Patents

Literature

41results about How to "Avoid performance fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for smelting and lower-pressure casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and low-pressure casting of an aluminum alloy wheel hub, which comprises: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining;2, transferring the molten aluminum alloy to a tundish from the liquid outlet of the smelting furnace, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into the tundish to perform modification and refinement treatment under a condition of a temperature of 710 to 730 DEG C, and blowing nitrogen to the tundish to perform secondary degassing of the molten aluminum alloy; 3, transferring the molten aluminum alloy in the tundish to a casting holding furnace, adding a slag decomposing agent into the holding furnace to remove slag and blowing nitrogen into the holding furnace to perform tertiary degassing; and 4, pressing the molten aluminum alloy into a mold by a method of prepressing, pressure stabilizing, pressurizing and pressure keeping to perform casting.The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

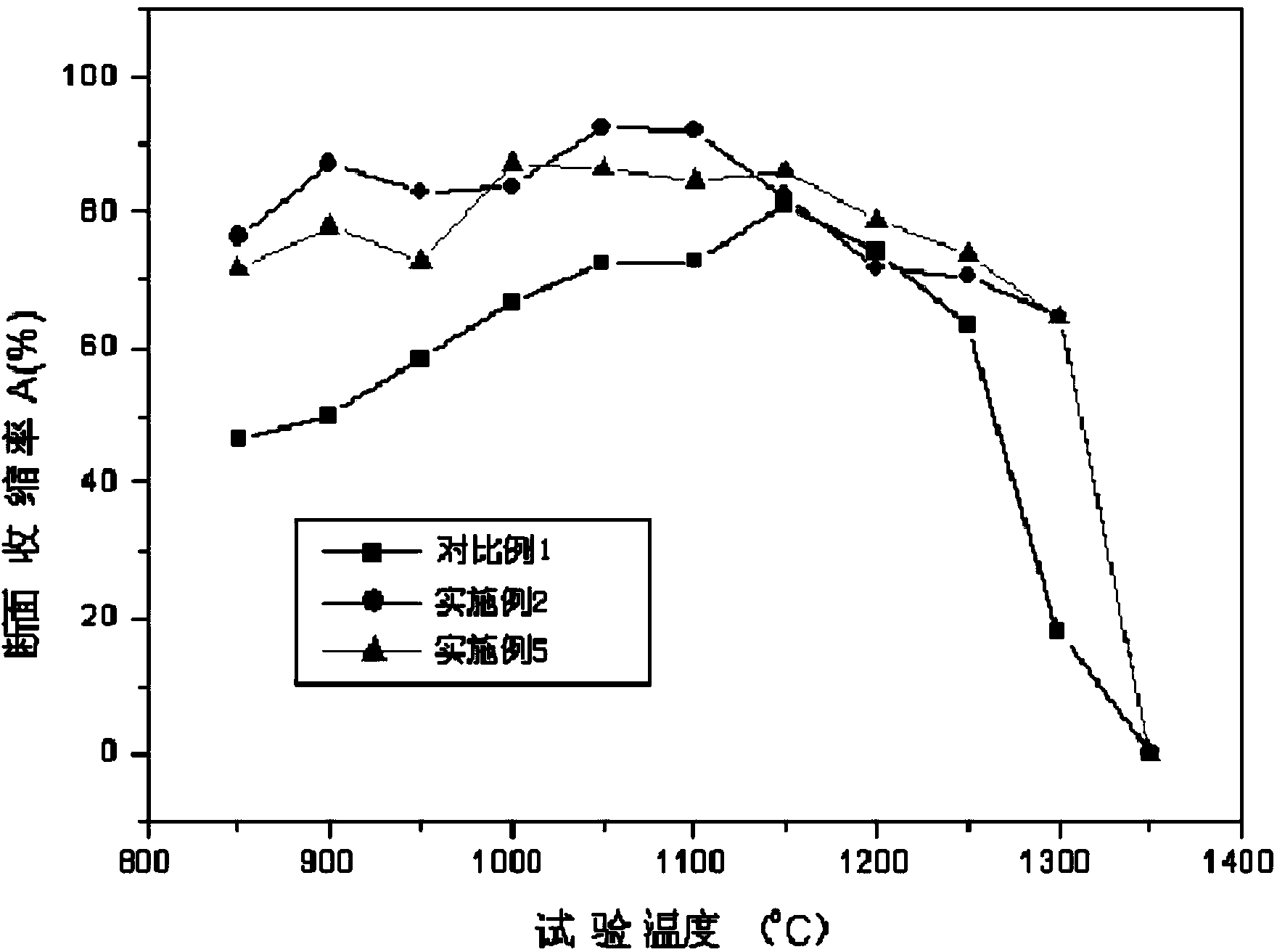

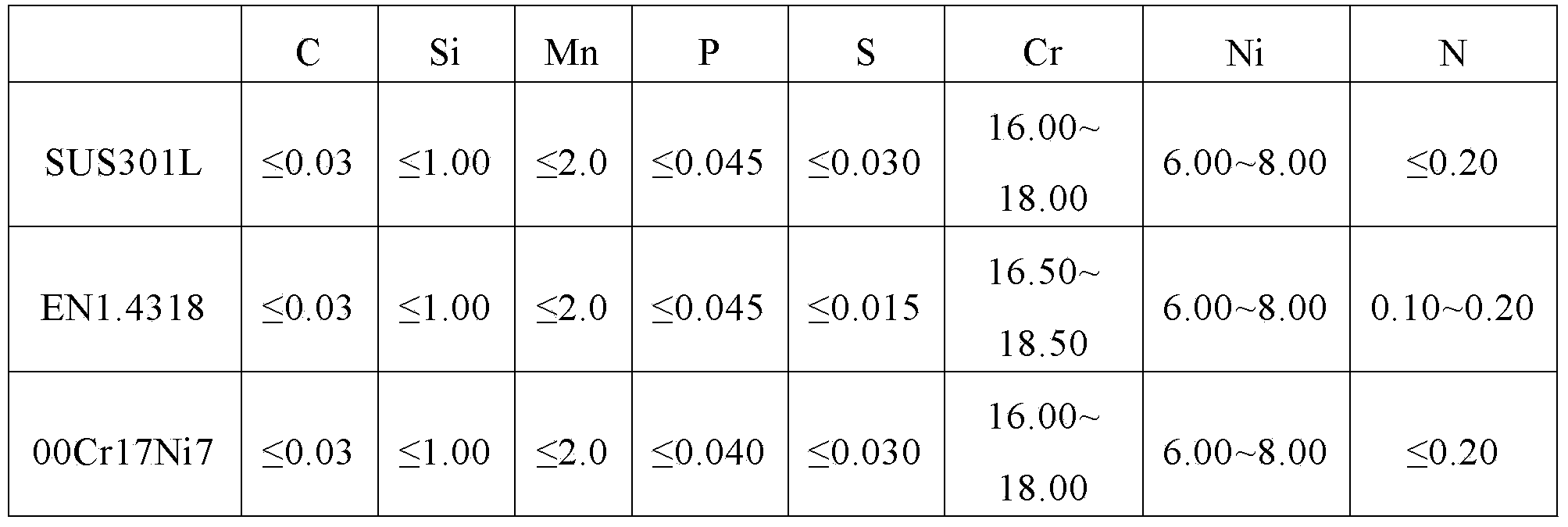

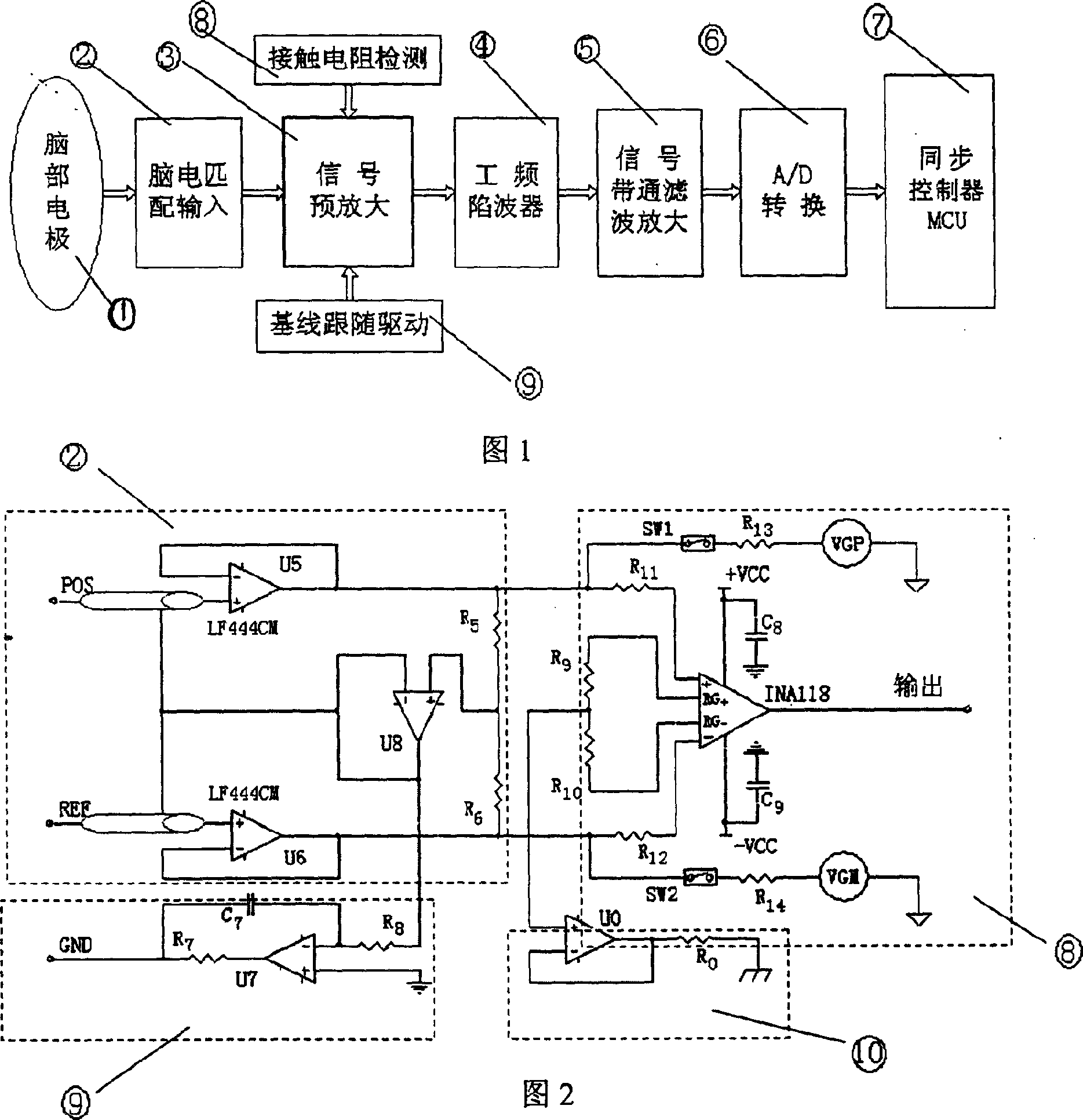

Austenitic stainless steel for urban rail vehicle face plates and manufacturing method of austenitic stainless steel

The invention discloses austenitic stainless steel for urban rail vehicle face plates and a manufacturing method of the austenitic stainless steel. The austenitic stainless steel comprises the following chemical compositions inpercentage by weight: less than 0.03% of C, 0.75-1.0% of Si, 6.5-8.0% of Mn, 16.0-17.5% of Cr, 3.0-4.5% of Ni, 0.15-0.25% of N, 0.5-1.0% of Cu, 0.02-0.05% of Ce, no greater than 0.040% of P, no greater than 0.03% of S, and the balance of Fe and inevitable impurities; the manufacturing method of the austenitic stainless steel comprises the following steps: through the operations of smelting, continuous casting, refining, tombarthite mixture block feeding, and soft stirring, continuous casting slabs are obtained by continuous casting, and the continuous casting slabs are heated; after hot rolling, cooling, reeling, air cooling, solution treating, shot blasting, acid cleaning, cold rolling and annealing acid cleaning are conducted, the finished product austenitic stainless steel is manufactured. According to the austenitic stainless steel for the urban rail vehicle face plates and the manufacturing method of the austenitic stainless steel, the oxidation of the edge part grain boundary caused by overheating of the slab edge part can be avoided; in the process of heating, a layer of dense chromium oxidation film with high adhesion is formed on the surface, the surface quality of the continuous casting slabs is protected, and the guarantee about surface quality control of stainless steel material used for the urban rail vehicle face plates can be provided.

Owner:BAOSTEEL STAINLESS STEEL

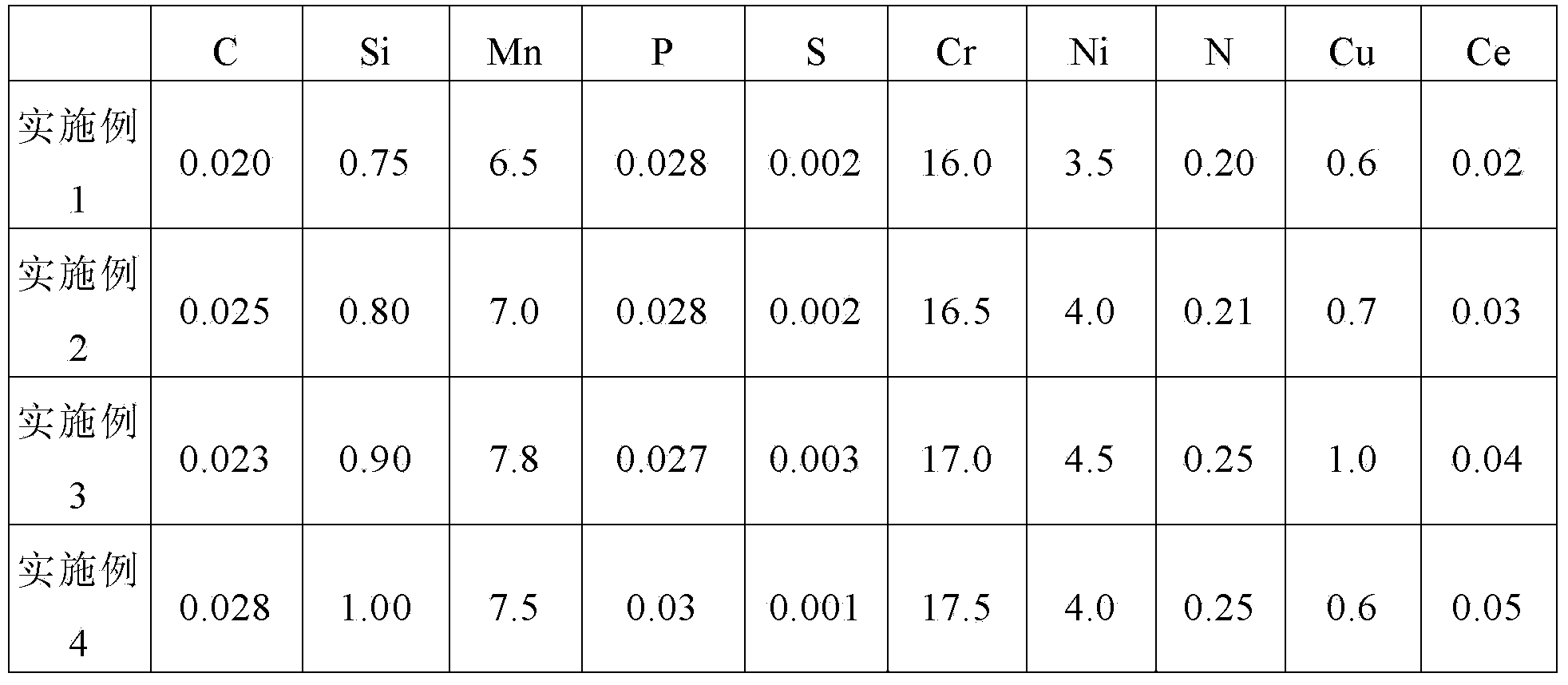

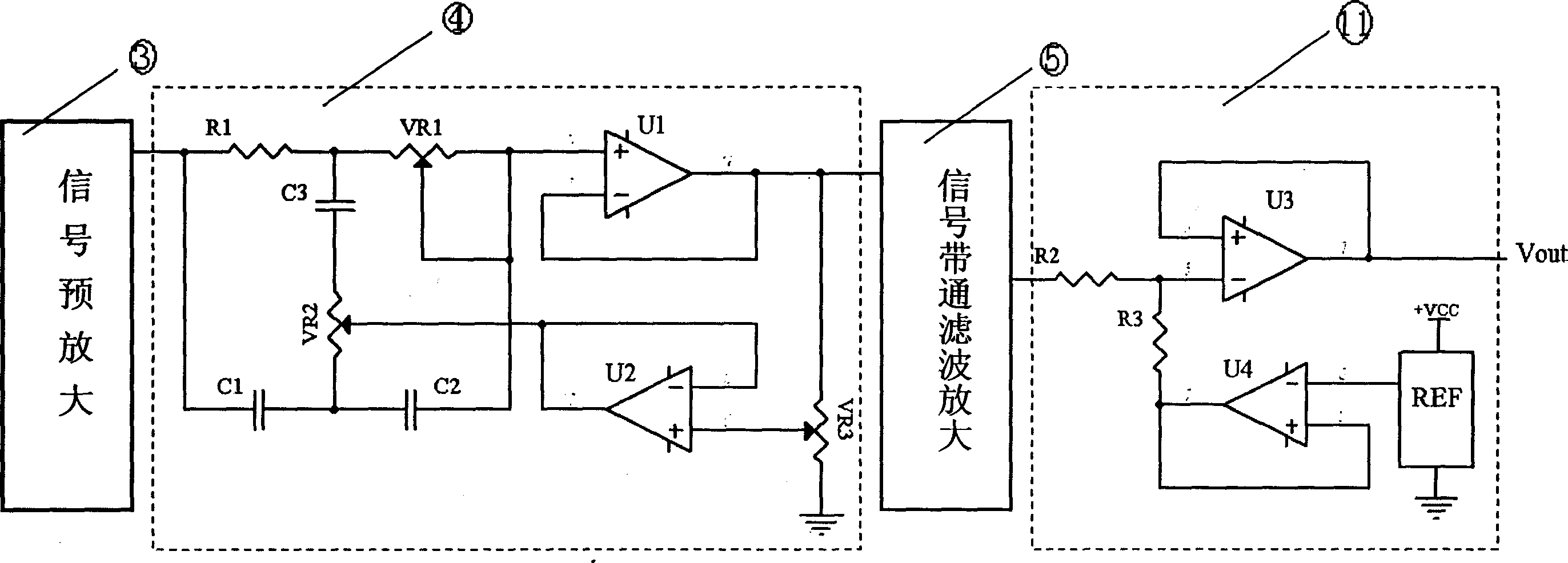

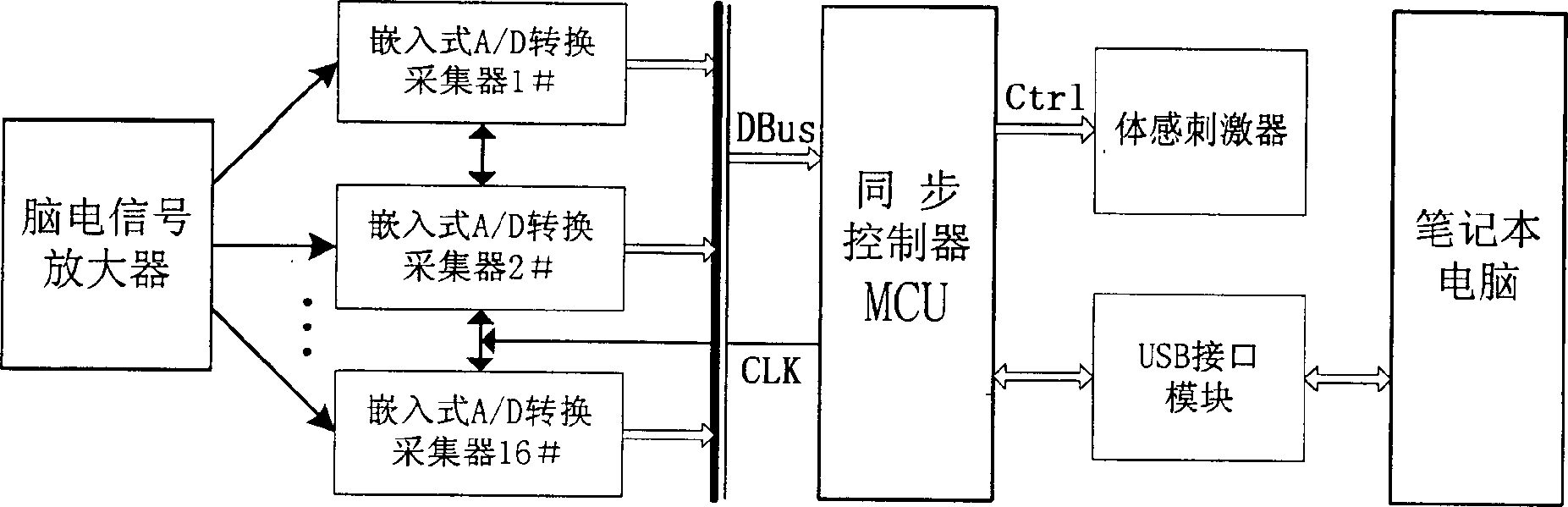

Electroencephalogram signal amplifier for portable event related brain potentiometer

InactiveCN1778273AImprove scalabilityImprove transmission efficiencyDiagnostic recording/measuringSensorsAudio power amplifierSynchronous control

An encephaloelectric signal amplifier for the portable event associated electrocortical potential instrument is composed of cerebral electrodes, encephaloelectric signal preamplifier, main frequency trap circuit, band-pass filtering amplifier, 16 embedded A / D converters, polarity switch and synchronous controller MCU. It can precisely acquire the bioelectric signals of human nerve, filter and amplify them, and record them at real time.

