Patents

Literature

572results about "Baking processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

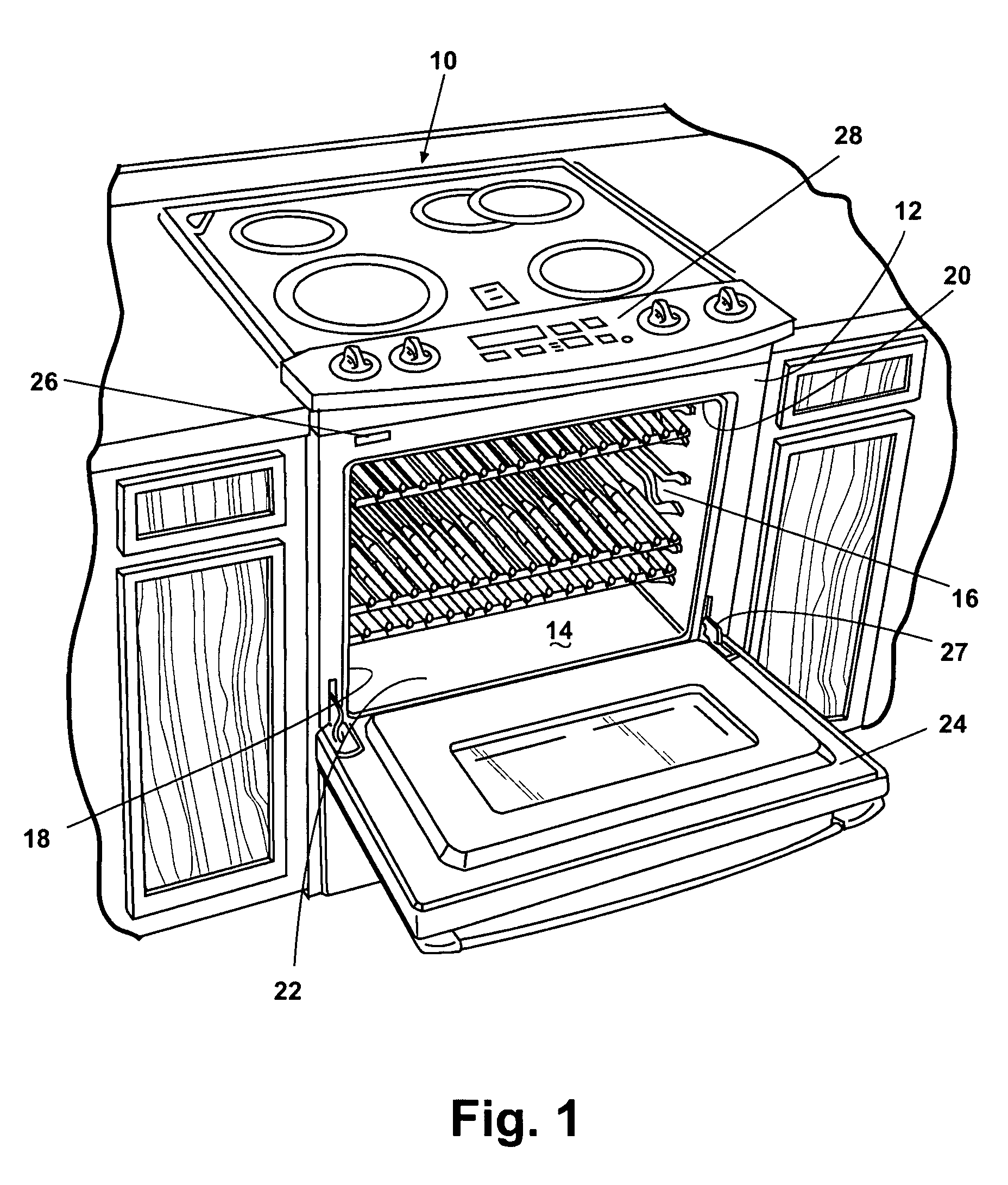

Convection oven

ActiveUS8378265B2Easy accessSelf-cleaning stoves/rangesElectrical heating fuelImpellerLiquid-crystal display

Owner:DUKE MANUFACTURING COMPANY

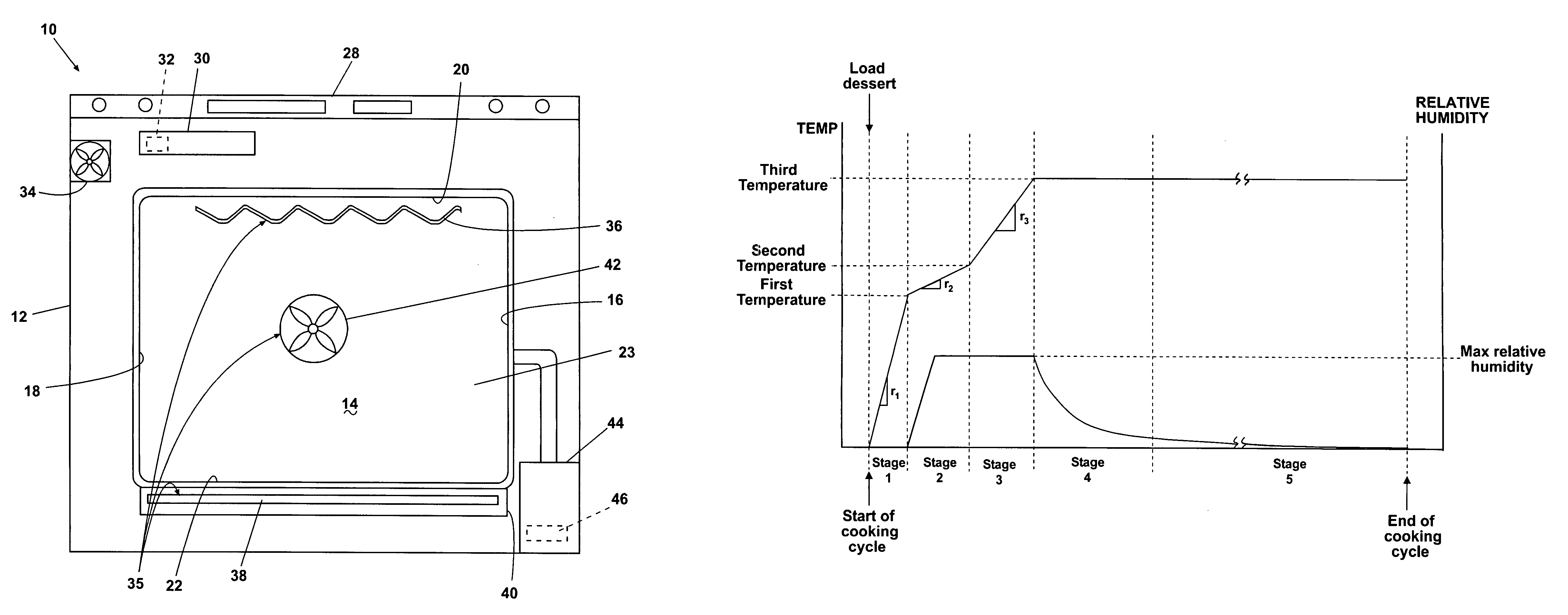

Method for baking a dessert using steam

A method of baking a dessert using steam in an automated household oven comprises a first heating step where a heating system preheats a cooking cavity to a first temperature at a first heating rate and a second heating step where the heating system preheats the cooking cavity from the first temperature to a second temperature at a second heating rate less than the first heating rate. The first temperature is preferably about the boiling point of water, and a steam system introduces steam into the cooking cavity to facilitate baking of the dessert after the cooking cavity reaches the first temperature. A convection fan of the heating system is active during the first and second heating steps to help circulate air and steam in the cooking cavity and becomes inactive later in the baking method.

Owner:WHIRLPOOL CORP

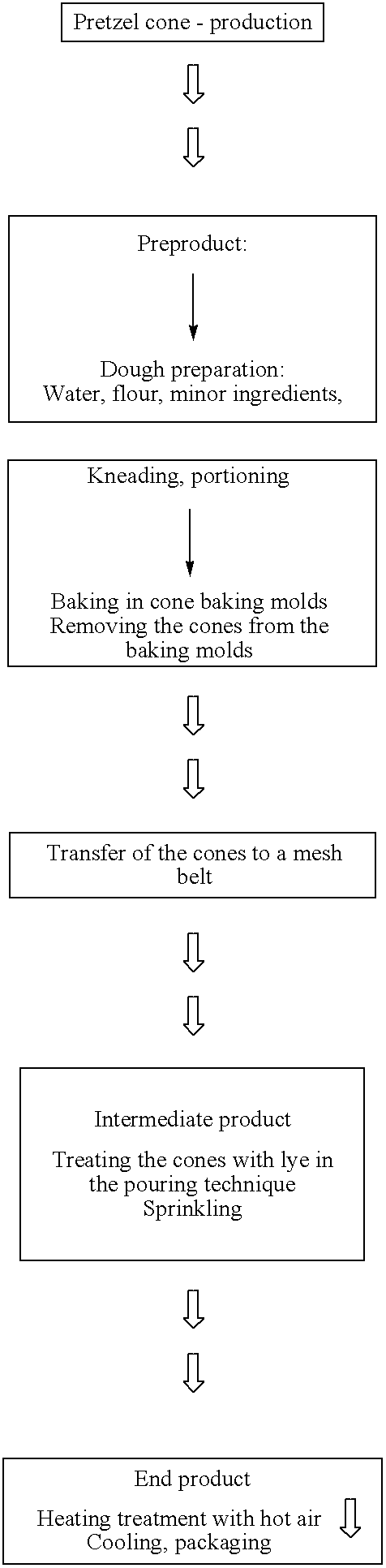

Method for producing baked objects, at least parts of which are a glossy brown

InactiveUS20060057269A1Adverse flavoring effectAdverse nutritional effectBaking mixturesPreservation by heat treatmentThermal treatmentMoisture

The invention relates to a method for producing objects, at least parts of which are a glossy brown. In a first step, an at least par-baked, dimensionally stable shaped body is produced, said body is treated as a dimensionally stable pre-product in a second step at least partially with lye. The intermediate product thus obtained can be sprinkled with a granular topping in an additional step. In the final step, the intermediate product is subjected to renewed thermal treatment, in order to brown the areas treated with lye and optionally reduce the moisture in its interior.

Owner:FRANZ HAAS WAFFELMASCHEN IND MBH

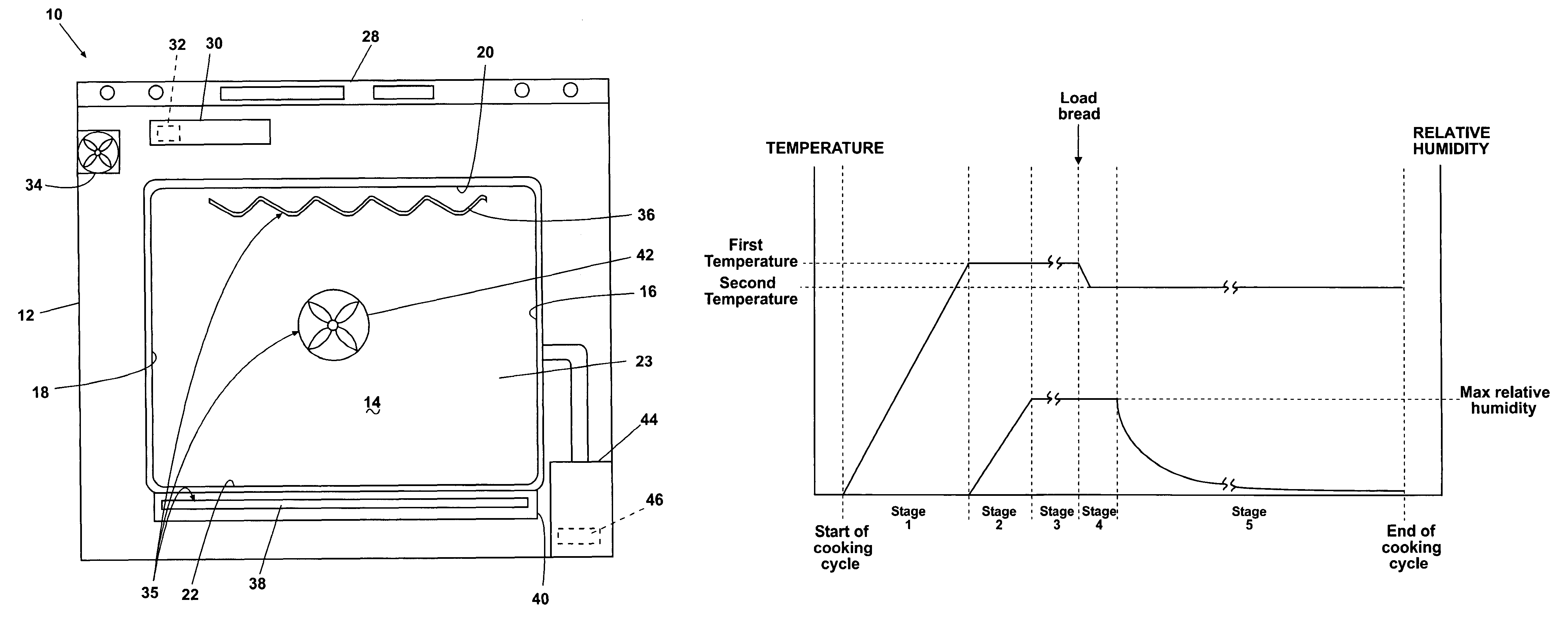

Method for baking bread using steam

A method of baking bread using steam in an automated household oven with a cooking cavity and a steam system for introducing steam into the cooking cavity comprises determining a presence of bread in the cooking cavity and introducing steam into the cooking cavity upon a positive determination of the presence of bread. After the positive determination, the steam is introduced into the cavity to maintain a desired relative humidity in the cavity for a predetermined period of time to aid in formation of a moist, flexible crust on the bread, and the amount of steam introduced into the cavity decreases after the predetermined period of time. The cavity can be preheated and prehumidified prior to the determining of the presence of the bread in the cooking cavity.

Owner:WHIRLPOOL CORP

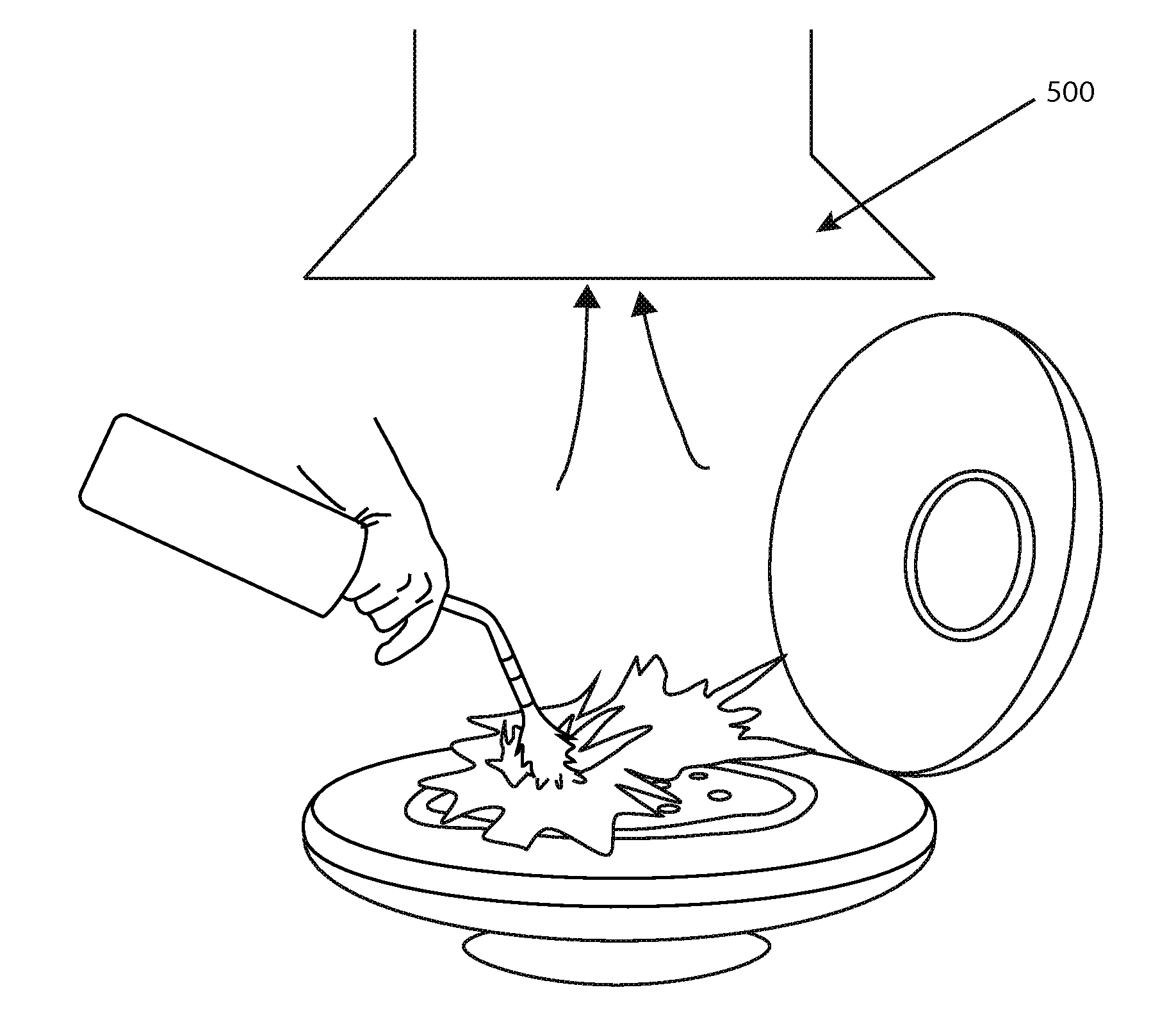

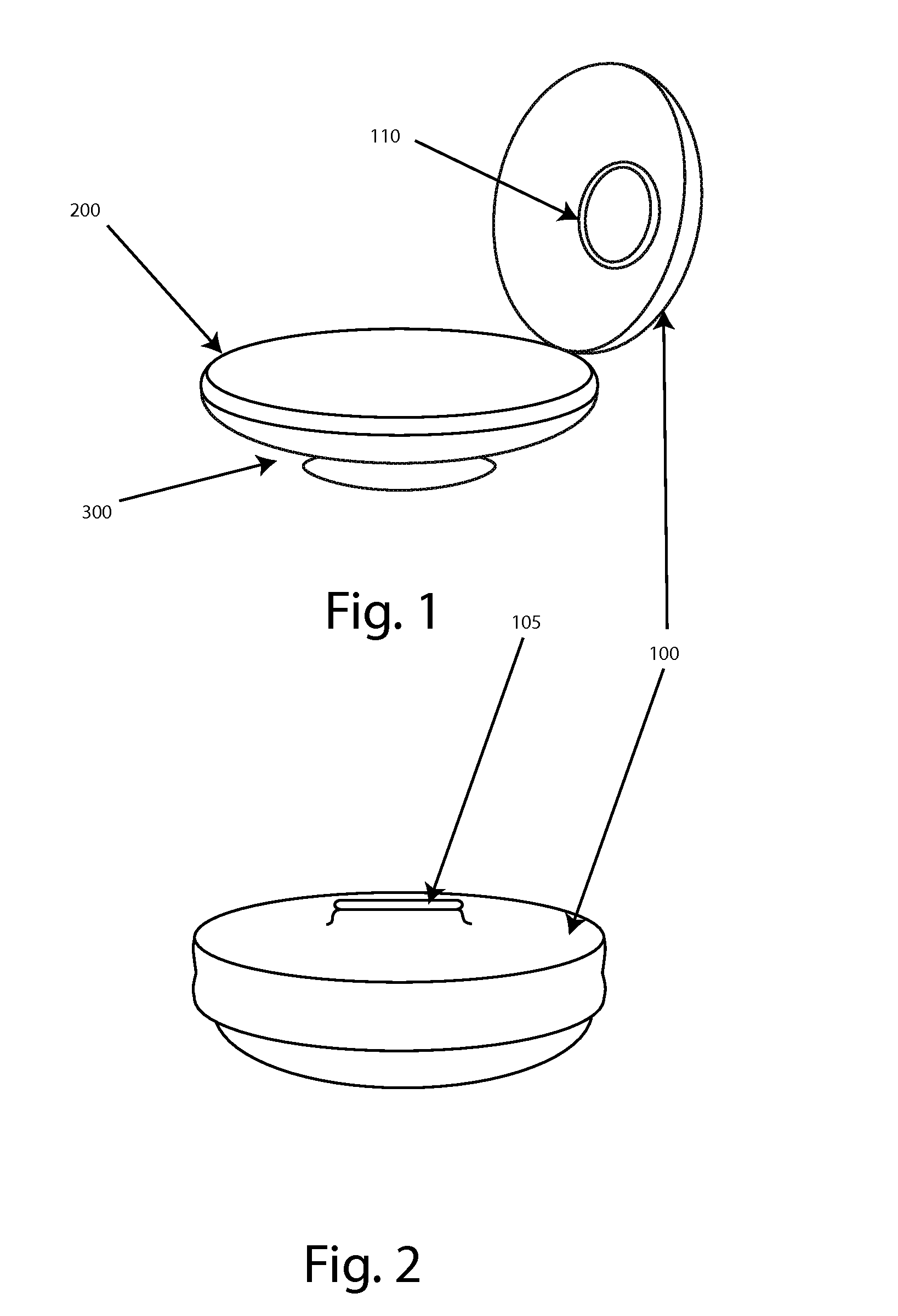

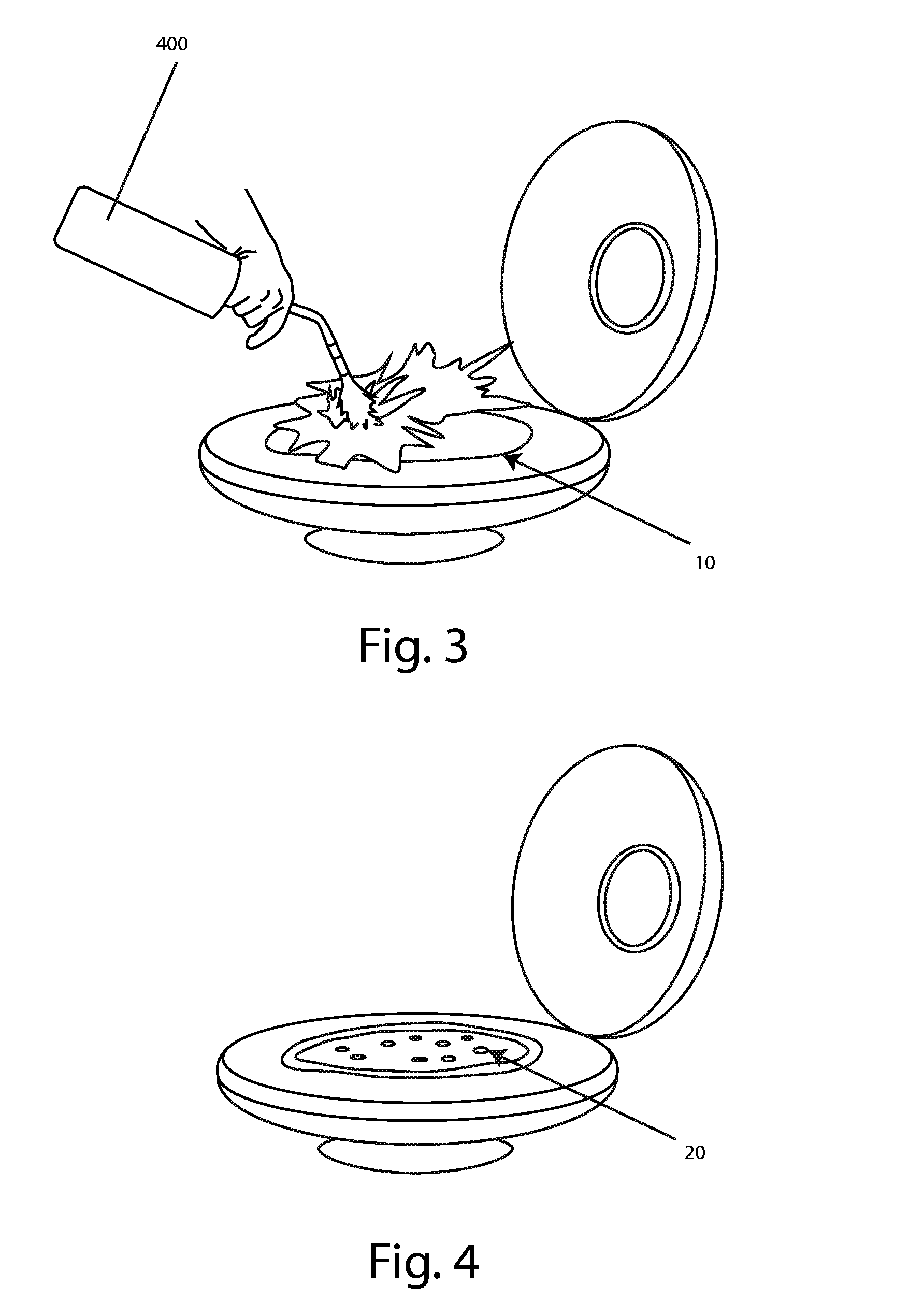

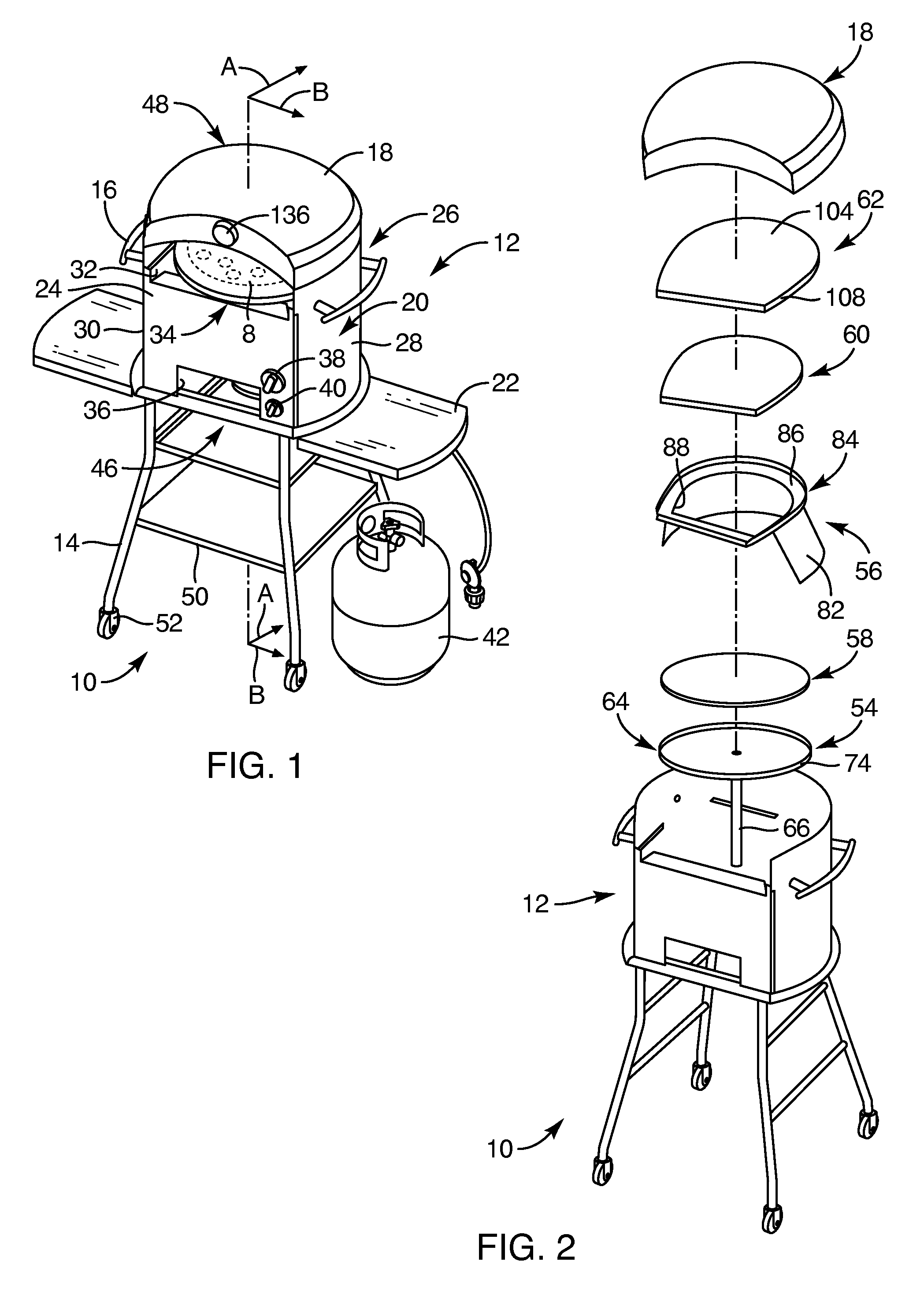

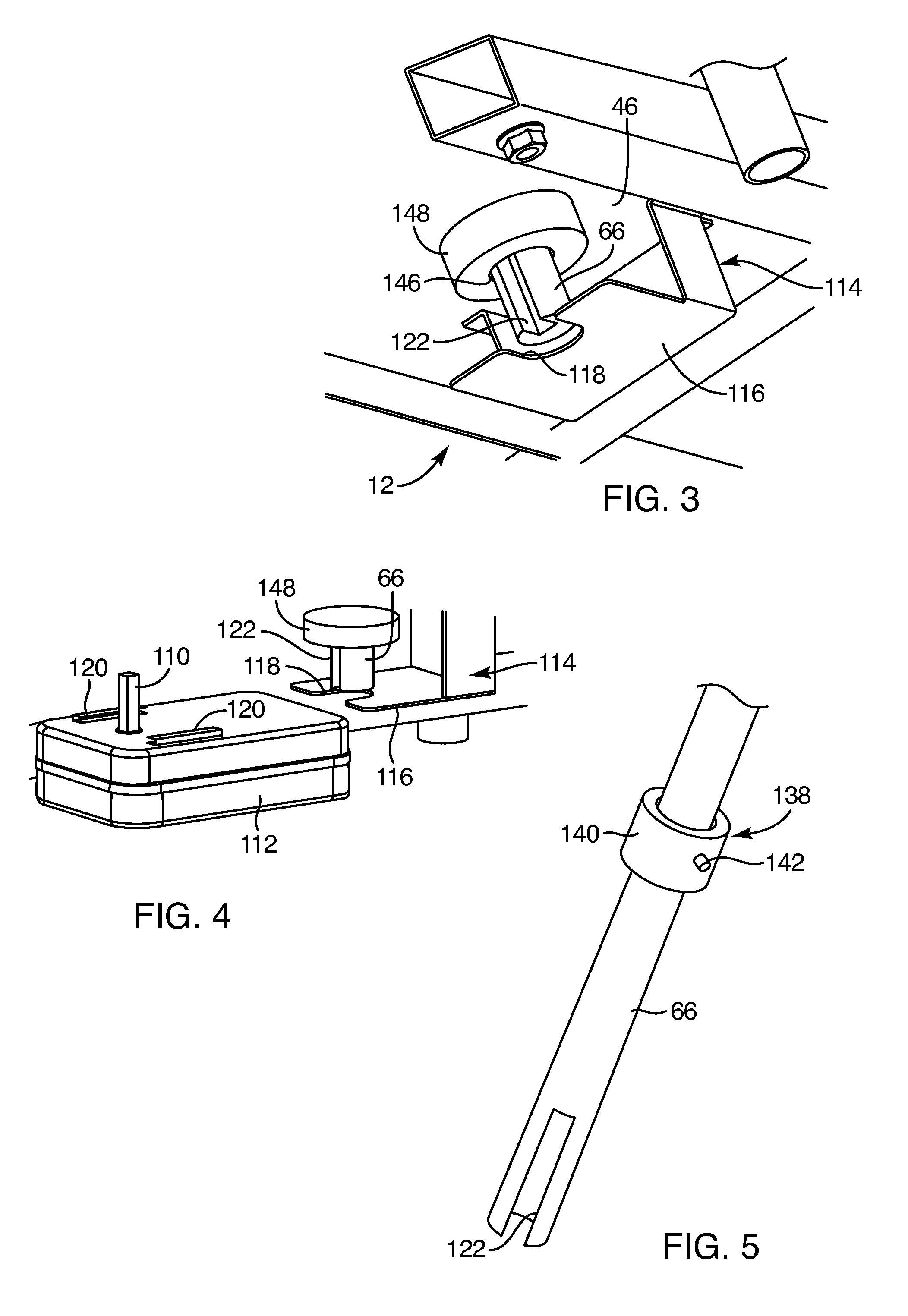

Method and Apparatus for Cooking Pizza

InactiveUS20120258229A1Increase heatImproved heat outputHot plates heating arrangementsBaking processesEngineeringHigh heat

