Patents

Literature

3236results about How to "Improve mixing uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

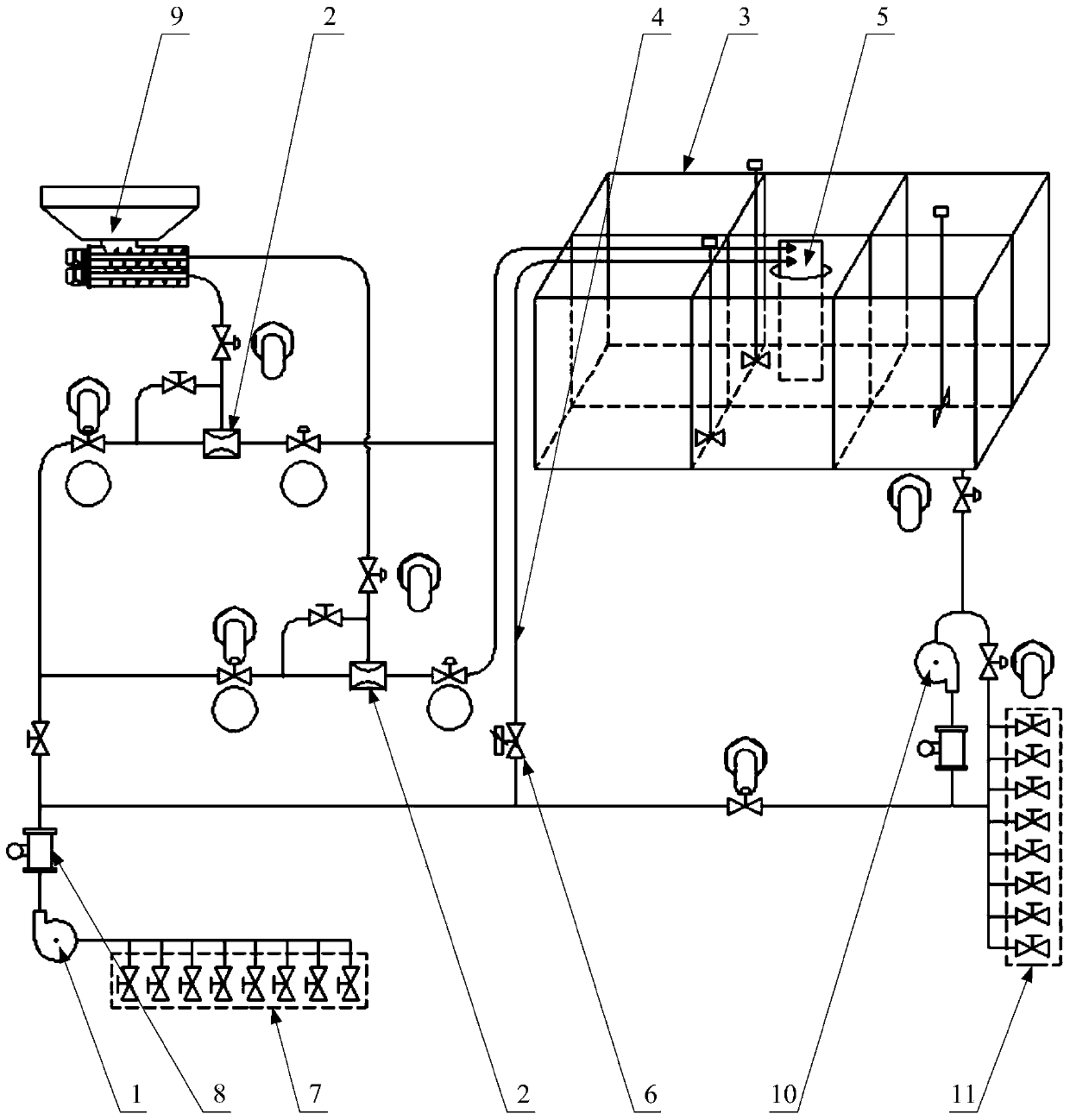

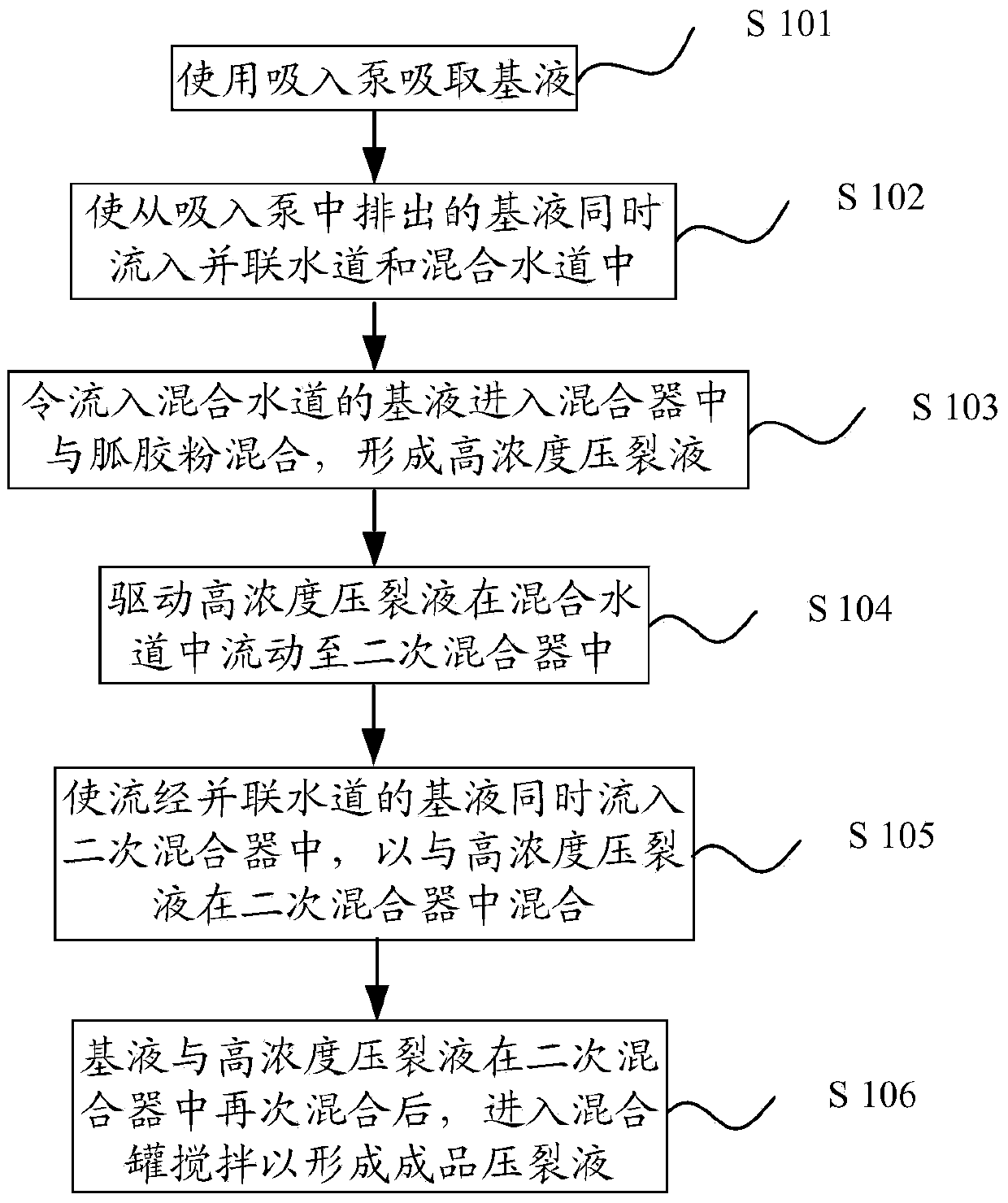

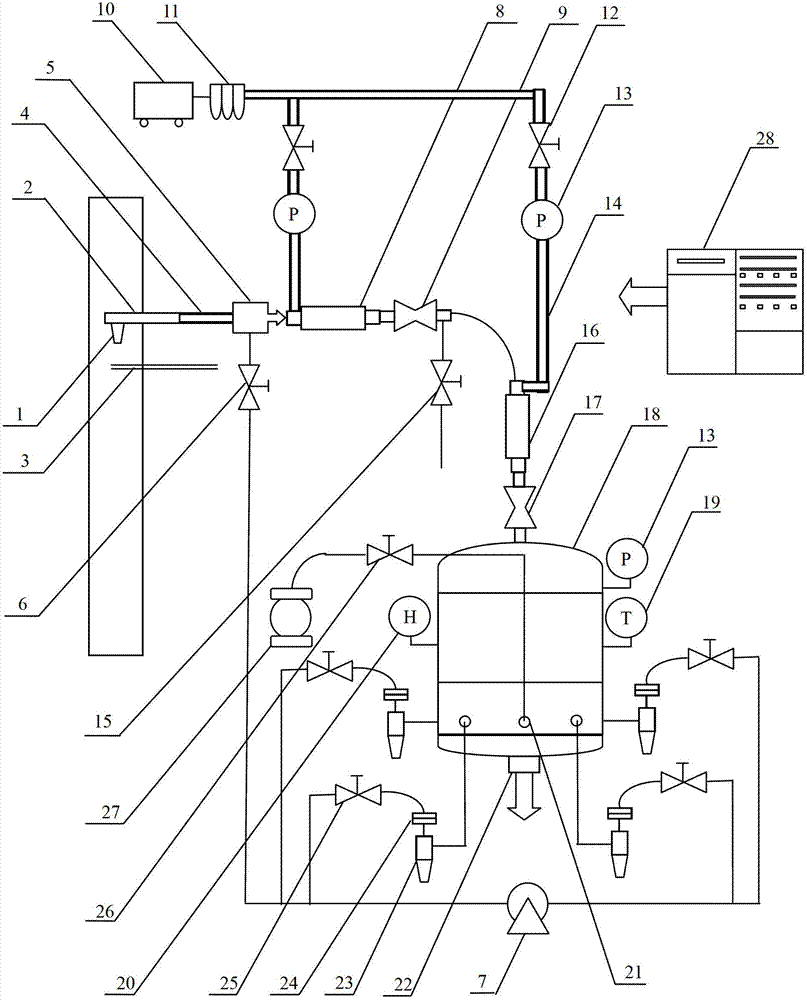

Blending system of fracturing fluid and blending technology of system

InactiveCN103990410AReduce concentrationImprove mixing efficiencyMixing methodsMixersFracturing fluidEngineering

The invention provides a blending system of a fracturing fluid. The blending system comprises a suction pump, a mixer, a mixing tank, a secondary mixer which is arranged between the mixer and the nixing tank and is used for mixing the fracturing fluid again, and a parallel-connection water channel, wherein one end of the parallel-connection water channel is communicated with the suction pump, the parallel-connection water channel and a mixing water channel of the mixer are connected in parallel, and the other end of the parallel-connection water channel is communicated with the secondary mixer. The blending system provided by the invention has the advantages that the parallel water channel is additionally arranged and is connected with the mixing water channel in parallel, a base solution is capable of simultaneously entering two routes, namely the mixing water channel and the parallel-connection water channel, not all of the base solution enters the mixing water channel, a condition that the limitation on blending efficiency is caused by the relatively small flow of the mixing water channel is avoided, the blending time is shortened, the blending energy consumption is reduced, the fracturing fluid is formed through multi-time blending in a double-route manner, the mixing uniformity is improved, and the quality of the fracturing fluid is further optimized. The invention also provides a fracturing fluid blending technology suitable for the blending system of the fracturing fluid.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

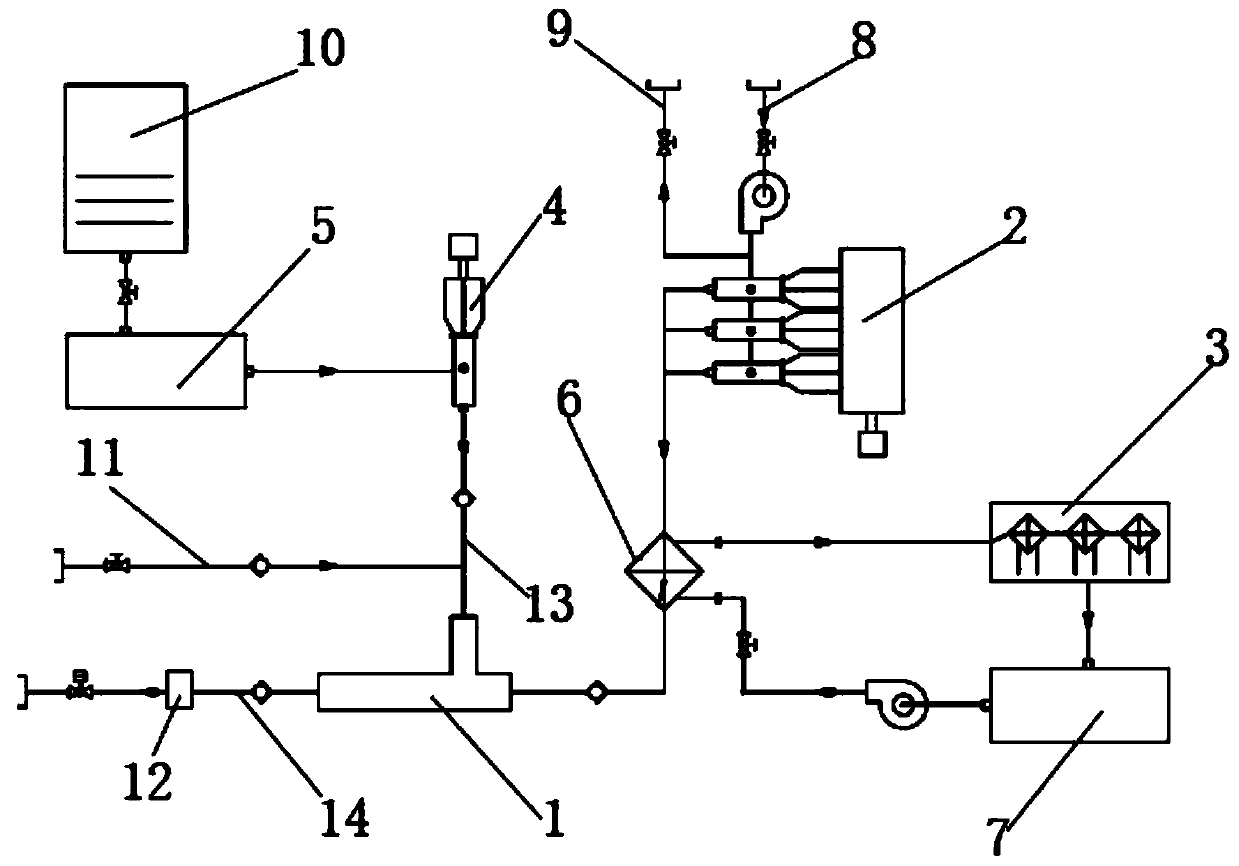

Device and method for preparing nitrogen foam cement

InactiveCN111206901ALow densityReduce energy consumptionSealing/packingHigh pressure waterNitrogen gas

The invention discloses a device and method for preparing nitrogen foam cement. The preparing device comprises a foam cement producer, a liquid nitrogen evaporator, a liquid nitrogen plunger pump, a foam liquid plunger pump, a foam liquid tank, a heat exchange system, a liquid nitrogen pipeline, a high-pressure cement paste pipeline, a first pipeline, a foam cement discharge pipeline and a densitydetecting device. The heat generated by a power unit, a hydraulic system and other devices in a nitrogen foam well fixing device is recovered through the heat exchange system, the recovered heat is used as a heat source of the liquid nitrogen evaporator, energy conservation and environment protection are realized, the energy utilization rate is high, and equipment input is low. Liquid nitrogen and foam liquid are pressurized through a high-pressure liquid nitrogen plunger pump and a high-pressure foam liquid plunger pump, the mixing uniformity is increased, and the density of foam cement is reduced. The density of the foam cement is detected in real time through the density detecting device, the flow of the liquid nitrogen and / or foam liquid is adjusted according to the density, and the density is simply controlled. By arranging a clear water tank, after operation ends, the equipment and pipelines are flushed, and the service life is polonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

