Balance control method for temperature field of utility boiler furnace

A furnace temperature and balance control technology is used in the field of power station boiler furnace temperature field control, power station boiler furnace temperature field balance control, and four-corner tangential coal-fired units, which can solve problems such as uneven furnace temperature field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The embodiment of the present invention adopts the following steps:

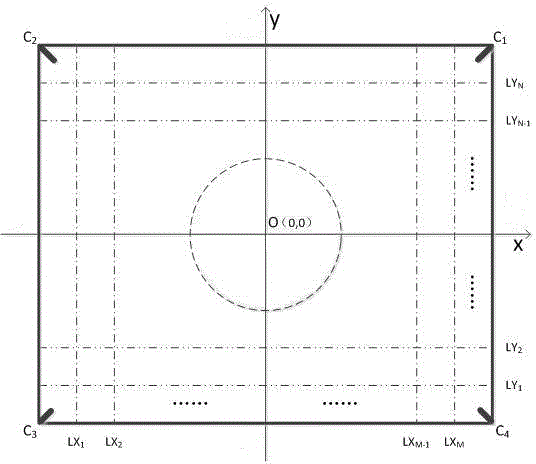

[0067] Step 1. Establish the reference coordinate system of the furnace section:

[0068] Take the geometric center of the furnace section as the origin of the reference coordinate system, take the line passing through the origin and along the transverse direction of the furnace section as the X axis of the reference coordinate system, and use the line passing the origin and along the longitudinal direction of the furnace section as the Y axis of the reference coordinate system;

[0069] Step 2: Arrange temperature sensors in the transverse and longitudinal directions of the furnace section:

[0070] 6 straight lines are evenly arranged on the furnace section parallel to the Y-axis to form 6 temperature measurement paths, from left to right are LX 1 , LX 2 ,..., LX n ,..., LX 6 , The temperature measuring devices are arranged on the 6 measuring paths, and the X-axis coordinates corresponding to each measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com