A pizza is prepared while it is constructed using a novel process and device. Dough is placed onto a thermal mass, followed by the use of a handheld very high heat source to sear the top surface of the dough. As the pizza dough remains in contact and continues to bake on the thermal mass, toppings are added. The toppings and dough can be selectively seared with the handheld device, and / or allowed to temper with or without the aid of a lid. The lid has a low profile and flat top and creates a minimal cooking volume when placed over the thermal mass. The searing occurs in sections and allows the pizza cook to selectively cook, char, comingle and caramelize the toppings and dough of the pizza.

Owner:MINDRUP JEF

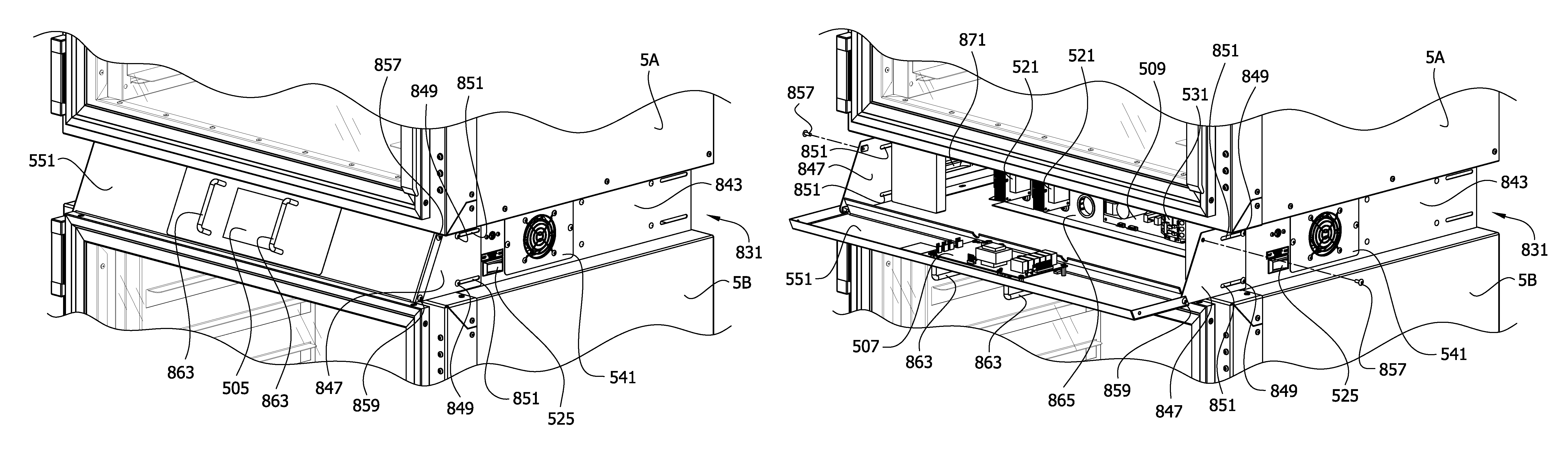

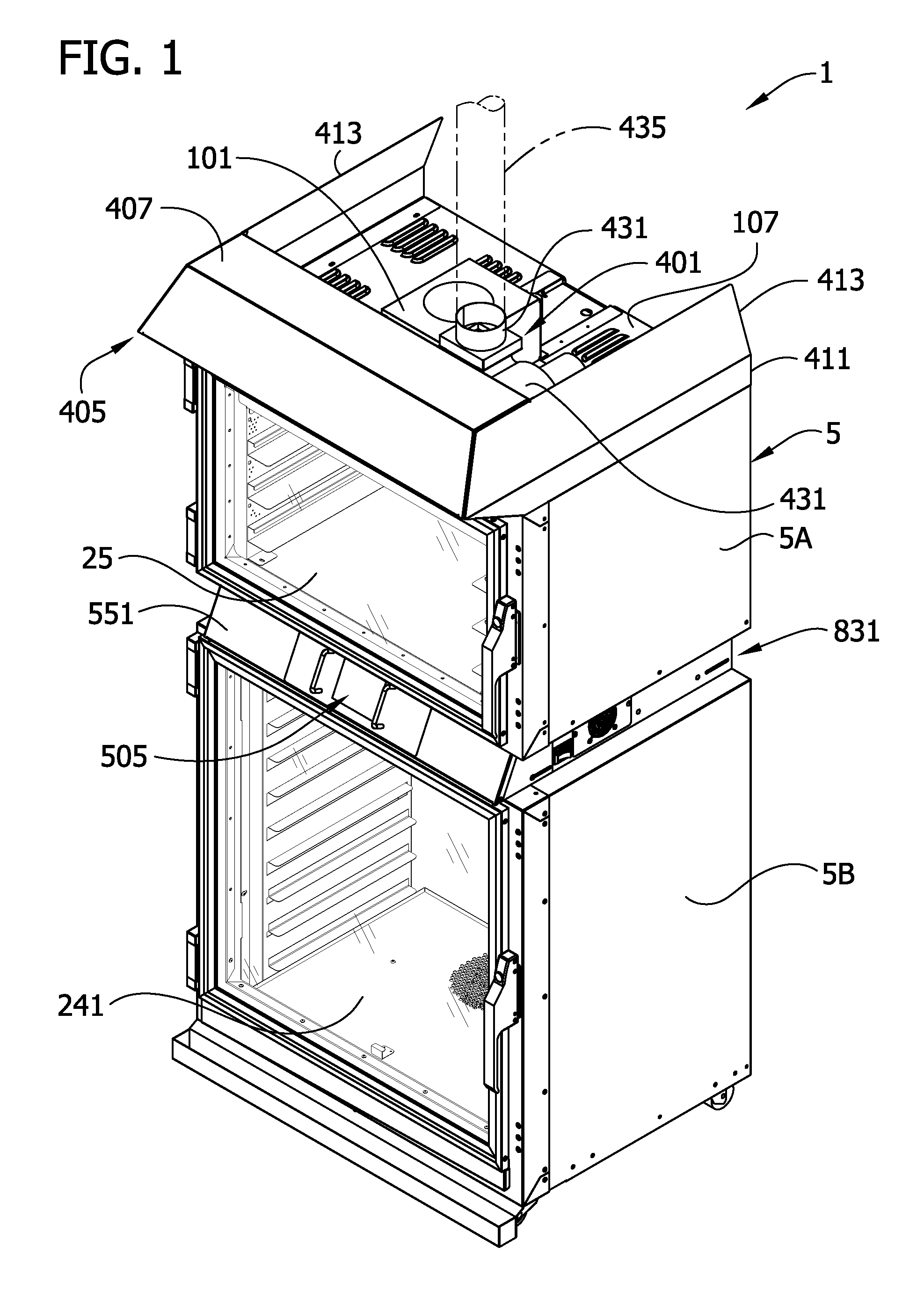

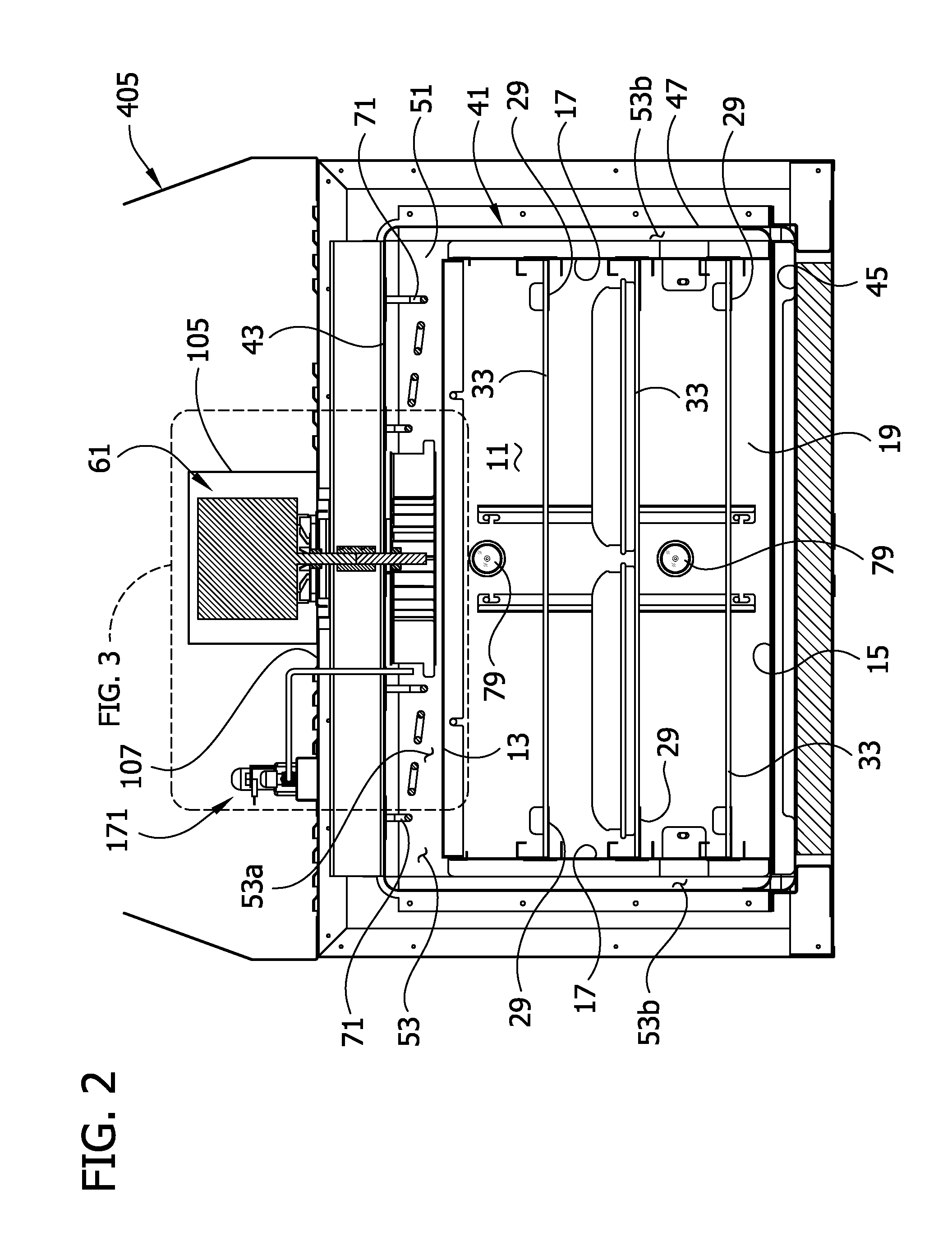

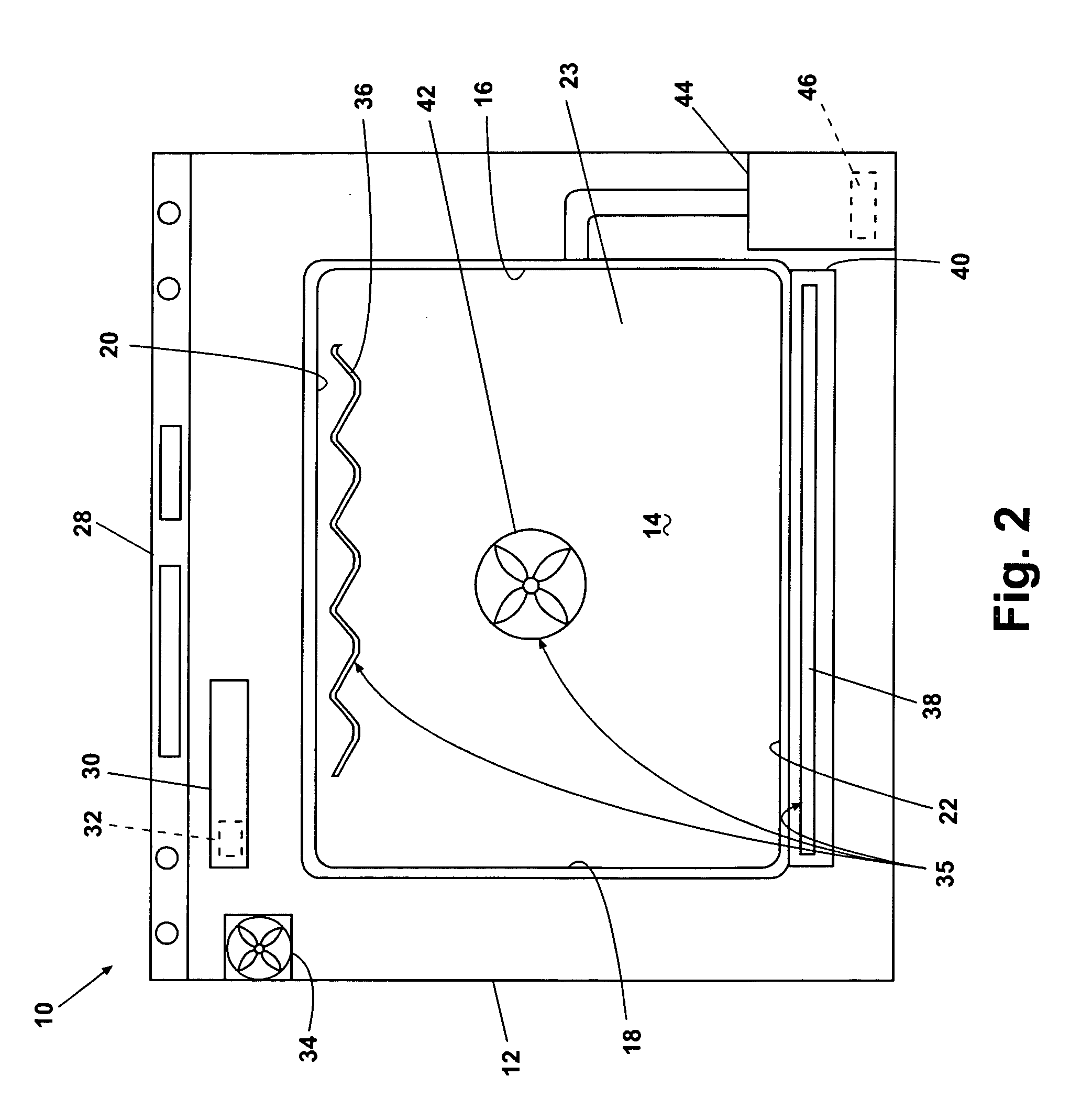

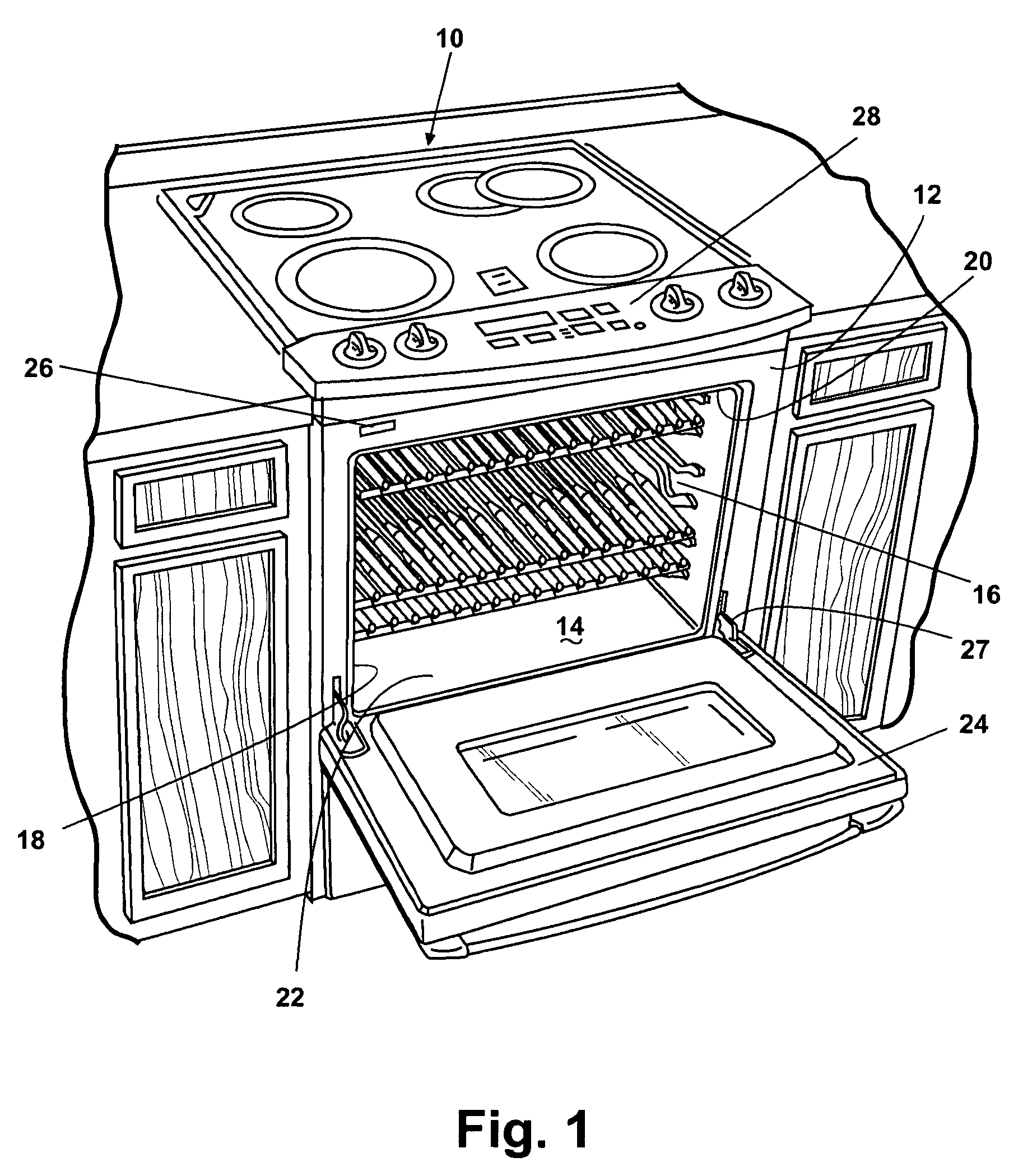

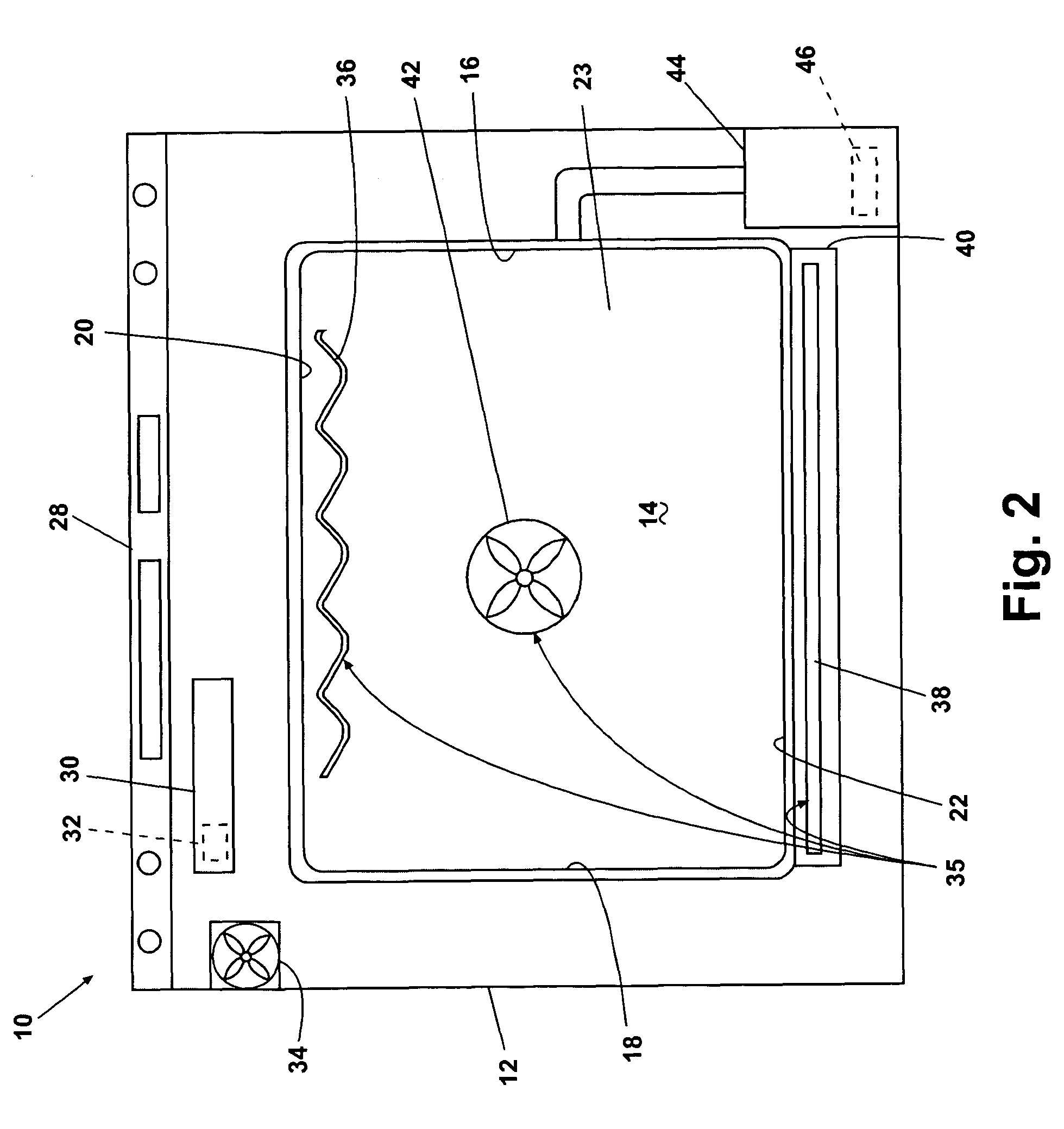

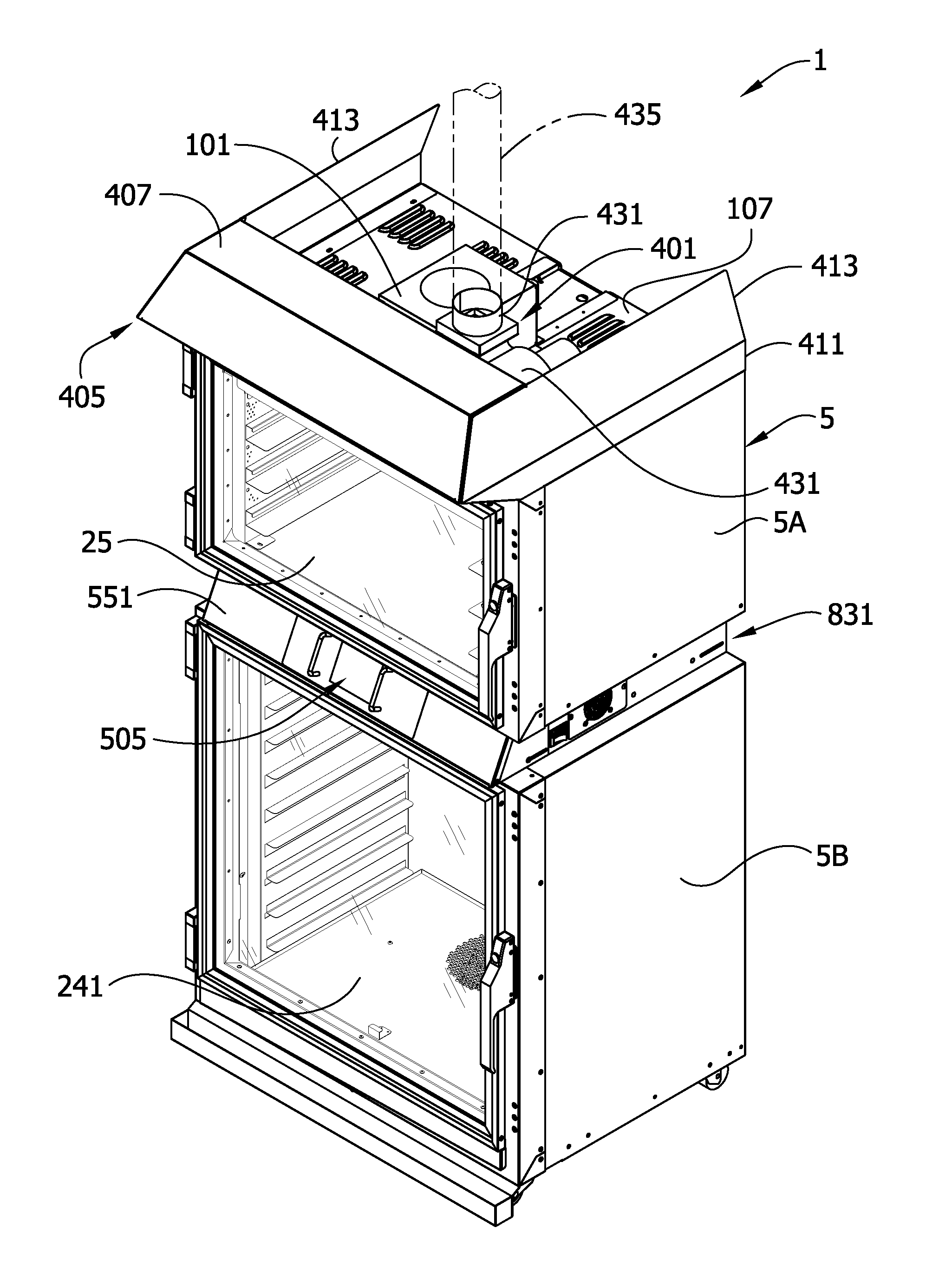

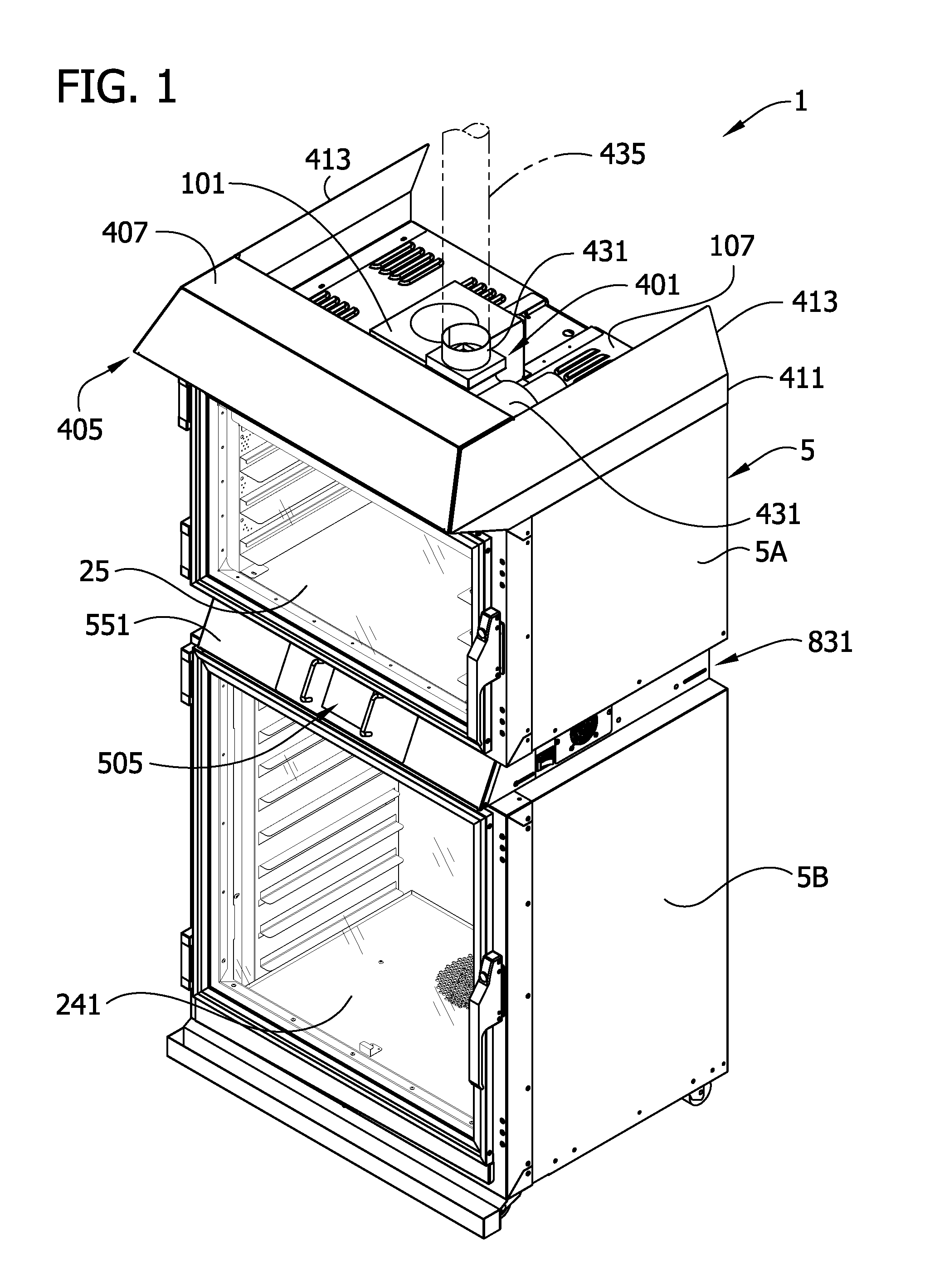

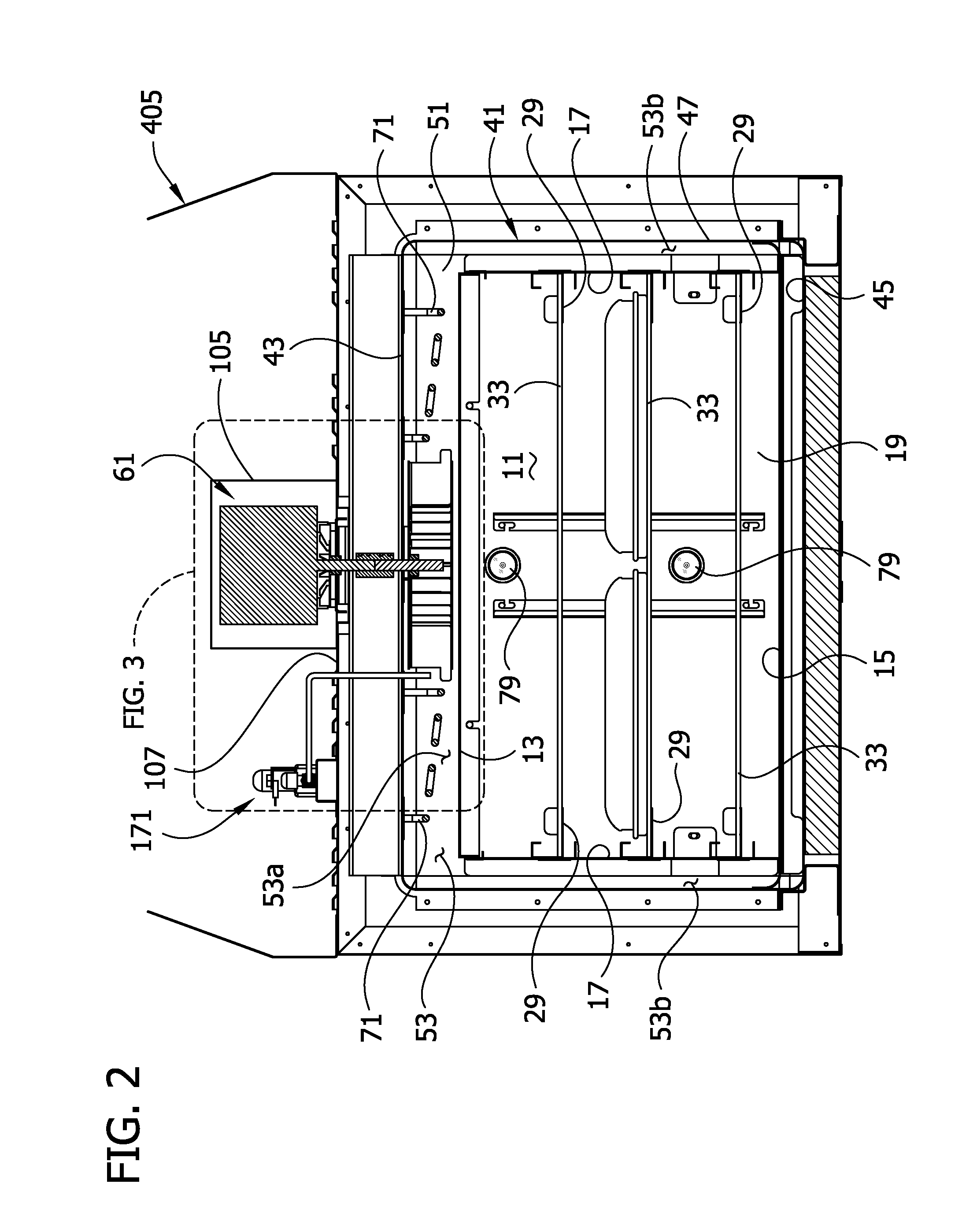

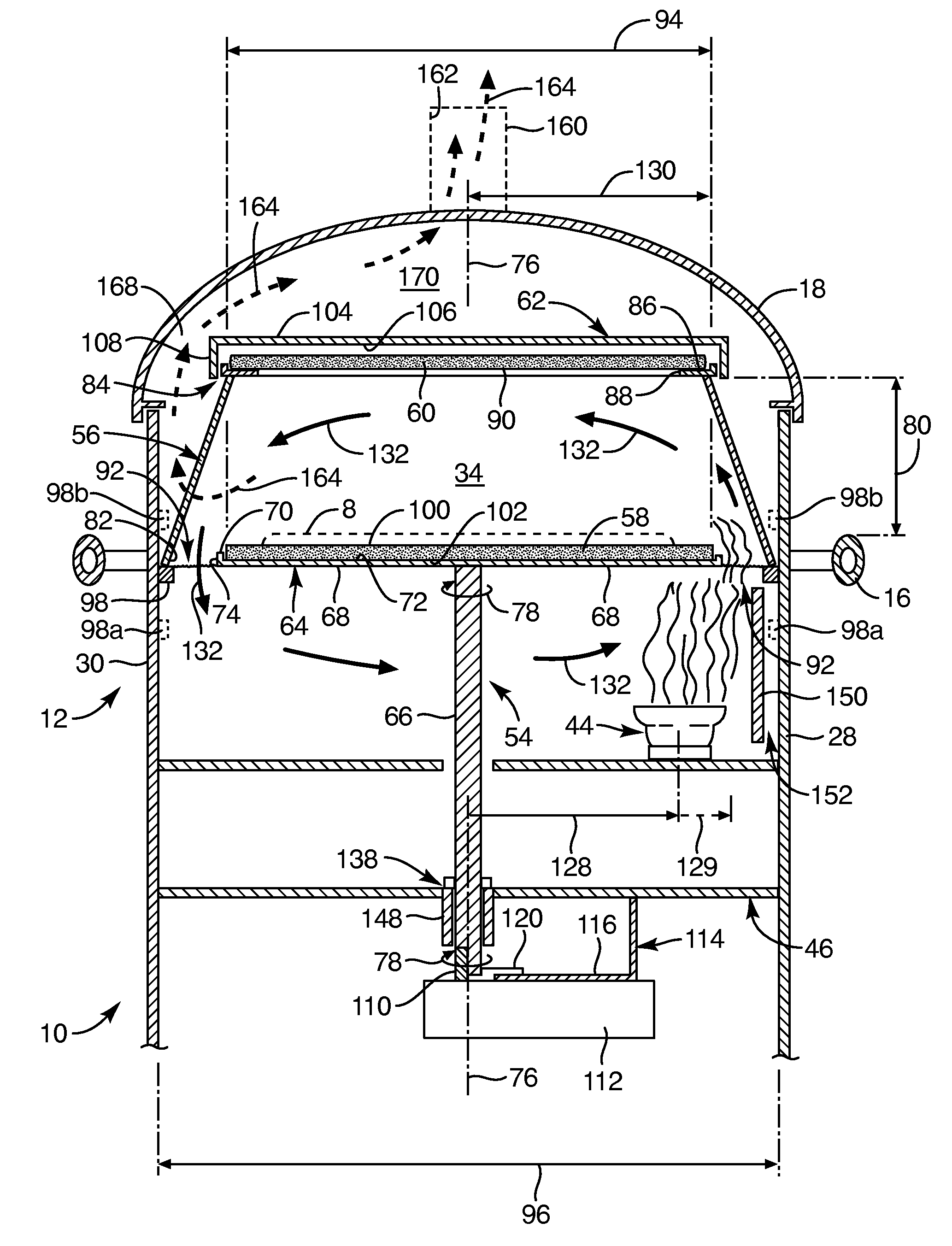

Convection oven

ActiveUS20100301034A1Easy accessDomestic stoves or rangesElectrical heating fuelImpellerLiquid-crystal display

A convection oven having a vapor collection system; water injection system; easily accessible electrical components; and a variable-speed, reversible blower is disclosed. The vapor collection system collects vapor from the cooking chamber during a cooking event, condenses the vapor, and drains the condensed vapor. The water injection system injects water for impact against a blower wheel for dispersion into the air circulating through the cooking chamber. The electrical components are housed within a housing that in a closed position conceals the components and in a closed position exposes the components for easy access. The rotational speed and direction of the variable-speed, reversible blower is controlled during a cooking event according to predetermined speed curves which may include one or more reversal events to achieve more uniform cooking of food. A main controller is programmable via an operator input (e.g., liquid crystal display touch screen) to control operating parameters of the oven.

