Patents

Literature

757results about How to "Sufficient heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

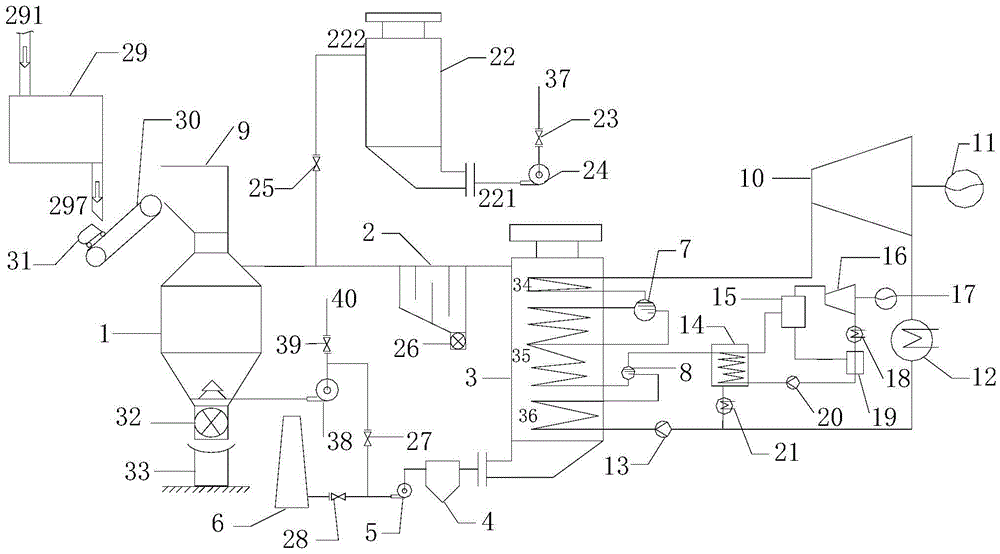

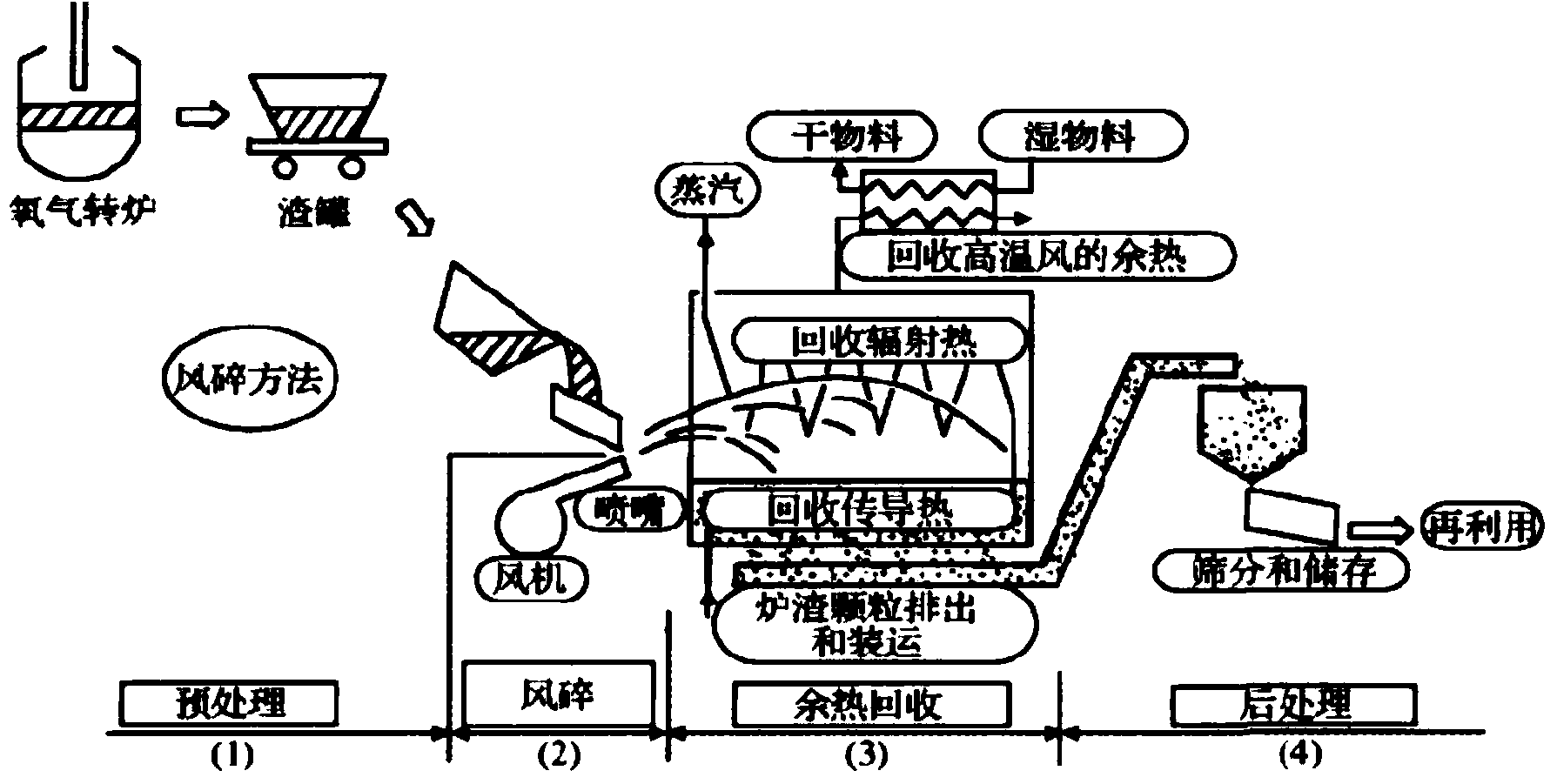

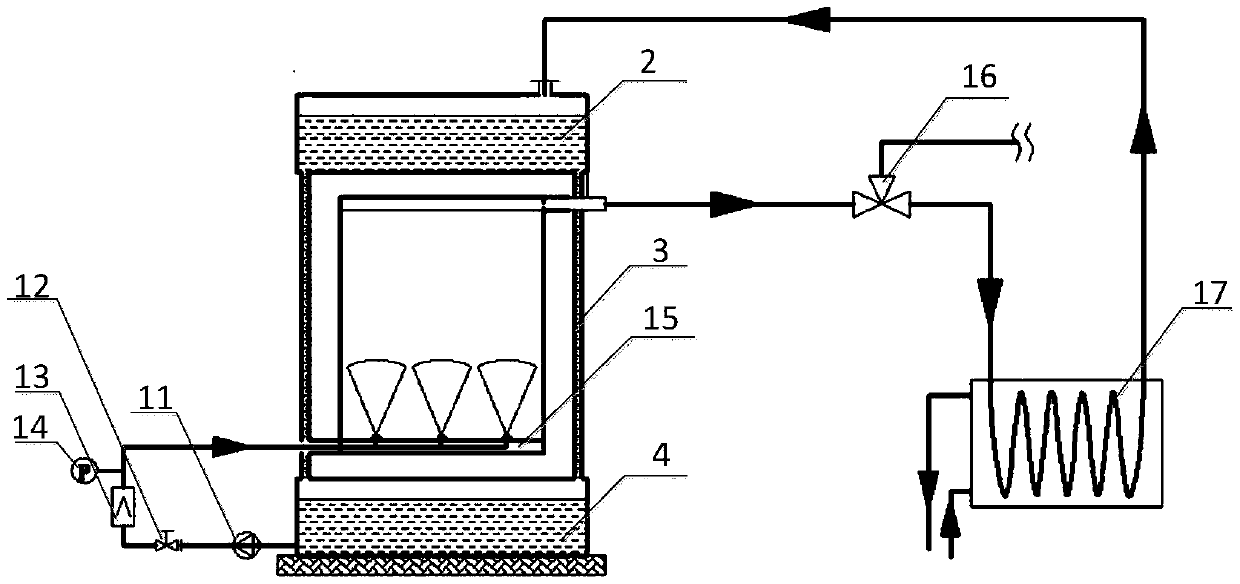

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

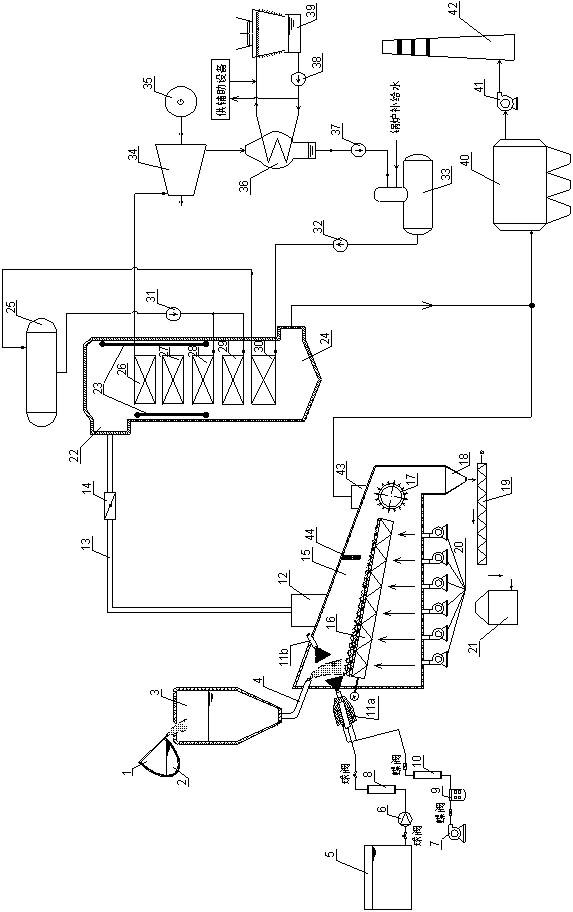

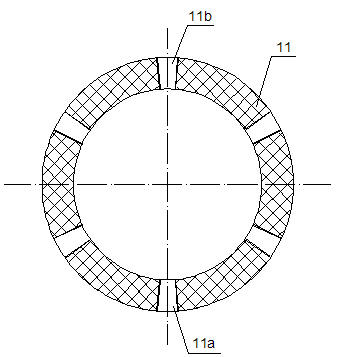

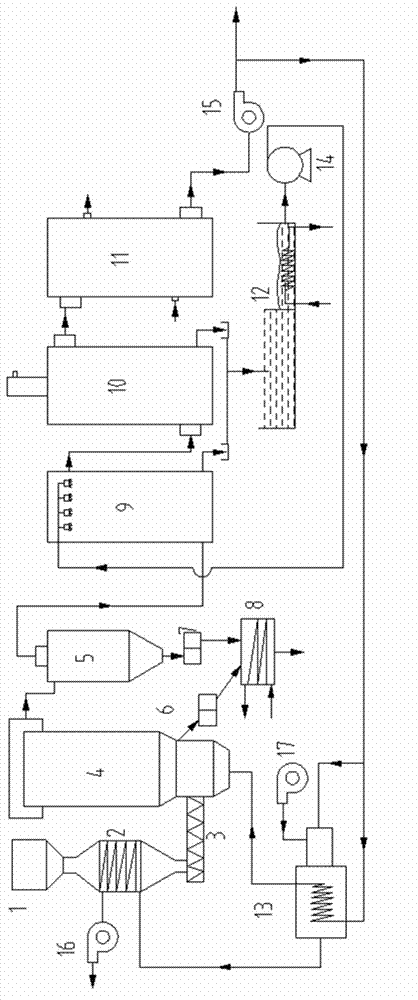

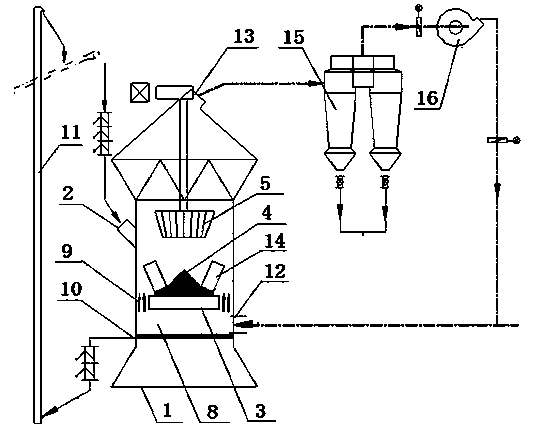

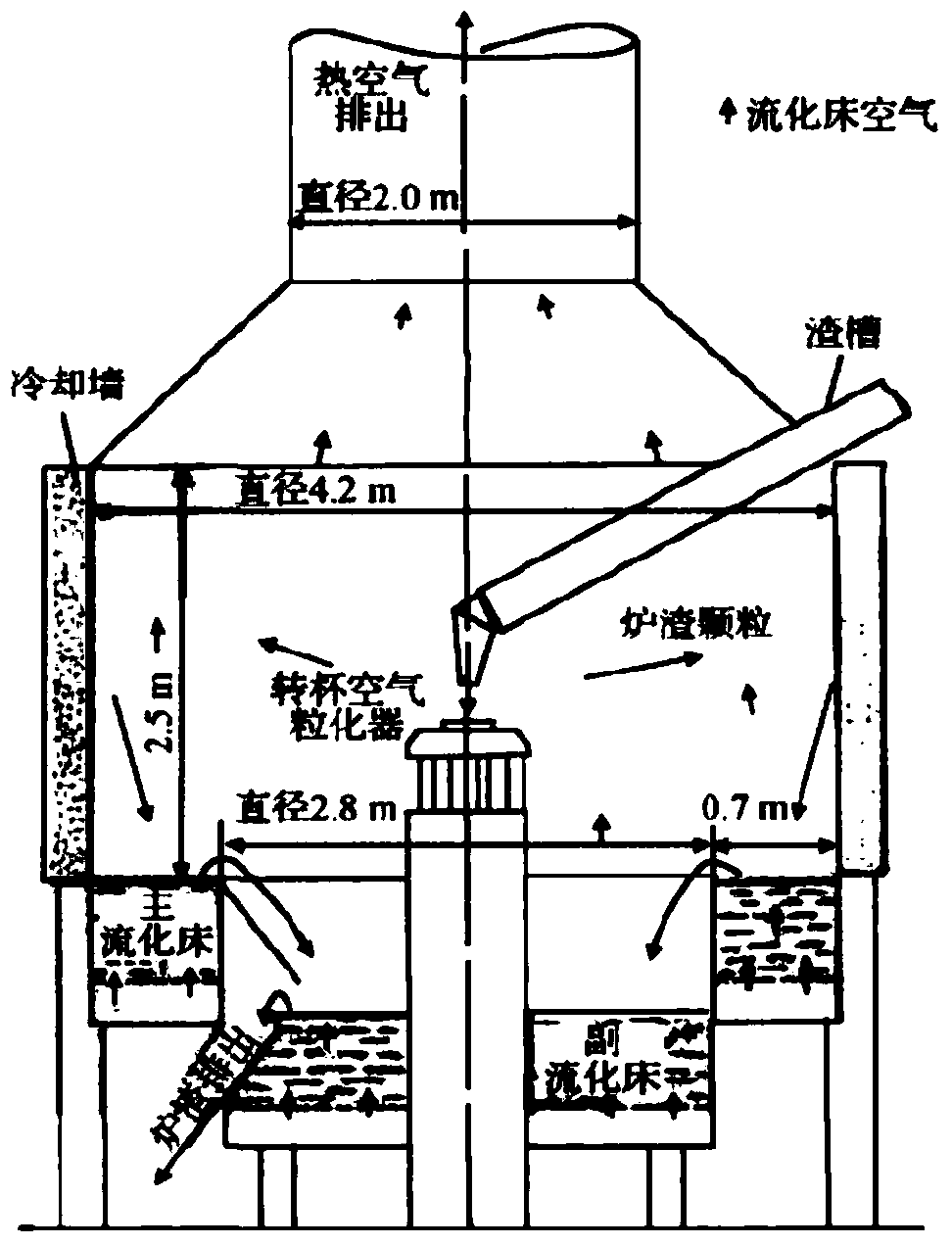

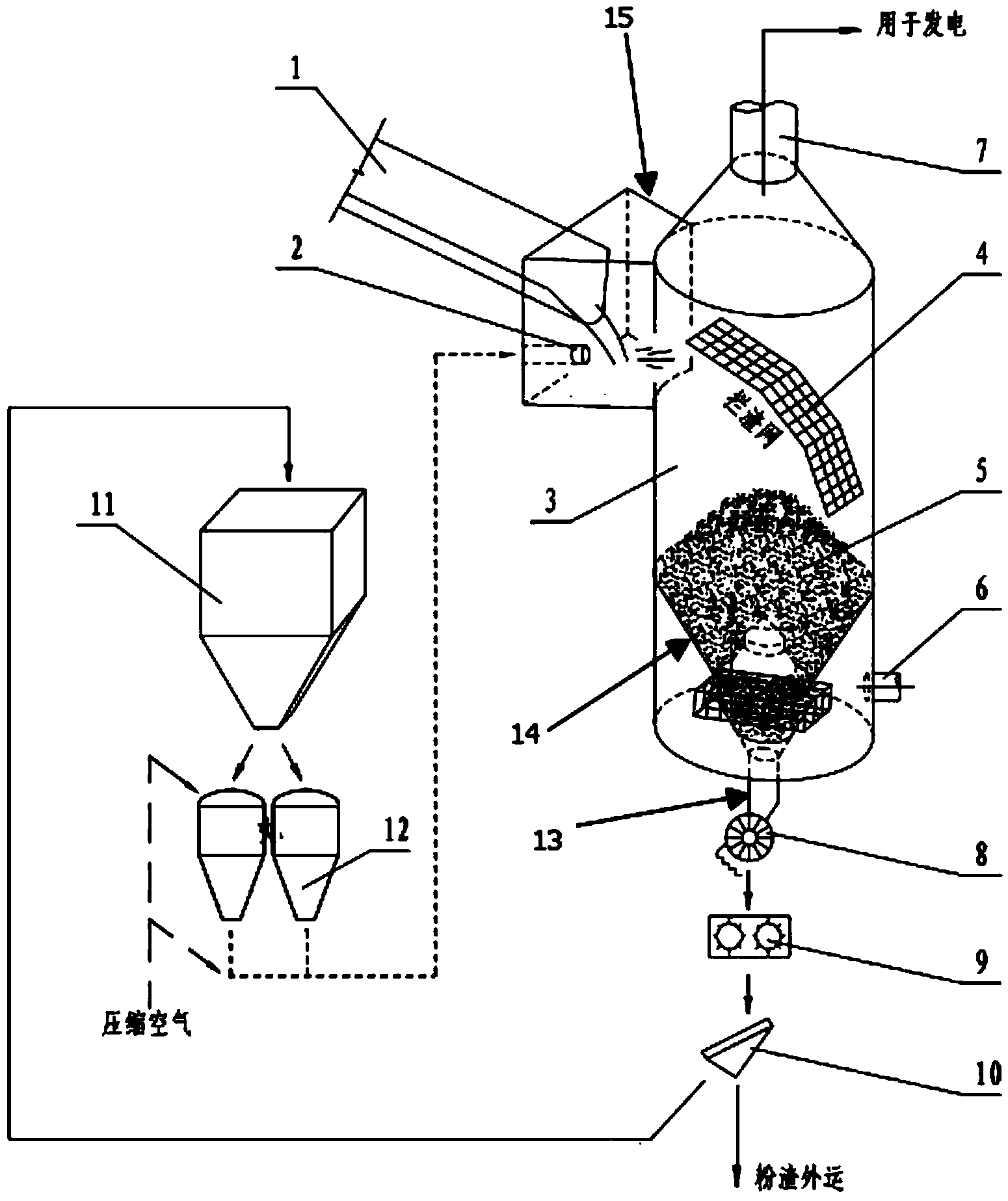

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

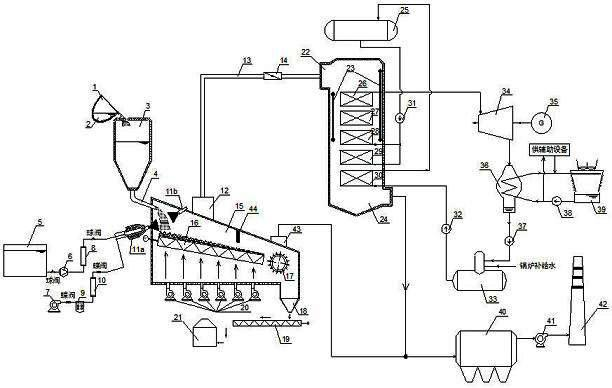

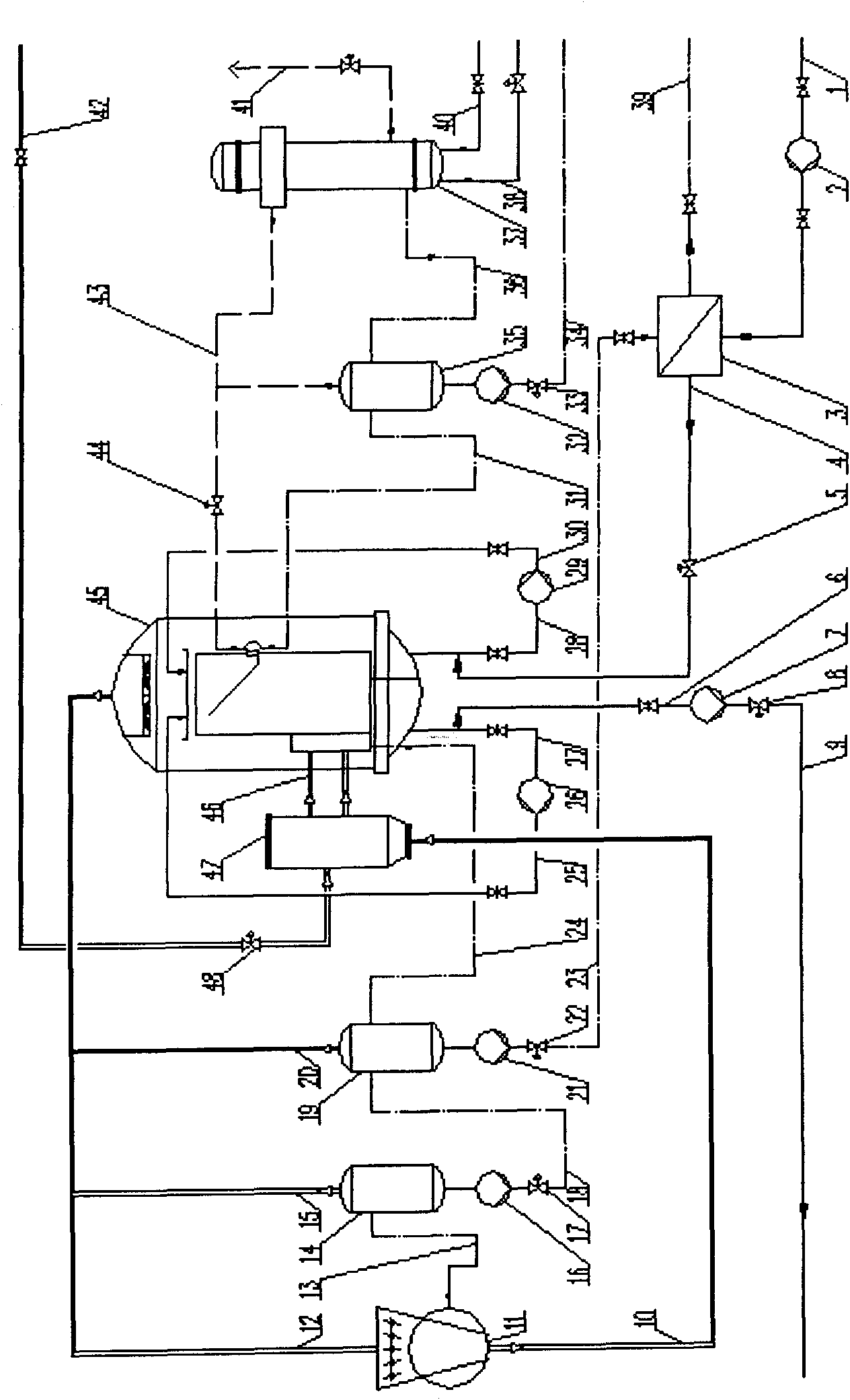

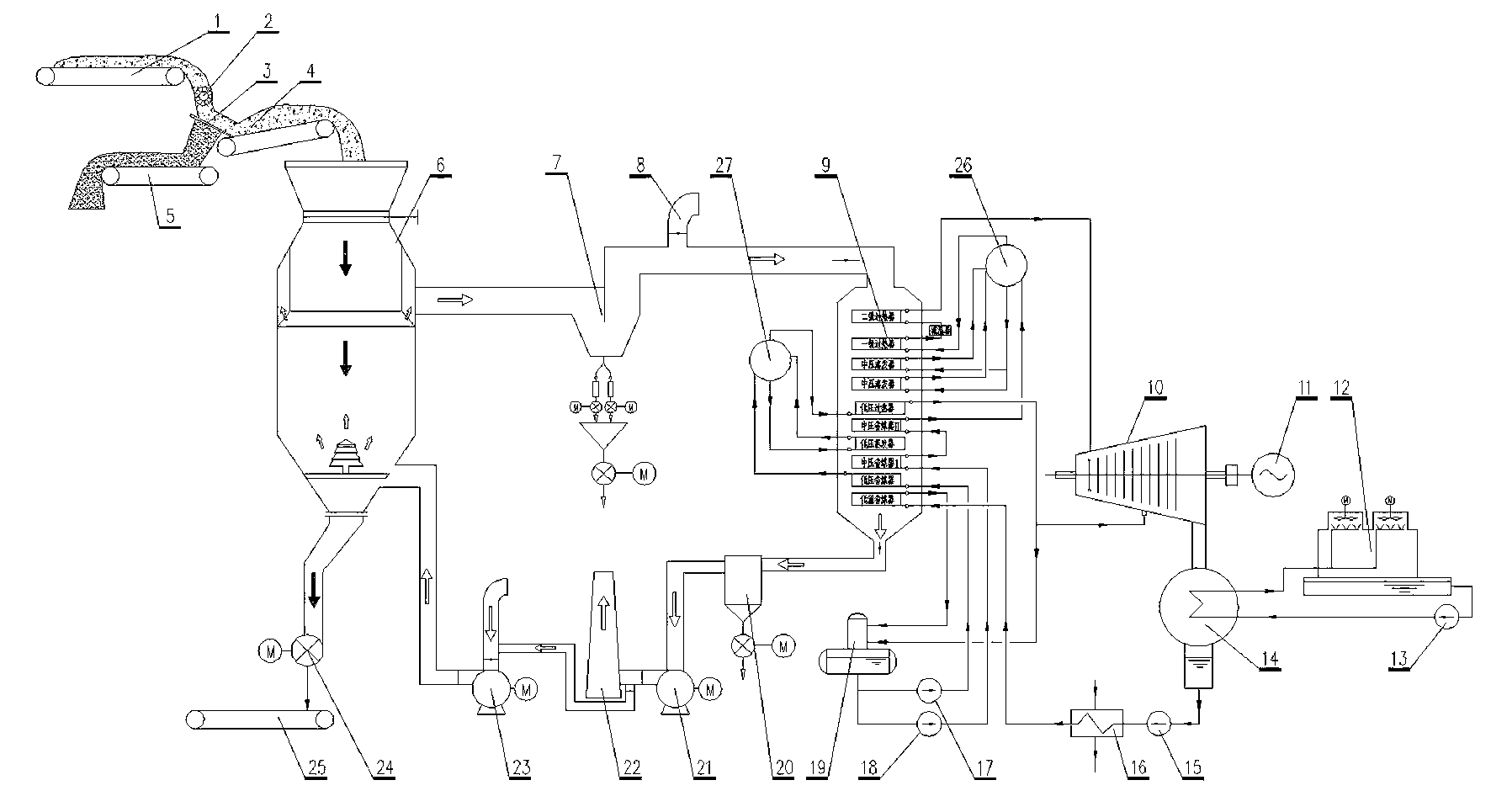

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialCogenerationMaterials science

