Patents

Literature

136results about How to "Improve the effect of gas-liquid separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

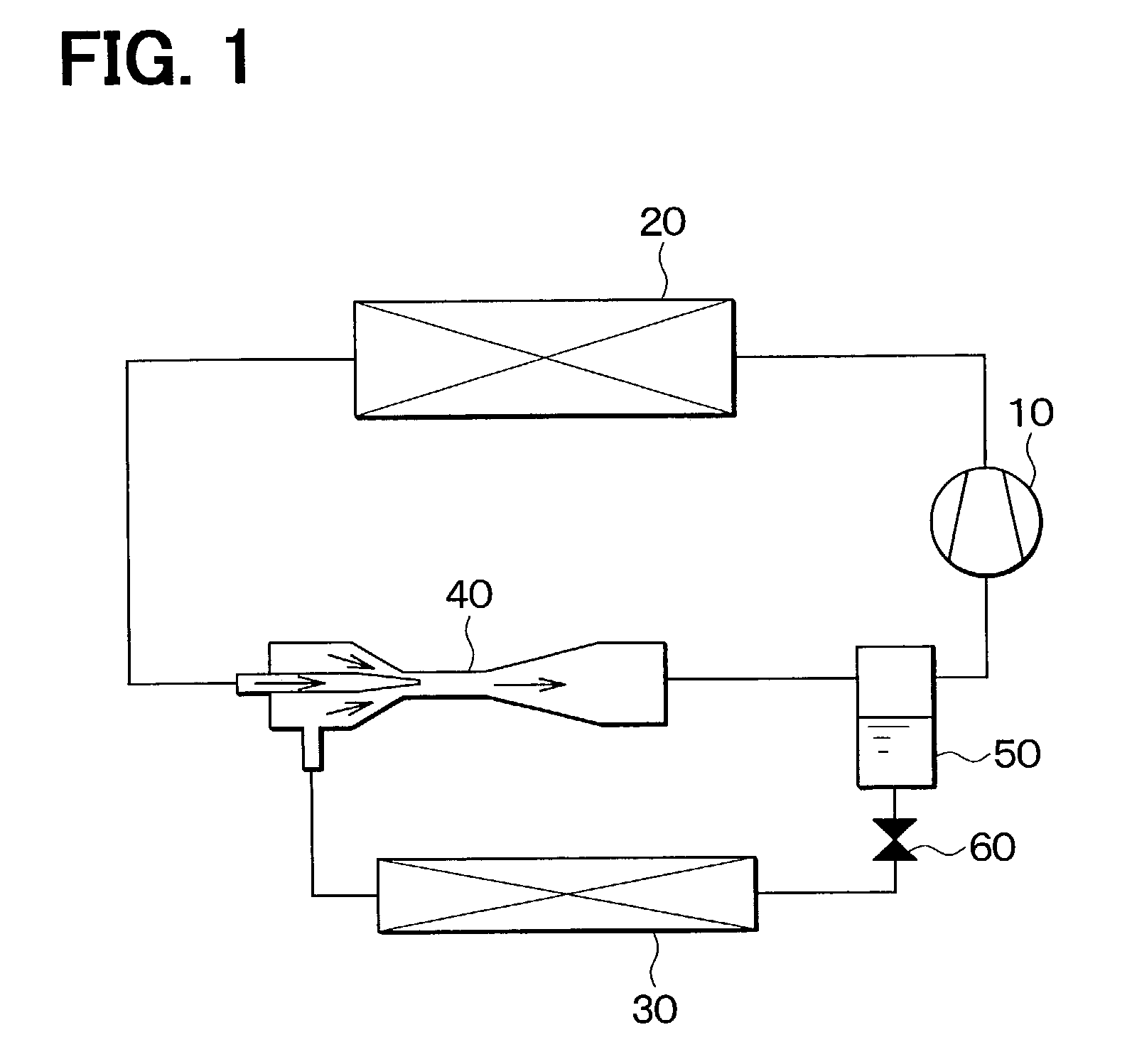

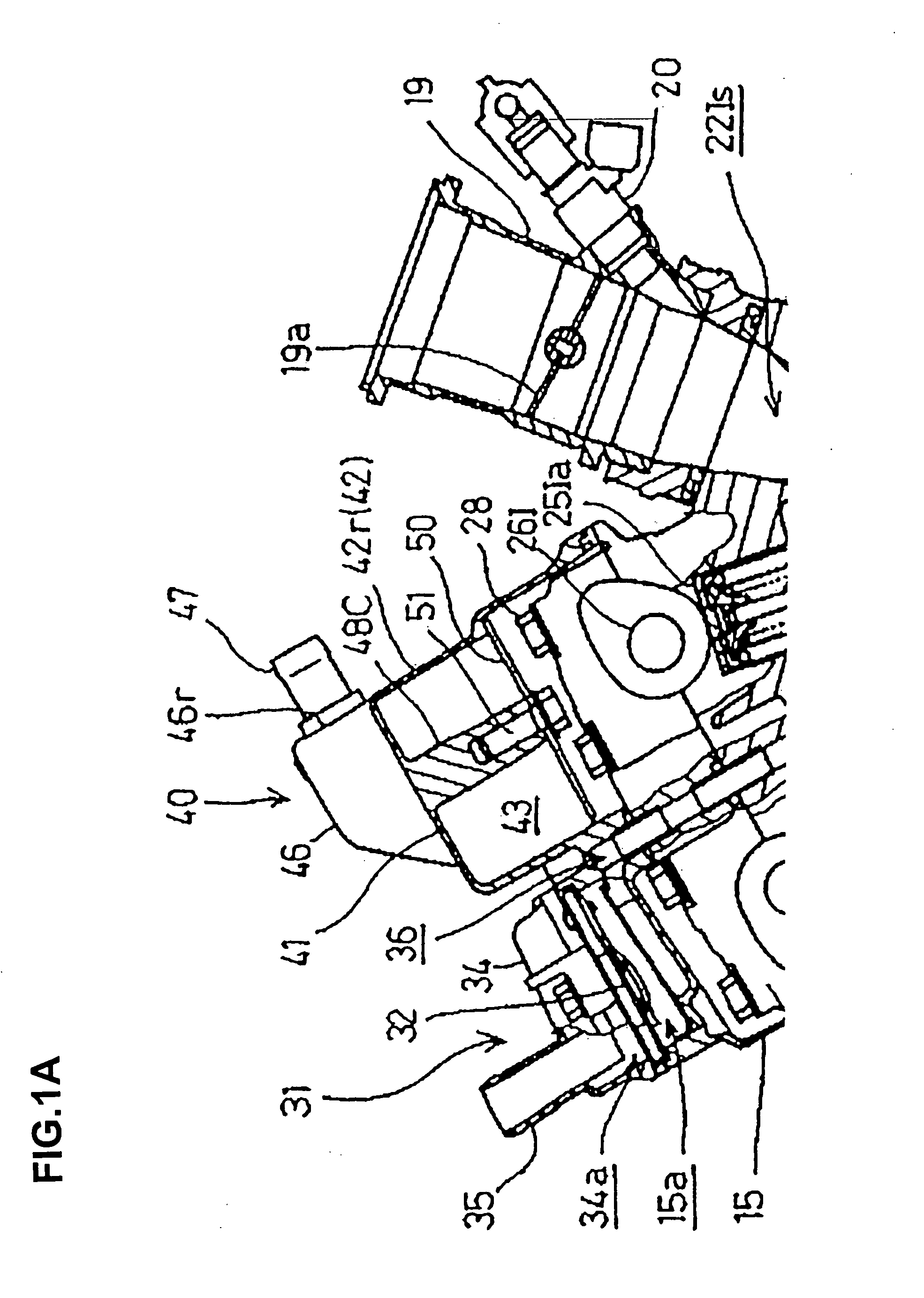

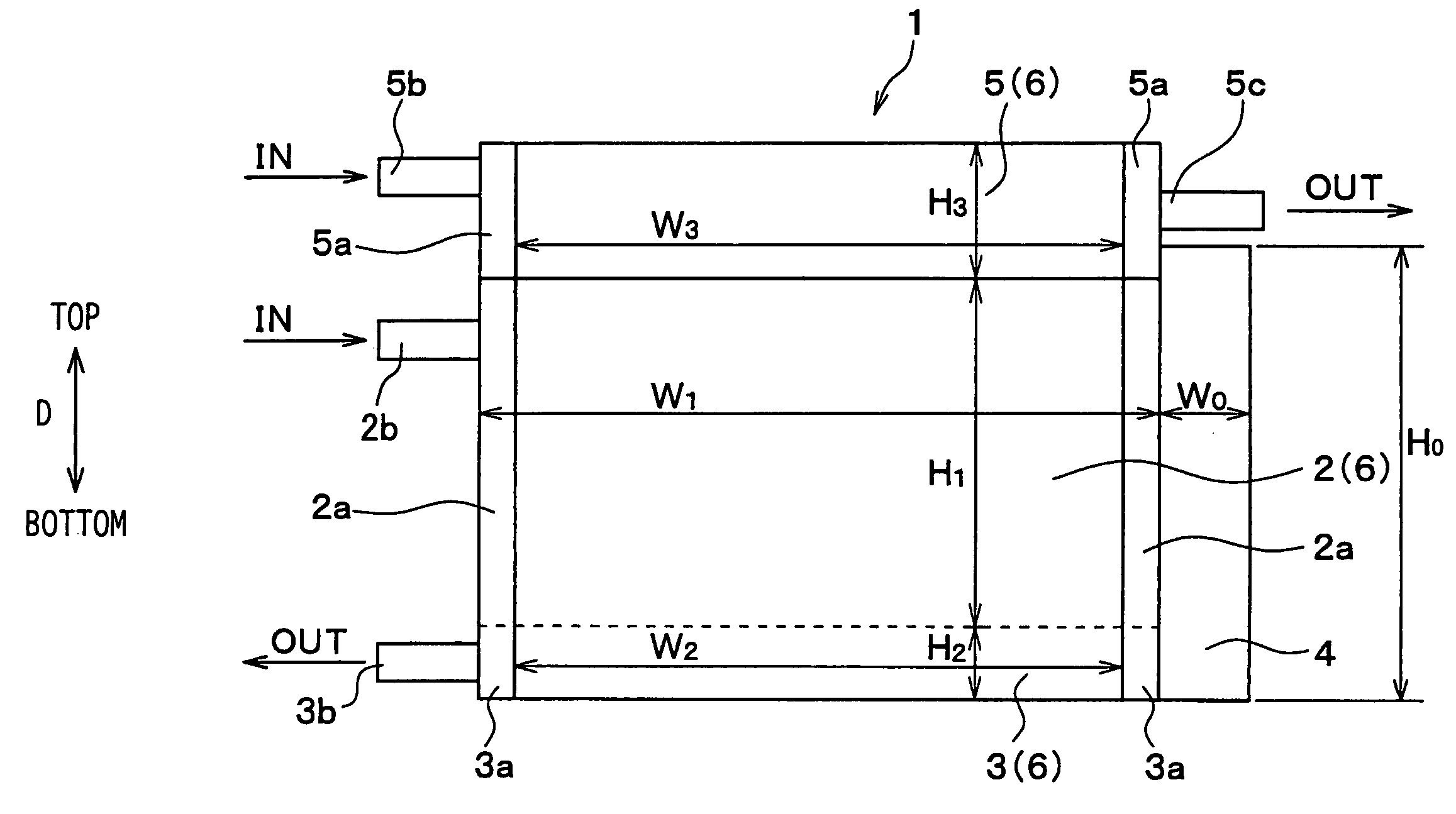

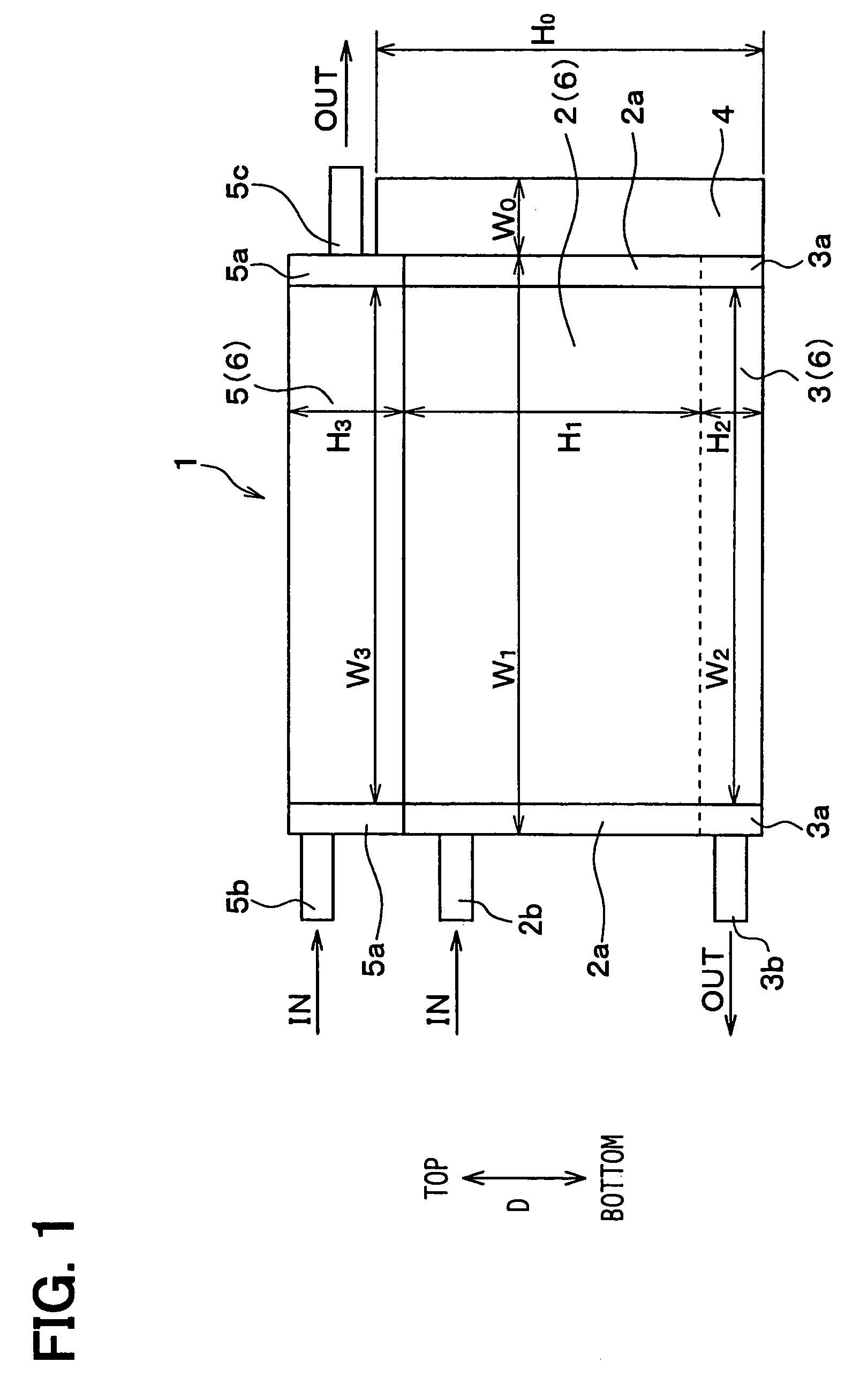

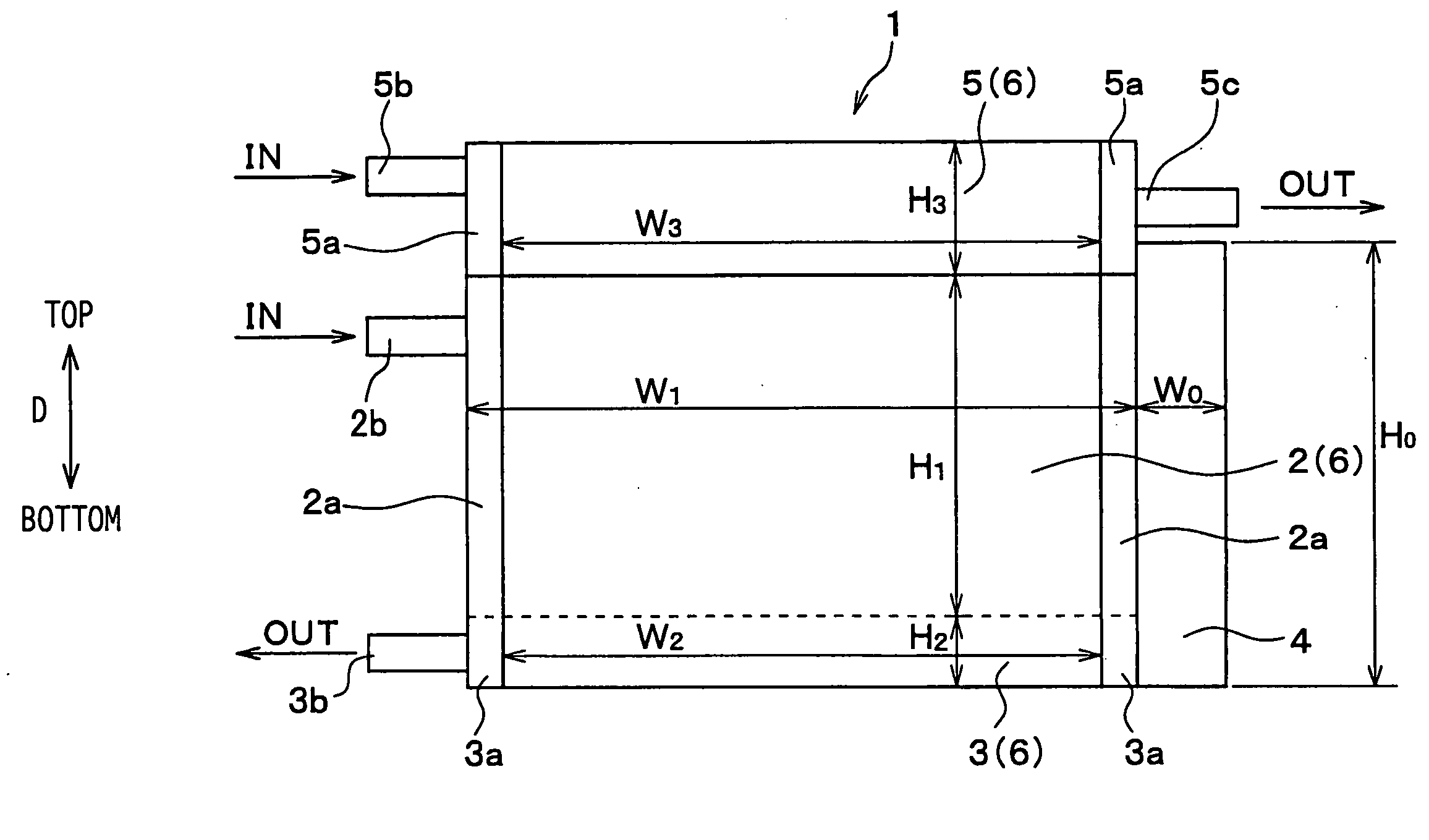

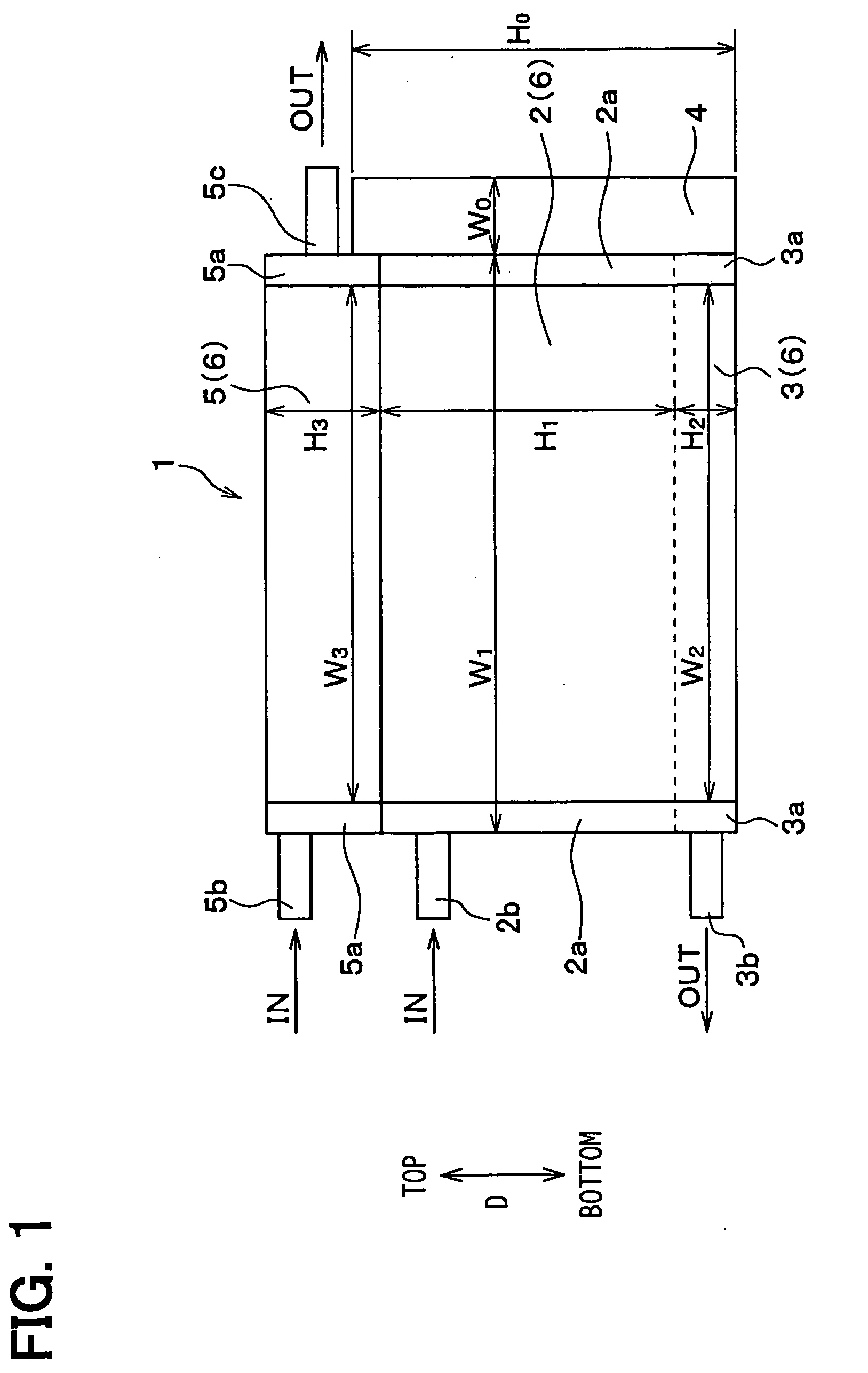

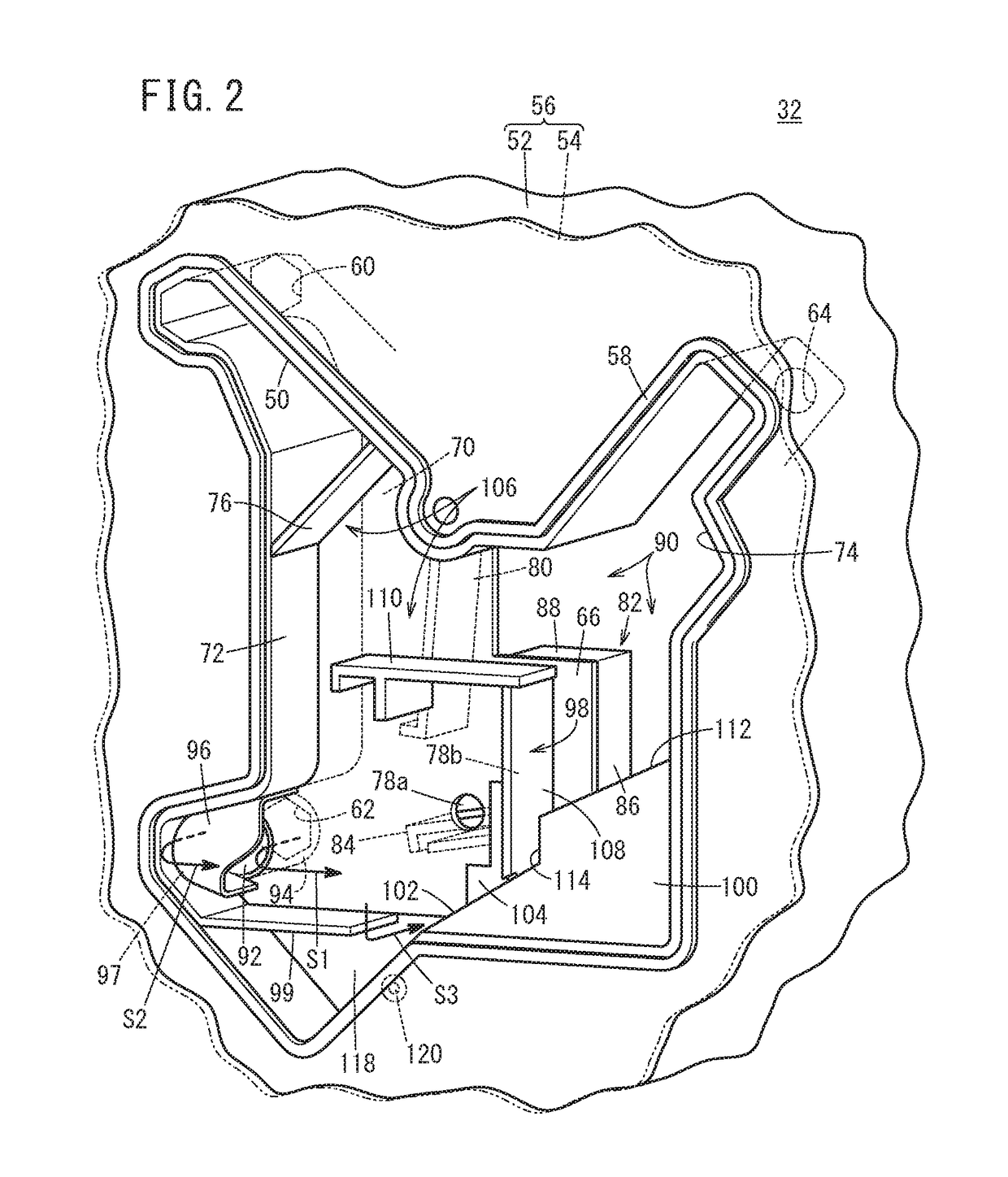

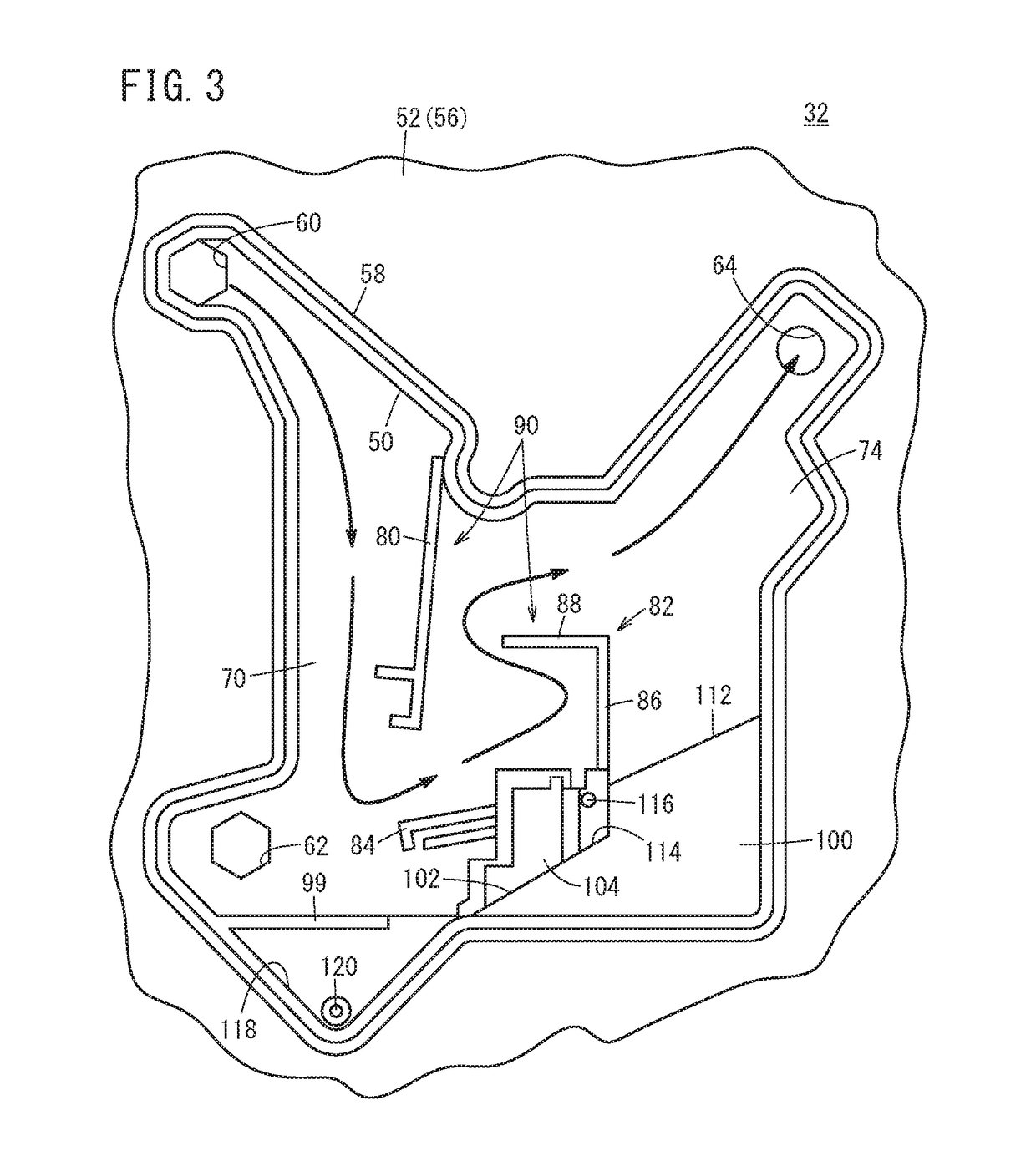

Heat exchanger module

ActiveUS20050056049A1Increase capacityImprove the effect of gas-liquid separationLiquid coolingCompression machines with non-reversible cycleEngineeringRefrigerant

