Patents

Literature

782 results about "Pressure injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Injection Pressure is the pressure applied on the injection screw when a material is being injected into the mold. It is useful for the treatment of the rock matrix. Injection Pressure enables test fluids to be injected into rock formations without causing breakdowns or fractures.

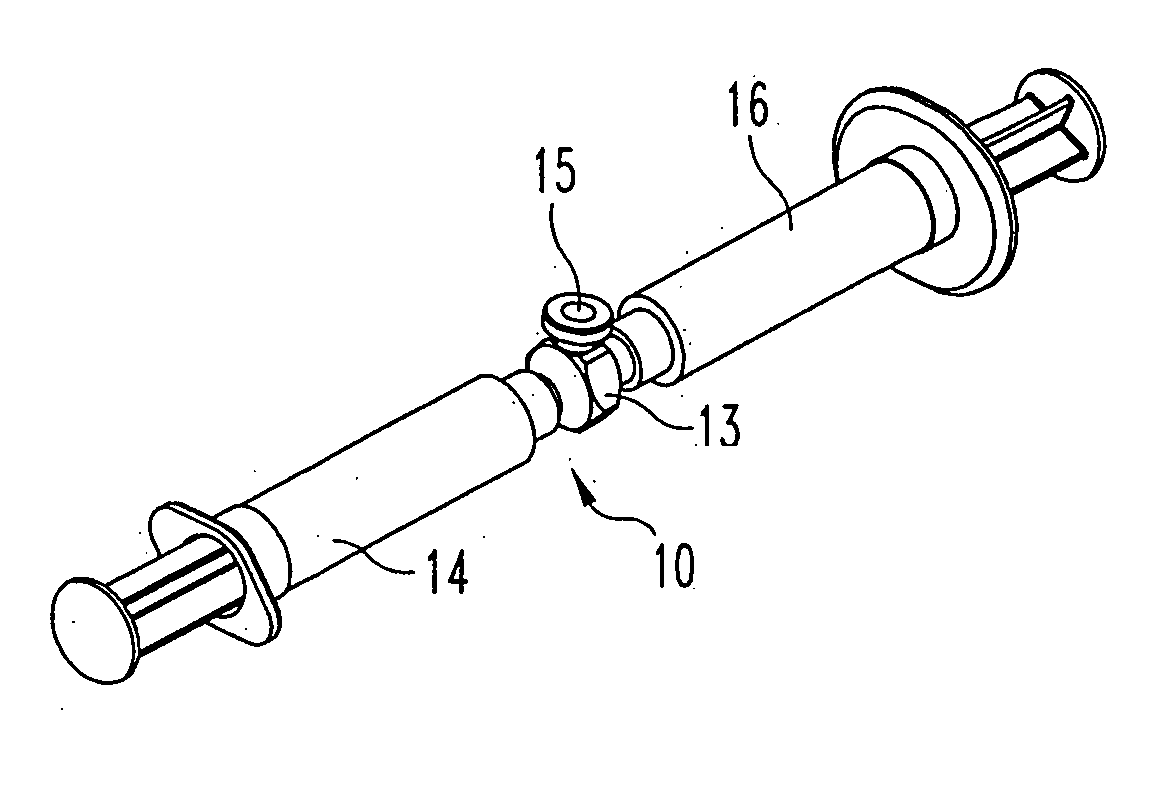

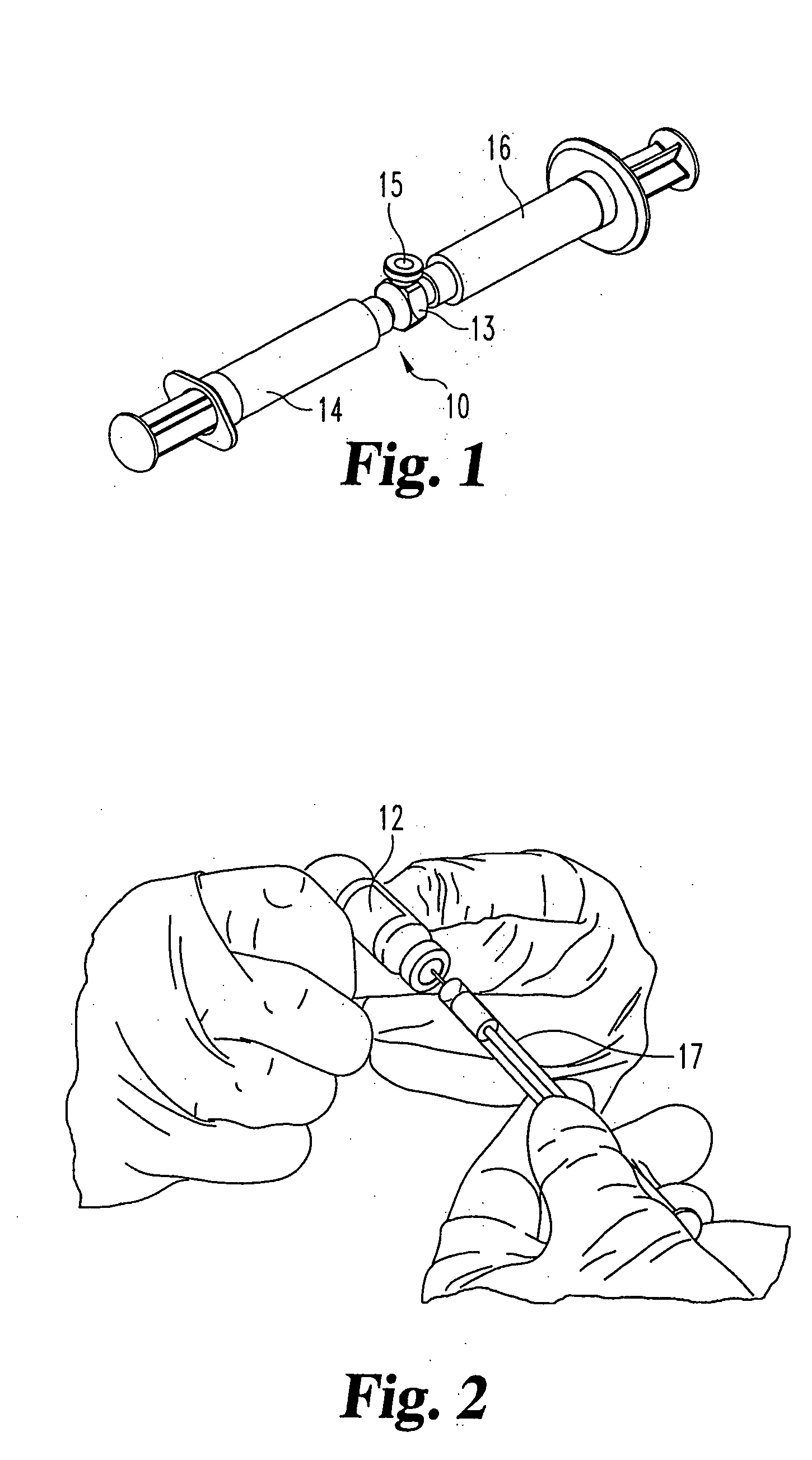

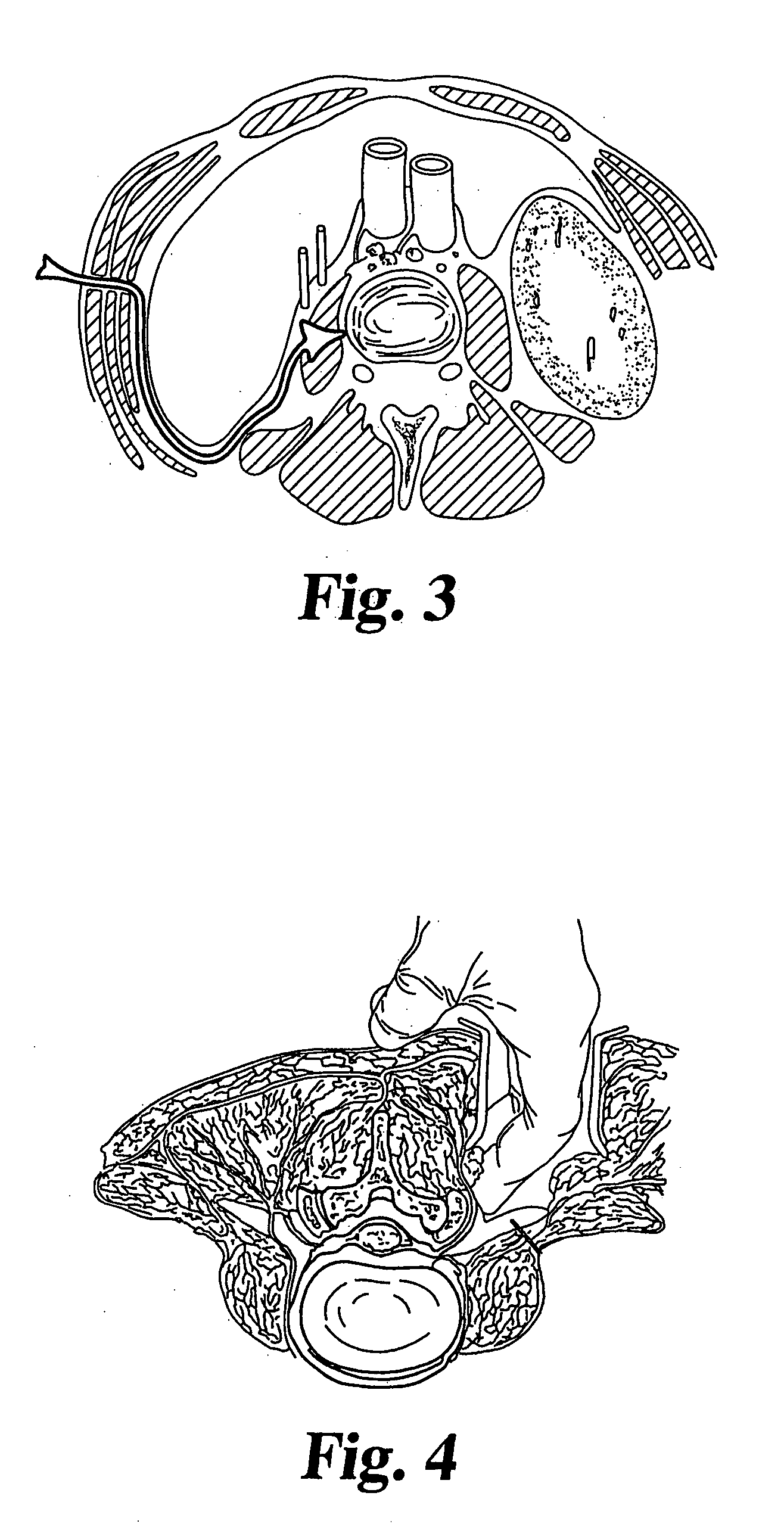

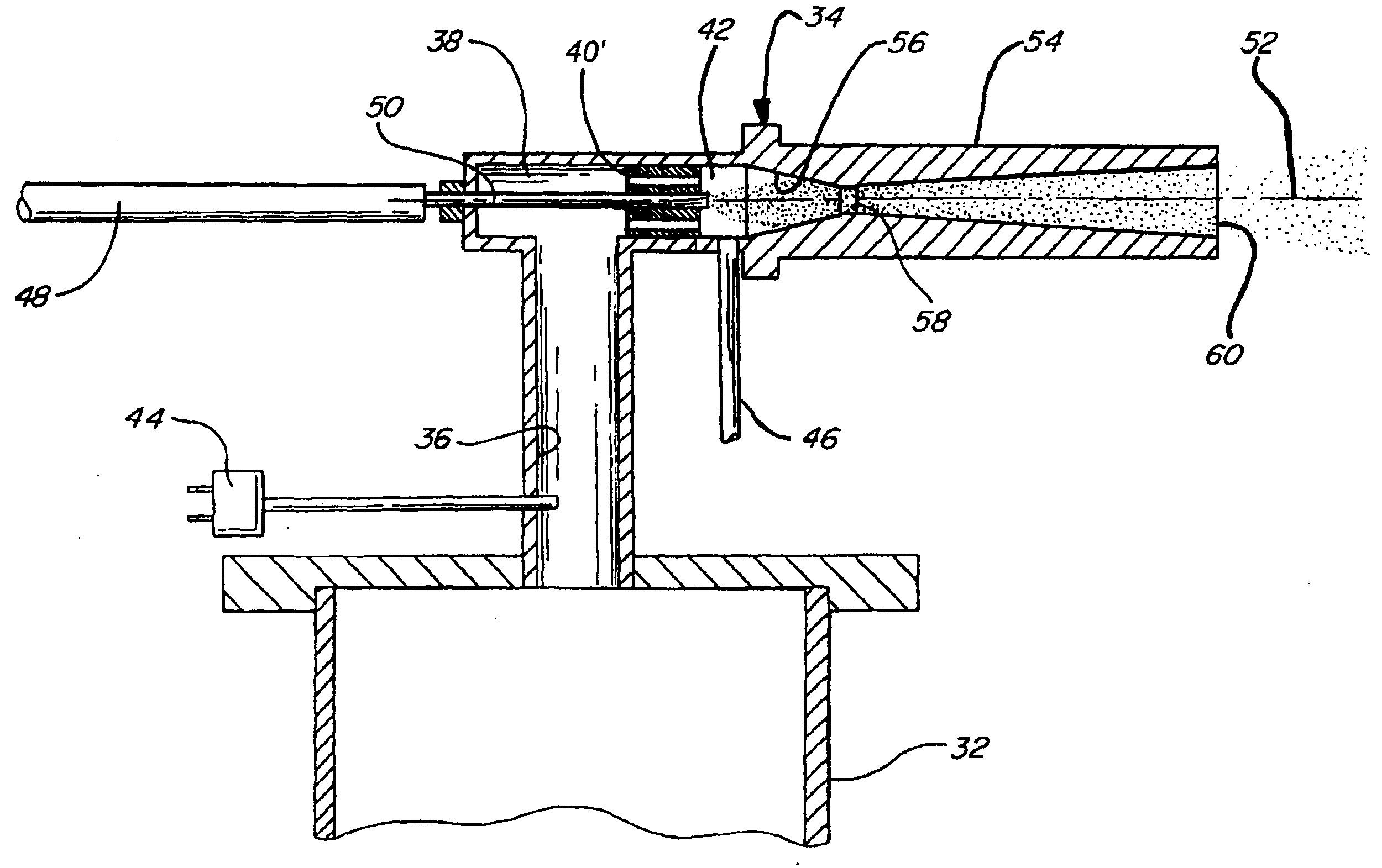

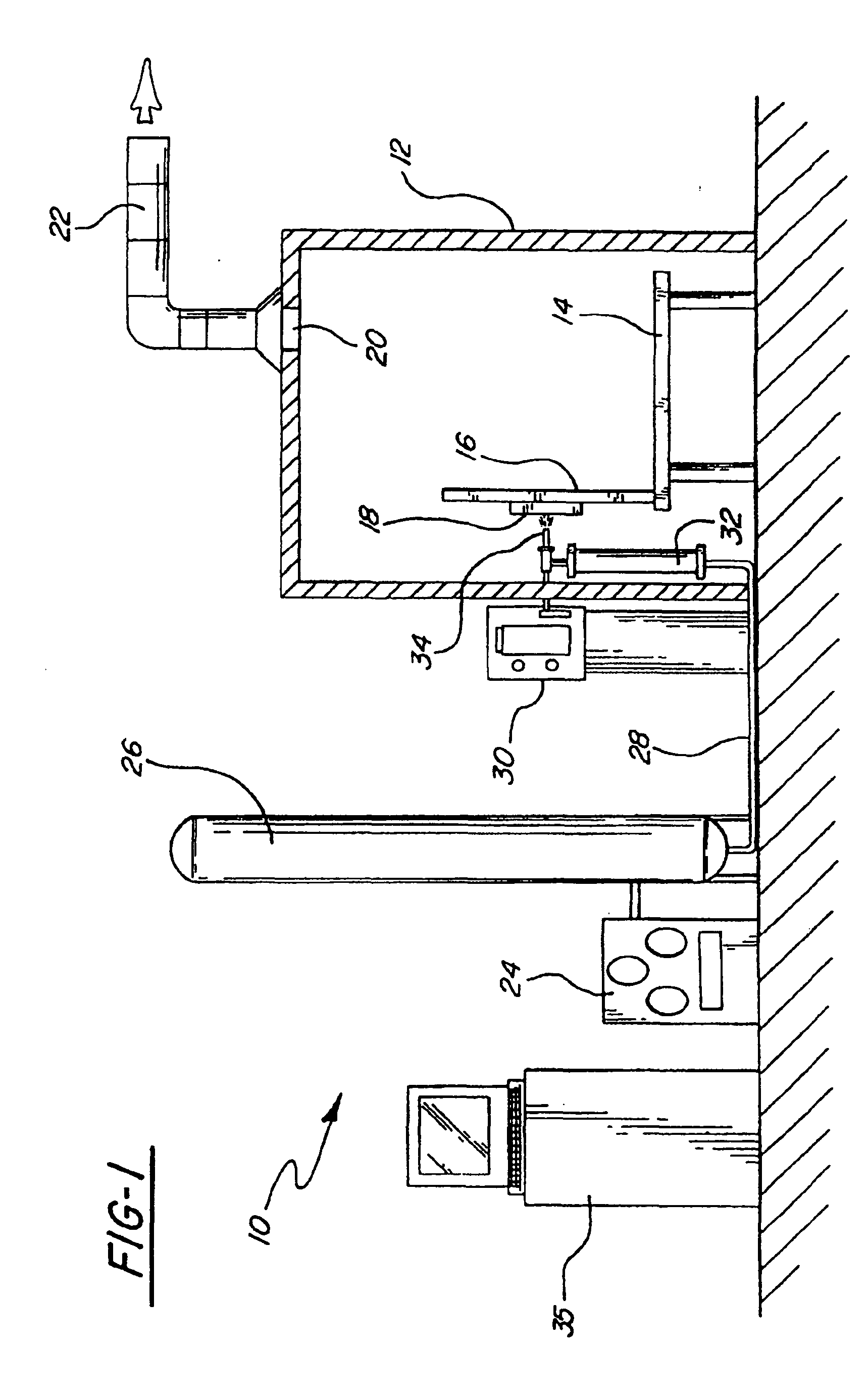

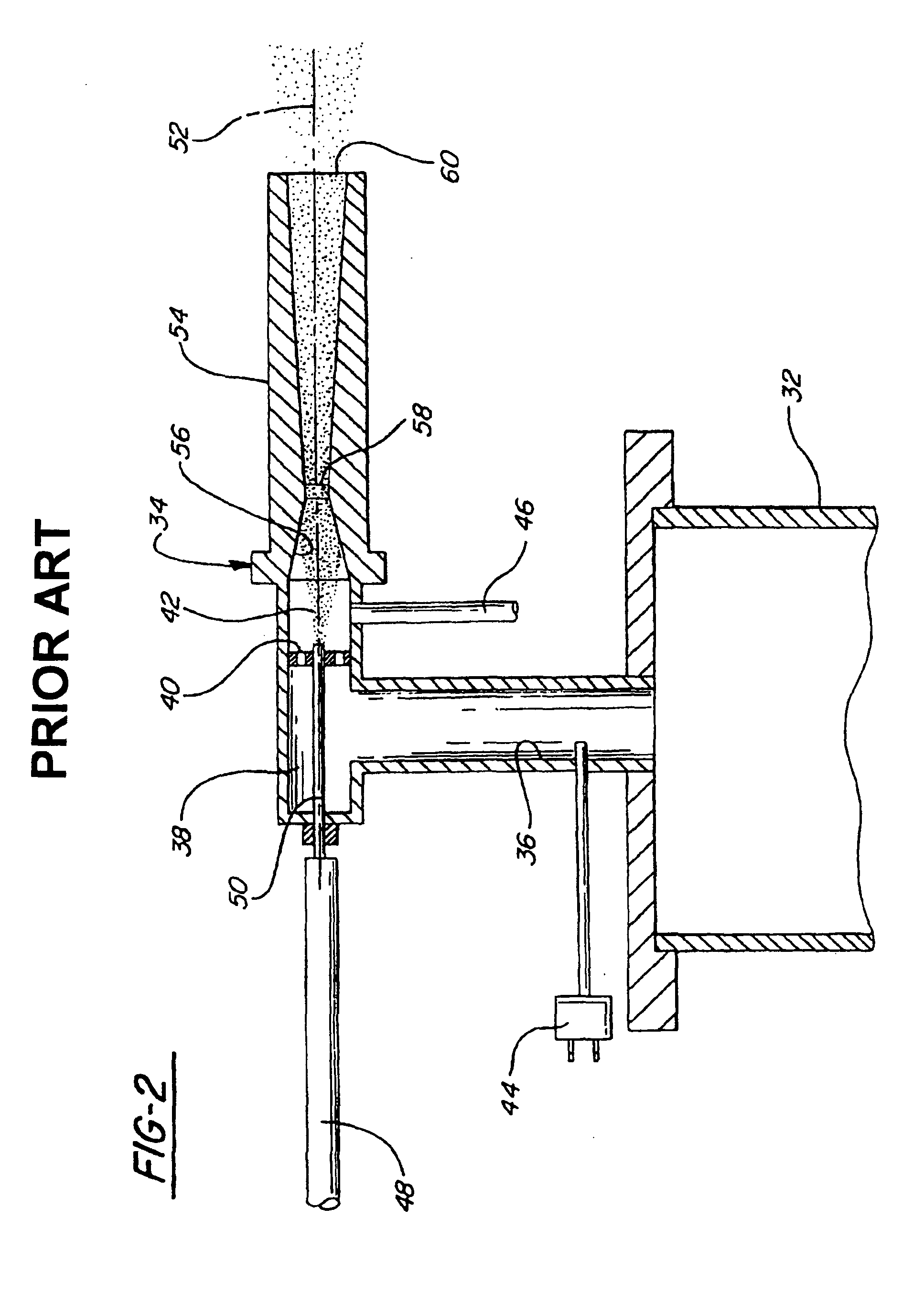

Devices for injecting a curable biomaterial into a intervertebral space

A vented needle is provided for use in sealably injecting biomaterial into an intradiscal space interiorly of the annulus of a spinal disc and for providing an exhaust for the intradiscal space. The vented needle comprises a compressible seal body for pressing against an outer surface of the annulus, and a needle extending through the seal. The needle may be configured to connect to a syringe for pressure injection of the biomaterial into the needle. The seal includes a vent extending therethrough the seal with an opening for communication with the intradiscal space and an opening for the discharge of excess biomaterial filling the intradiscal space. A kit of parts is also provided for use in the treatment of a spinal disc, the kit comprising the vented needle and an inflatable trial device. The trial device is adapted to be removably introduced into the intradiscal space and inflated therein with a medium capable of determining the size of said intradiscal space created by the removal of at least a portion of said nucleus pulposus.

