Circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages

A combustion chamber and intermediate stage technology, which is applied in the field of circumferentially graded low-polluting combustion chambers, can solve the problems of lean oil and unstable combustion in the main combustion area of the combustion chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

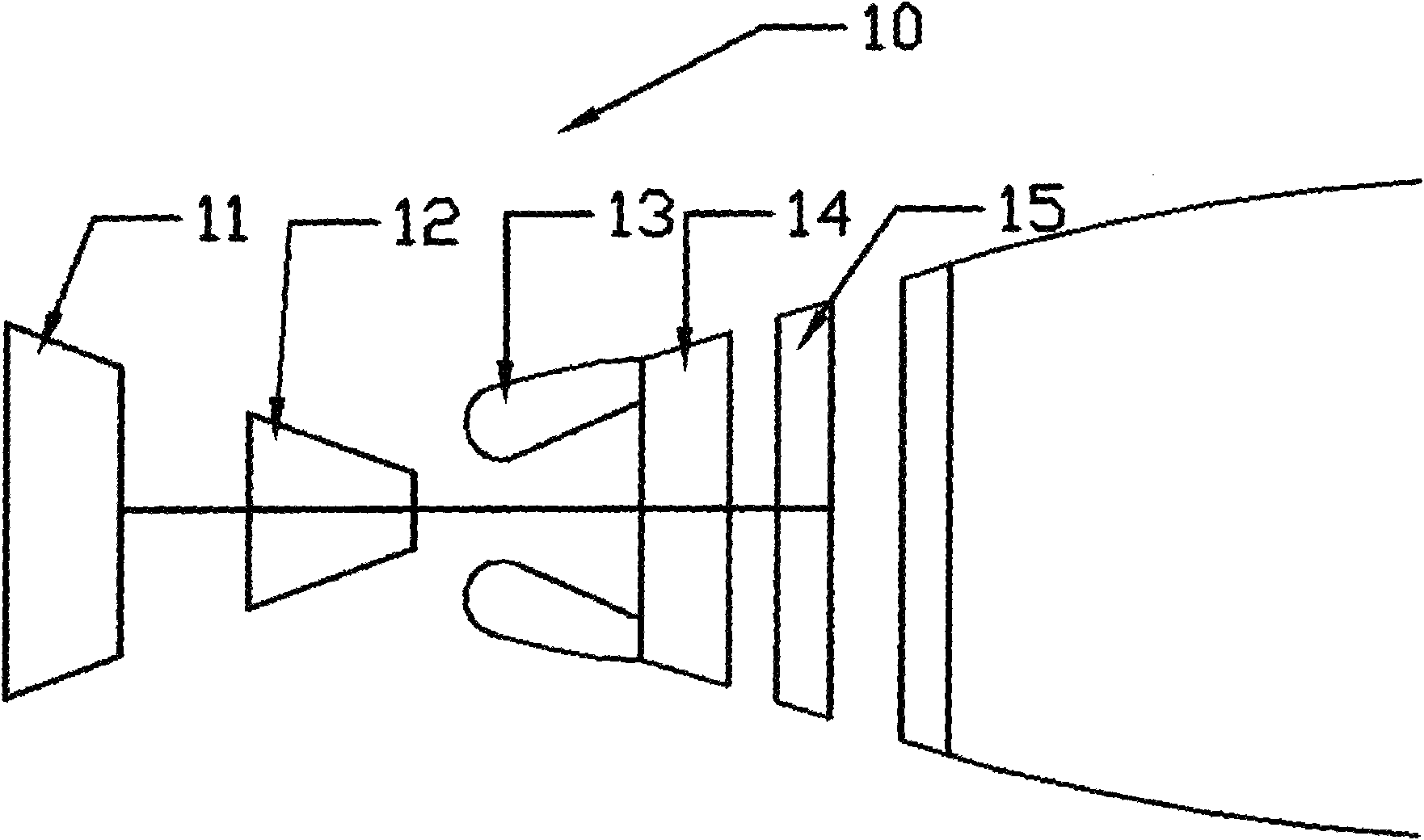

[0036] figure 1 is a schematic diagram of the engine 10 . Engine 10 includes a low-pressure compressor 11 , a high-pressure compressor 12 , a combustion chamber 13 , a high-pressure turbine 14 and a low-pressure turbine 15 . When the engine 10 is working, the air enters the high-pressure compressor 12 after being compressed