Patents

Literature

40results about How to "Realize gas-solid separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-separation type wet dust and gas separator of sweeper

ActiveCN103711096AIncrease storage capacityReduce kinetic energyCombination devicesRoad cleaningSprayerMechanical equipment

The invention relates to the technical field of sweeping mechanical equipment, in particular to a self-separation type wet dust and gas separator of a sweeper. The self-separation type wet dust and gas separator comprises a garbage can, an arc guide plate is connected in the garbage can, a garbage guide pipe is arranged on the garbage can in a penetrating mode, a dust falling sprayer pipe is arranged on the garbage can in a penetrating mode, and one end of the dust falling sprayer pipe is connected with a water nozzle. A separating box is arranged on the garbage can, two filtering plates are arranged in the separating box, airflow ventilation openings are formed in the two filtering plates respectively, and the airflow ventilation openings in the two filtering plates are arranged in a staggered mode. One end of the separating box is connected with the garbage can through an air pipe, a filtering net is arranged in the air pipe, the other end of the separating box is connected with a fan air suction pipe, the lower portion of the end, connected with the fan air suction pipe, of the separating box is connected with an automatic wet garbage outlet, the other end of the automatic wet garbage outlet is arranged in the garbage can, and a check valve is connected on the automatic wet garbage outlet. The self-separation type wet dust and gas separator replaces an original filtering net, work is reliable, the storage capacity of the garbage can is large, and manufacturing and using cost can be greatly lowered.

Owner:NANTONG MINGNUO ELECTRIC TECH CO LTD

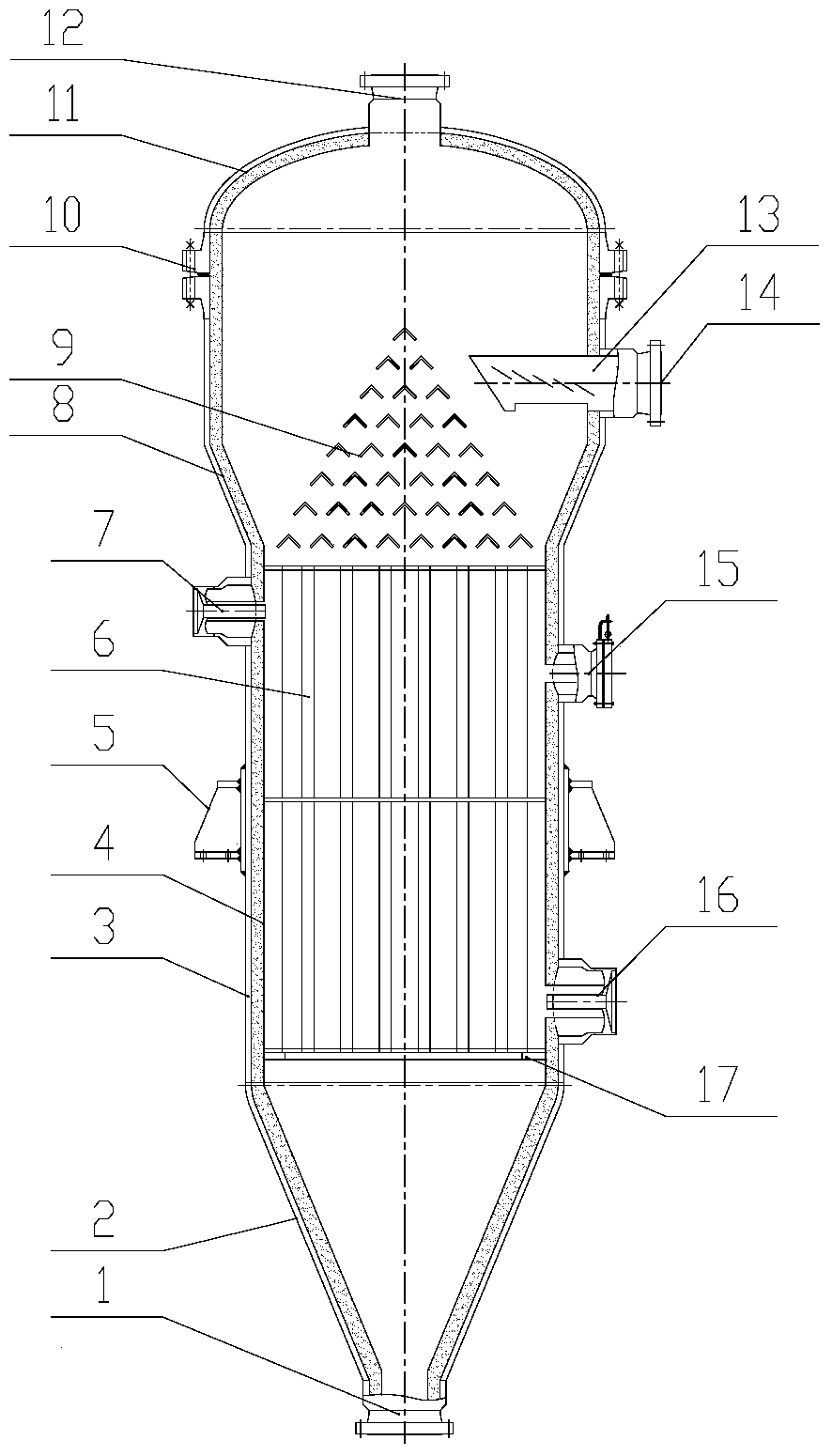

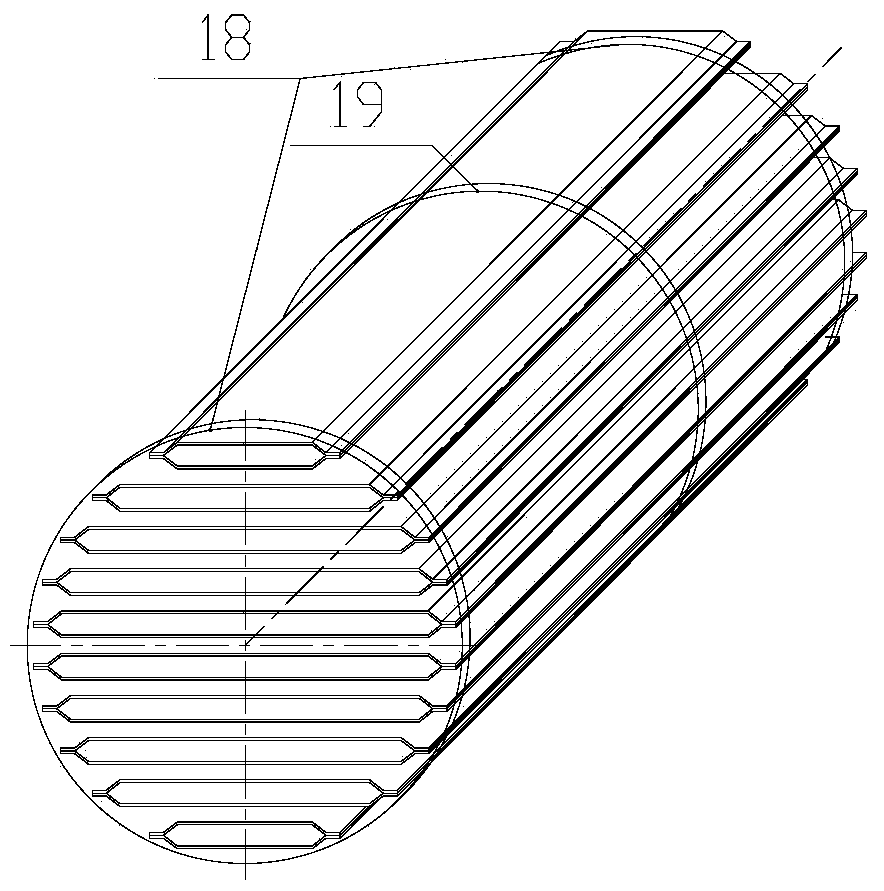

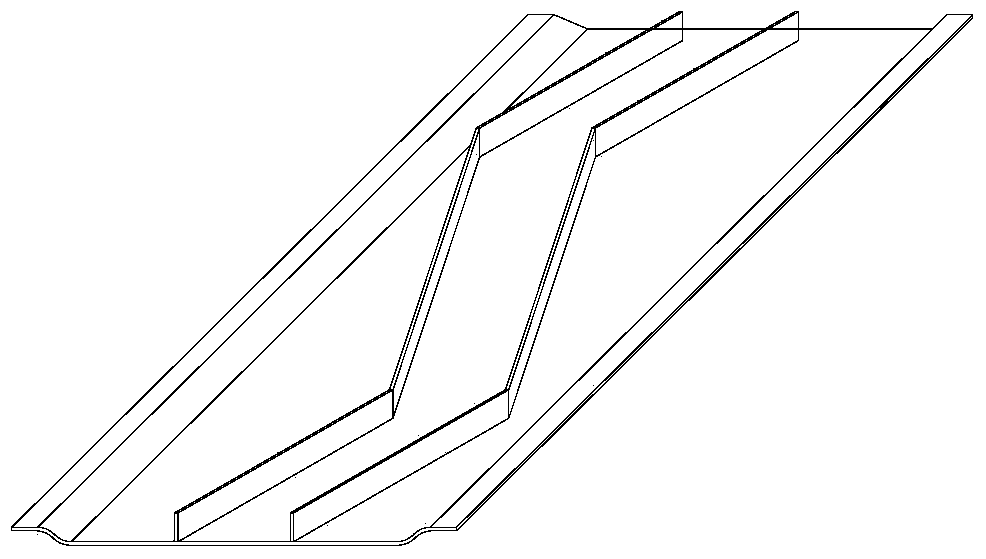

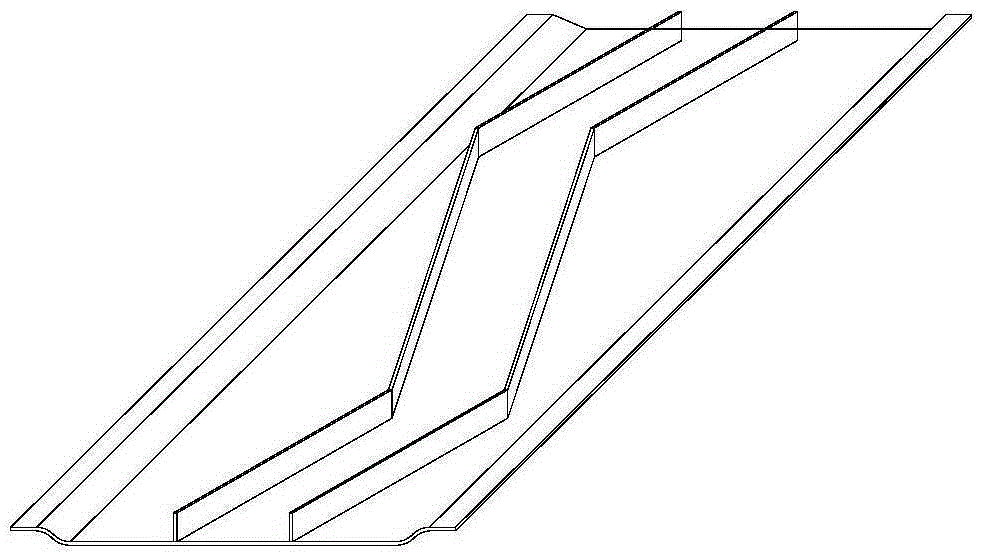

A detachable plate type indirect heating coal pyrolysis device

ActiveCN105238426BEvenly distributedSufficient heat exchangeIndirect heating destructive distillationSpecial form destructive distillationEngineeringCoal pyrolysis

The invention relates to a coal pyrolysis device, belongs to the technical field of coal quality improvement, and relates to a detachable plate type indirect heating coal pyrolysis device which comprises a casing. The top of the casing is provided with a coal feeding port and a pyrolytic gas outlet. The bottom of the casing is provided with a semi-coke discharging port. A detachable modularized heat exchange system is arranged below the coal feeding port in the casing and comprises one or more heat exchange modules in series connection in sequence. Each heat exchange module comprises a plate bundle, a tube plate and a supporting plate, at least one supporting plate is axially arranged on the circumference of the plate bundle, and the two ends of the plate bundle are fixed to the tube plate. The plate bundle is connected with the tube plate through a high temperature resistant expanding material. Along with the changes of environment temperature, the plate bundle and the tube plate are fastened or separated, and the heat exchange modules and the whole heat exchange system are detachably replaceable. Coal and high temperature gas undergo indirect type heat exchange in reverse flows on the two sides of a plate slice to achieve coal pyrolysis, so that high-quality pyrolysis gas is obtained, and energy consumption of a purification system is reduced.

Owner:CHANGZHENG ENG

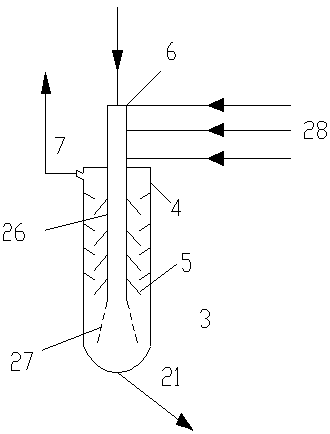

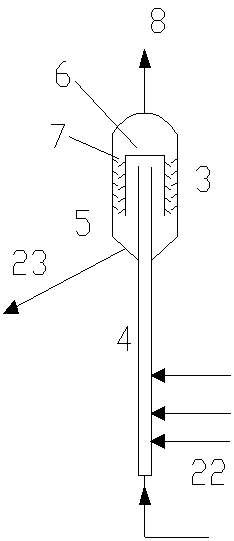

Entrained flow bed gasifier

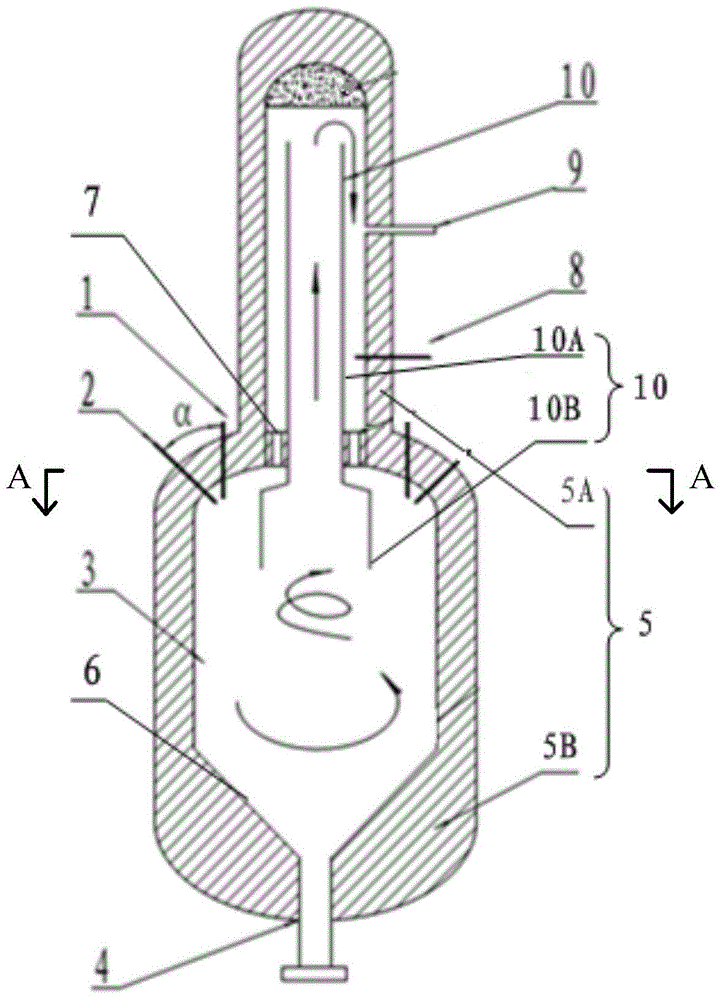

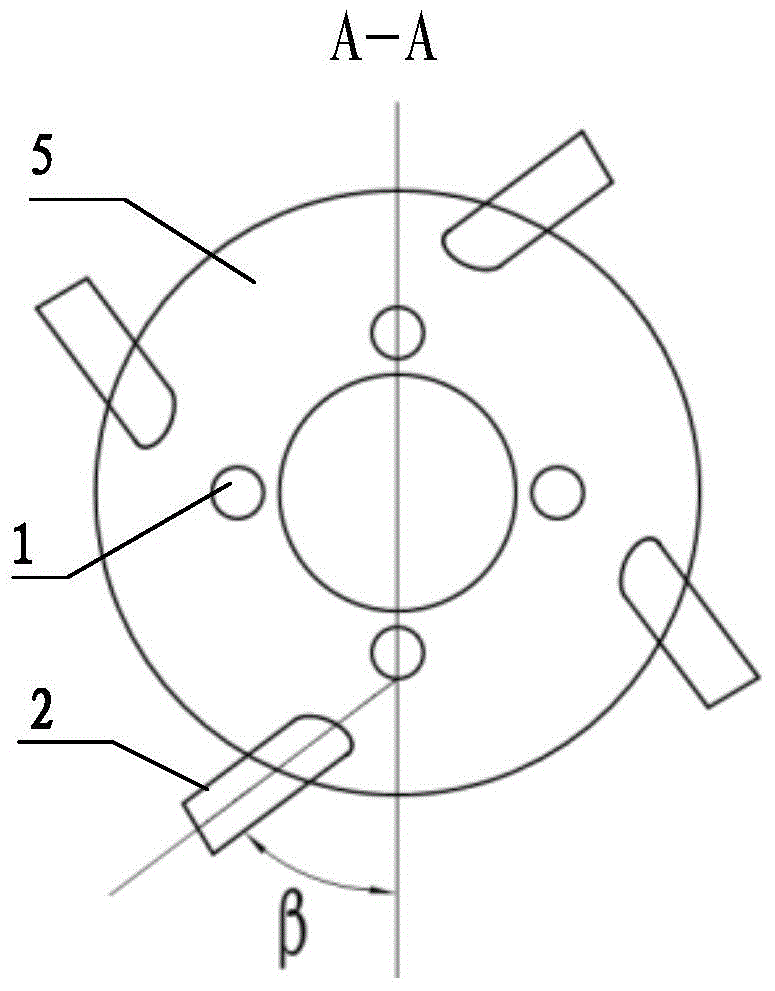

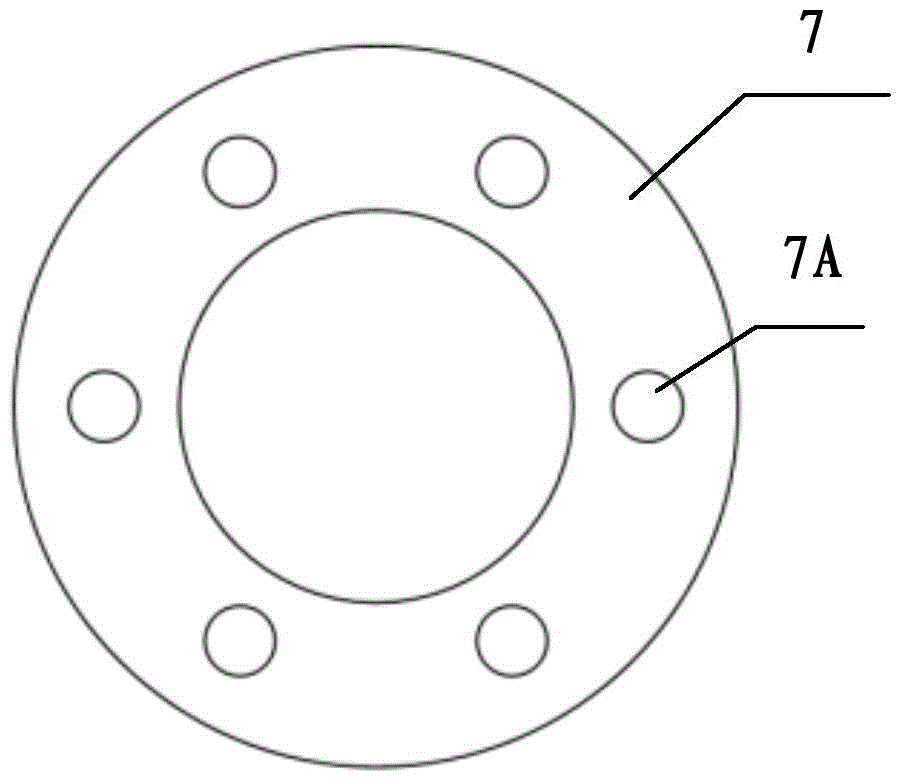

ActiveCN104388124AReduce entrainmentRealize gas-solid separationGaseous fuelsGranular/pulverulent flues gasificationHydrogenGas phase

The embodiment of the invention provides an entrained flow bed gasifier, belonging to the technical field of coal gasification. The entrained flow bed gasifier can effectively separate the solid particles from the generated gas phase in the gasification furnace and greatly lower the semicoke entrainment quantity of the product gas. The entrained flow bed gasifier comprises a furnace body, wherein the furnace body is obliquely provided with a hydrogen gas nozzle; the hydrogen gas nozzle and the vertical axis of the furnace body form a first included angle alpha; and the hydrogen gas nozzle and the horizontal central axis form a second included angle beta. The lower part of the furnace body is provided with a conical solid collecting tank. The entrained flow bed gasifier can be used for coal hydrogenation gasification reaction.