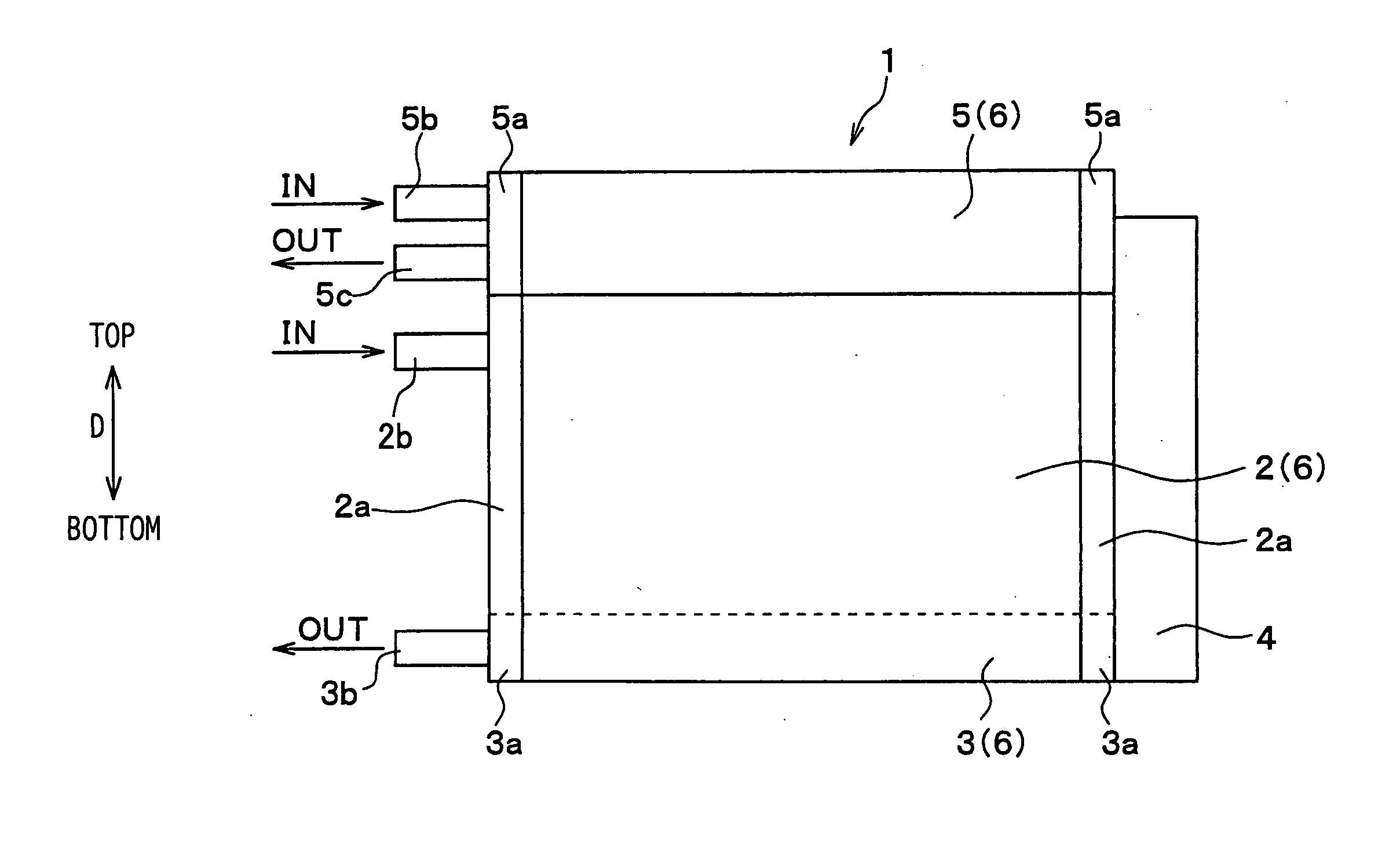

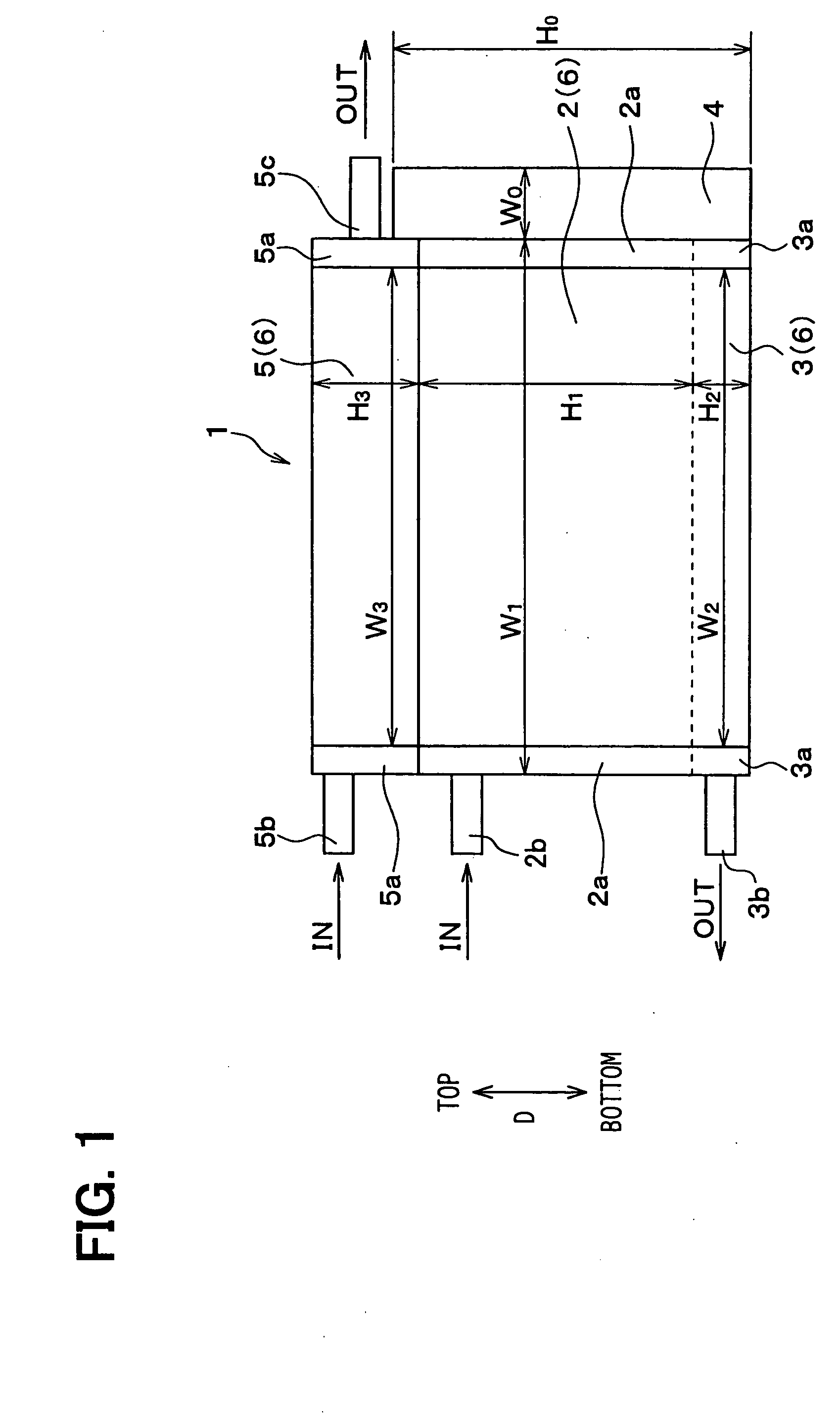

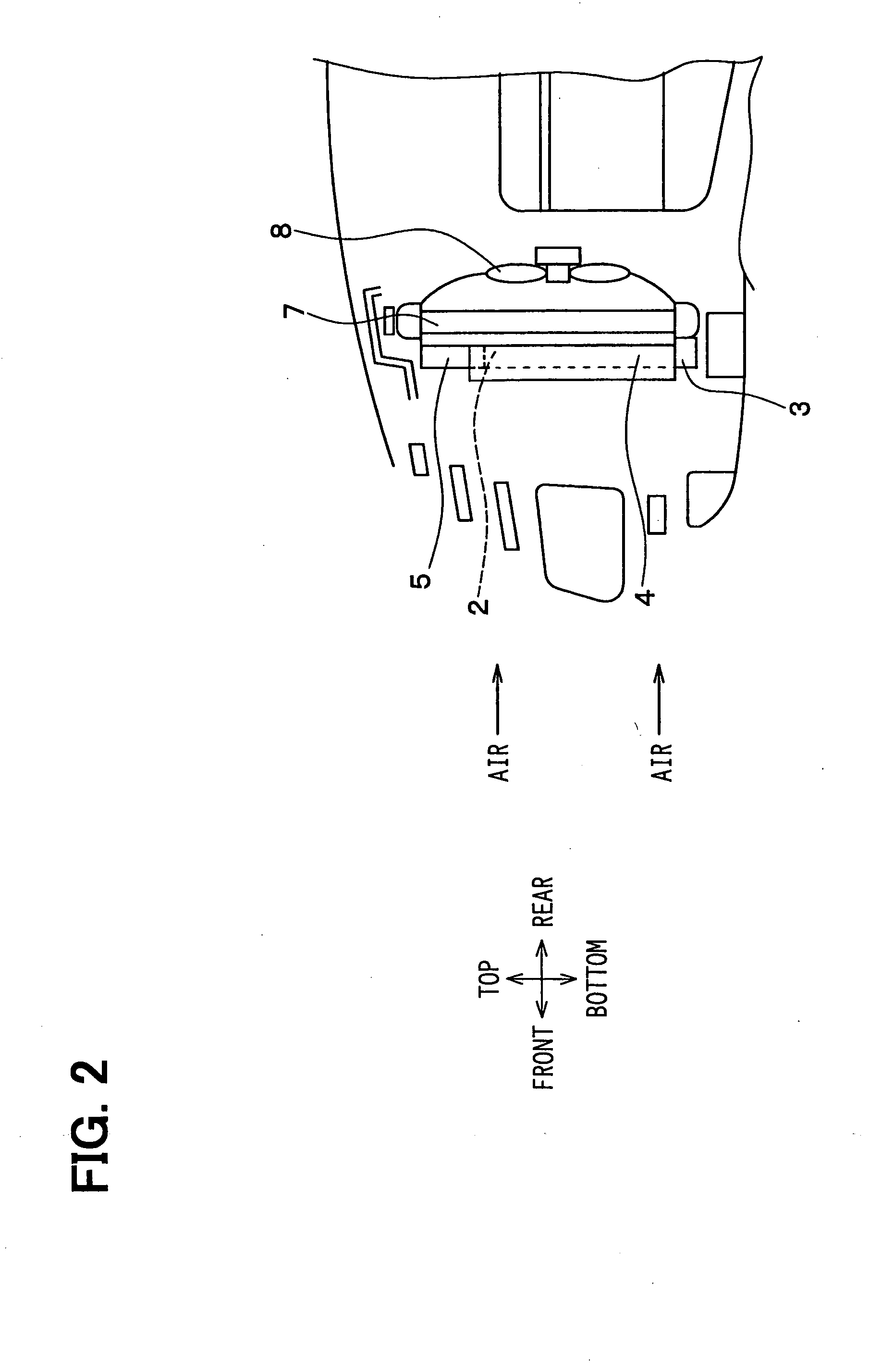

A heat exchanger module includes a condenser for condensing a refrigerant, a modulator, a sub-cooler for cooling liquid refrigerant supplied from the modulator, and a heat exchanger for cooling a fluid different from the refrigerant. The condenser, the sub-cooler and the heat exchanger are arranged in an arrangement direction substantially perpendicular to an air flow direction. Further, the modulator is disposed to extend in the arrangement direction. In the heat exchanger module, the modulator has a dimension that is larger than the sum of a dimension of the condenser and a dimension of the sub-cooler, and is not larger than the sum of the dimension of the condenser, the dimension of the sub-cooler and a dimension of the heat exchanger, in the arrangement direction. Accordingly, a capacity of the modulator can be effectively increased without increasing a largest outer side of the heat exchanger module.

Owner:DENSO CORP

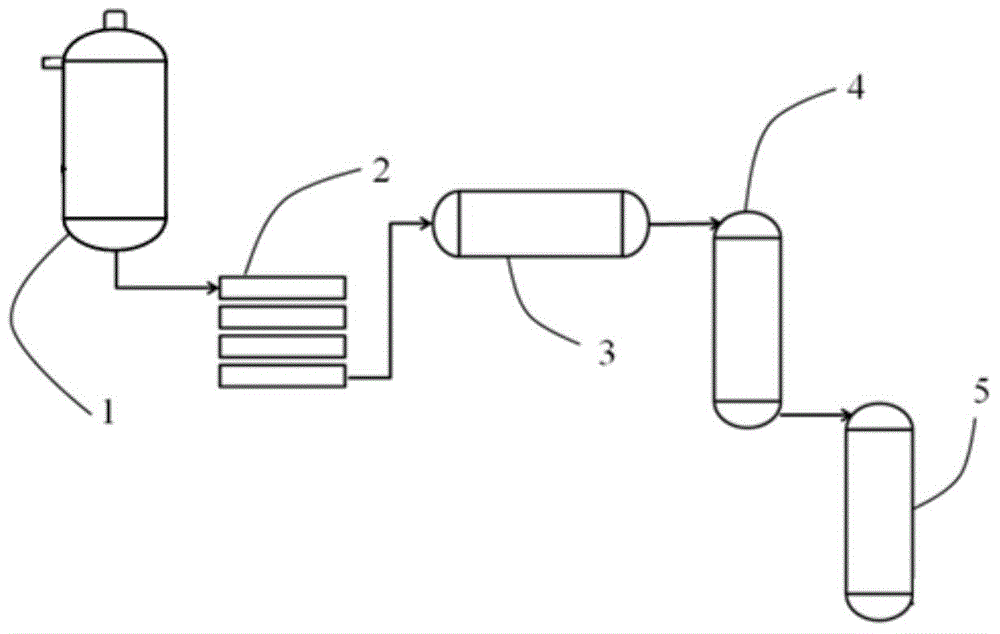

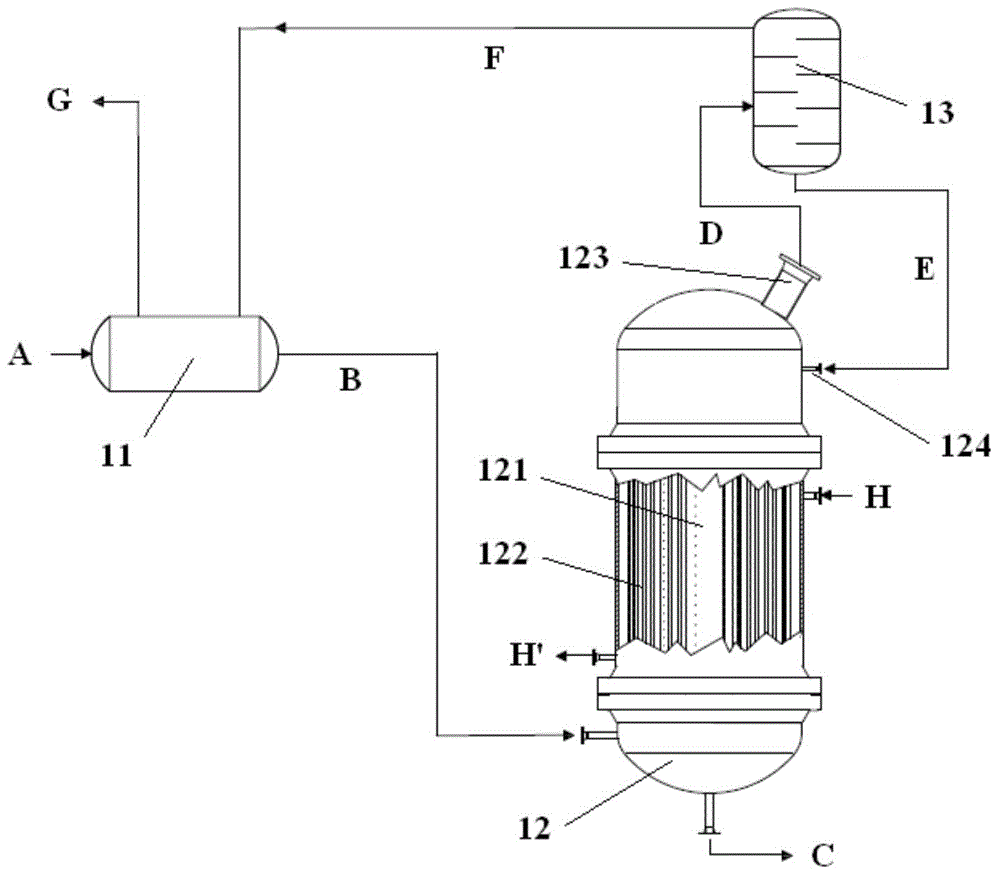

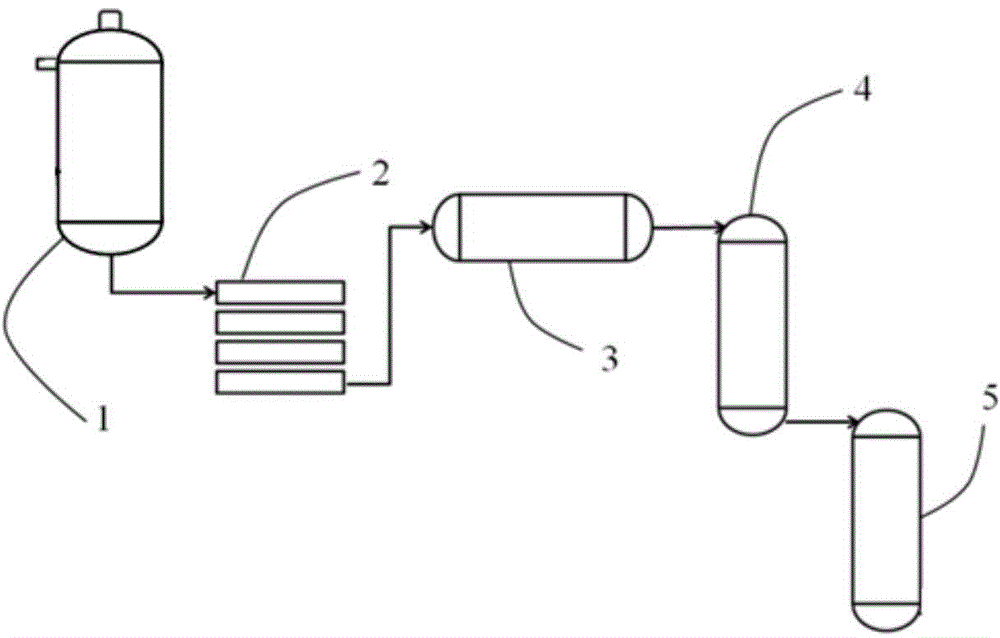

Production equipment and method of polyamide 5X

ActiveCN105885037ASuitable for continuous polymerization processGuaranteed uptimeEvaporator accessoriesChemical/physical/physico-chemical stationary reactorsPolyamideProcess engineering

The invention provides production equipment and method of polyamide 5X. The production equipment comprises a concentration device, a prepolymerization device, a pressure reducing device, a separating device and a final polymerization device which are connected in sequence. The concentration device, the prepolymerization device, the pressure reducing device, the separating device and the final polymerization device are adopted in the production equipment of polyamide 5X, operation of all production links is guaranteed, and the production equipment and method are especially suitable for producing polyamide 5X.

Owner:CATHAY R&D CENT CO LTD +2

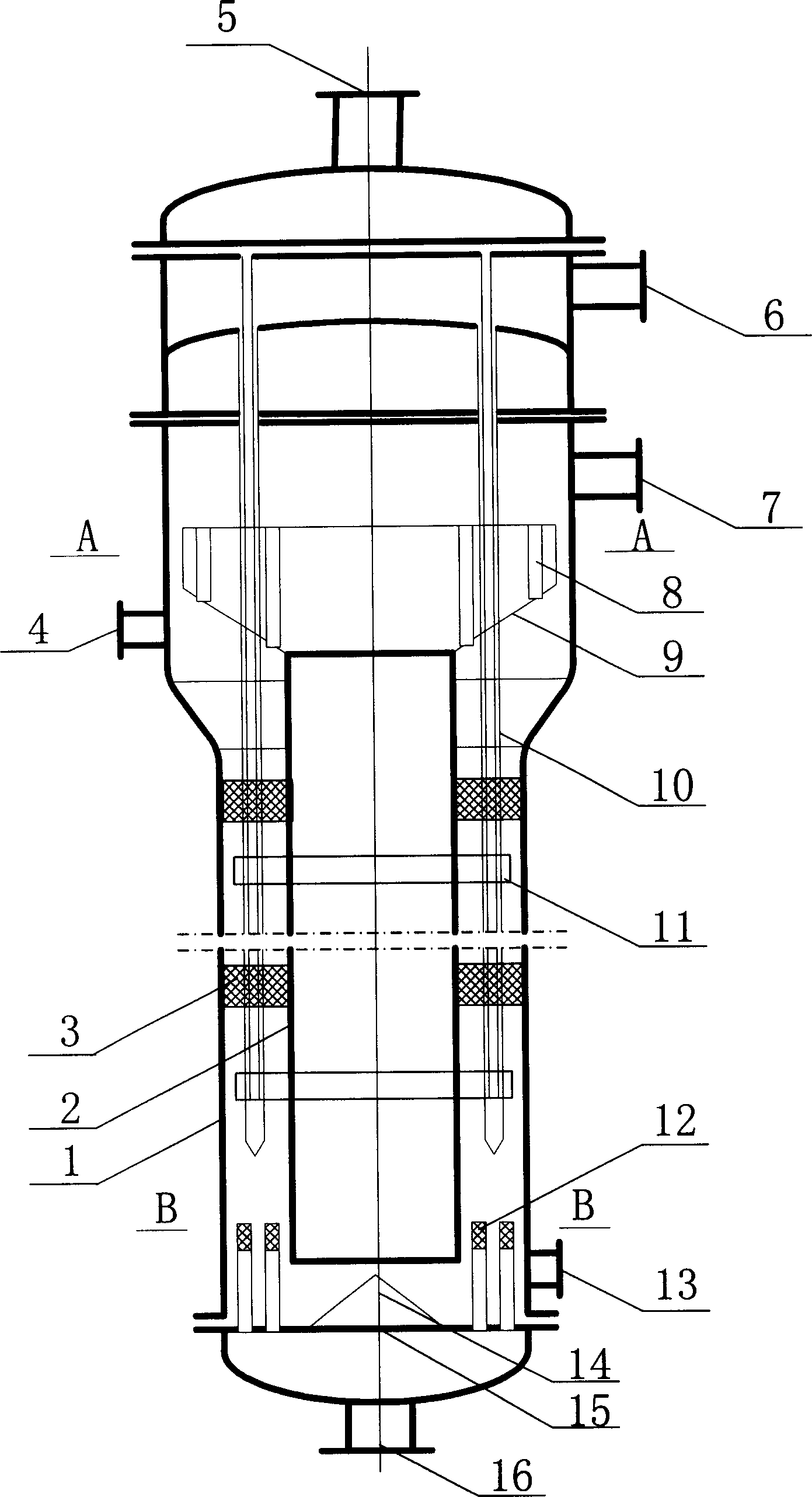

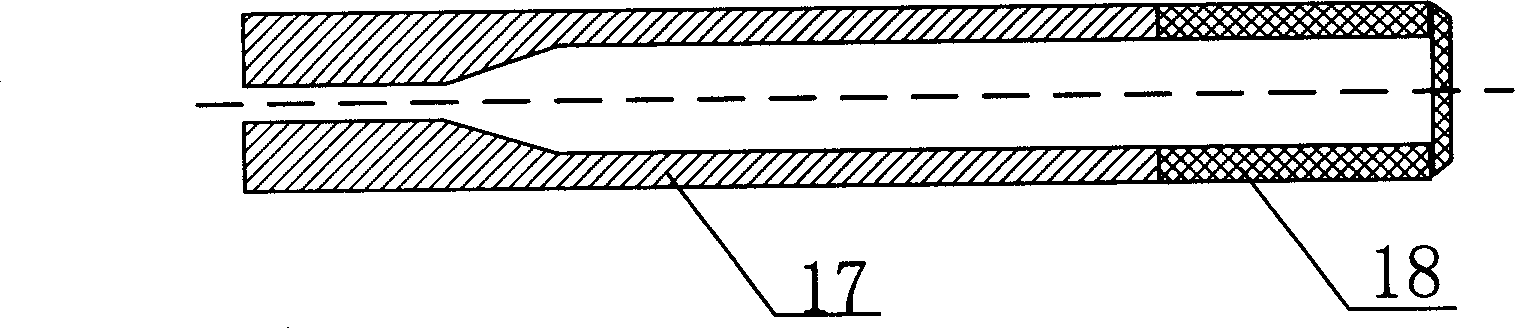

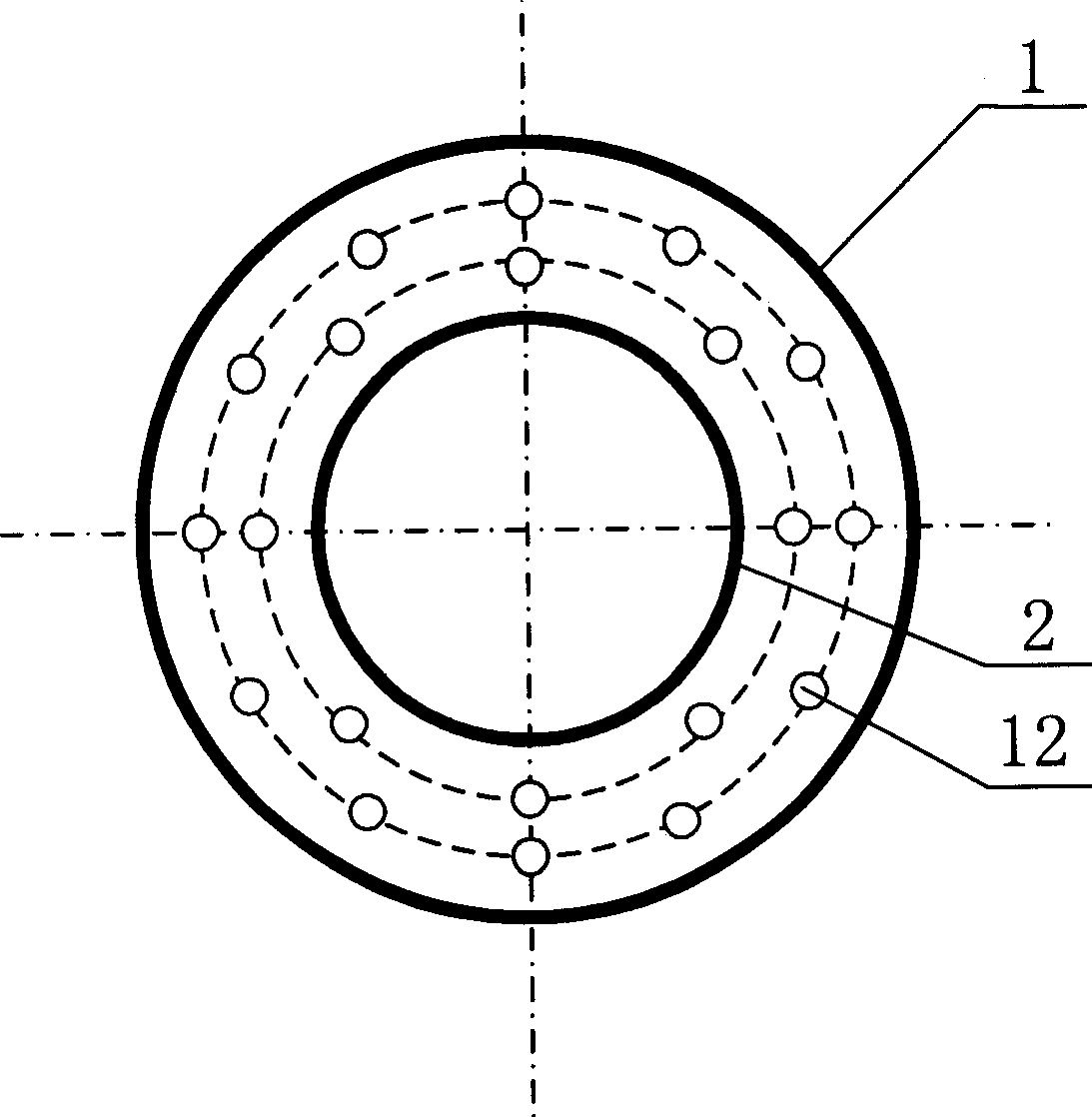

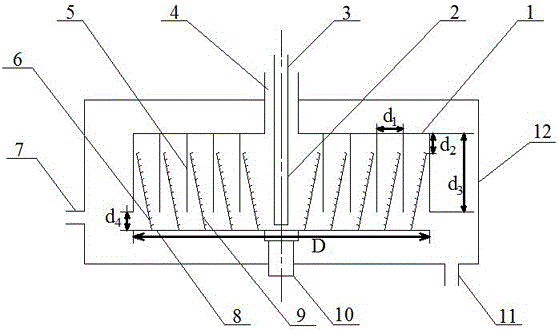

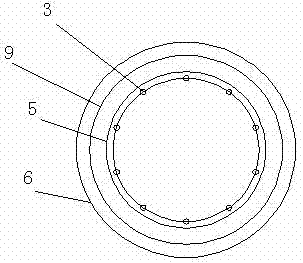

Annular space gas lifting type loop reactor

InactiveCN1605385AReduce production efficiencyAvoid entrainmentChemical/physical processesVapor–liquid separatorEngineering

The annular air-lift inner circulating reactor is one inner circulating reactor with high gas-liquid separating efficiency and excellent gas distributing effect. Technologically, the present invention features that the gas-liquid separator in funnel-fine pipe separating structure has complete gas-liquid separation; and that the sintered pipe gas distributor has relatively small initial bubble size resulting in excellent gas distributing effect. In order to improve flow and reinforce mass transfer, the annular air-lift pipe is provided with inner member; and in order to introduce out or in heat for reaction, the annular air-lift pipe is provided with heat exchange member of fingered or coiled pipe. The reactor has the features of high gas-liquid separating efficiency, high gas distributing effect, homogeneous radial gas distribution, homogeneous radial liquid speed distribution and no reverse fluid circulation.

