Patents

Literature

138results about How to "Improve slipperiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing microparticles of polylactic acid-based resin, microparticles of polylactic acid-based resin and cosmetic using same

ActiveCN103201319AEasy to manufactureHigh oil absorptionCosmetic preparationsMake-upMicroparticleSolvent

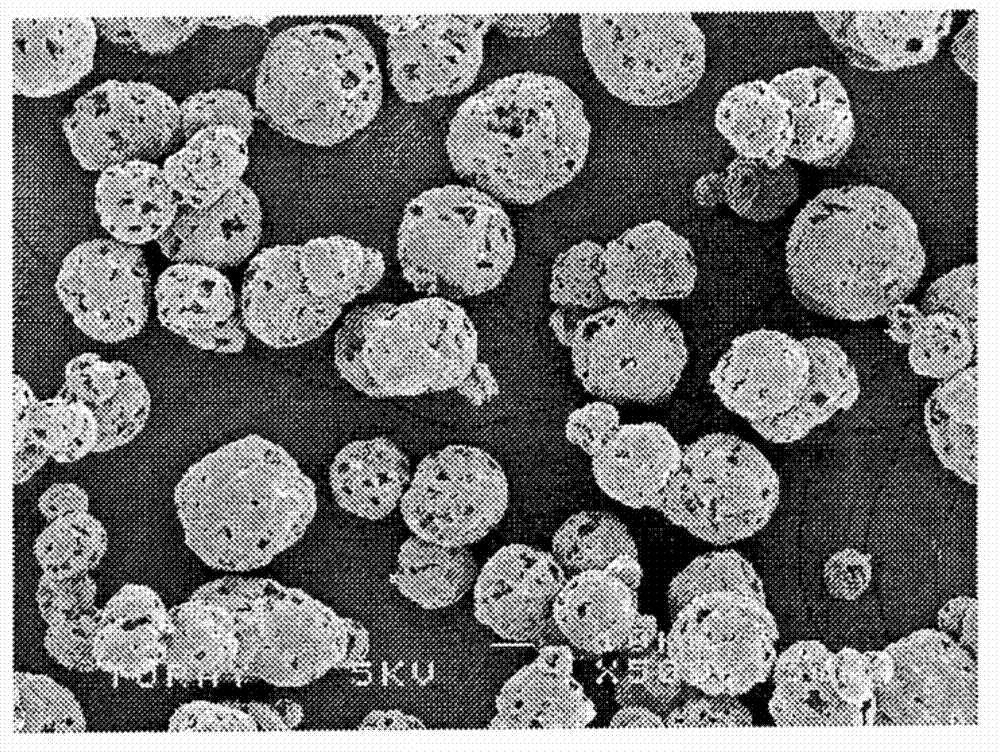

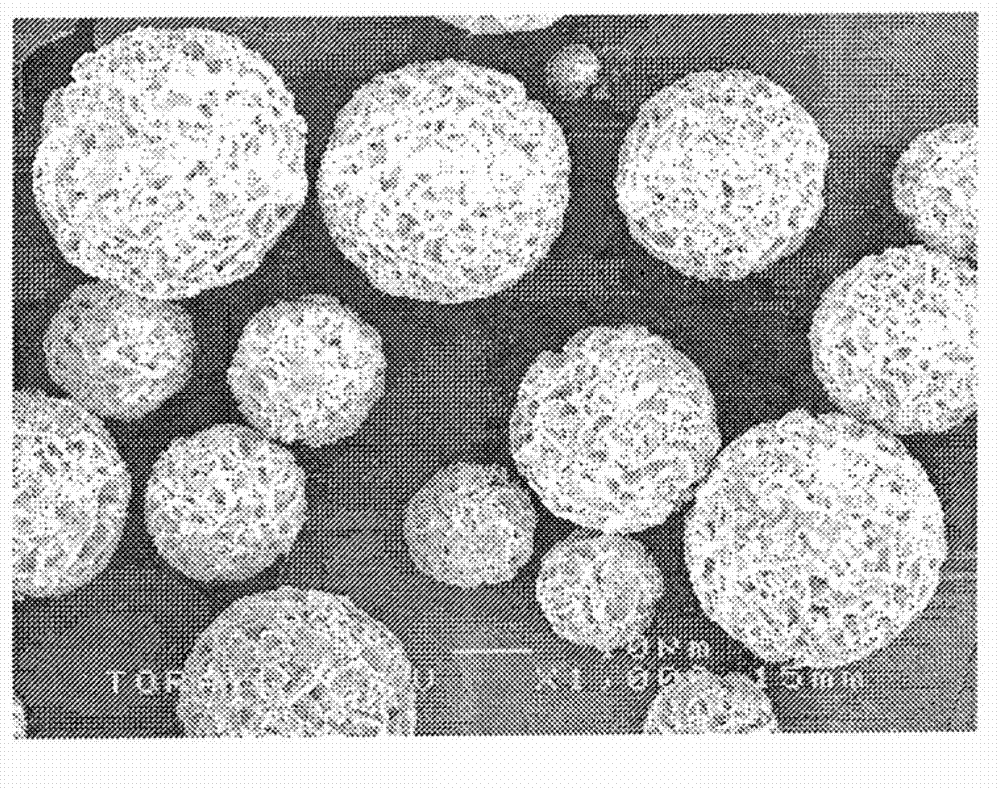

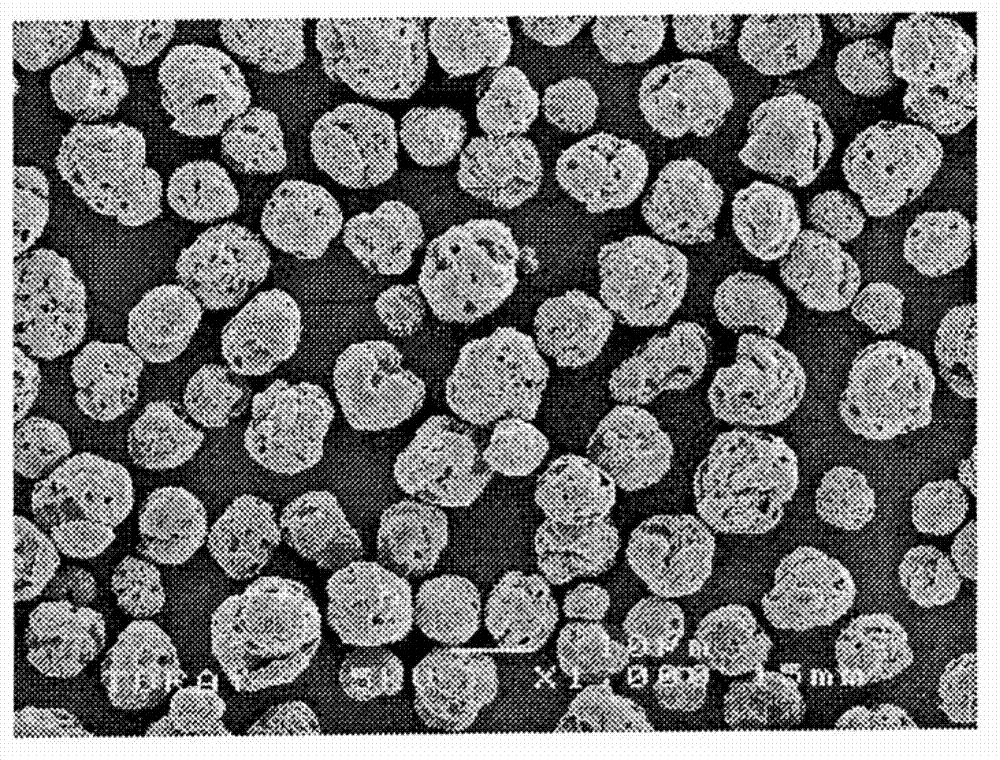

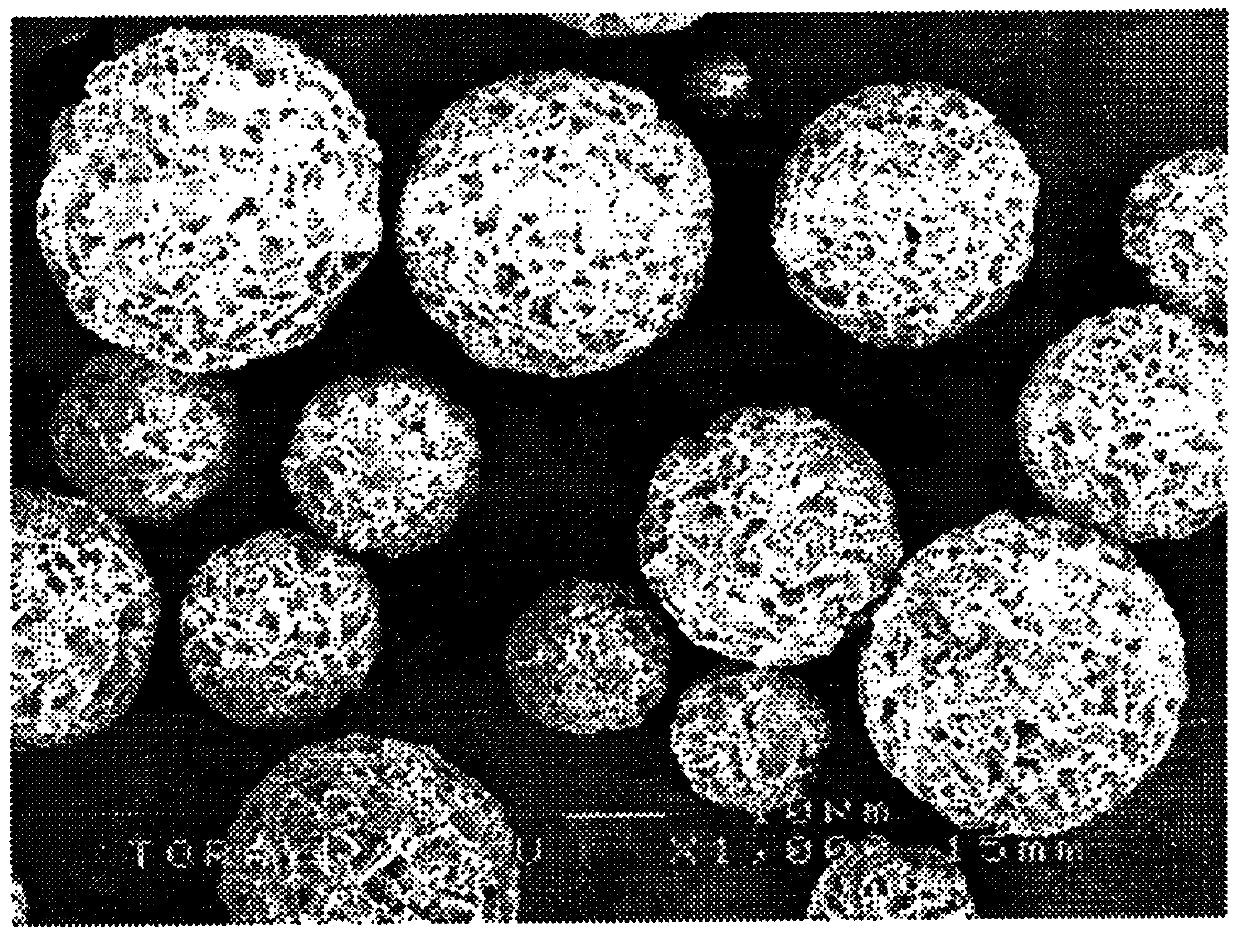

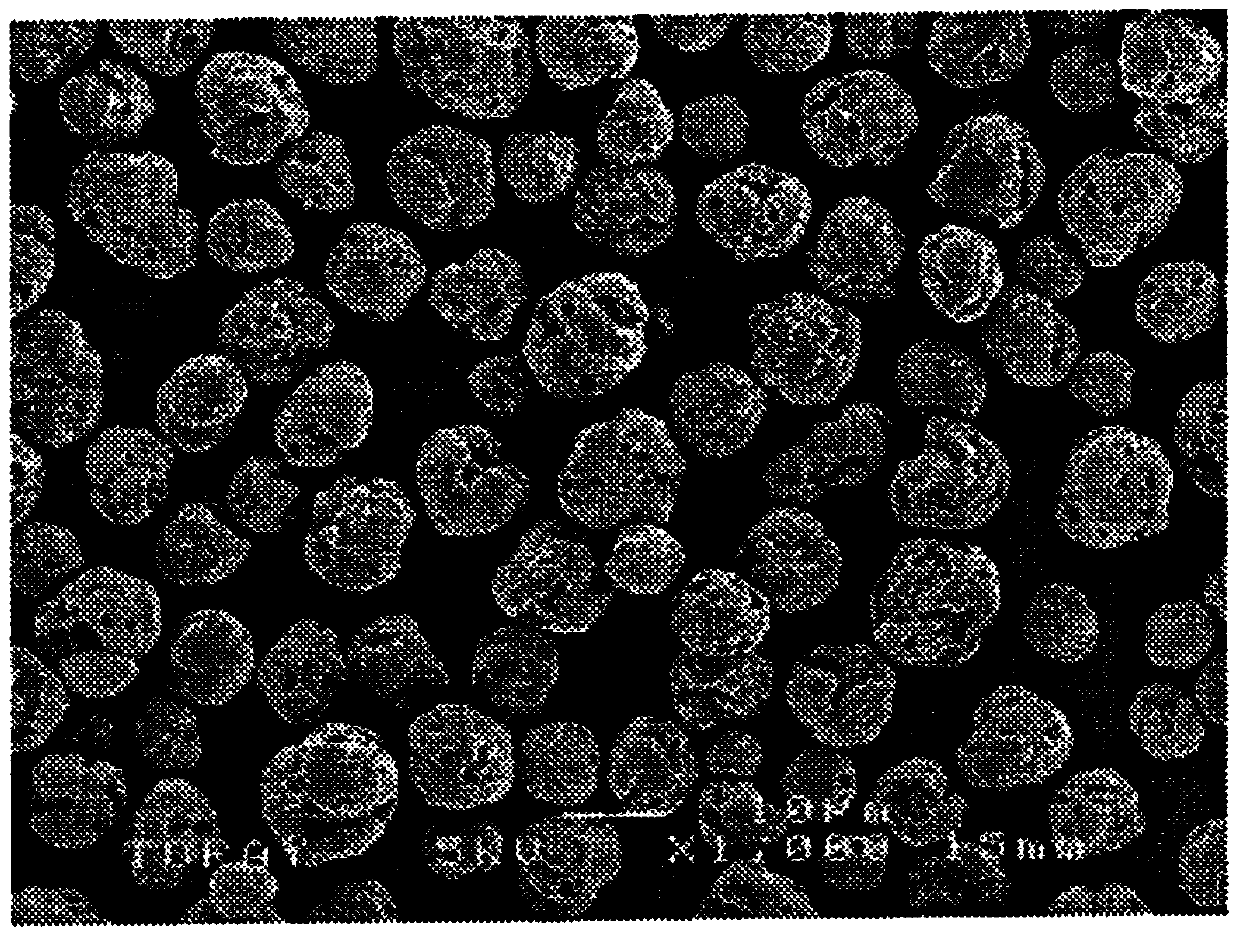

Provided are: a method for producing microparticles of a polylactic acid-based resin; porous microparticles of a polylactic acid-based resin, said microparticles having a small particle diameter, showing a high oil absorption ability and being appropriately usable for cosmetics; smooth-surfaced microparticles of a polylactic acid-based resin, said microparticles having a spherical form, showing a narrow particle diameter distribution and being appropriately usable for toners; and a cosmetic using the aforesaid microparticles of a polylactic acid-based resin. The method for producing microparticles of a polylactic acid-based resin comprises: dissolving a polylactic acid-based resin (A) and a polymer (B), which is different from polylactic acid-based resins, in an ether-type organic solvent (C); applying a shear force thereto to form an emulsion; and then contacting the emulsion with a poor solvent of the polylactic acid-based resin (A). According to this production method, porous microparticles of the polylactic acid-based resin, said microparticles having a fusion enthalpy of the polylactic acid-based resin (A) of 5 J / g or greater, having a small particle diameter and showing a high oil absorption ability, and smooth-surfaced microparticles of the polylactic acid-based resin, said microparticles having a fusion enthalpy less than 5 J / g, having a spherical form and showing a narrow particle diameter distribution, can be provided.