Owner:SPINEWAVE

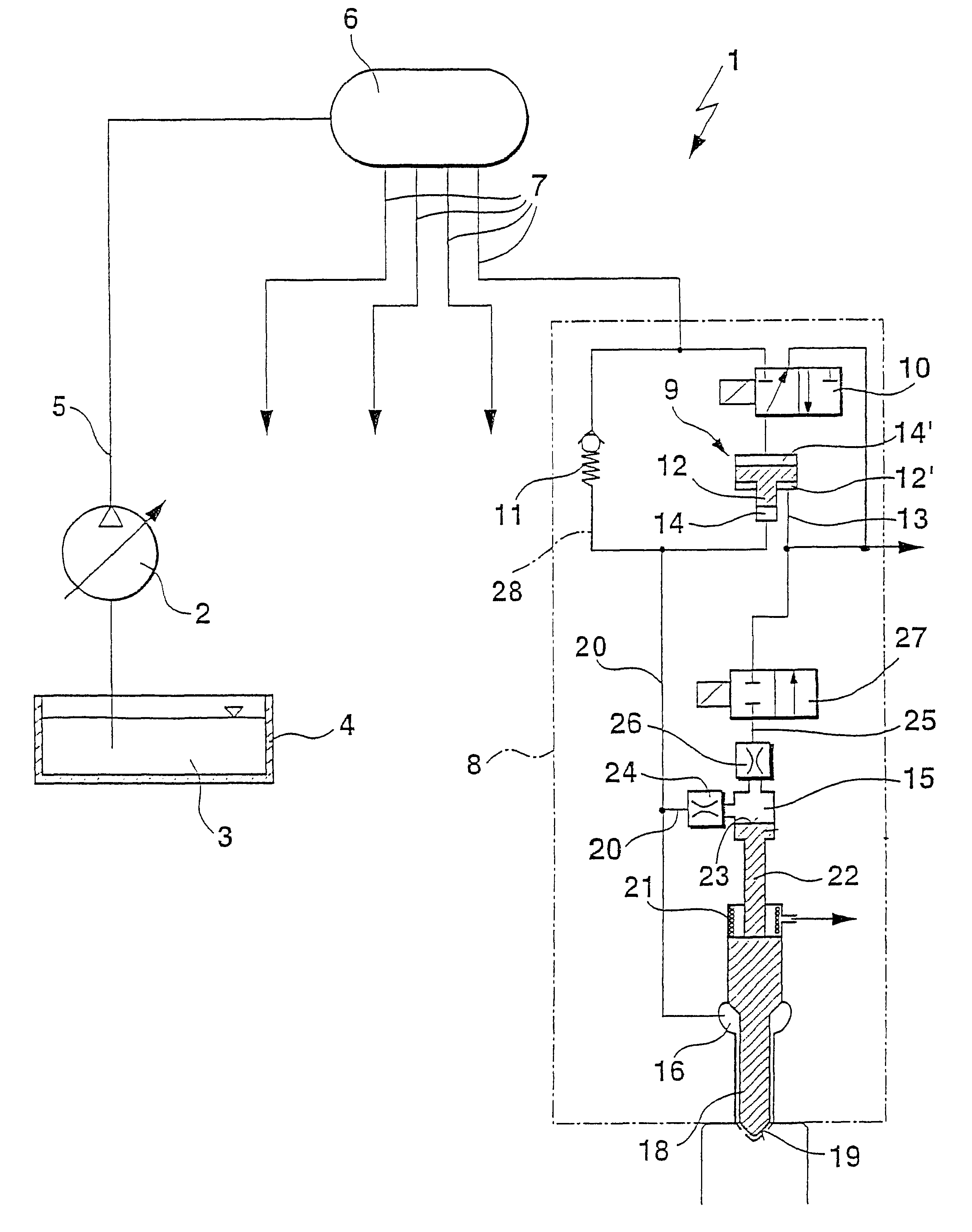

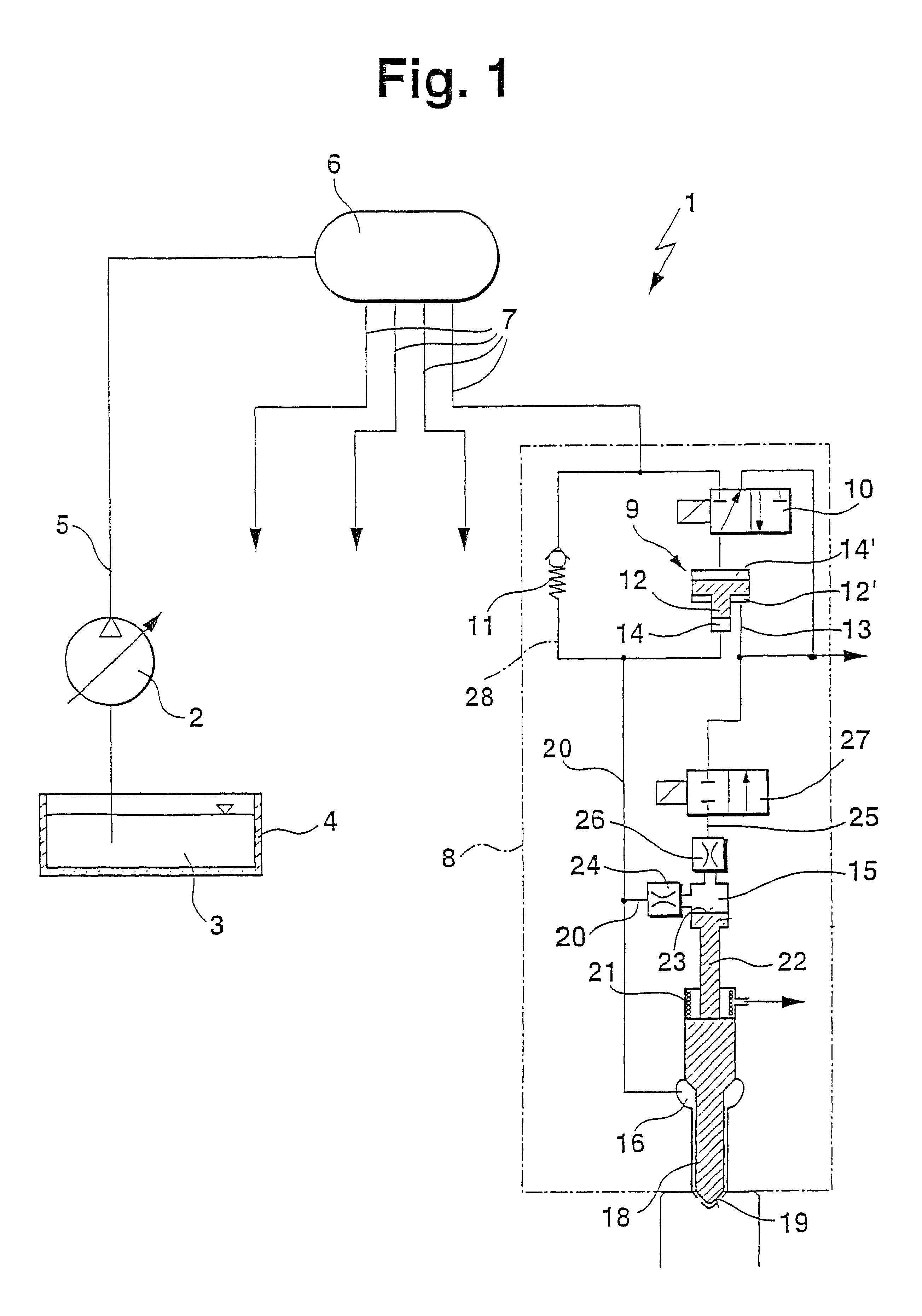

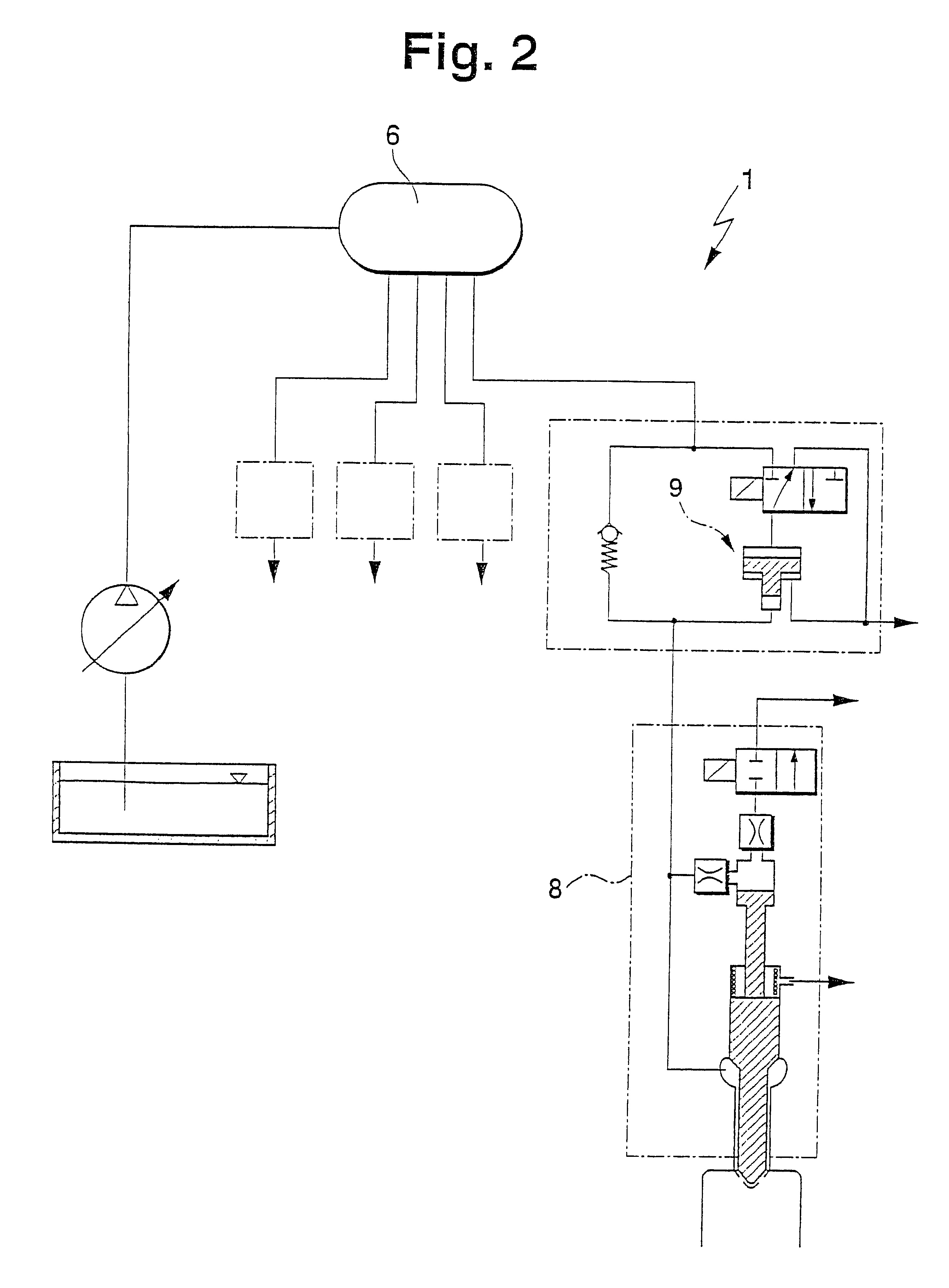

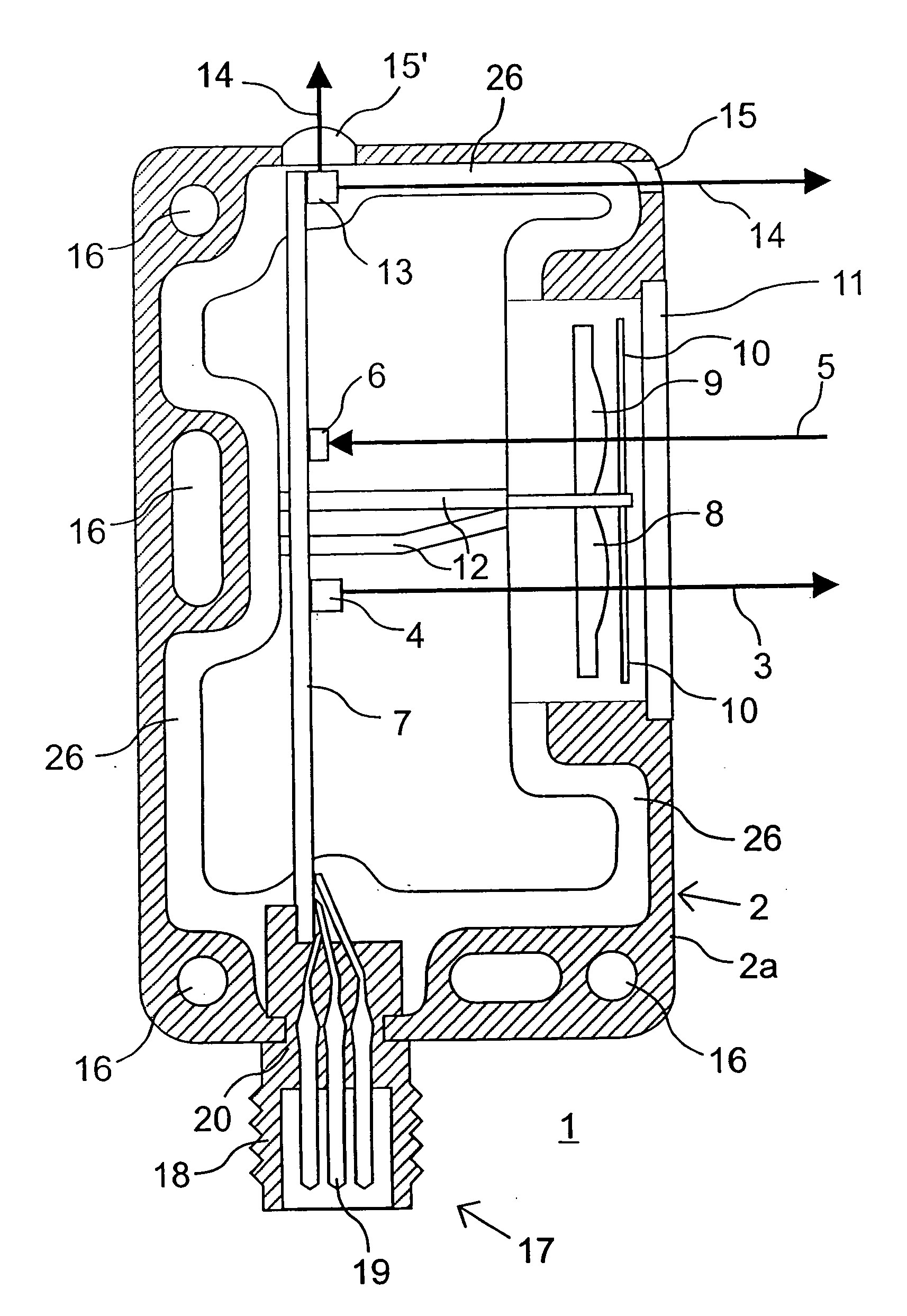

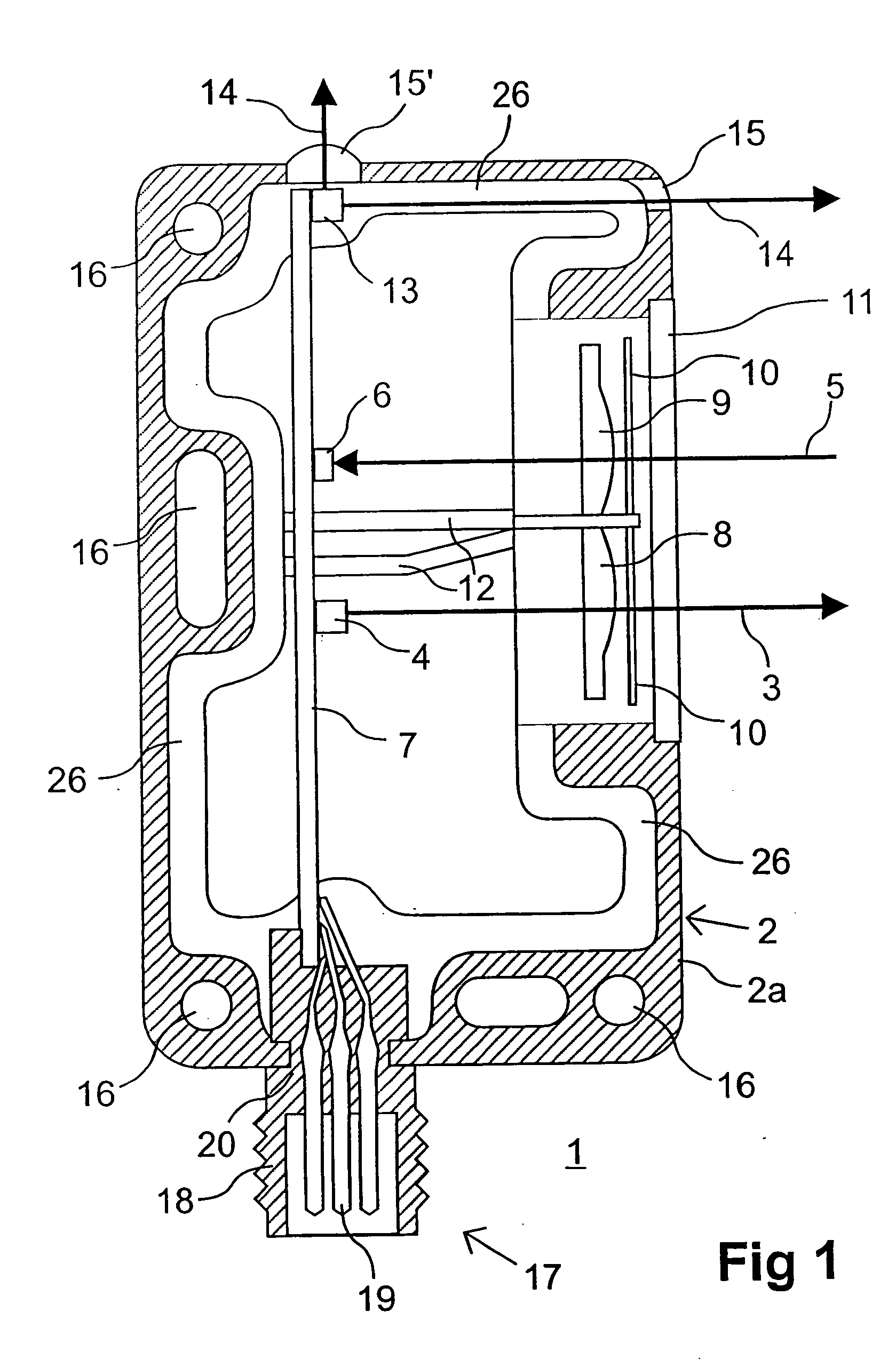

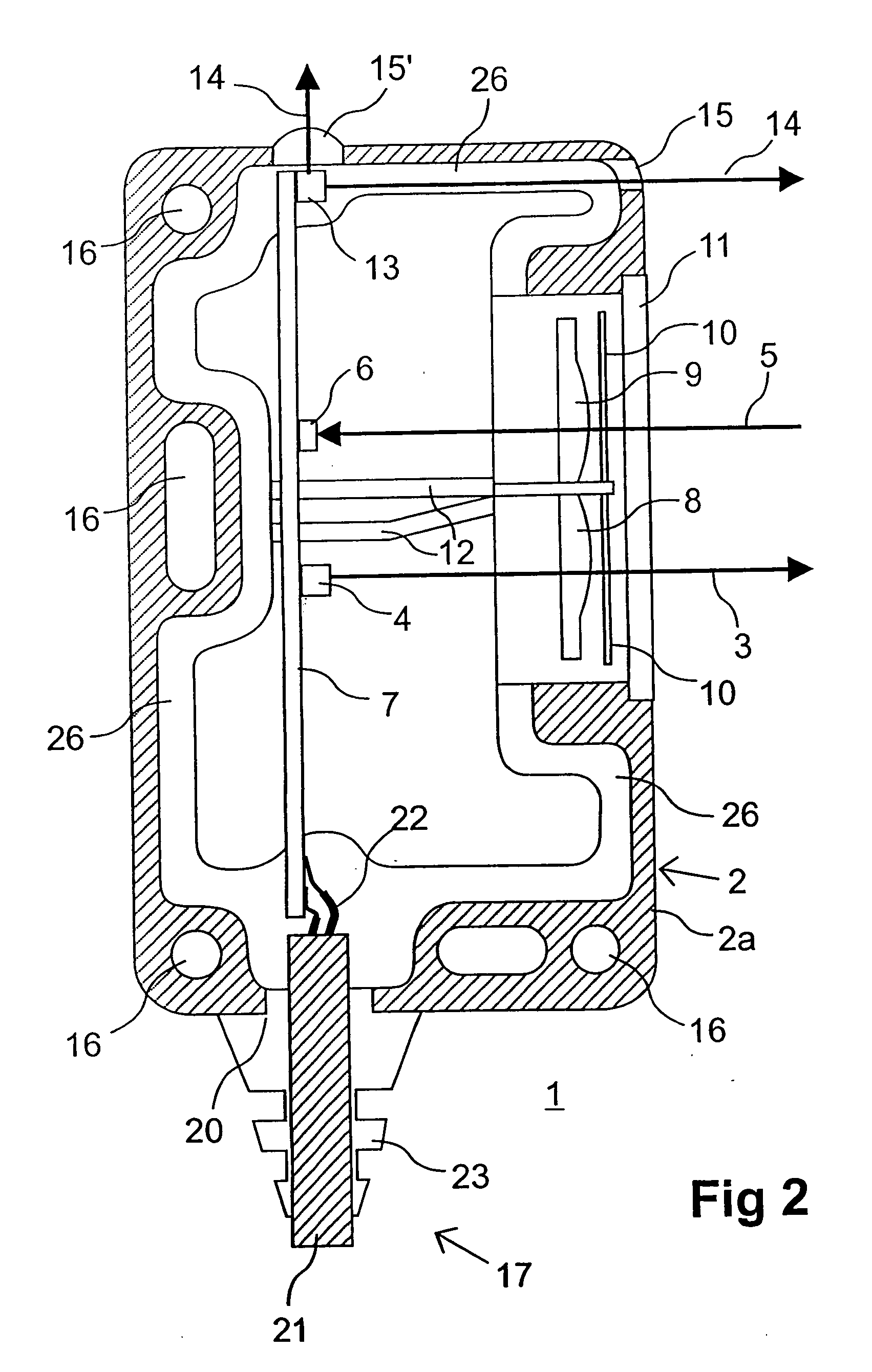

Fuel injection system which uses a pressure step-up unit

InactiveUS6453875B1Increase flexibilityIncrease injection pressureFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesEngineeringPiston

A fuel injection system has a pressure step-up unit, disposed between a pressure storage chamber and a nozzle chamber, whose pressure chamber communicates with the nozzle chamber via a pressure line. A bypass line connected to the pressure storage chamber is also provided. The bypass line communicates directly with the pressure line. The bypass line can be used for pressure injection and is disposed parallel to the pressure chamber, so that the bypass line is open regardless of the motion and position of a displaceable piston element in the pressure step-up unit. This enhances the flexibility of injection.