Owner:TSINGHUA UNIV

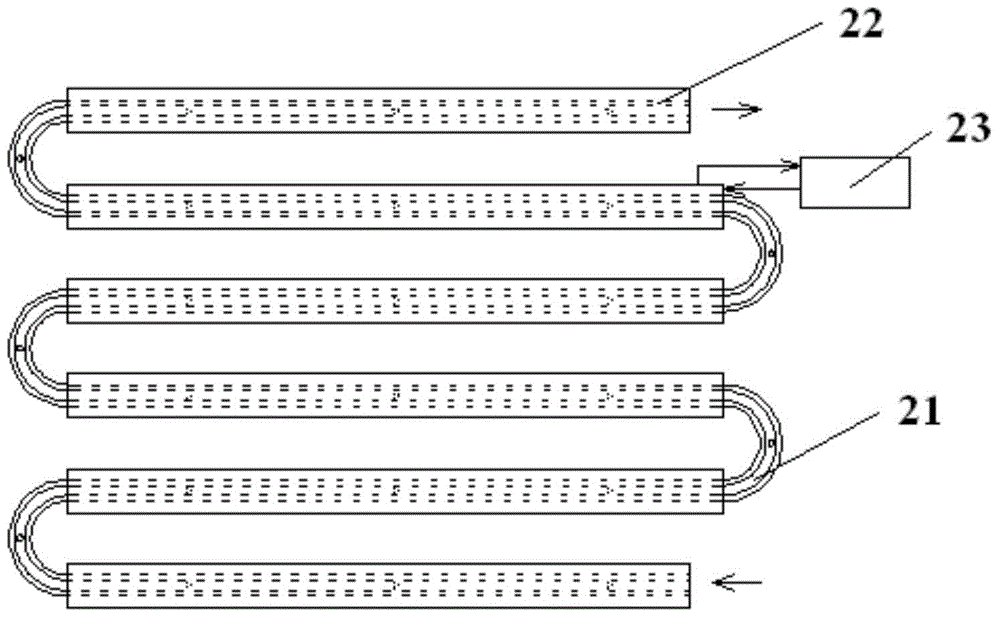

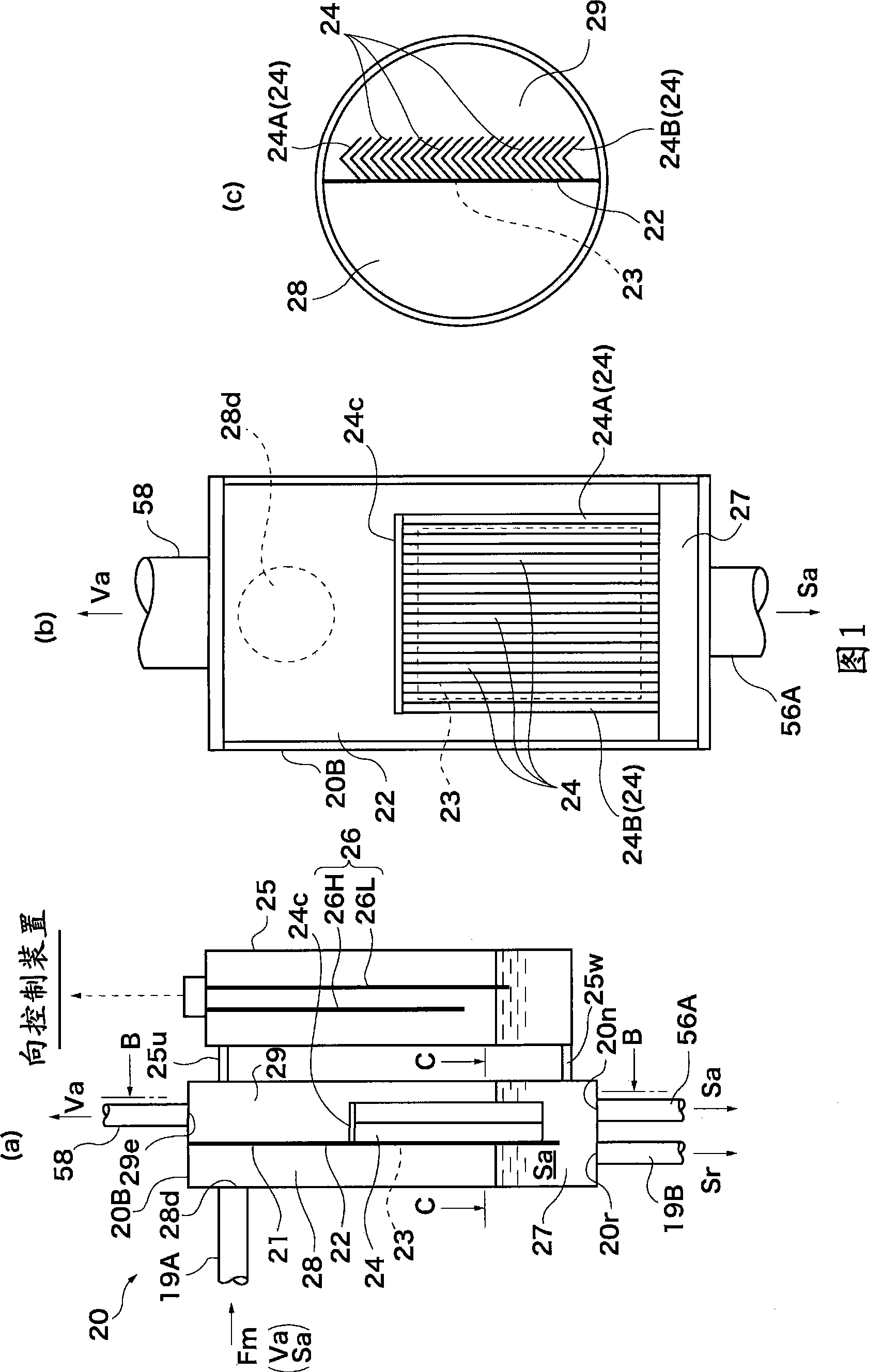

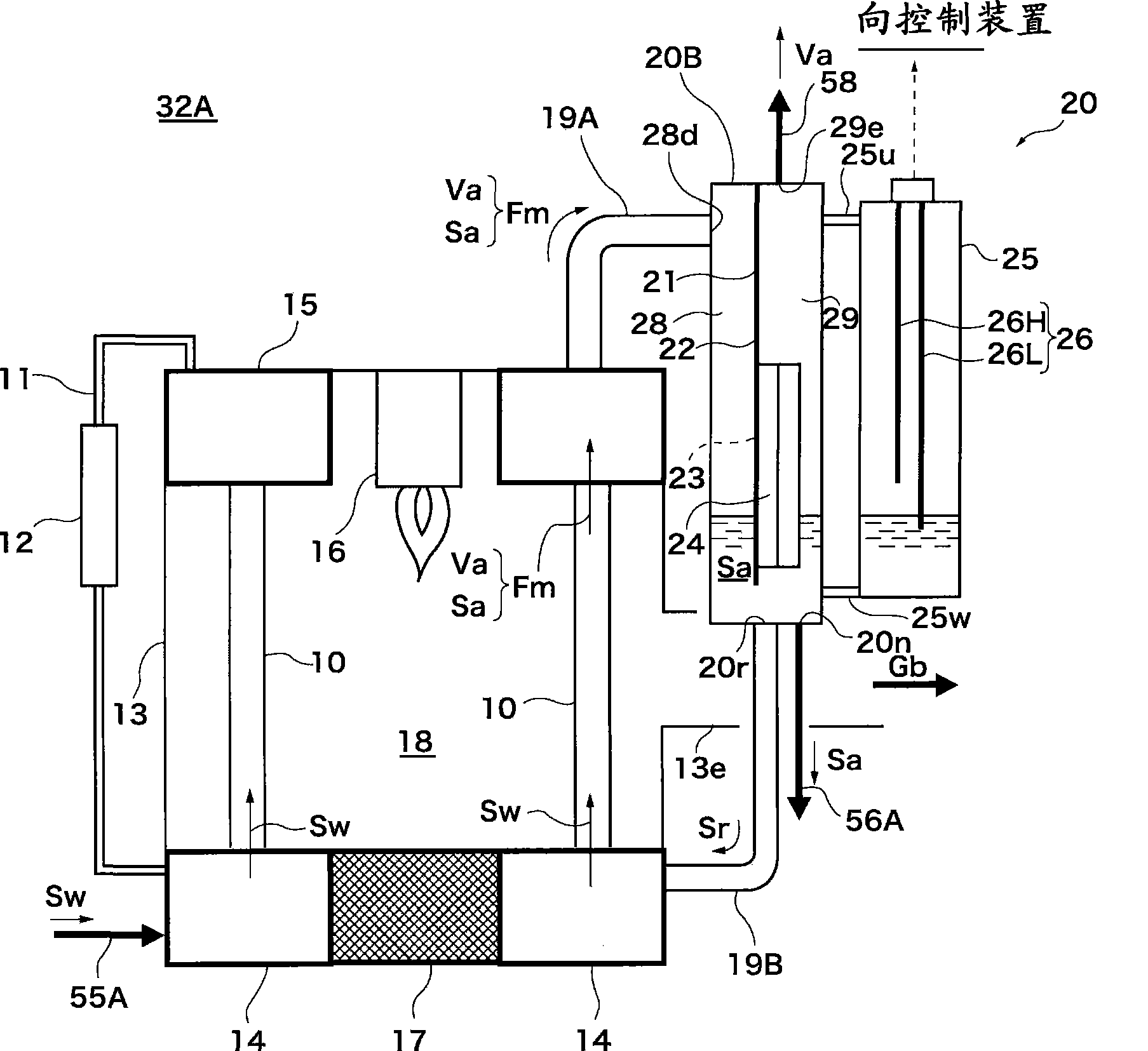

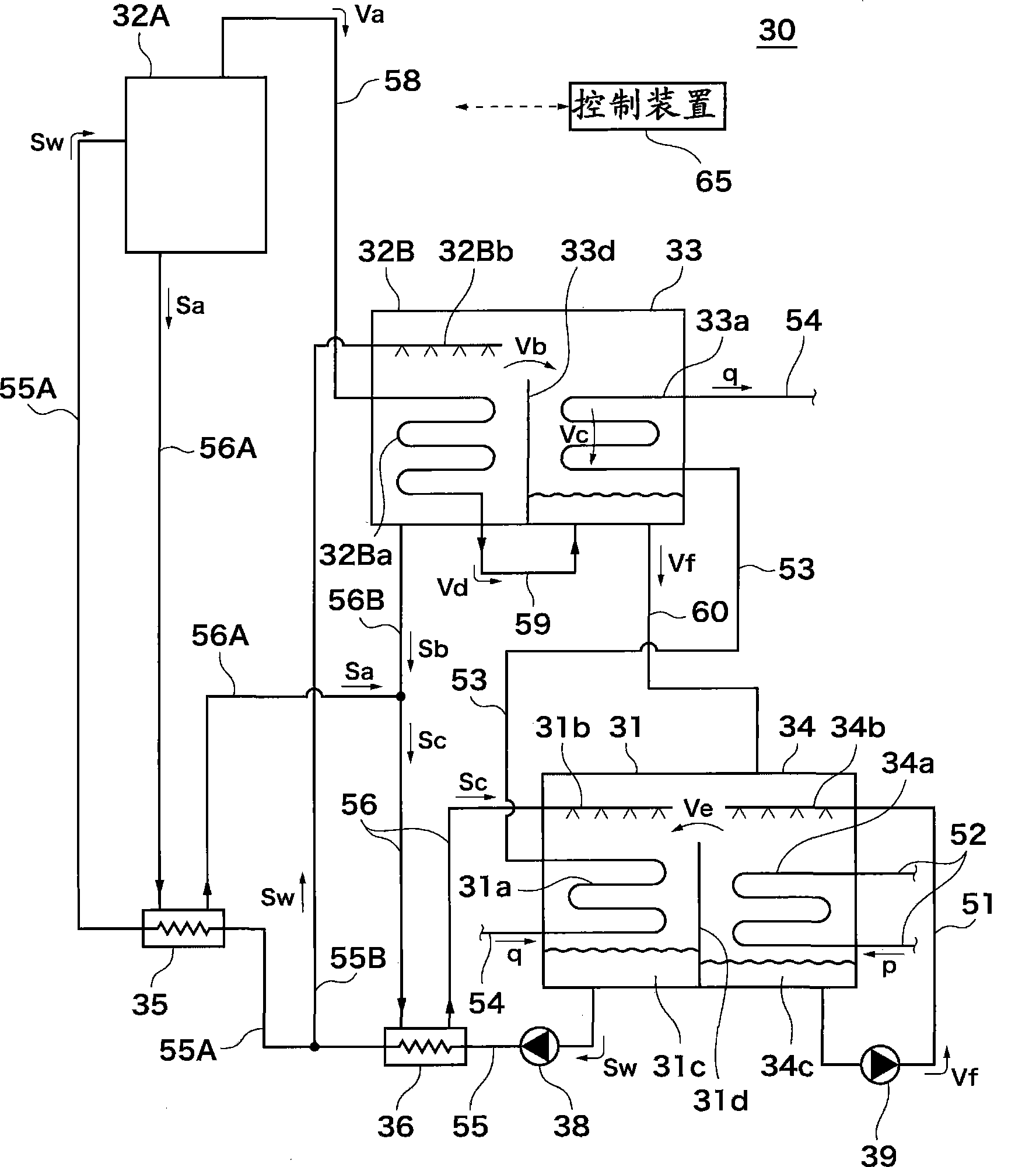

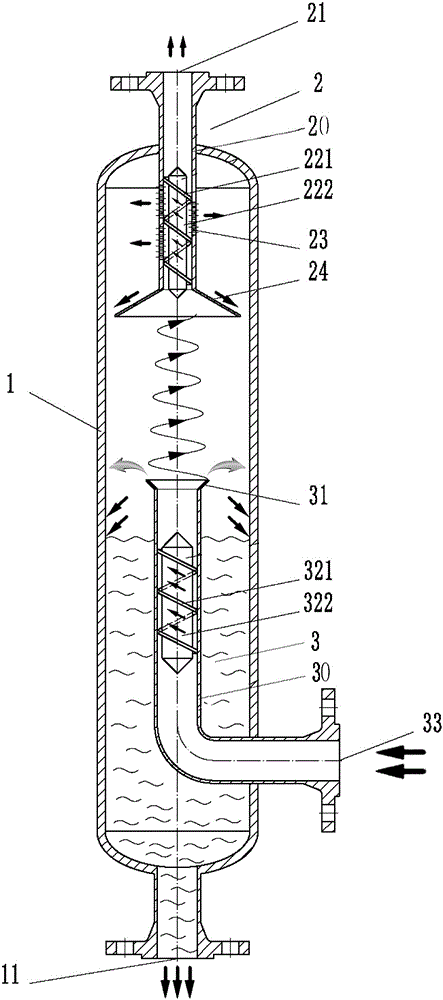

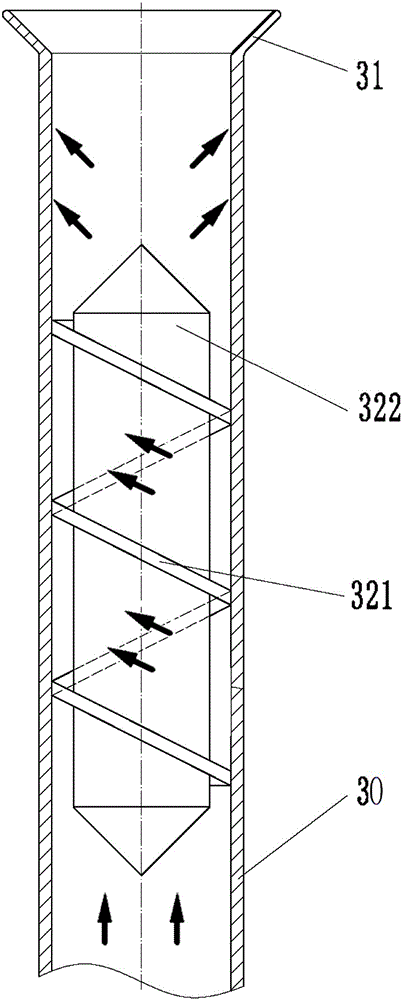

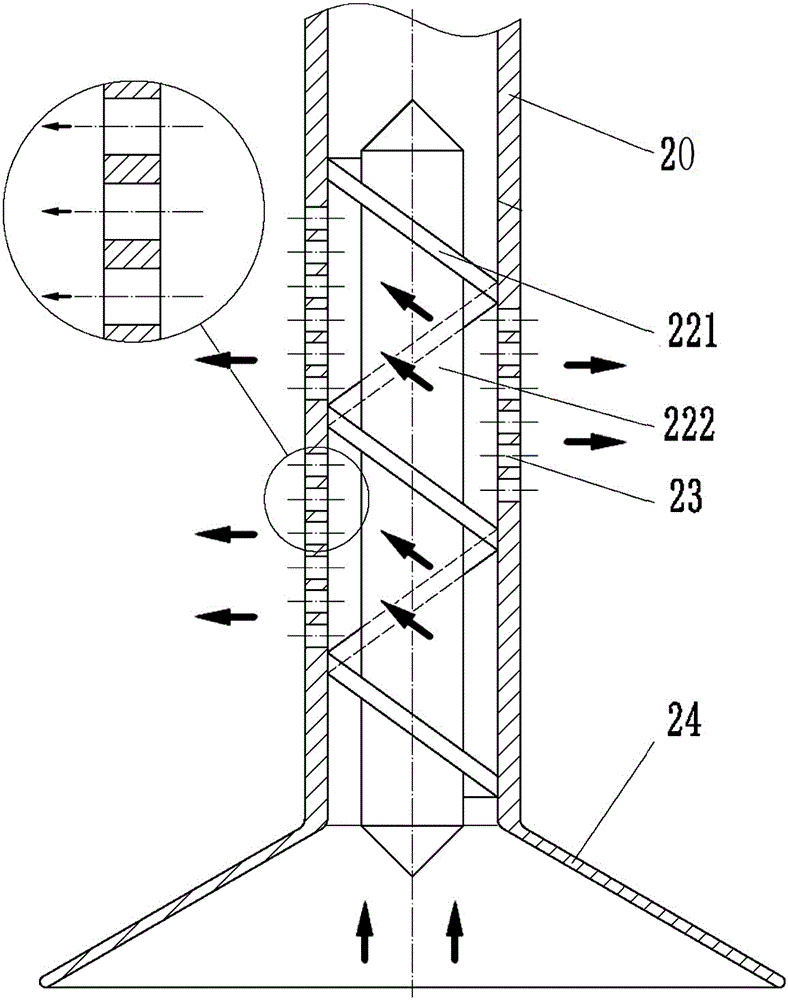

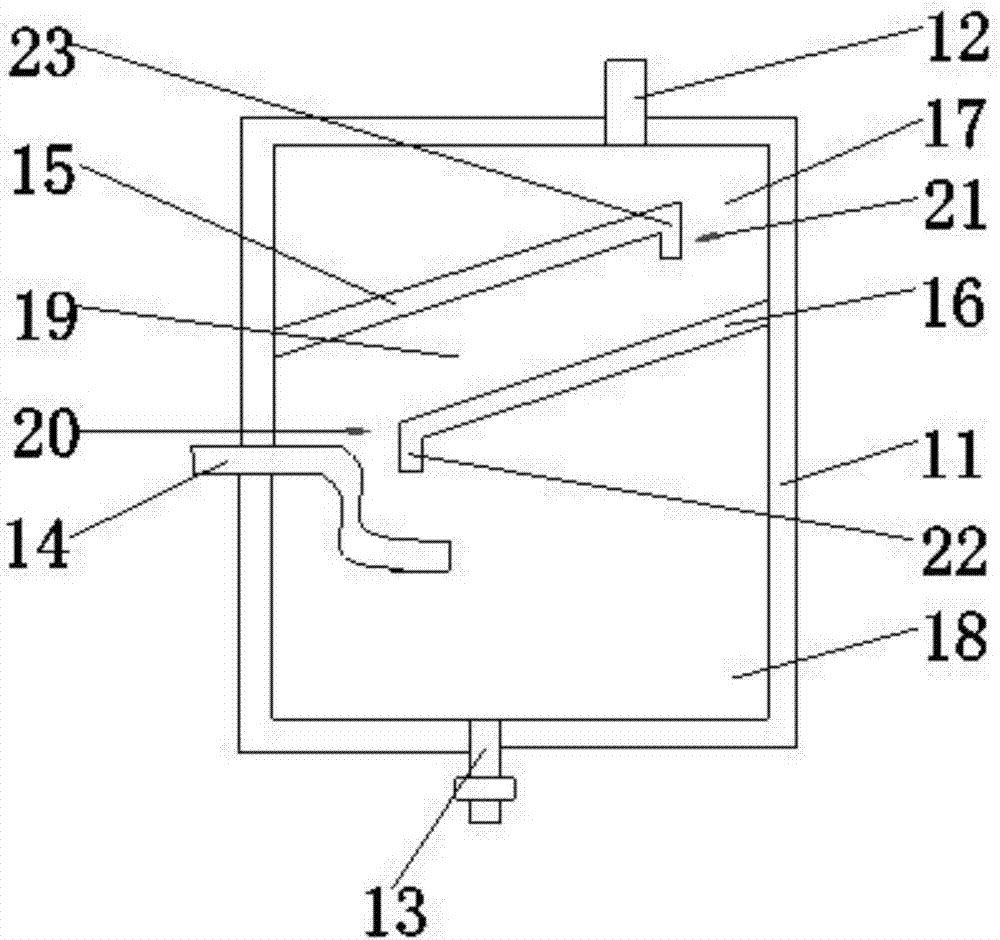

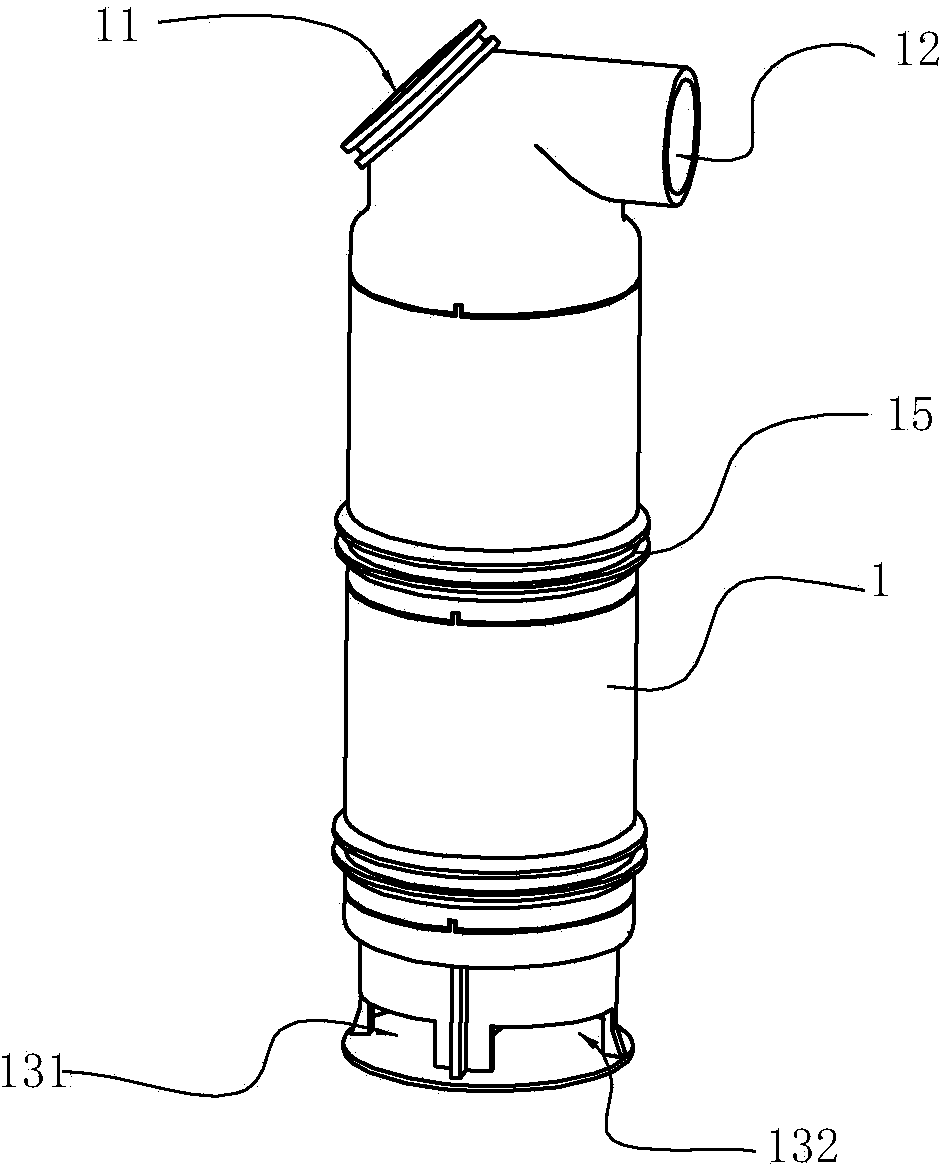

Gas-liquid separator, high temperature regenerator, absorption type refrigerator and absorption type heatpump

ActiveCN101373115AImprove the effect of gas-liquid separationEasy to separateHeat pumpsBoilers/analysersVapor–liquid separatorAbsorption heat pump

The invention provides a small gas-liquid separator with excellent property on gas-liquid separation, a high temperature regenerator provided with the gas-liquid separator, and an absorption refrigerating machine and an absorption heat pump. The gas-liquid separator (20) separates gas (Va) and liquid (Sa) from mixed fluid (Fm) with gas and liquid mixed, comprising a baffle (21) colliding the lead mixed fluid (Fm) so as to separate the liquid (Sa); a baffle (22) separating the internal of the gas-liquid separator (20) into an inlet chamber (28) and an outlet chamber (29), comprising a plate part (24) for colliding the mixed fluid (Fm) from which the liquid (Sa) is separated by use of the baffle (21) so as to separate the liquid (Sa) further; a lead-in opening (28d) is formed in the inlet chamber (28) so as to lead the mixed fluid (Fm); a gas lead-out opening (29e) is formed at the outlet chamber (29) so as to lead the gas (Va) separated from the mixed fluid (Fm) out.

Owner:EBARA REFRIGERATION EQUIP & SYST CO LTD

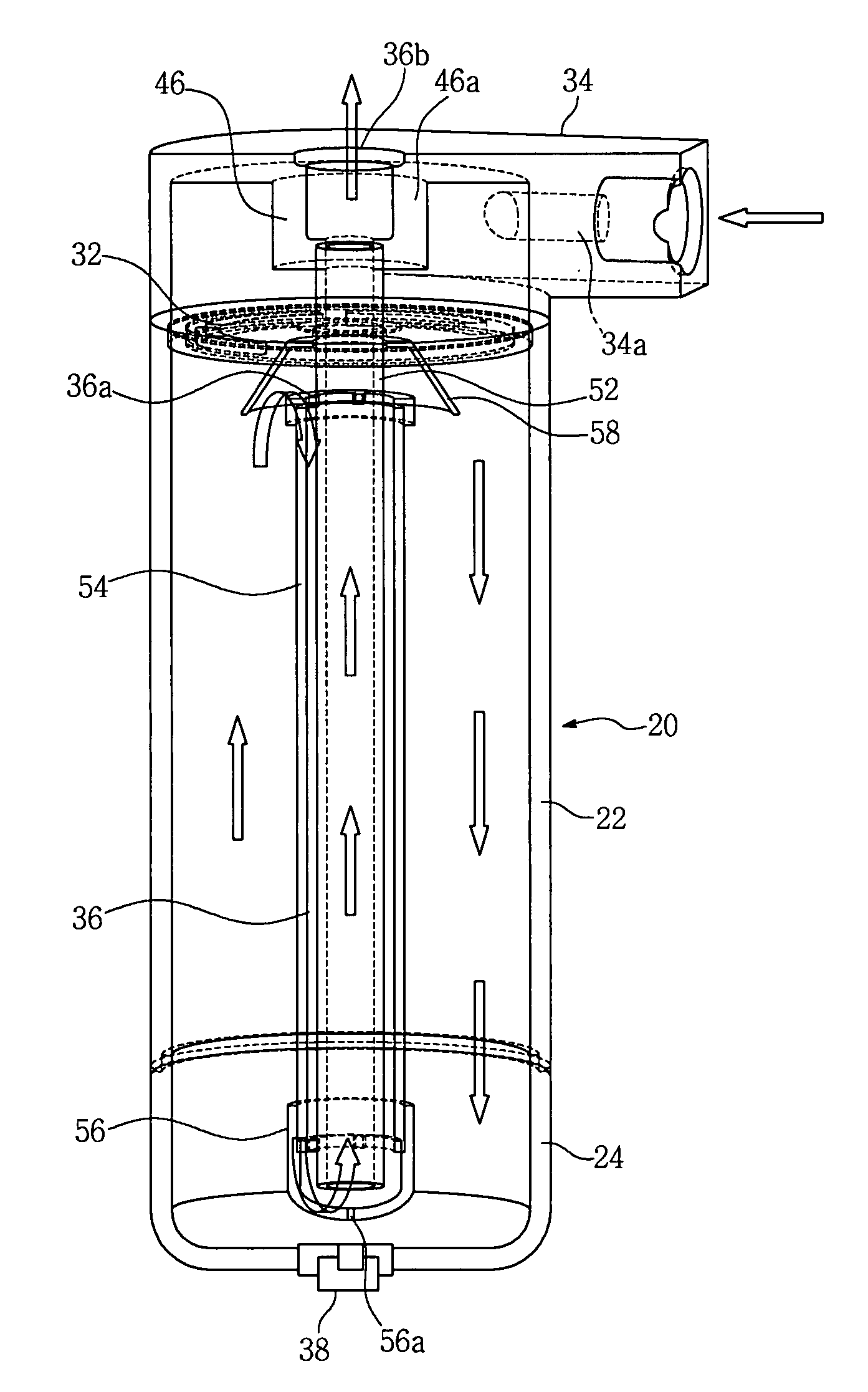

Accumulator of air conditioner

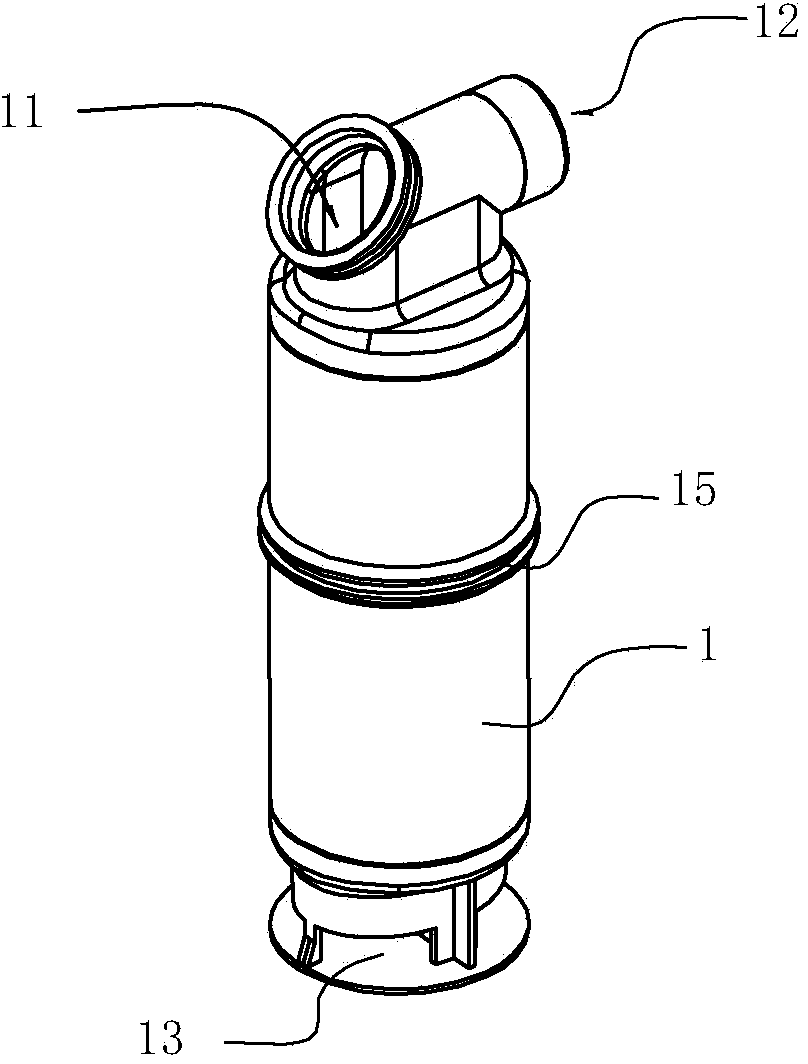

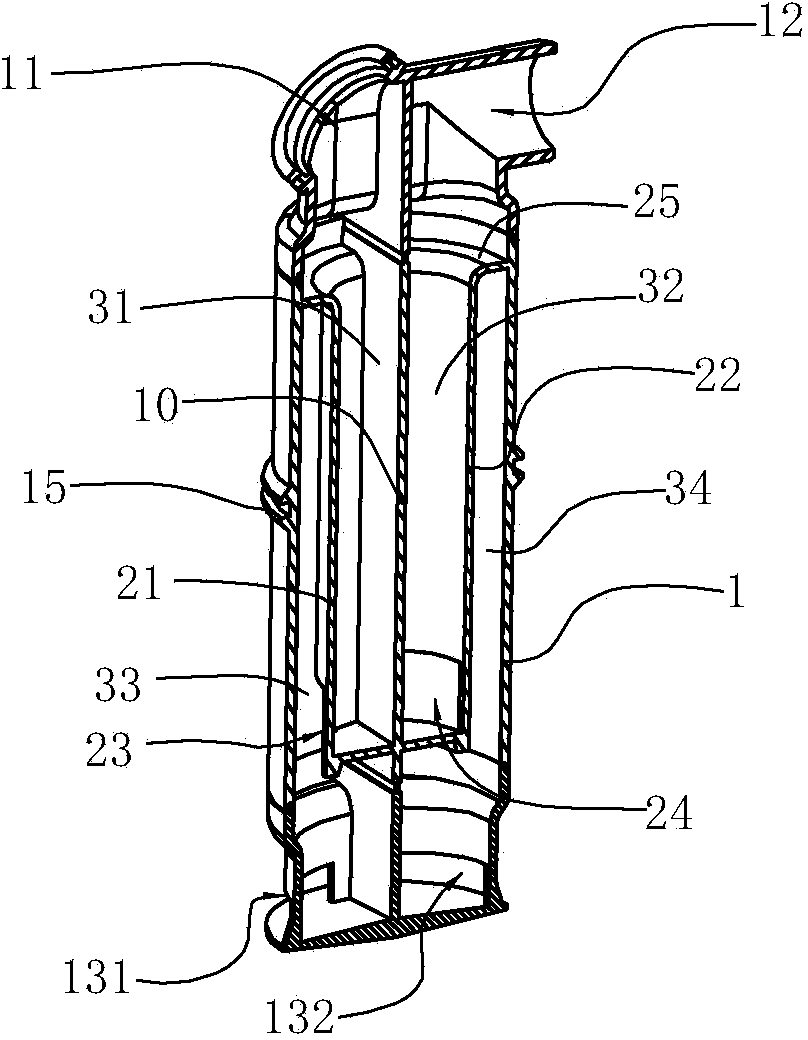

InactiveUS20080041093A1Improve the effect of gas-liquid separationConvenient spacingRefrigeration componentsNuclear engineeringCoolant flow

The present invention provides an accumulator of an air conditioner, in which a coolant outlet pipe is a dual pipe with an internal pipe and an external pipe, a return cap is combined to the lower end of the dual pipe, and a gas coolant flows from the upper portion inside a tank through a gas coolant inlet between the internal pipe and the external pipe, turns into the internal pipe at the return cap, and then continues flowing through the gas coolant outlet to an outer pipe. Therefore, the accumulator can be manufactured from a small tank, so that it can be easily mounted in a small space with high liquid-vapor separating performance and pressure resistance.