Owner:INST OF PSYCHOLOGY CHINESE ACADEMY OF SCI

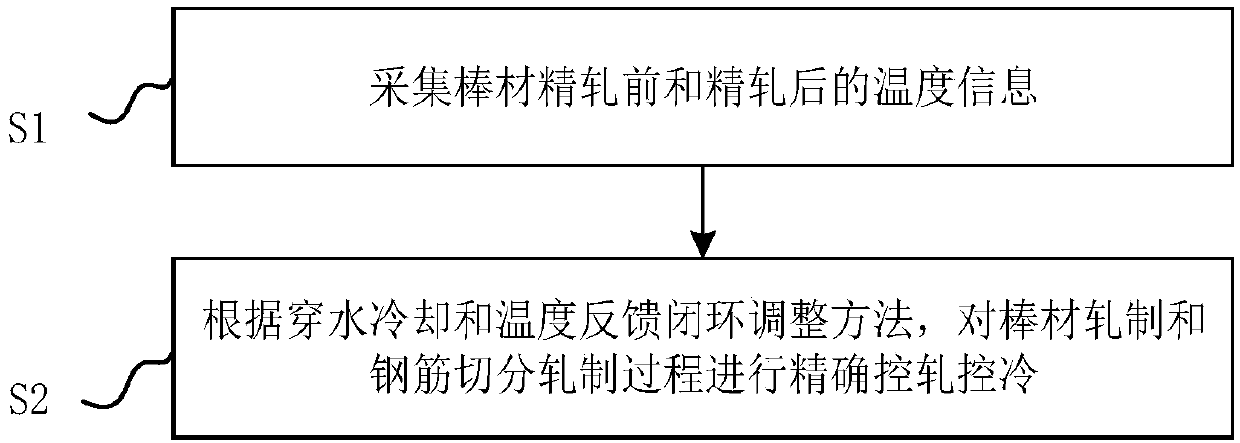

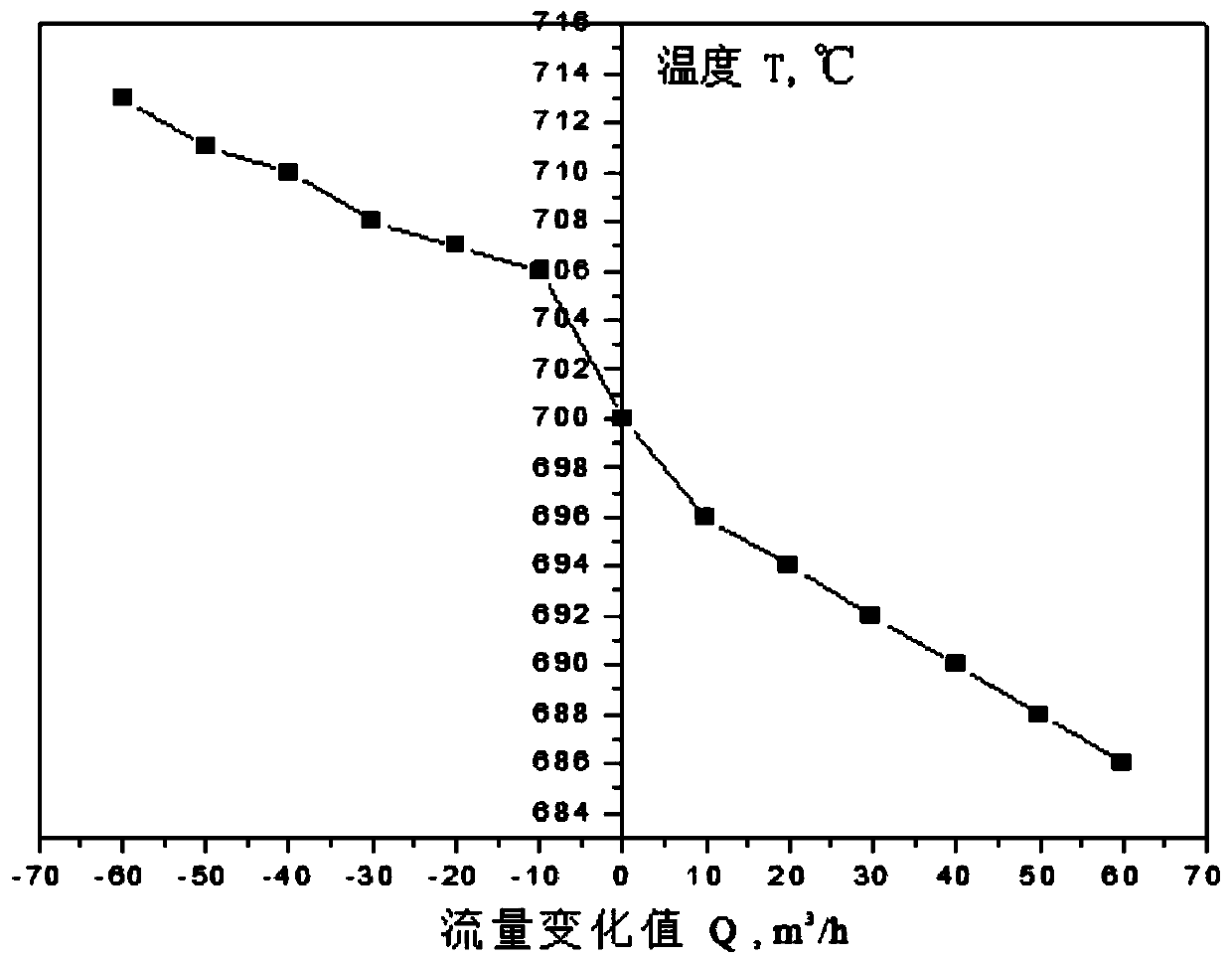

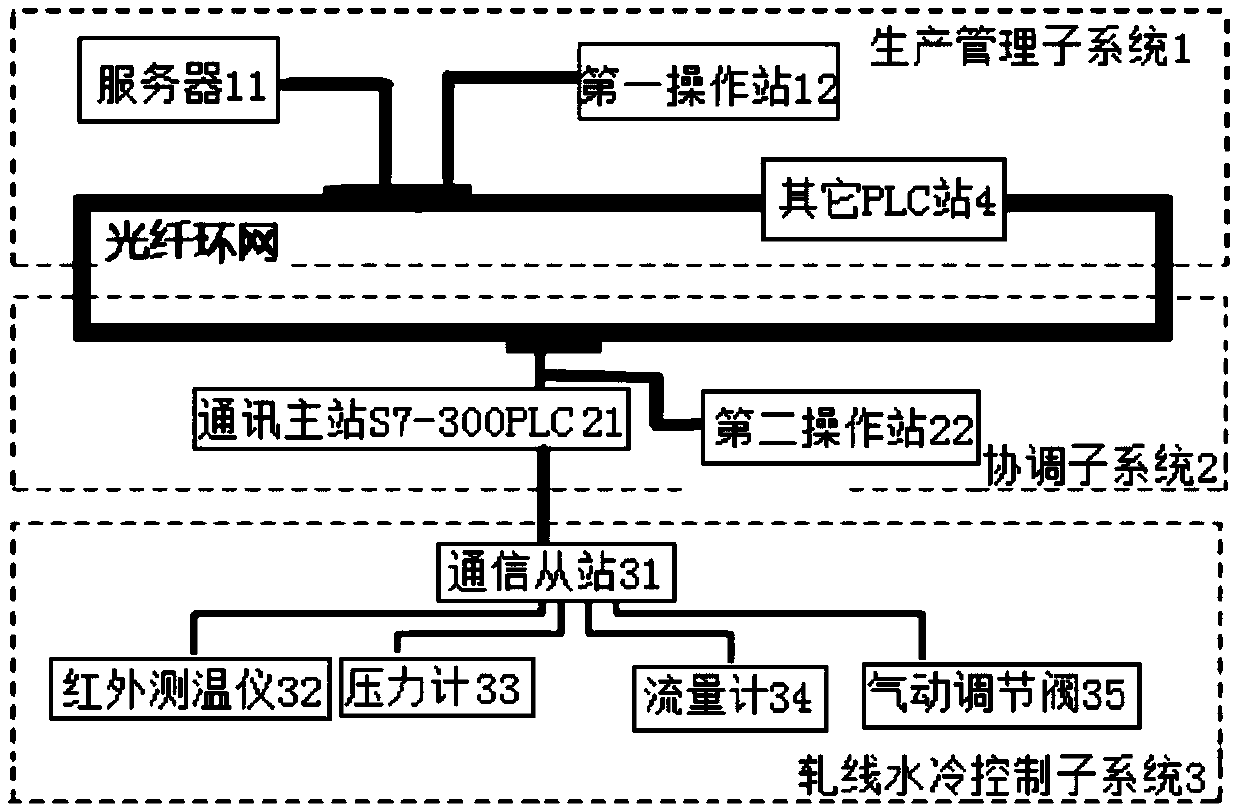

Water-cooling closed-loop control technological method and control system of stick materials

ActiveCN109675933AAchieving staged coolingReduce manufacturing costTemperature control deviceLoop controlControl system

The invention relates to a water-cooling closed-loop control technological method and control system of stick materials. The water-cooling closed-loop control technological method of stick materials comprises the following steps of collecting temperature information before finish rolling and after finish rolling of the stick materials; and according to through water cooling and a temperature feedback closed-loop regulating method, performing accurate rolling control and cooling control in the stick material rolling and reinforcing bar splitting rolling process. Through the adoption of the stick material water-cooling closed-loop control technological method disclosed by the invention, the stability of rolling control temperature and the stability of the cooling control technology can be realized, and the alloy usage quantity of the stick materials is reduced; the problems that the water cooling black circle tissue is generated on the surfaces of the stick materials and core surface hardness is poor caused by through water cooling are solved; and increasing the production benefits of a steel mill is facilitated. The method disclosed by the invention provides a technical thought foraccurately controlling a cooling technology for cooling the special steel stick materials including gears and the like after rolling, the problems of coarse crystal grains and cracking during cold shearing caused by unstable cooling technology of the special steel stick materials after rolling can be solved; and under the premise that the production cost of the stick materials of the steel mill isreduced, improving the product quality is facilitated, and the smooth operation of the production is promoted.

Owner:北京勤泽鸿翔冶金科技有限公司

Process for smelting and gravity casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and gravity casting of an aluminum alloy wheel hub, which comprises the following steps: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining; 2, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into a modification chamber to perform the combined modification and refinement treatment of the molten aluminum alloy in the modification chamber, and blowing nitrogen to the modification chamber to perform secondary degassing; 3, transferring the molten aluminum alloy into a using chamber to keep the temperature of the molten aluminum alloy between 690 and 720 DEG C for later use; and 4, pouring the melt in the using chamber into a mold by using an iron spoon at a speed, which increases first and then decreases, for 23 to 25 minutes at each time. The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

