Patents

Literature

968results about "Molten metal pouring equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

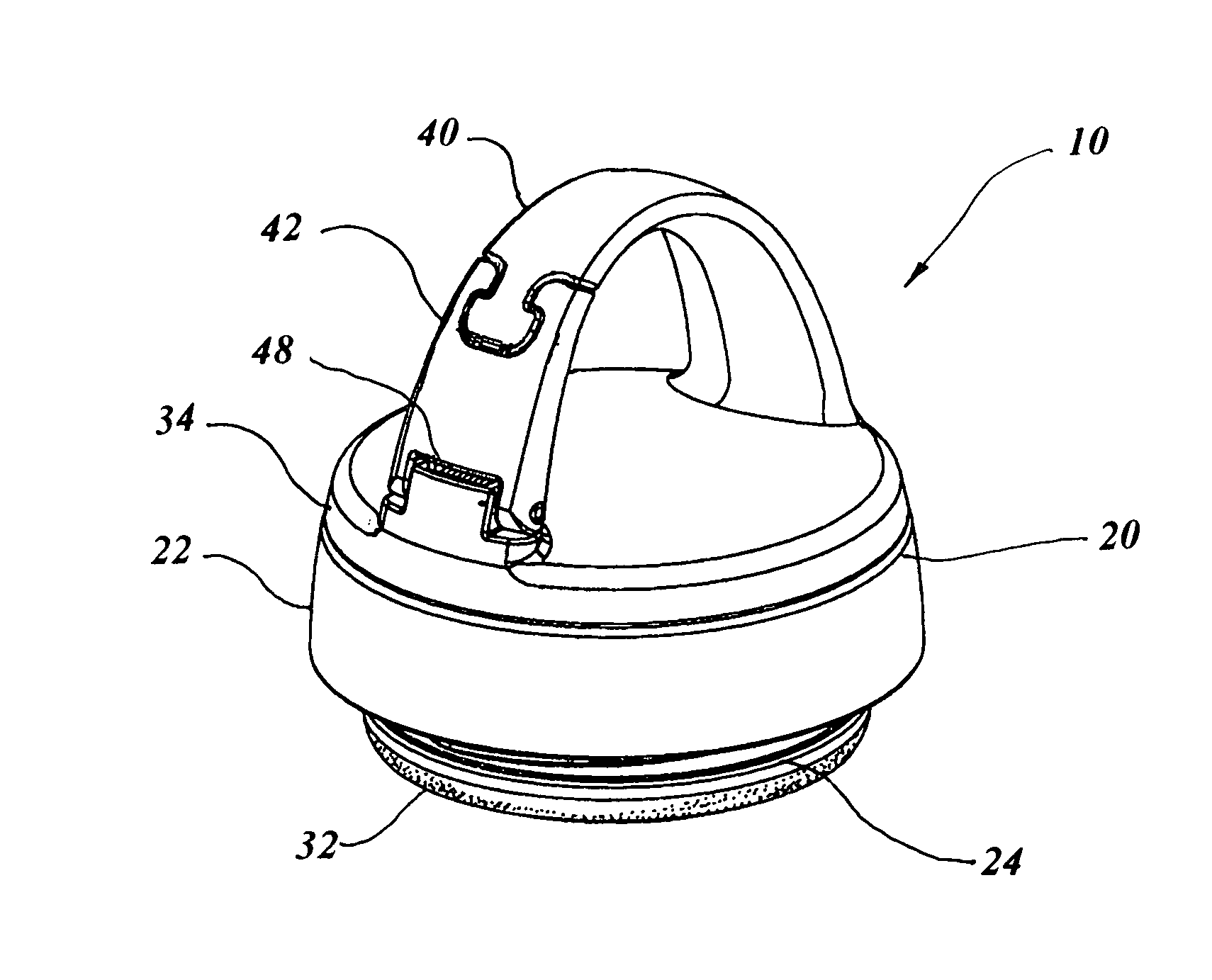

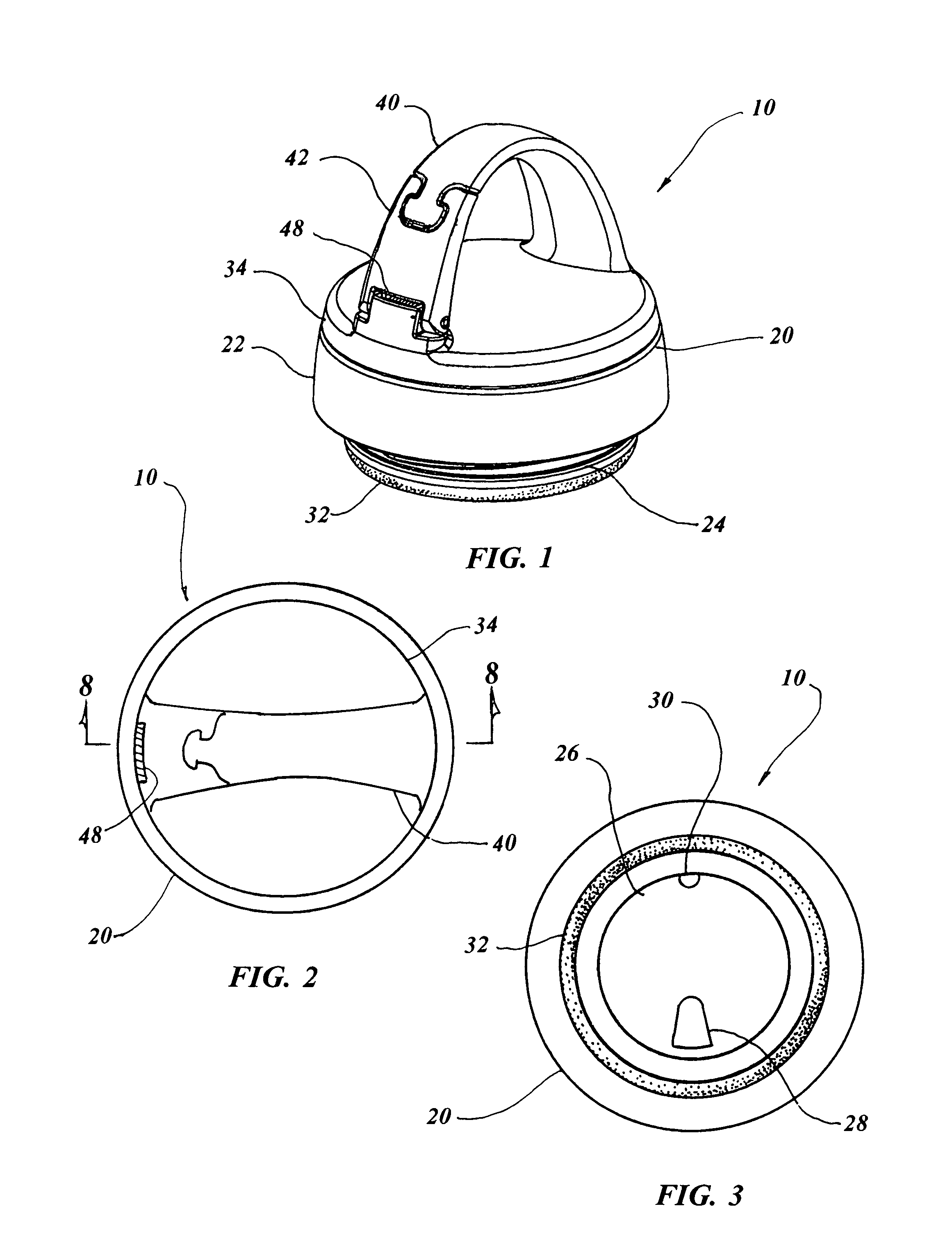

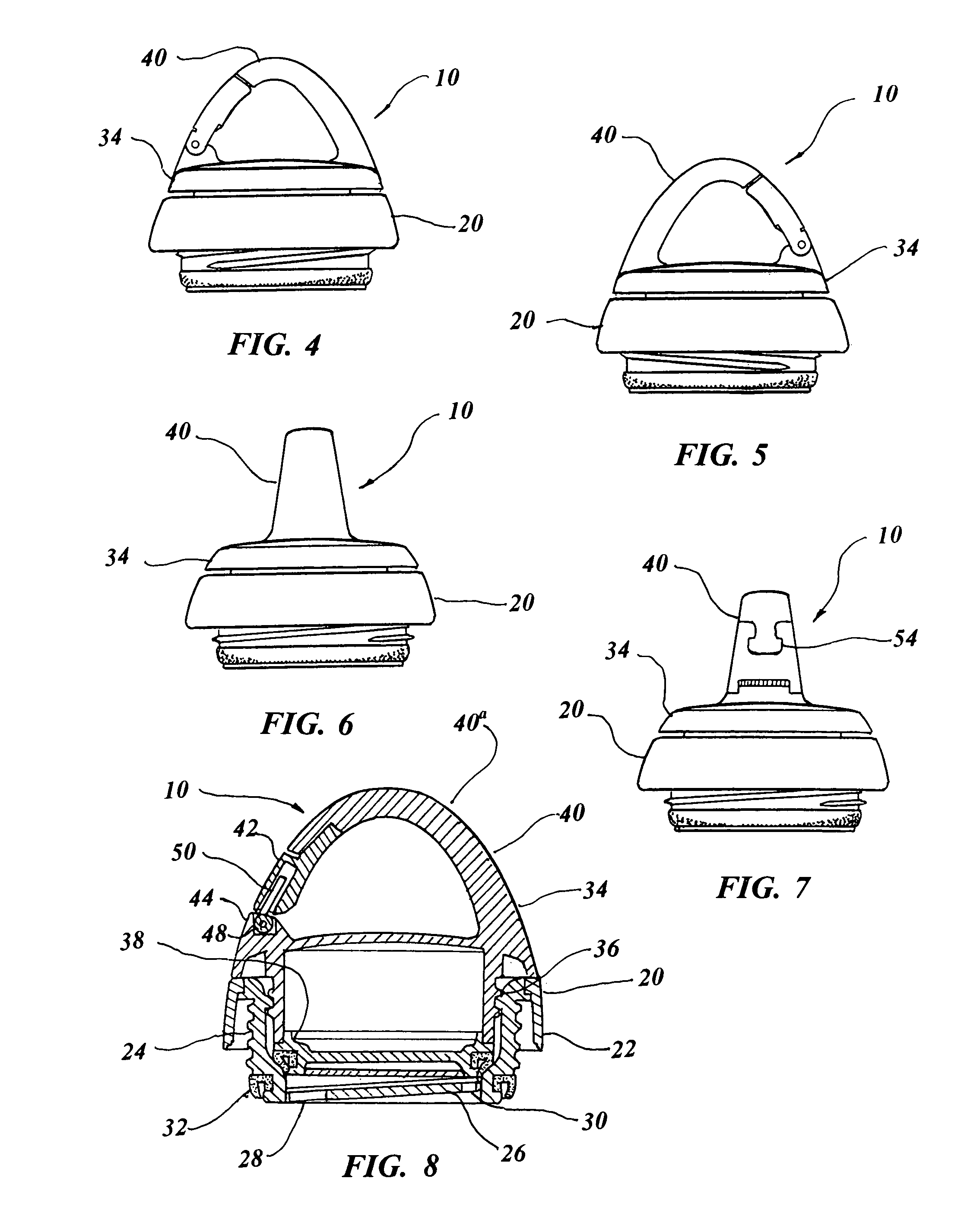

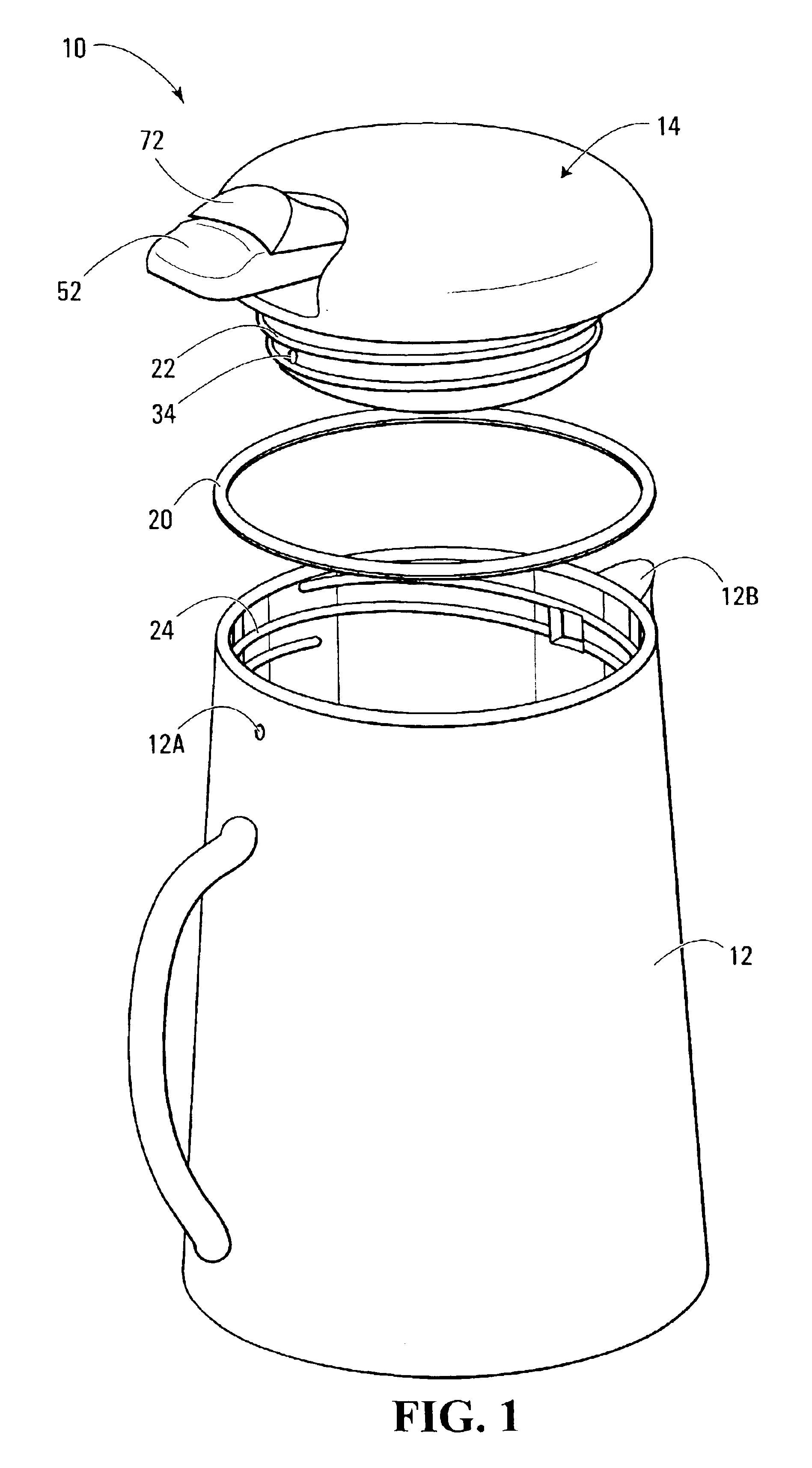

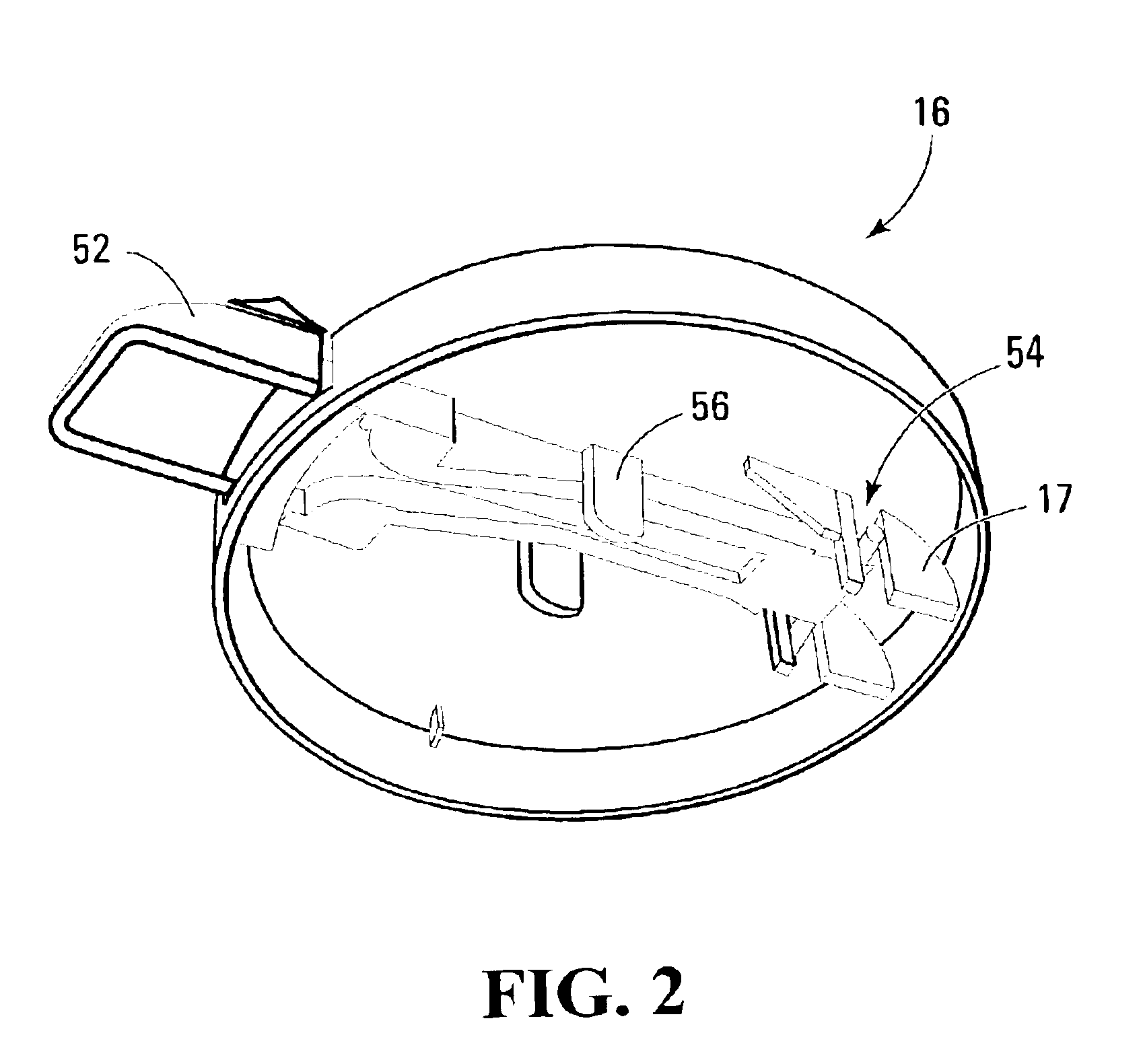

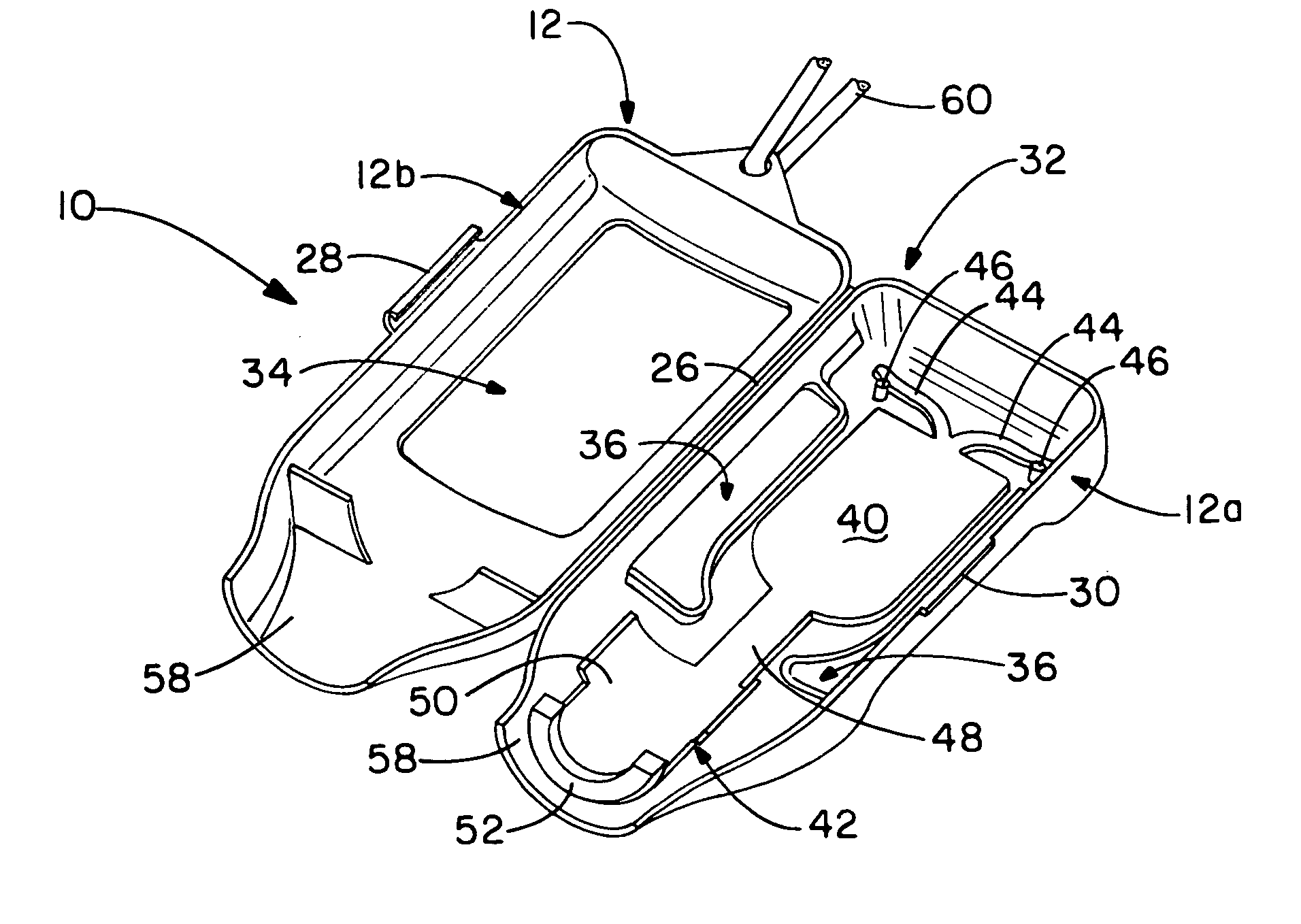

Latched handle container lid

A container lid with a latch handle is taught that incorporates a drinking lip, having a flared brim, configured to interface with a liquid container. A lip sealing ring is disposed on the drinking lip creating a watertight fit between the lip and the container. A lid body, having lid male threads, is configured to interface with container lid female threads, and the lid body includes a bottom cover which forms a dead air space for insulation purposes within the lid. The lid body incorporates a vertical arched handle with a snap-in hinged spring loaded latch for quick release attachment of the container lid and container securely to an object. A lid sealing ring is disposed on the lid body forming a watertight fit between the lid body and the container drinking lip.

Owner:LIN SHIN SHUOH

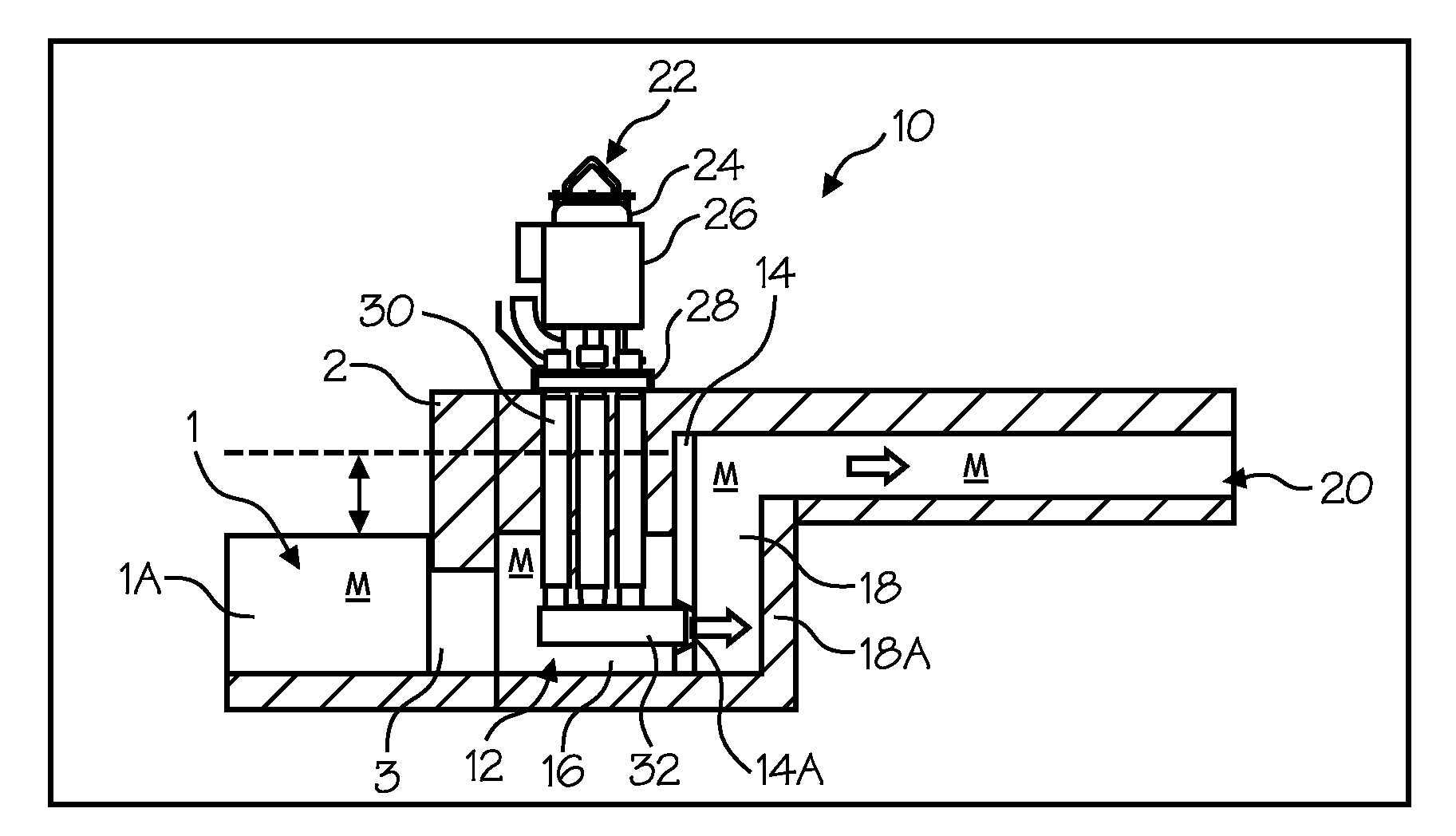

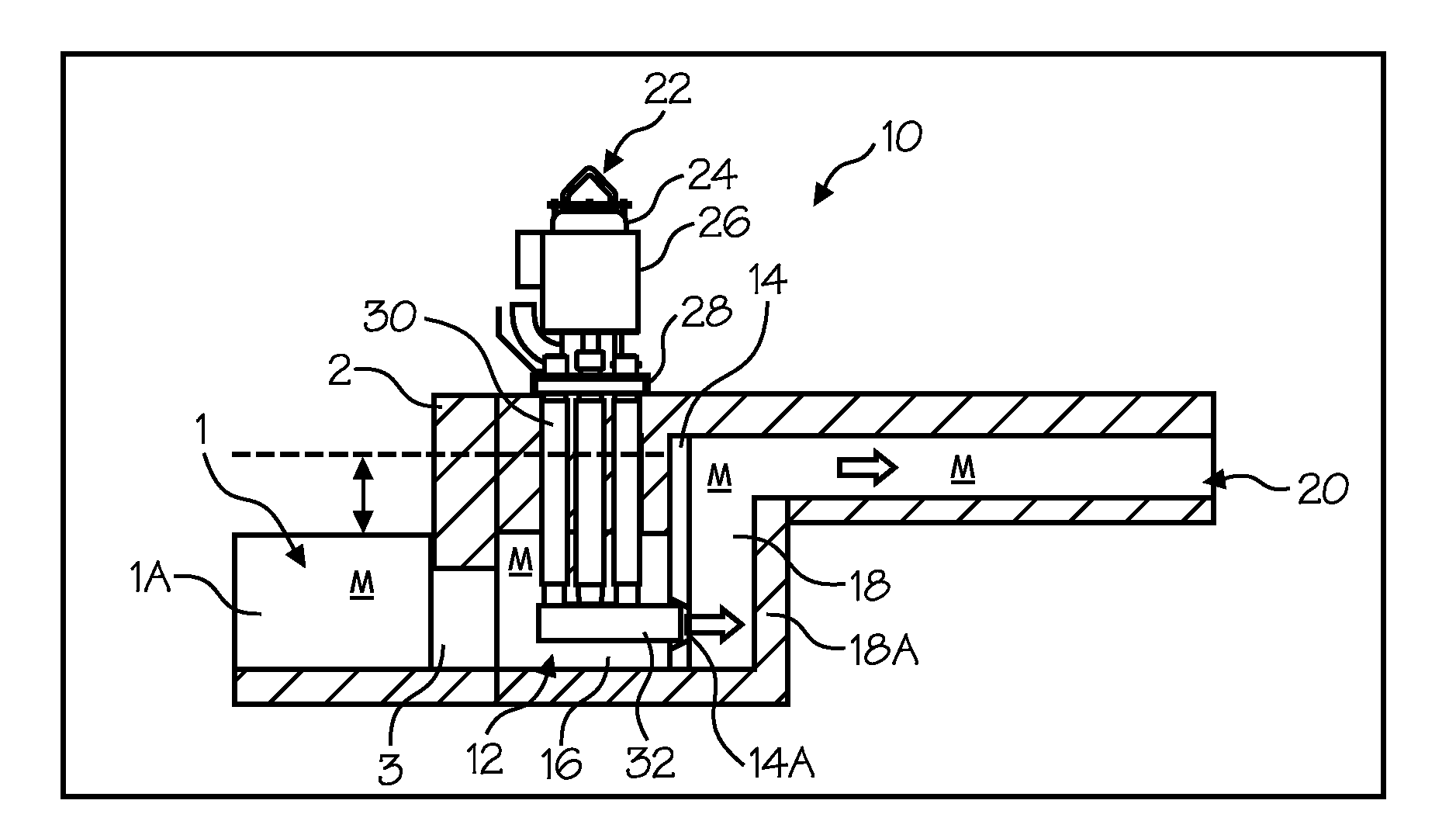

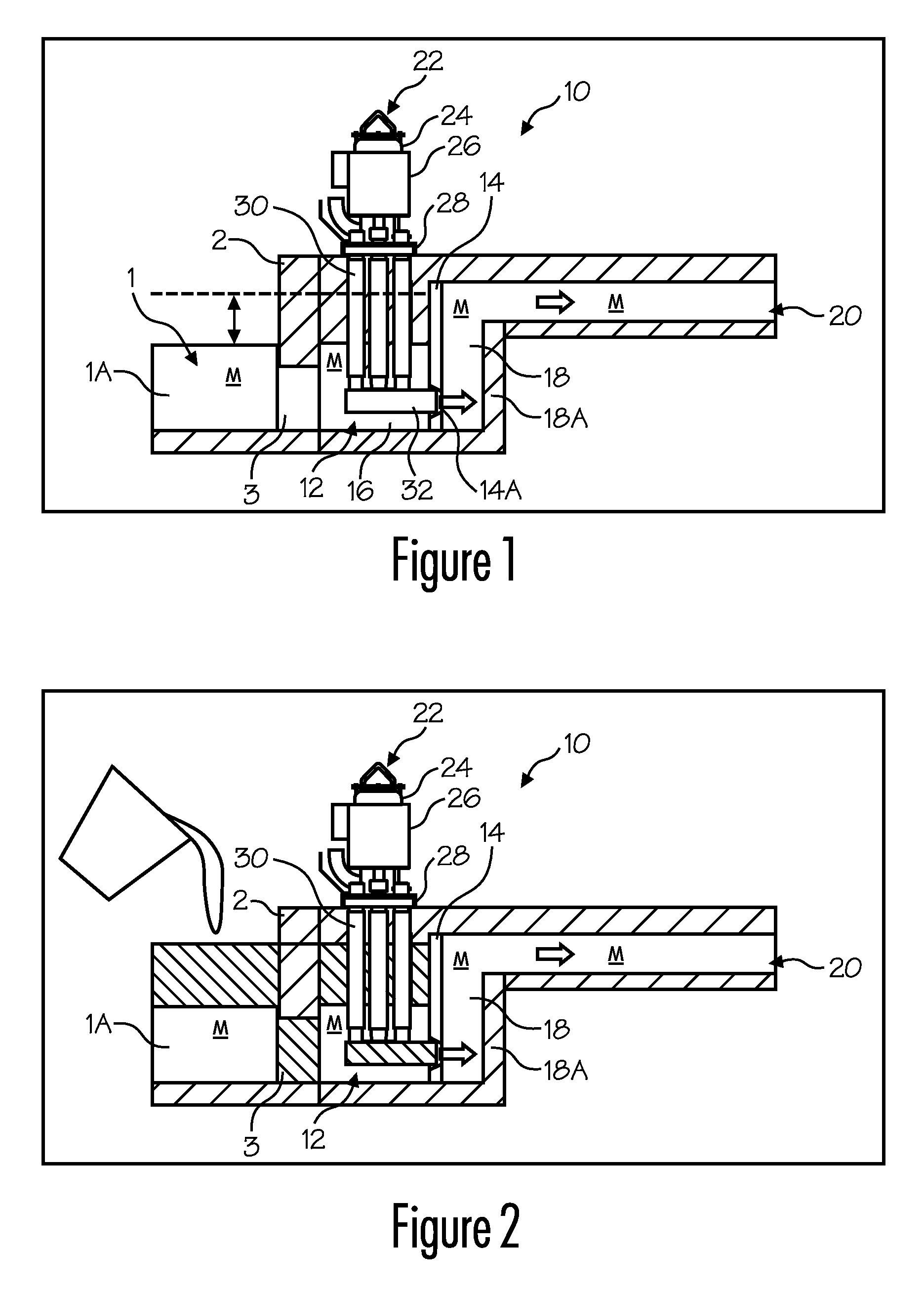

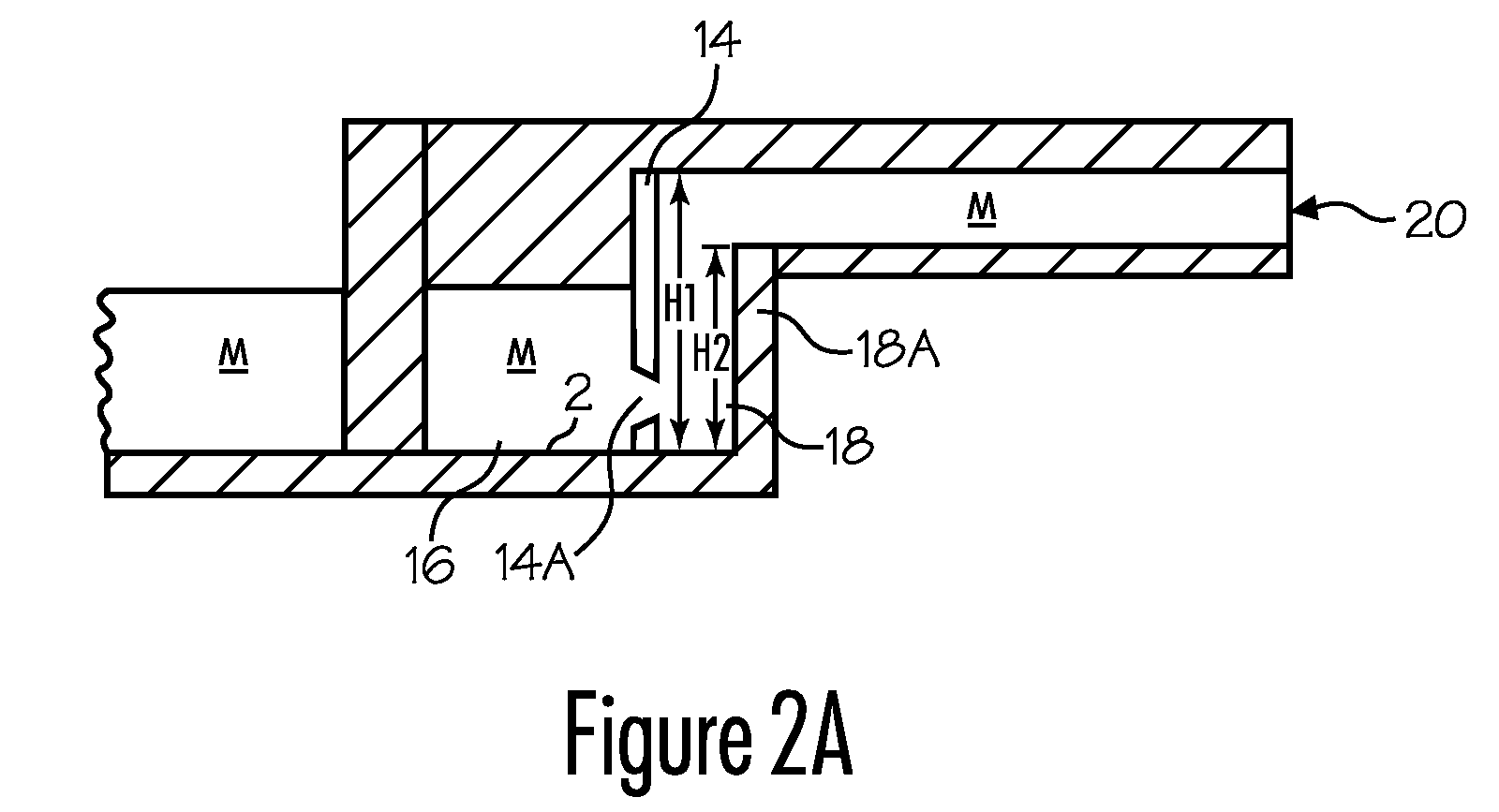

Transferring molten metal from one structure to another

ActiveUS20080314548A1Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsMolten metal supplying equipmentsDie castingMolten metal