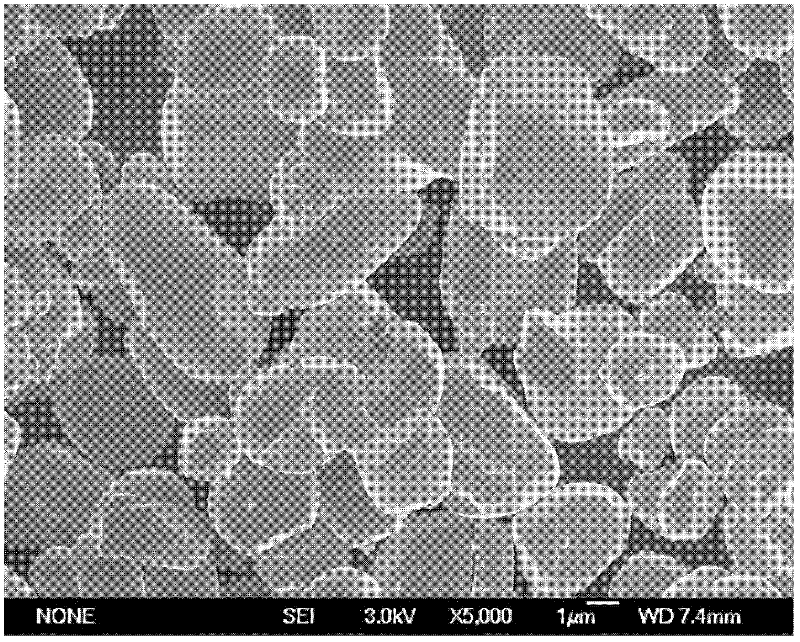

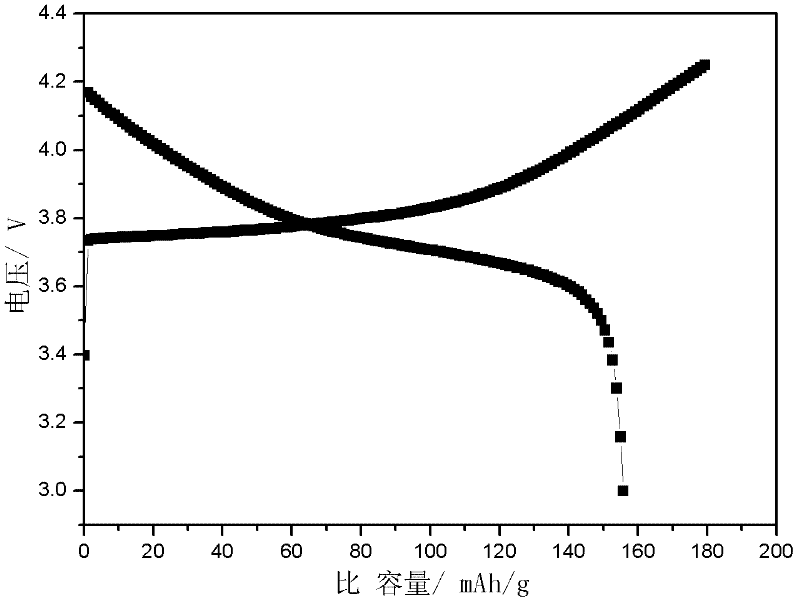

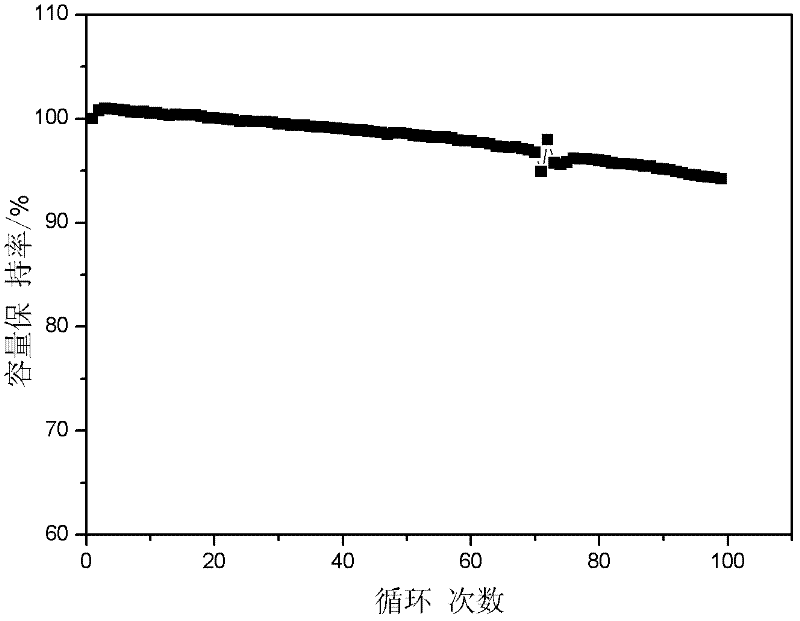

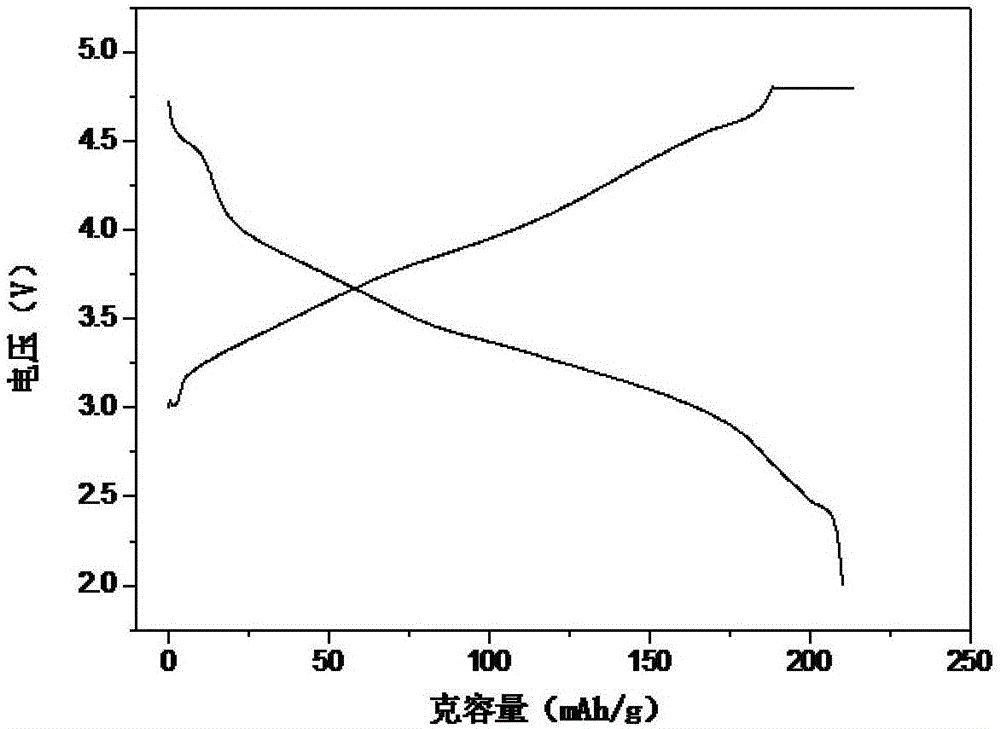

Preparation method of lithium ion battery ternary cathode material

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

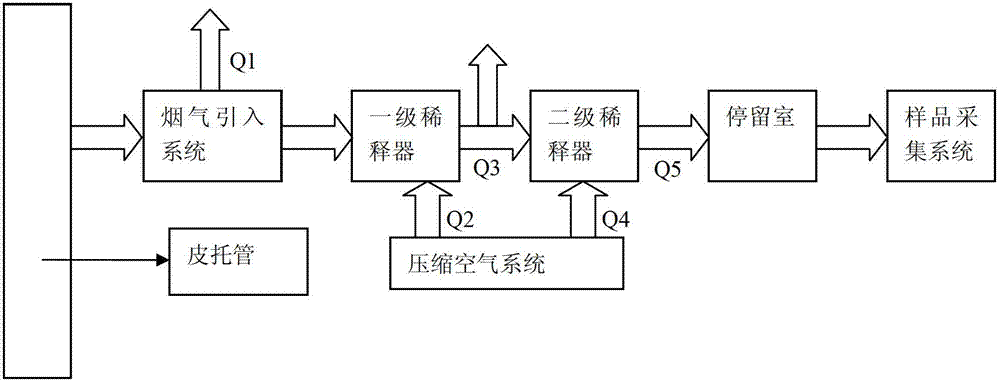

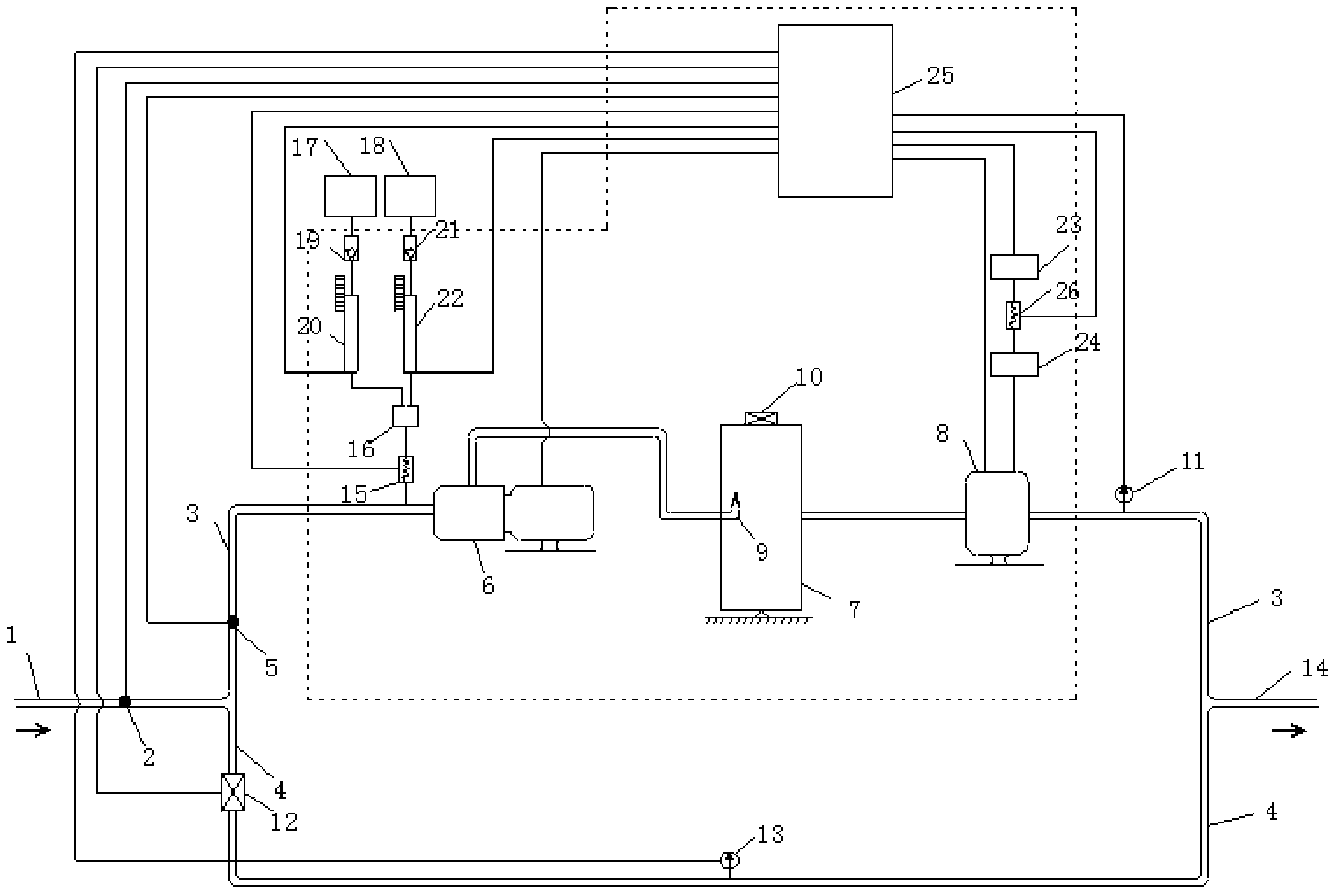

Dilution sampling system and sampling method of fixed source particles and volatile organic compounds

InactiveCN103091134AImprove mixing uniformityShorten the lengthWithdrawing sample devicesStop timeAutomatic control

The invention discloses a dilution sampling system and a sampling method of fixed source particles and volatile organic compounds, and belongs to the technical field of environmental monitoring. The dilution sampling system comprises a smoke introducing system, a diluting system, a stopping chamber, a sample collection system and a control and data collection system. The system can simulate the nucleation, condensation and coagulation processes of the fixed source smoke after being discharged to the atmosphere, can adopt a grain size classification sampling method of atmospheric particulate matters to sample the particulate matters, can adopt the atmospheric volatile organic matter sampling method to sample the volatile organic matters, and can realize the dynamic control of dilution ratio and the dynamic stopping time. Each part of the system has the advantages of high integration, high stability, automation in control, and easiness in operation.

Owner:BEIJING UNIV OF TECH

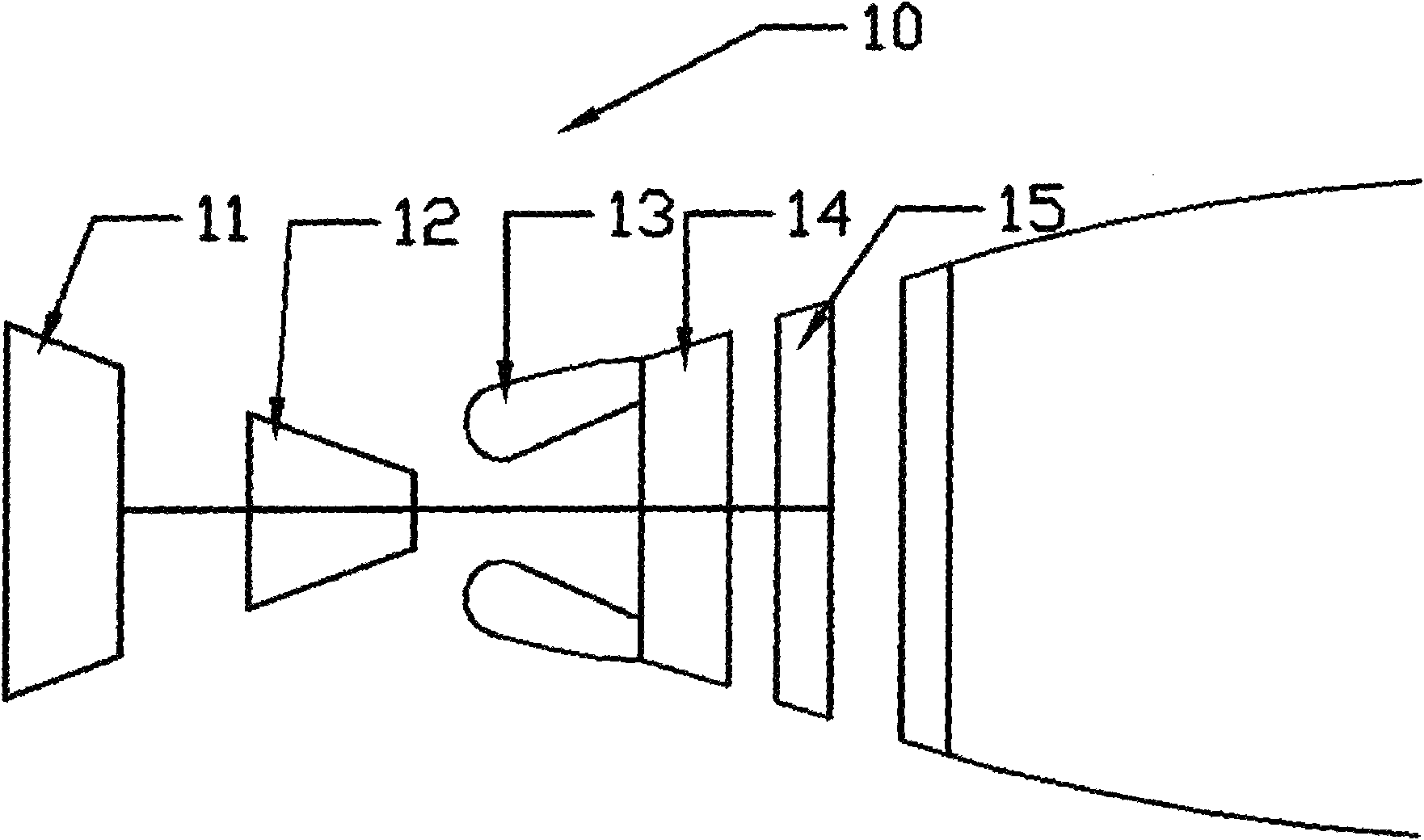

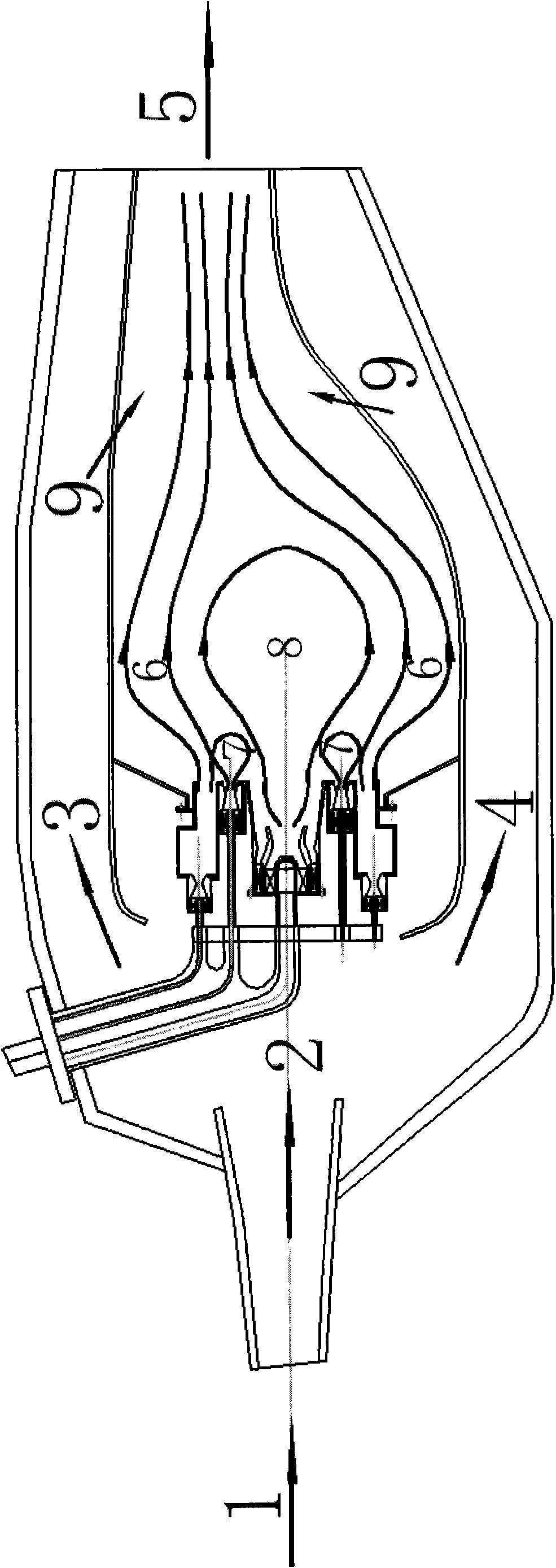

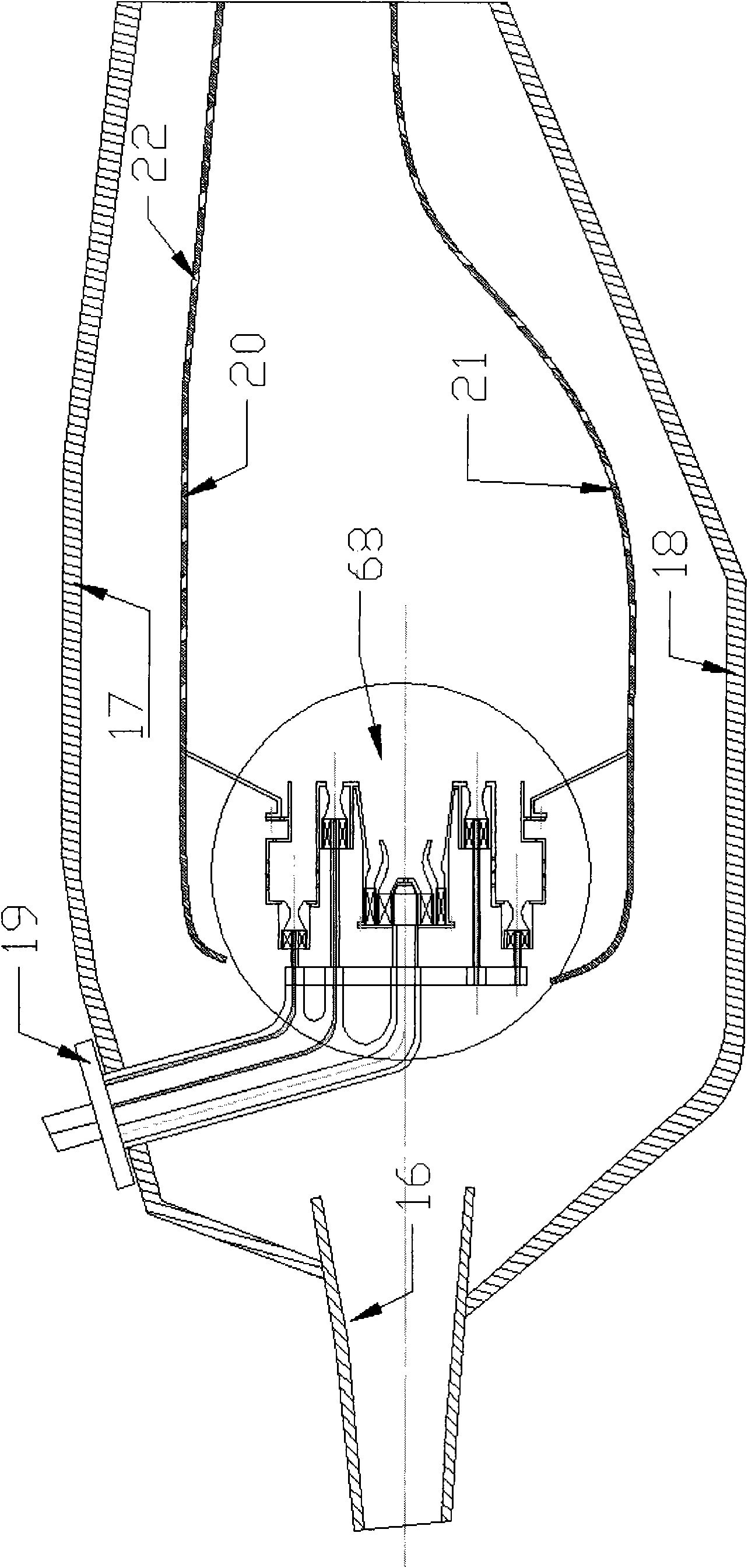

Circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages

InactiveCN102032598AImprove combustion stabilityIncrease the intermediate flame levelContinuous combustion chamberCombustion chamberLow speed

The invention discloses a circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages. The combustion chamber has a single annular cavity structure; a low-pollution combustion organization mode in which air grading is matched with fuel oil grading is adopted; all fuel gas is supplied by a duty stage, a middle stage and a main combustion stage; and fuel oil grading supply proportion is controlled accurately according to the operating condition of an engine and the requirement on stable low-pollution combustion. The duty stage has a combined structure in which two-stage axial spiral flow is matched with a venturi tube, and a formed low-speed reflux region can support stable combustion of the combustion chamber; the middle stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, and a formed middle flame stabilizing stage combustion region is used for intensifying and stabilizing flame in the main combustion stage; and the main combustion stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, so that an oil and gas mixed poor-oil premixing and pre-evaporation combustion mode is intensified and the emission of pollutants is further reduced greatly.

Owner:BEIHANG UNIV

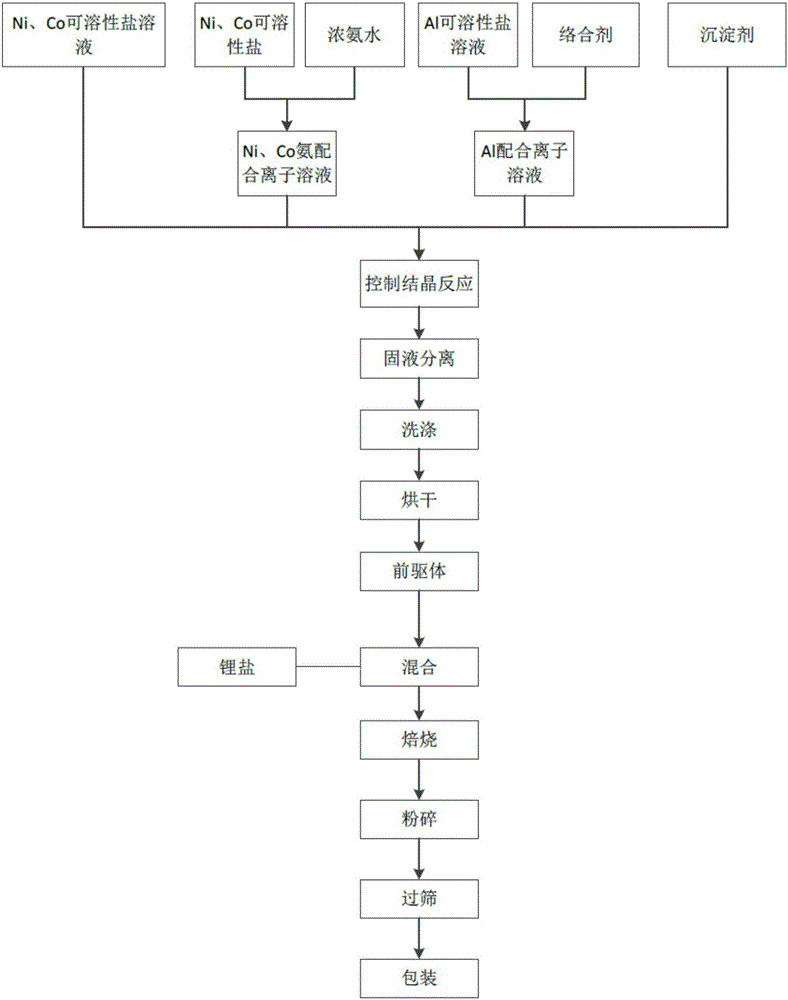

Nickel-cobalt-aluminum ternary precursor as well as preparation method thereof and preparing anode material and method

ActiveCN106299347AImprove mixing uniformityHigh tap densityCell electrodesReaction temperatureSlurry

The invention discloses a nickel-cobalt-aluminum ternary precursor as well as a preparation method thereof and a preparing anode material and a method. The preparation method comprises the following steps: dissolving soluble salts of Ni and Co into ammonia water so as to prepare a Ni and Co ammonia complex ion solution as a complexing agent solution, adding a complexing agent into an aluminum salt solution so as to prepare an Al complex ion solution as an aluminum source solution, combining and adding the Ni and Co soluble salt solution, a precipitant solution, the complexing agent solution and the aluminum source solution into a reaction kettle, controlling a reaction pH value and reaction temperature, controlling the reaction time to be at least greater than 10h, performing solid-liquid separation on slurry obtained through reaction, and washing and drying the obtained solid, thereby obtaining the nickel-cobalt-aluminum ternary precursor. A nickel-cobalt-aluminum ternary anode material can be prepared from a mixture of the precursor and a lithium salt through high-temperature thermal treatment in the presence of air or oxygen. The mixing uniformity of three elements of Ni, Co and Al can be effectively improved, and the tap density of the precursor material can be improved, and the spherical degree of granules can be increased.