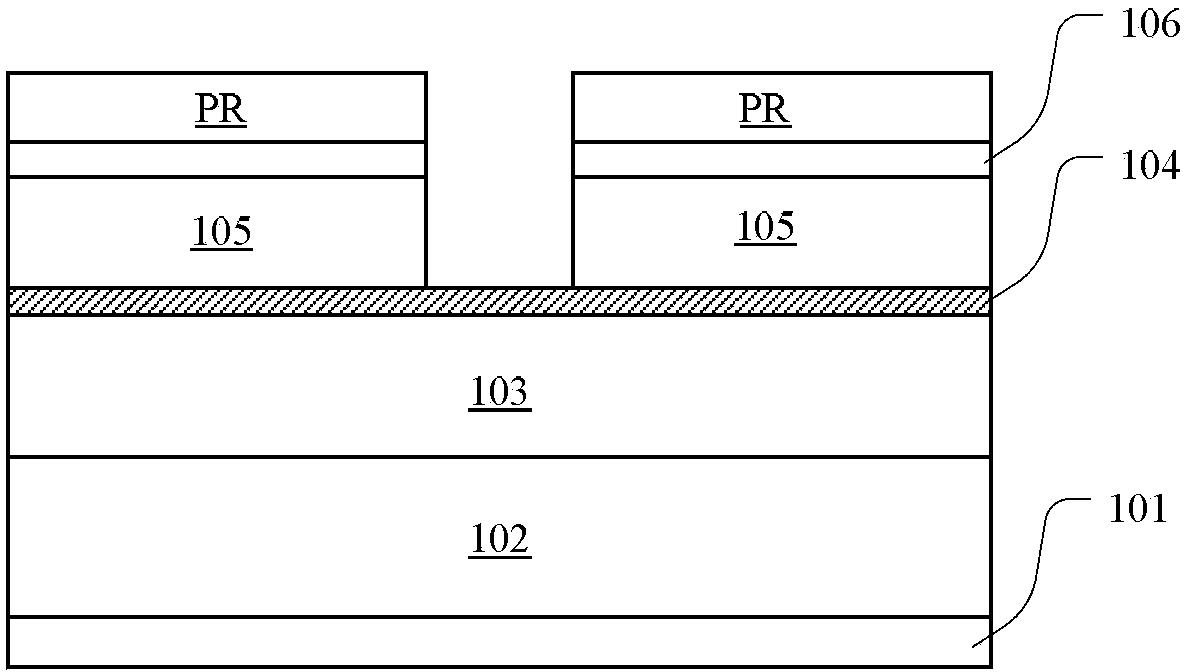

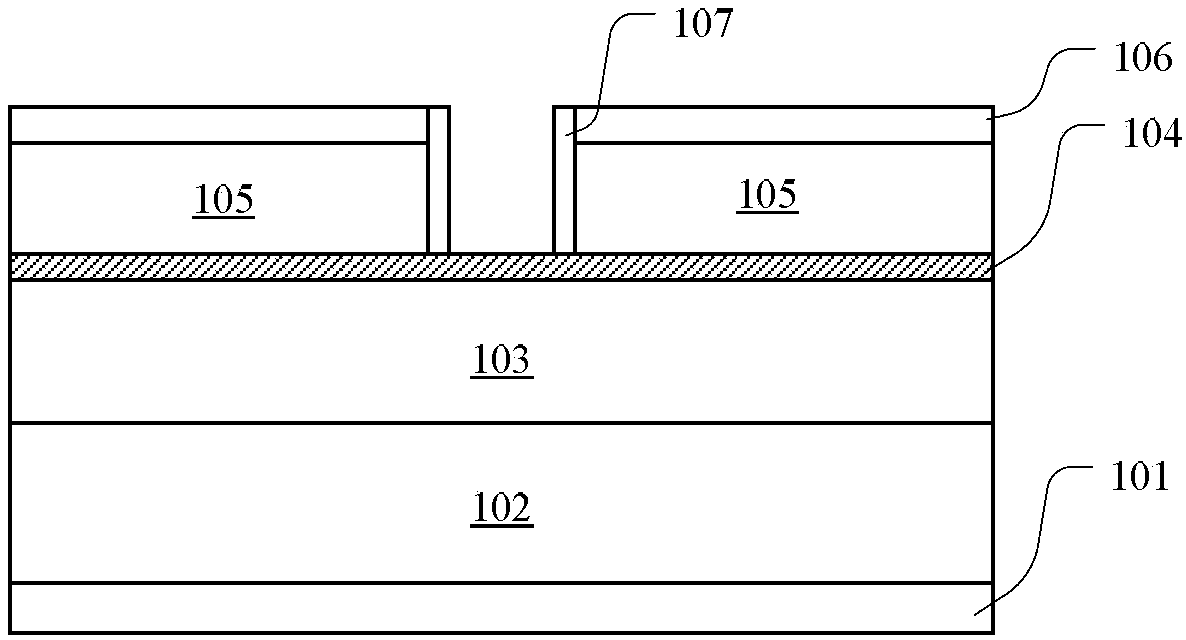

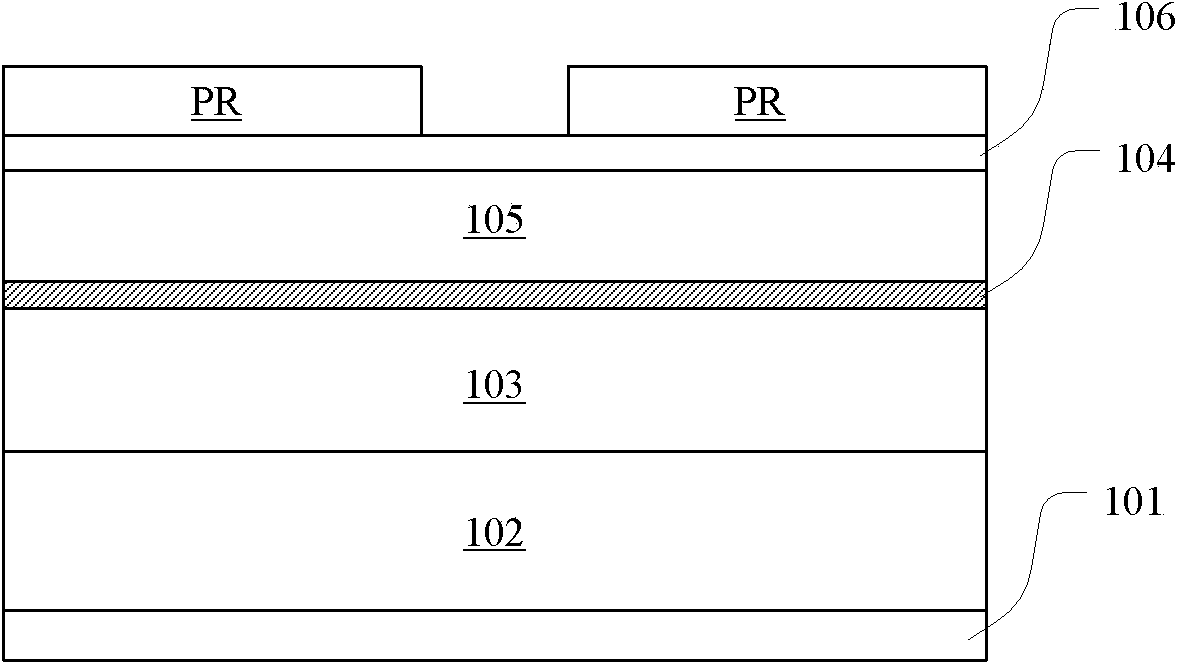

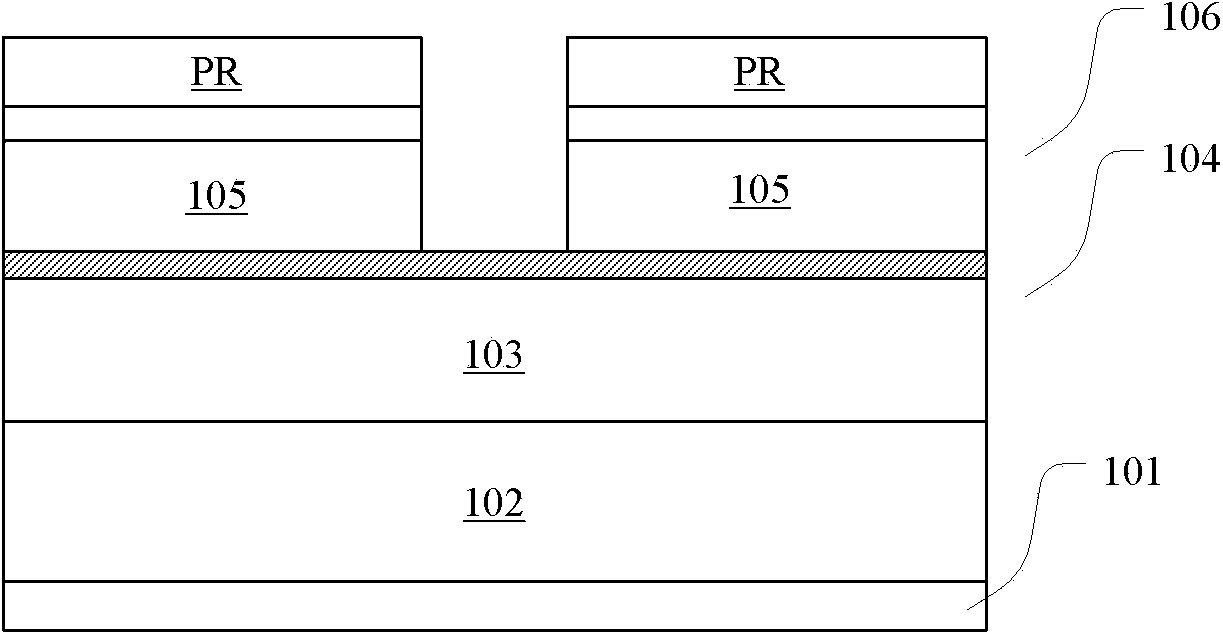

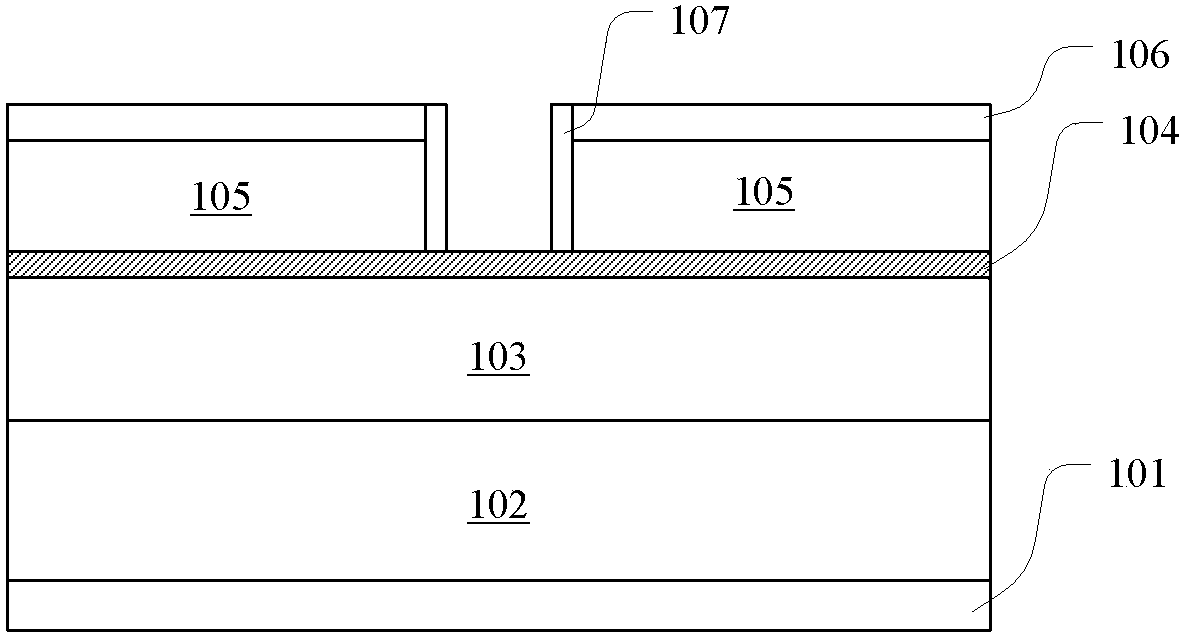

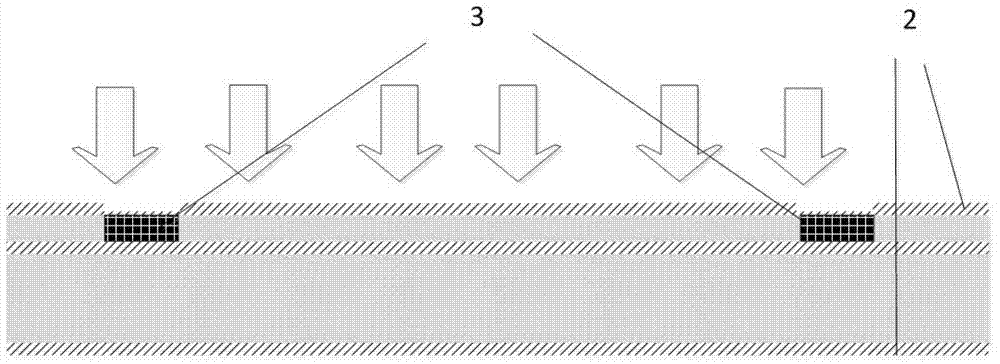

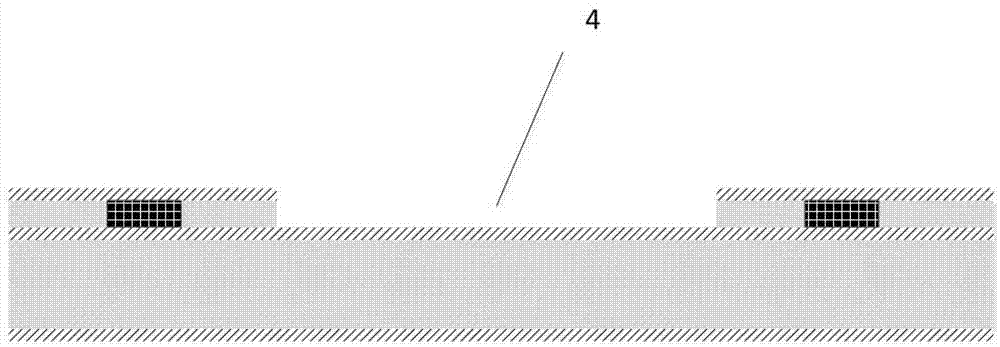

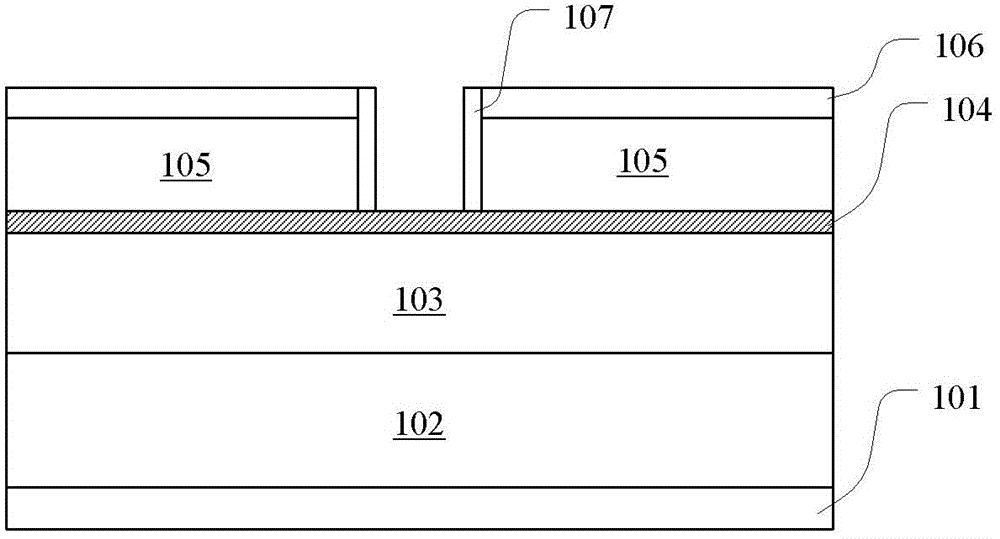

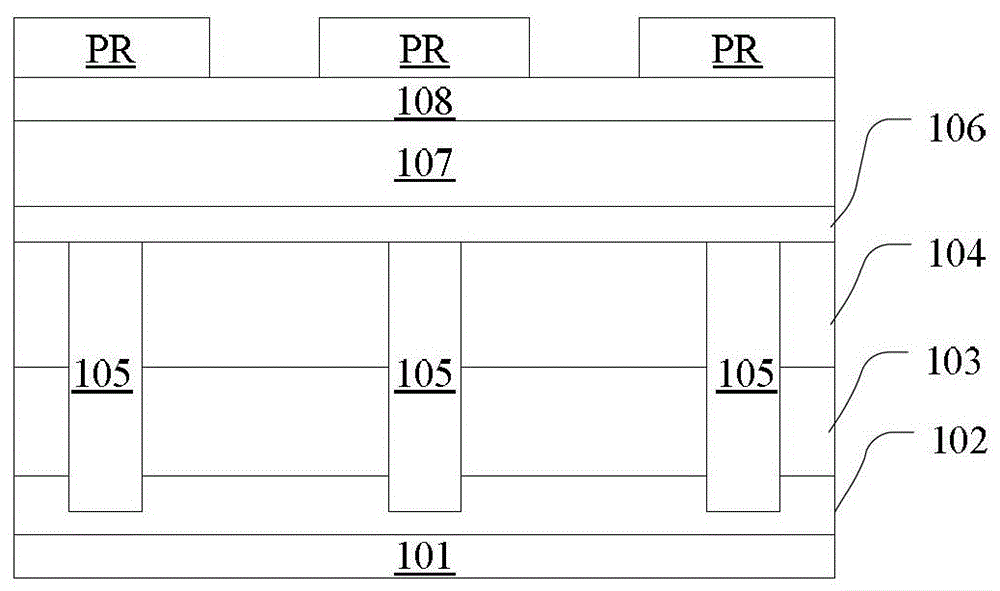

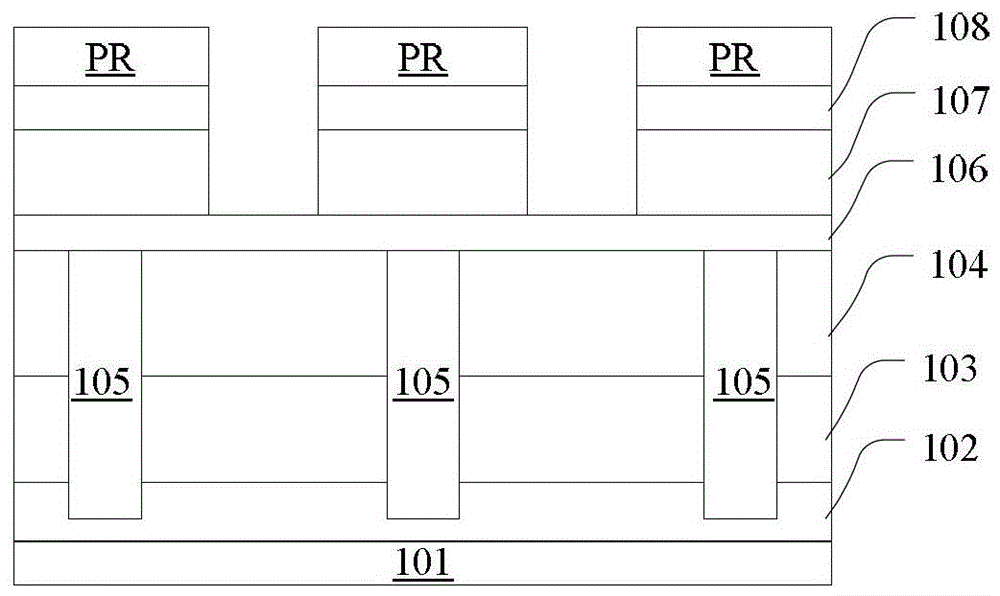

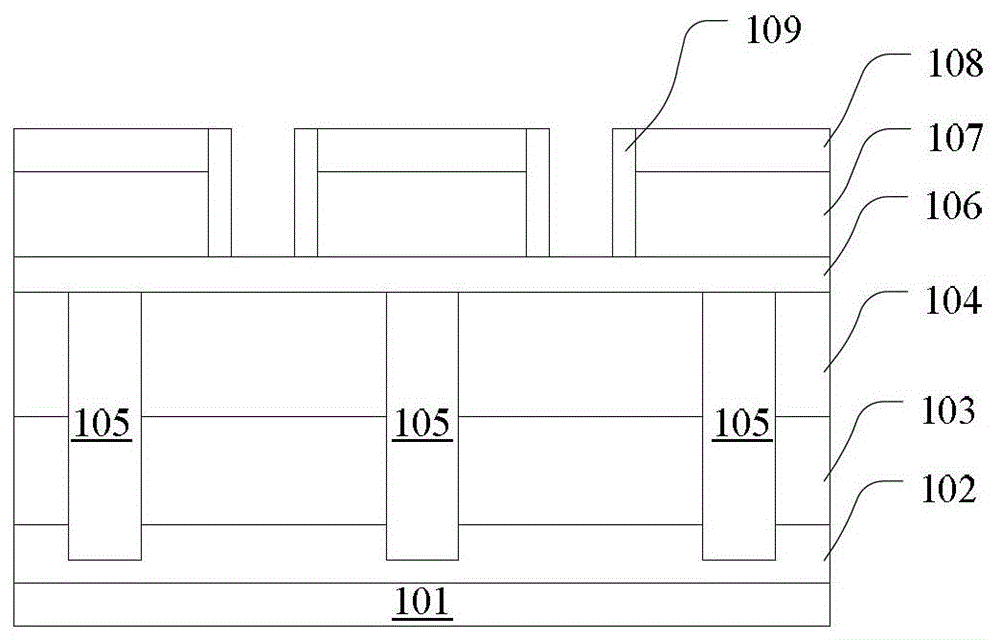

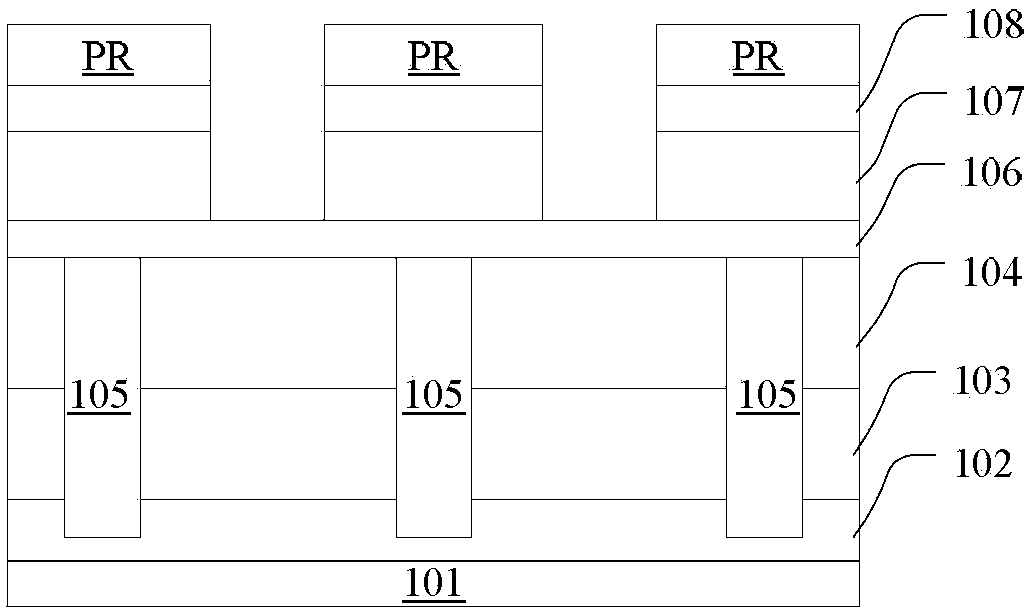

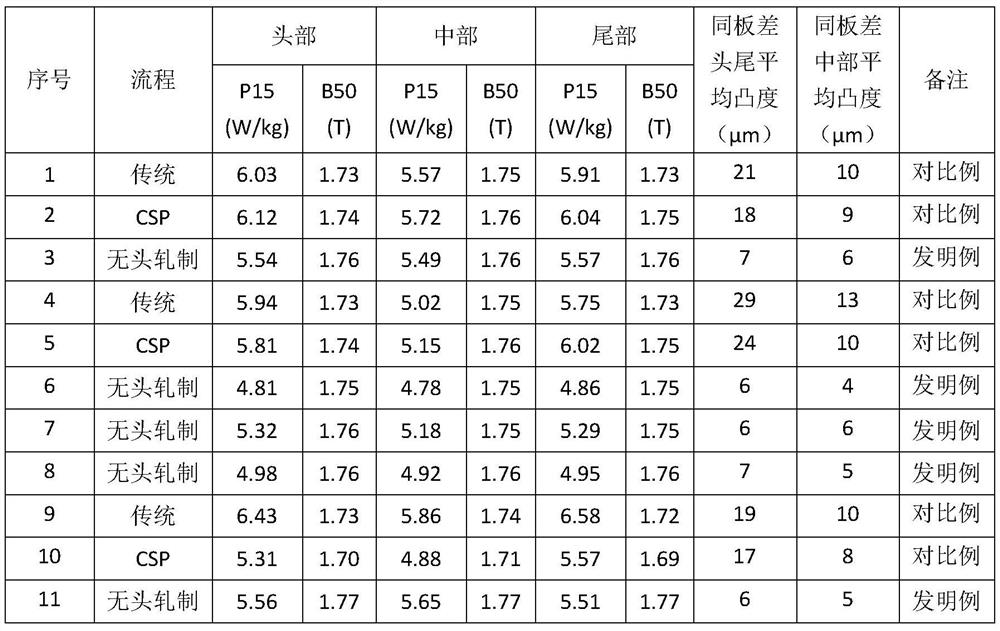

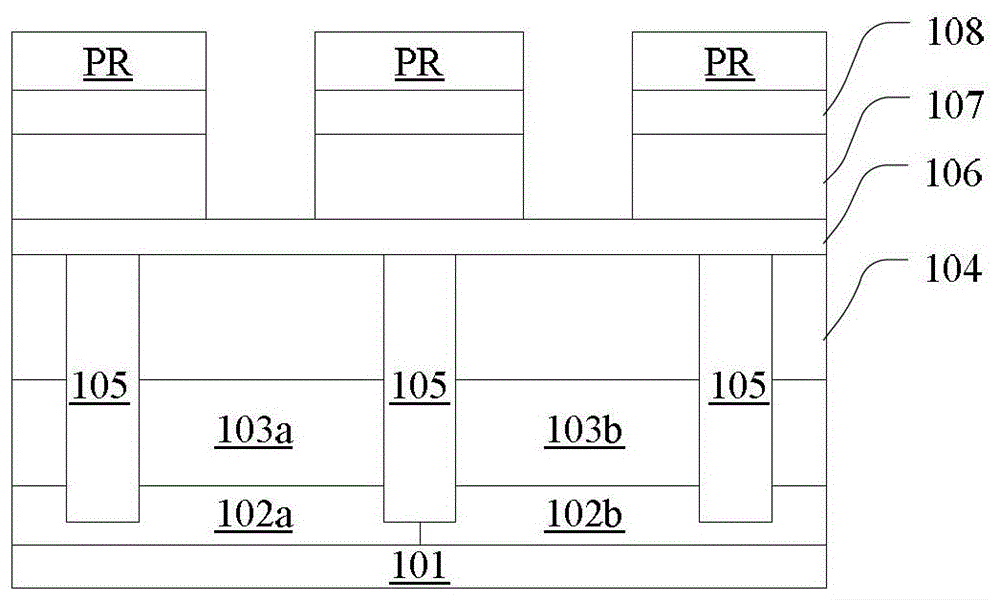

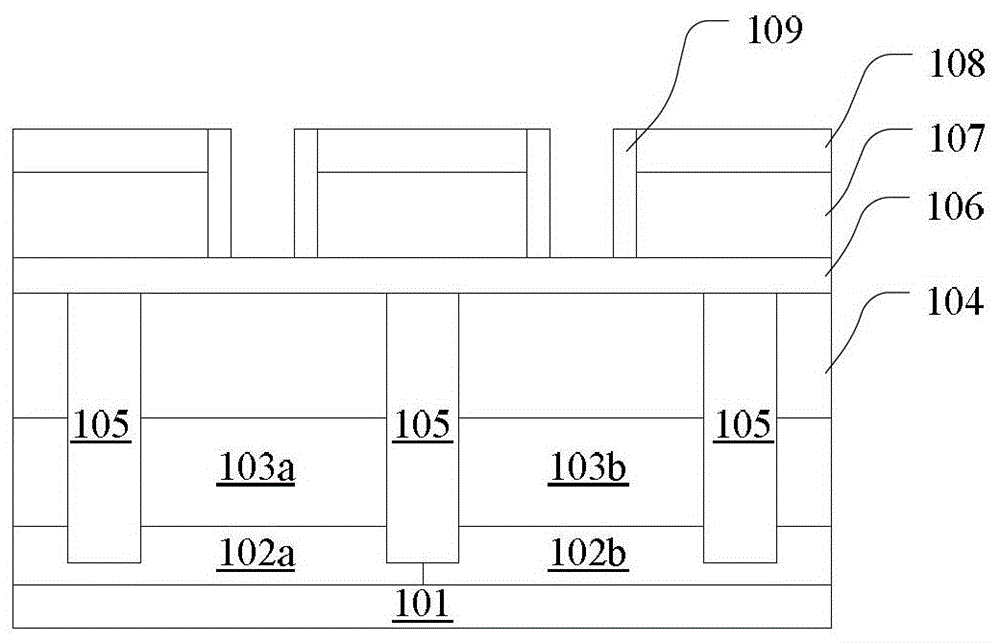

Semiconductor device and manufacturing method thereof

ActiveCN103985712AAvoid performance fluctuationsAvoid self-heating effectsTransistorSemiconductor/solid-state device manufacturingGate dielectricElectrical conductor

Disclosed are a semiconductor device and manufacturing method thereof, the semiconductor device comprising: a semiconductor substrate, a back-gate isolation structure in the semiconductor substrate, and neighboring field effect transistors on the back-gate isolation structure; each of the neighboring field effect transistors comprises a sandwich structure on the back-gate isolation structure, the sandwich structure comprising a back-gate conductor, a semiconductor fin on the two sides of the back-gate conductor, and respective back-gate dielectrics respectively isolating the back-gate conductor from the semiconductor fin; the back-gate isolation structure is part of the conductive paths of the back-gate conductors of the neighboring field effect transistors, and forms a PNPN junction or an NPNP junction between the back-gate conductors of the neighboring field effect transistors. The semiconductor device employs a back-gate isolation structure to apply different voltages to the back gate of one or more field effect transistors respectively, thus regulating the threshold voltage of each field effect transistor accordingly.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

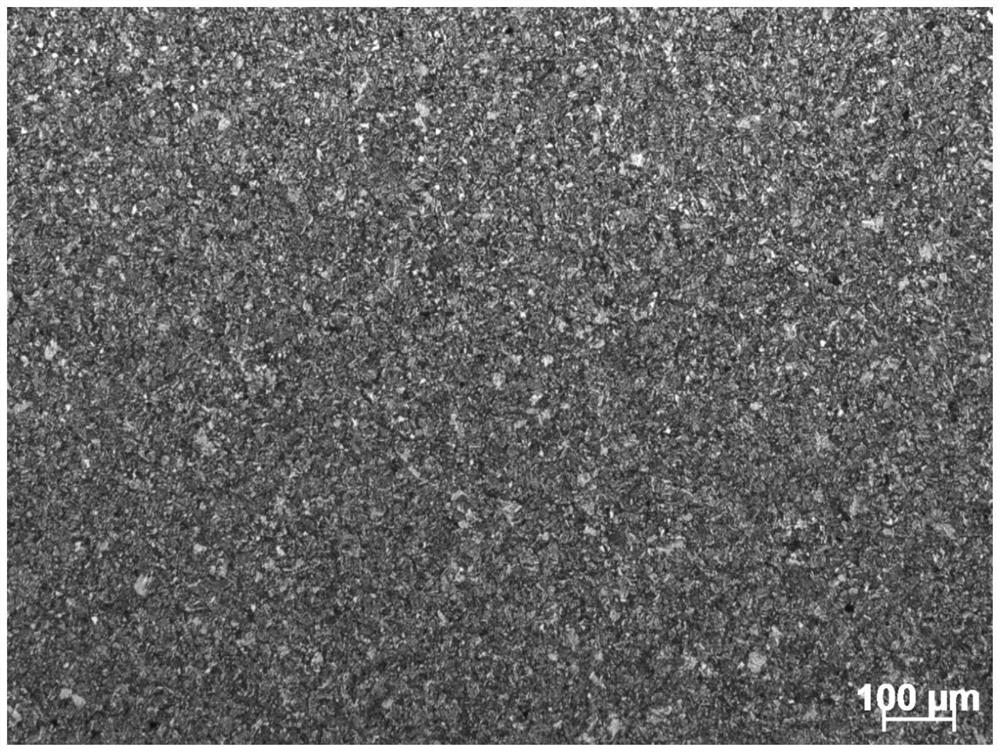

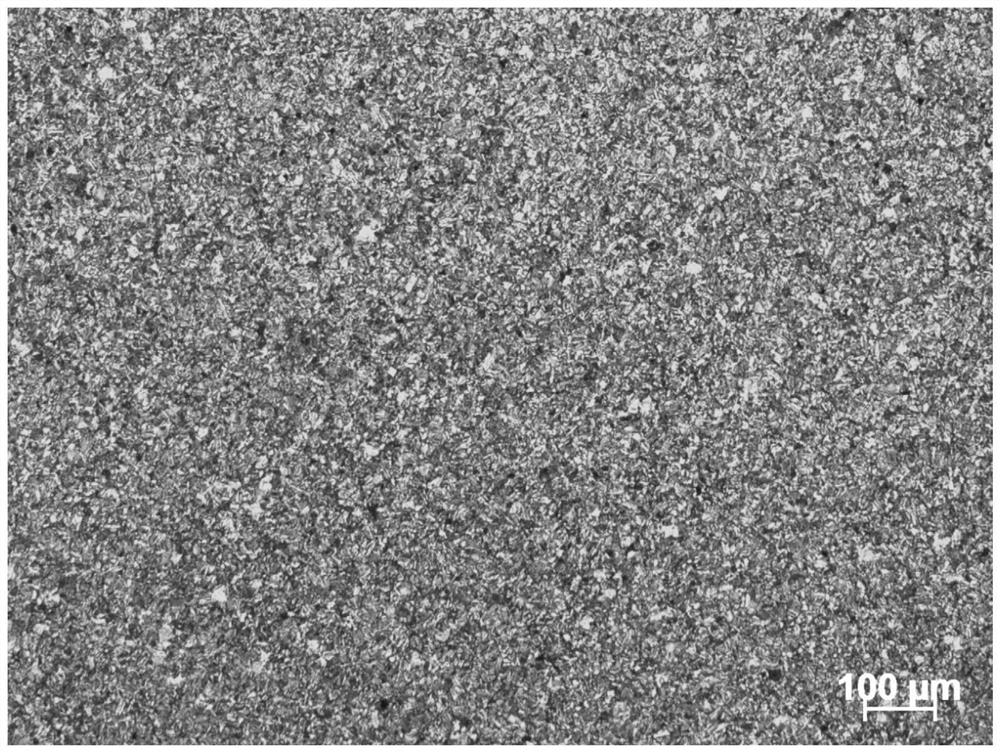

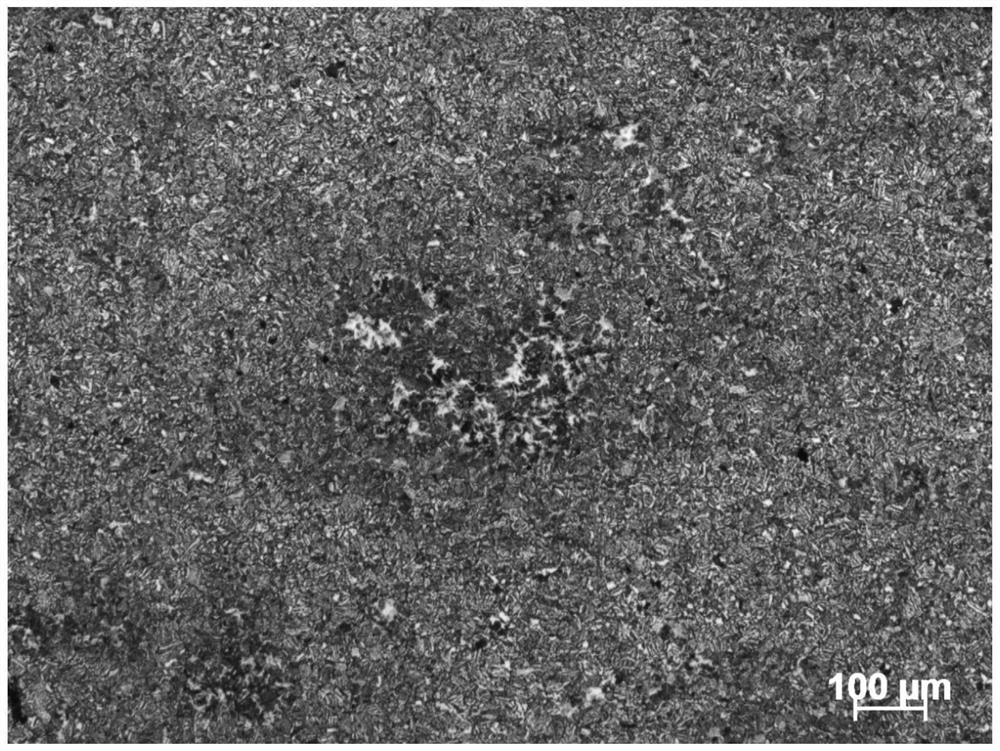

Steel for large-sized wind power fastener and manufacturing method of steel

ActiveCN110643881AAvoid performance fluctuationsReduce hardness differenceTemperature control deviceWork heating devicesUltimate tensile strengthWind power

