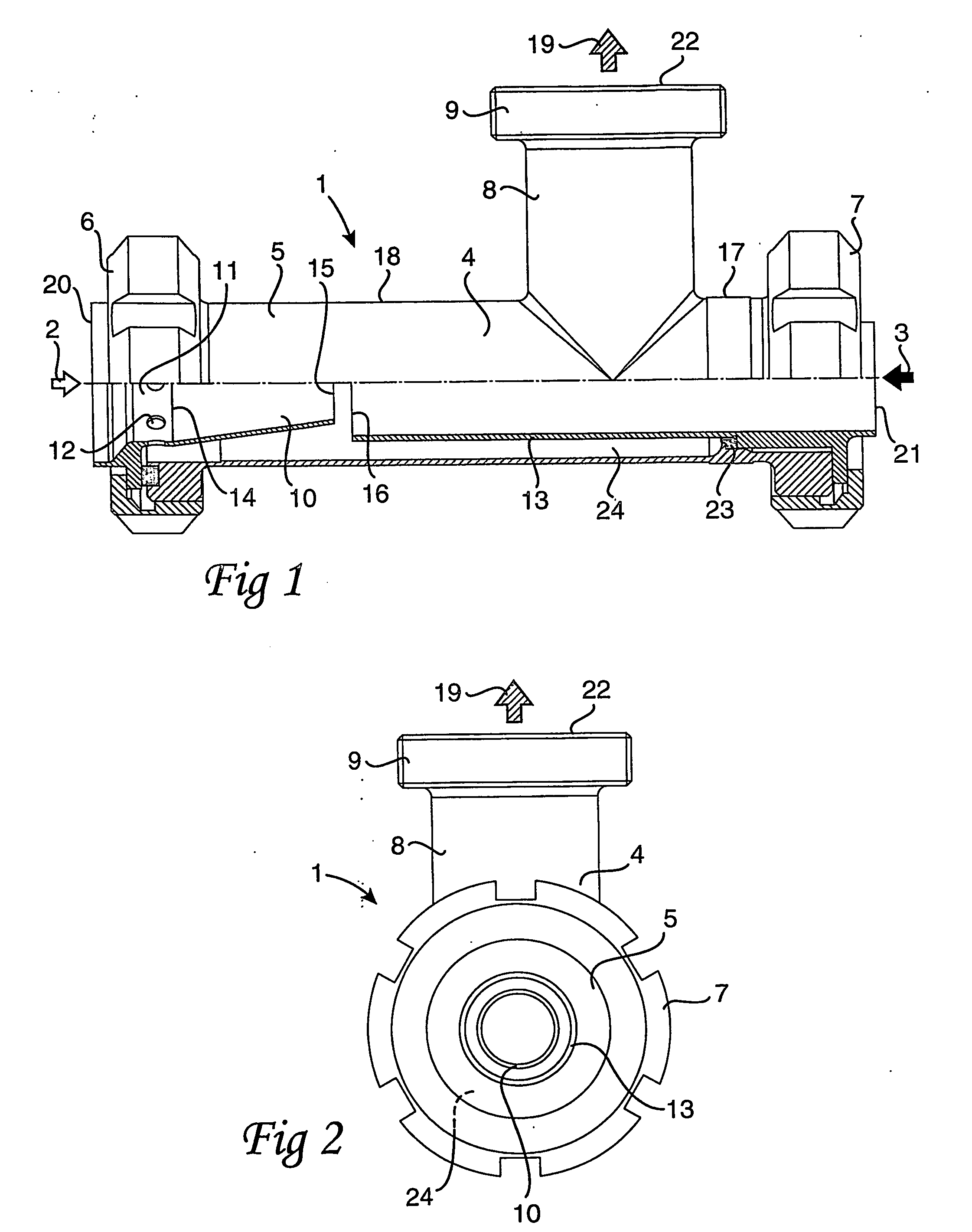

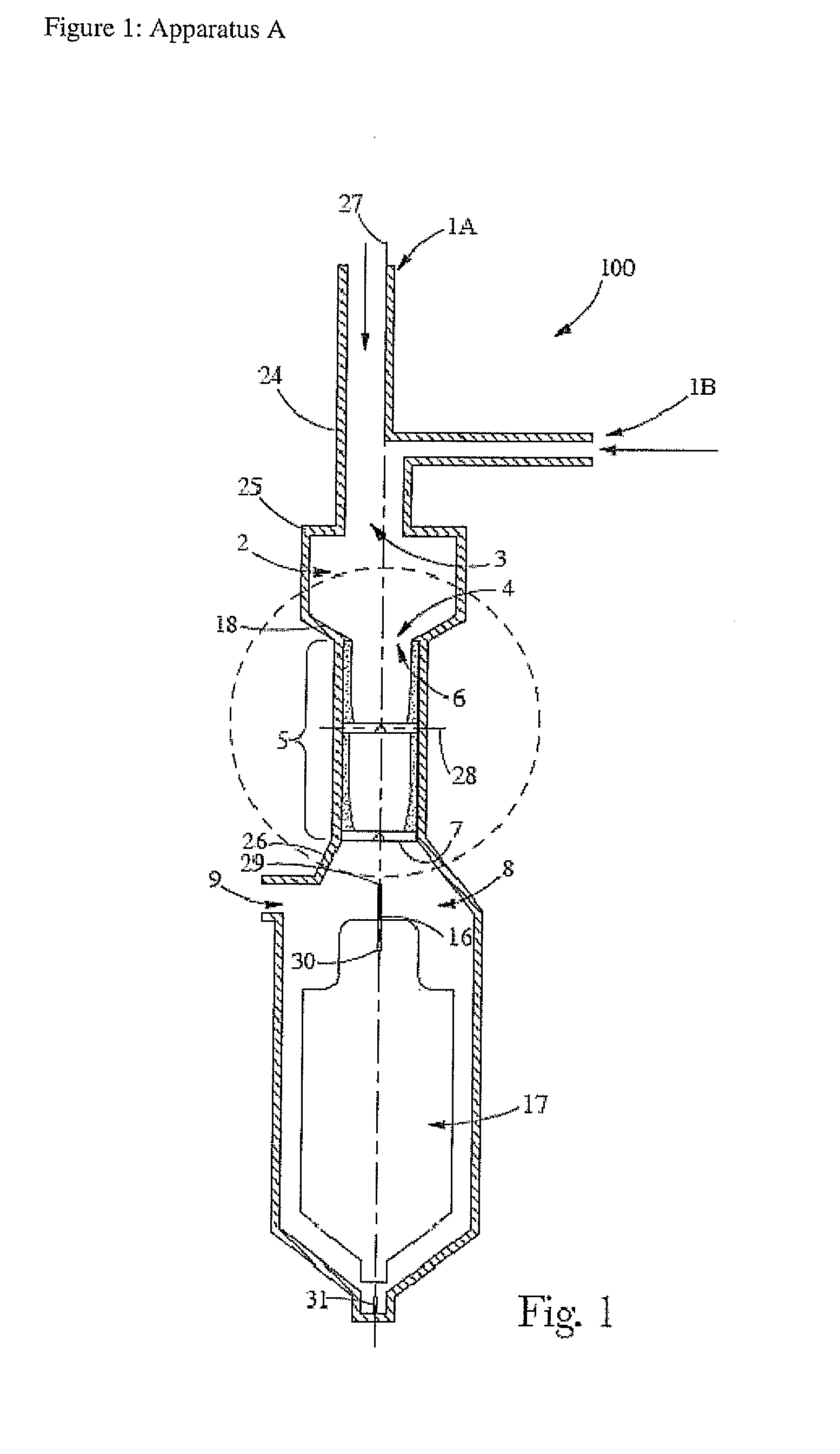

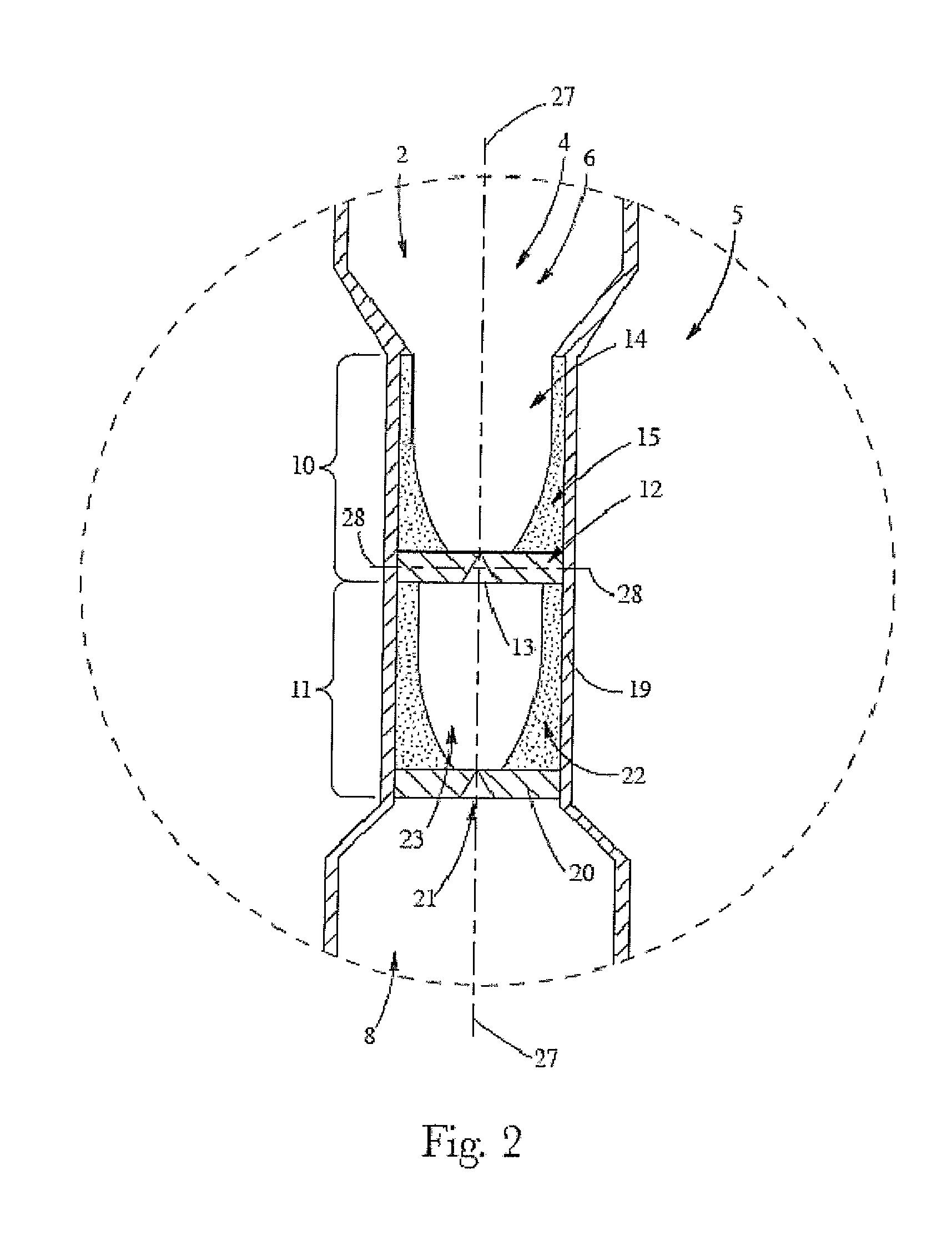

Method and an apparatus for the continous mixing of two flows

InactiveUS20070153625A1Improved cleaning possibilityIncrease demandFlow mixersTransportation and packagingStream flowEngineering

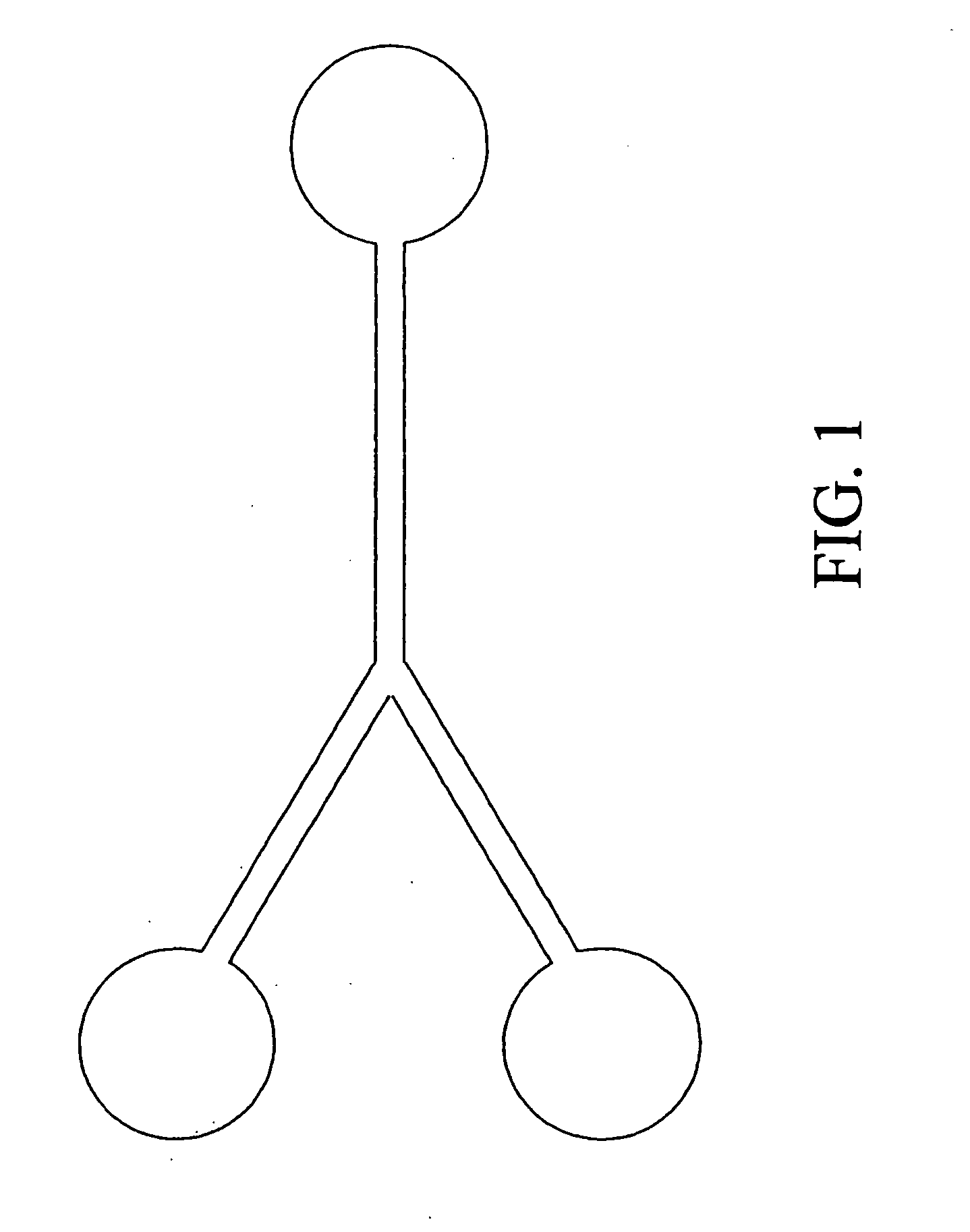

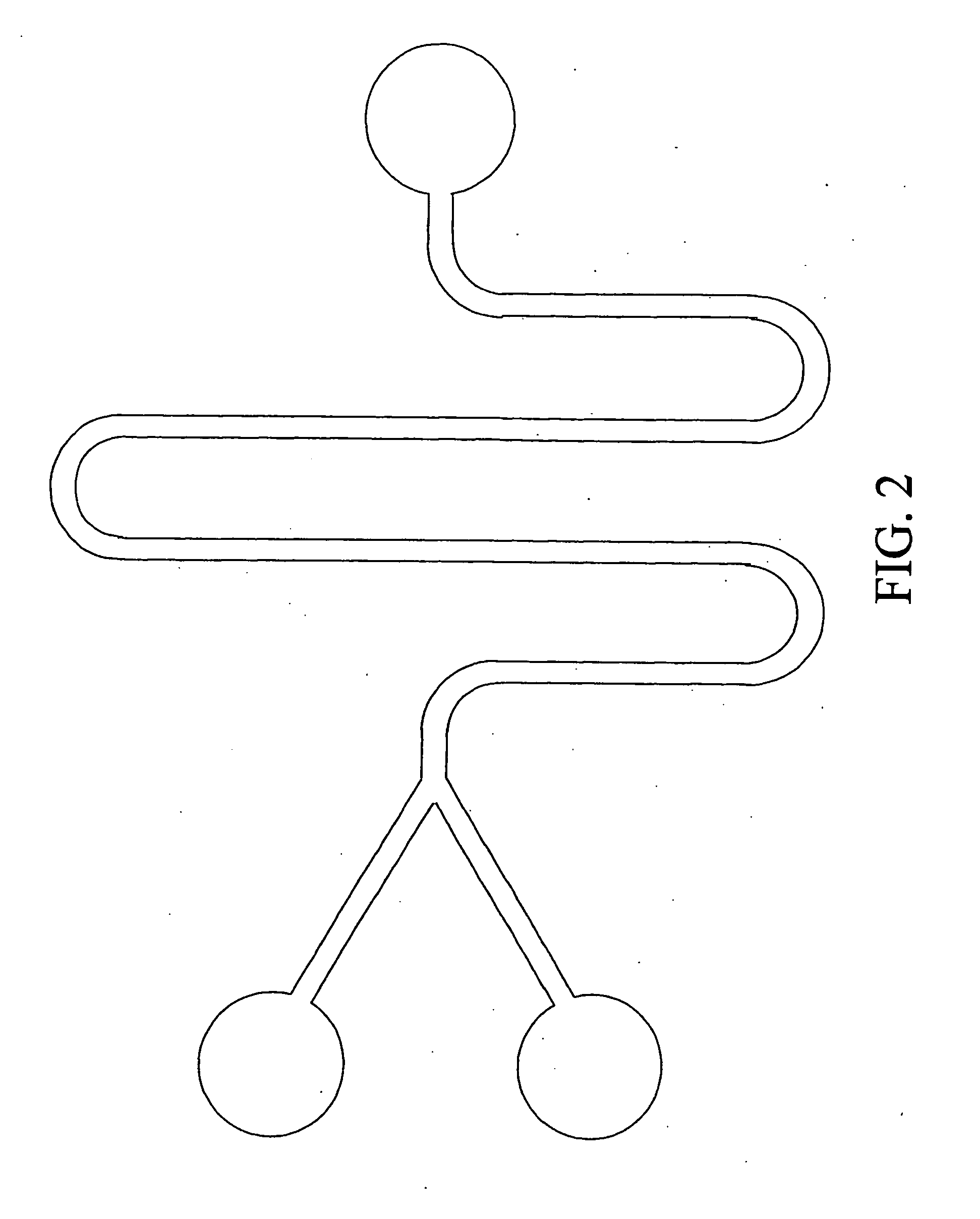

The disclosure relates to a method and an apparatus (1) for continuously mixing two flows, a first, larger flow (2) and a second, smaller flow (3). The second flow (3) is introduced counter-directed into the first flow (2). The apparatus (1) comprises a T pipe (4) where a first connection (6) constitutes an inlet (20) for the first flow. A second connection (7), at 180° in relation to the first connection (6), constitutes an inlet (21) for the second flow (3). The second flow (3) is led into the first flow (2) through a conduit (13) within the T pipe (4). The first connection (6) is provided with a conical portion (10) in which are provided a number of holes (12), so that the first flow (2) is throttled and divided up into a plurality of subflows immediately before the mixing operation. A third connection (9) is oriented at 90° in relation to the other connections (6, 7) and constitutes an outlet (22) for the intermixed flows (19), which implies that the intermixed flows (19) are caused to change direction immediately after the mixing.

Owner:TETRA LAVAL HLDG & FINANCE SA

Multiple stream high pressure mixer/reactor

InactiveUS6221332B1Improve reliabilityFew and less partCalcium/strontium/barium carbonatesPressurized chemical processStream flowLow density

Enhanced macromixing, mesomixing, and micromixing of multiple discrete reactant streams, particularly for precipitation reactions of low density pumpable fluids, are obtained by controlled continuous high pressure multiple reactant streams flowing into a chemical mixer / reactor. Individual reactant streams are pressurized to about 8,000 to 50,000 psi and achieve velocities up to about 250 meters / second in the final stage of the chemical mixer / reactor. Reactant flows are controlled by a combination of a fixed restriction and a variable driving pump.

Owner:MICROFLUIDICS INT

Microfluidic treatment method and device

InactiveUS20050161326A1Easily compiled into databaseAccurate gradientShaking/oscillating/vibrating mixersSludge treatmentGel electrophoresisMicrochip Electrophoresis

The present invention relates to a microchip apparatus using liquids. More specifically, the invention provides a liquid mixing apparatus comprising at least two microchannels for introducing liquids and a mixing microchannel that connects to the at least two liquid-introducing microchannels, wherein the liquids are transported from the respective liquid-introducing microchannels toward the mixing microchannel, the apparatus further comprising means for enhancing the mixing of the liquids that converge in the mixing microchannel. The invention also provides an electrophoretic apparatus and a microchip electrophoretic apparatus for denaturing gradient gel electrophoresis.

Owner:EBARA CORP

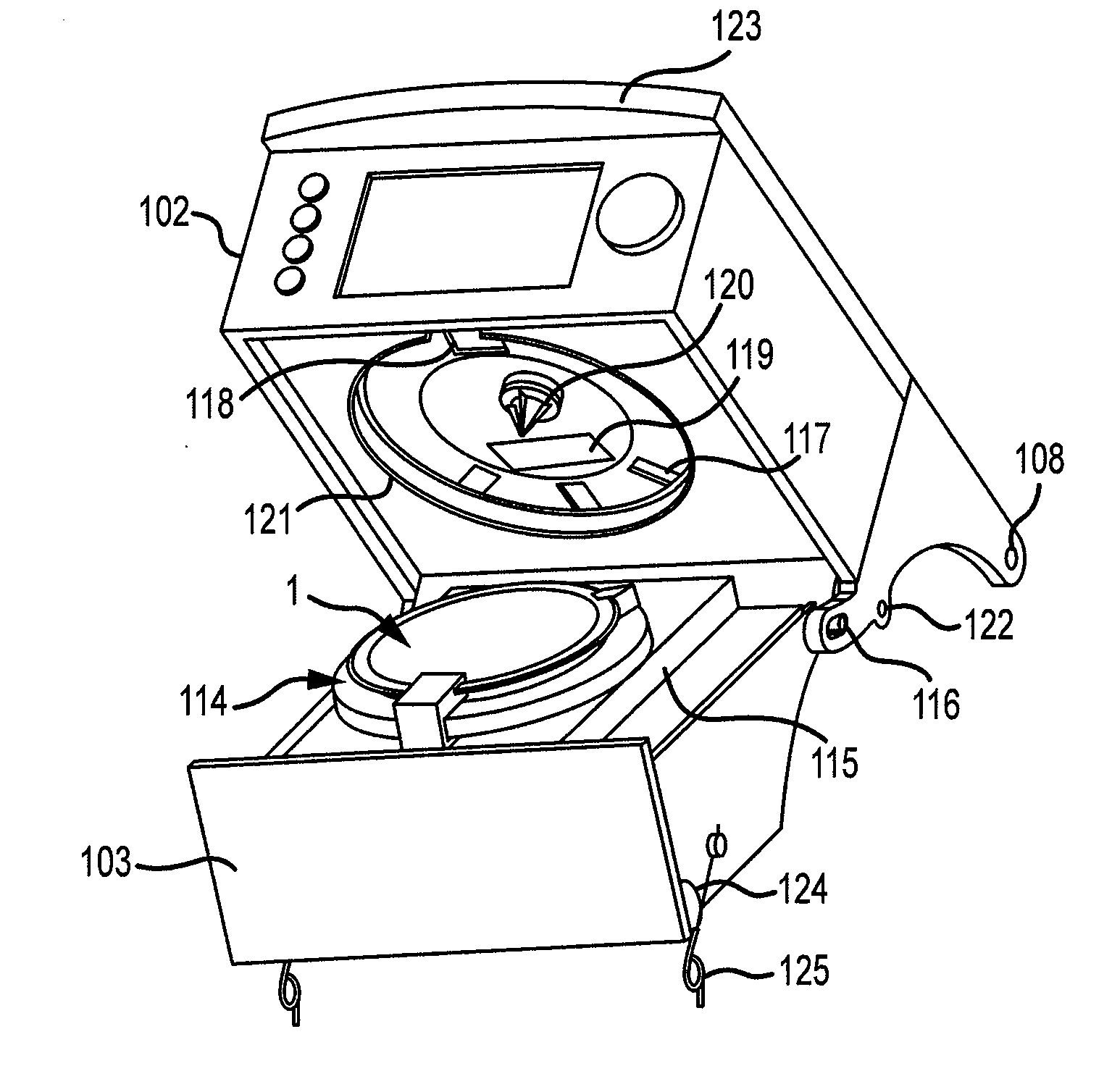

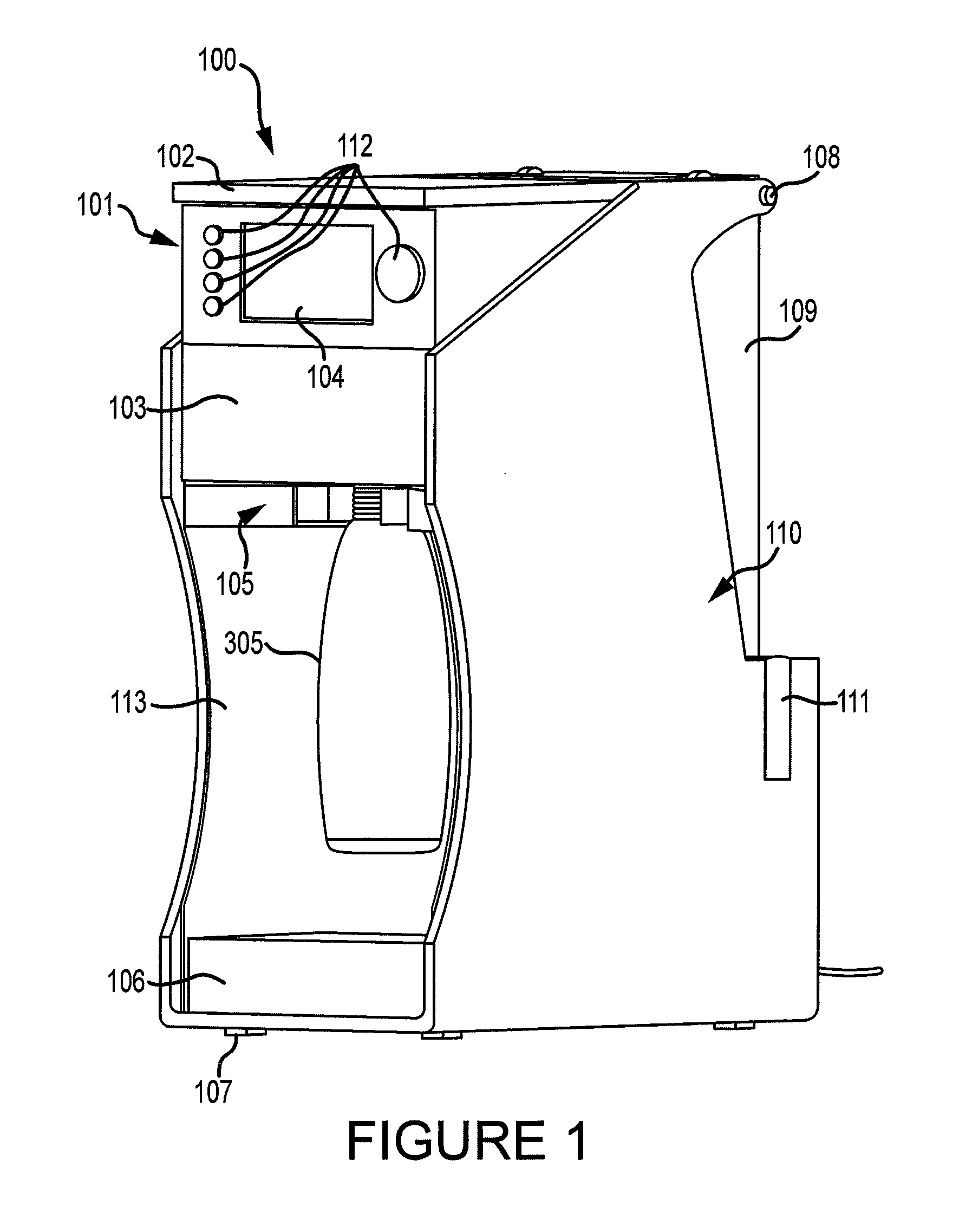

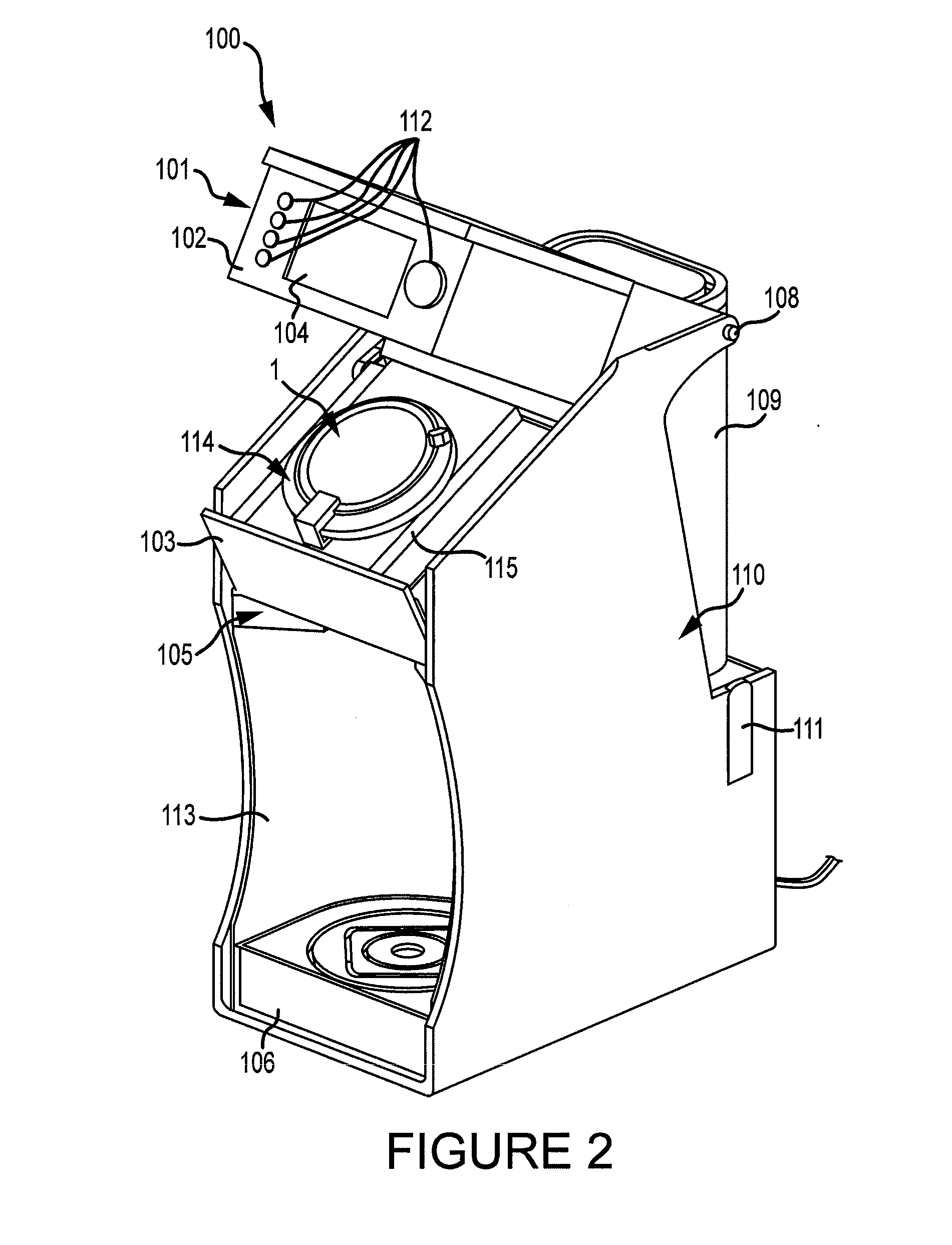

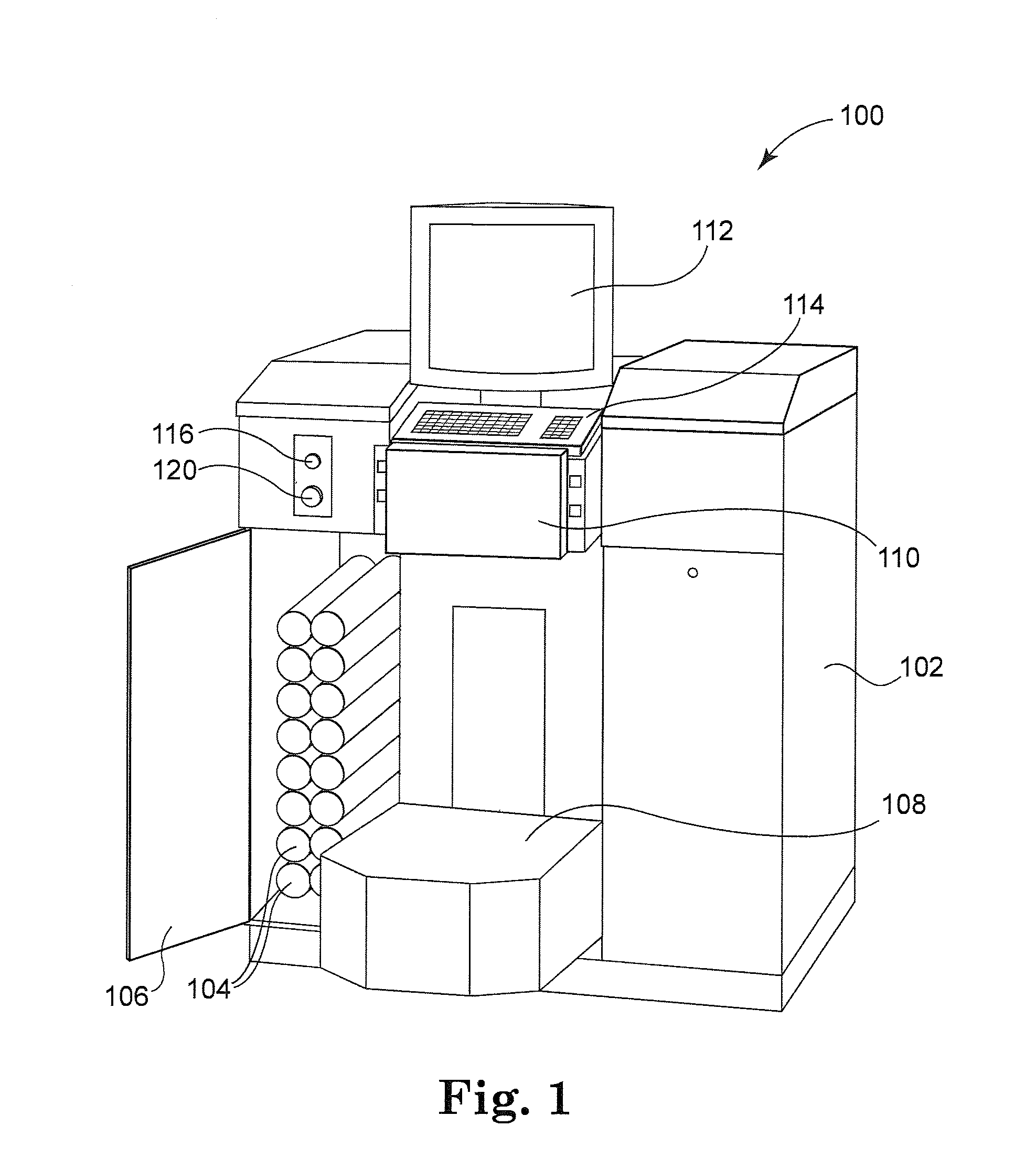

Apparatus and method for preparing a liquid mixture

A mixing apparatus, puncturing mechanism, and cartridge are disclosed. The mixing apparatus has a housing and a drawer with a recess. Corresponding cartridges may be inserted into the drawer and slid into the housing to facilitate mixing a liquid with contents of the cartridge. The liquid may originate from a reservoir in the mixing apparatus or a direct line. Also inside the housing of the mixing apparatus is the puncturing mechanism. The puncturing mechanism has a nozzle configured to puncture a lid of a cartridge and inject liquid to mix with the contents of the cartridge. The puncturing mechanism is further configured to drive an internal puncturing unit inside of the cartridge through a lower portion of the cartridge to allow liquid from the nozzle and contents of the cartridge to be dispensed into a receptacle.