Owner:ROBERT BOSCH GMBH

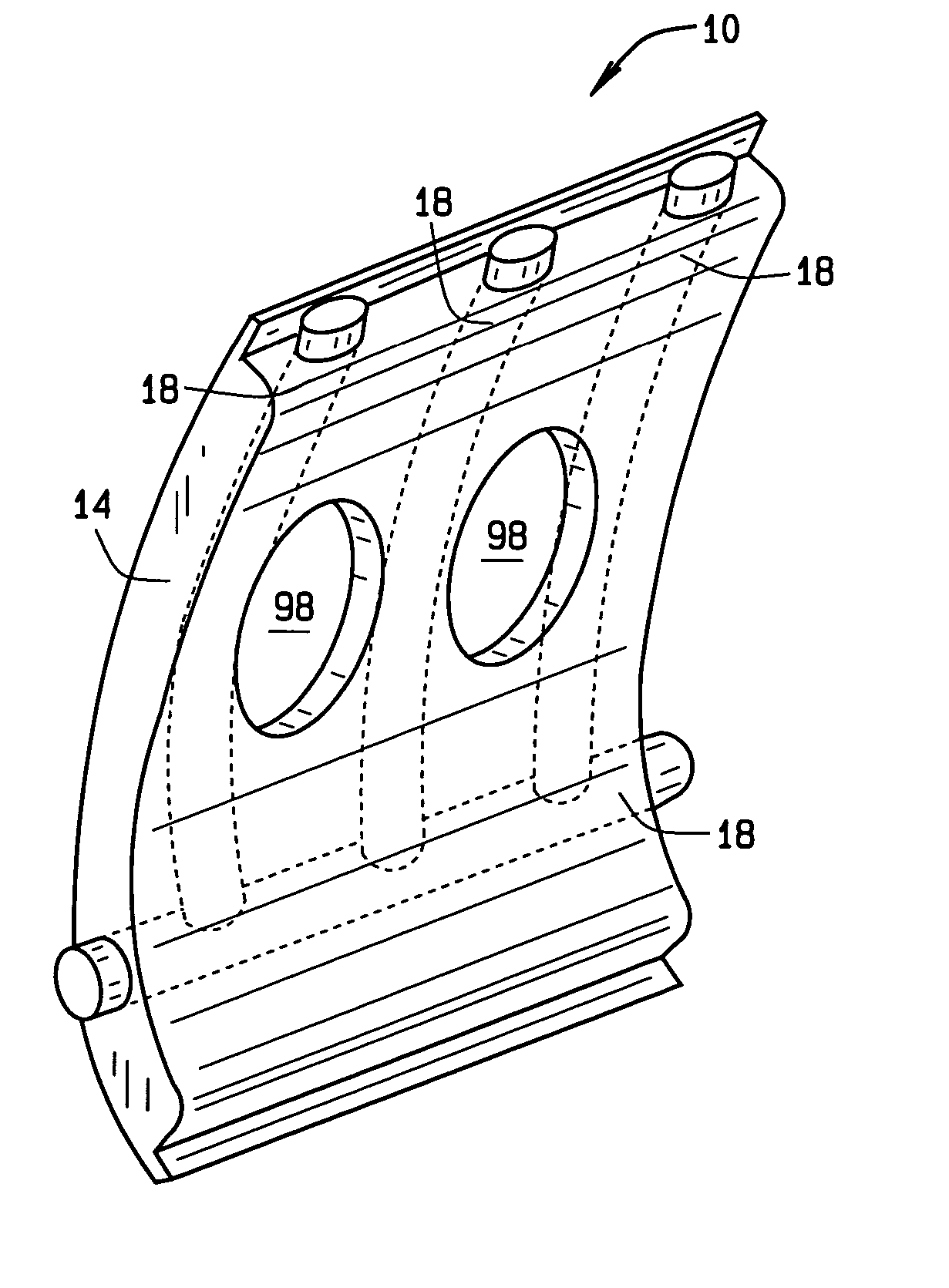

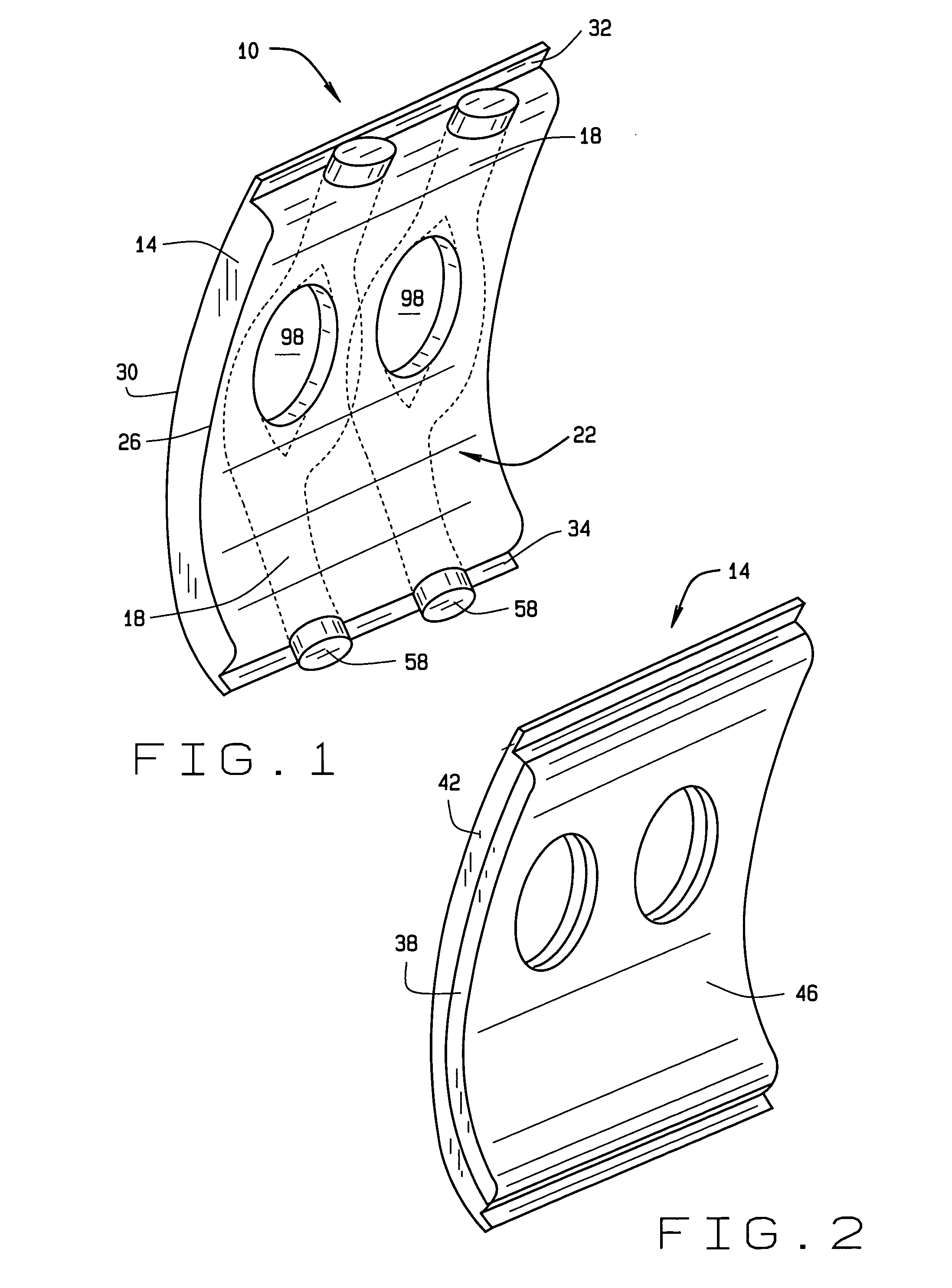

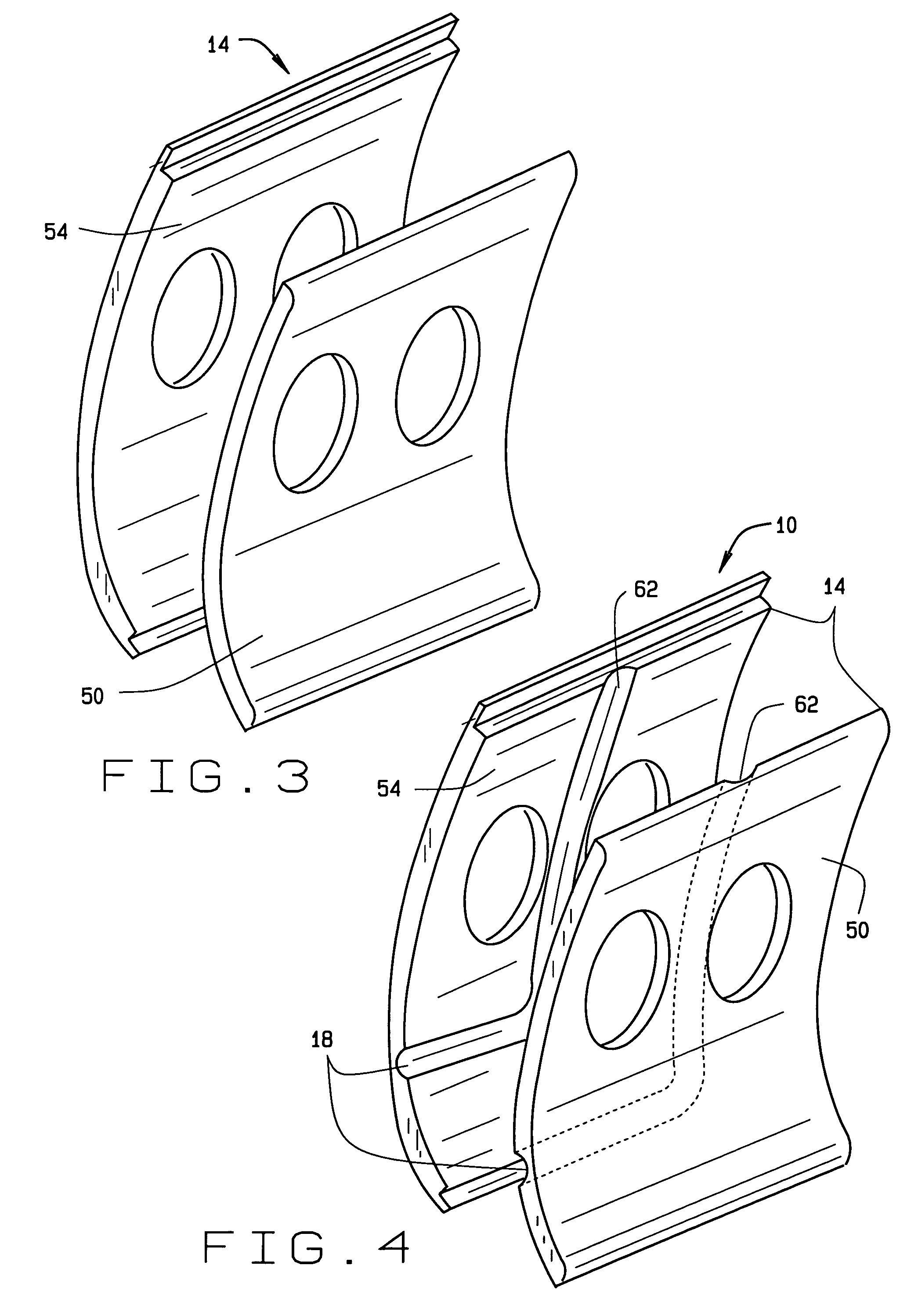

Sidewall panel integrated with insulation and air ducts

A mobile platform interior panel is provided that includes a body formed by a low pressure injection process and at least one of a duct and a layer of insulation integrated with the body. The low pressure injection process allows the duct and insulation to be integrated with the body simultaneously with the forming of the panel. More specifically, the duct is integrated with the panel by forming at least one internal cavity within the panel as the panel is formed. Additionally, the insulation is integrated with the panel by forming the panel using a low pressure injection material having desired insulative properties.

Owner:THE BOEING CO

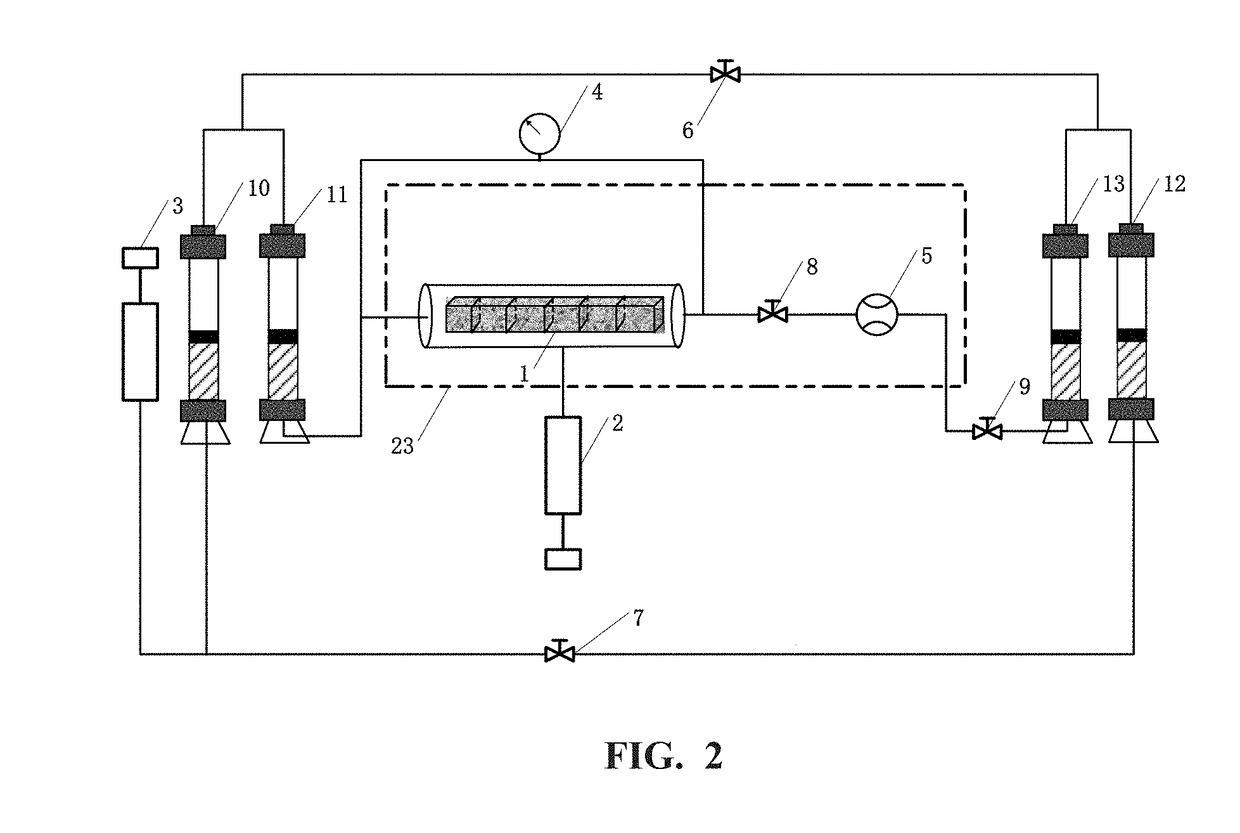

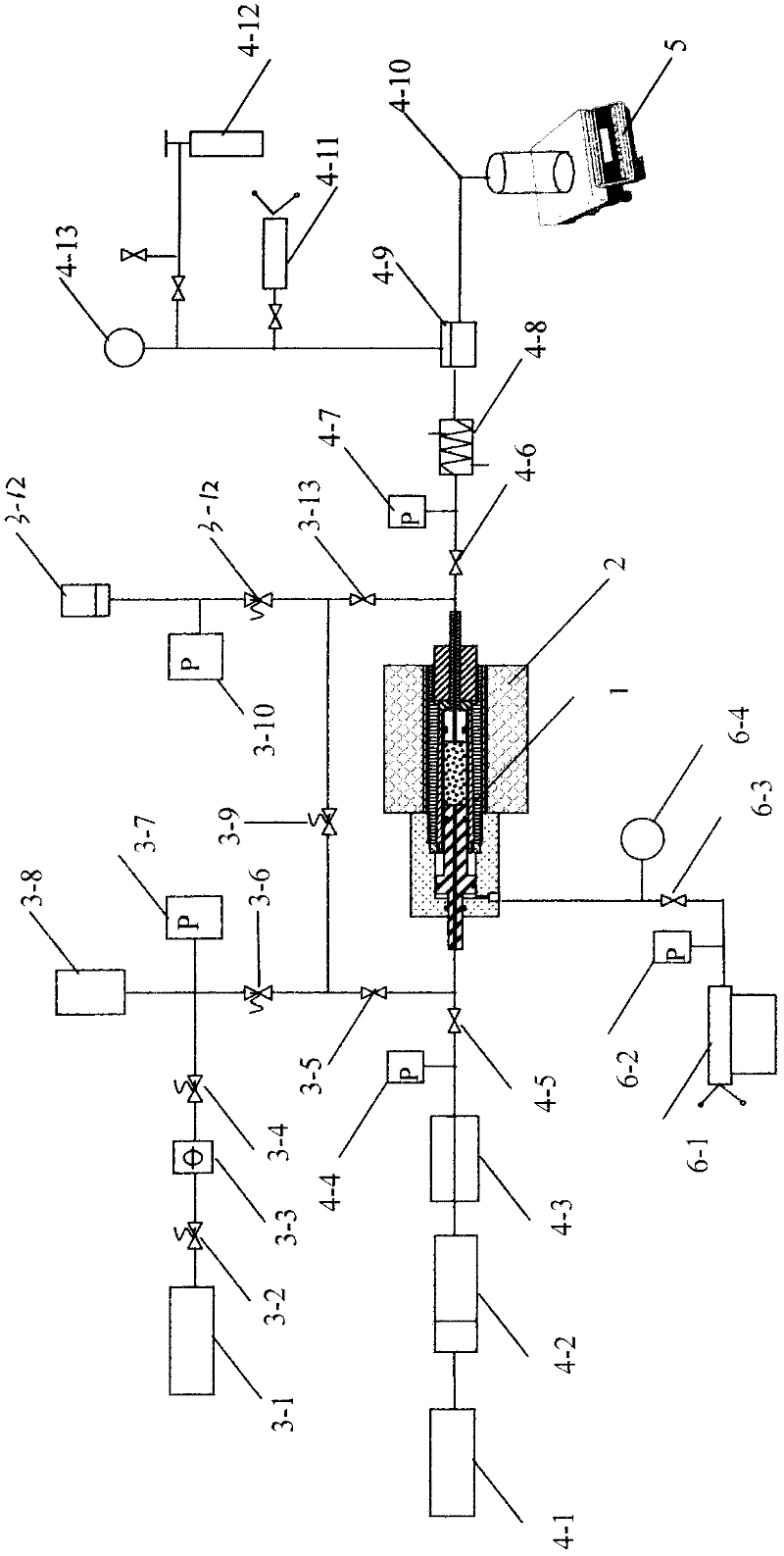

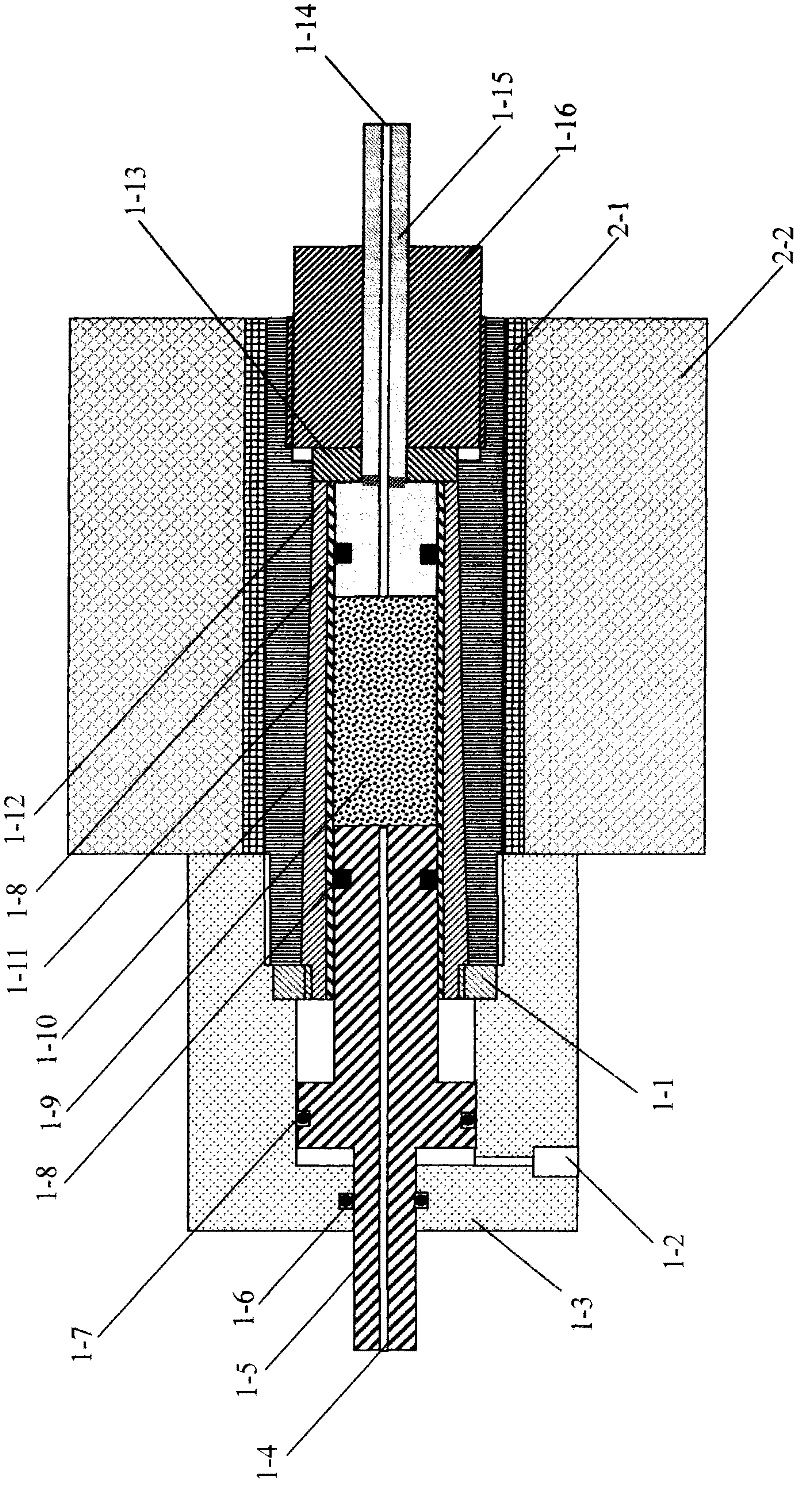

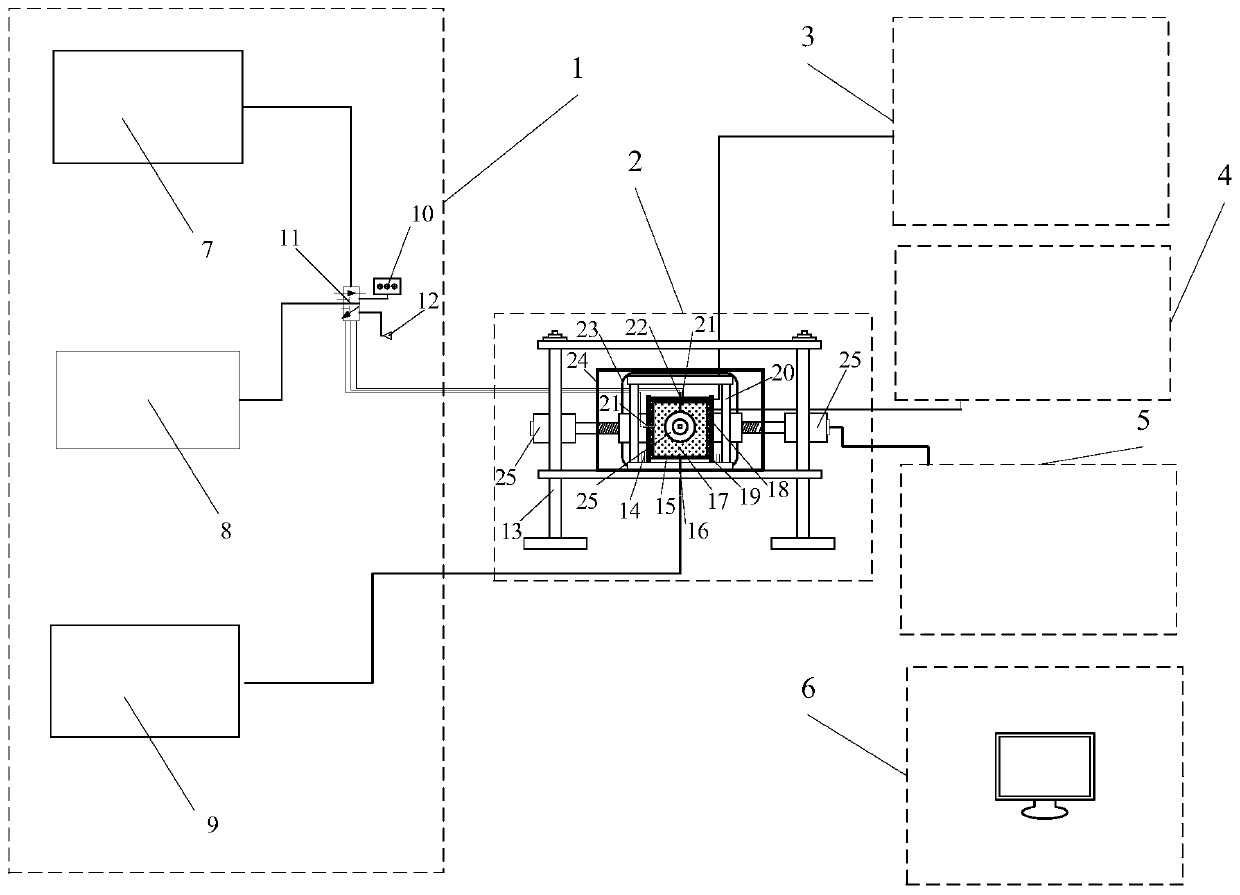

Apparatus and method for measuring apparent permeability of tight rock core

ActiveUS20180372611A1Accurate measurementEasy to operatePermeability/surface area analysisPressure difference measurement between multiple valvesRock coreDifferential pressure