Owner:DUKE MANUFACTURING COMPANY

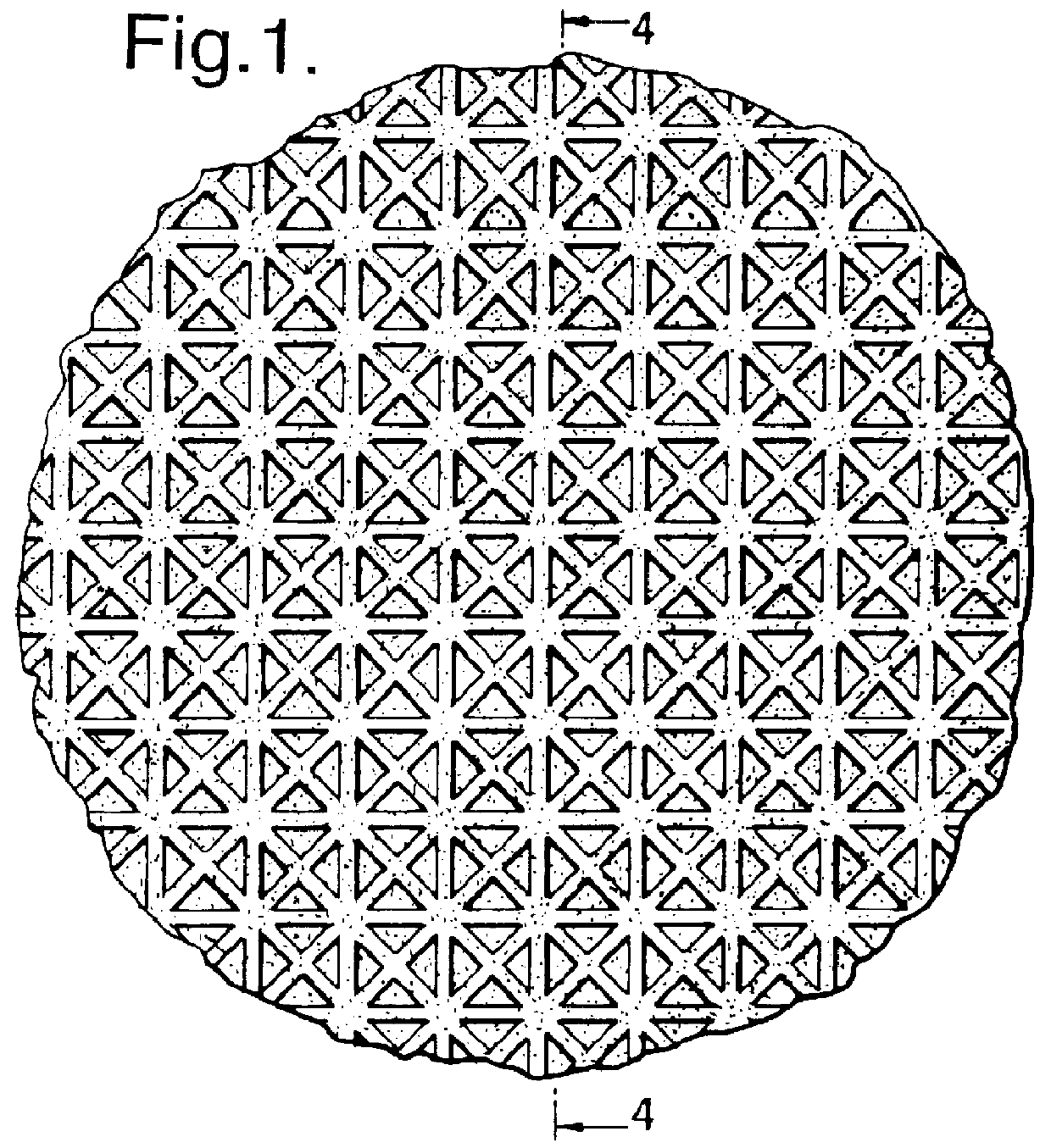

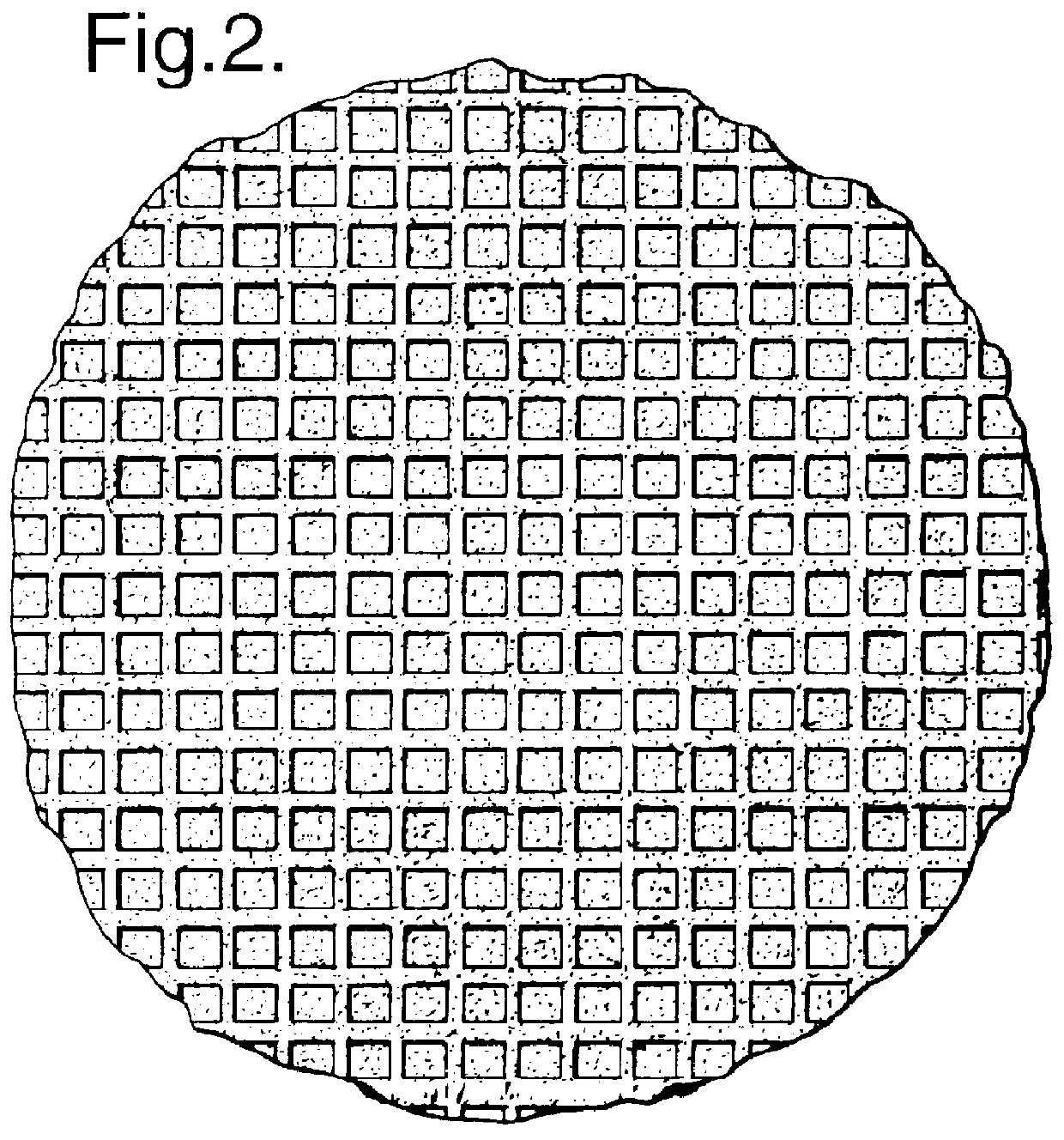

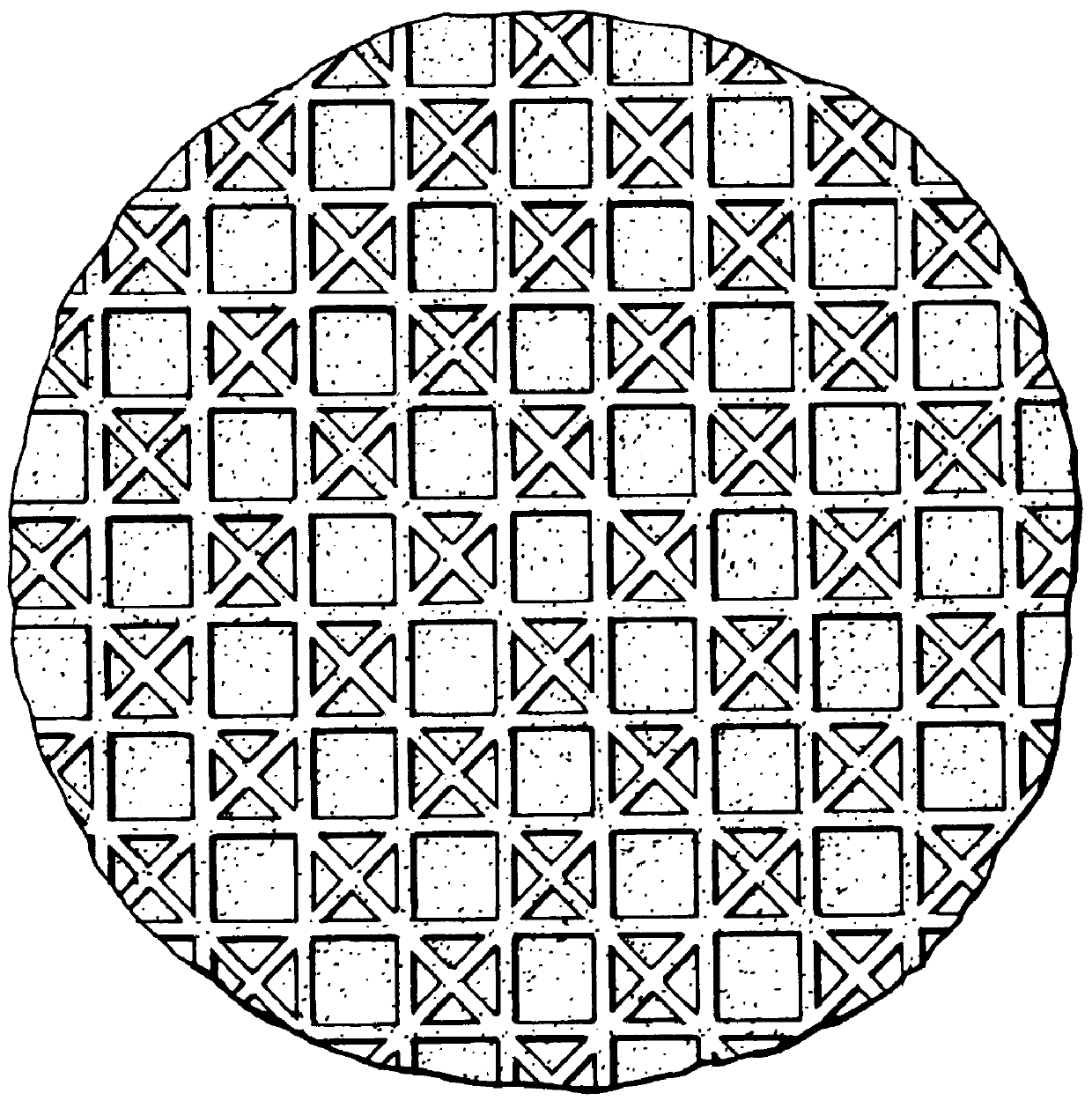

Wafer product and process of manufacture

A crisp, approximately circular wafer product is provided whereby the two surfaces of the wafer each have a pattern formed by ridges, the first surface having a pattern comprising at least two grid patterns superimposed on each other, one grid being at an angle of approximately 45 DEG to the other, the second surface having a single grid pattern, the pattern being at 45 DEG to the lower grid on the first surface.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Cake and processing process thereof

ActiveCN102696724ACrispy tasteBeautiful appearanceBaking processesBakery productsBiotechnologyPropionate

The invention relates to a cake and a processing process thereof. The cake comprises, by weight, 100 parts of low-gluten flour, 80-100 parts of egg white, 70-75 parts of egg yolk, 80-100 parts of sugar, 15-20 parts of milk, 15-20 parts of salt, 15-20 parts of whole milk powder, 5-10 parts of baking powder, 25-30 parts of honey, 8-10 parts of baking soda, 40-50 parts of oil, 5-10 parts of calcium propionate, 0.1-0.2 part of potassium sorbate and 10-15 parts of water. The cake is formed by fermentation, filling, primary baking, decapping, demolding, cooling, slicing, secondary baking, cooling, quick freezing, sterilization and packaging. The secondary baking process is added in the processing process so that the cake is crisp in taste from outside to inside and is a novel cake. Besides, thecake is attractive in appearance and good in taste, the grease content is low, dosage of a preservative is little, and compounding of calcium propionate and potassium sorbate enables the dosage of the preservative to be reduced and enables a shelf life to be prolonged.