Owner:FORMULANOW

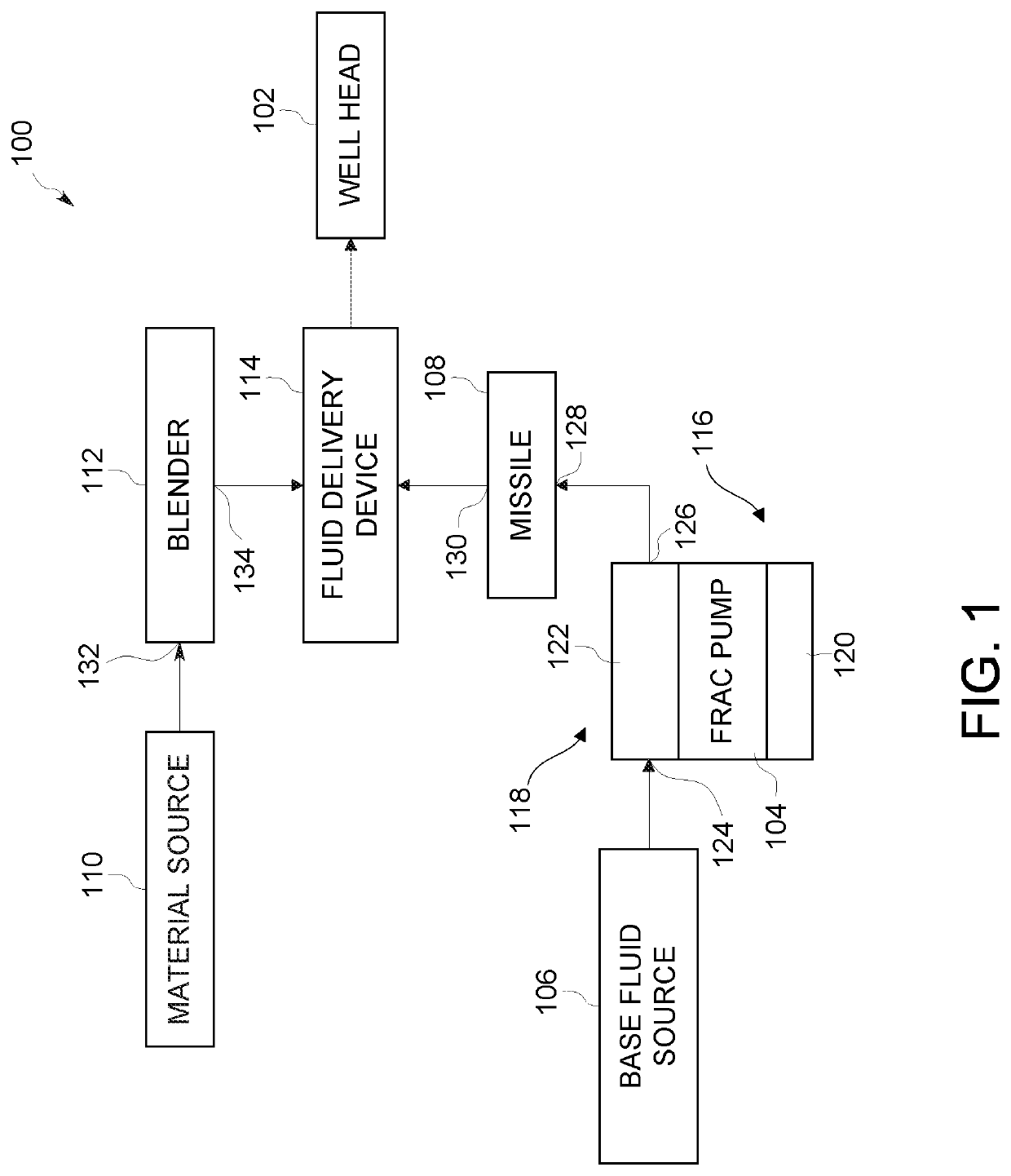

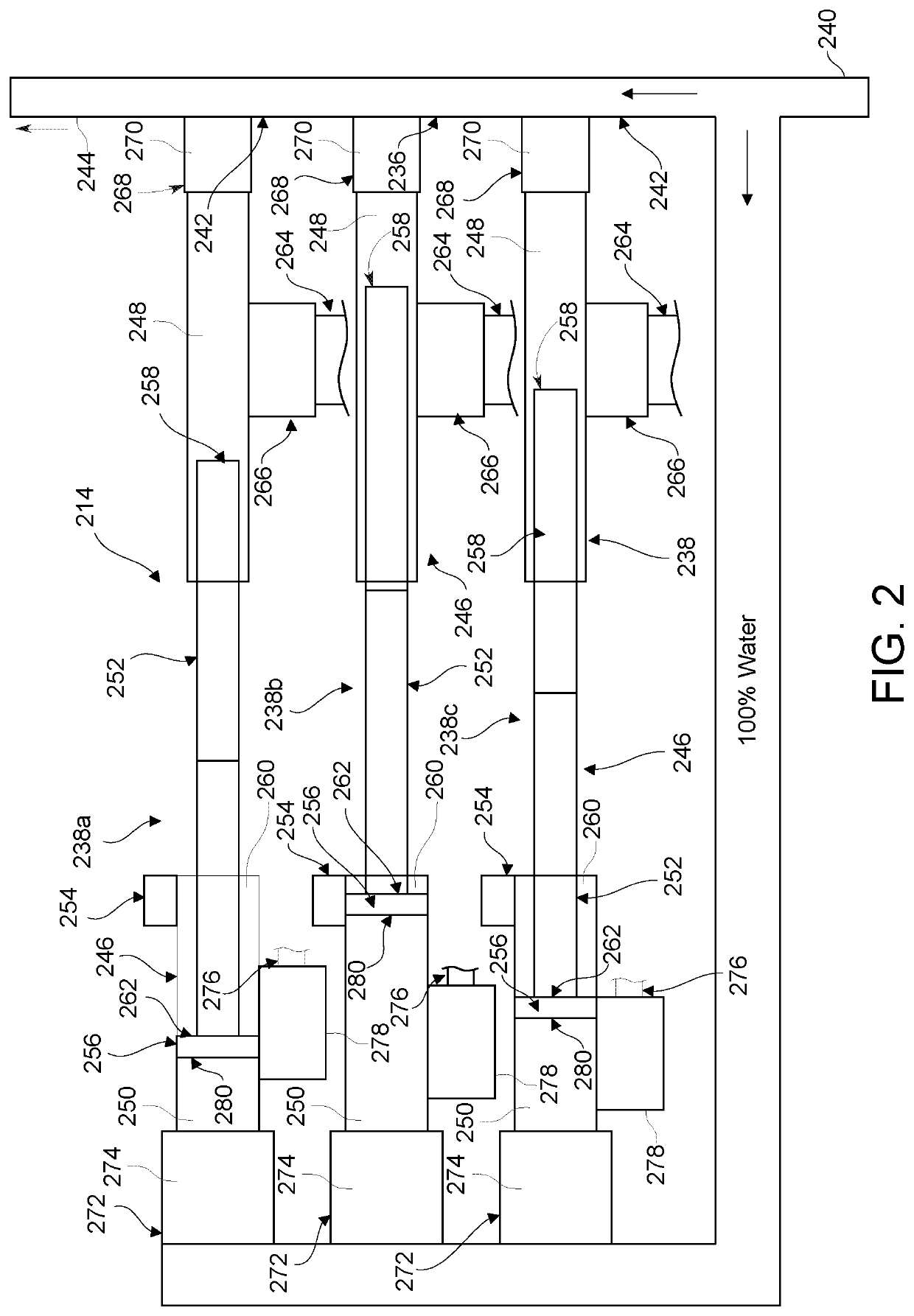

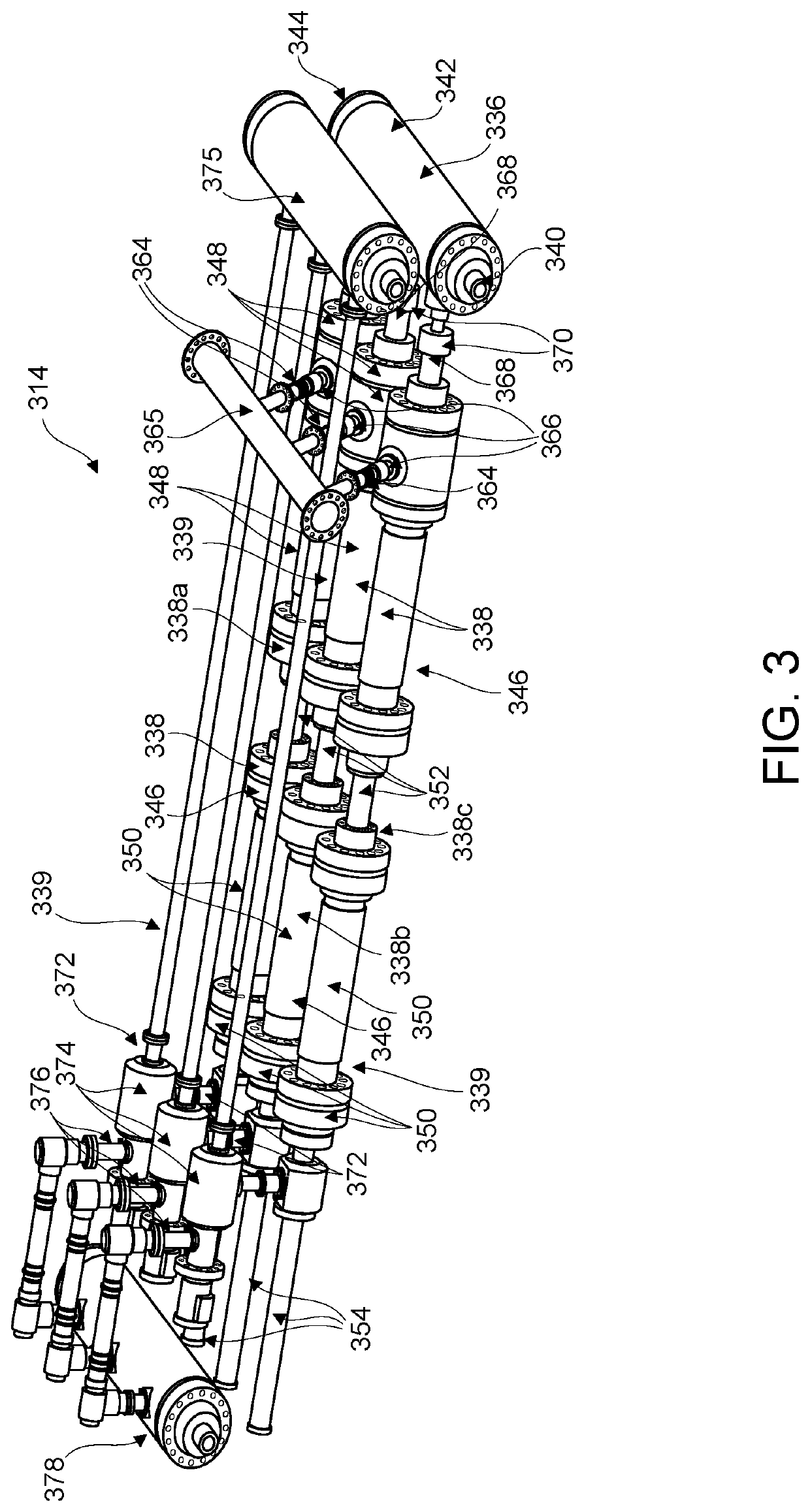

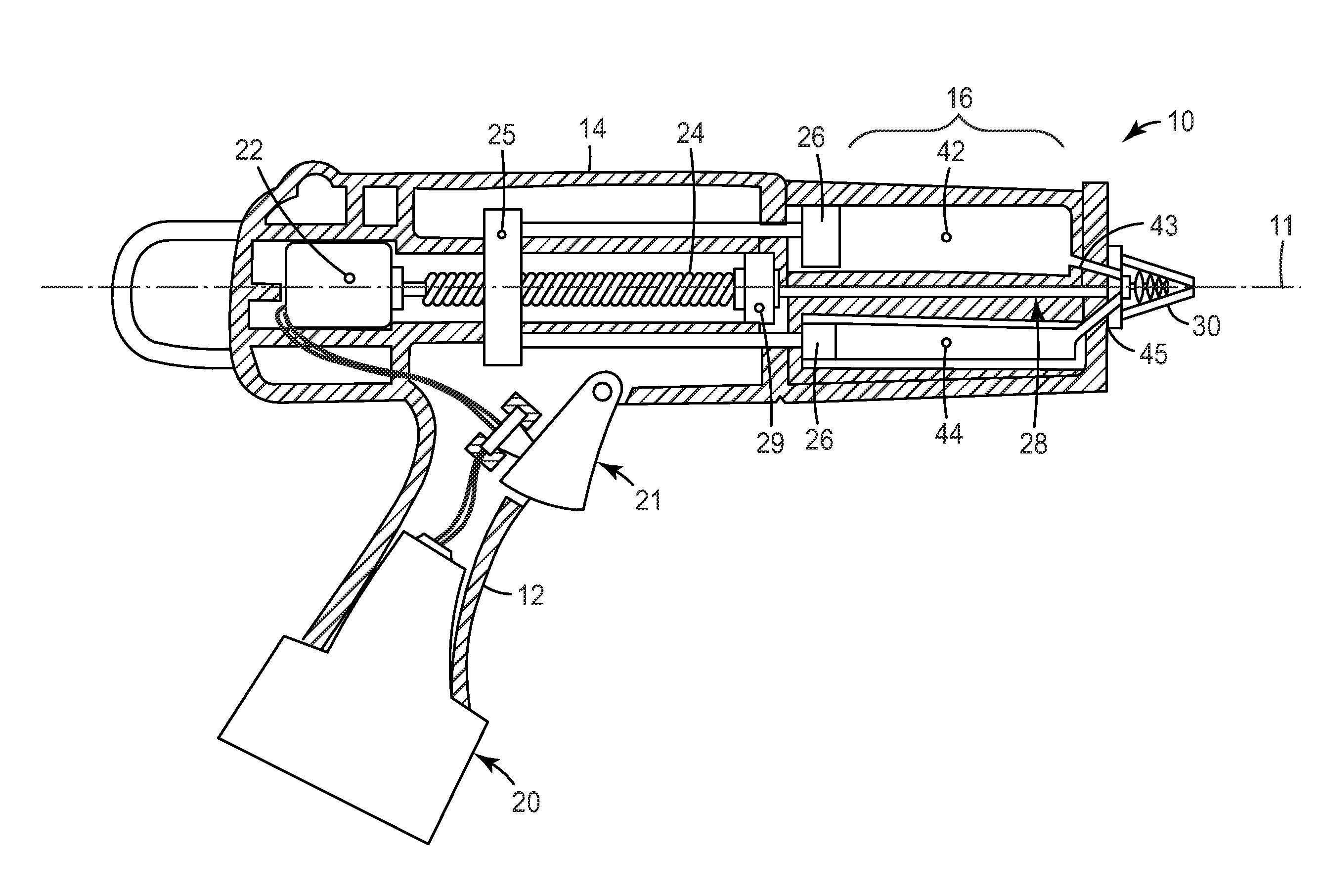

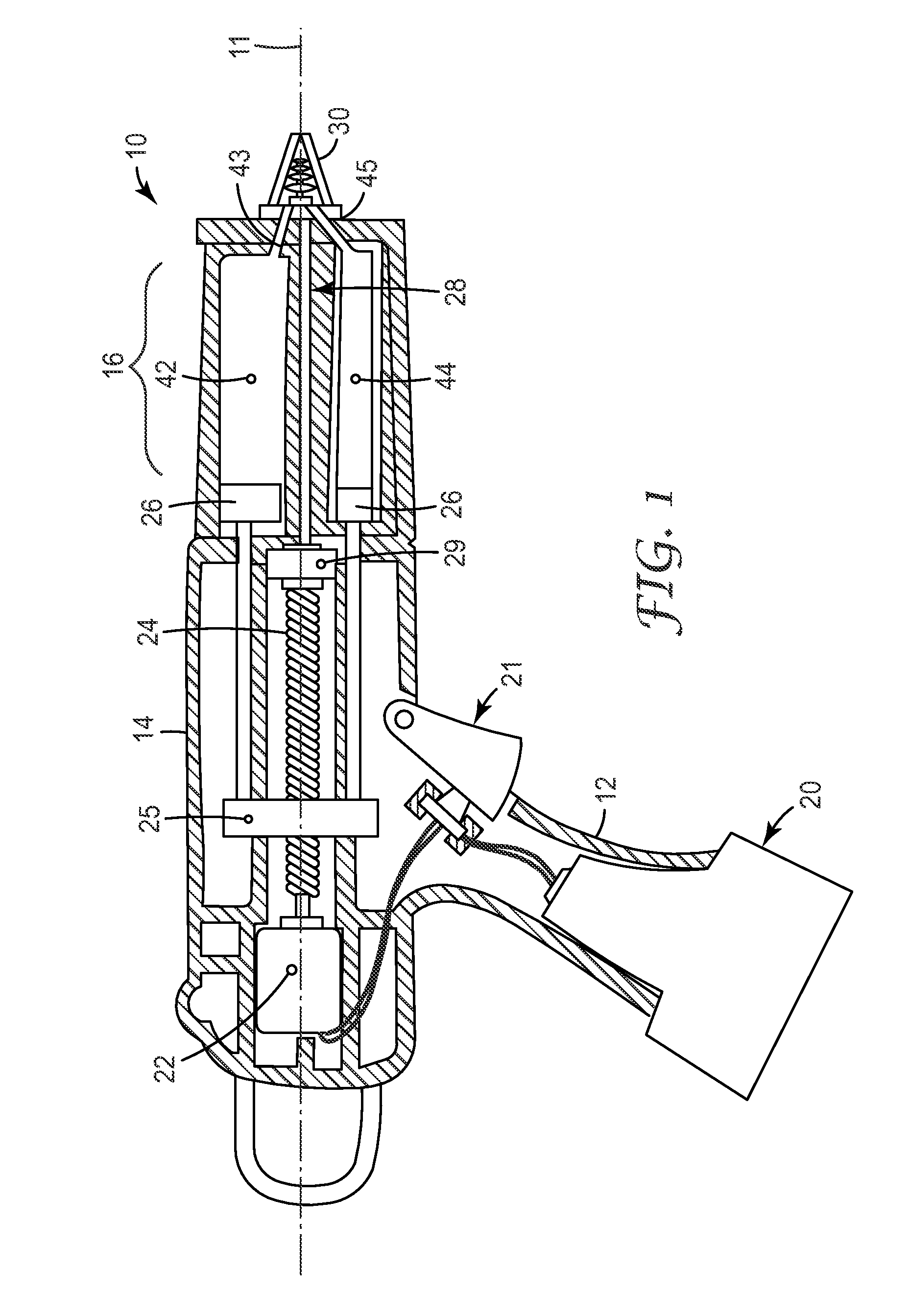

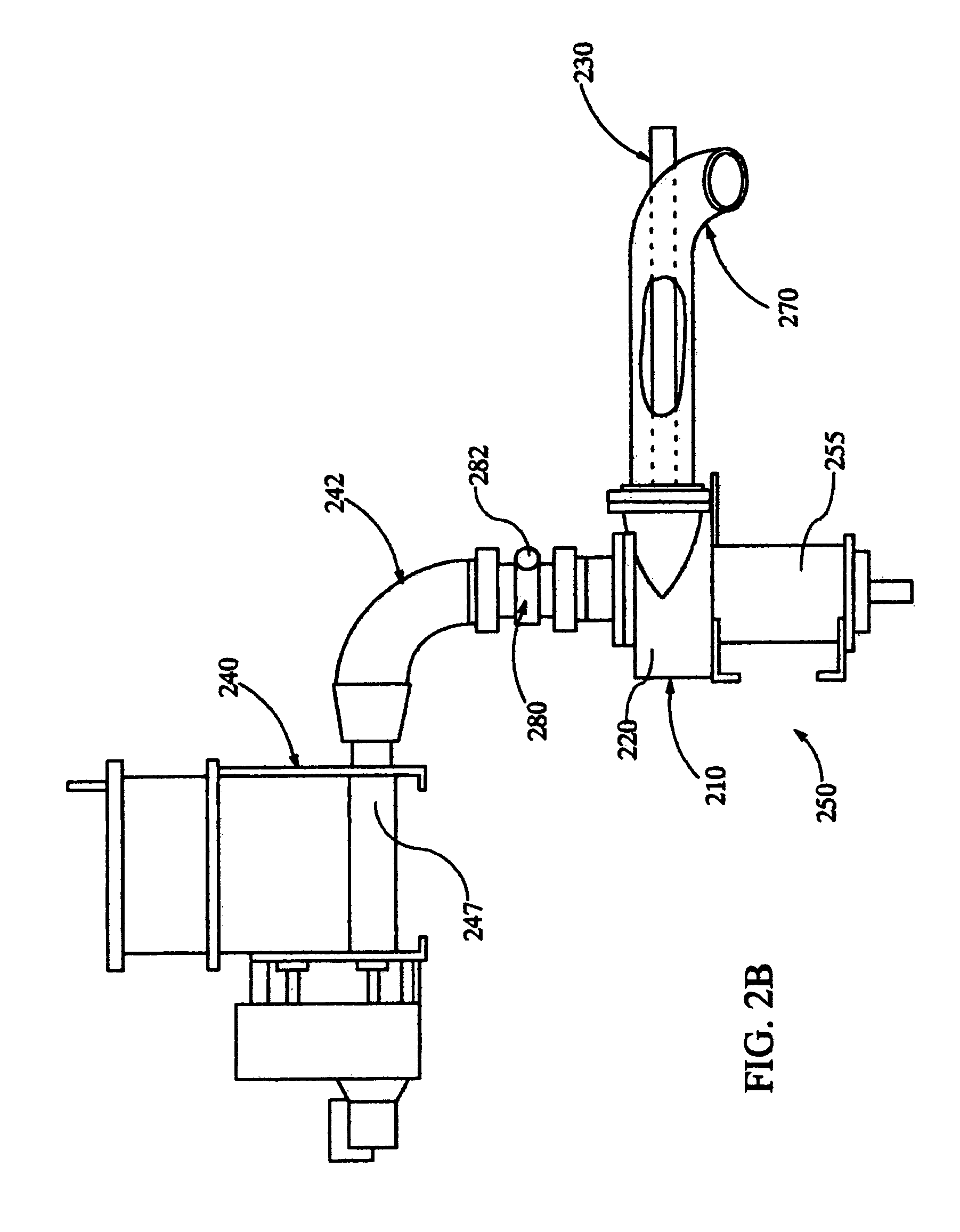

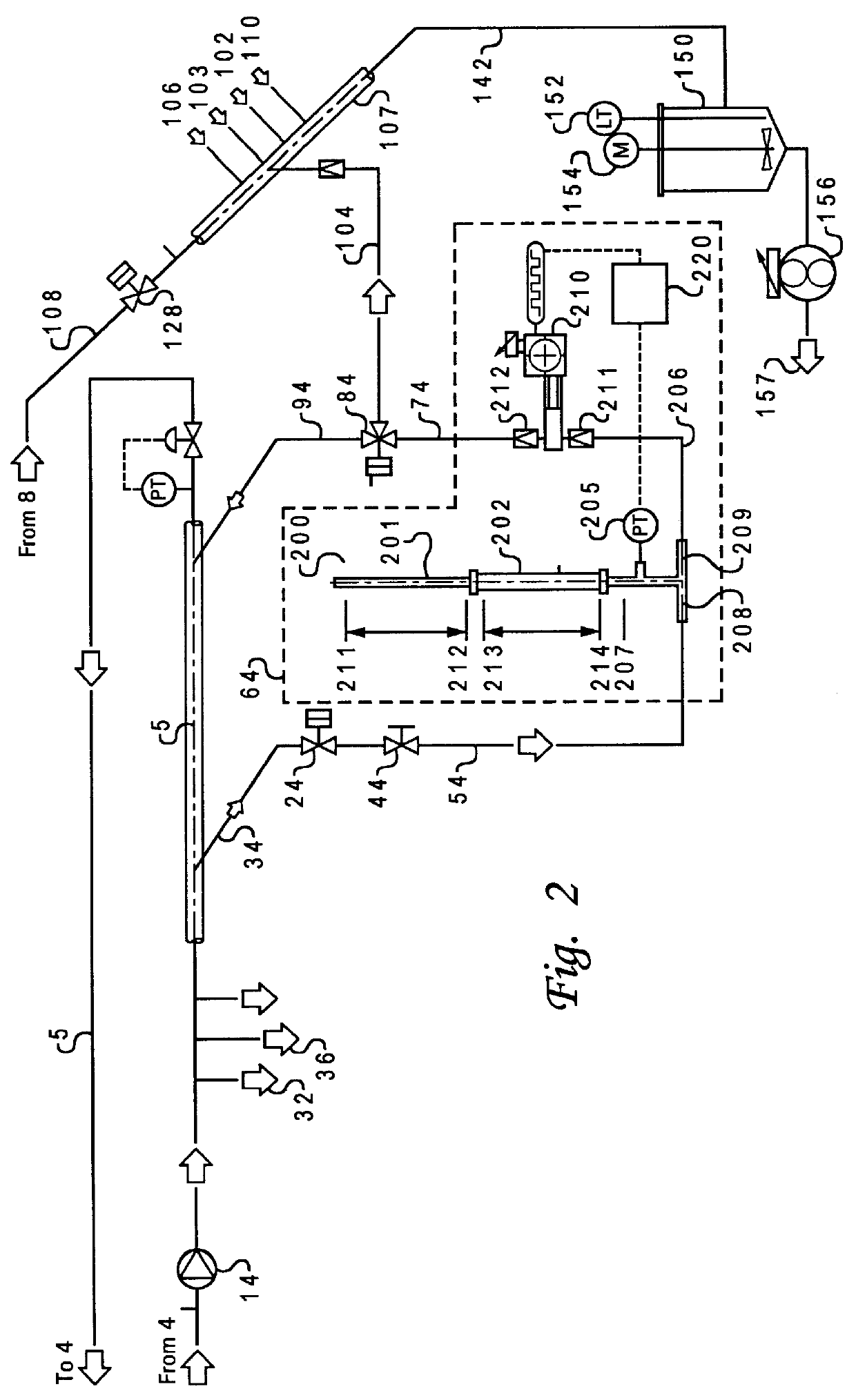

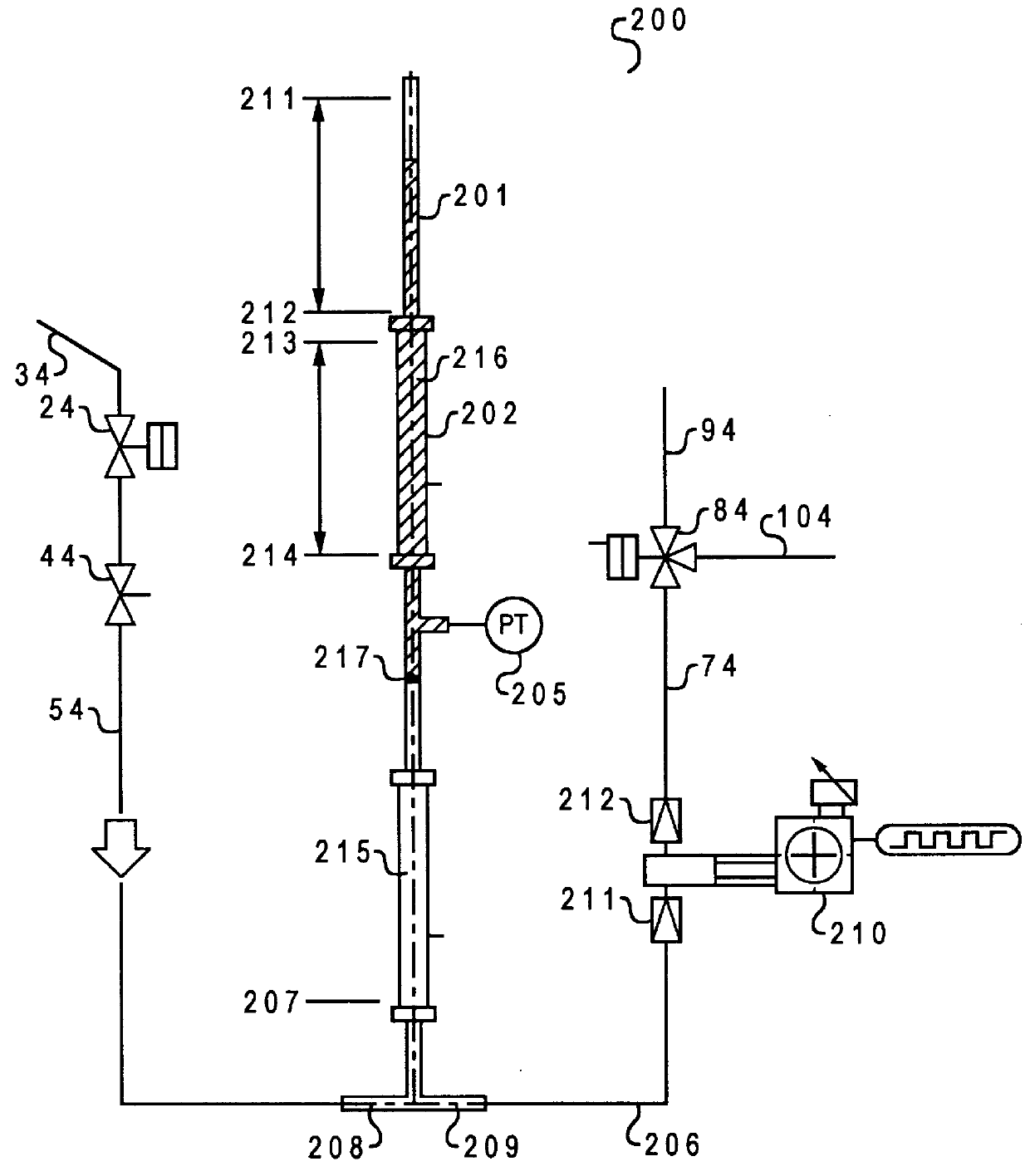

Fluid Delivery Device for a Hydraulic Fracturing System

ActiveUS20200291731A1Well formedRotary stirring mixersTransportation and packagingEngineeringCatheter

A syringe assembly for a hydraulic fracturing system includes a syringe having a material chamber, a base fluid chamber, and a piston. The material chamber is configured to be fluidly connected to a fluid conduit. The piston retracts to draw material into the material chamber. The piston extends to push the material into the fluid conduit. The syringe assembly includes a diverter fluidly connected to the base fluid chamber and moveable between first and second positions. The first position of the diverter fluidly connects the base fluid chamber to a base fluid reservoir of the hydraulic fracturing system and fluidly disconnects the base fluid chamber from an outlet of a frac pump of the hydraulic fracturing system. The second position of the diverter fluidly connects the base fluid chamber to the outlet of the frac pump and fluidly disconnects the base fluid chamber from the base fluid reservoir.