The present application provides an apparatus and a method for measuring apparent permeability of a tight rock core, the apparatus comprises: a rock core holder, a first high-pressure injection pump, a second high-pressure injection pump, a micro-differential pressure meter, a micro-flow meter, a first pressure control unit, a second pressure control unit, a first valve, a second valve, a third valve, and a fourth valve; the first pressure control unit comprises: a first pressure-resistant piston container and a second pressure-resistant piston container, both of which are divided into an upper cavity and a lower cavity by a piston, the upper cavities of the first pressure-resistant piston container and the second pressure-resistant piston container are filled with gases and communicate with each other, and the lower cavity of the first pressure-resistant piston container is filled with pump pressure-transmission liquids, and the lower cavity of the second pressure-resistant piston container is filled with experimental fluids.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

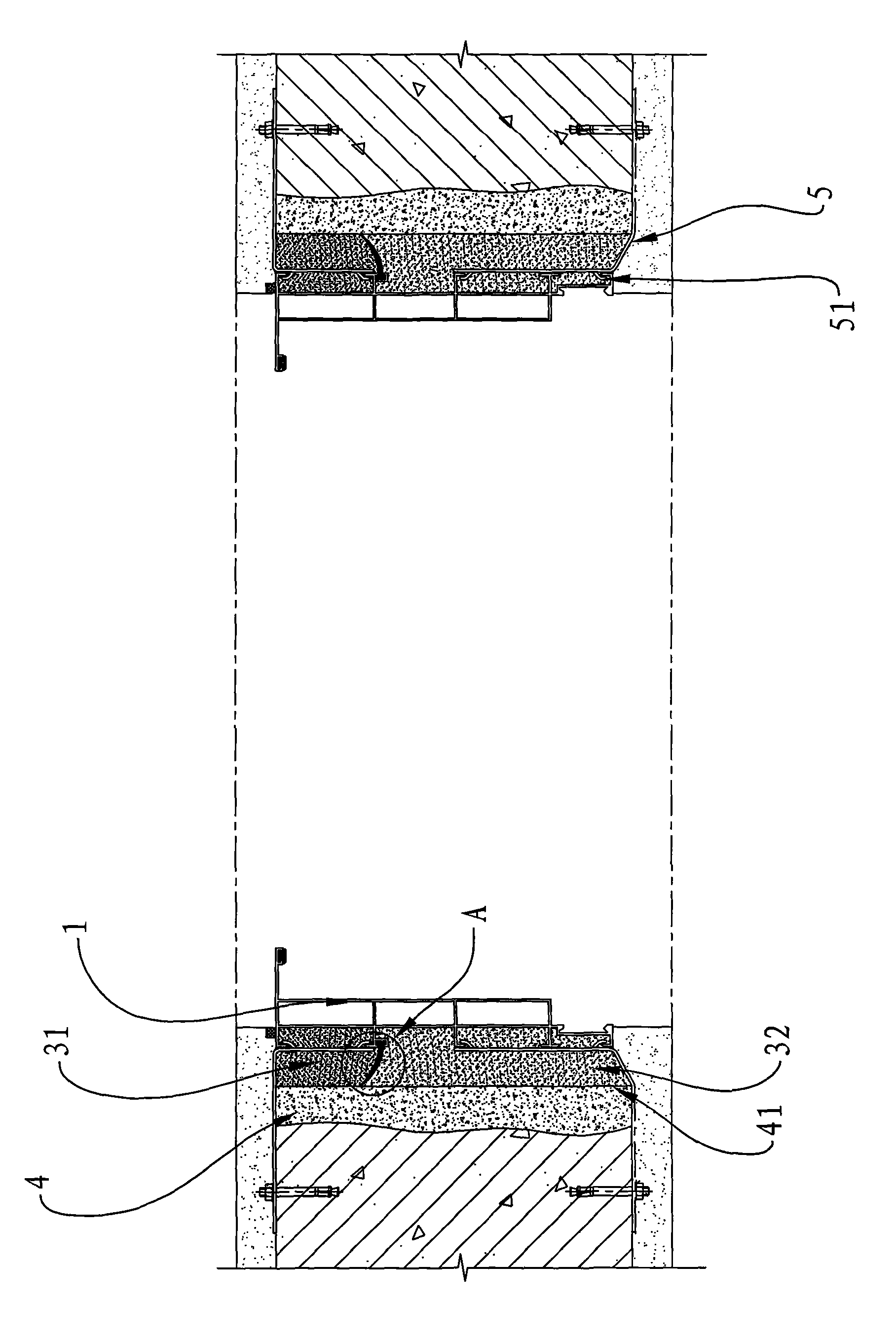

In-situ restoration device and in-situ restoration method of organic polluted soil and underground water

ActiveCN104174643ASimple design and operationEasy to disassembleContaminated soil reclamationWater/sewage treatment by oxidationRestoration deviceGroundwater remediation

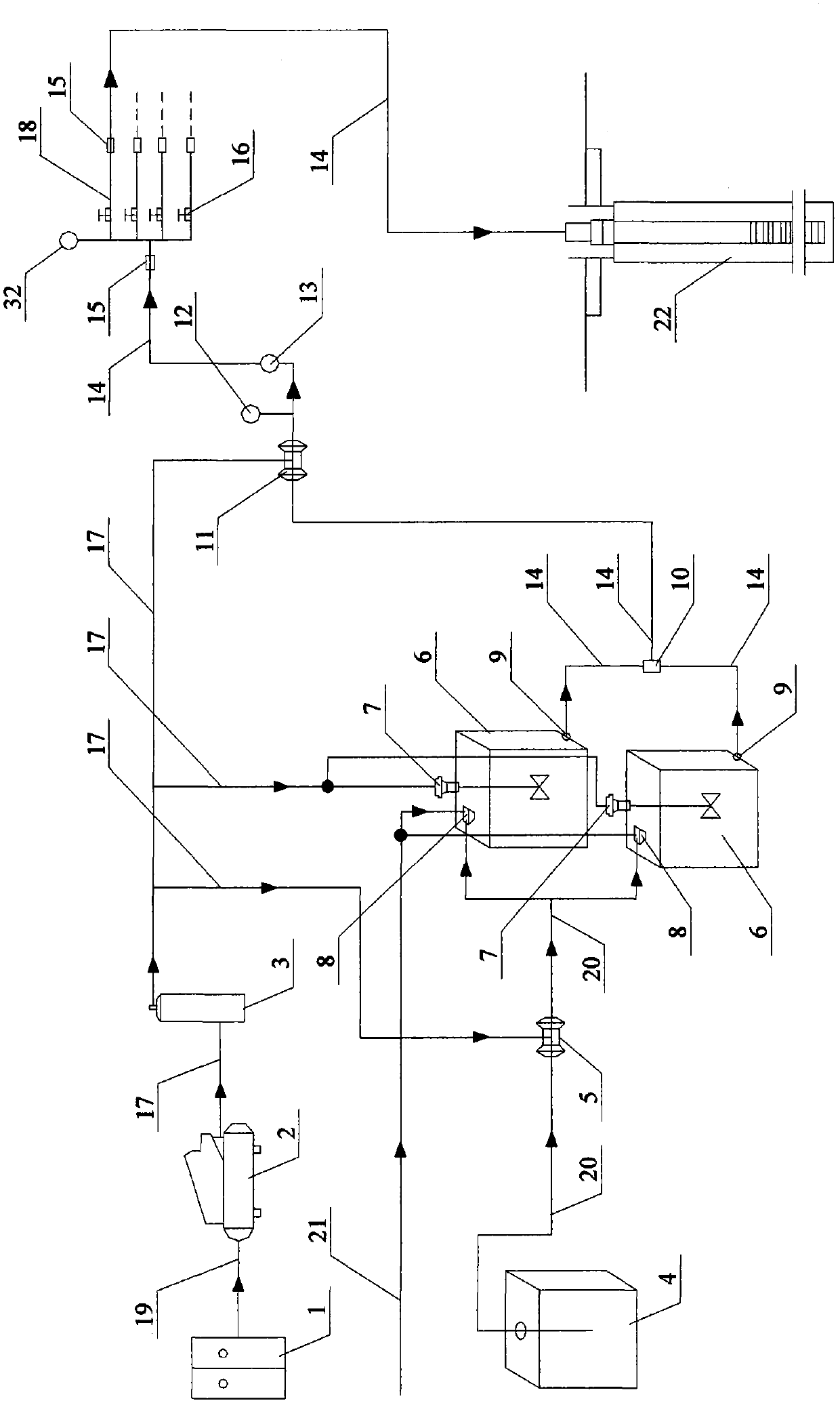

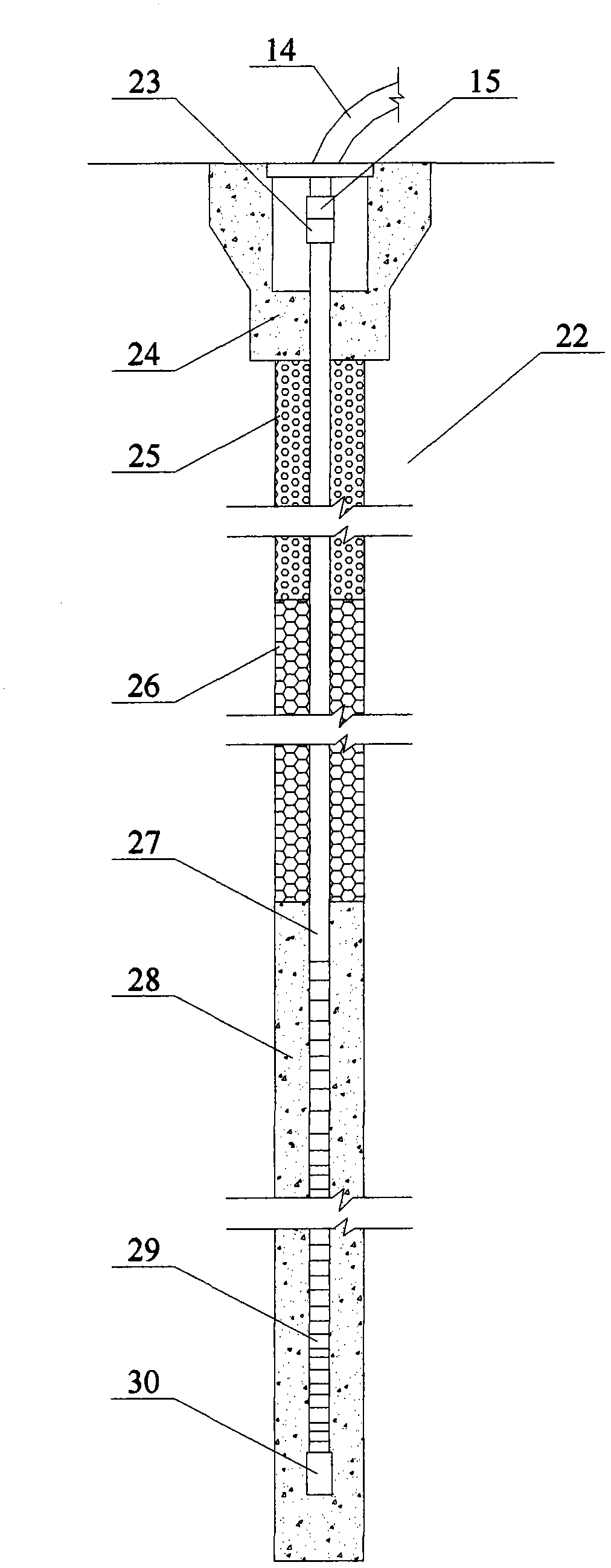

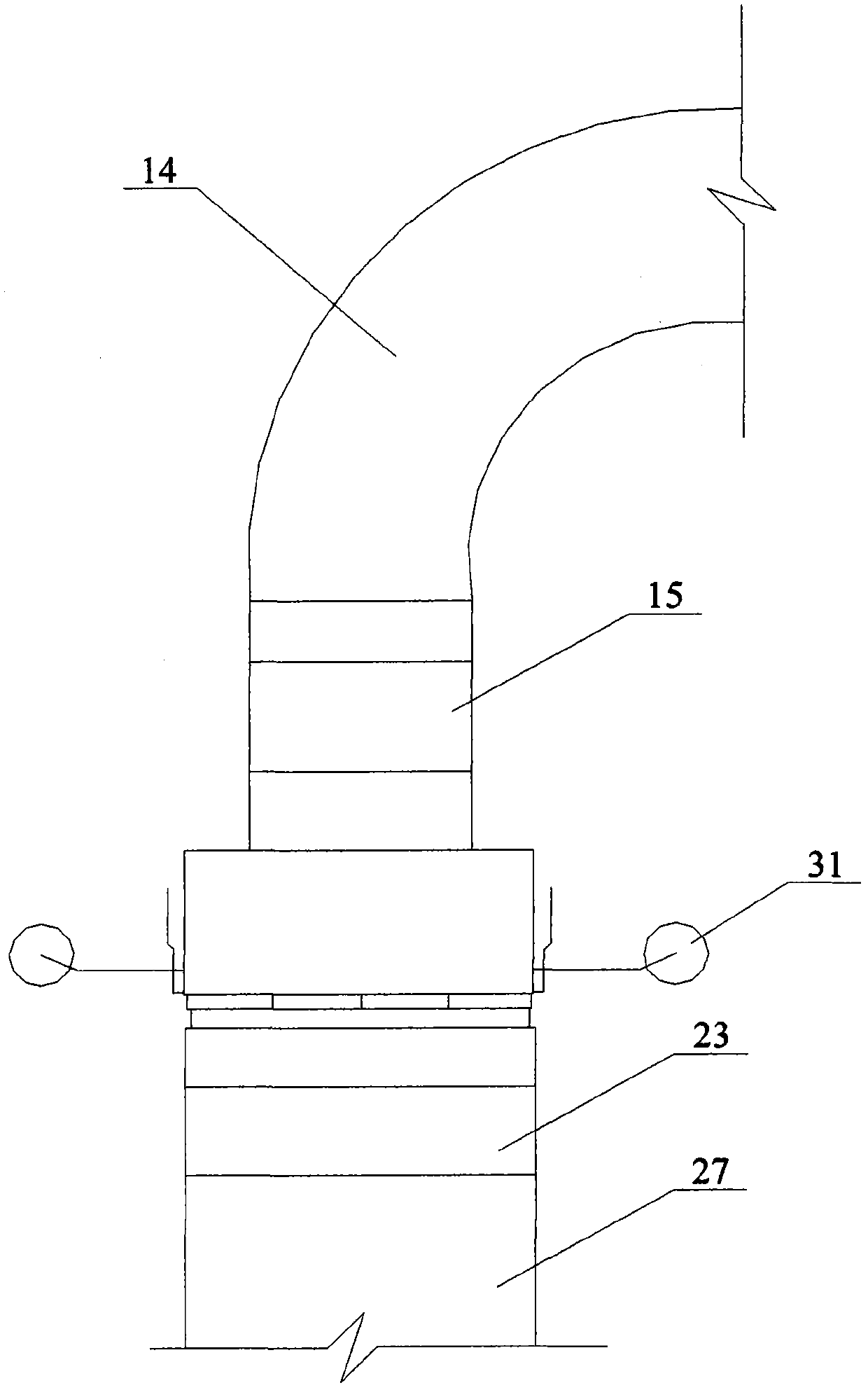

The invention provides an in-situ restoration device and an in-situ restoration method of organic polluted soil and underground water. The in-situ restoration device designed by the invention comprises a pneumatic source system, an agent dissolving and preparing system, an in-situ injection system and an injection well system. The in-situ restoration device is characterized in that the organic polluted soil and the underground water in a saturation layer and a non-saturation layer can be restored, injection wells are distributed at polluted areas according to the conditions of pollution distribution and hydrogeololgy and the like, and oxidizing agents prepared by the dissolving and preparing system are injected into the polluted areas by certain pressure through the injection system to restore target pollutants. The in-situ restoration device provided by the invention has the advantages that the injection wells are subjected to three-layer sealing by three sealing materials, the integration is good, the disassembly is fast and the economic and fast effects are achieved.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

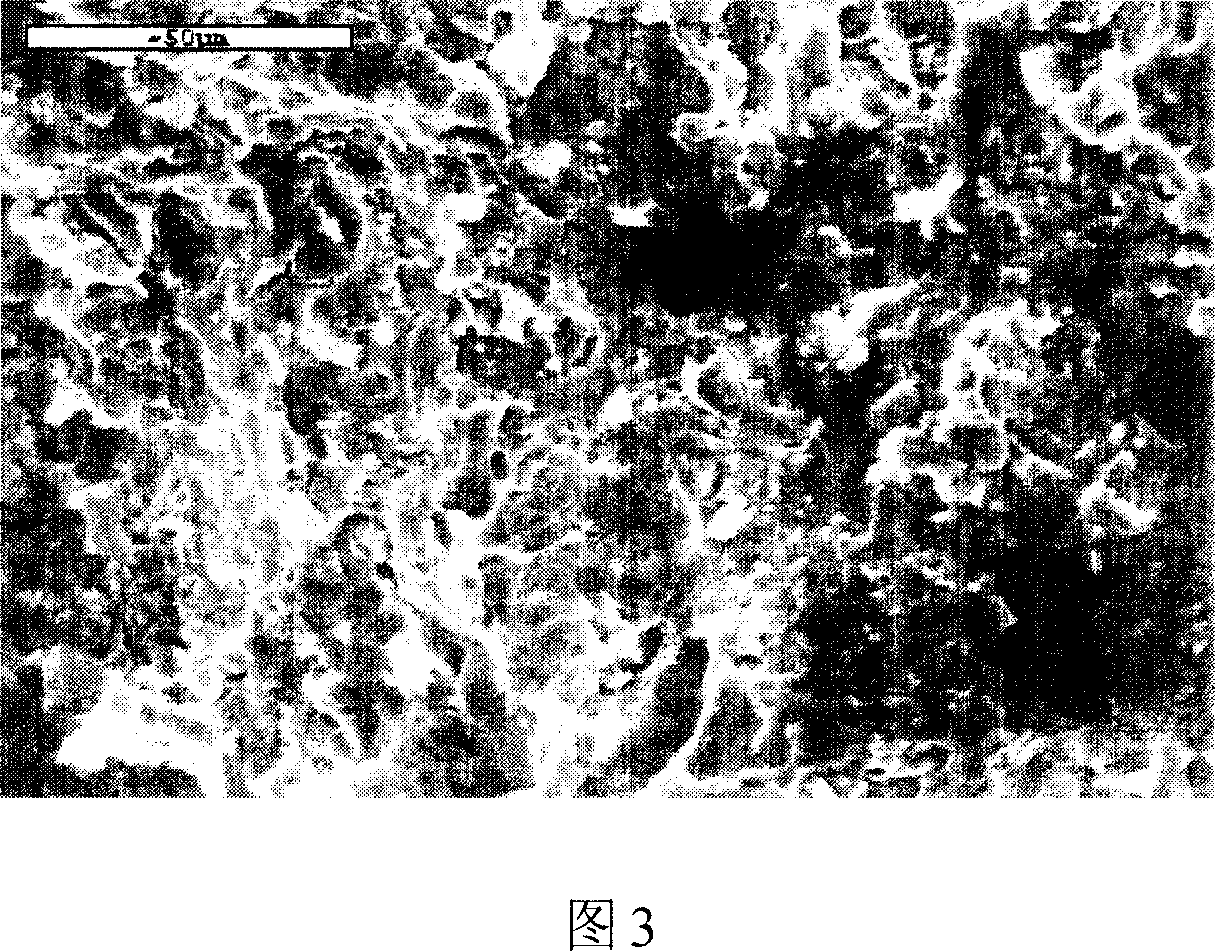

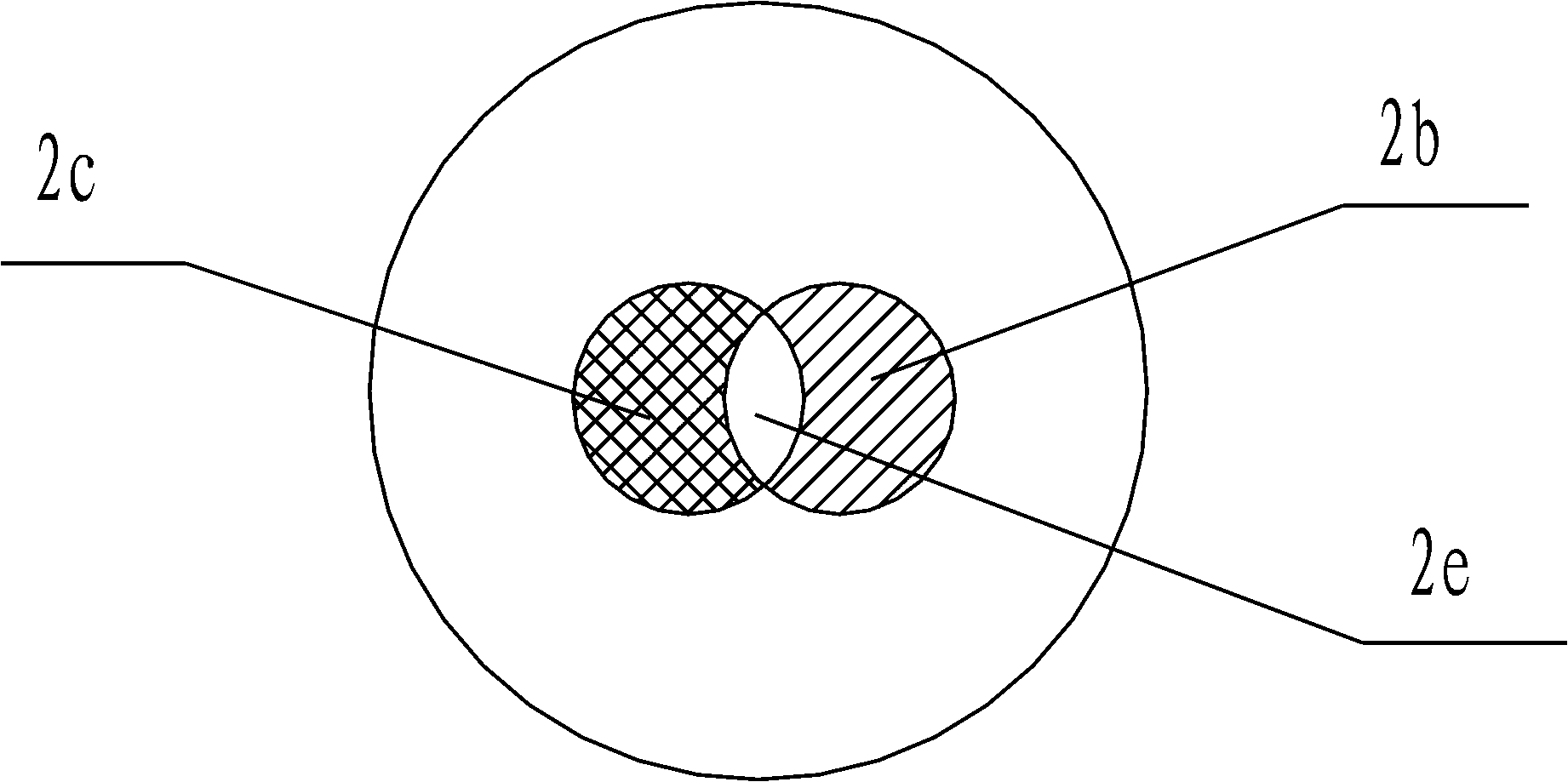

High strength and high toughness foamed SiC/Al material and its preparing method

The present invention relates to heterogeneous foamed ceramic / metal material, and is especially one kind of high strength and high toughness foamed SiC / Al material and its preparation process. The foamed SiC / Al material has basic units of closed polygonal ring to form connected 3D network structure, and each of the closed polygonal ring units is heterogeneous foamed ribs comprising SiC in 50-95 vol% and metal Al in 5-50 vol% and with the relative density not lower than 99 %. The foamed SiC / Al material is prepared through organic foam soaking, hot pressing to densify, pressure injection filling, thermal decomposition and reaction sintering. The preparation process is simple and low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