The invention discloses steel for a large-sized wind power fastener. The steel is prepared from the element components in percentage by mass: 0.38-0.45% of C, 0.20-0.35% of Si, 0.60-0.80% of Mn, lessthan or equal to 0.015% of P, less than or equal to 0.010% of S, 0.95-1.20% of Cr, 0.18-0.30% of Mo, 0.10-0.25% of Ni, 0.02-0.08% of Nb, 0.020-0.050% of Al, less than or equal to 0.008% of N, and thebalance of Fe and inevitable impurities. After heat treatment, the core part of the steel is provided with 90% or above of a martensitic structure, the surface hardness difference of the core part isless, especially the low-temperature impact property is excellent, the good mechanical properties are achieved, the tensile property meets the 10.9-grade strength requirements, and the machining usingrequirements for the steel for 48-65 mm of the large-sized wind power fastener by a user can be met.

Owner:NANJING IRON & STEEL CO LTD

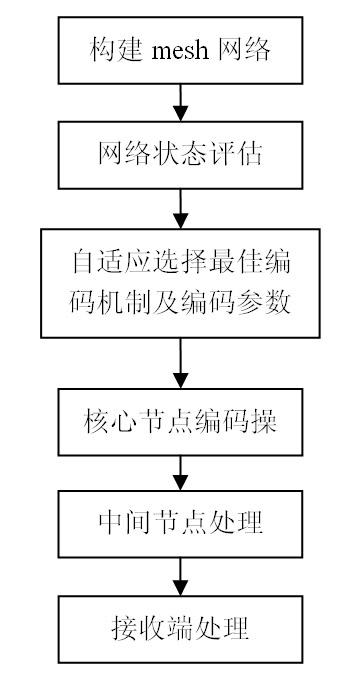

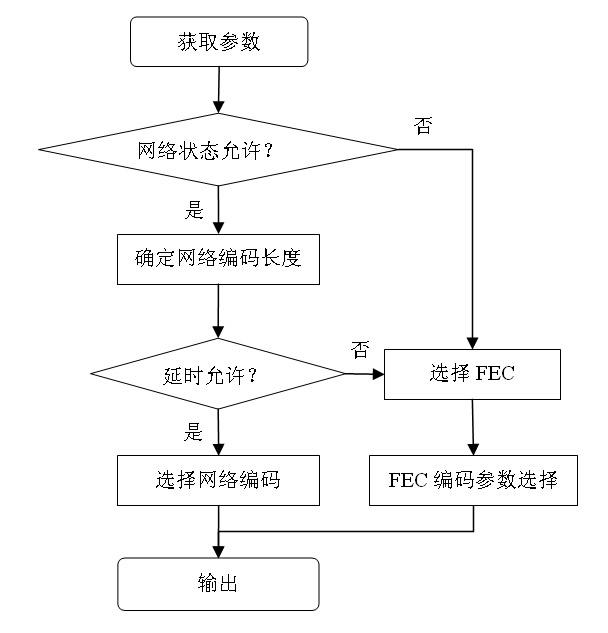

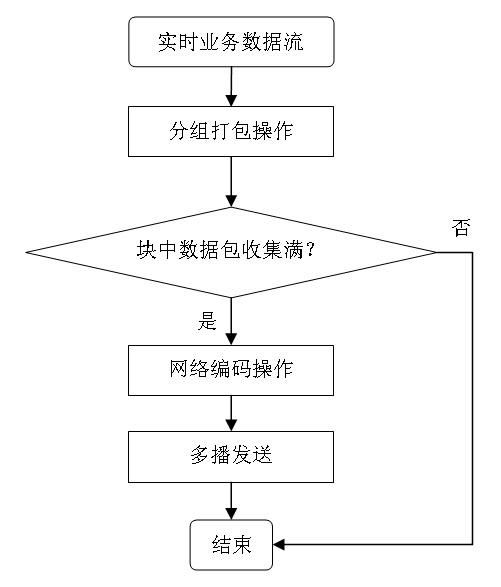

Real-time multicast method in wireless multi-hop network

InactiveCN102438207AAvoid performance fluctuationsAvoid wastingEnergy efficient ICTError preventionNetwork conditionsAdaptive selection

The invention discloses a real-time multicast method in a wireless multi-hop network. The method comprises the following steps of: constructing a mesh network; assessing a network condition; adaptively selecting an optimum coding mechanism and coding parameters; performing coding operating by using a core node; processing by using an intermediate node; and processing by using a receiving node. The real-time multicast method in the wireless multi-hop network designed in the invention is applied to a real-time multicast service in a mobile ad hoc network, the optimum coding mechanism and the parameter can be adaptively selected according to the current network condition, the reliability and throughput of the network are improved, the overall energy consumption of the network is reduced and the requirement on the real-time property of services can be met.

Owner:HOHAI UNIV

Composite toughening technology of cast aluminum alloy wheel hub

InactiveCN101760657AReduces mushy solidification tendencyReduce surface tensionHubsRare earthNitrogen gas

The invention relates to a composite toughening technology of a cast aluminum alloy wheel hub, comprising the following steps of: melting aluminium alloy melt into an aluminum alloy solution; adding Al-Sr intermediate alloy, mischmetal (Re) and Al-Zr intermediate alloy to the solution when the solution temperature reaches 710-730 DEG C under the condition of stirring to carry out composite modifying and refining treatment; and meanwhile, blowing nitrogen into the solution to remove harmful gas out of the solution. The technology not only can reduce alloy getter and improve the flowability of an aluminum solution, but also can ensure that the tissues and the performance of castings doe not fluctuate, thereby improving the quality of products.

Owner:郑东海

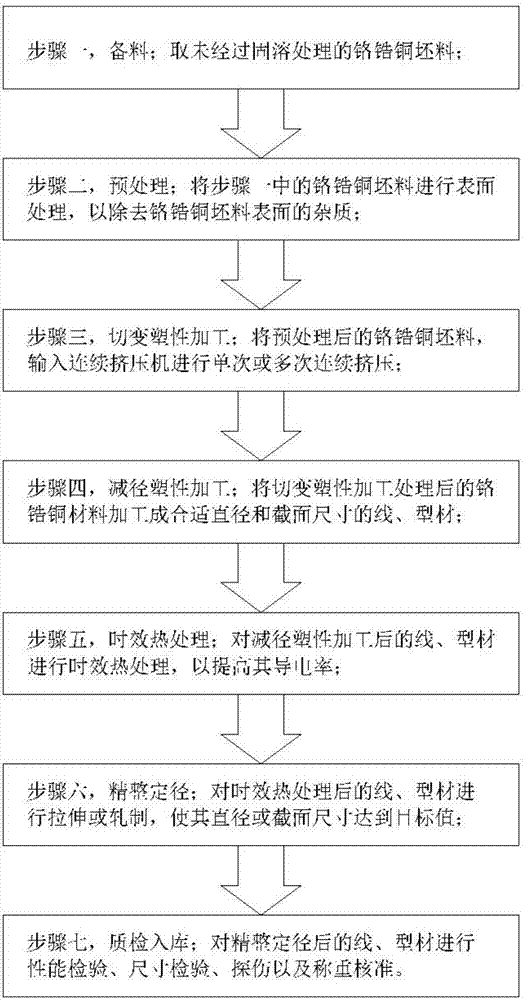

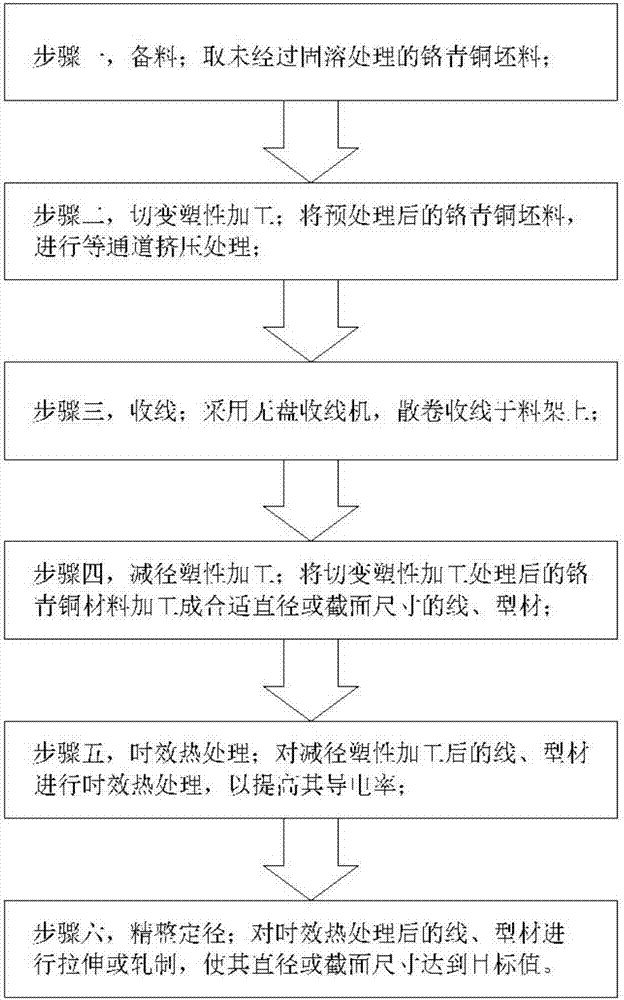

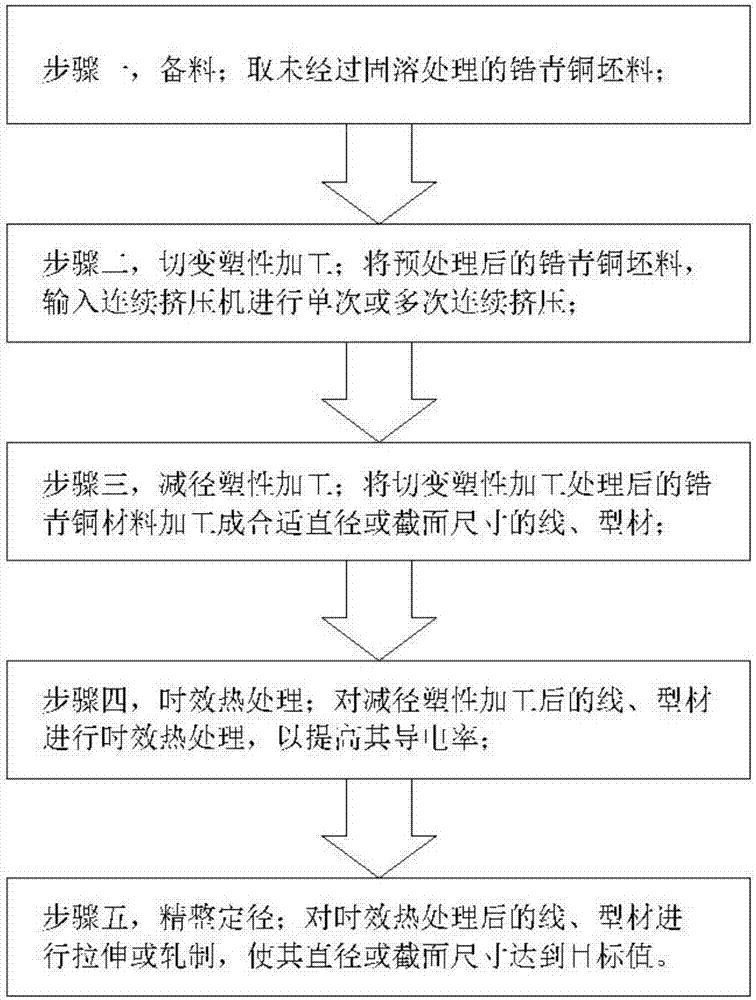

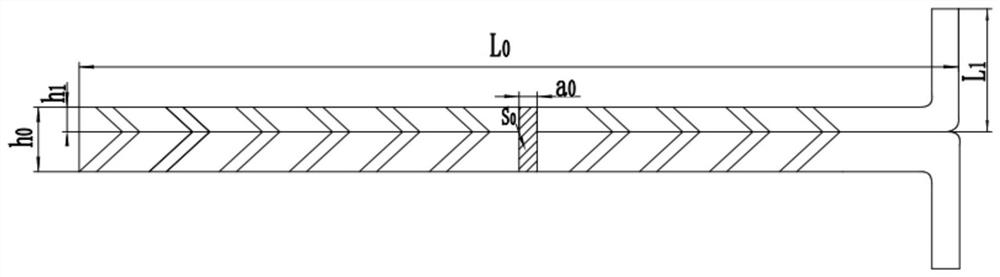

Shearing machining process for aging precipitation strengthened copper alloy material

ActiveCN106881373AAvoid performance fluctuationsShort manufacturing processMaterials preparationSolution treatment

The invention provides a shearing machining process for an aging precipitation strengthened copper alloy wire and profile and belongs to the field of material machining. The shearing machining process comprises the following steps that step one, material preparation is conducted, specifically, an aging precipitation strengthened copper alloy blank is taken and not subjected to solution treatment anymore; step two, shearing plastic machining is conducted, specifically, the aging precipitation strengthened copper alloy blank is input into a continuous extrusion machine to be subjected to a single time or multiple times of continuous extrusion; step three, reducing plastic machining is conducted, specifically, the material subjected to shearing plastic machining treatment is machined into a wire and a profile with the proper section and diameter; step four, aging heat treatment is conducted, specifically, the wire and profile subjected to reducing plastic machining is subjected to aging heat treatment to increasing the electric conductivity of the wire and profile; and step five, finishing sizing is conducted, specifically, the wire and profile subjected to aging heat treatment is subjected to rolling, forging or stretching machining to enable the section size or diameter of the wire and profile to reach a target value. By adoption of the shearing machining process, solution treatment is not needed, the preparation process is shortened, the technical problems that the solution temperature is not uniform, and solution treatment rapid quenching is difficult to achieve are solved, and material performance fluctuation caused by the technical problems is further avoided.

Owner:苏州中色华人铜业有限公司

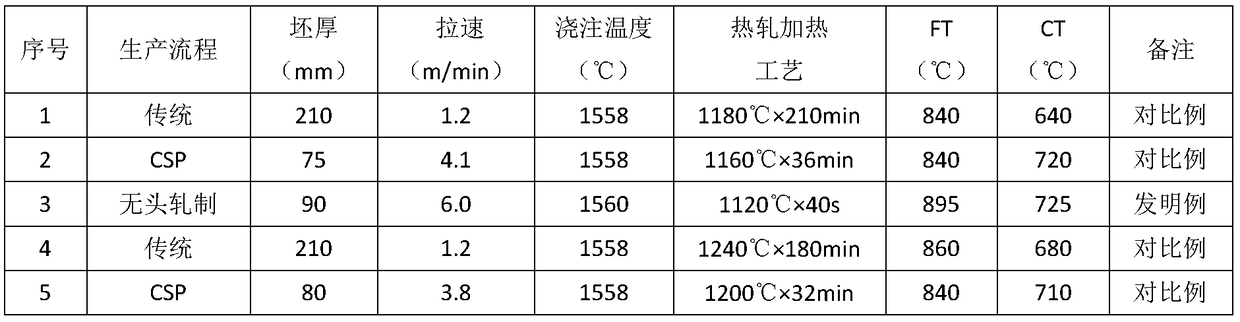

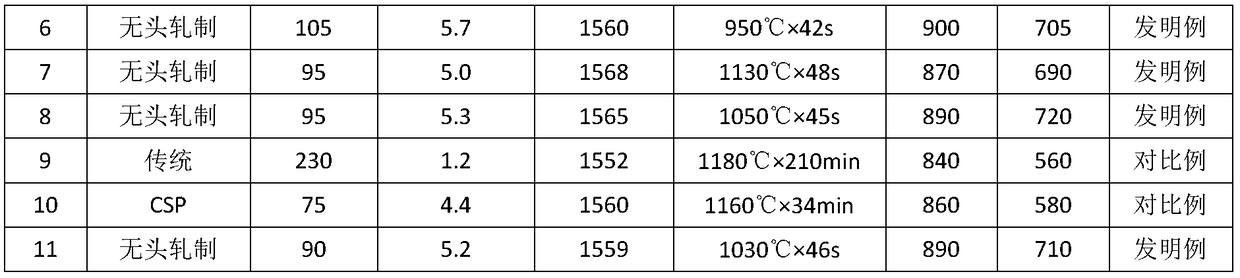

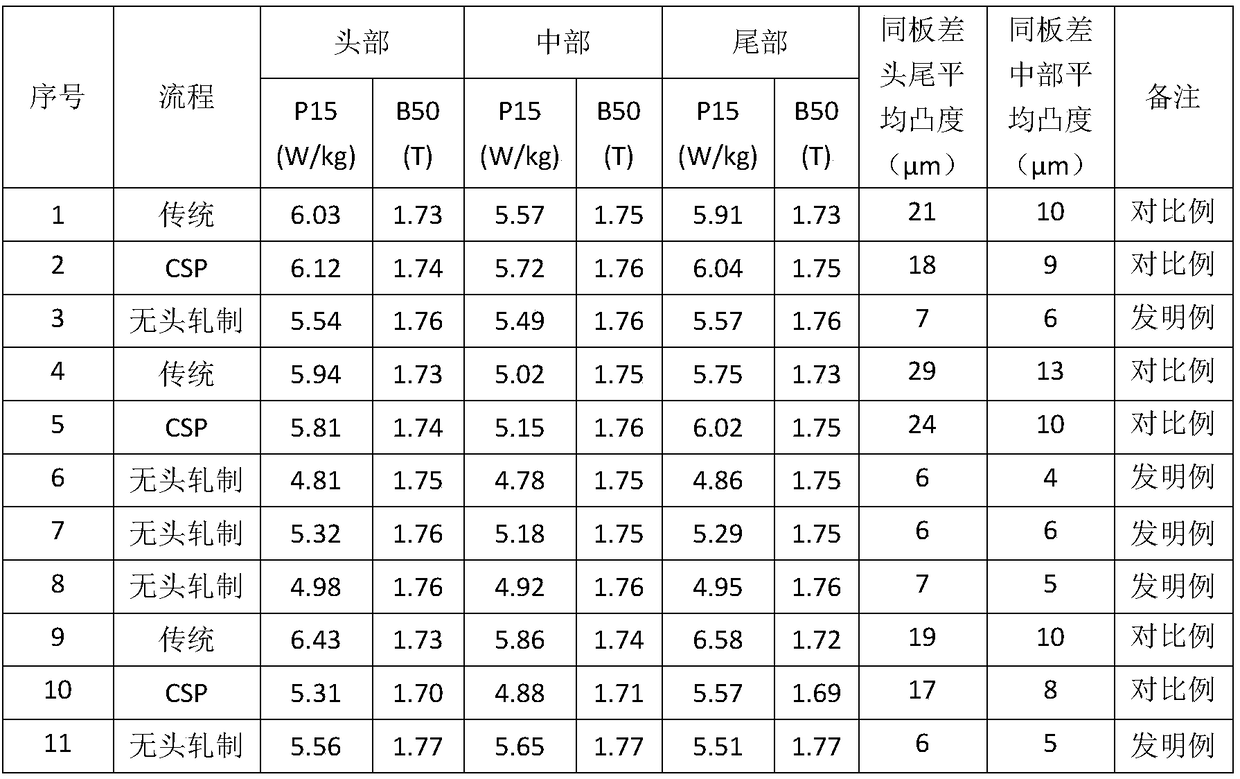

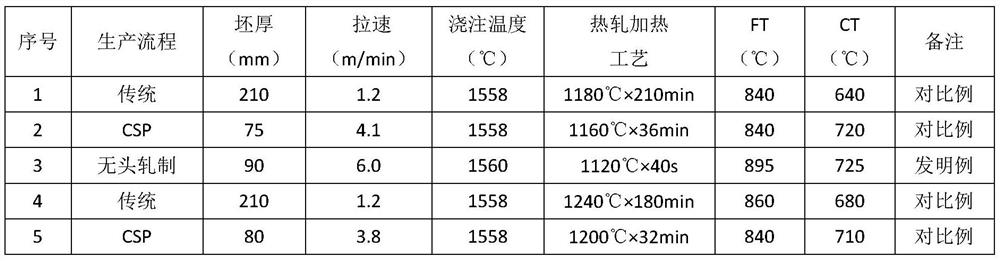

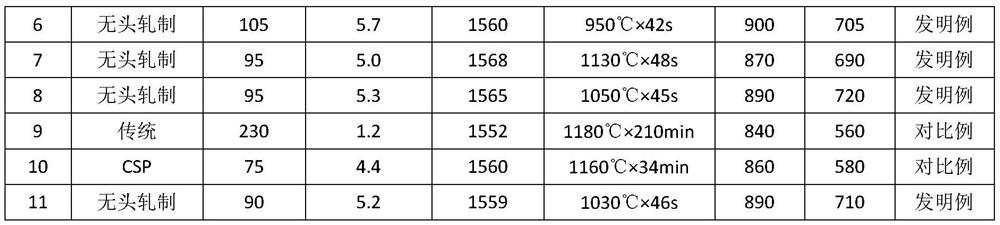

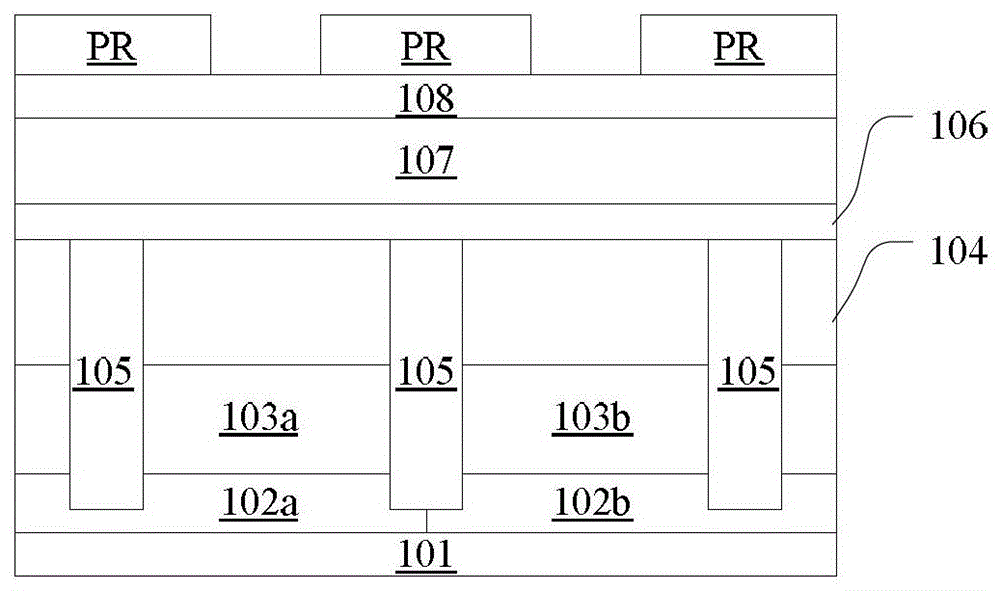

Method for producing non-oriented electrical steel in endless rolling mode through sheet billets

The invention belongs to the technical field of steel, and particularly relates to a method for producing non-oriented electrical steel in an endless rolling mode through sheet billets. The design components of the non-oriented electrical steel comprise, by mass, 0.0080% or the less of C, 1.0% or the less of Si, 0.010% or the less of Als, 0.5% or the less of Mn, 0.05% or the less of P, 0.008% or the less of S, 0.0080% or the less of N and the balance Fe and inevitable impurities.