Owner:SPM OIL & GAS INC

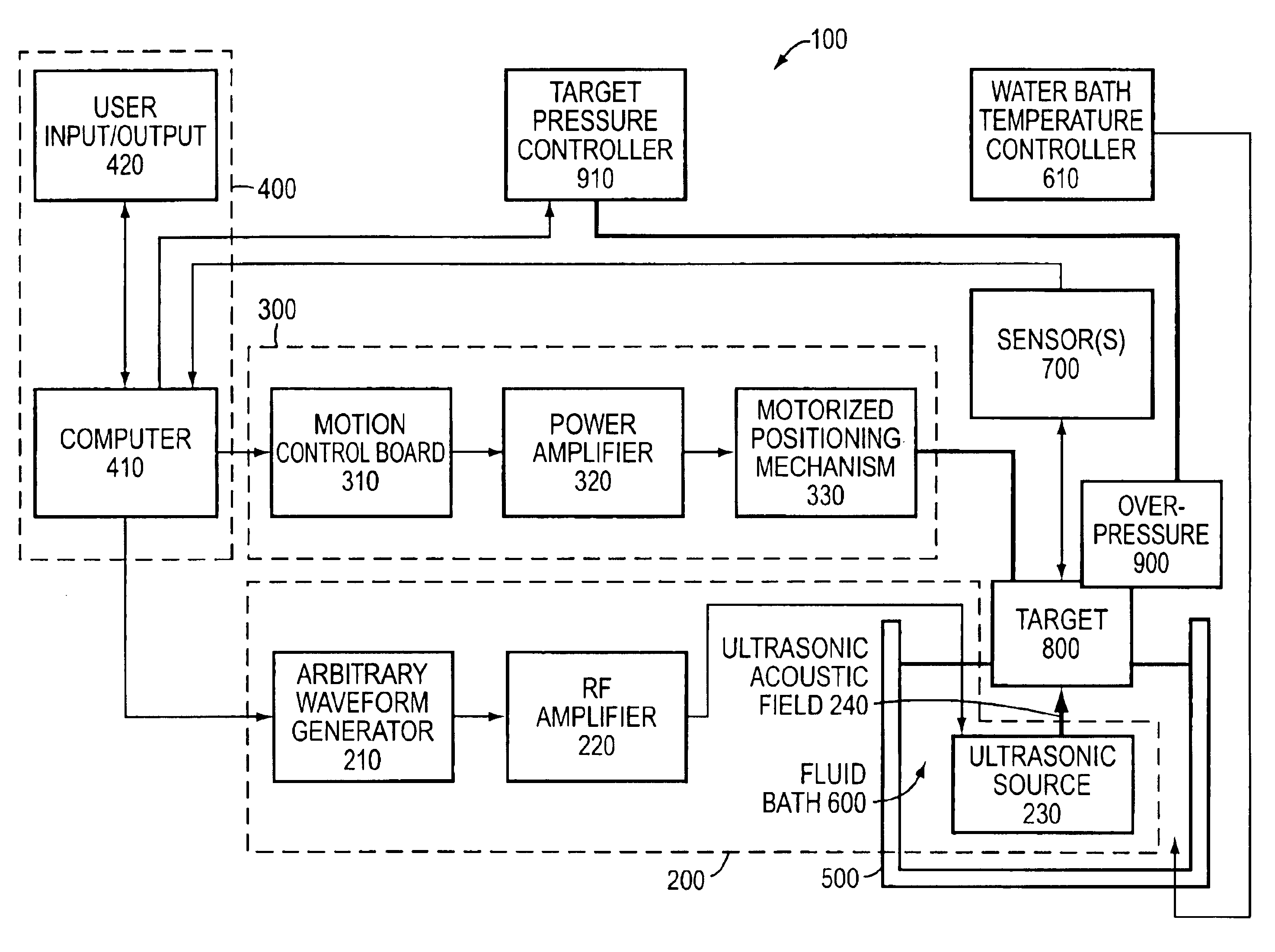

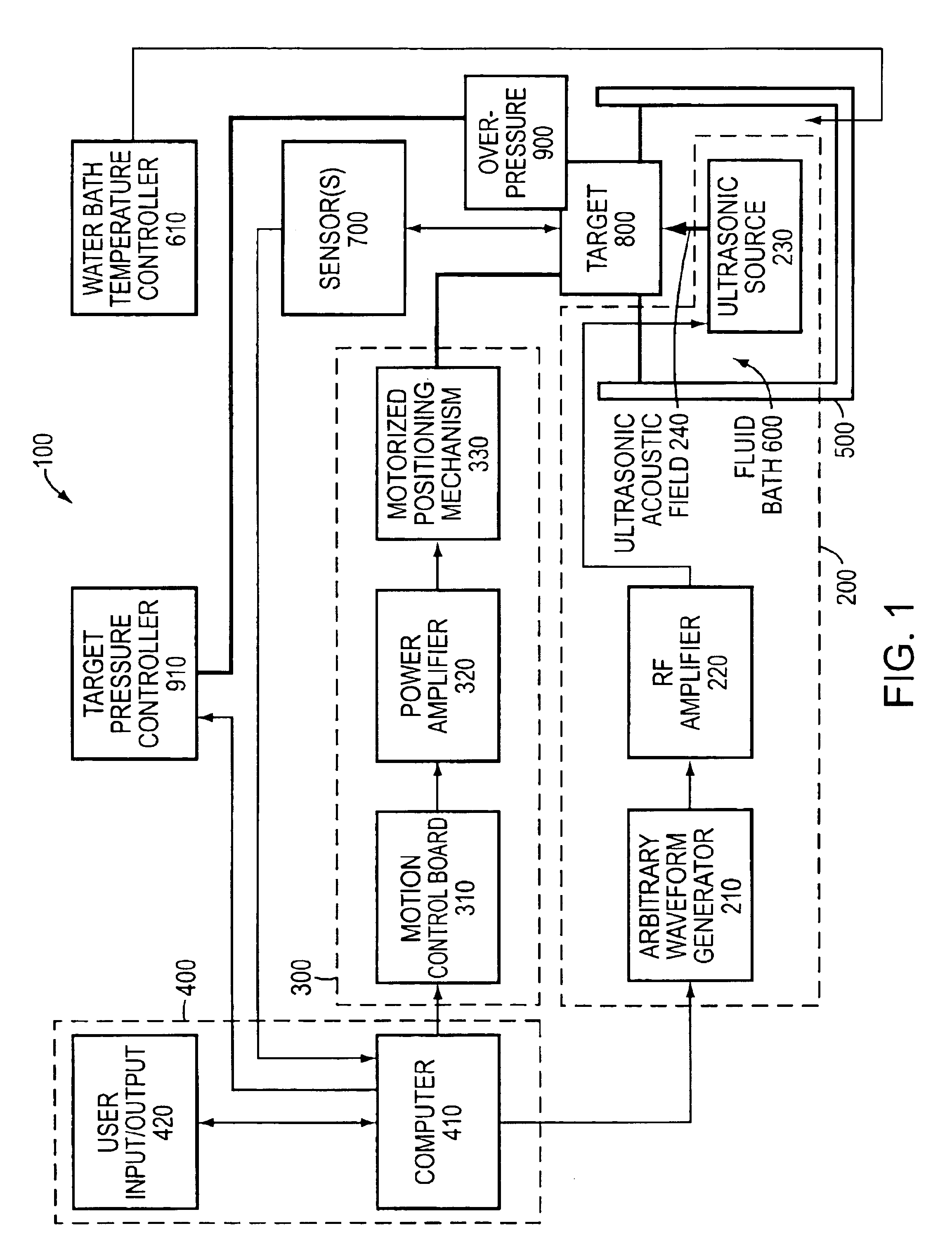

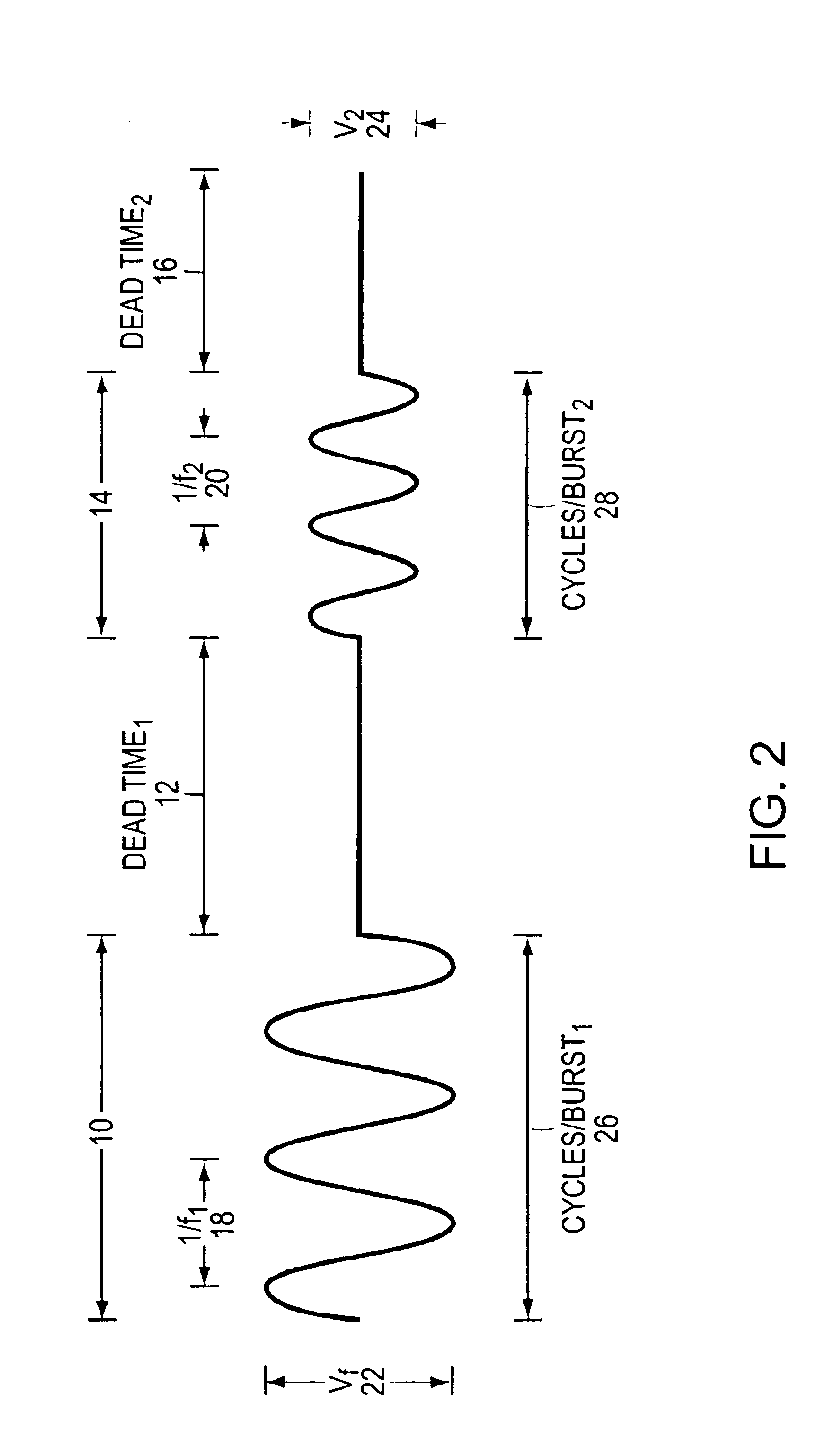

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS20100124142A1Improve reaction speedAccelerating molecular interactionSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

Mixing and dispensing curable multi-component materials

ActiveUS20080144426A1Eliminate needPromote conversionLiquid surface applicatorsRotary stirring mixersBiomedical engineering

Owner:3M INNOVATIVE PROPERTIES CO

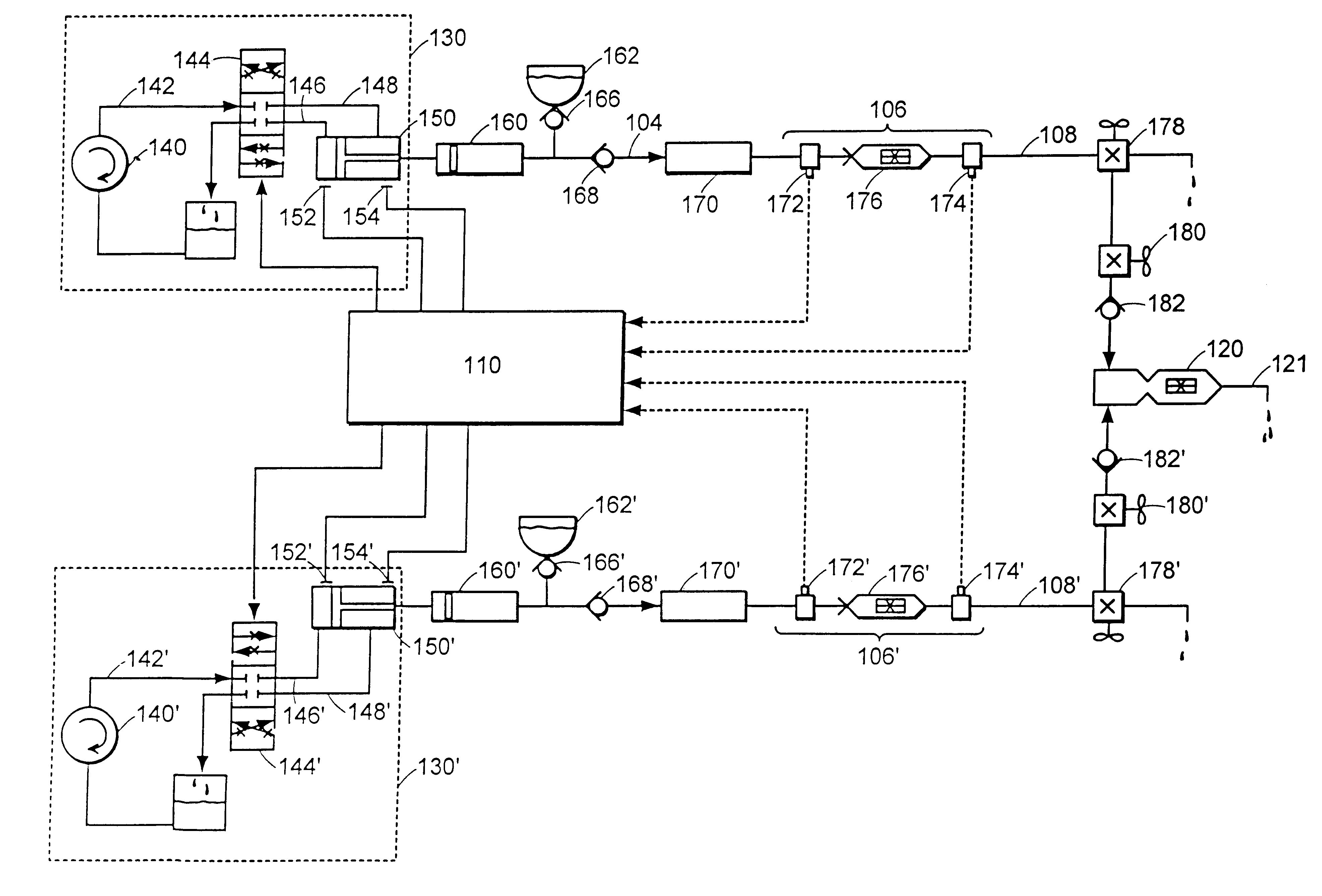

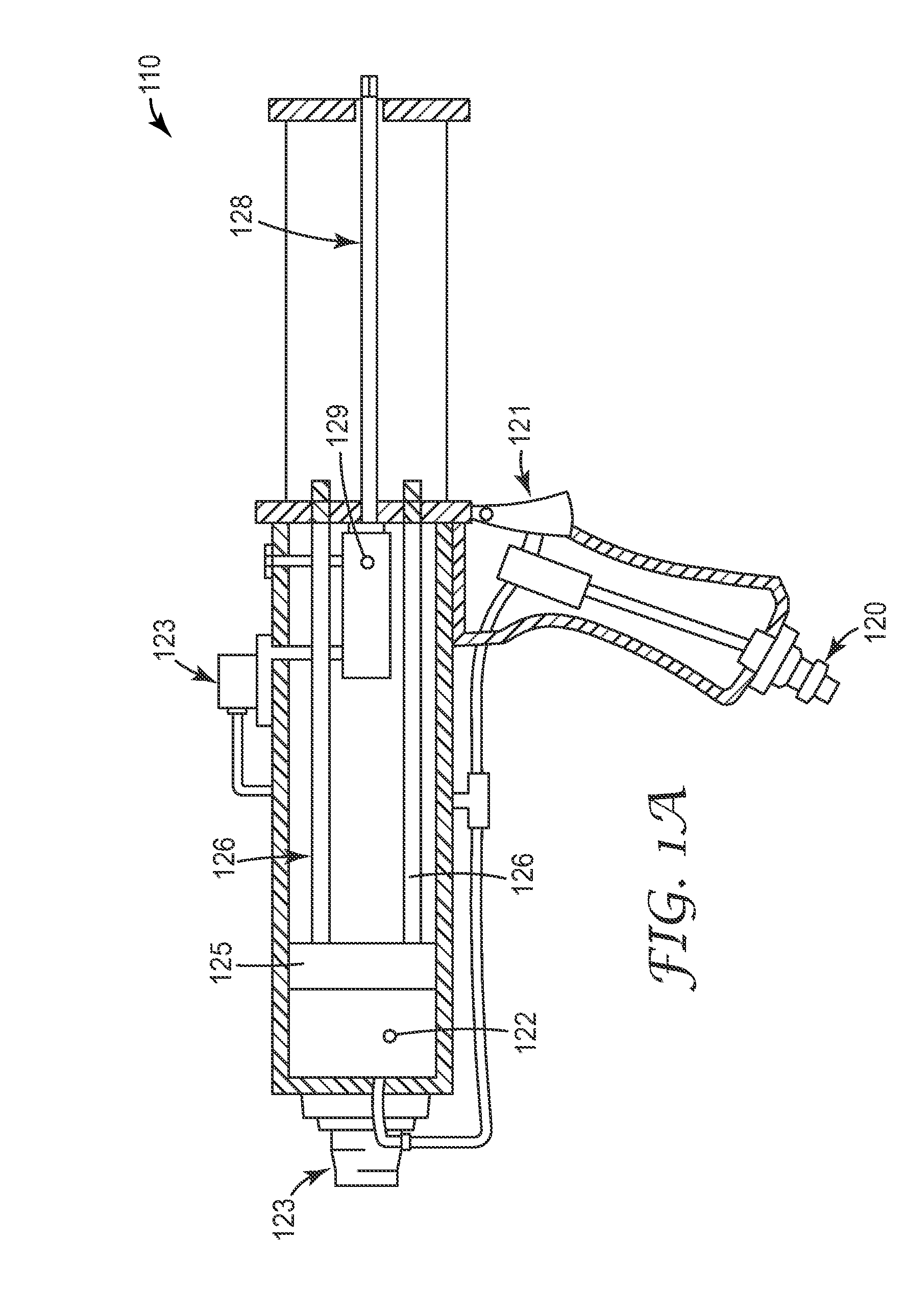

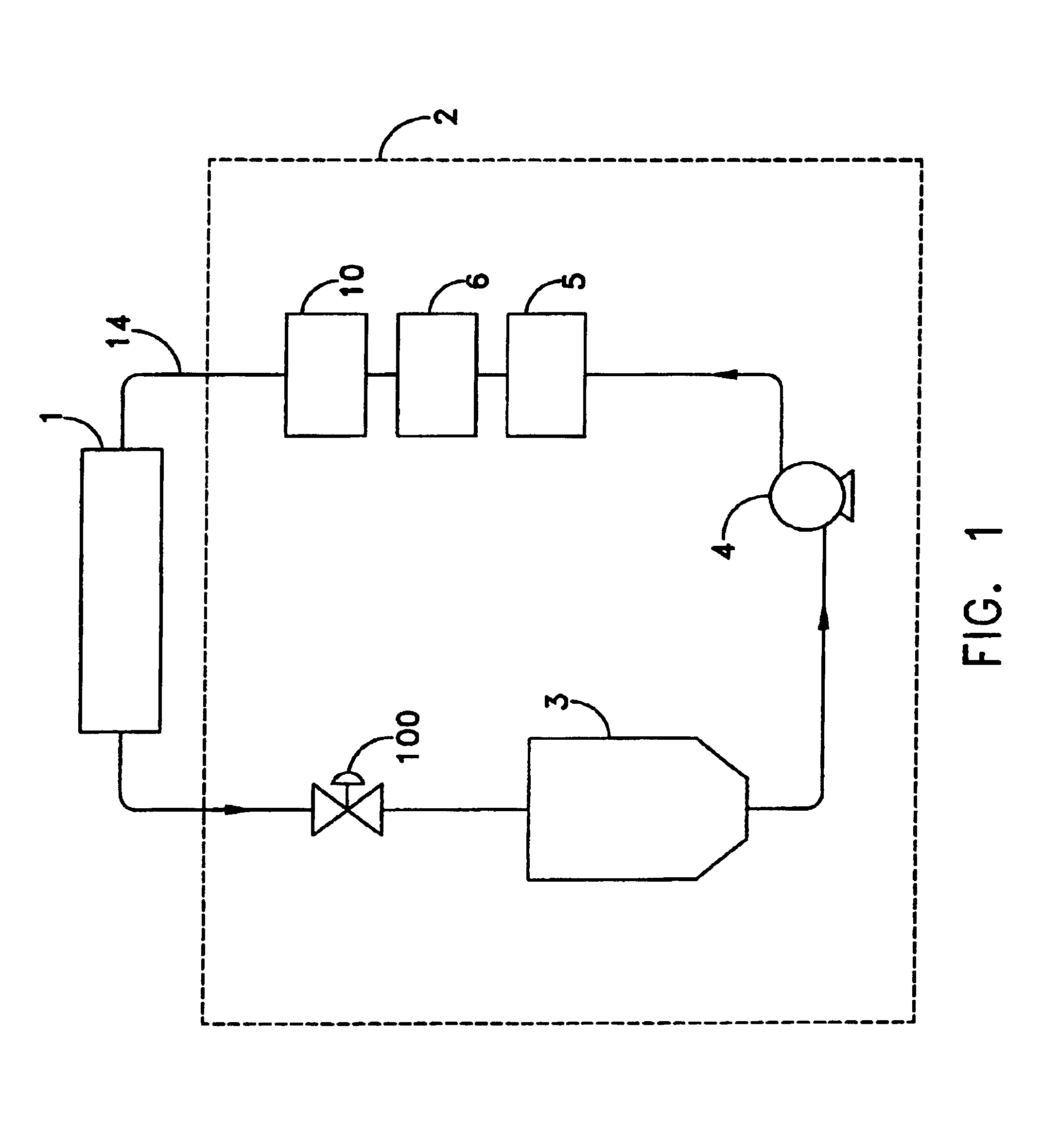

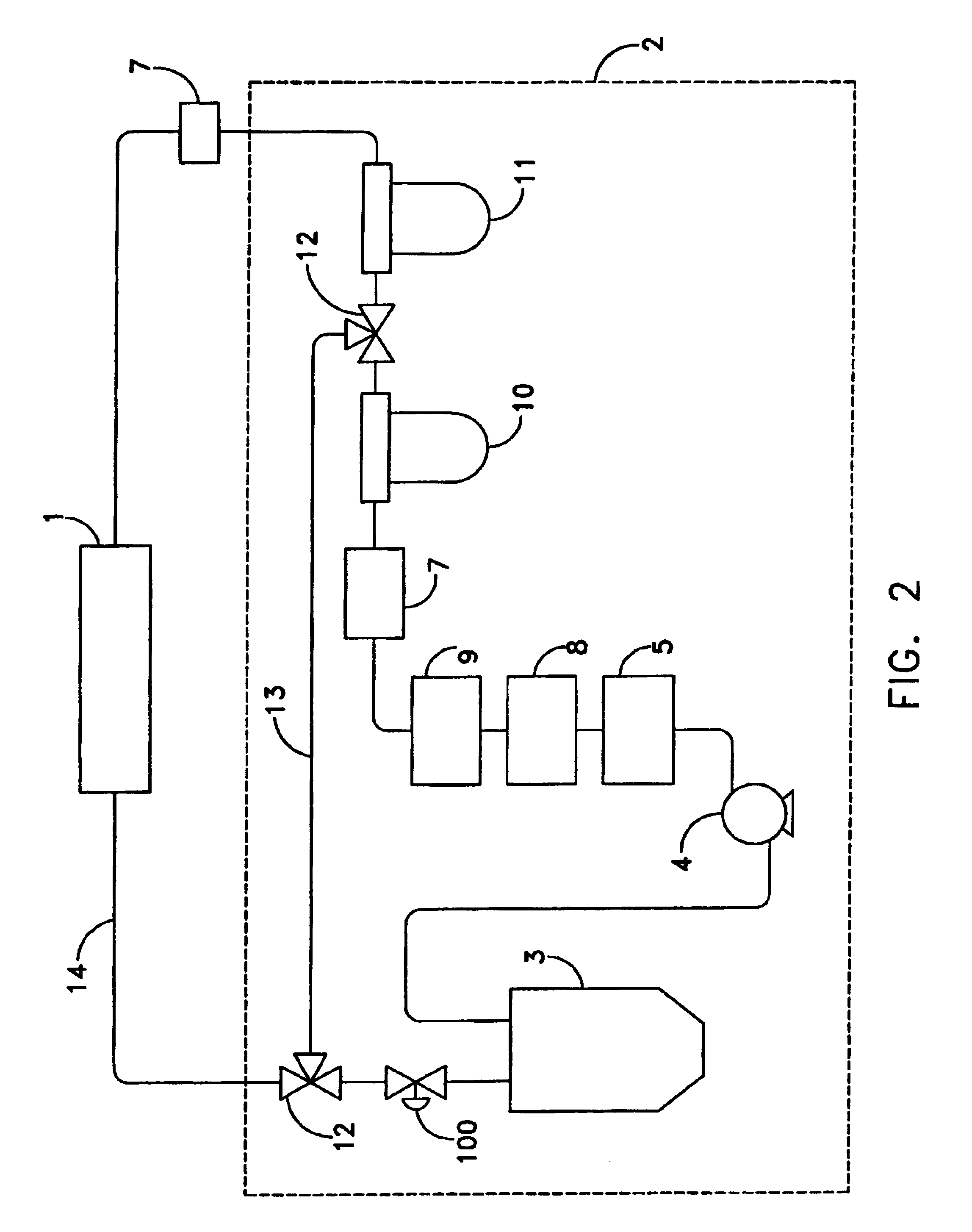

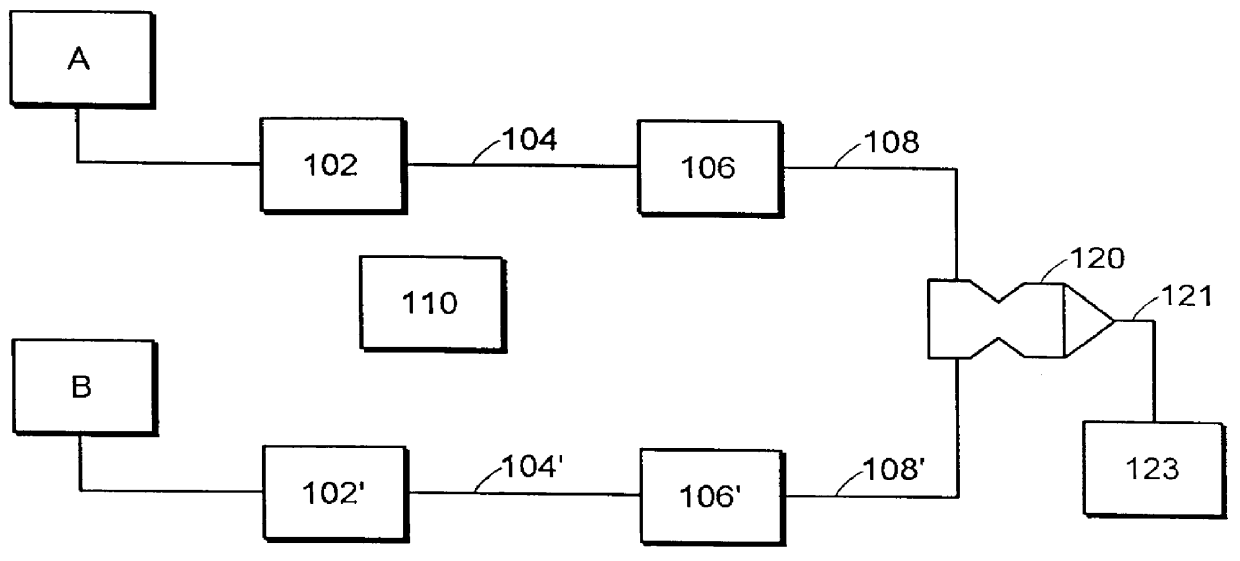

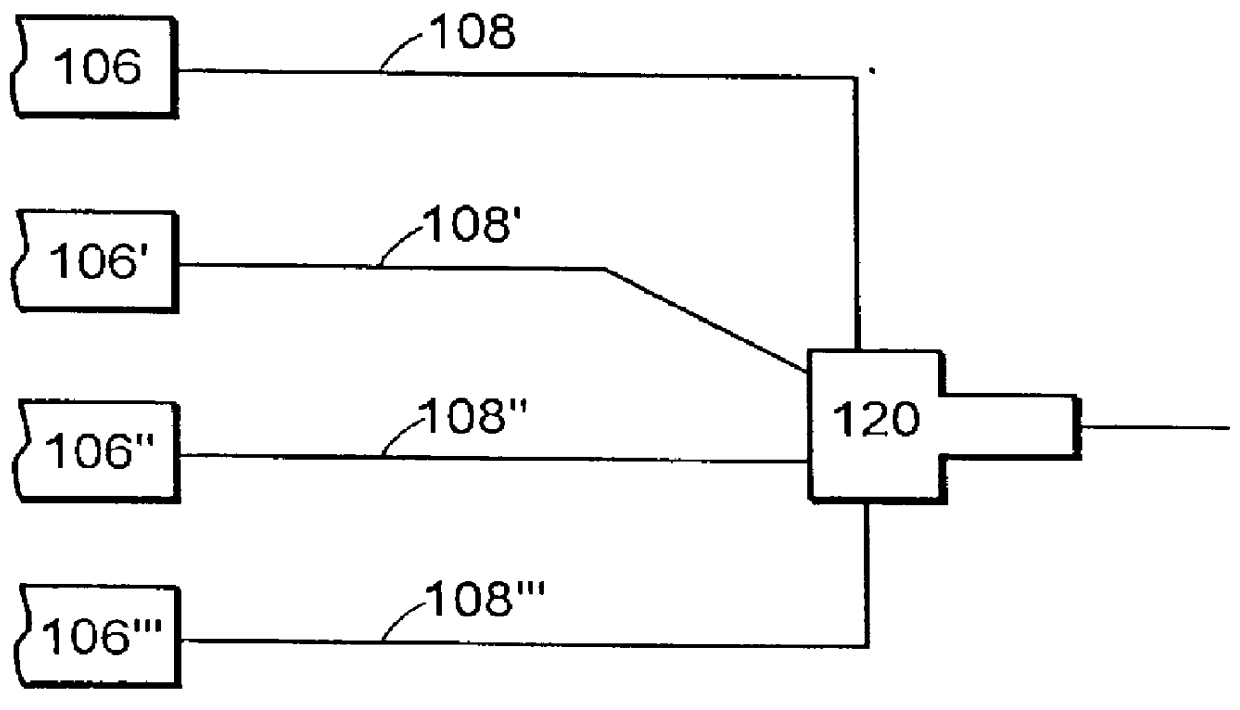

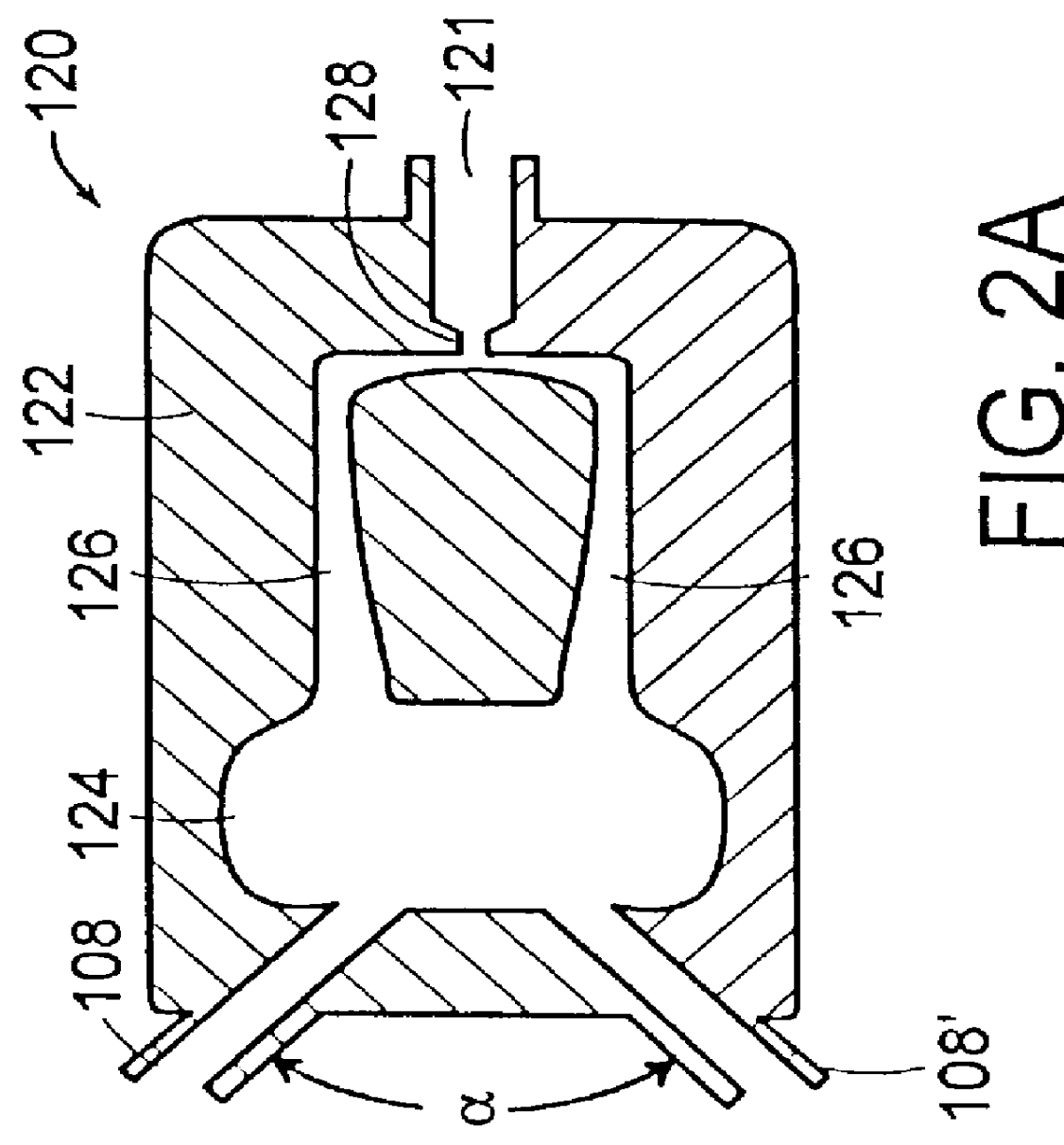

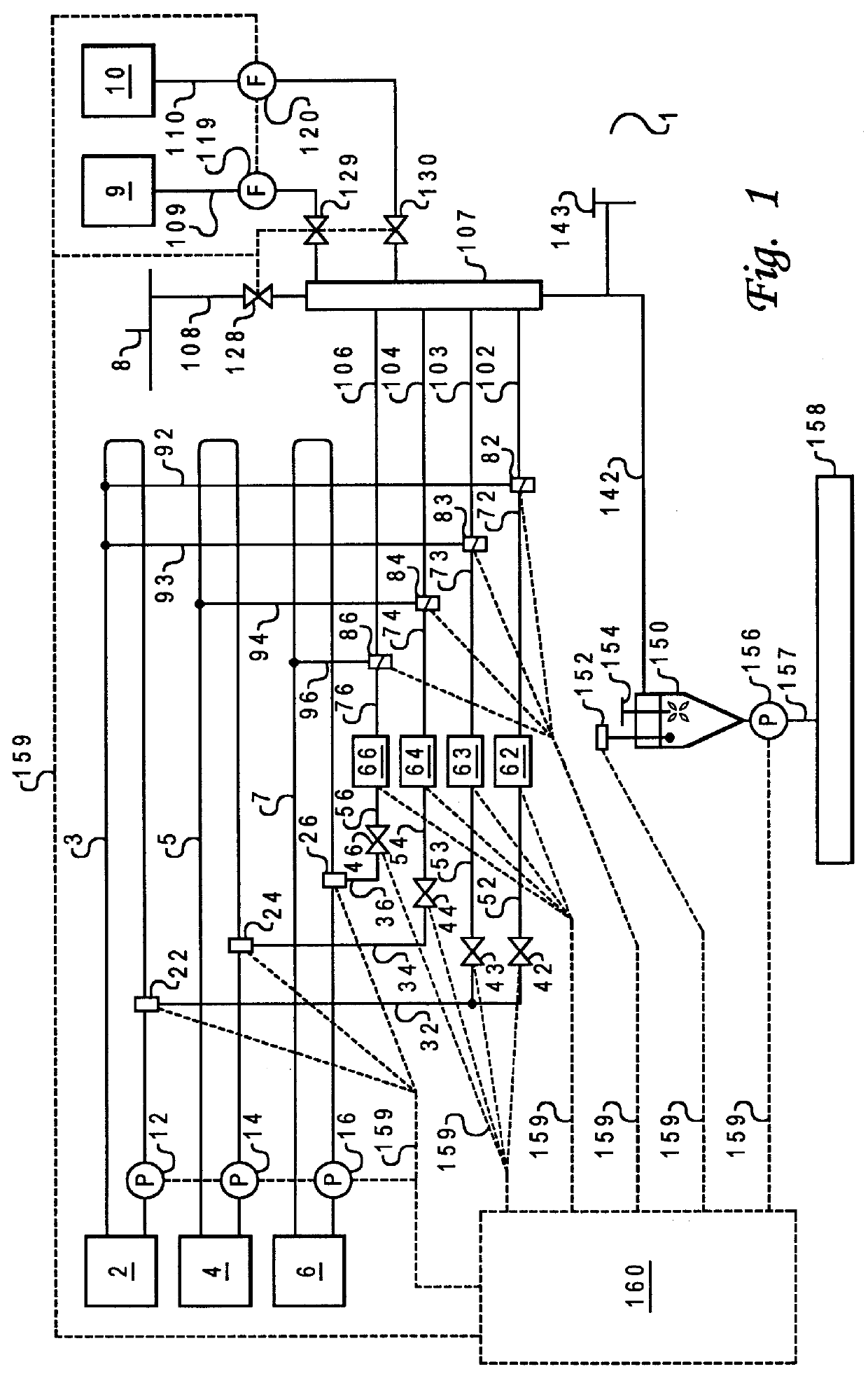

Method and apparatus for blending process materials

A method and apparatus for blending and supplying process materials. The method and apparatus are particularly applicable to the blending of ultra-high purity chemicals, the blending of abrasive slurries with other chemicals for the polishing of semiconductor wafers, and high-accuracy blending of chemicals. The apparatus may include a dispensing subsystem that supplies process materials to a mixing subsystem where they are blended with a static mixer. The method may include supplying process materials with a dispensing subsystem and blending the process materials in a static mixer.