Owner:ENN SCI & TECH DEV

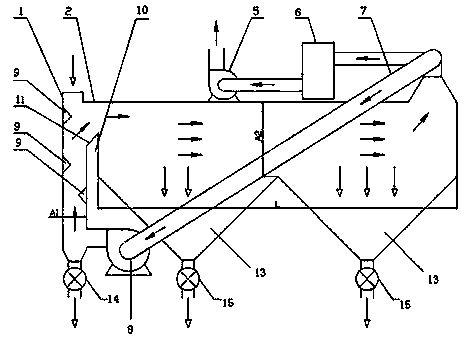

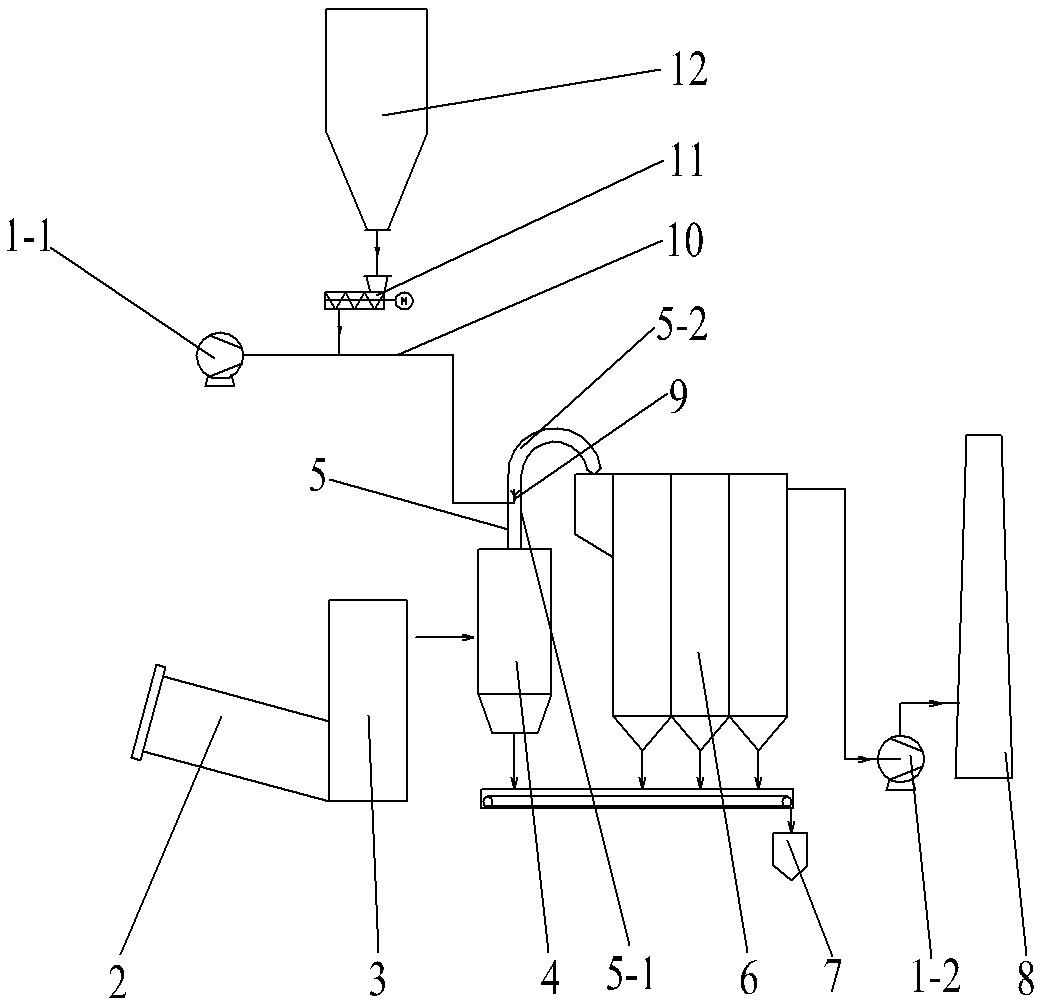

Device and method for removing acid gases in garbage incineration smoke at high temperature

ActiveCN102716643ATake advantage ofImprove removal efficiencyDispersed particle separationAir preheaterSorbent

The invention discloses a device for removing acid gases in garbage incineration smoke at the high temperature. The device comprises a material separation hopper, a primary feed hopper, a secondary feed hopper, a tertiary feed hopper, a primary cross flow moving bed reactor, a secondary cross flow moving bed reactor, a tertiary cross flow moving bed reactor, a primary adjustable star discharge device, a secondary adjustable star discharge device, a tertiary adjustable star discharge device, a smoke inlet, a smoke outlet, a recovery bin, a drier, an implementing bin, a fresh material implementing bin, a garbage incineration smoke pipeline and an air preheater. The invention further discloses a method for removing the acid gases in the garbage incineration smoke at the high temperature. According to the invention, multiple stages of cross flow moving bed reactors are adopted, the garbage incineration smokes at moderate and high temperatures sequentially pass through the cross flow moving bed reactors and are in contact with adsorbents in the reactors to perform multi-stage deep acid gas removal, reduce corrosion and blockage by the acid gases on pipelines and equipment, and achieve the exhaust of the garbage incineration smoke in a purifying way.

Owner:SOUTHEAST UNIV

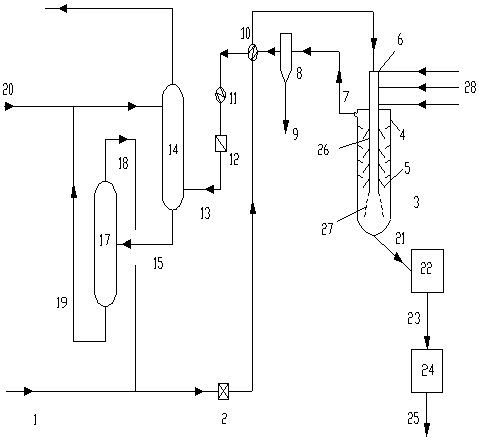

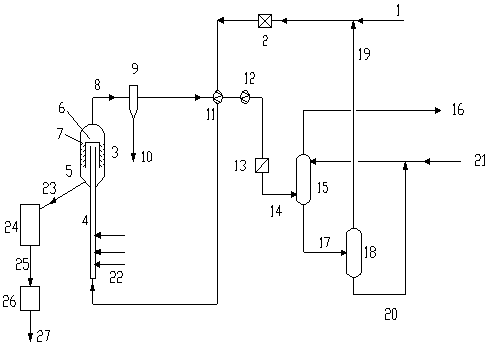

Novel hydrogen production method and hydrogen production system

ActiveCN106629592AImprove conversion rateHigh yieldGas treatmentDispersed particle separationIron powderGas phase

The invention provides a hydrogen production method. The method comprises the steps of enabling feed gas to enter a pyrolysis reactor in presence of iron powder so as to have reaction, and then separating reaction effluent to obtain a gas phase material and a solid phase material; enabling the gas phase material to enter a sulfur catcher for recovering elemental sulfur, and then enabling the gas phase material without the elemental sulfur to enter a desulfurization device and react with an absorbent to obtain hydrogen-rich gas and rich absorbing liquid; enabling the rich absorbing liquid to enter a regeneration tower to obtain a regenerated absorbent and desorbed gas; sending the solid phase material into a magnetic field separator, and separating to obtain ferrous sulfide and the iron powder. The invention also provides a hydrogen production system. After the hydrogen production method and the hydrogen production system are adopted, the decomposition rate of H2S is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

An ultra-low temperature exhaust gas energy-saving boiler

InactiveCN102297439AImprove running stabilityCause corrosiveLighting and heating apparatusSorbentEngineering

An ultra-low temperature smoke-exhausting energy-saving boiler relates to an energy-saving boiler capable of reducing pollution discharge. The invention aims to solve the problems of low fuel utilization efficiency caused by high dust concentration and high carbon content of fly ash in exhaust gas of existing coal-fired industrial boilers, and wear and tear of heat exchange equipment such as convection tube bundles and economizers at the tail of the boiler. The upper end of the furnace body communicates with the upper end of the vertical flue through the cyclone dust collector, the bottom end of the cyclone dust collector communicates with the furnace body, and a desulfurizer spout is opened on the upper end surface of the furnace body. The invention realizes the recycling of the desulfurizer in the effective area of high-temperature sulfur fixation, greatly reduces the SO3 content in the flue gas while improving the SO2 removal efficiency, and improves the energy efficiency of the boiler by more than 10%; the unburned carbon particles are sent back for reburning The carbon content of the fly ash can be reduced to less than 2%, and at the same time, it can improve energy efficiency and reduce equipment wear. The energy-saving boiler of the invention can be used not only for newly-built boilers, but also for technical transformation of existing boilers.

Owner:HARBIN INST OF TECH

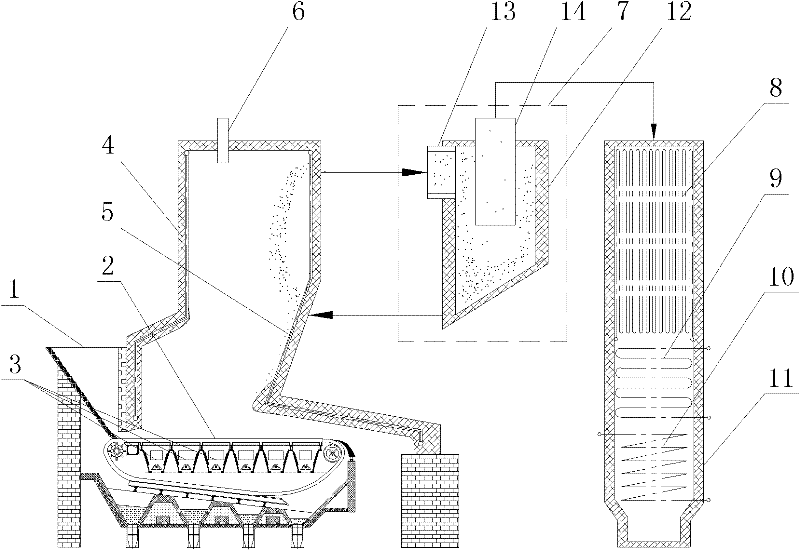

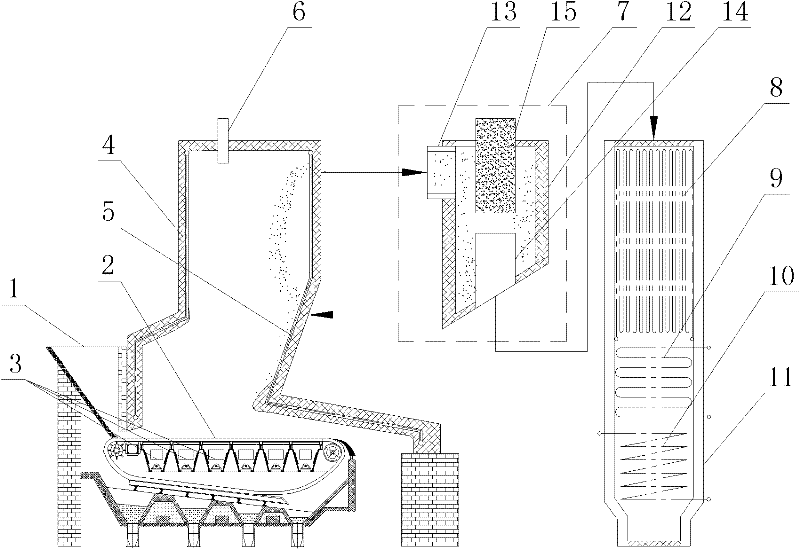

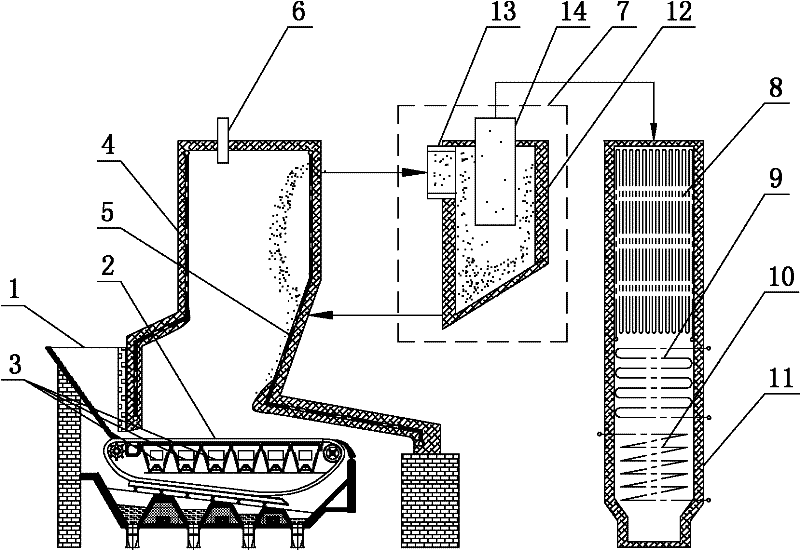

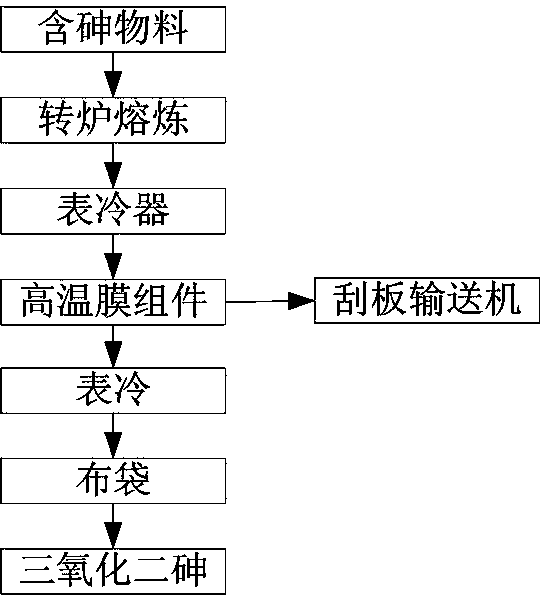

Method for selectively separating arsenic trioxide from non-ferrous metal smelter off-gas

InactiveCN103589869AAchieve selective separationRealize gas-solid separationProcess efficiency improvementArsenic compoundsGas solidArsenic pollution

The invention relates to a method for selectively separating arsenic trioxide from non-ferrous metal smelter off-gas, and belongs to the technical field of the non-ferrous metallurgy. The method is mainly characterized in that the off-gas enters a high temperature membrane module at a temperature of 500-700DEG C, so a gas traverses through a membrane filter core, and dusts are intercepted and adsorbed by a membrane through inertial impaction and the interception or diffusion effect to realize gas-solid separation. The method has the advantages of reasonable, controllable and stable process flow, high arsenic separation rate, high purity of the obtained arsenic extraction product, and no arsenic pollution in the smelting process.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

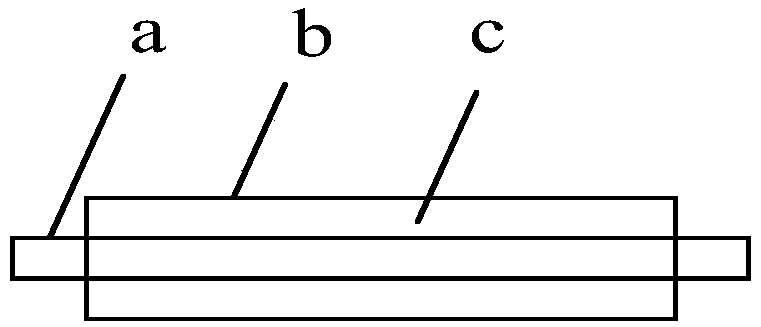

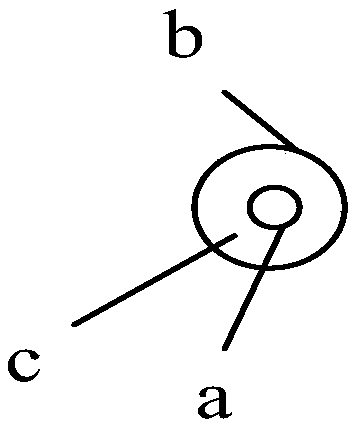

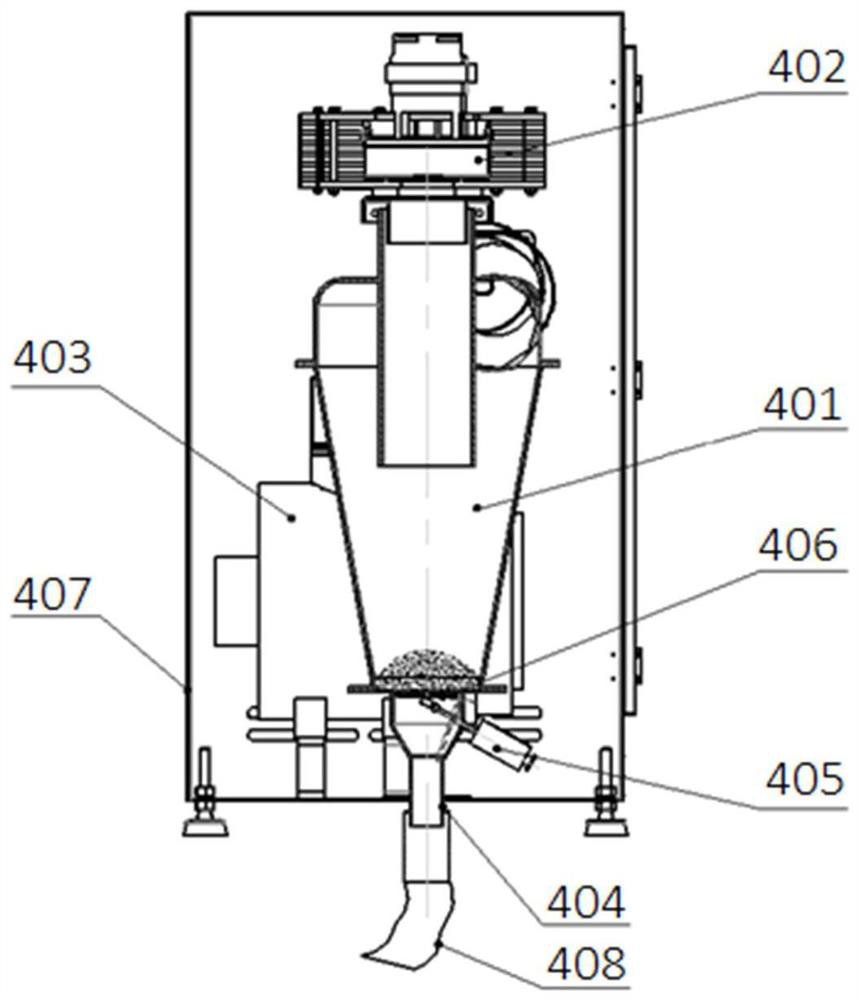

Powder selecting and collecting device

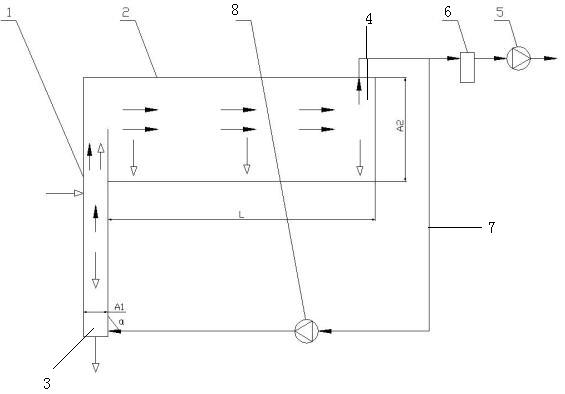

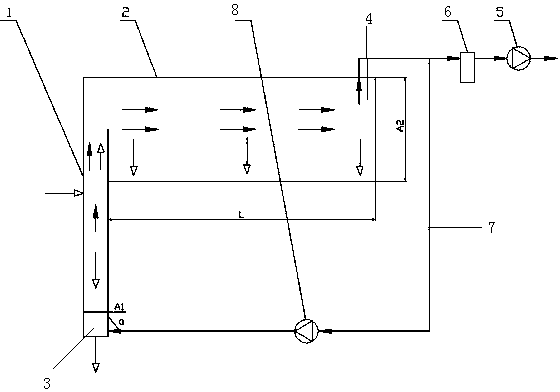

ActiveCN102366745AReduce energy consumptionReduce manufacturing costGas current separationDispersed particle separationAir velocityEngineering

The invention discloses a powder selecting and collecting device, which comprises a powder selecting pipe and a powder collecting pipe, wherein the upper part of the powder selecting pipe is provided with a feeding hole; the lower end of the powder selecting pipe is provided with a discharging hole; the powder selecting pipe and the powder collecting pipe are communicated with each other; the powder selecting pipe is arranged obliquely to the horizontal surface; the included angle alpha between the powder selecting pipe and the horizontal surface is more than or equal to 45 degrees and less than or equal to 90 degrees; the powder collecting pipe is arranged horizontally; the lower end of the powder selecting pipe is provided with an air inlet; the powder collecting pipe is provided with an air outlet far away from one end which is communicated with the powder selecting pipe; and the air outlet is connected with a draught fan. In the device, high air speed required by a powder selecting process of a centrifugal separating technology is not required, the aims of selecting powder and subsequently collecting powder can be fulfilled by setting the air speed at 2 meters per second in the powder selecting pipe, and the energy consumption is lowered; mostly importantly, powder selection and powder collection are performed in the powder selecting pipe and the powder collecting pipe which are communicated with each other but are not interfered with each other, so that the influence of airstream flow during centrifugal separation on powder collection is avoided, and the powder selecting and powder collecting efficiencies are increased; and the overall pressure loss of the device does not surpass 100 Pa which is only 5-10 percent of the pressure loss of the conventional centrifugal separation powder selecting system, and the energy-saving effect is remarkable.

