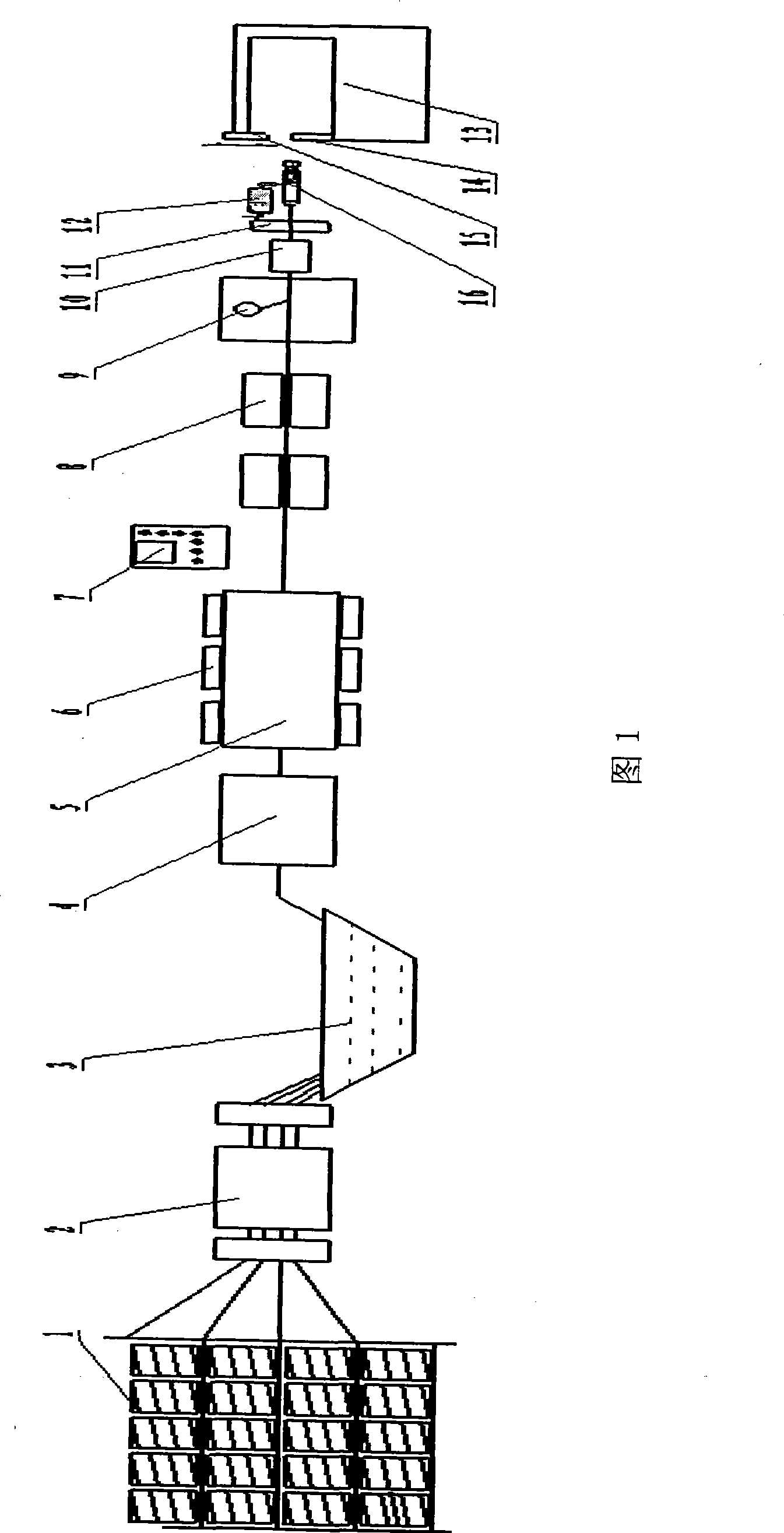

Preparation method and device of eccentric wear prevention pumping rod

A sucker rod and anti-eccentric wear technology, which is applied in the direction of drill pipe, earthwork drilling, drilling equipment, etc., can solve the problem of reducing the continuous coating cost and process complexity, low bonding strength between sucker rod and anti-wear block, The partial wear resistance of the cladding layer is not ideal enough to achieve the effect of reducing material cost, high strength and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