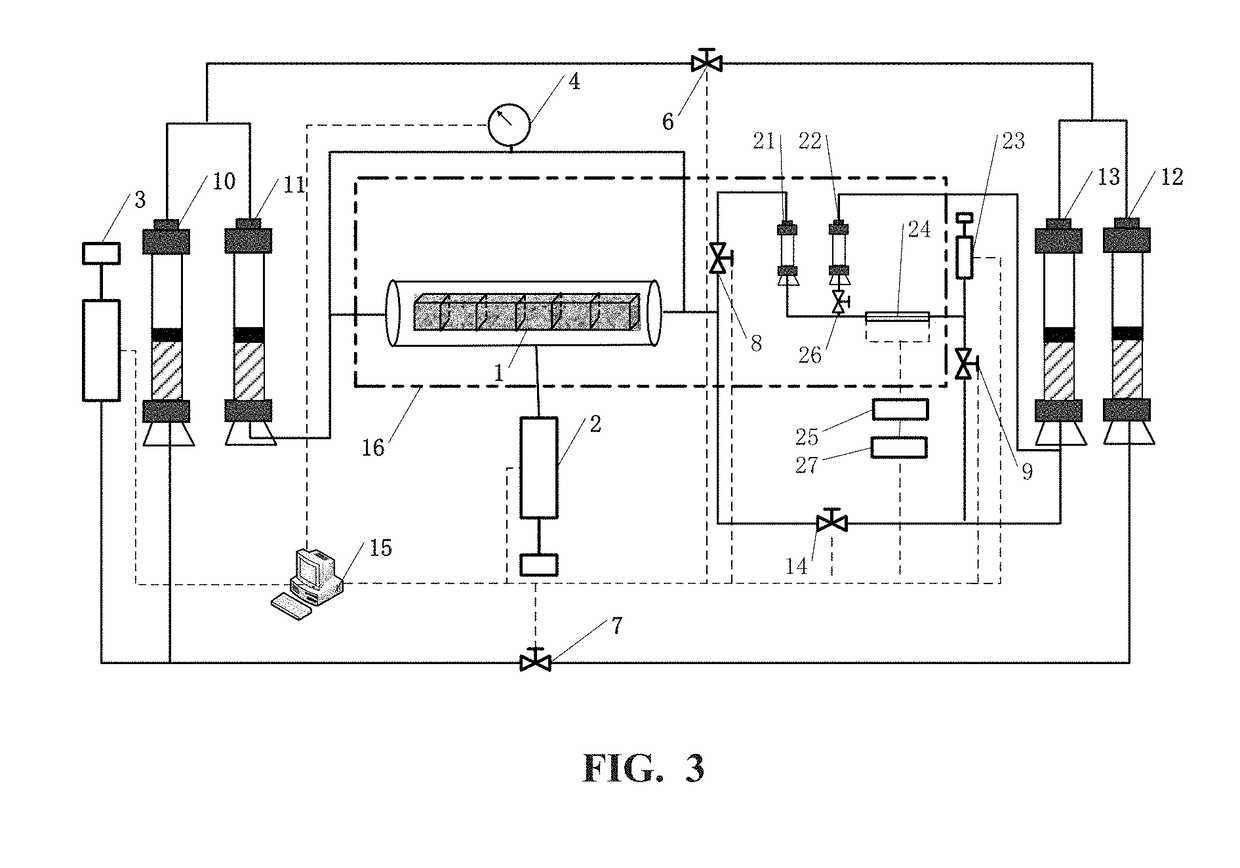

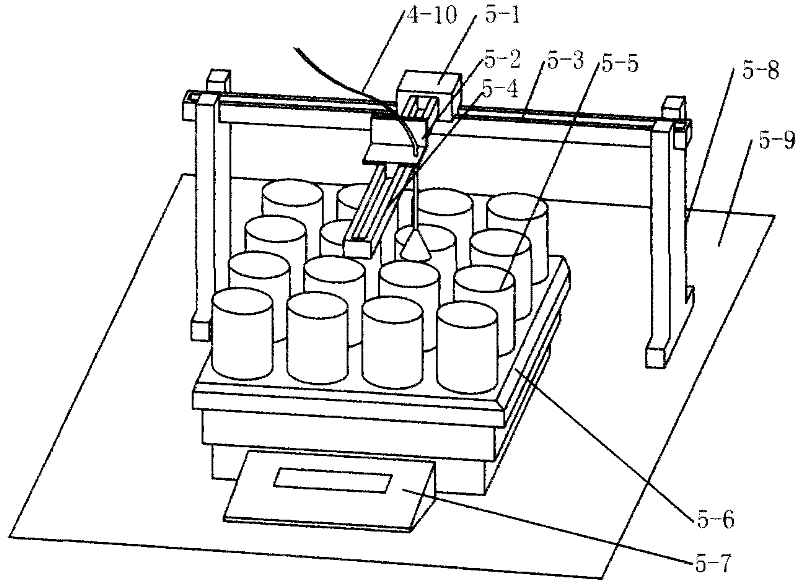

Diagenesis simulation experimental apparatus and method

ActiveCN102411044AEasy to operateGuaranteed experimental temperatureEarth material testingPermeability/surface area analysisAutomatic controlSolenoid valve

The invention relates to a diagenesis simulation experimental apparatus and method. The diagenesis simulation experimental apparatus comprises a rock core clamping mechanism, a heating mechanism, a gas porosity and permeability measurement process, a liquid injection and liquid permeability test process, an automatic continuous outlet-fluid metering and sampling mechanism, a burden pressure boost control mechanism, a fluid physical property detection mechanism and a data acquisition-calculation and automatic control mechanism, wherein, the inlet and outlet of the rock core clamping mechanism are respectively connected with the gas porosity and permeability measurement process and the liquid injection and liquid permeability test process; the heating mechanism is sheathed at the periphery of the rock core clamping mechanism, and the burden pressure injection port of the rock core clamping mechanism is connected with the burden pressure boost control mechanism; the outlet of the liquid injection and liquid permeability test process is connected on the automatic continuous outlet-fluid metering and sampling mechanism; the fluid physical property detection mechanism detects a fluid sample of the automatic continuous outlet-fluid metering and sampling mechanism; and the data acquisition-calculation and automatic control mechanism acquires, records, stores and calculates temperature, pressure and flow rate in an experiment and meanwhile controls operation of the corresponding solenoid valve and the automatic continuous outlet-fluid metering and sampling mechanism according to the experimental status.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

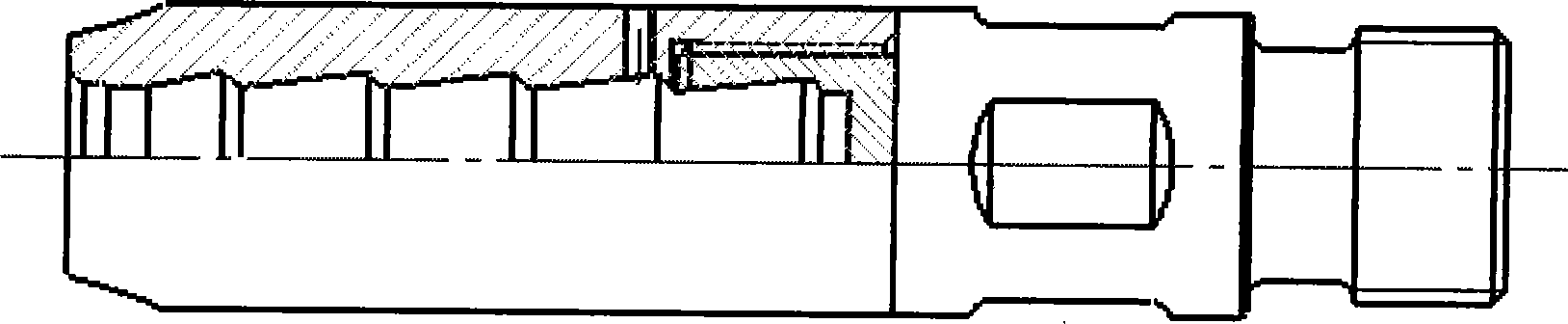

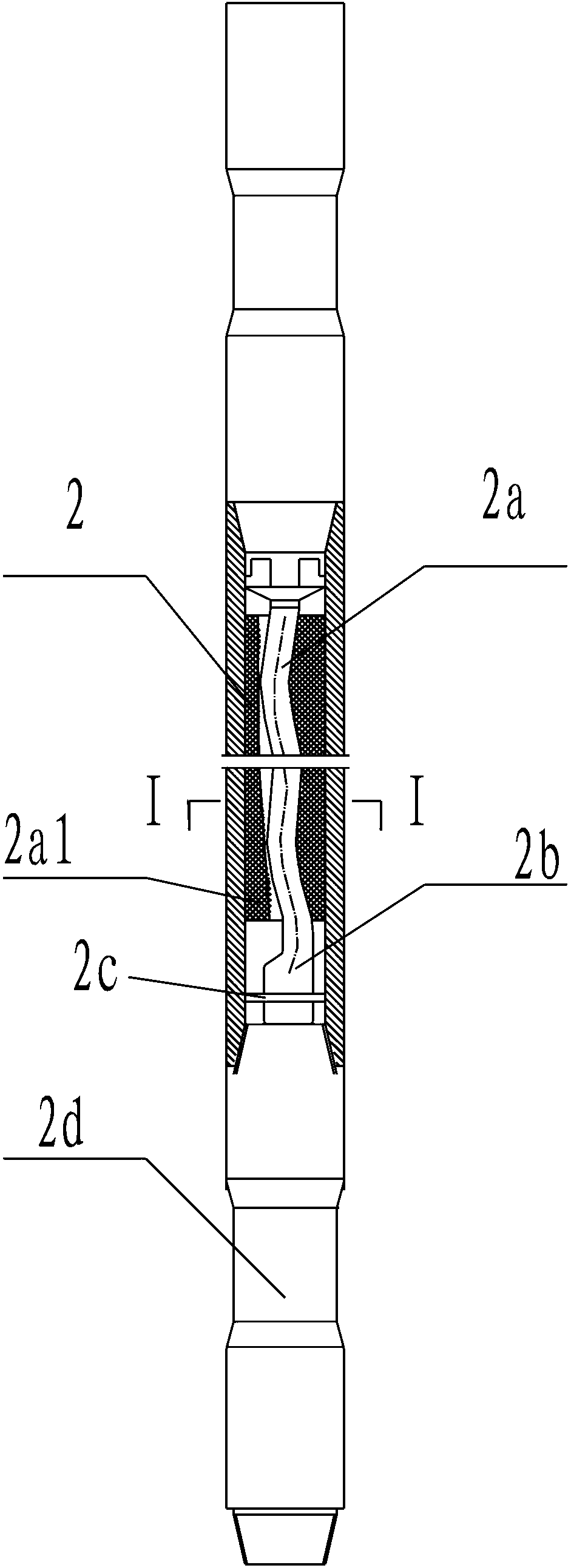

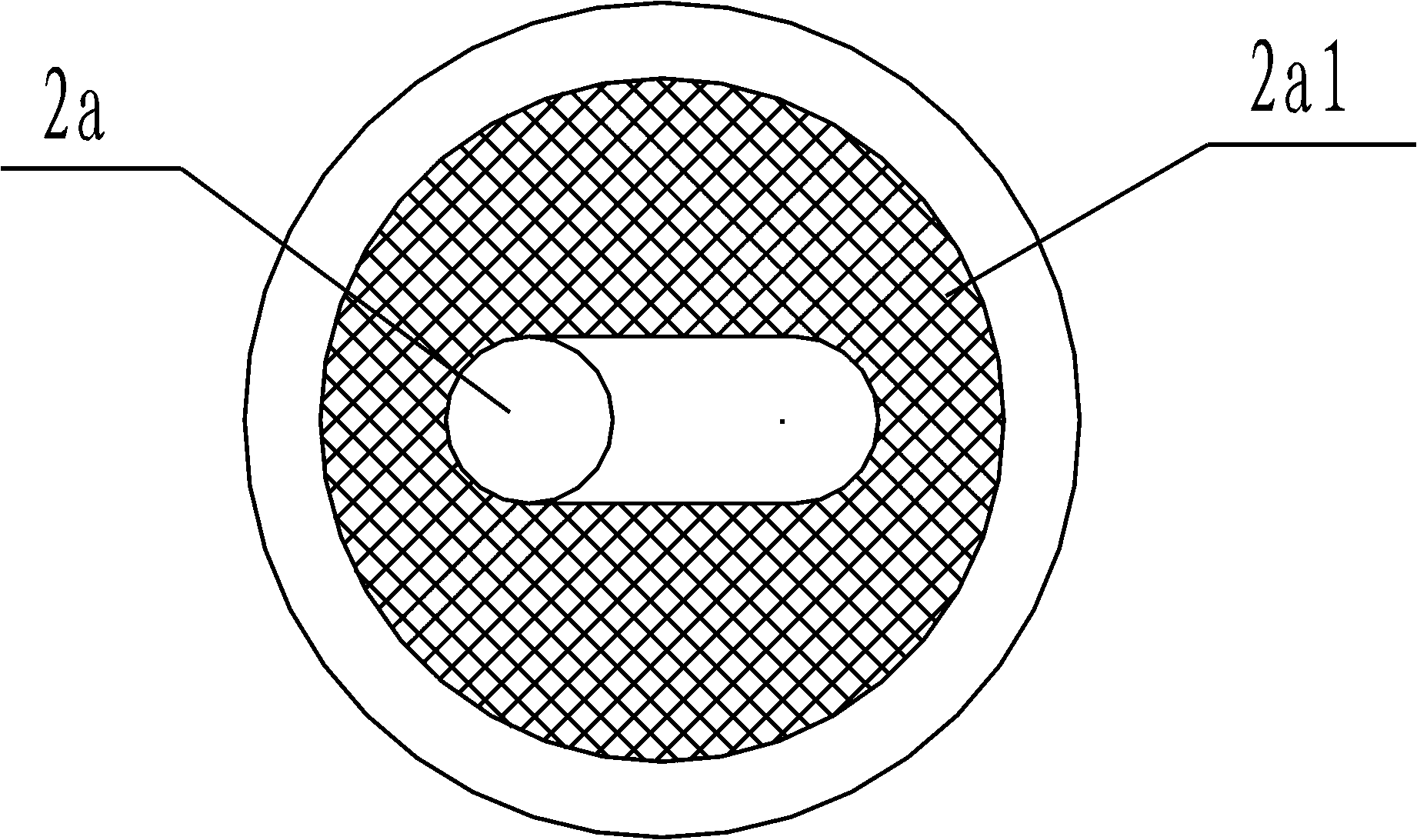

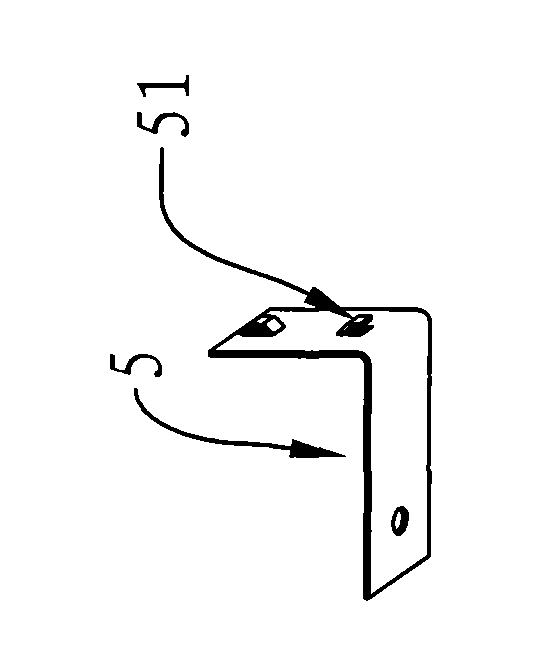

Preparation method and device of eccentric wear prevention pumping rod

InactiveCN101396874AExcellent performance of anti-eccentric wearPrevent slippageDrilling rodsDomestic articlesPre stressResin matrix

The invention relates to a method for preparing a composite material sucker rod which can prevent camber wear and a device thereof. Combining pultrusion and winding, fibre is immersed by resin matrix, and the composite material sucker rod is prepared by pultrusion, curing and shaping; the surface of the rod body is continuously wound with wearing fibre immersed by resin matrix glue after shaping; the rod body of the sucker rod, the surface of which is provided with a camber wear preventing layer of a spiral bar shape is obtained by curing; the rod body of the sucker rod is cut to be in fixed length, is connected with a metal joint by glue, and is treated in a joint curing furnace; the whole sucker rod is stretched by inherent stress. The surface of the rod body of the sucker rod is provided with the camber wear preventing layer of a spiral bar shape, thus having excellent camber wear preventing performance while ensuring a high intensity of the sucker body; the inverse cone structure of the metal joint and the pressure injection glue connection process ensure the joint part has the properties of high intensity and fatigue proof, the service life of which is consistent with the composite material rod body, and the reliability of the products is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