Owner:卓卫民

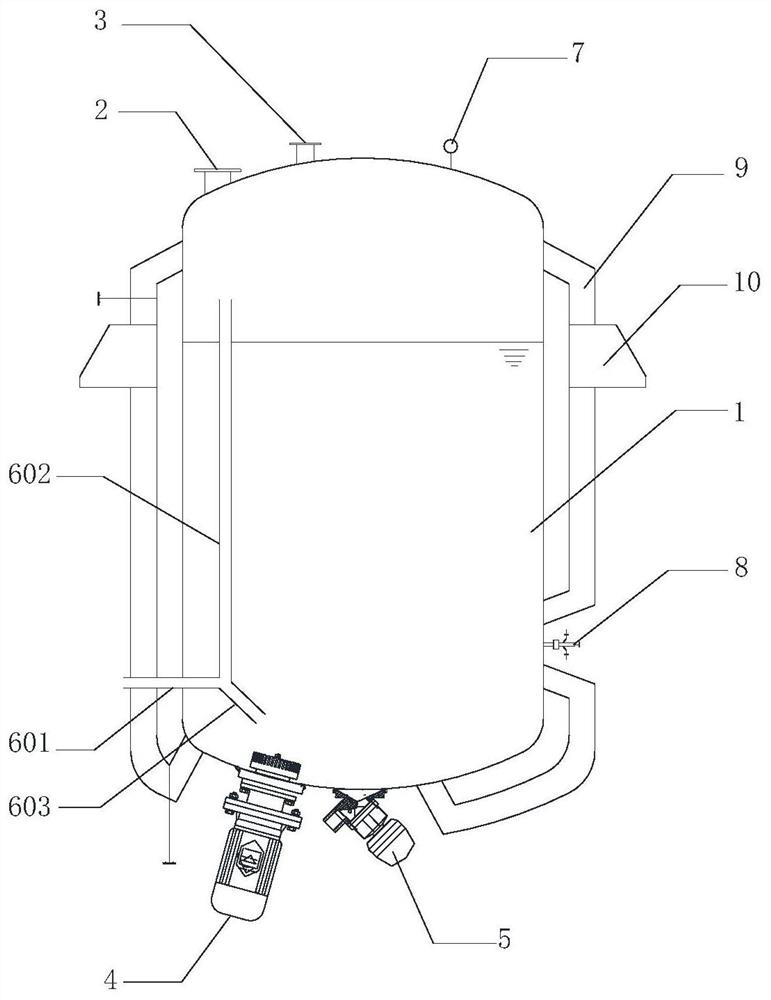

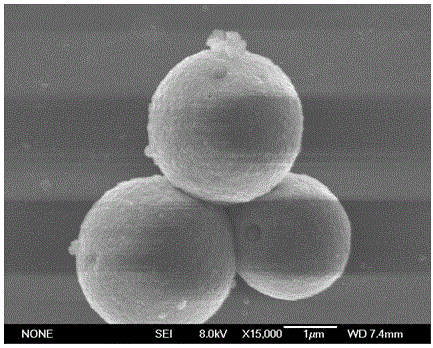

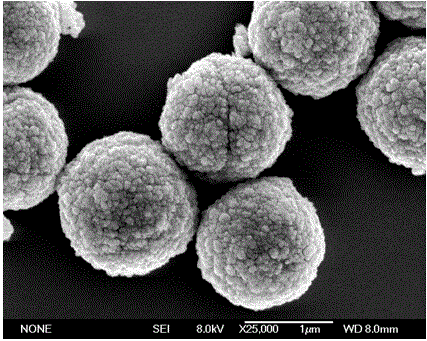

Preparation method of unsaturated fatty acid microcapsules

PendingCN112716014AHigh utilization rate of raw materialsReduce pollutionFood preservationFood shapingUnsaturated fatty acidEmulsion

The invention discloses a preparation method of unsaturated fatty acid microcapsules, which comprises the following steps: adding water into a vacuum emulsification tank provided with a gas-solid separator, blowing a wall material, an emulsifier and an antioxidant into the water in the vacuum emulsification tank by using inert gas through the gas-solid separator, and carrying out shear emulsification to obtain a pre-emulsified liquid; adding an unsaturated fatty acid core material into the pre-emulsified liquid, and sequentially performing shearing, emulsifying and homogenizing to obtain emulsified liquid; sterilizing the emulsified liquid; and carrying out spray drying on the sterilized emulsion, and sieving the obtained powder product to obtain the unsaturated fatty acid microcapsule. When the emulsified liquid is prepared, the vacuum emulsifying tank provided with the gas-solid separator is adopted for shearing and emulsifying, so that the utilization rate of raw materials is effectively improved; and the emulsified liquid is sterilized and then subjected to spray drying, so that the microcapsules are prevented from deteriorating under the action of microorganisms, and the shelf life of the product is prolonged.

Owner:浙江远大生物科技有限公司 +1

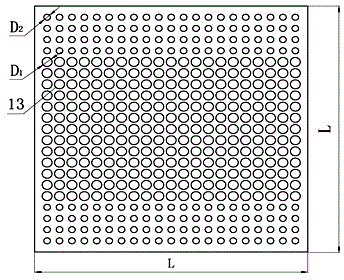

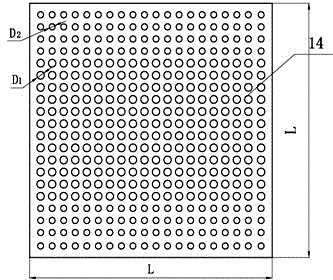

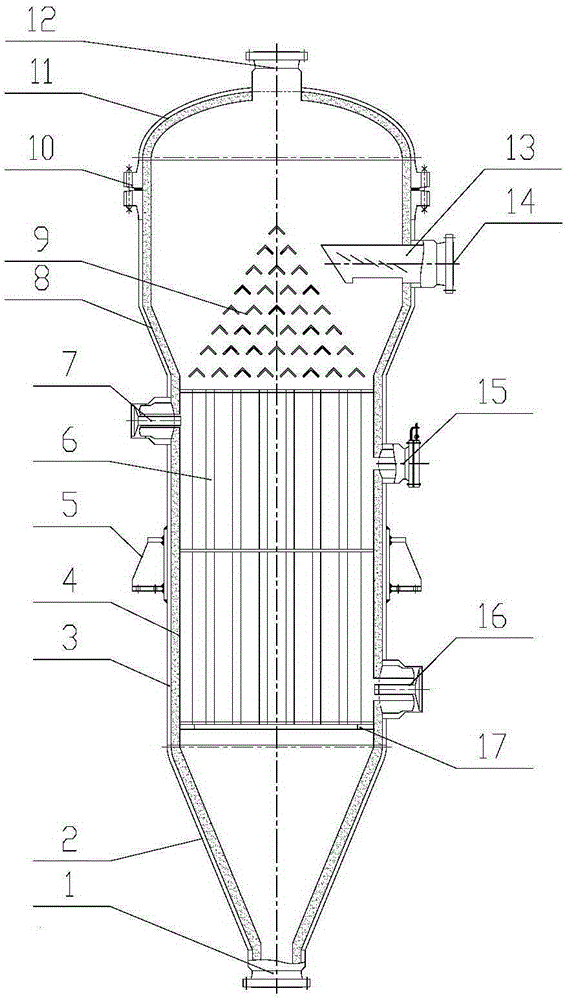

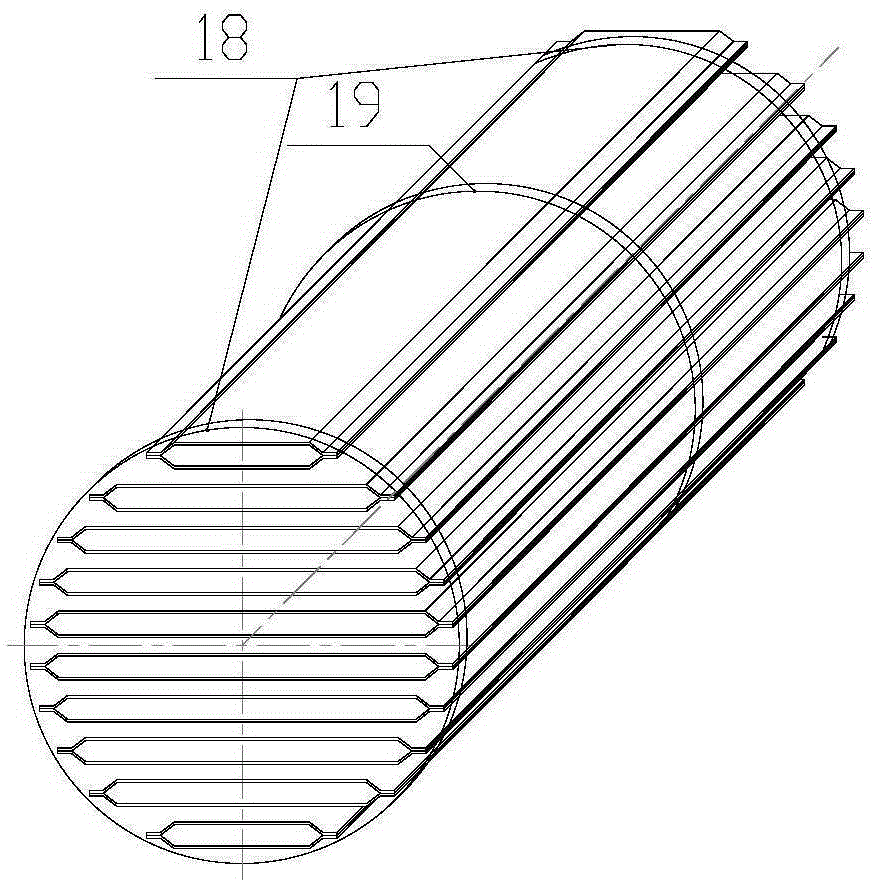

Detachable plate type indirect heating coal pyrolysis device

ActiveCN105238426AImprove heat transfer efficiencyPlay a disturbing roleIndirect heating destructive distillationSpecial form destructive distillationEngineeringCoal pyrolysis

The invention relates to a coal pyrolysis device, belongs to the technical field of coal quality improvement, and relates to a detachable plate type indirect heating coal pyrolysis device which comprises a casing. The top of the casing is provided with a coal feeding port and a pyrolytic gas outlet. The bottom of the casing is provided with a semi-coke discharging port. A detachable modularized heat exchange system is arranged below the coal feeding port in the casing and comprises one or more heat exchange modules in series connection in sequence. Each heat exchange module comprises a plate bundle, a tube plate and a supporting plate, at least one supporting plate is axially arranged on the circumference of the plate bundle, and the two ends of the plate bundle are fixed to the tube plate. The plate bundle is connected with the tube plate through a high temperature resistant expanding material. Along with the changes of environment temperature, the plate bundle and the tube plate are fastened or separated, and the heat exchange modules and the whole heat exchange system are detachably replaceable. Coal and high temperature gas undergo indirect type heat exchange in reverse flows on the two sides of a plate slice to achieve coal pyrolysis, so that high-quality pyrolysis gas is obtained, and energy consumption of a purification system is reduced.

Owner:CHANGZHENG ENG

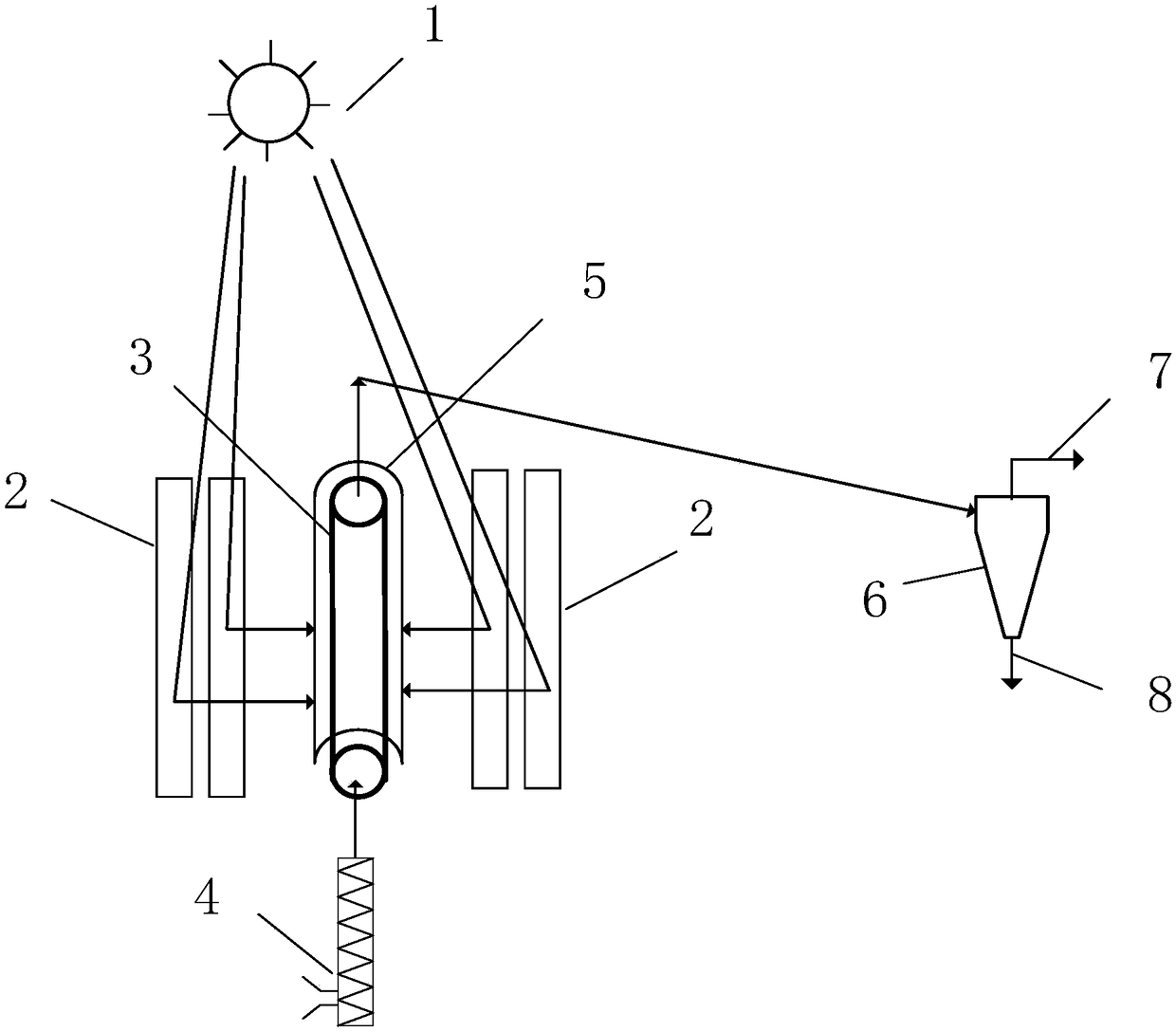

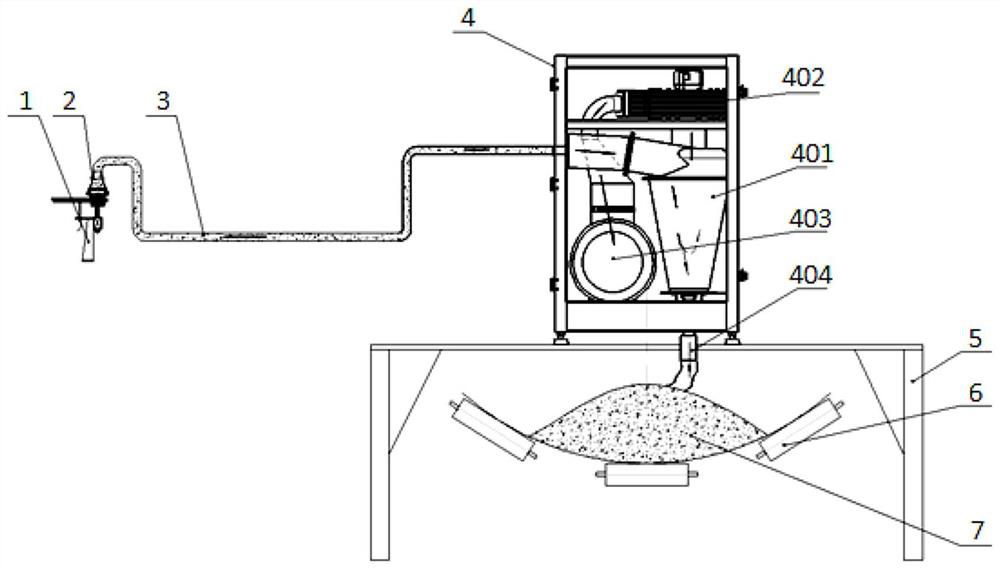

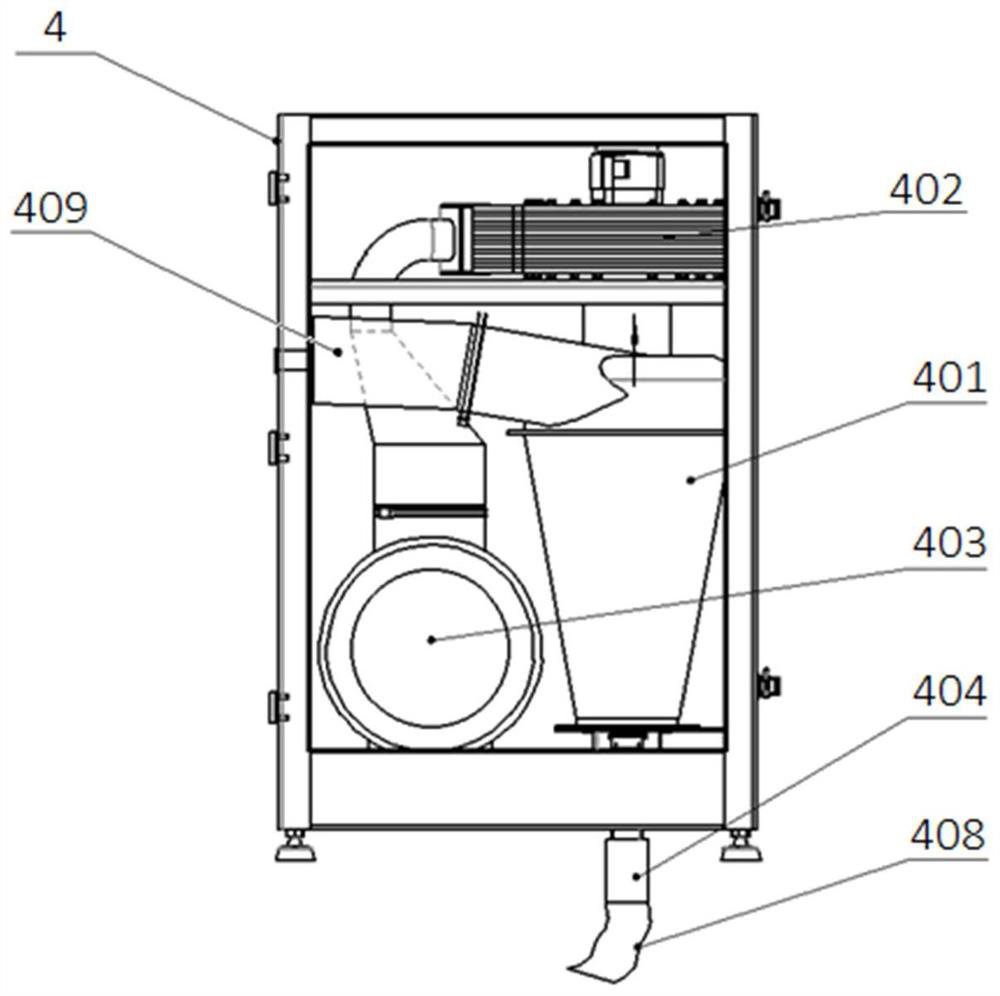

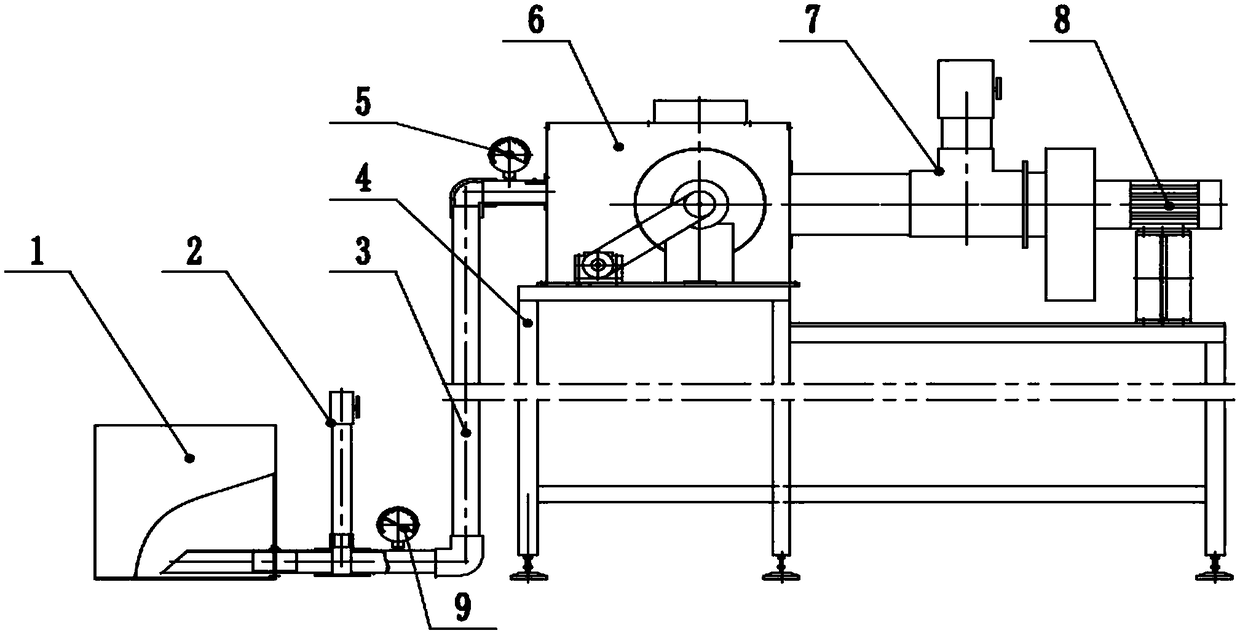

Device for low oxygen pyrolysis treatment of combustible rubbish by using Fresnel type solar energy