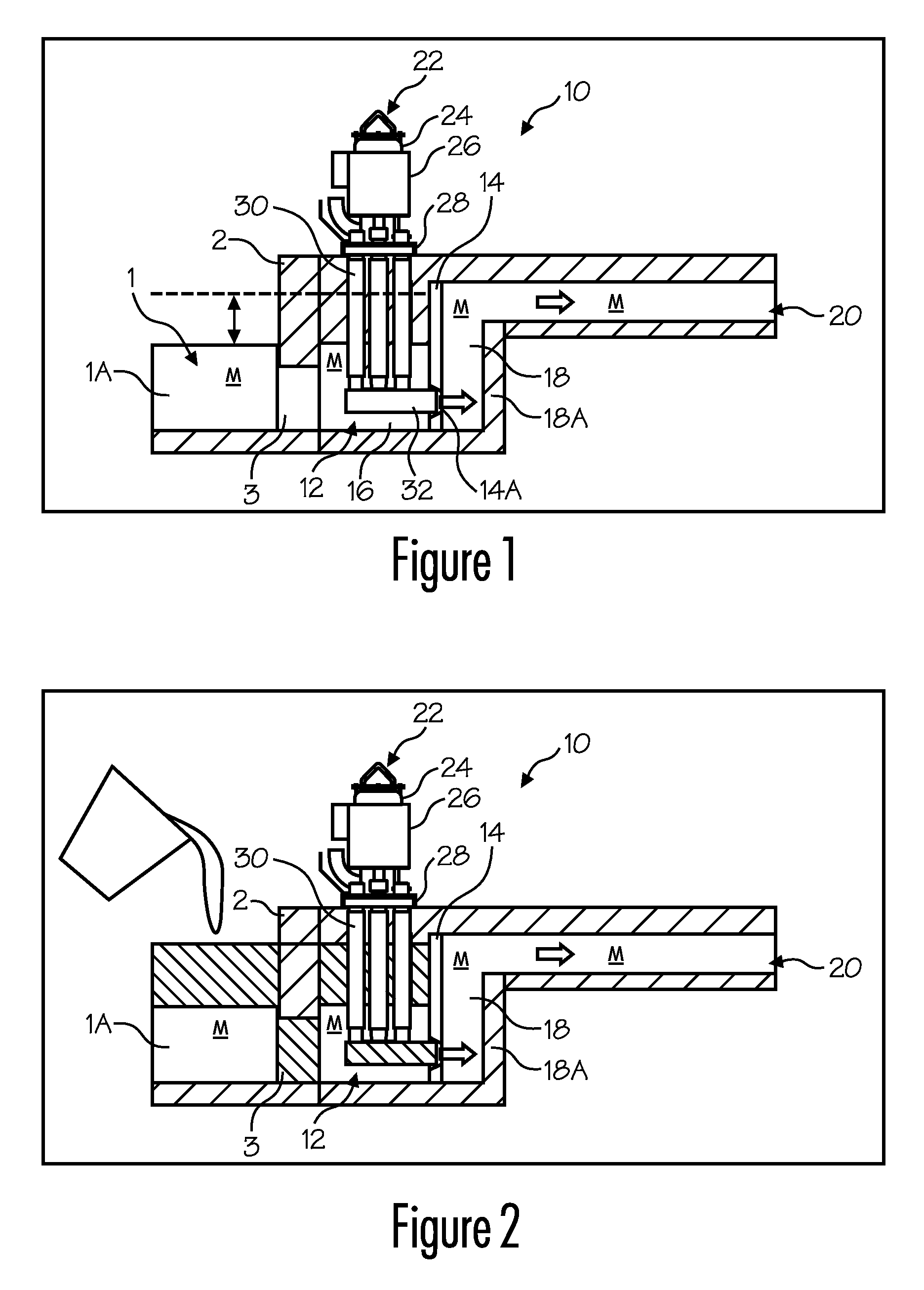

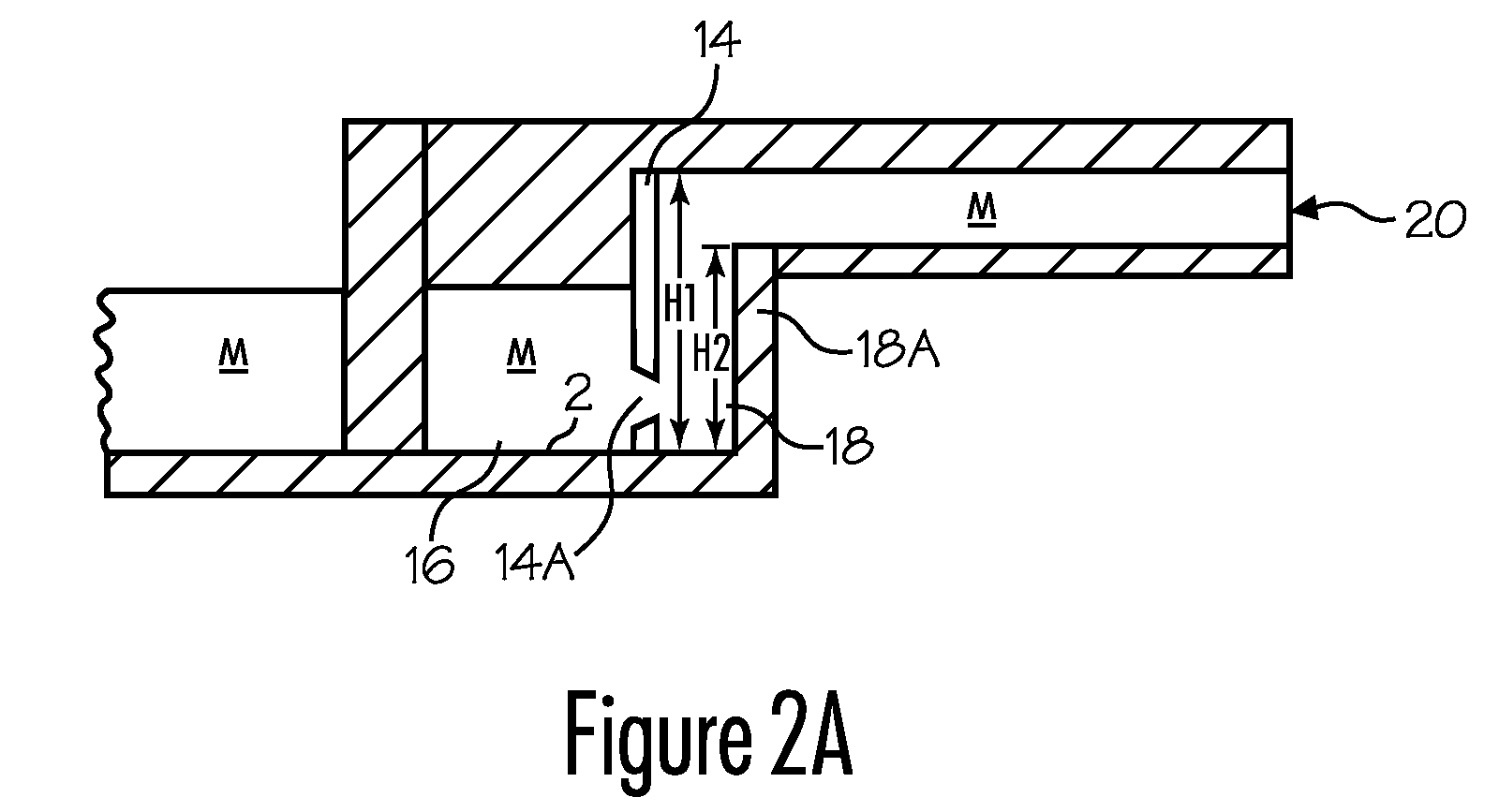

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

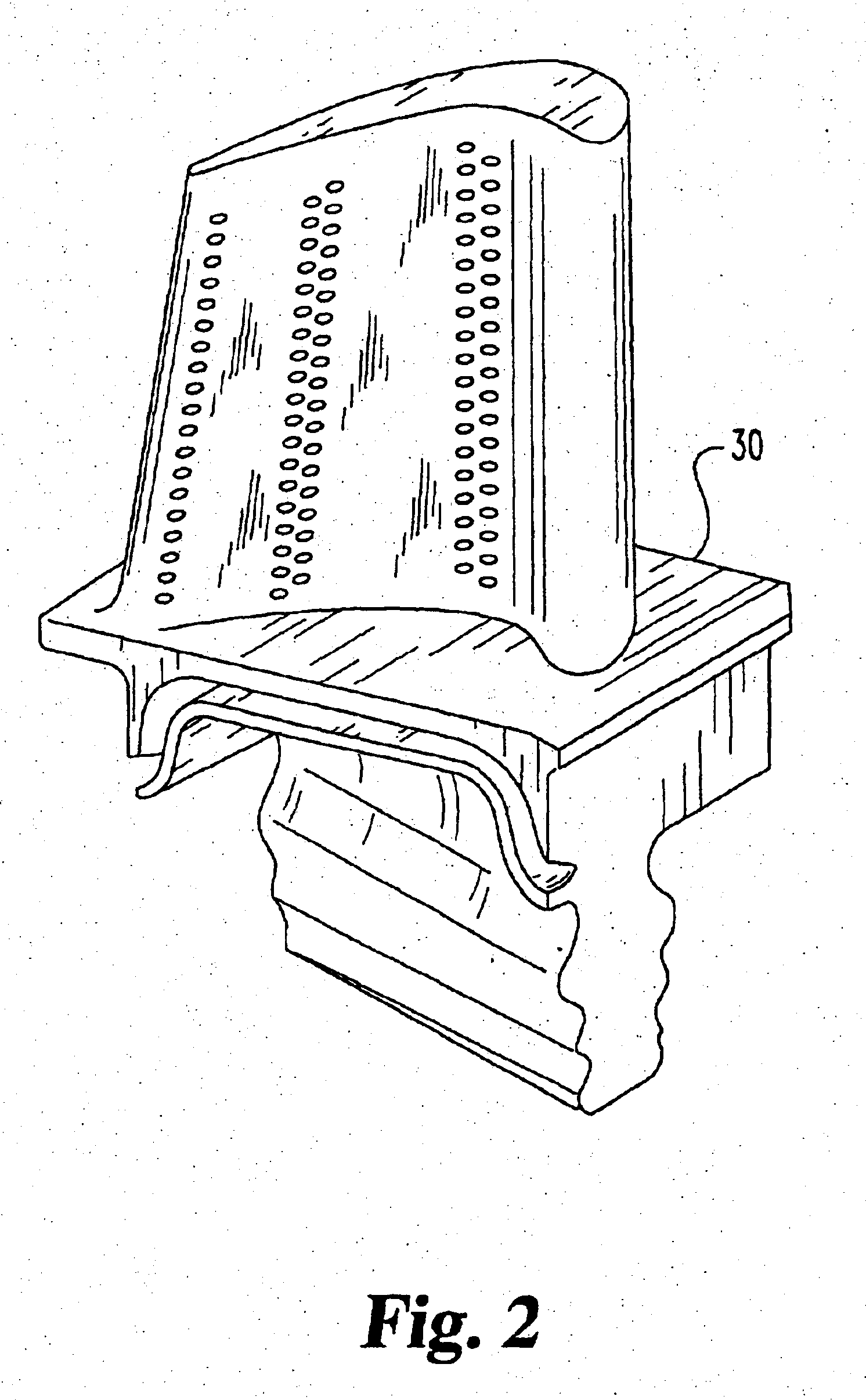

Bonded particle filters

InactiveUS7157043B2Significant portionMelt-holding vesselsMolten metal pouring equipmentsMolten metalMaterials science

An apparatus for filtering molten metal held in a vessel before the metal enters the dosing tube. The filtering apparatus includes an attachment portion that mounts to the dosing tube, a filter body connected to the attachment portion and a planar surface attached to an end of the filter body opposite the attachment portion. The filter body can include a beveled end opposite the attachment portion where the planar surface is attached. The apparatus can be made from a bonded-particle material made from silicon carbide or aluminum oxide held together by an aluminum-resistant binder.

Owner:METAULLICS SYST +1

Molten metal pressure pour furnace and metering valve

InactiveUS7279128B2Avoid flowMelt-holding vesselsMolten metal pouring equipmentsDifferential pressureMetallurgy

An apparatus and process are provided for discharging a dose of a molten metal from a pressure pour furnace. A heating chamber of the furnace is used to keep the molten metal at a selected temperature. A sealing port between the heating chamber and a pressure chamber allows selectively filling of the pressure chamber with molten metal from the heating chamber by inserting or removing a sealing means from the sealing port. The sealing means inserted in the sealing port also provides a means for preventing back flow of the molten metal to the heating chamber when the pressure chamber is pressurized. Differential pressure sensing of the pressure of the molten metal in the pressure chamber and the pressure of the pressurizing gas in the pressure chamber can optionally be used to achieve an accurate measured discharge from the pressure chamber as the level of molten metal decreases from repeated discharges of doses from the furnace. The sealing plate in which the sealing port is disposed and the sealing means selectively inserted or removed from the sealing port can be used as a metering valve between two molten metal containing components such as a launder and a pressure chamber of a pressure pour furnace.

Owner:HI T E Q

Investment casting mold design and method for investment casting using the same

ActiveUS7231955B1Molten metal pouring equipmentsMolten metal supplying equipmentsInvestment castingCasting mold

A method for investment casting includes the steps of positioning a base plate relative to a die; molding a first material between the die and at least a first surface portion of the base plate; securing one or more patterns to the base plate, the one or more patterns comprising a second material; applying one or more coating layers over at least portions of the one or more patterns and at least a portion of the first material; substantially removing the first material through an interior receptacle of a manifold body and the second material through an exterior receptacle of the manifold body to leave one or more shells formed by the coating layers; removing said base plate; introducing molten metal to the one or more shells through the interior receptacle of the manifold body; permitting the molten metal to solidify; and destructively removing one or more investment casting molds.

