Patents

Literature

214 results about "Clean-in-place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clean-in-place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. Up to the 1950s, closed systems were disassembled and cleaned manually. The advent of CIP was a boon to industries that needed frequent internal cleaning of their processes. Industries that rely heavily on CIP are those requiring high levels of hygiene, and include: dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics.

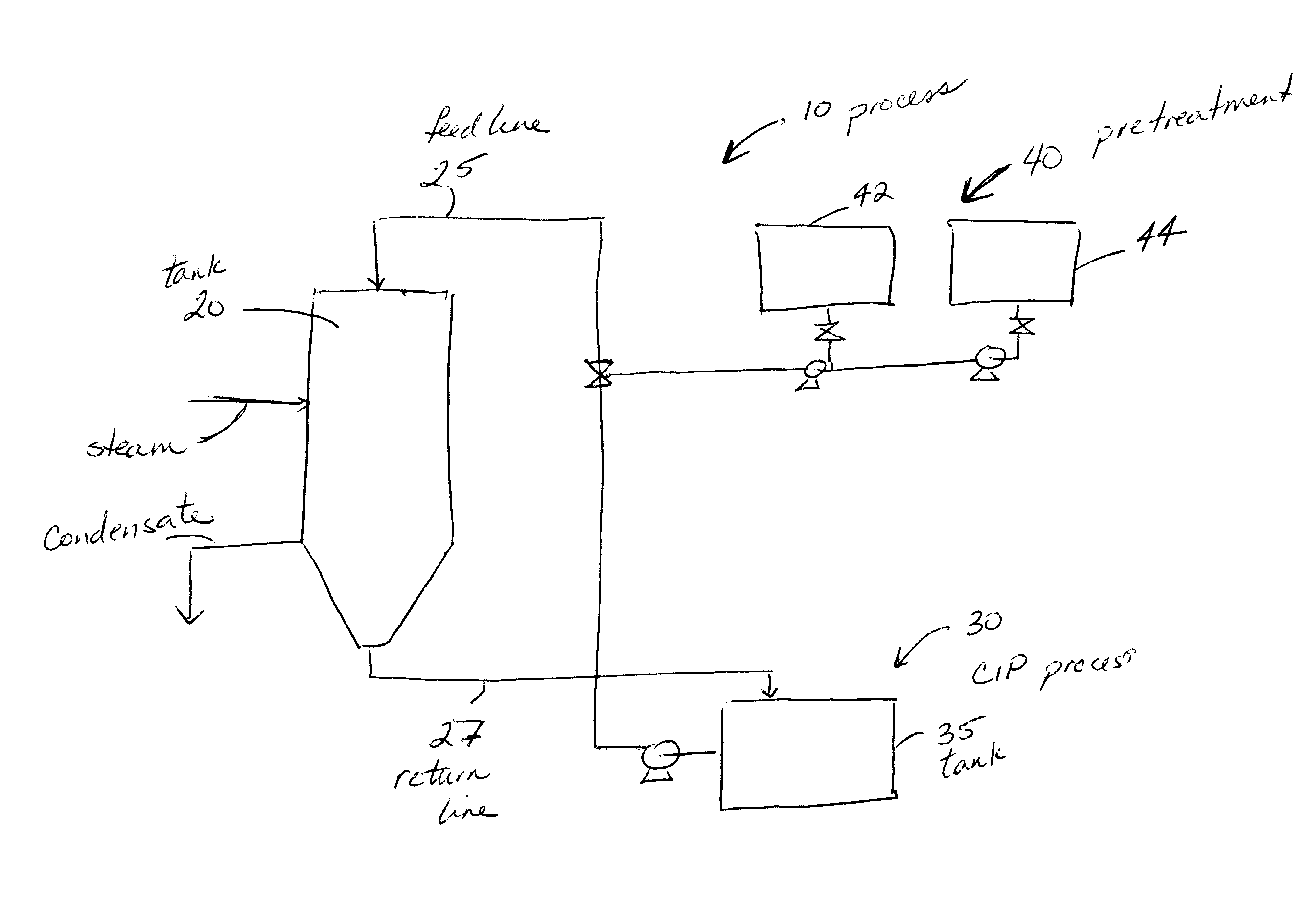

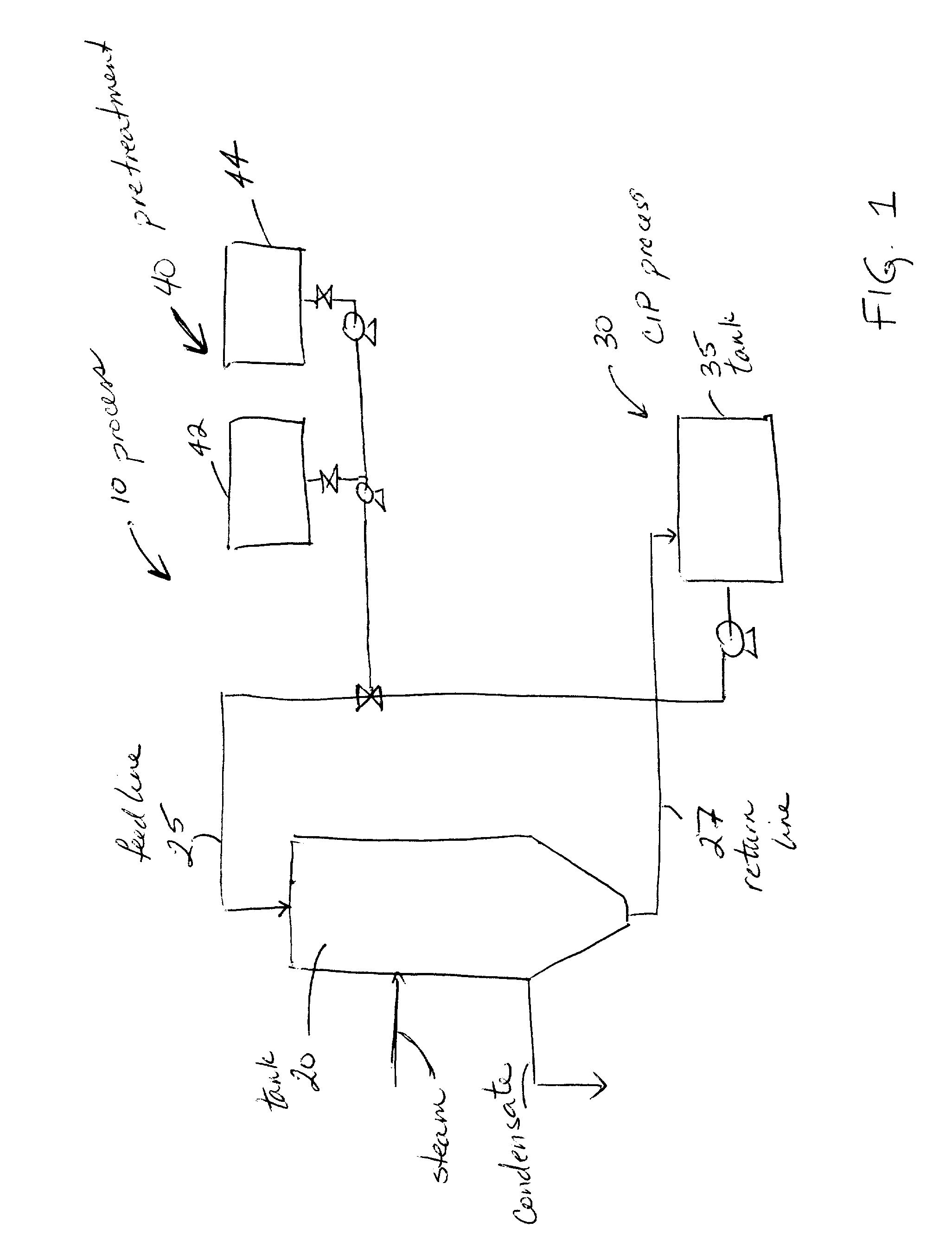

Methods for cleaning industrial equipment with pre-treatment

InactiveUS20080105282A1The result is validHigh degree of softeningSurface-active detergent compositionsNon-surface-active detergent compositionsAdditive ingredientIndustrial equipment

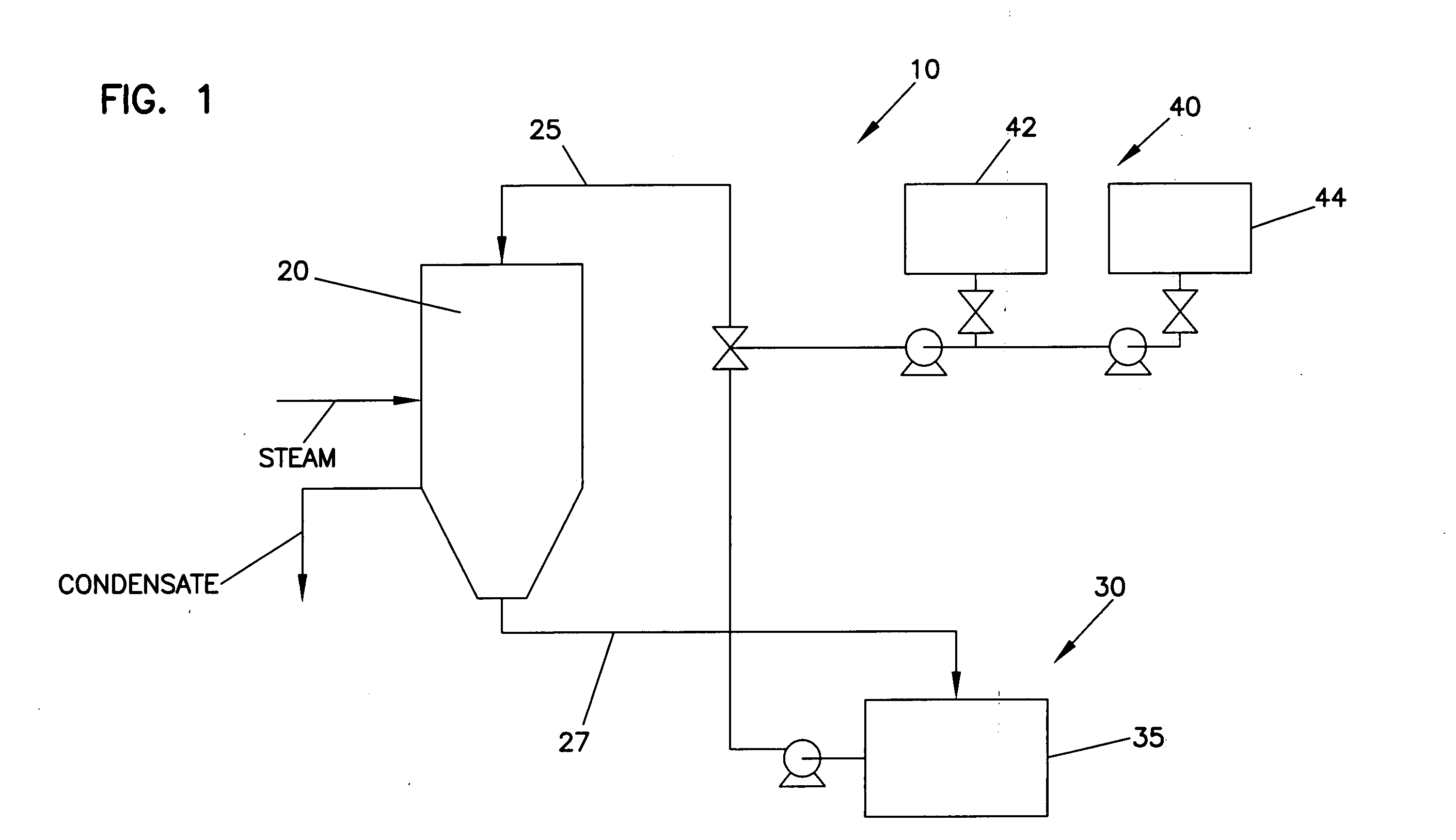

A method of cleaning equipment such as heat exchangers, evaporators, tanks and other industrial equipment using clean-in-place procedures and a pre-treatment solution prior to the conventional CIP cleaning process. The pre-treatment step improves the degree of softening of the soil, and thus facilitates its removal. The pre-treatment solution can be a strong acidic solution, a strong alkaline solution, or comprise a penetrant. A preferred strong acidic solution is an acid peroxide solution. In some embodiments, the pre-treatment may include no strong alkali or acid ingredient; rather, the penetrant provides acceptable levels of pre-treatment.