Owner:邱万来

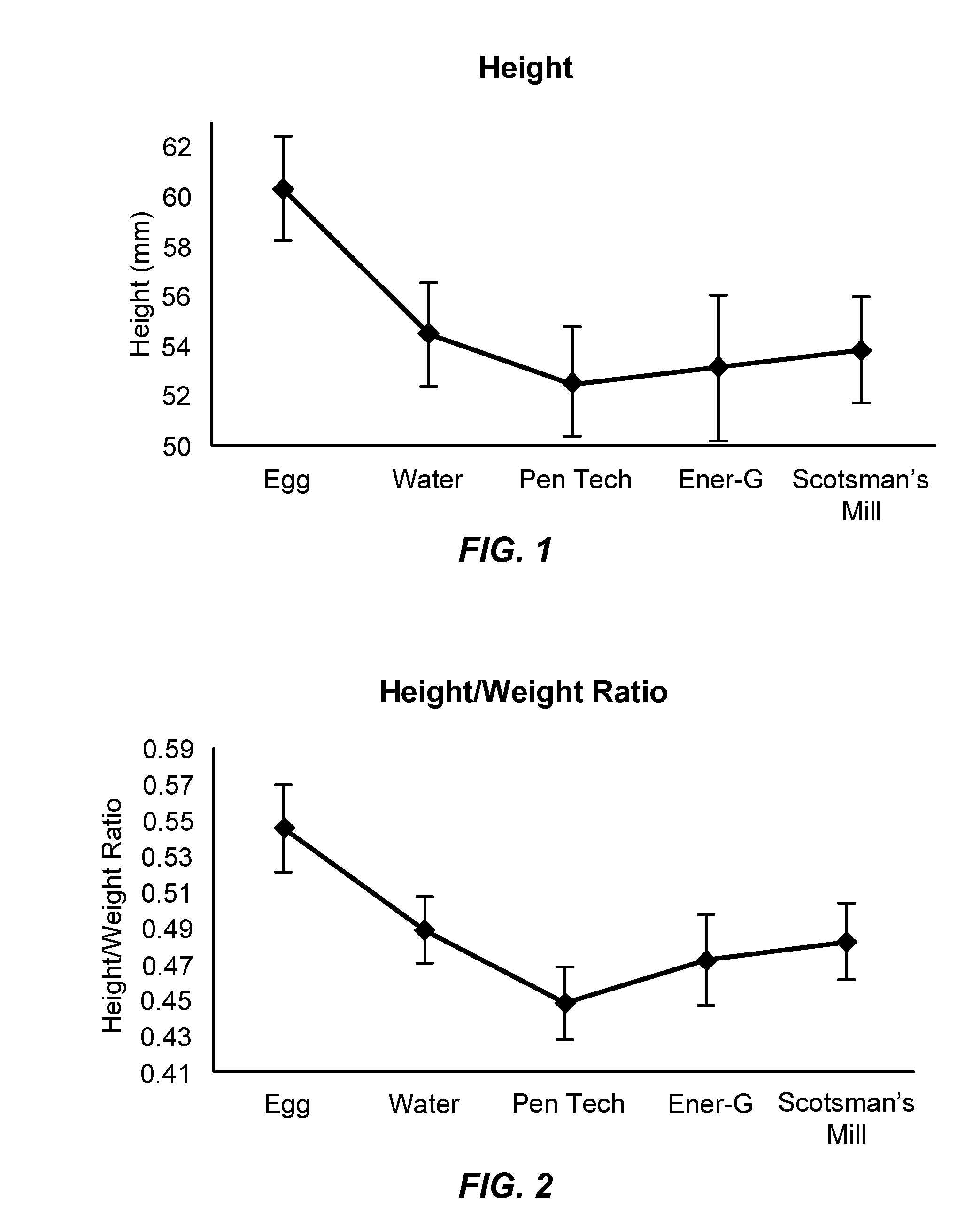

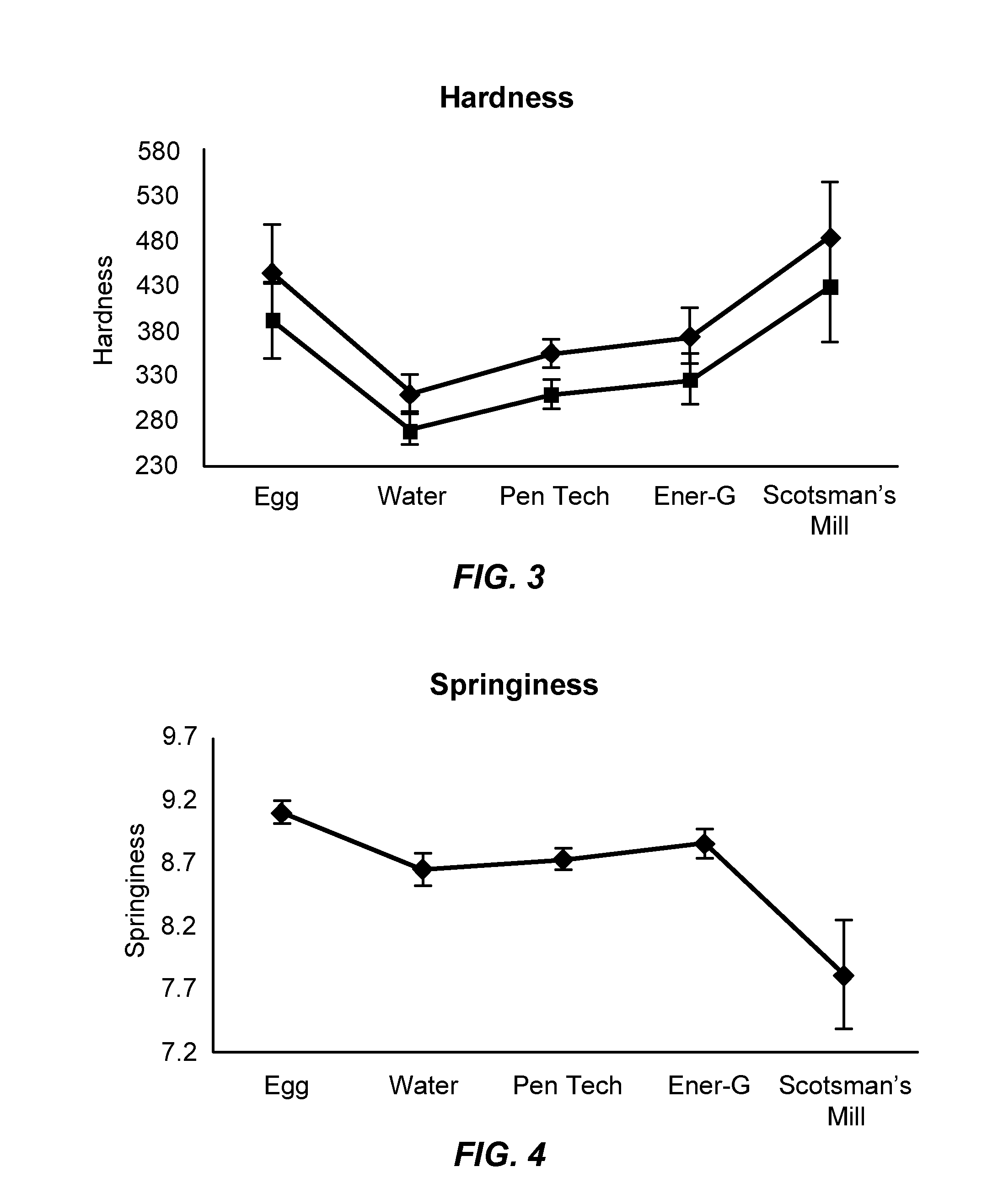

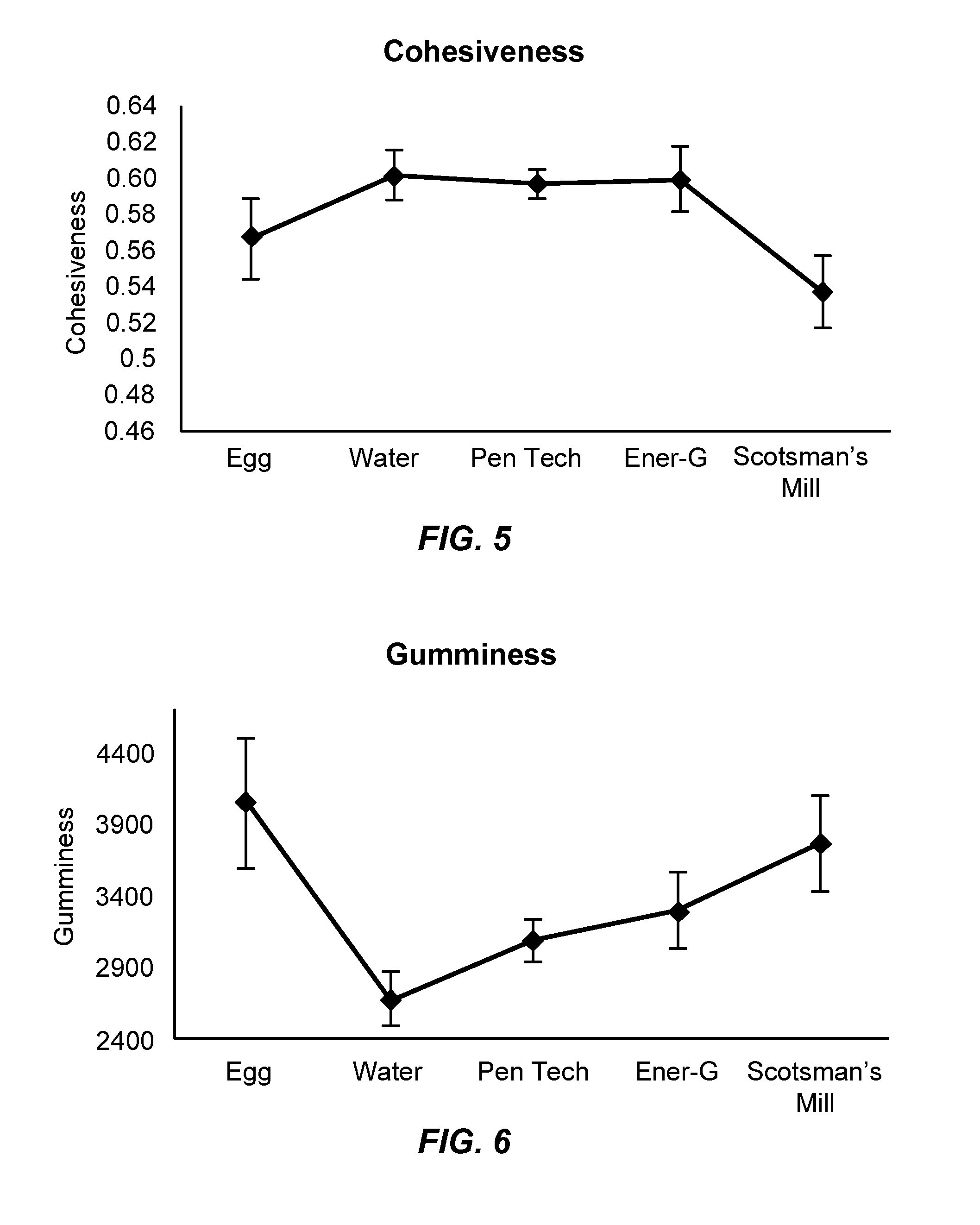

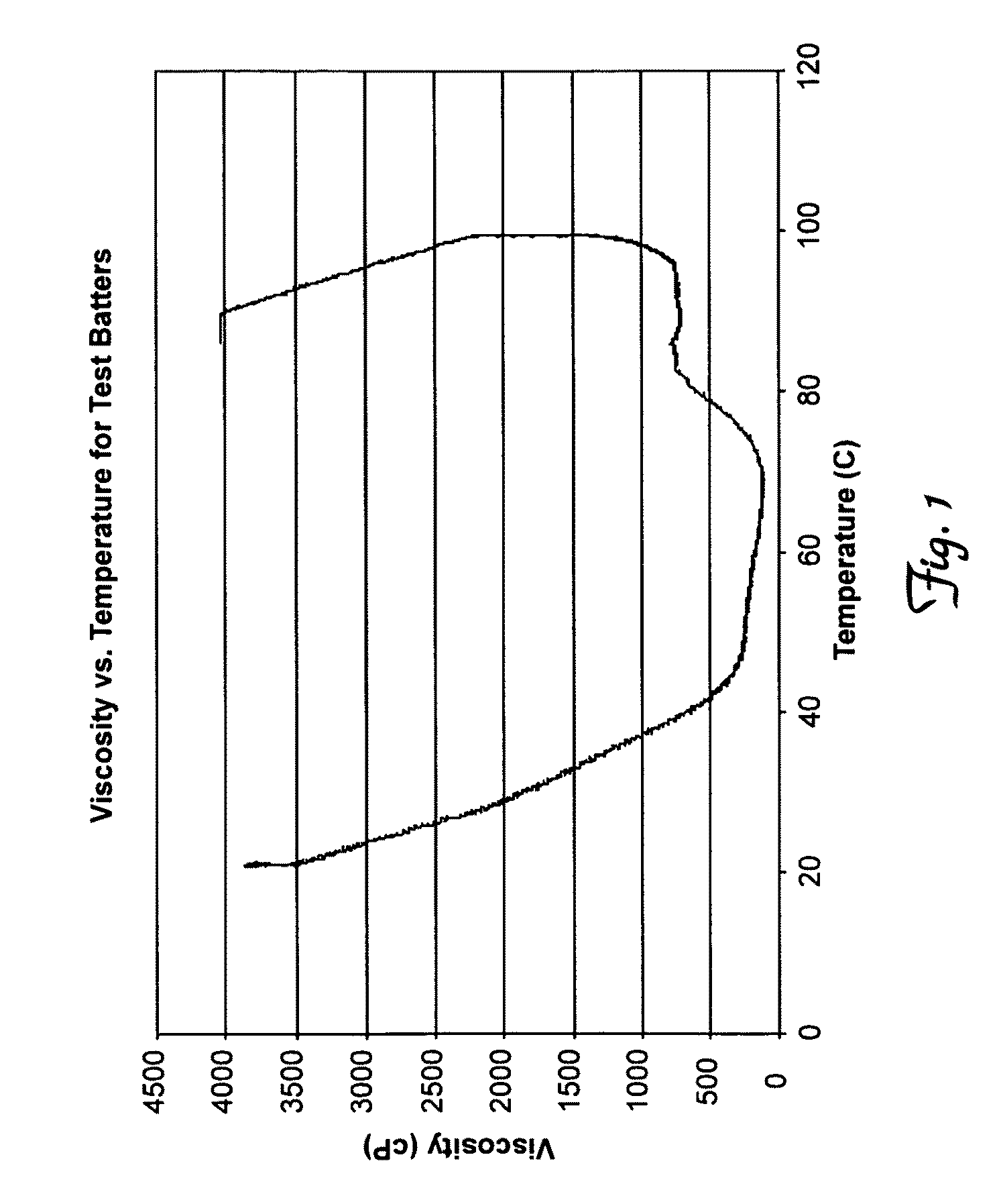

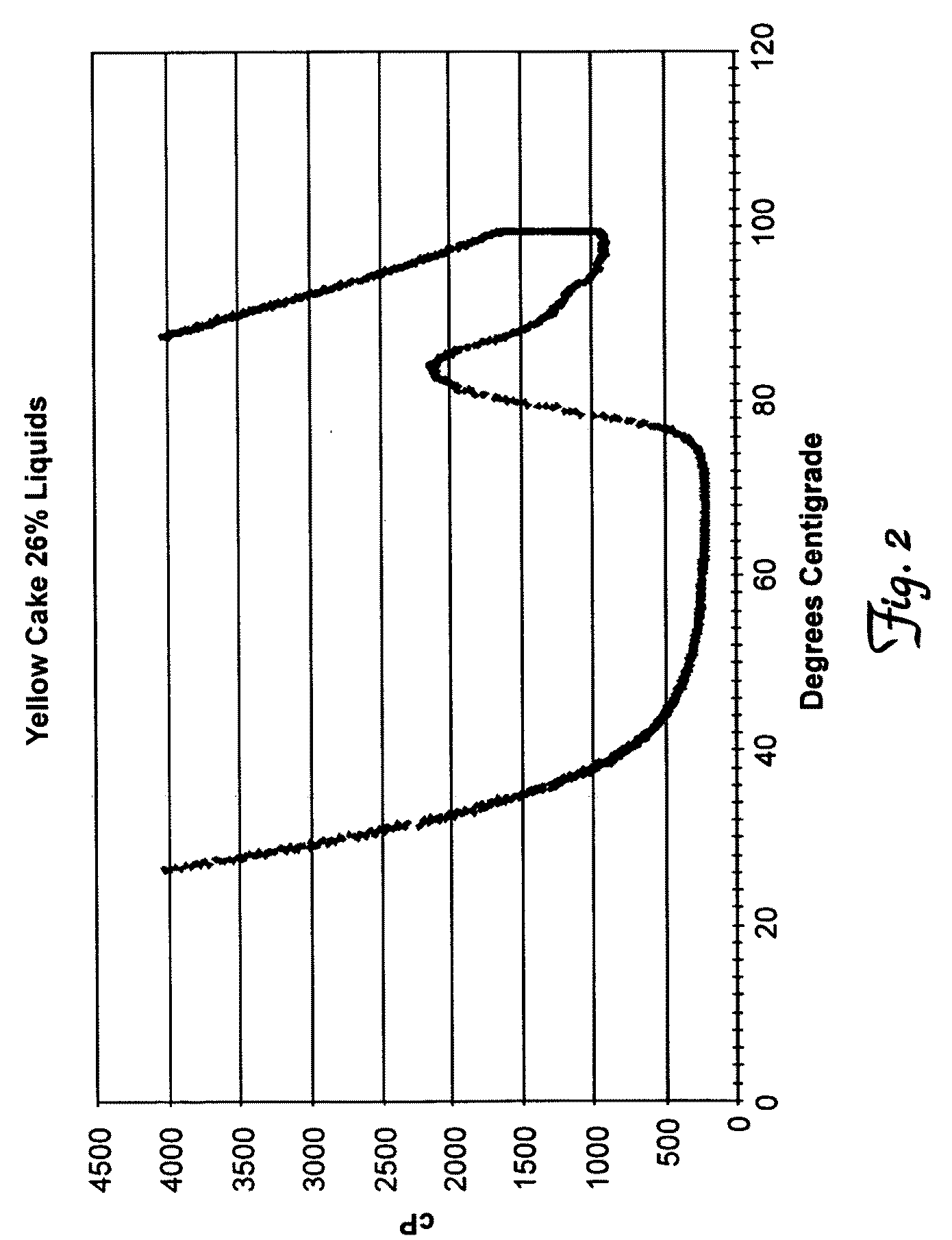

Plant-based egg substitute and method of manufacture

Disclosed herein are non-egg compositions that can be used as egg substitutes. The disclosure is directed to egg substitutes and methods of manufacturing the same, and compositions comprising the egg substitutes, including edible compositions such as baked goods and edible emulsions.

Owner:HAMPTON CREEK INC

Oil or fat composition

InactiveUS7060316B2Stable against thermal oxidationStable hydrolysisFatty acid esterificationFatty substance preservation using additivesOil and greaseCarboxylic acid

An oil or fat composition containing 15 wt % or more of diglyceride (component (A)) and 70 ppm or more, on the basis of the diglyceride, of an organic carboxylic acid (Component (B)).

Owner:KAO CORP

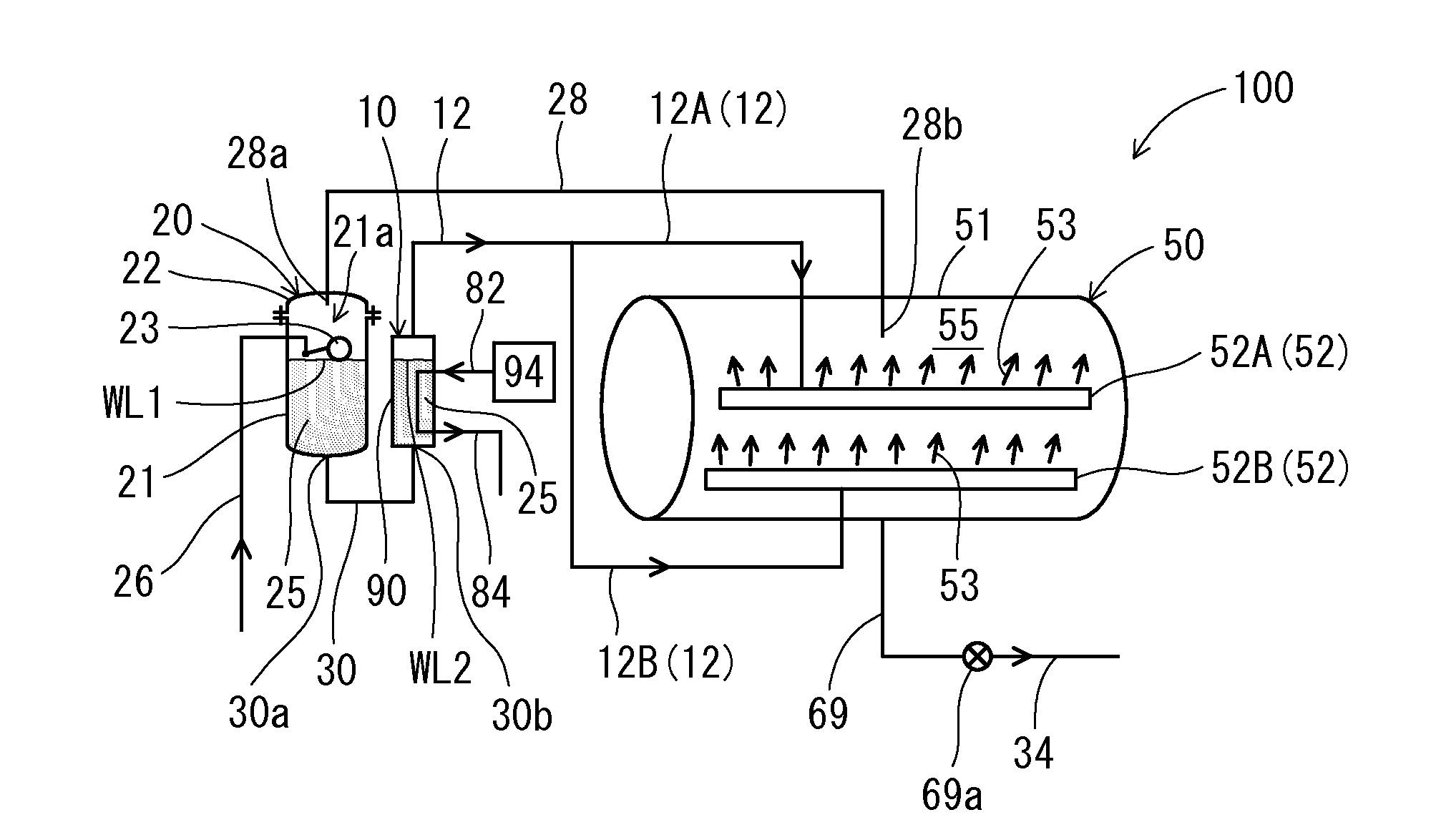

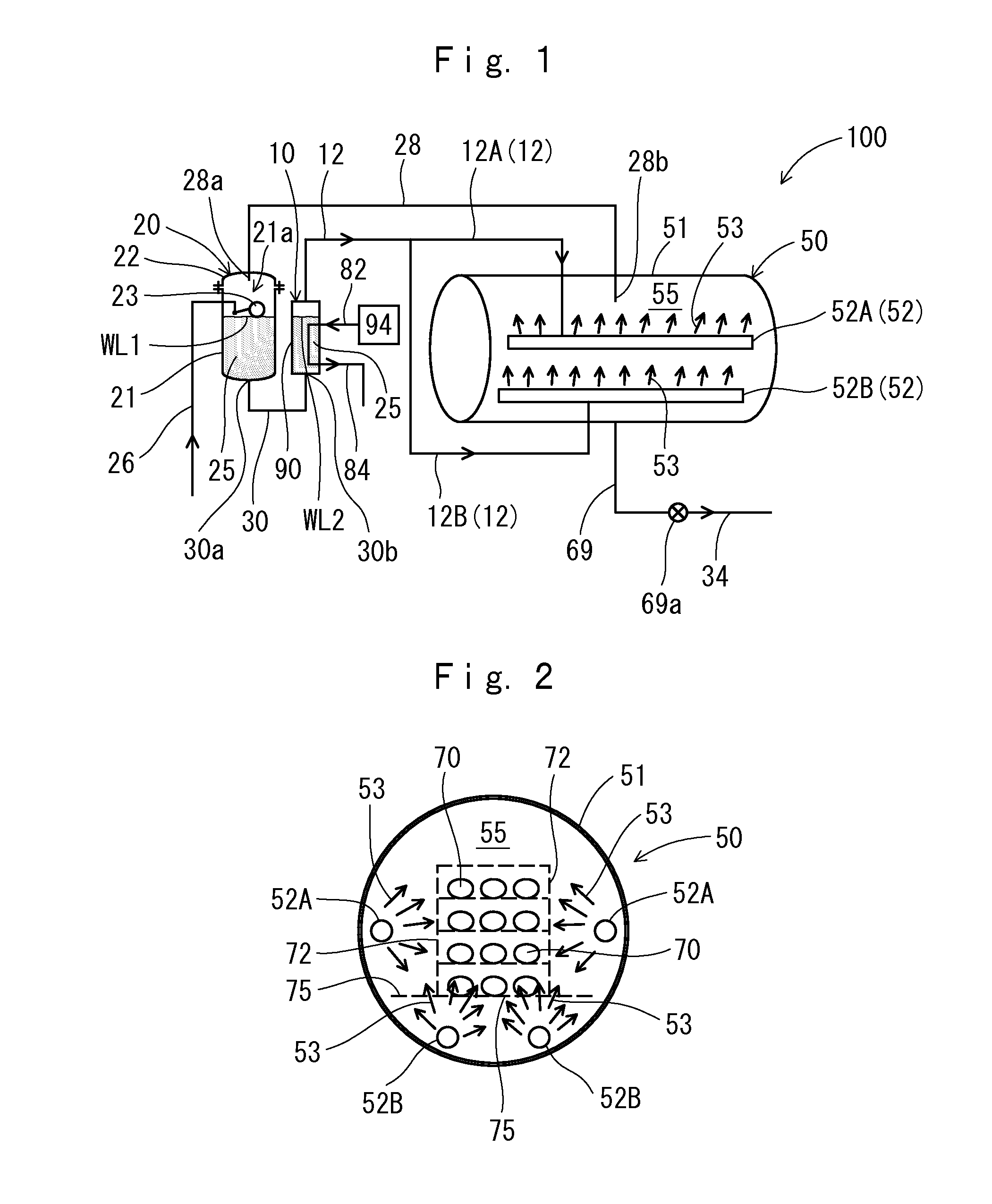

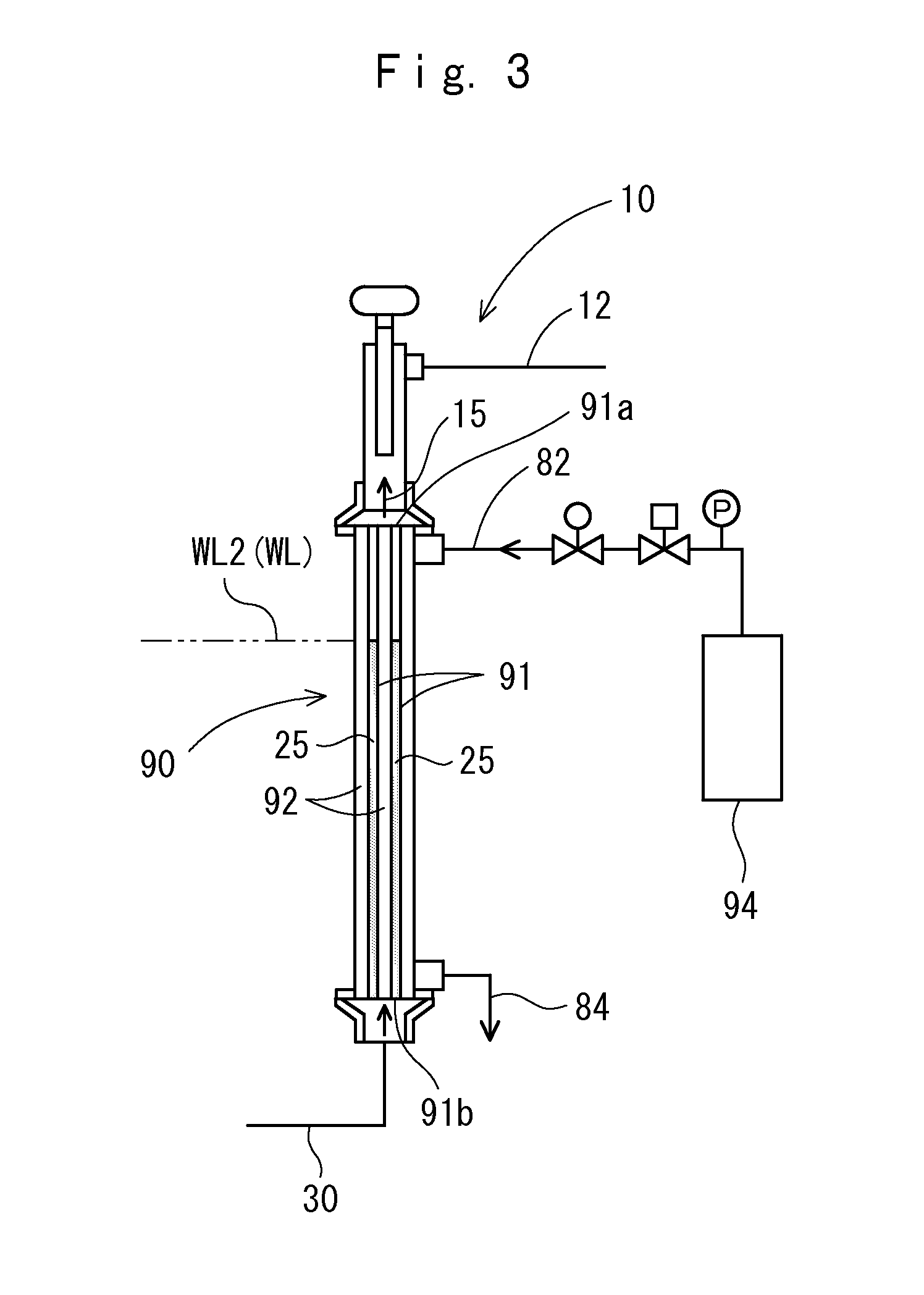

Retort sterilization device, heating device, heat sterilization method, and heat treatment method

ActiveUS20130071546A1Improve energy efficiencySuppress uneven heatingTea extractionTea substituesEngineeringSteam generation

A retort sterilization device includes a water steam generation device for generating water steam and a heating pot, connected to the water steam generation device, for accommodating retort food. The water steam generation device includes a heat exchanger for performing heat exchange between liquid flowing in a liquid path and heating vapor flowing in the vapor path. A top end of the liquid path of the heat exchanger is connected via a water steam supply pipe to a water steam ejection section located in an internal area of the heating pot. The heat exchanger is connected to a liquid container. A bottom end of the liquid path of the heat exchanger is connected to the liquid container via a communicating tube. The liquid container is coupled to the heating pot.