Owner:RTX CORP

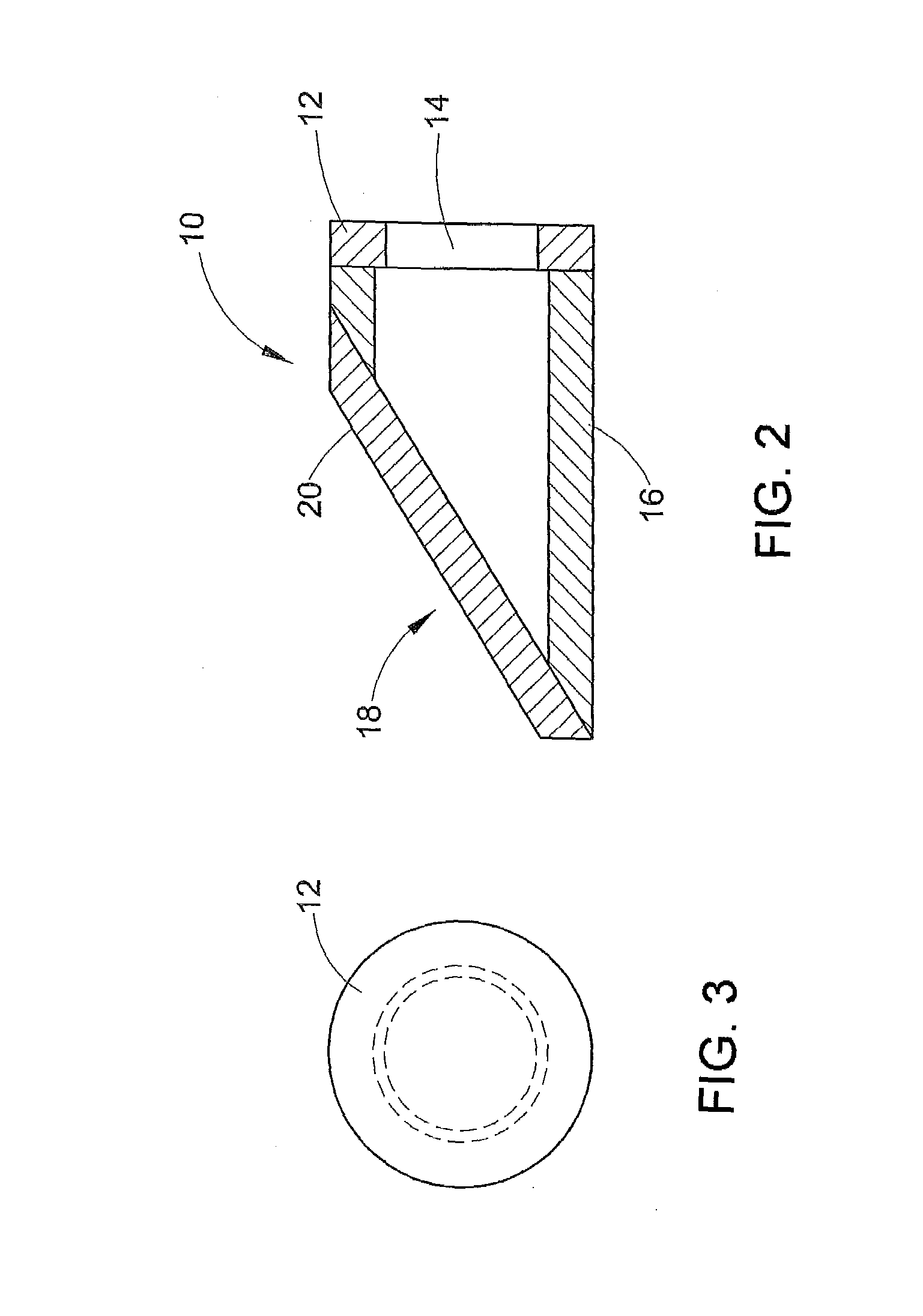

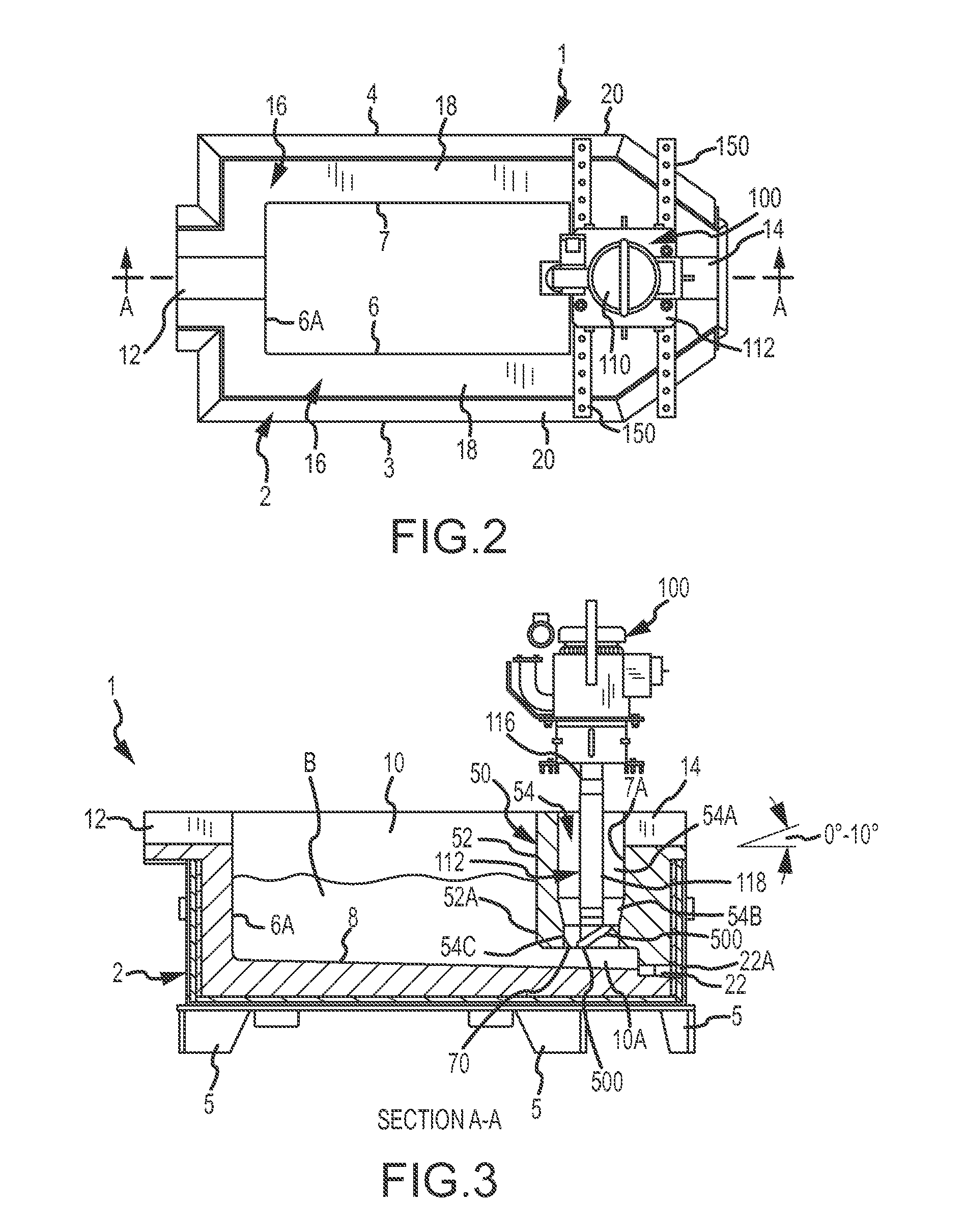

Method of forming transfer well

ActiveUS20160082507A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

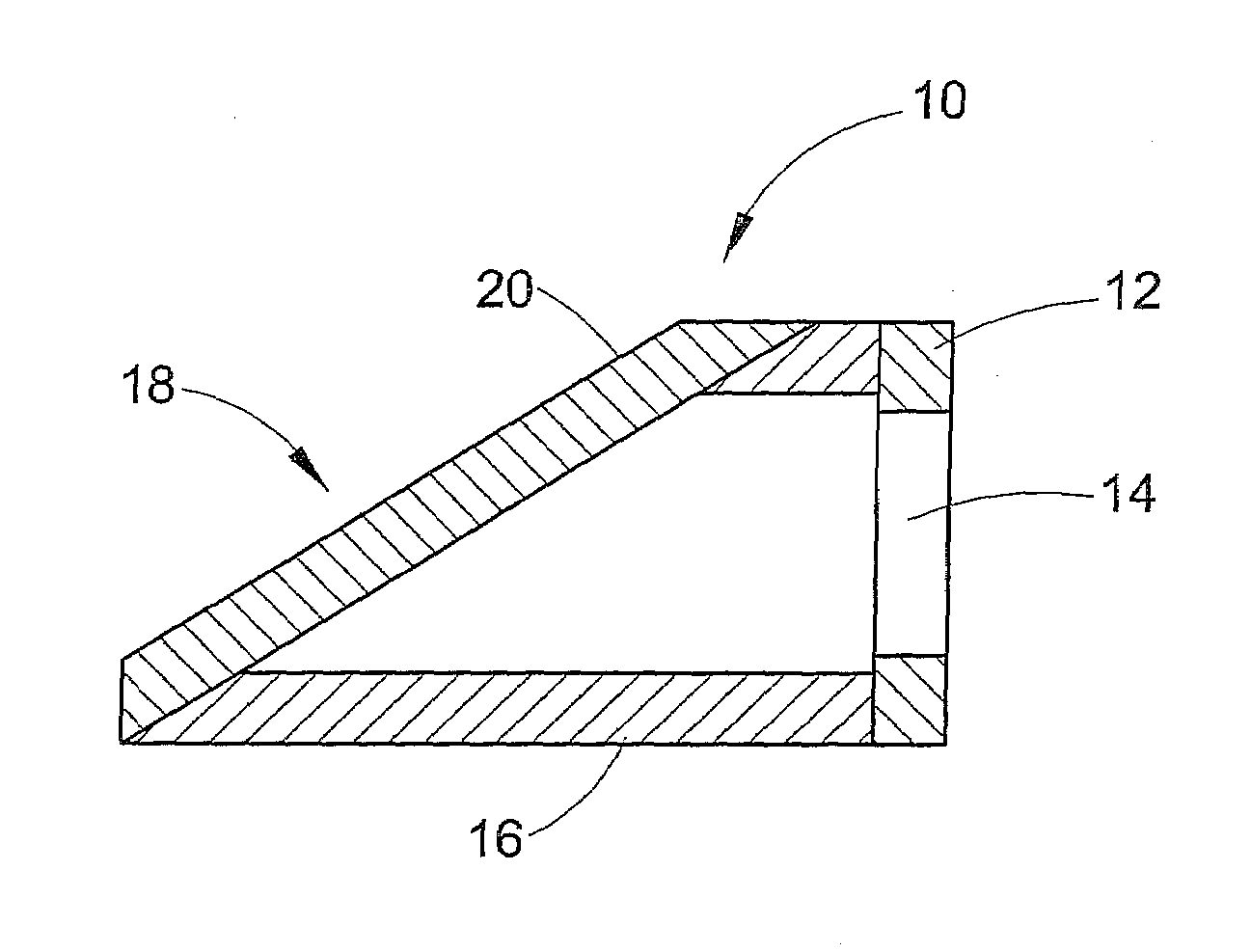

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

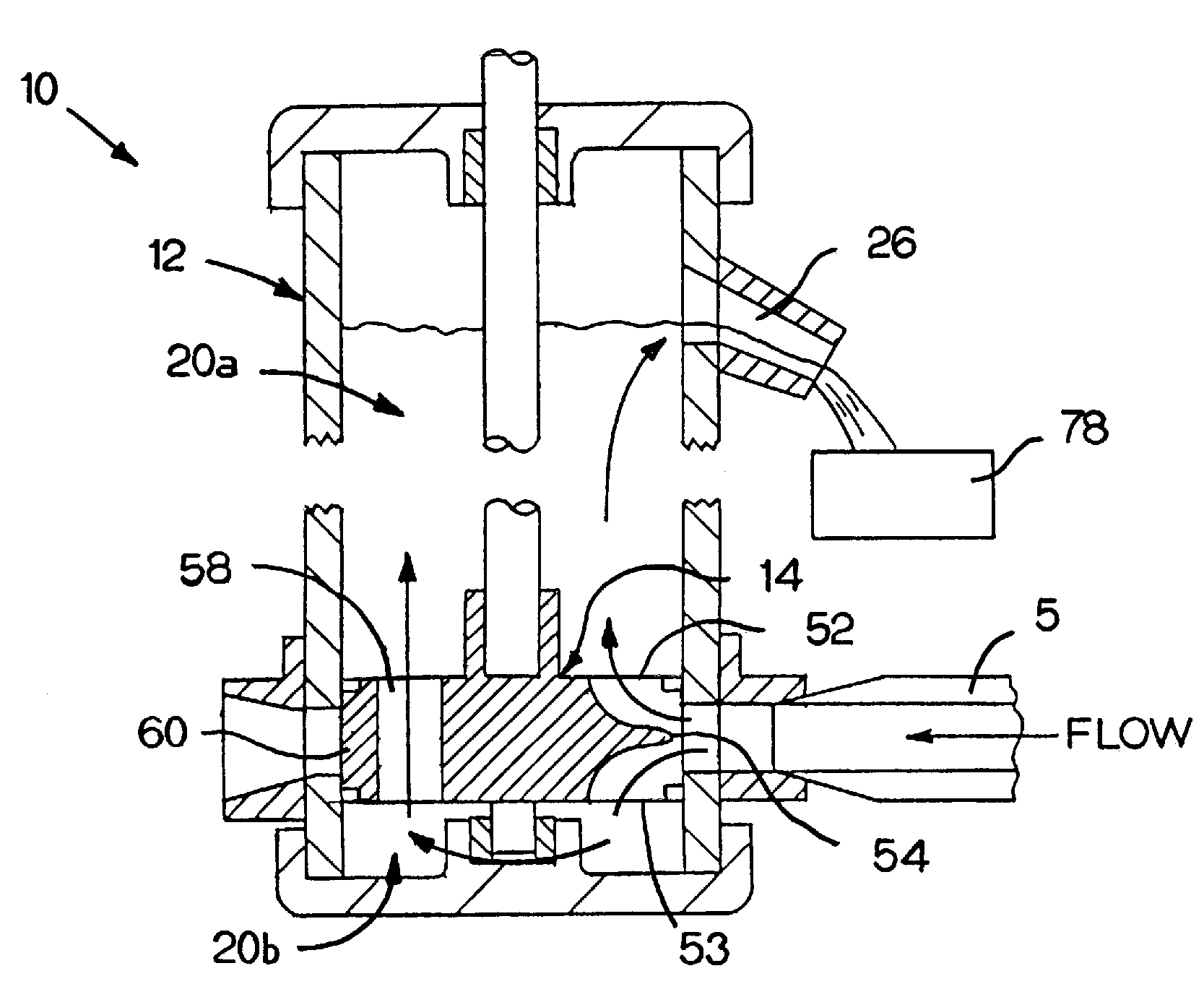

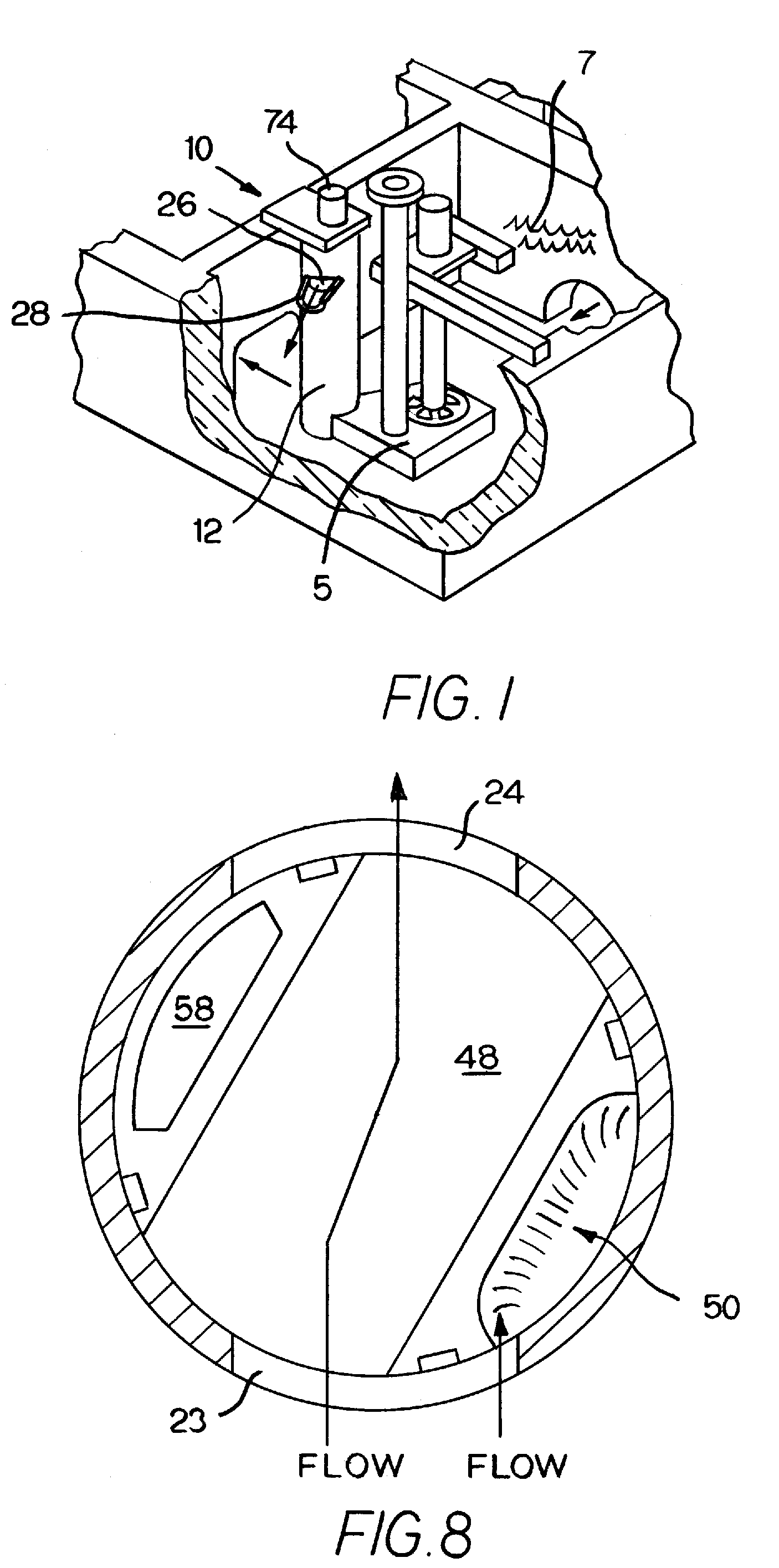

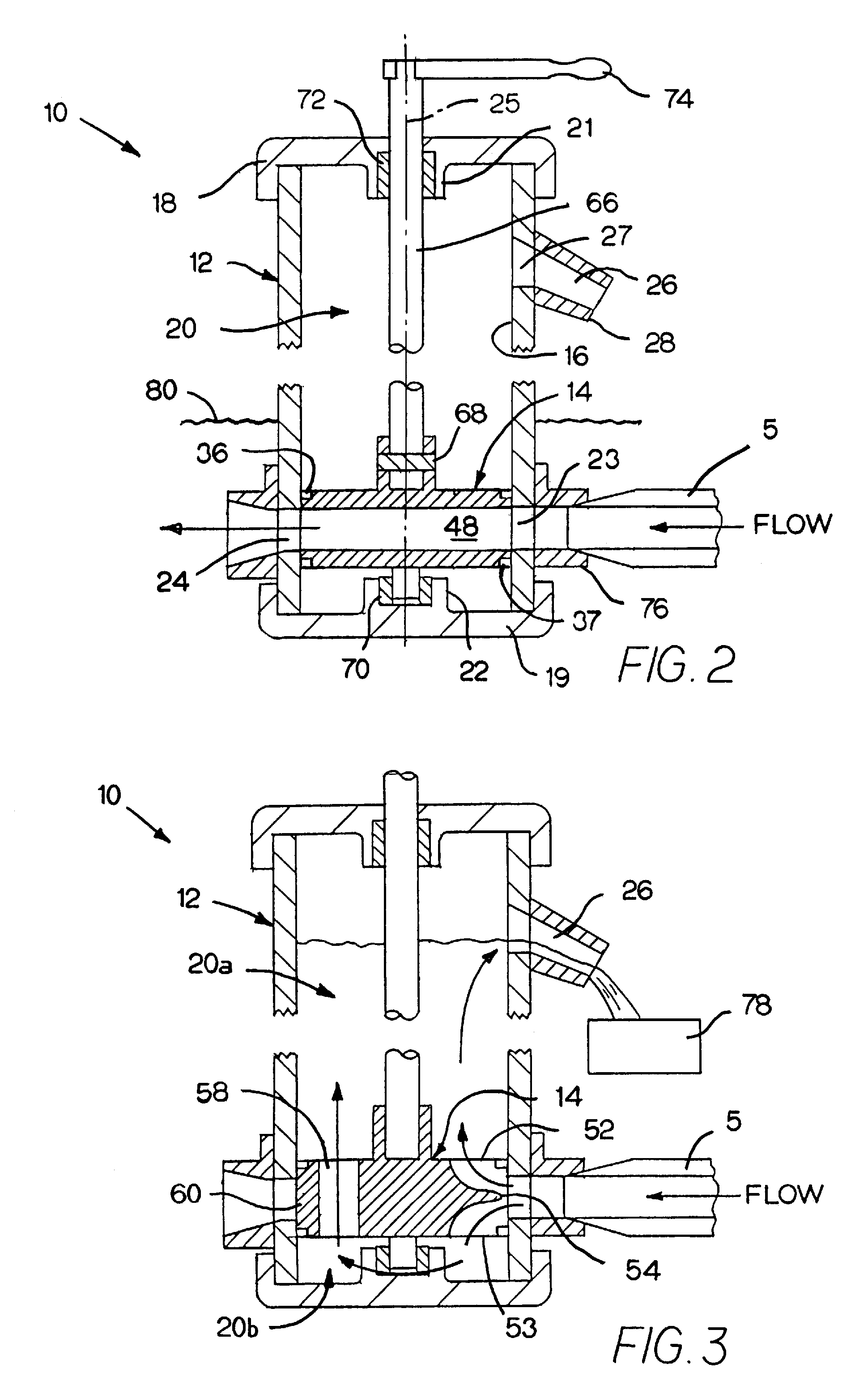

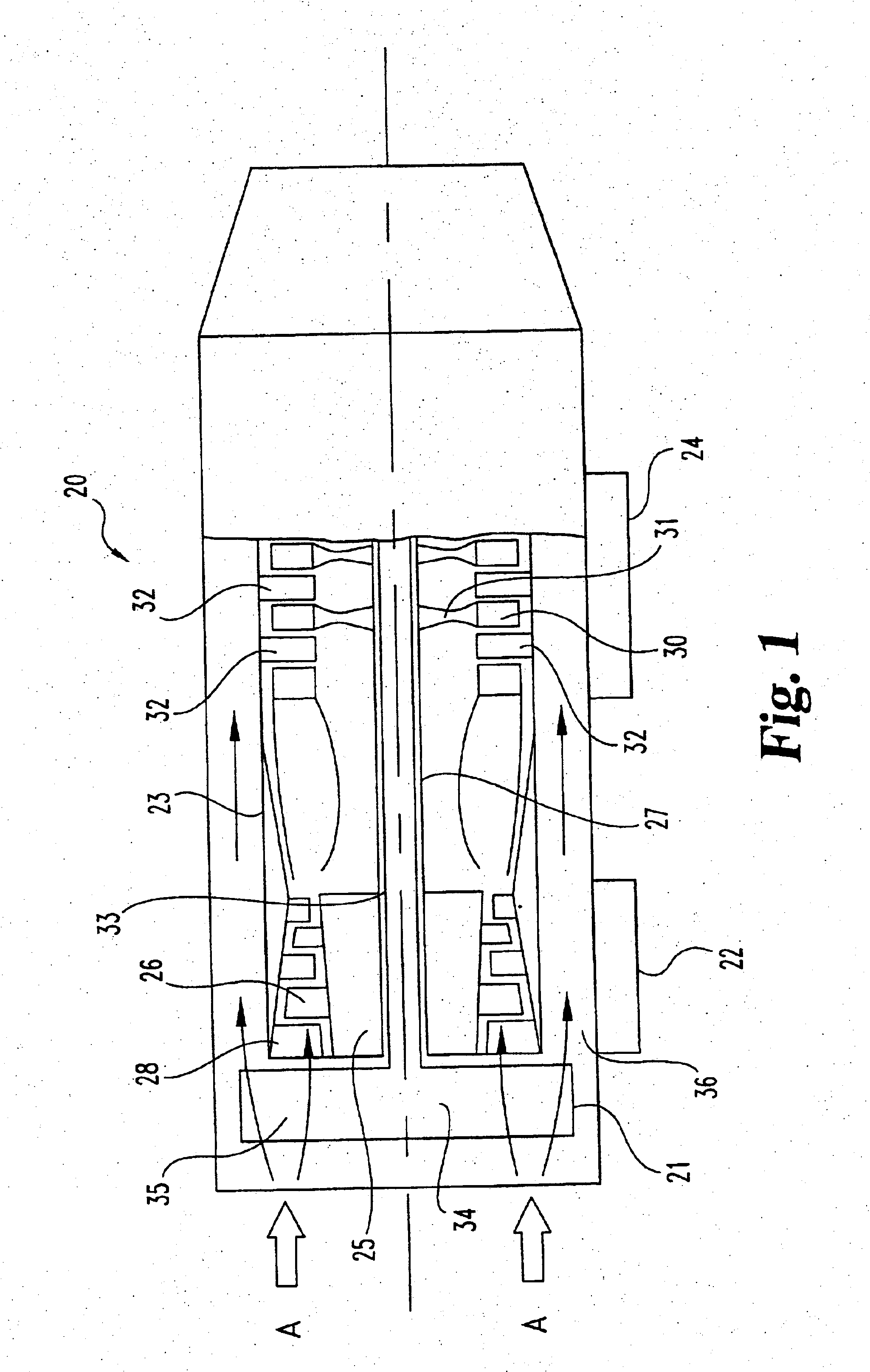

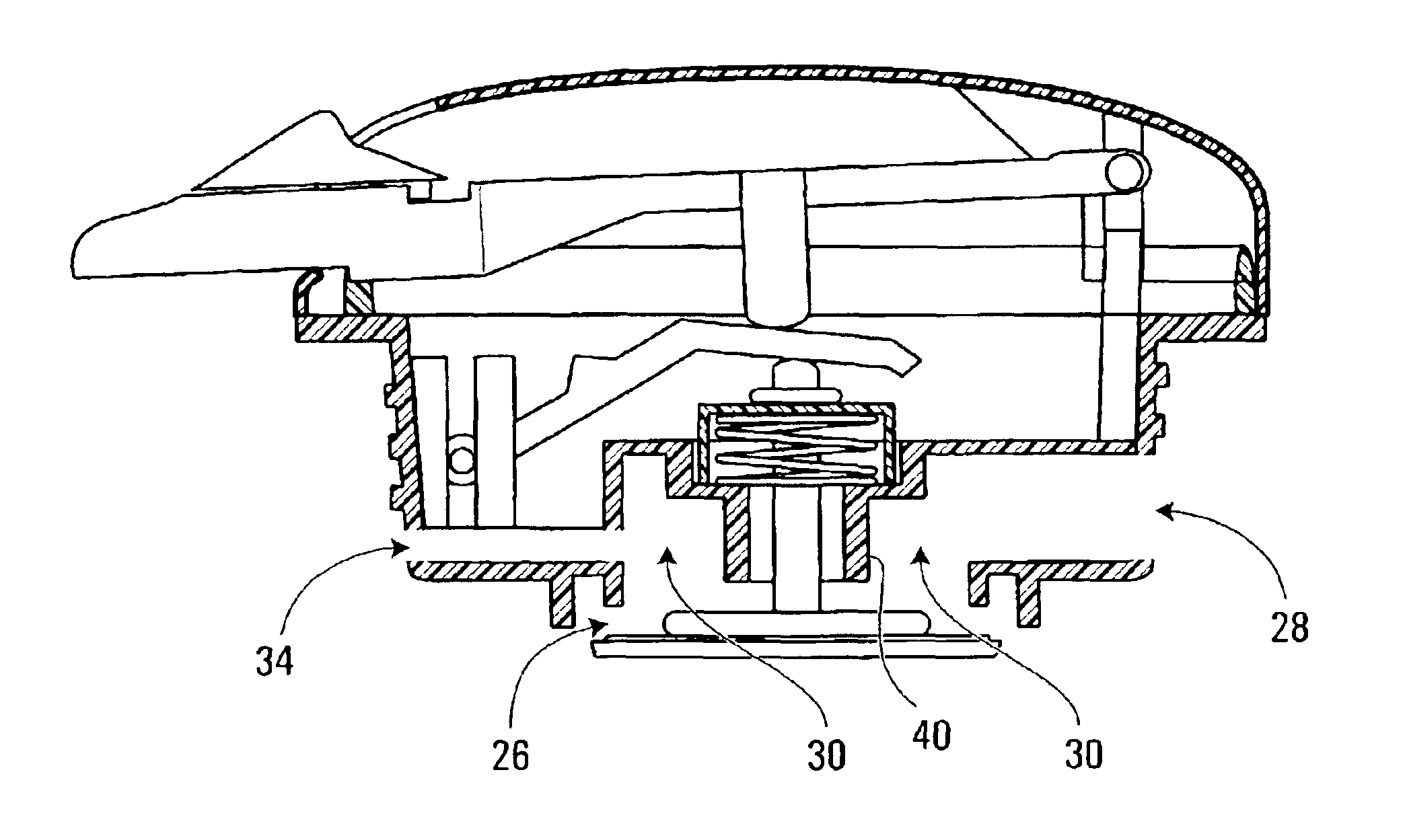

Dual recycling/transfer furnace flow management valve for low melting temperature metals

InactiveUS7543605B1Eliminate needIncrease flow rateMelt-holding vesselsMolten metal pouring equipmentsControl valvesFlow management

A furnace flow control valve for use within a bath of molten metal. The flow control valve includes a vertically-disposed elongated tubular stator, which is configured to receive flow from a molten metal pump. The valve has a rotor which is sealing rotatable within the stator between: a full re-circulation position, where flow from the pump passes un-hindered through the valve; a full transfer position, where flow from the pump is redirected into the vertically disposed stator and out of the valve; and a partial re-circulation / partial transfer position where flow from the pump both passes through the valve and is transferred up and out of valve through the stator.