Owner:ECOLAB USA INC

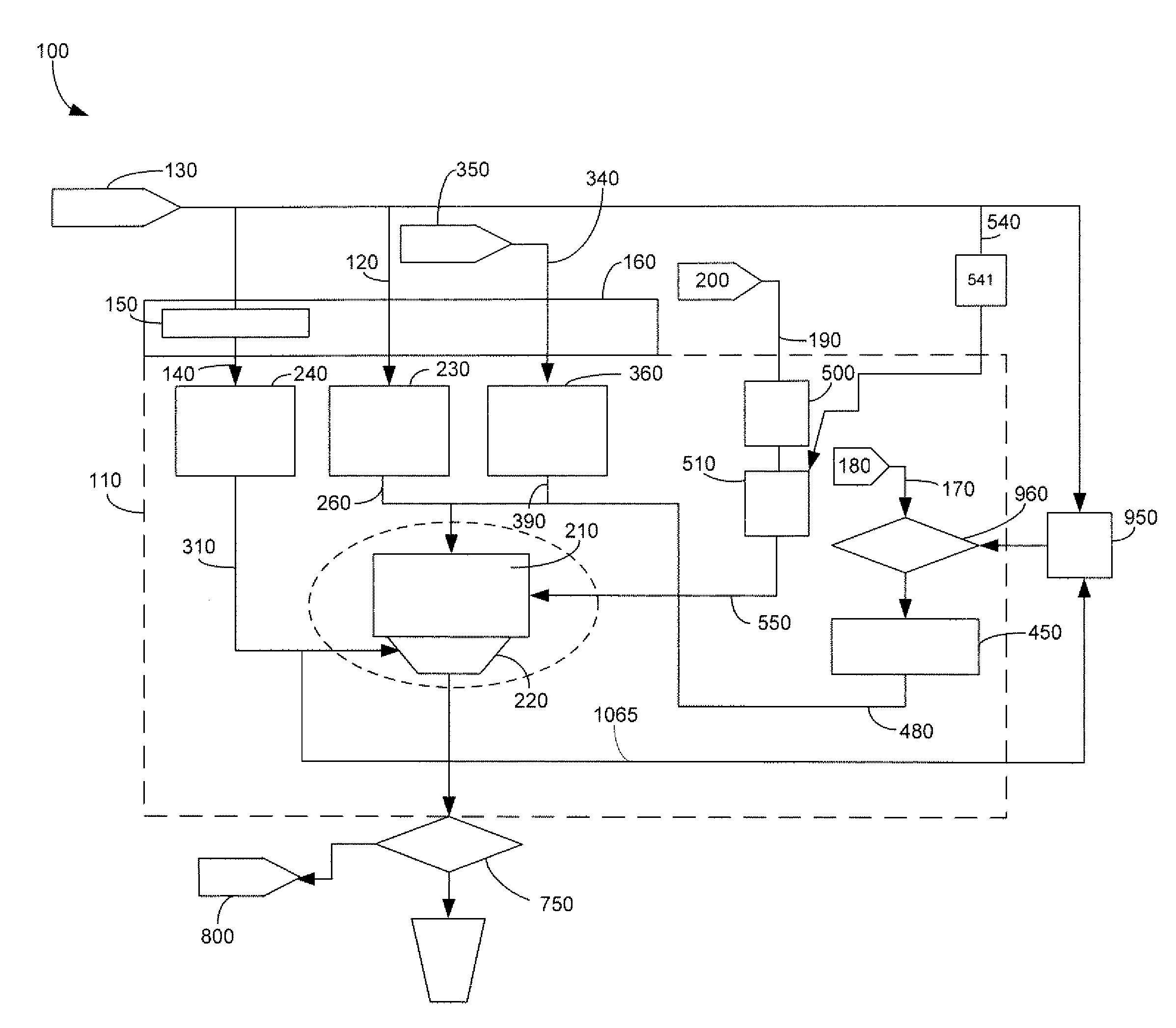

System and method for generation of point of use reactive oxygen species

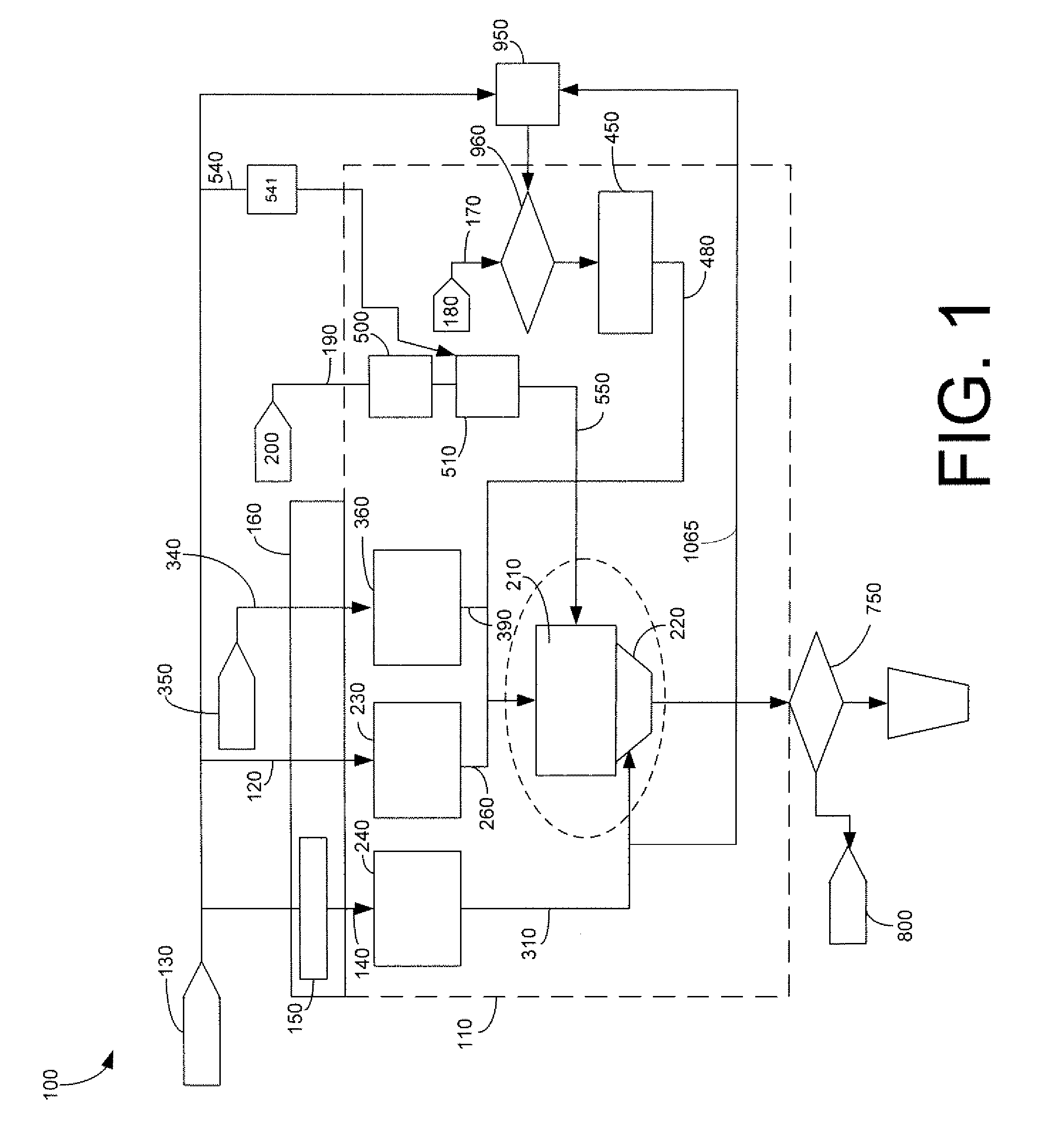

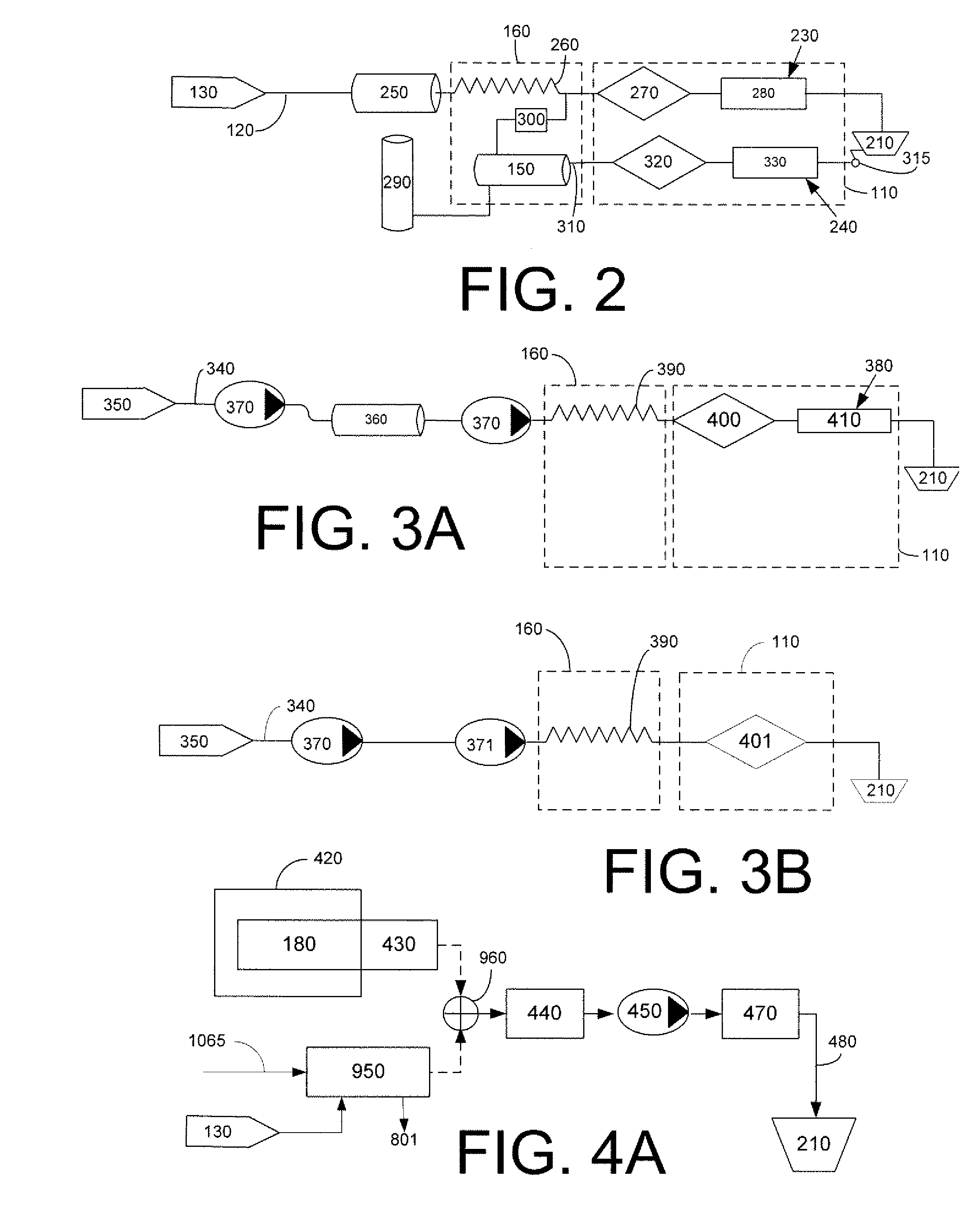

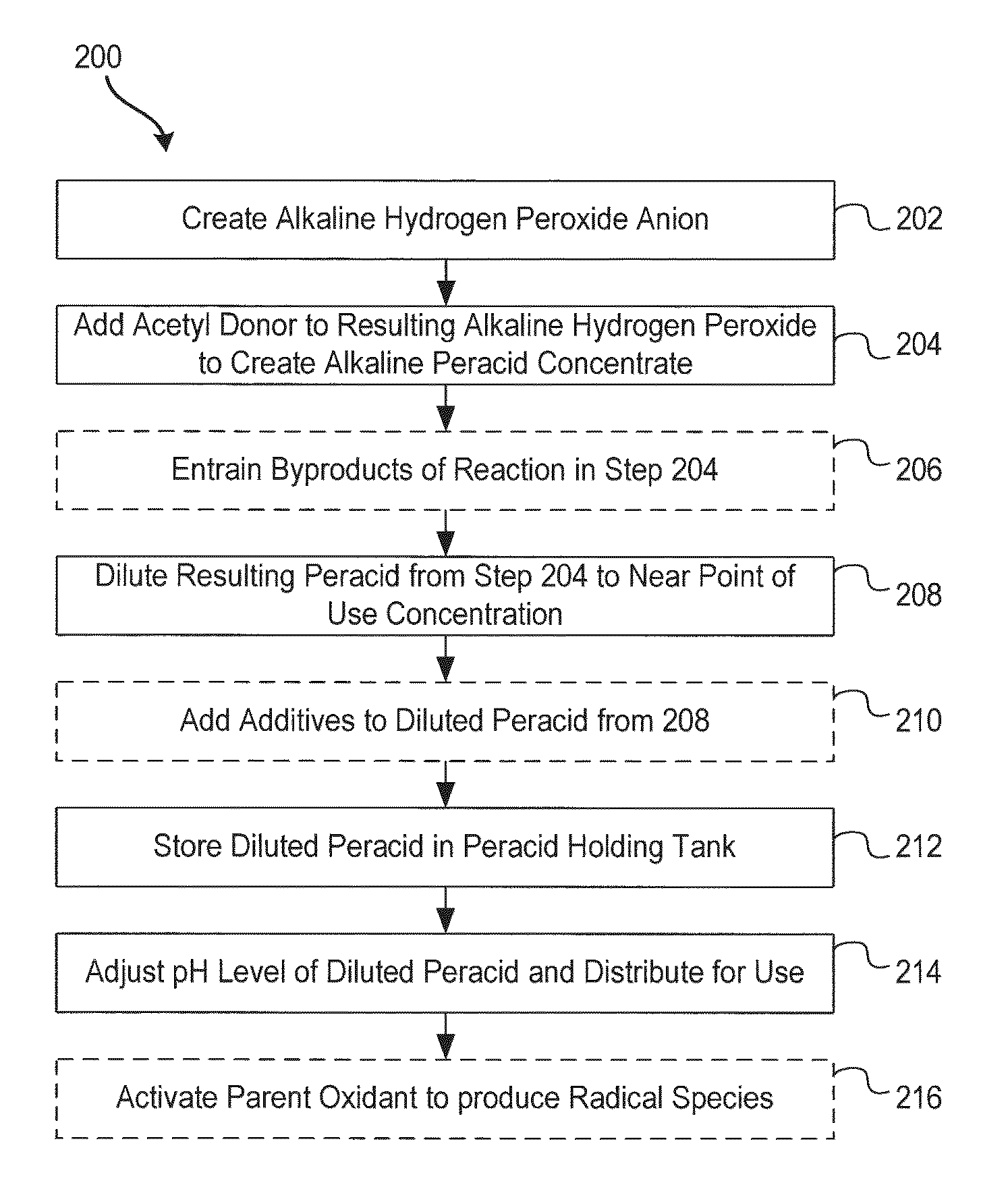

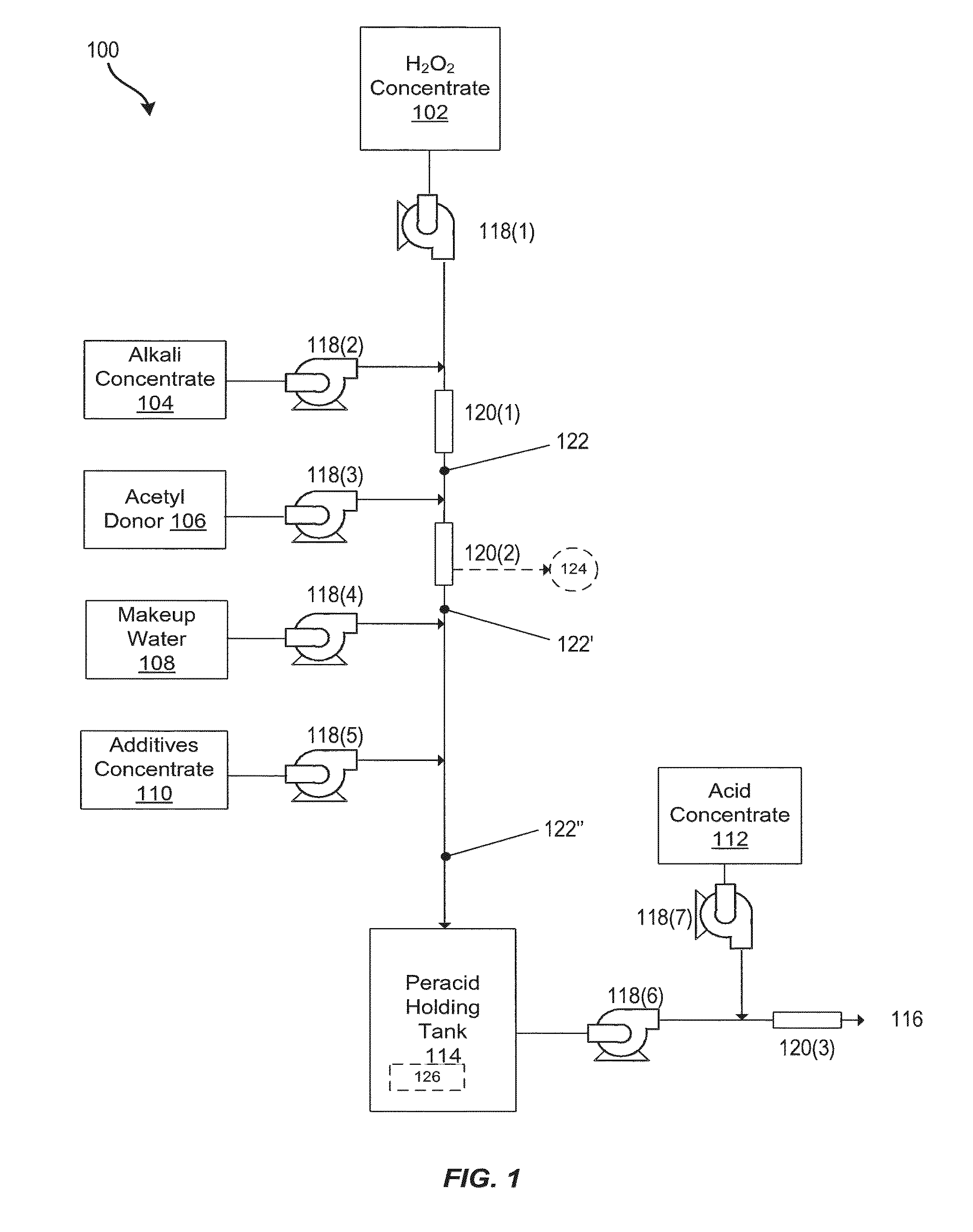

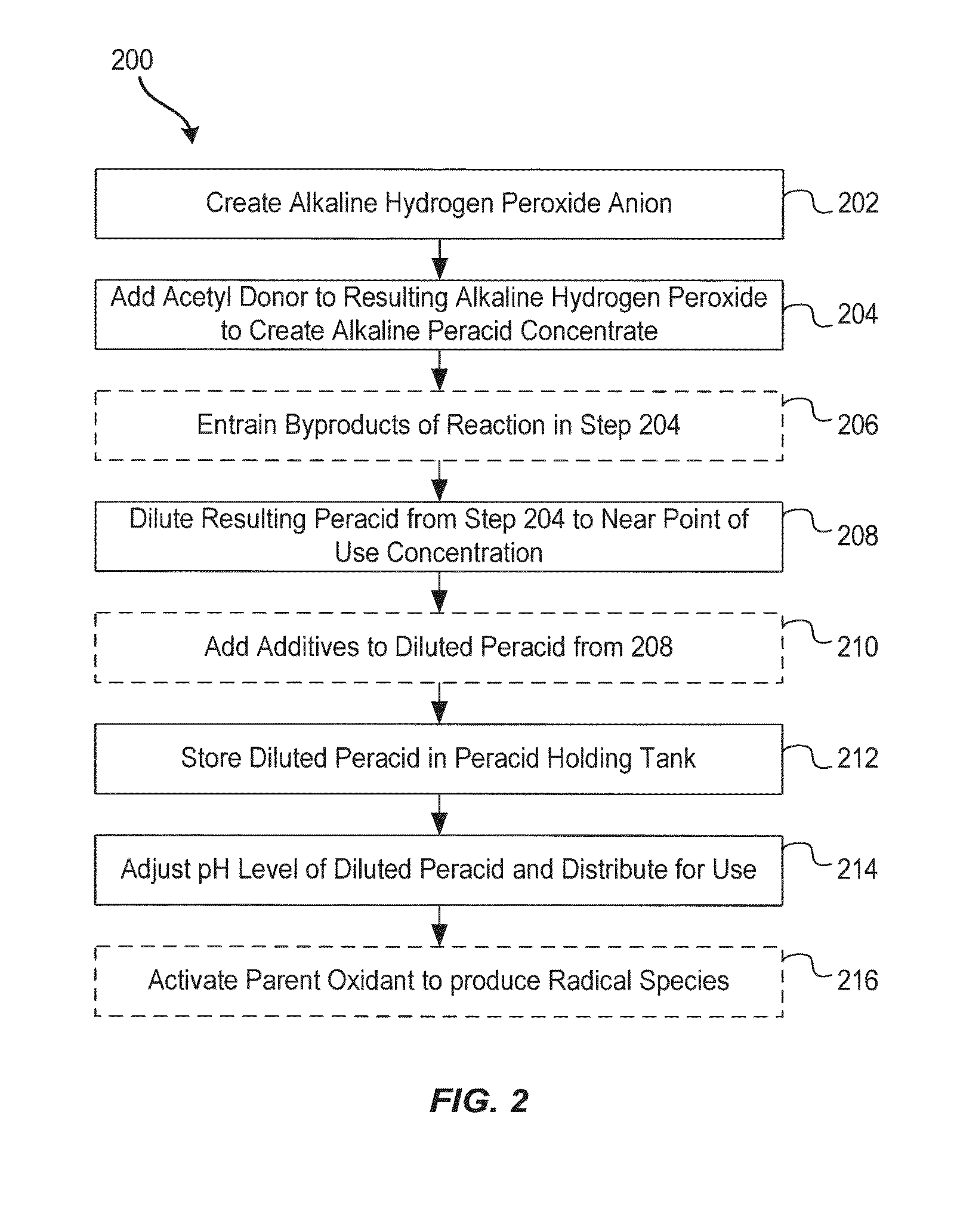

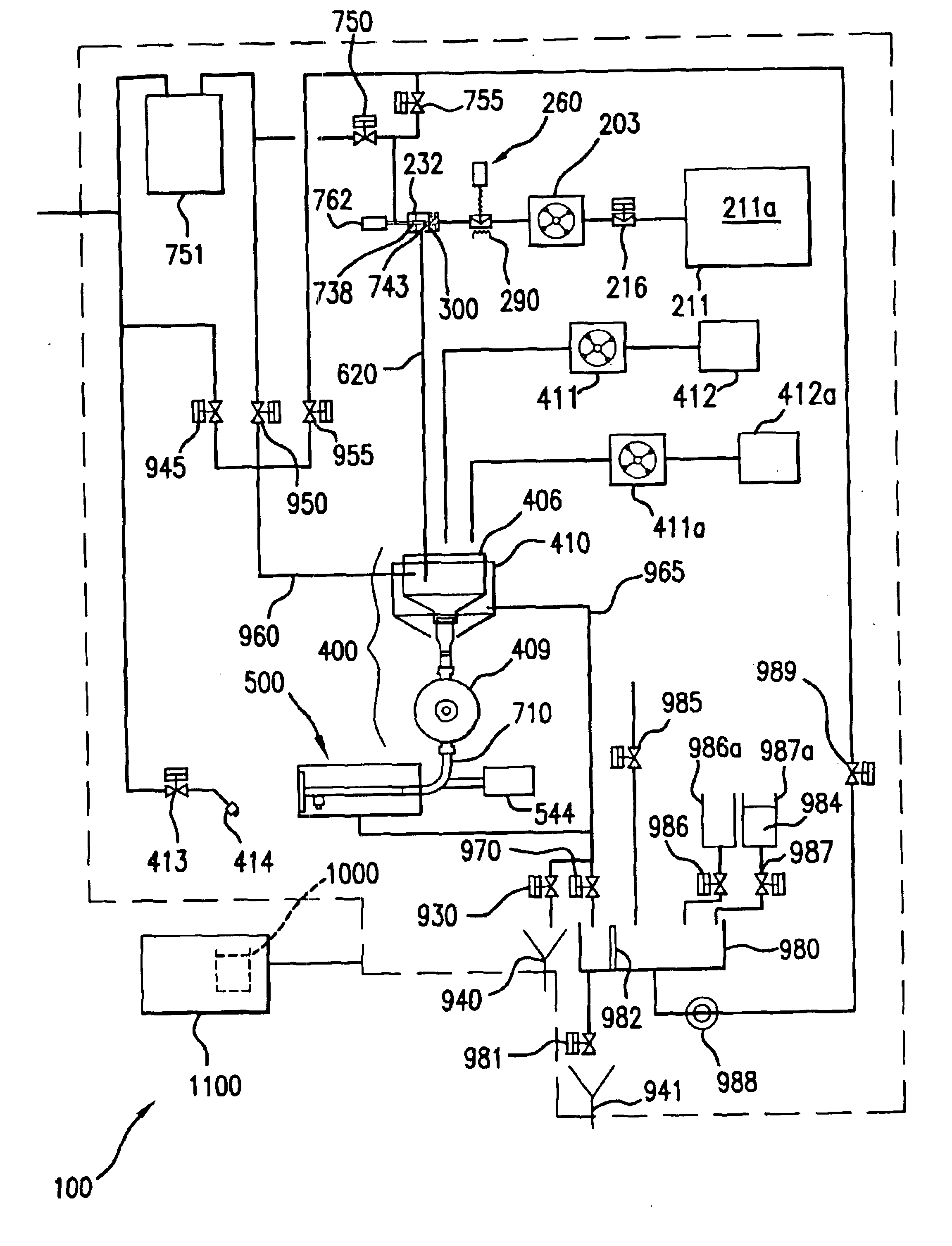

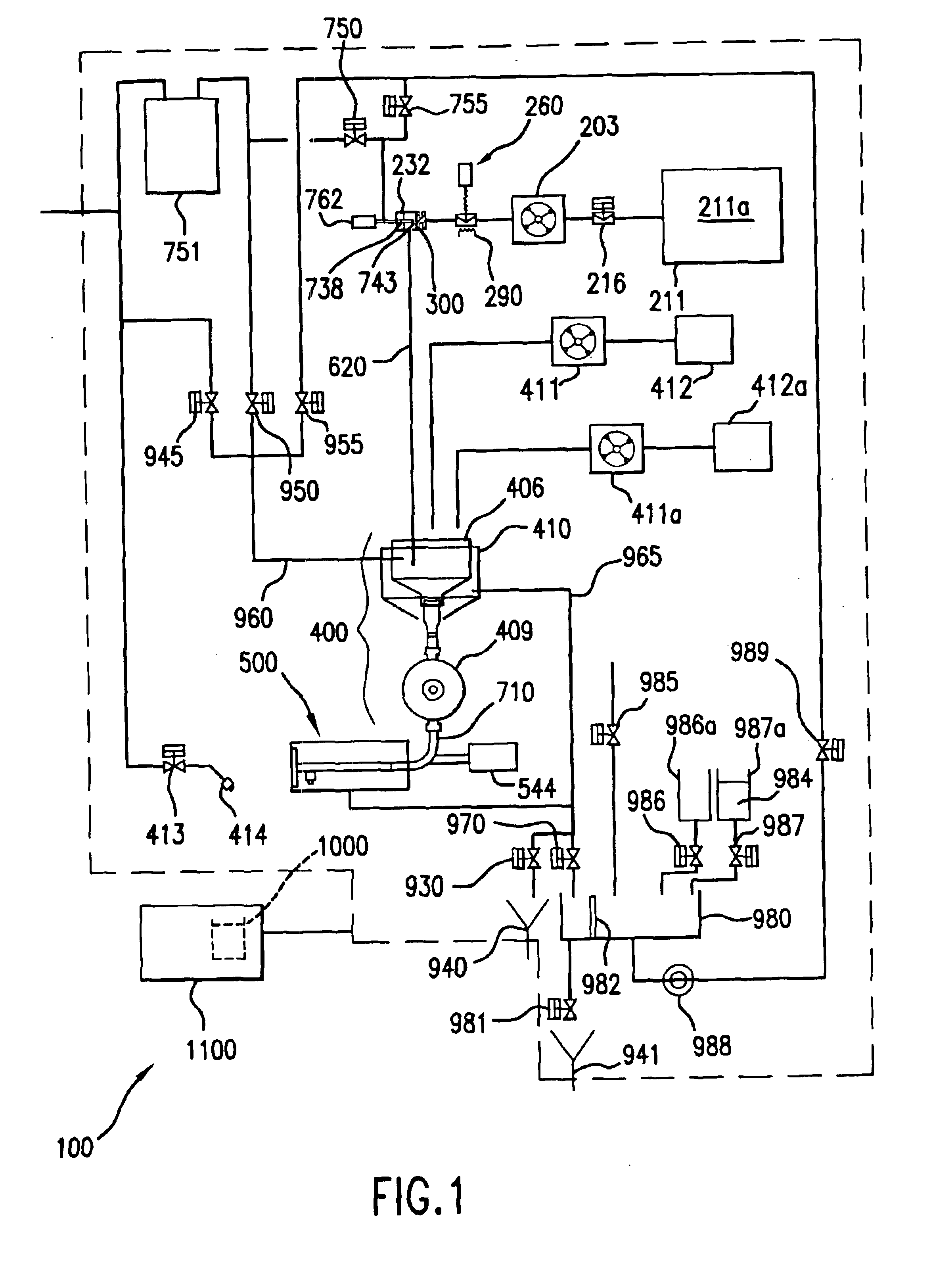

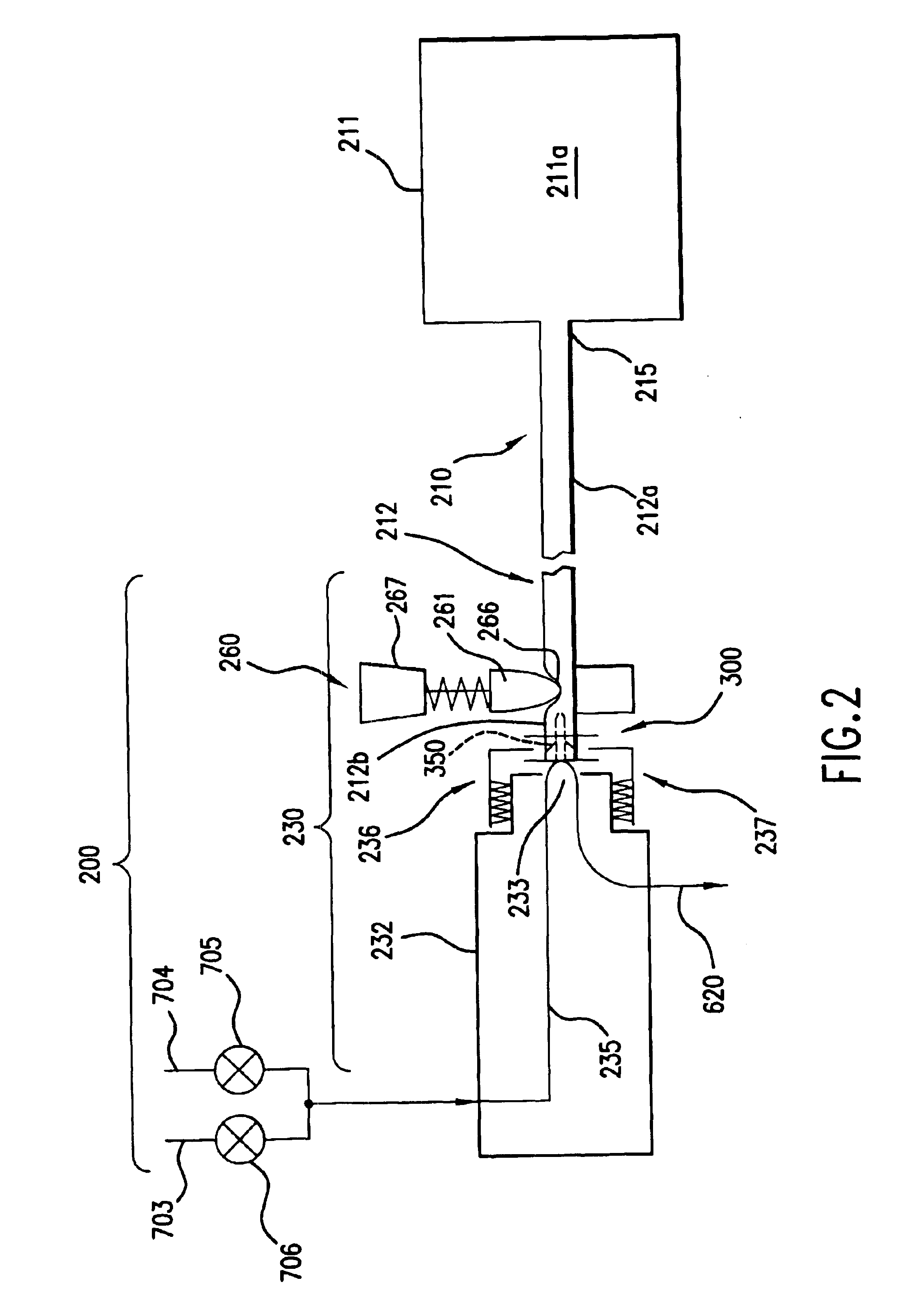

Systems and methods for generating reactive oxygen species formulations useful in various oxidation applications. Exemplary formulations include singlet oxygen or superoxide and can also contain hydroxyl radicals or hydroperoxy radicals, among others. Formulations can contain other reactive species, including other radicals. Exemplary formulations containing peracids are activated to generate singlet oxygen. Exemplary formulations include those containing a mixture of superoxide and hydrogen peroxide. Exemplary formulations include those in which one or more components of the formulation are generated electrochemically. Formulations of the invention containing reactive oxygen species can be further activated to generate reactive oxygen species using activation chosen from a Fenton or Fenton-like catalyst, ultrasound, ultraviolet radiation or thermal activation. Exemplary applications of the formulations of the invention among others include: cleaning in place applications, water treatment, soil decontamination and flushing of well casings and water distribution pipes.

Owner:CLEAN CHEM

Clean-in-place automated food or beverage dispenser

The invention relates to an automated food product dispenser comprising an interface connection configured to establish a supply of a milk-based fluid from a reservoir (for example, a container or a bag), a mixing device configured to receive the milk-based fluid and prepare a milk based product, a nozzle in fluid association with the mixing device for dispensing the milk based product, a product flowpath configured for directing the milk based product to flow from the interface connection through the mixing device to the nozzle, and a clean-in-place flowpath assembly located in the dispenser and comprising a supply of cleaning or sanitizing fluid and a flowpath which is configured to deliver the cleaning or sanitizing fluid to or through the product flowpath. The invention also relates to a method of using and machine readable program for controlling the automated food product dispenser of the invention.

Owner:NESTEC SA

Monitoring and Recording Device for Clean-In-Place System

InactiveUS20110197920A1Guaranteed functionHollow article cleaningLiquid dispensingClean-in-placeEmbedded system

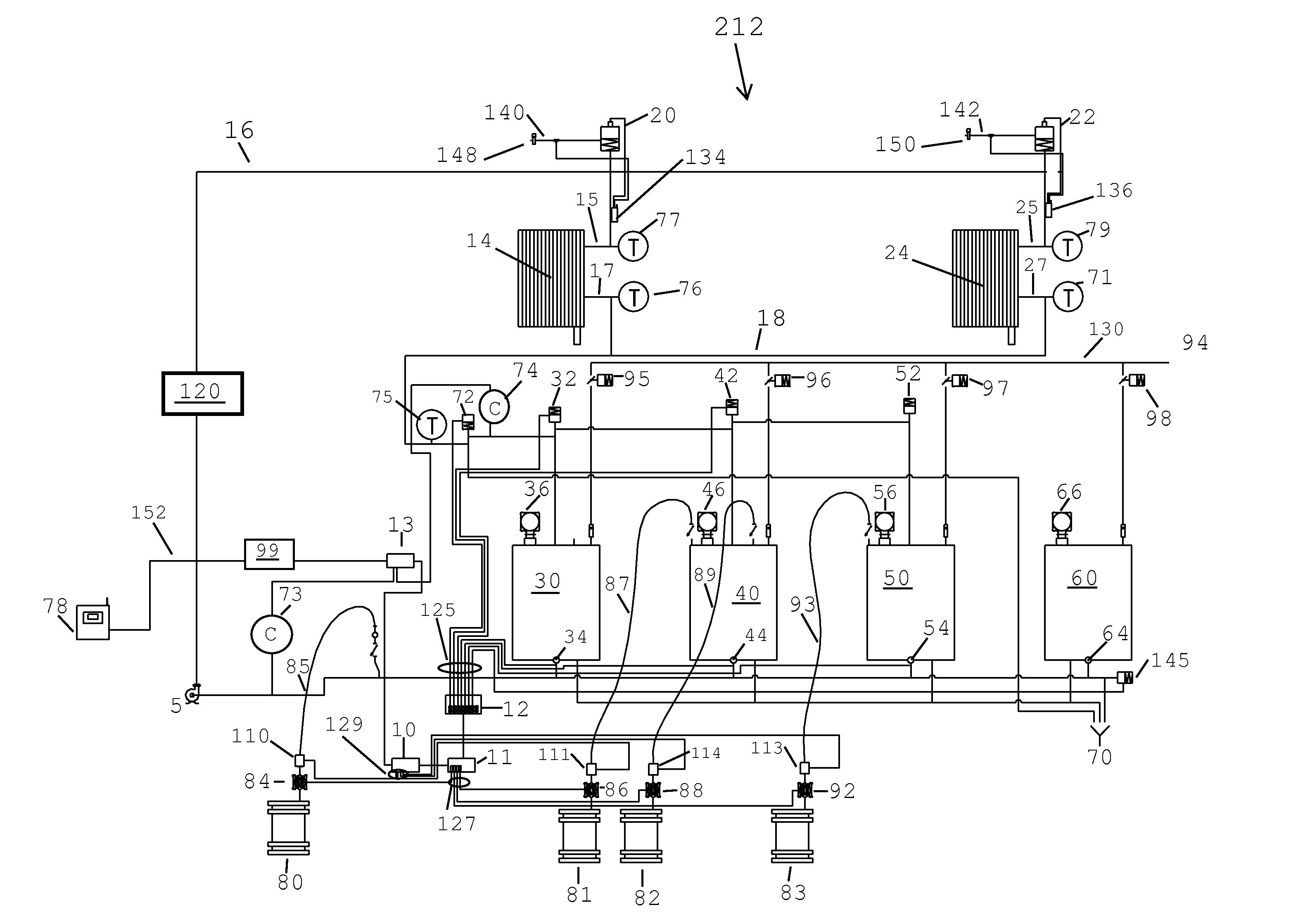

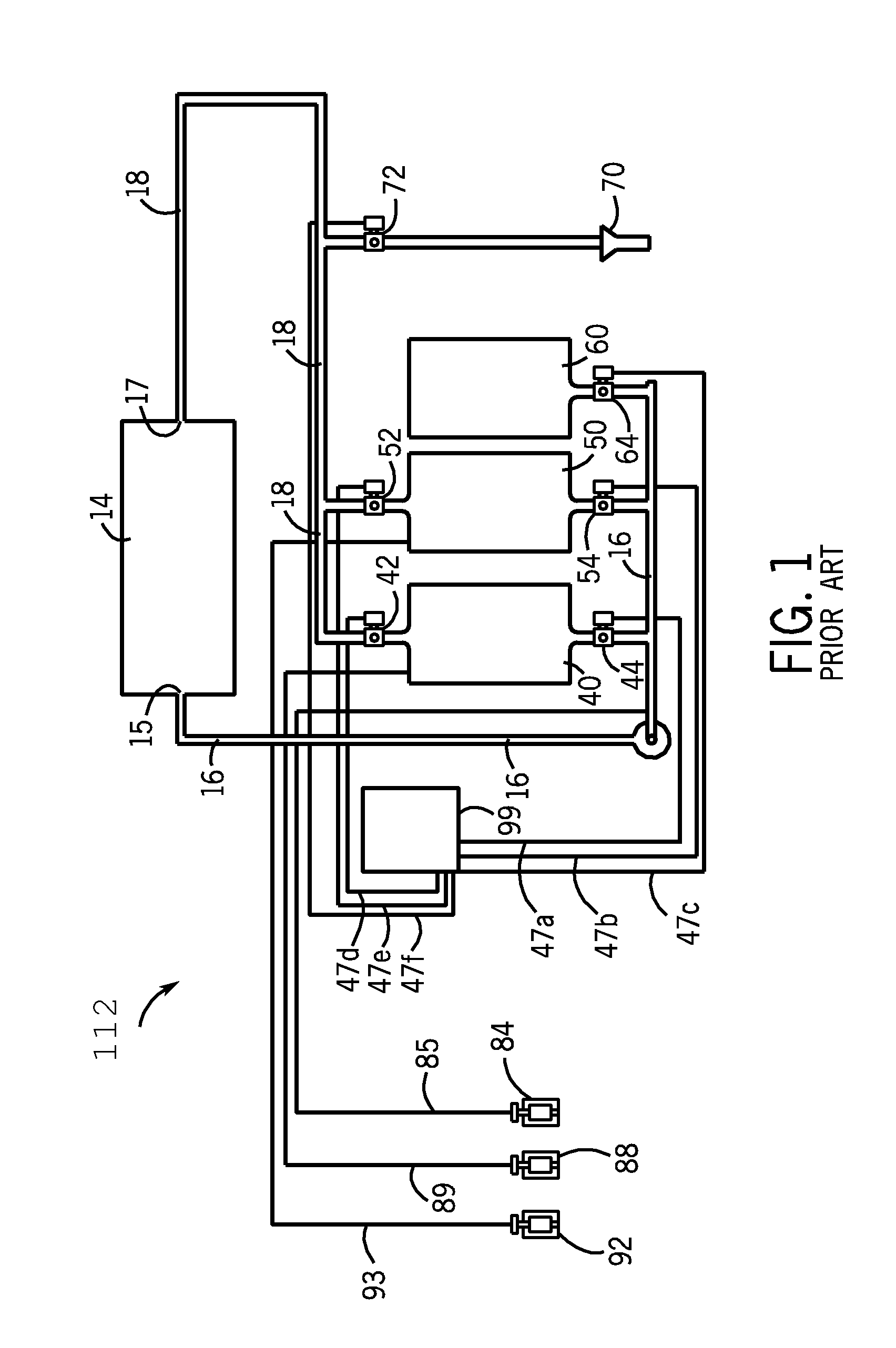

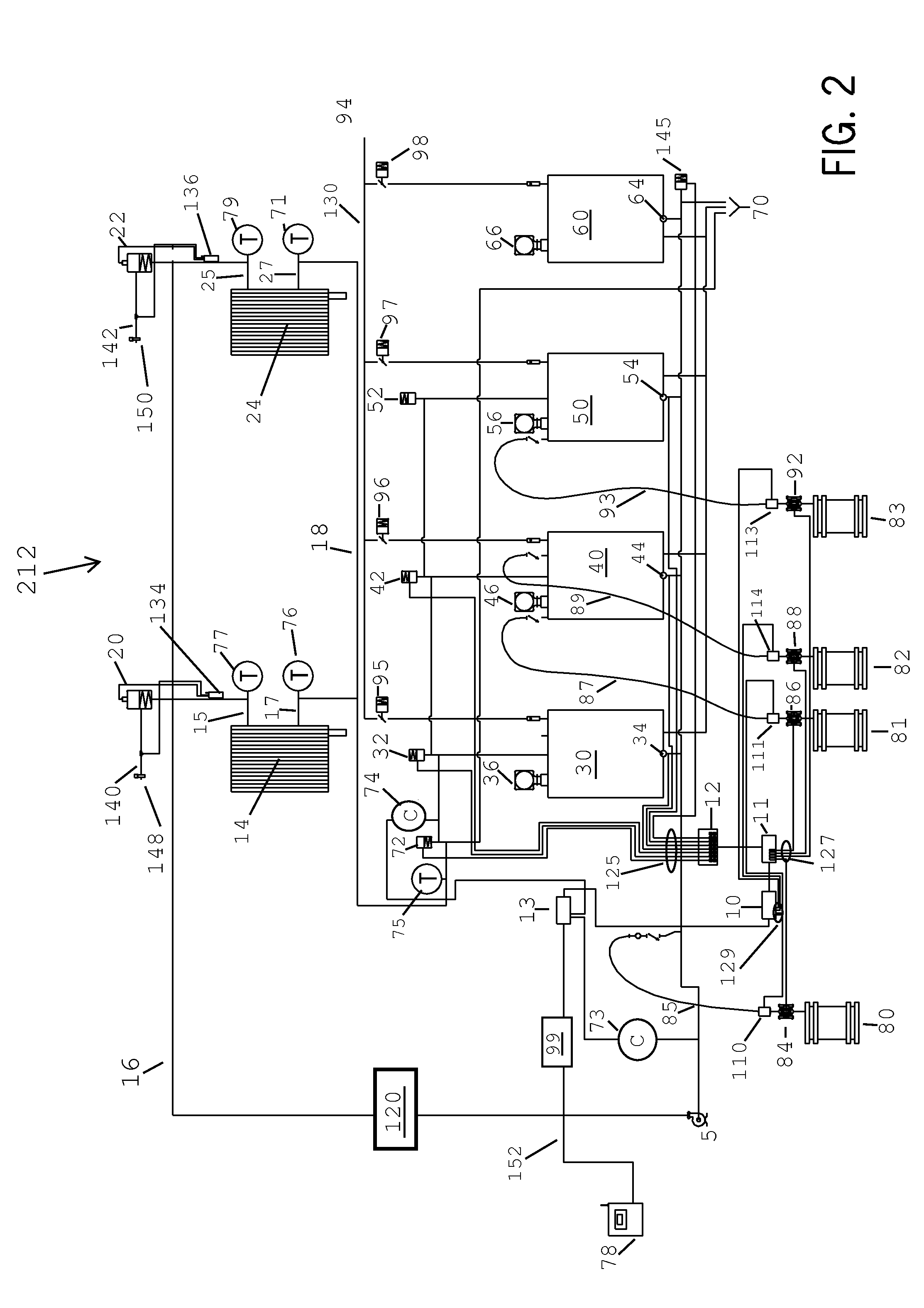

A controller and recorder is disclosed for controlling, monitoring, and recording concentrations, temperature, air flow, fluid flow, and valve position a cleaning system. The invention allows a user to monitor multiple outputs at one time to quickly and efficiently diagnose malfunctions in the cleaning system. The invention records and archives the outputs during operation of the cleaning system. The data may then be downloaded by a user and analyzed for malfunctions in the system. For example, the data may indicate malfunctioning valves or fouled sensors in the cleaning system.

Owner:KENOWSKI ANDY +1

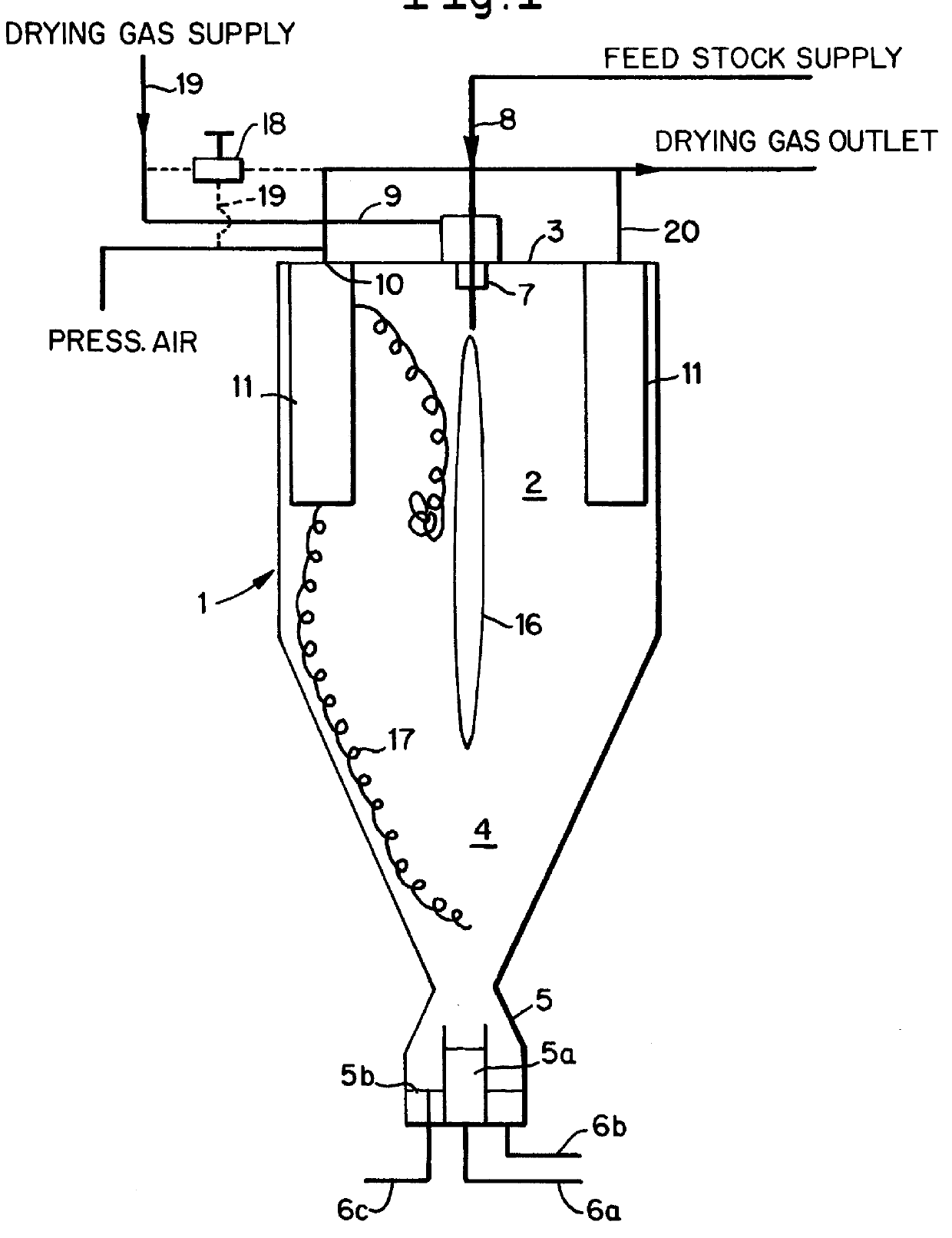

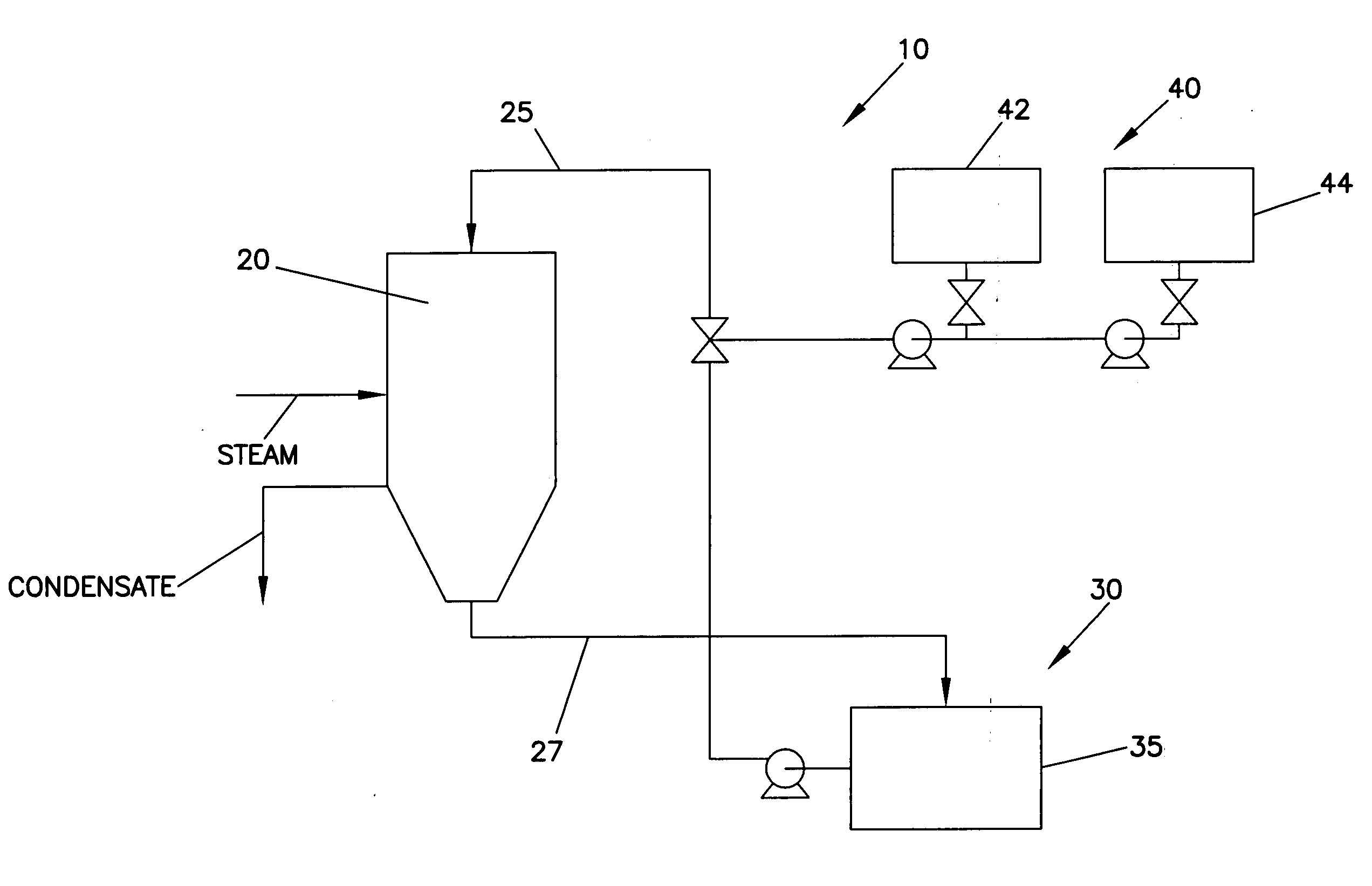

Spray drying method and apparatus and cleaning method for such an apparatus

InactiveUS6058624ALess complicated and more compact overall structureEasy to cleanDrying using combination processesDrying solid materials with heatEngineeringCleaning methods

