Patents

Literature

126results about How to "Enhanced radiation heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

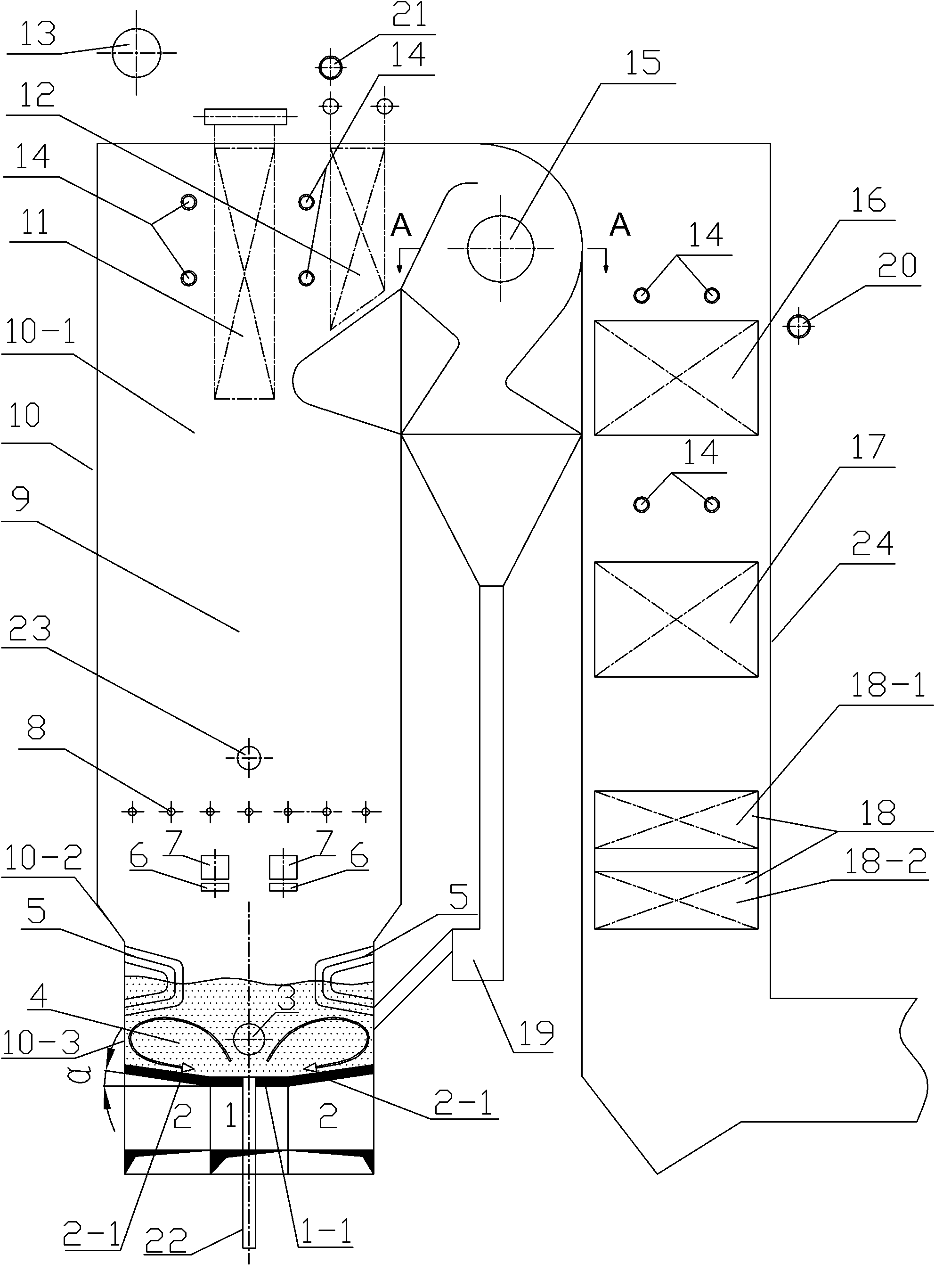

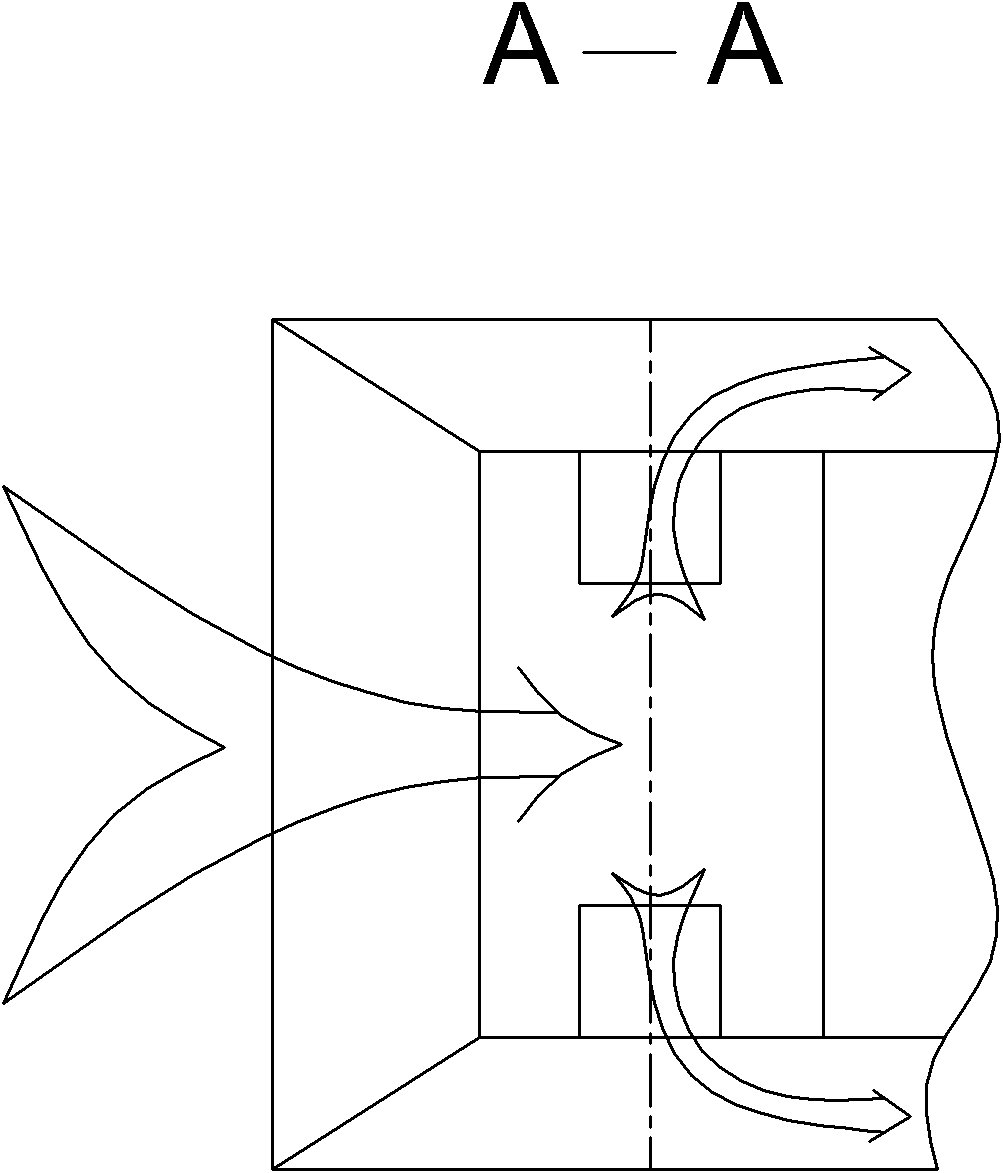

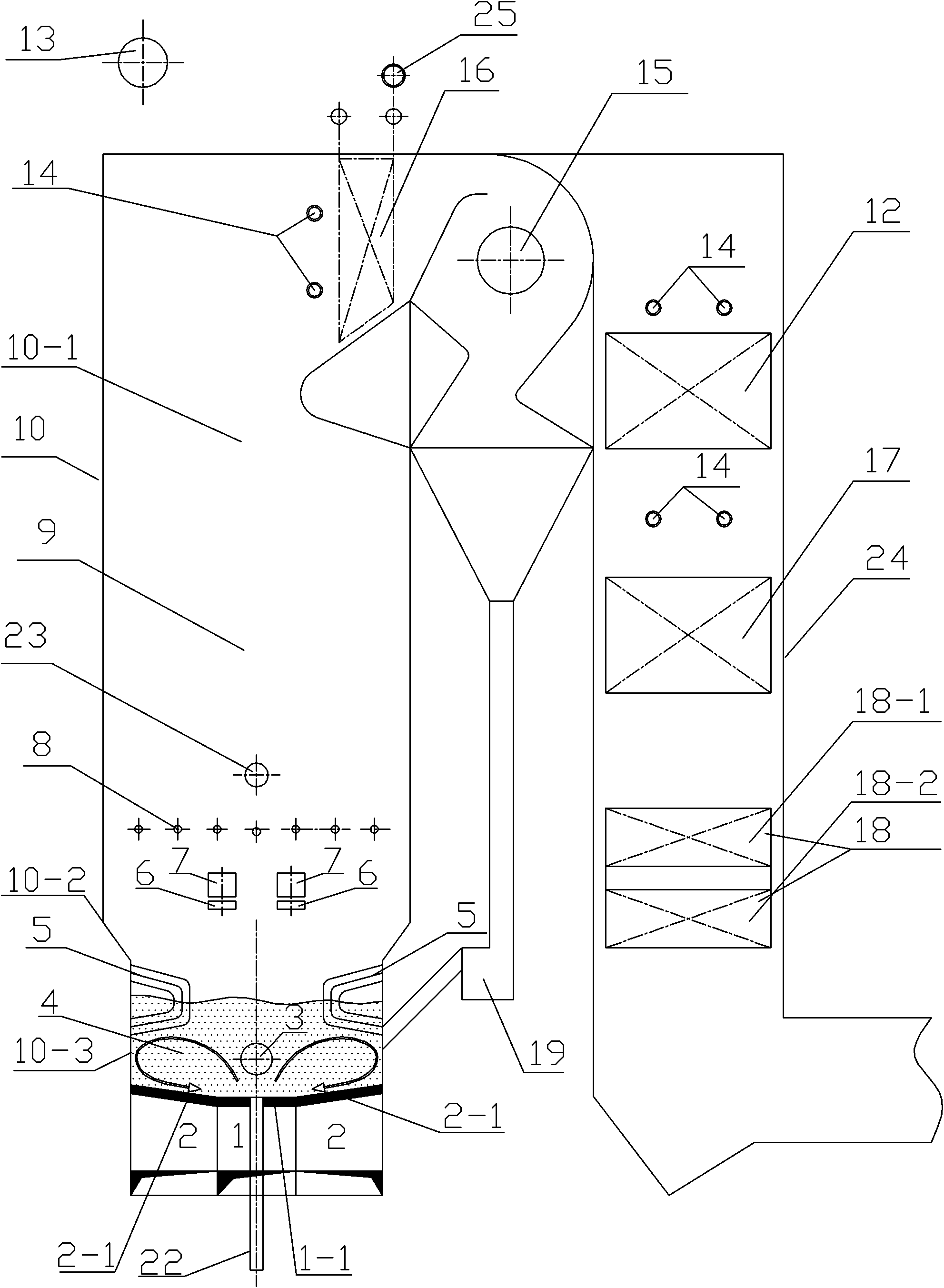

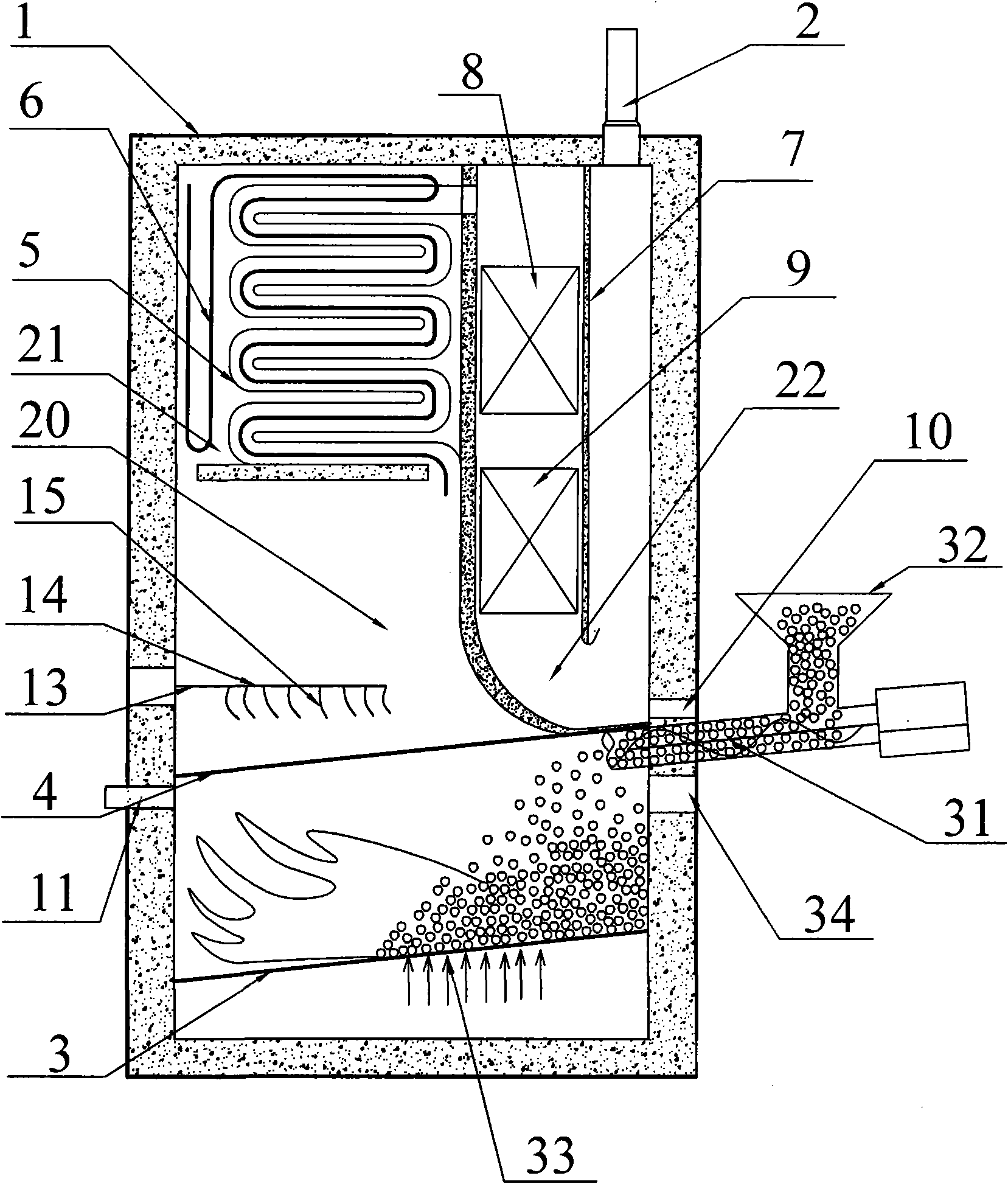

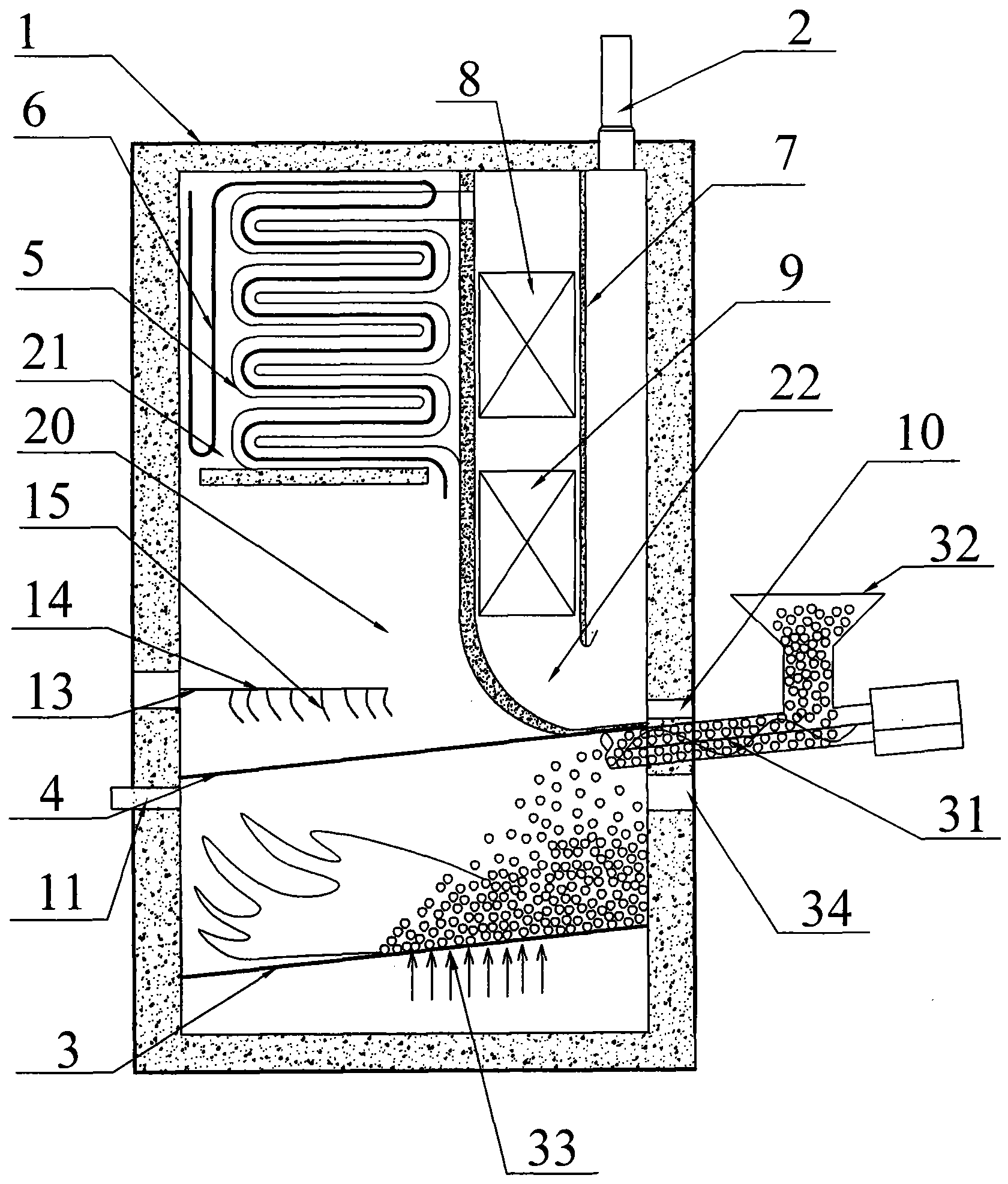

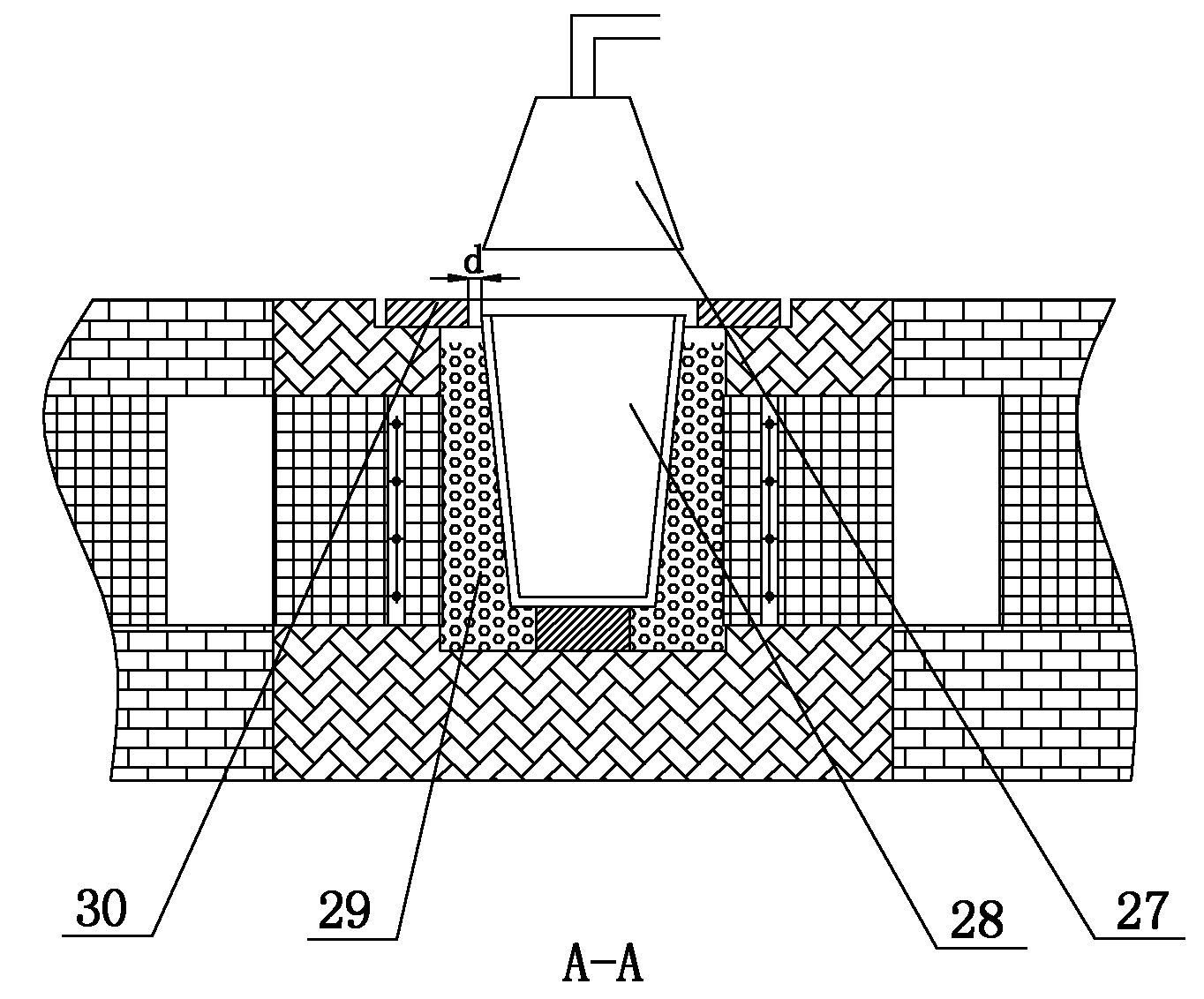

Low-ratio biomass circulating fluidized bed boiler and combustion method thereof

InactiveCN101949535AProlonged combustion residence timeSolve cokingFluidized bed combustionApparatus for fluidised bed combustionCombustionLow speed

The invention relates to a low-ratio biomass circulating fluidized bed boiler and a combustion method thereof, relating to a circulating fluidized bed boiler and a combustion method thereof and solving the problems of difficult feeding, grate slagging, bed material coking, tempering and output reduction, and the like existing in the operation of traditional grate furnaces and circulating fluidized bed boilers. A middle air chamber corresponds to the middle of a dense-phase area at the lower part, lateral grid plates are arranged between a lateral air chamber and the dense-phase area at the lower part, and a medium-temperature steam-cooled cyclone separator is arranged at the joint between a flue shaft at the tail part and a health outlet of a boiler body, respectively communicated with the flue shaft and the health outlet and communicated with the dense-phase area at the lower part through a material returner. The method adopts a negative-pressure feeding manner so that the fluidization air velocity of a high-speed area of the dense-phase area at the lower part is 4-5 m / s, the fluidization air velocity of a low-speed area is 1.5-2.0 m / s, the temperature of the dense-phase area at the lower part is 650-780 DEG C, and the material circulation ratio is below 10. The invention is suitable for the biomass circulating fluidized bed boiler for an electric power plant.

