Patents

Literature

274results about How to "Slow cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

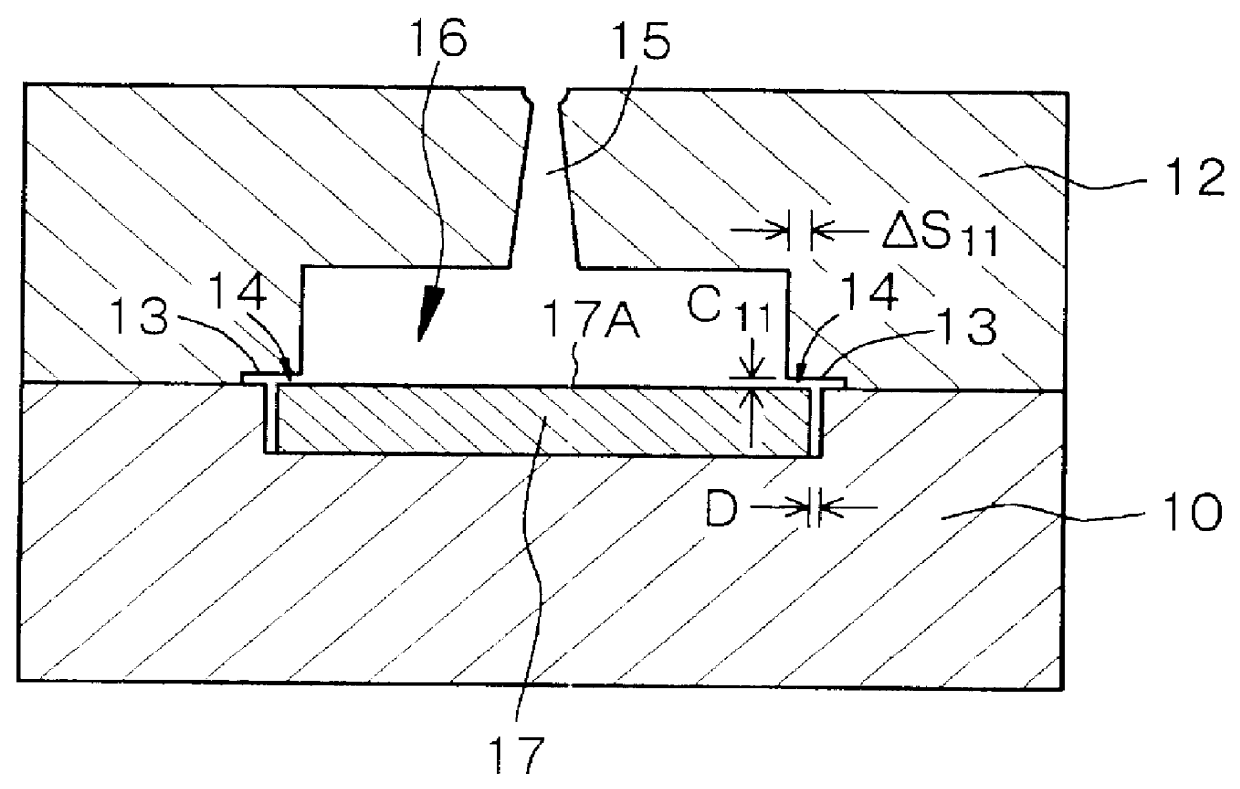

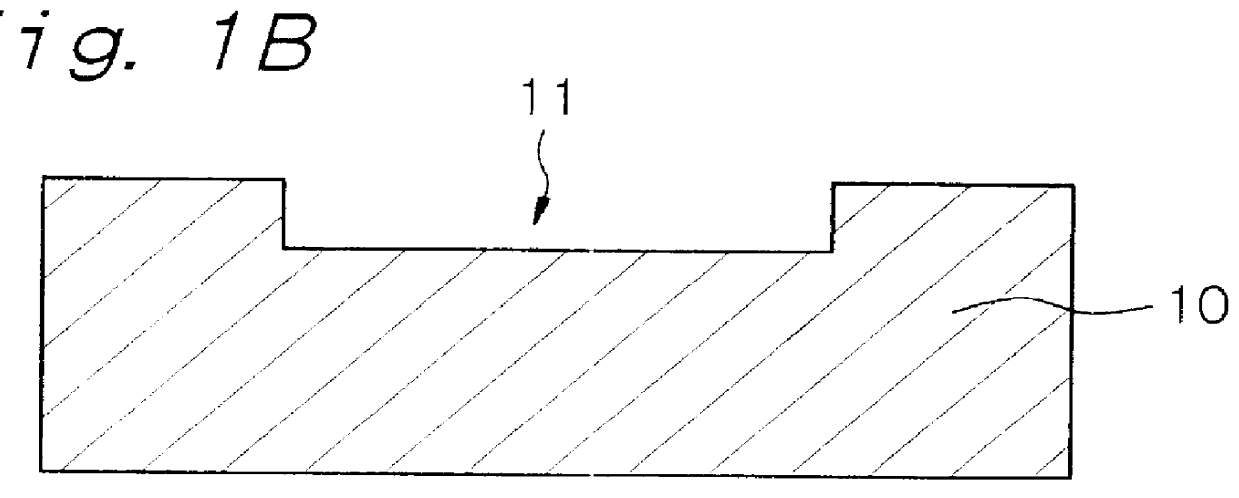

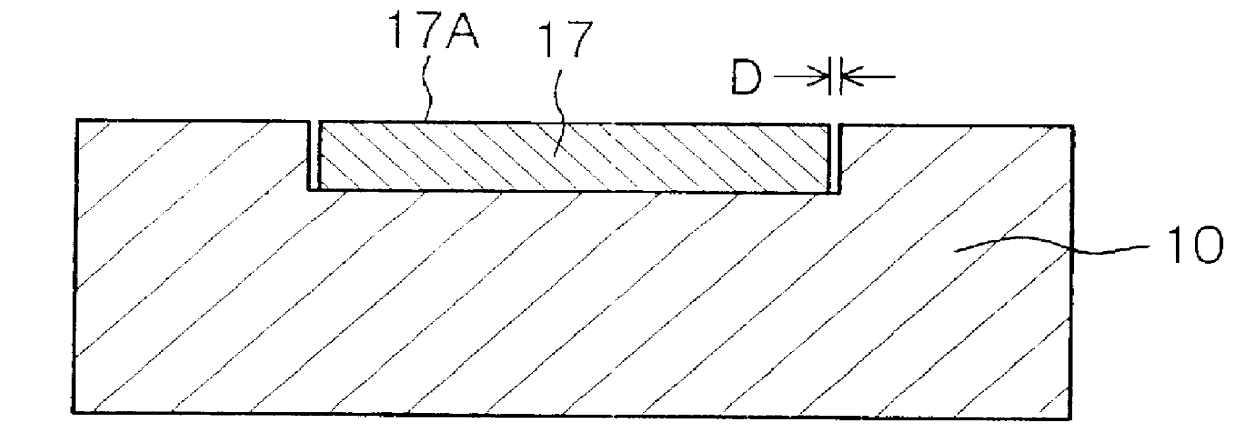

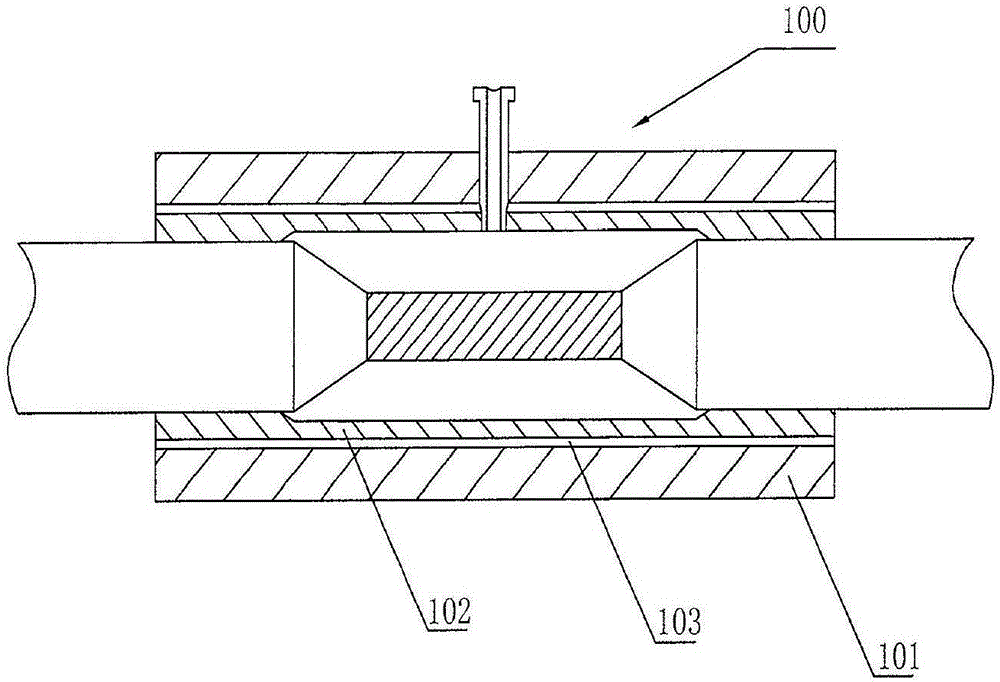

Mold assembly for molding thermoplastic resin and method of manufacturing molded article of thermoplastic resin

InactiveUS6165407AReduce residual stressReduce injection pressureConfectioneryOptical articlesMaterials scienceThermal conductivity

A mold assembly for molding a thermoplastic resin, which comprises; (a) a first mold member and a second mold member for manufacturing a molded article of a thermoplastic resin, (b) an insert block provided in the first mold member, said insert block constituting part of a cavity, having a thickness of 0.1 mm to 10 mm and being formed of a material having a thermal conductivity of 2x10-2 cal / cmxsecx DEG C. or less, and (c) a molten thermoplastic resin introduction portion provided in the second mold member, wherein an insert block covering portion is formed in the second mold member, and when the first mold member and the second mold member are clamped to each other, (A) a clearance between the insert block and the insert block covering portion is equal to, or less than, 0.03 mm, and (B) an amount of overlapping of the insert block and the insert block covering portion is equal to, or greater than, 0.5 mm.