Owner:TIANJIN B&M SCI & TECH

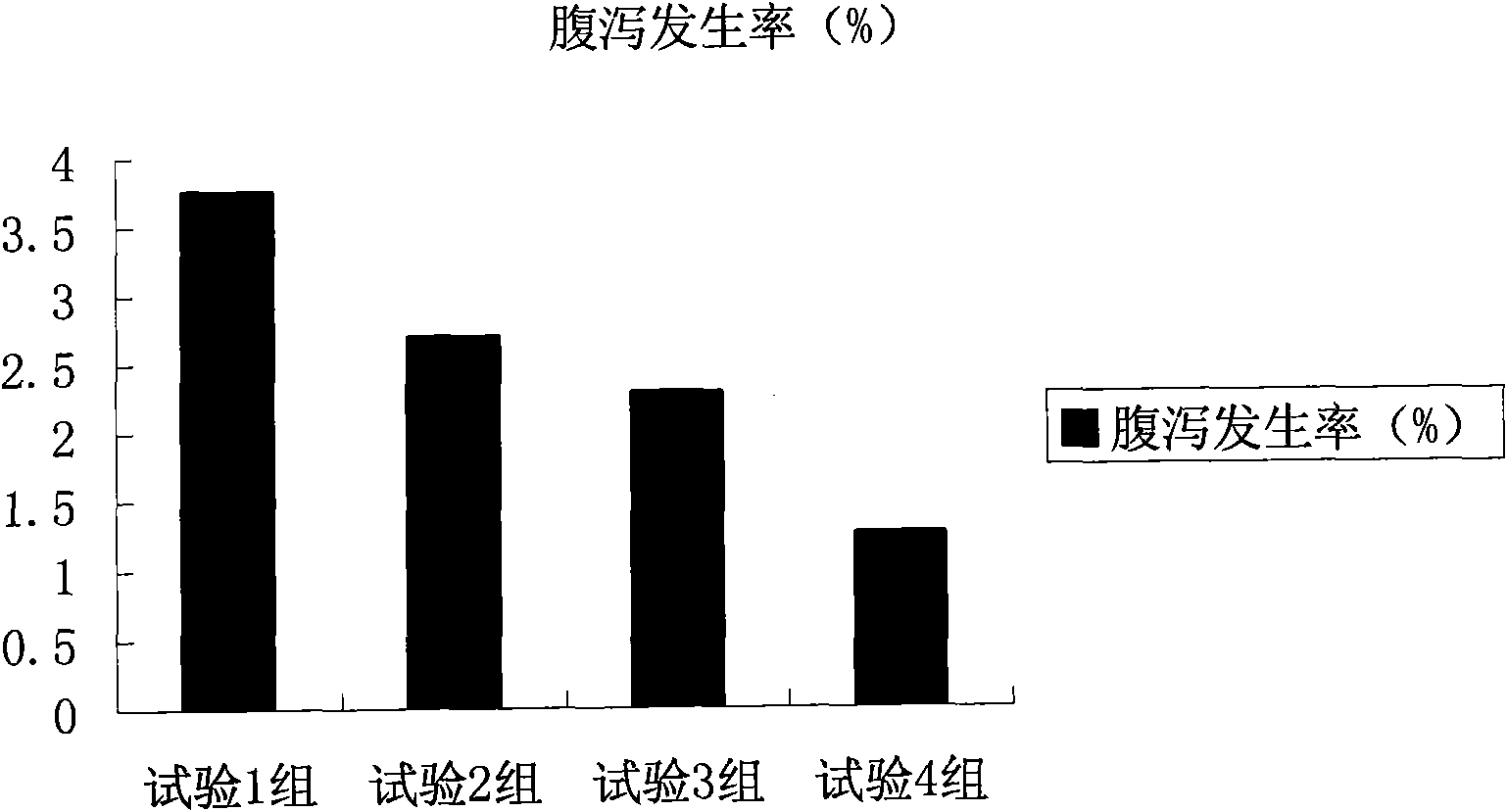

High efficiency livestock and poultry nutrition replenisher and preparation method thereof

ActiveCN101669578AAvoid direct contactImprove mixing uniformityAnimal feeding stuffAccessory food factorsSolubilityAnti stress

The invention provides a high efficiency livestock and poultry nutrition replenisher and a preparation method thereof, and the nutrition replenisher contains various vitamins, amino acids and electrolyte. Simultaneously, the multi-stage premixing process is adopted by the high efficiency livestock and poultry nutrition replenisher, so that the high mixing uniformity of ultra-trace elements can beensured; and furthermore, sanguinarine is introduced into drinking water nutrition replenisher and is processed by peridium treatment, and emulsification treatment is carried out on liposoluble vitamins, so that good water-solubility can be guaranteed. The high efficiency livestock and poultry nutrition replenisher has comprehensive nutrition, leads all nutrient components to be supplemented witheach other, can effectively prevent deficiency of the vitamins and the amino acids, maintains electrolyte balance, regulates the metabolism of organism, improves the feed conversion rate and the anti-stress capability, stimulates the immune function, reduces the occurrence of diseases, and has remarkable economic and social benefits as well as broad market prospect.

Owner:临沂福乐维生物科技有限公司

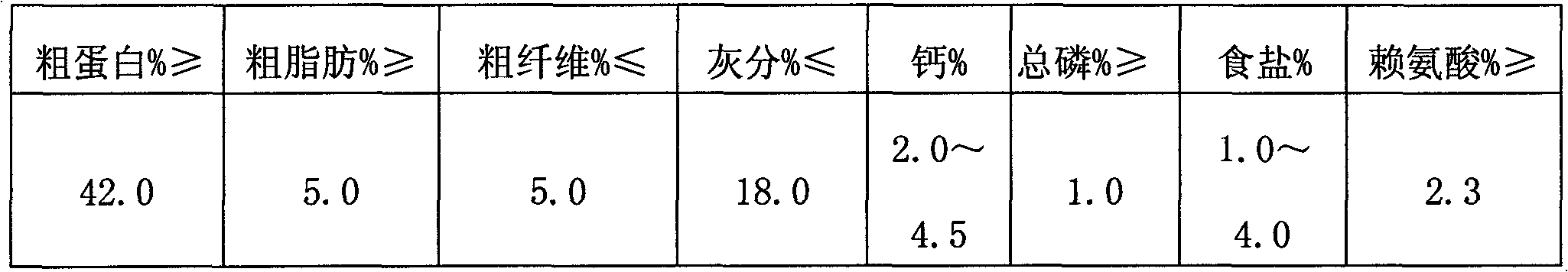

Health-care compound feed for prawns and production method thereof

InactiveCN102178078AGuaranteed FreshnessGood digestion and absorption rateFood processingClimate change adaptationAnimal sciencePrawn

The invention discloses a health-care compound feed for prawns and a production method thereof. The invention aims to provide a health-care compound feed for prawns, which can improve immunity in the prawns, utilization rate of feed and water quality, and a production method thereof. The formula of the raw material comprises the following components in part by weigh: 1 to 6 parts of imported white fish meal, 20 to 25 parts of steamed fish meal imported from Taiwan, 2 to 8 parts of steamed fish meal made in China, 18 to 22 parts of high-gluten wheat flour, 15 to 22 parts of peeled soybean pulp, 8 to 15 parts of peanut cakes, 2 to 6 parts of defatted shrimp meal, 1 to 3 parts of beer yeast cream, 1 to 3 parts of soyabean lecithin oil, 0.5 to 2 parts of refined fish oil, 0.5 to 2 parts of monocalcium phosphate and 1 to 4 parts of additive premix. The production method comprises: crushing, primary material mixing, secondary material mixing, hardening and tempering, granulating, braising, aging, drying, cooking, sieving and packaging. The invention can improve the breeding yield of pawns, reduce discharge pollution, improve water environment and the like.