Owner:湖南博茂节能环保科技有限公司

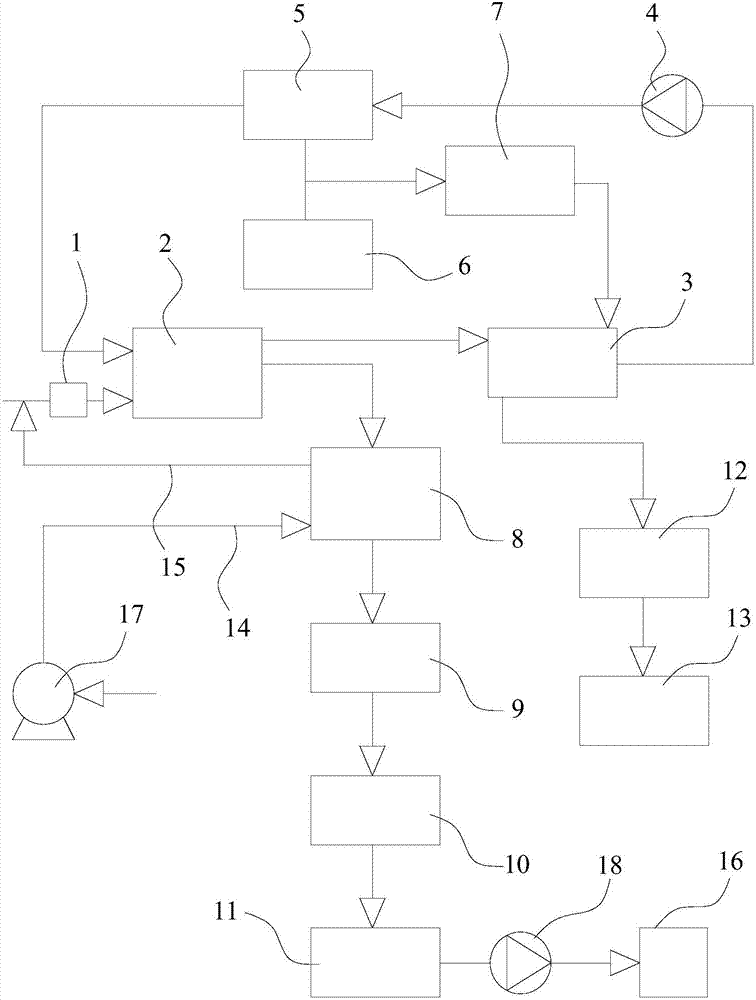

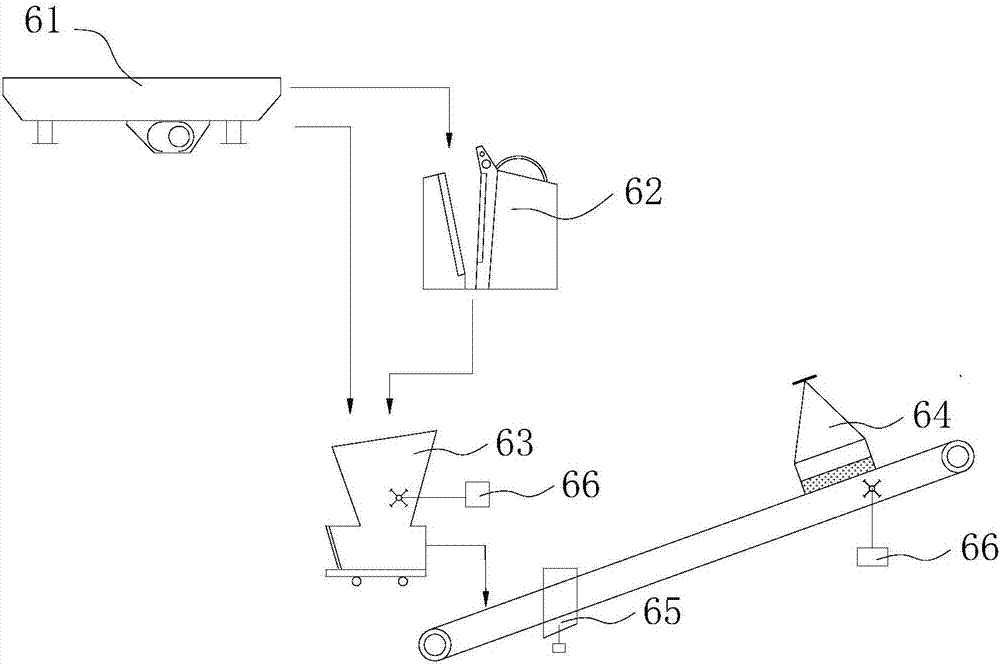

Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

ActiveCN107971330AReduce consumptionEmission reductionCombination devicesDispersed particle filtrationAir preheaterThermal desorption

The invention relates to an efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method. A burner is communicated with a high temperature oxidizingchamber, a high temperature smoke pipe of the high temperature oxidizing chamber is communicated with a rotary kiln heating processing system and an air heat exchanger, a high temperature air outletof the air heat exchanger is communicated with the burner, a smoke pipe of the air preheater is communicated with an inlet of a quench tower, an outlet of the quench tower is communicated with an inlet of a bag-type dust collector, an outlet of the bag-type dust collector is communicated with an inlet of a deacidification tower, an outlet of the deacidification tower is communicated with an air inlet of a second induced draft fan, and an outlet of the second induced draft fan is communicated with a chimney. A part of high temperature flue gas generated by the burner enters a rotary kiln thermal desorption reactor to achieve desorption of organic pollutant and soil drying pretreatment, organic matter enters the high temperature oxidizing chamber through a backflow pipe for burning treatment, and thorough oxidative degradation removal is achieved; and the other part of high temperature flue gas is used for increasing the temperature of combustion air through the air heat exchanger.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

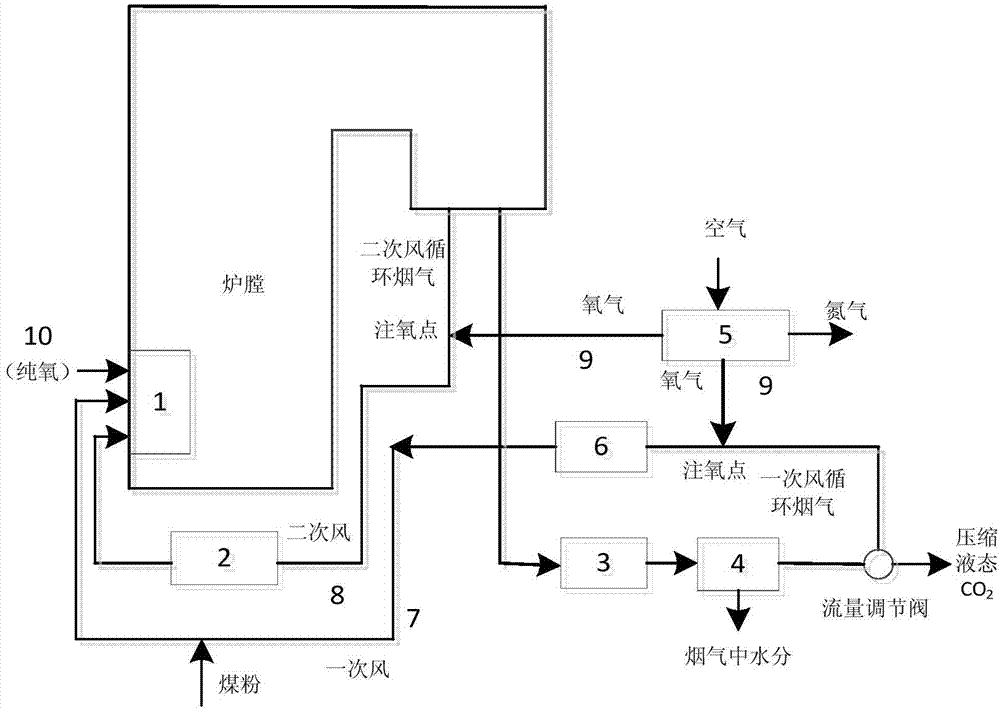

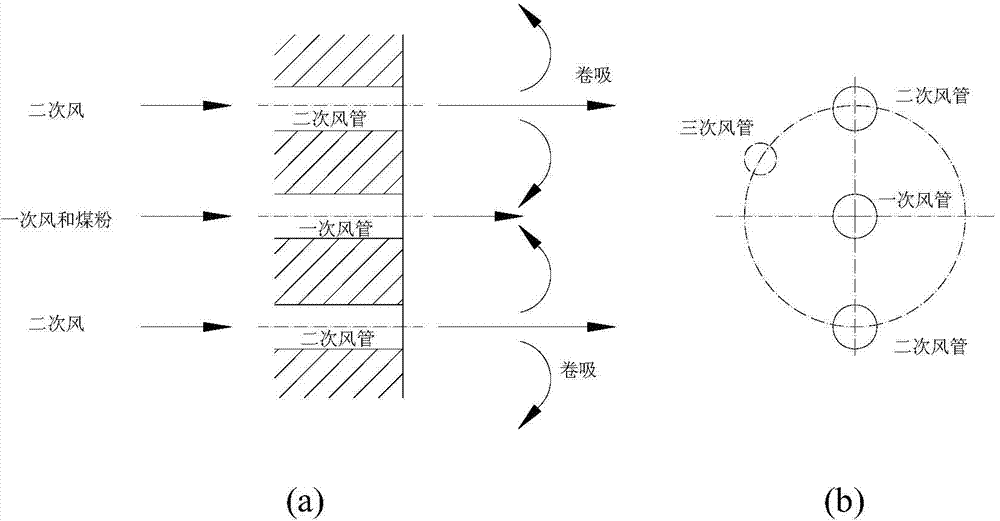

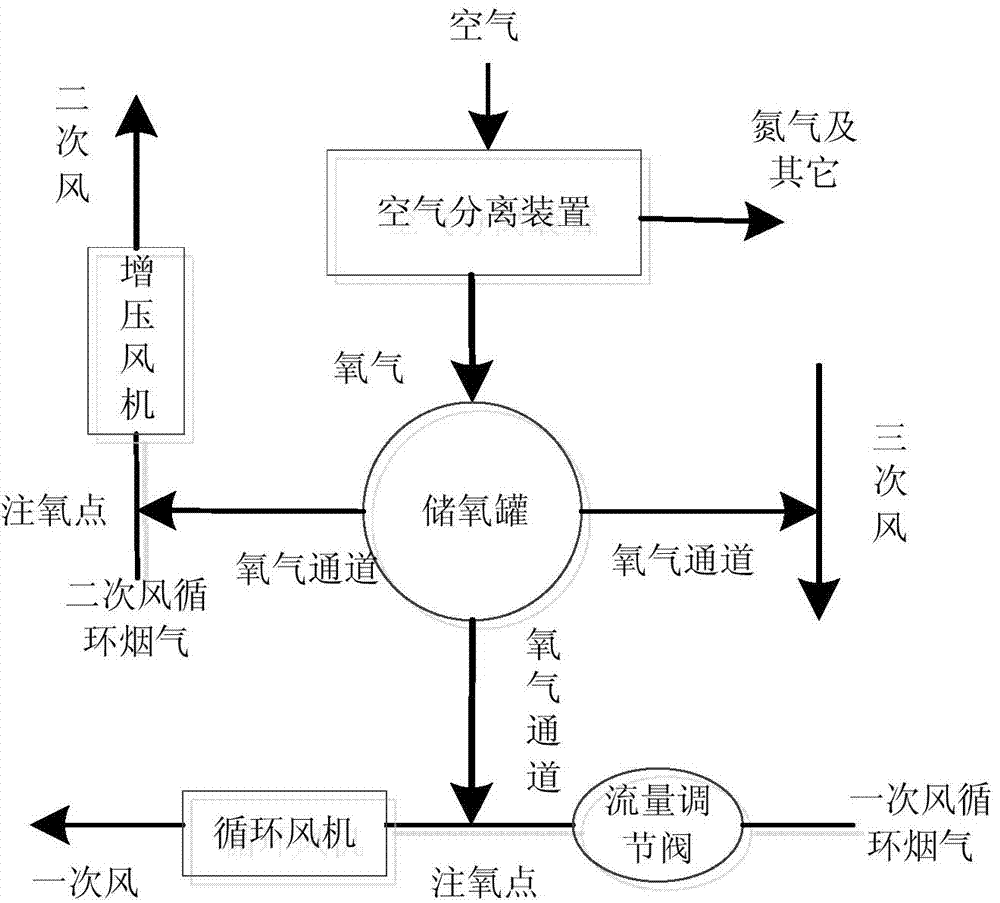

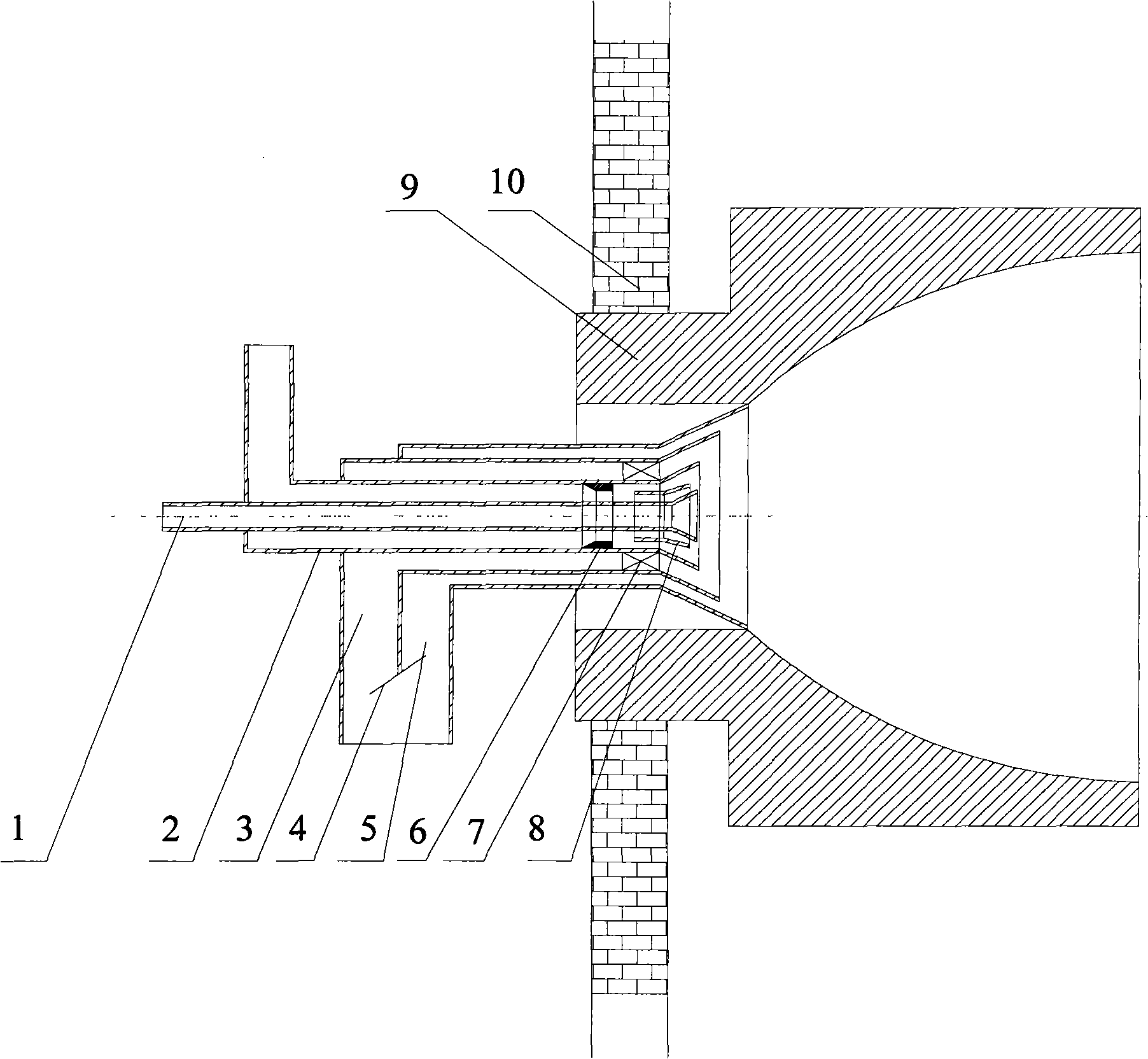

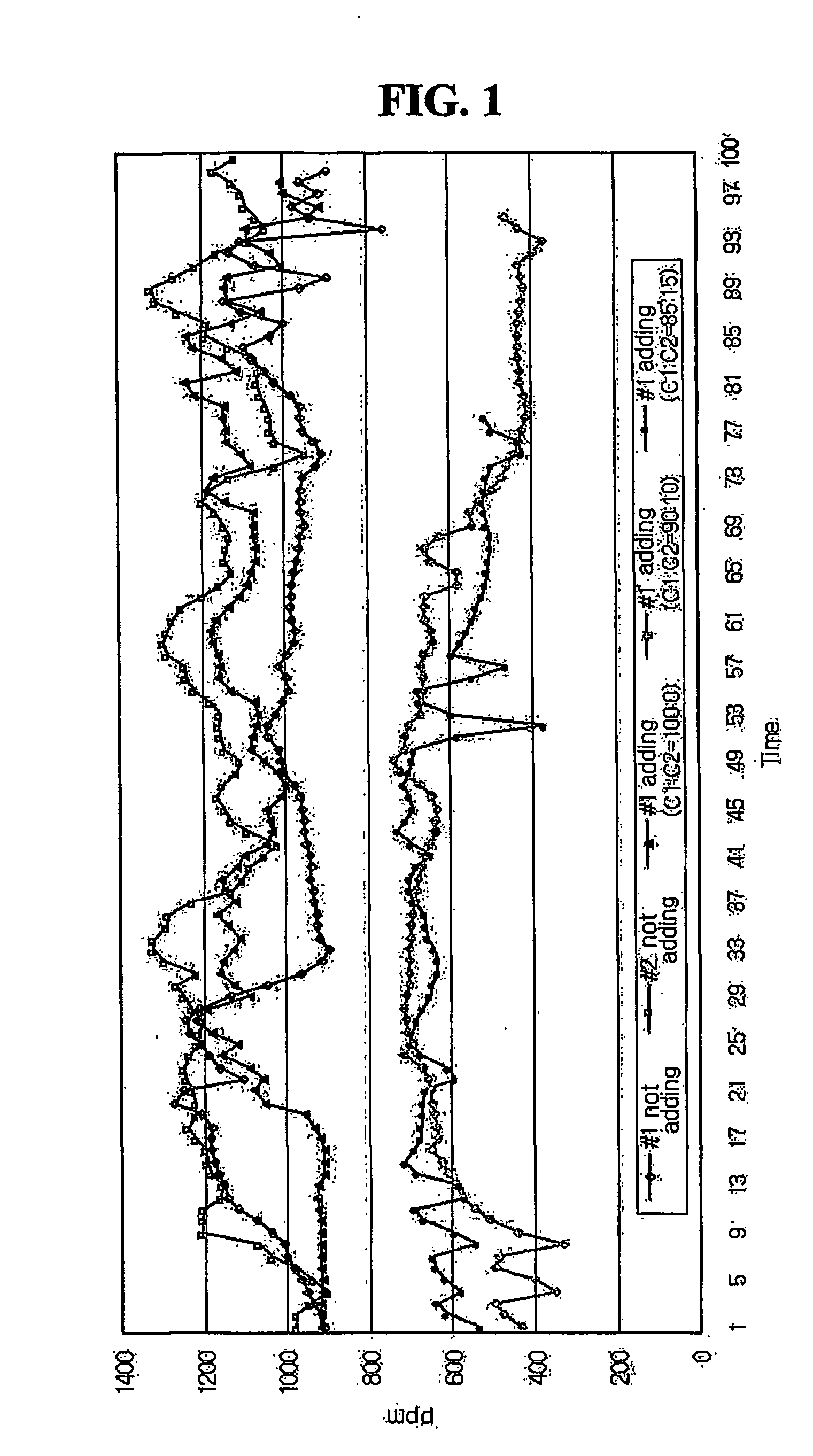

Method and system thereof for oxygen-enriched flameless combustion of coal powder

ActiveCN103615713AIncrease temperatureImprove heat utilization efficiencyDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationFlue gasInjection point

The invention discloses a method and a system thereof for oxygen-enriched flameless combustion of coal powder. By adopting the method, the stability, burn-off rate and radiative heat transfer of combustion can be improved through flameless combustion on the basis of enriching CO2 during oxygen-enriched combustion. High-temperature flue gas generated by the oxygen-enriched combustion is injected into a hearth in the form of high-speed jet flow through a direct-current flameless burner, and quick and uniform mixing of heat and quality in the hearth can be realized through high-speed jet flow entrainment. The system comprises an oxygen injection system, and a primary air oxygen-injection point is positioned between a circulating fan and a flow regulating valve; a secondary air oxygen-injection point is positioned between a booster fan and a hearth outlet; a primary air pipe of the direct-current flameless burner is positioned in the center, and a secondary air pipe is parallel to the primary air pipe and is circularly arranged around the primary air pipe; the booster fan with a high-pressure head is arranged on a secondary air duct, and secondary air is boosted and speeded up and then enters the hearth in the form of the high-speed jet flow. The heat utilization ratio of the method and the system can be improved by 10-25%, and the generation of NOX can be reduced by 15-40%.

Owner:HUAZHONG UNIV OF SCI & TECH

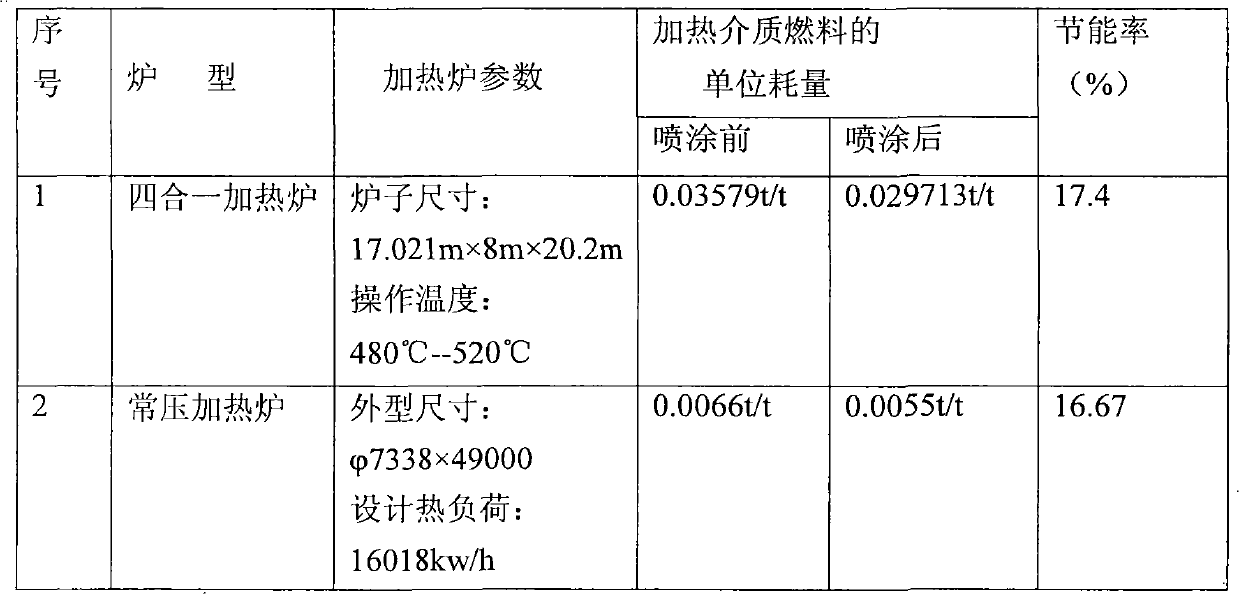

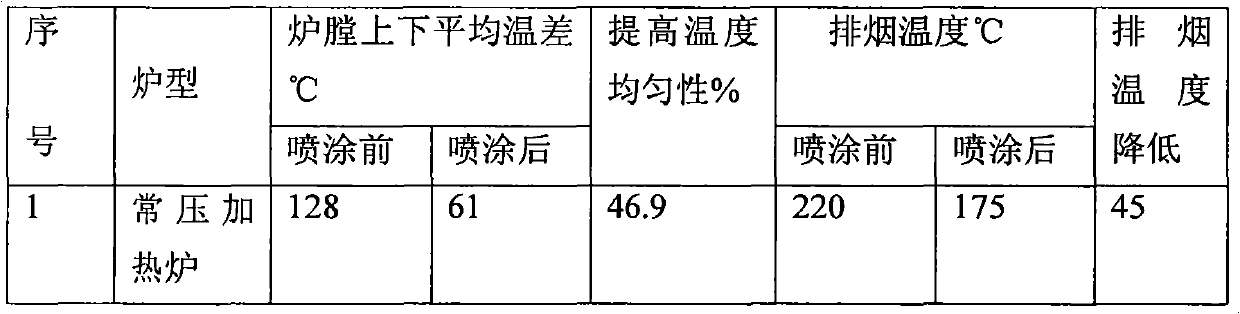

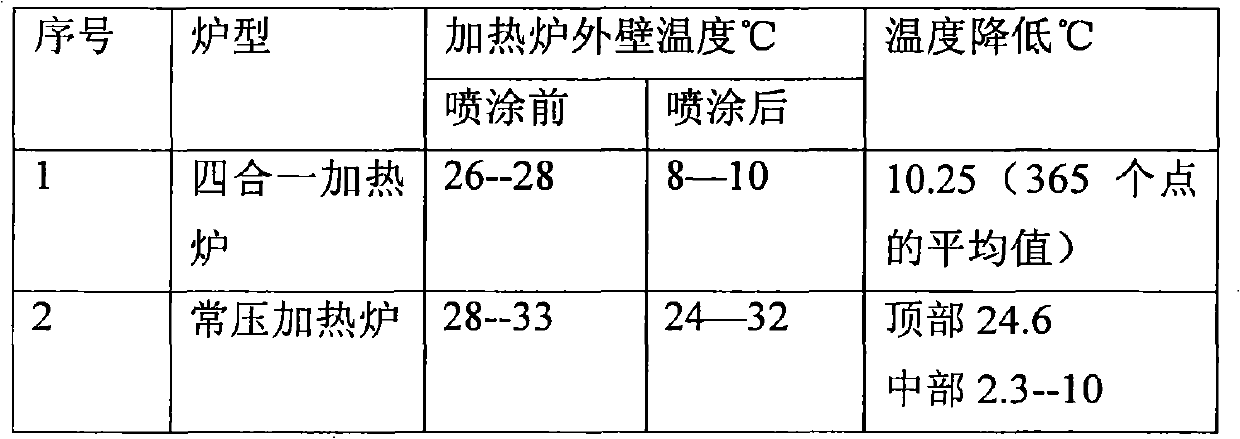

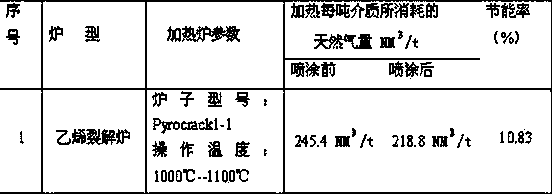

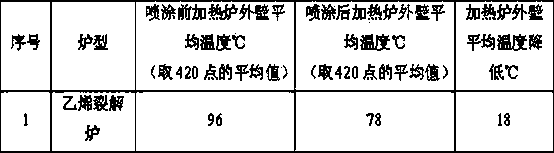

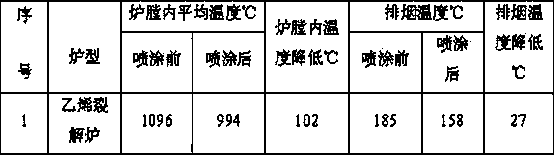

Ceramic coating used for heating furnace

InactiveCN102020475AExtended service lifeHas high temperature oxidation resistanceEmissivityRadiance

The invention relates to ceramic coating used for a heating furnace. The ceramic coating comprises the following components: ceramic micro powder, an inorganic bonding agent and a linear thermal expansivity regulator. The invention also provides a method for preparing the ceramic coating for the heating furnace. The ceramic coating has the characteristics of having improved radiance and thermal shock resistance, being efficient and energy-saving, prolonging the service life of furnace linings and furnace tubes, improving temperature uniformity and the like, as defined below: (1) the energy consumption is reduced, the energy is saved by more than 3 percent and pollutant discharge is reduced; (2) the temperature uniformity in the heating furnace is improved: (3) the metallurgy stability of the furnace tube of the heating furnace is improved, the coking and scaling of the furnace tub are delayed, and the absorbing capacity of the furnace tube can be maximized; (4) the emissivity of the surface of the refractory lining layer can be maximized so as to increase the secondary radiation of radiant heat (energy) and increase the efficiency of the radiant section; and (5) the outer wall temperature and the exhaust gas temperature of the heating furnace can be reduced by more than 5 percent.