Owner:DOOWON CLIMATE CONTROL

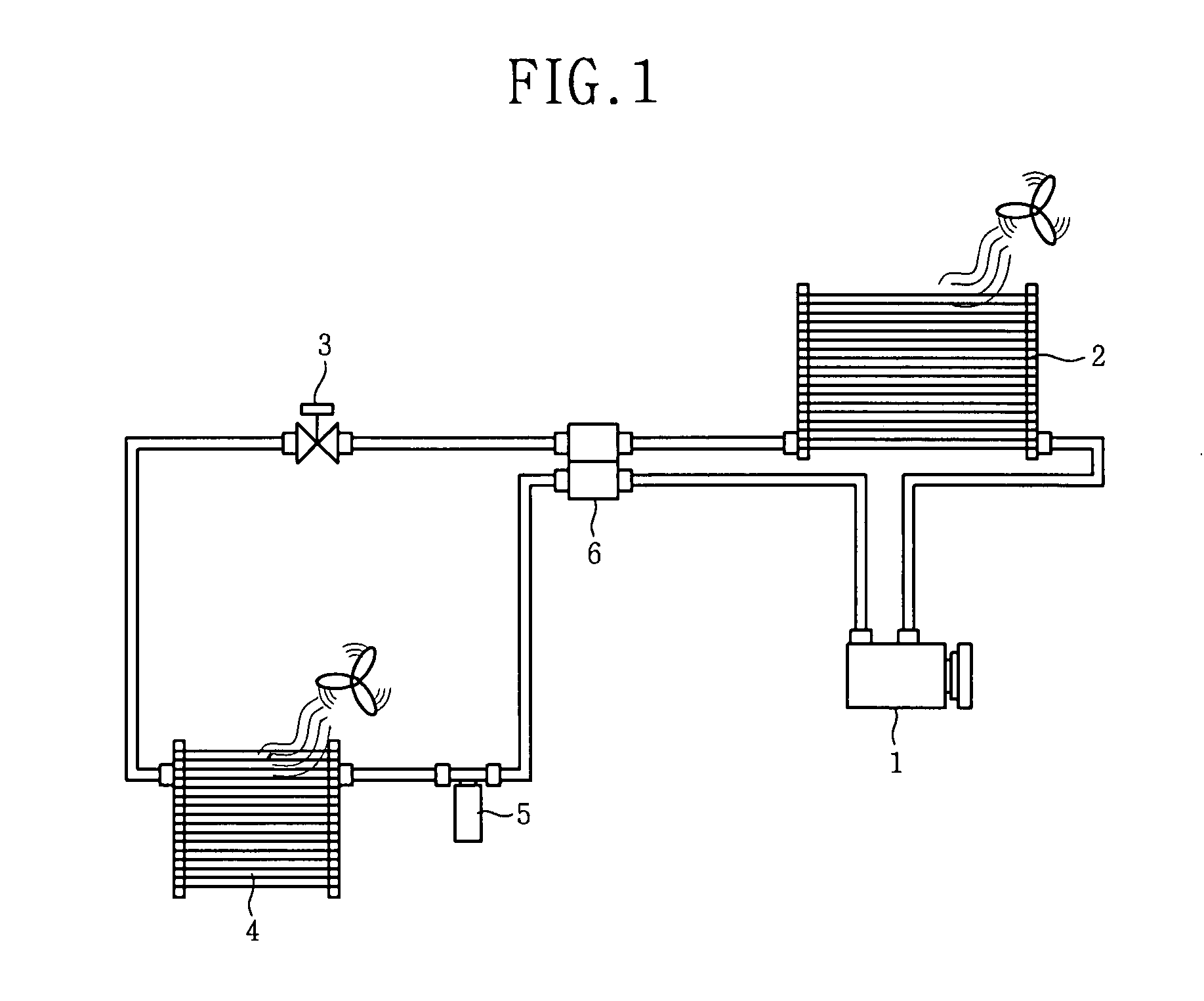

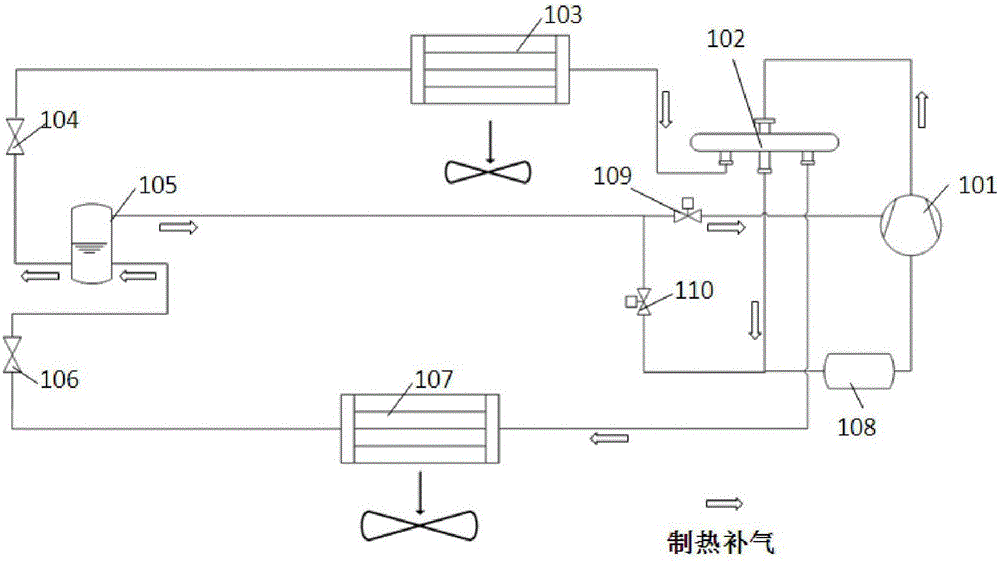

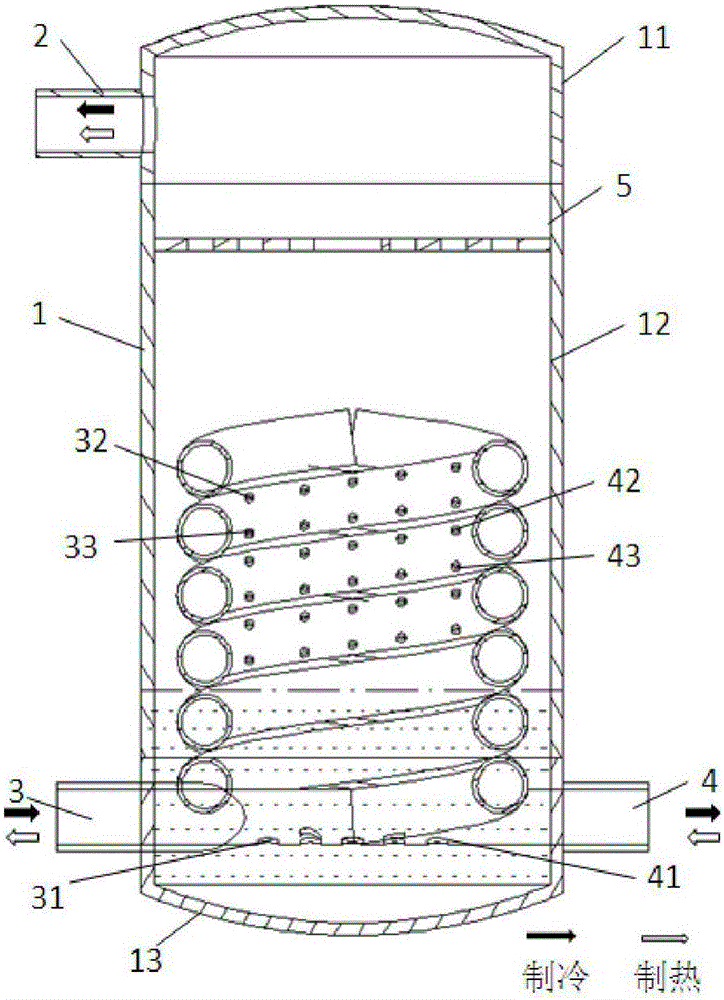

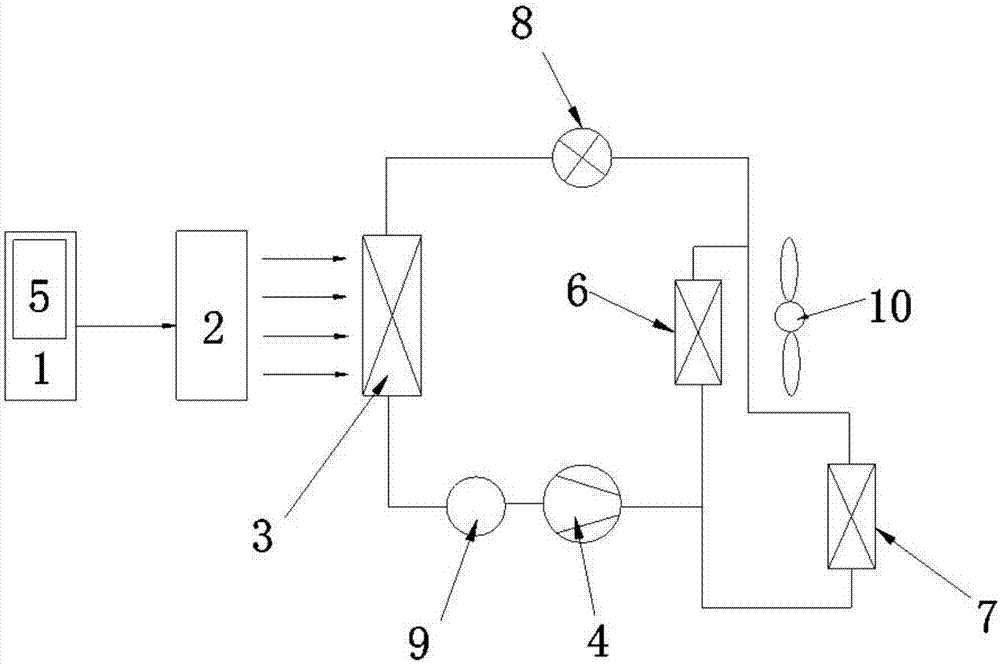

Air-supplying enthalpy-adding heat pump air conditioning system capable of promoting heat exchange performance of heat exchangers

ActiveCN105135738AImprove the effect of gas-liquid separationAddressing One-Way Flow RequirementsCompression machines with reversible cycleRefrigeration componentsFour-way valvePhase ratio

The invention discloses an air-supplying enthalpy-adding heat pump air conditioning system capable of promoting the heat exchange performance of heat exchangers. The air-supplying enthalpy-adding heat pump air conditioning system capable of promoting the heat exchange performance of the heat exchangers comprises an air-supplying enthalpy-adding compressor, a four-way valve, an outdoor side heat exchanger, an indoor side heat exchanger, an air-liquid separator and a double-direction spiral flash vessel, an air outlet pipe is arranged on the side wall of a barrel of the upper section of the double-direction spiral flash vessel, and a first refrigerant inlet and outlet pipe and a second refrigerant inlet and outlet pipe which extend to an inner cavity of the barrel are arranged on the side wall of the barrel at the lower end; the air outlet pipe is connected with a first magnetic valve and an air-supplying opening of the air-supplying enthalpy-adding compressor in sequence and simultaneously connected with a second magnetic valve and the air-liquid separator in sequence, the first refrigerant inlet and outlet pipe is connected with a first expansion valve and the outdoor side heat exchange in sequence, and the second refrigerant inlet and outlet pipe is connected with a second expansion valve and the indoor side heat exchange in sequence. According to the air-supplying enthalpy-adding heat pump air conditioning system capable of promoting the heat exchange performance of the heat exchangers, not only can heating air-supplying be achieved, but also high-temperature refrigeration air-supplying can be achieved, on the normal temperature refrigeration working condition that air-supplying is not needed, the flash vessel serves as the air-liquid separator, the air phase ratio of refrigerant at an inlet of each heat exchanger is reduced, and the heat exchange performance of the heat exchangers is promoted.

Owner:SOUTH CHINA UNIV OF TECH

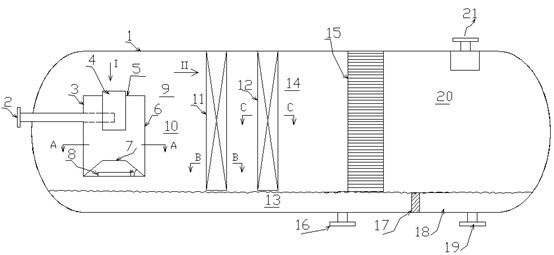

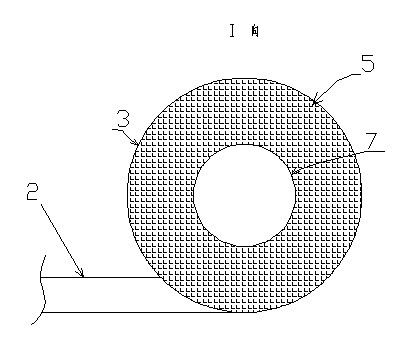

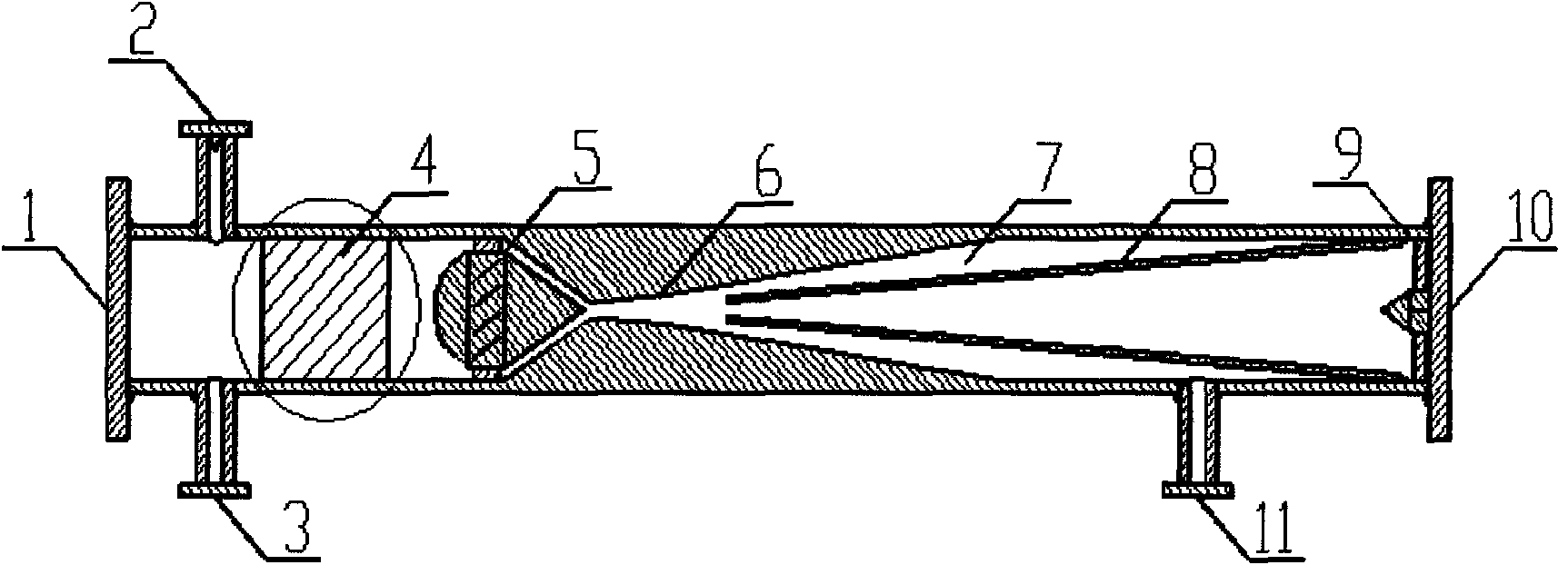

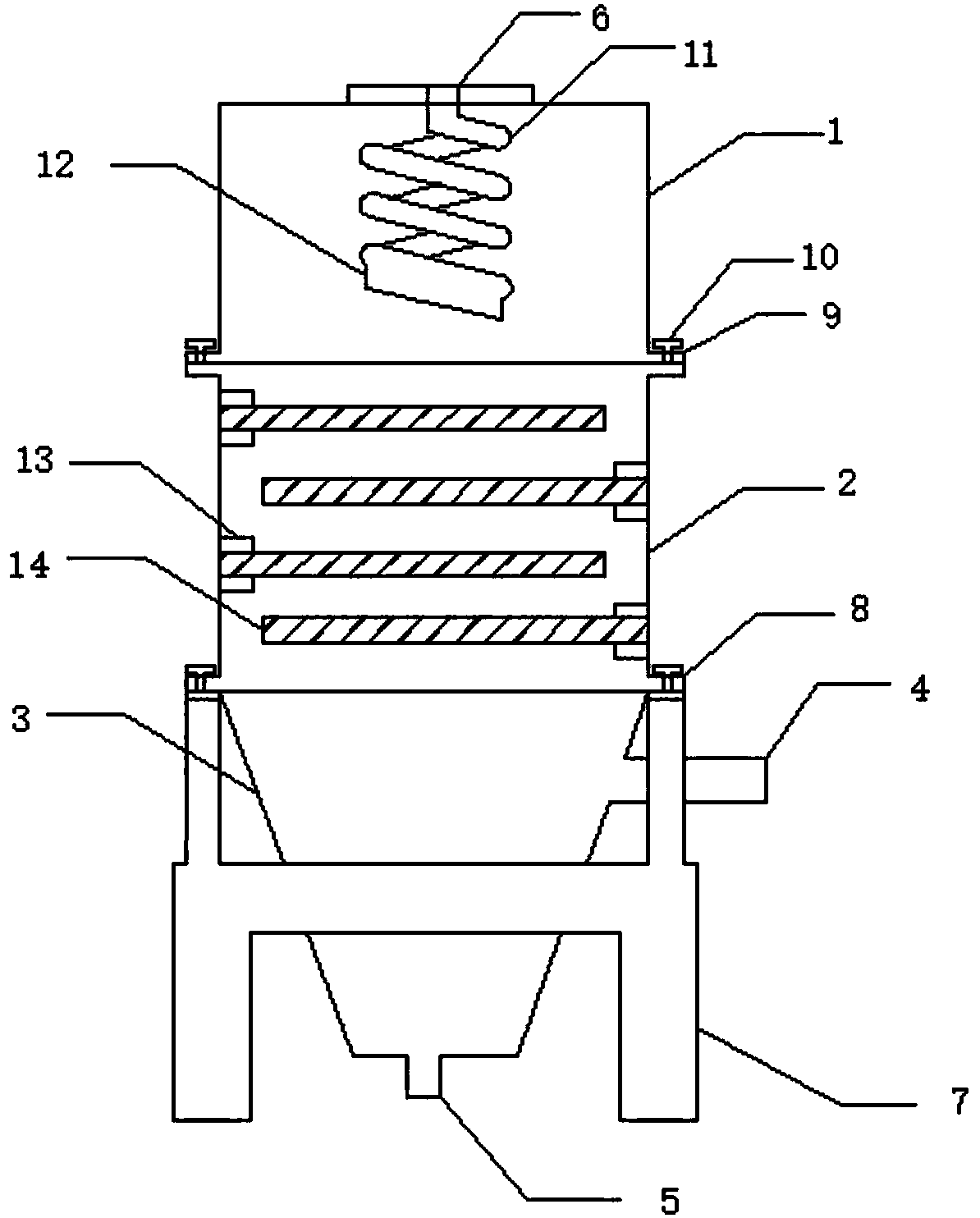

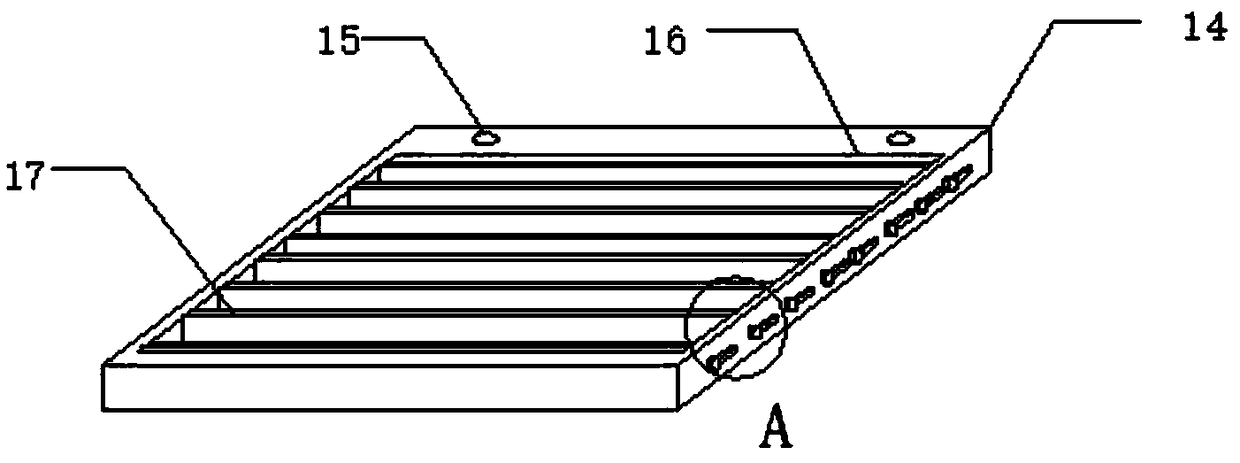

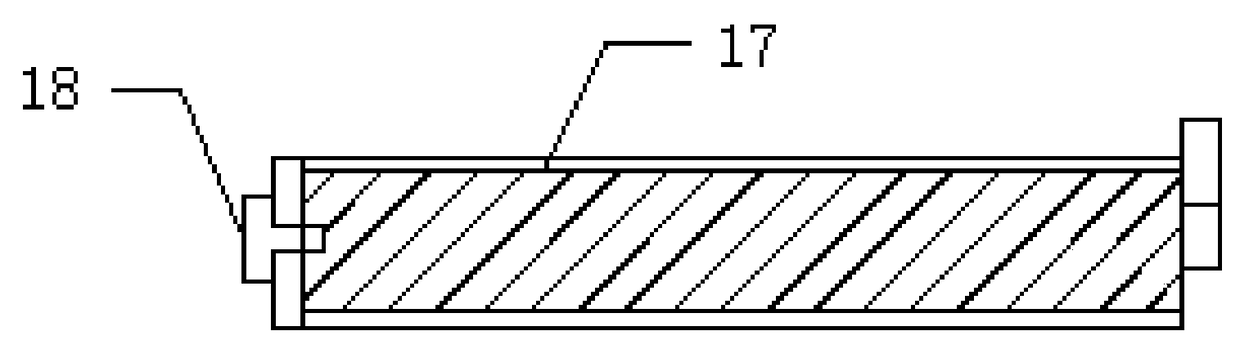

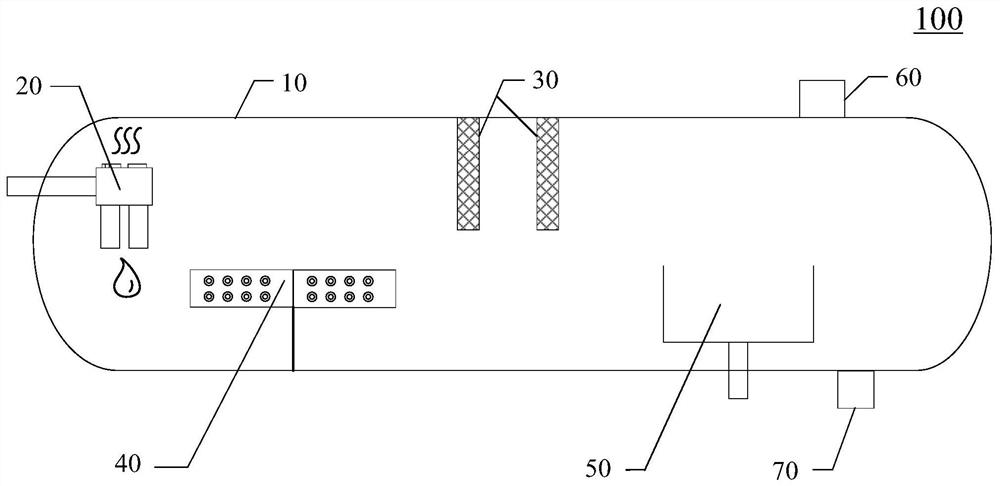

Efficient gas-liquid separator

InactiveCN102671470AImprove efficiencyReduce the overall heightDispersed particle separationEngineeringSewage

The invention discloses an efficient gas-liquid separator, wherein a charge port is arranged at the front end of a shell, a gas outlet is arranged above the rear section of the shell, a sewage outlet is arranged below the middle of the shell, and a liquid outlet is arranged below the rear end of the shell; an upper part in the shell is a gas-phase area, and a lower part in the shell is a liquid-phase area; a pre-separator, a first-layer blade-type filler, a second-layer blade-type filler, and a screen demister are sequentially arranged in the gas-phase area in the shell from a front end to a rear end, and a separation plate is arranged on the rear section of the liquid-phase area; and the pre-separator comprises a gas guide tube, a cover plate, a swirl tube, a circular-table separation plate, and a liquid guide groove. The efficient gas-liquid separator disclosed by the invention has the following advantages: an oil-gas mixed charging material sequentially passes through the pre-separator, the first-layer blade-type filler, the second-layer blade-type filler, and the screen demister, so that liquid drops with various grain diameters in the gas can be effectively separated. Under the same treatment capacity, the length of the efficient gas-liquid separator is reduced by 20-30% compared with that of the existing separator, thus lightening the weight of the separator, and reducing the manufacturing and transportation costs.

Owner:ZHEJIANG UNIV +1

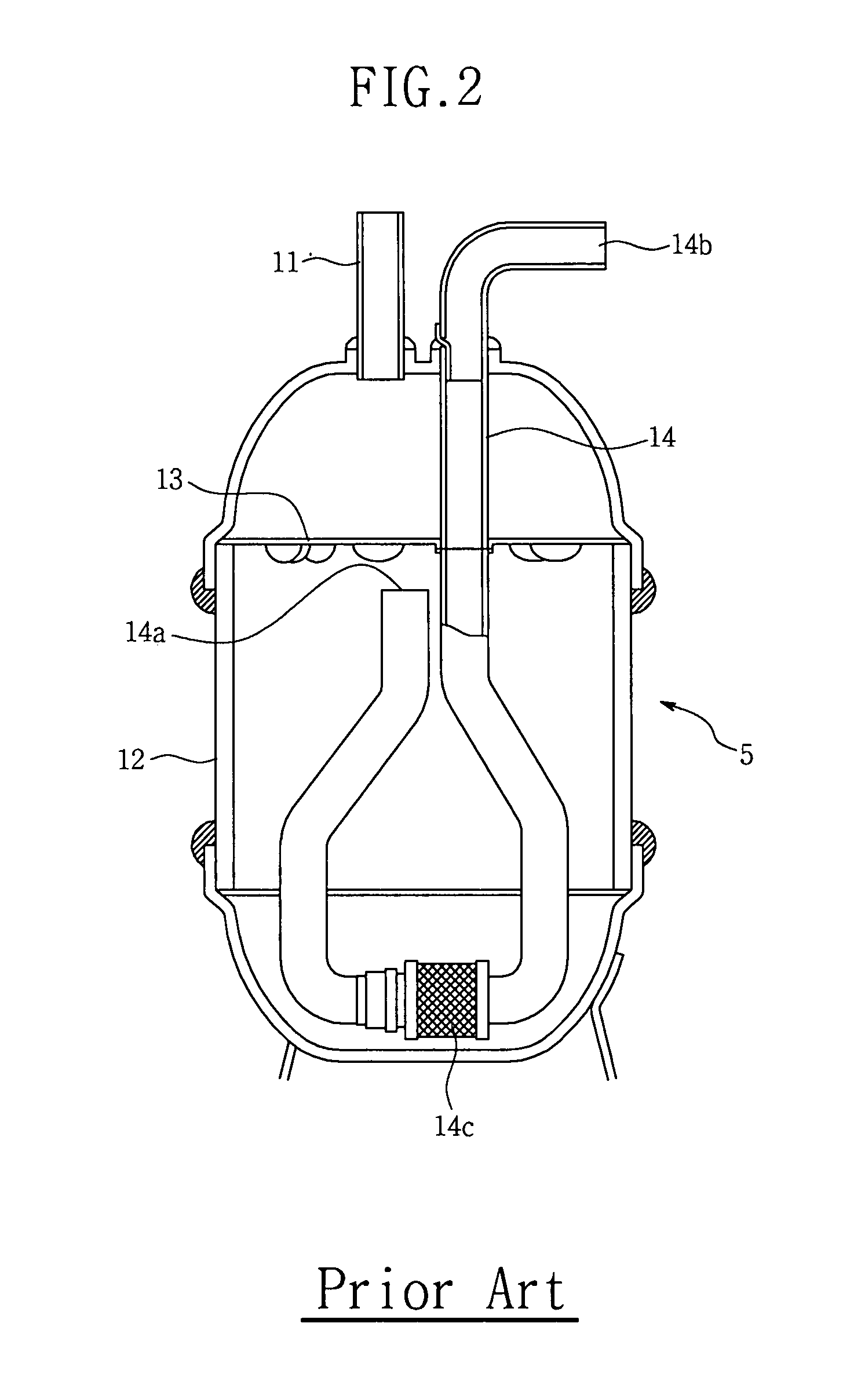

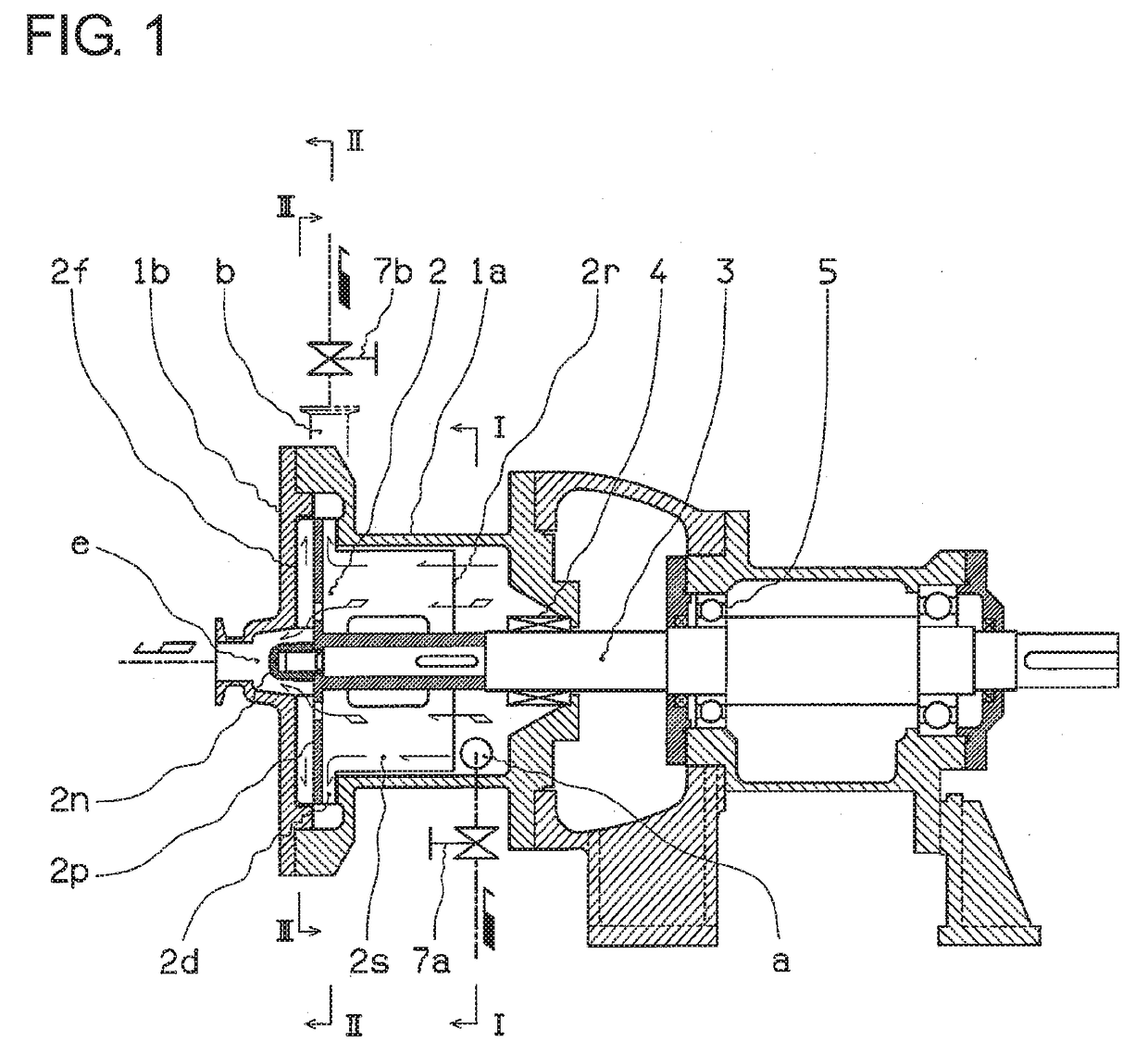

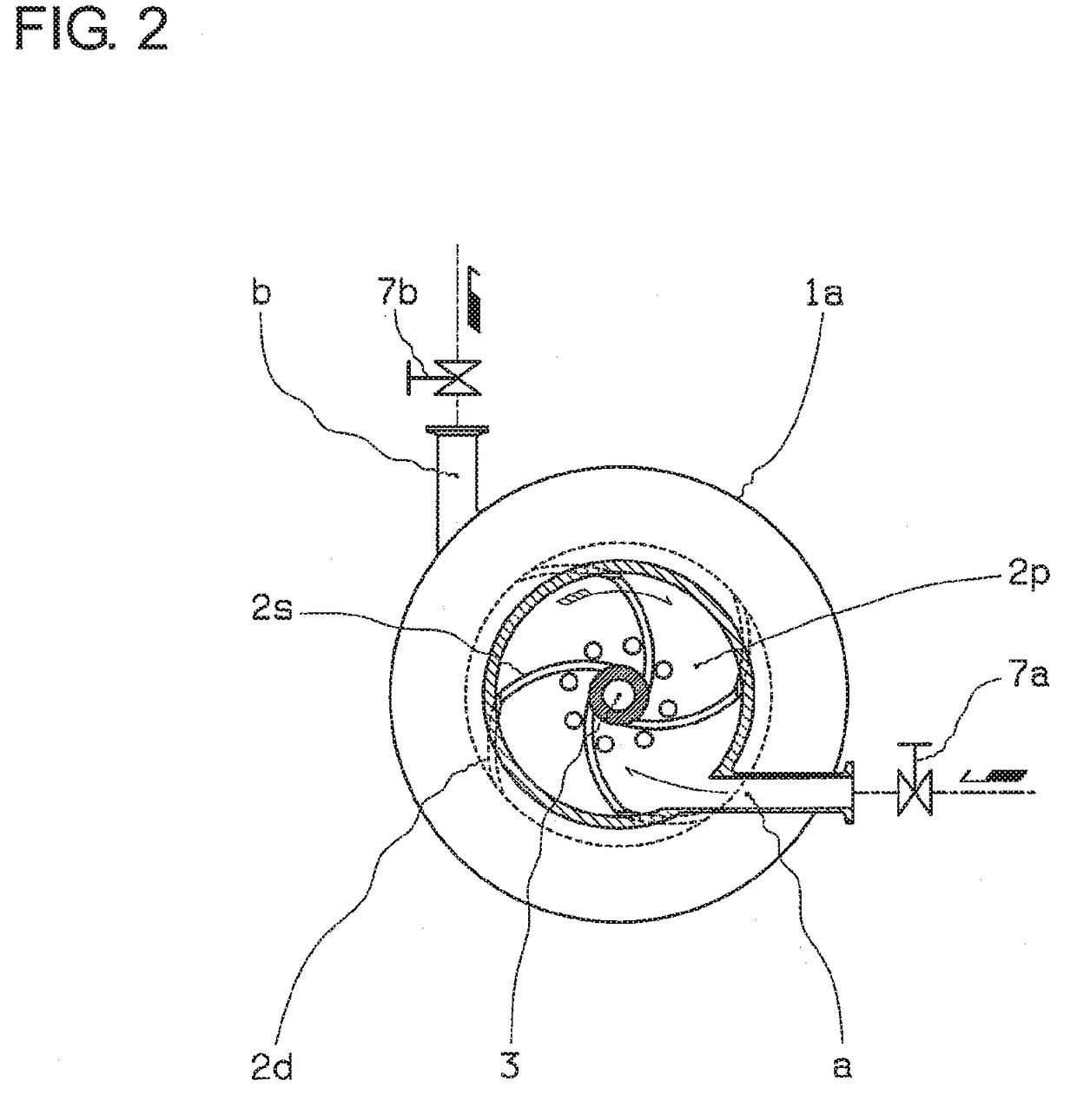

Gas-liquid separator and ejector refrigerant cycle using the same

InactiveUS7040117B2Reduce weight and sizeImprove performanceAir-treating devicesCompression machines with non-reversible cycleVapor–liquid separatorEvaporation

In an ejector refrigerant cycle, even if refrigerant is super-heated in an evaporator, super-heated gas refrigerant does not directly flow into a gas-liquid separator, so that boiling of refrigerant does not occur in the gas-liquid separator due to evaporation of refrigerant in the gas-liquid separator. When an equivalent inner diameter (D) of a tank body of the gas-liquid separator is set in a range of 2 cm–6 cm, and when a ratio of a vertical dimension (H) of the tank body to the equivalent inner diameter (D) thereof is larger than 1, a wall thickness of the tank body can be reduced while gas-liquid separation performance in the gas-liquid separator can be improved.

