Patents

Literature

342 results about "Back structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The back is an intricate structure of bones, muscles, and other tissues that form the posterior of the body's trunk, from the neck to the pelvis.

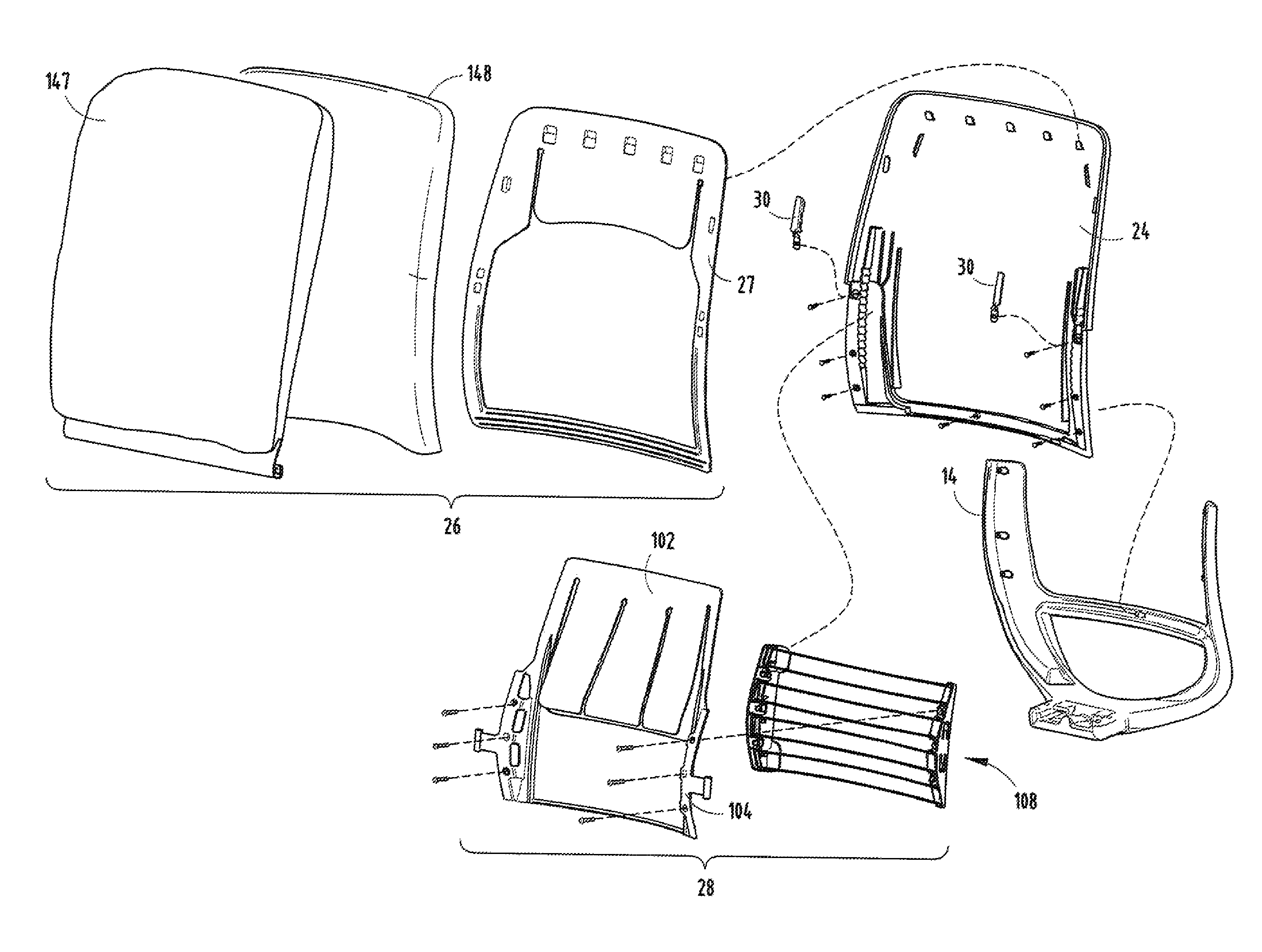

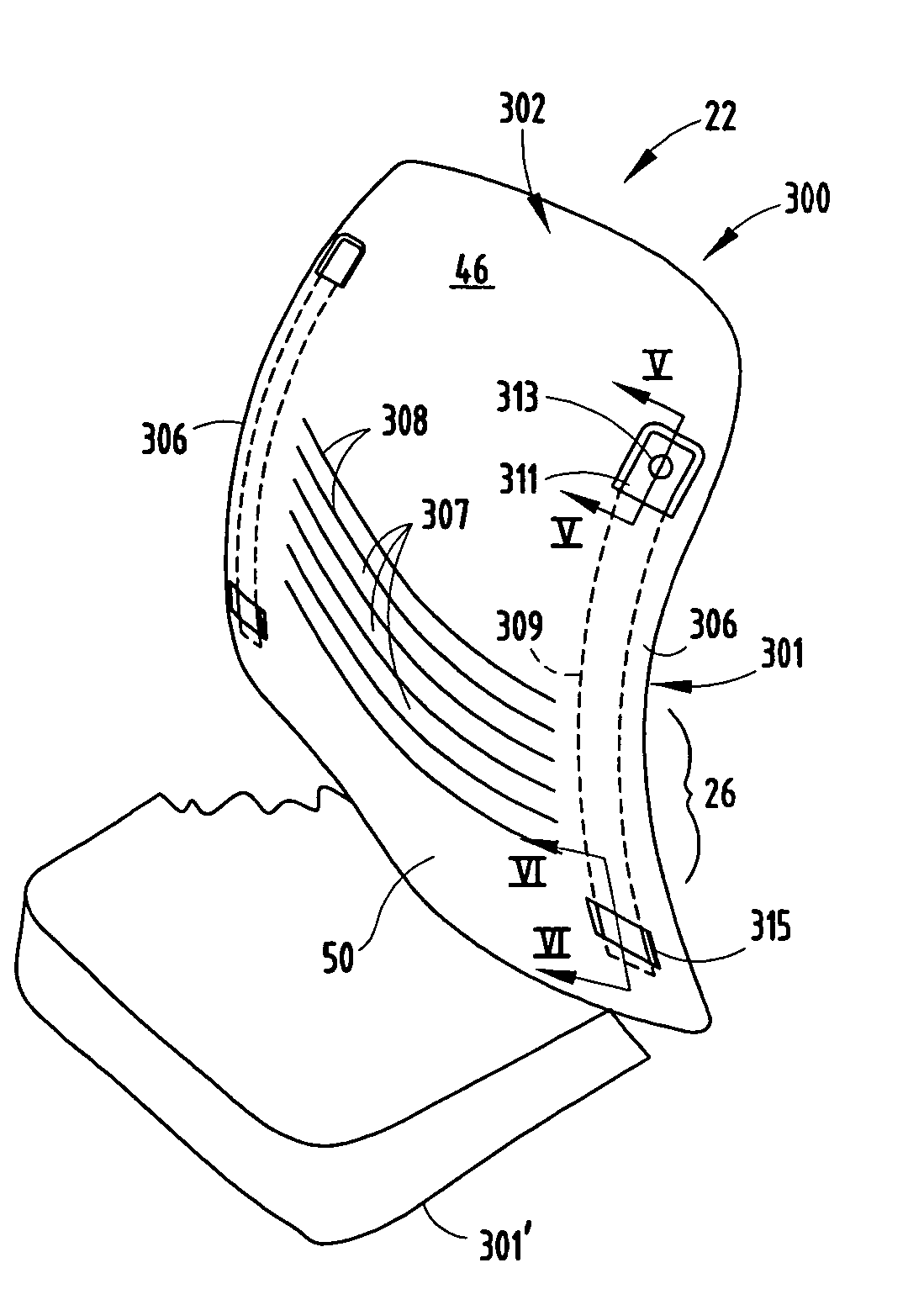

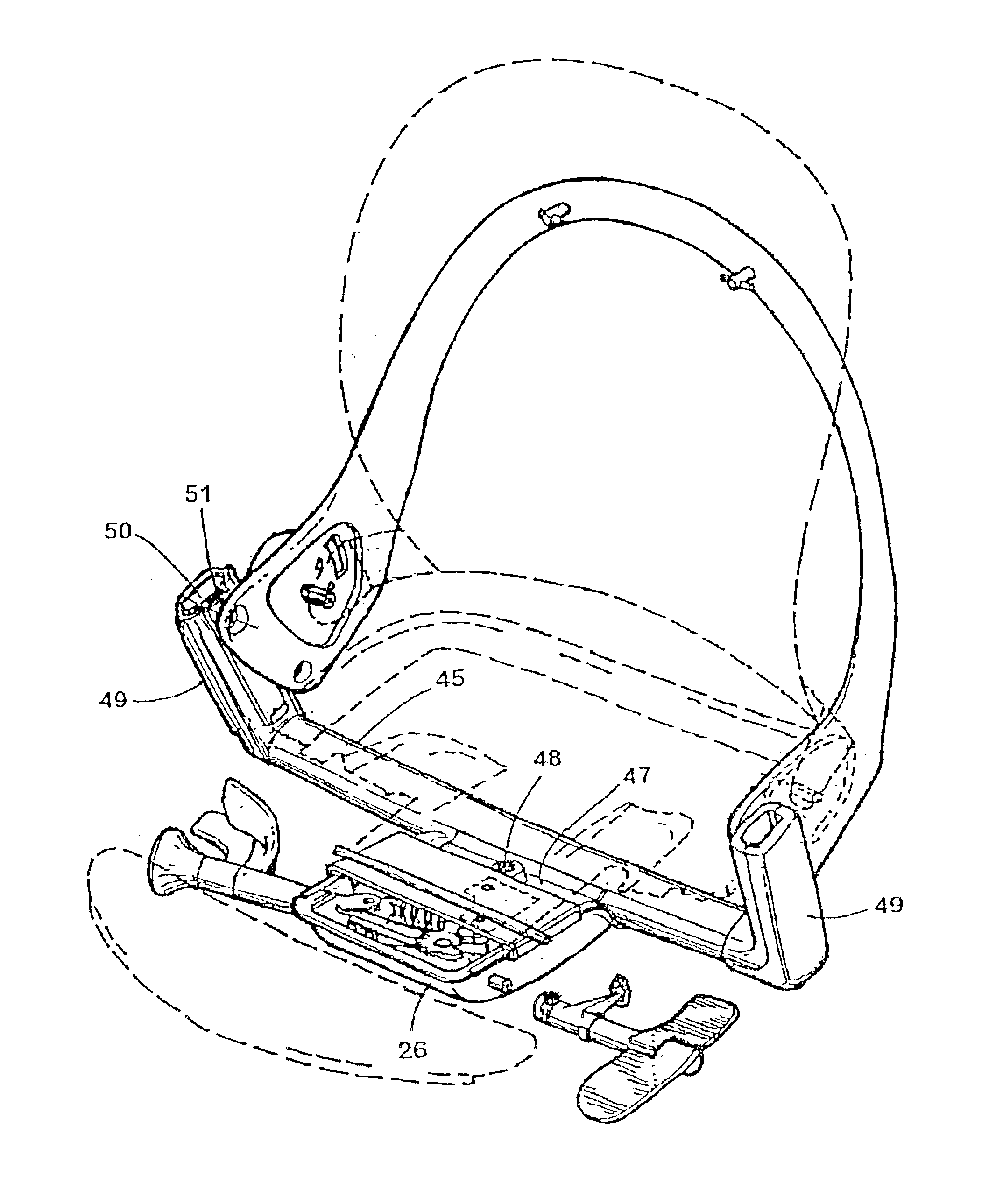

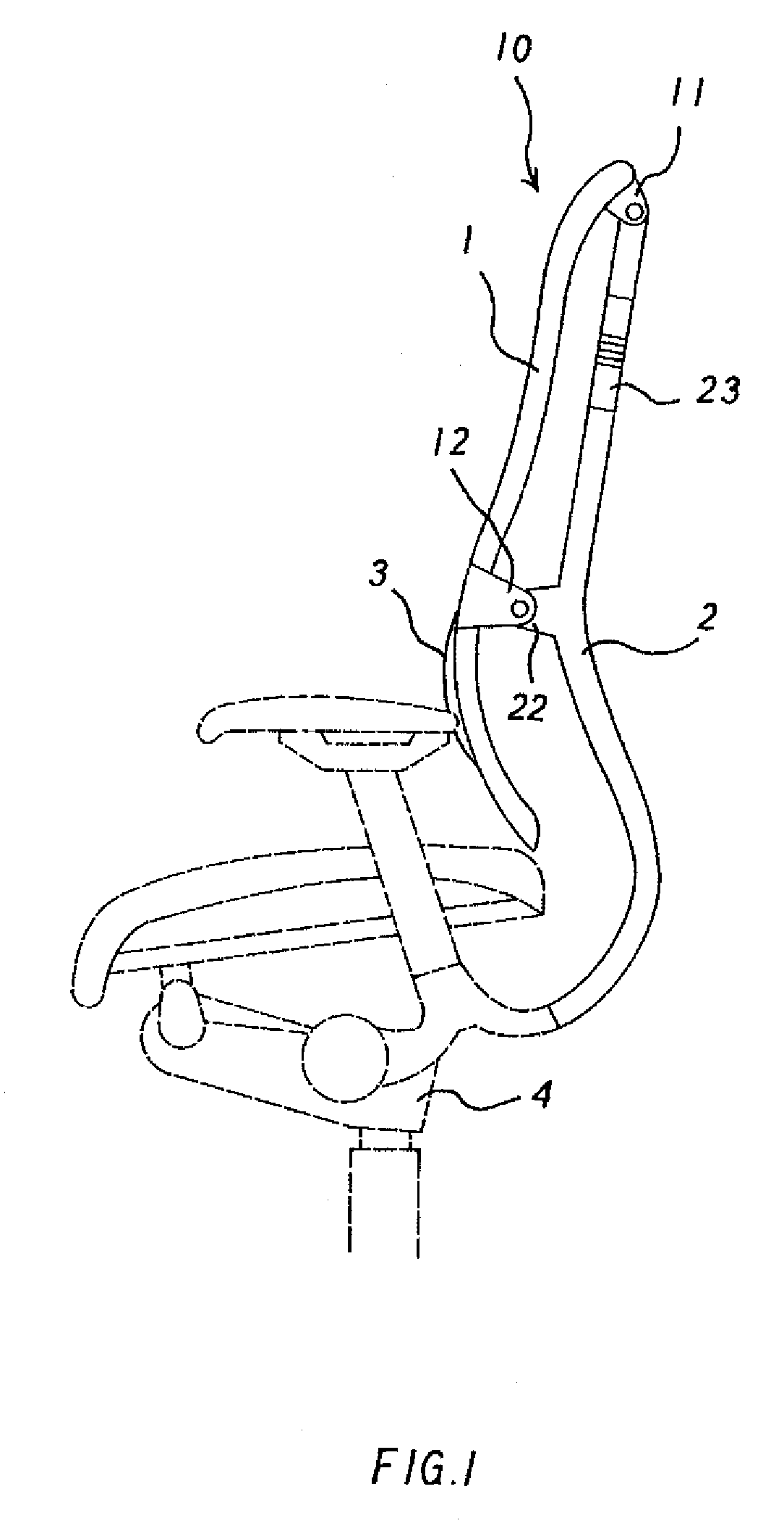

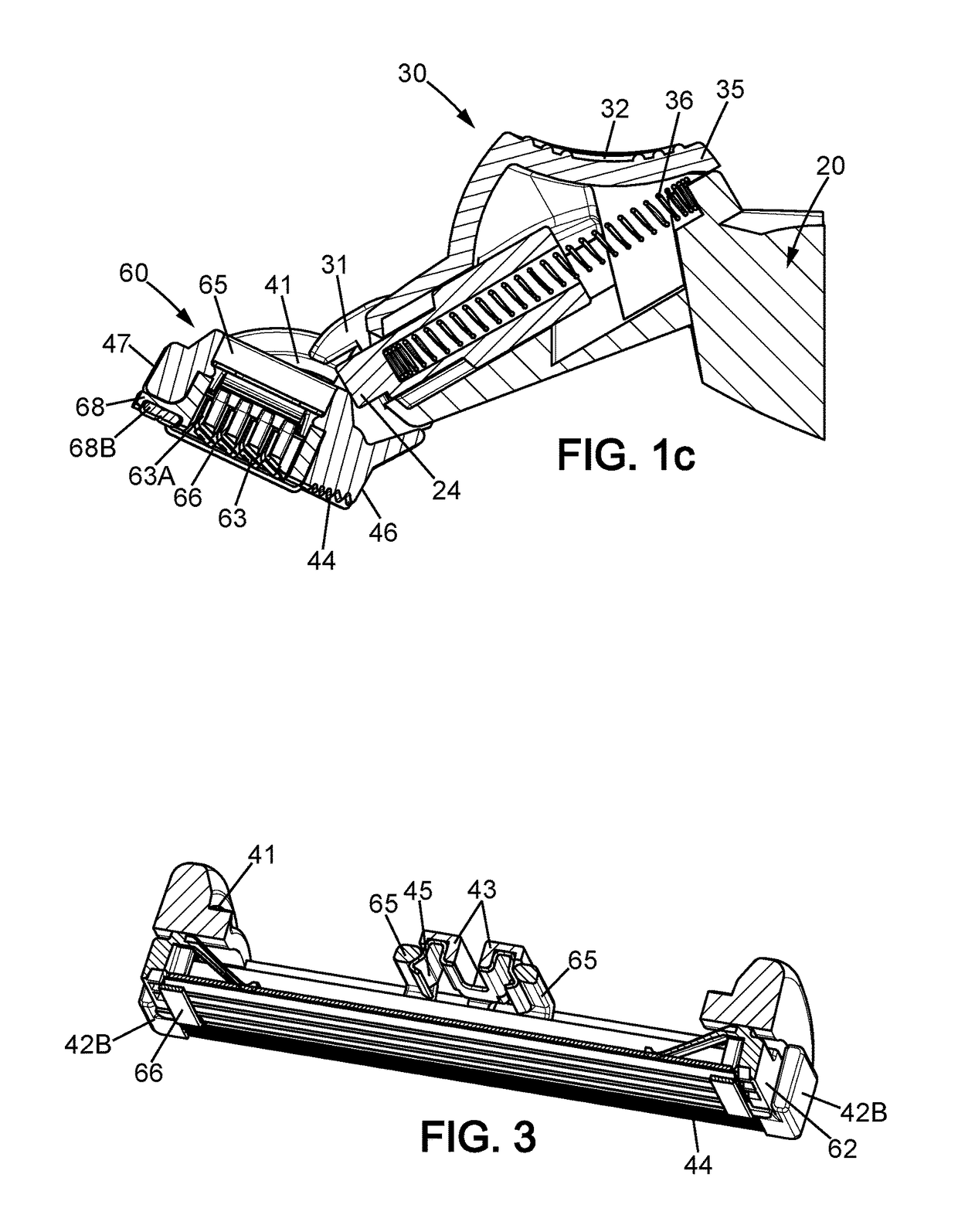

Chair back attachment and method of assembly

A chair includes a lower back frame, a back construction, including a back support attached to the lower back frame, a cushion assembly attached to the back support and a clip wedgingly engaged between the back support and the cushion assembly. The cushion assembly further includes an inner shell which includes two or more apertures and a hook extending downwardly and outwardly from each aperture. The clip further includes at least one angled ramp and at least one stop. The angled ramp is configured to allow the hook of the inner shell to slide through the angled ramp and the stop is configured to suspend sliding of the hook. Methods of assembling a back construction are also provided.

Owner:STEELCASE DEV INC

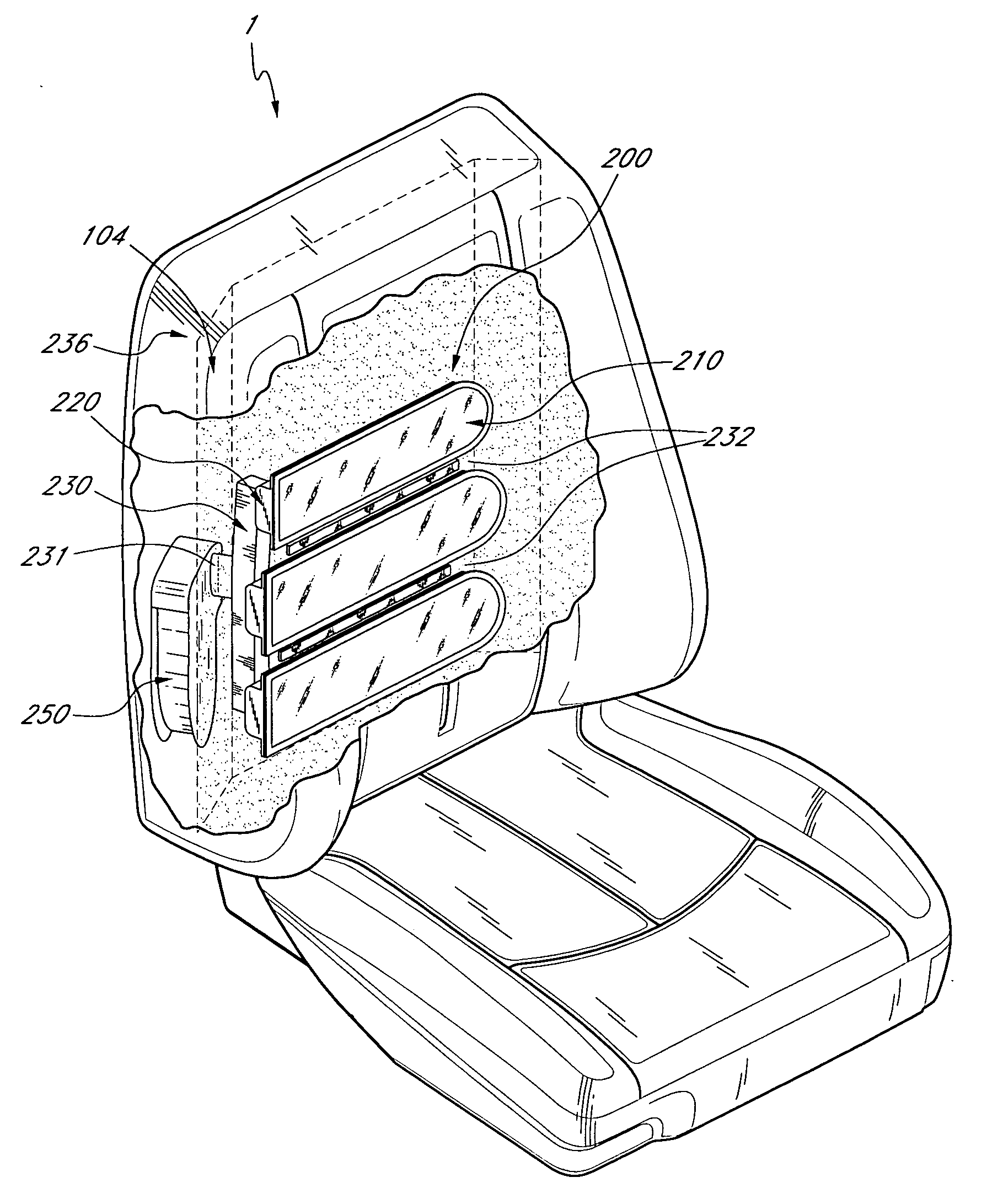

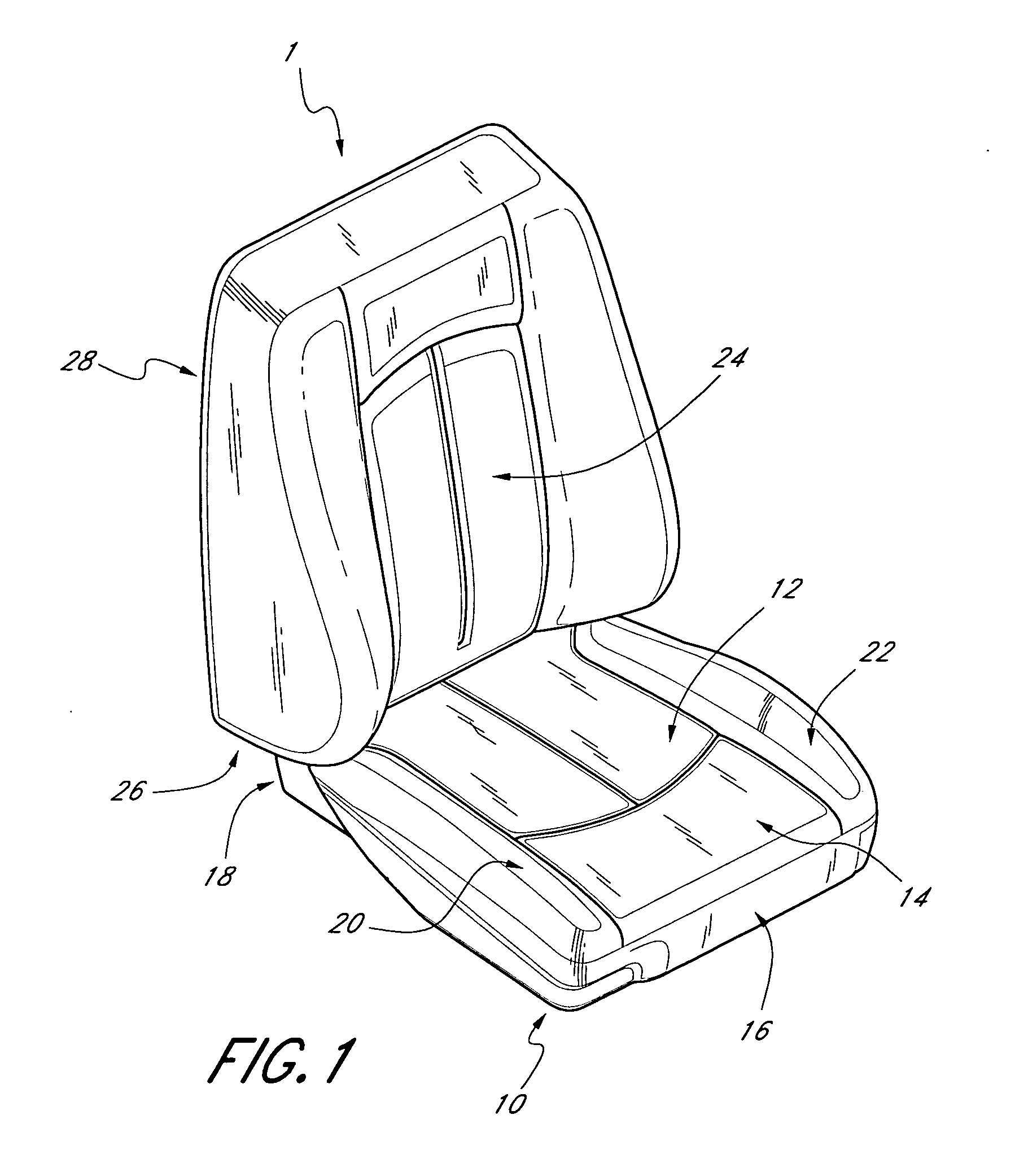

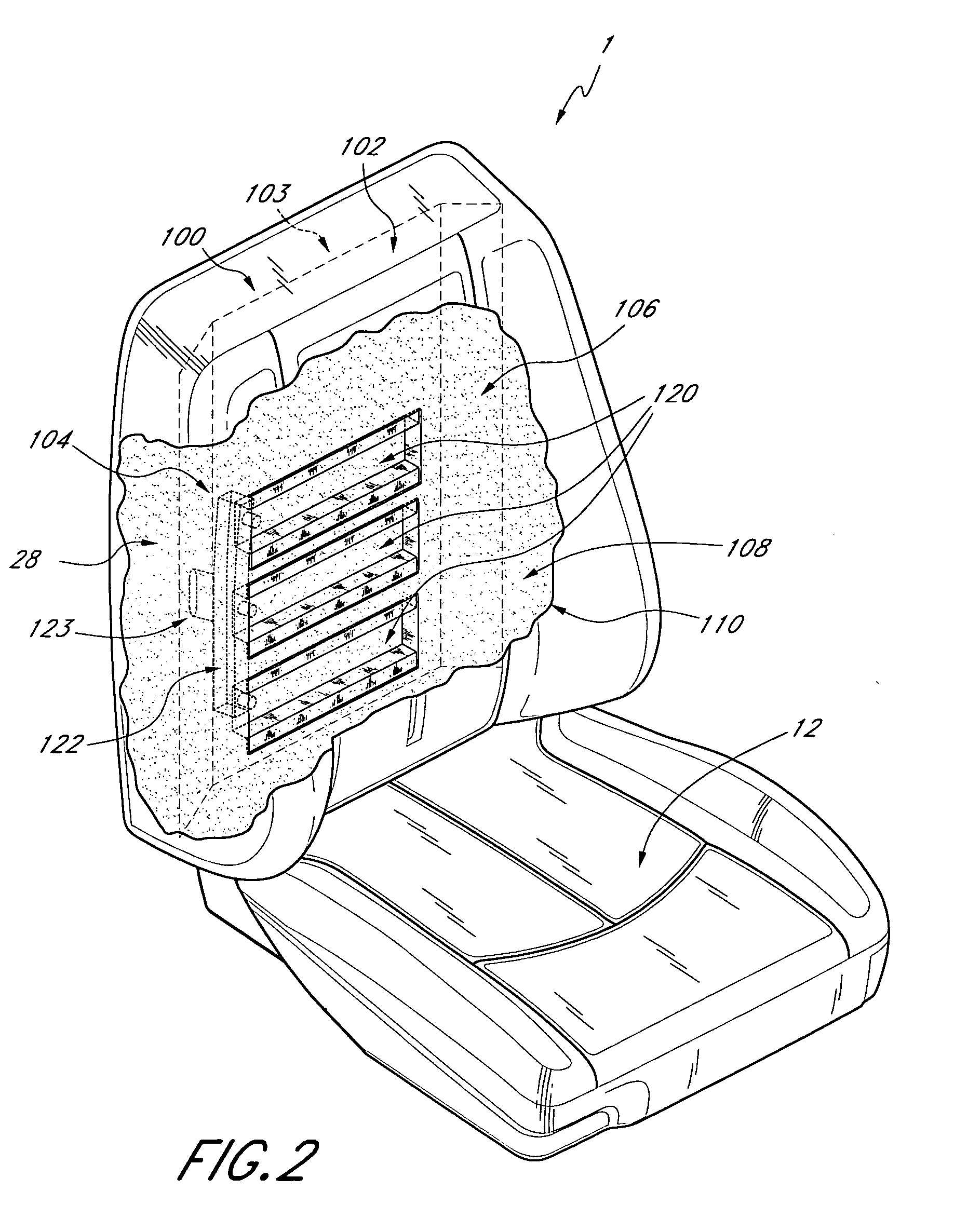

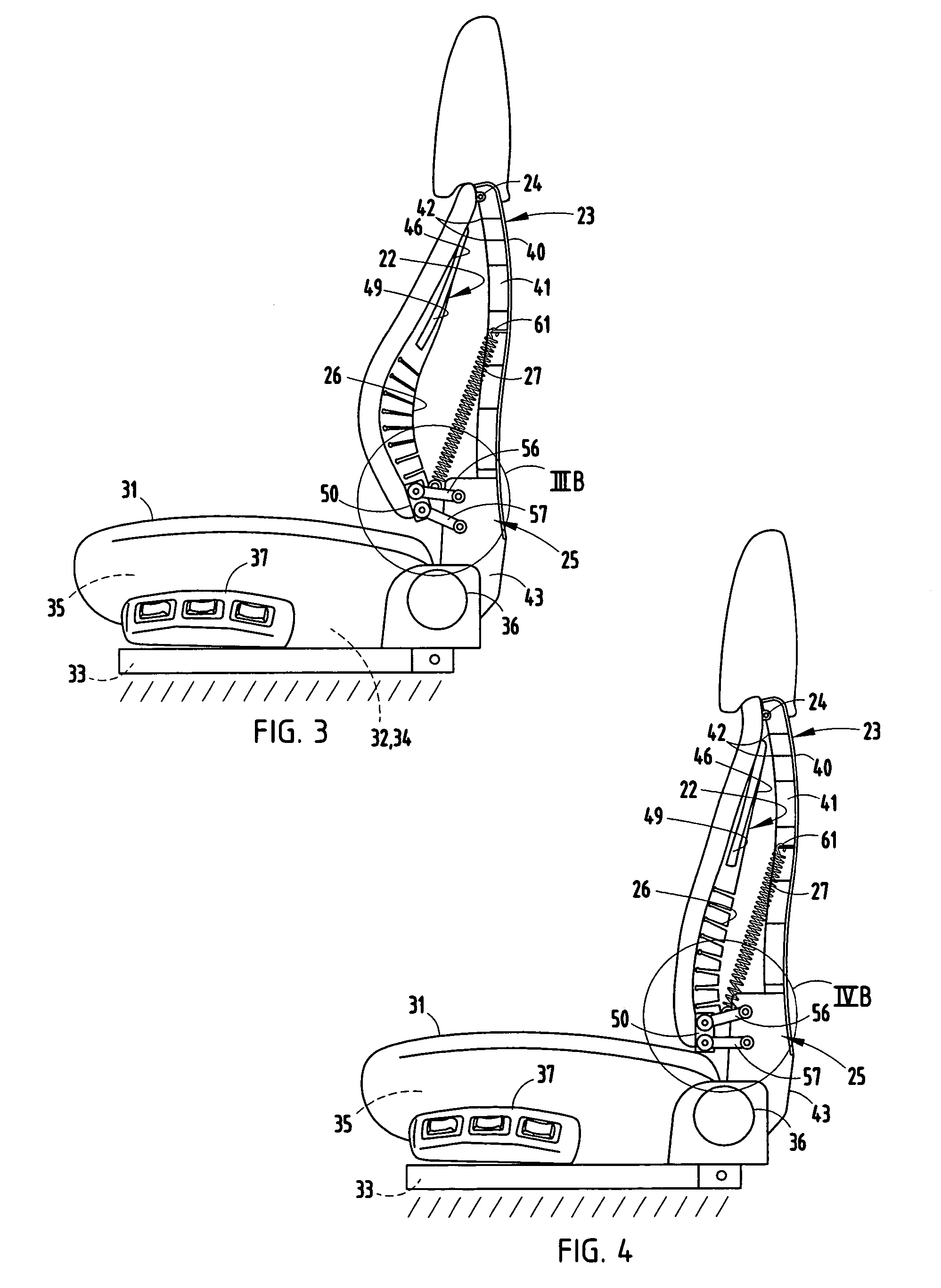

Climate controlled seat

A climate controlled seat assembly comprising a back structure within at least one forwardly extending side member, a seat cushion disposed on the front side of the back member, a fluid distribution system, and a climate control device. The climate control device is mounted on the rear side of the side member. A plenum duct places the fluid distribution system in fluid communication with the climate control device. The fluid distribution system is comprised of a plurality of channels. A plurality of inserts is disposed within each of a plurality of grooves in the seat cushion. The fluid provided by the climate control device through the plenum duct into the fluid distribution system adjusts the climate of the seat.

