Patents

Literature

604results about "Milk treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

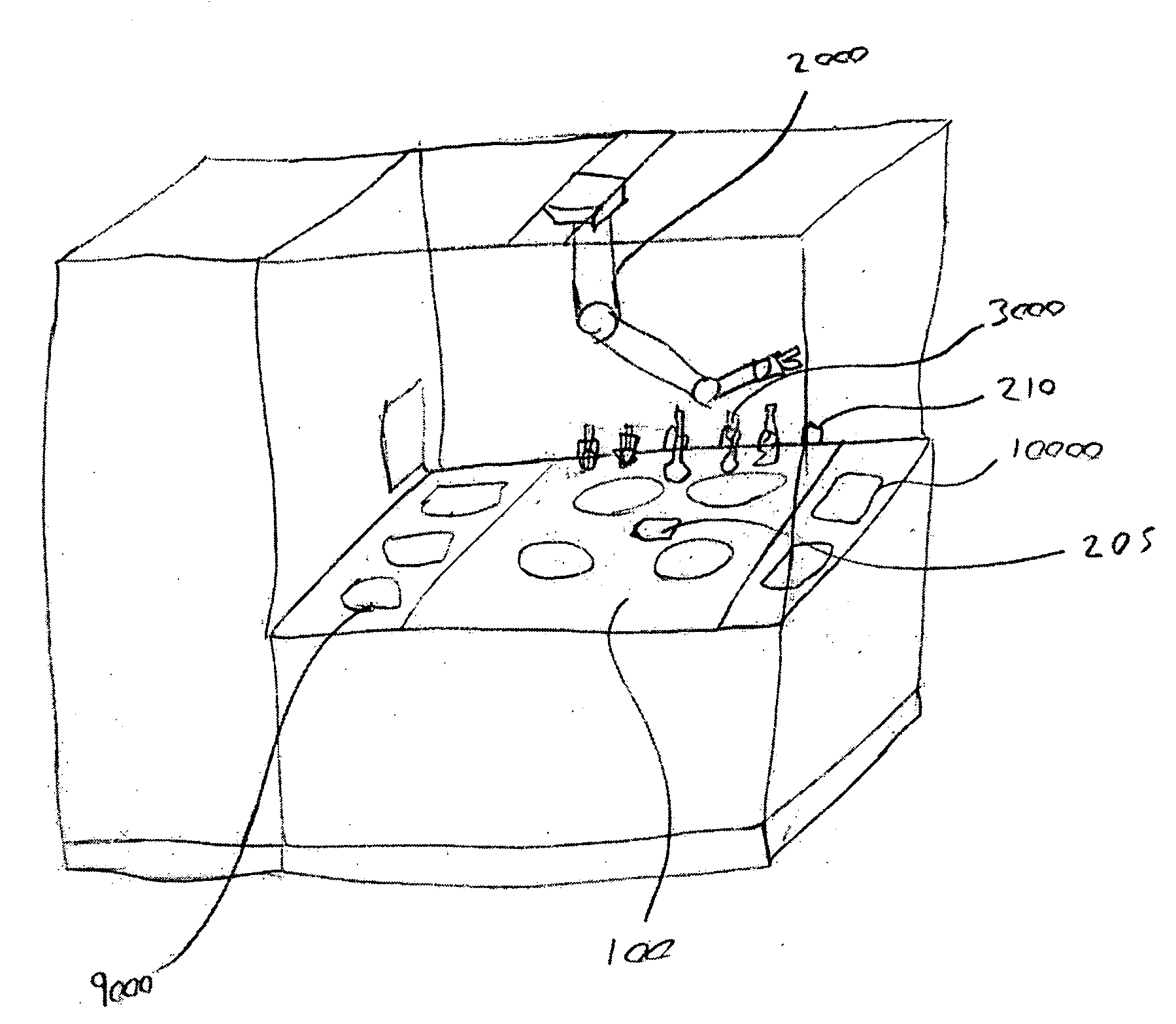

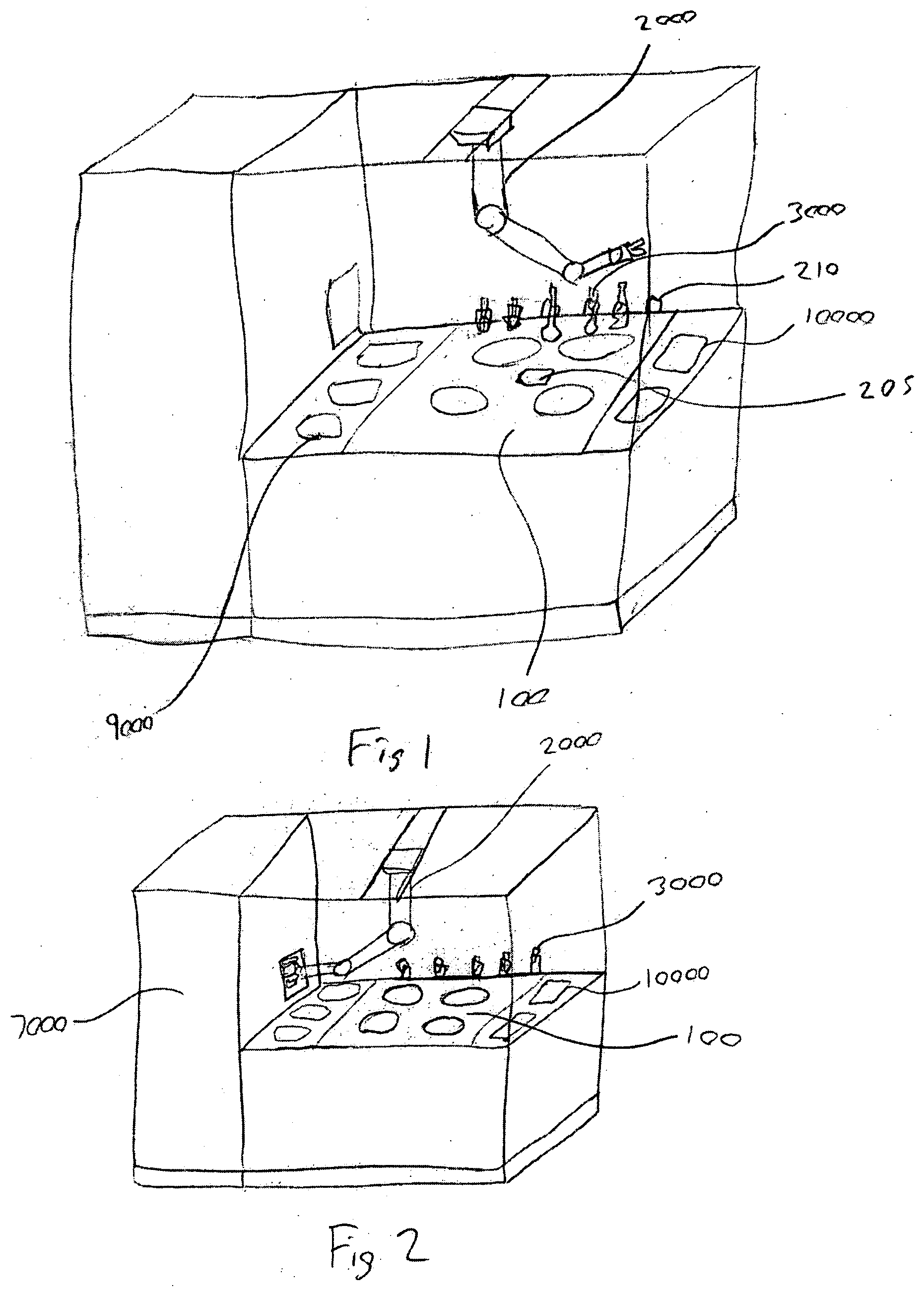

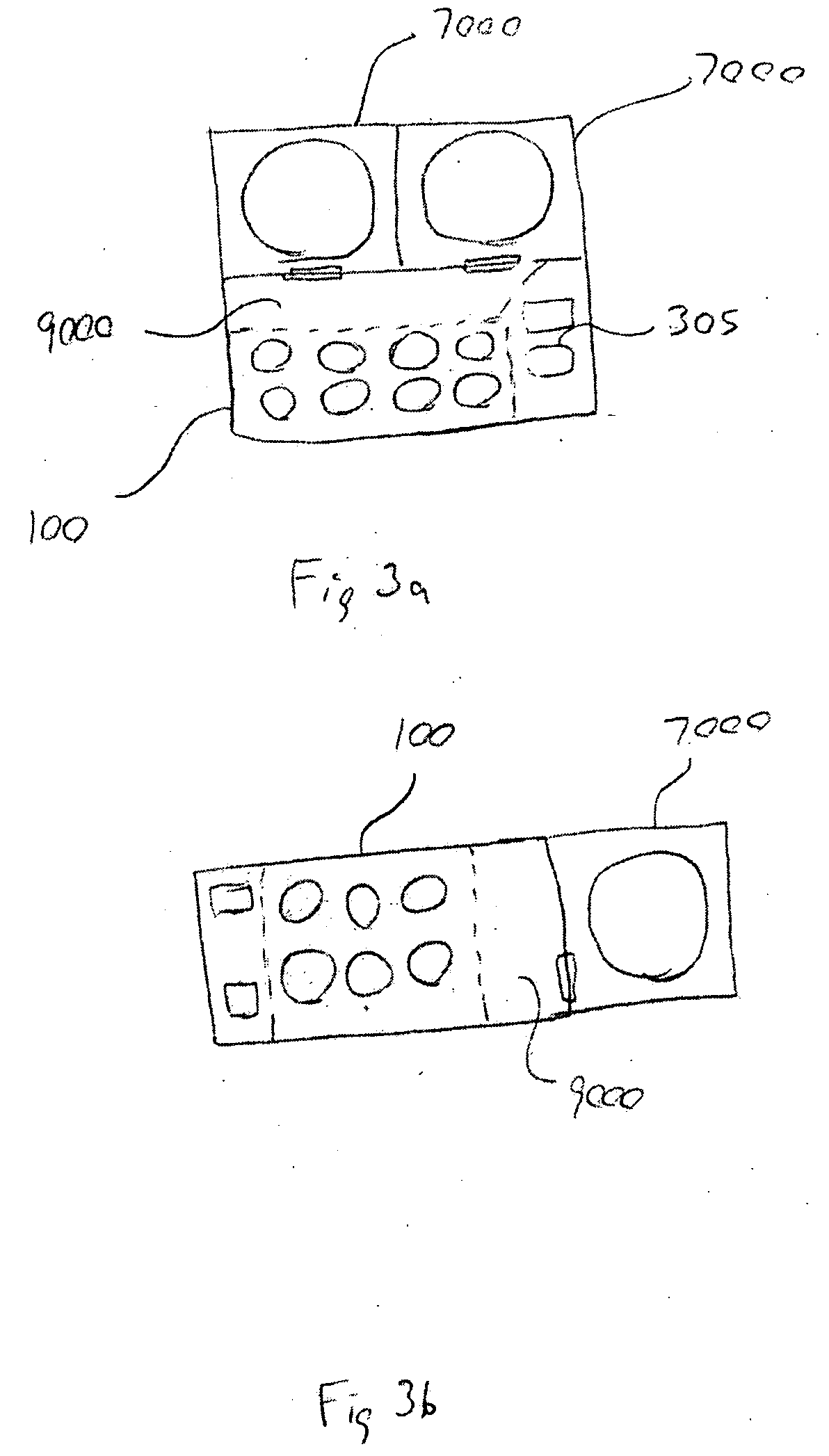

Food preparation system

InactiveUS20050193901A1Eliminate all packaging materialGood for foodFeeding apparatusRoasters/grillsAdditive ingredientControl system

An automated food preparation system is described. It allows precise, automated control of the food preparation process, and has the ability to perform an automated cleanup. It comprises at least one manipulator to process and move ingredients, a control system, an autonomously accessible ingredient storage system, and at least one cooking receptacle.

Owner:BUEHLER DAVID BENJAMIN

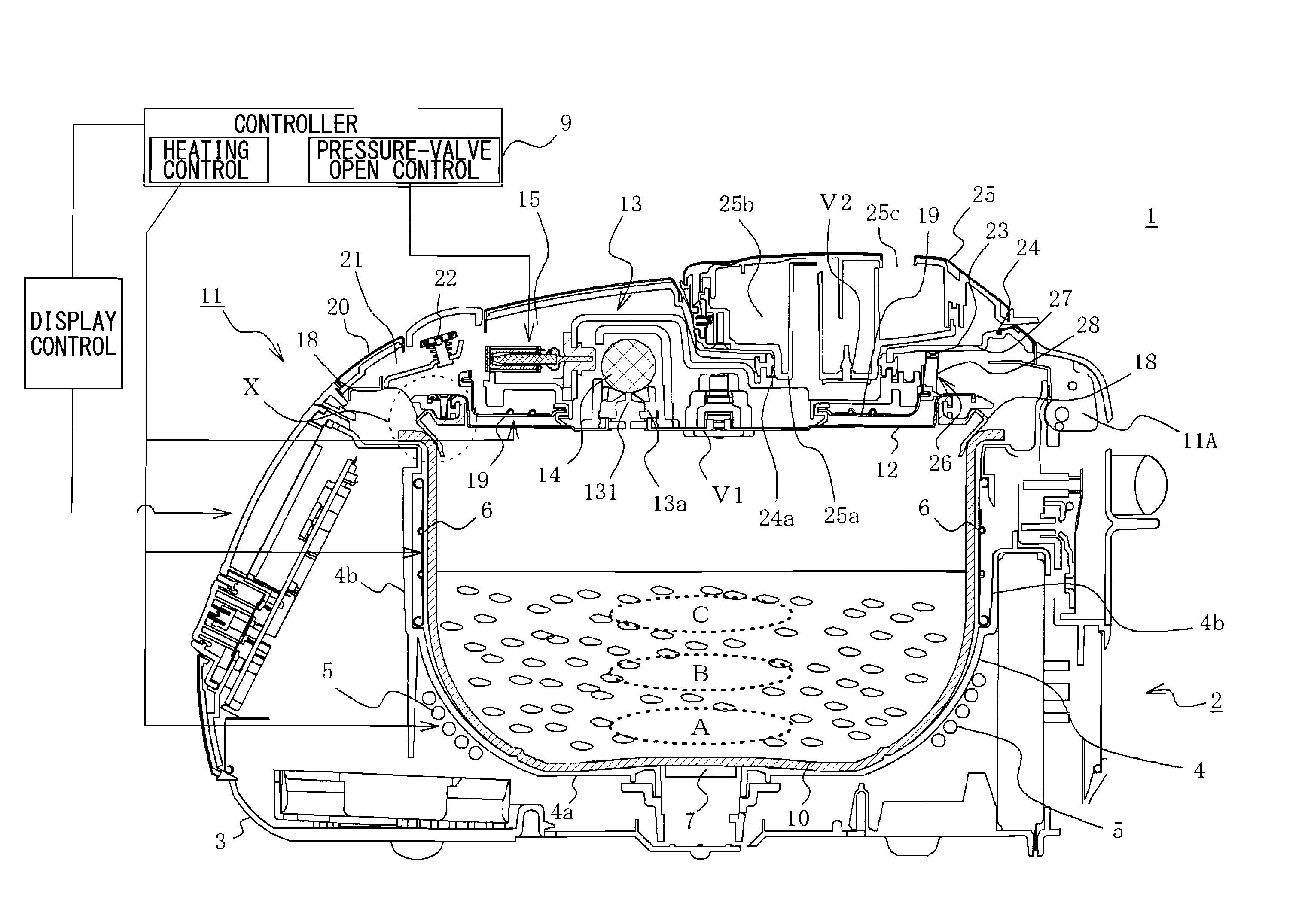

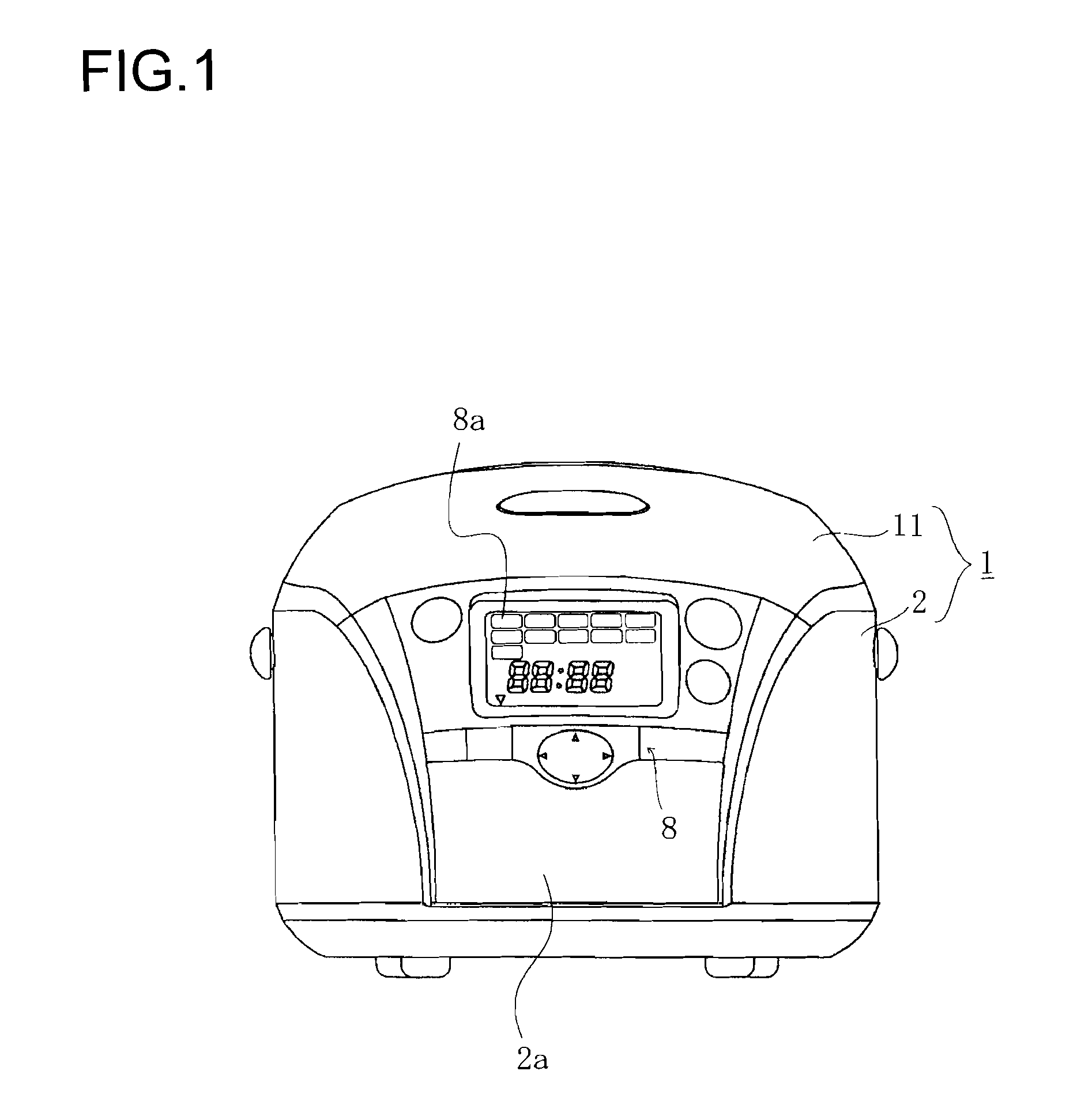

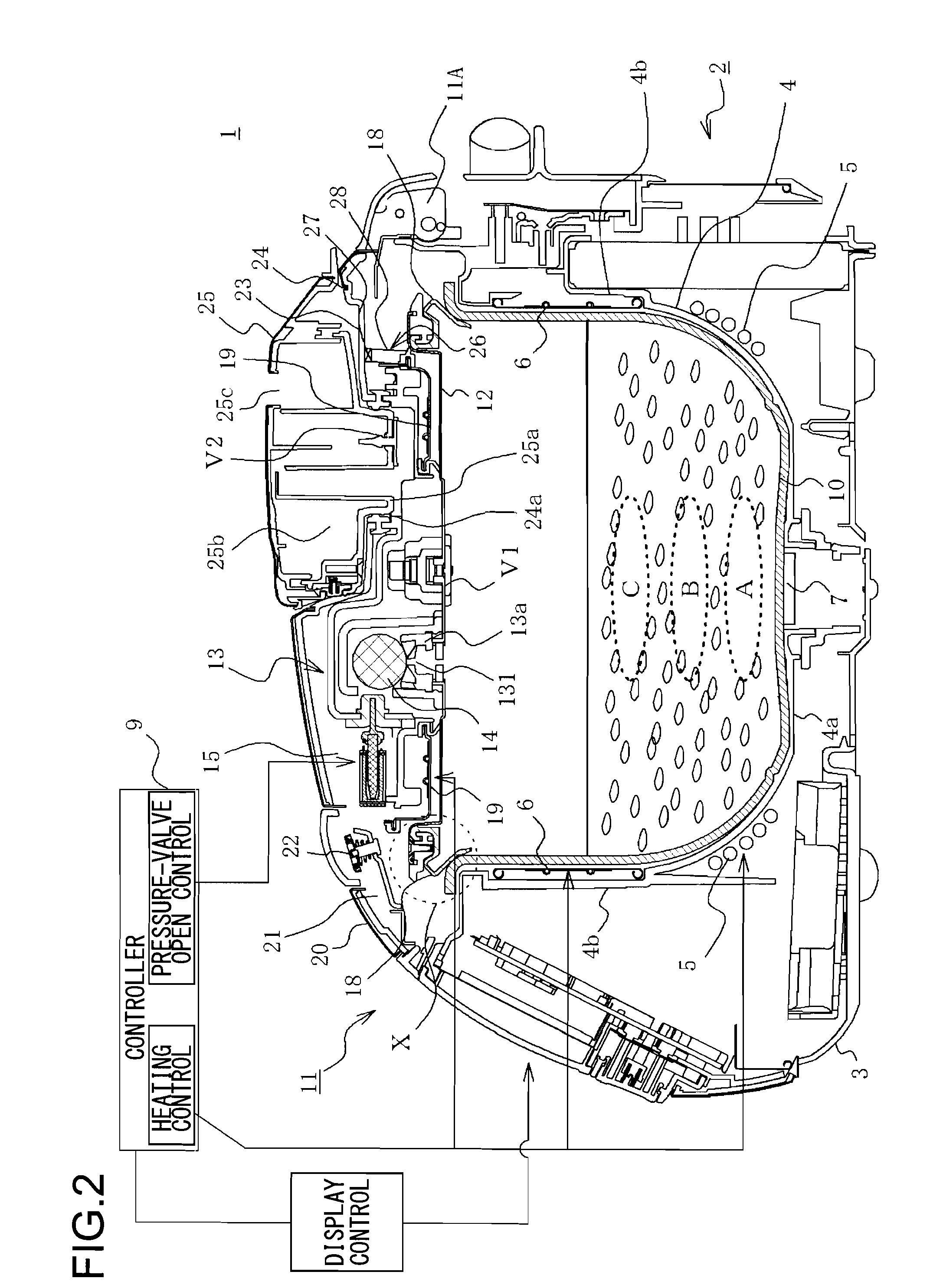

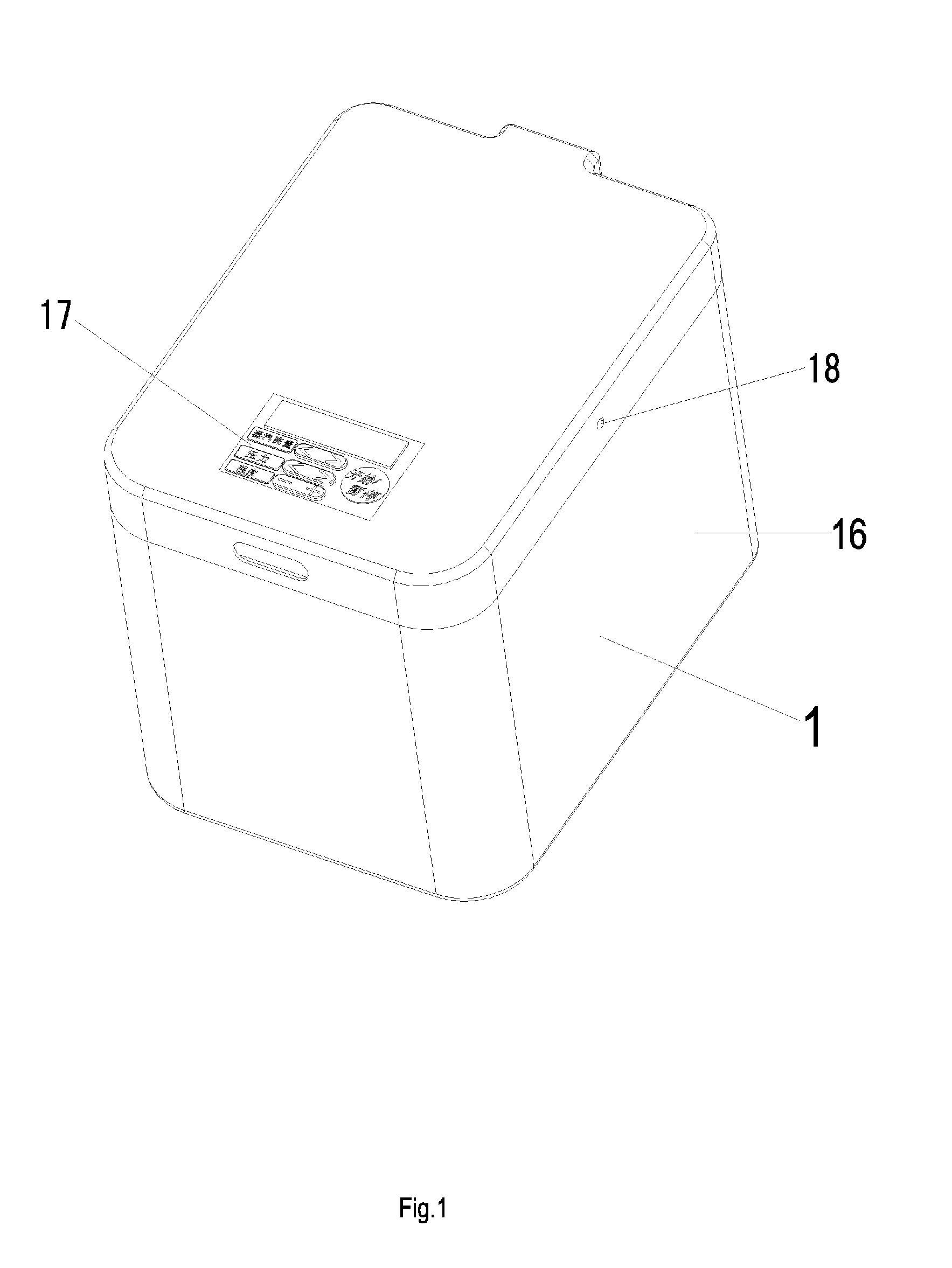

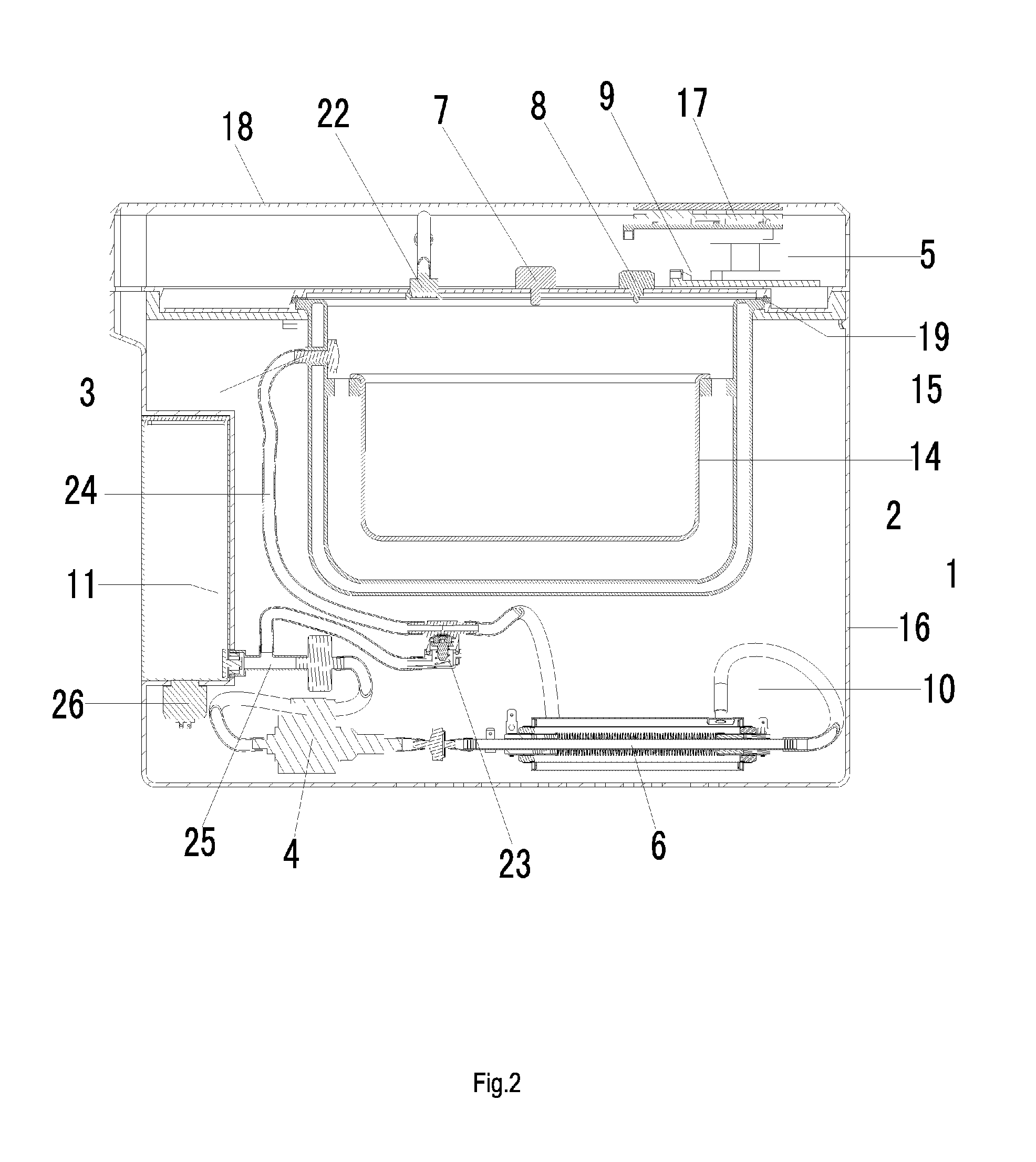

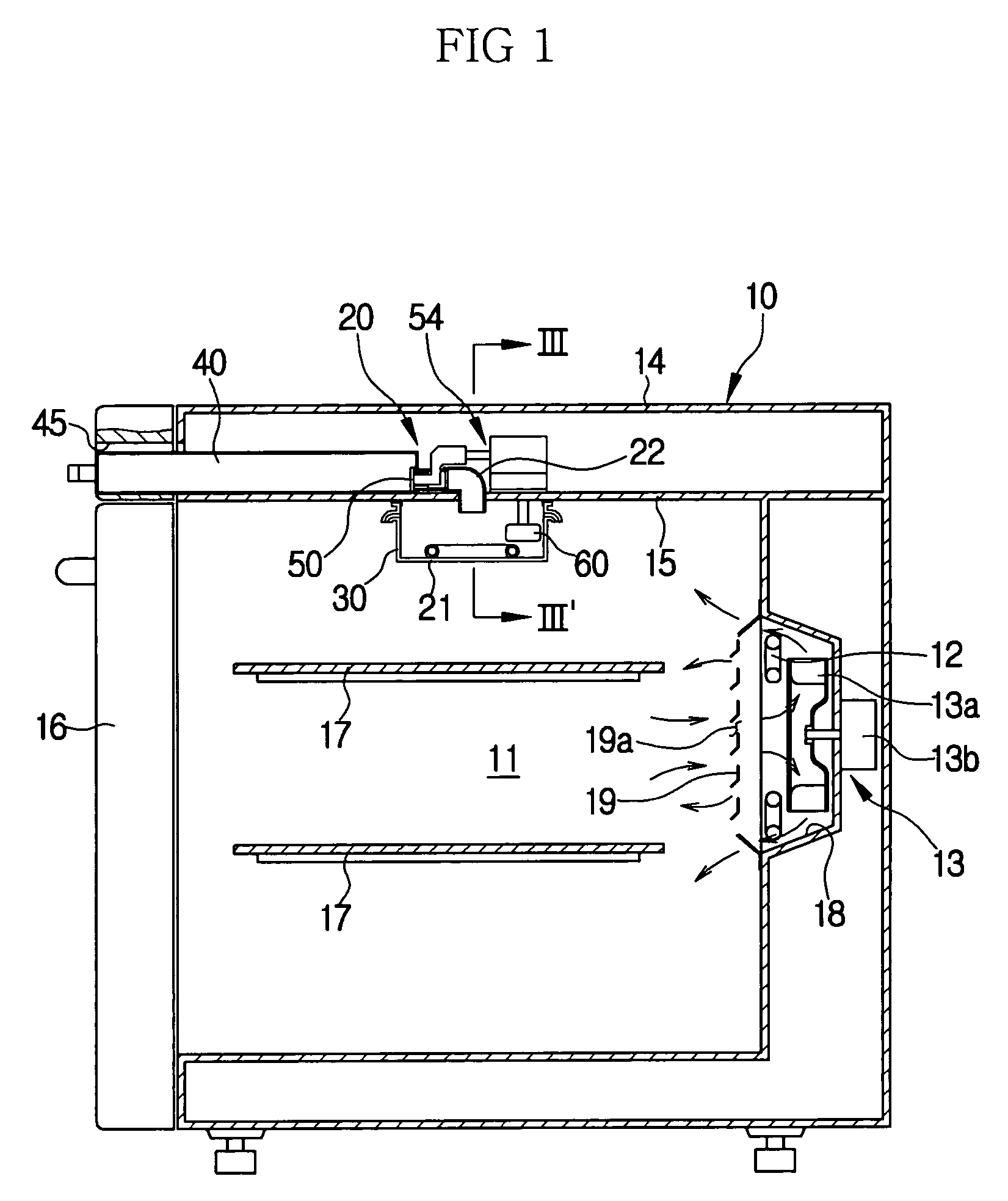

Electric rice cooker and method of cooking rice

InactiveUS20110003048A1Increase moistureUneven water absorptionBoiling over preventionMilk treatmentInternal pressureEngineering

An electric rice cooker capable of increasing the water content of rice by a simple structure. The electric rice cooker (1) has a pot (10) in which food substances to be cooked including water and rice are contained, heating device (5, 6, 19) for heating the food substances to be cooked in the pot, a lid (11) for closing the opening of the pot, and a controller (9) for performing rice cooking steps including a water absorption step for allowing the rice to absorb the water by controlling the heating devices. The controller (9) raises the internal pressure of the pot (10) to 1.05-1.18 atm in the water absorbing step to allow the rice to absorb the water.

