Novel casting powder and application thereof

A technology for mold slag and continuous casting mold slag, which is applied in the field of new mold slag, can solve the problems of deterioration of mold slag performance and lack of consideration, and achieve the effects of reducing defects such as longitudinal cracks and inclusions, increasing consumption, and reducing melting point and viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

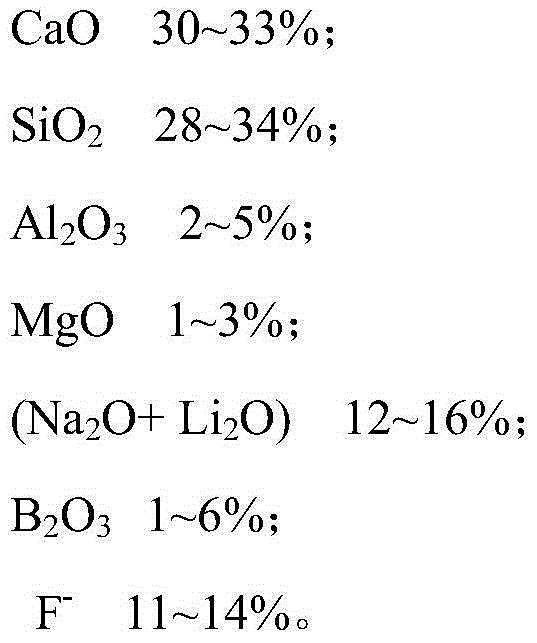

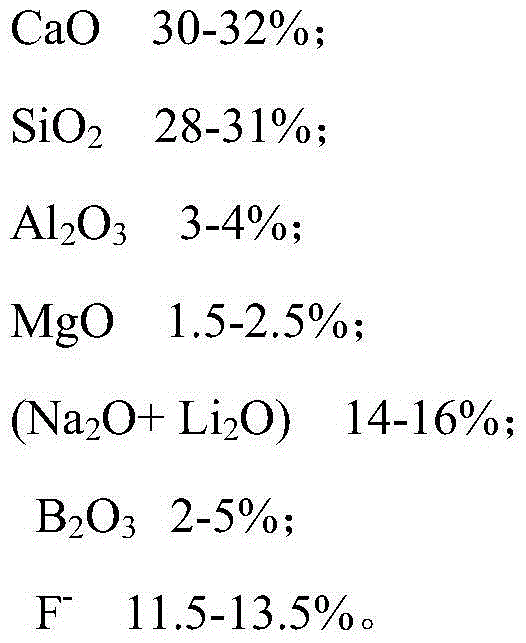

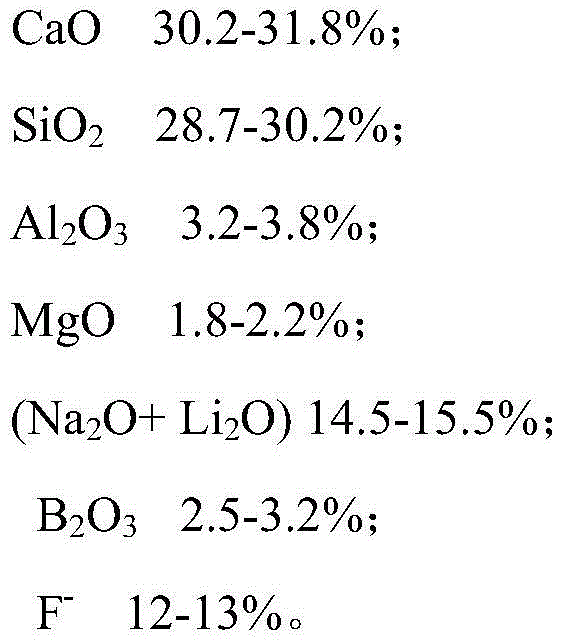

Method used

Image

Examples

Embodiment 1

[0035] A kind of mold flux, its composition mass percentage is: CaO: 30.2%, SiO 2 : 31.7%, Al 2 o3 : 3.6%, MgO: 2.0%, (Na 2 O+Li 2 O): 15.9% (Na 2 O / Li 2 O=4.3:1 mass ratio), B 2 o 3 : 3.1%, F - : 13.5%. The basicity of the mold flux CaO / SiO 2 is 0.95. The main physical properties of the mold flux measured by the above method are shown in Table 1. According to the design of this embodiment, the chromium-containing steel with mold flux Cr content of 10% and C content of 1.3% is continuously cast; the probability of longitudinal cracks and inclusions in the obtained slab is lower than 0.25%.

Embodiment 2

[0037] A high-carbon chromium-containing steel continuous casting mold powder, its composition mass percentage is: CaO: 31.7%, SiO 2 : 30.2%, Al 2 o 3 : 3.6%, MgO: 2.0%, (Na 2 O+Li 2 O): 15.9% (Na 2 O / Li 2 O=6.9:1 mass ratio), B 2 o 3 : 3.1%, F - : 13.5%. The basicity of the mold flux CaO / SiO 2 is 1.05. The main physical properties of the mold flux measured by the above method are shown in Table 1. According to the design of this embodiment, the chromium-containing steel with mold flux Cr content of 11% and C mass percentage content of 1.4% is continuously cast; the probability of longitudinal cracks and inclusions in the obtained slab is lower than 0.23%.

Embodiment 3

[0039] A high-carbon chromium-containing steel continuous casting mold powder, its composition mass percentage is: CaO: 33.0%, SiO 2 : 28.7%, Al 2 o 3 : 3.6%, MgO: 2.0%, (Na 2 O+Li 2 O): 15.9% (Na 2 O / Li 2 O=6.9:1 mass ratio), B 2 o 3 : 3.2%, F - : 13.6%. The basicity of the mold flux CaO / SiO 2 is 1.15. The main physical properties of the mold flux measured by the above method are shown in Table 1. According to the design of this embodiment, the chromium-containing steel with mold flux Cr content of 12% and C mass percentage content of 1.5% is continuously cast; the probability of longitudinal cracks and inclusions in the cast slab obtained is lower than 0.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com