Owner:AMERIGON INC

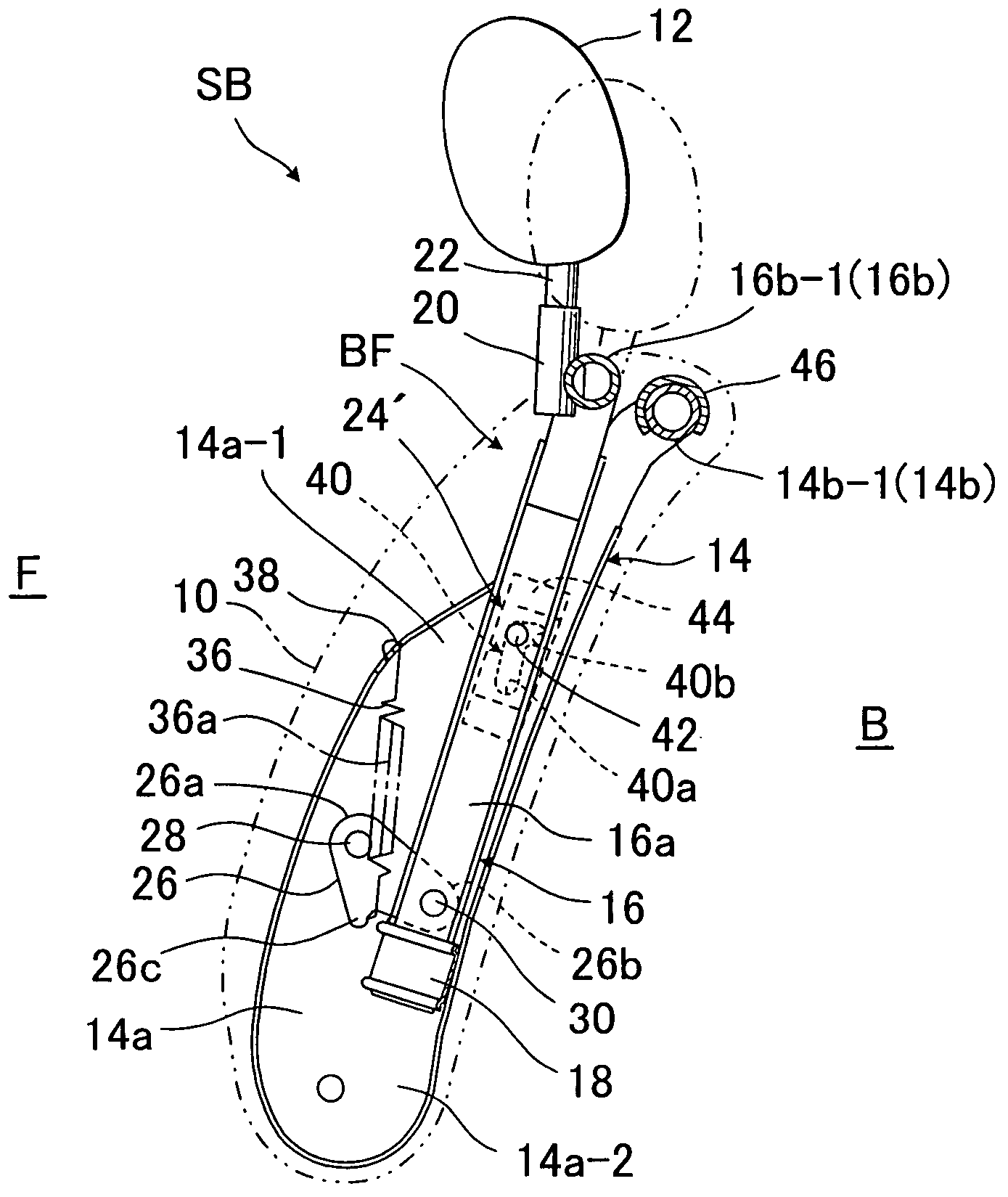

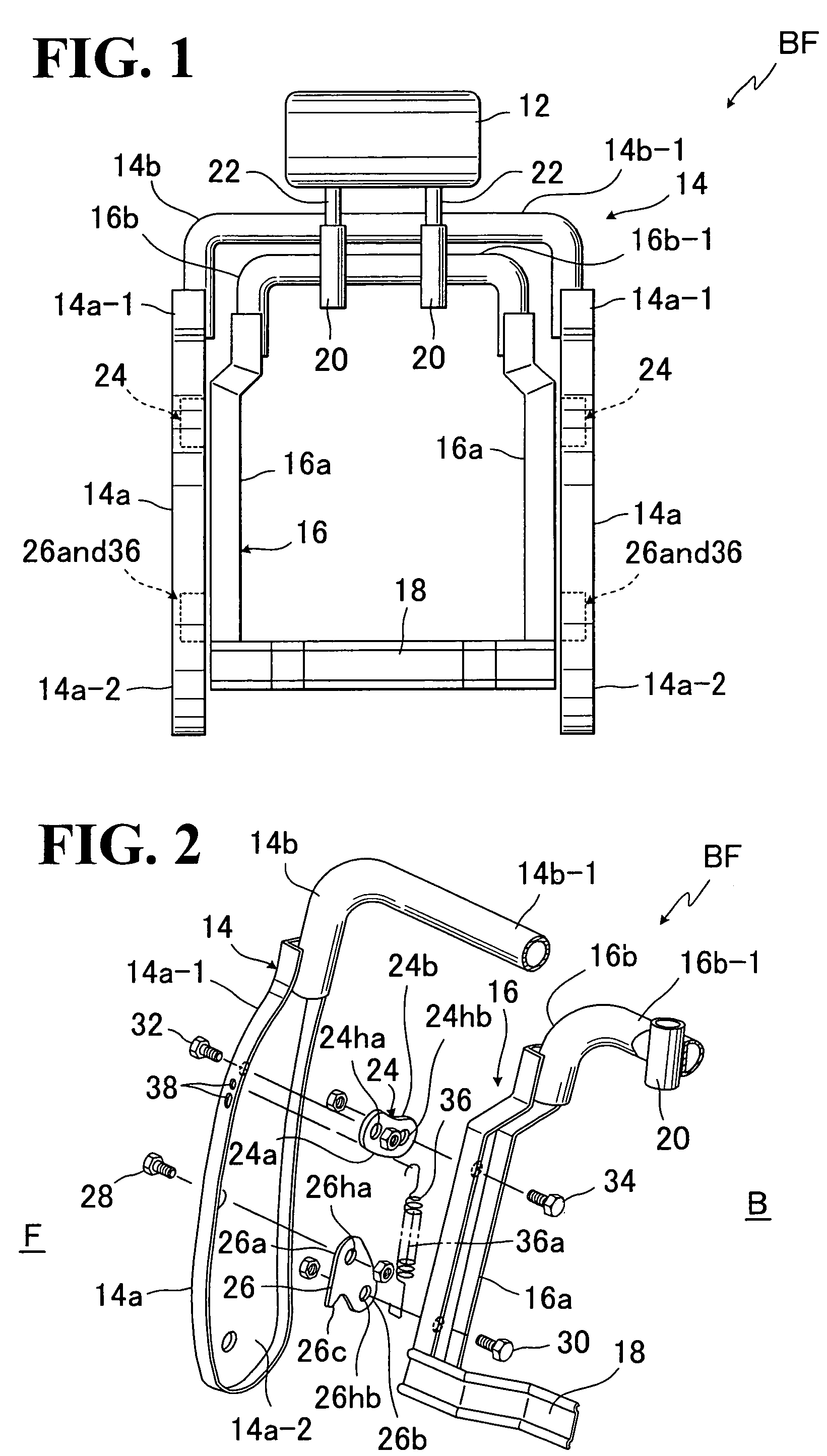

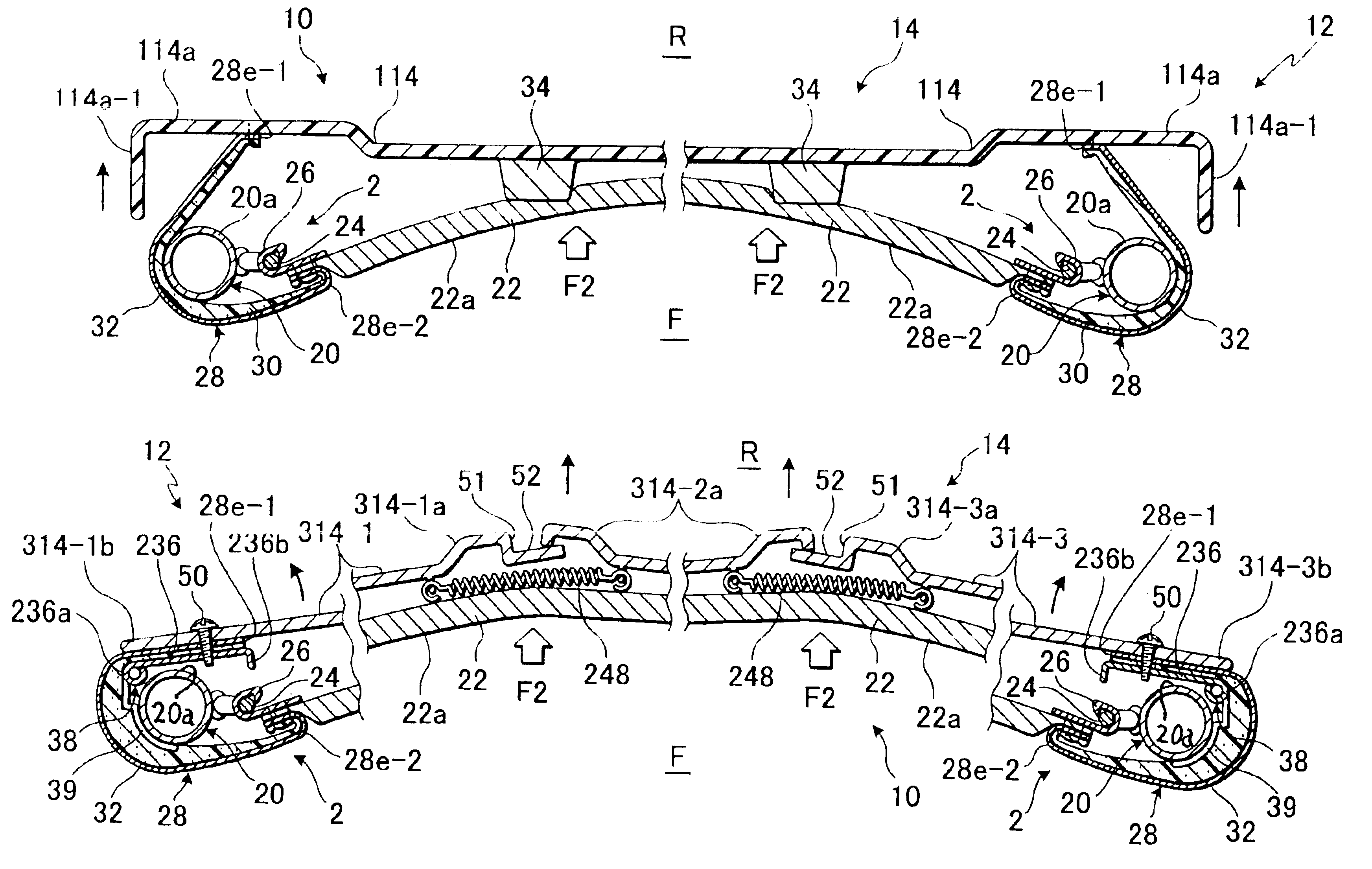

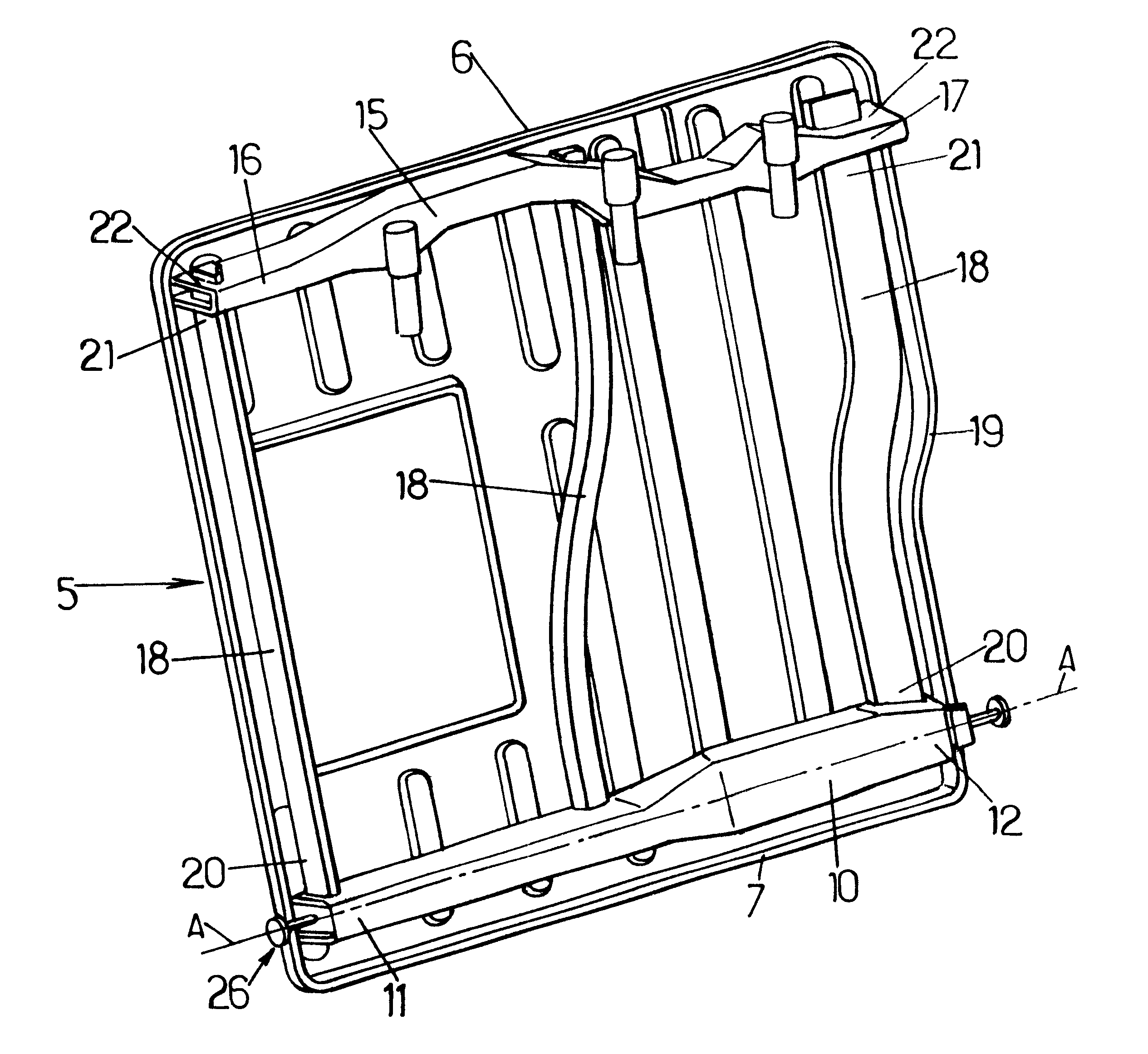

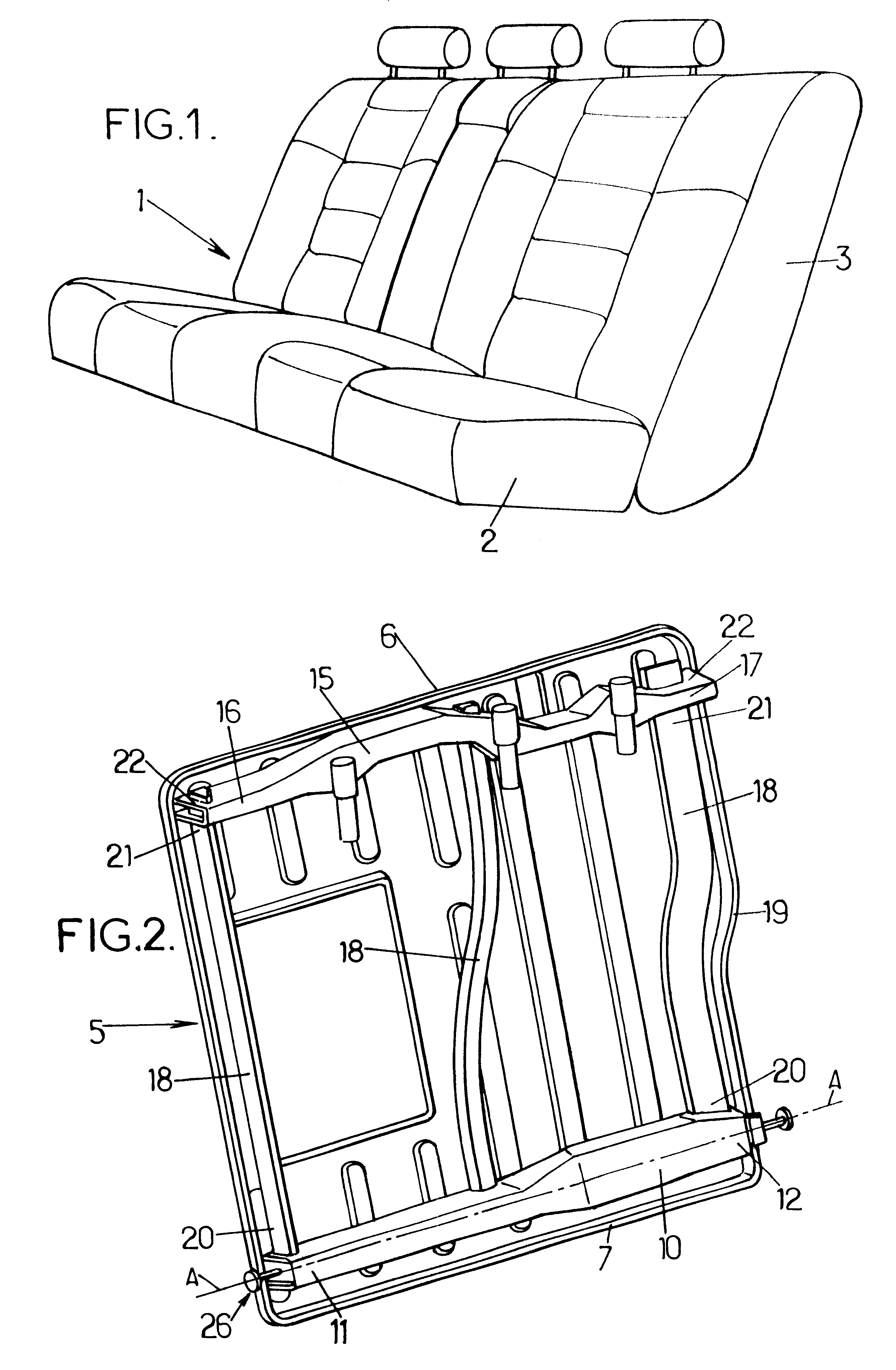

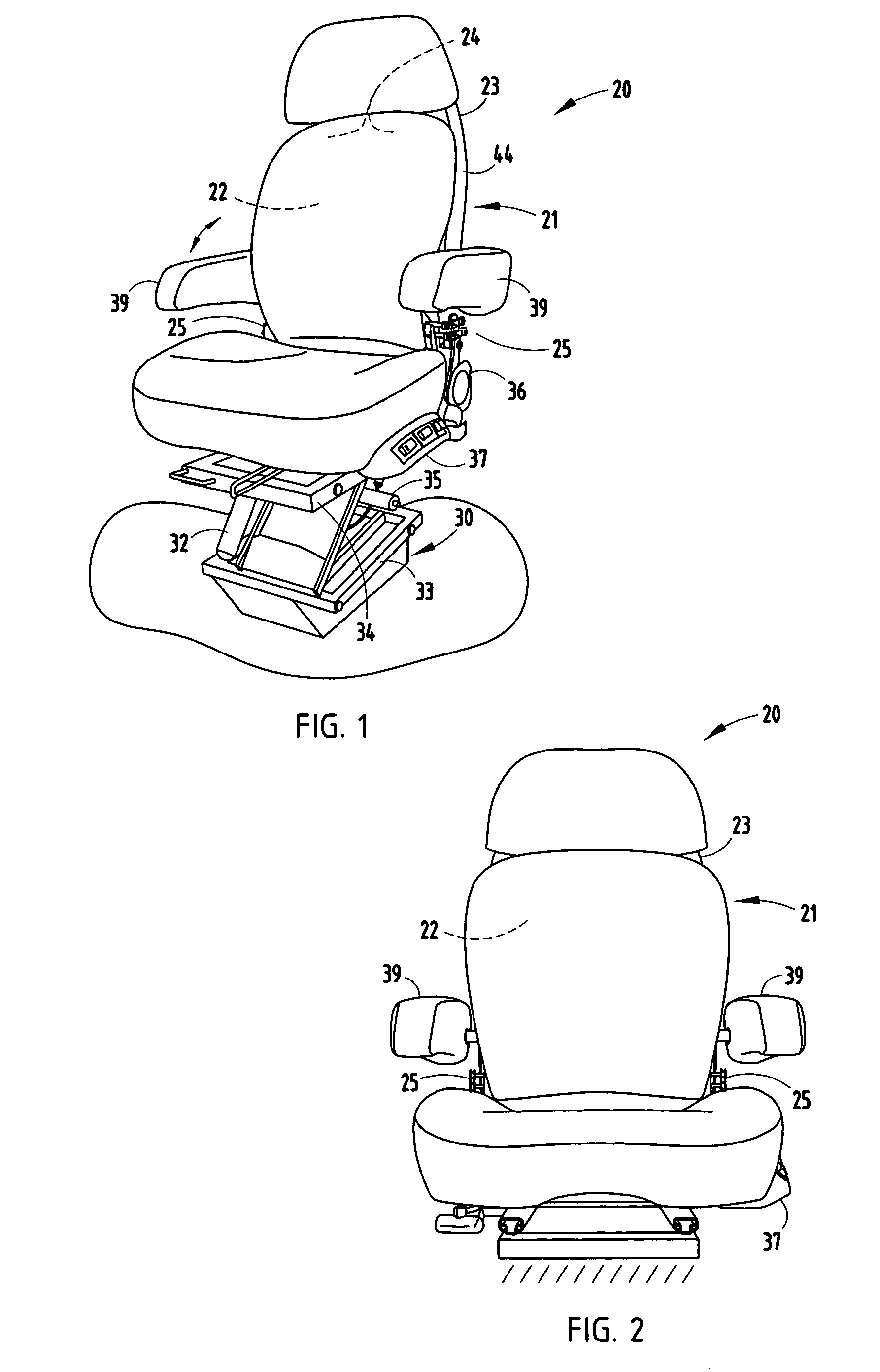

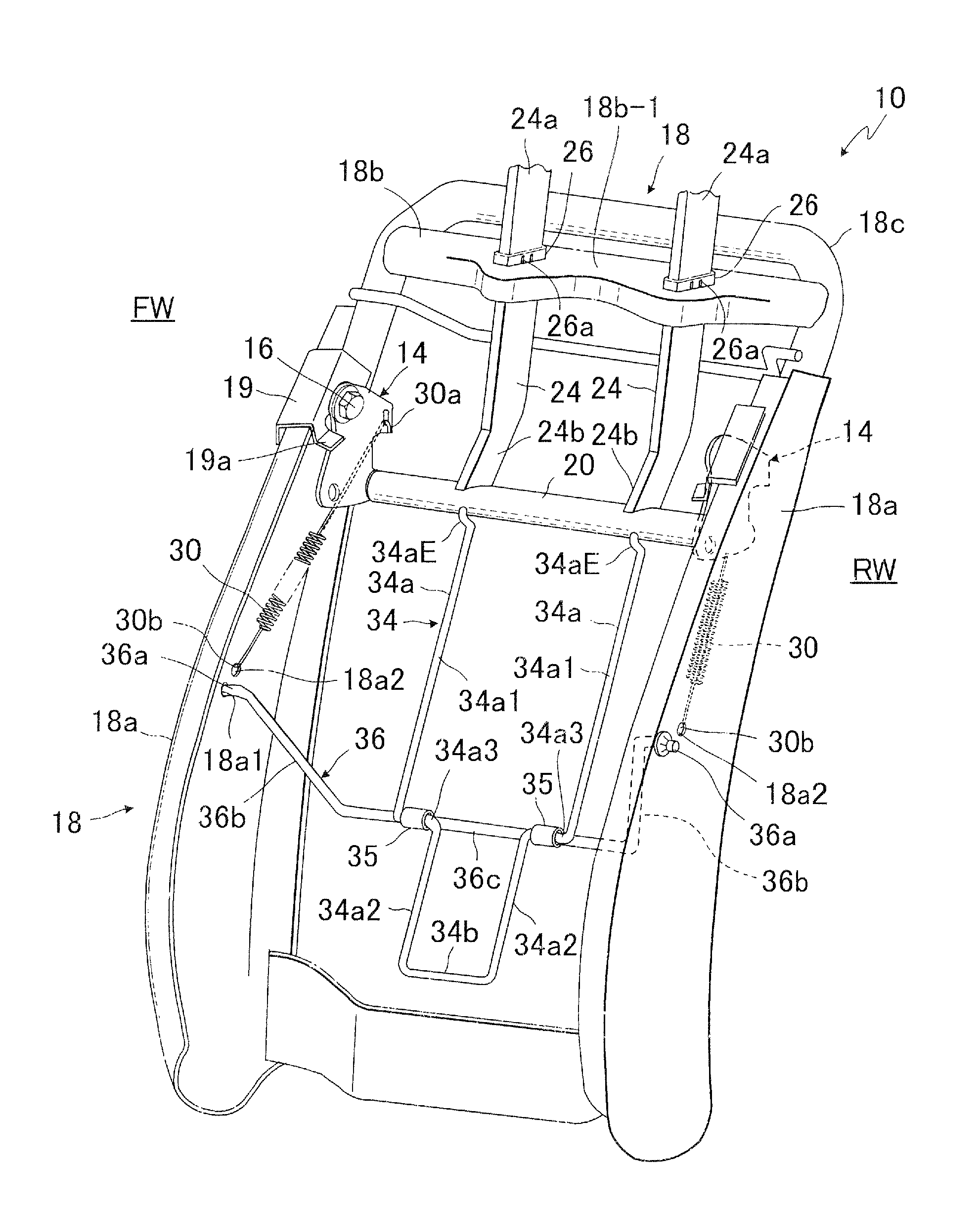

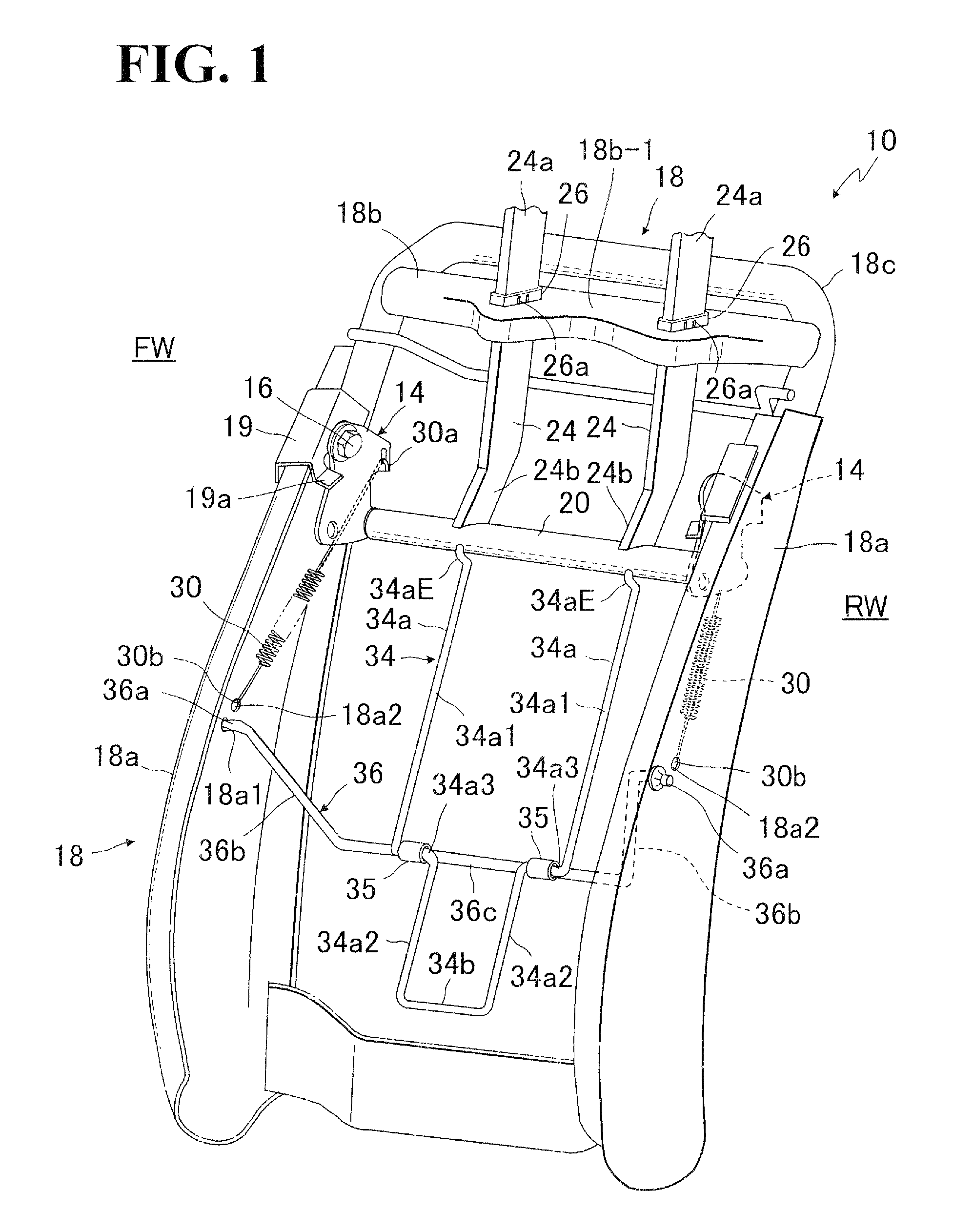

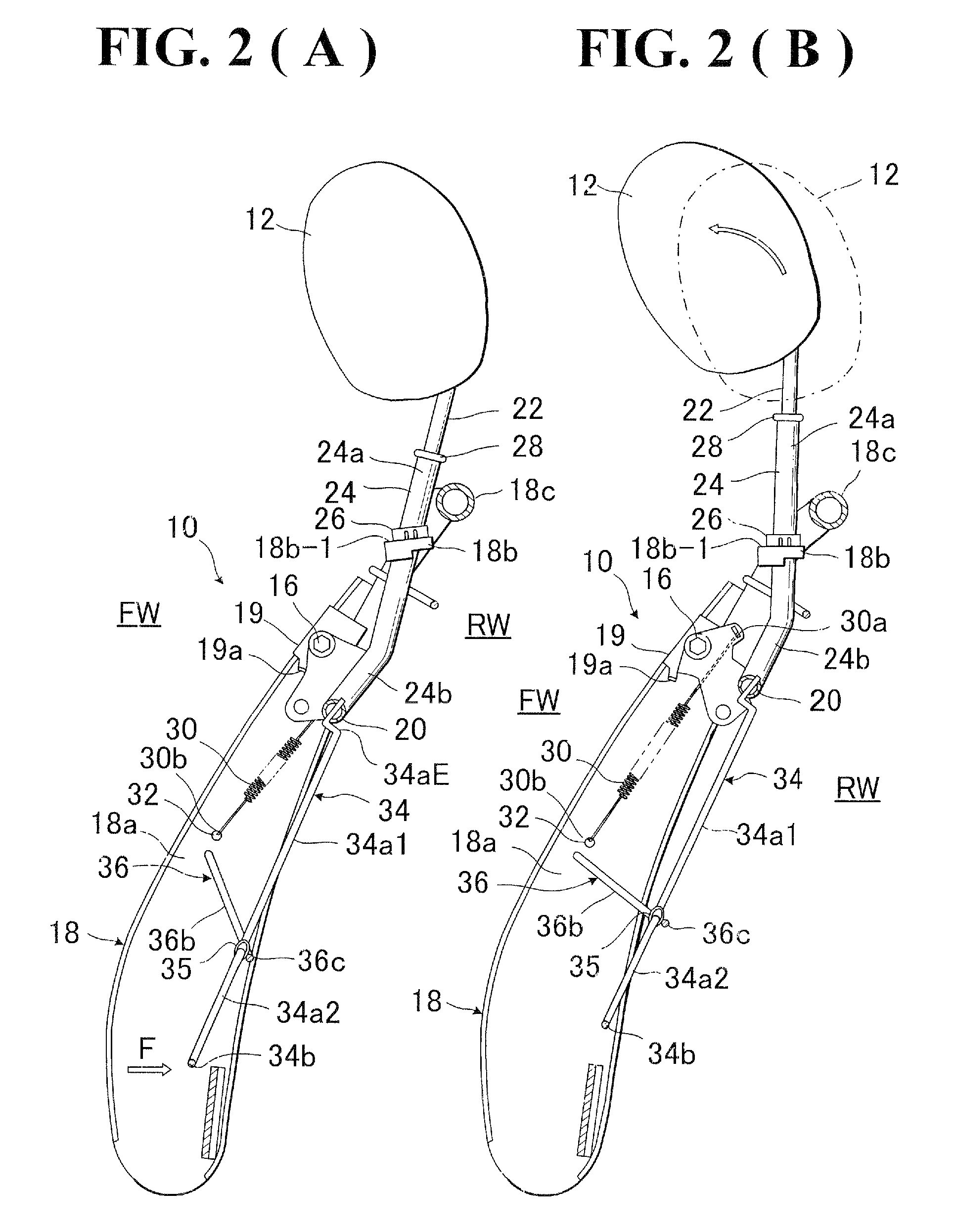

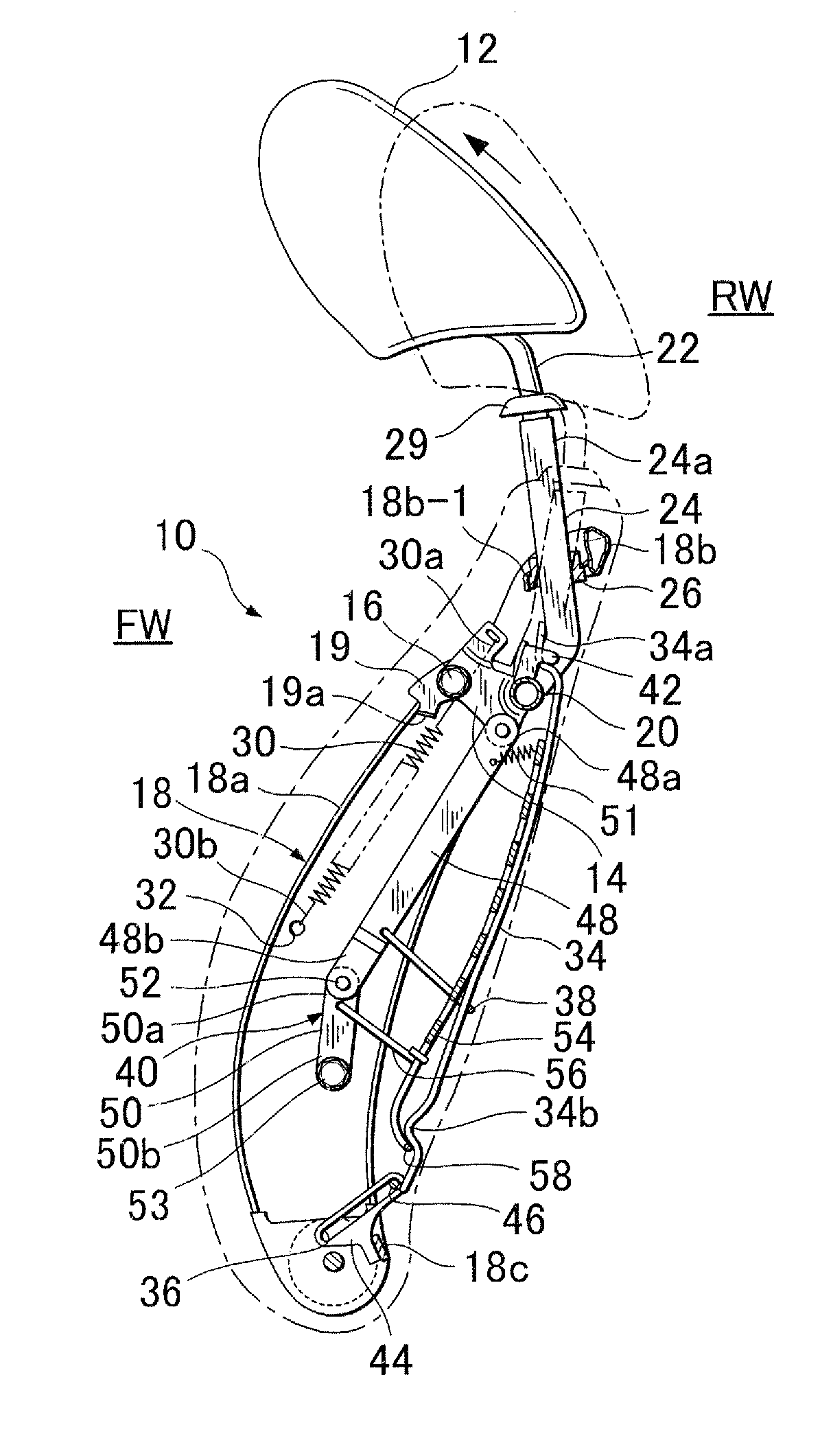

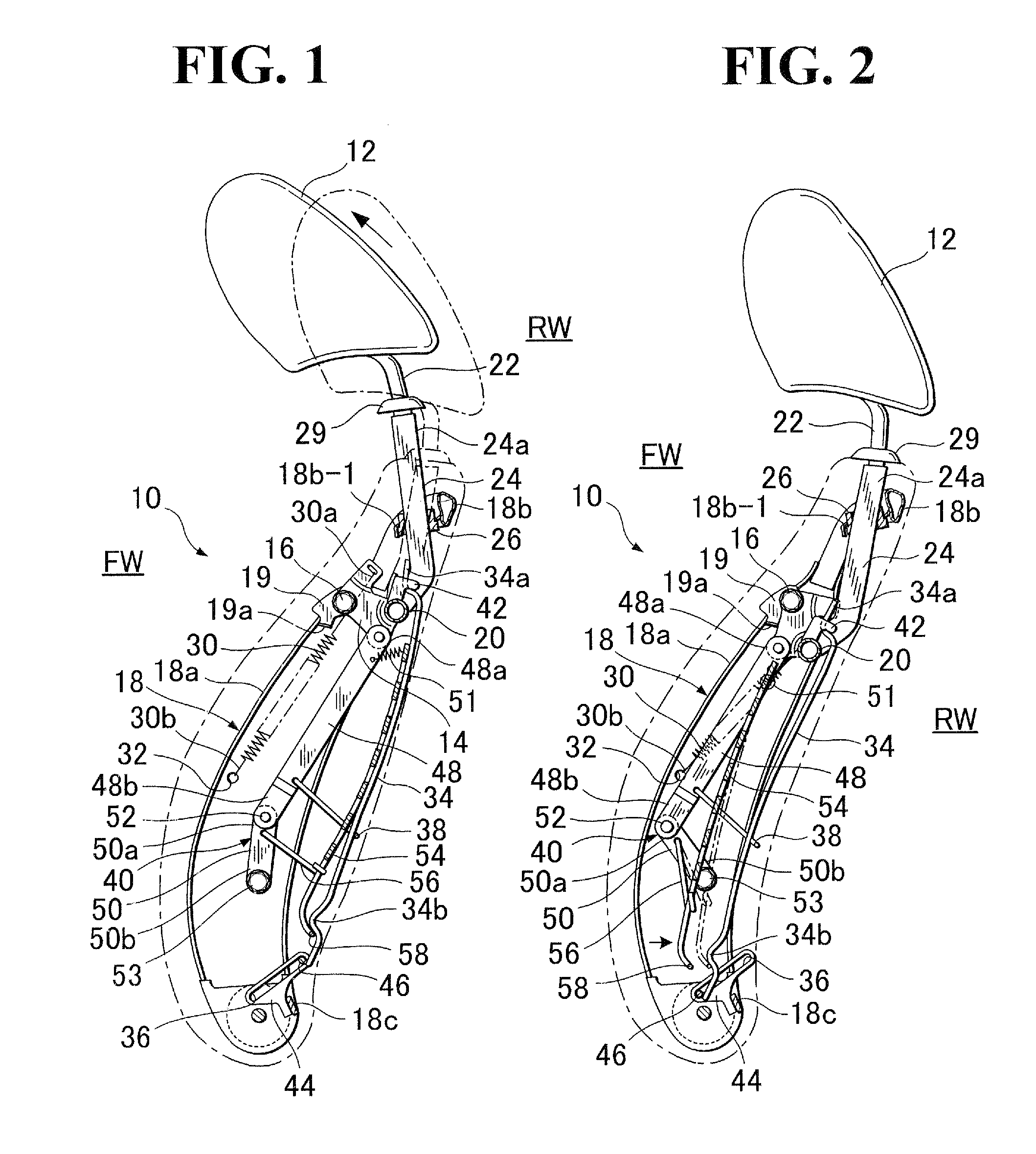

Seat back structure of vehicle seat

InactiveUS7530633B2Simple structureAccurate displacementVehicle seatsOperating chairsBack structureEngineering

In a seat back structure, an auxiliary frame having a pressure receiving portion and a headrest mounted thereon is movably provided in seat back frame via guide element and link element. The guide and link elements are respectively disposed in upper and lower portions respectively of the auxiliary and seat back frames. Biasing element is provided to the link element, such that a line of force of the former is positioned on one side of a pivotal point of the link element, thereby retaining the headrest at initial position, and that, when excessive backward load is applied to the pressure receiving portion, the link element is rotated to displace the line of force toward another side of the first pivotal point, whereby the auxiliary frame is displaced forwardly and upwardly of the seat back frame, thereby causing the headrest to move to a position for supporting a head of seat occupant.

Owner:TACHI S CO LTD

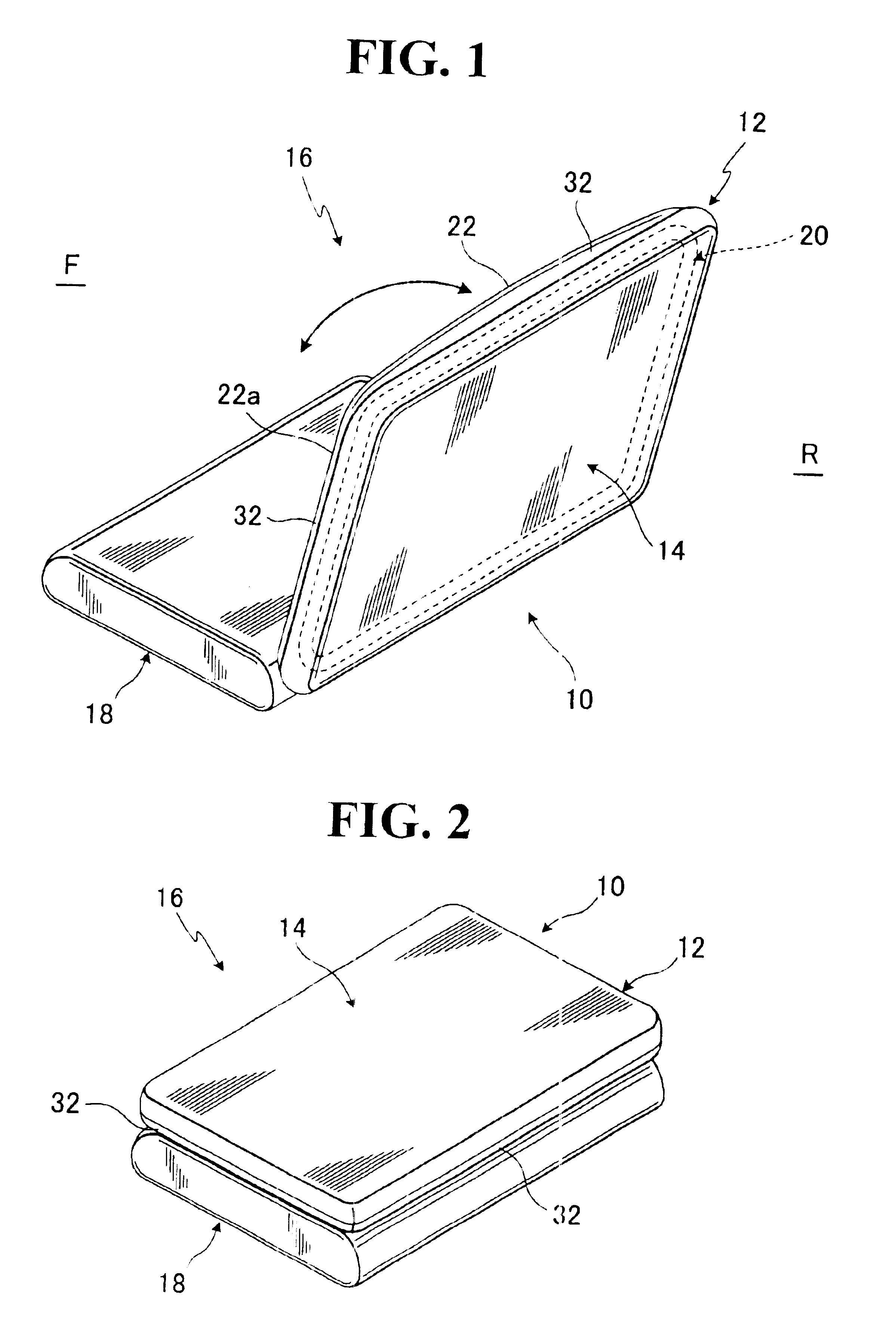

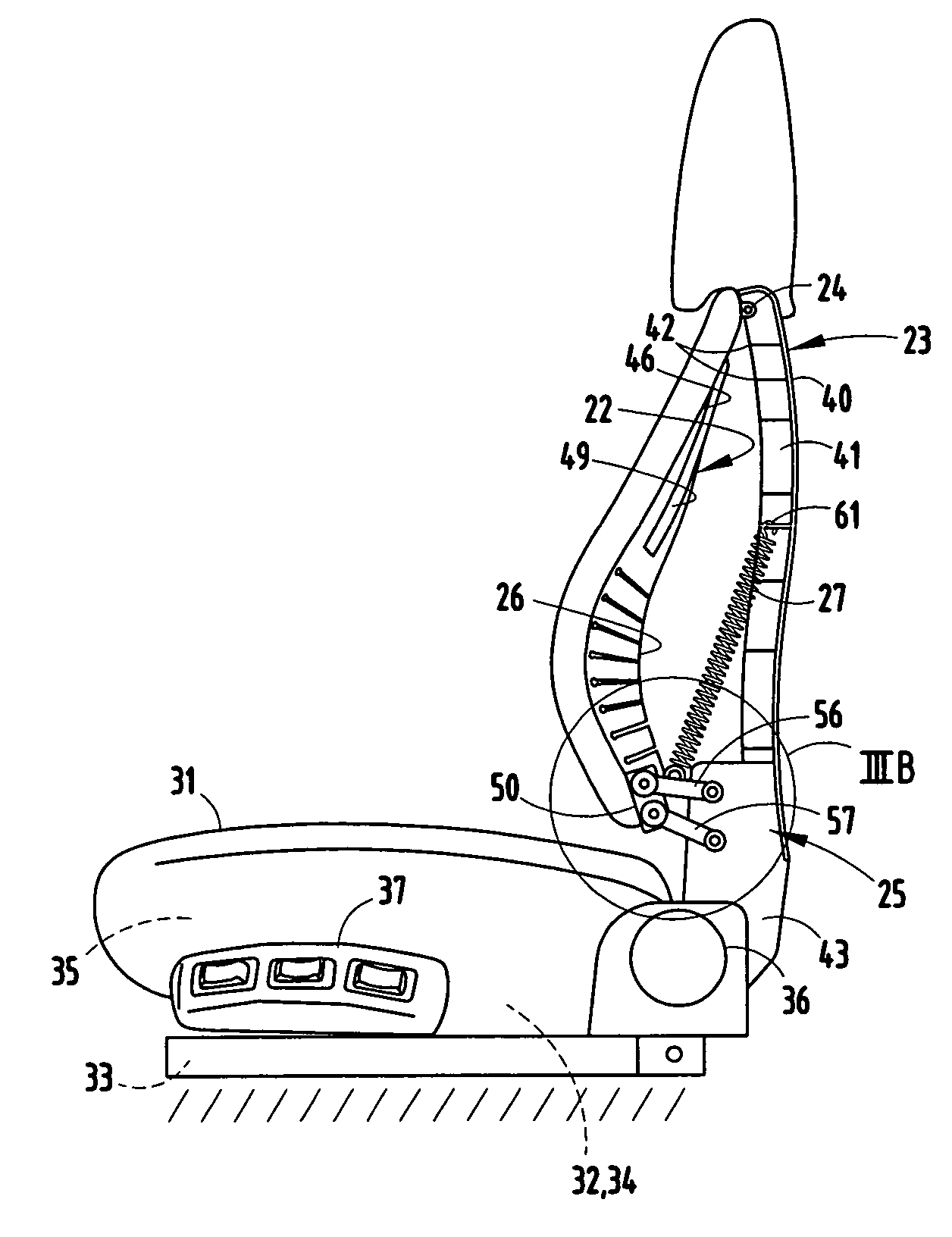

Seat back structure of vehicle seat

A seat back structure of vehicle seat which is reduced in thickness and yet deformable to provide a deep cushiony touch to a back of passenger. According thereto, an elastic back support element and a back board element are respectively provided in one and another sides of seat back, and a movable connection element is provided so as to allow displacement of the back board element from a home position, while allowing the elastic back support element to be resiliently warped. The back board element is normally biased by a biasing element of the home position. A stopper element is defined in the seat back for preventing movement of the back board element from the home position to the elastic back support element. The back board element per se may be formed by a plurality of plate elements connected movably with one another.