Owner:SANYO ELECTRIC CO LTD +1

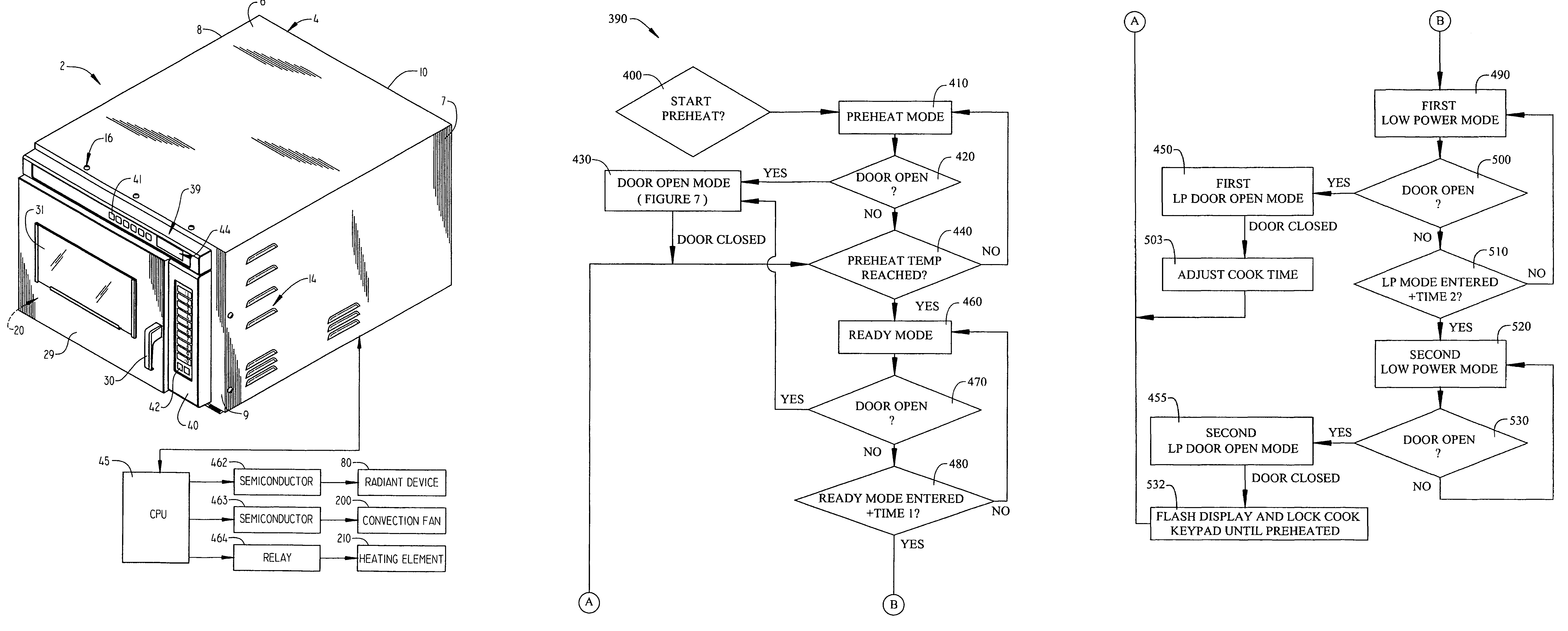

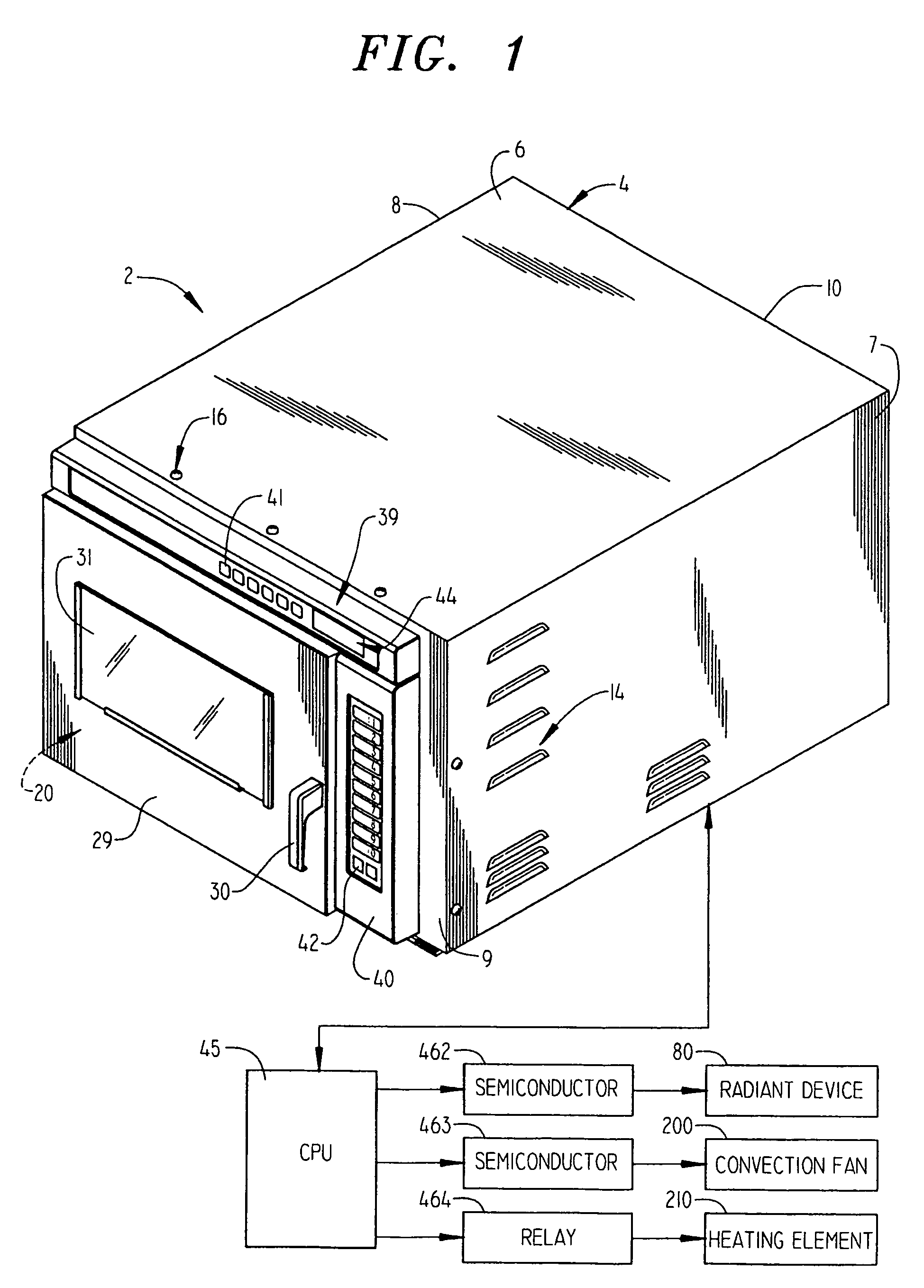

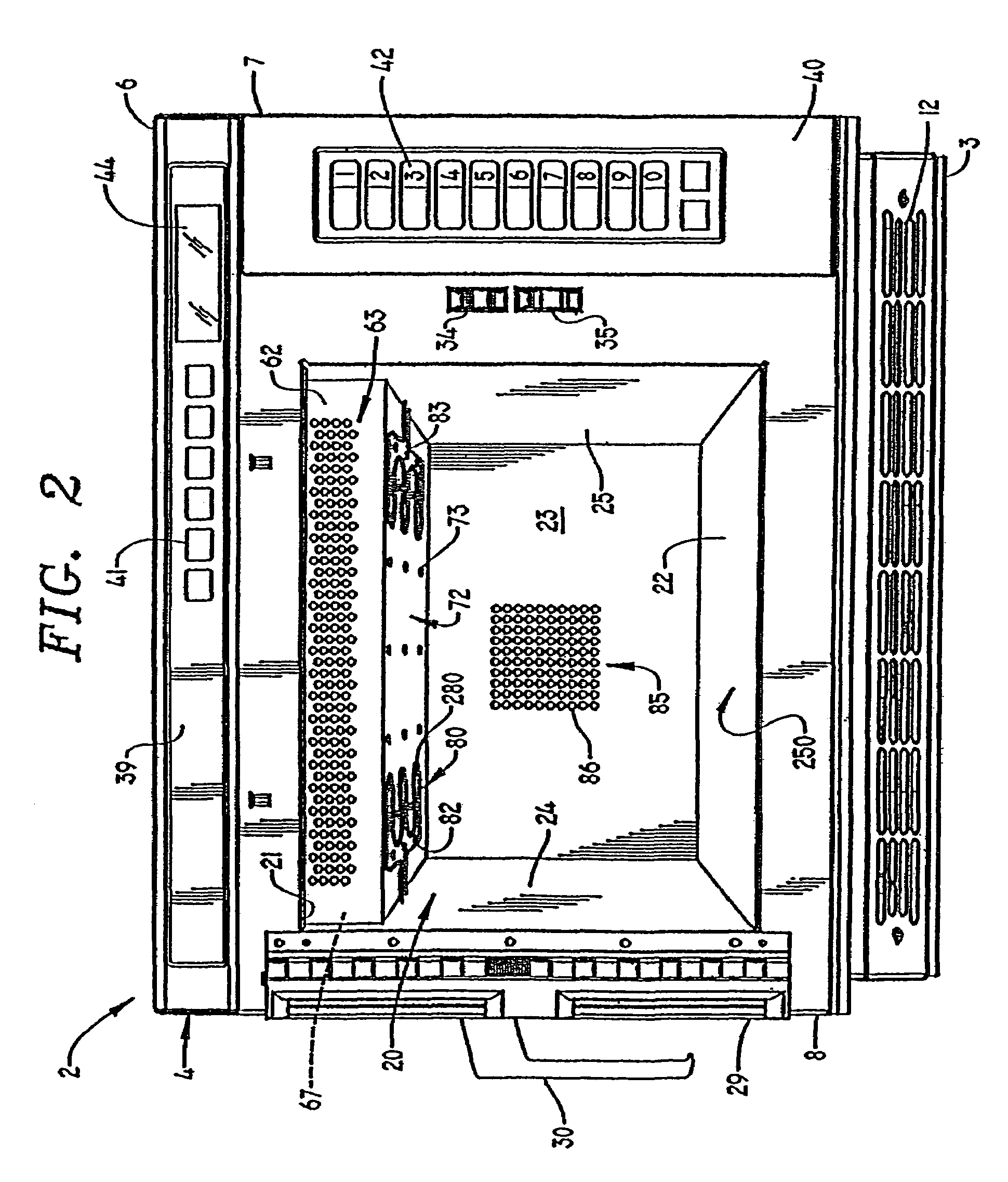

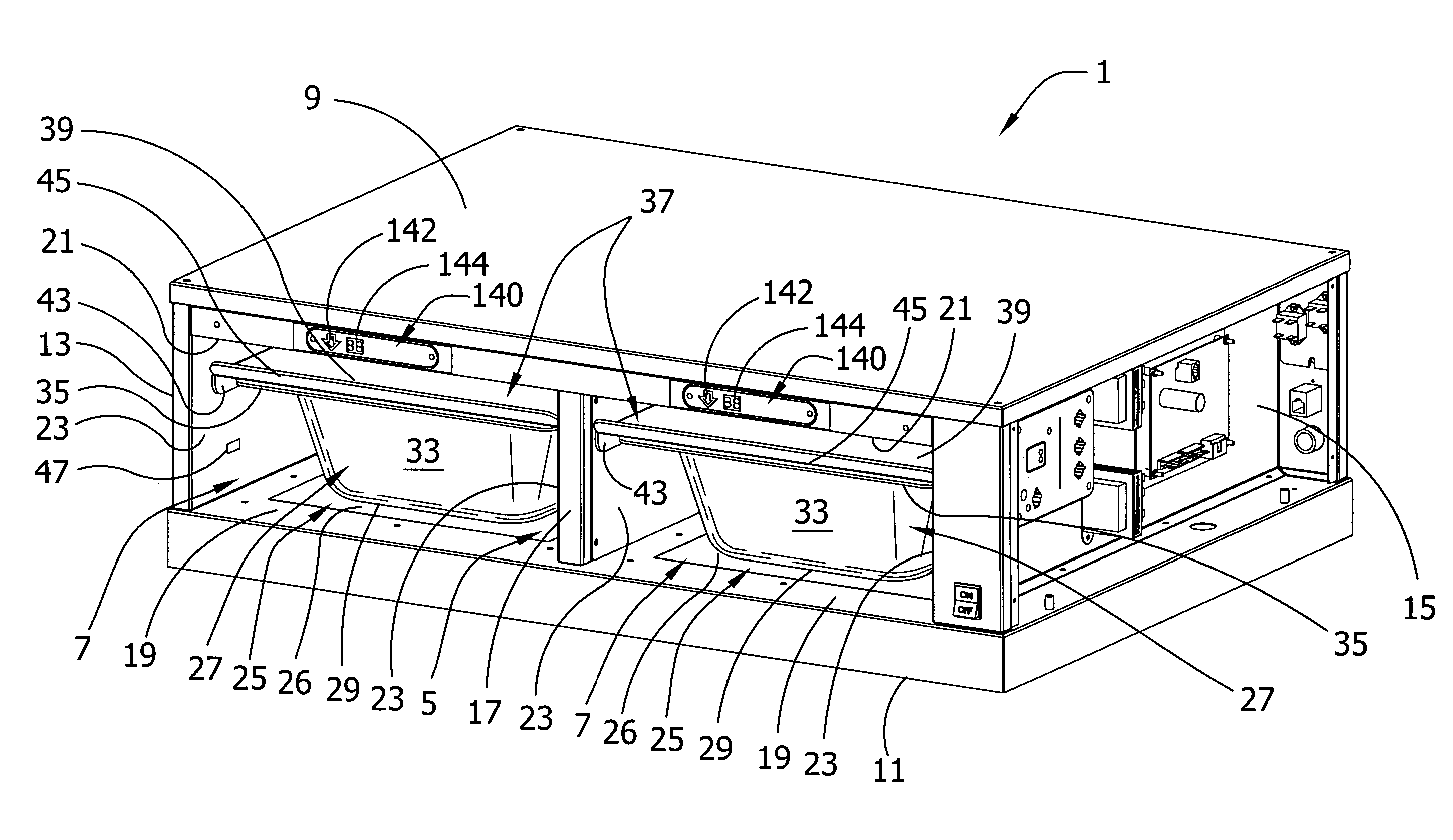

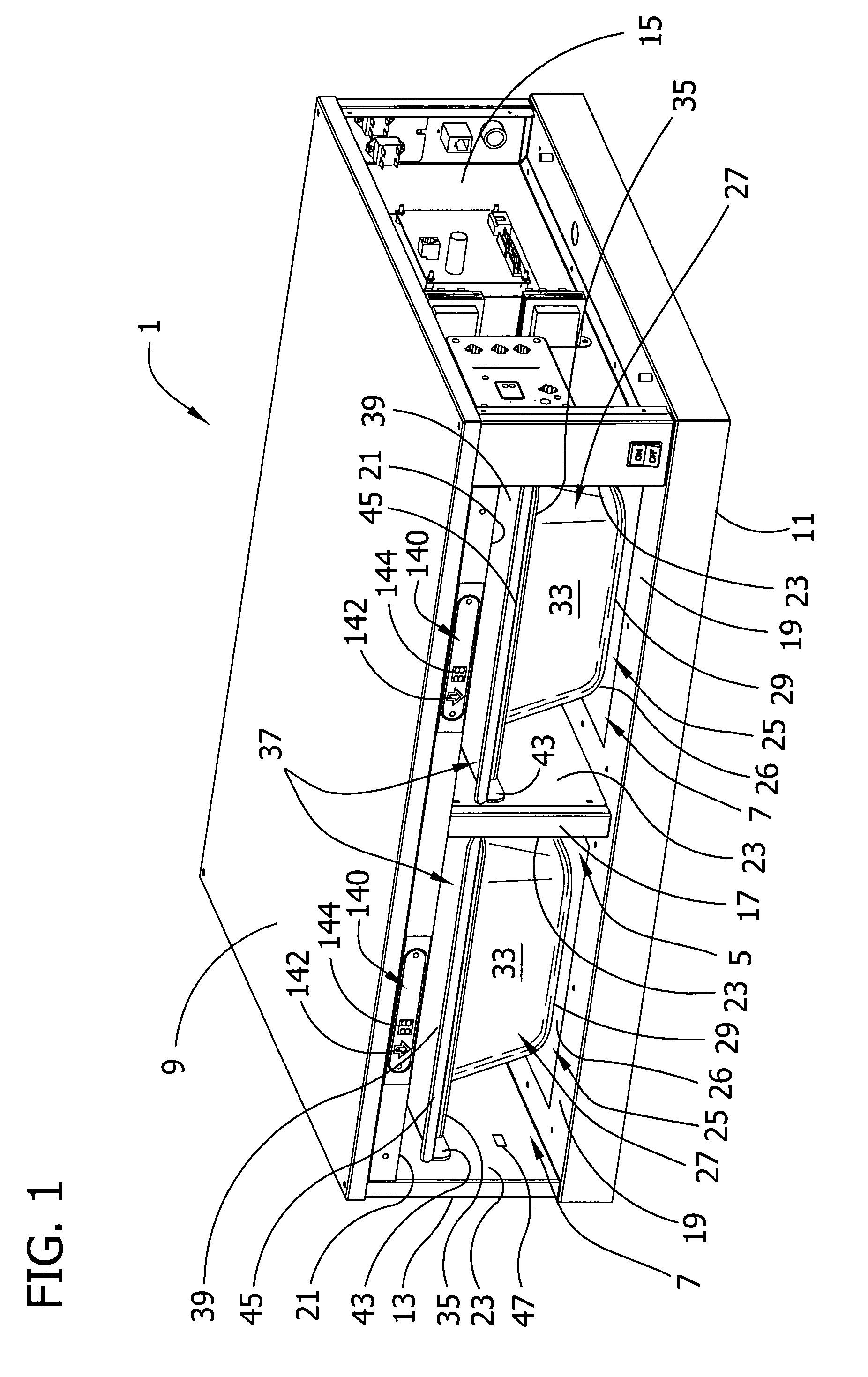

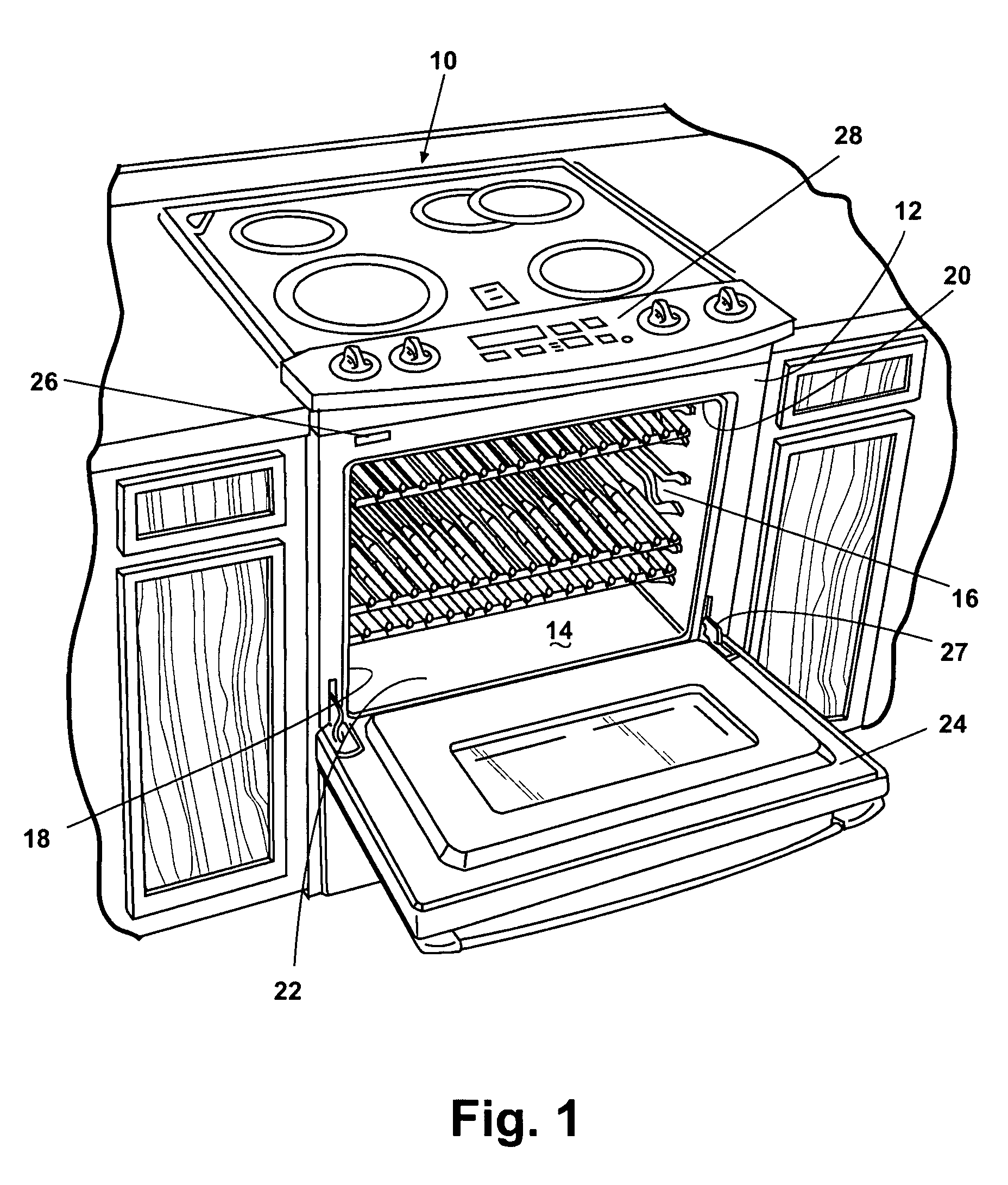

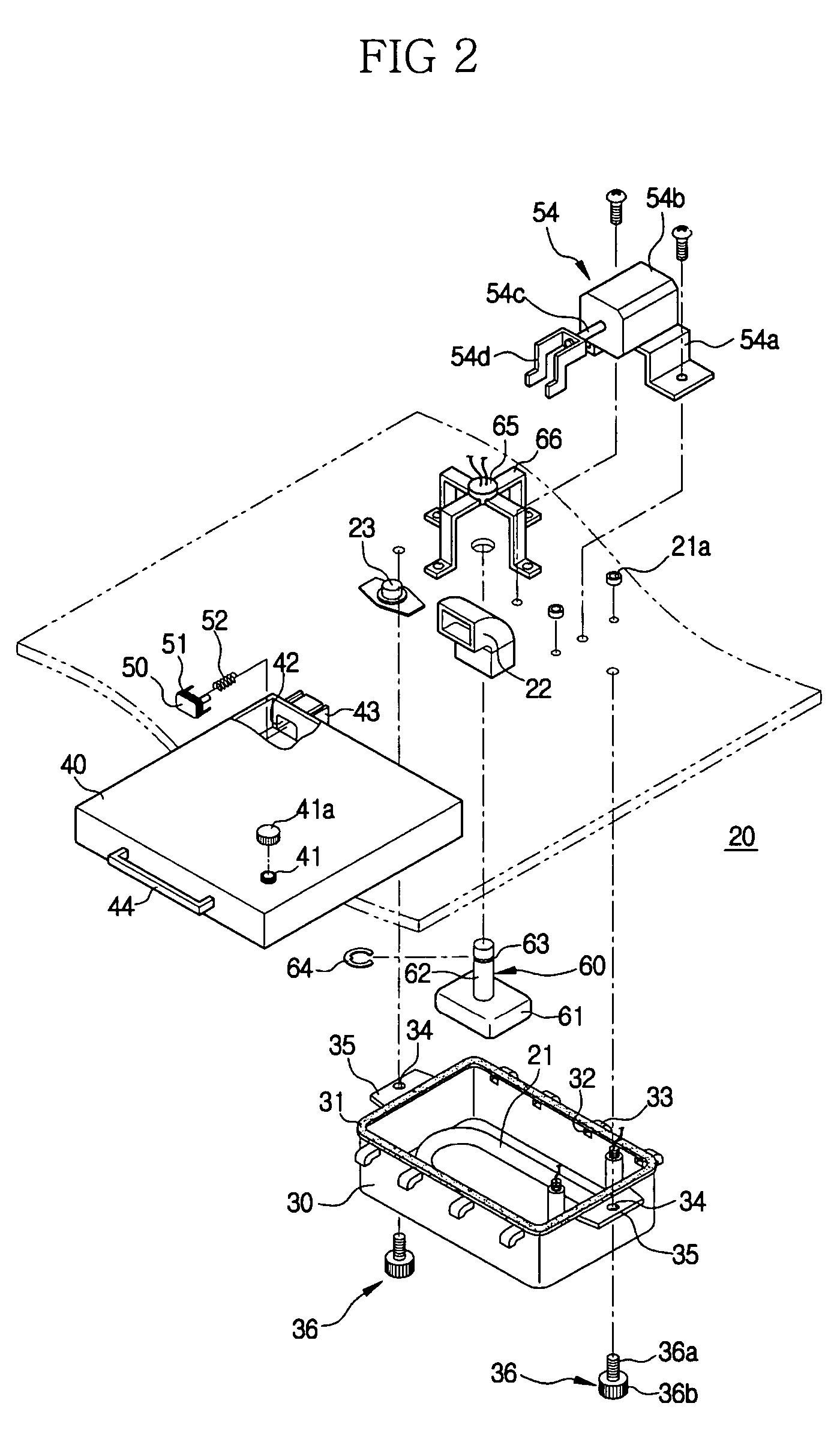

Operational modes for a cooking appliance employing combination cooking technology

A cooking appliance includes a controller for establishing a plurality of operating modes for heating an oven cavity. Specifically, the controller establishes one of a pre-heat mode, a ready mode, a first low power mode and a second low power mode for controlling a temperature of the oven cavity. Upon selecting a temperature for the oven cavity, the controller operates a radiant heating device, a convection fan and a convection heating device at full power to establish the selected temperature. After the selected temperature is achieved, the controller switches to a ready mode and reduces heat output of both the radiant heating device and the convection heating device, while also reducing fan speed. After respective periods of time in which a door of the appliance is not opened, the controller switches to first and second low power modes to conserve energy.

Owner:ACP OF DELAWARE

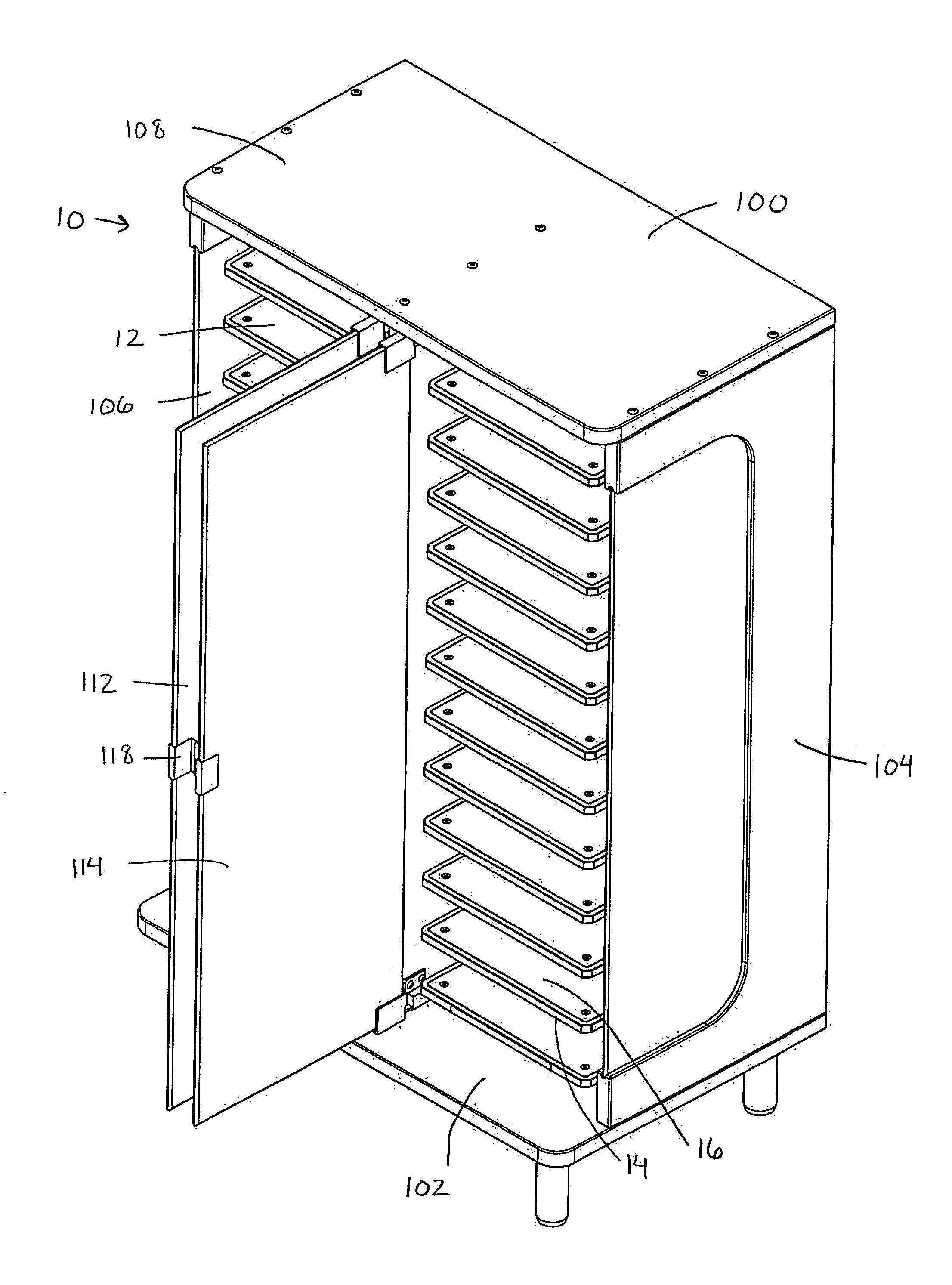

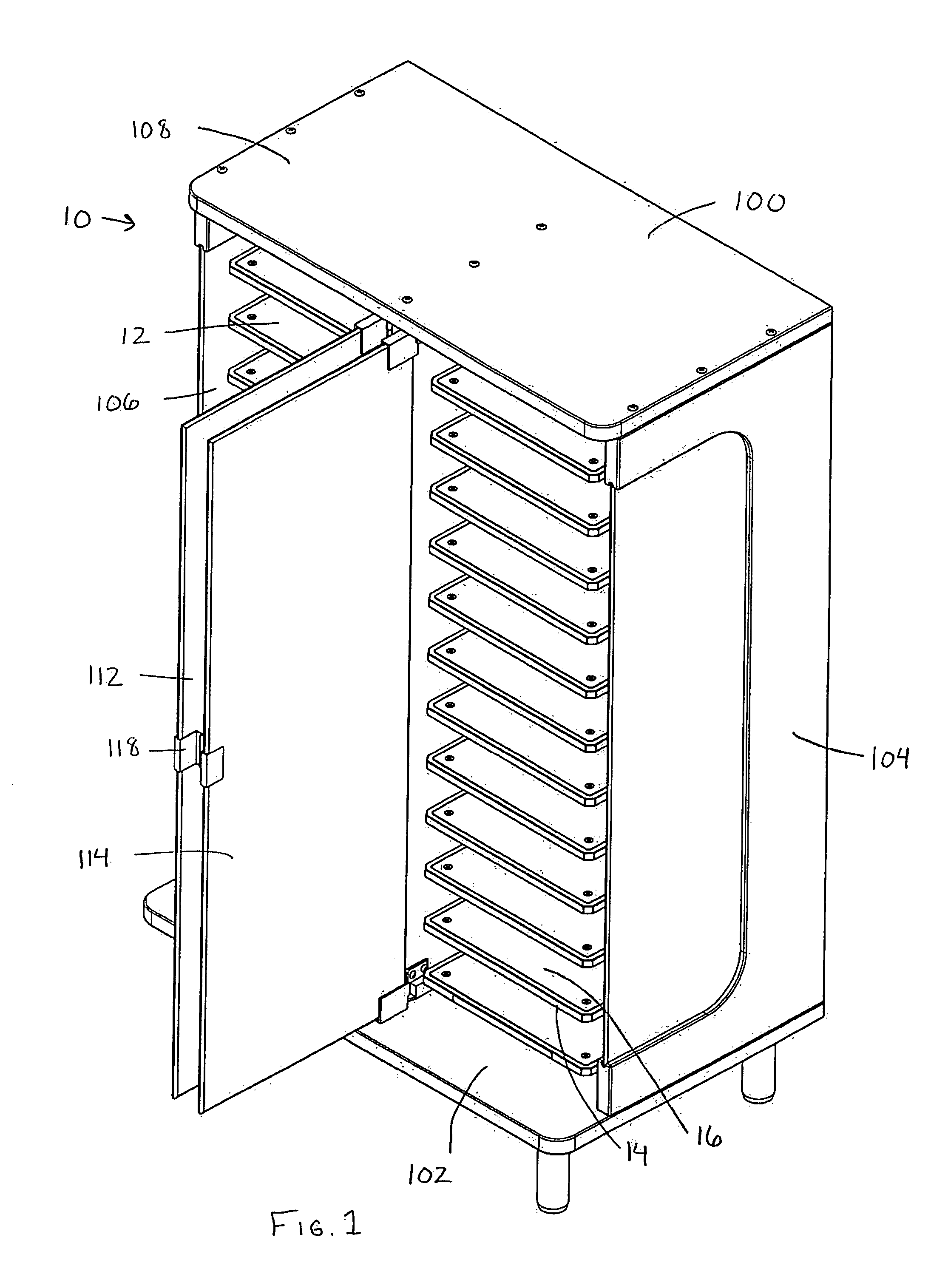

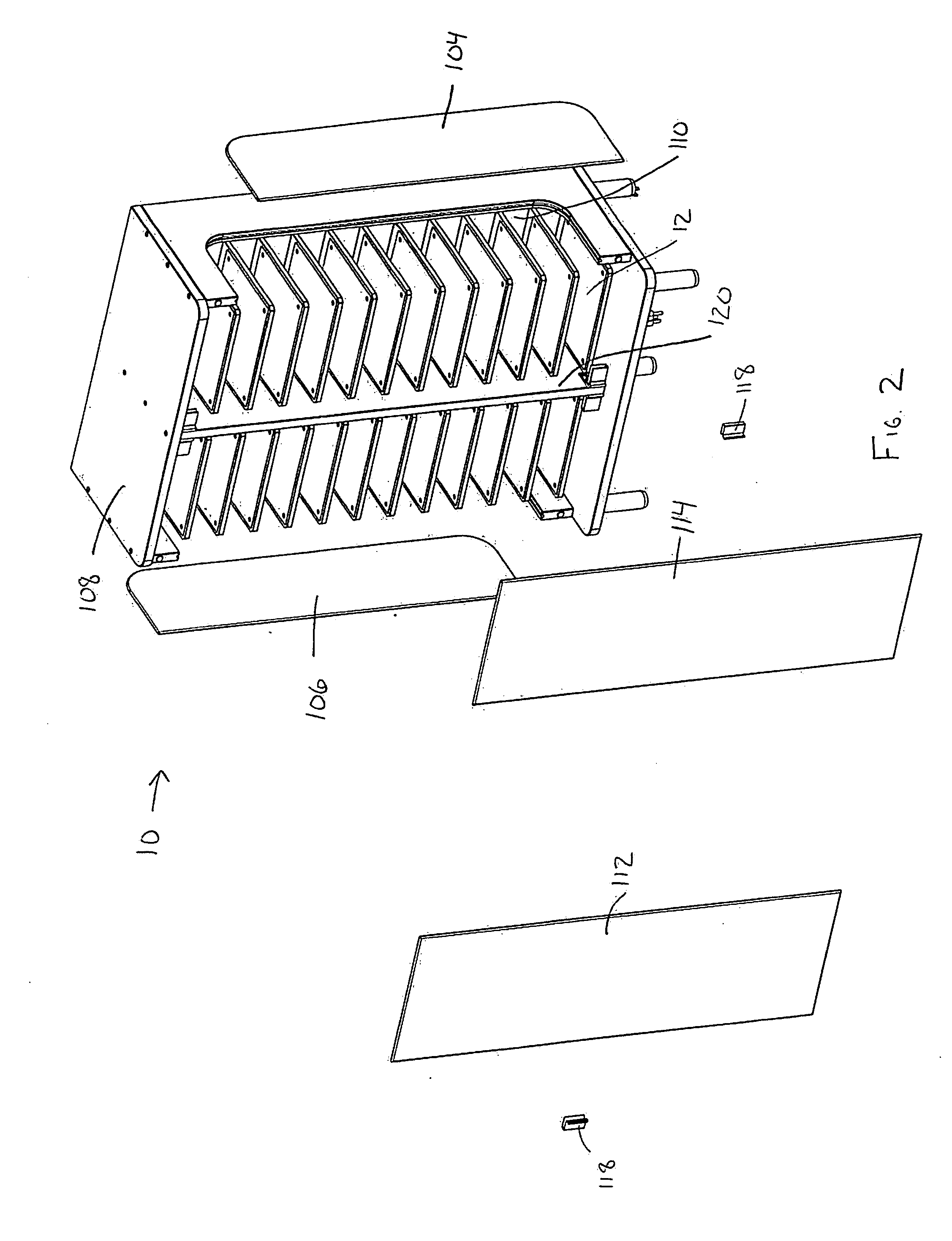

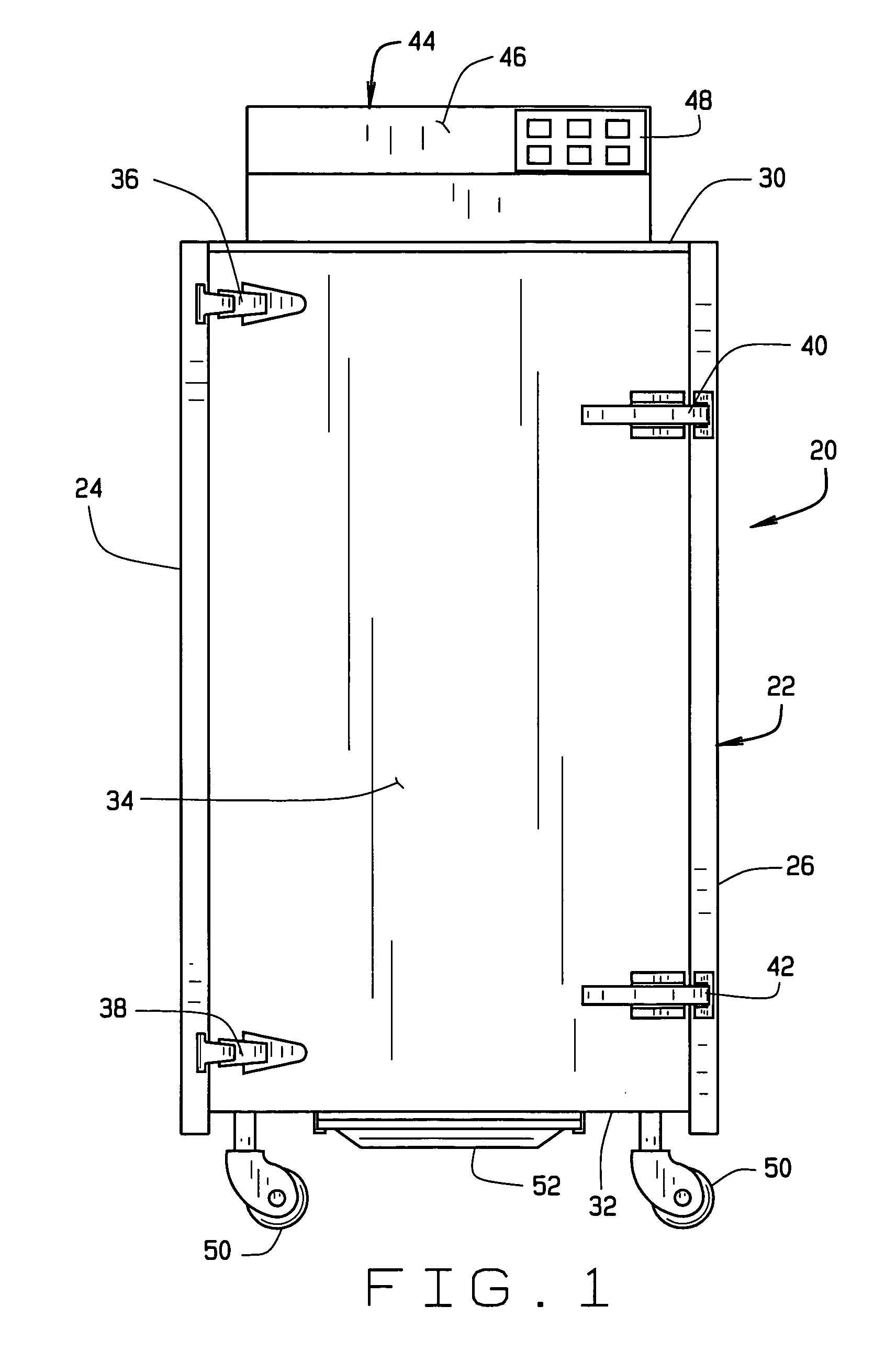

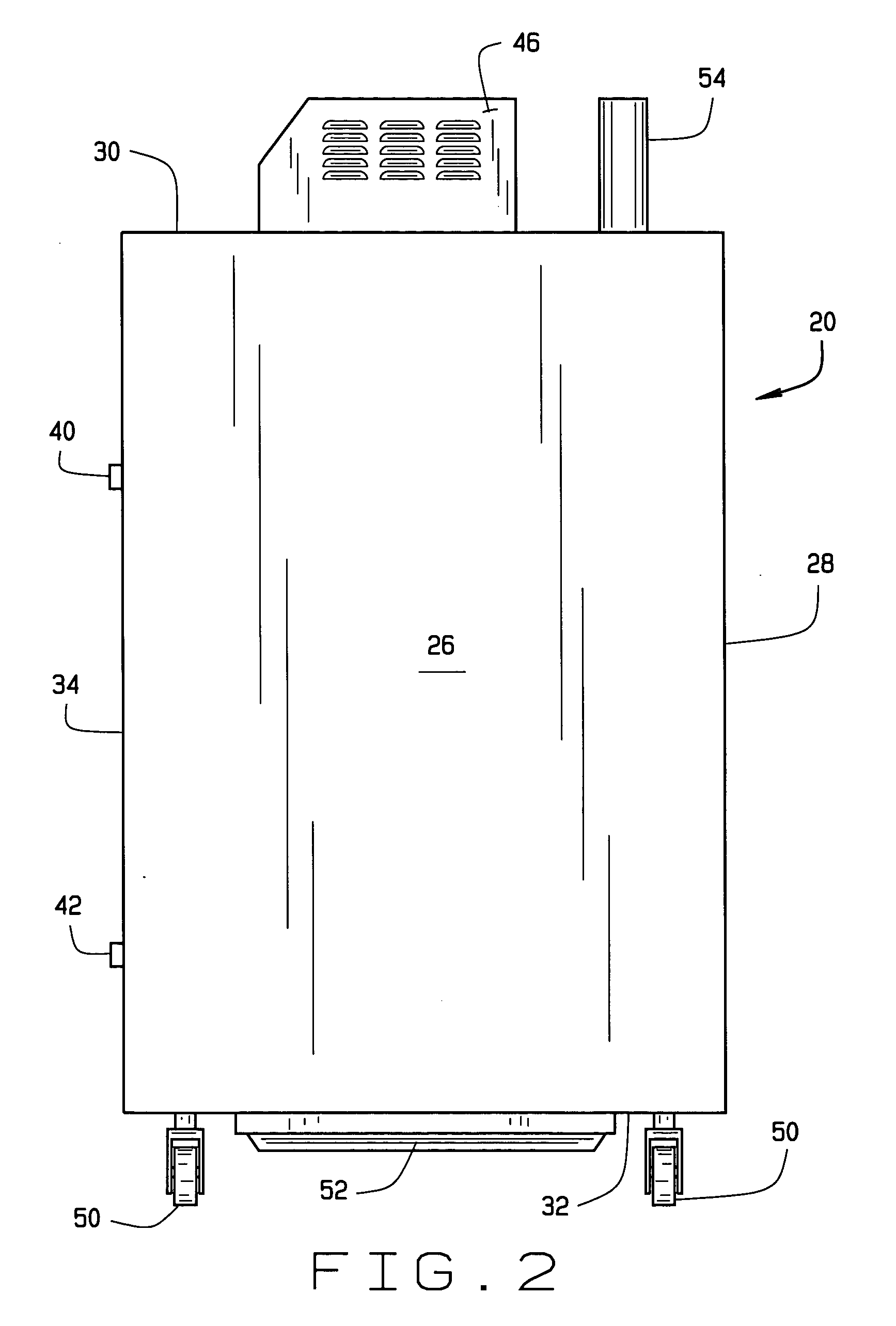

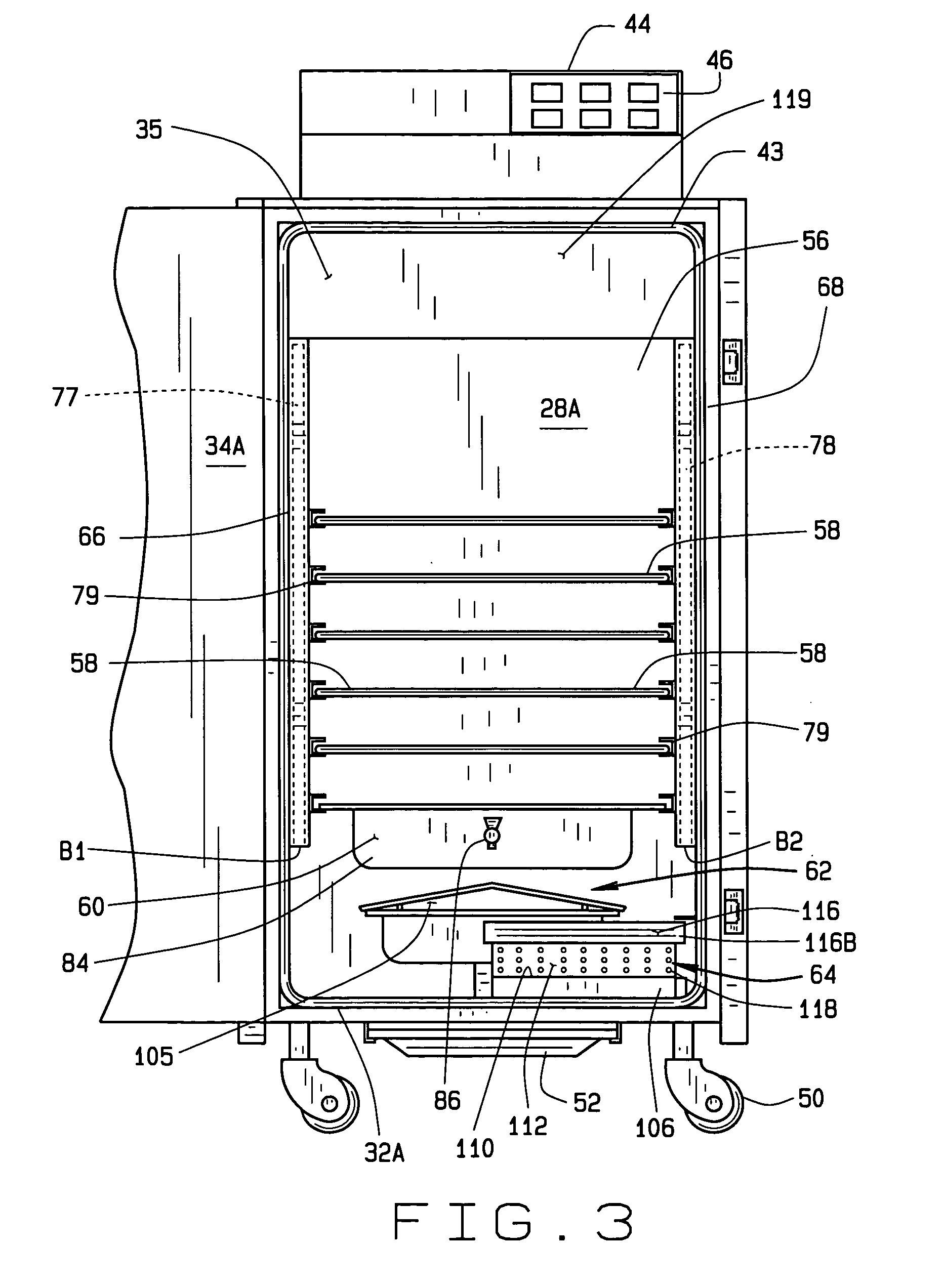

Food warming and holding device construction and method

Owner:HAVEN INNOVATION

Food warming apparatus

InactiveUS7328654B2Improve product qualityHeating up fastDomestic stoves or rangesElectrical heating fuelEngineering

Owner:DUKE MANUFACTURING COMPANY

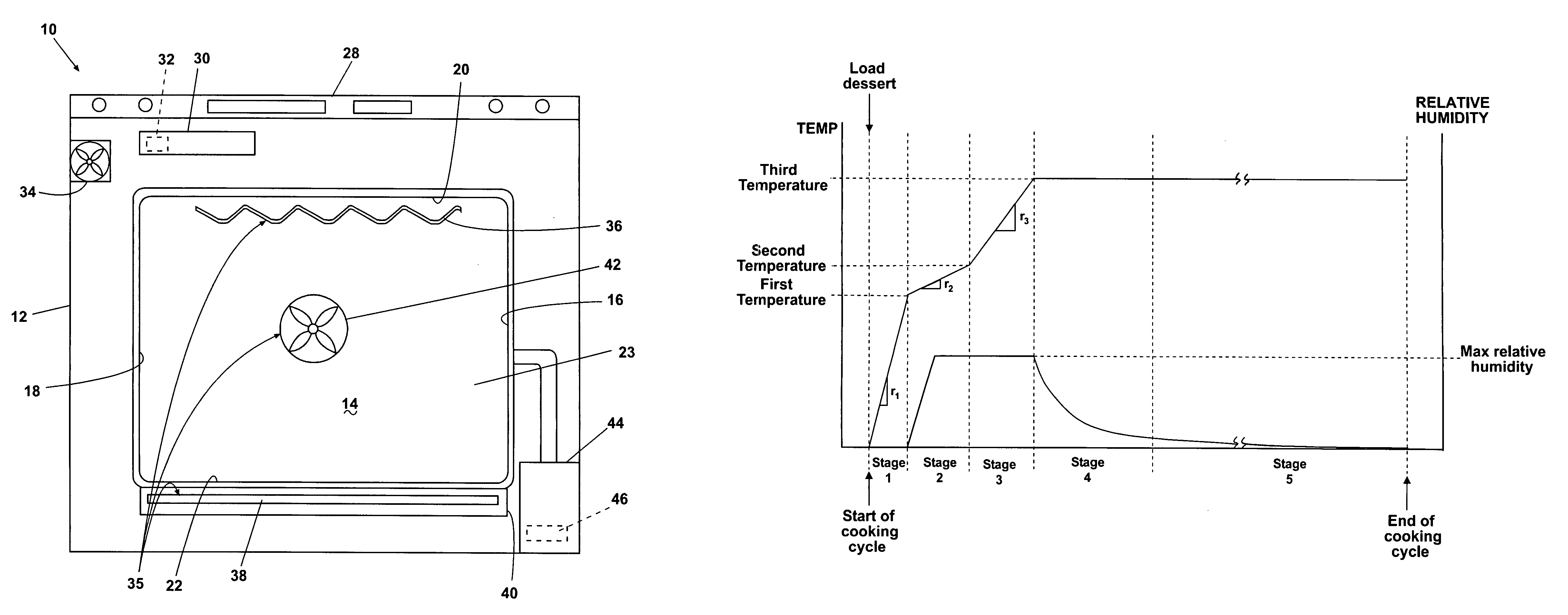

No waste cooking oven with multiple cooking functions

A multifunctional cooking oven for the preparation of food products including a cooking chamber, racks within the cooking chamber to support products to be prepared in the oven and a primary convection heat source. There is a drainable collection pan positioned below the racks to collect by-products rendered from the food products during preparation for later use. A steam source is positioned below the collection pan as well as a flavored smoke generator at the bottom of the preparation chamber. Airflow paths within the preparation chamber allow for the circulation of heat, steam and flavored smoke around the racks. The oven includes a programmable controller to control the primary heat source, the steam source and the flavored smoke generator that is programmed to operate any one of the heat source, the steam source and the flavor generator in any predetermined sequence, and for any predetermined duration of time to provide optimum preparation and flavoring of the products.