Owner:DENSO CORP

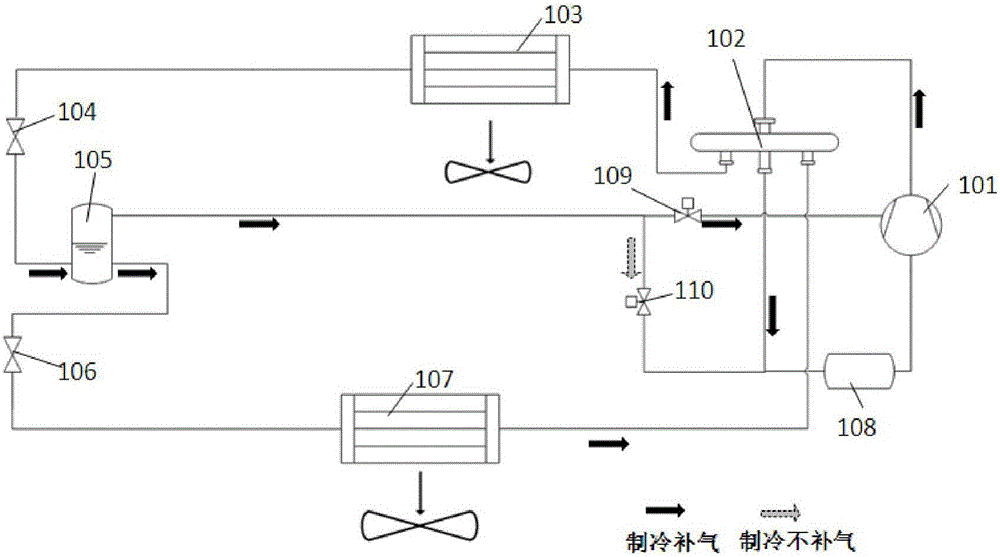

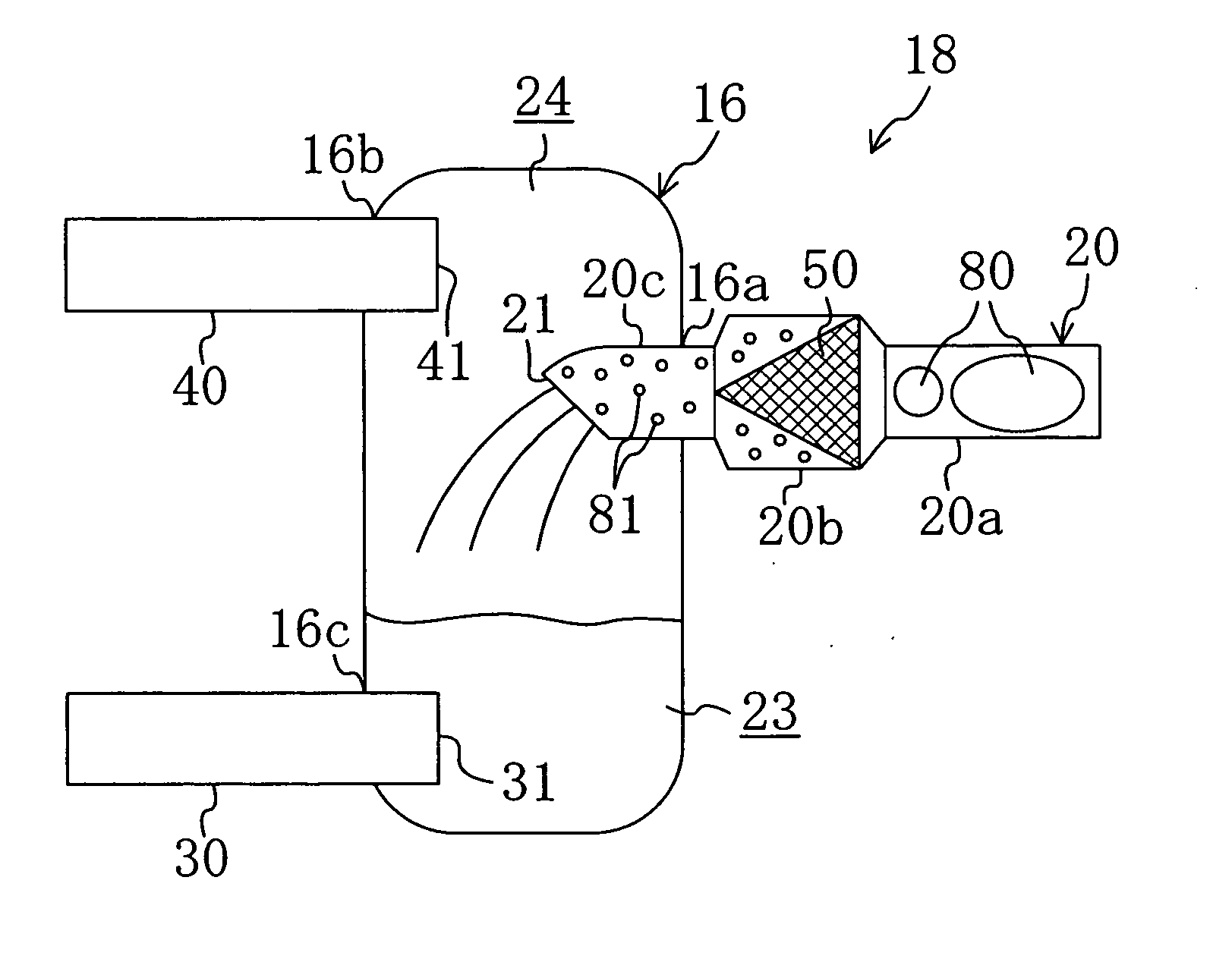

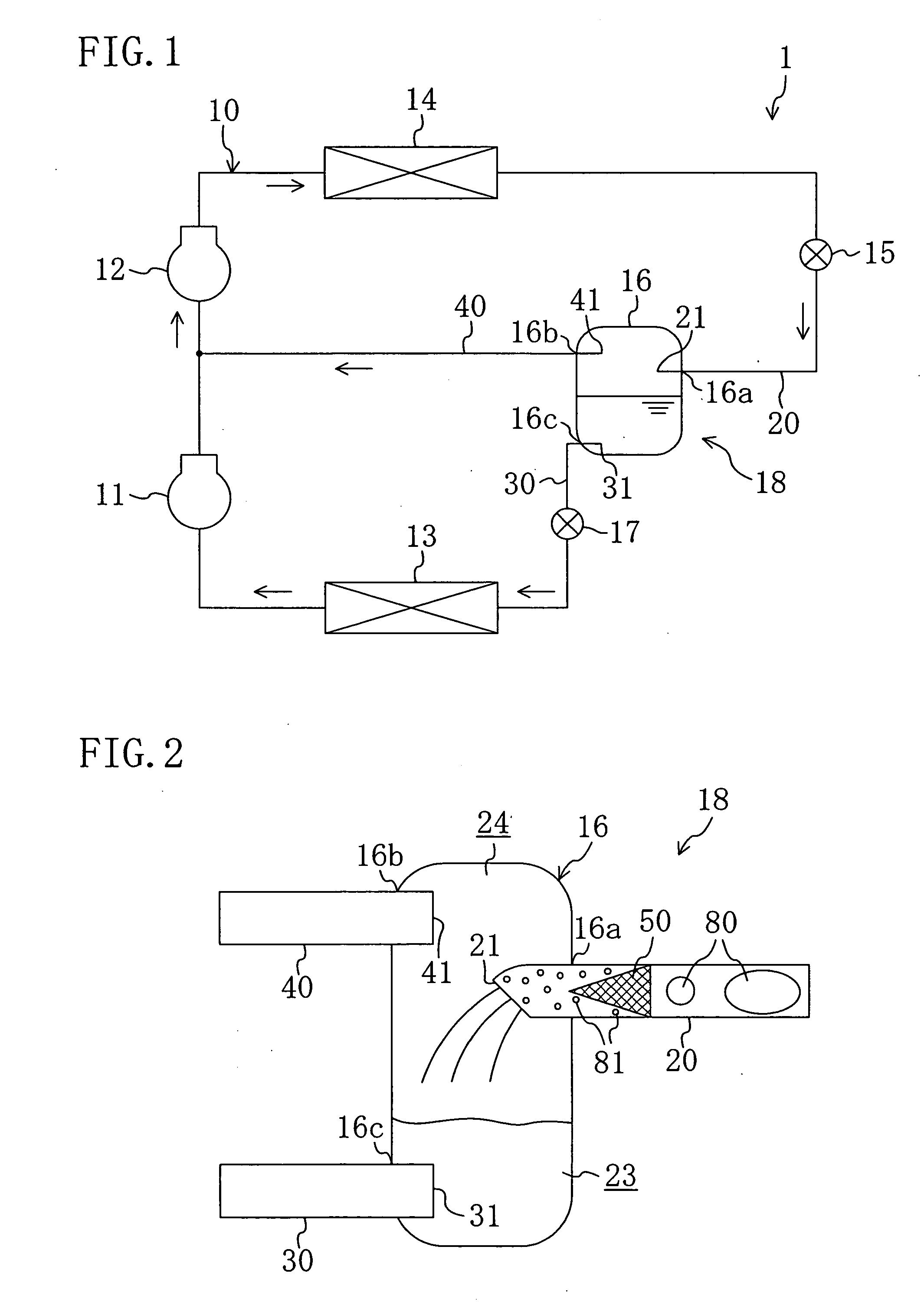

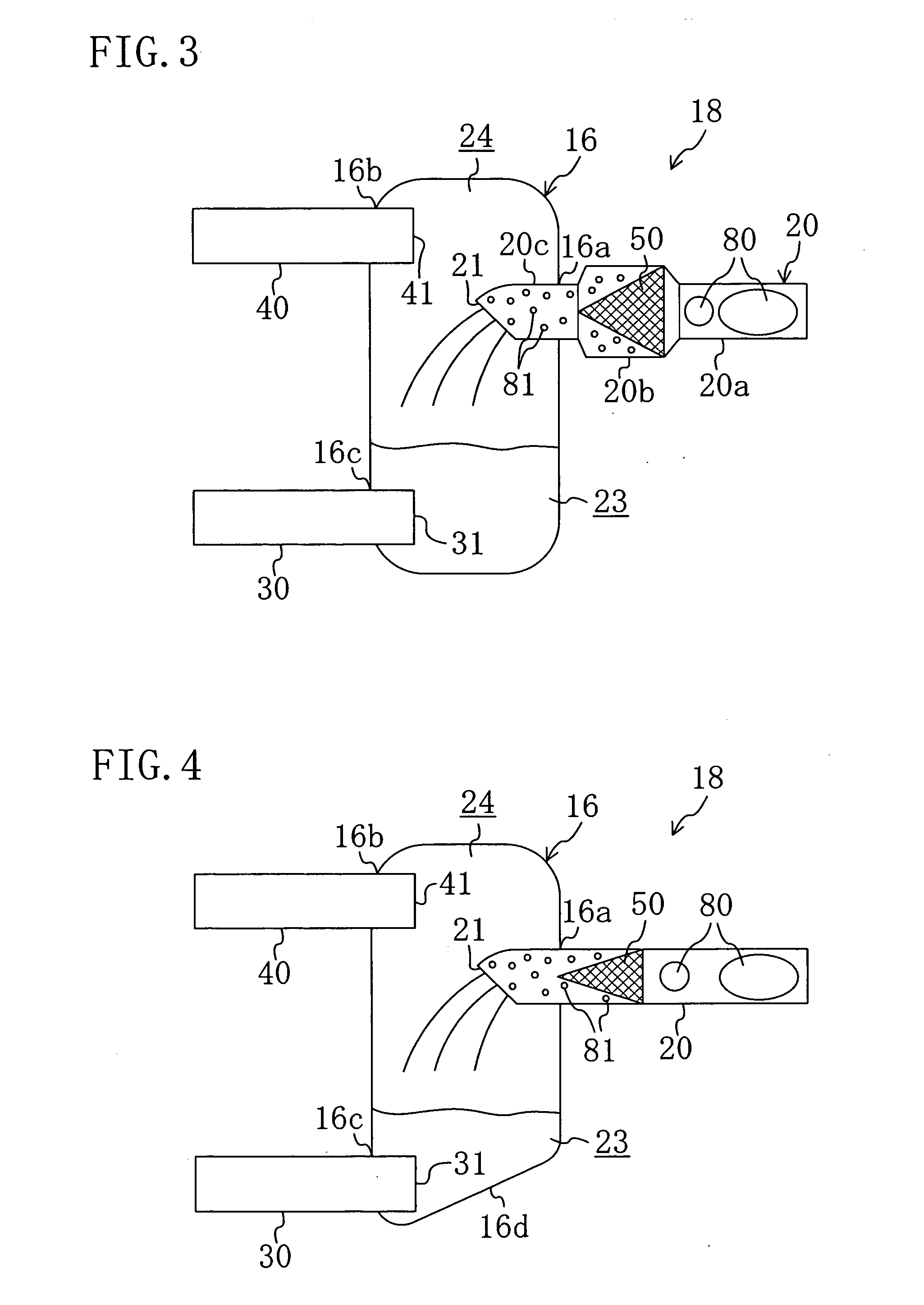

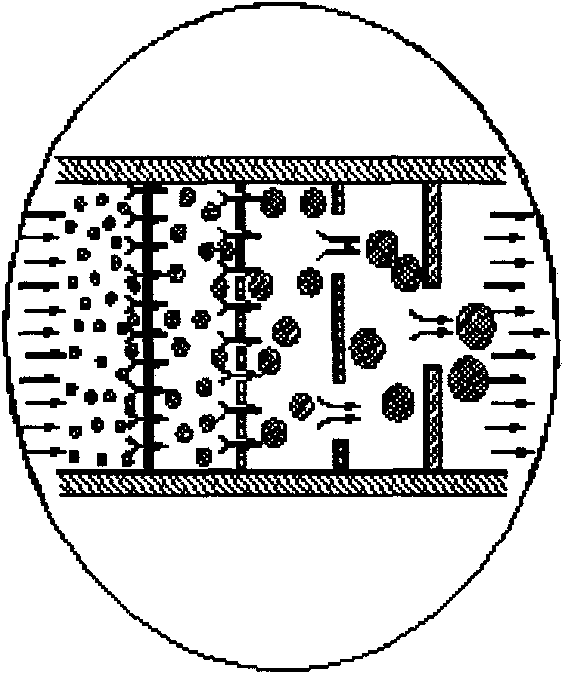

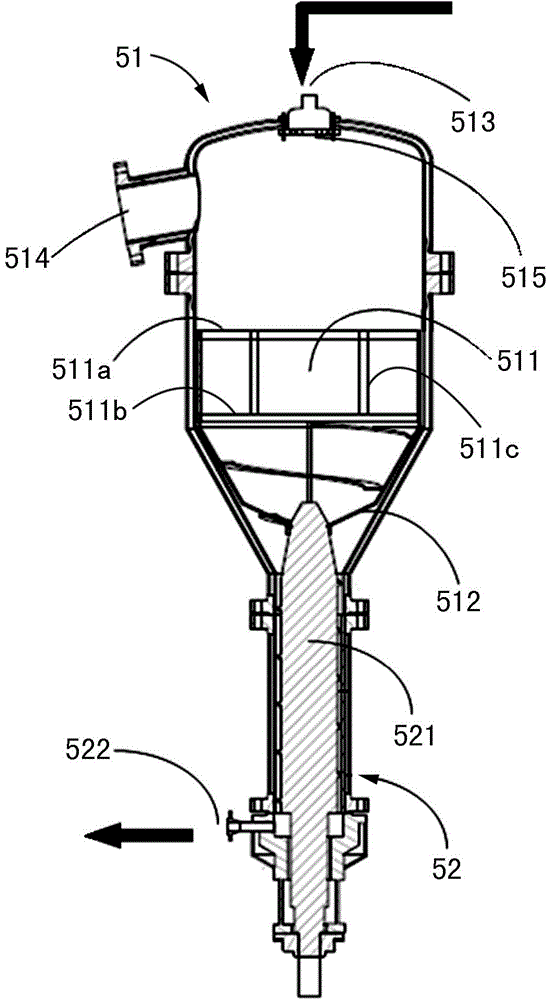

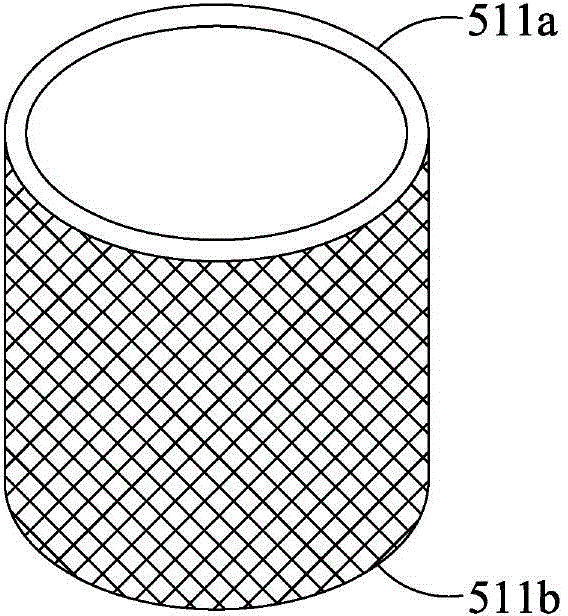

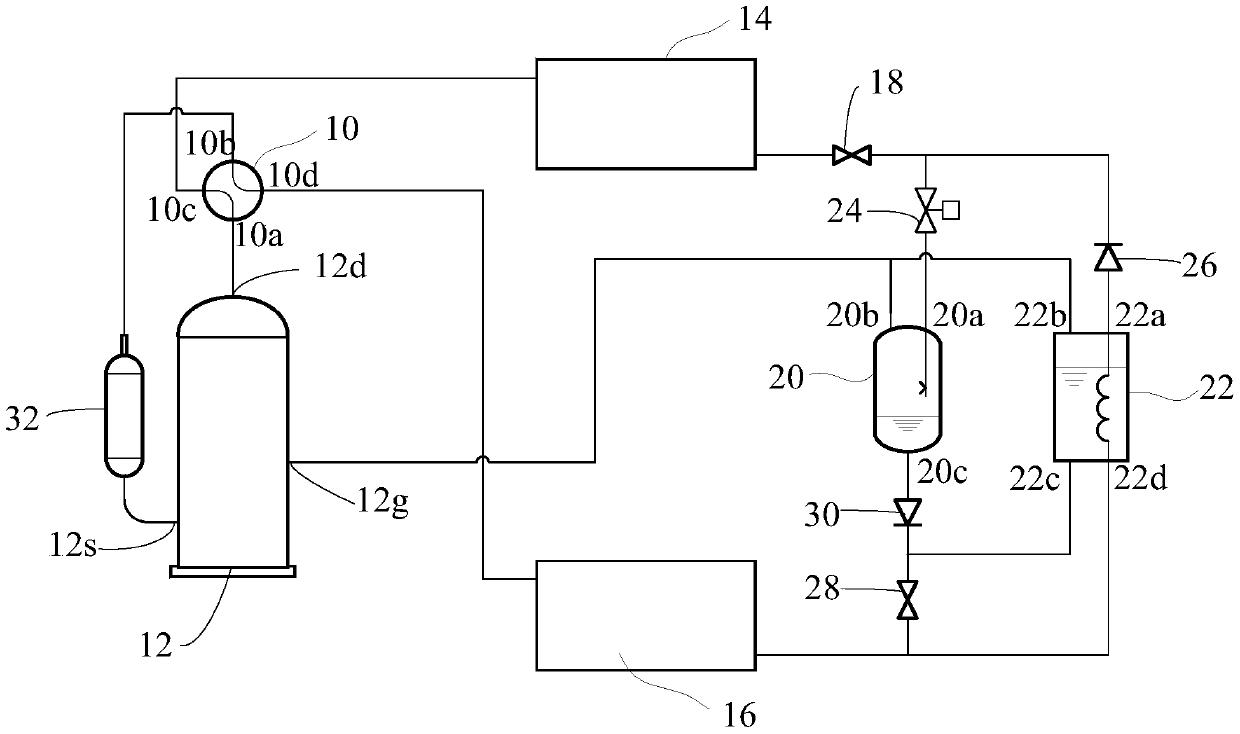

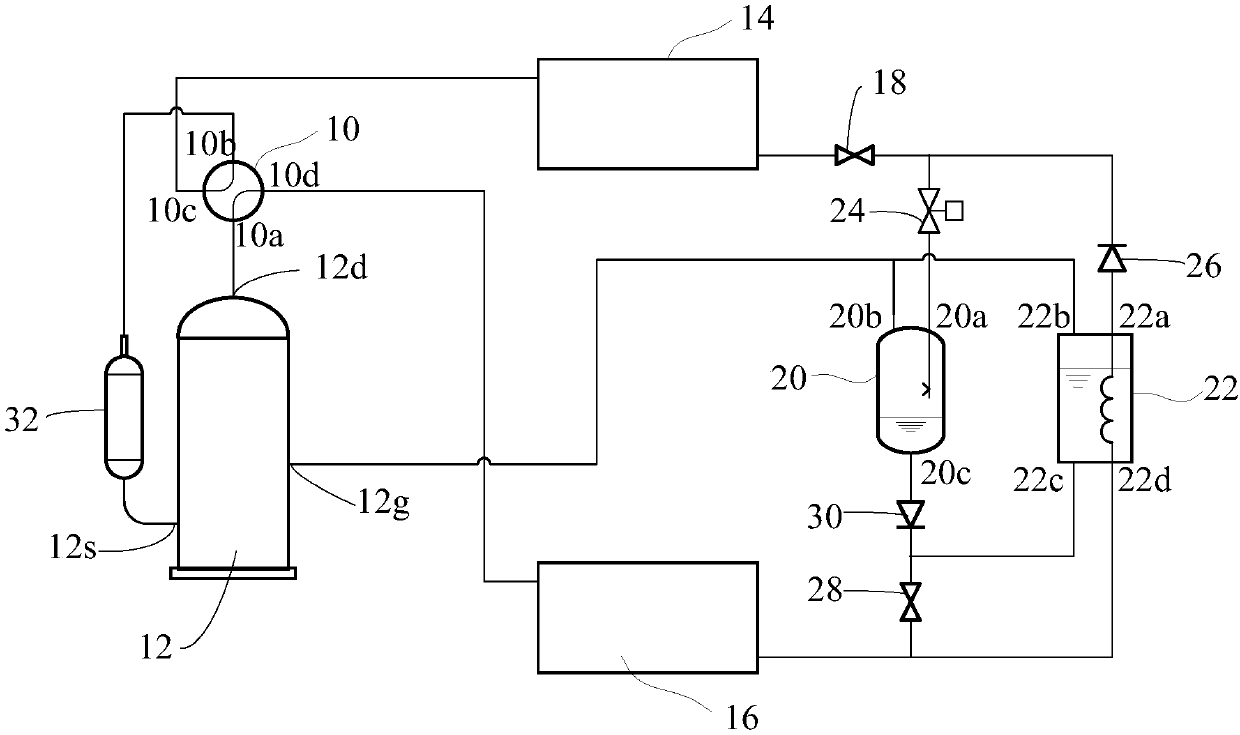

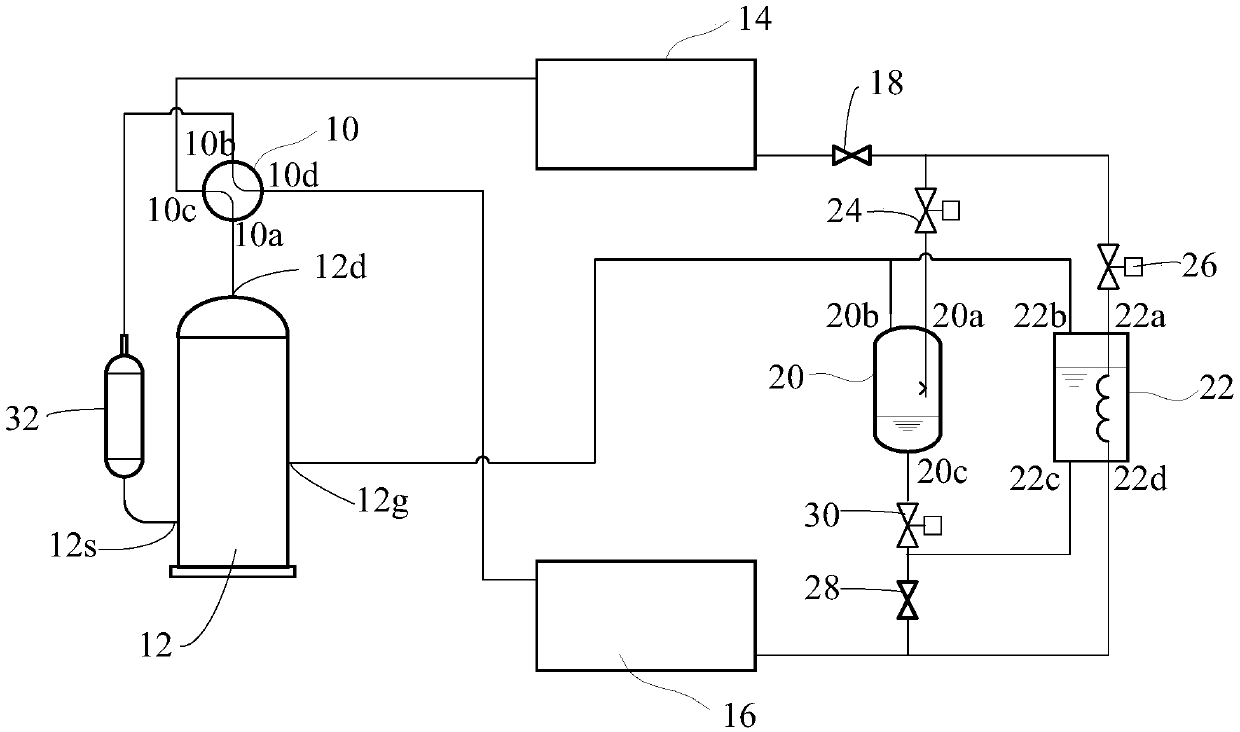

Gas-Liquid Separator and Refrigeration System With Gas-Liquid Seperator

InactiveUS20100154467A1Improve the effect of gas-liquid separationReduce distractionsCompression machines with non-reversible cycleFluid circulation arrangementVapor–liquid separatorLiquid state

A refrigeration system includes a refrigerant circuit including a gas-liquid separator (18) and operating in a two-stage compression and two-stage expansion refrigeration cycle. In the refrigerant circuit, intermediate-pressure gas-liquid two-phase refrigerant having flowed through an intermediate expansion valve after flowing through an outdoor heat exchanger is introduced through an inflow pipe (20) of the gas-liquid separator (18) into the vessel body (16) thereof and separated therein into liquid refrigerant and gas refrigerant. The liquid refrigerant flows out through a liquid outflow pipe (30), then flows through a main expansion valve and then through a refrigeration heat exchanger and is then sucked into a low-pressure stage compressor. The gas refrigerant flows out through a gas outflow pipe (40), is then fed to the suction side of a high-pressure stage compressor and is then sucked into the high-pressure stage compressor together with refrigerant discharged from the low-pressure stage compressor. The inflow pipe (20) is provided with a mesh member (50) for fragmentizing gas bubbles (80) of gas refrigerant in the gas-liquid two-phase refrigerant.

Owner:DAIKIN IND LTD

Composite baffling revolving bed mass transfer and reaction device

ActiveCN106622093AImprove uneven distributionIncrease contact timeDispersed particle separationLiquid-gas reaction processesContact timeGas phase

The invention particularly relates to a composite baffling revolving bed mass transfer and reaction device. The device comprises a static disk, a fluid distributor, a fluid inlet pipe, a gas outlet pipe, an upper guide flow plate, a lower guide flow plate, a gas inlet pipe, a moving disk, a rotating shaft, a fluid outlet pipe and a shell body; the static disk and the moving disk are placed in the shell body, and several concentric ring shaped guide flow plates with different diameters are arranged on the static disk; evenly distributed circular small holes are arranged on the upper guide flow plate, and several concentric circular cone shaped lower guide flow plates are arranged on the moving disk; evenly distributed puncture holes are arranged on the lower guide flow plate; the upper guide flow plate and the lower guide flow plate are aligned in a staggering manner; the static disk is fixedly connected with a gas outlet pipe, the moving disk is fixedly connected with the rotating shaft; one end of the rotating shaft crosses through the shell body and seals with the shell body. Through changing the flow path of the gas fluid flow body, the uniform gas fluid distribution is improved by fully using the inside diameter direction of a rotor and an axial space, the gas and fluid contact time is effectively prolonged; through adding the gas disturbance degree, the gas phase mass transfer efficiency is improved.