Owner:TACHI S CO LTD

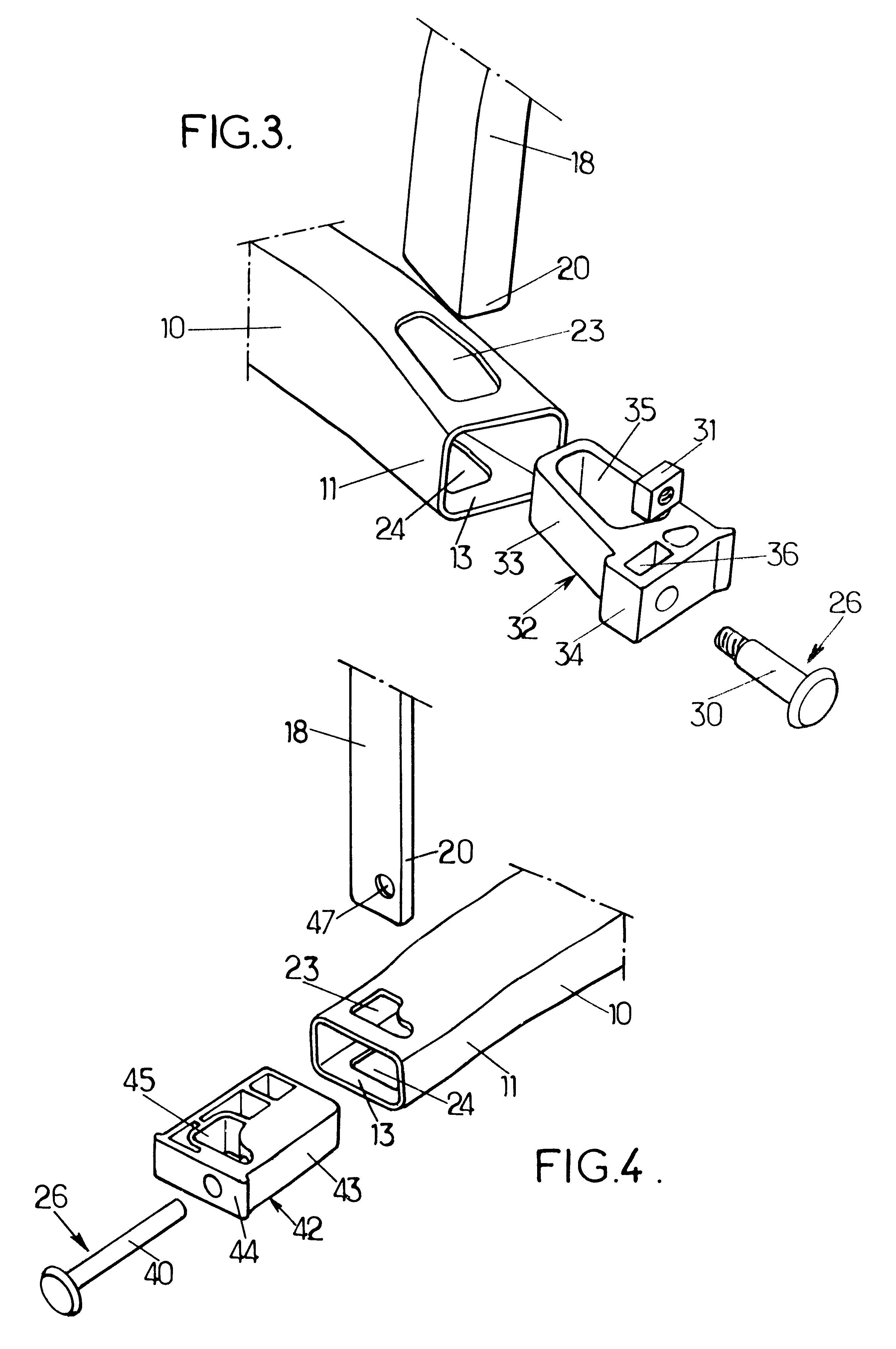

Automobile seat back structure articulated around fitted pivots

InactiveUS6347836B1Simple and efficient and inexpensive meanSeat framesStoolsBack structureEngineering

A seat back structure comprises a lower edge around which it is articulated and next to which is fixed a lower crosspiece the ends of which have pivoting means. These pivoting means are carried by a base which is itself added by fitting in the ends of the lower crosspiece.

Owner:BERTRAND FAURE EQUIP SA (FR)

Back construction for seating unit

A chair includes a base having a control assembly operably supporting a seat assembly and also a back assembly for movement about a seat tilt axis and a back tilt axis, respectively. The back assembly includes a flexible sheet supported at upper / outer corners by a back support structure and hanging downwardly. The flexible sheet includes a lower portion coupled to the back support structure by a tensioner for holding the lower portion rearwardly. A vertically-adjustable lumbar mechanism is adjustably supported on the back support structure and operably engages the flexible sheet for flexing a lumbar area of the flexible sheet forwardly to provide an optimal ergonomic horizontal and vertical convex shape for postural lumbar support.