Owner:深圳市澳华集团股份有限公司

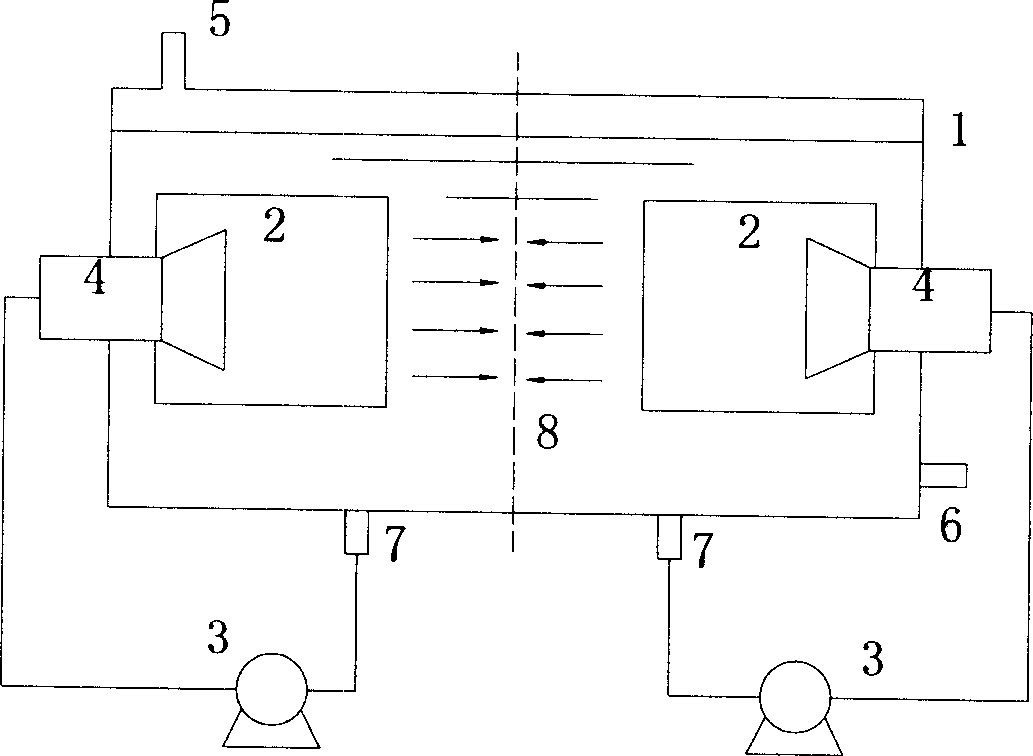

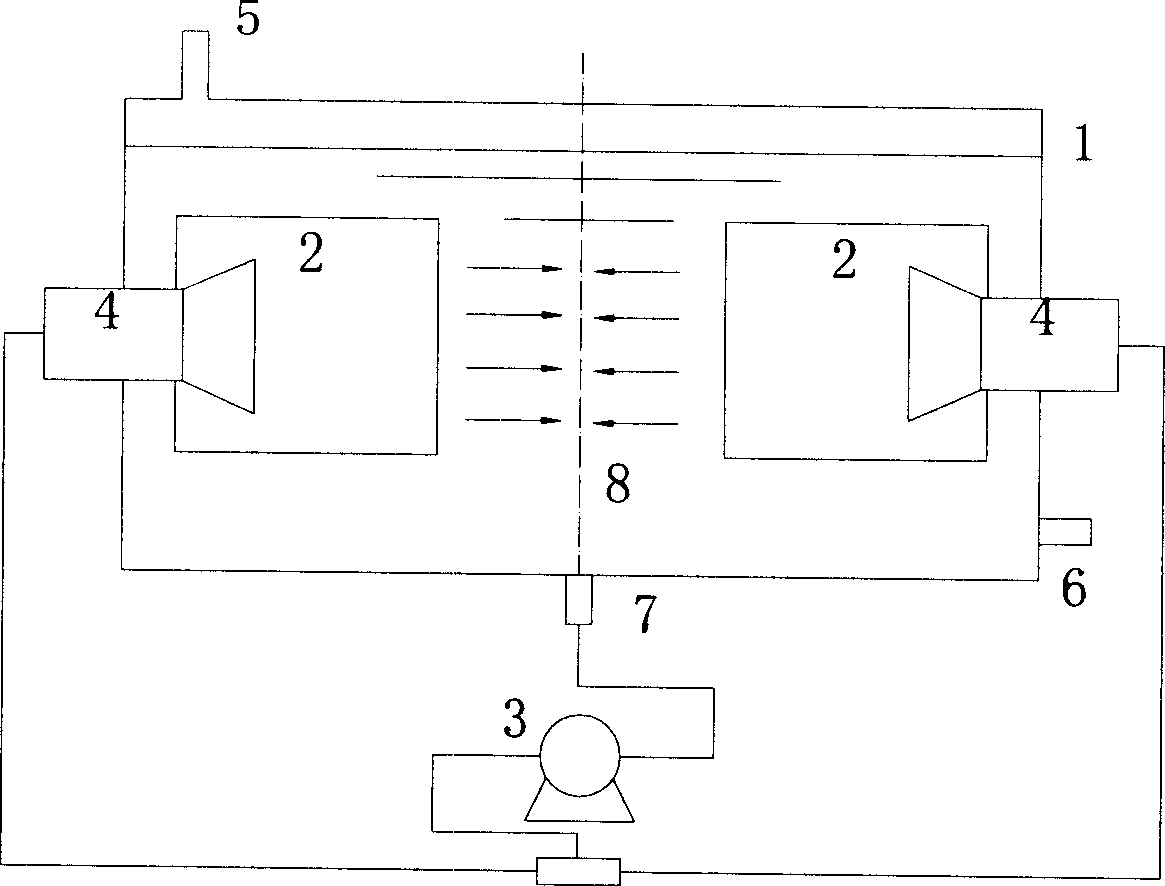

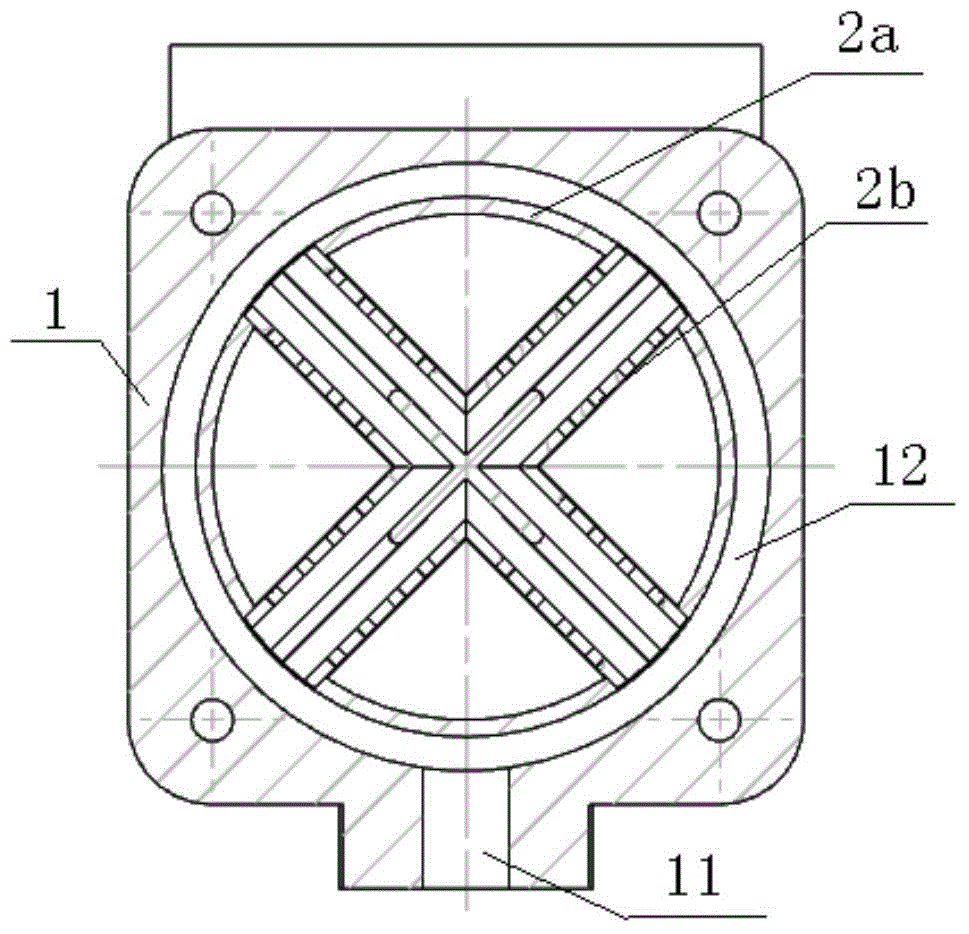

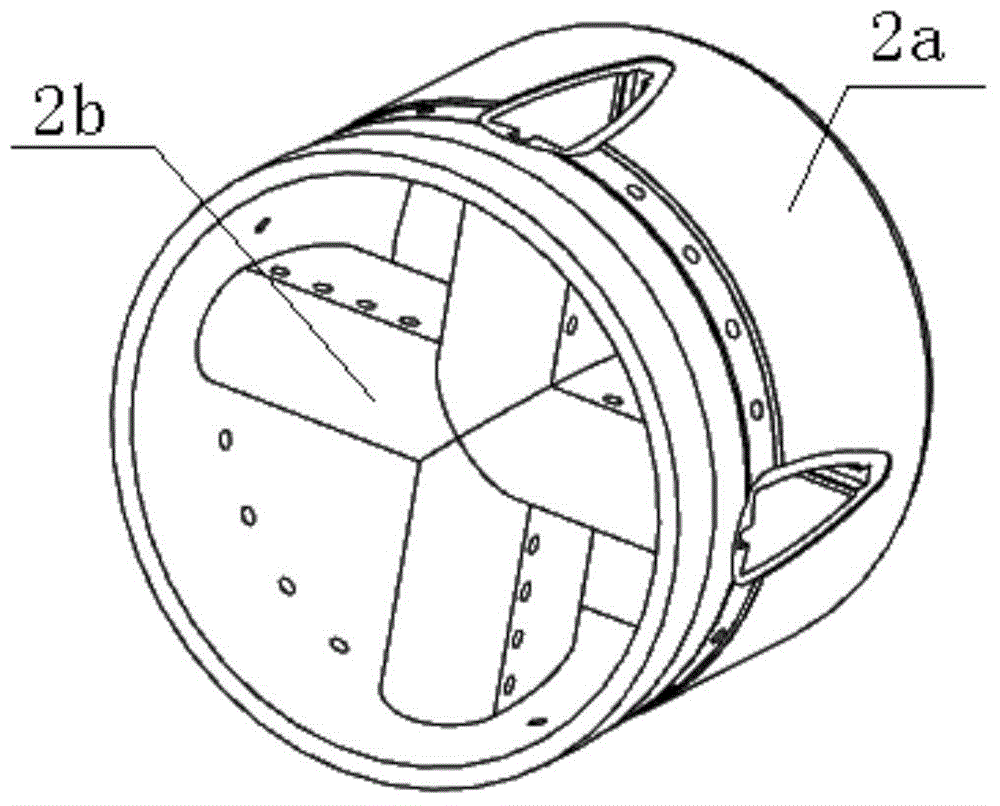

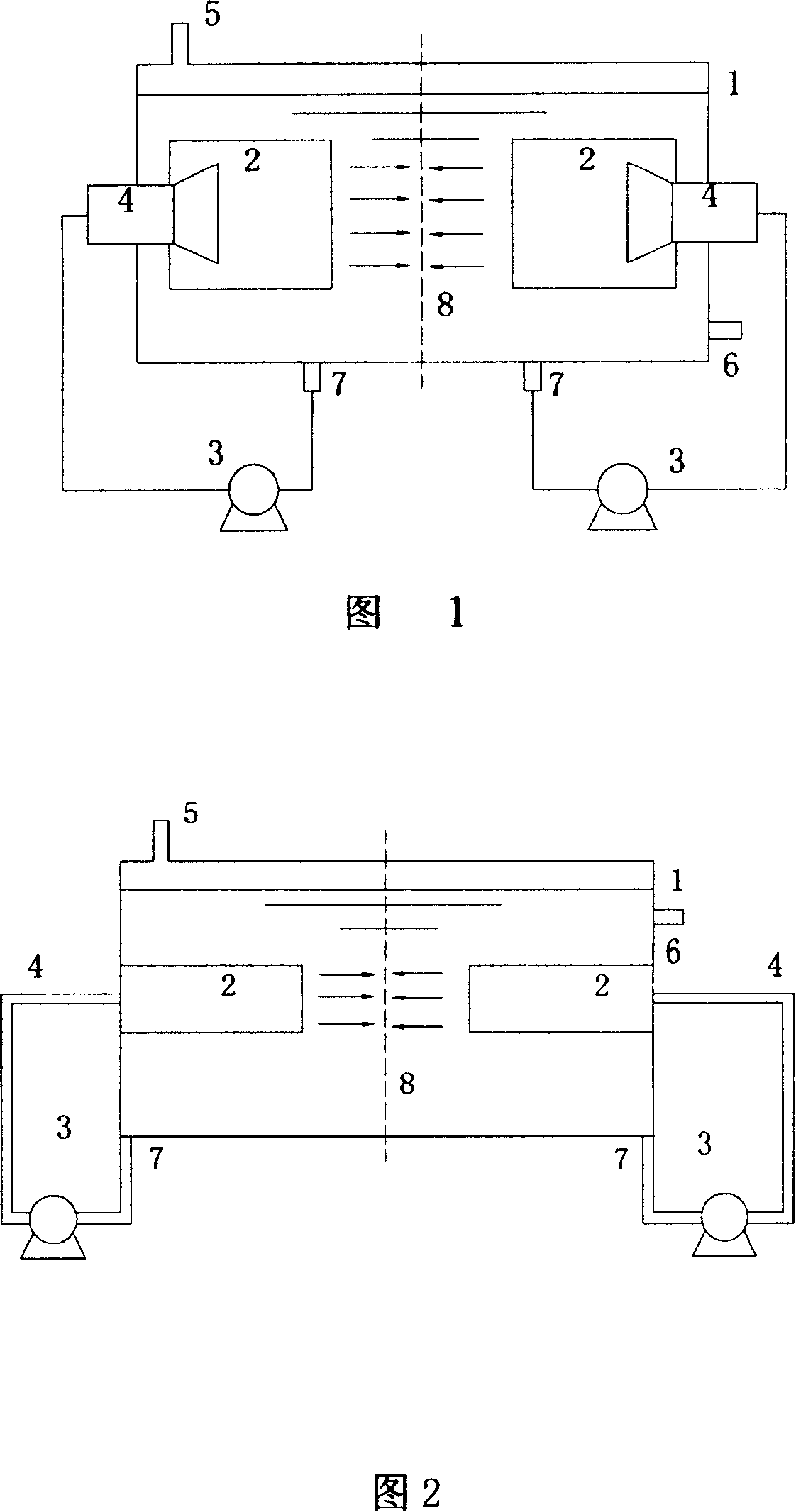

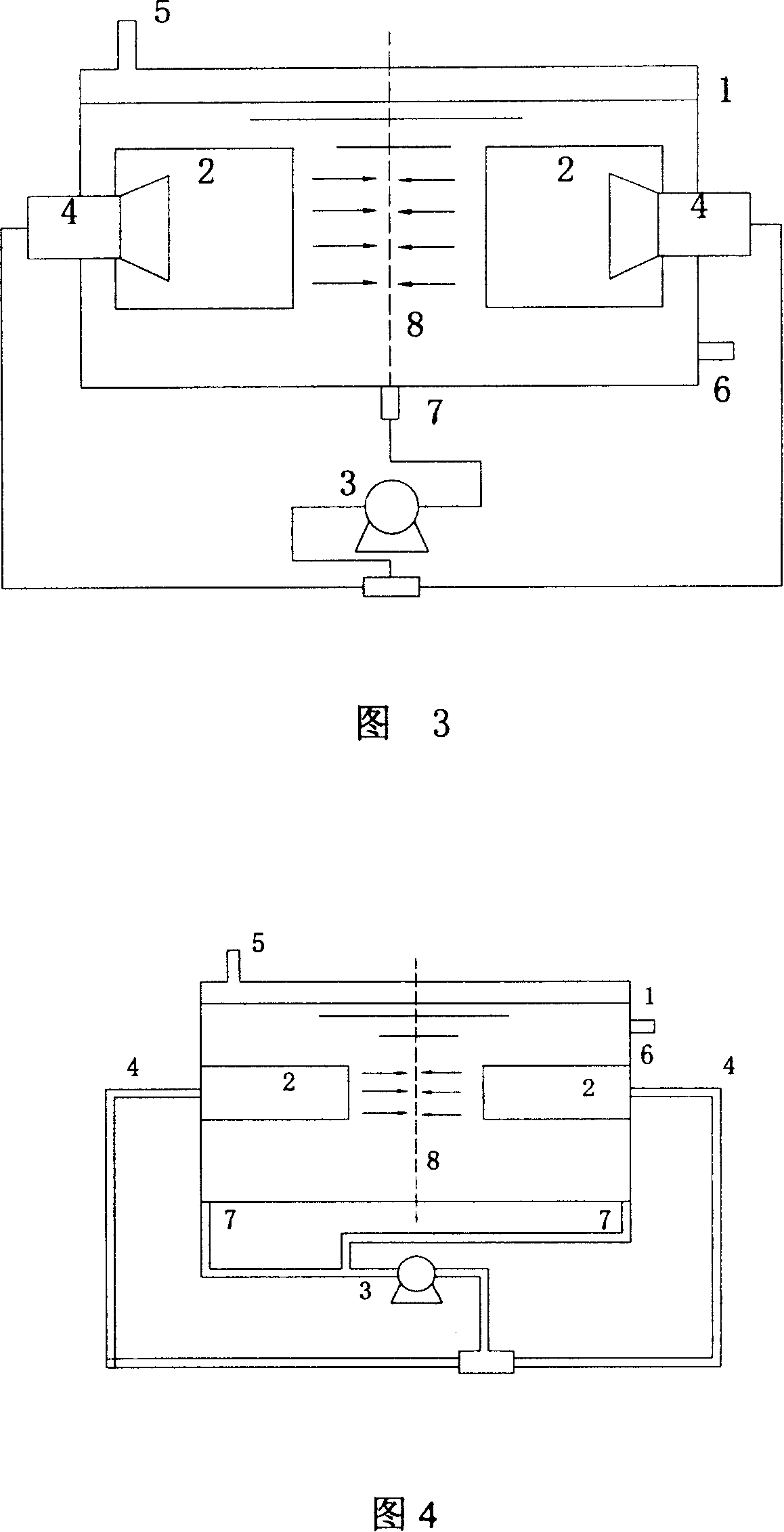

Impact flow reactor for liquid-phase reaction

ActiveCN1814344AImprove mixing uniformityImprove the uniformity of the reactionLiquid-liquid reaction processesFailure ratePropeller

This invention relates to an impact flow reactor used for liquid phase reaction. The reactor is cylindrical form, pipe or quadratic structure, two draft tubes are fixed between reactors, and one or two pumps are set out of the reactor, the exit of the pump is corresponding set at feed side of the tube. The reactant impact with each other after conveyed by materials pump and high speed flow by draft tubes, so the mixing of the reactant is availably improved. The reactor in this invention maintains the advantage of high efficiency mixing and homogeneous reaction of the existing reactor, and some disadvantages of existing reactor is avoided. Its structure plan is facilitated and cost is reduced because of the replacement of pump cycling outside of the reactor of the screw propeller type structure, and engineering problem of shake, radial sealing failure brought by the screw propeller type structure is reduced. It is easy for maintenance, and its failure rate is low, so it is propitious to reaction process of industry scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of metal matrix nanocomposites with high toughness

The invention relates to the composite technical field, in particular to a manufacturing method of metal matrix nanocomposites with high toughness. According to the manufacturing method, the size, distribution, interface structure of reinforcement bodies and the metal matrix micro-structure are effectively controlled by the combined composite process of twice ball-milling, discharging plasma in situ reaction sintering and the large strain plastic deformation technology, so that ultra-fine grain metal matrix composites with evenly distributed in situ authigenic nanoparticles and good interface combination are manufactured, and good matching of intensity and toughness is obtained.

Owner:泰州赛龙电子有限公司

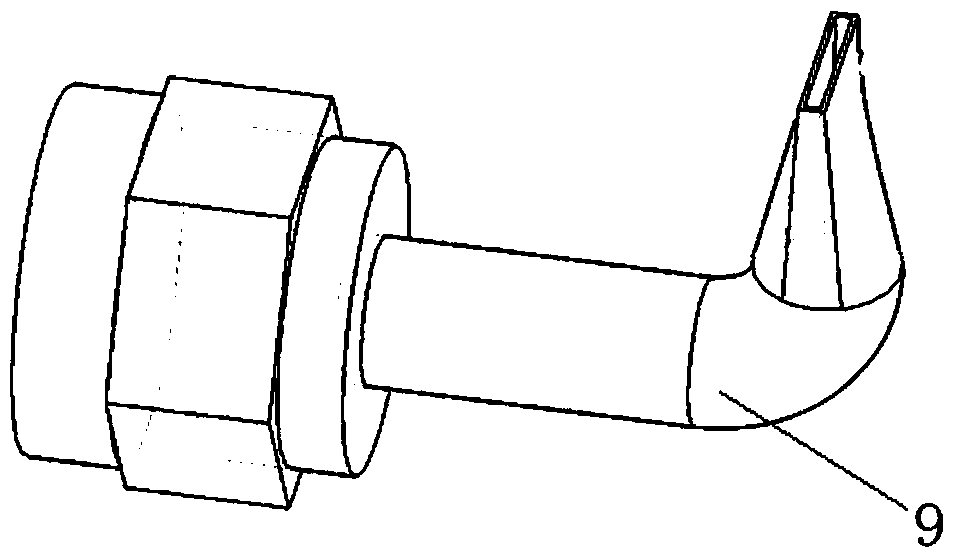

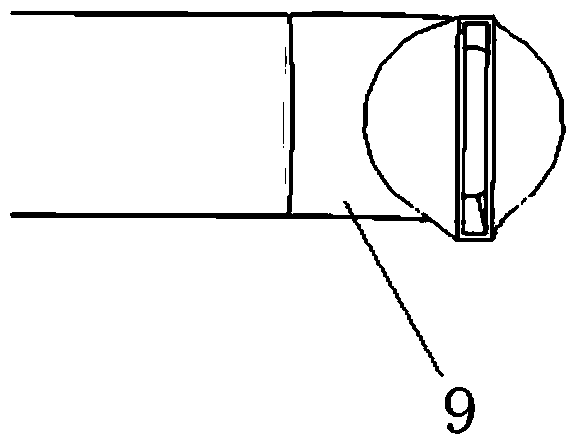

Micro-nano bubble oxygenation drip irrigation system and method

ActiveCN103858730AIncrease the degree of fragmentationSafeguard work pressureClimate change adaptationWatering devicesSpray nozzleMicro nano

The invention relates to a micro-nano bubble oxygenation drip irrigation system and a micro-nano bubble oxygenation drip irrigation method. The system comprises a water inlet main pipe, wherein the water inlet main pipe is connected with two branches in parallel, and a first branch is sequentially connected with a water pump, a pressure stabilizing tank and a pipe pump; a spray nozzle which stretches into the pressure stabilizing tank is arranged at an inlet end of the pressure stabilizing tank, and a pressure stabilizing valve is arranged at the top of the pressure stabilizing tank; a pressure gauge is arranged on an outlet pipeline of the pipe pump; a flow regulating valve and a pressure gauge are sequentially connected onto a second branch; the two branches converge to form a water outlet main pipe; the position, at an inlet of the water pump, of the first branch is connected with an outlet of an air pump through an electromagnetic valve and an inlet of the air pump is respectively connected with a pure oxygen source and an ozone source; a one-way valve and a gas flowmeter are sequentially arranged between the pure oxygen source and the air pump; a one-way valve and a gas flowmeter are sequentially arranged between the ozone source and the air pump; the pipe pump is electrically connected with a frequency conversion cabinet, the frequency conversion cabinet is electrically connected with a power distribution box through an electromagnetic valve and the power distribution box is electrically connected with a programmable controller; the flow regulating valve, the pressure gauges, the electromagnetic valves, the gas flowmeters, the water pump, the pipe pump and the power distribution box are respectively and electrically connected with the programmable controller.

Owner:CHINA AGRI UNIV

Preparation method of high-thermal-conductivity low-leakage phase-change composite

InactiveCN104371666AHigh phase change heat storage capacityLow phase change heat storage capacityHeat-exchange elementsMass ratioLow leakage

The invention discloses a preparation method of a high-thermal-conductivity low-leakage phase-change composite. The method includes: taking a phase-change material and thermal-conductive filler in the mass ratio of 0.1%-1% for melt mixing at the temperature above the melt temperature of the phase-change material for 10min, and taking out the mixture for cooling prior to breaking into granules to obtain modified filler; taking the phase-change material and a support material in the mass ratio of 0.1%-10% for melting at the temperature above the melting temperature of the support material and the phase-change material for 20min, and taking out the molten materials for cooling prior to breaking the materials into granules to obtain a modified support material; adding the modified thermal-conductive filler and the modified support material in the proportion of 1:9-9:1 into the phase-change material counting for 40-50% of total mass for melting the the temperature above the melting temperature of the support material and the phase-change material for 30min prior to obtaining a mixed composite; pouring the mixed composite into a preheated mould, applying certain pressure to the mould, maintaining the pressure for 20min, and performing cooling and demoulding to obtain the high-thermal-conductivity low-leakage phase-change composite. Compared with the prior art, the preparation method has the advantages of simplicity, low cost and chip and available raw materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

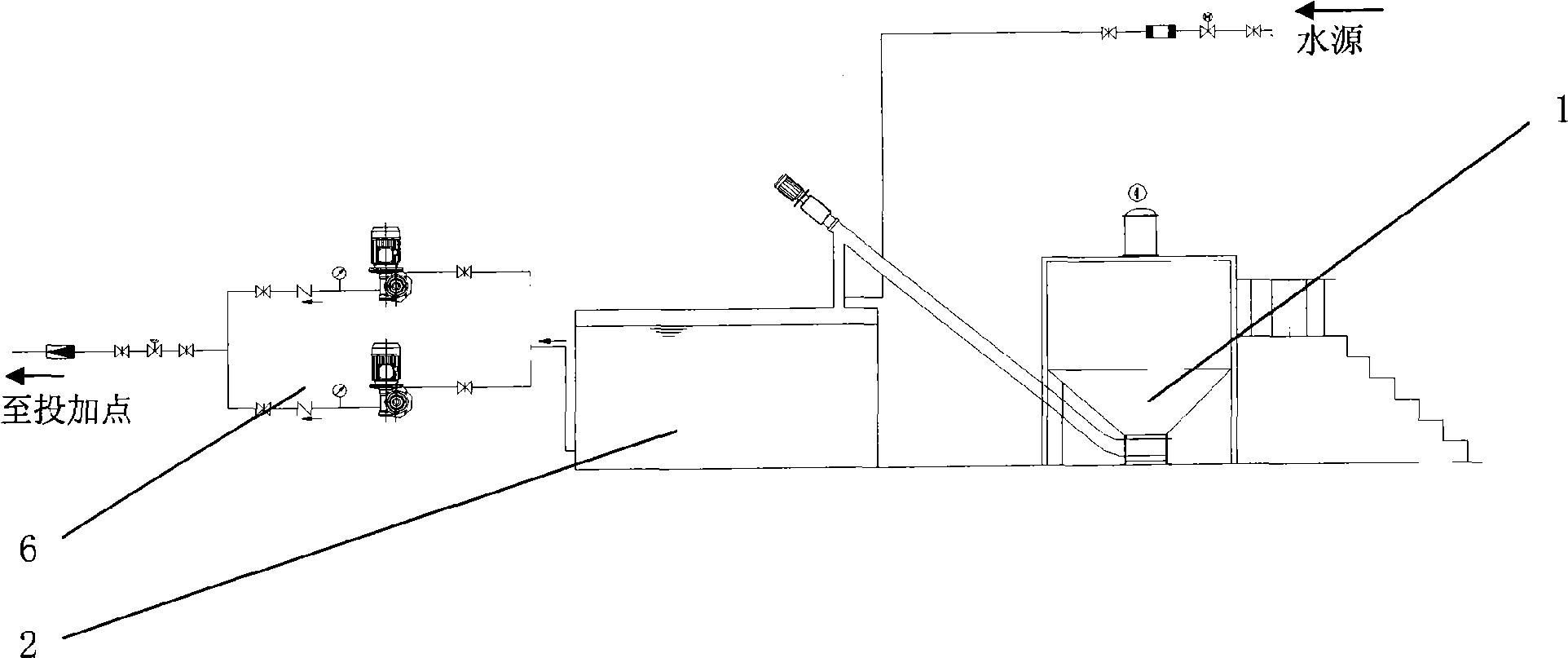

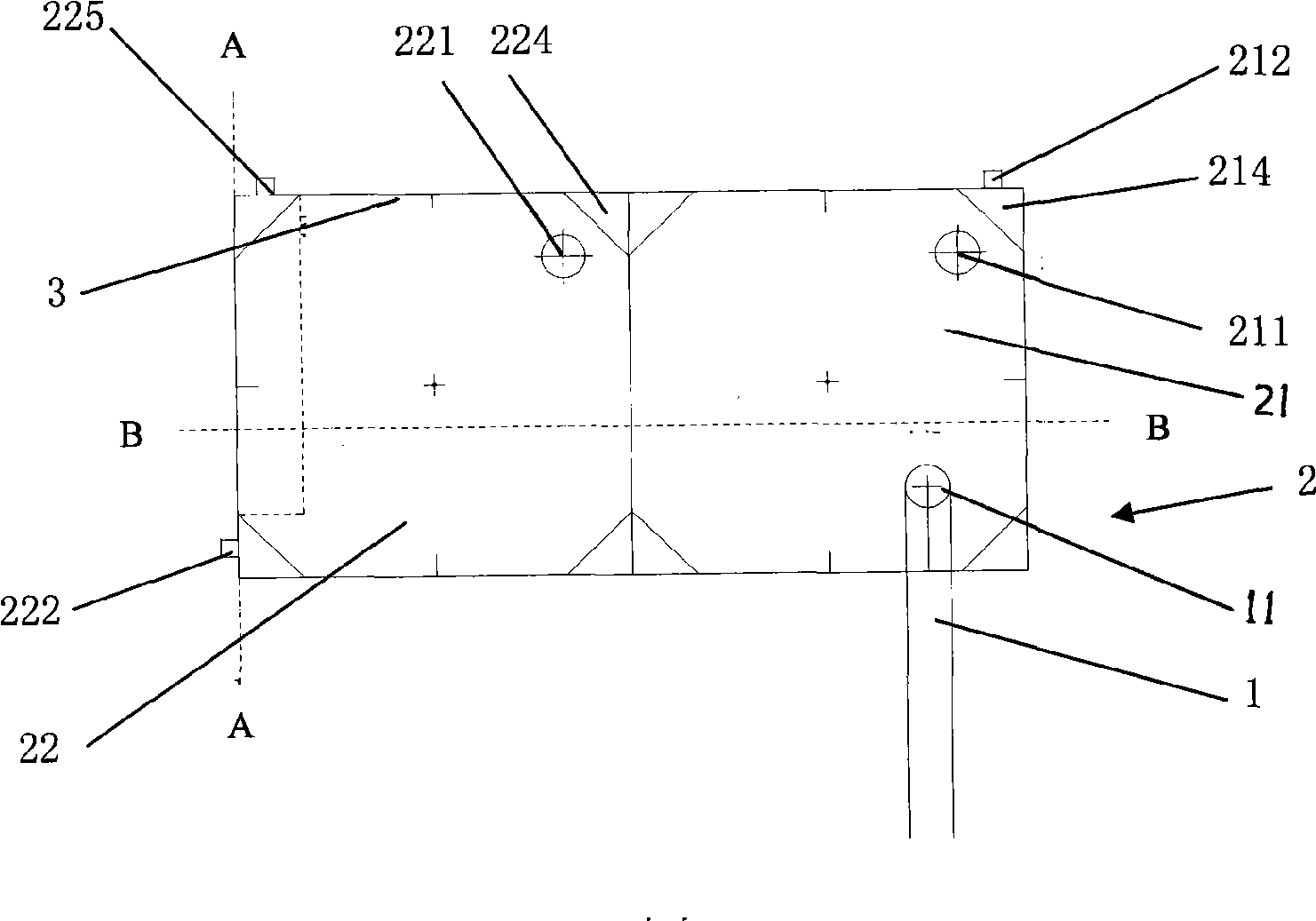

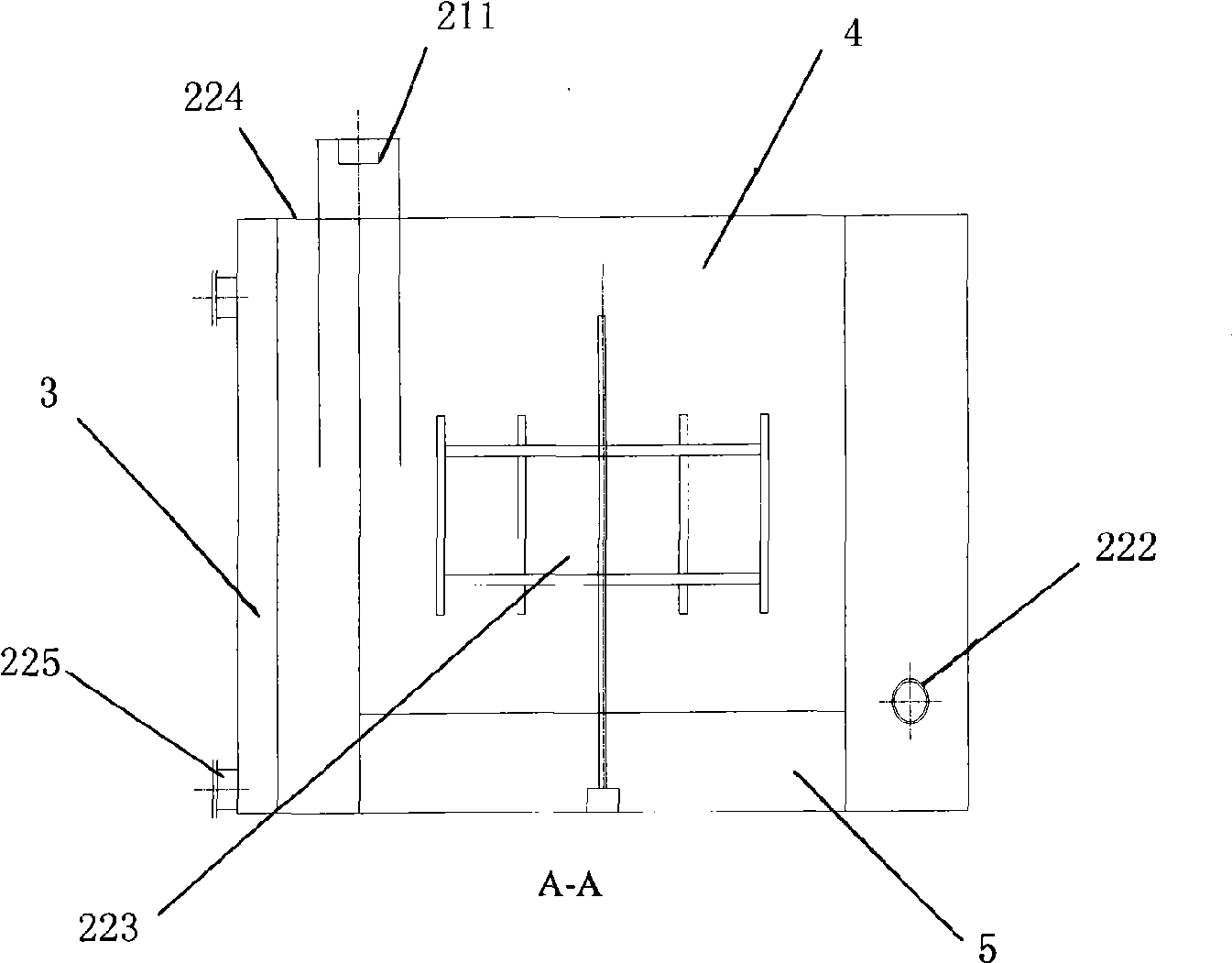

Automatic feeding apparatus preparing pool for powdered activated charcoal

InactiveCN101475239AImprove mixing uniformityWell mixedWater/sewage treatment by sorptionImpellerActivated carbon