Owner:TORAY IND INC

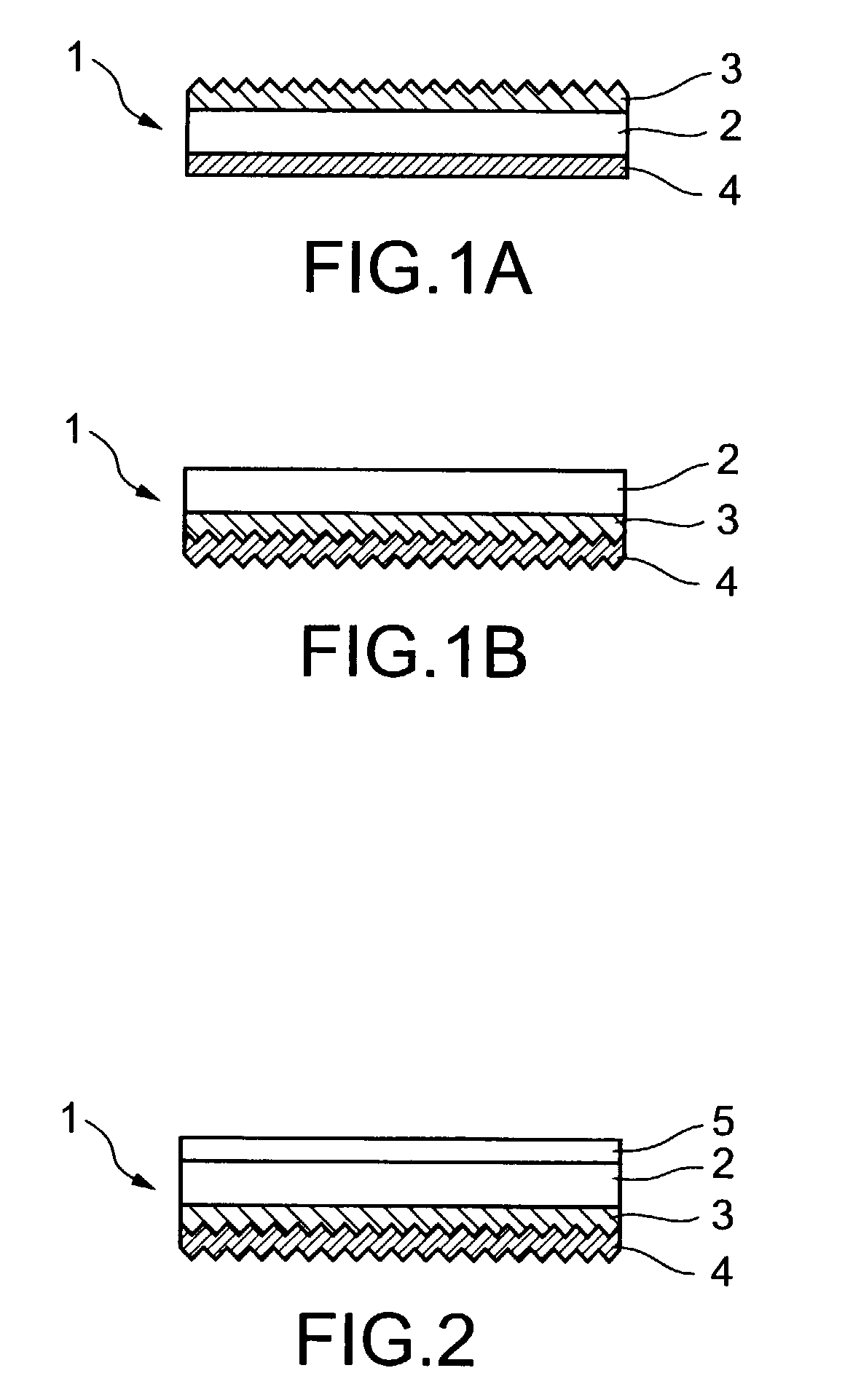

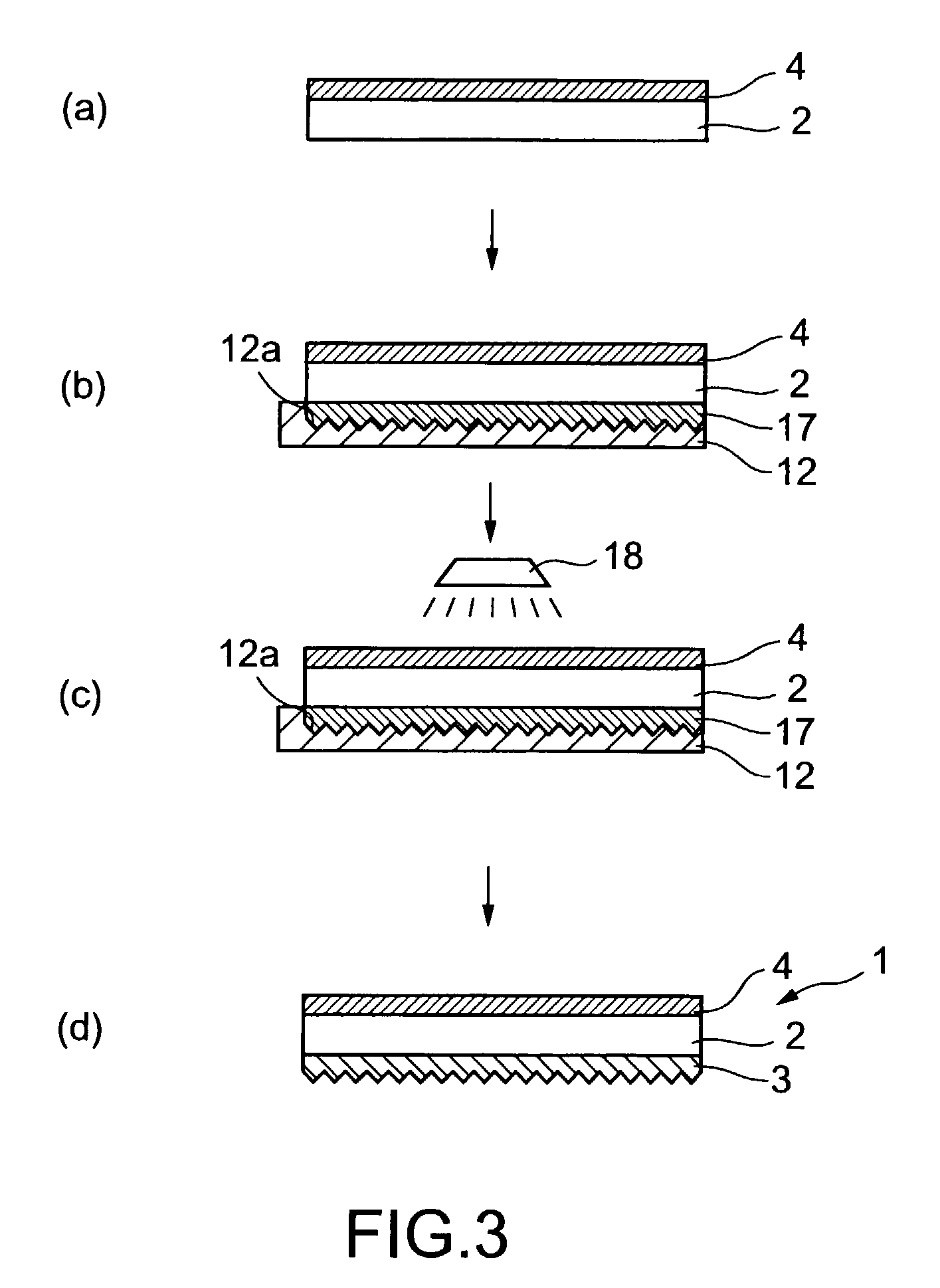

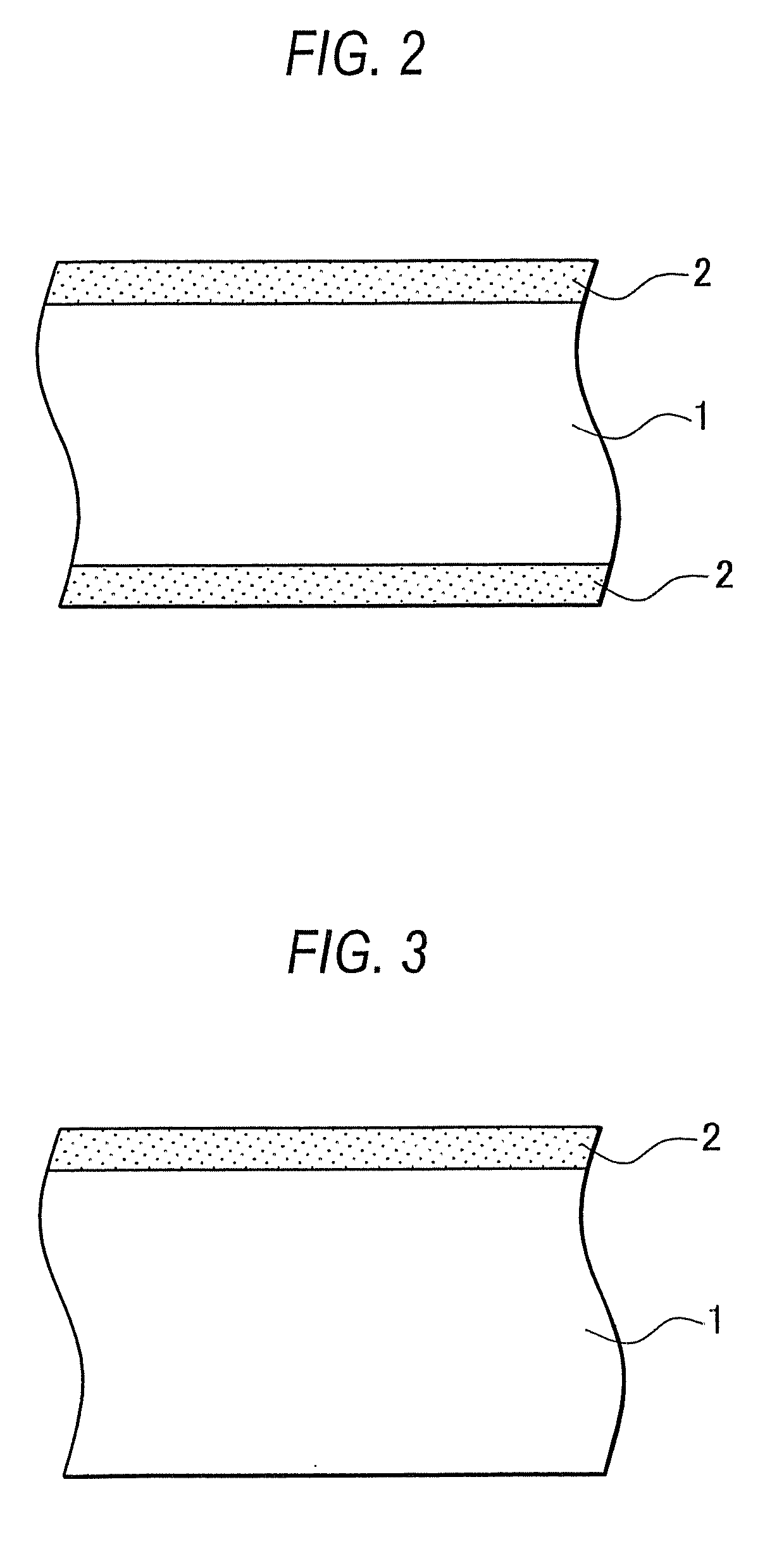

Transparent conductive film

InactiveUS6987354B2Good slipperinessEasy to produceConductive layers on insulating-supportsDischarge tube luminescnet screensTransparent conducting filmEngineering

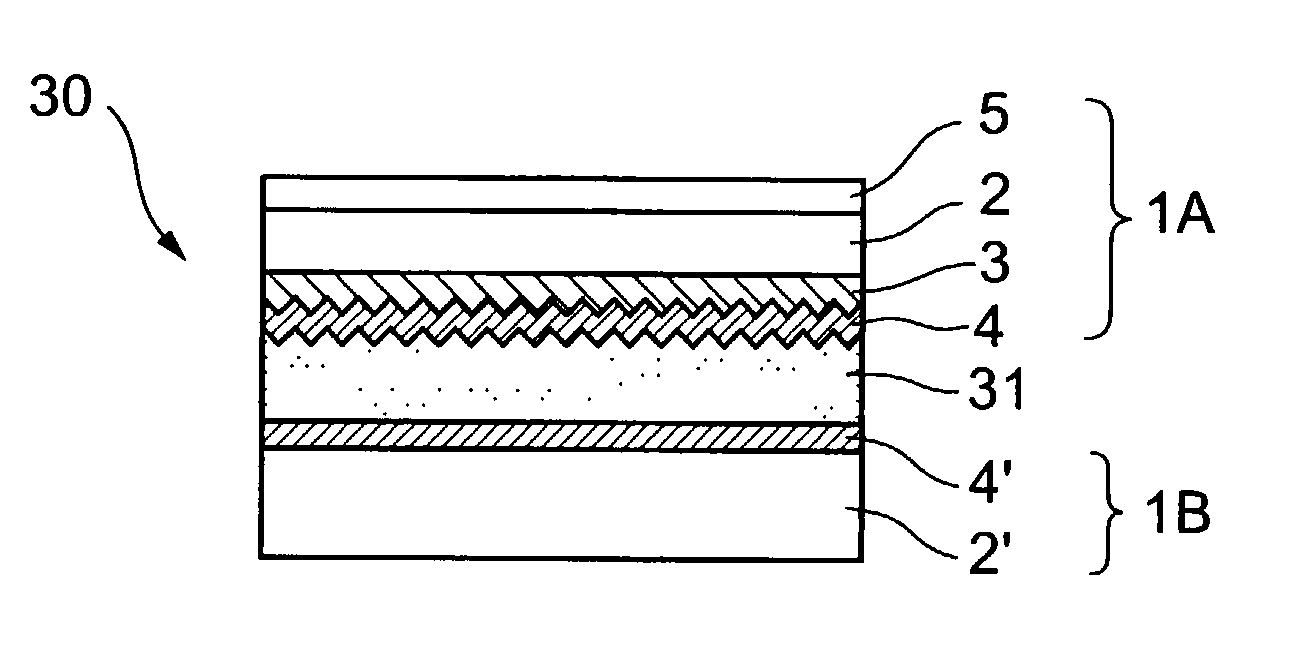

A transparent conductive film 1 comprises a transparent plastic film 2 and a transparent conductive layer 4 laminated to at least one surface of the transparent plastic film 2. The transparent conductive film 1, as a whole, has a haze value of 8 or less; and at least one of the two surfaces of the transparent plastic film 2, that is, the surface to which the transparent conductive film 4 is laminated and the other surface, is provided with fine irregularities having a maximum height (Rmax) of 0.5 to 2.0 μm. These fine irregularities preferably have a ten-point mean roughness (Rz) of 0.35 to 1.5 μm. The fine irregularities maybe provided as the surface structure of a fine irregularity layer 3 laminated to one surface of the transparent plastic film 2. The transparent conductive layer 4 may be laminated to the surface of the fine irregularity layer 3 formed on the transparent plastic film 2, or to the surface of the transparent plastic film 2 to which the fine irregularity layer 3 is not laminated.

Owner:DAI NIPPON PRINTING CO LTD

High-flowability elastic powder for 3D printing and preparation method of high-flowability elastic powder

The invention provides high-flowability elastic powder for 3D printing. The high-flowability elastic powder is characterized in that nano molybdenum disulfide modified elastic powder is adopted, and the high-flowability elastic powder is prepared from materials in parts by weight as follows: 100 parts of polyurethane resin, 10-20 parts of a solid flowable agent, 5-10 parts of inorganic filler, 1-5 parts of a lubricating agent and 0.5-2 parts of a coupling agent. Materials are dried by a vacuum drying box and uniformly mixed by a coulter type mixing machine, molybdenum disulfide is attached to the surface of the elastic powder after the mixture is dried by a spray drier, products have good uniformity and flowability, the particle diameters are uniform, the mechanical performance is excellent, and 3D printing of the elastic powder is realized; the production process is simplified, and operation and control are convenient.

Owner:福建慧思通三维技术有限公司

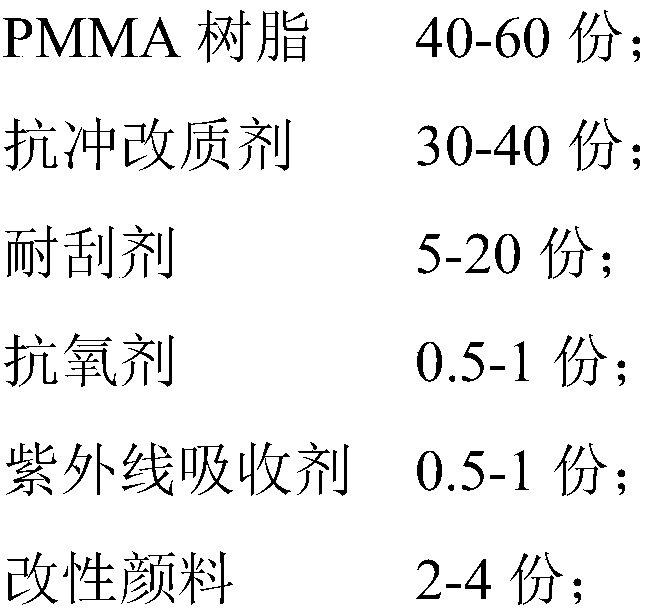

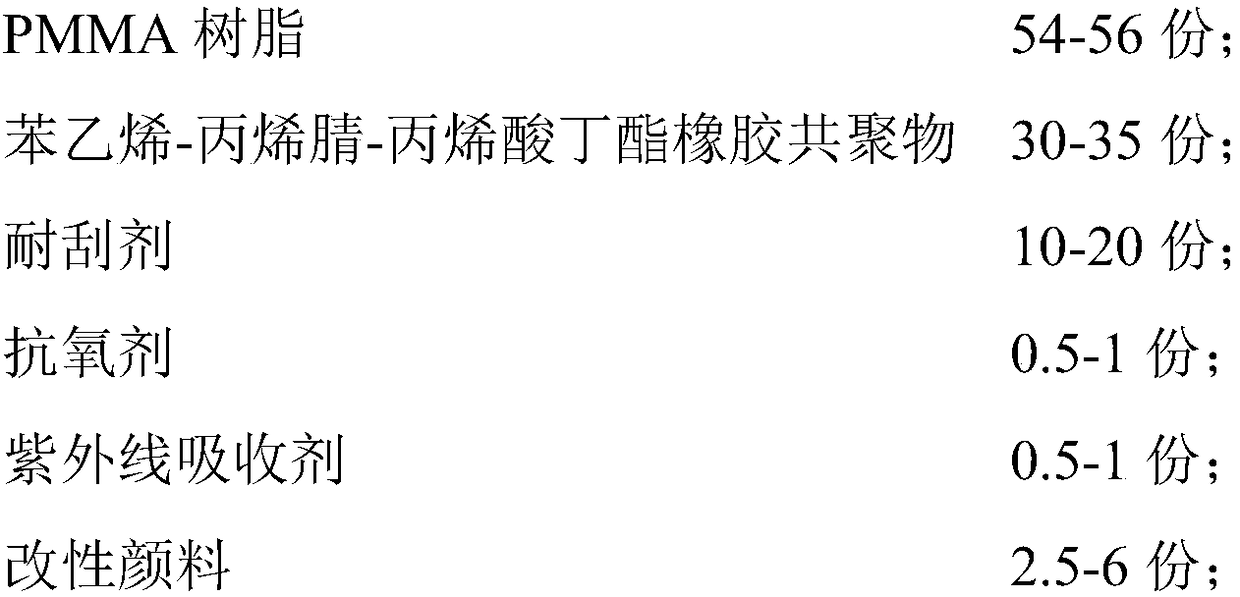

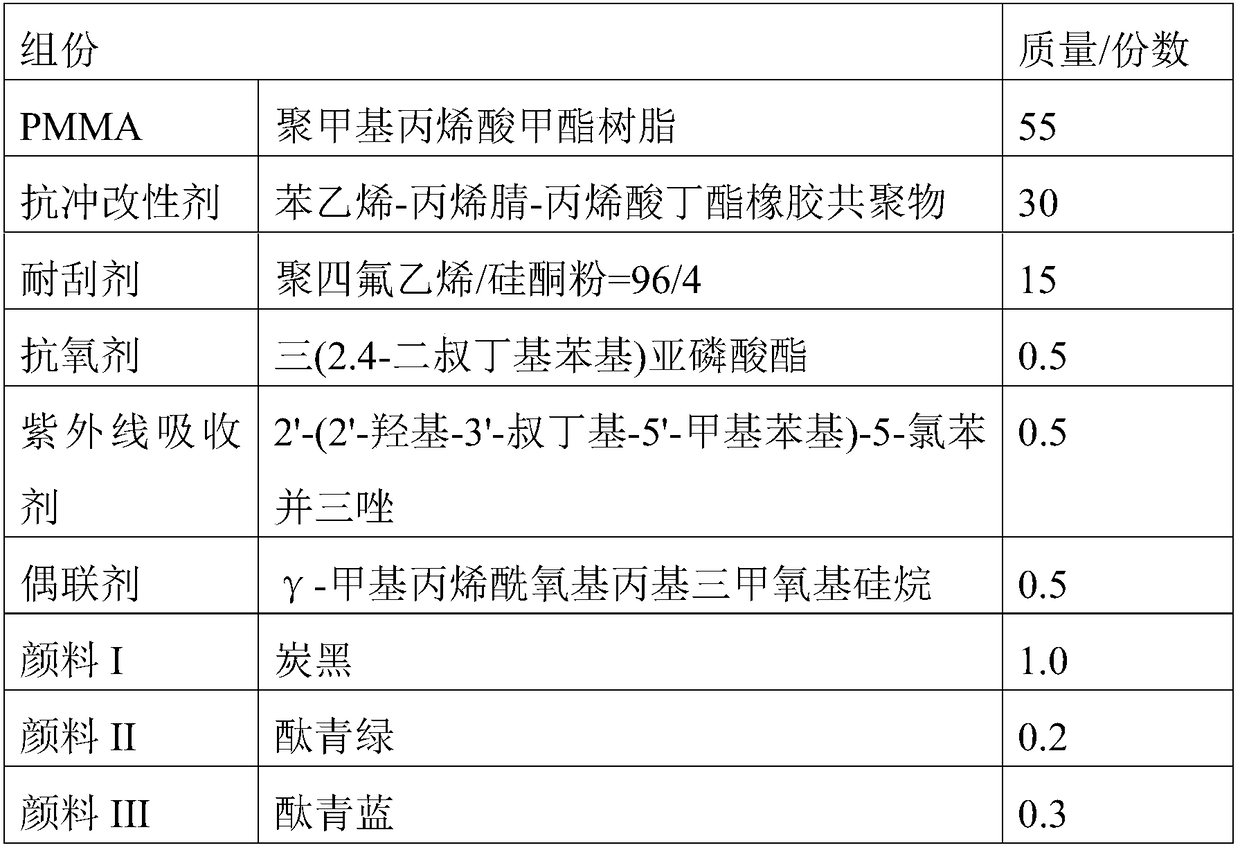

Spray-free, high-weather-resistant and scratch-resistant PMMA material and preparation method thereof

The invention relates to a spray-free, high-weather-resistant and scratch-resistant PMMA material and a preparation method thereof. The PMMA material comprises, by mass, the following raw materials: 40-60 parts of PMMA resin; 30-40 parts of an impact modifier; 5-20 parts of a scratch-resistant agent; 0.5-1 part of an antioxidant; 0.5-1 part of an ultraviolet absorbent; 2-4 parts of modified pigment; the scratch-resistant agent is prepared from, by mass, 95-98 parts of fluororesin and 2-5 parts of silicone powder. The PMMA material has excellent weather resistance and scratch resistance, and can meet the quality requirements of automobile exterior parts on the weather resistance and the scratch resistance.

Owner:FOSHAN KAIYUE GRAND SKY PLASTIC TECH CO LTD

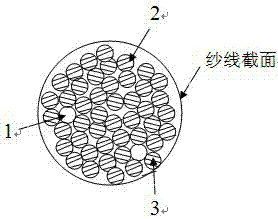

Flame-retardant antistatic yarn and fabric thereof

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Frozen dumpling modifying agent, preparation method thereof and application

InactiveCN101744021AImprove dough sticking rollerImprove sticking phenomenonDough treatmentPre-baking dough treatmentFreeze thawingEnzyme

The invention belongs to the technical field of frozen dumpling processing by additives, in particular to a frozen dumpling modifying agent, a preparation method thereof and application. The frozen dumpling modifying agent is prepared from the following components in percentage by weight via mixing: 35 to 42 parts of active soybean meal, 25 to 38 parts of konjaku flour, 5 parts of complex enzyme, 8 to 12 parts of carrageenin and 10 to 20 parts of modified starch. The modifying agent can adapt to the process requirements of the mechanized production of the frozen dumplings, improve the quality of finished products of the frozen dumplings, effectively improve the mechanical stirring resistance degree of the flour dough of the frozen dumplings, reduce the roll adhesion phenomenon of cheeks during the mechanized production, can simultaneously improve the boil resistance performance, the smooth performance and the freeze-thaw stability of the frozen dumplings, and improve the external appearance and the mouth feeling of the frozen dumplings.