Owner:MEGA FLUID SYST

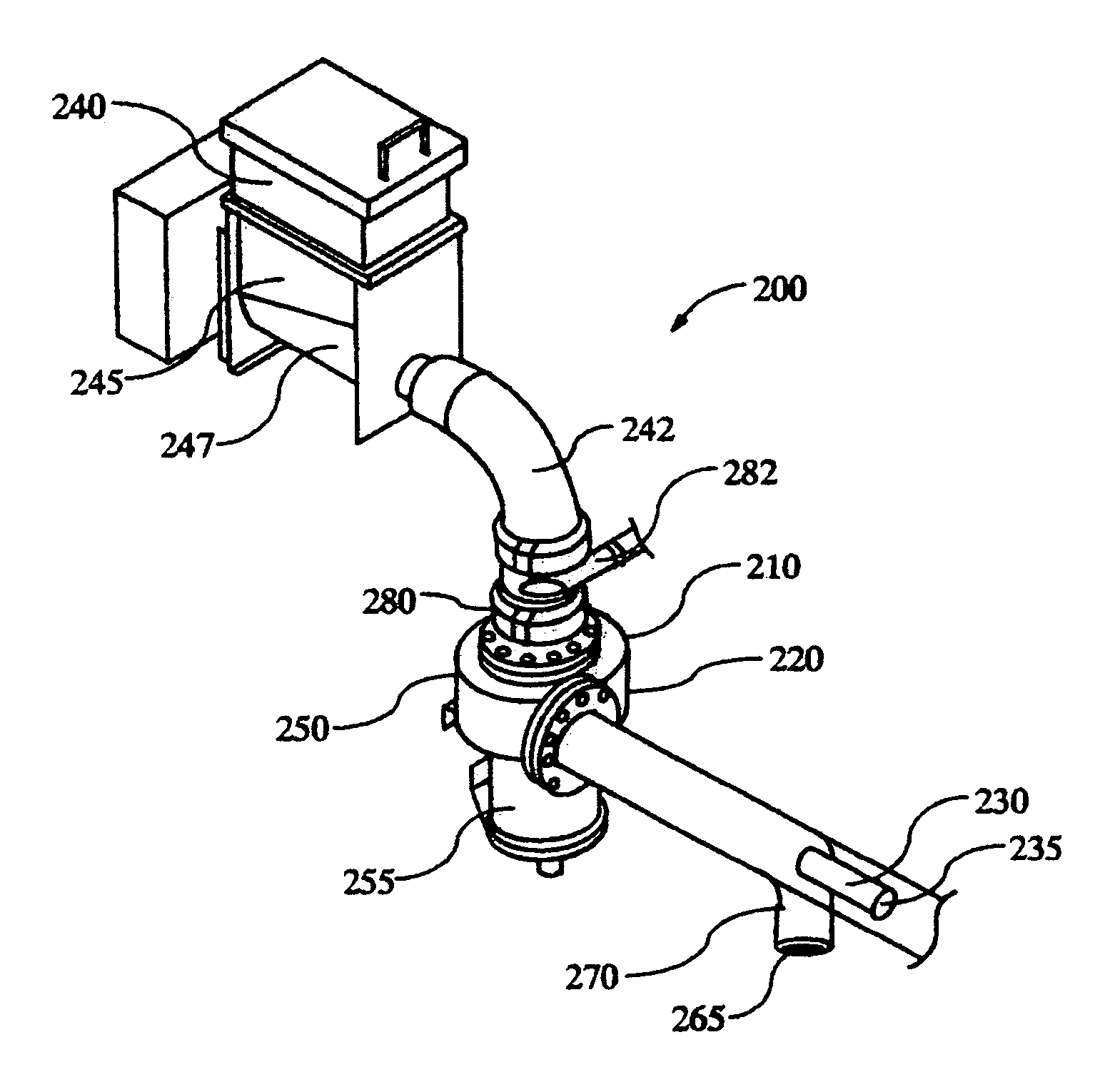

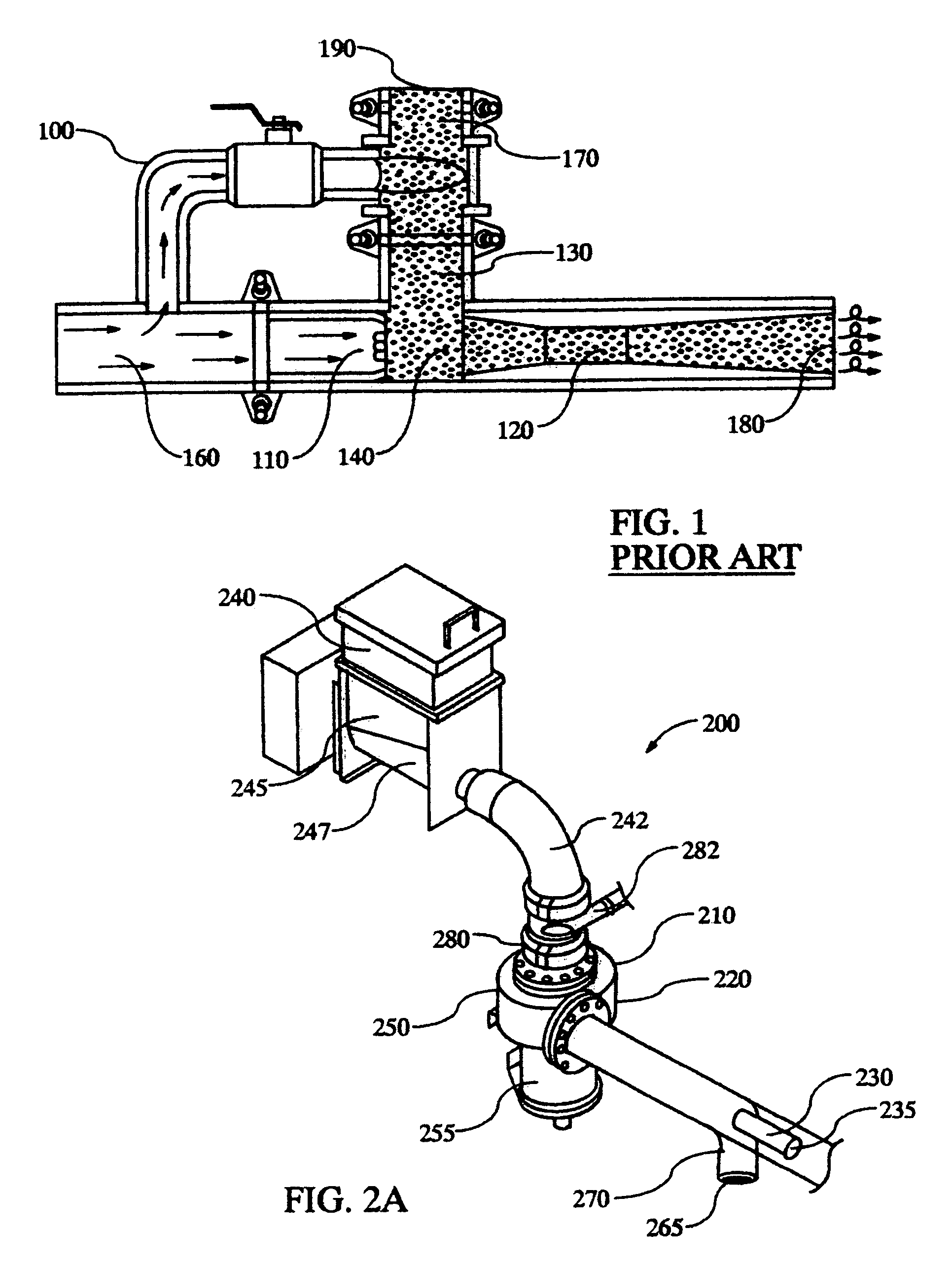

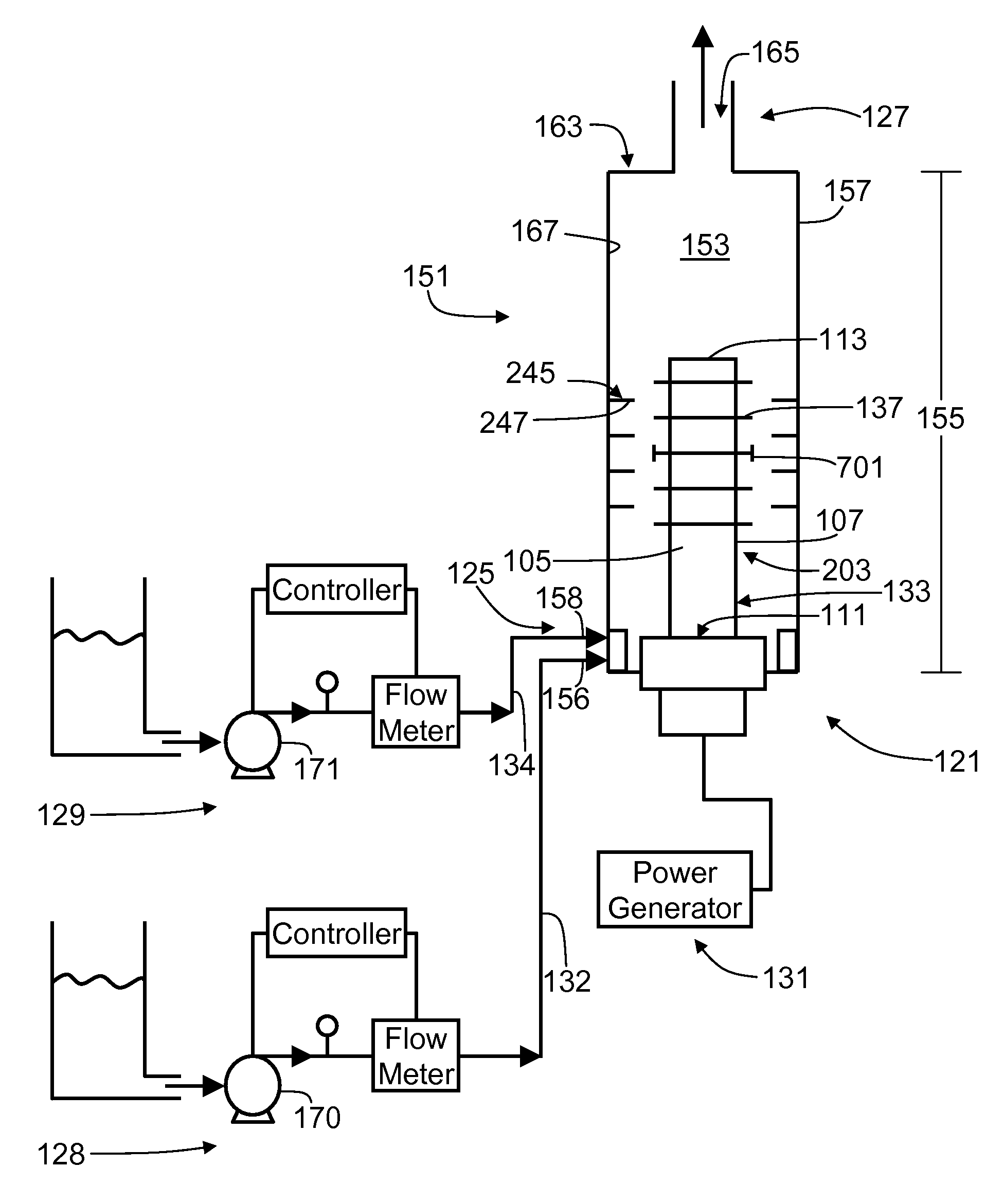

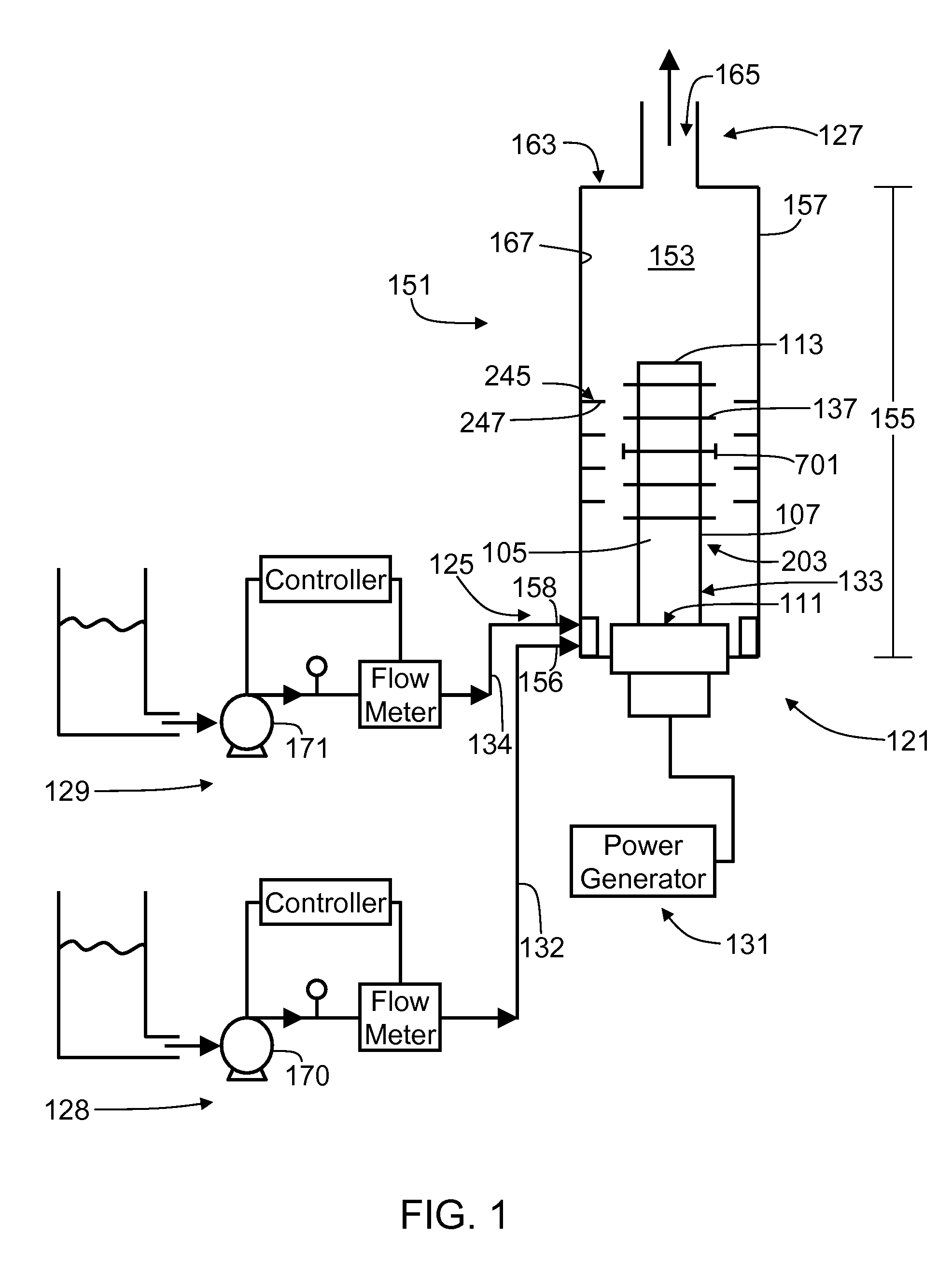

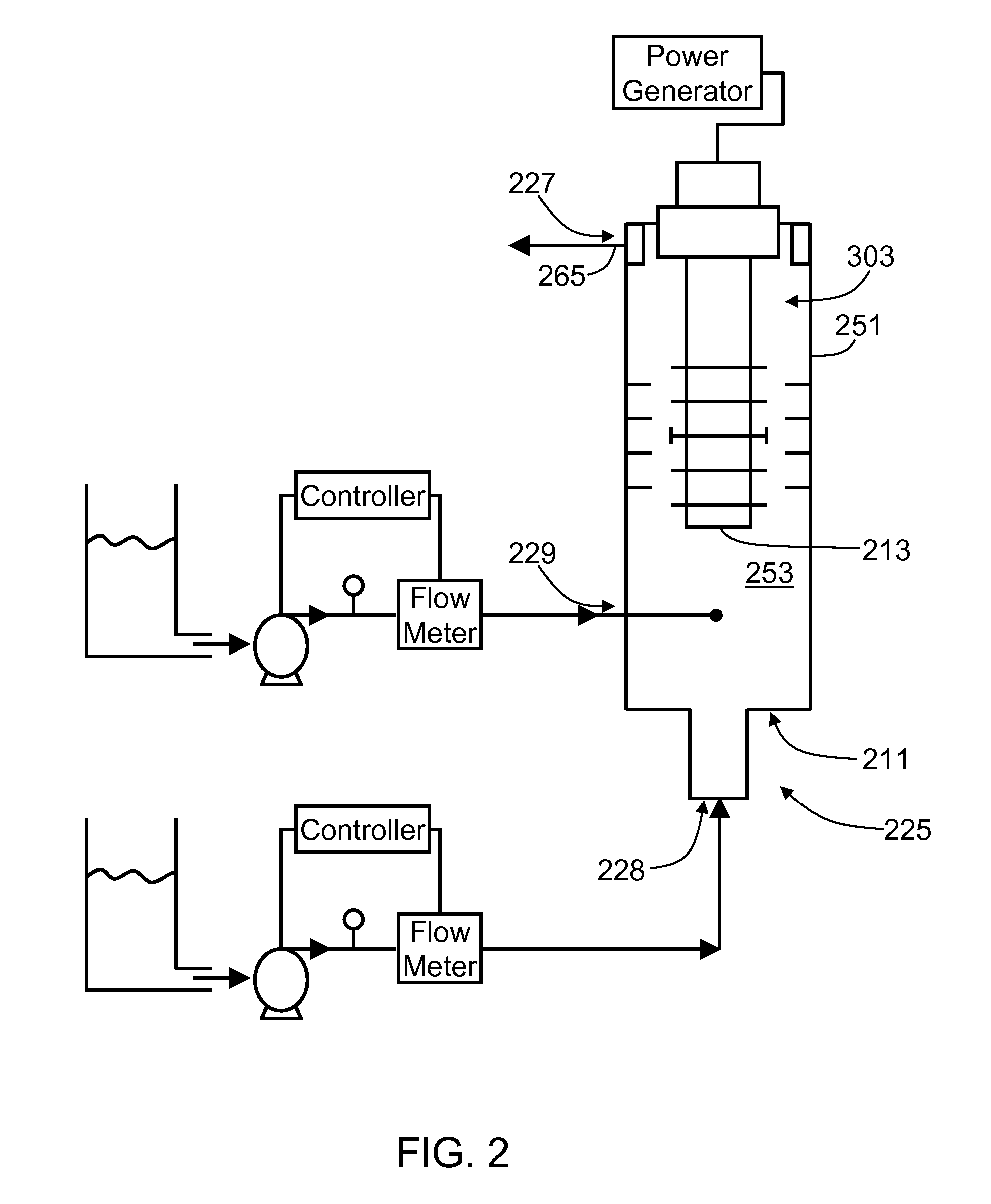

Method and apparatus for hydrating a gel for use in a subterranean formation

The present invention relates to a method and system for hydrating a gel for treating a wellbore penetrating a subterranean formation. The method includes directing a base fluid through an inlet into a mixer having an inner chamber housing a plurality of impellers extending radially from and rotating about a hub, causing a centrifugal motion of the base fluid, feeding a quantity of gel into the mixer, mixing the gel with the base fluid and discharging the now-hydrated gel from the inner chamber through an outlet of the mixer. A prewetting device may also be used. Thereafter, a variety of additives may be added to the gel fluid mix to form a fluid treatment to be introduced into a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Fabric care compositions

InactiveUS20130109612A1Cationic surface-active compoundsOrganic detergent compounding agentsMedicine

The present invention is directed to fluid fabric enhancing compositions and processes of making and using same. Such fluid fabric enhancing compositions have a desirable fabric enhancer active efficiency that is, at least in part, due to the particle index of such fluid fabric enhancing compositions. Certain chemical processing and physical processing methods are not required to produce such compositions.

Owner:THE PROCTER & GAMBLE COMPANY

Use of multiple stream high pressure mixer/reactor

InactiveUS6159442AHigh strengthMaintain good propertiesCalcium/strontium/barium carbonatesPressurized chemical processStream flowHigh pressure

Owner:MICROFLUIDICS INT

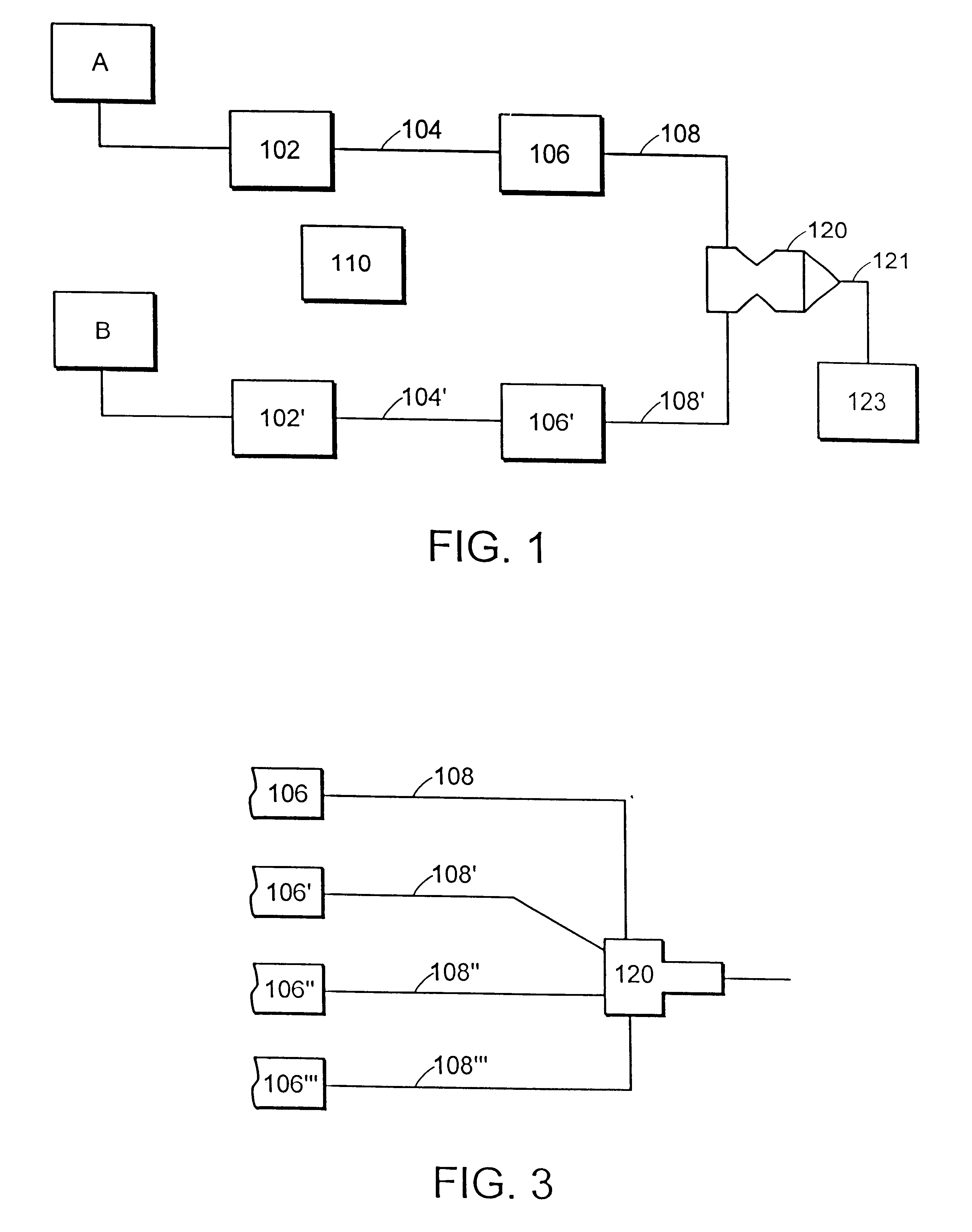

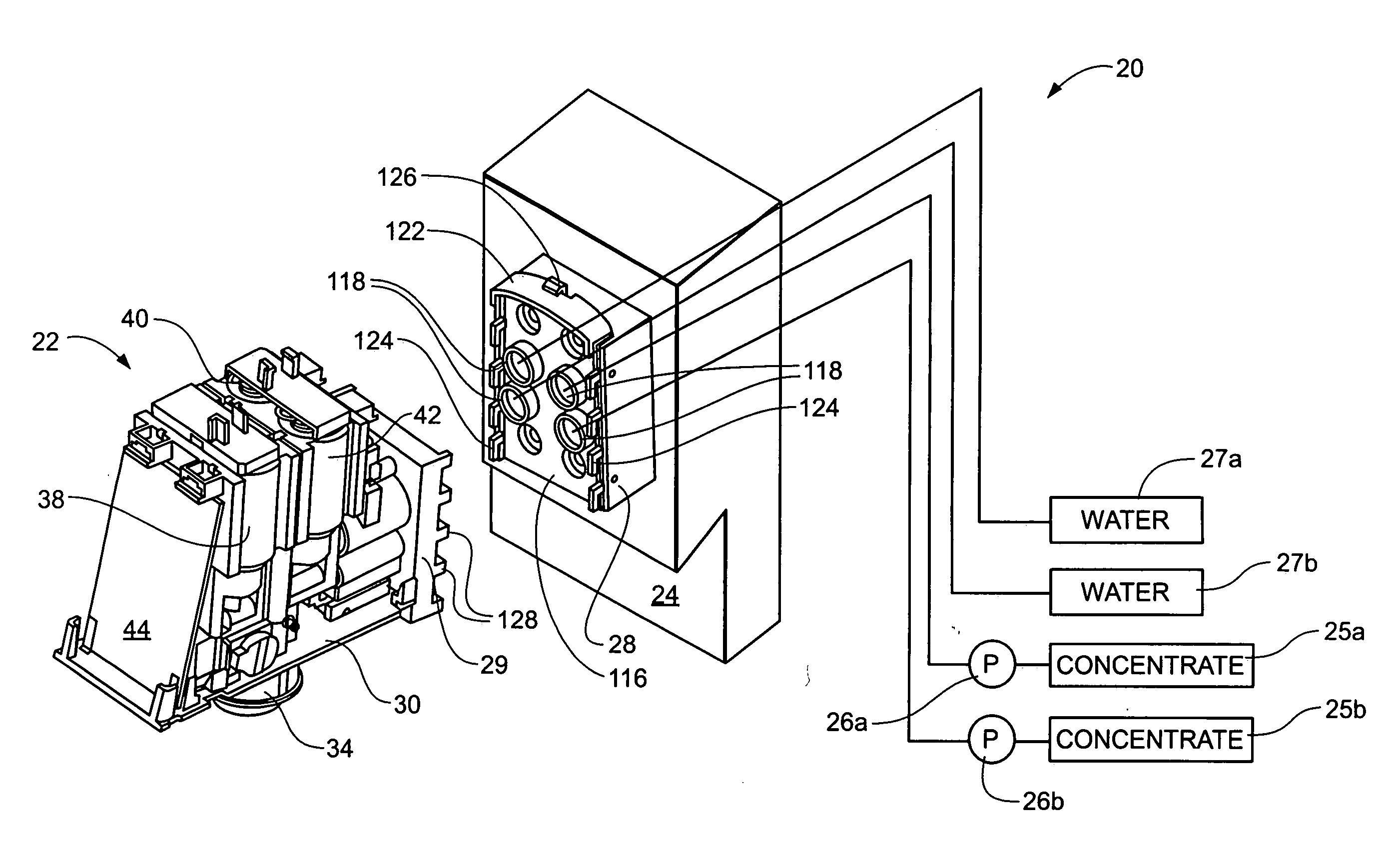

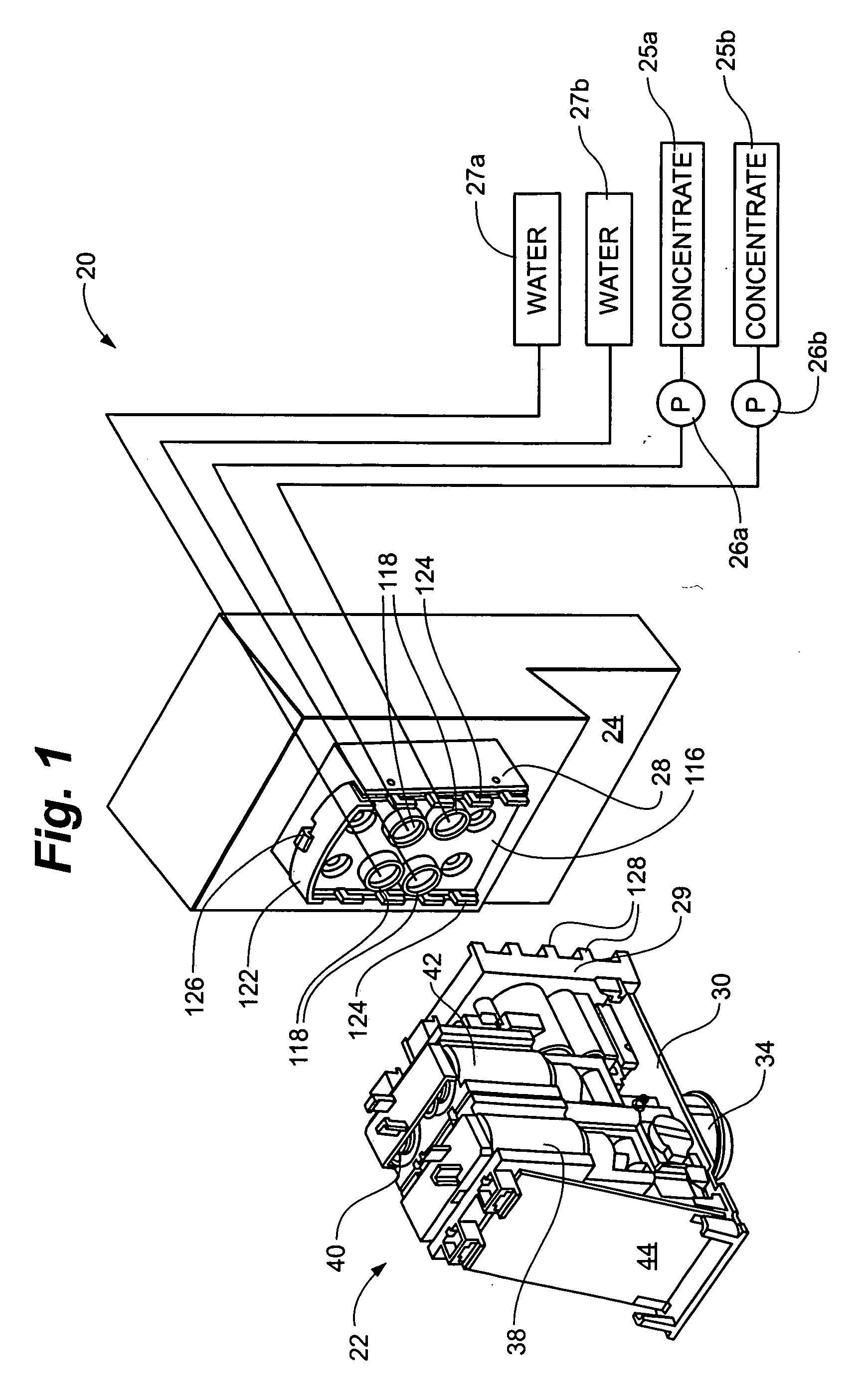

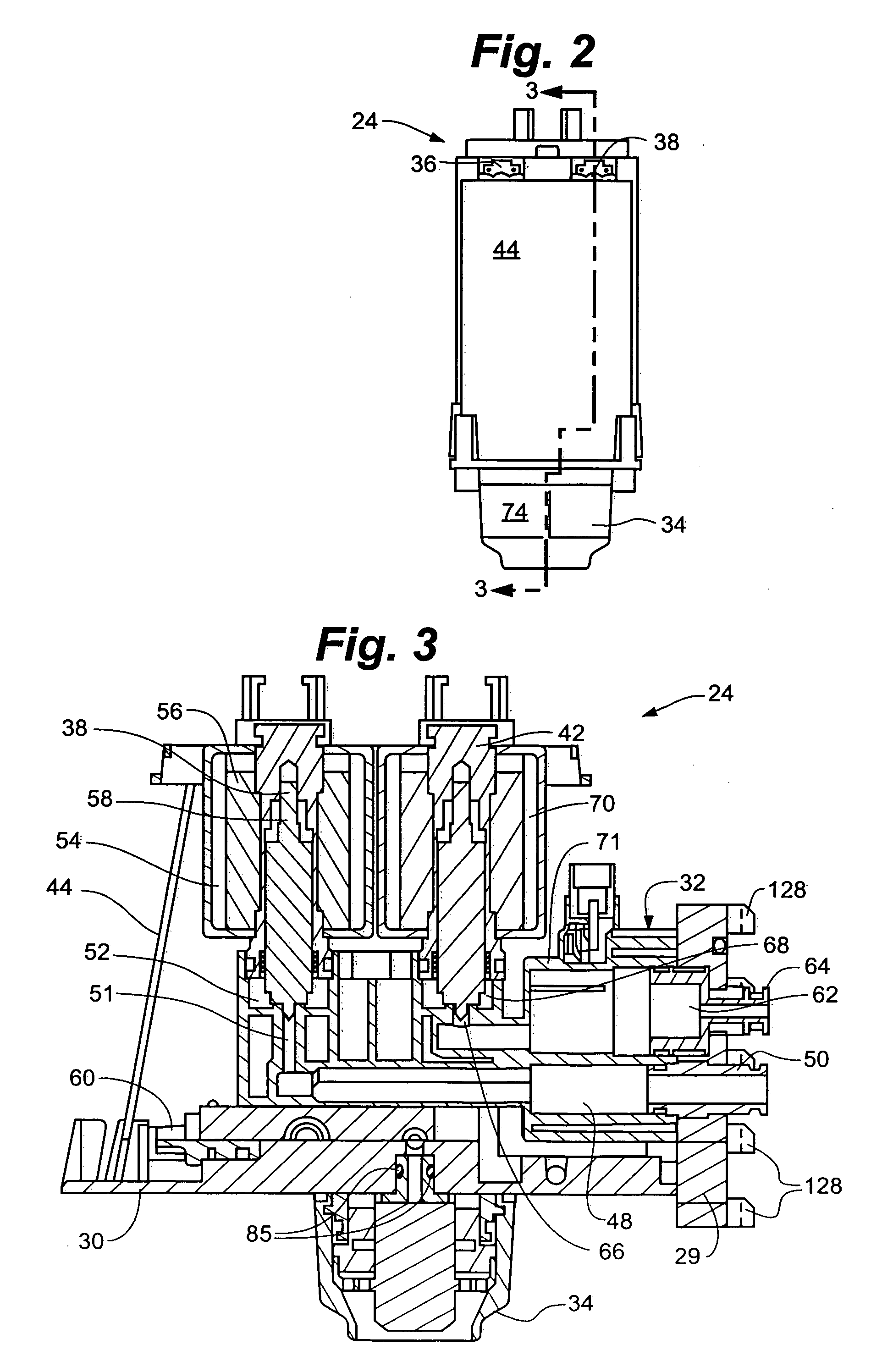

Beverage dispensing system with a head capable of dispensing plural different beverages

ActiveUS20060097009A1Minimize carbonation breakoutReducing pressurizationFlow mixersMixer accessoriesEngineeringGuide tube

A beverage dispensing system with a base to which a dispensing head is removably attached without additional fasteners, wherein beverage forming liquids are supplied through a plurality of separate conduits in the base. Each base conduit has a normally closed valve that normally blocks fluid flow. The dispensing head has at least one passageway that receives liquid from an associated one of the base conduits. A projection associated with each dispensing head passageway opens the associated conduit valve to allow fluid flow from the base to the head. Dispensing valves in the dispensing head are independently accountable to regulate the dispensing of the beverage. In one version of the invention, four liquids are supplied to the dispensing head through the conduits, namely two liquid concentrates; carbonated water; and non-carbonated water. By selective opening of the dispensing valves, a plurality of beverages are formed from combinations of one or more of the liquids. A dispensing head for dispensing at least one carbonated fluid includes an inlet opening and an outlet opening at each end of a passage extending through a body, the inlet opening having a smaller cross-sectional area than the outlet opening.