Owner:MITSUBISHI ENG PLASTICS CORP

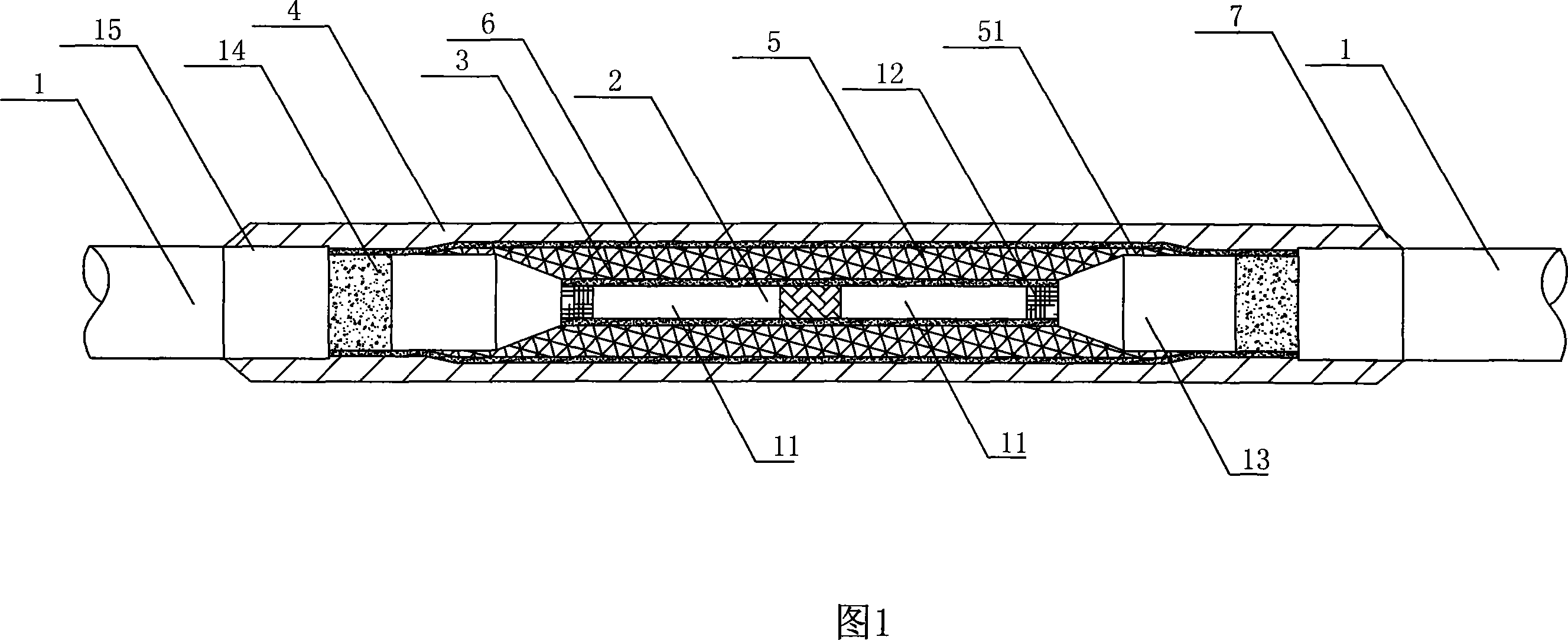

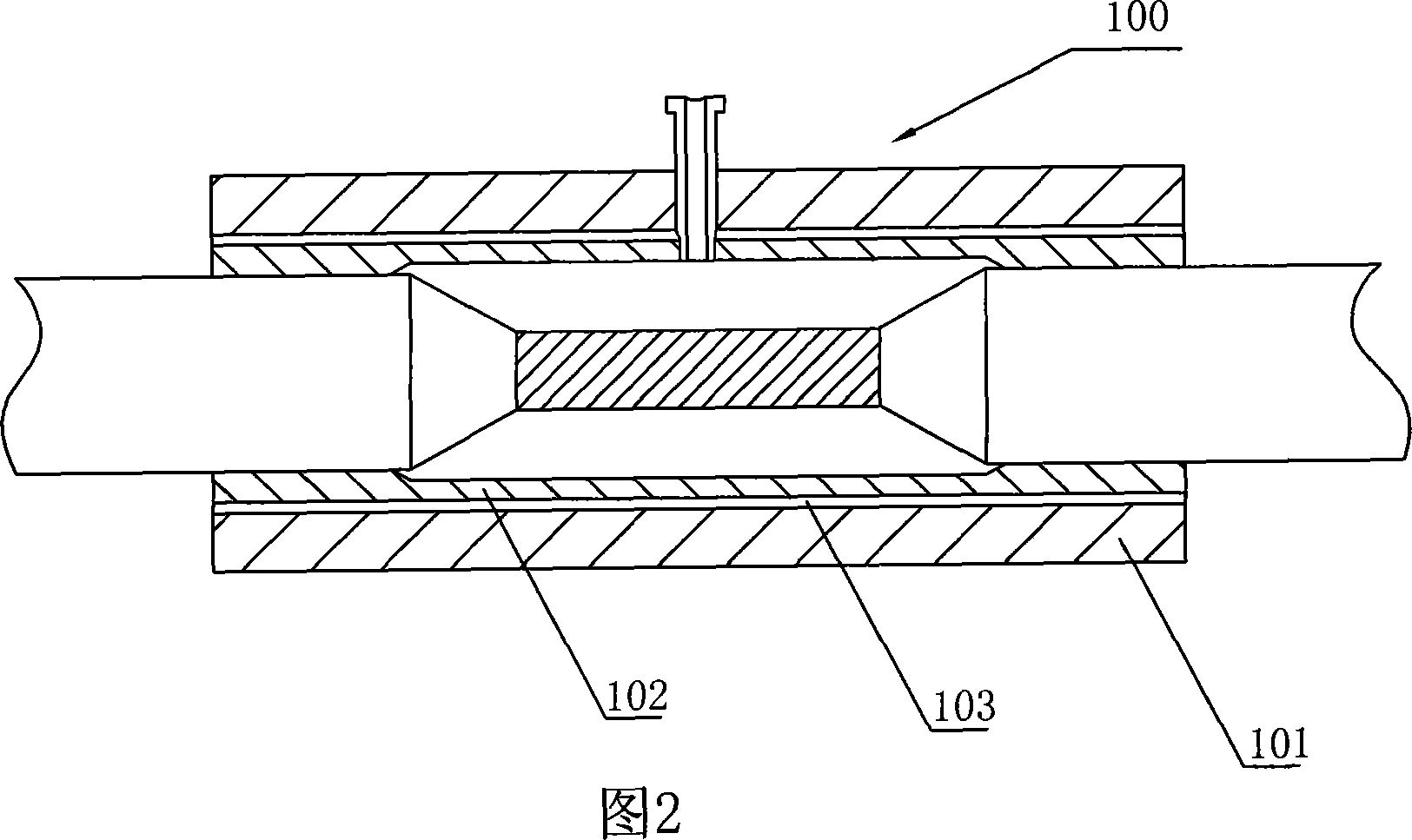

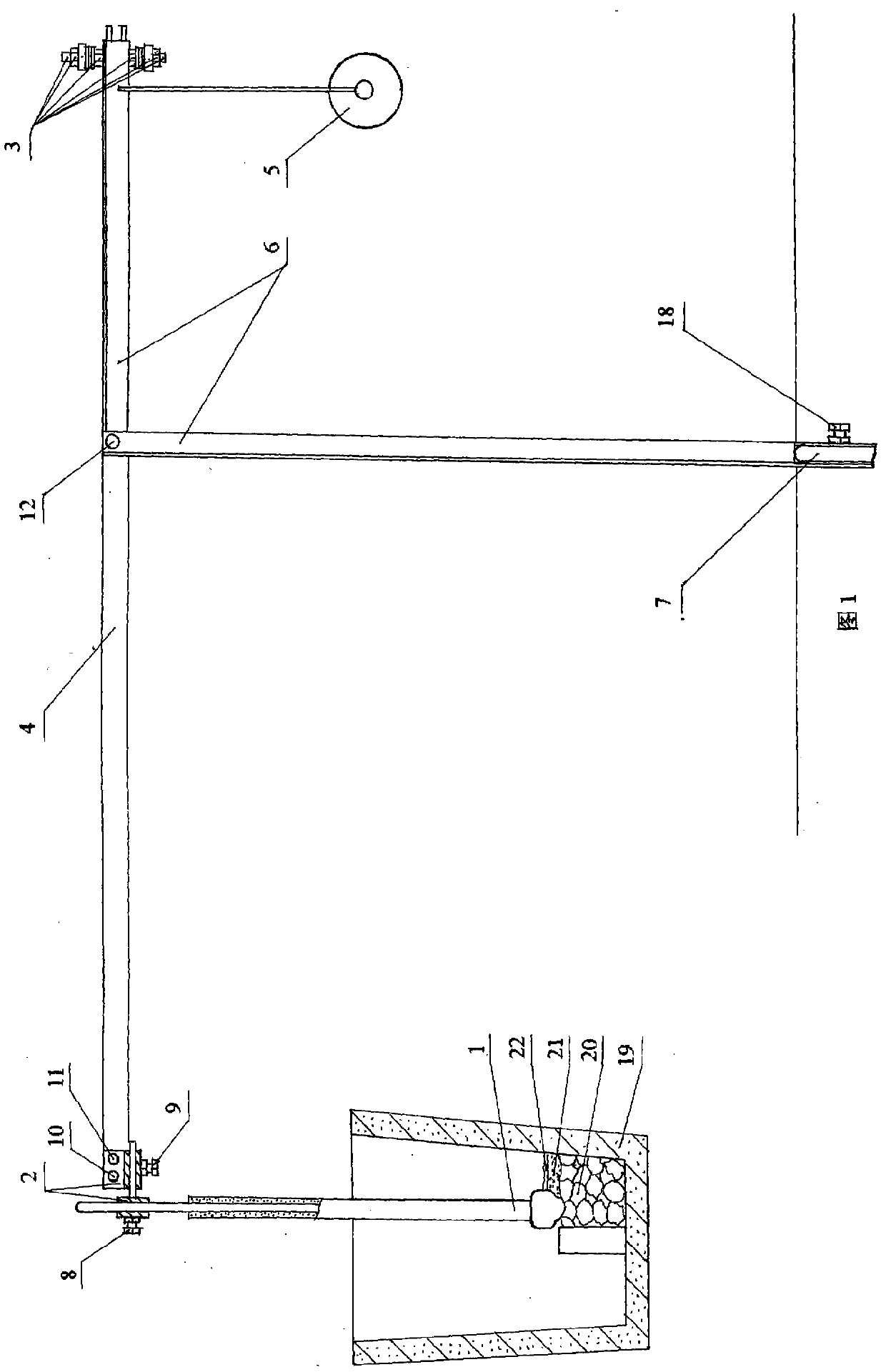

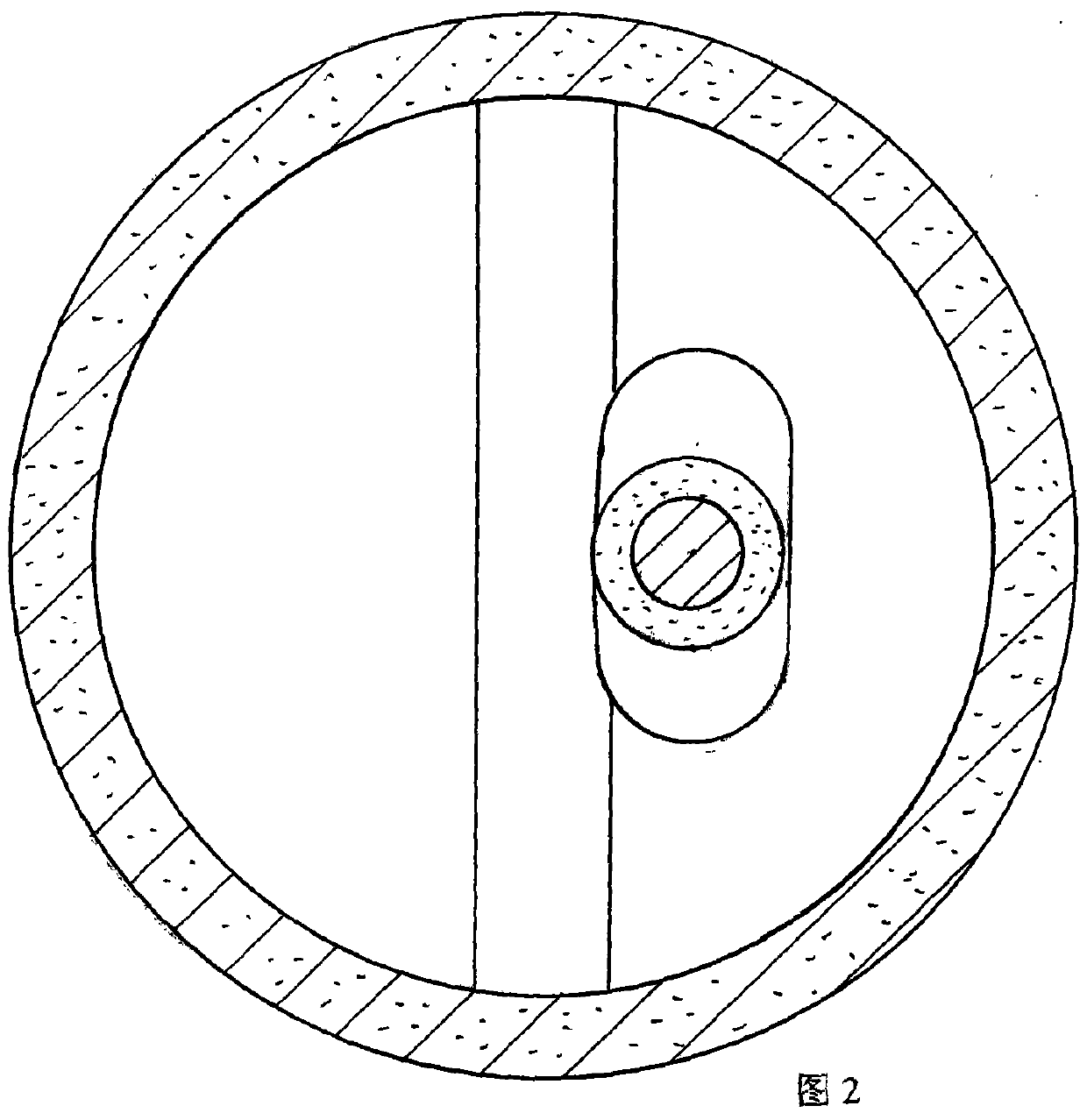

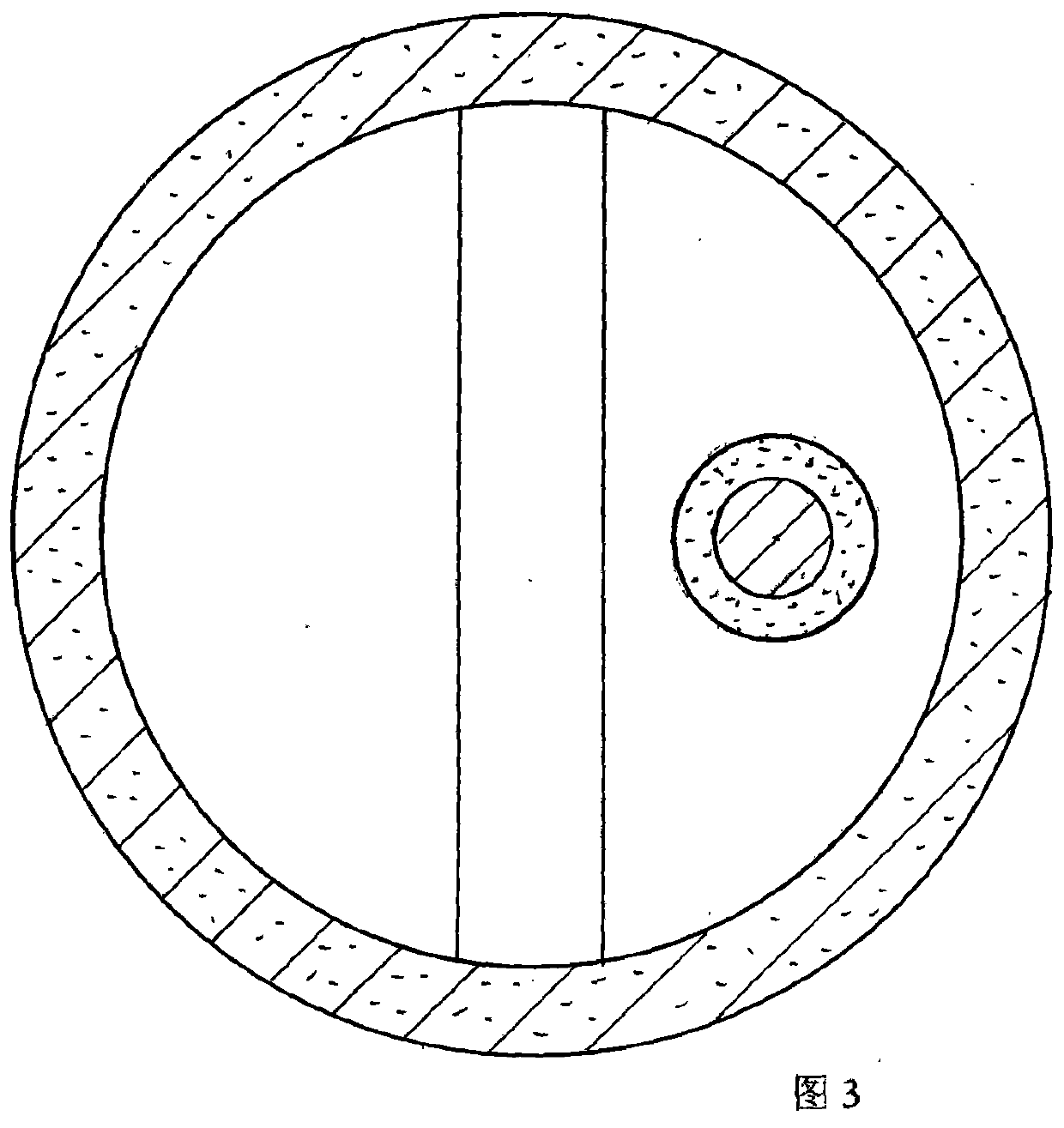

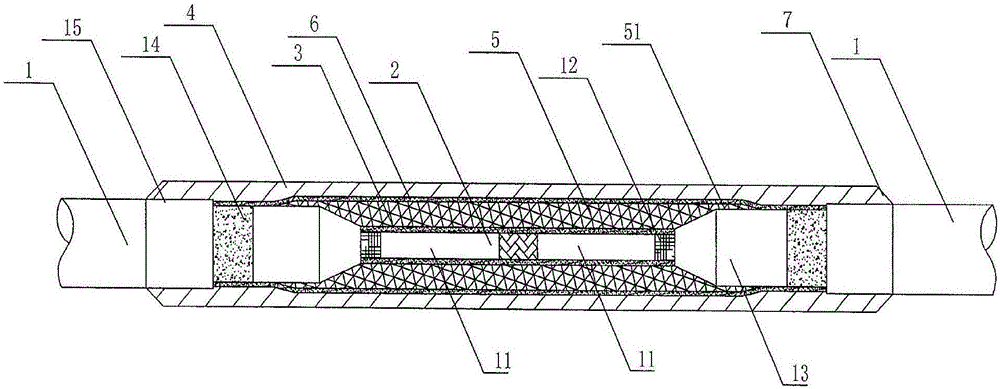

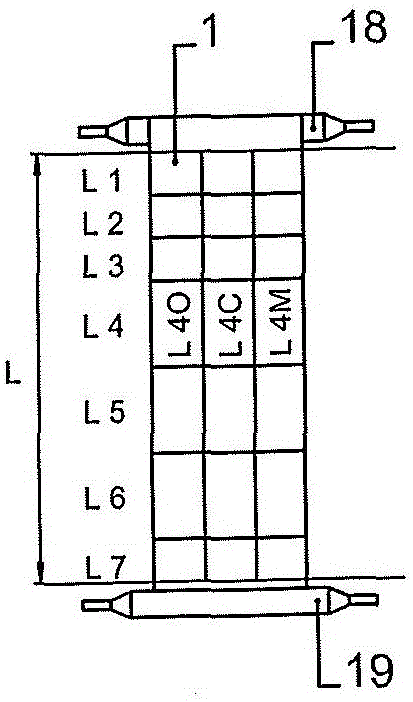

Soft joint for cross-linked polyethylene cable and producing method thereof

ActiveCN101068075AElectrical performance improvements and enhancementsEliminate void defectsCable junctionsApparatus for joining/termination cablesInsulation layerEngineering

This invention discloses a soft joint of a cross-linked polythene cable including an inner semiconductive layer and metal jacket sleeves, in which, two core leads between two cables are welded to form a core connection part, the inner semiconductive layer is combined with a preserved section of the inner screen layer of the cable characterizing in setting a polythene filled vulcanized insulation layer out of the inner semiconductive layer to be fused with the polythene insulation layer of the cable, and wrapping the polythene insulation of the cable with a transition connection section and an outer semiconductive layer combining with the preserved section of the outer screen of the cable is set out of the polythene filled vulcanized insulation layer, two ends of the metal jacket sleeve are welded with the out surfaces of lead protection pipe of the cable and set with slope connection sections.

Owner:宁波东方电缆股份有限公司

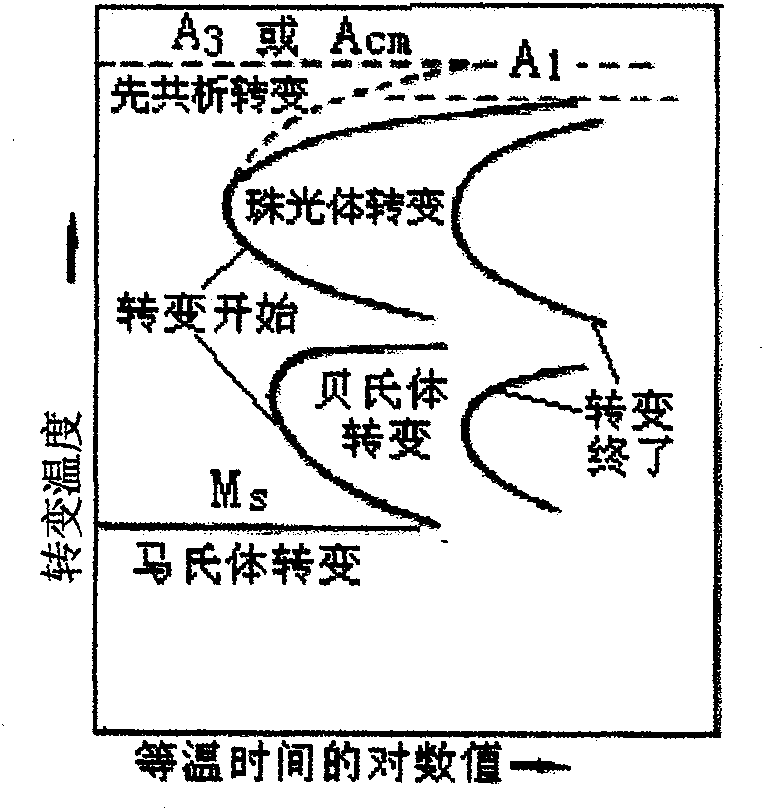

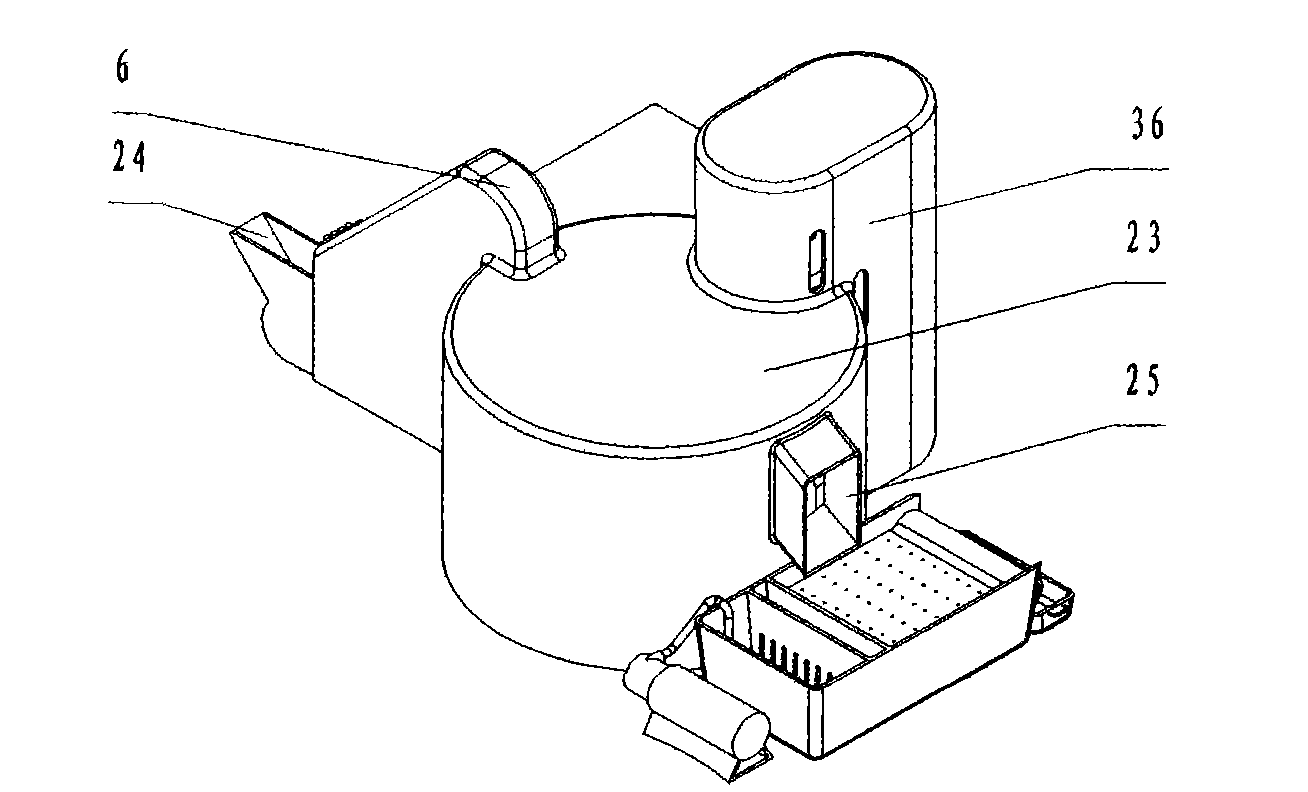

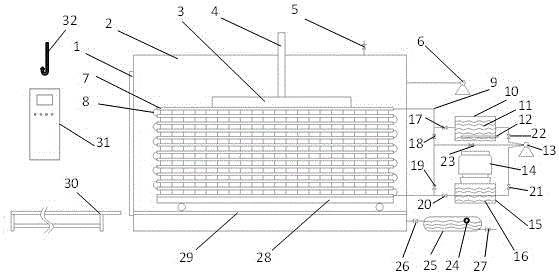

Heat treatment equipment and heat treatment method of metal parts

The invention relates to heat treatment equipment of metal parts, which comprises a heating device and charging barrels, wherein the charging barrels are installed on a rotating disk; the heating device is an electromagnetic induction heating device; the inner diameter of an induction coil is greater than the outer diameter of each charging barrel; when the induction coil is in a working state of energizing and heating, the induction coil is surrounded at the outer side of one of the charging barrels; and the inner cavity of each charging barrel for containing metal parts is a sealed space. The heat treatment method comprises the following steps: after the induction coil is lowered or the charging barrels are lifted and the corresponding charging barrel is sealed, filling inert gases, and heating to the set temperature; adding carbon and / or nitrogen, heating for the set time, and then, stopping heating; lifting the induction coil or lowering the charging barrels, rotating the rotating disk, pouring materials, quenching and cooling to complete the carburization and / or nitridation heat treatment process of the metal parts; simultaneously, rotating the charging barrels containing the metal parts to be treated by heating to the under part of the induction coil; and circularly working. The invention has the advantage of high efficiency and can realize continuous automatic production.

Owner:GUANGZHOU CCM ELECTRICAL APPLIANCE

Preparation method of heavy-calibre nickel base alloy thin-walled tubular product

The invention relates to a preparation method of a heavy-calibre nickel base alloy thin-walled tubular product, which comprises the steps of: 1, preparing a nickel base alloy tube blank by adopting a thermal backward extrusion process, wherein the extrusion temperature is 1000-1250 DEG C, the worker die preheating temperature is 450-550 DEG C, the extrusion speed is 25mm / s-60mm / s; 2, thinning through cold spinning with strong force, wherein the first pass of thinning rate is 20-75 percent, other passes of thinning rates are 25-30 percent, the deformation during thermal treatment (annealing or solution treatment) is 50-75 percent, the feeding ratio of two passes before a finished product is obtained is 0.5mm / n-0.7mm / n, and feeding ratios of other passes are 0.8mm / n-1.5mm / n; and 3, carrying out thermal treatment (annealing or solution treatment) on a semi-finished product or finished product, scouring and cleaning. The heavy-calibre nickel base alloy thin-walled tubular product processed by adopting the invention has the advantages of high material utilization rate, low cost and high additional value, is suitable for massive production, and has remarkable economic benefit and social benefit.