Owner:STEELCASE INC

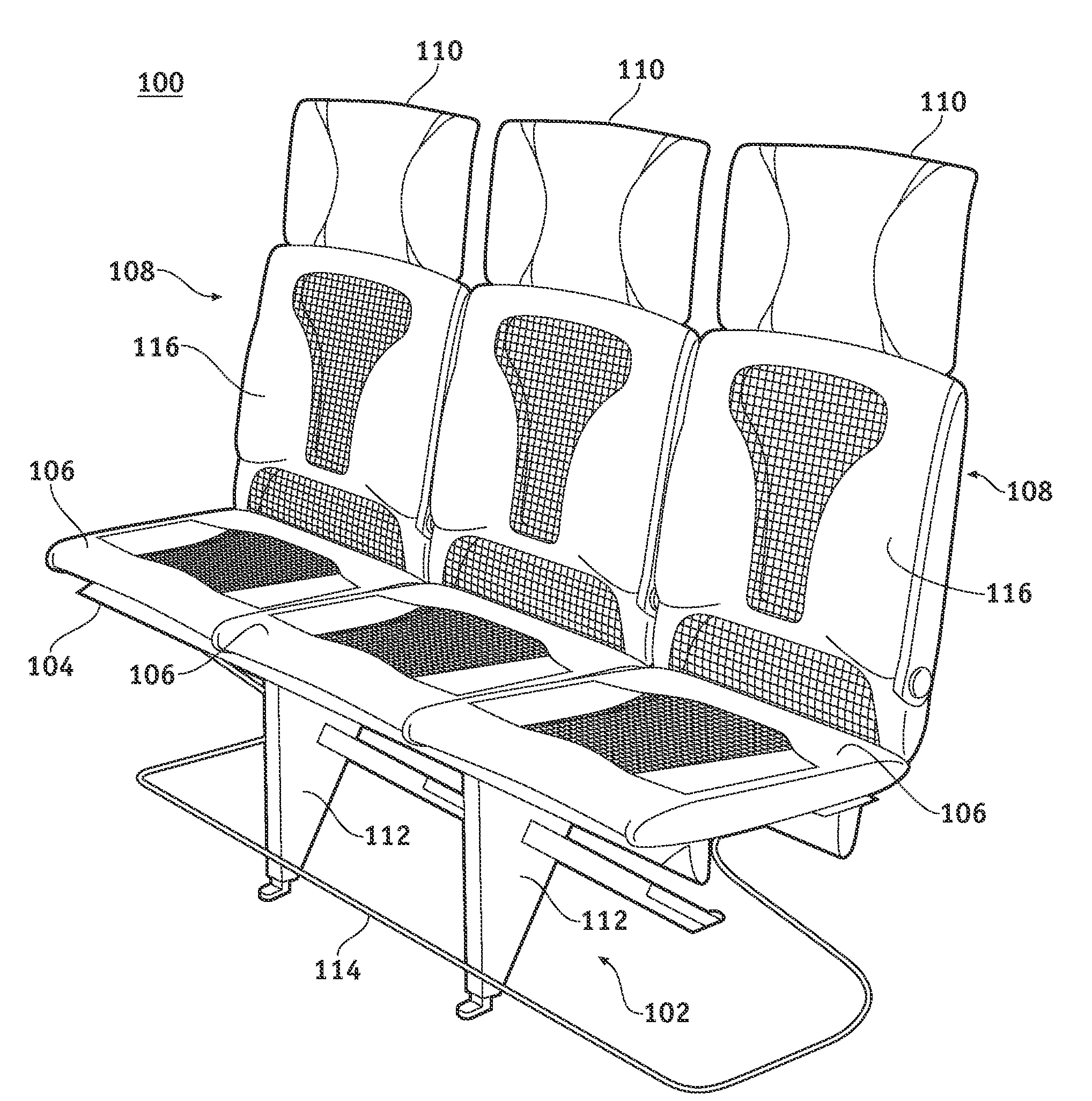

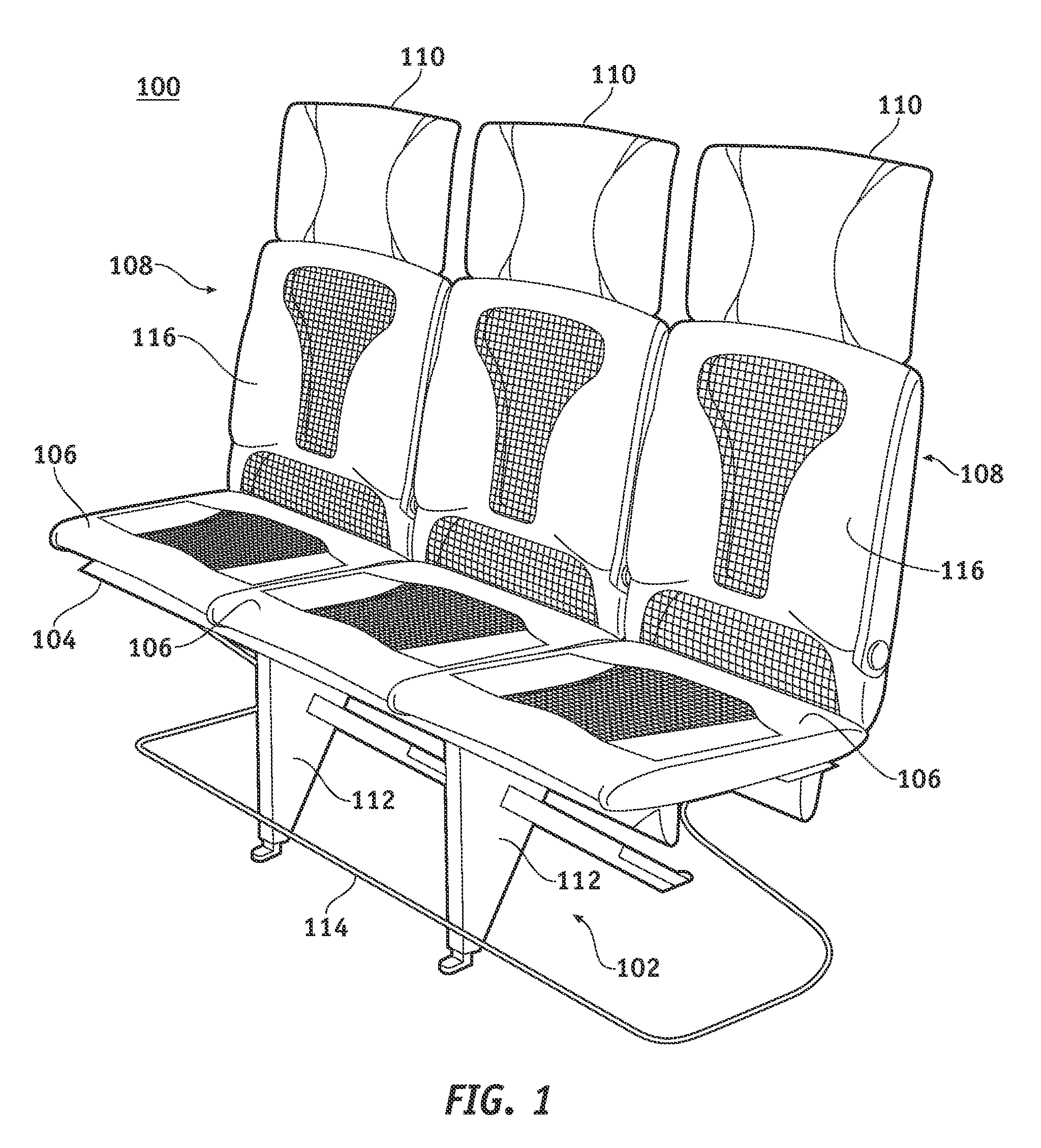

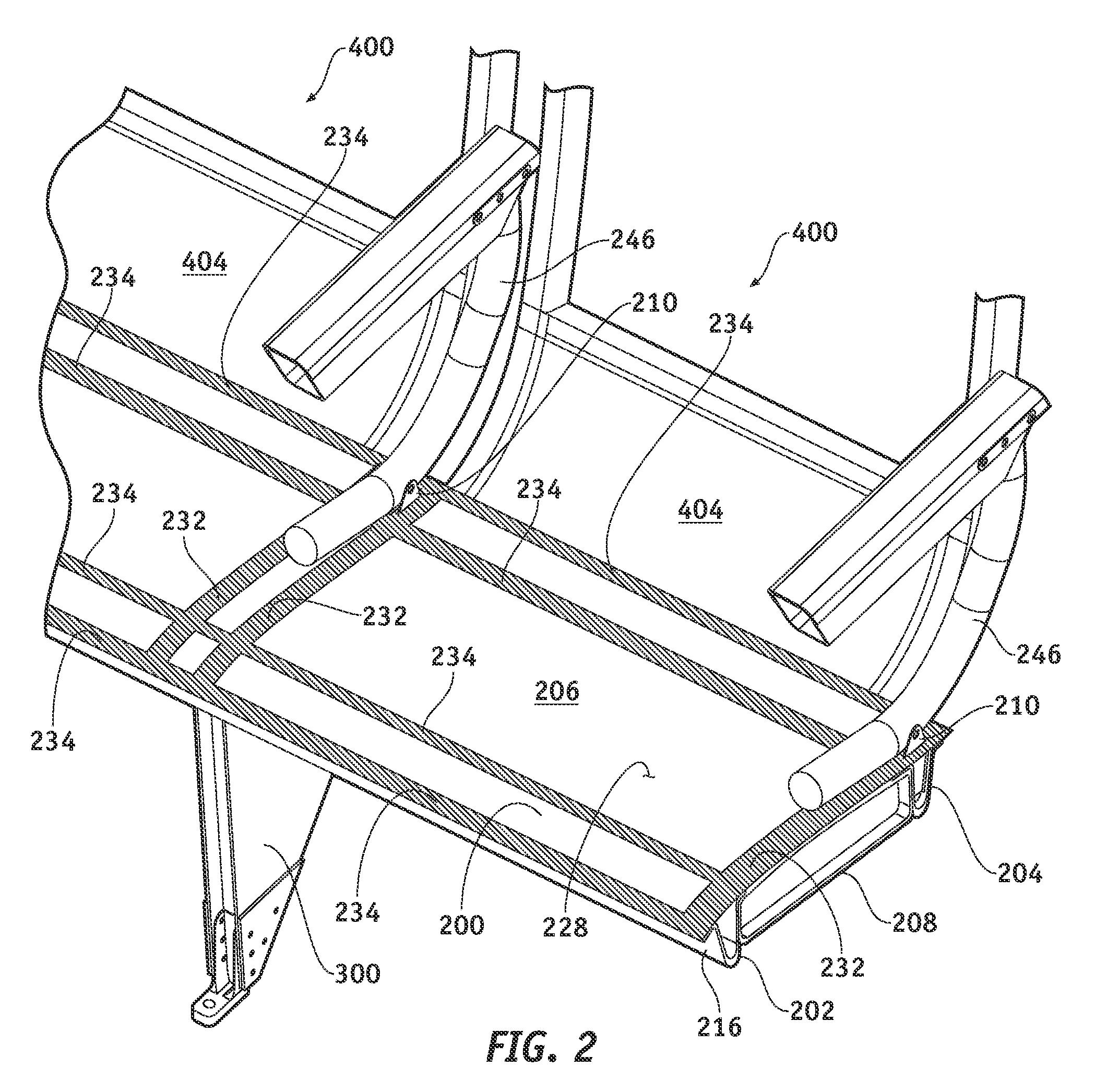

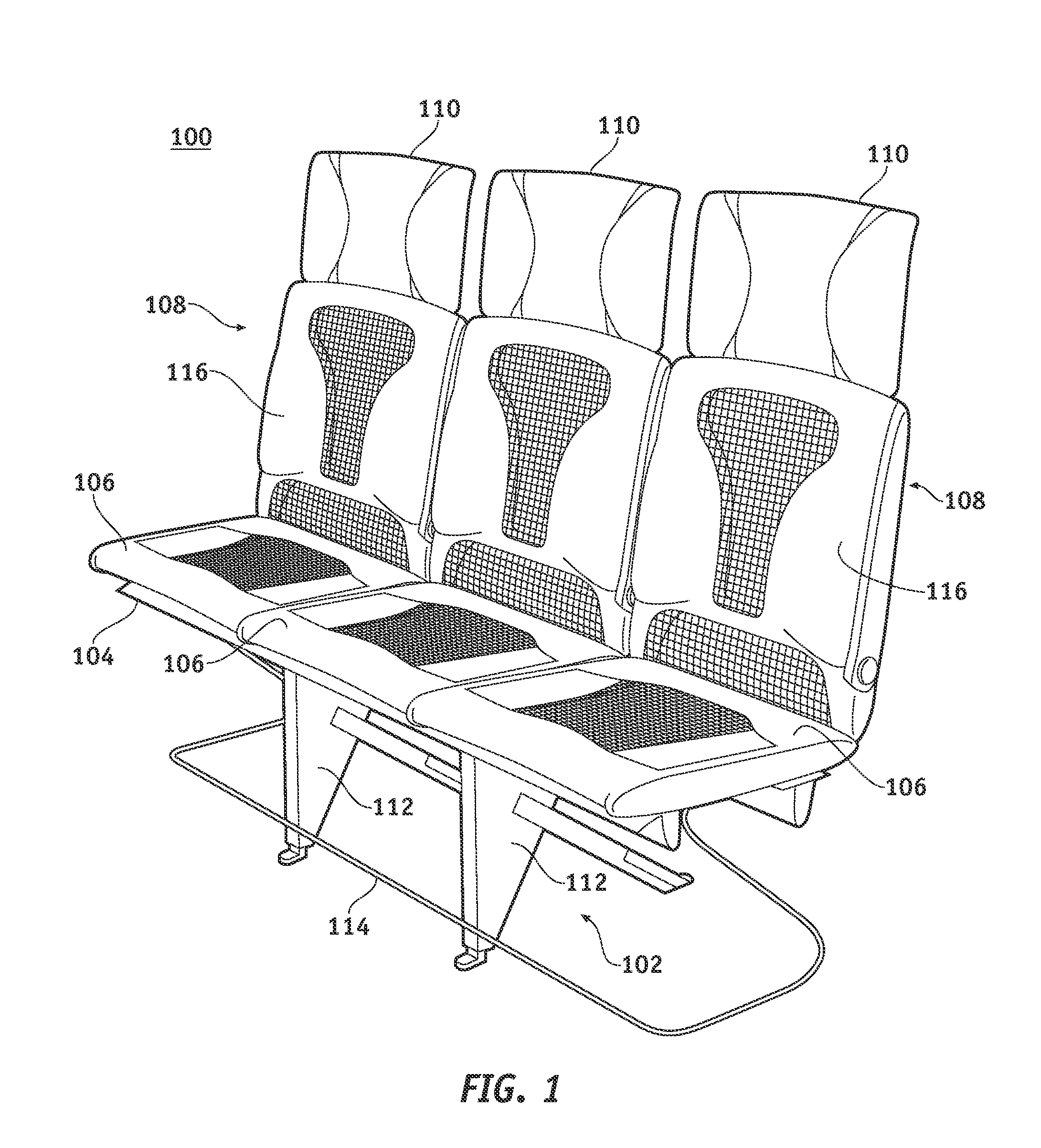

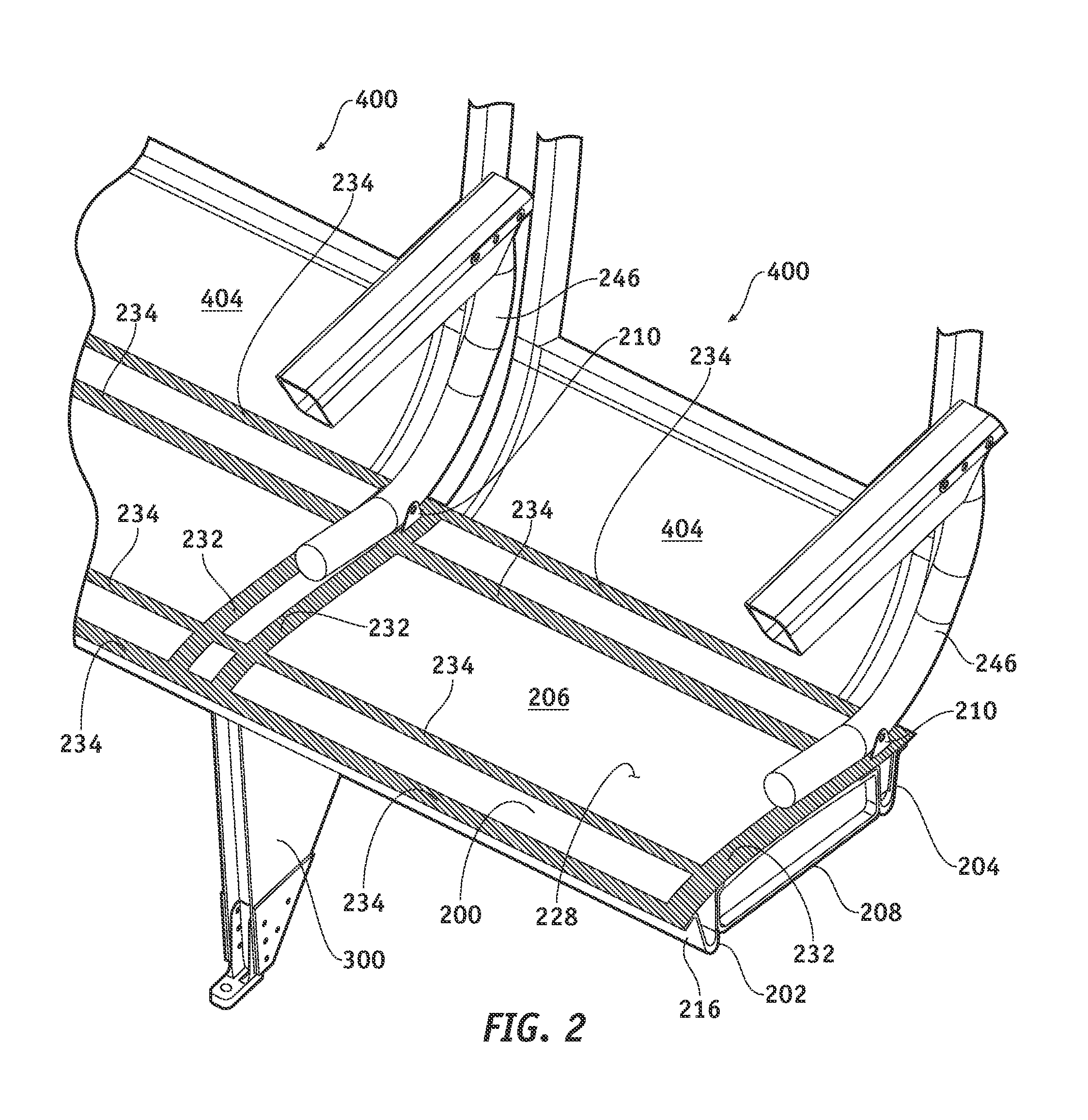

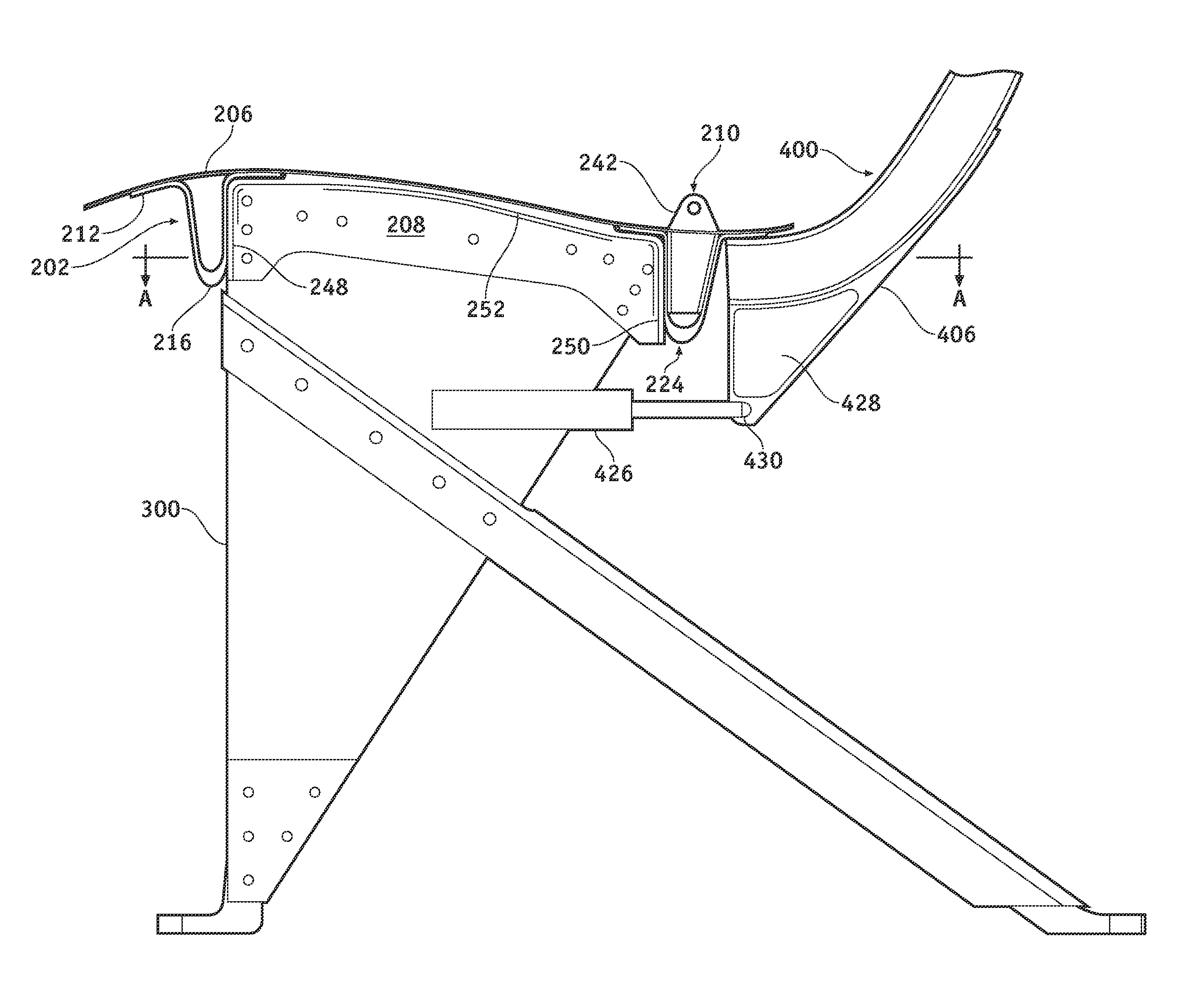

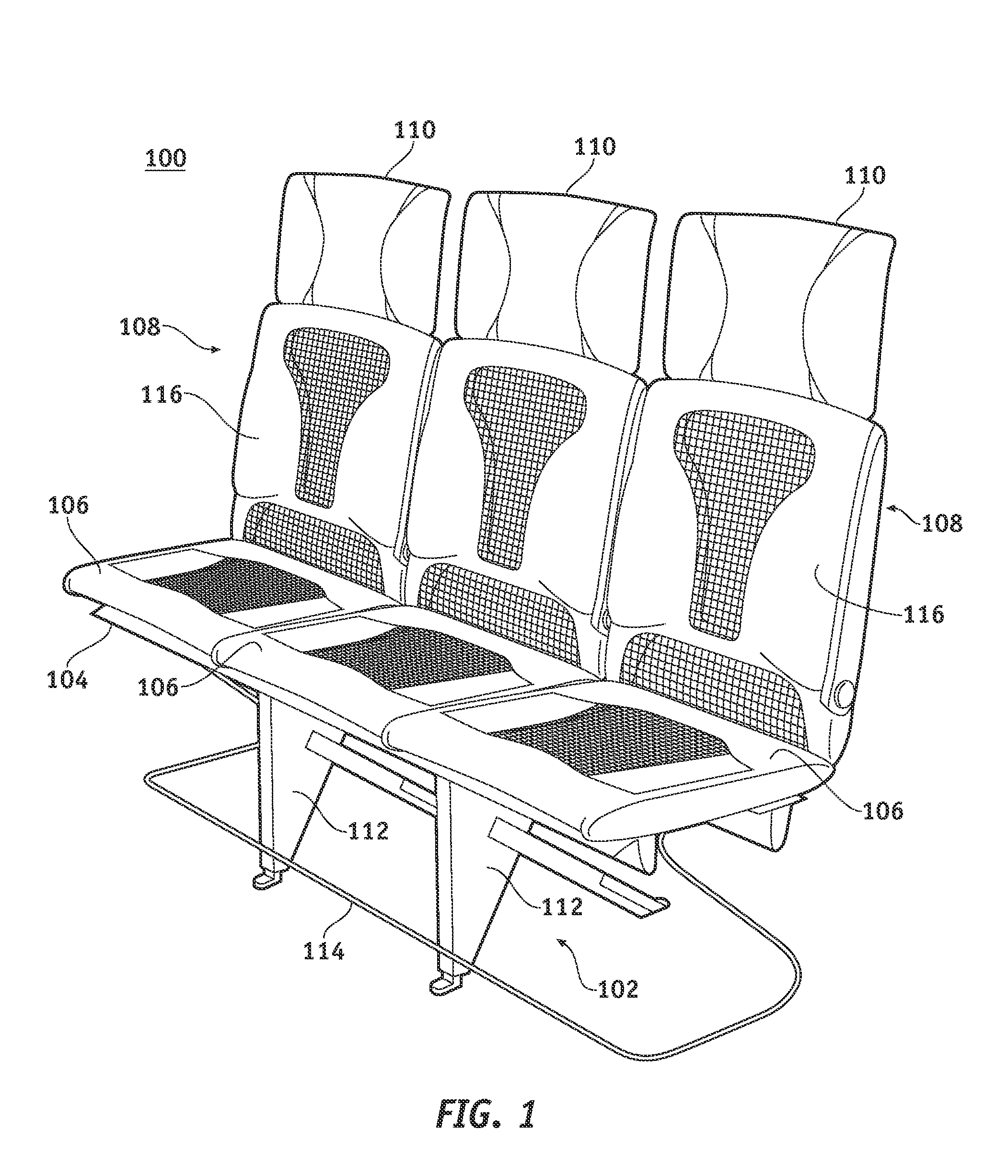

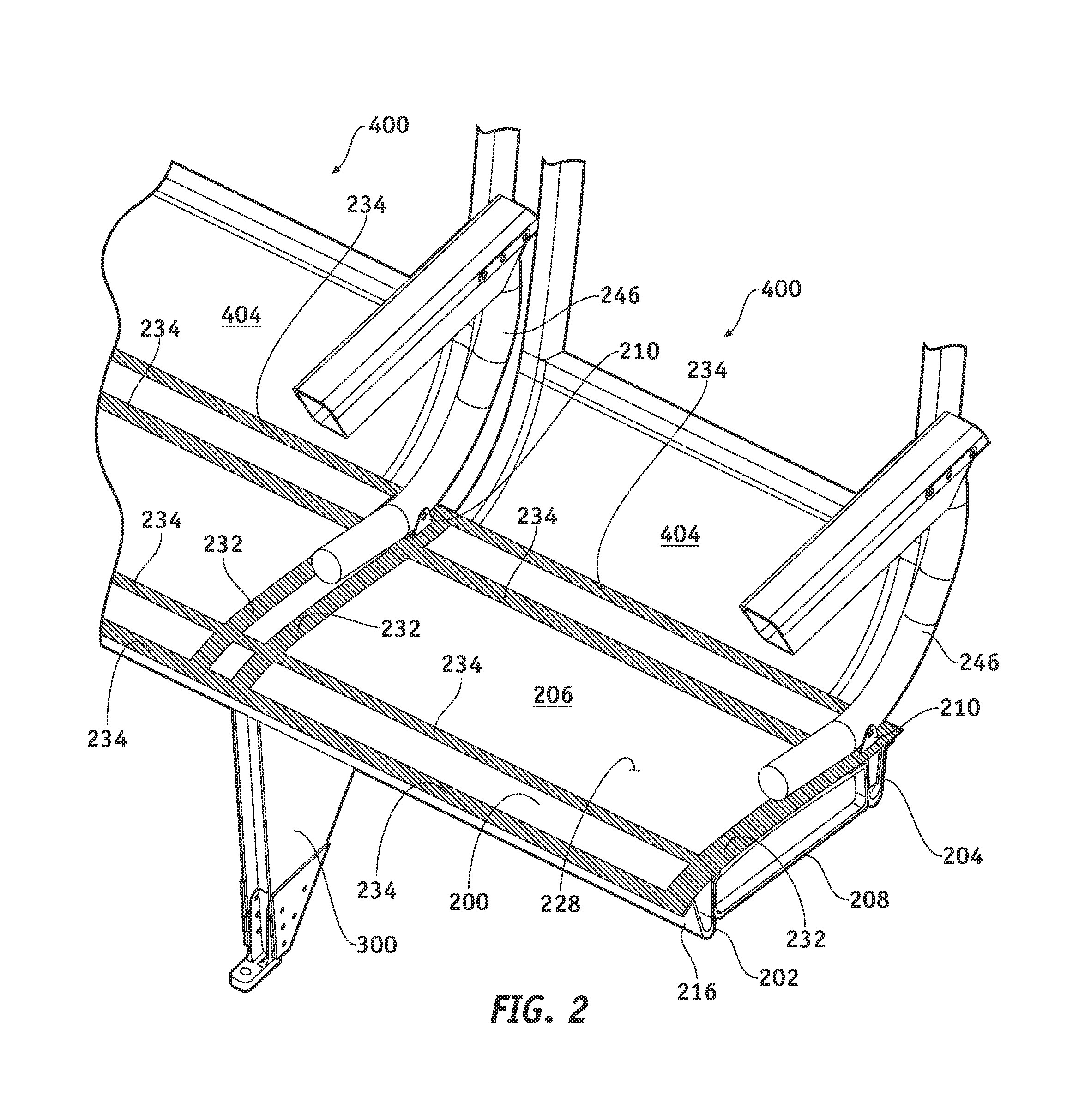

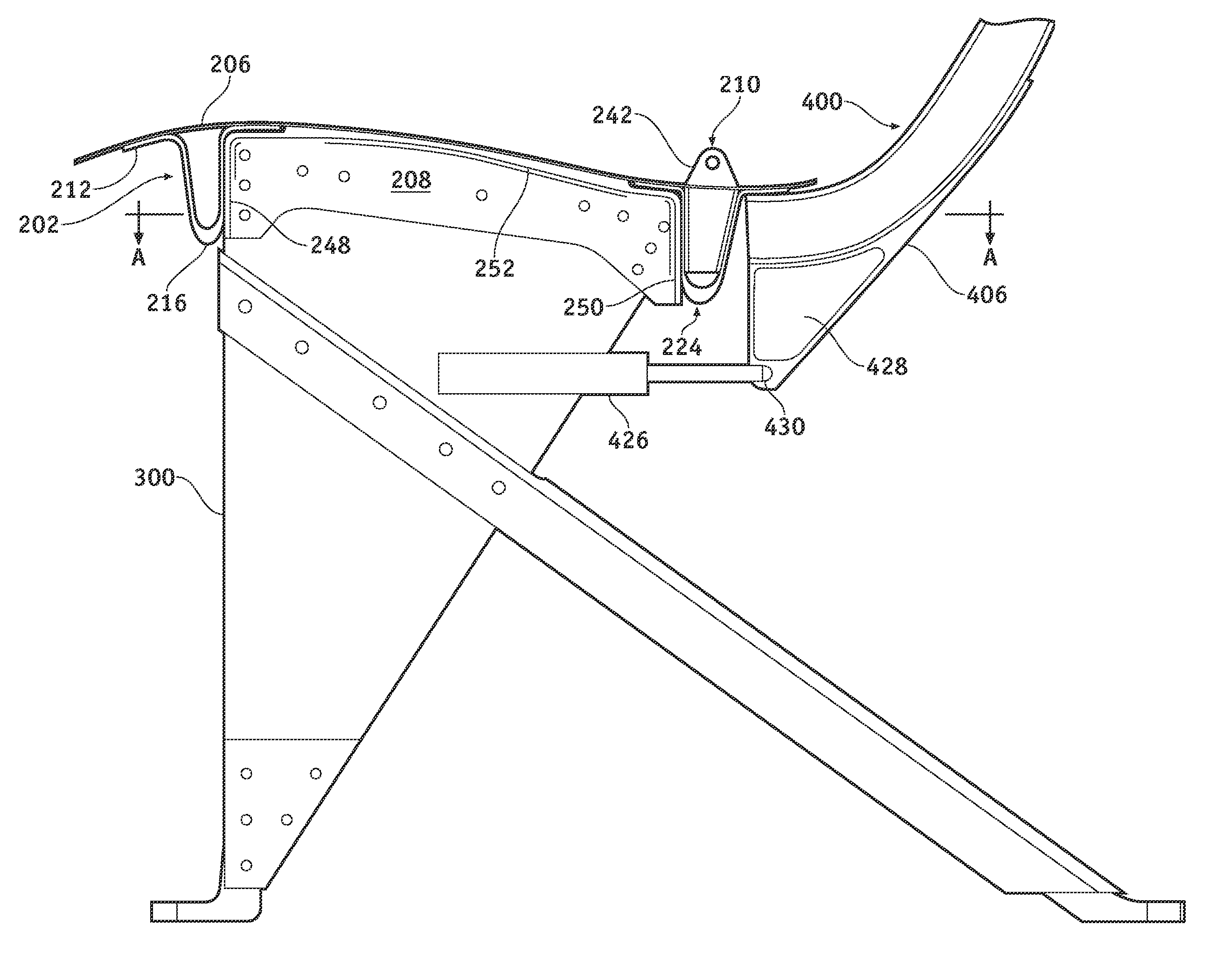

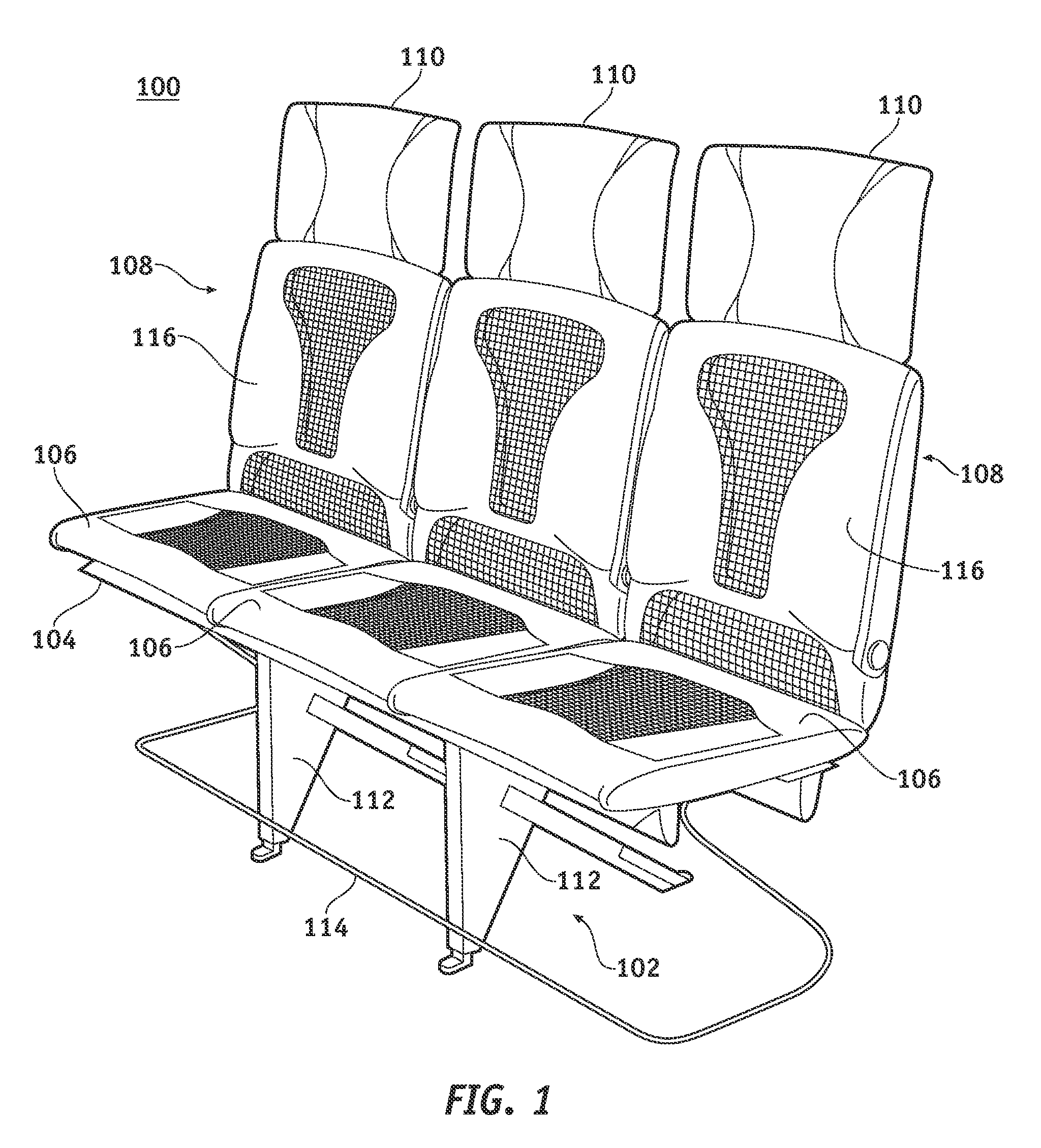

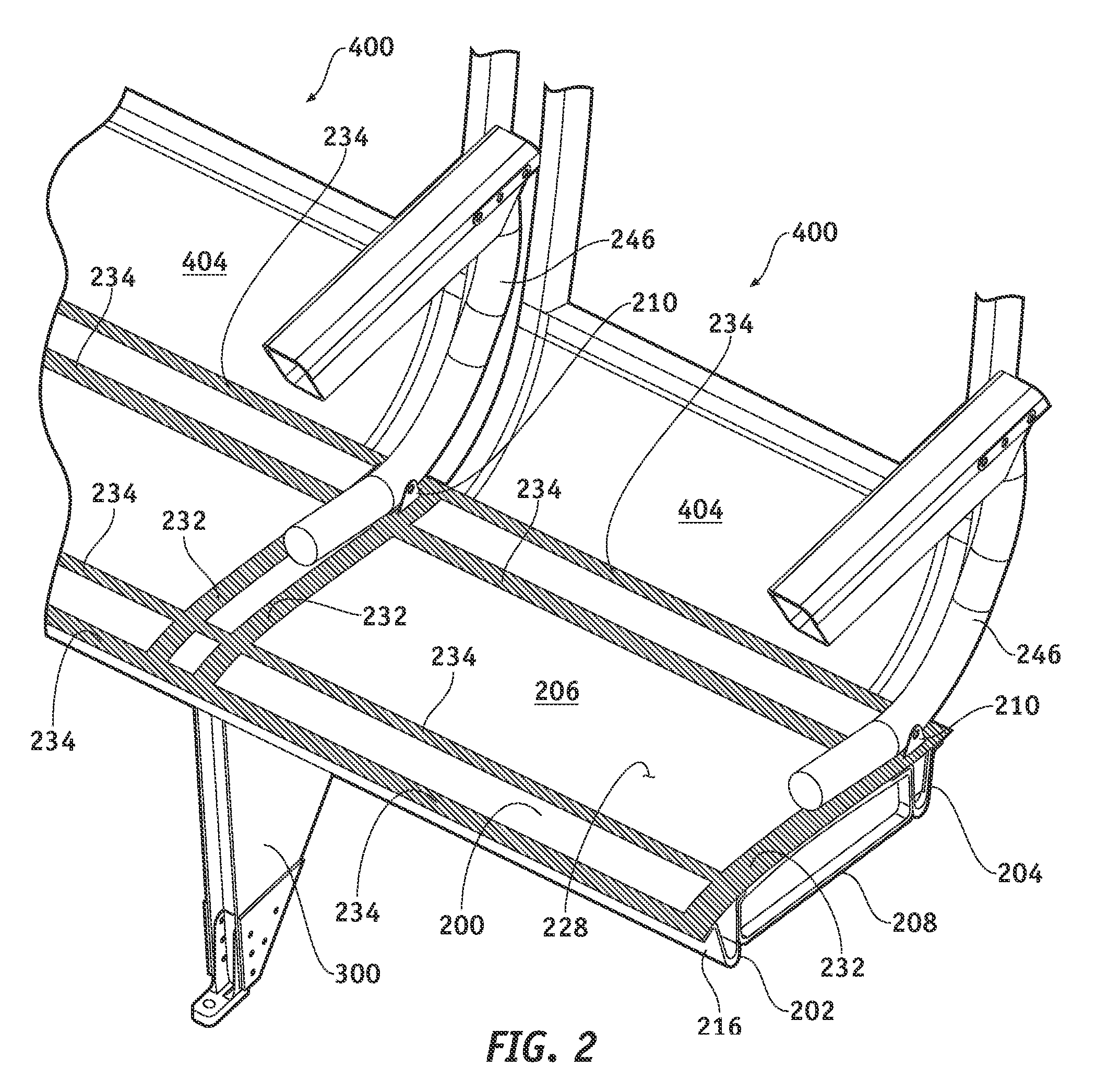

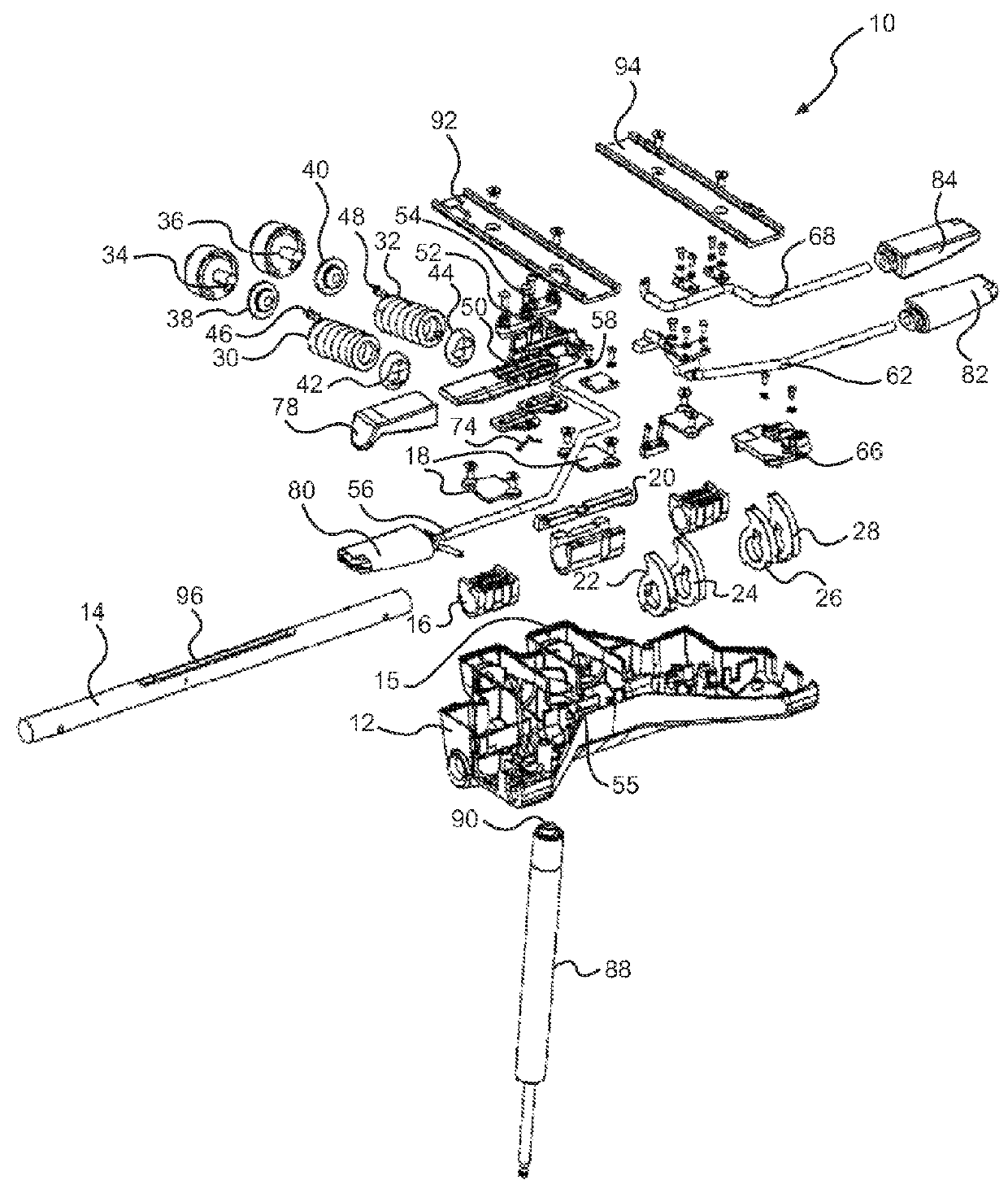

Composite seat back structure for a lightweight aircraft seat assembly

ActiveUS20080150342A1Reduce weightSmall sizeVehicle seatsSeating arrangementsManufacturing technologyBack structure

An aircraft passenger seat configured in accordance with an embodiment of the invention utilizes composite materials to achieve significant weight savings relative to conventional seat designs. The seat includes one or more lightweight composite support legs, a lightweight composite seat pan, and a lightweight composite seat back structure. The support legs are coupled to the seat pan, which is in turn coupled to the seat back structure. The support legs utilize composite frame elements that are formed as continuous compression molded composite extrusions. The seat pan includes composite fore and aft cross beams that are also formed as continuous compression molded composite extrusions. The aft cross beam includes a rear flange that serves as a flexible “hinge” for the seat back structure. The seat can leverage producible and relatively inexpensive composite manufacturing techniques such that the seat can be economically produced for use as an economy class seat.