The invention discloses a device and a process for generating power through efficient recovery of waste heat of sintered ores and belongs to the technical field of cogeneration. The device comprises a sintered ore cooling system, a waste heat power generating system and a smoke system, wherein the sintered ore cooling system and the waste heat cycling power generating system are connected through the smoke system to form a loop. The process comprises the steps of 1), cooling of sintered ores; 2) the smoke system; and 3) waste heat power generating. The device and the process for generating power through waste heat have the advantages that discharged waste heat is used fully during cooling of sintered ores, the electric energy production is improved significantly, the power rate of the system is reduced significantly, and the energy-saving effect is significant.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

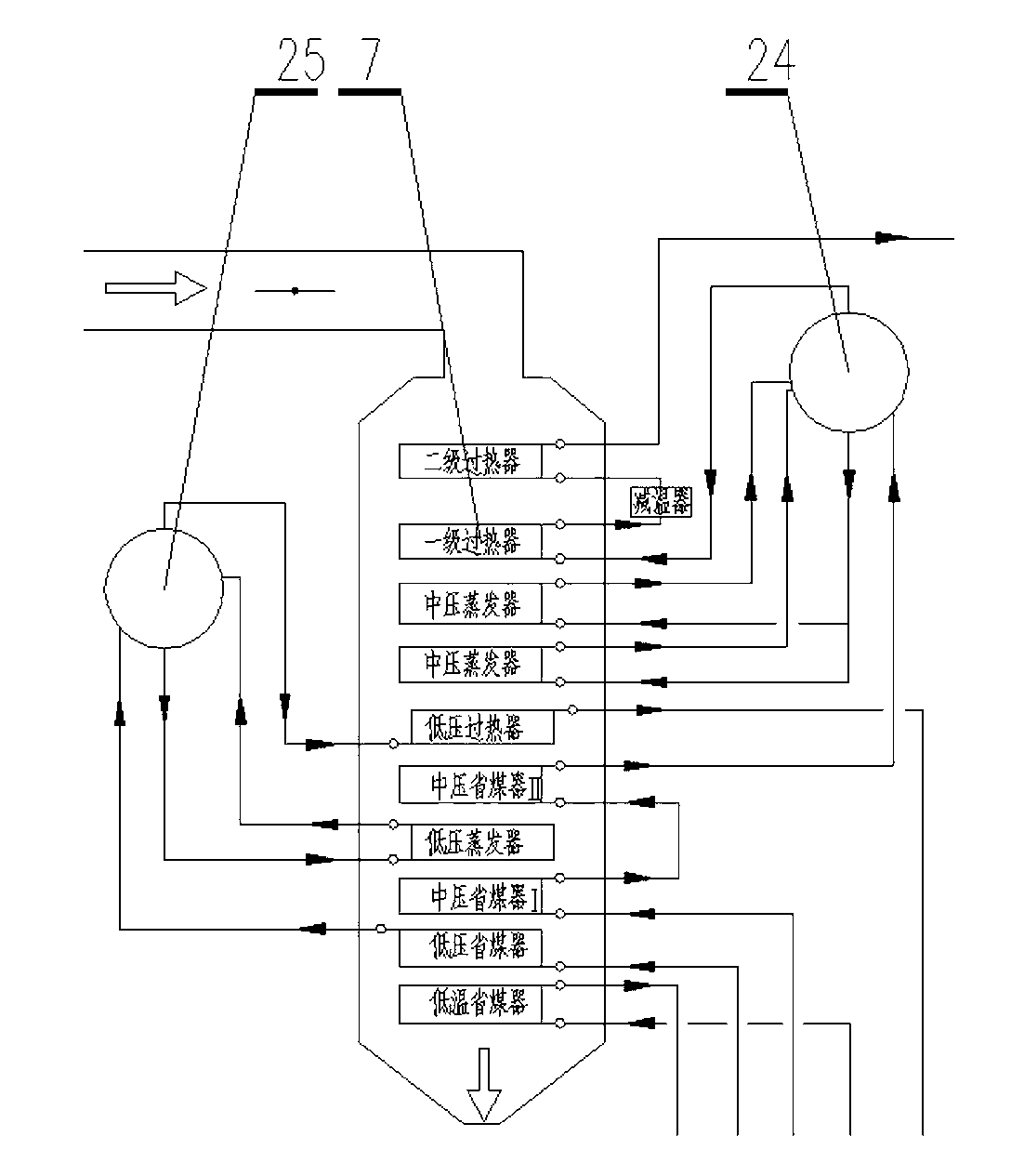

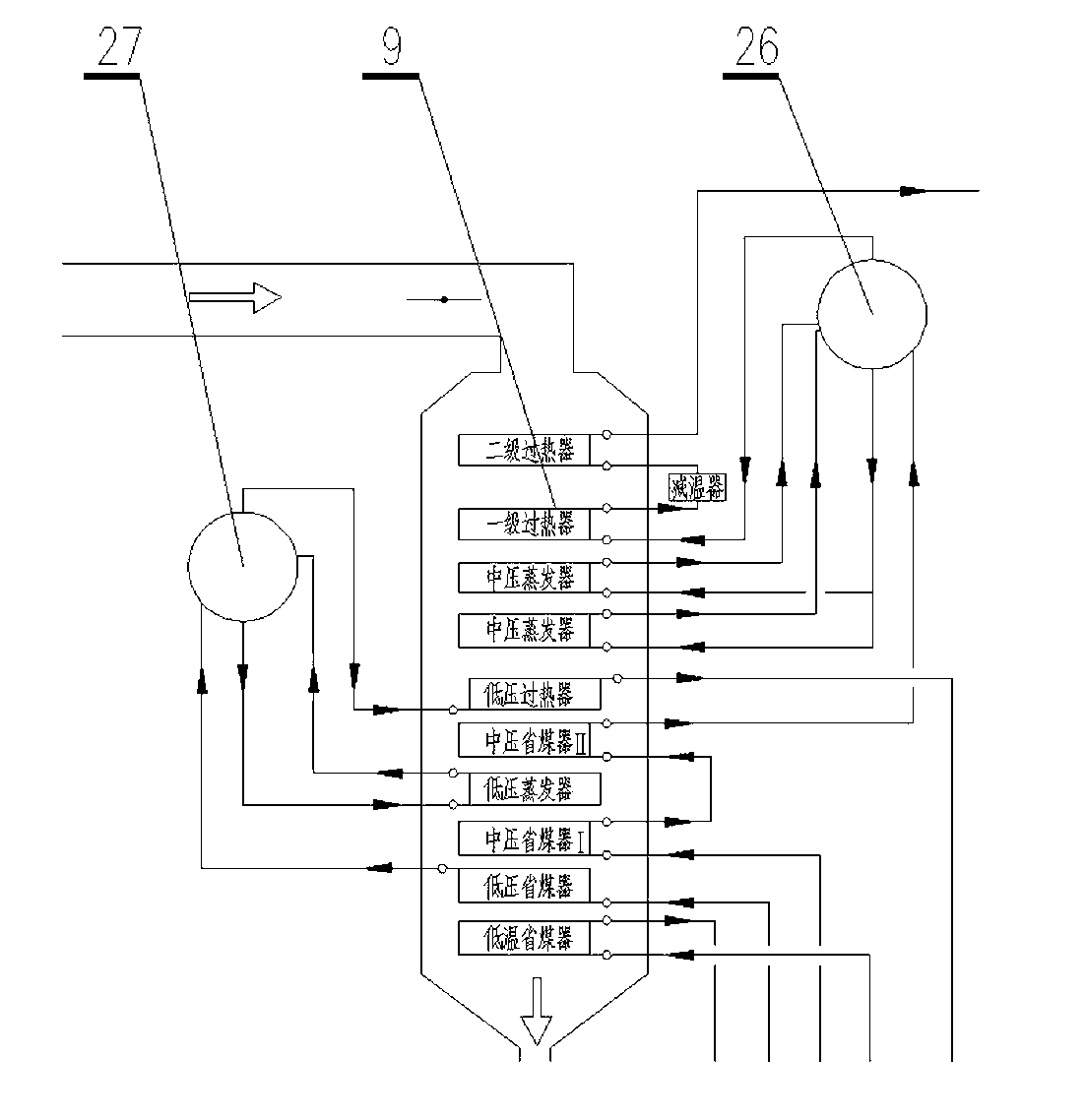

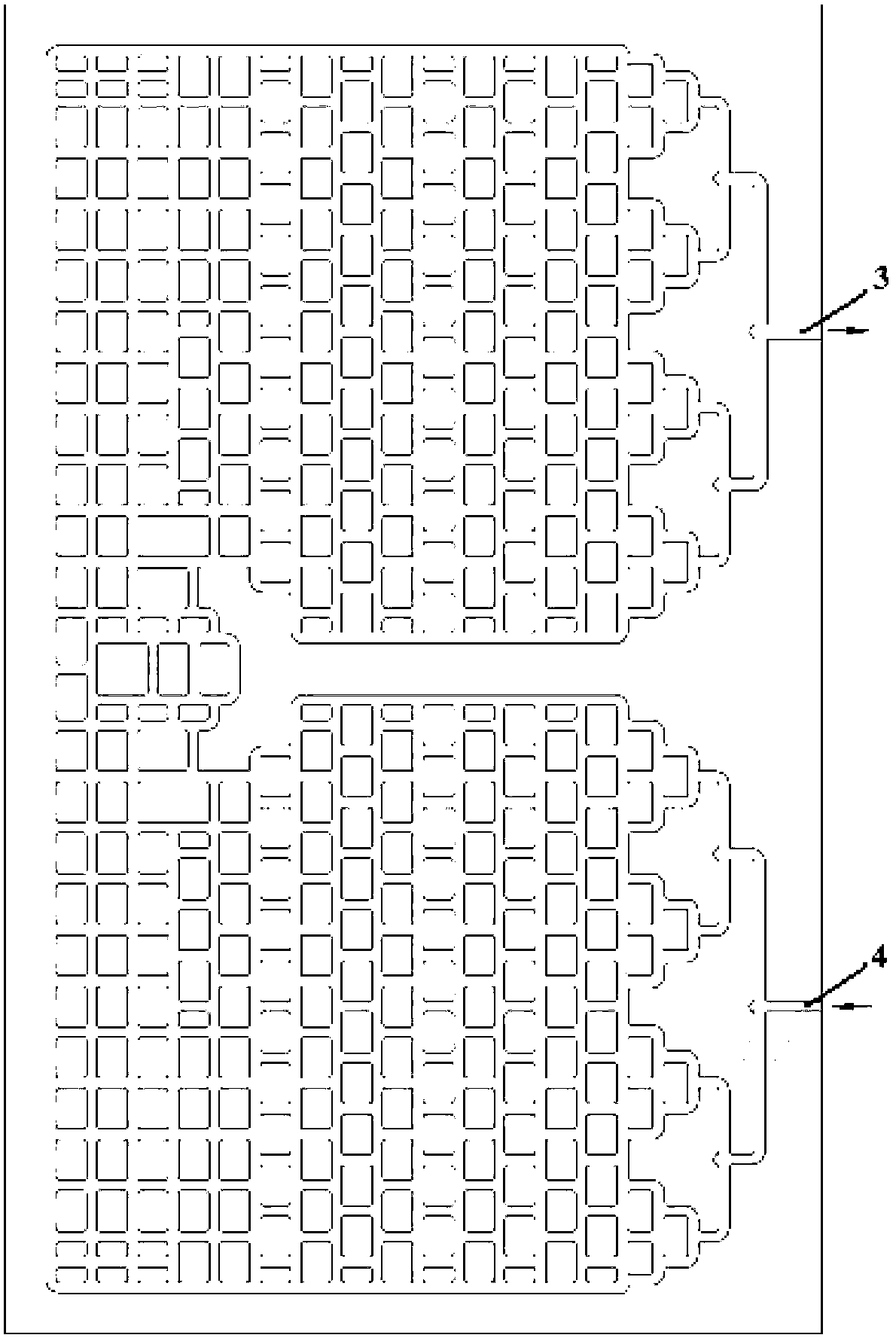

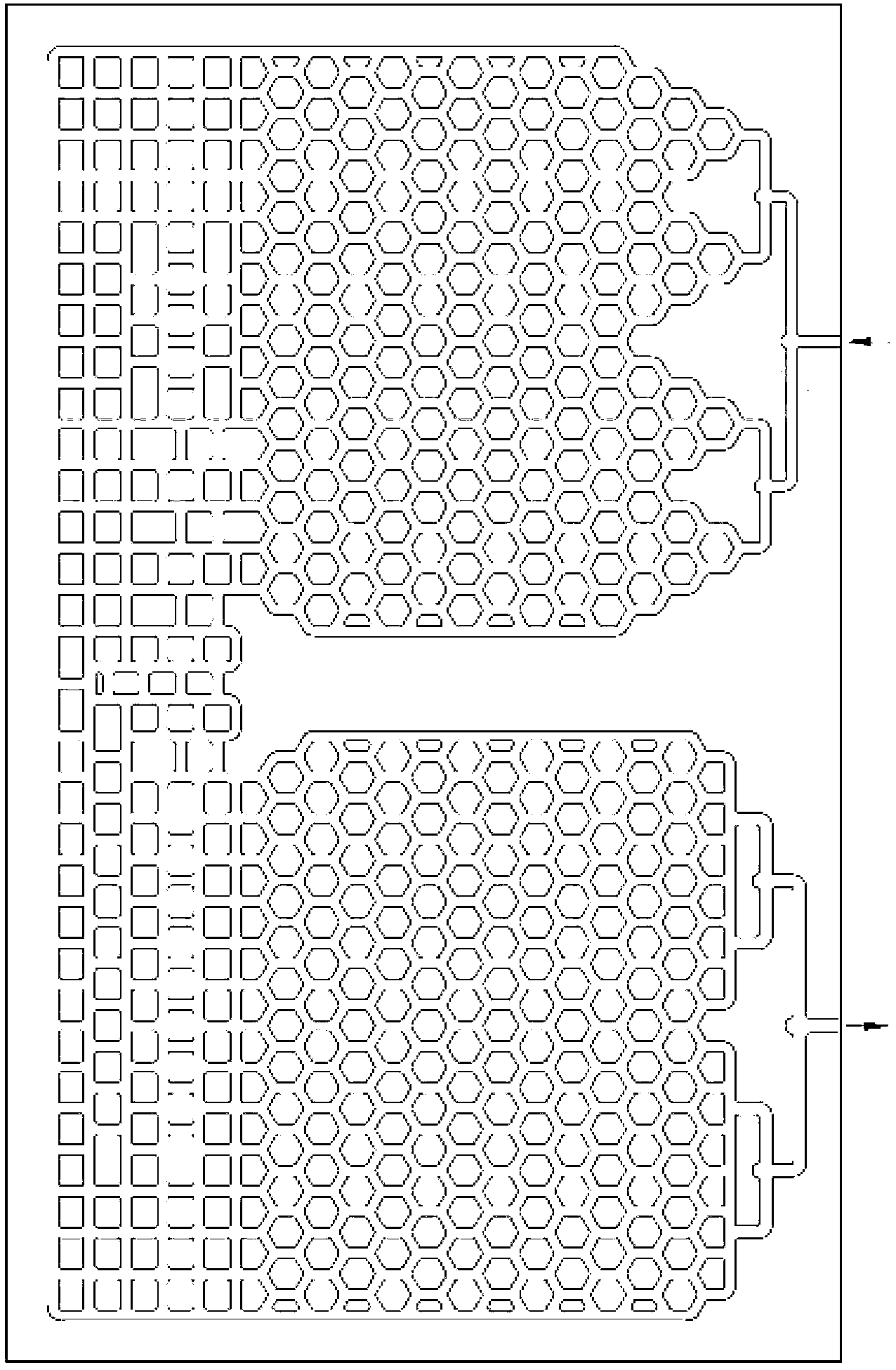

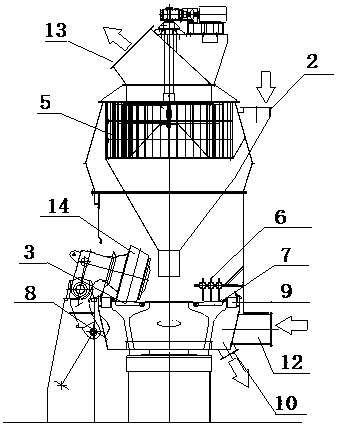

System used for sinter ore cooling and sensible heat efficient recycling

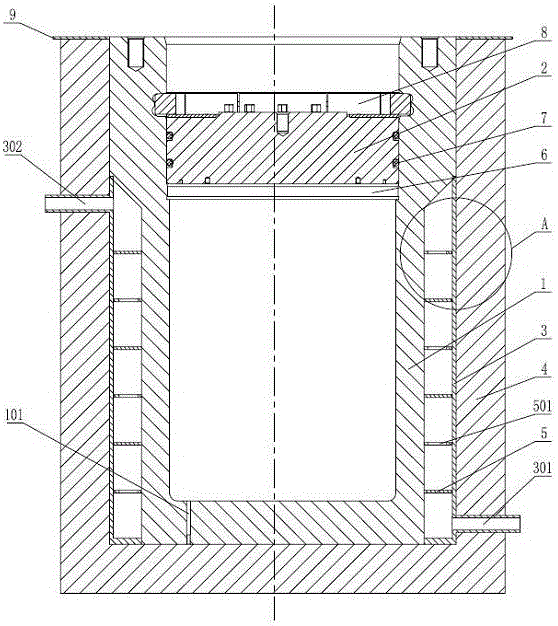

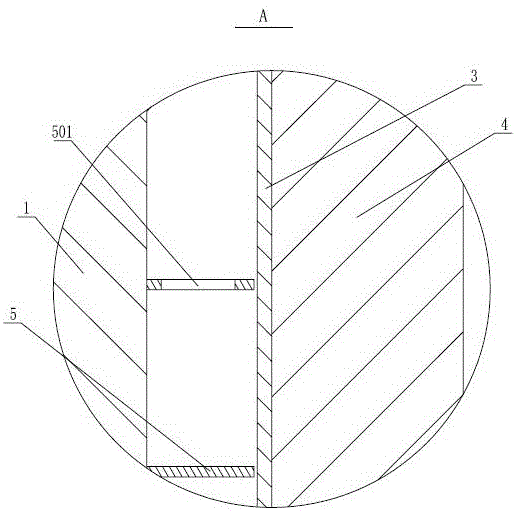

InactiveCN105627755AEfficient recyclingExtended sinter cooldownIncreasing energy efficiencyFurnace typesKilnMaterials science

A system used for sinter ore cooling and sensible heat efficient recycling comprises a stepping sintering machine used for sintering mixed iron ore materials, a vertical cooling kiln used for cooling sinter ore which is sintered and crushed, a feeding mechanism arranged between a discharging opening of the stepping sintering machine and a feed inlet of a material receiving funnel of the vertical cooling kiln, a gravity dust remover, a high-temperature smoke unit, a discharging machine, a belt conveyer and a vertical double-pressure waste heat boiler used for heat exchange, wherein the gravity dust remover and the high-temperature smoke unit are connected with a gas outlet in the upper portion of the vertical cooling kiln, and the discharging machine and the belt conveyer are arranged on a discharging opening of the vertical cooling kiln. A gas outlet of the vertical double-pressure waste heat boiler is connected with a gas inlet of a low-temperature gas unit, a gas outlet of the low-temperature gas unit is connected with a gas inlet in the lower portion of the vertical cooling kiln, and a heat exchange pipe of the vertical double-pressure waste heat boiler is connected with a power generation system. By means of the system, the sinter ore and cooling air can flow reversely in a closed space, cooling time of the sinter ore is prolonged, heat exchange is sufficient, heat efficiency of the system is greatly improved, and efficient recycling of sensible heat of the sinter ore is achieved.