Owner:北京安泰恒业科技有限公司

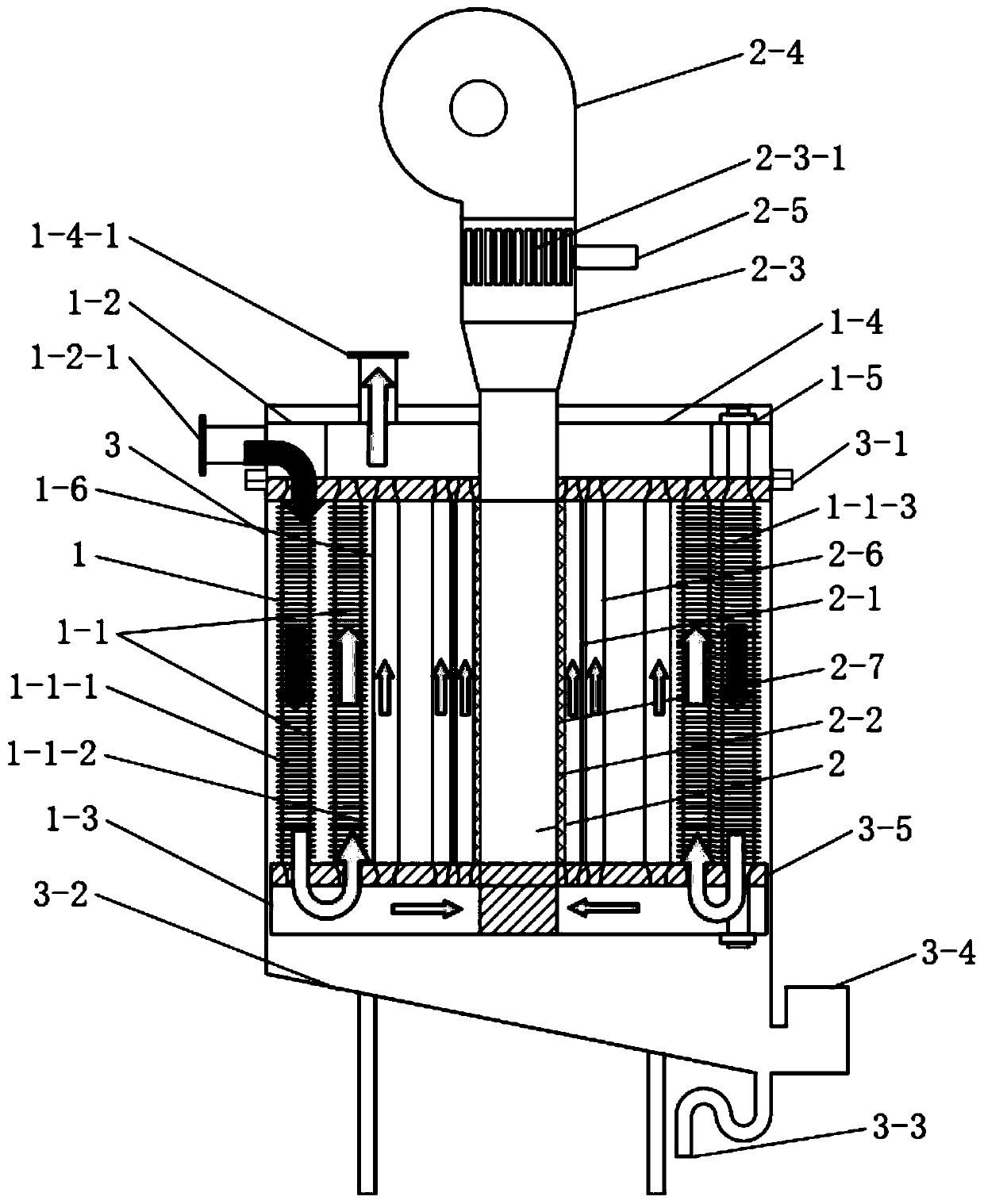

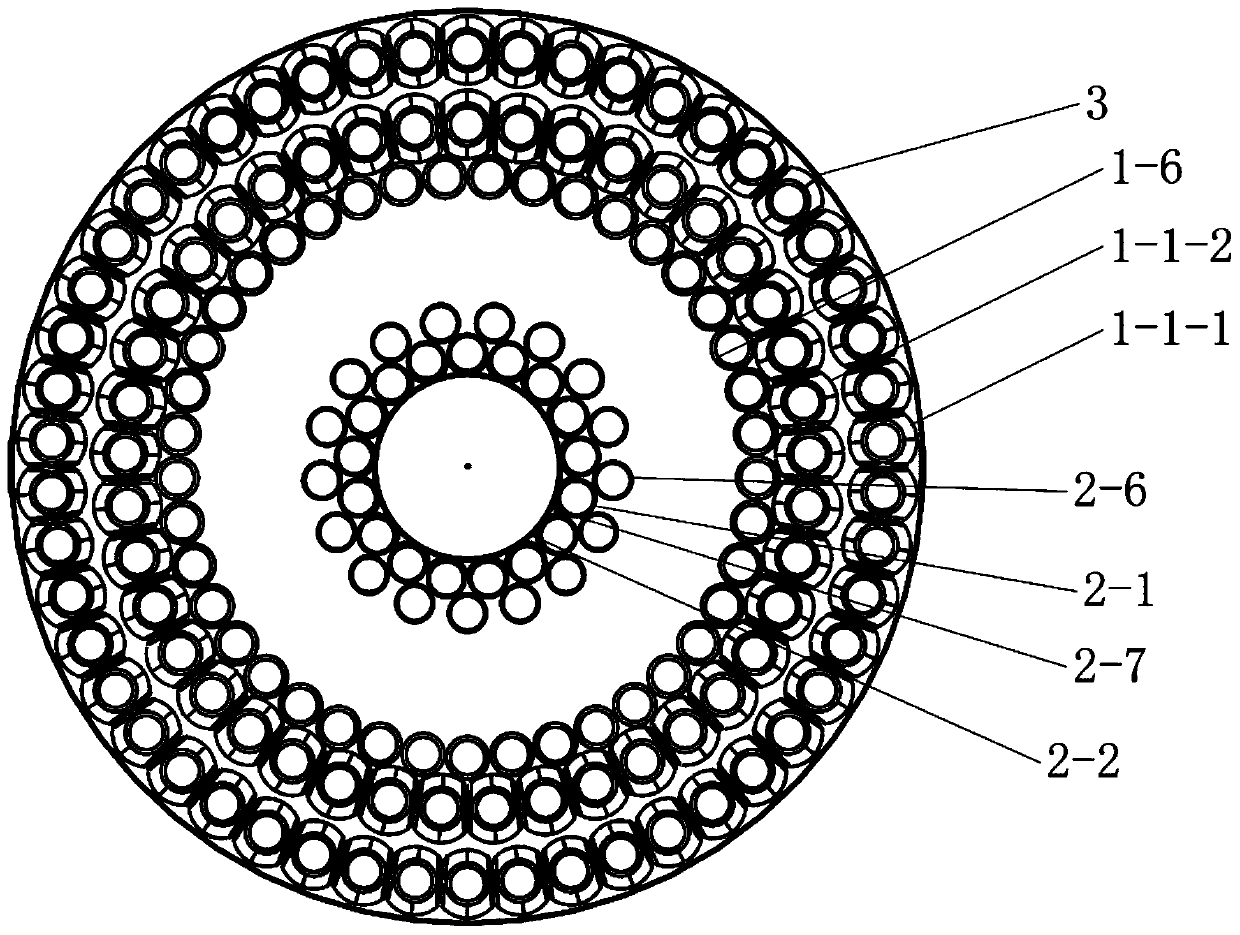

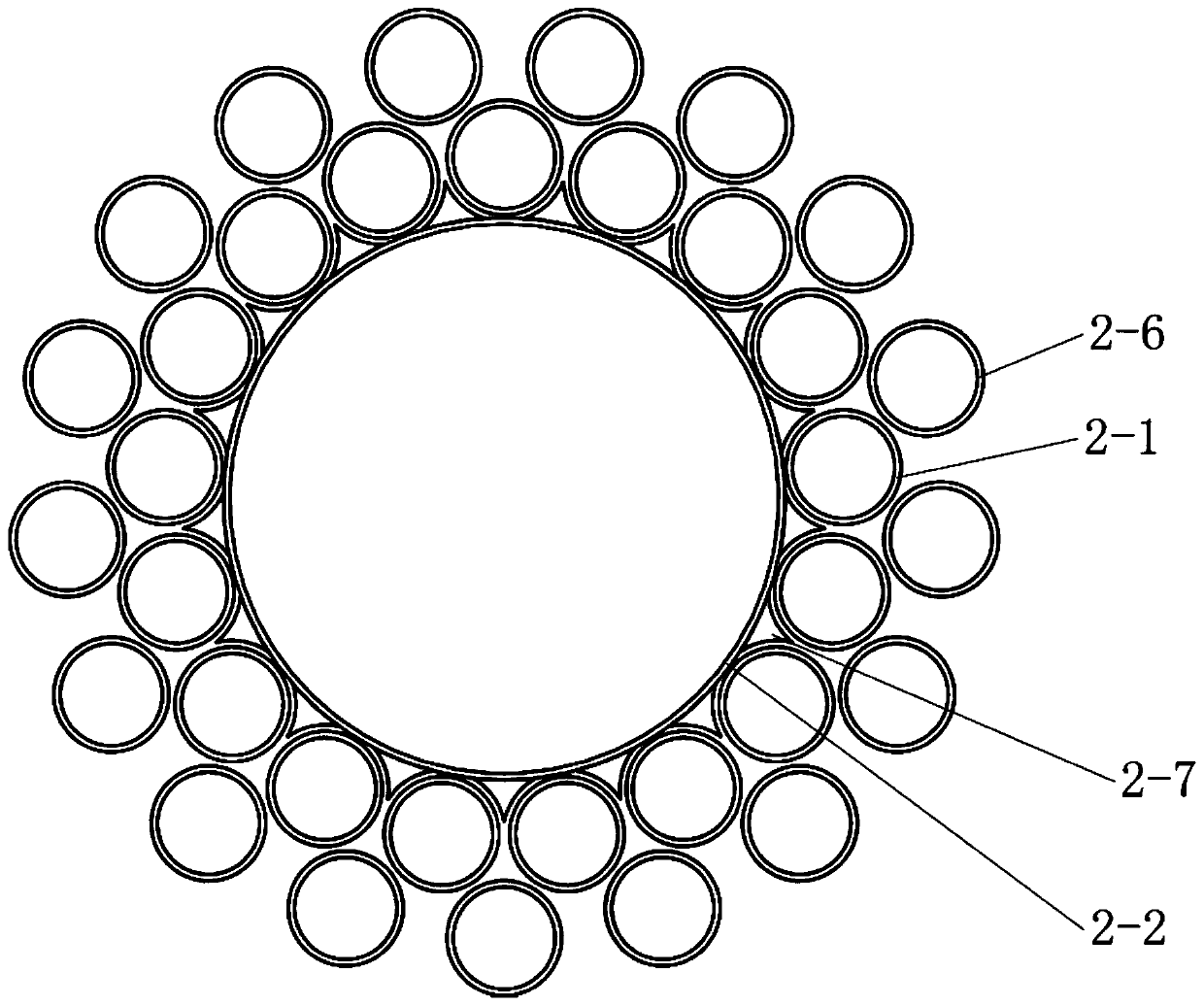

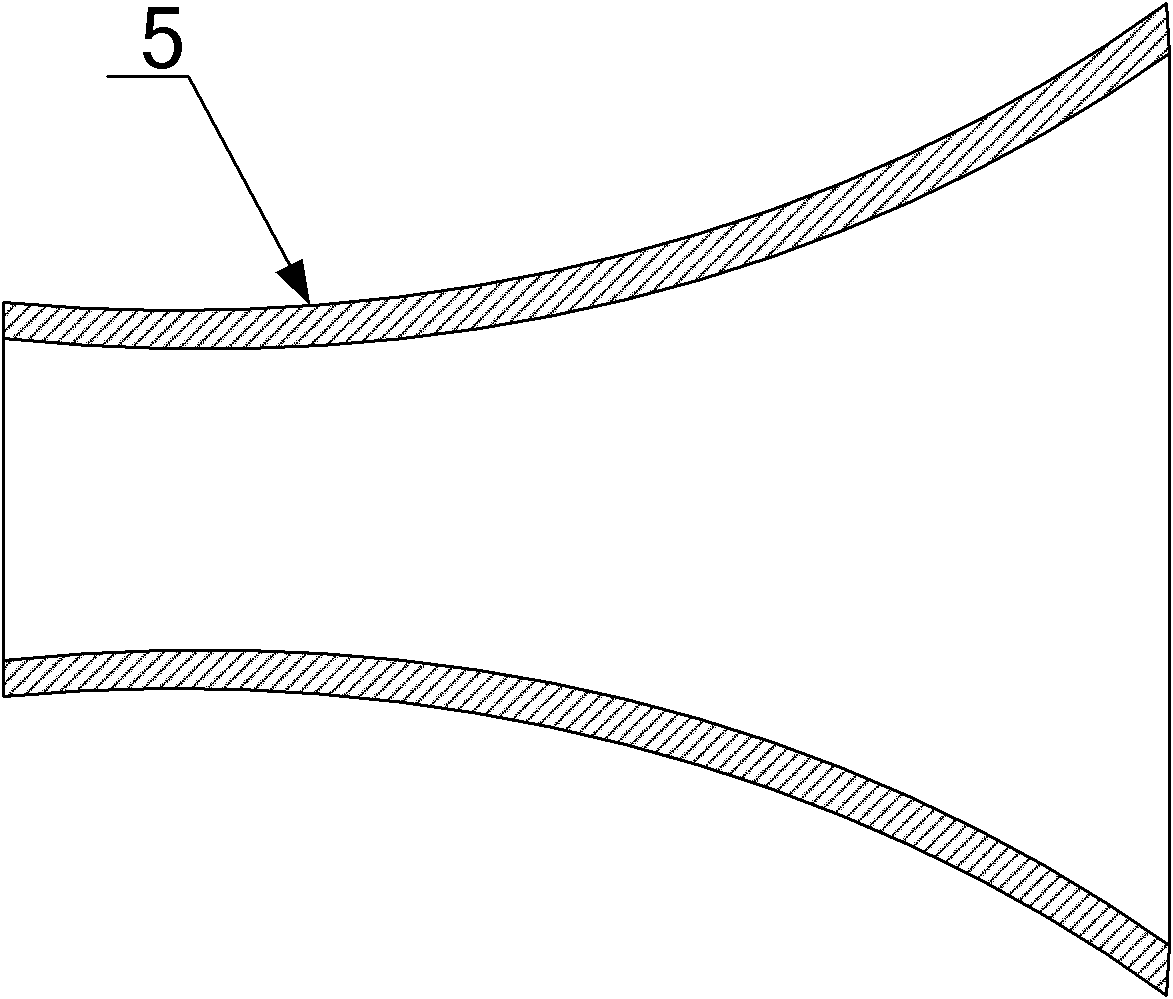

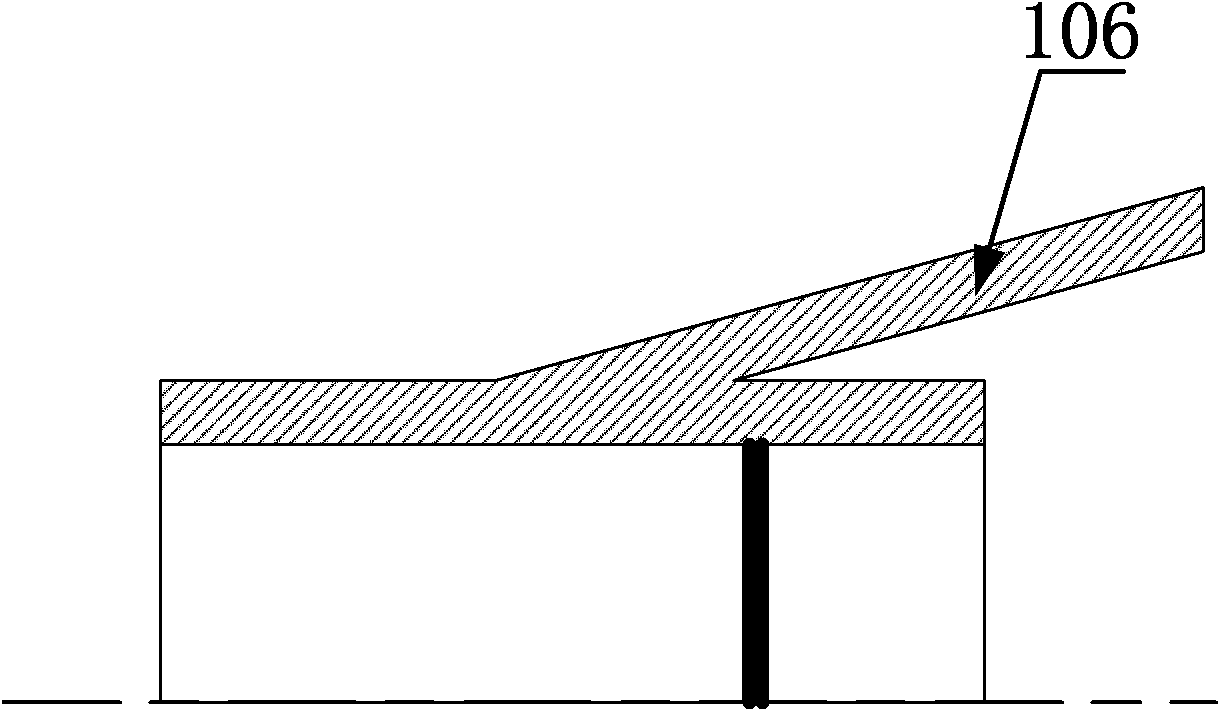

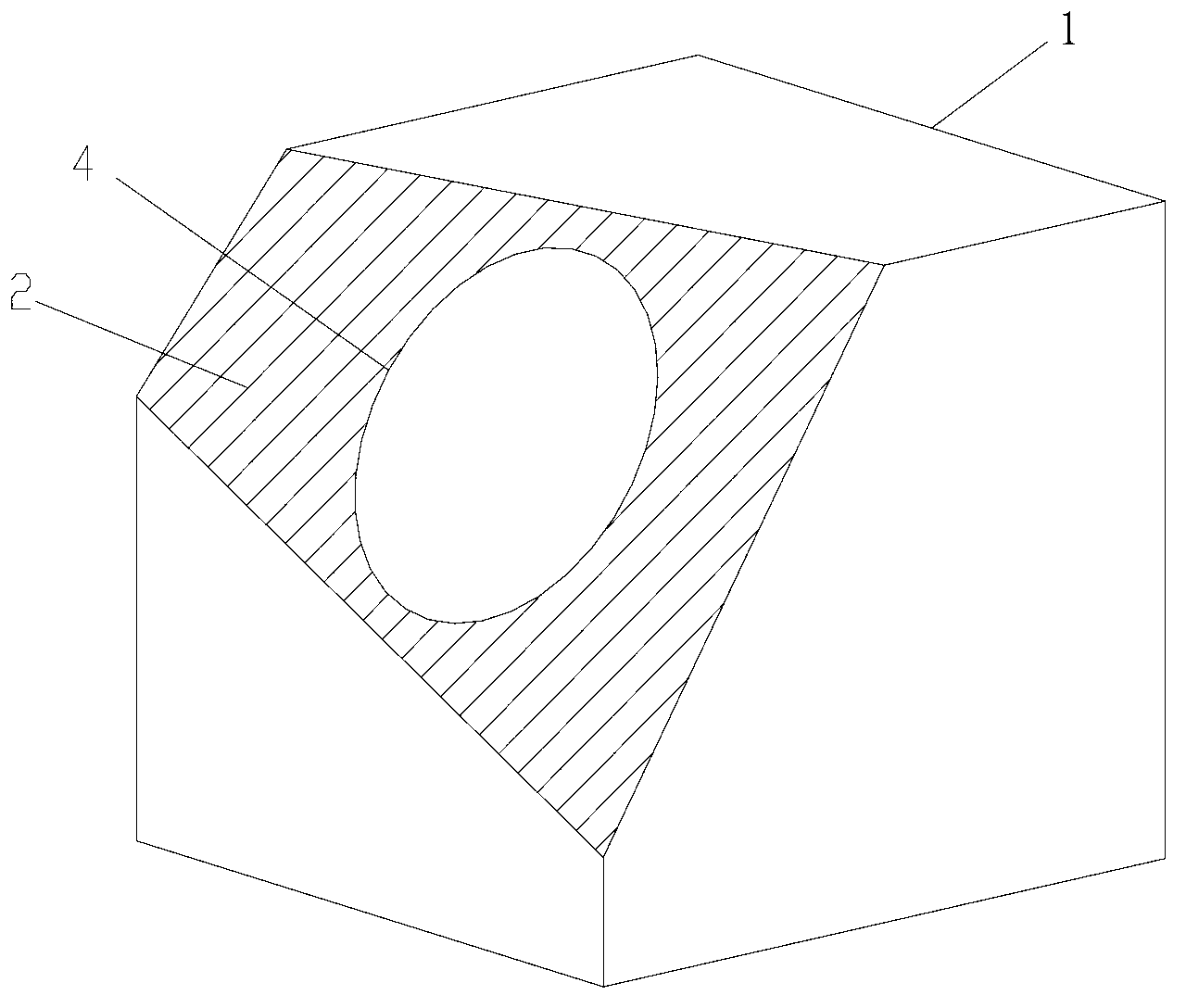

High-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler

PendingCN111141028AFully absorb radiation heat transferEnhanced radiation heat transferAir heatersGaseous fuel burnerCombustorAir blower

The invention provides a high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler comprises a combustor and a heat exchanger, wherein the full-premixed combustor mounted in the center of a boiler top plate consists of a booster fan, a premixing chamber and a water-cooling combustion head; a flame stabilizing pipe and an anti-tempering column of the water-cooling combustion head can realize high-adjustment-ratio water-cooling premixed combustion; the heat exchanger consists of a lap of water-cooling wall and one or more laps of fins uniformly arranged in the peripheral direction by bent edge folding fin pipes; an air blower feedsair into the premixing chamber for fully mixing with gas to enter an inner cavity of a hole plate of the combustion head; the air flows out from a fire hole, and is sprayed out from narrow gaps amongthe water-cooling pipes distributed in the peripheral direction; after the air flows out from the flame stabilizing pipe, the air is ignited to uniformly combust in the peripheral direction and the axial direction, and radiates and releases heat to an inner pipe ring; smoke flushes base pipes and fins of inner and outer ring fin pipes in sequence to reinforce heat exchange; and the smoke downwards flows into a dew bearing disc through gaps between a housing and an outer layer fin pipe, and is exhausted into atmosphere from a smoke outlet. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler is high in combustion load adjustment ratio, compact in heat exchange, low in nitrogen emission and high in heat efficiency.

Owner:XI AN JIAOTONG UNIV +1

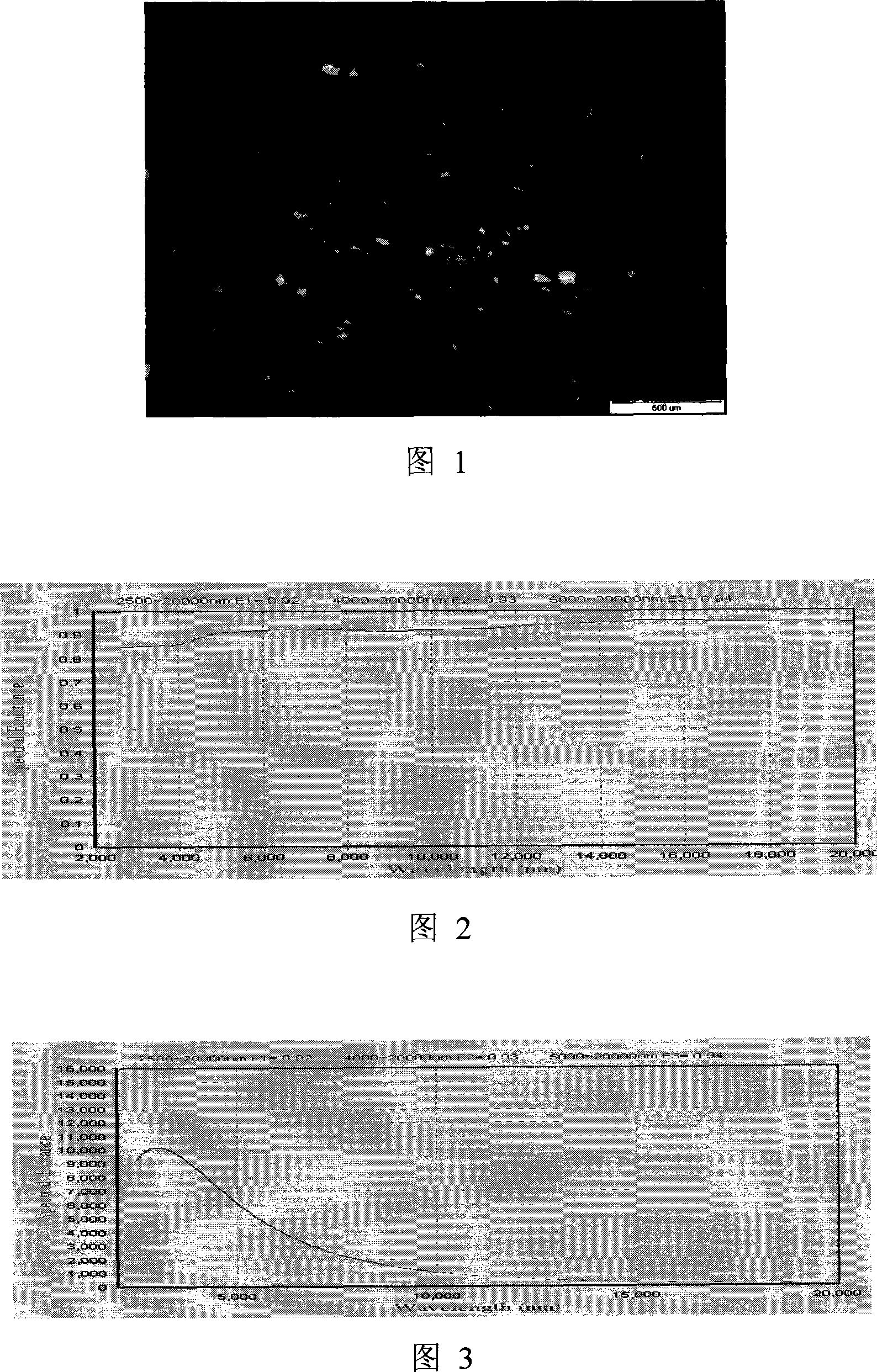

Infrared radiation porous ceramics on furnace lining firebrick and preparation method thereof

The invention relates to an infrared radiation porous ceramic used on the surface of lining firebrick and preparation method thereof. Slurry of the porous ceramic is made of aggregate and binder. The aggregate is made of the following compositions: light floating bead with 20-45 percent, Suzhou earth with 20-40 percent, aluminum oxide micro bead 5-15 with percent, magnesium oxide with 5-12 percent, high emissivity material with 5-15 percent, and coal powder with 1-5 percent. The preparation steps are as follows: 1. separate ball milling of Suzhou earth, magnesium oxide, high emissivity material to prepare for making the light floating bead and prepare for the aggregate processing; 2. the made slurry is sprayed to base, then the base is heated, sintered and cured in furnace. The invention can be sintered under a low temperature of 950-1200 DEG C and has high intensity, small density, low heat conductivity, high normal total emissivity of total infrared band 2.5-20 Mum. The invention can be made under no special equipment, is simple and practical, and can be broadly popularized.