Owner:河南兴泰科技实业有限公司

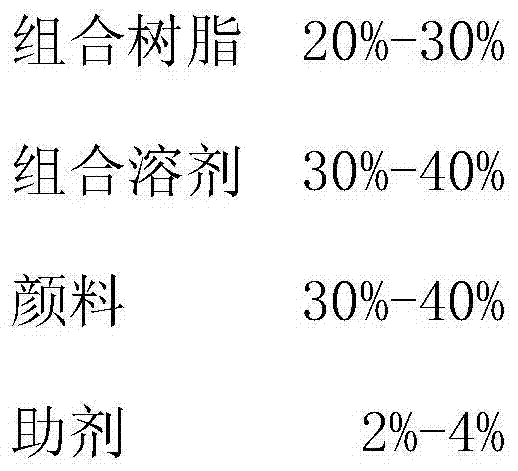

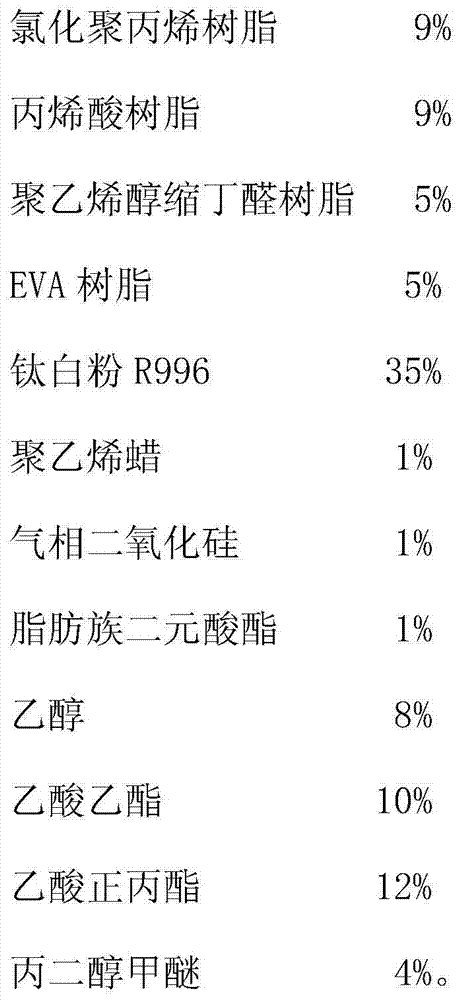

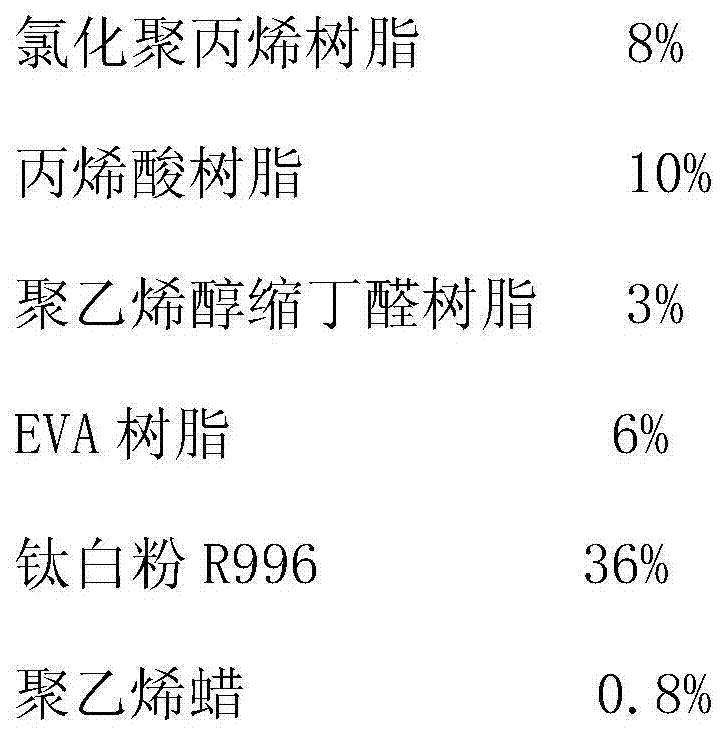

Environment-friendly white printing ink for printing of POF thermal contraction film and preparation method of white printing ink

ActiveCN104263075AImprove wear resistanceSlip efficiency solutionInksEnvironmental resistanceMass ratio

The invention discloses an environment-friendly white printing ink for printing of POF thermal contraction film and a preparation method of the environment-friendly white printing ink. The printing ink consists of the following components in percentage by weight: 20-30% of composite resin, 30-40% of a composite solvent, 30-40% of pigment and 2-4% of a auxiliary, wherein composite resin consists of chlorinated polypropylene resin, acrylic resin, polyvinyl butyral resin and EVA resin in mass ratio of (8-10): (8-10): (3-6): (3-6). After the printing ink cooperates with a POF thermal contraction film for printing, the printed film does not stick back and cause a filling-in phenomenon; printed products are environment-friendly, safe, non-toxic and recyclable; after the printing, the contraction film has strong wear resistance and smoothing property; the shallow version transfer property is excellent; the level reproducibility is good; excellent drying property, kneading resistance and good adhesion are provided; the adhesive force is improved by more than 20%; the blocking resistance is good; the printed products can be reeled; the scraper performance is good; images and texts after the printing do not fade and fall off.

Owner:CHENGDU PRESSTER NEW MATERIALS

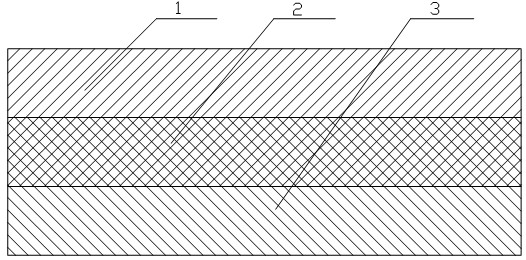

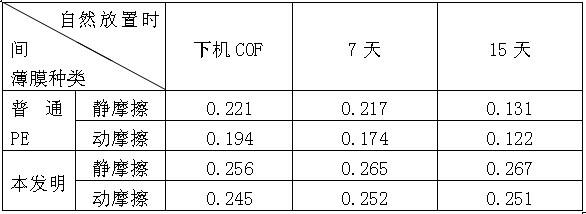

Highly-smooth polyethylene film and manufacturing method thereof

InactiveCN102673060AEvenly distributed and stableHigh Slippery Coefficient of FrictionFlexible coversWrappersHigh-density polyethyleneLow-density polyethylene

The invention discloses a highly-smooth polyethylene film and a manufacturing method thereof. The highly-smooth polyethylene film comprises an outer layer, a middle layer and an inner layer. The outer layer is made of, by weight ratio, 10:90-90:10 of low-density polyethylene and linear low-density polyethylene. The middle layer is made of, by weight ratio, 10:90-90:10 of low-density polyethylene and linear low-density polyethylene. The inner layer is made of, by weight ratio, 50:50:0.5-50:50:10 of low-density polyethylene, linear low-density polyethylene and anti-plastering agents. The manufacturing method includes mixing the outer layer, the middle layer and the inner layer by a quantitative batcher, adding the layers to an extruder to be subjected to plastifying extrusion, extruding the layers into film tubes by triple coextrusion die heads, and wrapping up the layers after the layers are blown up. Compared with the prior art, the highly-smooth polyethylene film is more precise and stable in friction coefficient and well solves the problems of slipping of composite films on a package machine and slipping agent precipitation.