Owner:PEPSICO INC

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS20060029525A1Increase fluid velocityAchieved mixedSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

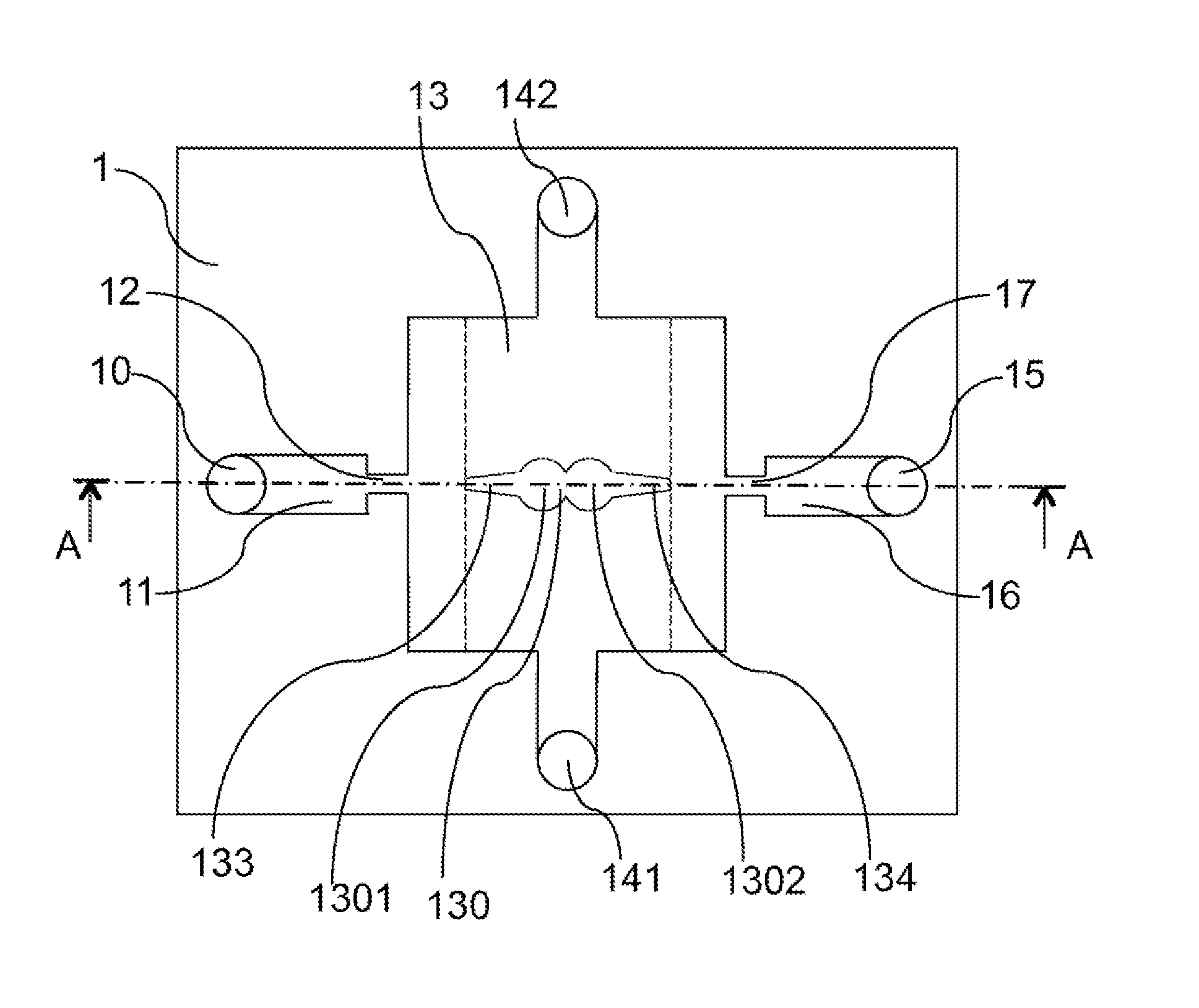

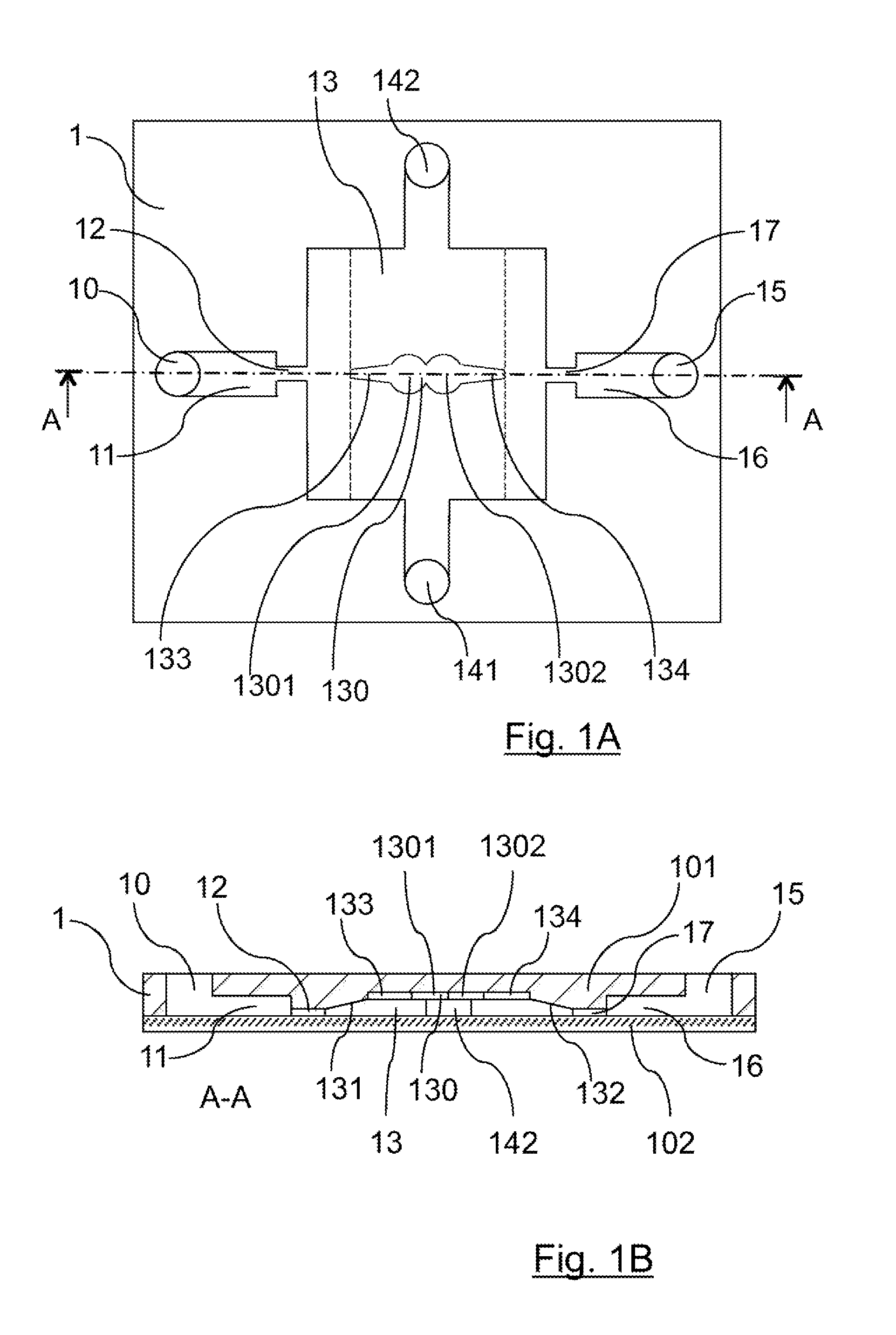

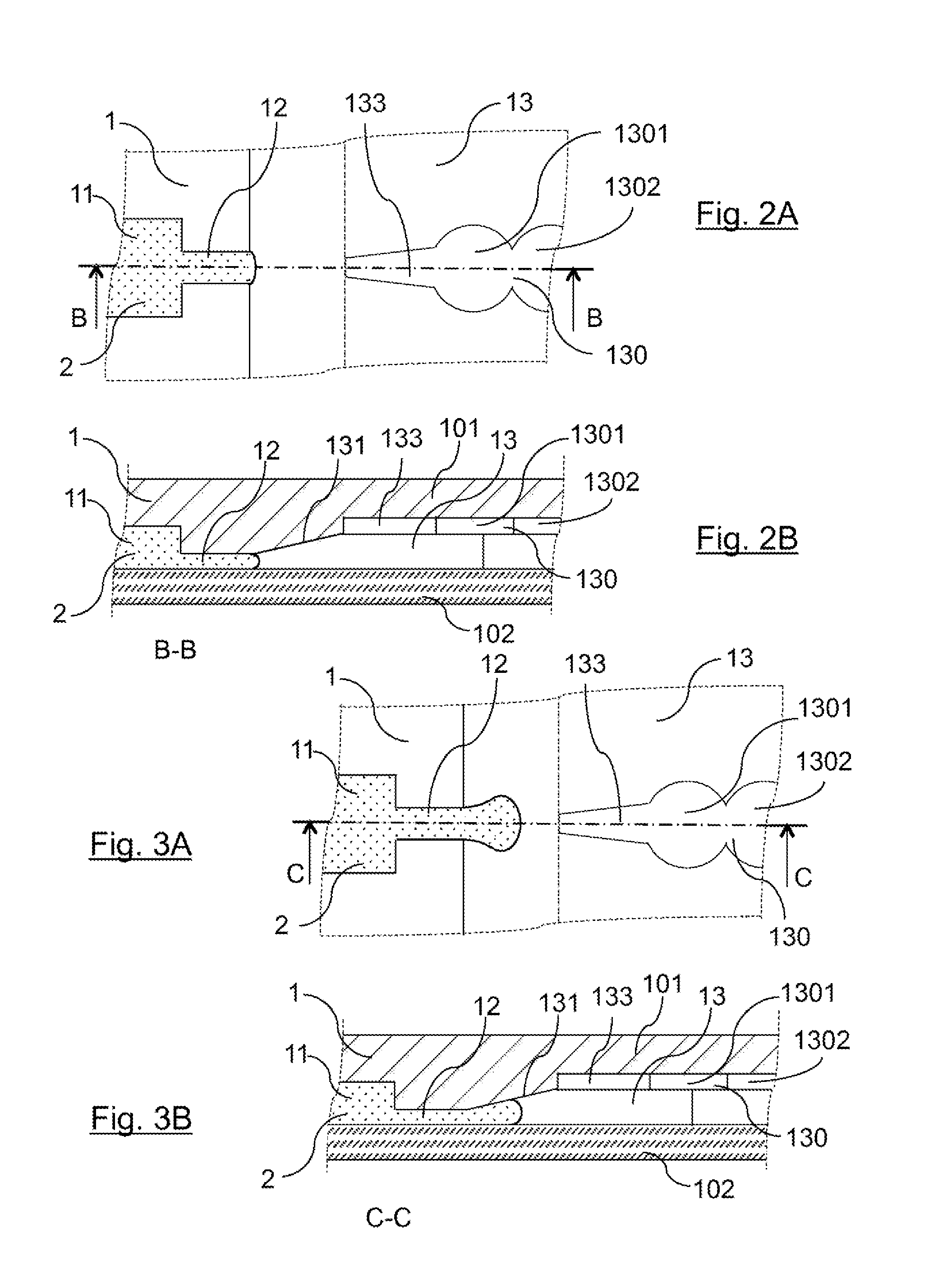

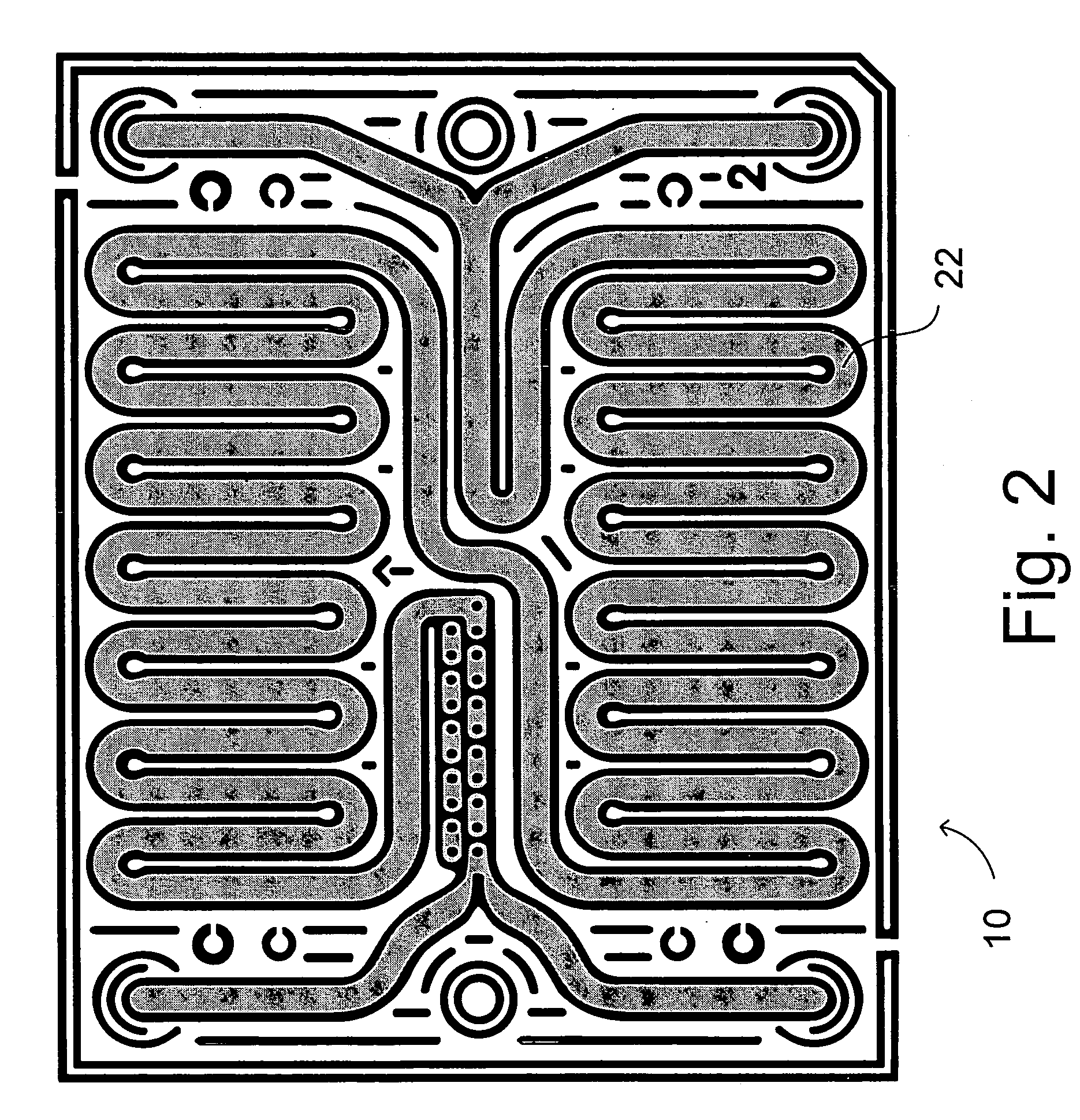

Microfluidic circuit allowing drops of several fluids to be brought into contact, and corresponding microfluidic method

ActiveUS20150258543A1Solve the complicated productionShaking/oscillating/vibrating mixersLaboratory glasswaresEngineeringSurface tension

The subject of the present invention is a microfluidic circuit in which are defined microchannels able to contain fluids and including at least one device for forming drops of a solution, guiding the drops to a storage zone in which one of the drops can be brought into contact with a drop of another solution, the walls of the microchannel portion forming the first drop-formation device diverging so as to cause drops of the first solution to detach under the effect of the surface tension of the first solution; the first guide include wall portions of the microchannels that diverge so as to cause the drops to move along under the effect of the surface tension of the first solution.

Owner:ECOLE POLYTECHNIQUE +1

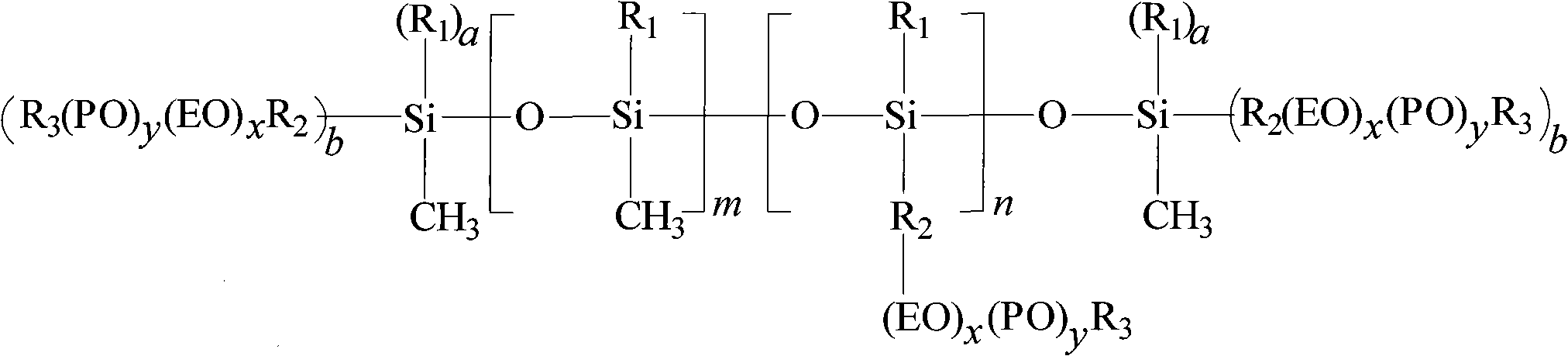

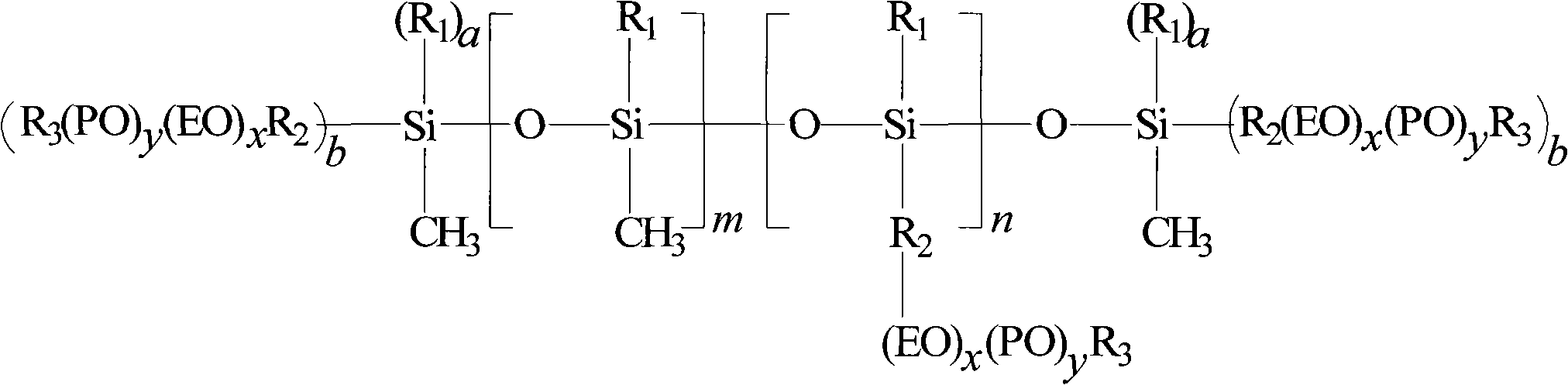

Method for dispersing highly viscous organosilicon mixture

The invention provides a method for dispersing high viscosity of silicone mixtures, which is characterized in that: an emulsion prepared by the method is composed of 5 to 25 percent of high viscosity of silicone mixtures, 4 to 25 percent of a high viscosity of silicone emulsifier, 0 to 15 percent of a normal emulsifier, 1 to 5 percent of a thickener and 60 to 90 percent of water; the preparation method comprises the steps that: (1) the high viscosity of silicone emulsifier, the normal emulsifier and the high viscosity of silicone mixtures are mixed, stirred and heated to the temperature of 50 to 80 DEG C and the heat is preserved for 20 to 60 minutes to guarantee full and even mixing of the silicone mixtures and the emulsifiers; (2) water is added slowly and the mixture is stirred quickly during phase transition to ensure that a W / O type emulsion is changed into an O / W type emulsion, and then water is continued to be added until the quality concentration of a crude emulsion gets to 40 to 60 percent; (3) the crude emulsion is carried out colloid mill to be further emulsified; (4) the mixture is diluted by a thickener aqueous solution. The method can obtain a stable emulsion of high viscosity of silicone mixtures and the storage and application stability of the emulsion are improved.

Owner:滁州四新科技有限责任公司

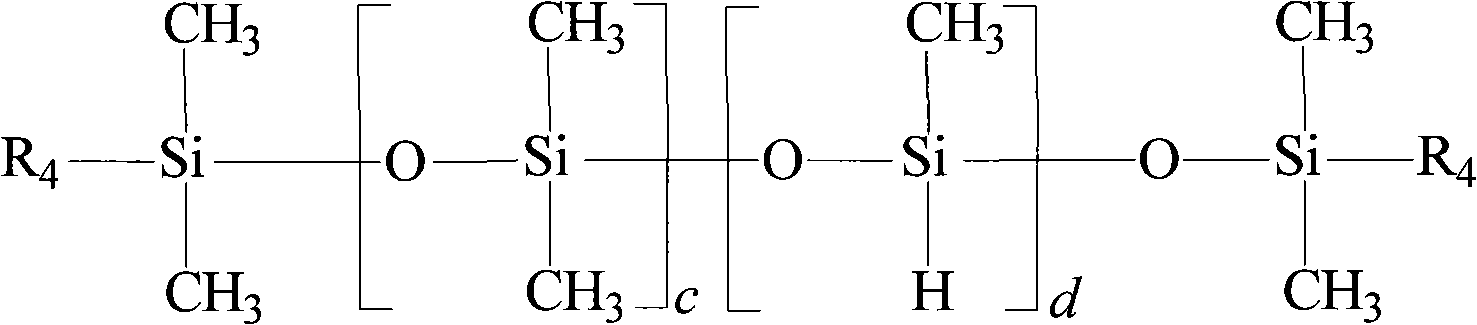

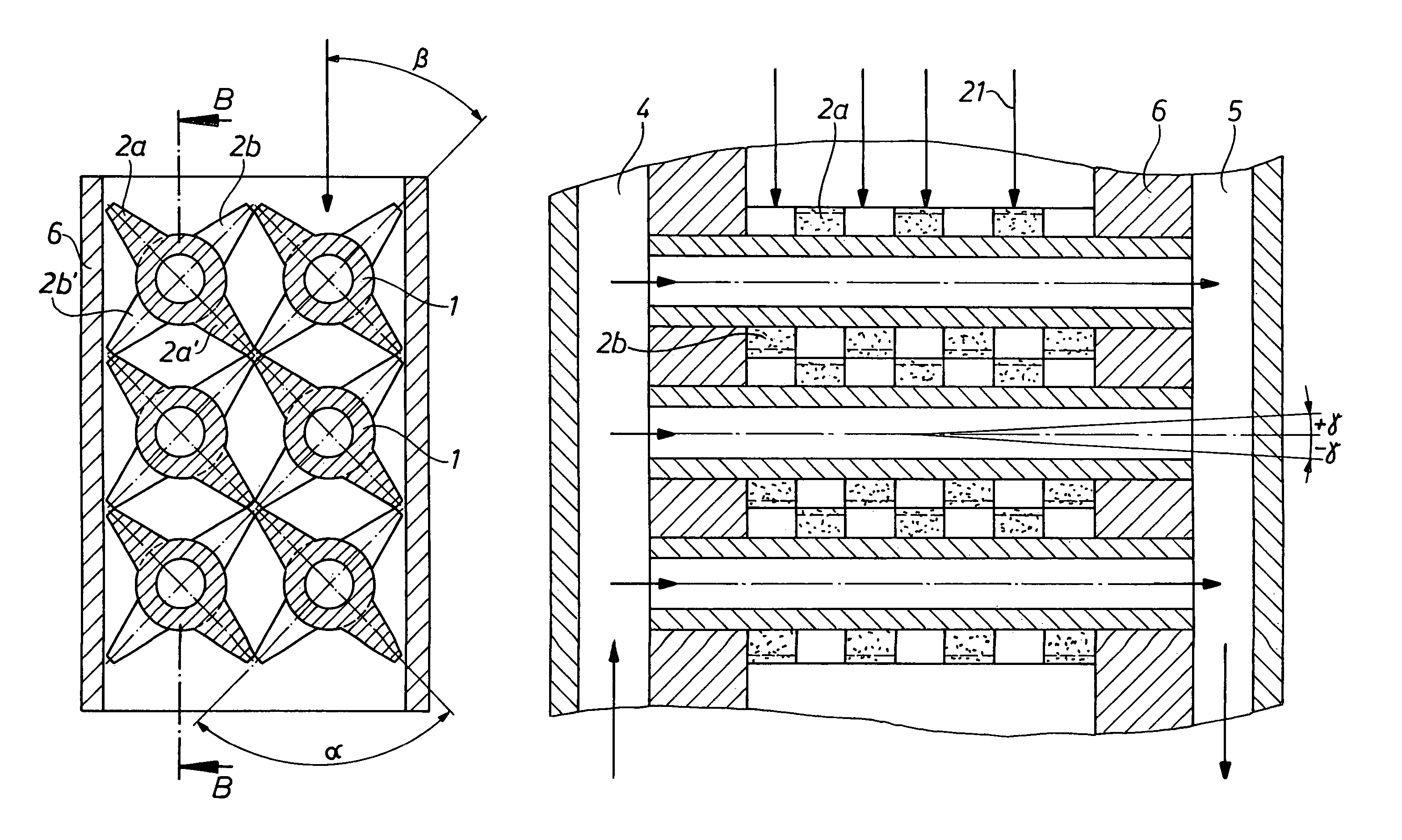

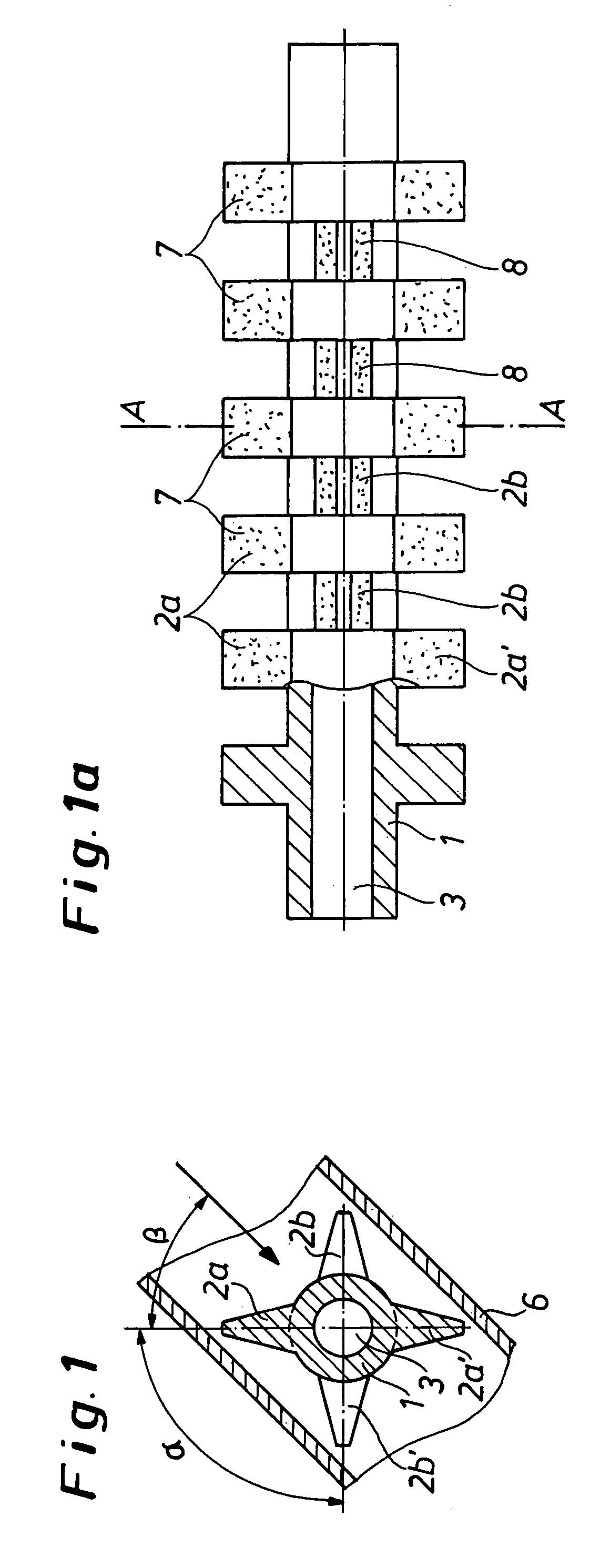

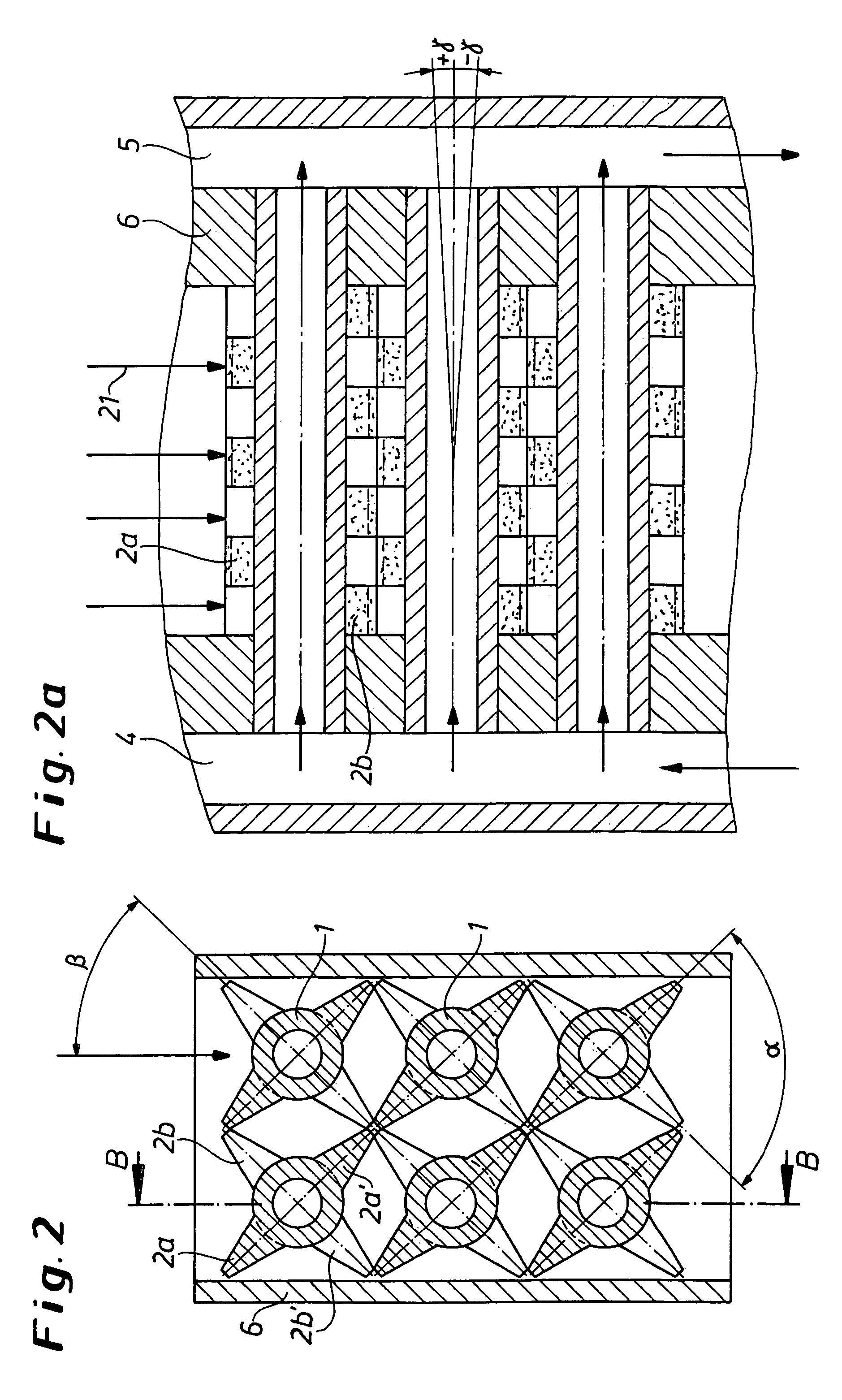

Mixer/heat exchanger

InactiveUS7220048B2Stable designIncrease heat transfer areaFlow mixersTransportation and packagingPlate heat exchangerEngineering

A combination static mixer and heat exchanger having heat exchanger tubes (1) which are provided over their circumference with fins (2a, 2b) which have a static mixing effect.

Owner:BAYER AG

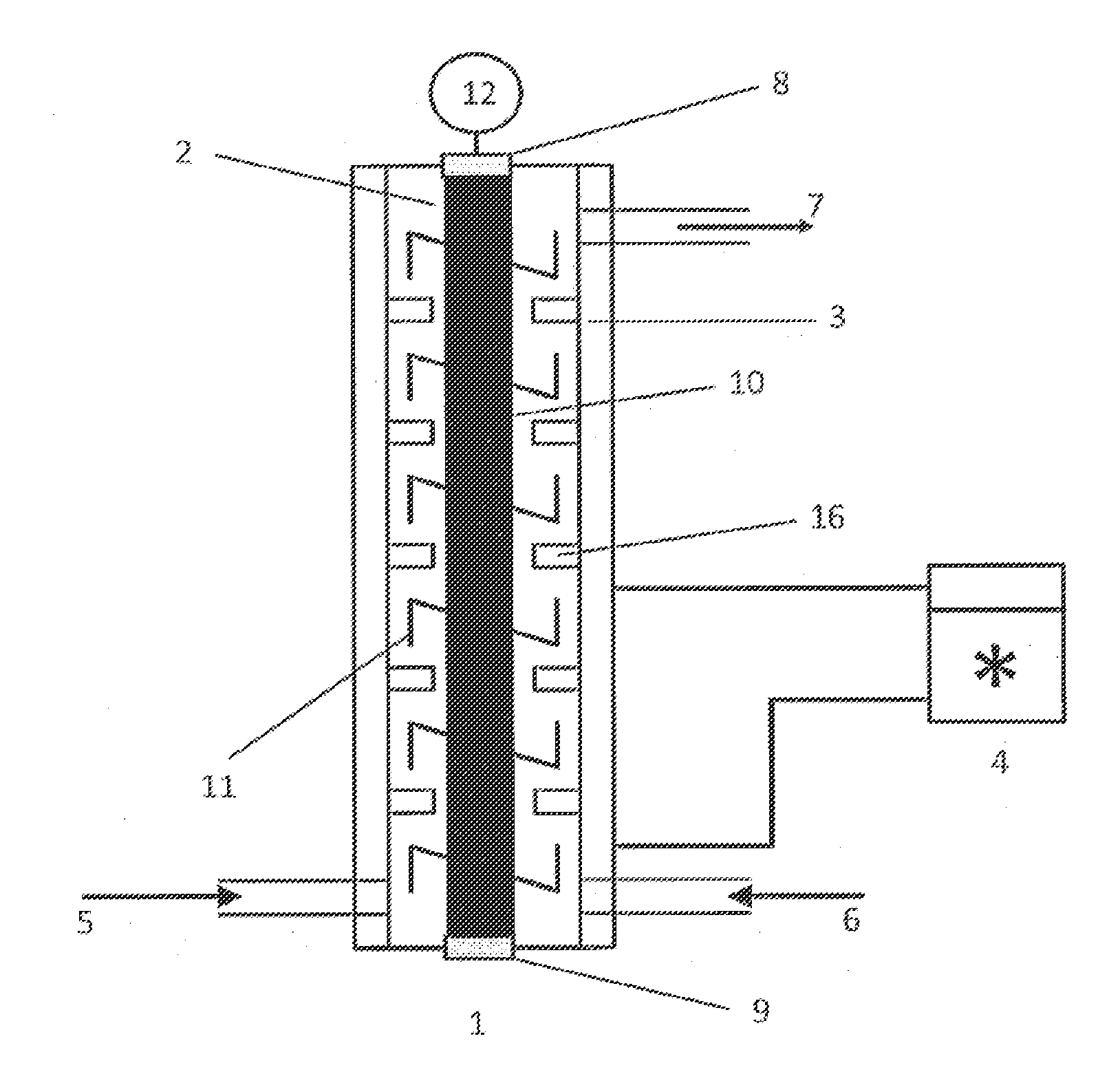

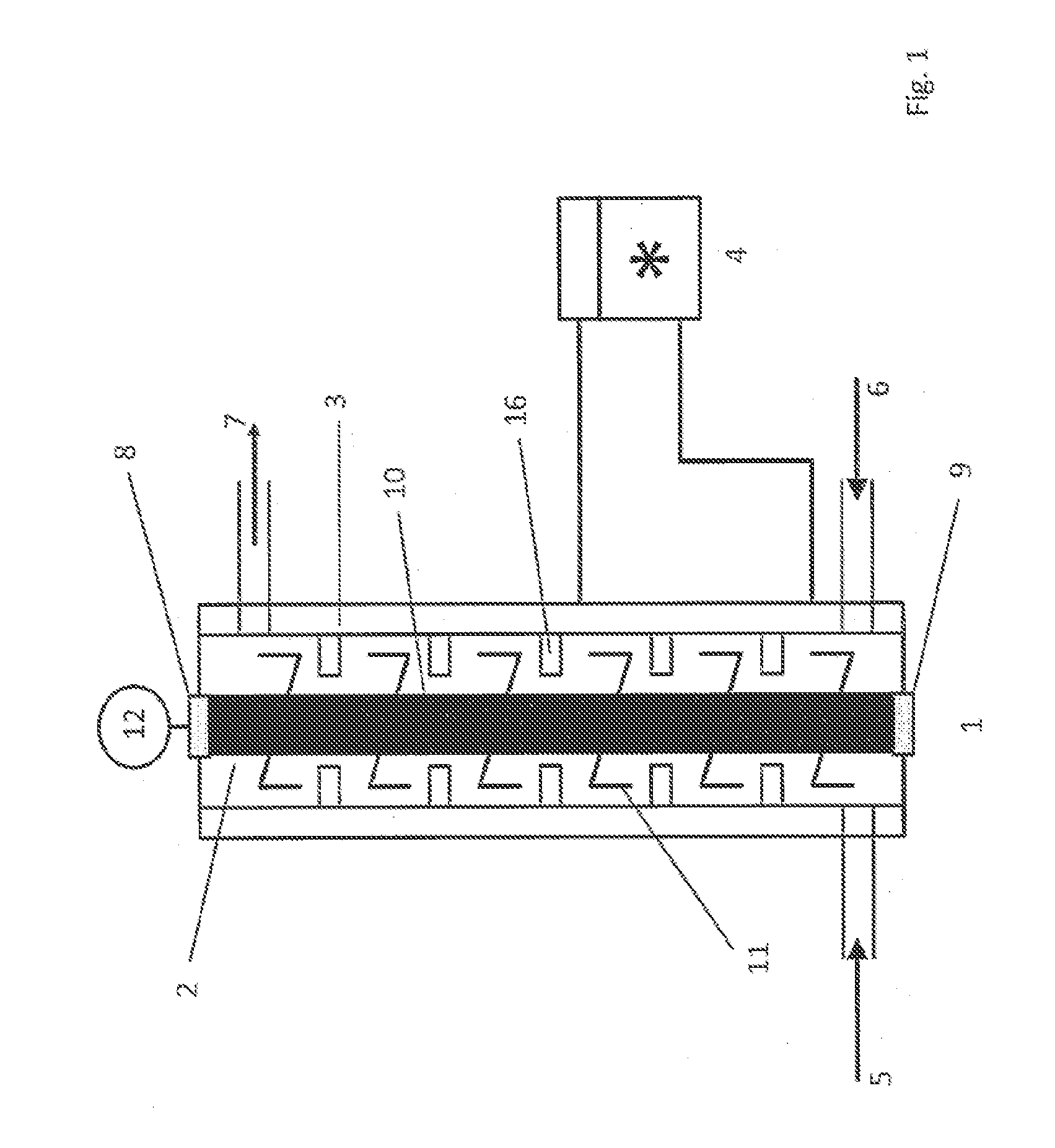

Emulsification device for continuously producing emulsions and/or dispersions

The invention relates to an emulsification device for continuously producing emulsions, nano-emulsions, and / or dispersions having a liquid crystalline structure, comprising a) at least one mixing system, b) at least one drive for the stirring element, and c) at least one delivery unit for each component or each component mixture.

