Optimization method for determining proportion of mixing light oil into heavy oil of ultra-deep well and light hydrocarbon mixer thereof

A technology for ultra-deep wells and heavy oil, which is applied in the field of heavy oil blending methods and tools, which can solve problems such as loss of fluidity and achieve high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

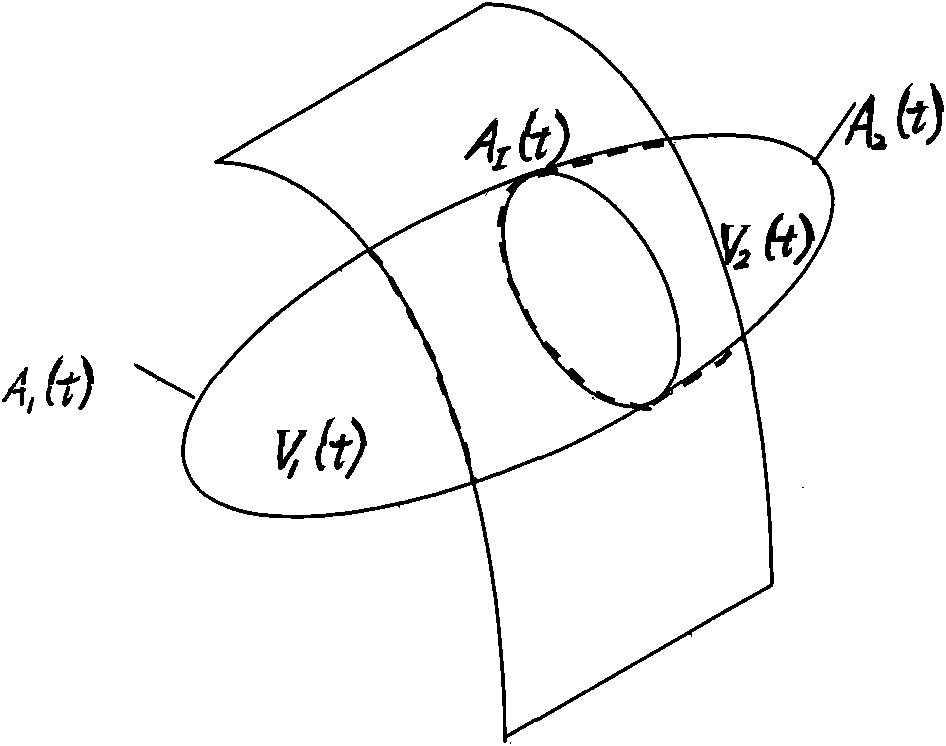

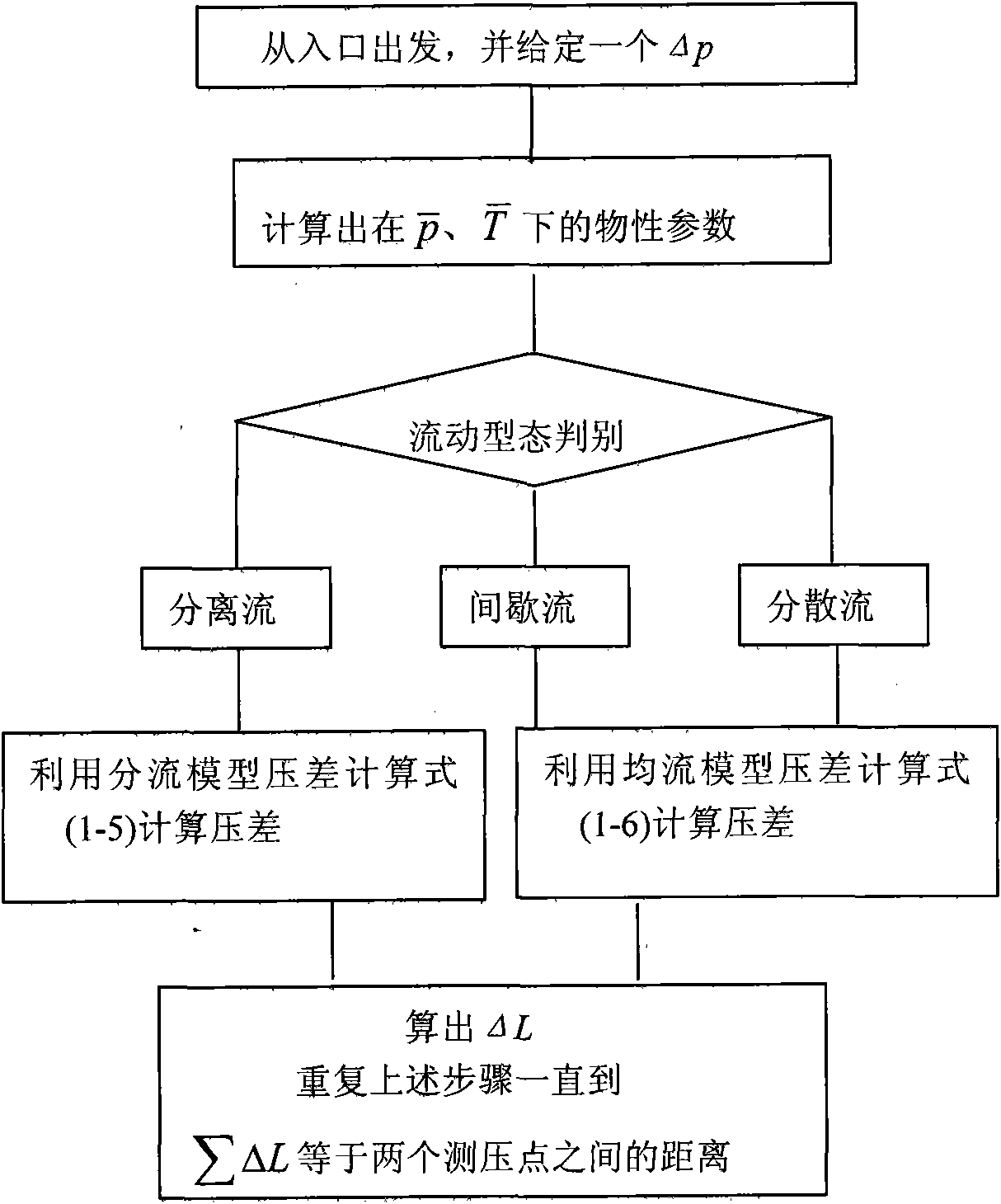

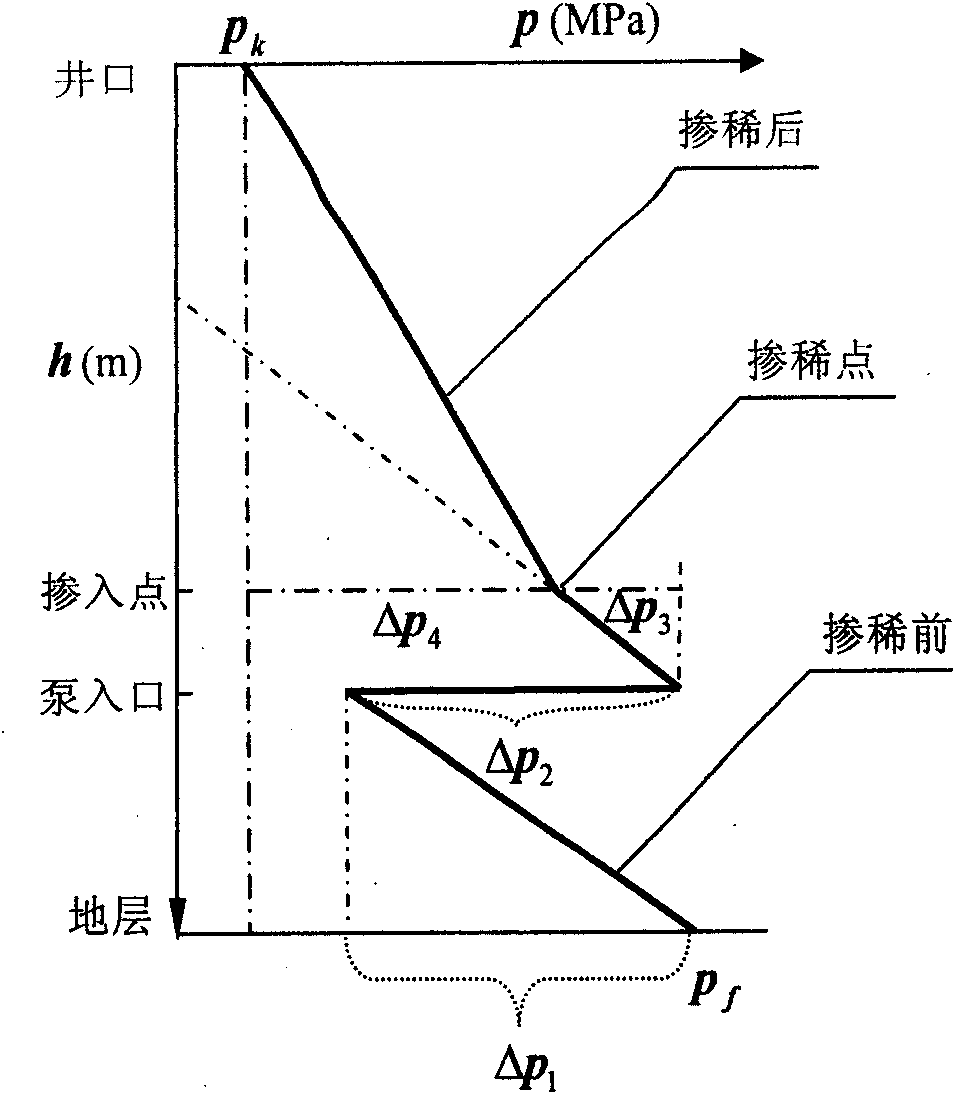

[0192] The invention proposes a multiphase flow comprehensive pressure drop calculation model of variable rheological mode in ultra-deep wells and a correction model for physical property simulation of heavy oil in ultra-deep wells, and the results have good correlation with PVT curves. According to the dilution method, the calculation method of the fluid temperature gradient in the ultra-deep well heavy oil mixed-dilution wellbore is given. By introducing the description and calculation technology of borehole trajectory, the problem of multiphase flow calculation in curved section of ultra-deep well is successfully solved, so that the parameter distribution law in any borehole shape can be calculated. On this basis, the dynamic analysis model of heavy oil mixed with thinner production is established, which realizes the simulation and analysis of heavy oil mixed with thinner production dynamics in ultra-deep wells, and based on this, the ratio of heavy oil mixed with thinner an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com