A detachable plate type indirect heating coal pyrolysis device

A coal pyrolysis and indirect technology, applied in the field of coal quality improvement, can solve the problems of not obvious improvement of heat transfer efficiency, affecting product quality, affecting heat exchange efficiency, etc., to ensure high efficiency and sustainability, and to facilitate cleaning and replacement , Increase the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

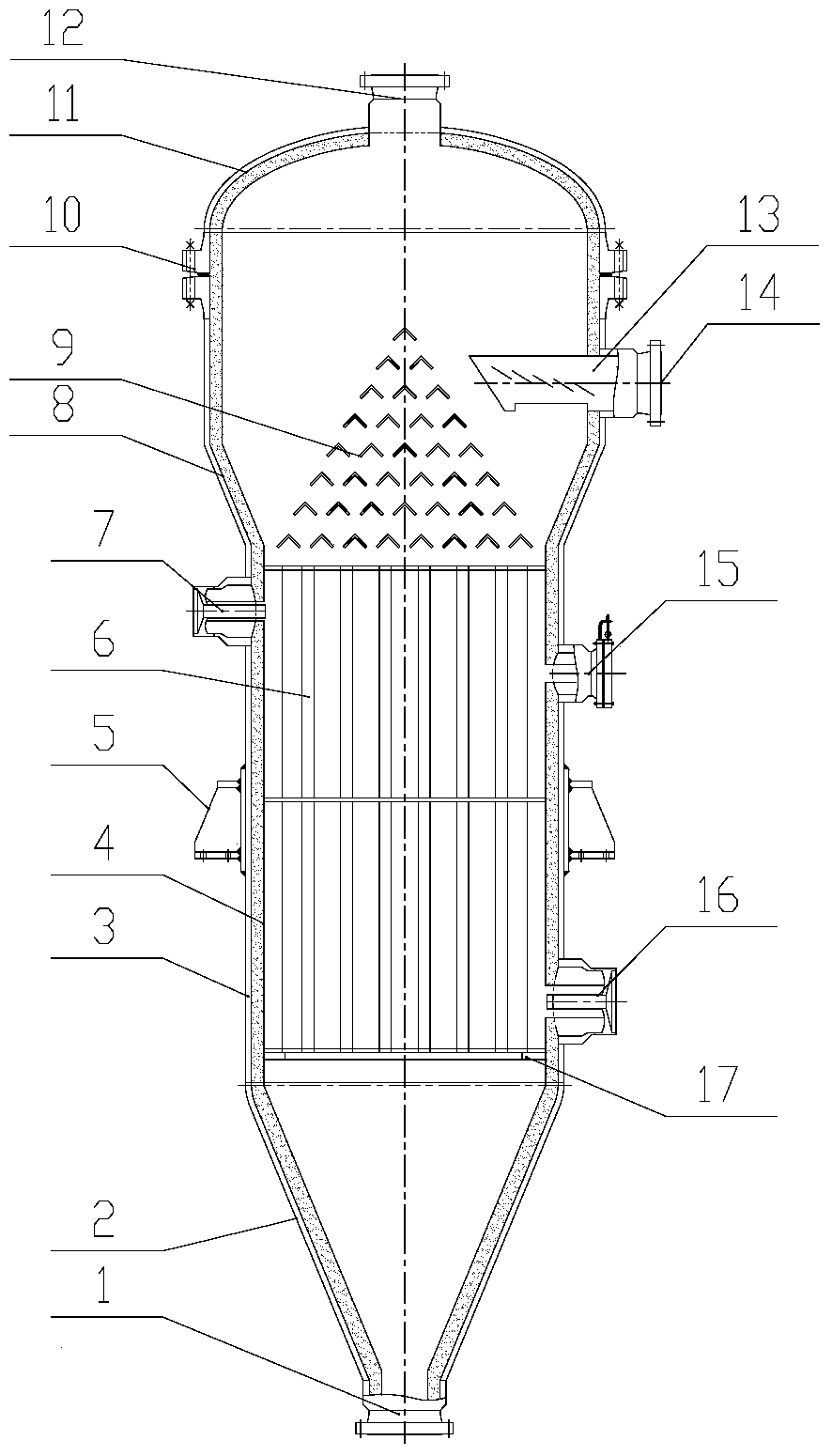

[0039] Please refer to figure 1 , figure 1 It is a structural schematic diagram of the coal pyrolysis device of the present invention.