InactiveCN108954322AReduce heat lossRealize the harmless treatment of garbageSolar heating energySolar heat collector for particular environmentSun trackingDecomposition

The invention provides a device for low oxygen pyrolysis treatment of combustible rubbish by using Fresnel type solar energy. The device for low oxygen pyrolysis treatment of combustible rubbish by using Fresnel type solar energy heats and distills organic matters by using the thermal instability of the organic matters in rubbish under the anaerobic condition or oxygen deficient condition so as tocause the splitting decomposition of the organic matters; various new gases, liquid and solids are formed after condensation; and fuel oil and combustible gases are extracted from the various new gases, liquid and solids. A reflector (2) which is fixed on the ground by a support and can realize single-axis sun tracking is used for reflecting part of sunlight of sun (1) to a solar energy vacuum pyrolysis pipe (3); heat is fed into rubbish in the solar energy vacuum pyrolysis pipe (3) by a screw conveyer (4), so that the low oxygen high-temperature pyrolysis of the rubbish is realized; rubbishproducts are fed into a pyrolysis product separator (6) along a pipeline (5) for gas-solid separation; pyrolysis gas products are led out by a gas leading-out pipeline (7); and pyrolysis solid products are led out by a solid leading-out pipeline (8).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

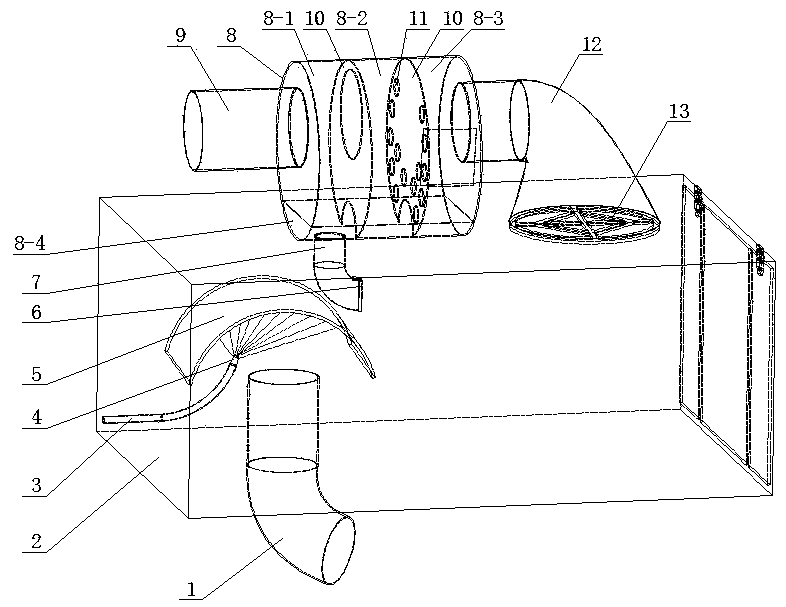

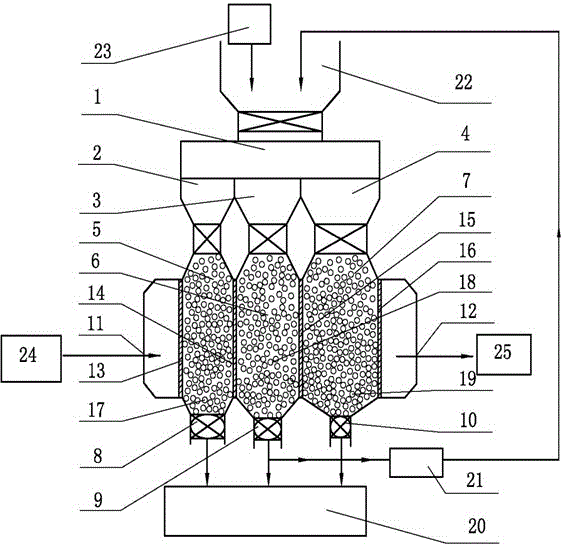

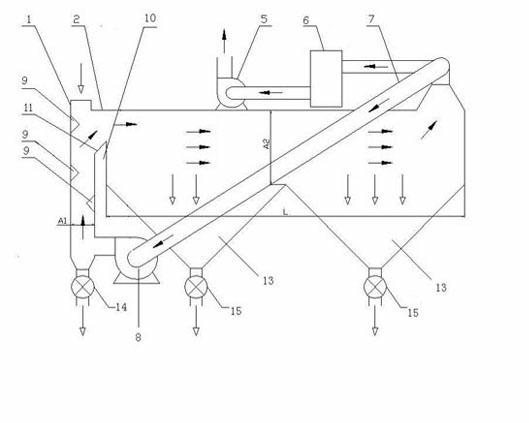

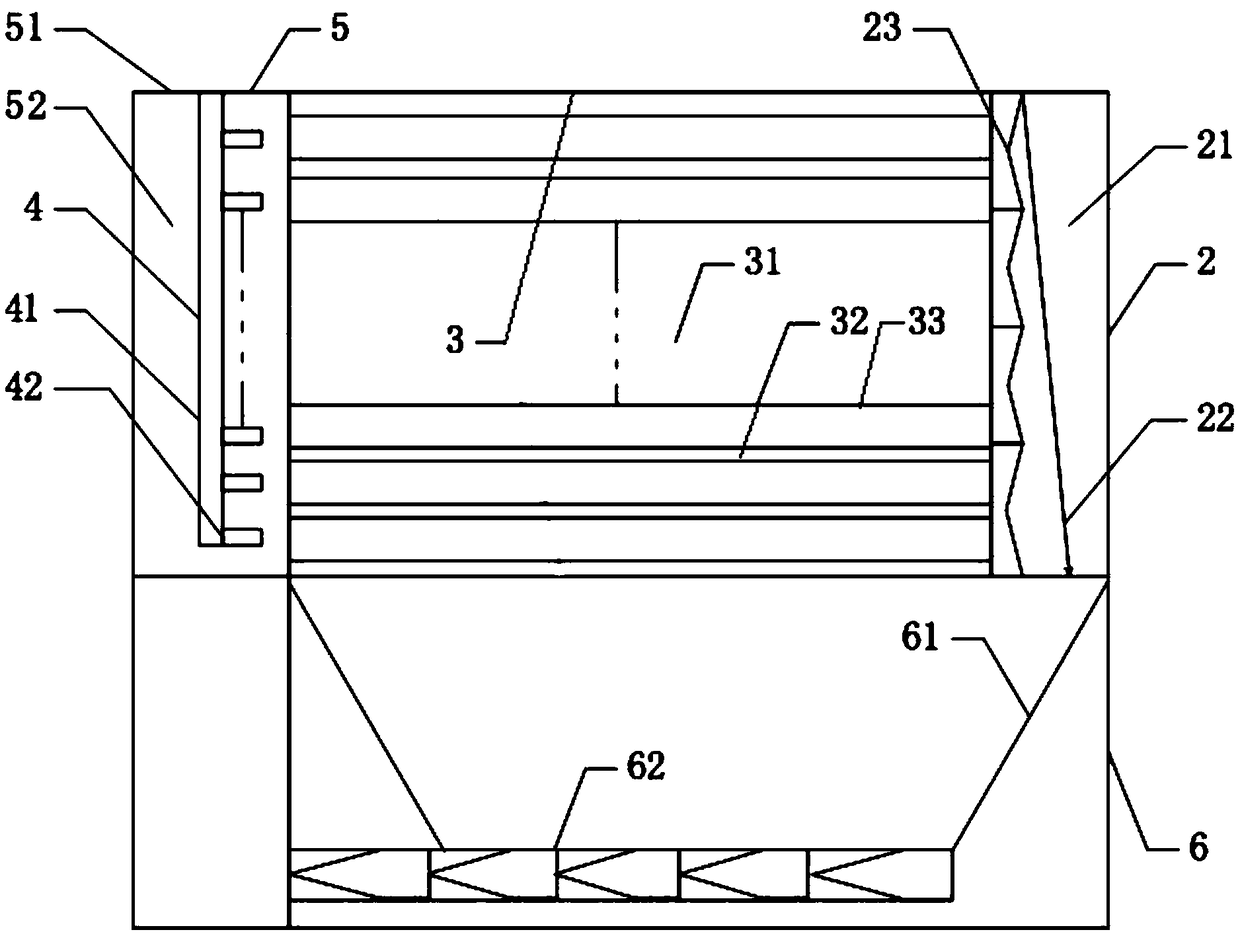

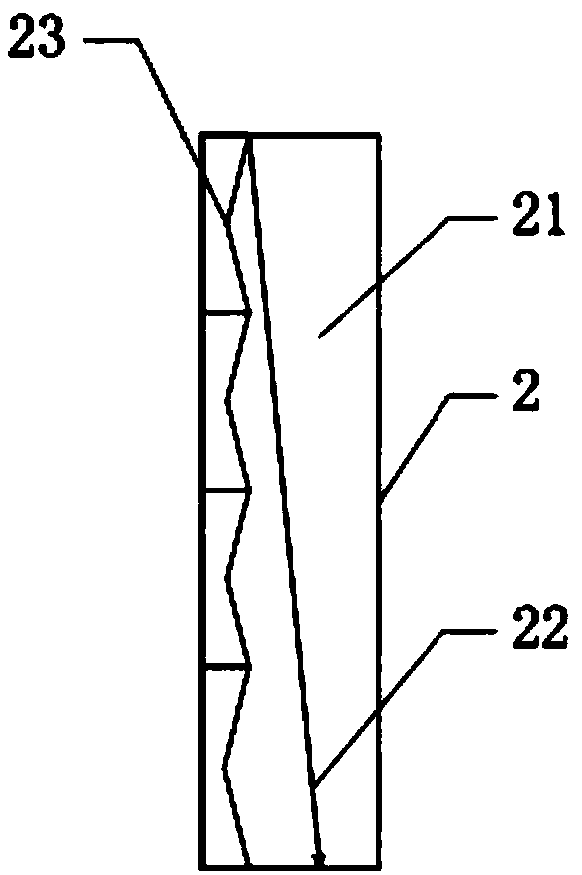

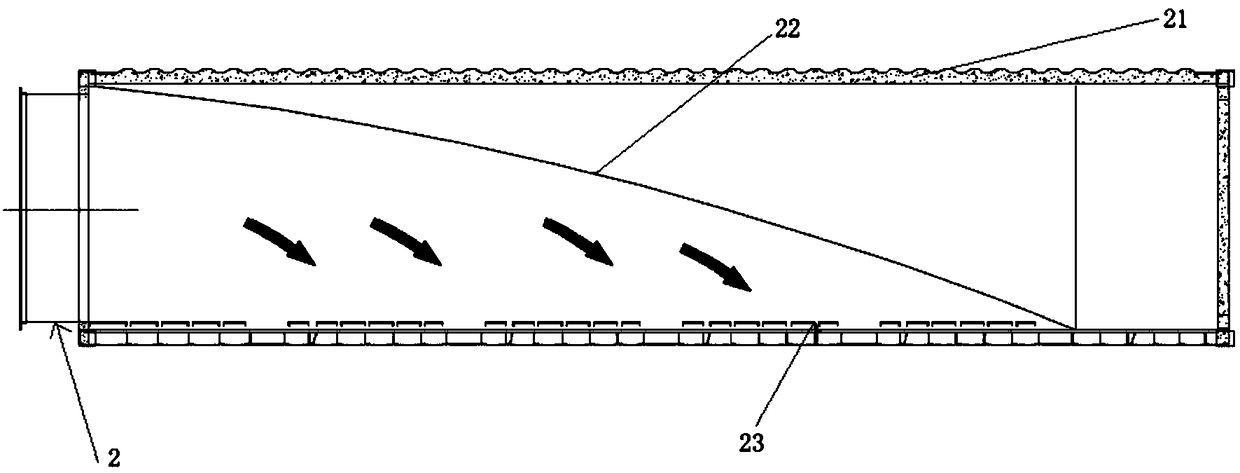

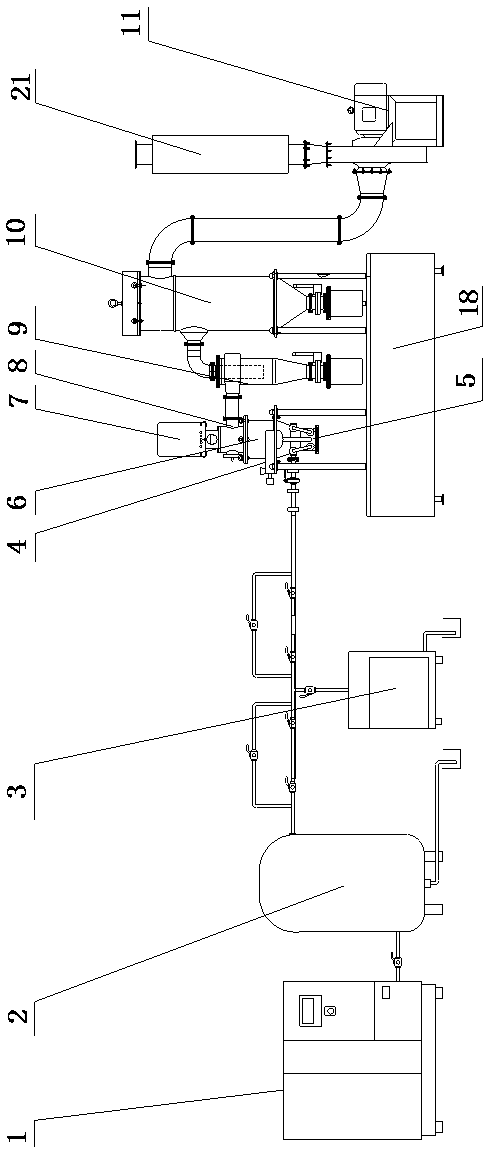

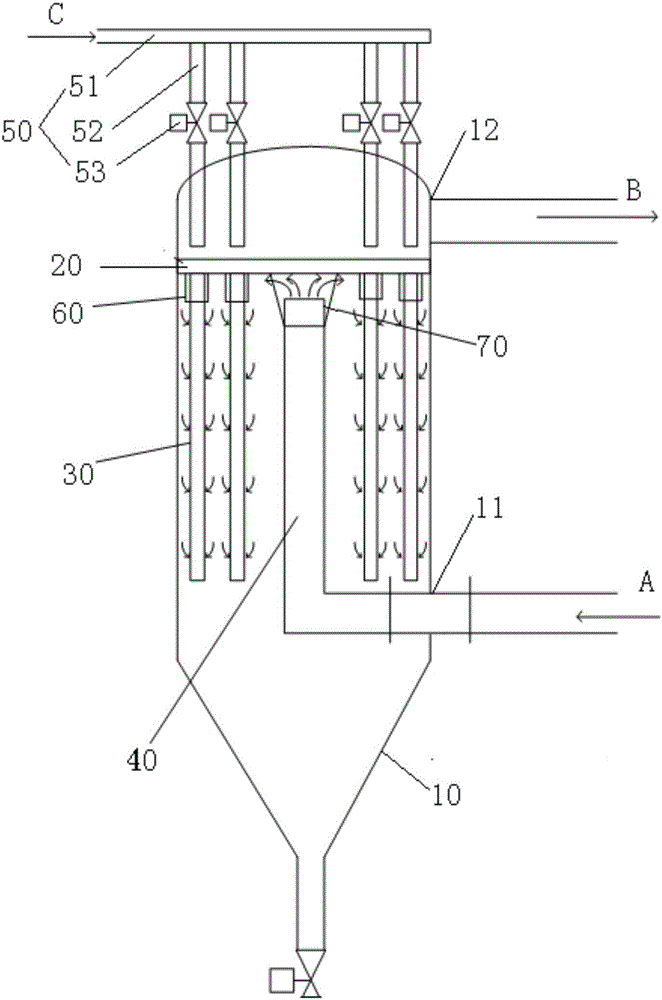

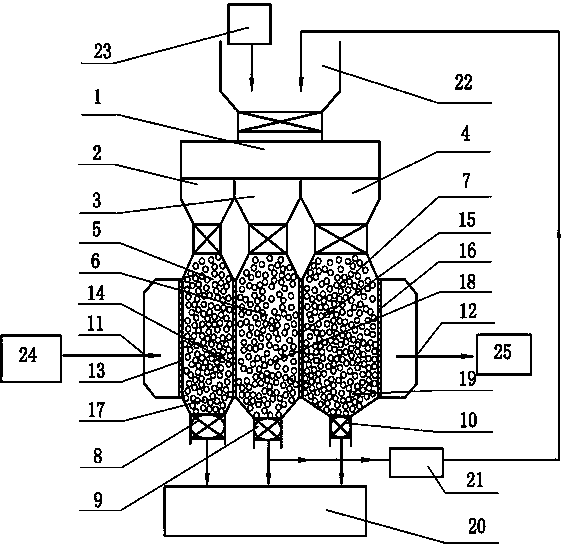