Owner:天津天丰钢铁股份有限公司 +2

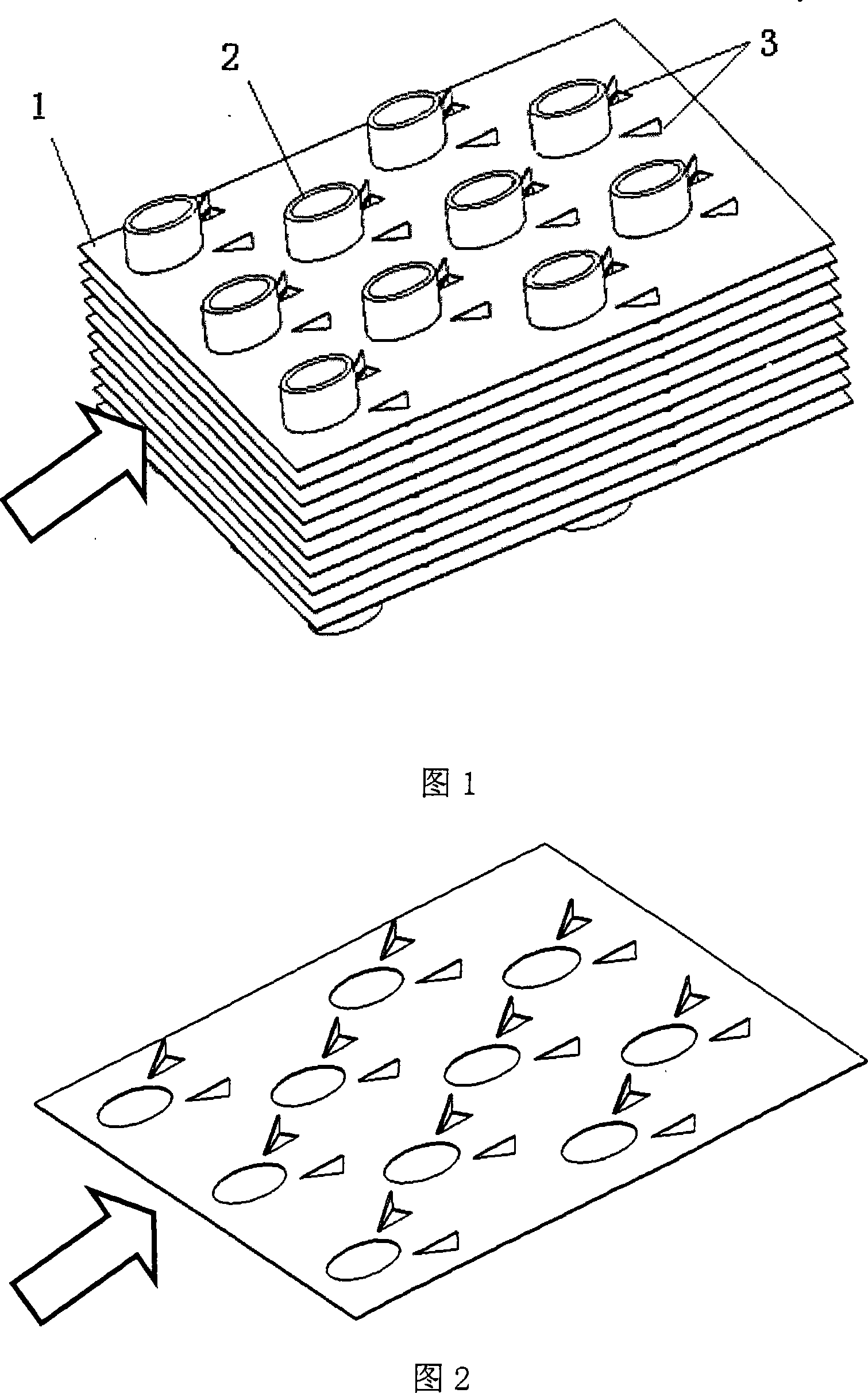

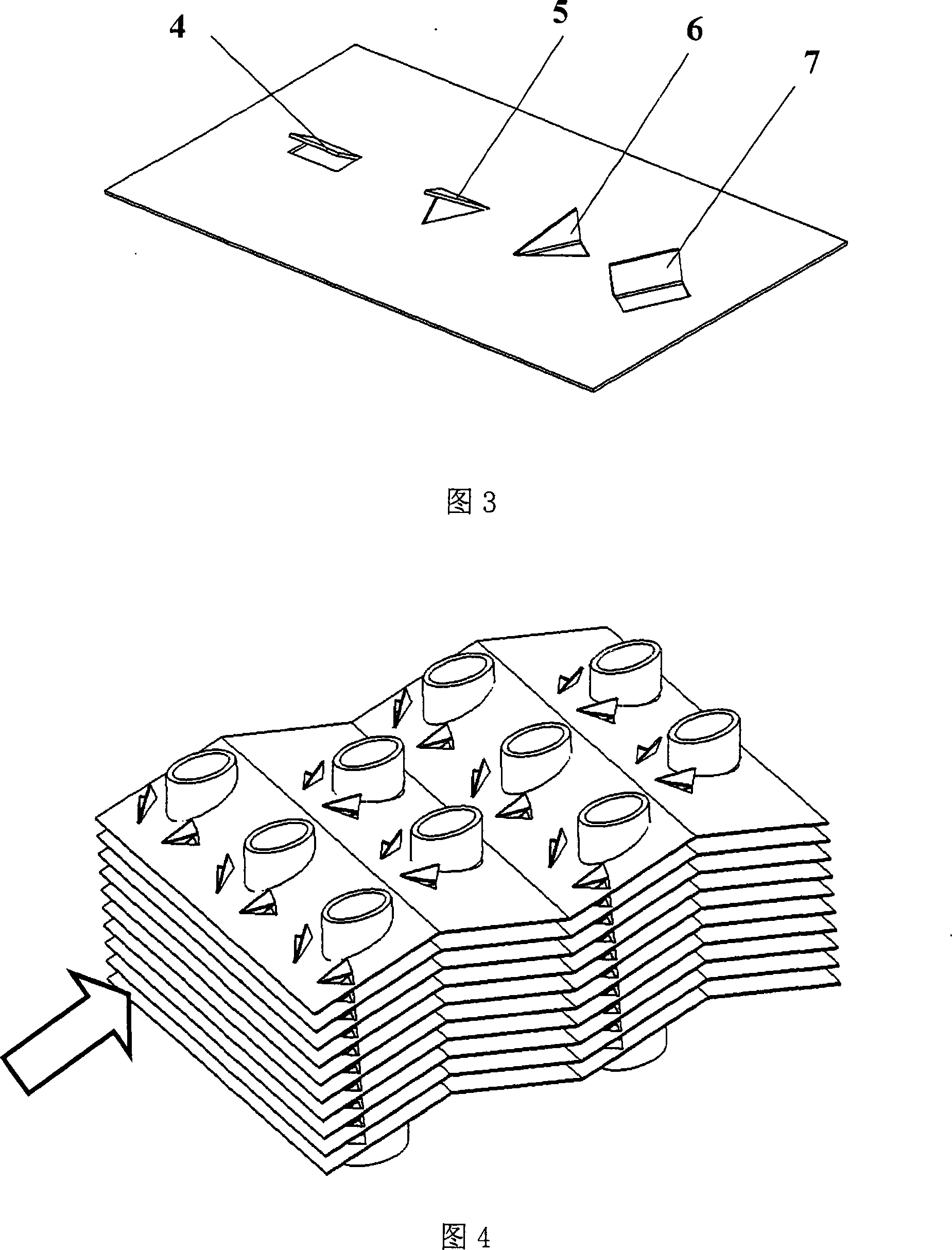

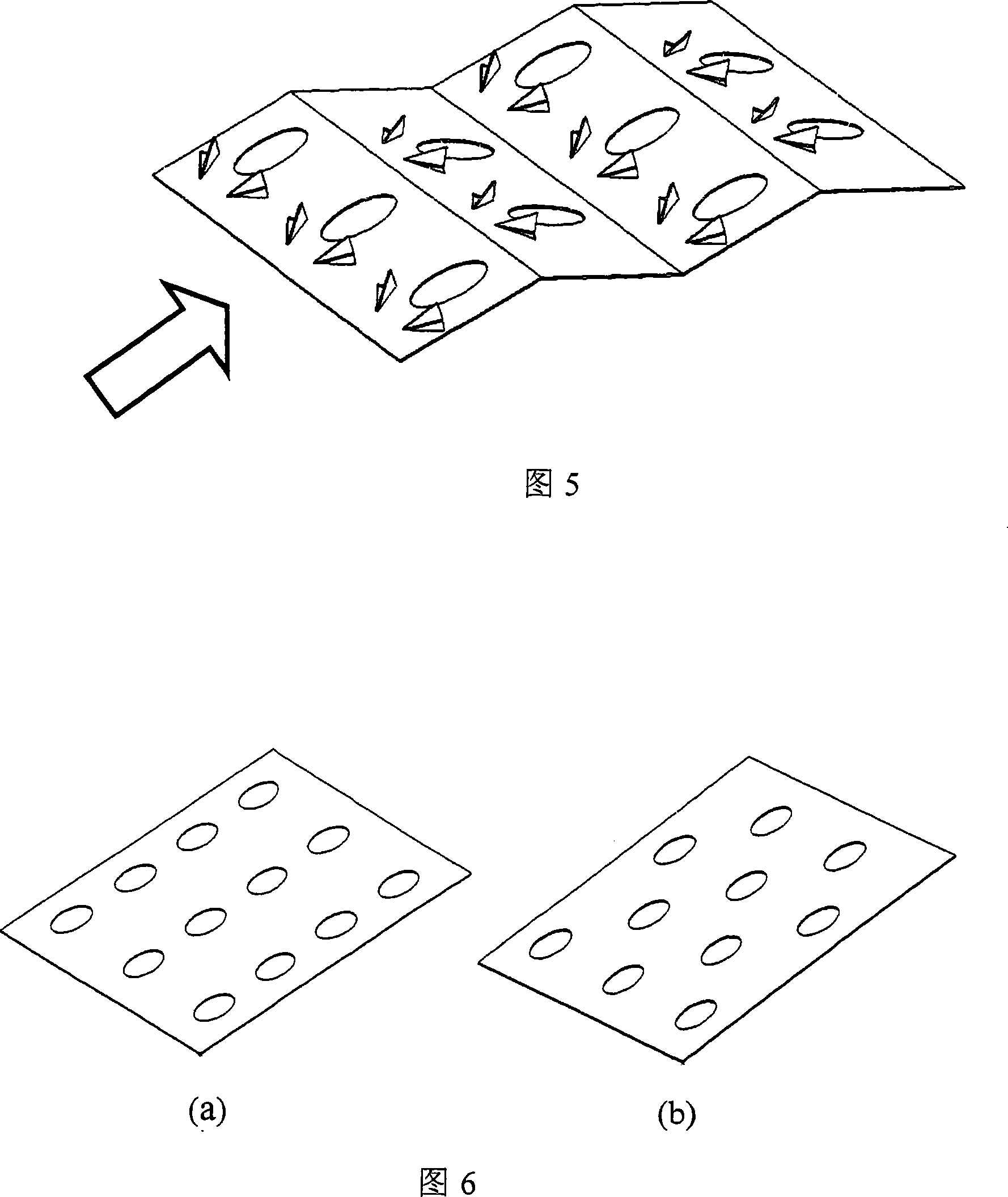

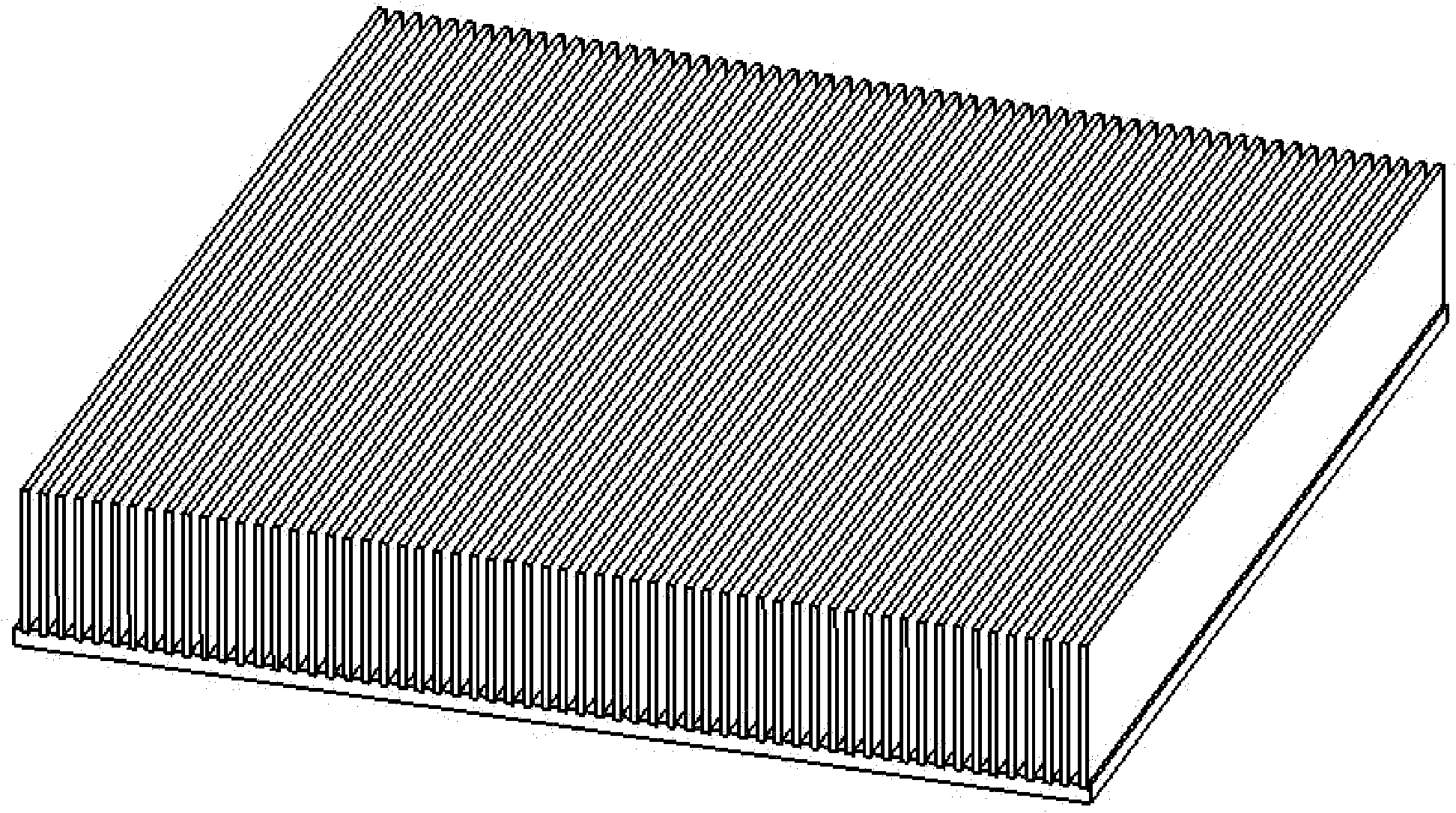

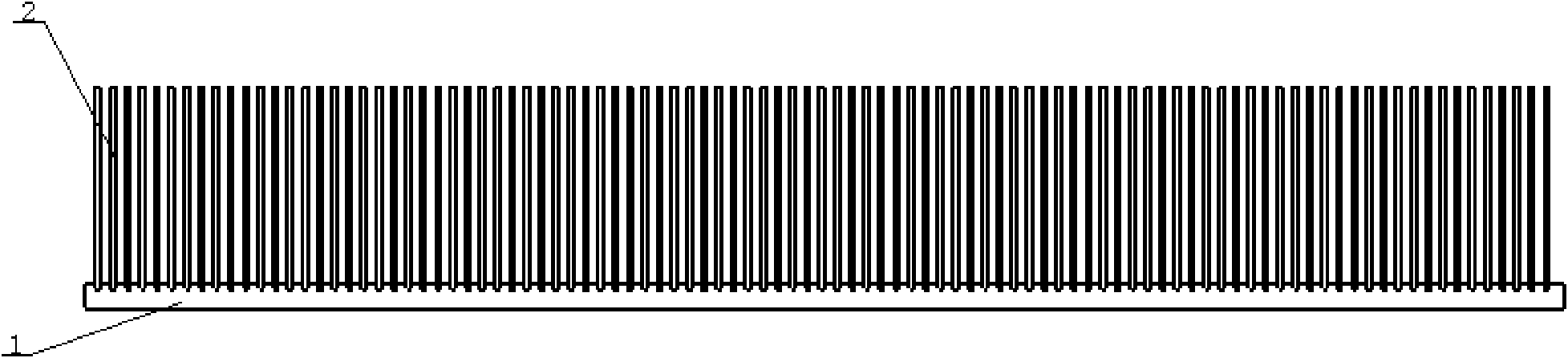

Finned heat exchanger

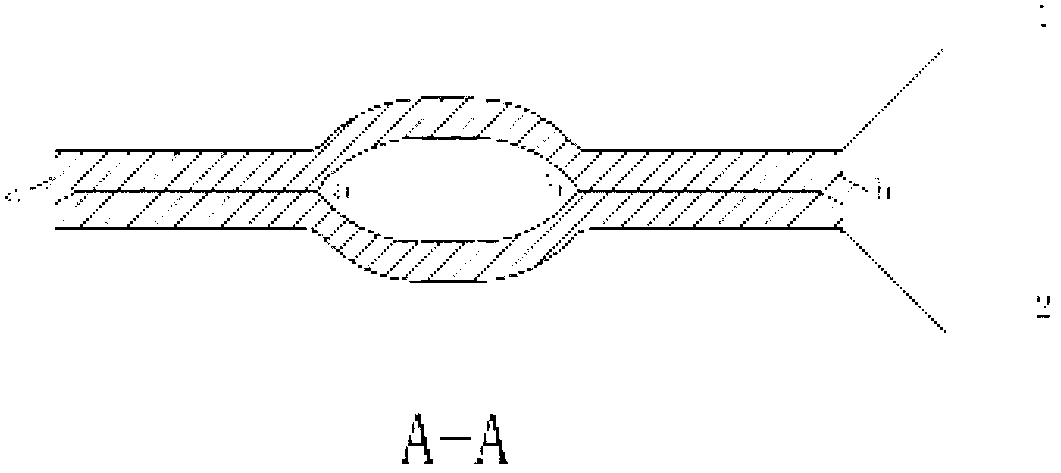

InactiveCN101245974AImprove heat transfer effectSmall sizeTubular elementsPlate heat exchangerGas phase

The invention relates to the field of heat exchangers, in particular to a fin-typed heat exchanger with high efficiency and low resistance, comprising a fin row which consists of fins and a heat exchange pipe which vertically passes through the fin row. The fin-typed heat exchanger is characterized in that the section of the heat exchange pipe is an ellipse shape; the fin is provided with a longitudinal vortex generator. The fin-typed heat exchanger can greatly improve the whole heat exchange performance of the heat exchanger but increases the flow resistance to small extent at the same time, and is mainly applied to gas-liquid heat exchange or gas-phase variable heat exchange.

Owner:XI AN JIAOTONG UNIV

Circulation evaporator

InactiveCN101811743ANon-deterministicLower evaporation temperatureWater/sewage treatment by heatingPapermakingSewage

The invention discloses an evaporator for performing innocent treatment on sewage in industries of papermaking and the like. In an existing device, a secondary steam pipe is connected to an inlet of a compressor; an outlet of the compressor is connected with a steam inlet of a steady head tank; the other steam inlet pipe of the steady head tank is connected with a fresh steam pipe of a boiler; a steam outlet of the steady head tank is connected with a falling-film evaporator which is at least provided with one circulating pipe connected with a circulating pump; an outlet of a stripper plant of the falling-film evaporator is communicated with a non-condensable air pipe and a heavily-polluted condensate water outlet pipe which is communicated with a water inlet of a heavily-polluted condensate water tank; a water outlet of the heavily-polluted condensate water tank is communicated with a heavily-polluted condensate water delivery pipe; and a condensation water outlet pipe of a condenser is communicated with the water inlet of the heavily-polluted condensate water tank.

Owner:兰州节能环保工程有限责任公司 +1

Energy-saving stove preheating premixed combustible gas by using after heat

ActiveCN102829495ATo achieve the purpose of warming upSufficient heat exchangeDomestic stoves or rangesIndirect carbon-dioxide mitigationCombustorWhole body

The invention relates to an energy-saving stove preheating premixed combustible gas by using after heat. The stove comprise a stove plate, a burner and a mixing chamber, wherein the burner is arrange in the middle of the bottom of the stove plate, and the burner is communicated with the mixing chamber; the stove also comprises a fume guide hood for guiding fume after heat in the stove plate to the outer wall of the mixing chamber to preheat the premixed combustible gas in the mixing chamber; a flanged edge contacting with a cooker is arranged at the border of the stove plate; the fume guide hood is communicated with the bottom of the stove plate, and is sleeved outside the mixing chamber; the fume guide hood is in sealed connection with the outer wall of the mixing chamber at the bottom; the fume guide hood is provided with an after heat discharge outlet; and the stove plate is internally provided with cellular porous ceramic which is obliquely erected through an energy gathering plate bracket. According to the energy-saving stove provided by the invention, the traditional fume emission notch at the upper part of the stove plate is omitted, direct discharge of fume whose after heat is not utilized is reduced; and through arranging the mixing chamber in the fume guide hood, a preheating device and the stove form a whole body, and the purpose of preheating the premixed combustible gas delivered into the stove can be achieved without need of splitting for independent use.

Owner:珠海歌林能源科技有限公司

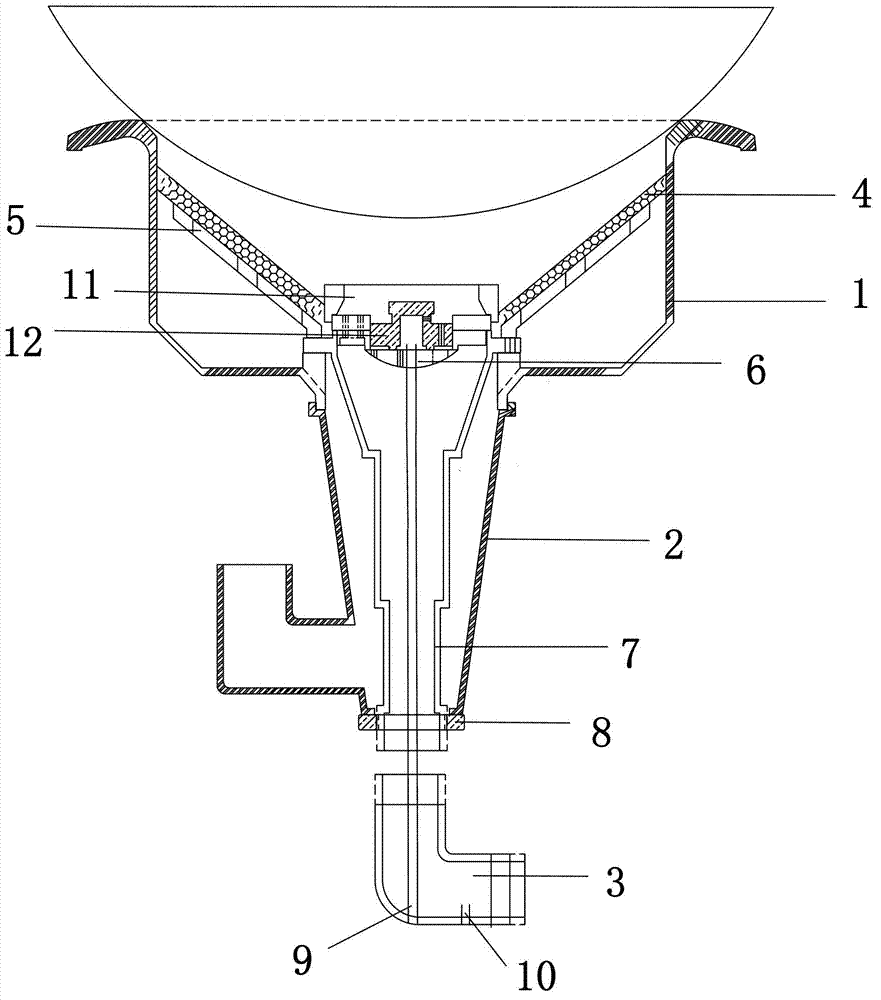

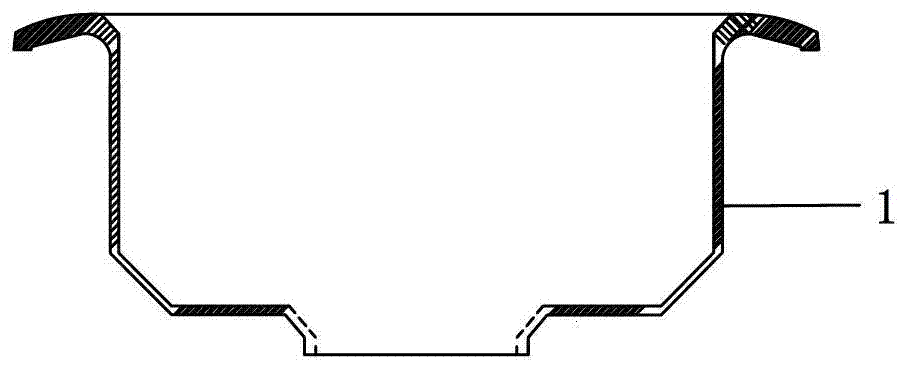

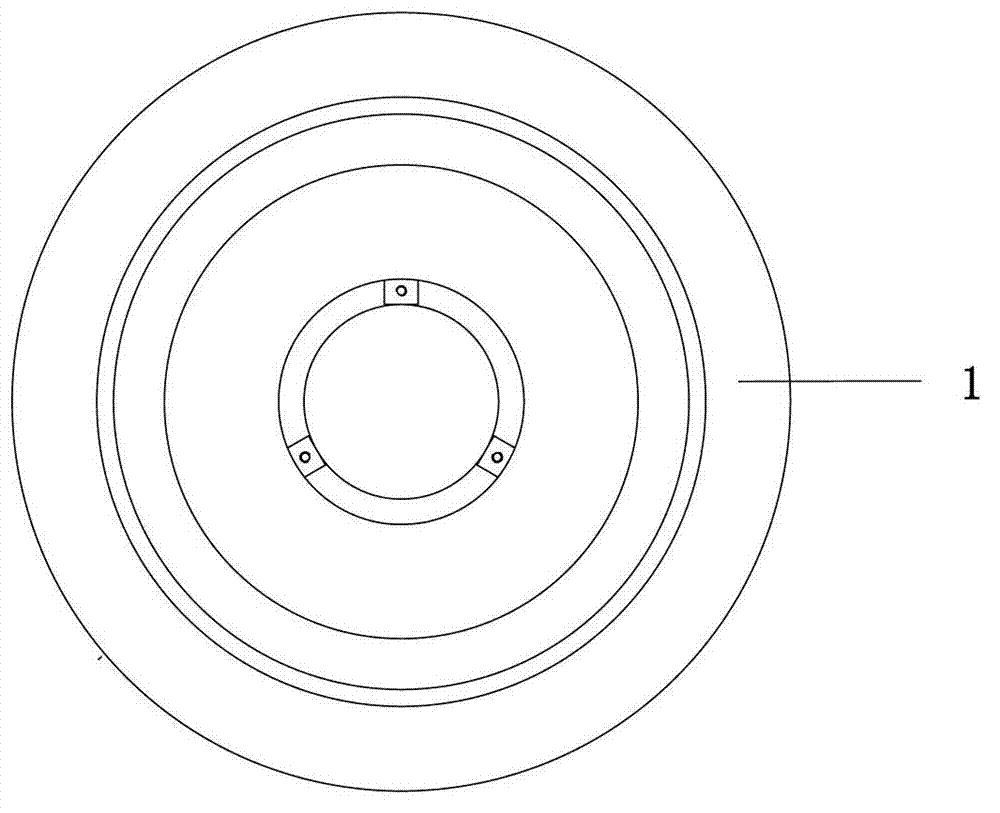

Condensing gas boiler

InactiveCN101782270AGuaranteed flow rateSufficient heat exchangeCorrosion preventionWater heatersCombustorCombustion chamber

The invention relates to a condensing gas boiler, which belongs to the technical field of heat exchange facilities. The condensing gas boiler mainly comprises a burner and a heat exchange device with smoke and water passages, wherein the heat exchange device comprises a horizontal heat exchanger and a V-shaped heat exchanger which are mutually connected in series; a first group of water pipes forming a roundabout flow passage are distributed at the circumference of the horizontal heat exchanger, and the middle part of the horizontal heat exchanger is provided with a cylindrical combustion chamber; the burner is arranged at one end of the cylindrical combustion chamber, and the smoke passes through the horizontal heat exchanger and enters the V-shaped smoke passage of the V-shaped heat exchanger through a downward through hole; a second group of water pipes forming a roundabout flow passage are distributed in the V-shaped smoke passage at intervals; and reverse heat exchange is formed between the water first flowing through the second group of water pipes and then the first group of water pipes and the smoke coming from the combustion chamber and flowing through the V-shaped smoke passage. The heat exchange is sufficient, the flow rate of the cooled smoke can be kept to ensure the heat exchange efficiency, and the condensing gas boiler has a reasonable structure and occupies small area.