Owner:有研科技集团有限公司

Method for preparing nano fluid for heat transfer medium of solar heat exchange system

InactiveCN101735775AImprove heat collection efficiencyFast heatingHeat-exchange elementsNanoparticleSURFACTANT BLEND

The invention relates to a method for preparing nano fluid for a heat transfer medium of a solar heat exchange system, which comprises the following steps: selecting one of Al2O3, TiO2, ZnO, Ni and Cu nano grains with the grain diameter of 5 to 100 nanometers as additive, selecting water or water / ethylene glycol or water / propylene glycol mixture as base solution, adding surfactant into the solution, and strongly stirring and ultrasonically oscillating to form the nano fluid which is used for the heat transfer medium of the solar heat exchange system, wherein the Al2O3, TiO2, ZnO, Ni or Cu nano grains account for 0.1 to 3 volume percent of the volume of the nano fluid. The practical detection result for placing the solar heat exchange system on the roof shows that the nano fluid can remarkably improve the heat collecting efficiency of the solar heat exchange system, has the advantages of high heating speed, low cooling speed, low cost and simple preparation process and can remarkably improve the heat collection and heat utilization efficiencies of the existing solar heat collecting system.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

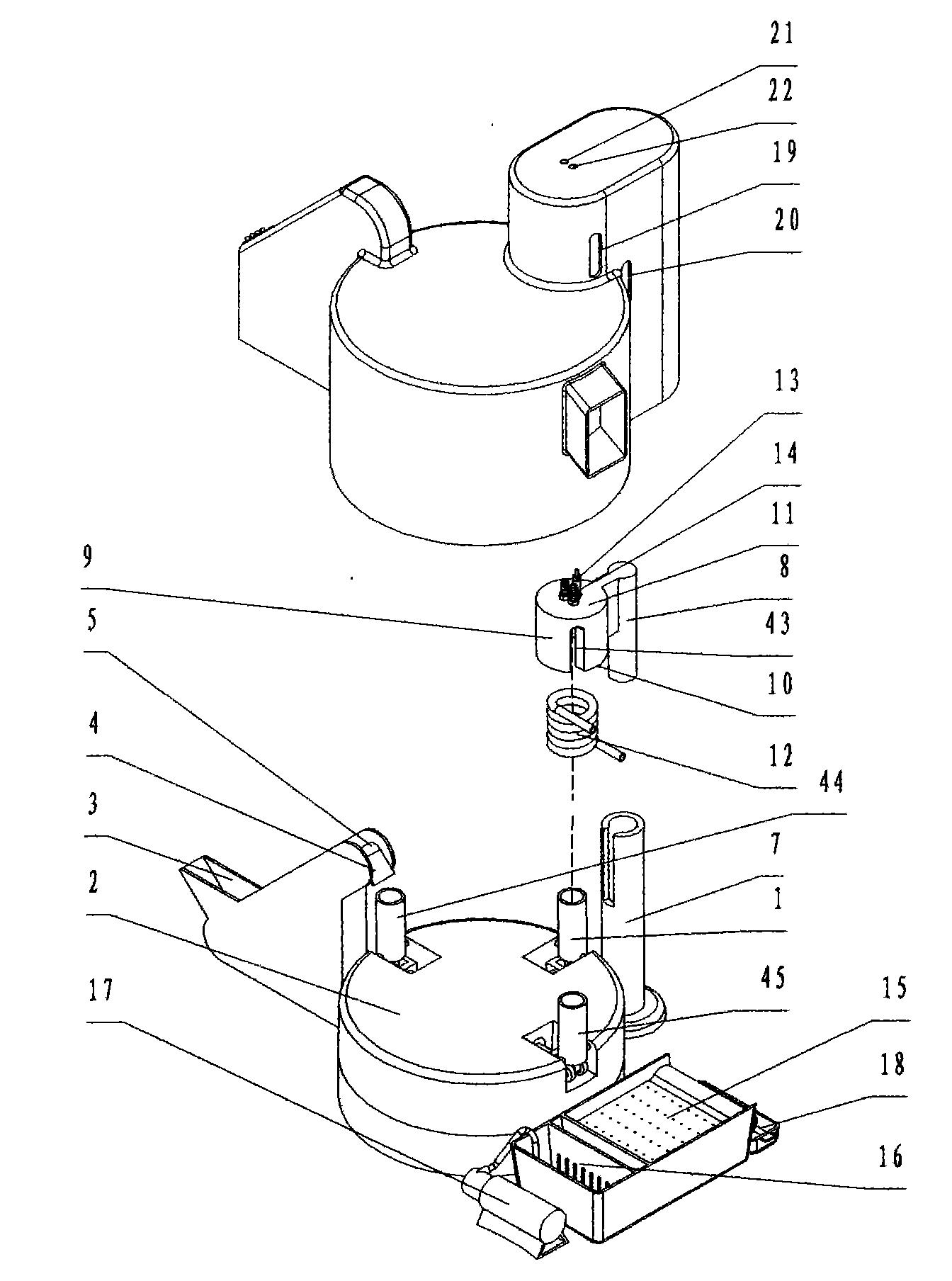

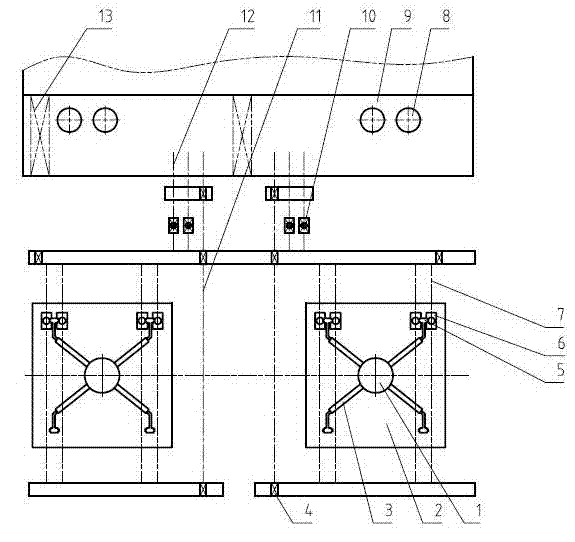

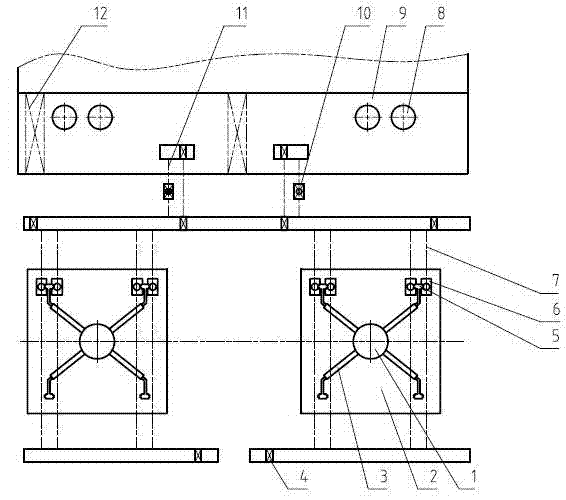

Spheroidizing treater and process

InactiveCN101029367AIncrease Mg contentCancel the secondary smelting processDuctile ironUltimate tensile strength

A spheroidizing treater for producing spheroidal graphite cast iron is carried out by adjusting bearing rod head and dam seam and controlling iron-water and nodulizer contact. It adopts waste-heat one-step method and controls spheroidizing reactive time and strength; the spheroidizing agent consists of Mg<=20%, RE<=3% and Si<=65%. It's simple, cheap and can be used for large-scale continuous production.

Owner:河北贝广电力设备有限公司

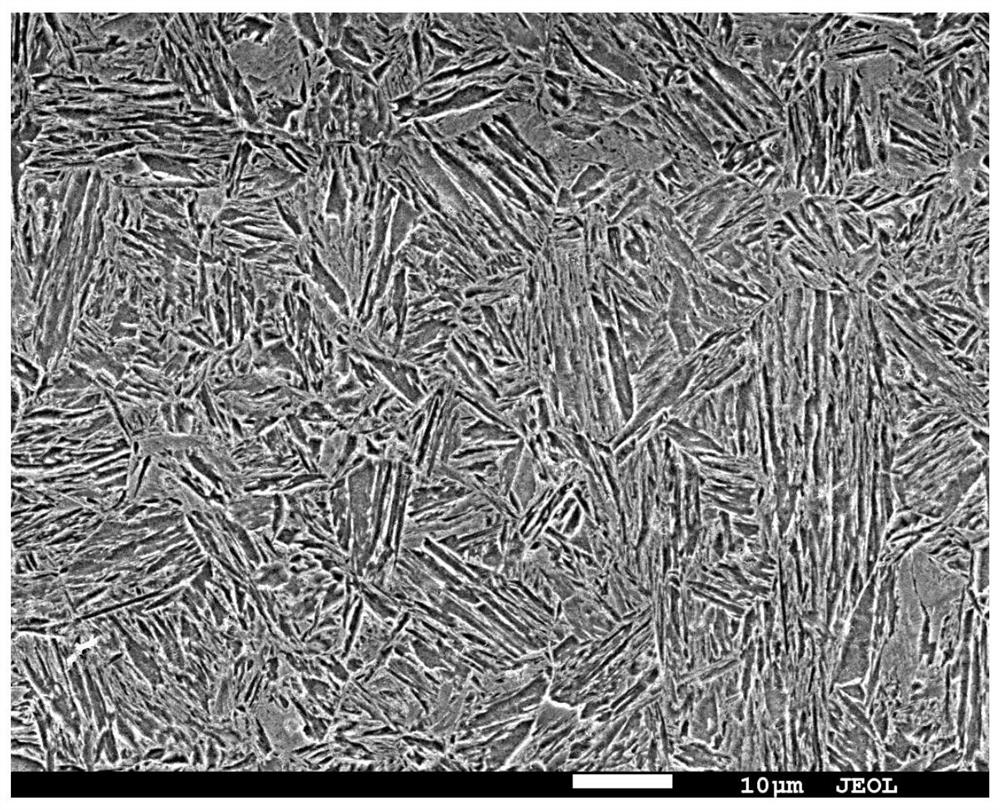

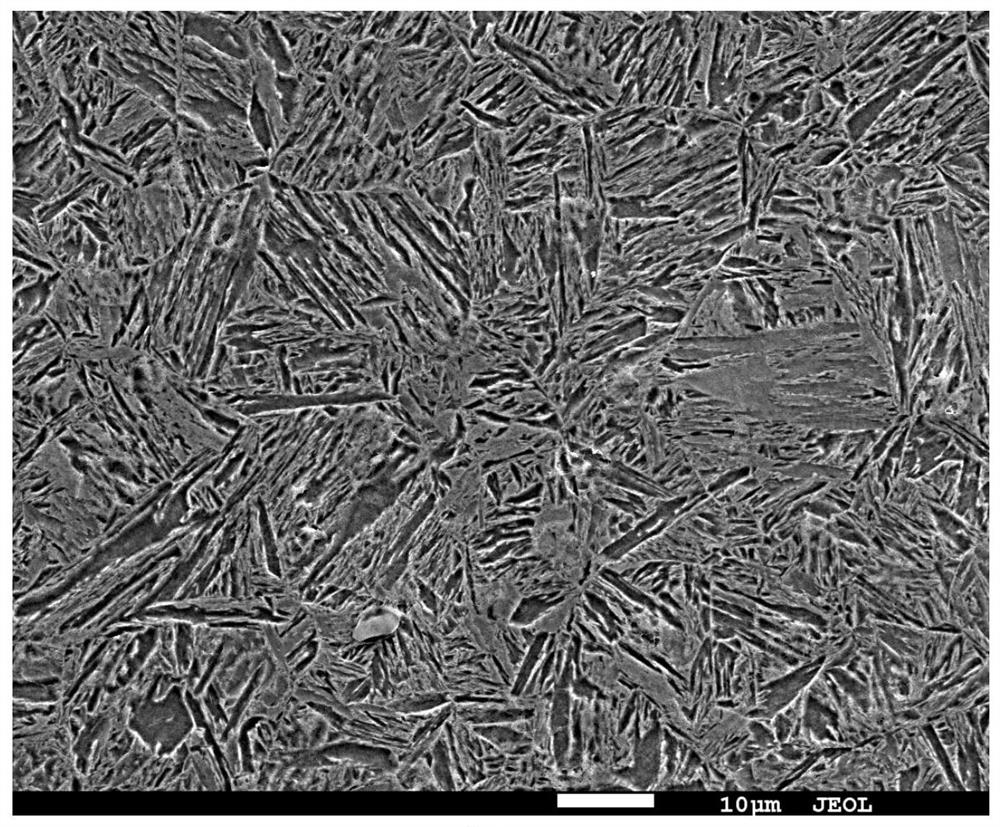

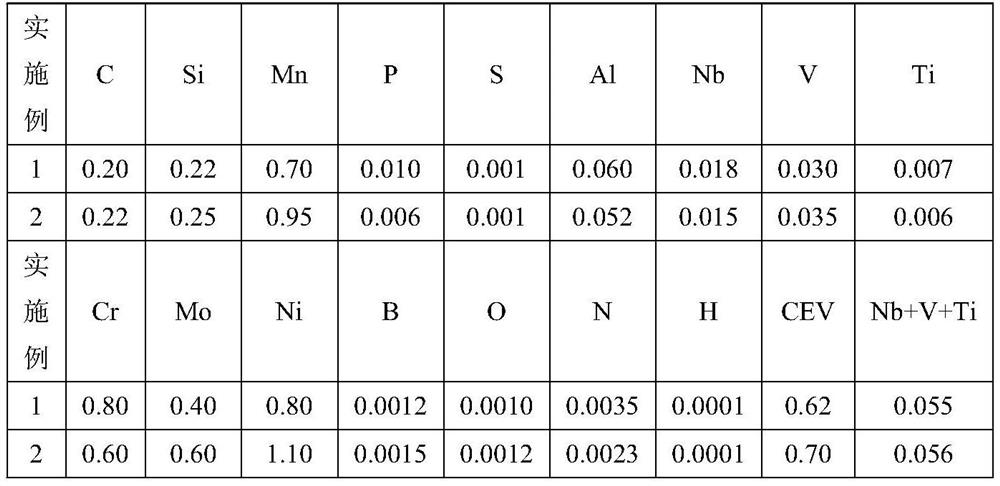

Production method of large-thickness high-toughness yield strength 1100MPa-grade ultrahigh-strength steel plate

ActiveCN111996437ADecreased cardiac performanceGuaranteed StrengthFurnace typesProcess efficiency improvementSteelmakingTemperature control

The invention relates to a production method of a large-thickness high-toughness yield strength 1100 MPa-grade ultrahigh-strength steel plate. The production method comprises the technological processes of converter or electric furnace steelmaking, LF refining, VD or RH vacuum degassing, Ca treatment, continuous casting, casting blank slow cooling diffusion treatment, heating, rolling, steel plateslow cooling diffusion treatment, quenching and tempering. Slow cooling diffusion treatment is carried out by adopting casting blank and steel plate offline residual heat. The casting blank slow cooling diffusion starting temperature is controlled to be 600-700 DEG C, the diffusion time is longer than or equal to 48 hours, and the diffusion ending temperature is smaller than or equal to 300 DEG C; the diffusion starting temperature of the steel plate is greater than or equal to 300 DEG C and the diffusion time is greater than or equal to 24 hours. By means of the two slow cooling diffusion processes, the content of harmful gas in the finished steel plate is greatly reduced, distribution of different chemical elements is homogenized, generation of internal stress of the steel plate is reduced, and a good foundation is laid for improving the ultralow-temperature impact toughness of the steel plate and the uniformity of the performance in the thickness direction.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

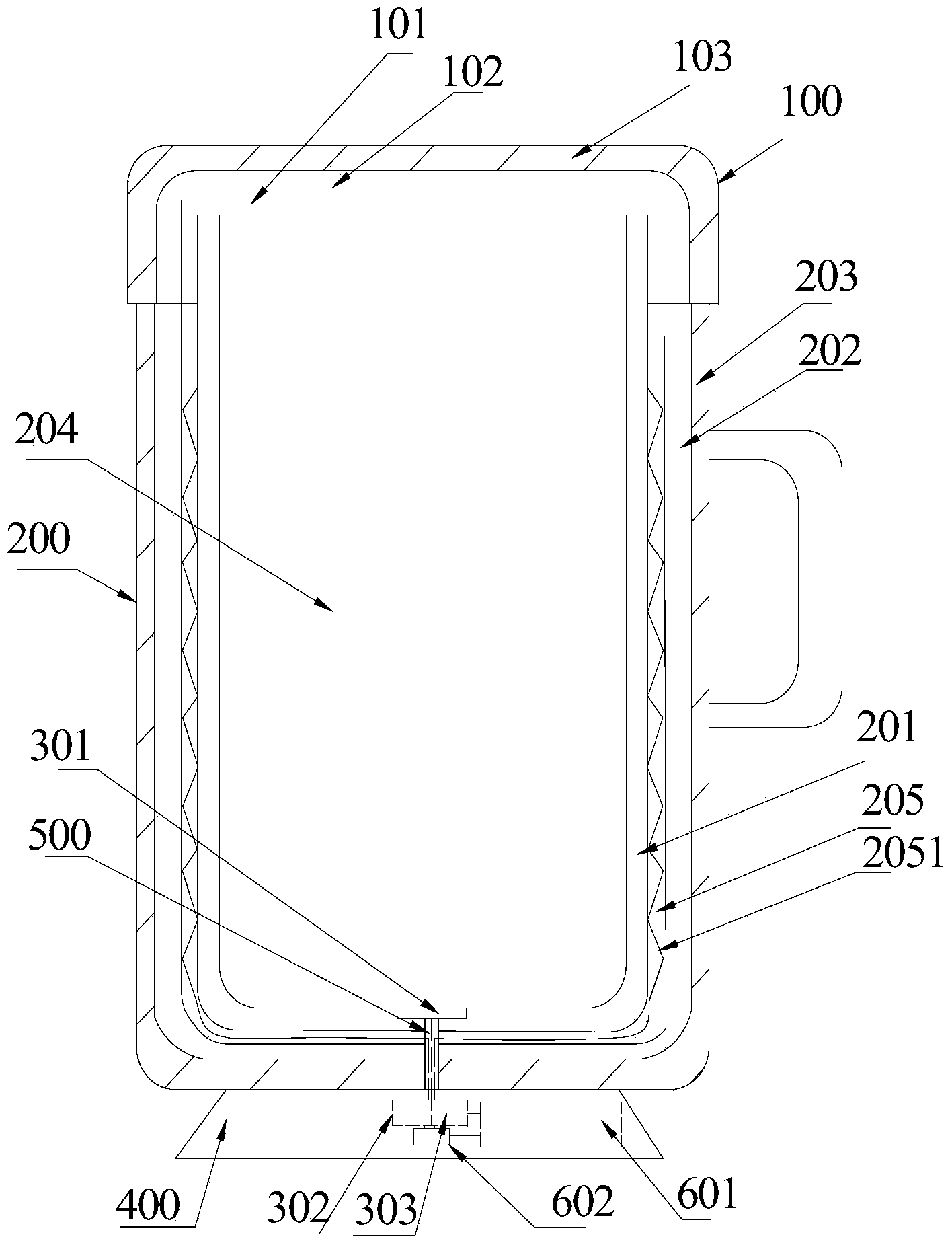

Novel heat-preserving cup

InactiveCN103622425ANot easy to loseSmall temperature differenceWarming devicesDrinking vesselsHeat conductingElectrical and Electronics engineering

The invention provides a heat-preserving cup which comprises a cup body and a cup cover, wherein both the cup body and the cup cover have inner walls made from heat conducting materials, and the peripheries of the inner walls of the cup body and the cup cover are respectively coated with first and second heat storage layers. Heat storage matters are packaged in the heat storage layers. The peripheries of the first and second heat storage layers are respectively coated with heat-preserving layers. A base is further arranged at the bottom of the heat-preserving cup. The base is internally provided with a power supply and a power supply switch. A heating layer is further arranged between the first heat storage layer and the inner wall of the cup body. The heating layer is internally provided with a heating wire which is connected with the power supply. The power supply switch is used for controlling on-off of the heating wire. The heat-preserving cup provided by the invention has the characteristic of a good lasting heat-preserving effect.