Owner:浙江粤海包装新材料有限公司

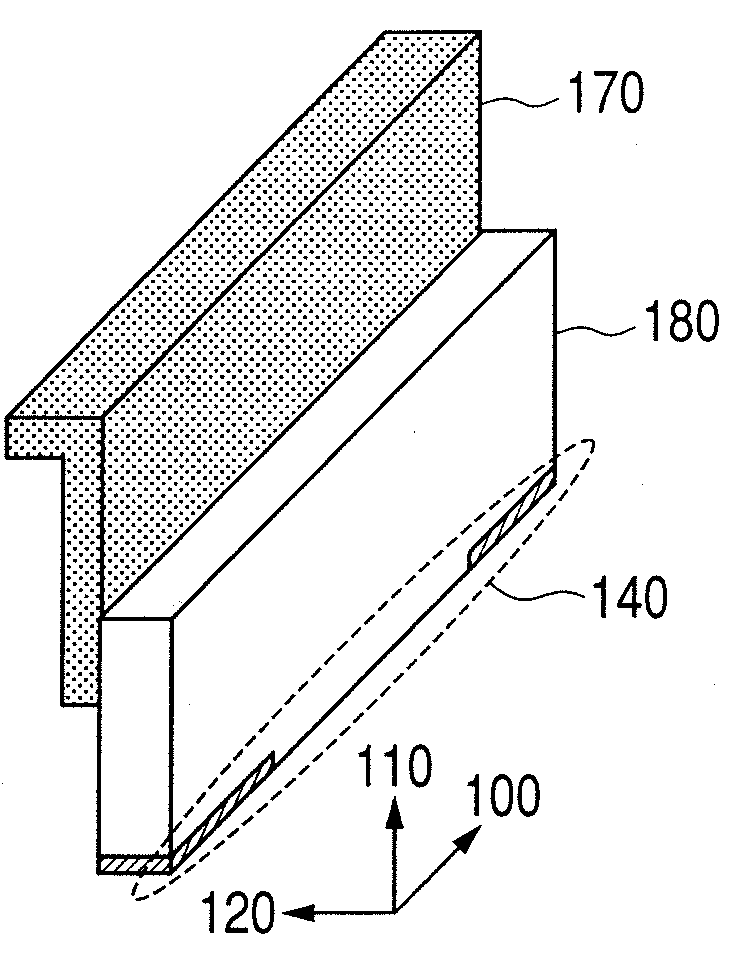

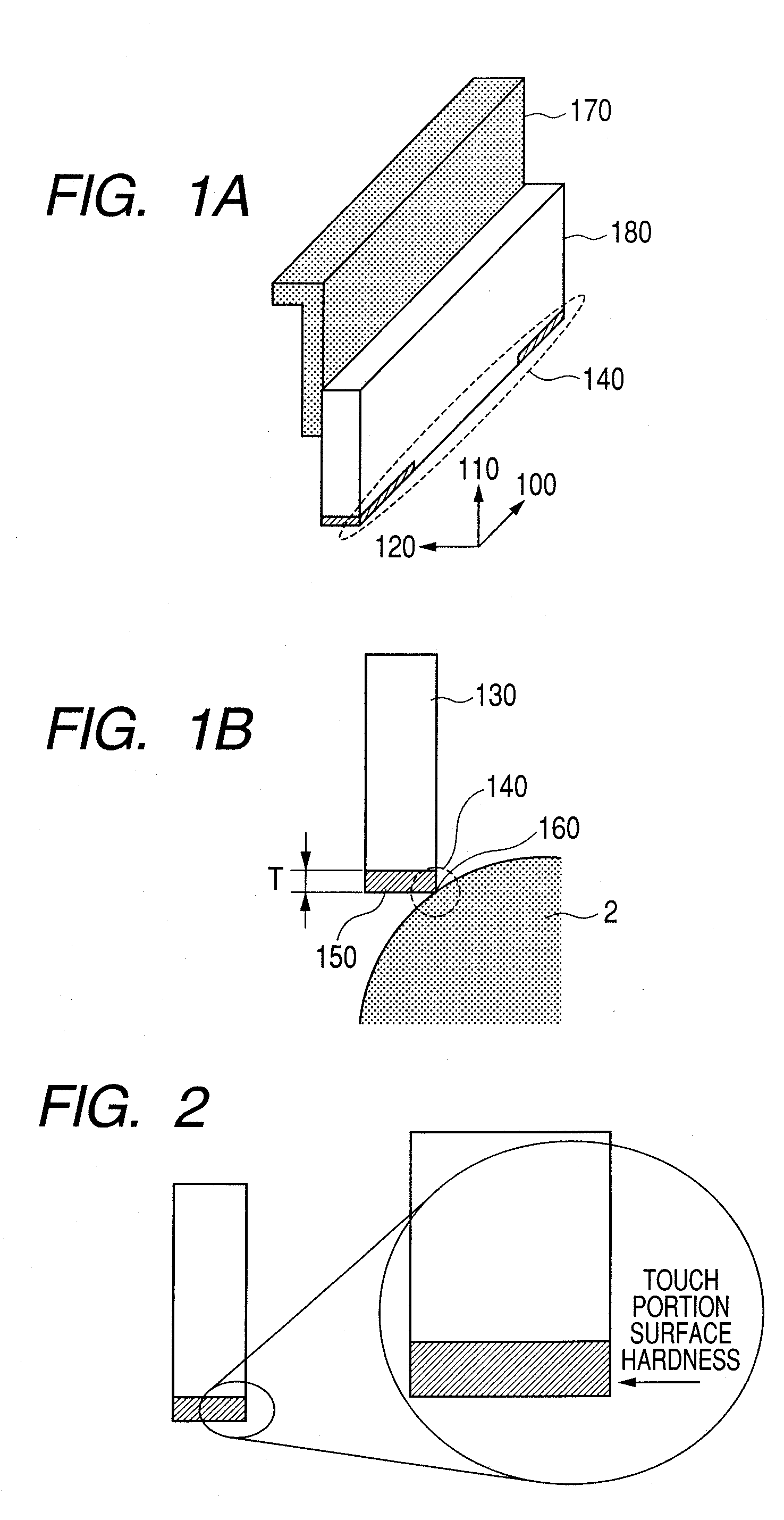

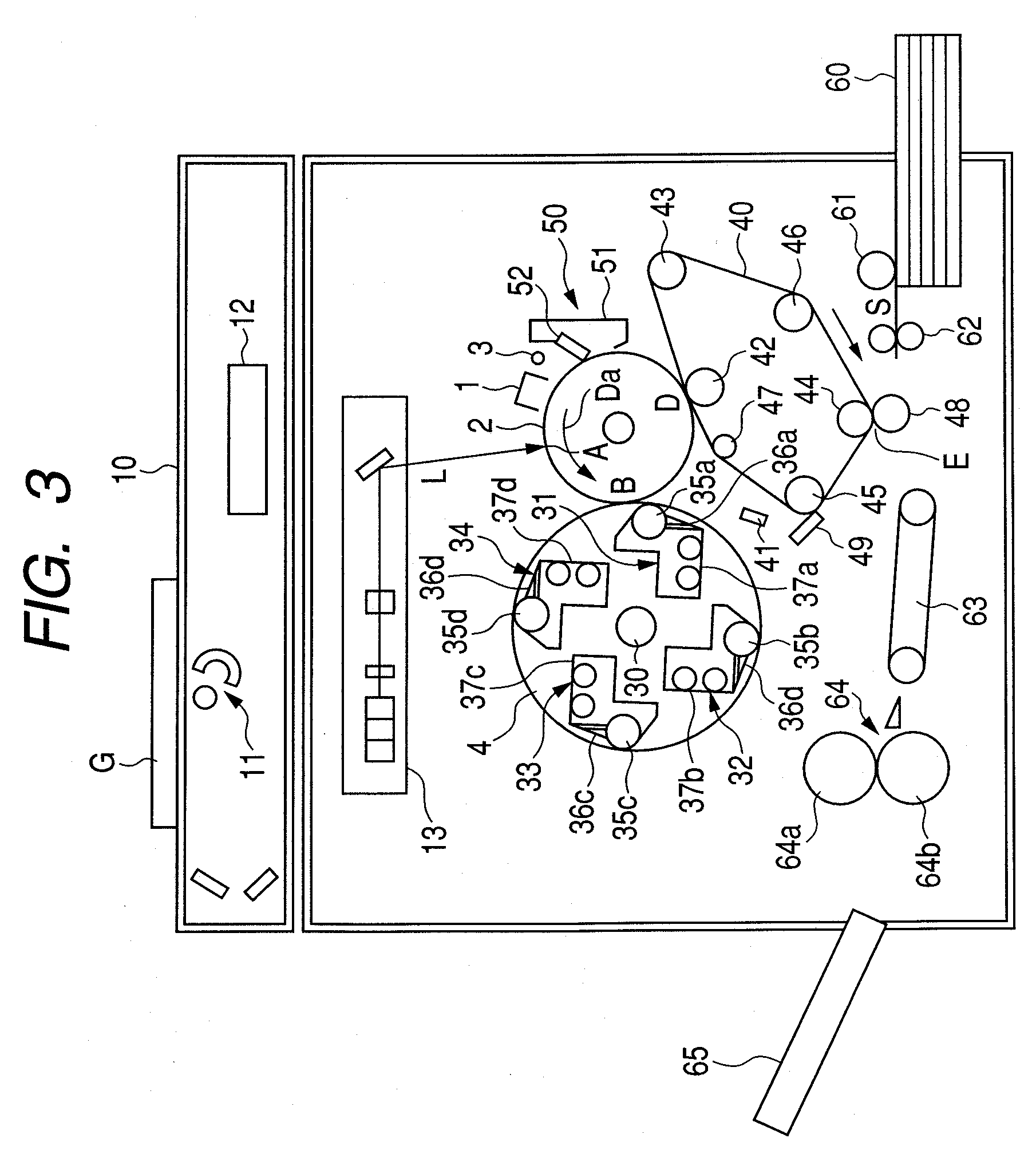

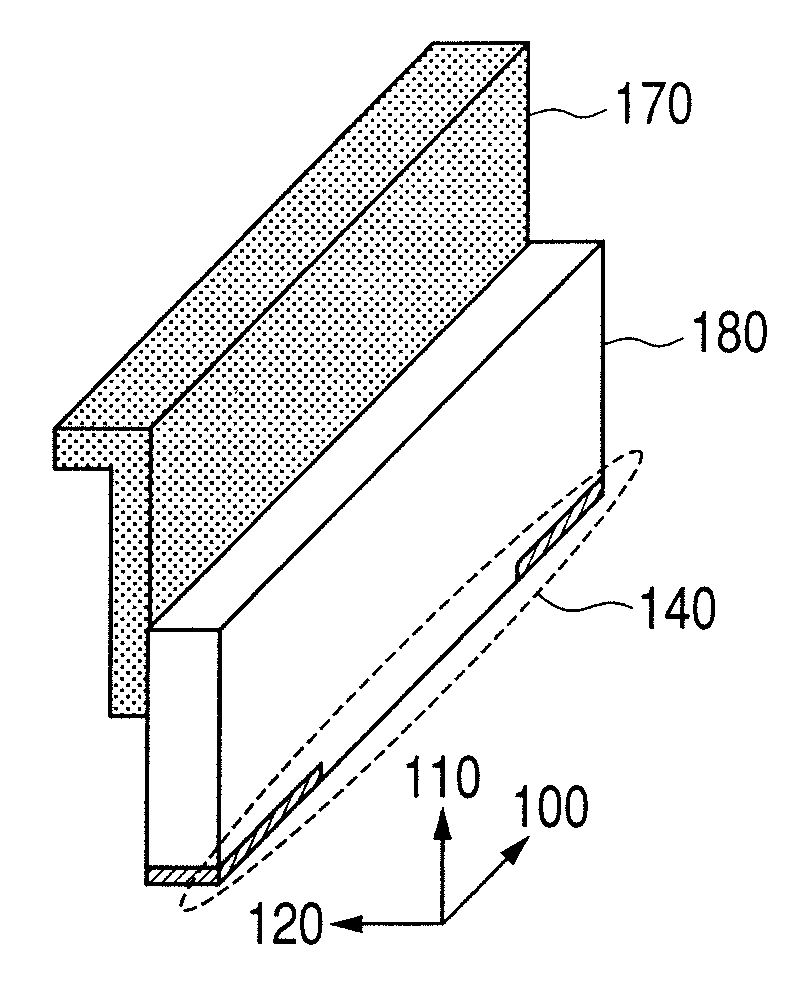

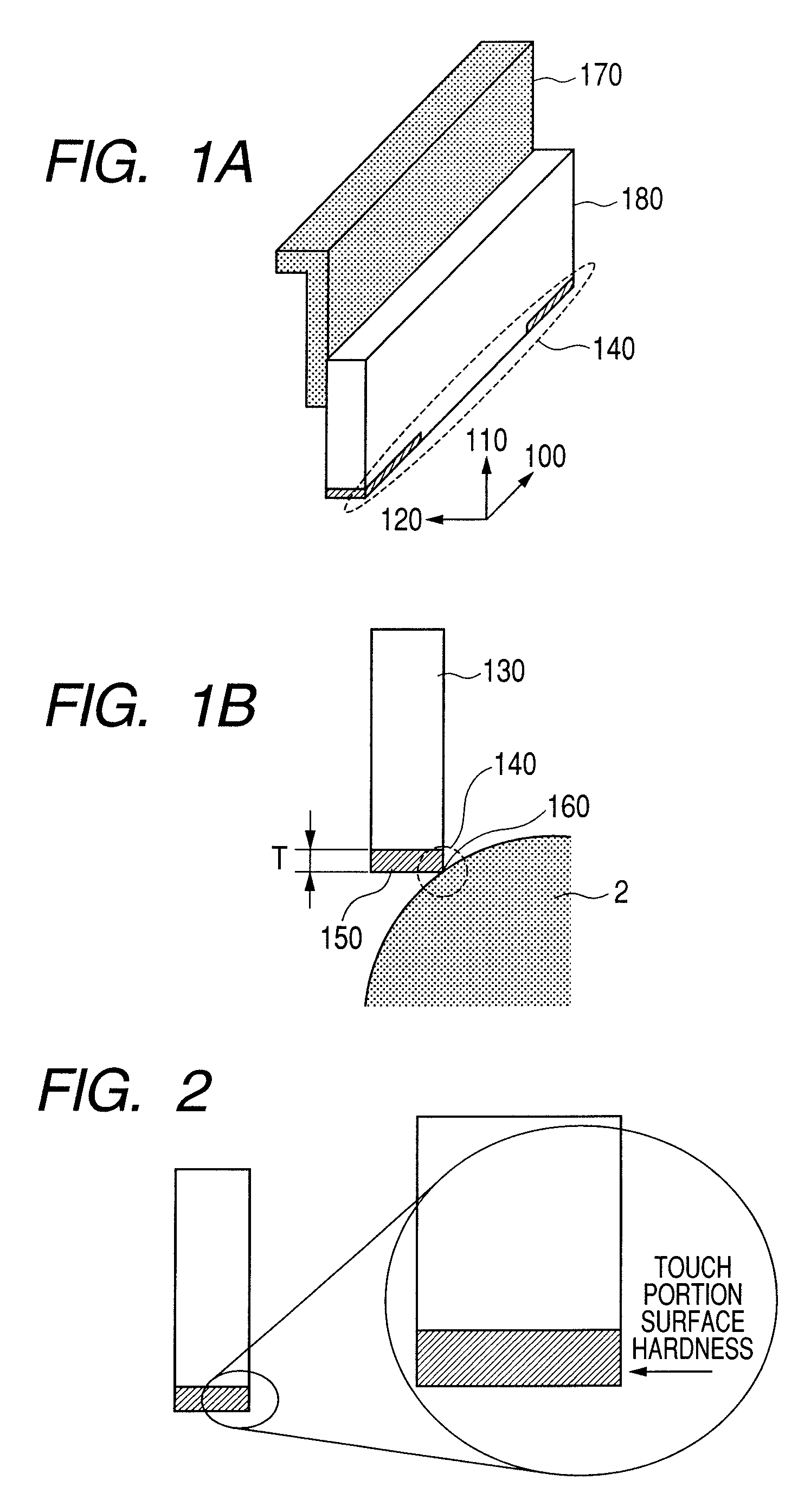

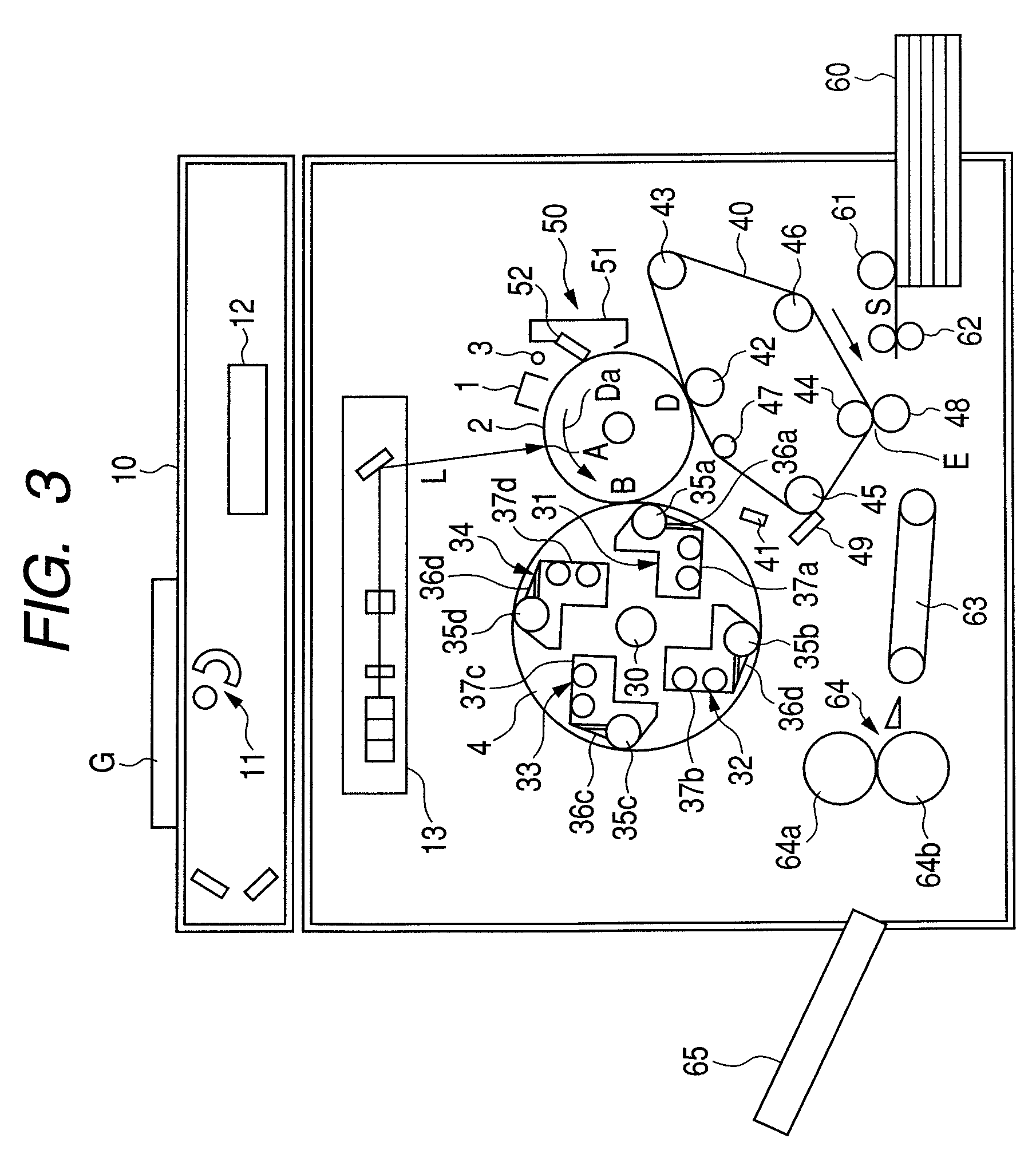

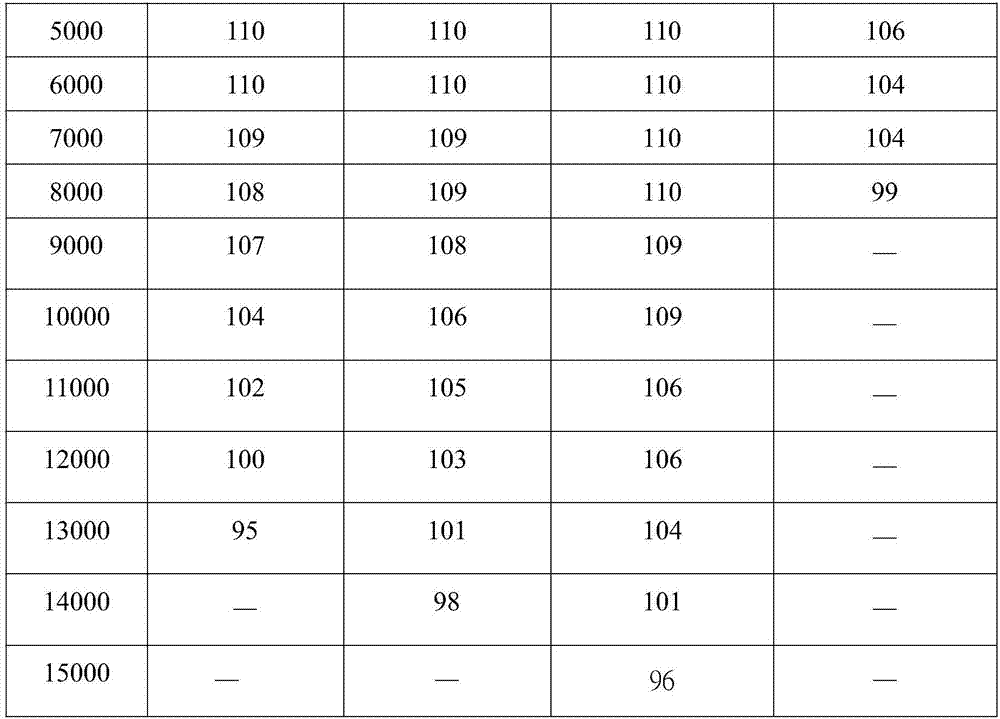

Electrophotographic cleaning blade, process for producing electrophotographic cleaning blade, and electrophotographic apparatus

An electrophotographic cleaning blade is provided which is free of blade turning-up coming from both end portions of the blade in its lengthwise direction. The cleaning blade having a blade formed of a polyurethane resin, which is to come into touch with the surface of a photosensitive drum of an electrophotographic apparatus to remove a toner remaining thereon, and a support member which holds the blade. The blade has a polyurethane resin portion having a dynamic hardness of 0.05 mN / μm2 or more and 0.16 mN / μm2 or less and a high-hardness portion having a dynamic hardness 1.3 times or more and 30 times or less the dynamic hardness of the polyurethane resin portion, provided at each end portion of the blade in its lengthwise direction at its part coming into touch with the photosensitive drum.

Owner:CANON KK

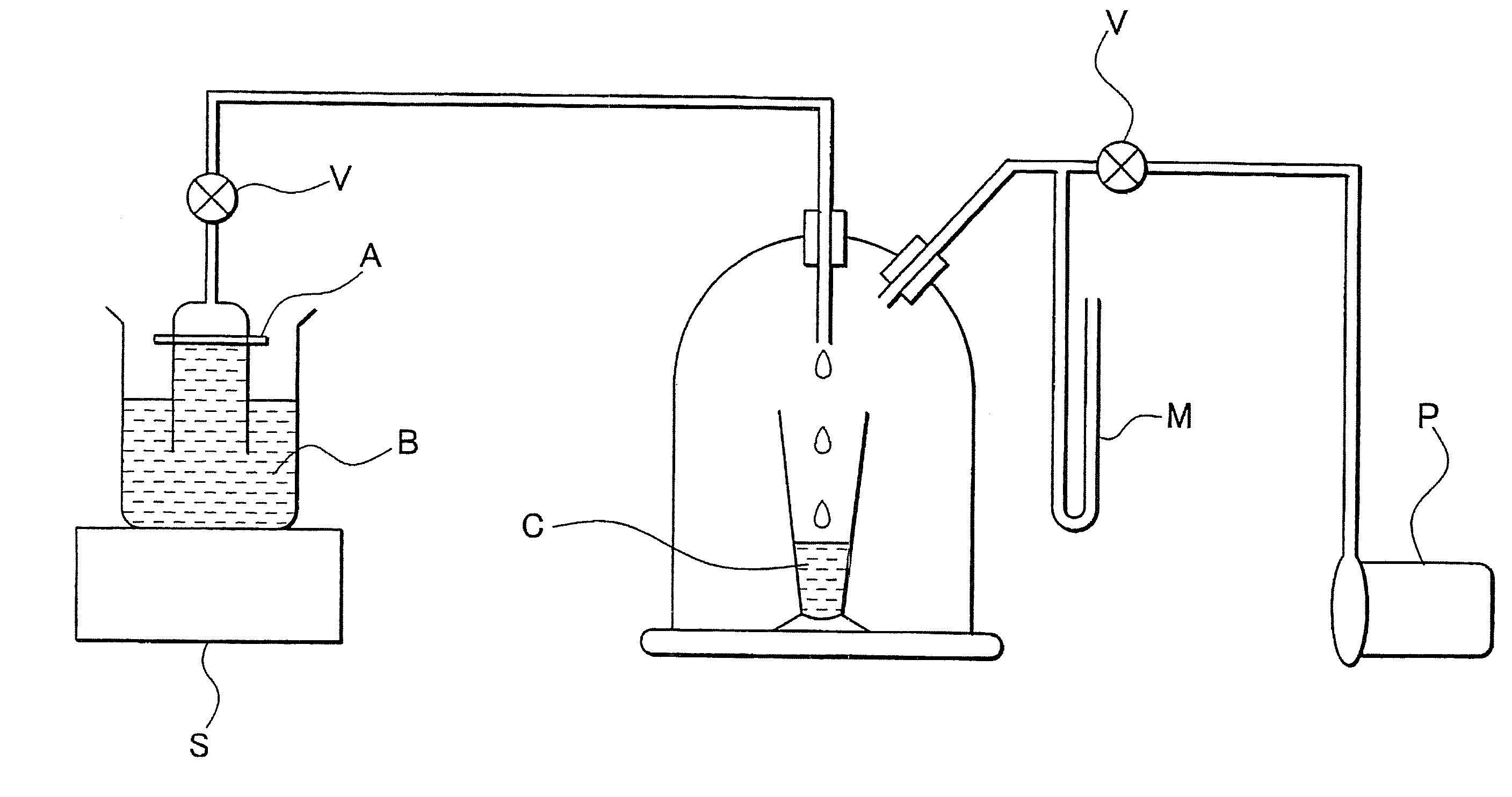

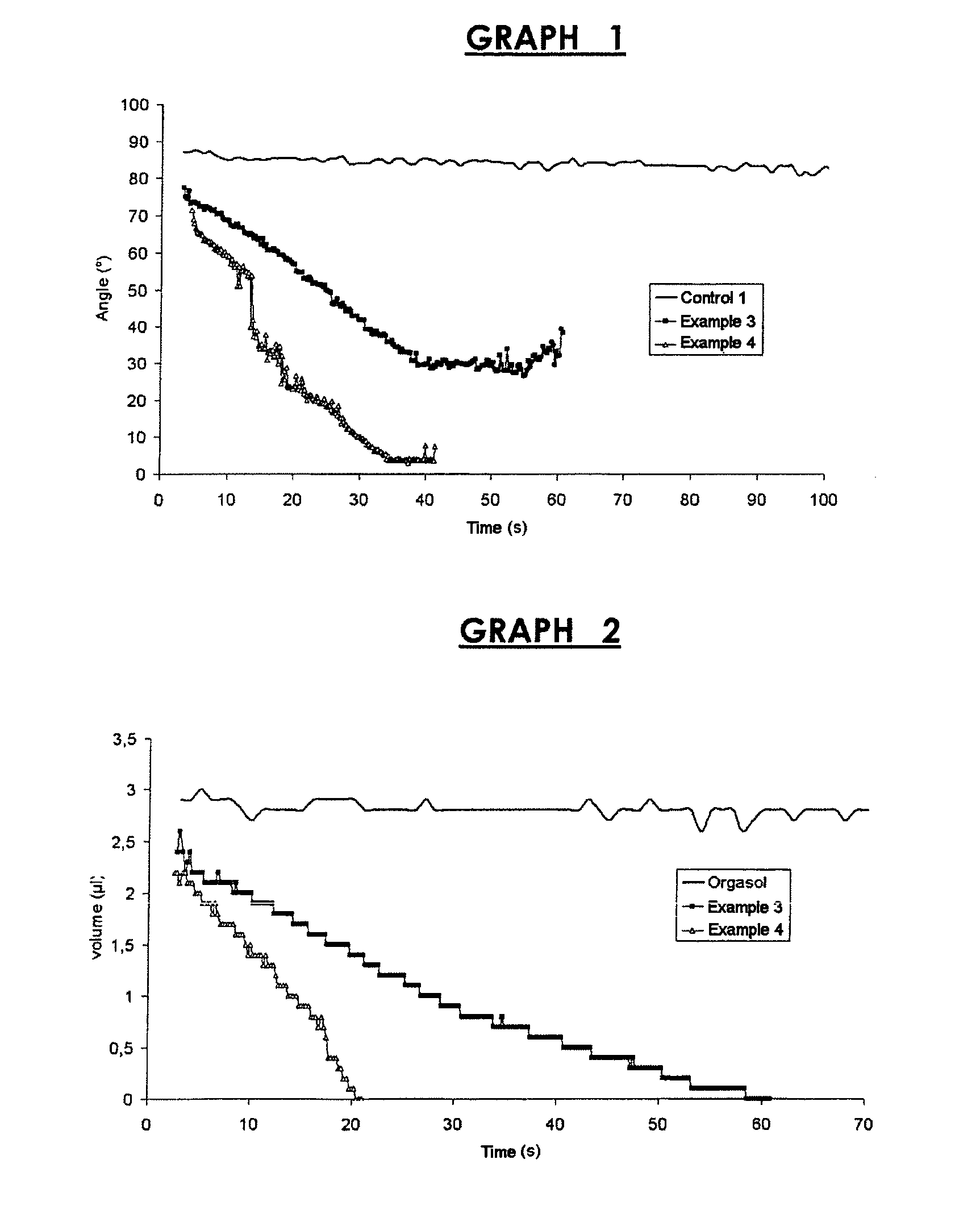

Method of Producing Cyclic Polyolefin Film, Cyclic Polyolefin Film Produced by the Production Method, Method of Preparing Liquid Dispersion of Fine Particles, Liquid Dispersion of Fine Particles and Method of Preparing Dope

InactiveUS20090081387A1Good slipperinessReduced frictional injury damageLiquid crystal compositionsSynthetic resin layered productsOrganic solventPolymer science

A method of producing a cyclic polyolefin film comprising: dissolving or dispersing a cyclic polyolefin resin and at least one compound selected from a higher fatty acid and a derivative of the higher fatty acid in a solvent; a casting step; a drying step; and a taking-up step; and a method of preparing a liquid dispersion of fine particles, which comprises: subjecting fine particles, an organic solvent and a dispersant to a dispersing treatment, wherein the dispersant contains a cyclic olefin resin.