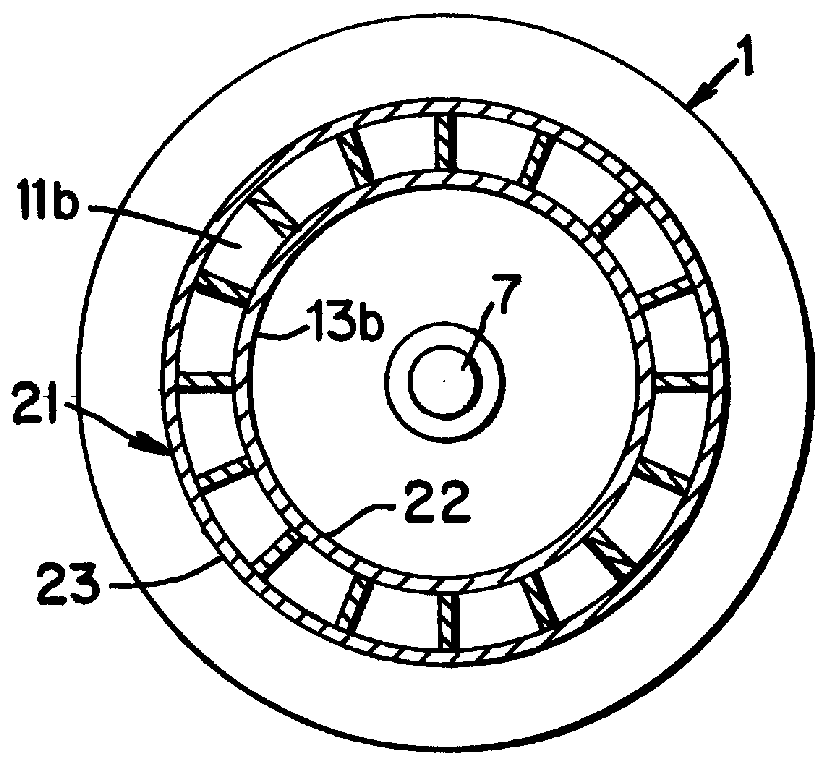

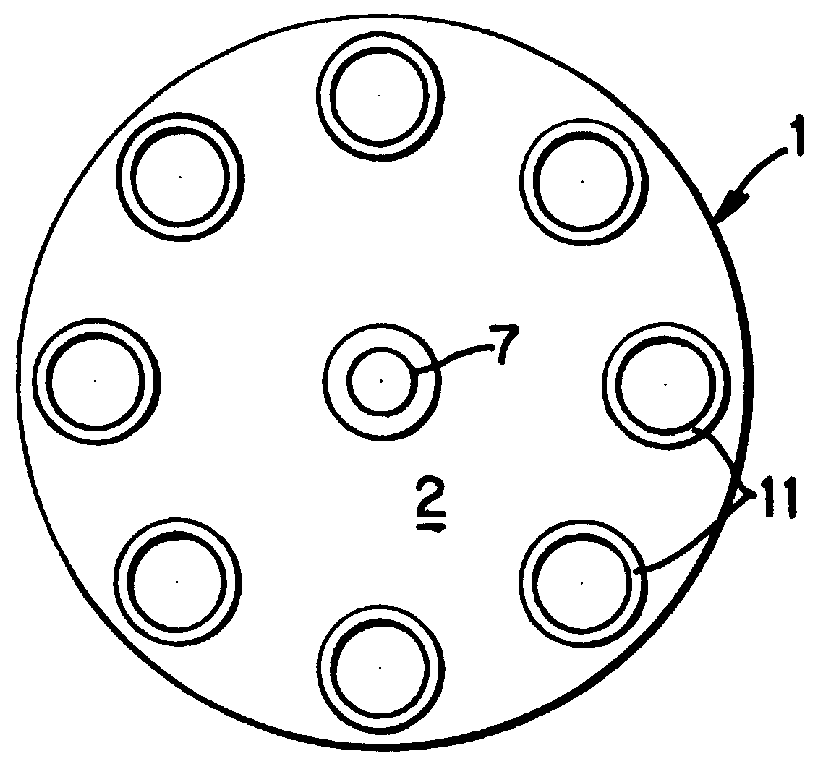

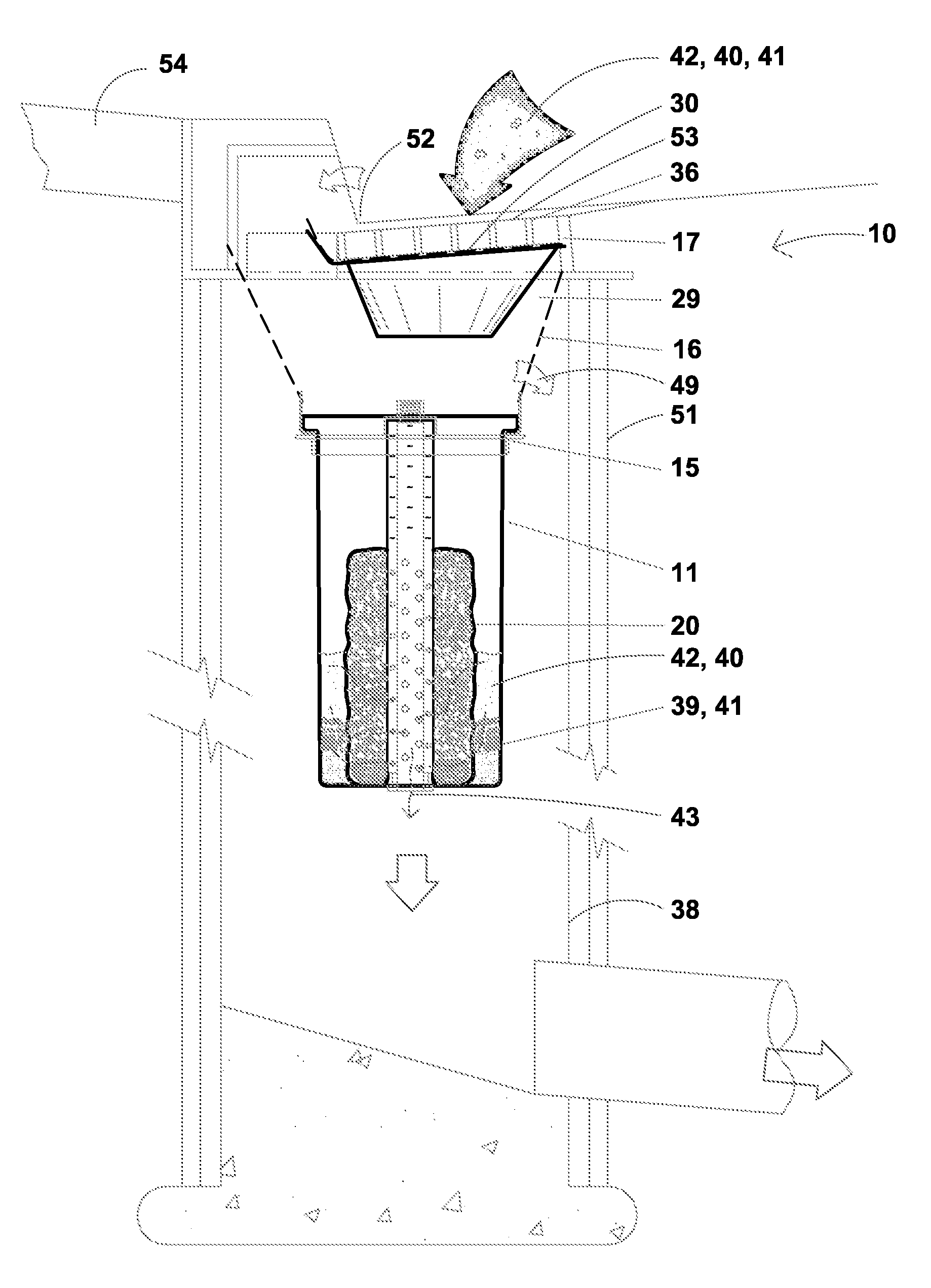

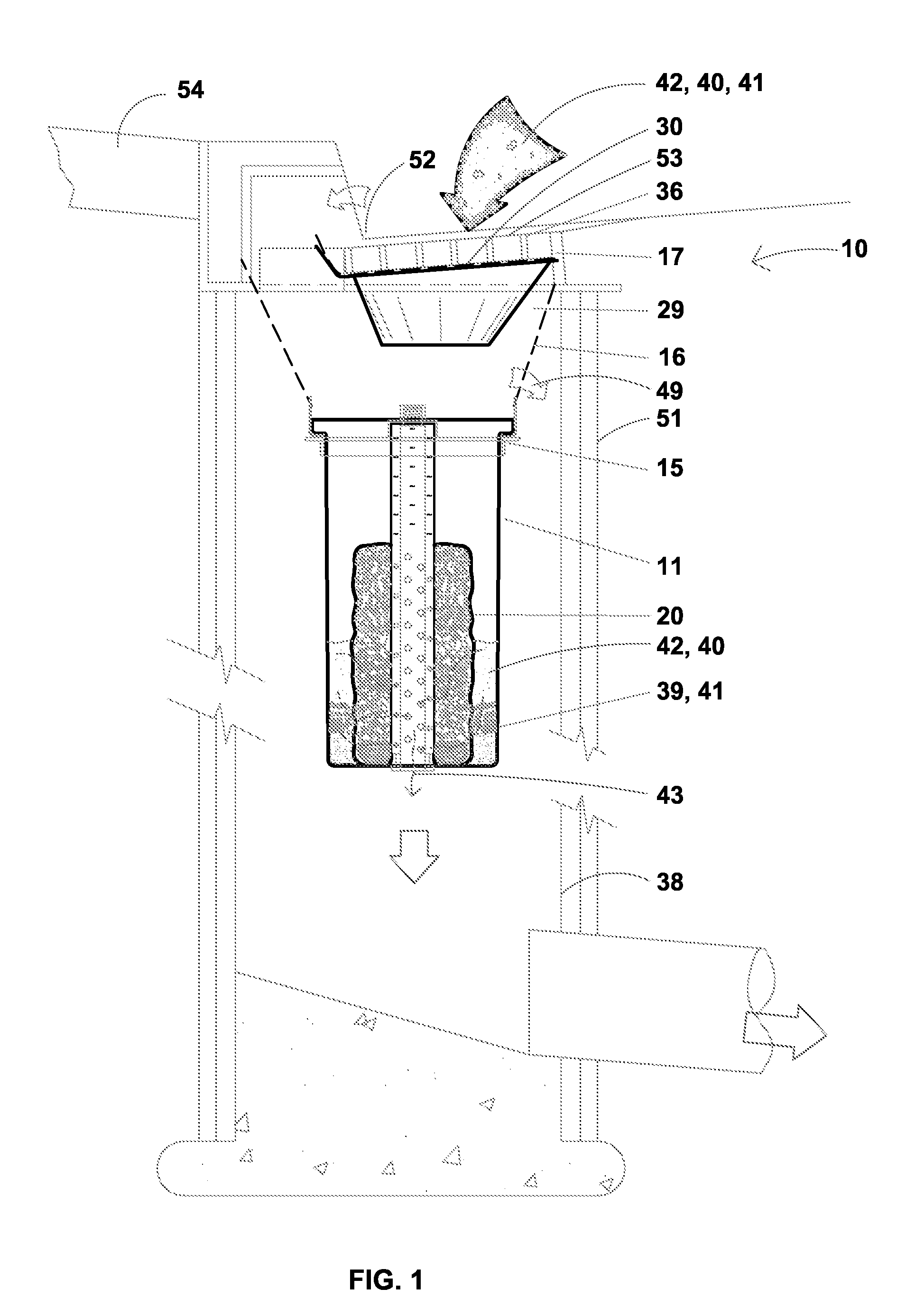

PCT No. PCT / DK97 / 00078 Sec. 371 Date Feb. 25, 1997 Sec. 102(e) Date Feb. 25, 1997 PCT Filed Feb. 20, 1997 PCT Pub. No. WO97 / 14288 PCT Pub. Date Apr. 24, 1997In fluidized spray drying of a feedstock to produce an agglomerate product by means of at least one spraying device (7) arranged in the upper part (2) of a vertically disposed drying chamber (1), in a lower part of which a fluid-bed is accommodated, a drying gas introduced into a processing zone (16) of the chamber (1) is exhausted through an integrated arrangement of filter elements (11) in the upper chamber part (2) to retain and allow agglomeration of the particles carried by the flow of drying gas on the filter elements (11). By intermittent supply of reverse flow gas pulses to the filter elements (11) the retained particles are released and returned to agglomeration zones (16, 17). The drying gas is introduced at a rate producing at the filter walls (13) a flow rate amounting to at least 150 cubic meters per hour per square meter of filter wall surface. In the non-operative condition of the spray drying apparatus the filter elements (11) may be cleaned-in-place by supplying a cleaning liquid to the interior of the elements.

Owner:NIRO

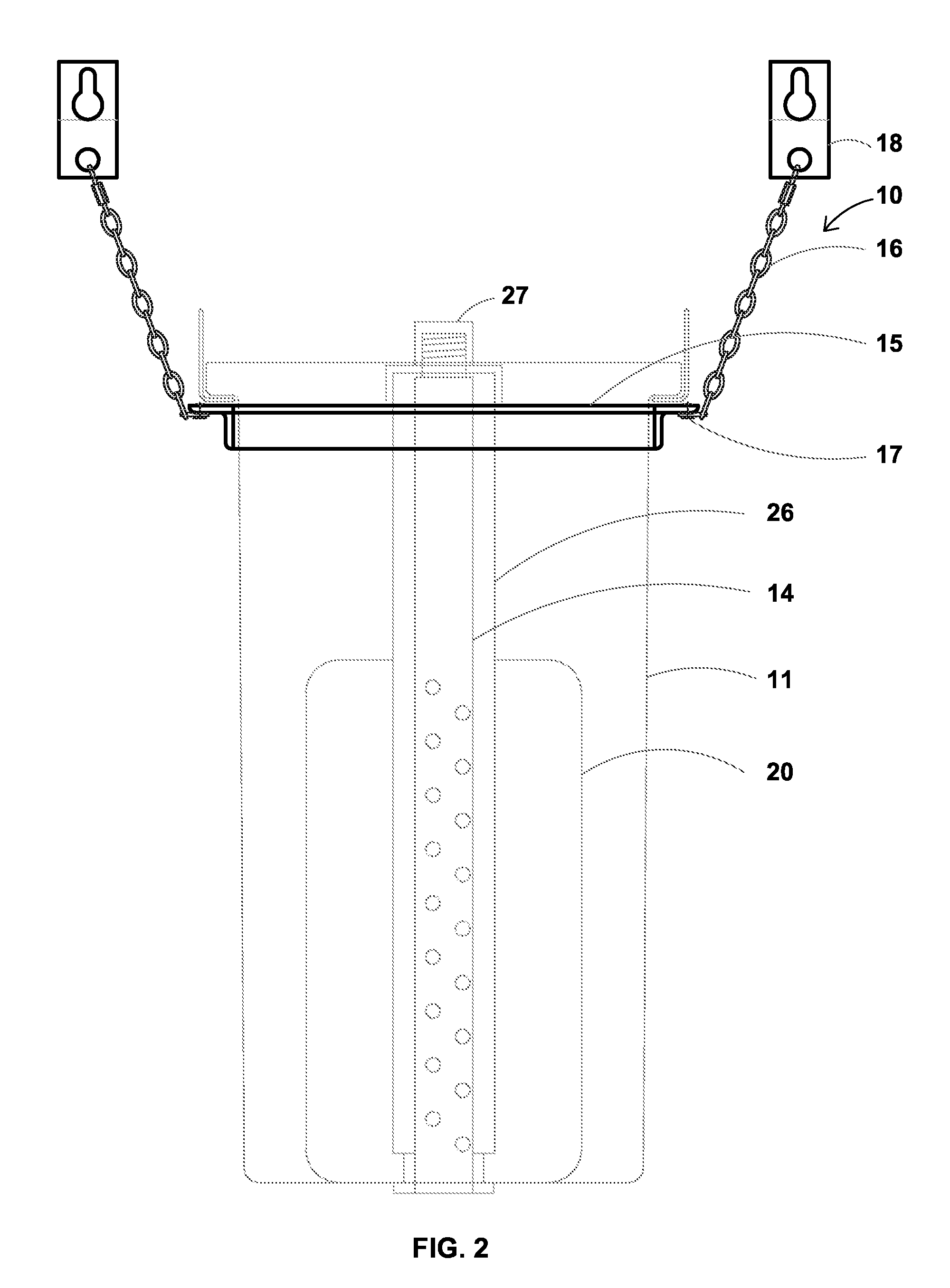

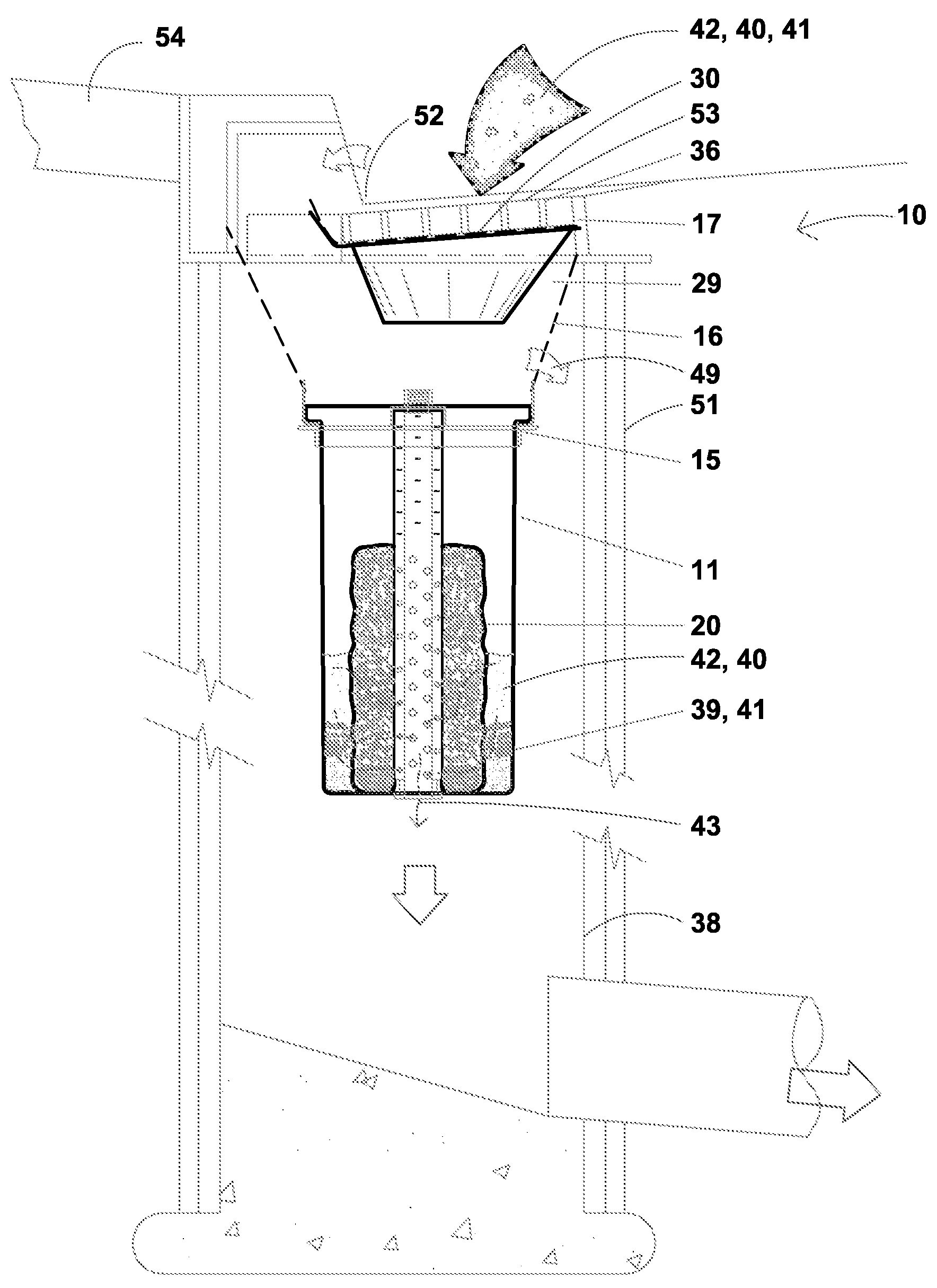

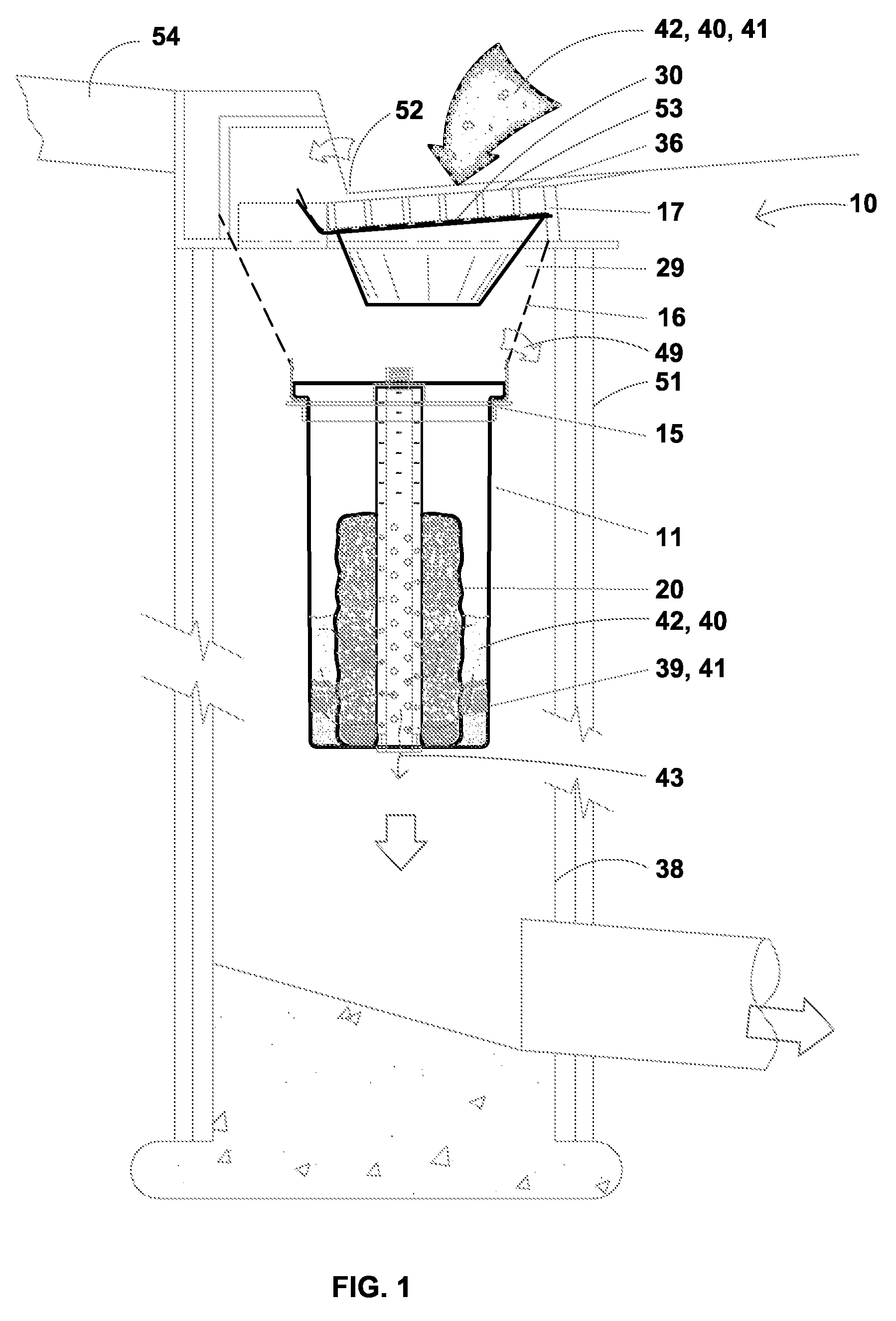

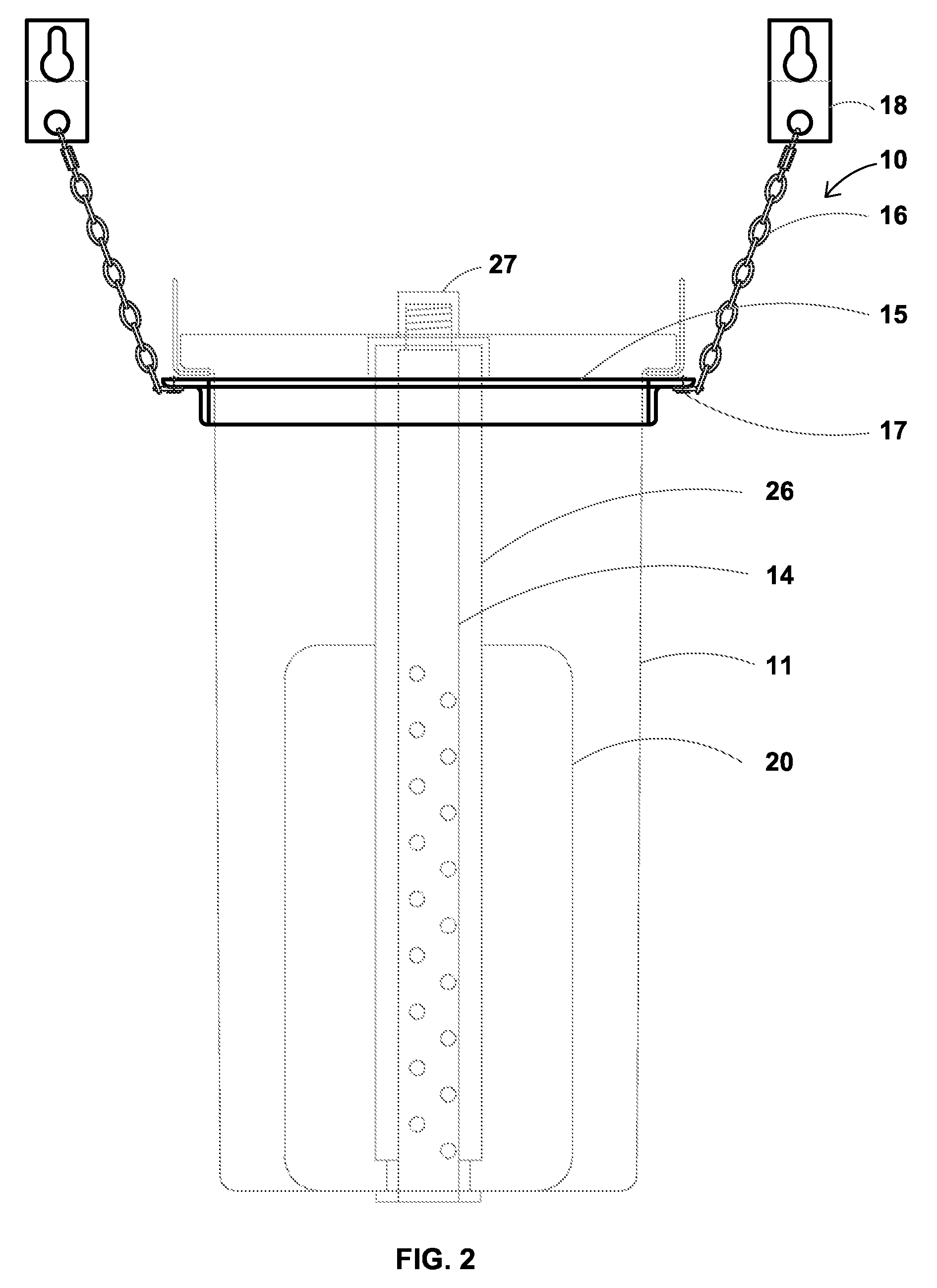

Catch basin filter absorber apparatus and method for water decontamination

ActiveUS20080073277A1Great emphasisEasy to installFatty/oily/floating substances removal devicesGround-workActivated carbonStormwater treatment

A storm water treatment device that is installed under the grate of new or existing catch basins, and more commonly referred to as an insert. The catch basin decontamination apparatus has a universal housing and support ring that allows one design to fit most applications. Adjustable chains allow for proper position below grate and a semi-flexible molded or rigid deflector directs incoming drain water to the housing. A slip-on filter / absorber cartridge fits over a perforated drain tube, in the center of the housing, allowing the drain water to first pass through the filter / absorber media before exiting through the drain tube and out the bottom of the housing. The filter / absorber cartridge includes a variety of absorber materials that absorb oil and repel water. Activated carbon, microbes and other site specific absorbents can be used in the replaceable slip-on cartridge. A leaf pre-strainer helps prevent leaves and debris from entering the housing. A clean in place suction tube and clod buster form of the apparatus aids in cleaning the housing.

Owner:INVENTIVE RESOURCES

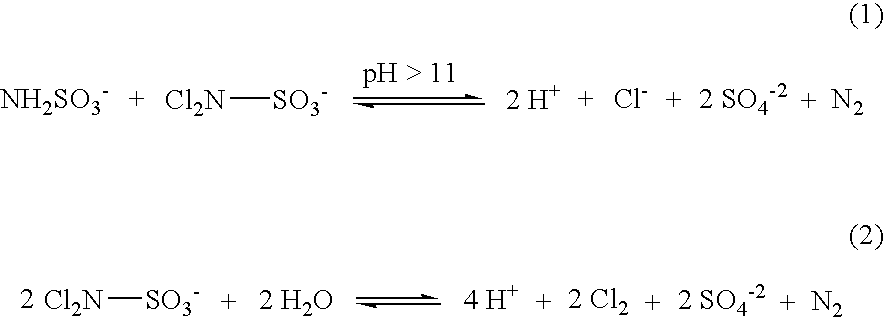

Stabilized chlorine bleach in alkaline detergent composition and method of making and using the same

InactiveUS20060089285A1Enhancing composition 's cleaning powerUse cleanOrganic detergent compounding agentsInorganic non-surface-active detergent compositionsHypochloriteBleach

Liquid, shelf-stable alkaline cleaning compositions with chlorine bleach comprising a chlorine bleach capable of forming a hypochlorite in water, a bleach stabilizer selected from the group consisting of compounds having at least one NH— or NH2— moiety capable of reacting with the hypochlorite to form NCl—, NHCl— or NCl2— compounds, and from about 5-50% by weight of a metal hydroxide. Compositions according to the present invention are highly alkaline preferably presenting a pH of at least about 11.5. The compositions provide sustained hypochlorite bleach functionality and long term bleach stability even in the presence of surfactants. The bleach compositions are useful in cleaning and sanitizing household, institutional, and industrial hard surfaces including clean-in-place systems and food processing equipment.

Owner:DELAVAL HLDG AB

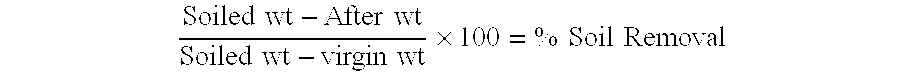

Methods for cleaning industrial equipment with pre-treatment

ActiveUS20060046945A1The result is validHigh degree of softeningInorganic/elemental detergent compounding agentsSurface-active detergent compositionsIndustrial equipmentPre treatment

A method of cleaning equipment such as heat exchangers, evaporators, tanks and other industrial equipment using clean-in-place procedures and a pre-treatment solution prior to the conventional CIP cleaning process. The pre-treatment step improves the degree of softening of the soil, and thus facilitates its removal. The pre-treatment solution can be a strong acidic solution, a strong alkaline solution, or comprise a penetrant. A preferred strong acidic solution is an acid peroxide solution. In some embodiments, the pre-treatment may include no strong alkali or acid ingredient; rather, the penetrant provides acceptable levels of pre-treatment.