Owner:江门市新会金瓶金属制品有限公司

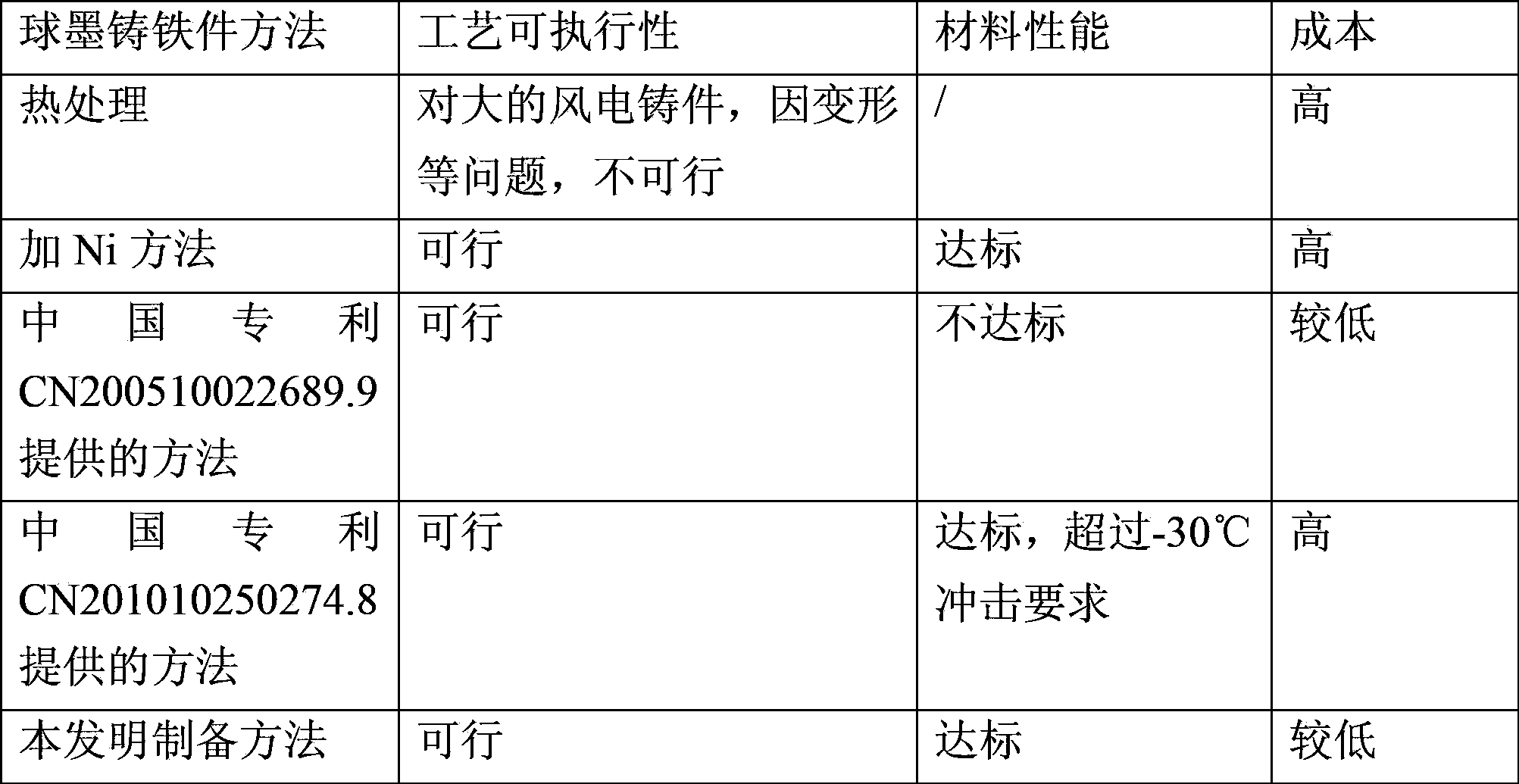

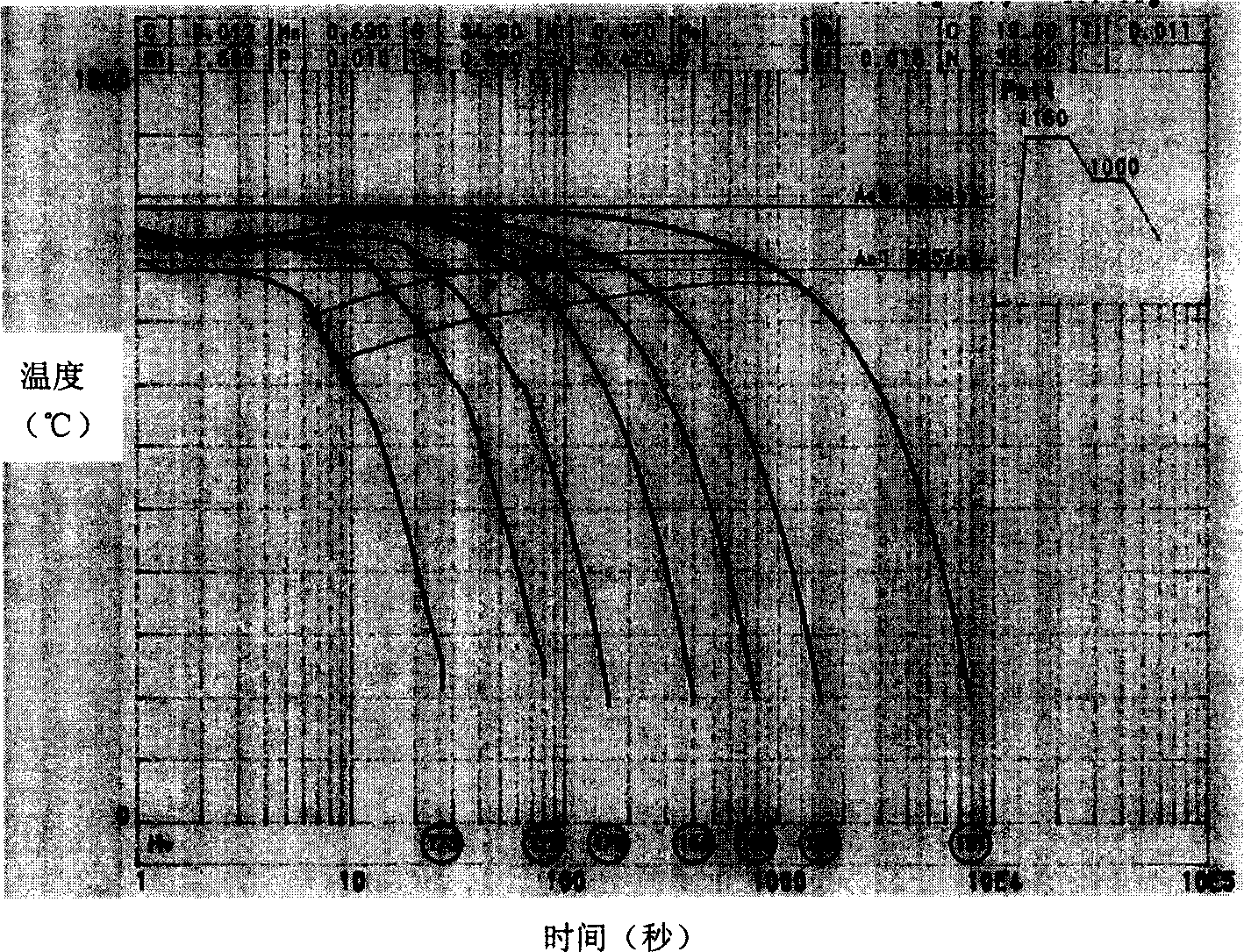

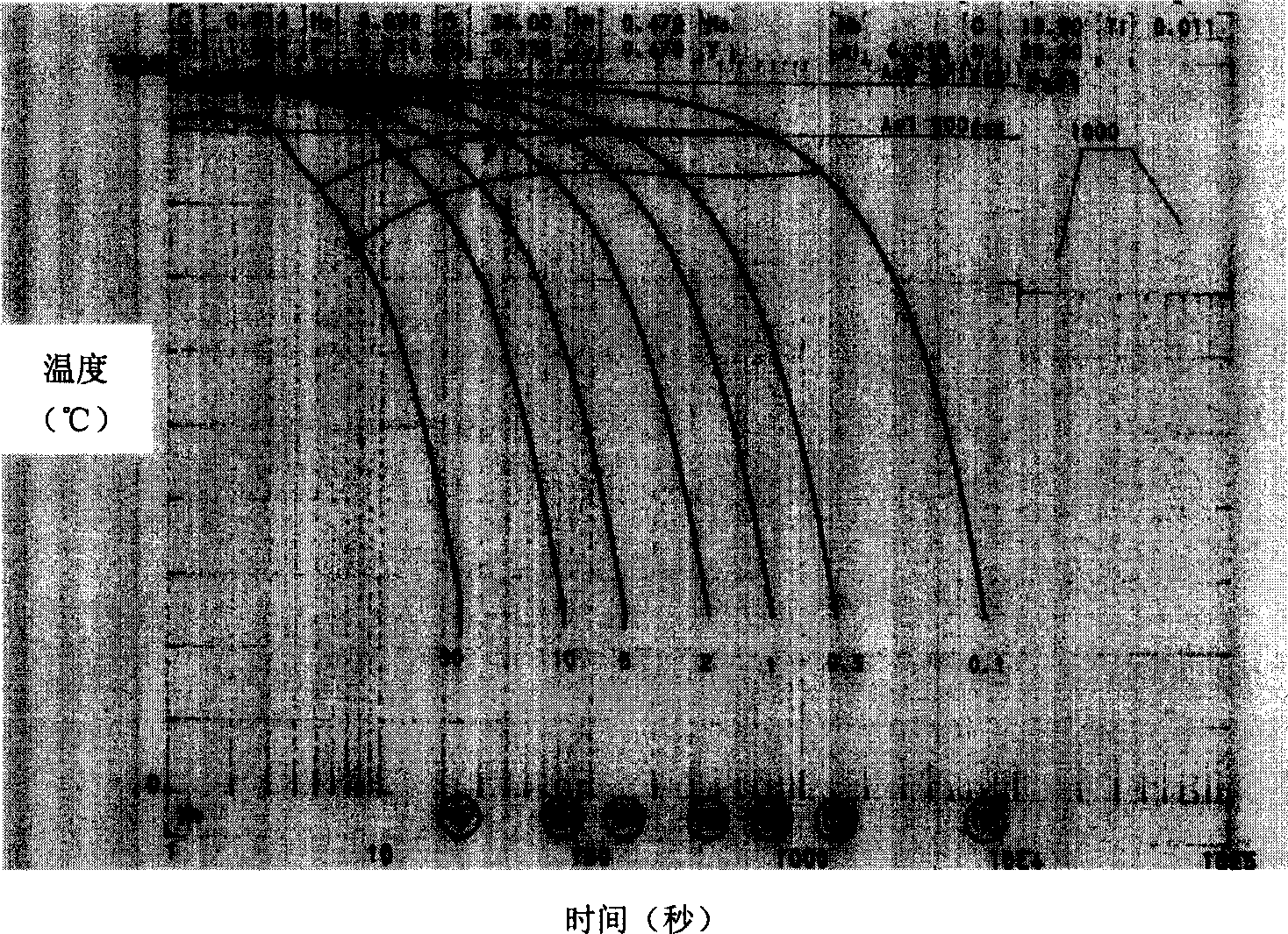

Preparation method of megawatt wind power high-strength high-toughness low-temperature (-30 DEG C) spheroidal graphite iron casting

ActiveCN103898396AMeet low temperature impact performance requirementsLow costFoundry mouldsFoundry coresElectricityRare earth

The invention belongs to the technical field of cast iron, and particularly relates to a preparation method of a megawatt wind power high-strength high-toughness low-temperature (-30 DEG C) spheroidal graphite iron casting. According to the method, under the conditions of no thermal processing, no alloy element nickel and no specific rare earth spheroidizing agents and adoption of domestic pig iron, by reasonable component control and addition of the microelement Sb, a test lug is obtained with relatively low spheroidizing and inoculating processing cost and not only meets impact toughness at -30 DEG C but also meets the GJS-400-18U-LT tensile property. A megawatt wind power casting can be obtained and the nesting performance of the body of the casting can reach 80% of that of the test lug. The preparation method fills the gap of absence of materials meeting the GJS-400-18U-LT and the toughness at -30 DEG C in China.

Owner:JIANGSU JIXIN WIND ENERGY TECH +1

Method and equipment for drying and carbonizing wood integrally on vacuum condition

InactiveCN106426473AShorten carbonization timeImprove processing efficiencyDrying solid materials without heatWood treatment detailsWood dryingHeating cooling

The invention provides equipment for drying and carbonizing wood integrally. The equipment comprises a pressure adjusting system, a heating and cooling system, a material loading, transporting and pressurizing system and a water drainage system; an exo-box heat conduction oil pipe of the heating and cooling system penetrates through a treatment box and is welded to a wall of the treatment box for being sealed; a water inlet valve of the water drainage system is connected to the treatment box and a water drainage box through connection pipelines; and an outer wall of a hydraulic cylinder of the material loading, transporting and pressurizing system is welded to the treatment box in a sealed mode. The equipment has the advantages that the repeated loading, stacking, heating and cooling steps of the drying and heat treating steps of wood are reduced, so that the processing efficiency is improved, and the energy consumption is lowered; a processing method is flexible and multipurpose and the equipment is multifunctional; the whole drying and carbonizing treatment is carried out on the vacuum and negative pressure conditions, the content of air in the treatment box is small, and the oxygen content is low; carbonized wood making contact with a hot plate can be fast cooled; and the wood can be prevented from being deformed, warped and cracked in the vacuum drying and vacuum carbonizing stages.

Owner:GUANGDONG YIHUA TIMBER IND

Soft magnetic structure steel possessing good low temperature toughness and easy welding preformance and its manufacturing method

InactiveCN1534105AEliminate internal stressImprove electromagnetic performanceMagnetic materialsVolumetric Mass DensityMagnetic flux

An easily weldable soft-magnetic structure steel with better low-temp toughness contains C (0.01-0.02 wt.%), Si (1-2), Mn (0.6-1.0), P (0-0.015), S (0-0.008), Al (0.001-0.01), Cr (0-0.6), Cu (0.2-0.6), Ti (0.005-0.02), Ni (0-1.0), Mg (0.001-0.008), [0] (0.001-0.008), N (0.001-0.006), Ca or REM (0-0.005) and Fe (rest). Its advantages are high strength, low-temp (-30- -40 deg.C) impact toughness, weldability, resistivity and magnetic flux density, better resistance to magnetic ageing and atmosphere corrosion, and low cost.

Owner:TONGJI UNIV +1

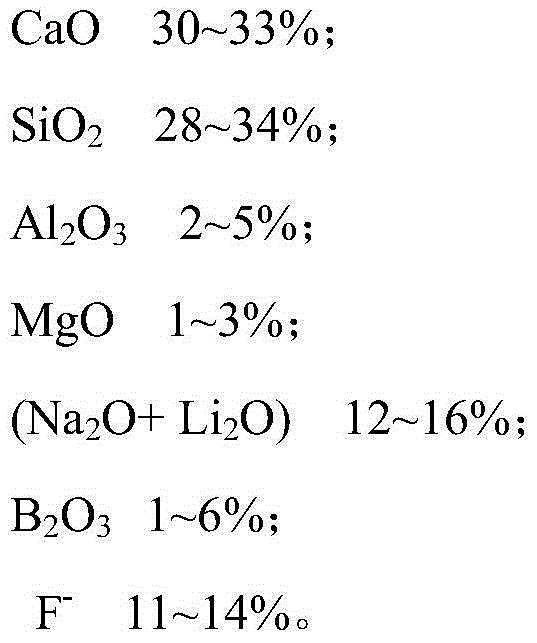

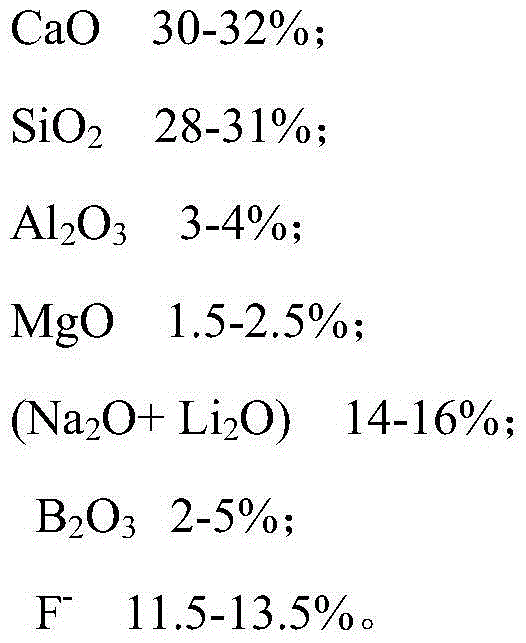

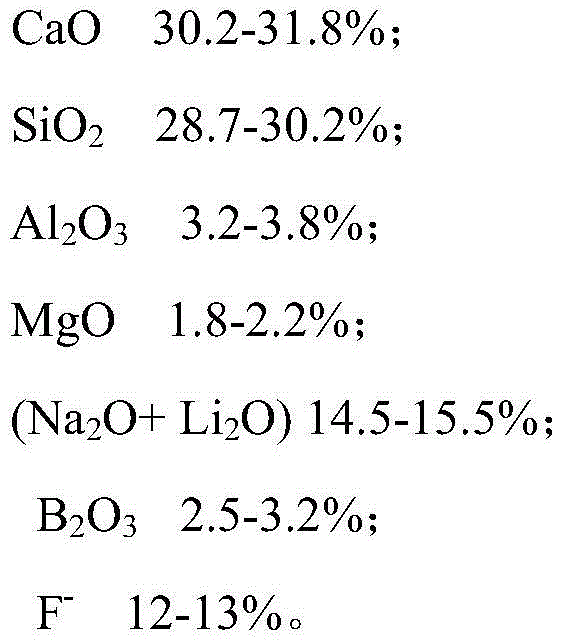

Novel casting powder and application thereof

The invention relates to novel casting powder and application thereof, and belongs to the technical field of steel continuous casting powder. The casting powder comprises the following components according to mass percentage, 30-33% of CaO, 28-34% of SiO2, 2-5% of Al2O3, 1-3% of MgO, 12-16% of (Na2O+Li2O), 1-6% of B2O3, and 11-14% of F-. The casting powder has the characteristics of low melting point (950 to 1,050 DEG C), low viscosity (the viscosity is 0.06 to 0.10Pa.s at the temperature of 1,300 DEG C), high crystallization temperature (1,215 to 1,302 DEG C) and the like. The casting power designed by the invention is suitable for the continuous casting of high-carbon chromium-containing steel of which the mass percentage of C is 1.3-1.8% and the mass percentage of Cr is 10-15%. When the casting powder is applied to the continuous casting production of a high-carbon chromium-containing steel slab, Cr2O3 and other impurities with a high melting point in a crystallizer can be effectively absorbed, the infiltration capability of the casting powder is improved, and the slow cooling of a meniscus is implemented, so that the objectives of increasing the lubricating of a casting blank, controlling the heat transferring at the meniscus, reducing the cracking and inclusion of the casting blank and improving the quality of the casting blank are achieved.

Owner:CENT SOUTH UNIV

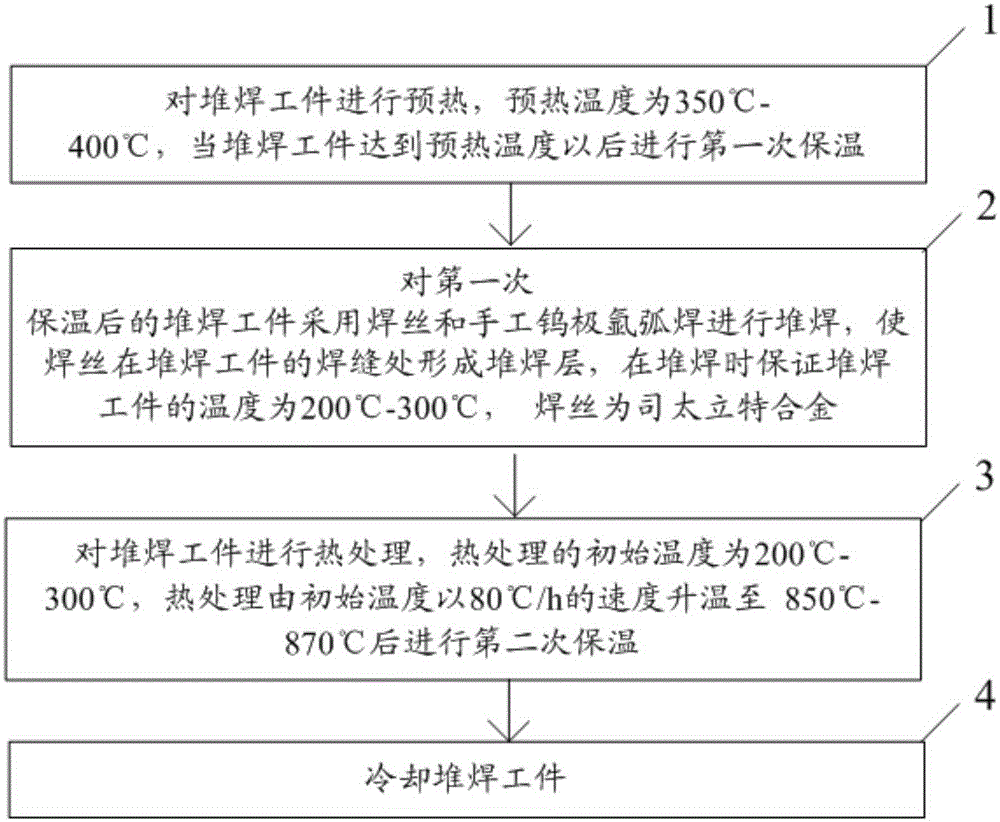

Welding method for conducting build up welding through stellite alloy

InactiveCN105171186AReduce cooling rateSlow coolingArc welding apparatusWelding/cutting media/materialsStellite alloyAlloy

The invention discloses a welding method for conducting build up welding through stellite alloy, and belongs to the field of welding. The method includes the steps that the first time of heat preservation is conducted after a build up welded workpiece is preheated; build up welding is conducted through a welding wire and manual argon tungsten-arc welding by means of the build up welded workpiece after the first time of heat preservation so that the welding wire can form a build up welded layer at the weld joint of the build up welded workpiece, wherein it is ensured that the build up welded workpiece is 200 DEG C to 300 DEG C in the build up welding process, and the welding wire is made of stellite alloy; after welding is completed, thermal treatment is conducted on the build up welded workpiece, wherein the initial temperature of thermal treatment is 200 DEG C to 300 DEG C, and the second time of heat preservation is conducted after the initial temperature of thermal treatment is raised to 850-870 DEG C at the speed of 80 DEG C per hour; and cooing is conducted. According to the method, the build up welded workpiece is preheated, the cooling speed of the weld joint can be decreased through preheating, the welded build up welded workpiece can be slowly cooled, a product is prevented from generating welding cracks especially cold cracks, and meanwhile it can be ensured that the build up welded layer has high strength.