Owner:MORANDO JORGE A

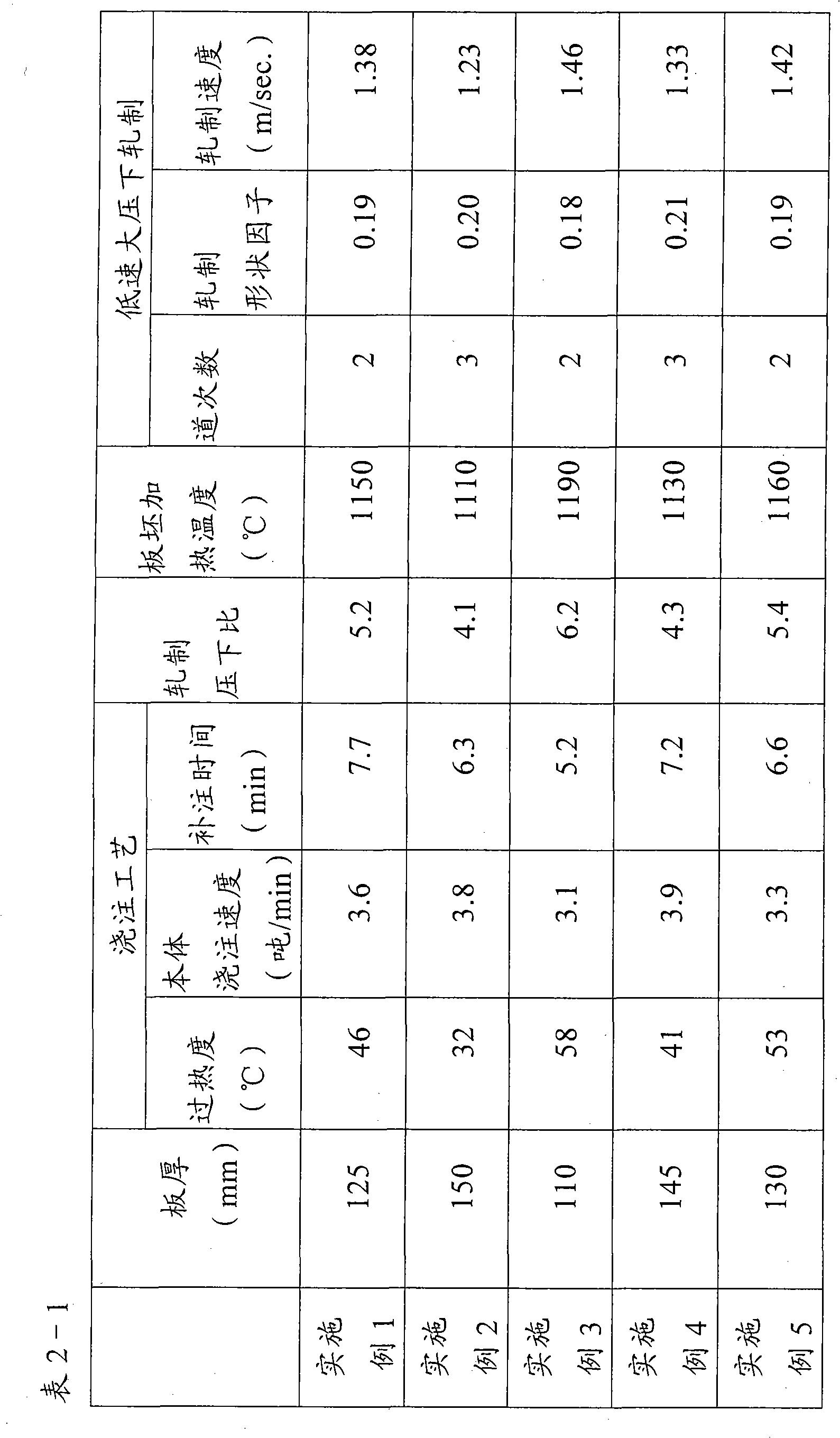

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

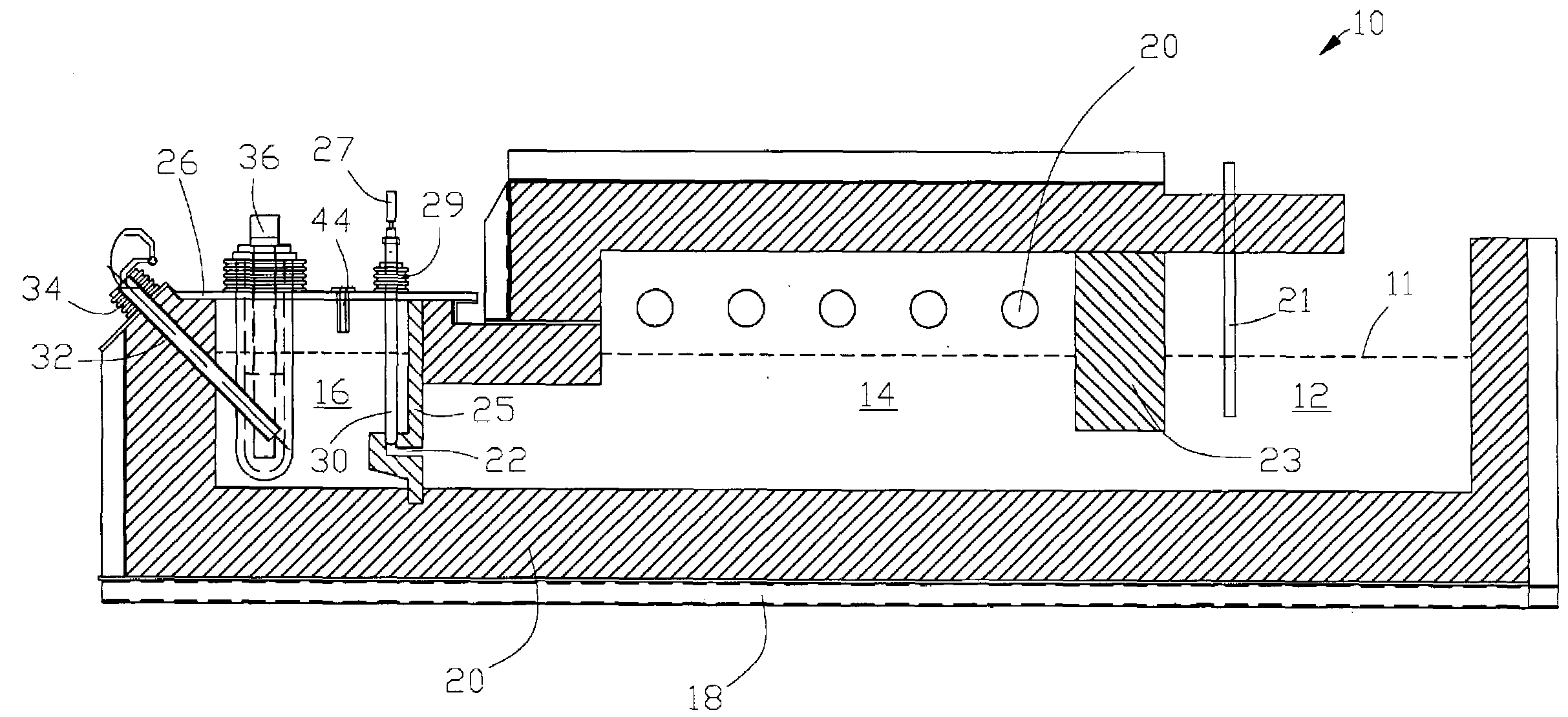

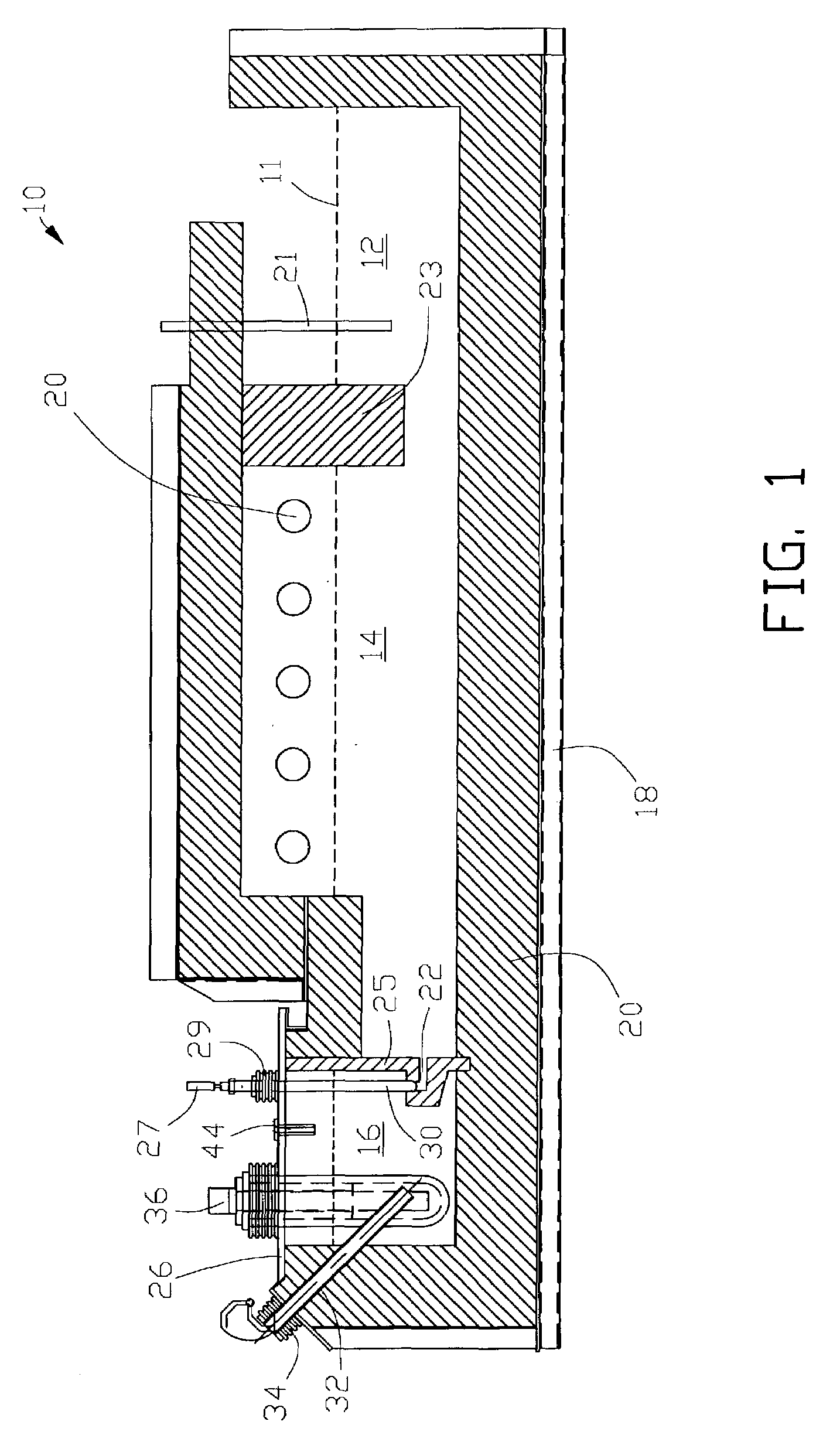

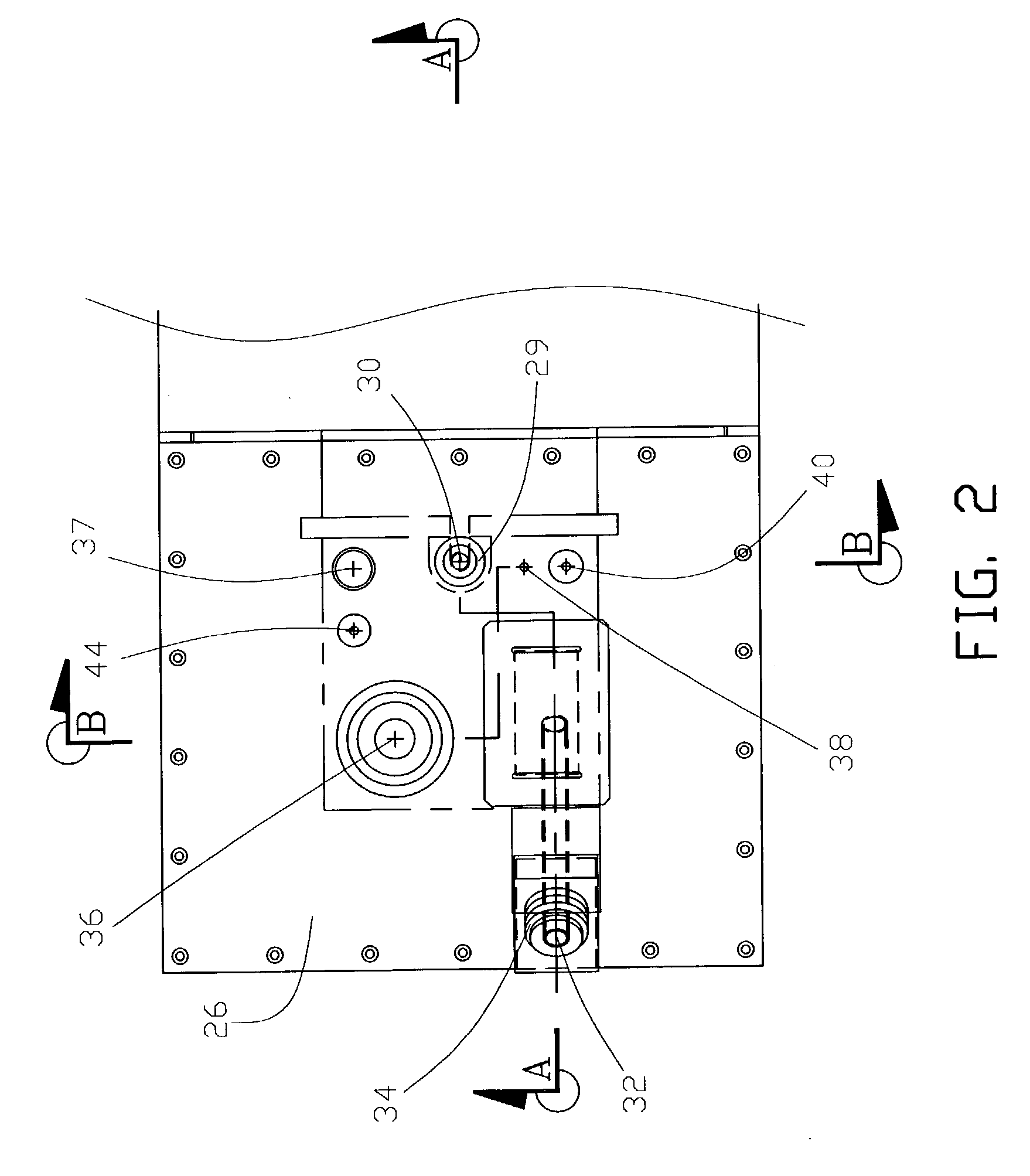

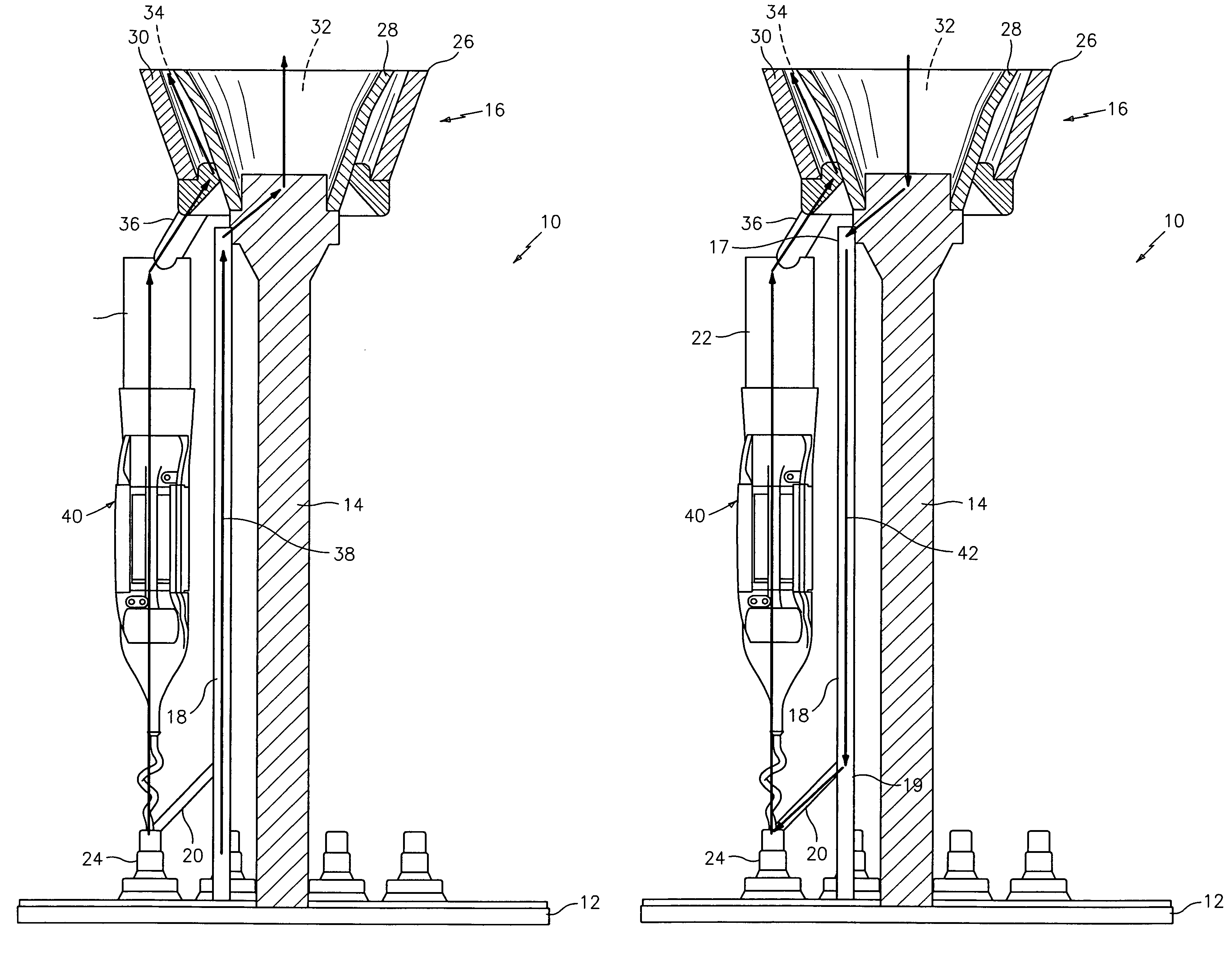

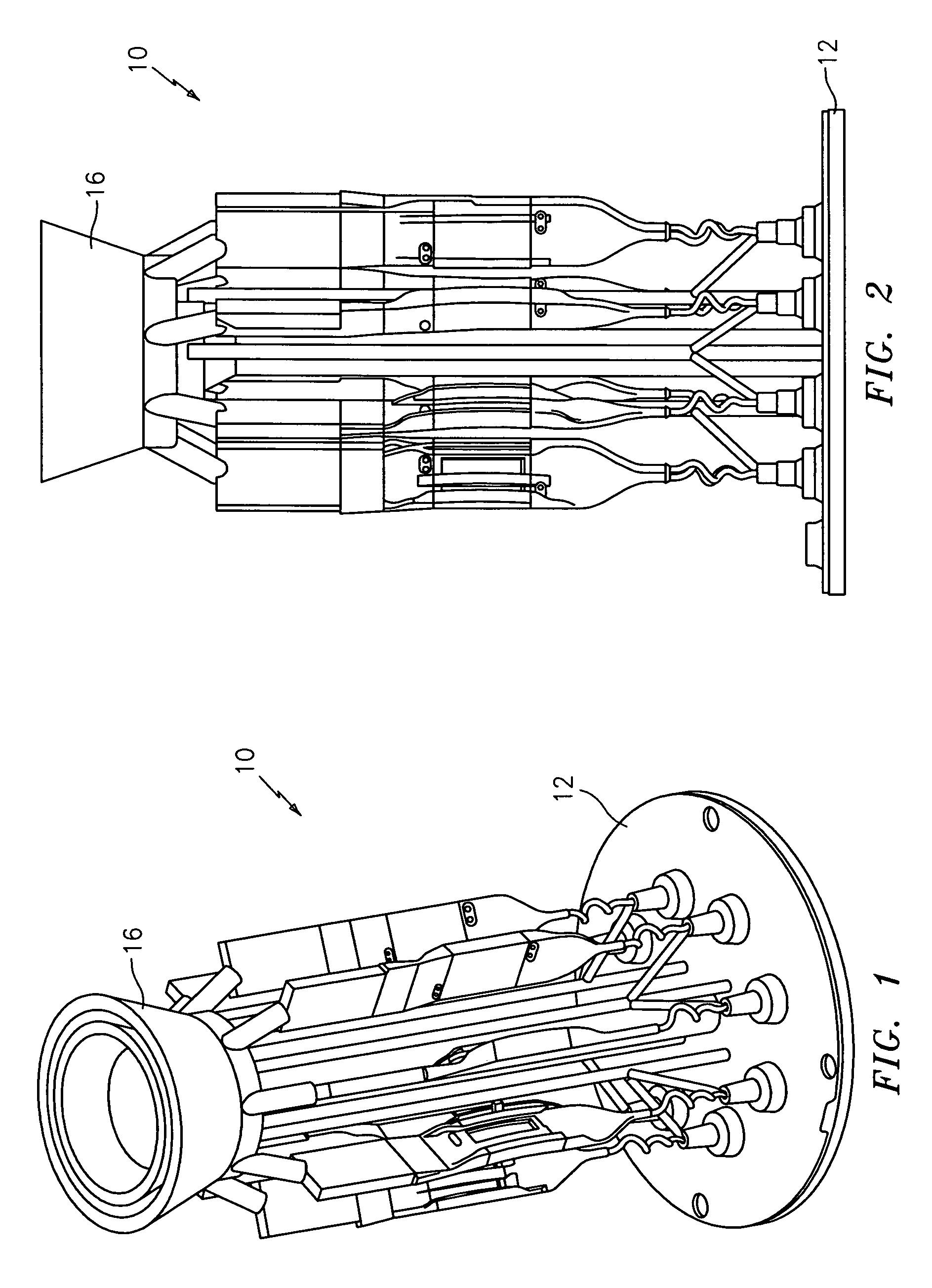

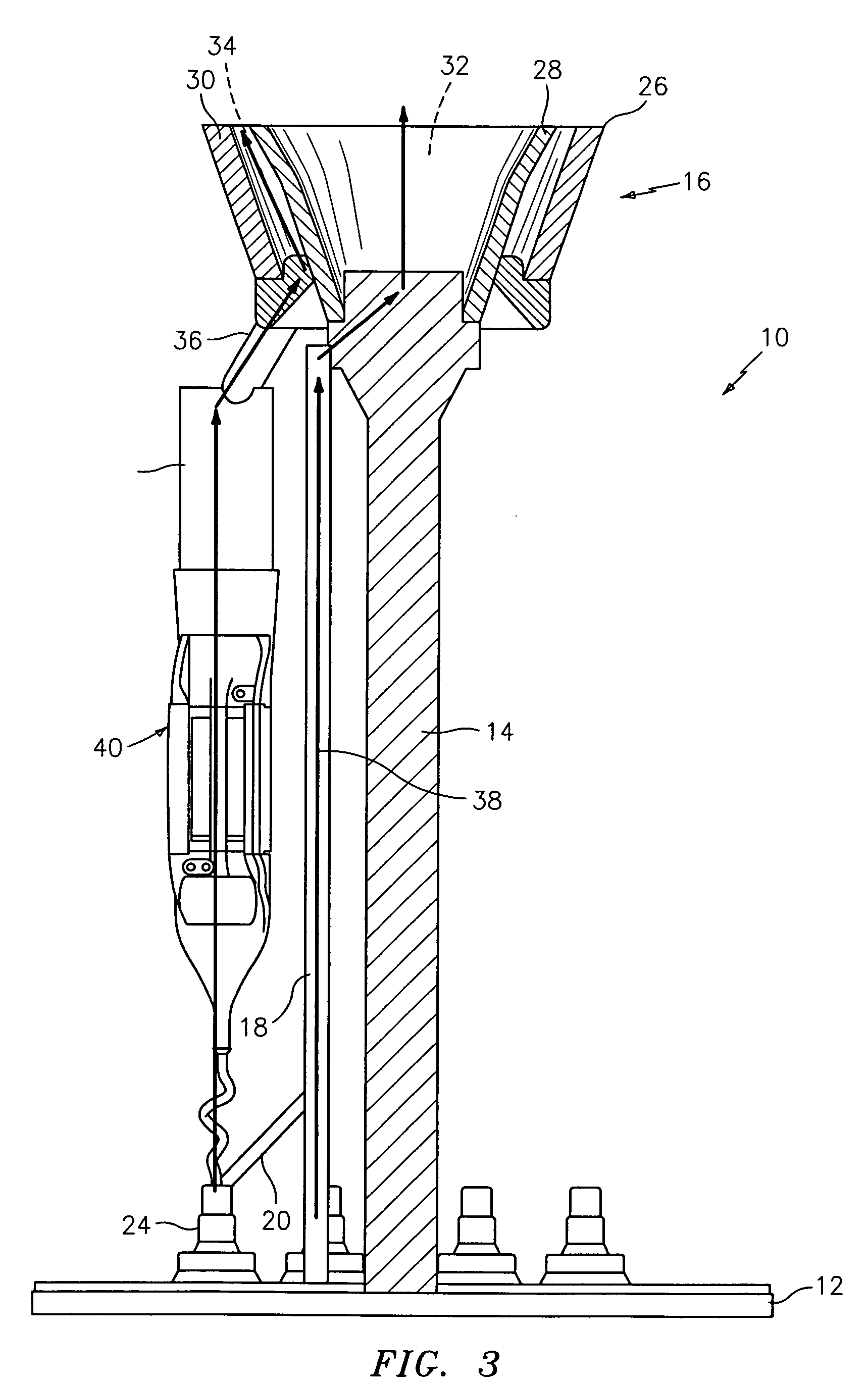

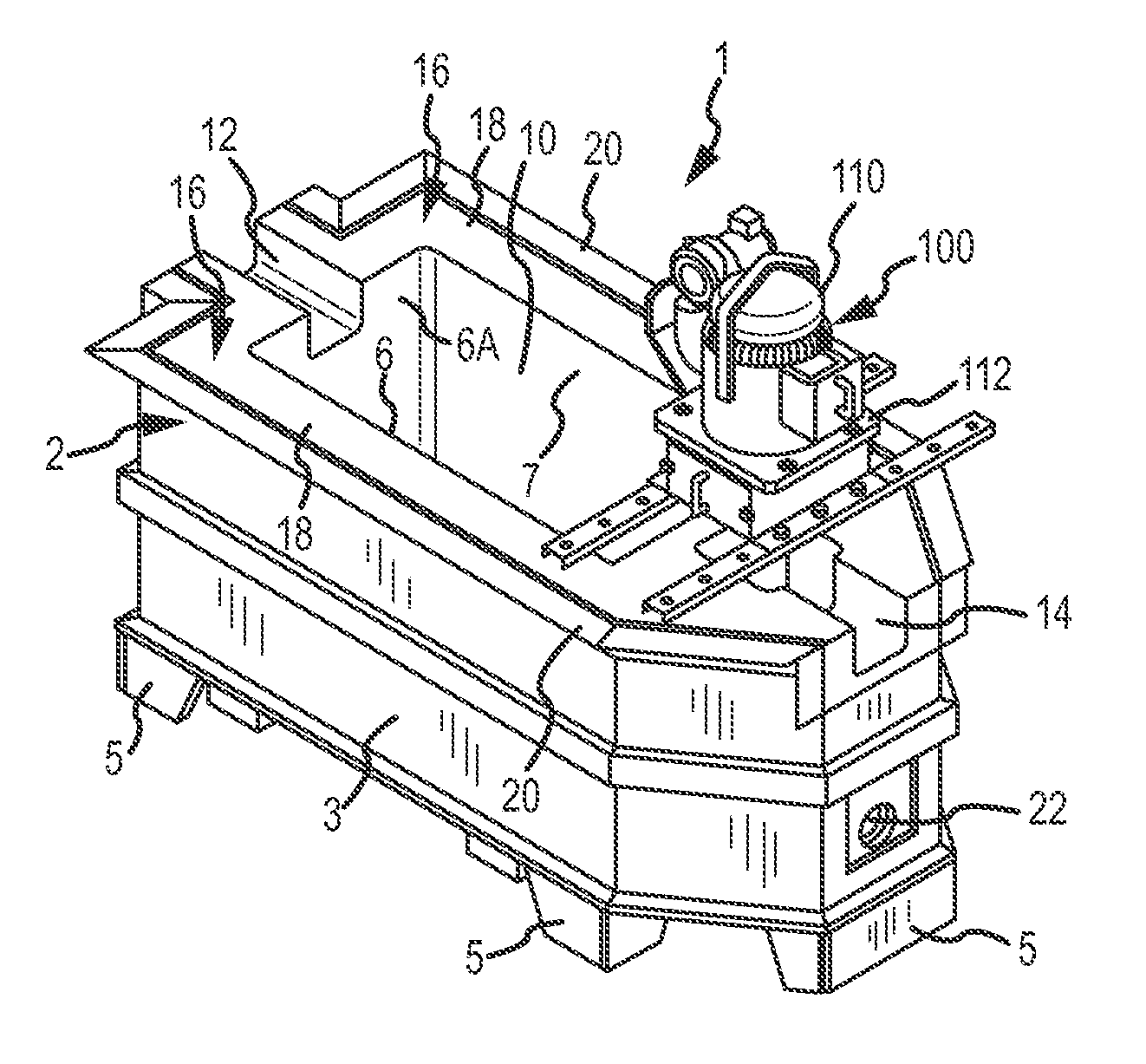

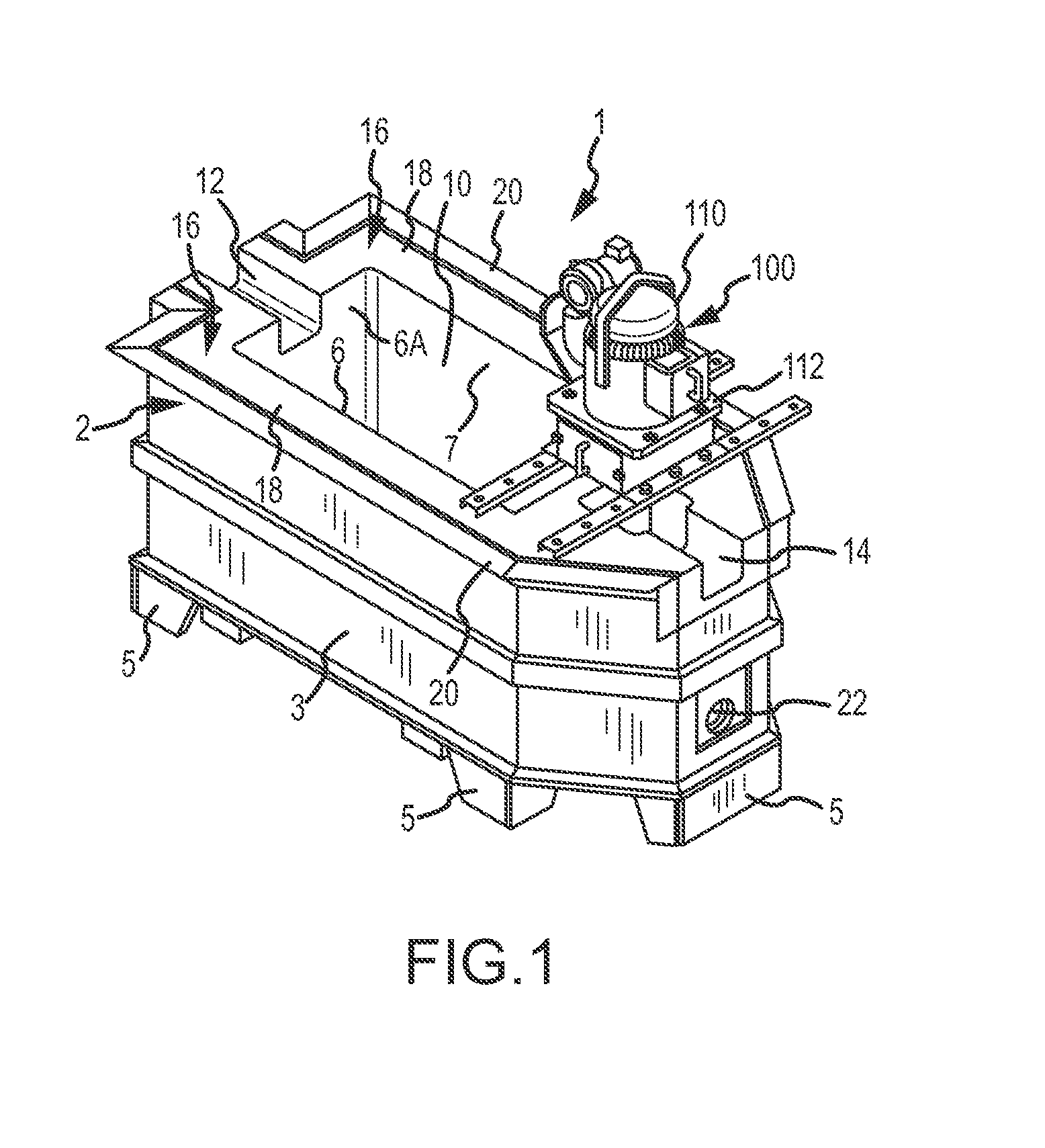

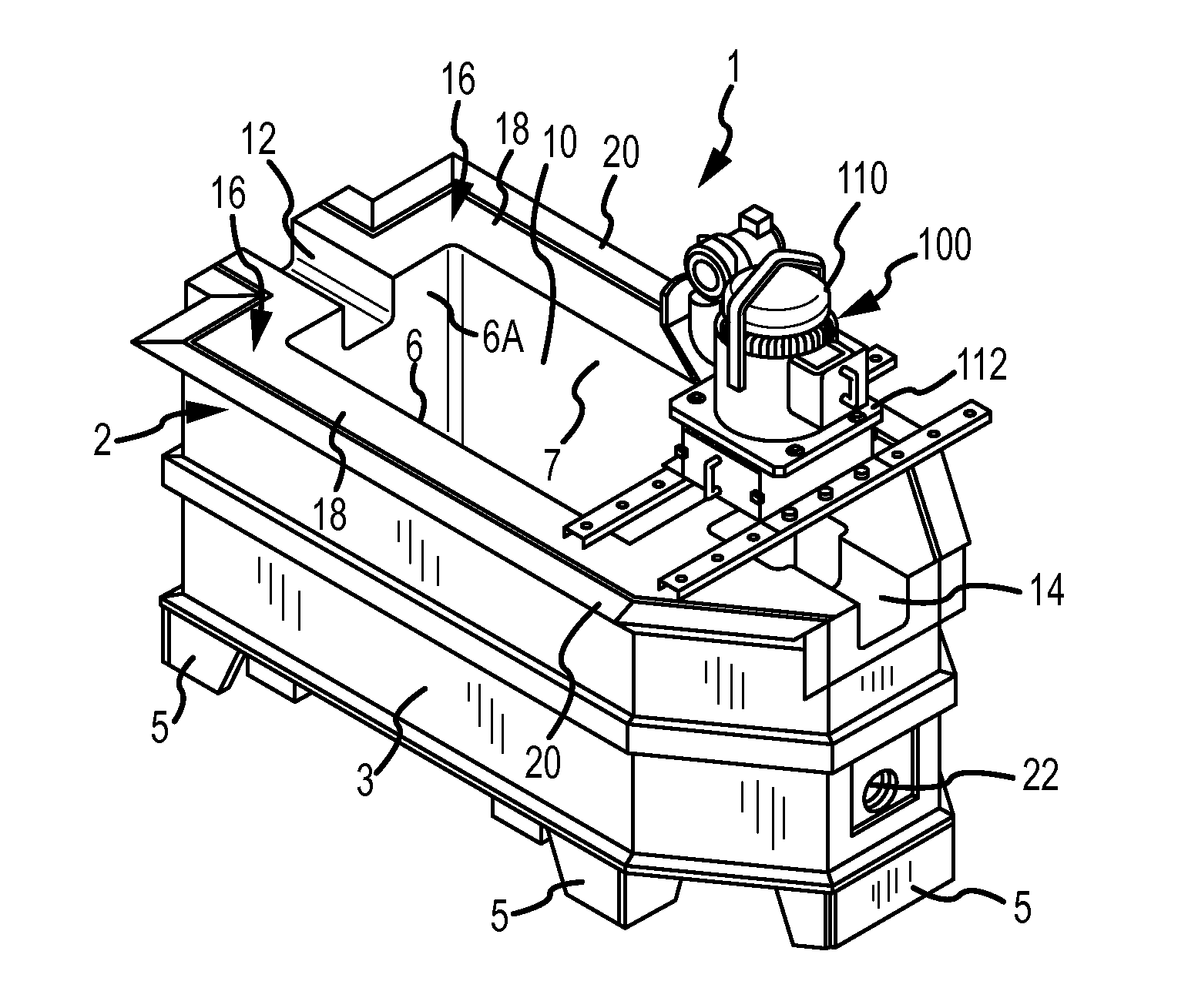

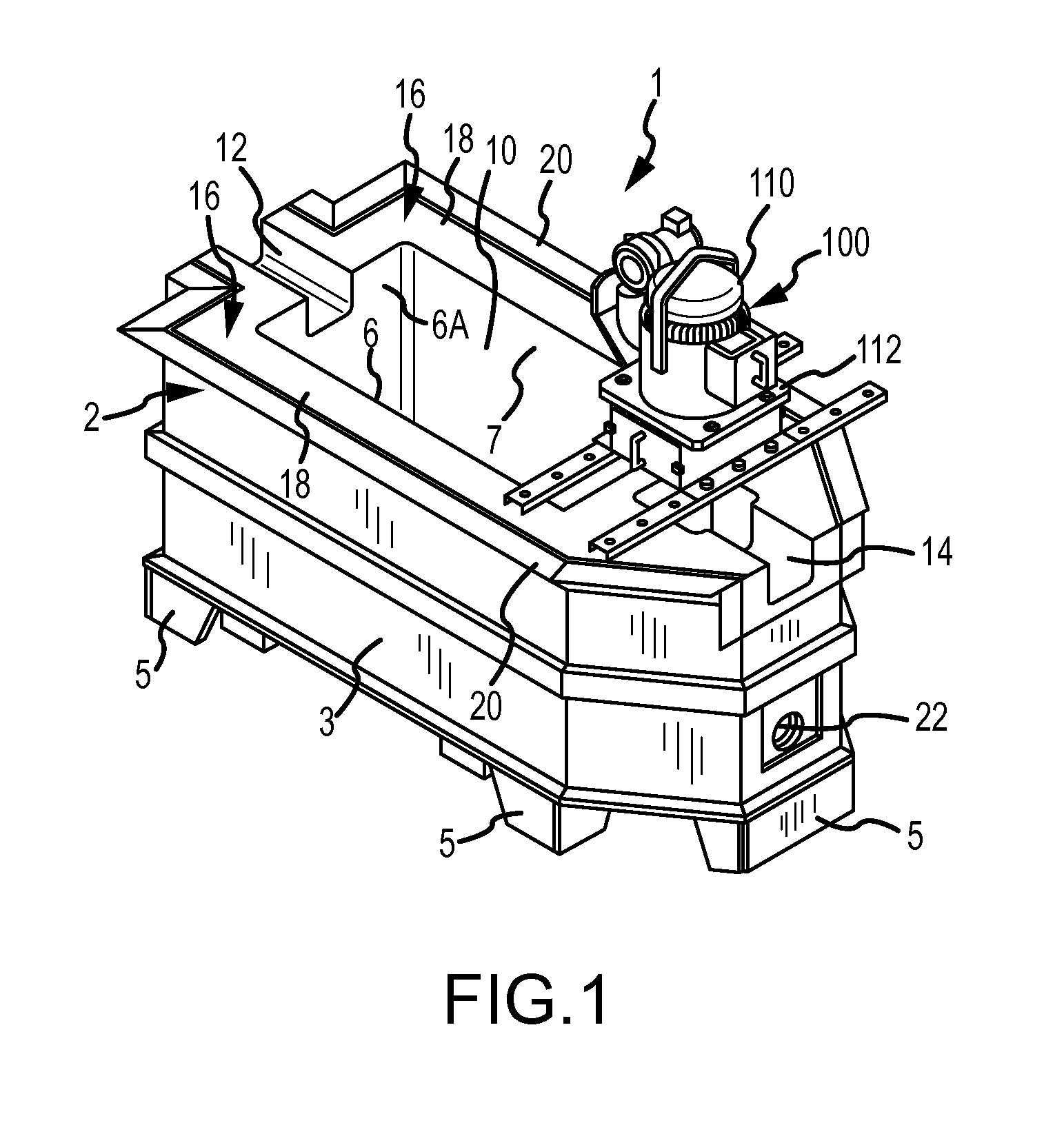

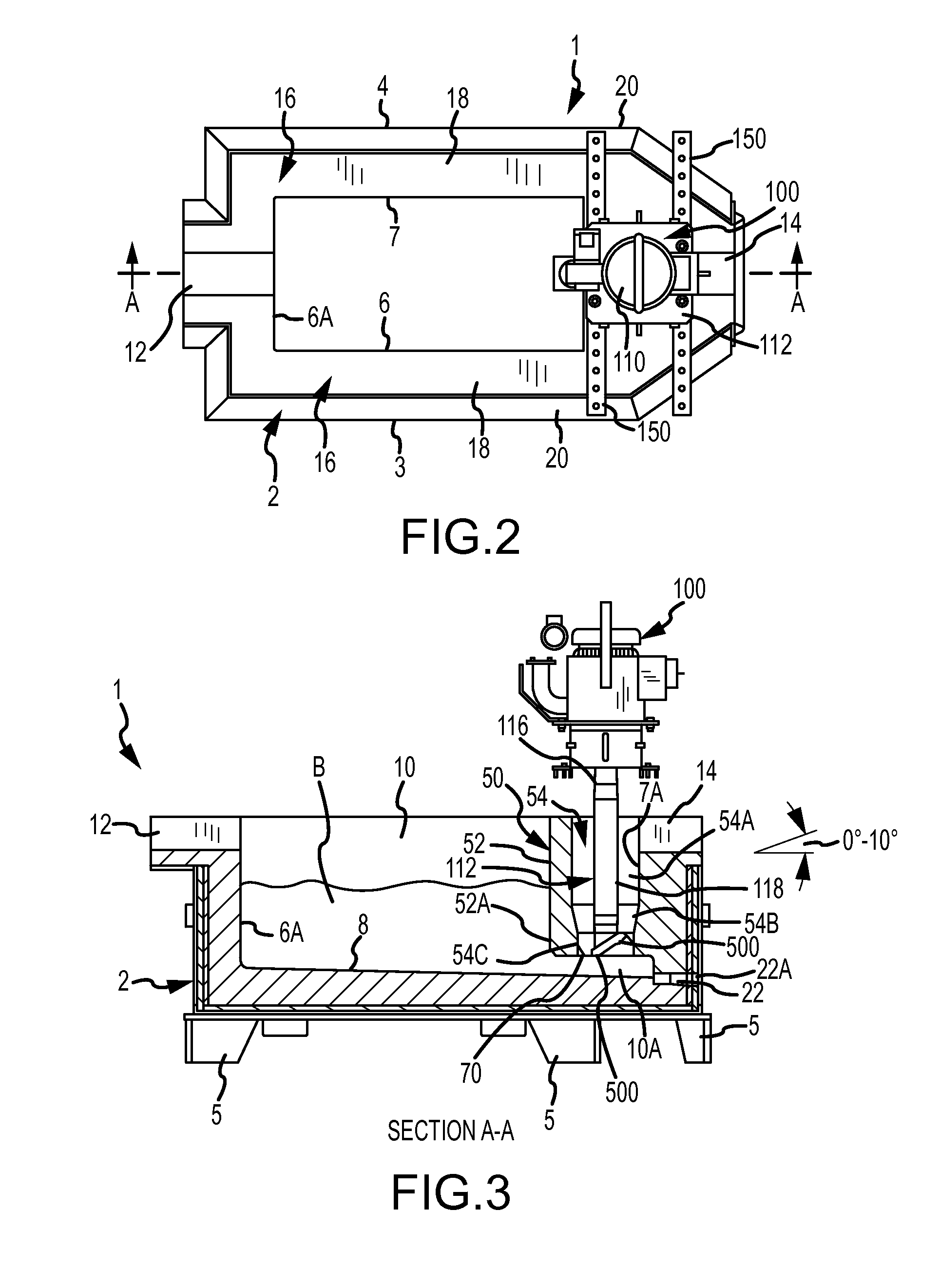

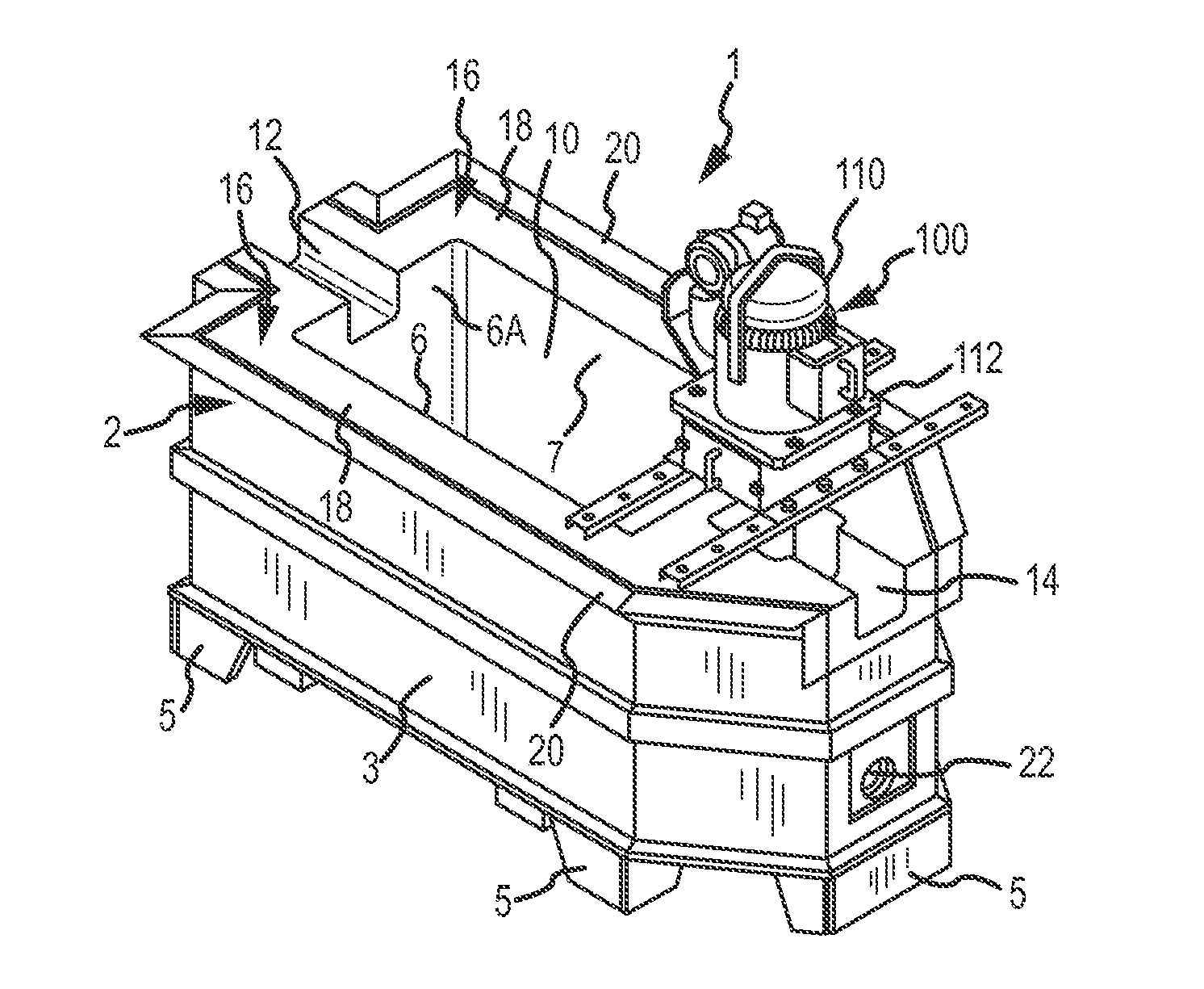

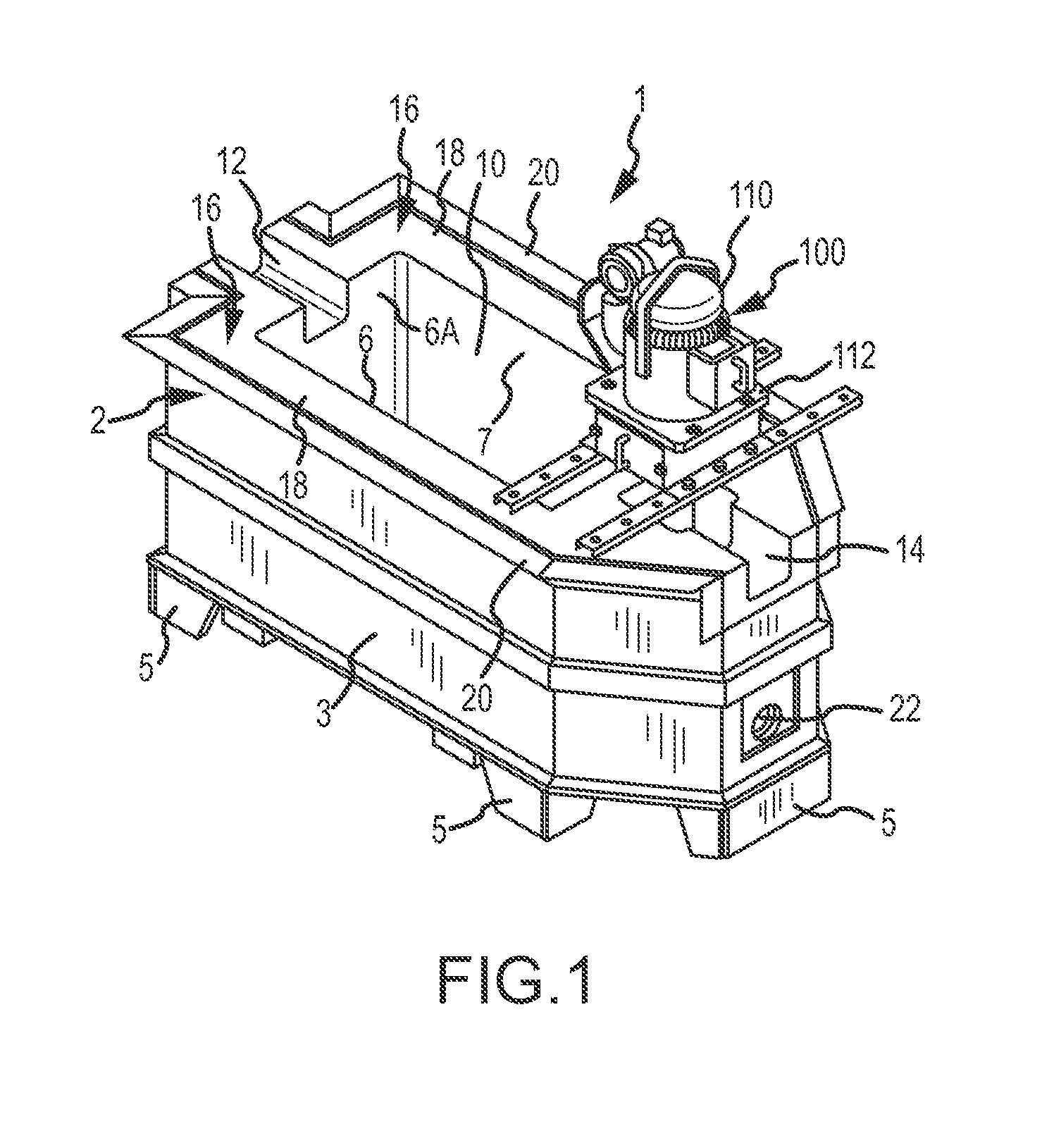

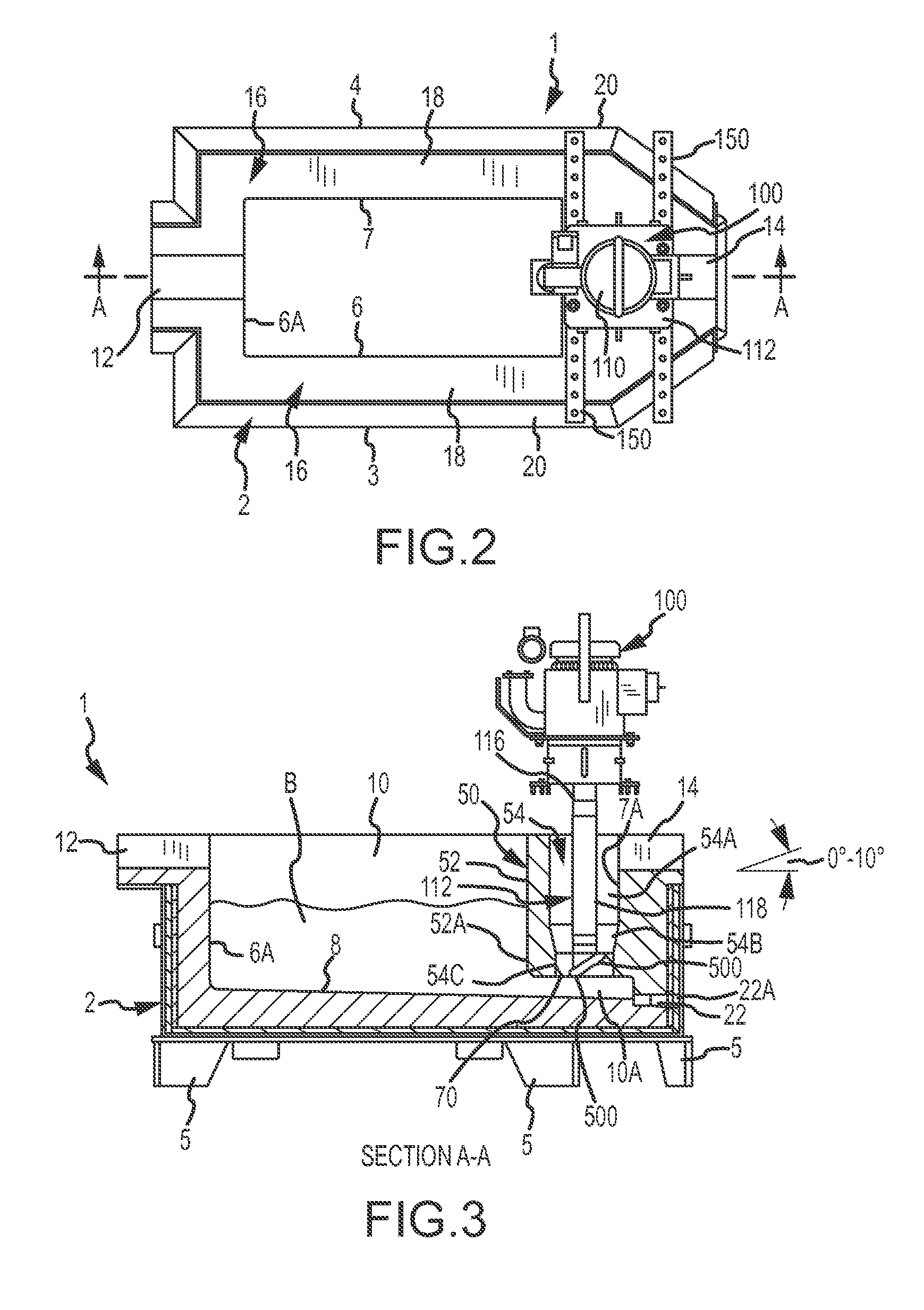

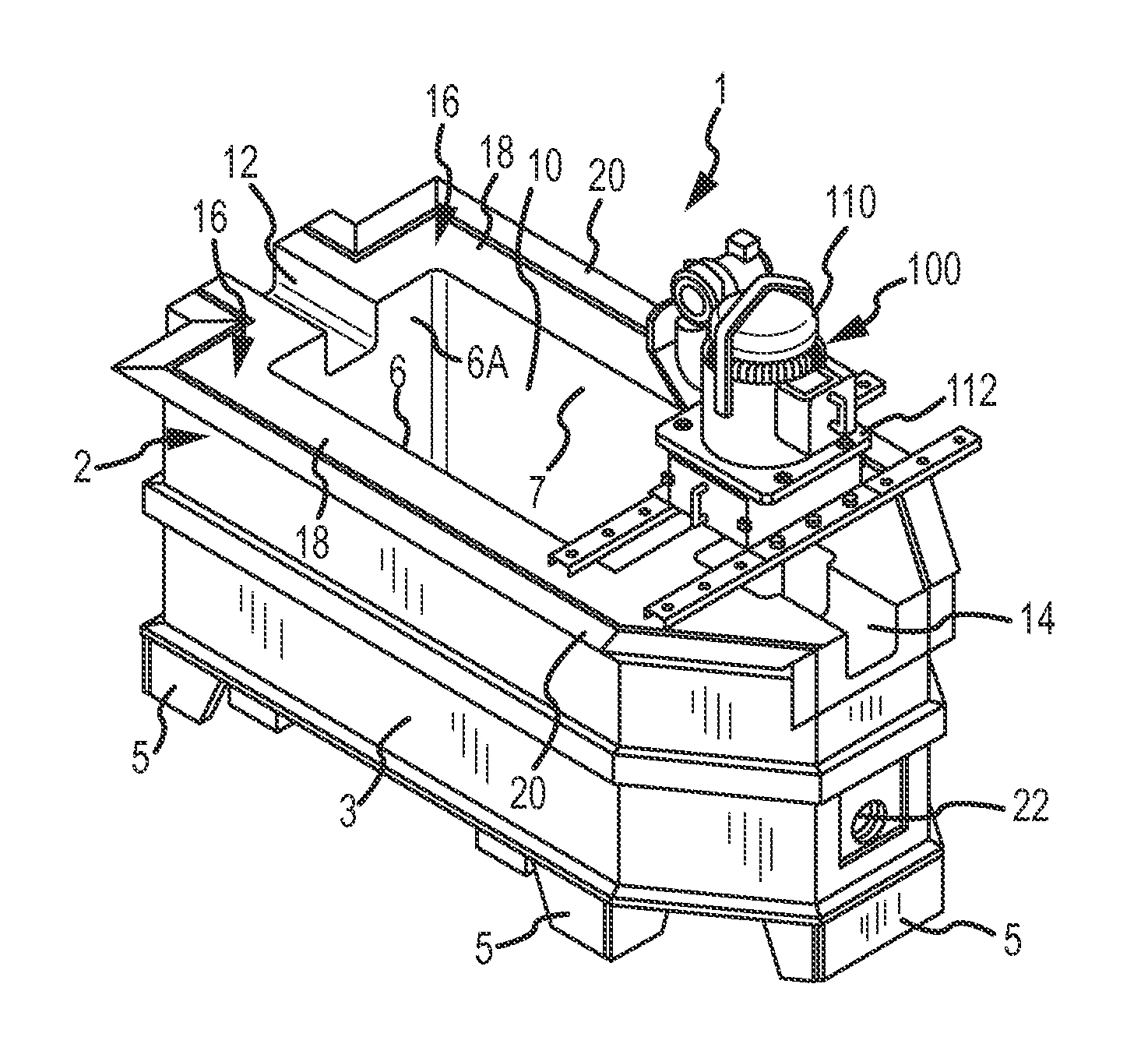

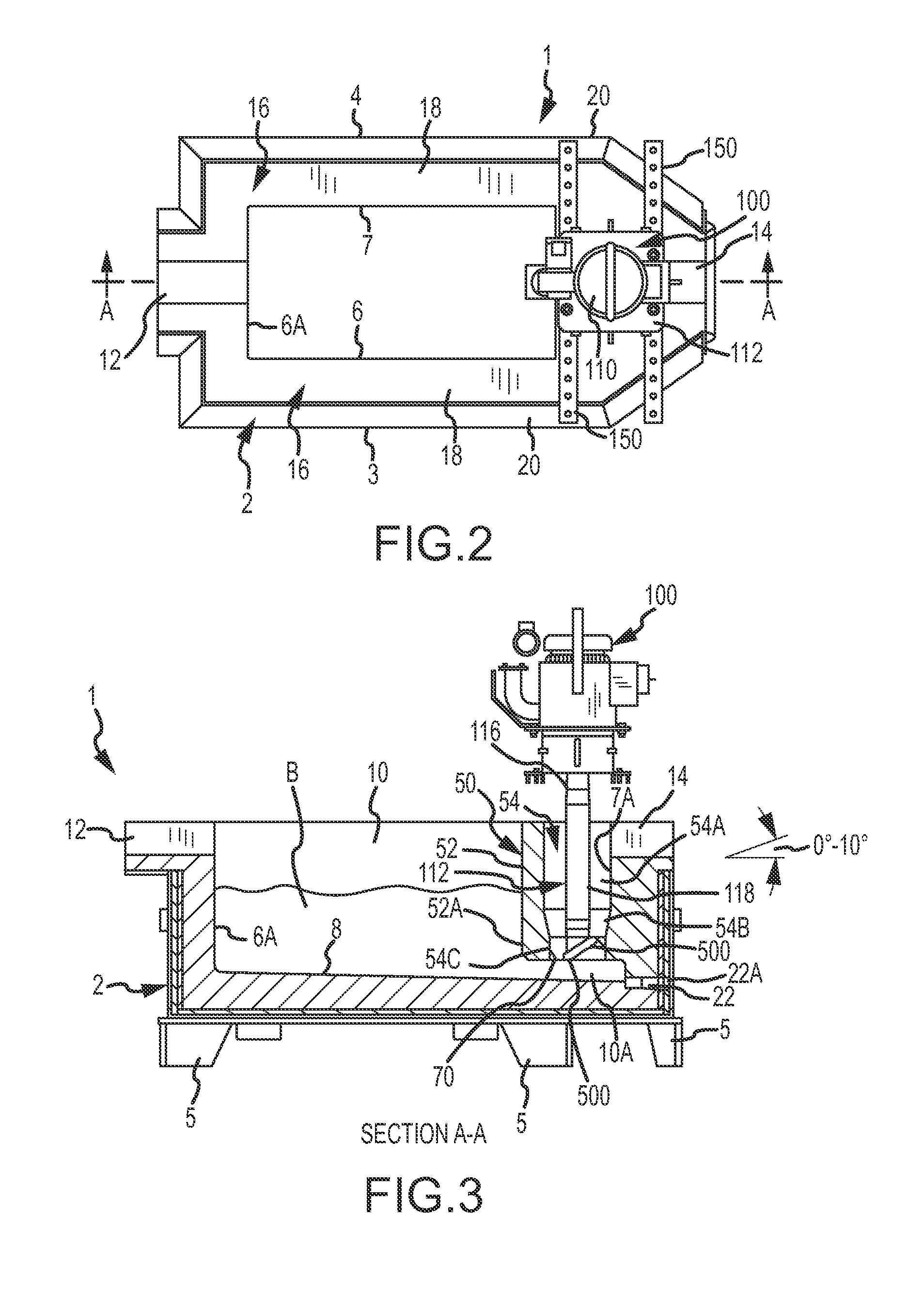

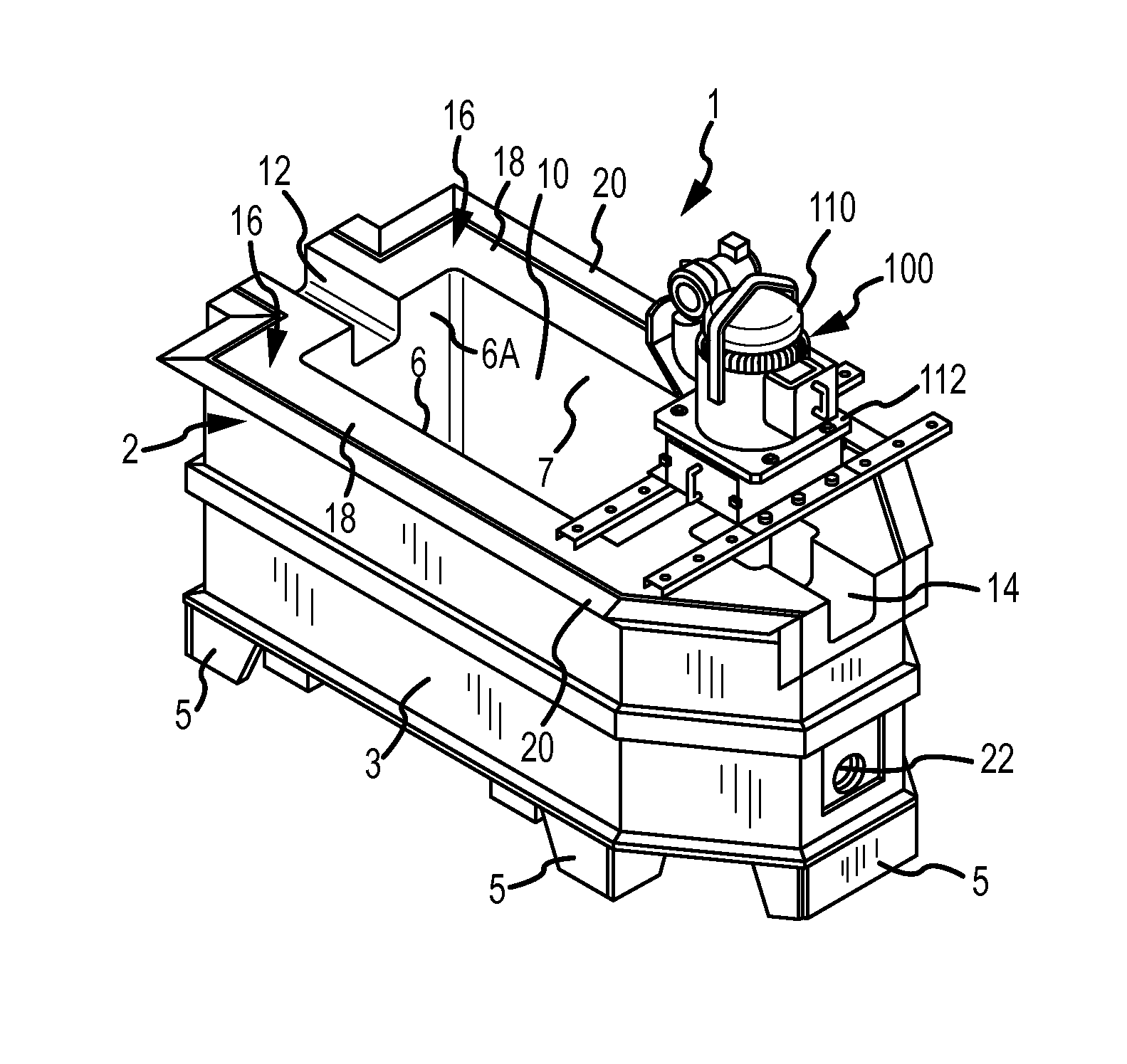

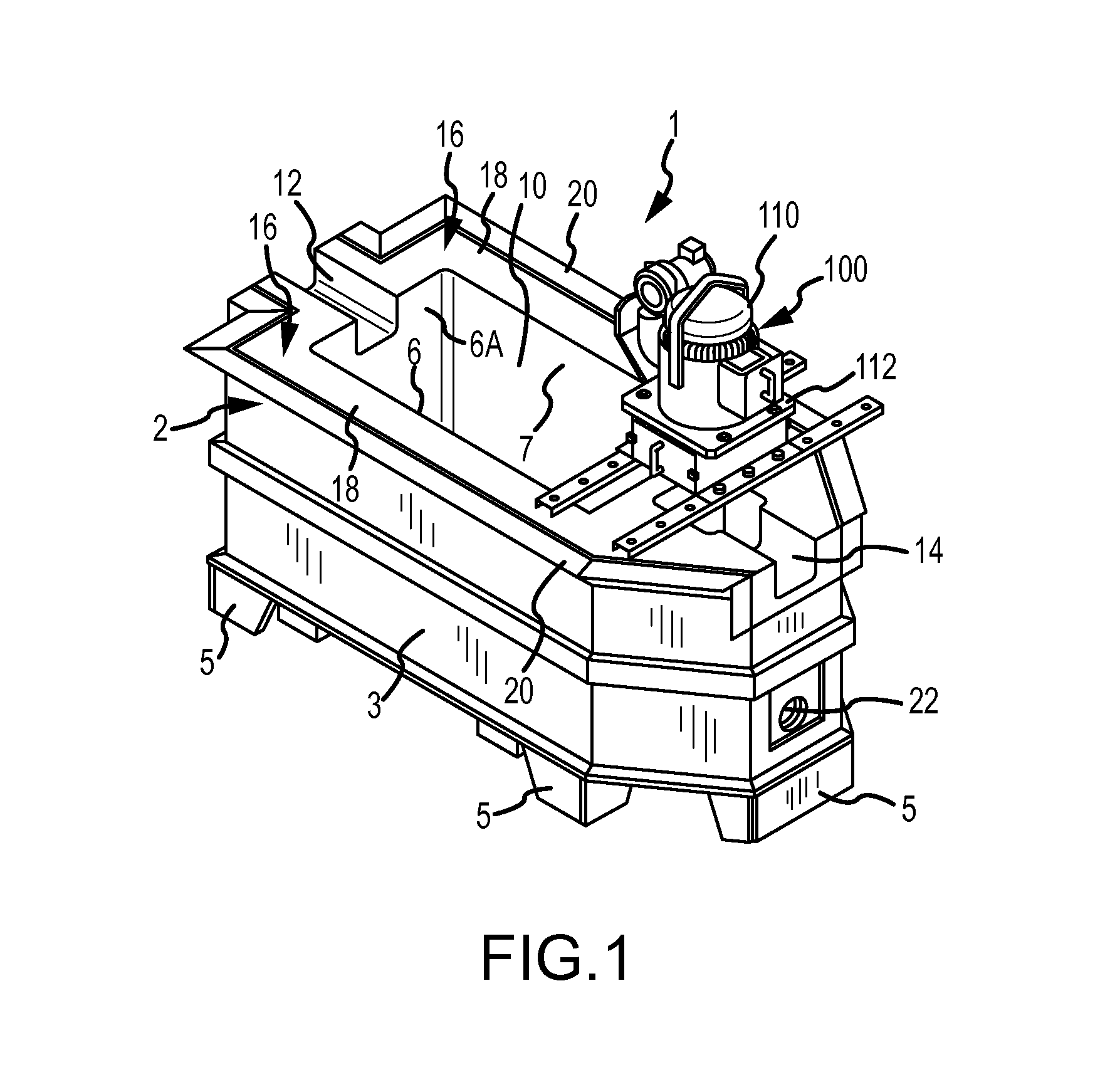

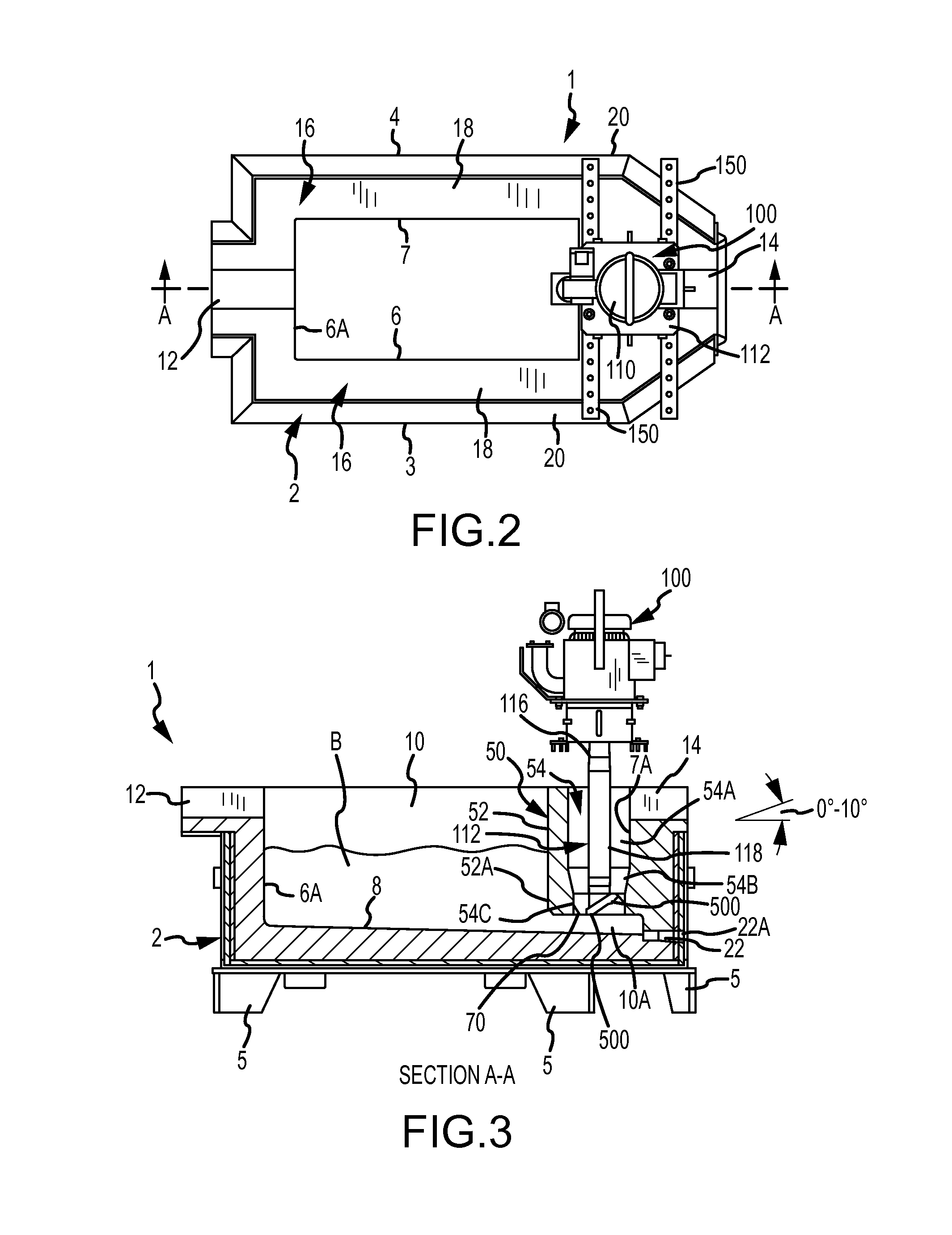

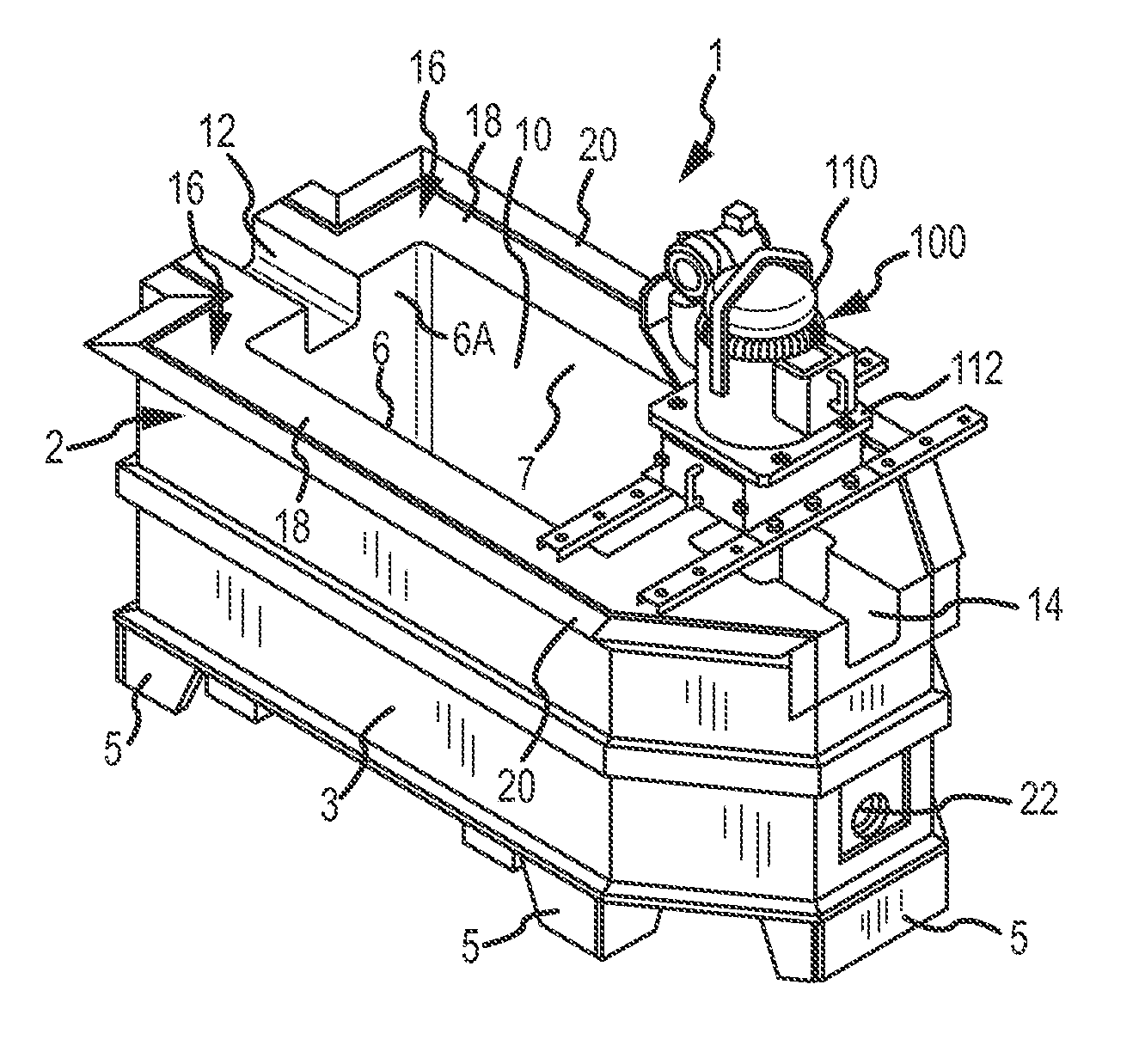

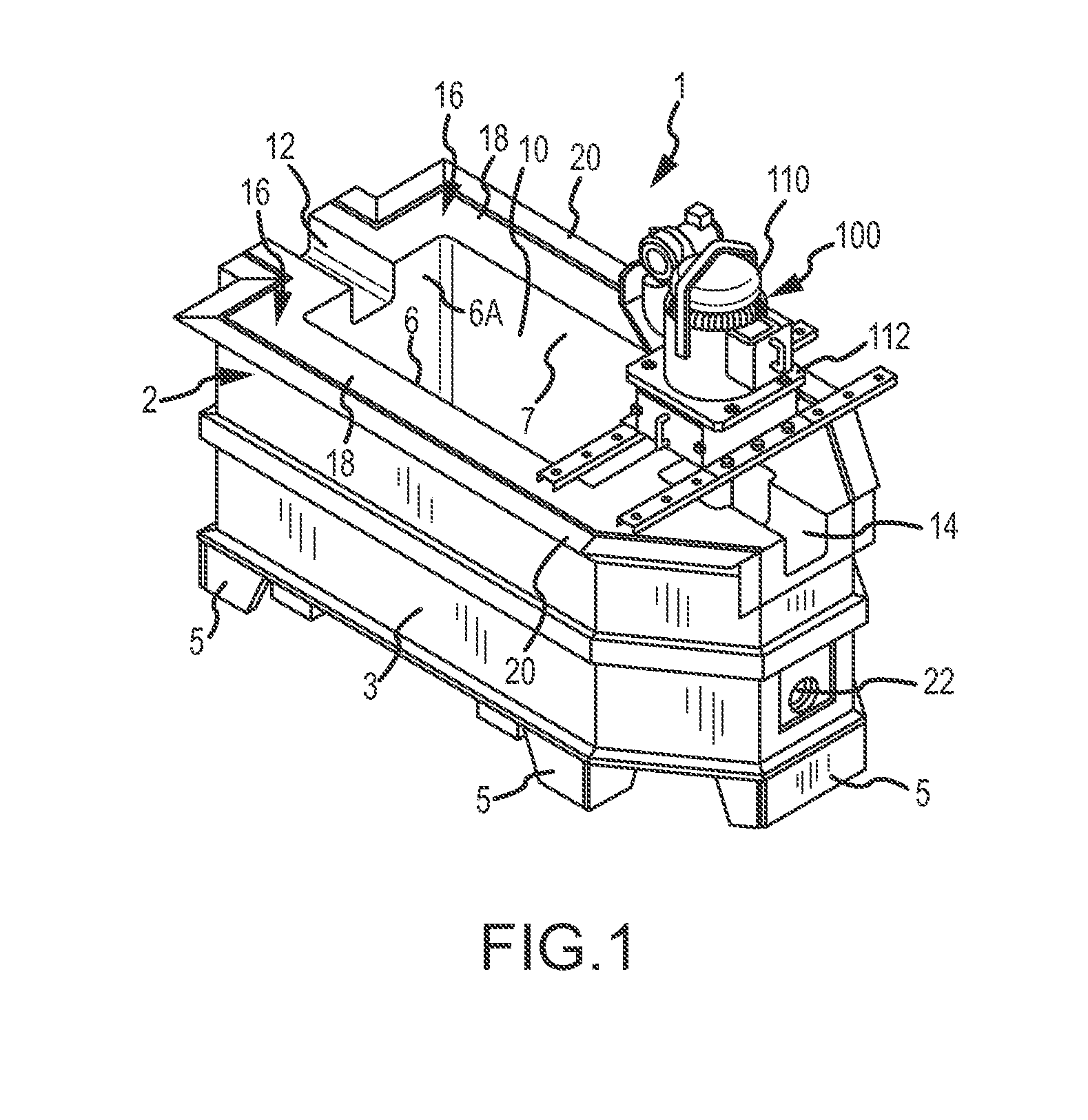

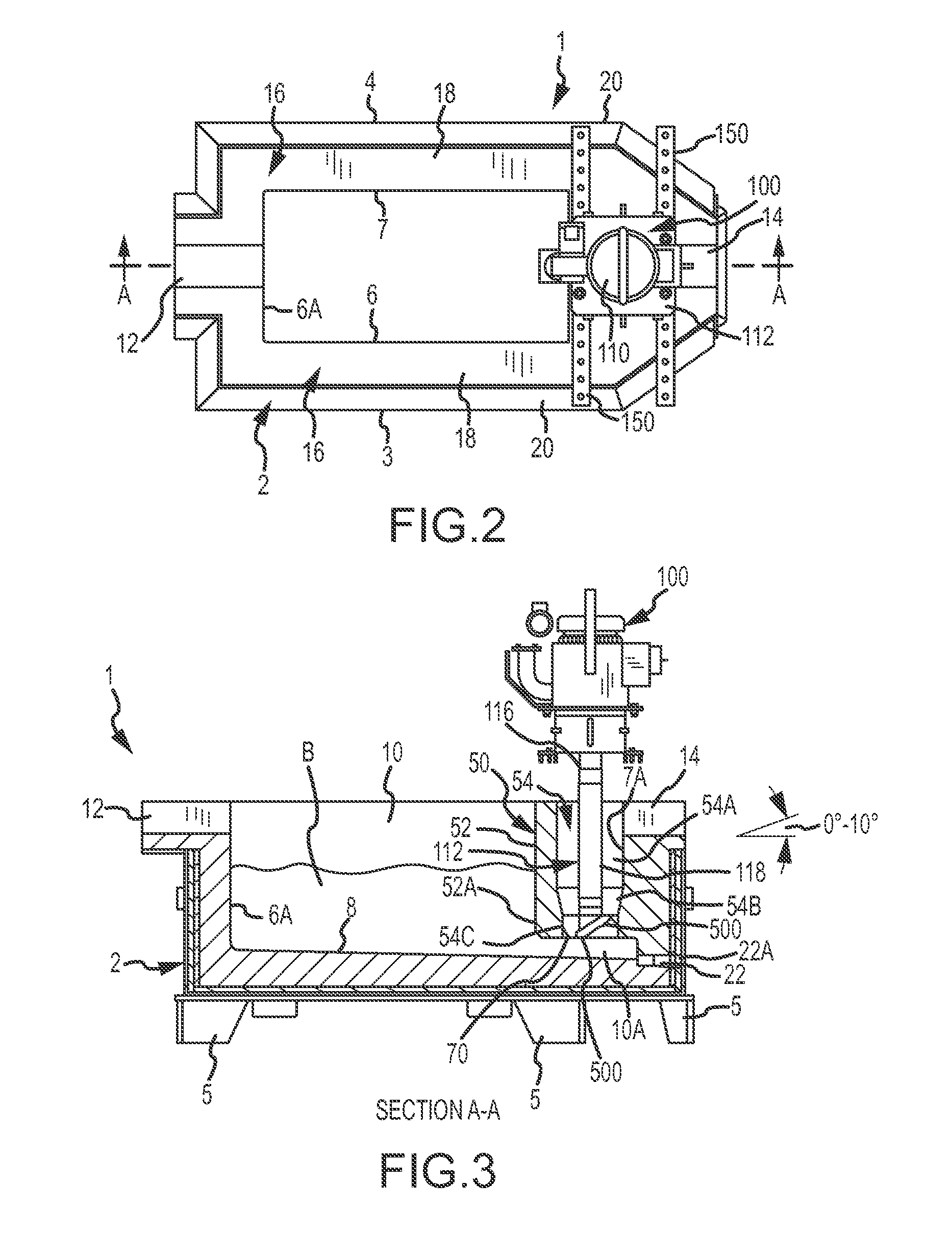

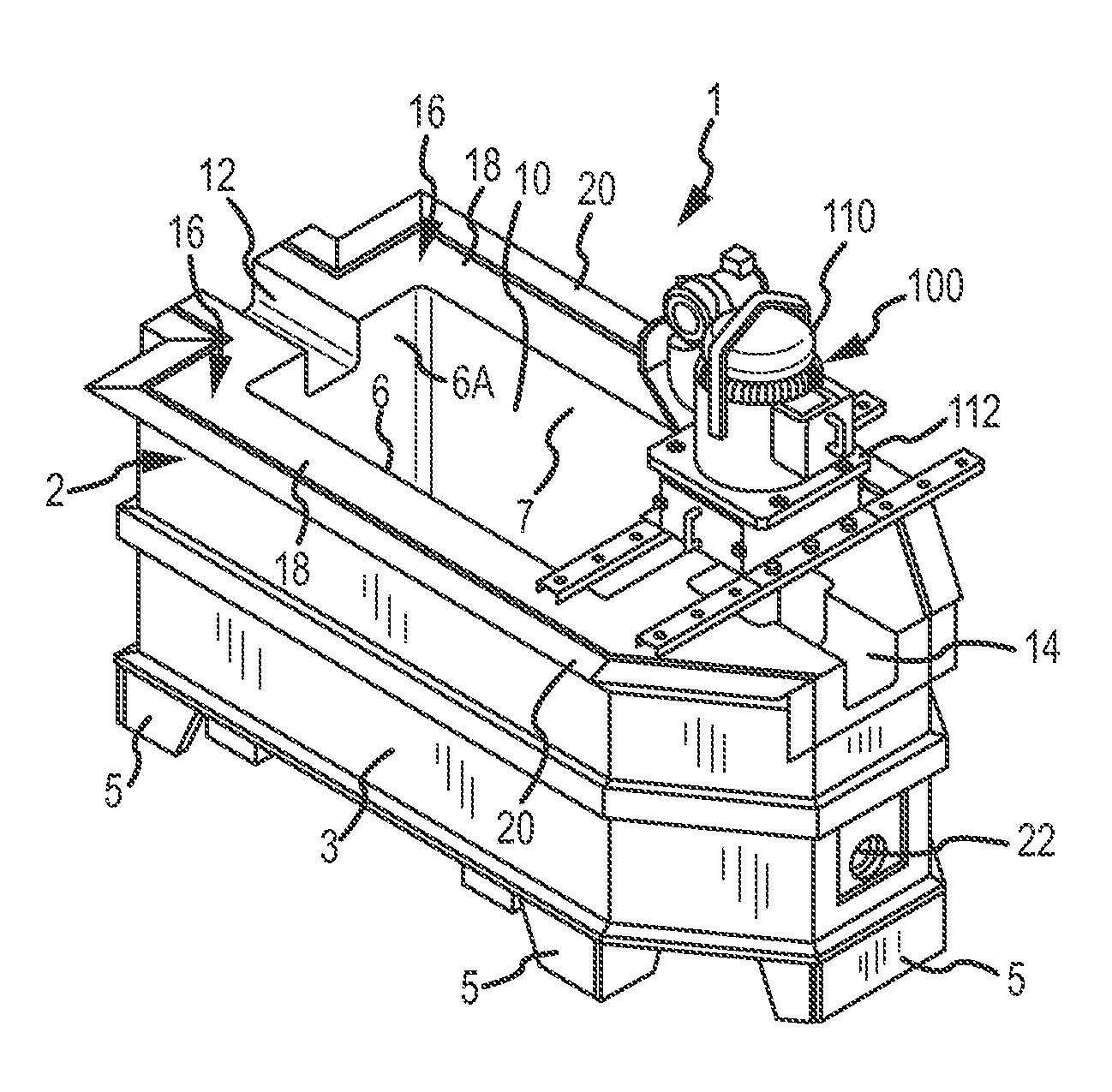

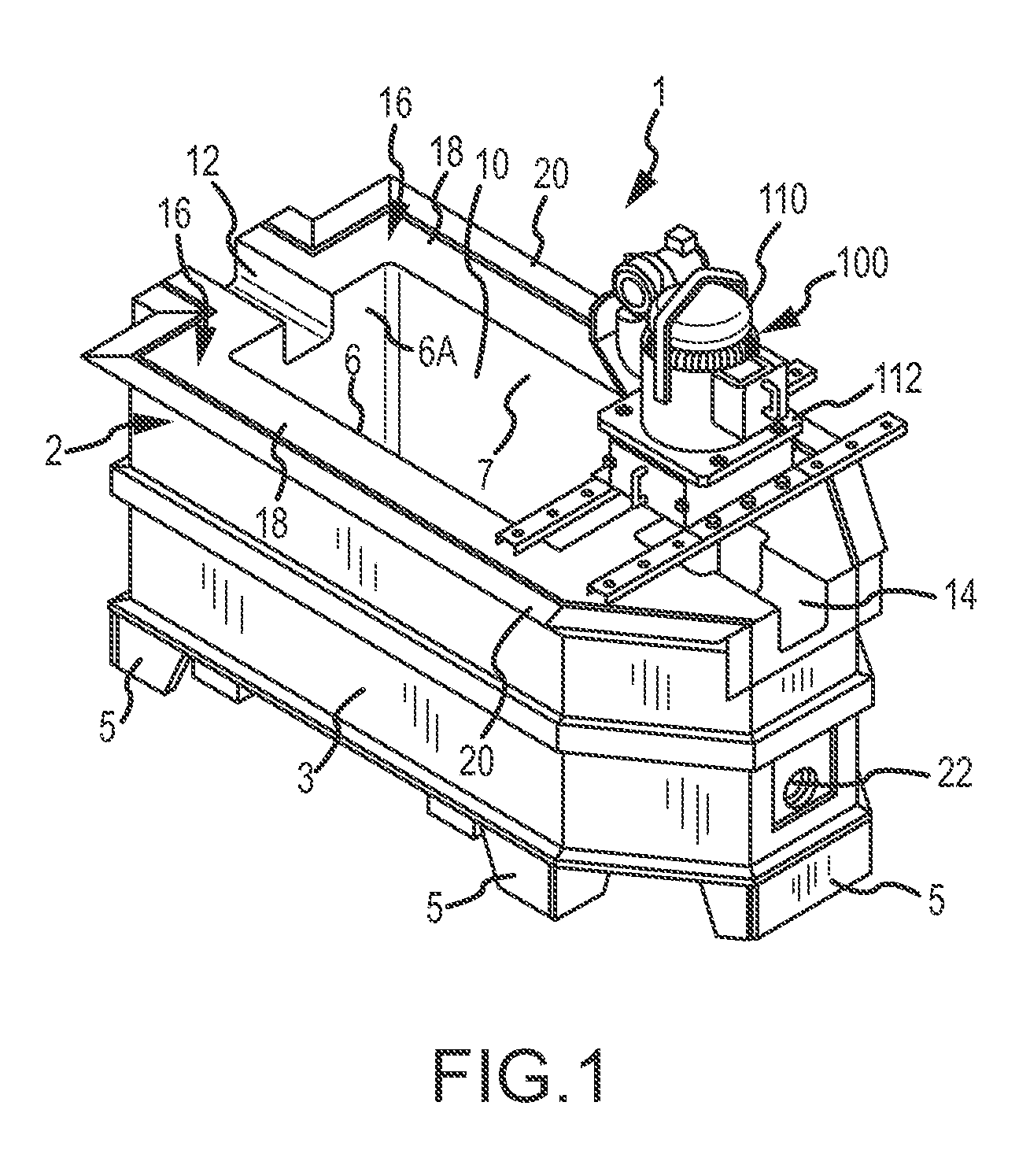

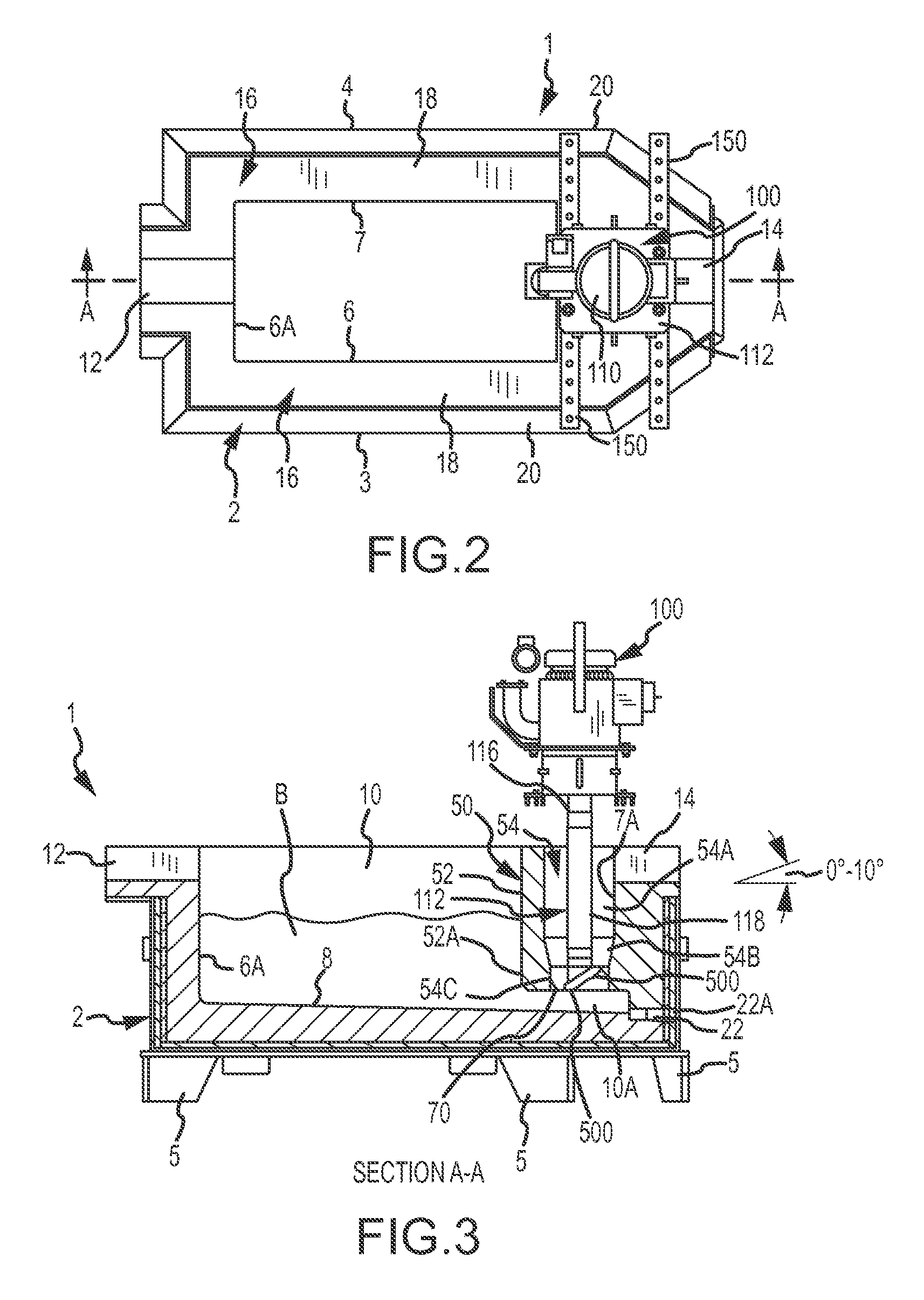

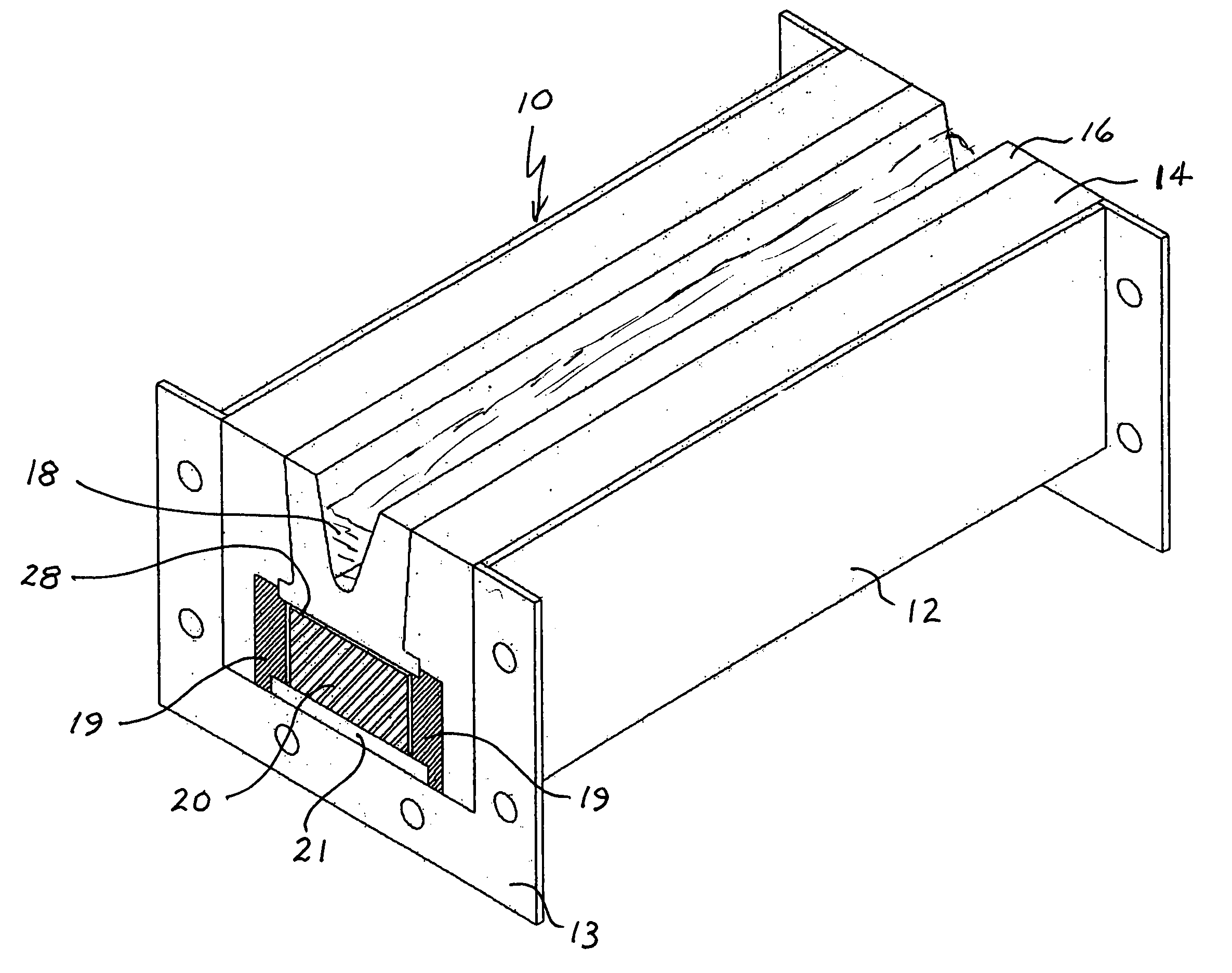

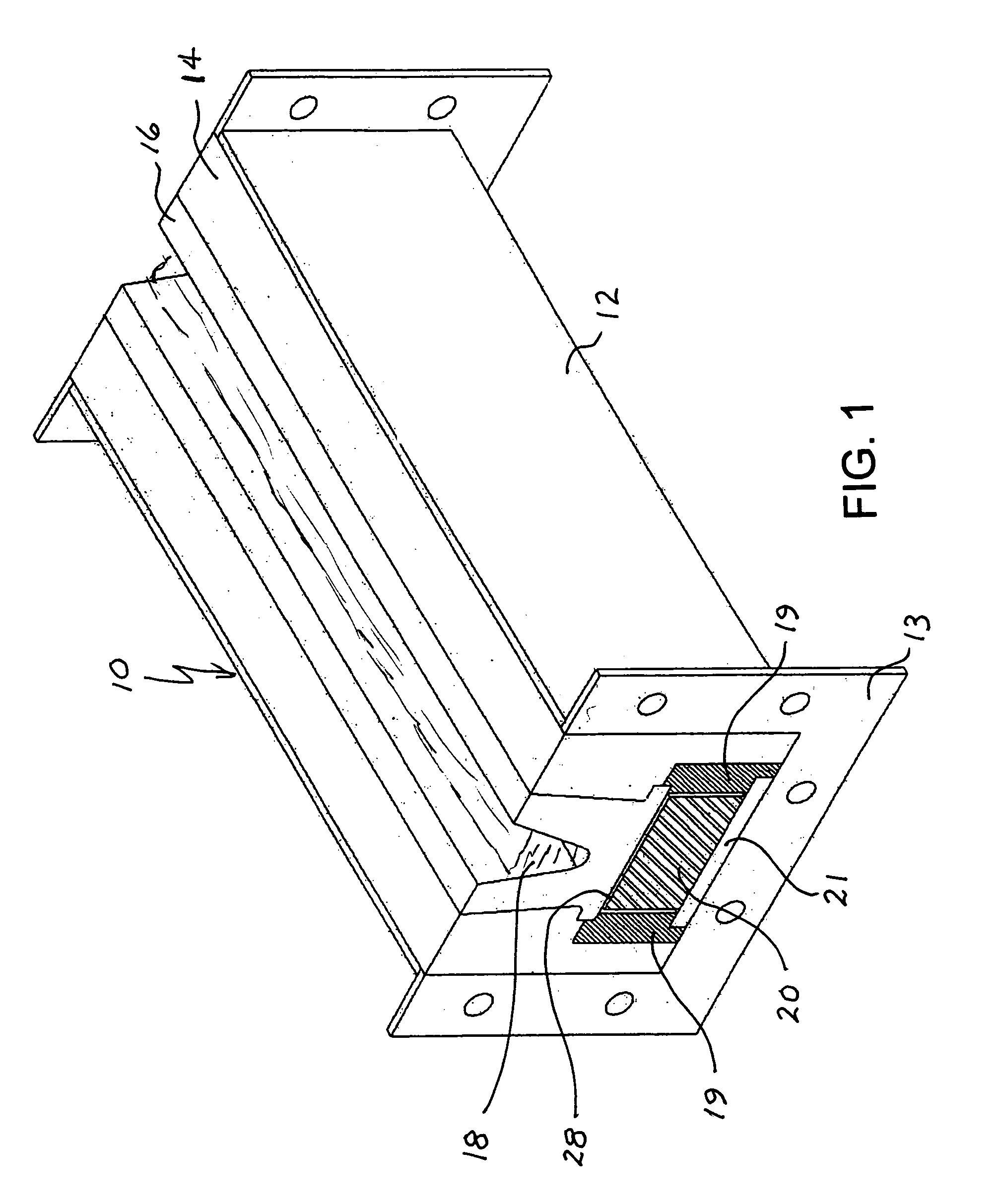

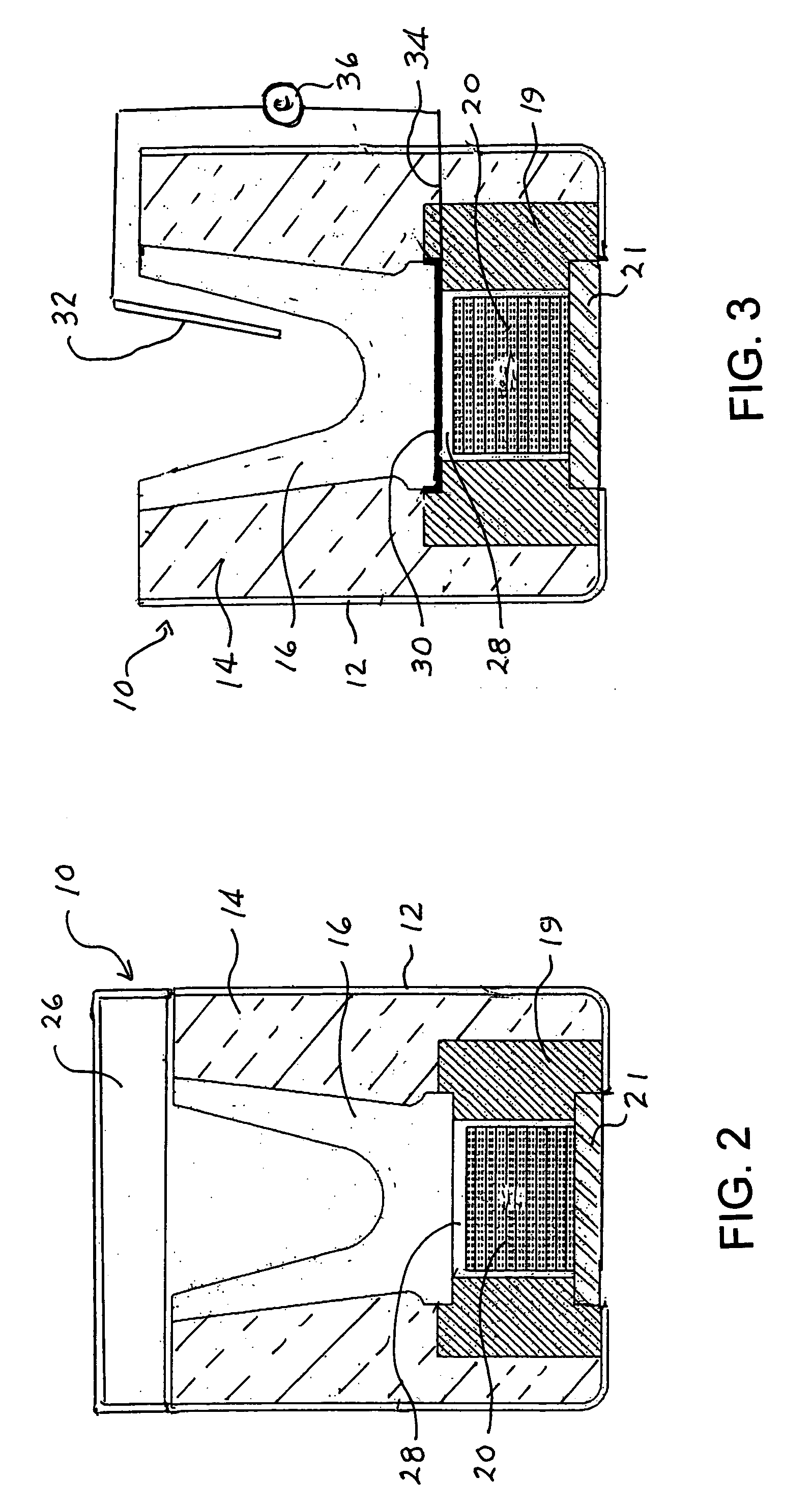

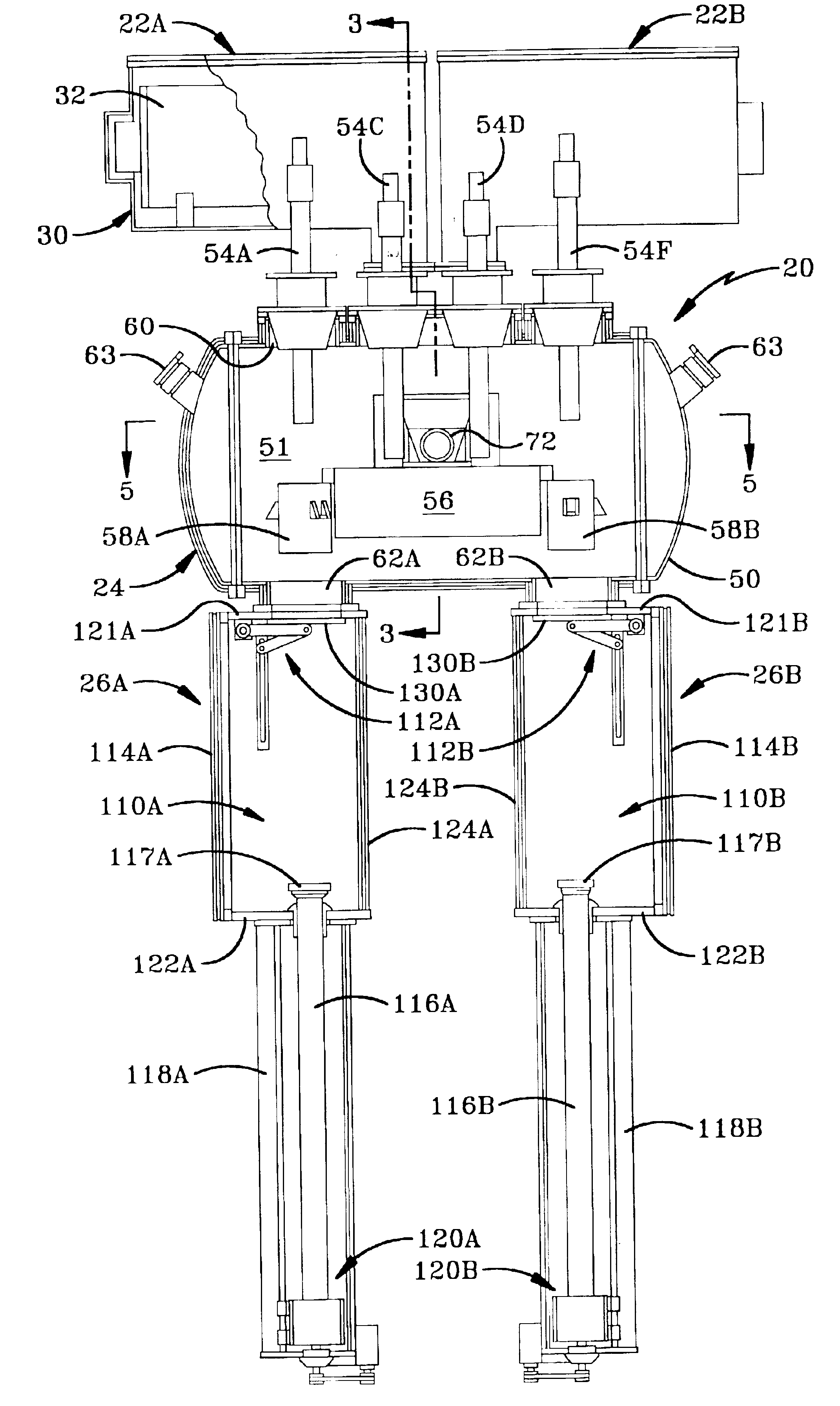

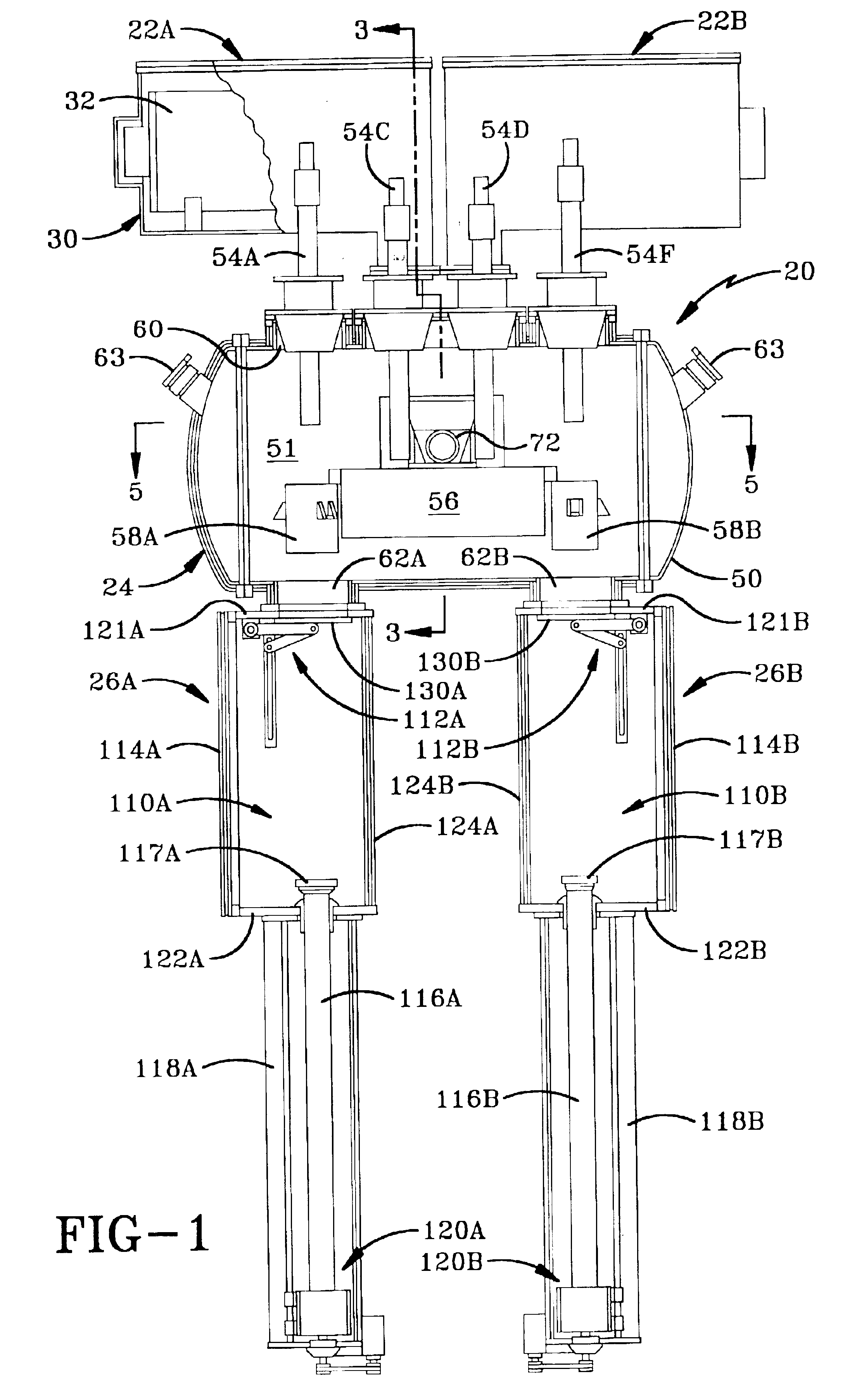

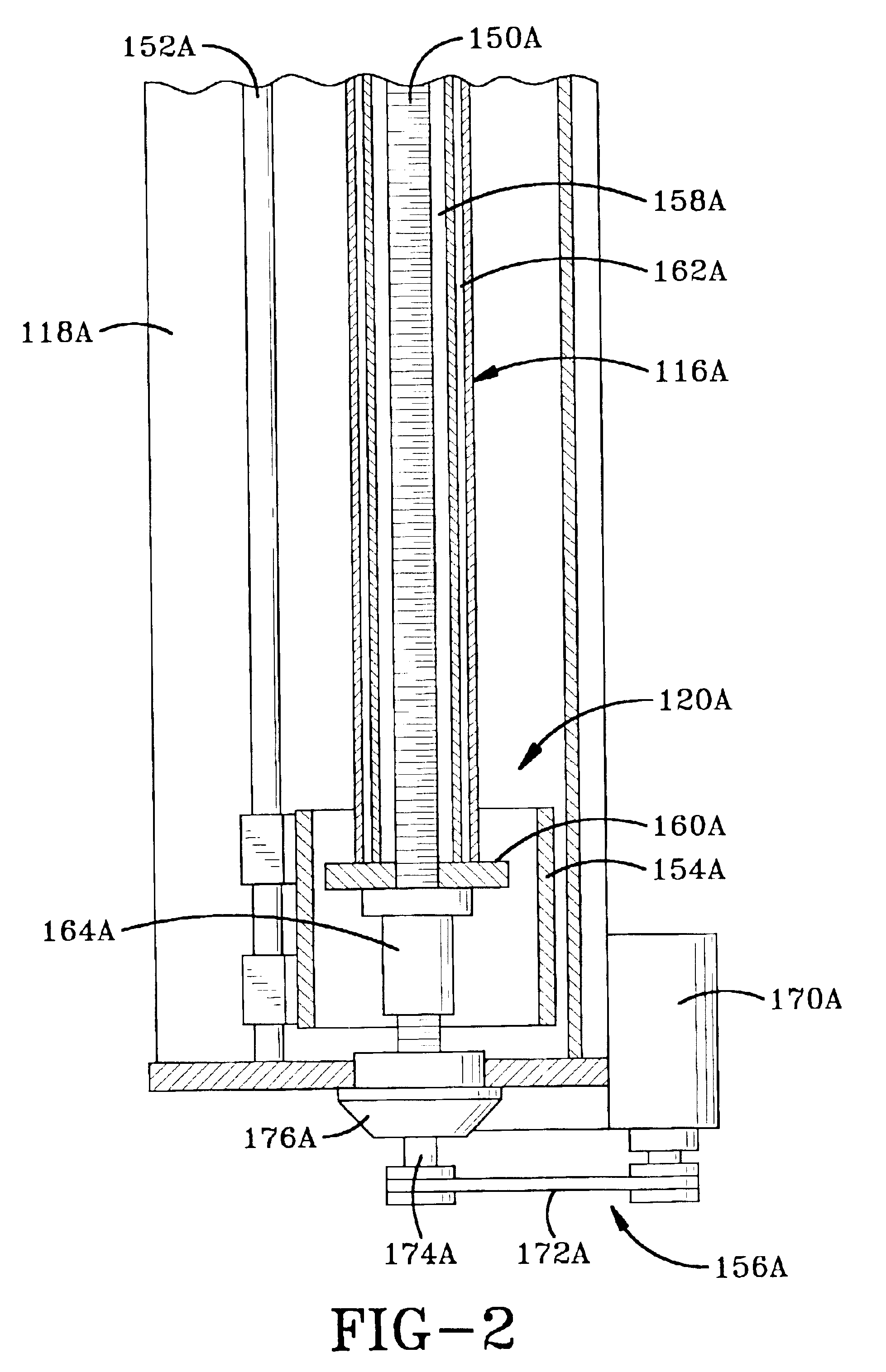