Owner:A O SMITH CHINA WATER HEATER CO LTD

Ice preventing and removing system for aircraft wing

The invention discloses an ice preventing and removing system for an aircraft wing. The system comprises a waste gas treatment device, an air pump, a shell, an evaporator, a condenser, an air line and a liquid line, wherein engine waste gas treated by the waste gas treatment device is introduced into the shell to heat the evaporator, working media are vaporized after being heated in the evaporator and then led out through the air line, and then the working media are cooled into liquid in the condenser located on the skin and give out heat, and finally flow back to the evaporator through the liquid line to finish the whole circulation. According to the system, the vapor-liquid two-phase flow phase change heat transfer design concept is adopted, vapor-liquid phase conversion of the working media is utilized to transmit heat, and then the purpose of preventing and removing ice on the aircraft wing is achieved; engine waste gas of an airplane is utilized as the heat source to increase the comprehensive utilization rate of airplane energy.

Owner:BEIHANG UNIV

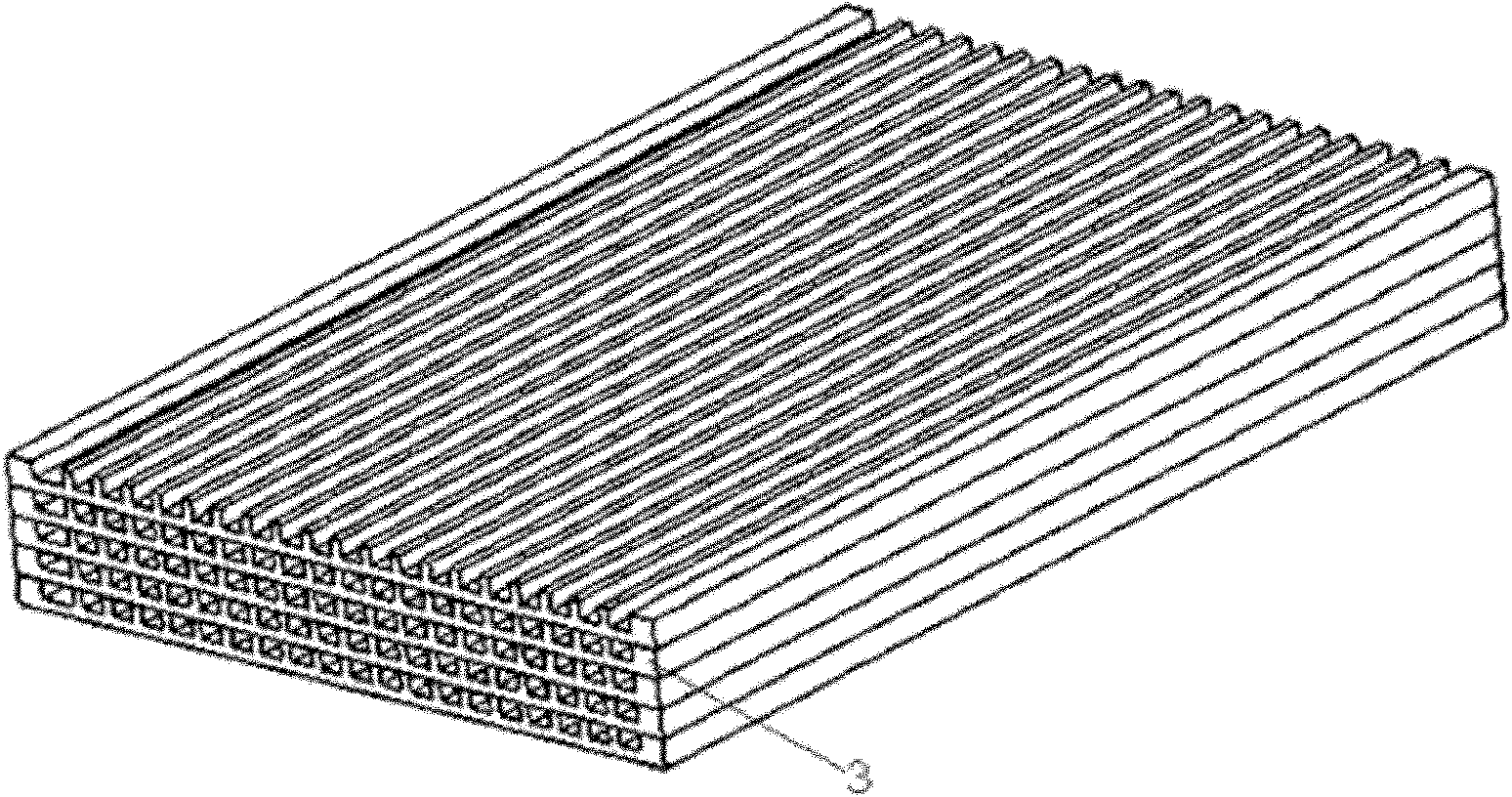

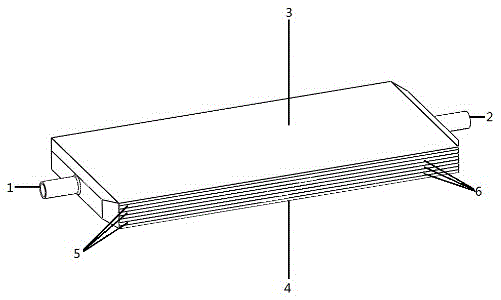

Metal and conductive plastic composite micro heat exchanger

ActiveCN102109291AImprove machinabilityQuick exportSemiconductor/solid-state device detailsSolid-state devicesMicro structureEngineering

The invention discloses a metal and conductive plastic composite micro heat exchanger, belonging to the technical field of heat exchangers. In the heat micro-exchanger, a shell with heat insulating function is sleeved outside the heat exchanger to protect internal panels; a seal head for distributing or collecting fluid is welded on the shell, and mouths of cold and heat fluid inlet and outlet pipes are welded on the seal head; and particular structures can be arranged according to requirements. The heat micro-exchanger is characterized in that the internal panels comprise a metal substrate and a plastic micro-structure, wherein metal is used as a conductive substrate, and the conductive plastic of a micro-structure is compounded on the metal substrate. By the metal and conductive plastic composite heat micro-exchanger, the processing cost is greatly reduced, and the micro-channel made of plastic is difficult to scale compared with that made of metal materials.

Owner:BEIJING UNIV OF CHEM TECH

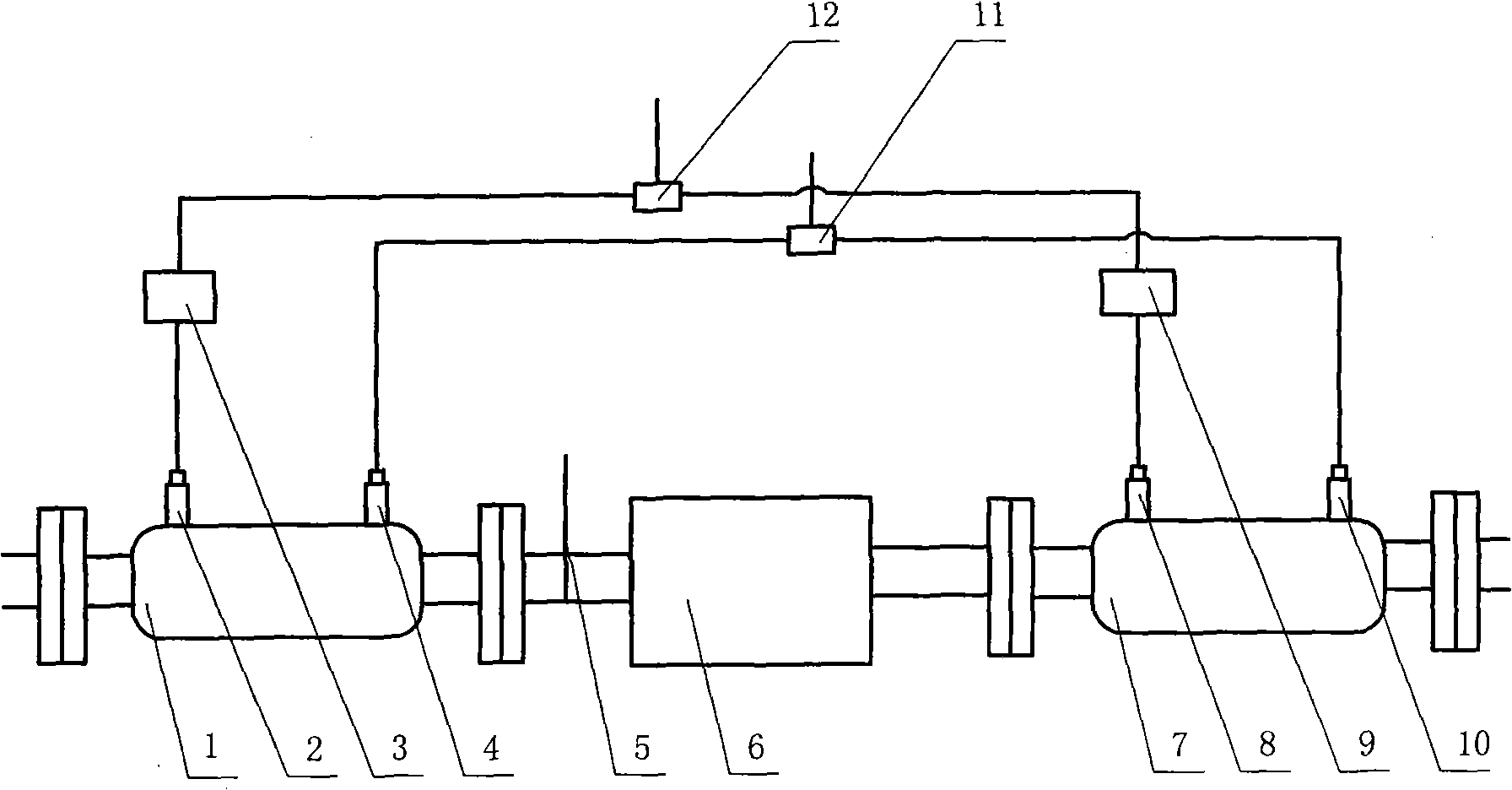

Waste gas high-efficiency cooling system with high EGR efficiency

InactiveCN101526048ASmall sizeIncreased durabilityNon-fuel substance addition to fuelInternal combustion piston enginesNuclear engineeringExhaust fumes

The invention relates to a waste gas high-efficiency cooling system with high EGR efficiency, which comprises a cooler and an EGR valve and has the innovative points: the system includes a precooler, an aftercooler and an EGR valve; wherein, the precooler is used for cooling high temperature large flow rate waste gas introduced from an exhaust system; the aftercooler is used for cooling the circulated waste gas which is introduced from the precooler and cooled by the precooler; and the EGR valve is connected and installed between the precooler and the aftercooler in series, and used for adjusting the flow rate of the waste gas. The invention is scientific and reasonable in design, and is especially used for high EGR efficiency (70-80%) waste gas cooling in an oxy-fuel combustion engine based on waste gas recycling. The waste gas high-efficiency cooling system has the advantages of high cooling efficiency, small occupying space, convenient installation, high durability, etc.

Owner:TIANJIN UNIV

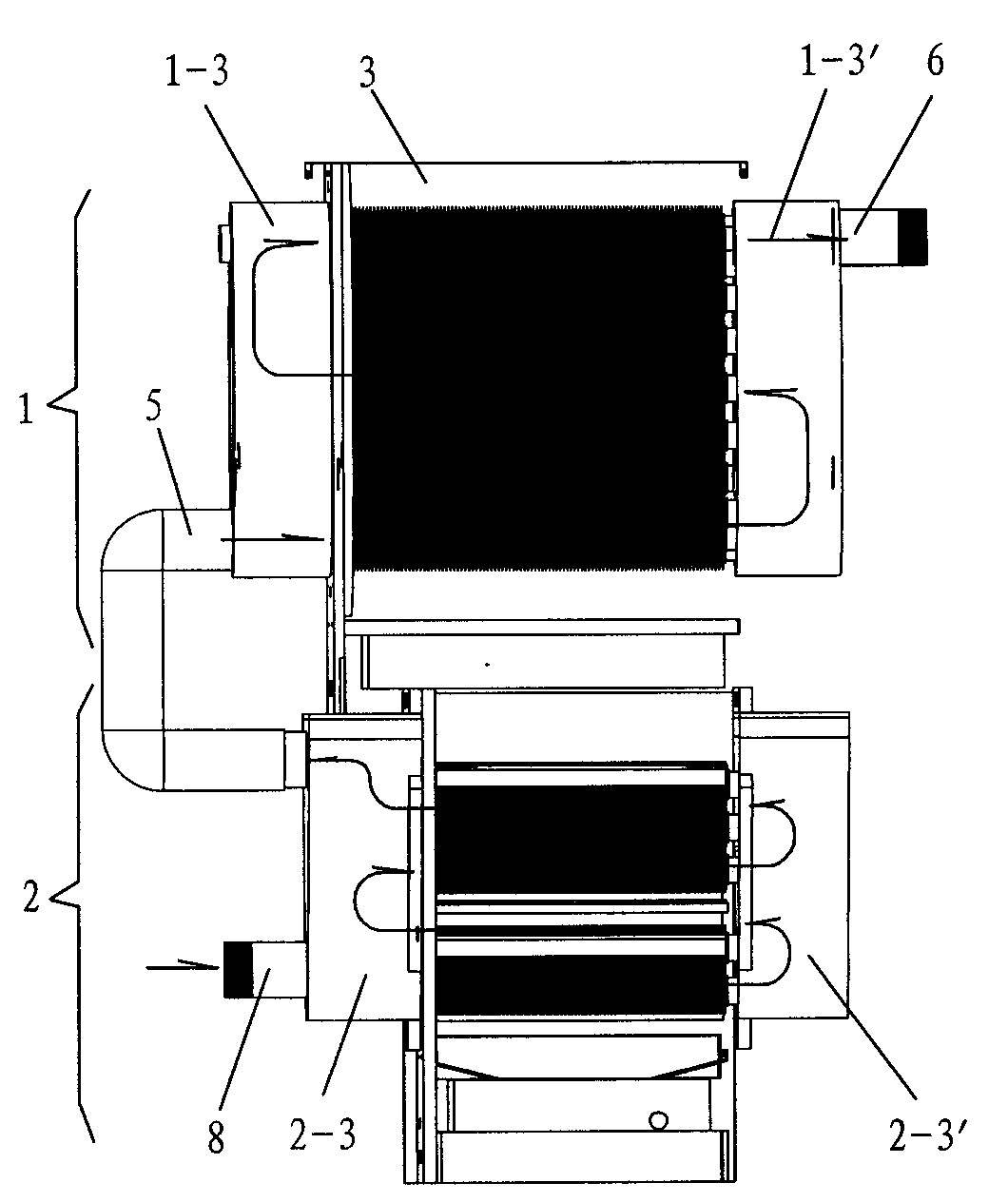

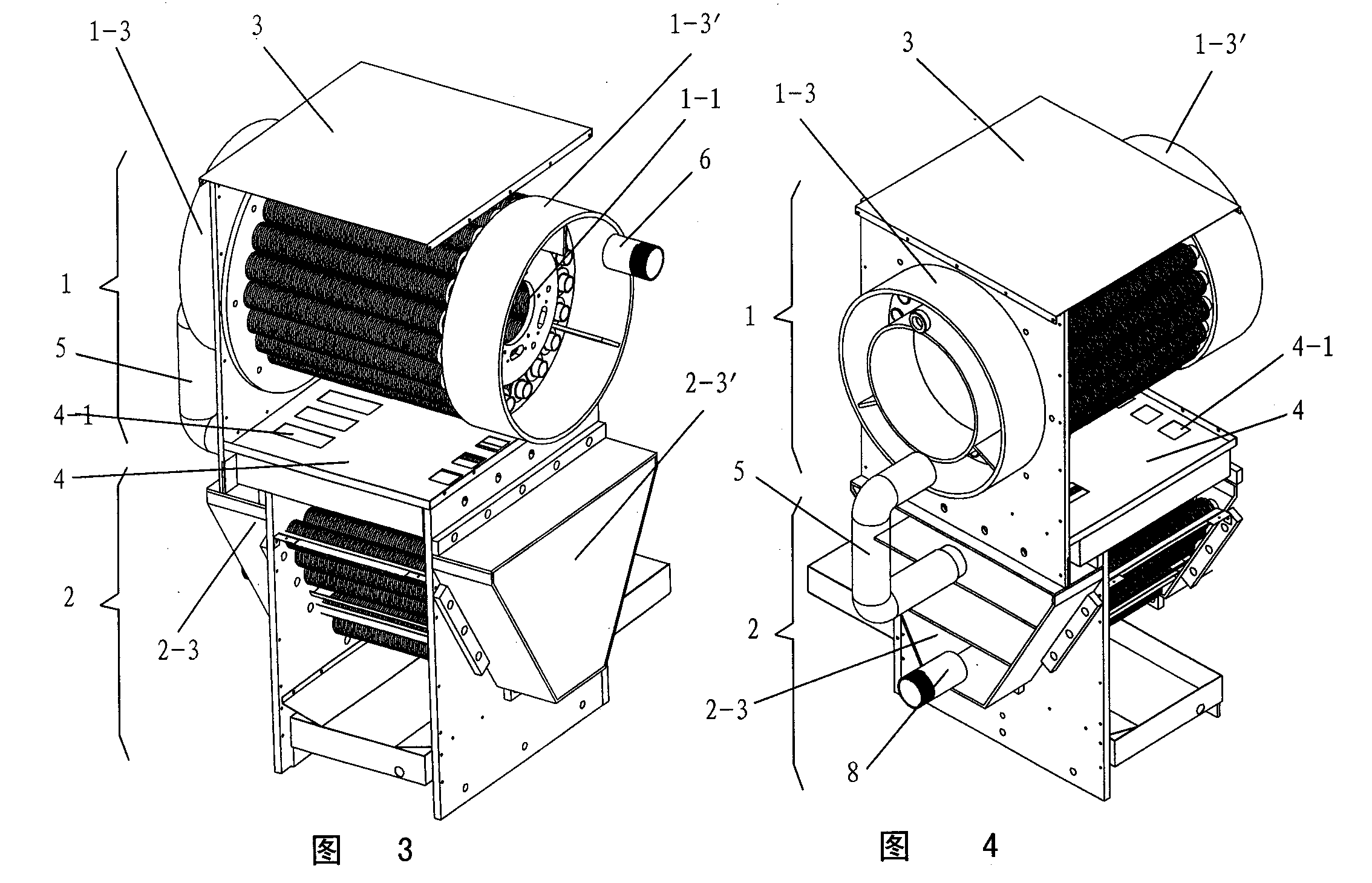

Drum-shaped evaporator and cabinet air conditioner with drum-shaped evaporator

ActiveCN103776203AReduce throughReduced velocity across the evaporatorEvaporators/condensersSpace heating and ventilation detailsEngineeringAirflow

The invention provides a drum-shaped evaporator and a cabinet air conditioner with the drum-shaped evaporator. The drum-shaped evaporator comprises a drum-shaped evaporator body, one of the inner circumference side and the outer circumference side of the evaporator body is the air inlet side, and the other is the air outlet side. The cabinet air conditioner comprises a casing, the upper portion of the casing is provide with an air outlet, the lower portion of the casing is provided with an air inlet, and the drum-shaped evaporator located between the air inlet and the air outlet is further arranged in the casing in the vertical direction. By arranging the evaporator into the drum shape, enabling one of the inner circumference side and the outer circumference side to be the air inlet side and enabling the other to be the air outlet side, even if air flow flows into the drum-shaped evaporator from the periphery of the drum-shaped evaporator or flows out of the drum-shaped evaporator to the periphery of the drum-shaped evaporator, a heat exchange area between the air flow and the evaporator is the whole circumference, the heat exchange area of the evaporator is effectively enlarged, the speed of the air flow penetrating through the evaporator is reduced, the air flow and the evaporator perform heat exchange fully, and the heat exchange effect is improved.