Owner:RIZHAO STEEL HLDG GROUP

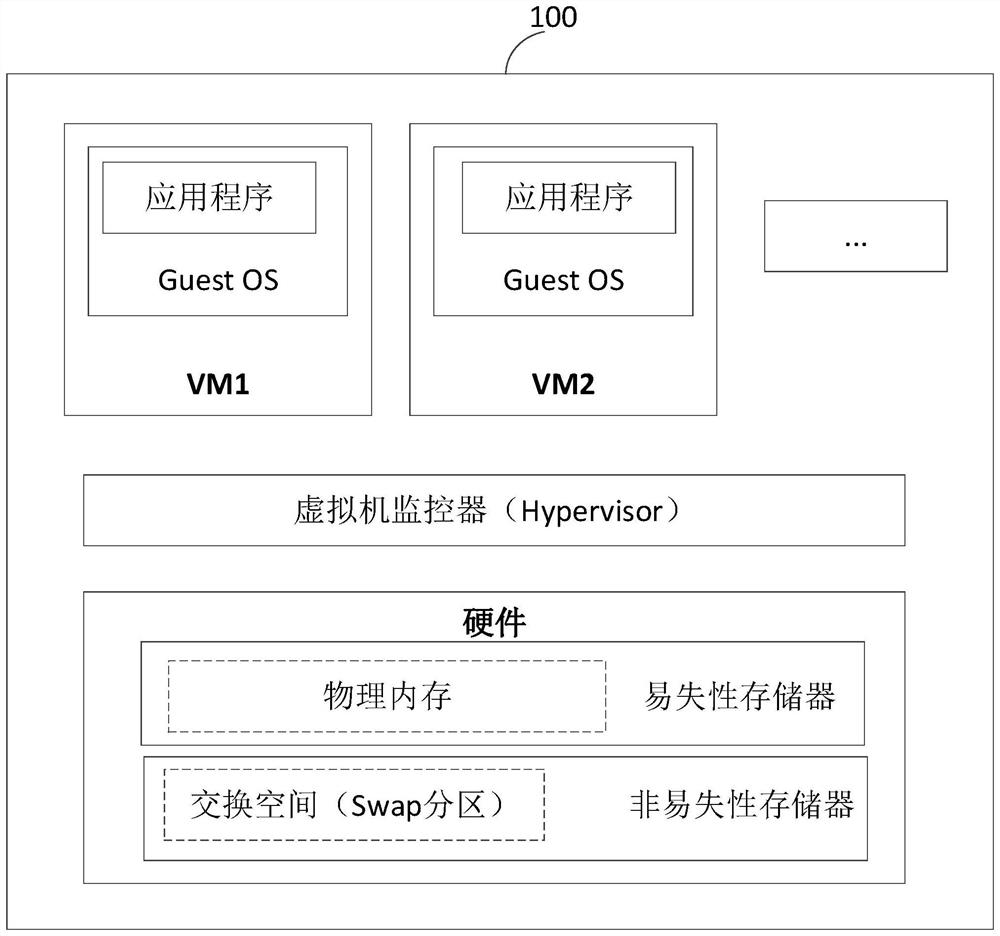

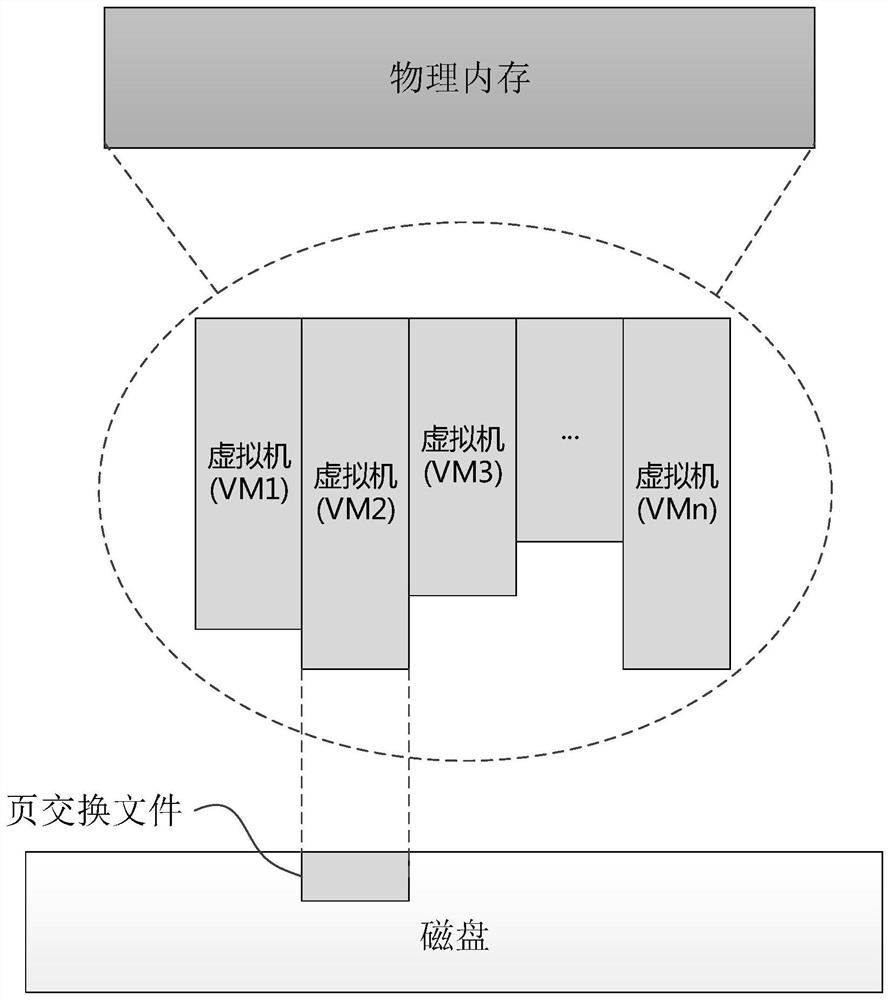

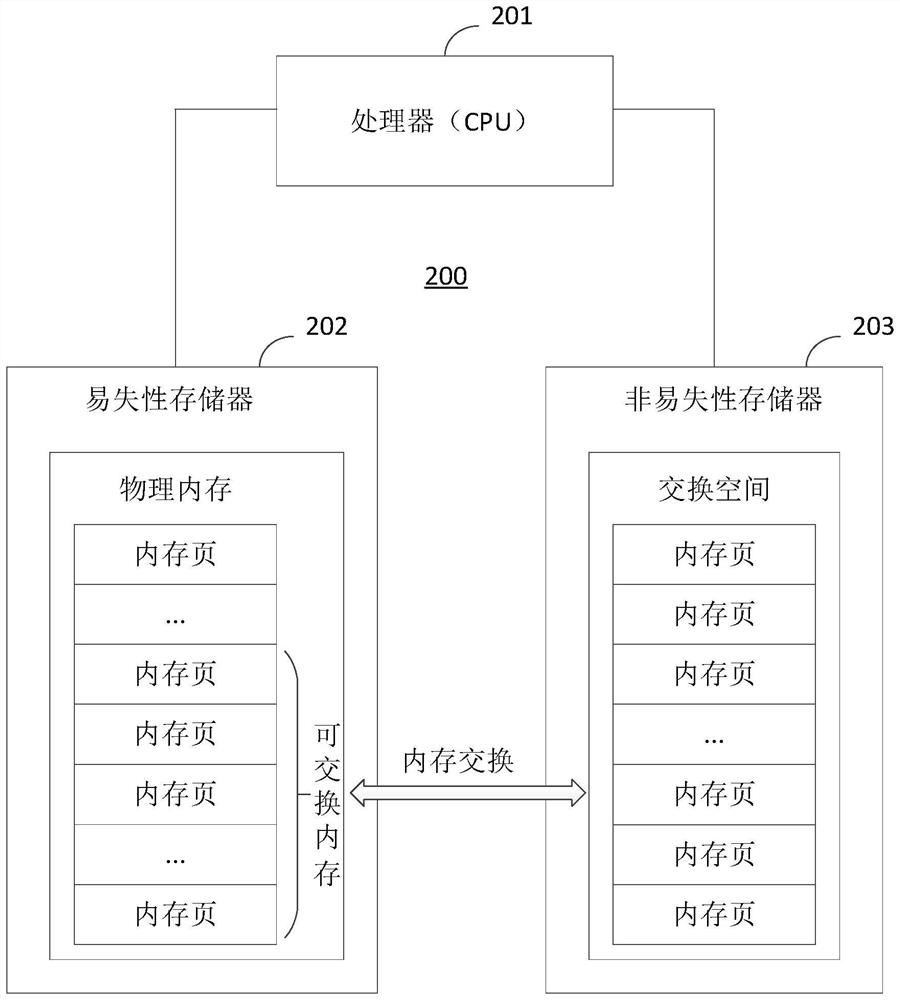

Virtual machine memory management method and equipment

PendingCN112579251AImprove stabilityAvoid ability to declineMemory architecture accessing/allocationMemory adressing/allocation/relocationOperational systemTerm memory

The invention provides a virtual machine memory management method and equipment. The method comprises the following steps: identifying a non-operating system memory of a virtual machine from total memory allocated to the virtual machine; wherein the total memory comprises the memory of the virtual machine and the management memory of the virtual machine monitor; wherein the memory of the virtual machine comprises the memory of an operating system of the virtual machine and the memory of a non-operating system of the virtual machine; taking a memory of a non-operating system of the virtual machine as an exchangeable memory; and storing the data in the exchangeable memory into a nonvolatile memory. The problem of obvious reduction of the performance of the computer in an excessive submissionscene of the virtual machine can be avoided, the running stability of the virtual machine is improved, and the user experience is improved.