Owner:ZHONGBEI UNIV

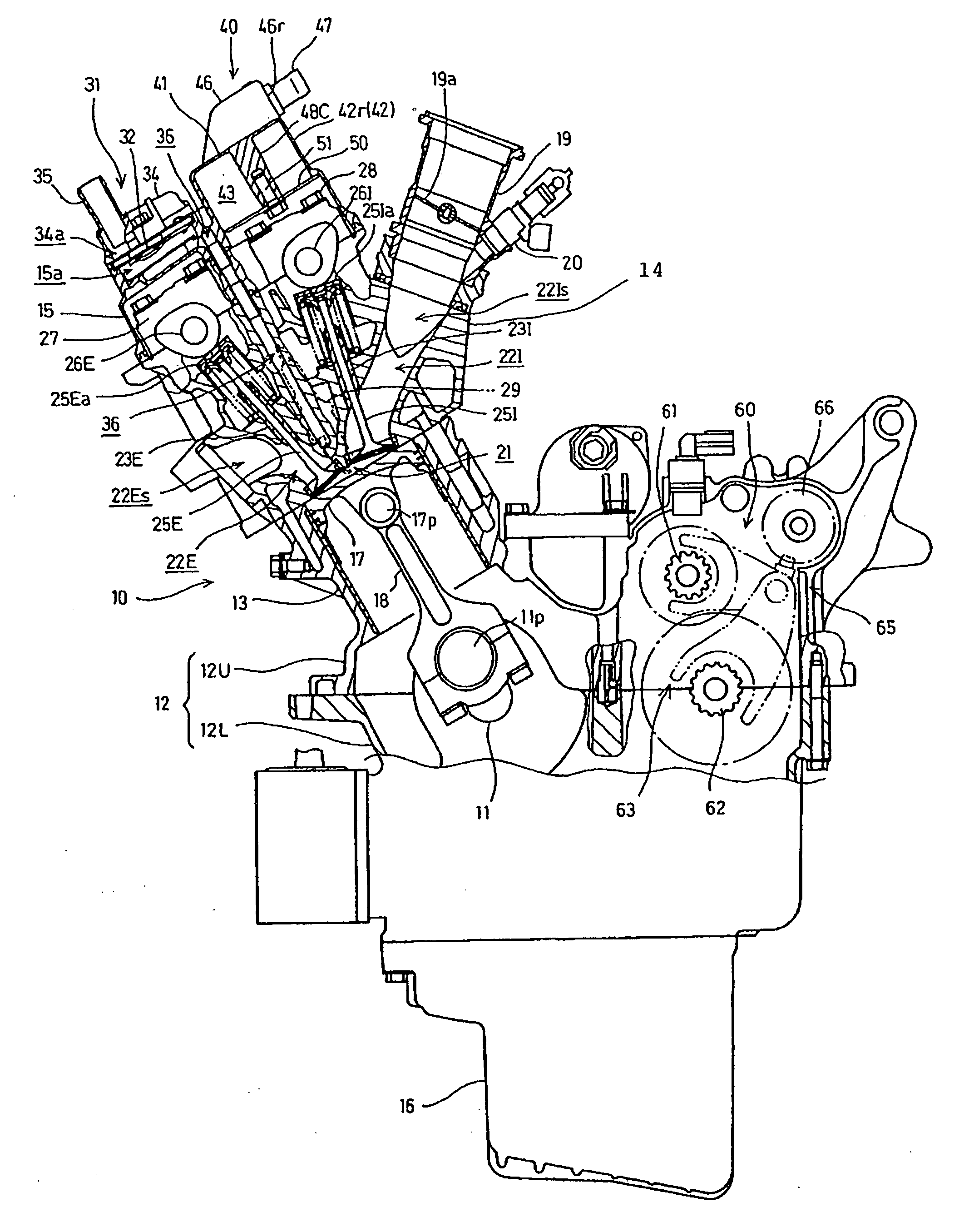

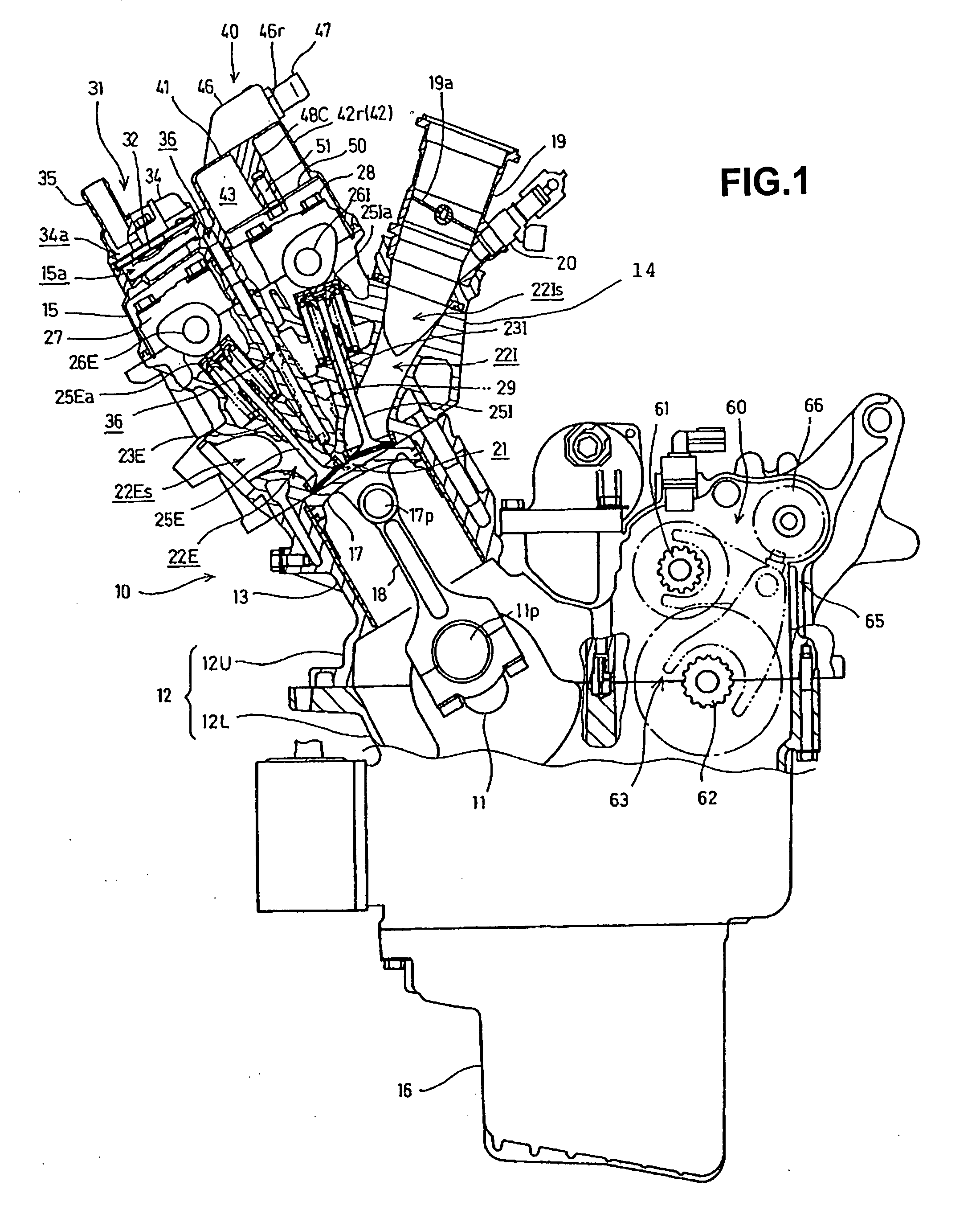

Engine cylinder head cover with integral breather apparatus, and engine incorporating same

InactiveUS20080011280A1Improve liquidityImprove the effect of gas-liquid separationCasingsCombustion-air/fuel-air treatmentBreatherCylinder head

A breather apparatus for an internal combustion engine which, when casting a cylinder head cover, can improve the fluidity of molten metal and promote gas-liquid separation through effective use of an entire breather chamber. A breather apparatus for an internal combustion engine has a cylinder head cover in which a breather chamber is formed. In the breather chamber, a number of ribs extend from a side wall included in a peripheral wall of the chamber obliquely relative to a direction in which blowby gas flows in through inflow ports. The ribs extend up to where they are continuous with respective fixing bosses. The ribs include projecting lower edge portions which are partly cut out, forming respective concave portions.

Owner:HONDA MOTOR CO LTD

Vortex tubular gas-liquid separator

ActiveCN105148625AEliminate the effects ofEfficient separationDispersed particle separationVapor–liquid separatorLiquid ratio

The invention discloses a vortex tubular gas-liquid separator. The vortex tubular gas-liquid separator comprises a vertical shell, wherein a primary spiral separation device and a secondary spiral separation device are installed in the shell. A two-level centrifugal separation way is adopted, the liquid content of a separated gas phase is reduced to 3 percent or less, the gas content of a liquid phase is reduced to 1 percent or less, so that the metering, sampling and purifying of the gas phase and the liquid phase are guaranteed, the harms of gas-liquid mixed fluid, such as vibration, gas corrosion and corrosion on downstream equipment and pipelines are reduced, and the vortex tubular gas-liquid separator has the advantages of simplicity and compactness in structure, easiness in manufacturing and the like. Under the situations of large and frequent variation of flow and gas-liquid ratio as well as a slug flow, the vortex tubular gas-liquid separator can achieve good gas-liquid separation effects, is widely applicable to various gas-liquid separation fields and particularly suitable for the gas-liquid separation field having high requirements on the separation rate, can achieve a gas-liquid separation effect of a liquid-gas ratio of 1: 100 and can separate a liquid drop with a minimum diameter more than or equal to 5 micrometers.

Owner:山东华盛荣油气装备有限公司

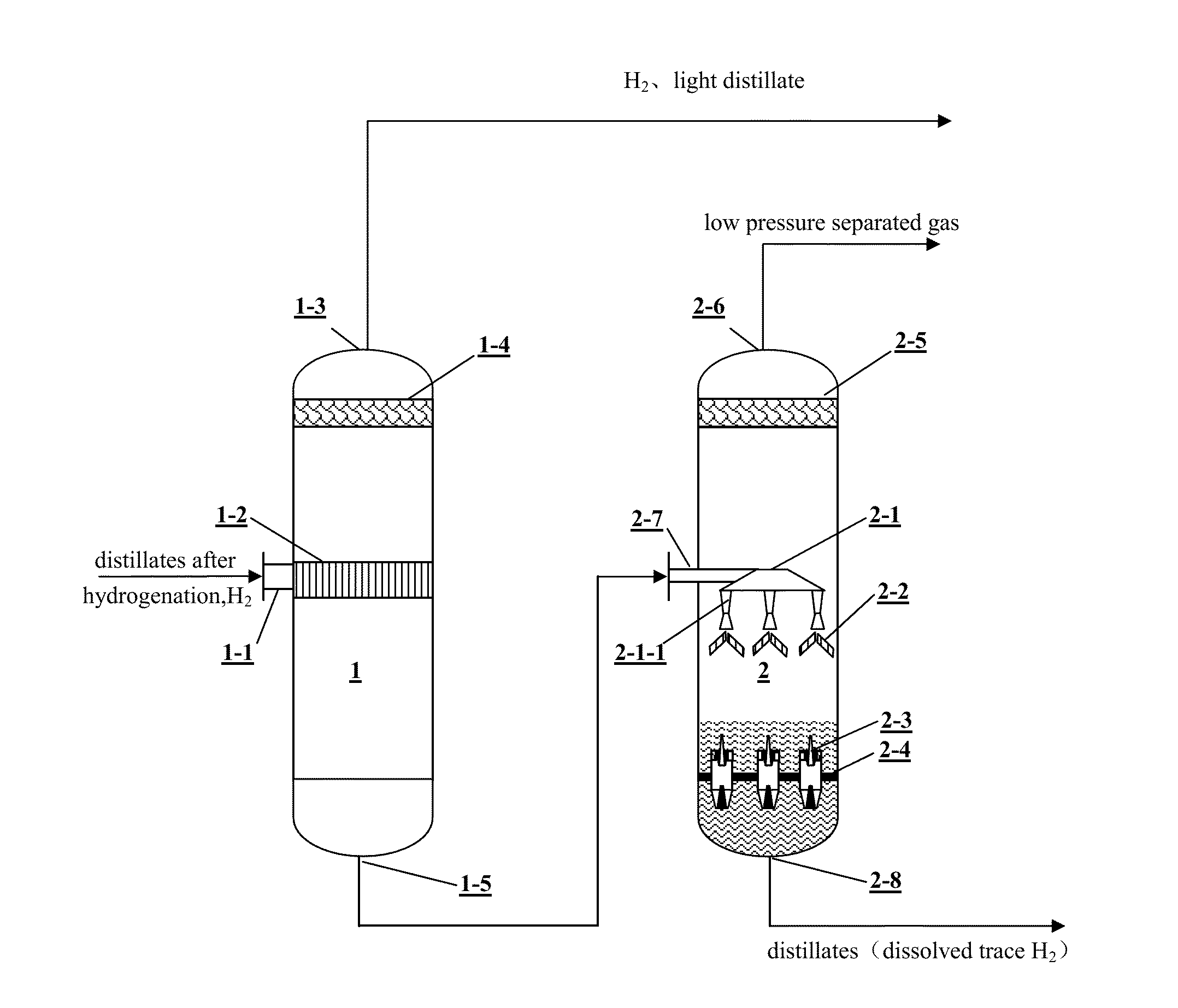

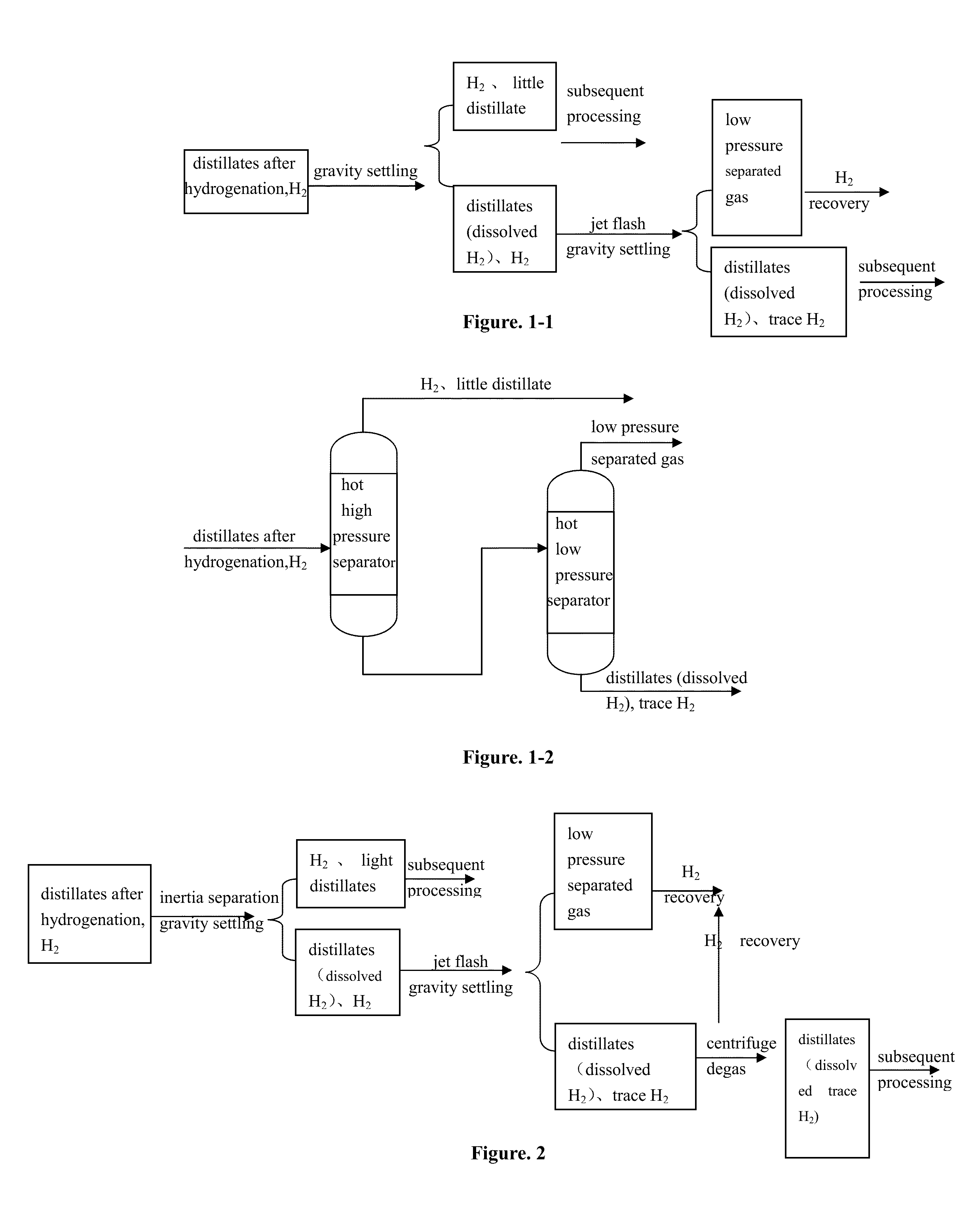

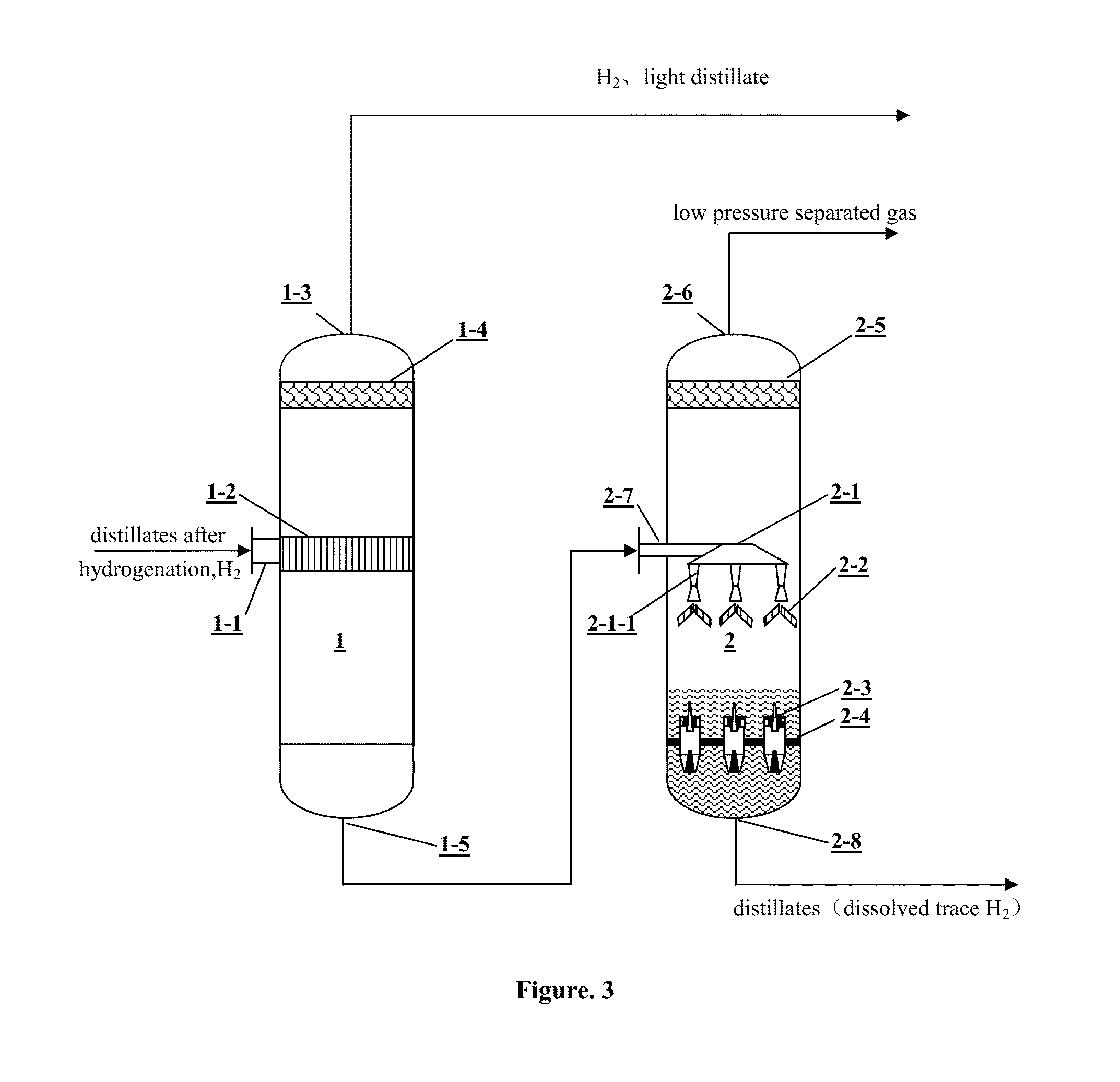

Method and apparatus for improving hydrogen utilization rate of hydrogenation apparatus

InactiveUS20160038854A1Improve gas-liquid separationSeparation efficiency can be improvedRefining by heating/coolingTreatment with plural serial refining stagesChemistryInertia

A method and apparatus for improving a hydrogen utilization rate in a hydrogenation hot high-pressure separation process. Hydrogenated distillate oil, a gas product and hydrogen pass through an inertia separation distributor arranged in an inlet of a hot high-pressure separator under high pressure for preliminary gas-liquid separation, and a gas phase goes to a subsequent system; a liquid phase goes into a hot low-pressure separator. Releases a part of low-pressure separated gas (mainly hydrogen) after preliminary separation through an injection flash separator in the hot low-pressure separator, and is divided into a gas phase and a liquid phase based on gravitational settling; hydrogen and some micro bubbles that are still dissolved in hot low-pressure separated oil under the pressure are separated from the oil through a centrifugal degassing device; the gas phase exits from the apparatus after carried liquid droplets are removed completely through hydrocyclone separation or coalescence separation, and distillate oil goes to a subsequent facility.

Owner:EAST CHINA UNIV OF SCI & TECH

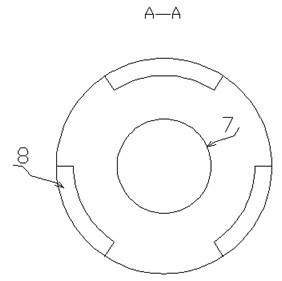

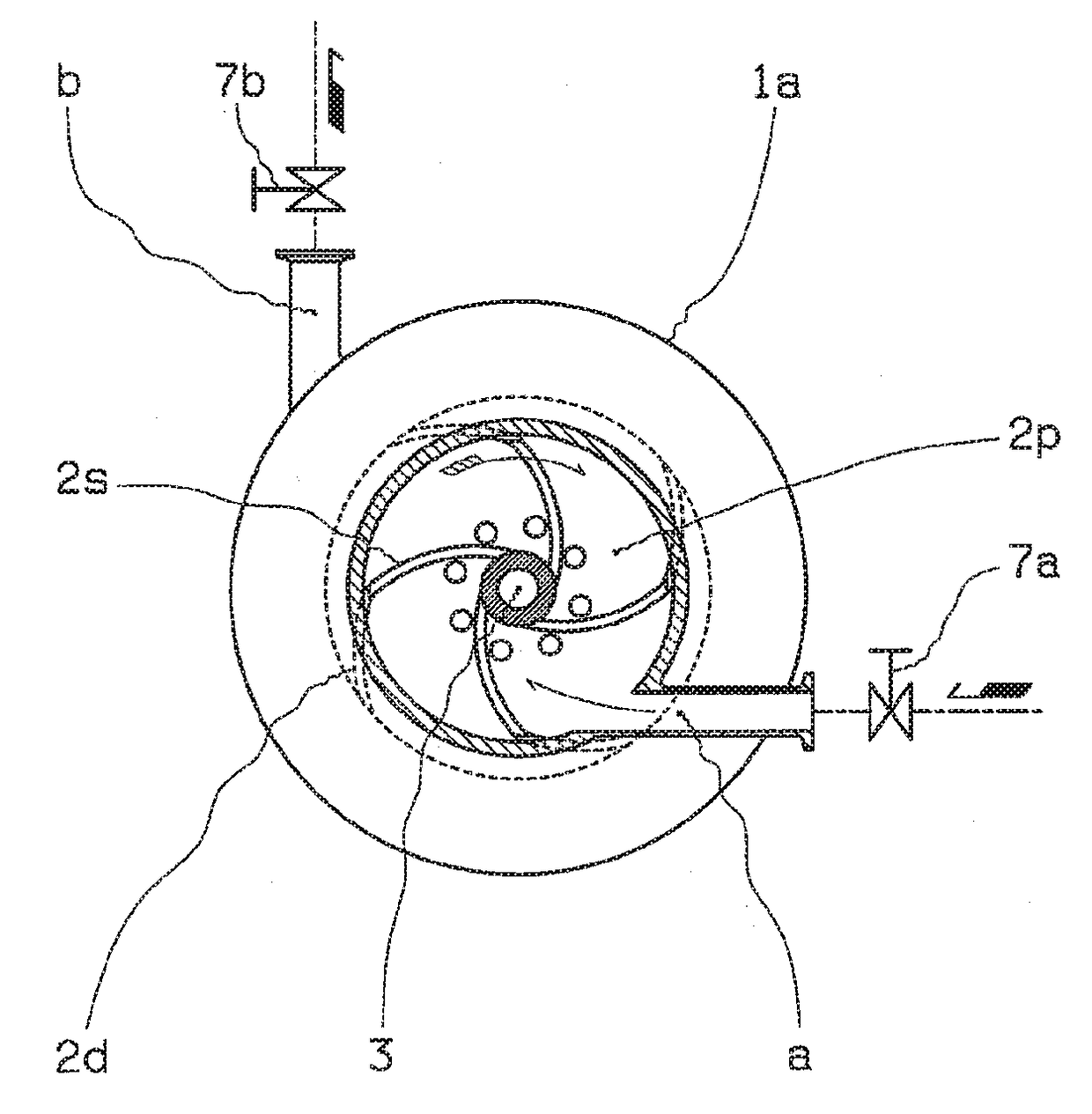

Gas-liquid separator

ActiveUS20170326488A1Increase in sizeEasy to cleanLiquid degasificationSuction filtersImpellerVapor–liquid separator

The present invention provides a gas-liquid separator with enhanced performance and easy operation, capable of performing gas-liquid separation such as advanced defoaming or degassing, and with a structure that facilitates easy CIP cleaning and disassembly cleaning, allowing it to meet sanitary specifications.This gas-liquid separator for gas-liquid separation performed by centrifugal force of an impeller mounted on a shaft which is supported by a bearing part and rotates in a casing comprises: the axial end of the impeller farther from the bearing part being positioned with clearance from the inner wall of the casing so as to slide on the inner wall of the casing; an exhaust outlet of the casing disposed in a position opposite the sliding impeller part; a vacuum device connected to the exhaust outlet; a discharge impeller part providing discharge force to the passing fluid formed around the axial end of the impeller; a discharge outlet of the casing disposed in a position opposite the discharge impeller part; and a suction inlet of the casing disposed in a position closer to the bearing part than the discharge outlet.

Owner:YOKOTA SEISAKUSHO

Heat pump air-conditioning system with waste heat recovery function

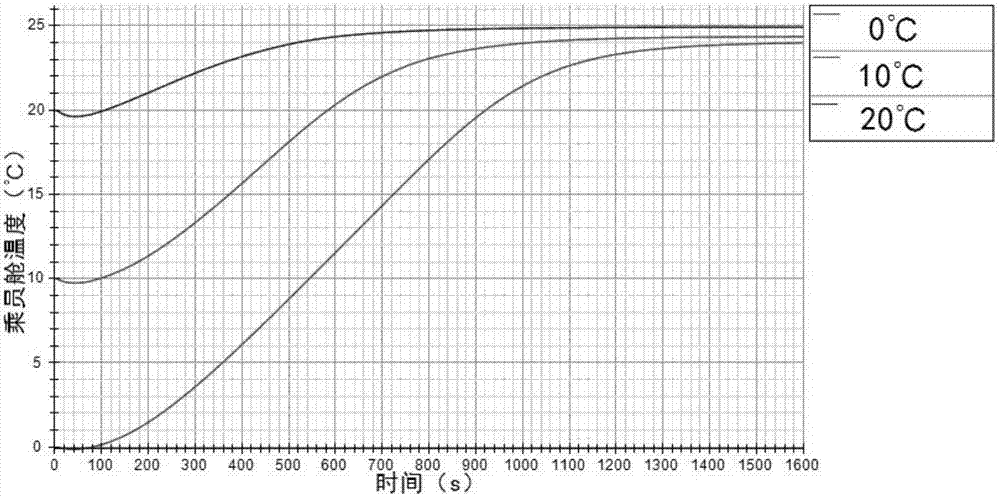

PendingCN107187294ASimple structure and principleIncrease heating capacityAir-treating devicesHeat recovery systemsProcess engineeringRecovery function

The invention discloses a heat pump air-conditioning system with a waste heat recovery function. The system comprises an oil liquid circulation module, an engine cooling module, an evaporator and a compressor, the oil liquid circulation module is communicated with the engine cooling module, the engine cooling module is arranged on one side of the evaporator, an expansion valve is arranged on a pipeline between the evaporator and an indoor condenser and an outdoor condenser, a gas-liquid separator is arranged on a pipeline between the evaporator and the compressor, the compressor is communicated with the indoor condenser and the outdoor condenser separately, and a blower is further arranged on one side of the indoor condenser. The heat pump air-conditioning system with the waste heat recovery function is simple in structure principle, heating can be effectively conducted by adopting waste heat of automobile exhaust gas, the heat supplying capability of a heat pump is improved, and the energy is saved.