Owner:GREE ELECTRIC APPLIANCES INC

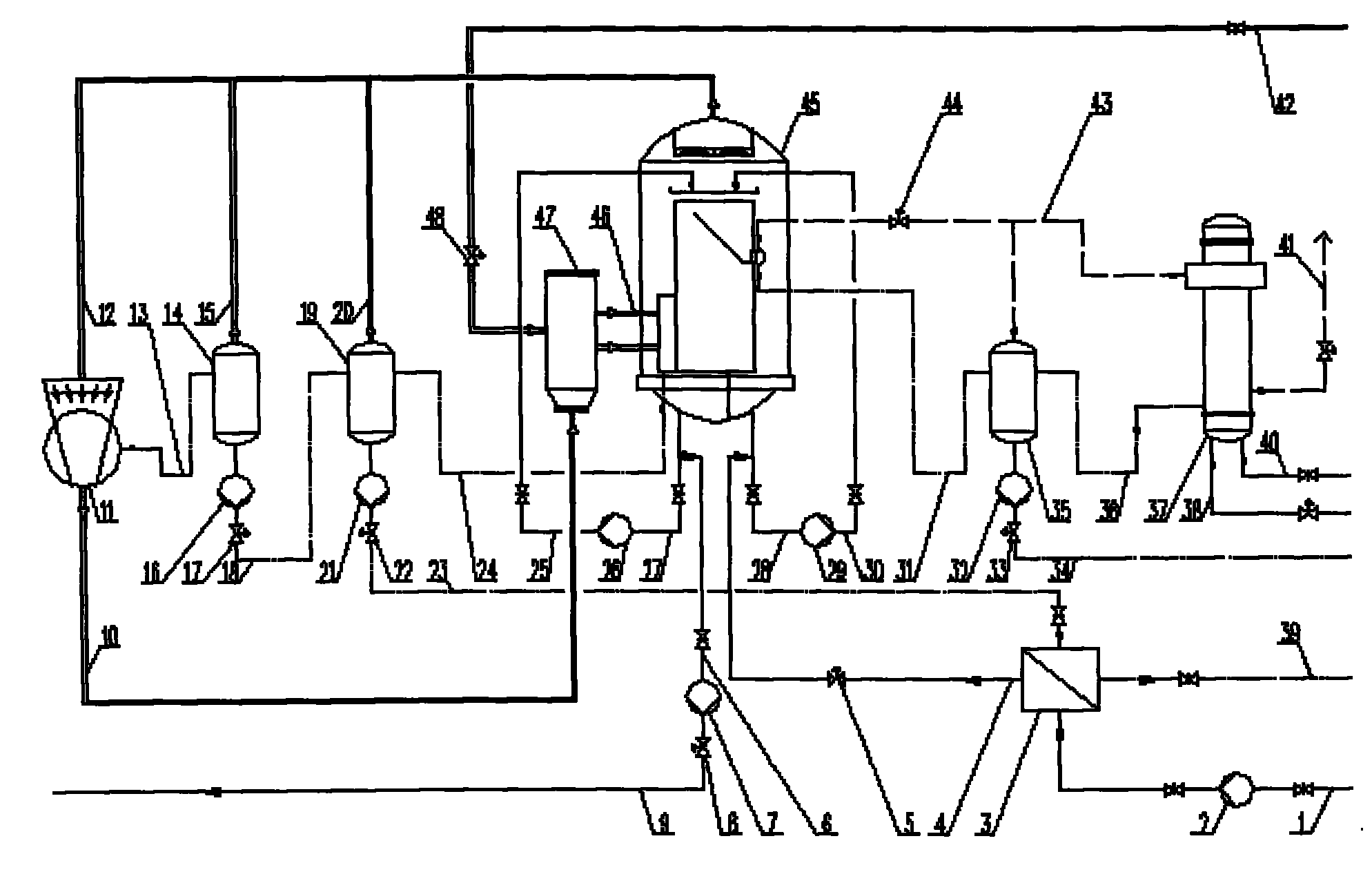

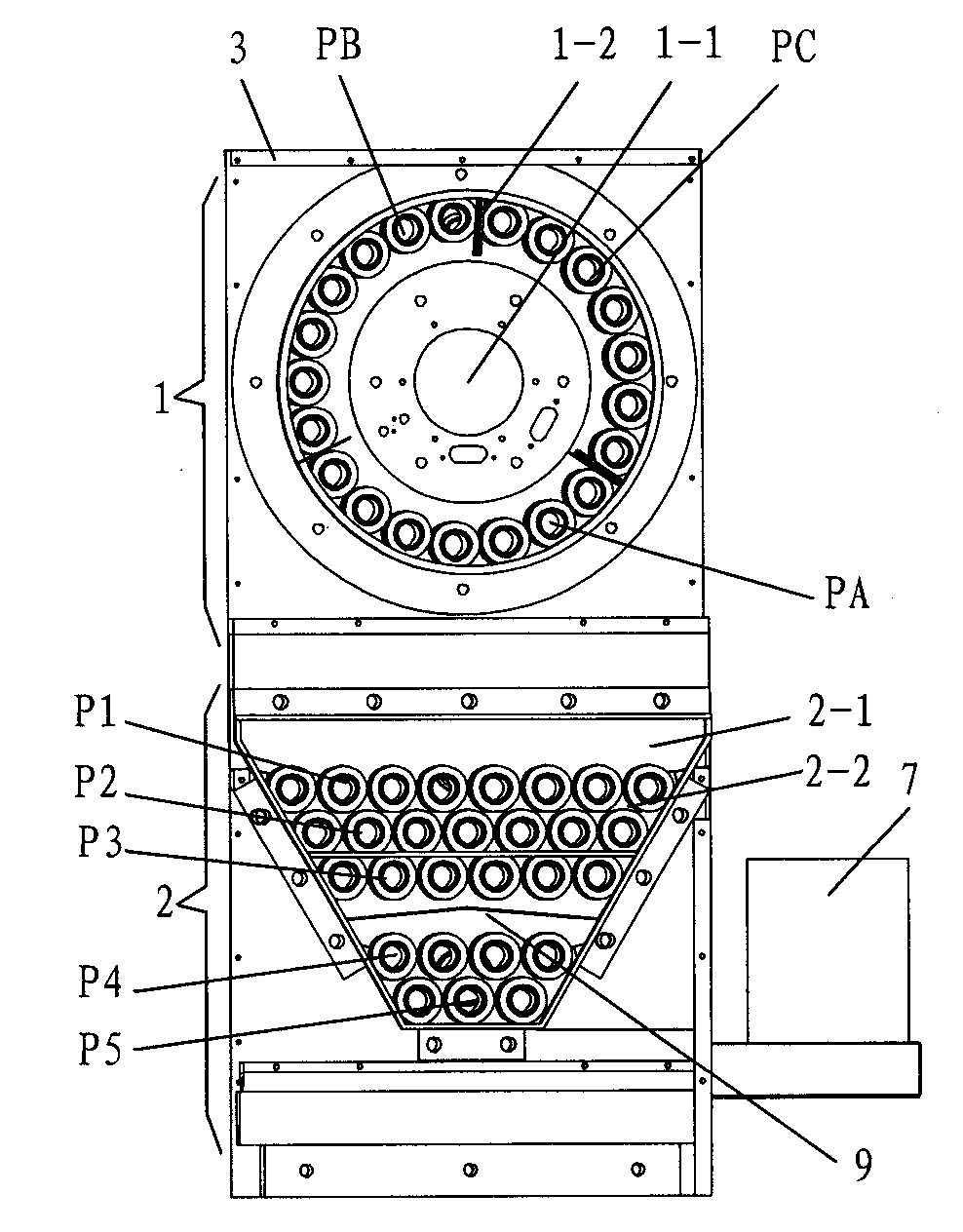

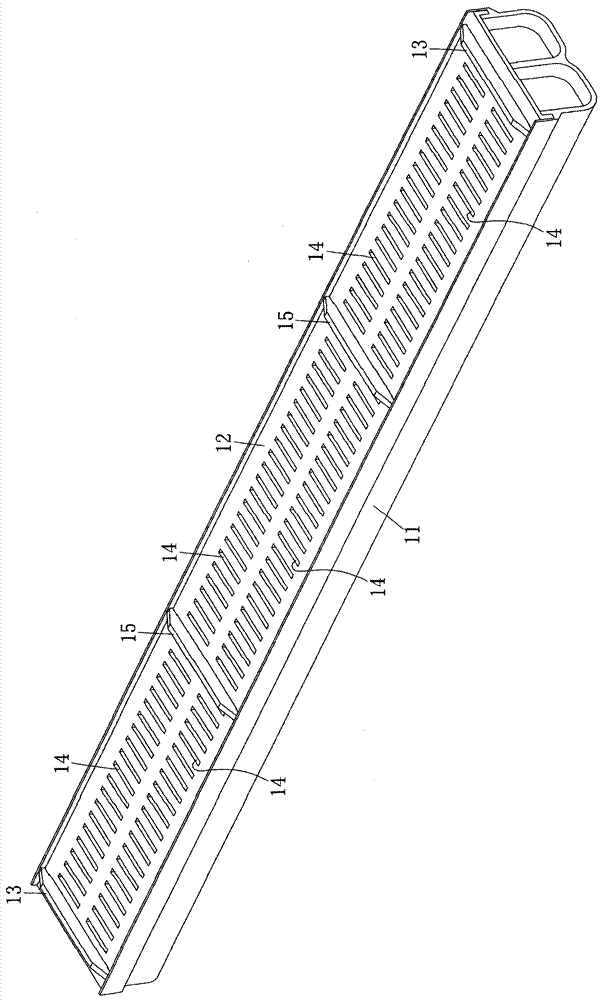

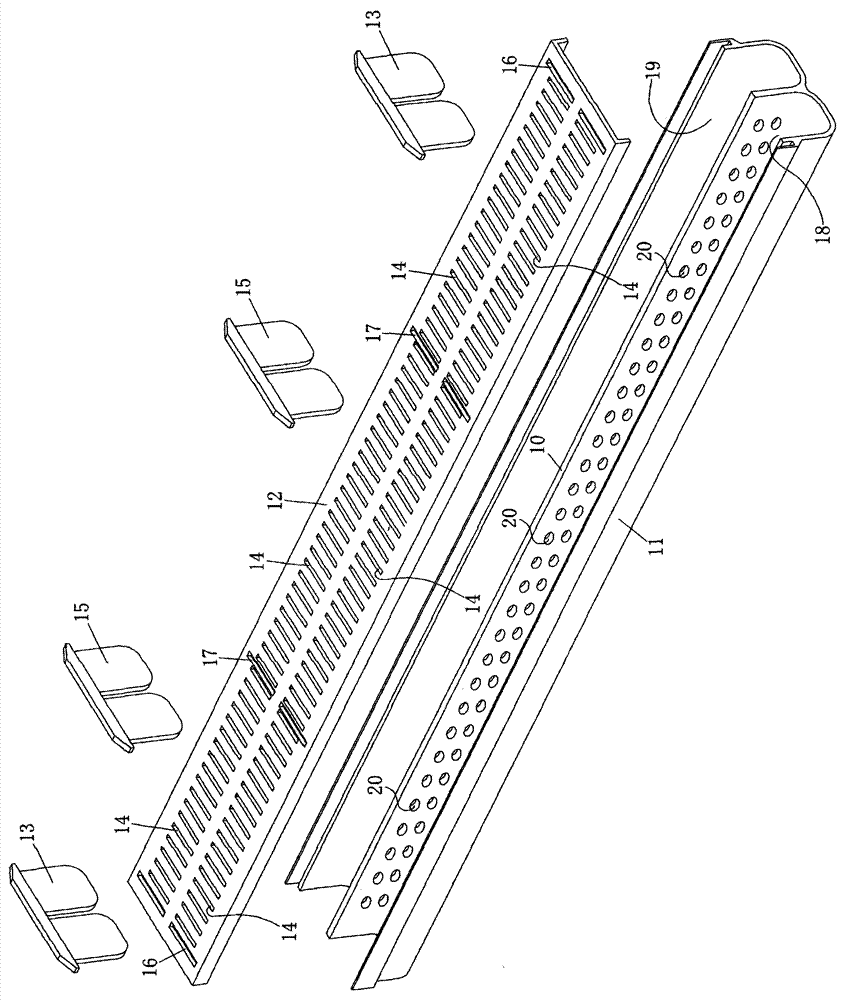

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

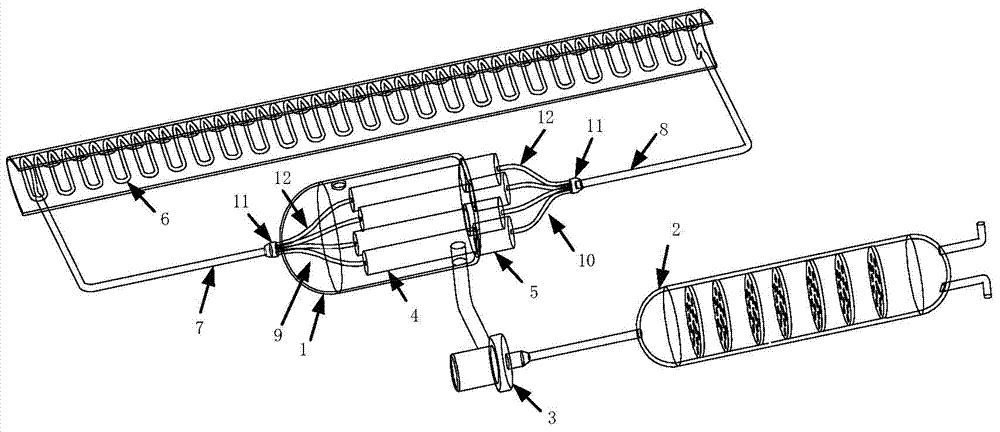

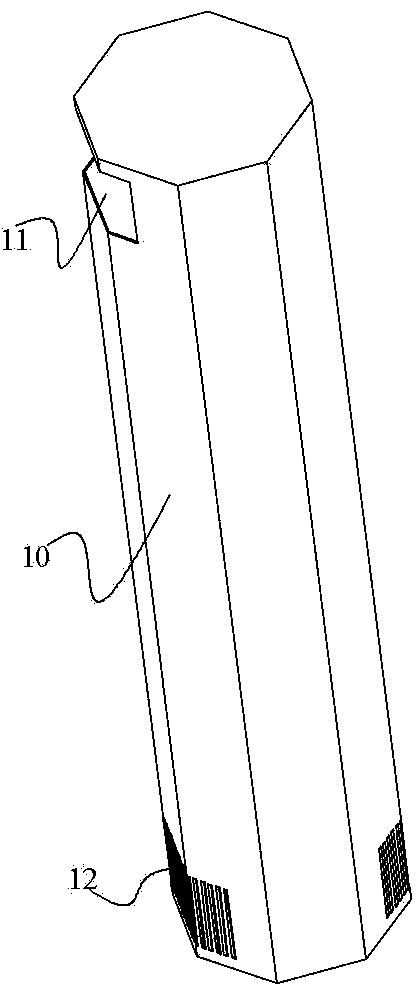

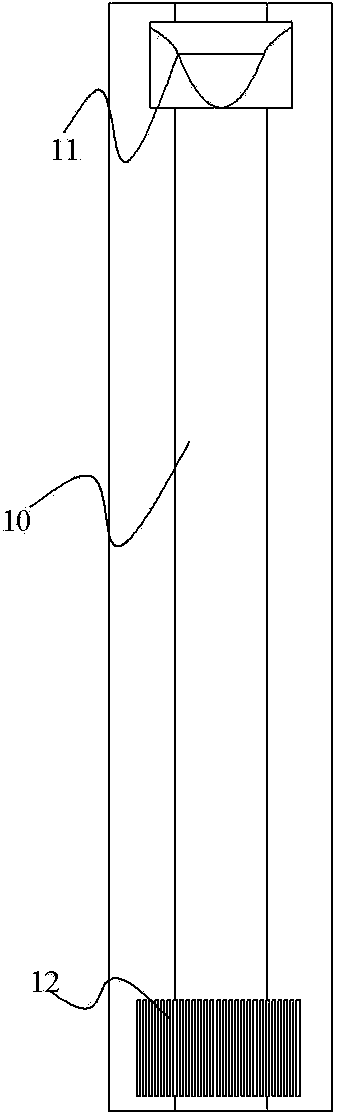

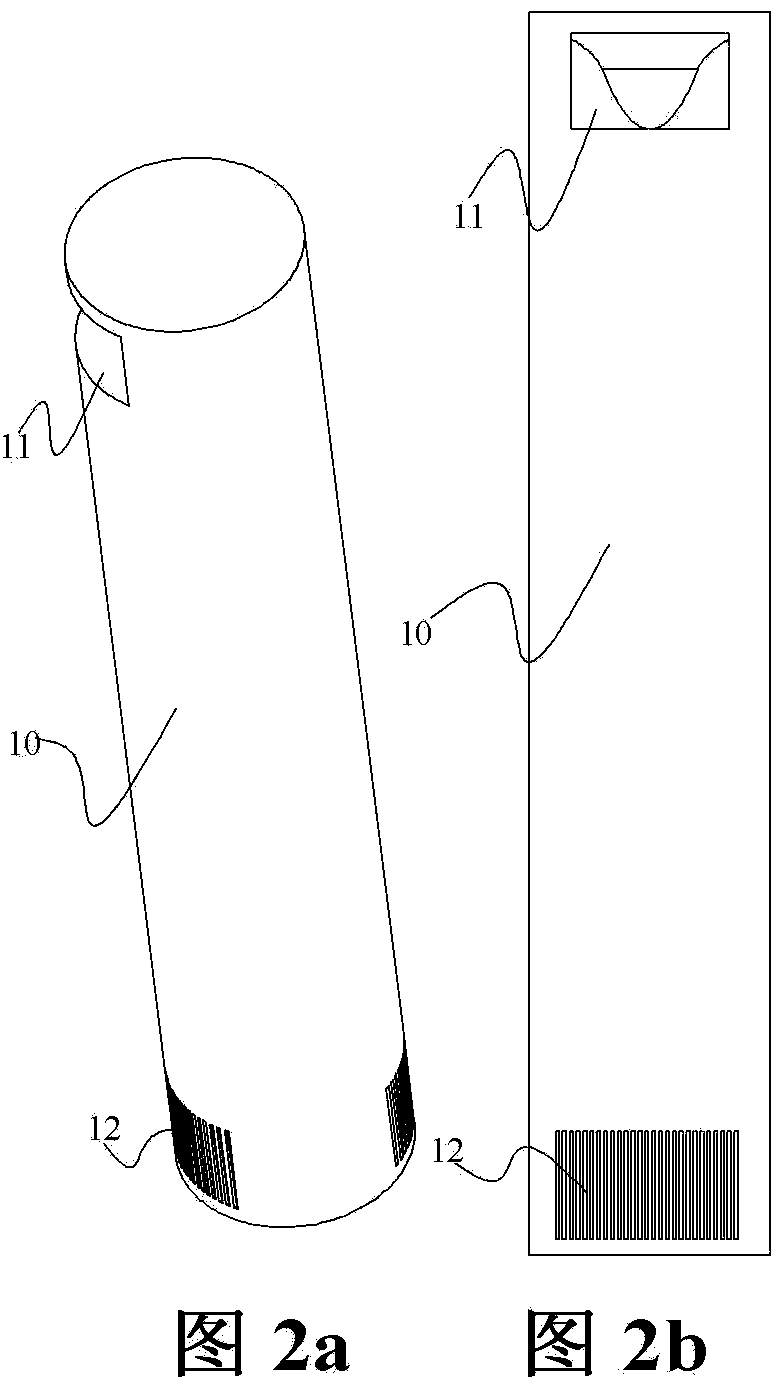

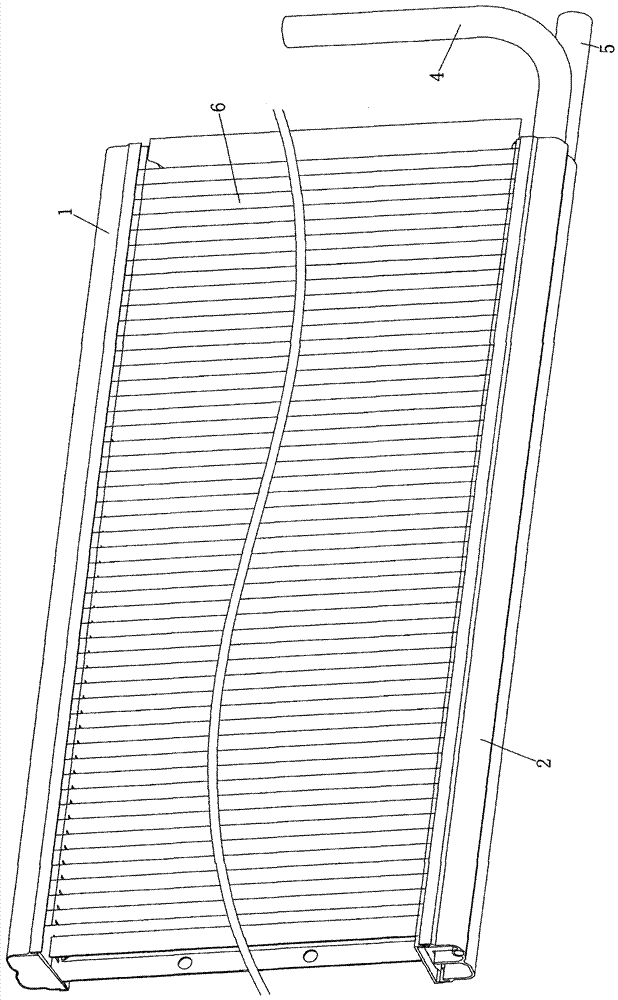

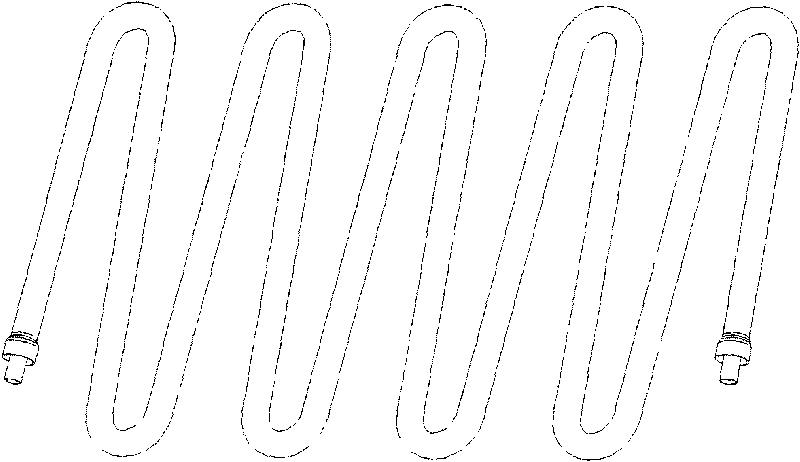

Inflation-type compound-channel evaporator for solar direct-expansion heat pump water heater

ActiveCN103017418ASimple structureEasy to installSolar heating energyEvaporators/condensersRefrigerantEvaporator

The invention discloses an inflation-type compound-channel evaporator for a solar direct-expansion heat pump water heater. The inflation-type compound-channel evaporator comprises an upper pressing plate and a lower pressing plate which are in close fit with each other. A compound channel network is formed between the upper pressing plate and the lower pressing plate through inflation. Flowing refrigerant which is used for absorbing heat for evaporation is arranged in the compound channel network. The inflation-type compound-channel evaporator for the solar direct-expansion heat pump water heater has the advantages of simple structure, attractive appearance, high practicability, low cost and the like, and can enable the solar direct-expansion heat pump water heater to adapt to different climate and weather conditions.

Owner:SHANGHAI JIAO TONG UNIV

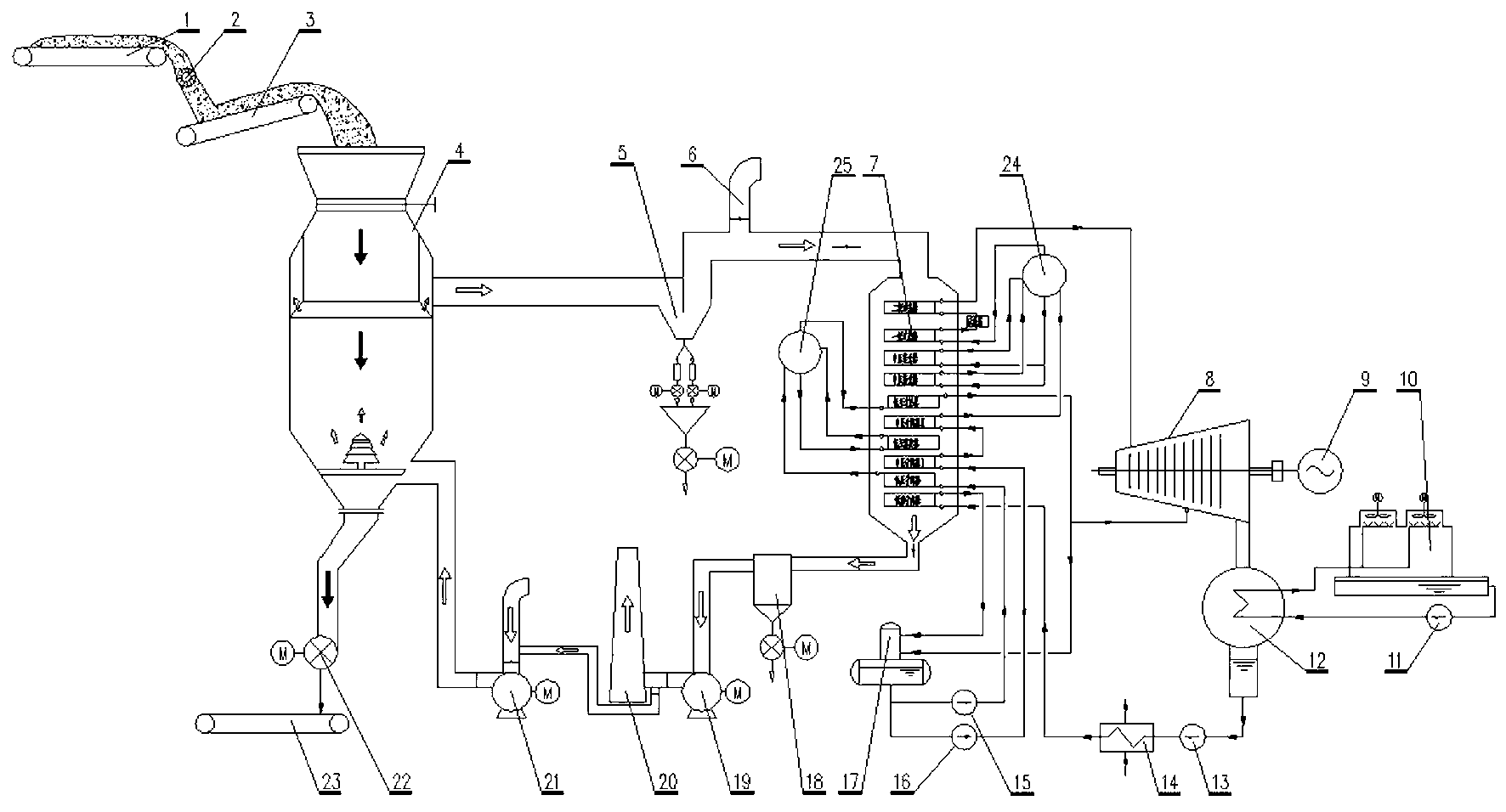

Lignite complete cycle high-efficiency dry distillation quality improving system and method

ActiveCN102925179ASolve efficiency problemsResolve resistanceDirect heating destructive distillationSpecial form destructive distillationIntercoolerEngineering

The invention provides a lignite complete cycle dry distillation quality improving system and method. A bottom outlet of a vertical drying furnace of the lignite complete cycle dry distillation quality improving system is connected with a spiral charging machine, the outlet of the spiral charging machine is connected with a fluidization dry distillation furnace; the bottom of the fluidization dry distillation furnace is connected with a coal gas outlet of a hot blast heater, the top of the fluidization dry distillation furnace is connected with a cyclone dust collector; the feeding hole of the fluidization dry distillation furnace is connected with the spiral charging machine, the discharge hole of fluidization dry distillation furnace is an overflow port in the side wall at the bottom, and the fluidization dry distillation furnace is connected with a gas-solid heat exchanger by virtue of a first U-shaped seal valve; the outlet of the cyclone dust collector is connected with a spray tower, the bottom of the cyclone dust collector is connected with the gas-solid heat exchanger by virtue of a second U-shaped seal valve; the discharge hole of the spray tower is connected with the feeding hole of an electrical tar precipitator, liquid at the bottom of the spray tower and liquid at the bottom of the electrical tar precipitator are converged and then are communicated into a mechanical clarification tank; and the discharge hole at the upper part of the electrical tar precipitator is connected with the feeding hole of an intercooler, and the discharge hole of the intercooler is connected with a pressurization fan. The lignite complete cycle dry distillation quality improving method provided by the invention is a direct contact heat exchange process and has the characteristics of full heat exchange and high thermal efficiency.

Owner:BEIJING PURENERGY TECH DEV

Deep sea high-temperature high-pressure environment simulator

ActiveCN106111218AEffective simulationRegulating pressureAir-pressure/air-lock chambersEngineeringHigh pressure

The invention relates to a deep sea high-temperature high-pressure environment simulator. The deep sea high-temperature high-pressure environment simulator comprises a barrel body with an opening in an upper end, the opening of the upper end of the barrel body is covered with a plug cover, and the plug cover and the barrel body are sealed to form a sealed cavity; a pressurizing opening is formed in the barrel body, a jacket is arranged outside the barrel body, the jacket coats the periphery of the sealed cavity, an inlet for temperature adjusting mediums and an outlet for the temperature adjusting mediums are formed in the jacket, and heat preservation cotton is jointed to the outer wall surface of the jacket and the outer wall surface which is not coated with the jacket on the barrel body; and a plurality of partition boards are fixedly connected to the outer wall surface of the sealed cavity, and are distributed at intervals in the height direction of the sealed cavity, and a diversion hole is formed in each partition board. The deep sea high-temperature high-pressure environment simulator disclosed by the invention can effectively simulate the high-temperature high-pressure environment of deep sea, pressure and temperature can be adjusted, and besides, the deep sea high-temperature high-pressure environment simulator is simple in structure and reliable to work.

Owner:中国船舶重工集团公司第七〇二研究所

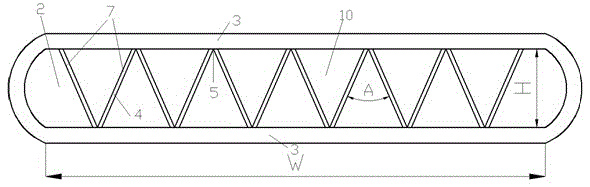

Heat exchanger with triangular through holes different in bottom side lengths

ActiveCN105605945AEvenly distributedSolve the problem of uneven internal pressureStationary conduit assembliesHeat exchanger casingsEngineeringMicro heat exchanger

The invention provides a heat exchanger which comprises two collecting boxes and heat exchange tubes, wherein the heat exchange tubes are arranged between the two collecting boxes; the heat exchange tubes are flat heat exchange tubes; fins are arranged in the flat tubes; the fins comprise inclined parts; a fluid channel is partitioned by the inclined parts into a plurality of small channels; the larger the distance between the flat tubes and an inlet tube is, the larger the lengths h of the bottom sides of the isosceles triangular communication holes in the flat heat exchange tubes are. According to the heat exchanger, as the lengths h of the bottom sides of the isosceles triangular communication holes are changed along with the distance between the flat heat exchange tubes and the inlet tube, fluid can be enabled to flow to the heat exchange tubes with small flow resistance and far away from the inlet tube, the fluid can be uniformly distributed inside the heat exchange tubes, the heat exchange efficiency can be improved, and the service life can be prolonged.