Owner:TOMODA SELLING & SAILING +3

Soft shaped tortillas

Owner:GENERAL MILLS INC

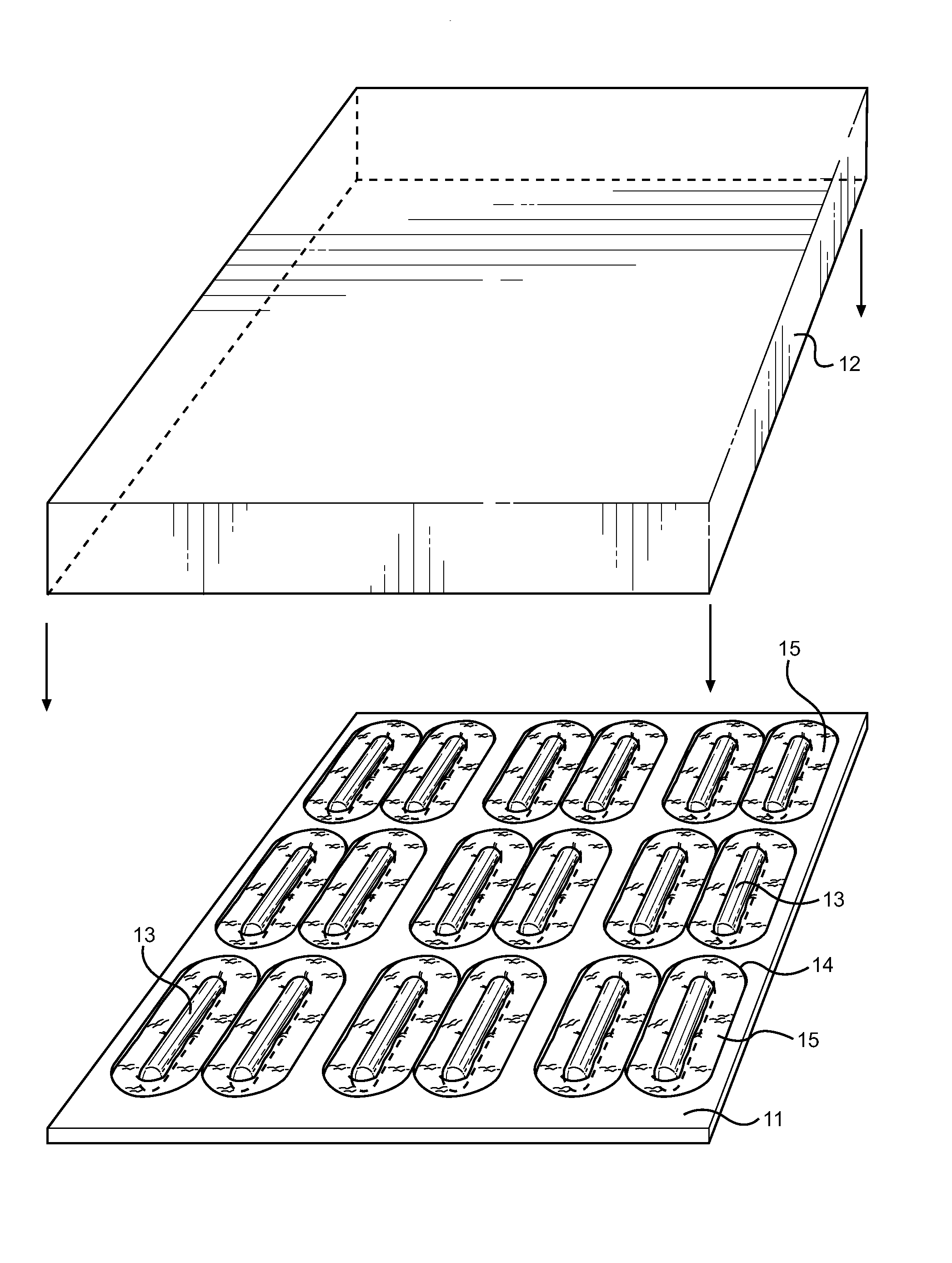

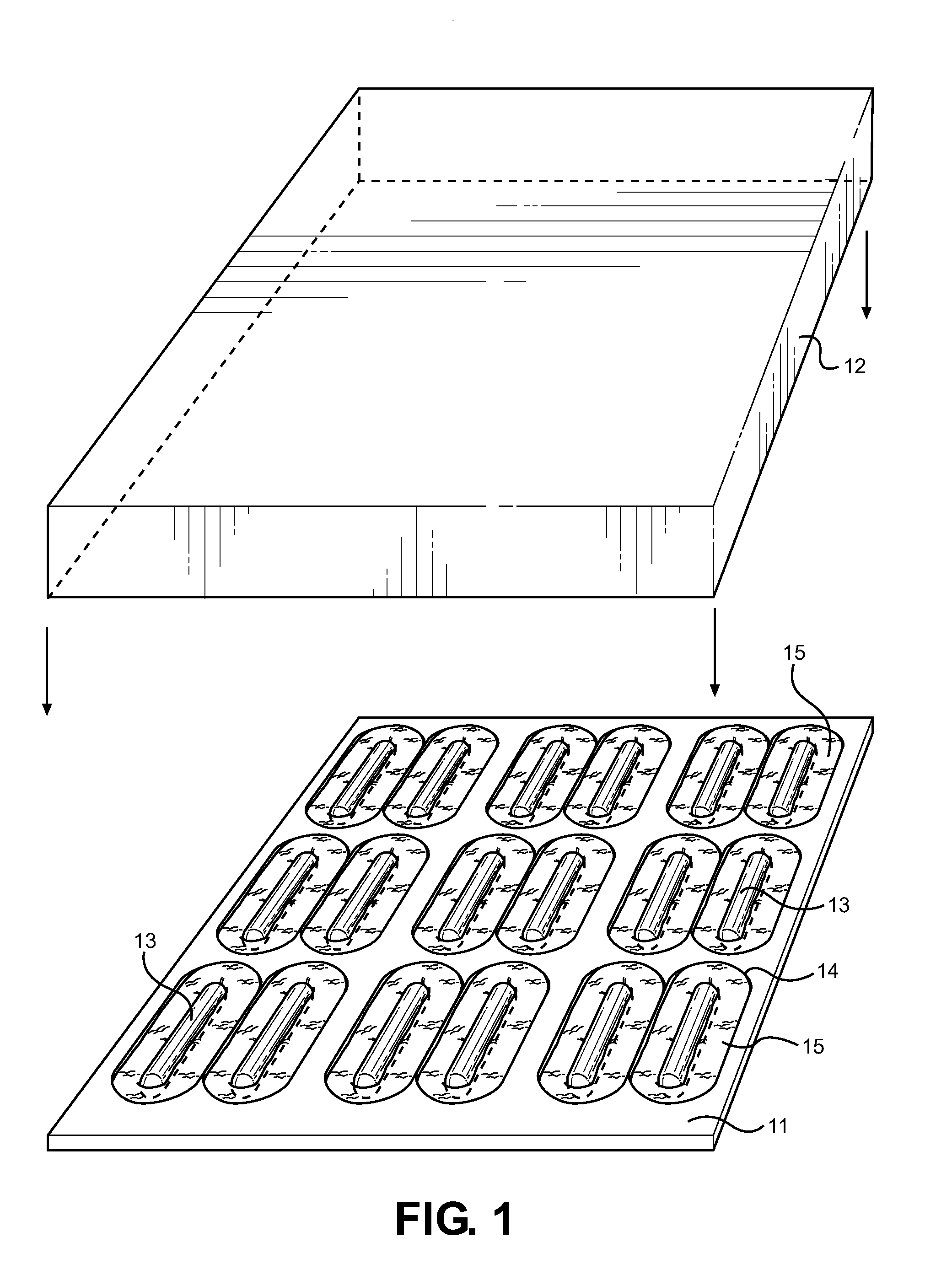

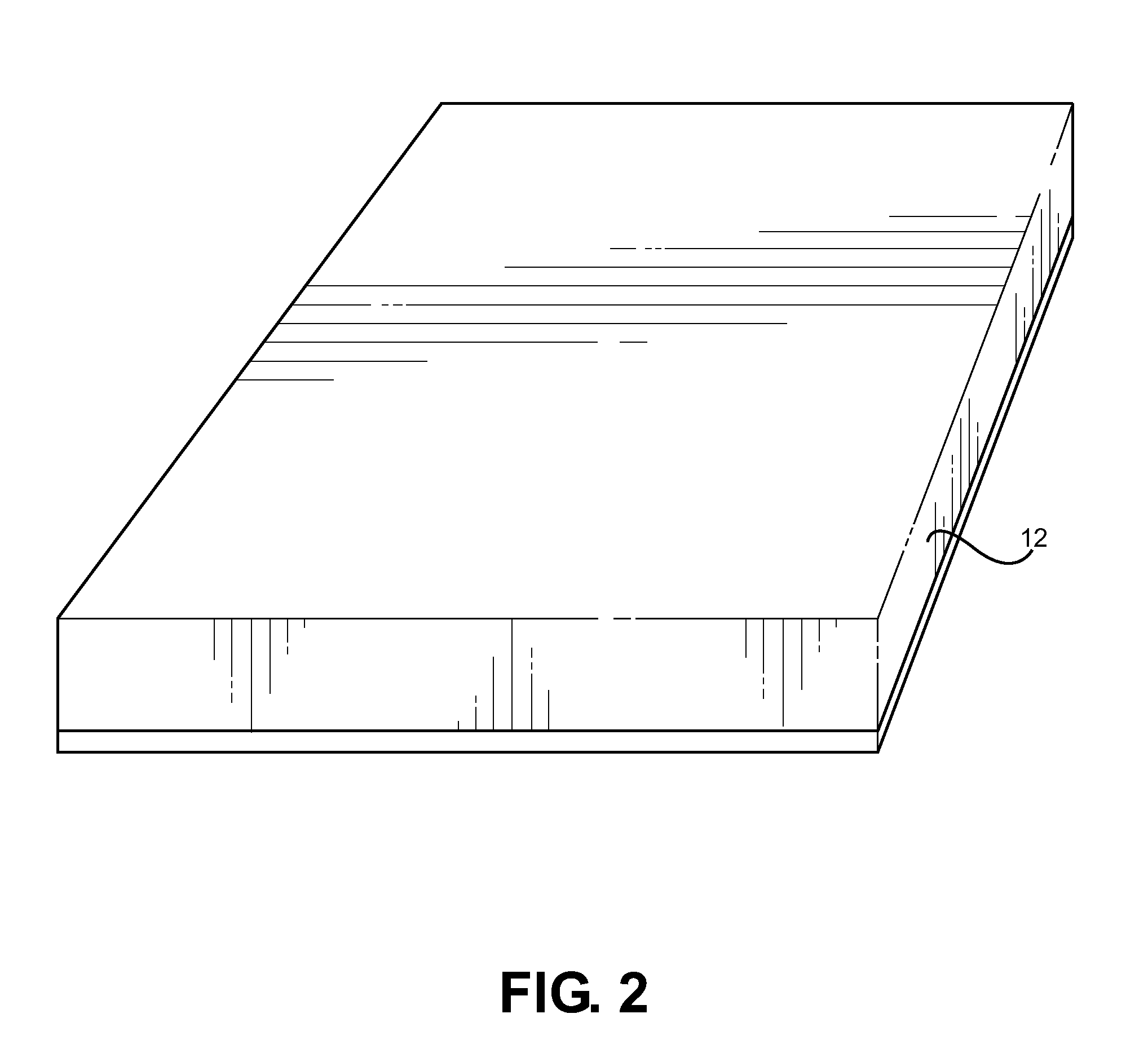

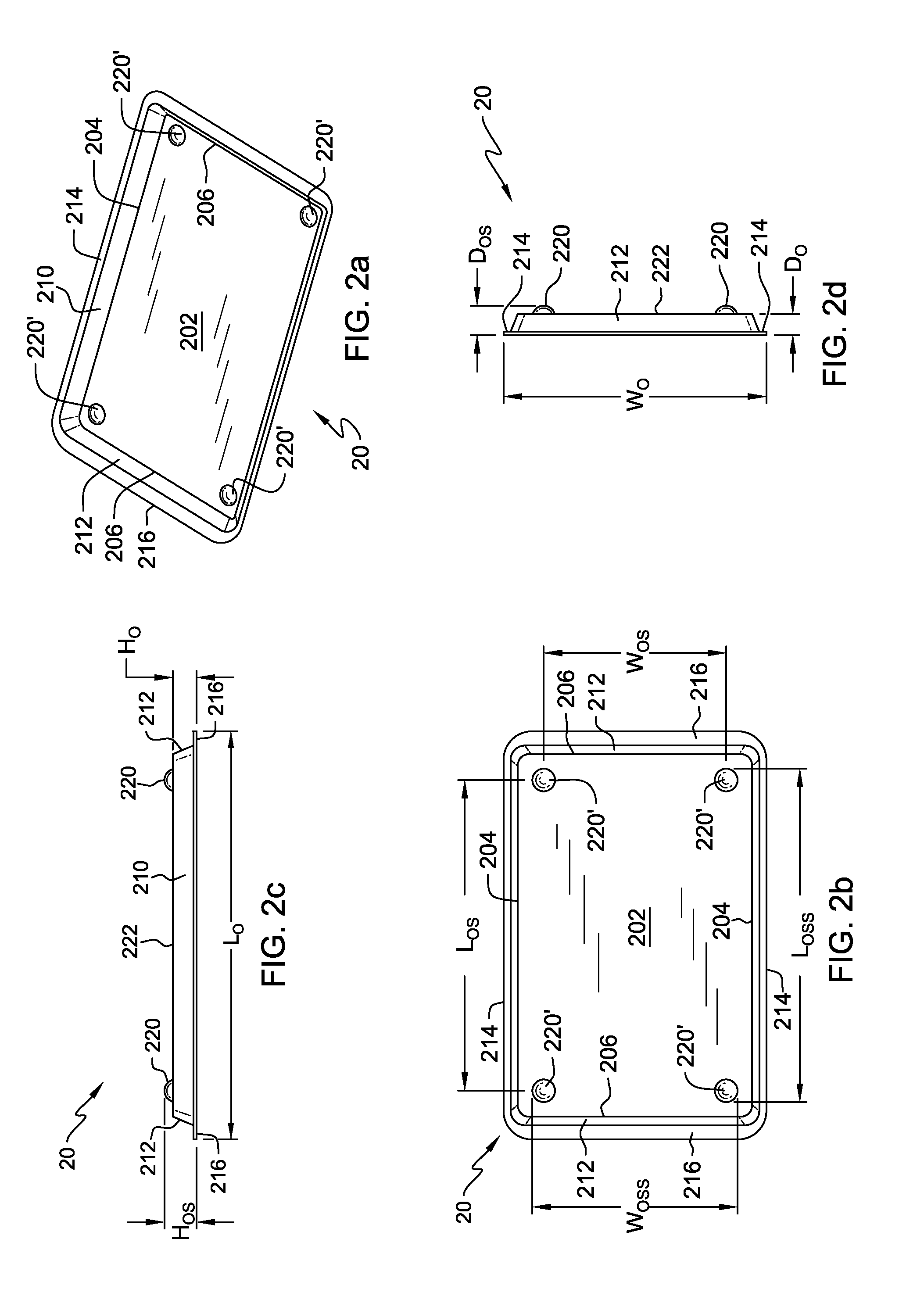

Hollow Sandwich Bun Mold and Method of Use

A sandwich bun mold device and method for use are provided for creating sandwich buns having hollow interior regions. The device comprises a bread mold pan having a plurality of mold recesses disposed along its surface, a pan cover, and a plurality of inserts of varying size and shape. To make the buns, a user places yeast bread dough in the mold recesses and then selects a desired insert size that will correspond to the size of the hollow interior region after the bun has cooked. The insert is then placed on the bread dough and the pan cover is placed onto the pan. A user bakes the assembly until the buns are cooked, removes the cover and inserts, and inverts the device to remove the freshly prepared buns.

Owner:MEIKLE SHIRLEY

Method for controlling snack product blistering through the use of solid lipid particles

InactiveUS6893673B2Reduce moisture contentAvoid blistersDough treatmentLeguminous plant bakery productsLipid particleRoom temperature

An improved method for controlling blister formation in fabricated, expanded snack products by utilizing discrete, solid lipid particles. These lipids must be solid at room temperature with a melting point above 100° F. such that they remain discrete and solid when mixed with the dough and are subsequently sheeted or extruded. During the toasting, frying, or baking step, the solid, lipid particles melt and soften and disrupt the starch matrix, thus allowing steam to escape and preventing blisters. The blisters are only prevented, however, in the localized area where a solid, lipid particle exists. Thus, by changing the level of solid, lipid particles in the dough, the size of resulting blisters can be controlled.

Owner:FRITO LAY NORTH AMERICA INC

System, device, and method for baking a food product

Owner:NORTH ATLANTIC IMPORTS

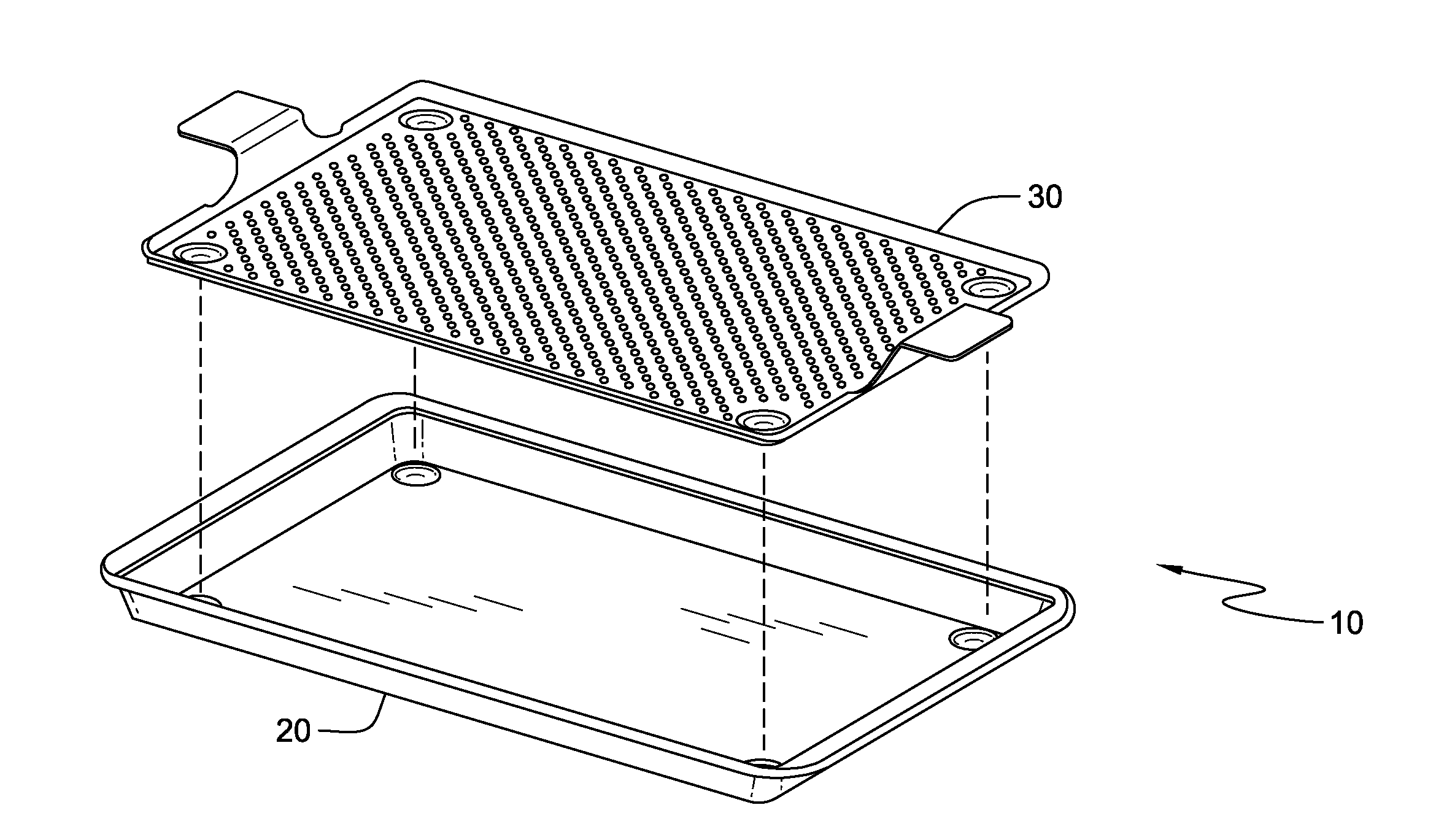

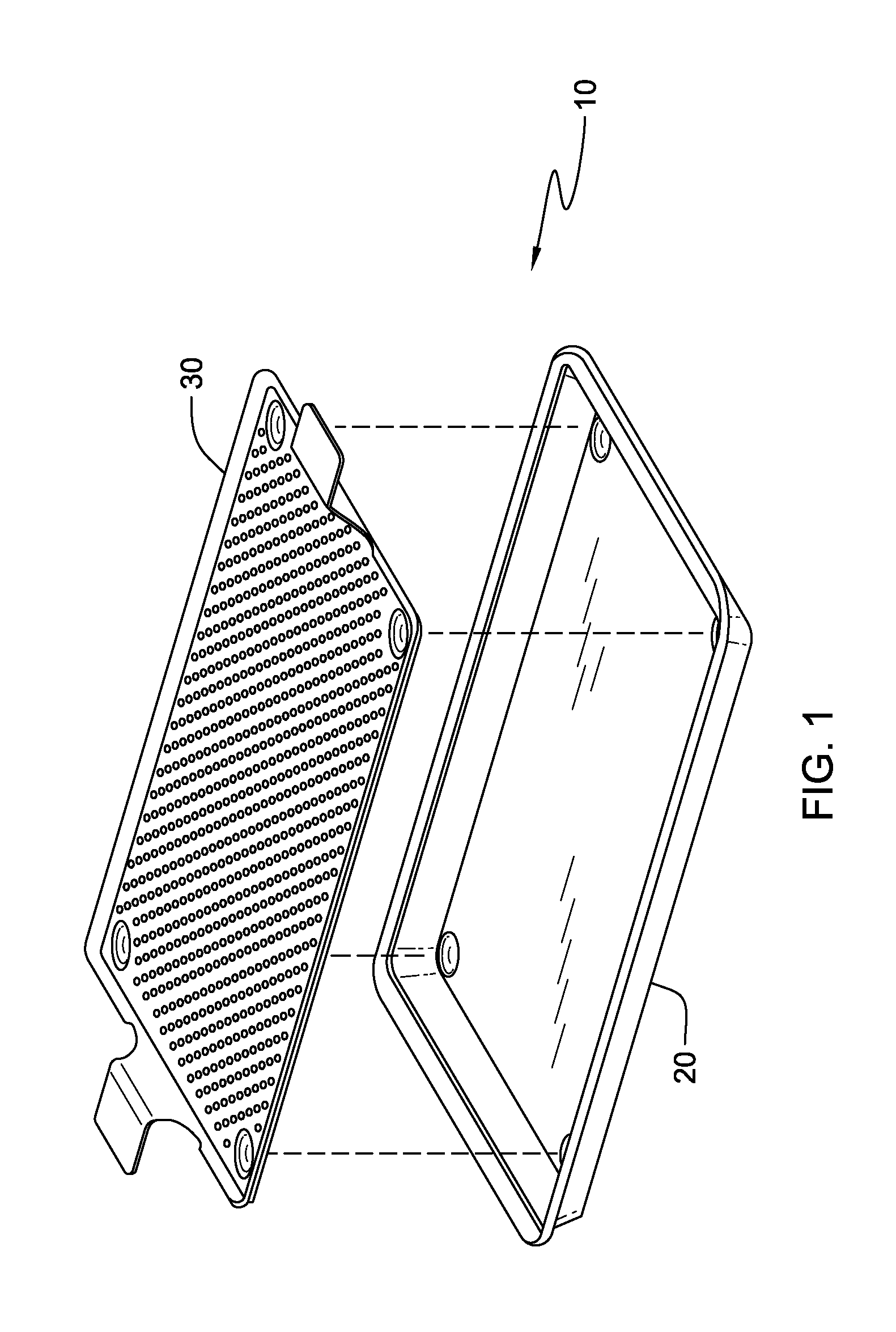

Combination baking pan and cooling rack

InactiveUS20140065278A1Quantity minimizationMilk preservationCooking vesselsCooking & bakingBaked goods

A baking device for baking and cooling baked goods includes a rectangular baking pan formed from a single sheet of metal with planar opposing baking and bottom pan surfaces, including indentations positioned at four corners to extend out as protrusions from the bottom pan surface as standoffs. The baking device also includes a complementary rectangular cooling rack formed from a single sheet of metal with planar opposing baking and bottom rack surfaces, including indentations or depressions formed in the baking rack surface and positioned at four corners to extend out as protrusions from the bottom cooling rack surface and a plurality of small gauge holes. Dimensions of the cooling rack and baking pan are ensure that the cooling rack seats snugly in the baking pan so that the bottom cooling rack surface contacts and presses against the baking pan surface in an assembled state.

Owner:FERIOLA MICHAEL +5

Heat-treated food which has been wrapped in a pastry of wheat flour dough for cooking in a microwave oven

According to the present invention, there may be provided a heat-treated food which has been wrapped in a pastry of wheat flour dough for cooking in a microwave oven and which is capable of reproducing the so-called crispy feeling as well as favorable flavor and taste just cooked, said heat-treated food tending to migrate water to the heat-treated surface from the inside ingredients during its distribution and storage terms. The present invention relates to a heat-treated food wherein the inside ingredients have been wrapped in a pastry of wheat flour dough for cooking in a microwave oven and whose heat-treated surface is in contact with a microwave heat susceptor.

Owner:AJINOMOTO CO INC

Extrudable Food Composition

InactiveUS20070154609A1Improve propertiesBaking mixturesAnimal feeding stuffIngested foodFood products

A process for making an extruded food product includes providing an extrudable food composition that comprises at least one of alkenylsuccinate starch and emulsifying protein. The extrudable food composition is extruded through a die to form an extruded food product. Optionally, the process can further comprise heating the extrudable food composition before and / or during the extrusion of the composition through the die, whereby the composition is at least partly cooked.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

Gluten-free baked products and methods of preparation of same

InactiveUS20090092716A1Level of optimizationReduce probabilityDough/pre-mixesLeguminous plant bakery productsAdditive ingredientDelivery system

The present invention provides an ingredient delivery system and methods of producing a gluten-free bakery product using an oven to produce quality gluten-free bakery products made by this method.

Owner:CARGILL INC

Method for the production of food products having reduced fat content

InactiveUS20070122536A1MaintenanceLow in fatLeguminous plant bakery productsBaking mixturesSalt contentFat content

Methods for the production of food products comprising wheat and / or rye flour and added fat, said method comprising substituting the flour with 0.5-100% w / w of waxy wheat flour, wherein said waxy wheat flour replaces fat content in said food product by 20-100% w / w are described. Also described is use of waxy wheat in the preparation of a food product with a reduced fat content.

Owner:WESTON FOODS

Preparation method for fresh-keeping steamed breads

ActiveCN103652599AUnique preparation processStraight shapeDough treatmentPre-baking dough treatmentYeastPreservative

The invention discloses a preparation method for fresh-keeping steamed breads, which particularly comprises the following continuously performed steps: preparing leaven, kneading leaven, kneading leaven and dough, mixing dough, shaping, fermenting and steaming. A yeast is fermented for 4-6 times by using a culture medium so as to obtain the leaven; in a room with the natural temperature, the steaming temperature is 97-100 DEG C, when the centers of the steamed breads are heated over 97 DEG C and the temperature is kept for more than 30 minutes, the steamed breads are prepared; the fresh-keeping package, inspection, observation and storage of the steamed breads are performed in an online manner. According to the preparation method, the leaven is obtained via fermentation for 4-6 times to ferment the dough, adding any anticorrosive is needless, and gas exchange during package is needless. After inspection, the fresh-keeping period of the steamed breads prepared by adopting the method can reach 90 days at the normal temperature.

Owner:张斌社

Xylitol biscuit and production method thereof

InactiveCN103371208AReduce heatSoft tasteDough treatmentBaking processesSodium bicarbonateGlucose polymers

The invention relates to a biscuit, particularly to a xylitol biscuit and a production method thereof. The xylitol biscuit comprises 100kg of self-raising flour, 100kg of strong flour, 20kg of egg liquid, 25kg of xylitol, 2.5kg of salt, 20kg of butter, 1.5kg of ammonium bicarbonate, 1.5kg of sodium bicarbonate, 20kg of edible palm oil and 15kg of wheat gluten. The xylitol biscuit is low in calorie, produces no glucose, has blood sugar and blood fat reducing functions due to addition of the xylitol and tastes crisp and soft.