Owner:CLARIANT INT LTD

Agitation/deaeration device

InactiveUS20070025180A1Readily apparentPrinted circuit assemblingRotating receptacle mixersEngineeringPulley

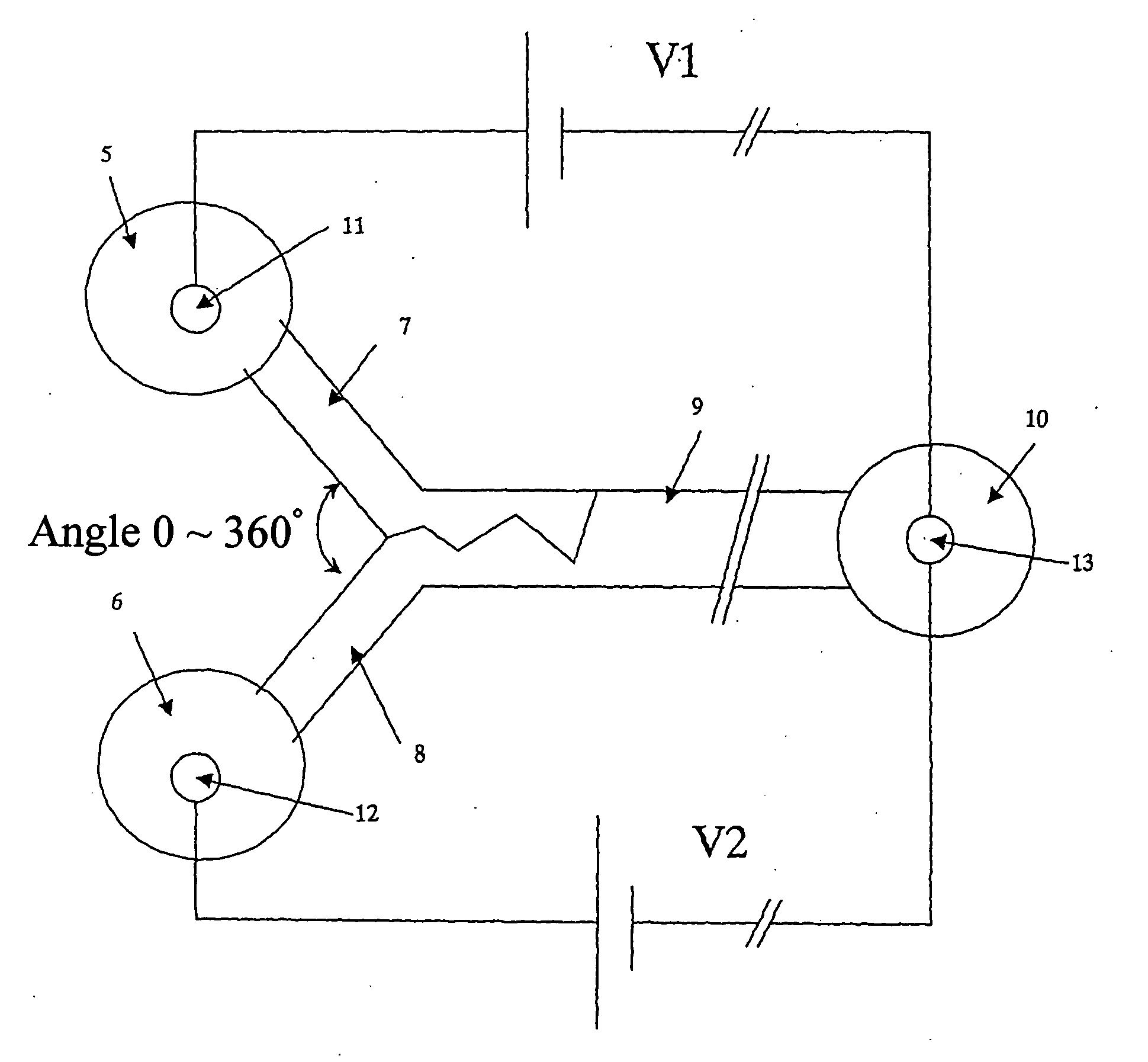

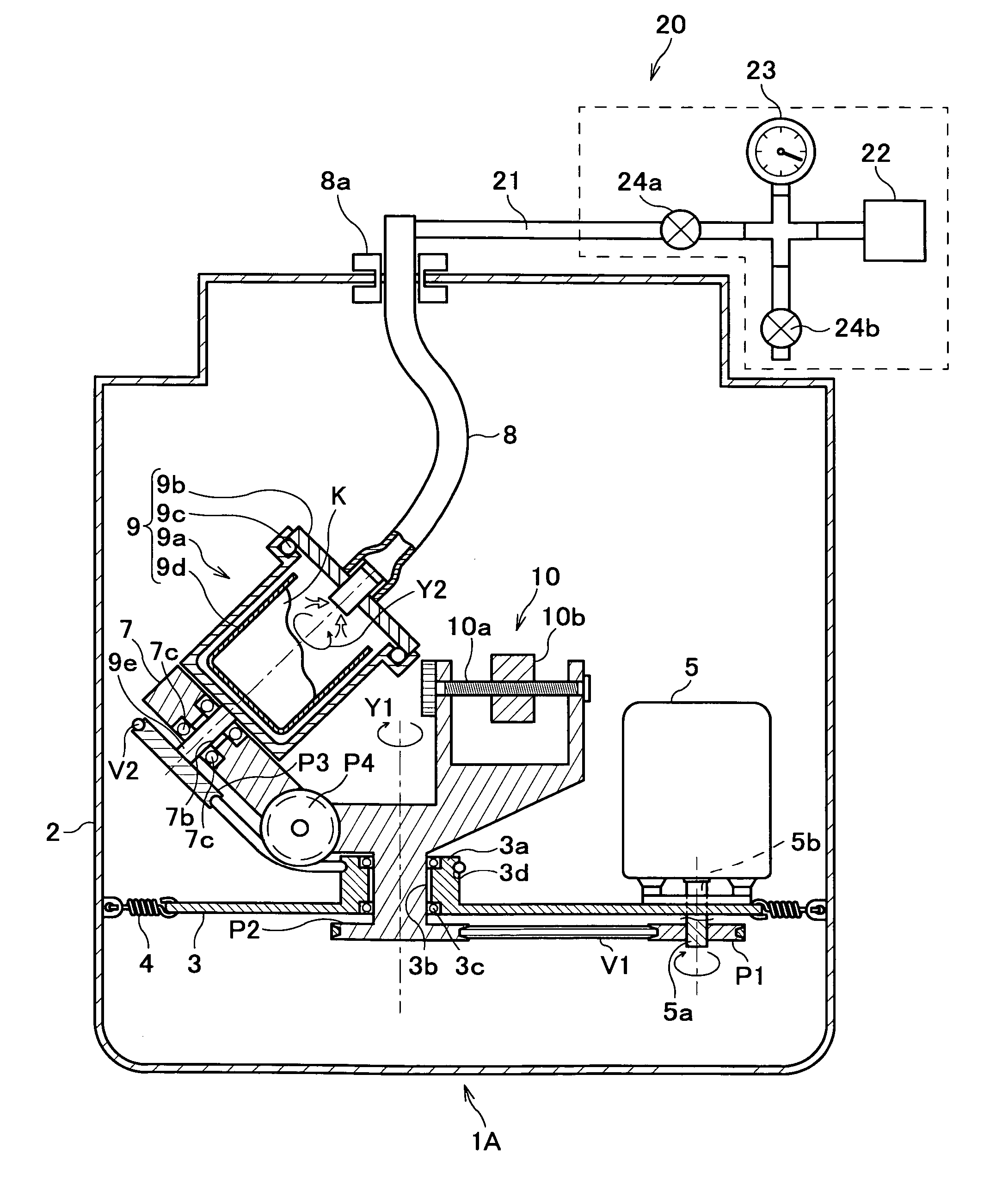

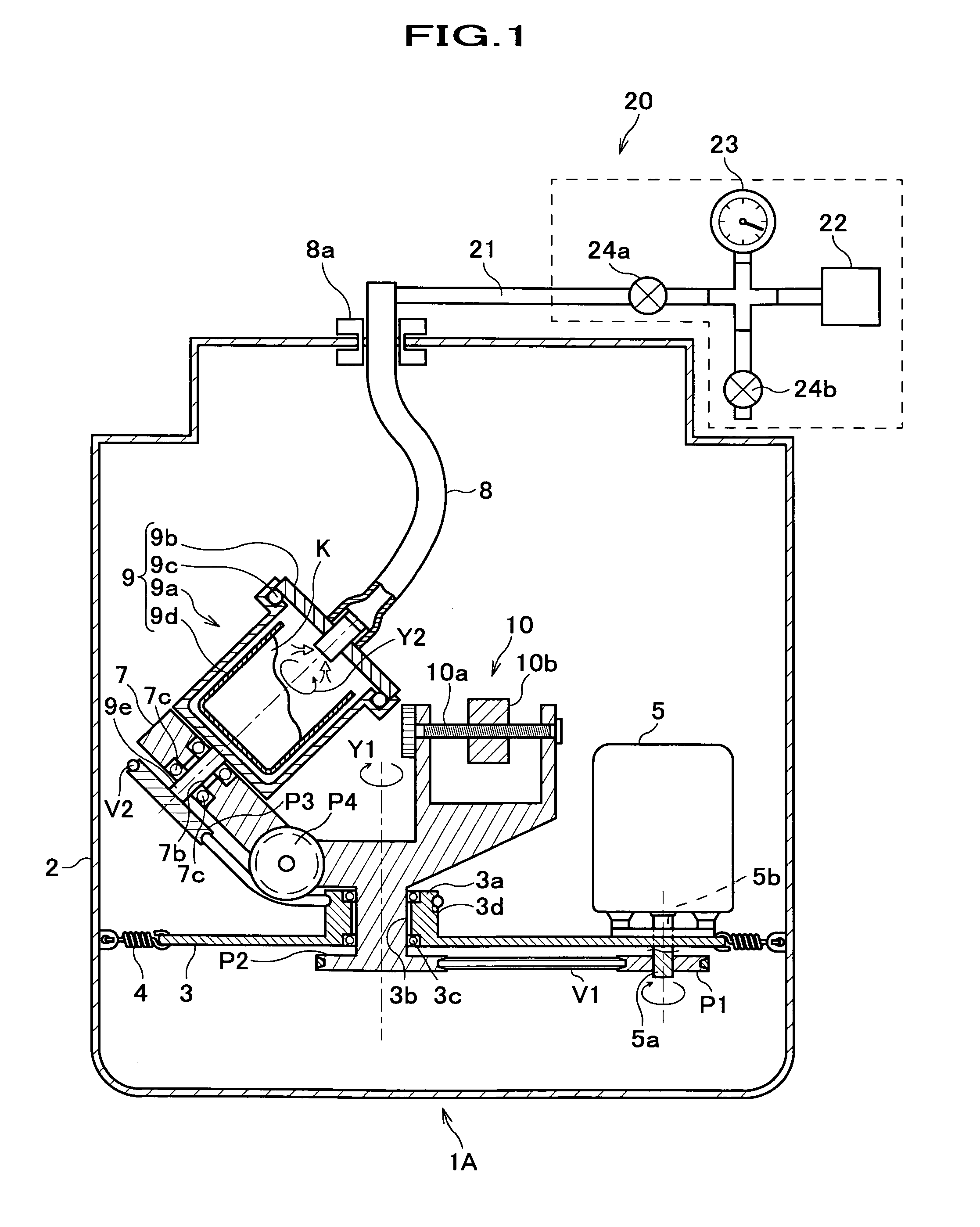

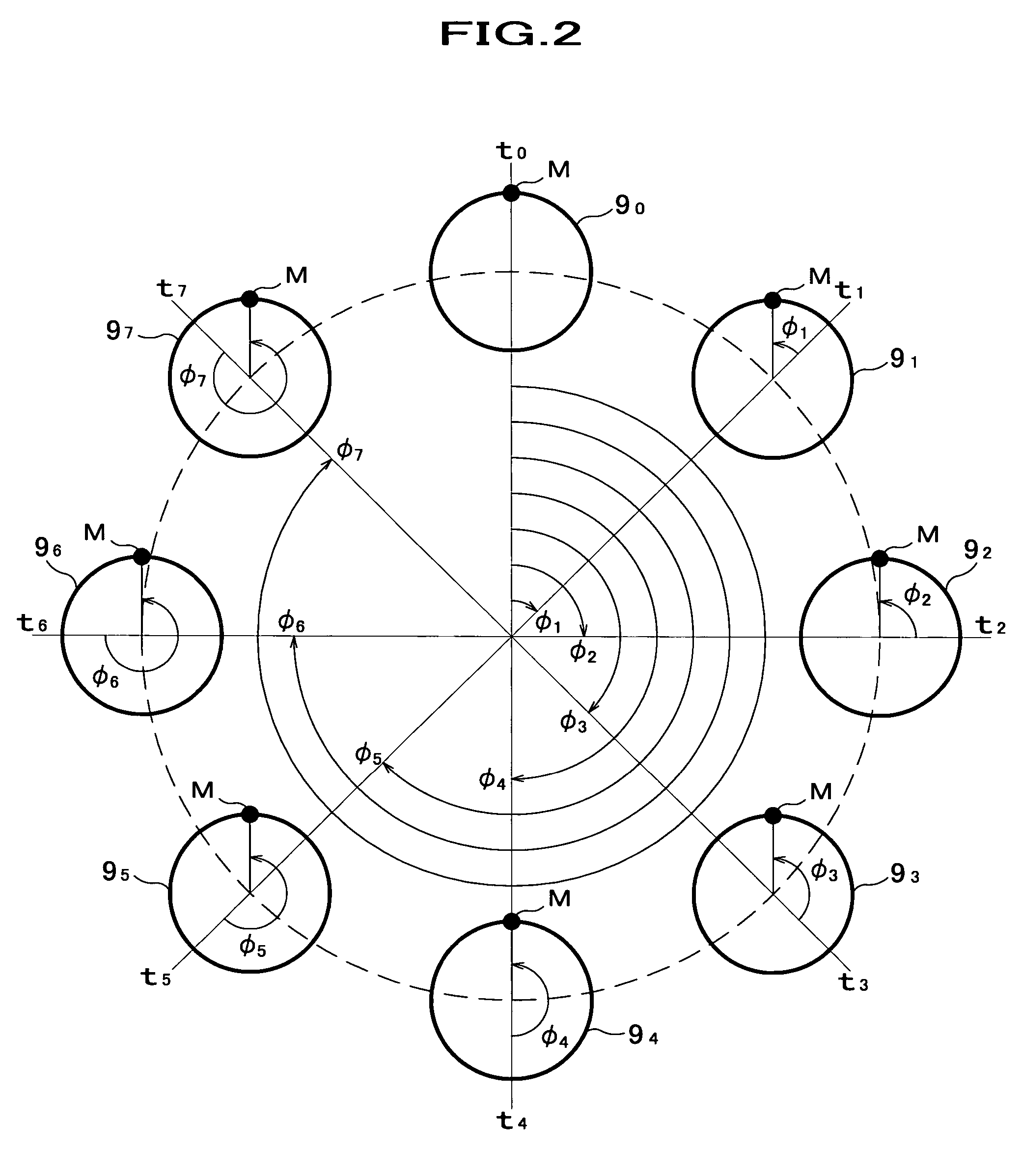

An agitation / deaeration apparatus is provided which causes a container containing a viscous to-be-kneaded object to be rotated and revolved simultaneously, to agitate and deaerate the to-be-kneaded object, wherein piping (wiring) connecting the container and an external device is prevented from twisting even when the container rotates. In an agitation / deaeration apparatus (1A) which performs agitation and deaeration of a to-be-kneaded object (K) by causing a container (9) accommodating a to-be-kneaded object (K) to be rotated about a rotation axis (Y2) of the container (9) and revolved about a revolution axis (Y2), provided are: a first rotation drive mechanism (motor 5) configured to drive and rotate a revolution table (7); a second rotation drive mechanism (a round-belt groove 3d, a pulley P3) configured to rotate the container (9) in a reverse direction at the same rotational speed relative to the revolution table (7); one or more of distribution means (a suction tube 8) of which one end is connected with the container (9) and the other end is connected with the external device.

Owner:THINKY

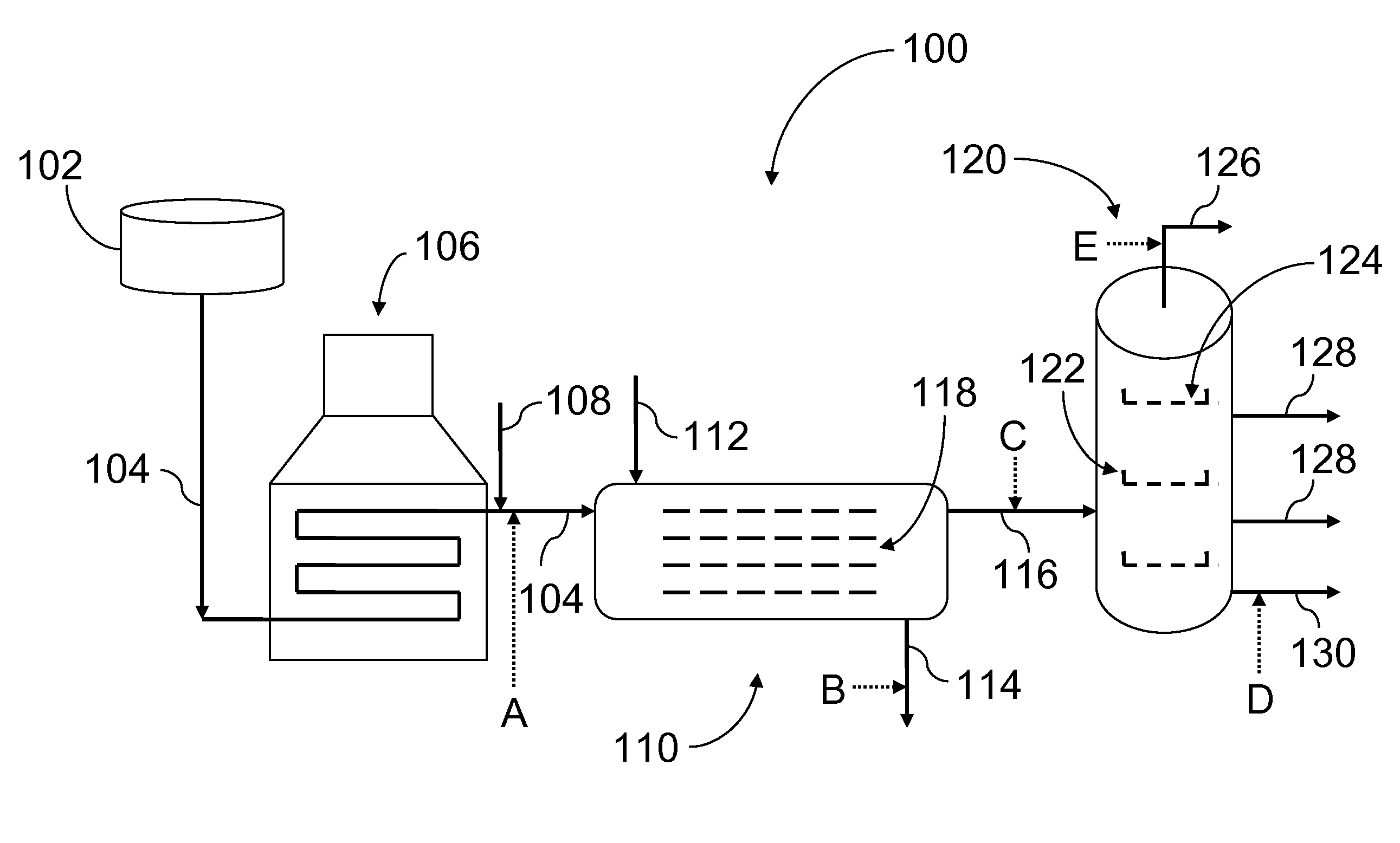

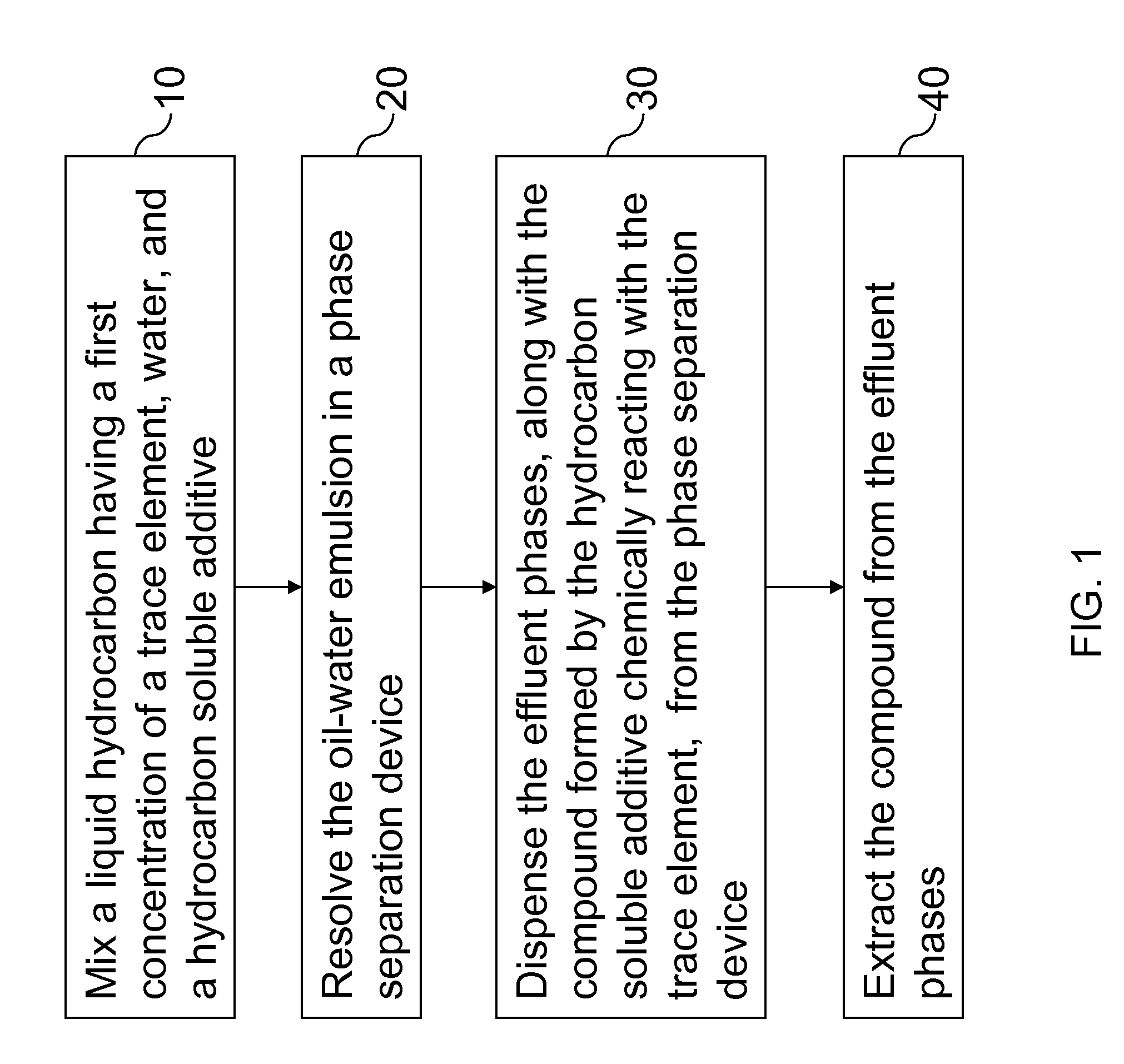

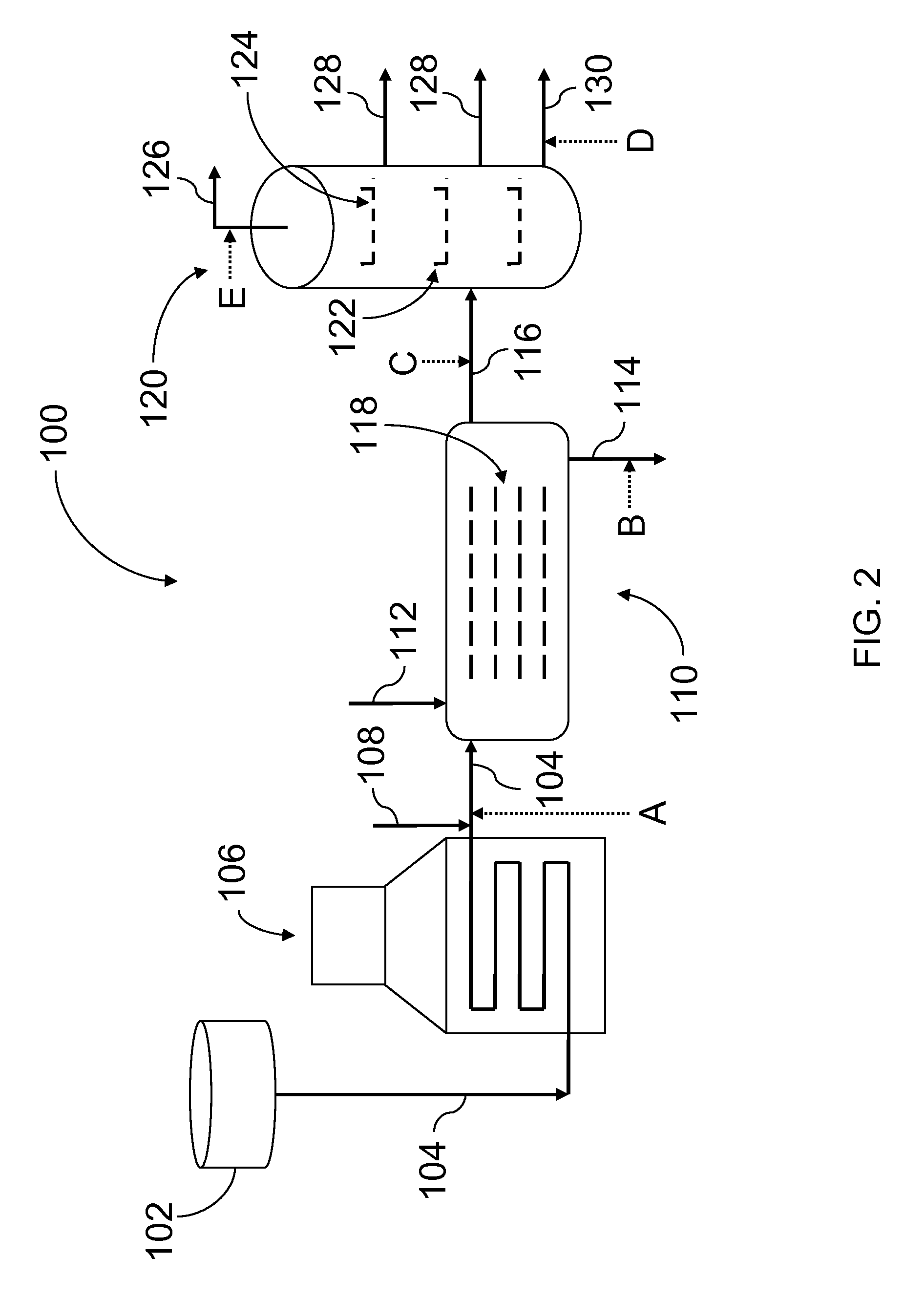

System and method for separating a trace element from a liquid hydrocarbon feed

InactiveUS20100000910A1Easy to removeEasy to separateTransportation and packagingRefining by water treatmentChemical reactionTrace element

The present invention is generally directed to removing a trace element from a liquid hydrocarbon feed. The liquid hydrocarbon feed, containing the trace element, is mixed with the water along with a hydrocarbon-soluble additive. While being mixed, a compound, which in some cases is preferably insoluble, is formed by the hydrocarbon-soluble additive chemically reacting with the trace element. A phase separation device, such as a desalter or an oil-water separator, receives the oil-water emulsion containing the compound and resolves the mixture to produce the compound, effluent brine, and effluent liquid hydrocarbon with a reduced concentration of the trace element as compared to the liquid hydrocarbon feed. In some embodiments, the present invention is directed to removing elemental mercury from a liquid hydrocarbon feed. A hydrocarbon-soluble sulfur-containing additive, typically an organic polysulfide, is mixed with the liquid hydrocarbon feed and water. The hydrocarbon-soluble, sulfur-containing additive reacts with the mercury, rapidly forming an agglomeration of mercuric sulfide which is then dispensed with the effluent brine or the effluent liquid hydrocarbon.

Owner:CHEVROU USA INC

Continuous dispensing system for liquids

InactiveUS6010032ALower Level RequirementsOpening closed containersBottle/container closureEngineeringDip-coating

The present invention relates to the continuous production of coated, dyed, printed, or painted materials by dip coating, spraying or printing in which a plurality of flowable materials including a liquid color concentrate are fed to a continuous mixing chamber with a substantially continuous input and output. The liquid color concentrate is dispensed by a dispensing apparatus including at least a first substantially vertical hollow chamber; a controllable pump device having an inlet fluidly connected to an outlet of said first hollow chamber for pumping the liquid color concentrate to the mixing chamber; a sensor for outputting substantially continuously a signal dependent upon a height of a liquid in the first hollow chamber; and a control device suitable for controlling at least one flow rate determining characteristic of the controllable pump in response to the output signal of the sensor so as to maintain the flow rate of the liquid to be dispensed through the pump device at a predetermined value. The method and apparatus are particularly useful in the manufacture of printed carpets.