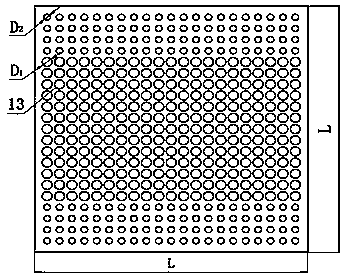

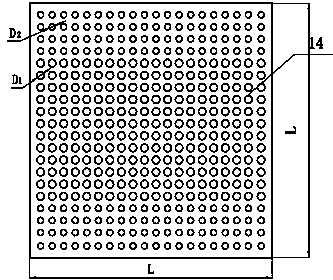

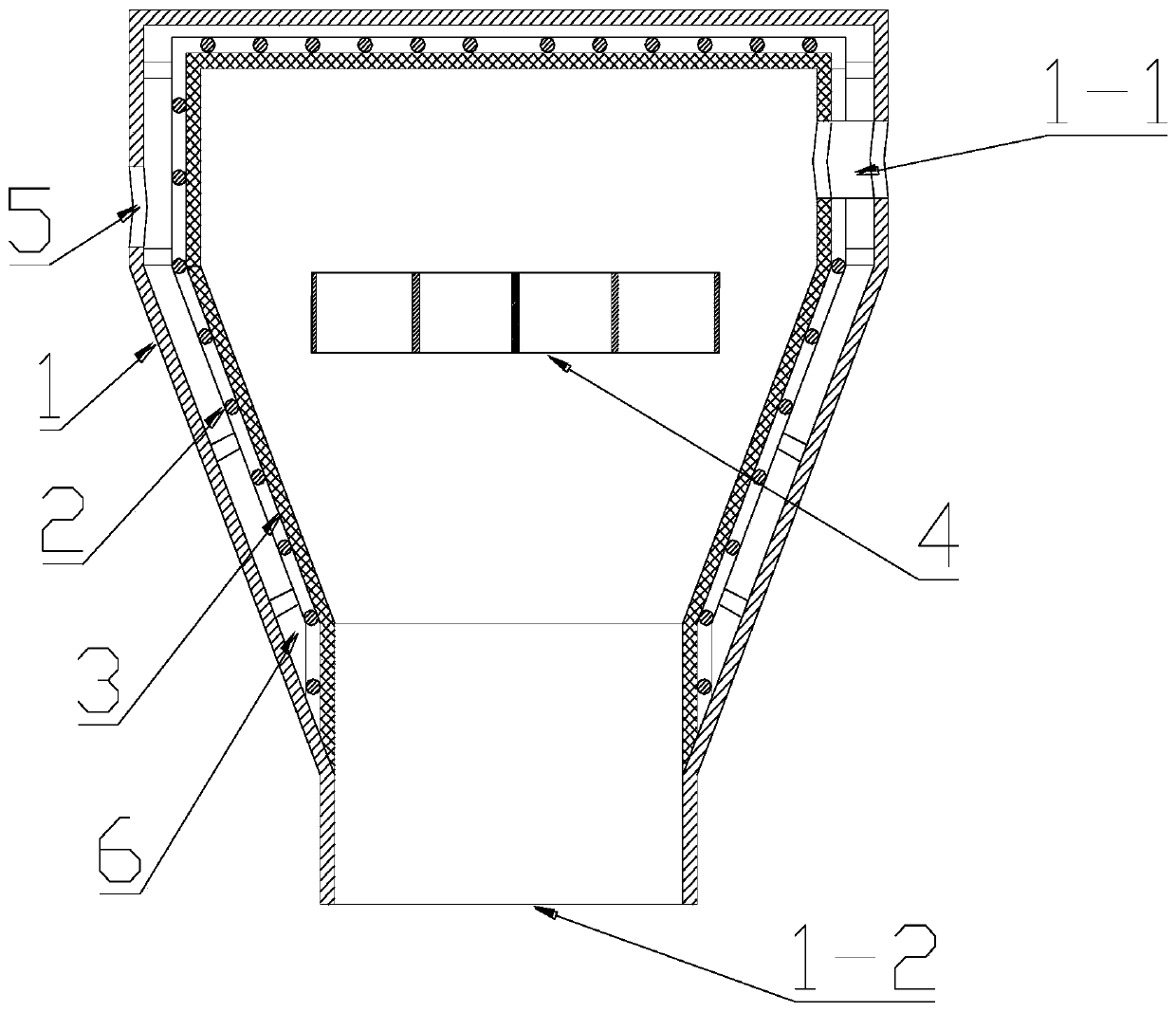

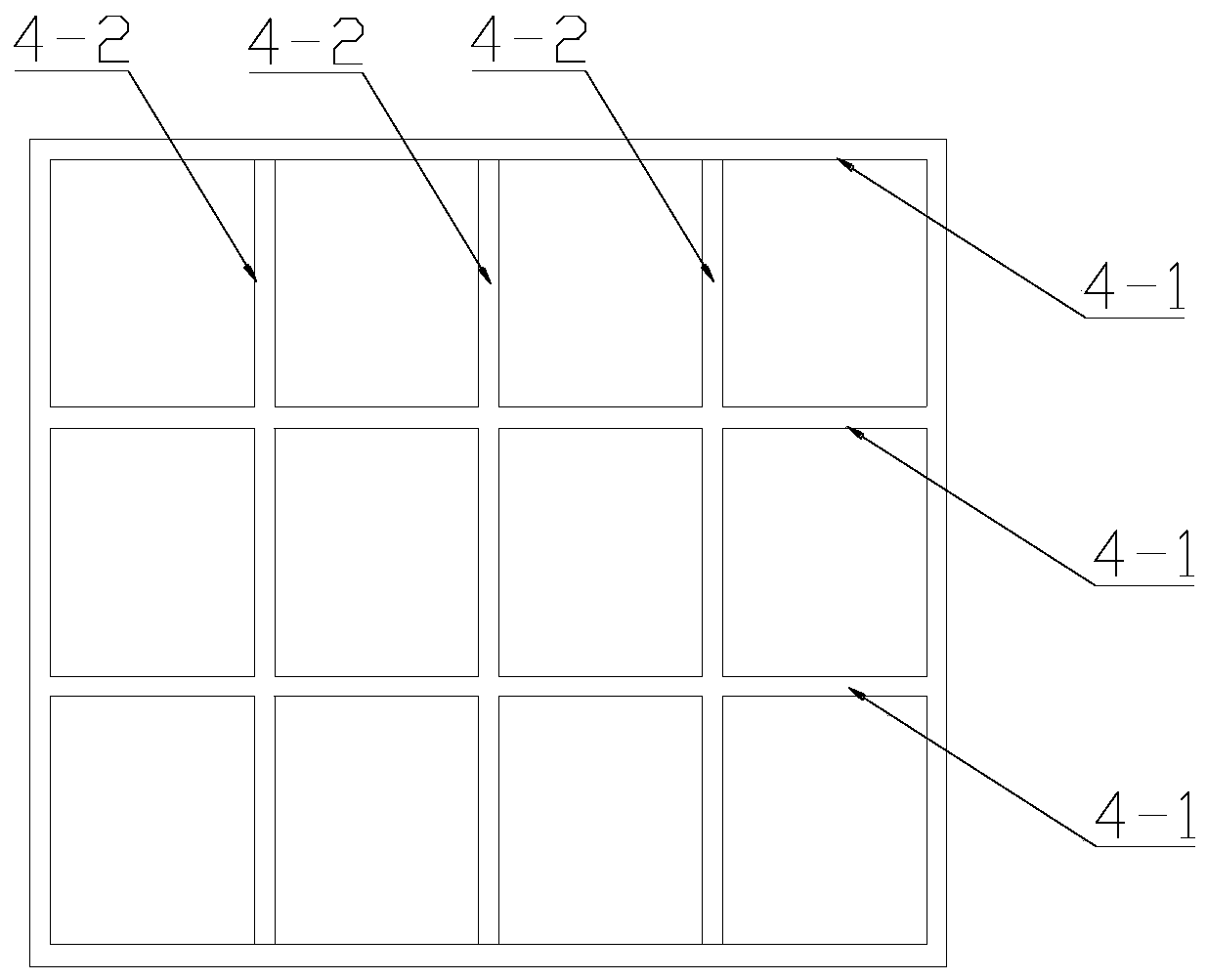

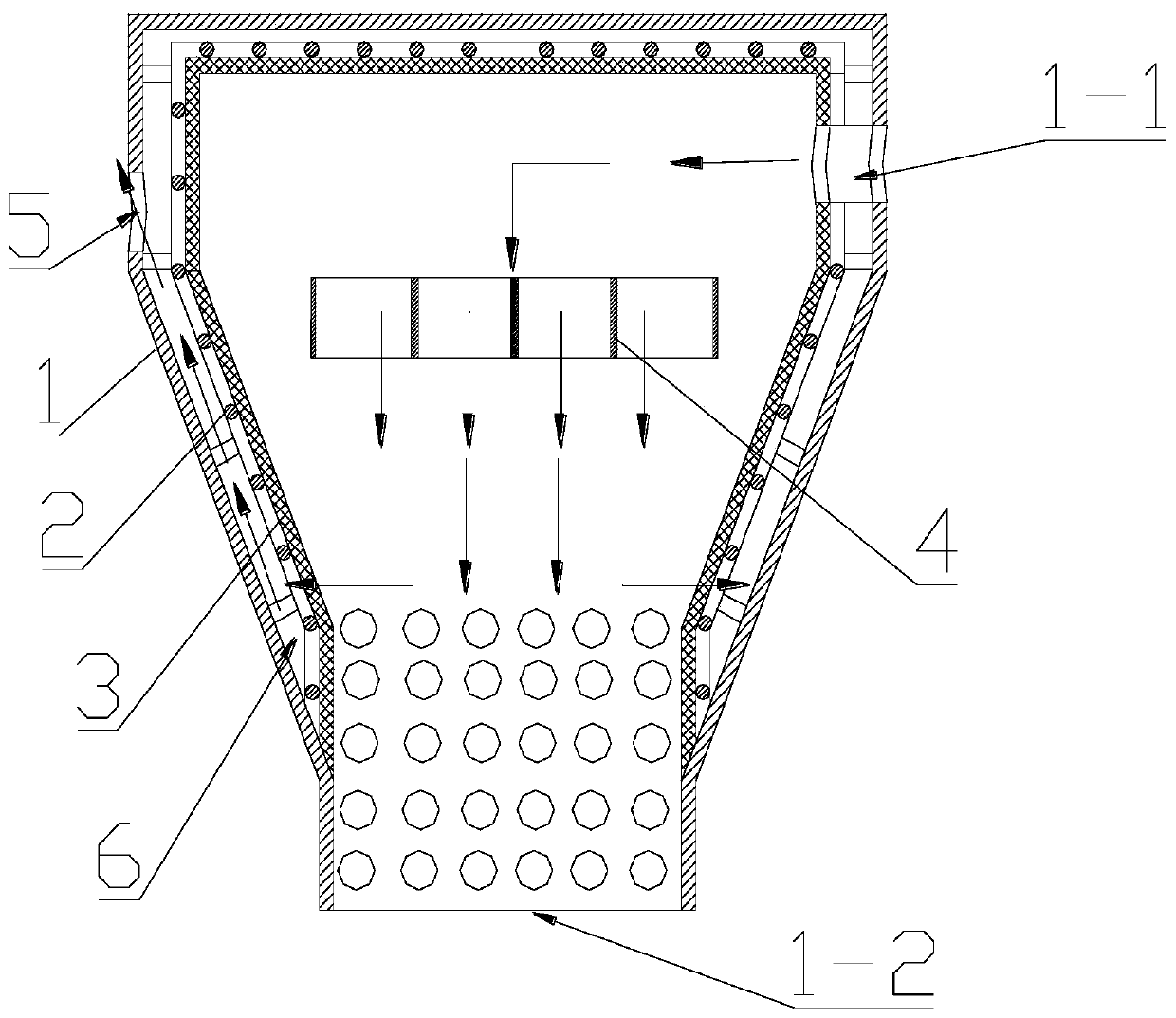

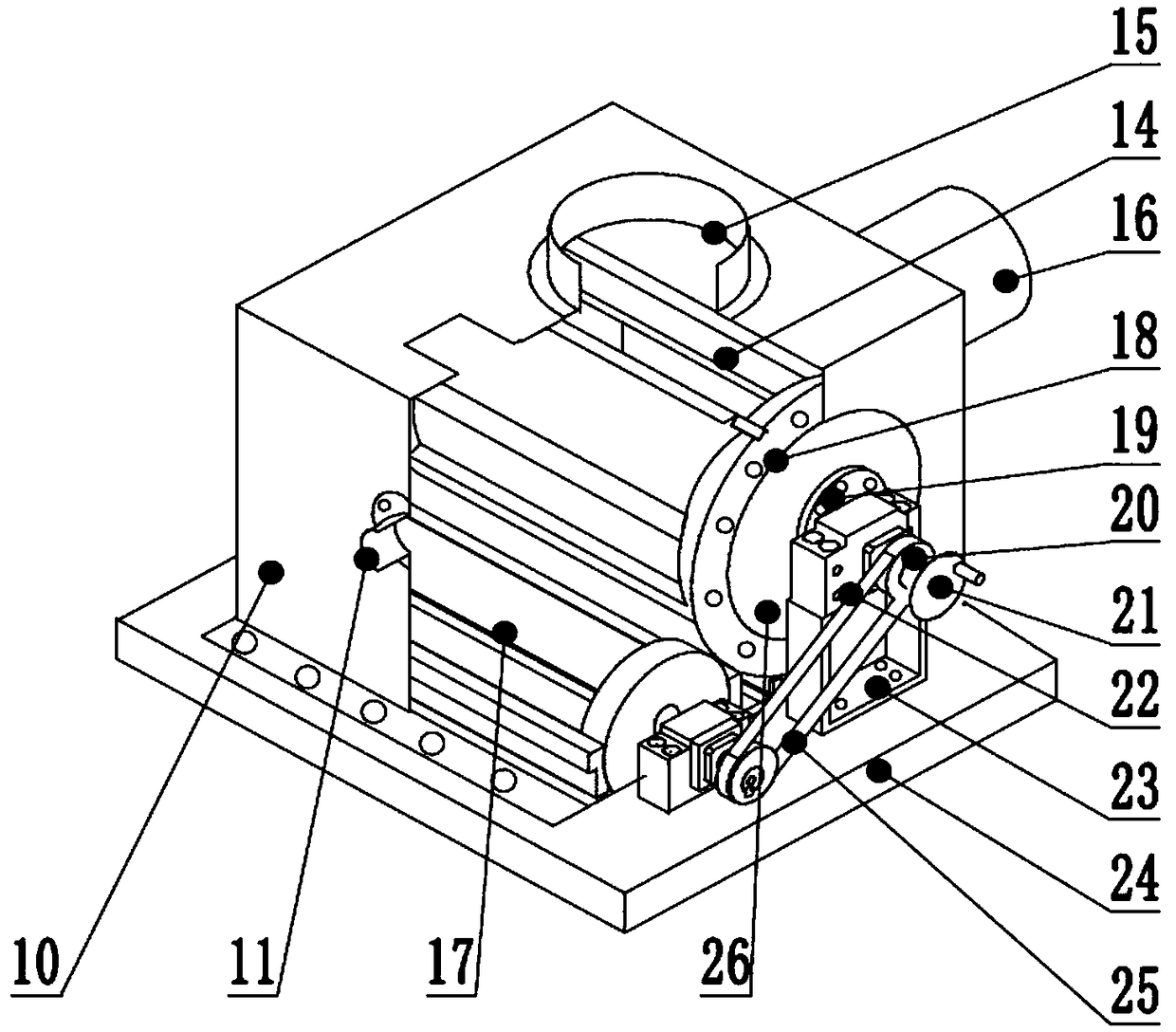

Modular dust collector system and control method thereof

PendingCN109316850AShorten the timeCut costsGas treatmentDispersed particle filtrationPush pullEngineering

The invention discloses a modular dust collector system and a control method thereof, relating to the technical field of dust collectors, in order to solve the technical problems of low on-site mounting efficiency, long construction period and high cost of existing dust collectors. In the modular dust collector system of the present invention, an air-inlet flow-guiding device is in communication with a filtering device, and the air-inlet flow-guiding device adopts a box structure and includes: a dust air inlet passage, a dust flow guide plate, and a gas flow uniform distribution board; the filtering device comprises: a dust collector dust gas box body and a dust filter bag; an air outlet device is in communication with the filtering device, wherein the filtering device is an integrated drawer-type push-pull structure; the air outlet device comprises: a dust collector purified gas box body and an air outlet channel; an ash-cleaning device is disposed in the dust collector purified gas box body, and the ash-cleaning device comprises: a reverse blowing structure and a spray-blowing pipe; an ash collecting device is communicated with the filtering device, and adopts a box structure, and the upper part region of the box structure is provided with an ash hopper and the lower part region of the box structure is provided with an ash conveying mechanism.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