Owner:ROBERTSON MICHAEL L

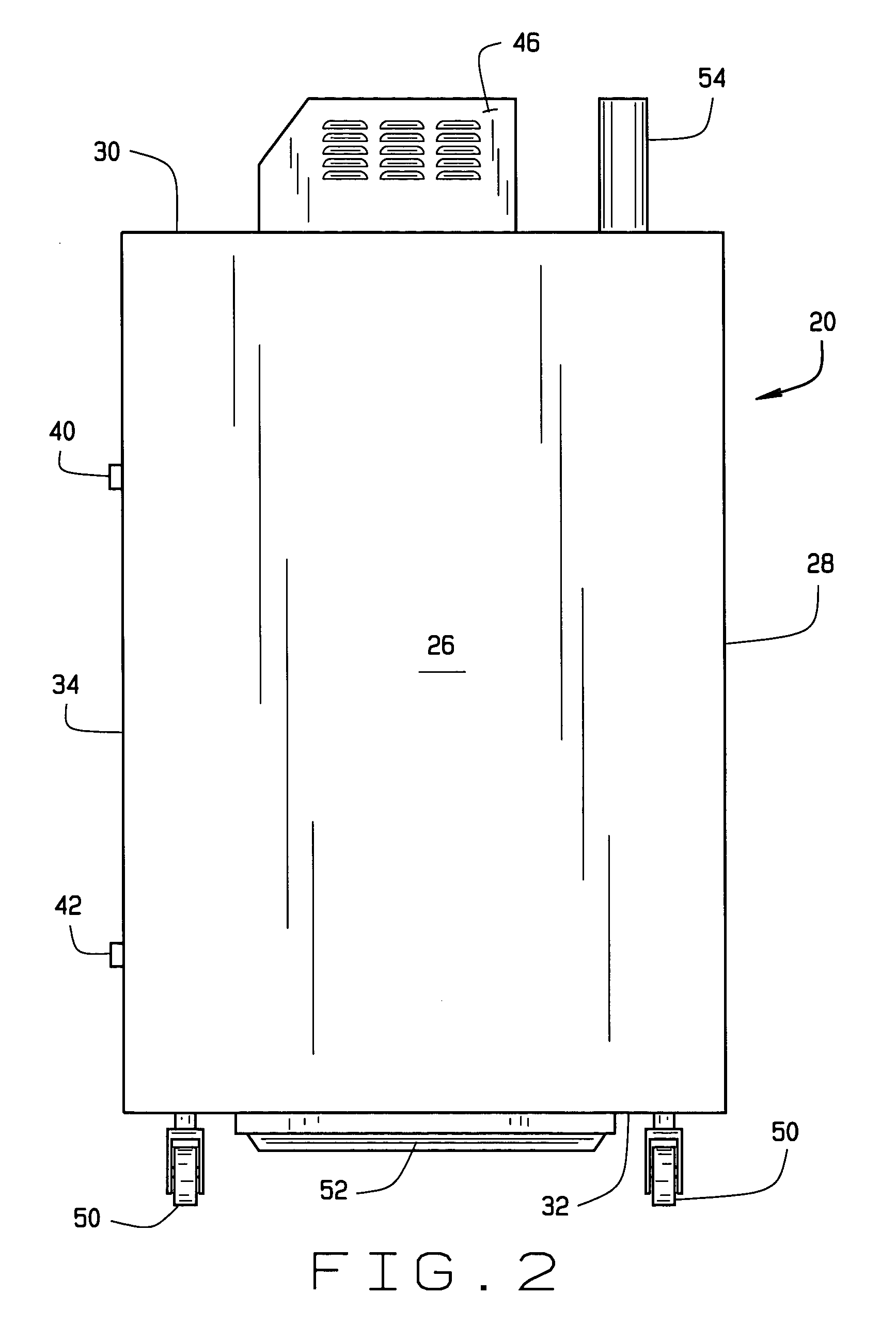

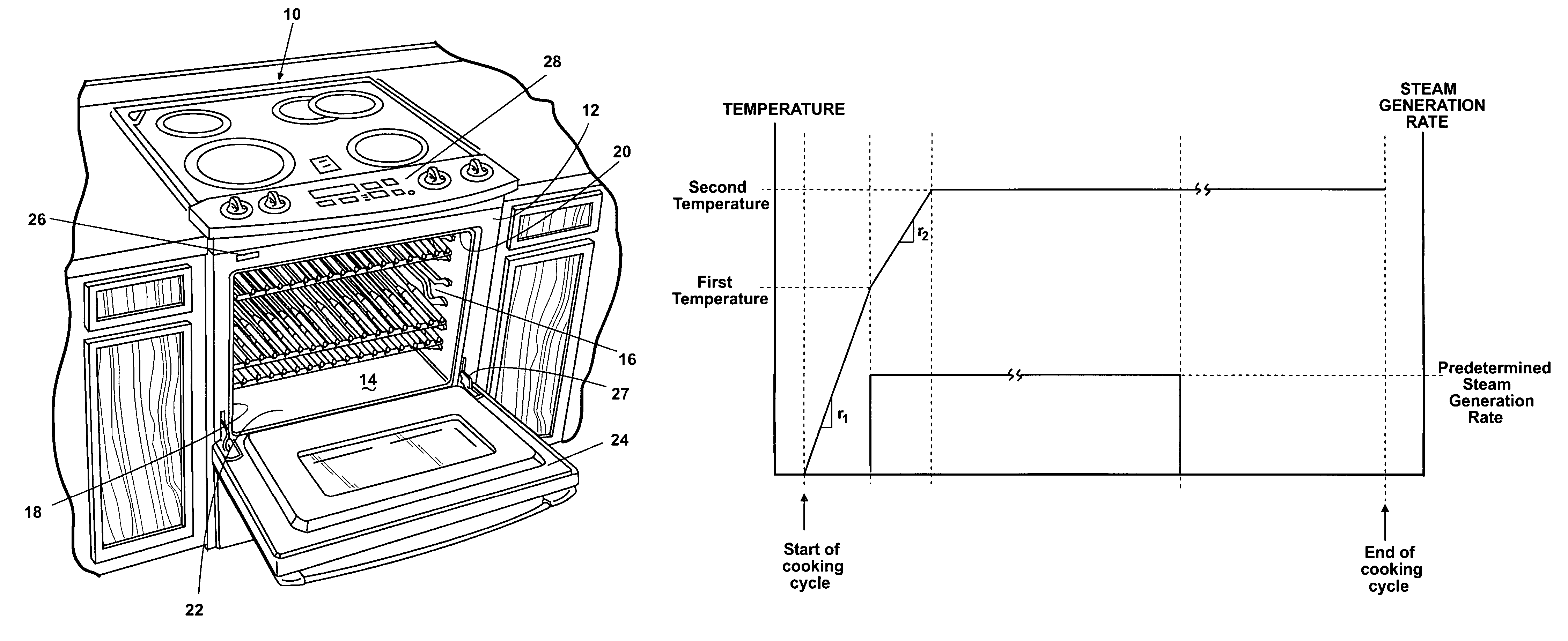

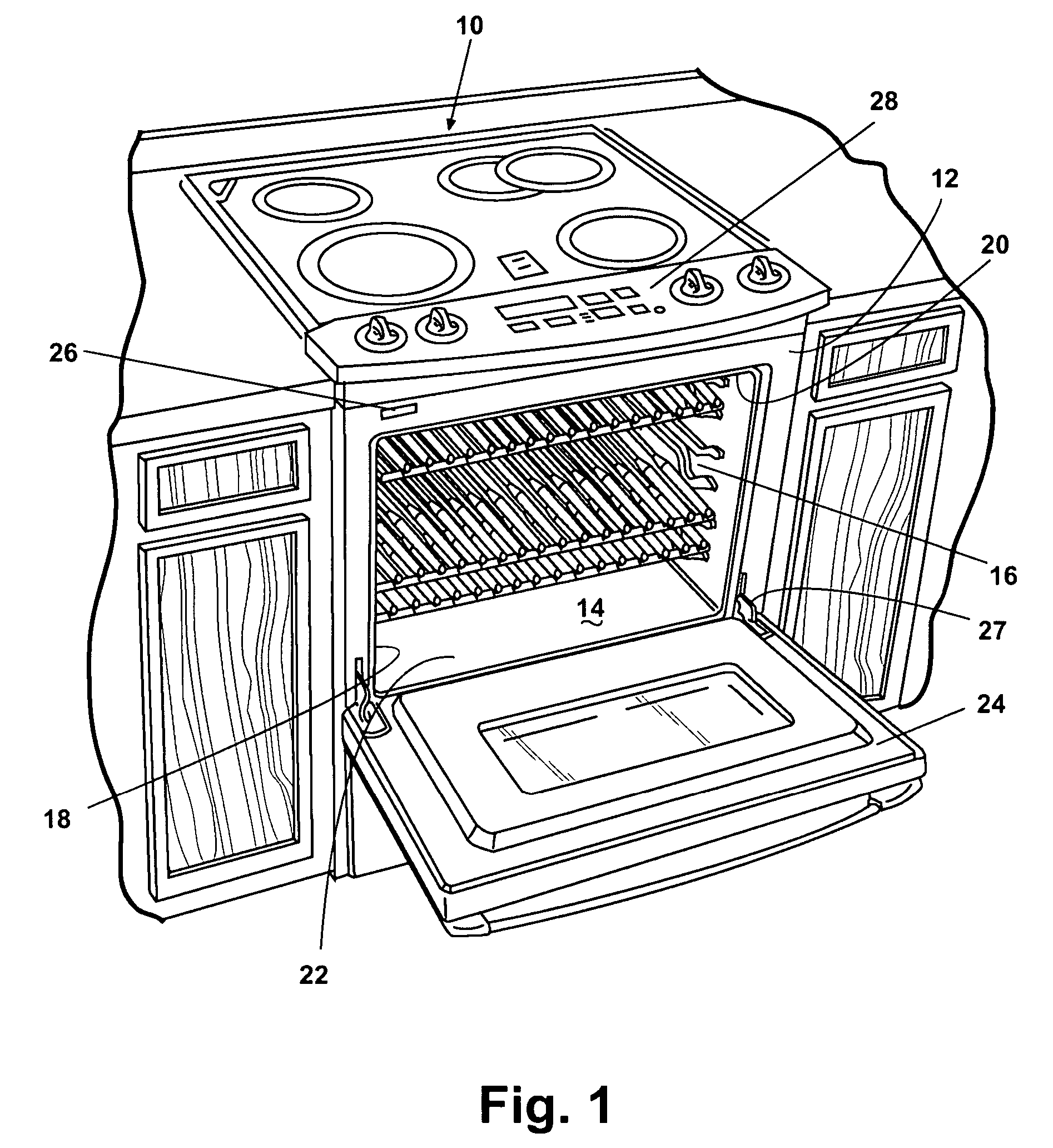

Method for baking a dessert using steam

A method of baking a dessert using steam in an automated household oven comprises a first heating step where a heating system preheats a cooking cavity to a first temperature at a first heating rate and a second heating step where the heating system preheats the cooking cavity from the first temperature to a second temperature at a second heating rate less than the first heating rate. The first temperature is preferably about the boiling point of water, and a steam system introduces steam into the cooking cavity to facilitate baking of the dessert after the cooking cavity reaches the first temperature. A convection fan of the heating system is active during the first and second heating steps to help circulate air and steam in the cooking cavity and becomes inactive later in the baking method.

Owner:WHIRLPOOL CORP

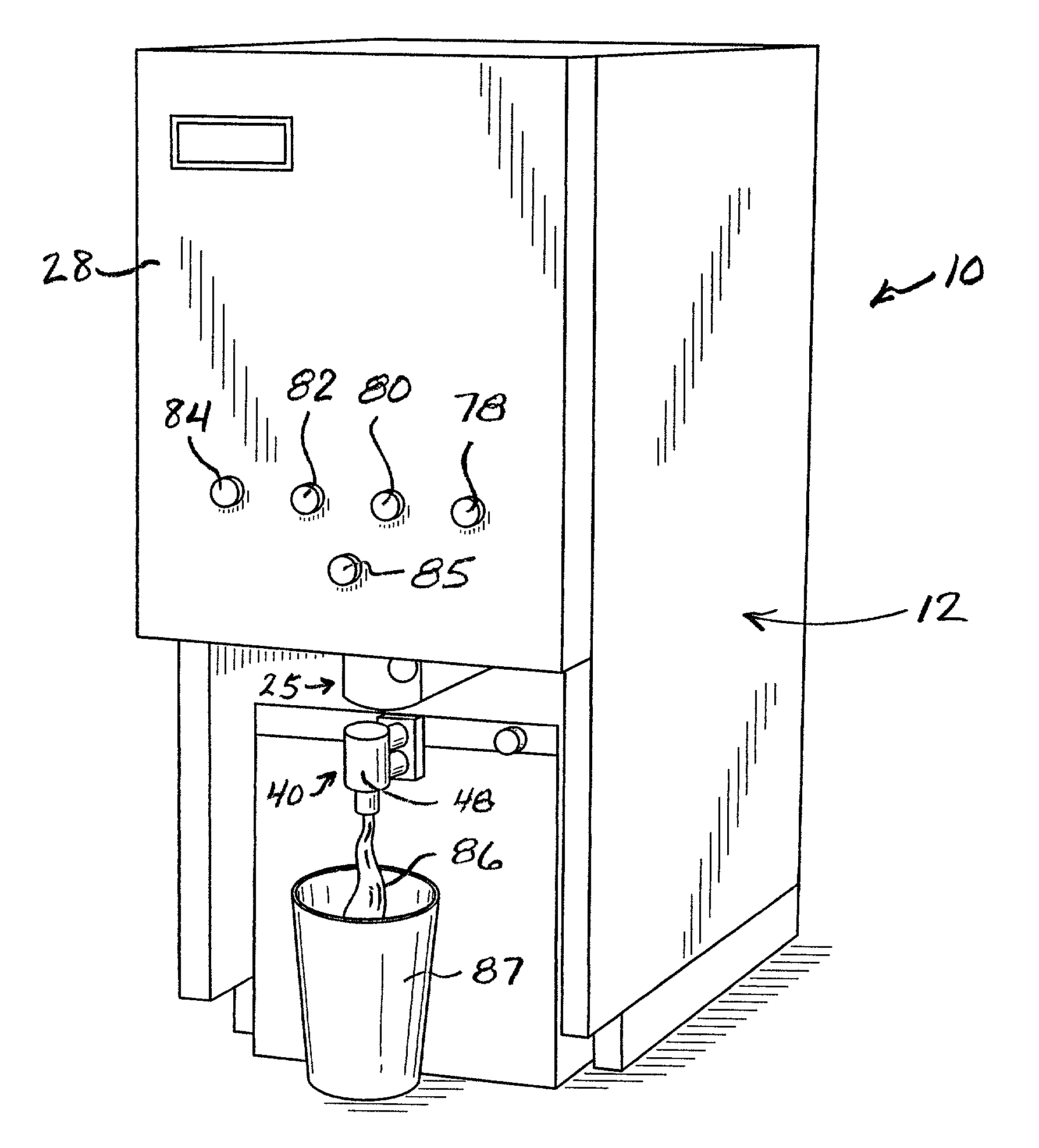

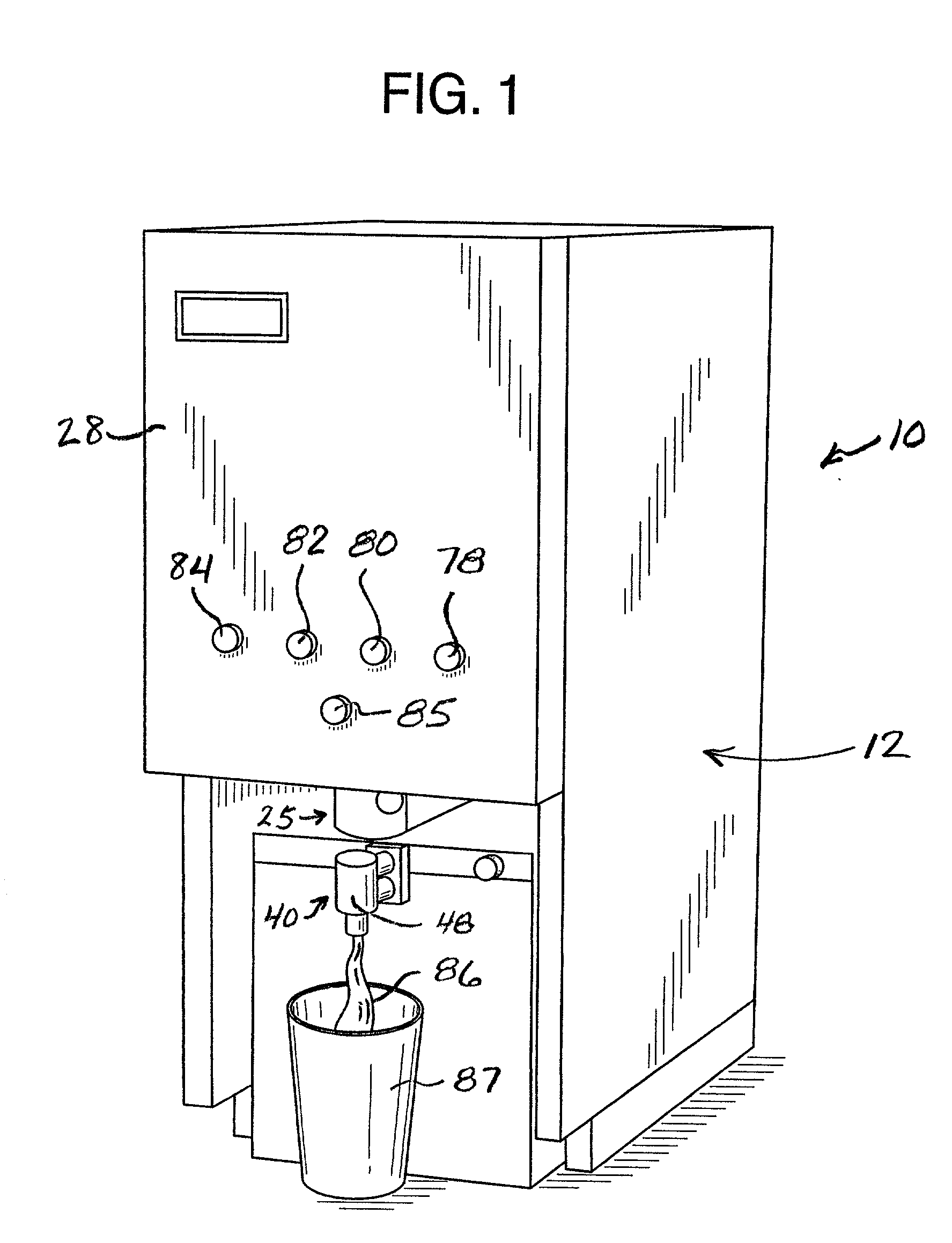

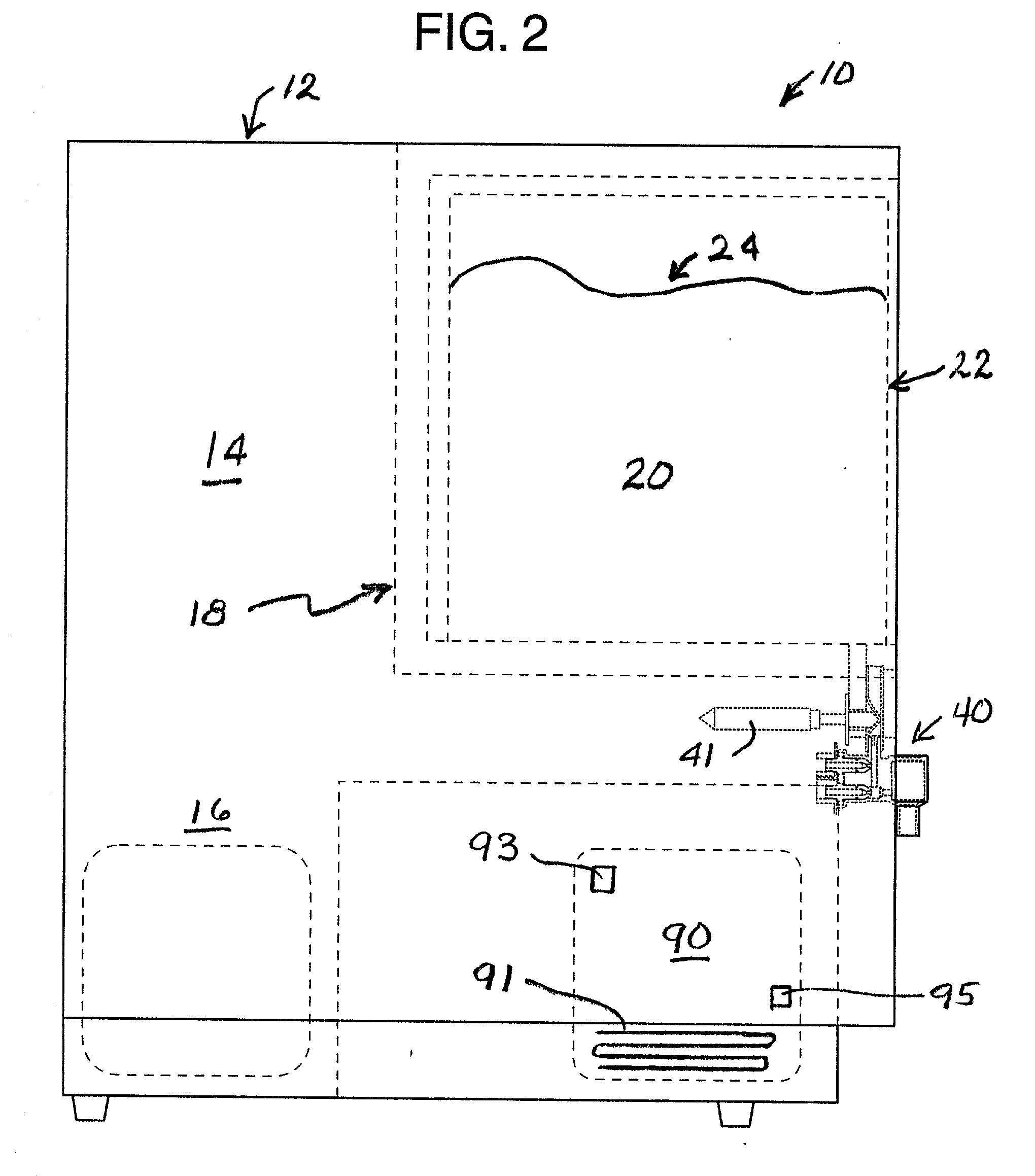

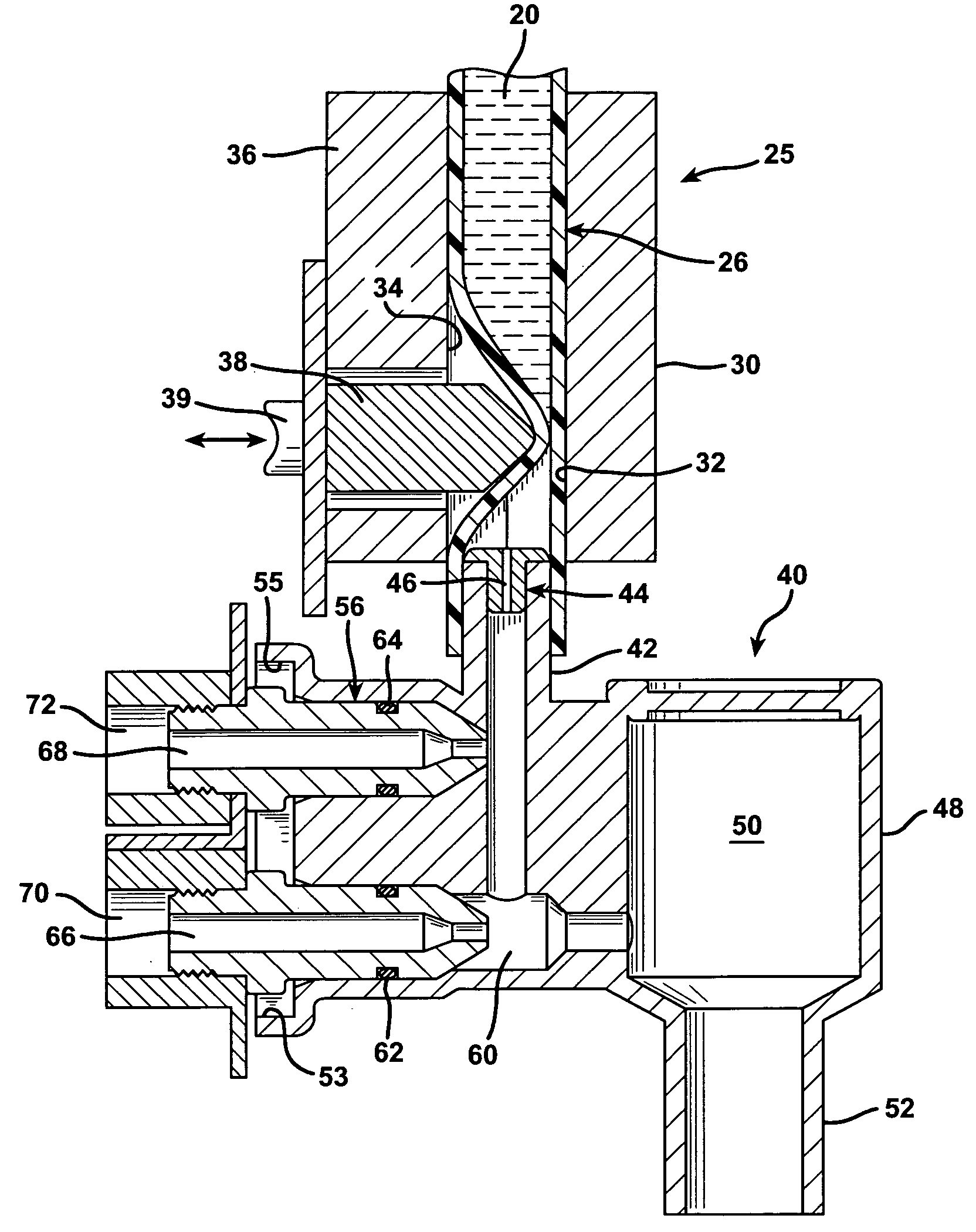

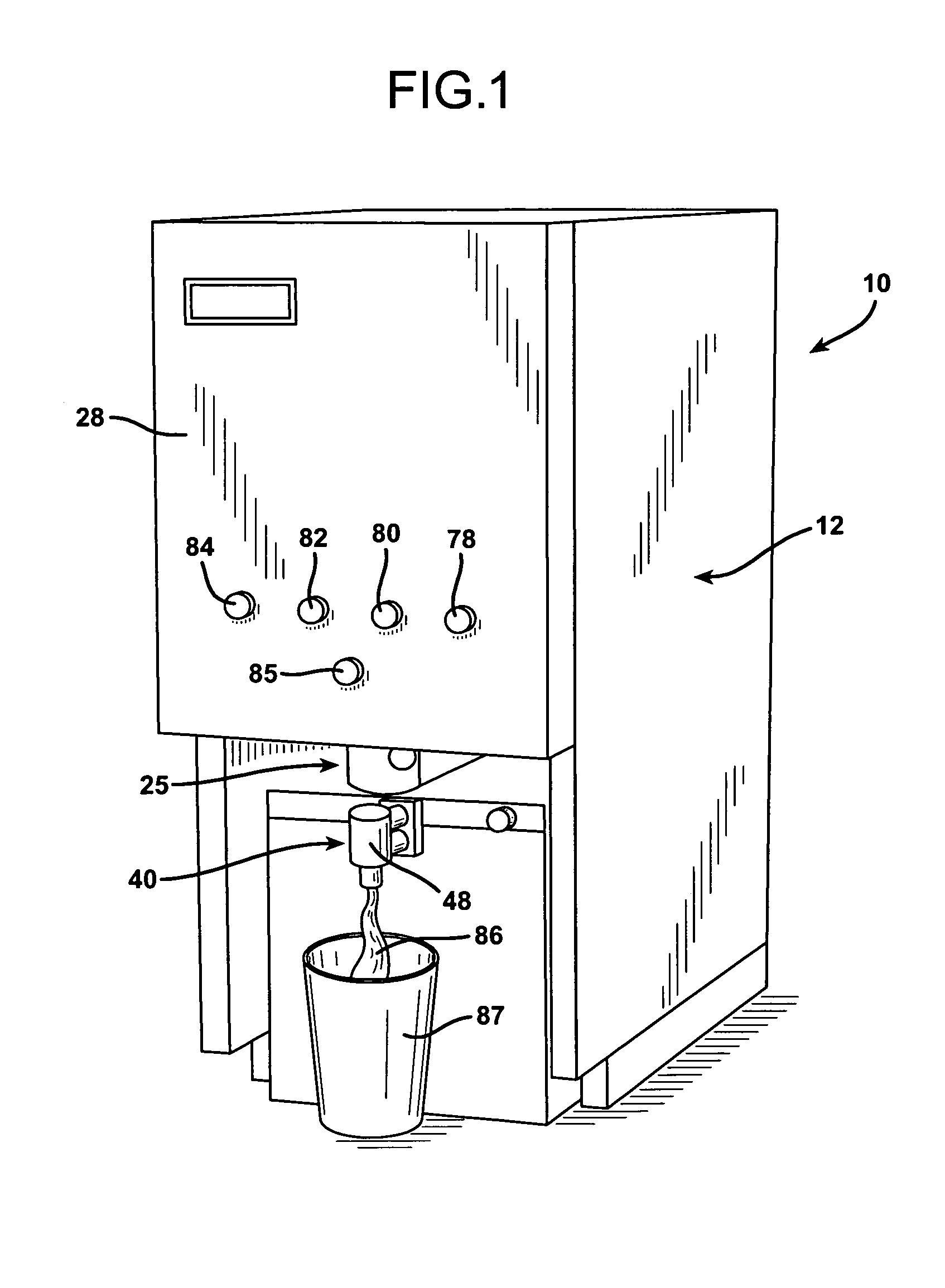

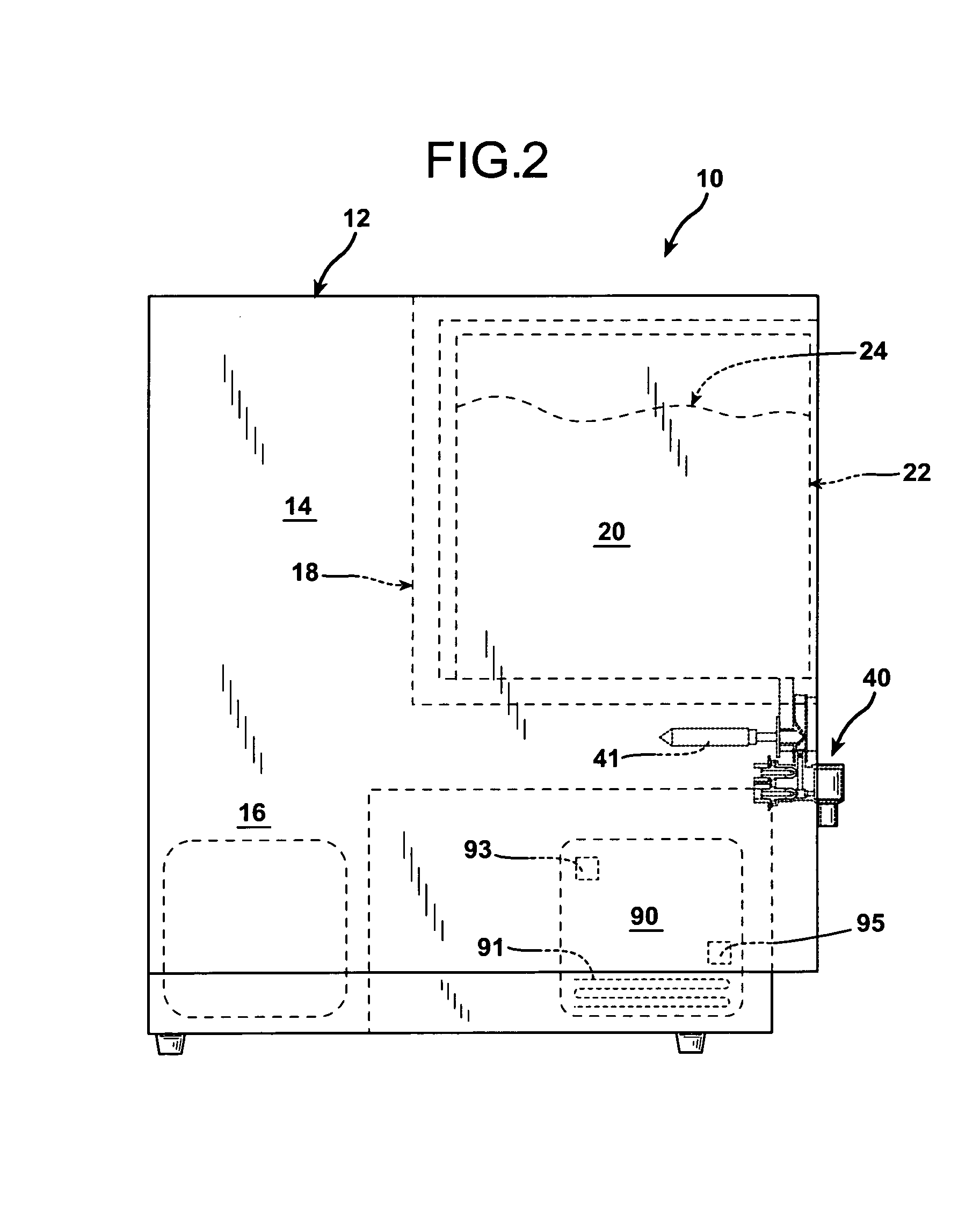

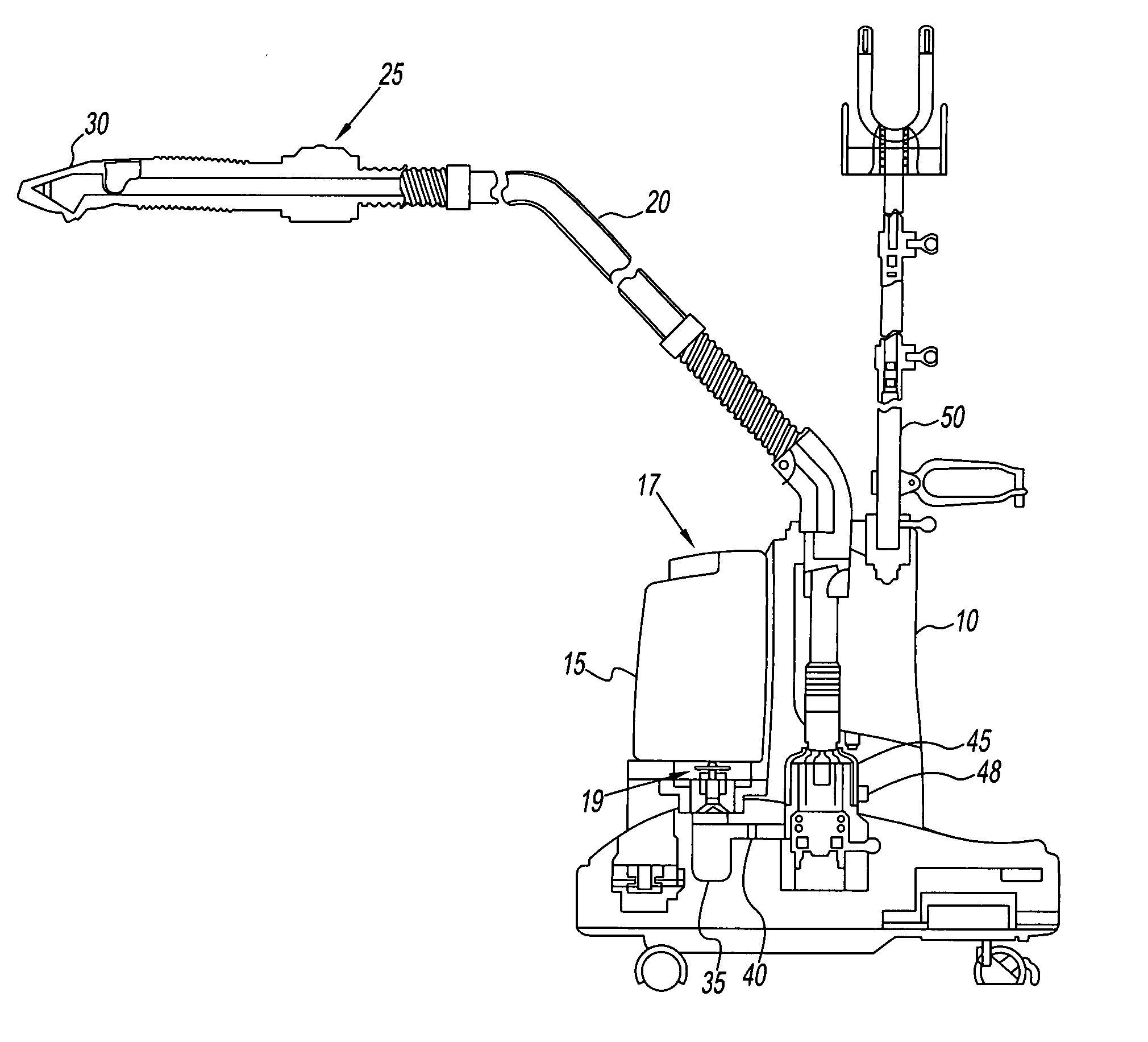

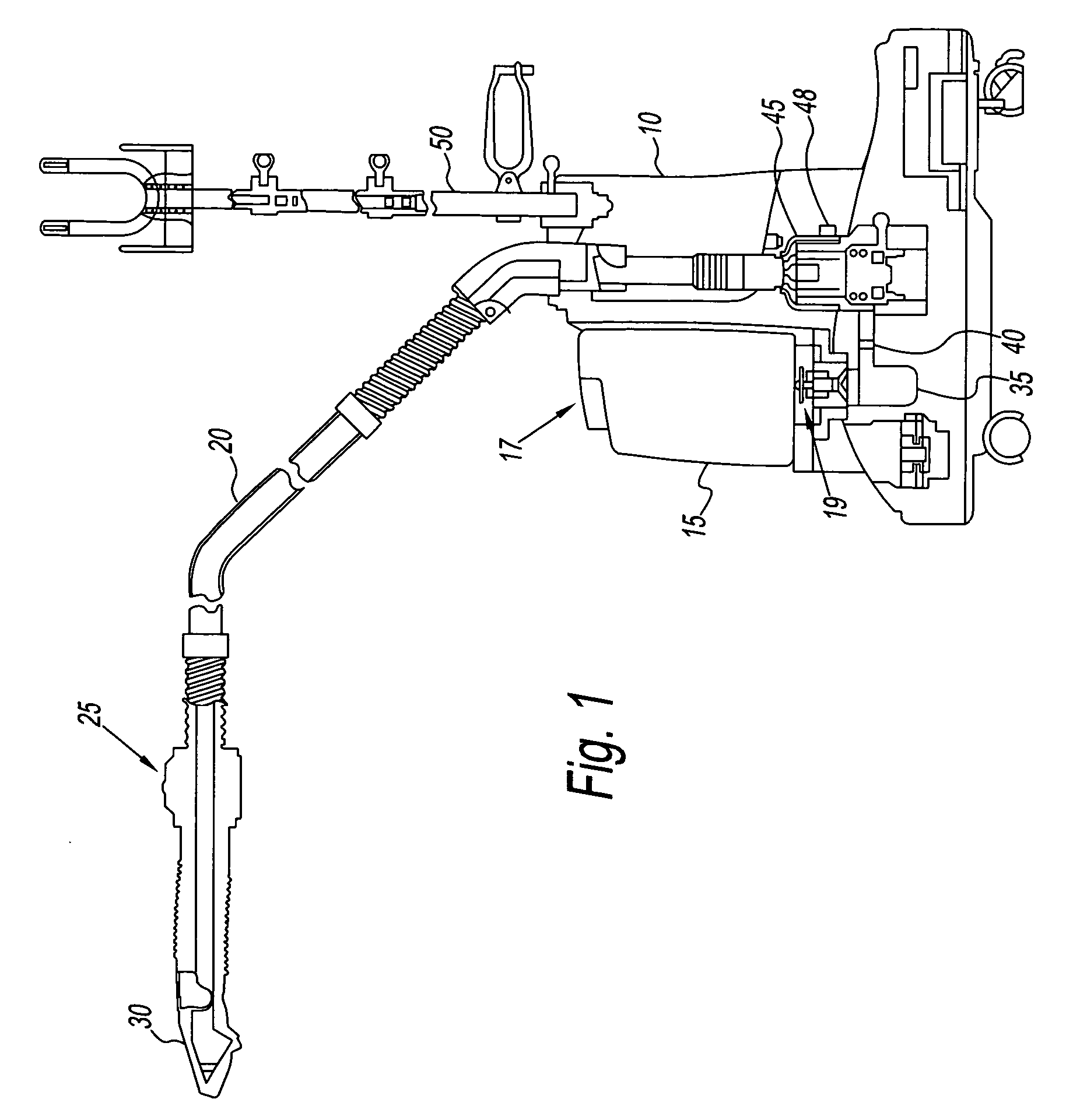

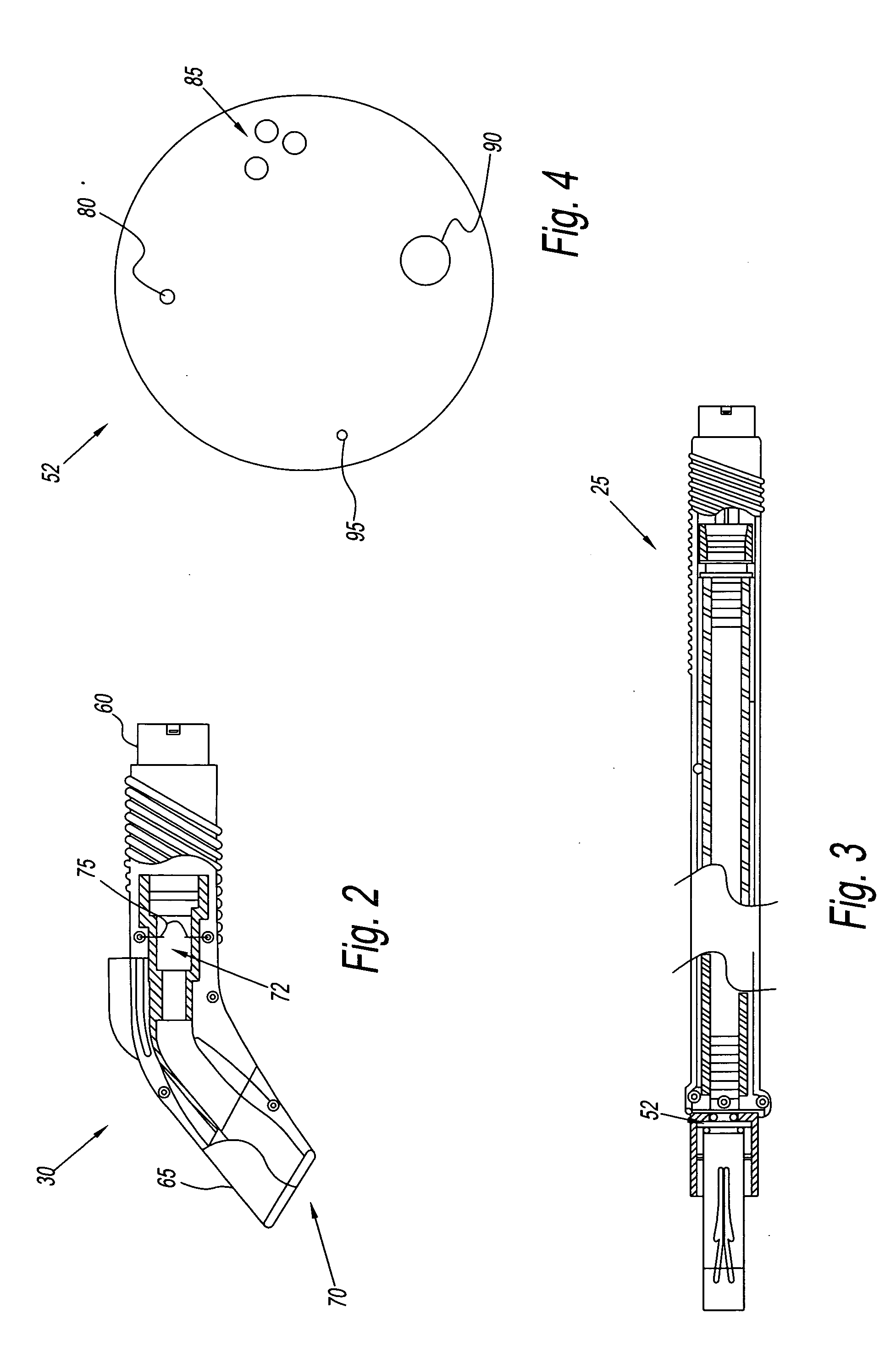

Hot dairy-based beverage dispenser

InactiveUS20030232115A1Improve temperature consistencyAvoid flowMilk treatmentSpace heating and ventilationPositive pressureAtmosphere

A dispensing unit for dispensing hot, dairy-based beverages has a self-contained refrigerated unit located above a venturi-type emulsification foaming head. The dispensing unit has particular applicability to the dispensation of foamy, hot milk for use in beverages such as cappuccino and nonfoamy, hot milk for use in beverages such as coffee latte, hot chocolate, and other hot dairy-based beverages. The refrigeration unit accommodates a "bag in box" cold milk storage container of the type widely used in food service establishments. The dispensing unit employs a pinch valve that avoids direct contact between the milk and the valve components. The refrigerated milk is stored above the level of the foamer head so that the flow of milk results partially from gravitational force on the milk, and is not totally dependent upon venturi suction created in the foamer head. Also, selective actuation of beverage choice switches generates commands to produce different beverages at different temperatures. This is achieved by raising or lowering the steam temperature from a standby temperature as an immediate response to depression of a selection button. Air utilized in creating a foamy hot milk mixture may be supplied at a positive pressure above atmospheric pressure, rather than merely through venturi suction from the ambient atmosphere. In addition, following the dispensation of each portion of a beverage, the system automatically discharges a quantity of purging water to clean out the air line and air nozzle, so as to avoid contamination of those components by contact with milk flowing through the foamer head.