Owner:HUAWEI TECH CO LTD

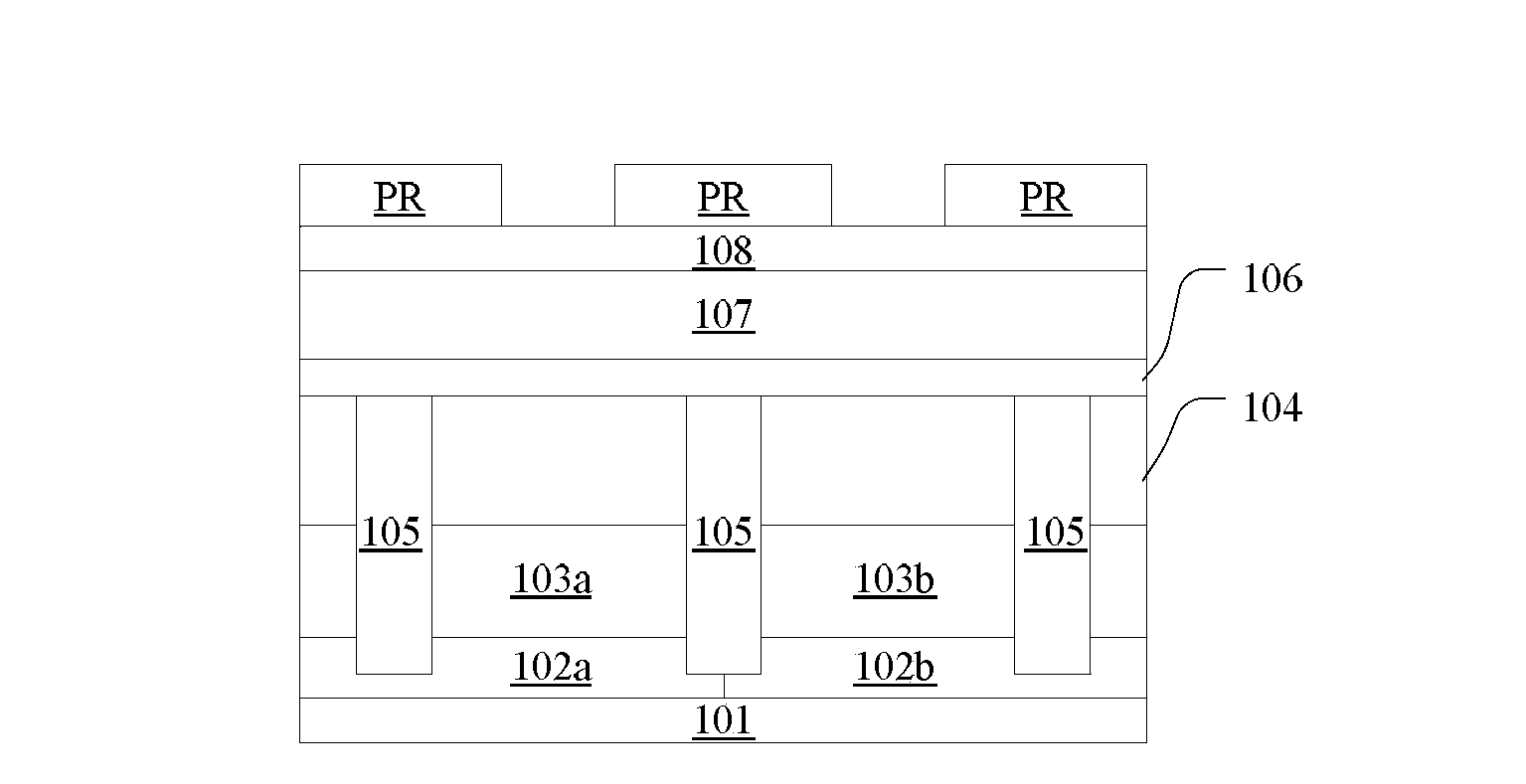

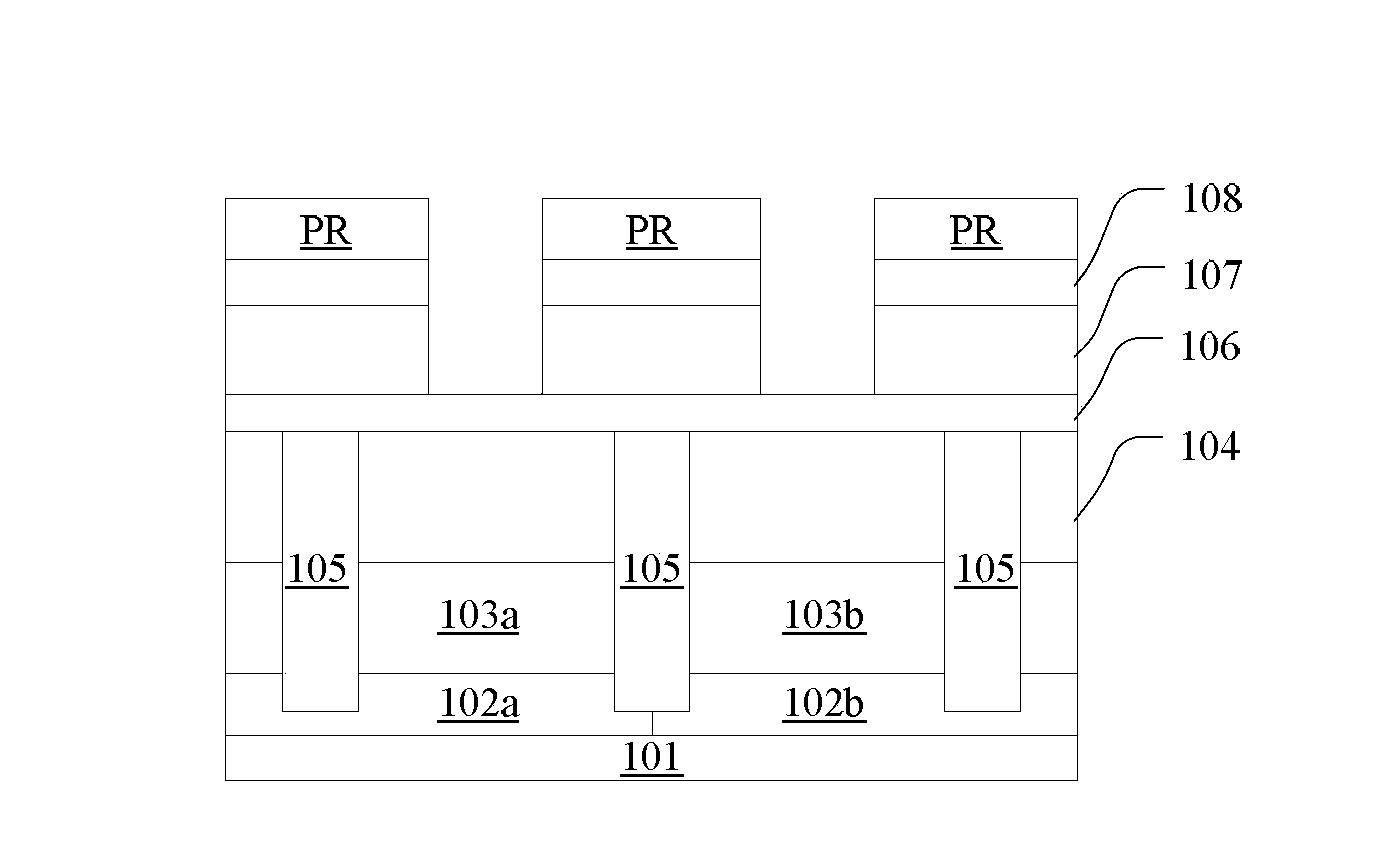

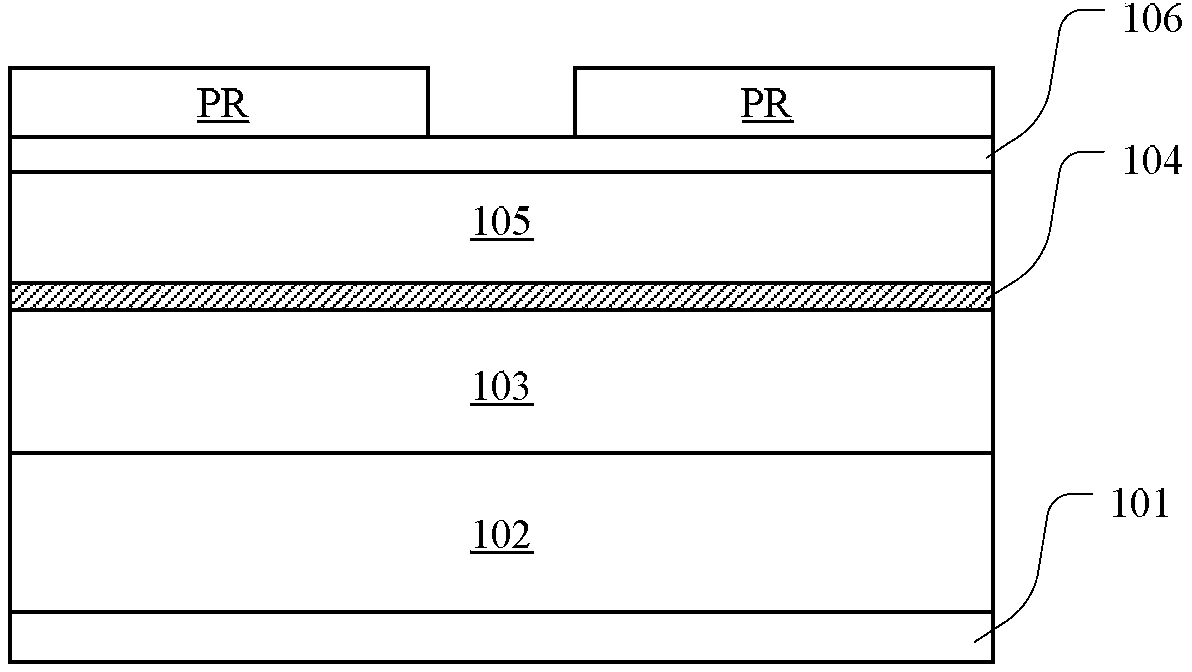

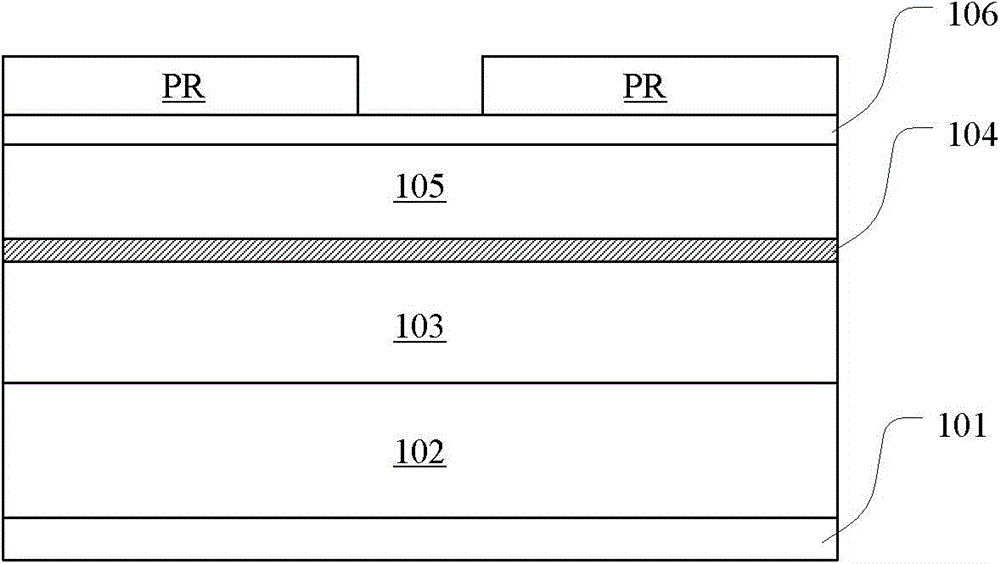

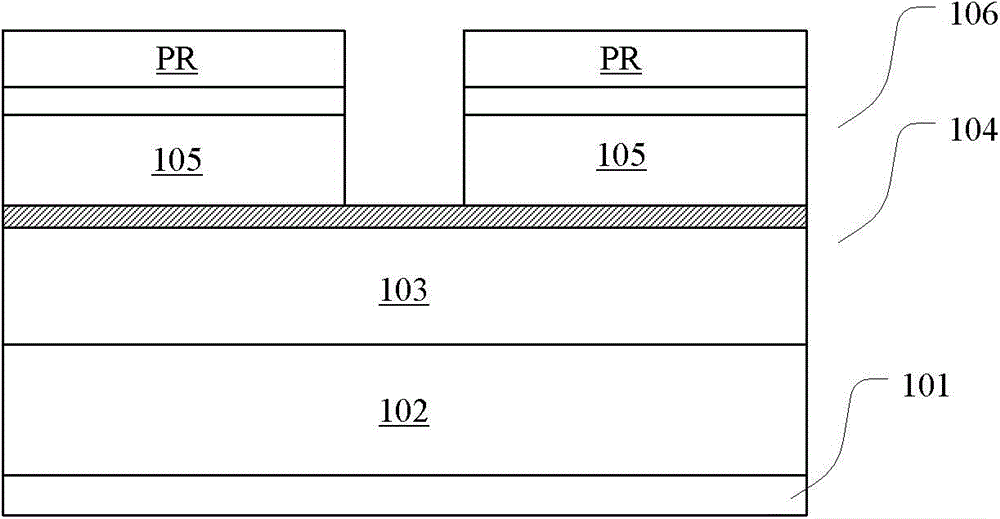

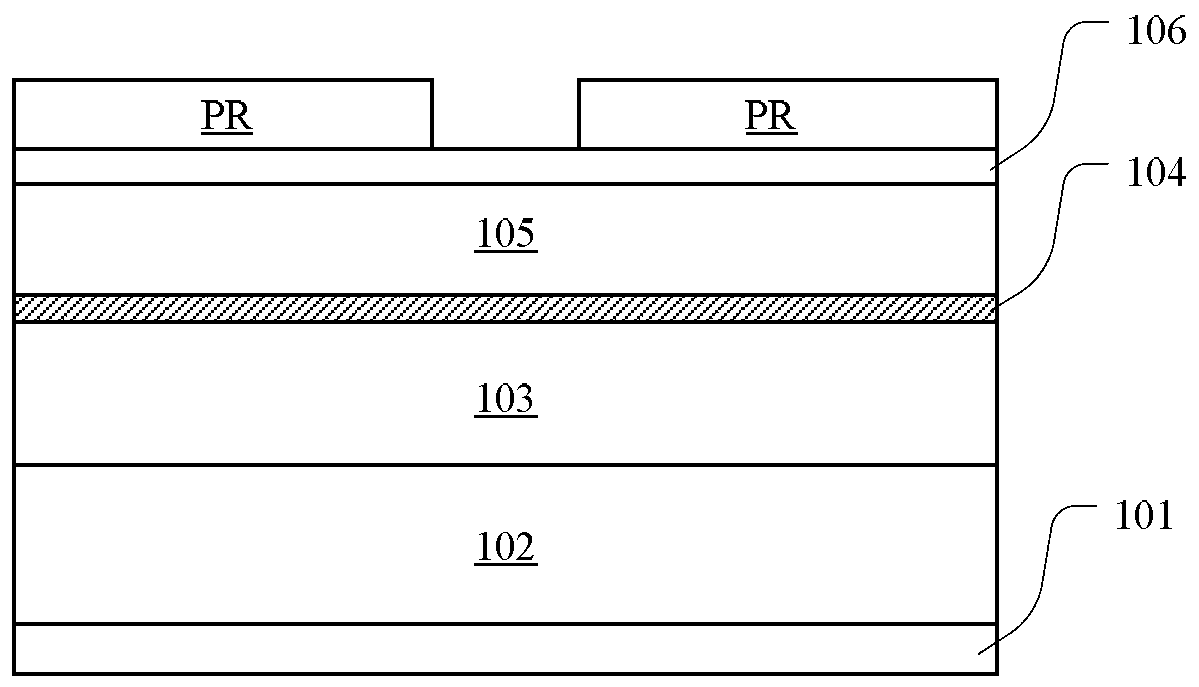

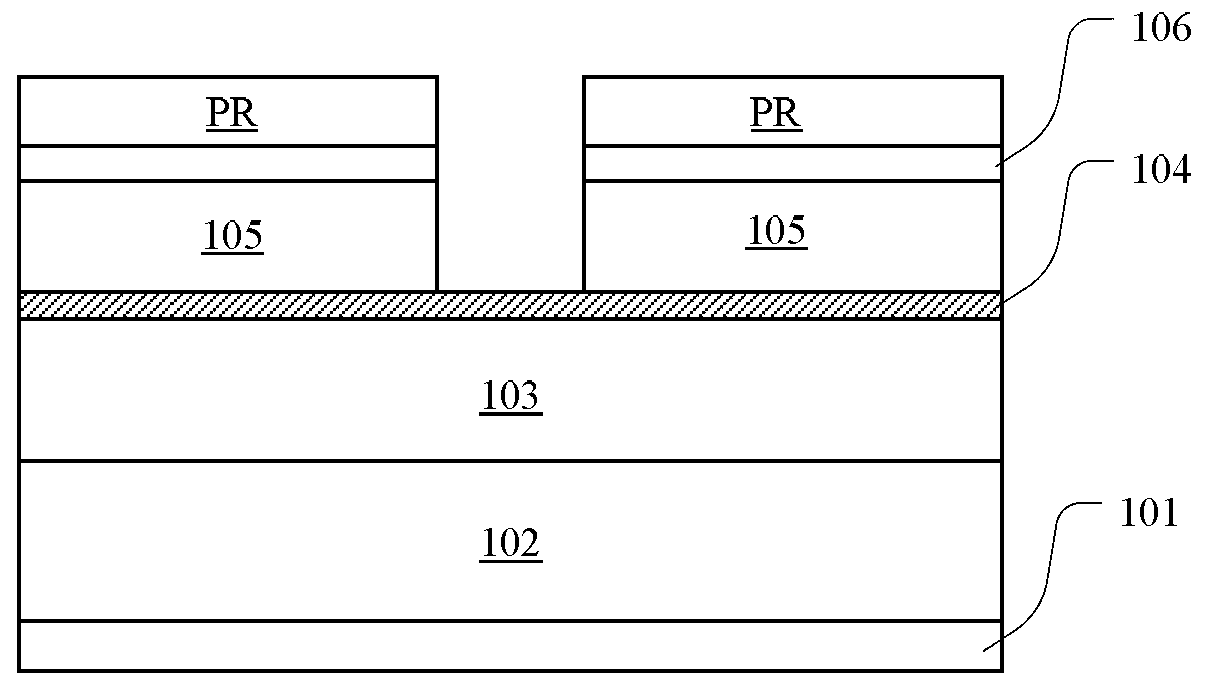

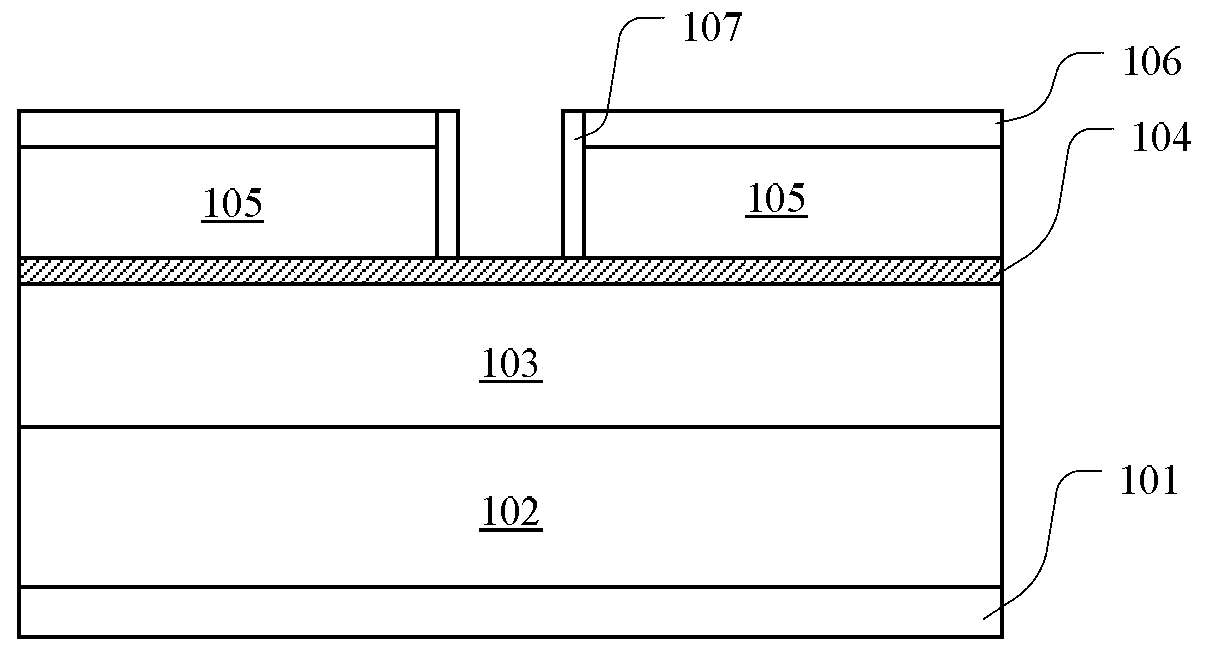

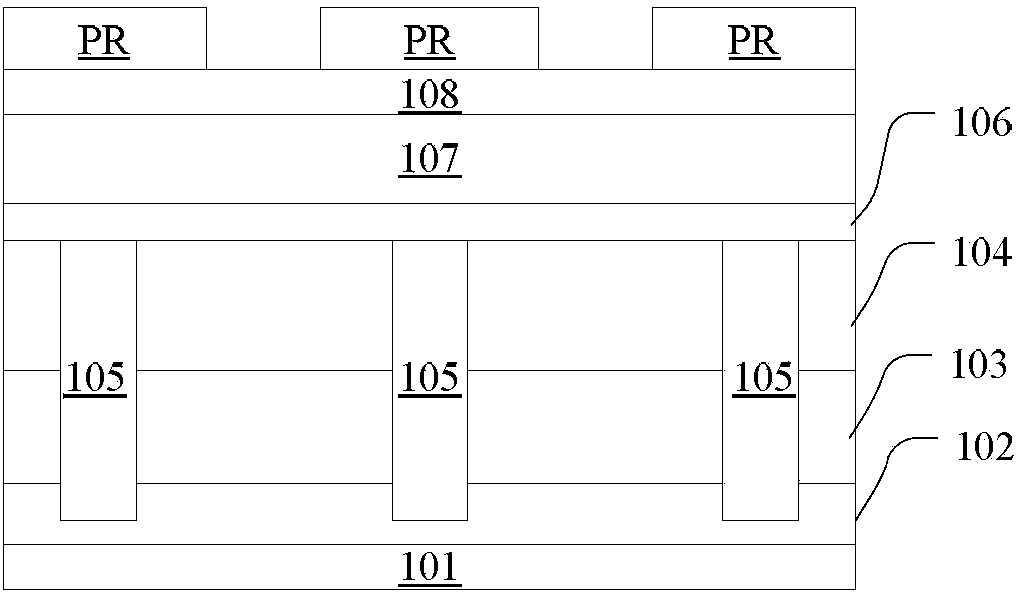

Semiconductor device and manufacturing method thereof

ActiveCN103985754AAvoid performance fluctuationsAvoid self-heating effectsSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricElectrical conductor

Disclosed are a semiconductor device and manufacturing method thereof, the semiconductor device comprising: a semiconductor substrate, a well region in the semiconductor substrate, a sandwich structure located on the well region, a penetration resistance layer located below semiconductor fins, a front-gate stack intersecting with the semiconductor fins, and a source region and a drain region connected with a channel region provided by the semiconductor fins. The sandwich structure comprises a back-gate conductor, the semiconductor fins located on the two sides of the back-gate conductor, and respective back-gate dielectrics each isolating the back-gate conductor from the semiconductor fins; the well region is part of the conductive path of the back-gate conductor; and the front-gate stack comprises a front-gate dielectric and a front-gate conductor, and the front-gate dielectric isolates the front-gate conductor from the semiconductor fins. The semiconductor device realizes high integration and low power consumption.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

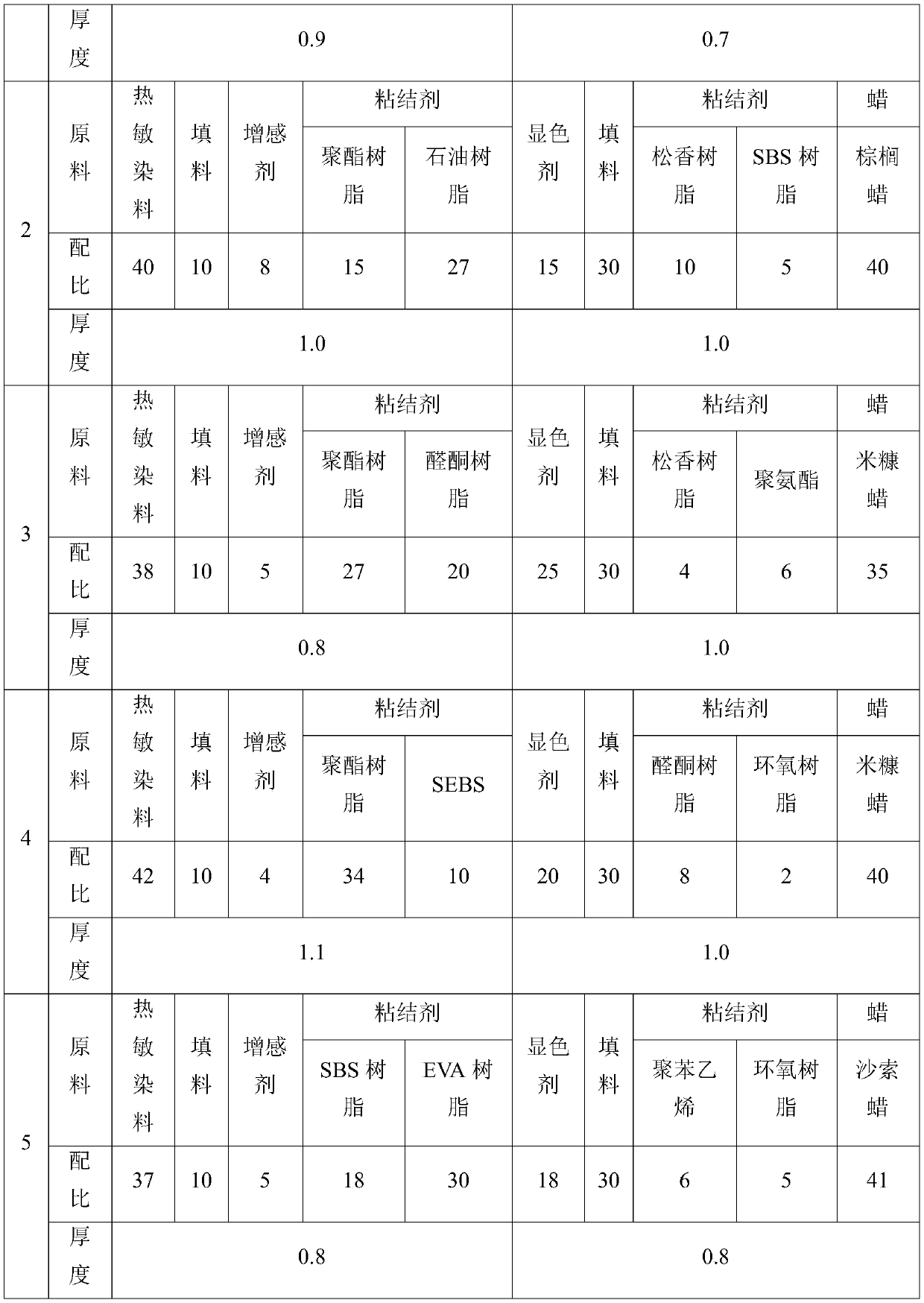

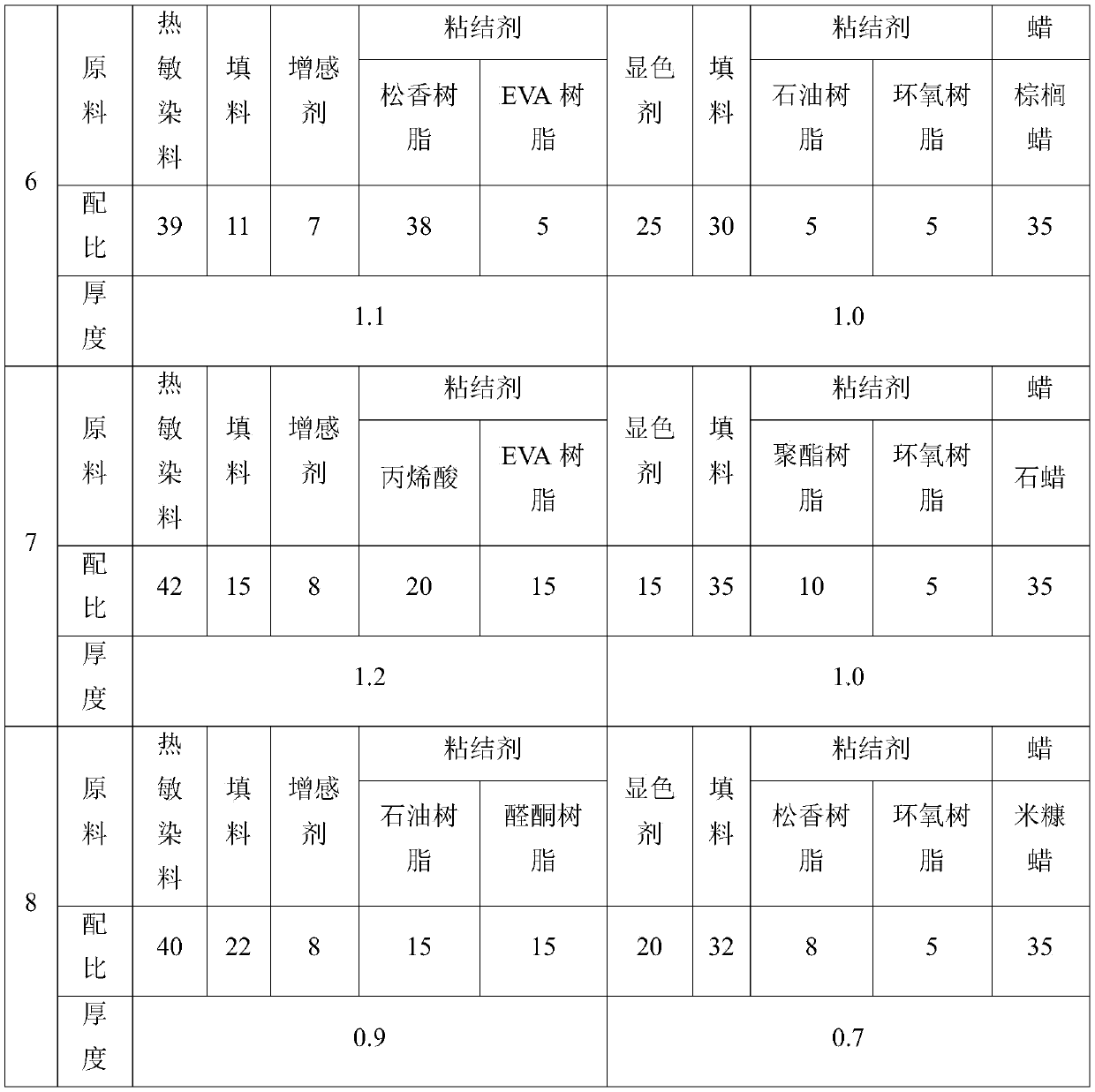

Coated heat-sensitive paper and processing technology thereof

ActiveCN110735358AImprove slipperinessImprove scratch resistanceNon-fibrous pulp additionCoatings with pigmentsWeather resistancePaper based

The invention tries to solve the problems existing in the existing heat-sensitive paper printing through a film coating technology; the invention provides coated heat-sensitive paper and a processingtechnology thereof. The coated heat-sensitive paper comprises a paper base and a heat-sensitive color developing agent layer, and further comprises a film layer, one side of the film layer is coated with a heat-sensitive dye layer, the other side of the film layer is coated with a lubricating layer, and the film layer is compounded on the surface of the paper base in the mode that the heat-sensitive dye layer faces the heat-sensitive color developing agent layer through a film coating process. Compared with existing heat-sensitive paper, the coated heat-sensitive paper shows higher smoothness,scratch resistance, physical and chemical corrosion resistance, weather resistance and durability and smaller thermal damage, is non-toxic and dust-free, and avoids potential safety hazards to humanhealth.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