Transfer well system and method for making same

ActiveUS20130292426A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transferring molten metal from one structure to another

ActiveUS8337746B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsStirring devicesDie castingMolten metal

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer vessel and method of construction

ActiveUS20130299525A1Significant comprehensive benefitsFormation of dross in the ladle or launder are greatly reduced or eliminatedMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer and degassing system

ActiveUS20130306687A1Keep the flowReduce the possibilityMelt-holding vesselsMolten metal pouring equipmentsEngineeringMolten metal

Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain and degas molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel is pulled through the vessel by the pump as it is degassed. This helps maintain a generally constant flow of molten metal through the degassing vessel. Other aspects relate to a system and method for efficiently performing maintenance on components positioned in a vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transfer well system and method for making same

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer vessel and method of construction

ActiveUS9409232B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Method and apparatus for production of a cast component

InactiveUS6932145B2Minimize transmission of heatGas turbine plantsFrom frozen solutionsCasting moldMolten metal

A system for producing cast components from molten metal. One form of the present invention includes a system for the precision pouring of molten metal within a casting mold.

Owner:ROLLS ROYCE CORP

Heated trough for molten metal

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

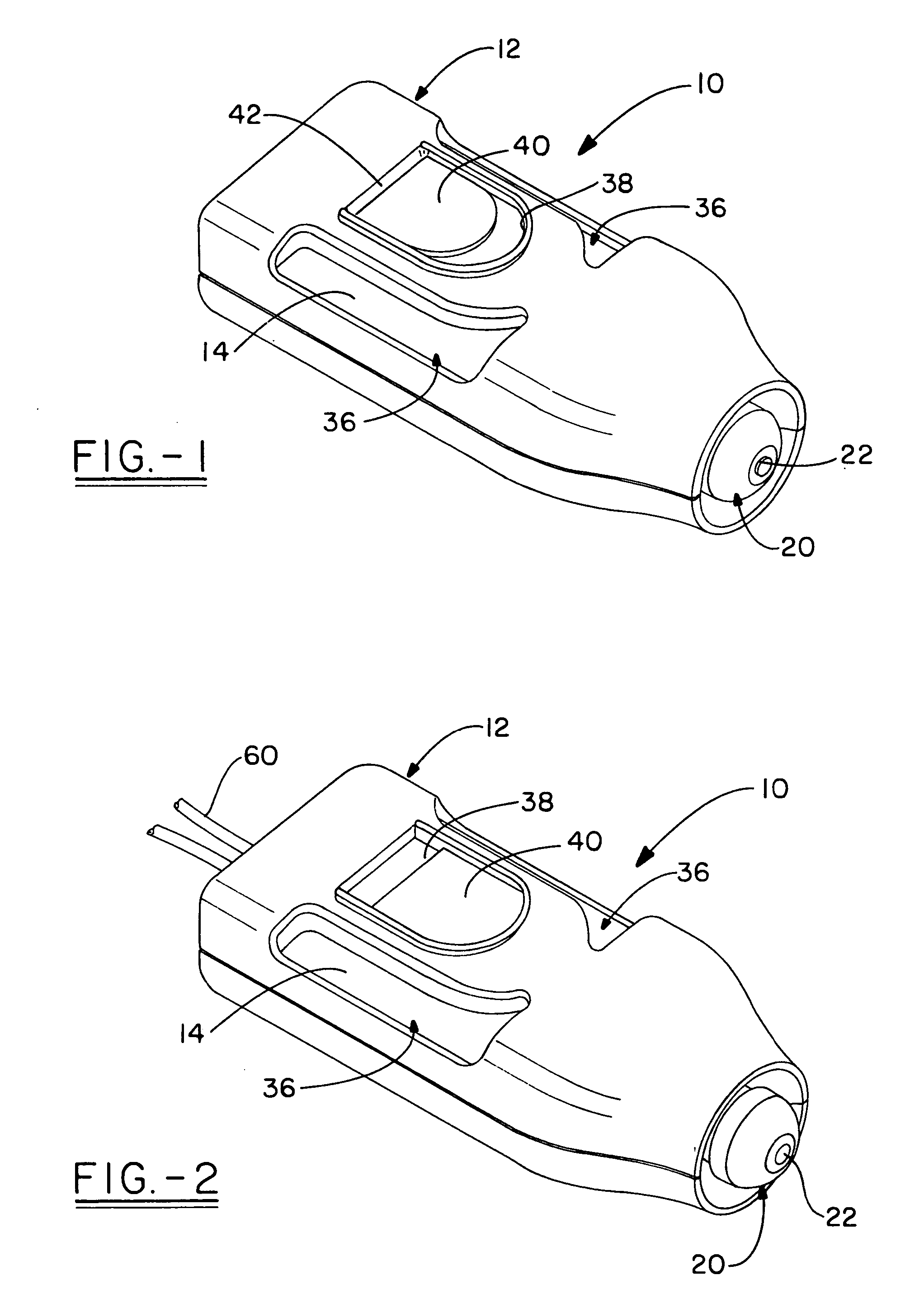

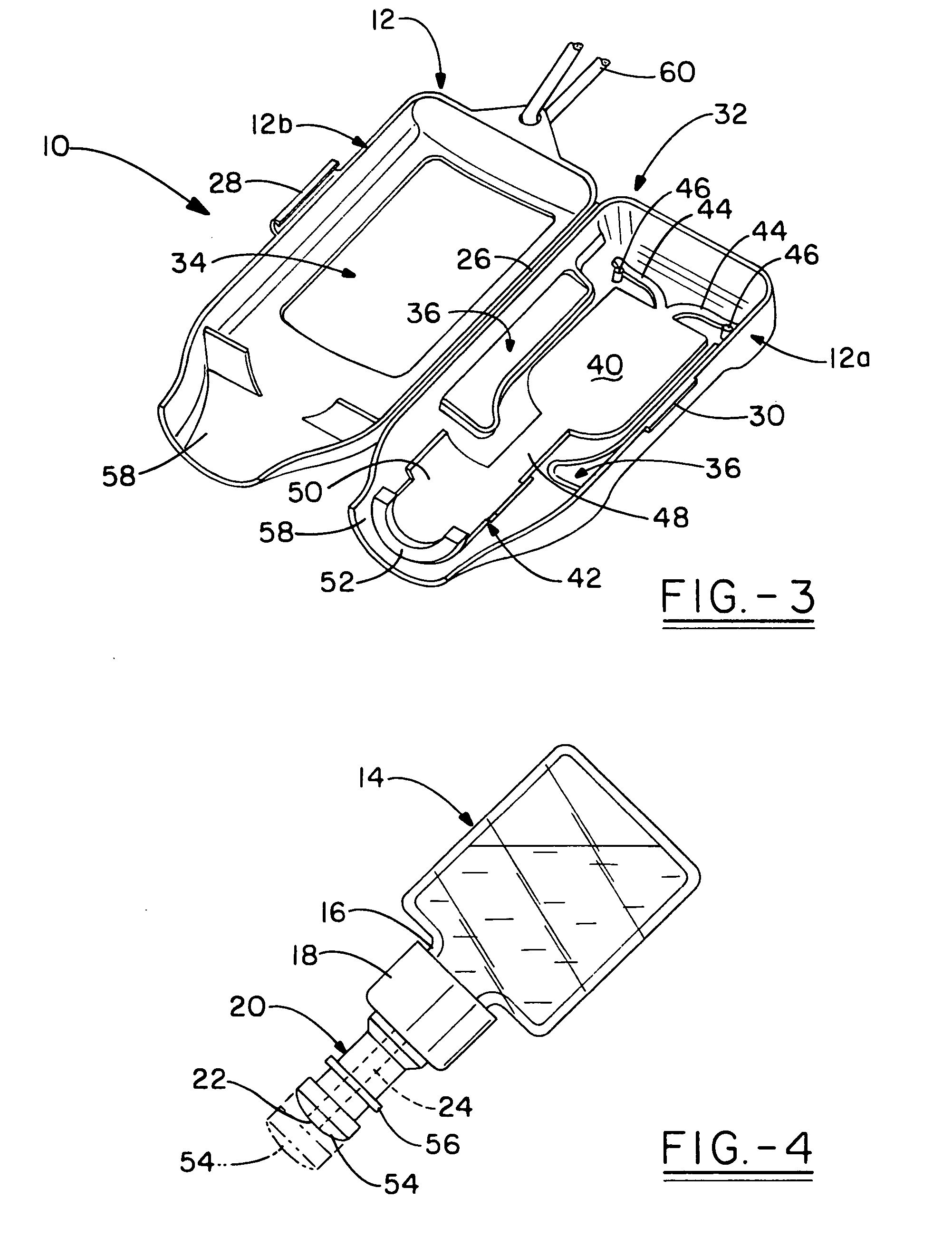

Cap for a container

InactiveUS6935536B2Reduce probabilityAvoid accidental dischargeMelt-holding vesselsMolten metal pouring equipmentsEngineeringActuator

Cap for a container, including a body having an inlet, a spout and a passageway therebetween. The cap also includes a valve movable between a first position wherein the passageway is blocked and a second position wherein the passageway is at least partly unblocked, the valve being biased towards the first position. Furthermore, the cap includes an actuator mounted to the body and engaging the valve. Selective control of the state of the valve is associated with movement of the actuator in a different direction than for securing the valve in the open position. The combination of movements required to lock the valve in the open position is sufficiently complex to reduce its probability of opening unintentionally. Meanwhile, the combination of movements is simple enough to be performed by a single finger.

