Production method of large-thickness high-toughness yield strength 1100MPa-grade ultrahigh-strength steel plate

A yield strength and production method technology, which is applied in the field of large-thickness, high-toughness, 1100MPa-grade ultra-high-strength steel plates, and can solve the problem that the low-temperature impact toughness of large-thickness steel plates is difficult to guarantee, the mechanical properties of the surface and the core of the steel plate are greatly different, and the ultra-low temperature of large-thickness steel plates is difficult to guarantee. Difficult impact toughness and other problems, to achieve the effect of fine grains, reducing the performance of the core and reducing the internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

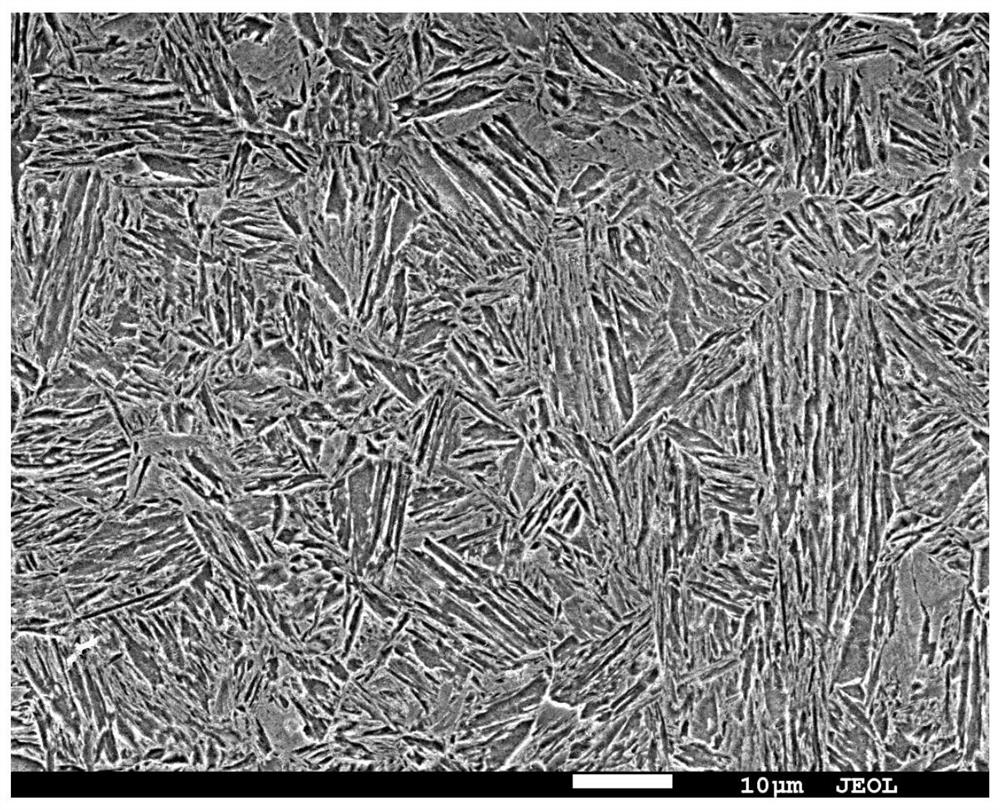

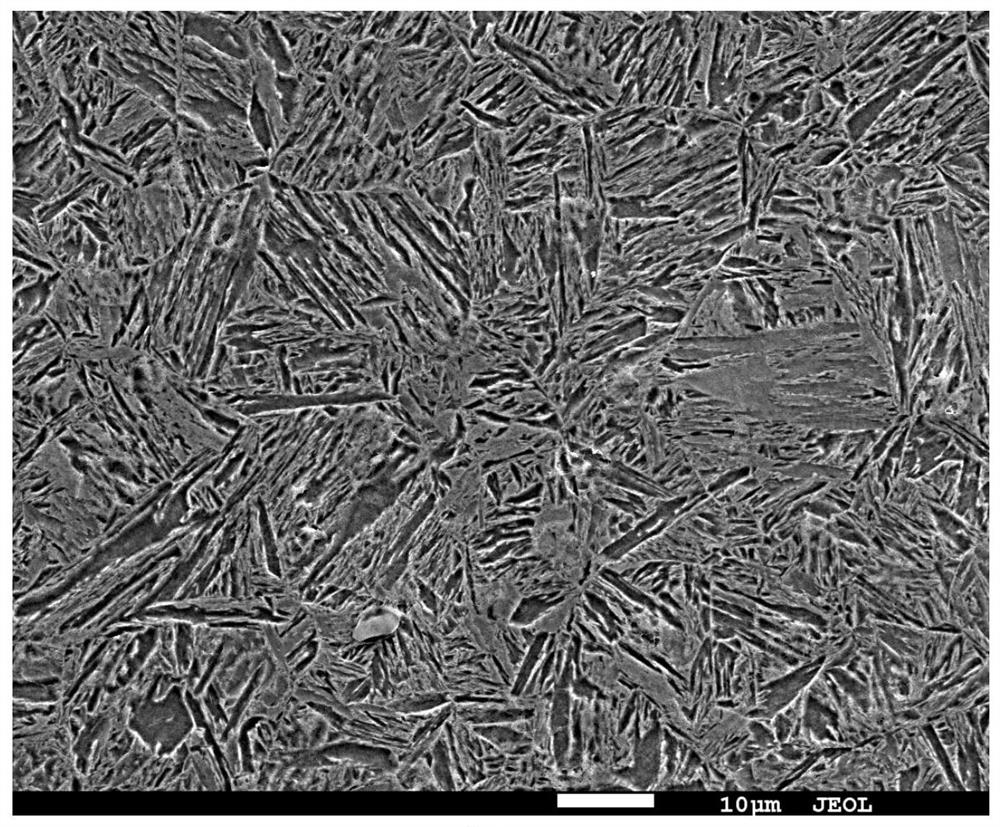