Owner:武钢集团有限公司

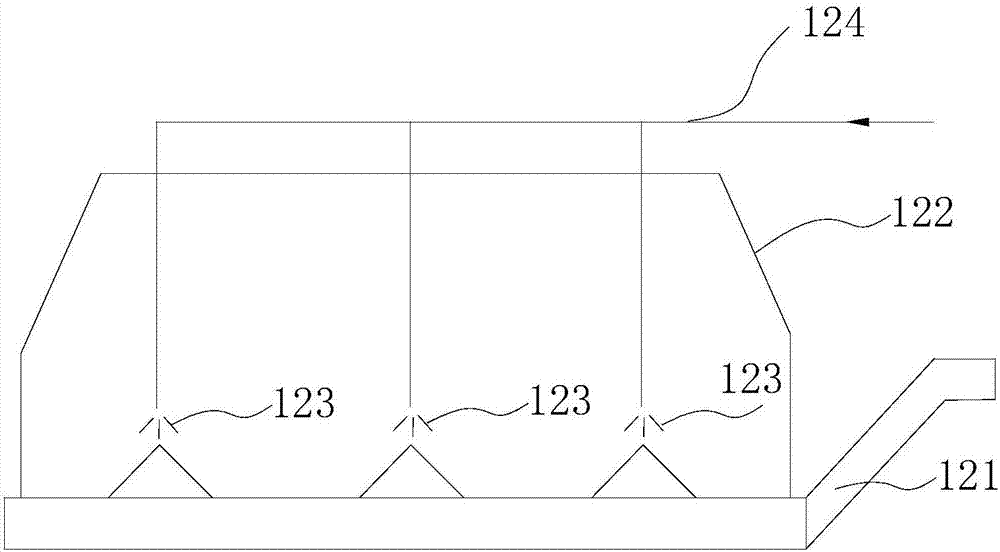

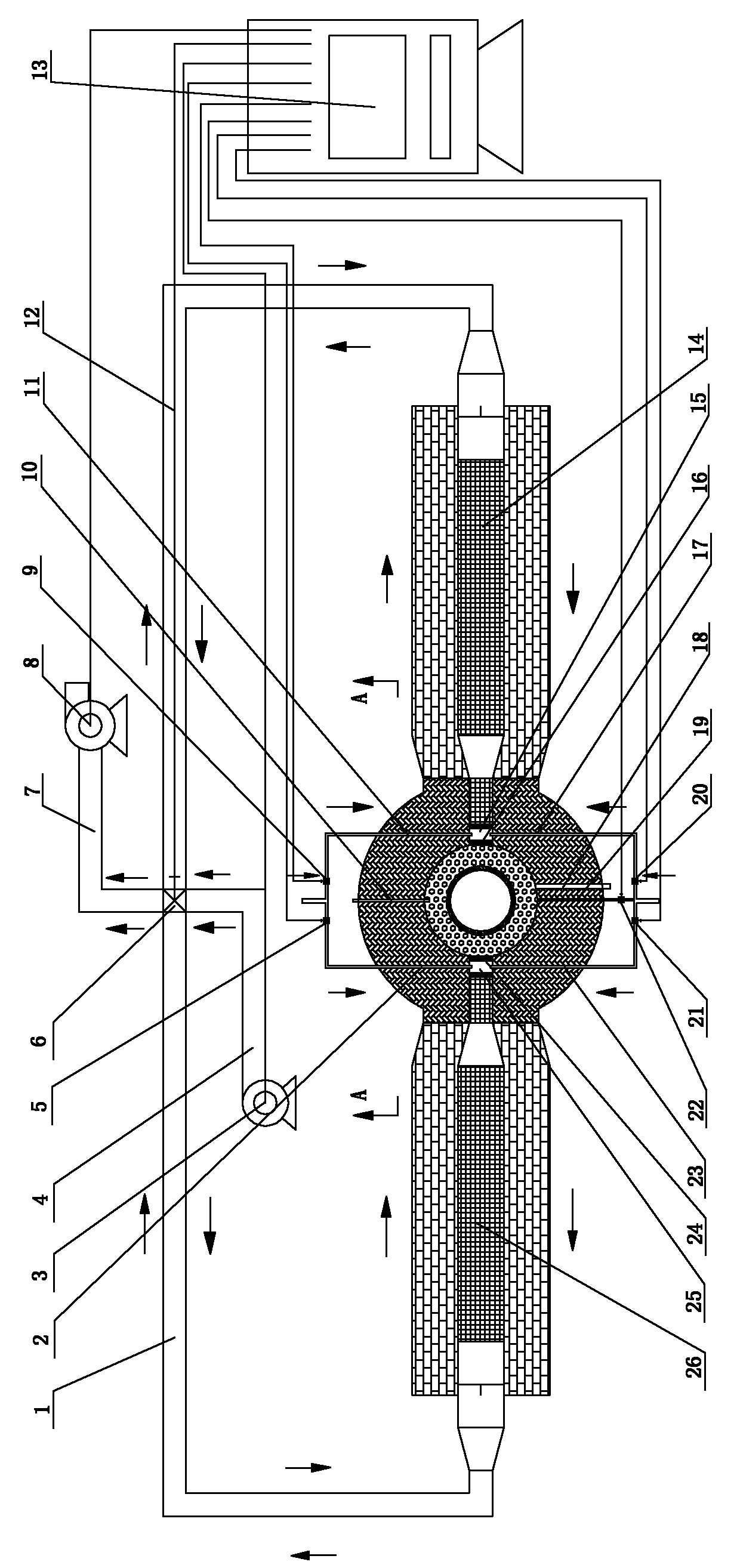

Method for reducing emission of carbon dioxide by circulating fluidized bed temperature flue gas circulation oxygen combustion

InactiveCN101634449ARealize rational utilizationHigh thermal efficiencyFluidized bed combustionDispersed particle separationResource utilizationWater vapor

The invention relates to a method for reducing emission of CO2 by circulating fluidized bed temperature flue gas circulation oxygen combustion, which is a method for realizing CO2 emission reduction applied in a circulating fluidized bed boiler based on the technology of temperature flue gas circulating oxygen combustion. The method comprises the following steps: feeding fuel and desulfurater into the circulating fluidized bed boiler, taking the gas mixture of O2 and circulating flue gas as combustion agent, passing through the heating surface at the tail by the flue gas generated by combustion, heating O2 (concentration is 96.5%-98.5%) from an air separation unit, generating temperature flue gas at the temperature of 140-150 DEG C, taking the gas mixture composed of 30%-70% of the temperature flue gas and O2 as oxidant to delivery to a furnace for combustion, carrying out dedusting by a deduster, multi-level condensation and dehydration and compression on the residual flue gas (volume concentration of CO2 is larger than 95%), and realizing resource utilization or storing in a sealing manner. The circulating glue gas is rich in vapor, entrainment unburned carbon and active desulfurater; the method enhances radiant heat exchange in the furnace, solves the problem of insufficient amount of convection heat transfer, improves combustion efficiency and desulfuration efficiency of the furnace, and can realize near-zero emission of gas pollutant; besides, the method can also lower comprehensive power consumption of space division and CO2 compression, and improve generating efficiency.

Owner:SOUTHEAST UNIV

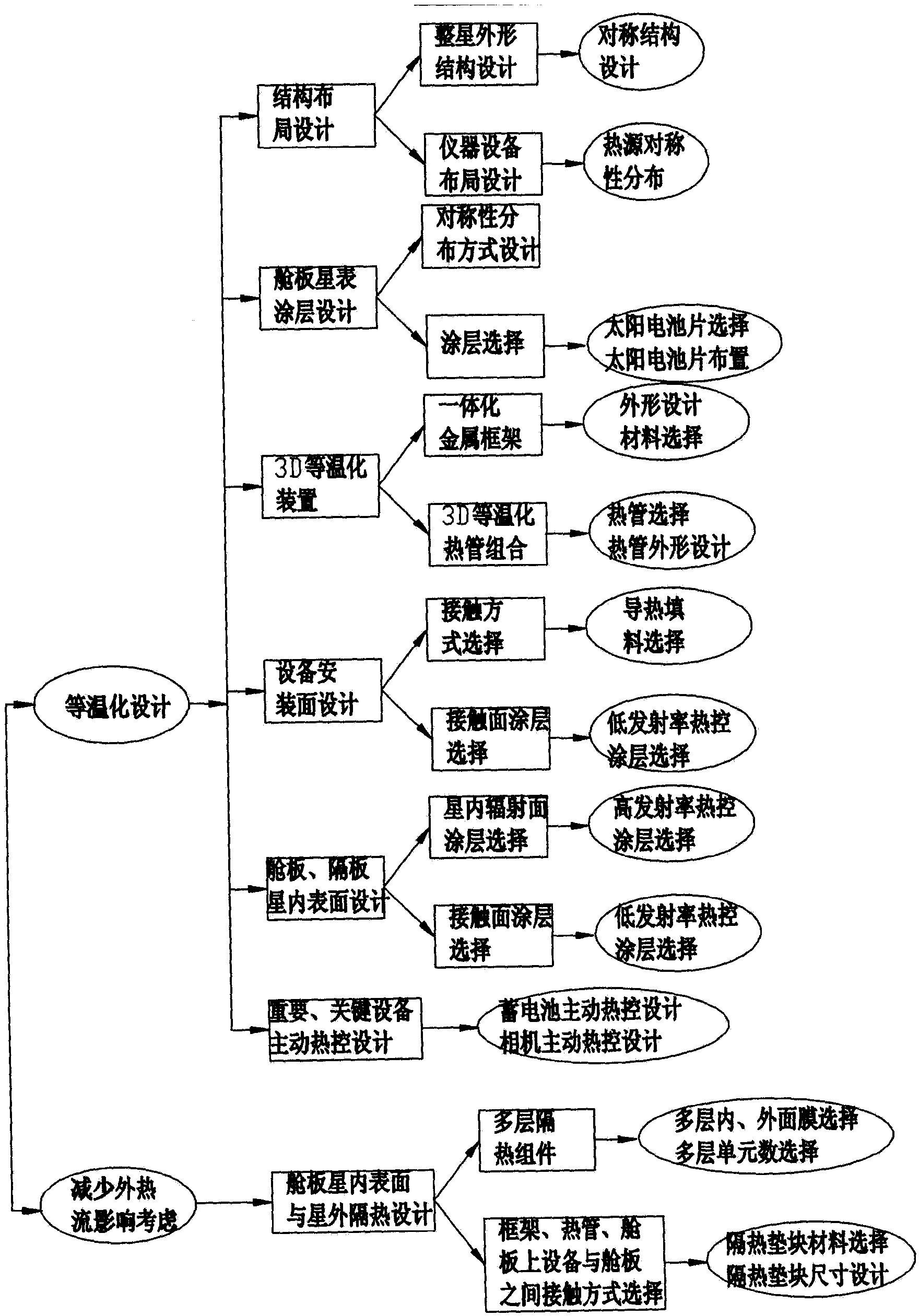

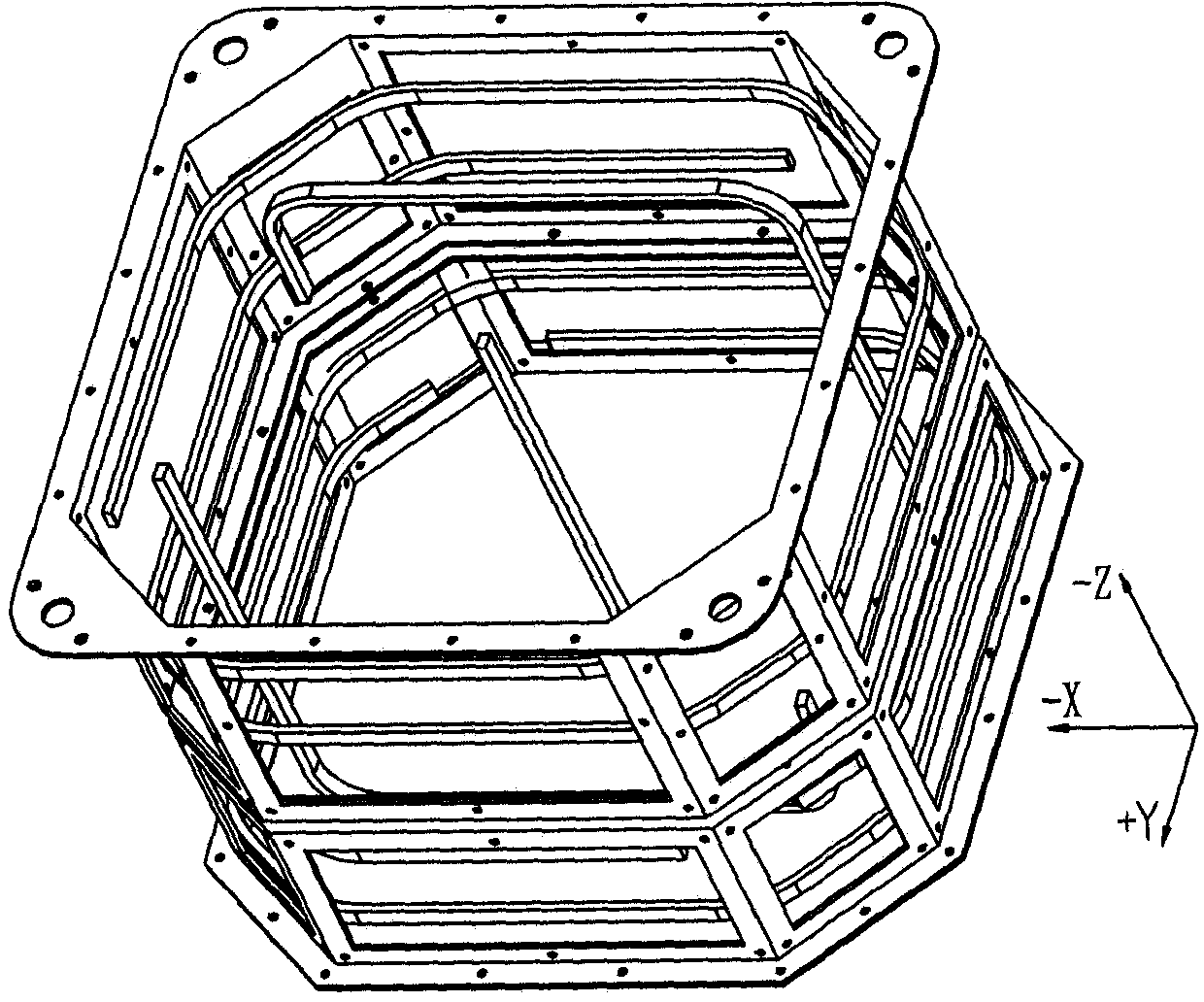

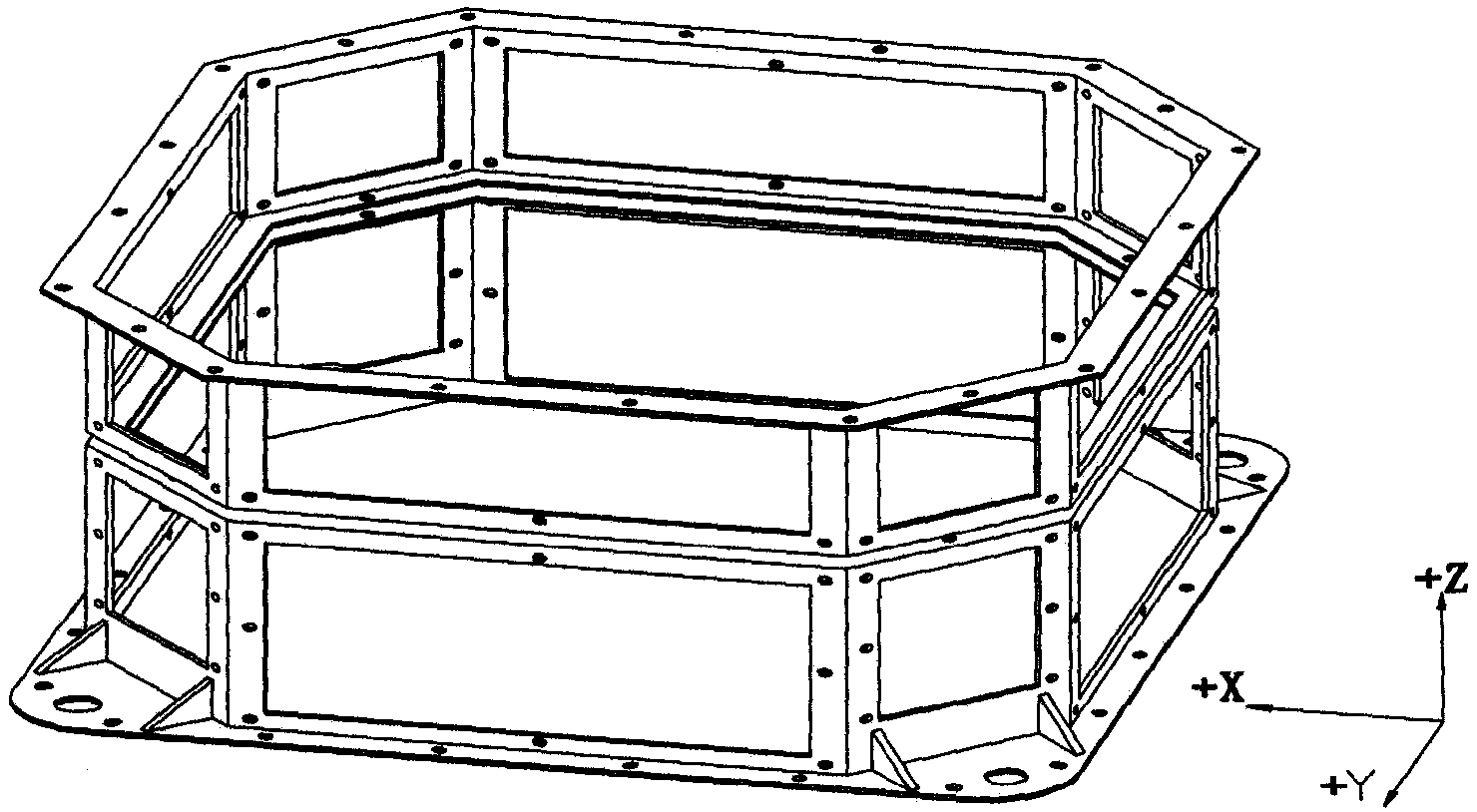

Thermal Control Method for Attitudeless Satellite

ActiveCN105659752BSolve the problem of guaranteeing temperature levelsEnhanced radiation heat transferCosmonautic environmental control arrangementSystems designGallium arsenate

The thermal control method of the non-attitude satellite, paste or spray the high-emissivity thermal control coating on the equipment in the star, fill the thermal conductive filler between the equipment installed on the partition and the installation surface, and spray the high-emissivity thermal control coating on the inner surface of the rest of the structure star Floor. The inner surface of the cabin board is covered with multi-layer heat insulation components to reduce the impact of drastic changes in heat flow outside the outer orbit of the star. Except for the installation surface of the instrument and equipment, the structural star module is pasted with third-order gallium arsenide solar cells. From the perspective of top-level system design, the present invention is based on the whole star isothermal design idea, fully utilizes the whole star structure heat storage, and utilizes solar cells as energy supply equipment and temperature control means at the same time, and adopts three-dimensional direction 3D isothermal heat pipe combination and integration The 3D isothermal device composed of a metal frame solves the problem of ensuring the temperature level of the entire satellite when there is no attitude control.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