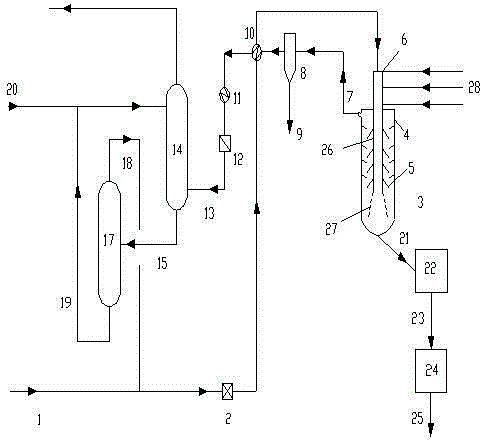

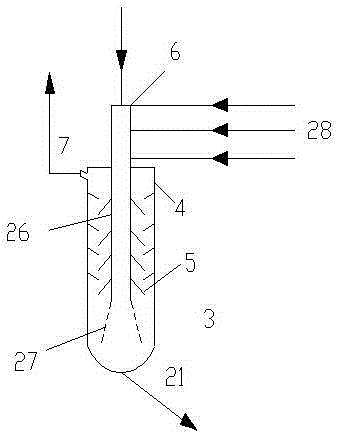

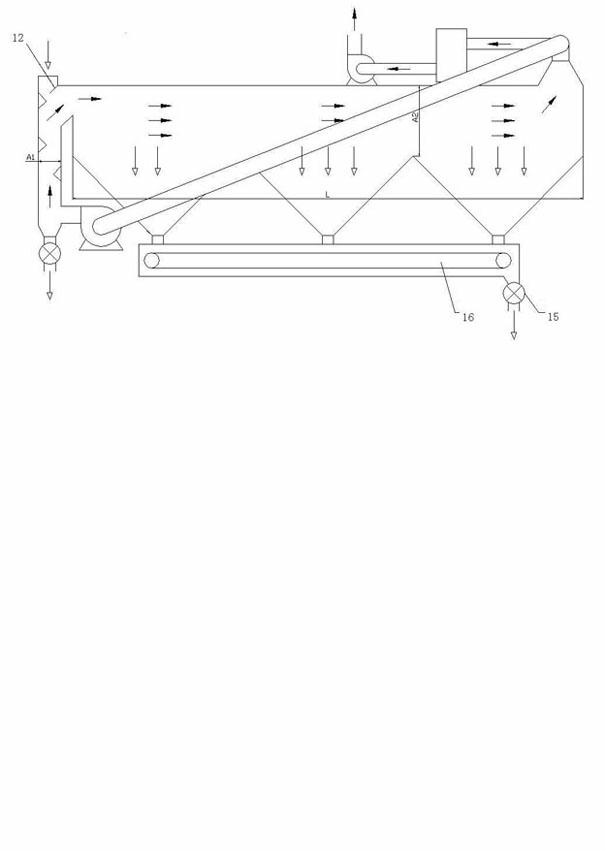

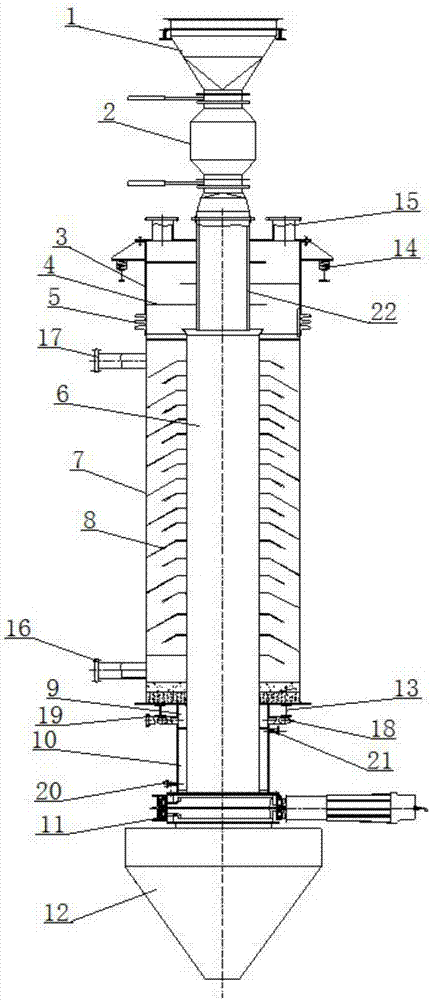

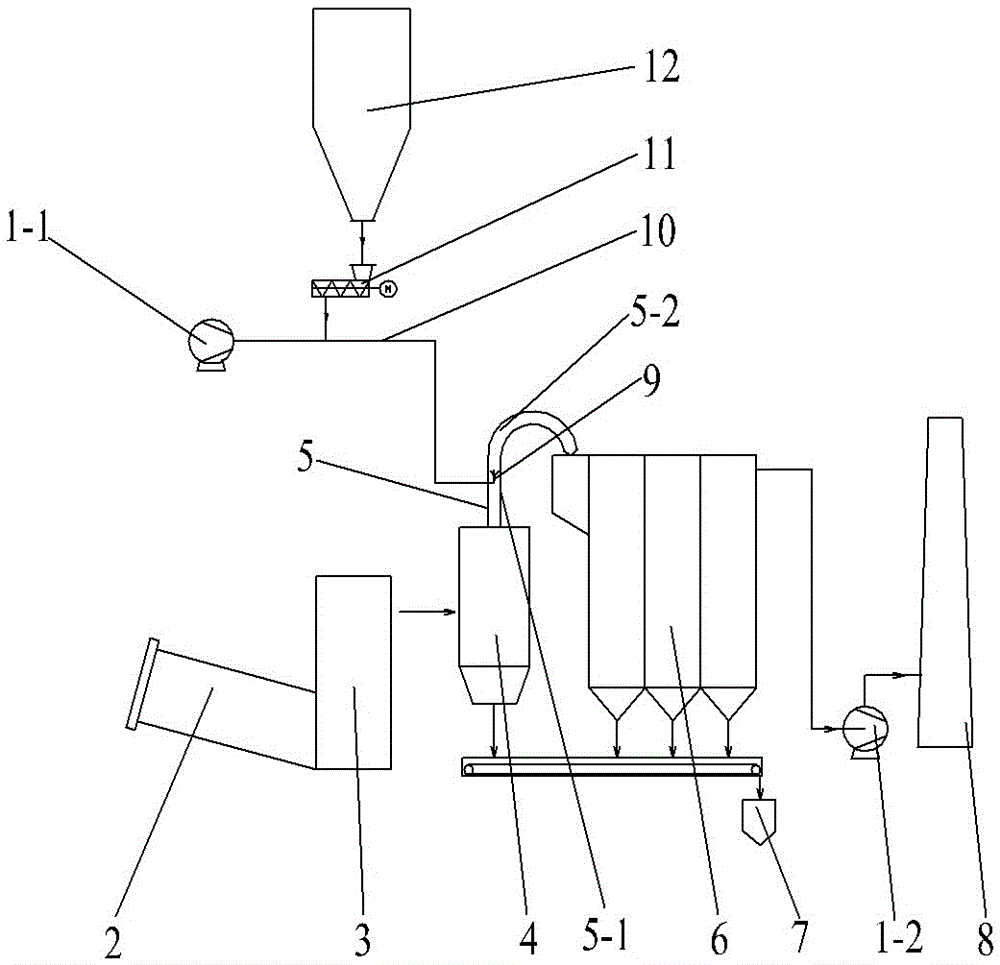

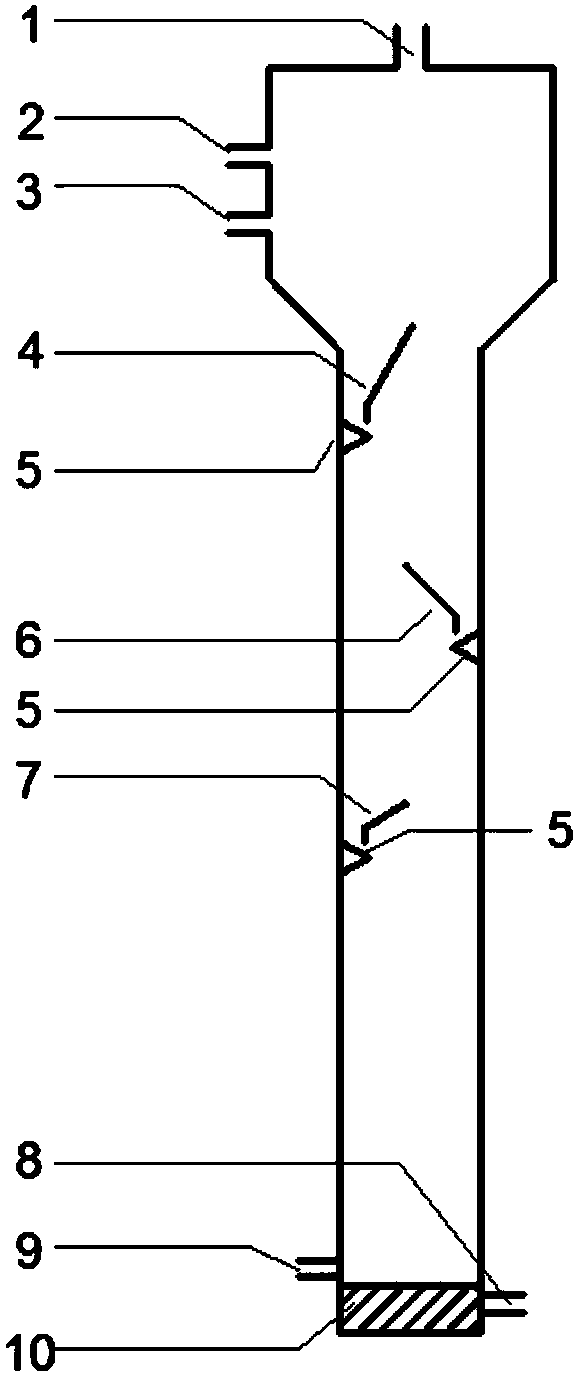

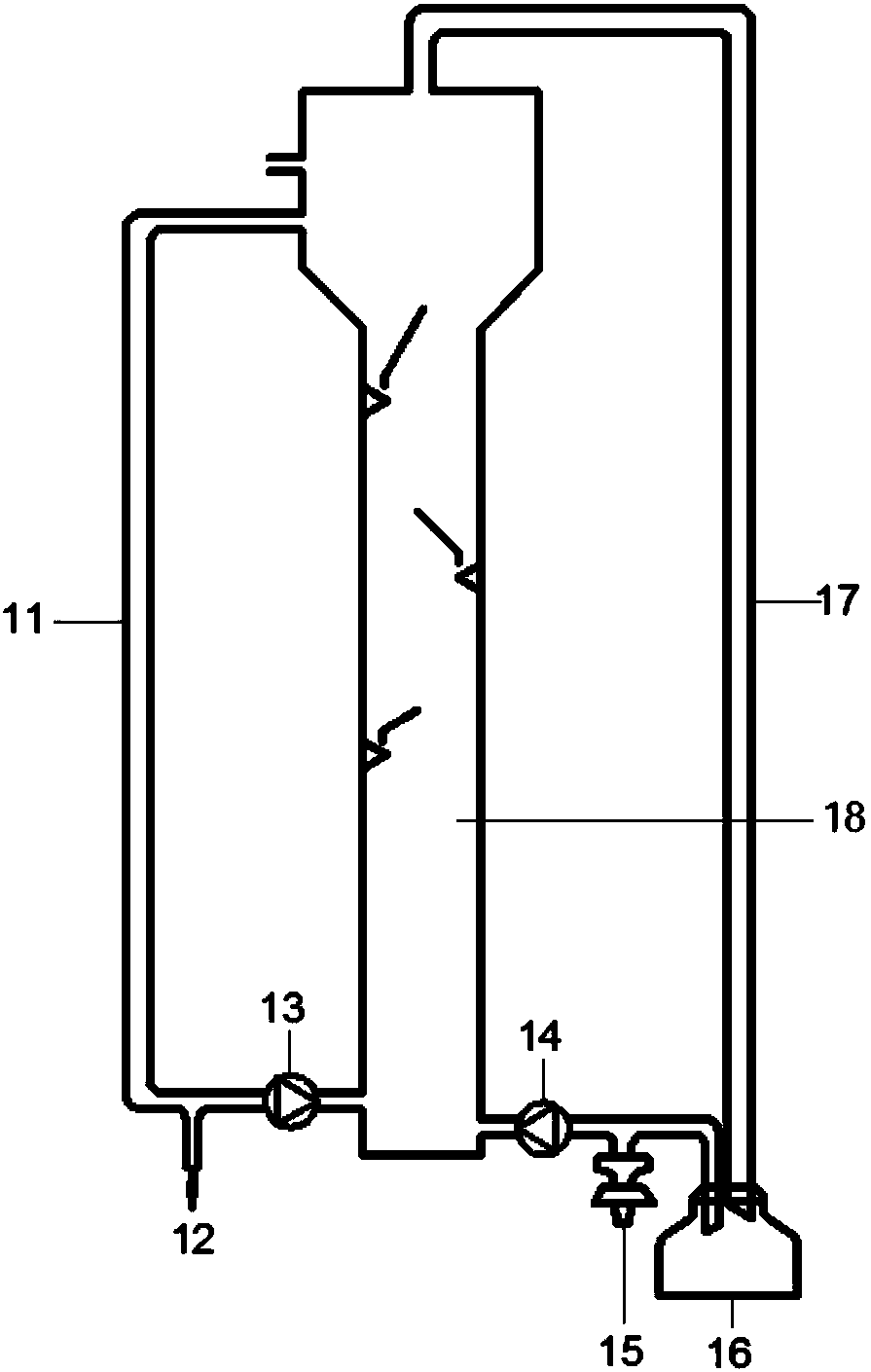

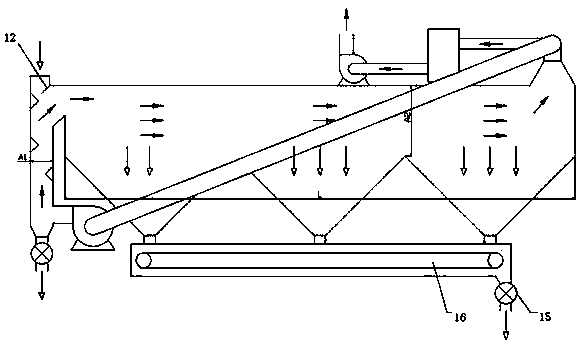

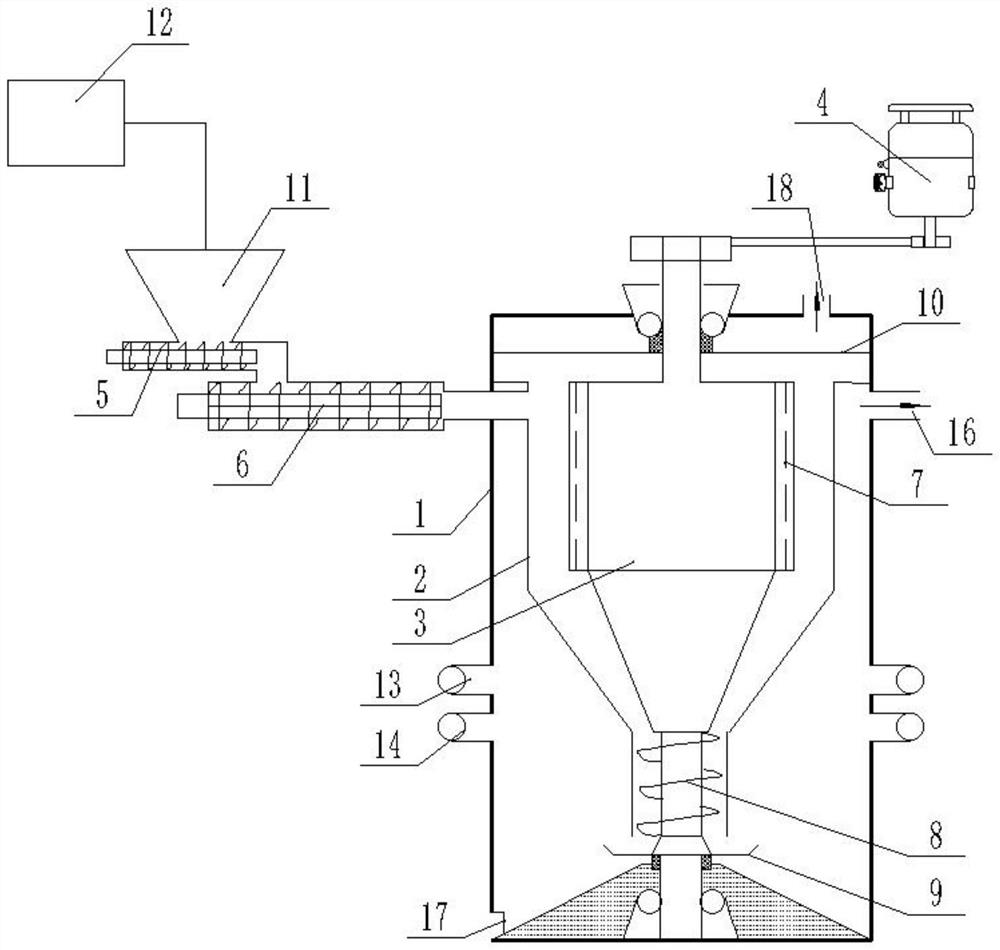

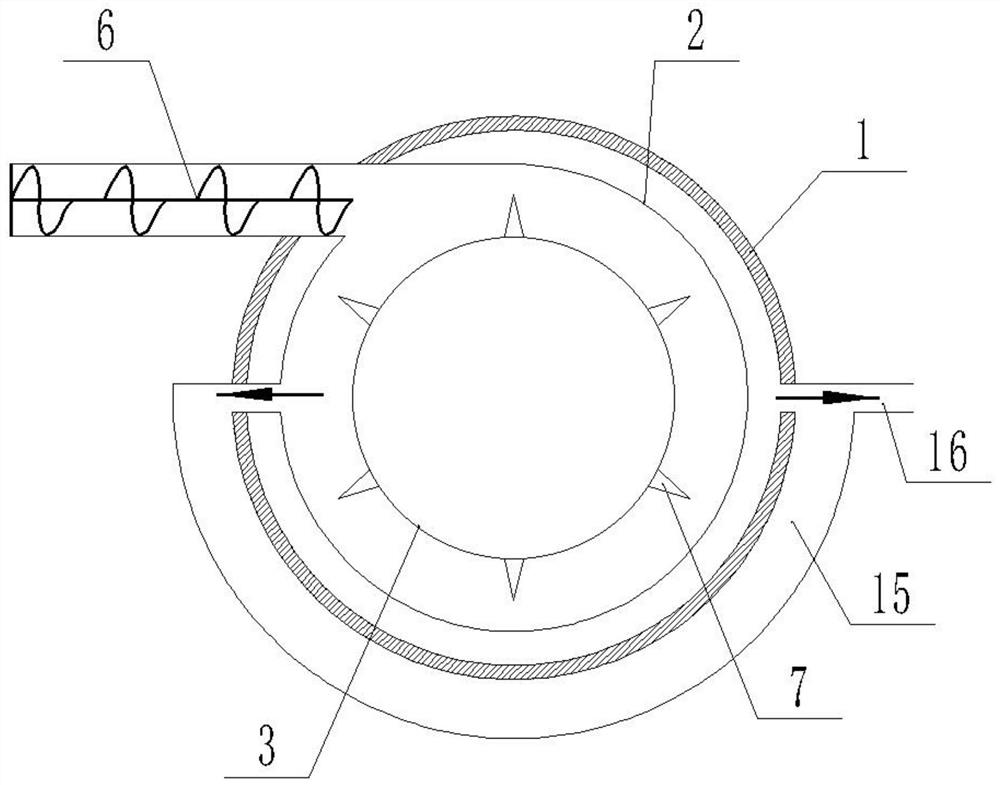

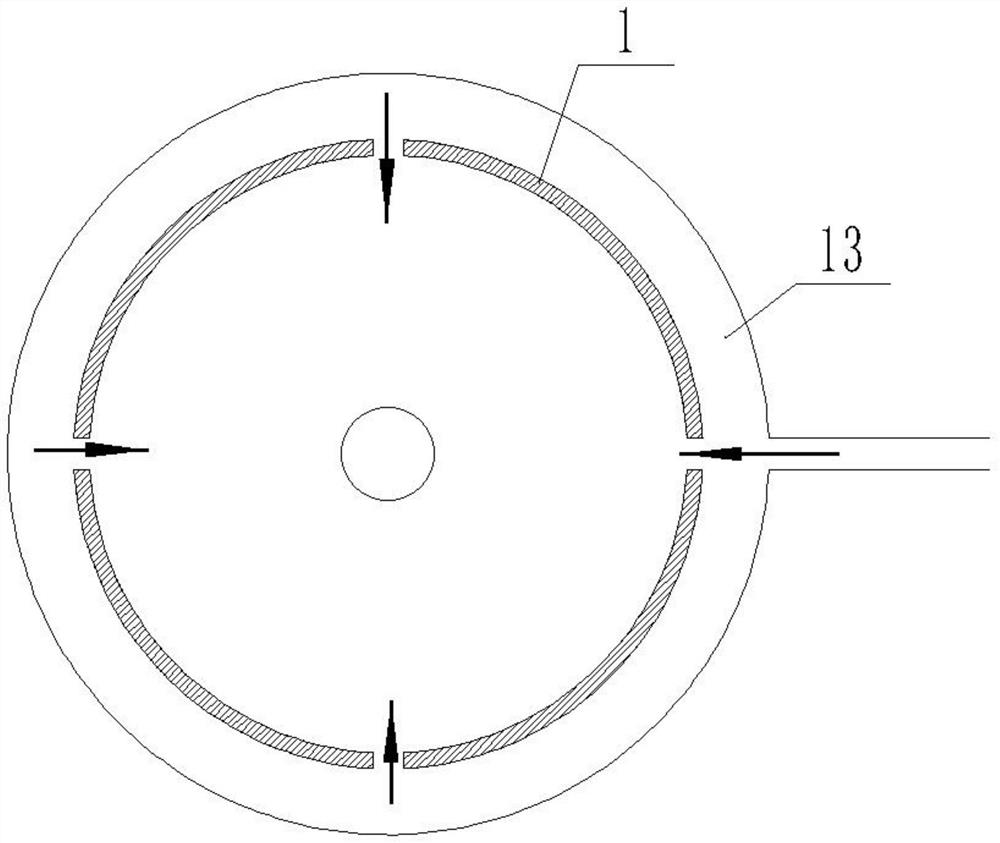

High-efficiency biomass treatment tar poly-generation pyrolysis furnace

InactiveCN107267176AReduce coking rateRealize gas-solid separationBiofuelsGasification processes detailsCooling chamberTar

A high-efficiency biomass treatment tar poly-generation pyrolysis furnace comprises a feed bunker (1), a lock bucket (2), a settling chamber (3), a reaction chamber, a cooling chamber and a discharged charcoal bunker (12), the lower end of the settling chamber (3) is connected with the reaction chamber, the lower end of the reaction chamber is connected with the cooling chamber, the bottom end of the cooling chamber is connected with the discharged charcoal bunker (12), a feed hose tube (22) is arranged in the settling chamber (3), the top end of the lock bucket (2) is connected with the outlet of the feed bunker (1), the bottom end of the lock bucket (2) is connected with the inlet of the feed hose tube (22) of the settling chamber (3), the inner wall of the settling chamber (3) is provided with a deflector separator (4), the deflector separator (4) is connected with the outer wall of the feed hose tube (23), and the top of the settling chamber (3) is provided with a pyrolysis gas outlet (15). The deflector separator (4) realizes gas-solid separation, so dusts in combustible gas are separated, the combustible gas is purified, and the coking rate of a purification system is reduced.

Owner:武汉光谷蓝焰新能源股份有限公司

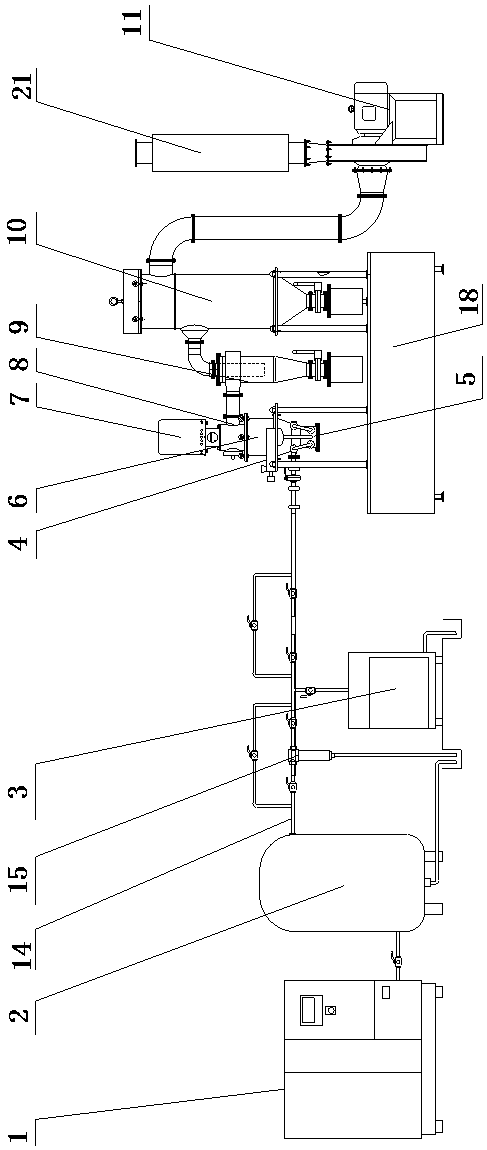

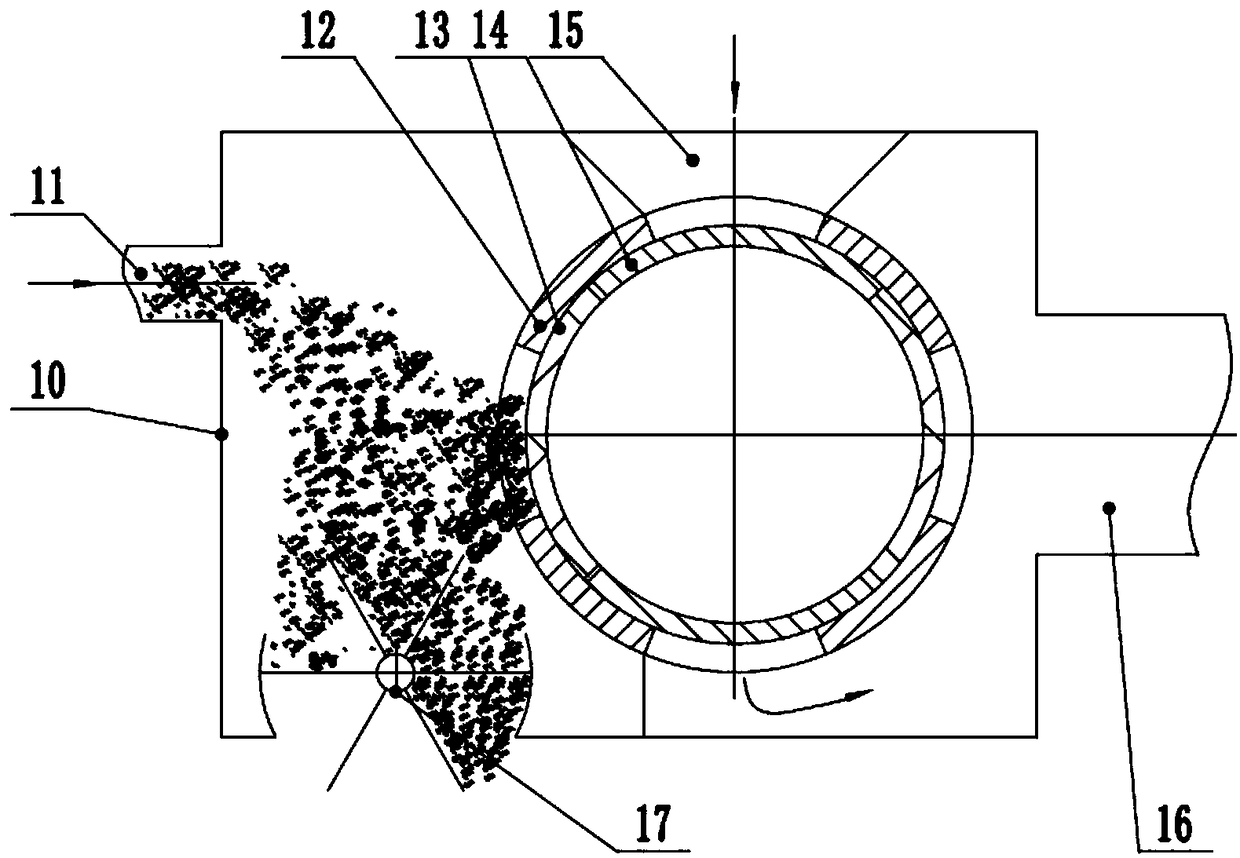

Ultrafine pulverizing and grading device for capsule drug and technical method thereof

PendingCN109731658ASmall granularityReasonable designVortex flow apparatusGrain treatmentsOil freeEngineering

The invention provides an ultrafine pulverizing and grading device for a capsule drug and a technical method thereof, and belongs to the technical field of pulverizing devices. The device comprises anair source system, an ultrafine pulverizing mechanism, a grading mechanism and a collecting mechanism, wherein the air source system comprises an oil-free air compressor, an air storing tank which isconnected to the oil-free air compressor, and an air freezing dryer which is connected to the air storing tank; the air freezing dryer is connected to the pulverizing mechanism; the ultrafine pulverizing mechanism comprises a feeder, an ultrafine pulverizing chamber which is connected to the feeder, and a first discharging port which is connected to the ultrafine pulverizing chamber; the gradingmechanism comprises a grading chamber, a grading wheel which is arranged in the grading chamber, a motor which is connected to the grading wheel, and a second discharging port which is formed in the upper part of the grading chamber; the collecting mechanism comprises a cyclone collector which is connected to the second discharging port, and a pulse reverse-blowing cloth dust collector which is connected to the cyclone collector; and the pulse reverse-blowing cloth dust collector is connected to an induced draft fan. The device is novel in structure, reasonable in design, capable of pulverizing, grading and collecting the drug in one time, and free from dust pollution.