Owner:WUHAN MARINE MACHINERY PLANT

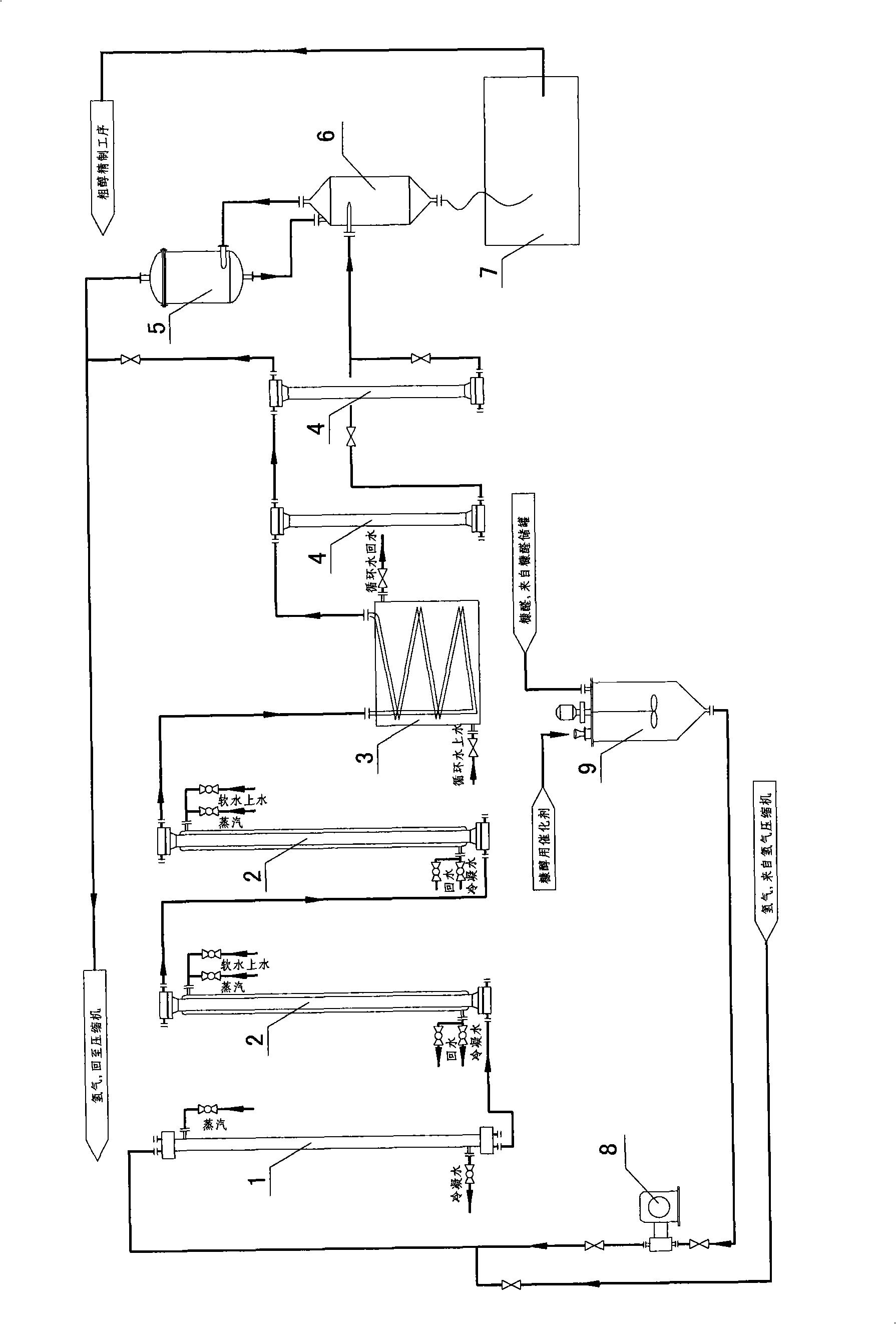

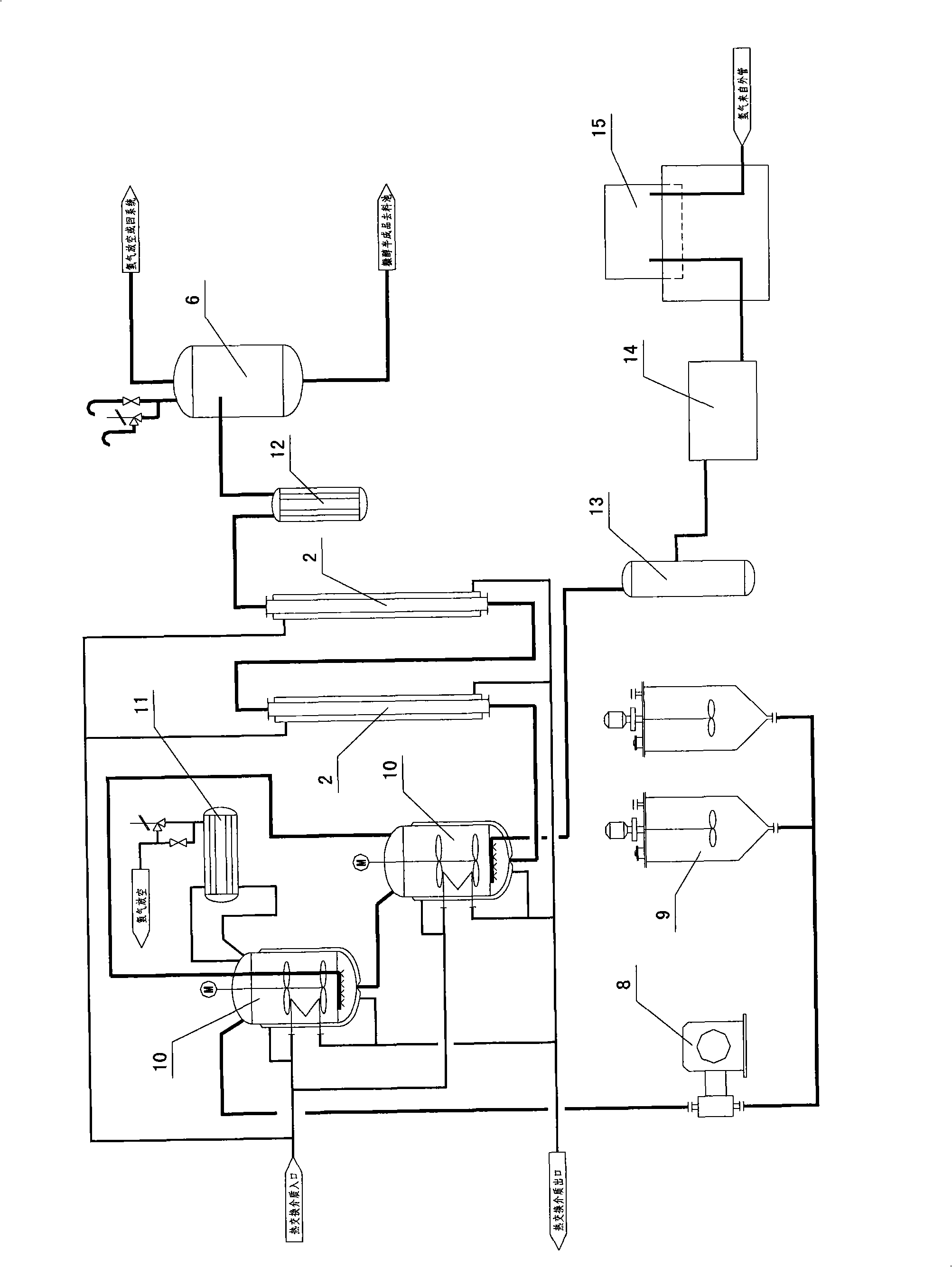

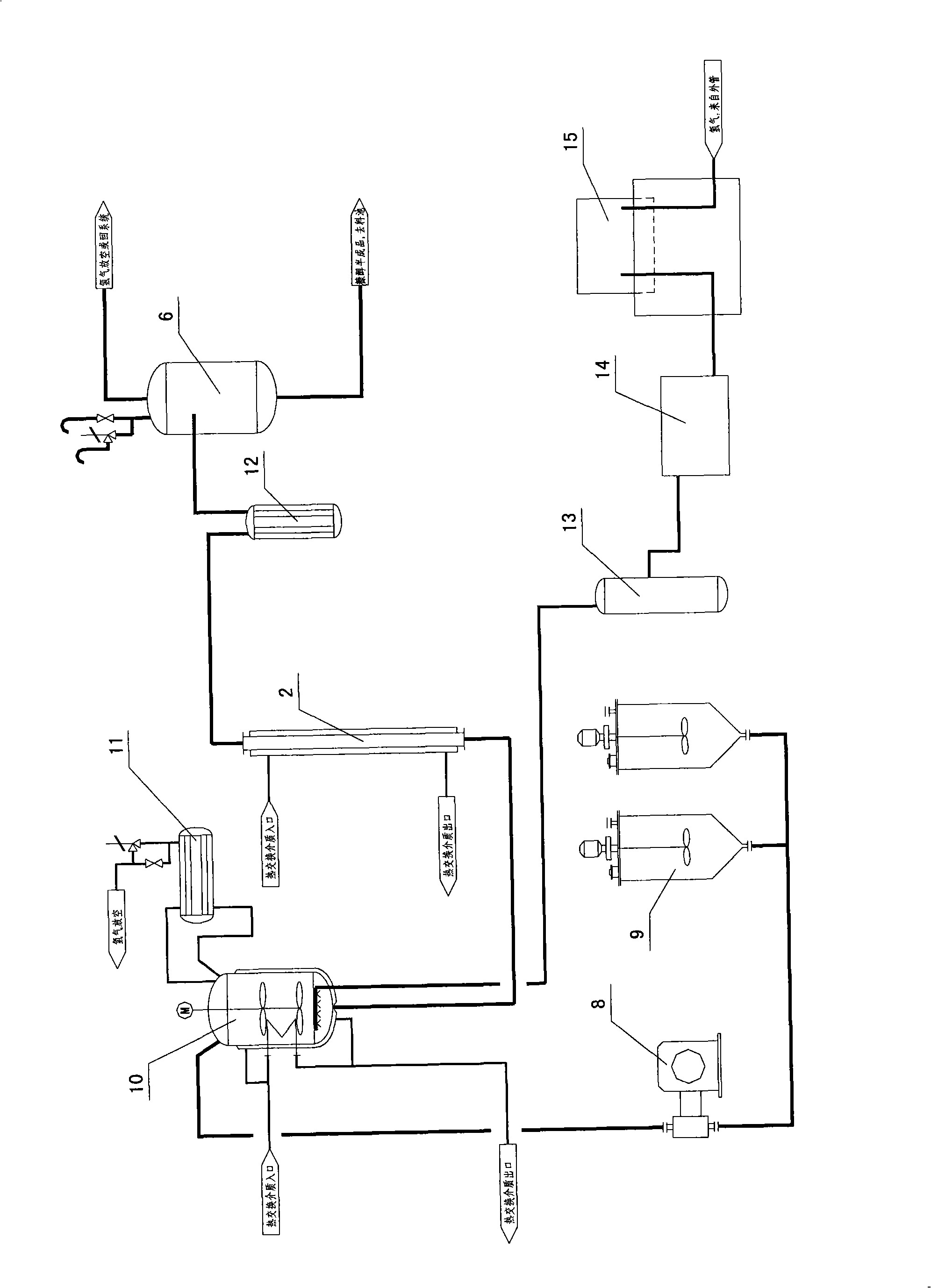

Method and system for preparing furfuryl alcohol by furfural liquid phase hydrogenation

The invention relates to a method for preparing furfuryl alcohol by taking furfural as a material through hydrogenation and a system thereof. The method disclosed in the invention includes the steps as follows: one or a plurality of complete mixing flow reactors and one or a plurality of plug-flow reactors are connected in series for combined-use; reaction materials are continuously arranged in the reactors for continuous reaction so as to obtain the furfuryl alcohol, wherein, the reaction materials include the material of furfural, a catalyst and hydrogen. The invention also relates to a system used in the method. The method of the invention has the advantages of low reaction temperature, stable operation as well as less material and energy consumption.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Method for making dry white wine through red grape varieties

The invention discloses a method for making dry white wine through red grape varieties. The method is characterized by comprising the process steps of determining of the grape picking period, harvesting of grapes, ear-by-ear selection, peduncle removal, grain-by-grain selection, crushing, low-temperature juice taking, low-temperature clarification, juice separation and temperature increasing, low-temperature alcohol fermentation, tank transferring, ageing or storage, fining, freezing, sterilization, filling and the like. In this way, the produced dry white wine is pale yellow or straw yellow in color, clarified, transparent and glossy. The dry white wine has the pure, active, elegant, fresh and rich fruit aroma; the wine after ageing also has complicated and rich ageing fragrance, and is soft in mouthfeel, fresh, tasty and refreshing.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Manufacturing method for colored fluorine-free imitation ceramic glaze

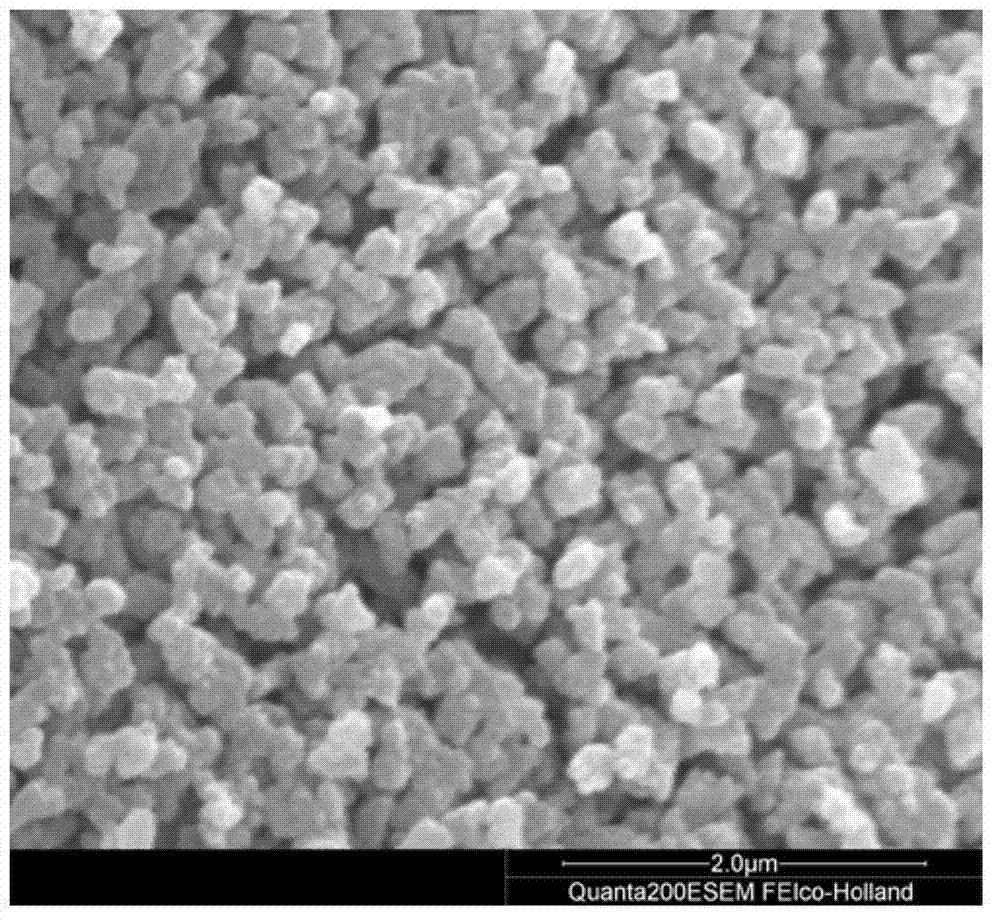

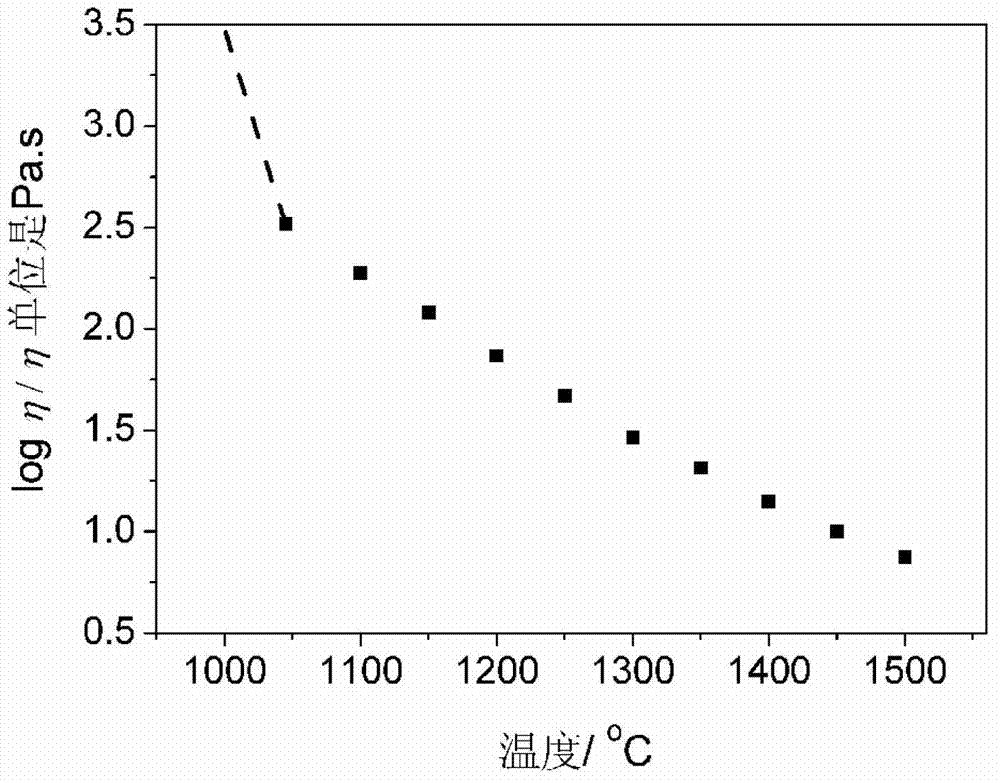

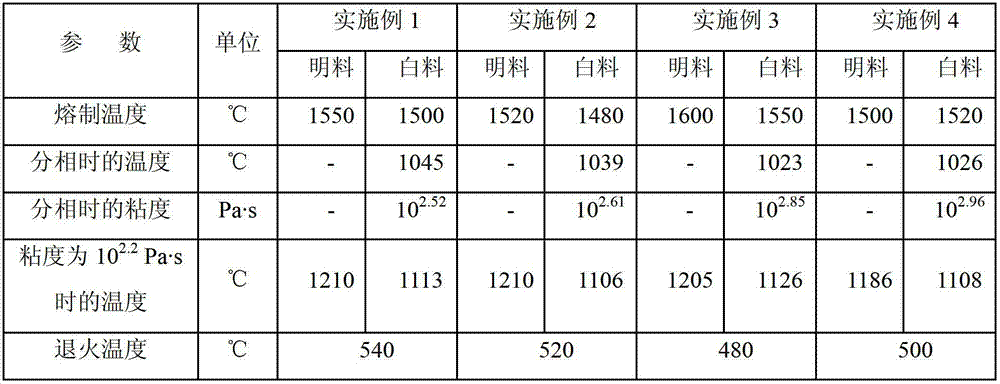

ActiveCN102786202AReduce cooling rateSlow coolingGlass blowing apparatusDevitrificationPhase splitting

A manufacturing method for colored fluorine-free imitation ceramic glaze belongs to the field of advanced glass materials. According to the manufacturing method, a melt jacking blowing method is adopted, and the five-layer colored fluorine-free imitation ceramic glaze is prepared by dip blowing according to the sequence of bright material, white material, bright material, pigment and bright material. The manufacturing method overcomes the defect that the traditional imitation ceramic glass production greatly depends on the initial temperature of glass melt phase-splitting or devitrification and the cooling speed during forming; and meanwhile, the manufacturing method realizes very good opacifying effect under the condition of lower phosphorous content, and the common defects of uneven opacifying degree, stripe and the like are not liable to occur.