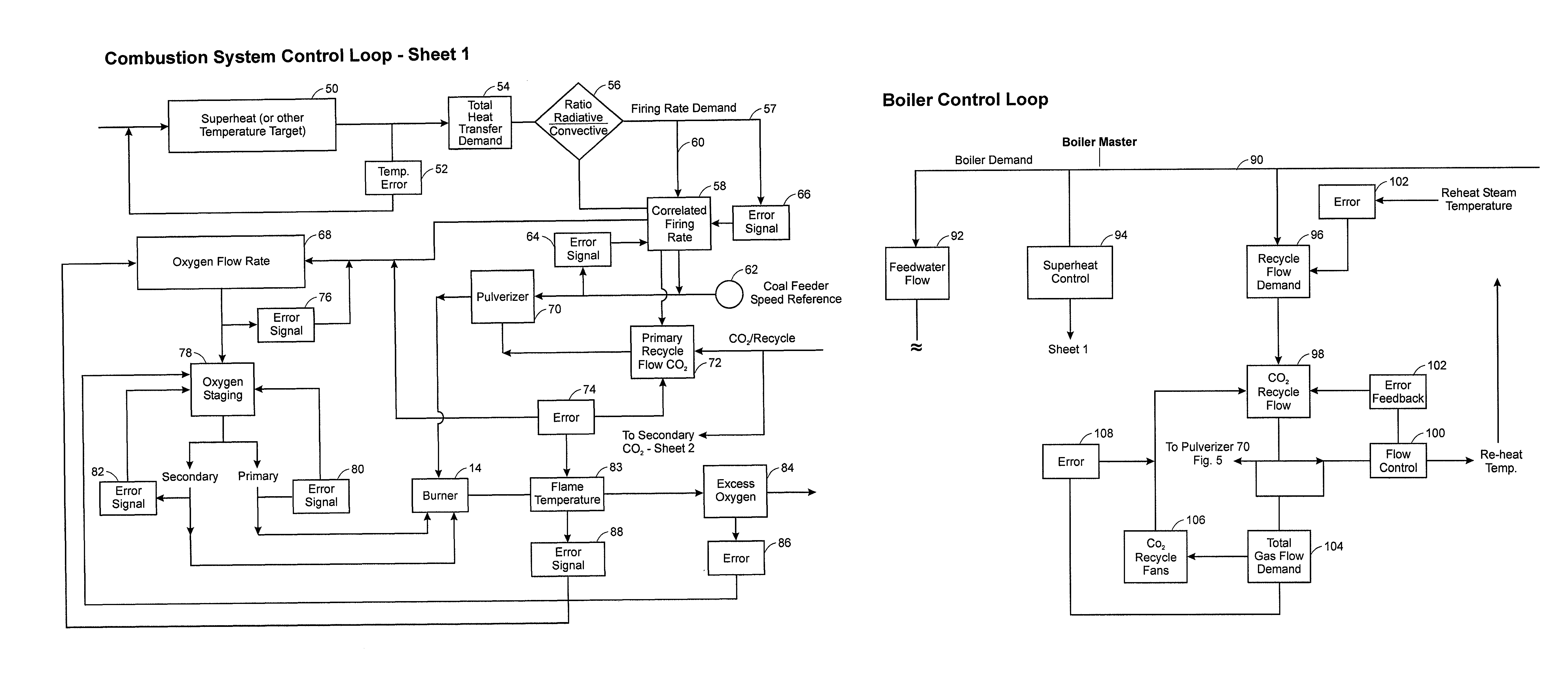

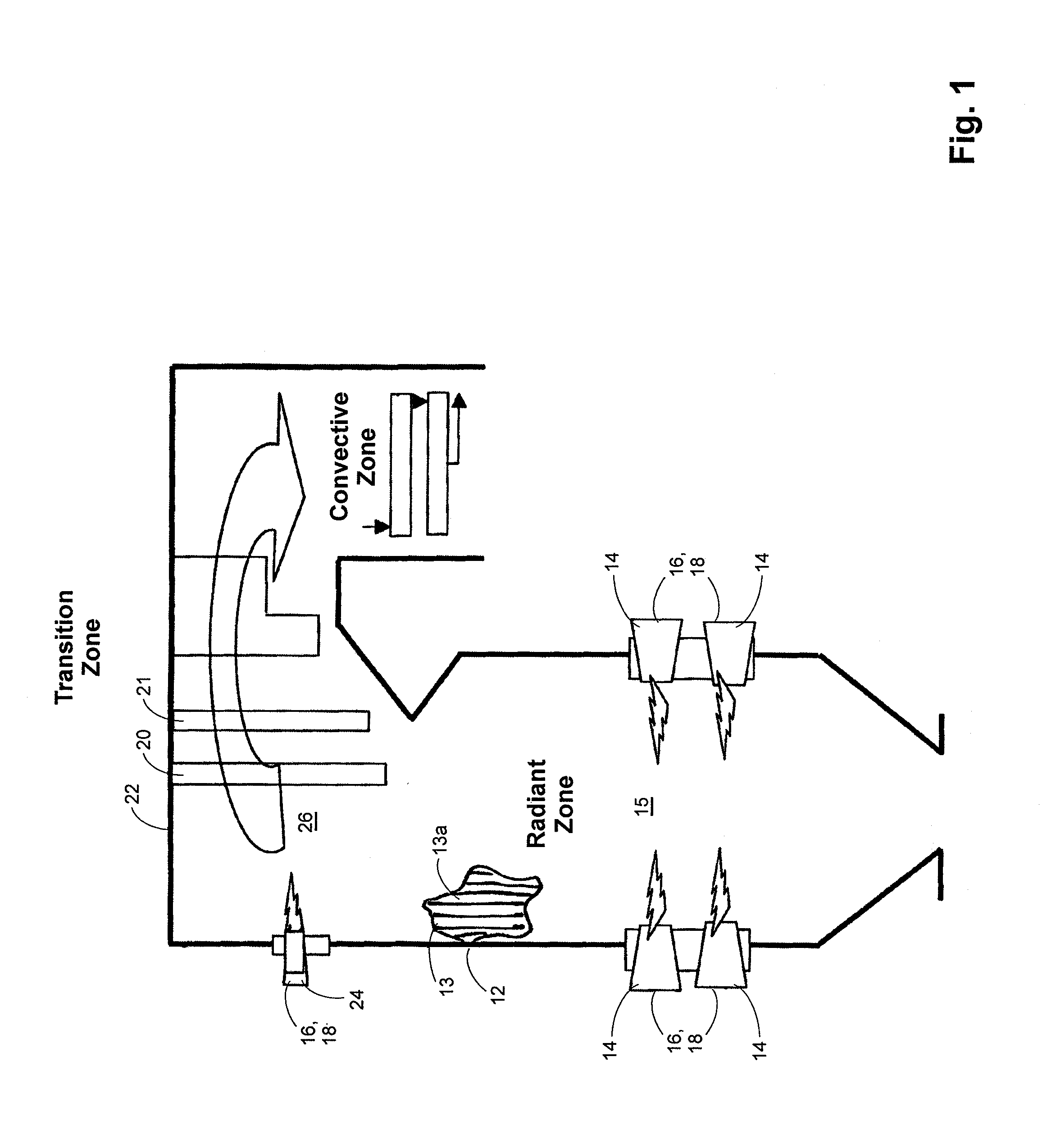

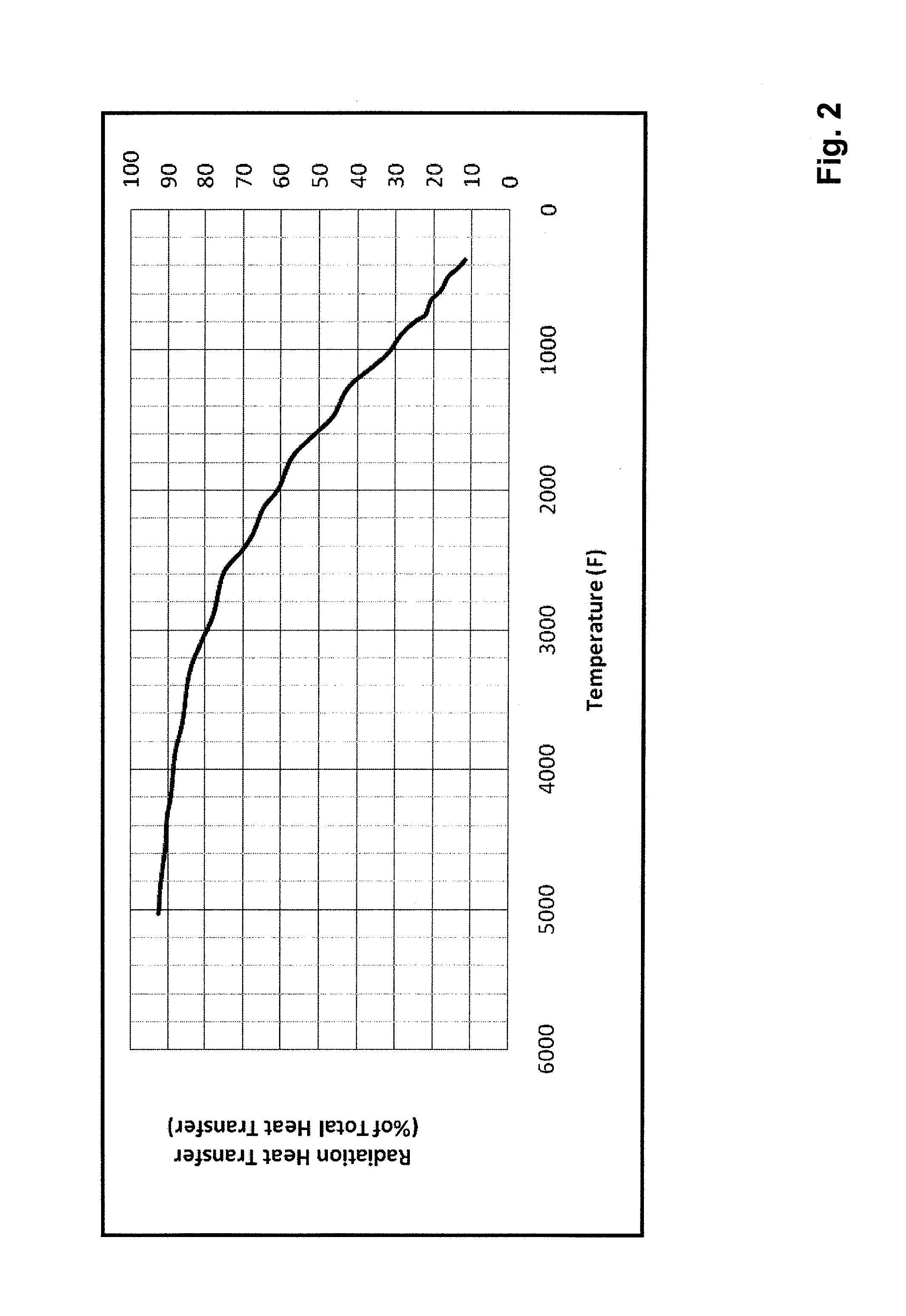

Oxy-fuel combustion system with closed loop flame temperature control

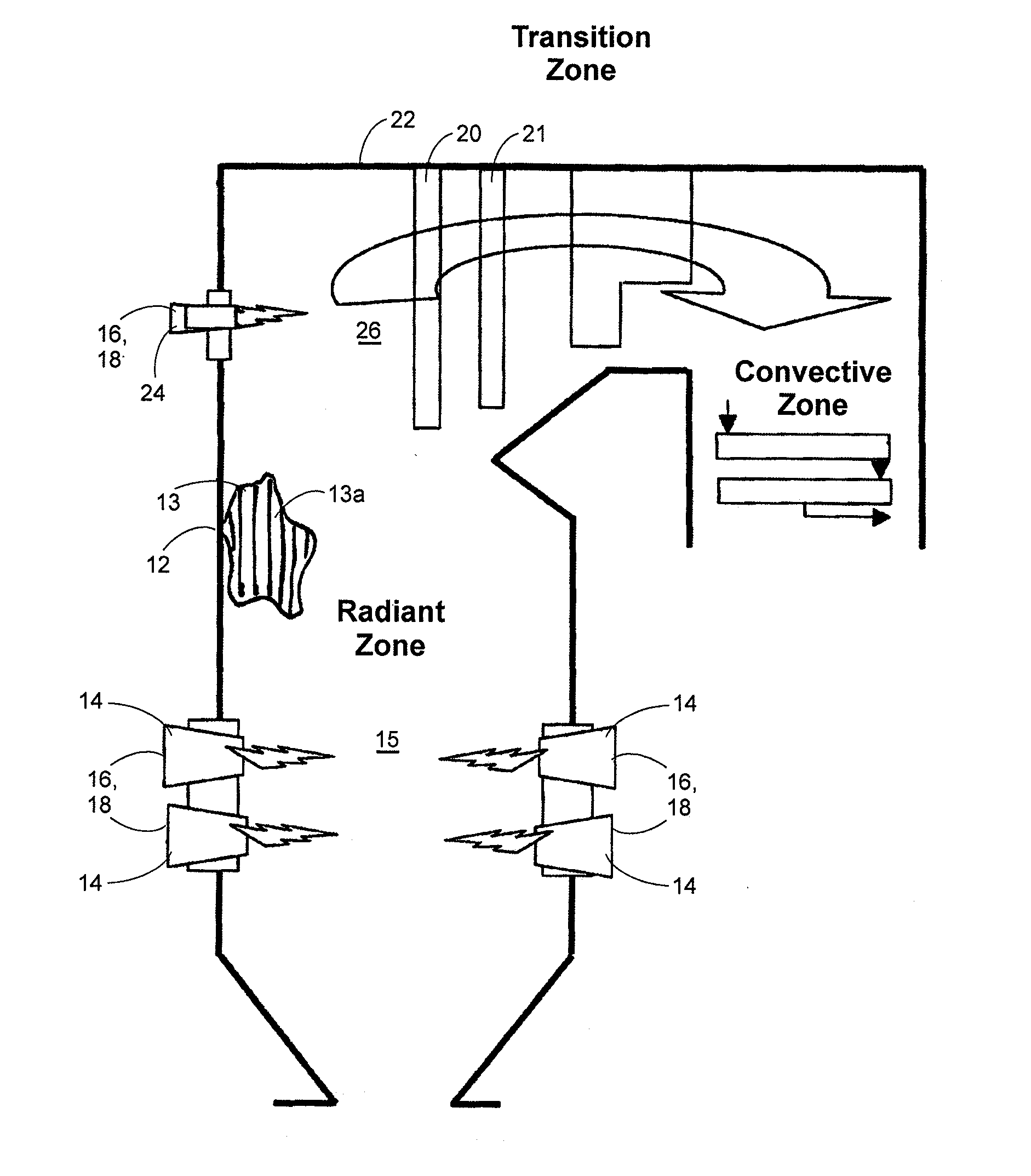

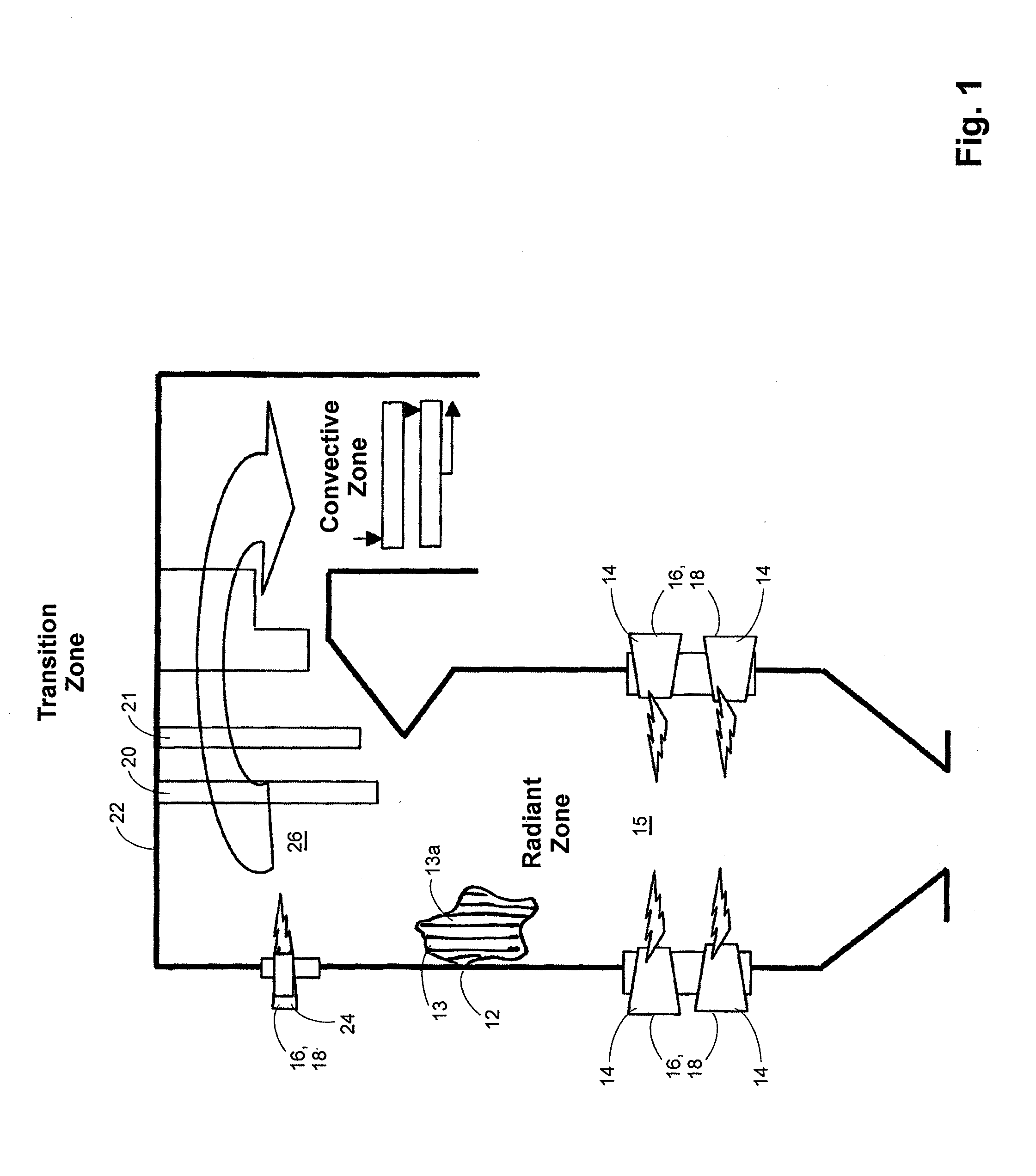

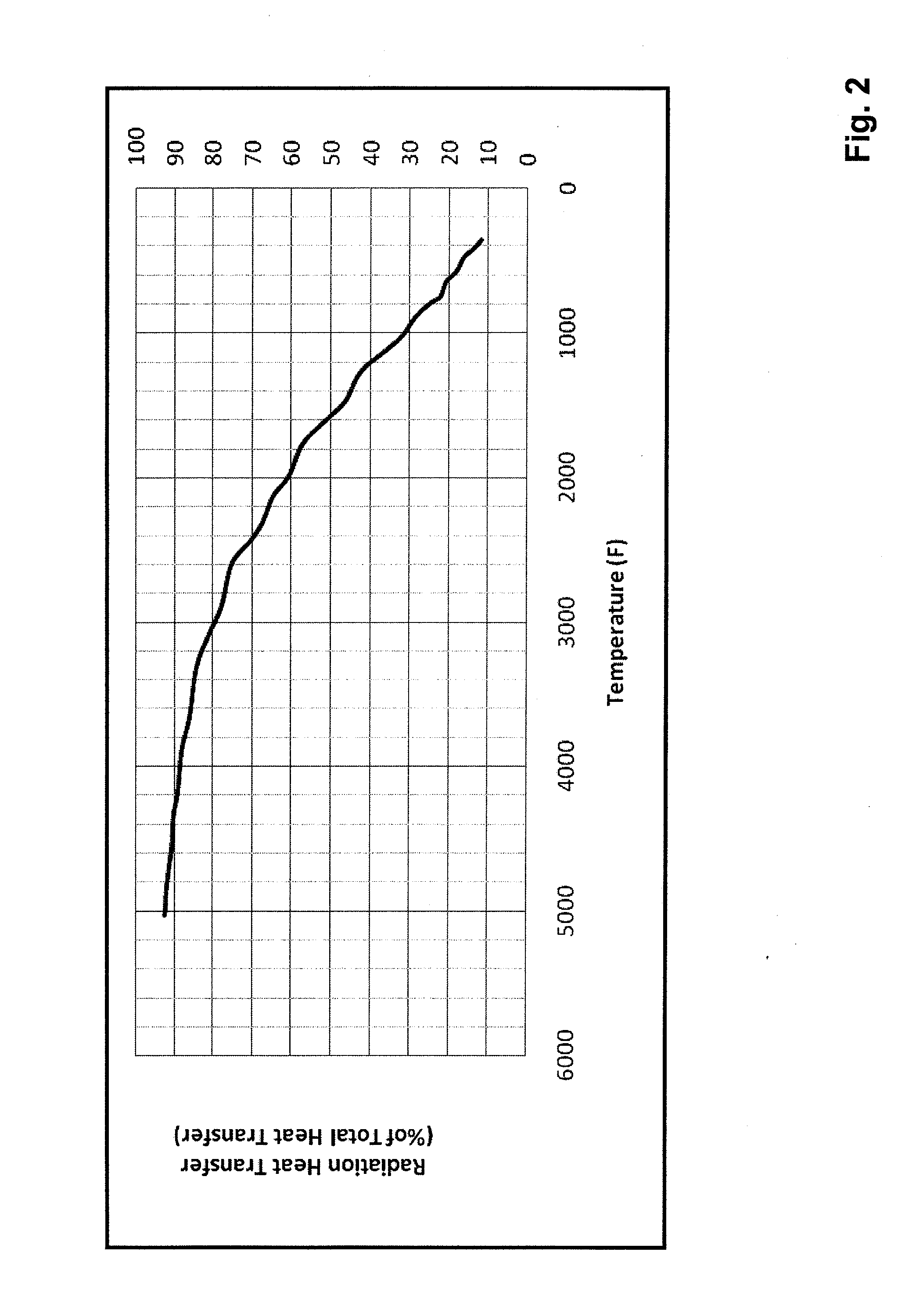

ActiveUS20100062381A1Improve efficiencyMaximize flame temperatureFuel supply regulationFurnace typesOxy-fuelEngineering

A control system for an oxy-fuel combustion process is disclosed for use with a boiler or furnace which dynamically controls the flame temperature of each burner involved in the combustion process to dynamically maximize the flame temperature. The boiler or furnace used in conjunction with the combustion process in accordance with the present invention is configured with a radiant, i.e. line of sight, heat zone and a convective heat zone. By dynamically maximizing the flame temperature of the various burners within the boiler or furnace, the radiant heat transfer is optimized. By optimizing the radiant heat transfer within the boiler or furnace, the efficiency of the boiler or furnace is significantly improved.

Owner:JUPITER OXYGEN CORP

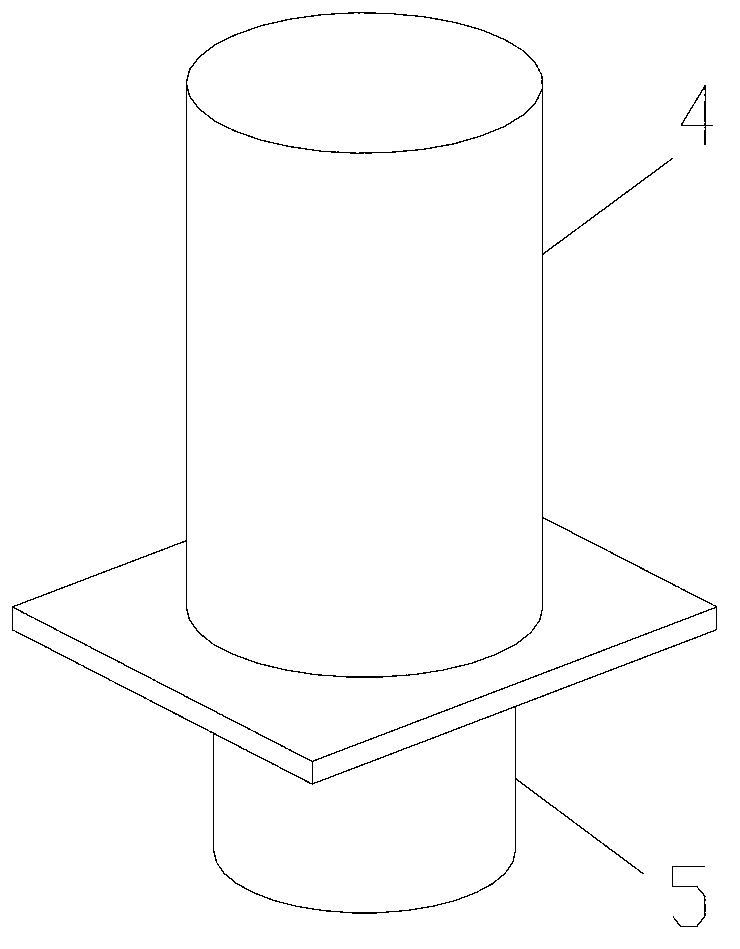

Biomass fuel combustion device

ActiveCN101839475ASlight disturbancePromote combustionDouble grateSolid fuel combustionCombustion chamberPollutant emissions

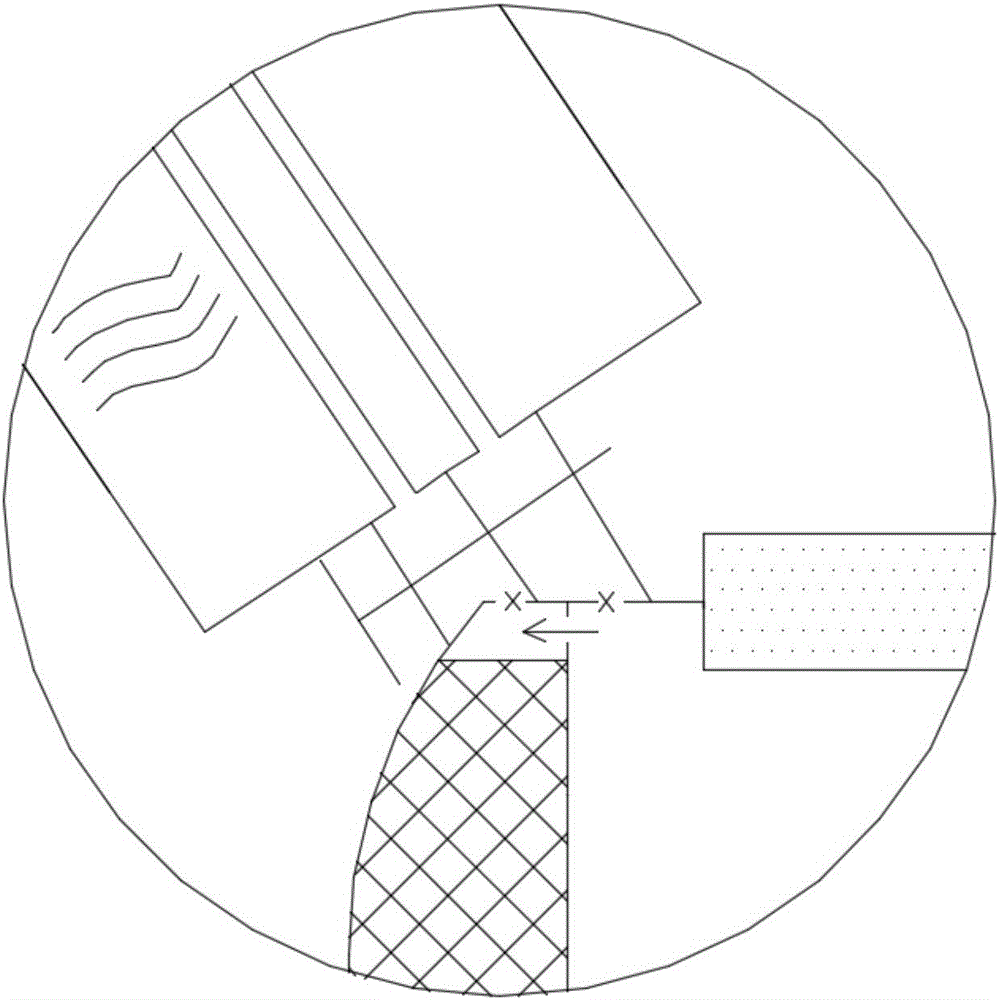

The invention discloses a biomass fuel combustion device, and provides a biomass fuel combustion device which has the advantages of high combustion efficiency and less pollutant discharge. The biomass fuel combustion device of the invention comprises a vertical combustion furnace (1), wherein a smoke discharging channel (2) is arranged on the vertical combustion furnace (1); a combustion chamber (20) and a heat exchange chamber (21) are arranged in the vertical combustion furnace (1); an upper grate (3) and a lower grate (4) are arranged in the combustion chamber (20); the combustion chamber (20) is provided with a feeding device which is positioned on the side wall of the vertical combustion furnace (1) and is communicated with the combustion chamber (20); a primary air inlet (33), a secondary air inlet (34) and a tertiary air inlet device are respectively arranged in the corresponding positions of the vertical combustion furnace (1); a smoke pipe (5) and a hot water pipe (6) are arranged in the heat exchange chamber (21); and the smoke pipe (5) is respectively communicated with the combustion chamber (20) and the smoke discharging channel (2) through gas flow. The invention can be widely applied to the field of boilers.