Owner:FUJIFILM CORP

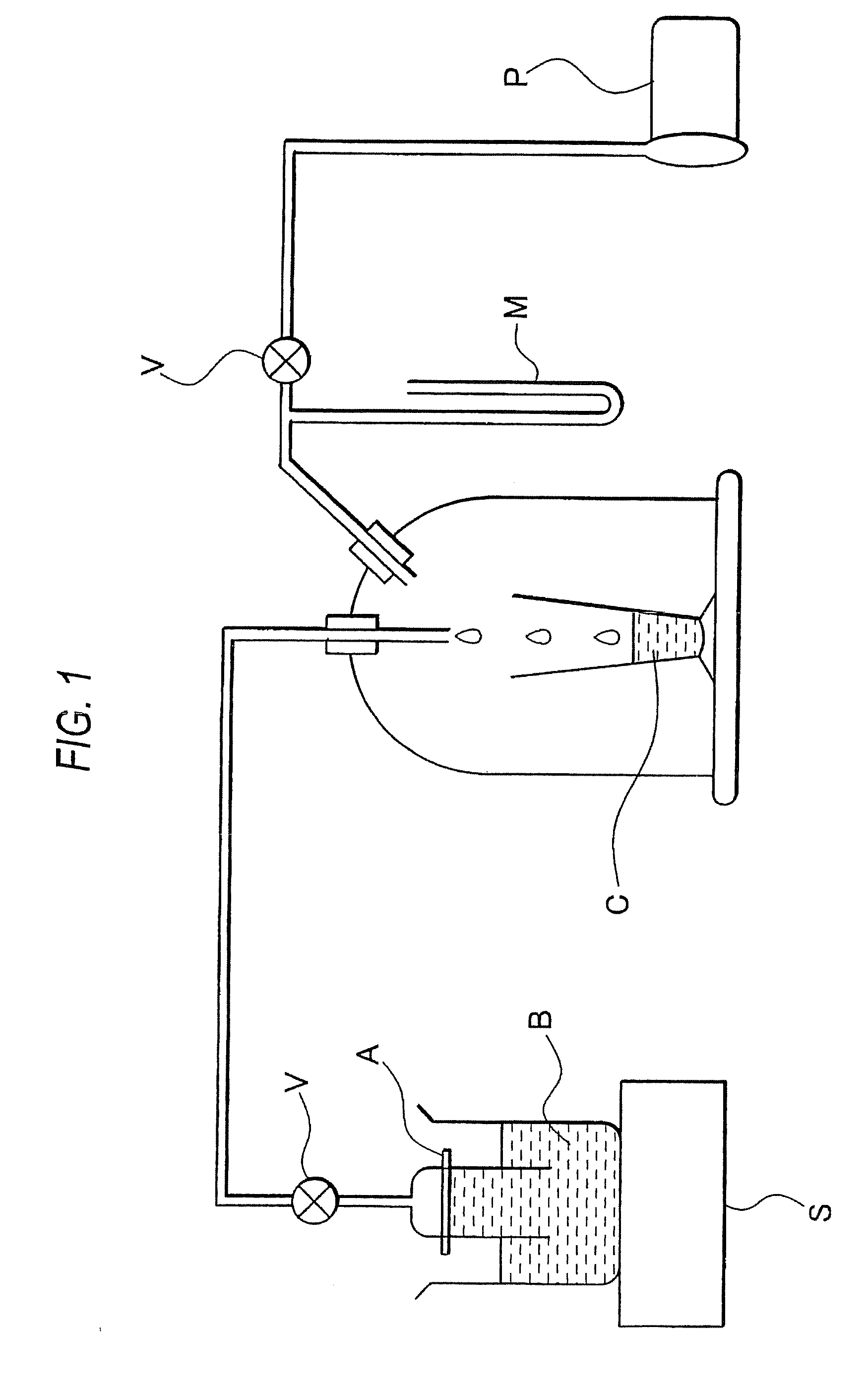

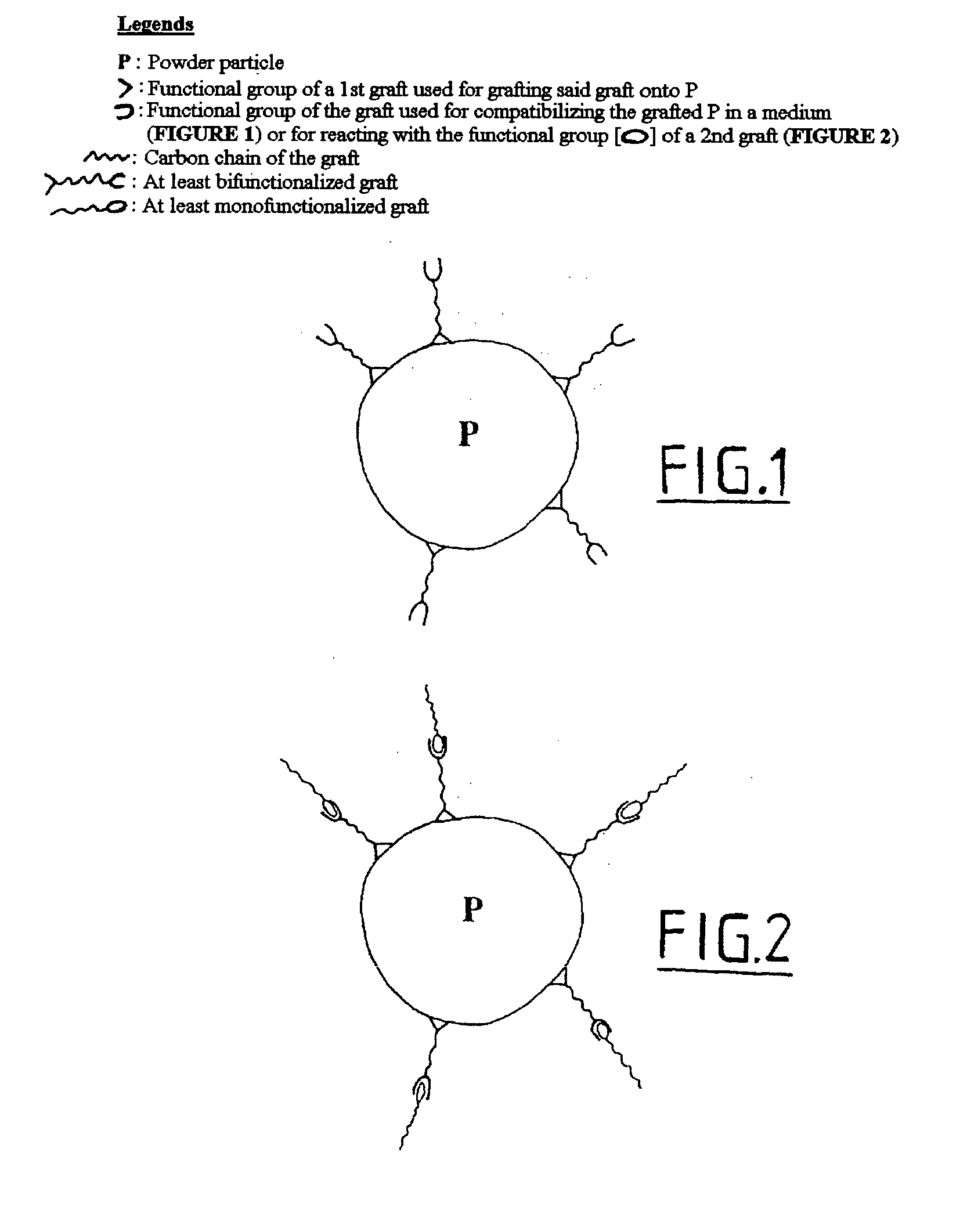

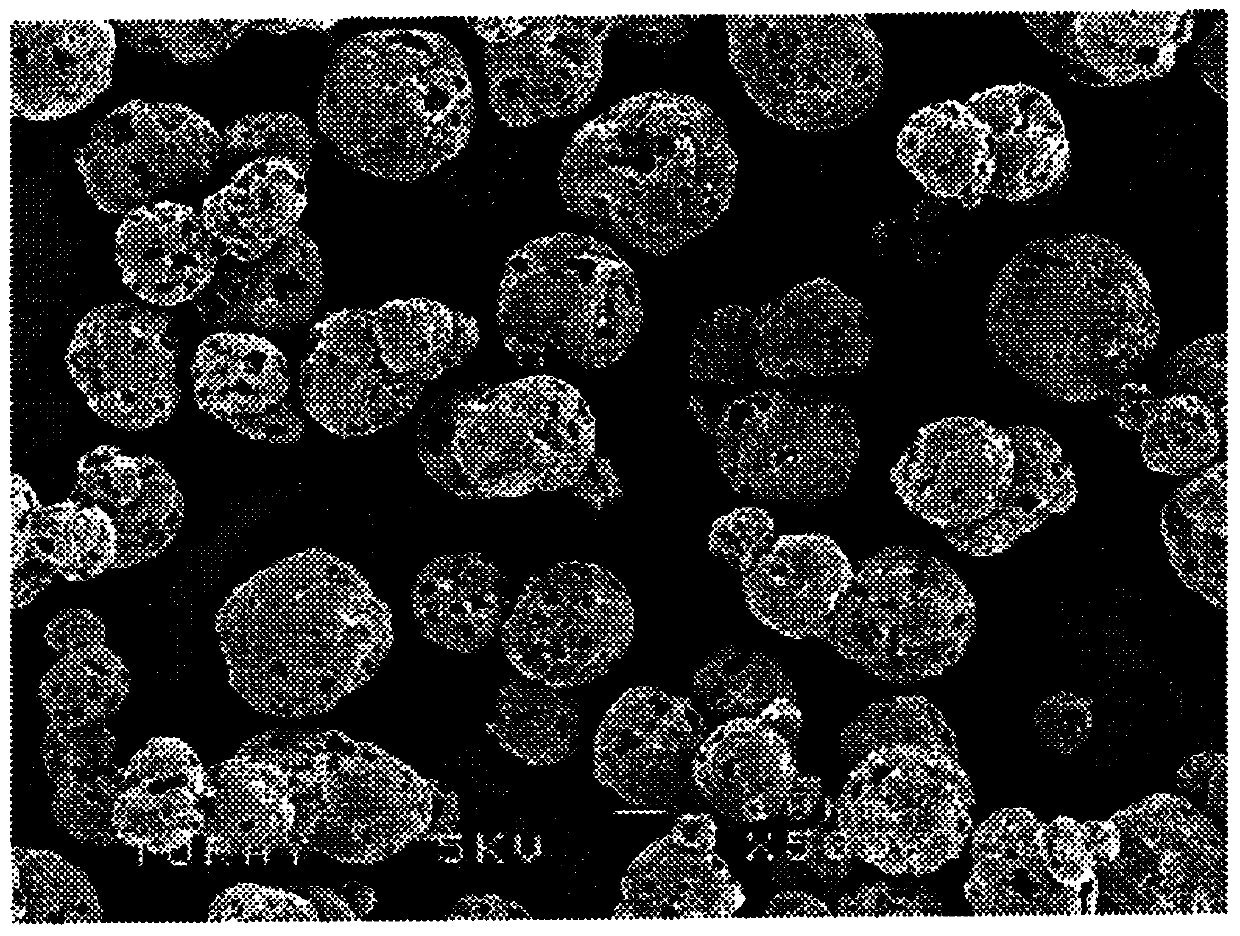

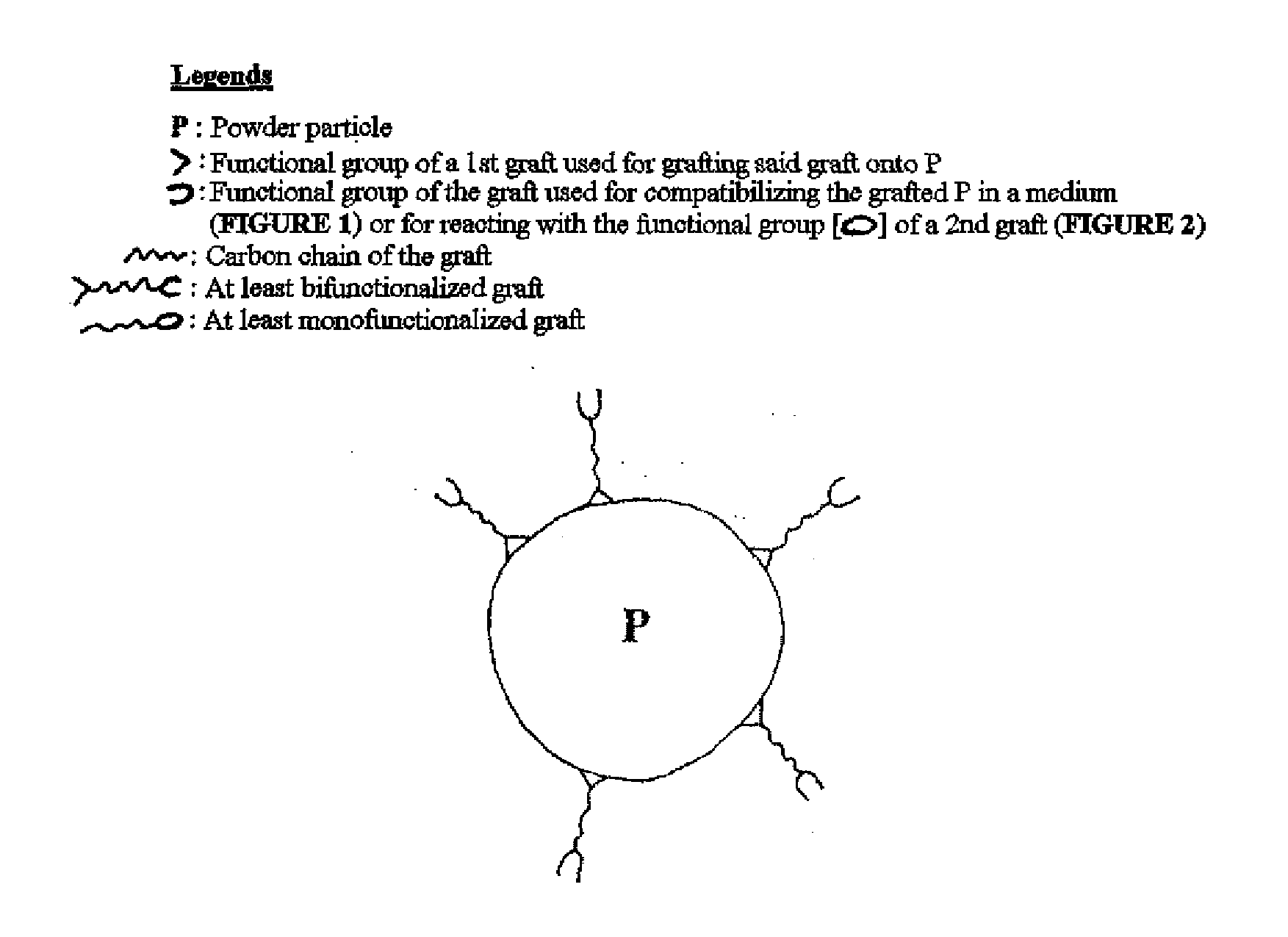

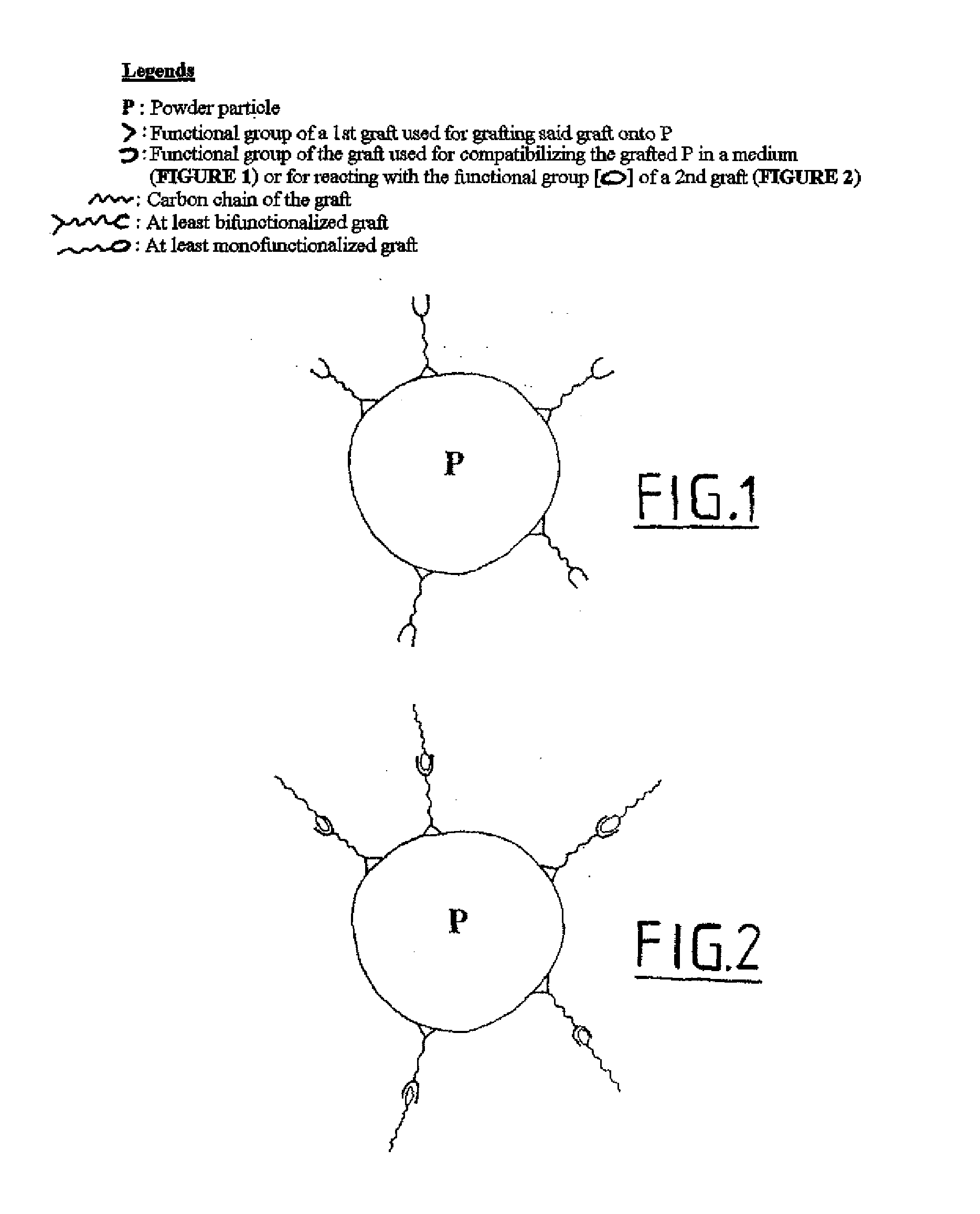

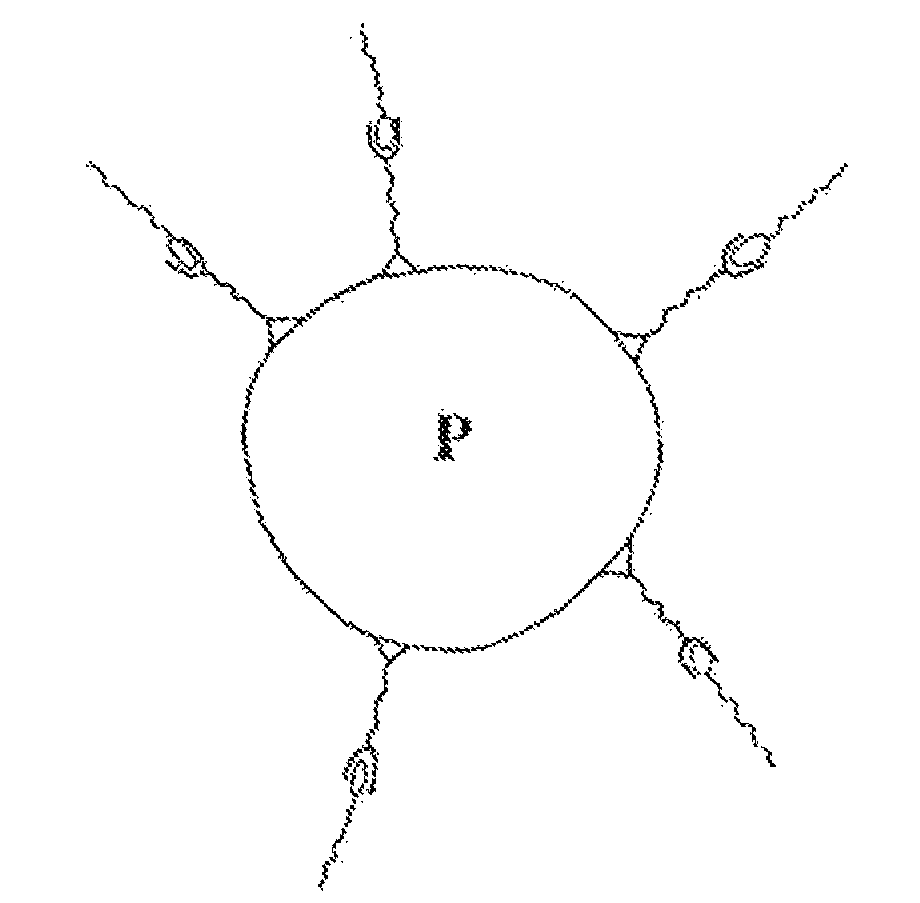

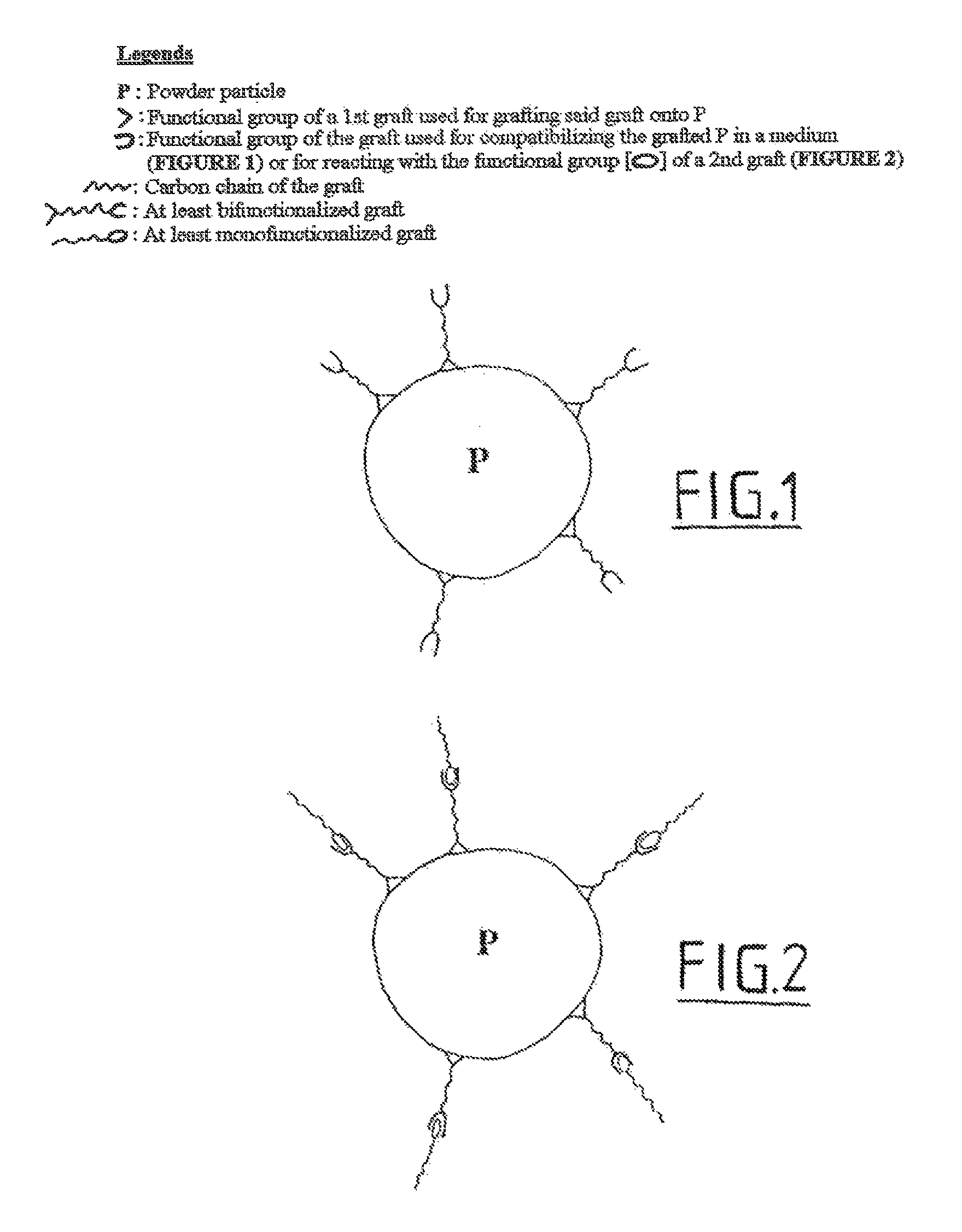

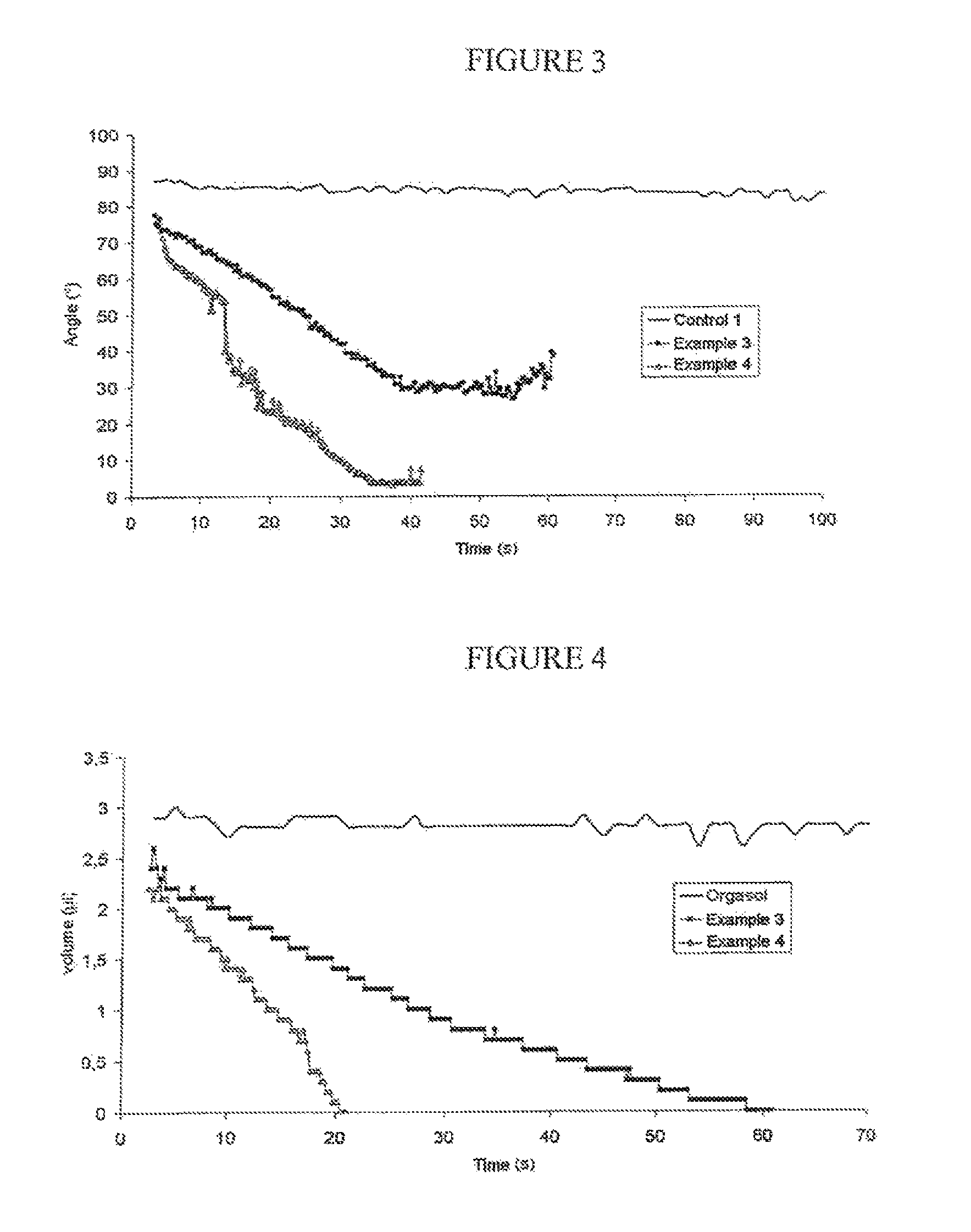

Crafting onto a polyamide powder by gamma-irradiation

The subject of the invention is a process for producing polyamide, copolyamide, polyolefin, copolyester amide or fluorocarbon resin powder particles on to the surface of which has been grafted at least one functionalized grafting monomer, characterized in that it comprises: a) a step of blending the polyamide or copolyamide powder particles with the functionalized grafting monomer; followed by b) a step of irradiating the powder impregnated with functionalized grafting monomer resulting from a) with photons (γ-radiation) or electrons (β-radiation), with a dose ranging from 0.5 to 15 Mrad. The invention also relates to the particles grafted in this way and to the compositions containing such particles.