Owner:ECKENHAUSEN ROLAND B +1

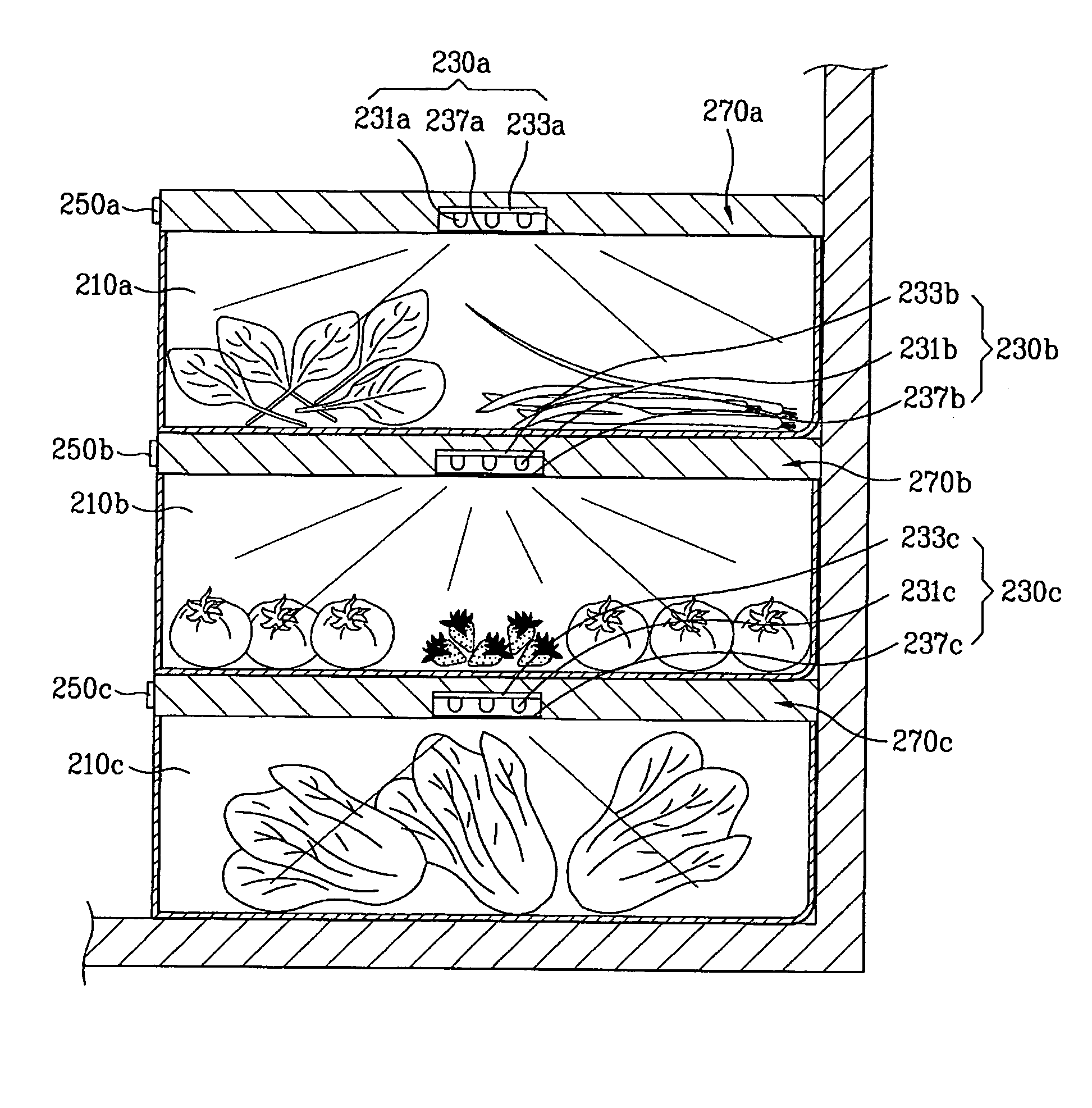

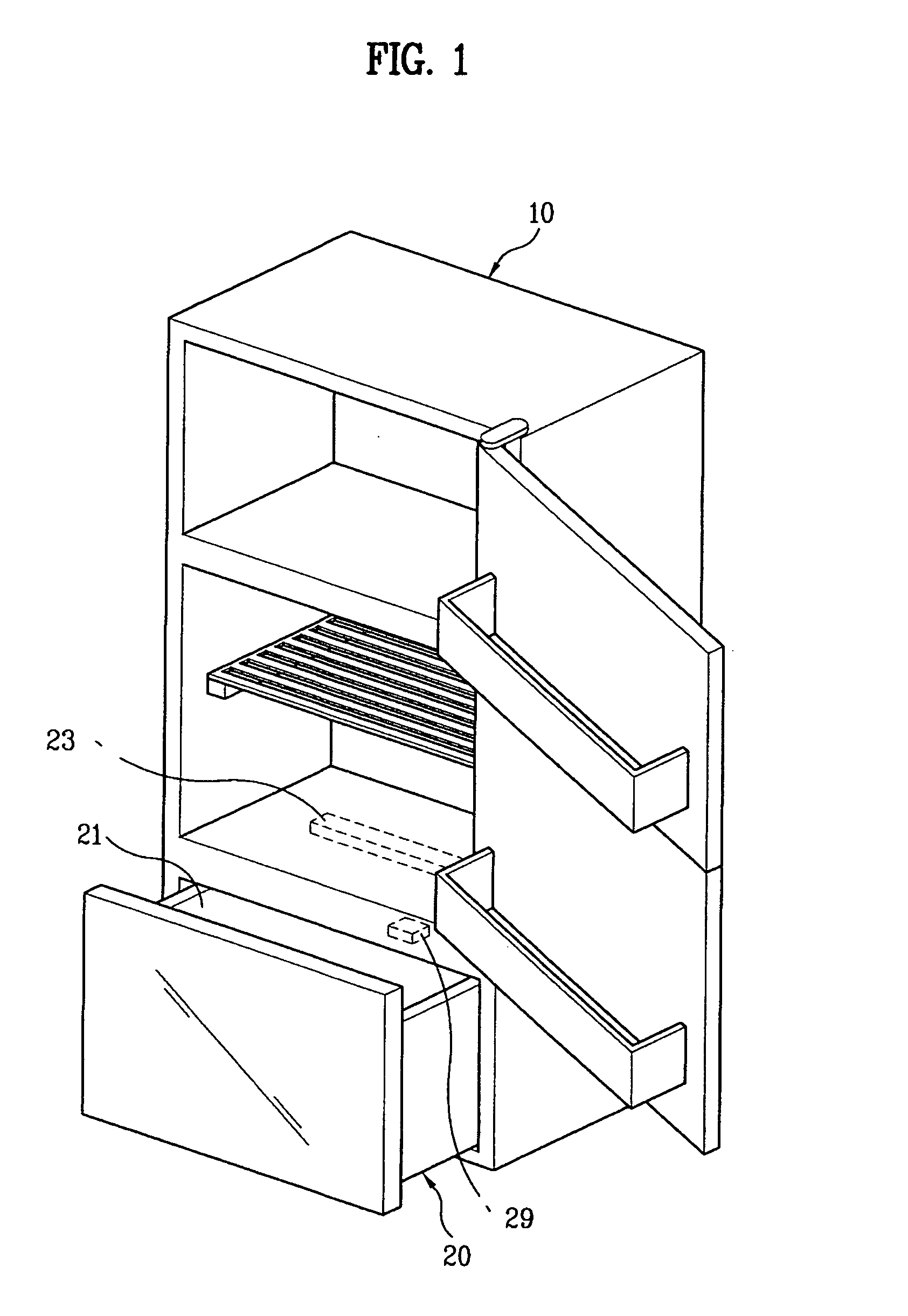

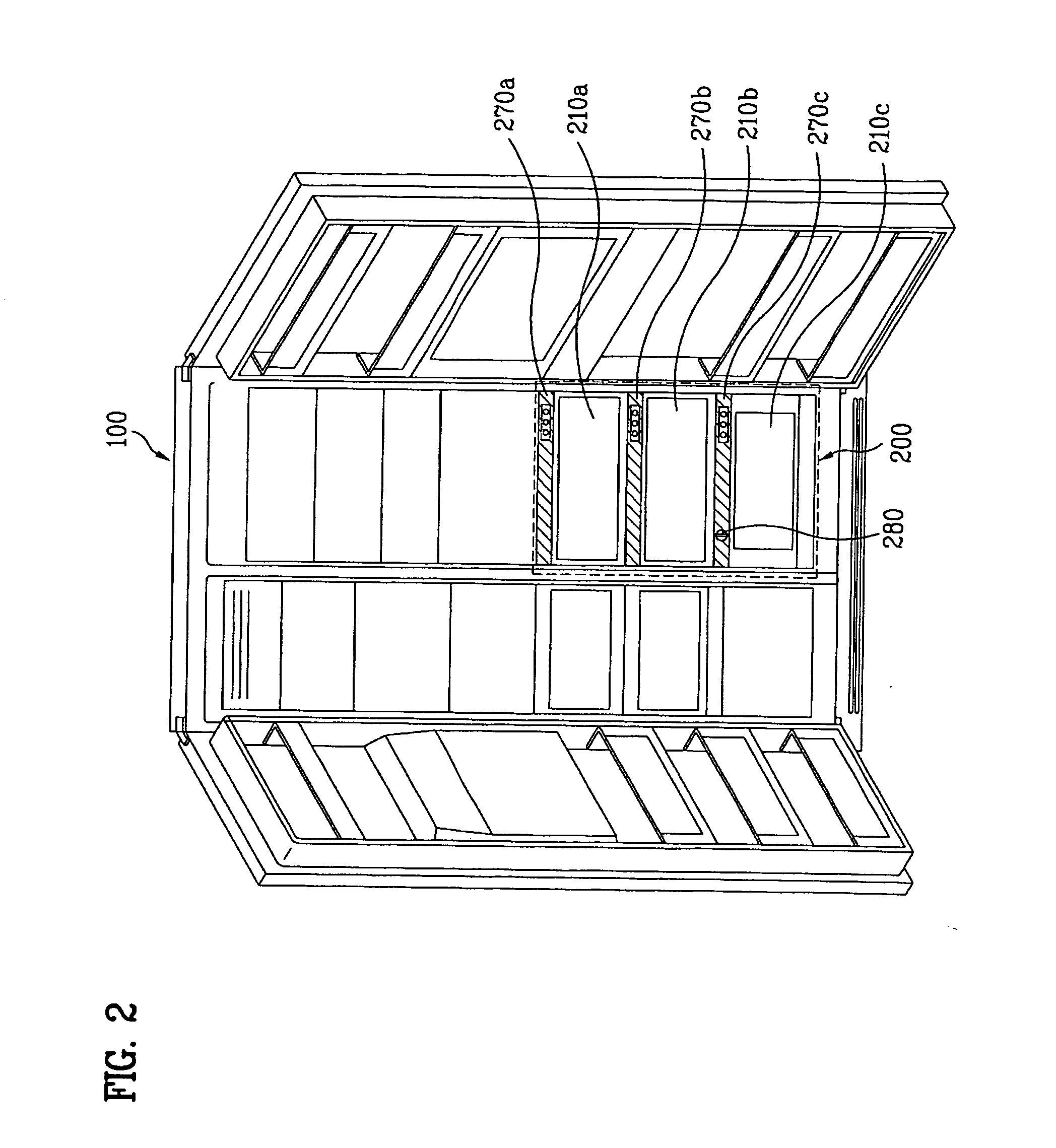

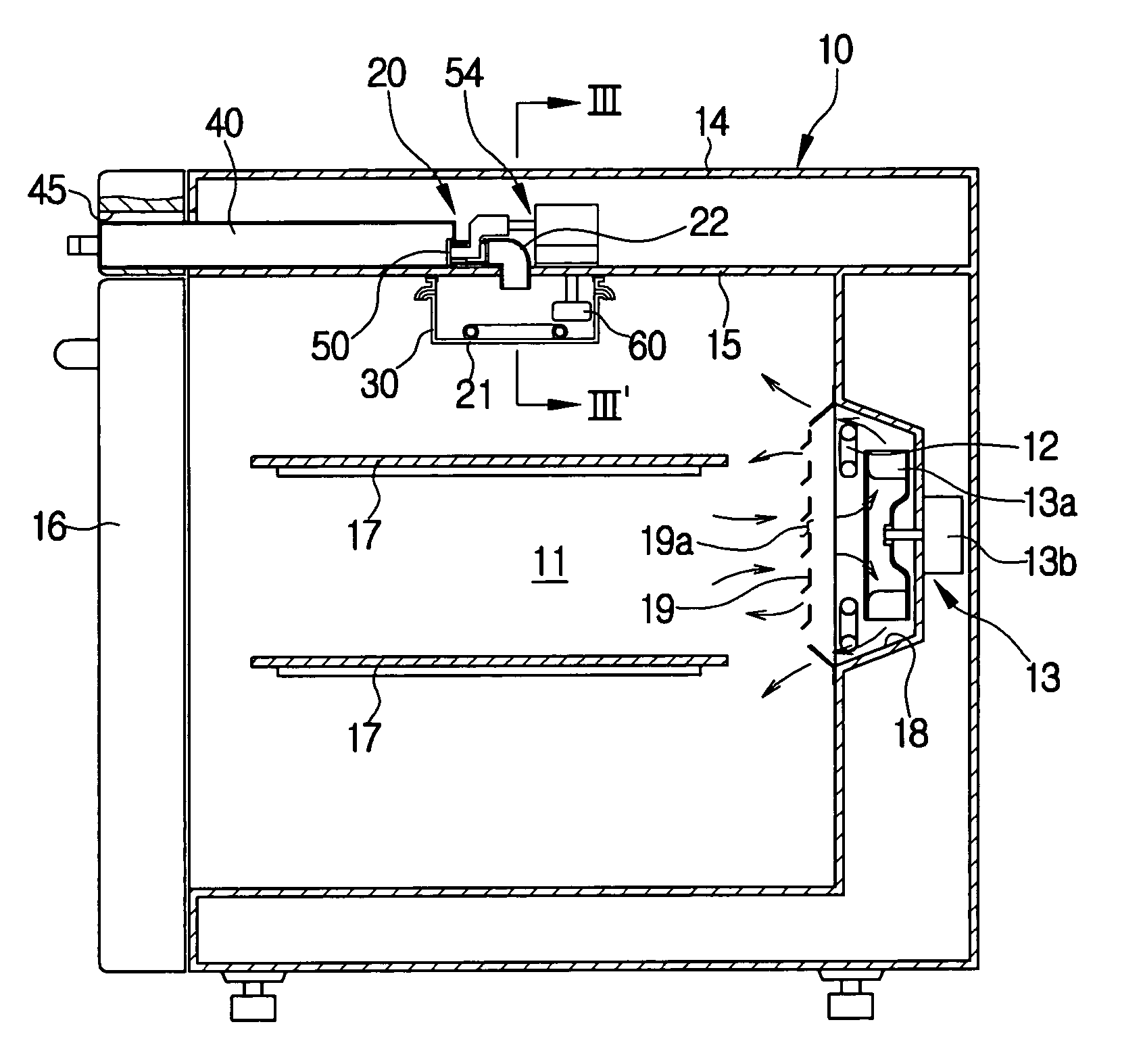

Refrigerator and method for keeping food using the same

ActiveUS20070104841A1Simple structureEffectively maintain freshnessMilk preparationMilk preservationEngineeringLength wave

A refrigerator and a method for keeping food using the same are disclosed, in which freshness is maintained for a long time through an improved structure and decrease of nutritive elements contained in food is inhibited. The refrigerator includes a main body, keeping compartments provided in the main body, keeping food, and irradiation devices irradiating light of a visible ray area to the keeping compartments. The irradiation devices switch a wavelength of irradiated light depending on a set standard. The refrigerator further includes a sensor sensing whether food is contained in the keeping compartments. The refrigerator further includes purification devices provided in the keeping compartments to remove ethylene generated from the food kept in the keeping compartments. The irradiation devices switch the wavelength of the light to correspond to color of the food kept in the keeping compartments.

Owner:LG ELECTRONICS INC

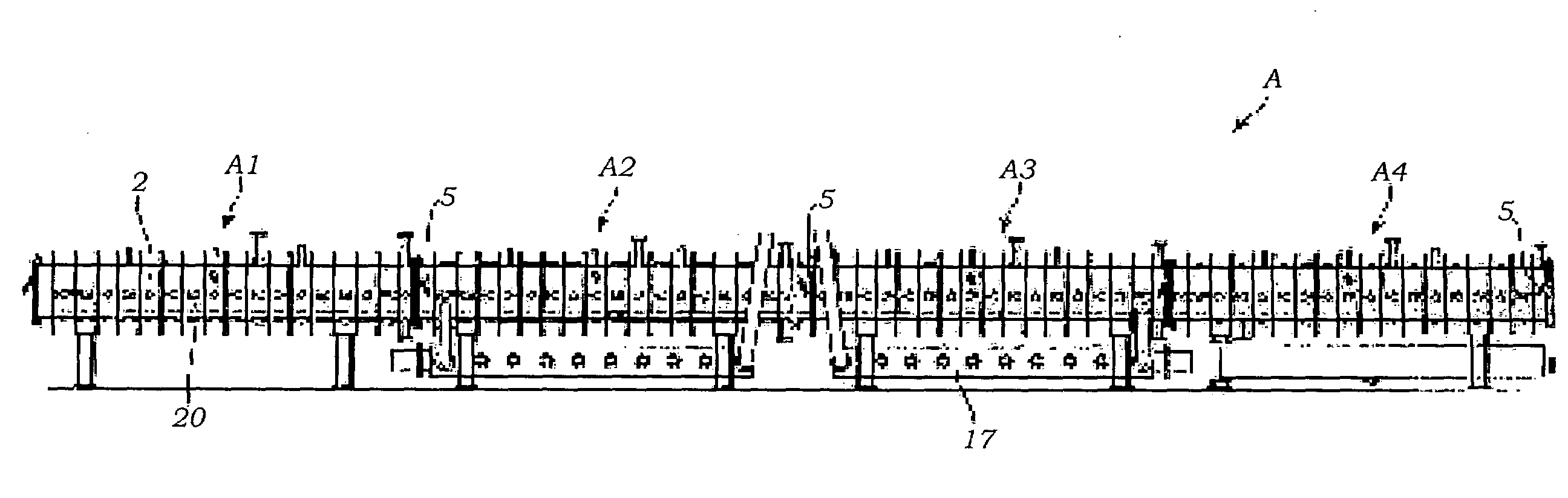

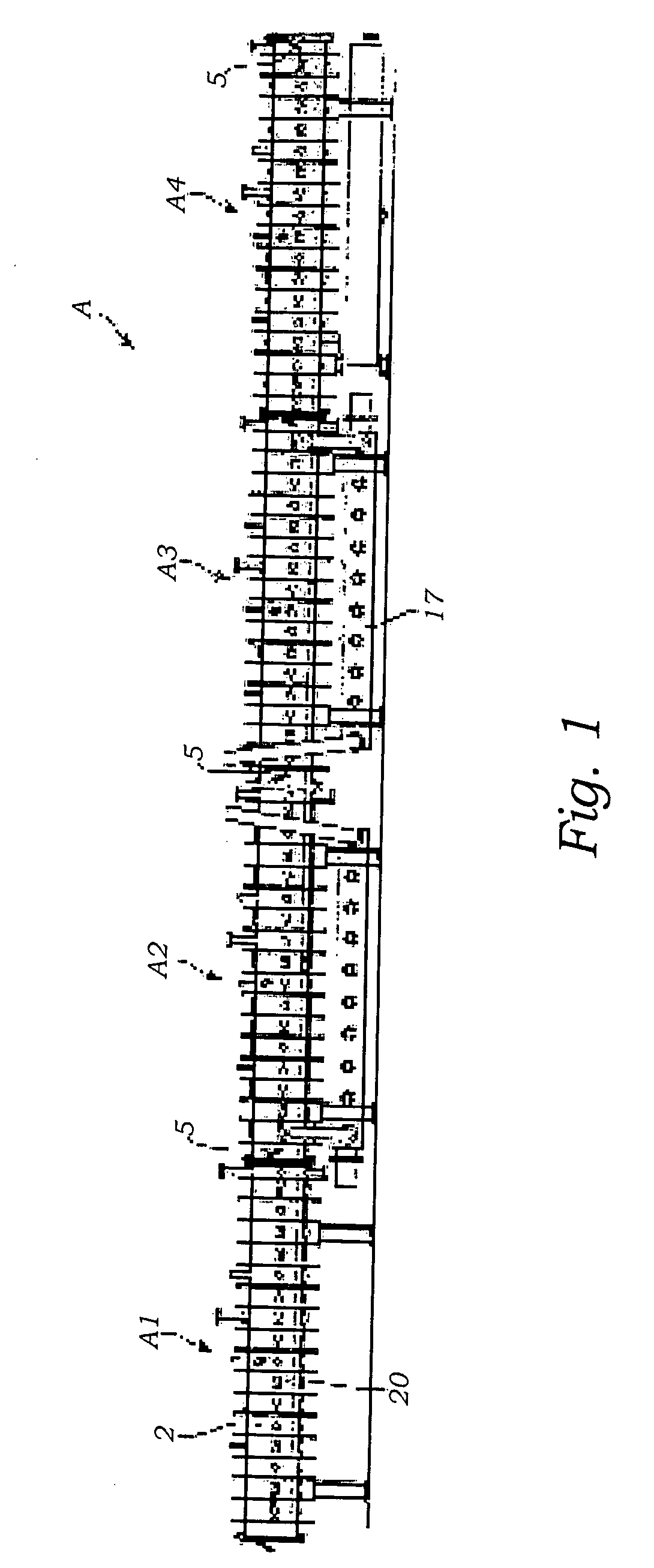

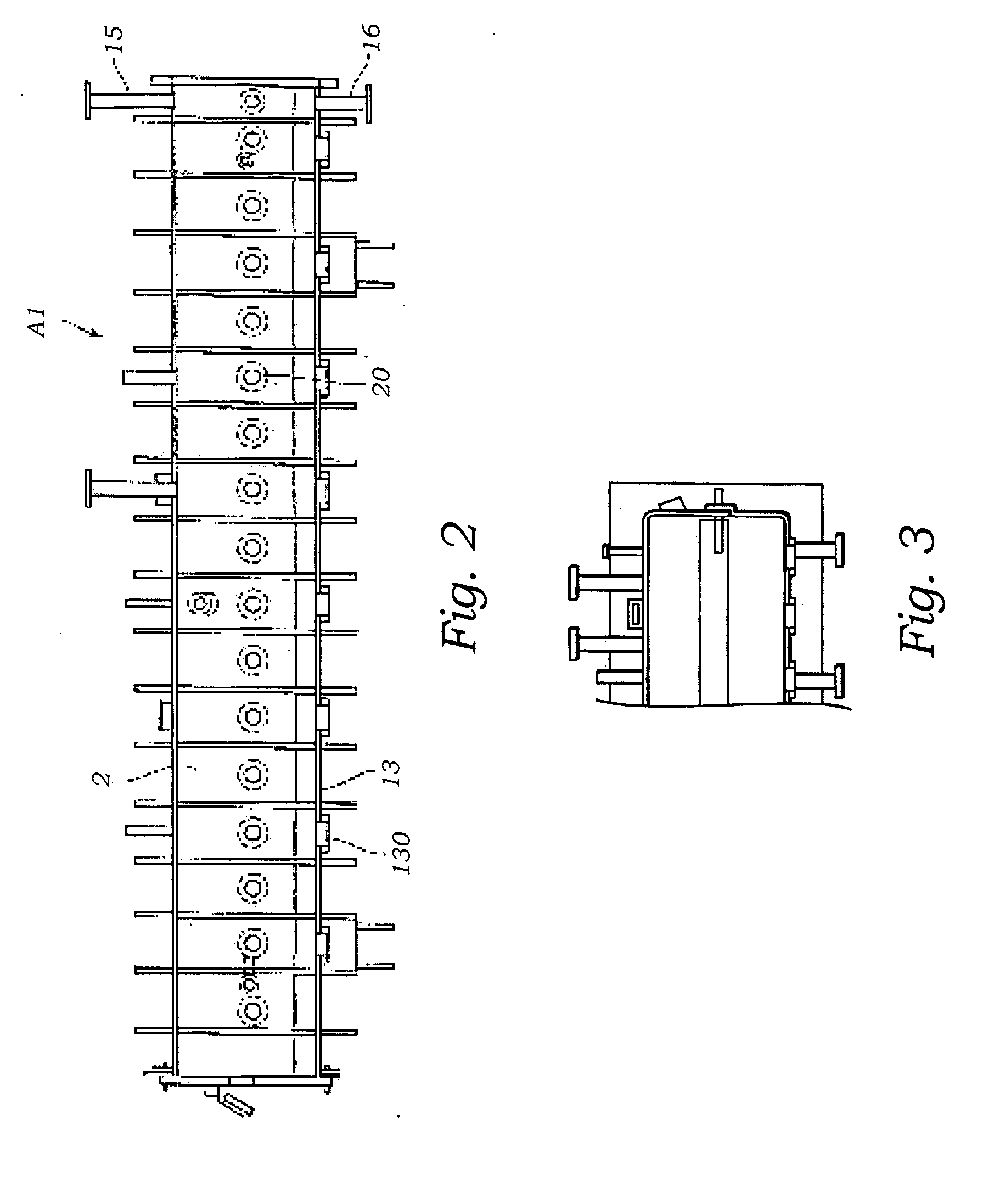

Tunnel for conditioning of products, especially for sterilization of food in prepackaged containers

ActiveUS20090283517A1Reduce maintenanceIncreases useful treatment capacityDough treatmentDisinfectionControl systemClosed loop

Tunnel is provided for conditioning of food products, especially for sterilization of food in containers or vessels of the heat-sealed type, in which the conditioning unit has: 1) an active temperature and pressure control system provided in at least one magnetron supported heating stage, which provides for balancing of the pressure within the heat-sealed vessels or containers; 2) a conveyor which conveys the heat-sealed vessels or containers through the stages along the conditioning unit which contains mechanisms that move the conveyor outside of the conditioning tunnel, and 3) doors operating like check valves that separate the conditioning stages, but still provide for continuous linear feed of products through conditioning tunnel. In preferred embodiment, the conditioning tunnel in includes a plurality temperature sensors, such as linear pyrometers for measuring the temperature of for mapping the temperature of products within the tunnel Moreover, preferably the conveyor is adjustable to move forward and rearward, and the magnetrons, which preferably operate at approximately 915 Mhz and 2400 Mhz, are adjustable to provide a controllable movement and amplitude. A controller is connected to the temperature sensors, conveyor and magnetrons to cause the conveyor to move products forward or rearward, or cause the magnetrons to move the magnetic field relative to the food products to more thoroughly and evenly cook the food products. Movement of the magnetron electromagnetic field and / or conveyor is controlled by software which utilizes the temperature and / or density measurements in a closed loop process to ensure uniform heating of the products.

Owner:MACKAY JEFFREY H +3

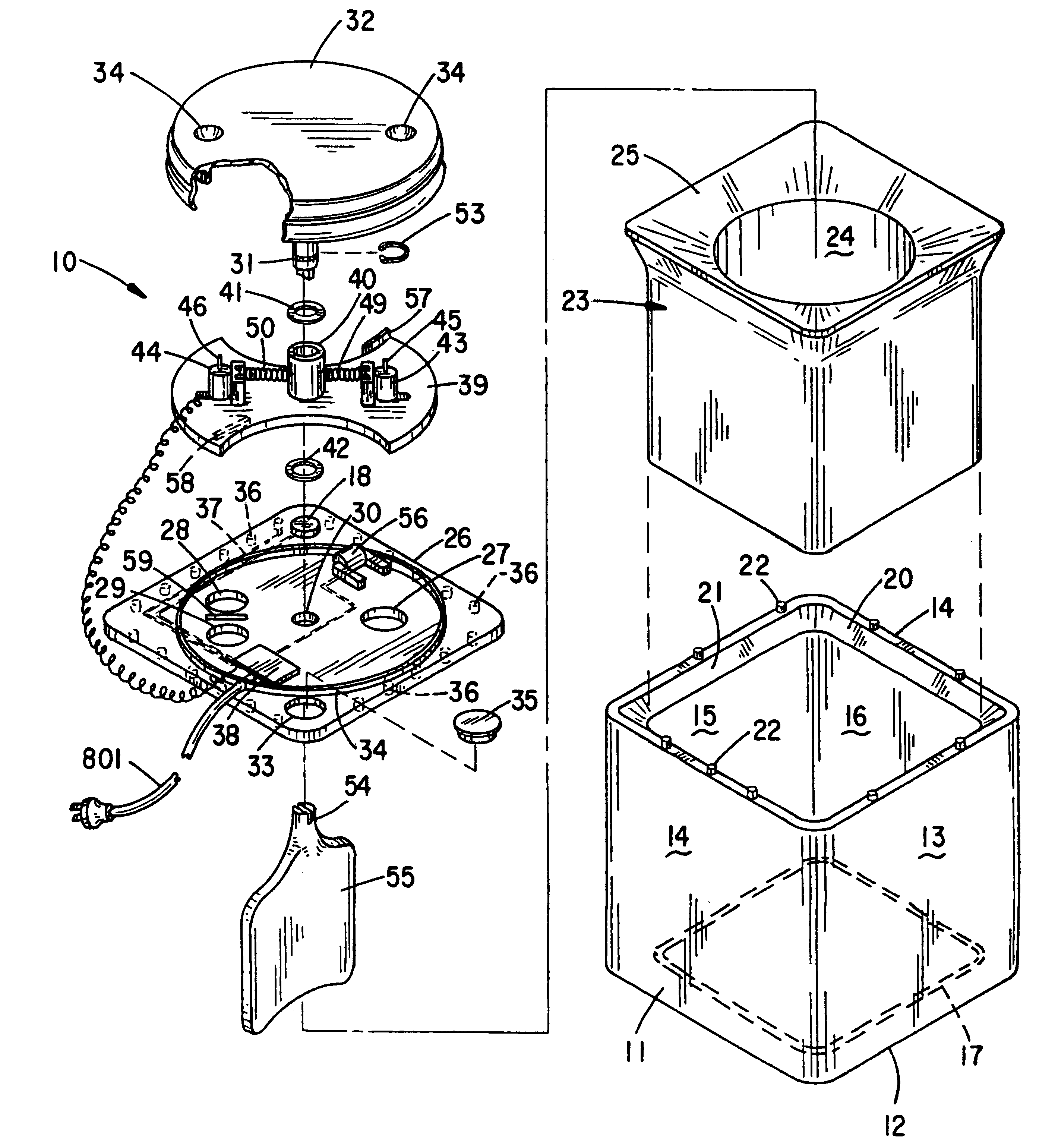

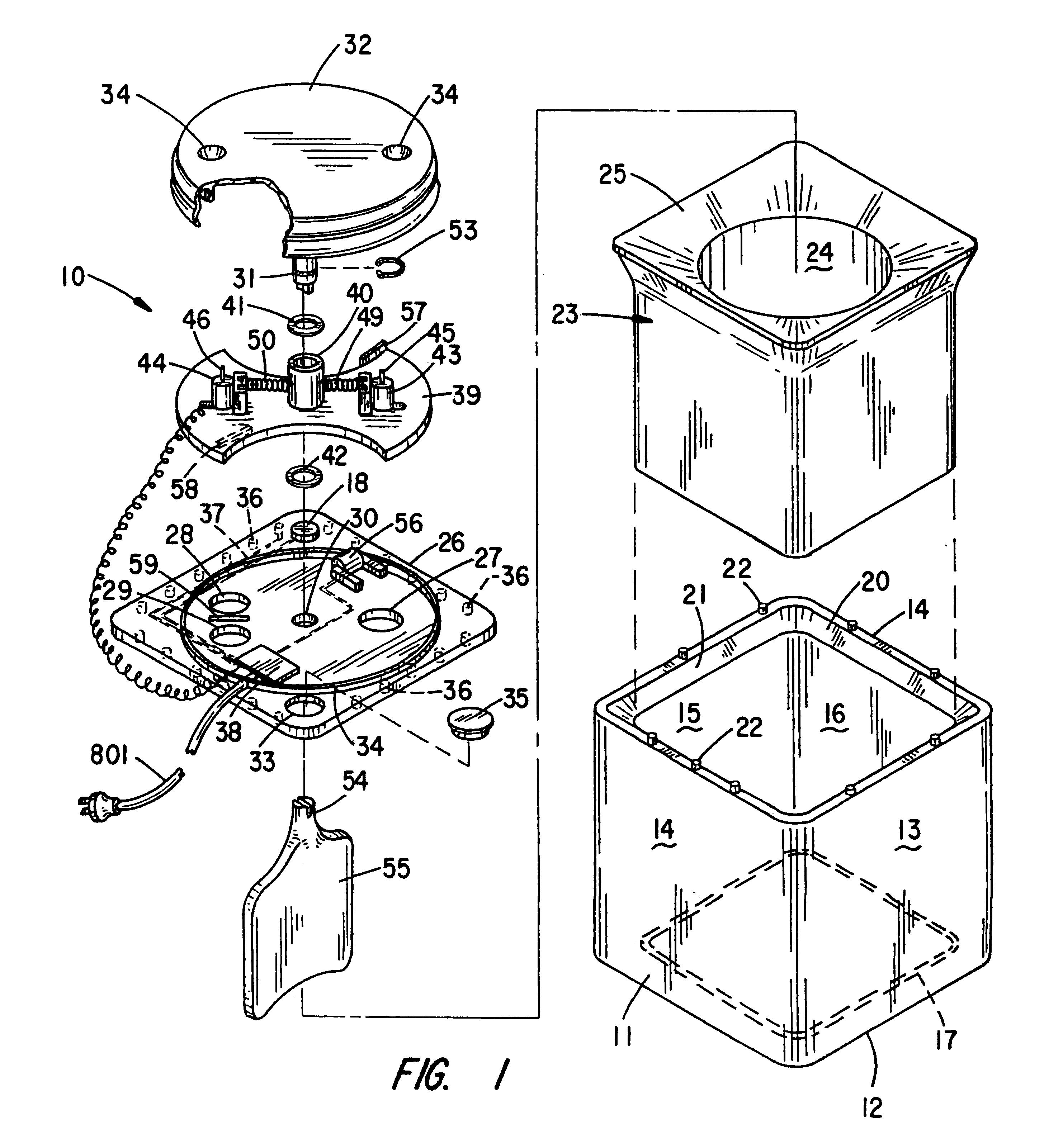

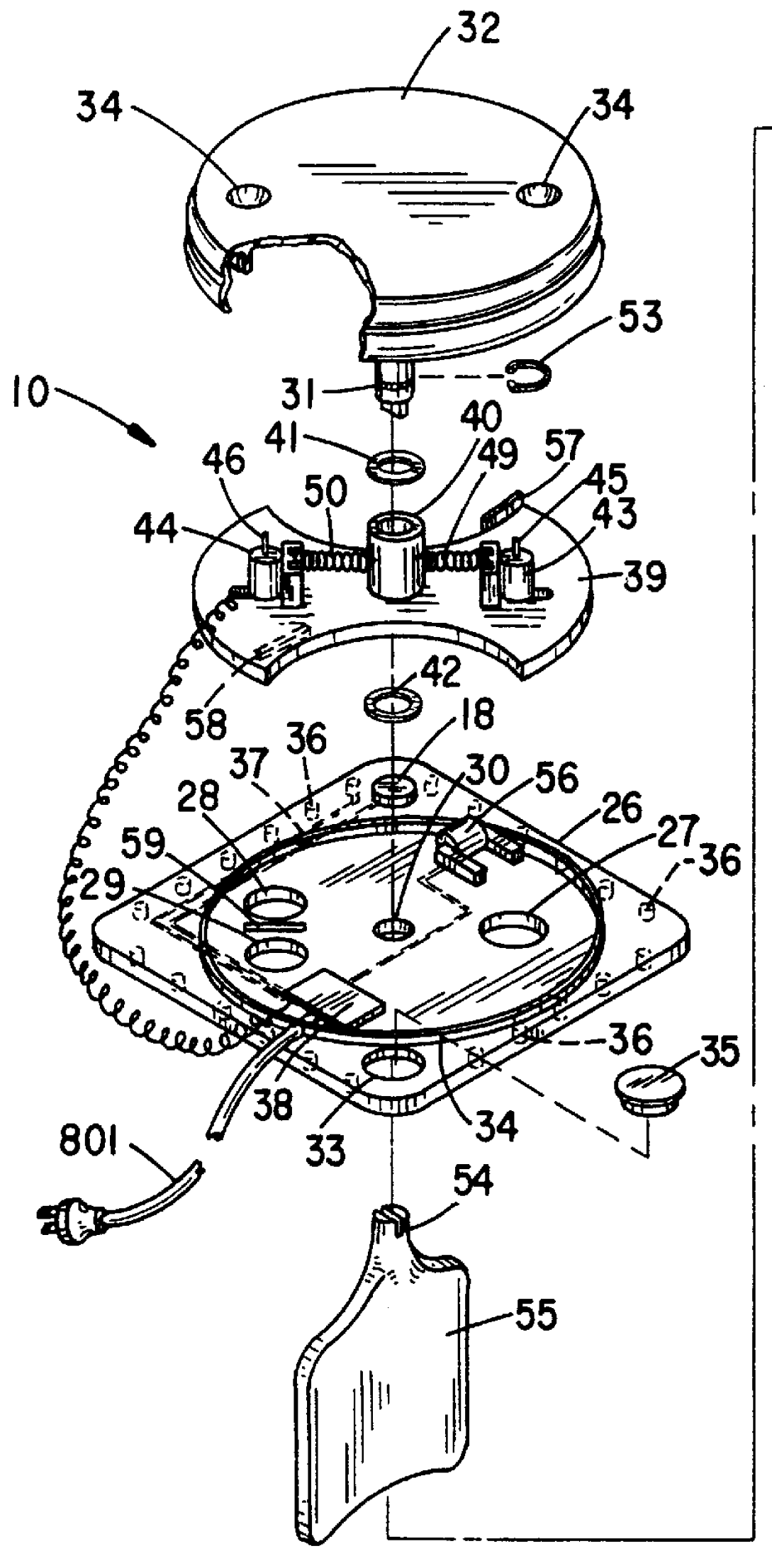

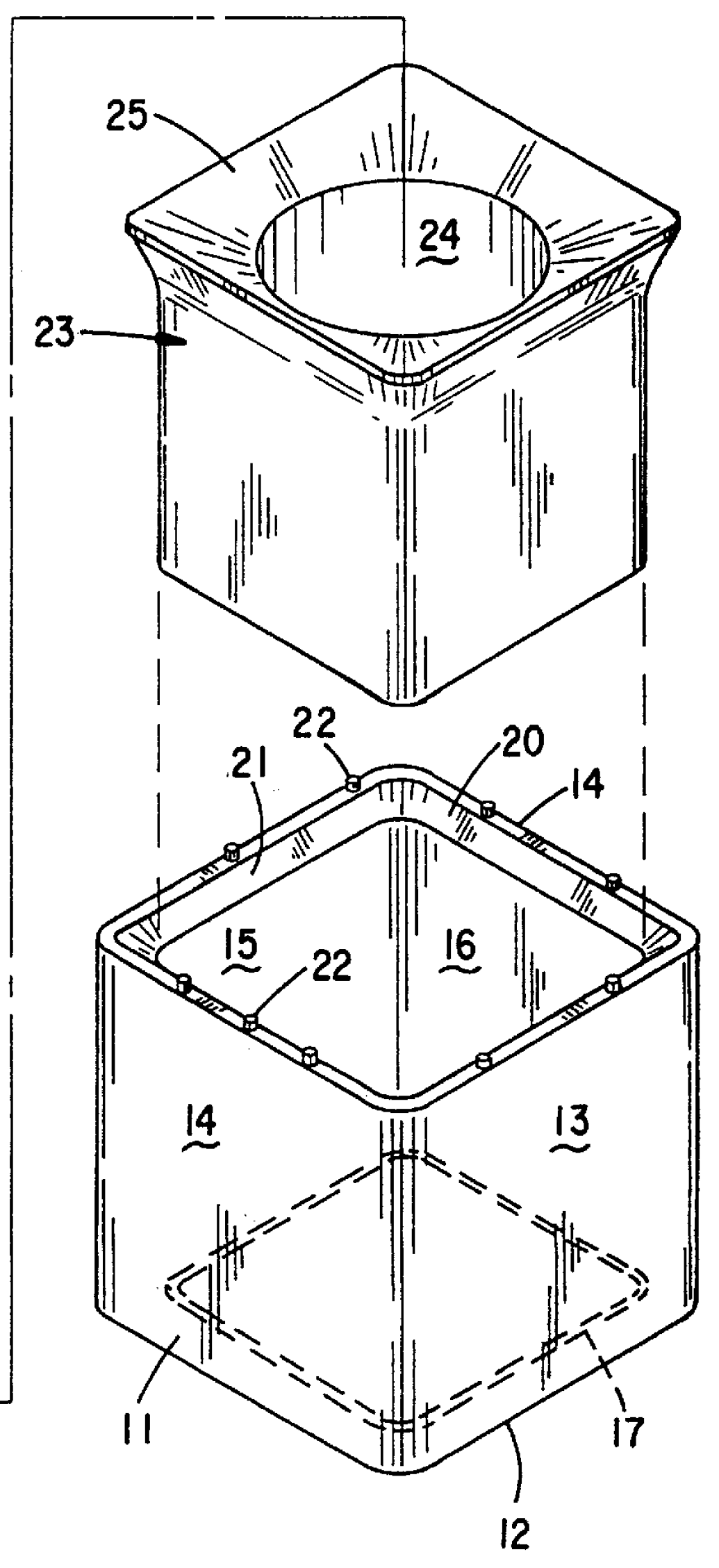

Home yogurt/cheese making machine

InactiveUS6213007B1Improve the immunityAutomatic control devicesMilk preservationCheesemakingMotor drive

A kitchen appliance for preparing yogurt, soft frozen yogurt and ice cream, hard frozen yogurt and ice cream, and cheese. The appliance includes a housing having a base and side walls defining an open top. A motor-driven paddle device is rotationally journaled with respect to the cover and base and the motor therefor is adapted to be driven either continuously or with a predetermined duty cycle, dependent upon the product being made. Also mounted on either the cover or the base is a vent hole occluder that is normally positioned to block the vent holes in the cover or base, but which shifts to a second position uncovering those vent holes when the consistency of the product being produced, as tested by the paddle motion or other apparatus reveals that a predetermined cultured state has been reached. Shifting of the occluding device from the covering position to the open position also actuates a switch to shut off the drive motor and a warming element. When a frozen yogurt product is desired, a pre-chilled freezing bowl can be placed in the housing and the paddle used to scrape the frozen yogurt from the walls of the freezing bowl.