Owner:ECOLAB USA INC

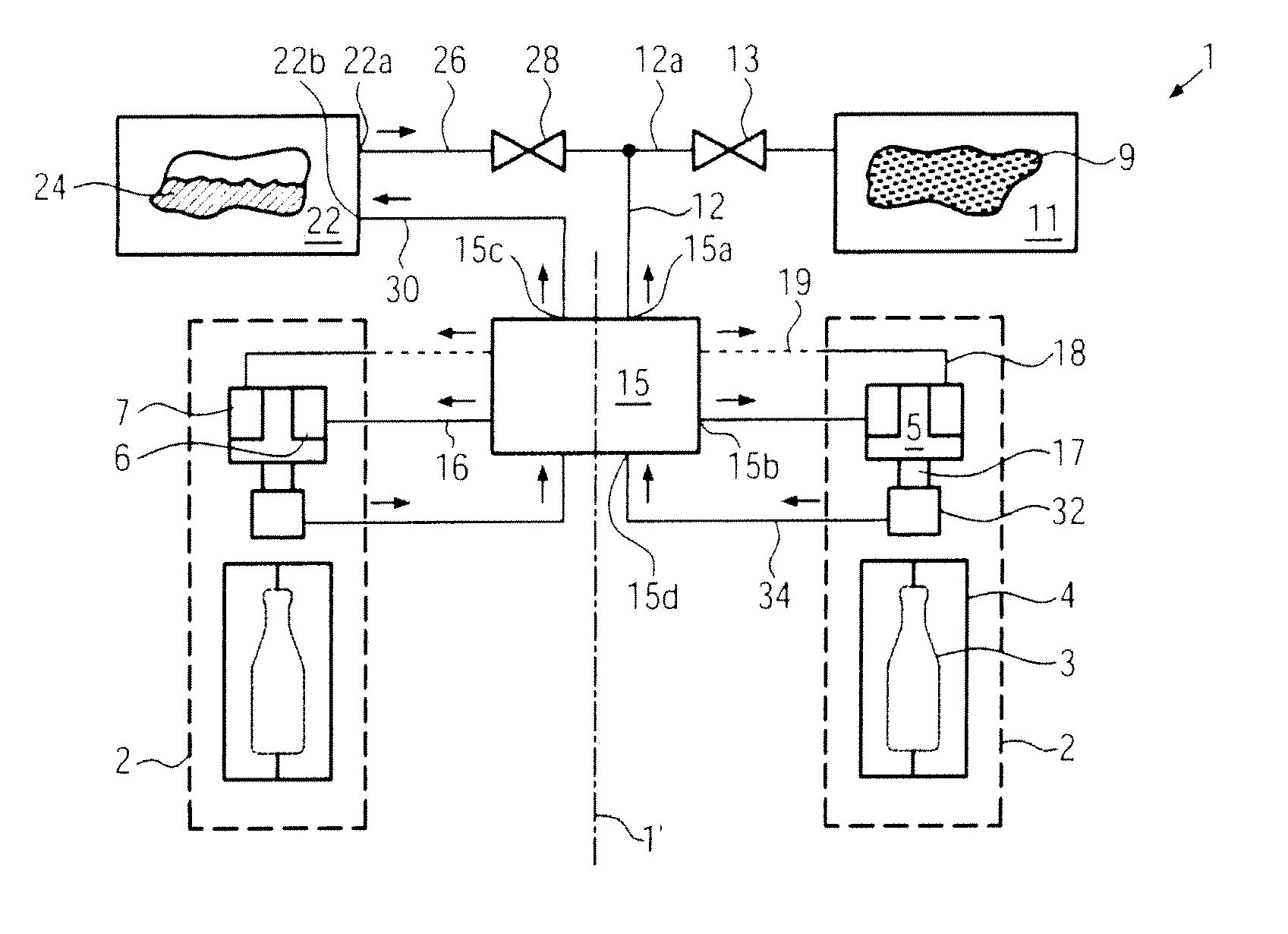

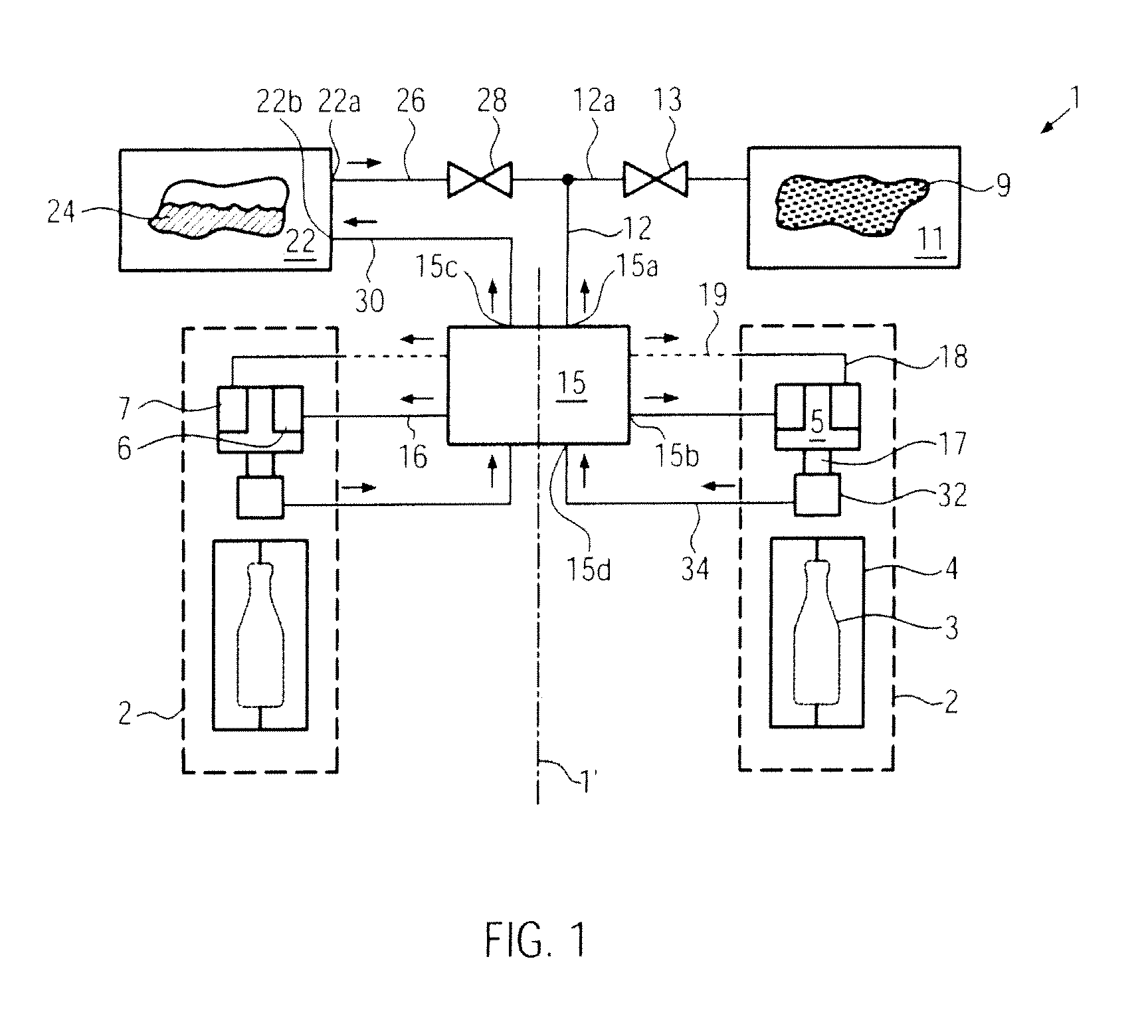

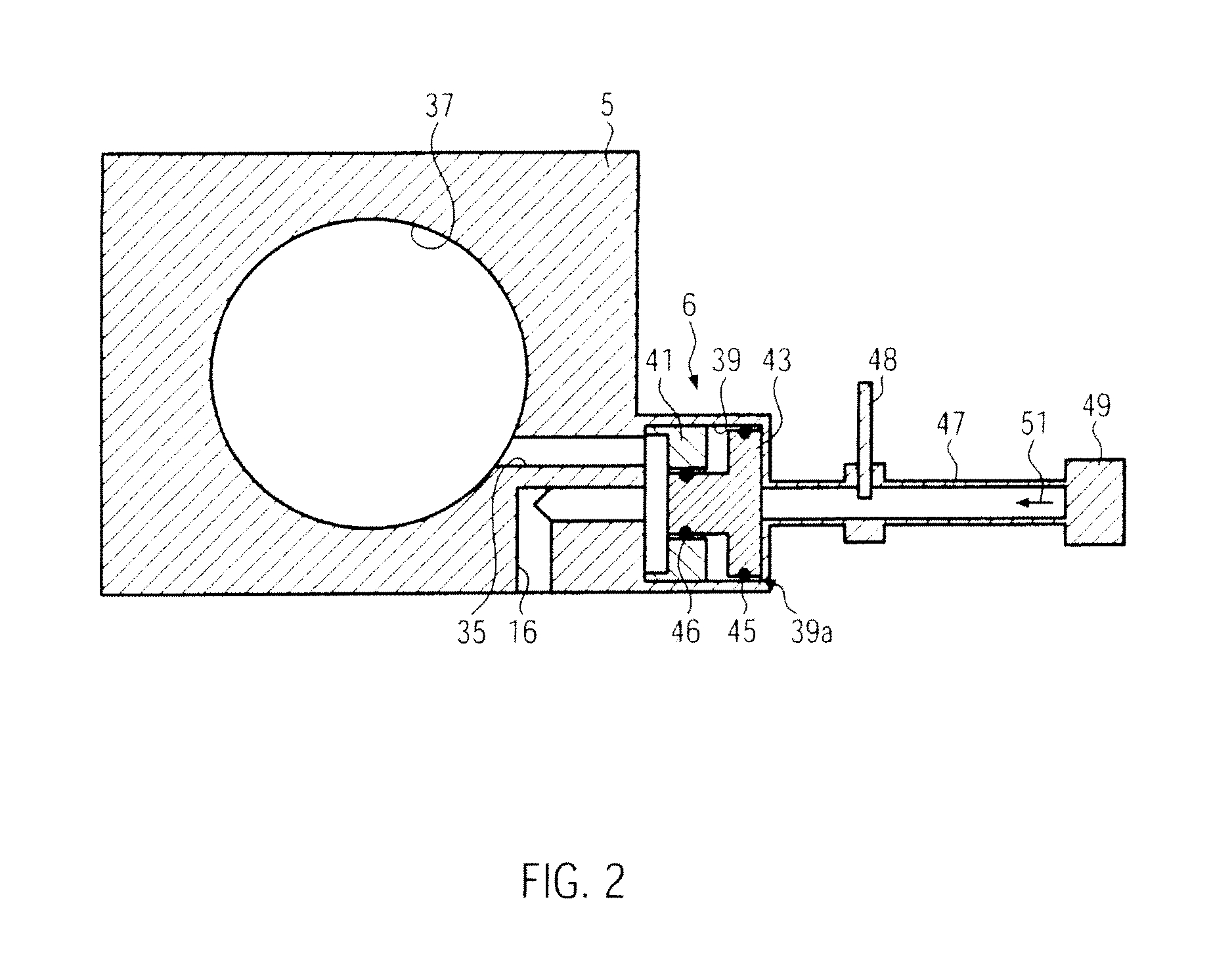

Blow Molding Machine with CIP System for Producing Plastic Bottles, Particularly PET Bottles

ActiveUS20100303946A1The process is simple and fastSterilized more easilyConfectioneryHollow article cleaningBlow moldingEngineering

A blow molding machine for producing plastic bottles, particularly PET bottles, including a plurality of blow molding stations, which have assigned thereto valve blocks with control valves and blowing nozzles for introducing or discharging blowing air; and a cleaning-in-place (CIP) system for cleaning the blow molding machine. Since the valve blocks are configured such that they can be included in the CIP process, the system components, such as the blowing nozzle, which are particularly important for the production of PET bottles in terms of hygiene, can be cleaned and sterilized without disassembly.

Owner:KRONES AG

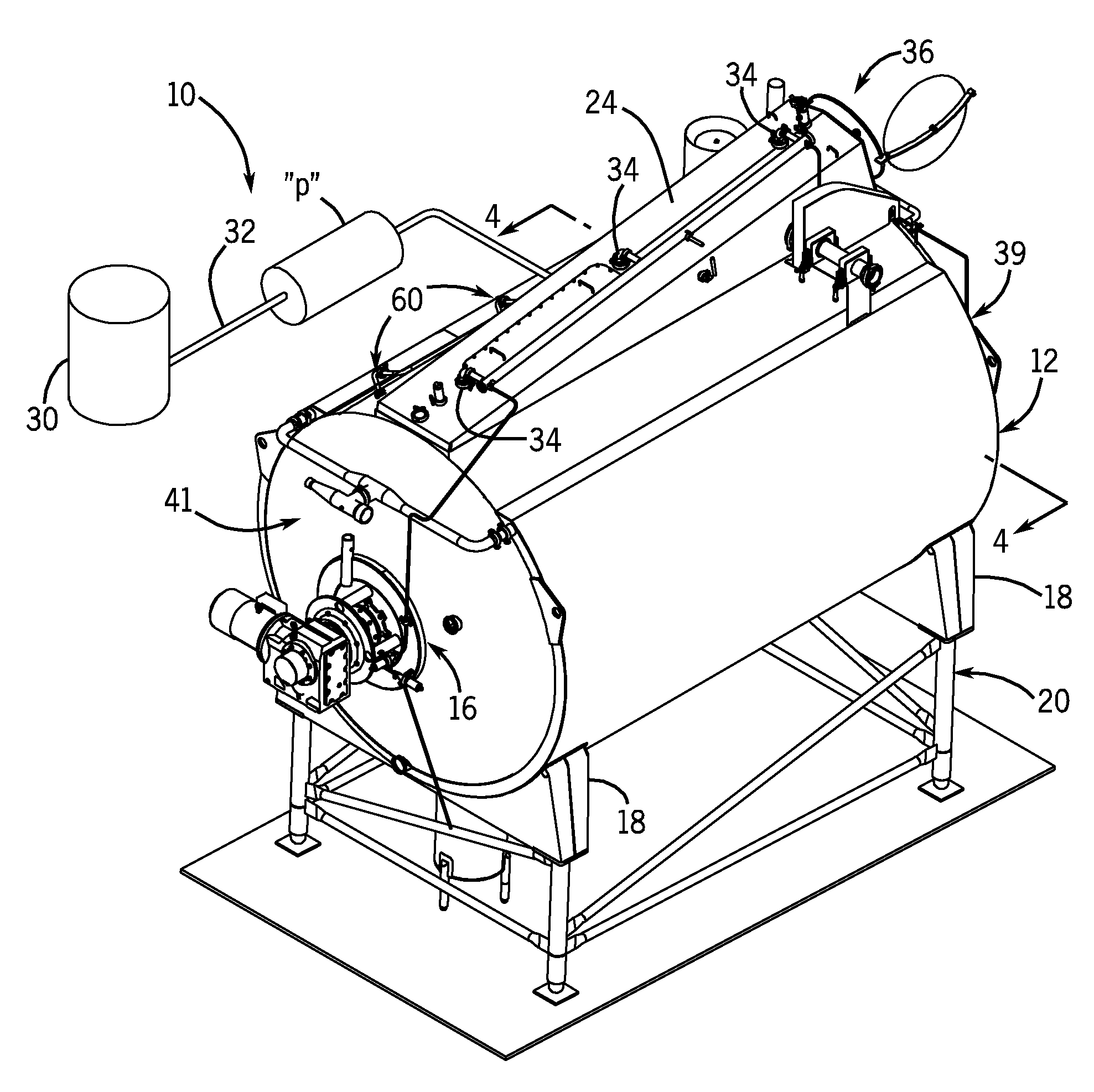

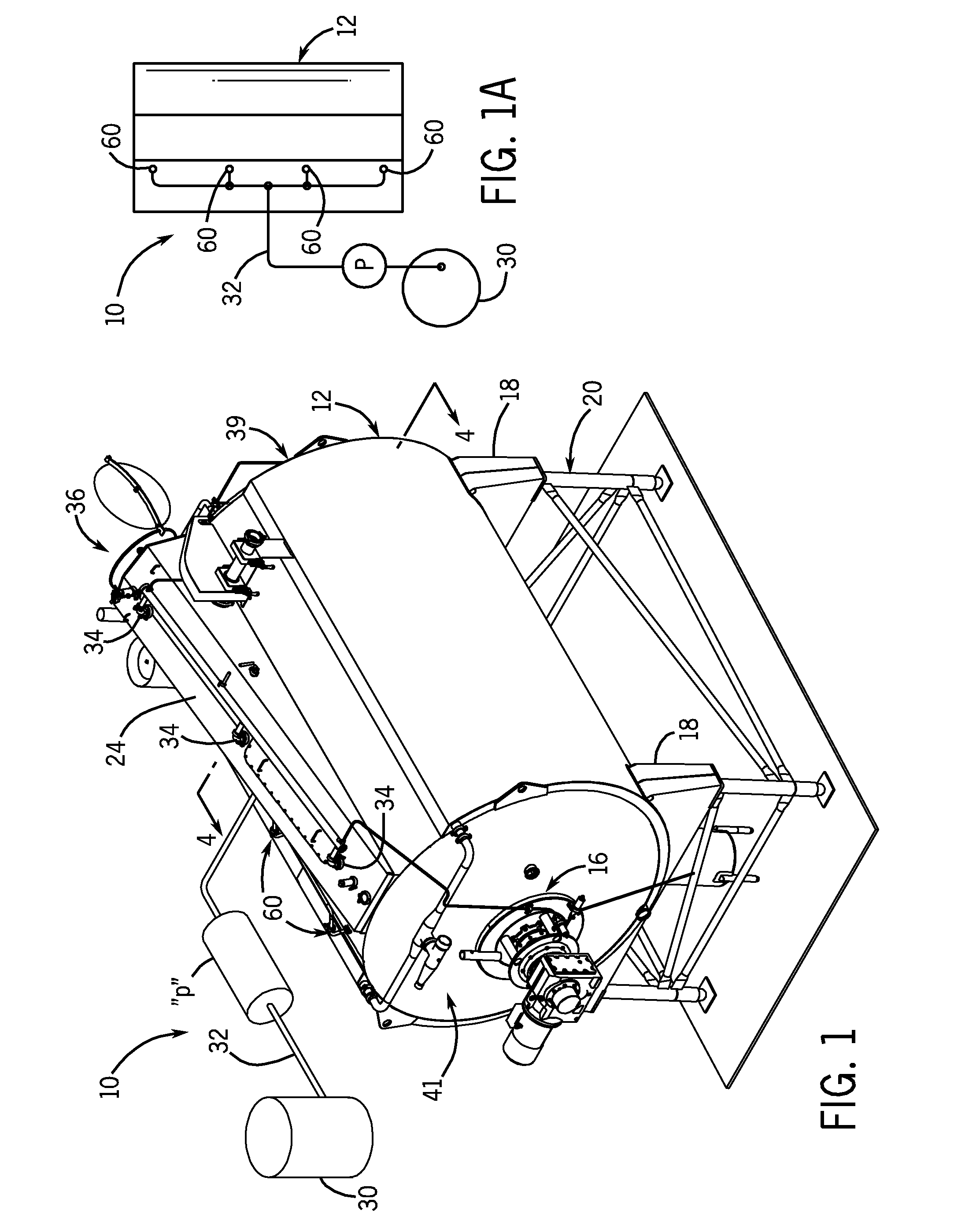

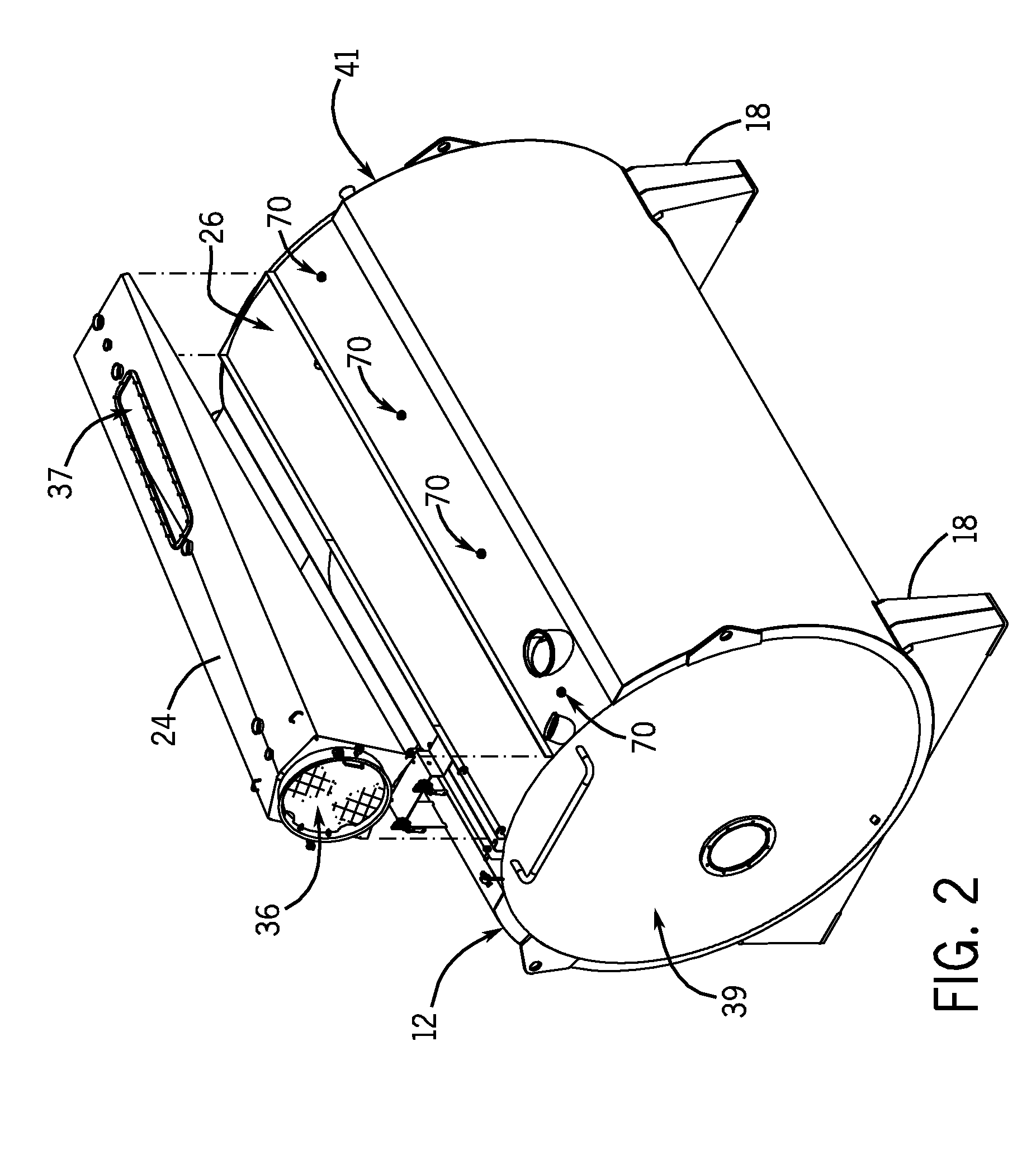

Cheese vat having fluid accessible seal assembly

ActiveUS20080131313A1Uniform and even wearMinimize production timeEngine sealsMilk treatmentEngineeringClean-in-place

A cheese process vat is disclosed. The cheese process vat includes an enclosure and a shaft assembly, preferably a shaft assembly having a shaft and a plurality of agitator panels arranged on the shaft. The cheese process vat preferably further includes a shaft seal assembly having a fluid accessible clean-in-place chamber. Methods of using the respective cheese process vats are also disclosed.

Owner:ADVANCED PROCESS TECH

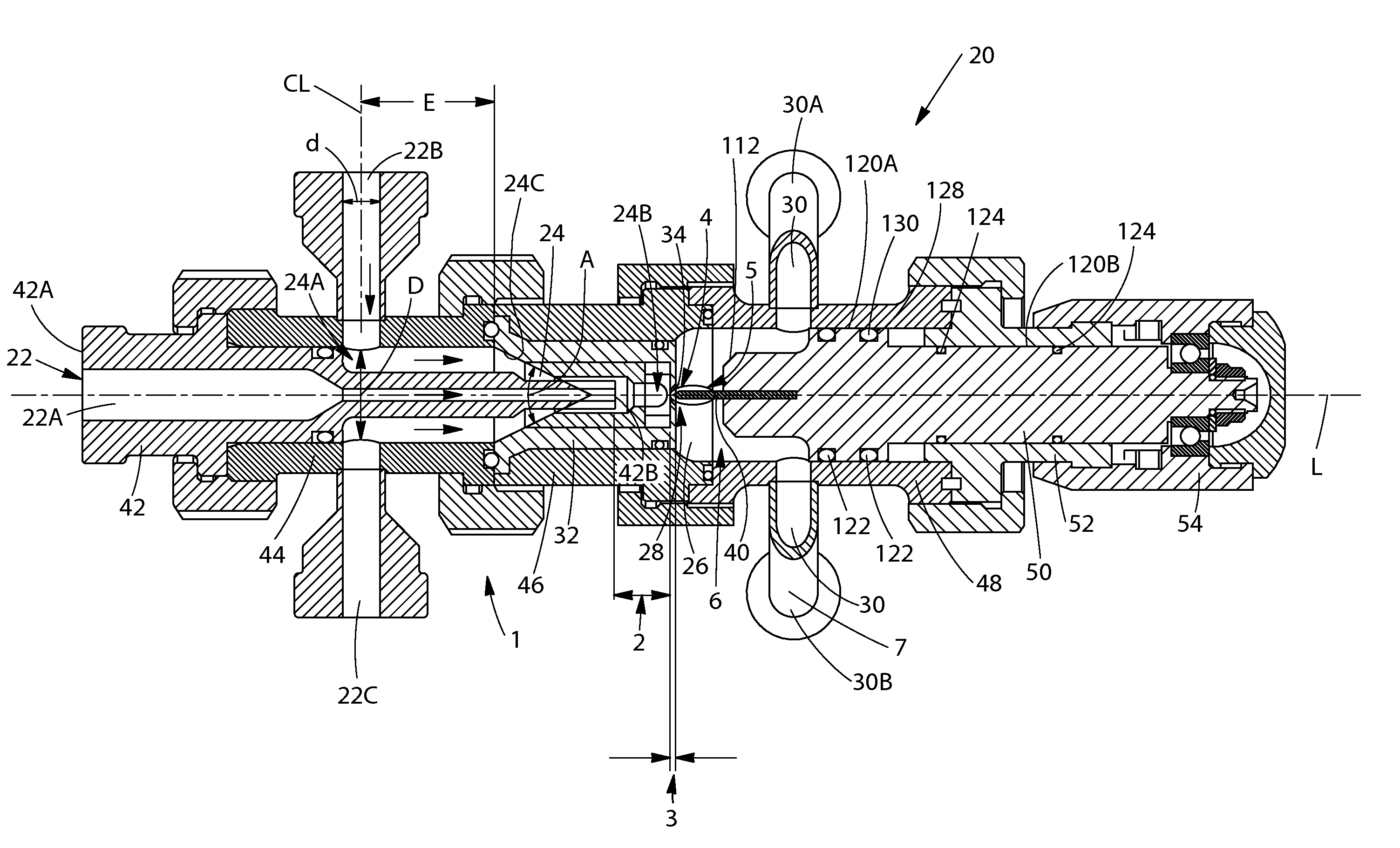

Apparatus and method for mixing by producing shear and/or cavitation, and components for apparatus

An apparatus and method for mixing by producing shear and / or cavitation, and components for the apparatus are disclosed. In one embodiment, the apparatus includes a mixing and / or cavitation chamber with an element such as an orifice component that is located adjacent the entrance of the cavitation chamber. The apparatus may further include a blade, such as a knife-like blade, disposed inside the mixing and / or cavitation chamber opposite the orifice component. In one version of such an embodiment, the apparatus is configured to be cleaned in place. The apparatus may, be provided with at least one drain in liquid communication with the mixing chamber. If the apparatus comprises a blade, the apparatus may further include a blade holder that is movable so that the distance between the tip of the blade and the discharge of the orifice can be varied. In this or other embodiments, the apparatus is configured to be scalable. In this, or other embodiments, the apparatus is provided with an injector that is movable so that the distance between the discharge end of the injector and the orifice can be adjusted. A process for mixing by producing shear and / or cavitation in a fluid is also contemplated herein.