Owner:ARKEMA FRANCE SA

Electrophotographic cleaning blade, process for producing electrophotographic cleaning blade, and electrophotographic apparatus

ActiveUS7778585B2Improve slipperinessBlocking may occurElectrography/magnetographyHardnessEngineering

An electrophotographic cleaning blade is provided which is free of blade turning-up coming from both end portions of the blade in its lengthwise direction. The cleaning blade having a blade formed of a polyurethane resin, which is to come into touch with the surface of a photosensitive drum of an electrophotographic apparatus to remove a toner remaining thereon, and a support member which holds the blade. The blade has a polyurethane resin portion having a dynamic hardness of 0.05 mN / μm2 or more and 0.16 mN / μm2 or less and a high-hardness portion having a dynamic hardness 1.3 times or more and 30 times or less the dynamic hardness of the polyurethane resin portion, provided at each end portion of the blade in its lengthwise direction at its part coming into touch with the photosensitive drum.

Owner:CANON KK

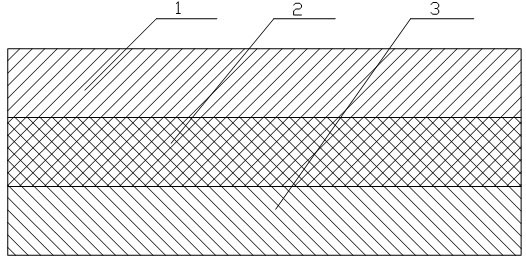

Super-slide type biaxial tension polypropylene thin film for easy-quit package retraction tobacco

The invention relates to a super-smooth type dual-direction extension polypropylene film used by a retractable cigarette with the package easy to be taken down, comprising a structure of an upper layer, an intermediate layer and a lower layer. The upper layer is added with macromolecular silicone accounting for 1 to 3 percent Mw (namely more than 100,000) of the total weight of polypropylene biopolymer basal material as lubricant and 0.1 to 0.5 percent of cross-link methyl acrylate as anti-adhesiveness agent. The intermediate layer is added with hydrogen oil resin accounting for 10 to 30 percent of the total weight of the polypropylene basal material as erection strengthening agent and 0.2-1.0 percent of alkyl (C14-18) double (2-hydroxyethyl group) amine as anti-static agent. The lower layer is added with macromolecular silicone accounting for 1 to 3 percent Mw (namely more than 100,000) of the total weight of polypropylene triopolymer basal material as lubricant and 0.1 to 0.5 percent of cross-link methyl acrylate as anti-adhesiveness agent. The film has small internal friction and good erection and static electricity prevention, and can enable the cigarette package to be easily taken down from the film.

Owner:江苏恒创包装材料有限公司

Perfluoropolyether-modified silane compound, surface treatment composition comprising same and thin film

ActiveCN107057056AGood smoothnessExcellent antifoulingAntifouling/underwater paintsPaints with biocidesChemistrySurface finishing

The invention discloses a perfluoropolyether-modified silane compound,a surface treatment composition comprising the same and a thin film. The structure of the perfluoropolyether-modified silane compound is as shown in F(CF2CF2O)m(CF2O)nCF2CH2{CH2}p[O(CH2)3]bSi(CH3)a{(CH2)3Si(OCH3)3}3-a, wherein p and b are independent numbers separately; if p and b are 0 at the same time, a can be 1, or if p and b are 1 at the same time, a is 0; and m and n are independent numbers separately. The perfluoropolyether-modified silane compound has good self-assembled monomolecular coating property, and can be used for forming the thin film which has high durability, relatively good smoothness and excellent antifouling property and scratch resistance.

Owner:龙岩思康新材料有限公司

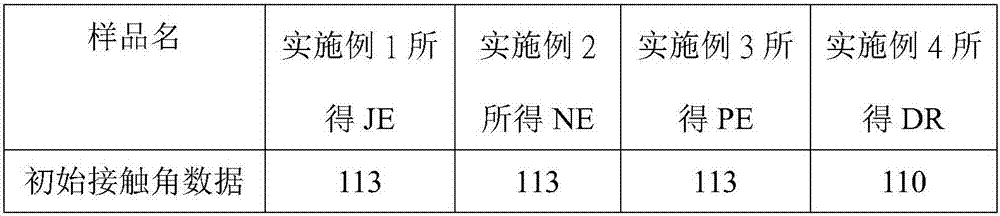

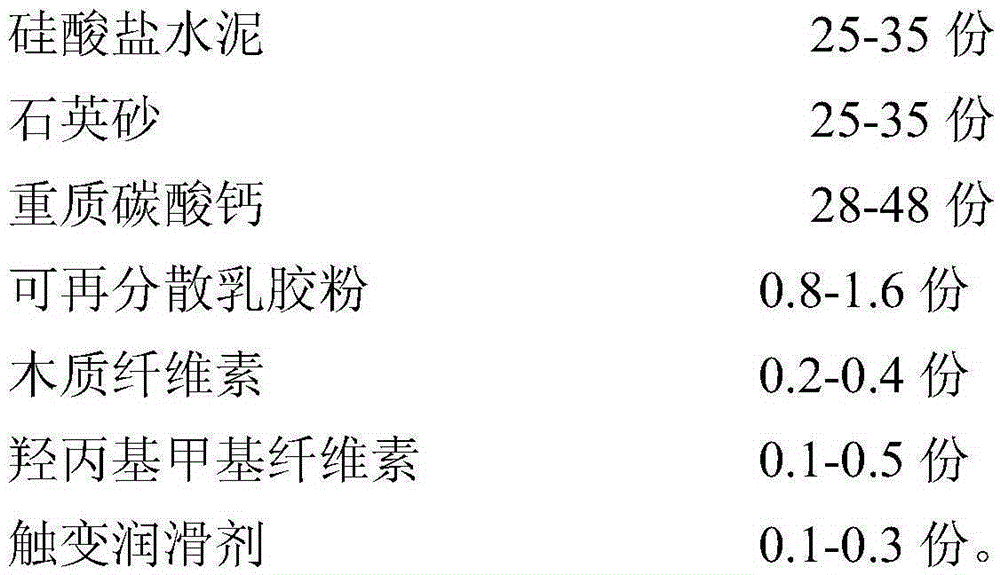

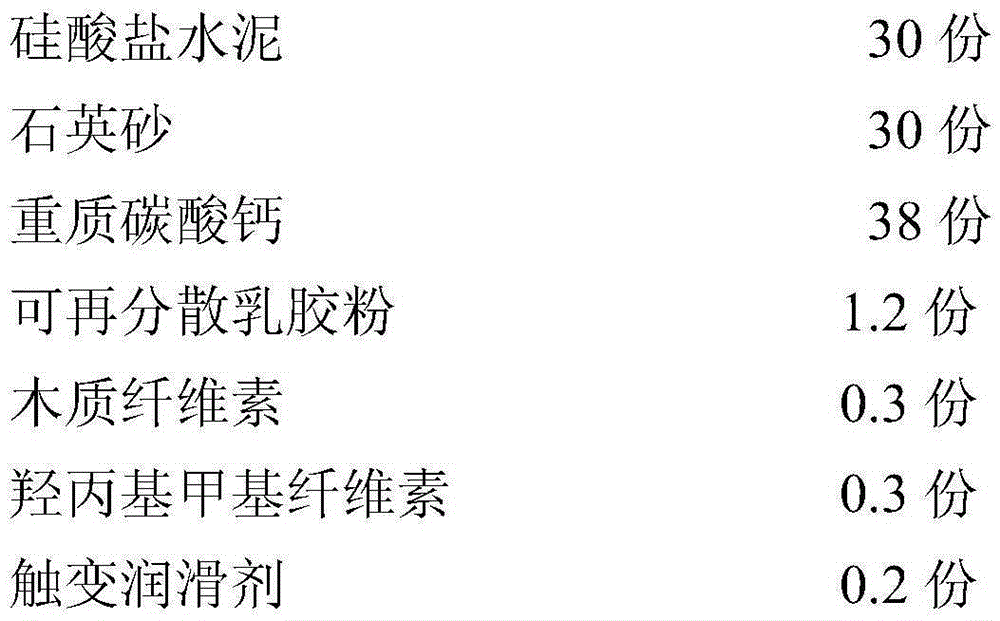

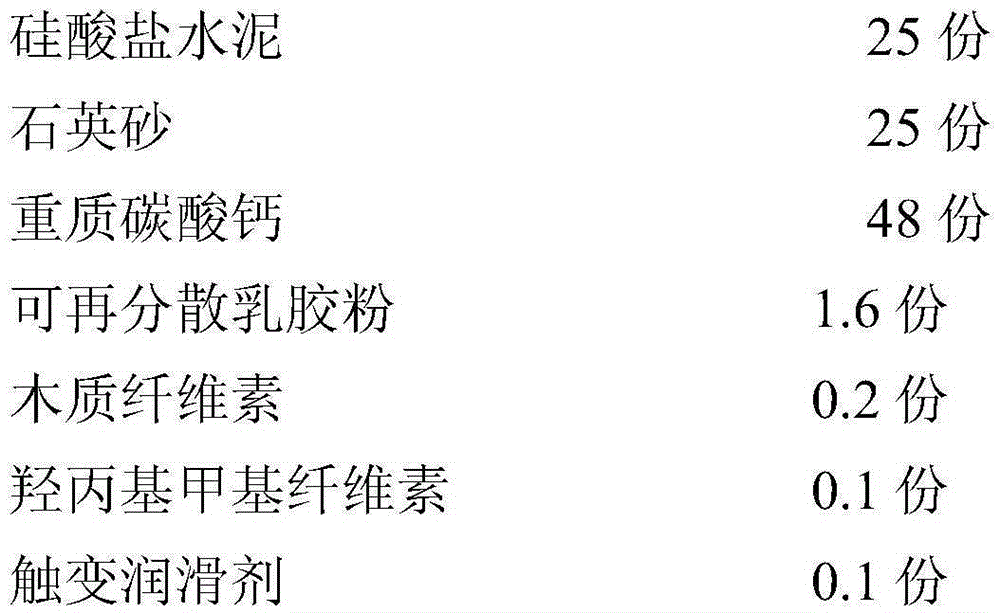

Interior wall putty and preparation method thereof

InactiveCN105419447AStrong adhesionGood construction performanceFilling pastesPortland cementMethyl cellulose

The invention relates to an interior wall putty which is obtained by mixing putty powder and water in a ratio of 100:(33-36), wherein the interior putty powder is prepared from the following components in parts by weight: 25-35 parts of Portland cement, 25-35 parts of quartz sand, 28-48 parts of ground calcium carbonate, 0.8-1.6 parts of re-dispersible latex powder, 0.2-0.4 part of lignocellulose, 0.1-0.5 part of hydroxypropyl methyl cellulose and 0.1-0.3 part of thixotropic lubricant. The invention has the following advantages: the interior wall putty prepared by proportioning the components has excellent adhesion, the bonding strength can reach 1.0MPa, the water resistance is good while the application property is perfect, and the interior wall putty is environment-friendly and healthy.

Owner:SKSHU PAINT

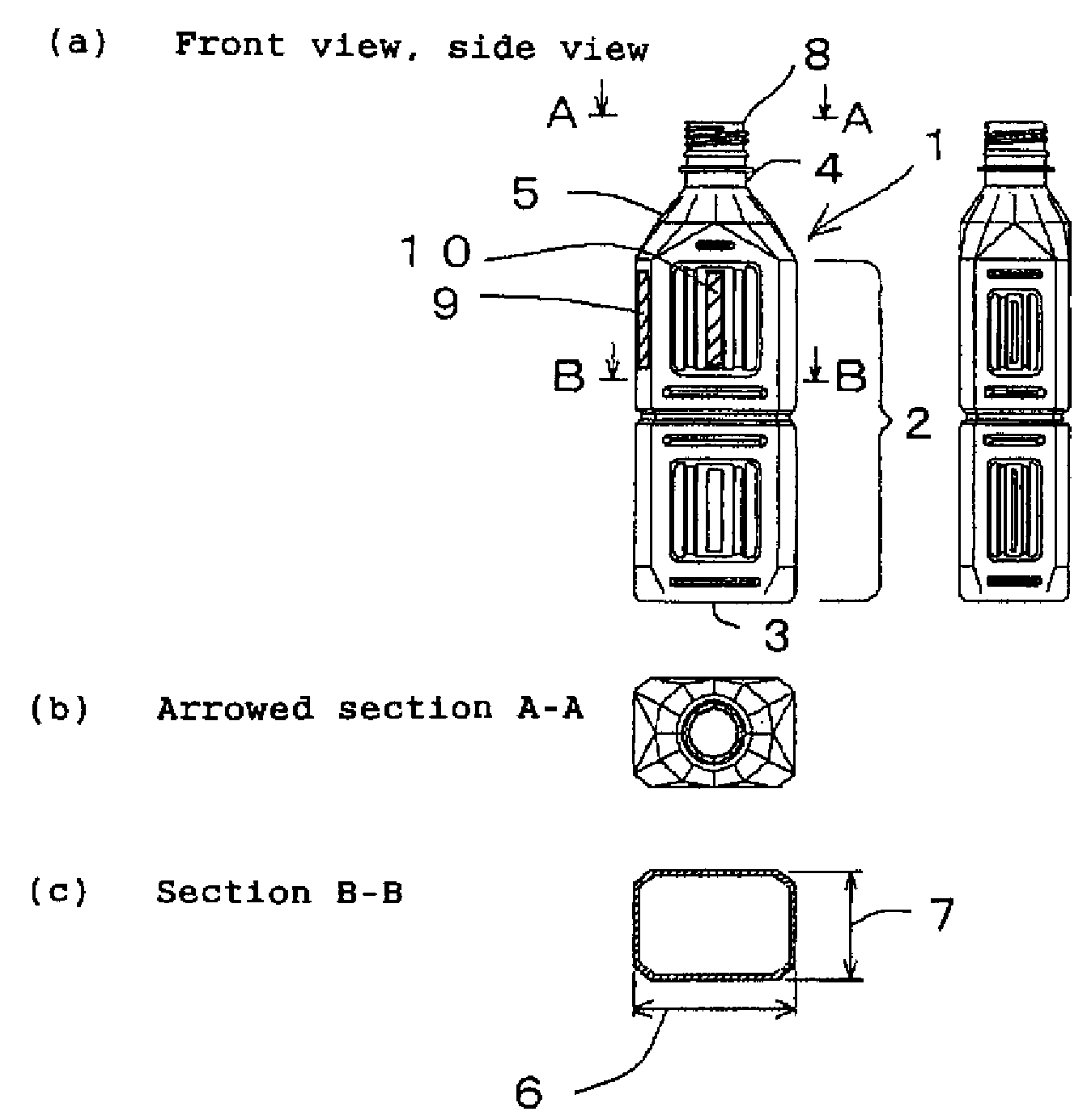

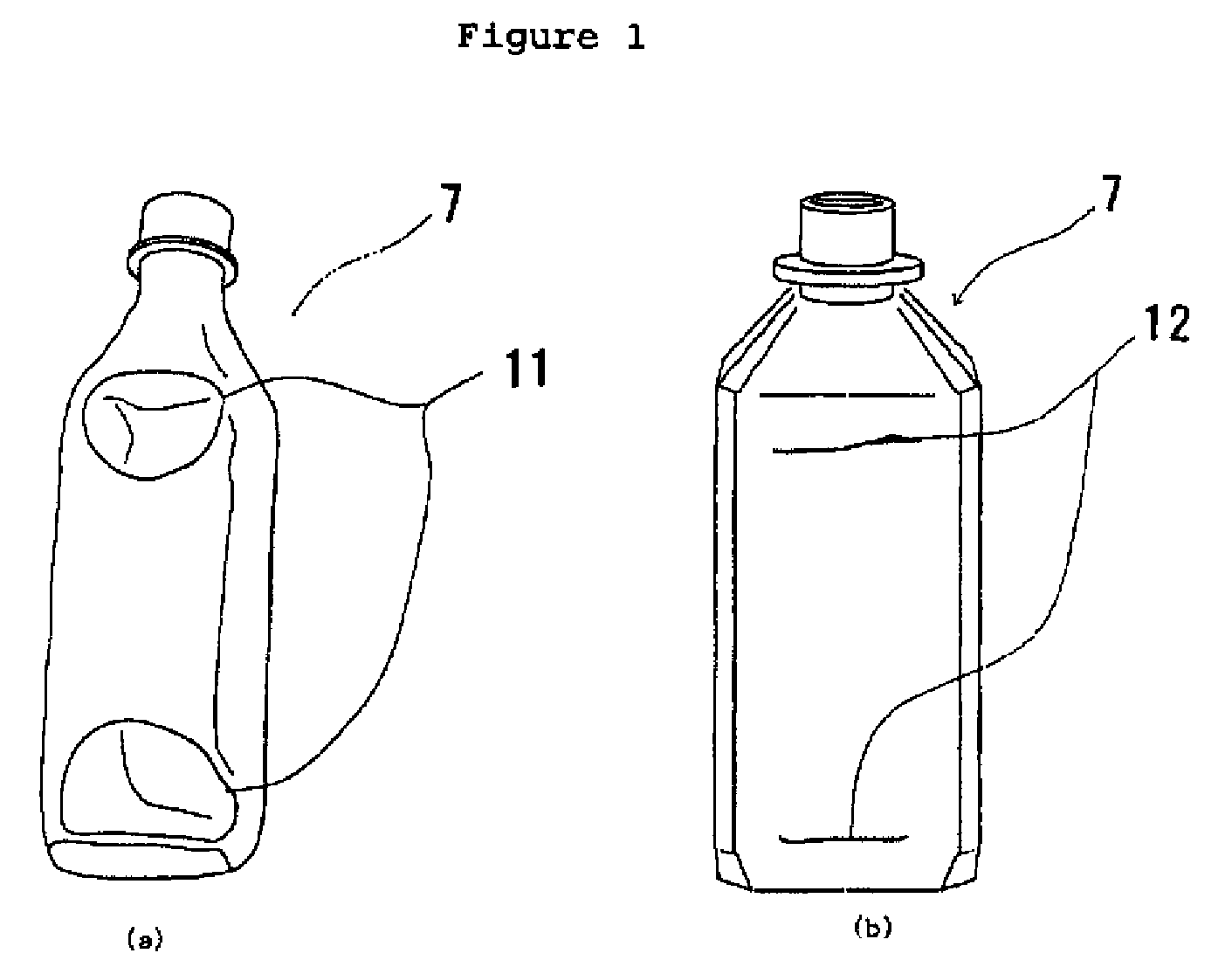

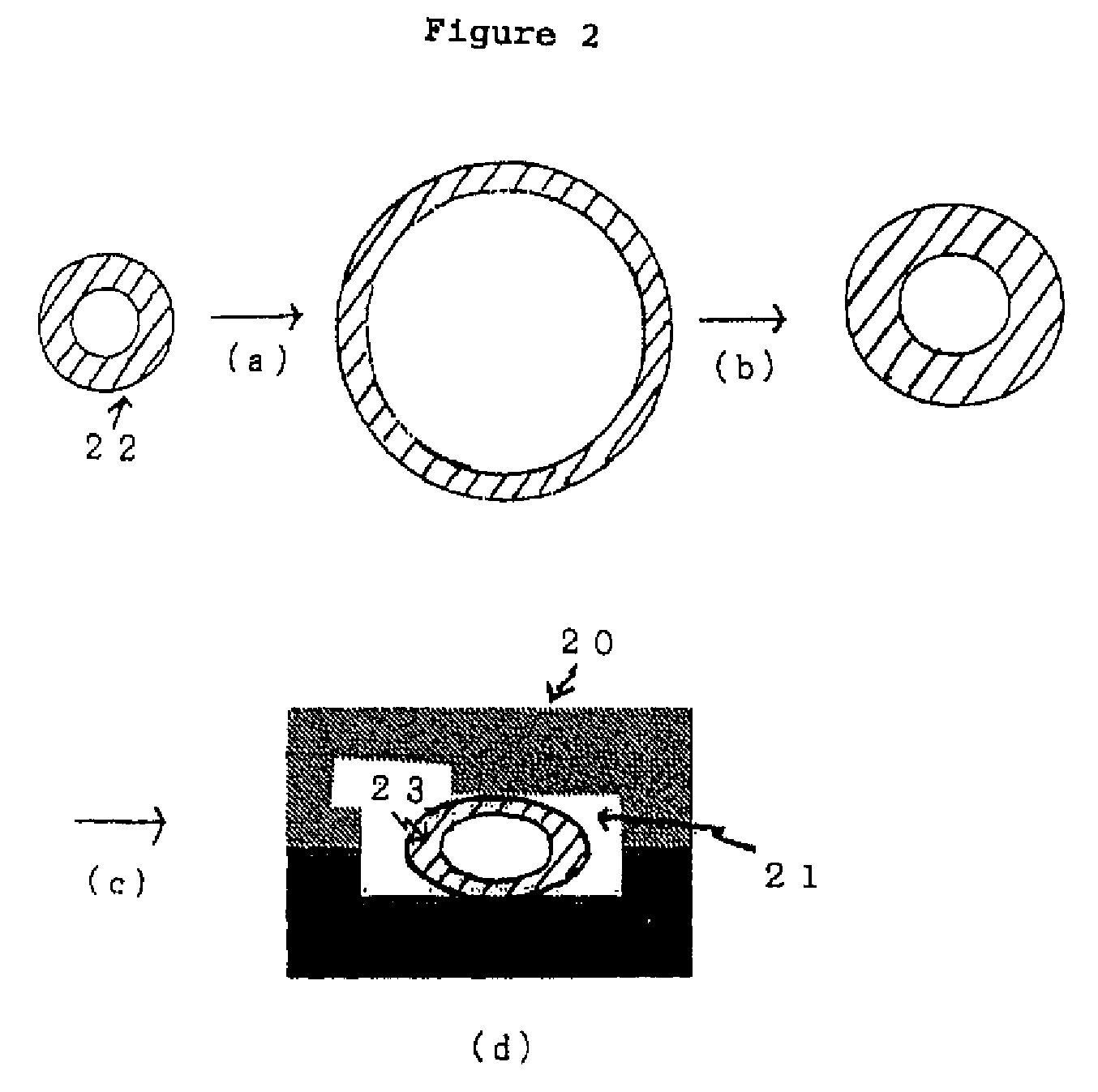

Flat container comprising thermoplastic resin and method for molding the same

ActiveUS20090130352A1Large caliberUniform wall thicknessBottlesSynthetic resin layered productsBlow moldingHeat resistance