Owner:彭紫薇

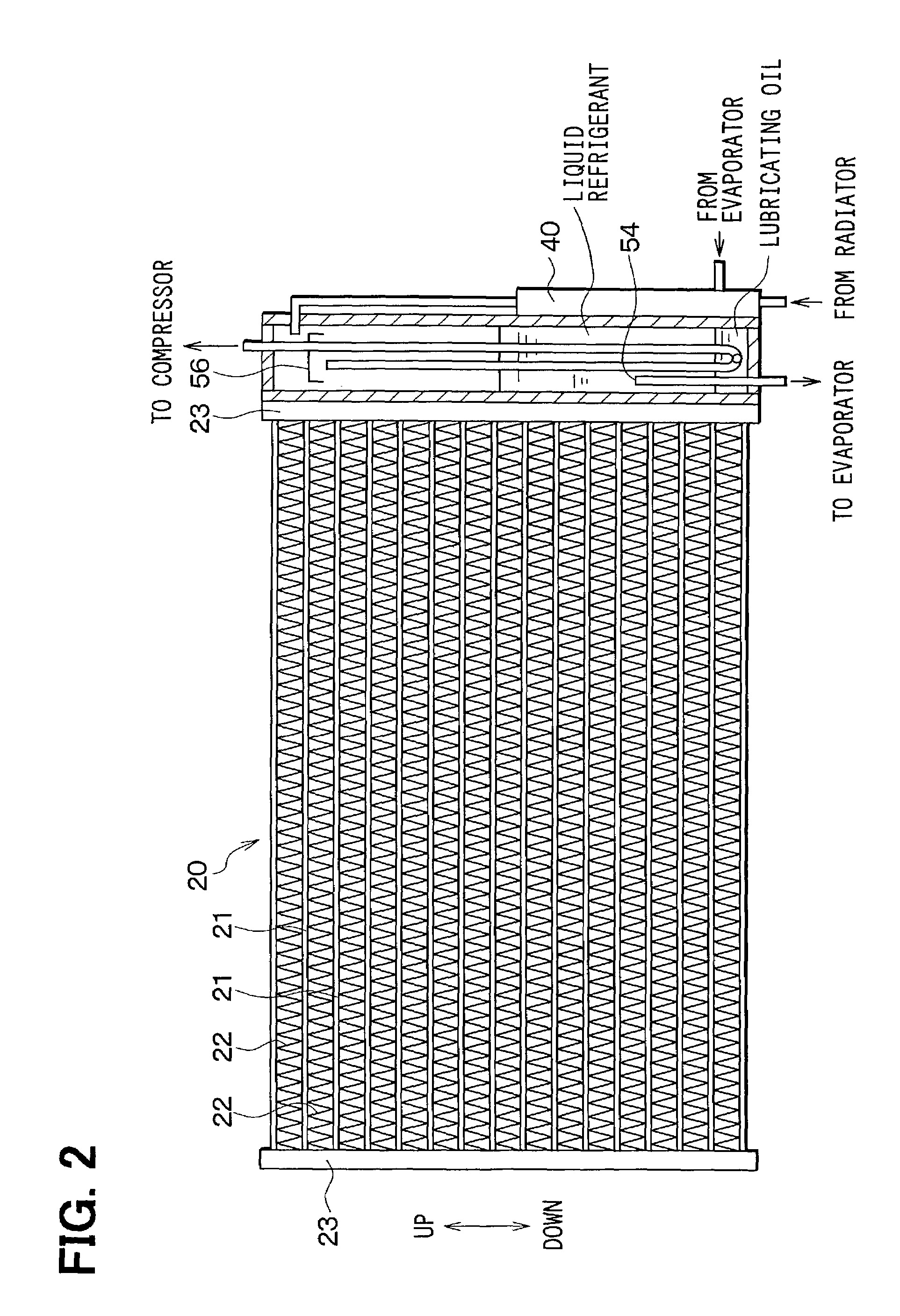

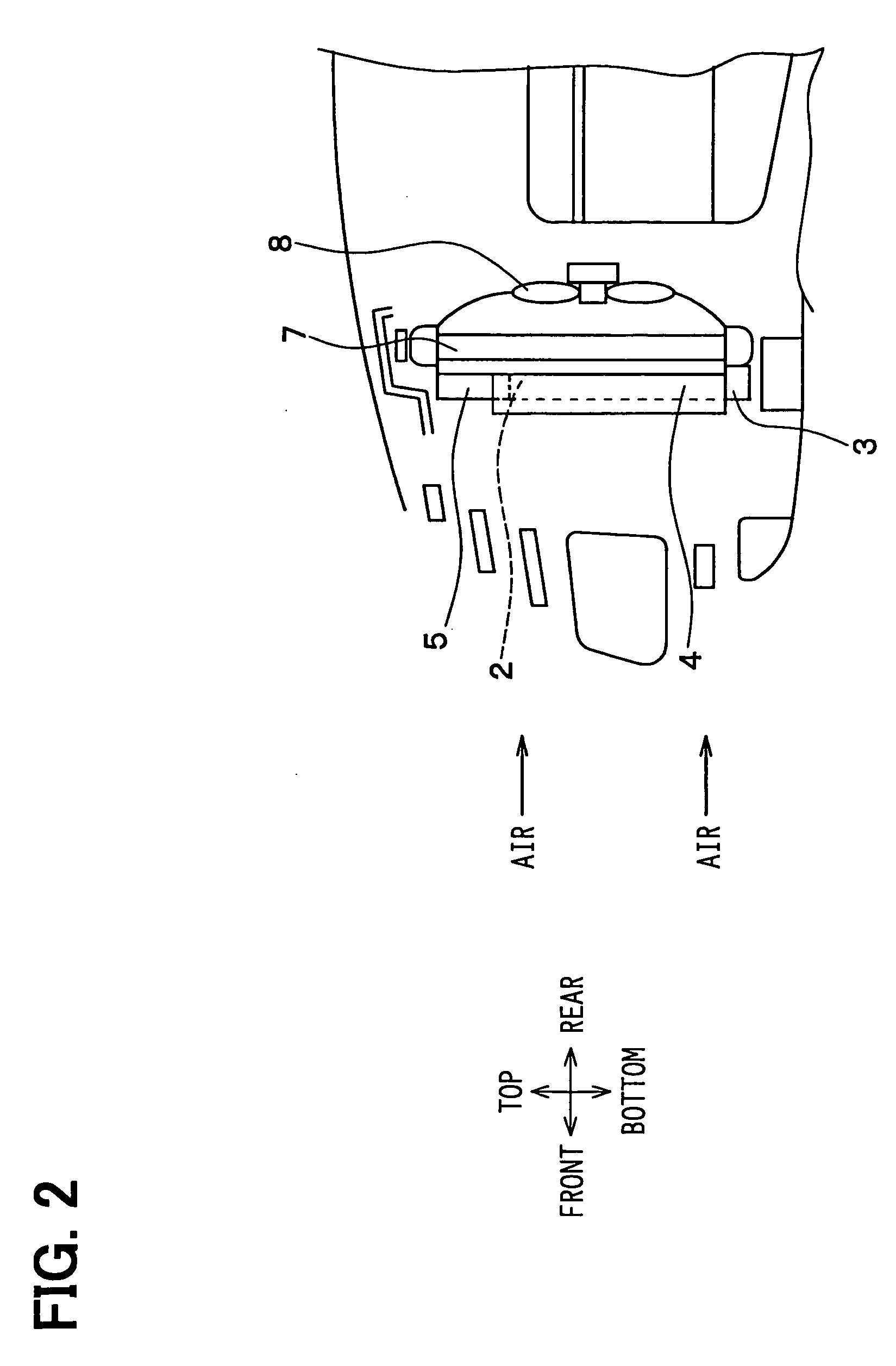

Vehicular heat exchanger module

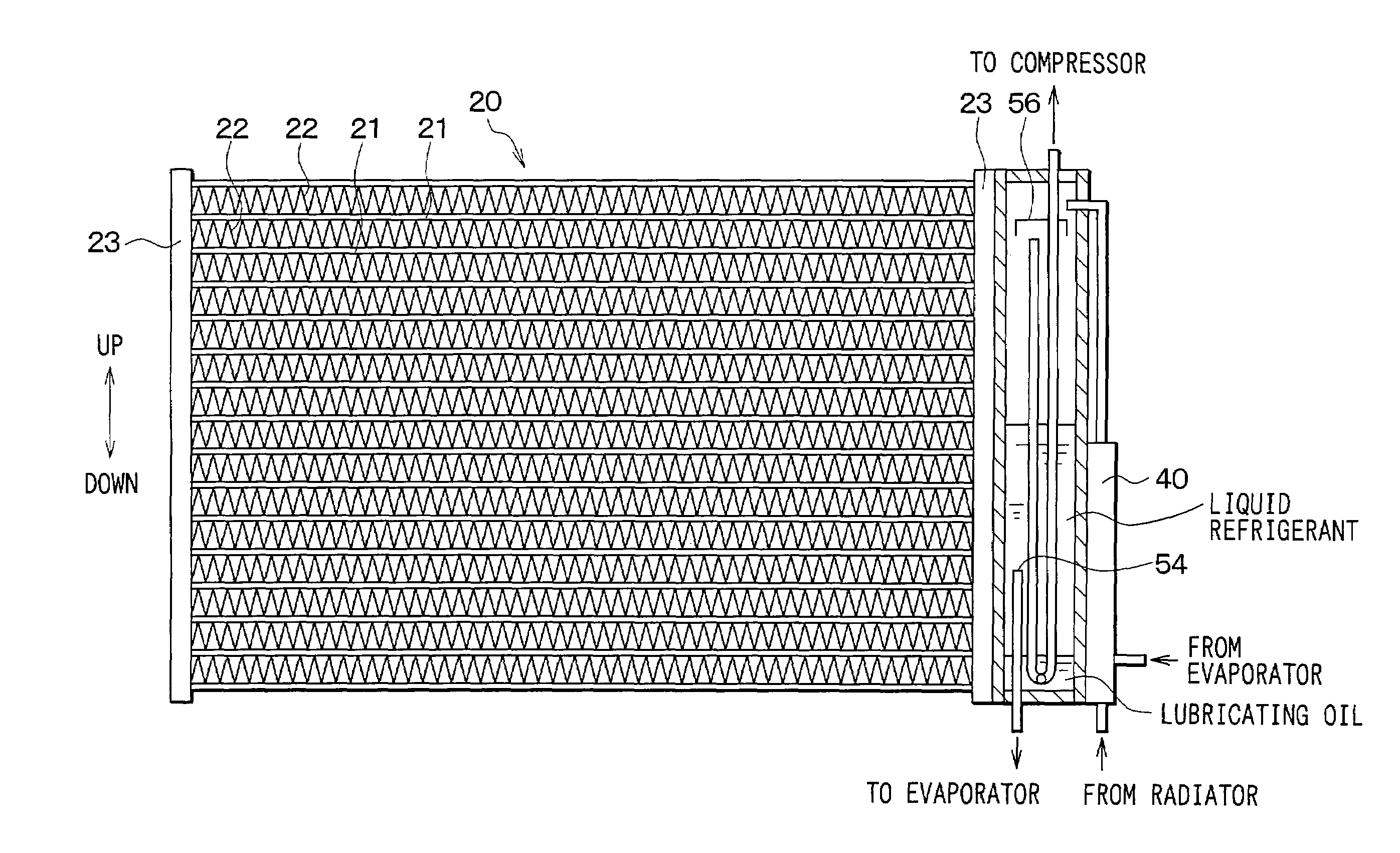

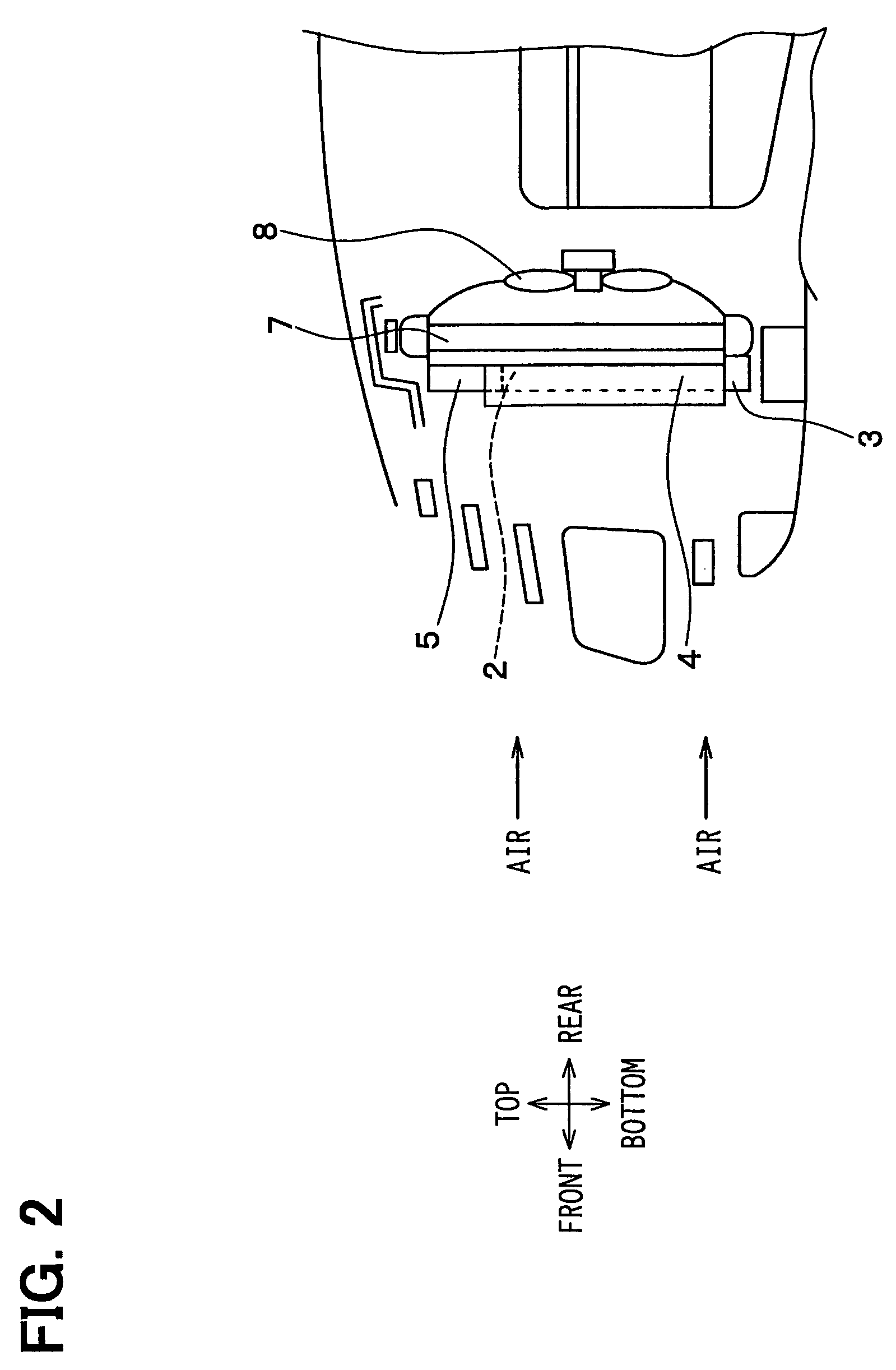

ActiveUS7591148B2Increase capacityImprove the effect of gas-liquid separationLiquid coolingCompression machines with non-reversible cycleEngineeringRefrigerant

A heat exchanger module includes a condenser for condensing a refrigerant, a modulator, a sub-cooler for cooling liquid refrigerant supplied from the modulator, and a heat exchanger for cooling a fluid different from the refrigerant. The condenser, the sub-cooler and the heat exchanger are arranged in an arrangement direction substantially perpendicular to an air flow direction. Further, the modulator is disposed to extend in the arrangement direction. In the heat exchanger module, the modulator has a dimension that is larger than the sum of a dimension of the condenser and a dimension of the sub-cooler, and is not larger than the sum of the dimension of the condenser, the dimension of the sub-cooler and a dimension of the heat exchanger, in the arrangement direction. Accordingly, a capacity of the modulator can be effectively increased without increasing a largest outer side of the heat exchanger module.

Owner:DENSO CORP

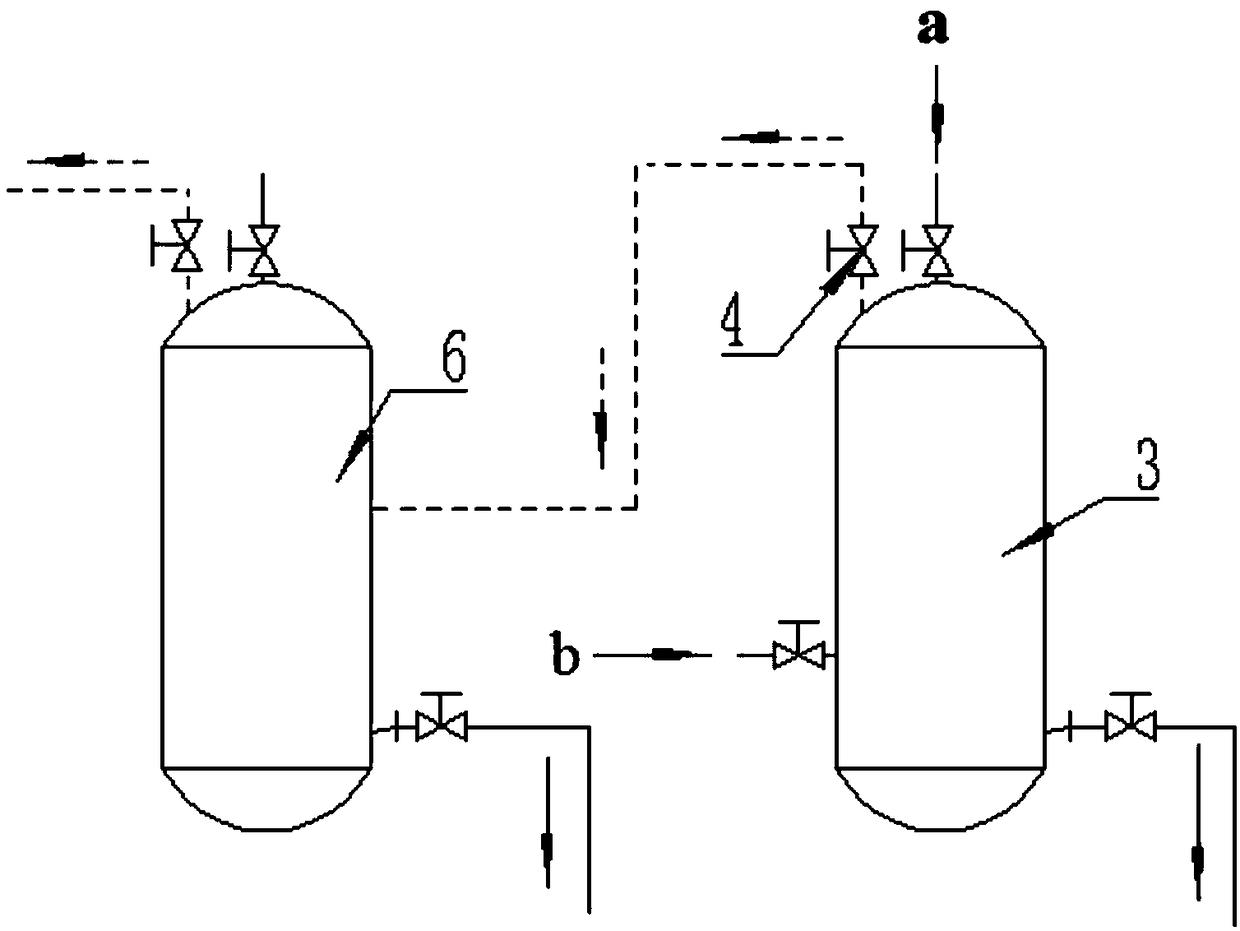

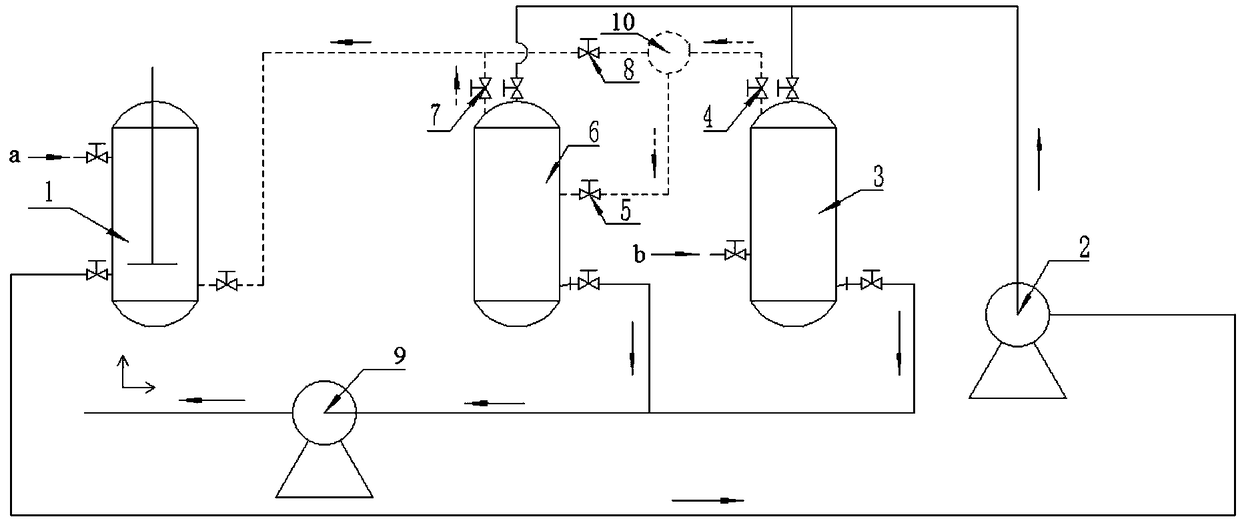

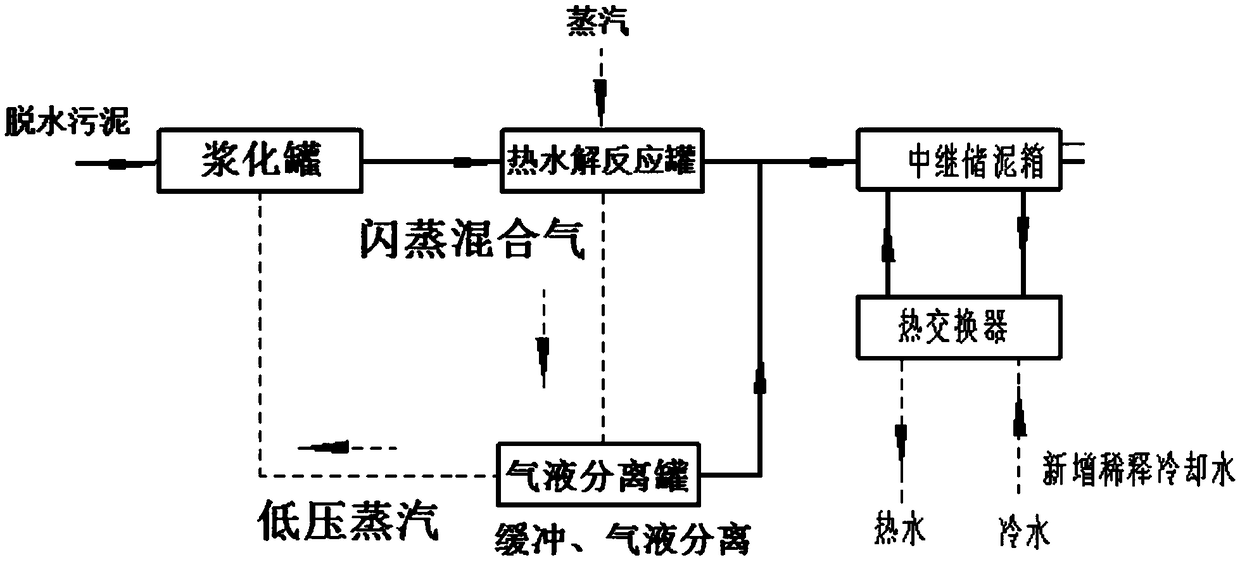

Pyrohydrolysis flash separation device, pyrohydrolysis flash separation technology, pyrohydrolysis system and pyrohydrolysis technology

PendingCN108840548ASmall pressure fluctuationsReduce vibrationSludge treatment by thermal conditioningSludge treatment by pyrolysisTreatment needRelief valve

The invention discloses a pyrohydrolysis flash separation device, a pyrohydrolysis flash separation technology, a pyrohydrolysis system and a pyrohydrolysis technology. The pyrohydrolysis flash separation device comprises a pyrohydrolysis reaction tank and a gas-liquid separation tank which are communicated through a pipe, wherein a pressure relief valve is arranged on the pipe therebetween. By the pyrohydrolysis flash separation technology, the pyrohydrolysis flash separation device is used for flash separation. The pyrohydrolysis system comprises a slurrying tank, a mud inlet pump, the pyrohydrolysis reaction tank and the gas-liquid separation tank which are sequentially communicated end to end through pipes; the pressure relief valve is arranged on the pipe between the pyrohydrolysis reaction tank and the gas-liquid separation tank. By the pyrohydrolysis technology, the pyrohydrolysis system is used for pyrohydrolysis. The pyrohydrolysis flash separation device and the pyrohydrolysis system have the advantages of small floor area, low production cost, a high safety production factor and the like, and the pyrohydrolysis flash separation technology and the pyrohydrolysis technology have the advantages of a simple process, easy operation, high treatment efficiency, a good gas-liquid separation effect and the like, so that actual treatment needs can be met and an application prospect is very good.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

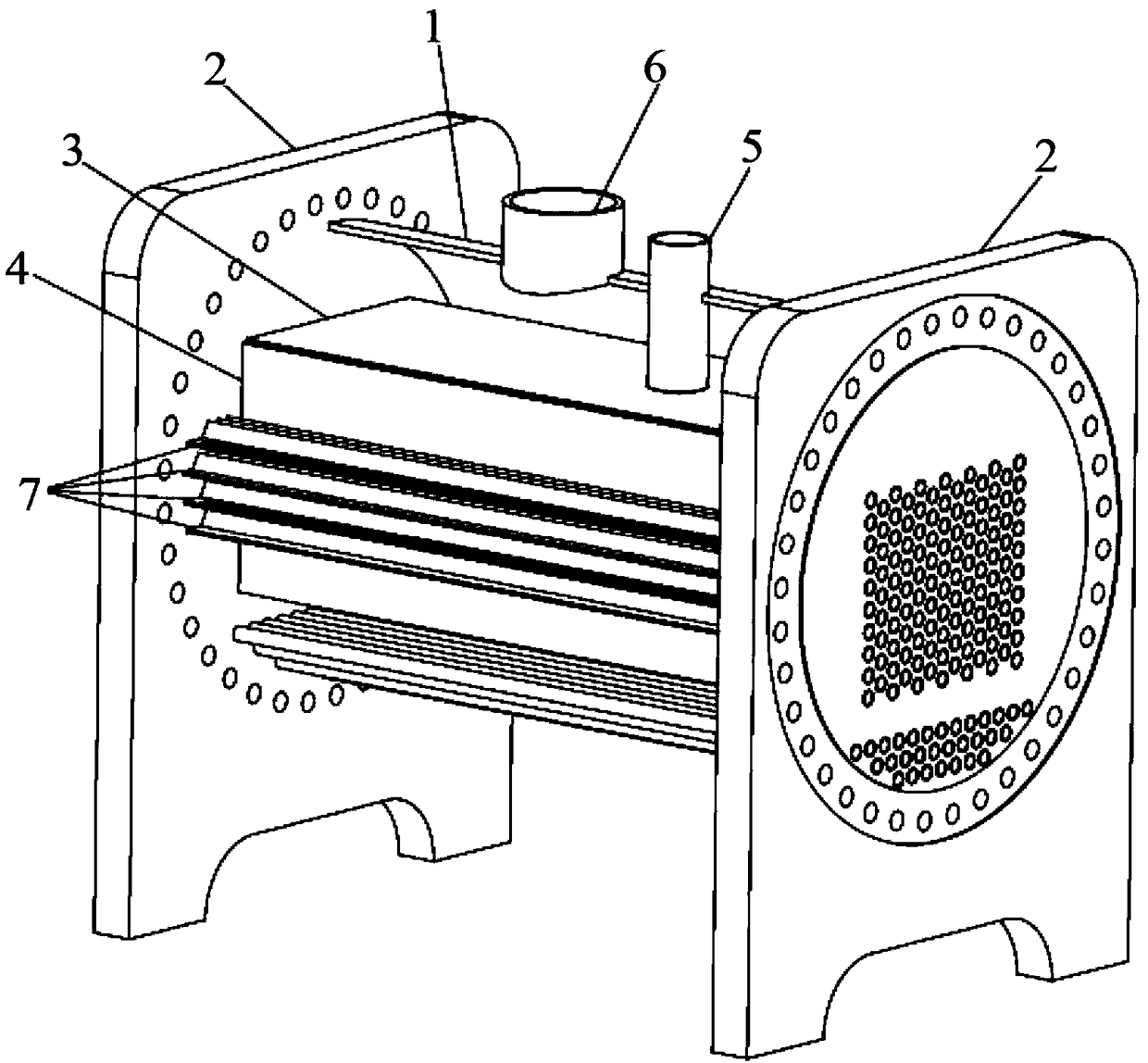

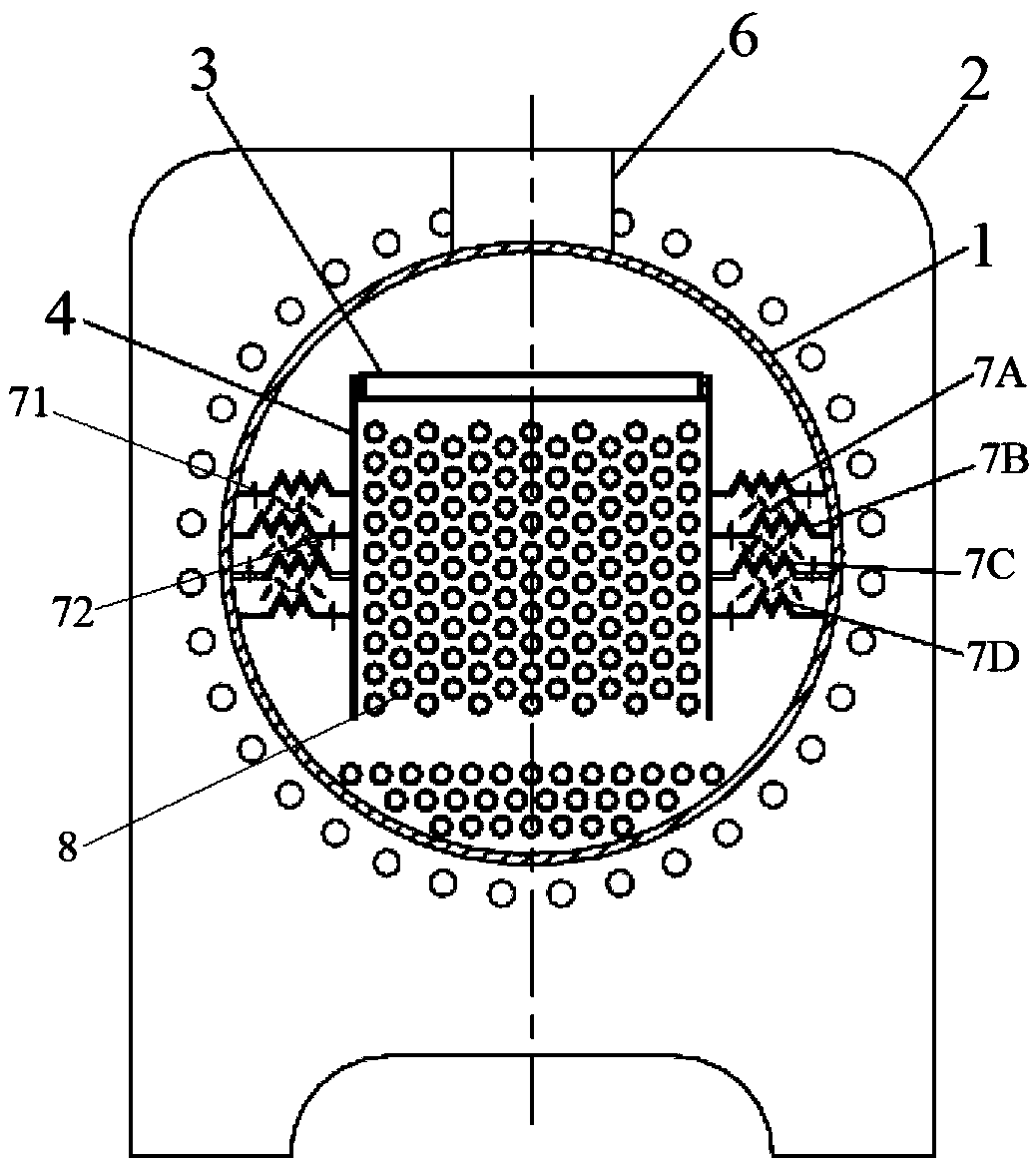

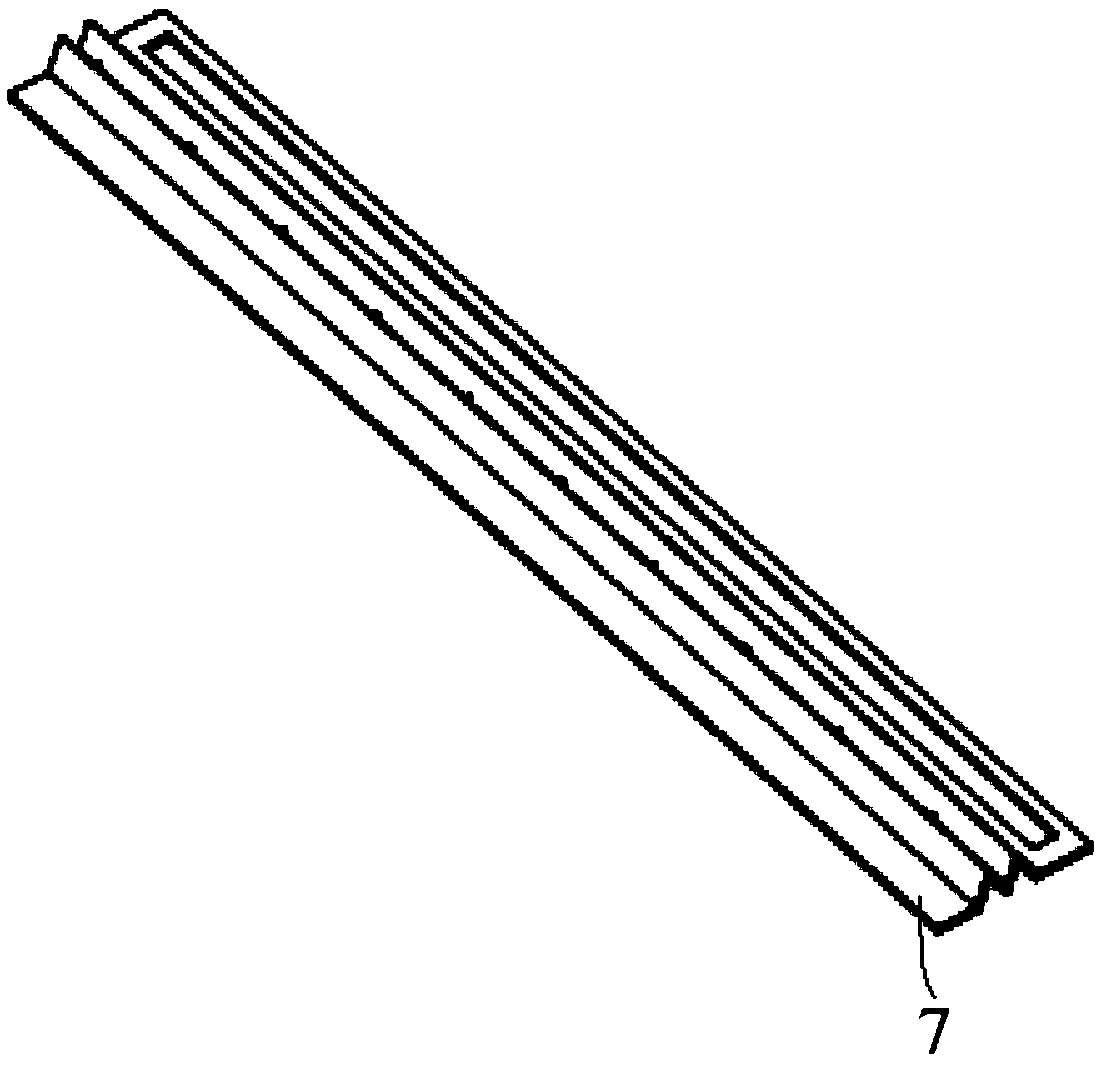

Heat exchanger module

ActiveUS20080282730A1Increase capacityImprove the effect of gas-liquid separationLiquid coolingCompression machines with non-reversible cycleComputer moduleEngineering

A heat exchanger module includes a condenser for condensing a refrigerant, a modulator, a sub-cooler for cooling liquid refrigerant supplied from the modulator, and a heat exchanger for cooling a fluid different from the refrigerant. The condenser, the sub-cooler and the heat exchanger are arranged in an arrangement direction substantially perpendicular to an air flow direction. Further, the modulator is disposed to extend in the arrangement direction. In the heat exchanger module, the modulator has a dimension that is larger than the sum of a dimension of the condenser and a dimension of the sub-cooler, and is not larger than the sum of the dimension of the condenser, the dimension of the sub-cooler and a dimension of the heat exchanger, in the arrangement direction. Accordingly, a capacity of the modulator can be effectively increased without increasing a largest outer side of the heat exchanger module.

Owner:DENSO CORP

Natural gas dehydration method using pre-nucleating supersonic vortex tube

ActiveCN102166464ASmall particle sizeControl the number of nucleiDispersed particle separationGaseous fuelsSolid particleLarge particle

The invention relates to a natural gas dehydration method using a pre-nucleating supersonic vortex tube, which comprises the following steps of: introducing a raw material gas into a raw material gas separator and a raw material gas filter separator to remove large particles, cooling the raw material gas, removing fine solid particles through a fine filter, and introducing the raw material gas into the pre-nucleating supersonic vortex tube; adding a nucleating agent from a nucleating agent inlet or discharging the nucleating agent from a nucleating agent outlet, forming proper particle size through a coalescent nucleating device, generating vortex rotation in a vortex generator, and accelerating and cooling the raw material gas through a Laval nozzle; introducing the raw material gas intoa liquid separating cavity under the action of centrifugal force, and introducing the raw material gas into a gas-liquid separator through a condensate outlet; eliminating the vortex of a gas flow inthe center of the tube through a rectifier, introducing a gas mixture separated from a dry gas outlet and the gas-liquid separator into a gas-gas heat exchanger, exchanging heat with the raw materialgas to heat the raw material gas, exporting the gas mixture, introducing water separated from the raw material gas separator, the raw material gas filter separator and the gas-liquid separator into awater storage tank, and discharging the water. After water-containing natural gas is treated by the natural gas dehydration process using the pre-nucleating supersonic vortex tube, the dew point of water reaches subzero 5 DEG C, and the exporting requirement is satisfied.