Owner:南京奥优美特压铸技术有限公司

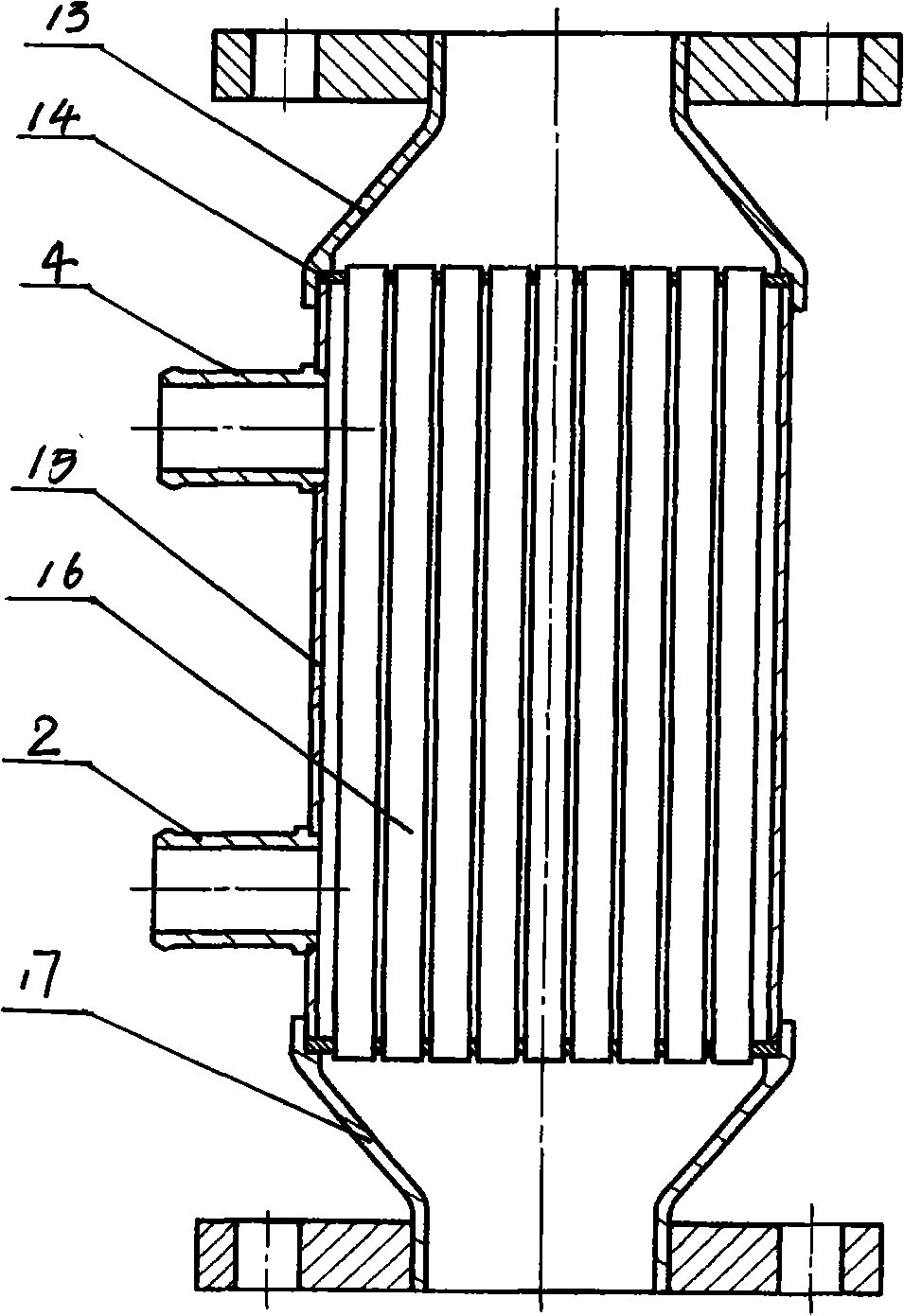

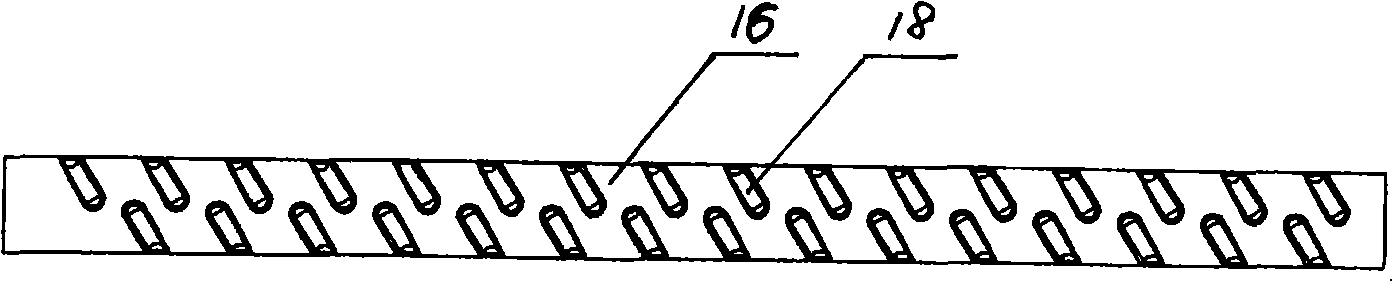

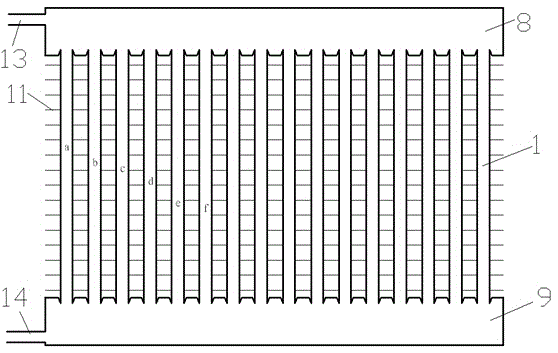

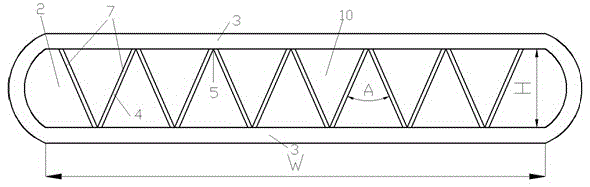

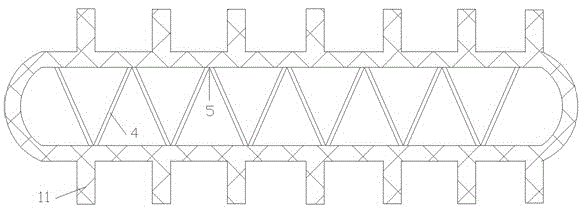

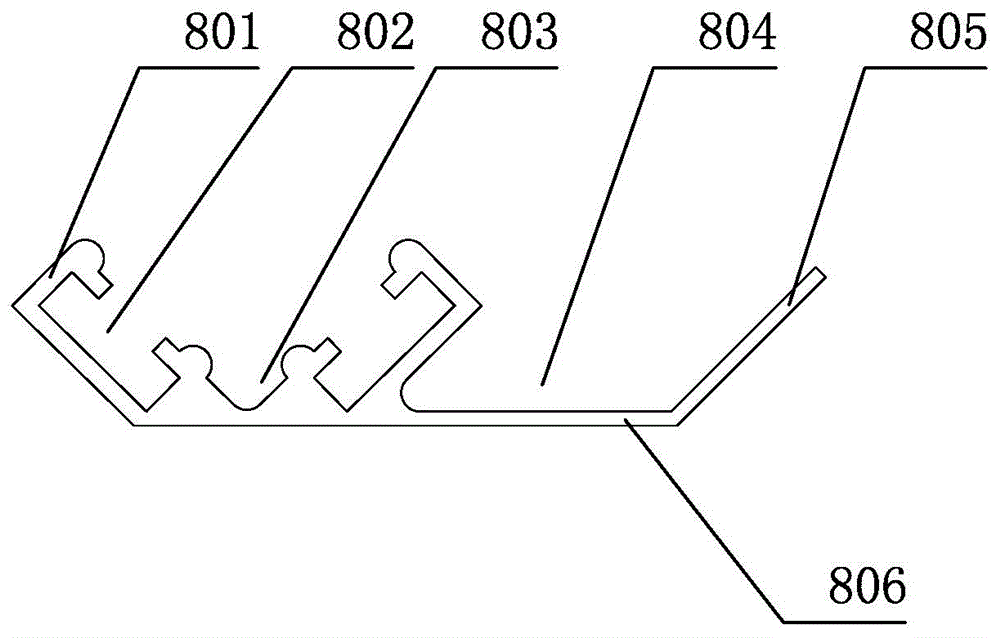

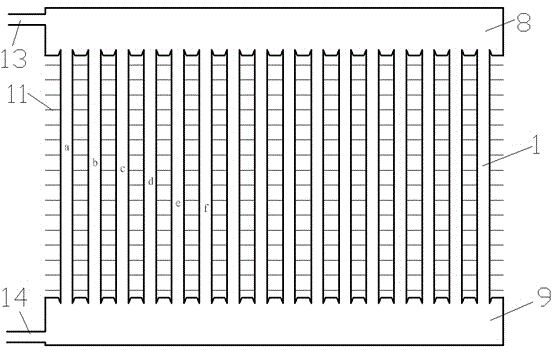

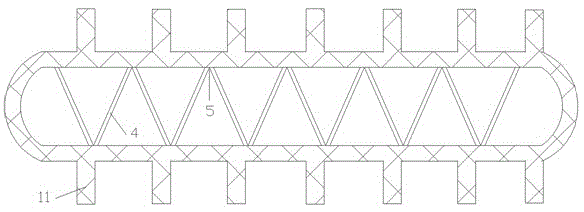

Parallel flow heat exchanger with double-row flat tubes and air-conditioning device with heat exchanger

InactiveCN103697631ASufficient heat exchangeLess prone to problemsEvaporators/condensersBusiness efficiencyEngineering

The invention relates to a parallel flow heat exchanger with double-row flat tubes. An upper collecting main is formed by buckling an upper collecting main cover plate onto an upper collecting main matrix; a lower collecting main is formed by buckling a lower collecting main cover plate onto a lower collecting main matrix; both ends of the double-row flat tubes are respectively inserted a flat tube cutting hole of the upper collecting main and a flat tube cutting hole of the lower collecting main, wherein one row of flat tubes are communicated with a buffer cavity and an overflow cavity, and the other row of flat tubes are communicated with a reflux cavity and a confluence cavity; a liquid inlet cavity is arranged on the lower collecting main matrix in the buffer cavity; the liquid inlet cavity is communicated to the buffer cavity through a plurality of spray holes in the wall body of the liquid inlet cavity; a liquid inlet pipe is externally connected at the port of the liquid inlet cavity; a liquid outlet pipe is arranged on a lower collecting main end plate on one end of the lower collecting main; the liquid outlet pipe is communicated to the confluence cavity. Refrigerant fully flows through the heat exchange flat tubes for twice, the flow resistance is small, a flow path is long, linear eddy does not easily occur along, the heat exchange of the parallel heat exchanger with double-row flat tubes is fuller, the heat exchange efficiency is high, the energy efficiency ratio of the air-conditioning device of the heat exchanger can be improved, the overall structure is simple, the manufacturing is easy, and the installation is convenient.

Owner:浙江金宸三普换热器有限公司

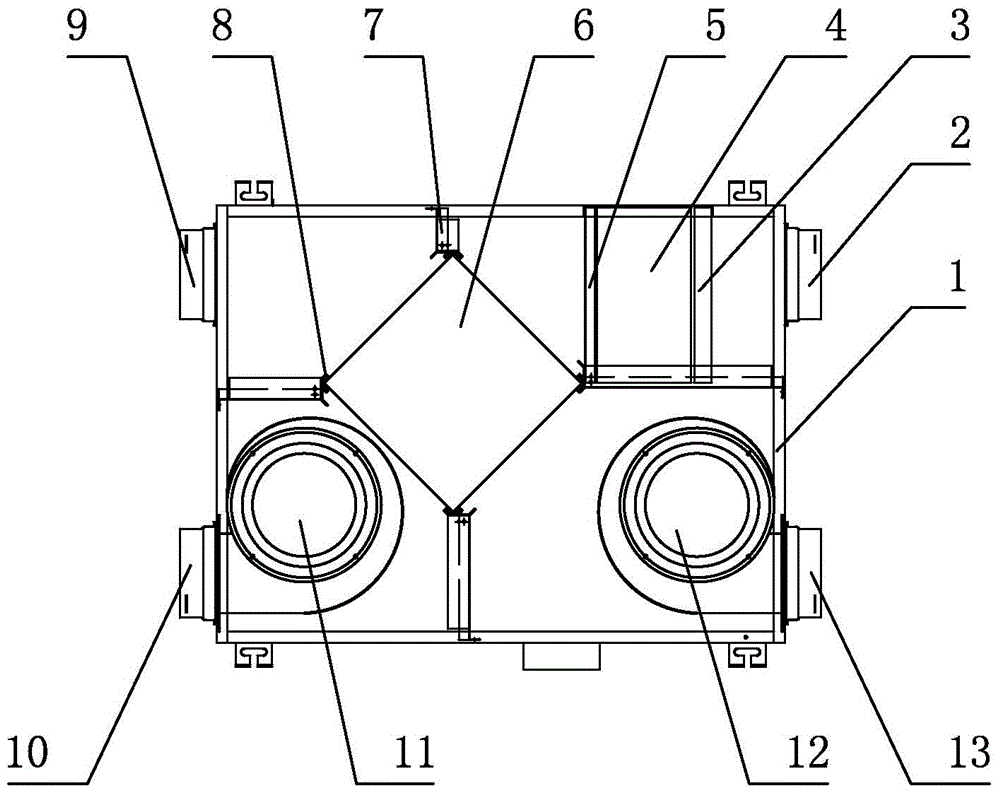

Fresh air ventilator

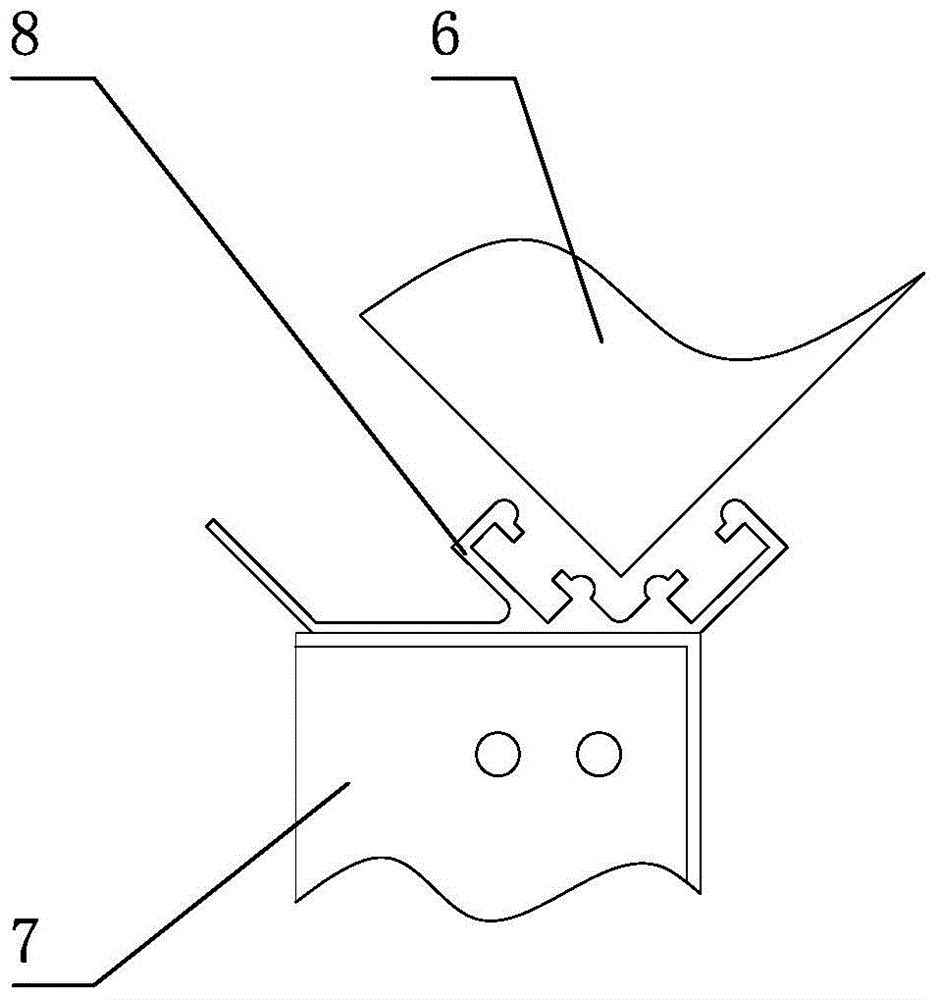

InactiveCN104315601AKeep freshEasy to installEnergy recovery in ventilation and heatingLighting and heating apparatusPlate heat exchangerFresh air

The invention relates to a fresh air ventilator and belongs to the field of vented exhaust equipment. The fresh air ventilator comprises an enclosure and a partition plate support in the enclosure; space in the enclosure is divided into a fresh air inlet passage, a fresh air outlet passage, an exhaust air inlet passage and an exhaust air outlet passage through the partition plate support; a filter, a high-voltage static box and an ozone filter are arranged in sequence along an air inlet direction in the fresh air inlet passage; a fresh air fan is arranged in the fresh air outlet passage; an exhaust air fan is arranged in the exhaust air outlet passage; a plate heat exchanger is arranged at the hubs of the fresh air inlet passage, the fresh air outlet passage, the exhaust air inlet passage and the exhaust air outlet passage, and is fixedly arranged on the partition plate support through mounting buckles. The fresh air ventilator disclosed by the invention has the advantages that substances, such as impurities, dust and ozone, in air can be effectively filtered out to ensure the freshness of the air; the energy is saved, and the environment is protected; the heat exchanger is convenient to install and maintain.

Owner:ZIBO QIYU AIRCONDITION ENERGY RECOVERY EQUIP

Direct air-cooling unit system with plate-type evaporative condenser unit adopted

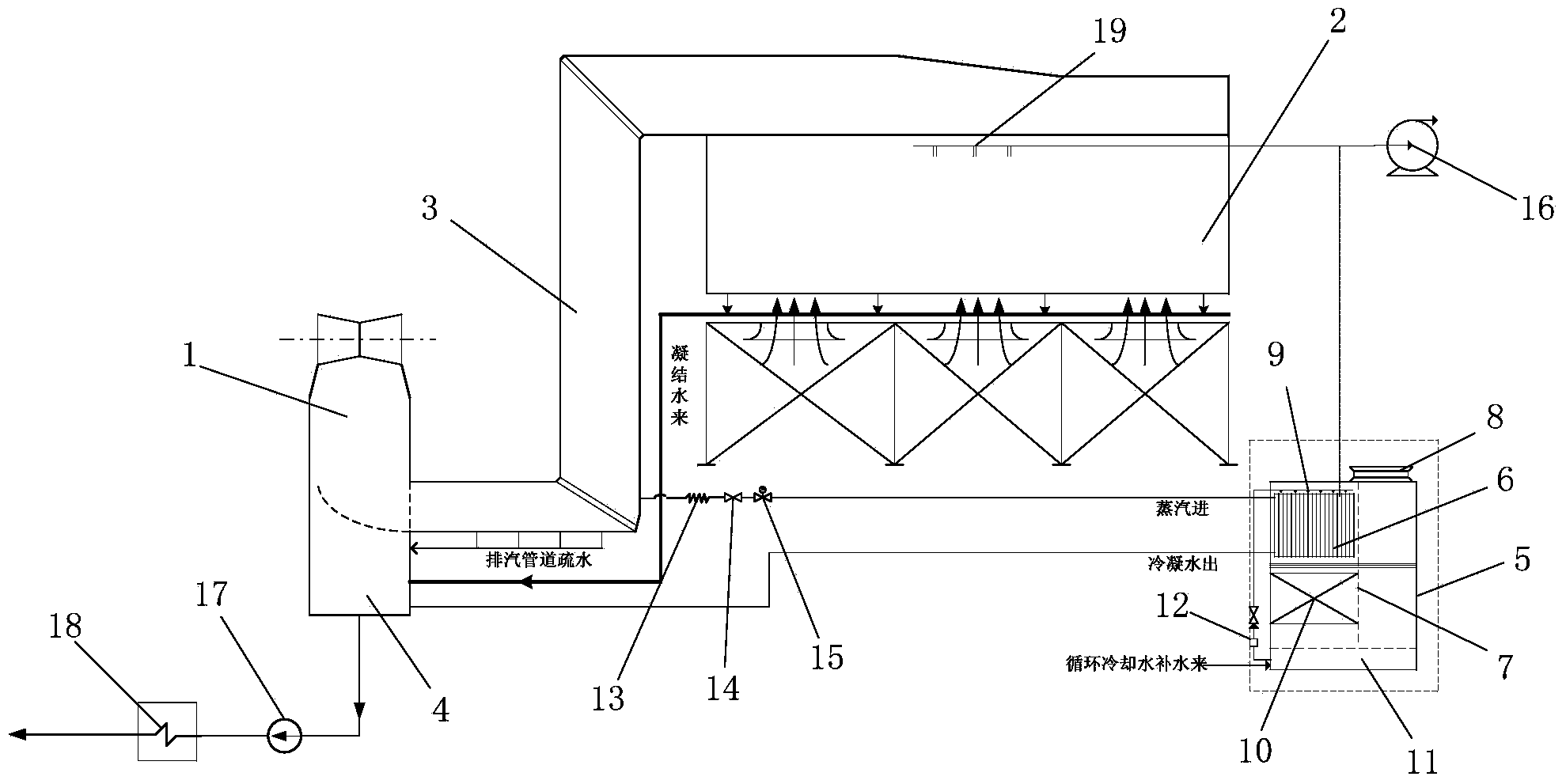

ActiveCN103527267AReduce exhaust pressureReduce heat loadSteam/vapor condensersMachines/enginesUnit systemEngineering

The invention discloses a direct air-cooling unit system with a plate-type evaporative condenser unit adopted. The direct air-cooling unit system comprises a low pressure cylinder, an air cooled condenser and the plate-type evaporative condenser unit, wherein an exhaust steam pipe is communicated with a dead steam inlet of the plate-type evaporative condenser unit through a pipeline to send part of dead steam discharged by a turbine to the plate-type evaporative condenser unit to be cooled, and a condensed water outlet of the air cooled condenser and a condensed water outlet of the plate-type evaporative condenser unit are both communicated with a condensed water tank arranged blow the lower pressure cylinder through pipelines. According to the direct air-cooling unit system with the plate-type evaporative condenser unit adopted, steam discharged by the turbine is introduced into the air condense to be condensed through the steal discharging pipeline connected with the lower pressure cylinder, a pipeline communicated with the dead steam inlet of the plate-type evaporative condenser unit is further arranged on the steal discharging pipeline to introduce part of the dead steam discharged by the turbine to the plate-type evaporative condenser unit to be condensed, so that the thermal load entering the air cooled condenser is reduced, and then steam discharging pressure of the turbine is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Technology and device for baking and grinding high-moisture chalk through vertical mill

The invention discloses a technology for baking and grinding high-moisture chalk through a vertical mill and belongs to the field of cement raw materials prepared by adopting high-moisture chalk raw materials. Clammy chalk with the moisture more than 25% is fed onto an inner refiner plate of the vertical mill from a feeding mouth of the vertical mill; hot wind passes through a wind chamber, a wind ring and a chamber above the refiner plate from a hot wind inlet and discharges out of the vertical mill from a hot wind outlet; zone control is performed on the moisture of materials inside the mill; the moisture of the materials is dried step by step; a powder selecting machine, the feeding mouth and the hot wind outlet are arranged at the upper part of the vertical mill; the refiner plate and mill grinding rollers are arranged inside the vertical mill; a cloth scraping plate is arranged above the refiner plate; a retaining ring is arranged at the edge of the refiner plate; the height of the retaining ring exceeds 150 mm; the wind chamber is arranged below the refiner plate; the wind chamber is communicated with the chamber above the refiner plate through the wind ring; the hot wind inlet of the mill, a material scraping device and a feeding back port are arranged in the wind chamber, the feeding back port is connected with the feeding mouth through an outer circulating system of the mill. The invention provides a simpler and energy-saving preparation technology and device for preparing the cement raw materials by adopting the high-moisture chalk raw materials.

Owner:成都建筑材料工业设计研究院有限公司 +1

Heat-pipe heat exchanger and heat exchange method

InactiveCN102519284ASimple structureEasy maintenanceIndirect heat exchangersThermal energyEngineering

The invention relates to the field of thermal energy and power engineering, in particular to a heat-pipe heat exchanger and a heat exchange method. The heat-pipe heat exchanger comprises a heat pipe housing, at least one radiator, at least one heat collector, a heat insulating layer and an exhaust liquid-filling port, wherein the heat pipe housing comprises a single inner space, a heat transfer medium is filled into the lower portion of the inner space, each radiator is filled with a radiating medium, the radiators are positioned on the lower portion of the inner space and immersed in the heat transfer medium, each heat collector is filled with a heat collection medium, the heat collectors are positioned on the upper portion of the inner space and above the liquid level of the heat transfer medium, the heat insulating layer warps the outer wall of the heat pipe housing, the exhaust liquid-filling port is reserved at the top of the heat pipe housing or on the upper portion of the lateral wall of the heat pipe housing, the heat transfer medium is filled into the heat pipe housing through the exhaust liquid-filling port, and gas in the heat pipe housing is exhausted through the exhaust liquid-filling port. The heat-pipe heat exchanger is simple in structure, convenient in maintenance and better in heat exchange effect.