The invention realizes easy manufacturing of a flat container molded by blow molding, in which the wall thickness of a container wall is made uniform, and which provides improved mechanical strength, heat resistance, etc. and has a good appearance.The flat container obtained by the blow molding of a polyester resin is characterized in that the container has a flatness ratio of not less than 1.3, and in that its body has a wall thickness ratio of a maximum wall thickness to a minimum wall thickness of not more than 1.6, a difference in elongation between a maximally stretched portion and a minimally stretched portion of not more than 150% in a tensile test at 95° C., a crystallinity of not less than 30%, and a difference in TMA non-load change between a maximally stretched portion and a minimally stretched portion of not more than 500 μm at 75° C. and 100° C.

Owner:TOYO SEIKAN GRP HLDG LTD

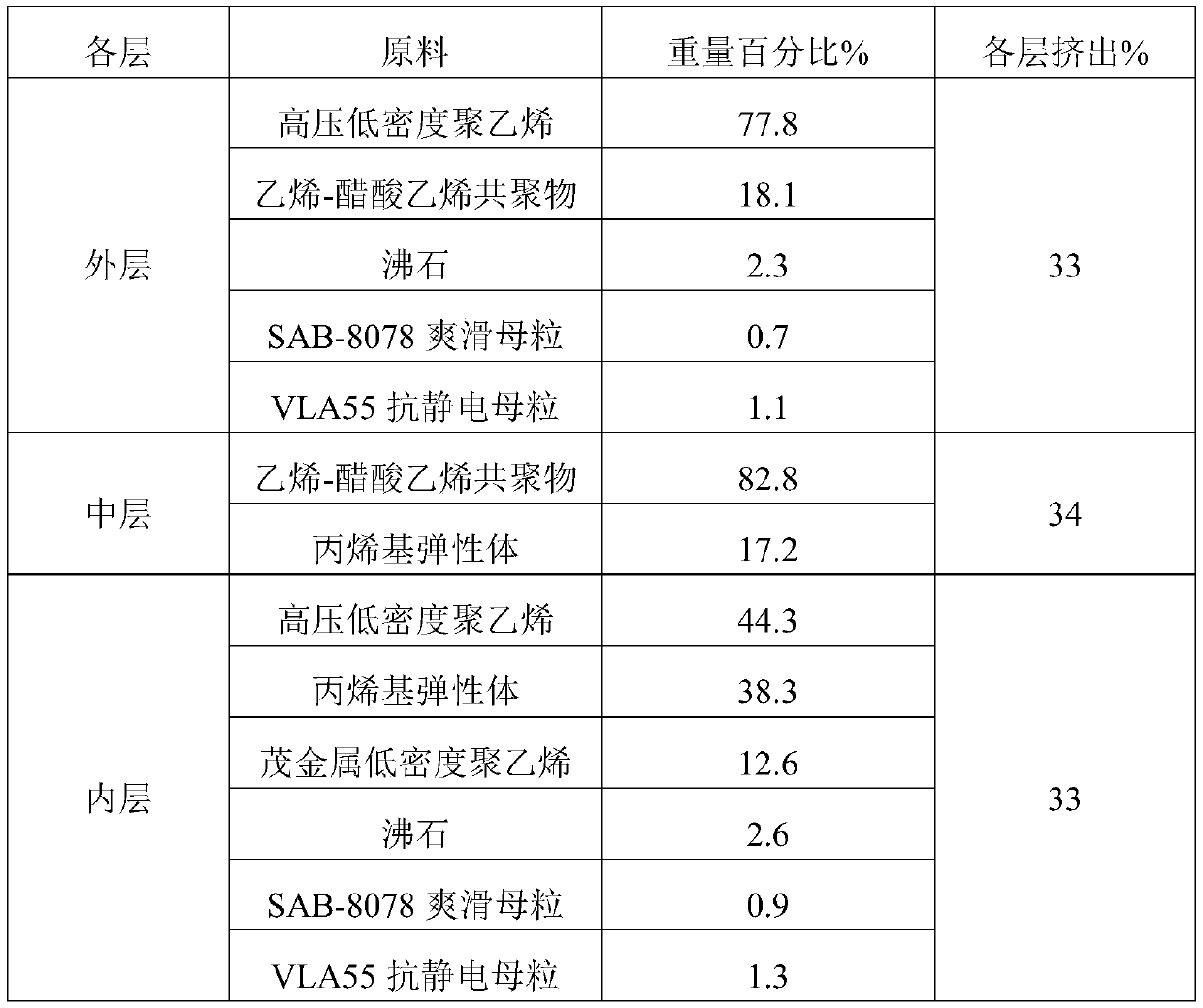

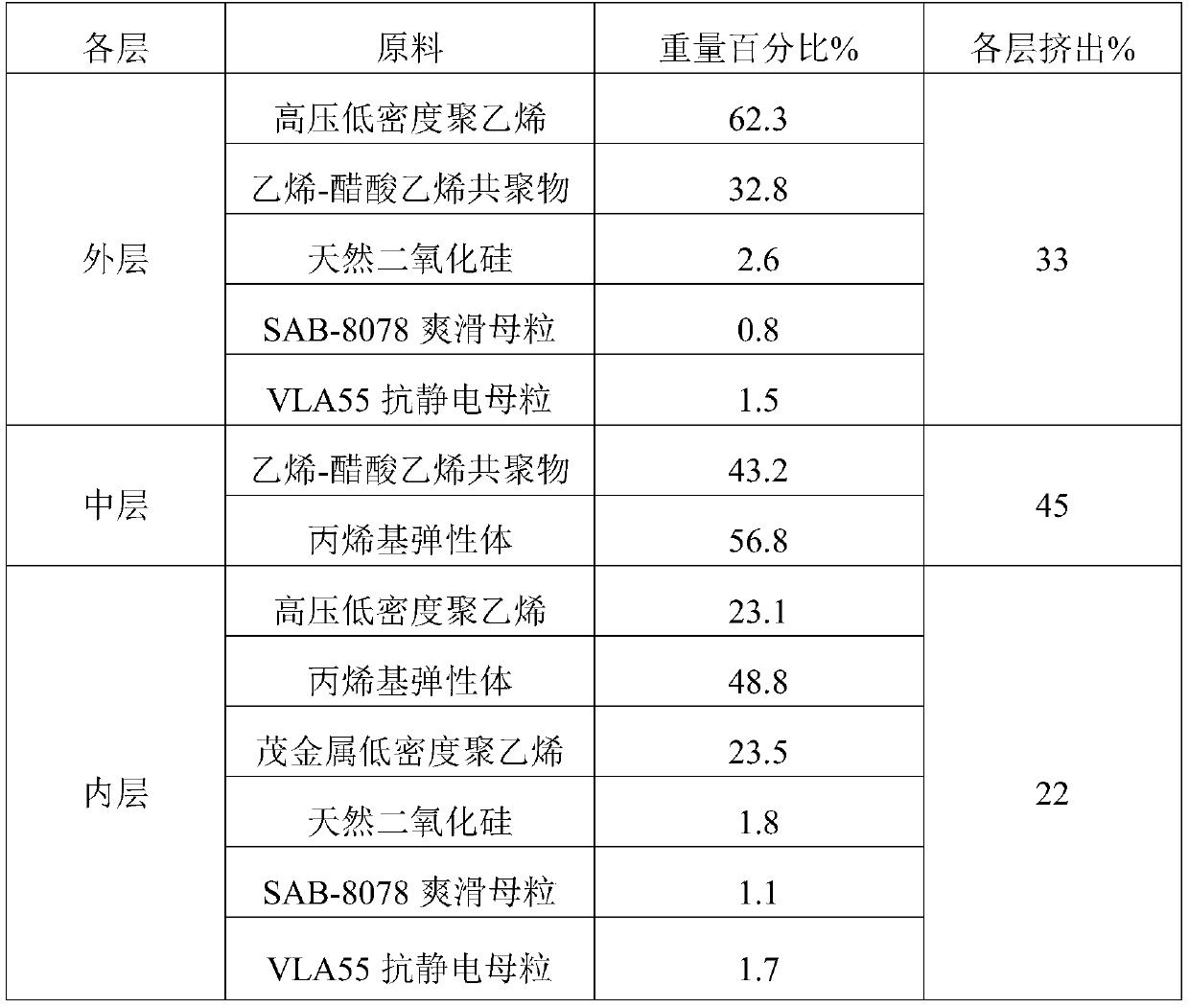

Heat shrinkable film and preparation method and application thereof

ActiveCN110978702AImprove performanceAchieve reductionFlexible coversWrappersVinyl acetateThermal shrinkage

The invention provides a high-performance heat shrinkable film which has the advantages of low shrinkage temperature, high shrinkage speed, low water vapor transmission rate, high transparency and thelike. The heat shrinkable film is prepared by adopting a three-layer co-extrusion film blowing method and comprises an outer layer, a middle layer and an inner layer. The mass ratio of the outer layer to the middle layer to the inner layer is (1-3): (1-3): (1-3); the outer layer comprises high-pressure low-density polyethylene, an ethylene-vinyl acetate copolymer, an anti-sticking master batch, asmooth master batch and an antistatic master batch; the middle layer comprises an ethylene-vinyl acetate copolymer and a propenyl elastomer; and the inner layer comprises high-pressure low-density polyethylene, metallocene low-density polyethylene, a propenyl elastomer, an anti-sticking master batch, a smooth master batch and an antistatic master batch. According to the heat shrinkable film, thetensile strength and the elasticity modulus are improved and the bag breaking rate is effectively reduced; the heat shrinkage rate reaches up to 75% after treatment at 130 DEG C for 20 seconds, the light transmittance is greater than 90% and the haze and glossiness are greatly improved.

Owner:江门市华龙膜材股份有限公司

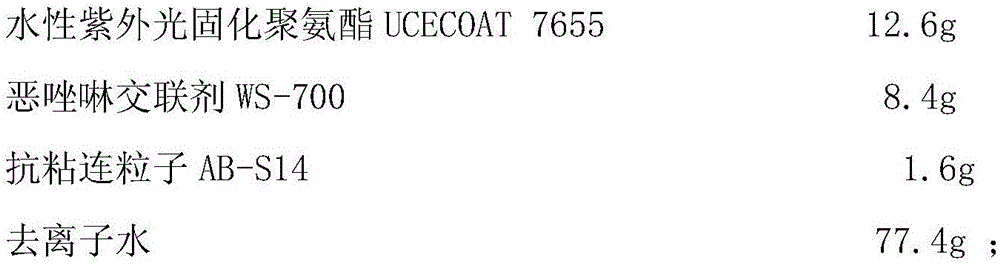

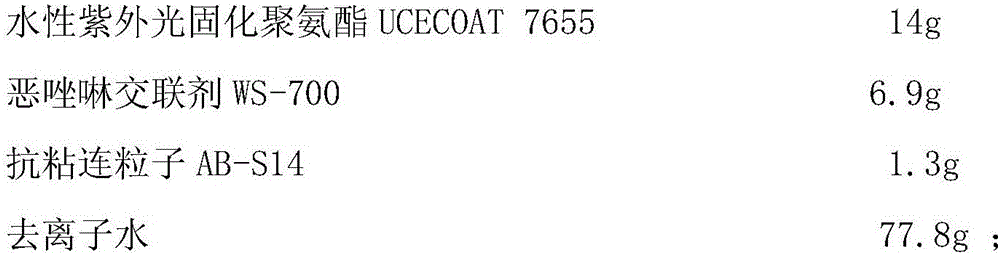

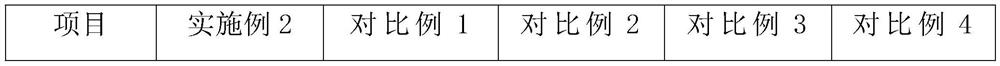

Optical polyester film and method of manufacture thereof

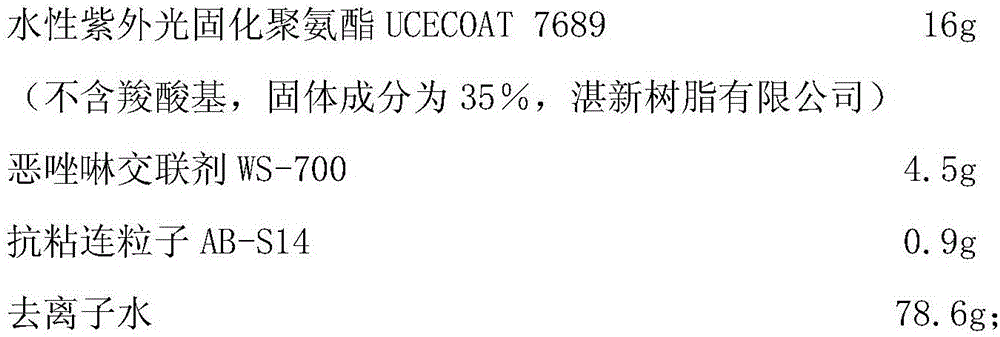

ActiveCN105754128AStrong adhesionExcellent reworkabilityPolyurea/polyurethane coatingsFlat articlesWater basedPolyester

The invention discloses an optical polyester film and a method of manufacture thereof.In the optical polyester film, at least one side of a biaxially stretched basic film is coated with a bottom coating, the bottom coating is made from the components according to percent by weight: 63-96% of water-based ultraviolet-cured polyurethane resin free of carboxylic acid, 3-30% of oxazoline cross-linking agent, and 1-7% of nano-scale anti-blocking particles that are 80 to 200 nm in particle size.The optical polyester film has excellent adhesion and high transparency, has good bonding resistance and is applicable to high-end film material fields such as LCD (liquid crystal display) display device field and high-end IMD (in-mod decoration) processing.

Owner:HEFEI LUCKY SCI & TECH IND

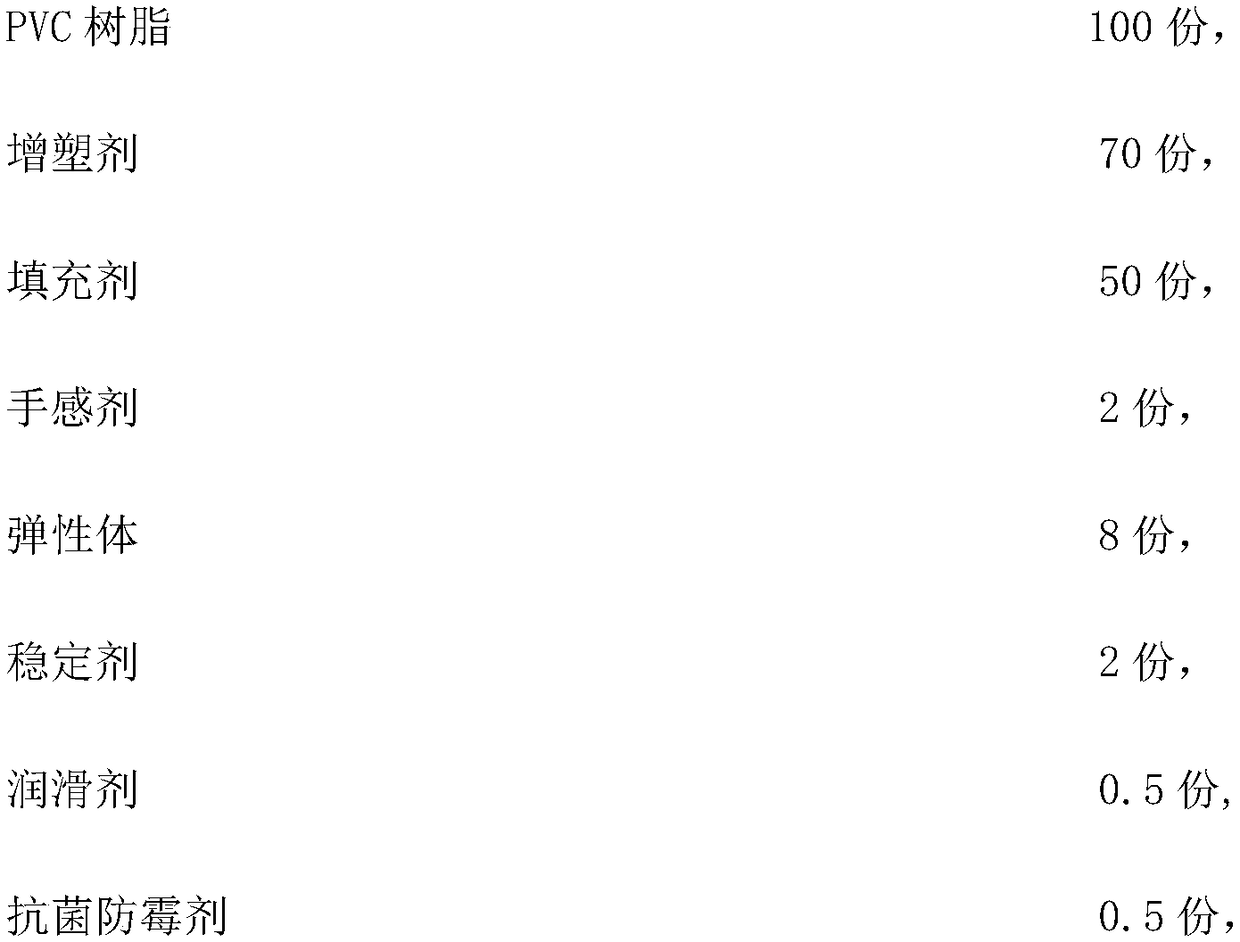

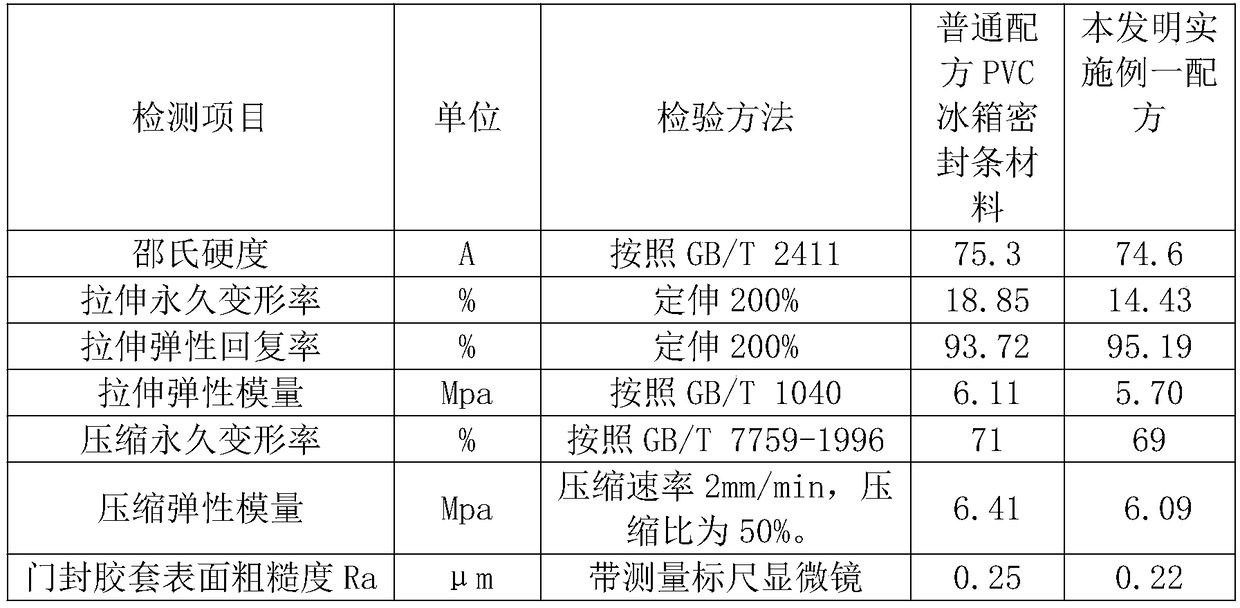

Smooth and delicate PVC door sealing material and preparation method thereof

The invention discloses a smooth and delicate PVC door sealing material and a preparation method thereof. The smooth and delicate PVC door sealing material is composed of PVC resin, plasticizer, filler, feeling agent, elastomer, stabilizer, lubricant and antibacterial mildew preventive. The preparation method for the smooth and delicate PVC door sealing material includes the steps of weighing; powder mixing; mixing; extrusion forming and hot cutting. According to the smooth and delicate PVC door sealing material and the preparation method thereof, the problem that an existing soft PVC materialincreasingly cannot meet the requirements of the market for the surface softness and fine texture of the product is solved. A polar group in the feeling agent and a PVC material system generate an attachment point by H bond bonding, a smooth main chain in the feeling agent is attached to the surface of the PVC material to form a smooth and continuous film, a convex-concave phenomenon of the product surface is improved, the surface roughness and surface defects are reduced, the smoothness and softness are improved, the smooth and delicate texture degree of the product surface can be improved lastingly, and the smooth and delicate PVC door sealing material is suitable as a low temperature flexible refrigerator door sealing material.