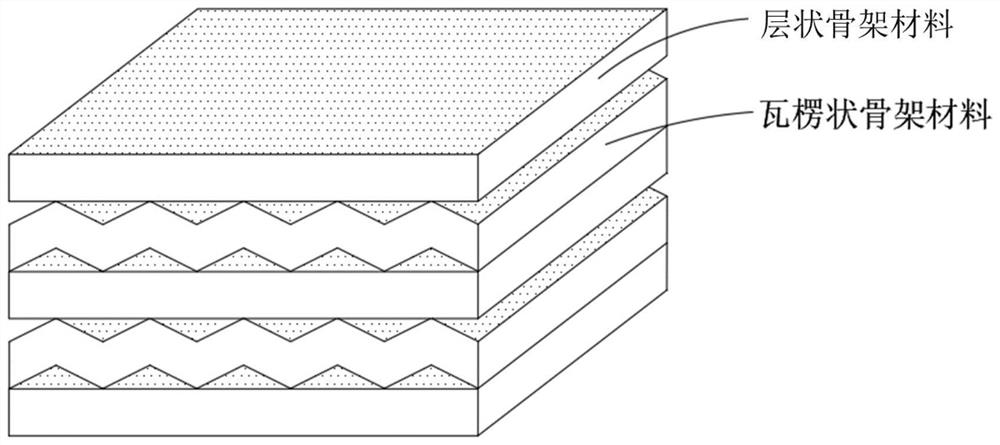

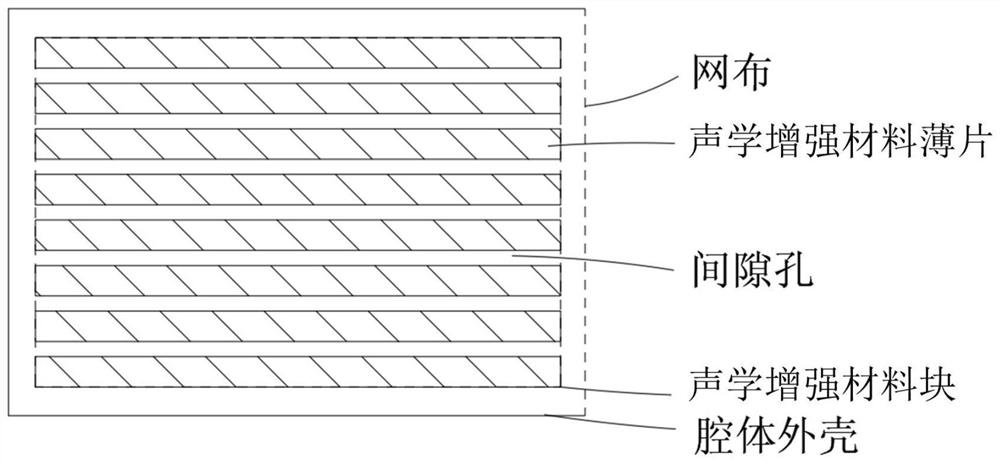

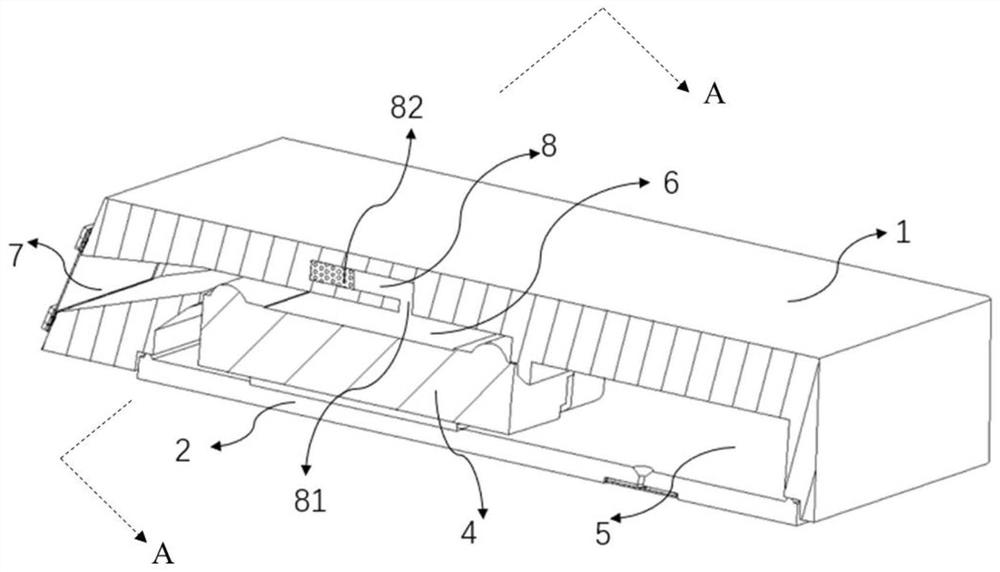

Acoustic reinforcing material block, application of acoustic reinforcing material block, micro loudspeaker and application of micro loudspeaker

PendingCN114801343AAvoid performance fluctuationsHigh mechanical strengthElectrostatic transducer loudspeakersPaper/cardboard layered productsVertical planeAdhesive

The invention provides an acoustic reinforcing material block and an application thereof, and a micro loudspeaker and an application thereof. A structural framework of the acoustic reinforcing material block is formed by a single-layer framework material or formed by alternately laminating more than two layers of framework materials, and the raw materials of the acoustic reinforcing material block further comprise a porous material, an adhesive and an assistant which are loaded in the structural framework. The invention further provides a miniature loudspeaker, the miniature loudspeaker comprises an upper shell, a lower shell and a loudspeaker unit, the upper shell and the lower shell form an inner cavity, the loudspeaker unit is located in the inner cavity, a sound outlet hole is formed in one side of the upper shell, and the inner cavity is divided into a front cavity and a rear cavity by taking a vertical plane where the side face, opposite to the sound outlet hole, of the loudspeaker unit as a boundary; the front cavity is communicated with the sound outlet hole; the front cavity is provided with a sound outlet hole; a front cavity resonant cavity communicated with the front cavity is arranged in the upper shell, and the front cavity resonant cavity is filled with acoustic reinforcing materials. The miniature loudspeaker can effectively improve the flatness of the high-frequency performance curve of the loudspeaker.

Owner:SSI NEW MATERIAL (ZHENJIANG) CO LTD

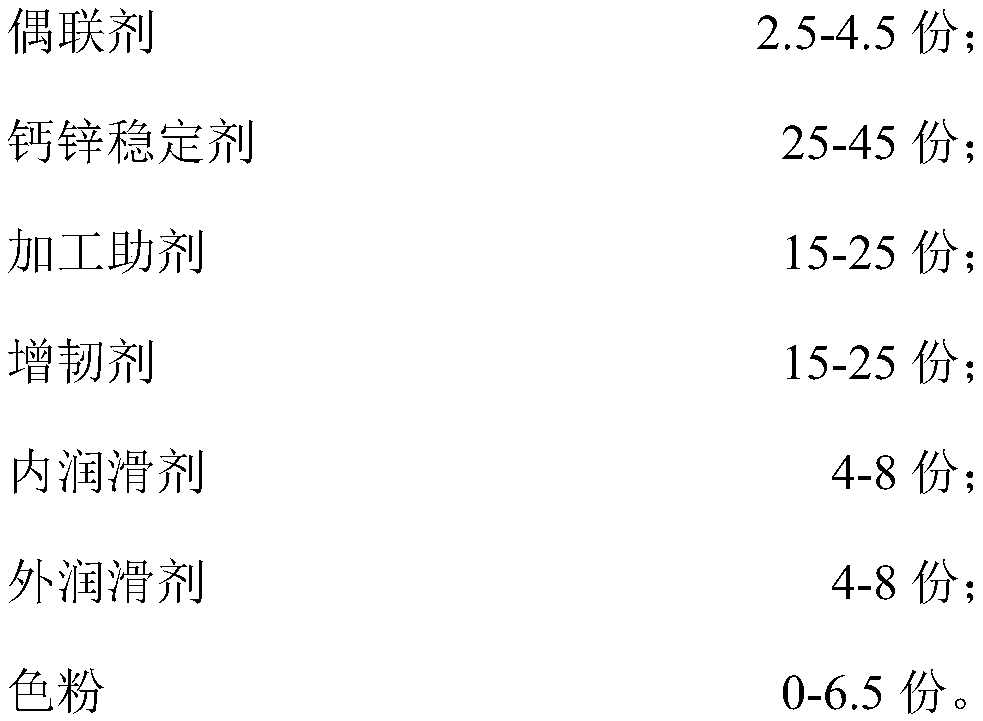

Bag type environment-friendly auxiliary special for PVC (polyvinyl chloride) floor substrate production and preparation method thereof

The invention belongs to the technical field of organic and inorganic composite materials and discloses a bag type environment-friendly auxiliary special for PVC floor substrate production and a preparation method thereof. The bag type environment-friendly auxiliary special for PVC floor substrate production is composed of, by weigh part, 2.5-4.5 parts of coupling agent, 24-45 parts of calcium-zinc stabilizer, 15-25 parts of processing auxiliaries, 15-25 parts of flexibilizer, 4-8 parts of internal lubricant, 4-8 parts of external lubricant and 0-6.5 parts of toner. The preparation method of the bag type environment-friendly auxiliary special for PVC floor substrate production comprises the steps of (1) premixing the calcium-zinc stabilizer and the coupling agent at a weight ratio of 10:1at 100 DEG C; (2) mixing and drying the mixture above, the processing auxiliaries, the internal lubricant, the external lubricant and the toner according to the preset proportional ratio at 80 DEG C;(3) screening the mixture obtained in the step (2); (4) weighing, measuring and packaging the screened materials. The bag type environment-friendly auxiliary special for PVC floor substrate productionimproves the dispersibility of various auxiliaries and enhances compatibility of calcium powder and PVC resin powder, and by screening and controlling raw materials, avoids the physical and mechanical performance deficiency caused by raw material difference.

Owner:百尔罗赫新材料科技有限公司

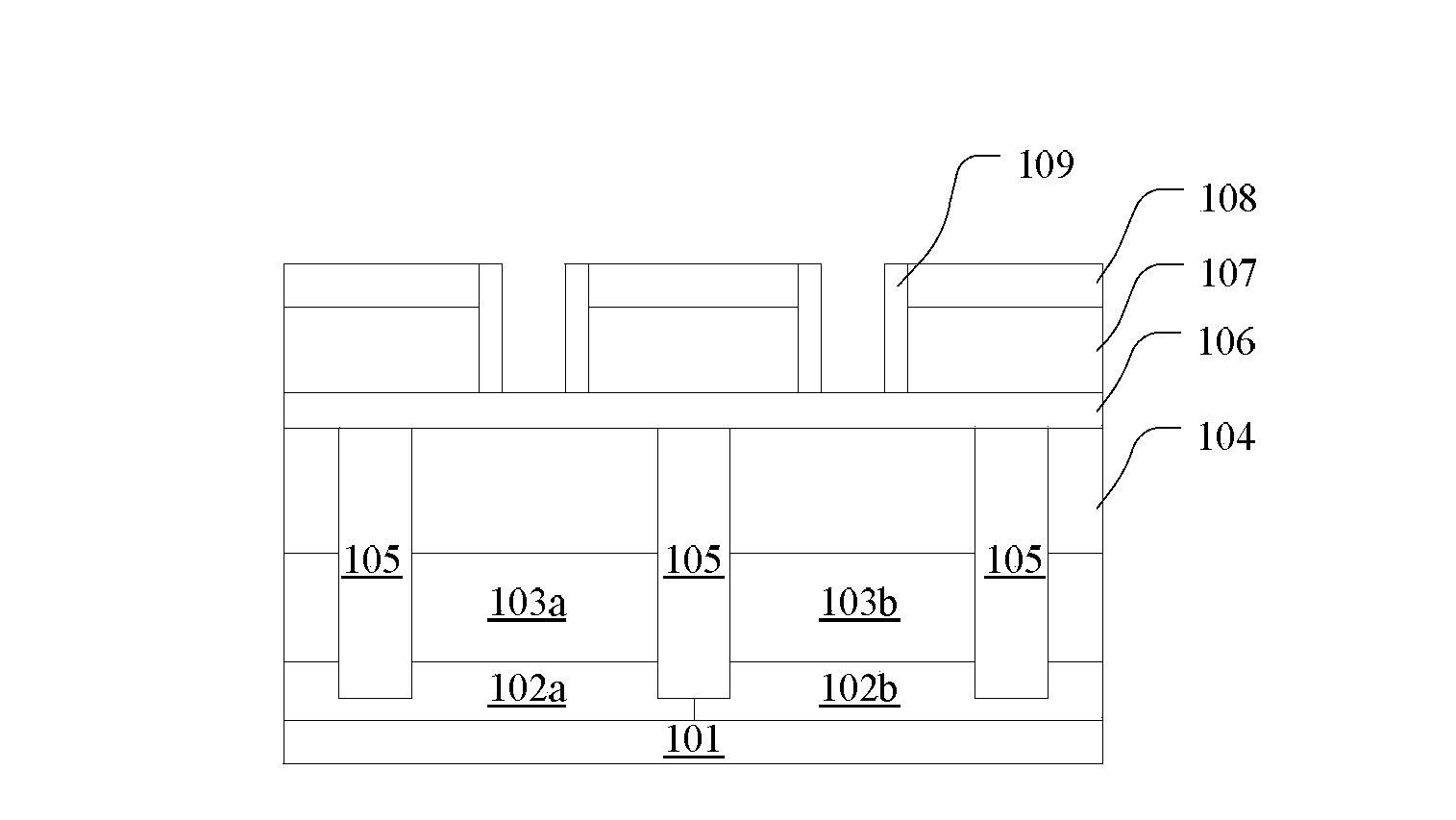

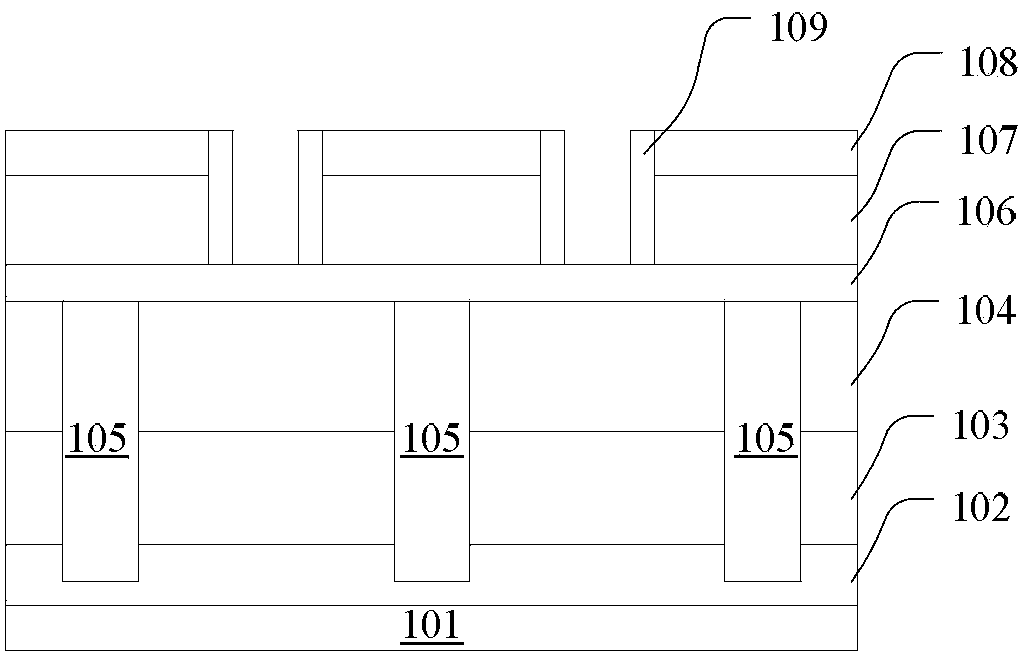

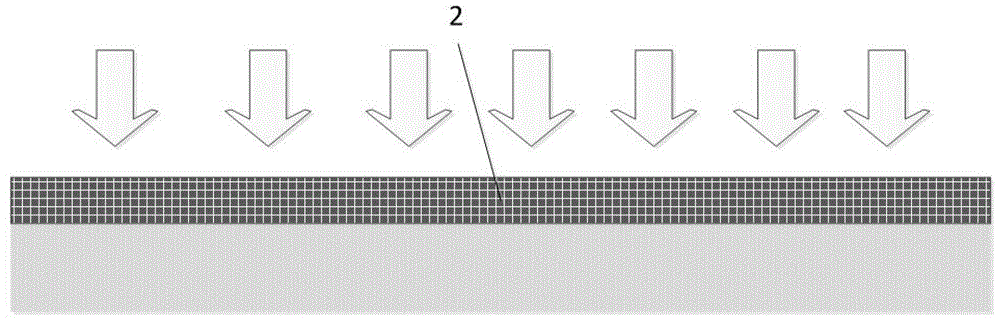

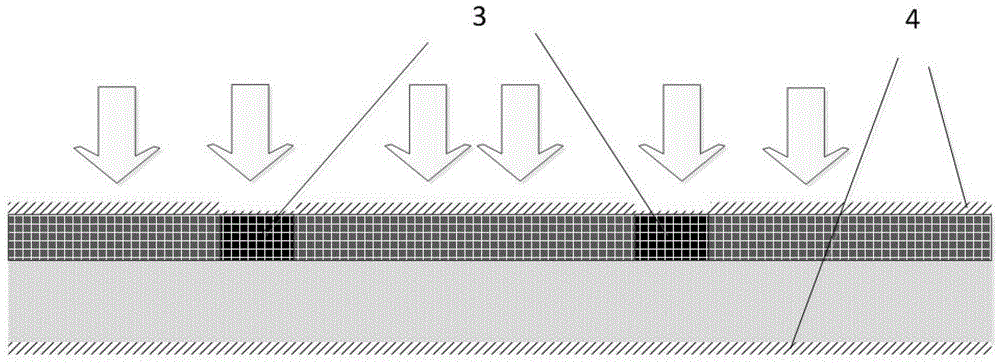

FLASH device and manufacturing method thereof

ActiveCN104078466AAvoid performance fluctuationsAvoid self-heating effectsTransistorSolid-state devicesDielectricElectrical conductor

The invention discloses a FLASH device and a manufacturing method thereof. The semiconductor device comprises a semiconductor substrate, a well region in the semiconductor substrate, a sandwich structure located on the well region, a front grid stack, an insulating cap, a source region and a drain region, wherein the sandwich structure comprises a back grid conductor, semiconductor fins located on the two sides of the back grid conductor, and back grid dielectrics separating the back grid conductor and the semiconductor fins respectively; the well region serves as a part of a conductive path of the back grid conductor; the front grid stack is intersected with the semiconductor fins, and comprises a floating grid dielectric, a floating grid conductor, a control grid dielectric and a control grid conductor which are arranged sequentially; the floating grid dielectric separates the floating grid conductor and the semiconductor fins; the insulating cap is located above the back grid conductor and the semiconductor fins, and separates the back grid conductor and the control grid conductor; and the source region and the drain region are connected with a channel region provided by the semiconductor fins. The semiconductor device can achieve high integration and low power consumption.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

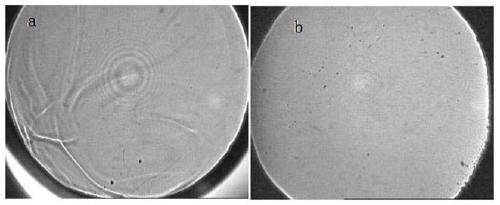

MEMS (Micro Electro Mechanical System) piezoresistive type absolute pressure sensor based on SOI (Silicon on Insulator) silicon chip

InactiveCN102980695BReduce processing difficultyImprove yieldDecorative surface effectsForce measurement using piezo-resistive materialsElectrical resistance and conductanceChip size

The invention provides an MEMS (Micro Electro Mechanical System) piezoresistive type absolute pressure sensor based on an SOI (Silicon on Insulator) silicon chip, which comprises a substrate provided with a quadrilateral slot and four groups of piezoresistors manufactured on the side wall of the slot, wherein the four groups of piezoresistors form a Wheatstone bridge; the two opposite side walls of the quadrilateral slot are arranged along a crystal orientation (100) of the substrate, and the other opposite side walls of the quadrilateral slot are arranged along a crystal orientation (101) of the substrate. The MEMS piezoresistive type absolute pressure sensor comprises the following manufacturing steps: photoetching and defining a P type heavily-doped lead contact area on the front surface of the substrate for ion implantation and high-temperature thermal annealing; photoetching and defining the shape of the slot on the front surface of the substrate and etching the quadrilateral slot; doping the piezoresistors on the side walls through P type ion implantation light doping and carrying out high-temperature thermal annealing; manufacturing a lead hole and a metal lead; and scribing. The MEMS piezoresistive type absolute pressure sensor has the beneficial effects that no strain film is contained, the chip size of the sensor can be reduced, the anti-overload capacity of the sensor is remarkably increased, and the process reliability and the device yield are improved.