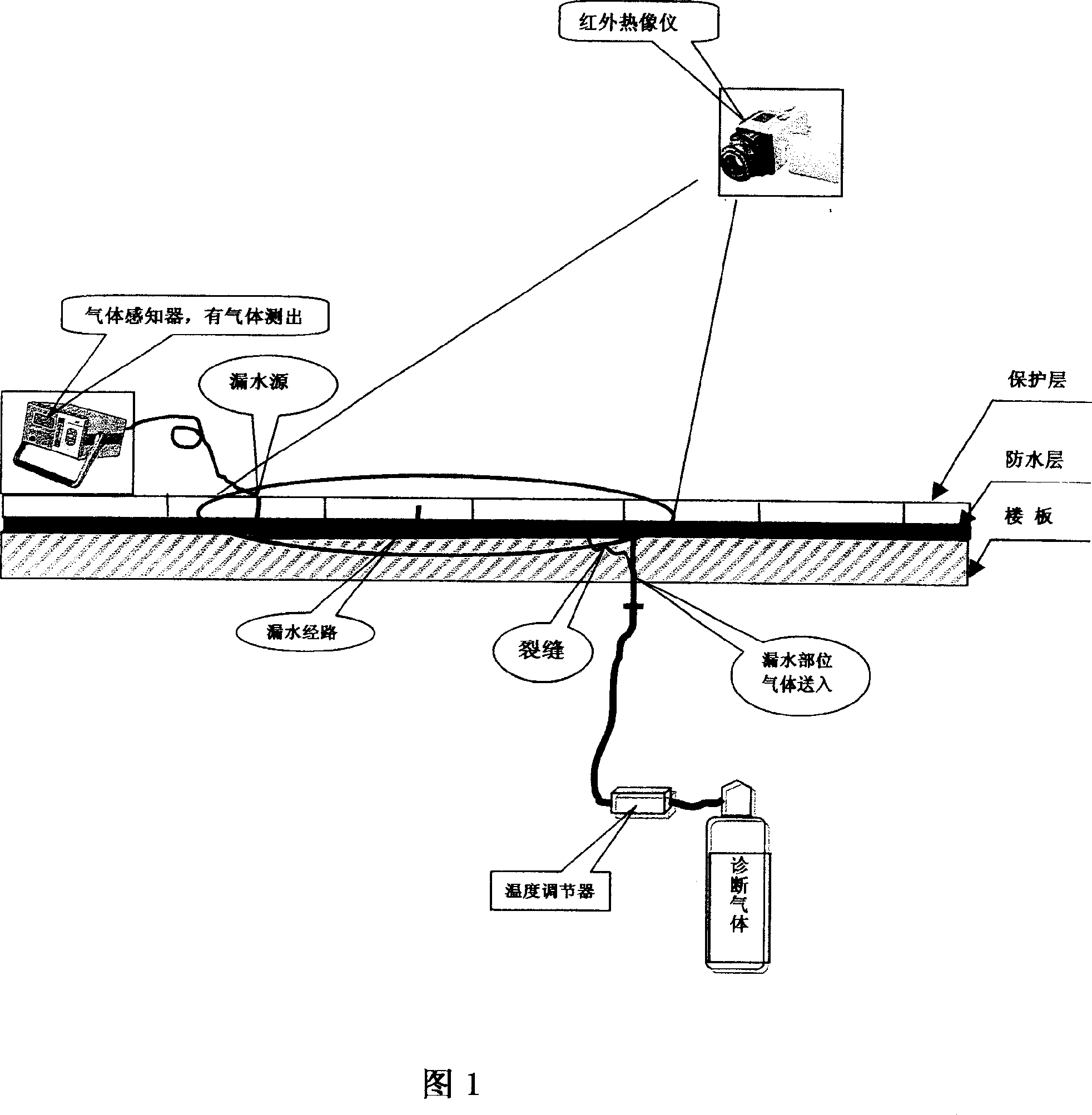

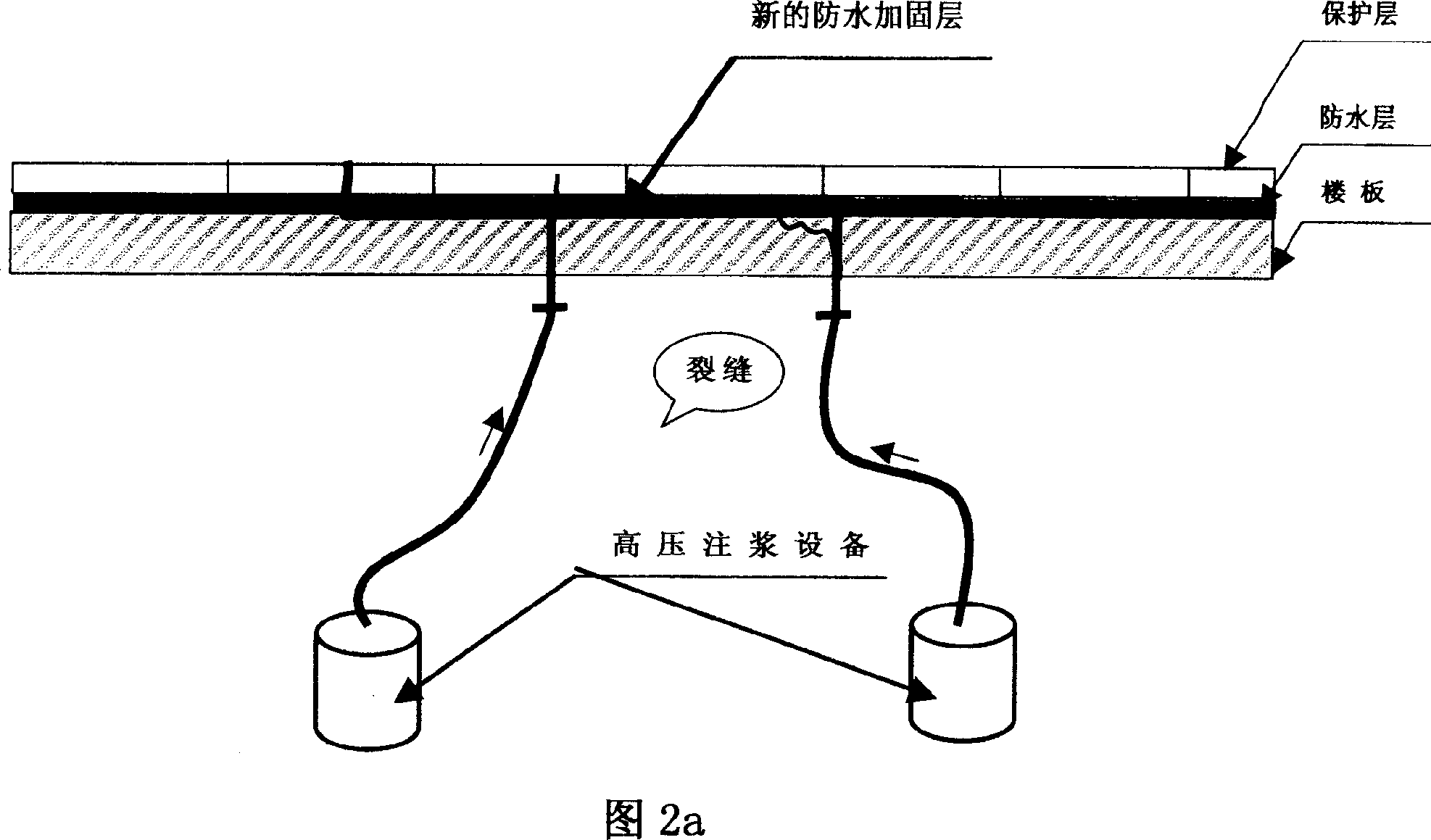

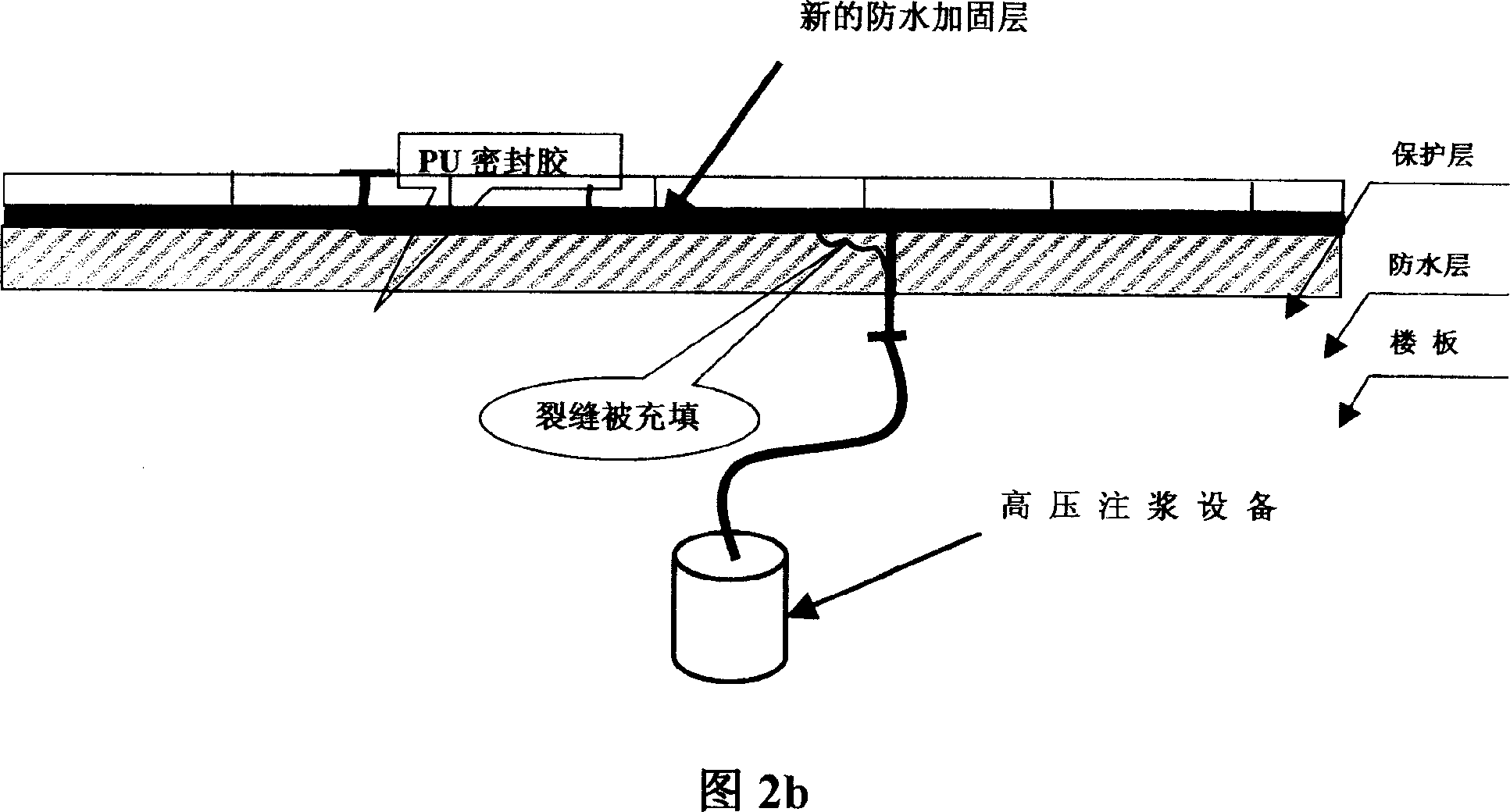

Method for detection and stopping leak for concrete buildings leakage source

InactiveCN1924534AIntuitiveImprove efficiencyBuilding insulationsFluid-tightness measurement using fluid/vacuumEmulsionWater leakage

This invention belongs to measurement technique field and fixing technique field which is suitable for concrete architecture water leakage test method, which comprises the following steps: sending carbon dioxide gas from the leakage part on the architecture; then testing the gas outside the architecture and judging the leakage source according to the gas sensor situation; injecting the liquid emulsion into the leakage path crack or honeycomb hollow part to seal the leakage, which is characterized by adopting the infrared sense for analysis technique testing to judge the leakage source; adopting pressure injection to seal the leakage separately.

Owner:李海军

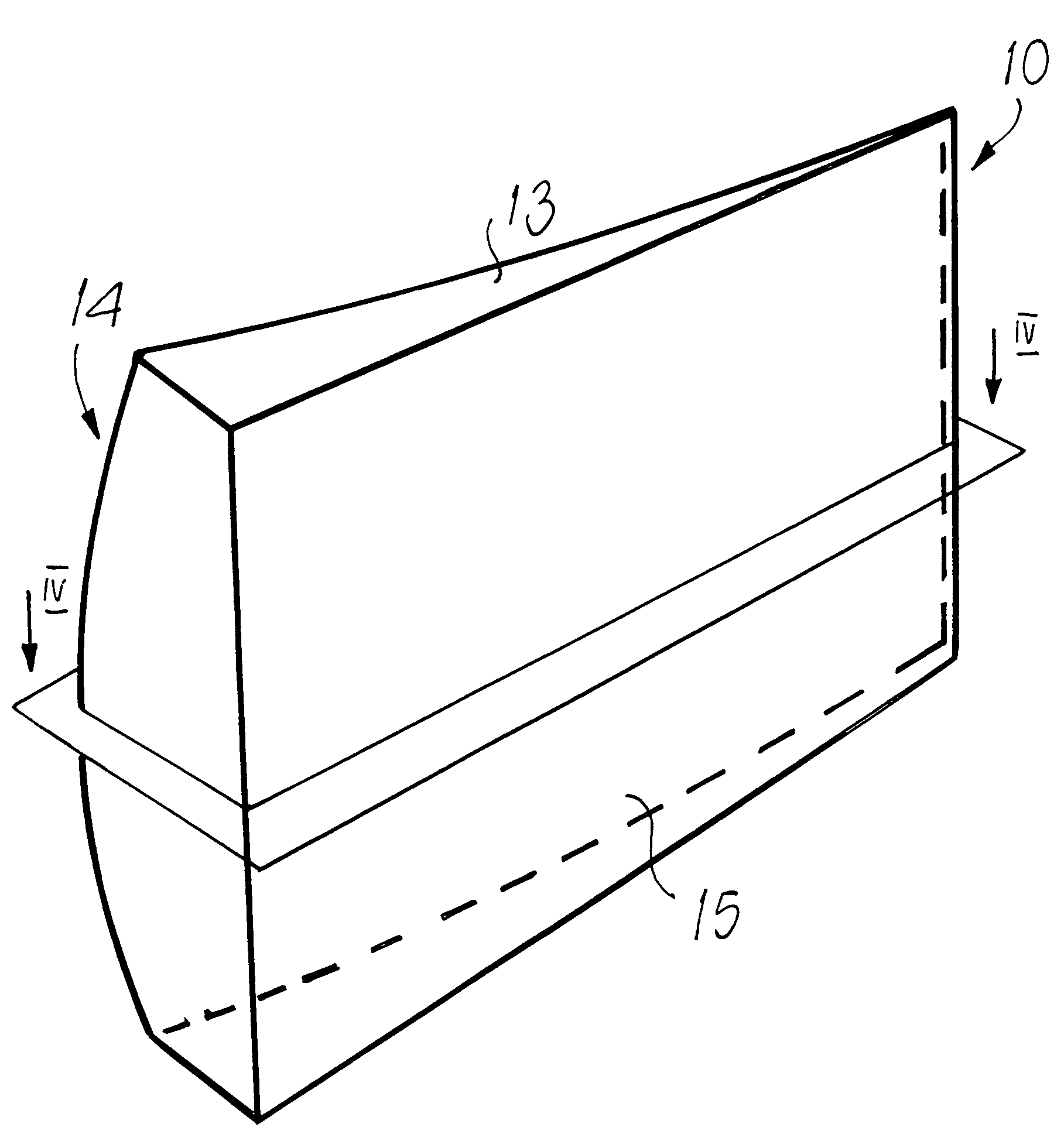

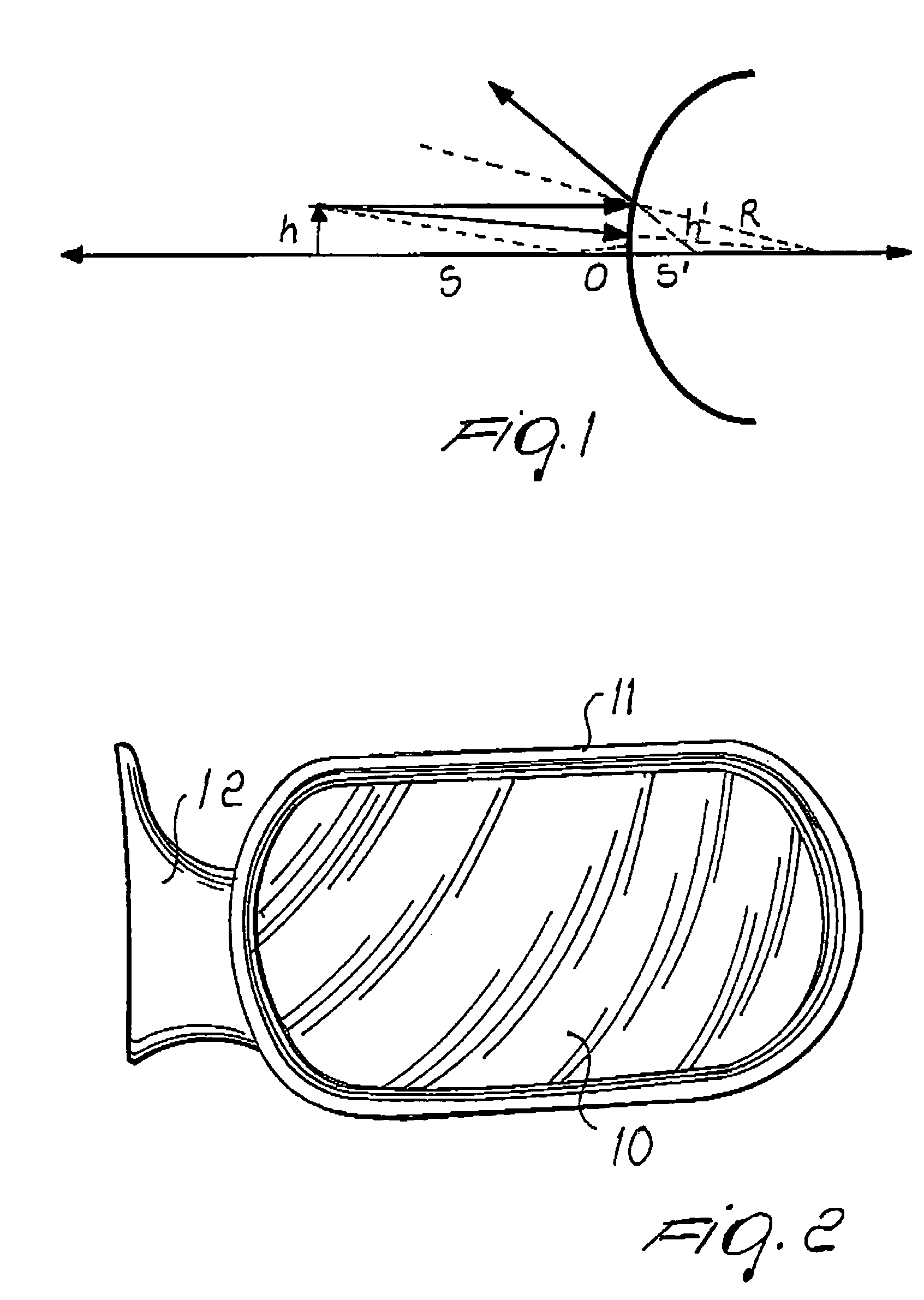

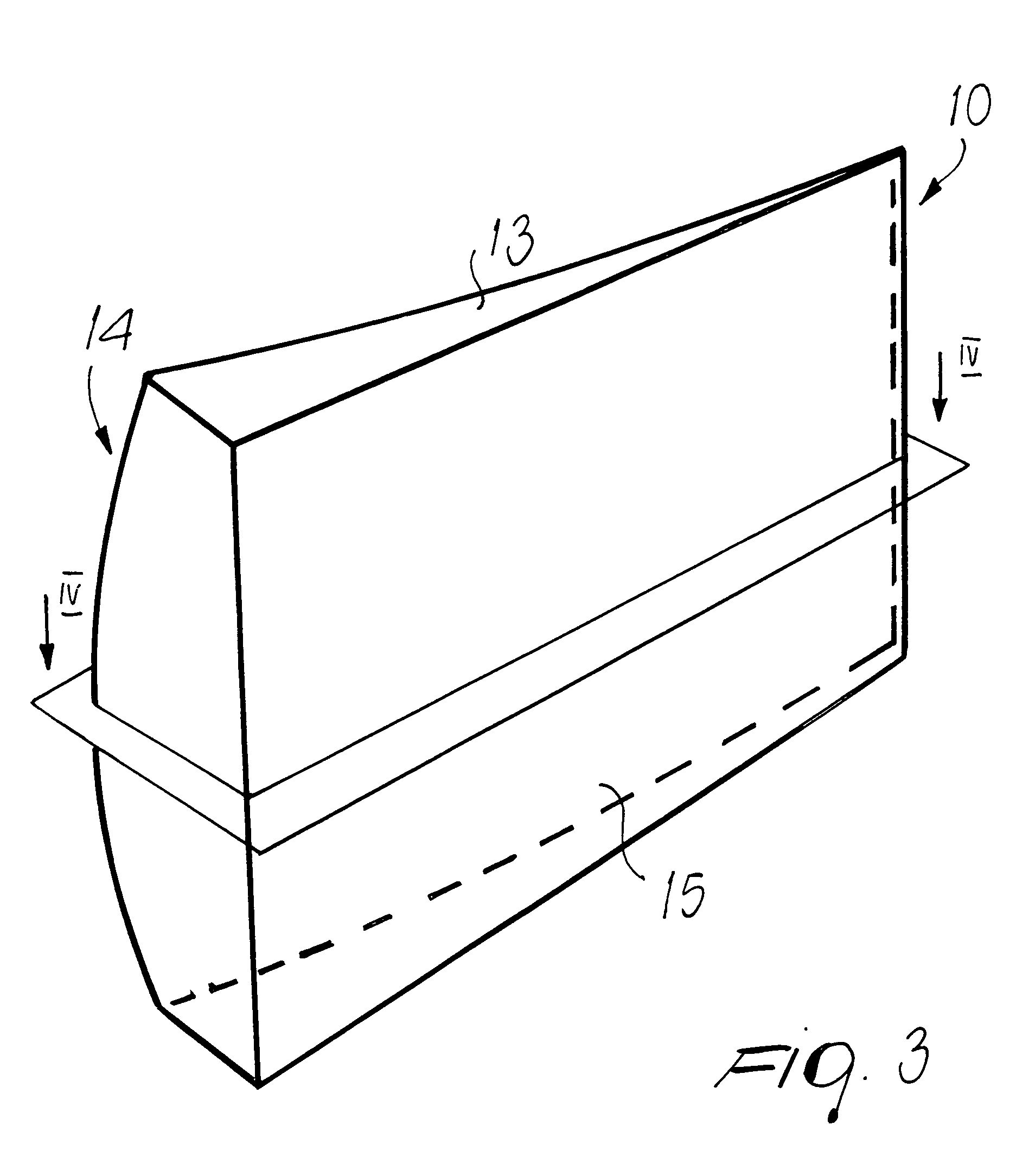

Vehicle rear-view mirror with wide viewing angle and reduced image distortion

InactiveUS7025469B1Eliminate the problemWide viewing angleMirrorsVehicle cleaningClassical mechanicsReflective layer

A mirror with wide viewing angle and reduced image distortion, to be used as an external rear-view mirror for vehicles which is obtained monolithically by pressure injection-molding or gravity casting of a highly transparent material and its external incident surface is flat, while the reflective rear part is obtained by means of an aspheric surface which is generated by the rotation, about an axis which is ideally parallel to the centerline axis of the vehicle, of a curve which determines, with good approximation, a profile which avoids significant deformation of the reflected images.