Owner:湖南兆丰新能源技术有限公司

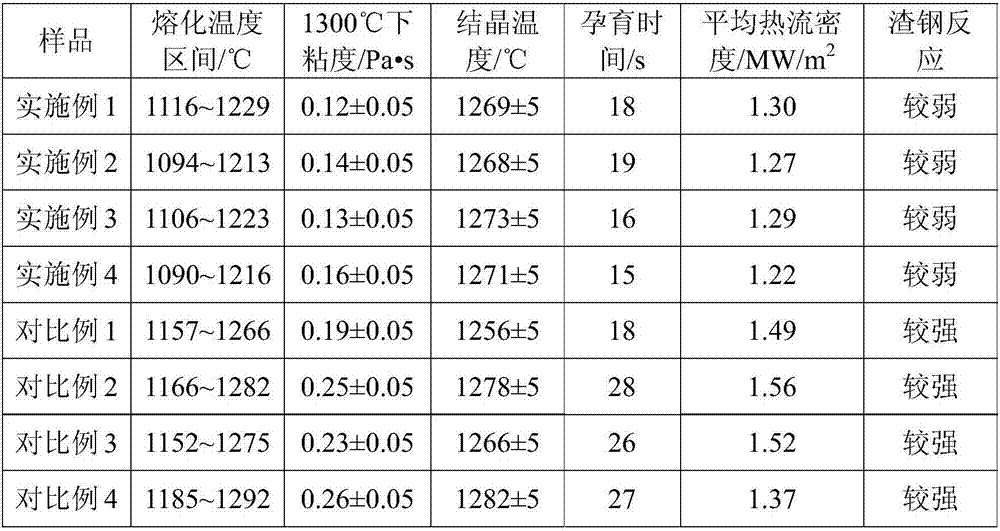

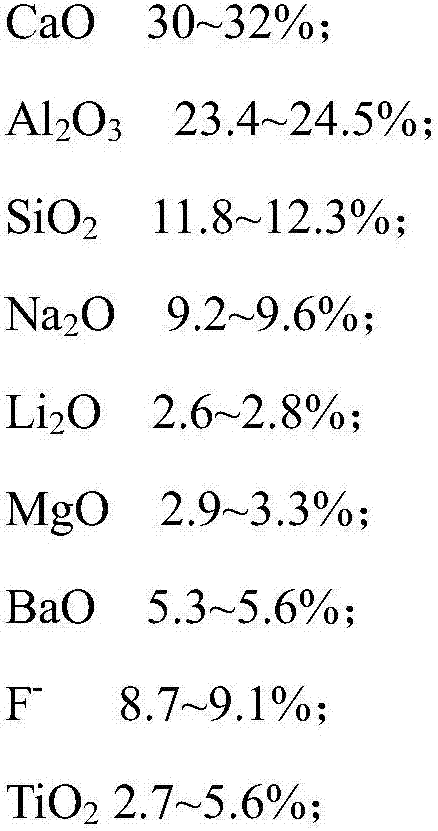

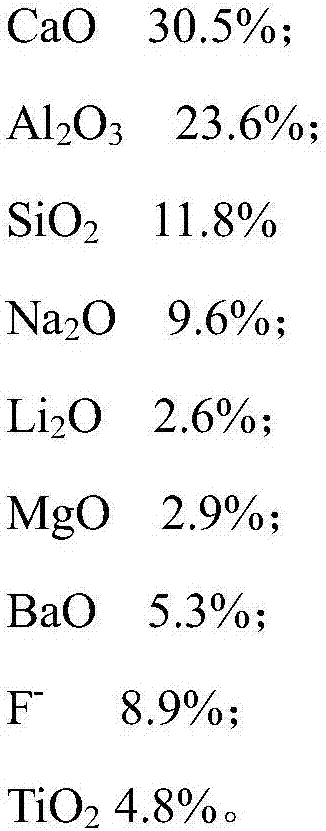

TiO2 containing high-aluminum steel protection slag and application thereof

The invention discloses TiO2 containing high-aluminum steel protection slag. The TiO2 containing high-aluminum steel protection slag comprises following oxides including, by mass percent, 30%-45% of CaO, 16%-24.5% of Al2O3, 8%-16% of SiO2, 8%-15% of Na2O, 1%-5% of Li2O, 2%-6% of MgO, 3%-7% of BaO, 6%-10% of F<-> and 2.7%-7% of TiO2, and (CaO+BaO) / Al2O3 ranges from 1.0 to 2.1. The protection slag is low in melting point and viscosity, and the crystallization property is good. The protection slag is particularly suitable for continuous casting of high-aluminum steel with the Al mass percent content ranging from 1.5% to 2.5%. When the protection slag is used, the slag steel reaction degree in the continuous casting process can be effectively weakened, and the crystallization property and the lubricating property of the protection slag in the continuous casting process become more stable; and the probability that concaves, cracks, inclusions and other quality defects happen to the surfaces of casting blanks is greatly reduced.

Owner:CENT SOUTH UNIV

High-temperature low-tar biomass gasifier

InactiveCN101280199ARaise the gasification reaction temperatureIncrease disturbanceCatalytic crackingSpecial form destructive distillationSlagTar

Disclosed is a high temperature low tar biomass gasification device which is characterized in that the gasification device is composed of the sequential connection of a feeding unit, a gasifier, a tar catalytic cracking reaction cylinder and a heat exchanger; the gasifier is designed to the sleeve structure through an inner cylinder and an outer cylinder; an annular hollow cavity is formed between the inner cylinder and the outer cylinder; a preheating hopper which is hoisted on the lower end surface on top of the gasifier and communicated with the feeding unit is arranged in the inner cylinder; the bottom part of the inner cylinder is a slag storage chamber; the annular hollow cavity is used as the preheating cavity of the gasification agent; the inlet of the gasification agent is communicated with the annular hollow cavity; the outlet of the annular hollow cavity is the vent hole arranged on the lateral wall of the slag storage chamber; the combustion gas generated in the inner cylinder leads to the tar catalytic cracking reaction cylinder through the combustion gas outlet; the heat exchange medium is the generated combustion gas in the tar catalytic cracking reaction cylinder and the cold gasification agent; the gasification agent outlet of the heat exchanger is communicated with the gasification agent inlet of the gasifier. The high temperature low tar biomass gasification device has the advantages of avoiding the external heat source, simple and compact structure, improving the heat value of the combustion gas, improving the gasification efficiency and lowering the tar content obviously.

Owner:HEFEI UNIV OF TECH

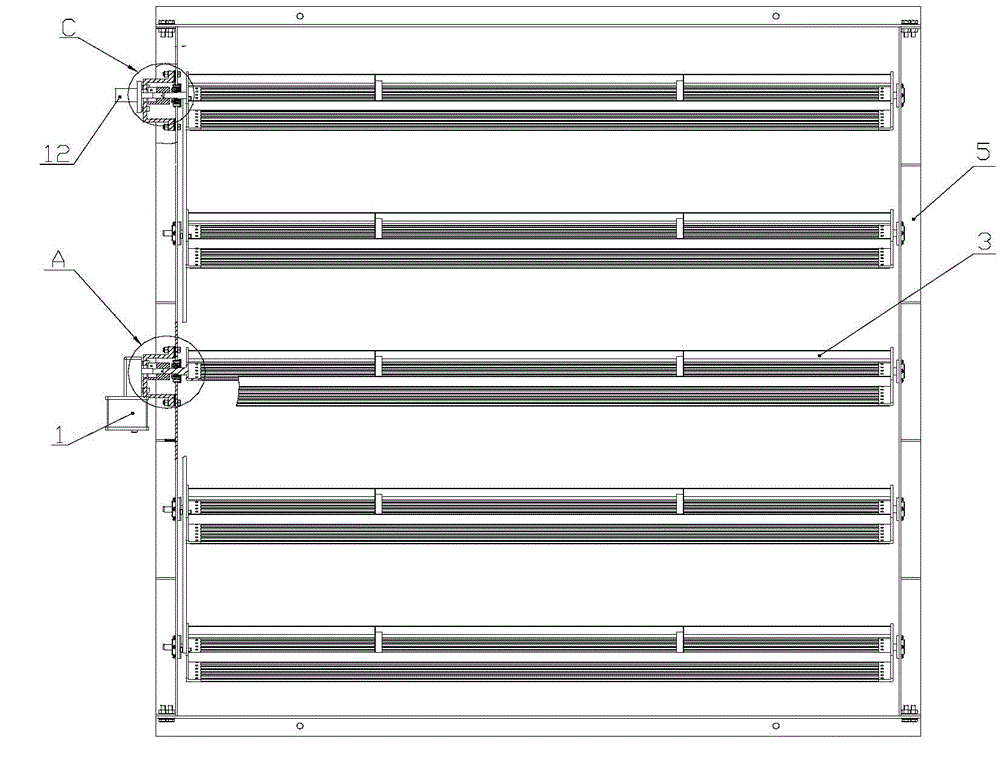

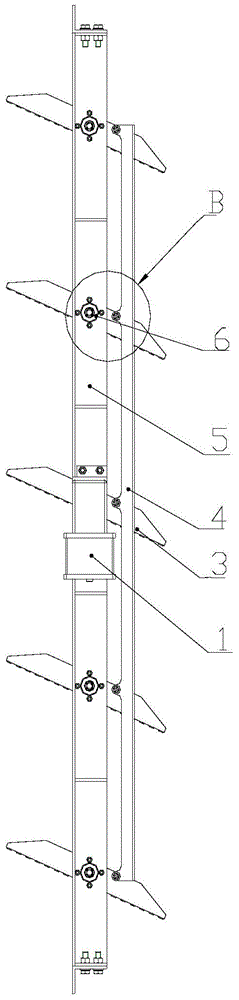

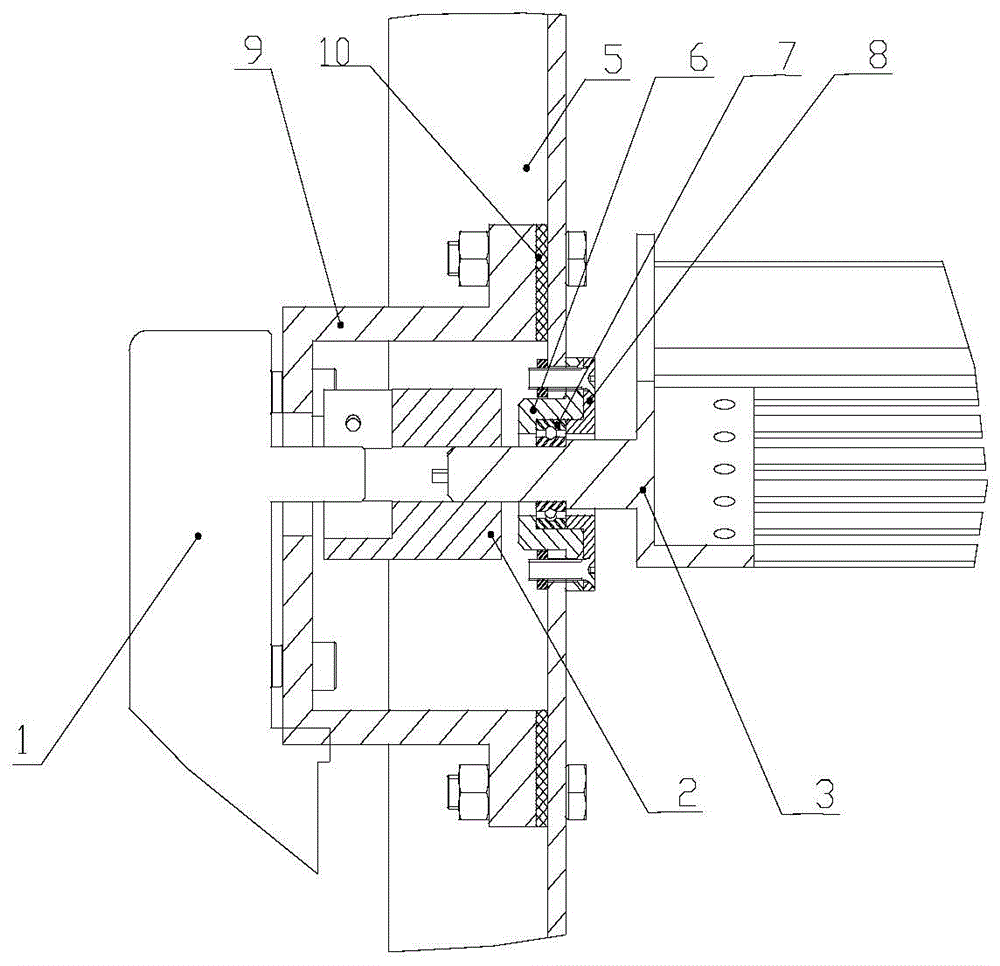

Shutter type rotatable infrared heating cage

InactiveCN106275523ALow temperature rangeSlow coolingCosmonautic condition simulationsOhmic-resistance heatingCouplingEngineering

The invention discloses a rotatable shutter type infrared cage used in a vacuum heat test process of a spacecraft. The rotatable shutter type infrared cage mainly comprises an infrared cage main framework, a gear motor, a coupling, connecting rods, pin shafts, heating assemblies, bearings, bearing seats, and an angle sensor, wherein a motor mounting seat of the gear motor is arranged on the side surface of the main framework; an output shaft of the gear motor on the motor mounting seat is coaxially connected with one of infrared heating units through the elastic coupling; a plurality of infrared heating units are connected through the connecting rods in parallel connection and are separately fixed through the pin shafts; when the connecting rods in parallel connection, the pin shafts and the heating units are combined together, all the heating units can form a parallel connection mechanism, and under the action of the connecting rods in parallel connection, the heating units synchronously rotate. During simulation of low-temperature environment, the heating units rotate through driving units, so that heating tapes rotate by 90 degrees, heating tape surfaces are vertical to the surface of the spacecraft, the shielding of heating tape strips to the spacecraft is reduced, the area of the spacecraft relative to heat sink radiation is enlarged, and the temperature falling rate of the spacecraft is increased.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

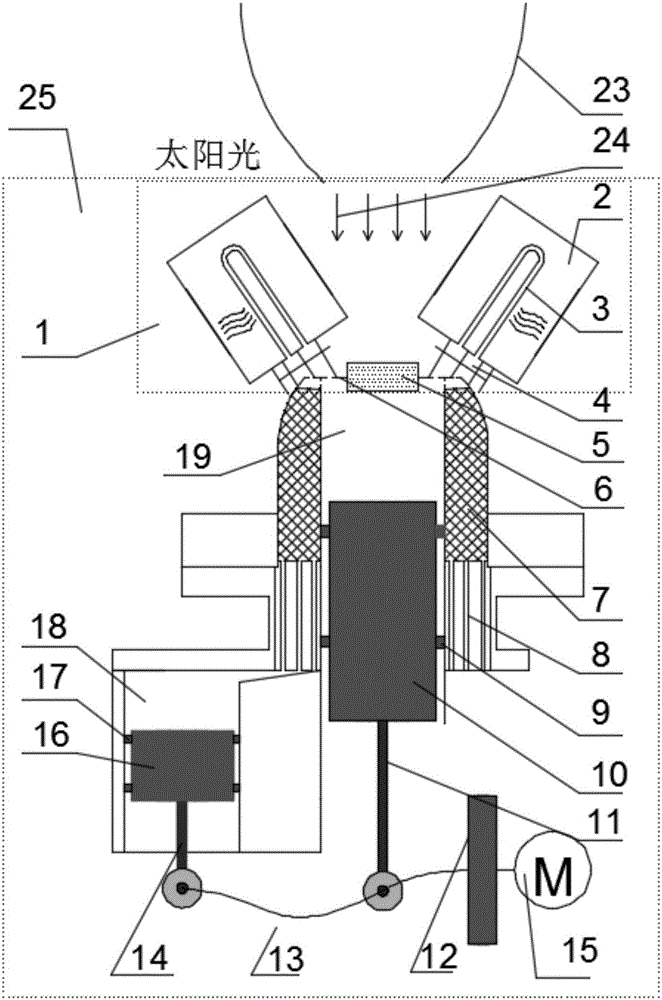

Characteristic absorption spectrum radiation heat absorber, Stirling engine and operation method

ActiveCN106089612AFast absorptionEffective absorptionSolar heating energyFrom solar energyEngine efficiencyCombustion chamber

The invention relates to a characteristic absorption spectrum radiation heat absorber, a Stirling engine and an operation method. By means of the radiation heat absorber, radiation energy can be fast absorbed by working medium gas in the Stirling engine, and when solar energy is insufficient, stable operation of the Stirling engine is ensured by adopting an auxiliary heating mode. A fast heat absorbing heater adopting characteristic absorption spectrum gas to absorb heat mainly comprises a heater base, an optical energy converting device, a heating tube, a combustion chamber and a heating tube valve. The optical energy converting device converts solar energy into radiation energy adjacent to a characteristic absorption peak of the working medium gas, and the working medium directly absorbs radiation energy stereoscopically. The radiation heat absorber is beneficial for enhancing radiation heat exchange at the hot end of the Stirling engine, efficiently using high-temperature energy of a focus sunlight center and reducing the dead volume of the hot end, solves the tube bursting problem of the Stirling heater, improves the engine efficiency, achieves photo-thermal complementary utilization and improves stability of the engine.

Owner:ZHEJIANG UNIV

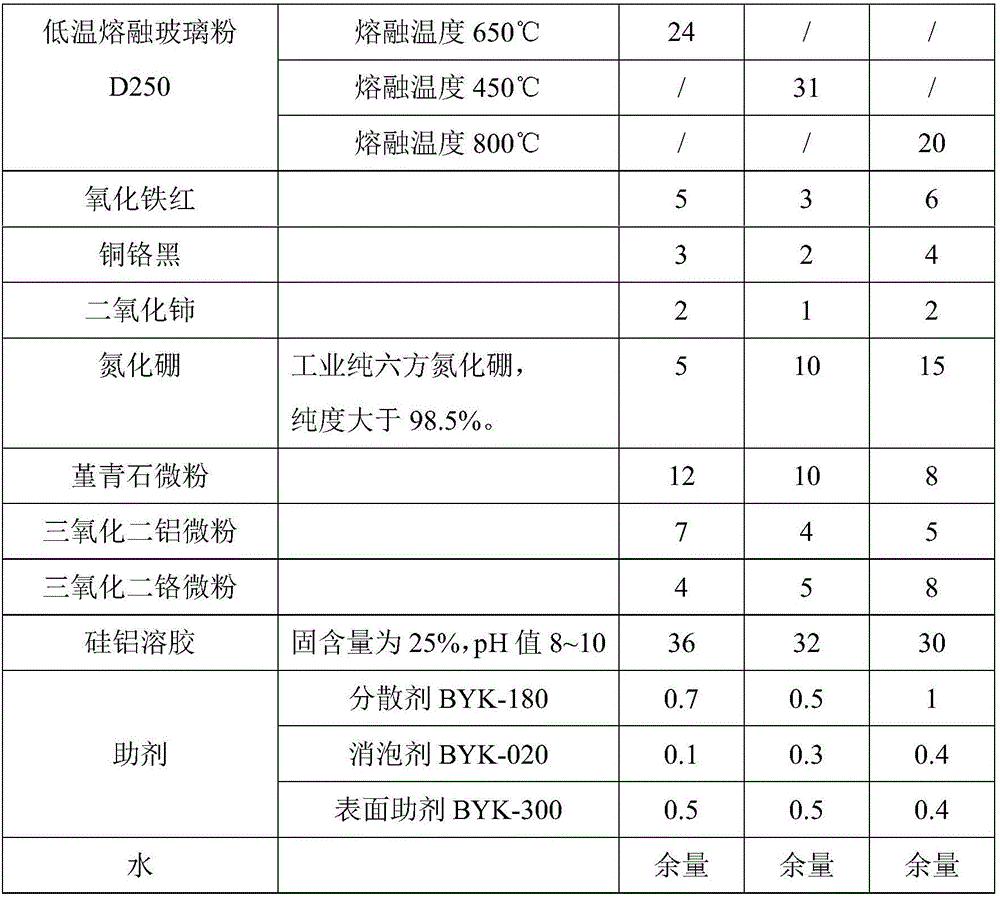

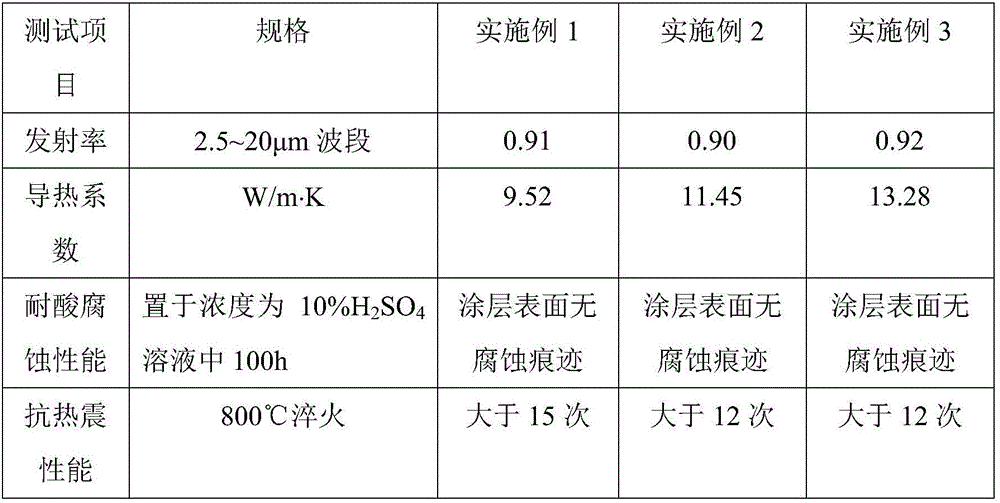

Low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and preparation method and application thereof

The invention discloses a low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and a preparation method and an application thereof. The paint comprises the following raw materials: low-temperature molten glass powder, iron oxide red, copper-chrome black, cerium dioxide, boron nitride, iolite micro powder, alumina micro powder, chromium sesquioxide micro powder, 20-50% of silicon aluminium sol, 0.5-3% of an auxiliary agent, and the balance of water. The method comprises the following steps: a metal matrix is processed, then the surface of the metal matrix is uniformly coated with a paint and dried in shade; and the coated metal matrix is heated at the temperature of 650-900 DEG C to form the low-temperature sintering high-heat conduction ceramic paint. The paint has the advantages of easy acquisition of the raw materials and low cost, is tightly combined with the metal matrix, has effective high temperature oxidation resistance, acid corrosion resistance and abrasion resisting effects of a heating furnace flue heat exchanger on a metal heat exchanger, ceramic coating surface is smooth and clean, slag buildup of the heat exchanger is effectively reduced, the service life of the metal heat exchanger is prolonged, and the heat exchange efficiency effect is increased.

Owner:武汉钢铁有限公司

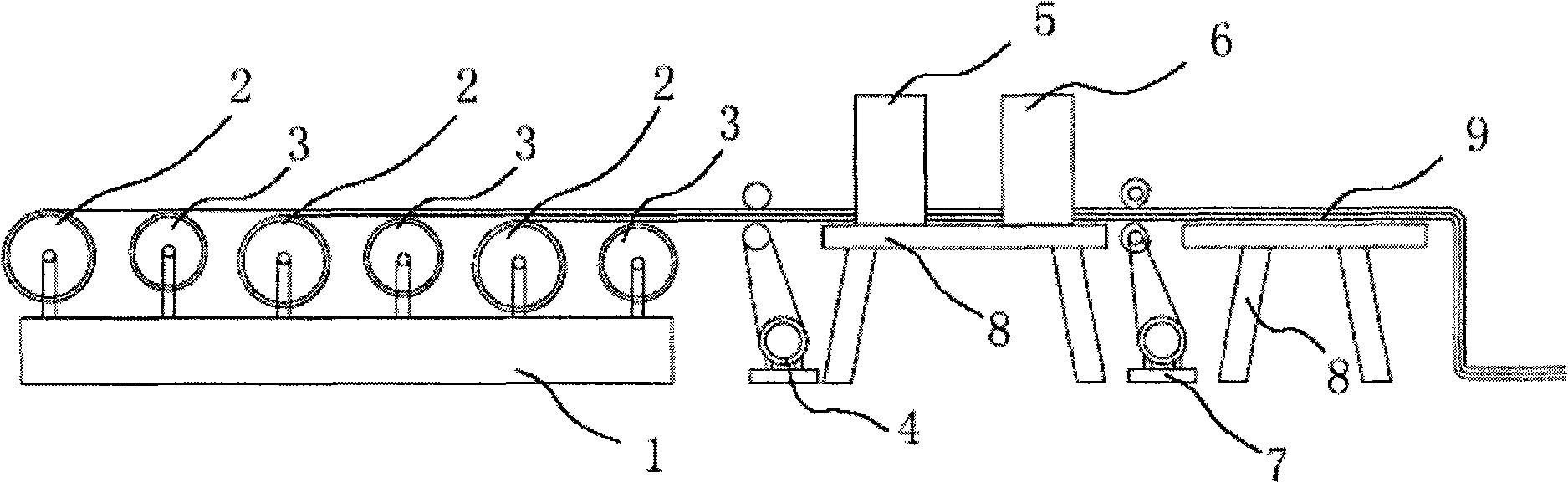

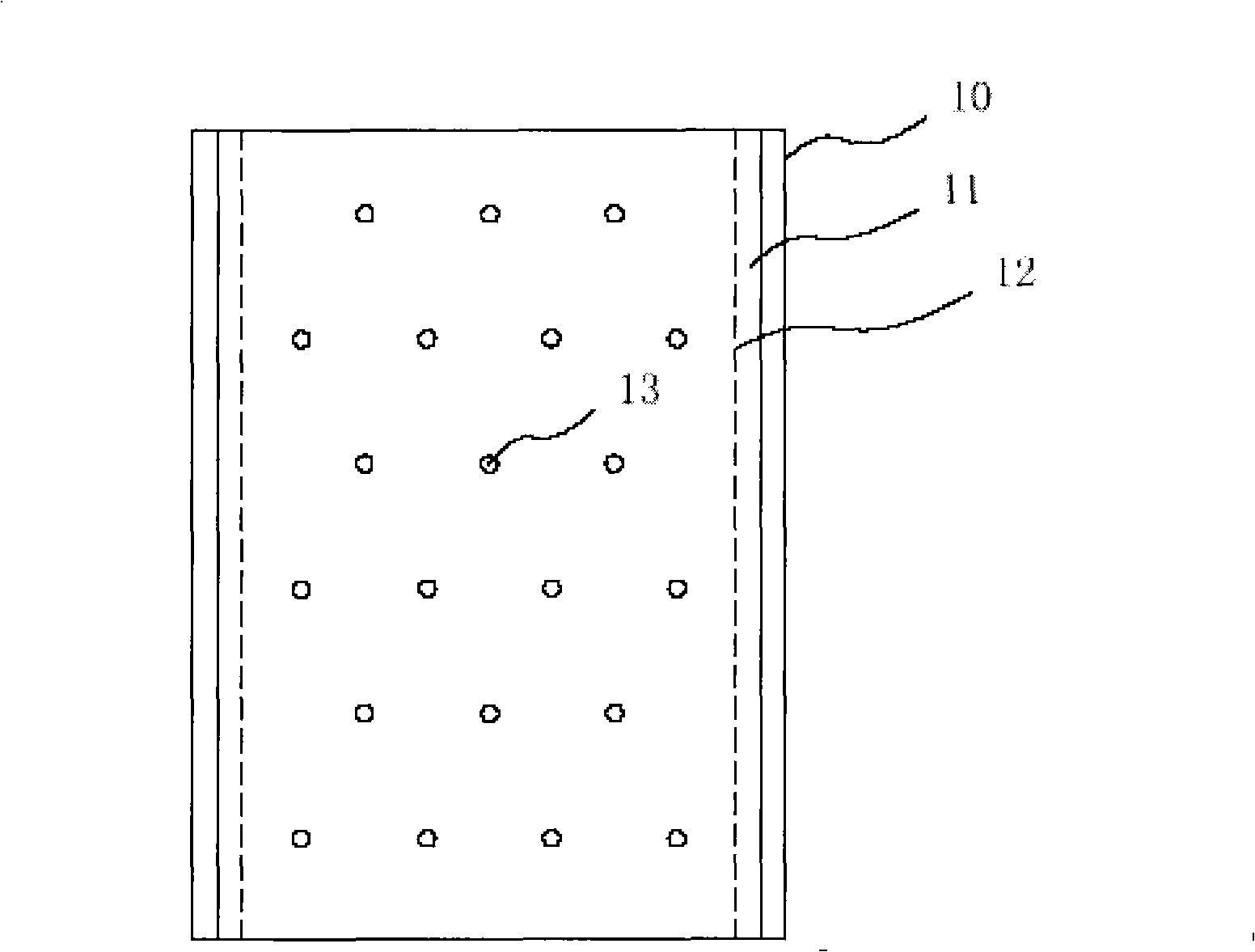

High vacuum multiple layer heat insulation quilt manufacture method

InactiveCN101285548AReduce workloadSave dressing timeThermal insulationPipe protection by thermal insulationProcess engineeringCryogenic engineering

The invention provides a method for making a microvacuum multilayer heat-insulating quilt, belonging to cryogenic engineering and cryogenic technical field. The method comprises the following steps of: preparing a mechanized production line; a plurality of reflecting layers and heat insulating layers is sewed into a quilt by seams after the plurality of reflecting layers and heat insulating layers are alternately combined on the production line according to certain requirements; and the quilt is evenly penetrated to make holes. The microvacuum multilayer heat-insulating quilt made by using the method reduces workloads for winding heat-insulating materials, shortens binding period, guarantees that the heat insulation quilt can not loose during using, and even can improve vacuumizing efficiency and maintain high vacuum degree between interlayer on the premise of a guarantee of excellent and stable heat insulation performance, thereby the method has more advantages of lot manufacturing and producing of cryogenic storage and transportation equipment, and prominent economic benefit and social benefit in cryogenic engineering.