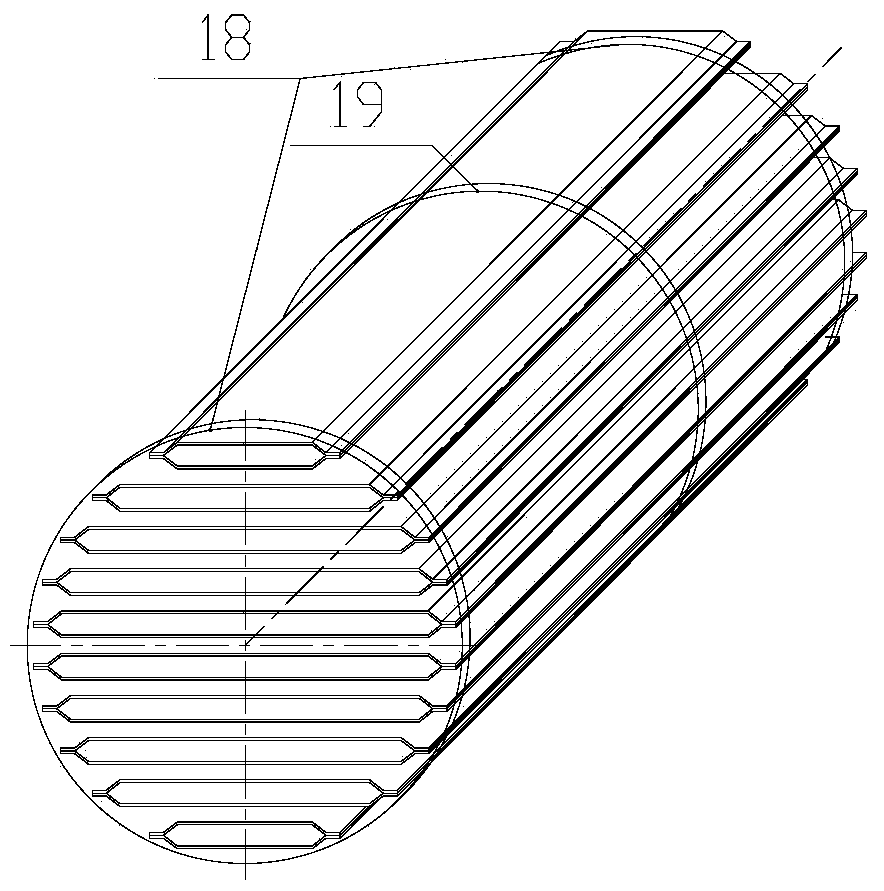

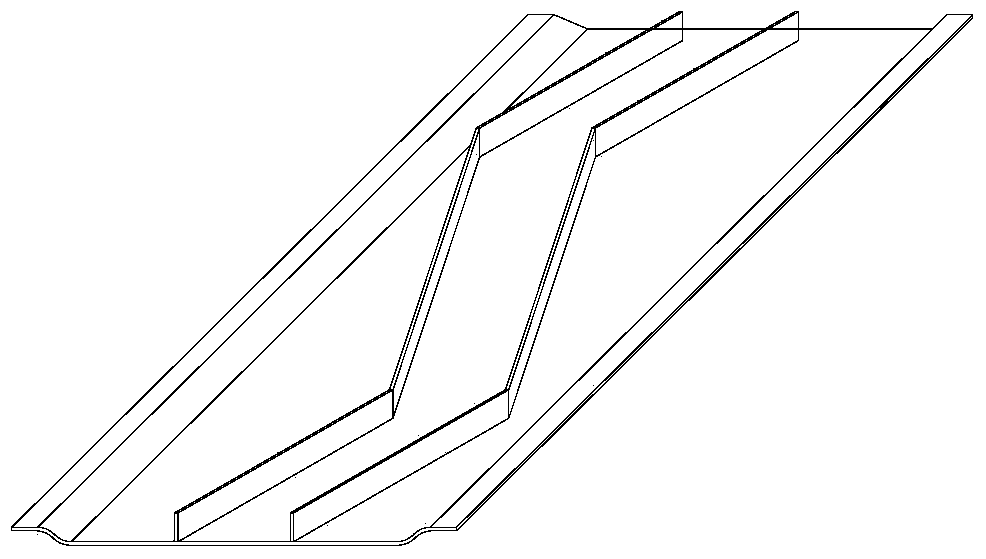

[0040] The present invention provides a detachable plate-type indirect heating coal pyrolysis device, which includes a shell, a coal distributor 9 and a detachable modular heat exchange system.

[0041] The shell is composed of a lower head 2 , a lower cylinder 3 , an upper cylinder 8 and an upper head 11 . Among them, the lower head 2 is funnel-shaped, and the lower cylinder 3 is a cylinder. The lower head 2 and the lower cylinder 3 are welded into one body according to the requirements of the pressure vessel. The material port 1, the lower part of the lower cylinder body 3 is provided with a high-temperature gas inlet 16, and the upper part is provided with a high-temperature gas outlet 7 and a manhole 15. The upper cylinder 8 has an enlarged section, the diameter of which is larger than that of the lower cylinder 3, and the upper head 1...

Embodiment 2

[0047] The preferred embodiment of the present invention is the cogeneration process of lignite pyrolysis gasification, mainly using the synthetic gas produced by dry coal gasification as the heat source of lignite pyrolysis, and the high temperature and high pressure semi-coke produced by lignite pyrolysis is directly fed into the gas Furnace as raw material for gasification. After drying, the lignite pulverized coal enters the pyrolysis device of the present invention from the coal feed port 12 on the top of the equipment after being lifted to about 4.5MPa, and enters into the plate tubes arranged in parallel through the coal distributor 9, and the pulverized coal moves downward at a certain speed . Synthesis gas at 4.5MPa and about 800°C produced by the dry coal pulverized gasifier enters the flow channel between the plates and tubes from the high-temperature gas inlet 16 of the lower cylinder 3, and indirectly heats the lignite on the other side of the plate to about 550°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com