Marine splash environment simulation test device

An environmental simulation test and marine technology, which is applied in the field of marine equipment, can solve the problems of inappropriate comprehensive simulation, strong corrosion and aging effects of materials and angles, and large test workload, so as to achieve accurate and reliable test data, and adjustable and controllable splash angle. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples.

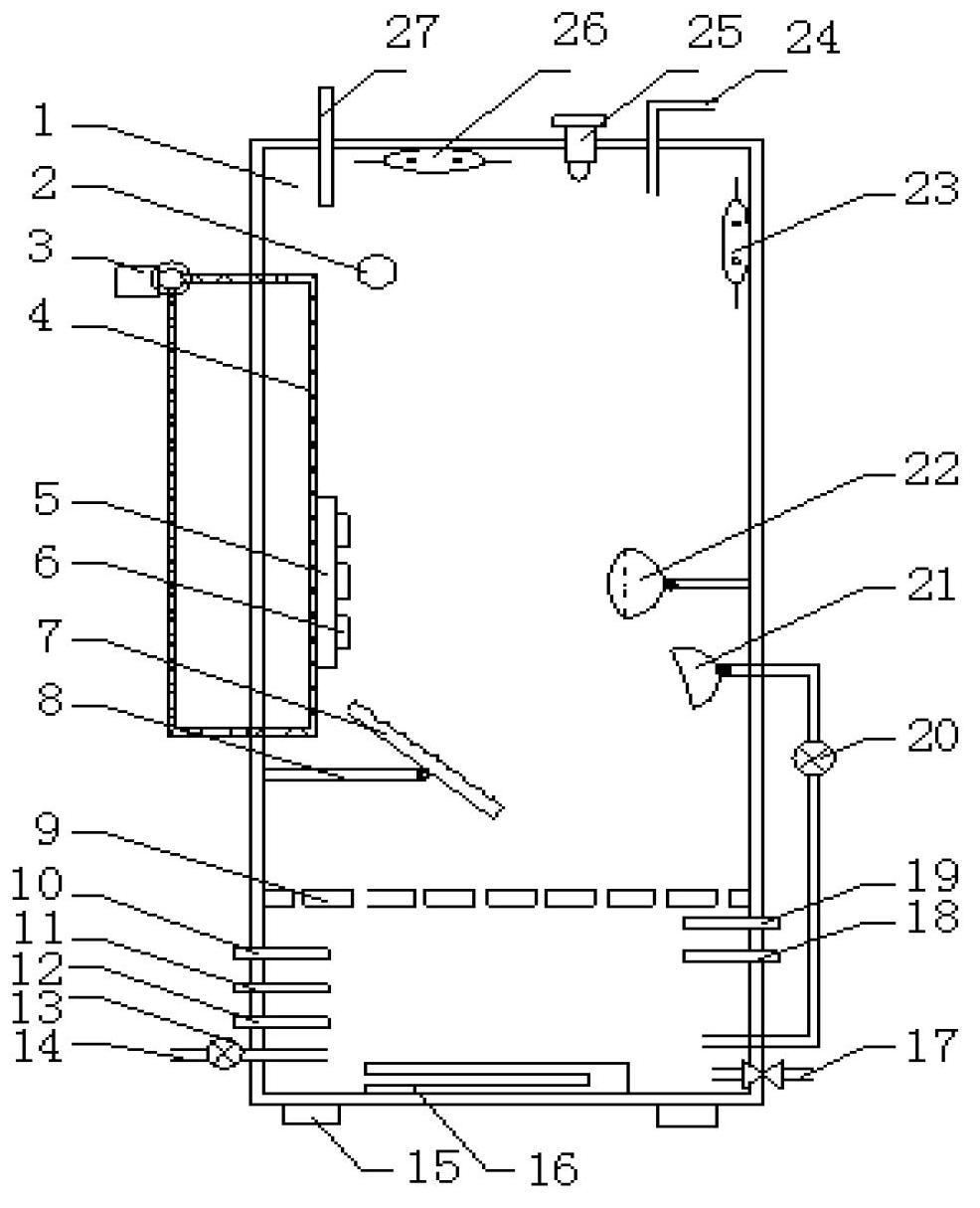