Owner:LANDE ARNOLD J

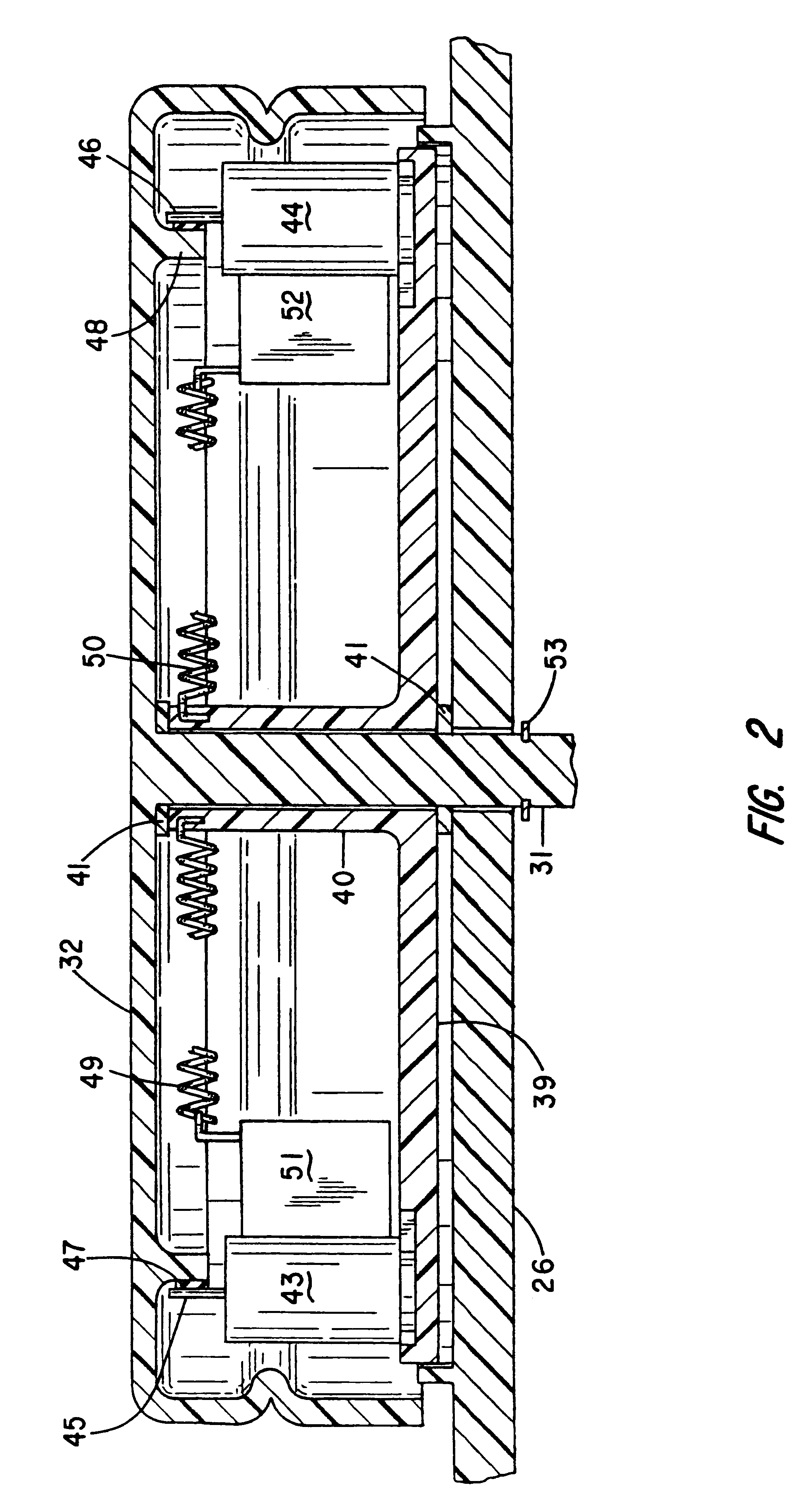

Hot dairy-based beverage dispenser

InactiveUS7021206B2Reduce eliminateConstant flowLighting and heating apparatusUsing liquid separation agentPinch valveEngineering

A dispensing unit for dispensing hot, dairy-based beverages has a self-contained refrigerated unit located above a venturi-type emulsification foaming head. The dispensing unit has particular applicability to the dispensation of foamy, hot milk for use in beverages such as cappuccino and nonfoamy, hot milk for use in beverages such as coffee latte, hot chocolate, and other hot dairy-based beverages. The refrigeration unit accommodates a “bag in box” cold milk storage container of the type widely used in food service establishments. The dispensing unit employs a pinch valve that avoids direct contact between the milk and the valve components. The refrigerated milk is stored above the level of the foamer head so that the flow of milk results partially from gravitational force on the milk, and is not totally dependent upon venturi suction created in the foamer head.

Owner:ECKENHAUSEN ROLAND B +1

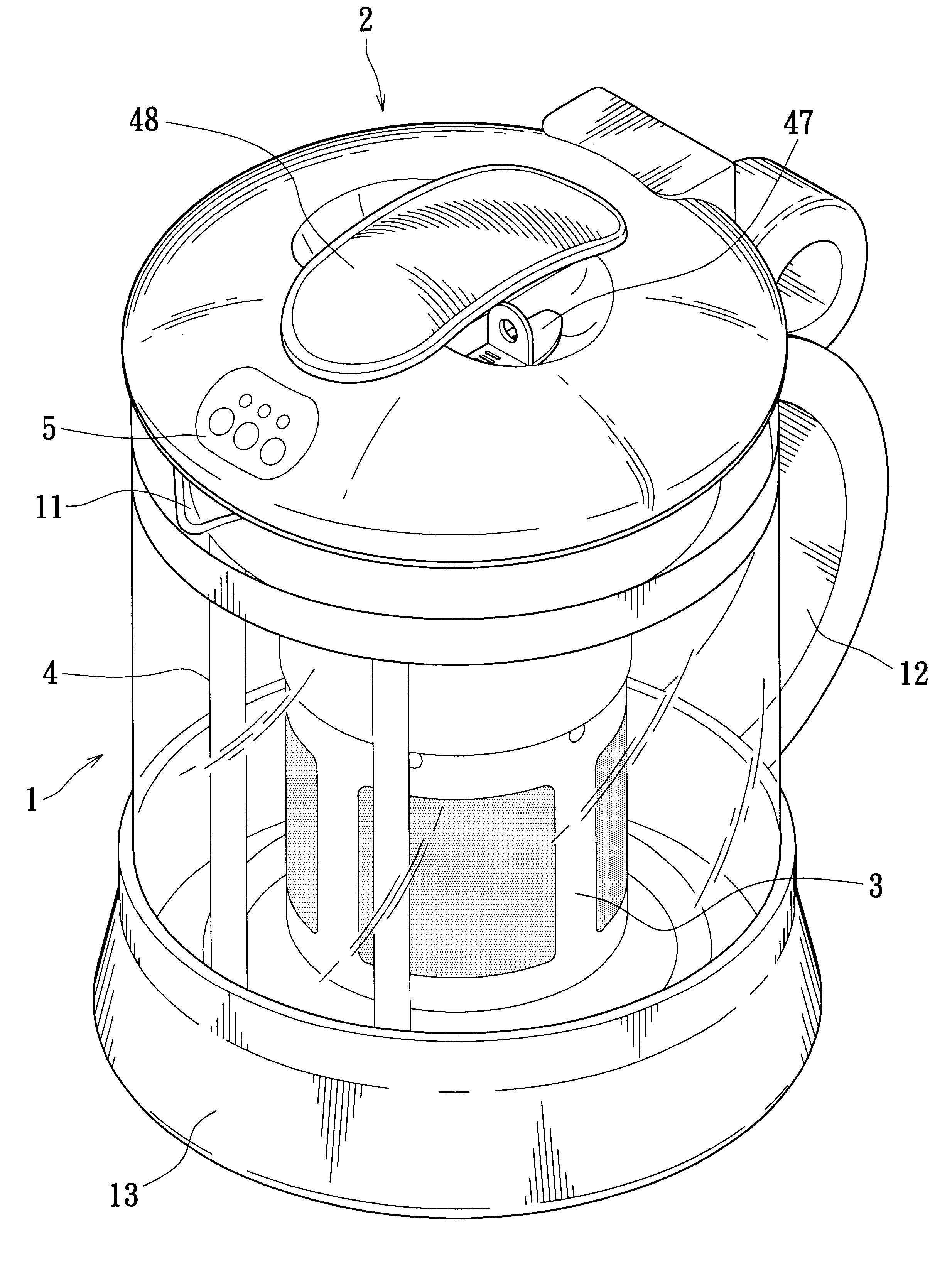

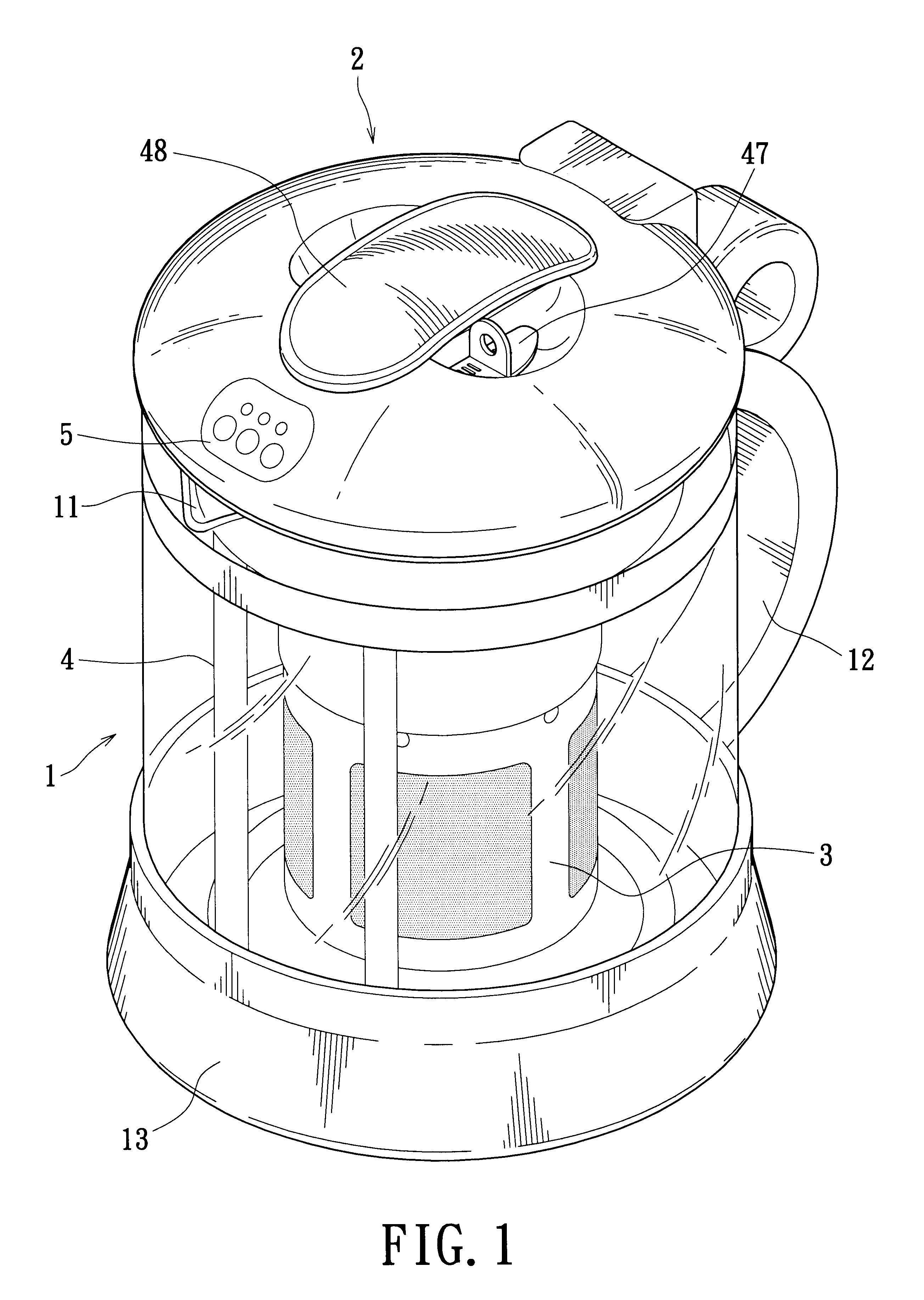

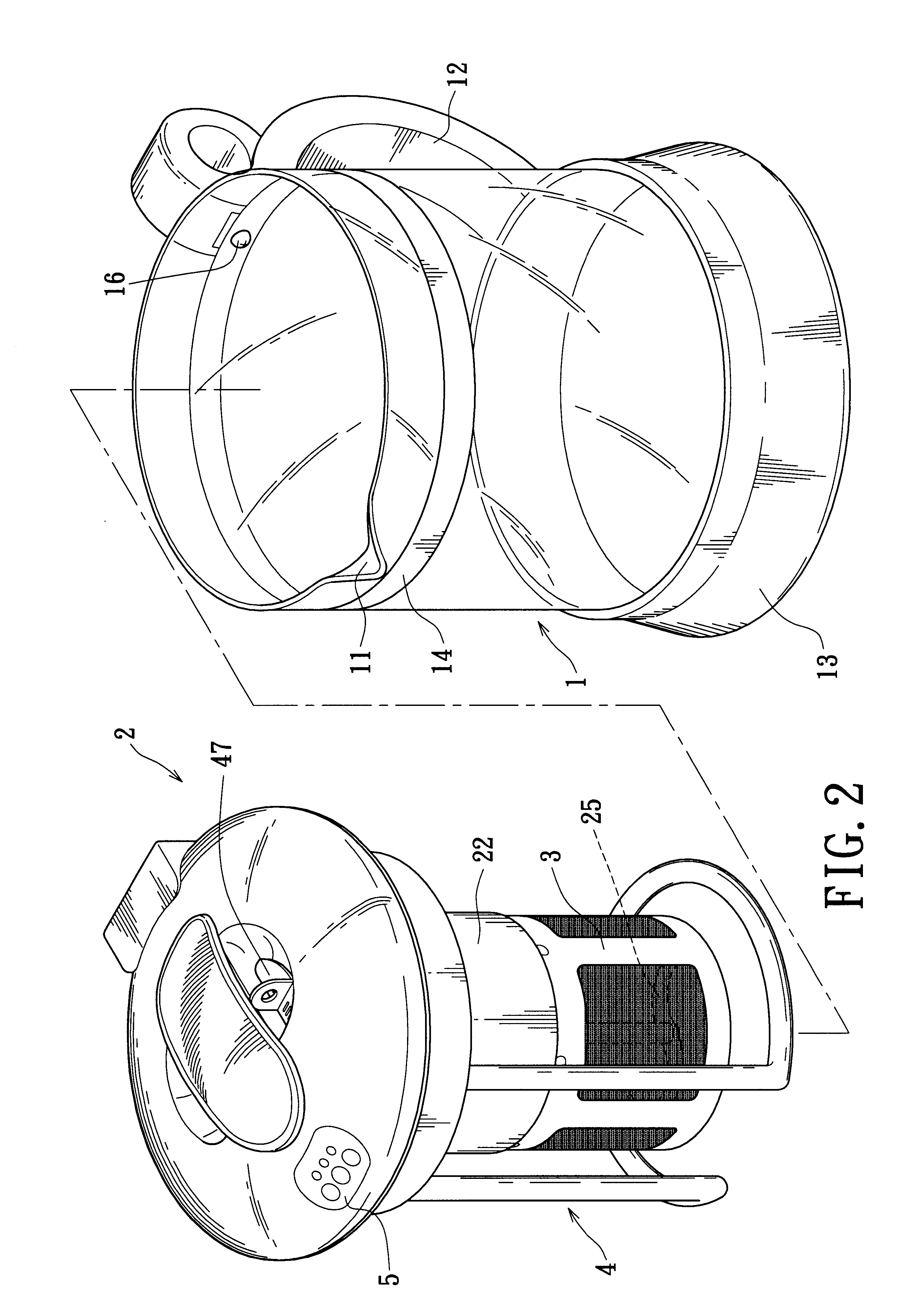

Pressure cooker

A pressure cooker (1) comprises: a pressure vessel (2) for containing items to be cooked; an inlet (3) in a wall of the pressure vessel (2) for receiving steam from a steam source; and a pump (4) for pumping the steam from the steam source into the pressure vessel (2) through the inlet (3), wherein the pump (4) produces a maximum pressure below a maximum safety pressure for the pressure vessel (2).

Owner:TOP ELECTRICAL APPLIANCES IND

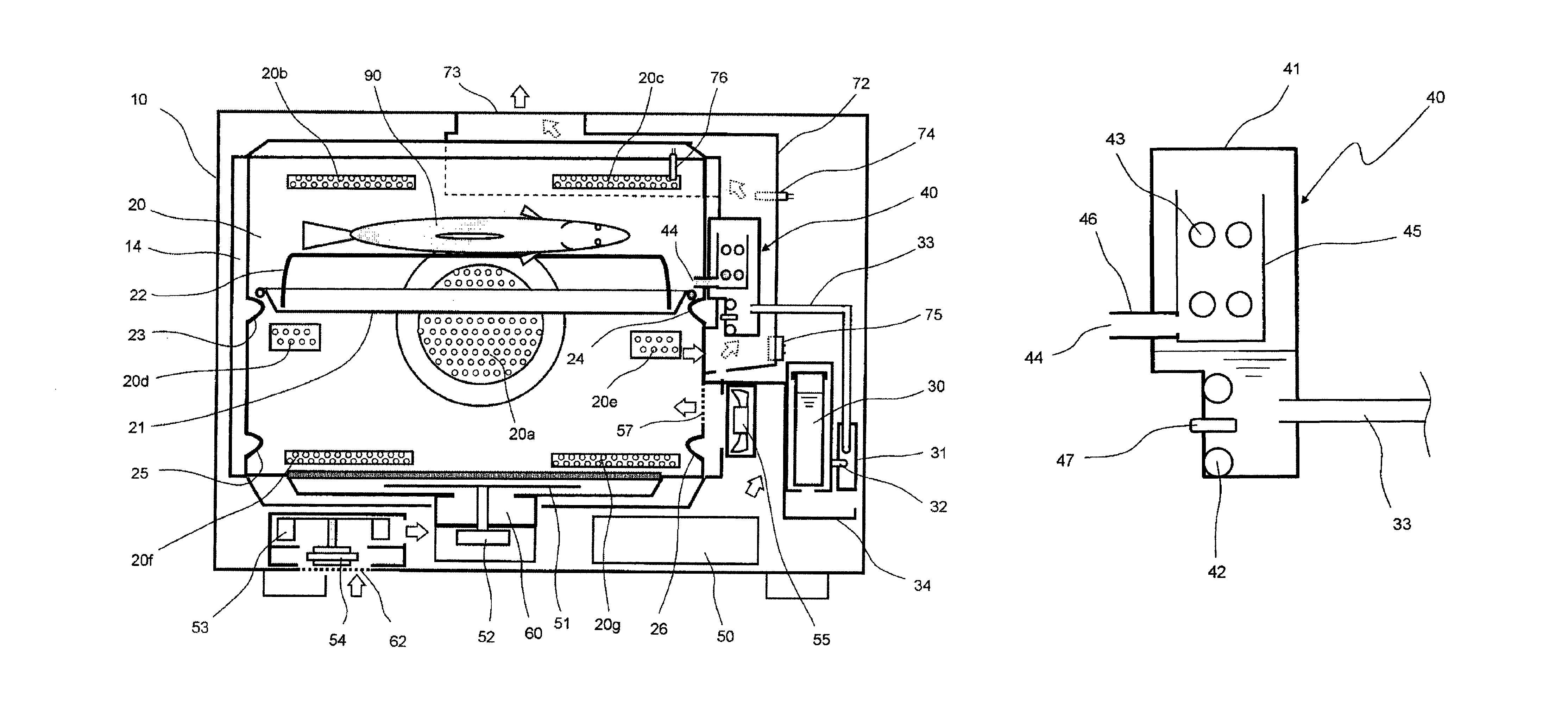

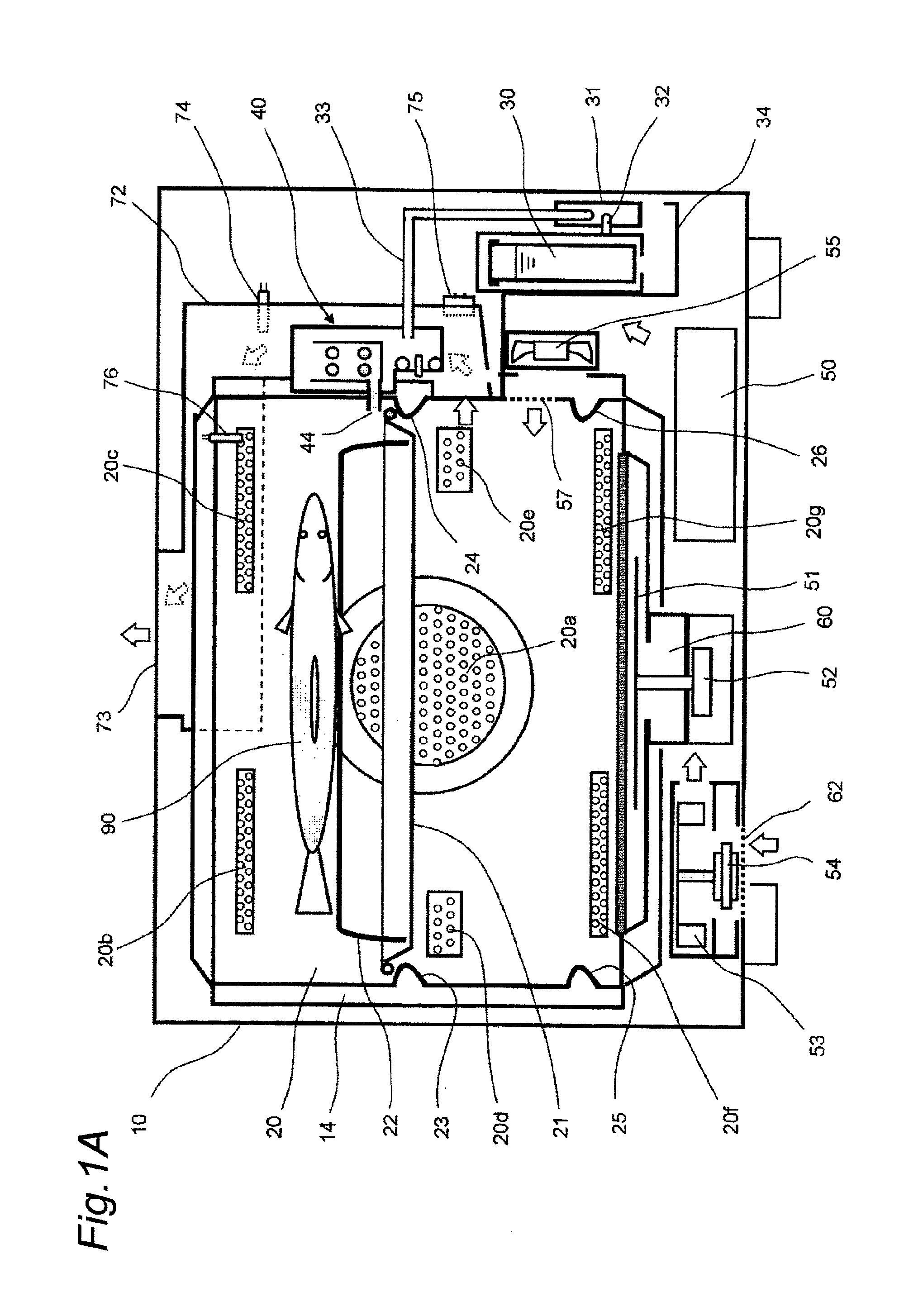

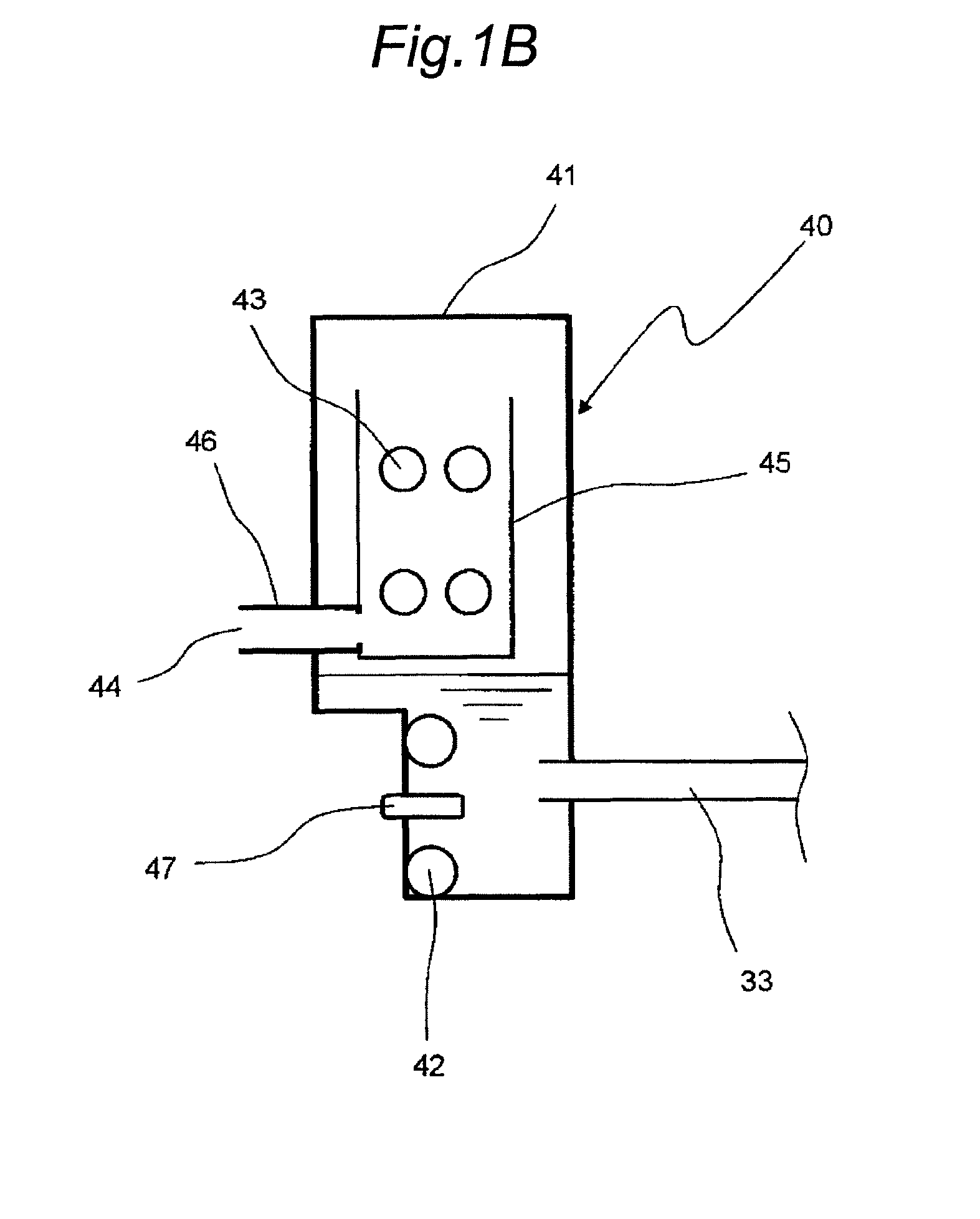

Cooking appliance

ActiveUS8695487B2Simple structureLow costDomestic stoves or rangesBaking ovenEngineeringSteam generation

Disclosed is a cooking appliance provided with: a water tank (30) disposed inside a main case (10); a steam-generation device (40) that generates steam by heating water supplied from the water tank (30); a heating chamber (20) to which steam from the steam-generation device (40) is supplied; an exhaust duct (72), provided inside the main case (10), for expelling exhaust from inside the heating chamber (20) to outside the main case (10); an exhaust temperature sensor (74) that measures the temperature of the exhaust air inside the exhaust duct (72); and a steam-generation decision unit that, upon cooking in which steam is supplied from the steam-generation unit (40) into the heating chamber (20), uses information on a physical quantity (the exhaust temperature measured by the exhaust temperature sensor (74)), which indirectly indicates whether there is water in the steam-generation device (40), to decide whether or not to halt steam generation, including the case in which the water tank (30) is out of water.

Owner:SHARP KK

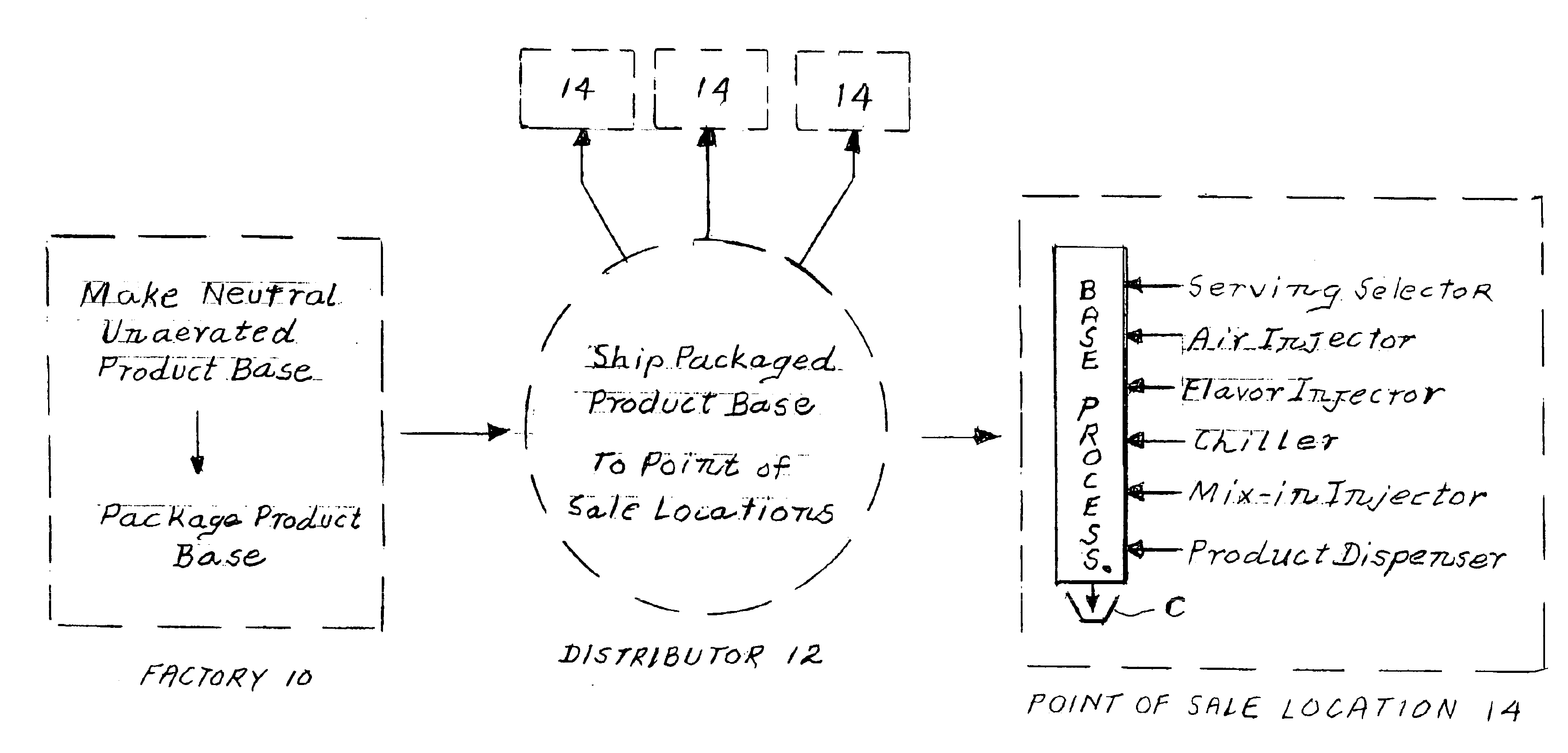

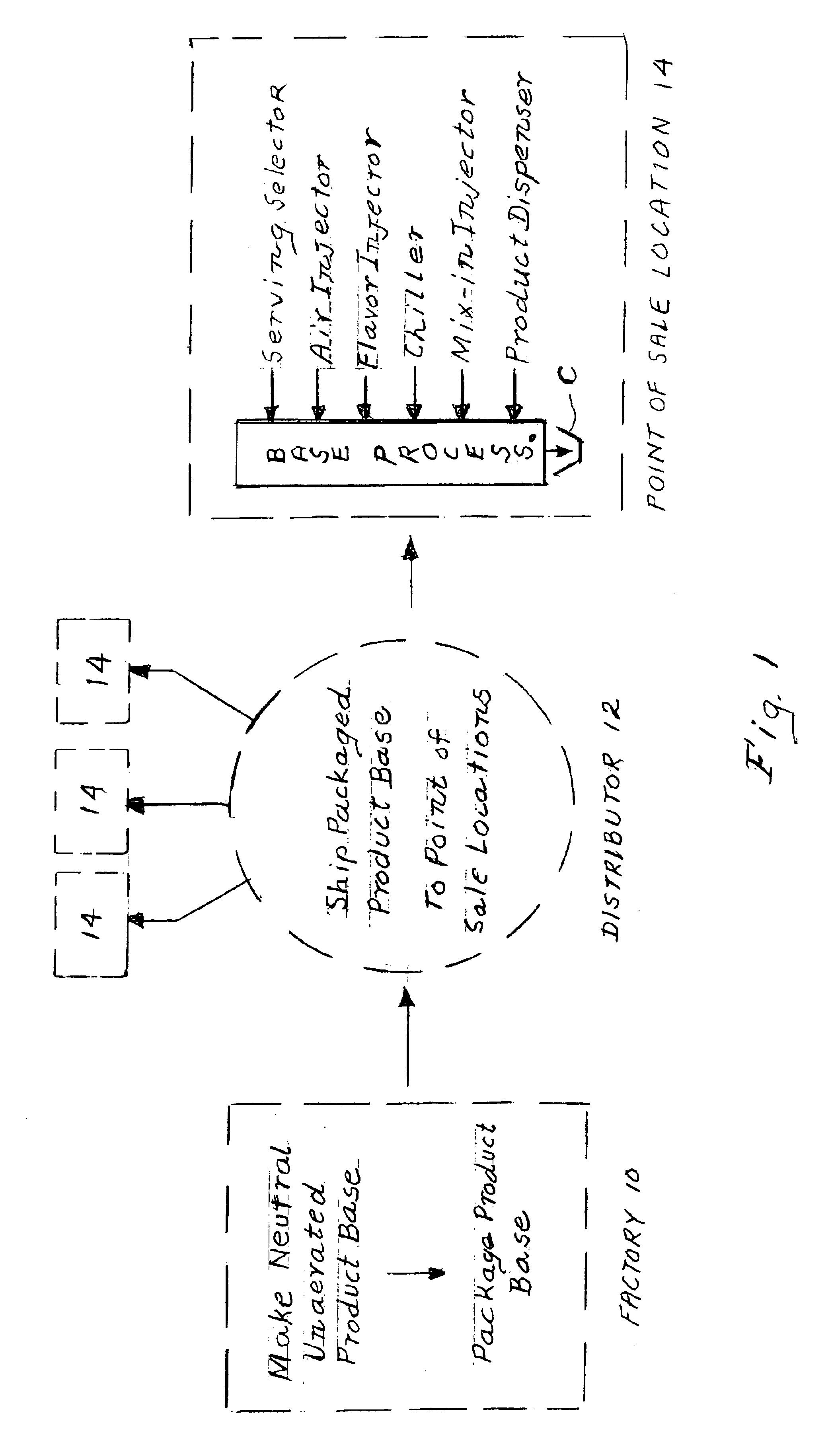

Efficient manufacture and distribution of chilled solid food products

InactiveUS6941858B2Lower requirementImprove production efficiencyMilk preservationMilk treatmentDistribution systemCommon carrier

An efficient manufacturing and distribution system for food products that are normally served at temperatures well below ambient uses a two stage manufacturing process. In the first stage, a neutral base product is prepared in bulk and is shipped to point of sale at ambient temperatures by common carrier, private trucking, parcel express, mail, etc. At the point of sale, a user selected quantity of it is finished to the specification of the user by aerating it, adding flavorings, mix-ins, etc. as desired, chilling it, and delivering it to the consumer.