Owner:TRUDEAU 1889

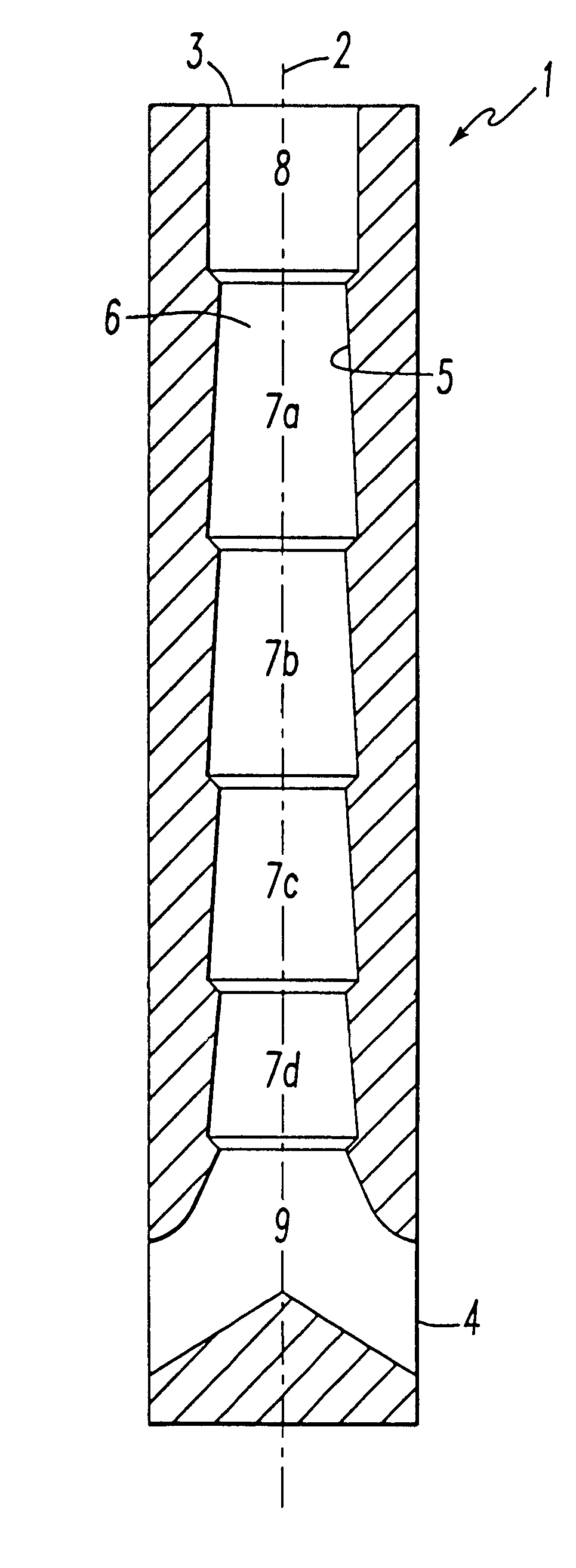

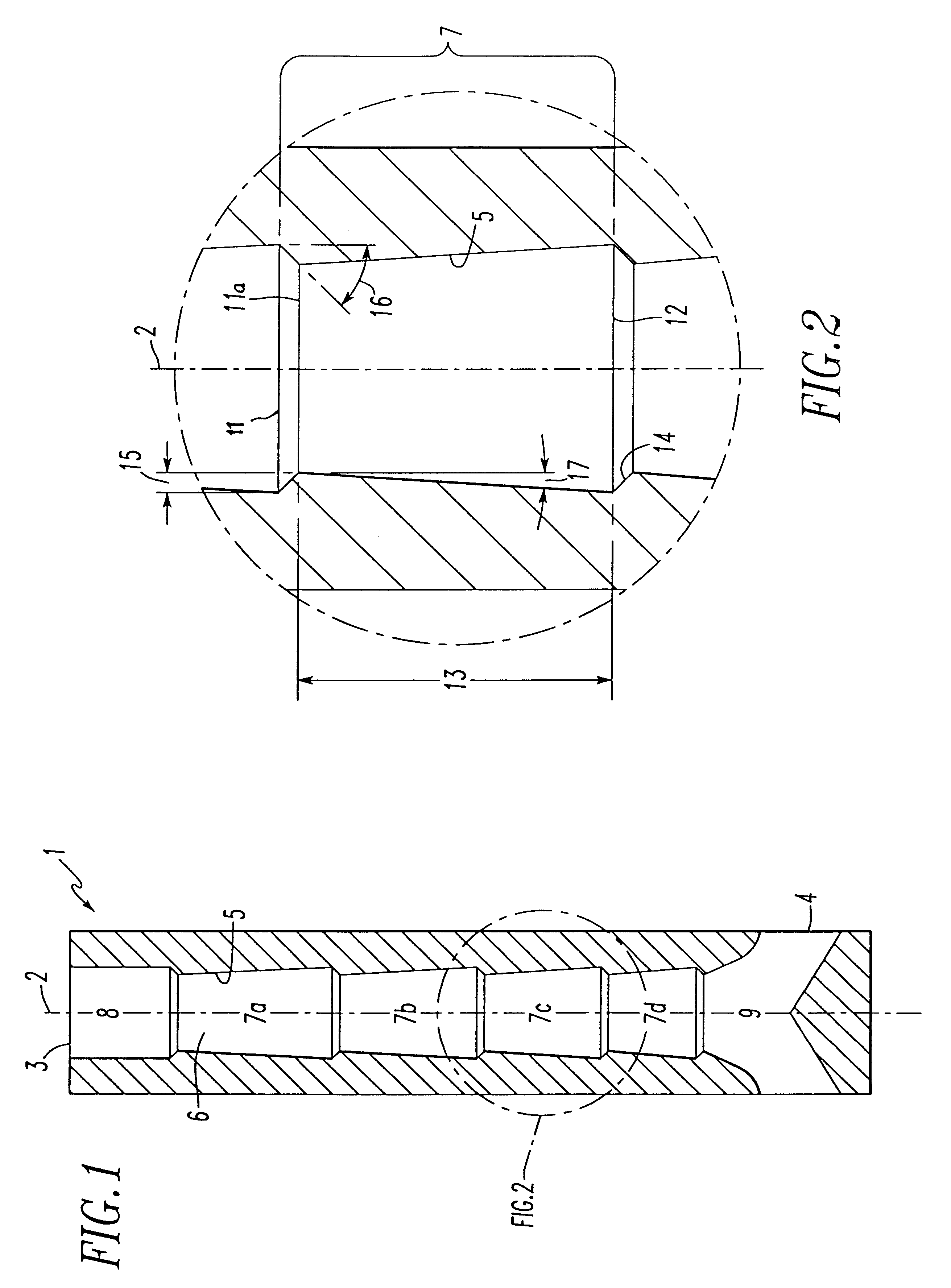

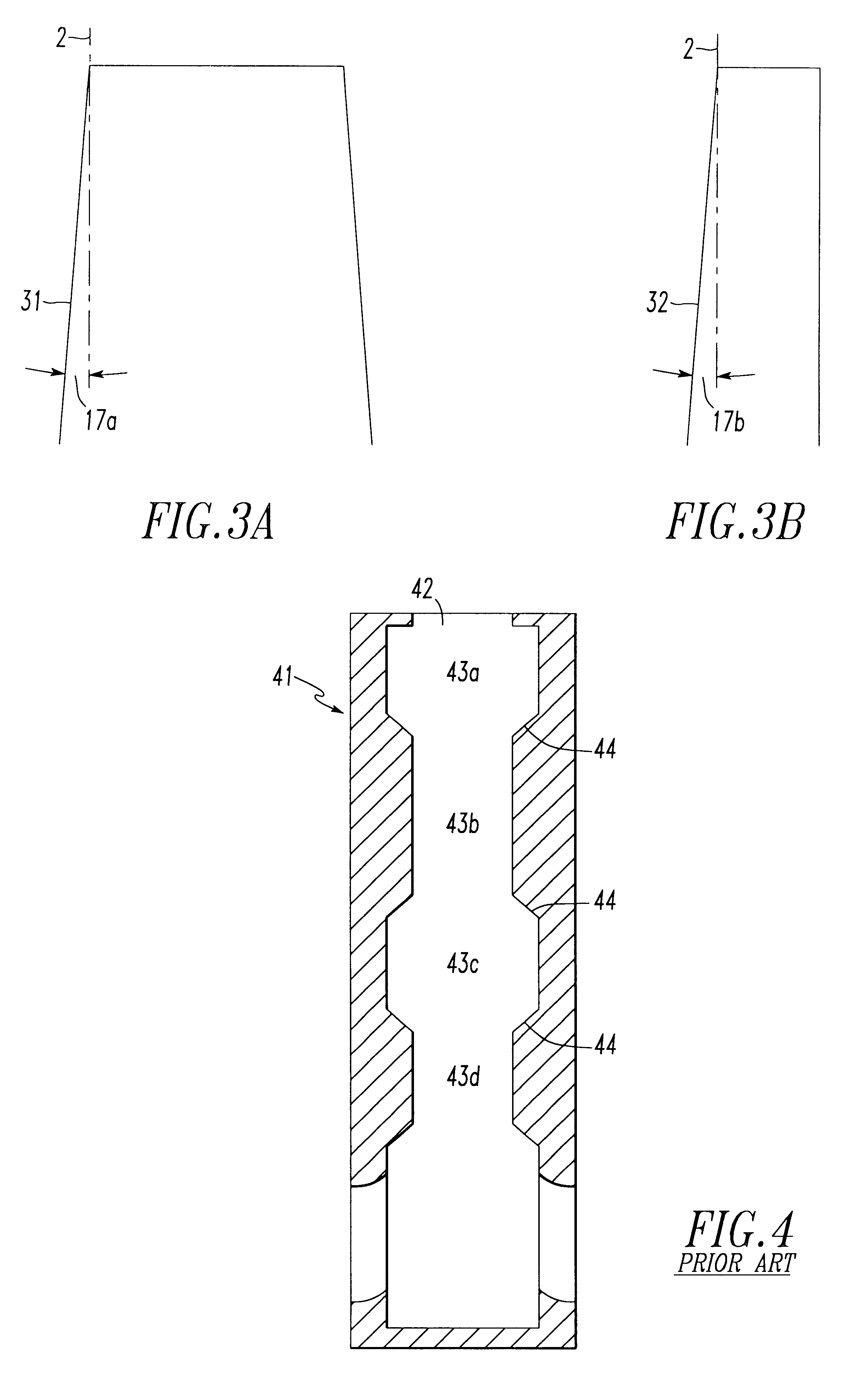

Pour tube with improved flow characteristics

A pour tube for use in the continuous casting of a stream of molten metal has a bore comprising a plurality of fluidly connected sections that improve the flow of molten metal through the bore. The sections reduce asymmetric flow of the molten metal stream and the likelihood of precipitates clogging the bore. Each section comprises a converging portion and a diverging portion. The converging portion deflects the stream toward the center of the bore, while the diverging portion diffuses the stream. The sections may comprise a plurality of frusto-conical sections. The cross-sectional areas of the sections may increase, decrease, or remain the same size from an upstream to a downstream position.

Owner:VESUVIUS USA CORP

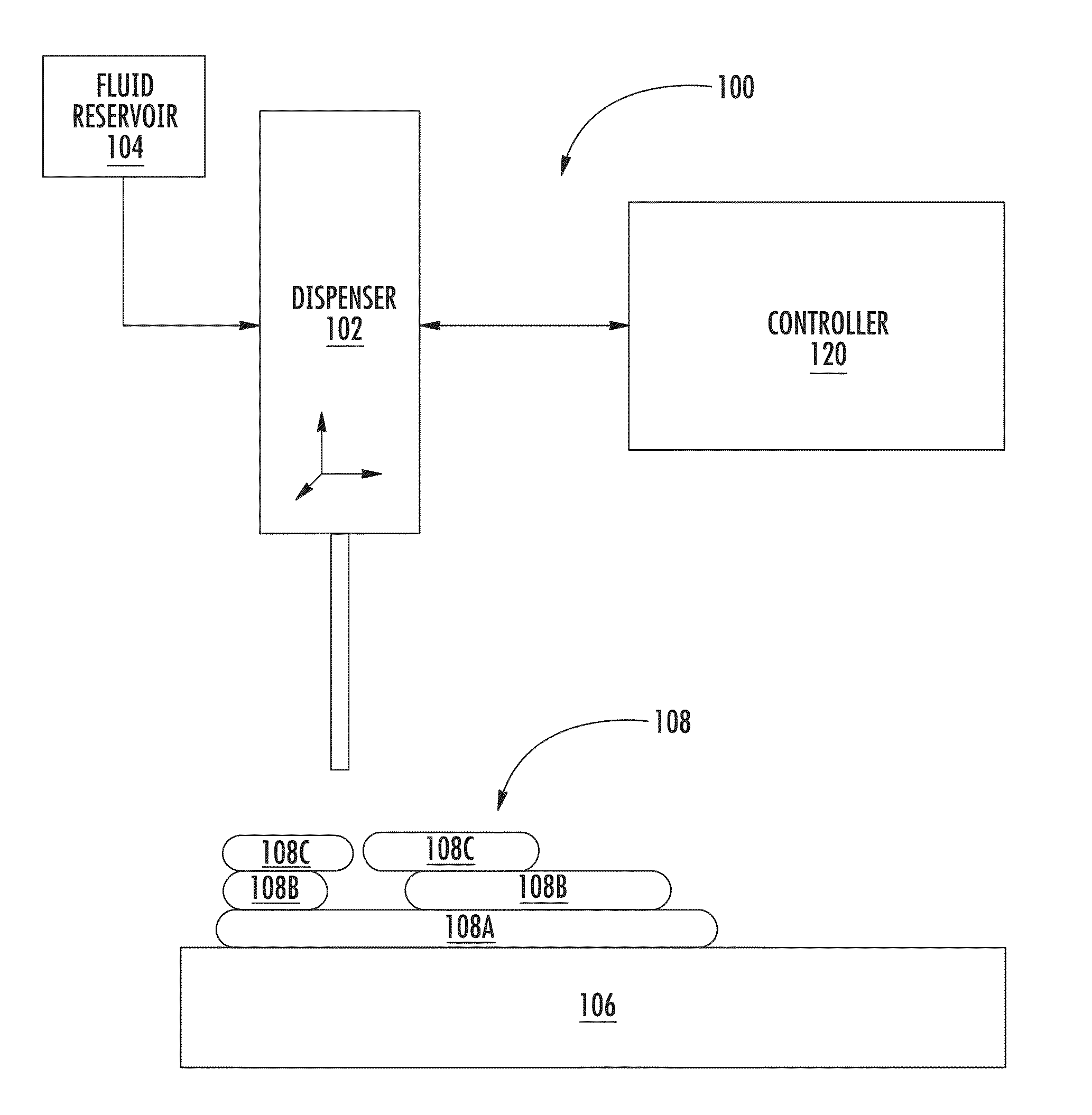

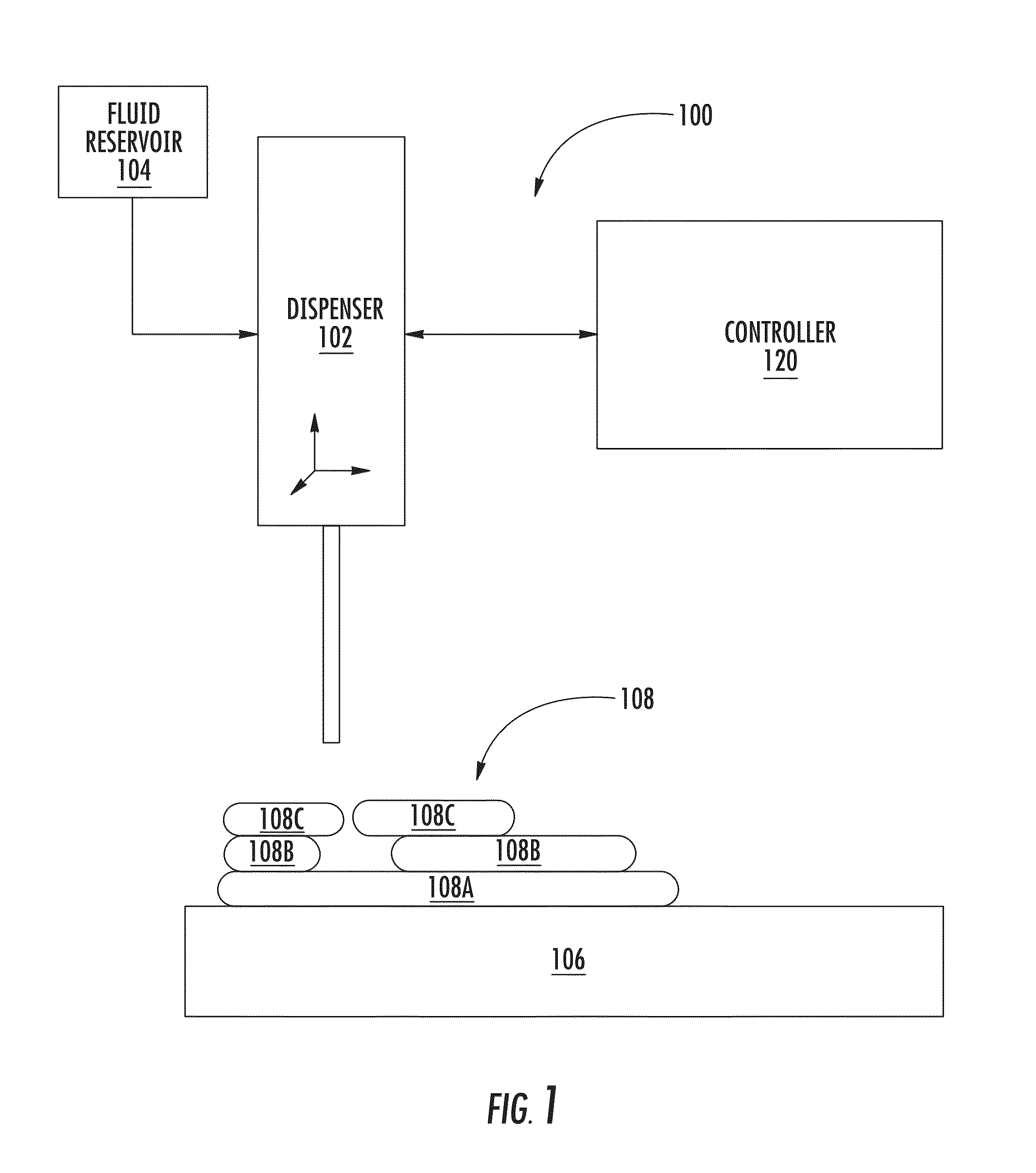

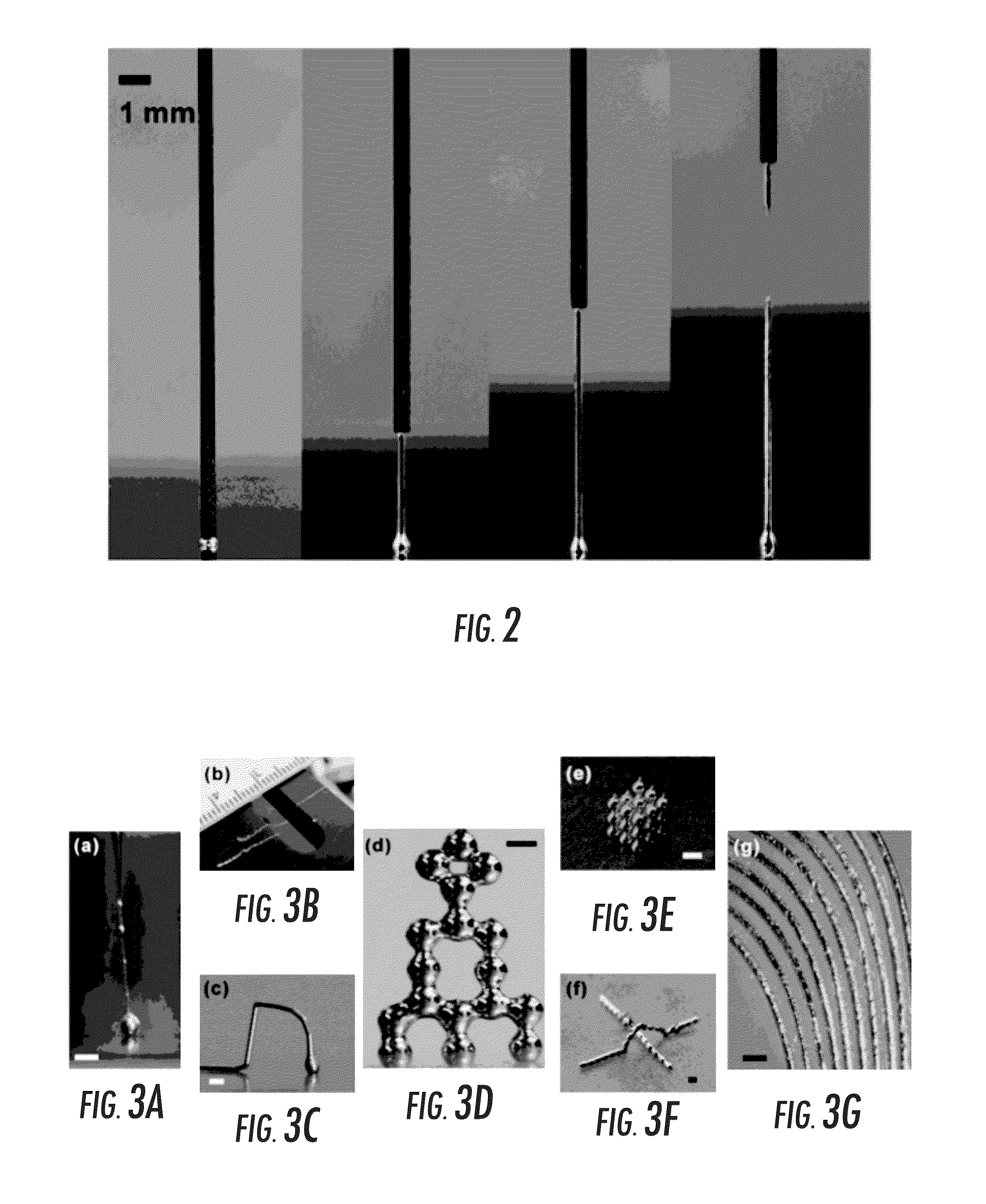

Three-Dimensional Printing of Metallic Materials

InactiveUS20150217367A1Additive manufacturing apparatusMolten metal pouring equipmentsSolid regionMetallic materials

Methods of printing metallic objects include providing parameters of an object for printing, and controlling a deposition of a fluid metallic material to form the object. At least an outer surface region of the fluid metallic material is converted to a solid region after deposition.

Owner:NORTH CAROLINA STATE UNIV

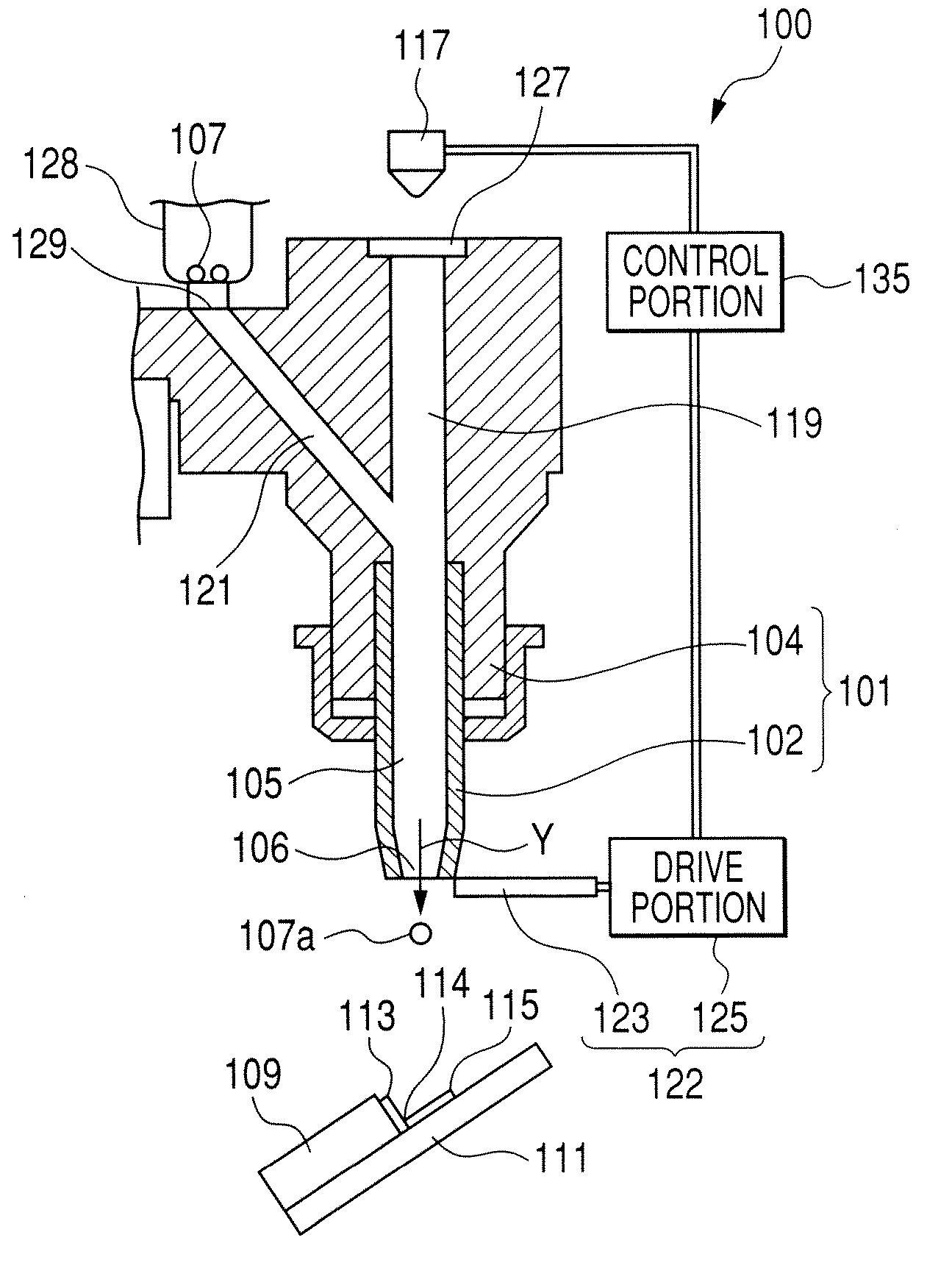

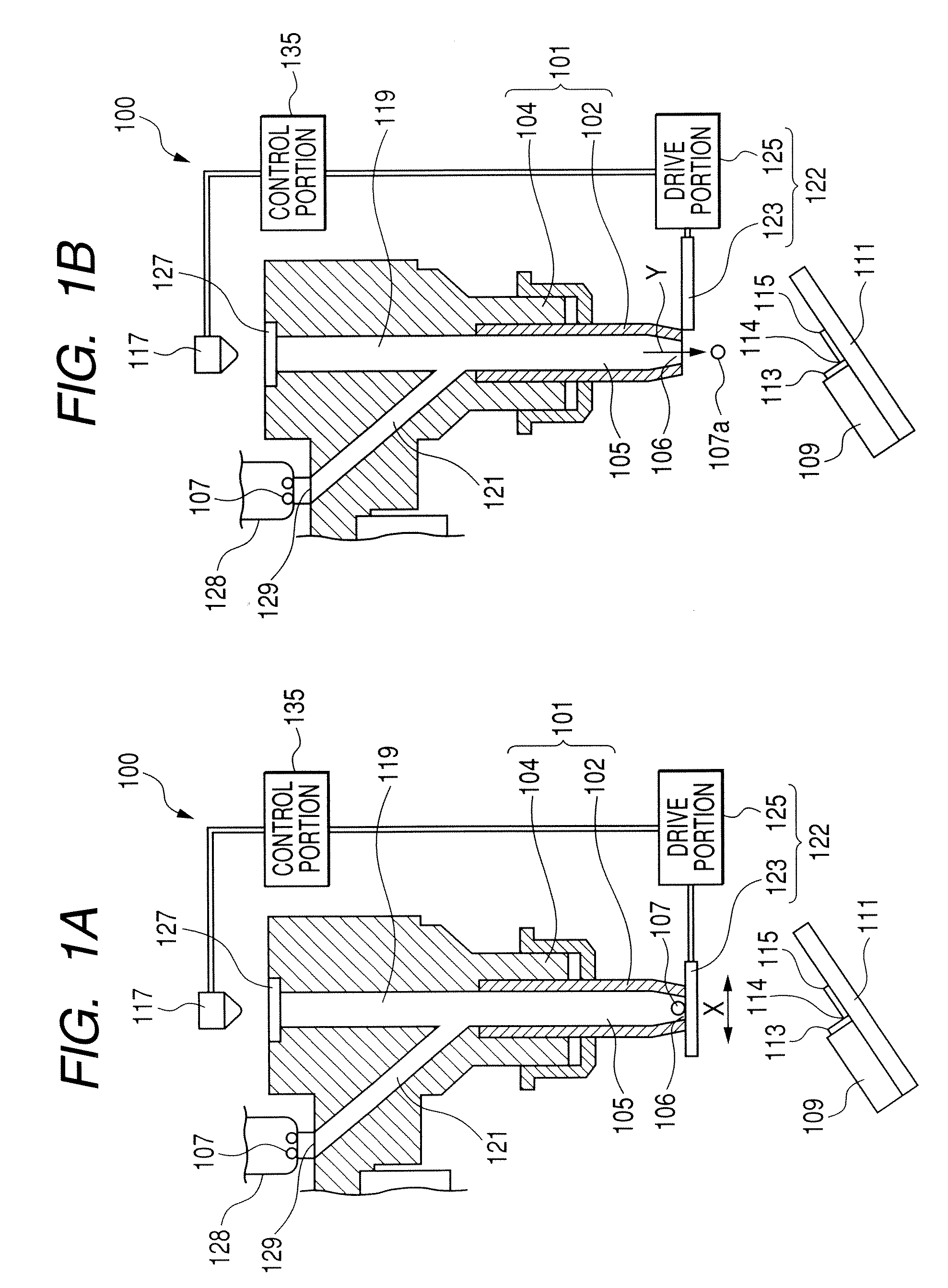

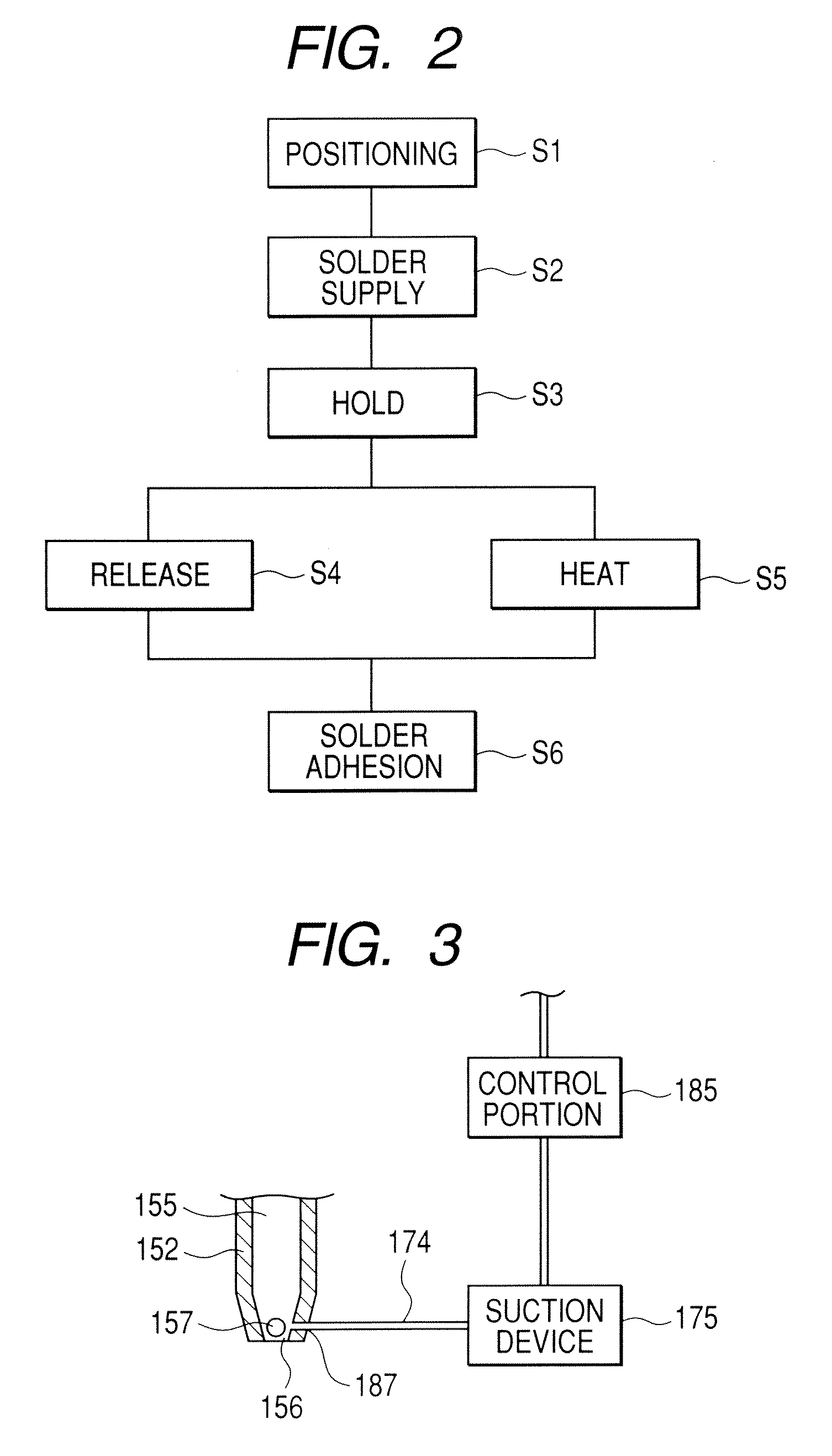

Soldering method, soldering device, bonding method, bonding device, and nozzle unit

Provided is a nozzle unit for use in a bonding device in which bonding between a first member and a second member is effected by providing a bonding member that has been melted by heating at a bonding position where the first member and the second member are to be bonded to each other. The nozzle unit includes: a cylindrical nozzle assembly having an accommodating space accommodating the bonding member, and an opening which allows ejection of the bonding member accommodated in the accommodating space onto the bonding position, which has a diameter larger than the diameter of the bonding member, and which communicates with the accommodating space; and a holding / releasing member for releasably holding the bonding member within the accommodating space.