Owner:XIHUA UNIV

Heat exchanger provided with area-varying communication holes

InactiveCN105571209AEvenly distributedSolve the problem of uneven internal pressureEvaporators/condensersTubular elementsEngineeringHeat exchanger

The invention provides a heat exchanger. The heat exchanger comprises two headers and heat exchanging tubes which are arranged between the two headers; each heat exchanging tube is a flat heat exchanging tube; fins are arranged in each flat tube; each fin comprises an inclined part; the inclined parts are used for isolating fluid passages to form a plurality of small passages; each inclined part is provided with communication holes; the communication holes in different flat heat exchanging tubes are different in area; the farther the distance from each communication hole to an inlet tube is, the larger the area of the communication hole in the flat tube is. According to the heat exchanger provided by the invention, the area of each communication hole is set to vary along with the distance away from the inlet tube, so that a fluid can flow into the heat exchanging tube which is small in flow resistance and far away from the inlet tube; therefore, the fluid can be uniformly distributed in the heat exchanging tubes, the heat exchange efficiency is improved, and the service life is prolonged.

Owner:青岛酒店管理职业技术学院

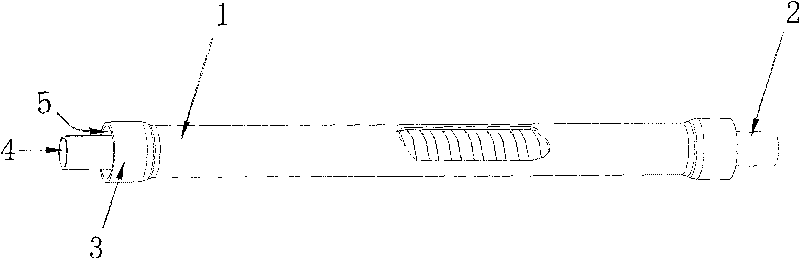

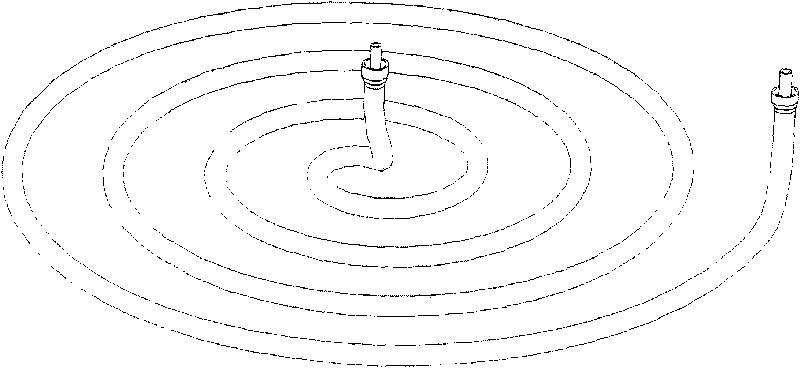

Spiral-tube heat exchanger

InactiveCN101738109AImprove heat transfer effectSimple processStationary tubular conduit assembliesPlate heat exchangerWater channel

The invention relates to a spiral-tube heat exchanger which comprises a refrigerant channel and a water channel, and is characterized in that a spiral tube is arranged inside an outer tube, and the two ends of the spiral tube are exposed outside; the tube wall inside the outer tube where the spiral tube is arranged takes on screw thread shape; and the inner wall of the outer tube is matched with crest of screw thread of the outer wall of the spiral tube, and the inner wall of the outer tube is connected with the crest of screw thread of the outer wall of the spiral tube into a whole by soldering, so that a sealing surface is formed. The inner wall of the spiral tube also takes on screw thread shape. The two ends of the outer tube are provided with flareouts. The water channel is arranged at the inner side of the spiral tube, and the refrigerant channel is positioned at a thread channel between the outer side of the spiral tube and the inner side of the outer tube. The spiral-tube heat exchanger has the advantages that refrigerant is contacted with water by a clapboard, so that the heat transfer efficiency is high, the thermal resistance is low, the flow path of the refrigerant can be greatly increased within a limited space, full heat exchange can be realized, and the heat exchange capability of the heat exchanger can be improved within a limited space. The spiral-tube heat exchanger can be widely applied to the products such as a wall hanging instant heating type heat pump water heater and the like which need smaller installation space and high unit volume heat exchange quantity.

Owner:江秋良 +1

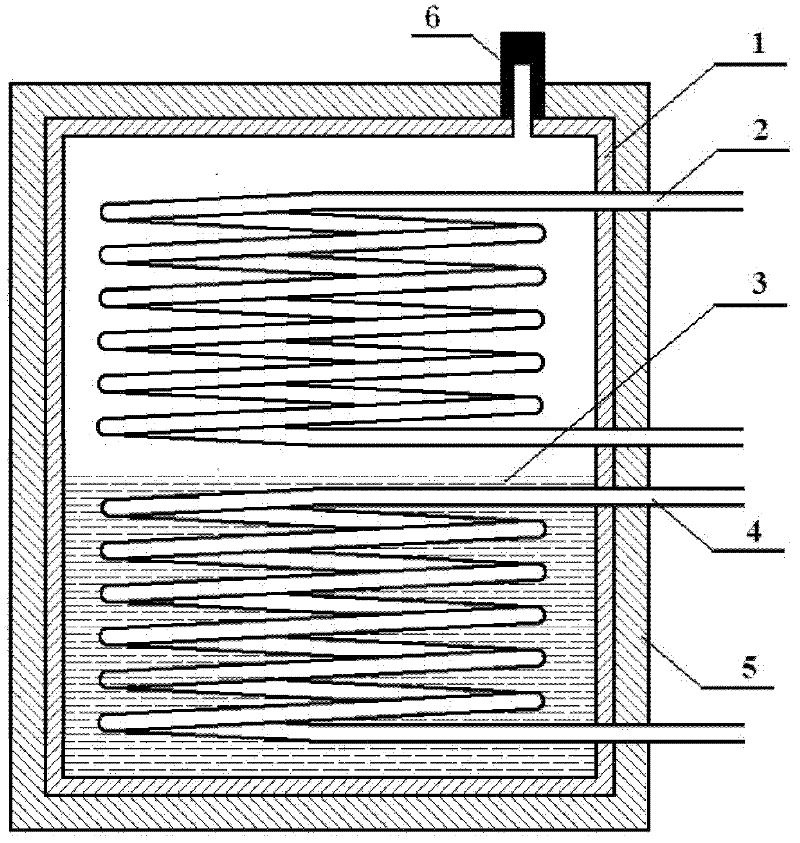

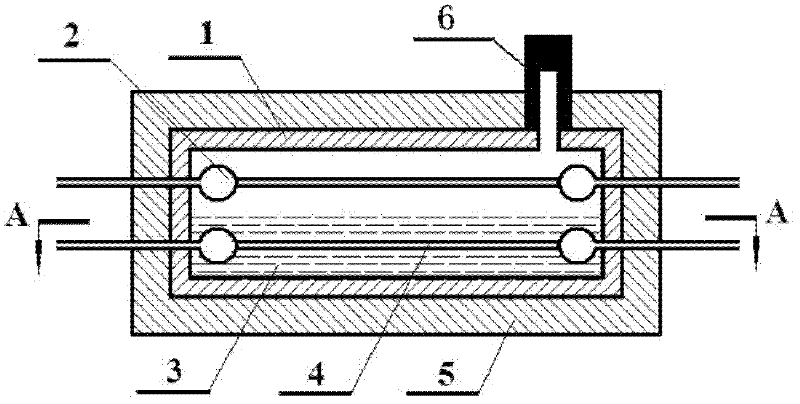

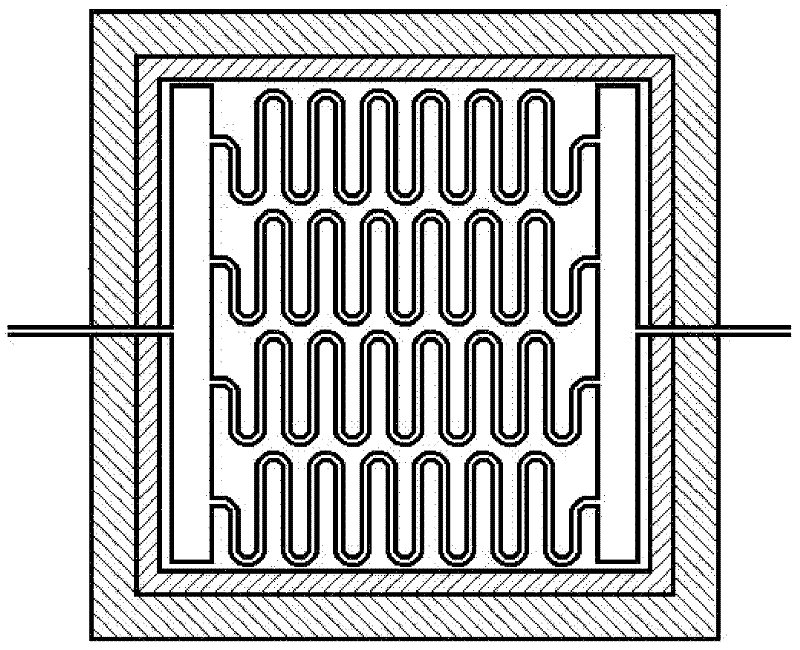

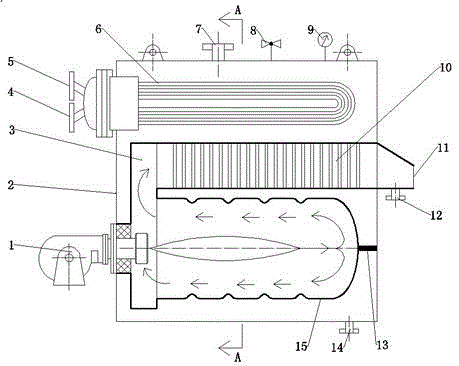

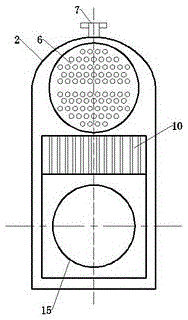

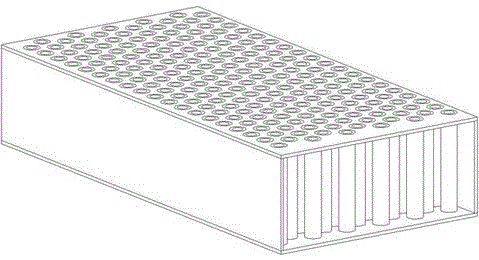

Water tube type vacuum boiler with central reverse flames

The invention discloses a water tube type vacuum boiler with central reverse flames. The vacuum boiler mainly comprises a combustor, a casing, a flue gas transfer chamber, a container, a water tube type heat exchanger and a U-shaped tube heat exchanger. The vacuum boiler is characterized in that the boiler casing is formed by butt-jointing an upper arc-shaped barrel and a lower cuboid casing, the U-shaped tube heat exchanger is located at the upper part of the casing, and the container, the flue gas transfer chamber and the water tube type heat exchanger are located at the lower part of the casing; the container is waved, the front end of the container is welded on the flue gas transfer chamber, and the back end is welded on an ellipsoidal gland; a central reverse flame combustion manner is adopted; a plurality of vertical heat exchange tubes are arranged in the water tube type heat exchanger, flue gas inlets of the heat exchange tubes are welded on the flue gas transfer chamber, and flue gas outlets are connected with an exhaust tube. The boiler keeps a certain vacuum degree inside during running, boiler water boils at the temperature lower than 100 DEG C after being heated, steam rises and condenses outside the U-shaped tube heat exchanger to release heat to heat return water in the tube, and condensate water flows back into the boiler. The boiler is compact in structure and higher in heat efficiency and occupies small area, and no external heat exchanger is required.

Owner:ZHENGZHOU UNIV

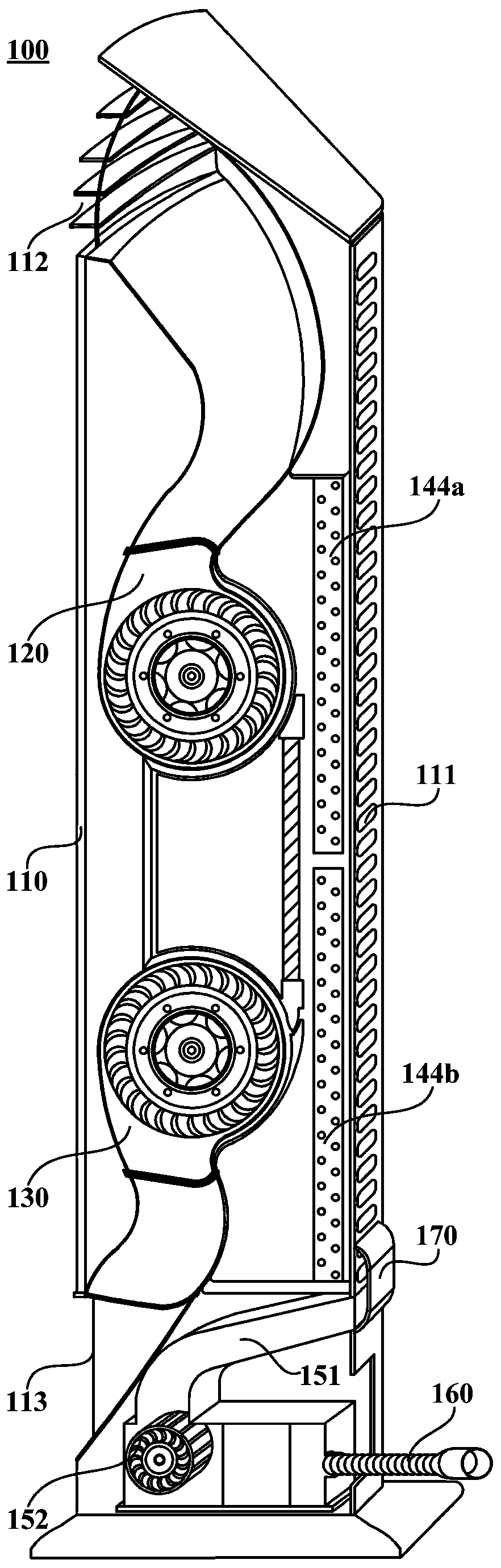

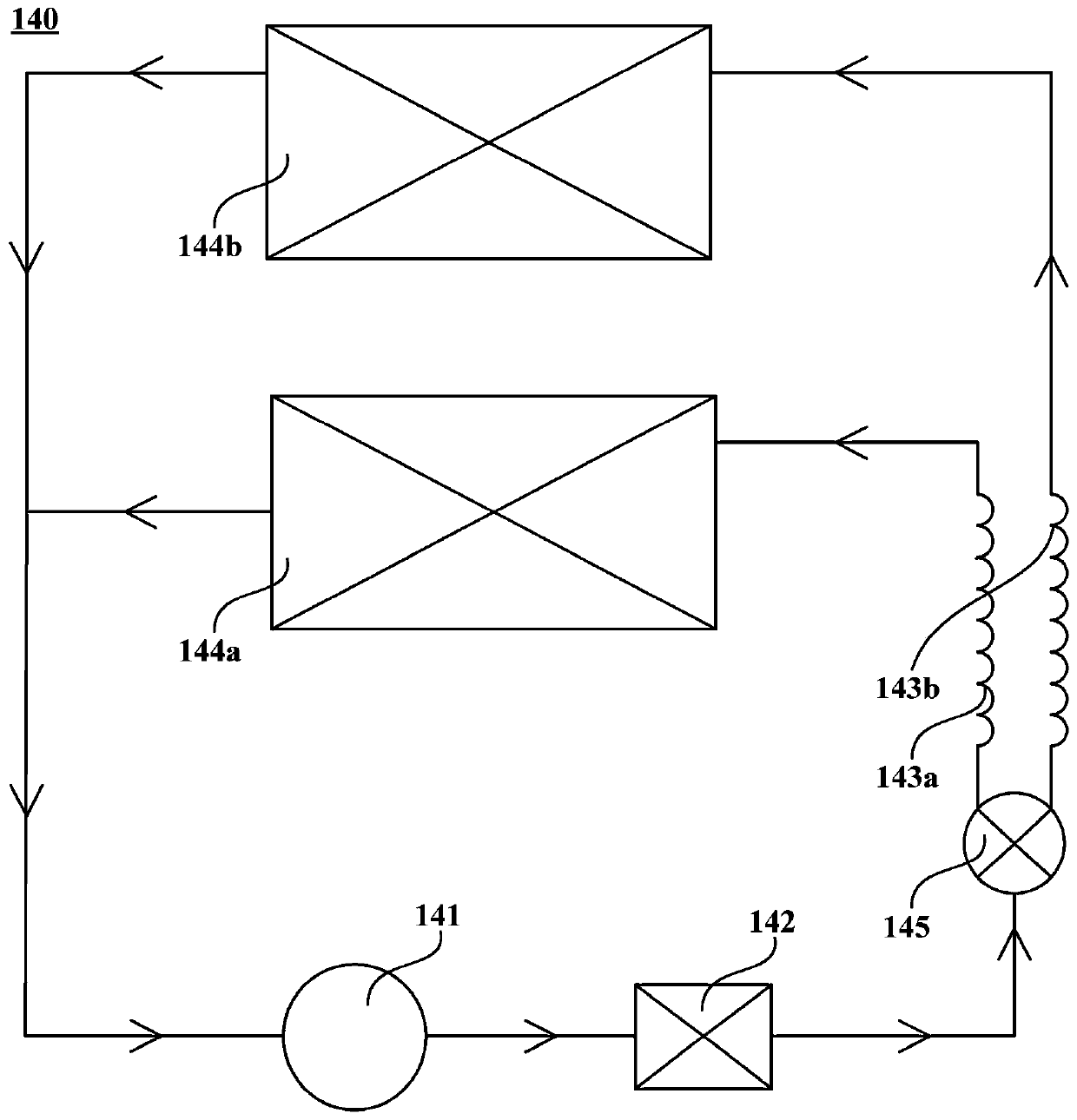

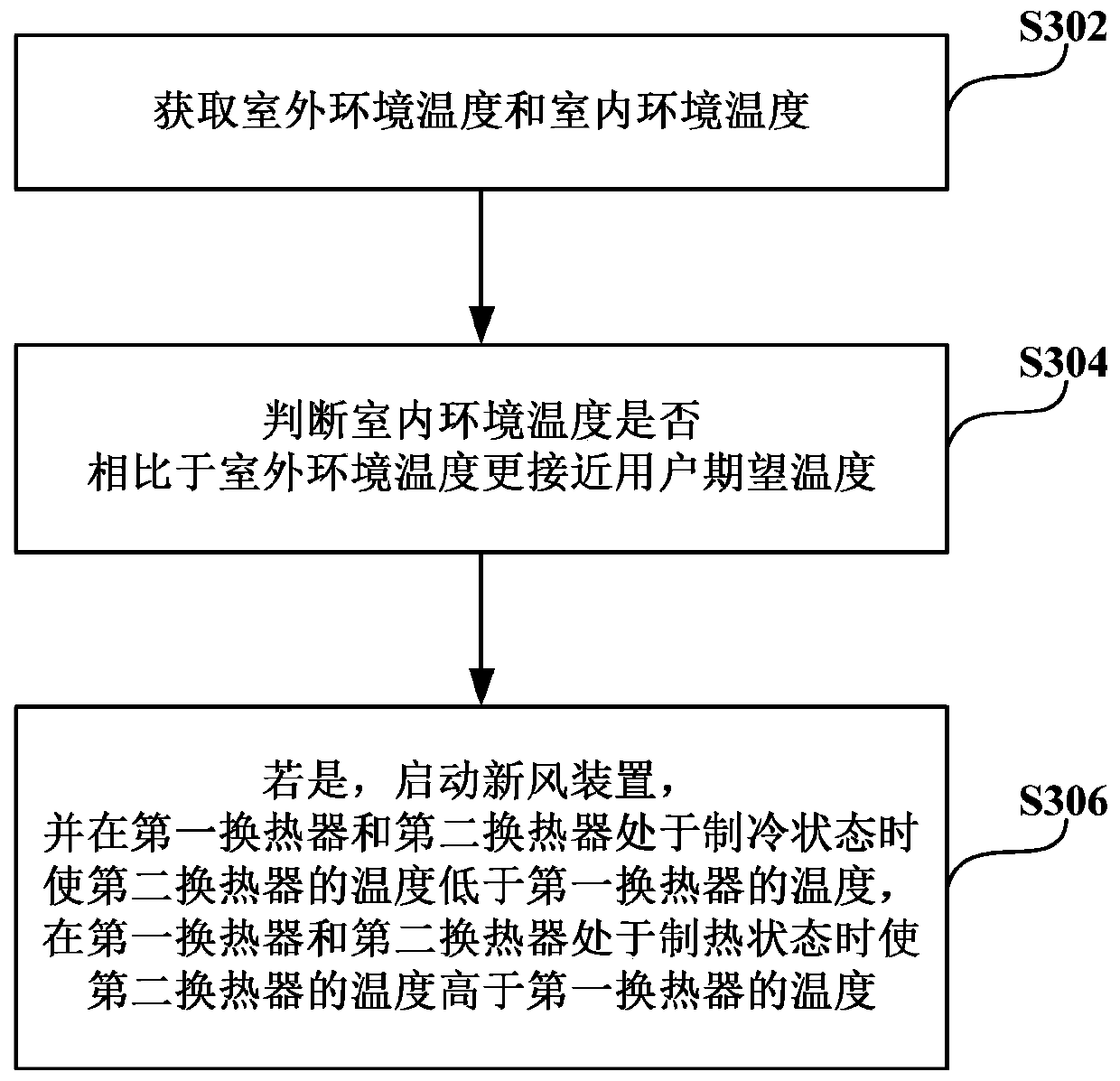

Control method for air conditioner indoor unit and air conditioner indoor unit

ActiveCN110470031AAvoid discomfortImprove heat transfer efficiencyMechanical apparatusSpace heating and ventilation safety systemsFresh airTemperature difference

The invention provides a control method for an air conditioner indoor unit and the air conditioner indoor unit. The air conditioner indoor unit comprises a first air supplying fan, a second air supplying fan, a first heat exchanger, a second heat exchanger and a fresh air device, wherein the first heat exchanger is arranged on an air inlet flow path of the first air supplying fan, the second heatexchanger is arranged on an air inlet flow path of the second air supplying fan, and the fresh air device conducts flow guiding on outdoor air to the upstream position of the second heat exchanger. The control method comprises the steps that the outdoor ambient temperature and the indoor ambient temperature are obtained; whether the indoor ambient temperature is closer to the temperature expectedby a user than the outdoor ambient temperature or not is judged; if yes, the fresh air device is started, the temperature of the second heat exchanger is lower than that of the first heat exchanger when the first heat exchanger and the second heat exchanger are in a refrigeration state; and when the first heat exchanger and the second heat exchanger are in a heating state, the temperature of the second heat exchanger is higher than that of the first heat exchanger, the outdoor air is fully subjected to heat exchange, and the temperature difference between an air flow blown by a first air outlet and an air flow blown by a second air outlet is decreased.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

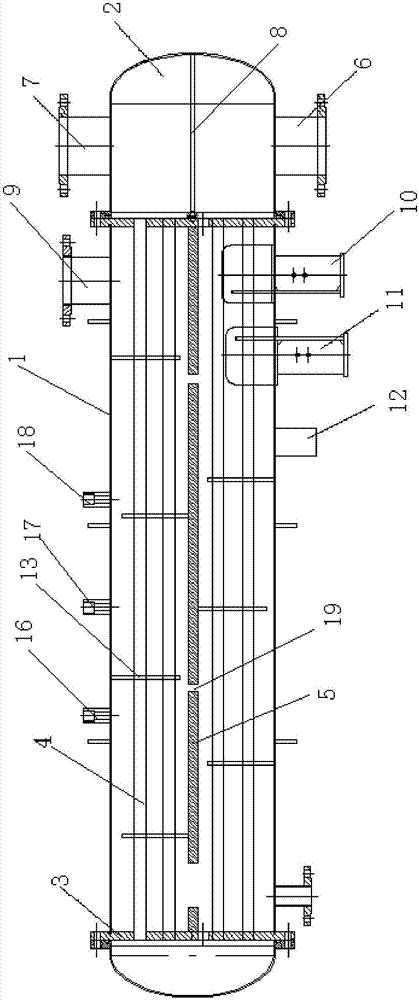

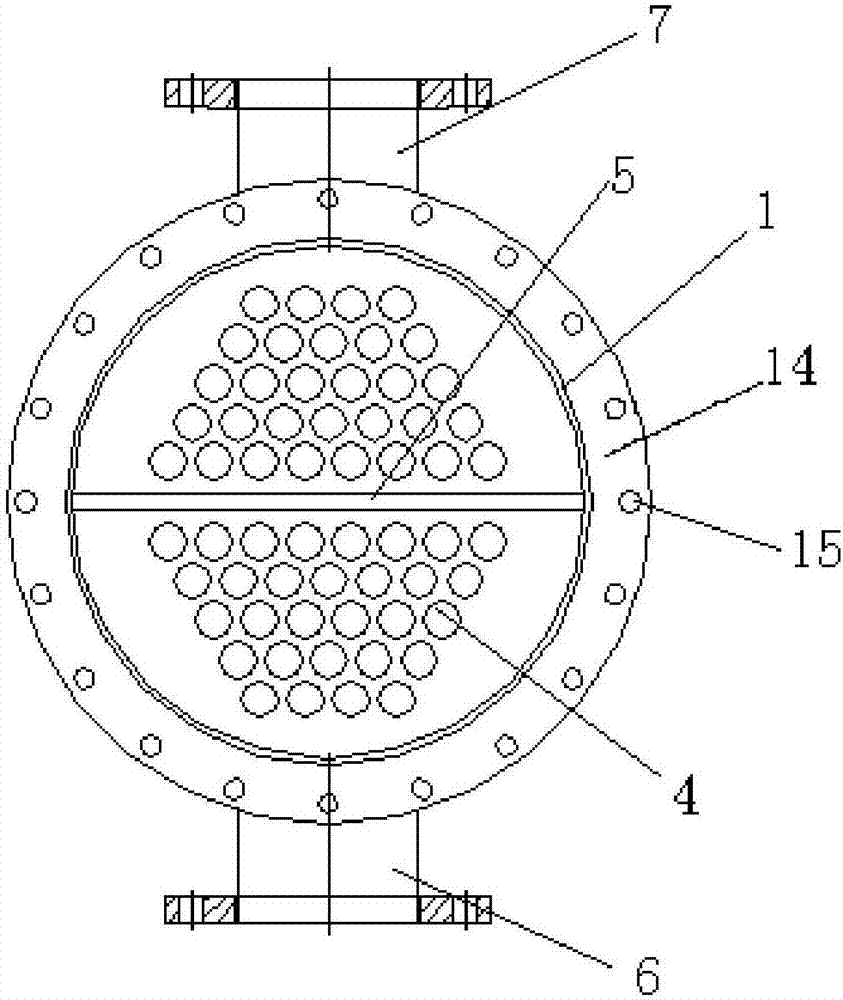

Horizontal heater structure with high heat utilization rate

InactiveCN107490303AReasonable useAchieve reasonable utilizationSteam/vapor condensersHeat exchanger casingsThermal energyEngineering