by the low-pressure compressor 11, and the high-pressure air enters the combustion chamber 13 of the present invention to burn, and the fuel injection system injects fuel into the high-pressure airflow, and the fuel injection system in the combustion chamber 13 is fully and effectively burned, and the high-temperature and high-pressure gas formed enters the high-pressure turbine 14 and the low-pressure turbine 15, thereby pushing the turbines to do work.

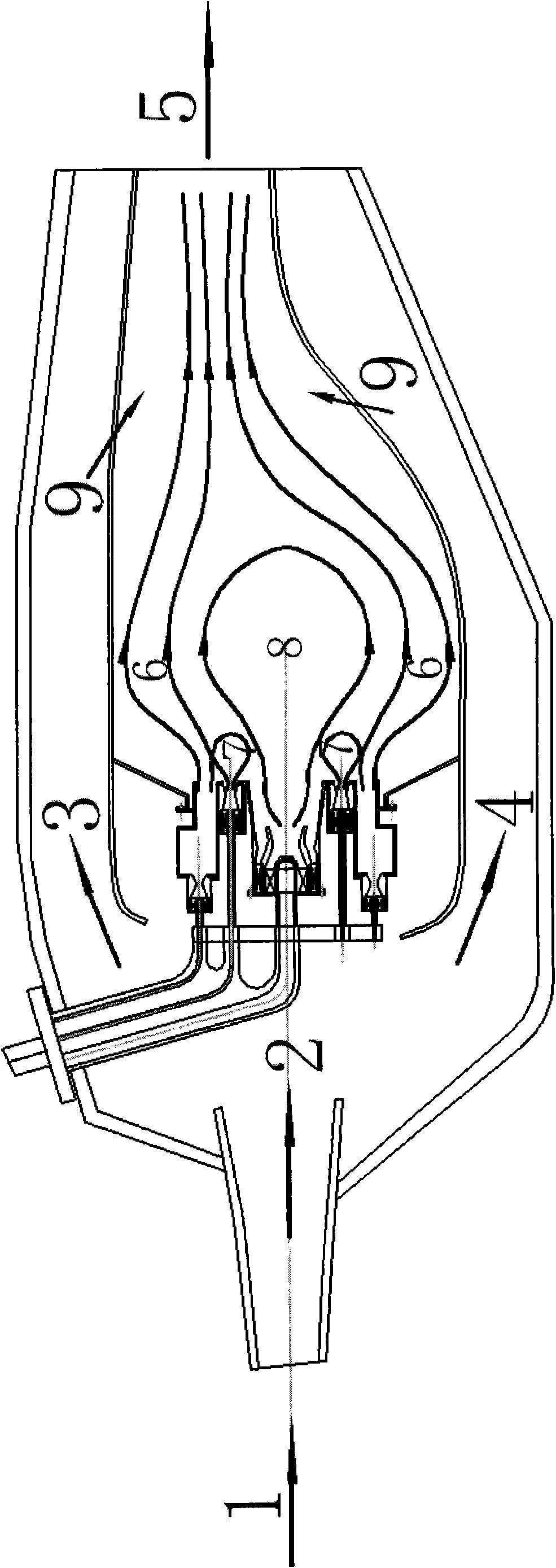

[0037] figure 2 It is a working schematic diagram of a circumferentially graded low-pollution combustion chamber with multi-swirl intermediate flame-stabilizing stages designed by the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com