Owner:PETROCHINA CO LTD

Falling-film type evaporator and air conditioner

PendingCN109357441AImprove the effect of gas-liquid separationFully captureEvaporators/condensersHeat exchanger casingsDual actionLiquid state

The invention discloses a falling-film type evaporator and an air conditioner. The falling-film type evaporator comprises a chamber with a gas outlet, a heat exchanger tube group arranged in the chamber and a liquid blocking structure, wherein the liquid blocking structure is arranged between the heat exchange tube group and the inner wall of the chamber, and is provided with a bent gas outlet channel; and a refrigerant which exchanges heat with the heat exchange tube group reaches the gas outlet through a gas outlet channel. The falling-film type evaporator is equipped with the liquid blocking structure, so that the refrigerant which exchanges heat with the heat exchange tube group needs to pass through the bent gas outlet channel to reach the gas outlet, and the bent gas outlet channel forms turbulent flow on the refrigerant; and under dual action of turbulent flow and gravity, the liquid blocking structure sufficiently catches the liquid-state refrigerant, so that gas-liquid separating ability of the falling-film type evaporator is improved.

Owner:GREE ELECTRIC APPLIANCES INC

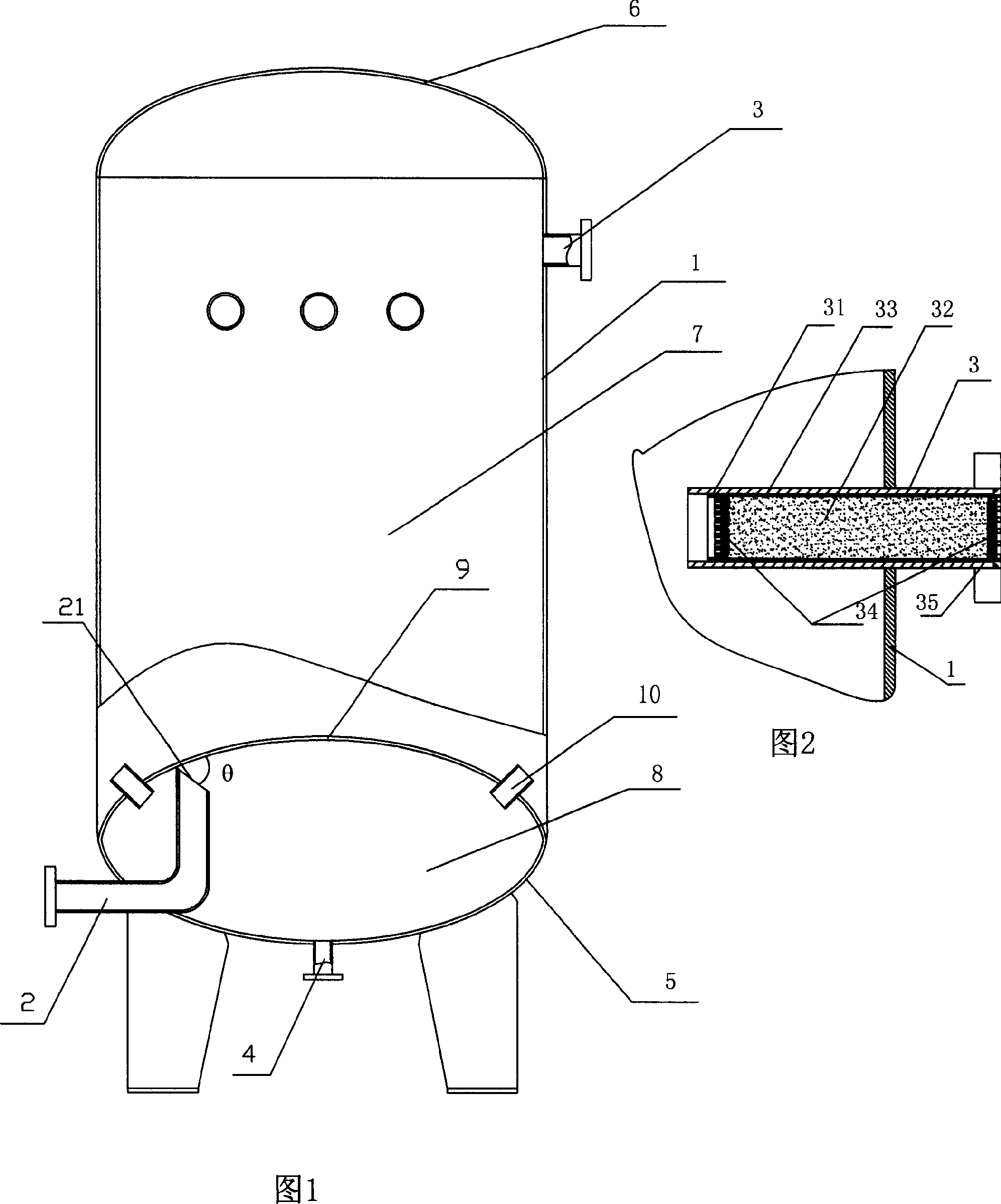

Gas storage tank with gas-liquid separating function

The invention discloses gas receiver with gas liquid separation function. It is cylindrical form tank structure. And it includes cylinder body, upper and under end plate. The cylinder body is set gas outlet tube. The under end plate has drainer. Its features are that the lower part of the cylinder body is set inner end plate; and it is divided gas receiver into gas inlet area and gas storing area; the inner end plate is sphere and set at least one gas out joint pipe; the whole sectional area ratio of gas inlet tube and gas out joint pipe is 1:1.5-2. Its advantages are that there is no need to prepare another oil-water separator; and it can save the cost.

Owner:周新建

Sulfuric acid waste gas desulfurization method

ActiveCN108380003AEasy to handleReduce pollutionDispersed particle separationParticulatesVapor–liquid separator

The invention belongs to the technical field of sulfuric acid waste gas treatment, and in particular relates to a sulfuric acid waste gas desulfurization method. The method comprises the following steps: introducing sulfuric acid waste gas into a cyclone dust collector to remove solid particles in the sulfuric acid waste gas; introducing the sulfuric acid waste gas subjected to dust removal into an aerosol chamber, wherein the aerosol chamber contains a great deal of water vapor; dissolving the sulfuric acid gas in the water vapor so as to realize separation of sulfuric acid and the waste gas;introducing the sulfuric acid waste gas discharged from the aerosol chamber into a gas-liquid separator, and removing the liquid in the sulfuric acid waste gas by using the gas-liquid separator; discharging part of the water vapor along with the waste gas, and separating sulfuric acid liquid in the waste gas by using the gas-liquid separator so as to realize the recovery of the sulfuric acid; introducing the sulfuric acid-free waste gas discharged from the gas-liquid separator into a purification tower, purifying the waste gas by means of the purification tower and then directly discharging the purified waste gas into the atmosphere. The method adopts a classification and segmentation treatment way of solid, liquid and gas, realizes effective treatment of the sulfuric acid waste gas, andhas the characteristics of being good in desulfurization effect, little in environmental pollution and less in equipment investment, and the like.

Owner:安徽金森源环保工程有限公司

Apparatus and final polymerization for preparing polyamide 5X, and production equipment and method of polyamide 5X

ActiveCN105085904AReduce formationWell mixedChemical/physical/physico-chemical processesPolyamideEngineering

The present invention provides an apparatus and a method for preparing a polyamide 5X. The apparatus is a the final polymerization apparatus comprising a final polymerization kettle, an extrusion cylinder connected with the final polymerization kettle, a conveying screw arranged in the extrusion cylinder, and a frame-type agitator arranged in the final polymerization kettle and connected to the conveying screw. The frame-type agitator comprises a stirring frame and a screw band connected with the stirring frame. The apparatus for preparing polyamide 5X employs the through holes in the side wall of the stirring frame to constantly scrape the kettle wall, thereby reducing the formation of gels; while the materials can flow on the inner and outer sides of the stirring frame through the through holes, so as to enhance the stirring effect, evenly mix the materials and reach good molecular weight uniformity of the polymer obtained by the final polymerization; and the apparatus realizes good gas-liquid separation in the system, and helps the final polymerization reaction. The invention further provides production equipment and method of polyamide 5X.

Owner:CATHAY R&D CENT CO LTD +2

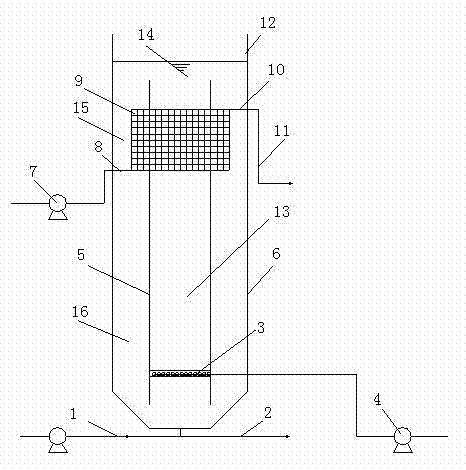

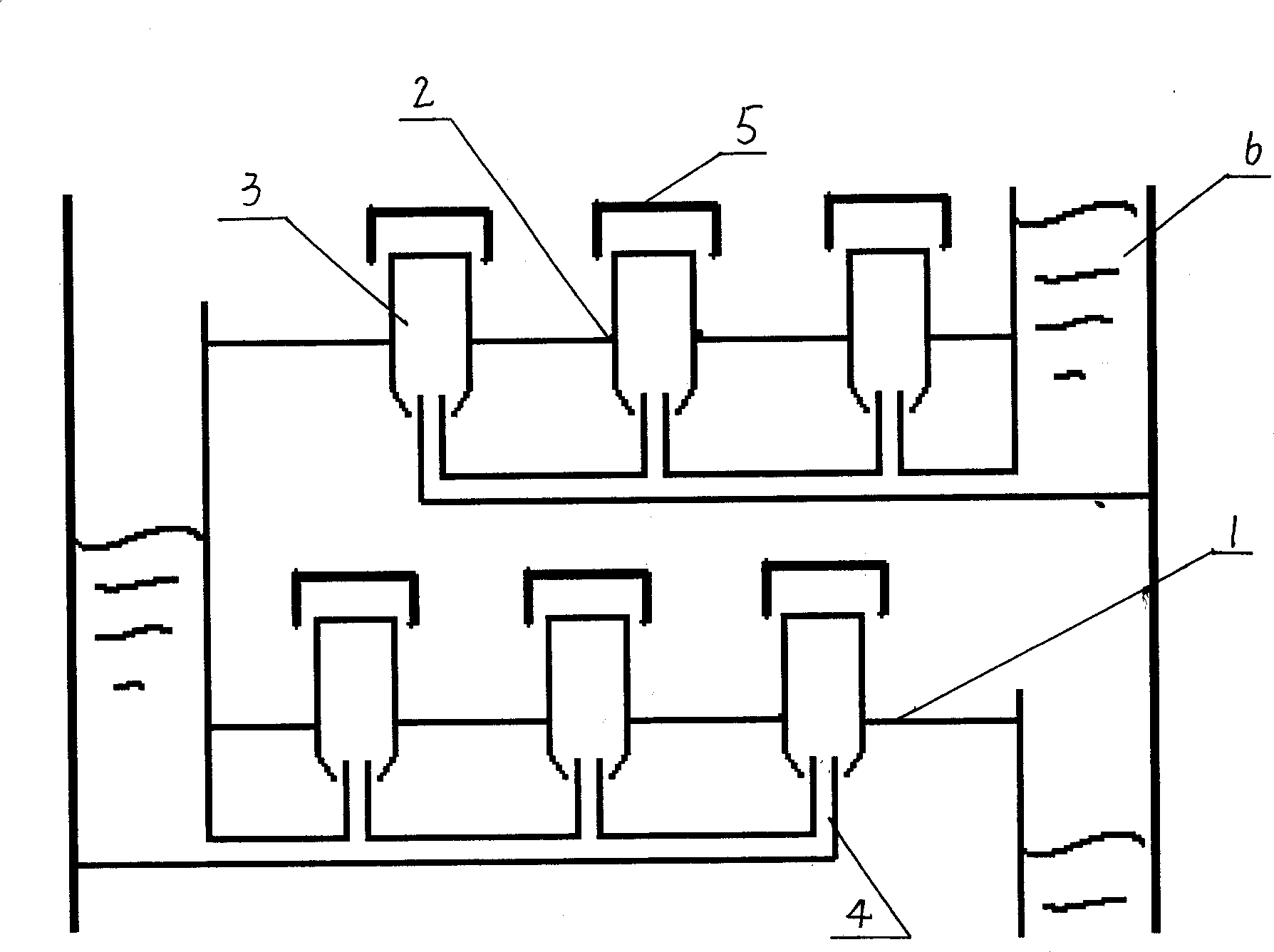

Integrated rainwater or architectural intermediate water treatment device utilizing air-lift internal loop biological enhancement bentonite dynamic membrane

InactiveCN103693739AEasy to updateImprove the effect of gas-liquid separationTreatment with aerobic and anaerobic processesActivated sludgeMembrane fouling

The invention relates to an integrated rainwater or architectural intermediate water treatment device utilizing an air-lift internal loop biological enhancement bentonite dynamic membrane. The appearance of the overall device takes on a cylinder; the device is structurally divided into four parts, namely a main reaction region, a gas-liquid separation region, a dynamic membrane reaction region and a backflow zone. The device provides power through an air diffusion system at the bottom of the device, and circulating flow of a mixed solution composed of biological enhancement bentonite and activated sludge in each region inside the device is achieved. In the process, dynamic balance of aerobic region, an anoxia region and an anaerobic region is achieved inside the device due to difference of dissolved oxygen concentration; reactions such as oxidation of organic matters, and nitrogen and phosphorus removal are respectively carried out, so that pollutants in water can be removed. In the circulating process of the mixed solution, a part of mixed solution is subjected to solid-liquid separation inside the dynamic membrane reaction region, and the target of effectively controlling membrane pollution is achieved due to a fluid flow state of taking unique push flow as a main factor and complete mixing as an auxiliary factor inside the device. The integrated rainwater or architectural intermediate water treatment device has the advantages of high pollutant removing efficiency, stable system operation, small floor area and the like.

Owner:上海国研建筑科技有限公司

Efficient high-speed vapour-liquid mass transfer structure form

ActiveCN1978024AImprove efficiencyImprove separation efficiencyFractional distillationVapor liquidEngineering

The present invention relates to a high-effective high-speed vapor-liquid mass transfer structure. It includes the following several portions: column tray, tray hole, vapor riser, distribution pipe, top cover, downflow spout and mass transfer element. Said invention also provides the concrete structure of the above-mentioned every portion and connection mode of all the above-mentioned portions. Said structure can eliminate scale effect of column equipment, and can enhance mass transfer process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

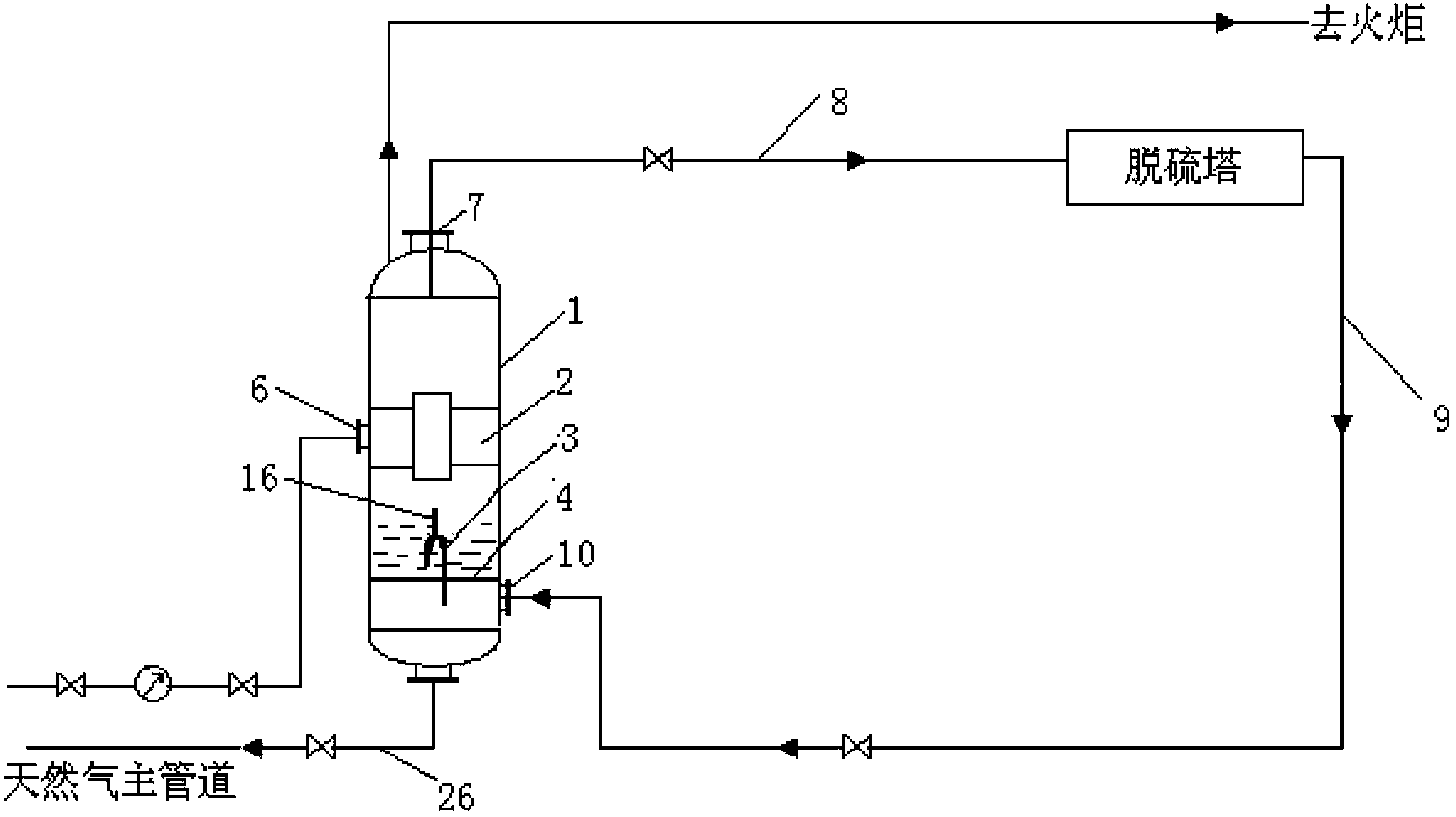

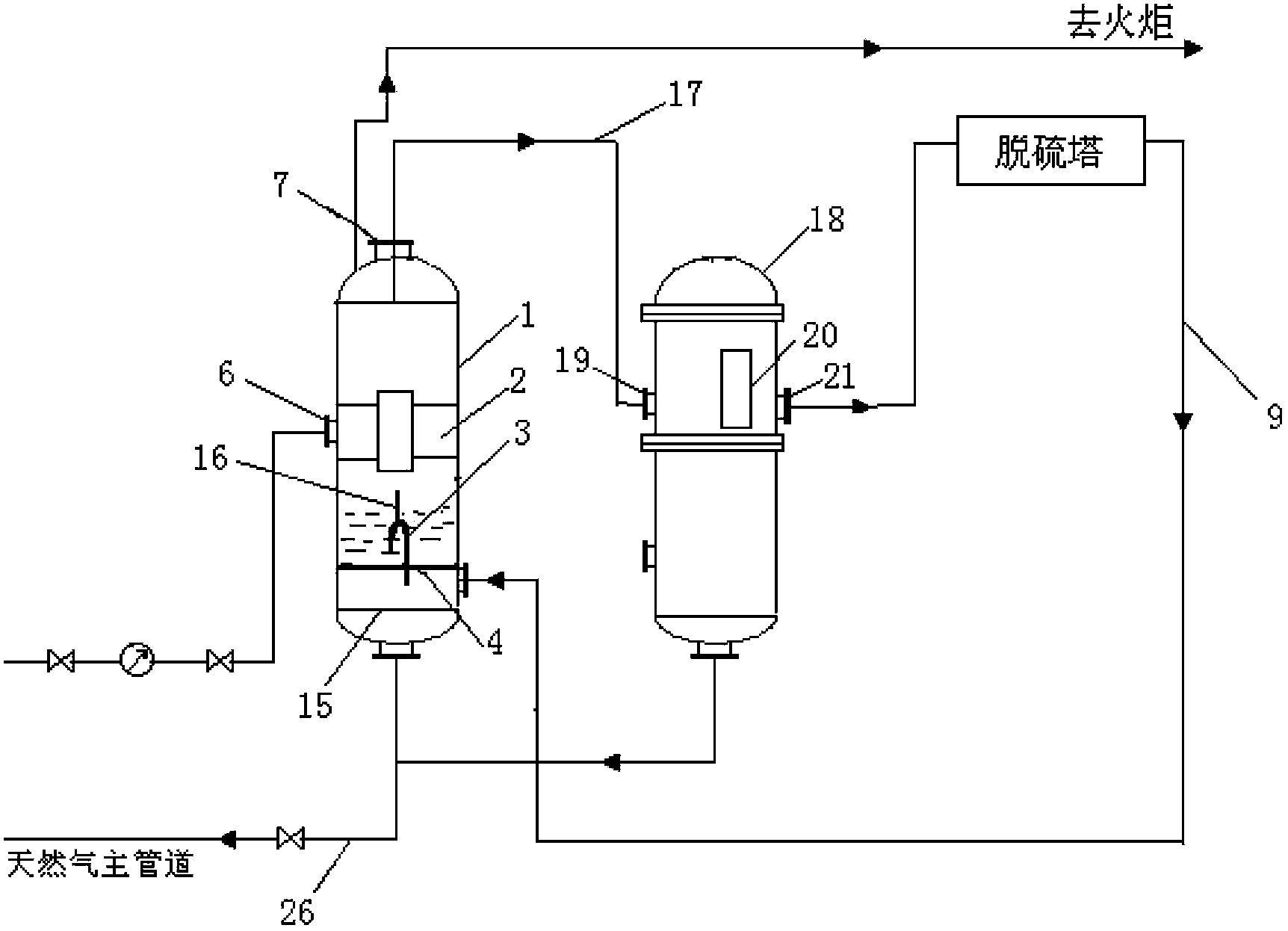

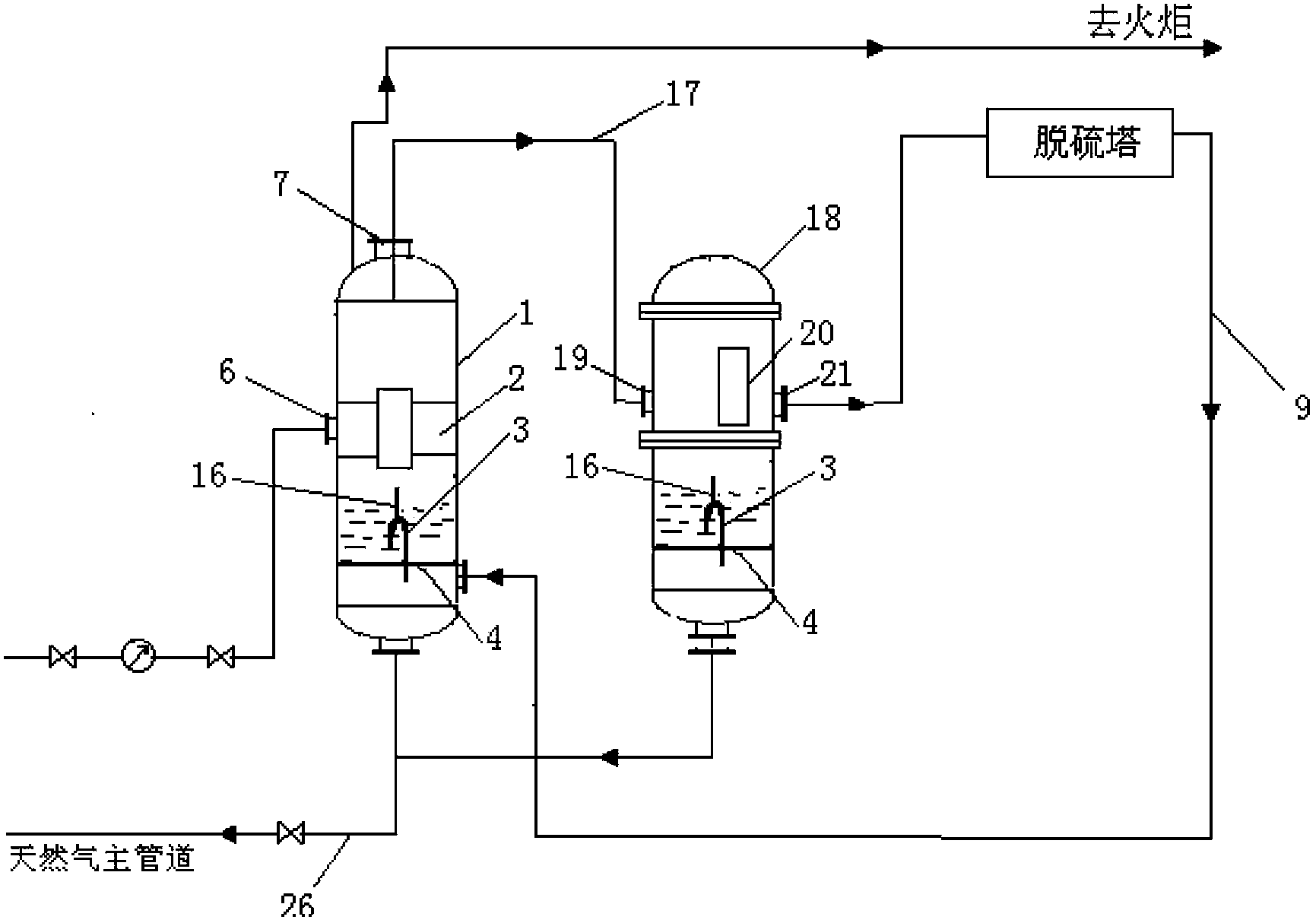

Natural gas desulfuration and liquid-removing device and desulfuration technology thereof

The invention provides a natural gas desulfuration and liquid-removing device and a desulfuration technology thereof, and belongs to the technology field of chemical engineering. The natural gas desulfuration and liquid-removing device comprises a natural transportation pipeline, a gas-liquid separation tank, and a desulfuration device. The bottom of the gas-liquid separation tank is provided with a liquid collecting plate and an inverted U-shaped pipe, the separated liquid from the gas-liquid separation tank slowly drops into a lower cavity, which is arranged below the liquid collecting plate, through the inverted U-shaped pipe, then desulfurated natural gas in induced into the lower cavity, which is arranged below the gas-liquid separation tank, the liquid in the cavity is atomized through a huge flow of natural gas, and then the atomized liquid is brought back to the natural gas main pipeline with the desulfurated natural gas. The natural desulfuration and liquid-removing device and the desulfuration technology thereof have the advantages of low cost of desulfuration device, environment-friendly desulfuration technology, and resource saving.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Gas-liquid separator

ActiveCN112755594AImprove the effect of gas-liquid separationImprove separation efficiencyCombination devicesRefining by centrifugal forceVapor–liquid separatorEngineering

The invention discloses a gas-liquid separator, which comprises a cyclone foam breaking device, a demisting separation device, a defoaming paddle and a foam buffer chamber are arranged in a cavity of the gas-liquid separator, and a gas outlet and a liquid outlet are arranged outside the cavity of the gas-liquid separator; the cyclone foam breaking device comprises an upper outlet and a lower outlet, the cyclone foam breaking device is used for separating the gas-liquid mixture into a gas mixture and a liquid mixture, the gas mixture escapes from the upper outlet, and the liquid mixture flows out from the lower outlet; the demisting separation device is arranged at the top of the cavity and is used for condensing liquid in the gas mixture; the defoaming paddle is used for defoaming the liquid mixture; the foam buffer chamber is used for storing a liquid mixture higher than a preset liquid level height and performing foam elimination on the liquid mixture in a chemical mode; the gas outlet is formed in the top of the cavity; and the liquid outlet is formed in the bottom of the cavity. According to the gas-liquid separator disclosed by the embodiment of the invention, mechanical and chemical modes are combined, so that the defoaming efficiency of a gas-liquid mixture is improved.

Owner:PETROCHINA CO LTD

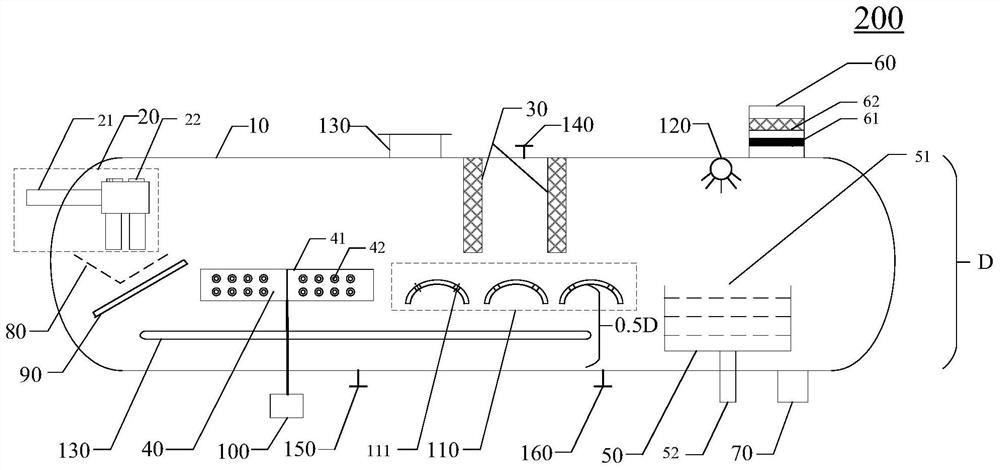

Gas-liquid separator

ActiveUS20180375122A1Guaranteed uptimePreventing situationDispersed particle separationMotive system fuel cellsVapor–liquid separatorProduct gas

Owner:HONDA MOTOR CO LTD

Gas-liquid separation device and hard surface cleaner with same

InactiveCN103654630AHas the function of gas-liquid separationSimple structureSuction cleanersMachine detailsHard-surface cleanerSurface cleaning

The invention provides a gas-liquid separation device and a hard surface cleaner with the gas-liquid separation device. The gas-liquid separation device comprises a shell. The bottom end of the shell is sealed, an air inlet and an air suction port are formed in the two sides of the top end of the shell respectively, the internal space of the shell is divided by a middle board into two side spaces which are not communicated, the two side spaces are respectively provided with at least one separating board, the internal space of the shell is divided into buffer zones and storage zones through the separating boards in the radial direction of the space, each buffer zone and the storage zone located in the same side are communicated through an opening formed in the side face of the bottom of the corresponding separating board, the storage space of each layer is communicated with the buffer space of the lower layer at the same side, the side face of the bottom of the portion, corresponding to the storage space on the lowest layer, of the shell is provided with a water outlet communicated with the external environment. According to the gas-liquid separation device and the hard surface cleaner with the gas-liquid separation device, the gas-liquid separation function and the anti-toppling and anti-backward-flow function are achieved, the structure is simple, the gas-liquid separation effect is good, the machining efficiency, the production efficiency and the assembly efficiency are extremely high, and the volume and the space are saved.

Owner:NINGBO LUCKY SNOW MECHANICAL EQUIP MFG & TRADING

Air conditioner system

PendingCN110966791AImprove cooling efficiencyImprove heating efficiencyMechanical apparatusFluid circulation arrangementEngineeringInjection air

The invention provides an air conditioner system which comprises a reversing assembly, an indoor heat exchanger and an outdoor heat exchanger. The air conditioner system further comprises a compressor, a first throttling element, a flash evaporator and an economizer. The compressor comprises an exhaust port, an intermediate air injection port and an air suction port; the first throttling element is arranged between the indoor heat exchanger and the outdoor heat exchanger; the flash evaporator is arranged between the first throttling element and the outdoor heat exchanger and comprises a refrigerant inlet, an air outlet and a liquid outlet, the refrigerant inlet is connected with the first throttling element, and the liquid outlet is connected with the outdoor heat exchanger; the economizeris arranged in parallel with the flash evaporator and comprises a first pipe port, a second pipe port, a third pipe port and a fourth pipe port, the first pipe port is connected with the first throttling element, the second pipe port and the air outlet are both connected with the middle air injection port, and the third pipe port and the fourth pipe port are connected with the outdoor heat exchanger. When in the refrigerating mode and the heating mode, the flash evaporator or the economizer can be selected respectively, so that the refrigerating efficiency and the heating efficiency of the air conditioner system can be optimized respectively, and the annual energy utilization efficiency is improved.

Owner:GUANGDONG MEIZHI PRECISION MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com