Owner:PROCTER & GAMBLE CO

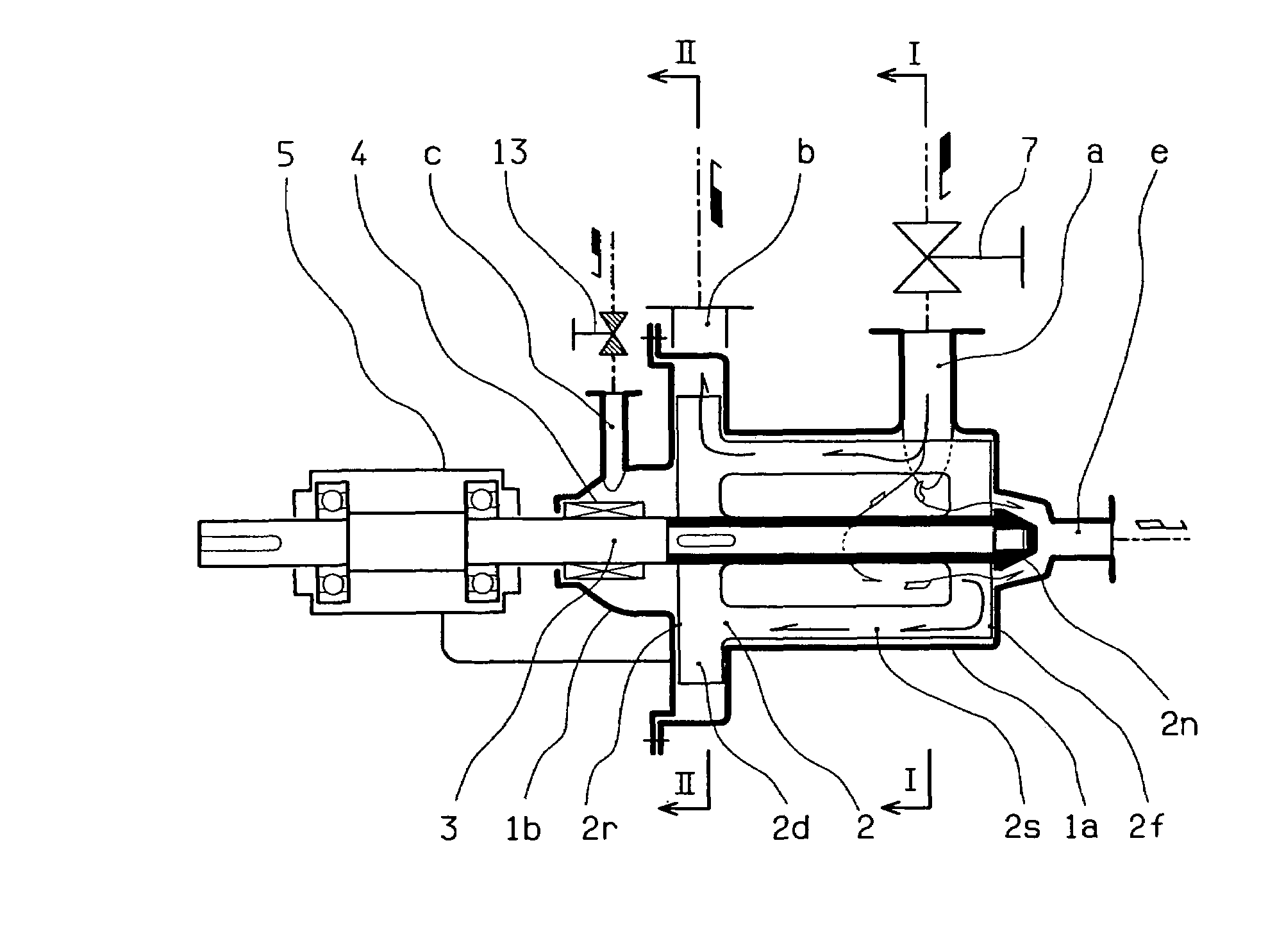

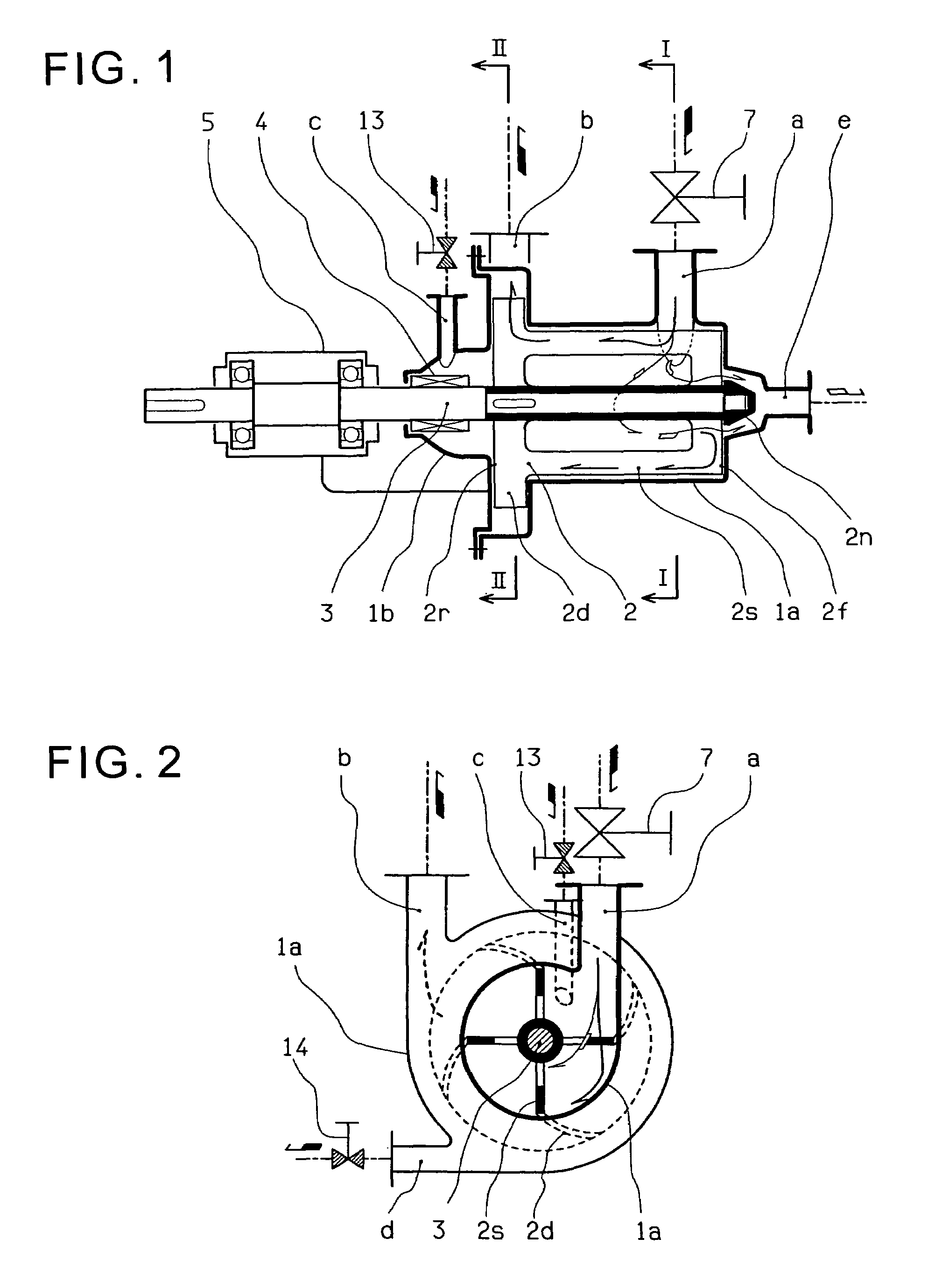

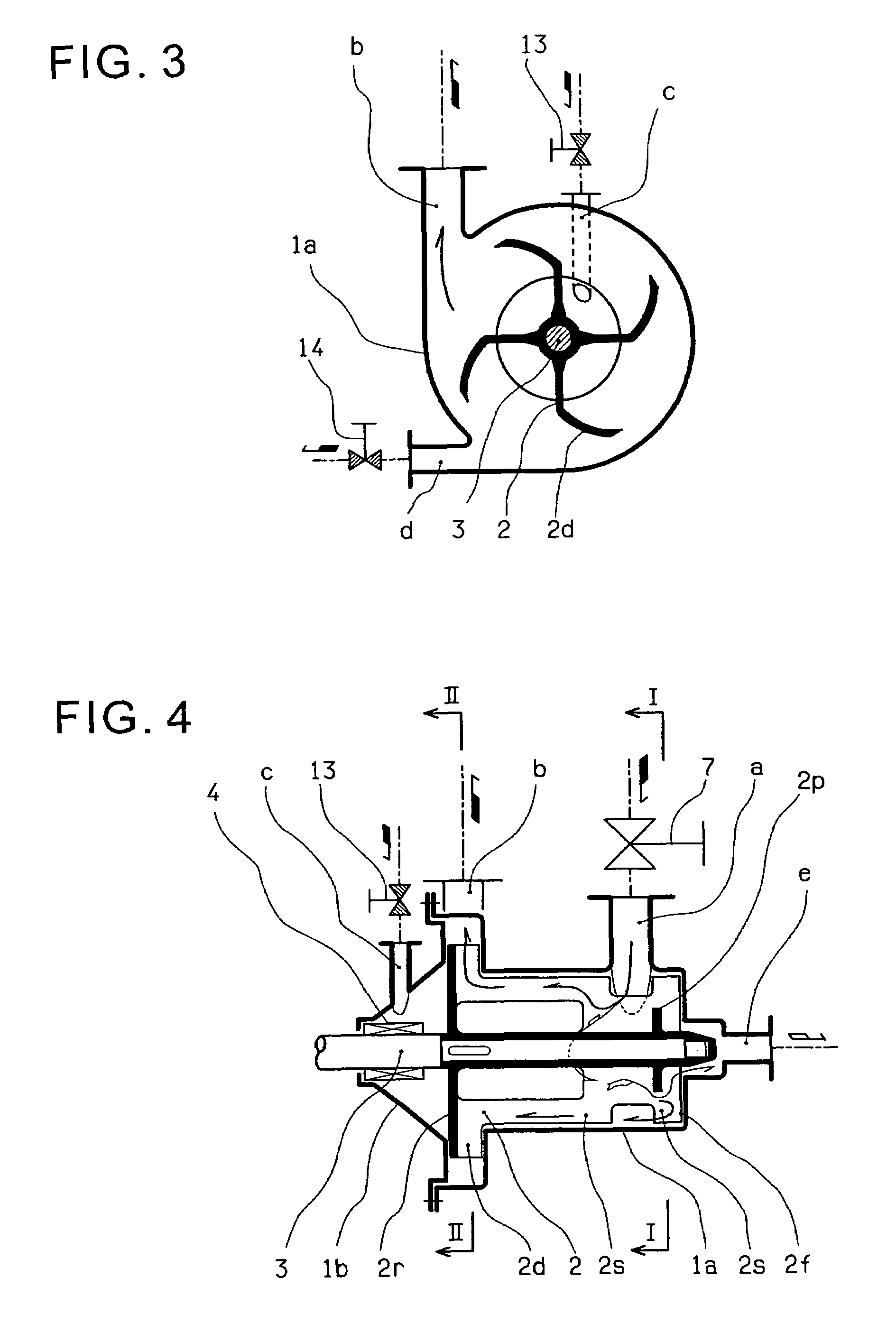

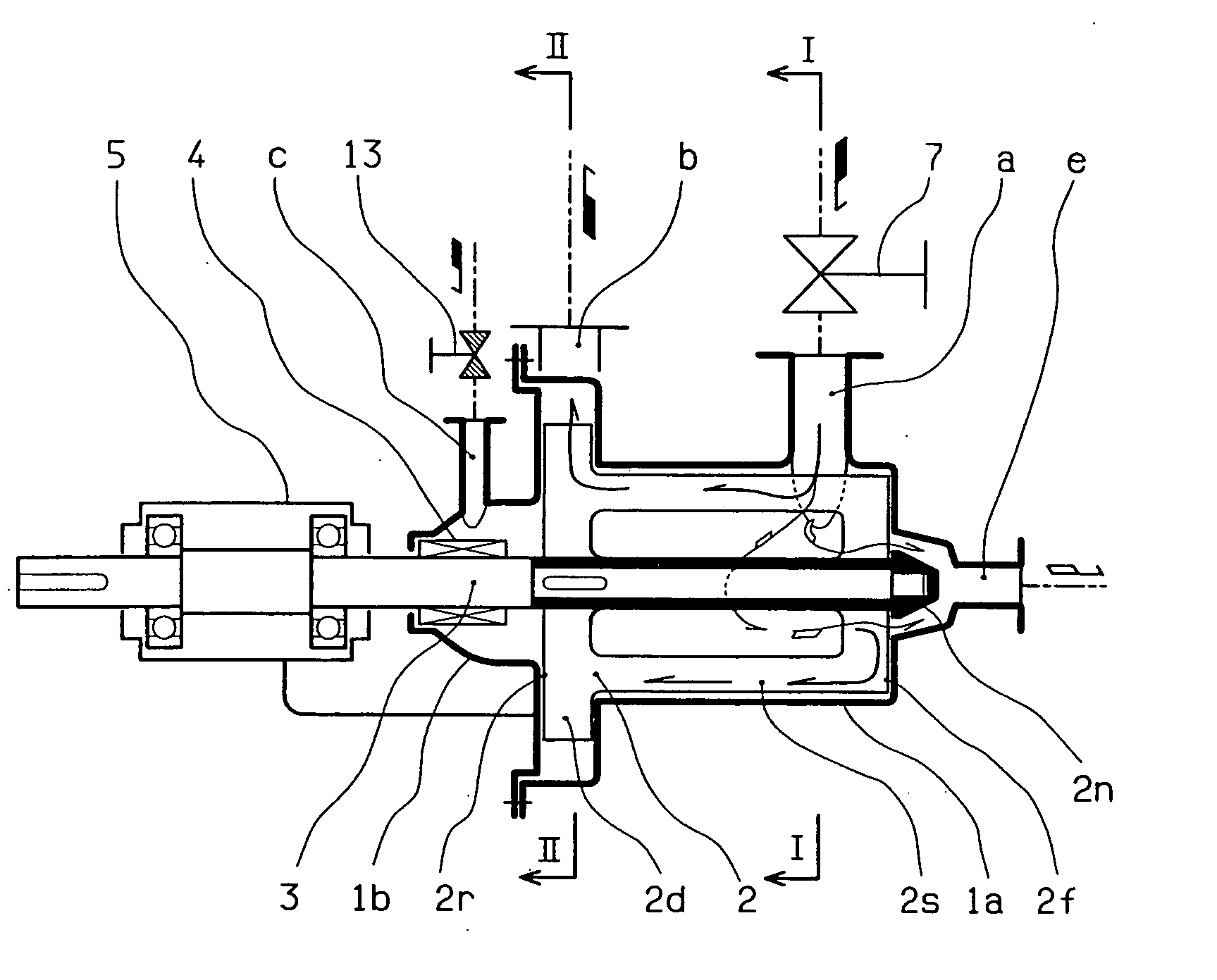

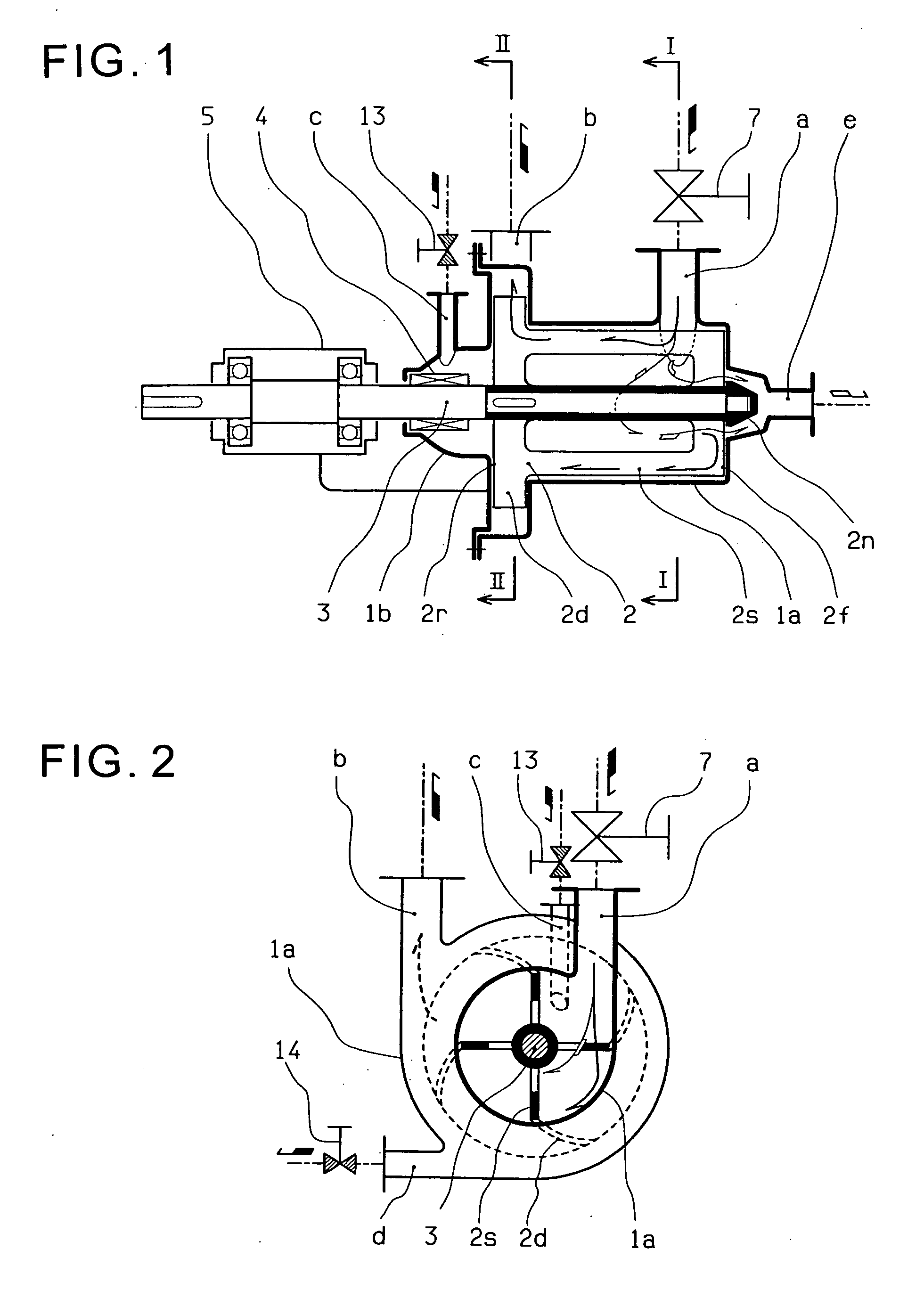

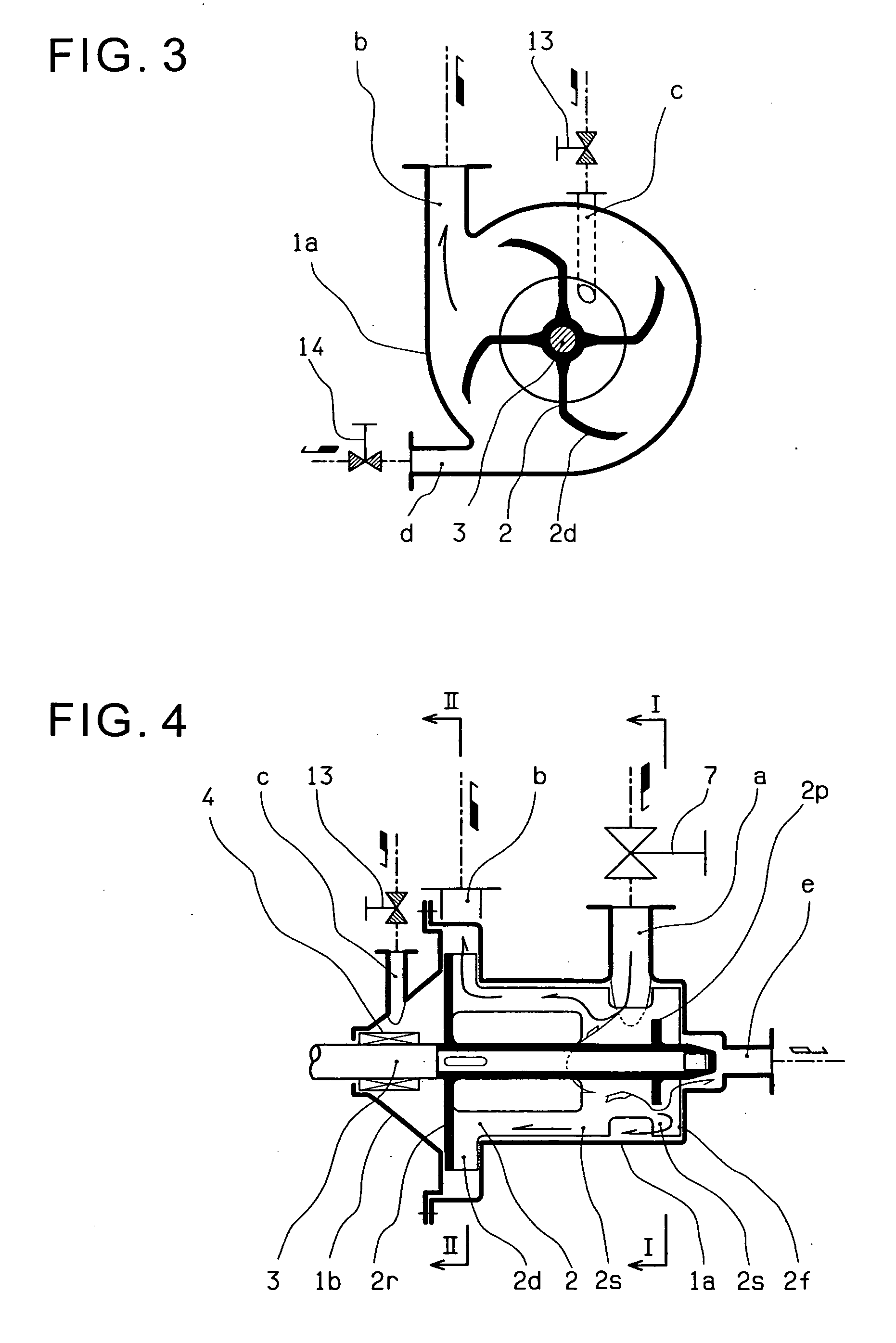

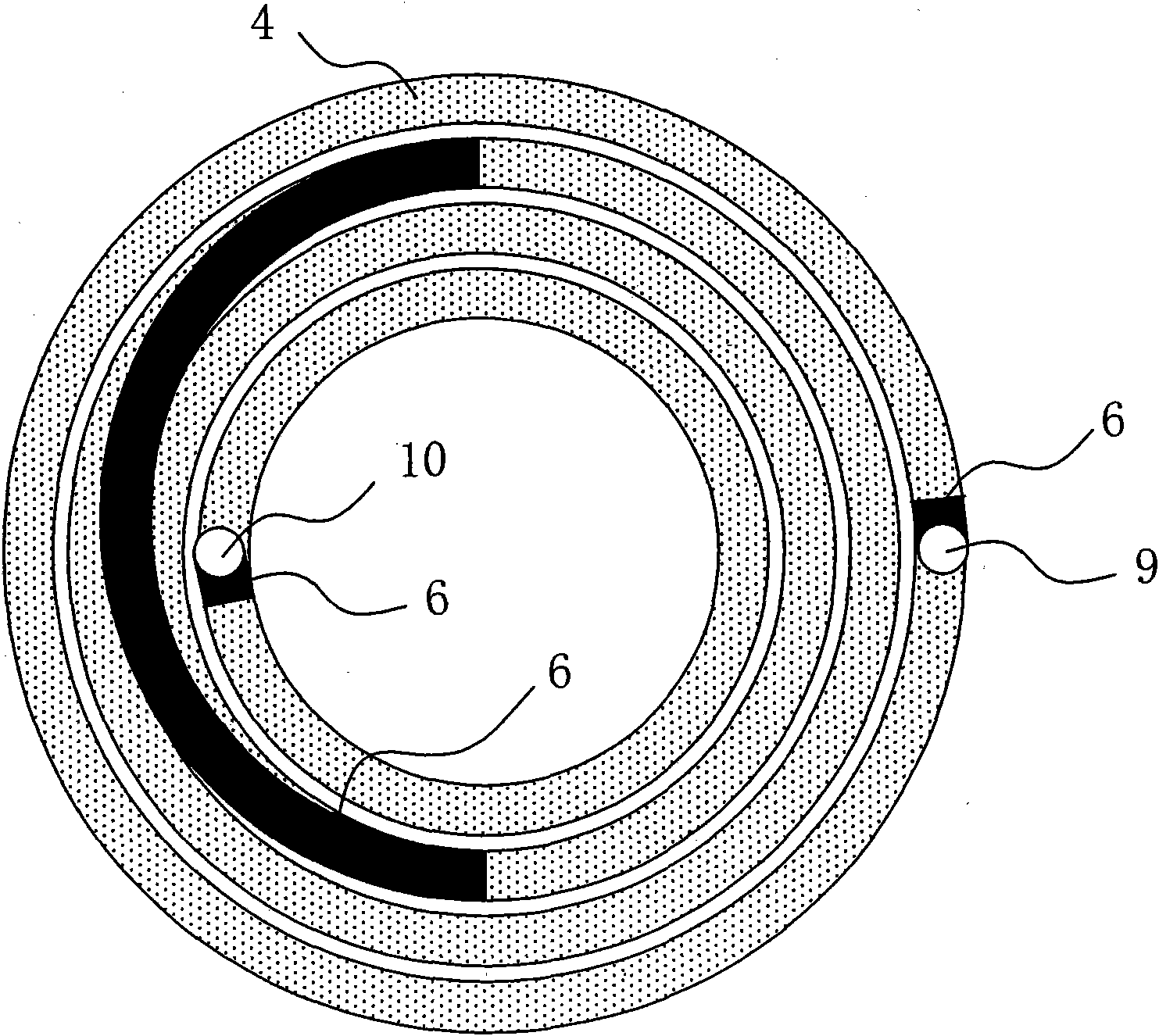

Gas-liquid separator

The present invention provides a gas-liquid separator with enhanced performance and easy operation, enabling to perform gas-liquid separation such as advanced defoaming or degassing, and facilitating easy cleaning with CIP (Cleaning In Place) and COP (Cleaning Out Place) ability that meets sanitary specifications.This gas-liquid separator for gas-liquid separation performed by centrifugal force of an impeller mounted on a shaft which rotates in a casing comprises: a discharge impeller part providing discharge force to the passing fluid formed on an axial end of the impeller; a discharge outlet of the casing disposed in a position opposite the discharge impeller part; the other axial end of the impeller being formed to slide on the inner wall of the casing; an exhaust outlet of the casing disposed in a position opposite the sliding impeller part; vacuum means connected to the exhaust outlet; and a suction inlet of the casing disposed in a position between the discharge outlet and the exhaust outlet.

Owner:YOKOTA SEISAKUSHO

Gas-liquid separator

ActiveUS20060064954A1Improve the effect of gas-liquid separationEasy to takeCombination devicesLiquid degasificationImpellerVapor–liquid separator

The present invention provides a gas-liquid separator with enhanced performance and easy operation, enabling to perform gas-liquid separation such as advanced defoaming or degassing, and facilitating easy cleaning with CIP (Cleaning In Place) and COP (Cleaning Out Place) ability that meets sanitary specifications. This gas-liquid separator for gas-liquid separation performed by centrifugal force of an impeller mounted on a shaft which rotates in a casing comprises: a discharge impeller part providing discharge force to the passing fluid formed on an axial end of the impeller; a discharge outlet of the casing disposed in a position opposite the discharge impeller part; the other axial end of the impeller being formed to slide on the inner wall of the casing; an exhaust outlet of the casing disposed in a position opposite the sliding impeller part; vacuum means connected to the exhaust outlet; and a suction inlet of the casing disposed in a position between the discharge outlet and the exhaust outlet.

Owner:YOKOTA SEISAKUSHO

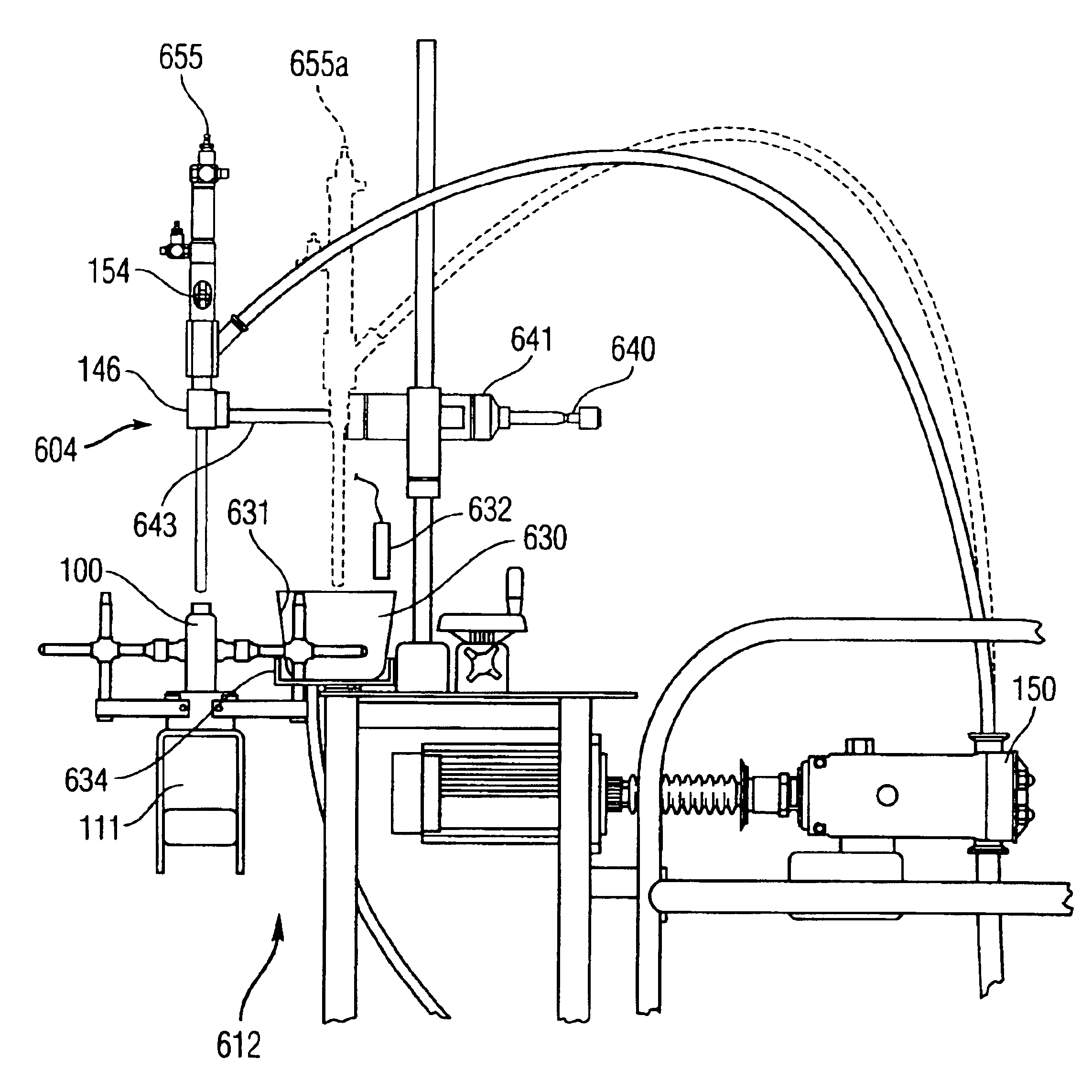

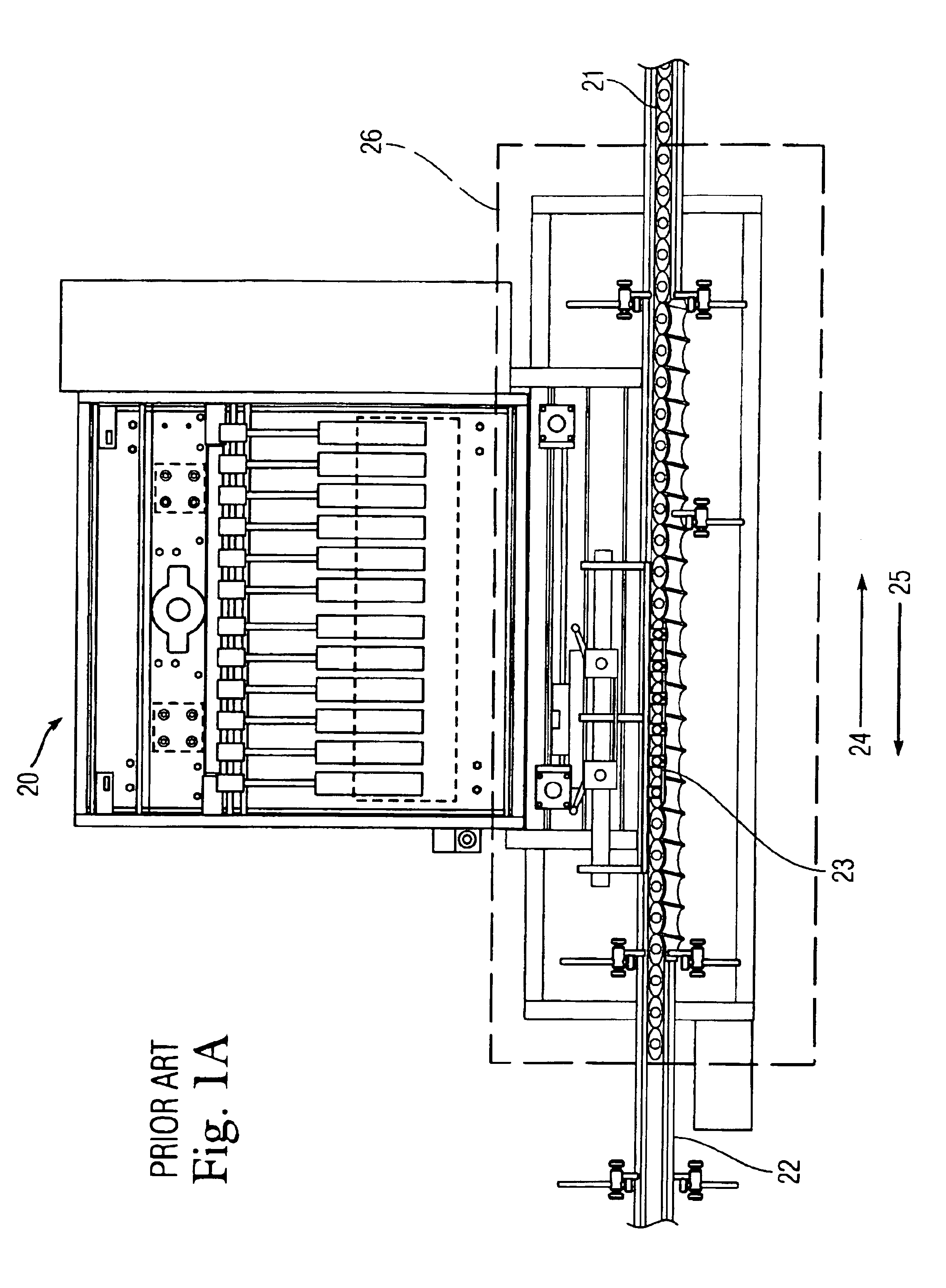

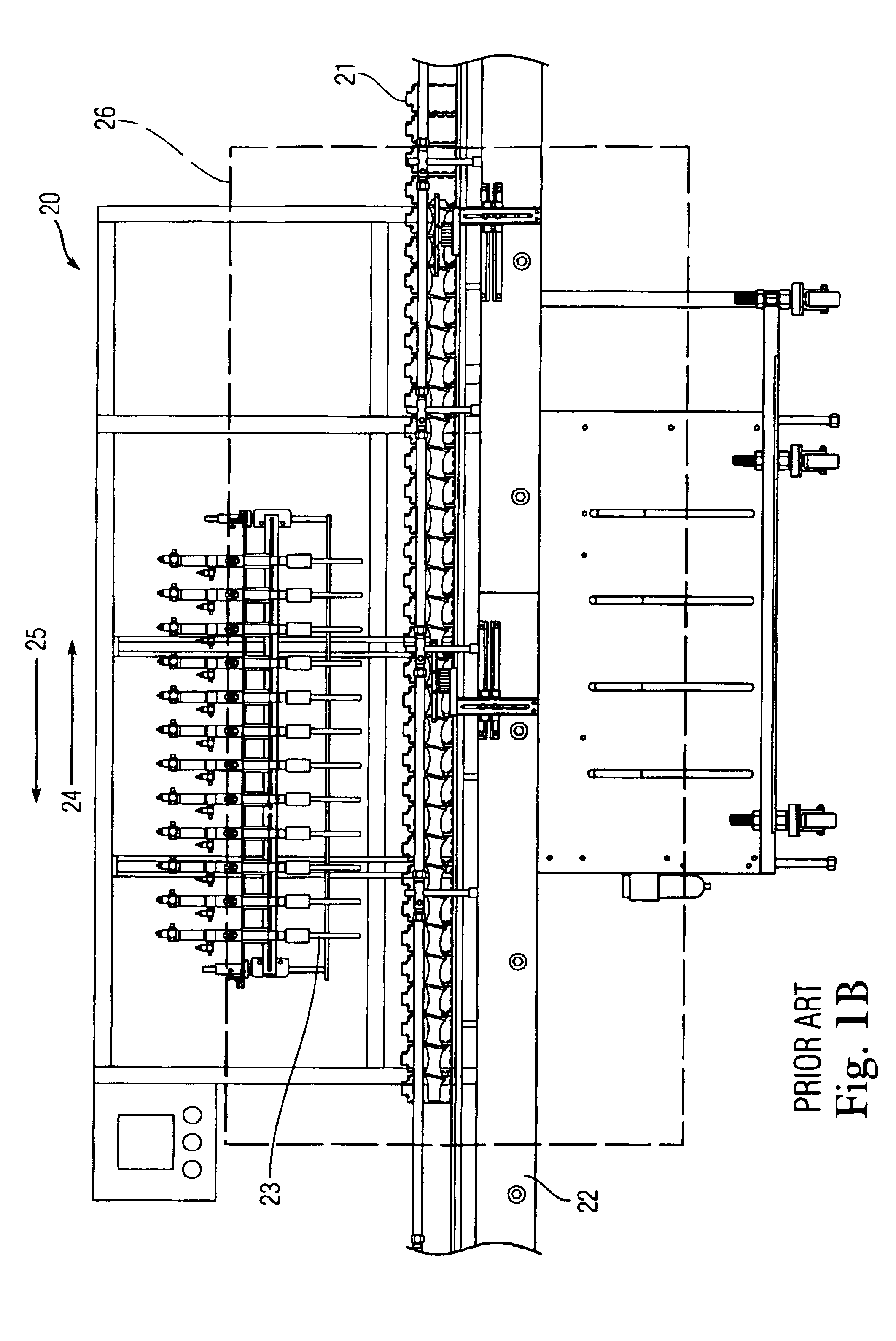

Liquid filling system with improved set-up and fill weight calibration/verification capabilities

InactiveUS6941981B2Improve system securityImprove accuracyLiquid fillingSolid materialProduction rateEngineering

An improved method and apparatus for a liquid filling system is herein disclosed incorporating means for generating greater overall production rate efficiencies (i.e. number of filled containers per minute per filling station) for automatic systems utilizing diverter valve and / or walking beam (i.e. continuous-motion) filling technologies with, for example, non-traditional ratios between the number of filling stations and the number of filling nozzles. The methods / apparatus disclosed herein also incorporate means to more efficiently changeover and clean up, in either a clean-in-place (CIP) or clean-out-of-place (COP) configuration, the product contact parts that become “dirty” when used in a production environment. Finally, an improved method and apparatus designed to provide a means for priming and air purging the product contact path of liquid filling machinery, a fill volume calibration procedure, and a fill weight verification cycle is also herein described.