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings. The embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0048] The production process flow of the ultra-high-strength steel of the present invention is: converter or electric furnace steelmaking -> LF refining -> VD or RH vacuum degassing -> Ca treatment -> continuous casting -> casting slab slow cooling diffusion treatment -> heating- >Rolling->steel plate slow cooling diffusion treatment->quenching->tempering

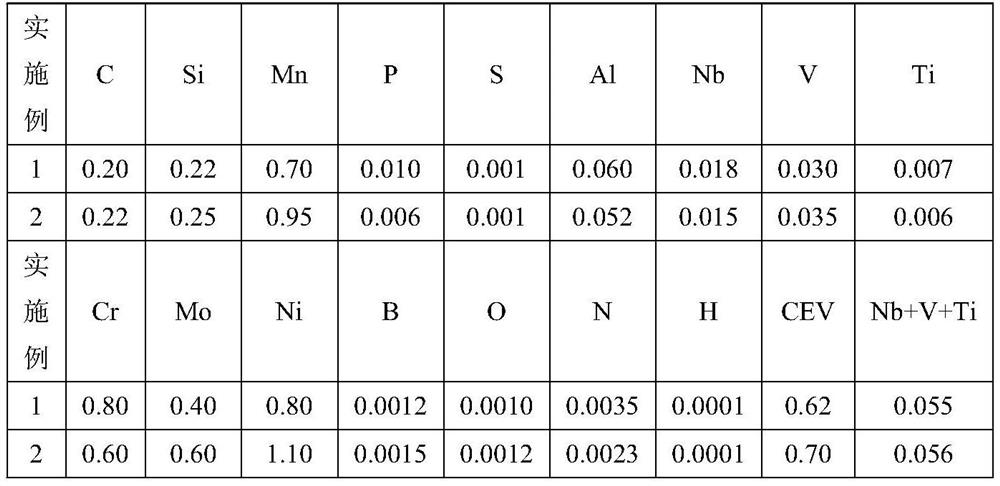

[0049] The production method of the large-thickness high-toughness yield strength 1100MPa grade ultra-high-strength steel plate of the embodiment 1-2 of the present invention comprises the following steps:

[0050] (1) Smelting: use electric furnace or converter for smelting, then send it to LF furnace for refining and RH vacuum degassing treatment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com