The invention provides a blending tank of automatic adding equipment for powdered activated carbon. The blending tank is arranged at the front end of the adding equipment; a stirring device is arranged in the blending tank; powdered activated carbon is fed into the blending tank through a feeding device, stirred and made into carbon-in-pulp; and the carbon-in-pulp is conveyed to a coagulation tank and added through the adding equipment, wherein the blending tank is a two-segment type blending tank; a feeding port of the feeding device is connected with a first blending tank; a flow-reducing type impeller stirring device is arranged in the first blending tank; a baffle is arranged between the first blending tank and a second blending tank; the first blending tank and the second blending tank are communicated through the water-passing end face of the bottom of the baffle; a paddle-board type stirring device is arranged in the second blending tank; and a material outlet of the second blending tank is connected with the adding equipment. The blending tank has the advantages that the blending tank adopts the two-segment type blending tank is adopted, improves the mixture uniformity of the powdered activated carbon and water through primary stir and then intensive stir so as to achieve deep blending, is provided with a flow disturbing baffle to ensure the intensive mixing of the activated carbon and water in a turbulence state, produces no dust in the process of adding dust, and improves working environment.

Owner:上海环境保护有限公司

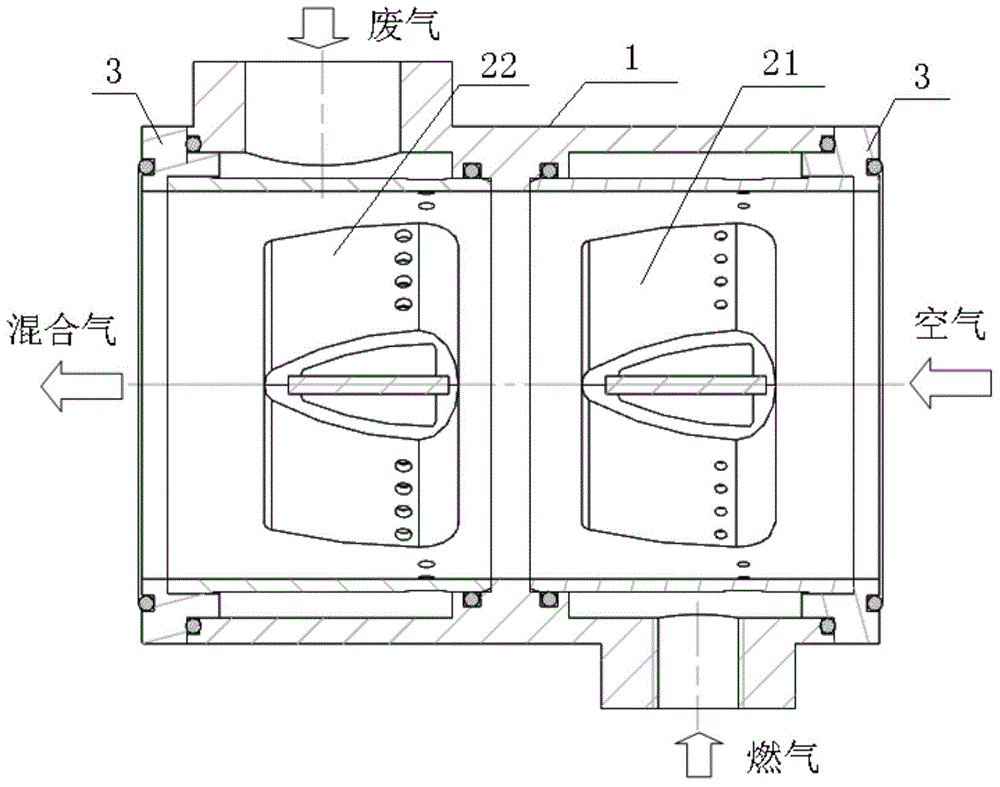

Mixer

InactiveCN105065143ASimplify the layout processSimplify the installation processNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesProcess engineering

The invention discloses a mixer which comprises a cylindrical shell, a fuel gas mixing core and an EGR mixing core. An air inlet is formed in one end of the cylindrical shell. A mixed gas outlet is formed in the other end of the cylindrical shell. A first cavity and a second cavity communicated with each other are formed in the cylindrical shell. A fuel gas inlet is formed in the side wall, close to the first cavity, of the cylindrical shell. A waste gas inlet is formed in the side wall, close to the second cavity, of the cylindrical shell. The fuel gas mixing core is sleeved with the first cavity. Fuel gas flowing through the fuel gas inlet and air flowing through the air inlet can enter the fuel gas mixing core so as to be mixed to form fuel gas mixed gas. The EGR mixing core is sleeved with the second cavity. The fuel gas mixed gas and waste gas flowing through the waste gas inlet can enter the EGR mixing core and are mixed and exhausted through the mixed gas outlet. By the adoption of the mixer, the integration of parts of an engine is effectively improved, the mixing evenness of fuel gas, air and waste gas in the gas engine is improved, and emission of harmful substances of the engine is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

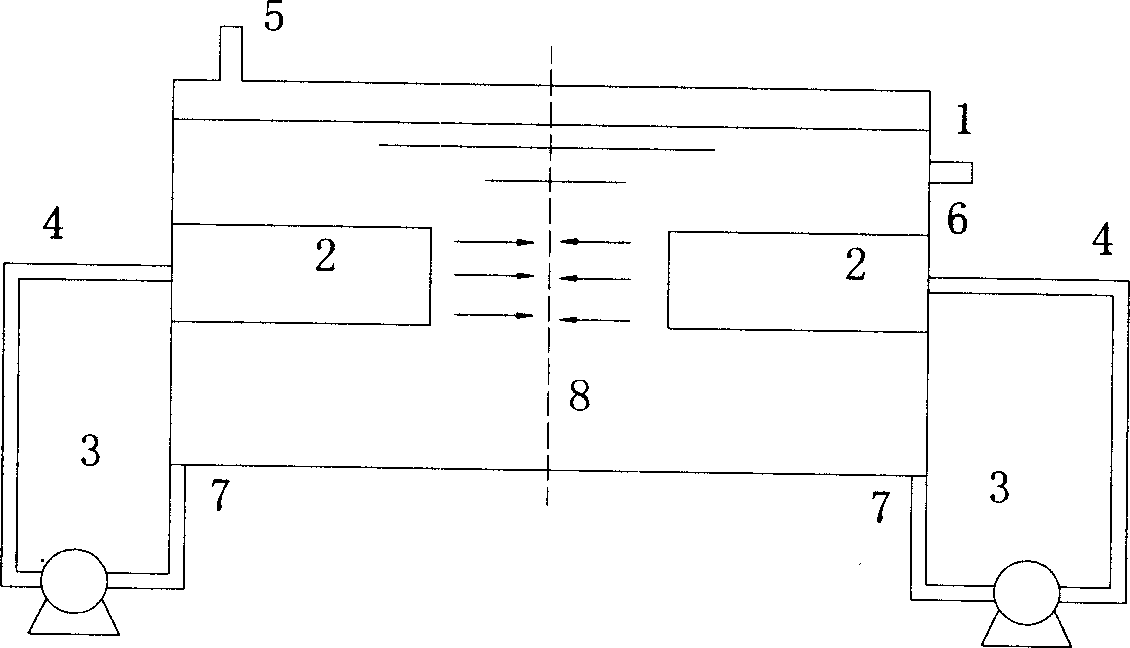

Impact flow reactor for liquid-phase reaction

ActiveCN100364656CImprove mixing uniformityImprove the uniformity of the reactionLiquid-liquid reaction processesFailure ratePropeller

This invention relates to an impact flow reactor used for liquid phase reaction. The reactor is cylindrical form, pipe or quadratic structure, two draft tubes are fixed between reactors, and one or two pumps are set out of the reactor, the exit of the pump is corresponding set at feed side of the tube. The reactant impact with each other after conveyed by materials pump and high speed flow by draft tubes, so the mixing of the reactant is availably improved. The reactor in this invention maintains the advantage of high efficiency mixing and homogeneous reaction of the existing reactor, and some disadvantages of existing reactor is avoided. Its structure plan is facilitated and cost is reduced because of the replacement of pump cycling outside of the reactor of the screw propeller type structure, and engineering problem of shake, radial sealing failure brought by the screw propeller type structure is reduced. It is easy for maintenance, and its failure rate is low, so it is propitious to reaction process of industry scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

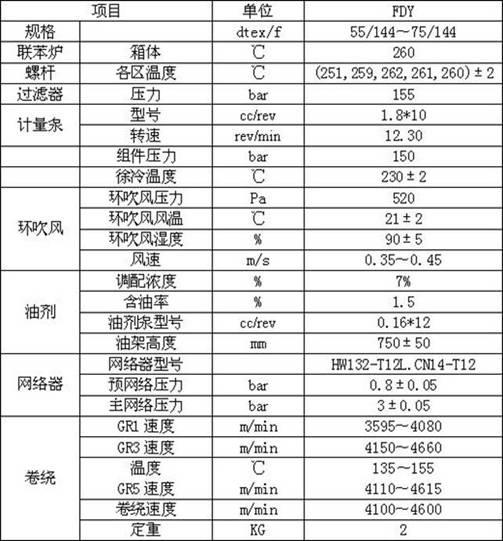

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

High-concentration emulsion treatment method and treatment system

InactiveCN107601774AReduce pollutionImprove recycling ratesMultistage water/sewage treatmentHigh concentrationFenton reagent

The invention discloses a high-concentration emulsion treatment method and a treatment system. The system comprises a waste emulsion storage tank, an acidification reaction tank, an oil separation tank, a Fenton reaction tank, a press filter, an evaporating pot and a biochemical device sequentially; the biochemical device comprises a filtrate collection tank, an anaerobic tank, a facultative anaerobic tank, an aerobic tank, a biological aerated filter, an MBR (Membrane Bioreactor) membrane tank, a reverse osmosis tank, a chemical oxidation pond and a recycled water tank which are sequentiallyconnected; the acidification reaction tank is connected with a dosing tank which is used for adding a demulsifier, and the Fenton reaction tank is connected with a dosing tank II for adding a Fenton reagent, a dosing tank III for adding a demulsifier and a dosing tank IV for adding liquid alkali / lime hydrate. The treatment method comprises the steps of collecting treatment, acidification, primarycoagulative precipitation, secondary coagulative precipitation, evaporation treatment, biochemical treatment and second-stage biochemical treatment. The system and the method have the effects of highdemulsification capability, applicability to the treatment of a variety of emulsions, high recovery and reutilization rate and high purification treatment capacity.