Owner:E M E NV +1

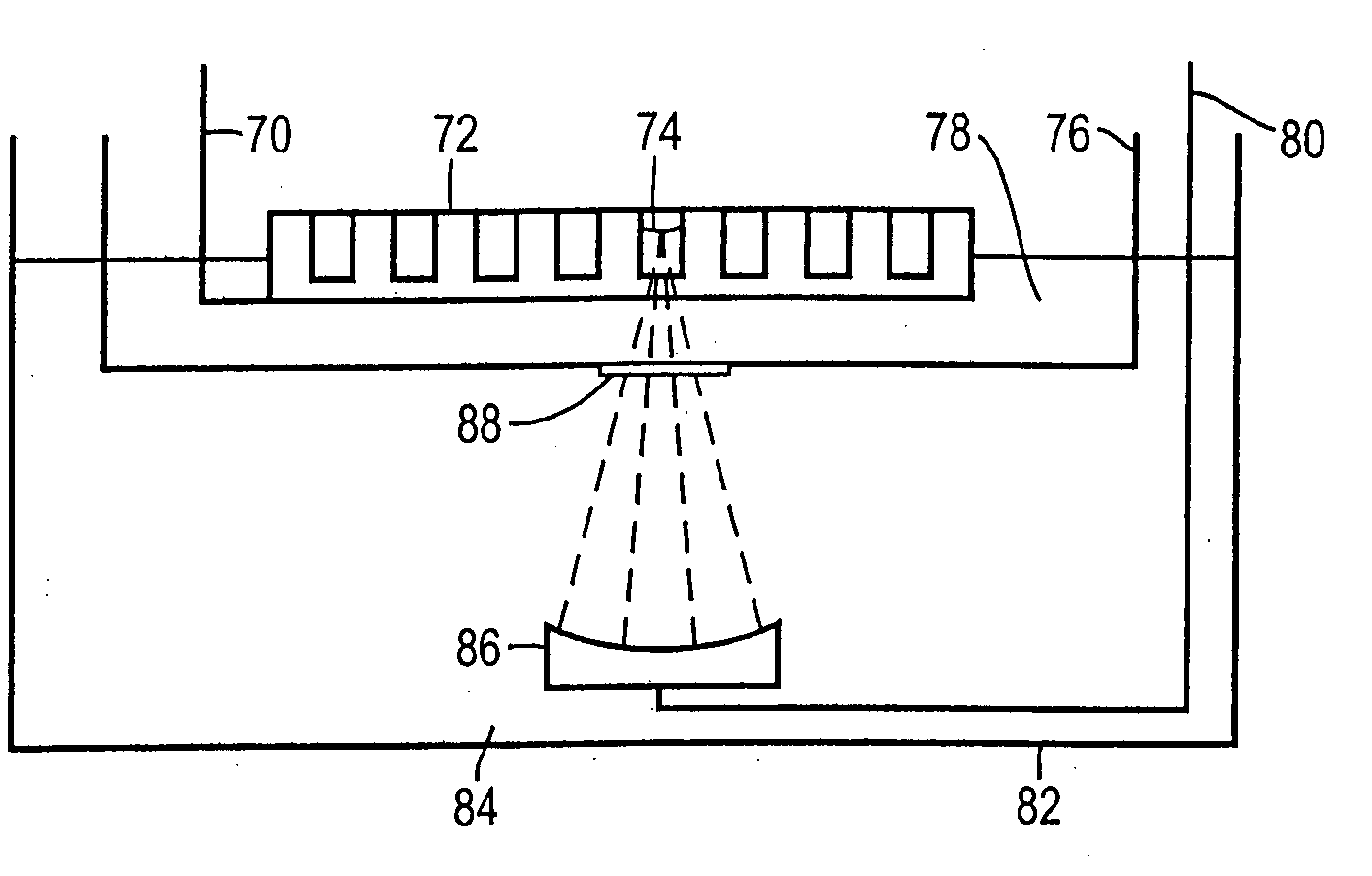

Ultrasonic treatment chamber for preparing emulsions

InactiveUS20090166177A1Shaking/oscillating/vibrating mixersCircuit elementsUltrasonic cavitationEmulsion

An ultrasonic mixing system having a treatment chamber in which at least two separate phases can be mixed to prepare an emulsion is disclosed. Specifically, at least one phase is a dispersed phase and one phase in a continuous phase. The treatment chamber has an elongate housing through which the phases flow longitudinally from a first inlet port and a second inlet port, respectively, to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the phases within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the phases being mixed in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

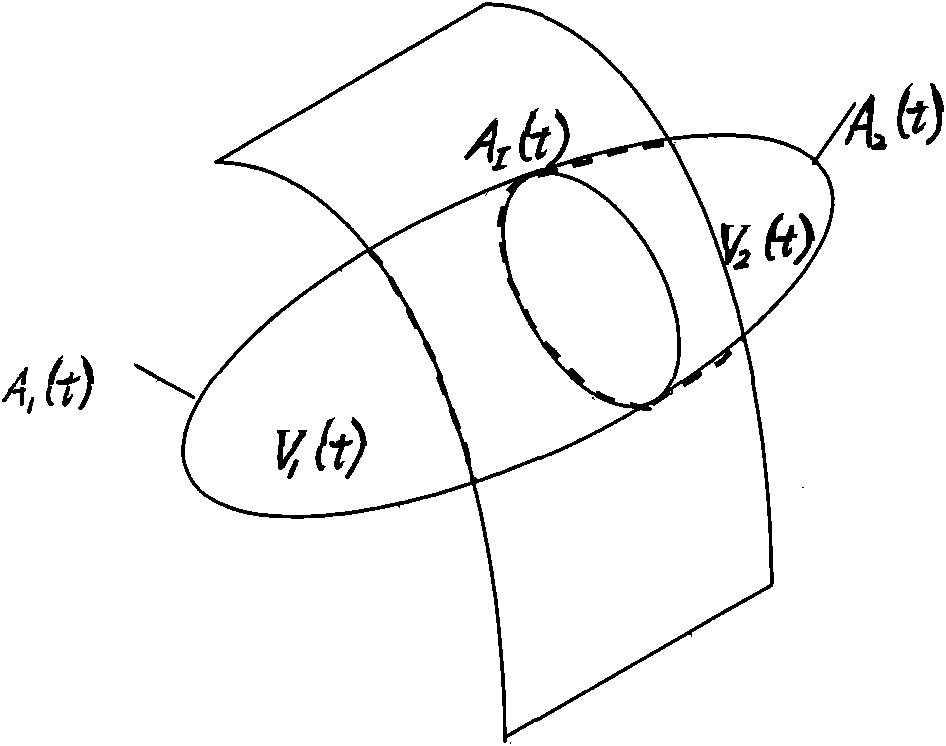

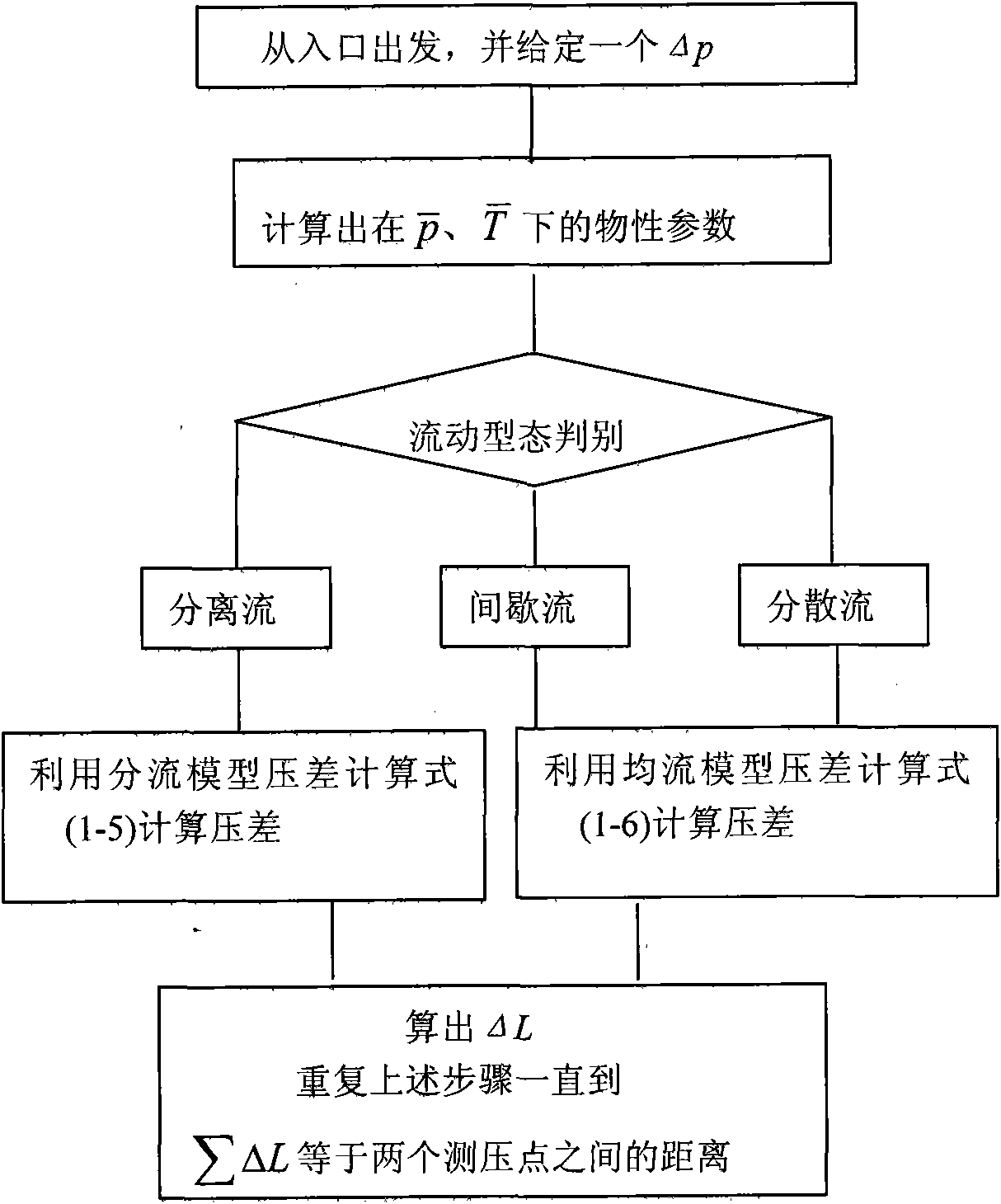

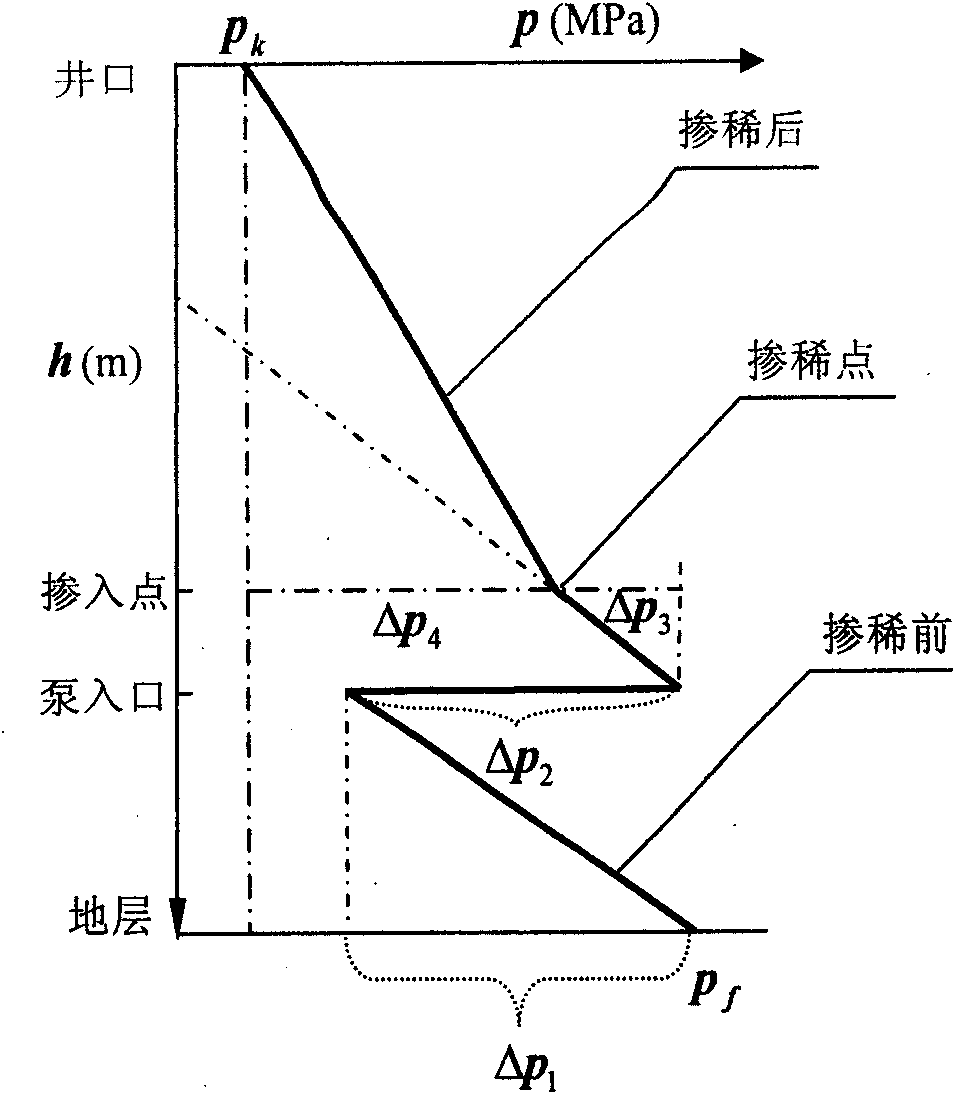

Optimization method for determining proportion of mixing light oil into heavy oil of ultra-deep well and light hydrocarbon mixer thereof

ActiveCN101684727ARealize simulationRealize analysisFluid removalEmulsificationVolumetric Mass DensityMulti phase

The invention discloses an optimization method for determining the proportion of mixing light oil into heavy oil of an ultra-deep well and a light oil mixer thereof. The method comprises the steps of: 1) establishing a multi-phase flow comprehensive pressure drop calculation model and a correction model; 2) deriving a calculation method for the temperature gradient of a fluid in a shaft of a light oil mixing well; 3) performing the multi-phase flow calculation of bent well sections of the ultra-deep well, and calculating the distribution rule of parameters in a borehole shape; 4) establishing an analysis model of production performance of mixing the light oil into the heavy oil; and 5) optimizing the proportion and production parameters of mixing the light oil into the heavy oil. The method realizes the simulation and analysis to the production performance of mixing the light oil into the heavy oil of the ultra-deep well. The production performance of mixing the light oil into the heavy oil of the ultra-deep well are quantificationally analyzed and simulated and the distribution rule of parameters such as pressure, density and velocity along the shaft can be obtained. The method can optimize the proportion and the production parameters of mixing the light oil into the heavy oil according to the productivity of an oil well. The optimum light oil mixing proportion and mixing pressure are preferably selected. The method and the mixer have extremely strong industrial applicability.

Owner:CHINA PETROLEUM & CHEM CORP +1

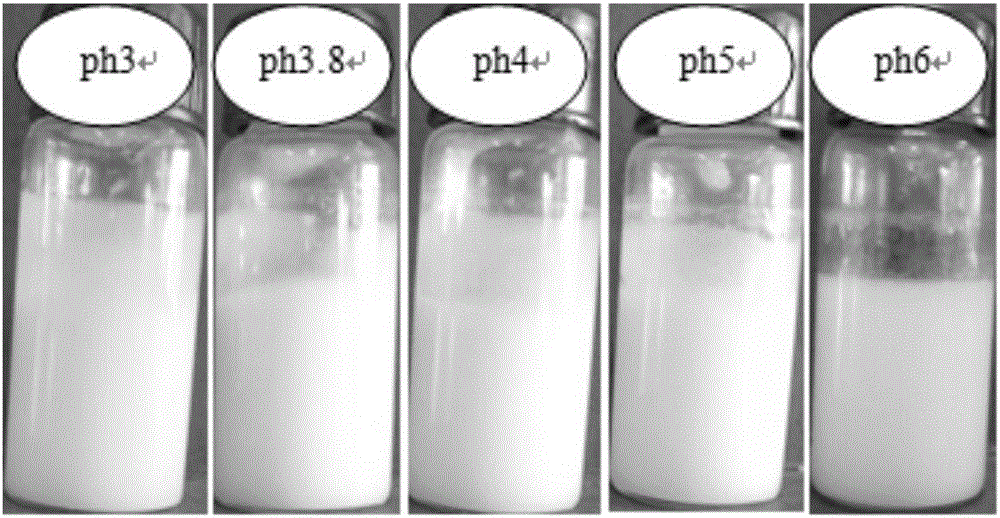

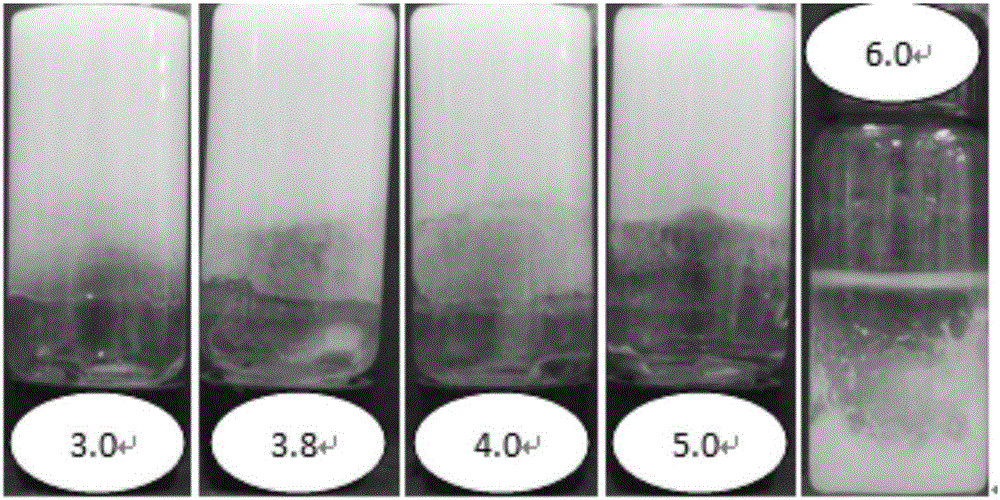

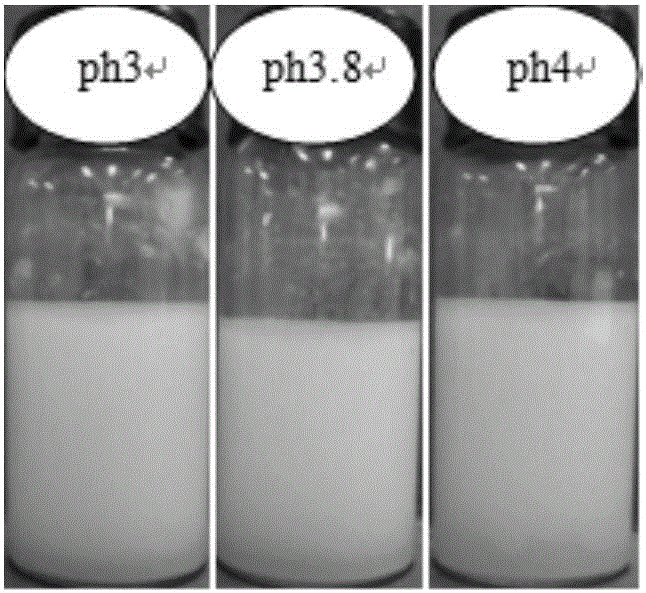

High internal phase gel-like zein Pickering emulsion and preparation method thereof

InactiveCN106579327AEffective embeddingGelatinousCosmetic preparationsToilet preparationsAlcoholPickering emulsion

The invention discloses a high internal phase gel-like zein Pickering emulsion and a preparation method thereof. The preparation method comprises (1) dissolving zein in an alcohol solution, (2) preparing a pectin aqueous solution, (3) pouring the solution obtained by the step (1) into the pectin aqueous solution and carrying out homogenization and rotary evaporateion, (4) adjusting the pH of the solution obtained by the step (3) to 3.0 to 5.0, and (5) mixing the solution and oil and carrying out shearing emulsification to obtain the high internal phase gel-like zein Pickering emulsion. The high internal phase gel-like zein Pickering emulsion has high stability and good viscoelasticity and can embed a large amount of oil. The preparation method has the advantages of low requirements on equipment, simple processes and operation easiness. The preparation method has a good prospect in the application of a novel nutrient deliverying carrier and a food structure modification base material.

Owner:SOUTH CHINA UNIV OF TECH

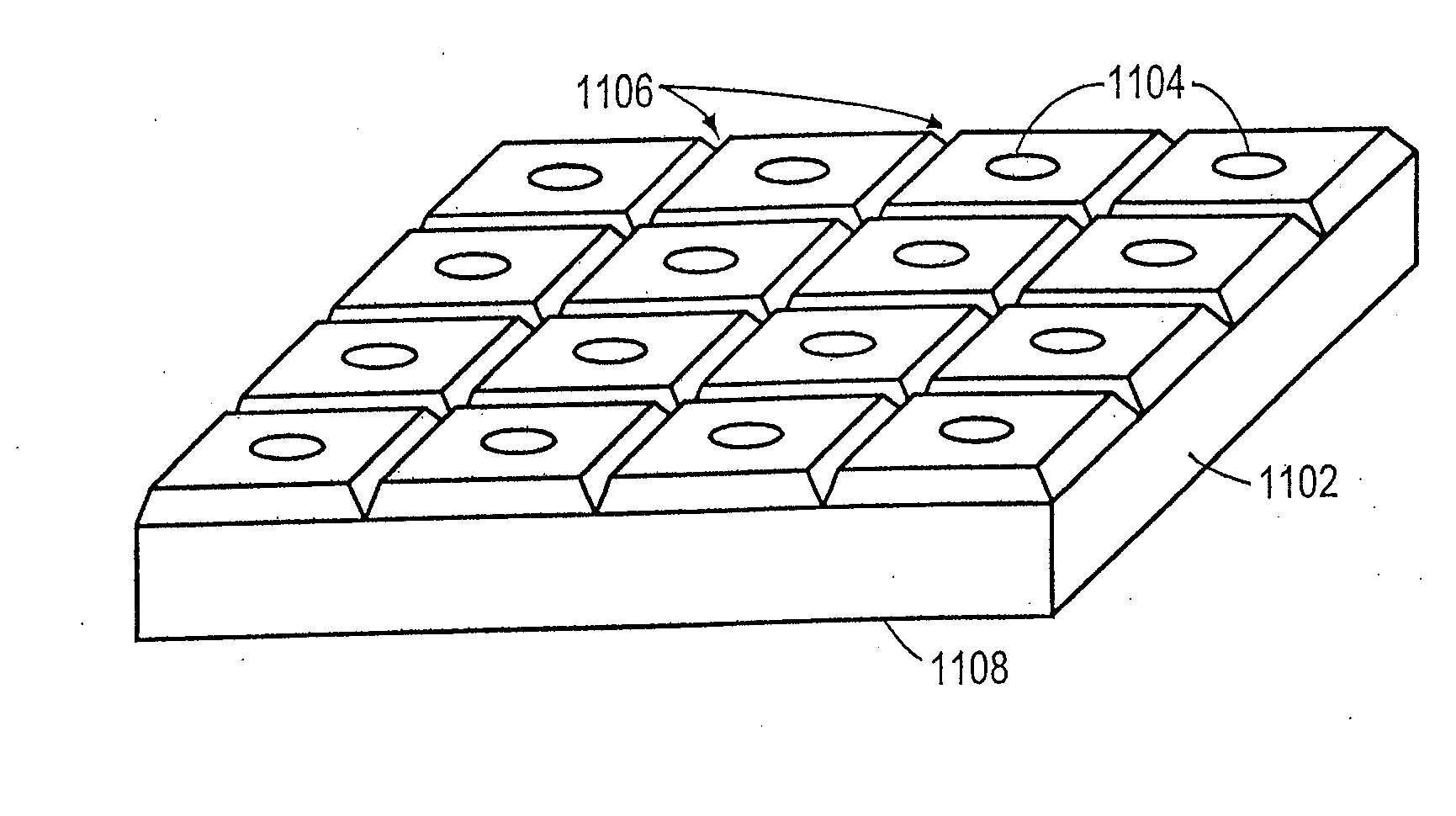

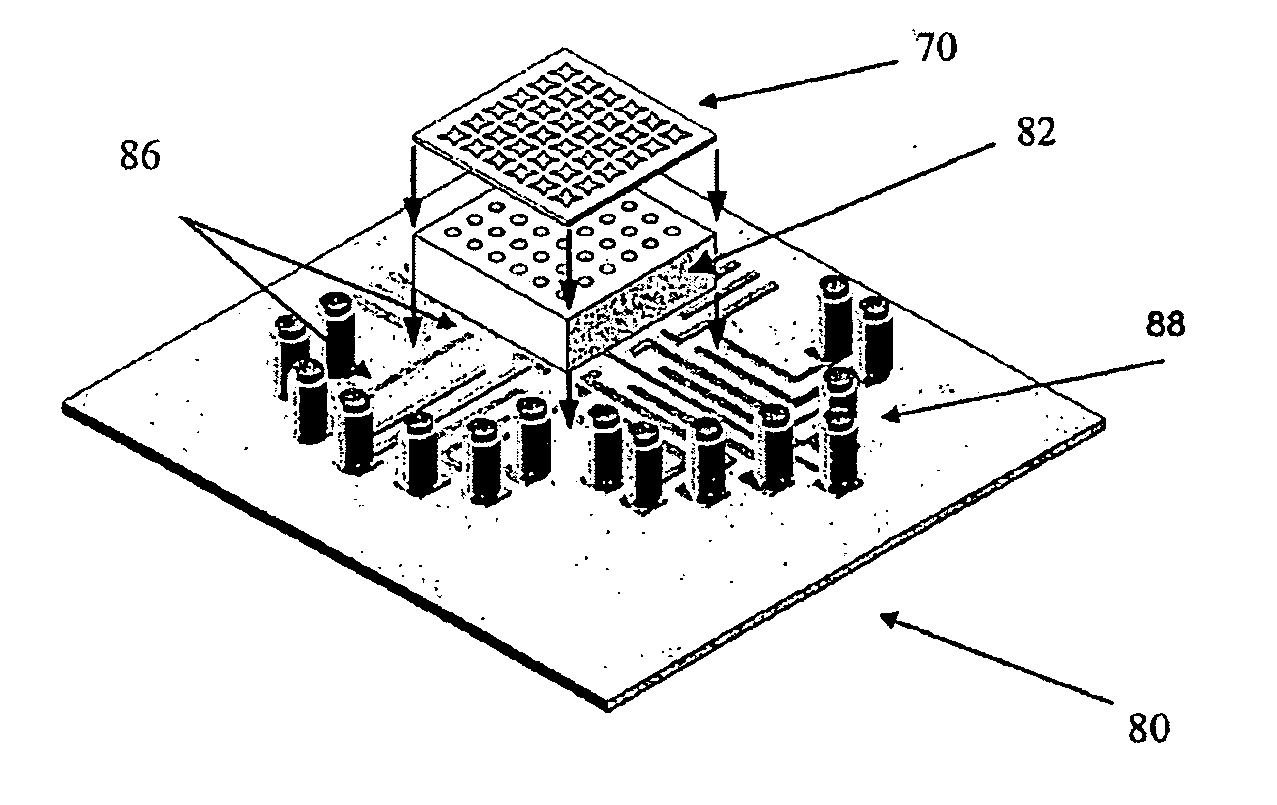

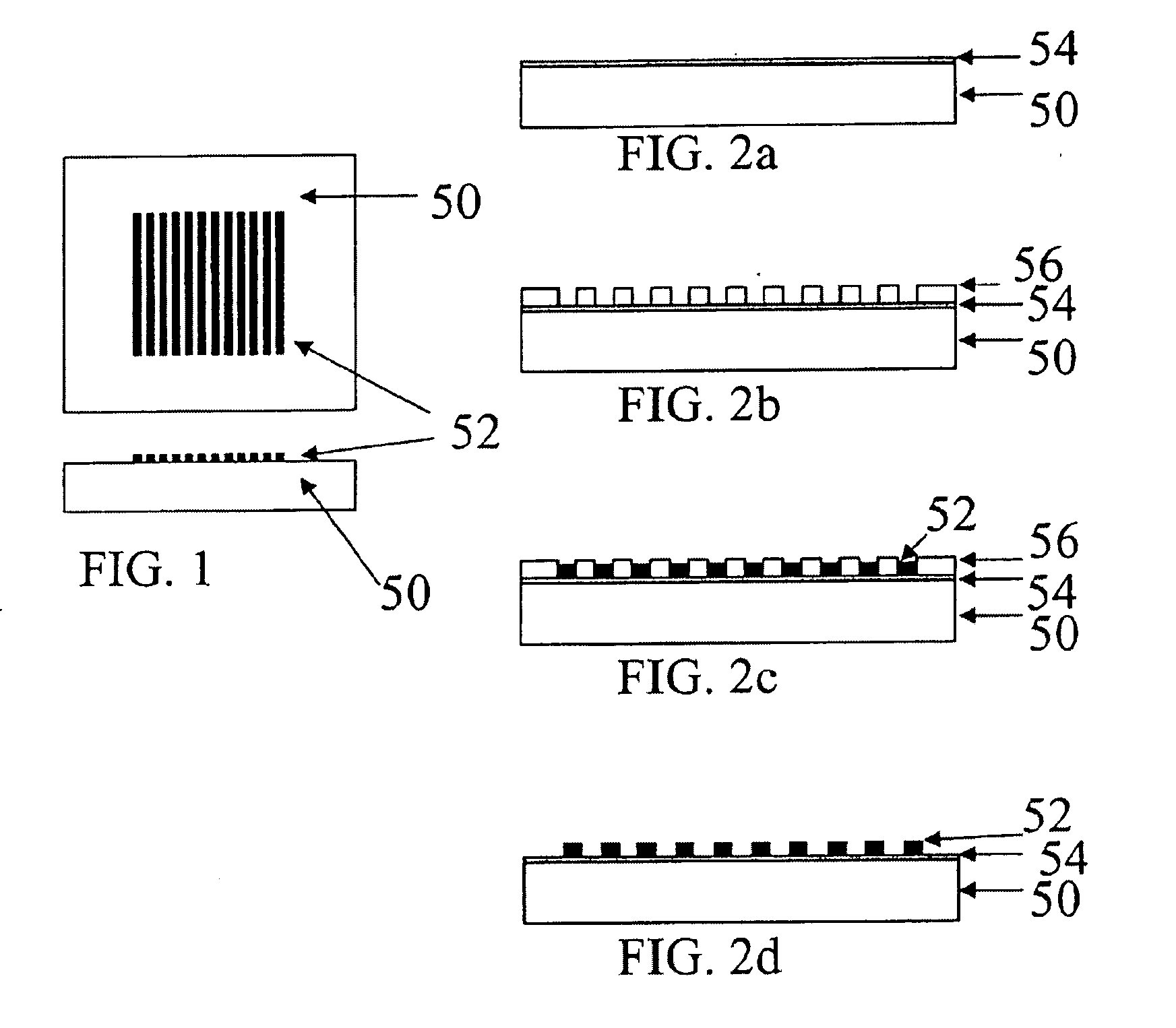

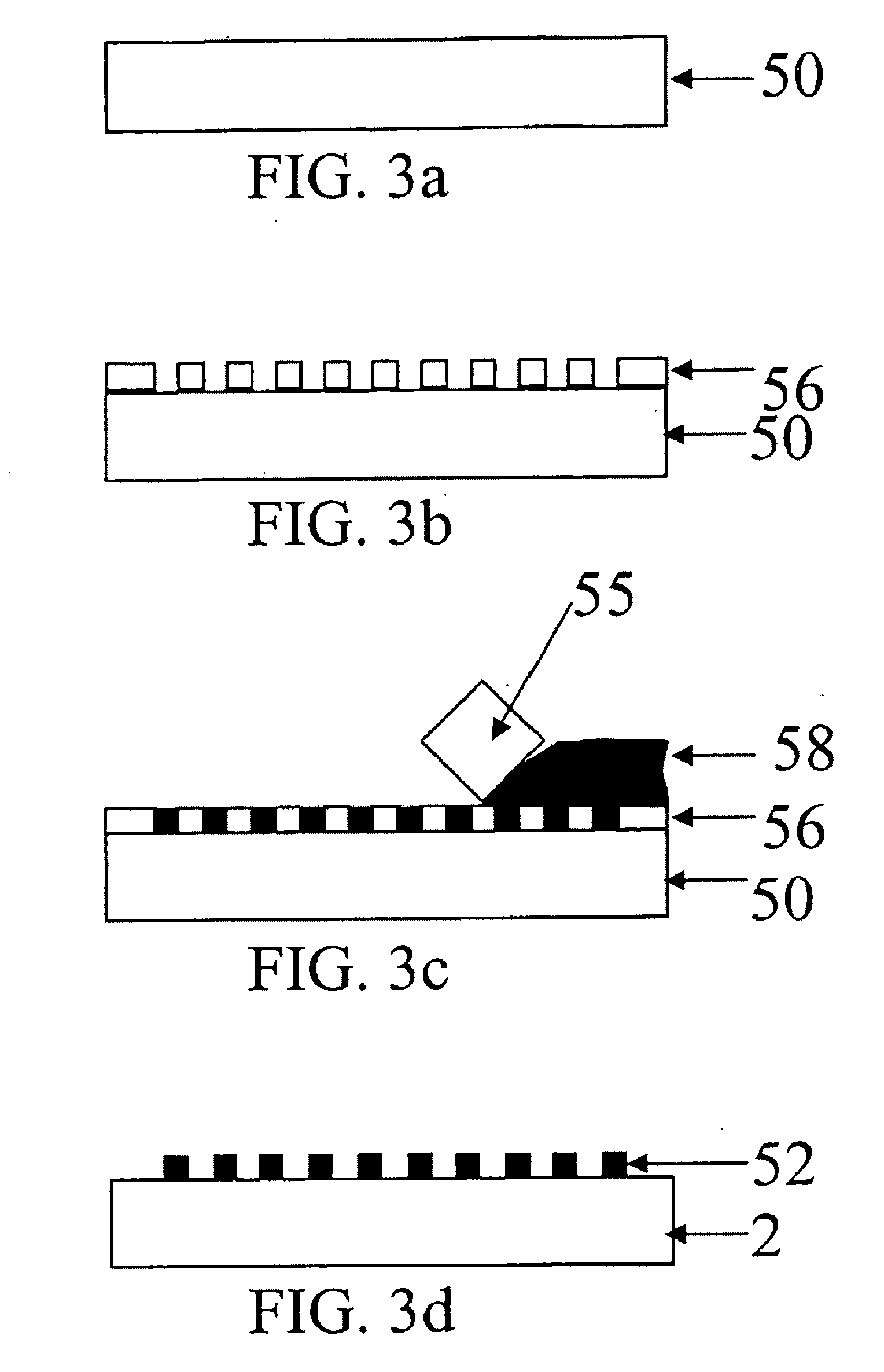

Magnetic bead-based arrays

InactiveUS20080187472A1Easy to separateEasy to replaceSequential/parallel process reactionsFlow mixersFluorescenceMagnetic bead

The present invention relates to magnetic particle separators using micromachined magnetic arrays and more particularly, to magnetic particle separators or manipulators using controlled magnetization on micromachined magnetic arrays for the separation of cells and other biological materials. The present invention also pertains to using such devices for the separation and analysis of biological materials for immunoassays, DNA sequencing, protein analysis, and biochemical detection applications. The present invention can also be viewed as a novel method for fabricating fully integrated permanent magnet components within any microelectromechanical system (“MEMS”) structures. The present invention also provides a magnetic particle separation and manipulation system for rapid separation and accurate manipulation of magnetic particles in two-dimensional electromagnetic arrays, which utilize high throughput biological analyses. A disposable cartridge can be produced in low cost using a low cost substrate such as plastic or other polymer, glass, or metal. Magnetic flux is generated by conventional or micromachined electromagnets a platform system consisting of magnetic flux sources, magnetic flux guidance, and a microprocessor control interface. By controlling direction of electric currents into inductors on the platform system, arbitrary magnetic poles can be generated on Permalloy structures of the cartridge to separate and manipulate magnetic particles. The magnetic particle separator and manipulator in the present invention can be easily combined with automated detection systems such as a fluorescent monitoring system.

Owner:AHN CHONG H +2

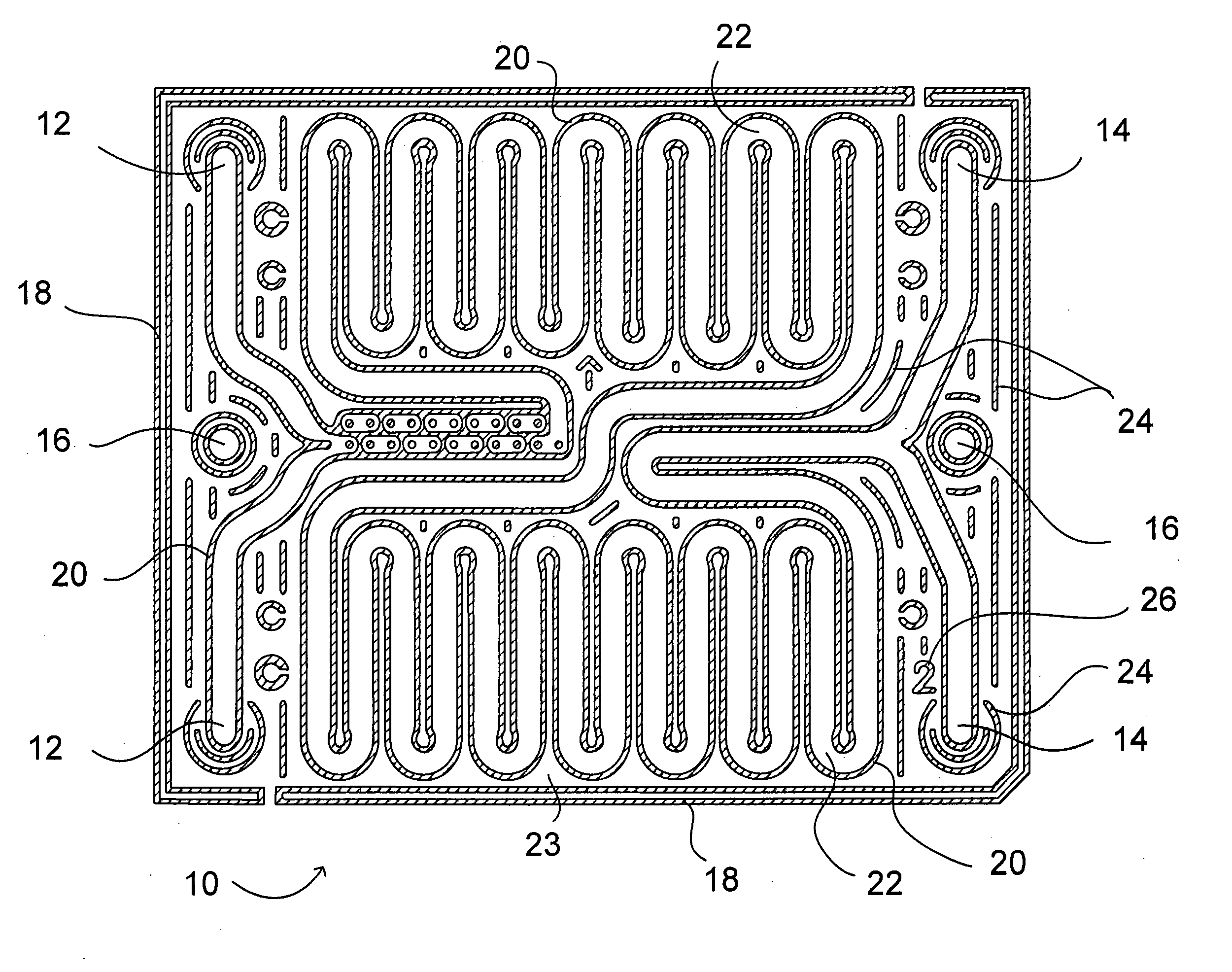

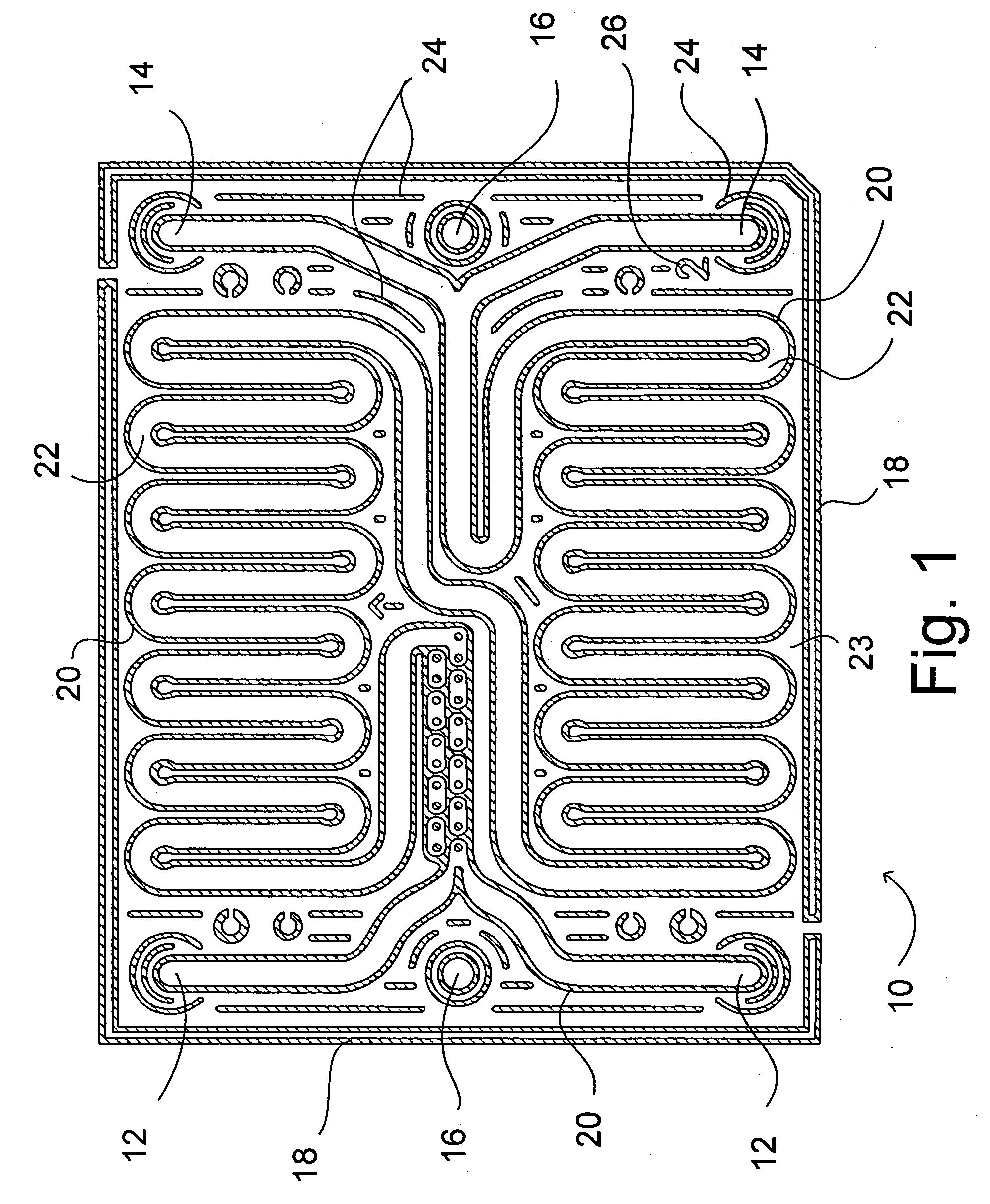

High performance microreaction device

InactiveUS20060171864A1Fast mixing performanceQuick mixFlow mixersTransportation and packagingEngineeringGlass-ceramic

A microfluidic device includes a thermal buffer fluid passage and a reactant passage having mixing and dwell time sub-passages all defined within an extended body, the dwell-time sub-passage having at least 1 ml volume, and the mixing sub-passage being in the form of a unitary mixer not requiring precise splitting of flows to provide good mixing. The device is desirably formed in glass or glass-ceramic. The unitary mixer is structured to generate secondary flows in the reactant fluid and is preferably closely thermally coupled to the buffer fluid passage by sharing one or more common walls.