Owner:淄博市宝泉轻工制品有限公司

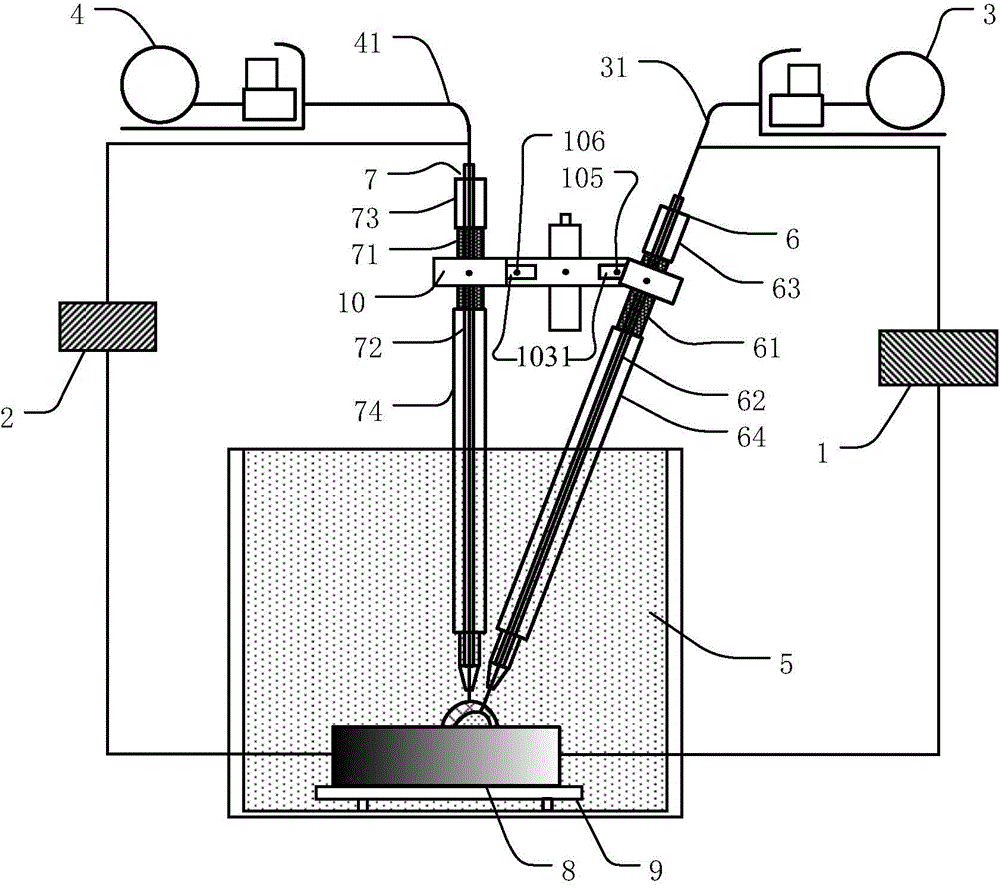

Double-wire underwater wet welding device and method

InactiveCN104400181AStable combustionIndependently adjustable welding parametersElectrode supporting devicesElectric arcBase metal

The invention relates to a double-wire underwater wet welding device and a double-wire underwater wet welding method. The welding device comprises a master welding gun power supply, a slave welding gun power supply, a master wire conveyor, a slave wire conveyor, a master welding gun and a slave welding gun, wherein the master welding gun and the slave welding gun are respectively connected to the master welding gun power supply and a slave welding gun power supply, a master welding wire and a slave welding wire are respectively conveyed to the end parts of the master and slave welding guns through the master and slave wire conveyors, the master welding gun and the slave welding gun are respectively arranged to form a certain angle with a workpiece to be welded, and a certain distance is kept between the front end of the master welding gun and the front end of the slave welding gun. According to the double-wire underwater wet welding device and method, the two welding wires in the master and slave welding guns are heated mutually, and the energy of electric arc is fully used, so that the deposition rate is greatly improved, and the problem that the underwater wet welding molten bath and the base metal cannot be fully fused is overcome.

Owner:HARBIN INST OF TECH AT WEIHAI

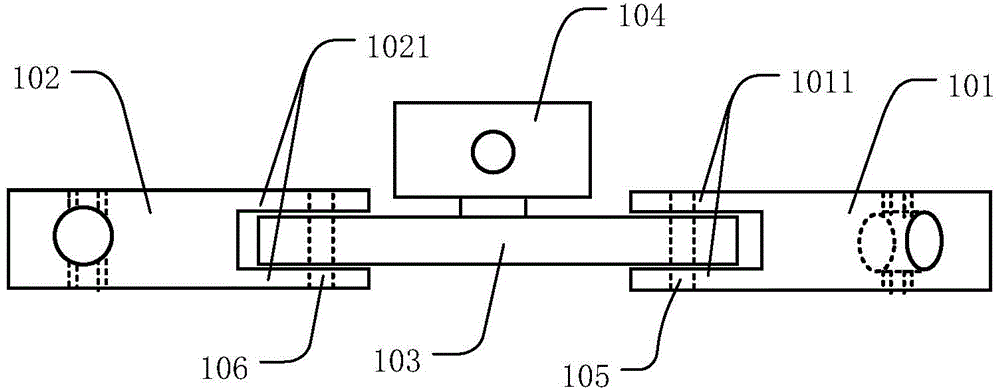

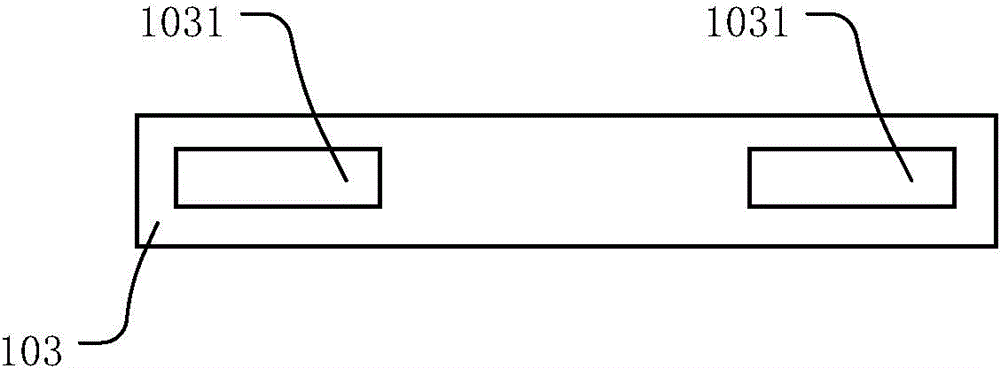

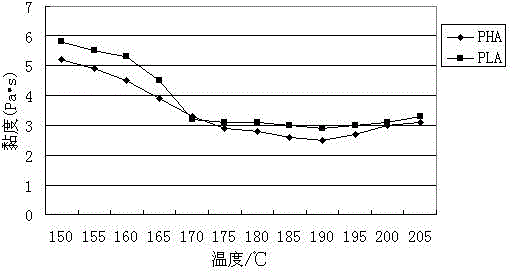

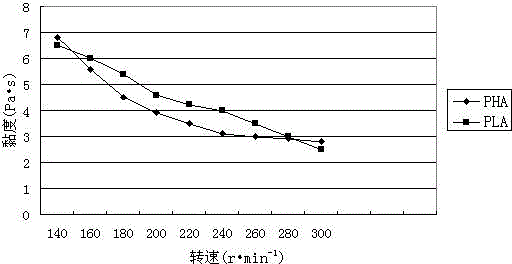

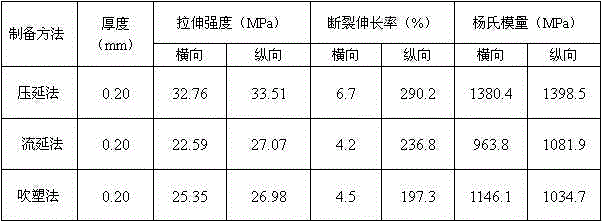

Degradable PHA/PLA mixture film and preparation method thereof

The invention discloses a degradable PHA / PLA mixture film and a preparation method thereof. The degradable PHA / PLA mixture film comprises, by weight, 30-40 parts of PHA resin and 60-70 parts of PLA resin. Based on the total weight of the PHA and PLA, the degradable PHA / PLA mixture film comprises, by weight, 4.5-12% of a plasticizer, 0.8-1.5% of an inorganic filling material, 0.2-0.7% of an anti-oxidant, 0.3-0.5% of a lubricant and 0.1-0.3% of an antistatic agent. The PHA resin and PLA resin are ground to form powder, the power and other auxiliary agents are blended, are fed into an extruder and are subjected to fusion plasticization, and the extruded product is subjected to calendaring slice formation, taking-away, stretching, cooling, traction, reeling and cutting. The preparation method has simple and easy processes. The degradable PHA / PLA mixture film has performances satisfying usage requirements on a card-based industry, a printing industry and a package industry.

Owner:江苏华信高新材料有限公司

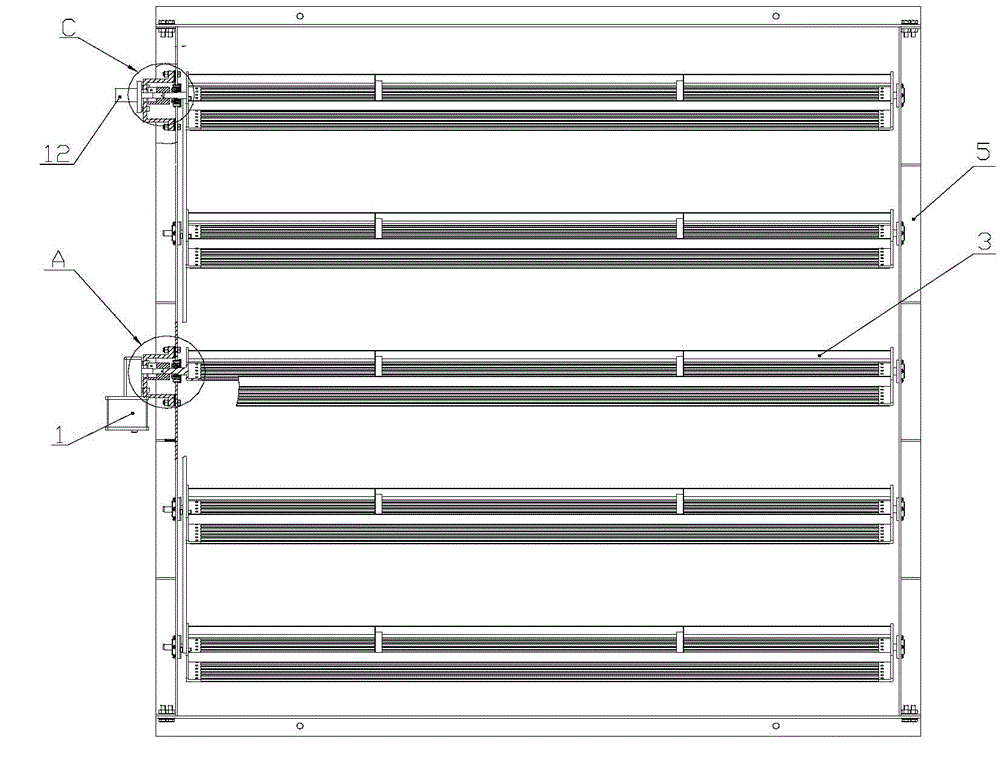

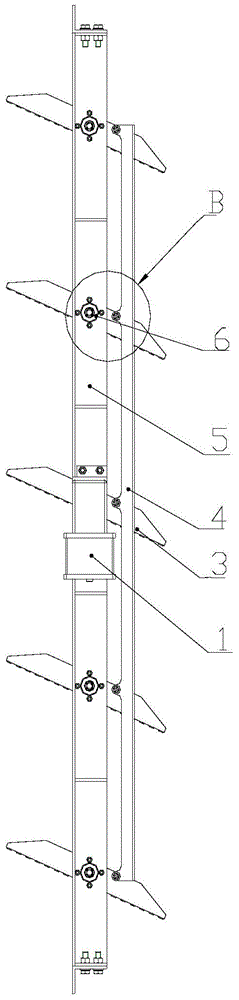

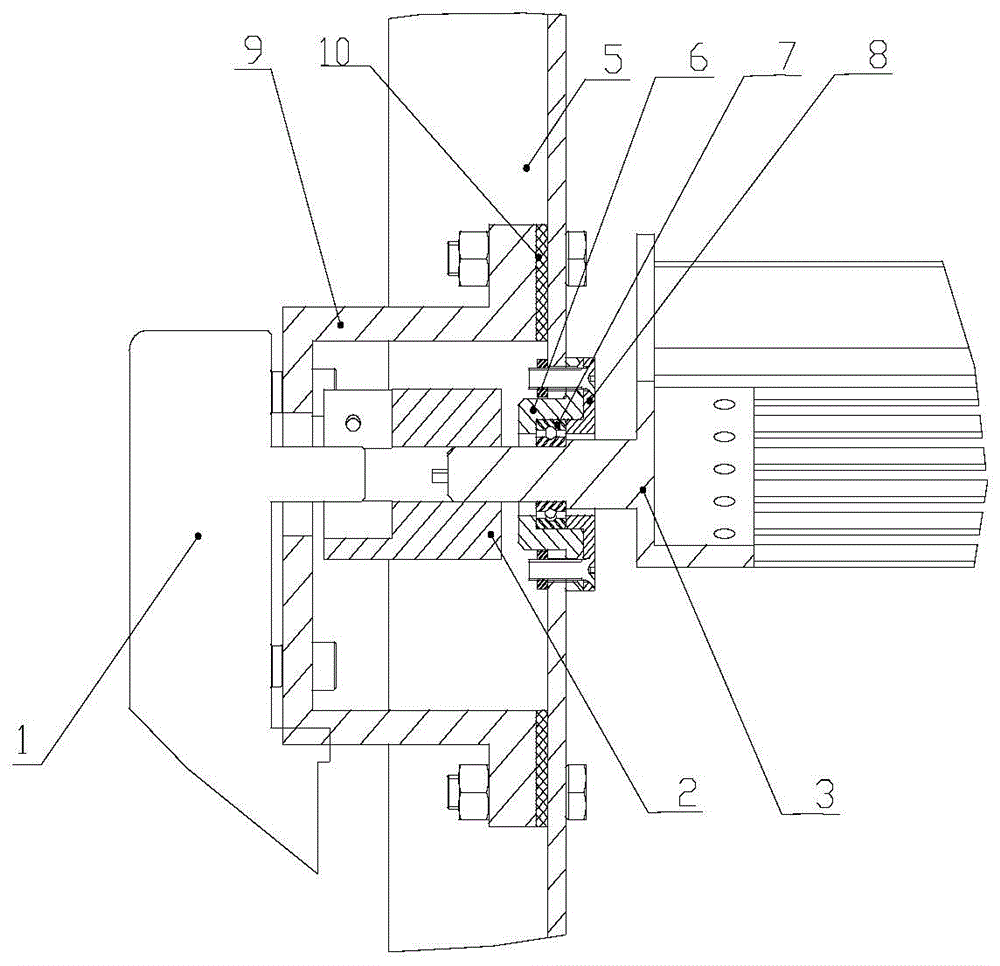

Shutter type rotatable infrared heating cage

InactiveCN106275523ALow temperature rangeSlow coolingCosmonautic condition simulationsOhmic-resistance heatingCouplingEngineering

The invention discloses a rotatable shutter type infrared cage used in a vacuum heat test process of a spacecraft. The rotatable shutter type infrared cage mainly comprises an infrared cage main framework, a gear motor, a coupling, connecting rods, pin shafts, heating assemblies, bearings, bearing seats, and an angle sensor, wherein a motor mounting seat of the gear motor is arranged on the side surface of the main framework; an output shaft of the gear motor on the motor mounting seat is coaxially connected with one of infrared heating units through the elastic coupling; a plurality of infrared heating units are connected through the connecting rods in parallel connection and are separately fixed through the pin shafts; when the connecting rods in parallel connection, the pin shafts and the heating units are combined together, all the heating units can form a parallel connection mechanism, and under the action of the connecting rods in parallel connection, the heating units synchronously rotate. During simulation of low-temperature environment, the heating units rotate through driving units, so that heating tapes rotate by 90 degrees, heating tape surfaces are vertical to the surface of the spacecraft, the shielding of heating tape strips to the spacecraft is reduced, the area of the spacecraft relative to heat sink radiation is enlarged, and the temperature falling rate of the spacecraft is increased.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Composite synergistic close-graded ultrathin wearing layer asphalt mixture

InactiveCN103588423AEasy constructionImprove workabilitySolid waste managementAsphaltButadiene-styrene rubber

The invention discloses a composite synergistic close-graded ultrathin wearing layer asphalt mixture which comprises the following ingredients in parts by mass: 100 parts of mineral aggregate, 5.4-5.8 parts of SBS (styrene-butadiene-styrene) modified asphalt and a composite synergist with the mass accounting for 0.30-0.40% of the total mass of the mineral aggregate, wherein the mineral aggregate comprises the following ingredients by mass percentage: 95-96% of basalt aggregate and 4-5% of limestone mineral powder. The workable performance and high temperature property of the asphalt mixture are improved mainly by adding the composite synergist which mainly comprises polyoxyethylene, and the thin curing asphalt mixture which is low in cooling rate, easy to compact, good in workable performance, strong in high temperature stability, good in skid resistance and small in paving thickness is provided by optimizing graduation of the asphalt mixture, the amount of asphalt and volume indexes of the asphalt mixture.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

Rapid molten iron conveying method and device combination between interfaces of molten iron and molten steel

The invention relates to a rapid molten iron conveying method and a device combination between interfaces of molten iron and molten steel and belongs to the technical field of metallurgical industry. A molten iron conveying line is configured between a blast furnace or a blast furnace group center line and a converter or a converter group center line, and the molten iron conveying line is configured on one side of a blast furnace casting house; from the blast furnace casting house down into a converter charging aisle, the molten iron conveying line is provided with at least one interruption to divide the molten iron conveying line into a blast furnace side molten iron conveying line and a converter side molten iron conveying line which are connected with each other through a transition device, a molten iron conveying unit consists of a molten iron conveying carrier vehicle and a molten iron jar located on the molten iron conveying carrier vehicle, and the molten iron conveying unit is operated on the molten iron conveying line from the blast furnace casting house down into a converter workshop. According to the rapid molten iron conveying method and the device combination between the interfaces of molten iron and molten steel, a molten iron conveying mode from the blast furnace to a converter is changed, layout of conveying lines is changed, and purposes of saving investment and reducing energy consumption are achieved.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

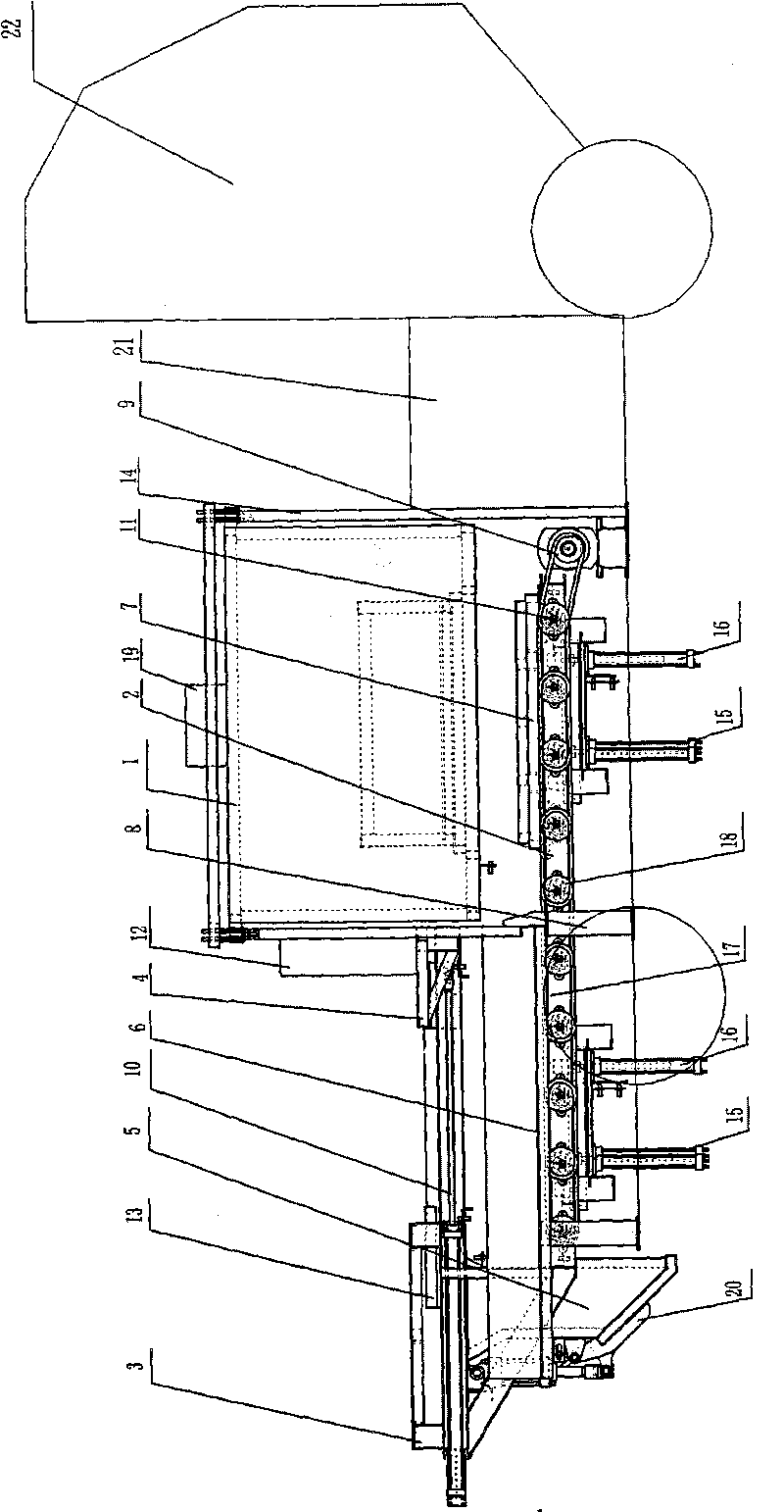

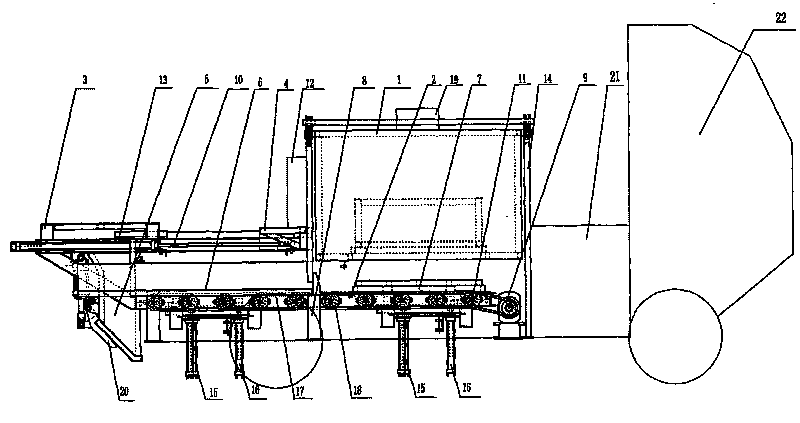

Microwave heating device for fast repairing asphalt pavement

The invention discloses a microwave heating device for fast repairing an asphalt pavement. A furnace body bracket is connected with a microwave furnace body component, a microwave generator is installed in an inner cavity of the microwave furnace body component, the left side of the furnace body bracket is connected with a front part platform device, a discharging device and a control cabinet, a guide angle steel and a tail bracket are connected to the discharging device, the guide angle steel is connected with an operation platform through a connecting rod piece, a heat preservation material storing device is connected below the operation platform, a motor and a reducer are in rolling connection with a synchronizer through a belt or a chain, a plurality of roll wheels are distributed on a motive track at intervals, a closed chain is sleeved on each roll wheel, a lifting device is installed at the upper end of the motive track, the lower end of the left side of the furnace body bracket is connected with supporting legs, and a ventilation opening is arranged at the upper end of the microwave furnace body component, therefore, the invention has the advantages of enhancing the pavement repairing speed, heating quantitative mixture at any time and anywhere according to the needs, removing a long distance transportation link, improving the aggregate performance, overcoming the asphalt ageing, realizing environmental protection, energy saving and equipment automation and lowering the labor intensity and the pavement repairing cost and is suitable for fast repairing the asphalt pavement.