Owner:MOOBELLA ACQUISITION +1

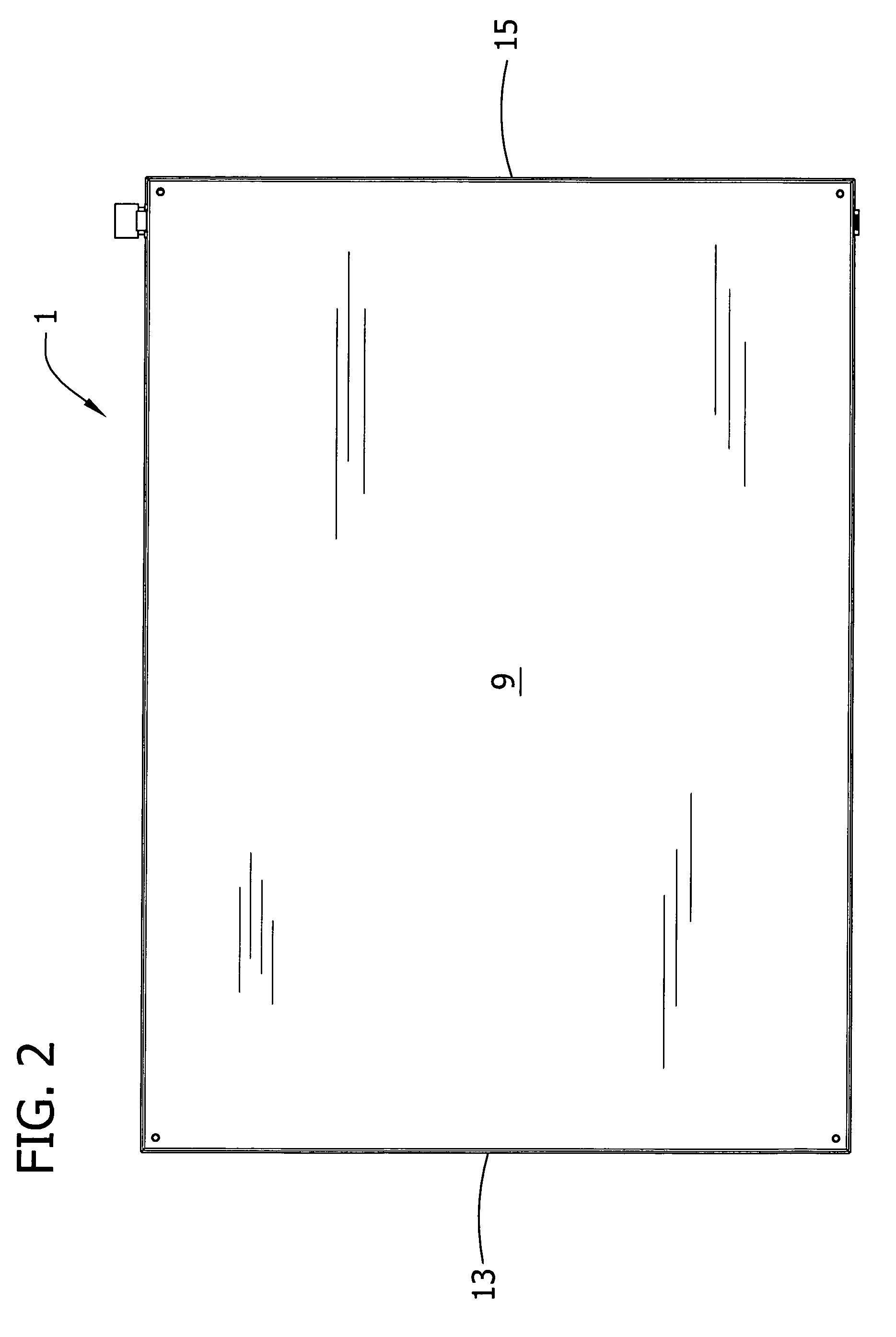

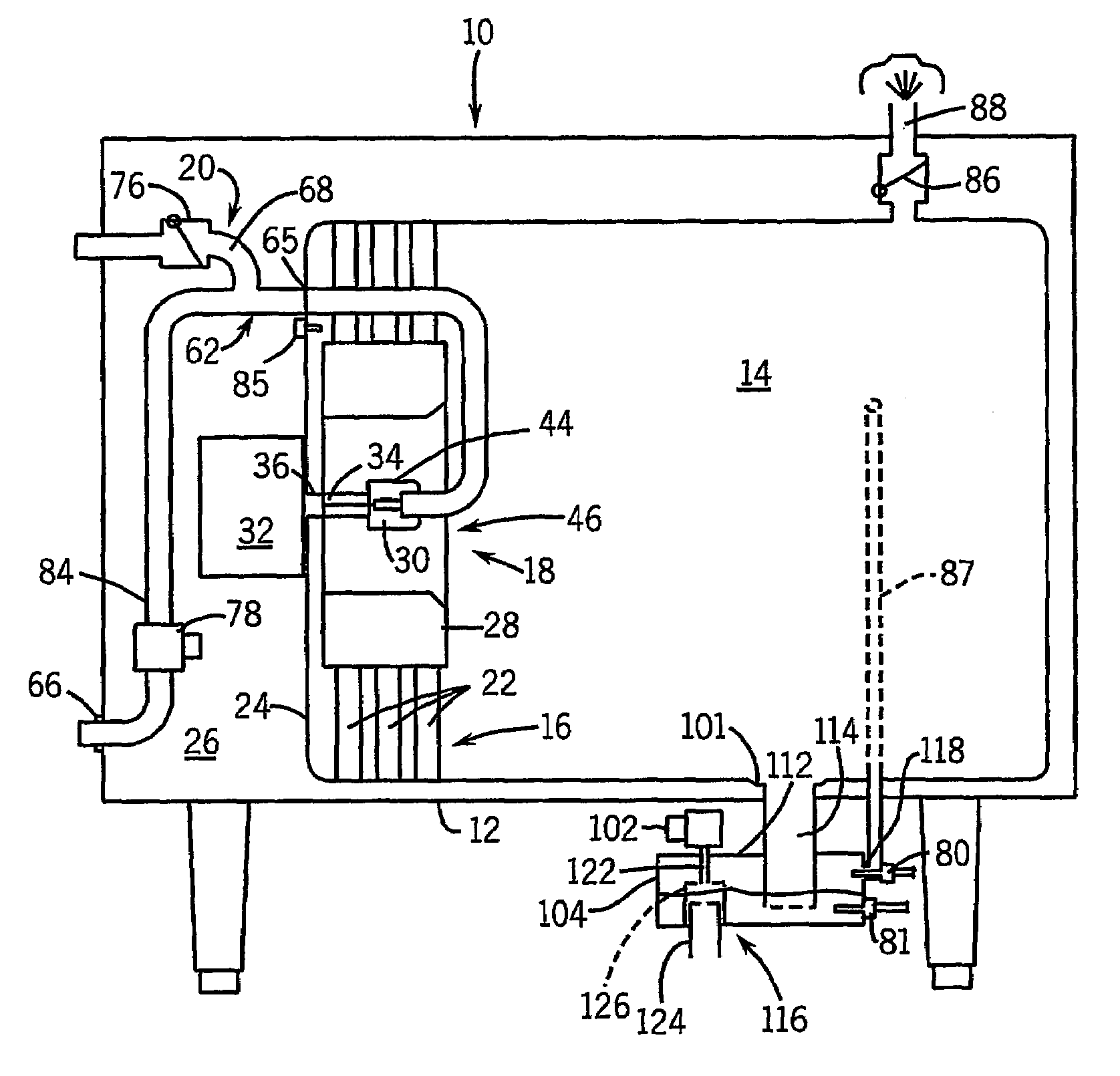

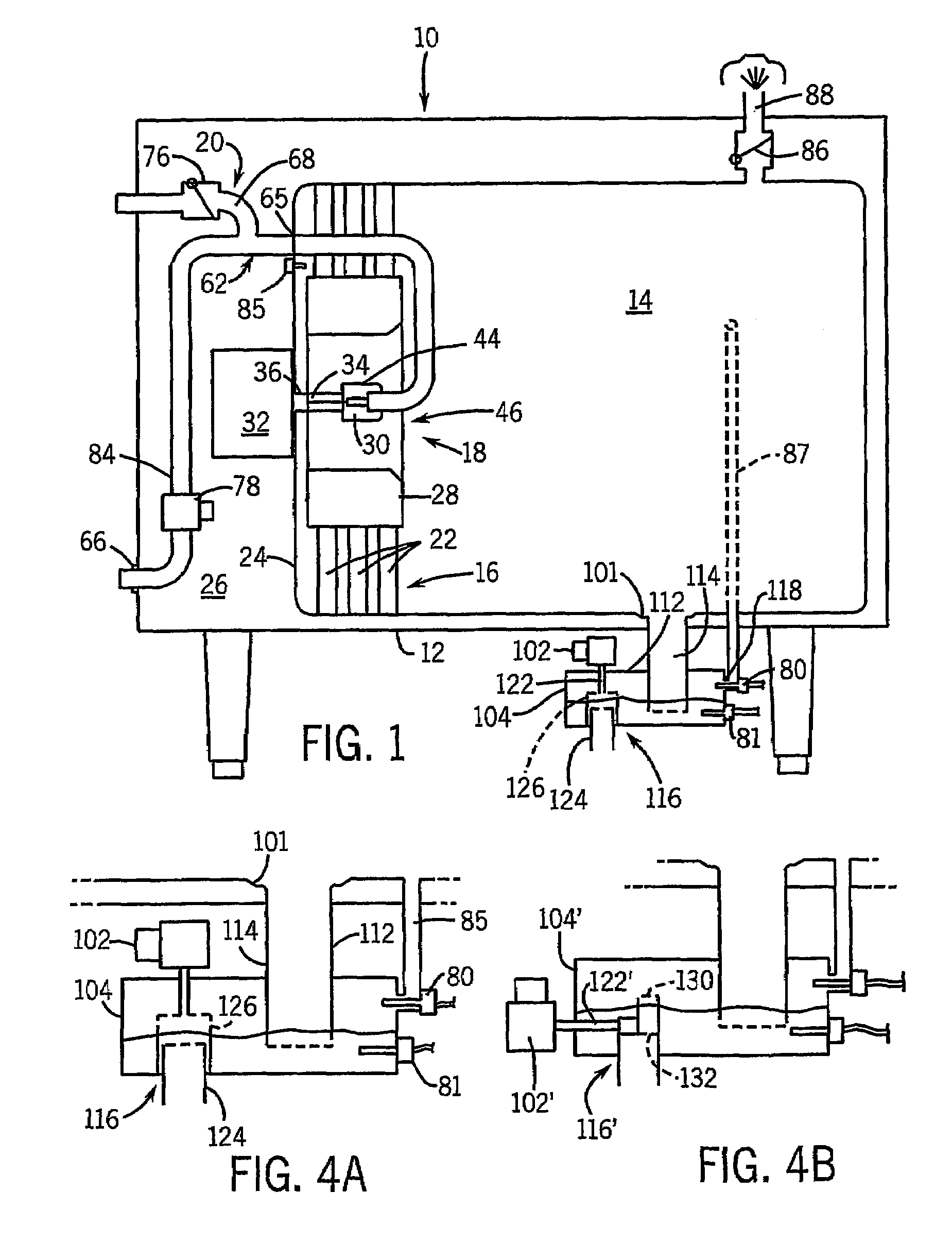

Commercial frozen food preparation apparatus sanitation

ActiveUS20110088558A1Reducing even eliminating needMilk treatmentRotary stirring mixersFood contactEngineering

A machine prepares semi frozen food products and / or beverages from pre-prepared (e.g. frozen) cups. A user chooses the desired frozen cup, inserts it into the machine, chooses how they would like it prepared from a range of thickness options, and the machine then opens a sealed chamber door and inserts the product upward into the chamber and prepares the product by blending it in the cup. Upon removal of the product and resealing of the chamber door, the cleaning mechanisms provide thorough cleaning of all food contact surfaces and the chamber interior. Automatic high temperature steam sanitation takes place in the chamber if the machine is not used for an extended period of time, thus greatly reducing or eliminating the need for manual cleansing and sanitation by an attendant and ensuring healthy food preparation at all times.

Owner:F REAL FOODS LLC

Home yogurt/cheese making machine

A kitchen appliance for preparing yogurt, soft frozen yogurt and ice cream, hard frozen yogurt and ice cream, and cheese. The appliance includes a housing having a base and side walls defining an open top. A motor-driven paddle device is rotationally journaled with respect to the cover and base and the motor therefor is adapted to be driven either continuously or with a predetermined duty cycle, dependent upon the product being made. Also mounted on either the cover or the base is a vent hole occluder that is normally positioned to block the vent holes in the cover or base, but which shifts to a second position uncovering those vent holes when the consistency of the product being produced, as tested by the paddle motion or other apparatus reveals that a predetermined cultured state has been reached. Shifting of the occluding device from the covering position to the open position also actuates a switch to shut off the drive motor and a warming element. When a frozen yogurt product is desired, a pre-chilled freezing bowl can be placed in the housing and the paddle used to scrape the frozen yogurt from the walls of the freezing bowl.

Owner:LANDE ARNOLD J

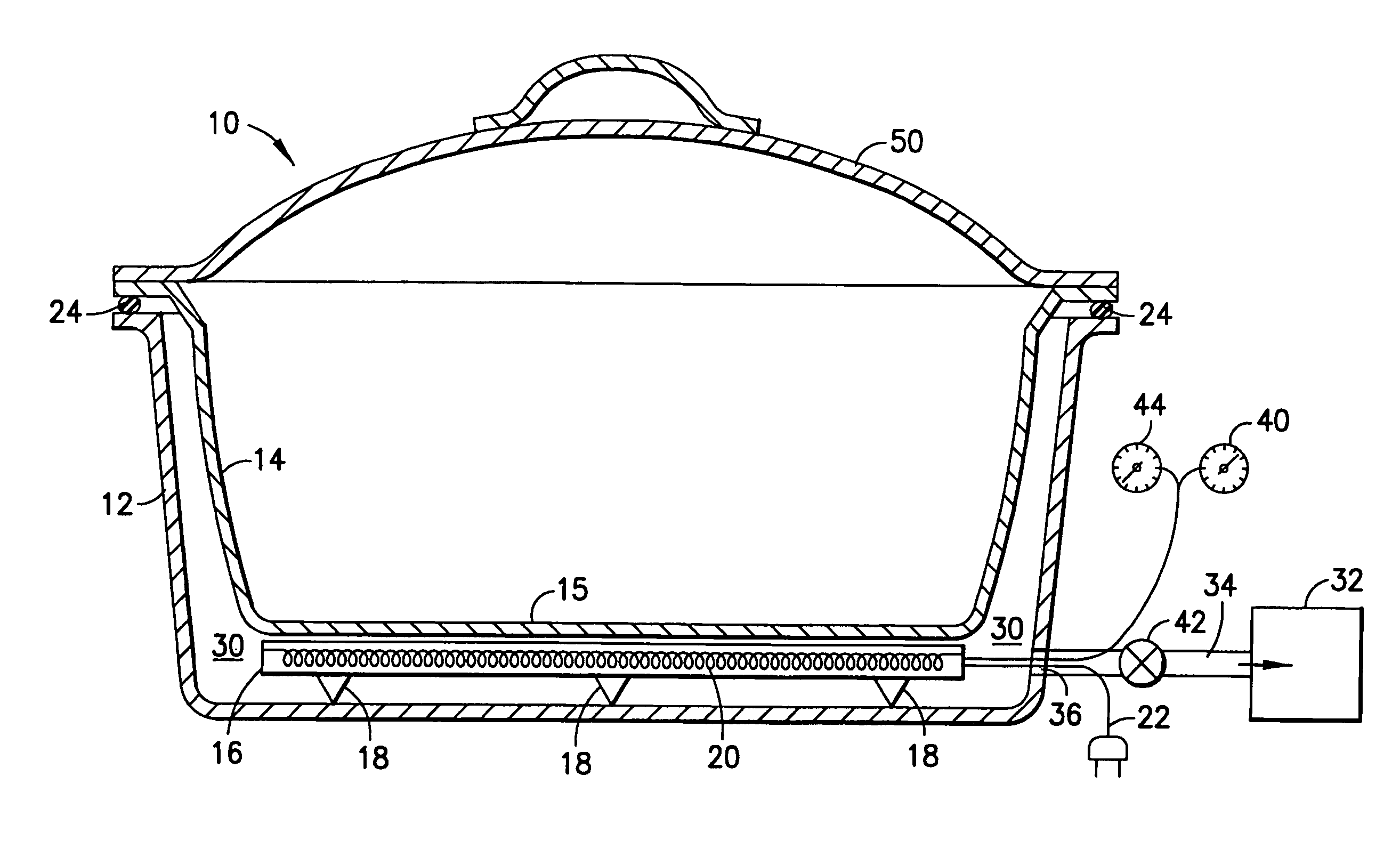

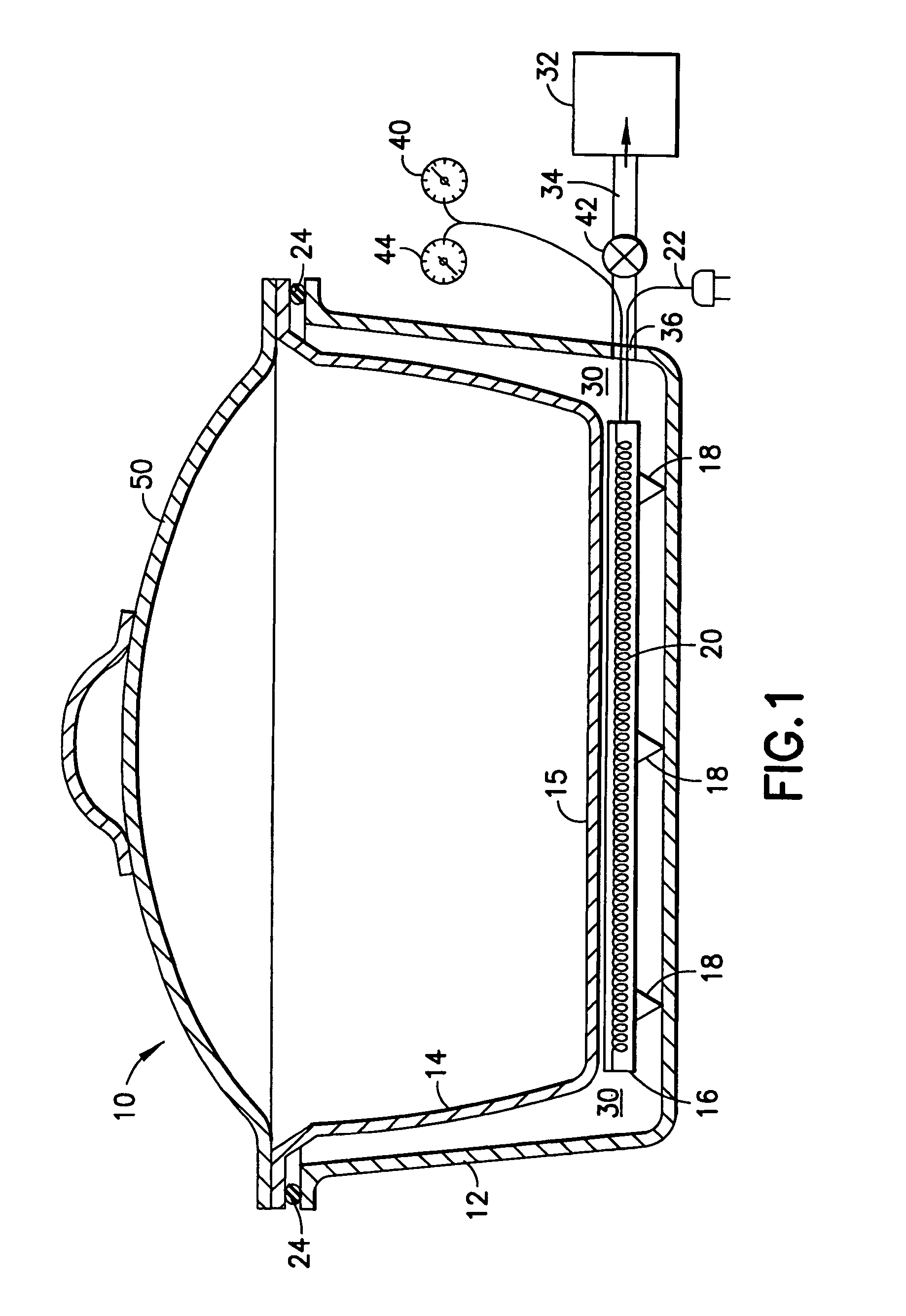

Vacuum cooking or warming appliance

Owner:CLAD METALS

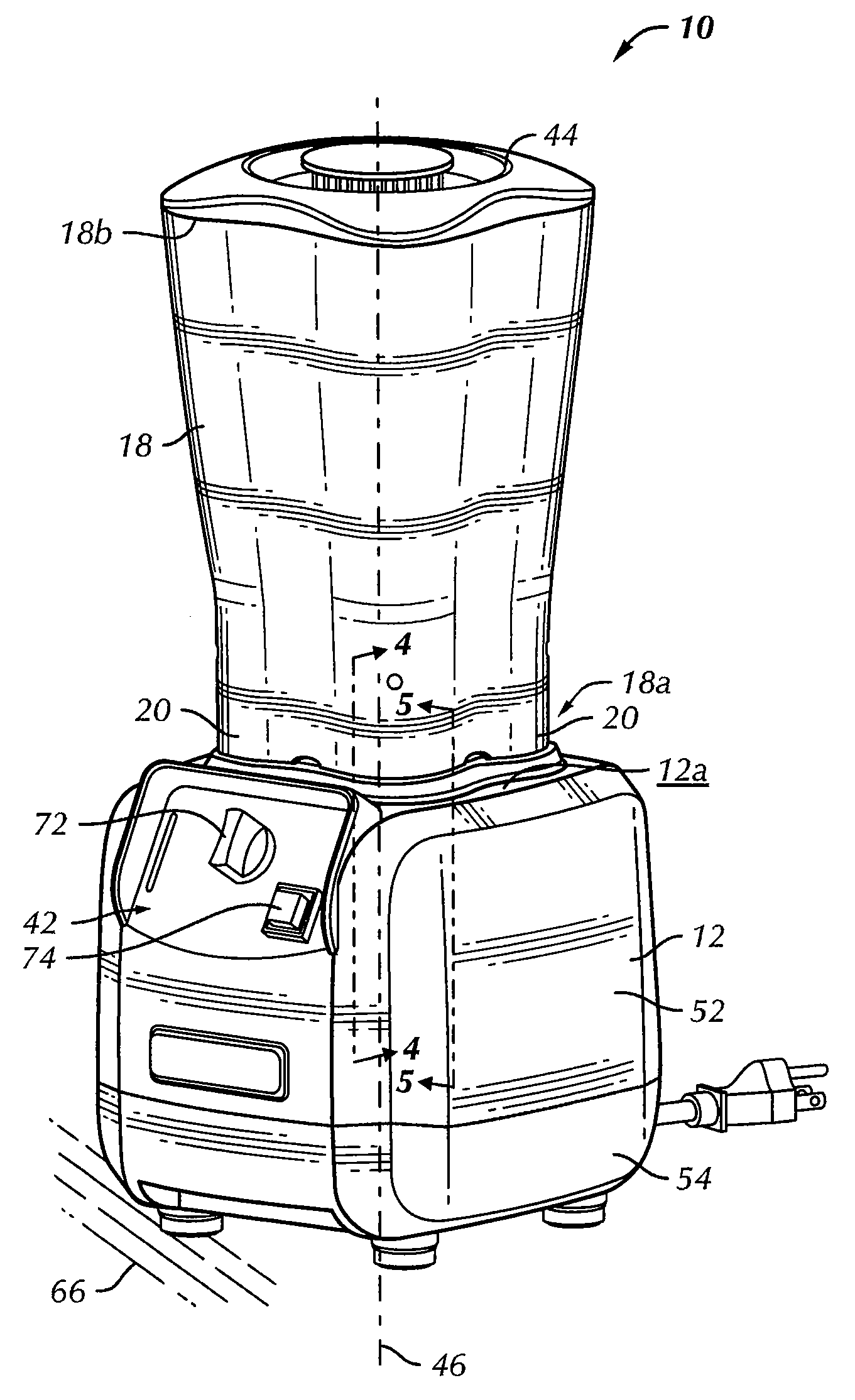

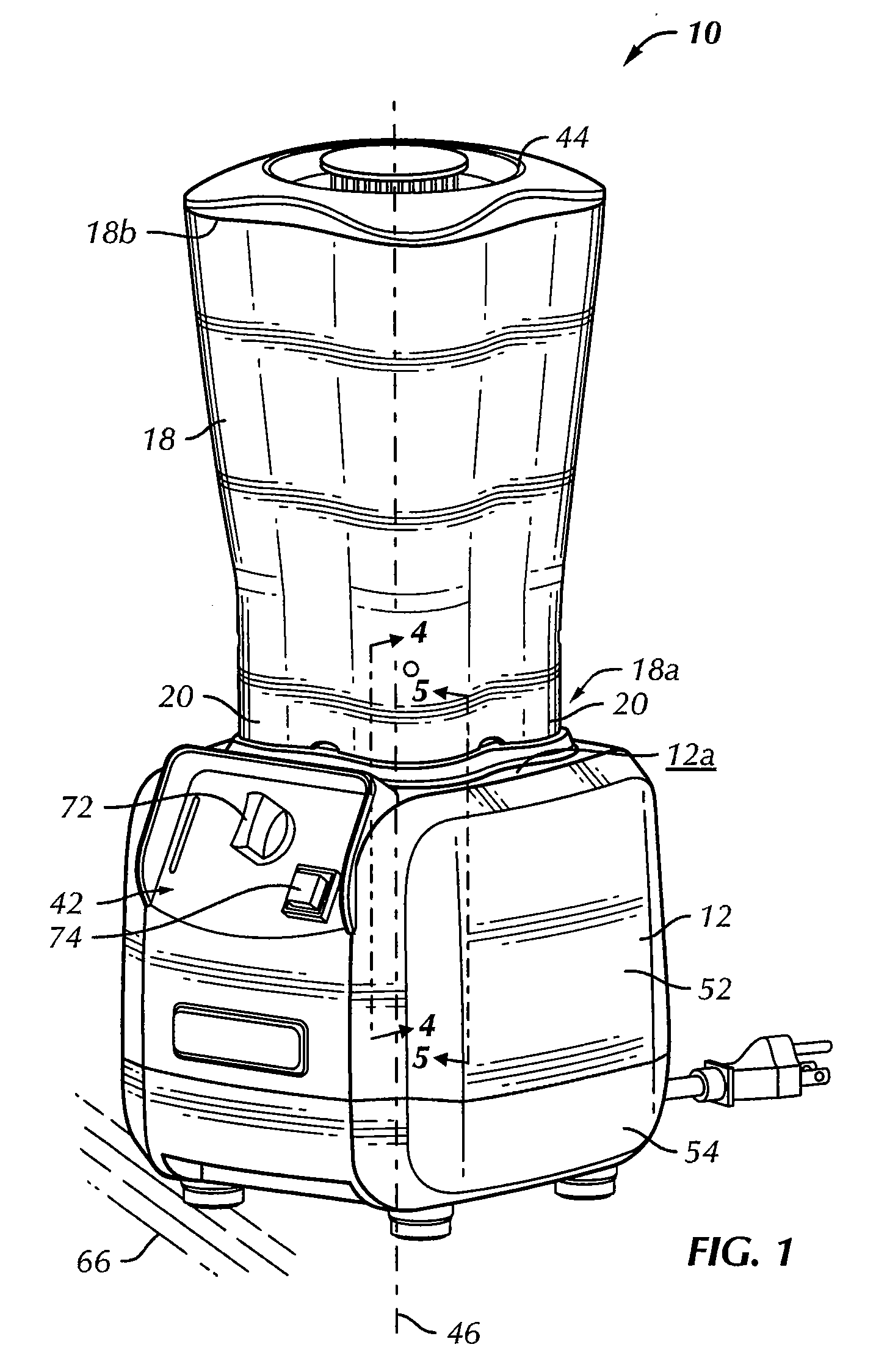

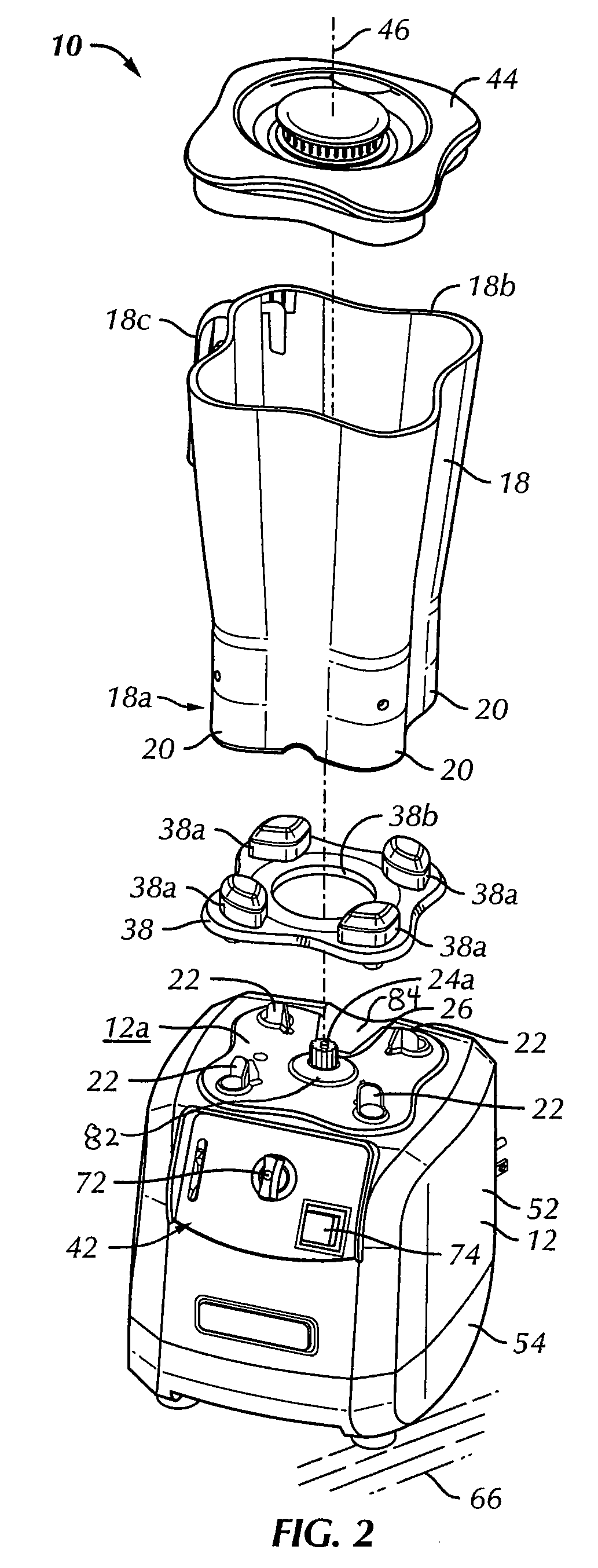

Durability Monitoring and Improvement of a Blender

A blender for blending foodstuff includes a base enclosing a motor and having an upper mounting surface. A jar sensor is secured to the base proximate the upper mounting surface and a jar is removably mountable to the base on the mounting surface. The jar includes a closed end and an actuator is mounted proximate the closed end. The jar sensor detects the presence of the actuator when the jar is mounted to the base in an operating position. The motor is powered when the jar sensor detects the presence of the actuator in the operating position. A motor temperature indicator is positioned on a control panel on the base and a temperature sensor is in communication with the motor temperature indicator. First and second cordsets are adaptable for removable mounting to the base for powering the motor.

Owner:HAMILTON BEACH BRANDS

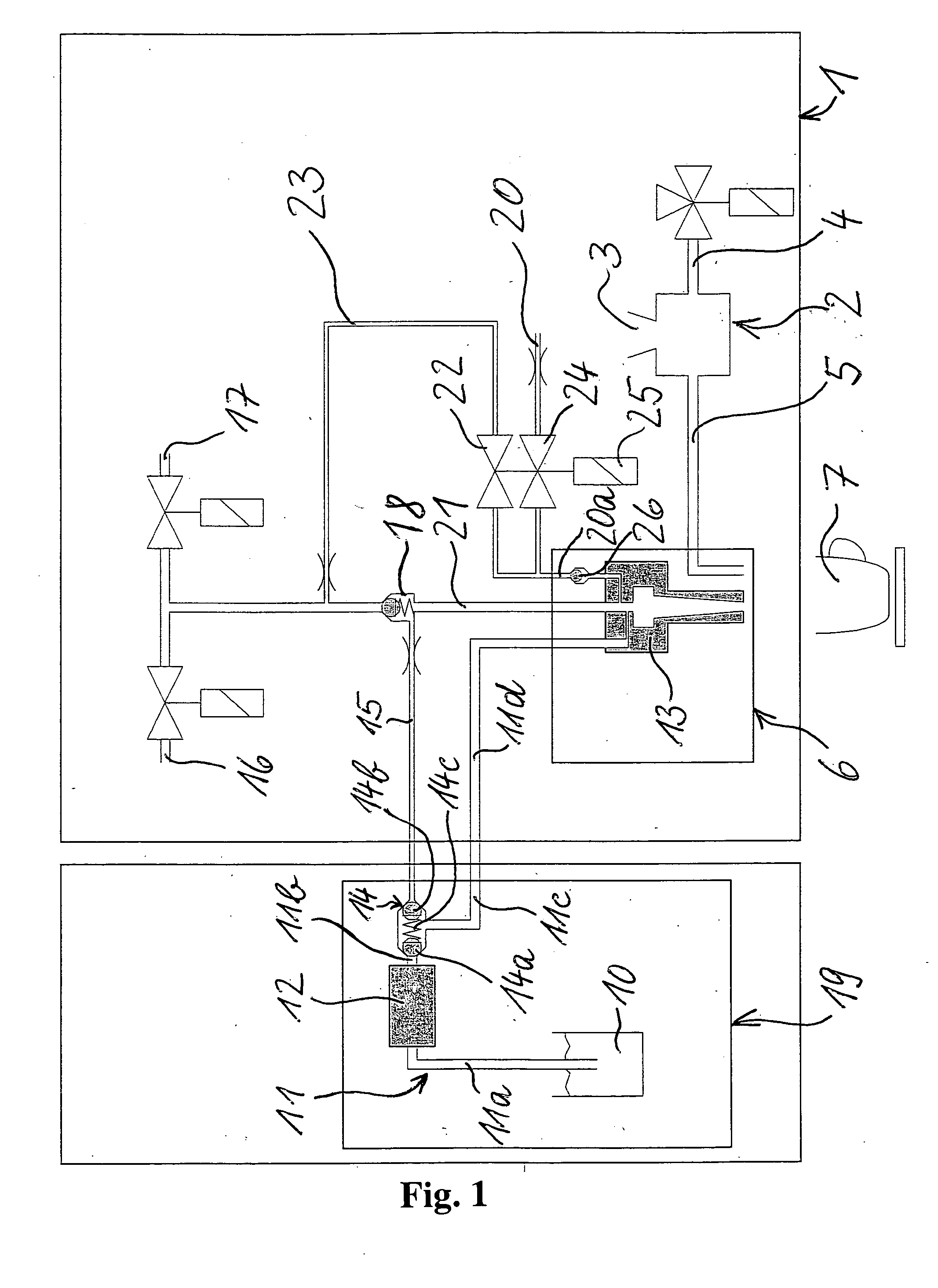

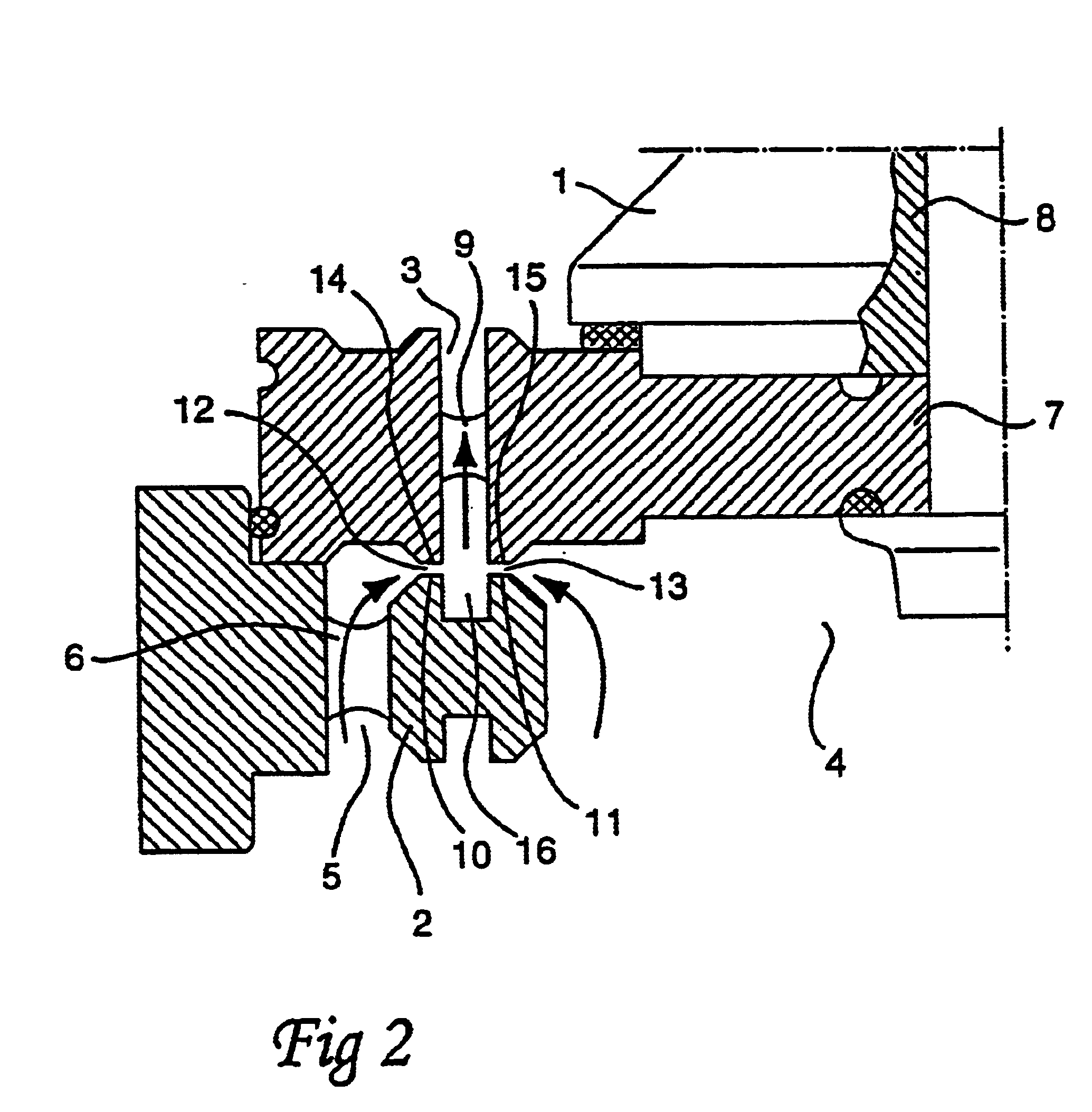

Device for producing milk foam

ActiveUS20050172833A1Reduce penetrationReduce expensesMilk preservationMilk treatmentMilk supplyVALVE PORT

A device is provided for producing milk foam, in particular in combination with an automatic coffee machine, which has a mixing chamber (13) to which milk, air, and rinsing medium can be supplied via various supply lines (11, 20, 21), wherein the supply of the rinsing medium to the mixing chamber takes place at least partially via the milk supply line (11). Here it is essential that the air supply line (20), at least with its end segment (20a) connected to the mixing chamber (13), can be selectively connected via a valve (22) to a line (23) having rinsing medium.

