Sulfuric acid waste gas desulfurization method

A waste gas desulfurization and sulfuric acid technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as economic losses, leakage of purification towers, and corrosion of internal components of purification towers, achieving low environmental pollution and low equipment investment , better effect of gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

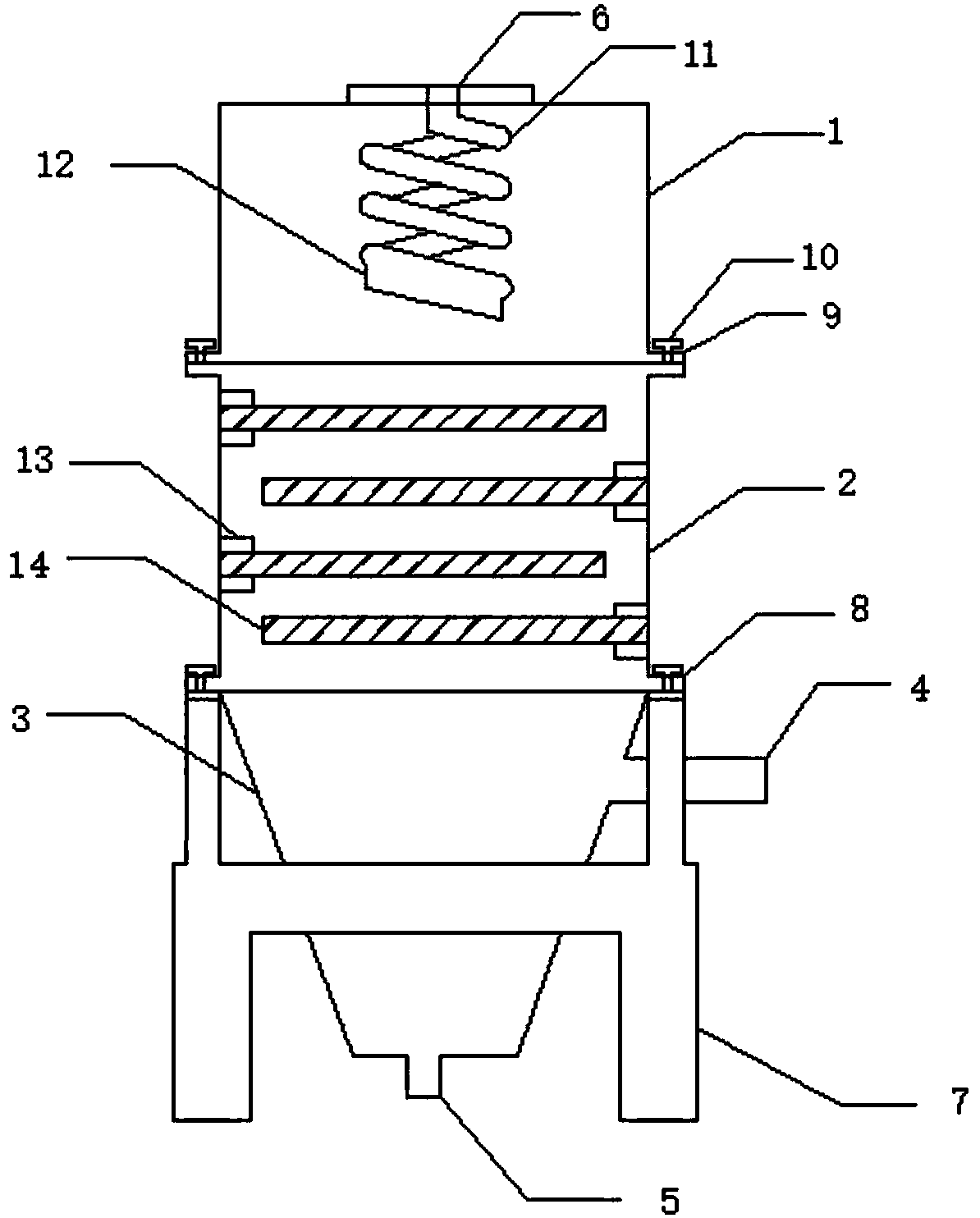

Method used

Image

Examples

Embodiment approach

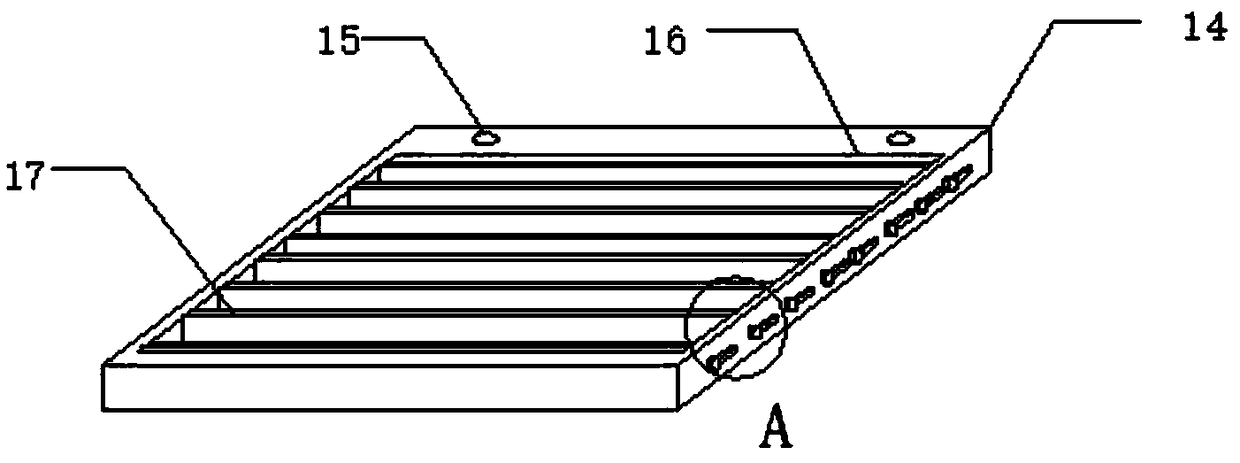

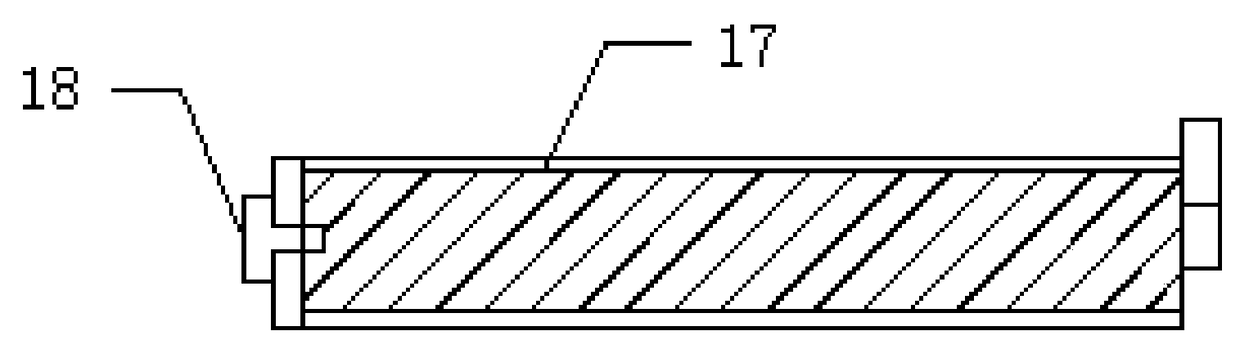

[0034] As an embodiment of the present invention, the diameter of the circular pipe of the separation pipe 11 is gradually reduced, and the pipe wall on the lower side of the separation pipe 11 is provided with a tapered drain hole, and the opening end of the tapered liquid drain hole is located in the separation pipe. 11 inside. The tapered liquid discharge hole is conducive to the accumulation of liquid, which is conducive to the timely discharge of liquid and prevents the gas from taking the liquid away again.

[0035] Further, a separator is installed in the separation pipe 11, and a plurality of separators are arranged at intervals along the separation pipe 11, and the separator is used to separate gas and liquid; the separator includes a water throwing pan 21 and a water throwing motor 22, the The water throwing tray 21 is installed in the separation pipe 11 with the center of the circle. The water throwing motor 22 is used to drive the water throwing tray 21 to rotate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com