Owner:ROSEN ROBERT A

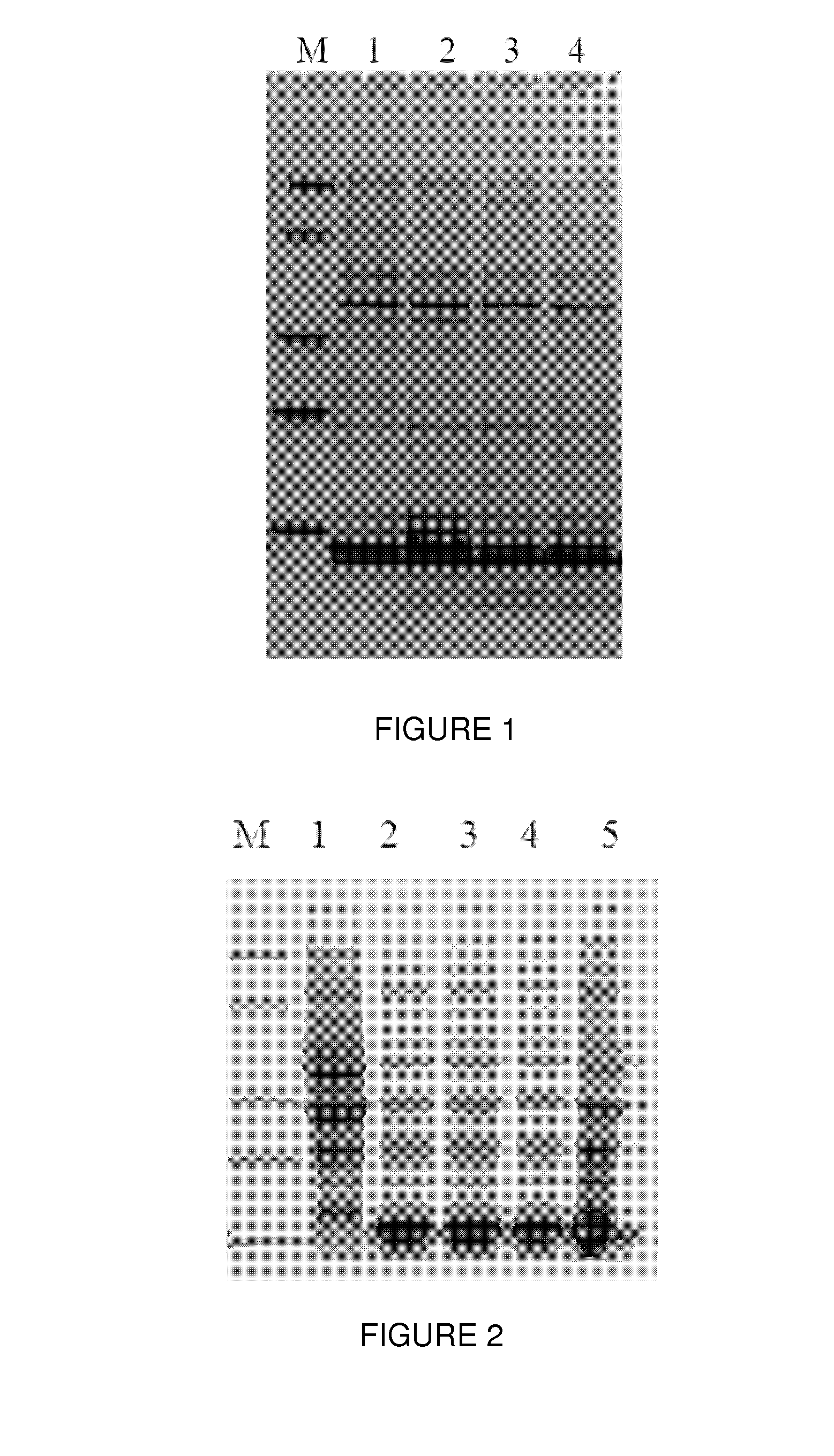

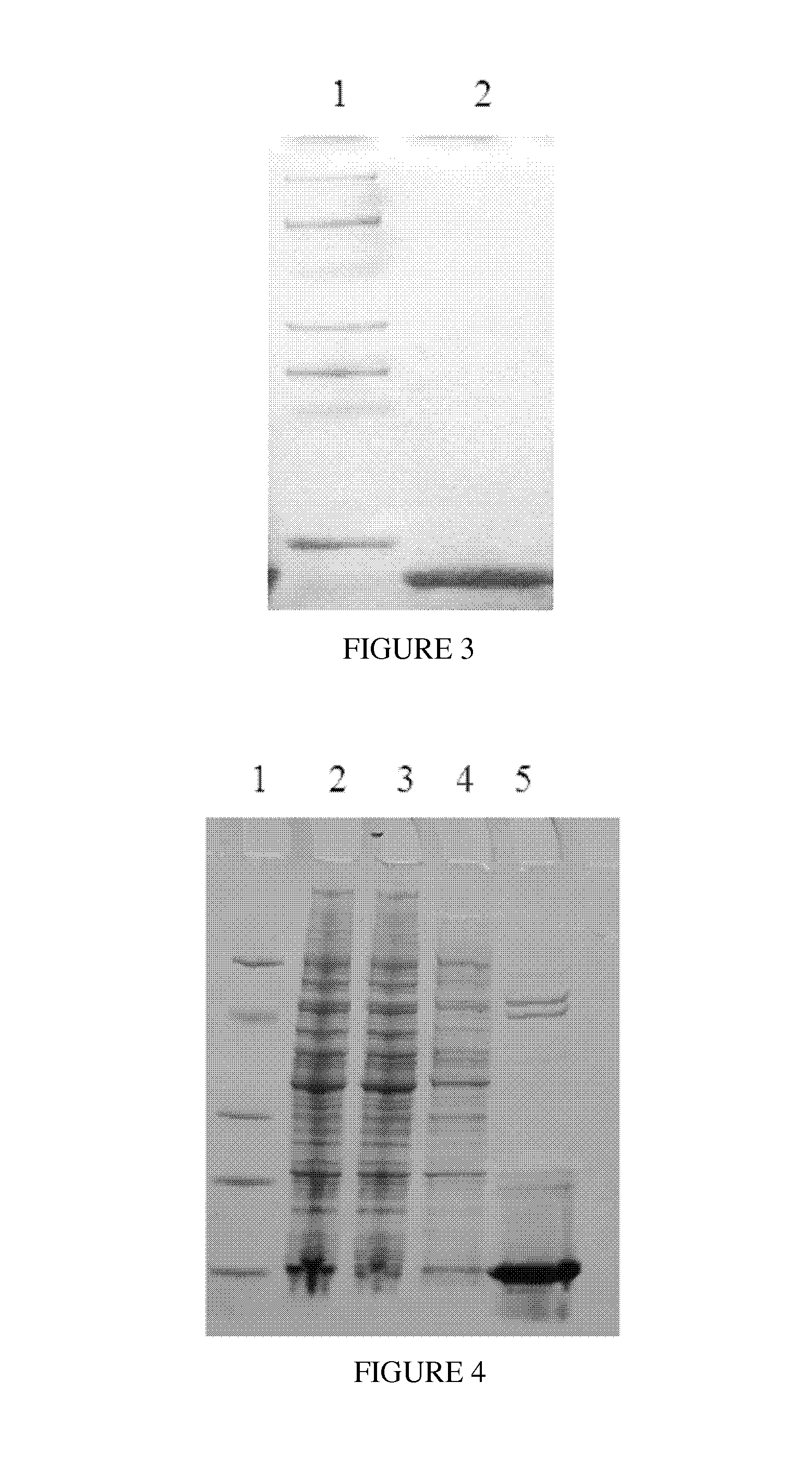

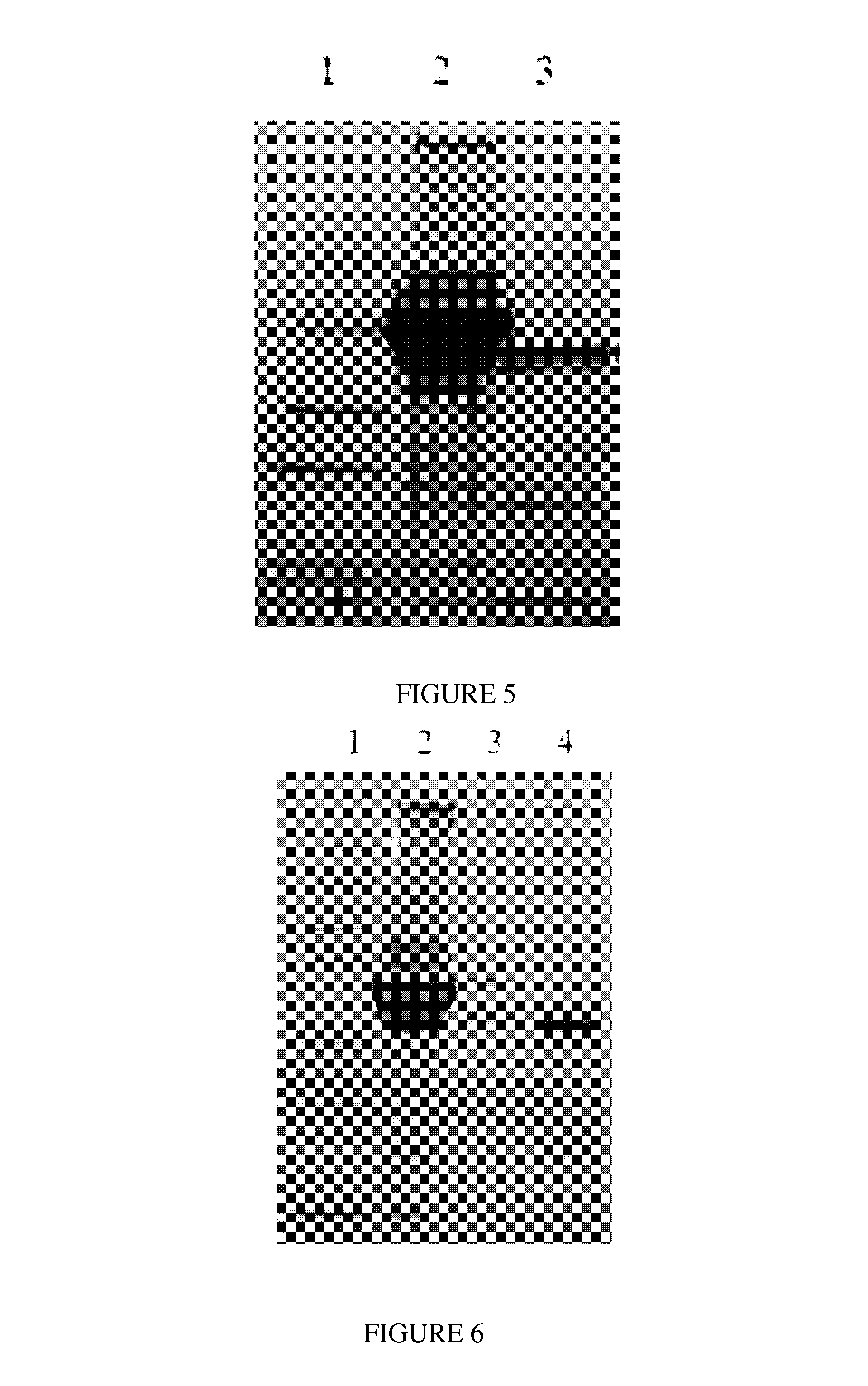

Kind of mutated proteins a with high alkali resistance feature and application thereof

ActiveUS20160237124A1Maintain chemical stabilityBonded firmlyAntibody mimetics/scaffoldsPeptide preparation methodsComplementarity determining regionImmunoglobulin region

A series of protein A mutants having high alkali resistance, and methods of using the protein A mutants are provided. The protein A mutants have a high binding affinity for regions of immunoglobulin proteins other than the complementarity determining regions. The protein A mutants can be coupled to a solid support for immunoglobulin isolation, or conjugated to a label for immunoglobulin detection. This series of protein A mutants has high chemical stability under alkaline conditions of pH 13-14, and can also be used as chromatography ligands for purification procedures that use alkaline solutions under harsh conditions, such as Clean-In-Place (CIP). Also provided are methods of immunoglobulin separation and purification, and alkali regeneration of affinity chromatography medium that uses protein A as a ligand.

Owner:NANJING GENSCRIPT BIOTECH CO LTD

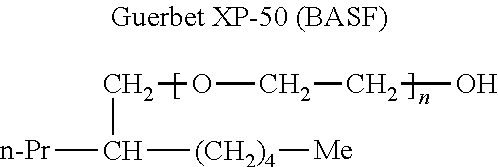

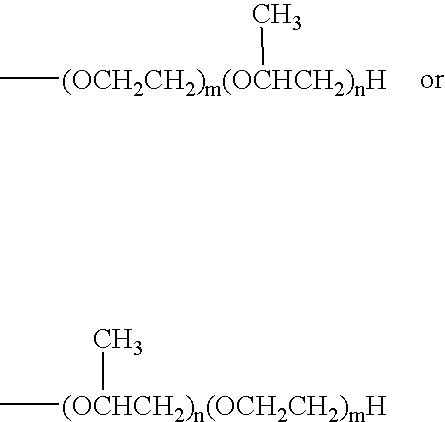

Surfactant blends for cleaning filtration membranes

ActiveUS20140274857A1Organic detergent compounding agentsNon-ionic surface-active compoundsFiltration membraneClean-in-place

The present invention relates to the field of membrane separation processes and clean in place compositions for cleaning such membranes. The cleaning compositions can remove proteins, fats, and other food, beverage, and brewery based soils and offer an environmentally friendly alternative surfactant system to NPE. According to the invention, surfactants and polymers useful for this process are unpredictable and specific surfactants, polymers, and combinations of the same are disclosed for use alone, as part of a cleaning composition. Methods of use of the same are also included.

Owner:ECOLAB USA INC

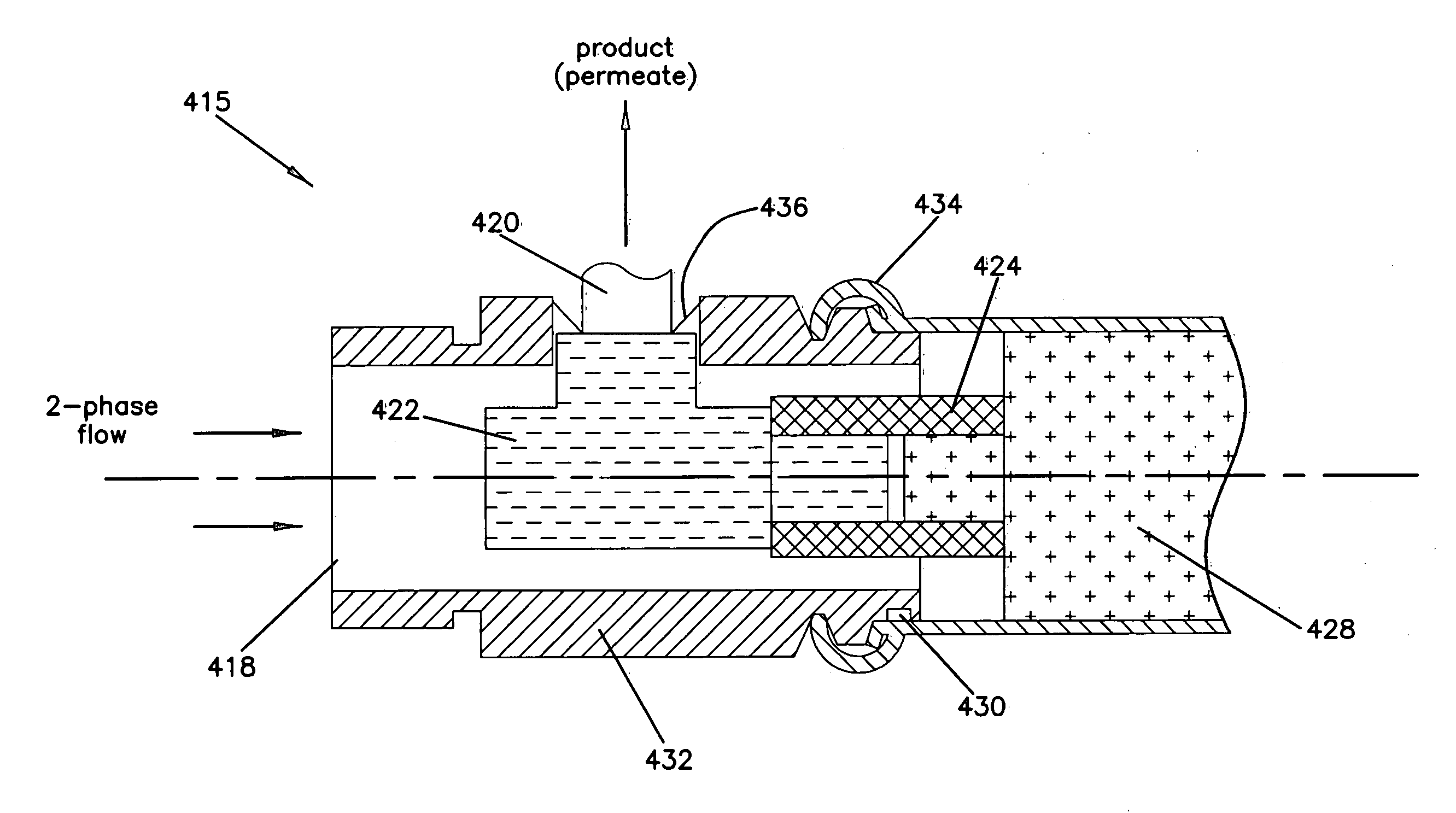

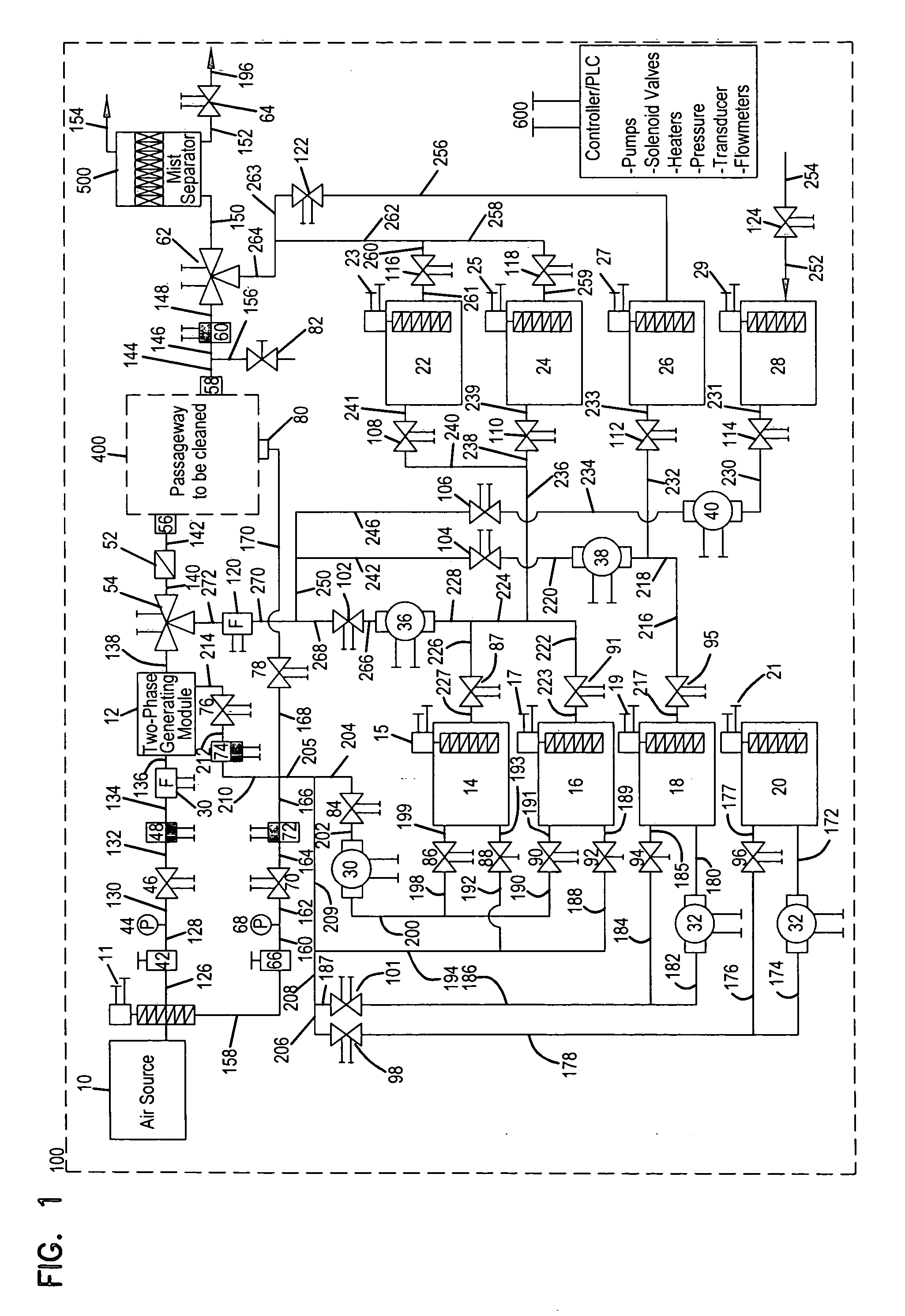

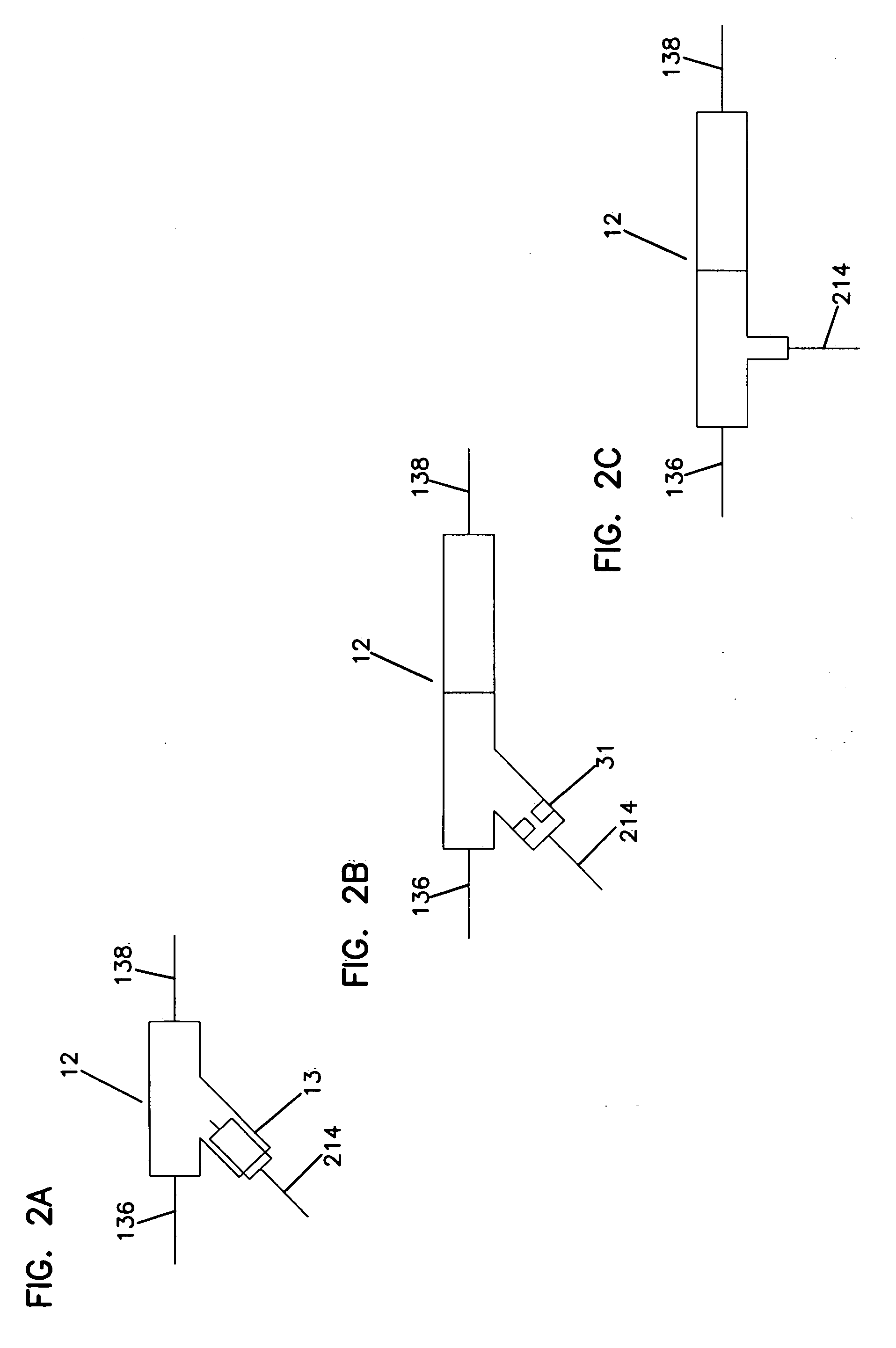

Apparatus and method for cleaning pipelines, tubing and membranes using two-phase flow

InactiveUS20090229632A1Inorganic/elemental detergent compounding agentsDiagnosticsVolumetric Mass DensityProcess industry

An apparatus and method for cleaning passageways and the like with a two-phase mixture of gas under pressure and an aqueous cleaning solution. The two-phase cleaning mixture is generated in a module and is passed out of the module at a predetermined rate that determines droplet size, velocity and droplet density at the pipeline surface to be cleaned. The droplets impact the walls of the passageway to be cleaned, thereby fragmenting, eroding and removing contaminants in said passageway. These are then flushed out of the passageway by the two-phase flow. The flow of cleaning solution can be steady or pulsed. The apparatus and process include a clean-in-place system that is useful in food, beverage, pharmaceutical and similar process industries.