Owner:TDK CORPARATION

High-strength abrasion-proof cast steel lining board and manufacturing method thereof

InactiveCN101173343ASimple production processImprove wear resistanceMolten metal pouring equipmentsFurnace typesChemical compositionEconomic benefits

The invention relates to a lining plate of cast steel with high strength and abrasion resistance and the fabrication method, belonging to the technical field of metal abrasion-resistant material. The chemical composition of the lining plate (in weight ratio) is that: 0.25 to 0.45 C, 1.0 to 2.0 Mn, 0.8 to 1.5 Cr, 0.003 to 0.008 B, 0.02 to 0.08 Al, 0.04 to 0.15 Ti, 0.02 to 0.10 La, 0.02 to 0.10 Ce, 0.02 to 0.08 Ba, 0.02 to 0.10 Ca and Fe and other inevitable micro impurity retaining; wherein, the sum of Si, Mn and Cr is more than 3.5 and lower than 4.5, while the sum of the La and Ce is more than 0.05 and lower than 0.18. The lining plate of cast steel can be fabricated with an electric stove and a method of sand sell molding. Therefore, the tensile strength of the lining plate is as high as to 1450 to 1600 MPa, the hardness reaches to 50 to 55 HRC; the abrasion resistance is good; and the impact toughness reaches 65 to 80 J / cm2. The lining plate can neither fracture nor peel in use, with much better service performance than the Mn13 high manganese steel lining plate. With the steel cuttings adopted as the main materials, the lining plate has the advantages of simple fabricating technique, low manufacturing cost, and can improve the operating efficiency of ball mill and lower the material-grinding cost, therefore is possessed with good economic benefit.

Owner:BEIJING UNIV OF TECH

Personal squeeze bottle dispenser

A personal squeeze bottle dispenser has a clamshell housing adapted to receive a squeeze bottle having a push / pull dispensing valve. A slide mechanism is received within the housing and has a collar at one end engaging the push / pull valve, and a spring at the other end to effect automatic return of the slide mechanism upon termination of a dispensing cycle. The spring biases the push / pull valve to the closed position. The clamshell housing is configured with an opening for a thumb pad of the slide mechanism to achieve opening of the push / pull valve and accommodating pressure upon the squeeze bottle. An opening on the backside of the housing, opposite the thumb pad, is also provided to allow the user's fingers to access the squeeze bottle for the application of dispensing force.

Owner:KANFER JOSEPH S

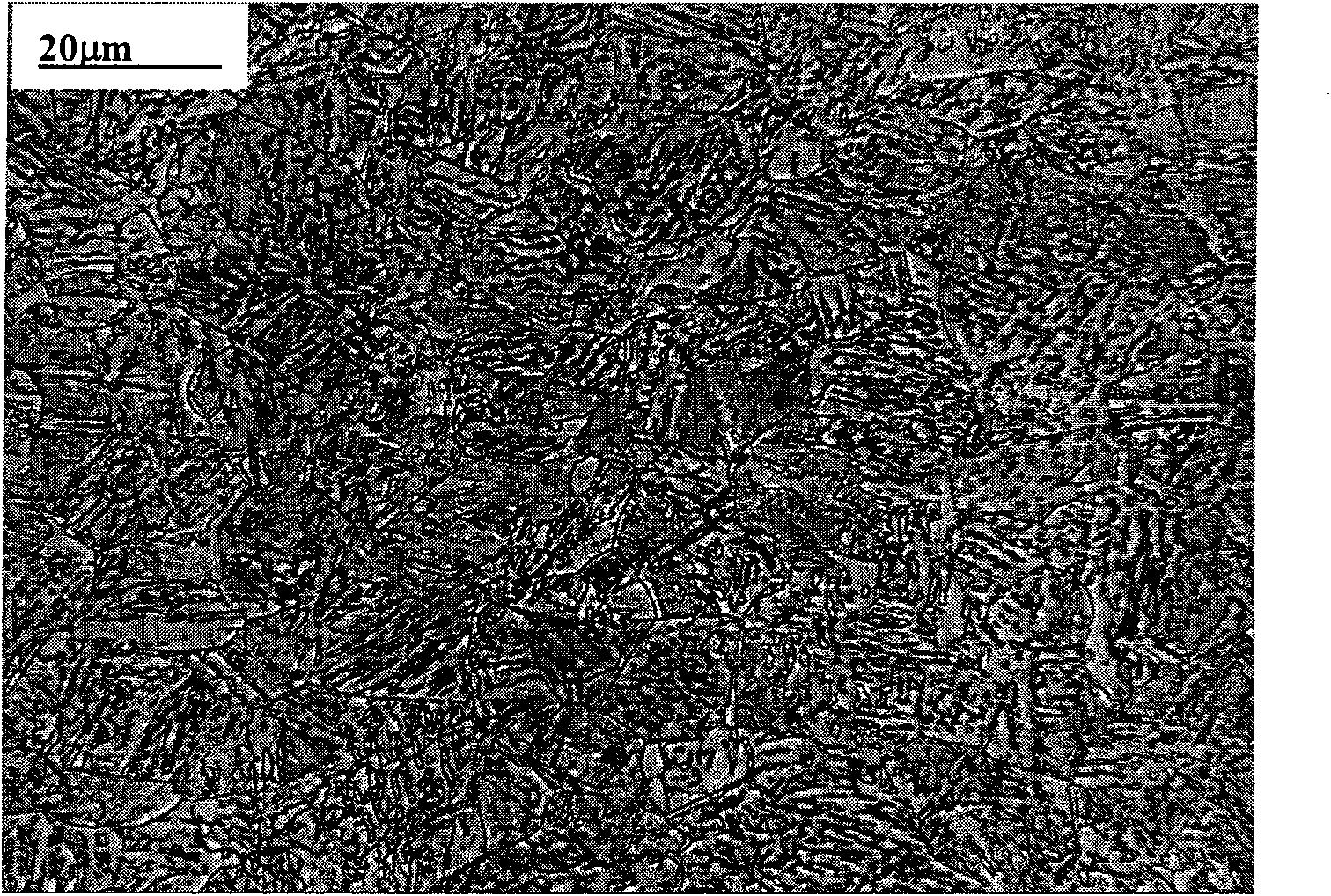

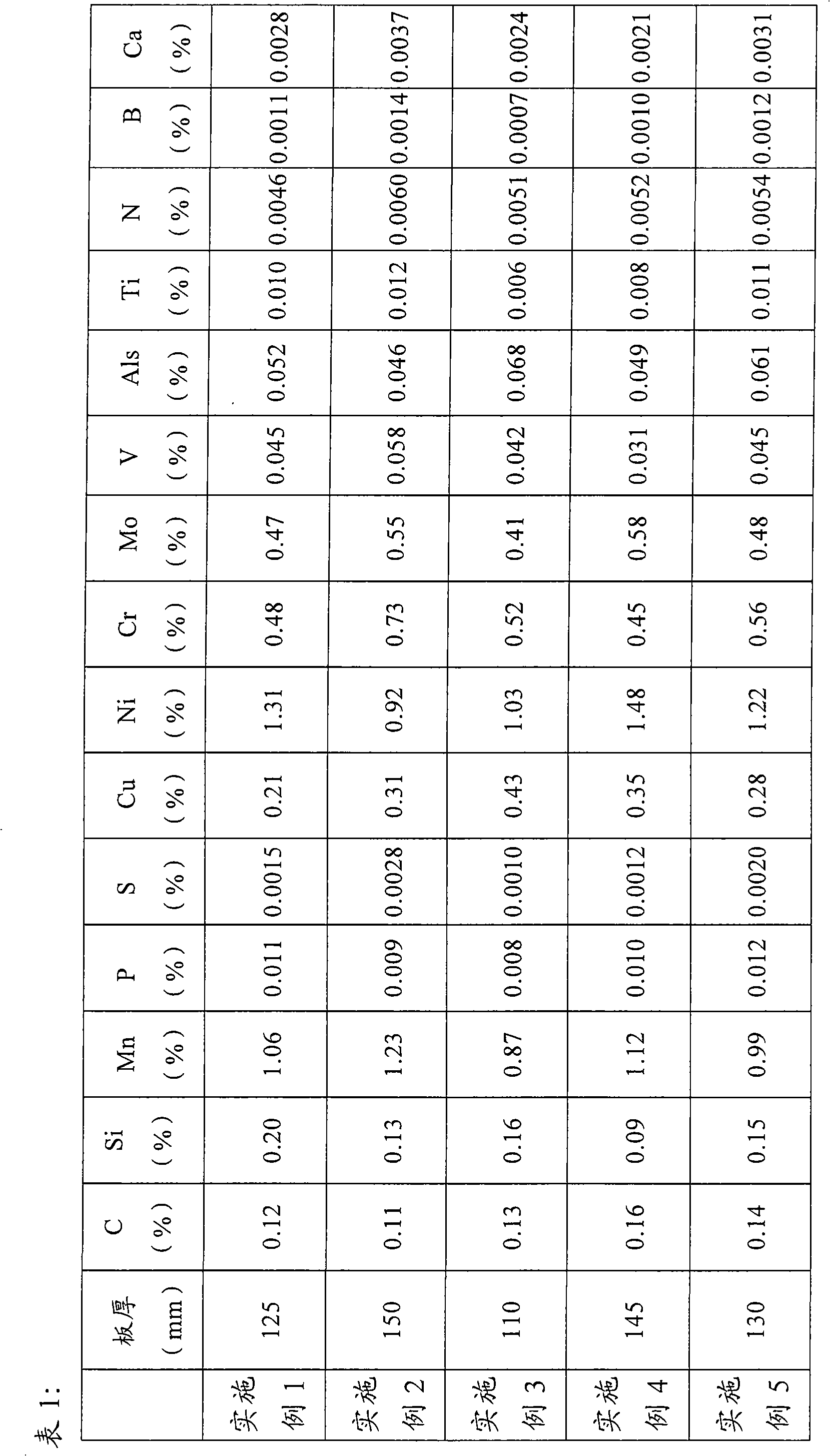

Quenched and tempered steel sheet and manufacturing method thereof

ActiveCN101962741AStrong plastic matchingSimple welding processRoll force/gap control deviceMolten metal pouring equipmentsSheet steelChemical composition

The invention provides a 80kg extra-thick quenched and tempered steel sheet. The steel sheet comprises the following chemical compositions: 0.10 to 0.16 percent of C, less than or equal to 0.20 percent of Si, 0.85 to 1.25 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0030 percent of S, 0.20 to 0.45 percent of Cu, 0.90 to 1.50 percent of Ni, 0.45 to 0.75 percent of Cr, 0.40 to 0.65 percent of Mo, 0.030 to 0.060 percent of V, 0.045 to 0.070 percent of Als, 0.006 to 0.012 percent of Ti, less than or equal to 0.0060 percent of N, 0.0006 to 0.0014 percent of B, 0.001 to 0.005 percent of Ca, and the balance of iron and inevitable impurities, wherein the chemical compositions meet the following conditions that: the Mn equivalent / C is more than or equal to 10 and less than or equal to 20; the Als is more than or equal to (Mn equivalent / c)*(N-0.292Ti); the Ni equivalent is more than or equal to 1.15 percent; the Mo equivalent is more than or equal to 0.25 percent; Ca / S is more than or equal to 0.80 and less than or equal to 3.00, and (Ca)(S)0.18 is more than or equal to 5*10<-4> and less than or equal to 2.5*10<-3>; and F*DI equals to the effective hardenability index Deff and is more than or equal to 1.00*t. The invention also relates to a method for manufacturing the quenched and tempered steel sheet. The technology of optimal recrystallization controlled rolling+offline quenching and tempering is adopted to ensure that the microstructure of the finished product steel sheet is a fine tempered bainite and tempered martensite, the average colony size is less than 25mu m, and excellent obdurability / plasticity matching and uniform mechanical performance along the direction of the sheet thickness can be acquired.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength casted air-colled bainite wear-resisting steel and preparing method

InactiveCN1775983AImprove mechanical propertiesImprove toughnessMolten metal pouring equipmentsFoundryWear resistant

The invention relates to a high strength foundry air cooling bainite wear resistant steel that the chemical constituents is 0.32-0.65 C, 0.8-3.0 Si, 1.2-3.0 Mn, 0.5-0.8 Cr, 0.3-0.8 Cu, 0.001-0.008 B, 0.18-0.35 Al, 0.05-0.15 Y, 0.05-0.20 Ti, 0-0.12 Mg, 0-0.12 Ca, 0-0.15 Zn, and 0.10<Mg+Ca+Zn<0.25, the else is Fe and trace impurities. The process includes the following steps: smelting waste steel, pig iron, ferrochrome iron and copper board, adding ferrosilicon and ferromanganese preliminary deoxidation into melting down and alloying; heating to 1600-1660 degree centigrade after adjusting the constituents adding aluminum deoxidatioin and alloying and blast furnace tapping; putting the compounding modification particle of Yt, boron, titanium, magnesium, calcium, and zinc on the bottom of pouring ladle, taking modification process to the molten steel; molding the molten steel after modification process into normal matrix for casting. The invention could prolong the useful life of antifriction component, improve working efficiency, and have good economic benefit.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

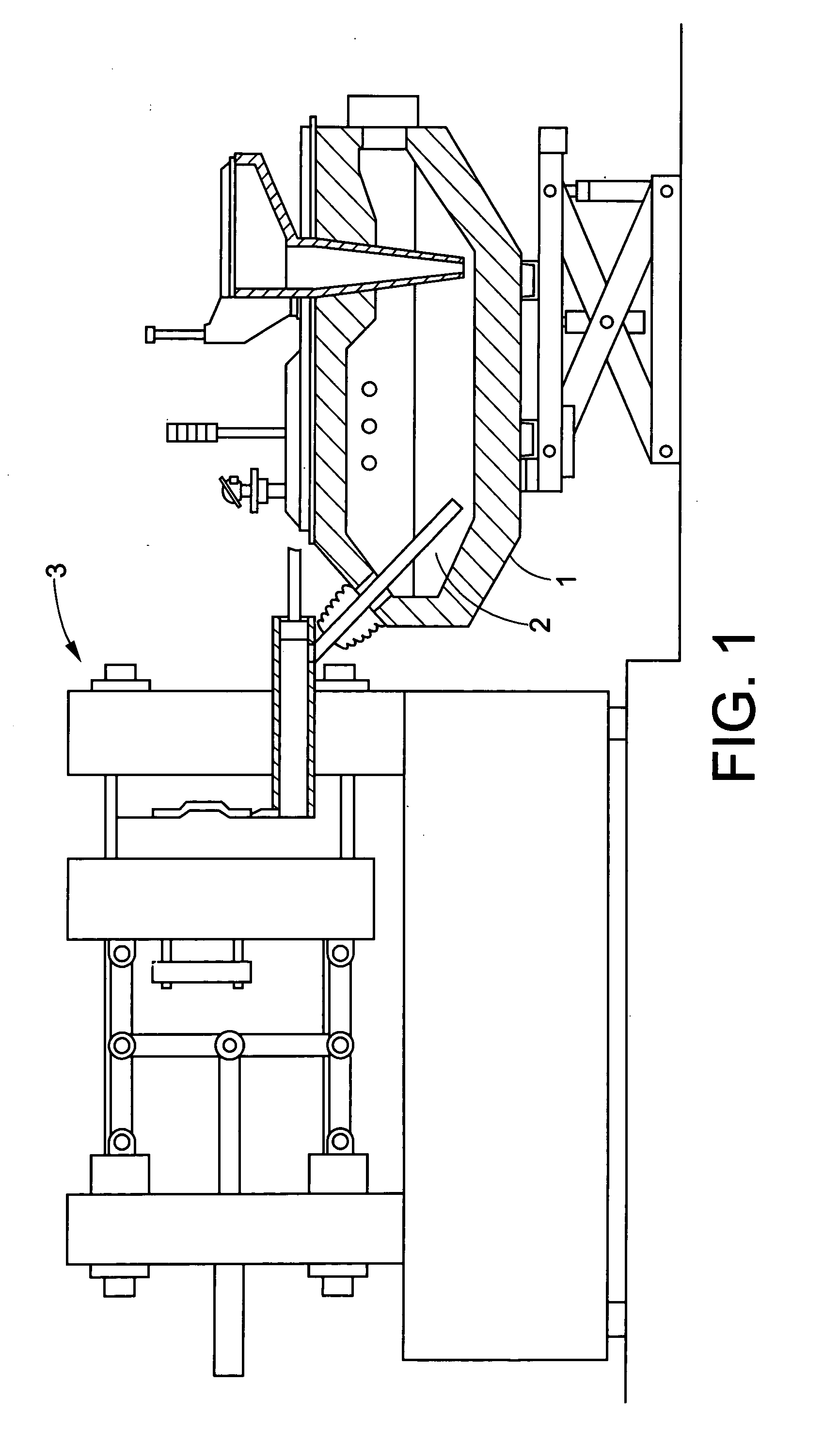

Method and apparatus for alternating pouring from common hearth in plasma furnace

A method and apparatus for alternating pouring into molds, casts or refining hearths from a common hearth in a furnace. The apparatus provides a main hearth, a plurality of optional refining hearths, and a plurality of casting molds or direct molds whereby the refining hearths and molds define at least two separate ingot making lines. The main hearth alternatively pours into a first ingot making line while the other line is prepared, and vice versa allowing for continuous melting.

Owner:RETECH SYSTEM LLC

Medium carbon bearing steel and its preparation method

InactiveCN101186995AGuaranteed hardenabilityLow costMolten metal pouring equipmentsTemperature control deviceForeign matterChemical composition

The invention relates to medium carbon bearing steel and process for preparation, belonging to the technical field of bearing steel material and process technology. According to weight percentage, the range of the chemical components of the medium carbon bearing steel includes that C holds 0.50% to 1.0%, Si is 0.60% to 1.50%, Mn takes 0.50% to 1. 20%, Mo is 0.15% to 1.0%, V takes 0.15% to 1.0%, Cr and Ni are equal to or less than 0.30%, Cu is equal to or less than 0.15%, S is equal to or less than 0.025%, P is equal to or less than 0.025%, B takes 0.0005% to 0.0035%, (O) is equal to or less than 15*10-6%, (H) is equal to or less than 2*10-6%, the rest is Fe and unavoidable foreign matters. The invention also provides the process for preparing beating steel, and round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The bearing steel can substitute for carburizing bearing steel, such as G20CrNi2Mo and the like, to be applied, and can substitute for import bearings in the field of rolling mills and the like. The invention can reduce the manufacture cost of the bearing and the utilization cost.

Owner:LAIWU IRON & STEEL GRP

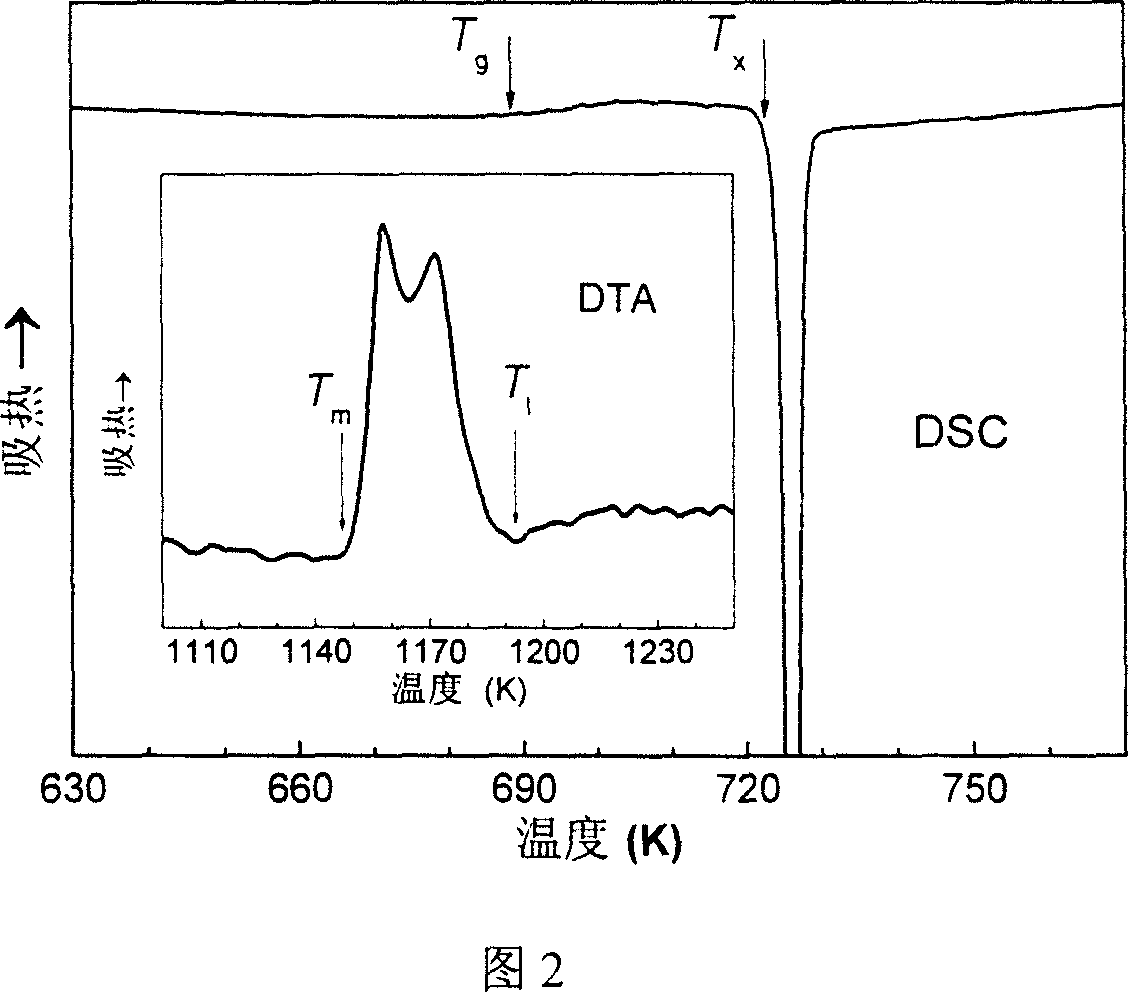

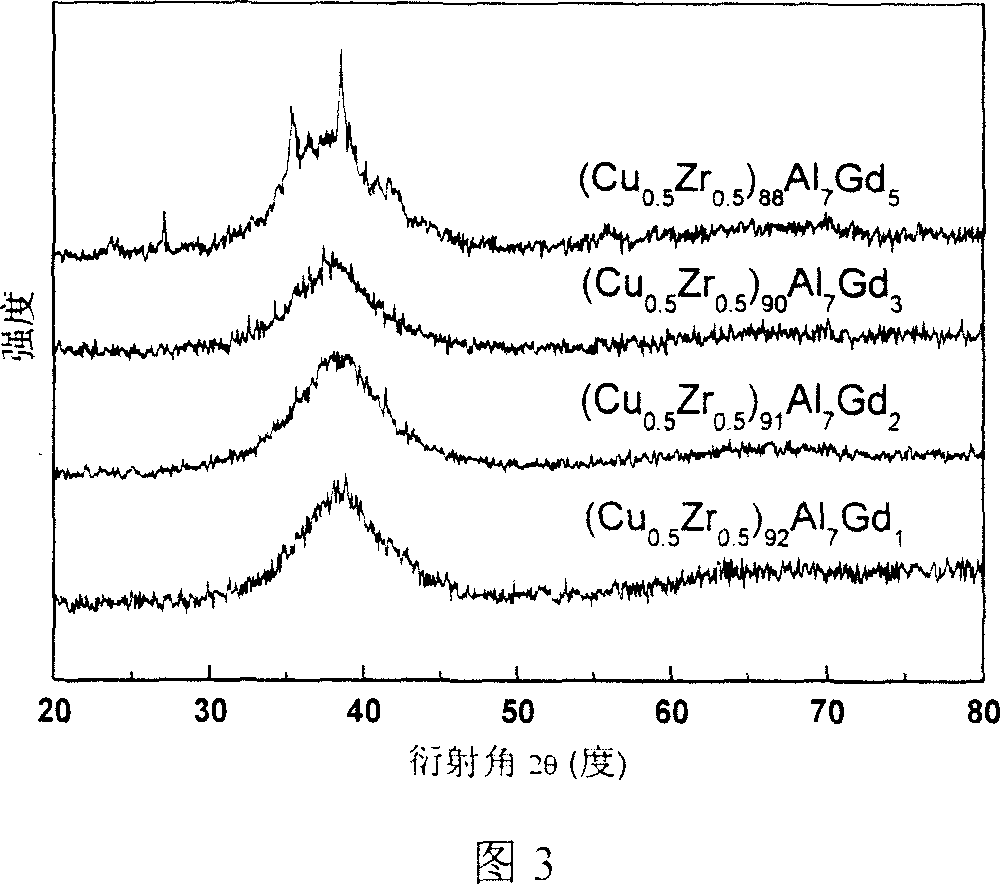

Copper-zirconium based amorphous alloy, and preparation method

InactiveCN1958831AImprove mechanical propertiesHigh plastic deformationMolten metal pouring equipmentsElectric arc furnaceAmorphous metal

This invention relates to a Cu-Zr-based amorphous alloy, whose general formula is (Cu1-xZrx)aAlbMc, where, x is 0.40-0.60; a is 80-100; b is 0-14; c is 0-20; a + b + c is 100; M is Y, La, Ce, Pr, Nd, Gd, Tb, Dy, Ho, Er, Ti, Ag, Ga, Hf, Ta, Nb, Ni, Co or Fe. The preparation method comprises: (1) mixing Cu, Zr, Al and M according to the ratio in Ti-adsorbed Ar atmosphere in an arc furnace, smelting and cooling to obtain mother alloy ingot; (2) re-melting the mother alloy ingot in air, and casting into a water-cooling metal mold to obtain the Cu-Zr-based amorphous alloy. The alloy has high glass formation ability, high crystallization inhibition and large size at a very low cooling speed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

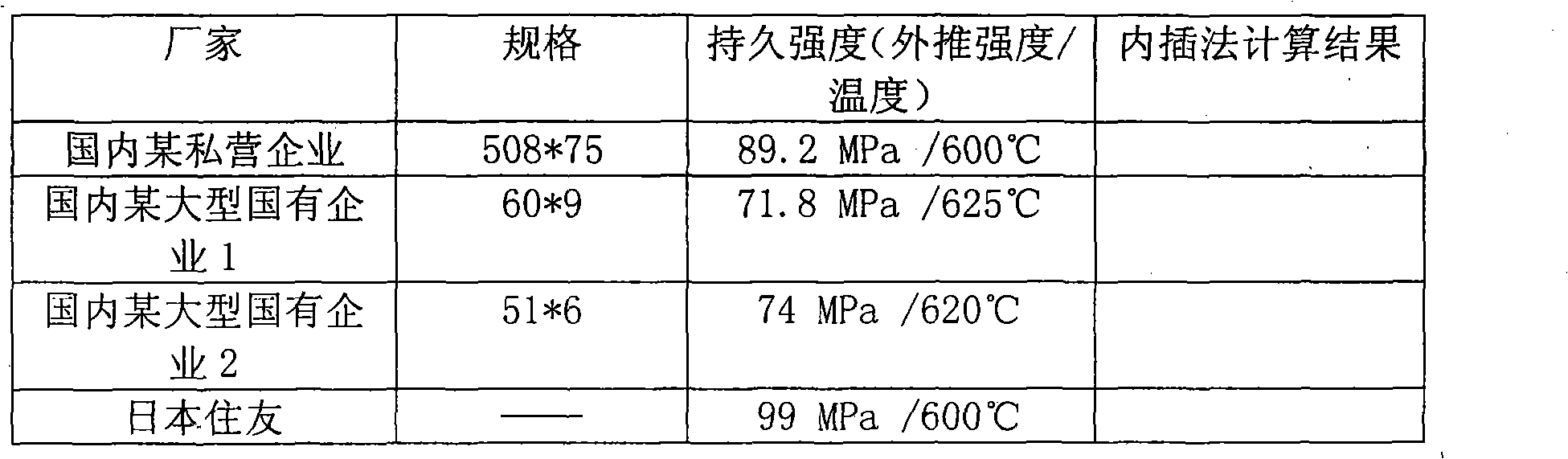

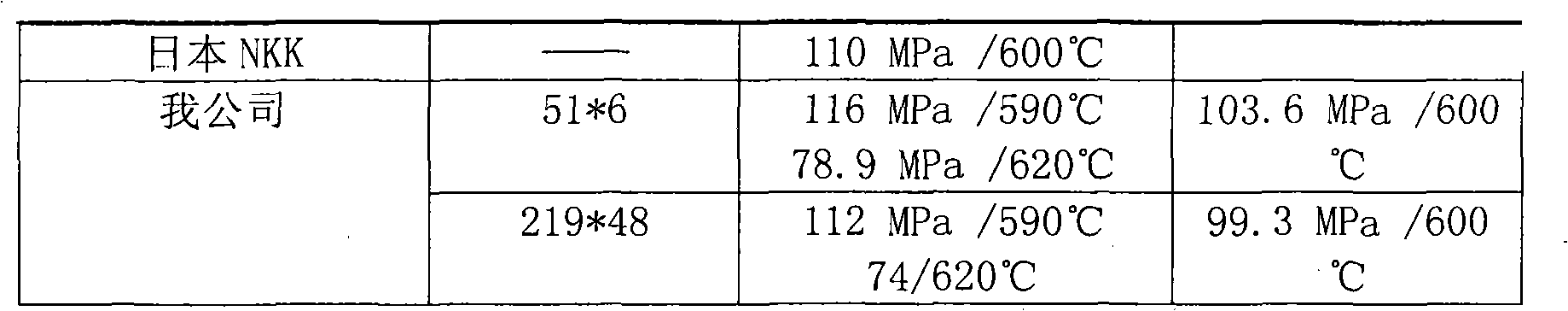

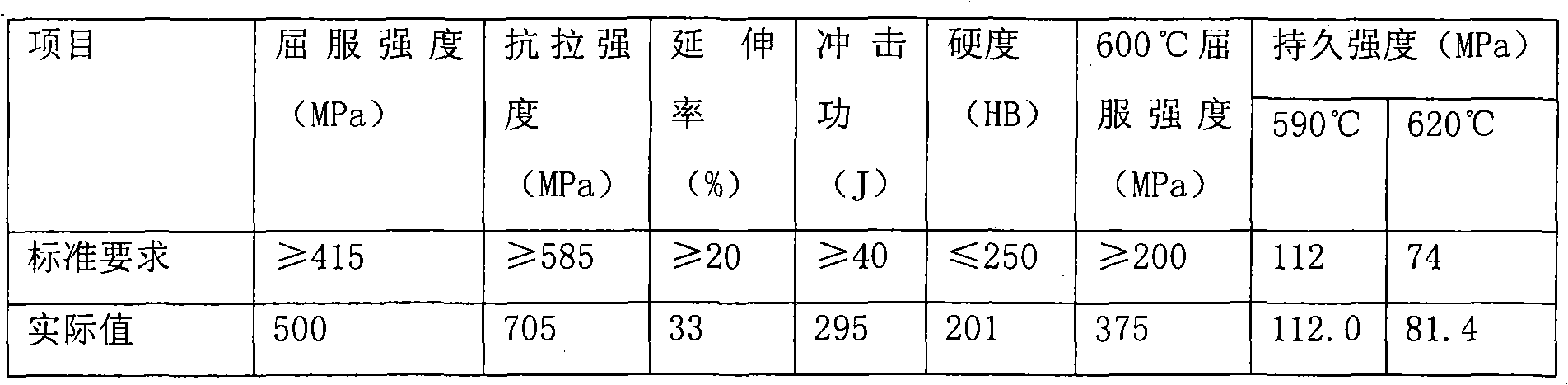

Hot-rolling seamless steel pipe applicable to high temperature of 580-620 DEG C and high pressure of 24-30MPa and production method thereof

The invention provides a hot-rolling seamless steel pipe applicable to high temperature of 580-620 DEG C and high pressure of 24-30MPa and a production method thereof. The steel pipe comprises the components by weight percentage of 0.08-0.12% of C, 0.20-0.50% of Si, 0.30-0.60% of Mn, 0-0.020% of P, 0-0.010% of S, 0-0.40% of Ni, 8.00-9.50% of Cr, 0.85-1.05% of Mo, 0-0.20% of Cu, 0-0.015% of Al, 0.18-0.25% of V, 0.06-0.10% of Nb, 0.030-0.070% of N and the balance of Fe. Simultaneously, the invention also provides the production method for producing the hot-rolling seamless steel pipe. The steelpipe and the production method have the effects that the performance of the steel pipe completely meets the requirement of ASME SA-335M standard on the tension and hardness and meets the requirement of GB5310 on impacting and duration strength, the steel pipe has excellent high-temperature performance, is applicable to the high-temperature bearing parts such as a steam pipeline, a connecting box and the like, which are used for high-temperature and high-pressure corrosive environment; and the duration strength under the temperature of 590 DEG C is 112MPa and the duration strength under the temperature of 620 DEG C is 81.4MPa.

Owner:TIANJIN PIPE GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com