Owner:CORNING INC

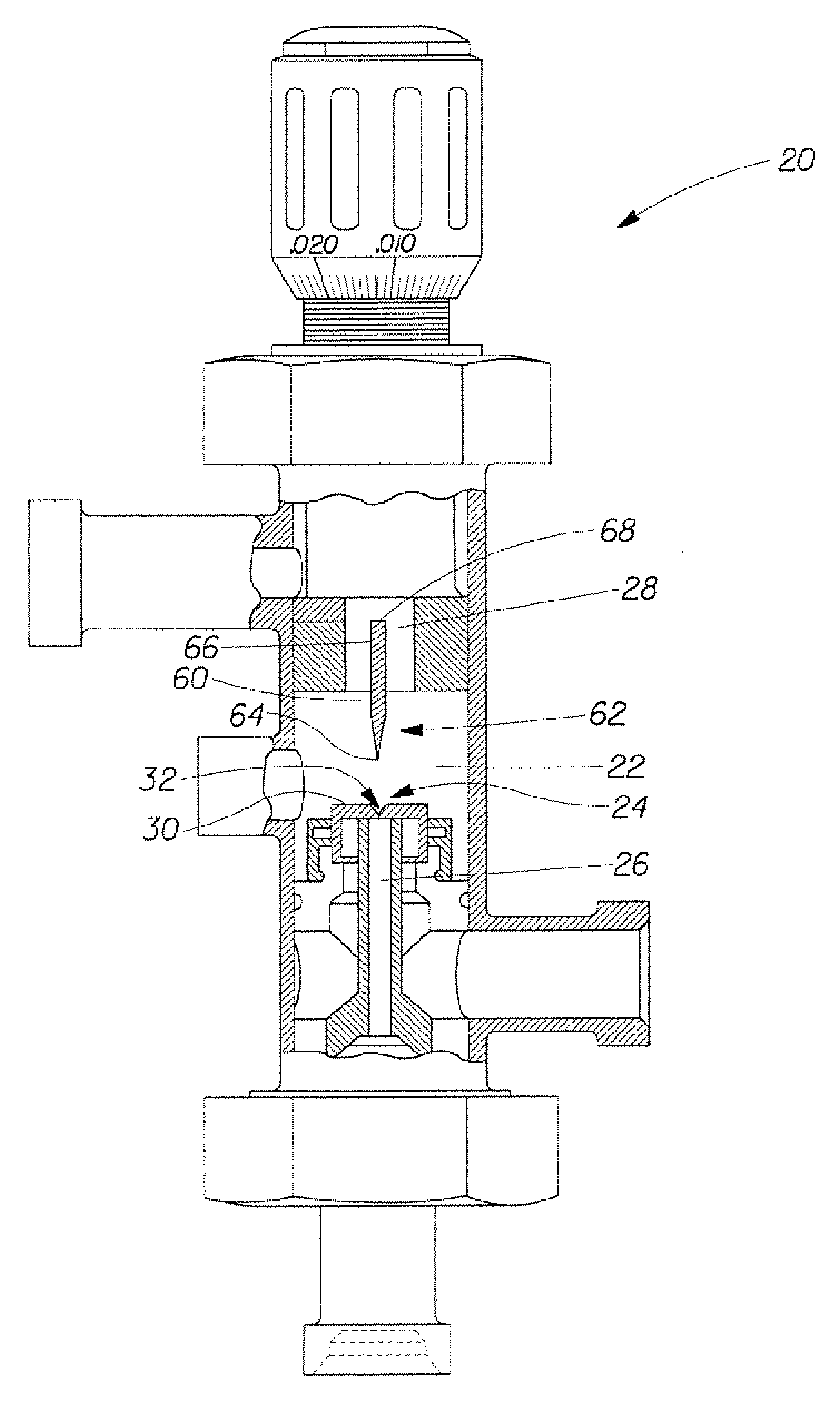

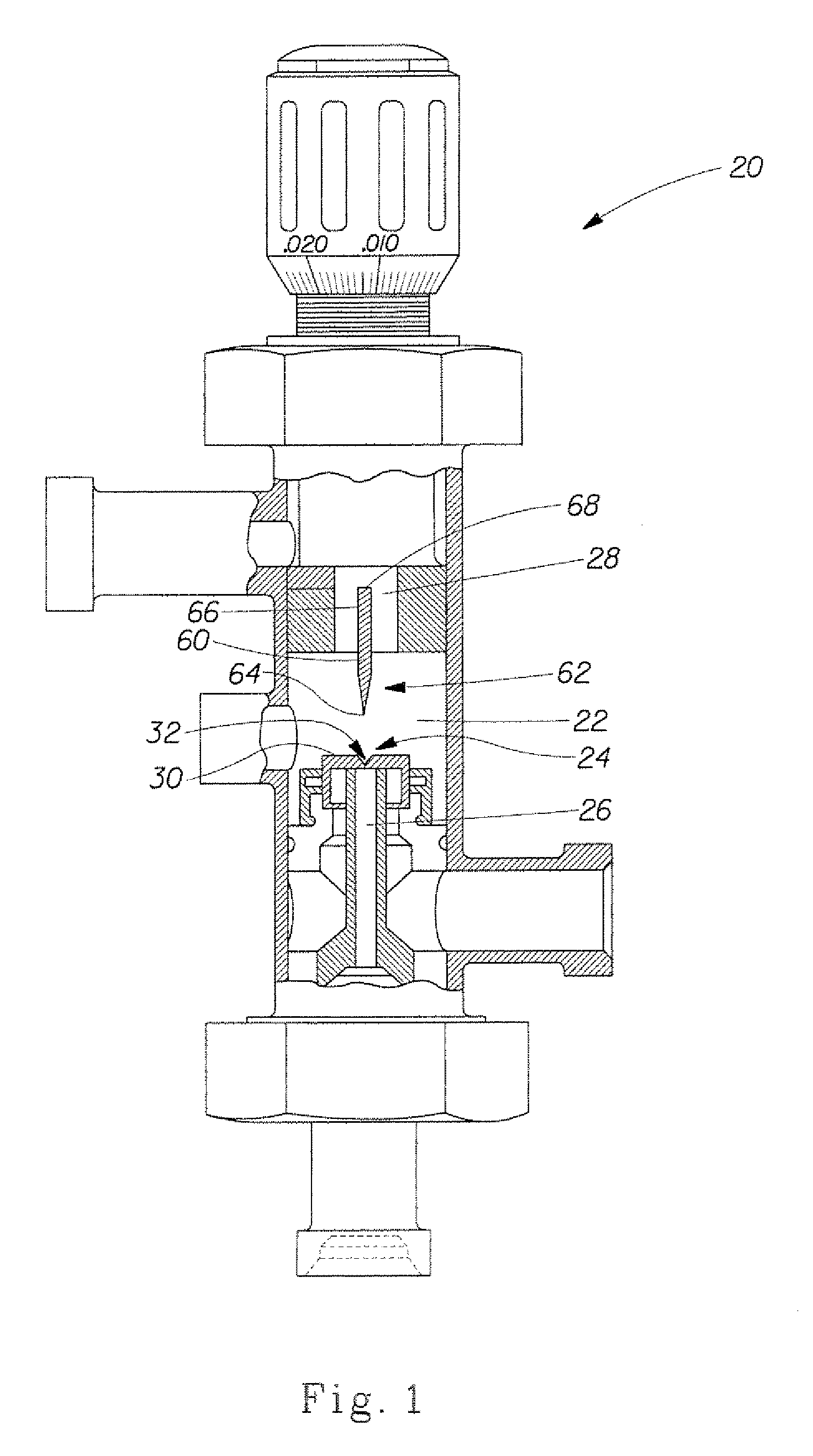

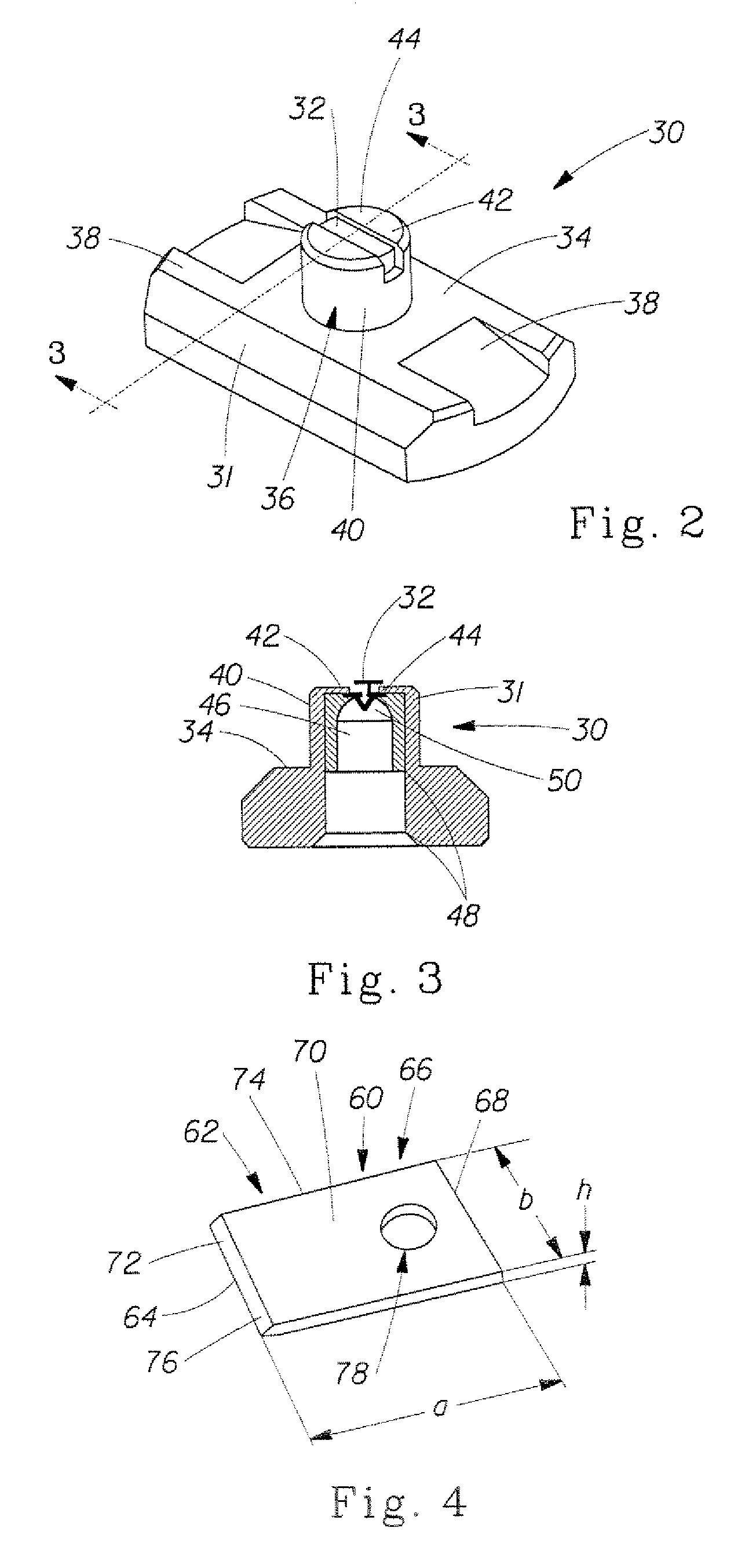

Apparatus and method for mixing by producing shear and/or cavitation, and components for apparatus

ActiveUS20090003123A1Improved vibration characteristicsSalicyclic acid active ingredientsShaking/oscillating/vibrating mixersMulti materialCavitation

An apparatus and method for mixing by producing shear and / or cavitation, and components for the apparatus are disclosed. In one embodiment, the apparatus includes a mixing and / or cavitation chamber with an element such as an orifice component that is located adjacent the entrance of the cavitation chamber. The apparatus may further include a blade, such as a knife-like blade, disposed inside the mixing and / or cavitation chamber opposite the orifice component. In one version of such an embodiment, at least some of the portions of the orifice component surrounding the orifice and / or the blade are made of a material or materials that have a Vickers hardness of greater than or equal to about 20 GPa. A process for mixing by producing shear and / or cavitation in a fluid is also contemplated herein.

Owner:THE PROCTER & GAMBLE COMPANY

Bituminous emulsions, their method of preparation and their use for the production of materials and road pavements

InactiveUS20060086288A1Improve cohesionSolve the lack of cohesionEmulsificationBuilding insulationsEmulsionMetallurgy

The present invention relates to bitumen emulsions that can be used in roadmaking applications for the production of cold mixes, emulsion-stabilized gravel and road pavements obtained at ambient temperature, the cohesion of which at young age is substantially improved over the cold mixes, emulsion-stabilized gravel and road pavements of the prior art. These bituminous emulsions are characterized by a median diameter of 0.6 μm or less, and preferably 0.5 μm or less.

Owner:CECA SA

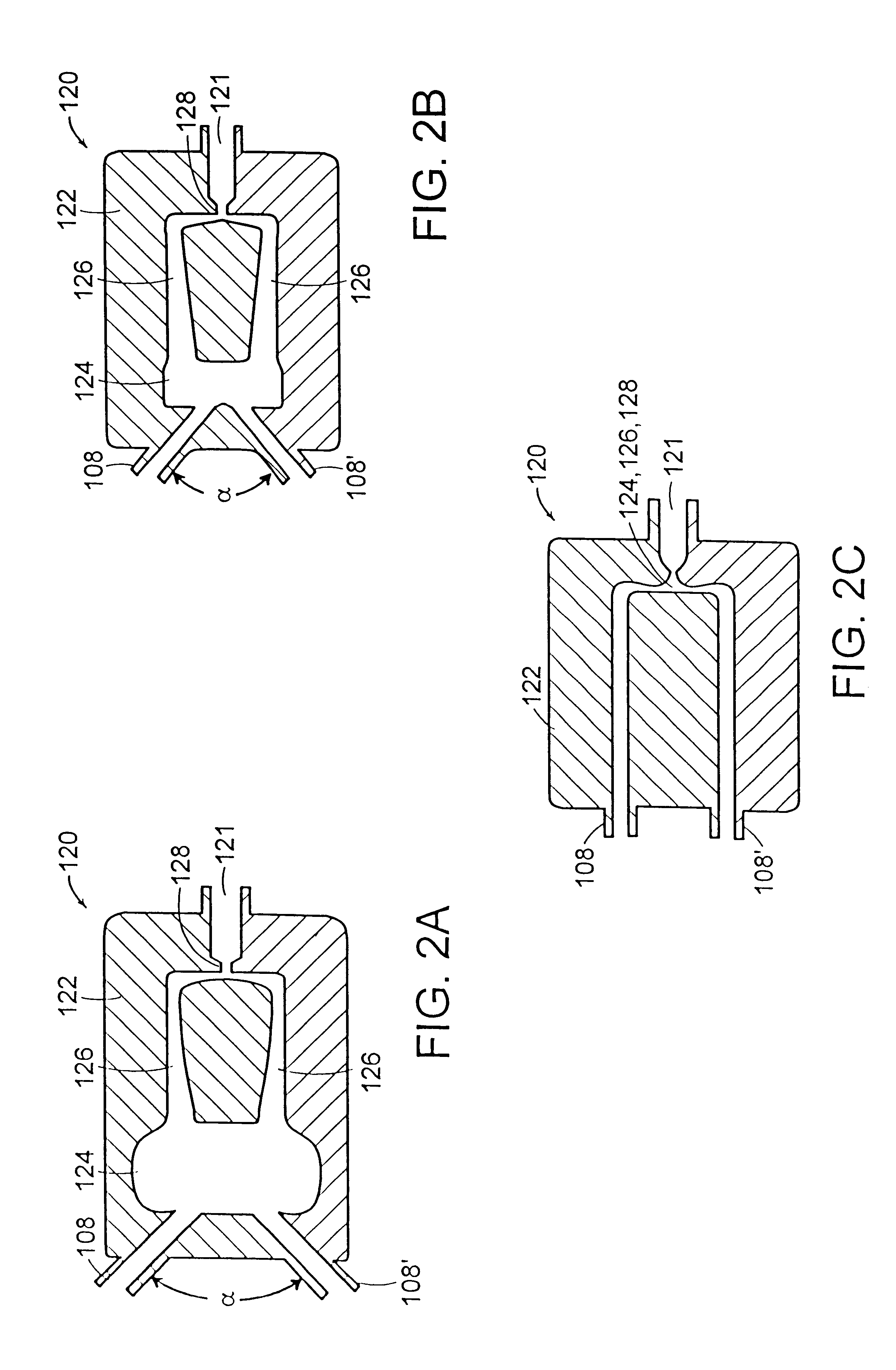

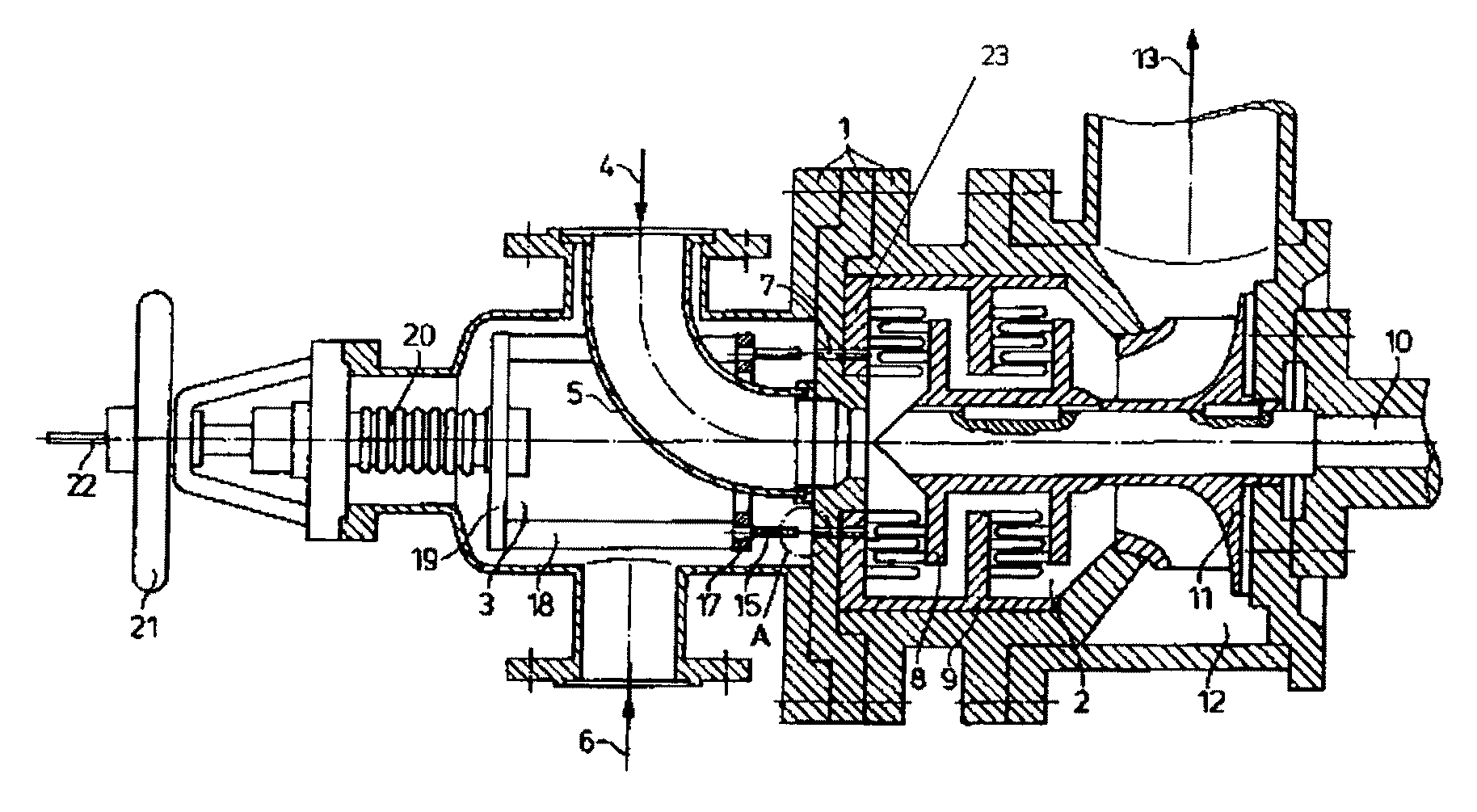

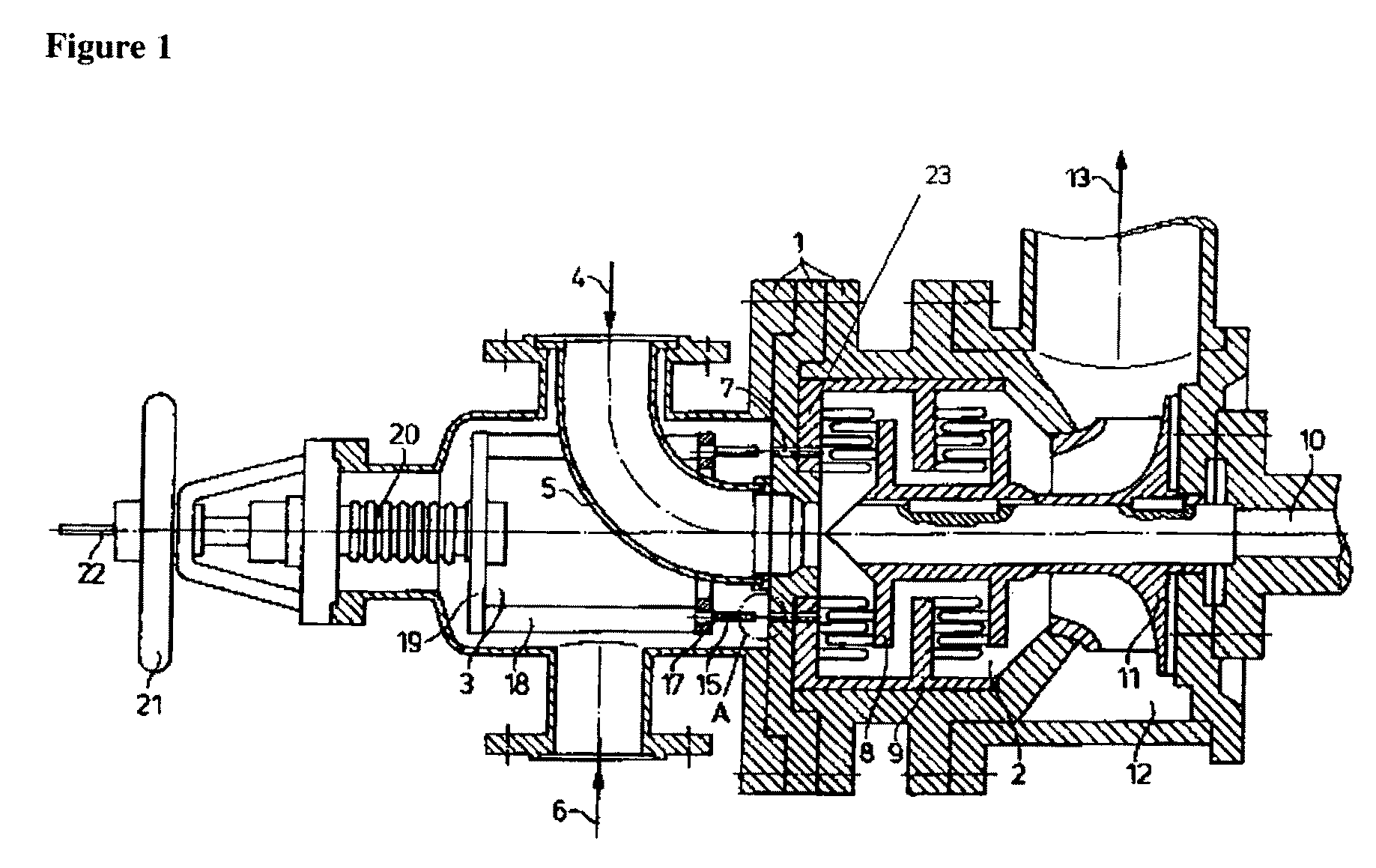

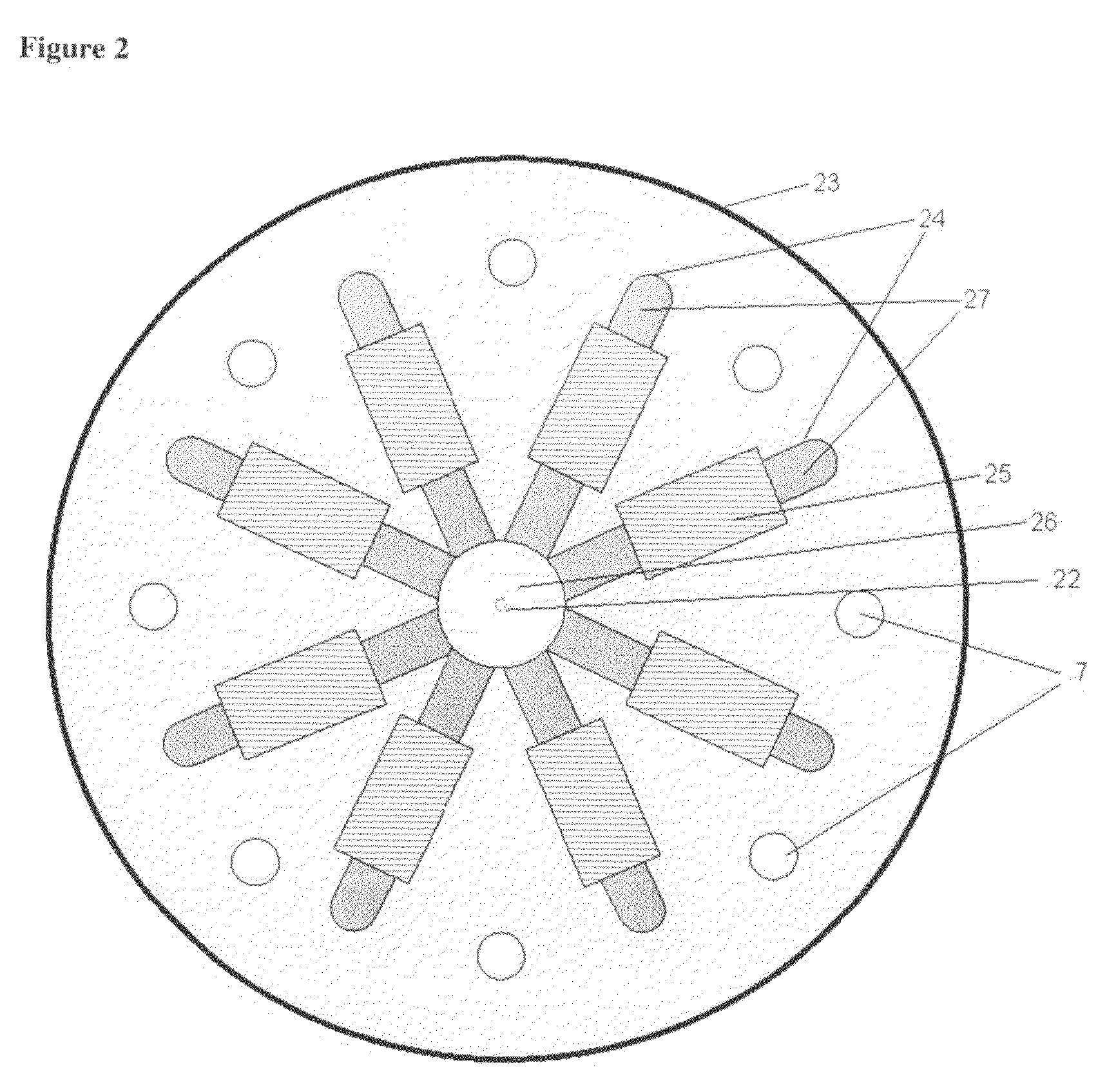

Process and mixing unit for the preparation of isocyanates by phosgenation of primary amines

InactiveUS8079752B2Isocyanic acid derivatives preparationOrganic compound preparationMixed materialsEngineering

The invention relates to a mixer reactor of the rotor-stator type. This mixer reactor comprises a substantially rotationally symmetric housing which has a distributing chamber, a mixing chamber, a front plate that modifies the cross-section of the housing between these two chambers, and there are separate inlets into the mixing chamber for at least two substances and an outlet for removing the mixed material or product. The inlet for the first substance is provided in the axis of rotation of the mixing chamber. Two or more channels are aligned radially outward from this inlet, and the first substance is transported through these channels and into the mixing chamber. The inlet for the at least second substance is constructed in the form of a plurality of openings in the front plate, these inlet openings being are arranged rotationally symmetrically to the axis of rotation. Each of these inlet openings for the at least second substance has a corresponding pin which can be displaced in the axial direction.

Owner:BAYER MATERIALSCIENCE AG

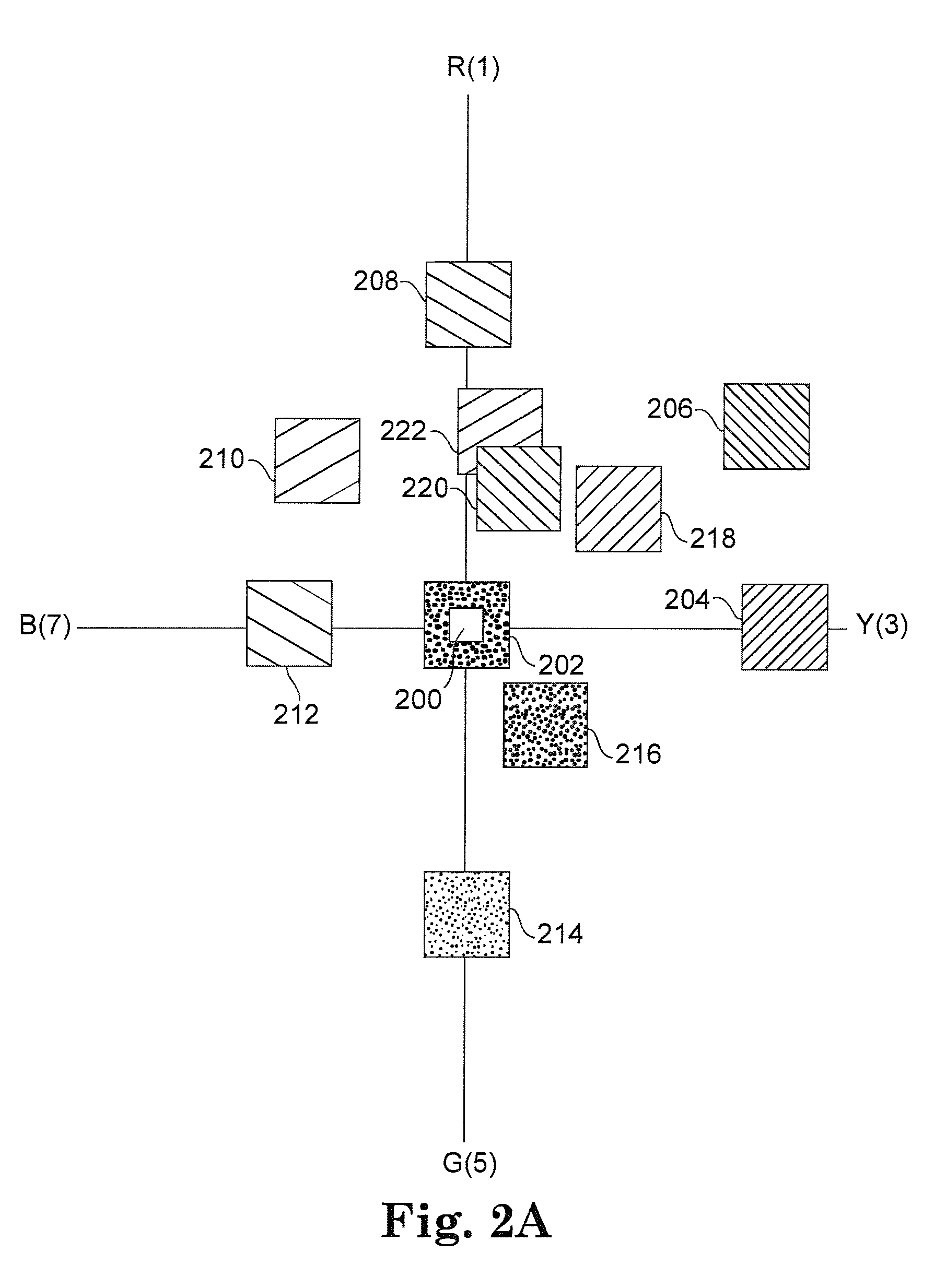

Expanded color space architectural paint and stain tinting system

White-pigmented and unpigmented base paints and stains are custom-tinted using an automated colorant dispenser having a minimum fluid dispensing quantity less than 0.01 fluid ounce (<0.3 cm3) and an array of colorants including a green-hued colorant having a color strength greater than that of a comparison colorant containing 12 wt. % PG7 pigment, a blue-hued colorant having a color strength greater than that of a comparison colorant containing 7 wt. % PB15:2 pigment, and a red-hued colorant having a color strength greater than that of a comparison colorant containing 17 wt. % PR209 pigment. The green-hued or blue-hued colorants are dispensed into the base paint or stain whenever a green-hued or blue-hued tint is required. Light pastel tints in small containers and strong colors in large containers may be prepared without requiring the use of additional colorants having the same general hue and lower color strength.

Owner:SWIMC LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com