Owner:OLYMPUS CORP

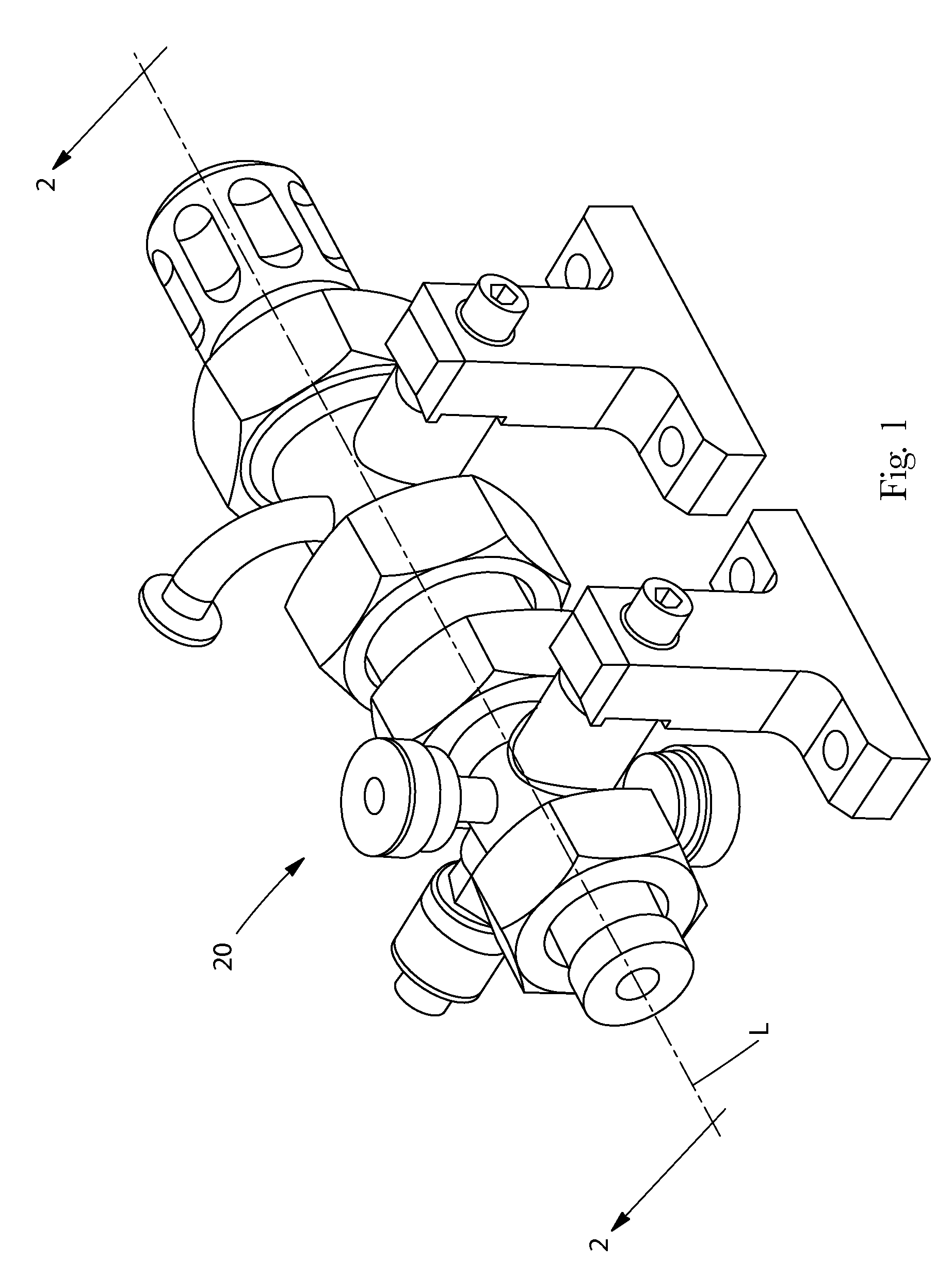

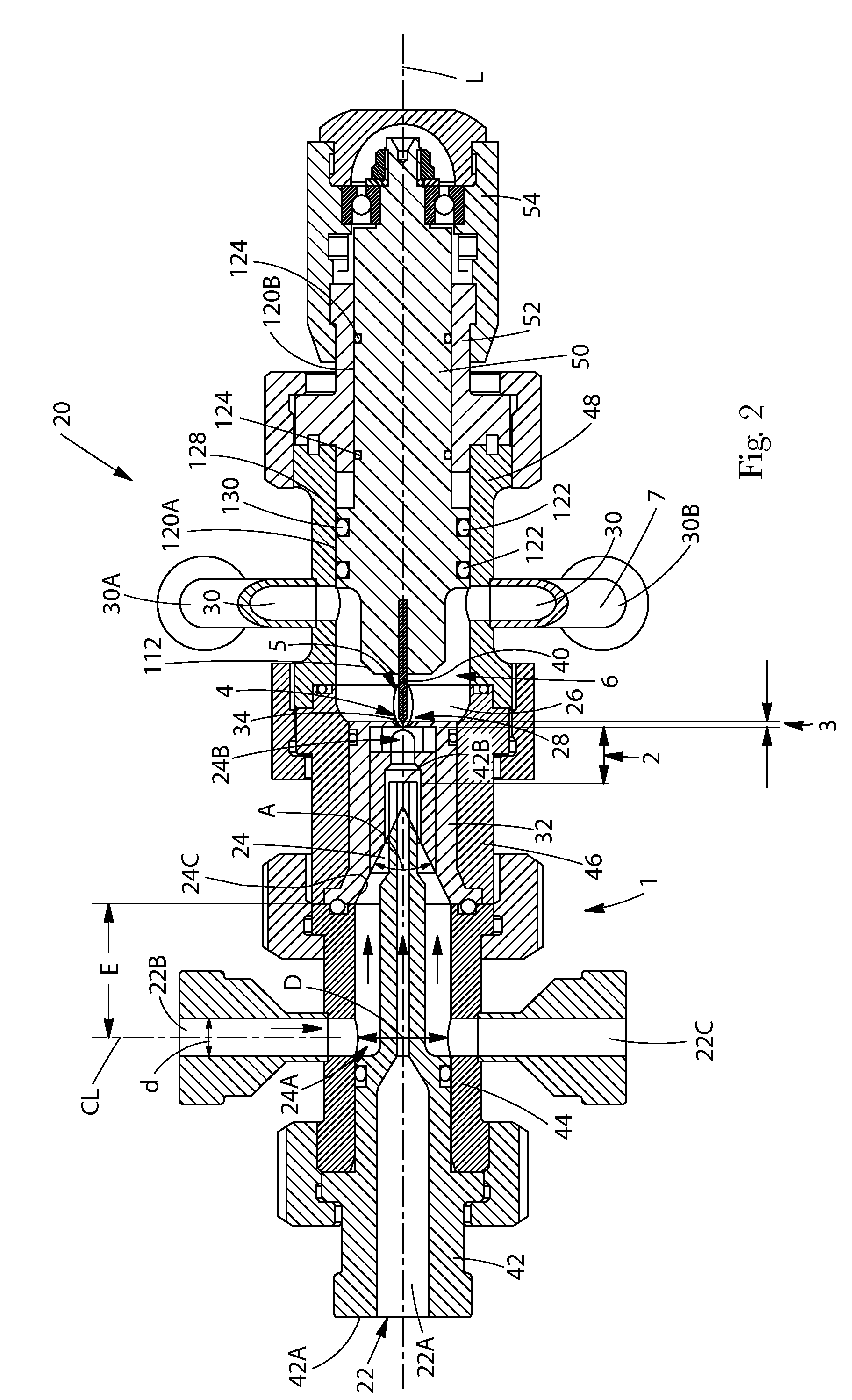

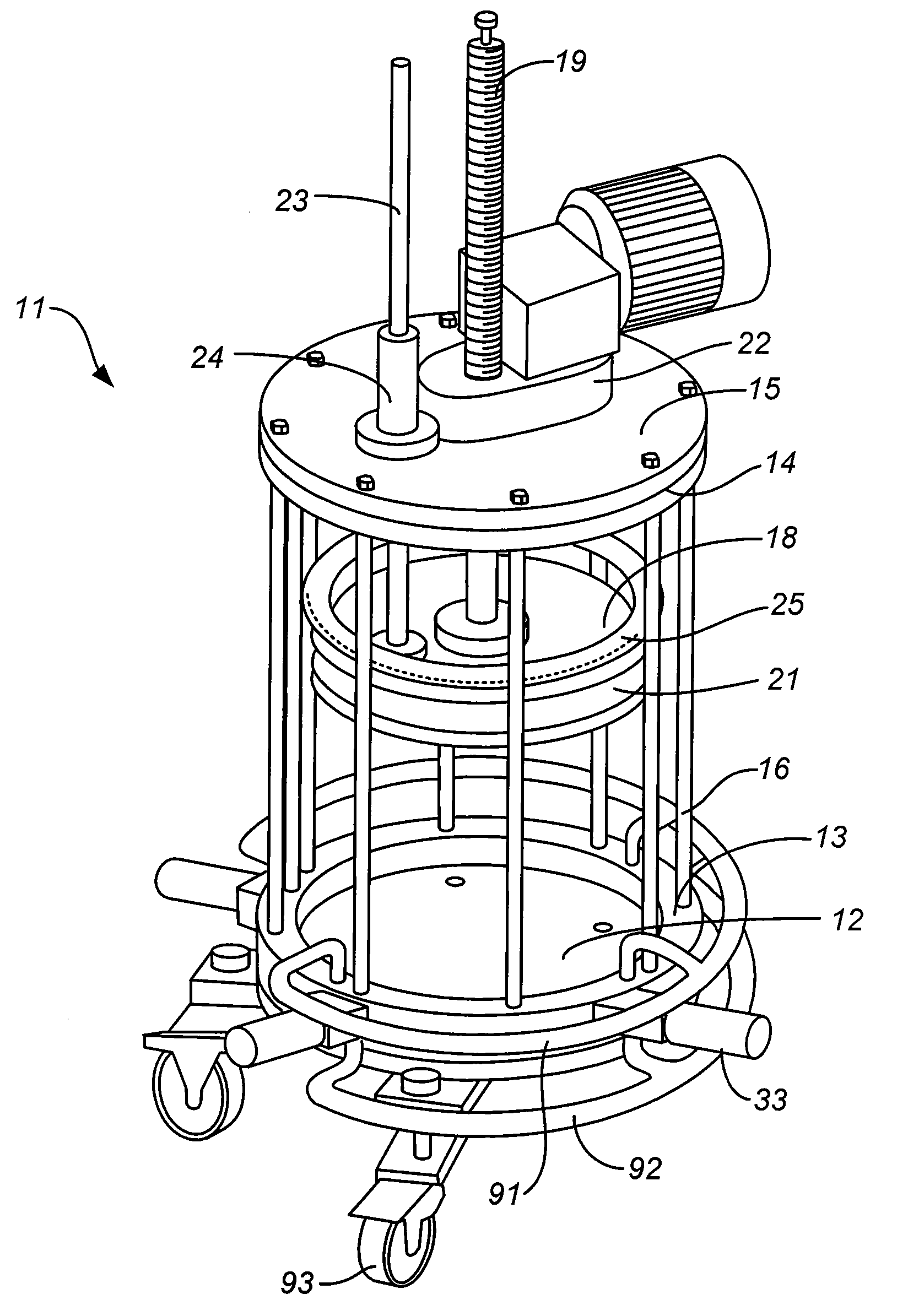

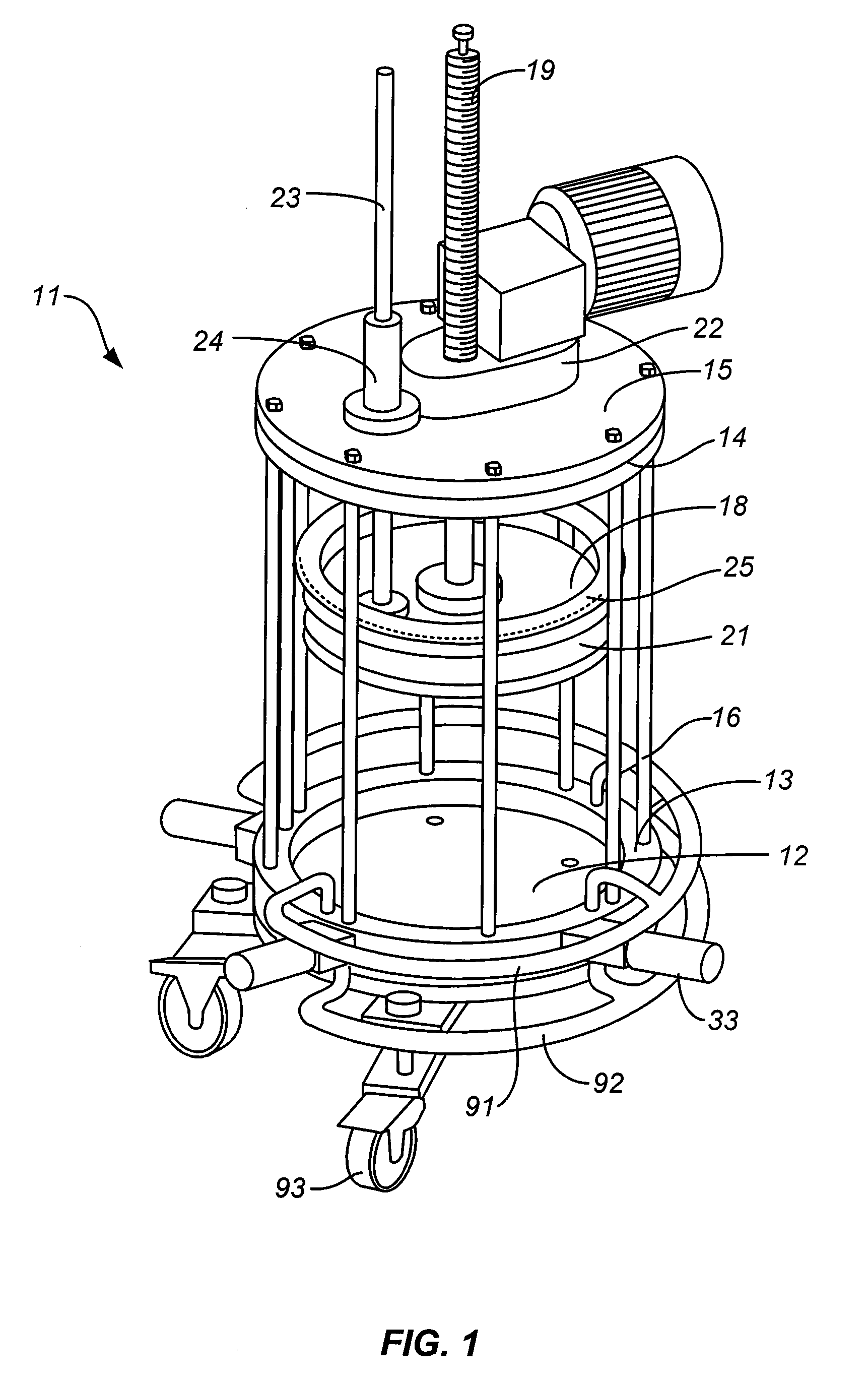

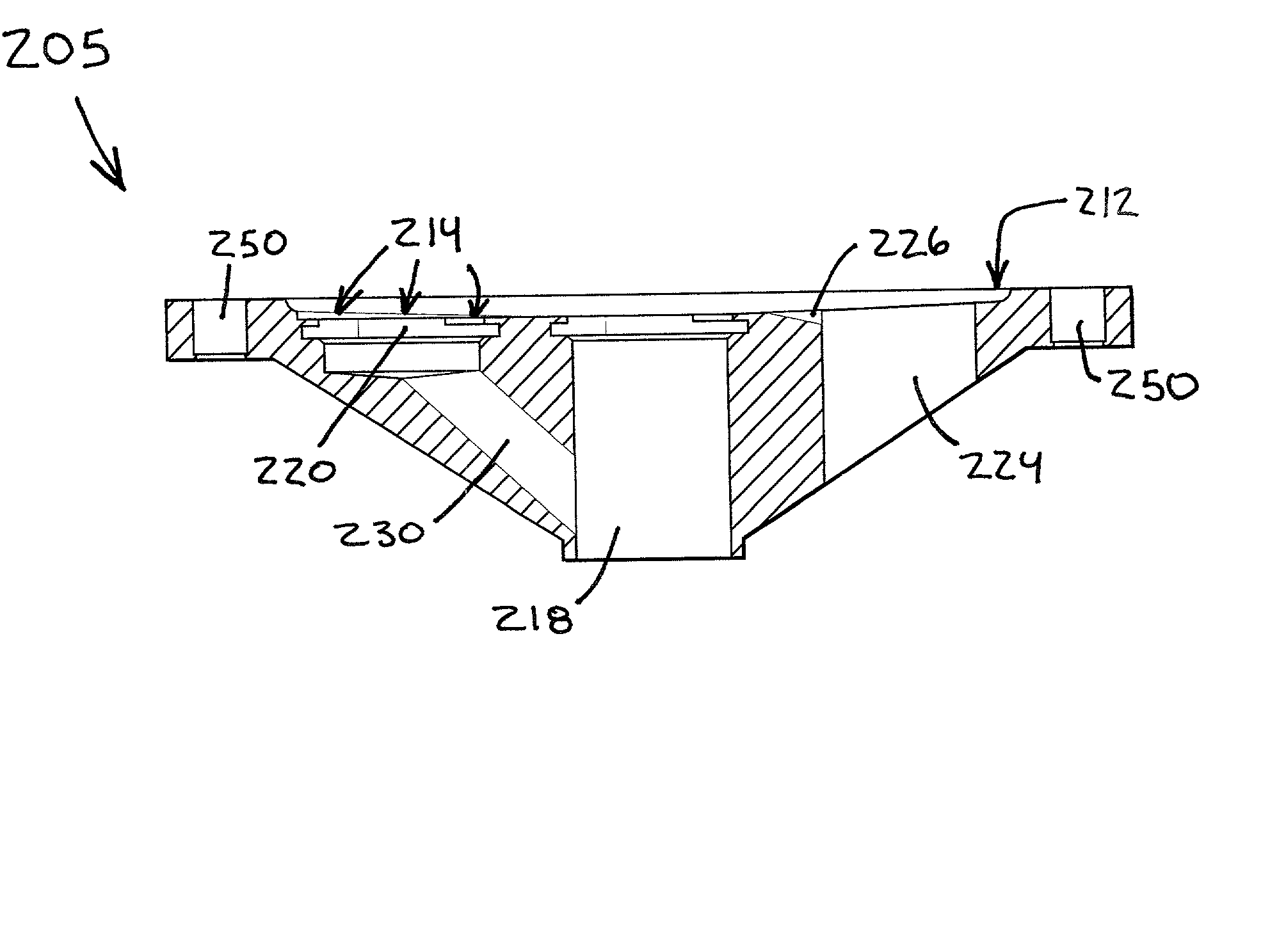

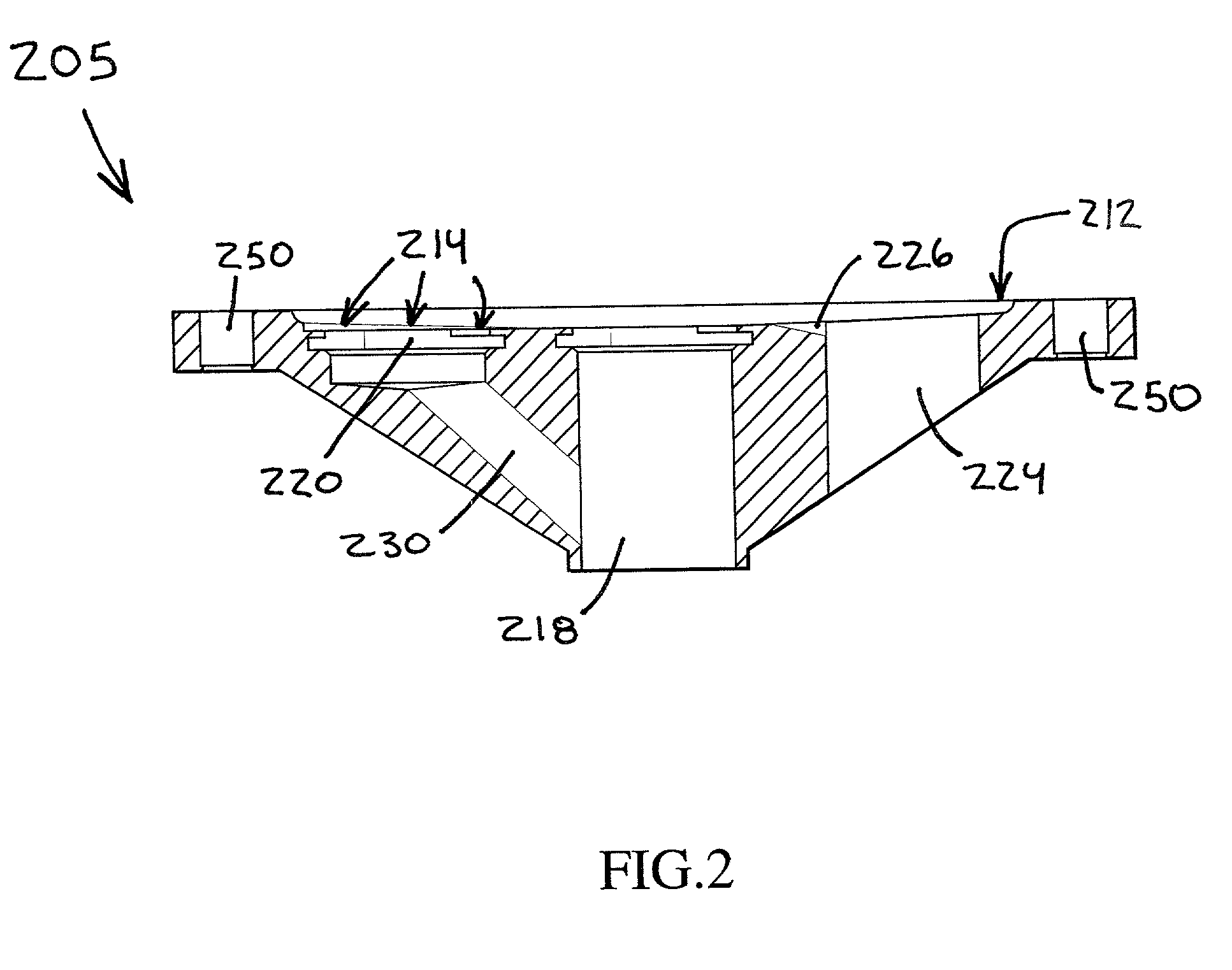

Chromatography column with pack, unpack, and clean-in-place features

A preparative chromatography column is equipped with one or more valves that can each be used to both inject a column packing into the column or withdraw used packing from the column, in addition to cleaning the supply and discharge lines associated with the valve itself, all by moving a movable plug within the valve body and all without protruding into the column interior. Each valve is mounted on the lateral wall of the column just above the filter plate at the column floor, and the plug is movable between a closed position in which the end surface of the plug is flush with the inner wall of the column and an open position in which the plug is recessed within the bore. Each valve has two additional ports in its valve body, positioned such that when the plug is closed, both ports are open to the valve bore, and when the plug is open, at least one of the ports is open to the bore. The position of the plug within the valve bore determines the valve function.

Owner:VERDOT IPS2

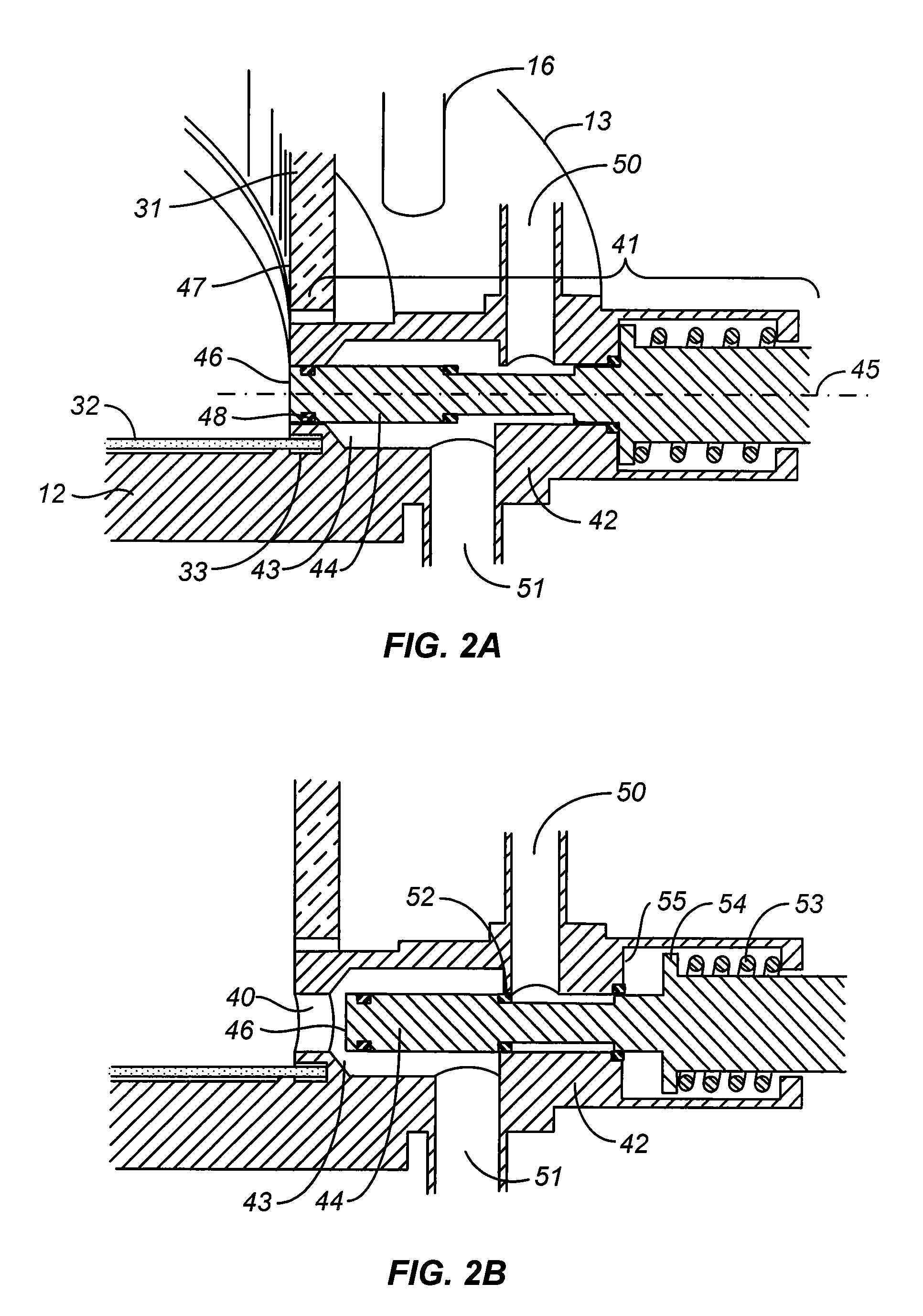

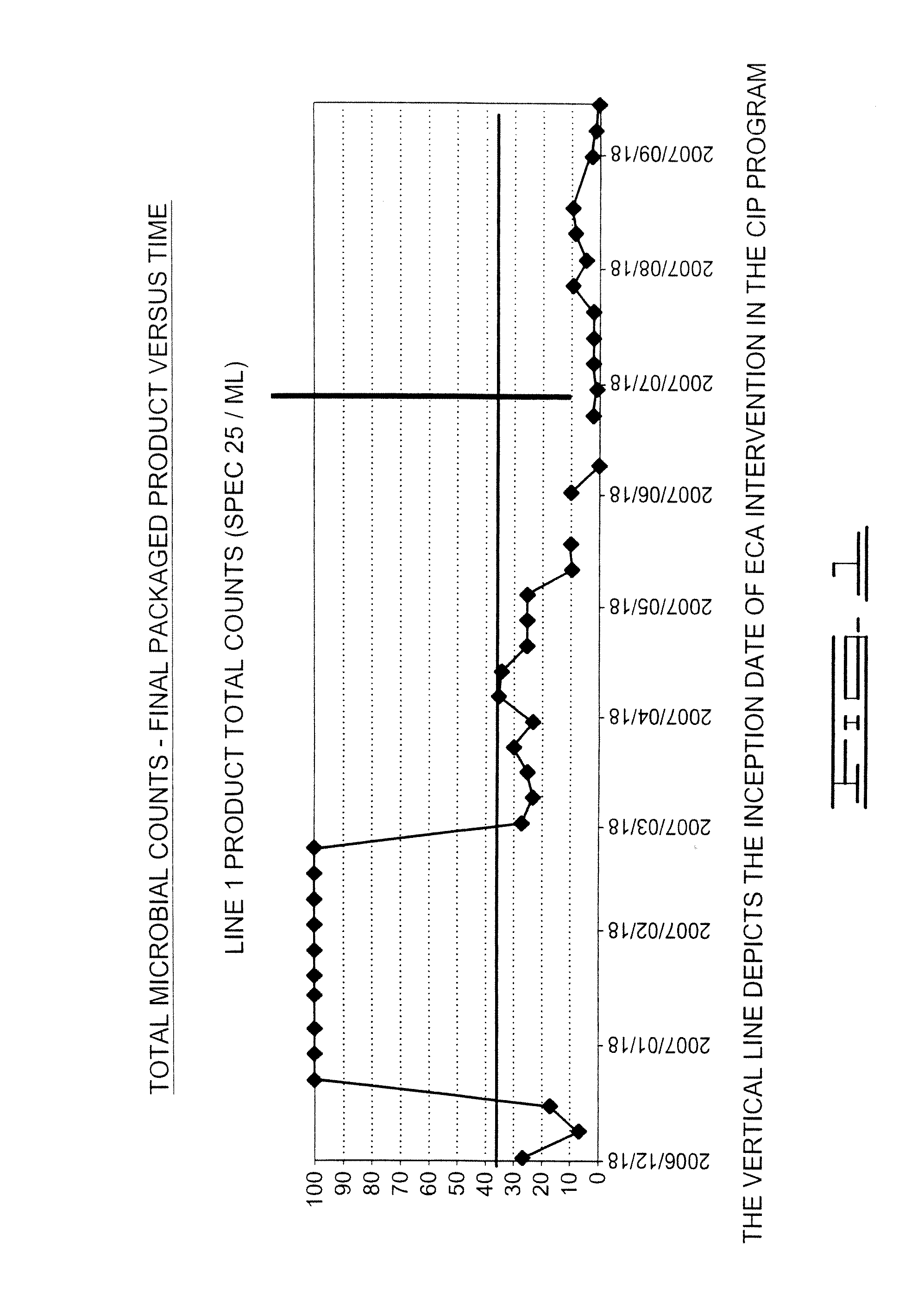

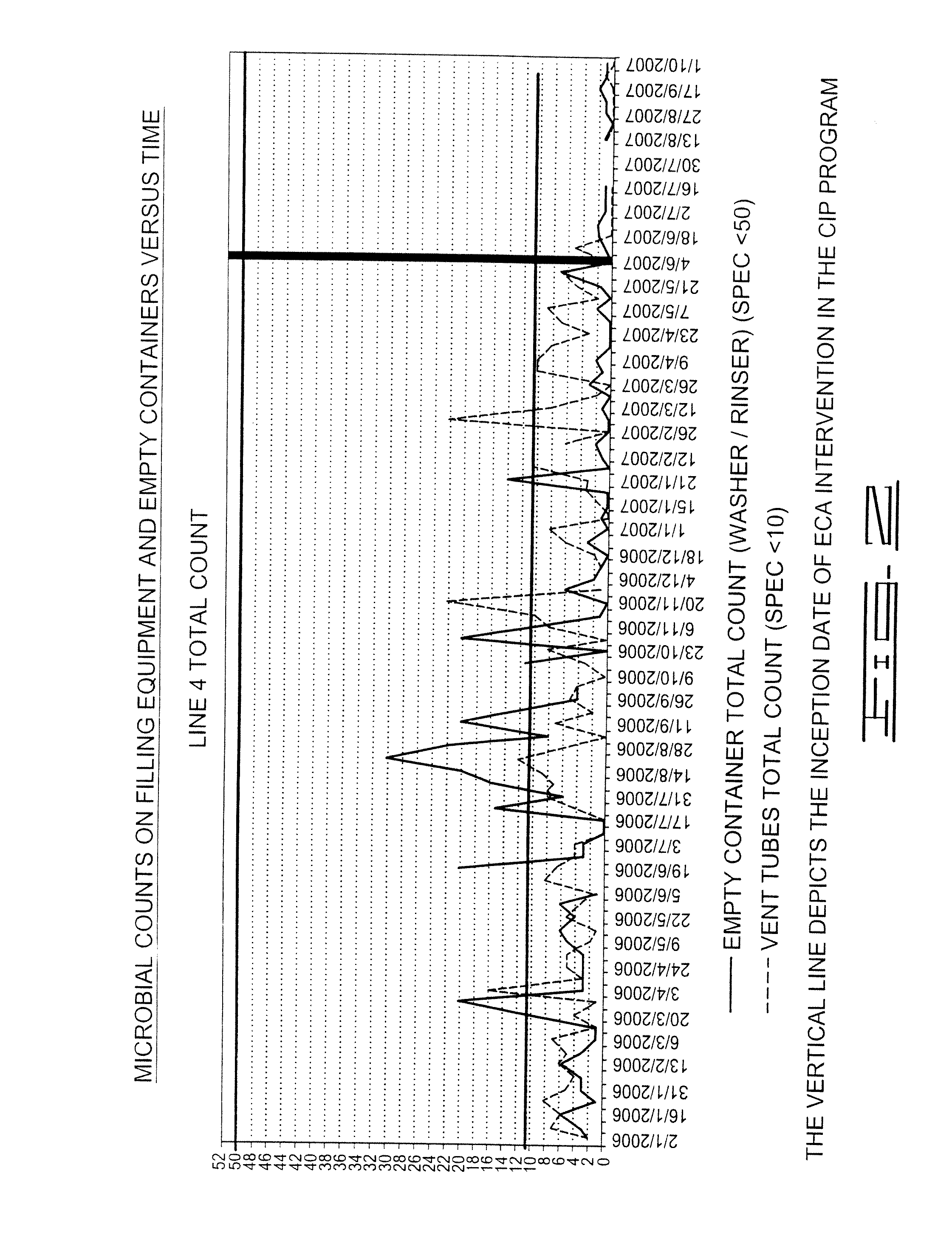

Beverage manufacture, processing, packaging and dispensing using electrochemically activated water

ActiveUS20090199866A1Reducing eliminating needEliminate the problemWater treatment parameter controlSpecific water treatment objectivesBiofilm growthAdditive ingredient

A system using electrochemically-activated water (ECAW) for manufacturing, processing, packaging, and dispensing beverages including: (a) using ECAW to neutralize incompatible residues when transitioning from the production of one beverage to another; (b) using ECAW to rehabilitate and disinfect granular activated charcoal beds used in the feed water purification system; (c) producing a carbonated ECAW product and using the carbonated ECAW for system cleaning or disinfecting; (d) using ECAW solutions in the beverage facility clean-in-place system to achieve improved microbial control while greatly reducing water usage and reducing or eliminating the use of chemical detergents and disinfectants; (e) further reducing biofilm growth in the processing system, and purifying ingredient water without the use of chlorine, by adding an ECAW anolyte to the water ingredient feed stream; and / or (f) washing the beverage product bottles or other packages with one or more ECAW solutions prior to packaging.

Owner:RADICAL WATERS INT LTD +1

Catch basin filter absorber apparatus for water decontamination

ActiveUS7479221B2Easy to installLow costFatty/oily/floating substances removal devicesGround-workActivated carbonAbsorbent material

Owner:INVENTIVE RESOURCES

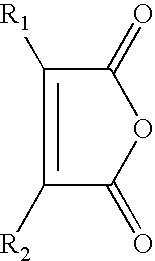

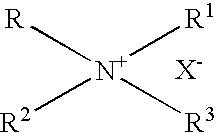

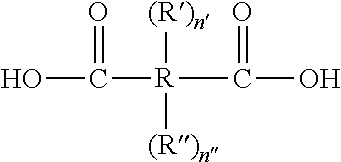

Composition and method for road-film removal

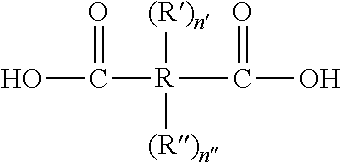

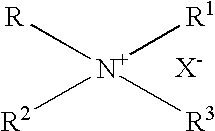

InactiveUS6864220B2Cationic surface-active compoundsOrganic detergent compounding agentsOrganic acidHydrotrope

A concentrate and a ready-to-use or diluted formulation for an aqueous vehicle cleaner can remove a wide range of different types of traffic film using either low pressure application, hand pressure application, water jet spray apparatus, clean-in-place systems or other manual or mechanical washing systems. The compositions may comprise, for example, one or more solutions that each or collectively contain or comprises:a) at least one anionic surfactant;b) at least one poly[oxyalkylene] ammonium cationic surfactant; andc) an alkaline agent.Optional additional ingredients may comprise at least one polycarboxylic acid chelating agent (preferably an aminocarboxylic acid chelating agent), at least one non-ionic or amphoteric surfactant, at least one hydrotrope, inorganic and / or organic acids and at least one silicate. The alkaline agent may provide a pH (when the finished product is diluted to 0.5 to 5% by weight in water) will be between about 9 to 13. The concentrate may be provided as a one-part or two part solution. Certain formulations have been found to be shelf stable as one-part concentrate or ready-to-use solutions, even with significantly different properties amongst the components. The compositions of the invention are also used in cleaning processes for surfaces, especially vehicle surfaces in car wash systems. The compositions are used in such processes where there are single or multiple liquid application steps.

Owner:ZEP IP HLDG LLC

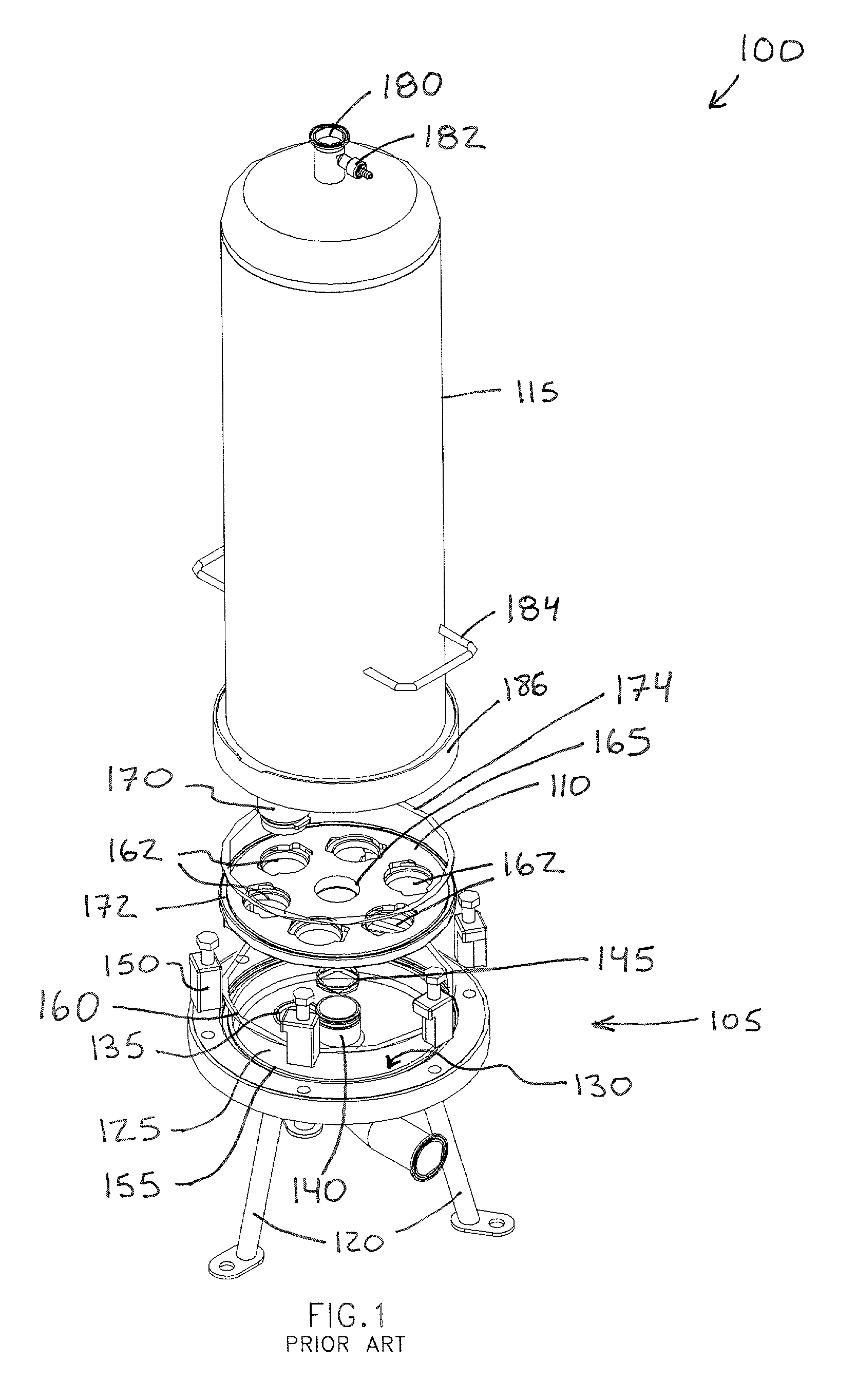

Integrated filter housing with associated cleaning system and method

InactiveUS20020130092A1Effective and safe and efficient cleaningReduce the amount requiredWater/sewage treatmentMembrane filtersEngineeringClean-in-place

A multiround filter housing apparatus, cleaning system and method are provided. A filter housing having an integrated base that includes an integral cartridge plate, a plurality of cartridge filter bores, an inlet manifold and an outlet manifold is presented. The upper face of the integral cartridge plate is recessed to facilitate drainage of product and cleaning media. The lower portions of the cartridge filter bores are connected to the outlet port by additional sloped bores, thereby eliminating the need for a collection chamber. A spray device assembly is provided to facilitate a complete "Clean-in-Place" system in conjunction with the filter housing of the present invention.