Owner:厦门东江环保科技有限公司

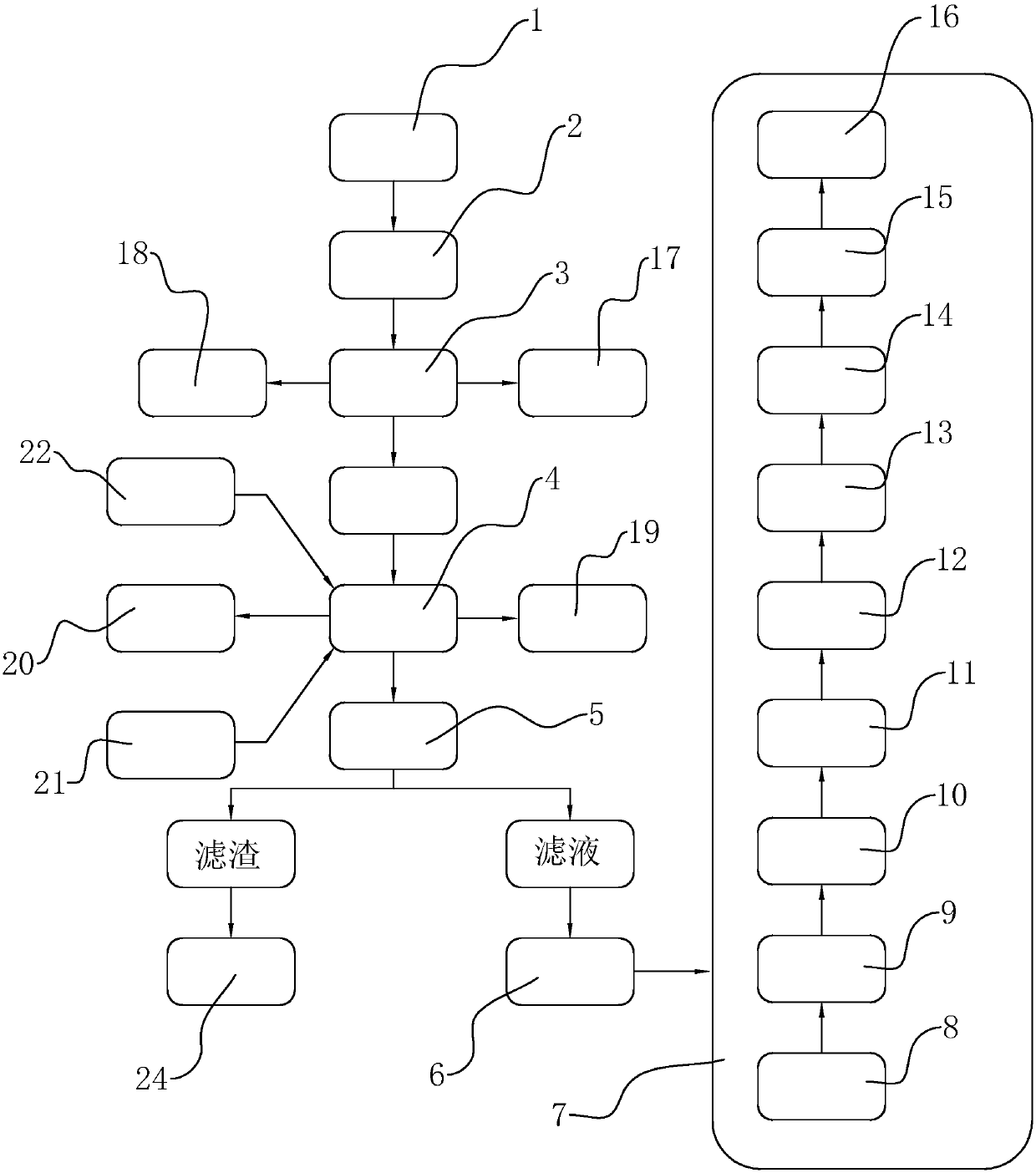

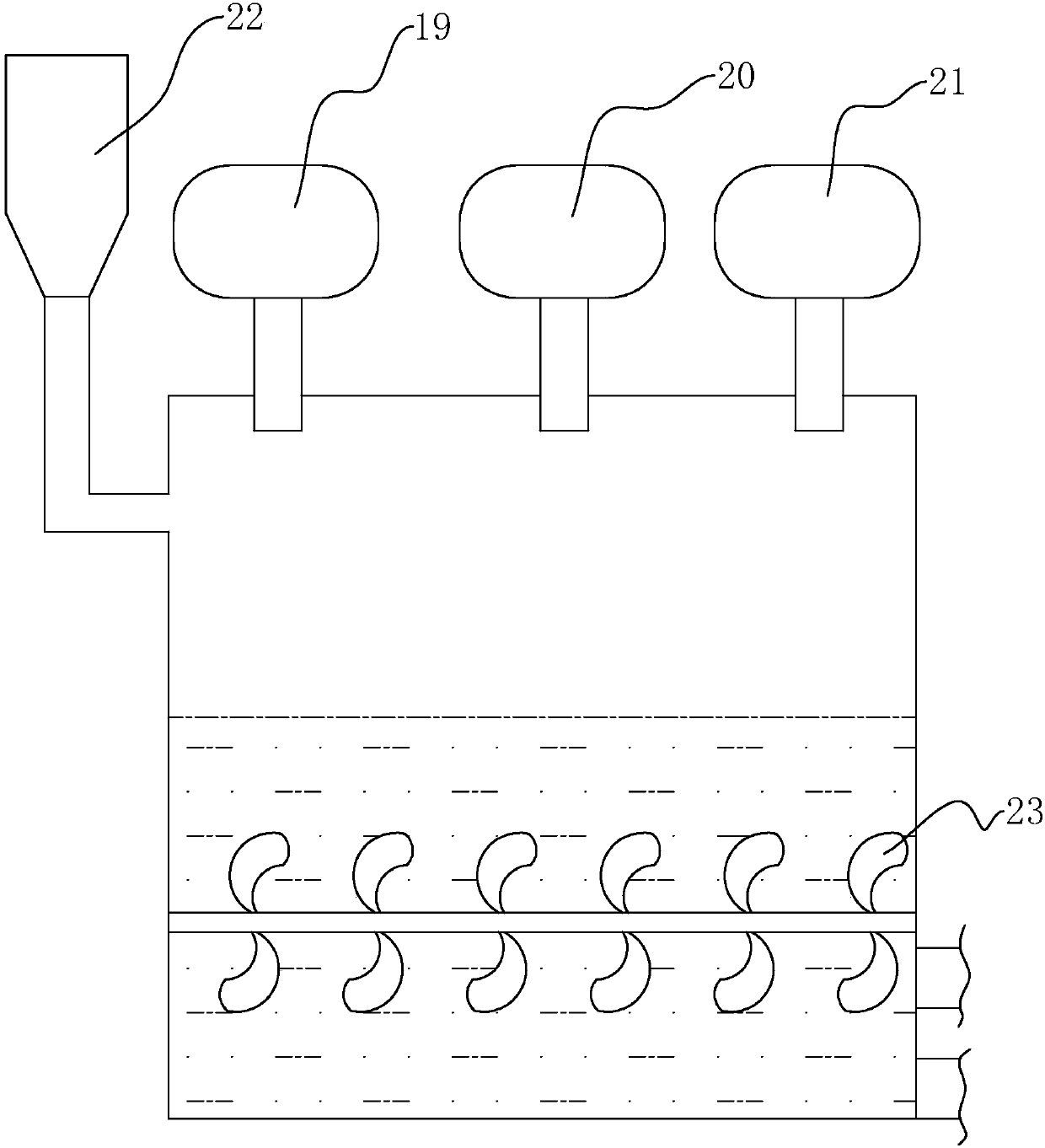

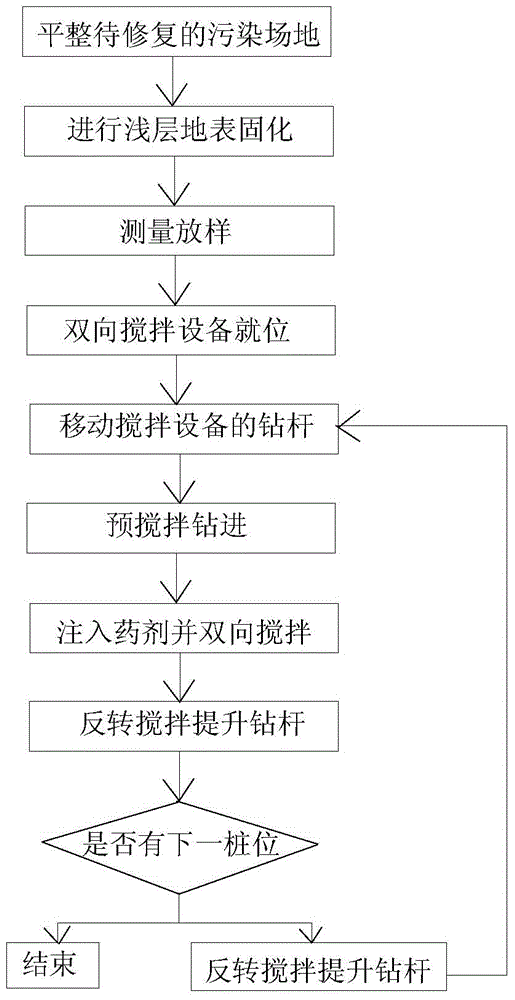

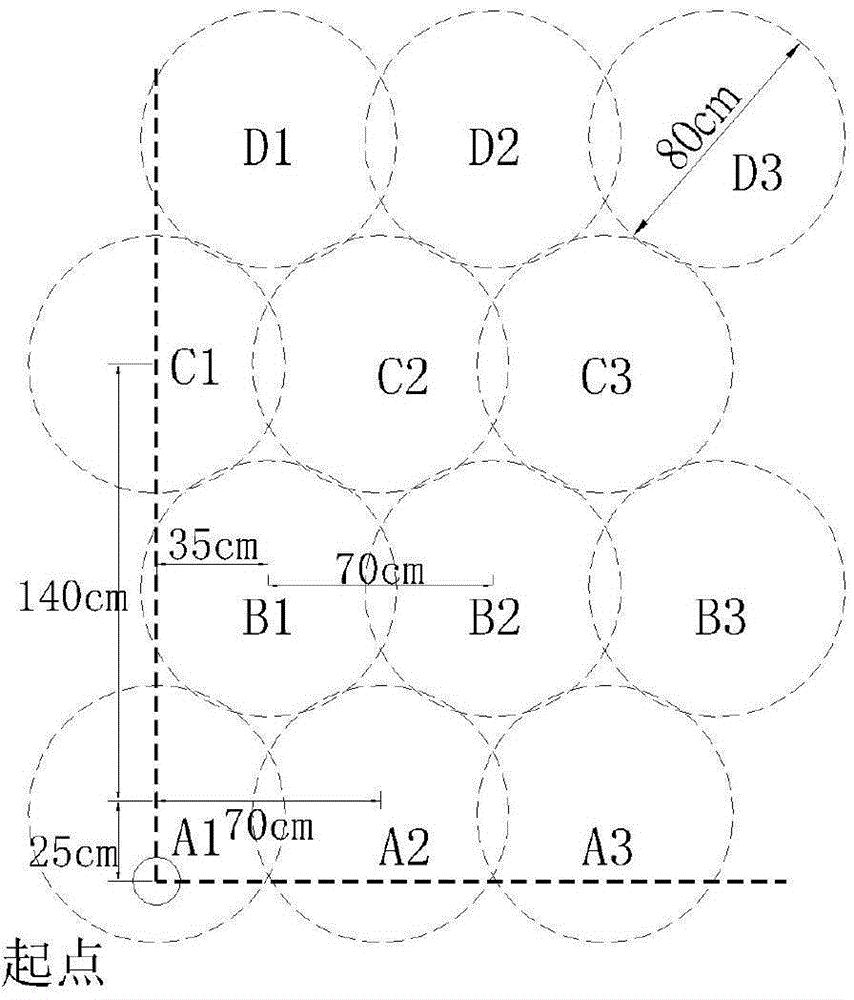

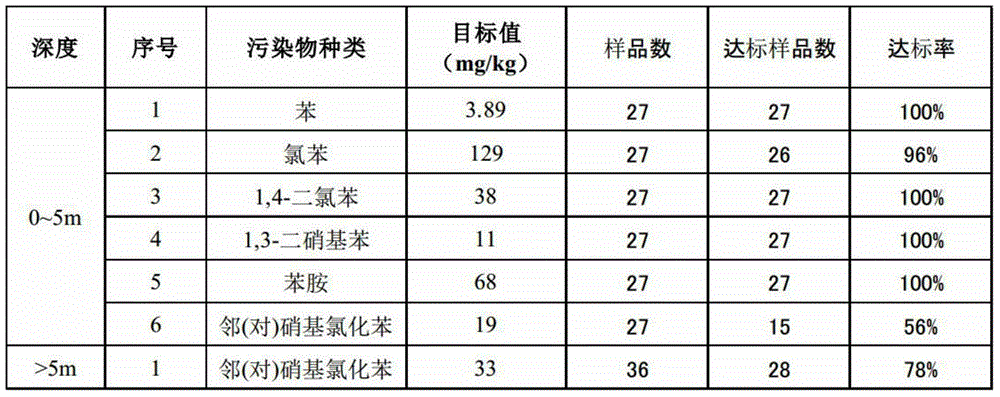

Method for remedying organism contaminated field by using bidirectional stirring injection method

ActiveCN104624629AImprove utilization efficiencyReduce lossesContaminated soil reclamationDrillInjections methods

The invention discloses a method for remedying an organism contaminated field by using a bidirectional stirring injection method. The method comprises the following steps: (1) flattening the contaminated field; (2) performing shallow layer ground hardening; (3) staking out in survey; (4) locating bidirectional stirring equipment in place; (5) moving a drilling rod of the bidirectional stirring equipment; (6) performing pre-stirring drilling; (7) drilling a drill rod, injecting a medicine and stirring bidirectionally, namely, injecting the medicine through an inner tube of a conveying pipeline, injecting a mixed solution of a catalyst and a buffer agent from a pipeline between the inner tube and the outer tube of the conveying pipeline, and mixing and stirring the medicine, the catalyst, the buffer agent and soil at the bottom of the conveying pipeline; (8) lifting up the drill rod through opposite stirring; and (9) moving the drill rod to a next pile site, and repeating the step (5) to (8) until the soil in all pile sites is remedied. By adopting the method, the loss of ground mixed medicines can be reduced, the reaction velocity and the reaction time can be effectively controlled, the problem that grout spills out and turns up from the ground surface can be effectively solved, and the remediation efficiency can be improved.

Owner:SOUTHEAST UNIV +2

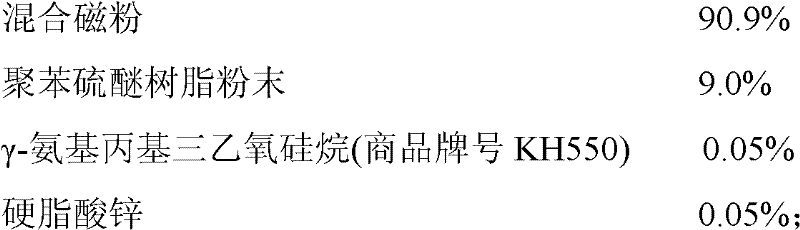

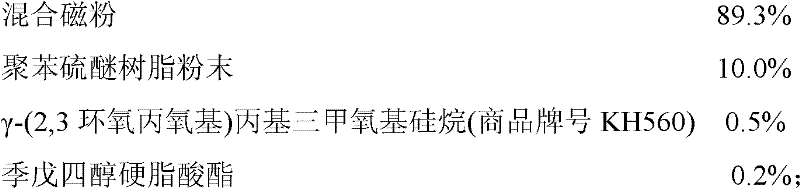

Injection molding permanent magnet composite material containing polyphenylene sulfide and preparation method thereof

ActiveCN102504534AExcellent overall performanceExcellent magnetic propertiesMagnetic powderNeodymium iron boron

An injection molding permanent magnet composite material containing polyphenylene sulfide includes the following components by mass: 78% to 91% of mixed magnetic powder, 8% to 21% of polyphenylene sulfide resin and 0.05% to 1% of coupling agents. The mixed magnetic powder includes the following components by mass: 50% to 96% of neodymium iron boron permanent magnetic powder, 1% to 49% of samariumiron nitrogen permanent magnetic powder and 1% to 45% of ferrite permanent magnetic powder. A preparation method of the injection molding permanent magnet composite material includes the following processing steps: (1) preparing multi-element composite magnetic powder, (2) mixing and pelleting and (3) injection molding.

Owner:SICHUAN UNIV

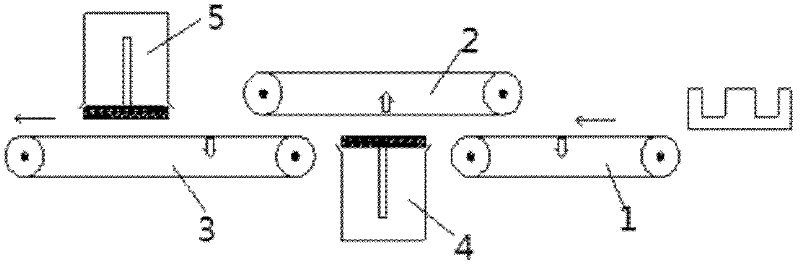

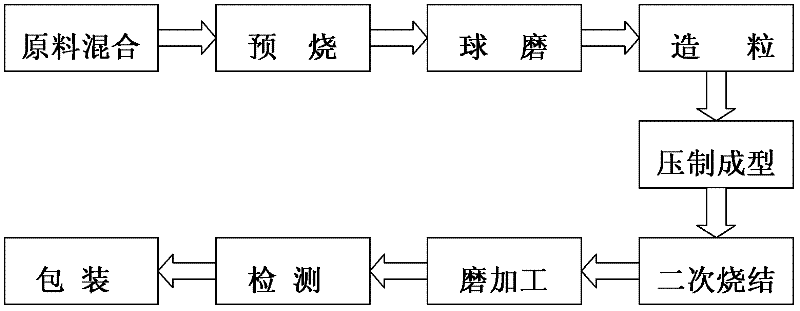

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

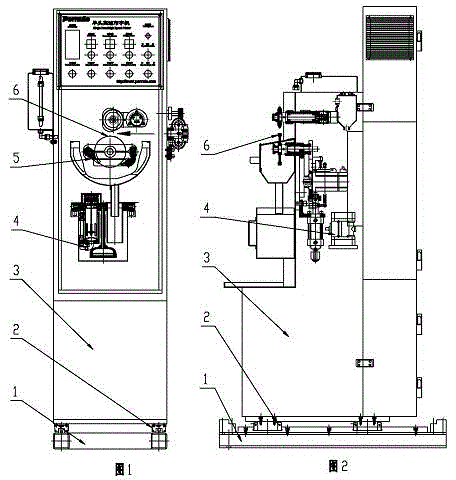

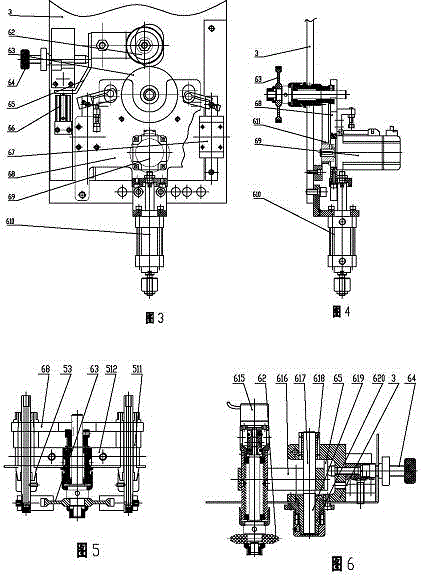

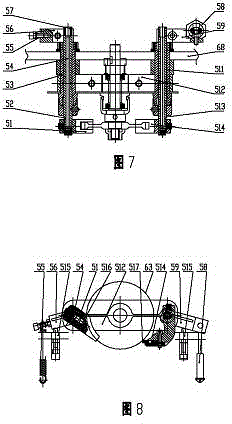

High-speed printer for cables

The invention discloses a high-speed printer for cables. The high-speed printer for the cables comprises a frame, an ink supply device, a printing mechanism and an inkjet component, wherein the ink supply device, the printing mechanism and the inkjet component are supported on the frame. The ink supply device is communicated with an ink delivery hole of the inkjet component, an ink nozzle of the inkjet component is adjacent to a printing wheel of the printing mechanism, the printing wheel of the printing mechanism is driven by an adjustable-speed motor, a swing arm pressure regulating device is connected to a pressing wheel support arm of the printing mechanism, and a pressing wheel is in driving connection with an encoder. The ink nozzle of the inkjet component is fixedly connected to a nozzle shaft, the ink delivery hole is formed in the nozzle shaft, a printing wheel support seat is connected to a nozzle shaft support seat, and the ink supply device is provided with an ink viscosity regulating device. The high-speed printer for the cables has the advantages that the high-speed printer is capable of guaranteeing operating synchronism of the printing wheel and the cables and pressure stability of the pressing wheel, controlling ink viscosity difference and improving ink cleanliness; meanwhile, a nozzle component is succinct and compact in structure, so that high-speed printing for the cables can be guaranteed.

Owner:JIANGSU SINGCHEER MACHINERY

Preparation method of lithium iron phosphate material

InactiveCN103258995AImprove mixing uniformityGood repeatabilityCell electrodesPhosphorus compoundsLithium iron phosphateLithium-ion battery

The invention discloses a preparation method of a high-tap density lithium iron phosphate material. The method comprises the following steps: mechanically mixing iron orthophosphate, a lithium source and a composite carbon source, transferring to a wet stirring ball milling device, adding a certain amount of deionized water and dispersant to form uniform suspension liquid, carrying out nano-ball milling on the obtained suspension liquid, spray-drying to obtain a precursor, and firing and crushing the obtained precursor to obtain the high-tap density lithium iron phosphate material. The lithium iron phosphate material prepared by the method disclosed by the invention has the characteristics of good processability, excellent electrochemical properties and the like when being used as a positive pole material of a lithium ion battery, and the preparation method is low in production cost, free of exhaust pollution, and convenient for commercial mass production.

Owner:郑州瑞普生物工程有限公司

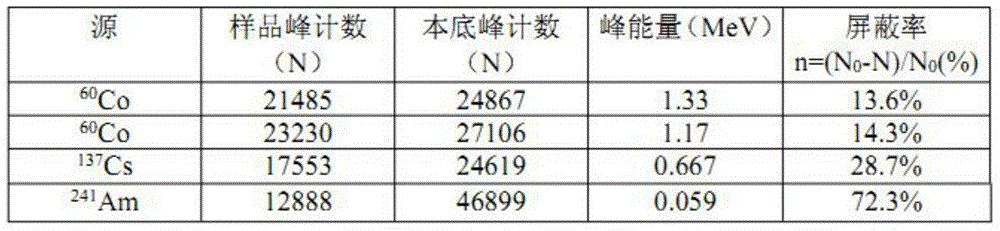

Gamma radiation protective clothing preparing method

ActiveCN104900282AEnvironmentally friendlyImproves compatibility and mixing uniformityLaminationLamination apparatusMicro nanoRadiation protection

The invention discloses a gamma radiation protective clothing preparing method. Micro-nano grade Gamma radiation protective clothing functioning powder prepared via ball milling is added to a rubber base body for mixing; then fabrics immersed into adhesives is flattened and stuck to glue; Gamma radiation protective fabrics are achieved via vulcanization formation; and at last the Gamma radiation protective clothing is prepared. The Gamma radiation protective clothing is soft, comfortable to wear and has high screening factor; the preparation technology is simple; and high production rate and low machining cost can be achieved.

Owner:陕西核安安全设备有限公司

Molten-slag-resistant spray paint for lade and application method thereof

The invention provides molten-slag-resistant spray paint for a ladle. The molten-slag-resistant spray paint comprises the following components in percentage by weight: 70-80 percent of aggregate, 16-25 percent of a bonding agent, 1-10 percent of a molten-slag-resistant functional additive and 0.01-1 percent of an additional additive, wherein the bonding agent is a composite bonding agent, and comprises silica powder, silicate cement, sodium silicate powder and bentonite. A method for applying the spray paint comprises the following steps: firstly, preparing a mixture in the weight ratio; secondly, adding water in an amount of 5-8 percent based on the weight of the mixture under strong stirring; and lastly, spraying the mixture onto a molten slag resisting position on the ladle through a spray gun. Compared with the prior art, the molten-slag-resistant spray paint provided by the invention has the advantages of high strength, high molten slag resistance, molten slag erosion resistance, oxidation resistance and high thermal shock resistance. Moreover, a waste sliding plate reclaimed material is taken as a main component for the aggregate of the molten-slag-resistant spray paint, so that the production cost of the molten-slag-resistant spray paint is lowered greatly, and high comprehensive benefit is achieved.

Owner:北京利尔高温材料股份有限公司

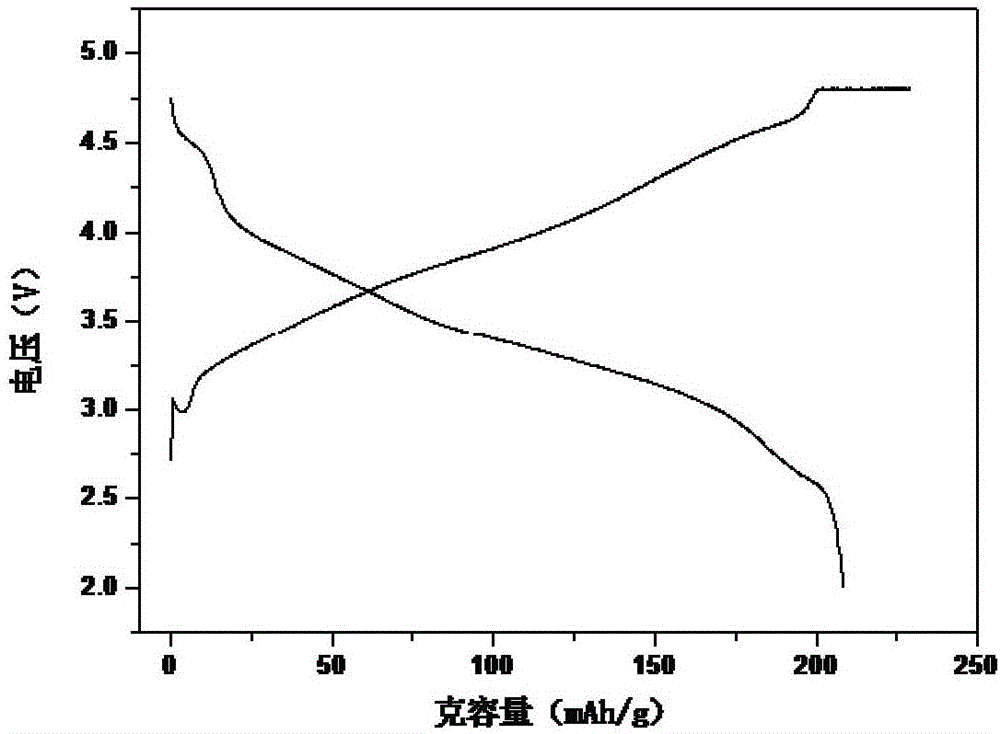

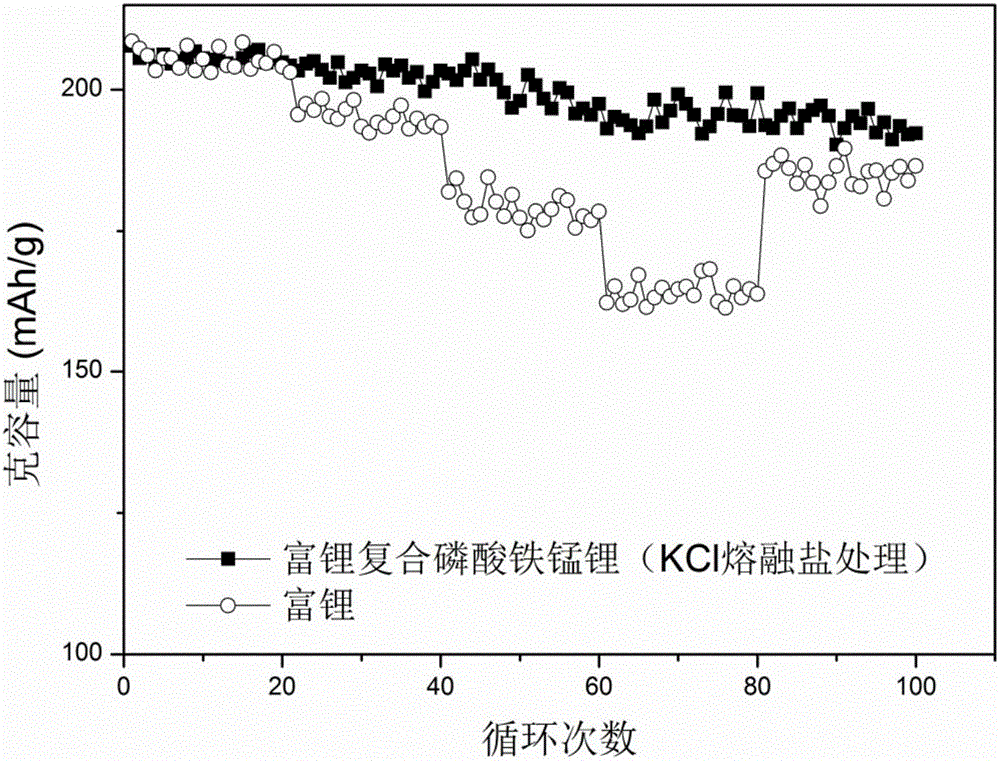

Lithium-rich manganese-based cathode material with coated and compounded surface and preparation method of lithium-rich manganese-based cathode material

