Water tube type vacuum boiler with central reverse flames

A vacuum boiler and water tube technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of high heat resistance and sealing performance requirements of the smoke transfer chamber, easy cracks at the welds, structural Insufficient tightness and other problems, to achieve the effect of prolonging the normal operation cycle, increasing the radiation heat transfer, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

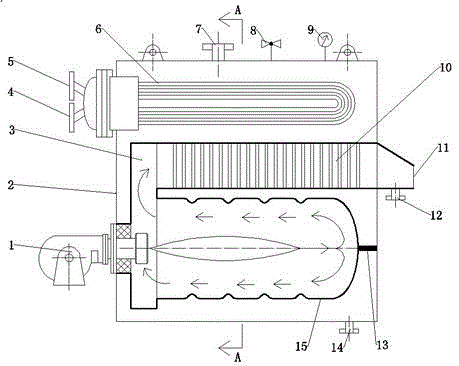

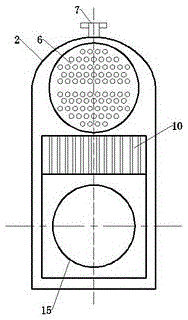

[0017] The specific implementation of the water tube type central backfiring vacuum boiler will be further described below in conjunction with the accompanying drawings.

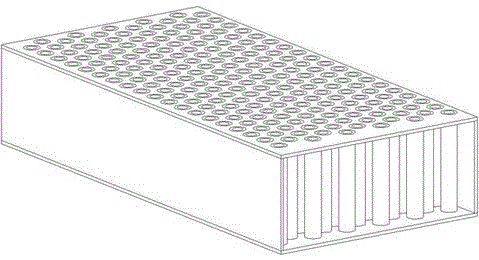

[0018] The manufacturing process of the water tube type central backfiring vacuum boiler: first make the smoke chamber, weld the oval head to one end of the furnace, and then weld the other end of the furnace to the smoke chamber, and the furnace is fixed to the shell by braces On the body; the water-tube heat exchanger is formed by vertically butting and welding four flat plates. A plurality of heat exchange tubes are vertically fixed on the tube plate by welding, and the heat exchange tubes are arranged in an equilateral triangle staggered manner on the tube plate; the U-shaped tube heat exchanger is formed by welding several U-shaped tubes on the tube plate , Fix the U-shaped tube heat exchanger on the upper part of the shell, and the inlet and outlet water pipes of the U-shaped tube heat exchanger are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com