Owner:河南福森药业有限公司

Device and method for removing dioxin in incinerator smoke carrying airflow

ActiveCN106122983AAvoid safety hazardsSave investment costGas treatmentElectrostatic separationCombustion chamberEngineering

The invention provides a device for removing dioxin in incinerator smoke carrying airflow. The device is low in cost and can be effectively suitable for removing of dioxin in high-temperature smoke, and potential safety hazards are avoided. The invention further provides a method for removing dioxin in incinerator smoke carrying airflow. The device comprises an incinerator. The incinerator is connected with a secondary combustion chamber and then communicates with an inlet of a stabilizer. An outlet of the stabilizer communicates with an electrostatic dust collector. The electrostatic dust collector communicates with an exhaust chimney through a fan I. A dust collection hopper is arranged below the electrostatic dust collector. A flue is mounted between the stabilizer and the electrostatic dust collector. Nozzles are mounted in the flue and connected with a quantitative conveying controller and a fan II through an ejection pipeline. The quantitative conveying controller is connected with an adsorbent storage bin. A modified nano activated silica adsorbent is stored in the adsorbent storage bin.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD +1

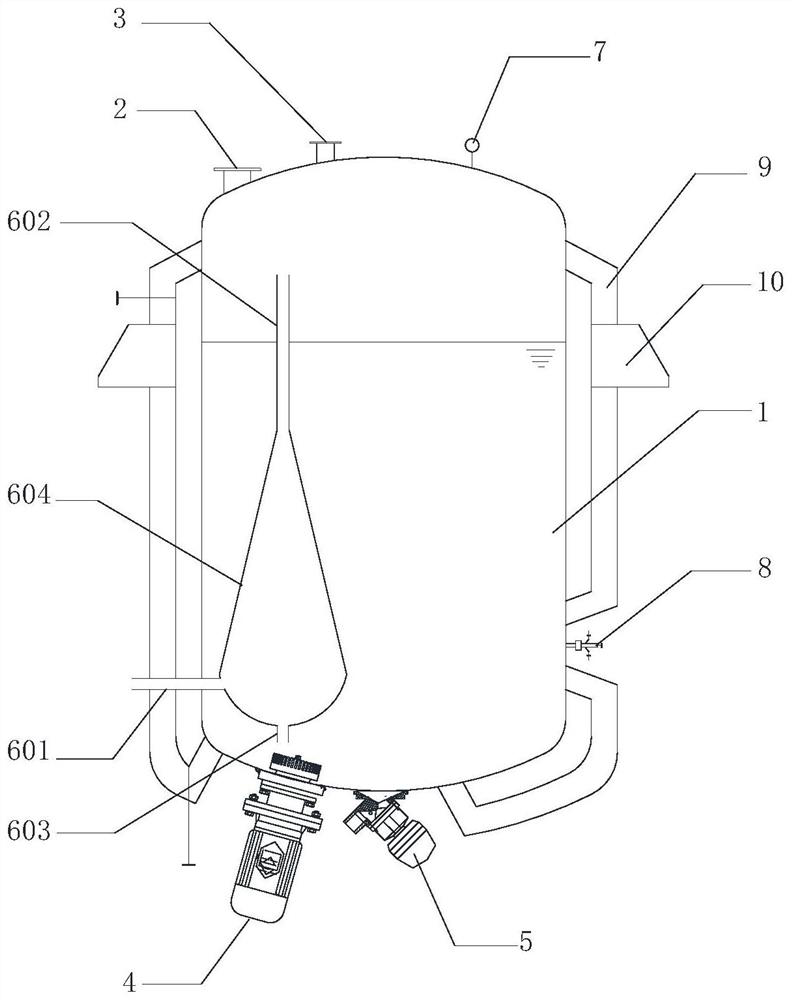

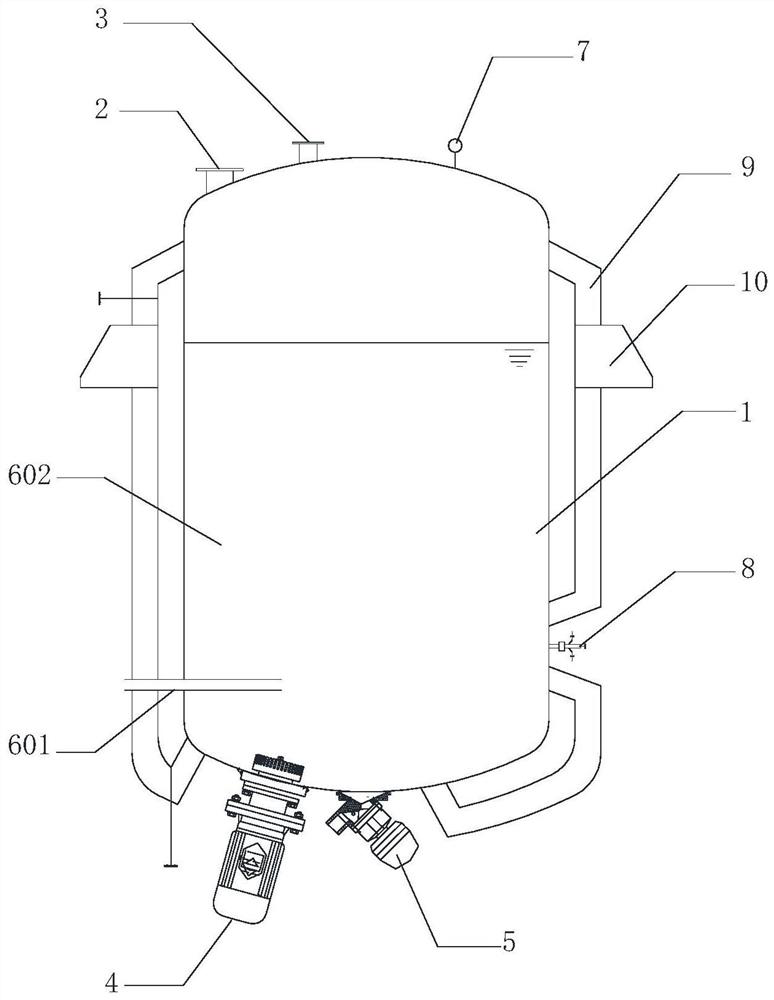

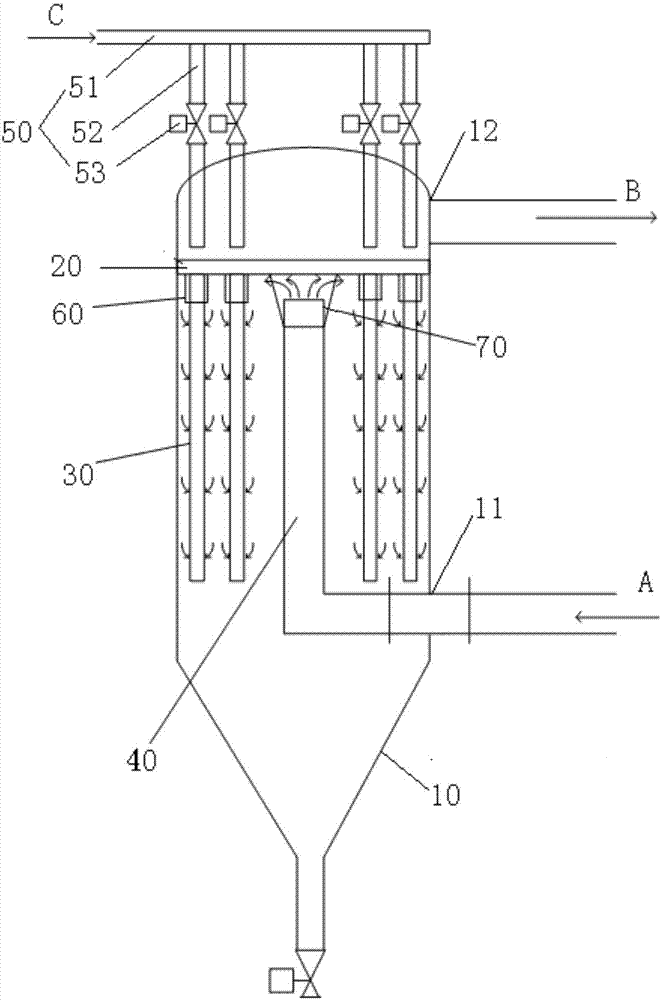

Circulation degassing fluidized bed bioreactor

ActiveCN108148739ARealize gas-solid separationSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholEngineering

The invention relates to the field of alcohol fermentation, in particular to a circulation degassing fluidized bed bioreactor which can improve fermentation efficiency and shorten fermentation period.The bioreactor comprises a reactor body, a gas circulation system and a liquid circulation system, three baffle plates with a certain height and angle and three anti-aeration plates with a certain height and angle are arranged inside the reactor body along the height direction, and immobilized particles move upwards under thrust of gas and liquid and under the buoyancy action of bubbles generatedby the immobilized particles and collide with the baffle plates to realize gas-solid separation. Liquid-solid separation is realized within a circulation area formed among the baffle plates and the anti-aeration plates. By changing hydraulic paths of gas, liquid and solid, particle loss is effectively decreased, the volume load of the bioreactor is improved, and the fermentation period is shortened. The bioreactor is simple in structure and low in manufacturing cost and has a wide popularization and application prospect in industries such as alcohol fermentation.

Owner:SHENYANG AGRI UNIV

Sample material discharging method and device and detecting system

PendingCN111762576ARealize gas-solid separationFull gas-solid separationDispersed particle filtrationControl devices for conveyorsThermodynamicsProcess engineering

The invention relates to the technical field of metallurgical equipment, in particular to a sample material discharging method and device and a detecting system. The sample material discharging devicecomprises a feeding opening and a discharging opening. The device further comprises at least one gas and solid separating mechanism connected between the feeding opening and the discharging opening,a negative pressure generating mechanism and a sealing cover, wherein the negative pressure generating mechanism communicates with the gas and solid separating mechanism and is used for enabling a negative pressure environment to be formed in the gas and solid separating mechanism, the sealing cover is arranged between the gas and solid separating mechanism and the discharging opening, the sealingcover is used for being in the closing state under the effect of the negative pressure environment, and partitioning the gas and solid separating mechanism from the discharging opening, and the sealing cover is in the opening state when the negative pressure environment disappears, and communicating the gas and solid separating mechanism with the discharging opening. According to the method and the device, the operation efficiency of the device can be improved, the maintaining and repairing process of the device is simplified, and thus production and sample detecting efficiency is improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Dust removal filtering device and method

ActiveCN105688522ARealize gas-solid separationReduce loadDispersed particle filtrationTransportation and packagingFilter elementWaste management

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

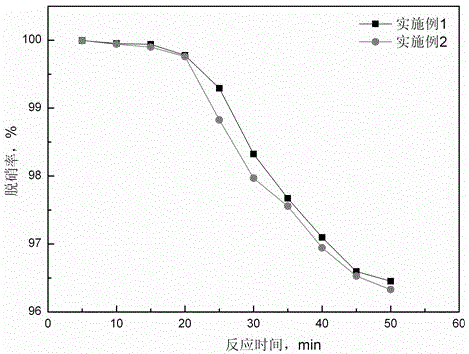

Denitration agent for flue gas denitrification as well as preparation method and application of denitration agent

InactiveCN105107368ALow priceContinuous recyclingDispersed particle separationCalcium hydroxideFlue gas

The invention discloses a denitration agent for flue gas denitrification as well as a preparation method and an application of the denitration agent. According to the denitration agent and the preparation method, titanium dioxide, attapulgite clay or imvite particles are adopted as an inert carrier, calcium hydroxide and yttrium hydroxide are dissolved into glycerol so that calcium hydroxide and yttrium hydroxide react with a sulphur source so as to generate denitration agent particles; the denitration agent particles react with NOx gas in flue gas in a denitration reactor, so as to reduce the NOx gas into non-toxic and harmless N2 gas, after reaction, the denitration agent is fluidized and then enters into another reactor to react with gasified synthetic gas inside the reactor, so as to be regenerated into denitration agent particles with denitrification property, then the denitration agent particles return to the denitration reactor. The denitration agent as well as the preparation method and the application thereof have the advantages that the preparation process is simple in technology, strong in controllability, safe and reliable, and free of secondary pollution, the prepared denitration agent is high in denitration efficiency, and the technical problems that in the denitration process in the prior art, the catalyst is high in price and difficult to recycle, and the like are solved.

Owner:田红景

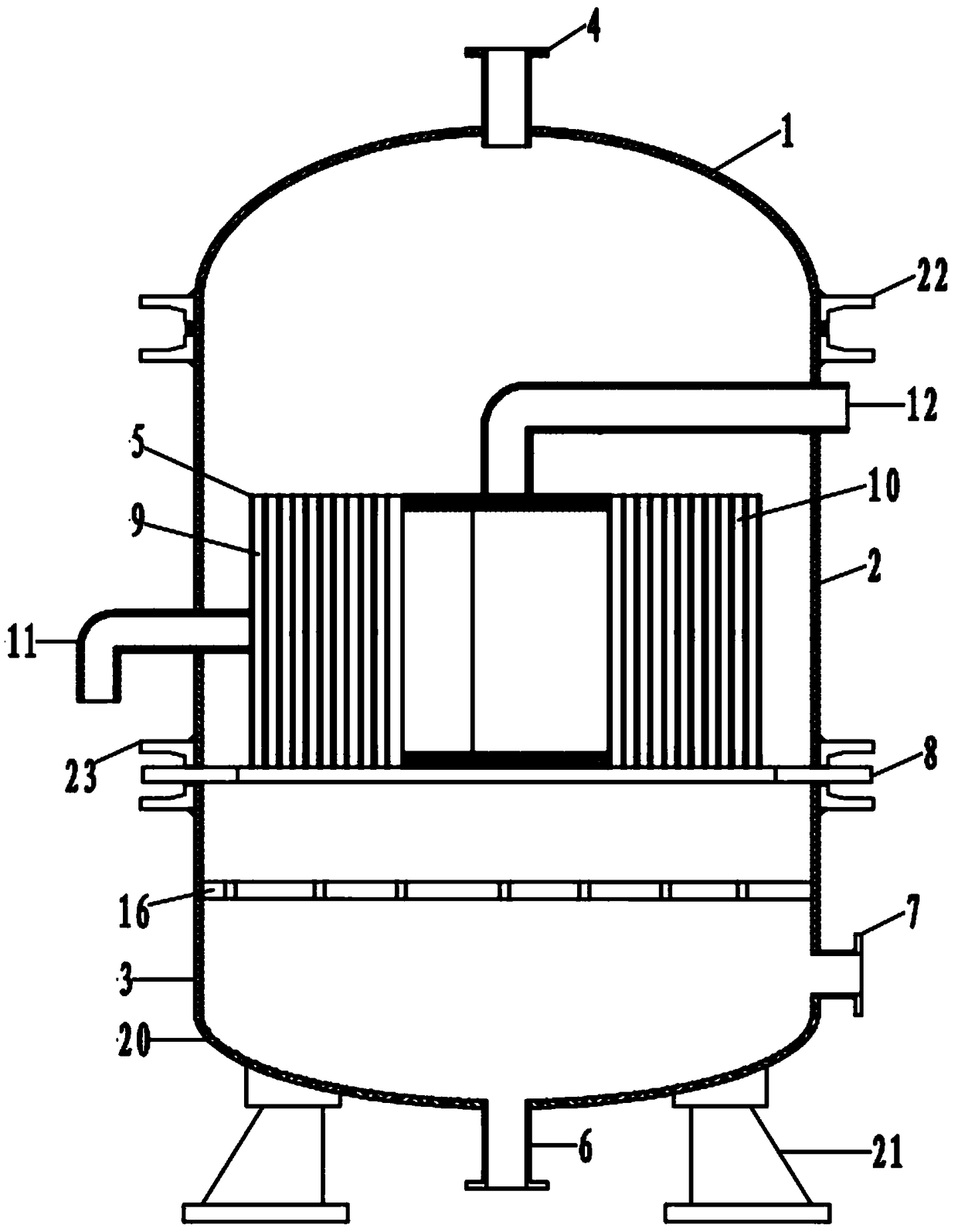

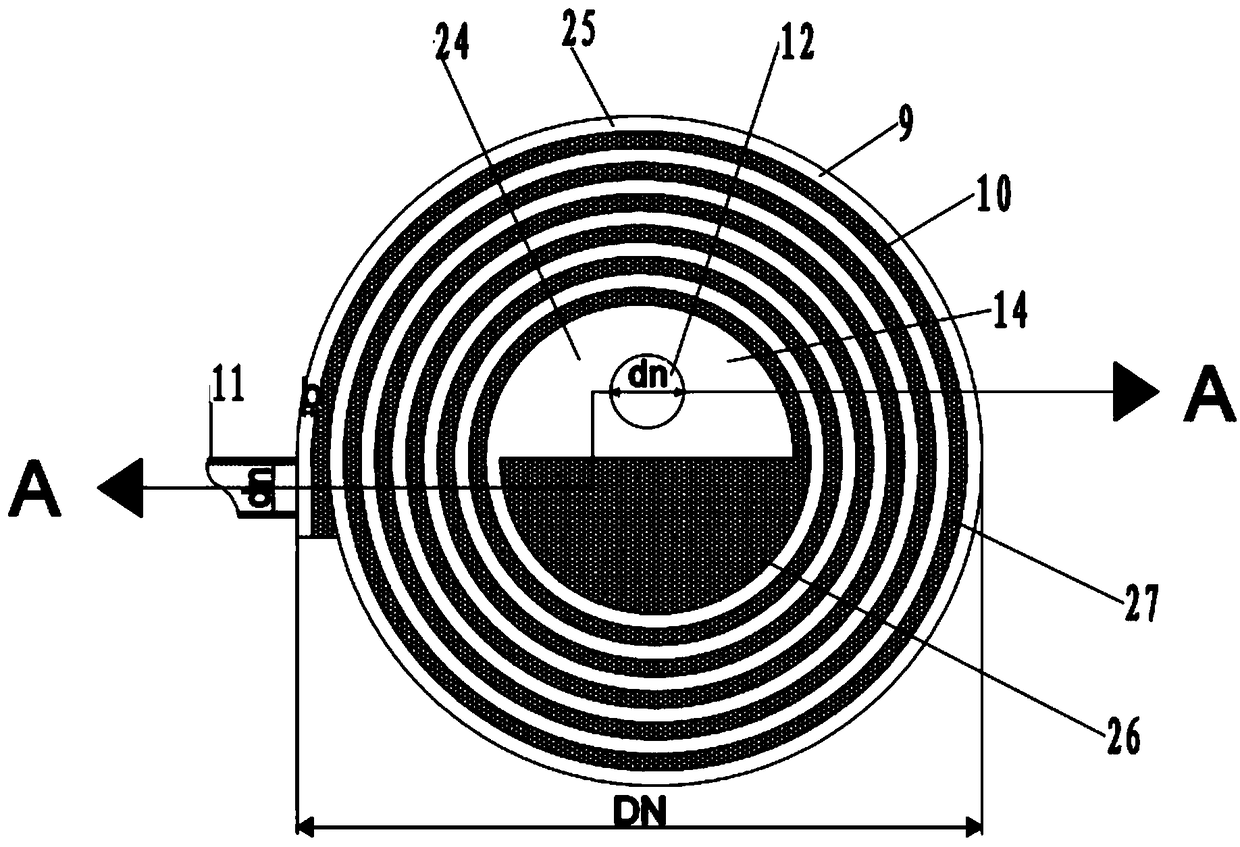

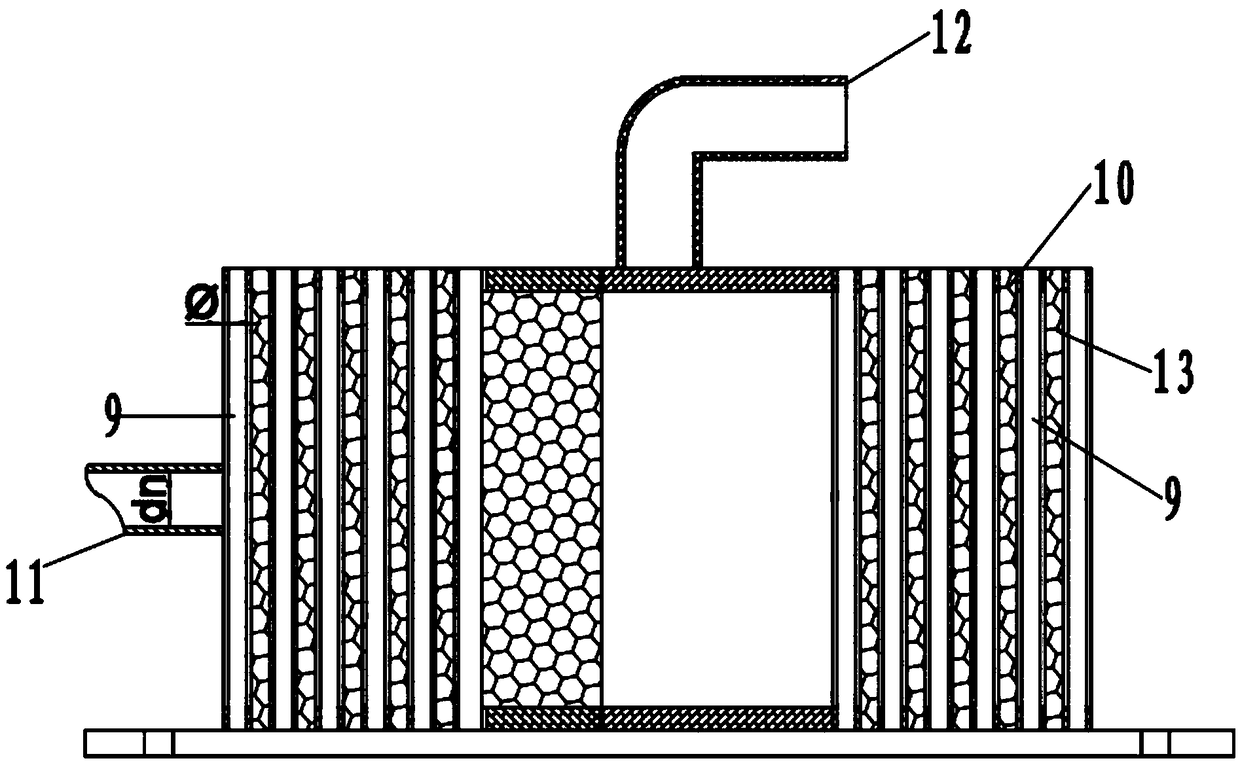

Spiral plate type thermochemical high-temperature energy storage and release reaction device