Owner:FRANKE TECH & TRADEMARK LTD

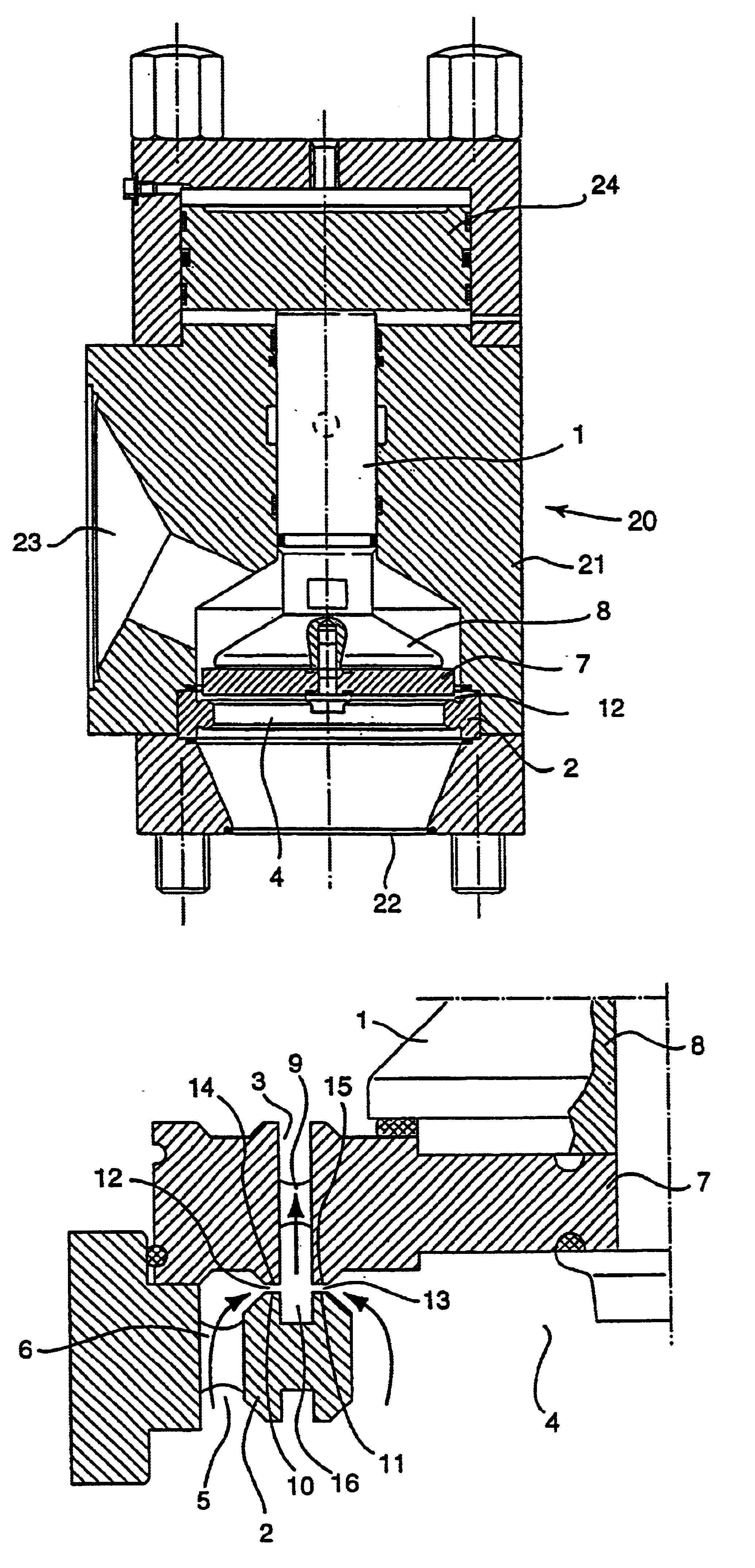

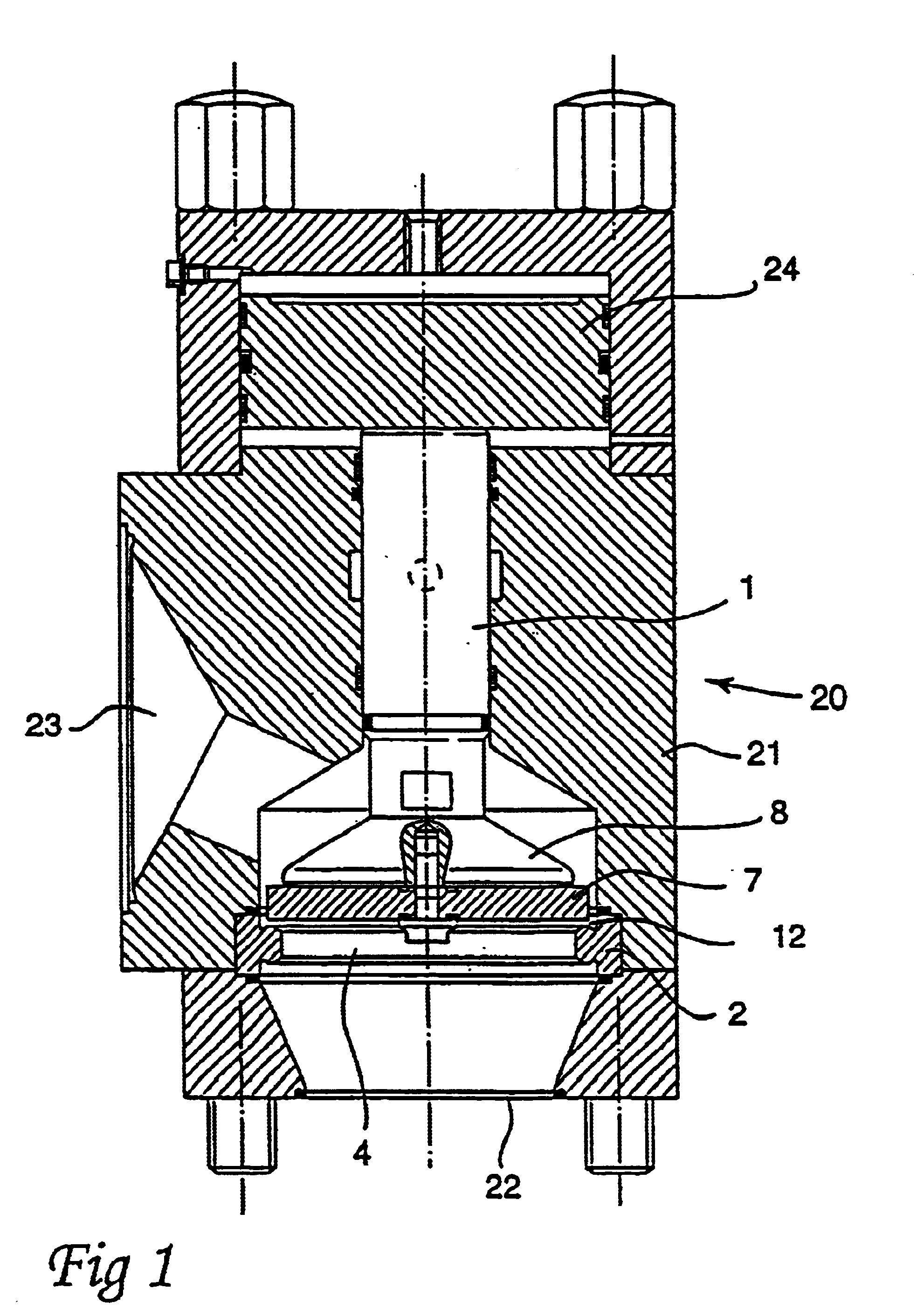

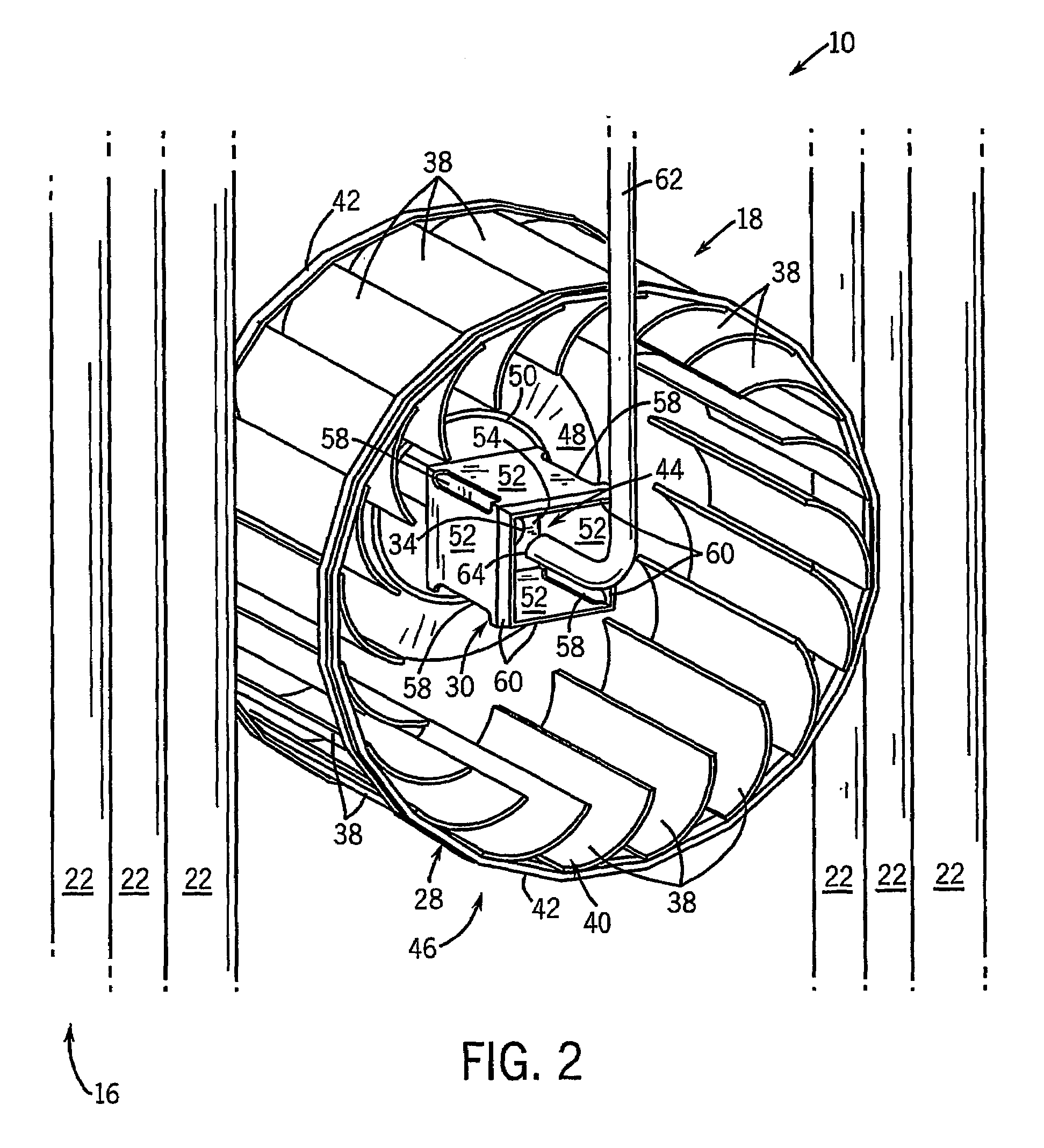

Method of homogenization

InactiveUS6705755B1Efficient and improved homogenizationSimple designFlow mixersMilk treatmentEmulsionEngineering

The invention relates to a method of homogenization of a pressured liqueform emulsion, such as milk. The liquid is caused to pass at least two concentrically placed homogenization gaps (12, 13) which are form in the space between two narrow surface (10, 11)on a fixed valve seat (2) and two narrow surfaces (14, 15) on a movable valve cone (1). When the liquid passes out the homogenization gaps (12, 13) a first homogenization takes place. The homogenization is rendered more efficient in that the liquid, when it passes out from one of the homogenization gaps (12) at high speed and in a restricted space meets the liquid out from one or more of the other homogenization gaps (13).

Owner:TETRA LAVAL HLDG & FINANCE SA

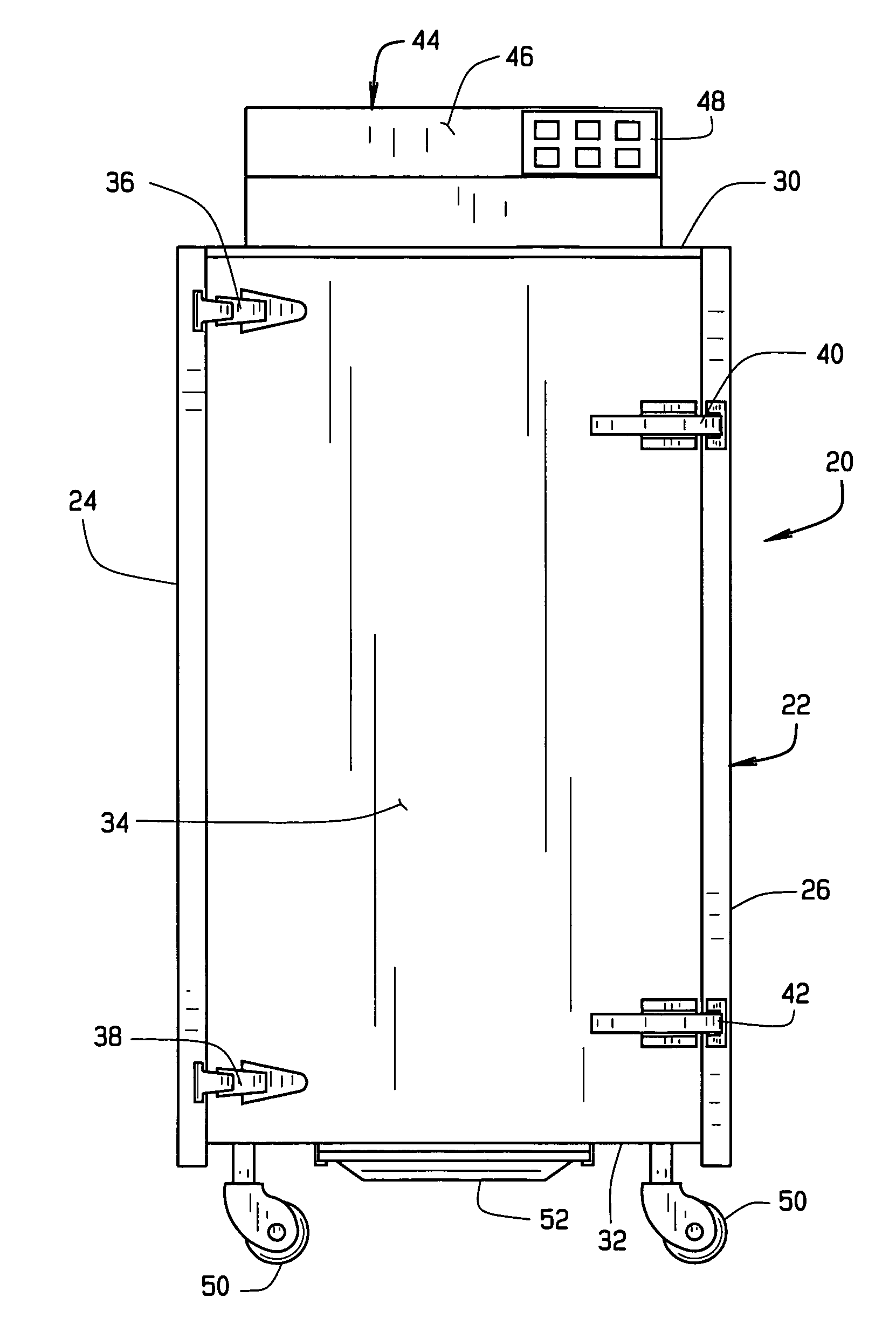

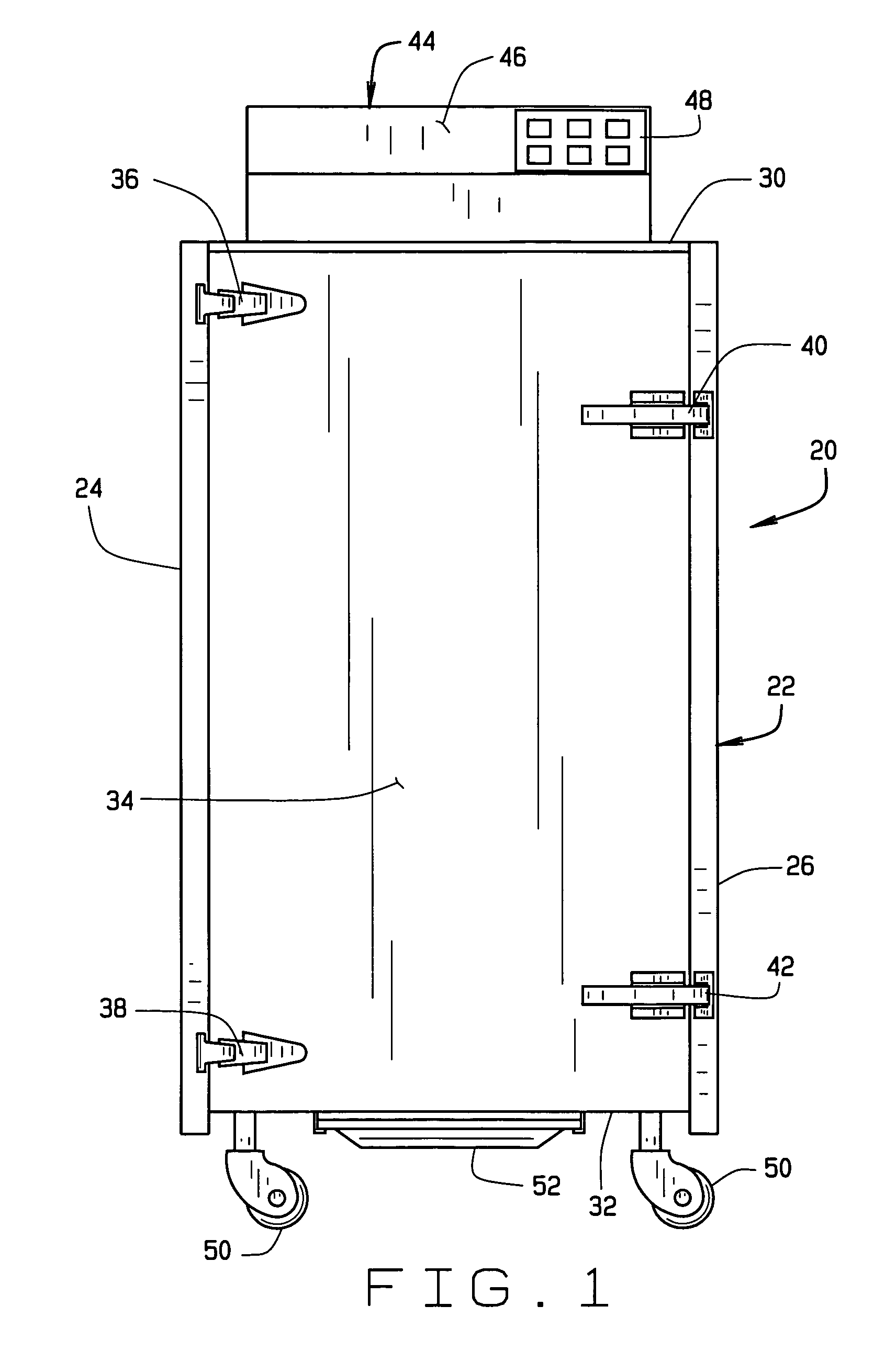

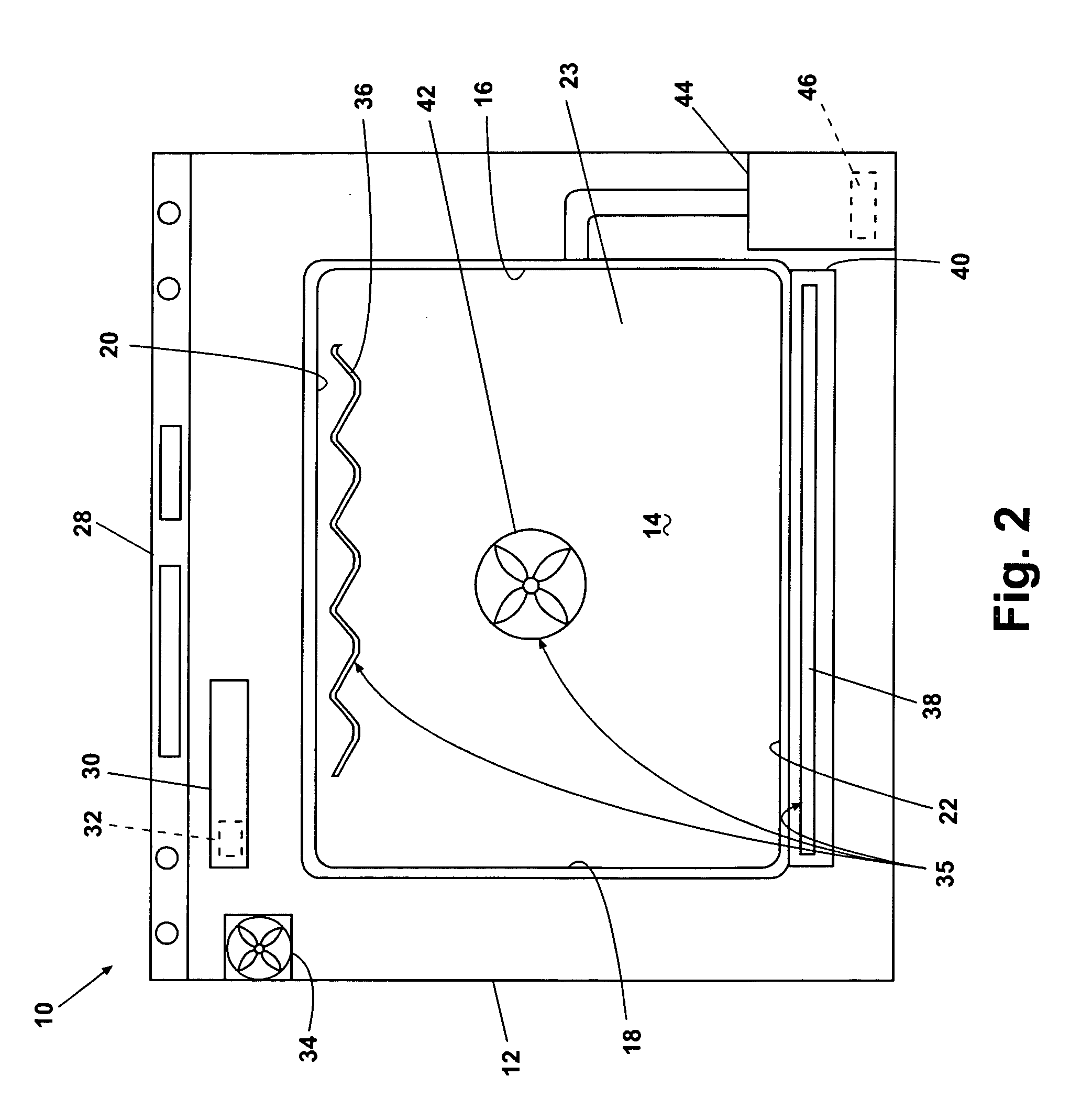

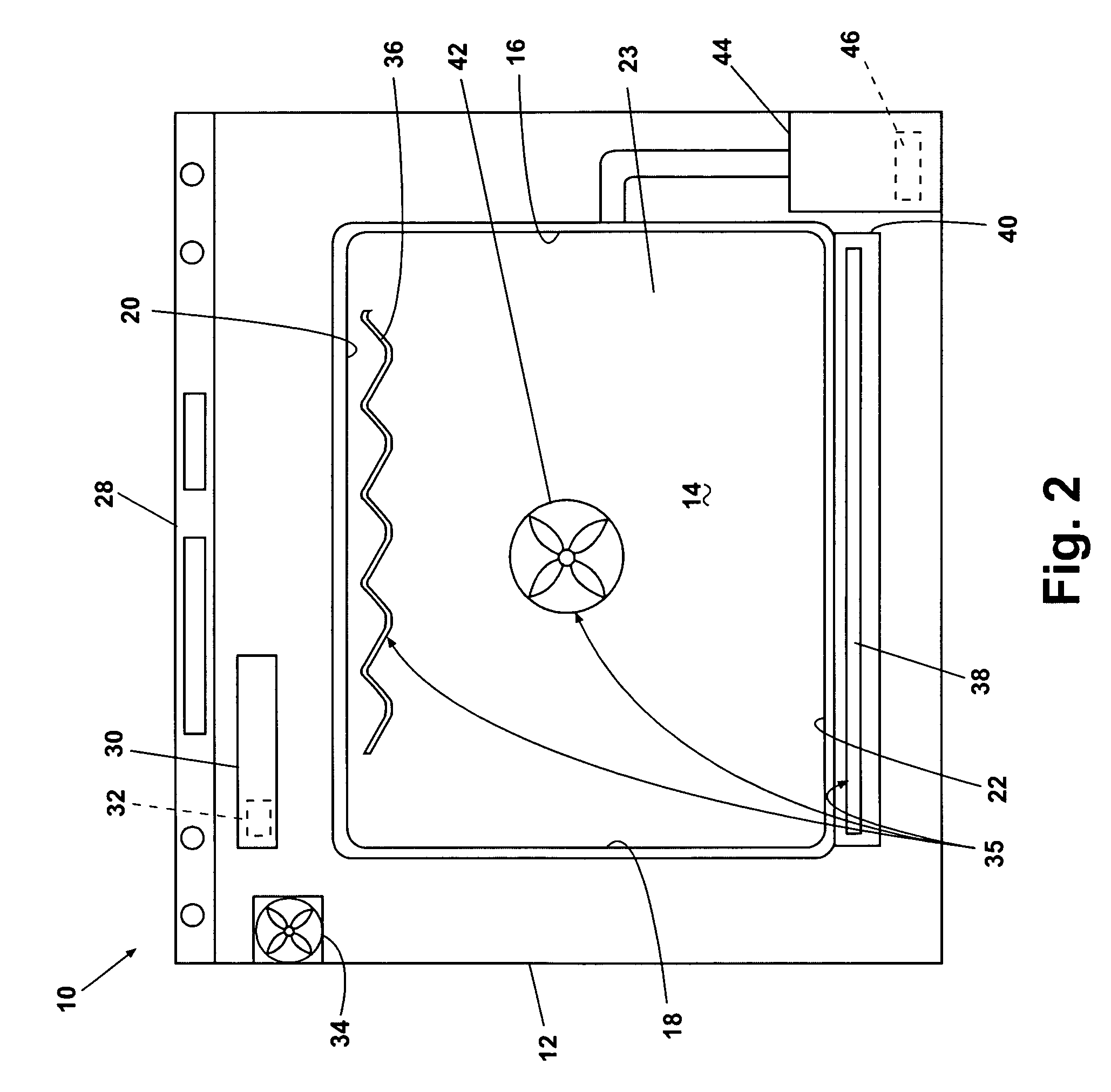

Humidity control system for combination oven

InactiveUS6987246B2Increase surface areaImprove thermal efficiencyDomestic stoves or rangesMilk treatmentSteam cookingControl system

A combination oven for the preparation of food has a cooking chamber containing heating elements, a fan and an atomizer for radiant, convective or steam cooking. The humidity within the cooking chamber is controlled by a water valve and either by forcing dry air into the cooking chamber and venting the humid air or by using a pressure box. Without any moving parts, the pressure box controls air exchange of the cooking chamber according to the level of water within the pressure box and the pressure in the cooking chamber. The oven has a condensate tank to collect condensation drained from the cooking chamber. The pressure box and condensate tanks form water barriers effectively isolating the cooking chamber from the vent and drain during cooking until venting is required.

Owner:ALTO SHAAM

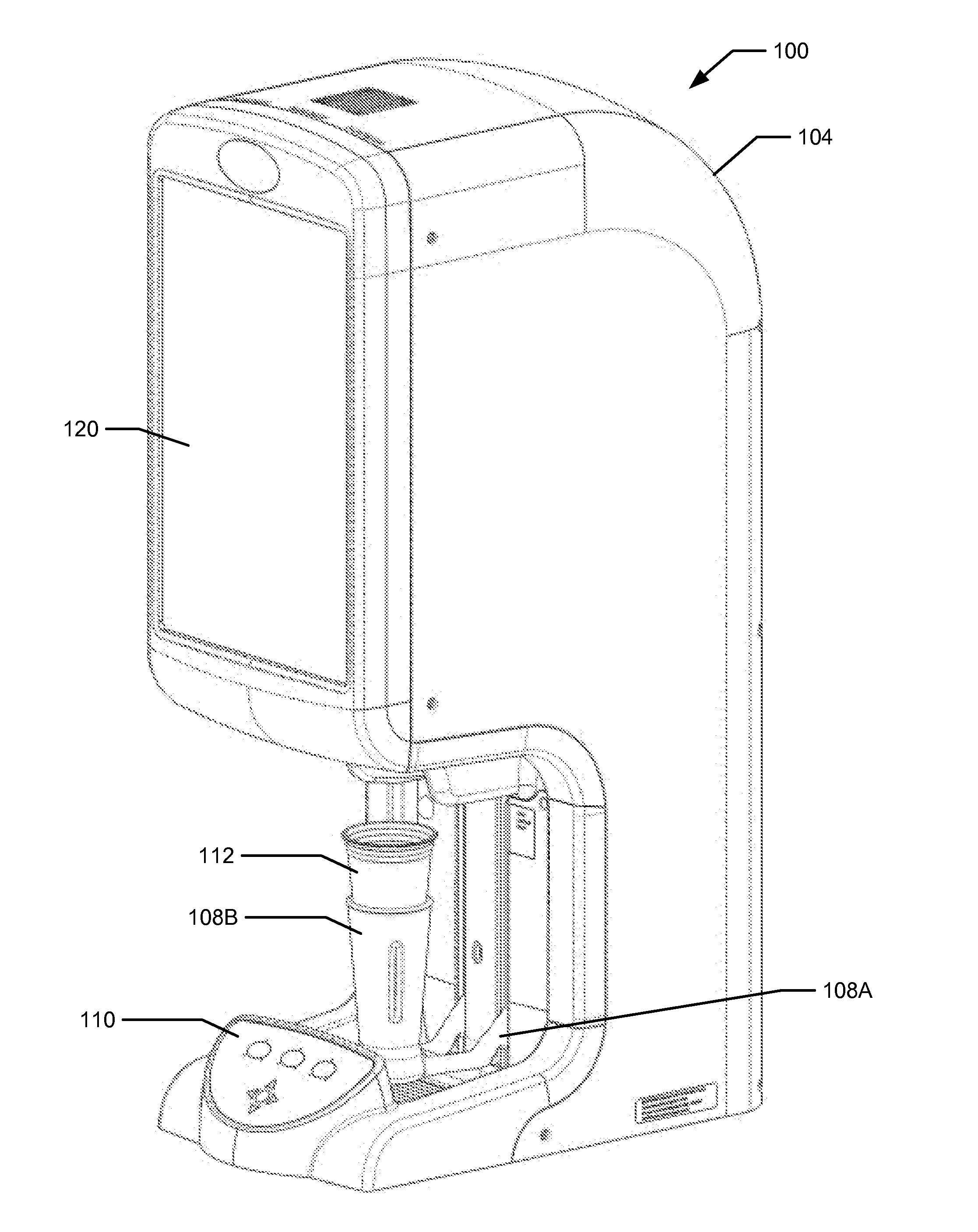

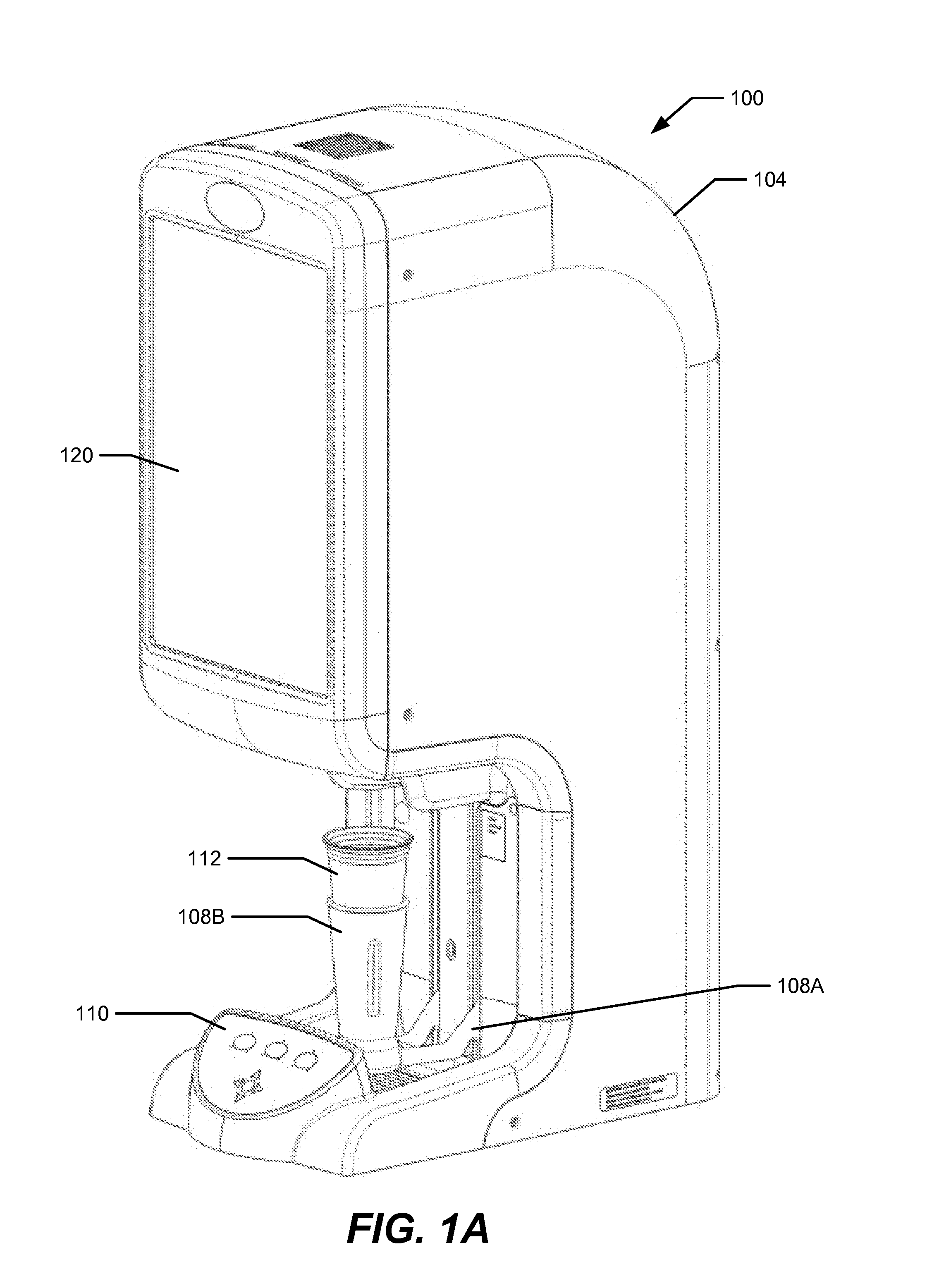

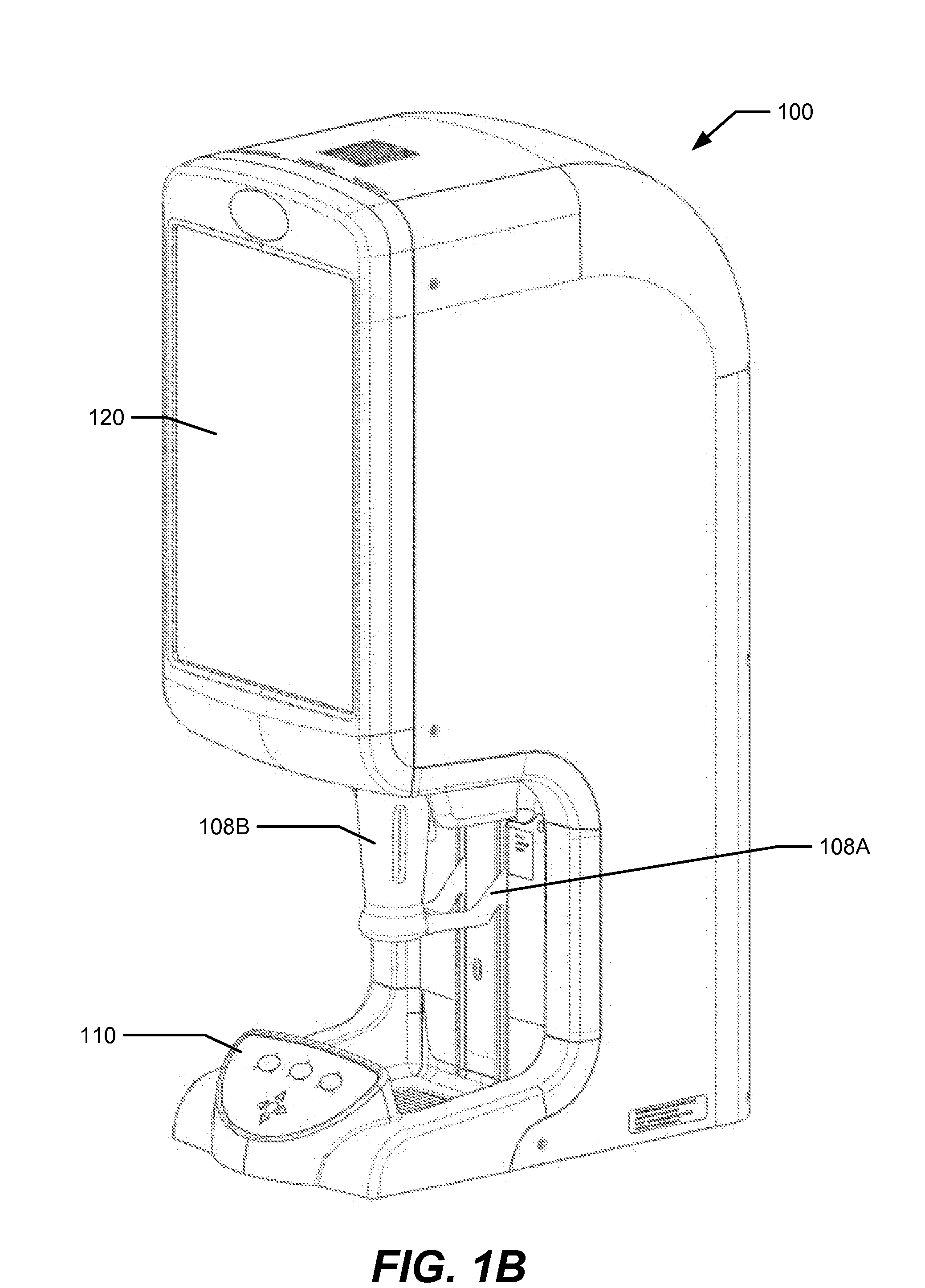

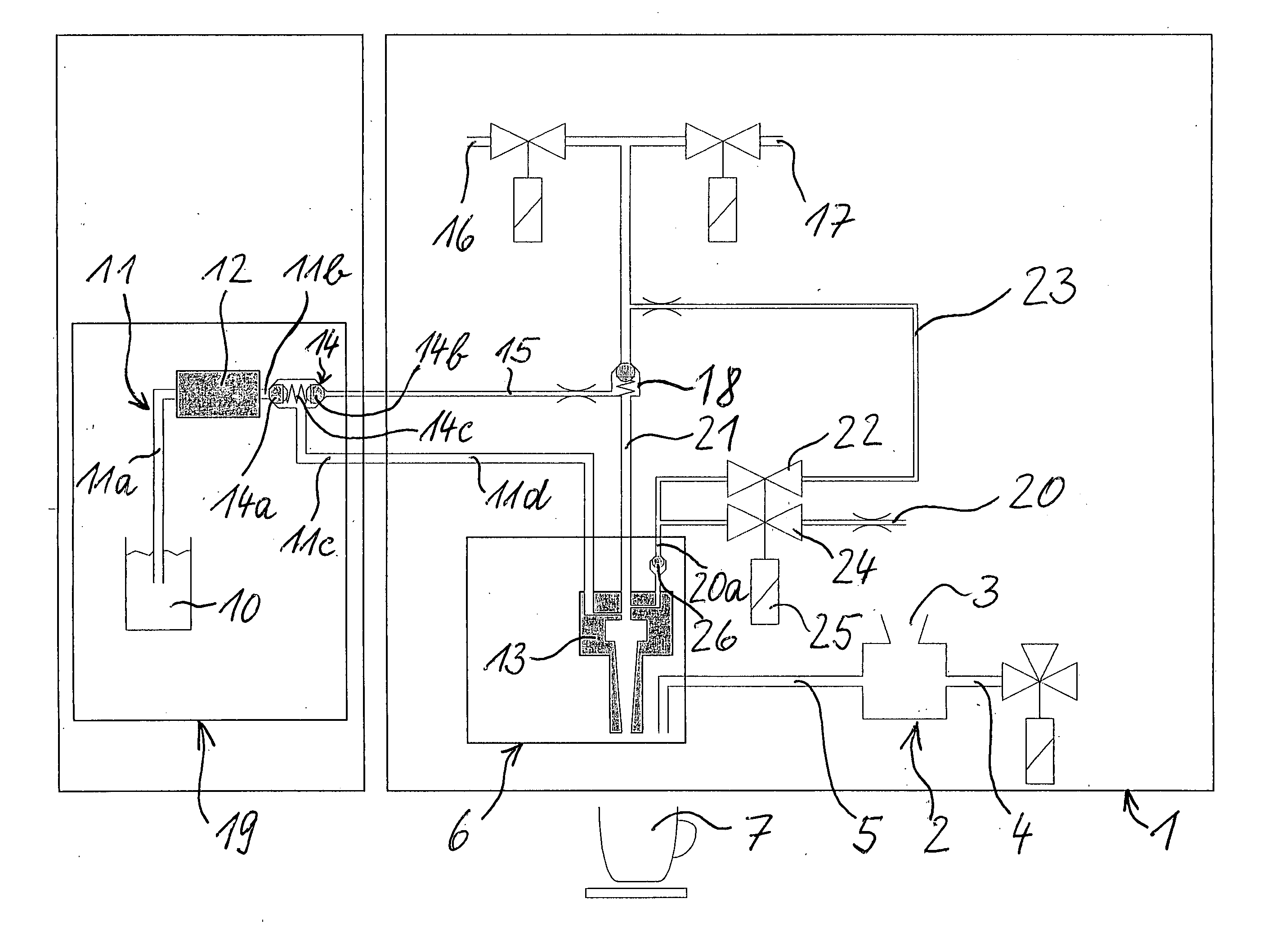

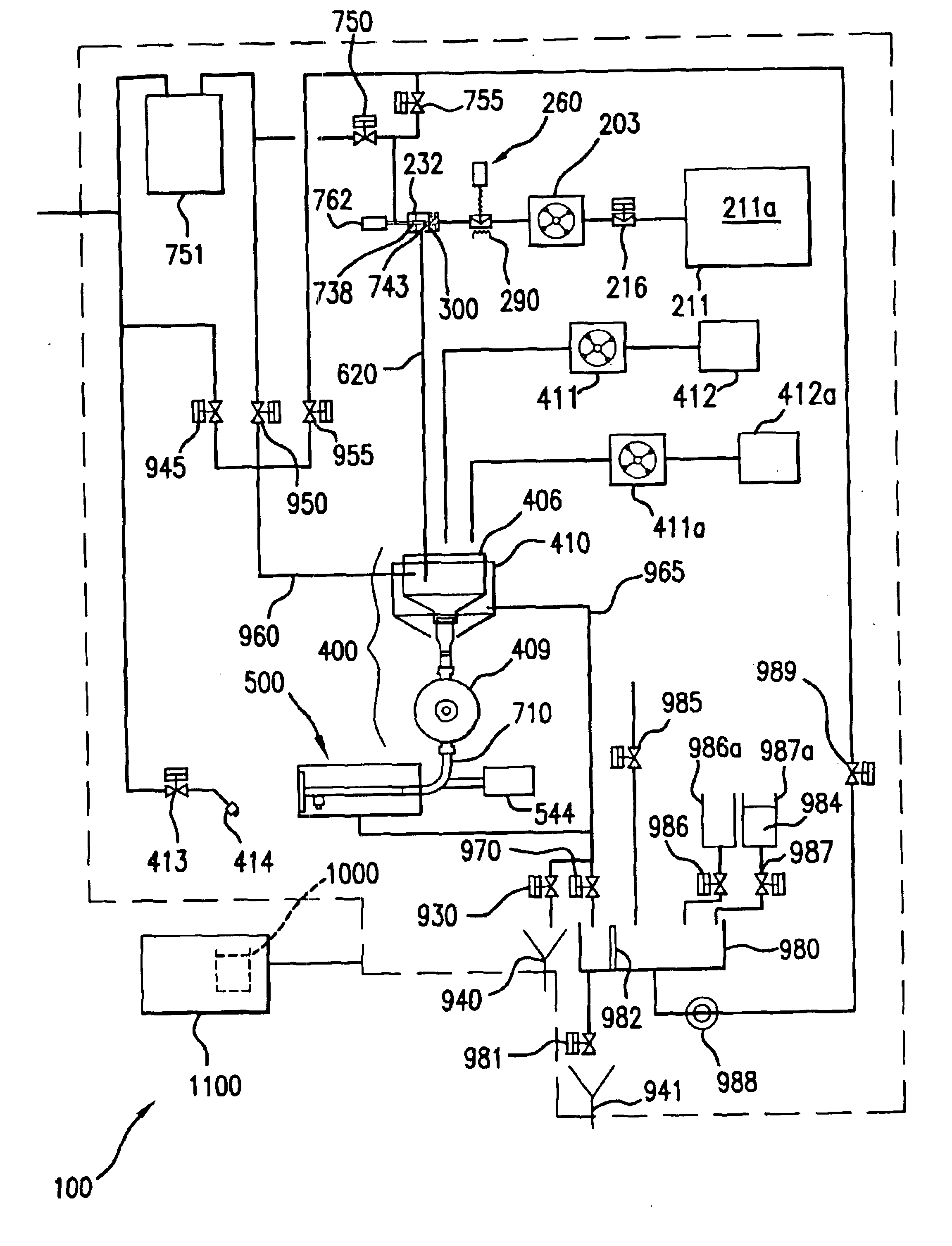

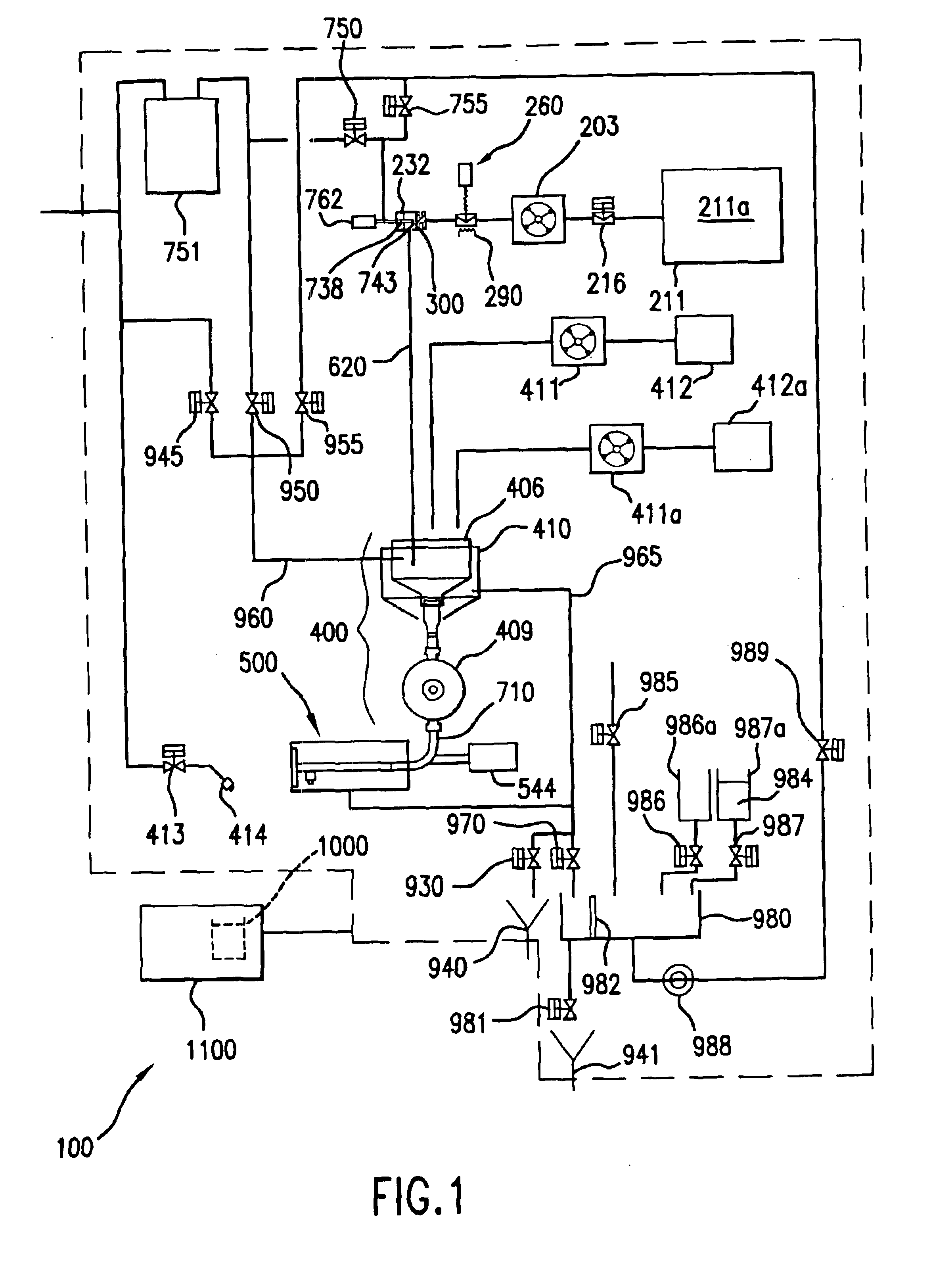

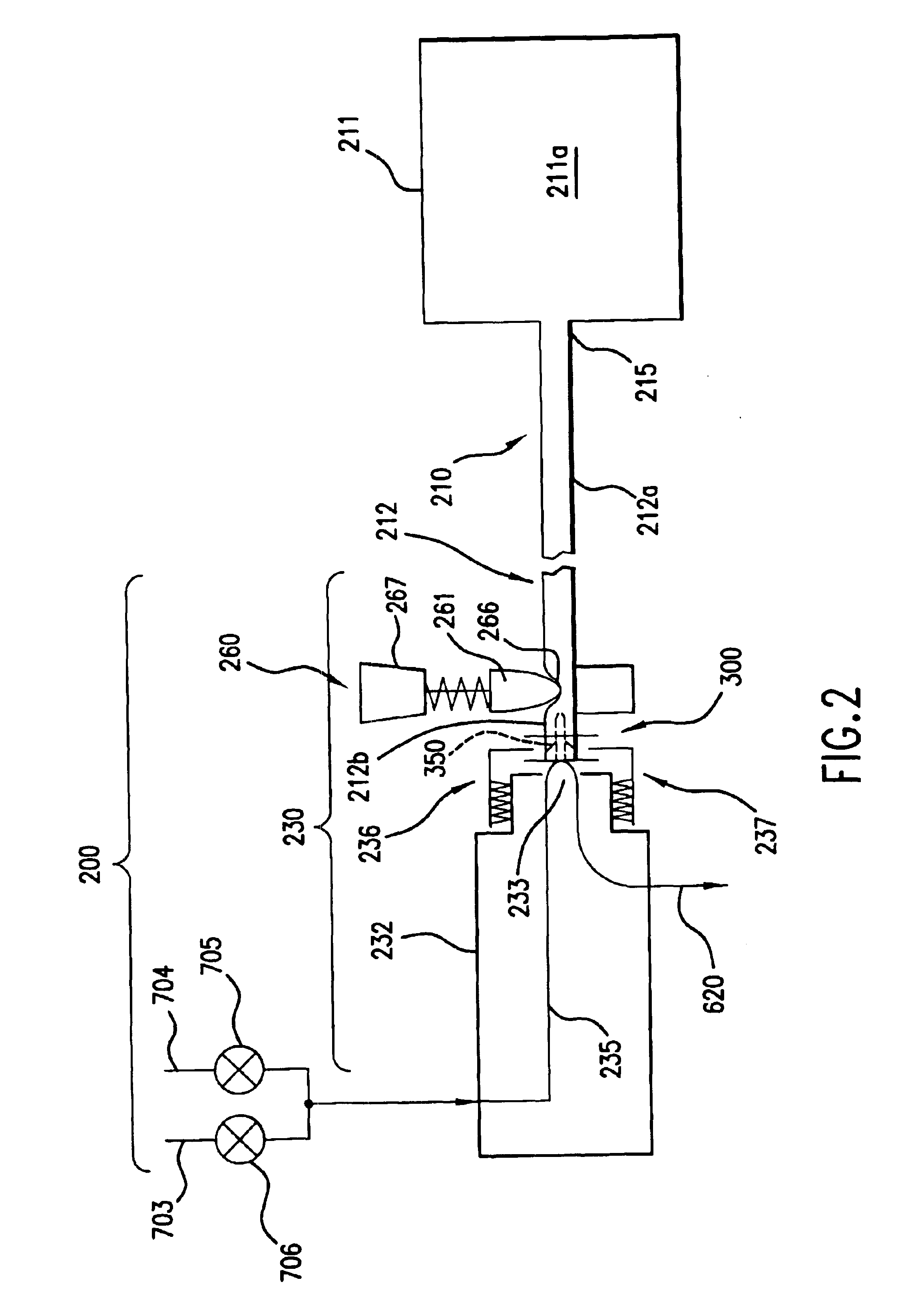

Clean-in-place automated food or beverage dispenser

The invention relates to an automated food product dispenser comprising an interface connection configured to establish a supply of a milk-based fluid from a reservoir (for example, a container or a bag), a mixing device configured to receive the milk-based fluid and prepare a milk based product, a nozzle in fluid association with the mixing device for dispensing the milk based product, a product flowpath configured for directing the milk based product to flow from the interface connection through the mixing device to the nozzle, and a clean-in-place flowpath assembly located in the dispenser and comprising a supply of cleaning or sanitizing fluid and a flowpath which is configured to deliver the cleaning or sanitizing fluid to or through the product flowpath. The invention also relates to a method of using and machine readable program for controlling the automated food product dispenser of the invention.