Owner:张东省

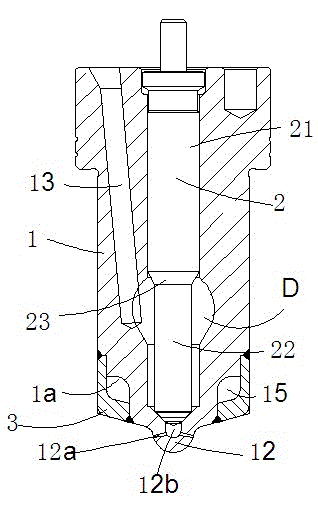

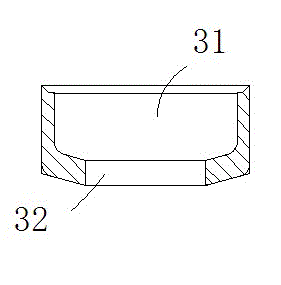

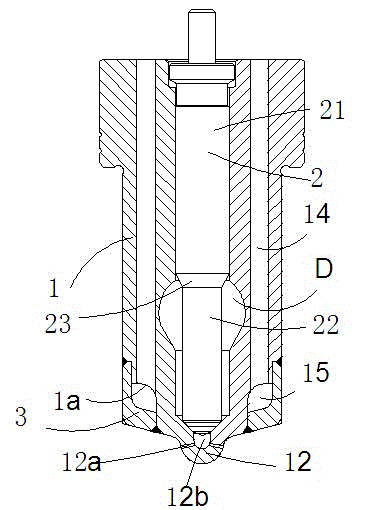

Cooling-type needle valve coupling with carbon deposition prevention effect

ActiveCN102979654ASlow coolingImprove cooling effectFuel injection apparatusMachines/enginesCouplingCooling chamber

The invention discloses a cooling-type needle valve coupling with a carbon deposition prevention effect. The cooling-type needle valve coupling comprises a needle valve body and a needle valve, which are assembled with each other. The needle valve is assembled in a valve chamber which is machined in the needle valve body; an annular clearance passage, through which a high pressure fuel passes, is formed between the outer circumference of the lower rod body of the needle valve and the inner wall of the valve chamber; and the annular clearance passage is communicated with an oil inlet passage. The cooling-type needle valve is characterized in that a cooling water jacket is fixedly mounted to the lower part of the needle valve body, a cooling chamber is formed between the cooling water jacket and the needle valve body, the needle valve body is provided with at least one group of cooling annular passages, the cooling annular passages are communicated with the cooling chamber, the opening at the two ends of each cooling annular passage are formed in the upper surface of the needle valve body; at least two jet holes are formed in the front end of the needle valve body and are communicated with the annular clearance passage. The cooling-type needle valve coupling has the advantages of smart structure, good performance, low oil consumption, less carbon deposition in the nozzle and long service life and can meet the needs for oil-fuel injector needle-valve couplings in marine diesel engines.

Owner:YUYAO SHUCHUN MACHINERY

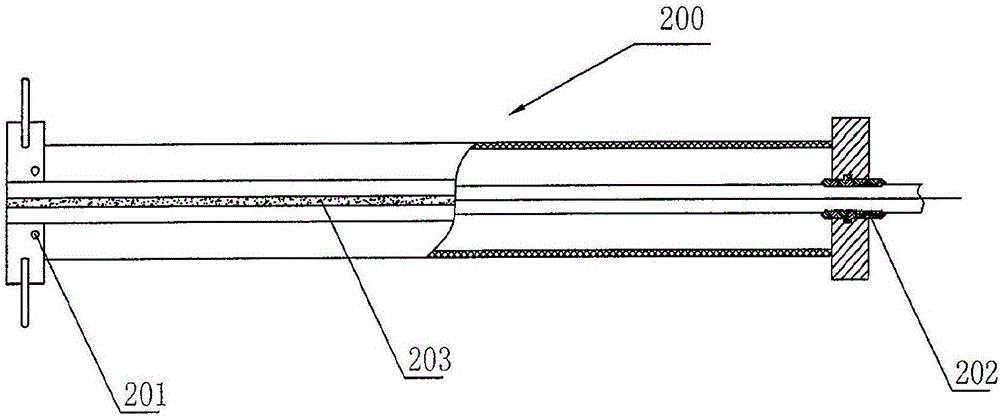

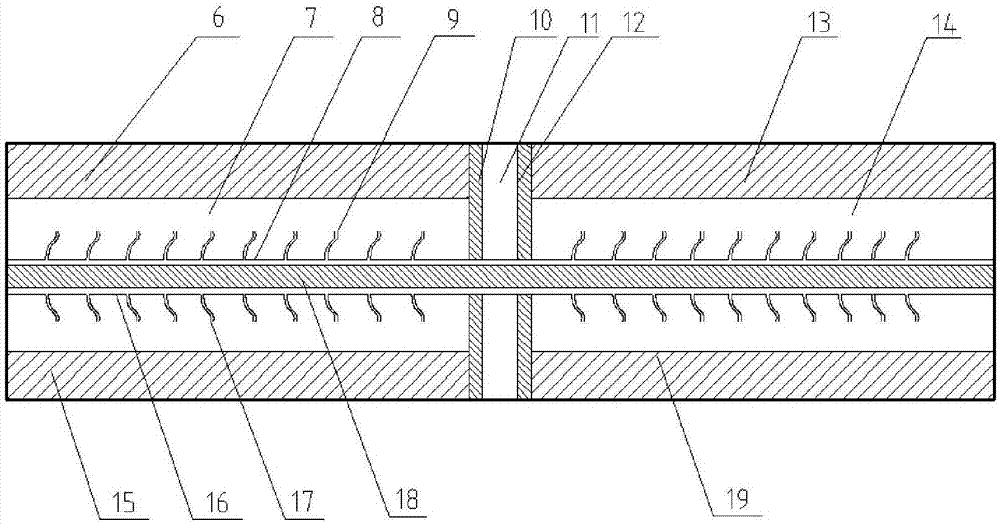

Preparation method of crosslinked polyethylene cable connector

InactiveCN106374397AElectrical performance improvements and enhancementsEliminate void defectsApparatus for joining/termination cablesAnti stressEngineering

The invention relates to a cable connector, in particular to a preparation method of a crosslinked polyethylene cable connector. The preparation method comprises the following steps: firstly, peeling and cutting insulating layers at two ends of a cable so that a core of the cable is exposed; secondly, cutting the crosslinked insulating layers on two sides of the connector to be conical; thirdly, setting an anti-stress cone at the end of the cable, and fixing the treated cable to two ends of an insulating forming die, wherein the insulating forming die comprises a metal outer die and an elastic lining die, an elastic die expansion gap is formed between the metal outer die and the elastic lining die, and the temperature of an inner cavity of the insulating forming die is raised to be 120 DEG C; fourthly, after performing cleaning drying treatment on the surface of the insulating layer, setting an outer semi-conducting layer in combination with an outer shielding layer reserved section of the cable; and fifthly, wrapping a metal belt on the surface of the outer semi-conducting layer in a gap manner, using an oxyhydrogen flame to firmly weld two ends of the metal belt and the outer surface of a lead protective tube so as to form a metal projective sleeve tube, and then using the oxyhydrogen flame to trim welding surfaces at two ends of the metal protective sleeve tube so as to form a slope connecting section.

Owner:重庆三峡电线电缆科技股份有限公司

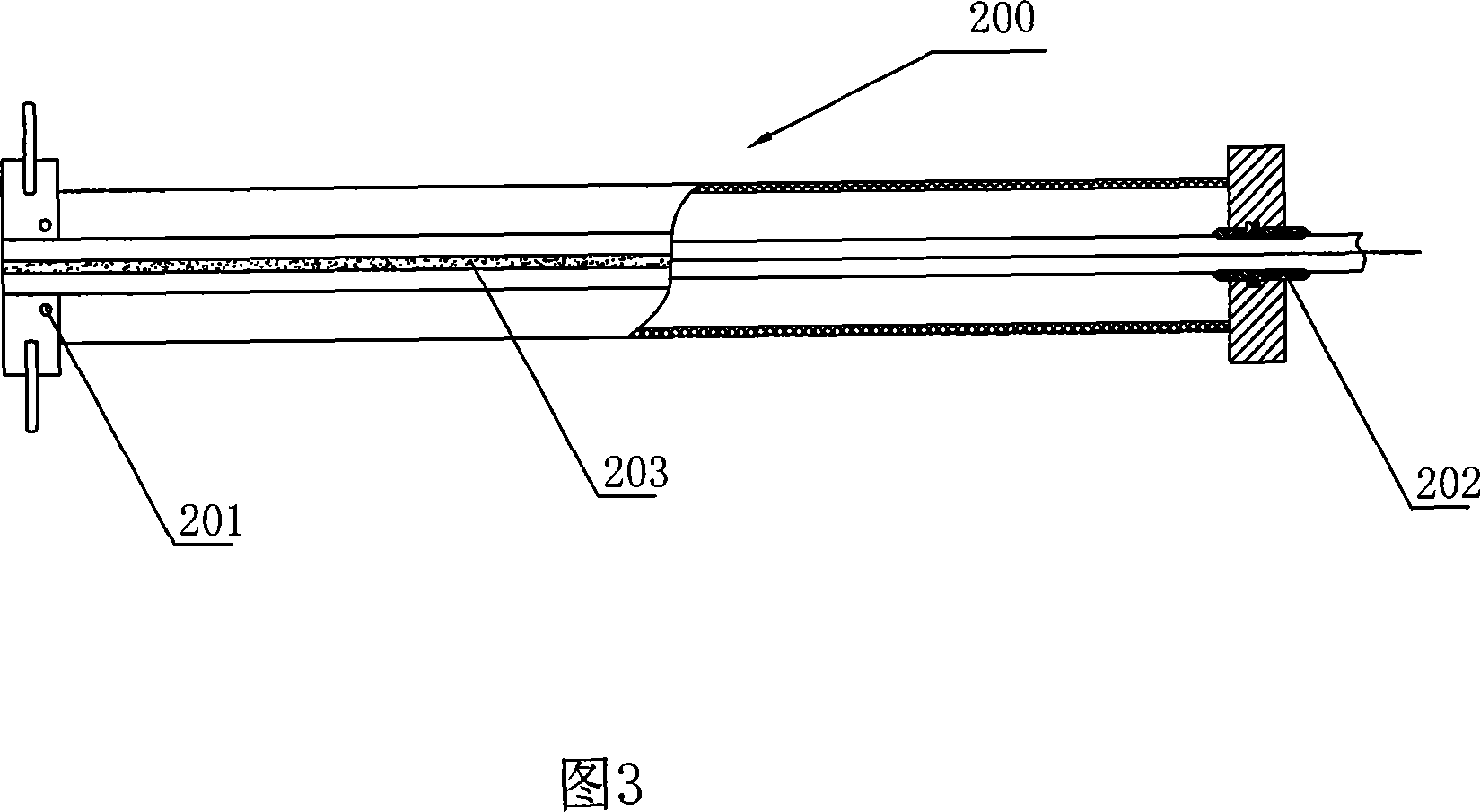

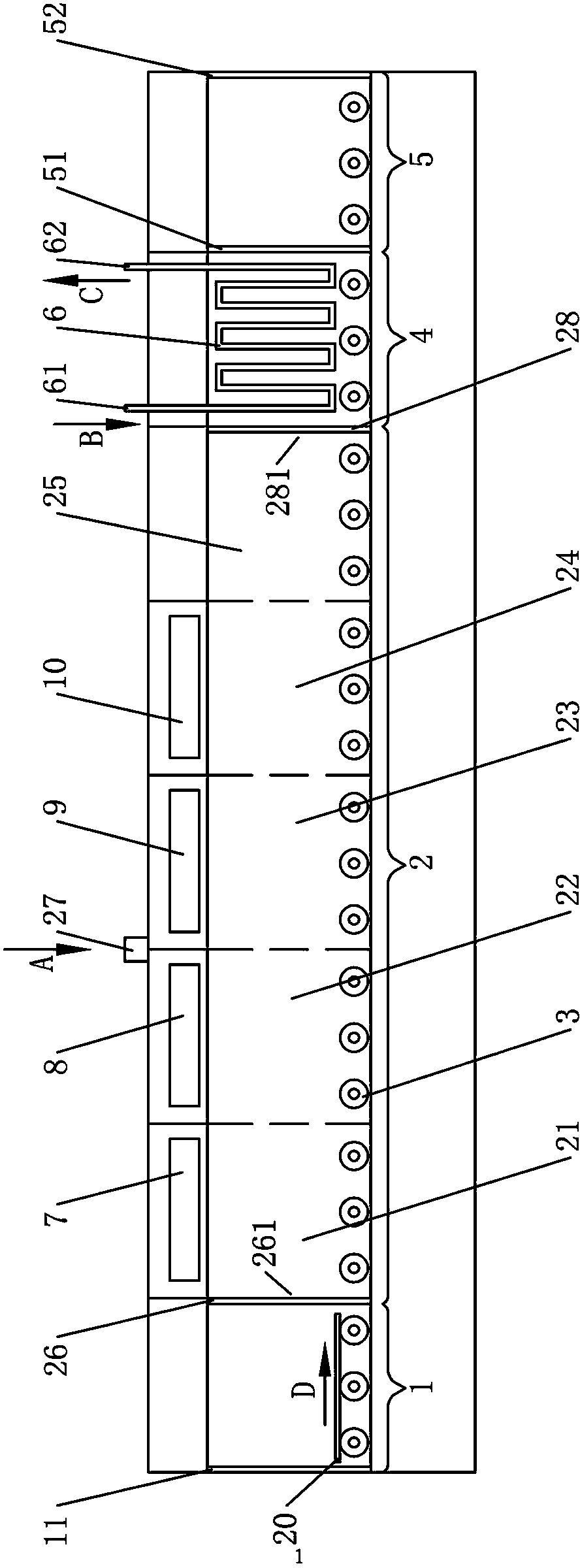

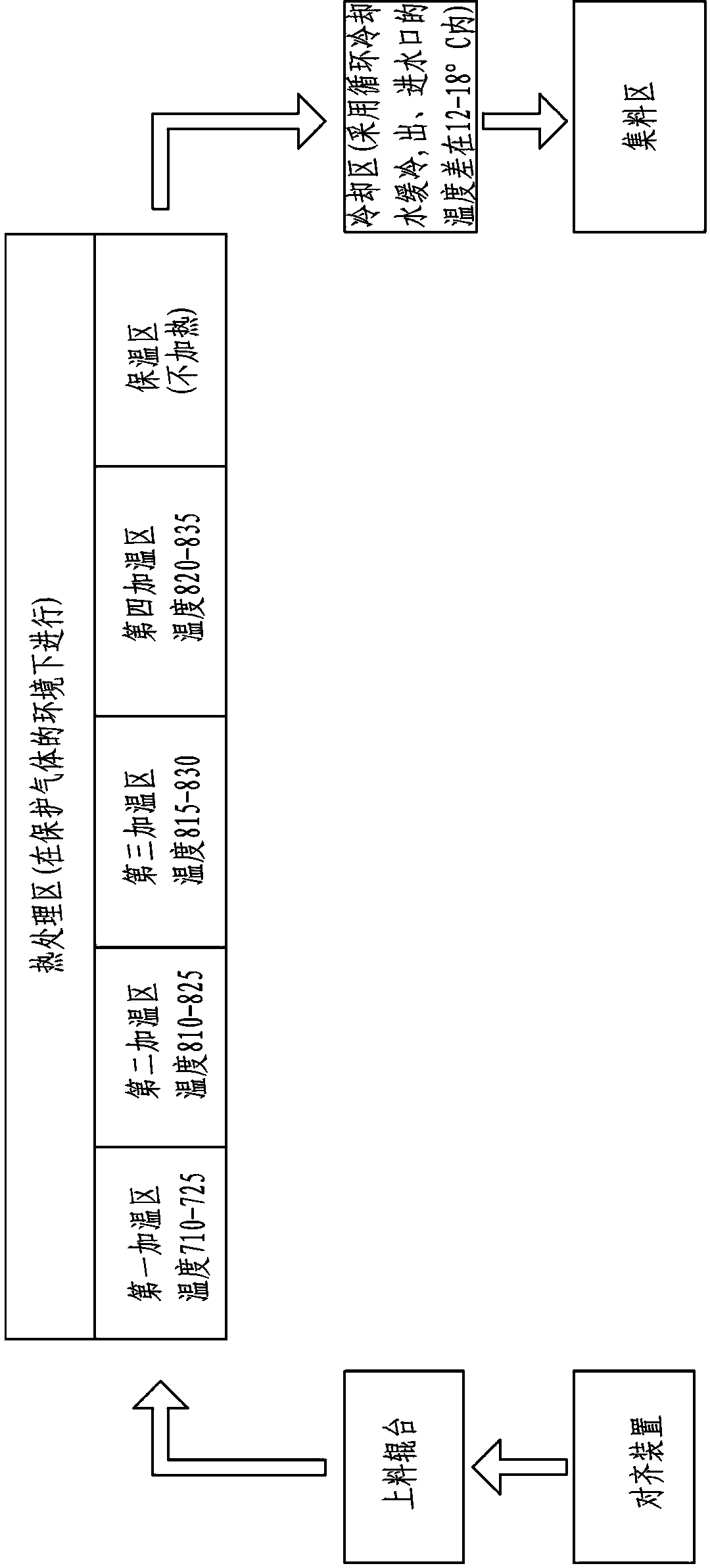

Steel pipe annealing equipment and steel pipe annealing technology

ActiveCN103710512AIncrease productivitySlow coolingFurnace typesHeat treatment furnacesShielding gasHardness

The invention relates to steel pipe annealing equipment and a steel pipe annealing technology. The steel pipe annealing equipment comprises the following technological processes: A. conveying a steel pipe to a feeding roller table through an alignment device, and conveying at the speed of 16-27m / h; B. enabling the steep pipe to enter a thermal treatment furnace via an inlet sealing box and carrying out closed heat treatment on the steel pipe, and continuing to move the steel pipe forwards in the thermal treatment furnace at the speed of 16-27m / h, wherein the steel pipe orderly passes through a first heating area, a second heating area, a third heating area, a fourth heating area and a heat preservation area inside the thermal treatment furnace; the heating temperatures of the first heating area, the second heating area, the third heating area and the fourth heating area are orderly increased, and the thermal treatment furnace is filled with protective gas in the closed thermal treatment process; C. slowly cooling the steel pipe by a cooling box adopting circulating cooling water to cool after the steel pipe is discharged from the thermal treatment furnace; and D. enabling the steel pipe to enter an aggregate area through an outlet sealing box to finish the overall process after the steel pipe is discharged from the cooling box. By adopting the technology, the inner stress of the material after pipe welding can be removed, the steel pipe is uniform in hardness, high in tensile strength and high in ductility, the yield strength is reduced, and the steel pipe is flexible.