Owner:ALLEGHENY BRADFORD CORP

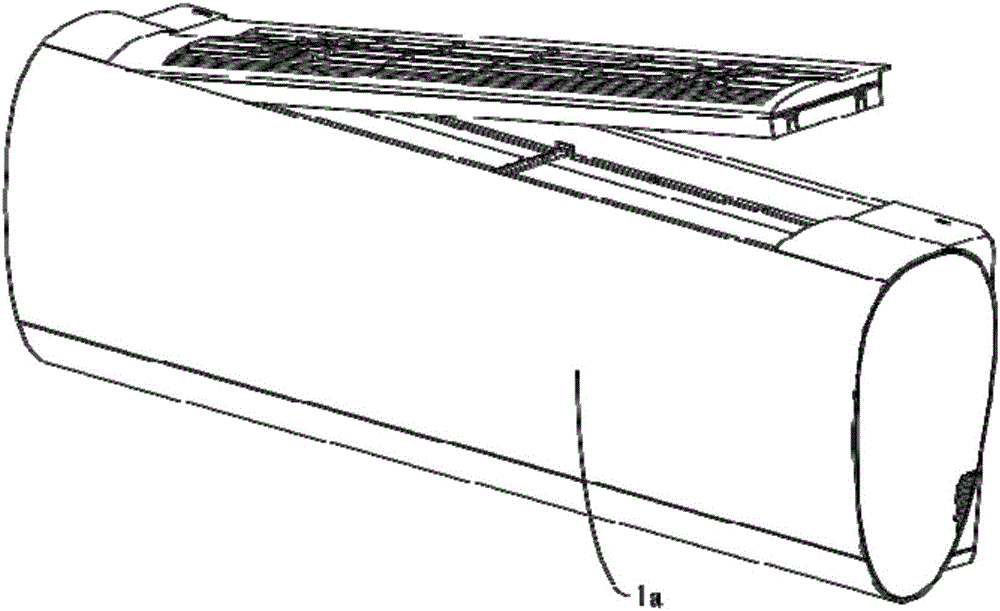

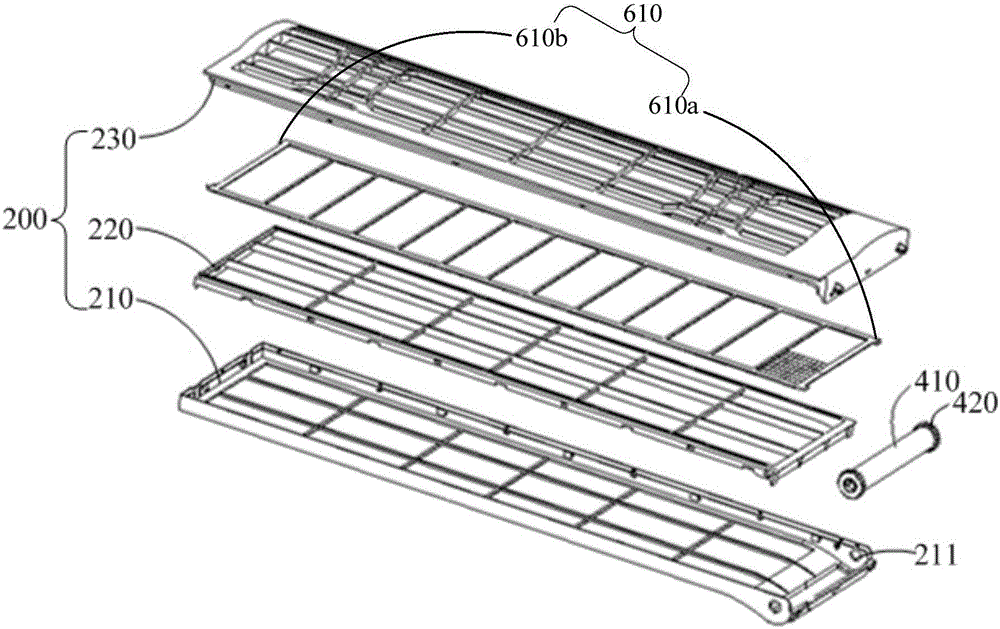

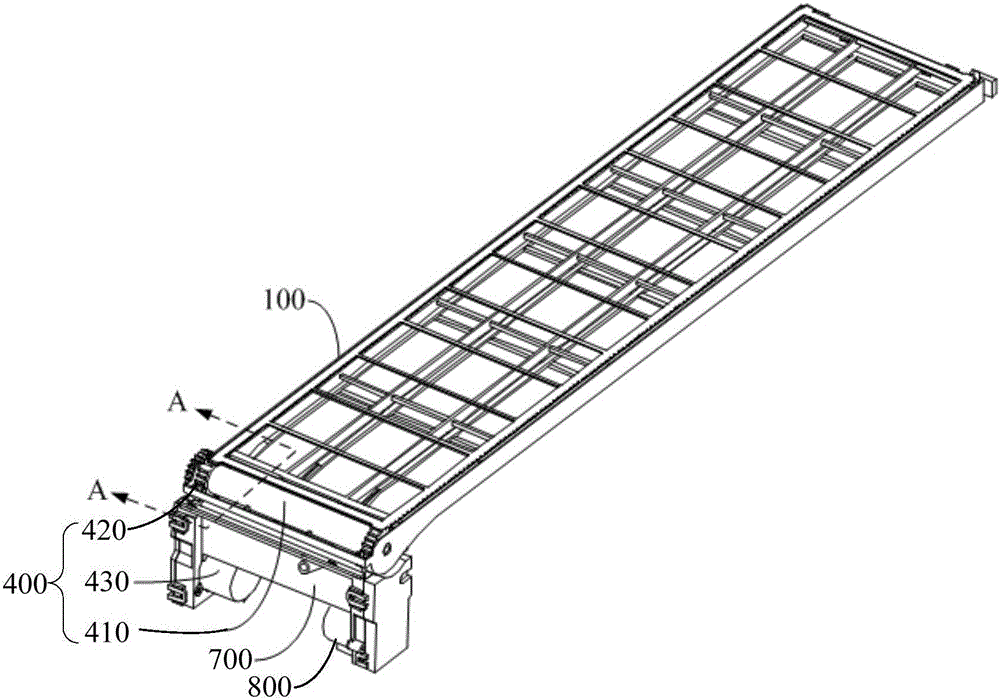

Air conditioner and self-cleaning control method for air conditioner

InactiveCN106016521AGuaranteed to move in placeMove in place to ensureMechanical apparatusSpace heating and ventilation safety systemsControl theoryClean-in-place

The invention discloses an air conditioner and a self-cleaning control method for the air conditioner. The air conditioner comprises a filter screen support, a filter screen and a dust removing brush making contact with the surface of the filter screen so as to clean the filter screen. The filter screen support is provided with a driving device used for driving the filter screen to move. The air conditioner further comprises a position detecting device used for detecting the moving position of the filter screen and a controller electrically connected with the driving device and the position detecting device. The controller is used for controlling the operation state of the driving device according to the moving position, detected by the position detecting device, of the filter screen. The position detecting device is used for detecting the moving position of the filter screen, the controller is used for controlling the operation state of the driving device according to the moving position, detected by the position detecting device, of the filter screen, and therefore it can be guaranteed that the filter screen can move in place in each time of cleaning, and then it is ensured that the filter screen can be cleaned in place.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Sanitizing and cleaning composition and its use for sanitizing and/or cleaning hard surfaces

ActiveUS7943565B2Low foamingReduce the smellInorganic/elemental detergent compounding agentsBiocideBiotechnologyOrganic acid

Owner:JOHNSONDIVERSEY INC

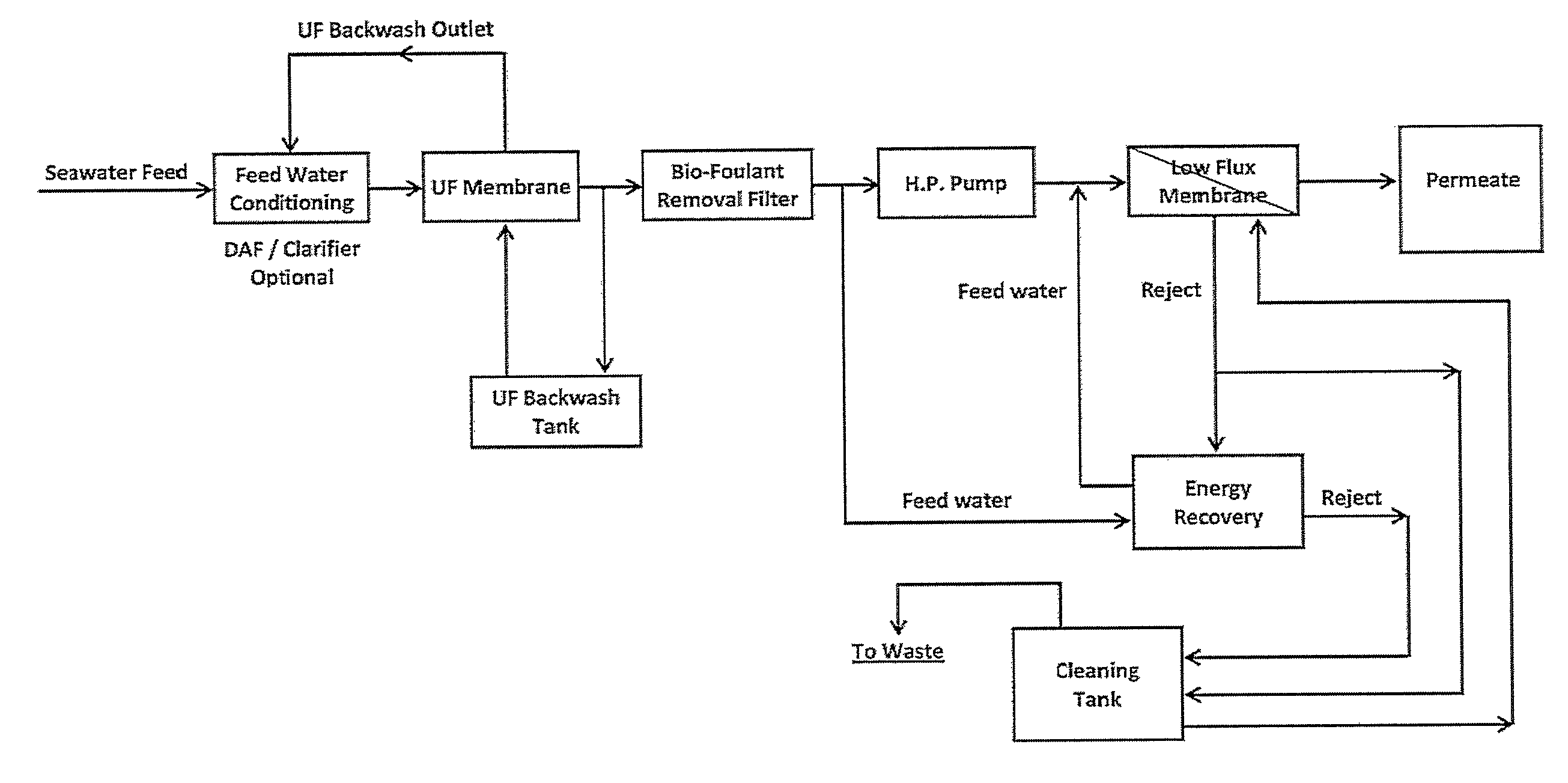

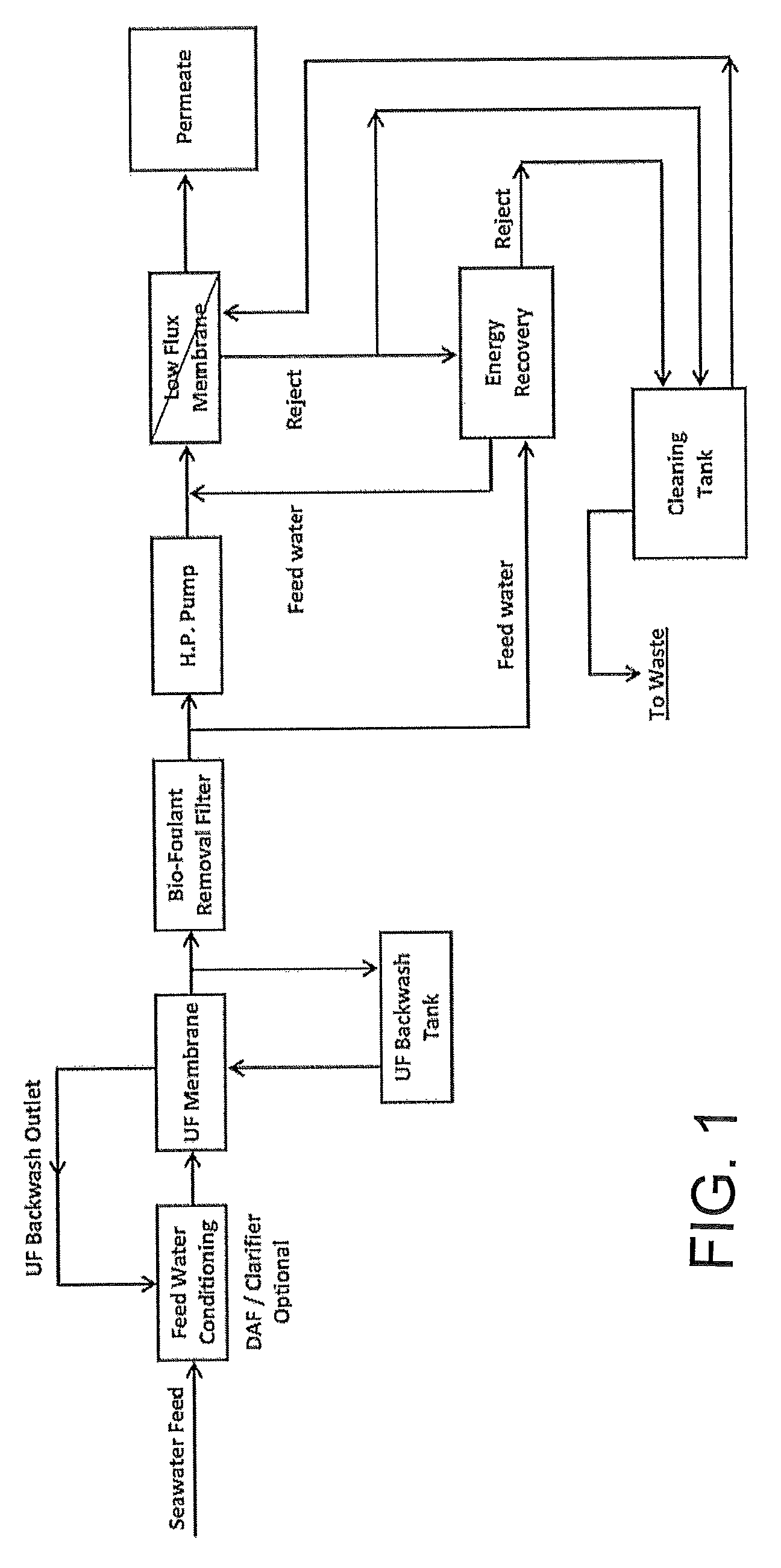

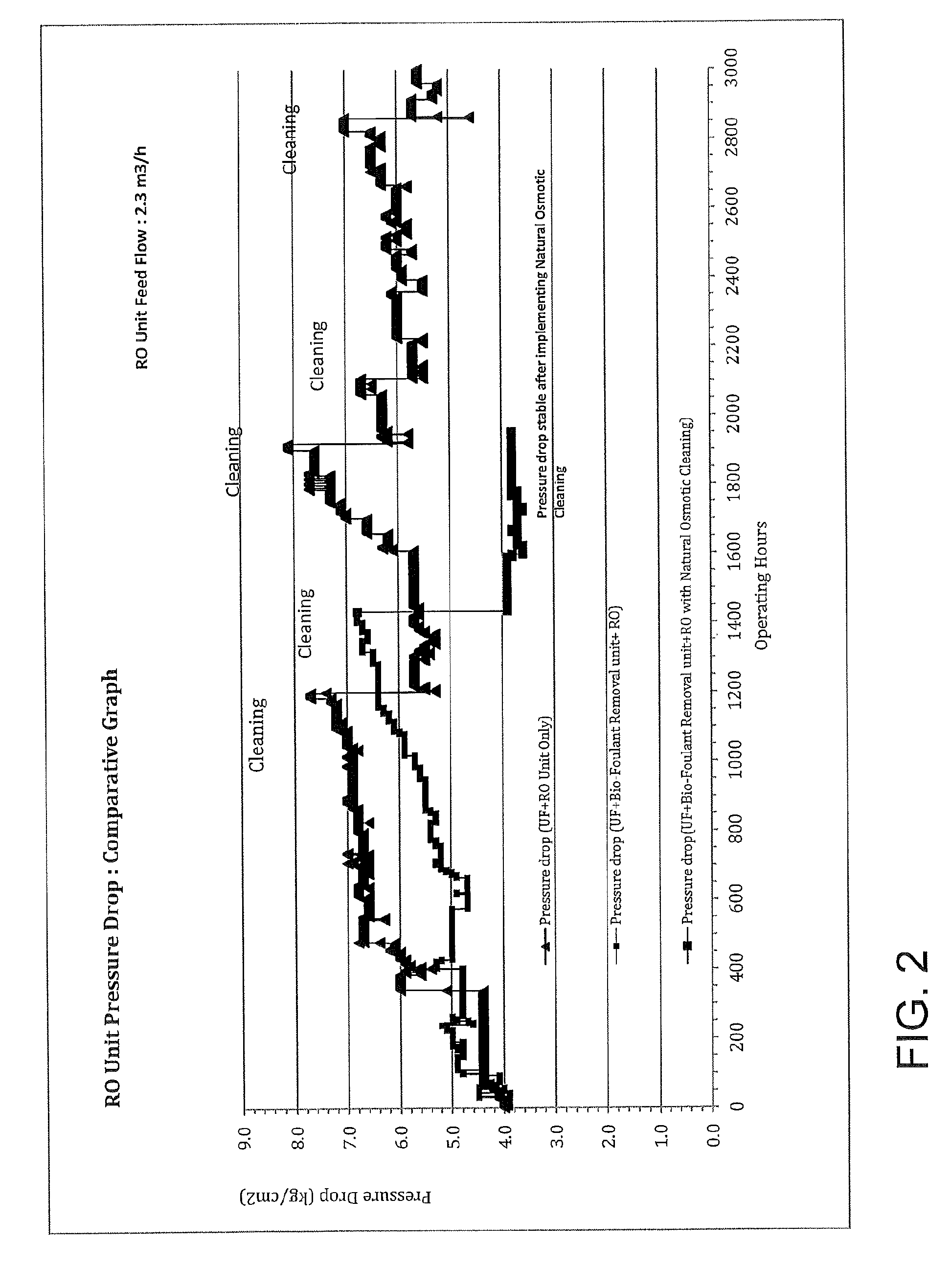

Low energy reverse osmosis process

ActiveUS8980100B2Prevent buildupReduce energy consumptionUltrafiltrationSolid sorbent liquid separationBrackish waterUltrafiltration

We provide a system and method for reverse osmosis treatment of water, including seawater and brackish water. Methods and systems of embodiments of the invention may include, for example, ultrafiltration followed by biofoulant removal, both of which precede reverse osmosis. In preferred embodiments the system is run at a low flux. For example, a flux of 6-8 GFD may be used with seawater. Additional embodiments may provide the above process in conjunction with a reverse-osmosis membrane cleaning system. The membrane cleaning system is a “clean in place” system that includes use of the natural pressure differential in the reverse osmosis system to remove biofoulants and their precursors.

Owner:AQUATECH INT LLC

Fluorometric method for monitoring a clean-in-place system

InactiveUS20060286676A1Less harshTesting beveragesChemiluminescene/bioluminescenceClean-in-placeChemical substance

The invention pertains to a method for fluorometrically monitoring a Clean-In-Place (“CIP”) system and for fluorometrically monitoring the dosage of chemical added to the CIP system. Monitoring of the said CIP system can be based upon fluormetrically monitoring the fluorescent tracer, chemical or both, which are added to the CIP system.

Owner:ECOLAB USA INC

Composition and method for road-film removal

InactiveUS20020128169A1Improved metal protectionCationic surface-active compoundsOrganic detergent compounding agentsOrganic acidHydrotrope

A concentrate and a ready-to-use or diluted formulation for an aqueous vehicle cleaner can remove a wide range of different types of traffic film using either low pressure application, hand pressure application, water jet spray apparatus, clean-in-place systems or other manual or mechanical washing systems. The compositions may comprise, for example, one or more solutions that each or collectively contain or comprises: a) at least one anionic surfactant; b) at least one poly[oxyalkylene] ammonium cationic surfactant; and c) an alkaline agent. Optional additional ingredients may comprise at least one polycarboxylic acid chelating agent (preferably an aminocarboxylic acid chelating agent), at least one non-ionic or amphoteric surfactant, at least one hydrotrope, inorganic and / or organic acids and at least one silicate. The alkaline agent may provide a pH (when the finished product is diluted to 0.5 to 5% by weight in water) will be between about 9 to 13. The concentrate may be provided as a one-part or two part solution. Certain formulations have been found to be shelf stable as one-part concentrate or ready-to-use solutions, even with significantly different properties amongst the components. The compositions of the invention are also used in cleaning processes for surfaces, especially vehicle surfaces in car wash systems. The compositions are used in such processes where there are single or multiple liquid application steps.

Owner:ZEP IP HLDG LLC

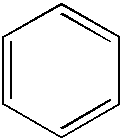

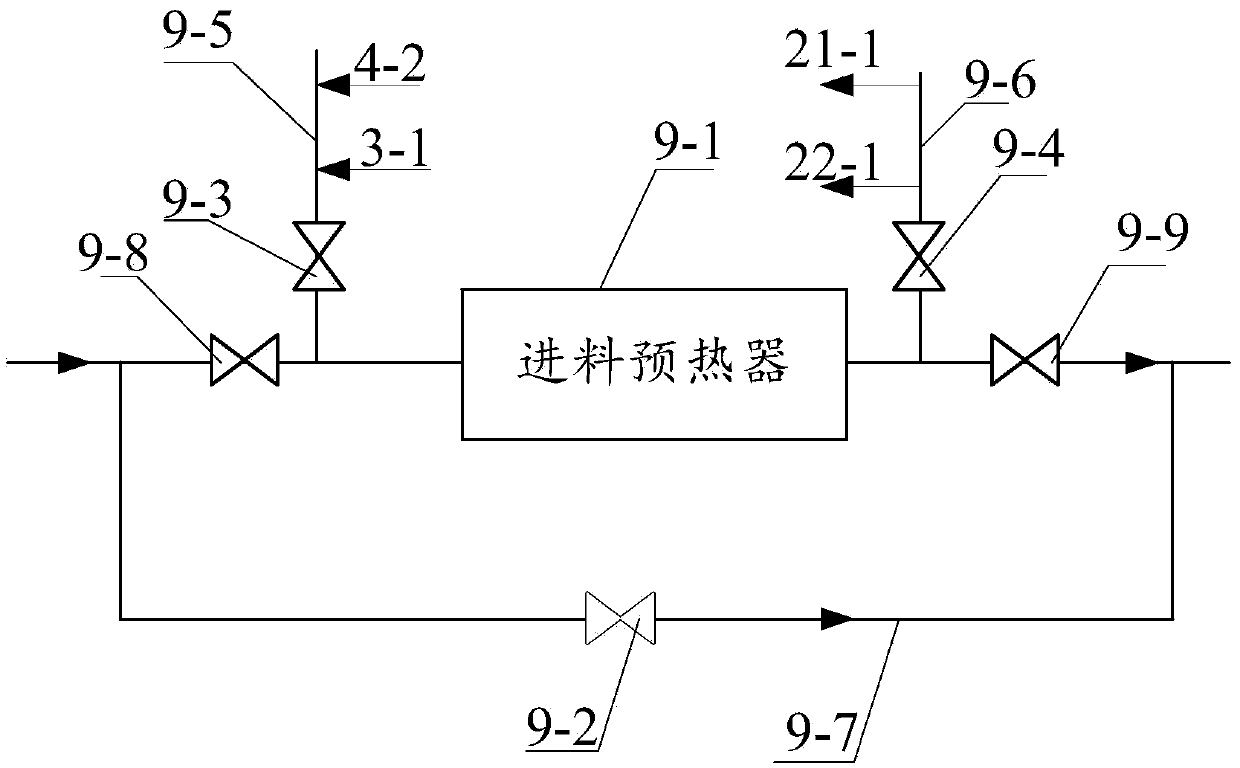

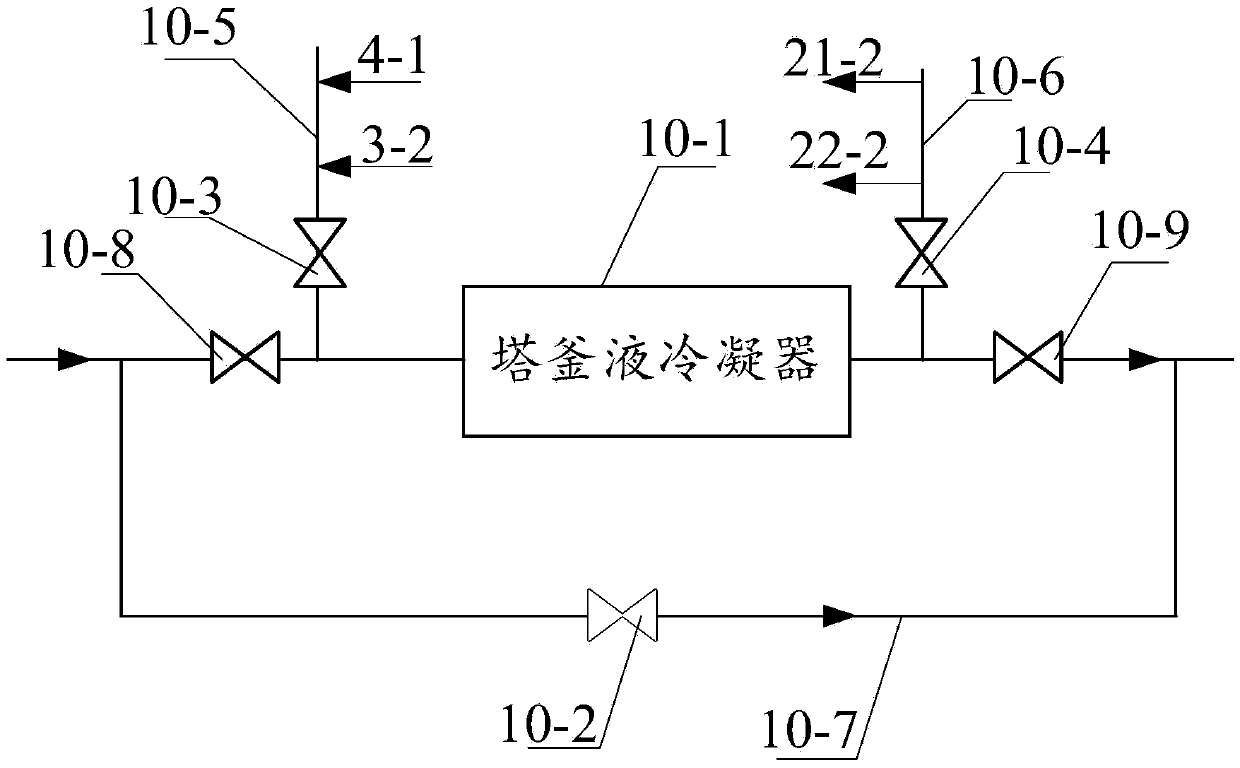

Clean-in-place system for distillation device, preparation for cleaning liquid, and cleaning method

ActiveCN105363237AEasy to cleanShorten cleaning timeDistillation regulation/controlCleaning using liquidsDistillationHeat transfer efficiency

The invention discloses a clean-in-place system for a distillation device, preparation for a cleaning liquid, and a cleaning method. The clean-in-place system comprises: the liquid outlet of a dilute alkali preparation unit is respectively connected with the liquid inlet of a first CIP pump and the liquid inlet of a second CIP pump; the liquid outlet of a citric acid blending unit is respectively connected with the liquid inlet of the first CIP pump and the liquid inlet of the second CIP pump; the liquid outlet of the first CIP pump and the liquid outlet of the second CIP pump are connected with the distillation device through a cleaning liquid inlet main pipeline; the liquid outlet of the first CIP pump is respectively connected with the dilute alkali preparation unit and the citric acid blending unit; the distillation device is respectively connected with the dilute alkali preparation unit and the citric acid blending unit through a cleaning liquid recycling main pipeline; the distillation device is connected with a process water inlet main pipeline and a process water outlet main pipeline; and the dilute alkali preparation unit and the citric acid blending unit are correspondingly connected with a process water inlet pipeline. The clean-in-place system provided by the invention solves the technical problem of influences on mass-transfer and heat-transfer efficiencies due to blockage of the distillation device in the process of preparation of ethanol by using a conventional coal-gas biological fermentation process, and realizes convenient and rapid cleaning in place for the distillation device.

Owner:河北首朗新能源科技有限公司

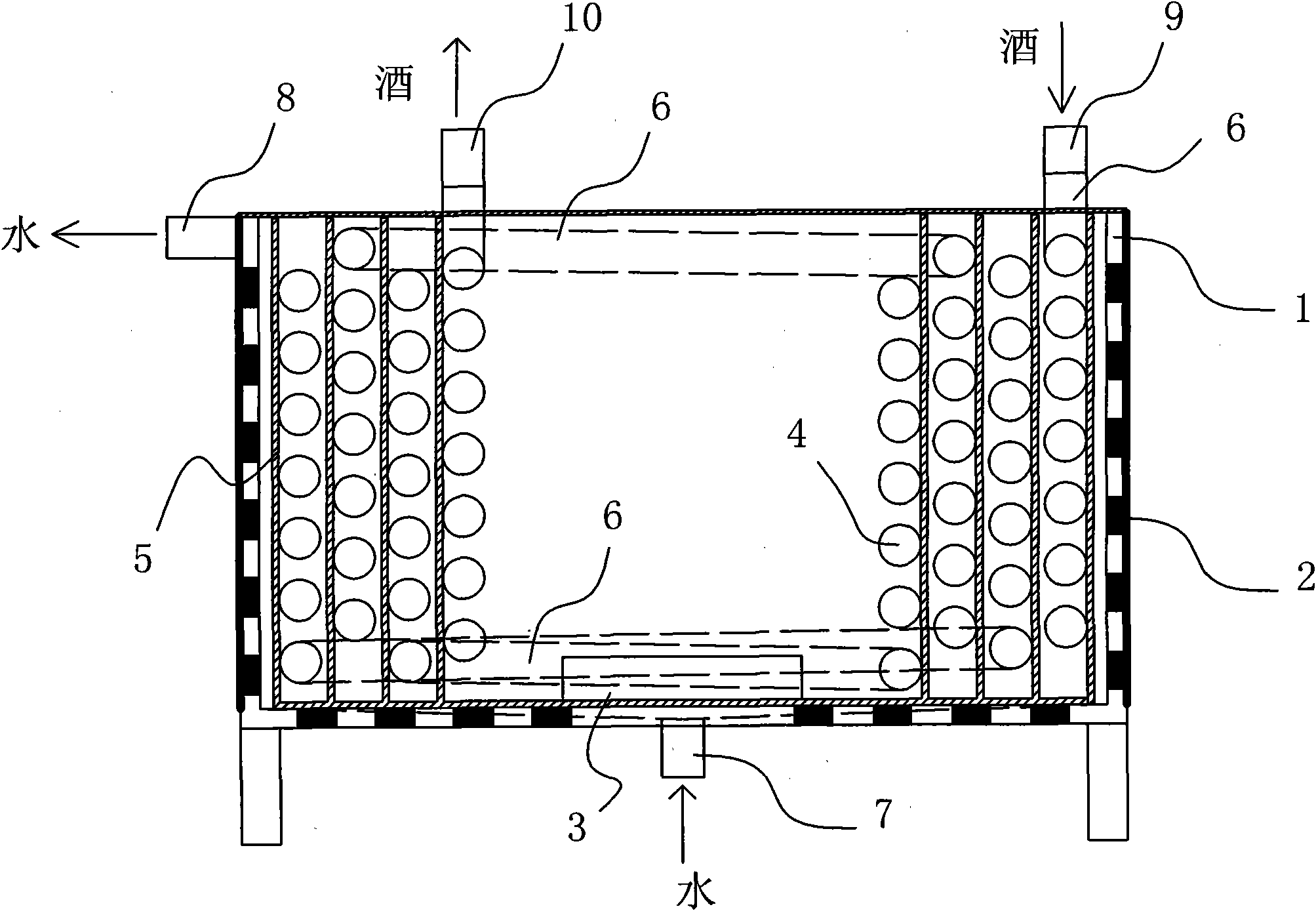

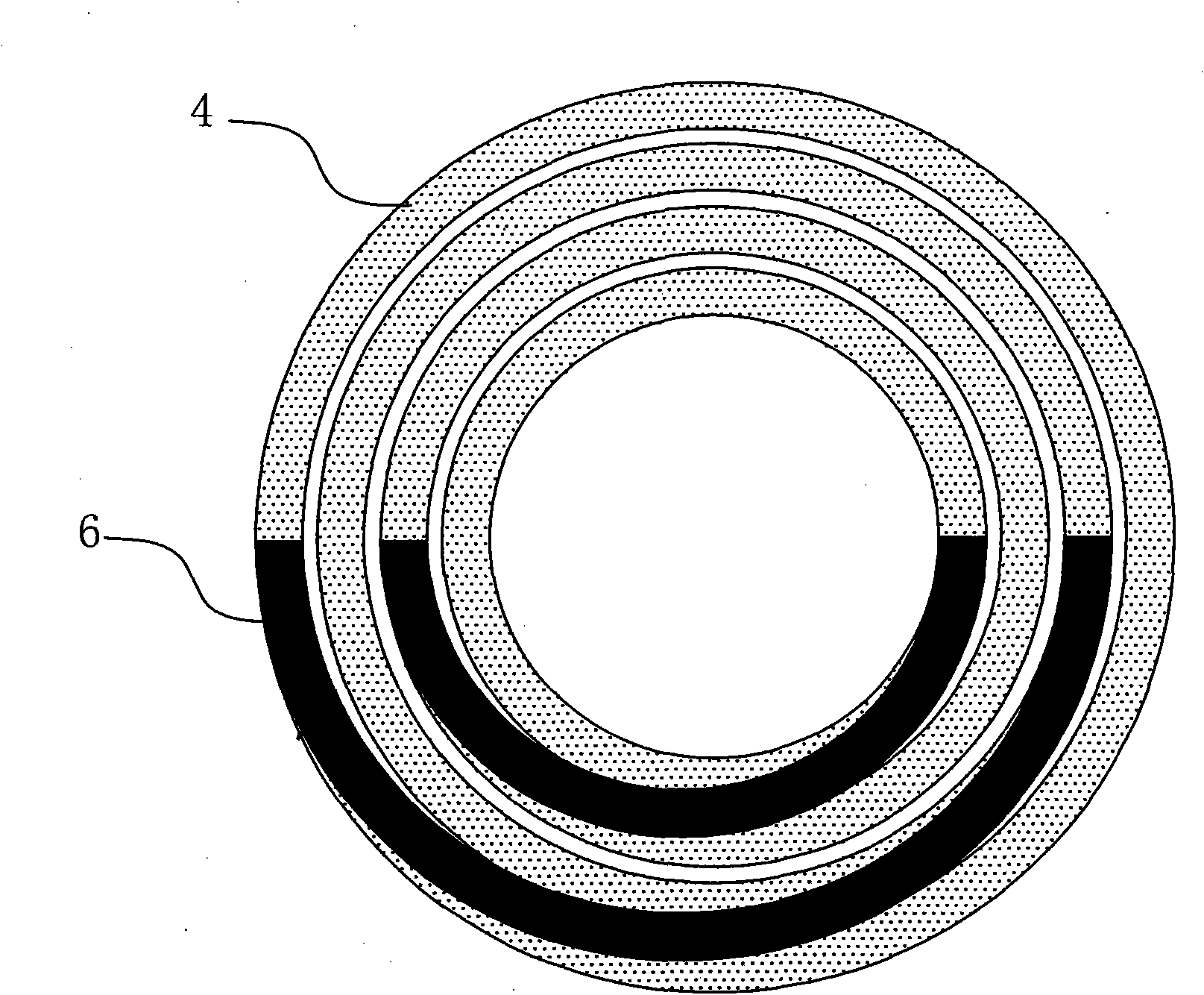

Pipeline type ultrasonic treatment device for promoting aging of liquor

InactiveCN102093947APromote associationHigh affinityAlcoholic beverage preparationFlavorMultiple forms

The invention discloses a pipeline type ultrasonic treatment device for promoting aging of liquor. The pipeline type ultrasonic treatment device is characterized by comprising a treatment chamber, ultrasonic transducers and a plurality of layers of circulation pipelines; the treatment chamber is provided with a water inlet and a water outlet; the circulation pipelines are positioned inside the treatment chamber; and the ultrasonic transducers are installed on the side surface and the bottom surface of the treatment chamber, and the side surface and the bottom surface of the treatment chamber to form an ultrasonic emission surface for ultrasonic treatment of the liquor in the circulation pipelines. The pipeline type ultrasonic treatment device provided by the invention combines the synergetic temperature effect and the propagation characteristics of ultrasonic wave, and can distinctly improve the taste and flavor of liquor. The device has simple structure, multiple forms, low production cost, continuous production, and safe and sanitary process, and is convenient for cleaning-in-place (CIP). Also, the device can be flexibly added into the original process, so as to facilitate industrial application.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com