Owner:SHANGHAI JIAO TONG UNIV

High temperature resistant far infrared nano paint and preparation method thereof

InactiveCN101602613AImprove adhesion strengthImprove thermal shock resistanceCeramicwareMetallurgyFar infrared

The invention relates to a high temperature resistant far infrared nano paint, which is made into porous ceramic with low heat conductivity and high infrared emission rate after sintering, and belongs to the technical field of high temperature resistant far-infrared paint. The component of the paint mainly comprises ZrO2, Cr2O3, Al2O3, Fe2O3, MnO2, Co2O3, MgO, Suzhou earth, bentonite, active carbon, and coal powder, and the high temperature resistant far infrared nano paint is prepared by grinding the raw materials into fine powder in nanometer stage (500nm or less), mixing them in proportion in the silicochromium aluminum composite sol and mixed solution of carboxy methyl cellulose, and forming a viscous suspension liquid. The paint can be sprayed or brushed onto the inner wall surface of the hearth after ash cleaning, and sintered in the temperature range of 900-1200 DEG C., so as to form a porous ceramic with certain strength, which is low in ceramic density, low in heat conductivity, high in 2.5-20 mu m full infrared wave band normal direction full emissivity (0.91-0.95).

Owner:张彦文

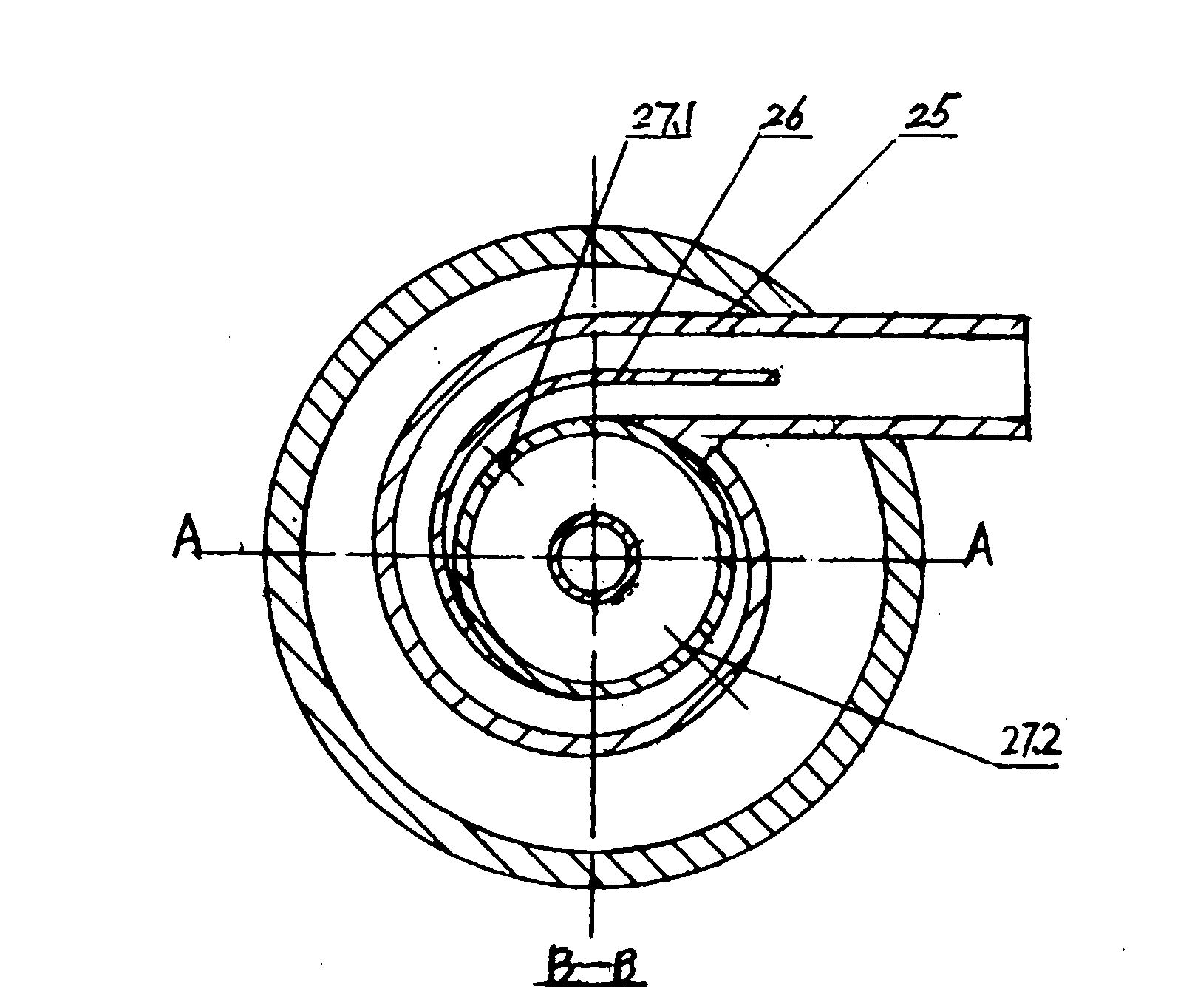

Spiral-flow type fishtail high-efficiency energy-saving burner

ActiveCN103629705AHeating up fastHeat up fastDomestic stoves or rangesStoves/ranges topsAir preheaterEngineering

The invention discloses a spiral-flow type fishtail high-efficiency energy-saving burner. The spiral-flow type fishtail high-efficiency energy-saving burner comprises a burner and a hearth. The burner comprises a spiral-flow type air register, a cylindrical channel, a return pipe, combustion gas holes and an air preheater. The hearth comprises a furnace ring and an expansion cover. The expansion cover is a hollow interlayer and comprises an inner expansion cover, a middle expansion cover and a flue gas chamber between the inner expansion cover and the middle expansion cover. An upper opening of the inner expansion cover and a lower opening of the furnace ring form an annular flue gas shunting opening and the annular flue gas shunting opening is communicated with the flue gas chamber, flue gas holes, the air preheater and a gas outlet hole. The outer wall of the middle expansion cover is provided with a hot water sleeve. The hot water sleeve is provided with a water inlet and a water outlet. A temperature-resistant heat-collection corrosion-resistant sleeve is arranged in the inner expansion cover and the lower periphery of the temperature-resistant heat-collection corrosion-resistant sleeve is provided with a flue gas backflow hole communicated with the flue gas chamber. When the spiral-flow type fishtail high-efficiency energy-saving burner burns, the flame in a fishtail shape radially burns closely to the surface of the inner expansion cover, a pan clings to the furnace ring and is closely heated and high-temperature flue gas goes through the flue gas chamber from the annular flue gas shunting opening and then enters into the air preheater to heat air so that the hearth has a high temperature, foods can be heated fast and work efficiency is high. The spiral-flow type fishtail high-efficiency energy-saving burner is environmentally friendly, saves energy, can supply hot water and can effectively improve a kitchen environment.

Owner:湖北满天星节能环保科技有限公司

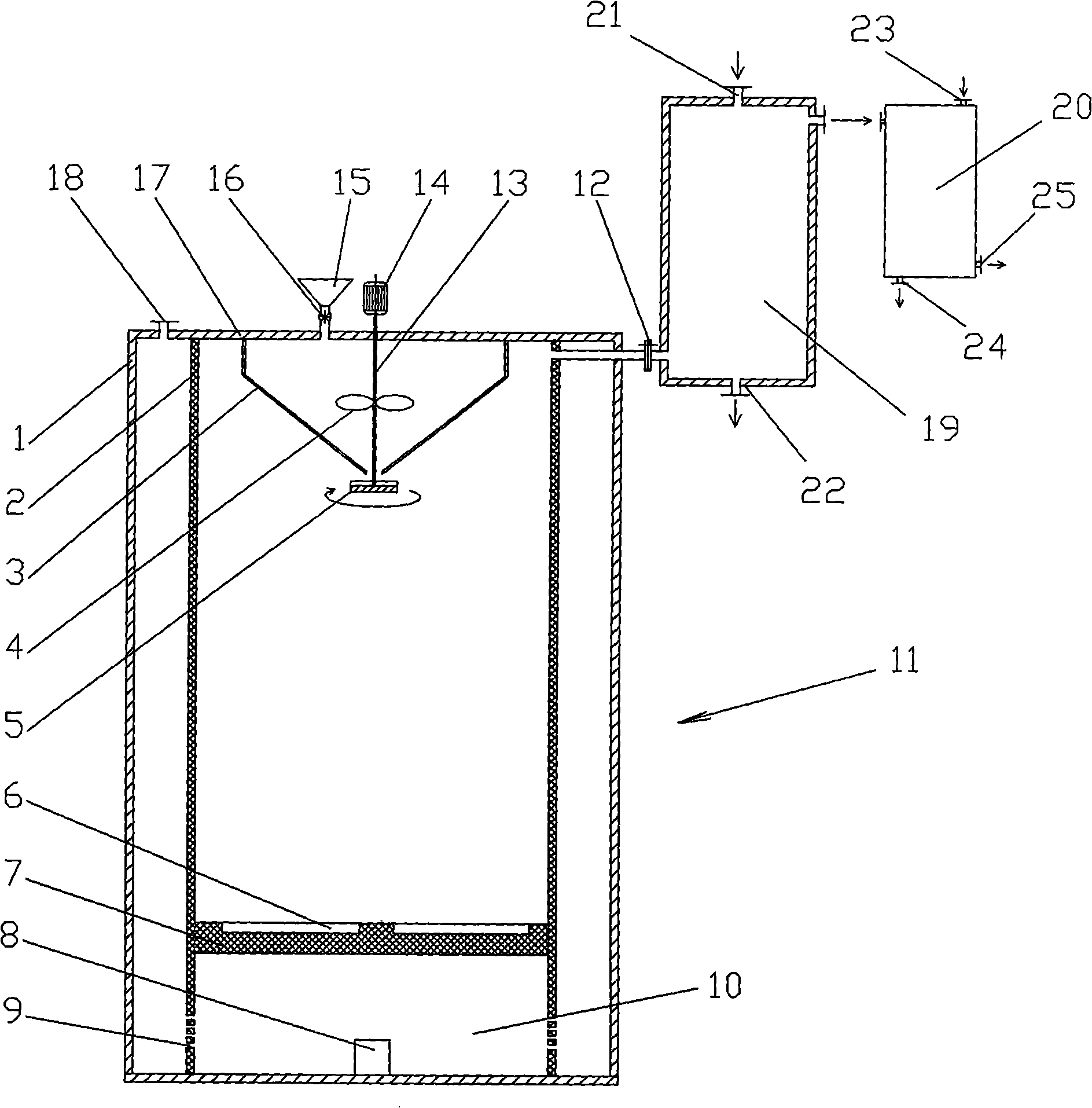

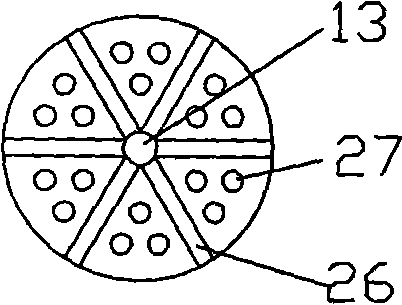

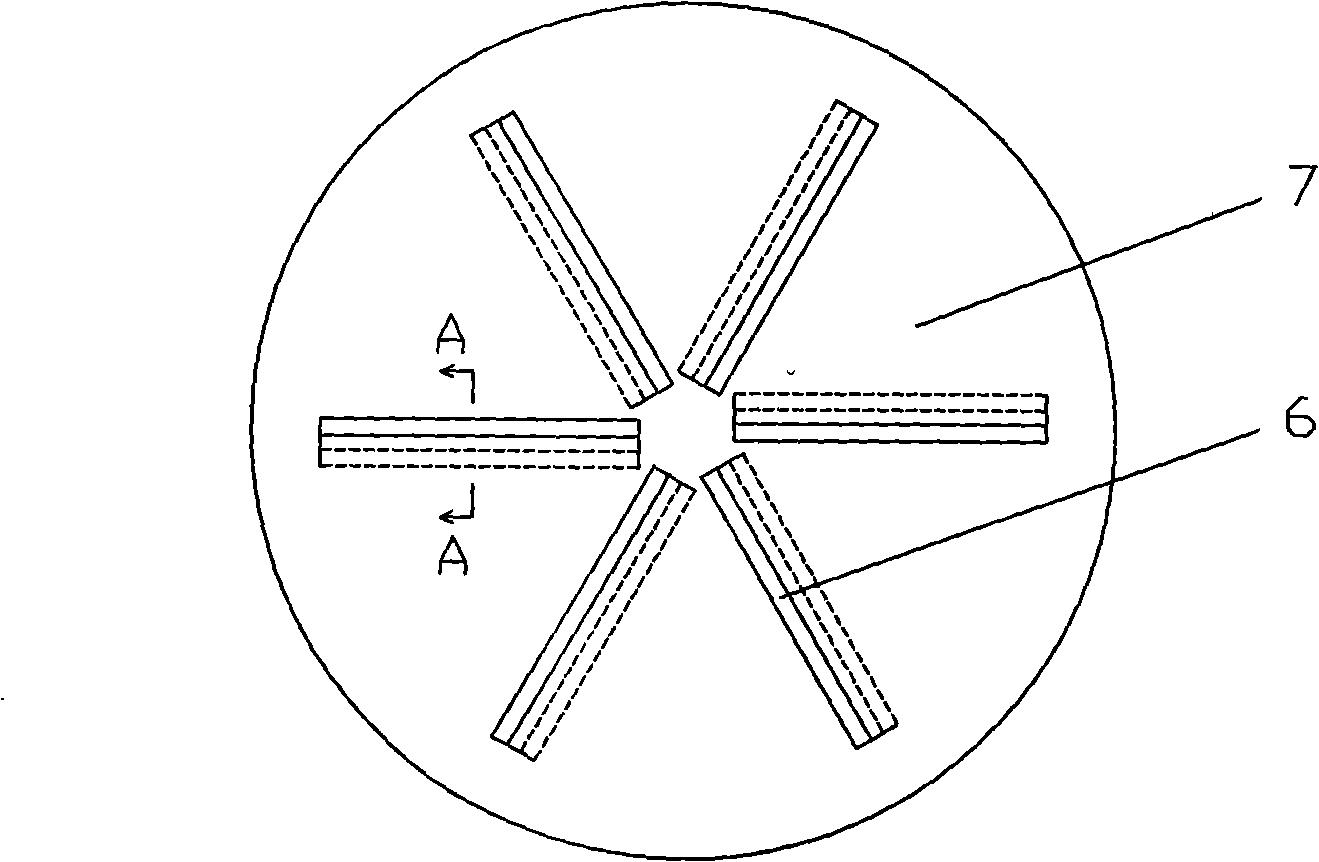

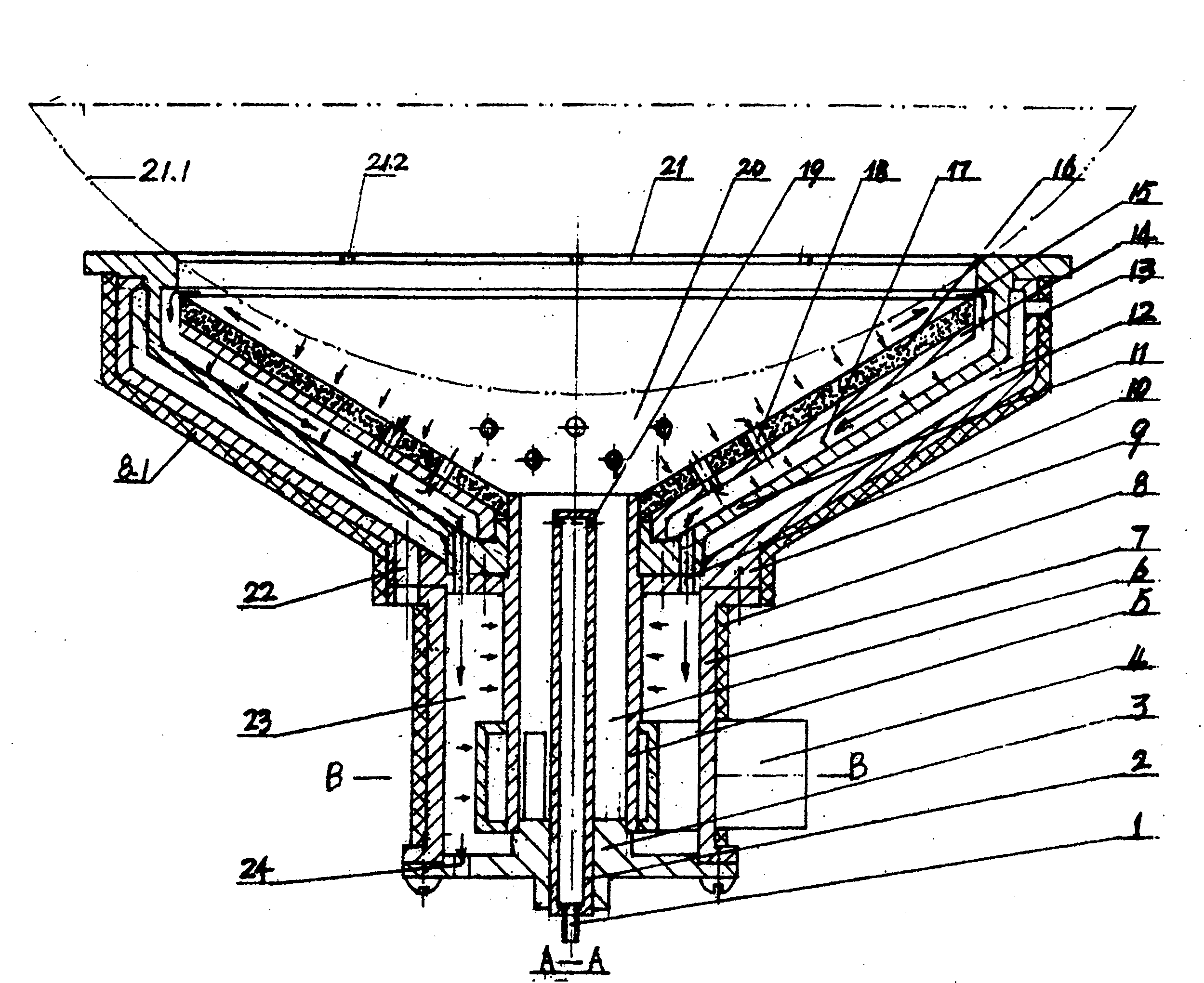

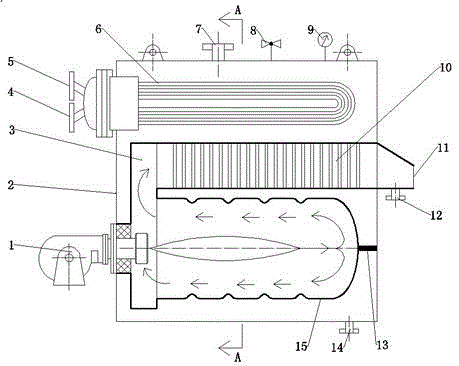

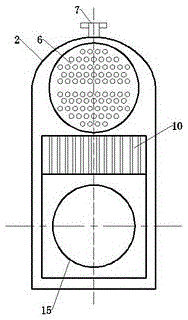

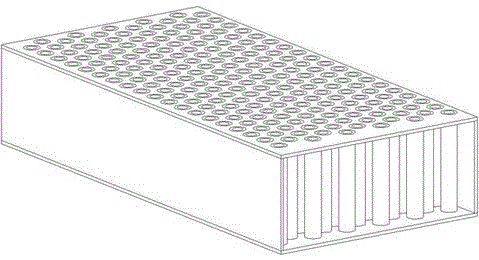

Water tube type vacuum boiler with central reverse flames

The invention discloses a water tube type vacuum boiler with central reverse flames. The vacuum boiler mainly comprises a combustor, a casing, a flue gas transfer chamber, a container, a water tube type heat exchanger and a U-shaped tube heat exchanger. The vacuum boiler is characterized in that the boiler casing is formed by butt-jointing an upper arc-shaped barrel and a lower cuboid casing, the U-shaped tube heat exchanger is located at the upper part of the casing, and the container, the flue gas transfer chamber and the water tube type heat exchanger are located at the lower part of the casing; the container is waved, the front end of the container is welded on the flue gas transfer chamber, and the back end is welded on an ellipsoidal gland; a central reverse flame combustion manner is adopted; a plurality of vertical heat exchange tubes are arranged in the water tube type heat exchanger, flue gas inlets of the heat exchange tubes are welded on the flue gas transfer chamber, and flue gas outlets are connected with an exhaust tube. The boiler keeps a certain vacuum degree inside during running, boiler water boils at the temperature lower than 100 DEG C after being heated, steam rises and condenses outside the U-shaped tube heat exchanger to release heat to heat return water in the tube, and condensate water flows back into the boiler. The boiler is compact in structure and higher in heat efficiency and occupies small area, and no external heat exchanger is required.

Owner:ZHENGZHOU UNIV

Adjustable type petroleum coke powder strengthening and burning device

InactiveCN101539292ACatch fire quicklyEasy to catch firePulverulent fuel combustion burnersCombustorMature technology

The invention relates to an adjustable type petroleum coke powder strengthening and burning device which comprises a high-temperature heat storage cavity and an adjustable type multi-stage burner. Aiming at the characteristics of low volatile component content and high burning NOx content of the petroleum coke powder, the device adopts a method for combining techniques of strengthening the heating-up speed of the petroleum coke powder, reducing the ignition heat, and the like so as to achieve the stable ignition and low-pollution burning of the petroleum coke powder. The depth of both the high-temperature heat storage cavity and a flaring structure of a central pipe for inserting in a hearth can be adjusted so as to adapt to the influence of the load change of a burning device. The device has strong pertinence and has the characteristics of convenience, adjustment, mature technology, high burning efficiency and convenient processing and manufacturing.

Owner:XI AN JIAOTONG UNIV

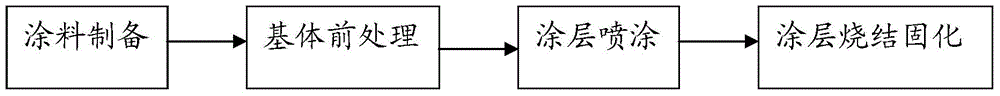

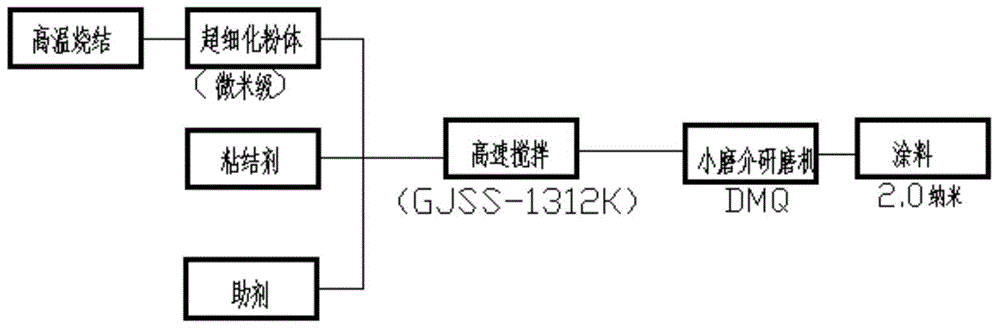

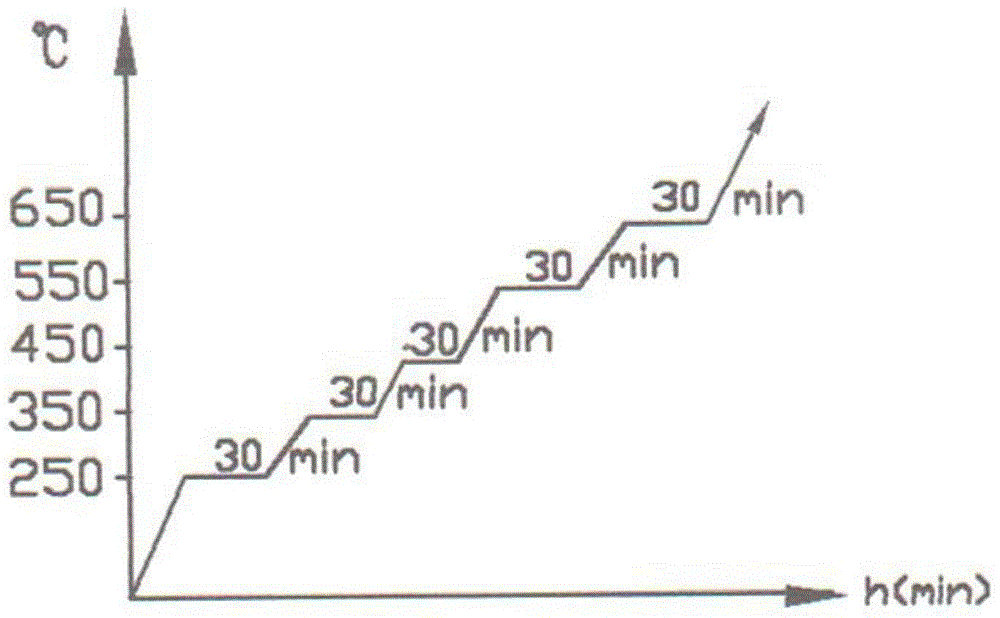

Preparation method of high-emissivity energy-saving infrared radiation coating

ActiveCN104098936AEnhanced radiation heat transferIncrease surface temperatureChemical industryCoatingsEmissivityCeramic coating

The invention discloses a preparation method of a high-emissivity energy-saving infrared radiation coating. The preparation method comprises steps as follows: step one, preparation of coating materials; step two, pretreatment of a base body; step three, spraying of the coating; and step four, sintering and curing of the coating. The coating is stable in structure under high-temperature sintering, performance is comprehensively promoted, the emissivity of the coating cannot be attenuated and aged during use, and the service life of the coating is longer than six years; glazing ceramic coating with a compact structure is formed on the furnace lining surface, the service life of a furnace is prolonged by more than two times, and maintenance and overhaul workload of a furnace lining, consumption of raw materials and maintenance cost are reduced.