ActiveCN106450211AImprove cycle stabilitySolve temperature problemsCell electrodesSecondary cellsManganeseLithium-ion battery

The invention provides a lithium-rich manganese-based cathode material with a coated and compounded surface and a preparation method of the lithium-rich manganese-based cathode material. A lithium-rich manganese-based cathode material xLi2MnO3-(1-x)LiMO2 is used as a raw material, and is mixed and coated with a lithium ferric manganese phosphate material LiFeyMn1-yMzPO4 / C, wherein the mass of the lithium ferric manganese phosphate material LiFeyMn1-yMzPO4 / C is 0.5 to 5% of the total mass of the lithium-rich manganese-based cathode material with the coated and compounded surface; M in the lithium-rich manganese-based cathode material xLi2MnO3-(1-x)LiMO2 is at least one of transition metals Mn, Ni and Co, and x is smaller than 1 and greater than 0; N in a lithium ferric manganese phosphate material LiFeyMn1-yNzPO4 / C is any two of metals Ti, Mg, Al and Zn, y is smaller than 1 and greater than 0.6, and z is smaller than 0.03 and greater than 0.005; carbon content is 2 to 4% of the mass of the LiFeyMn1-yNzPO4 / C. A lithium ion battery prepared by utilizing the lithium-rich manganese-based cathode material with the coated and compounded surface, which is provided by the invention, has ultrahigh cycling stability in a range of 0 to 30DEG C, and can obviously improve gram capacity playing at a temperature lower than 25 DEG C.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

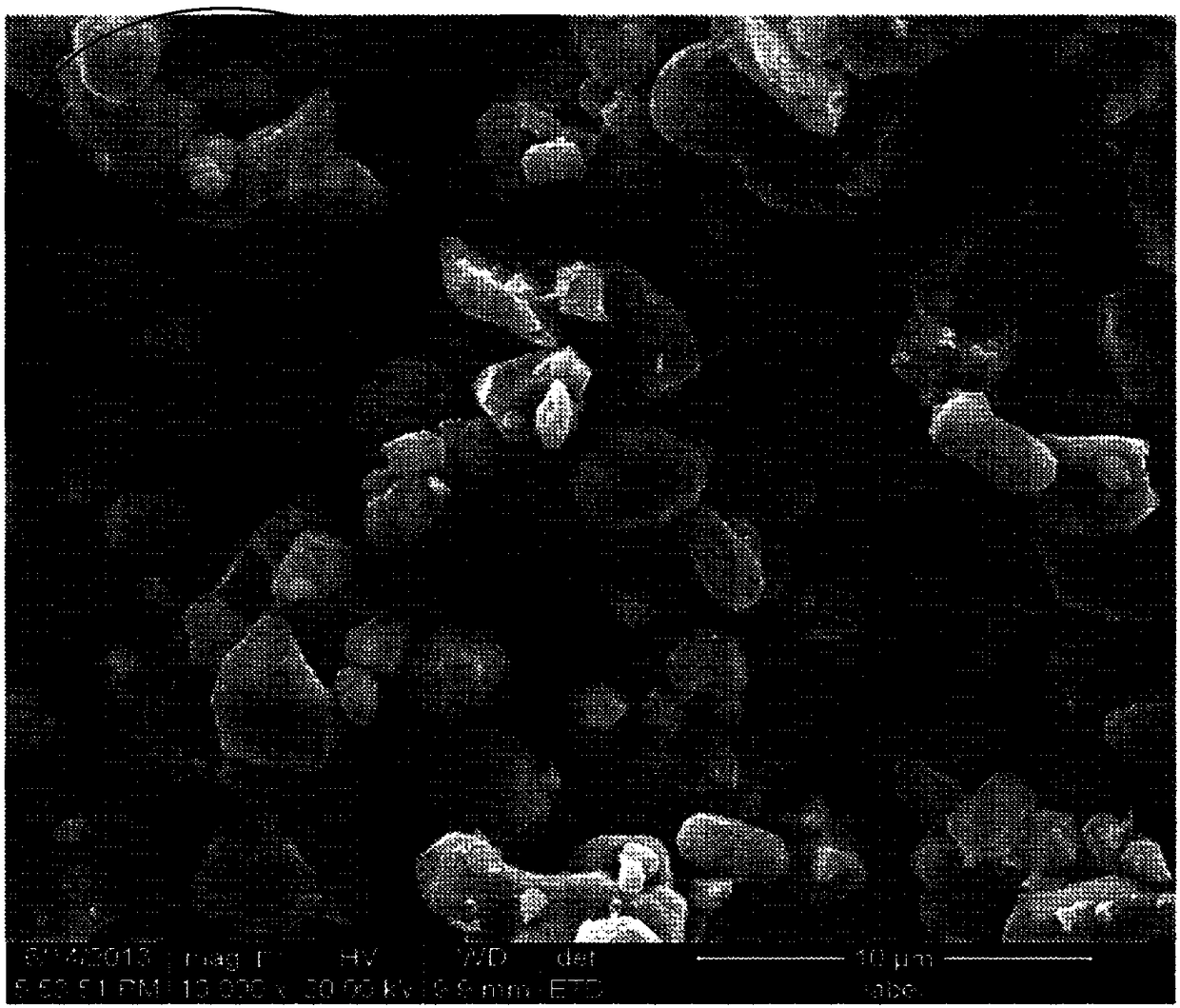

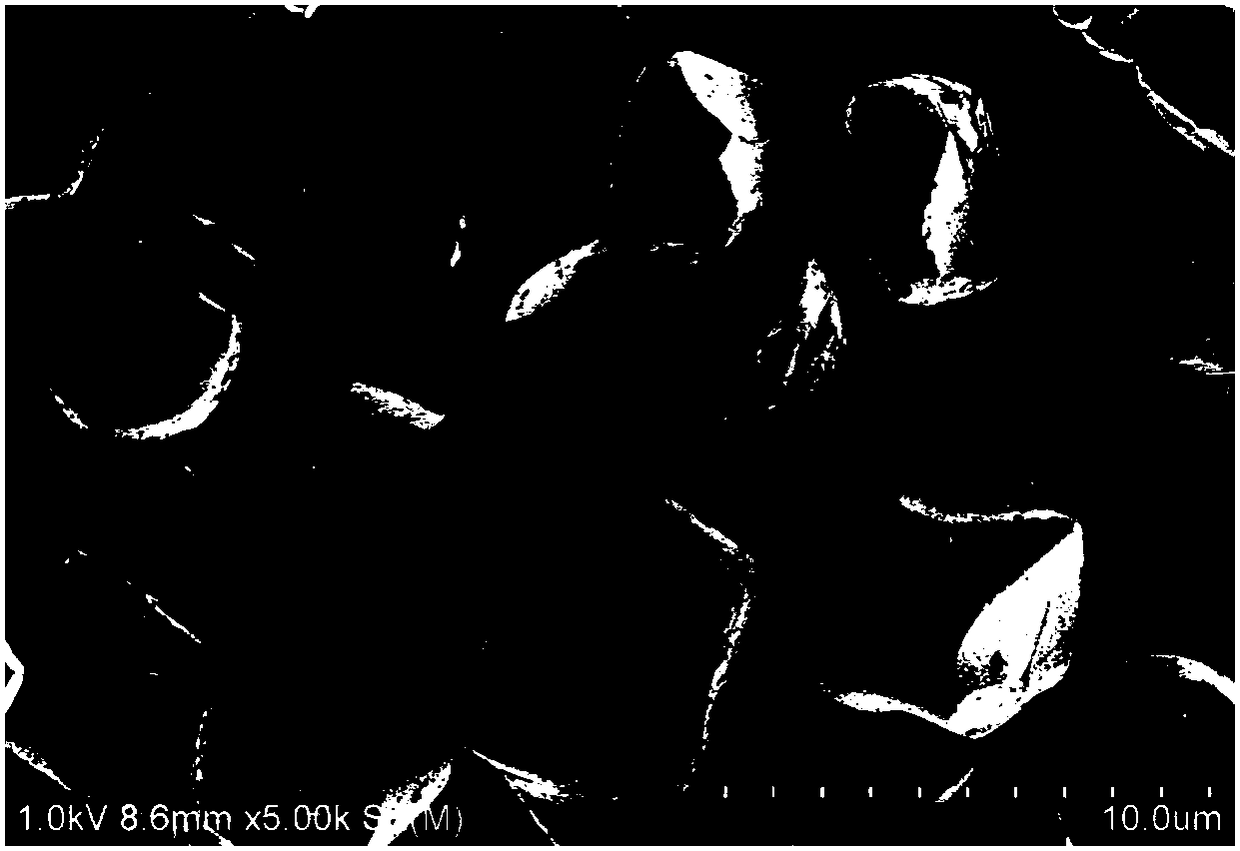

Single crystal lithium-rich manganese-based anode material, preparation method thereof, lithium ion battery

InactiveCN108598457ASmall particle sizeFacilitate functioningCell electrodesSecondary cellsManganeseSingle crystal

The invention relates to a preparation method of a single crystal lithium-rich manganese-based anode material. In the process of preparing a single crystal lithium-rich manganese-based anode materialby calcining a lithium-rich manganese-based material precursor, the method comprises the following steps: S1, firstly, pre-sintering the lithium-rich manganese-based material precursor, and carrying out crushing treatment to obtain scattered oxide of the lithium-rich manganese-based material precursor; S2, uniformly mixing the oxide of the lithium-rich manganese-based material precursor with a lithium source and then sintering to obtain the oxide of the lithium-rich manganese-based material precursor. More preferably, a small amount of additive is mixed while mixing lithium after pre-sinteringand crushing; and the mixed additive may induce crystal growth and grain boundary fusion, which is favorable for forming a single crystal and improving the structure of the crystal; pre-sintering andcrushing can reduce the particle diameter to a relatively desirable range, so that the sintered body has better kinetic performance and achieves better mixing uniformity when mixing lithium and mixing the additive, to promote the formation of the single crystal. By means of such a preparation method, a lithium-rich manganese-based anode material having a high degree of single crystallization anda uniform particle diameter can be obtained.

Owner:桑德新能源技术开发有限公司 +1

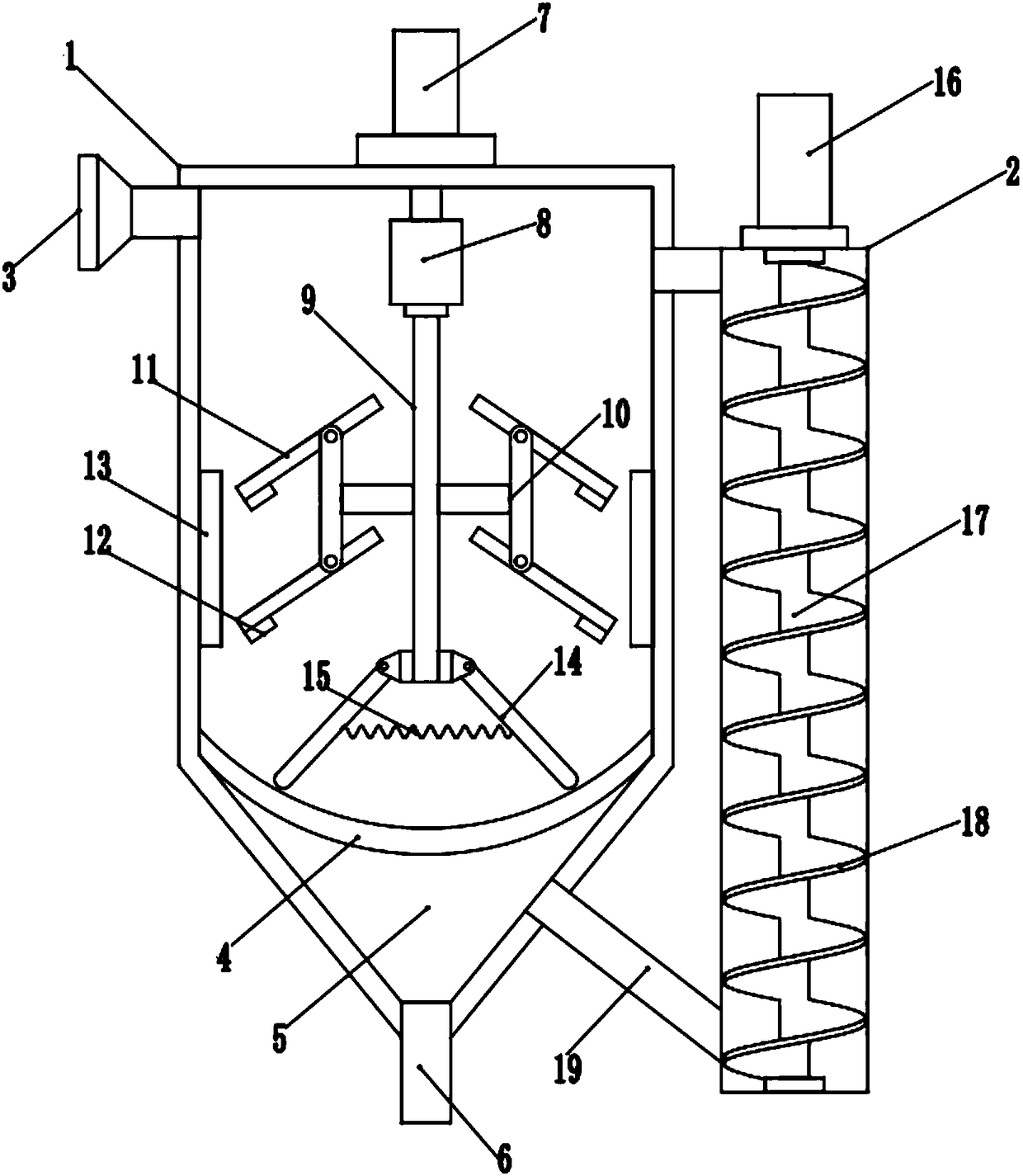

Feeding device for producing evenly mixed furniture plate

InactiveCN108114631AImprove mixing efficiency and mixing effectImprove the uniformity of mixingShaking/oscillating/vibrating mixersFlow mixersEngineeringMechanical engineering

The invention discloses a feeding device for producing an evenly mixed furniture plate. The feeding device comprises a mixing device and a hoisting device, an electric lifting device is fixedly connected with the top part of the mixing device, the bottom part of the electric lifting device extends and enters the interior of the mixing device and is fixedly connected with a stirring motor, a rotating shaft is connected with the bottom part of the stirring motor, a support frame is fixedly connected onto the rotating shaft, oscillating rods are hinged at the upper end and the lower end of the support frame, the hoisting device is arranged on the right side of the mixing device, the upper end and the lower end of the side wall on the left side of the hoisting device are respectively communicated with the interior of the mixing device through a communicating pipe, a hoisting motor is fixedly connected at the top part of the hoisting device, a rotating shaft is arranged in the hoisting device, and a screw blade is fixedly connected onto the surface of the rotating shaft by means of integrated molding. The feeding device regulates the heights of the oscillating rods and a stirring rod toimprove the mixing efficiency and the mixing effect of the materials of the furniture plate, the device uses the hoisting device to hoist the materials in the use process according to the mixing degree of the materials in an outlet, so that the degree of uniformity of mixing is improved.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

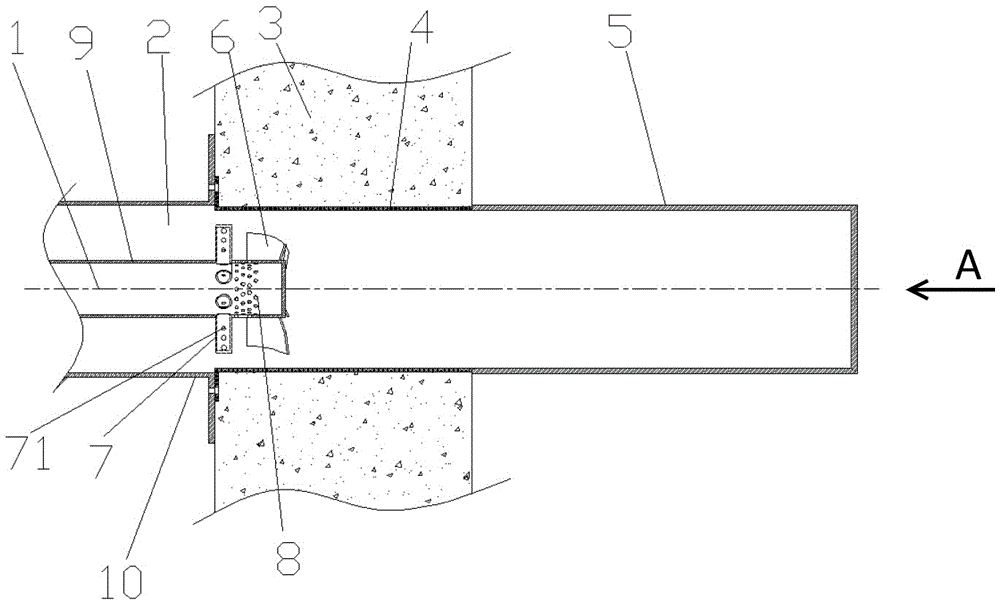

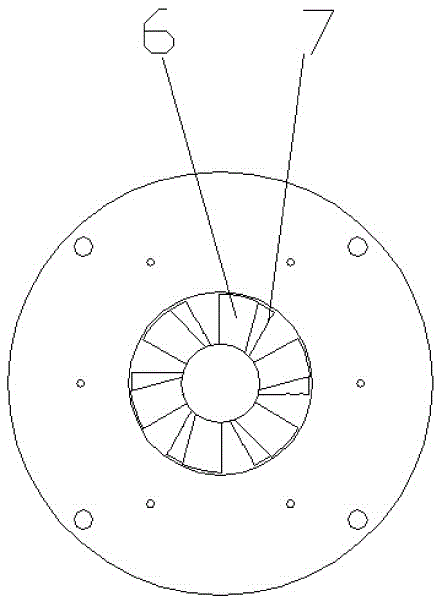

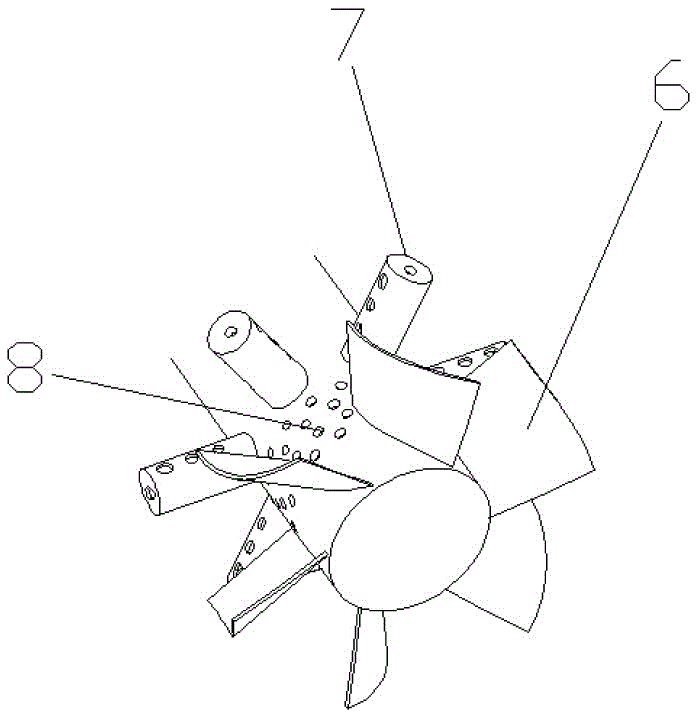

Metal surface combustor and gas premixing method thereof

InactiveCN105546533AShorten the mixing distanceImprove mixing uniformityGaseous fuel burnerCycloneCylindrical channel

The invention discloses a metal surface combustor and a gas premixing method thereof, solves the technical problem that the combustor can uniformly mix gas with combustion air in a shorter premixing channel, and belongs to the technical field of combustion of metal surface combustors. The metal surface combustor is characterized in that a metal throat is a cylindrical channel; the outer side surface is connected with a boiler front wall; one part extending into a hearth is an end-sealed microhole metal cylinder; the other end is connected with an air pipe as a whole; multiple gas spray guns and multiple cyclone blades are arranged at the tail end of the gas pipe in sequence; the gas uniformly enters the throat by spray holes in the gas spray guns and gas pipe holes in the gas pipes; meanwhile, the combustion air and the gas are hedged and uniformly mixed in the throat; and under stirring of the cyclone blades at the end part of the gas pipe, the uniform mixing is further accelerated, so that the mixing distance is shortened, the flame temperature nonuniformity caused by nonuniform gas mixing is effectively prevented, and the NOx emission is reduced.