Owner:NESTEC SA

No waste cooking oven with multiple cooking functions

A multifunctional cooking oven for the preparation of food products including a cooking chamber, racks within the cooking chamber to support products to be prepared in the oven and a primary convection heat source. There is a drainable collection pan positioned below the racks to collect by-products rendered from the food products during preparation for later use. A steam source is positioned below the collection pan as well as a flavored smoke generator at the bottom of the preparation chamber. Airflow paths within the preparation chamber allow for the circulation of heat, steam and flavored smoke around the racks. The oven includes a programmable controller to control the primary heat source, the steam source and the flavored smoke generator that is programmed to operate any one of the heat source, the steam source and the flavor generator in any predetermined sequence, and for any predetermined duration of time to provide optimum preparation and flavoring of the products.

Owner:ROBERTSON MICHAEL L

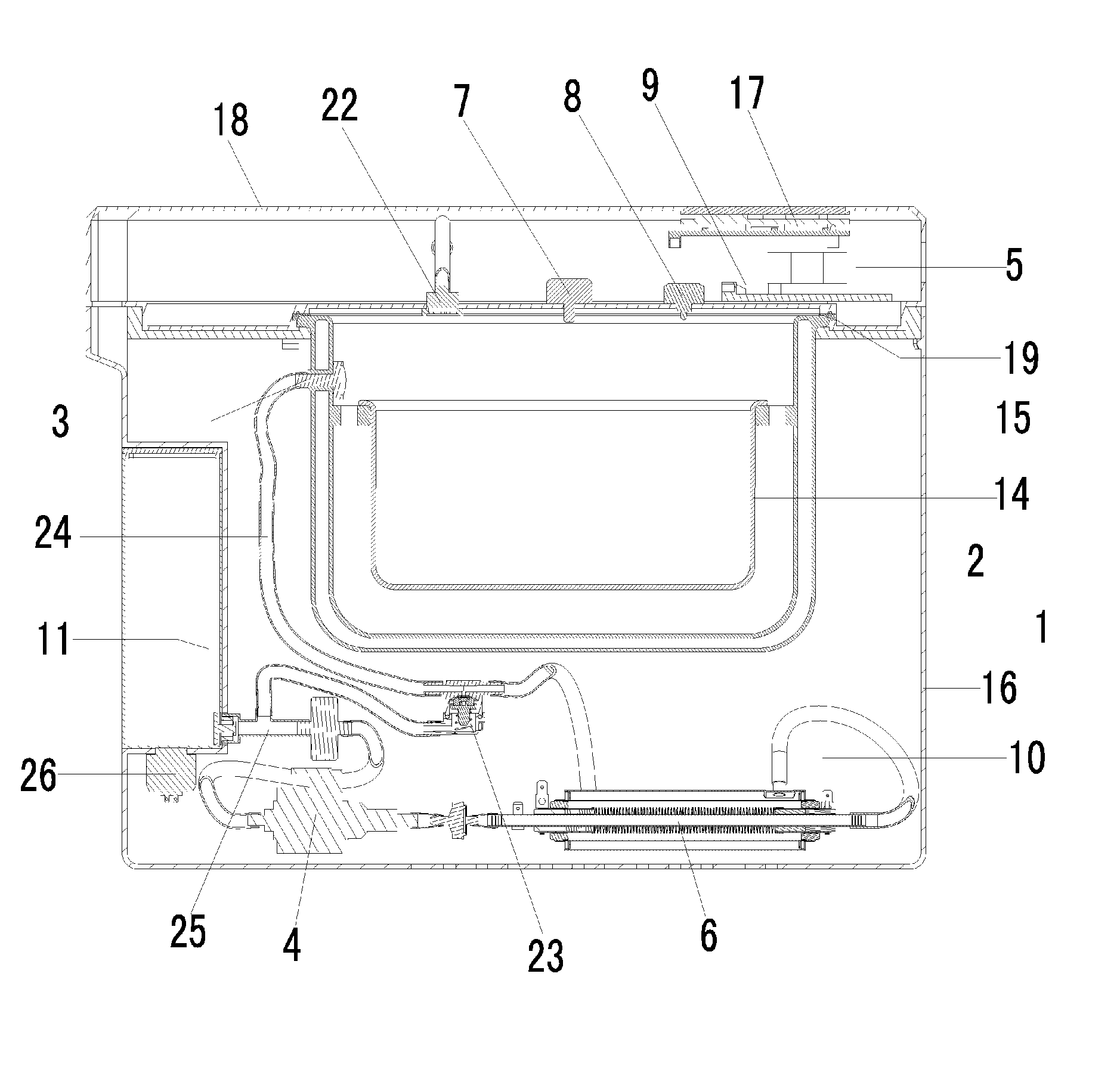

Means for making soybean milk

InactiveUS6247393B1Safe and hygienic useImprove the tightnessJuice extractionRotary stirring mixersMechanical engineeringSoybean meal

The present invention proposes an apparatus for making soybean milk, wherein a cover body is connected to the opening of a container, and a fixing tank is extended form the cover body toward the inside of the container. A motor is installed in the fixing tank. A reaming blade is extended from the motor. A through passage is installed downwards from a position away from the center of the cover through the fixing tank to a cup-shaped component. A fixedly-joining device is installed at the inner edge of the opening of the cup-shaped component to be correspondingly joined with a fixedly-joined device installed at the bottom end of the peripheral surface of the fixing tank. The reaming blade is placed in the cup-shaped component. The periphery of the cup-shaped component is formed to be a filtering net. An electro-thermal tube is connected from the bottom edge of the cover into the container. When soybeans are guided in via the through passage, a small sealing cap is used to cover on the opening of the through passage. After the apparatus is turned on, the soybeans are reamed by the reaming blade, and soybean juice flows into the container while soybean lees is left in the cup-shaped component. After water is added and boiled, the cover is removed and a sealing cap is covered on the container. The sealing cap has a filtering net at a position corresponding to that of the conduct mouth of the container such that soybean can be filtered and poured out.

Owner:CHANG KWEI TANG

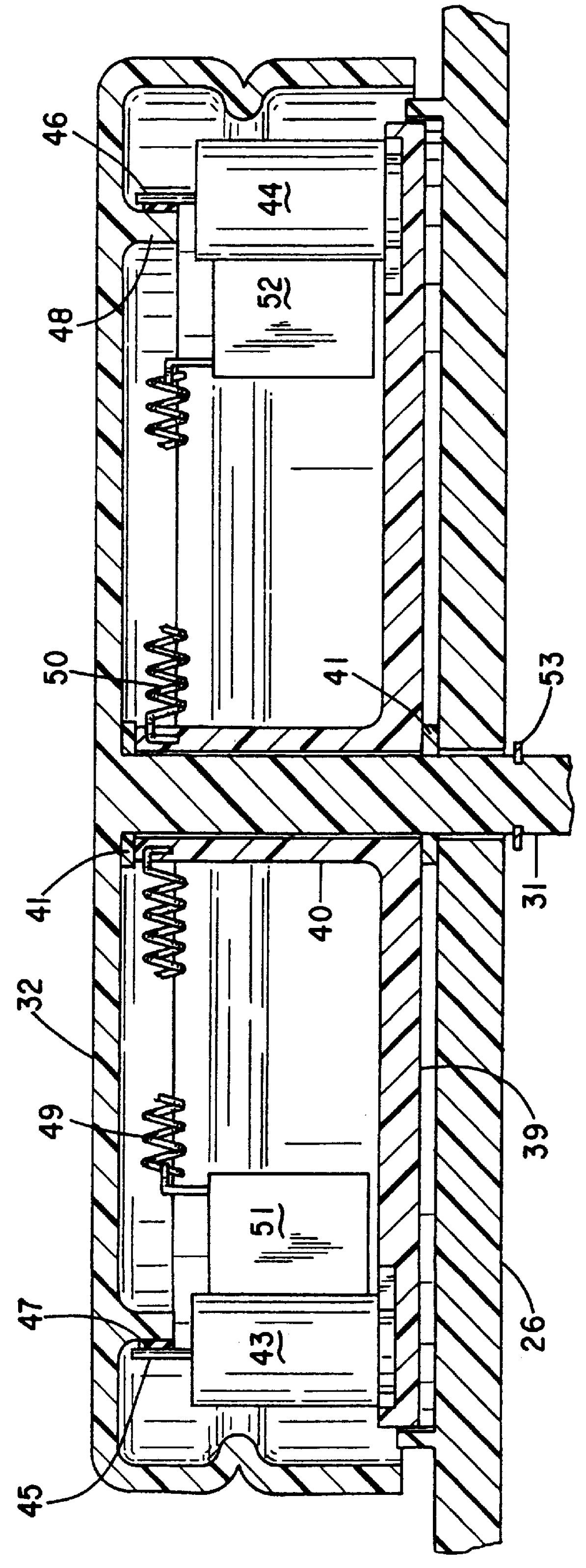

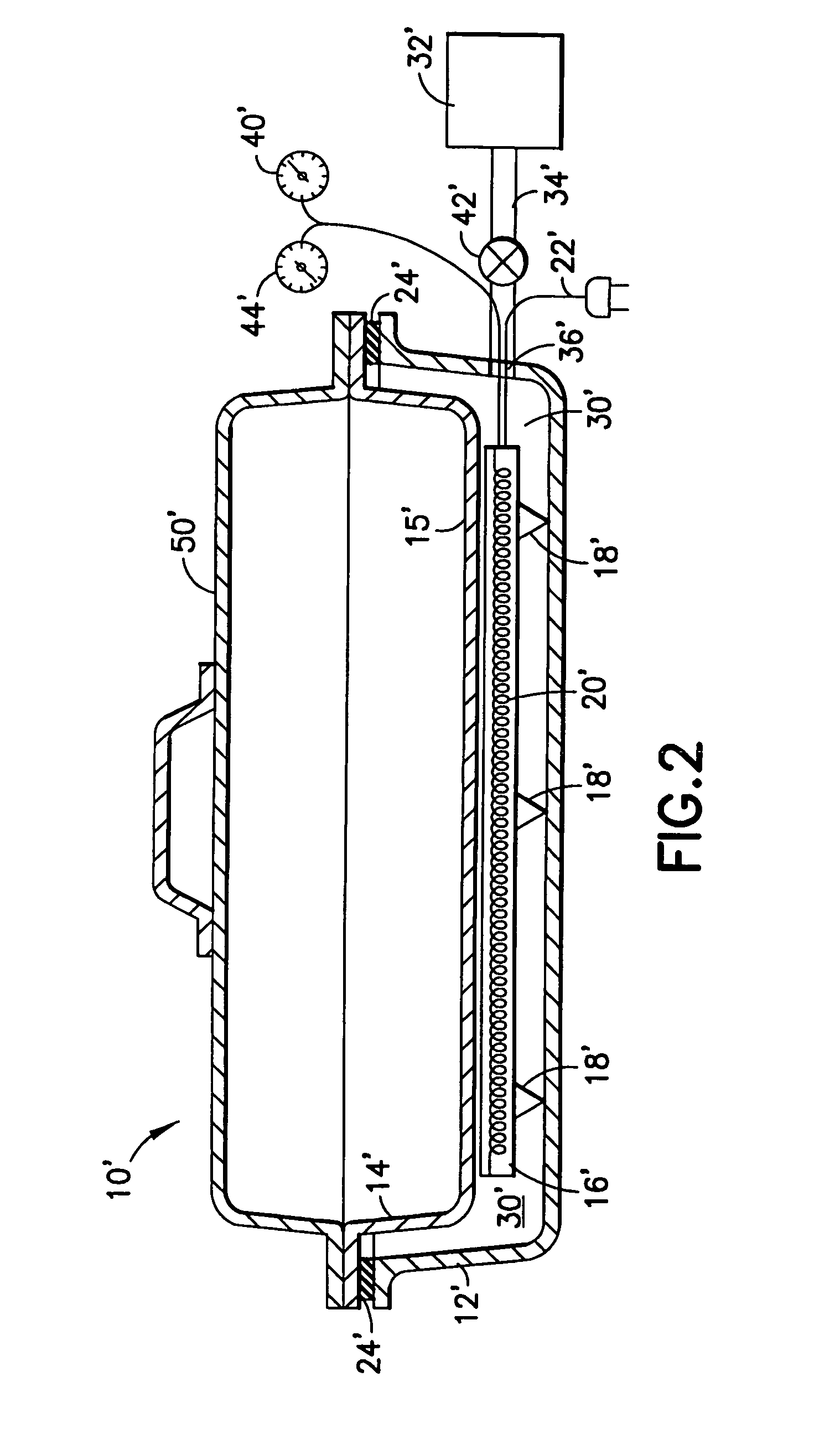

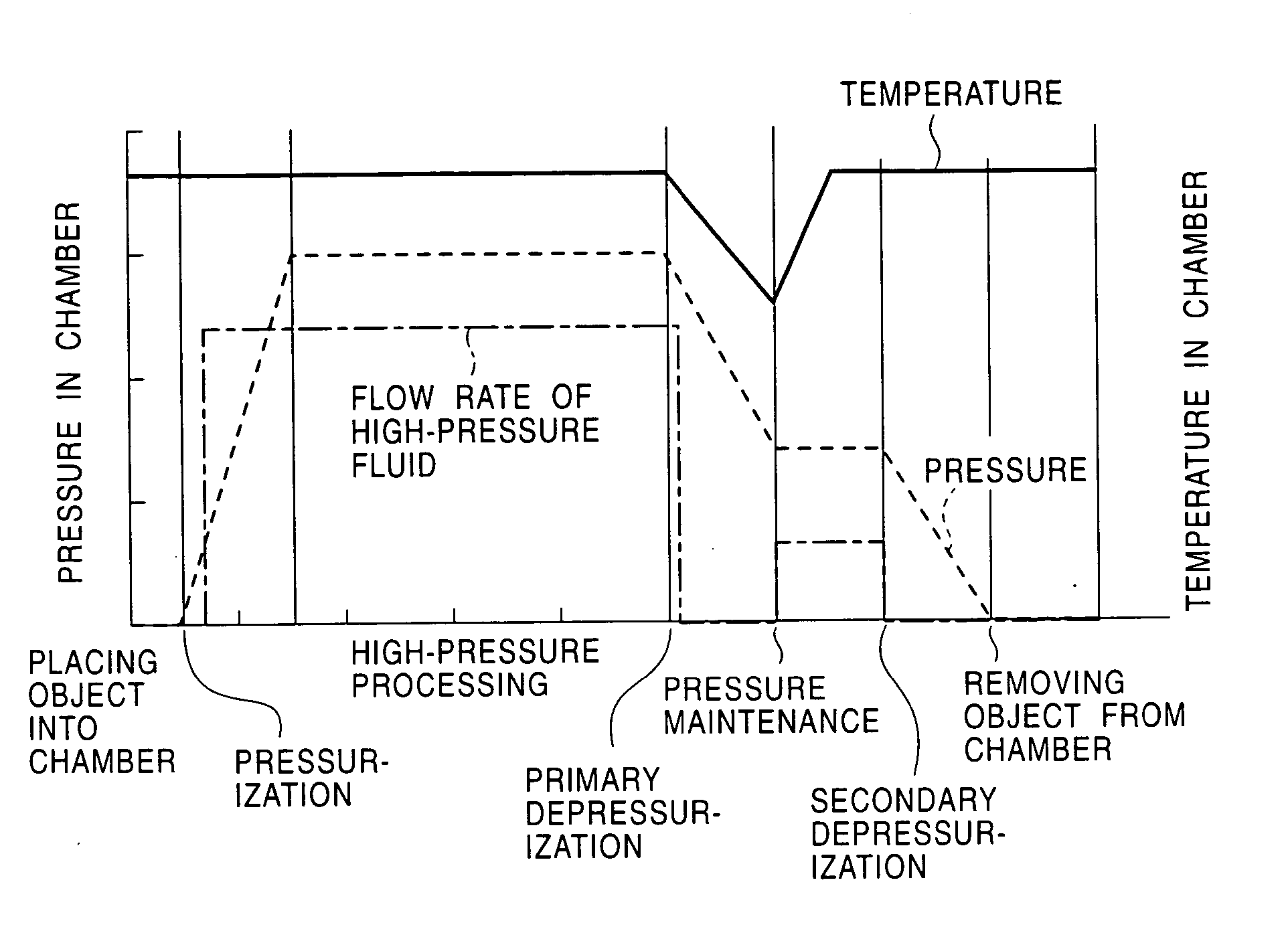

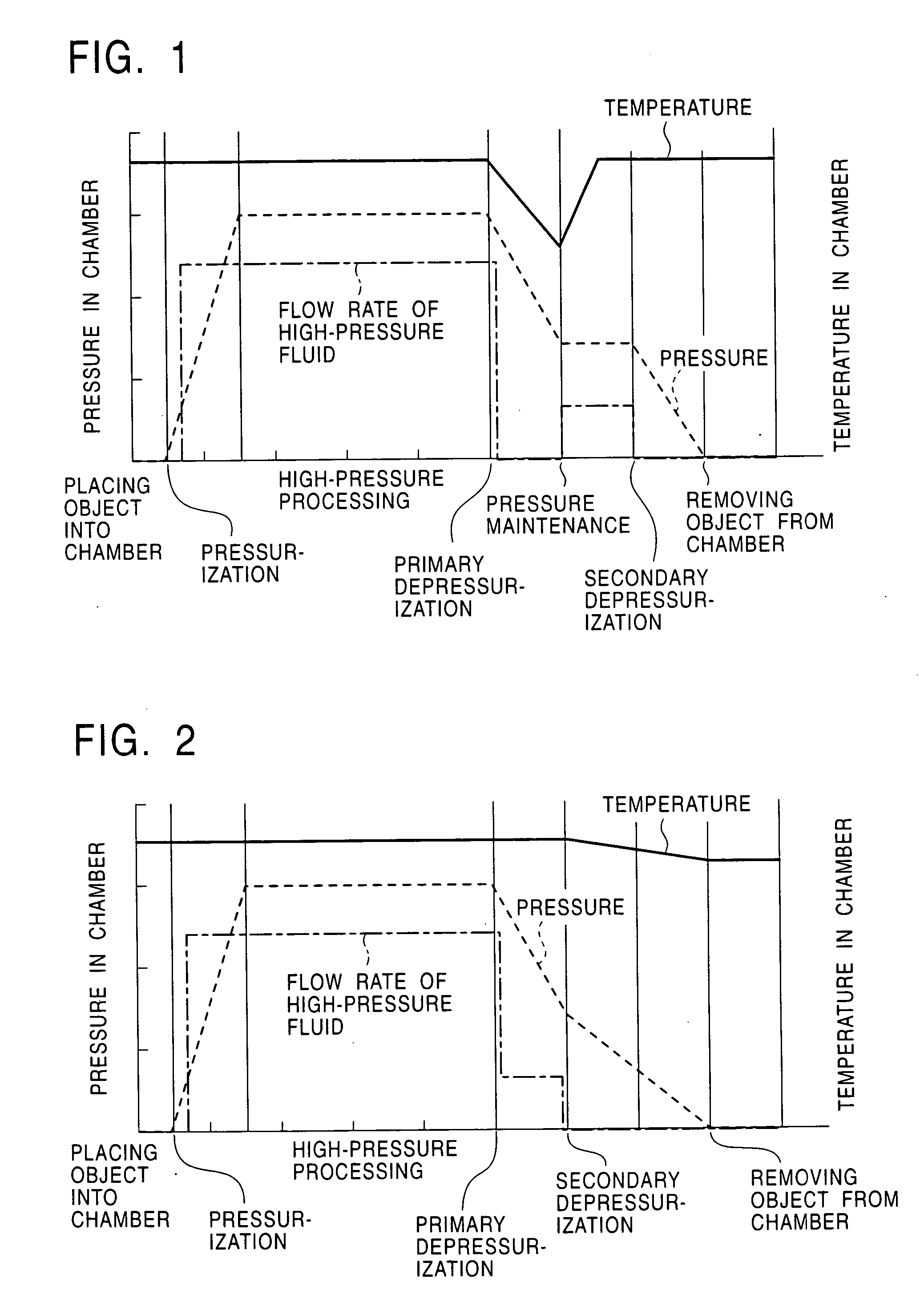

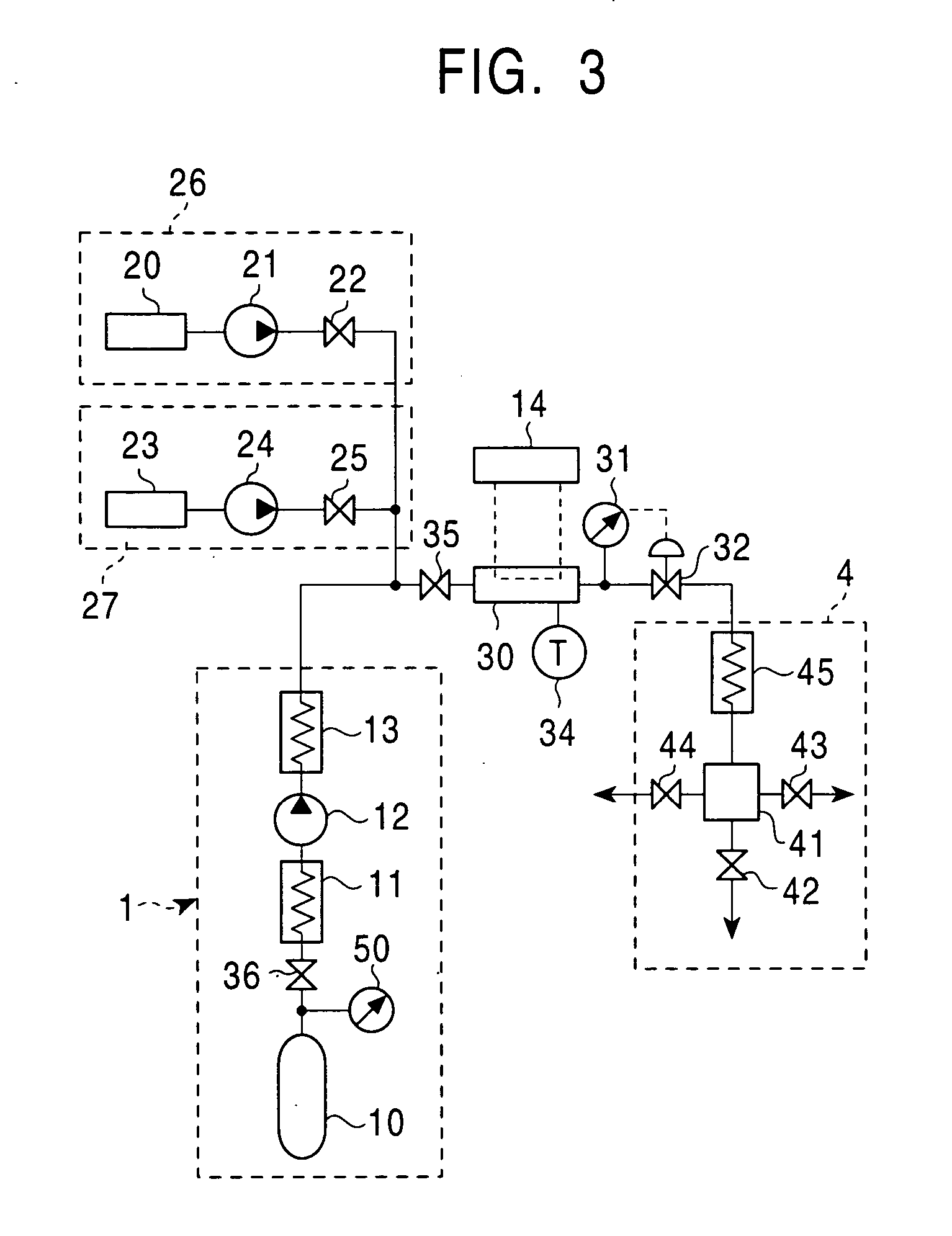

Method for high-pressure processing

InactiveUS20050051194A1Improve production yieldReduce pressureMilk treatmentSemiconductor/solid-state device manufacturingVapor liquidEngineering

An object is subjected to high-pressure processing by bringing at least a high-pressure fluid into contact with the object under pressure in a high-pressure processing chamber, and then the high-pressure processing chamber is depressurized while the temperature in the chamber is controlled to be maintained above a temperature achieved by an adiabatic expansion, the adiabatic expansion starting from the pressure and temperature at the end of the high-pressure processing step. To control in such a way, the temperature in the high-pressure processing chamber is controlled so as to suppress or recover a temperature descent caused by an adiabatic expansion during the depressurizing step. This solves a problem in which the temperature is decreased to the vapor-liquid phase coexistence region or a region in which a solid is deposited.

Owner:KOBE STEEL LTD

Garment steamer with improved heater and variable steam output

InactiveUS20050150261A1Constant deliveryFacilitate easy fillingHeating or cooling apparatusSteam generation heating methodsEngineeringSteam engine

A steamer for steaming and / or steam cleaning an object. The steamer includes a reservoir for containing a liquid therein, a pressurized boiler system for generating steam under pressure from a portion of the liquid in the reservoir, a thermostatic control device for controlling a flow rate of the liquid delivered from the reservoir to the pressurized boiler system, and at least one steam output discharge port having a variable aperture size in fluid communication with the output of the pressurized boiler system.

Owner:CONAIR CORP

Heating cooker having a steam generating unit

Owner:SAMSUNG ELECTRONICS CO LTD

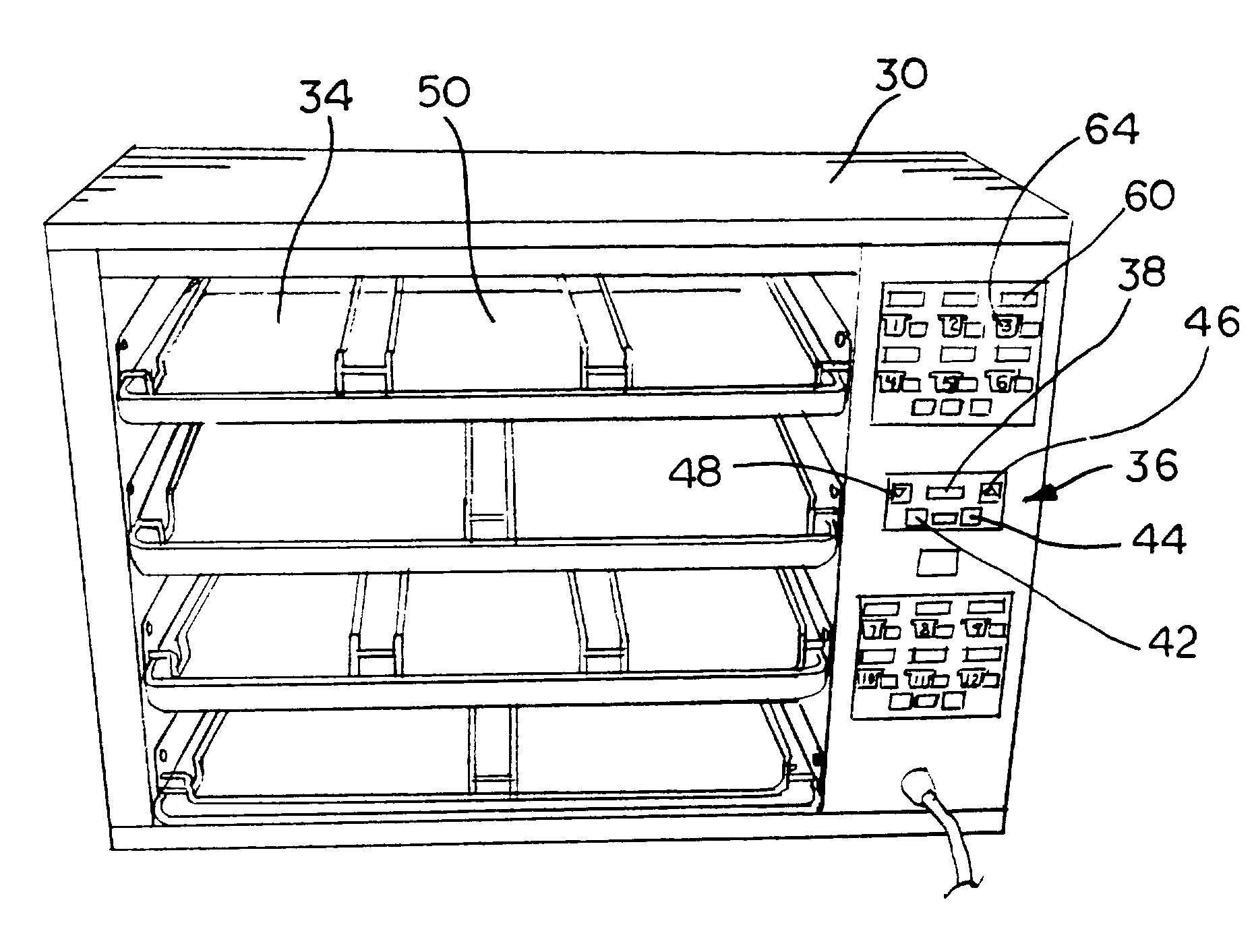

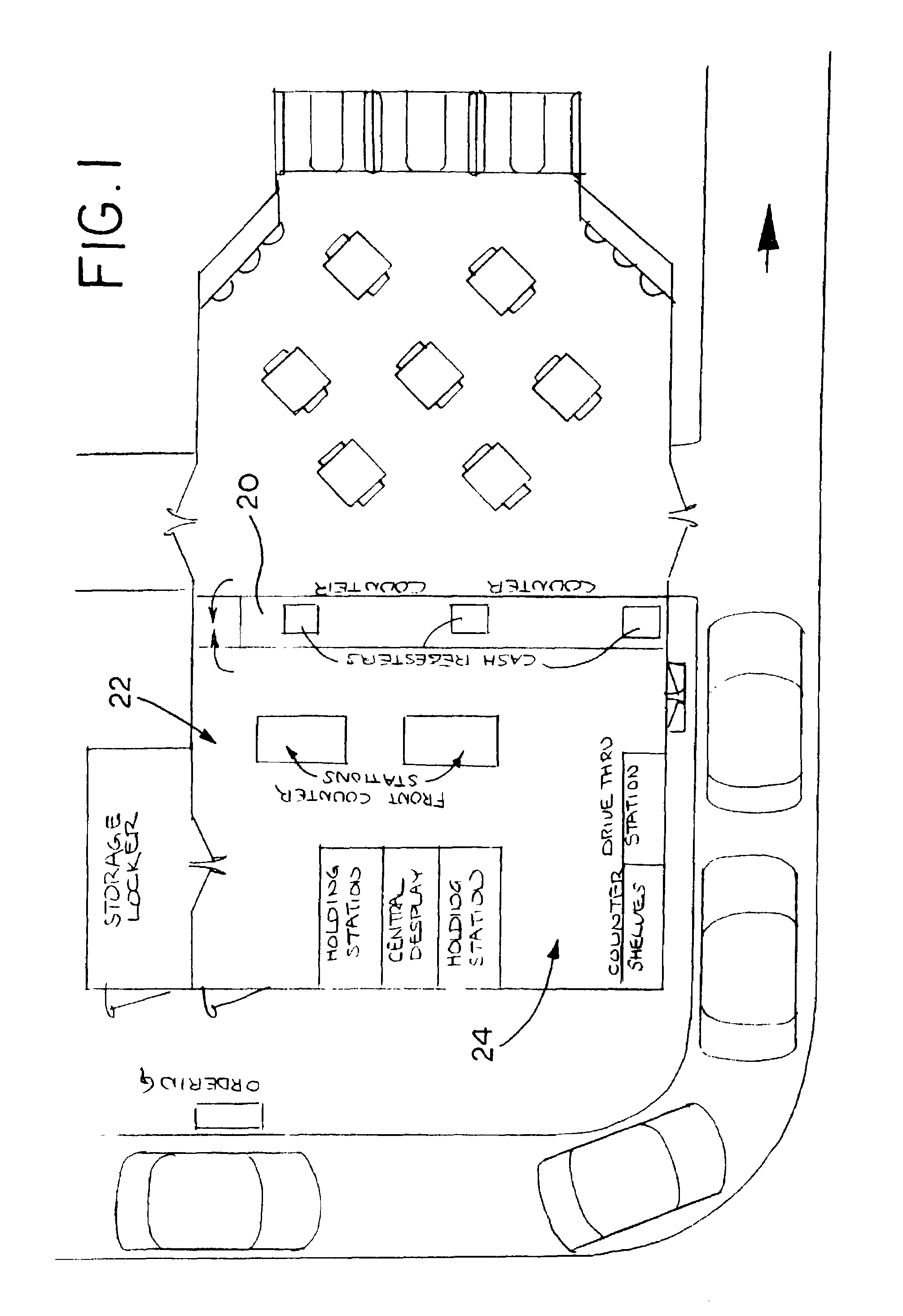

Food product timing system

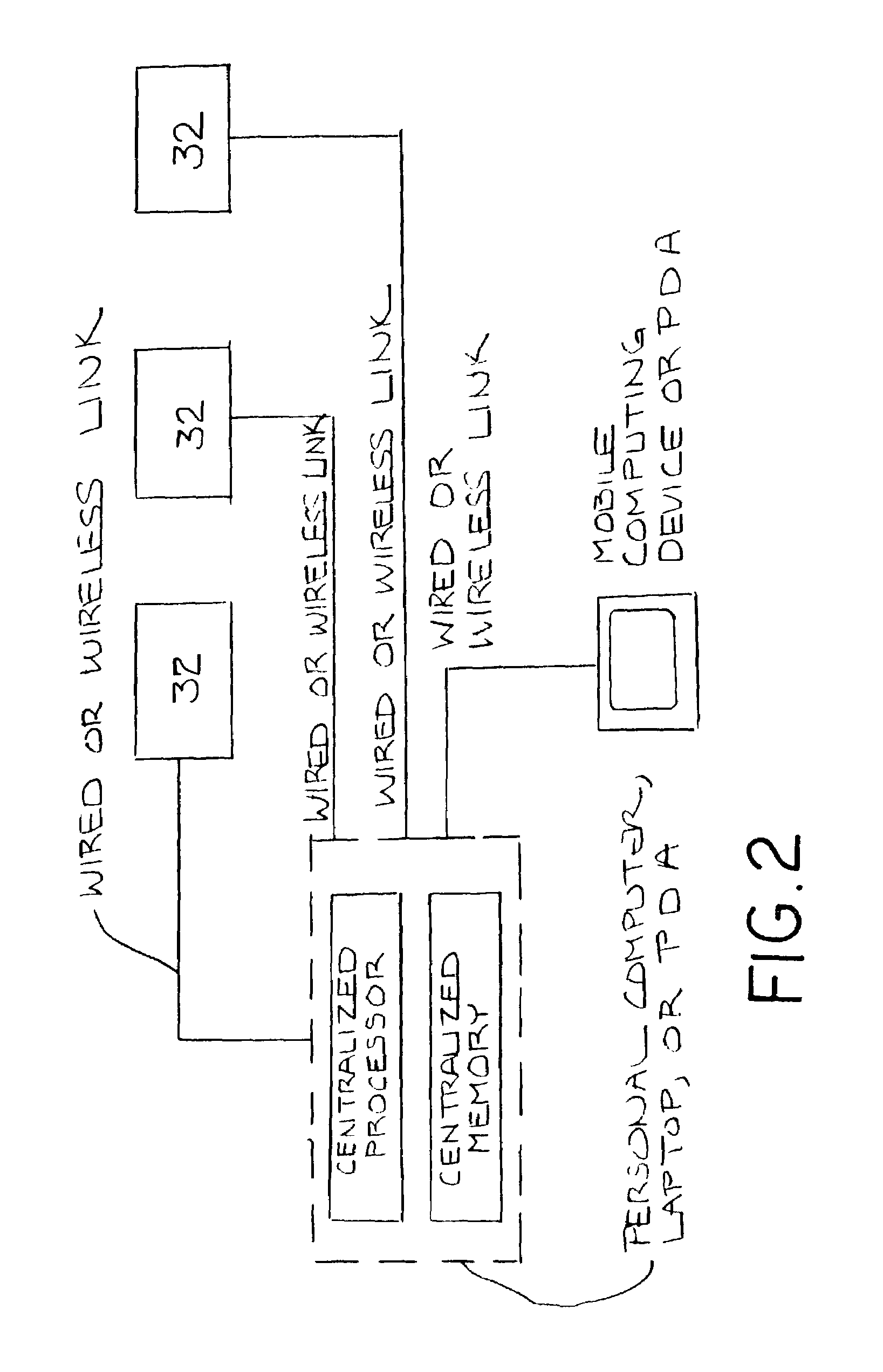

A food timing system is disclosed that includes a number of timer modules associated with food holding devices in a restaurant. The timer modules are connected in a network for communicating information about the food being held in food holding compartments of the food holding devices. Each timer module includes a plurality of timers, with each timer being associated with a food holding compartment of a food holding device. The timers measure the holding time of food in each food holding compartment and are capable of transferring the holding time to another timer when the food is transferred to a holding compartment associated with the other timer.

Owner:MARMON FOODSERVICE TECH INC

Method of steam cooking

Owner:WHIRLPOOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com