The invention discloses a horizontal heater structure with the high heat utilization rate. The horizontal heater structure comprises a horizontal and straight tank body. The tank body is composed of a cylinder body and oval sealing heads matched with the two ends of the cylinder body. Heat exchange conveying pipes are mounted in the cylinder body through flange pipe plates at intervals. Partitions for partitioning the heat exchange conveying pipes are mounted in the middles of the flange pipe plates, a feeding opening and a discharging opening are formed in the oval sealing head at the same end, the feeding opening is located in the lower end, the discharging opening is located in the upper end, and the feeding opening and the discharging opening are partitioned by a pass partition plate. A steam inlet is formed in the end, where the discharging opening is located, of the cylinder body. A steam outlet, a condensate outlet and an exhaust opening are formed in the end, where the feeding opening is located, of the cylinder body. Steam through holes are formed in the partitions near the oval sealing head at the other end, and baffle plates are distributed on the discharging pipes below the partitions and the feeding pipes above the partitions. By the adoption of the horizontal heater structure with the high heat utilization rate, the requirement that mother liquid is heated gradually in the conveying process is met, the steam heat energy is used reasonably, the sufficient heat exchange effect is achieved, and the reasonable utilization of resources is met.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

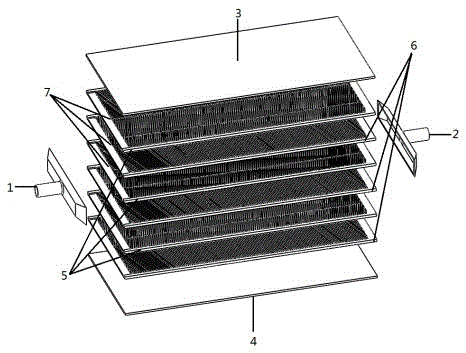

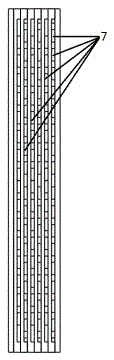

Microchannel heat radiator

InactiveCN105526813ASimple processEnhanced interactionHeat exchanger casingsStationary plate conduit assembliesEngineeringElectron

The invention relates to the technical field of heat radiation, particularly relates to a microchannel heat radiator and aims at further increasing the efficiency of the existing heat radiating device of an electronic device. The microchannel heat radiator comprises an upper cover plate, a lower cover plate, a fluid feeding unit, a fluid discharging unit and a plurality of heat exchange units, wherein each heat exchange unit is formed by reversely overlapping two heat exchange plates; each heat exchange plate is internally provided with a plurality of partition plates among which runners for allowing fluids to flow are formed; and the adjacent partition plates are intercrossed to form cavities. The partition plates of the adjacent heat exchange plates are crossed to form crossed and interconnected runners, so that the fluids can pass through different heat exchange plates; and due to the adoption of the flowing way, the flow paths of the fluids in the heat radiator are increased, flow routes are optimized, and heat exchange is more sufficient. In addition, due to the adoption of the design, the fluids in different runners can be mutually converged, hedged and dragged, the interaction between every two fluids can be enhanced, and the heat exchange effect can be improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

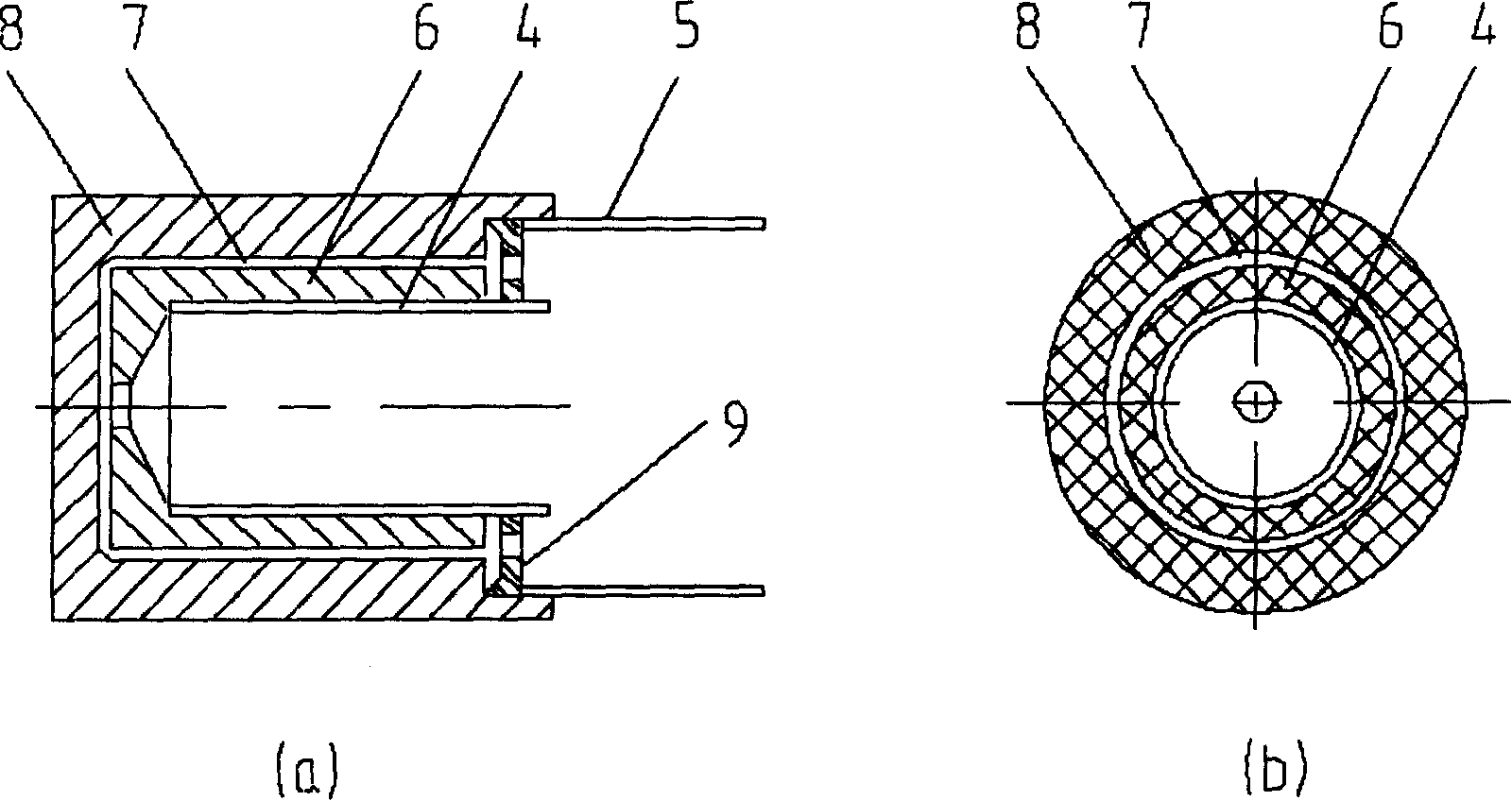

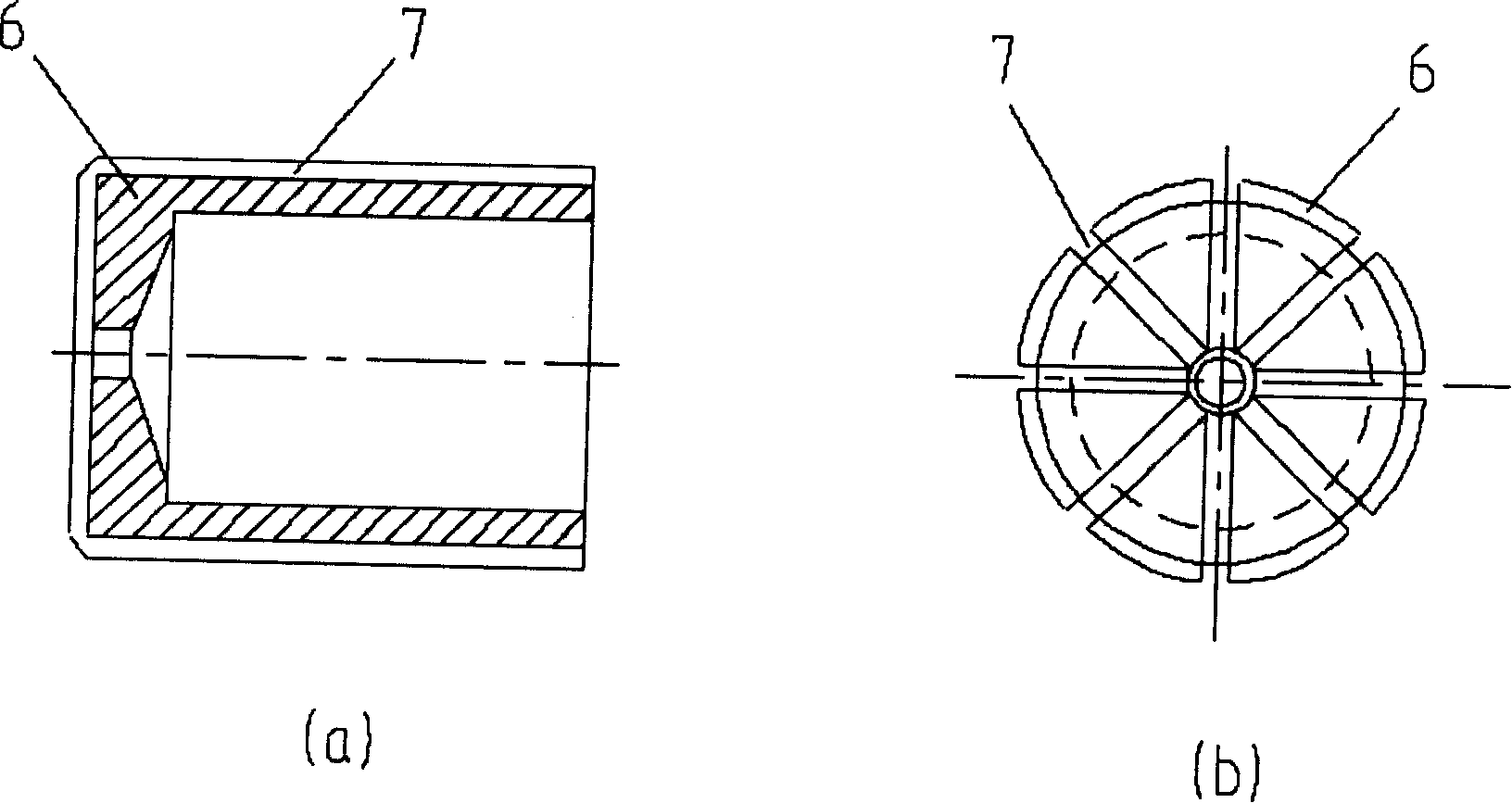

Dual-cooling-head slit-cooling coaxial neamal tube refrigerating machine

InactiveCN1851355ASimple structureGuaranteed tightnessCompression machinesGas cycle refrigeration machinesRefrigerationHeat transfer

The invention relates to double fixed junctions slit cooling finger coaxial vessel refrigerating machine. It belongs to refrigeration technical field. Line form compressor is connected to the hot end of the hold over. The cooling end of the vessel is formed a slit type cooling finger. Its bottom and out wall are set groove. The edge of the cooling end cover and the out wall of the hold over are welded. The invention simplifies cooling end structure, enhance heat transfer capability. Thus the performance of the coaxial vessel refrigerating machine is increased further.

Owner:SHANGHAI JIAO TONG UNIV

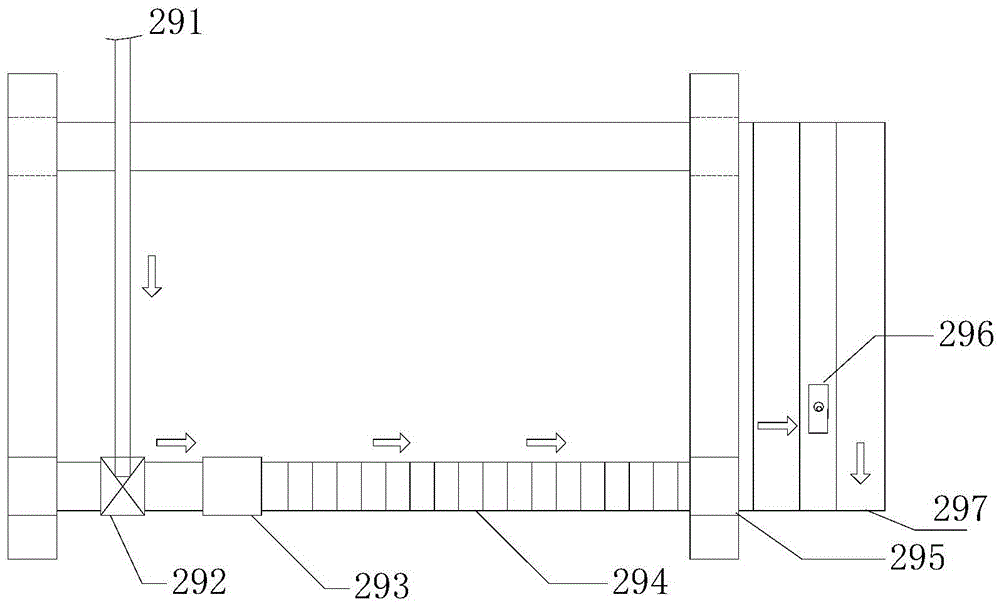

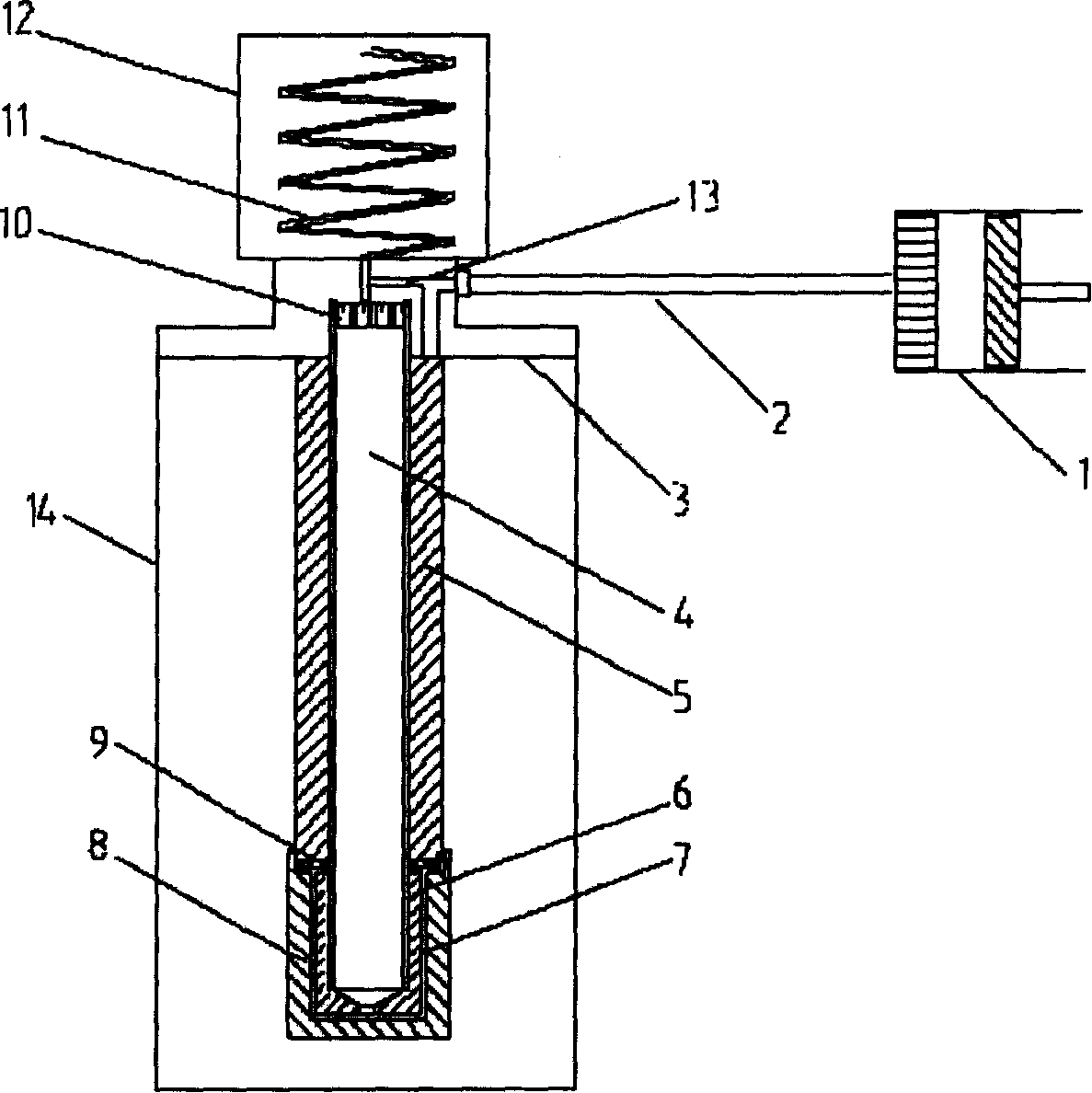

Afterheat recycling system utilizing slag-granule-jetting molten-slag-crushing process

The invention is suitable for the field of molten slag dry process treatment, and provides an afterheat recycling system utilizing a slag-granule-jetting molten-slag-crushing process. The system comprises a dry cooling tower, a granulated slag bin and a blowing tank, wherein an opening is formed in the upper end of the dry cooling tower; an air inlet is formed in the lower end of the dry cooling tower; a hot air outlet is formed in the top of the dry cooling tower; a discharging port is formed in the bottom of the dry cooling tower; an collection bin is also arranged inside the dry cooling tower; the bottom of the collection bin is communicated with the discharging port; a slag trough and a spray gun are arranged at the opening; the spray gun is positioned below the outlet of the slag trough; the outlet of the granulated slag bin is connected with the blowing tank; compressed air is used as a fluidization and transmission medium, and the outlet of the blowing tank is communicated with the spray gun. According to the afterheat recycling system utilizing the slag-granule-jetting molten-slag-crushing process, by adopting a pneumatic transmission way, slag granules are jetted so as to crush molten slag, and heat exchange on the slag granules and the molten slag can be performed, so that the flow of the cooling air is reduced; moreover, the molten slag is easily crushed by the slag granules, the obtained hot slag layer has certain voidage, and therefore, full heat exchange is facilitated. According to the system, higher temperature of the hot air can be acquired, the afterheat recycling quality is improved, and the generating efficiency is increased.

Owner:WISDRI ENG & RES INC LTD

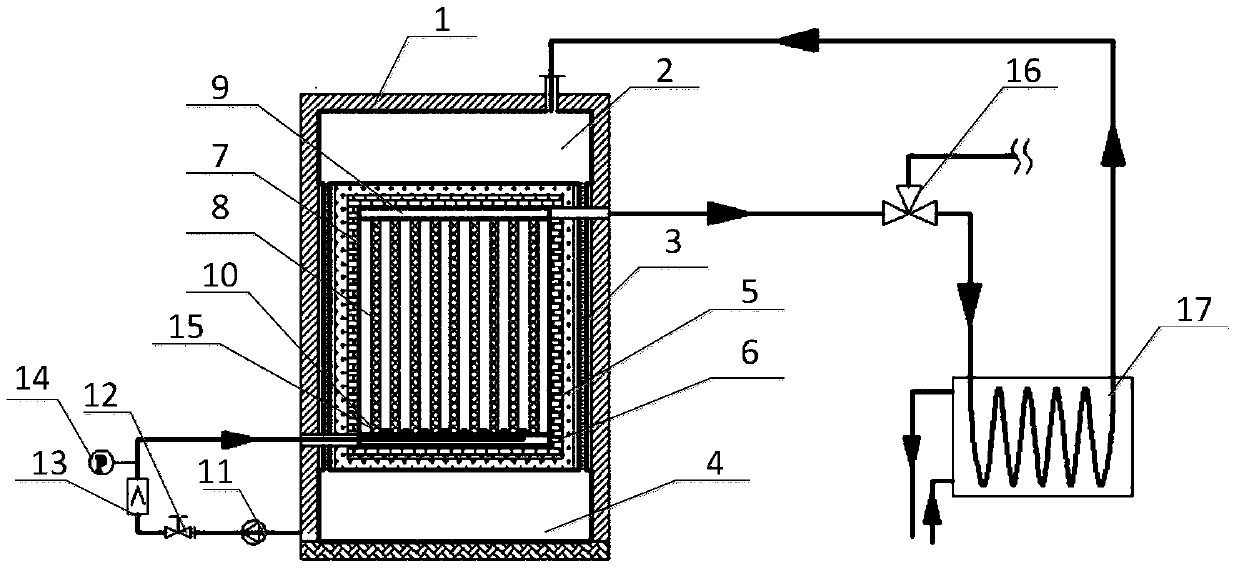

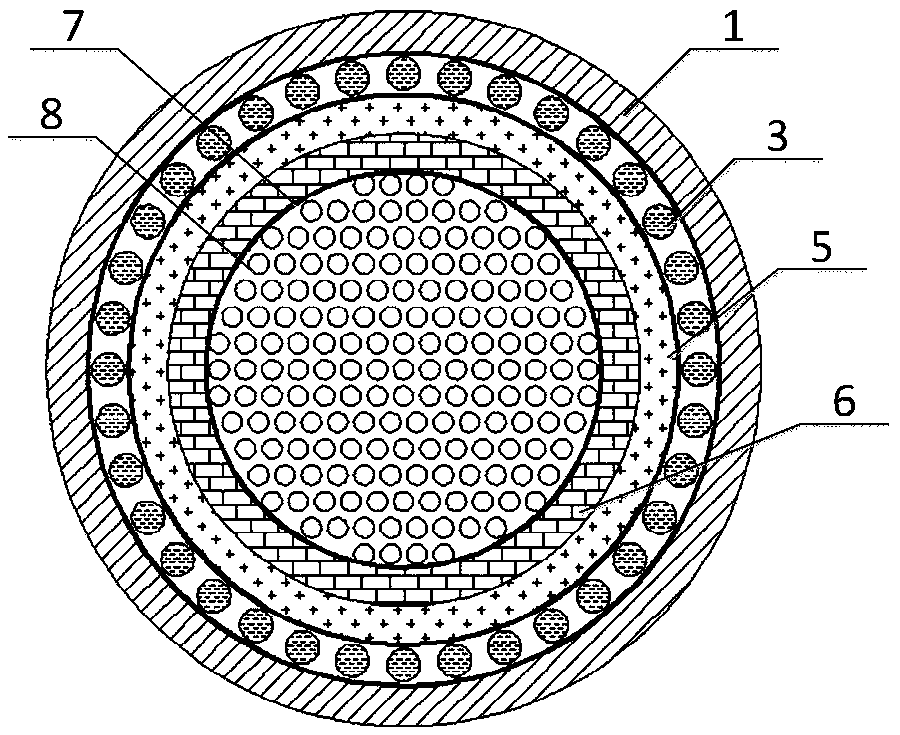

Ceramic-matrix high-temperature fused-salt phase-change heat-storage type off-peak electricity utilizing and steam generating device

ActiveCN105509019AHigh thermal conductivityStrong corrosion resistanceSteam generation using hot heat carriersElectric heatingWater pipe

The invention discloses a ceramic-matrix high-temperature fused-salt phase-change heat-storage type off-peak electricity utilizing and steam generating device. The ceramic-matrix high-temperature fused-salt phase-change heat-storage type off-peak electricity utilizing and steam generating device comprises a heat-storage pile, a heat-storage pile heat insulation structure, a heat transfer medium system and a heat exchange system. The heat-storage pile comprises a shell and a plurality of heat-storage units, fused salt is packaged inside the heat-storage units, and electric heating devices are arranged on the outer surfaces of the heat-storage units. The heat-storage pile heat insulation structure is arranged on the outer surface of the heat-storage pile and comprises heat conducting bricks, a phase-change heat insulation layer and a water-cooled wall from inside to outside, and the water-cooled wall comprises an upper water tank, a lower water tank and connection water pipes. A water pump of the heat transfer medium system is connected with the lower water tank through a pipeline, and atomizing spray heads are arranged at the bottom of the heat-storage pile and used for spraying atomized soft water into the heat-storage pile. A heat exchanger of the heat exchange system is connected with the heat-storage pile through a steam pipeline and is connected with the upper water tank through a water pipeline, and a three-way valve is arranged on the steam pipeline. The ceramic-matrix high-temperature fused-salt phase-change heat-storage type off-peak electricity utilizing and steam generating device has the advantages that electric energy can be converted into heat energy to be stored during off-peak electricity at night, and heat is obtained after the soft water is atomized during on-peak electricity in the daytime, so that hot water and steam are provided for users.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com