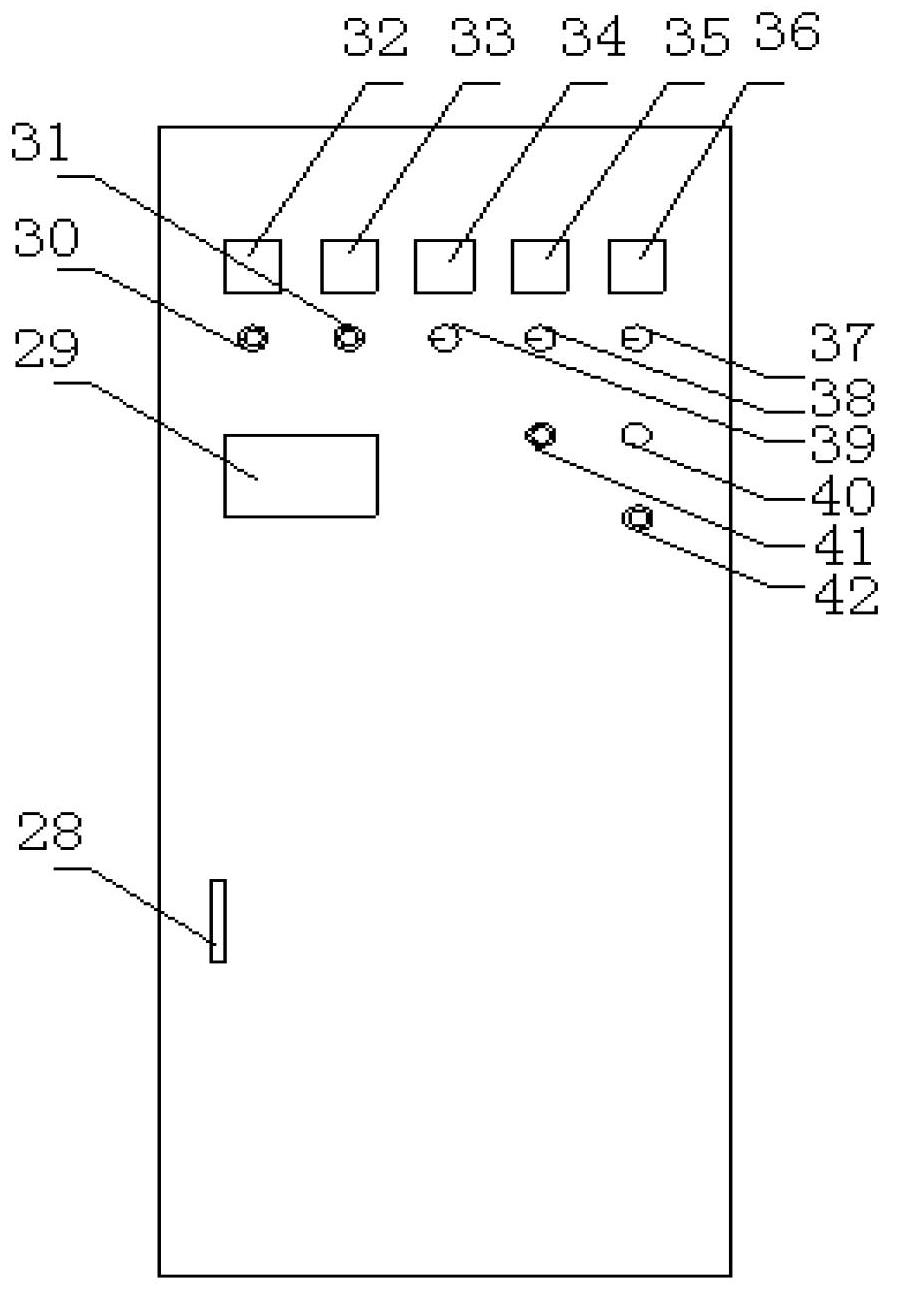

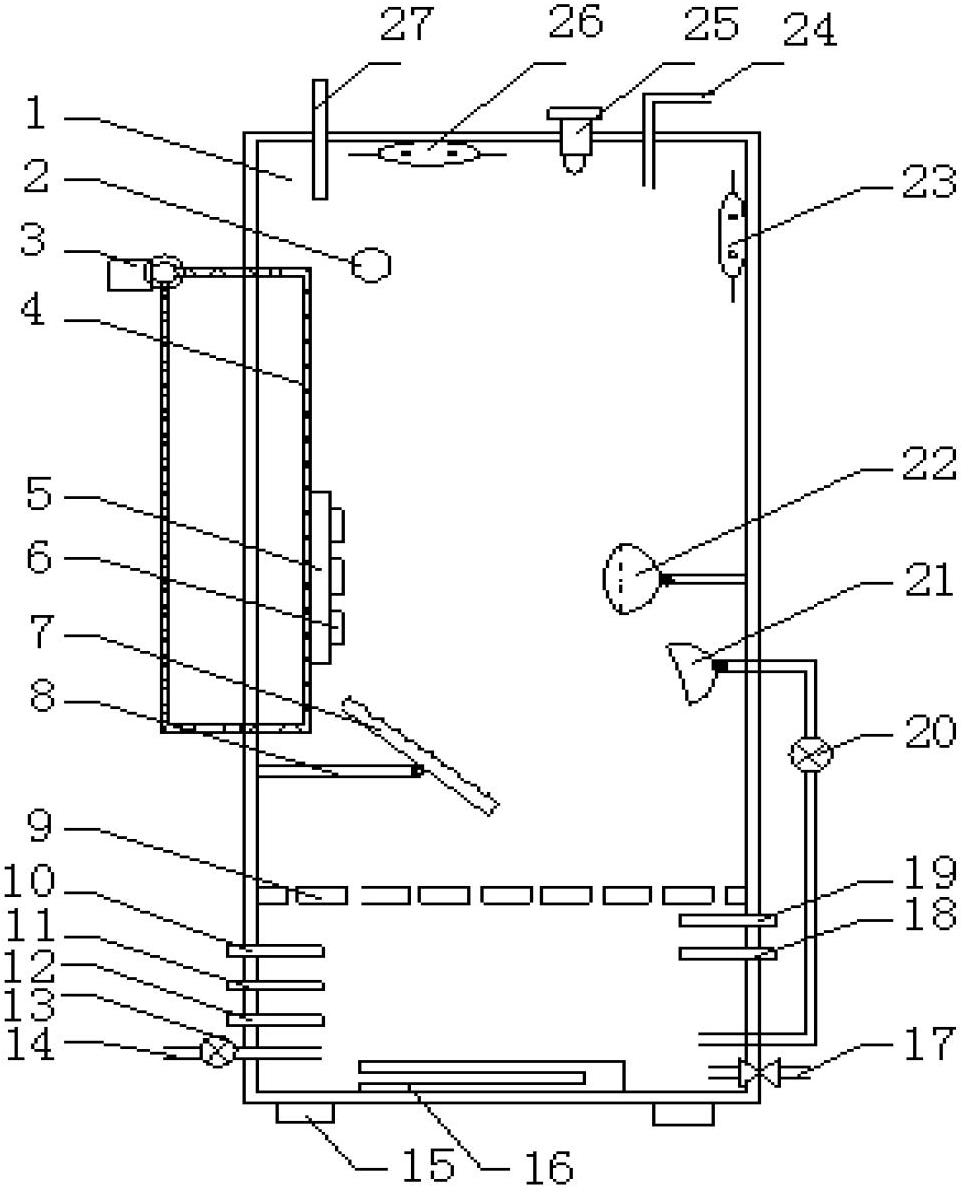

[0015]The main structure of this embodiment includes a test box 1, a test cable hole 2, a drive motor 3, a transmission rod 4, a sample frame 5, a test sample 6, a splash plate 7, a splash plate angle adjustment rod 8, a partition 9, Water temperature sensor 10, salinity sensor 11, pH sensor 12, water inlet pump 13, water inlet 14, fixed support 15, heating pipe 16, drain port 17, dissolved oxygen sensor 18, liquid level controller 19, water spray pump 20. Nozzle 21, blower fan 22, ultraviolet lamp 23, gas outlet 24, ventilation and humidity remover 25, infrared heating lamp 26, cabinet temperature sensor 27, cabinet door opening handle 28, programming controller 29, water temperature heating Switch 30, infrared heating switch 31, water temperature display unit 32, tank temperature display unit 33, salinity value display unit 34, pH value display unit 35, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com