Owner:广东志达精密管业制造股份有限公司

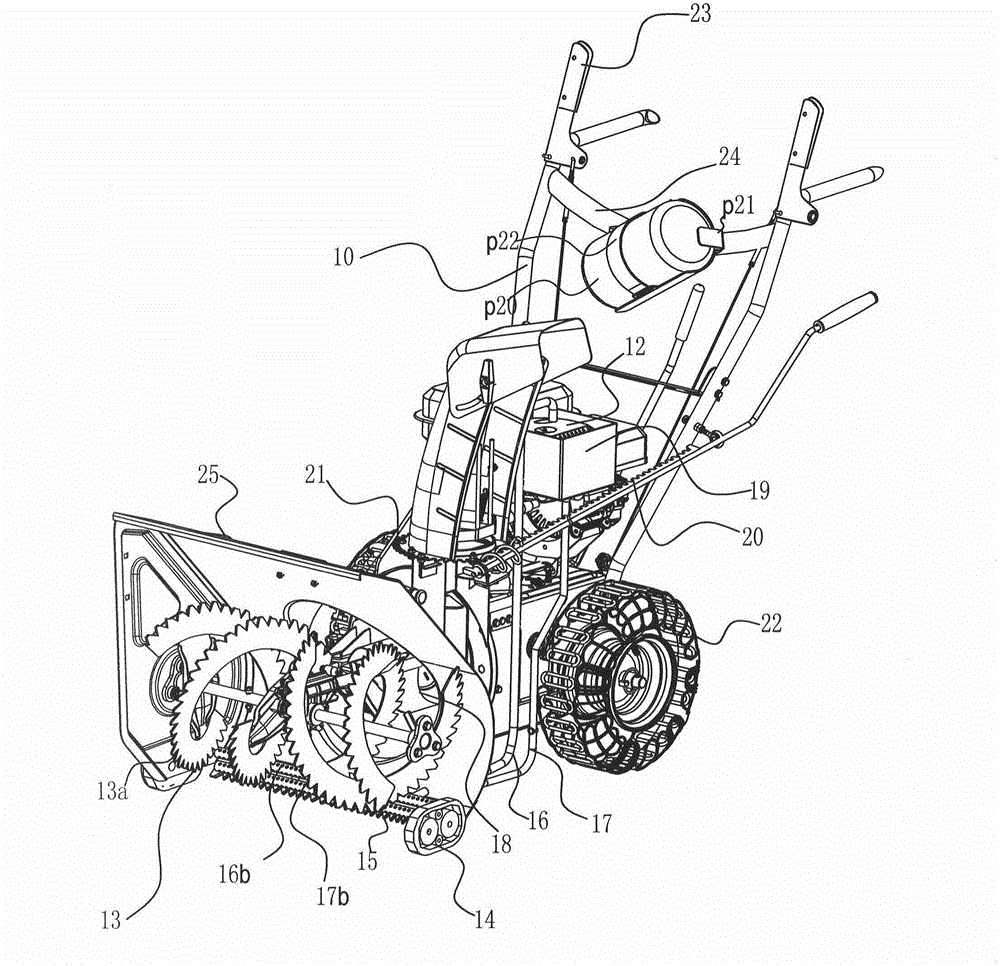

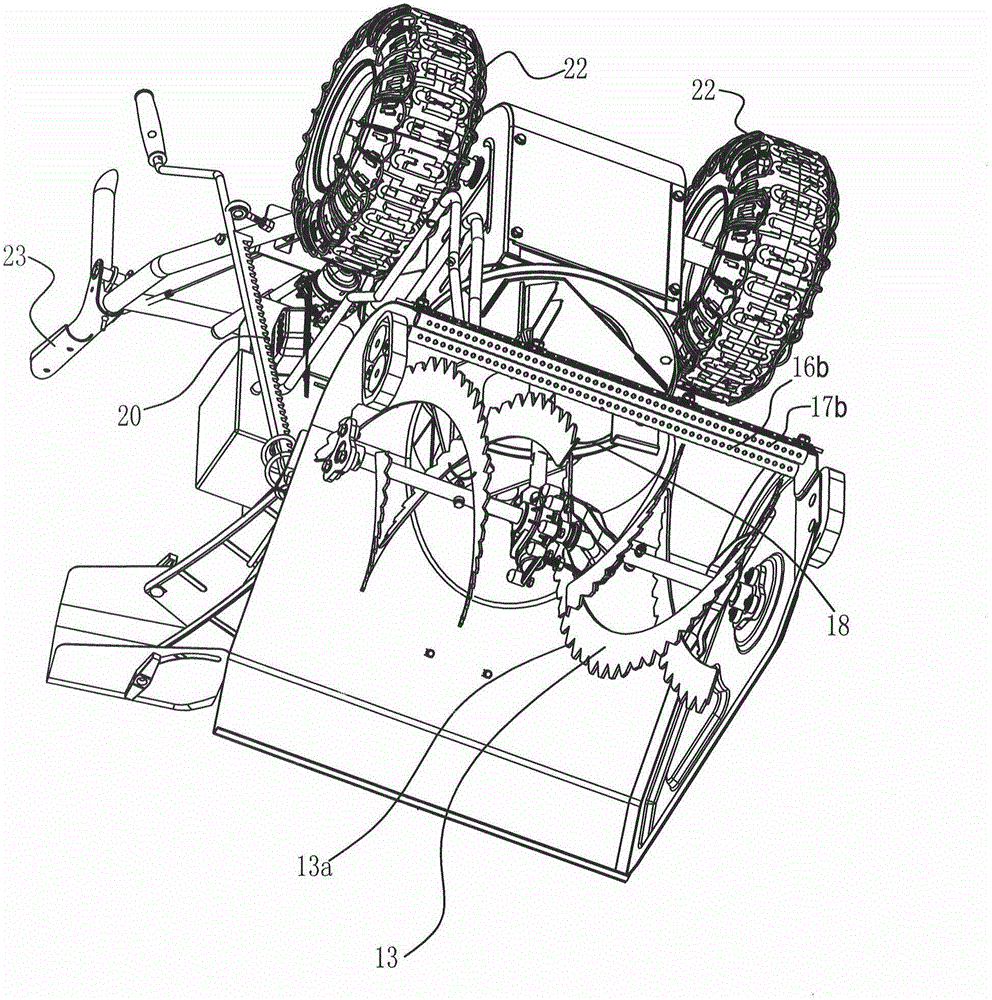

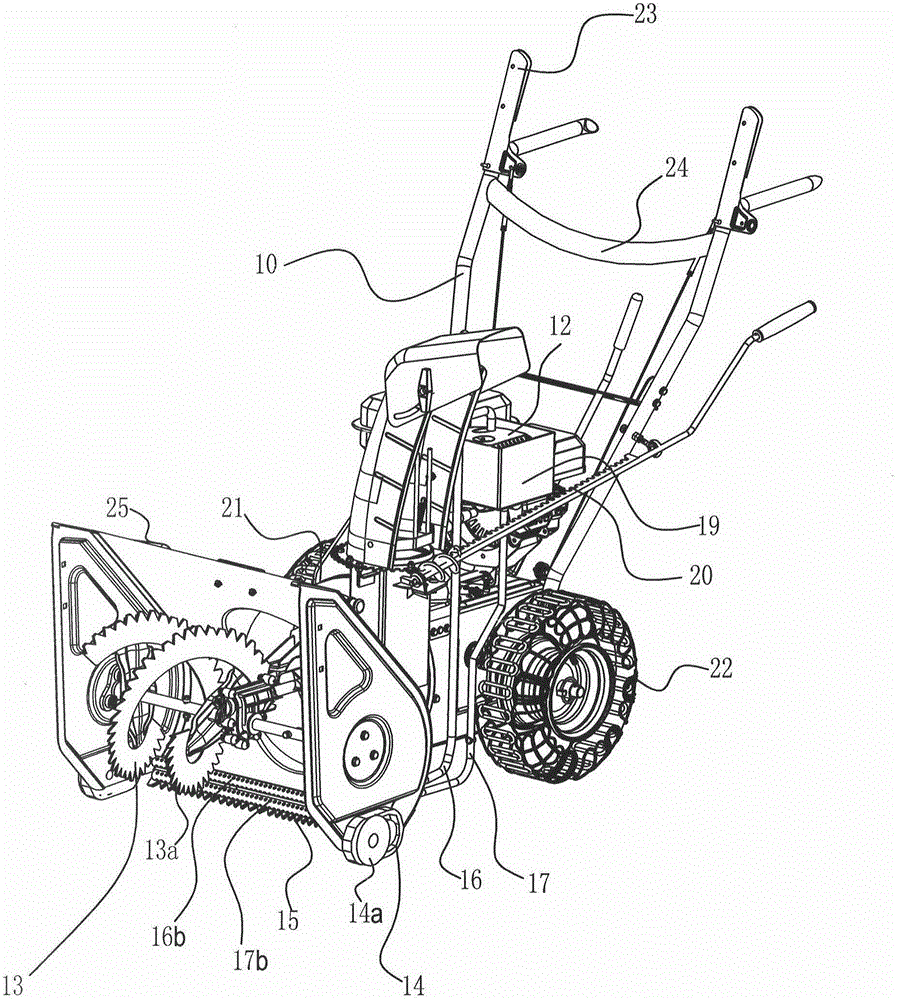

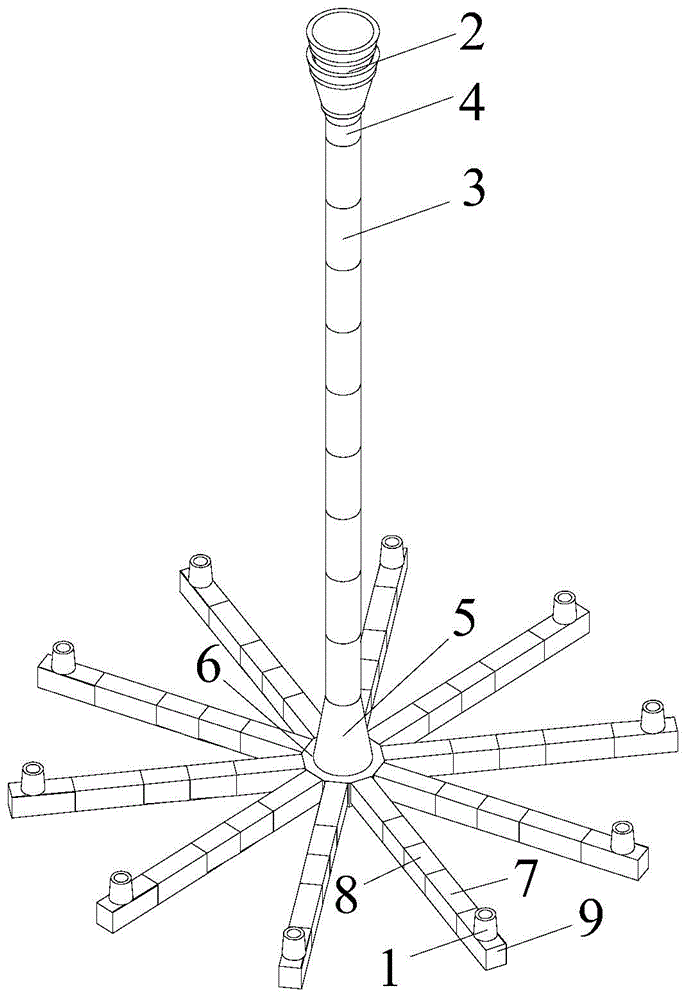

Antiskid snow-sweeper with air pipe driven by engine with LPG (Liquefied Petroleum Gas) mini-type gas tank

The invention discloses an antiskid snow-sweeper with an air pipe driven by an engine with an LPG (Liquefied Petroleum Gas) mini-type gas tank, i.e. a snow-sweeper with an antiskid chain, an ice-teeth snow-brush auger, a heat transfer gas tank and a front exhaust pipe, wherein the heat transfer gas tank is arranged on the engine and a silencer to cool, and guide hot vapor to the front of snow-sweeper to deice because ice is thermally fragile partially; furthermore, the heat waste gas is further guided to the snow-sweeper through the front exhaust pipe with a wedge silencer, so as to improve the silencing effect and exhaust primary exhaust gas closest to an operator away from the operator for good health, therefore the LPG mini-type gas tank is convenient to change and universal in all countries; in addition, the defects of being difficult to heat, cool and reduce noise and being unlikely to move due to slippage can be improved comprehensively, and the effects of counterweight skid resistance, waste absorption and health, thermal insulation and damping, deicing and snow blowing can be realized, therefore a new snow-sweeper can be created.

Owner:NINGBO DAYE GARDEN EQUIP

Steel ingot teeming runner system

The invention provides a steel ingot teeming runner system which comprises vertical cast tube, horizontal cast tubes, mold bottom bricks and a second kind center brick for connecting the vertical cast tube and the horizontal cast tubes, wherein the vertical cast tubes comprise funneled bricks, a plurality of cast tube bricks arranged below the funneled bricks, a first kind center brick connected between the funneled brick and the cast tube bricks and a joint brick for connecting the cast tube bricks and the second kind center brick; and the horizontal cast tubes comprise runner bricks and end runner bricks, the runner bricks are connected with the second kind center brick, and the end runner bricks are connected with tail ends of the runner bricks.

Owner:TAIYUAN HEAVY IND

Method and apparatus for continuous thermal treatment of steel strip

The invention relates to a method for continuous thermal treatment of a steel strip wherein: the steel strip passes through consecutive thermal treatment chambers; the steel strip is quickly cooled, in particular at more than 200 DEG C / sec, in at least one of the chambers by spraying liquid onto the steel strip, or by spraying a fluid made up of gas and liquid or spraying a combination of gas and liquid forming a mist; and, after the quick cooling, a protective metal layer is deposited on the steel strip by dip coating. The fluid sprayed for cooling the steel strip is a fluid with properties for acid-washing iron oxides or other alloy elements contained in the steel to be treated, in order to minimise the oxidation of the steel strip and reduce the oxides that may have formed on the steel strip such as to reduce or eliminate surface defects during the dip-coating operation. The fluid is sprayed at a pressure and at a distance from the steel strip such that the combined effect of the acid-washing property and the mechanical action of the sprayed fluid reduces the layer of oxides on the surface of the steel strip. The temperature of the steel strip at the end of the cooling step is the temperature necessary for carrying out the desired treatment cycle, in particular between 200 DEG C to 750 DEG C, typically higher than 200 DEG C.

Owner:FIVES STEIN SA

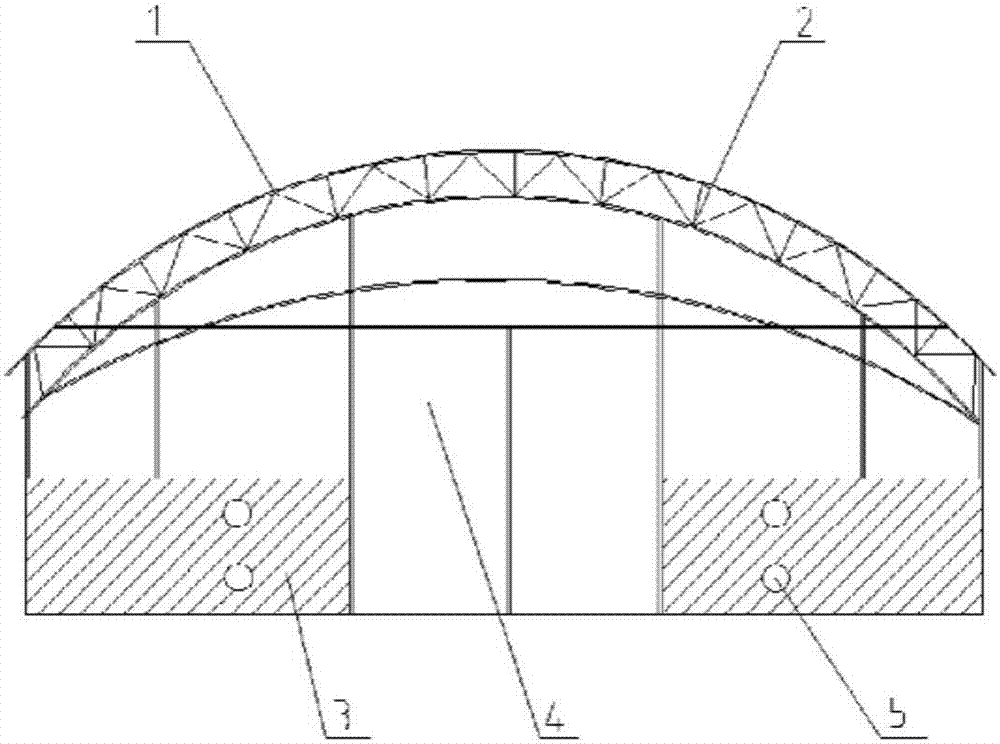

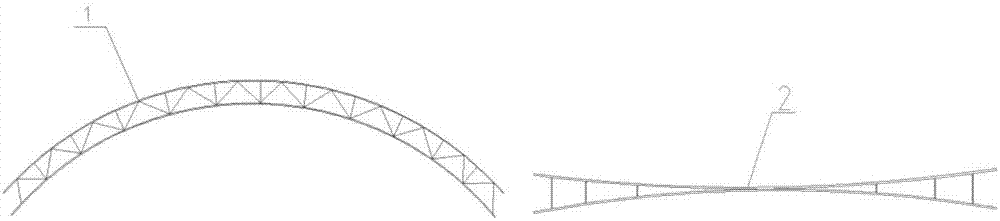

Multi-layered stereoscopic and composite tortoise and turtle high-efficient culturing system

InactiveCN107041338AReduce pollutionReduce labor intensityAnimal husbandryInternal layerGreenhouse warming

The invention discloses a multi-layered stereoscopic and composite tortoise and turtle high-efficient culturing system comprising a greenhouse, culturing pools, a greenhouse warming system, an aeration oxygenation device, a tortoise vegetable / turtle vegetable symbiotic system, a solid-liquid separation system and an intelligent forage releasing system. The greenhouse is divided into an internal layer and an external layer; a framework is in a truss structure; each greenhouse is provided with two culturing pools; a sunshield surface and a sunward surface of each culturing pool are co-existed; a heat source of the greenhouse warming system is heat produced during biomass combustion; and the aeration oxygenation device is arranged on two sides of a middle isle of the culturing pools. With a single-pipe multi-branch structure, a plurality of aeration points are provided; the tortoise vegetable / turtle vegetable symbiotic system is a multi-layered stereoscopic structure and contains a multi-layered culturing bed; the solid-liquid separation system can separate solids and liquid in sewage water of the culturing pools; and the solid wastes can be discharged to a dirt discharging pool and liquid flows back the culturing pool. The multi-layered stereoscopic and composite tortoise and turtle high-efficient culturing system is advantaged by energy conservation, environment protection, high efficiency and low cost.

Owner:ZHEJIANG UNIV

Silica gel composition and preparation method thereof

The invention provides a silica gel composition. The silica gel composition comprises a silica gel body consisting of components A and B in a mass ratio of 1 to 5, wherein the component A comprises, by mass, 34-83% of dimethyl polysiloxane, 12-65% of polymethylhydrosiloxane and 1-5% of catalysts; the component B is prepared from, by mass, 34-83% of dimethyl polysiloxane, 12-65% of polymethylhydrosiloxane and 1-5% of cross-linking agent; the silica gel composition further contains, based on the total mass of the silica gel body, 0.4-1% of fumed silica, 3.3-4% of prefoamed polymer microspheres and 20-30% of phase change paraffin or 40-50% of solid-state phase change microcapsules; wherein, the prefoamed polymer microspheres are prefoamed polystyrene microspheres, and shells of the prefoamed polystyrene microspheres are made of polystyrene. The silica gel composition is low in specific gravity and weight, has high thixotropy and a good phase change function and is particularly suitable for preparing silica gel prosthesis products. The invention further provides a preparation method of the silica gel composition. According to the preparation method, steps are few, the process is short, operation is easy and convenient, and preparation cost is low.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com