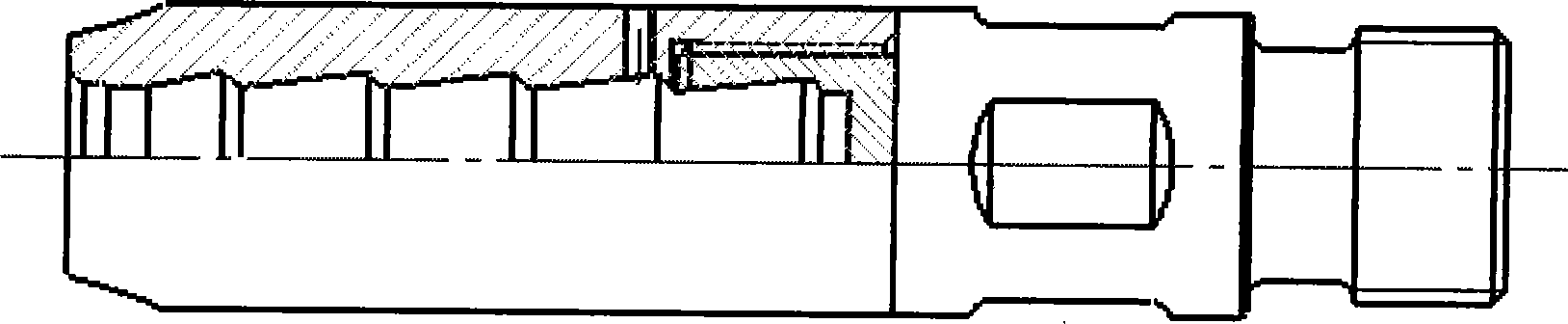

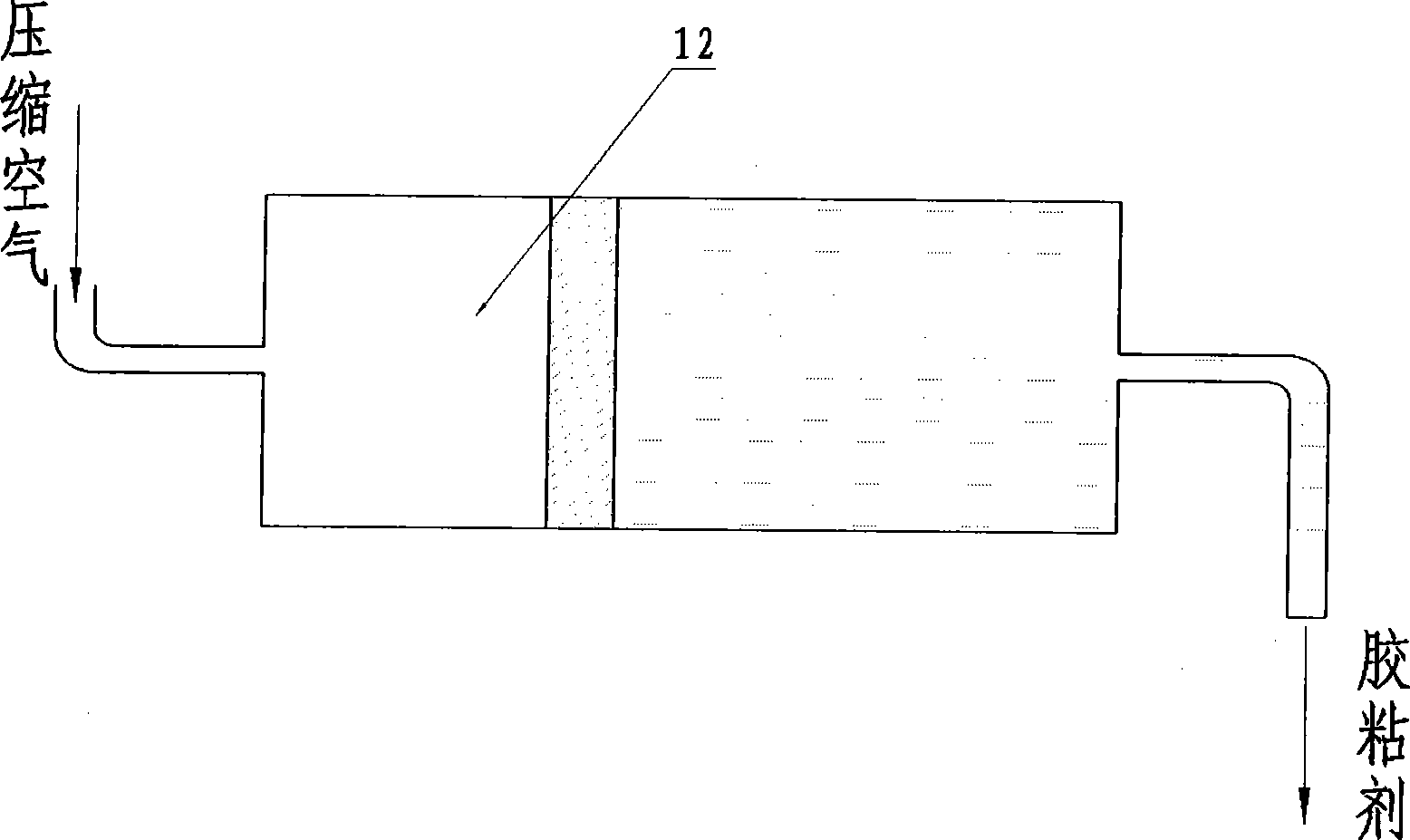

Embodiment 1

[0034] Example 1: A plurality of bundles of carbon fiber filaments are put into the surface treatment furnace through the wire rack and the wire hole of the wire collecting plate. The furnace temperature is 120°C, and the pulling speed is 0.4 m / min. The mass fraction of isophthalic unsaturated polyester resin S-685S:MEKP:BPO:zinc stearate in the tank is 100:1.5:1.5:1.5. The impregnated carbon fiber enters the preforming furnace with a preforming temperature of 85°C. After the initial gel preforming, it enters the mold for curing and molding. The mold is heated in three stages at temperatures of 110°C, 135°C, and 155°C. The formed composite material rod continues to advance longitudinally at a speed of 0.4 m / min, and two bundles of aramid fibers are wound on the composite material rod at a speed of 5 turns / min by a winding machine with 2 heads to form two threads with a pitch of 10 mm. Spiral tendons. The impregnation formula of the aramid fibers is the same as that of the pul...

Embodiment 2

[0035] Embodiment 2: According to implementation 1, change the carbon fiber in the pultrusion process to high-strength glass fiber, the furnace temperature of fiber heat treatment is 100 ° C, the pulling speed is 0.2 m / min, and the resin in the dipping tank is changed to epoxy resin, wherein E -51: Methyltetrahydrophthalic anhydride: DMP-30: Zinc stearate with a weight fraction of 100:85:2.0:1. The formed sucker rod is wound by a 6-head winding machine at a speed of 2.5 turns / min. Bunches of PBO fibers are formed to form six helical tendons with a pitch of 5 mm. The impregnation formula of the PBO fiber is the same as that of the pultrusion process, and the diameters of the six bundles of PBO fibers are all 1 mm. The composite sucker rod body after the anti-eccentric wear layer is wound and formed is glued to the metal joint. The adhesive used is an epoxy adhesive. The mass fraction of epoxy resin: curing agent: accelerator: filler is 100:80:1.5:15 , The viscosity at 25°C is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com