Shutter type rotatable infrared heating cage

A shutter type, infrared heating technology, applied in ohmic resistance heating, electric heating devices, electrical components and other directions, can solve the problems of affecting the cooling rate of the spacecraft, blocking the radiation heat exchange between the spacecraft and the heat sink, and prolonging the test time of the spacecraft. , to achieve the effect of saving test costs, reducing test time, and fully assessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

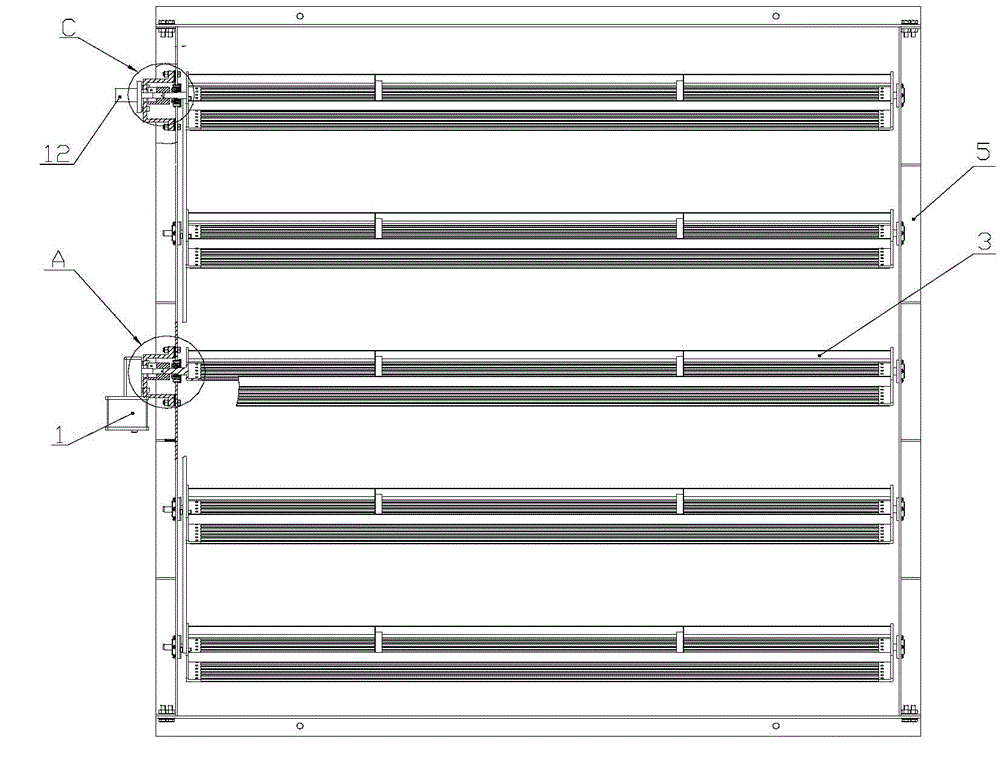

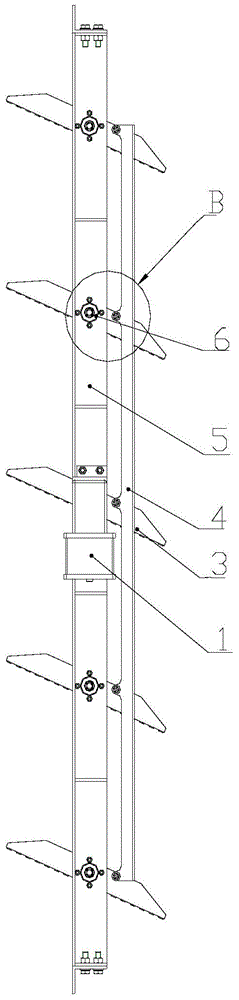

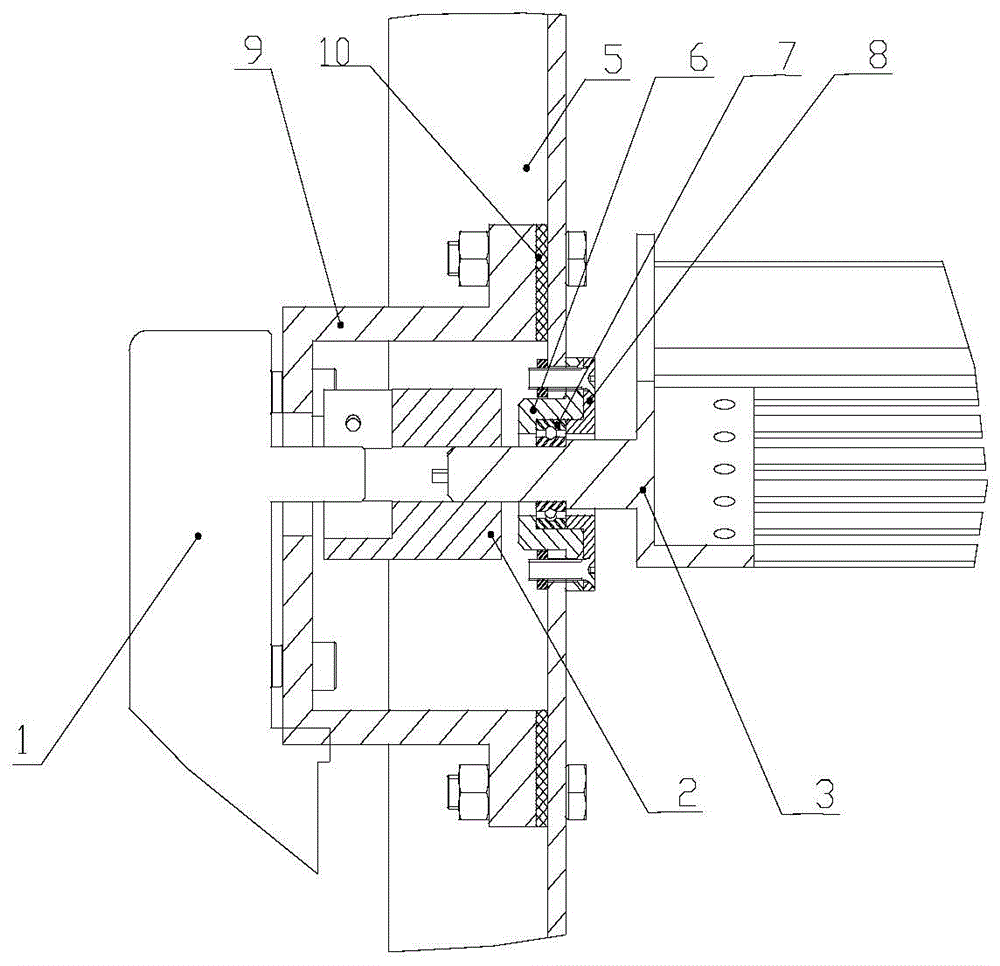

[0030] see figure 1 , Figure 1-2 Respectively, a front view and a side view of the louvered infrared cage of the present invention. The rotatable louver-type infrared cage used for the vacuum thermal test process of a spacecraft of the present invention mainly includes an infrared cage main frame 5, a reduction motor 1, a shaft coupling 2, a connecting rod 4 and a pin shaft 11, a heating assembly, a bearing 7 and Bearing seat 6 and angle sensor 12, the side of main frame 5 are provided with the motor mounting seat 9 of reduction motor 1, and motor mounting seat and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com