Owner:THE BOEING CO

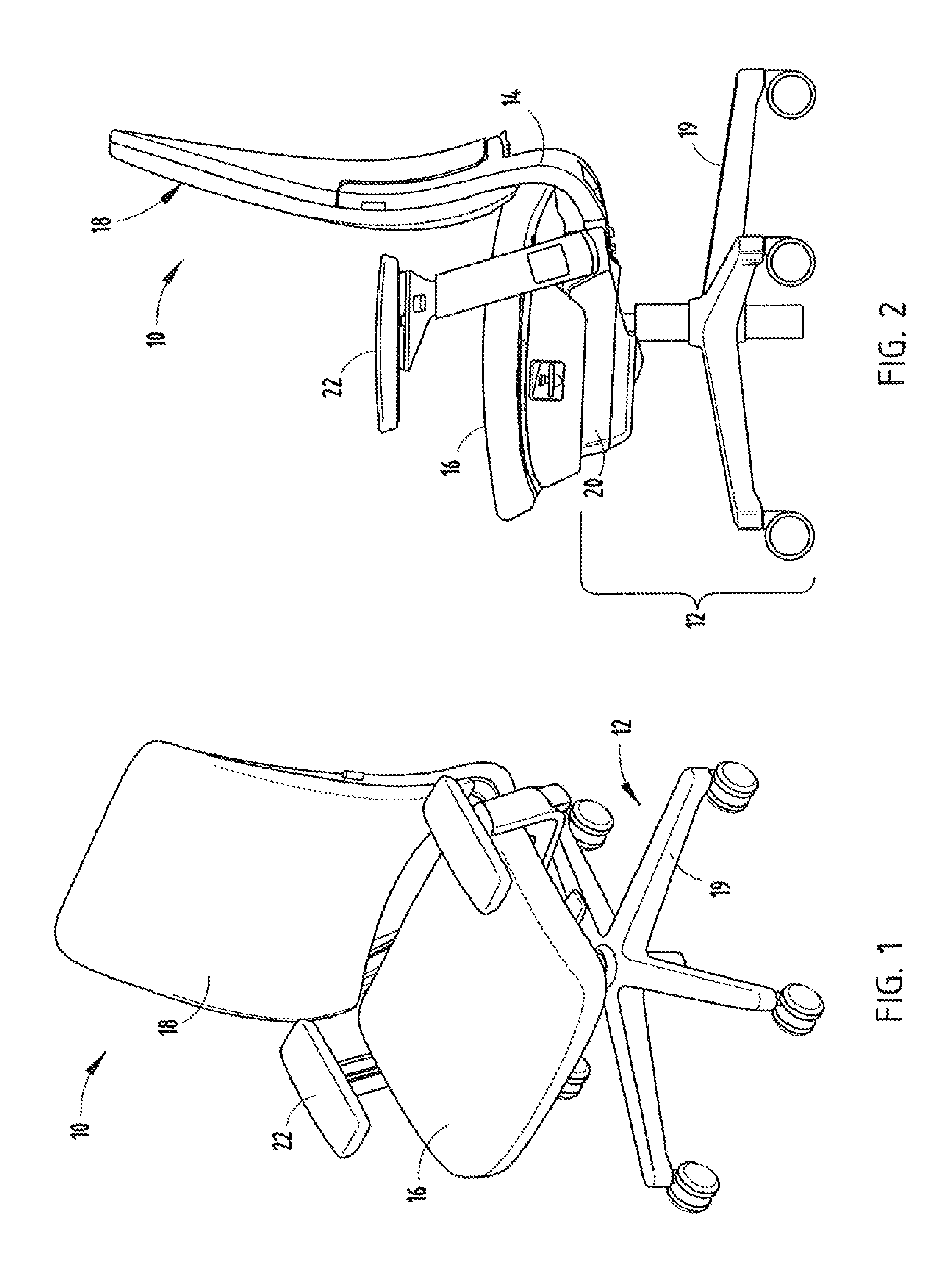

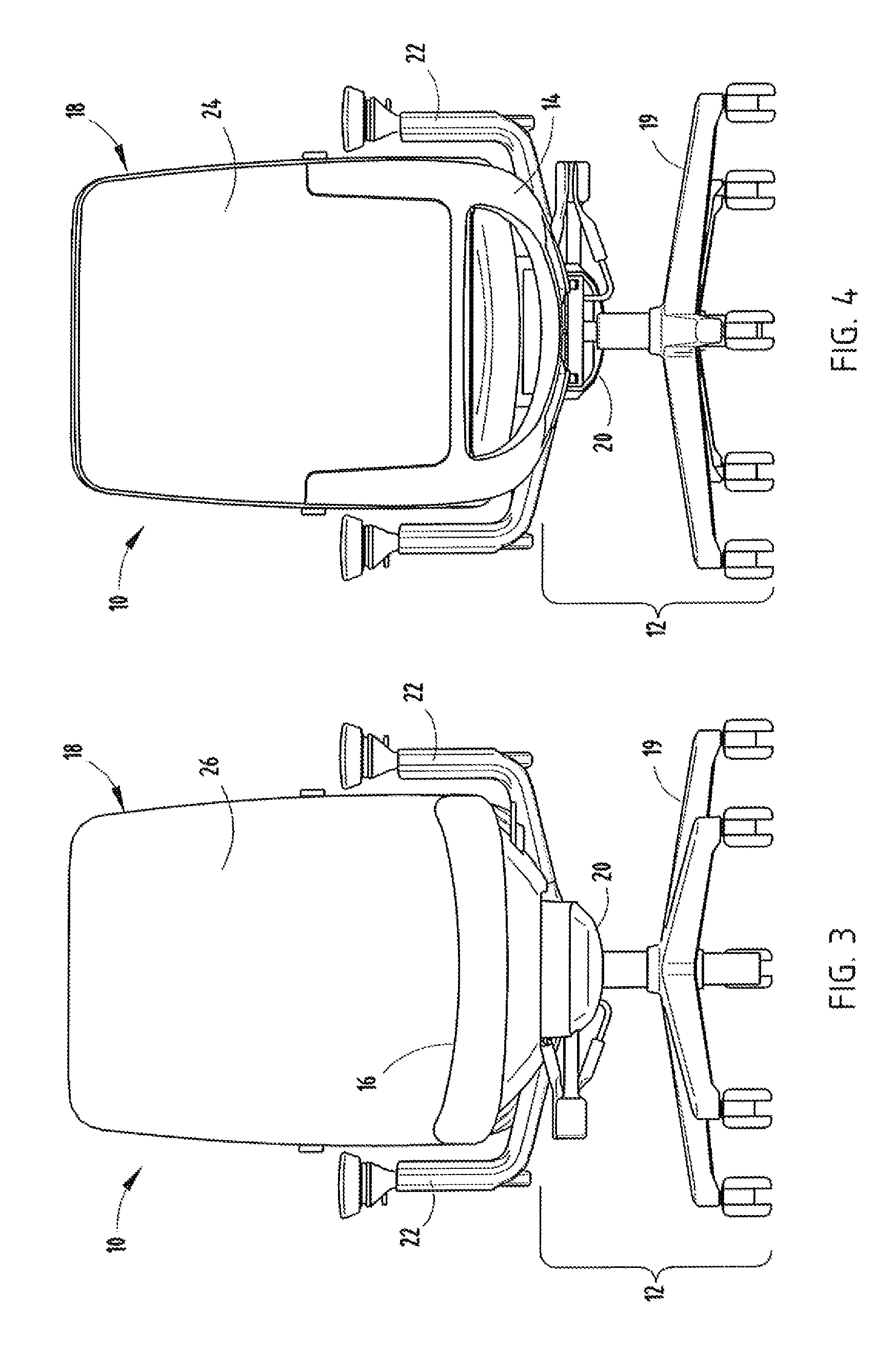

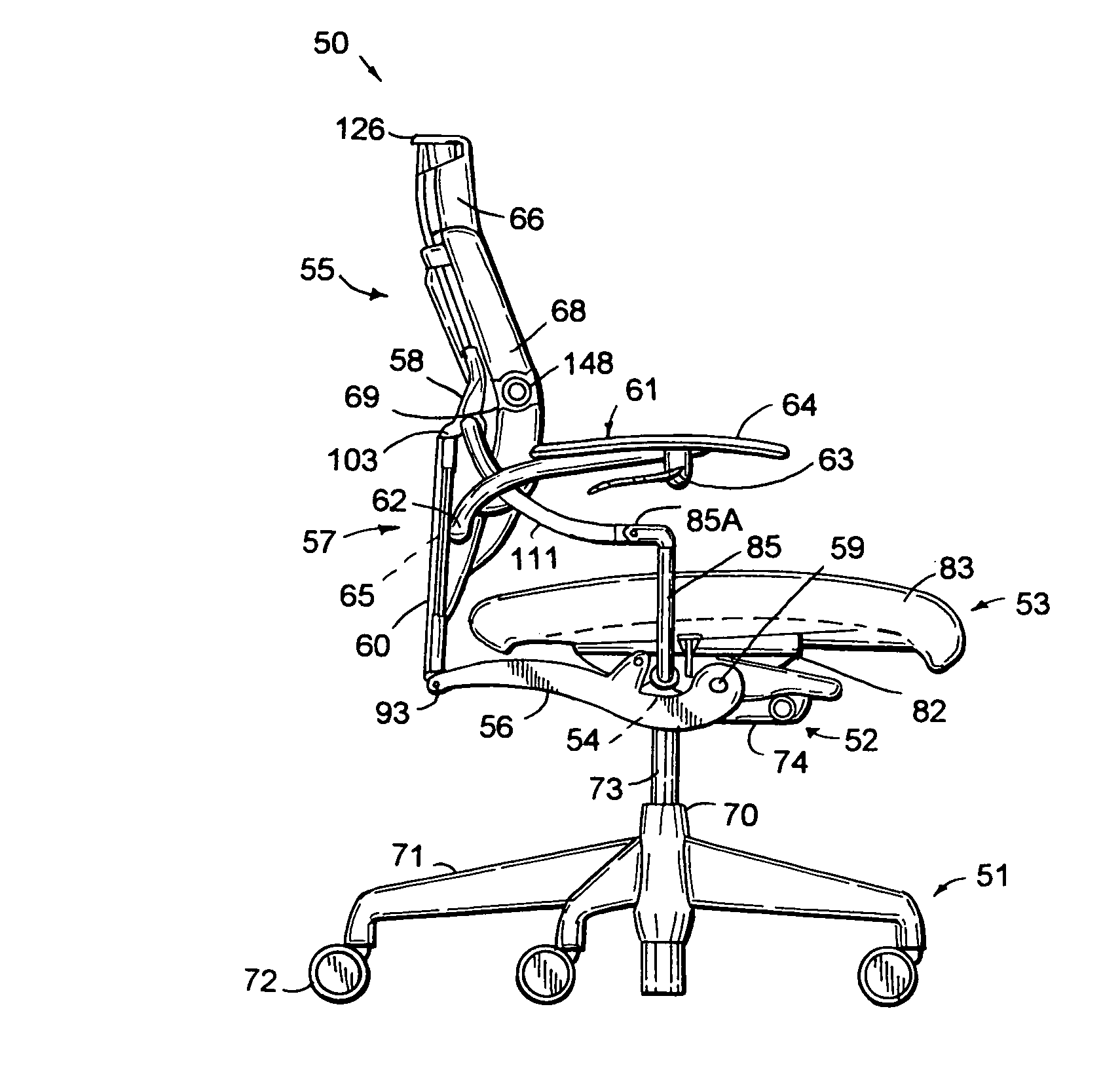

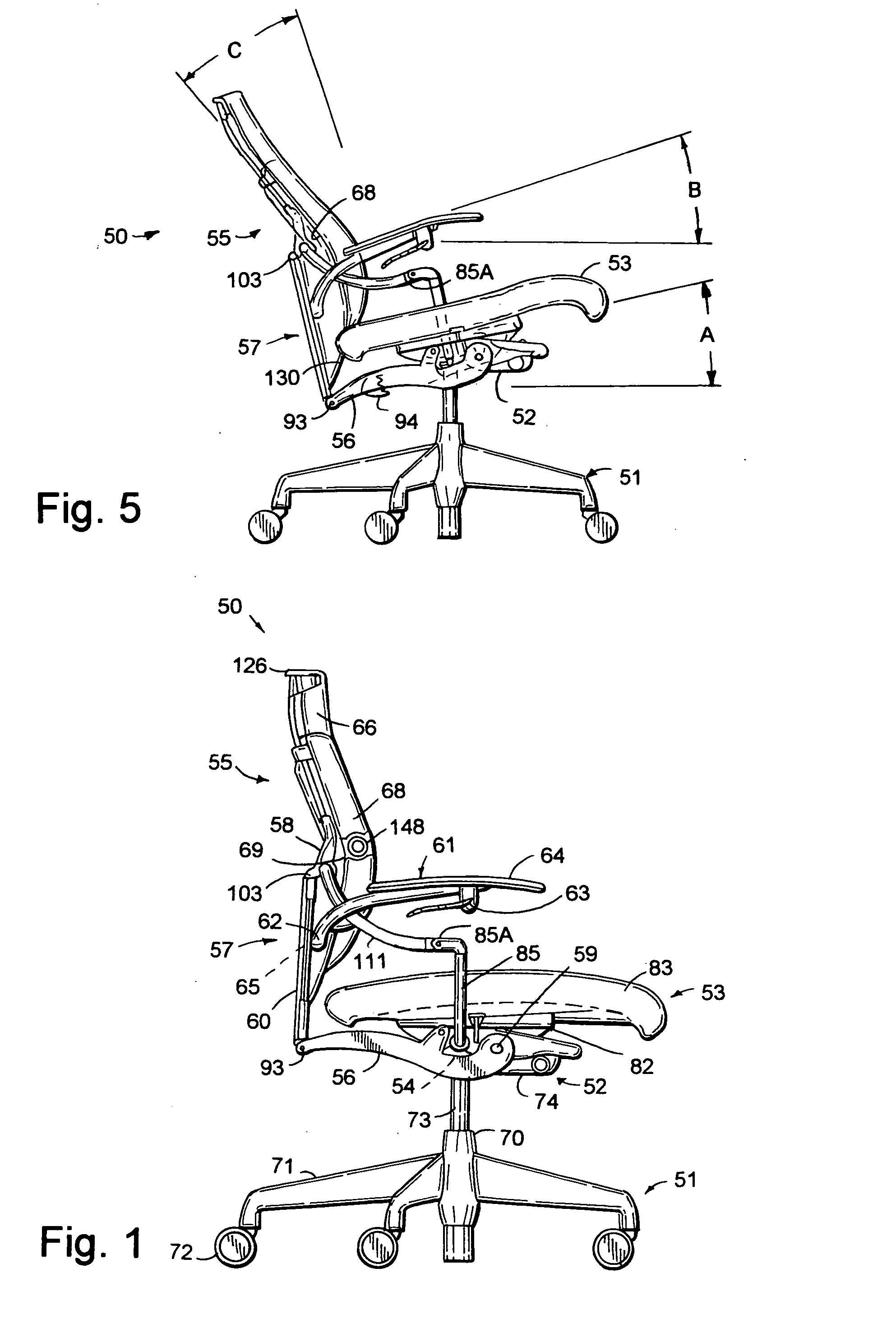

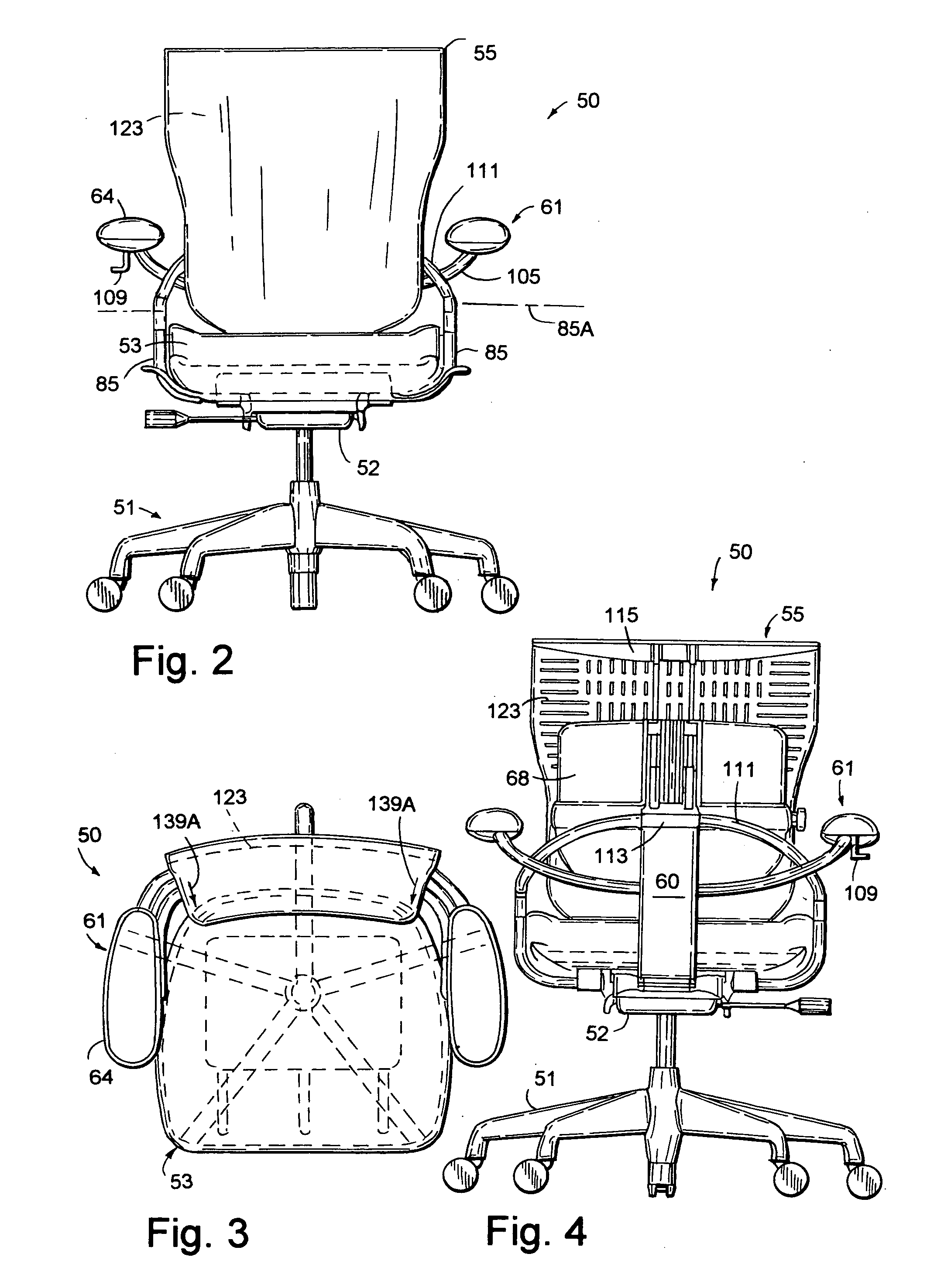

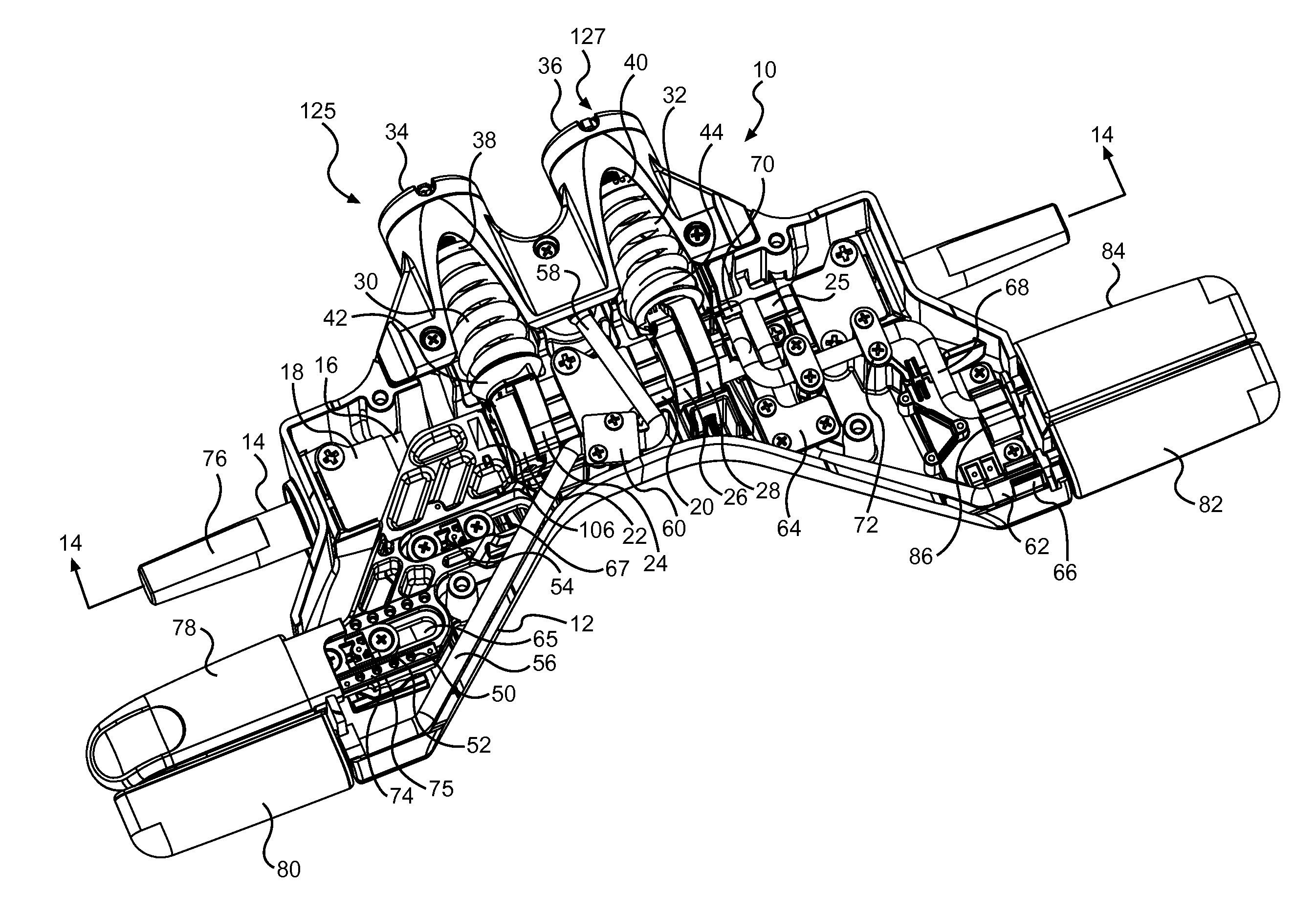

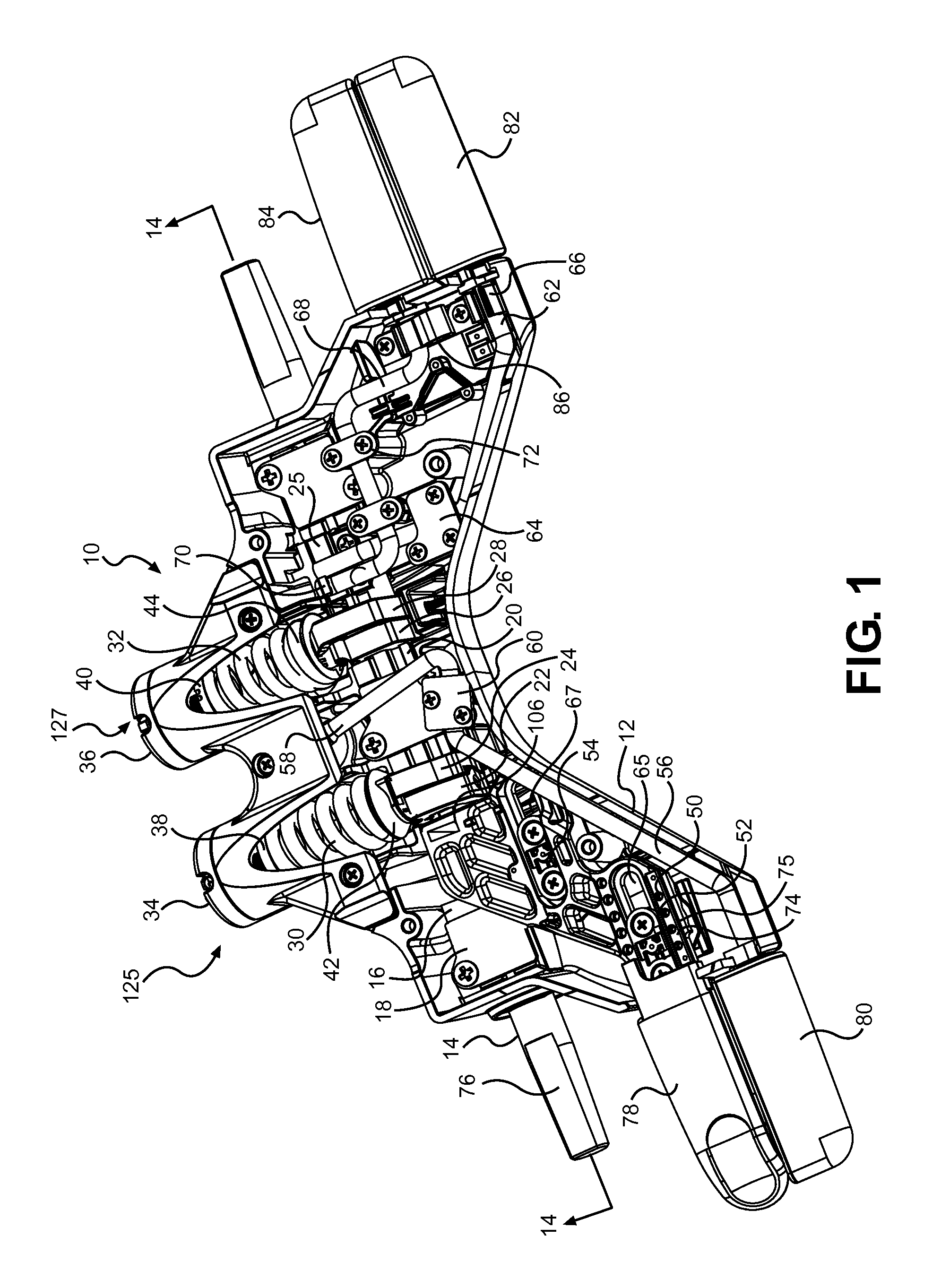

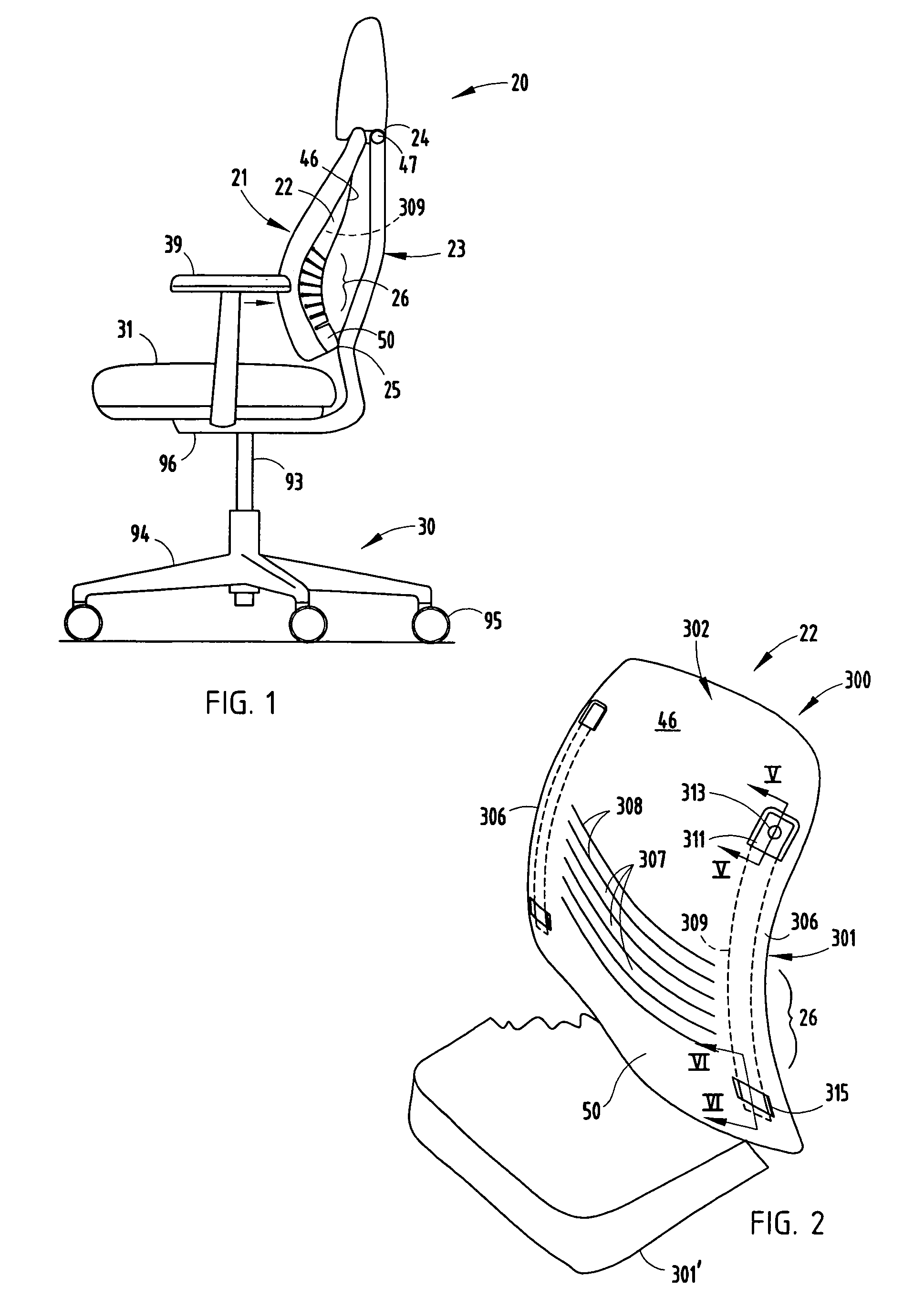

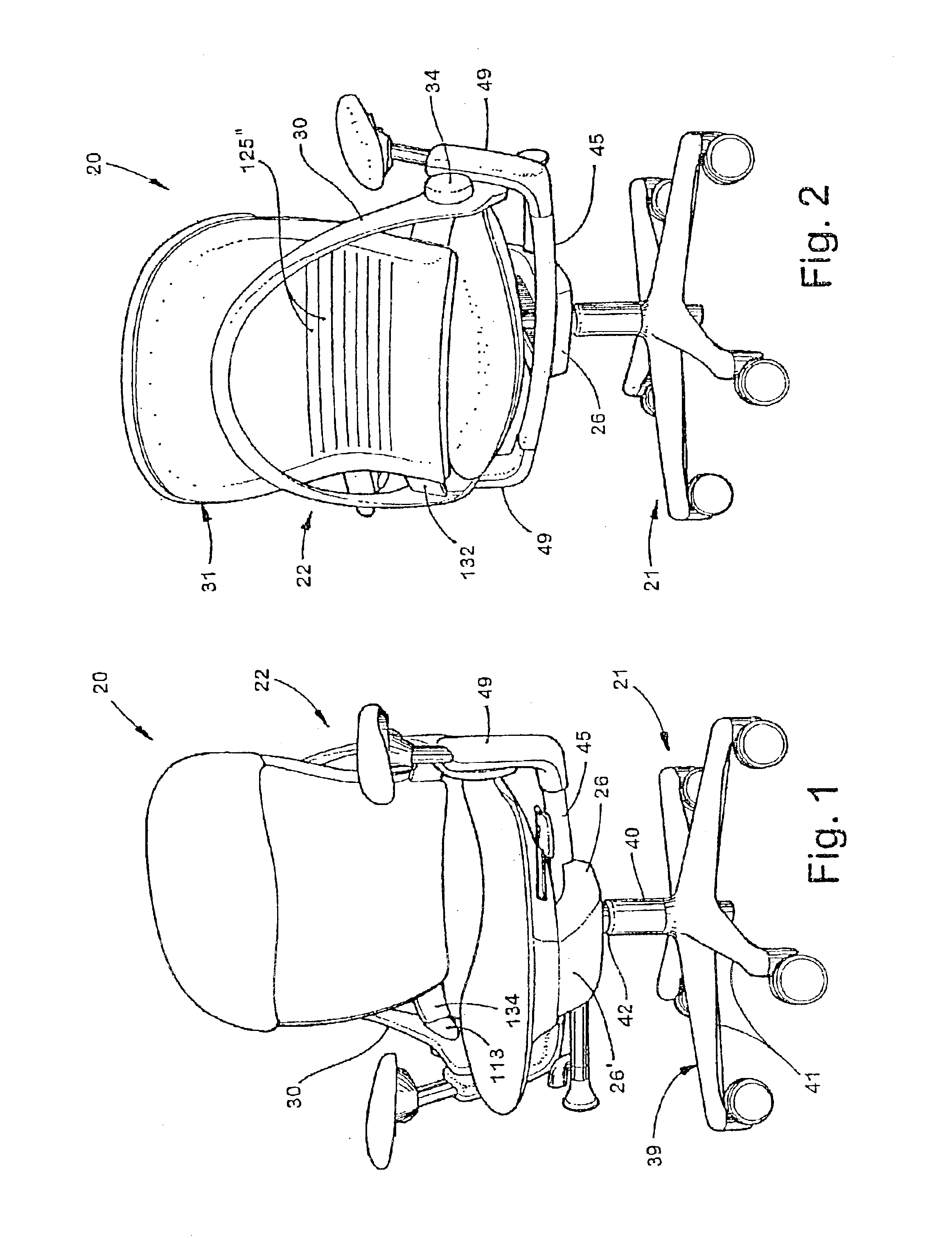

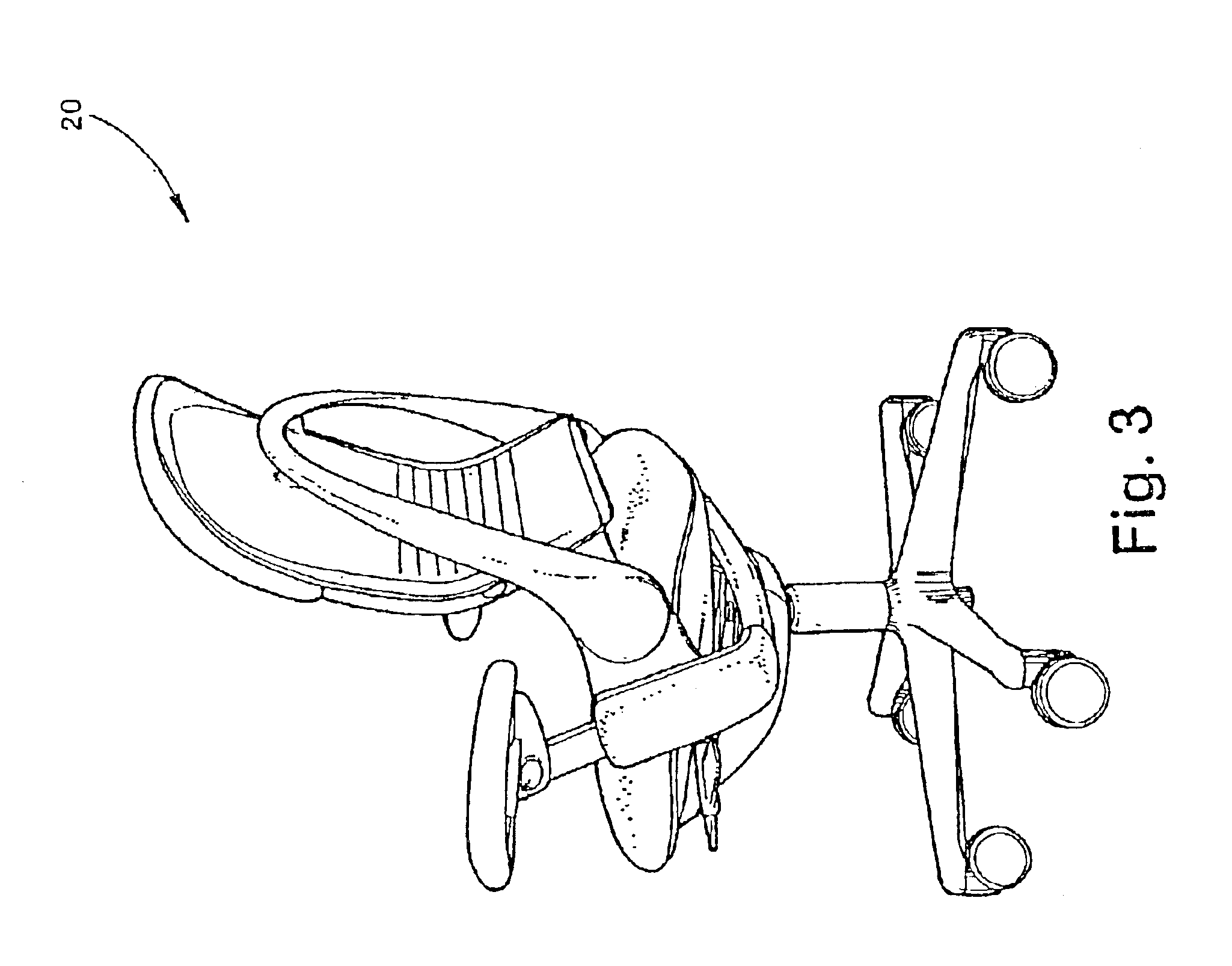

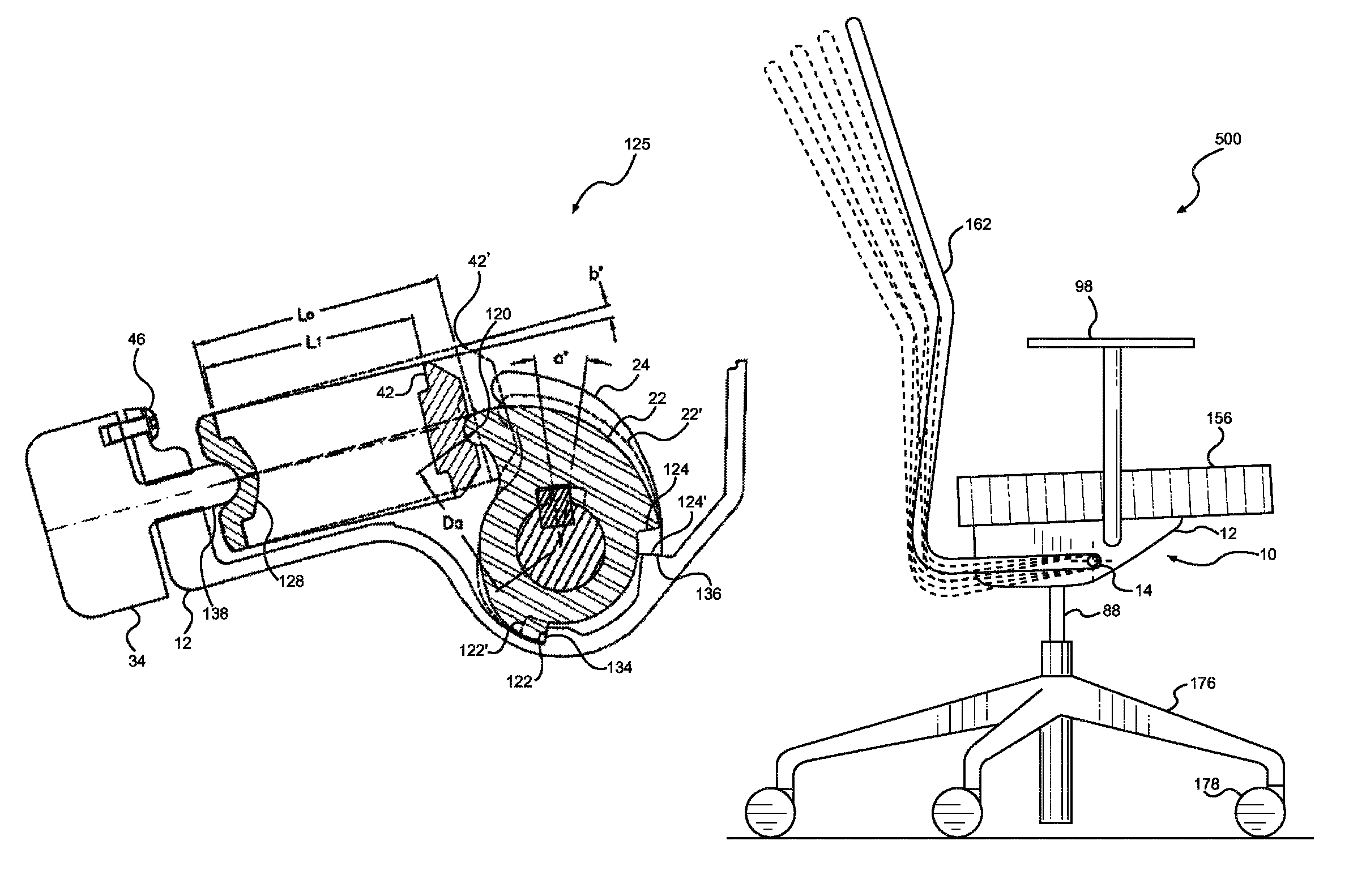

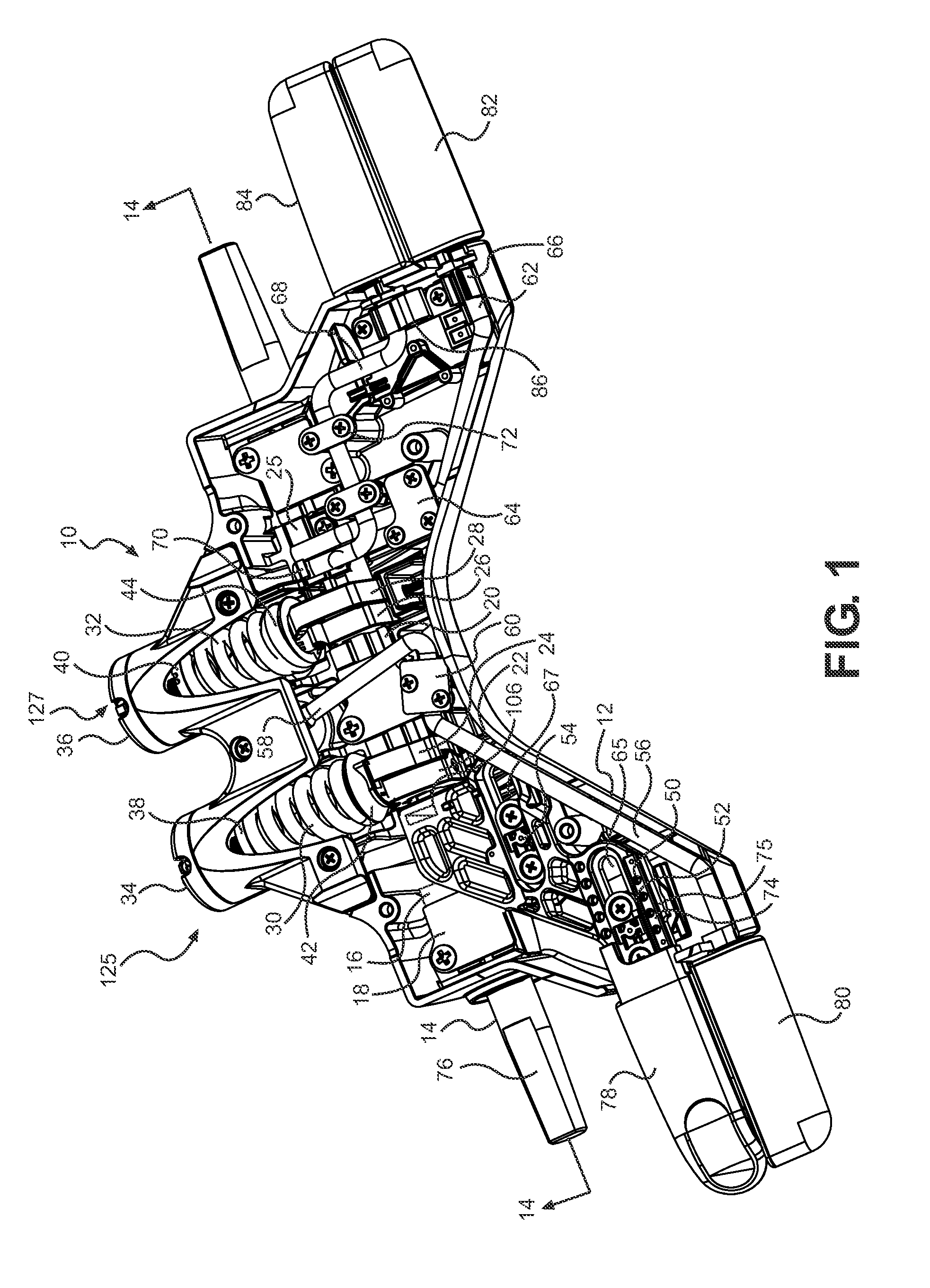

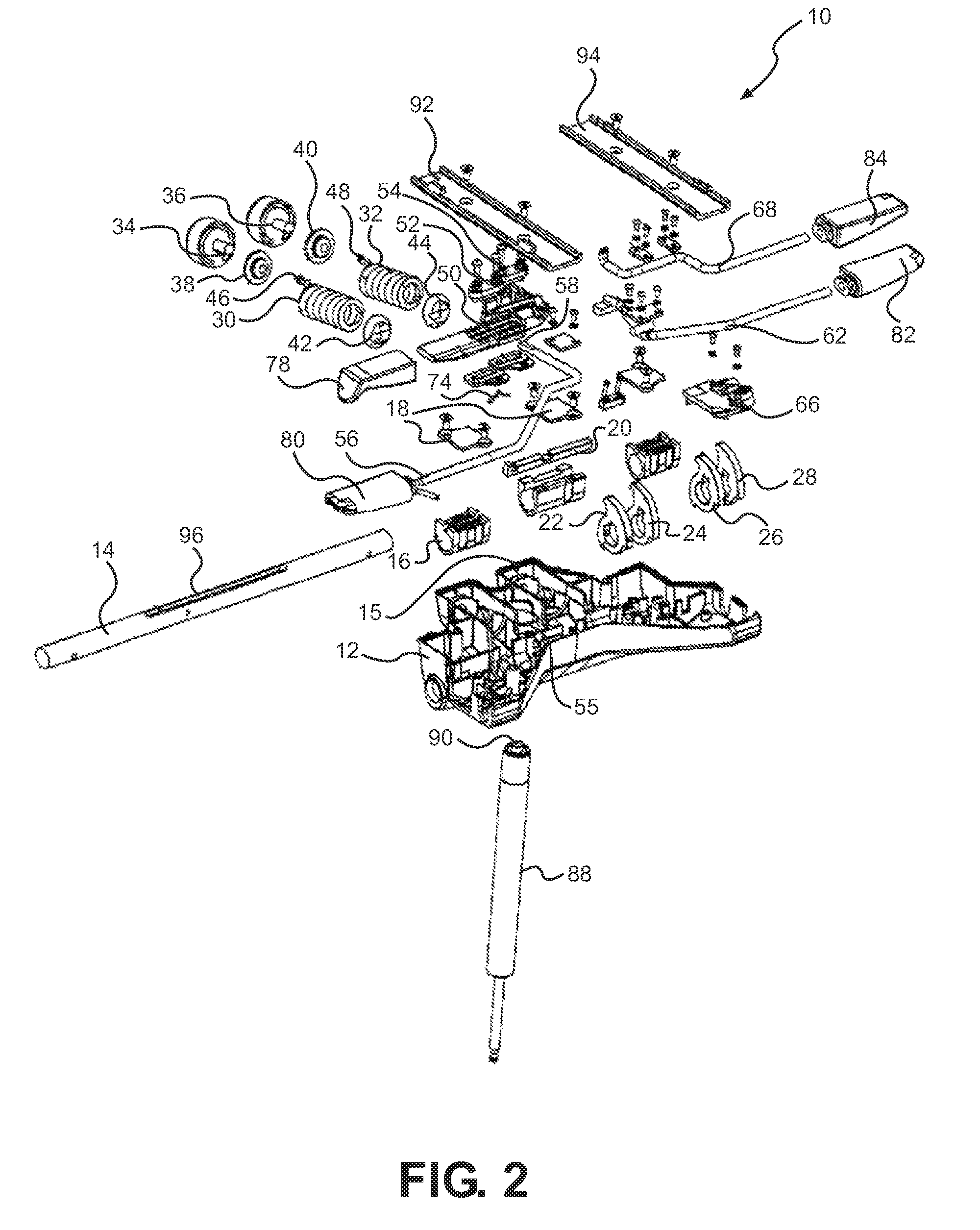

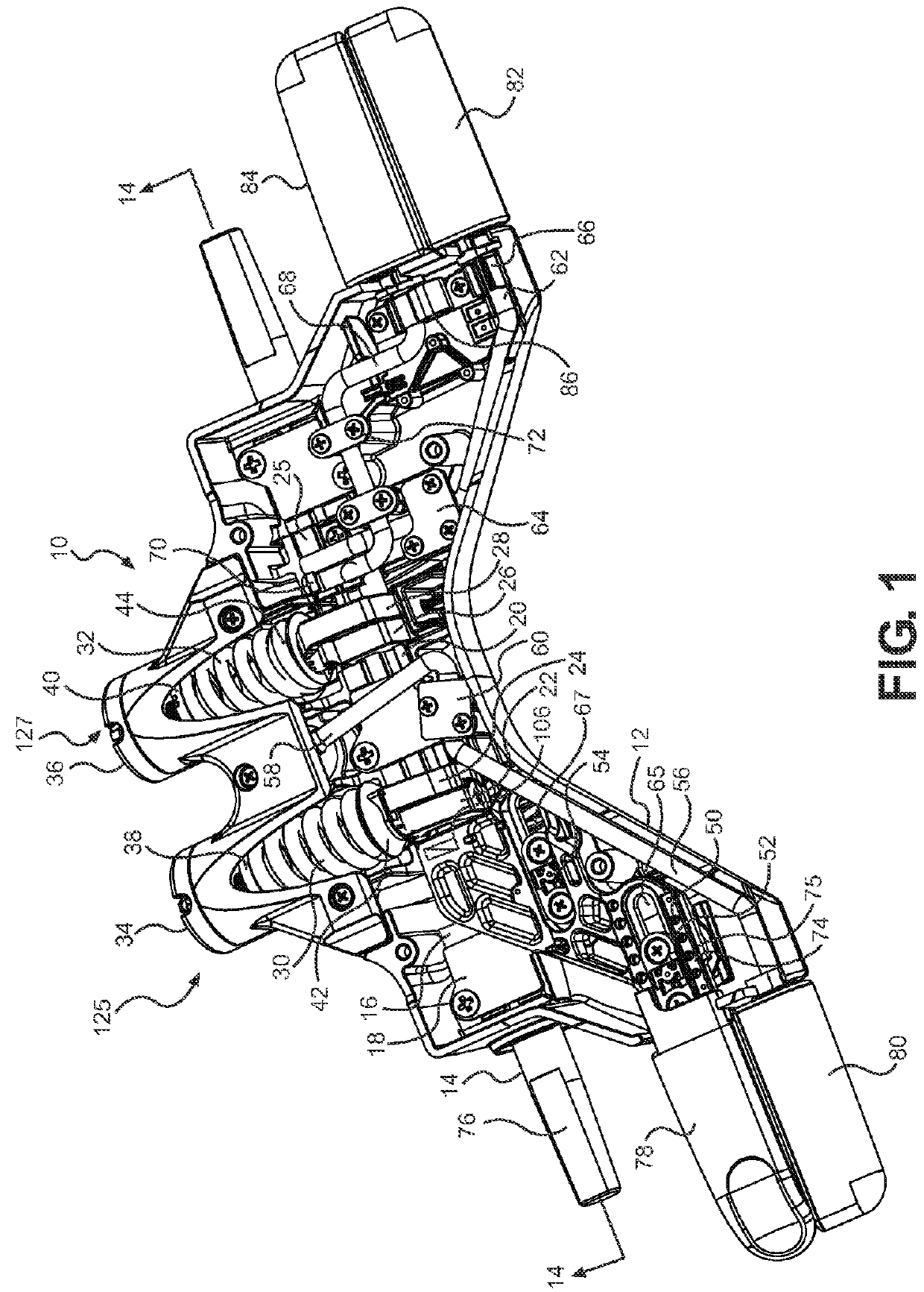

Mobile Task Chair and Mobile Task Chair Control Mechanism with Adjustment Capabilities and Visual Setting Indicators

ActiveUS20120032484A1Proper adjustment of task chair performance characteristics more convenient and accessibleOperating chairsDental chairsBack structureEmbedded system

A mobile task chair with a control mechanism with adjustment mechanisms and setting indicators. The mobile task chair has a mobile base structure, a control mechanism supported by the base structure, a seat bottom structure supported by the base structure, a seat back structure supported by the base structure, a mechanism for adjusting a physical setting of the mobile task chair, such as the pivoting resistance of the back structure, and a mechanism for providing a visual indication of the pivoting resistance of the mobile task chair.

Owner:CVEK SAVA

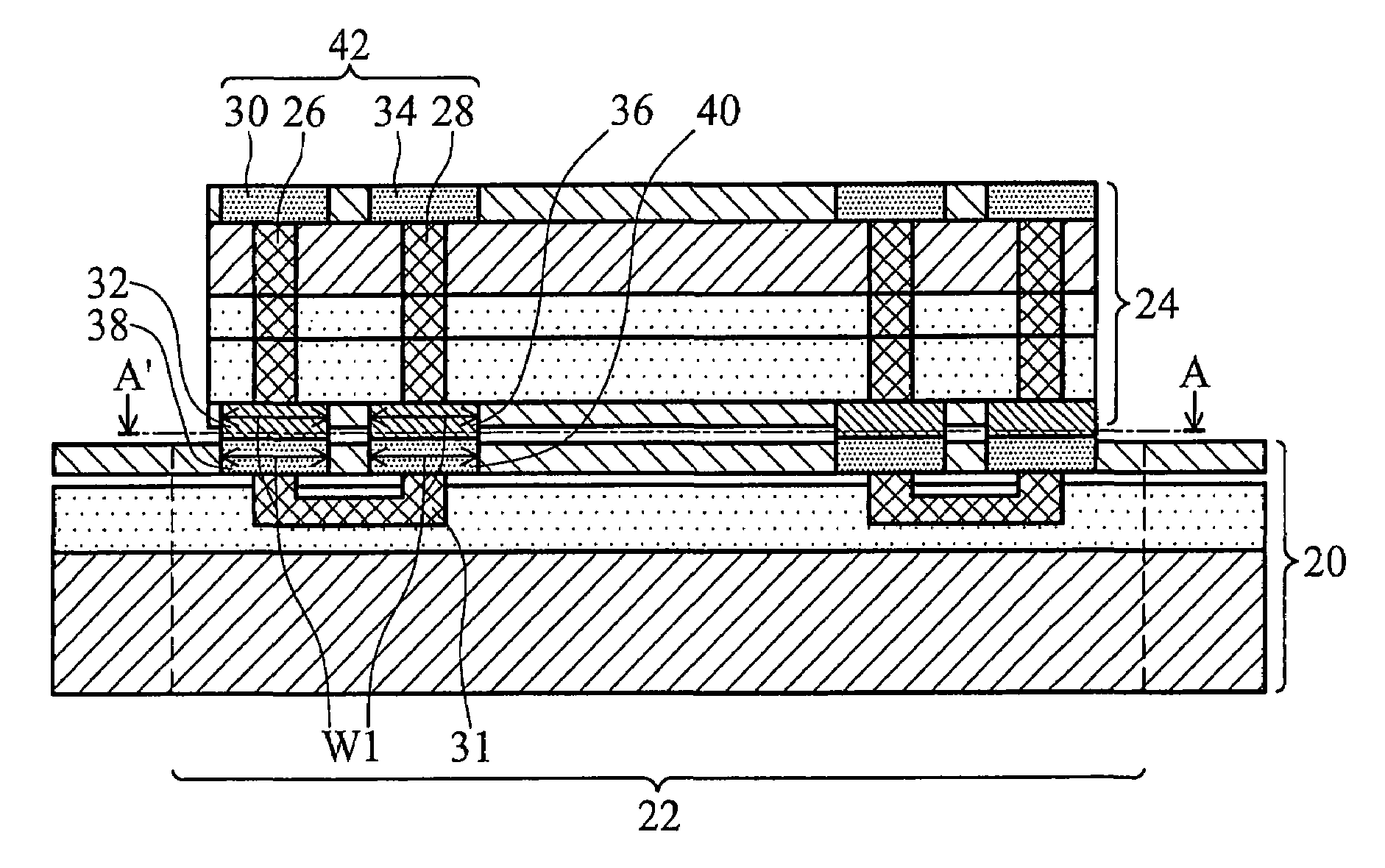

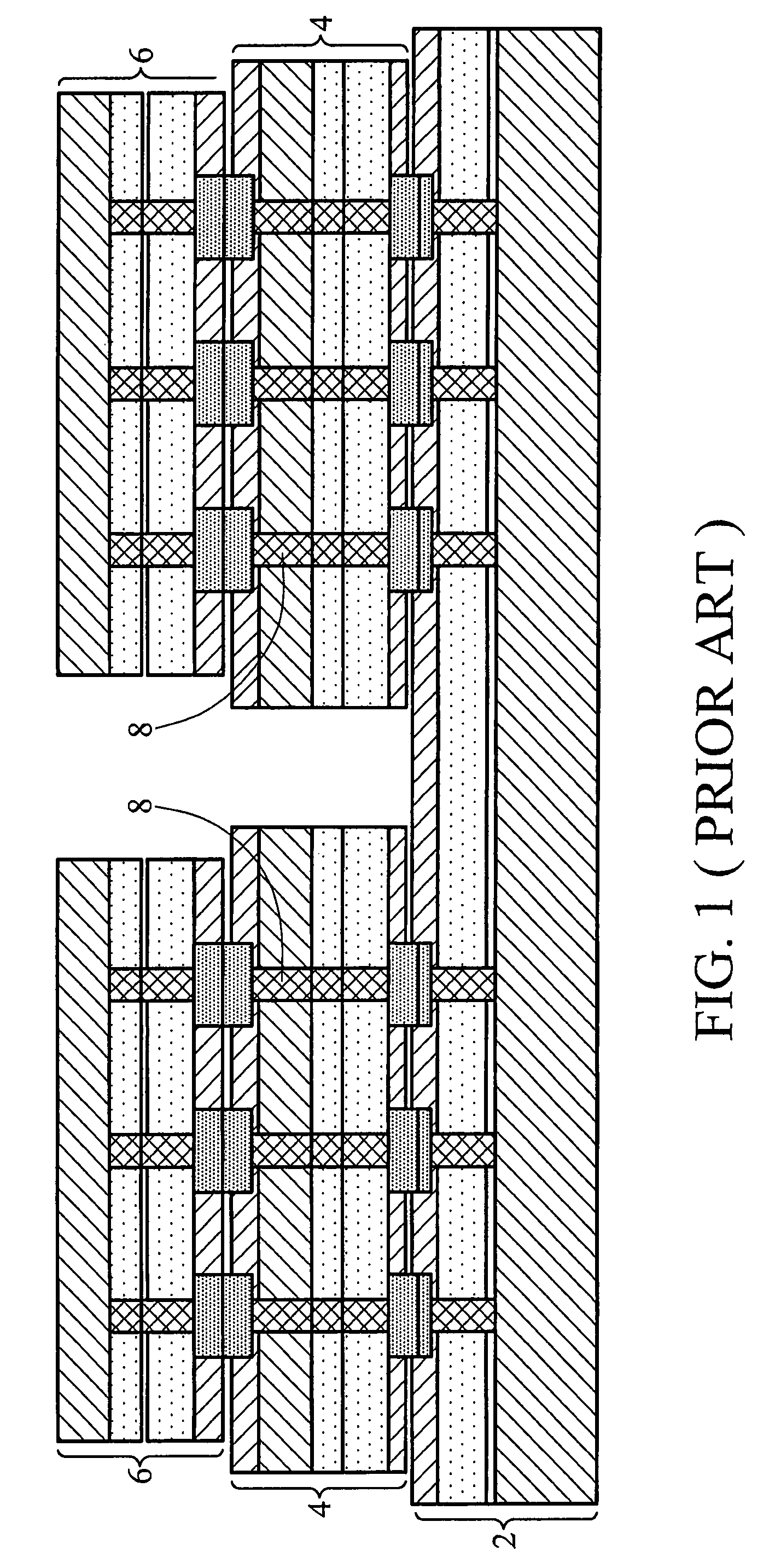

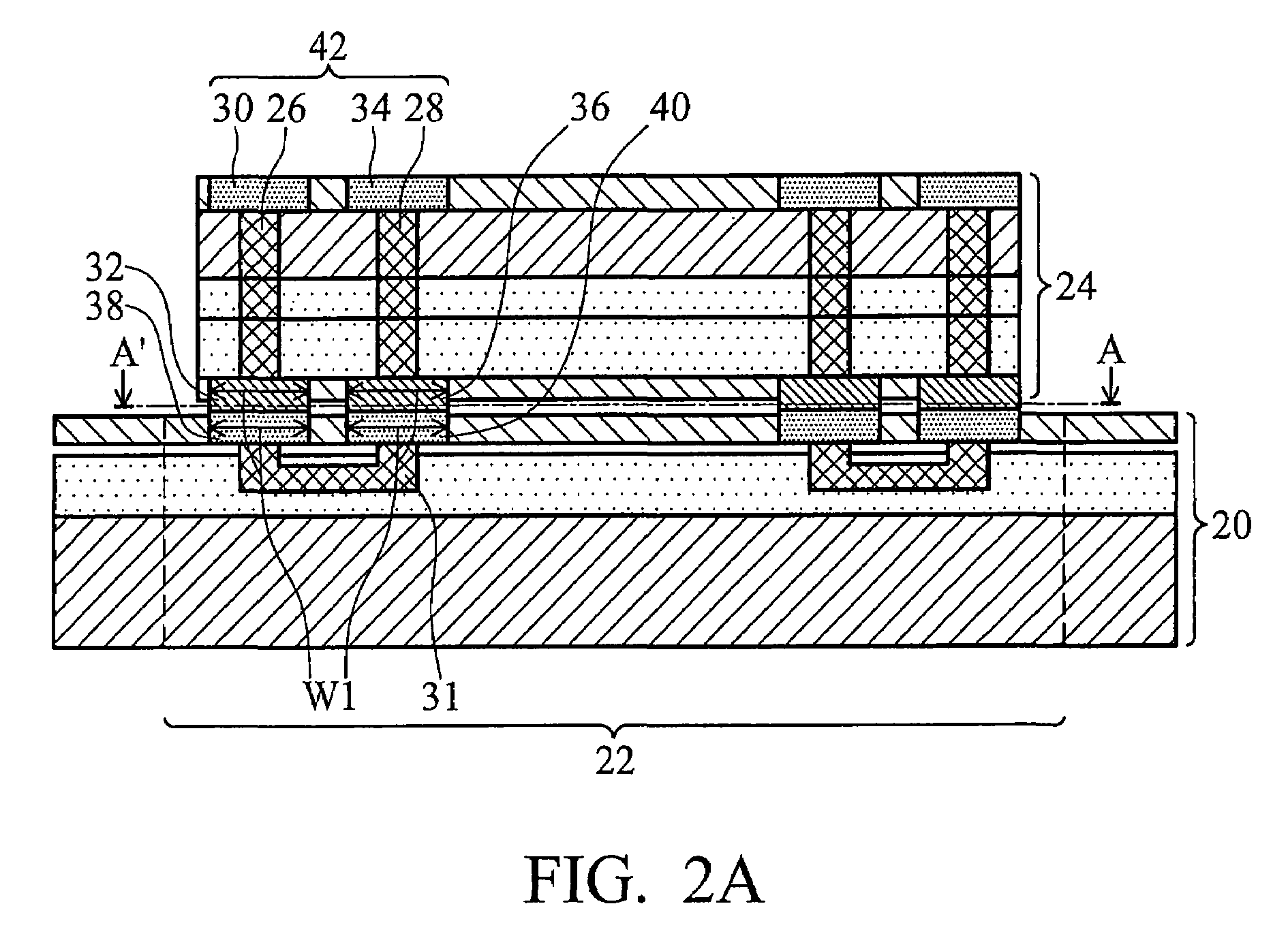

Test structures for stacking dies having through-silicon vias

InactiveUS7598523B2Reduce complexityImprove abilitiesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsBack structureEngineering

A semiconductor die including a test structure is provided. The semiconductor die includes a loop-back formed on a surface of the semiconductor die. The loop-back structure includes a first bonding pad on a first surface; and a second bonding pad on the first surface, wherein the first and the second bonding pads are electrically disconnected from integrated circuit devices in the semiconductor die. A conductive feature electrically shorts the first and the second bonding pads. An additional die including an interconnect structure is bonded onto the semiconductor die. The interconnect structure includes a third and a fourth bonding pad bonded to the first and the second bonding pads, respectively. Through-wafer vias in the additional die are further connected to the third and fourth bonding pads.

Owner:TAIWAN SEMICON MFG CO LTD

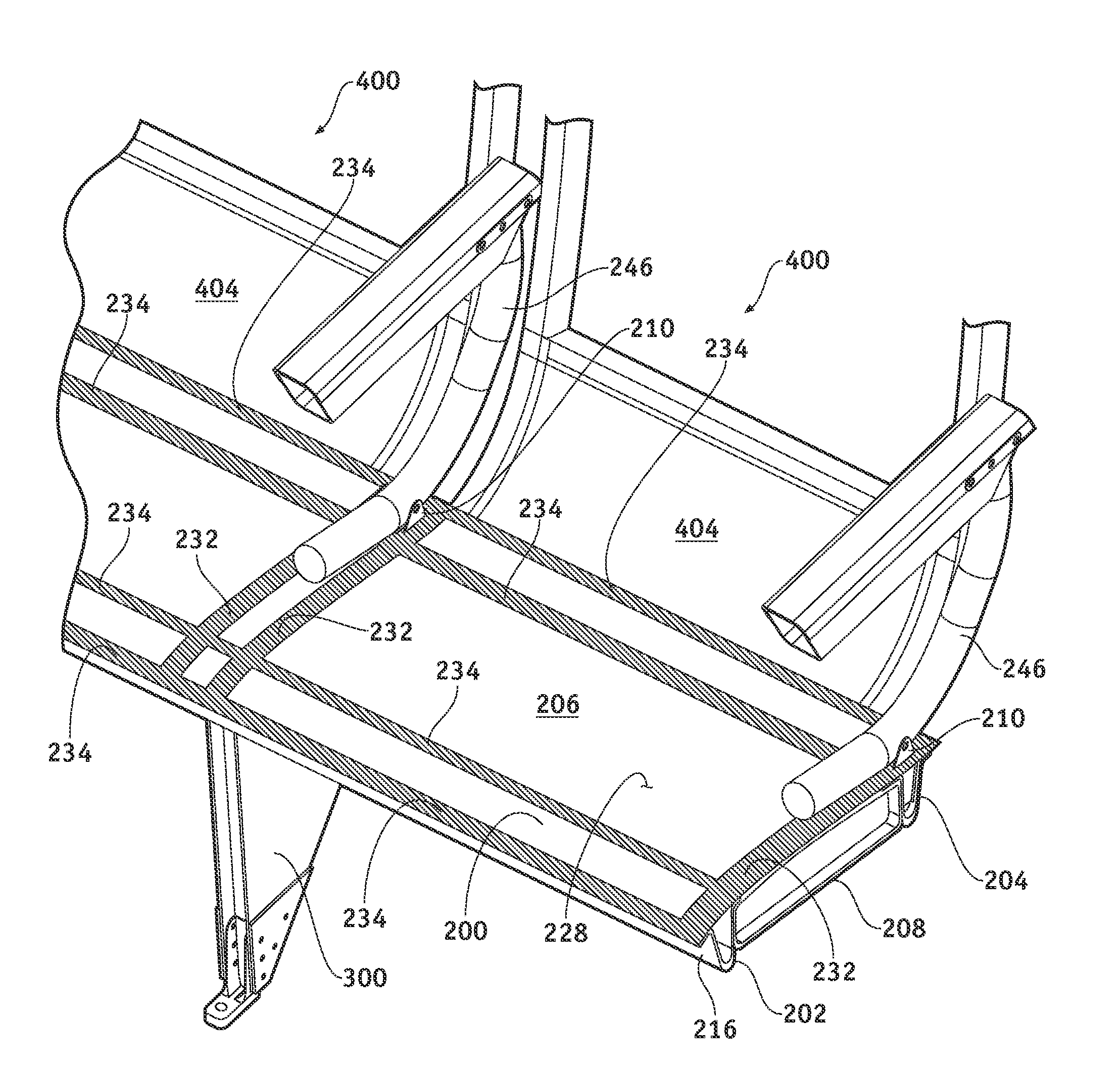

Composite seat pan structure for a lightweight aircraft seat assembly

InactiveUS7716797B2Reduce weightSmall sizeUpholstery manufactureSeating arrangementsManufacturing technologyBack structure

An aircraft passenger seat configured in accordance with an embodiment of the invention utilizes composite materials to achieve significant weight savings relative to conventional seat designs. The seat includes one or more lightweight composite support legs, a lightweight composite seat pan, and a lightweight composite seat back structure. The support legs are coupled to the seat pan, which is in turn coupled to the seat back structure. The support legs utilize composite frame elements that are formed as continuous compression molded composite extrusions. The seat pan includes composite fore and aft cross beams that are also formed as continuous compression molded composite extrusions. The aft cross beam includes a rear flange that serves as a flexible “hinge” for the seat back structure. The seat can leverage producible and relatively inexpensive composite manufacturing techniques such that the seat can be economically produced for use as an economy class seat.

Owner:THE BOEING CO

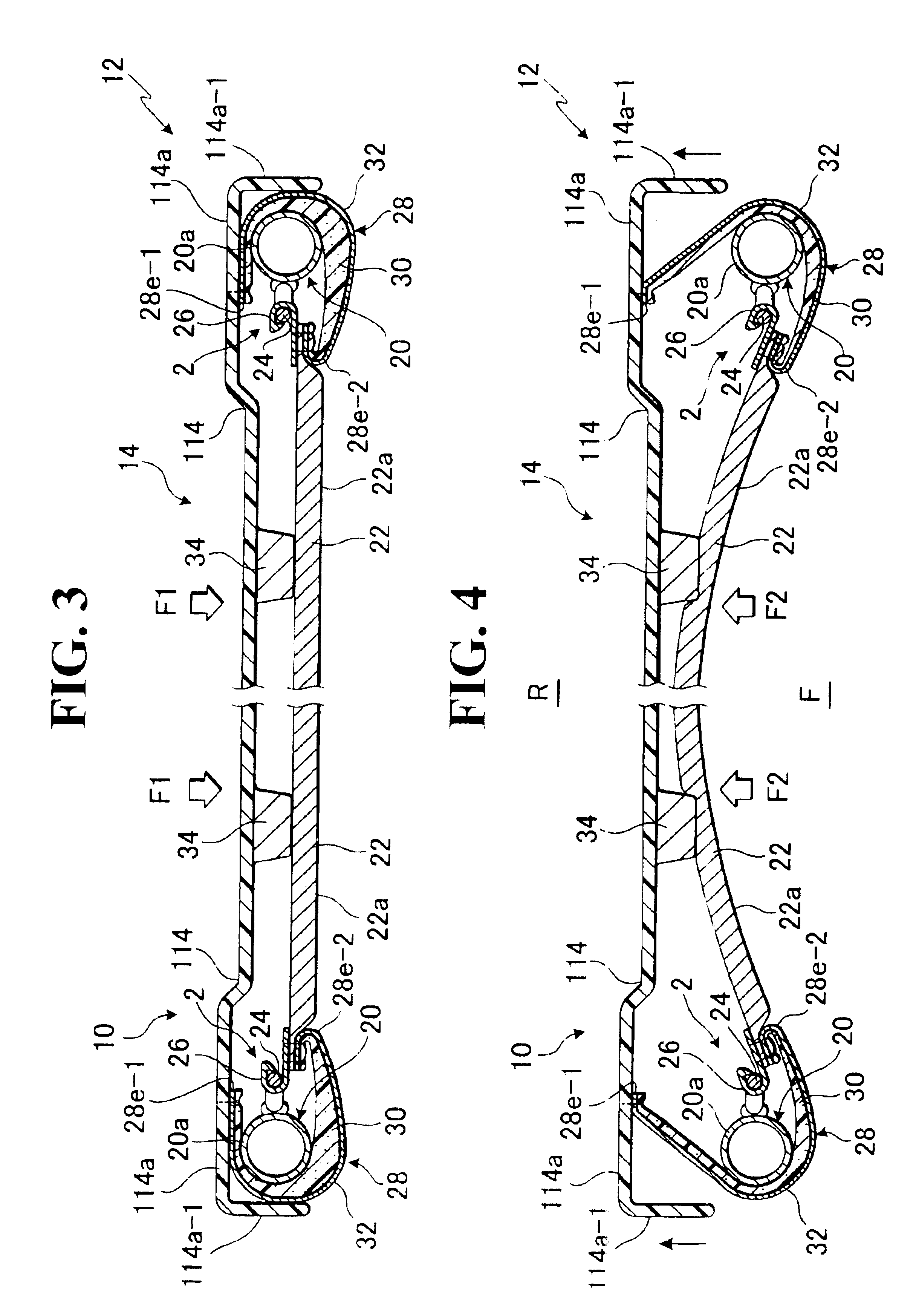

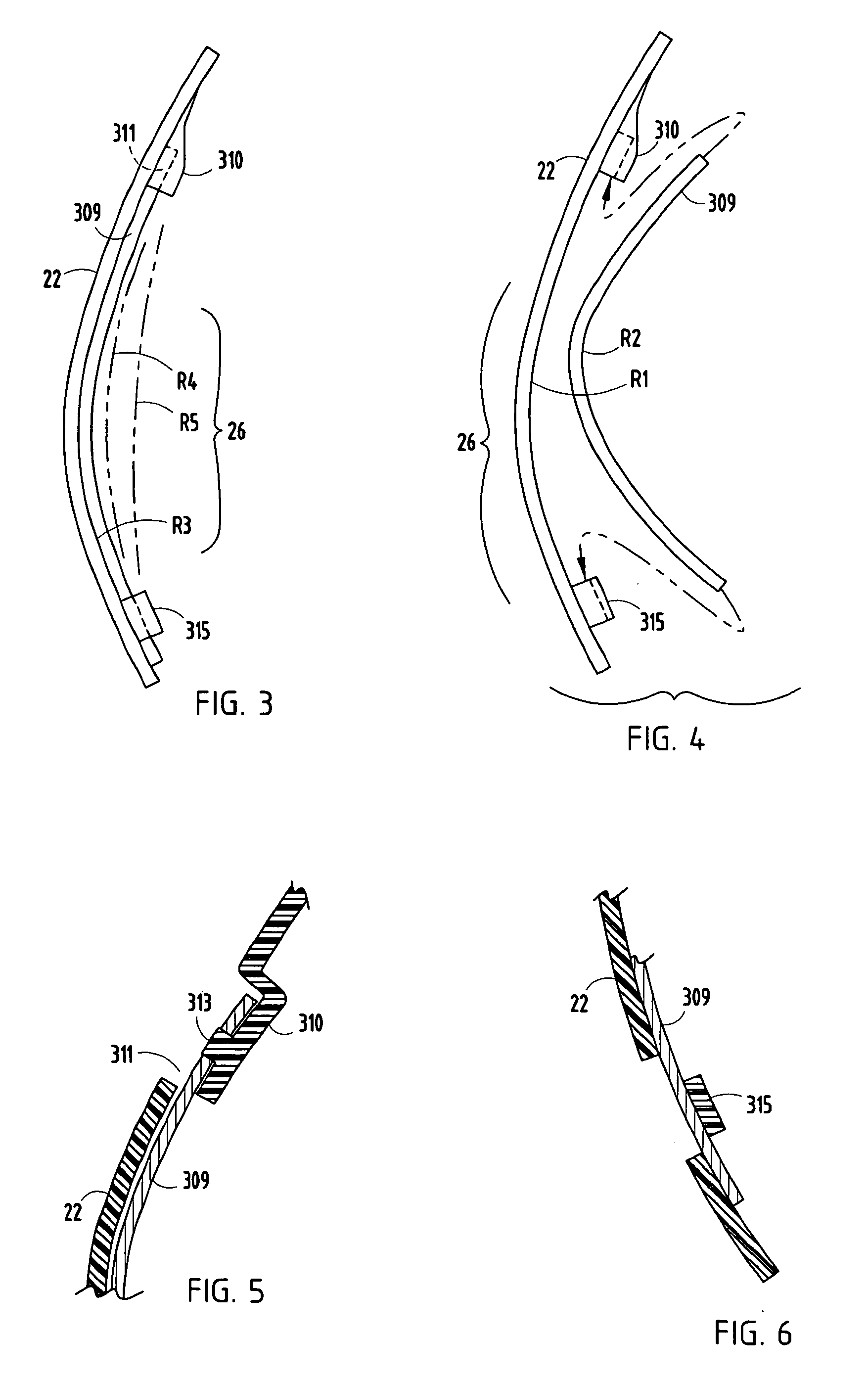

Back construction with flexible lumbar

A back construction includes a back shell mounted on a back frame at top and bottom connections, and a flexible lumbar section biased forwardly by a biasing device. The bottom connection is located rearward of the back shell to allow unencumbered sliding entry into the seating unit from a lateral side position, but the bottom connection defines a virtual pivot forward of its physical location to provide the desired path of flexure when the lumbar section is flexed. In one form, the bottom connection is a pair of non-parallel links of dissimilar length. In another form, the bottom connection is a follower with two bearings following a guide slot. In some variations, the force of the biasing device is variable. Seating units incorporating the back construction include a vehicle seat, a foldable portable stadium seat, and a wheelchair seat.