Owner:北京恩吉赛威节能科技有限公司

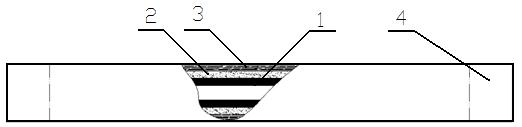

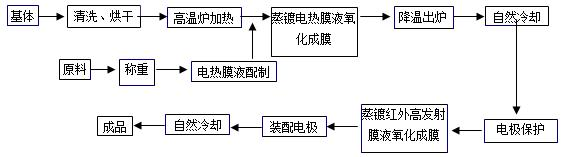

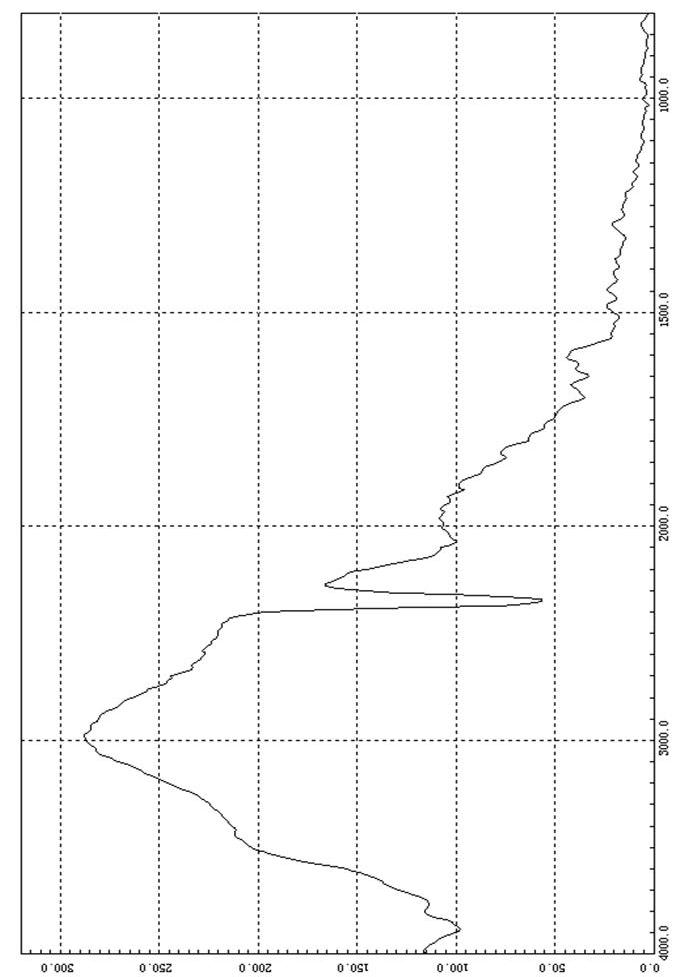

Infrared electric heating film heating tube with double-film layer structure as well as preparation method and application thereof

InactiveCN102036433AEnhanced Radiation Heat TransferReduce convective heat transferHeater elementsHeating element shapesIonElectric heating

The invention discloses an infrared electric heating film heating device with a double-film layer structure, which structurally comprises an electric heating film substrate and electrodes arranged on the two ends of the electric heating film substrate, wherein an electric conduction film layer and an infrared high emission film layer are sequentially evaporated on the surface of the electric heating film substrate. A preparation method of the infrared electric heating film heating device comprises the steps of: sequentially evaporating the electric conduction film layer and the infrared high emission film layer to the electric heating film substrate by using a high-temperature evaporation furnace, wherein an electric heating film solution comprises the components in parts by weight: 45-58 parts of stannic chloride, 0.3-2.0 parts of antimony butter, 0.4-1.2 parts of nickel trichloride, 0.3-1.0 part of indium chloride, 5-15 parts of ethanol / glycerol, 6-17 parts of inorganic acid, and 20-30 parts of deionized water, and an infrared high emission film solution comprises the components in parts by weight: 35-45 parts of manganous chloride, 15-20 parts of nickel dichloride, 5-10 parts of chromium trichloride, 5-15 parts of ethanol / glycerol and 20-30 parts of deionized water; and finally assembling the electrodes to obtain the infrared electric heating film heating device. In the invention, the double-film layer structure is adopted for the infrared electric heating film heating device, which can greatly enhance radiative heat transfer, reduce convection heat transfer, improve energy efficiency and save energy sources.

Owner:吕一诺

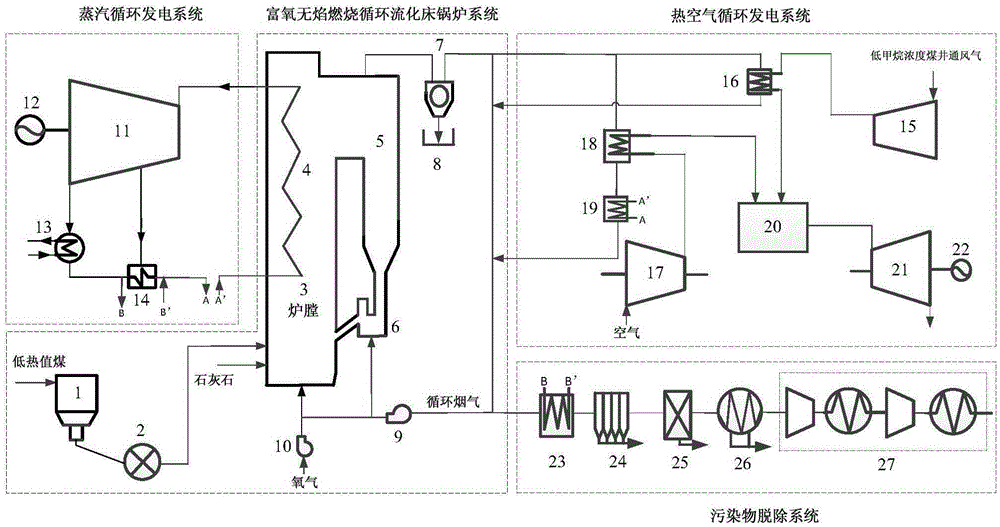

Low-calorific-value coal steam-hot air combined cycle power generation system

InactiveCN105257350AImprove stabilityImprove burnout rateFluidized bed combustionSteam generation plantsHigh pressureCoal

The invention discloses a steam-hot air combined cycle power generation system belonging to the technical field of low-calorific-value coal power generation. The system comprises an oxygen-enriched flameless combustion circulating fluidized bed boiler system, a steam cycle power generation system, a hot air cycle power generation system and a pollutant removing system, wherein the circulating fluidized bed boiler system produces high-temperature and high-pressure steam by means of low-calorific-value coal through high-temperature flue gas combined with the oxygen-enriched combustion technology to push a steam turbine to generate electricity; in the hot air cycle power generation system, air and coal mine ventilation air containing the low concentration of methane are compressed and heated and then are subjected to an oxidizing reaction in a high-temperature methane oxygenizer; produced high-temperature and high-pressure hot air is used for pushing an air turbine to do work. The steam-hot air combined cycle power generation system integrates steam cycle power generation and hot air cycle power generation, the utilization rate of the low-calorific-value coal can be increased, pollutants are reduced, the low-concentration methane in the coal mine ventilation air can also be effectively oxidized and eliminated, the greenhouse gas effect of the low-concentration methane is reduced, and the energy source, namely the low-concentration methane, can be fully utilized while the low-concentration methane is prevented from polluting the environment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

High-temperature nano radiation coating for heating furnace and preparation process thereof

The invention provides a high-temperature nano radiation coating for a heating furnace and a preparation process thereof. The coating comprises radiation function powder particles, an inorganic adhesive and an expansion coefficient regulator. The preparation process comprises the following steps: preparing the radiation function powder particles, preparing the expansion coefficient regulator, synthesizing the inorganic adhesive, mixing the radiation function powder particles, the inorganic adhesive and the expansion coefficient regulator, and filtering and grinding the obtained mixture so as to obtain the high-temperature nano radiation coating for the heating furnace. The high-temperature-resistant nano radiation coating disclosed by the invention has the characteristics of capability of increasing the radiance and the thermal shock stability, energy conservation and environmental friendliness, corrosion resistance, and capability of prolonging the service life of the heating furnace and raising the temperature uniformity, and the like. The technical indexes of the products provided by the invention are as follows: a temperature of 1800 DEG C can be resisted, the radiance epsilon is greater than or equal to 0.92, the thermal shock resistance (1300 DEG C) is greater than or equal to 5 times, the thickness of the coating is 0.1-0.2 mm, and the service life is greater than or equal to 6 years.

Owner:BDES BEIJING ENERGY SAVING TECH SERVICE

Industrial pulverized coal swirl combustion system using natural gas for supporting combustion

InactiveCN102116480AEnhanced Radiation Heat TransferUniform distribution of pulverized coal concentrationPulverulent fuel combustion burnersProcess engineeringCoal

The invention relates to an industrial pulverized coal swirl combustion system using natural gas for supporting combustion, and a central air channel, a primary air channel, a direct-flow natural gas channel, an internal swirl secondary air channel and an external swirl secondary air channel are sequentially superposed and arranged from inside to outside around the outer side surface of an ignition gun. The combustion system can improve a temperature field and enhance heat transfer by radiation with the help of the natural gas for supporting the combustion, and has the advantages of uniform rich-lean distribution of pulverized coal, high combustion efficiency, good combustion stability, extensive adaptability to coal types and low NOx emission.

Owner:XI AN JIAOTONG UNIV

Composition for preventing scaling, excluding of soot, clinker and sludge, and controlling flame in combustion apparatus

InactiveUS20060218853A1Improving radiant heat transfer systemPromote combustionGaseous fuelsSolid fuelsSludgeSoot

A fuel additive composition comprising hydrogen peroxide, an amine-based stabilizer, borax, and sodium hydroxide is disclosed. The composition is added to such fuel as coal, oil, and gas to facilitate combustion and remove impurities in a combustion apparatus, thereby improving thermal efficiency, and it reduces discharge of noxious gases such as SOx, NOx, and CO.

Owner:OH MI HYE

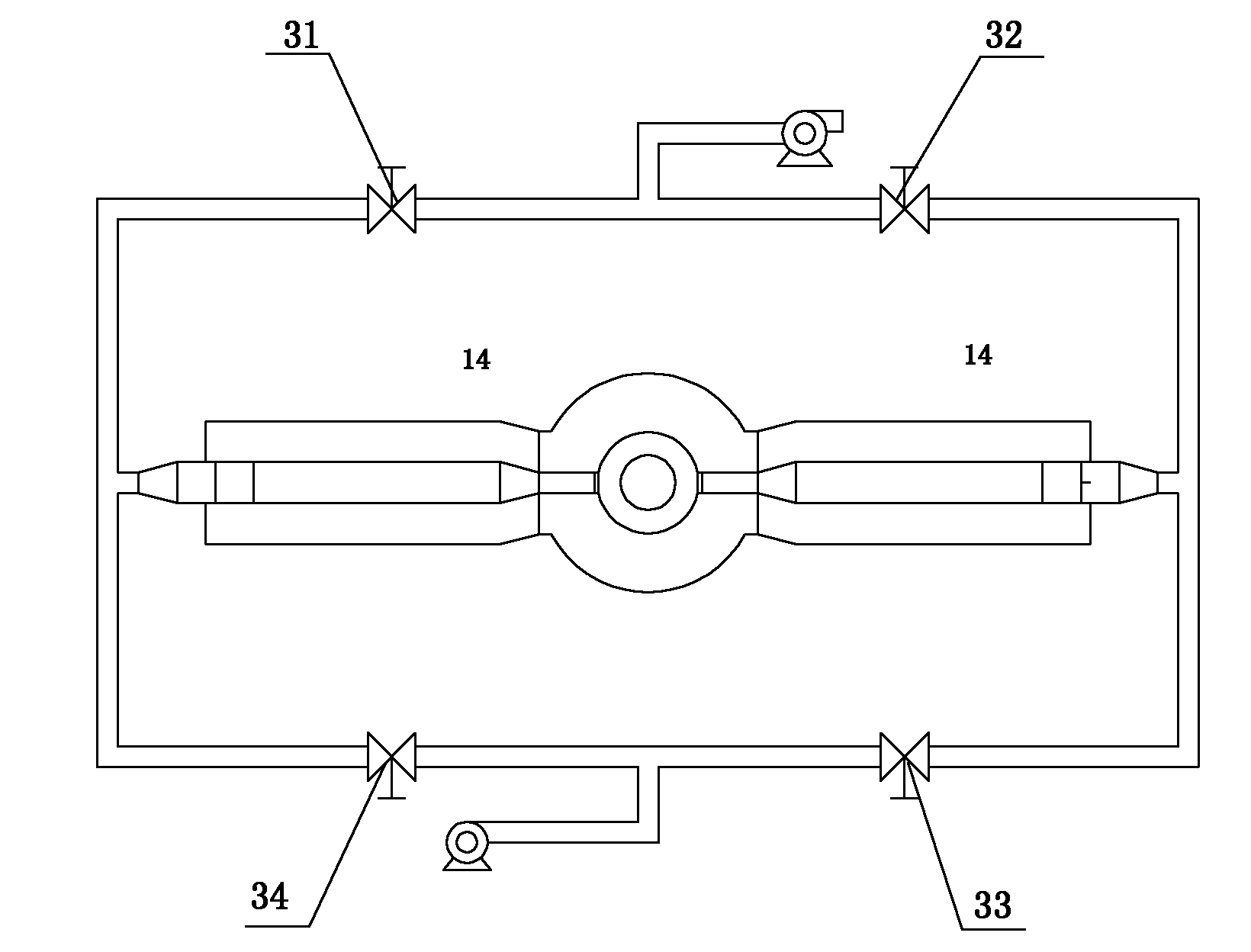

Reciprocating type porous medium gas burning metal smelting furnace

InactiveCN102243016AIncrease temperatureAchieve recyclingCrucible furnacesWaste heat treatmentPeriodic alternatingCombustion chamber

The invention discloses a reciprocating type porous medium gas burning metal smelting furnace which comprises a burning chamber and a metal accommodating container arranged in the burning chamber, wherein the burning chamber is connected with a first gas channel and a second gas channel, a first porous medium regenerative chamber is arranged in the first gas channel, and a second porous medium regenerative chamber is arranged in the second gas channel; the first gas channel and the second gas channel are evenly connected with a periodically reversing air supply mechanism, and the periodicallyreversing air supply mechanism comprises an air-smoke change valve controlled by a controller and is connected with an air supply channel and a smoke channel; and the combustion air and the high-temperature smoke are periodically and alternately reversed to flow through a porous medium high-efficient heat retainer, and the smoke waste heat is utilized to heat the combustion air. The metal smelting furnace provided with the invention has the advantages of short metal melting time, obvious energy-saving effect, high combustion efficiency, effective waste heat limited recycle, low energy consumption and low pollutant discharge.

Owner:ZHEJIANG UNIV

Radiation capsule for star sensor

ActiveCN103303498ASolve the cooling problemSimple designNavigation by astronomical meansCosmonautic safety/emergency devicesEmissivityHeat flow

The invention discloses a radiation capsule for a star sensor, and belongs to the technical field of thermal control design of star sensors. The radiation capsule comprises a capsule body, an optical solar reflector, a heater and a multi-layer thermal insulation component, wherein peripheral equipment is the star sensor; the star sensor comprises a light shield and a star sensing head; the radiating problem of the star sensor is solved through adopting the radiation heat exchange manner between the radiation capsule and the star sensor; heat conducting components such as a hot pipe are not required, so that the radiation capsule is simple and reliable in design; as the radiation capsule is adopted, the mismatching connection between the star sensor and a thermal control part is not caused; the requirement on the processing and mounting precision of the capsule is not high, the implementation difficulty is low, and the thermal control effect is easy to ensure; the optical solar reflector is stuck on the outer surface of the capsule body to enhance the radiation heat exchange with the cold space; coating with high infrared hemispherical emissivity is sprayed on the inner surface to enhance the radiation heat exchange with the star sensor; and the multi-layer thermal insulation component is arranged on an opening to prevent external heat flow from irradiating in the capsule body.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Oxy-fuel combustion system with closed loop flame temperature control

ActiveUS9353945B2Maximize flame temperatureEnhanced Radiation Heat TransferFuel supply regulationMuffle furnacesCombustion systemTemperature control

A control system for an oxy-fuel combustion process is disclosed for use with a boiler or furnace which dynamically controls the flame temperature of each burner involved in the combustion process to dynamically maximize the flame temperature. The boiler or furnace used in conjunction with the combustion process in accordance with the present invention is configured with a radiant, i.e. line of sight, heat zone and a convective heat zone. By dynamically maximizing the flame temperature of the various burners within the boiler or furnace, the radiant heat transfer is optimized. By optimizing the radiant heat transfer within the boiler or furnace, the efficiency of the boiler or furnace is significantly improved.

Owner:JUPITER OXYGEN CORP

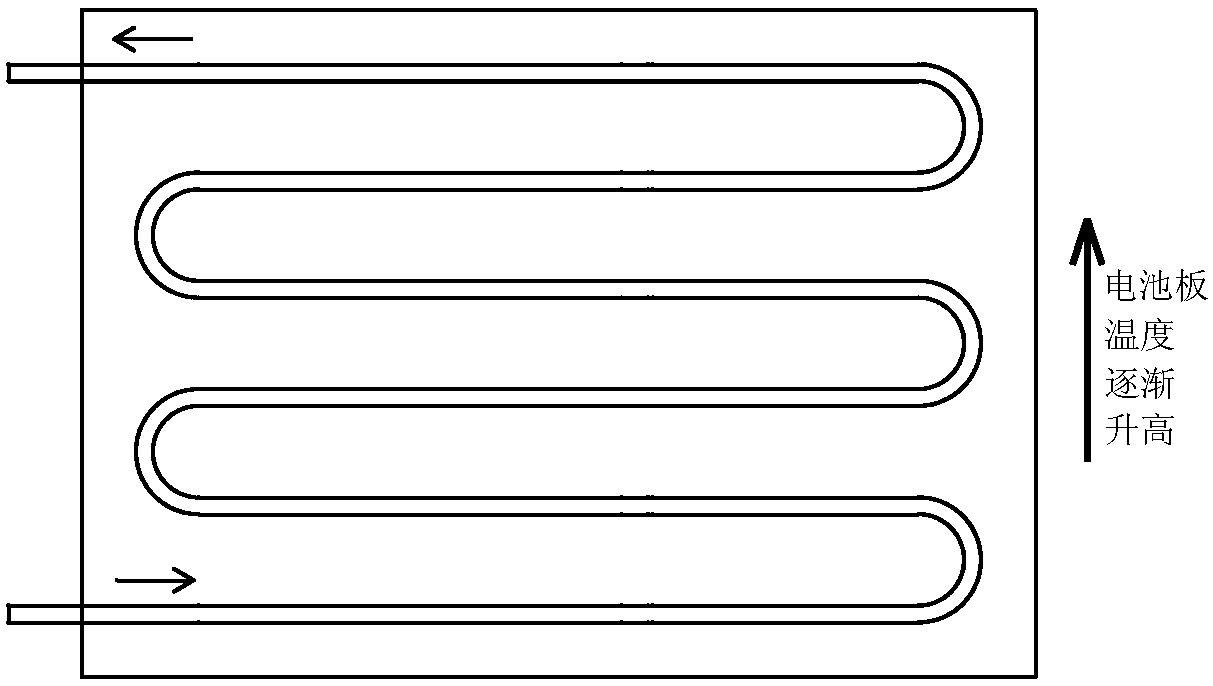

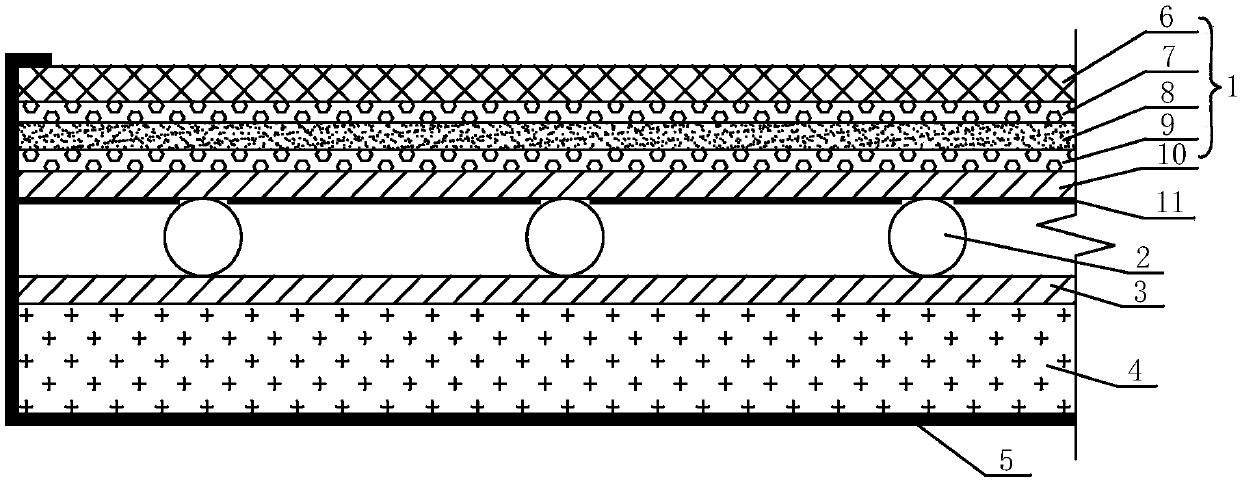

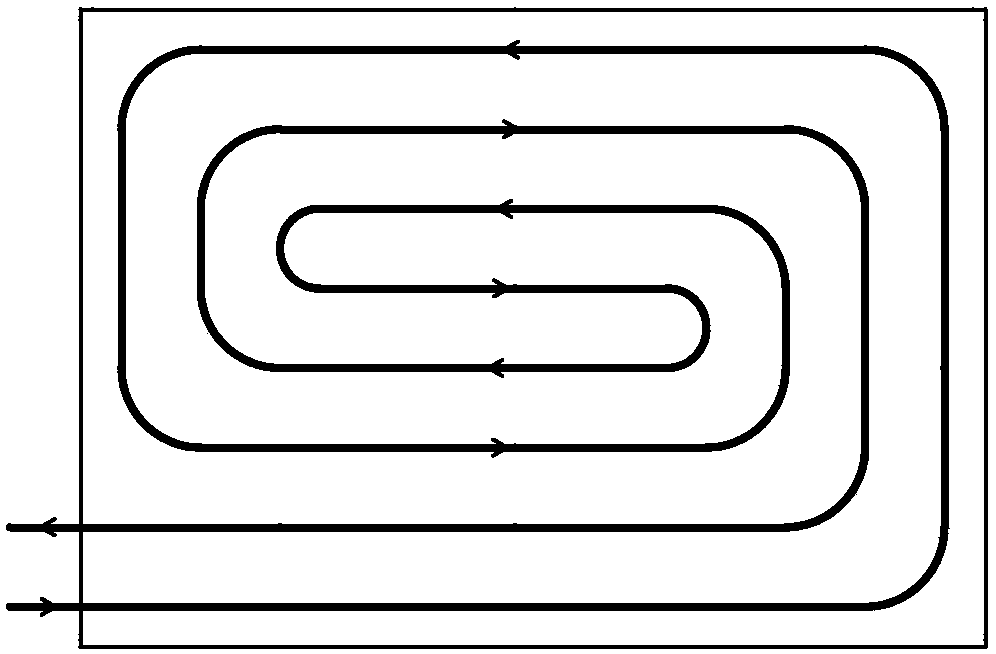

Solar photovoltaic photo-thermal comprehensive utilization device

PendingCN107623048AExtended heat transfer pathImprove heat transfer efficiencyPhotovoltaic energy generationSemiconductor devicesInsulation layerWorking temperature

The invention discloses a solar photovoltaic photo-thermal comprehensive utilization device. The device is characterized by comprising a solar cell panel. The solar cell panel comprises the tempered glass, an upper packaging layer, a solar cell sheet, a lower packaging layer and an upper thermal-arrest plate, wherein the tempered glass, the upper packaging layer, the solar cell sheet, the lower packaging layer and the upper thermal-arrest plate are sequentially stacked up from top to bottom. A lower thermal-arrest plate is arranged below the upper thermal-arrest plate. A heat exchange tube isarranged between the upper thermal-arrest plate and the lower thermal-arrest plate. A heat insulation layer is arranged on the lower surface of the lower thermal-arrest plate. The lower surface of theheat insulation layer, the peripheral side surface of the whole device and the edge of the upper surface of the toughened glass are provided with a back frame. According to the invention, the heat transfer efficiency of the heat exchange tube is obviously increased based on multiple heat transfer pathways and a higher heat exchange coefficient on the inner side of the heat exchange tube. Therefore, the heat collection efficiency of the solar photovoltaic photo-thermal comprehensive utilization device is improved. Moreover, the working temperature of a solar cell is effectively reduced and thephotovoltaic power generation efficiency is improved.

Owner:HUNAN INSTITUTE OF ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com