Owner:GIOVANNI MANFRE +1

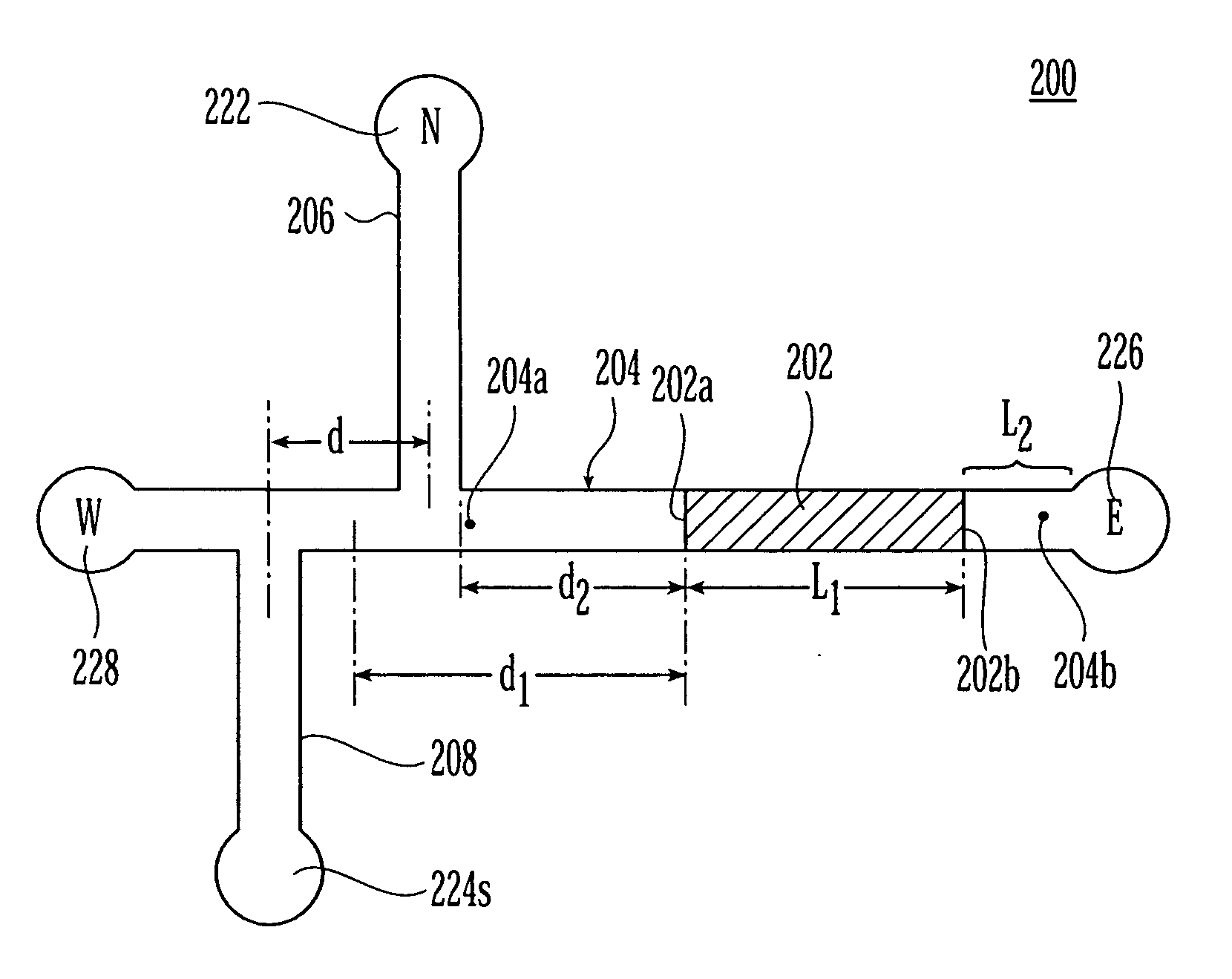

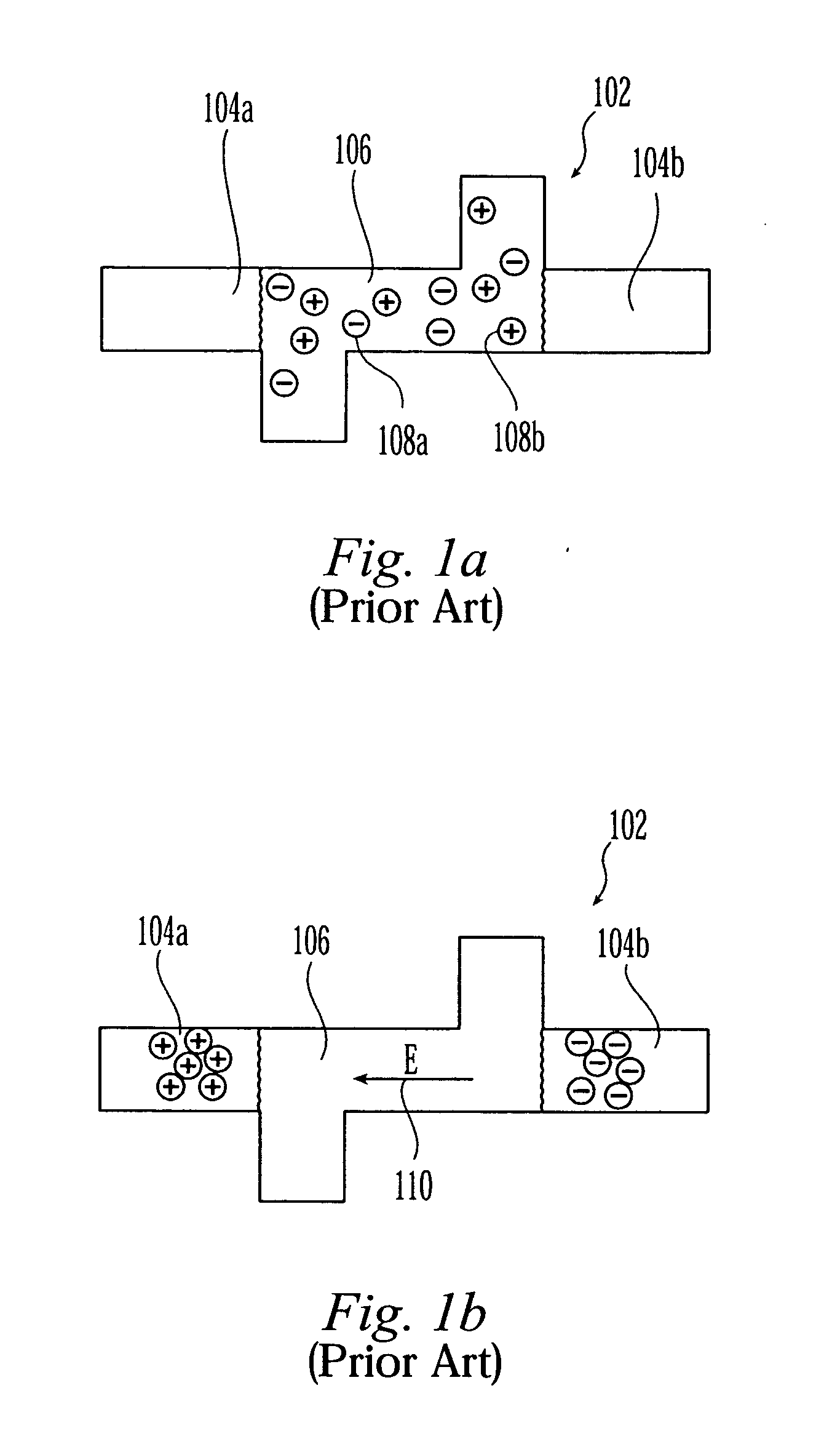

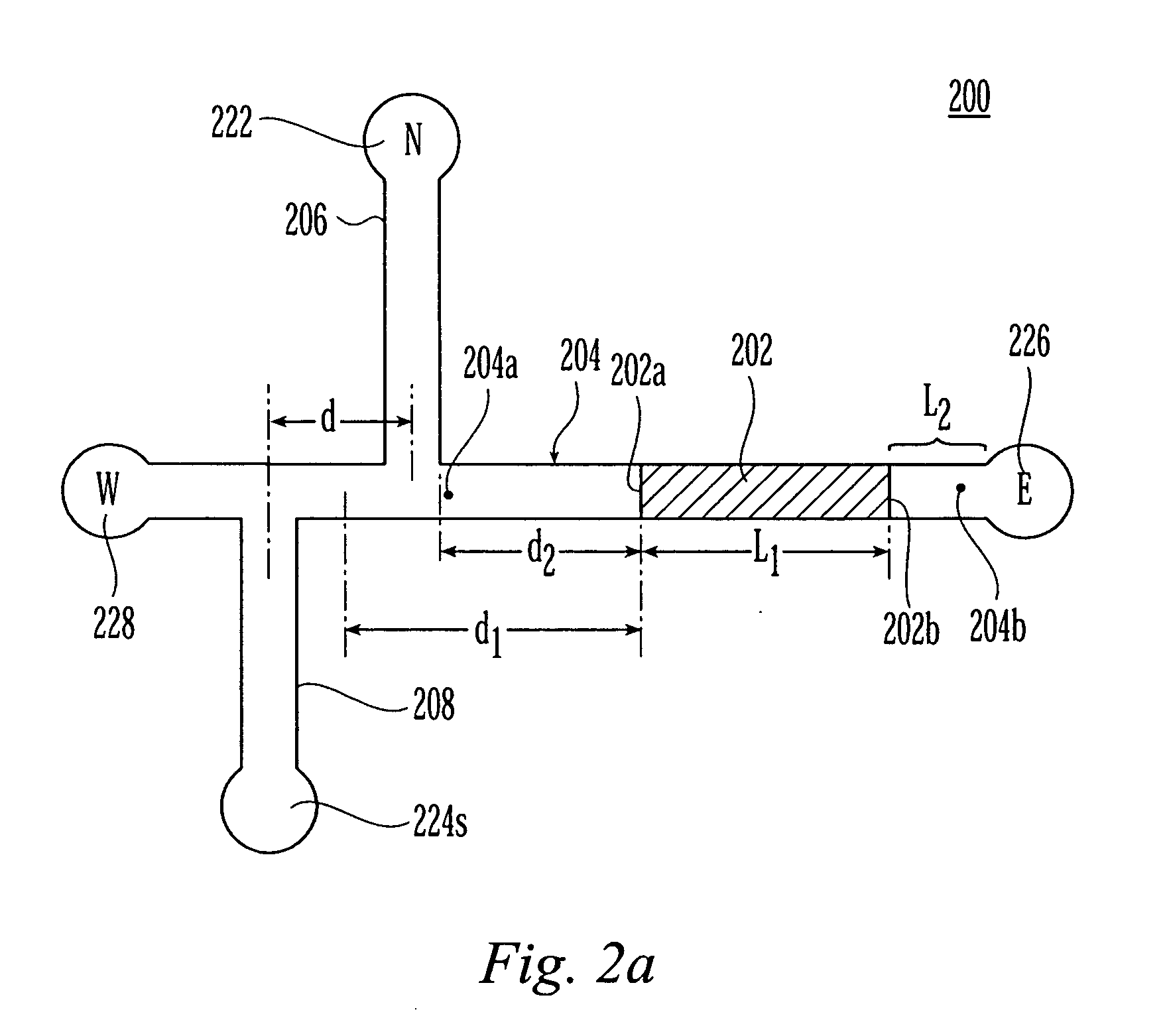

Microfluidic electrophoresis chip having flow-retarding structure

InactiveUS20060042948A1Reducing electrokinetic flow instabilityHigh hydraulic resistanceSludge treatmentVolume/mass flow measurementCapillary electrophoresisElectrophoresis

A capillary electrophoresis device and separation protocol uses a hydraulic resistance-providing structure (HRPS) in the main separation channel to separate the divide the main separate channel into an upstream portion and a downstream portion. The HRPS may take the form of a porous plug, or a solid plug provided with at least one shallow channel. A sample separates and migrates through the porous structure or the shallow channel, upon application of a voltage difference between the upstream and downstream sides. Among other things, the HRPS helps reduce electrokinetic flow in the presence of conductivity gradients and facilitates robust, high-gradient on-chip field amplified sample stacking. The HRPS also enables the use of a pressure-injection scheme for the introduction of a high conductivity gradient in a separation channel and thereby avoids flow instabilities associated with high conductivity gradient electrokinetics. The approach also allows for the suppression of electroosmotic flow (EOF) and benefits from the associated minimization of sample dispersion caused by non-uniform EOF mobilities. An injection procedure employing a single pressure-flow high-conductivity buffer injection step followed by standard high voltage control of electrophoretic fluxes of sample, may be employed.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

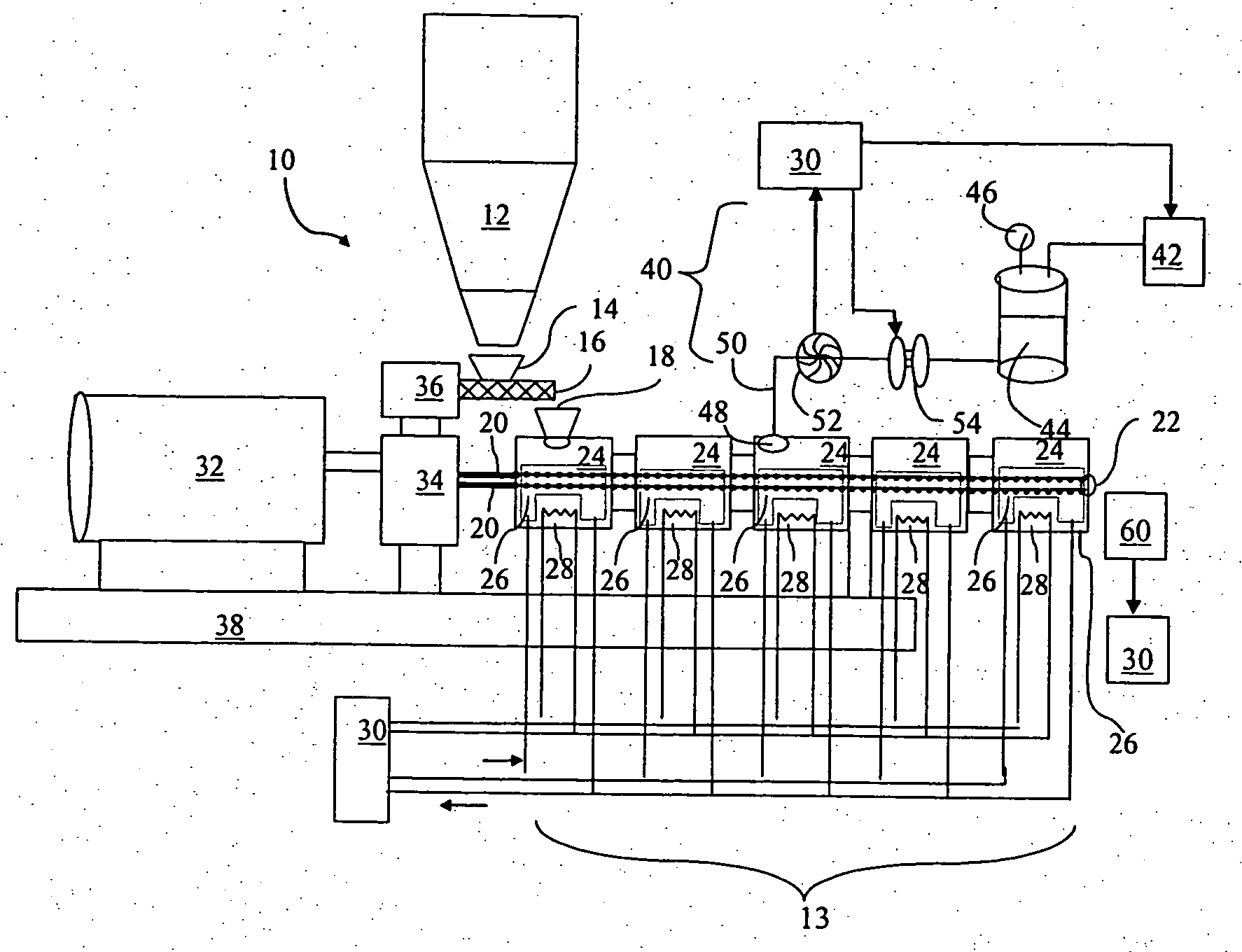

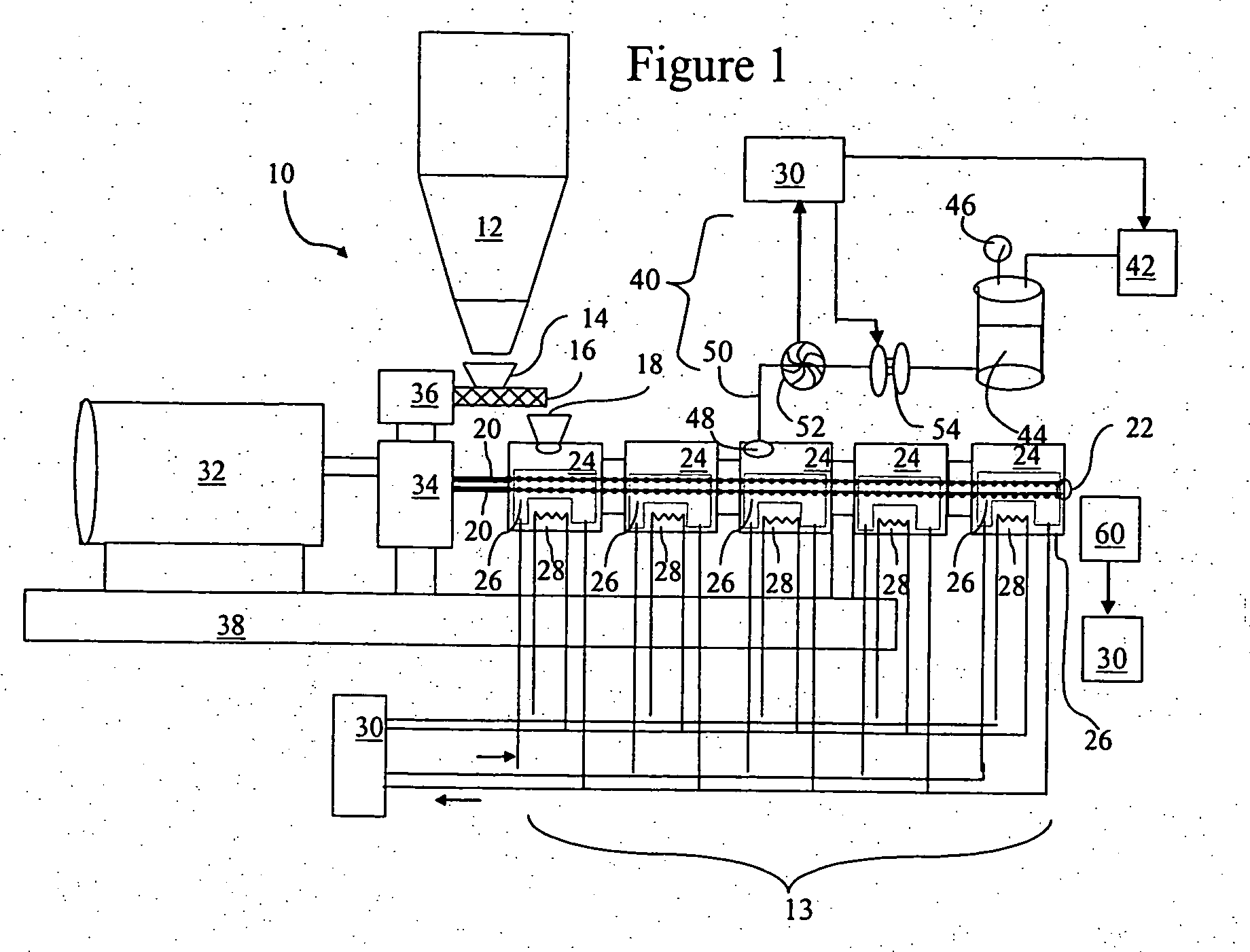

Apparatus for manufacturing thermosetting powder coating compositions with dynamic control including low pressure injection system

InactiveUS20050213423A1Reduce production lossSufficiently dispersedDough mixing/kneading machinesInjection portEngineering

A thermosetting powder coating composition extruder system including an extruder body and an injection system is disclosed. The extruder body includes segments surrounding one or more rotating screws. A first segment's main inlet receives material, such as from a pre-mix hopper, and a final segment's outlet discharges extrudate. A low pressure injector injects additives, particularly those that are hard to incorporate, into one or more segments at one or more injection positions at the main inlet or between the main inlet and the outlet. The injector includes a source of pressurization coupled to a pressure vessel, a pressure regulator maintaining the pressure at or below a given level, a flow regulator, and an injection port. A sensor adjacent the outlet monitors the physical characteristics of the extrudate and is coupled to a controller of the low pressure injector for dynamic control thereof.