Owner:JIANGSU MEIZIZI FOOD

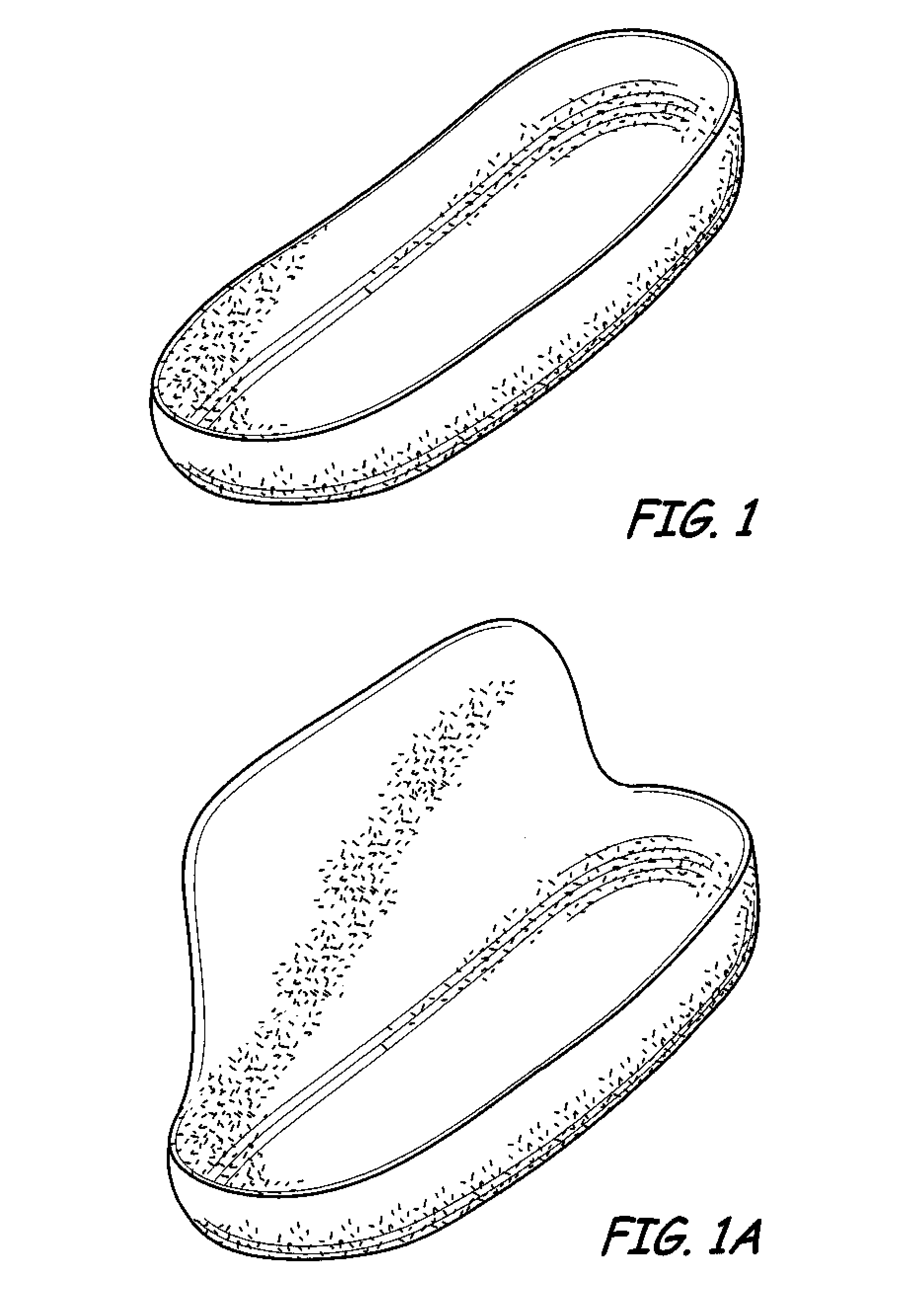

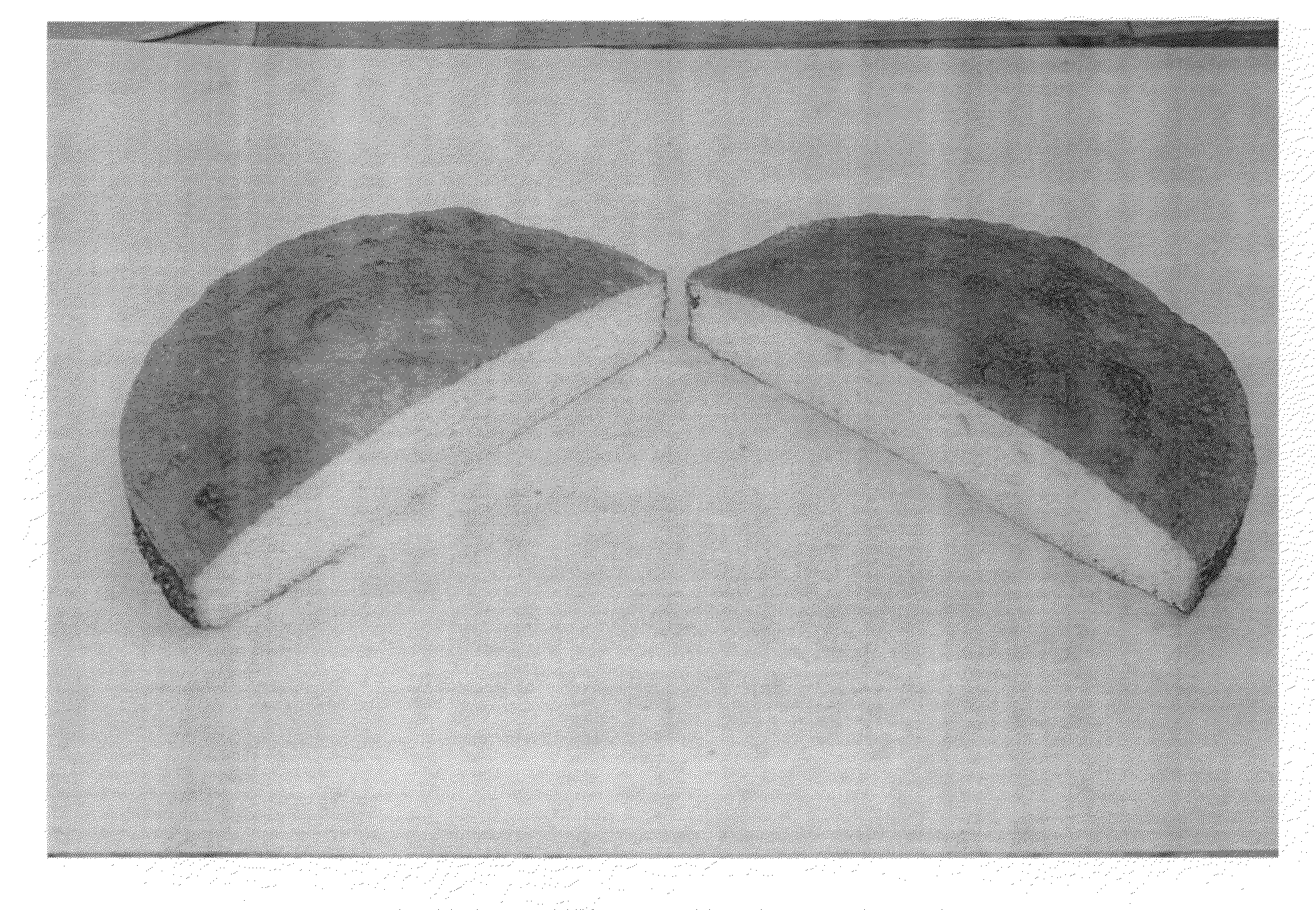

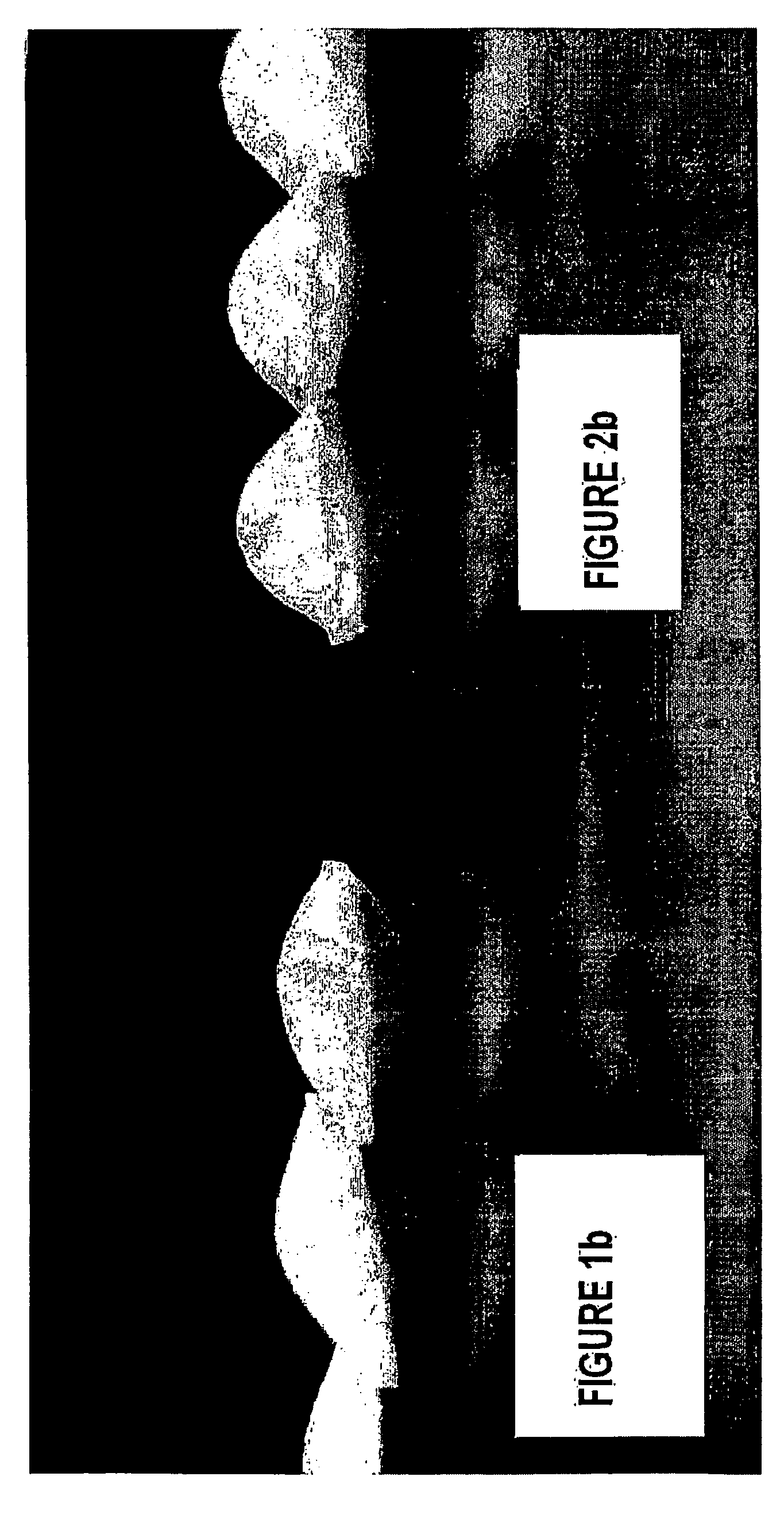

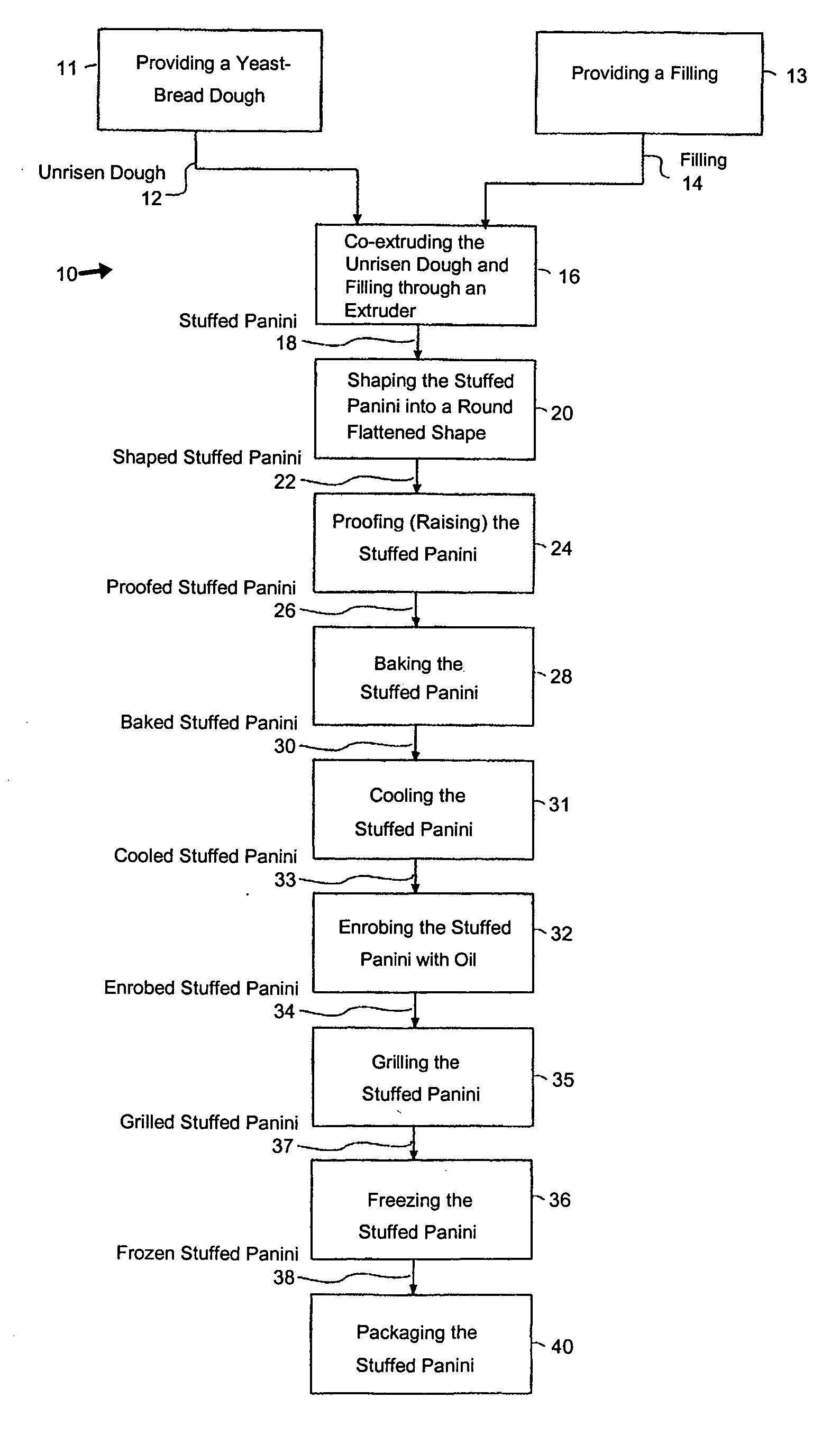

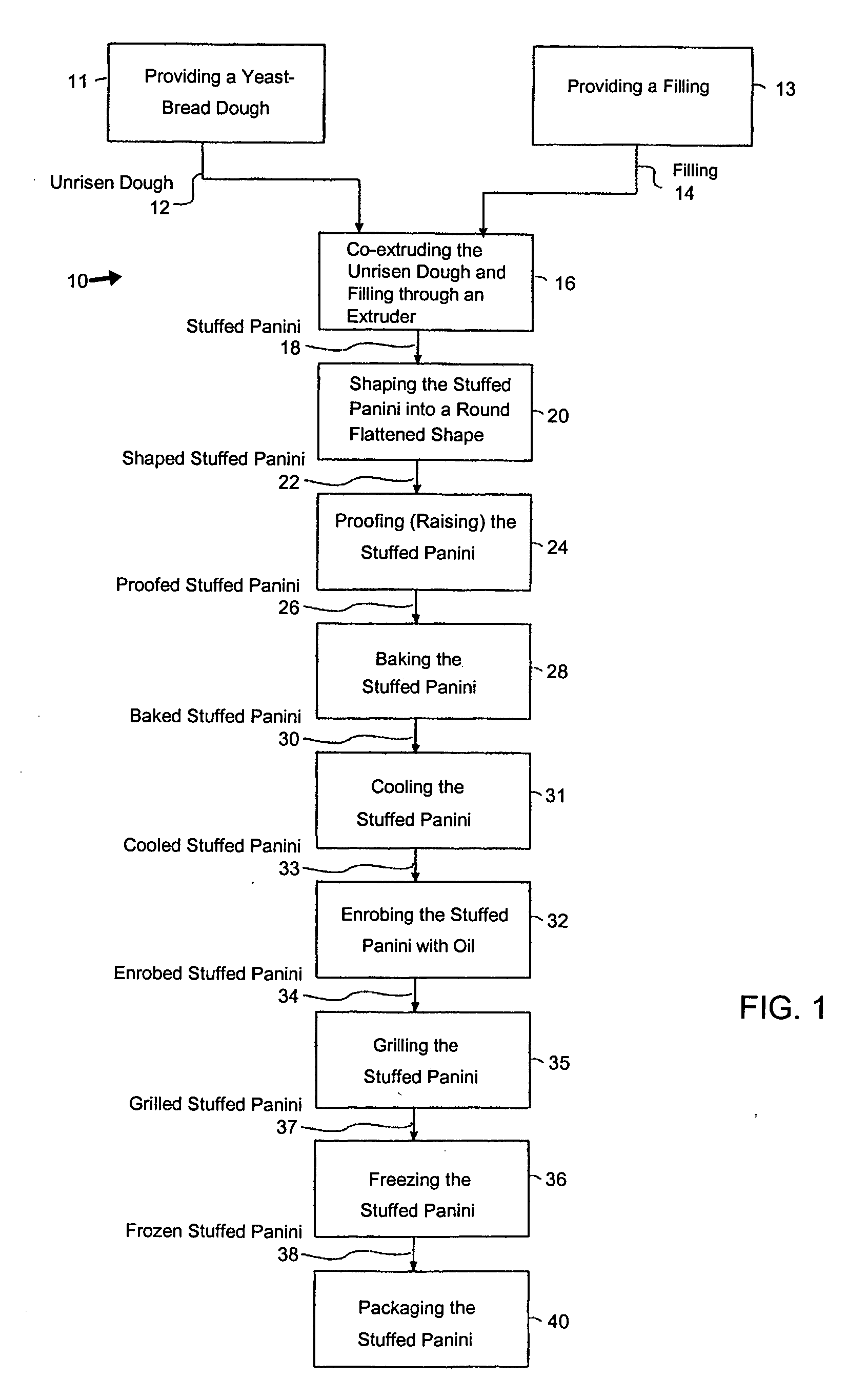

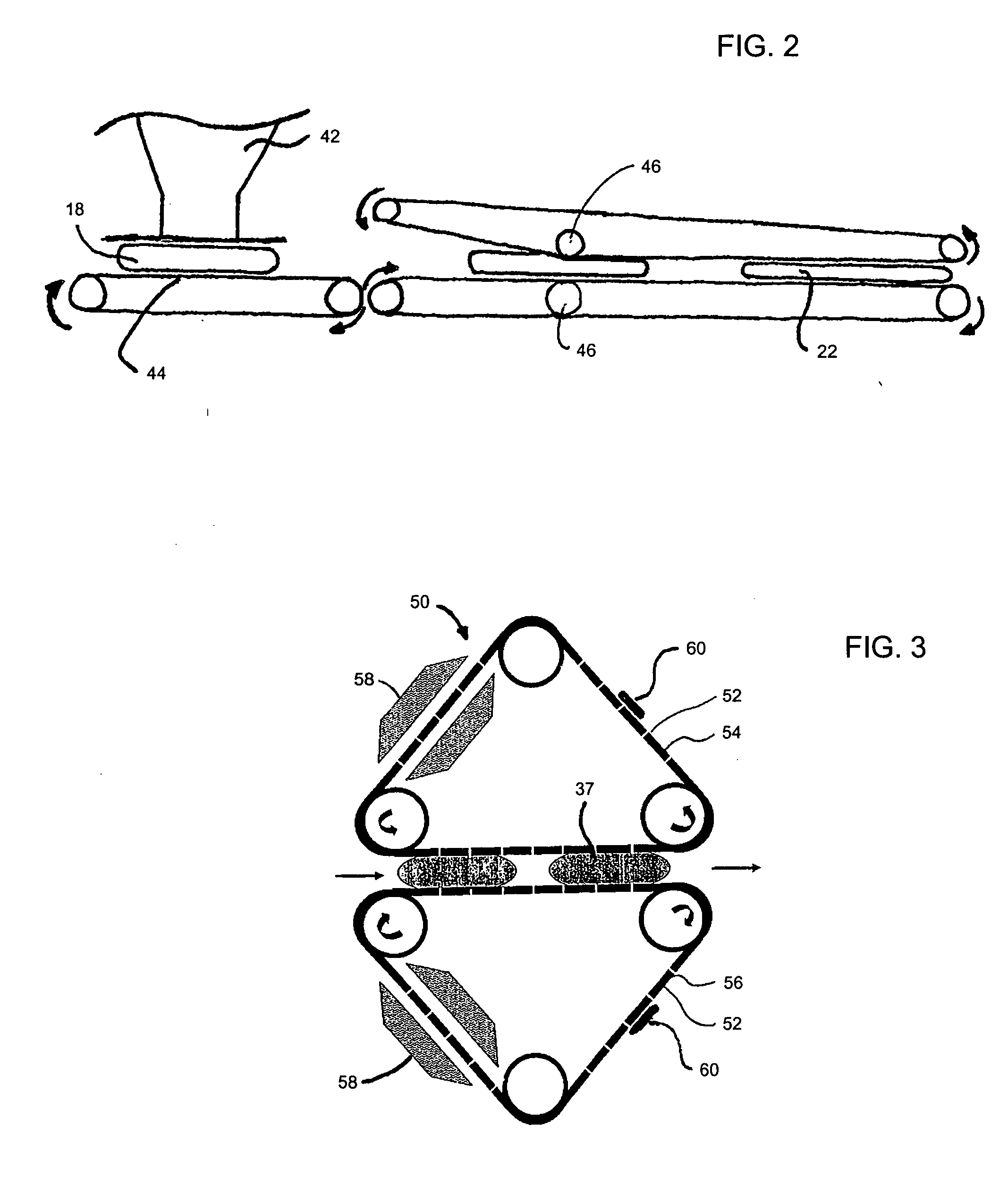

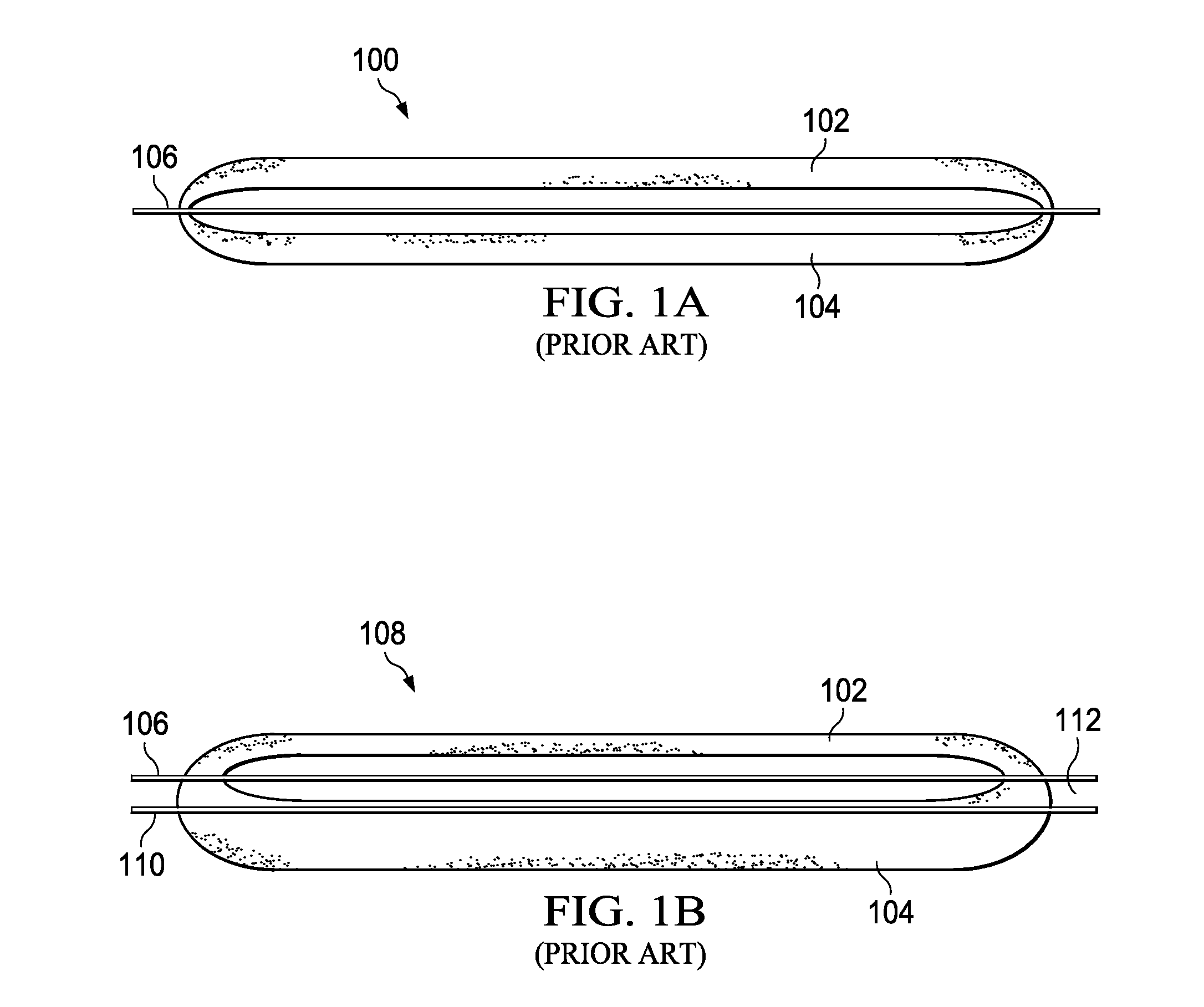

Frozen filled yeast-leavened bread product and a method for making the product

ActiveUS20070059413A1Eliminate leaksEliminate all of fillingPreservation by coolingBaking processesCooking & bakingFood science

A frozen, filled, yeast-bread product and a method for producing the same, the method including coextruding an unrisen yeast-bread dough and a filling through an extruder that is capable of at least encasing the filling with the unrisen yeast-bread dough to form a filled, unrisen yeast-bread dough; shaping the filled, unrisen yeast-bread dough into a consistent flattened shape; proofing, baking, cooling, enrobing, grilling and freezing the filled, unrisen yeast-bread dough to form a frozen, filled, yeast-leavened bread product that experiences substantially no leaking of filling from out of the bread product.

Owner:PAULUCCI JENO F

Cake powder quality improver and preparation method thereof

ActiveCN101485346AResistance useIncrease health functionDough treatmentBaking processesAmylaseCellulose

The invention relates to an agent for improving the quality of cake mix and a preparation method thereof. The agent for improving the quality of the cake mix comprises the following compositions in portion by weight: 0.6 to 5.5 portions of stearic propylene glycol ester, 1.5 to 6 portions of CSL / SSL, 0.02 to 0.6 portion of L-cysteine hydrochloride, 0.13 to 0.25 portion of lipase, 0.02 to 0.15 portion of alpha-amylase, 0.005 to 0.025 portion of neutral protease, 14.4 to 29 portions of mono / di-glyceride, 2.6 to 6 portions of gelatin, 6 to 30 portions of insoluble cellulose (CMC) and 37 to 56.3 portions of anticaking agent. The preparation method is to mix various raw materials in a cone-type mixer for 20 to 30 minutes according to proportion, and obtain finished products of the agent for improving the quality of the cake mix. The invention makes an emulsifier have better complementary relation with sensitive enzyme in the aspect of stabilizing the quality of flour, and fully reveals the synergistic reaction of the emulsifier and enzyme preparation.

