Medium carbon bearing steel and its preparation method

A bearing steel and steel technology, applied in the field of metallurgy, can solve the problems of high manufacturing cost of high-strength and tough rolling bearings, and achieve the effects of improving wear resistance, high comprehensive performance, and high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

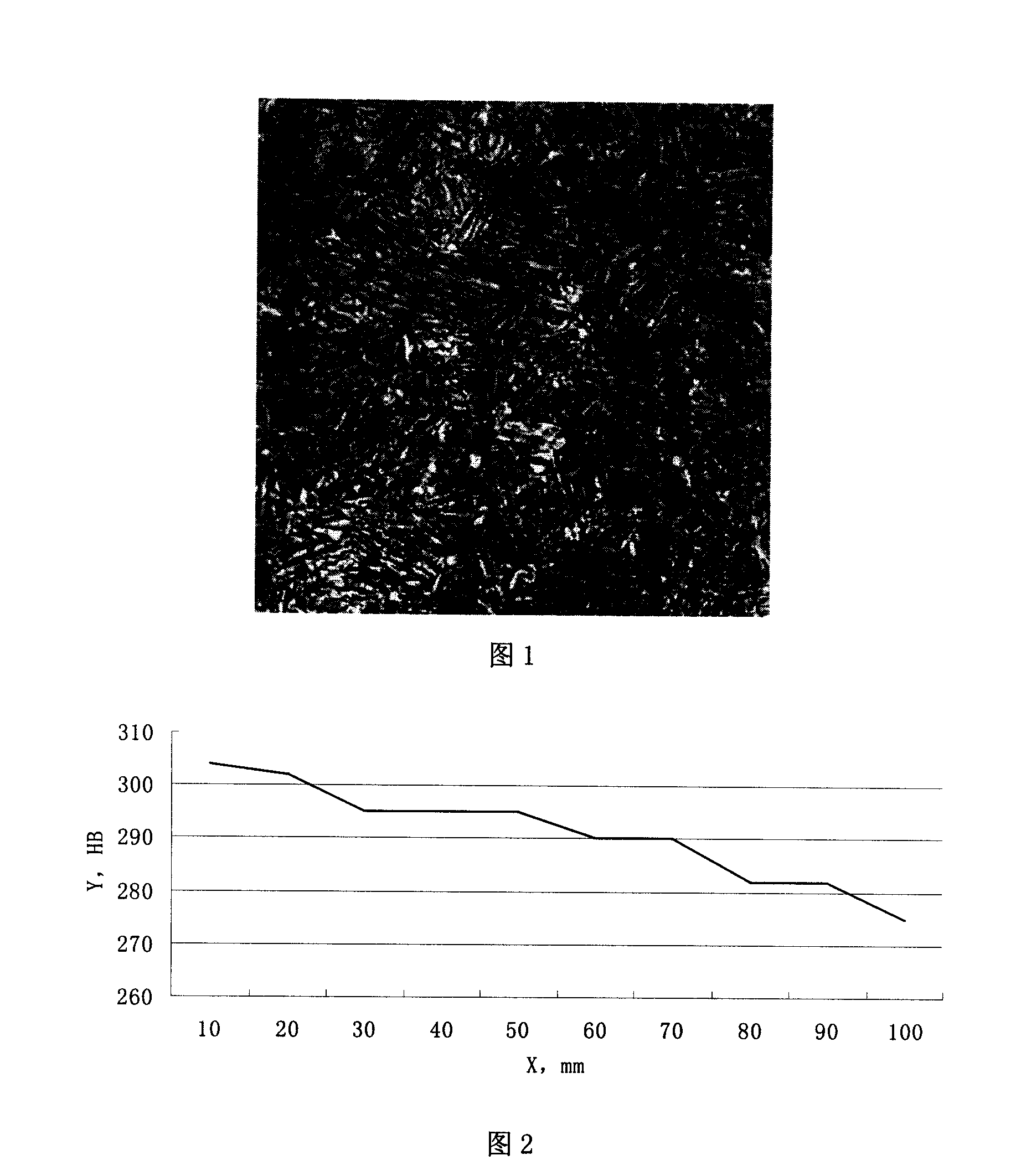

Image

Examples

Embodiment 1

[0036] How the present invention is implemented is specifically illustrated with the production process of Φ200mm specification steel.

[0037] The specific process steps are:

[0038] (1) Smelting and alloying, electric furnace smelting, tapping, refining outside the furnace, and vacuum degassing. The deoxidation and degassing smelting control of steel is strengthened through ladle blowing argon and vacuum degassing treatment, and the final deoxidation is fed to aluminum wire, and B iron is added after vacuum degassing treatment to ensure that the chemical composition, especially the effective boron content, meets the requirements, and the hydrogen content in the steel is not high. Greater than 2×10 -6 , the oxygen content is not more than 15×10 -6 .

[0039] (2) Pouring, mold casting, control of superheat, the superheat of molten steel in mold casting ladle is 70-80°C, and the control pouring speed is 390-250mm / min (3 tons of ingots), to ensure the quality of steel ingots...

Embodiment 2

[0049] How the present invention is implemented is specifically illustrated with the production process of Φ100mm specification steel.

[0050] The specific process steps are:

[0051] (1) Smelting and alloying, electric furnace smelting, tapping, refining outside the furnace, and vacuum degassing. Strengthen the smelting control of deoxidation and degassing of steel by blowing argon in the ladle and vacuum degassing treatment, feed the aluminum wire into the final deoxidation treatment, and add B iron after vacuum degassing treatment to ensure that the chemical composition, especially the effective boron content meets the requirements, and the hydrogen content in the steel Not greater than 2×10 -6 , the oxygen content is not more than 15×10 -6 .

[0052] (2) Pouring, continuous casting, control of superheat, continuous casting tundish superheat of 20-30°C, control of continuous casting casting speed of 0.55-1.0m / min (optimized according to billet shape), to ensure the qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com