Owner:ANHUI BANGRUI NEW MATERIAL TECH CO LTD

Method for producing microparticles of polylactic acid-based resin, microparticles of polylactic acid-based resin and cosmetic using same

ActiveCN103937012AEasy to manufactureHigh oil absorptionCosmetic preparationsMake-upEmulsionMicroparticle

Disclosed are a method for producing microparticles of a polylactic acid-based resin, porous microparticles of a polylactic acid-based resin, said microparticles having a small particle diameter, showing a high oil absorption ability and being appropriately usable for cosmetics, smooth-surfaced microparticles of a polylactic acid-based resin, said microparticles having a spherical form, showing a narrow particle diameter distribution and being appropriately usable for toners, and cosmetics using the aforementioned microparticles of a polylactic acid-based resin. The process for producing microparticles of a polylactic acid-based resin comprises: dissolving; forming an emulsion; and particulating.

Owner:TORAY IND INC

Food-therapy rice noodles and production method thereof

InactiveCN106036398AHigh nutritional valueIncrease elasticityFood ingredient functionsFood extrusionFood processingNutrient content

The invention discloses food-therapy rice noodles and belongs to fields of food and food processing. The food-therapy rice noodles comprises, by weight, 1000-2000 parts of brown rice flour, 300-500 parts of fresh rhizoma dioscoreae juice, 10-20 parts of maca powder, 10-20 parts of radix pueraiae powder, 10-20 parts of edible starch and 10-20 parts of lotus powder. The food-therapy rice noodles has the advantages that most of the nutritional value in brown rice is kept, the glue-like fresh rhizoma dioscoreae juice is used as the dry-wet juice for dough kneading, the nutritional components in the rhizoma dioscoreae can be obtained favorably, and the produced rice noodles is good in elasticity and air-holding capacity. The invention further provides a production method of the food-therapy rice noodles.

Owner:重庆中笃食品有限公司

Grafting onto a polyamide powder by gamma-irradiation

The subject of the invention is a process for producing polyamide, copolyamide, polyolefin, copolyester amide or fluorocarbon resin powder particles on to the surface of which has been grafted at least one functionalized grafting monomer, characterized in that it comprises:a) a step of blending the polyamide or copolyamide powder particles with the functionalized grafting monomer; followed byb) a step of irradiating the powder impregnated with functionalized grafting monomer resulting from a) with photons (γ-radiation) or electrons (β-radiation), with a dose ranging from 0.5 to 15 Mrad.The invention also relates to the particles grafted in this way and to the compositions containing such particles.

Owner:ARKEMA FRANCE SA

High-density dark green glaze

The invention mainly relates to the technical field of ceramic glaze processing, and discloses a high-density dark green glaze. The high-density dark green glaze is prepared from silicon dioxide, talcum powder, cerium oxide, lanthanum oxide, zirconium oxide, praseodymium oxide, cobaltous oxide, titanium dioxide, nano-zinc oxide, modified wollastonite, chlorite and table salt. The high-density darkgreen glaze is wide in raw material source, low in price, bright in color and fine in enamel, and has good fluidity and smearing performance, cracks and pinholes are avoided, the glaze surface is smooth and dense, and the grade of ceramic products is obviously improved. After the silicon dioxide, the talcum powder, the cerium oxide, the lanthanum oxide, the zirconium oxide and the praseodymium oxide are mixed and smashed, the mixture is firstly slowly heated and then rapidly heated, the praseodymium oxide is dark green through high-temperature heating, meanwhile, after the raw materials are heated at high temperature stage by stage, the fineness and the smoothness of the glaze can be improved, the density is high, and the cracks and the pinholes are avoided in the glazing process.

Owner:界首市伟盛古窑彩陶制作发展有限公司

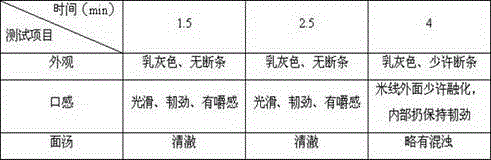

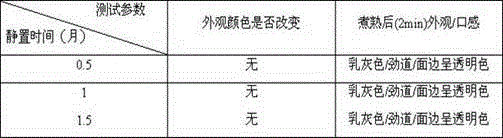

Preparation method of wrappers of quick-frozen wontons

InactiveCN104171821AGood cooking resistanceImprove slipperinessNatural extract food ingredientsFood preparationChemistryModified starch

The invention discloses a preparation method of wrappers of quick-frozen wontons. The method comprises the following steps: adding 1% to 2% of table salt, 0.1% to 0.3% of dietary alkali, 0.3% to 0.4% of modifier and 1.0% to 4.0% of modified starch into flour by taking the weight of the flour as a standard, then adding water accounting for 20% to 24% of total weight and mixing for 5 to 10 minutes in a mixer so as to obtain the wrappers. According to the method, the phenomena that the wrappers of the quick-frozen wontons are easily adhered to a machine and are easy to crack when being stored in a quick-freezing manner are effectively avoided, and the boiling fastness of the quick-frozen wontons is improved.

Owner:上海妙禾食品配送有限公司

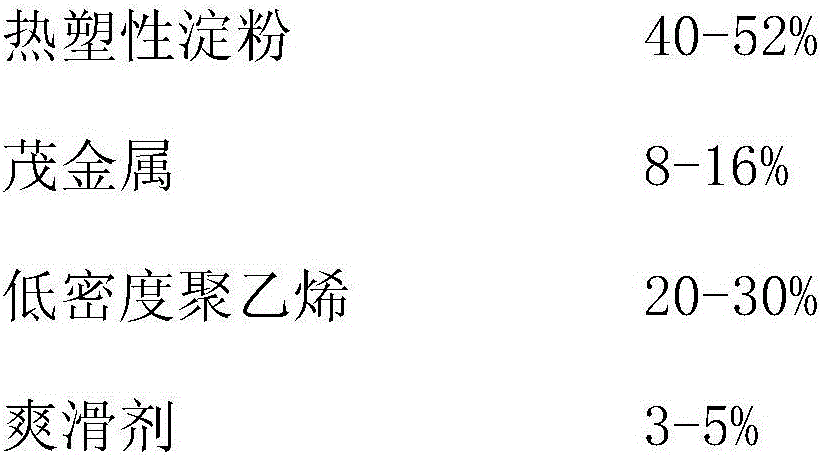

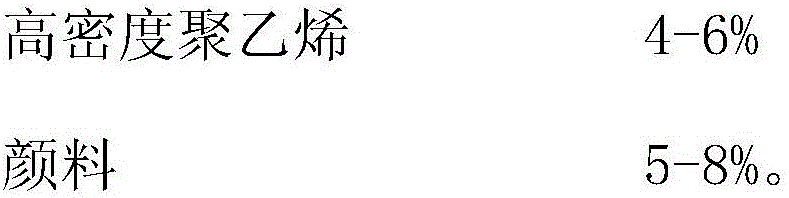

Biodegradable thermoplastic starch resin film and preparation method thereof

The invention relates to a biodegradable thermoplastic starch resin film. The composition and content of raw materials are as follows: thermoplastic starch 40-52%, metallocene 8-16%, low-density polyethylene 20-30%, smooth 3-5% of agent, 4-6% of high-density polyethylene, 5-8% of pigment; the preparation method of the biodegradable thermoplastic starch resin film comprises the following steps: mixing thermoplastic starch, metallocene, low-density polyethylene, smooth Agents, high-density polyethylene, and pigments are mixed by the mixer according to the above mass percentages, added to the film blowing unit, and plasticized, extruded, blown, drawn, and rolled by the blown film extruder, and then blown. Biodegradable thermoplastic starch resin film; Compared with the prior art, the present invention adopts special raw materials, such raw materials are green and environment-friendly bio-polyethylene, etc., so that the film produced can be biodegradable, bio-environmental, and reduce carbon dioxide emissions.

Owner:SHANGHAI FUKUSUKE IND

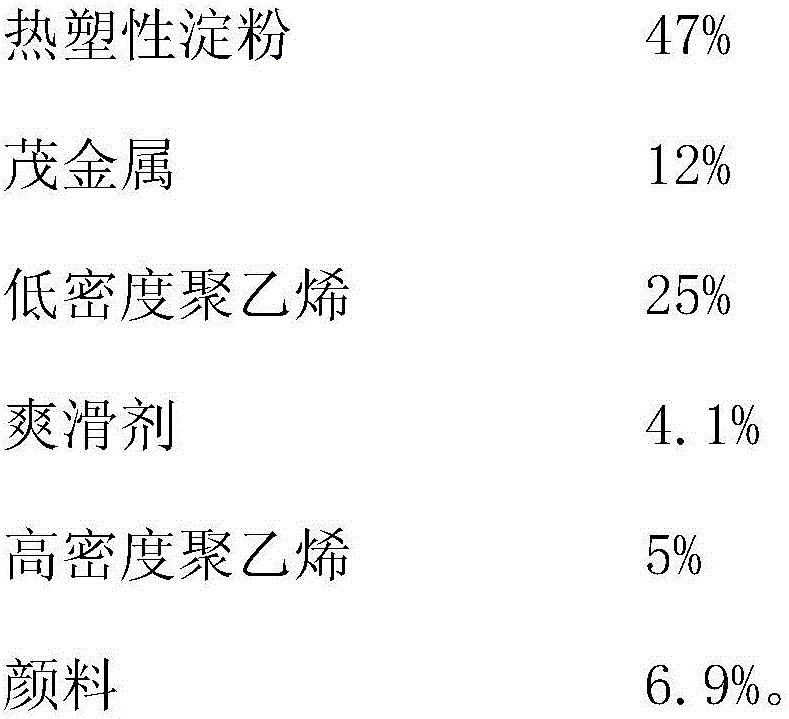

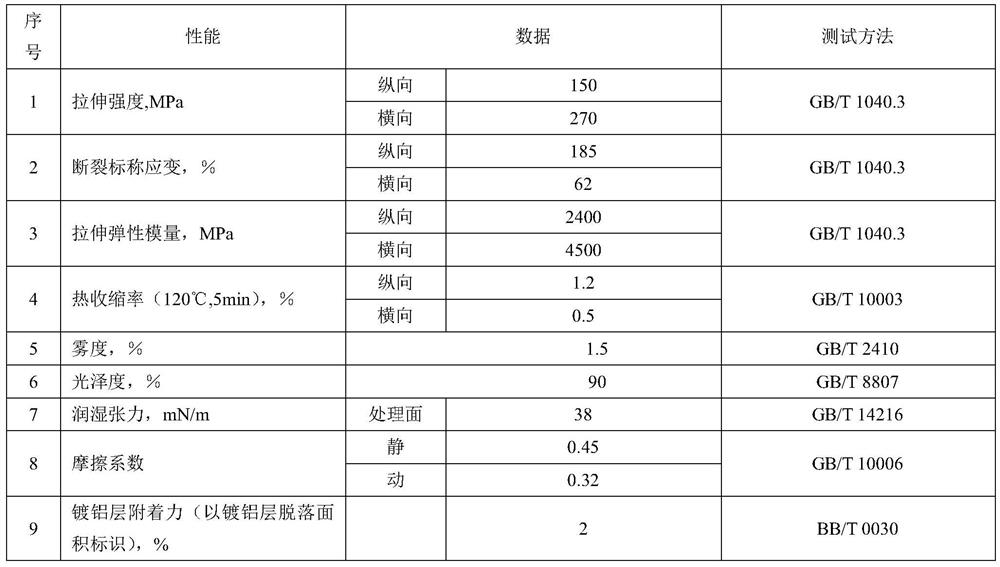

Low-rainbow-pattern polyester optical film coating liquid and preparation method thereof

ActiveCN111944411ALow hazeReduce rainbow streaksSynthetic resin layered productsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a low-rainbow-pattern polyester optical film coating liquid and a preparation method thereof. The low-rainbow-pattern polyester optical film coating liquid comprises the following components in percentage by weight: 10-50% of waterborne polyurethane, 10-50% of waterborne polyester, 0.1-1% of melamine resin, 0.5-1.5% of an organic solvent, 0.05-0.5% of a wetting agent, 0.1-1% of nanoparticles, 0.01-0.1% of a pH value regulator and the balance of deionized water. According to the invention, the coating liquid is prepared by setting the components and proportions thereof,the preparation process and parameters, and after the polyester film is subjected to online prime coating treatment by the coating liquid, the refractive index difference between the PET base materialand the hardened coating can be reduced, the rainbow pattern phenomenon of the optical film can be reduced, and the adhesive force with hardened layer glue can be enhanced; and the film has the characteristics of low haze, high light transmittance, light rainbow lines, good smoothness and strong adhesion to an optical functional coating, is suitable for manufacturing ITO films, IMD films, protective films and other films needing hardening processing, and is suitable for wide popularization and application.

Owner:江苏三房巷薄膜股份有限公司

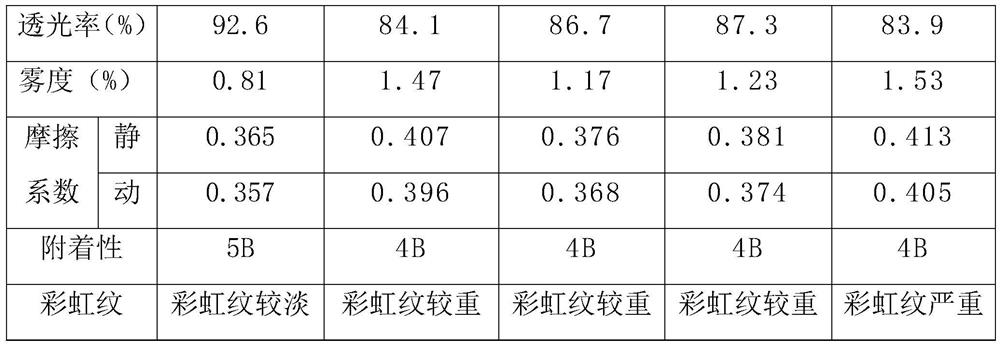

Non-fried instant dough sheets and high-temperature extruding-puffing production technology thereof

InactiveCN109006937AGuaranteed cookedMuscle strengtheningPre-baking dough treatmentBaking processesVegetable oilPotato starch

The invention discloses non-fried instant dough sheets and a high-temperature extruding-puffing production technology thereof. The non-fried instant dough sheets are prepared from the following raw materials in parts by weight: 20 parts of flour, 0.08 part of potato starch, 0.1 part of gluten powder, 0.08 part of edible salt, 0.03 part of vegetable oil, and 6 parts of clean water. The non-fried instant dough sheets are prepared by adopting a high-temperature technology at 200-230 DEG C, so that full cooking of the dough sheets is ensured; and thus, the extruded dough sheets are slightly yellow, and have bubbles of grain size at the outlet. Moreover, chewiness and smoothness of the dough are increased by adopting the extruding process so as to have taste improved; and the puffing process isadopted so as to to have rehydration property of the dough improved.

Owner:河南豫道农业科技发展有限公司

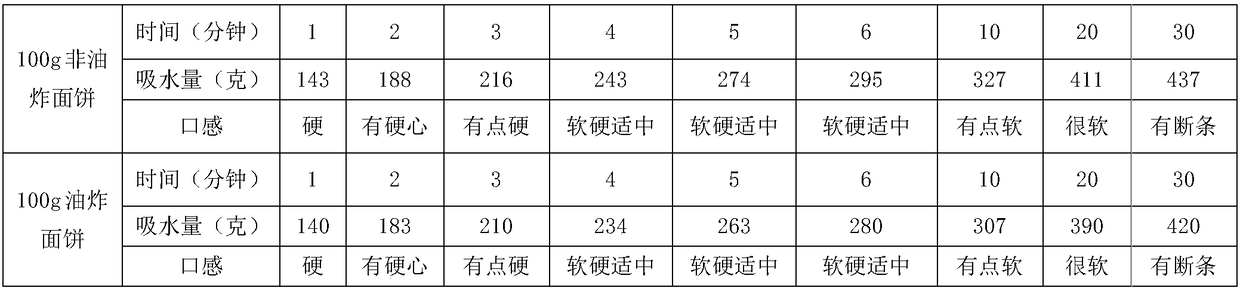

High-aluminizing-fastness BOPP base film for low-temperature laser mold pressing and preparation method thereof

ActiveCN111703159AGood molding performanceGood compatibilitySynthetic resin layered productsFlat articlesLow-density polyethylenePolypropylene

The invention discloses a high-aluminizing-fastness BOPP base film for low-temperature laser mould pressing, which consists of an outer surface layer, a middle layer and an inner surface layer, wherein the inner surface layer is a mould pressing layer and is prepared from the following raw materials in percentage by mass: 1 to 10 percent of anti-blocking master batch, 10 to 20 percent of maleic anhydride grafted modified polypropylene and the balance of modified mould pressing master batch; the modified mould pressing master batch is prepared by blending a propylene-butadiene-ethylene terpolymer, alpha-olefin and metallocene linear low-density polyethylene according to a mass ratio of (40-90) : (20-40) : (20-40). The invention also discloses a preparation method of the BOPP base film withhigh aluminizing fastness for low-temperature laser mould pressing. The BOPP base film disclosed by the invention can be used for mould pressing under a low-temperature condition of 80 DEG C, and thenlaser is carried out; the BOPP base film has the advantages of low mould pressing temperature, low thermal shrinkage rate, high aluminizing fastness, excellent physical properties, excellent opticalproperties and the like.

Owner:ANHUI GUOFENG PLASTIC

Anti-dazzle anti-fingerprint wear-resistant hardening liquid with rubber hand feeling, and preparation method thereof

PendingCN113683952AGood rubber skin feelGood slipperinessPolyurea/polyurethane coatingsPhotoinitiatorPolymer chemistry

The invention discloses an anti-dazzle anti-fingerprint wear-resistant hardening liquid with rubber hand feeling, and a preparation method thereof. The hardening liquid comprises, by weight, 40-50 parts of organic fluorine-silicon special modified polyurethane acrylic resin, 10-15 parts of special modified UV matte polyurethane acrylic resin, 5-10 parts of an acrylic monomer, 1-5 parts of a photoinitiator, 1-2 parts of fluorine-containing acrylic compound resin, 1-3 parts of a rubber skin feeling auxiliary agent, 4-5 parts of matting powder, 3-4 parts of wear-resistant powder, 1-2 parts of an anti-settling agent, 1-2 parts of a wetting dispersant and 20-30 parts of a solvent. The hardening liquid obtained by the invention is high in hardness, good in hand feeling, good in wear resistance and excellent in anti-fingerprint effect, can meet the higher requirements of the market on anti-glare hardening liquid, can be used for spraying and also can be used for shower coating, and compared with spraying, the shower coating can greatly reduce the production cost, avoid environmental pollution and relieve harm to human bodies.

Owner:湖南宏泰新材料有限公司

Grafting onto a polyamide powder by gamma-irradiation

The subject of the invention is a process for producing polyamide, copolyamide, polyolefin, copolyester amide or fluorocarbon resin powder particles on to the surface of which has been grafted at least one functionalized grafting monomer, characterized in that it comprises: a) a step of blending the polyamide or copolyamide powder particles with the functionalized grafting monomer; followed by b) a step of irradiating the powder impregnated with functionalized grafting monomer resulting from a) with photons (γ-radiation) or electrons (β-radiation), with a dose ranging from 0.5 to 15 Mrad. The invention also relates to the particles grafted in this way and to the compositions containing such particles.

Owner:ARKEMA FRANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com