Owner:中山市南方新元食品生物工程有限公司

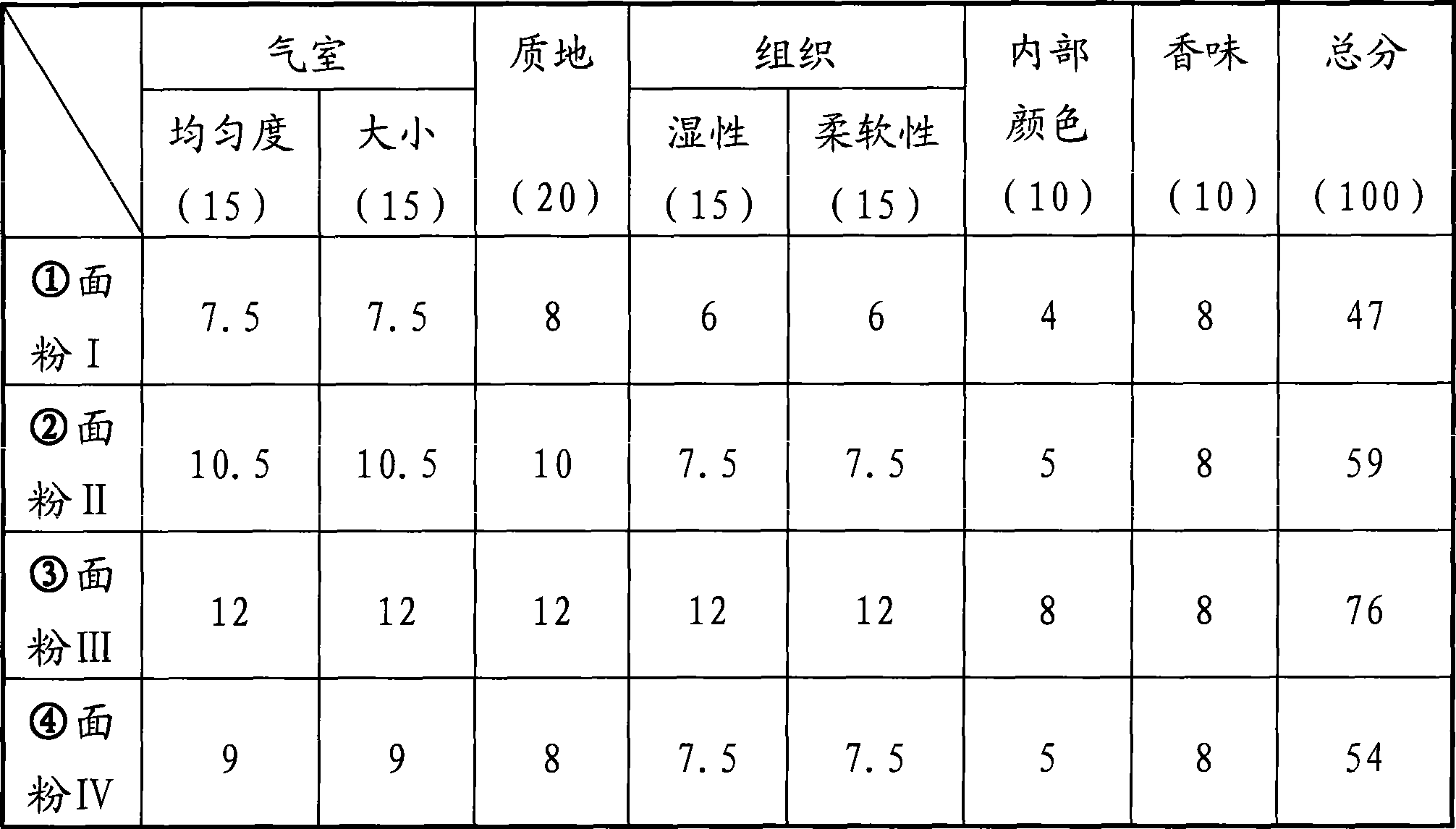

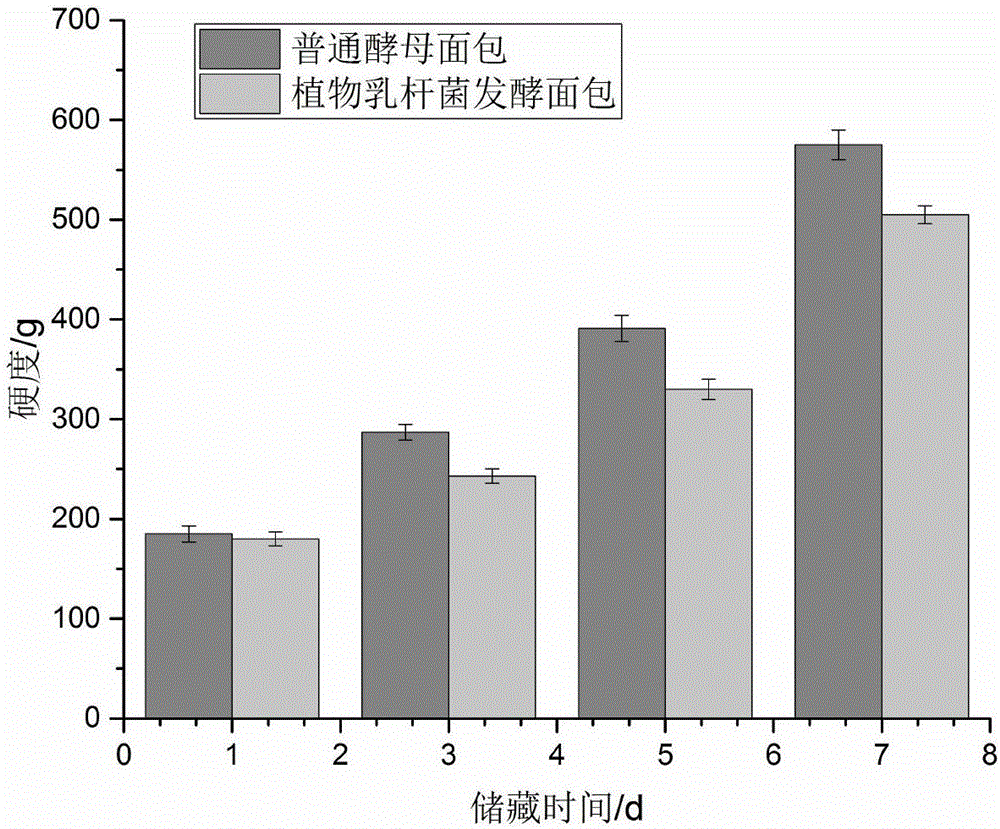

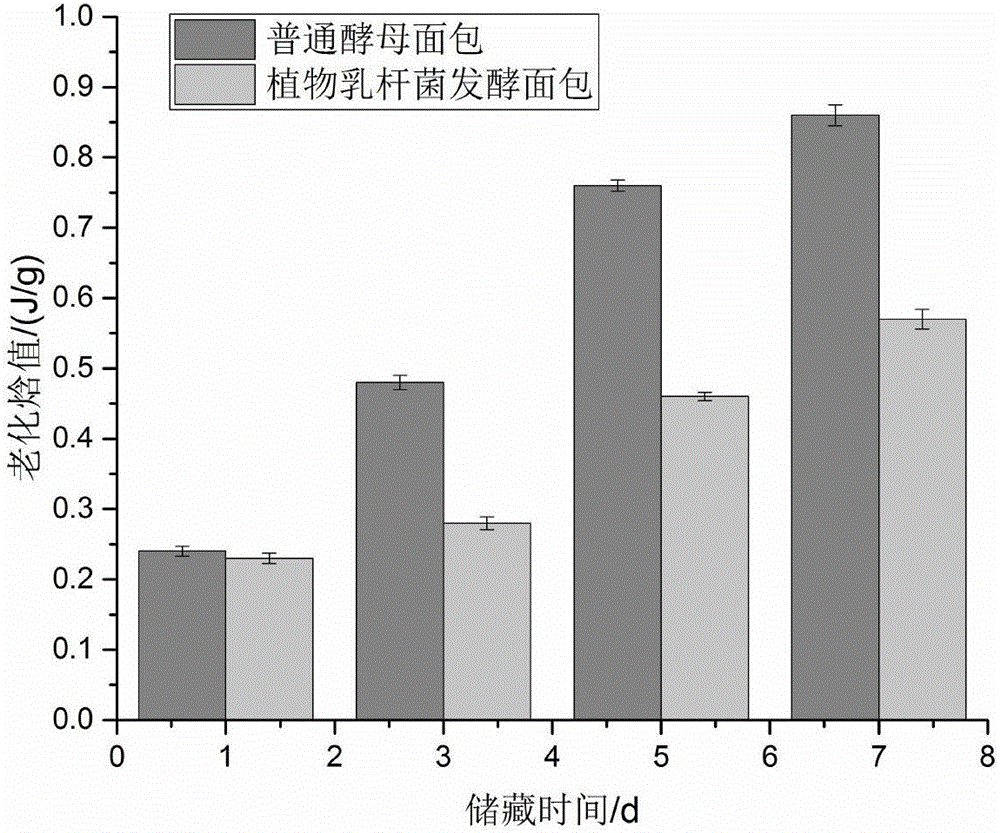

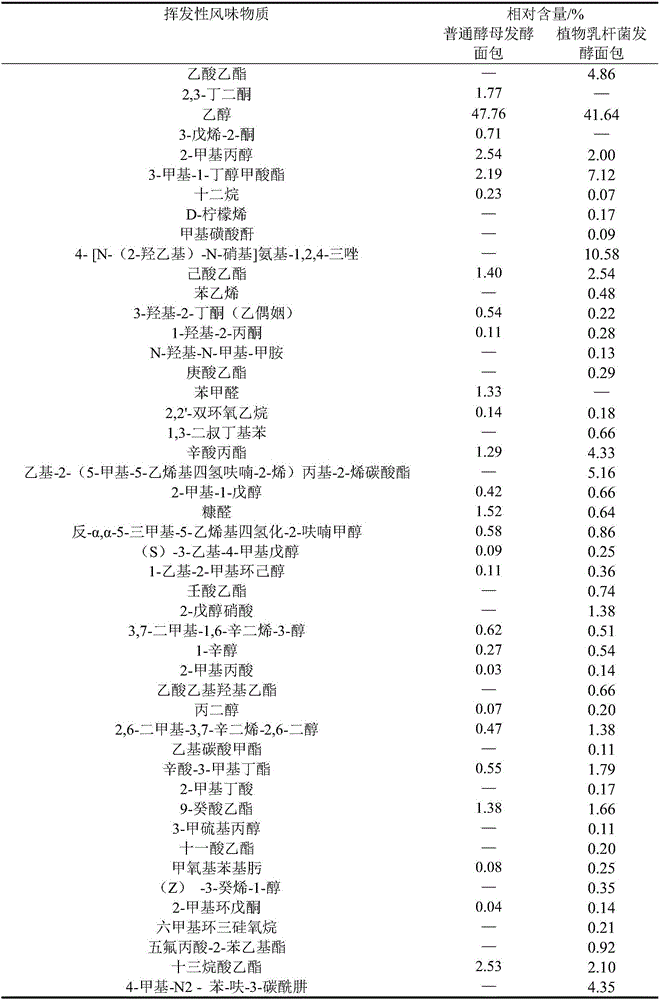

Lactobacillus plantarum and application thereof

ActiveCN106434460AExtended shelf lifeModerate acidity, not irritatingBacteriaPre-baking dough treatmentFlavorMicroorganism

The invention discloses lactobacillus plantarum and application thereof, and belongs to the technical field of food microorganisms. The lactobacillus plantarum WJ-02 is preserved in the China Center for Type Culture Collection with a preservation number CCTCC NO: M 2016406 on 20 July, 2016. When assisting in yeast fermentation, the strain has the advantages of improving the quality of fermented pastries and increasing flavor substances and content, the shelf life of prepared breads can be prolonged from 5 days to 14 days, the shelf life can be remarkably prolonged, the flavor of the breads can be effectively improved, and the lactobacillus plantarum can be applied to the fields of food and healthcare.

Owner:JIANGNAN UNIV

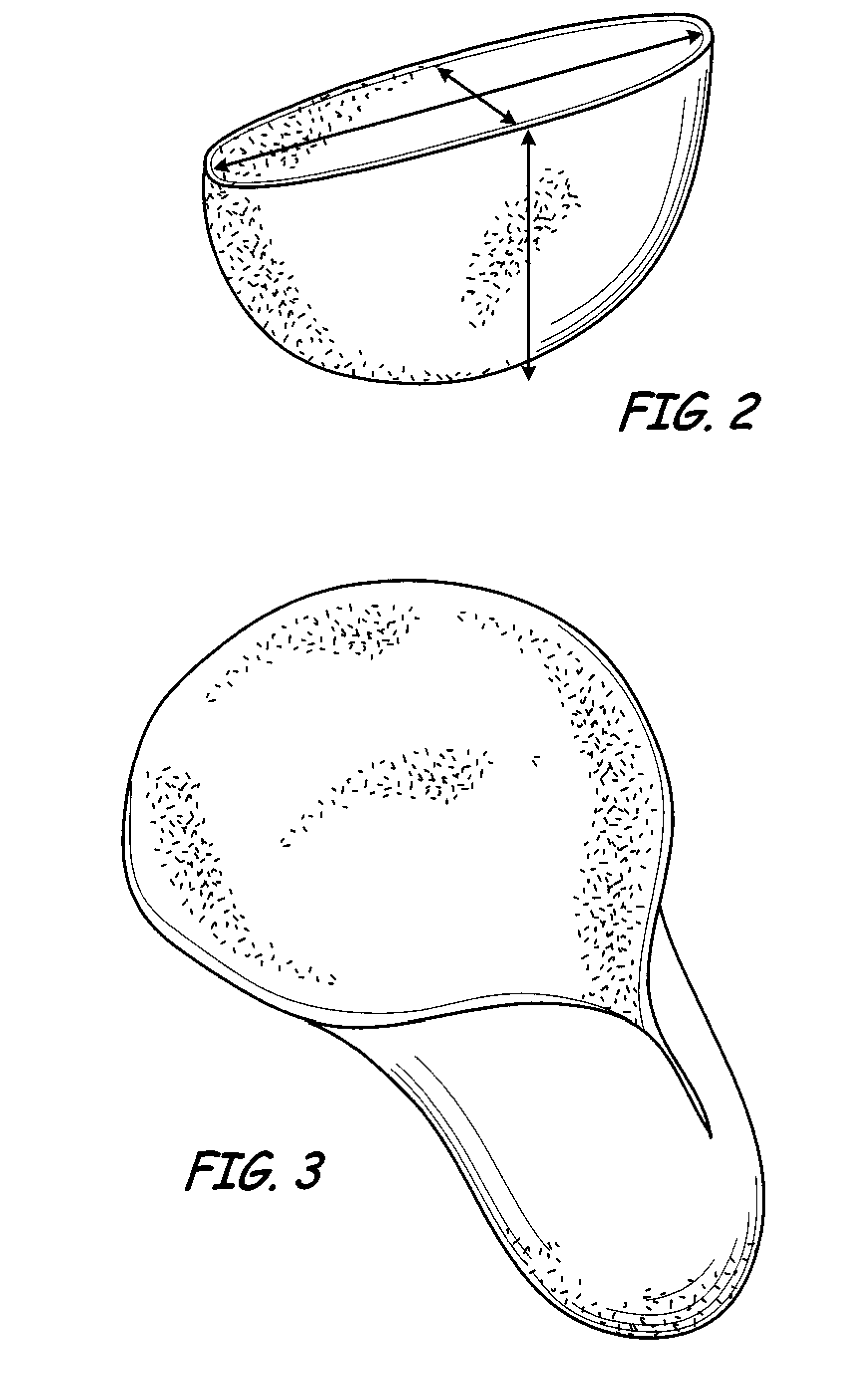

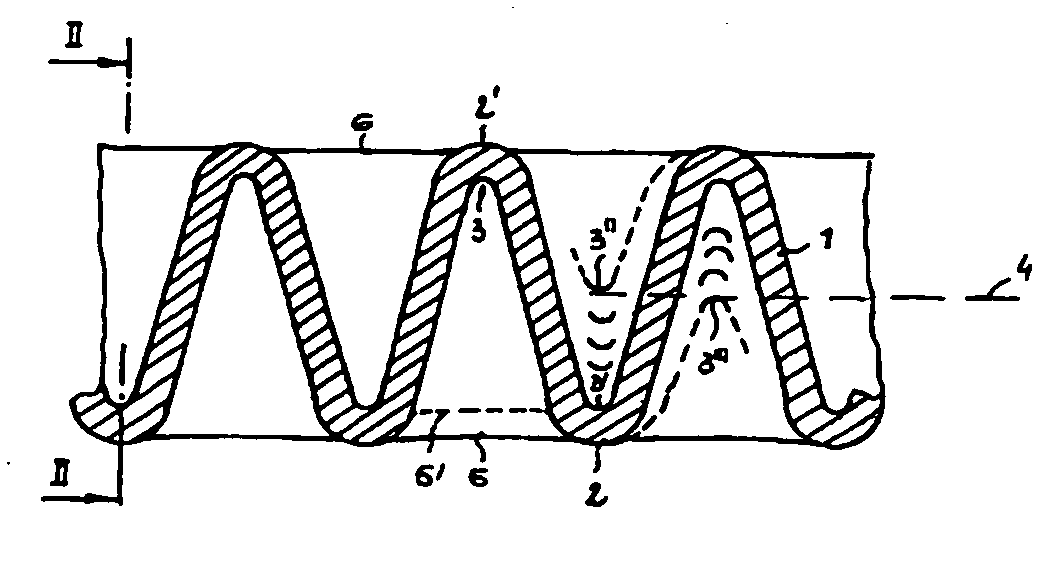

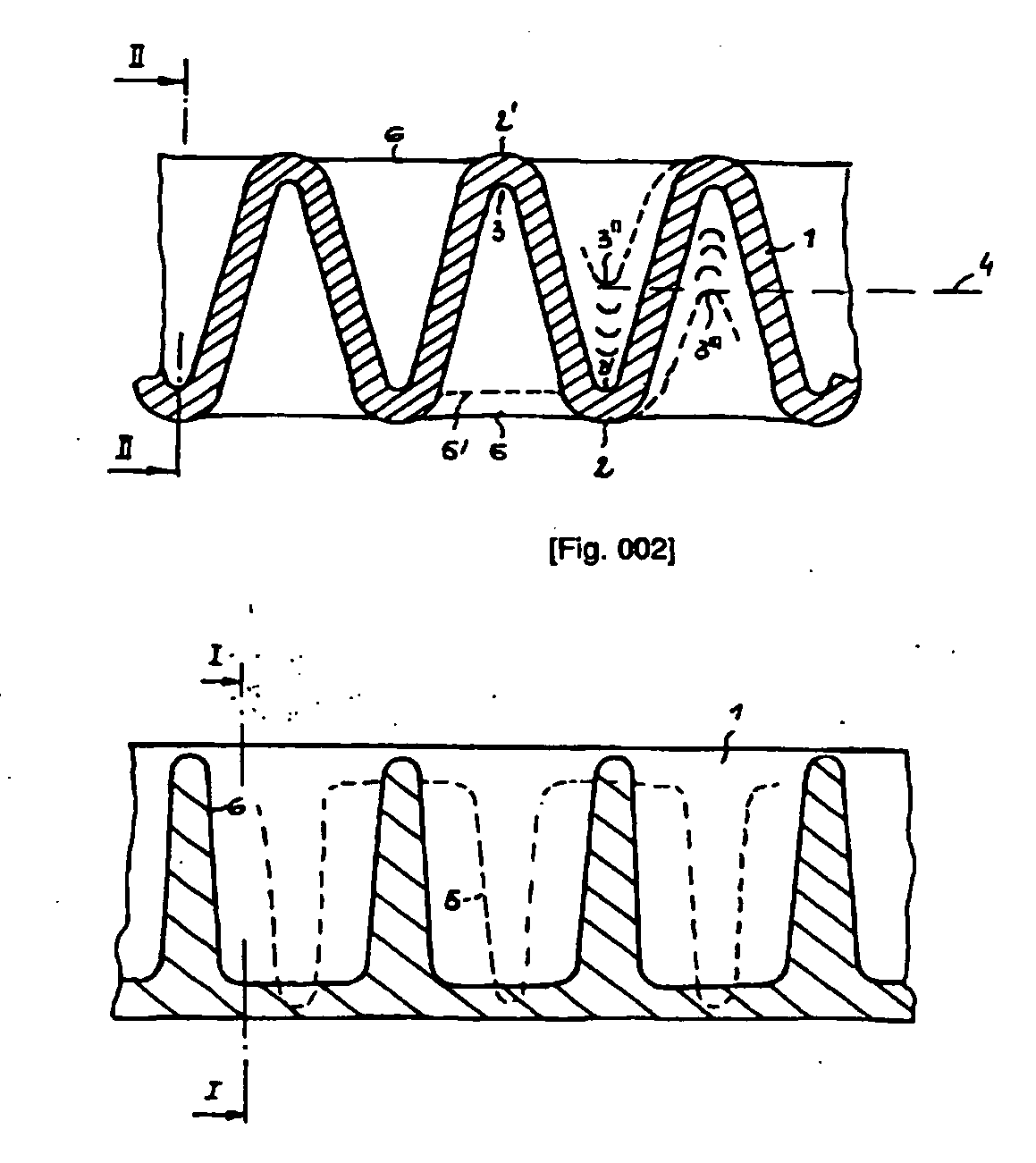

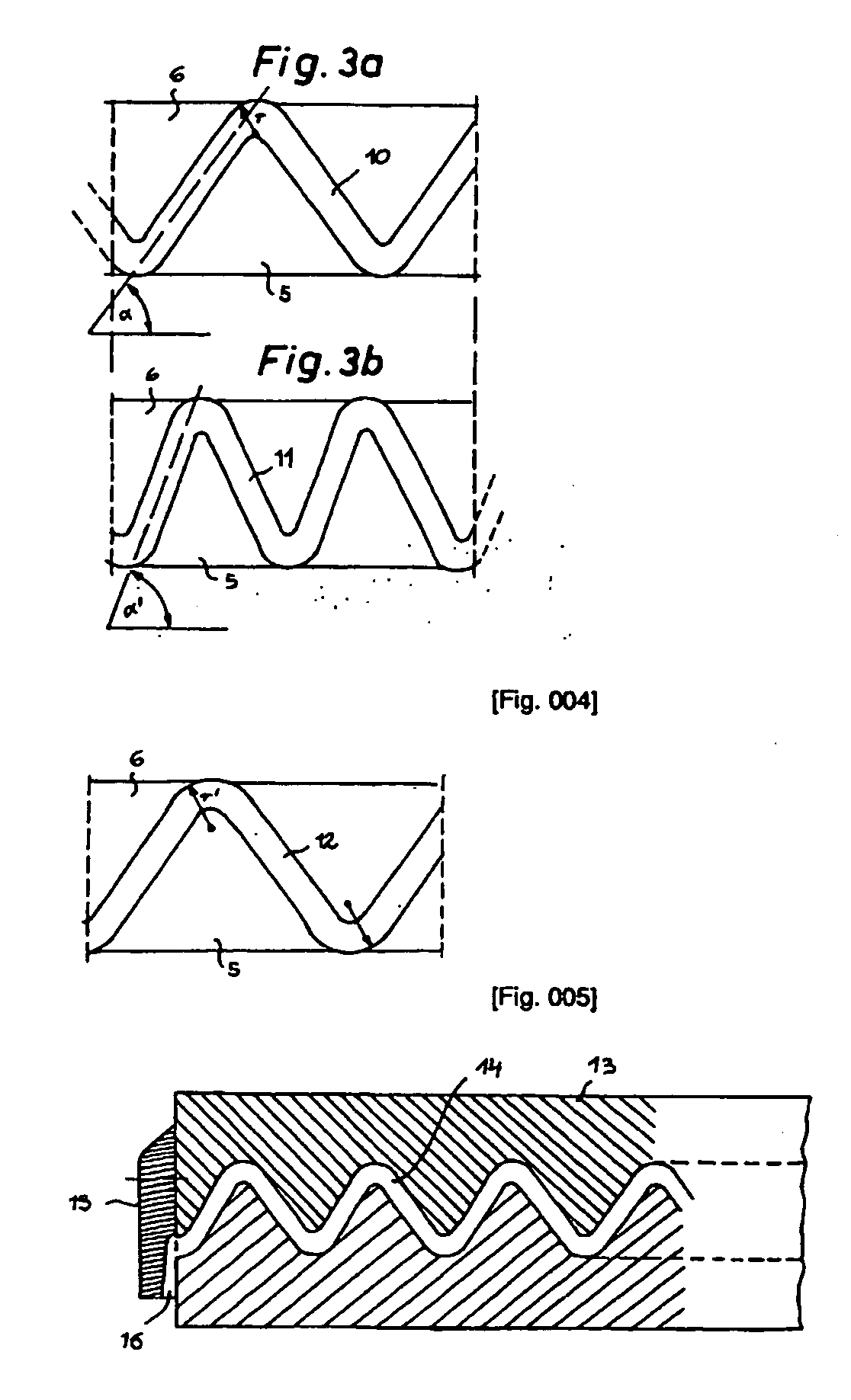

Waffle sheet

InactiveUS20070042085A1Thick spots in the dough are largely avoidedUniform colorFrozen sweetsConfectioneryEngineering

Disclosed is a waffle sheet as a long-life baked product, comprising one respective rib structure on opposite surfaces of a support layer. Said support layer has the shape of a corrugated plate (1, 10, 11, 12), e.g. with a sinusoidal or angular, trapezoidal undulation, the walls of said corrugated plate having the same thickness. Ribs (5, 5′, 6) which penetrate or bridge the wave troughs (3, 3′, 3″, 3′″) extend transversal to said undulation. The wave troughs (3, 3′, 3″, 3′″) of both surfaces or the top face and bottom face touch or penetrate an imaginary center line (4) of the cross-section of the waffle. The average wall thickness of the ribs (5, 5, 6) corresponds to the wall thickness of the corrugated plate (1, 10, 11, 12). The ribs (5, 5′, 6) extend at an angle from or perpendicular to the apex line of the waves. The ribs (6) in the wave troughs (3, 3′) located on the top face are offset by half a separation relative to the ribs (5, 5′) of the wave troughs (3, 3′″) located on the bottom face. The angles (α, α′) of the zigzag-type undulation (14) or the radii of curvature (r, r′) can be varied according to the amount of dough used per spatial unit. Also disclosed is a baking mold (13) comprising vapor bars (15) at the periphery thereof, said vapor bars (15) being provided with vapor slots on the undulation (14) which tapers as a slot.