Owner:PEKING UNIV

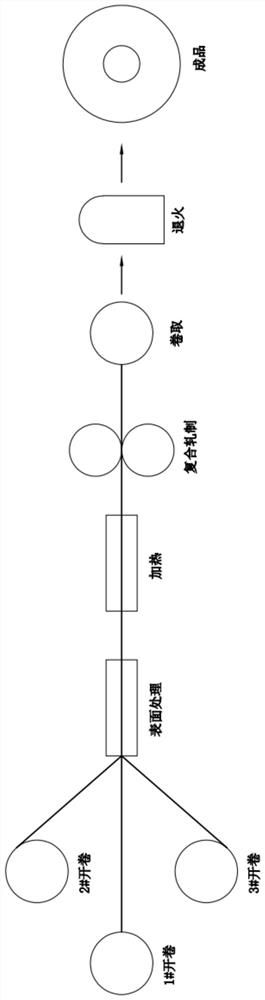

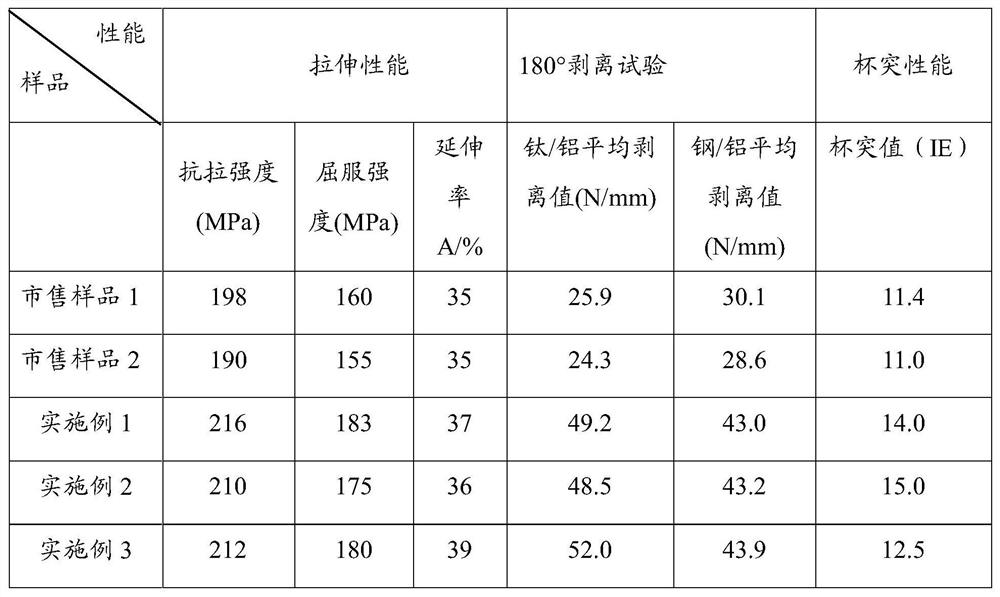

Layered titanium-aluminum steel composite strip coil material and preparation method thereof

ActiveCN112090961ACorrosion resistanceTitanium Corrosion ResistanceFurnace typesAuxillary arrangementsSS - Stainless steelTitanium

The invention discloses a layered titanium-aluminum-steel composite strip coil material and a preparation method thereof. According to the layered titanium-aluminum-steel composite strip coil material, an aluminum strip coil serves as a base material, a pure titanium strip coil is compounded on the upper surface of the aluminum strip coil, and a stainless steel strip coil is compounded on the lower surface of the aluminum strip coil; and the thickness ratio of the aluminum strip coil to the pure titanium strip coil to the stainless steel strip coil is 8: (1.5-3): (2-3). The production processflow comprises the steps of uncoiling, carrying out surface treatment, heating, rolling, coiling, annealing and obtaining a finished product coiled material, and the production processes in the process flow are continuous production line type production except annealing. The composite coiled material prepared by the method has the characteristics of being corrosion-resistant, wear-resistant, freeof toxicity, bacteria-resistant, and good in magnetic conductivity and thermal conductivity; and the interlayer binding force of the composite strip coil material is greatly improved.

Owner:新疆湘润新材料科技有限公司

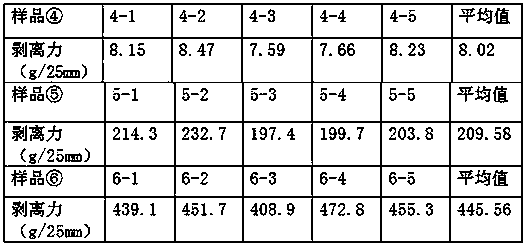

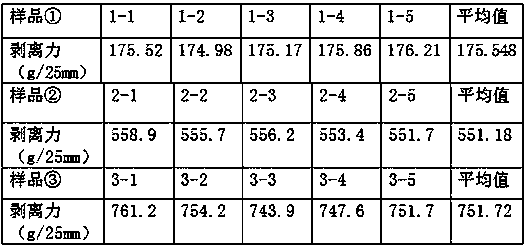

A kind of acrylic emulsion blending release force continuously adjustable pressure-sensitive adhesive formula and preparation method

ActiveCN106433524BDosage remains the sameThe degree of cross-linking reaction is consistentNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceLatex rubber

The invention relates to a formula of acrylic acid emulsion blending pressure sensitive adhesive with continually adjustable stripping resistance. By mixing two kinds of emulsions with different stripping resistance ranges, and adding a cross-linking constituent with a fixed proportion is added, continuous adjustment of the stripping resistance is achieved in a range of 5-500g. With A as a low-viscosity range 5-30 g / 25 mm and B 500-1000 g / 25 mm as a high-viscosity range, the continuous adjustment of the stripping resistance a pressure sensitive adhesive in the range of 5-500g is achieved by blending.

Owner:泰兴联创绝缘材料有限公司

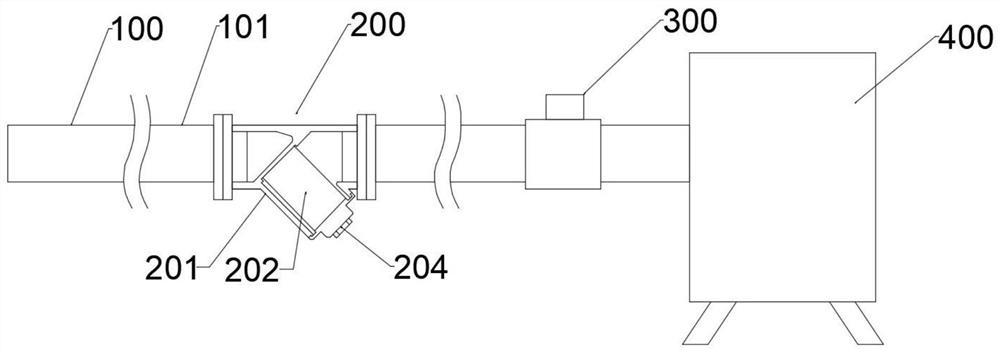

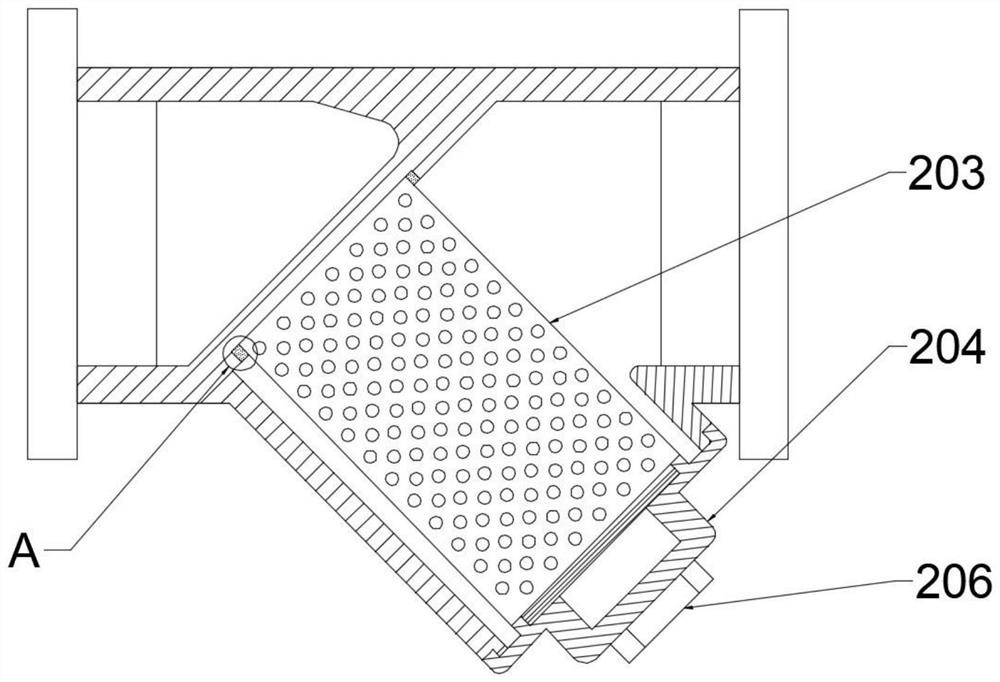

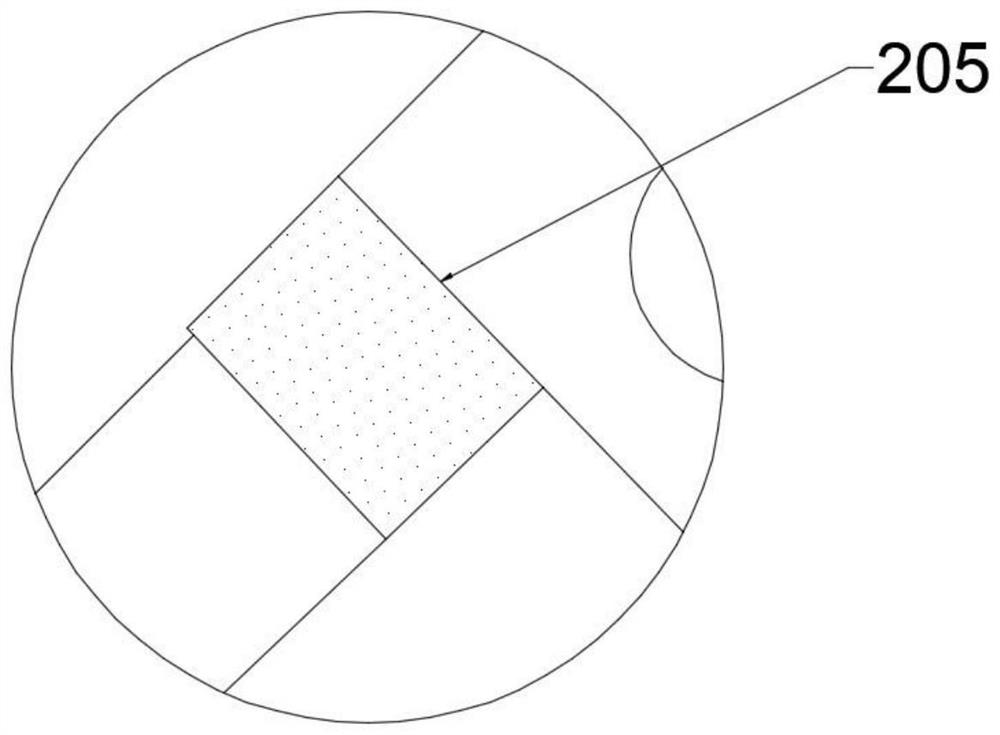

Coal gas filtering device suitable for annealing furnace

InactiveCN112251262AEffective filteringStable combustionFurnace typesGas dust removalThermodynamicsMechanical engineering

The invention provides a coal gas filtering device suitable for an annealing furnace. The device comprises a coal gas pipeline and a filtering device; the coal gas pipeline is arranged between a maincoal gas inlet pipe and the annealing furnace and is used for conveying coal gas to a nozzle in the annealing furnace; the filtering device is arranged on the coal gas pipeline and is used for filtering the coal gas; the filtering device comprises a shell and a filtering containing cavity formed in the shell; the filtering containing cavity is communicated with an air inlet and an air outlet of the shell; a filter element is arranged in the filtering containing cavity; the filter element is of a cylinder structure with the two ends open and the surface provided with a plurality of filtering holes; one end of the filter element is communicated with the air inlet, the other end of the filter element is detachably connected with a sealing cover movably mounted on the shell; the coal gas enters the annealing furnace through the gas inlet, the filter element and the gas outlet in sequence. Impurities such as tar in the coal gas can be effectively filtered out, blockage of the impurities ina coal gas electromagnetic valve and a nozzle is avoided, only the filtering device needs to be cleaned during cleaning, and the coal gas electromagnetic valve does not need to be frequently disassembled.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

flash device and its manufacturing method

ActiveCN104078466BAvoid performance fluctuationsAvoid self-heating effectsTransistorSolid-state devicesGate dielectricElectrical conductor

Disclosed is a FLASH device and a manufacturing method thereof. The semiconductor device includes: a semiconductor substrate; a well region in the semiconductor substrate; semiconductor fins, and respective back gate dielectrics that separate the back gate conductors from the semiconductor fins, wherein the well region acts as part of the conduction path of the back gate conductors; the front gate stack intersecting the semiconductor fins, the front gate The stack includes a floating gate dielectric, a floating gate conductor, a control gate dielectric, and a control gate conductor arranged in sequence, and the floating gate dielectric separates the floating gate conductor from the semiconductor fin; an insulating cap over the back gate conductor and over the semiconductor fin , and an insulating cap separating the back gate conductor from the control gate conductor; and source and drain regions connected to the channel region provided by the semiconductor fin. The semiconductor device can realize high integration and low power consumption.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Semiconductor device and manufacturing method thereof

ActiveCN103985756BAvoid performance fluctuationsAvoid self-heating effectsSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricElectrical conductor

Disclosed are a semiconductor device and manufacturing method thereof, the semiconductor device comprising: a semiconductor substrate, a back-gate isolation structure in the semiconductor substrate, and neighboring field effect transistors on the back-gate isolation structure; each of the neighboring field effect transistors comprises a sandwich structure on the back-gate isolation structure, the sandwich structure comprising a back-gate conductor, a semiconductor fin on the two sides of the back-gate conductor, and respective back-gate dielectrics isolating each back-gate conductor from the semiconductor fins; the back-gate isolation structure is part of the conductive path of the back-gate conductor of the neighboring field effect transistors, and forms a PNP junction or an NPN junction between the back-gate conductors of the neighboring field effect transistors. The semiconductor device employs a back-gate isolation structure to apply different voltages to the back gate of one or more field effect transistors respectively, thus regulating the threshold voltage of each field effect transistor accordingly.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Semiconductor device and manufacturing method thereof

ActiveCN103985754BAvoid performance fluctuationsAvoid self-heating effectsSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricElectrical conductor

Disclosed is a semiconductor device and a manufacturing method thereof. The semiconductor device includes: a semiconductor substrate; a well region in the semiconductor substrate; The semiconductor fins, and the respective back gate dielectrics that separate the back gate conductors from the semiconductor fins, wherein the well region serves as a part of the conductive path of the back gate conductors; the punch-through prevention layer located at the lower part of the semiconductor fins; A front gate stack where the sheets intersect, the front gate stack includes a front gate dielectric and a front gate conductor, and the front gate dielectric separates the front gate conductor from the semiconductor fin; and a source region connected to a channel region provided by the semiconductor fin and Drain area. The semiconductor device can realize high integration and low power consumption.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Semiconductor device and manufacturing method thereof

ActiveCN103985756AAvoid performance fluctuationsAvoid self-heating effectsSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricElectrical conductor

Disclosed are a semiconductor device and manufacturing method thereof, the semiconductor device comprising: a semiconductor substrate, a back-gate isolation structure in the semiconductor substrate, and neighboring field effect transistors on the back-gate isolation structure; each of the neighboring field effect transistors comprises a sandwich structure on the back-gate isolation structure, the sandwich structure comprising a back-gate conductor, a semiconductor fin on the two sides of the back-gate conductor, and respective back-gate dielectrics isolating each back-gate conductor from the semiconductor fins; the back-gate isolation structure is part of the conductive path of the back-gate conductor of the neighboring field effect transistors, and forms a PNP junction or an NPN junction between the back-gate conductors of the neighboring field effect transistors. The semiconductor device employs a back-gate isolation structure to apply different voltages to the back gate of one or more field effect transistors respectively, thus regulating the threshold voltage of each field effect transistor accordingly.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

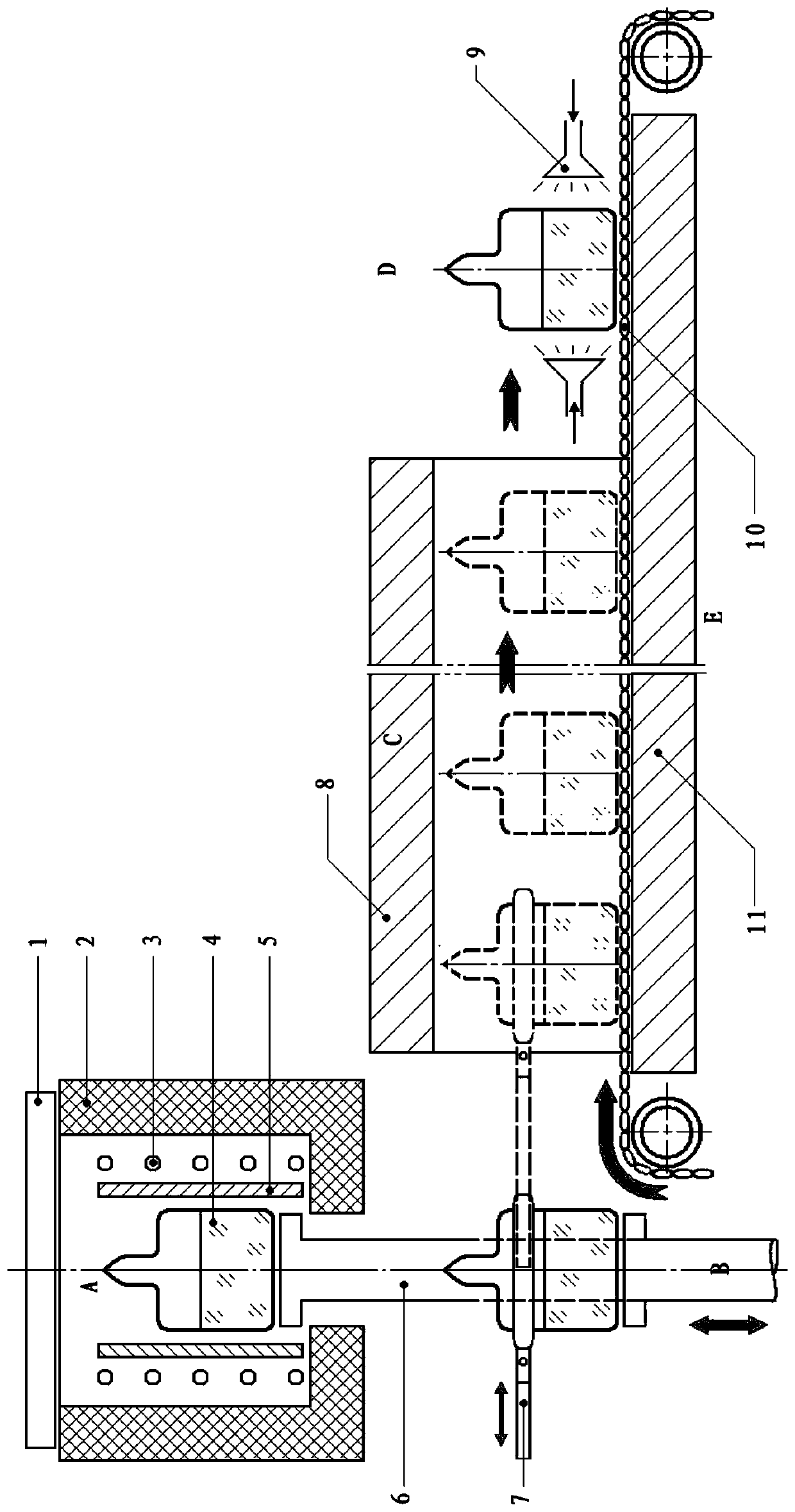

Chalcogenide glass and its preparation method and device

ActiveCN107056016BImprove melting efficiencyImprove uniformityGlass furnace apparatusGlass shaping apparatusTemperature controlThermal insulation

The invention provides chalcogenide glass as well as a preparation method and device thereof. The device comprises a melting module, a lifting module, a homogenizing module, a cooling module, a conveying module and a crucible, wherein the melting module comprises a furnace cover, a furnace body, medium-frequency induction coils and induction heating elements, a melting cavity is formed by the furnace cover and the furnace body, the bottom of the melting cavity is open, and the medium-frequency induction coils are located in the melting cavity; the lifting module is used for driving the crucible to perform first motion; the homogenizing module comprises a thermal insulation furnace and a temperature control system. With adoption of the device, the problems of low melting efficiency, high difficulty in control of composition performance consistency and the like of the chalcogenide glass in the prior art are solved effectively, efficient melting and batch preparation of high-quality chalcogenide glass can be realized well, and the practical level of infrared glass is further increased.

Owner:CHINA BUILDING MATERIALS ACAD

A method for producing non-oriented electrical steel by endless rolling of thin slabs

The present application belongs to the technical field of iron and steel, in particular to a method for producing non-oriented electrical steel by endless rolling of thin slabs. The mass percentage of non-oriented electrical steel composition design is: C≤0.0080%, Si≤1.0%, Als≤0.010%, Mn≤0.5%, P≤0.05%, S≤0.008%, N≤0.0080%, the rest are iron and inevitable impurities.

Owner:RIZHAO STEEL HLDG GROUP

Semiconductor device and manufacturing method thereof

ActiveCN103985712BAvoid performance fluctuationsAvoid self-heating effectsTransistorSemiconductor/solid-state device manufacturingGate dielectricElectrical conductor

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Mems piezoresistive pressure sensor with no strain film structure and manufacturing method thereof

InactiveCN102980694BReduce processing difficultyImprove yieldDecorative surface effectsForce measurement using piezo-resistive materialsCrystal orientationEngineering

The invention relates to an MEMS (Micro Electro Mechanical System) piezoresistive pressure transducer without a strain membrane structure. The MEMS piezoresistive pressure transducer comprises four groups of piezoresistors which are manufactured on a substrate and form a Wheatstone bridge, wherein two groups of opposite piezoresistors are arranged along a (100) crystal orientation, and the other two groups of opposite piezoresistors are arranged along a (110) crystal orientation. The manufacture method of the MEMS piezoresistive pressure transducer comprises the following steps: on the front of the substrate, adopting the required dose of the doping concentration of the piezoresistors to carry out P type ion implantation light doping and high temperature thermal annealing; on the front of the substrate, defining the lead contact region of P type heavy doping through photoetching, and carrying out heavy doping and high temperature thermal annealing through ion implantation; manufacturing a lead hole and a metal lead; defining the shape of the piezoresistors and a contact zone through the photoetching, and manufacturing piezoresistor stripes through an etching way; and performing scribing. The pressure transducer does not have the strain membrane structure, can reduce the chip size of the transducer, and can increase the anti-overload ability. The manufacture method is compatible with the process of a standard silicon piezoresistive pressure transducer, so that the cost is low, and the yield is high.

Owner:PEKING UNIV

Steel for large-scale wind power fasteners and manufacturing method thereof

ActiveCN110643881BAvoid performance fluctuationsReduce hardness differenceTemperature control deviceWork heating devicesHardnessUltimate tensile strength

The invention discloses a steel for large-scale wind power fasteners, the elemental composition of which is: C: 0.38-0.45%, Si: 0.20-0.35%, Mn: 0.60-0.80%, P≤0.015%, S≤0.010%, Cr: 0.95‑1.20%, Mo: 0.18‑0.30%, Ni: 0.10‑0.25%, Nb: 0.02‑0.08%, Al: 0.020‑0.050%, N≤0.008%, and the balance is Fe and Unavoidable impurities; after heat treatment, the core of the steel has more than 90% martensitic structure, the surface hardness difference of the core is small, especially the low temperature impact performance is relatively excellent, it has good mechanical properties, and the tensile properties meet the strength of 10.9 It can meet the user's processing and use requirements for 48mm-65mm large-scale wind power fastener steel.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com