Owner:STEELCASE INC

Composite leg structure for a lightweight aircraft seat assembly

ActiveUS20080290242A1Reduce weightSmall sizeVehicle seatsSeating arrangementsBack structureBack rests

An aircraft passenger seat configured in accordance with an embodiment of the invention utilizes composite materials to achieve significant weight savings relative to conventional seat designs. The seat includes one or more lightweight composite support legs, a lightweight composite seat pan, and a lightweight composite seat back structure. The support legs are coupled to the seat pan, which is in turn coupled to the seat back structure. The support legs utilize composite frame elements that are formed as continuous compression molded composite extrusions. The seat pan includes composite fore and aft cross beams that are also formed as continuous compression molded composite extrusions. The aft cross beam includes a rear flange that serves as a flexible “hinge” for the seat back structure. The seat can leverage producible and relatively inexpensive composite manufacturing techniques such that the seat can be economically produced for use as an economy class seat.

Owner:THE BOEING CO

Seating unit including novel back construction

Owner:STEELCASE INC

Back construction with flexible lumbar

Owner:STEELCASE INC

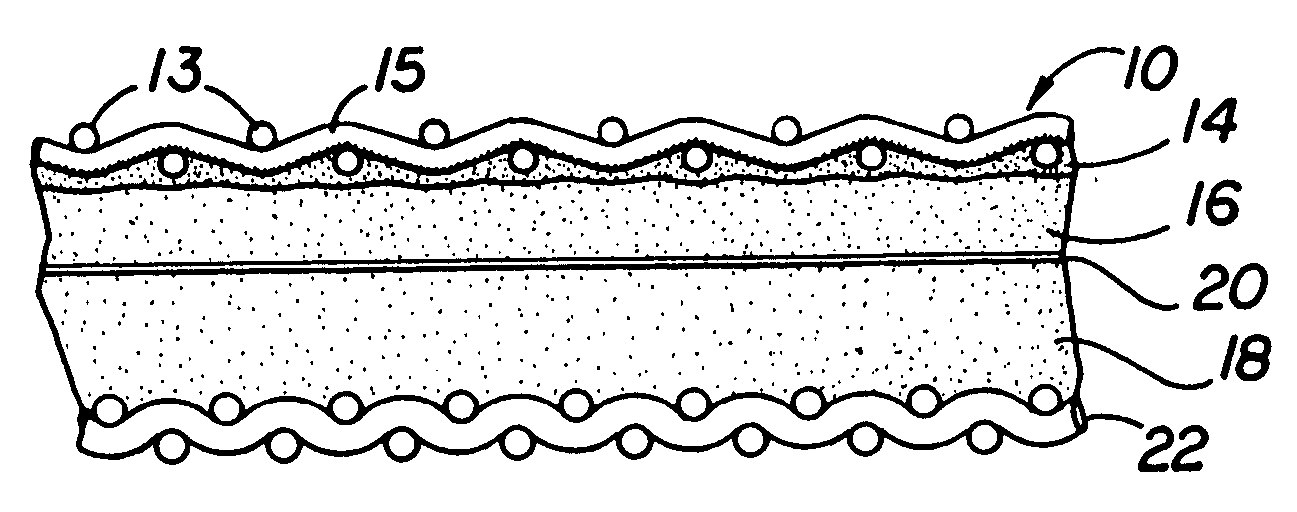

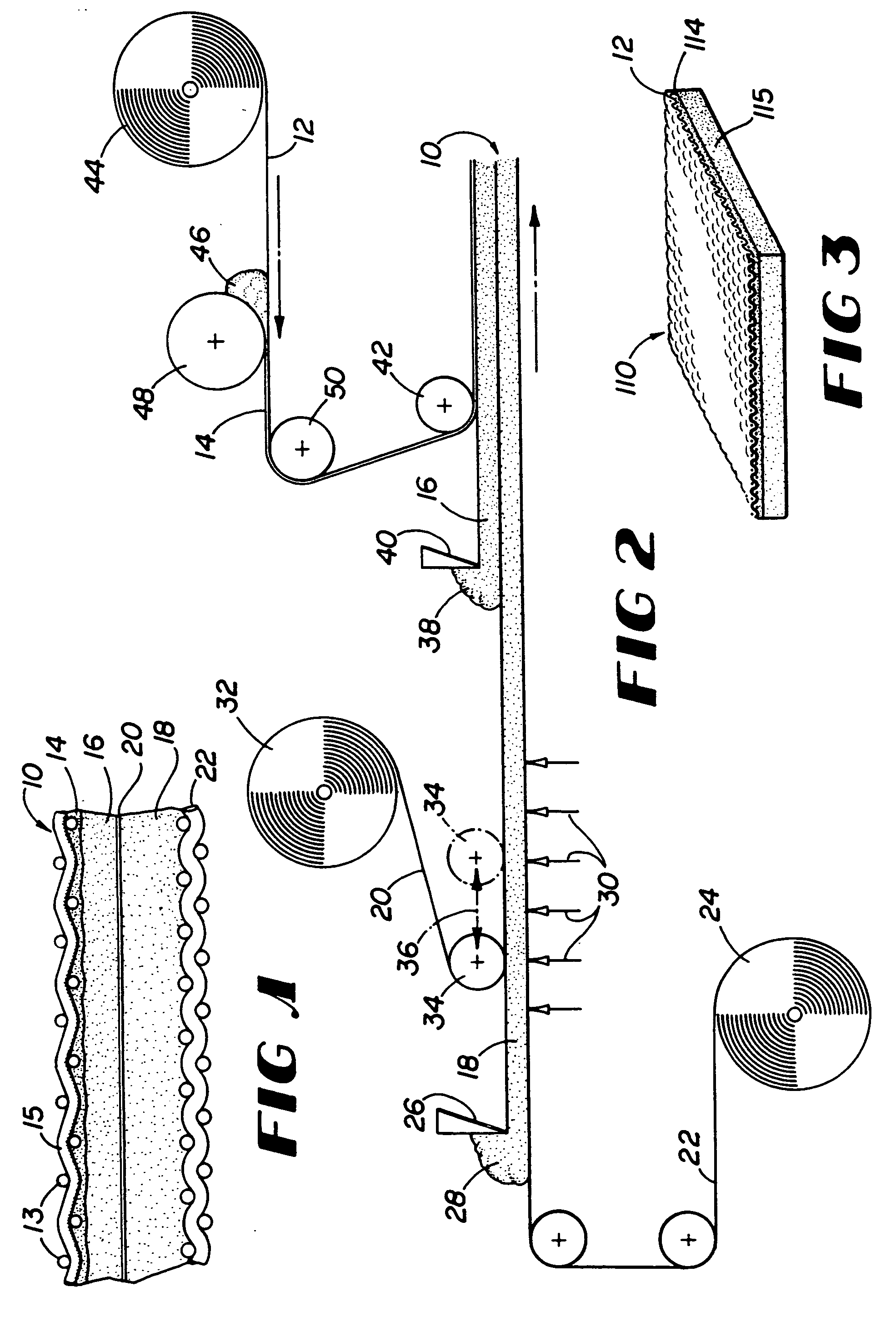

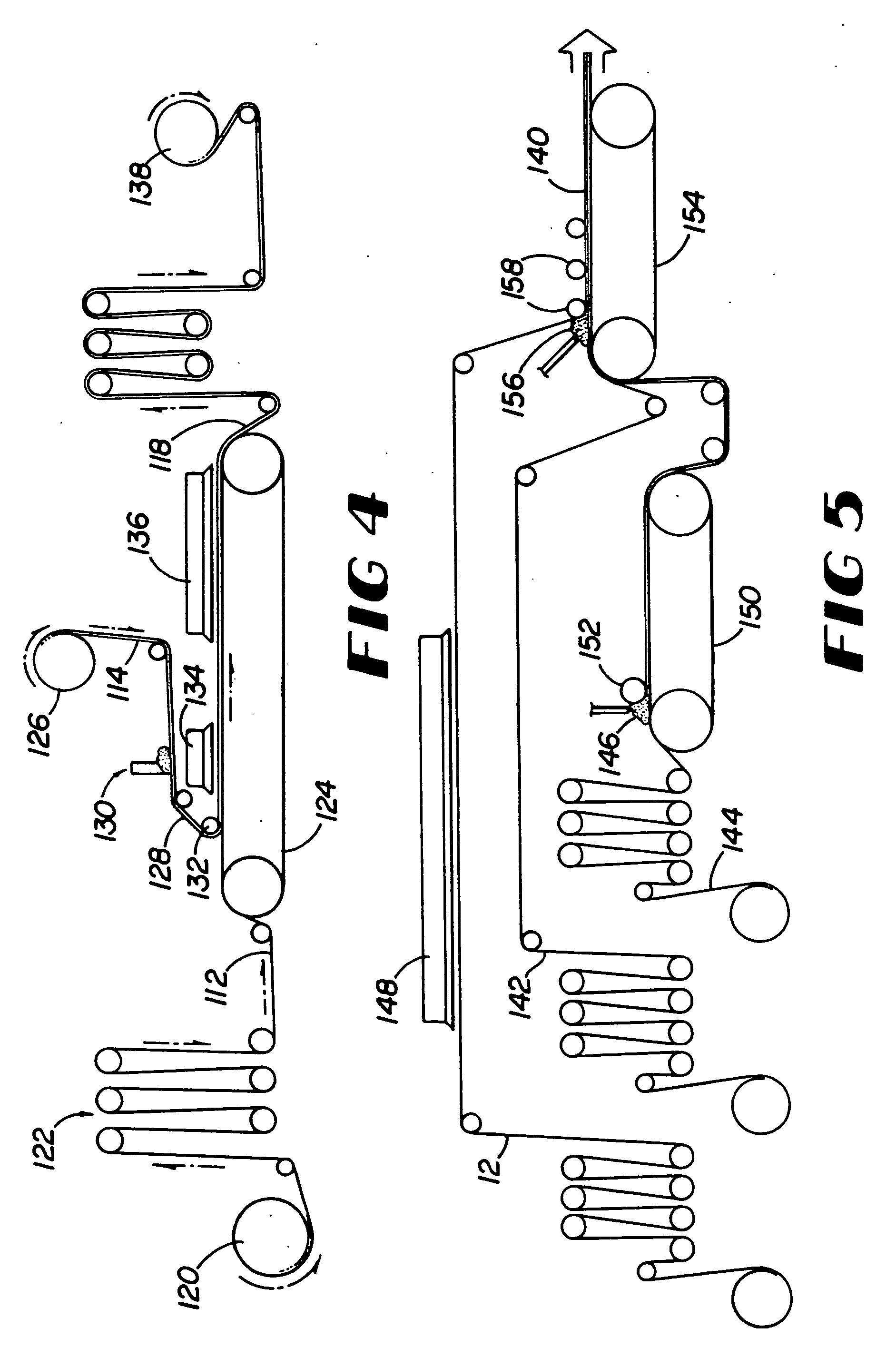

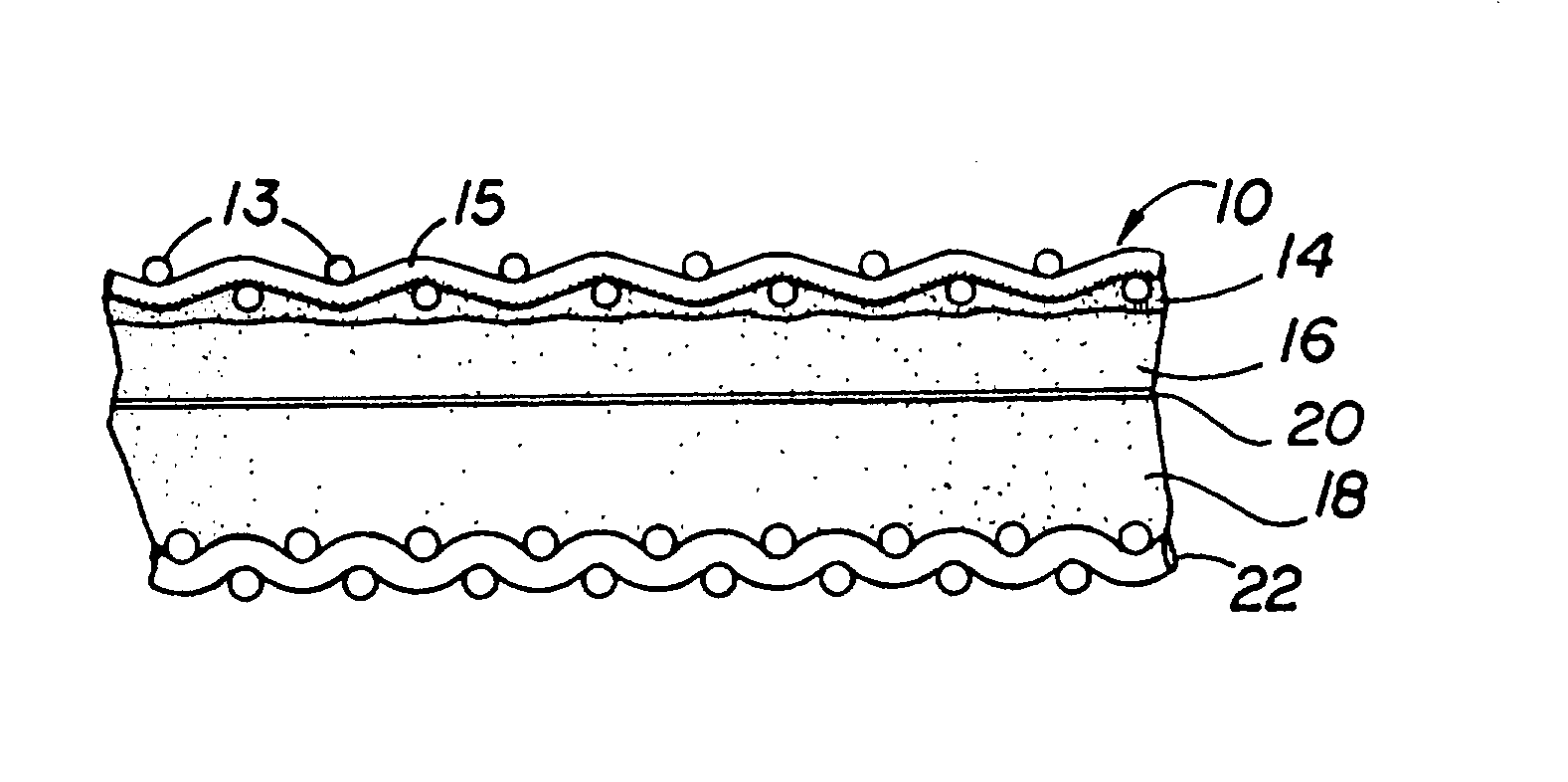

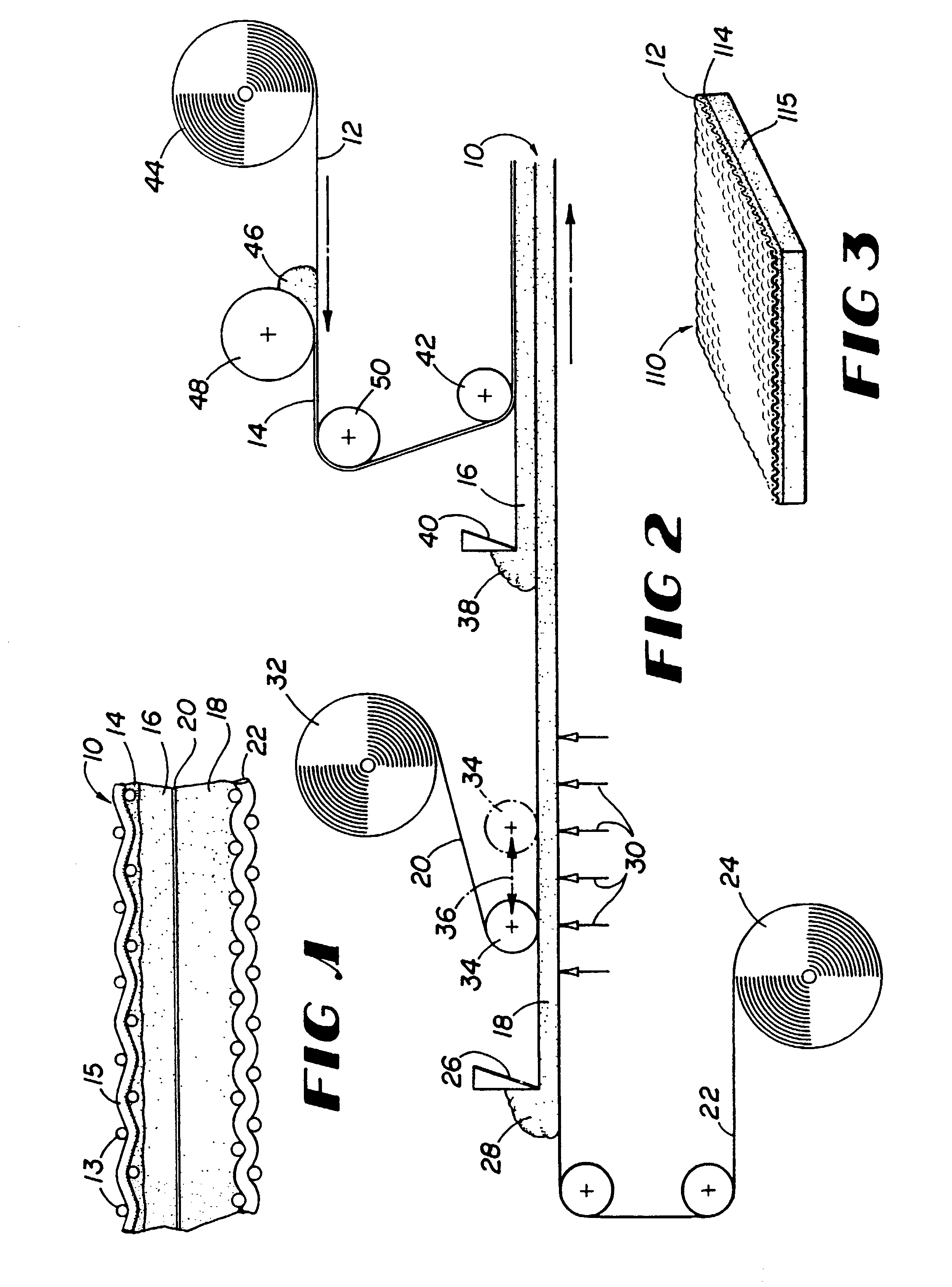

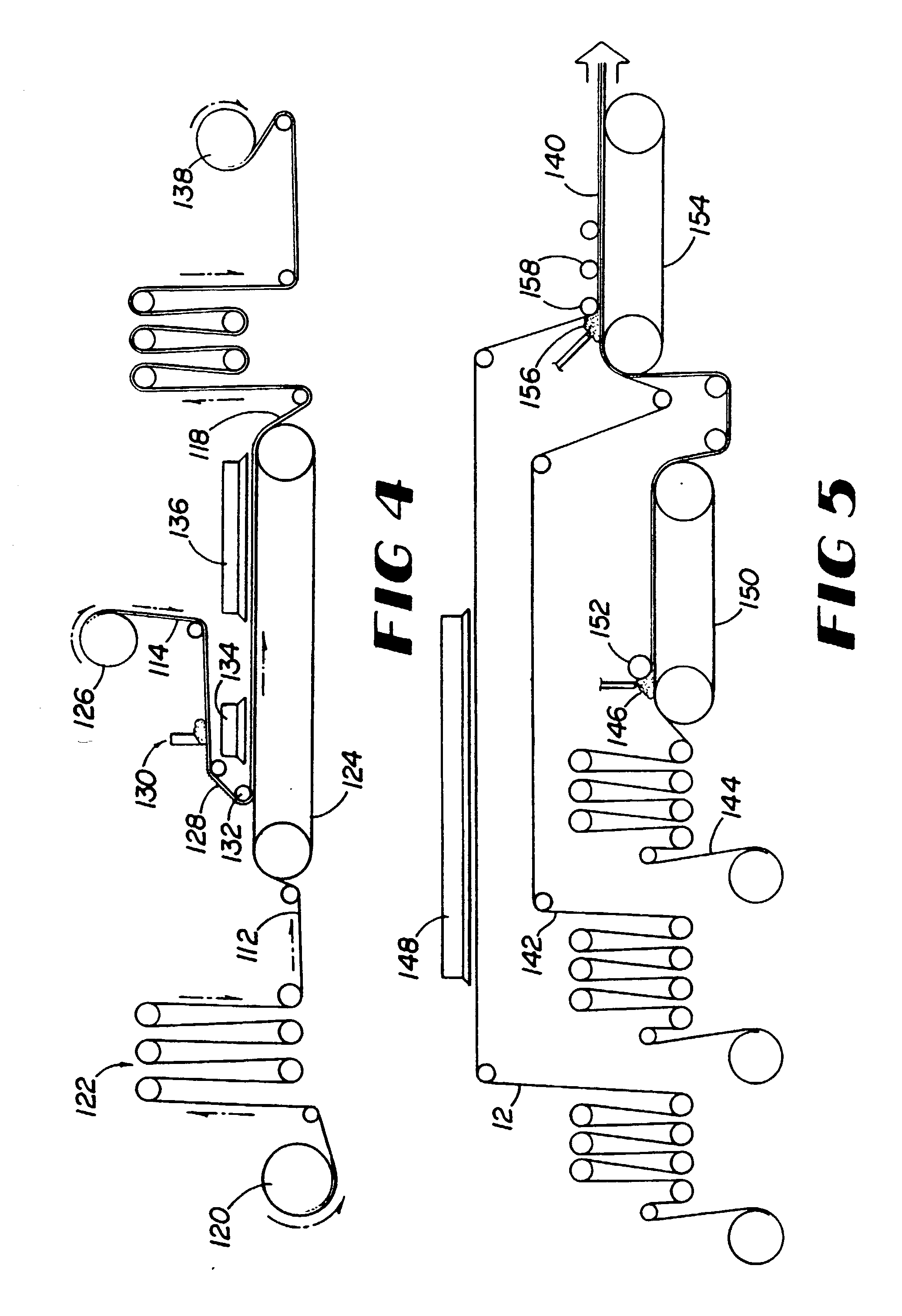

Floor covering with woven face

InactiveUS20040198120A1Increase rate of changeReduce the chance of changeSynthetic resin layered productsFloor coveringsYarnPolyester

Flooring that utilizes sophisticated, self-stabilizing, woven face fabric using relatively heavy "carpet weight" nylon, polyester, PTT or other yarns on modern Jacquard computer controlled looms to produce flat-weave fabrics that are bonded to engineered backing structures. Urethane modified bitumen may be used as a backing layer, and an optional latex precoat may be used on the fabric layer, together with an optional antimicrobial in the precoat.

Owner:SCOTT GRAHAM +2

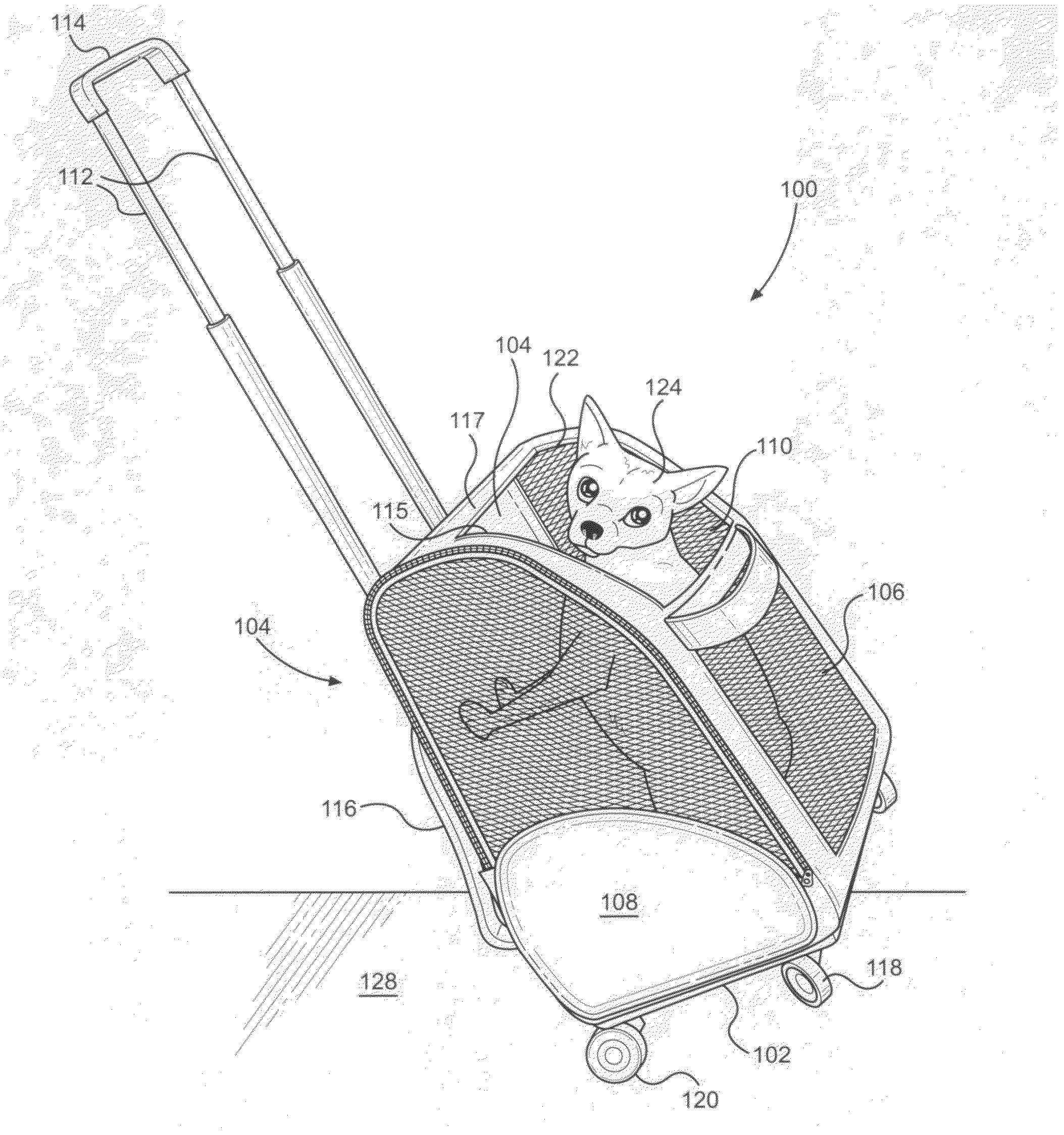

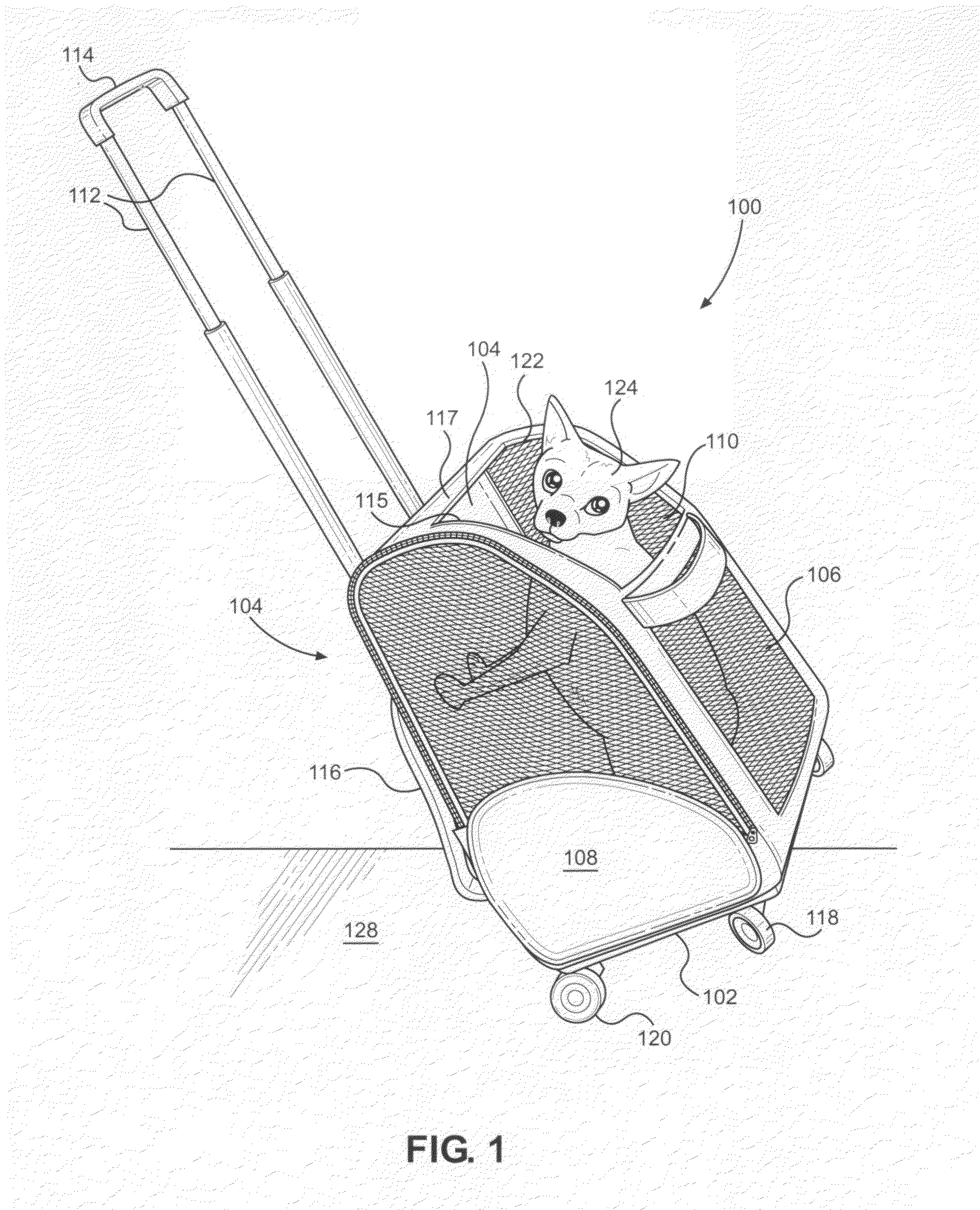

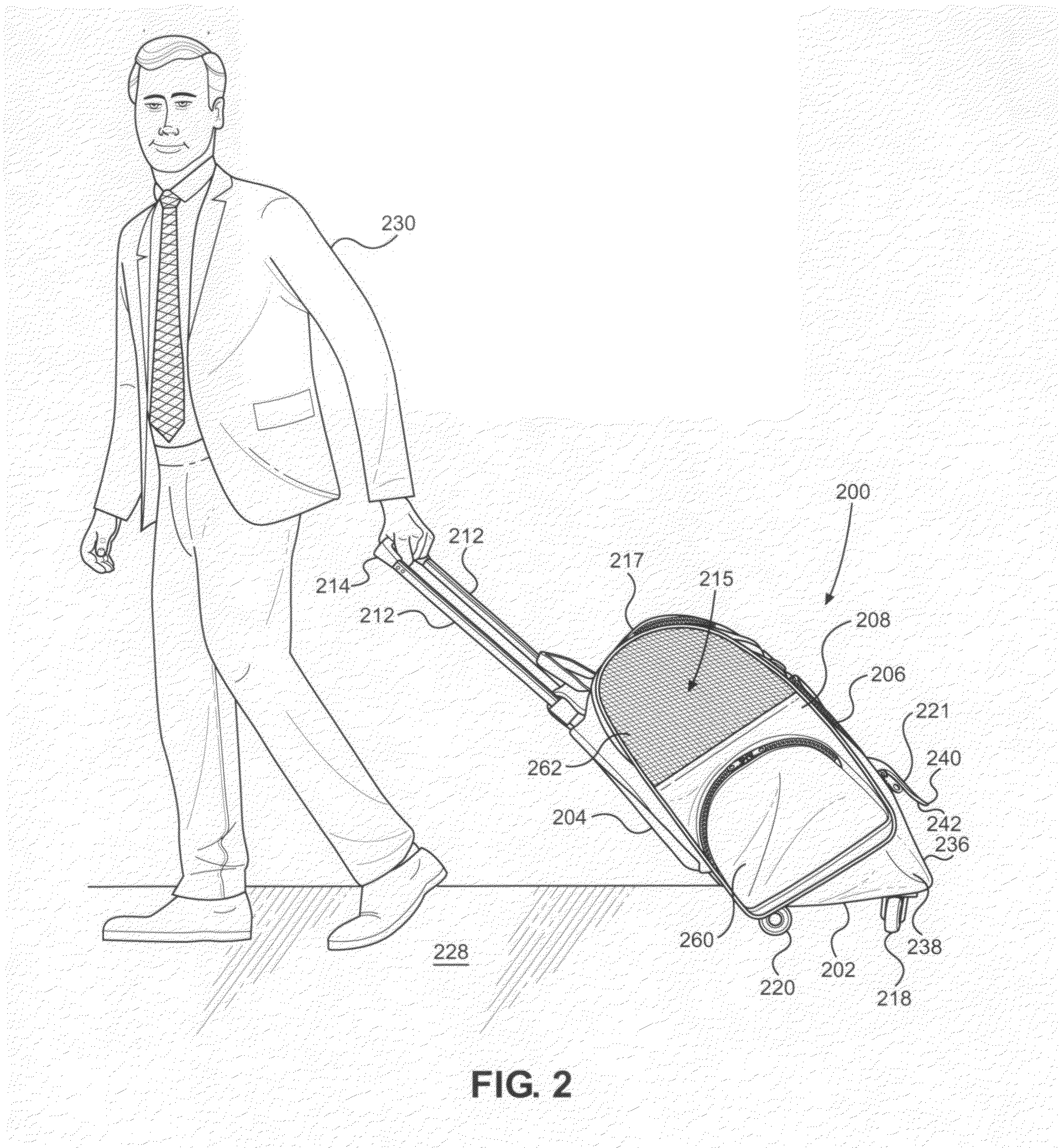

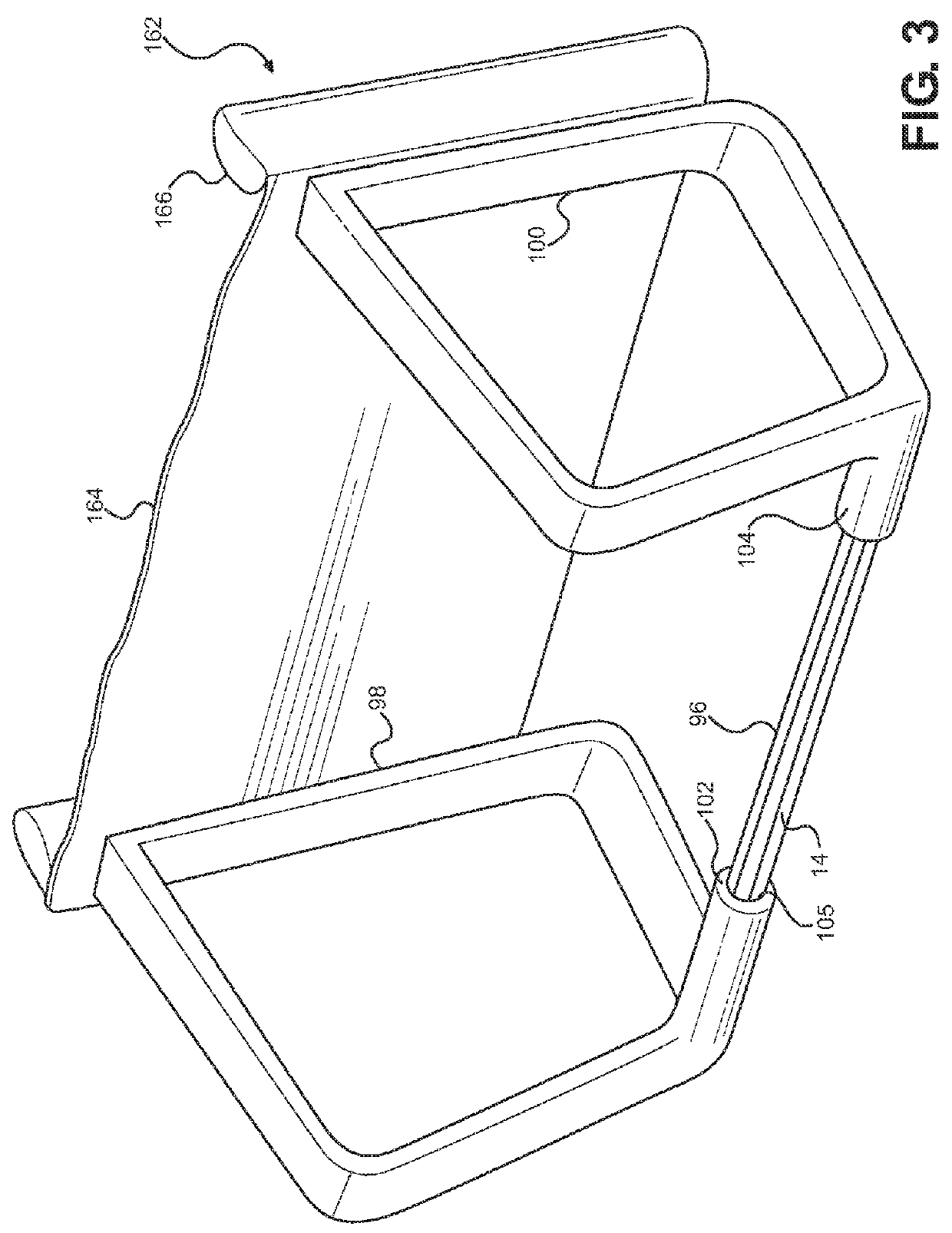

Roller carrier

A carrier structure includes a lower platform substantially parallel to a ground surface upon which the carrier is placed and moved; a back wall connected to a back edge of the lower platform at a connection structure, the back wall and lower platform defining a first angle; a front wall connected to a front edge of the lower platform and opposing the back structure; opposing side walls connected to opposing side edges of the lower platform, the back, front and opposing side walls forming a compartment; wherein the back wall is tiltable away from the front wall to define a second, obtuse angle, between the back wall and the lower platform, such that the lower platform is configured to remain substantially parallel to the ground surface.