Owner:A LOACKER

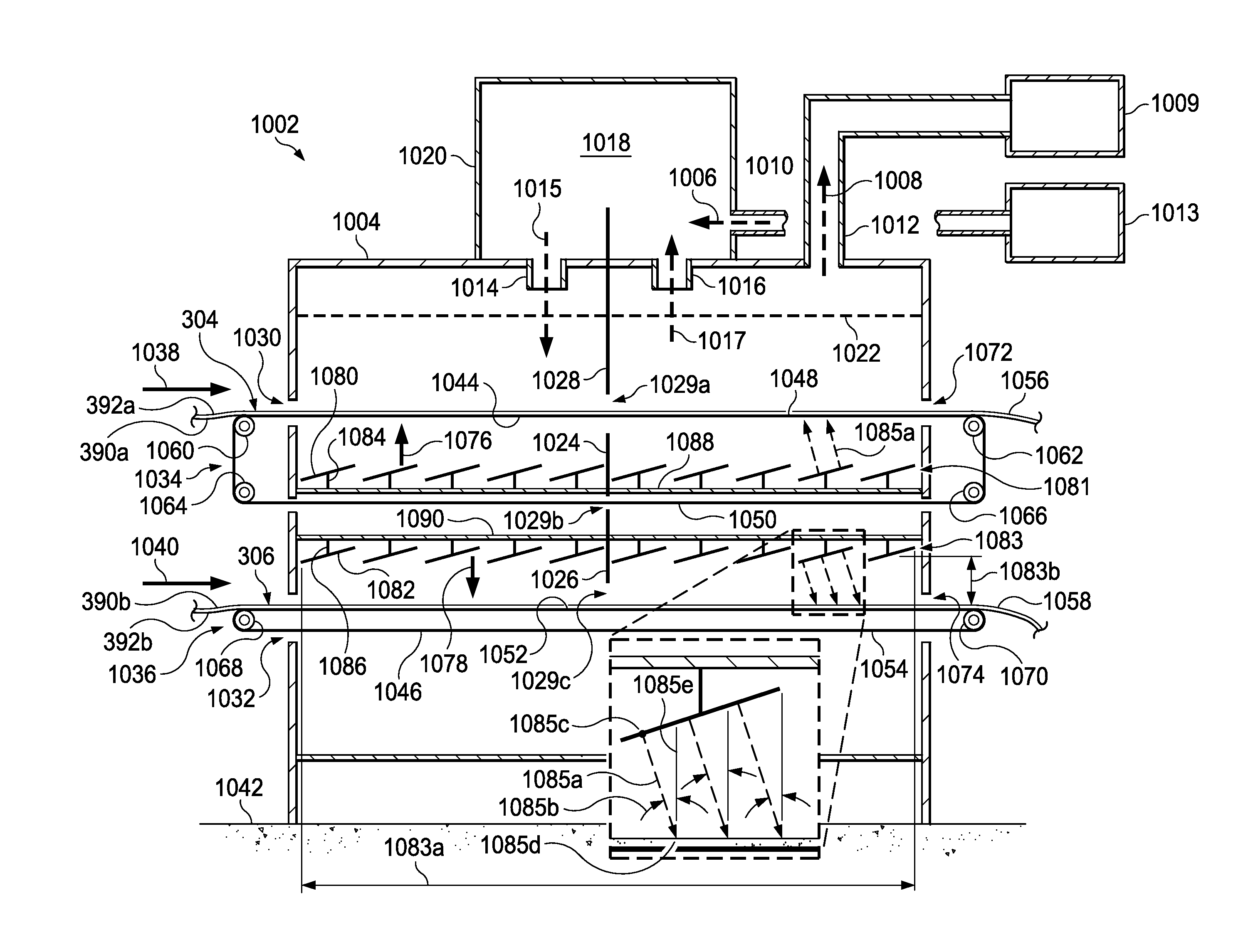

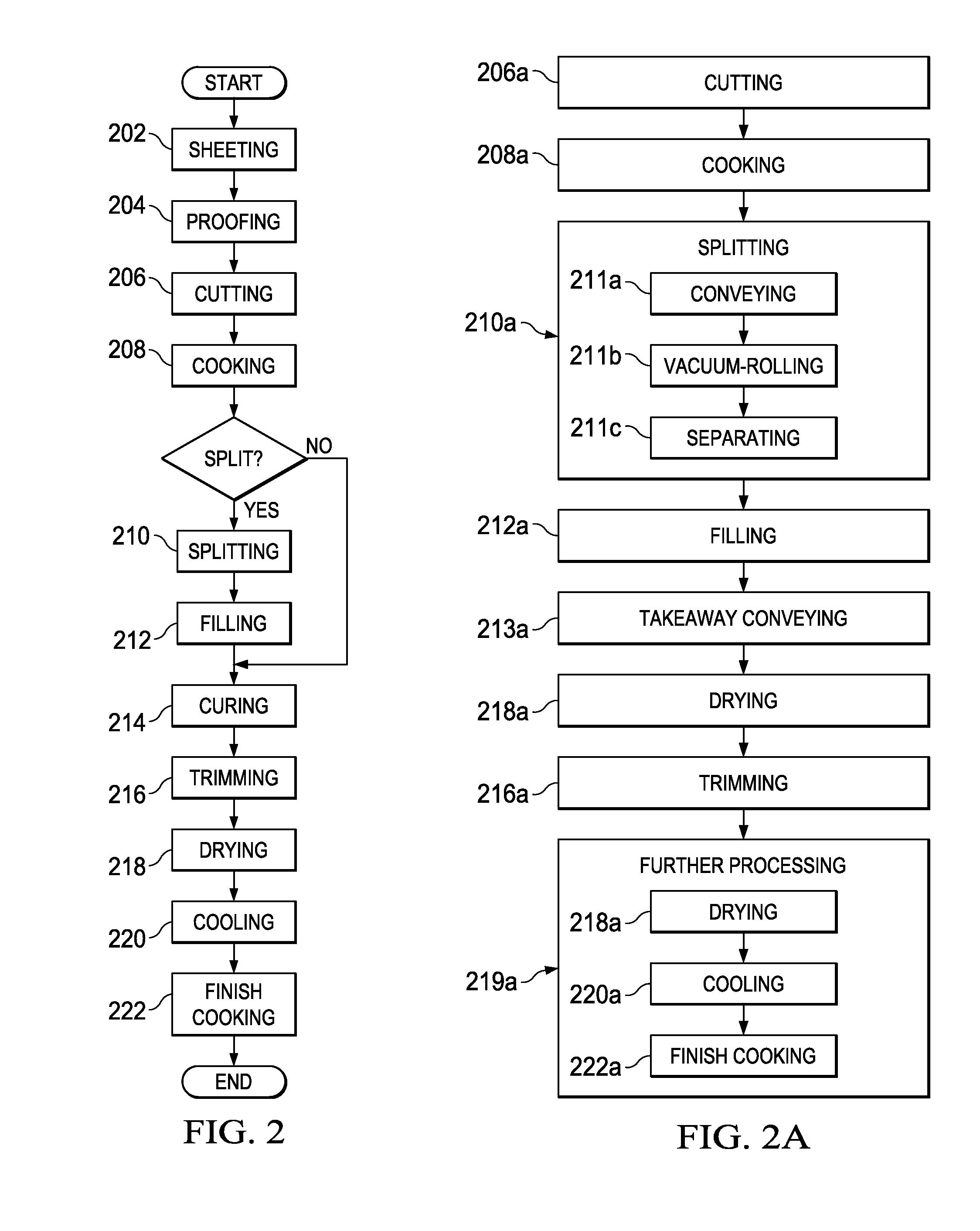

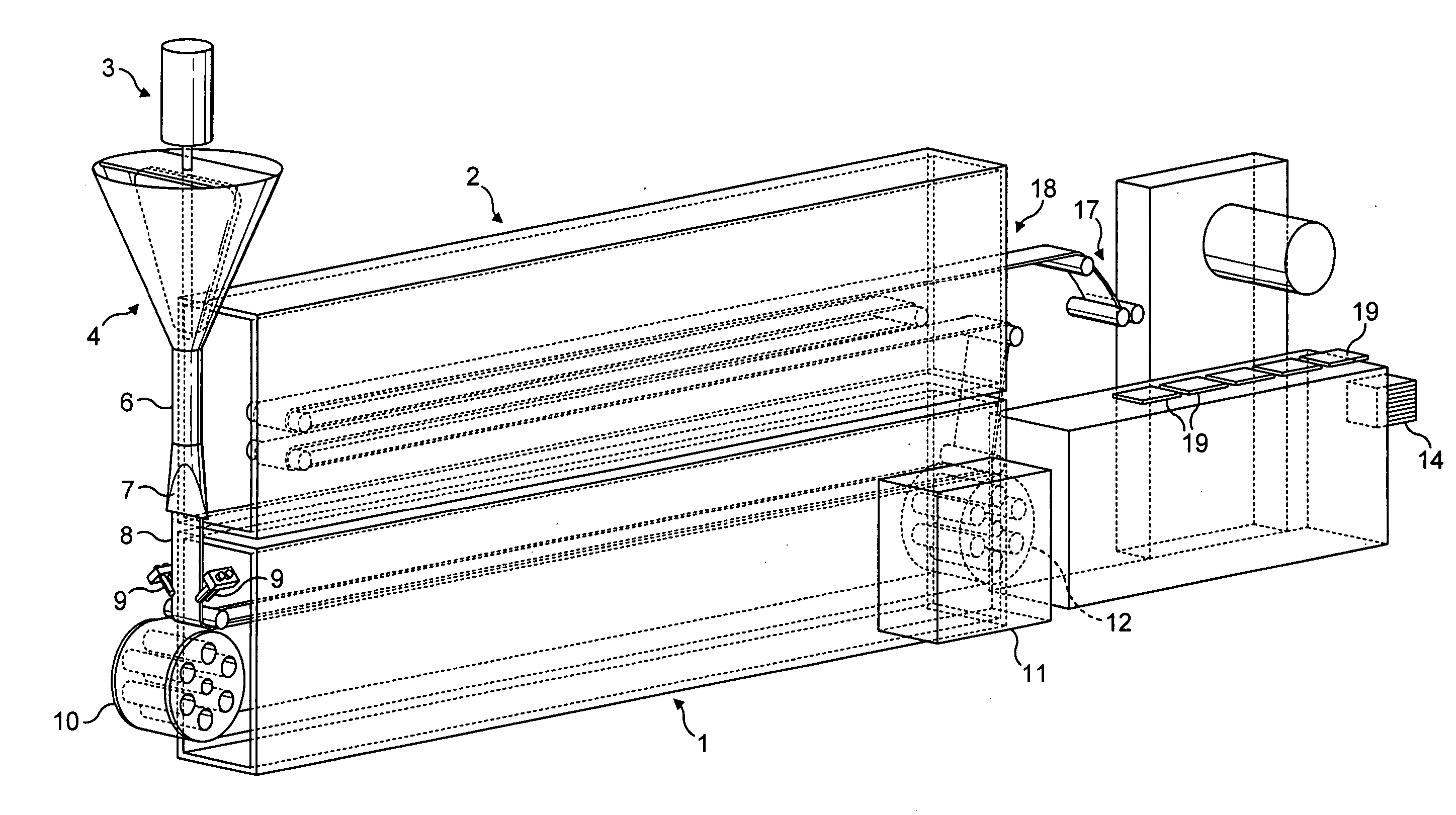

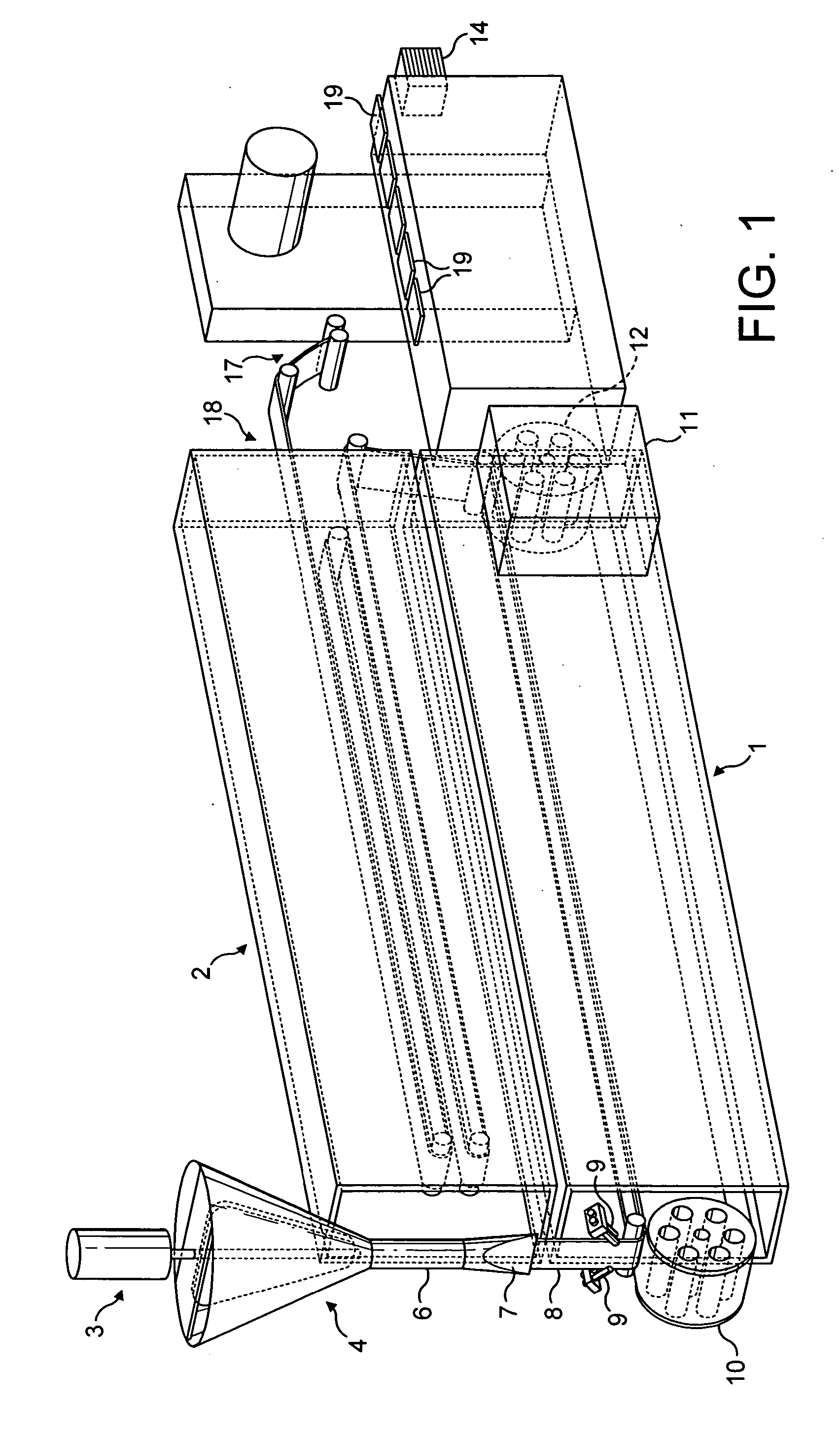

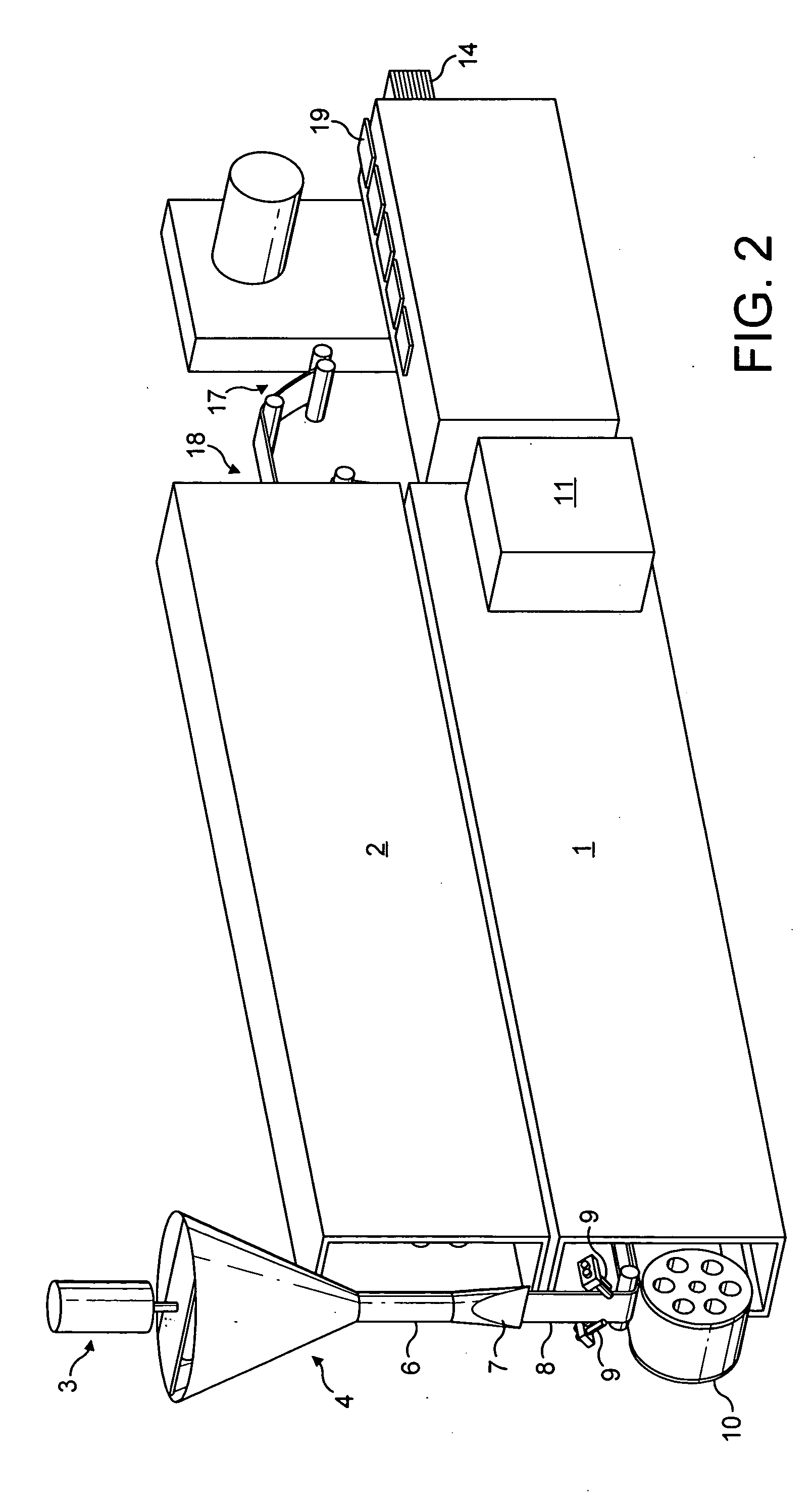

Continuous process and apparatus for making a pita chip

InactiveUS20150150270A1Eliminates and reduces disadvantageDrying solid materials with heatBaked article fillingEngineeringMechanical engineering

A method and apparatus for processing dough, for example, curing dough to make a pita chip. In a first aspect, the method comprises providing a first portion of dough on a first conveyor, conveying the first portion into an oven, directing a heating medium at the first portion using a first discharge array, and conveying the first portion out of the oven. In a second aspect, the apparatus comprises an oven, a first conveyor for conveying a first portion of dough, and a first discharge array. The oven comprises an oven housing, a first entrance of the oven housing for the first portion of dough, and a first exit of the oven housing for the first portion of dough. The first discharge array is positioned and oriented to direct a heating medium at the first portion of dough when the first portion of dough is positioned for conveyance by the first conveyor.

Owner:FRITO LAY NORTH AMERICA INC

Manufacture of baked dough products

Traditional unleavened dough breads are made by hand and in circular form. This is inefficient and the product is uneven in taste and texture, which is unsatisfactory and leads to wastage. It is also difficult to pack. In accordance with the invention, a continuous process of making baked unleavened dough products is described where an extruded strip of dough is passed through a heated oven section and the cooked dough strip then sized and cut into rectangular breads. The process is of particular value to mechanize the production of Saj bread, producing a product of a more even quality and more consumer-acceptable shape.

Owner:KHALAF RICHARD ANTHONY

Five-sectional timing and temperature-variable drying technology for processing rice flour

A five-step temp-varying baking technique for preparing the high-quality noodles from rice flour includes such steps as grinding rice grains, primary steaming, extruding, boiling in water, cooling, dripdrying, shaping, the first baking step at 30 deg.C for 0.5 hr, the second baking step at 45 deg.C for 1 hr, the third baking step at 55 deg.C for 3.5 hr, the fourth baking step at 40 deg.C for 1.5 hr, the fifth baking step at 30 deg.C for 0.5 hr, natural cooling, and packing.

Owner:FUJIAN NORMAL UNIV

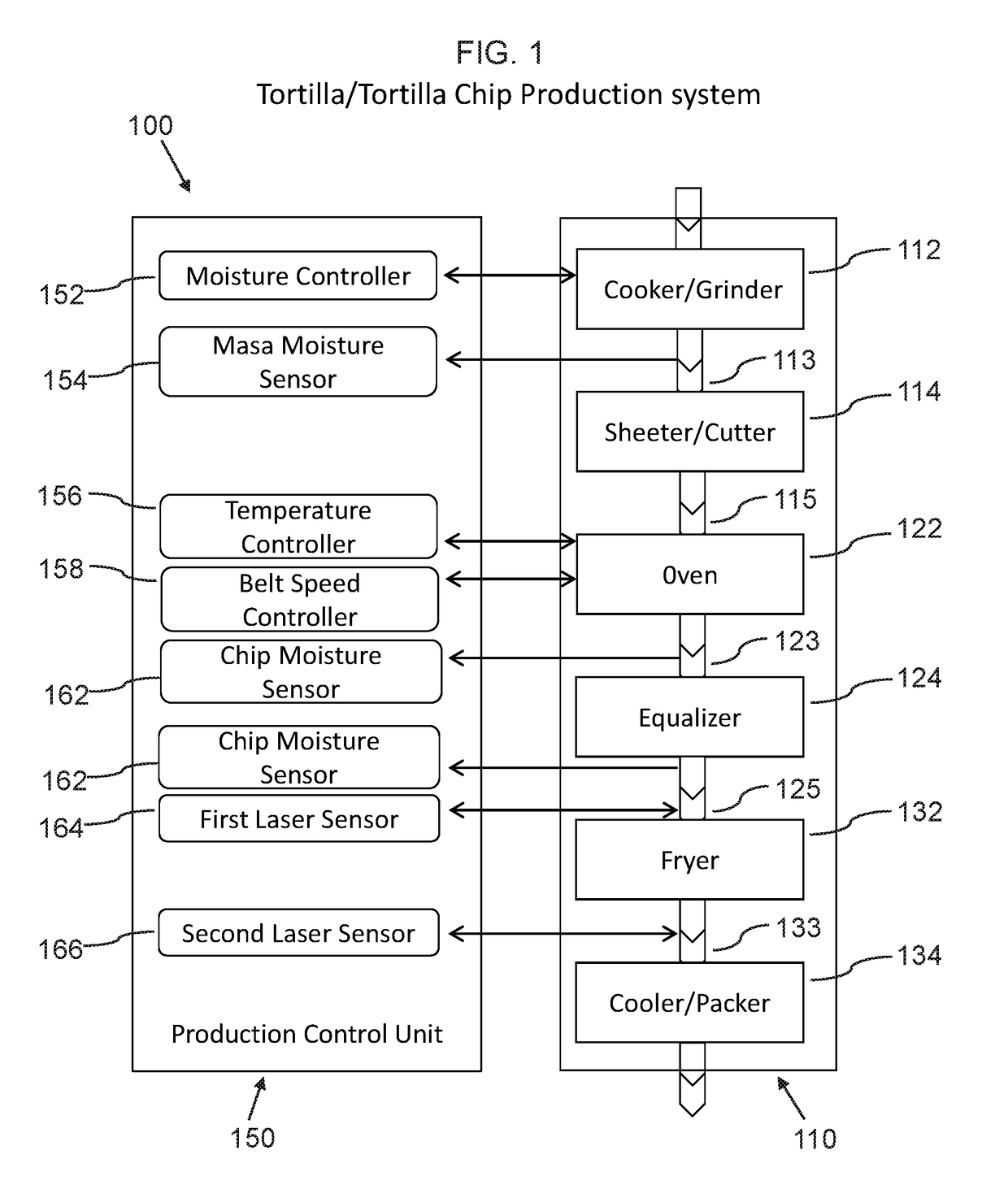

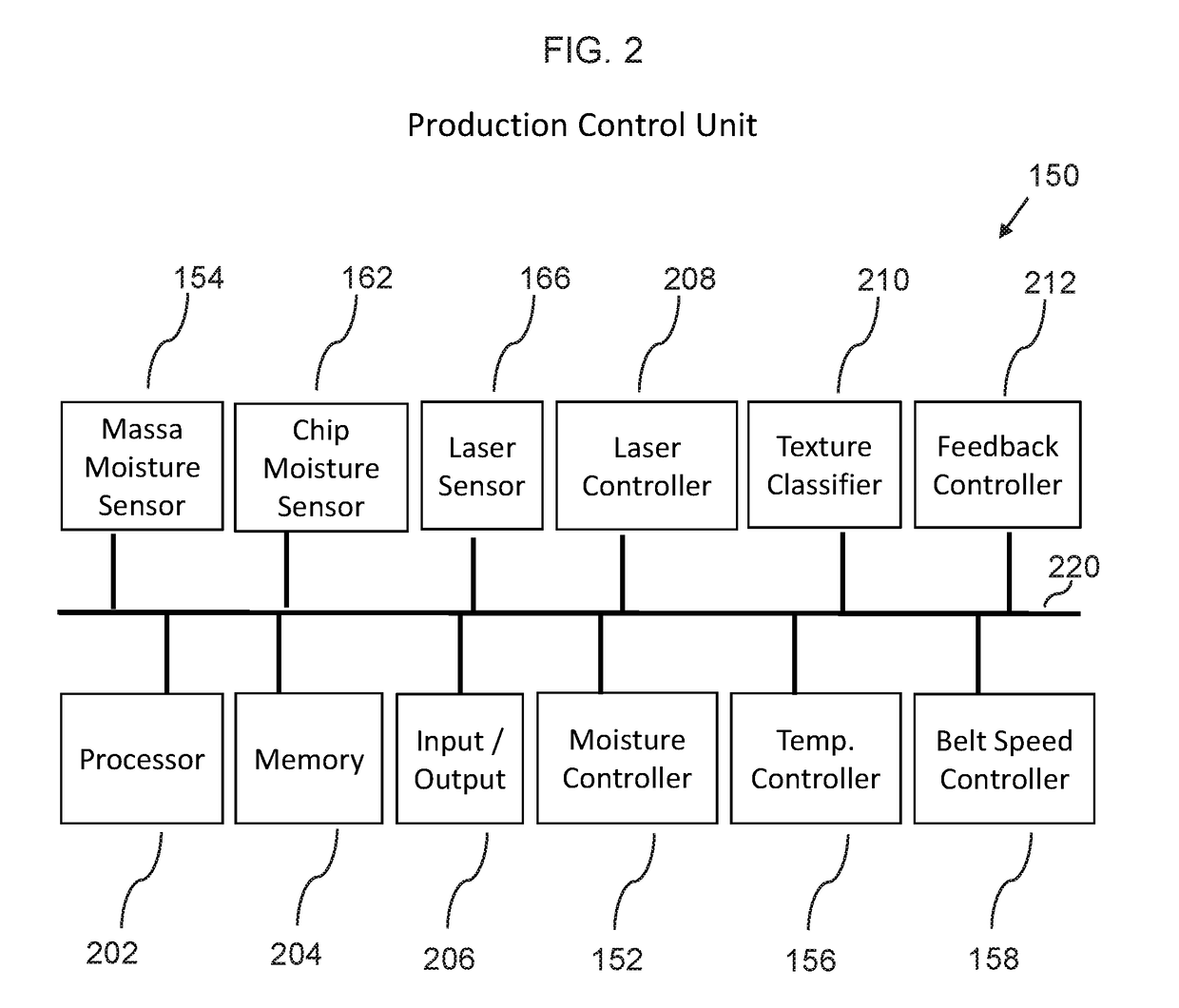

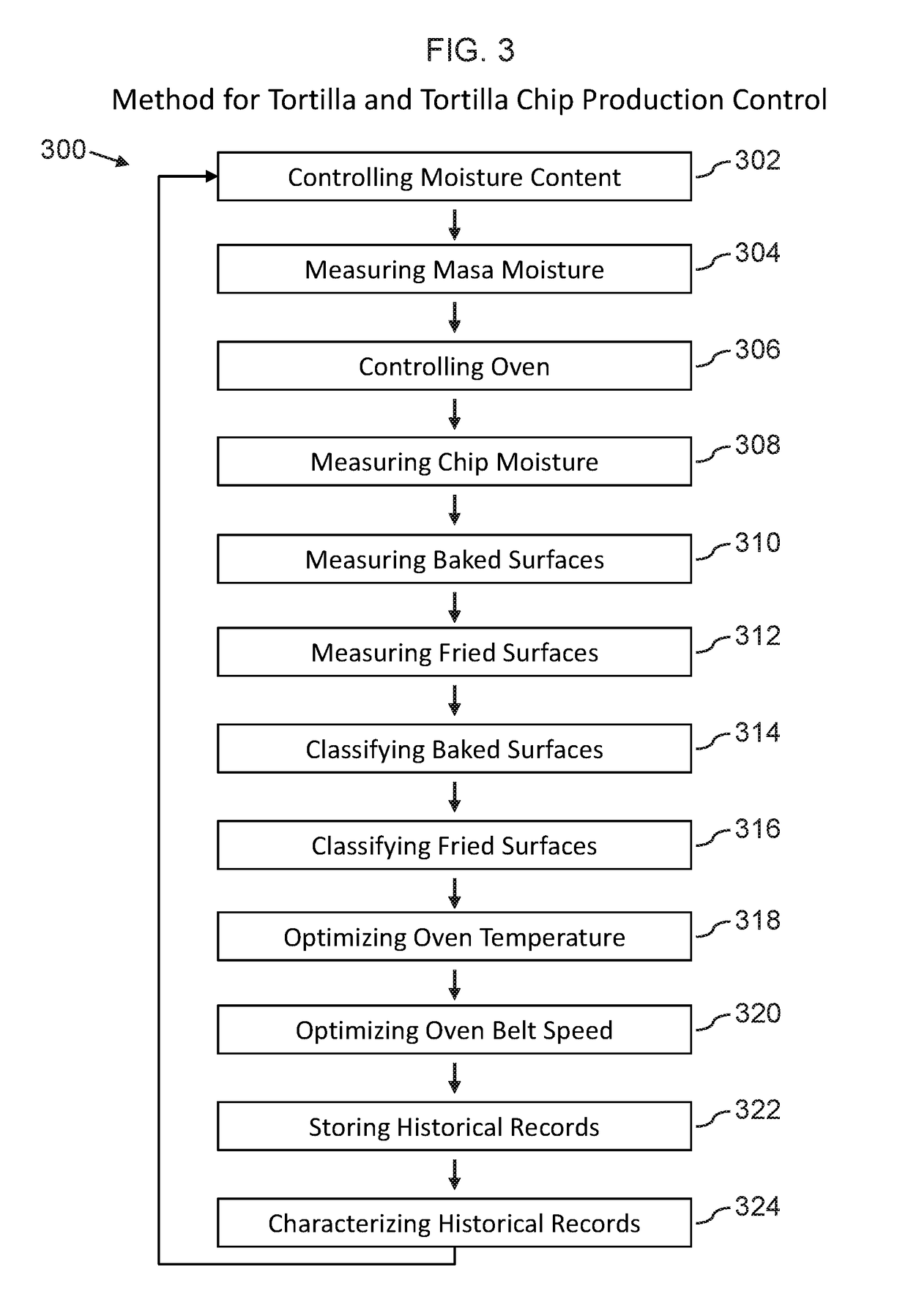

System, device, and method for moisture and texture detection and control in tortilla chip production

ActiveUS20170251679A1Increase temperatureDough-sheeters/rolling-machines/rolling-pinsBaking processesTortilla chipsBelt speed

A production system for moisture and texture detection and control in tortilla and tortilla chip production includes a production line, including a cooker / grinder, a sheeter / cutter, an oven, an equalizer, a fryer, and a cooler / packaging machine; and a production control unit, including a processor, non-transitory memory, an input / output component, a moisture controller, a temperature controller, a belt speed controller, a masa moisture sensor, a chip moisture sensor, laser sensors for measuring surface texture of baked and fried chips, a laser controller, a texture classifier, a feedback controller. Also disclosed is a method for production control, including controlling moisture content, measuring masa moisture, controlling oven, measuring baked surfaces, measuring fried surfaces, classifying baked surfaces, classifying fried surfaces, optimizing oven temperature, optimizing oven belt speed, storing and characterizing historical records.

Owner:BARTLETT BRIAN E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com