Owner:新疆海天祥瑞环保工程有限公司

EGR (exhaust gas recirculation) mixing device

ActiveCN104653354AWell mixedImprove mixing uniformityInternal combustion piston enginesNon-fuel substance addition to fuelProcess engineeringExhaust gas recirculation

The invention discloses an EGR (exhaust gas recirculation) mixing device, which comprises a gas mixer and an EGR mixer, wherein the gas mixer is used for mixing air and gas; the EGR mixer is communicated with a mixture gas outlet of the gas mixer; the EGR mixer comprises an EGR mixer body and EGR branch pipes arranged in the EGR mixer body; the inner wall of each EGR branch pipe and the inner wall of the EGR mixer body are both provided with a plurality of waste gas orifices used for spraying waste gas into the EGR mixer body. According to the EGR mixing device, the mixing evenness degree of the waste gas, the air and natural gas is higher, and reaches a top level in the industry.

Owner:成都耐尔特科技有限公司

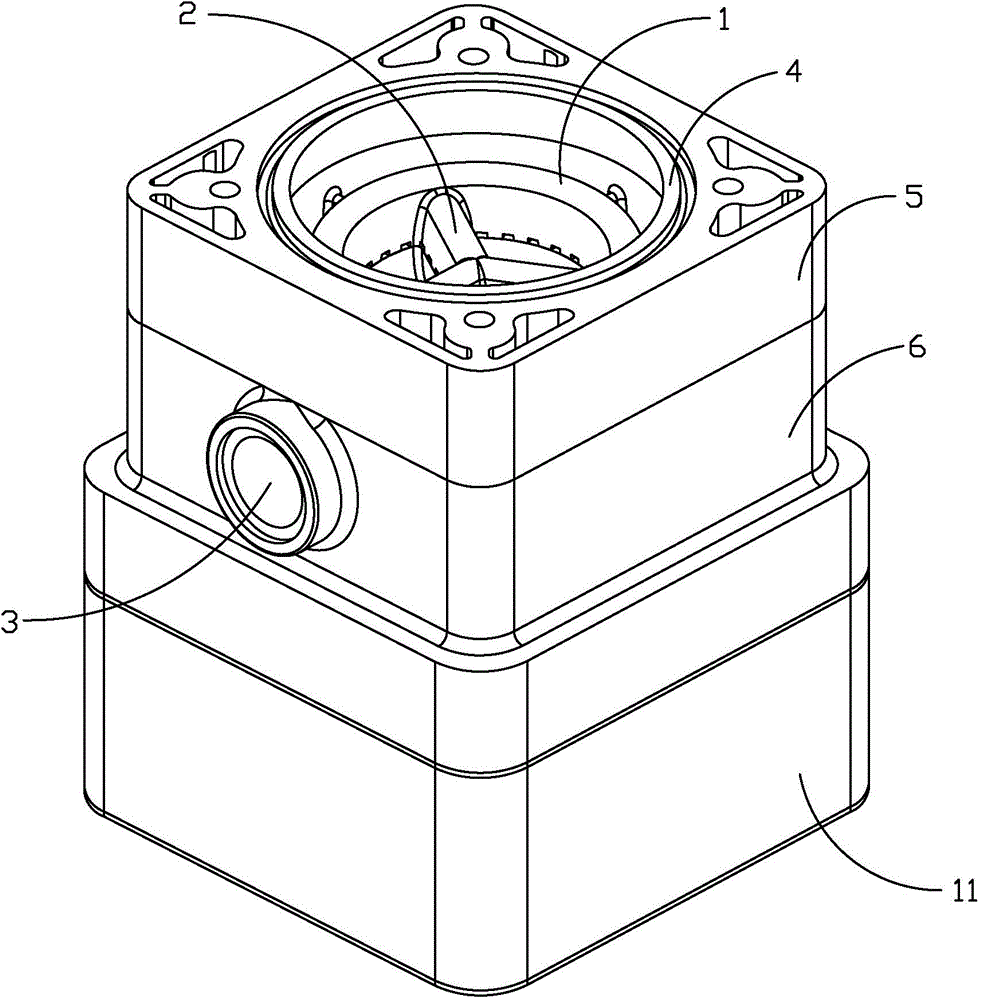

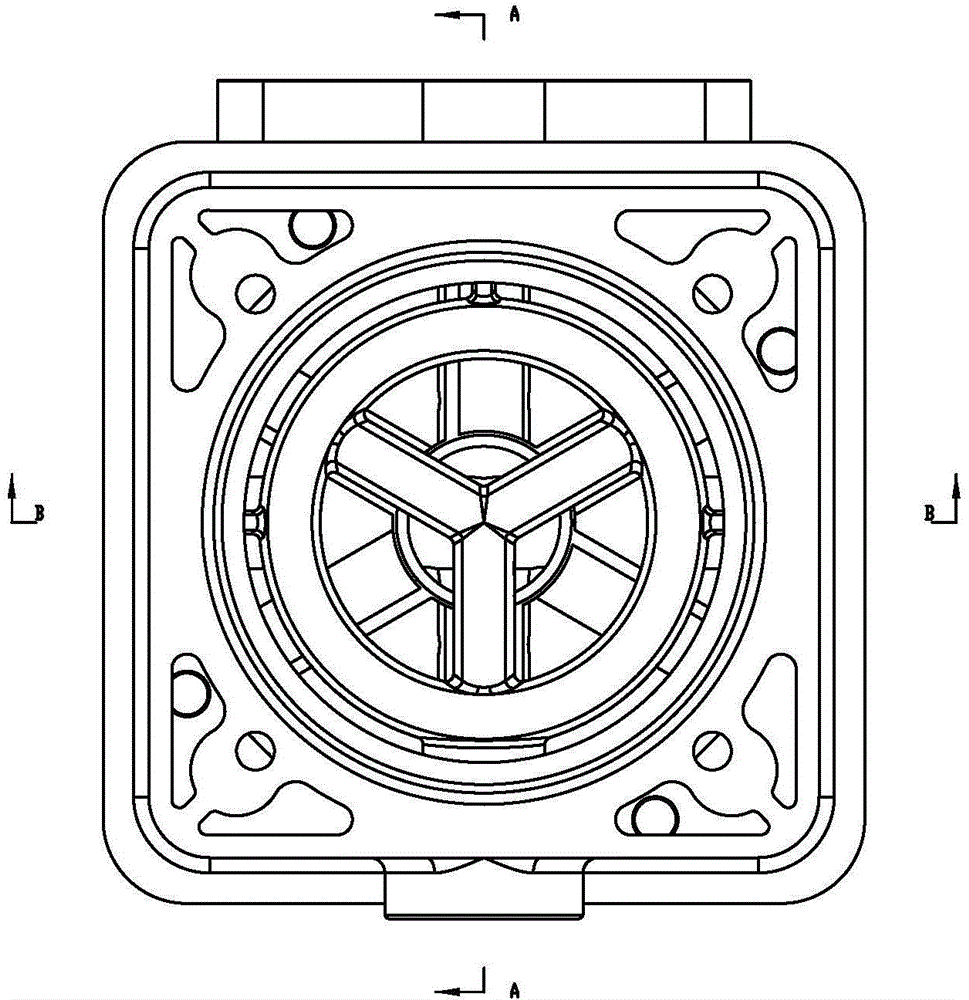

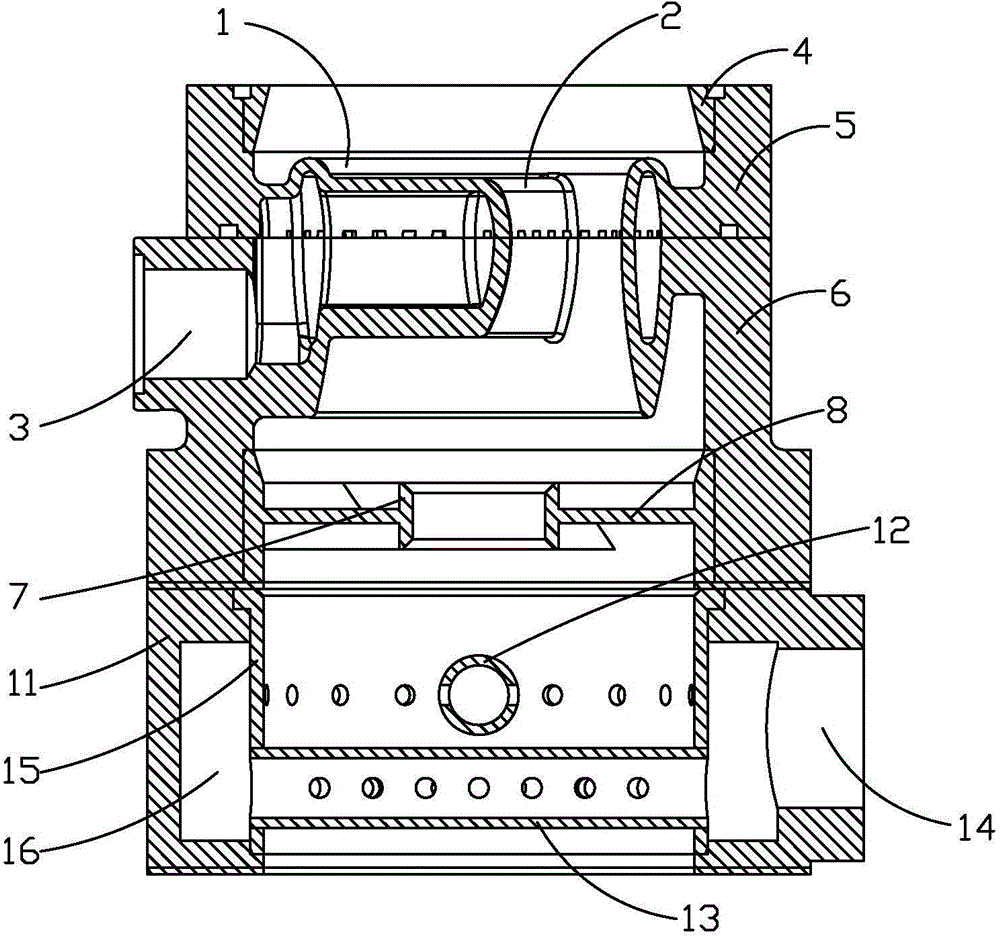

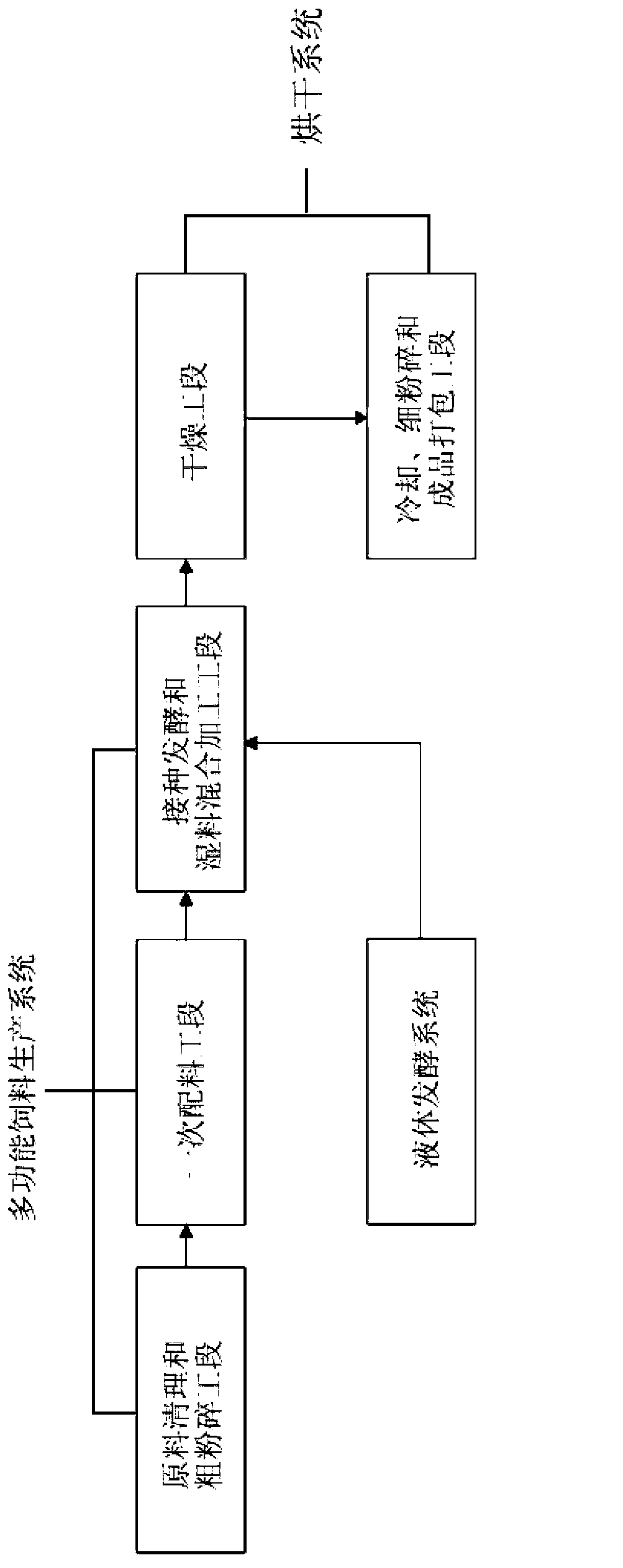

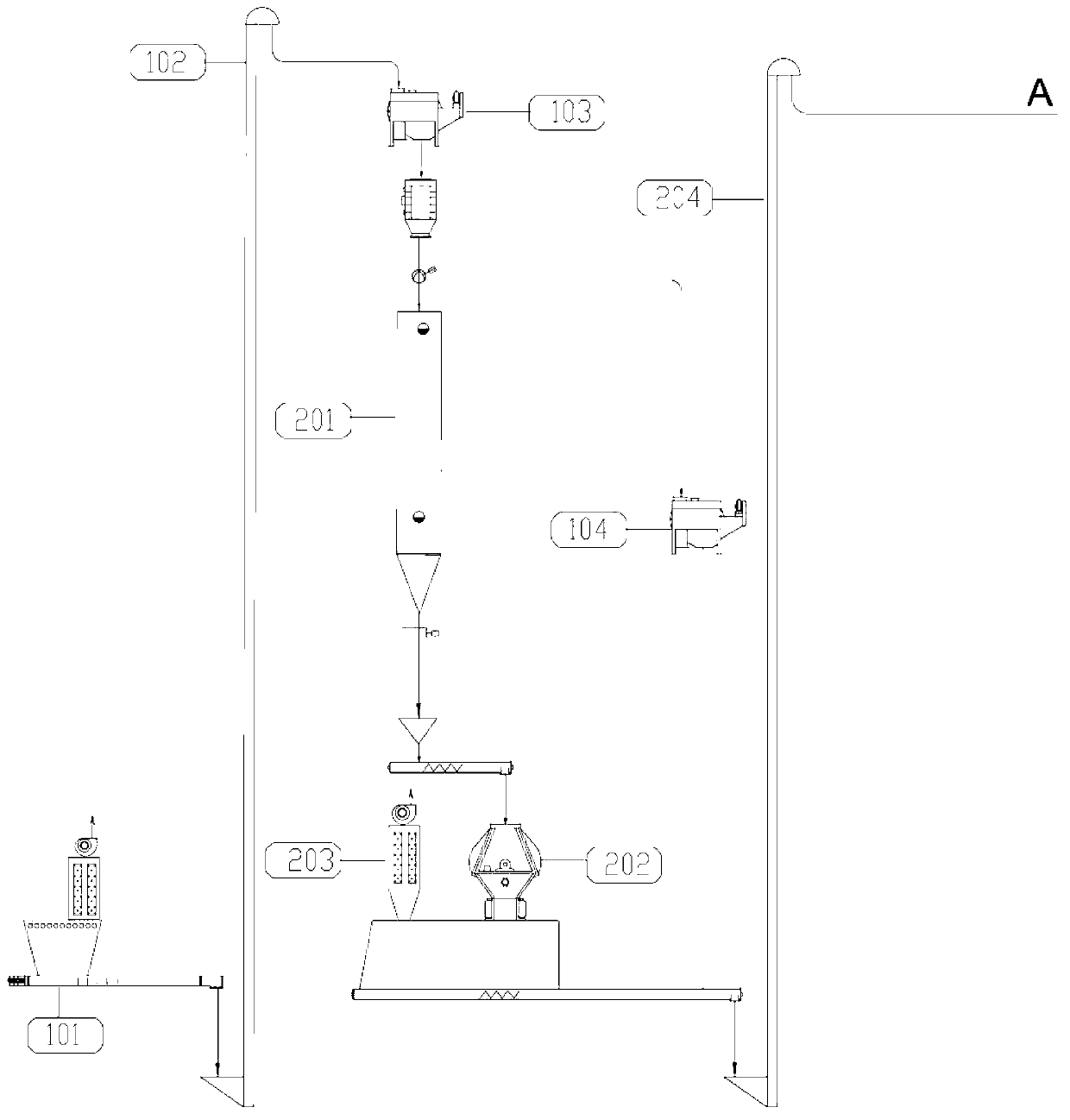

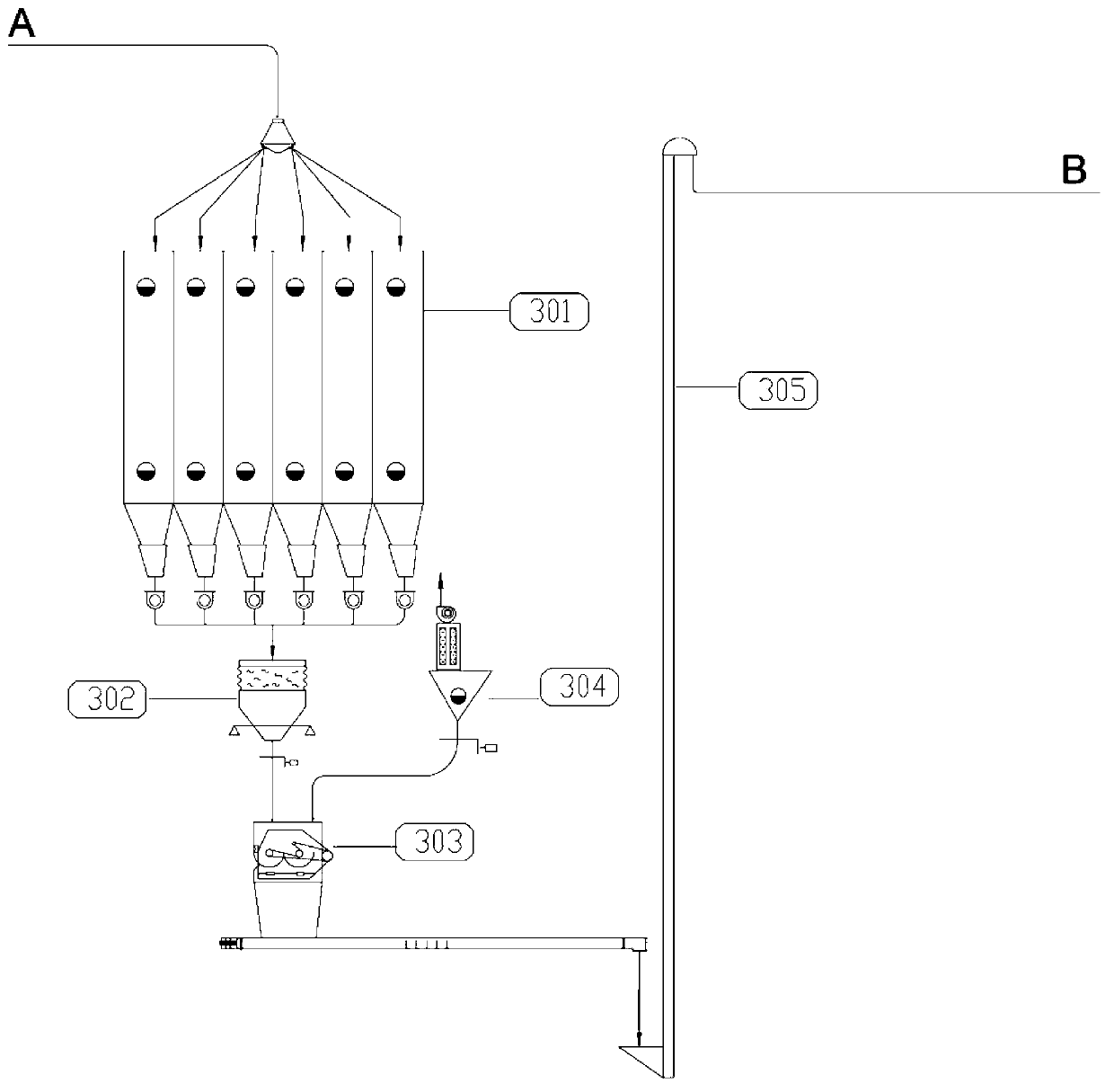

Production device and method of biological feeds

ActiveCN103126042ARealize continuous mass productionPrevent rustFeeding-stuffWork performanceAutomation

The invention provides a production device of biological feeds. The production device is composed of a multifunctional feed production system, a liquid fermentation system and a drying system, the multifunctional feed production system further comprises a raw material clearing and coarse grinding working section, a primary burdening working section and an inoculation fermentation and wet material mixing production working section, and the drying system further comprises a drying working section and a cooling, refine smashing and end product packing working section. The feed production device and a method are high in automation and mechanization degree, stable in working performance, high in work efficiency and simple and convenient to operate and achieve industrialization and large-scale production of probiotic fermented feeds.

Owner:张有聪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com