Owner:GEN 7 INC

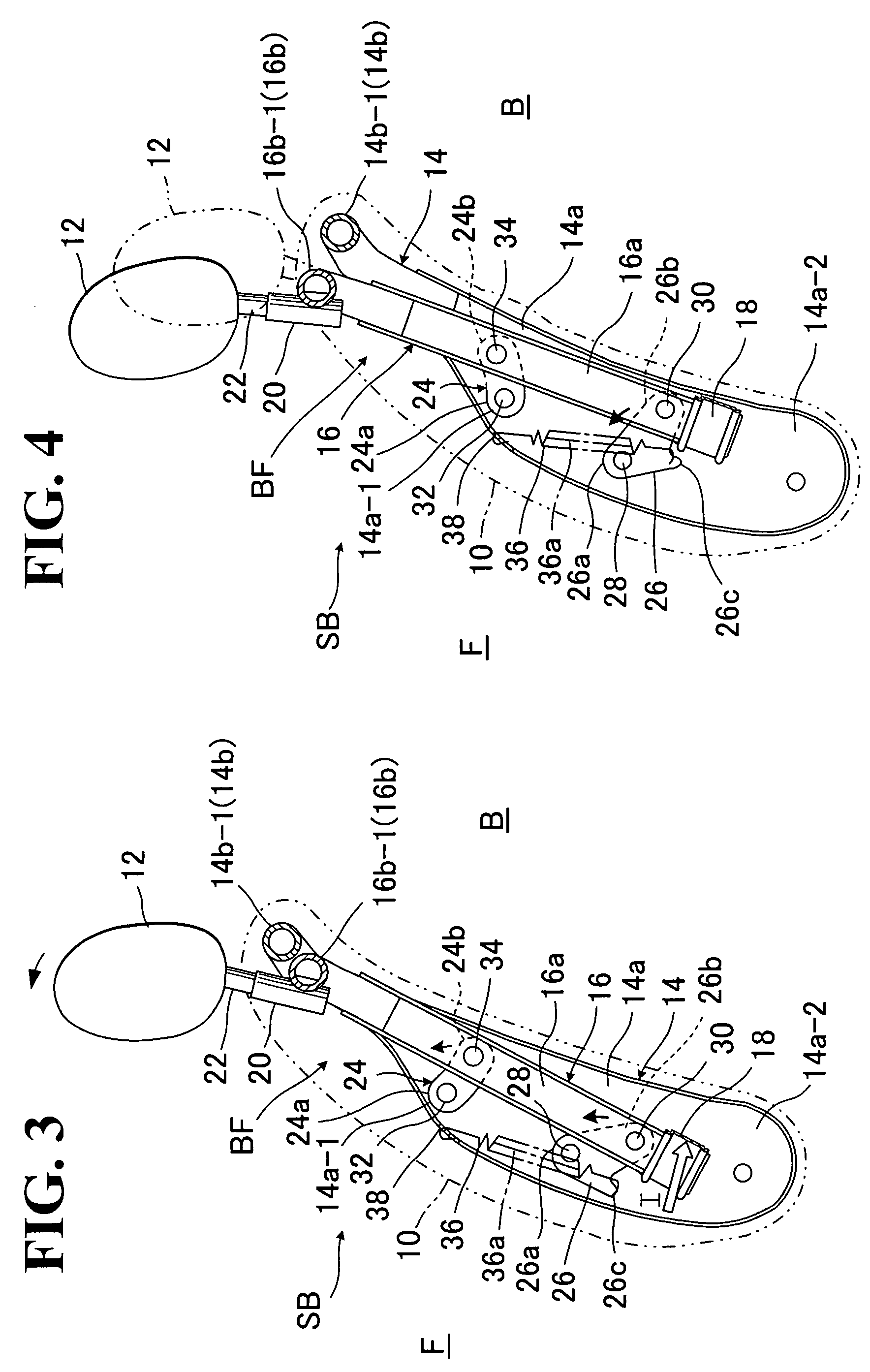

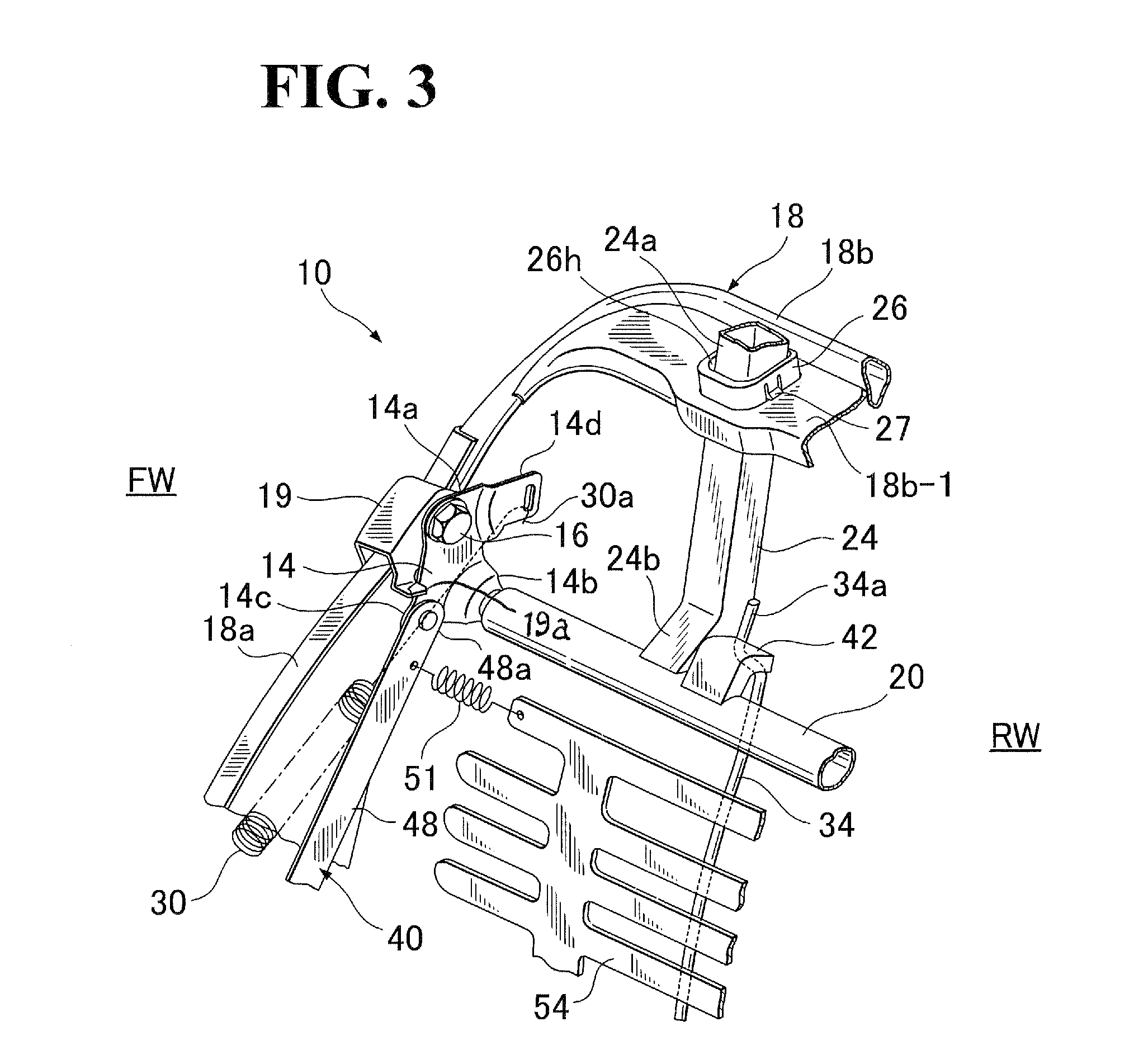

Seat back structure of vehicle seat

InactiveUS7758114B2Avoid excessive impactSimple structureVehicle seatsPedestrian/occupant safety arrangementDorsal partsBack structure

In a seat back with movable headrest, a pressure receiving element is movably provided, which includes pressure receiving regions for receiving loads applied from lumber and dorsal parts of seat occupant. The pressure receiving element is movably connected with a crank member which is movably provided between two lateral frame members of seat back frame. Further, that pressure receiving element is connected with a support shaft extended between a par of rotating links rotatably arranged on the respective afore-said two lateral frame members. A biasing element is provided to normally bias the headrest to a home position.

Owner:TACHI S CO LTD

Composite seat back structure for a lightweight aircraft seat assembly

ActiveUS7717519B2Reduce weightSmall sizeVehicle seatsSeating arrangementsBack structureManufacturing technology

An aircraft passenger seat configured in accordance with an embodiment of the invention utilizes composite materials to achieve significant weight savings relative to conventional seat designs. The seat includes one or more lightweight composite support legs, a lightweight composite seat pan, and a lightweight composite seat back structure. The support legs are coupled to the seat pan, which is in turn coupled to the seat back structure. The support legs utilize composite frame elements that are formed as continuous compression molded composite extrusions. The seat pan includes composite fore and aft cross beams that are also formed as continuous compression molded composite extrusions. The aft cross beam includes a rear flange that serves as a flexible “hinge” for the seat back structure. The seat can leverage producible and relatively inexpensive composite manufacturing techniques such that the seat can be economically produced for use as an economy class seat.

Owner:THE BOEING CO

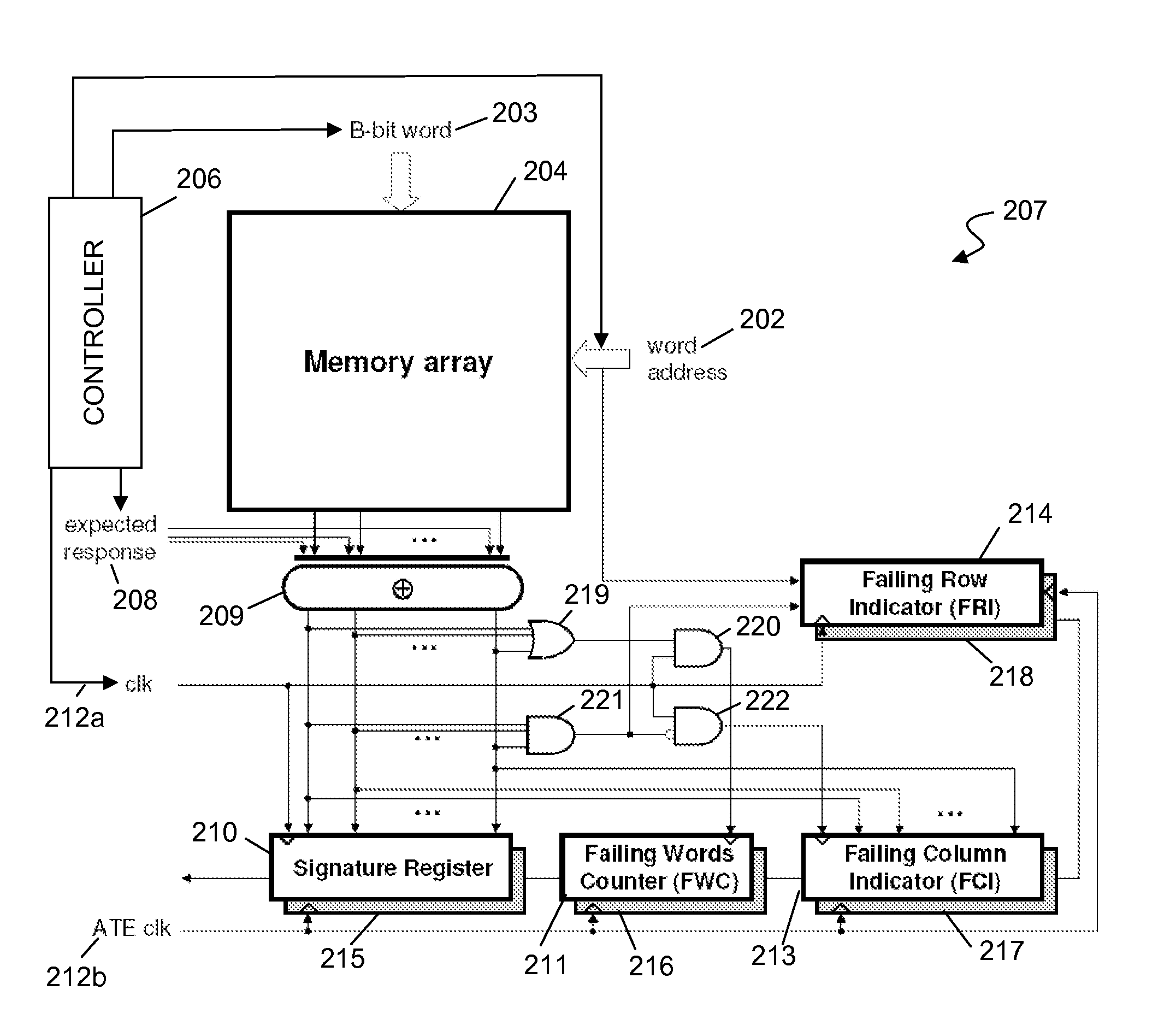

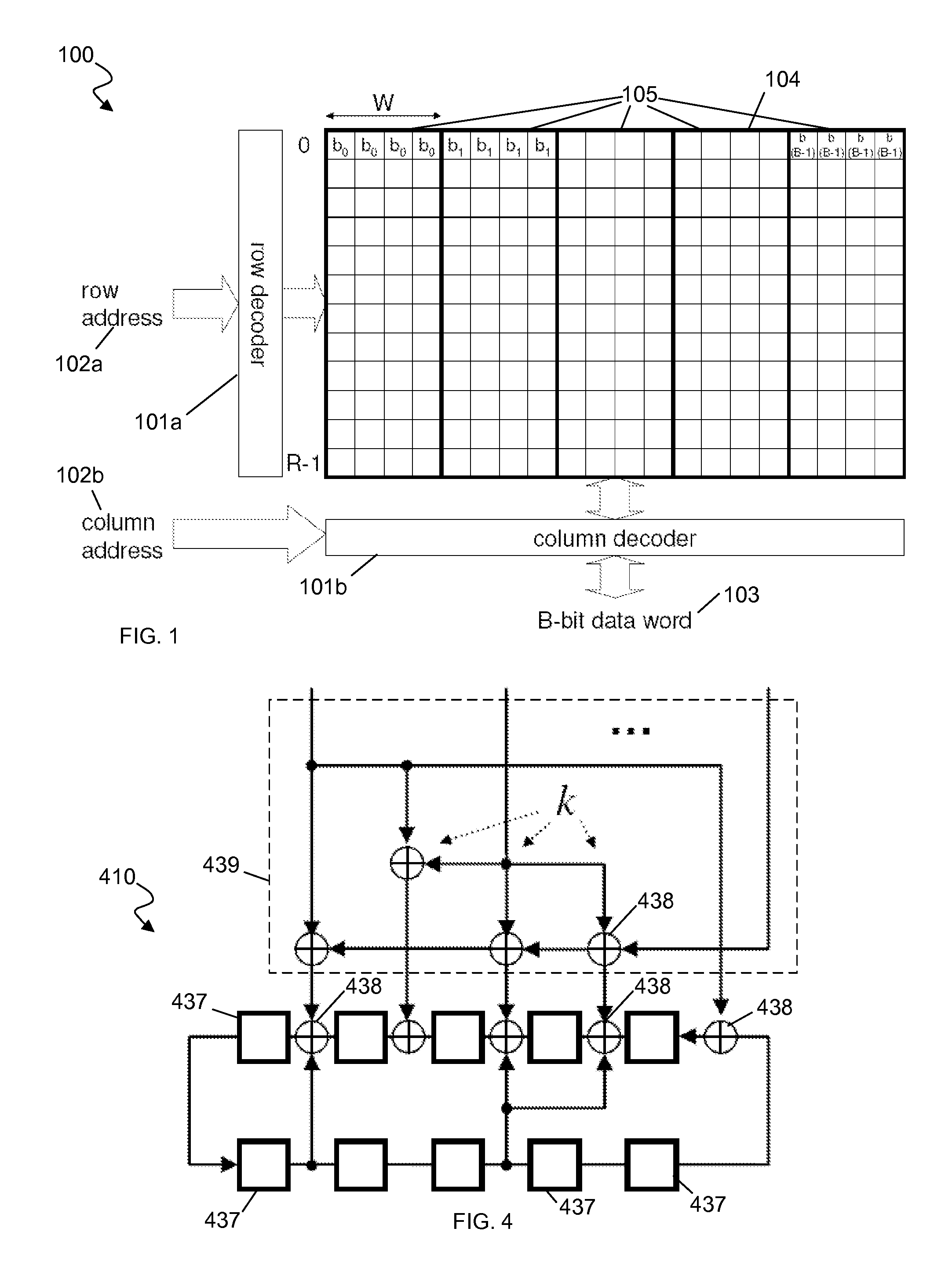

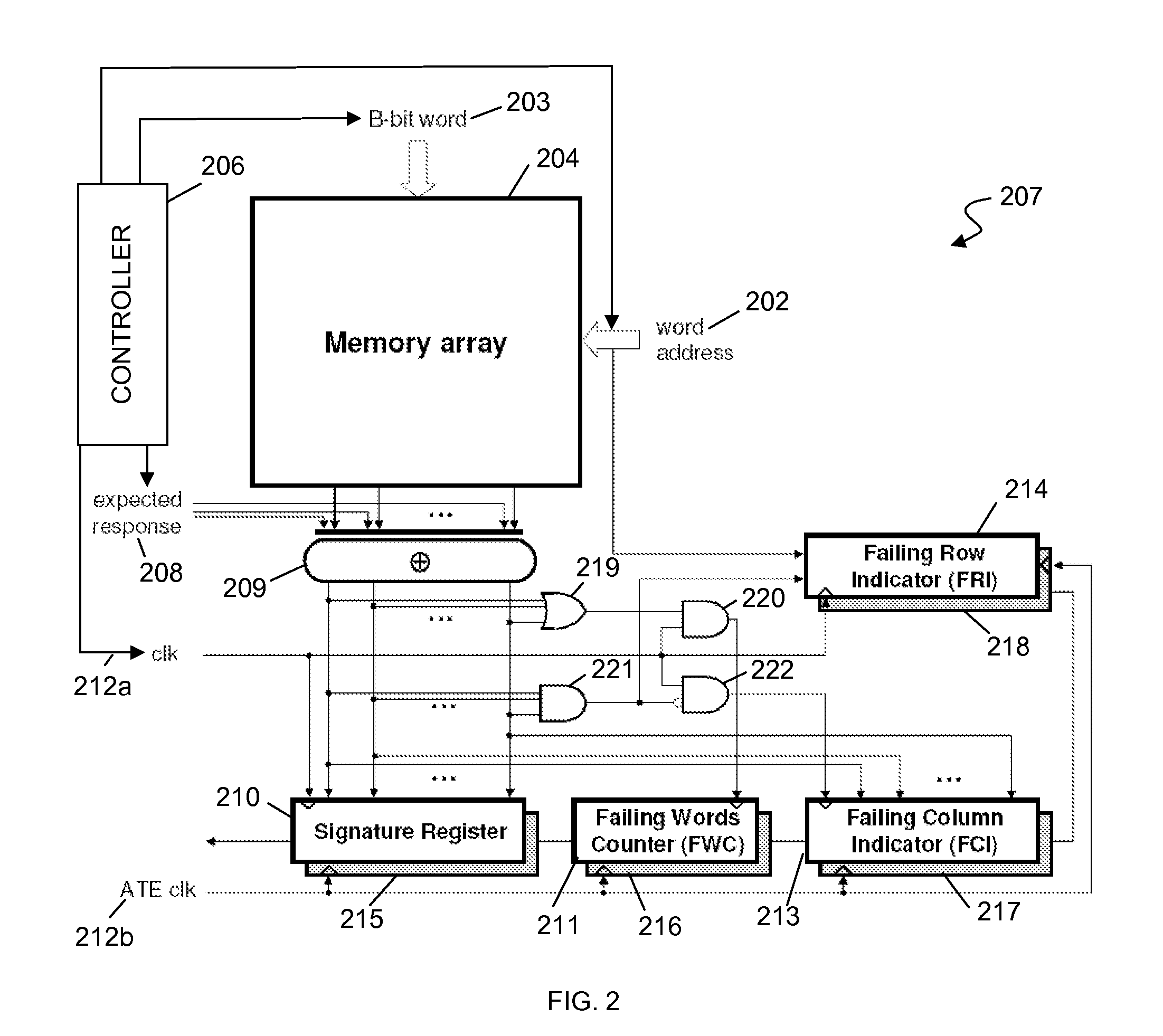

Fault diagnosis in a memory bist environment

InactiveUS20110055646A1Data failureProvide time efficiencyFunctional testingStatic storageBack structureAutomatic test equipment

Disclosed are methods and devices for temporally compacting test response signatures of failed memory tests in a memory built-in self-test environment, to provide the ability to carry on memory built-in self-test operations even with the detection of multiple time related memory test failures. In some implementations of the invention, the compacted test response signatures are provided to an automated test equipment device along with memory location information. According to various implementations of the invention, an integrated circuit with embedded memory (204) and a memory BIST controller (206) also includes a linear feed-back structure (410) for use as a signature register that can temporally compact test response signatures from the embedded memory array during a test step of a memory test. In various implementations the integrated circuit may also include a failing words counter (211), a failing column indicator (213), and / or a failing row indicator (214) to collect memory location information for a failing test response.

Owner:MENTOR GRAPHICS CORP

Floor covering with woven face

InactiveUS20030114062A1Small thicknessNot easy to wearSynthetic resin layered productsWoven fabricsPolyesterYarn

Flooring that utilizes sophisticated, self-stabilizing, woven face fabric using relatively heavy "carpet weight" nylon, polyester, PTT or other yarns on modern Jacquard computer controlled looms to produce flat-weave fabrics that are bonded to engineered backing structures. Urethane modified bitumen may be used as a backing layer, and an optional latex precoat may be used on the fabric layer, together with an optional antimicrobial in the precoat.

Owner:SCOTT GRAHAM +2

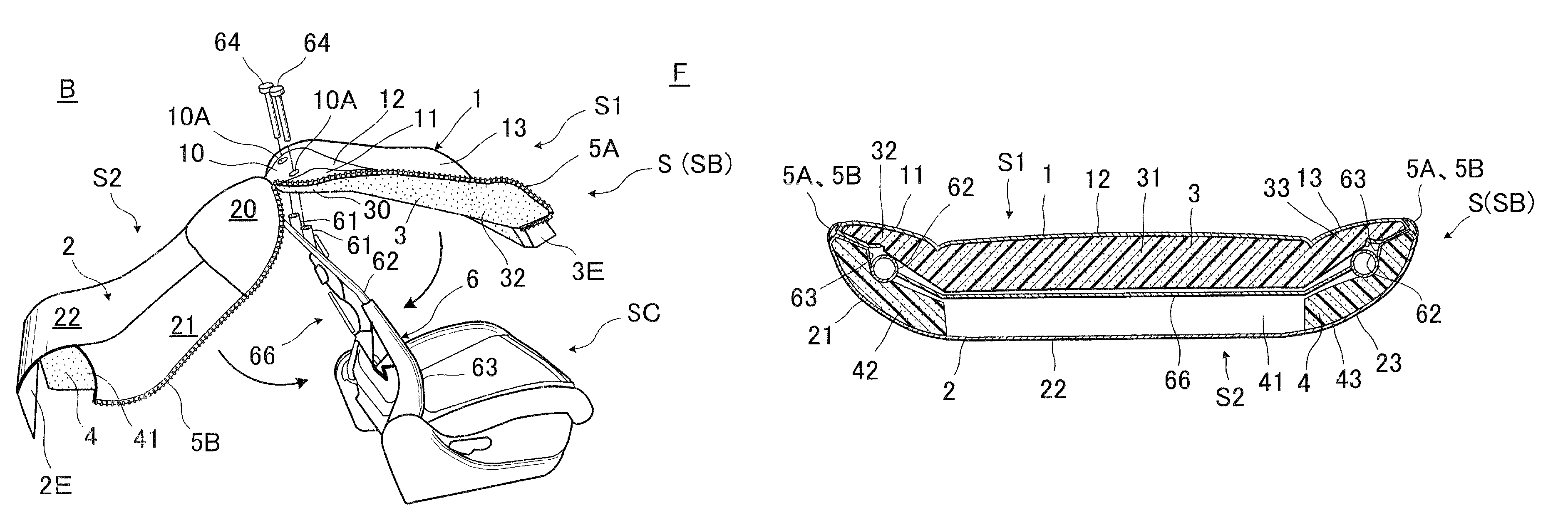

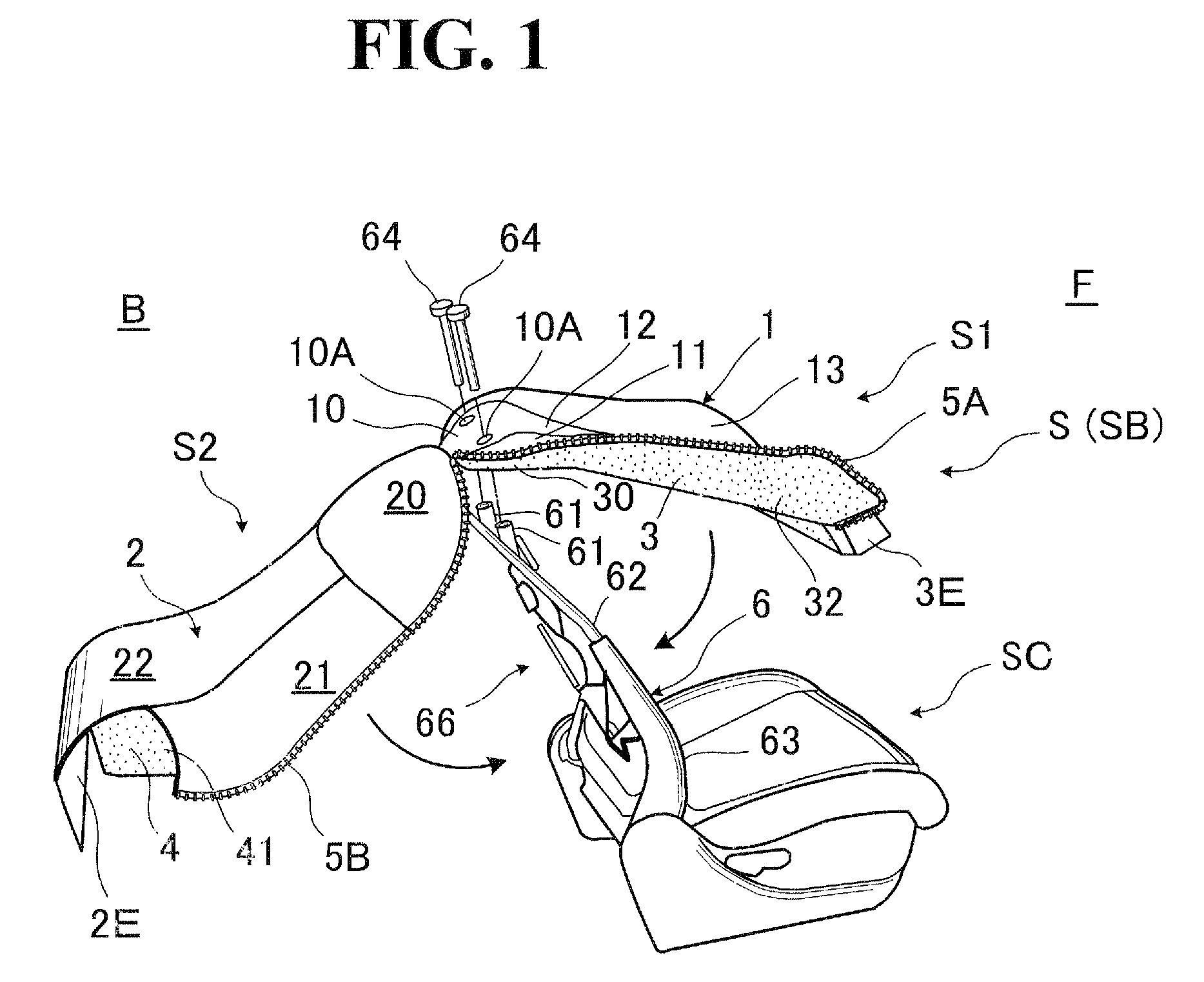

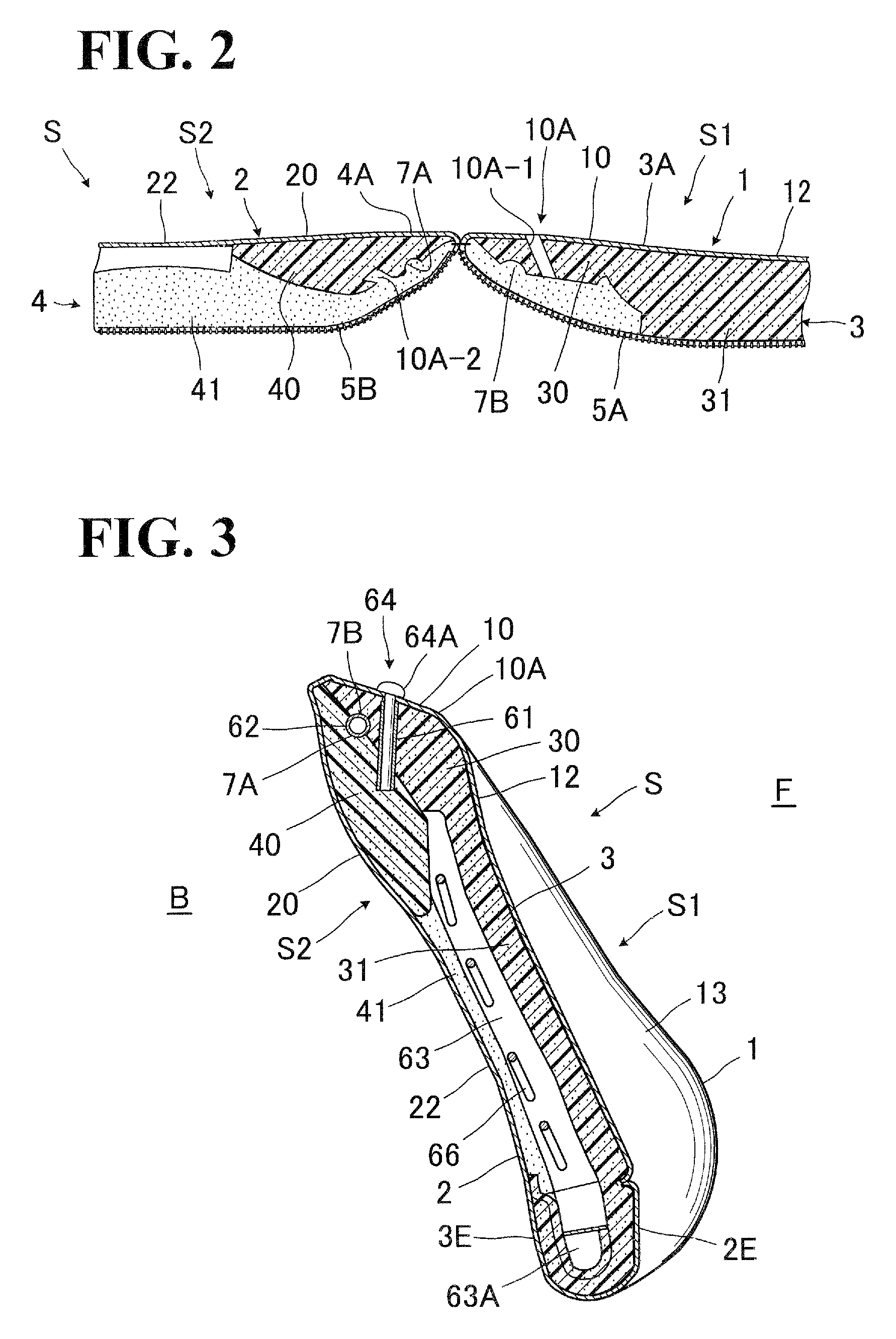

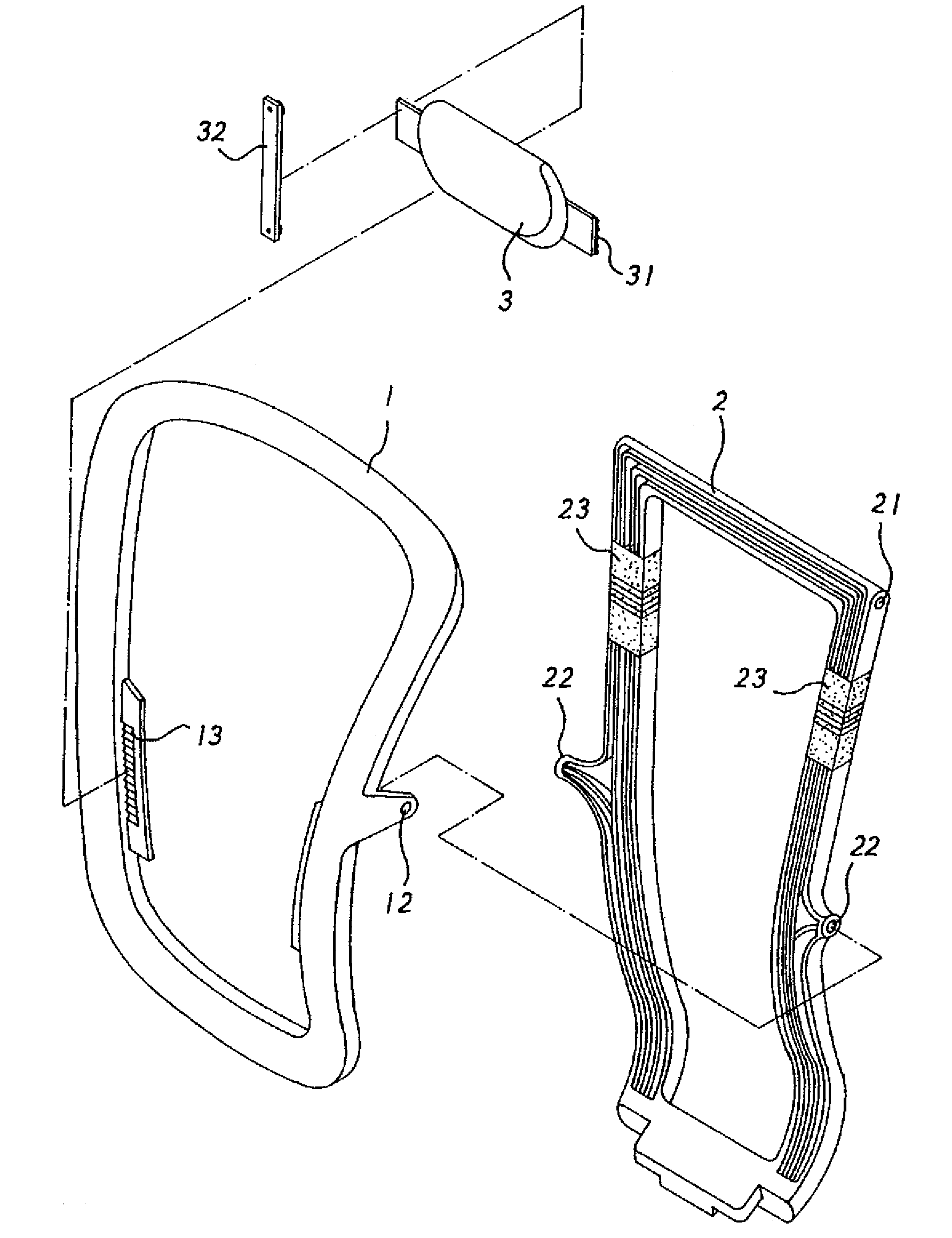

Seat back structure

InactiveUS7673939B2Simple structureWell formedVehicle seatsStuffed mattressesBack structureBack rests

Structure of seat back is provided, which comprises: a seat back frame; and an upholstery cover assembly including a forward upholster cover element and a backward upholstery cover element. Those two upholstery cover elements cover respective forward and backward sides of the seat back frame, with an upper region thereof secured on top portion of the seat back frame by a headrest stay holder element. Outer peripheral ends of those two upholstery cover elements are engaged together by an engagement element, so that substantially a whole of the seat back frame is covered with the upholstery cover assembly, thus forming a seat back.

Owner:TACHI S CO LTD

Back structure for a chair

A rack structure for a chair includes a chair back member having a frame and a mounting support. The frame includes a support cushion disposed on the front side thereof for supporting a user's waist correspondingly. The frame further includes two first connecting tabs fixed on the back sides of the top ends of two sides thereof individually and two second connecting tabs formed on and extending from the two sides thereof respectively. The mounting support is fixed onto a base and extends upwardly therefrom. The mounting support includes two coupling segments and two connecting projections arranged on the top ends and the intermediate sections of two sides thereof respectively. Between each coupling segment and each connecting projection is couplingly attached a resilient member. The first and second connecting tabs of the frame are connected with the coupling segments and the connecting projections of the mounting support individually.

Owner:WU YAO CHUAN

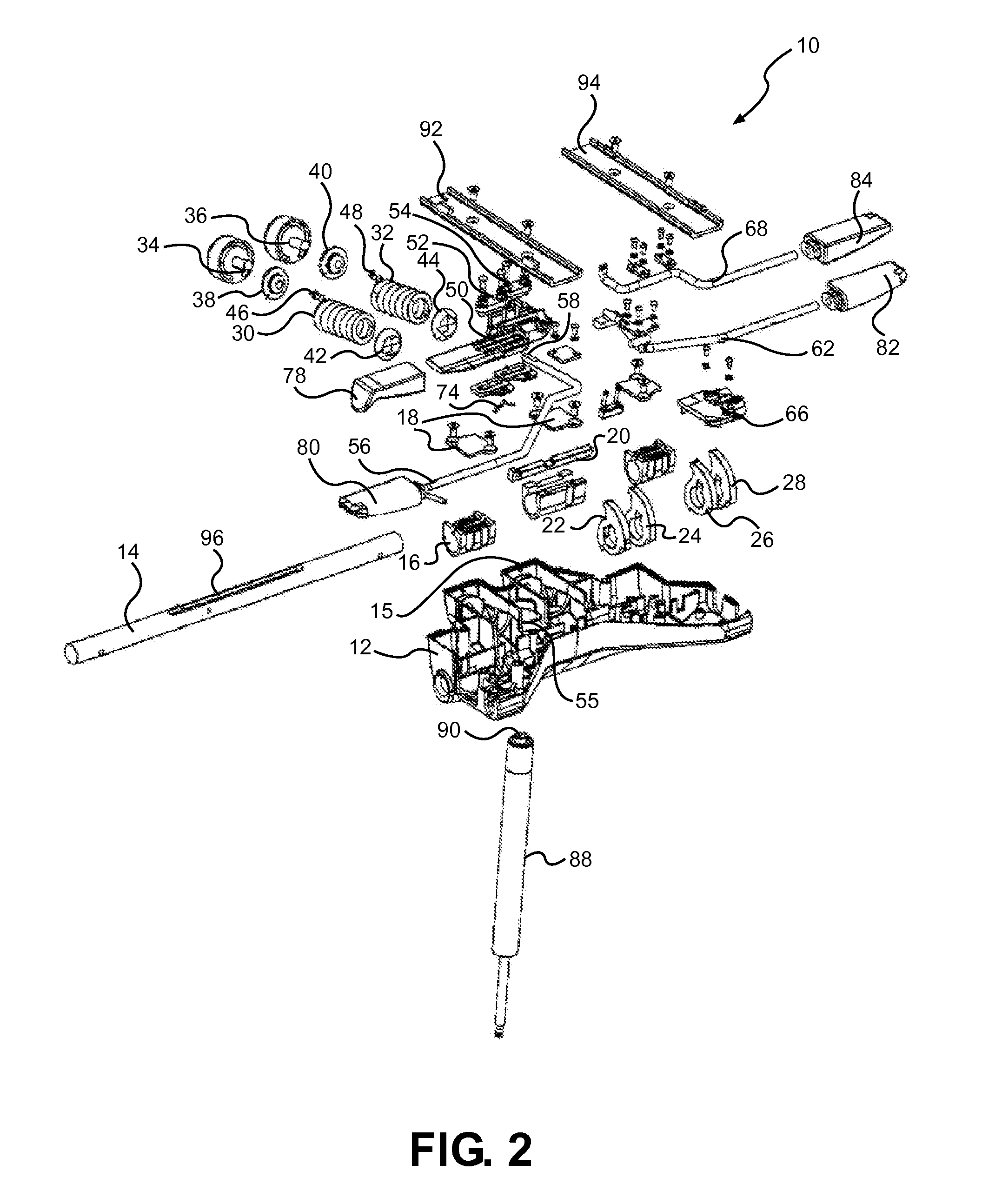

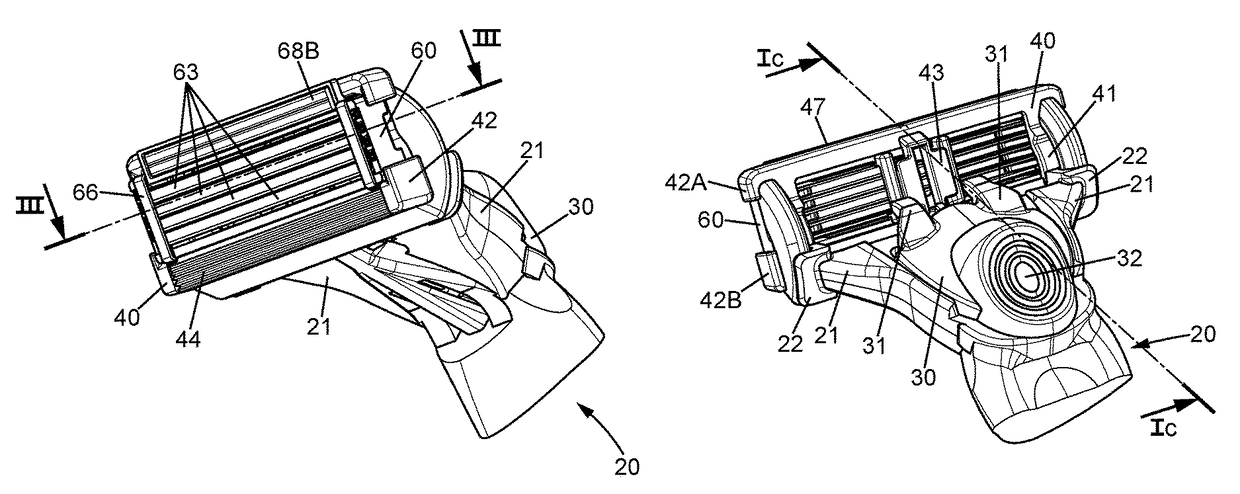

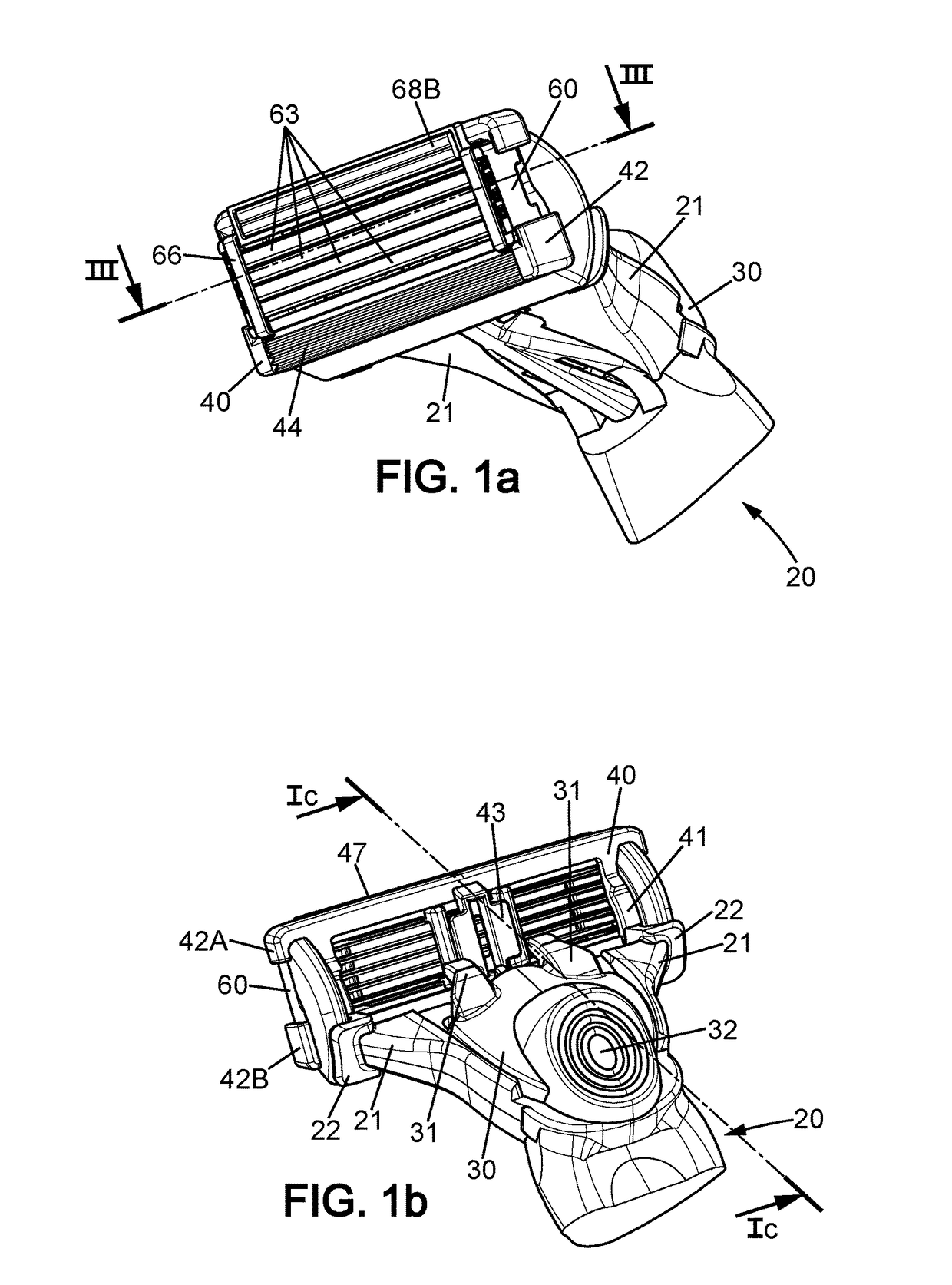

Shaver

ActiveUS9757870B2Easy to manufactureSimple structureMetal working apparatusBack structureMechanical engineering

A shaver comprising a handle with an elongated handgrip portion and a mounting portion, a shaver head attached to the mounting portion, the shaver head having a back structure. A removable cartridge is attached to the shaver head through an elastic member provided on the back structure of the shaver head.