PendingCN108627041AUniform heating effectUniform cooling effectSolar heating energySolar heat storageThermal energyWater vapor

The invention relates to the technical field of high-temperature heat energy storage, and discloses a spiral plate type thermochemical high-temperature energy storage and release reaction device whichcomprises a shell. A water steam outlet is formed in the upper end of the shell. A drain outlet is formed in the bottom of the shell. A water steam inlet is formed in the lower end of the shell. A grid plate and a reactor are arranged in the shell. The reactor comprises a first spiral channel and a second spiral channel. The first spiral channel and the second spiral channel are wound and adheredtightly in parallel. The inlet end of the first spiral channel is connected with one end of an inlet pipe. The other end of the inlet pipe penetrates out of the side wall of the second shell. The outlet end of the first spiral channel is connected with one end of an outlet pipe. The other end of the outlet pipe penetrates out of the side wall of the second shell. The spiral plate type thermochemical high-temperature energy storage and release reaction device has the beneficial effects that the reaction device is provided with two long spiral channels, a fluid can be uniformly heated and cooled in the fluid spiral channel, the structure is compact, and the heat utilization rate is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Powder selecting and collecting device

ActiveCN102366745BAchieve separationRealize the collectionGas current separationDispersed particle separationAir velocityEngineering

The invention discloses a powder selecting and collecting device, which comprises a powder selecting pipe and a powder collecting pipe, wherein the upper part of the powder selecting pipe is provided with a feeding hole; the lower end of the powder selecting pipe is provided with a discharging hole; the powder selecting pipe and the powder collecting pipe are communicated with each other; the powder selecting pipe is arranged obliquely to the horizontal surface; the included angle alpha between the powder selecting pipe and the horizontal surface is more than or equal to 45 degrees and less than or equal to 90 degrees; the powder collecting pipe is arranged horizontally; the lower end of the powder selecting pipe is provided with an air inlet; the powder collecting pipe is provided with an air outlet far away from one end which is communicated with the powder selecting pipe; and the air outlet is connected with a draught fan. In the device, high air speed required by a powder selecting process of a centrifugal separating technology is not required, the aims of selecting powder and subsequently collecting powder can be fulfilled by setting the air speed at 2 meters per second in the powder selecting pipe, and the energy consumption is lowered; mostly importantly, powder selection and powder collection are performed in the powder selecting pipe and the powder collecting pipe which are communicated with each other but are not interfered with each other, so that the influence of airstream flow during centrifugal separation on powder collection is avoided, and the powder selecting and powder collecting efficiencies are increased; and the overall pressure loss of the device does not surpass 100 Pa which is only 5-10 percent of the pressure loss of the conventional centrifugal separation powder selecting system, and the energy-saving effect is remarkable.

Owner:卓卫民

A dust removal and filtering device and method

ActiveCN105688522BRealize gas-solid separationReduce loadDispersed particle filtrationTransportation and packagingEngineeringFilter element

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

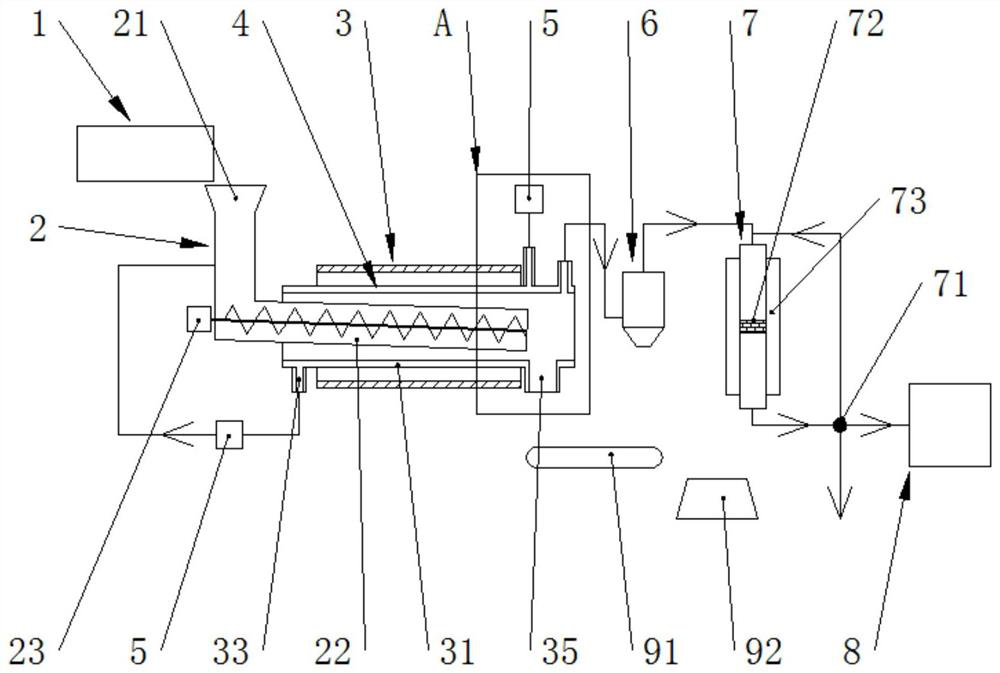

Self-heating vertical axial flow roller ablation pyrolytic reaction device

ActiveCN113025354AReduce moistureReduce oxygen contentBiofuelsEnergy inputThermodynamicsHeat carrier

The invention relates to a self-heating vertical axial flow roller ablation pyrolytic reaction device, and belongs to the technical field of renewable energy utilization. The device comprises a shell and a reaction cylinder arranged in the shell, a rotating shaft is arranged in the reaction cylinder, the upper end of the rotating shaft is connected with a variable frequency motor through a belt, the rotating speed of the rotating shaft can be adjusted, a first-stage spiral feeder and a second-stage spiral feeder are arranged outside the shell, the discharging end of the first-stage spiral feeder is communicated with the feeding end of the second-stage spiral feeder, and the discharging end of the second-stage spiral feeder is communicated with the upper part of the reaction cylinder. The device has the beneficial effects that the pyrolysis efficiency is improved, pushing of carrier gas and heating of a heat carrier are not needed in the reaction process, and the heating and cooling loads of the carrier gas are greatly reduced. Self-heating in the pyrolysis process is achieved, and effective utilization of energy is fully achieved. Different taper angles can adapt to the change of the size of the material, powdery, granular and other biomass raw materials can be pyrolyzed, and gas-solid separation and biomass pyrolysis can be better achieved.

Owner:SHANDONG UNIV OF TECH

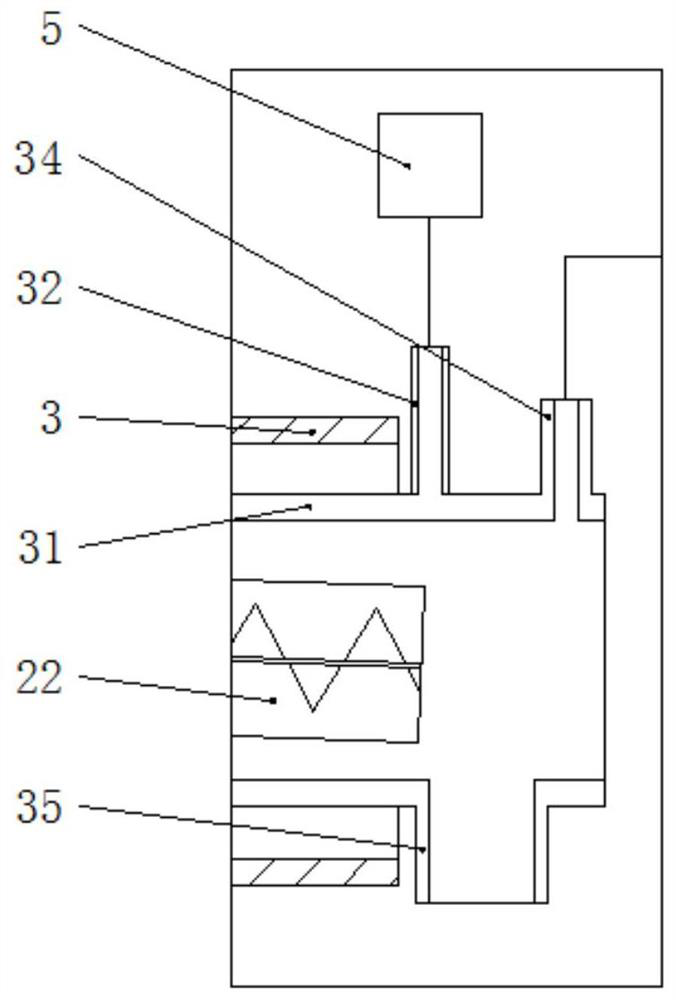

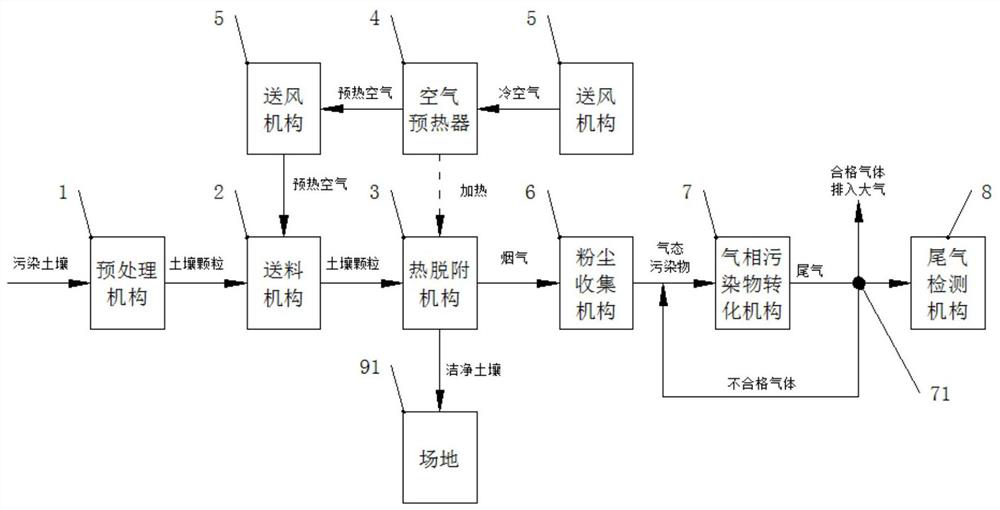

Fire disaster soil pollutant treatment device for electrical equipment of transformer substation

InactiveCN113275370AIngenious structureSimple structureGas treatmentDispersed particle separationAir preheaterTransformer

The invention relates to a fire soil pollutant treatment device for electrical equipment of a transformer substation. The fire soil pollutant treatment device comprises a pretreatment mechanism, a feeding mechanism, a thermal desorption mechanism, an air preheater, a dust collection mechanism, a gas-phase pollutant conversion mechanism and a tail gas detection mechanism; the pretreatment mechanism is positioned in front of the feeding mechanism; the feeding mechanism is arranged in the thermal desorption mechanism in a sleeving manner; the air preheater is embedded in the thermal desorption mechanism; a discharge hole of the feeding mechanism just faces the tail end of the thermal desorption mechanism; the tail end of the thermal desorption mechanism, the dust collection mechanism and the gas-phase pollutant conversion mechanism are sequentially communicated with one another through a pipeline; the tail end of the pipeline at the outlet end of the gas-phase pollutant conversion mechanism is communicated with a four-way valve; and one way of the four-way valve is communicated with the tail gas detection mechanism through a pipeline, one way of the four-way valve is communicated with the atmosphere through a pipeline, and the last way of the four-way valve is communicated with a pipeline arranged between the dust collection mechanism and the gas-phase pollutant conversion mechanism through a pipeline.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +4

A new hydrogen production method and system

ActiveCN106629592BImprove conversion rateHigh yieldGas treatmentDispersed particle separationIron powderDecomposition

The invention provides a hydrogen production method. The method comprises the steps of enabling feed gas to enter a pyrolysis reactor in presence of iron powder so as to have reaction, and then separating reaction effluent to obtain a gas phase material and a solid phase material; enabling the gas phase material to enter a sulfur catcher for recovering elemental sulfur, and then enabling the gas phase material without the elemental sulfur to enter a desulfurization device and react with an absorbent to obtain hydrogen-rich gas and rich absorbing liquid; enabling the rich absorbing liquid to enter a regeneration tower to obtain a regenerated absorbent and desorbed gas; sending the solid phase material into a magnetic field separator, and separating to obtain ferrous sulfide and the iron powder. The invention also provides a hydrogen production system. After the hydrogen production method and the hydrogen production system are adopted, the decomposition rate of H2S is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for removing acid gases in garbage incineration smoke at high temperature

ActiveCN102716643BTake advantage ofImprove removal efficiencyDispersed particle separationAir preheaterSorbent

The invention discloses a device for removing acid gases in garbage incineration smoke at the high temperature. The device comprises a material separation hopper, a primary feed hopper, a secondary feed hopper, a tertiary feed hopper, a primary cross flow moving bed reactor, a secondary cross flow moving bed reactor, a tertiary cross flow moving bed reactor, a primary adjustable star discharge device, a secondary adjustable star discharge device, a tertiary adjustable star discharge device, a smoke inlet, a smoke outlet, a recovery bin, a drier, an implementing bin, a fresh material implementing bin, a garbage incineration smoke pipeline and an air preheater. The invention further discloses a method for removing the acid gases in the garbage incineration smoke at the high temperature. According to the invention, multiple stages of cross flow moving bed reactors are adopted, the garbage incineration smokes at moderate and high temperatures sequentially pass through the cross flow moving bed reactors and are in contact with adsorbents in the reactors to perform multi-stage deep acid gas removal, reduce corrosion and blockage by the acid gases on pipelines and equipment, and achieve the exhaust of the garbage incineration smoke in a purifying way.

Owner:SOUTHEAST UNIV

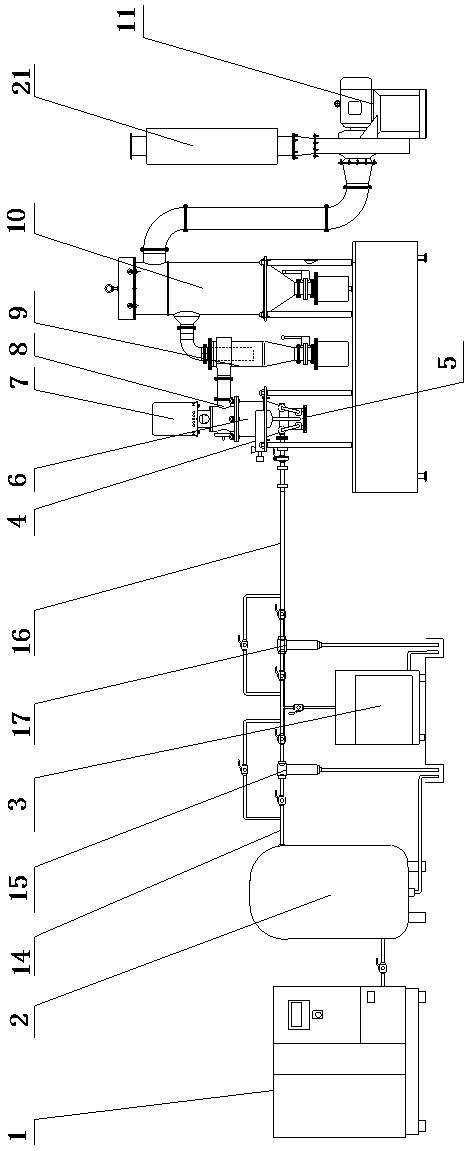

Buffer transition bin of foamed plastic vehicle-mounted cold pressing briquetting device

PendingCN111571861ASolve the problem of unsynchronized ergonomicsImprove processing efficiencyGas treatmentDispersed particle filtrationIn vehicleStructural engineering

The invention discloses a buffer transition bin of a foamed plastic vehicle-mounted cold pressing briquetting device. The buffer transition bin is arranged between a foamed plastic crushing device anda cold pressing device, and comprises a bin body and a conveying device, wherein the conveying device comprises a guide plate arranged on the bin body, an air supply feeding device and an exhaust device; the guide plate is arranged in an inner cavity of the bin body, and is provided with multiple guide gaps; the guide gaps communicate with the air supply feeding device; the exhaust device comprises an exhaust port formed in the bin body, and an isolation piece for preventing crushed foamed plastic from floating out from the exhaust port; and the isolation piece communicates with the exhaust port through an air way. The buffer transition bin can realize transition conveying of the foamed plastic between the crushing device and an extrusion device, and can quickly feed the foamed plastic into the extrusion device to improve the foamed plastic recovery efficiency.

Owner:广东致顺化工环保设备有限公司

A conveying experimental device for measuring the pneumatic conveying performance of expanded graphite bulk materials

The invention relates to a conveying experimental device for pneumatic conveying performance measurement of an expanded graphite loose material. The conveying experimental device comprises a hopper, a gas-solid separator, a negative pressure fan and a conveying pipeline and an adjusting detection device. The conveying pipeline is connected to the hopper and the gas-solid separator, a mixing proportional valve and a first negative pressure gauge are arranged in a position where the hopper is connected, a second negative pressure gauge is arranged on the right side, connected to the inlet of the gas-solid separator, of the conveying pipeline, and the right air outlet of the gas-solid separator is connected to the negative pressure fan through the adjusting detection device; in the gas-solid separator, a rotating screen with a minigroove metal net and a fixed sleeve in clearance fit form a gas-solid separating structure; the gas-solid separator comprises a sealed box body, the fixed sleeve, the minigroove metal net, the rotating screen, a star discharger, a rotating shaft and a bearing pedestal. The conveying experimental device provided by the invention solves the problems that the expanded graphite is liable to block the pipeline and the material is broken by means of an existing vacuum sucking and feeding mode, and meanwhile, the conveying experimental device can collect pneumatic conveying performance parameters of the expanded graphite particles in real time, thereby providing test equipment and method for researching pneumatic conveying basic data of ultralight loose materials.

Owner:YANSHAN UNIV

Device and method for removing dioxins from incinerator flue gas carried by airflow

ActiveCN106122983BAvoid safety hazardsRealize gas-solid separationGas treatmentElectrostatic separationCombustion chamberFlue gas

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD +1

A hydrogen production process method and system

ActiveCN106629593BPromote positive progressImprove conversion rateHydrogen productionProcess systemsGas phase

The invention provides a hydrogen production process method. According to the hydrogen production process method, raw material gas enters a pyrolysis reactor and is subjected to a reaction in the presence of iron powder, the reaction effluent is separated to obtain a gas phase material and a solid phase material, the gas phase material is recovered by a sulfur collector to obtain elemental sulfur, the obtained gas phase material enters desulfurization equipment and reacts with an absorbent to obtain a hydrogen-rich gas and a rich absorption liquid, the rich absorption liquid enters a regeneration tower to obtain a regenerated absorbent and desorption gas, and the solid phase material enters a magnetic field separator and is separated t obtain ferrous sulfide and iron powder. The present invention further provides a hydrogen production process system. With the method and the system f the present invention, the H2S decomposition rate can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com