Owner:BIC VIOLEX SA

Seat back structure of vehicle seat

InactiveUS20080012402A1Avoid excessive impactSimple structureVehicle seatsPedestrian/occupant safety arrangementBack structureEngineering

Owner:TACHI S CO LTD

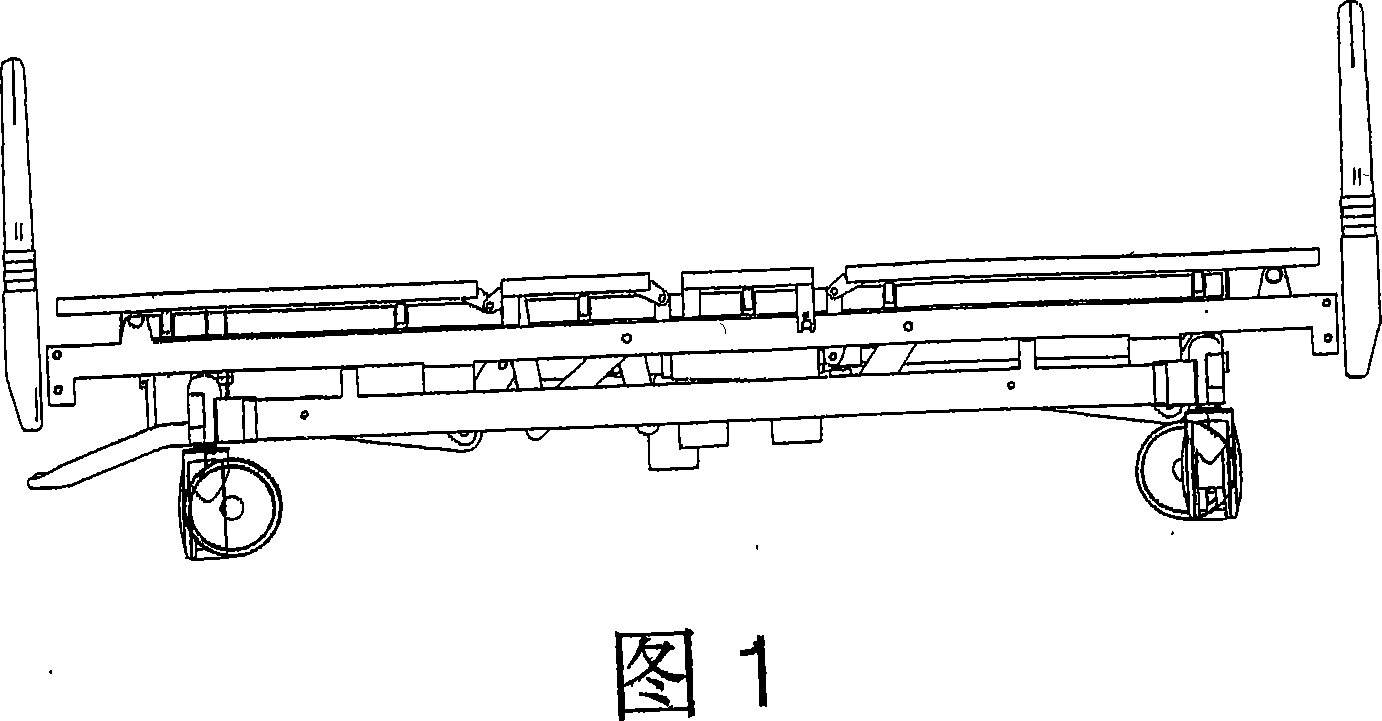

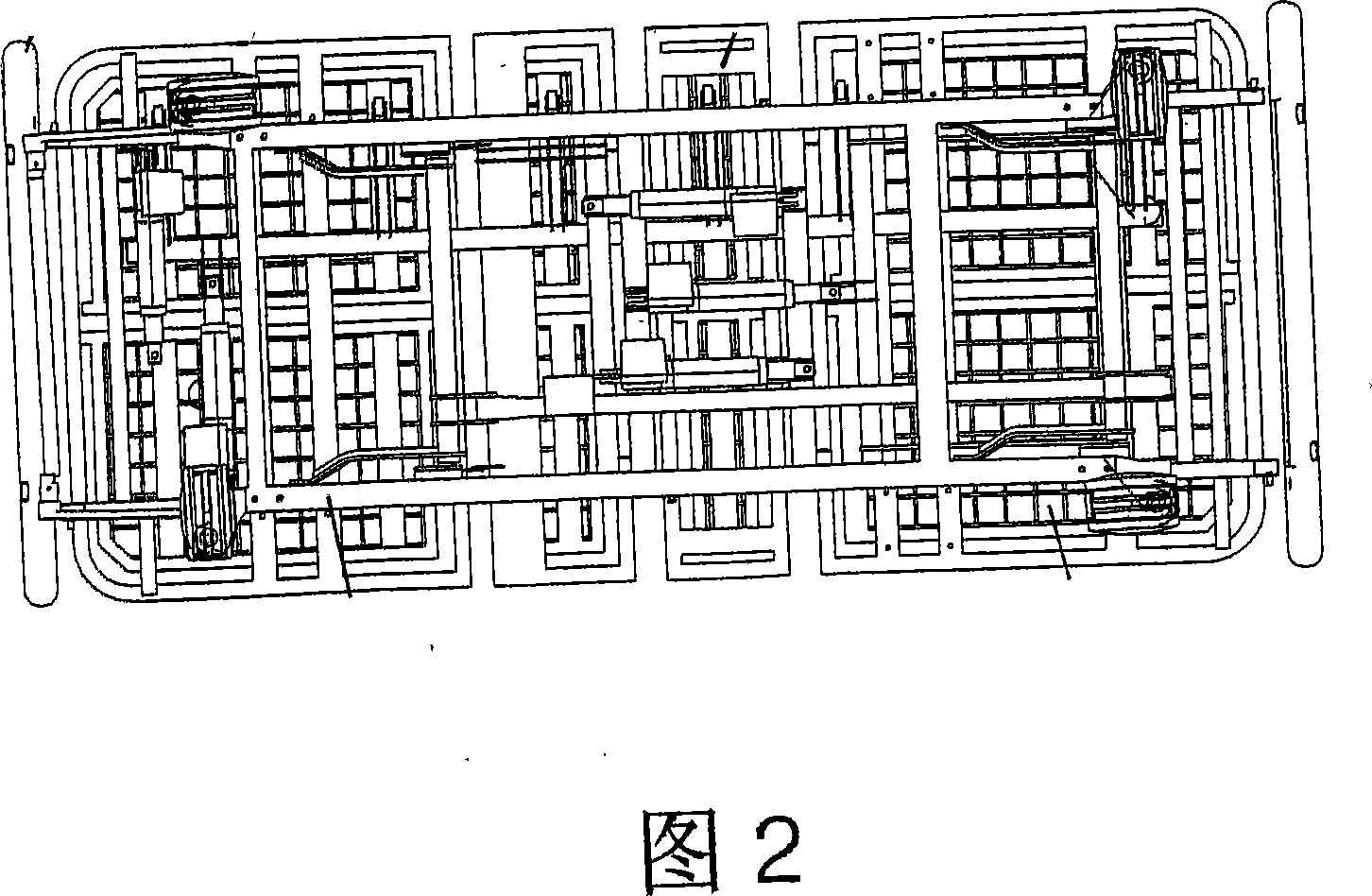

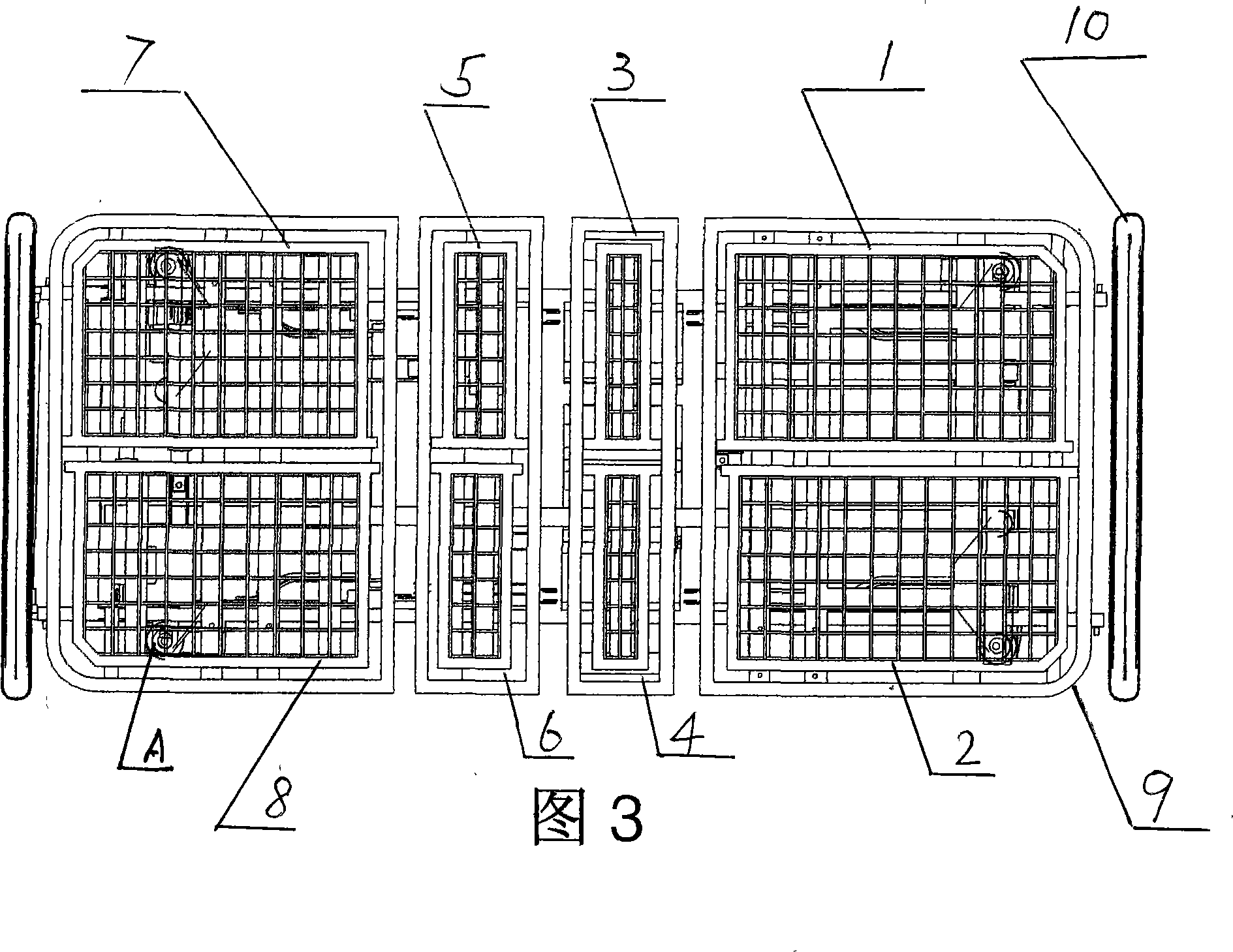

Multifunctional turning-over bed

The present invention is one kind of multifunctional turn-over bed to assist patient in changing posture, and the multifunctional turn-over bed has one headboard; one bed frame; eight bed boards, including two, one right and one left, turning over boards, two, one right and one left, buttock boards, two, one right and one left, thigh boards, two, one right and one left, shank boards, to constitute one symmetrical structure with four lower boards and four upper boards; one back structure with crank-rocker mechanism, and other parts. The present invention has novel structure and convenient use.

Owner:SHANGHAI PINXING SCI & TECH

Pivoting mechanism with gross and fine resistance adjustment

A pivoting mechanism with gross and fine adjustment with a housing, an elongate shaft pivotally retained by the housing, resiliently deformable members retained by the housing, cam members coupled to the shaft wherein the cam members are disposed to deform the resiliently deformable members when the cam members are pivoted, and a locking slide bar for selectively causing the cam members to pivot with the shaft to produce gross adjustments in pivoting resistance. First and second ends of the shaft can act as an output interface for outputting the pivoting resistance exhibited by the shaft to a seat back structure, a seat bottom structure, or some other structure. A threaded rod rotated by a handle can adjust an initial deformation of the first resiliently deformable member for fine pivoting resistance adjustment.

Owner:CVEK SAVA

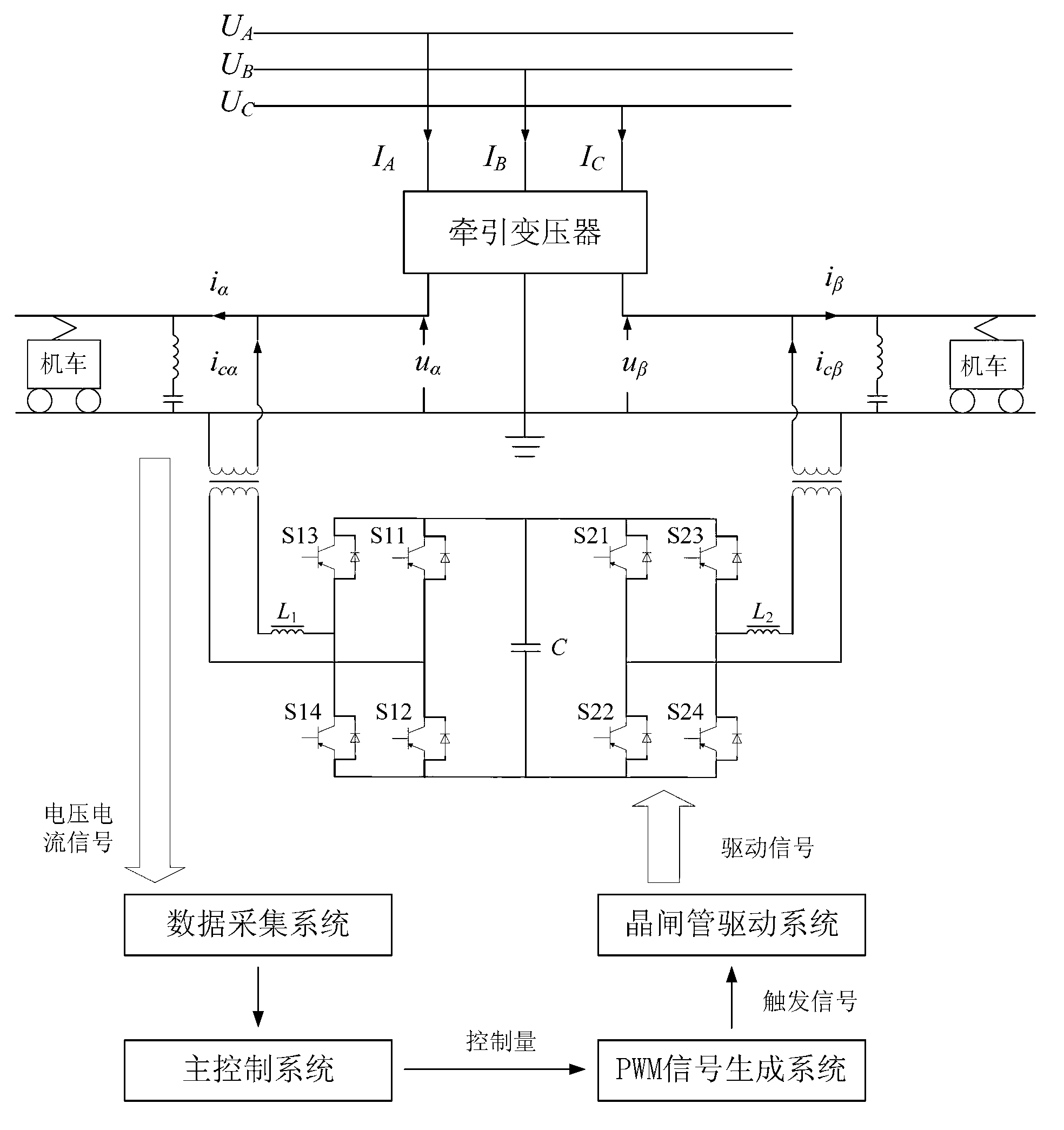

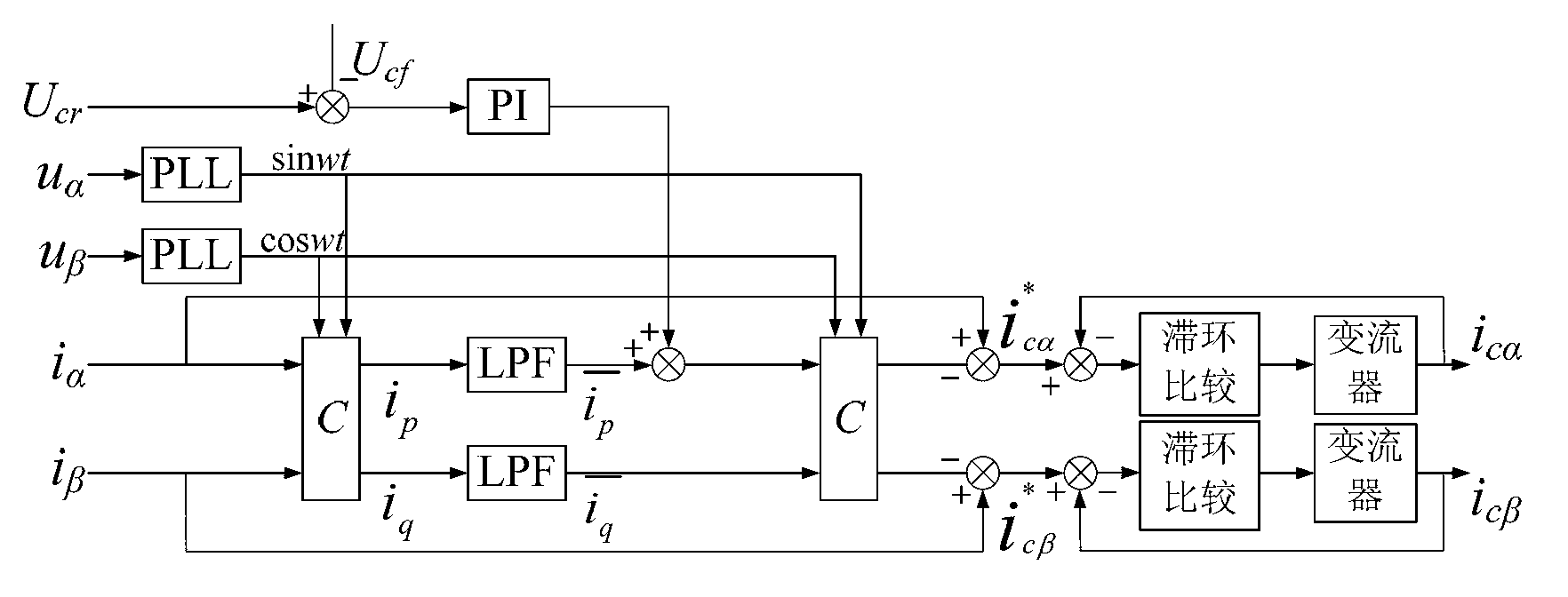

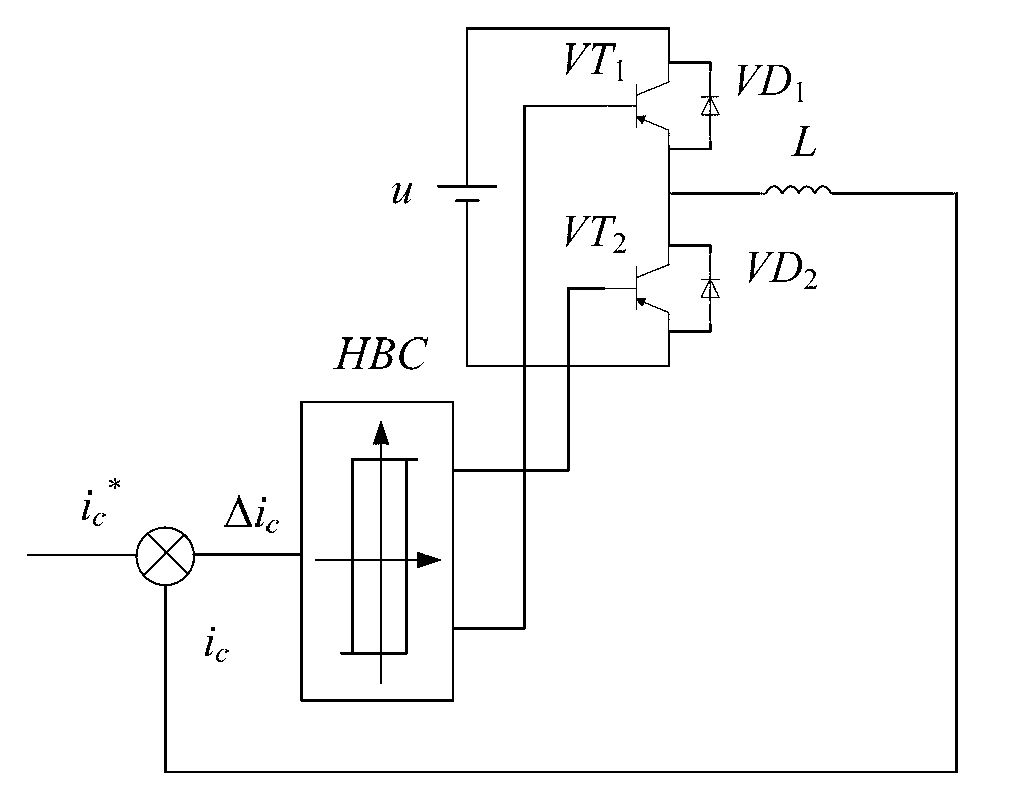

Two-phase STATCOM (Static Synchronous Compensator) management device on traction side of electrified railway, and control method of device

ActiveCN103023043AImprove effectivenessGood compensationFlexible AC transmissionReactive power adjustment/elimination/compensationCapacitanceBack structure

The invention discloses a two-phase STATCOM (Static Synchronous Compensator) management device on a traction side of an electrified railway, and a control method of the device. The device is connected with a two-phase power supply arms on a secondary side of a traction transformer in parallel, and comprises converter equipment and a control system. The converter equipment comprises two single-phase full-bridge inverters with a back-to-back structure form, and two groups of passive filters, wherein the transfer of active power between the two power supply arms can be realized through the control on capacitor voltage on a shared direct current side, and thus the load of two phases can be balanced; the two groups of passive filters are used for compensating harmonic wave and reactive power. The control system comprises a data acquisition system, a master control system, a PWM (Pulse-Width Modulation) signal generation system and a thyristor driving system. The device is arranged on a low-voltage side, so that the capacity demand of the device is reduced, the cost of the device is lowered, and the reliability of the device is improved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +3

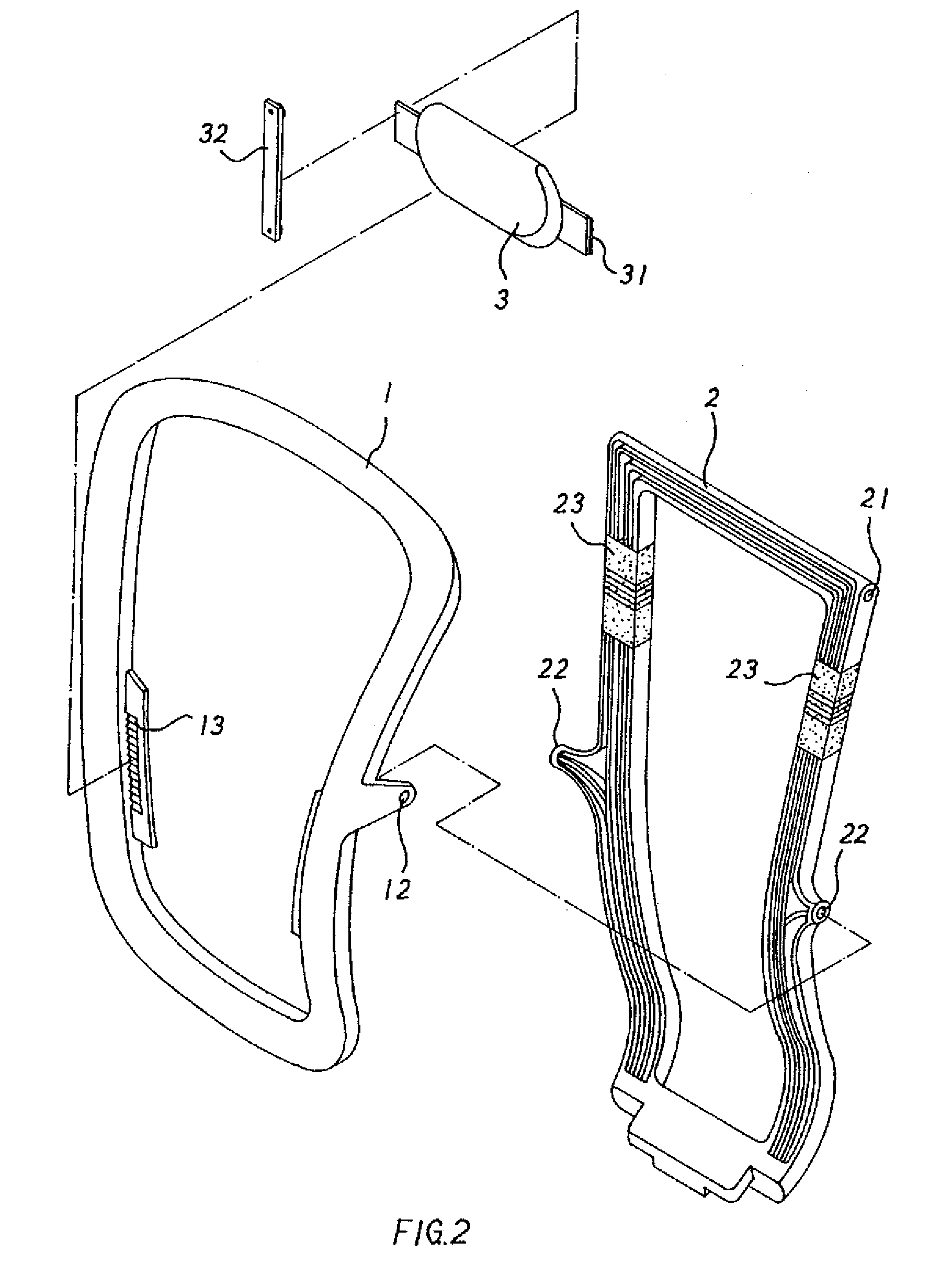

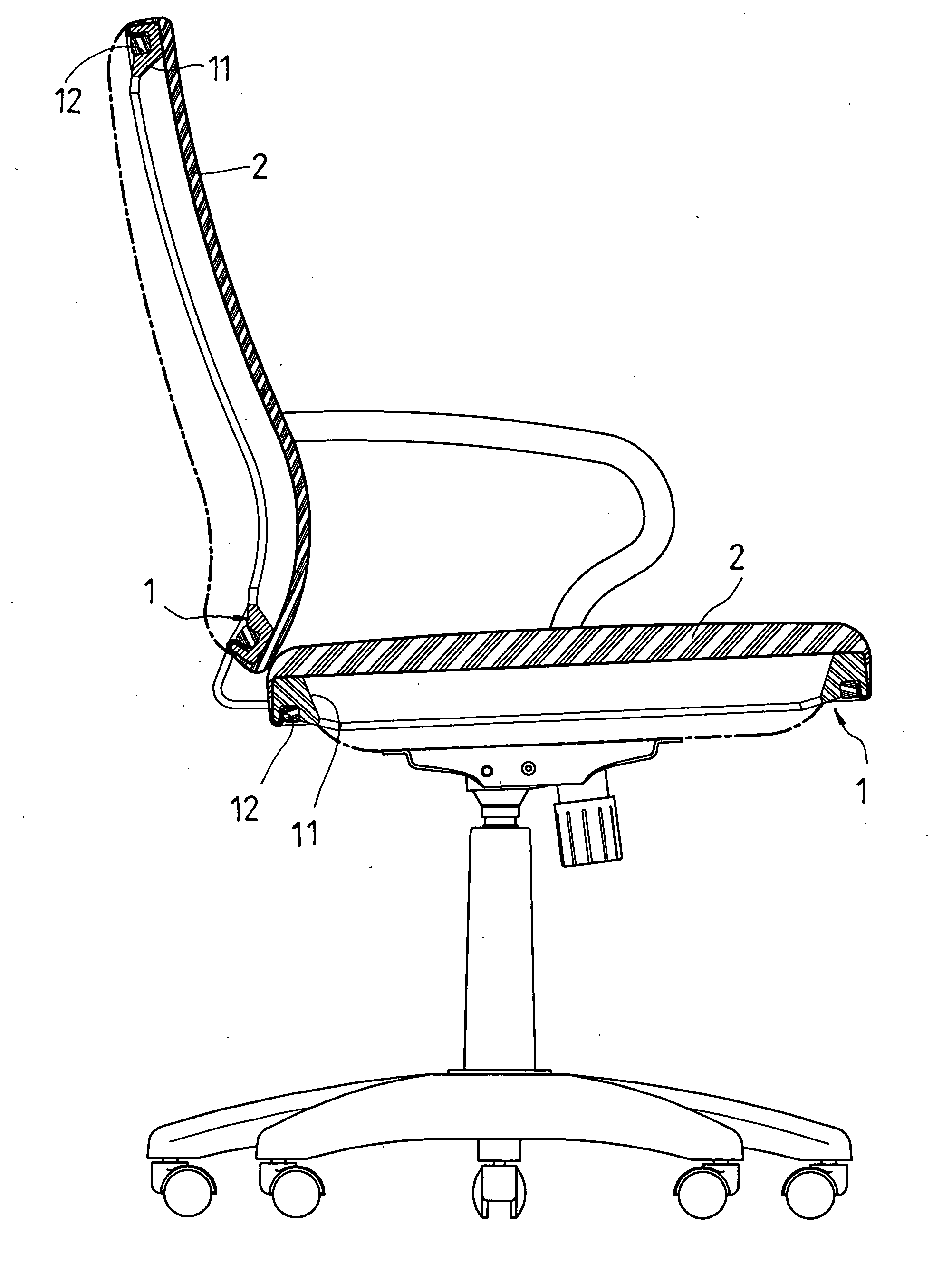

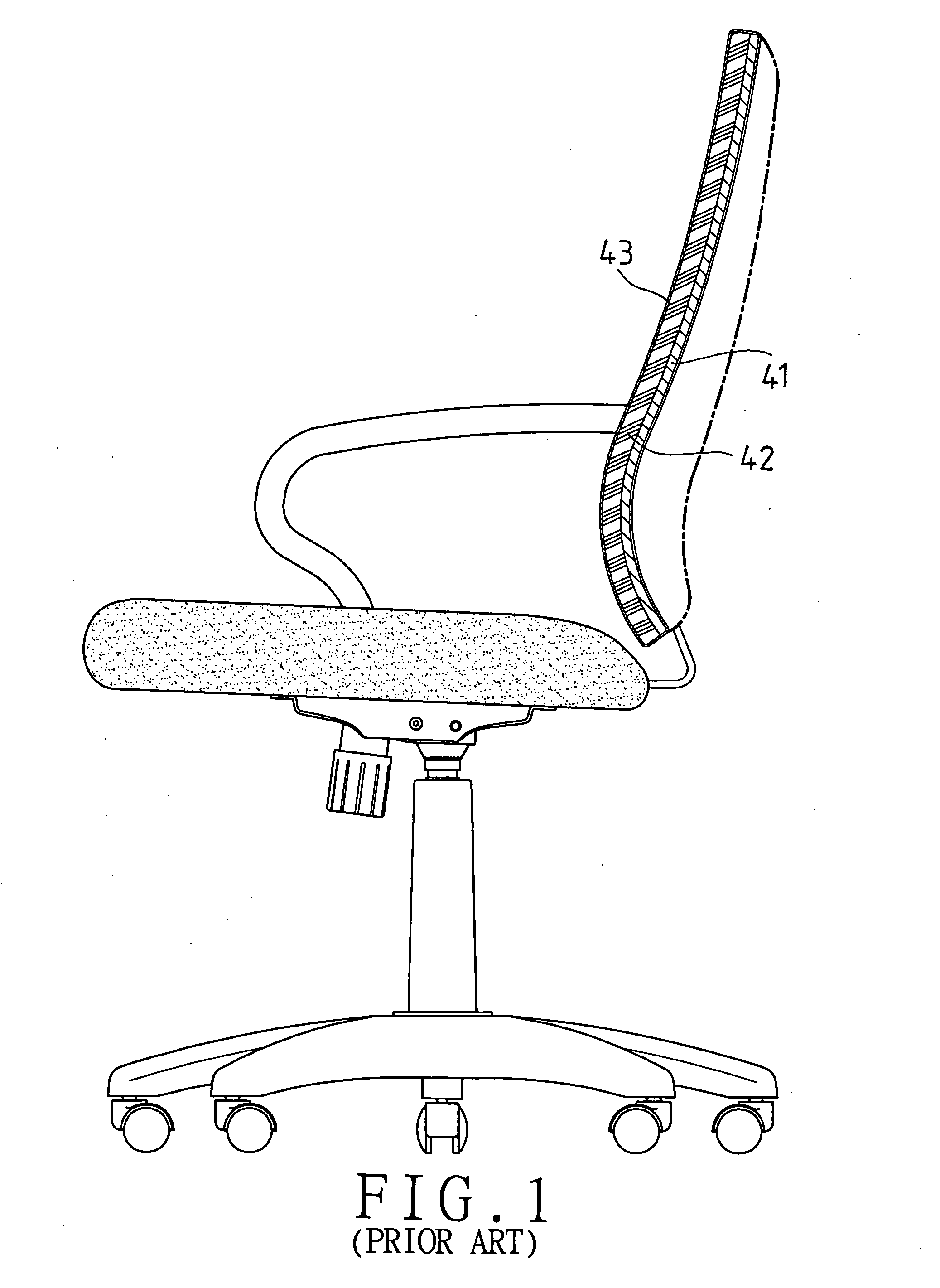

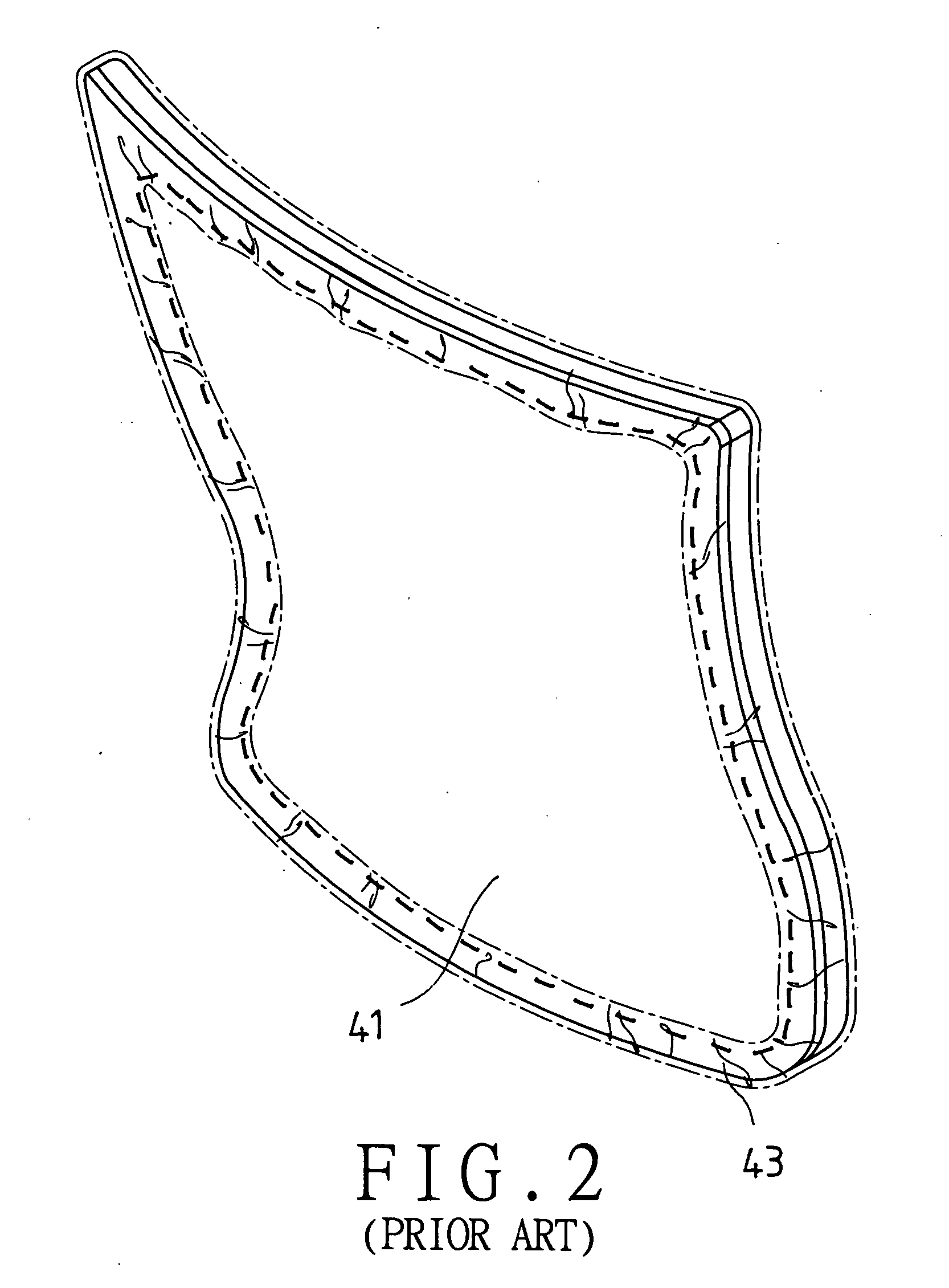

Chair seat and back structure

InactiveUS20070170756A1Simple structureIncrease the areaStuffed mattressesSpring mattressesBack structureEngineering

A chair seat and back structure includes a loop-shaped part with a space encompassed by an inner edge thereof, and an elastic covering part; the loop-shaped part has a curvature and a loop-shaped holding groove near to a circumferential edge thereof; the covering part positioned over the loop-shaped part, in tension and with a circumferential edge thereof being passed into the loop-shaped holding groove and secured to the loop-shaped part; therefore, the covering part will be changed in the shape by the sitter's body curvature, and the sitter's body will touch the chair with increased area.

Owner:RUSSELL INT CORP

Smart seating chair with IC controls, electronic sensors, and wired and wireless data and power transfer capabilities

ActiveUS9247828B2Proper adjustment of task chair performance characteristics more convenient and accessibleStoolsAdjustable chairsElectric power transmissionElectricity

A chair with a control mechanism with a base structure, a seat bottom structure supported by the base structure, a seat back structure supported by the base structure, a control mechanism supported by the base structure, a power source and means for electrically coupling the power source to the control mechanism and an electrical port, wireless transmitter, or other electrical communicator for producing electrical communication relative to the control mechanism. The power source can be a portable power source that plugs into the connector of the control mechanism. One or more electrical sensors can be retained relative to the seat bottom or seat back structures and memory can be provided for retaining data from the electrical sensor.

Owner:CVEK SAVA

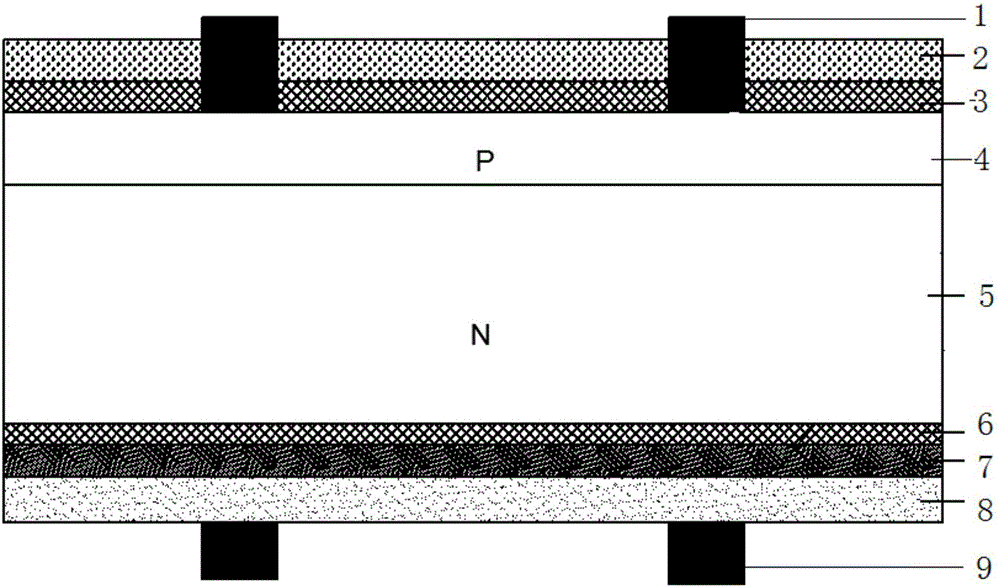

Rear surface passivation contact battery electrode structure and preparation method thereof

InactiveCN105870215AImprove conversion efficiencyImprove conductivityFinal product manufactureSemiconductor devicesBack structureTransparent conducting film

The invention discloses a rear surface passivation contact battery electrode structure and a preparation method thereof. A battery back structure comprises a tunneling layer which is arranged on the rear surface of a crystal silicon wafer and used for providing a passivation effect on the rear surface of a battery, the tunneling layer is provided with an N type doped crystal silicon layer used for a charge vertical conducting layer, the N type doped crystal silicon layer is provided with a transparent conducting film for an electric charge horizontal conducting layer, and the transparent conducting film is provided with a rear surface metal electrode for electric charge collection and a connection effect between battery pieces. According to the rear surface passivation contact battery electrode structure, the transparent conducting film / metal combination electrode is adopted so as to replace a conventional grid line electrode or an all metal back field electrode, so that the rear surface of the battery can serve as a light receiving surface, a shading area and the usage amount of conductive metal are remarkably reduced on the premise of guaranteeing good conductivity of the electrode, and the conversion efficiency of the battery is improved.

Owner:LONGI SOLAR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com