Owner:PPG IND OHIO INC

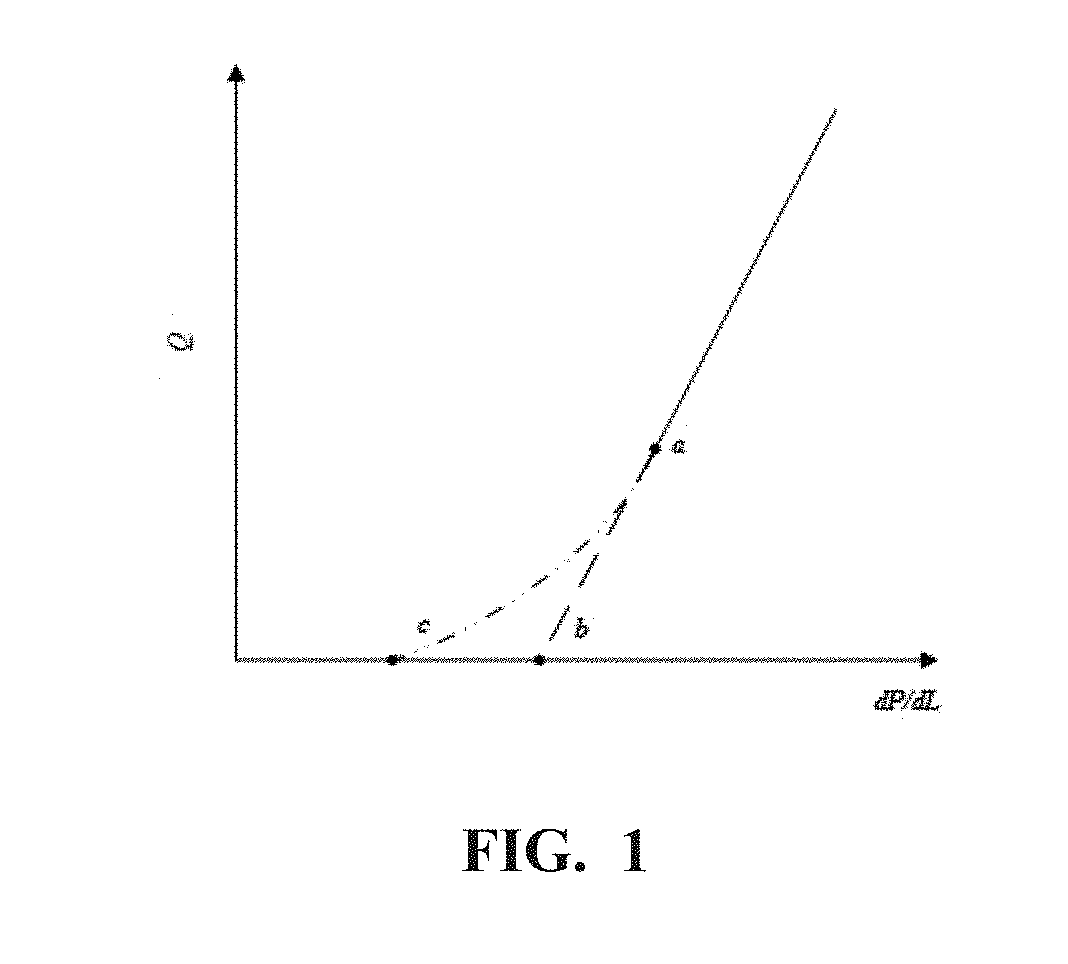

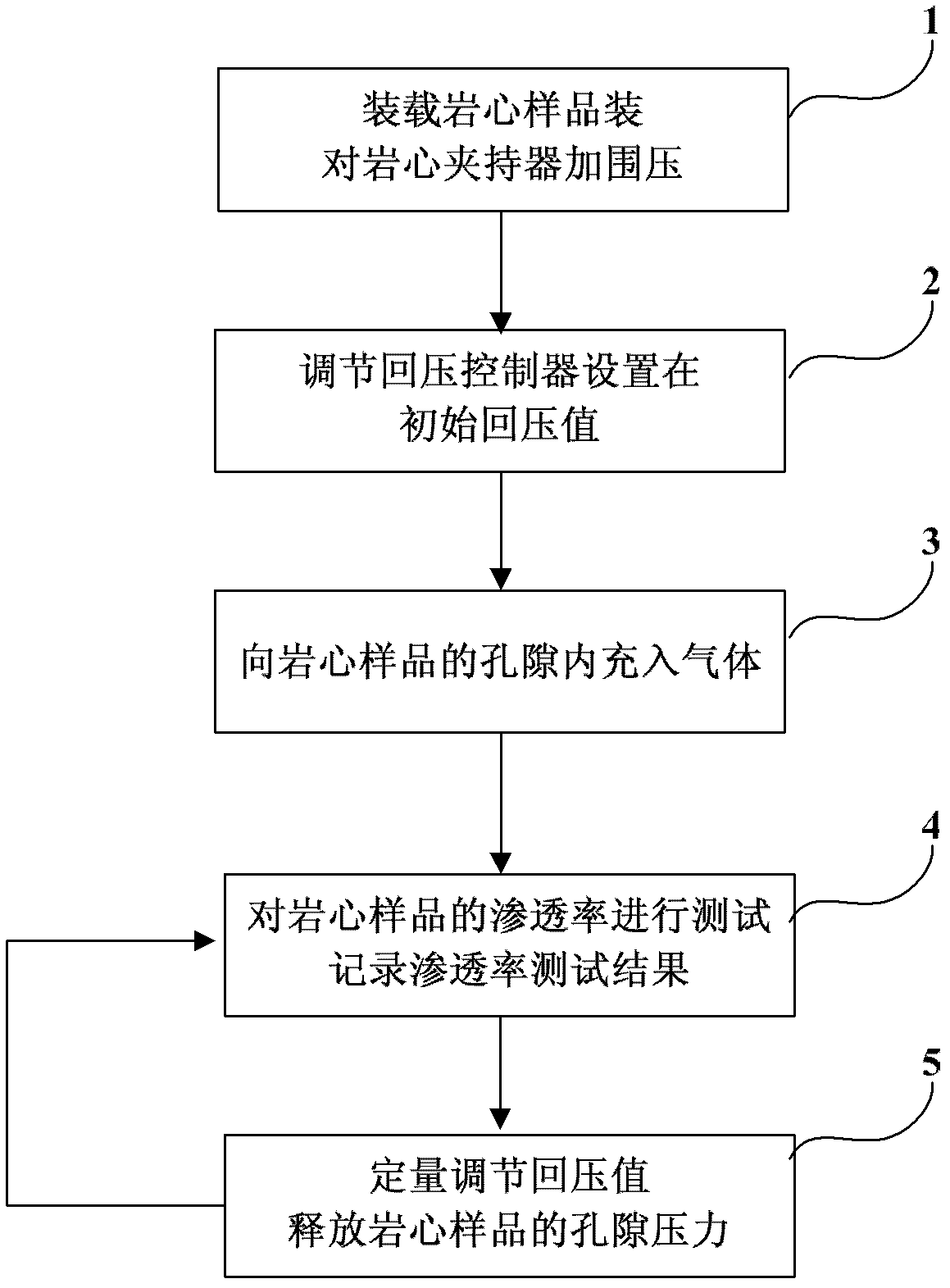

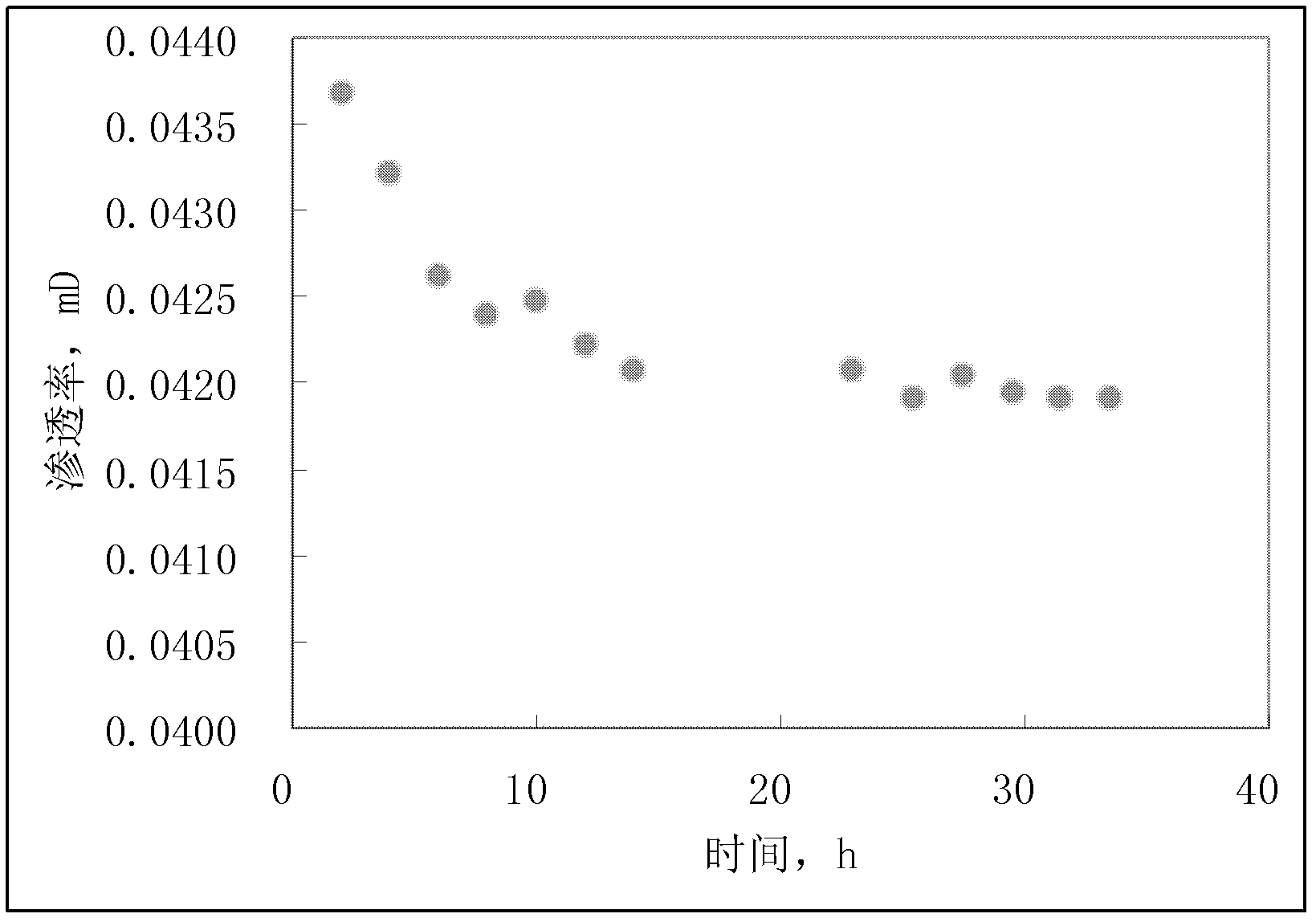

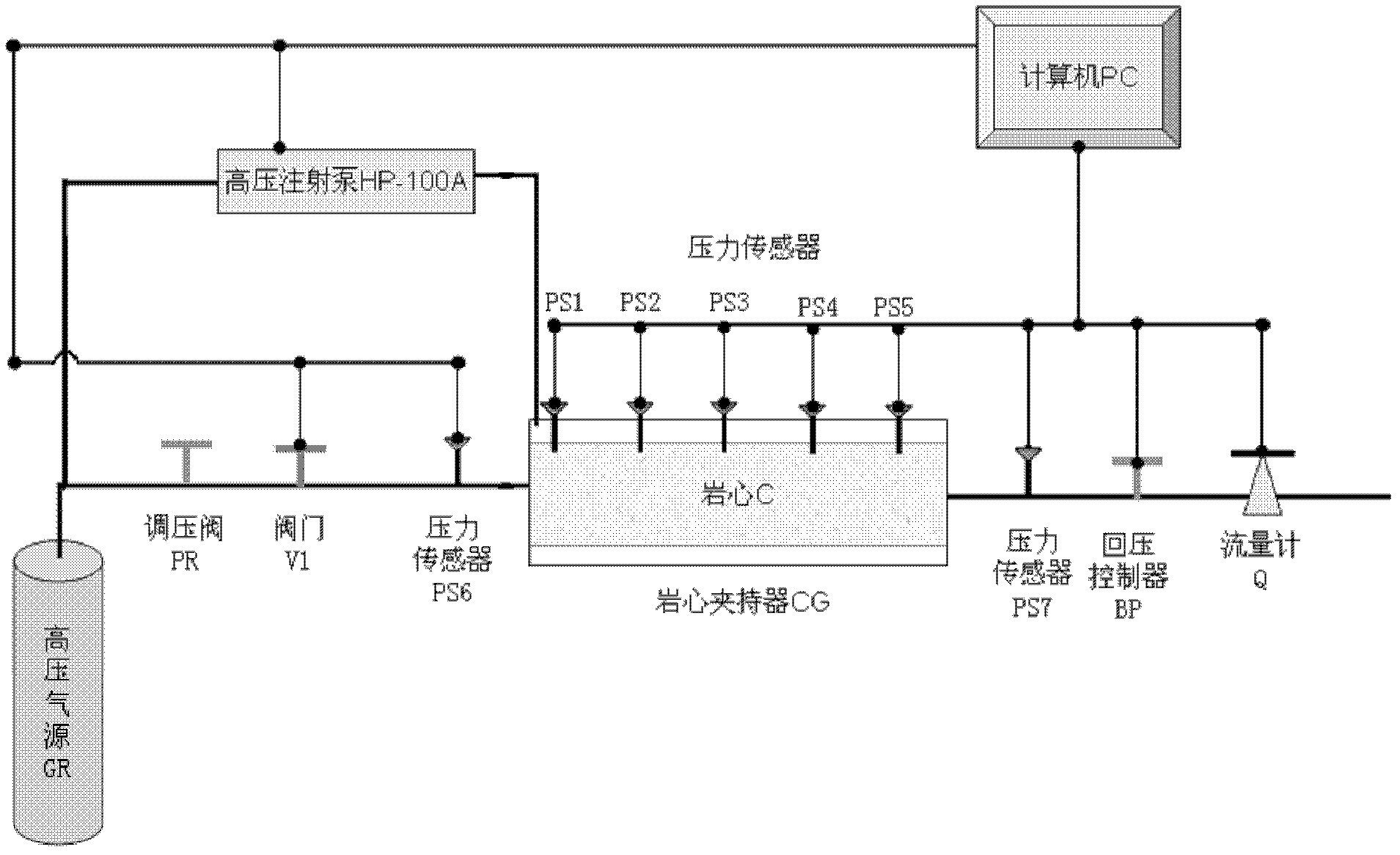

Core permeability experimental testing method and device under condition of stratum pressure

ActiveCN102507414APermeability SciencePermeability is accuratePermeability/surface area analysisExperimental testingEngineering

The invention provides a core permeability experimental testing method and a device under a condition of stratum pressure. The method comprises the steps of: installing a core sample in a core holder and applying confining pressure to the core holder through a high-pressure injection pump; adjusting a back pressure controller and setting pressure to an initial back pressure value; filling air into pores of the core sample, and after the pressure of the pores of the core sample is balanced, stopping filling air and cutting off an air source; and testing the permeability of the core sample and recording the permeability testing result. The experiment not only simulates pressure which is applied by an overlying rock stratum to the core sample in a stratum, but also simulates original stratum pressure applied by fluid in bypass pores to the core sample in the stratum. Therefore, the actual physical condition of the core sample in the stratum is fully simulated, and the permeability of the core sample which is tested based on the experimental testing method and the device is enabled to be more scientific and more accurate.

Owner:PETROCHINA CO LTD

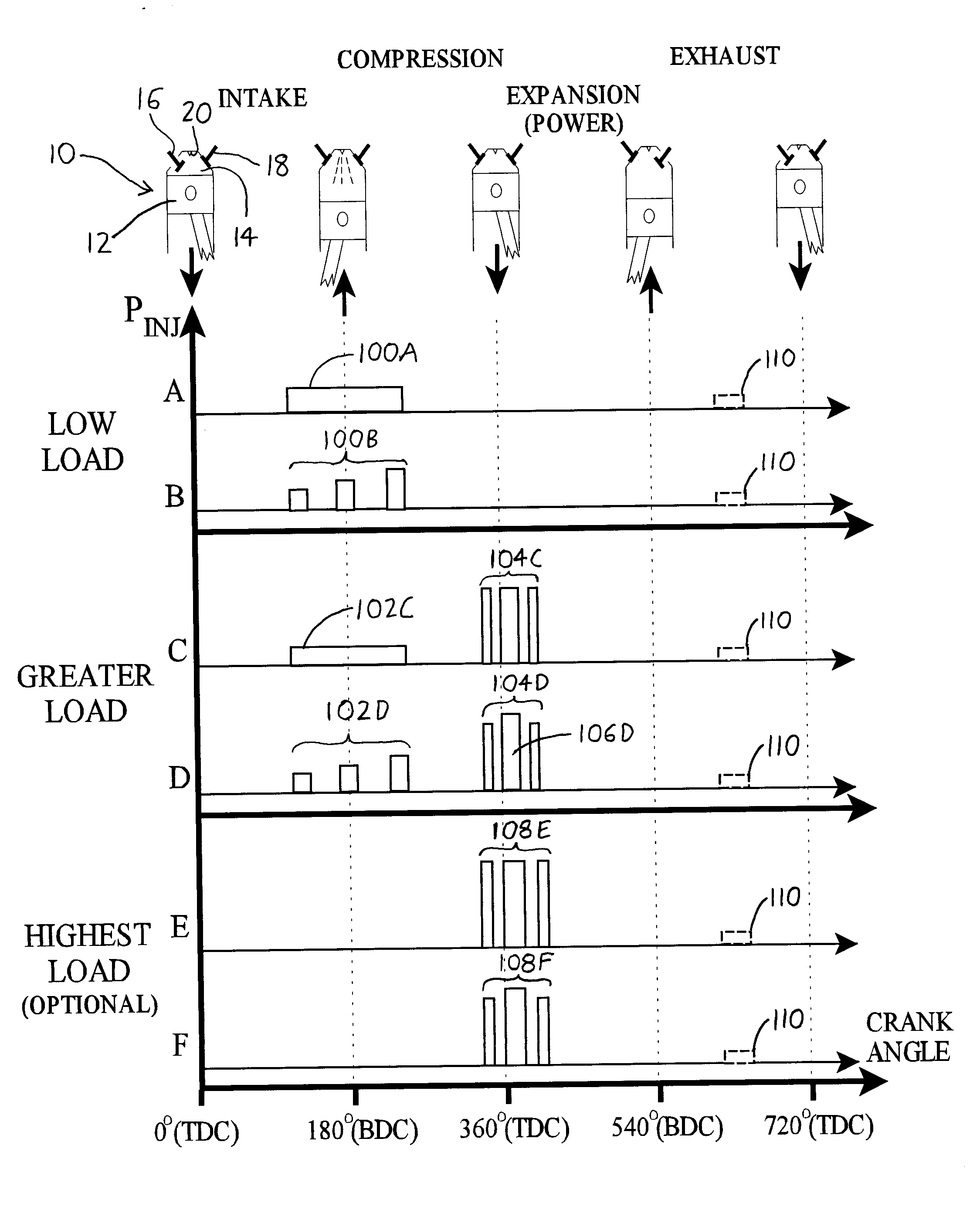

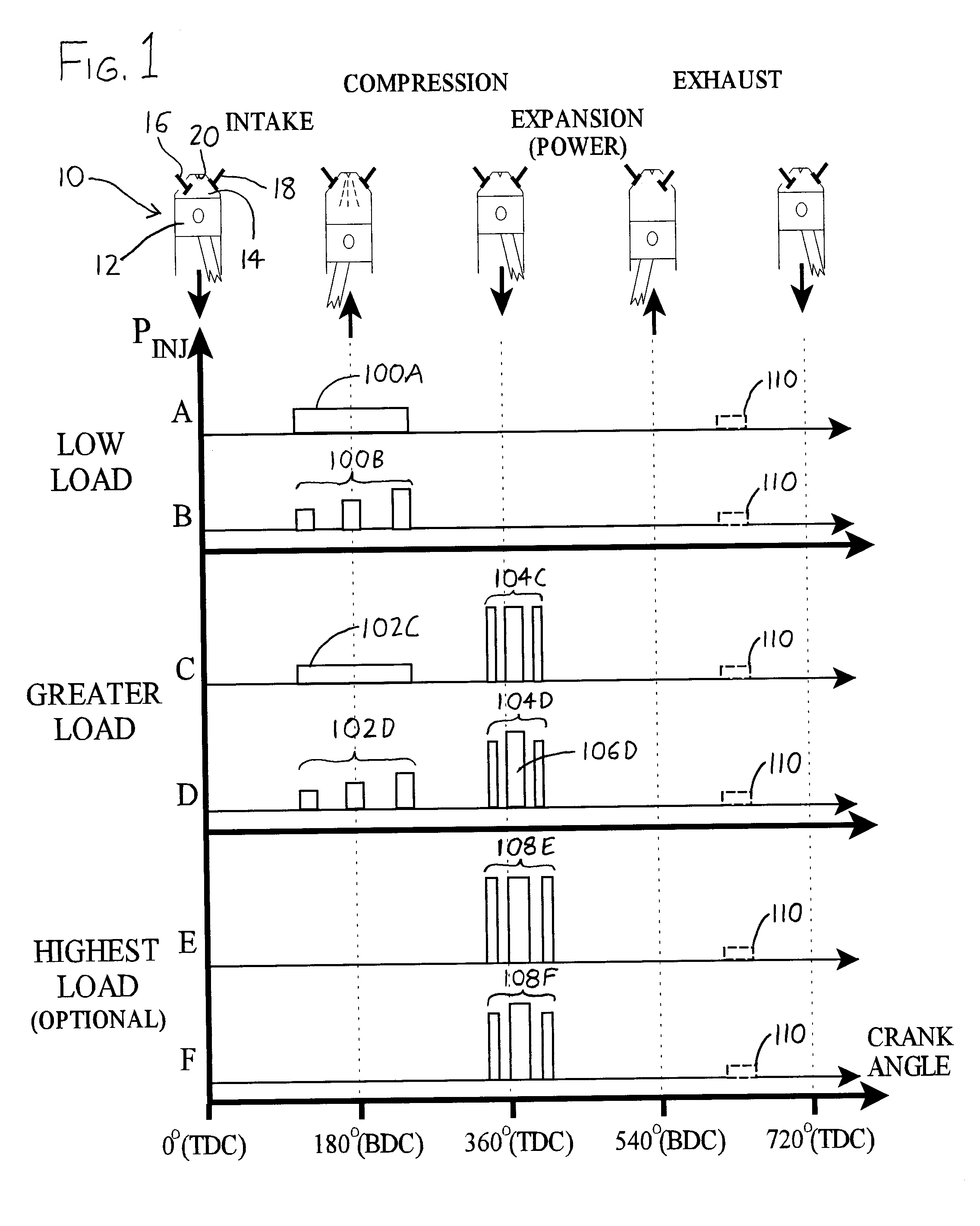

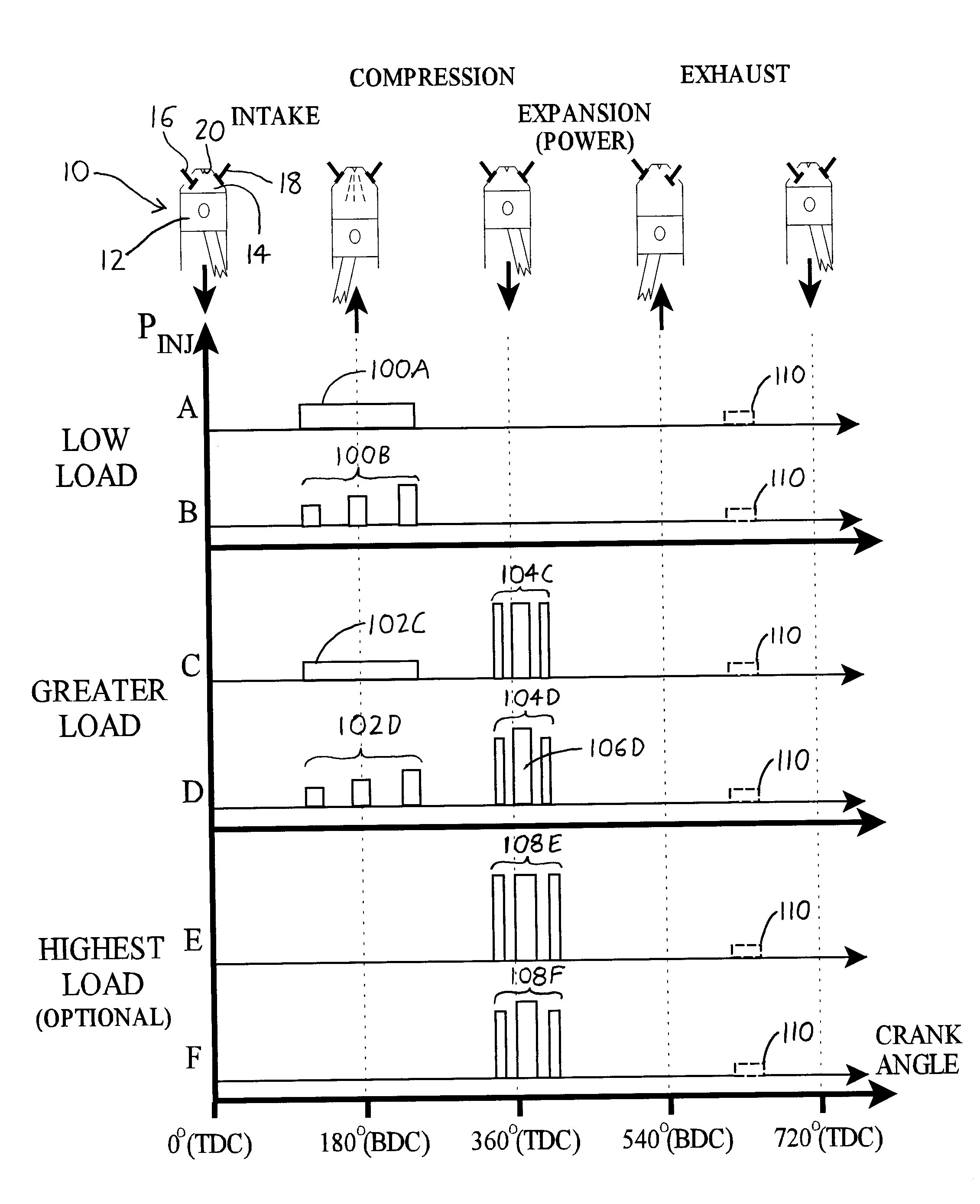

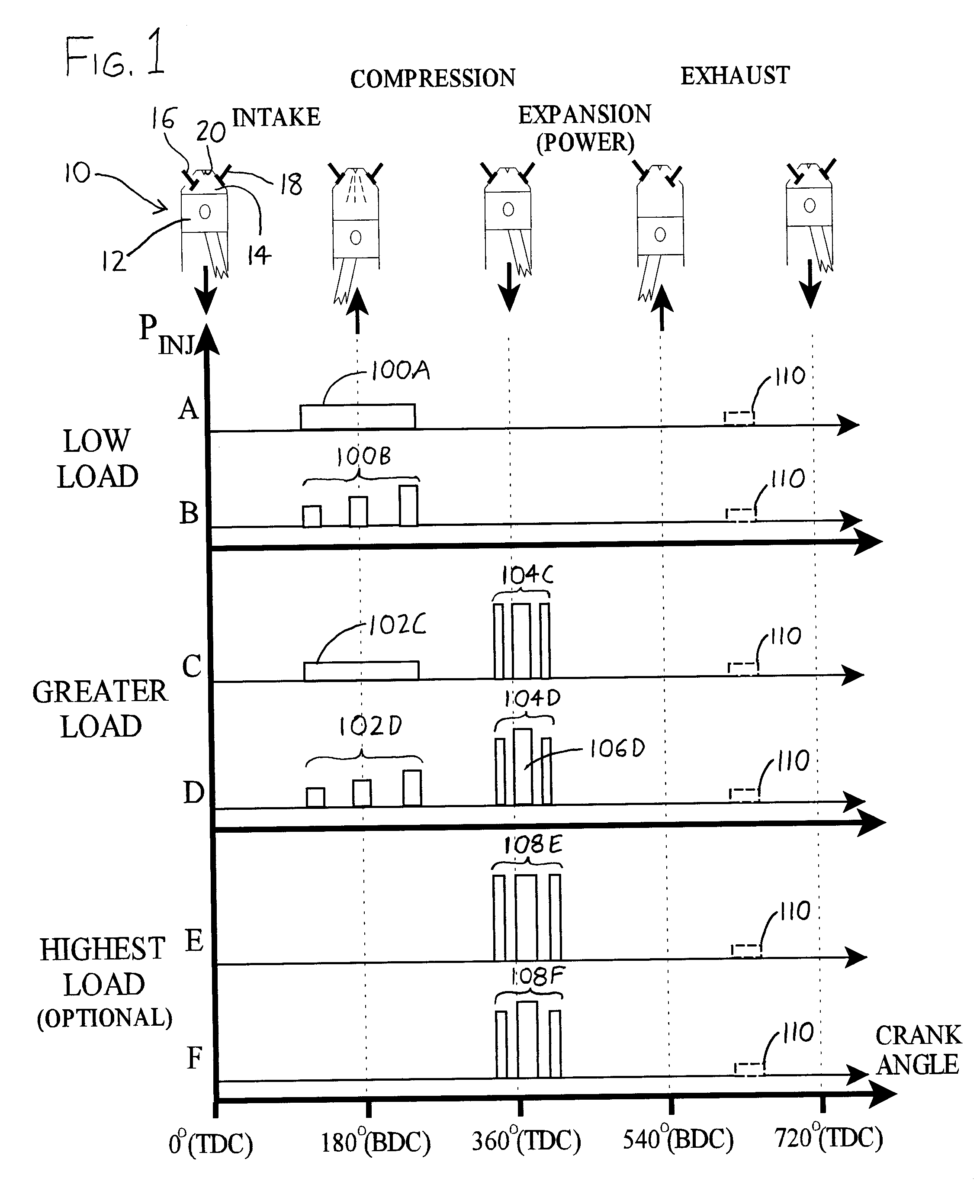

Adaptive engine injection for emissions reduction

ActiveUS20080295798A1High power outputIncrease injection pressureElectrical controlInternal combustion piston enginesInjection pressureCombustion

NOx and soot emissions from internal combustion engines, and in particular compression ignition (diesel) engines, are reduced by varying fuel injection timing, fuel injection pressure, and injected fuel volume between low and greater engine loads. At low loads, fuel is injected during one or more low-pressure injections occurring at low injection pressures between the start of the intake stroke and approximately 40 degrees before top dead center during the compression stroke. At higher loads, similar injections are used early in each combustion cycle, in addition to later injections which preferably occur between about 90 degrees before top dead center during the compression stroke, and about 90 degrees after top dead center during the expansion stroke (and which most preferably begin at or closely adjacent the end of the compression stroke). These later injections have higher injection pressure, and also lower injected fuel volume, than the earlier injections.

Owner:WISCONSIN ALUMNI RES FOUND

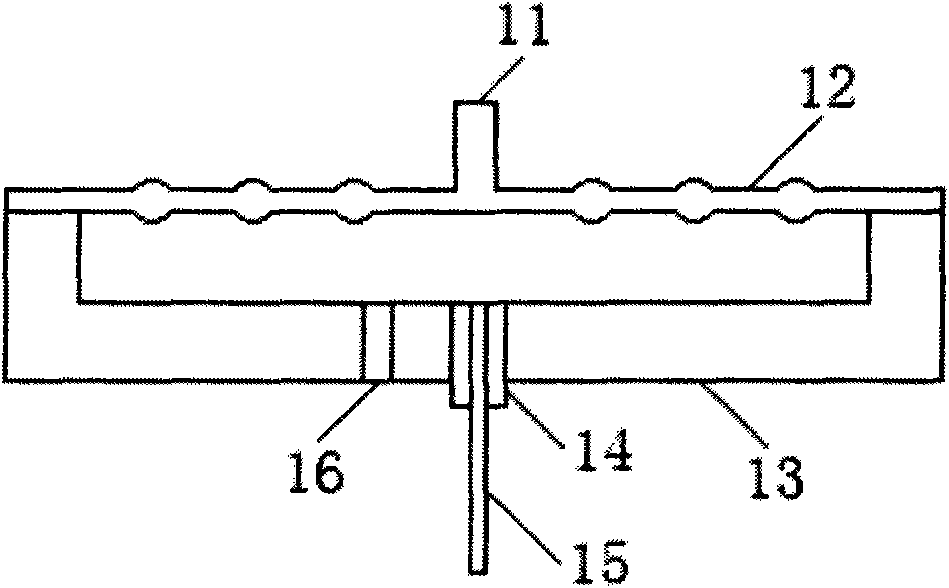

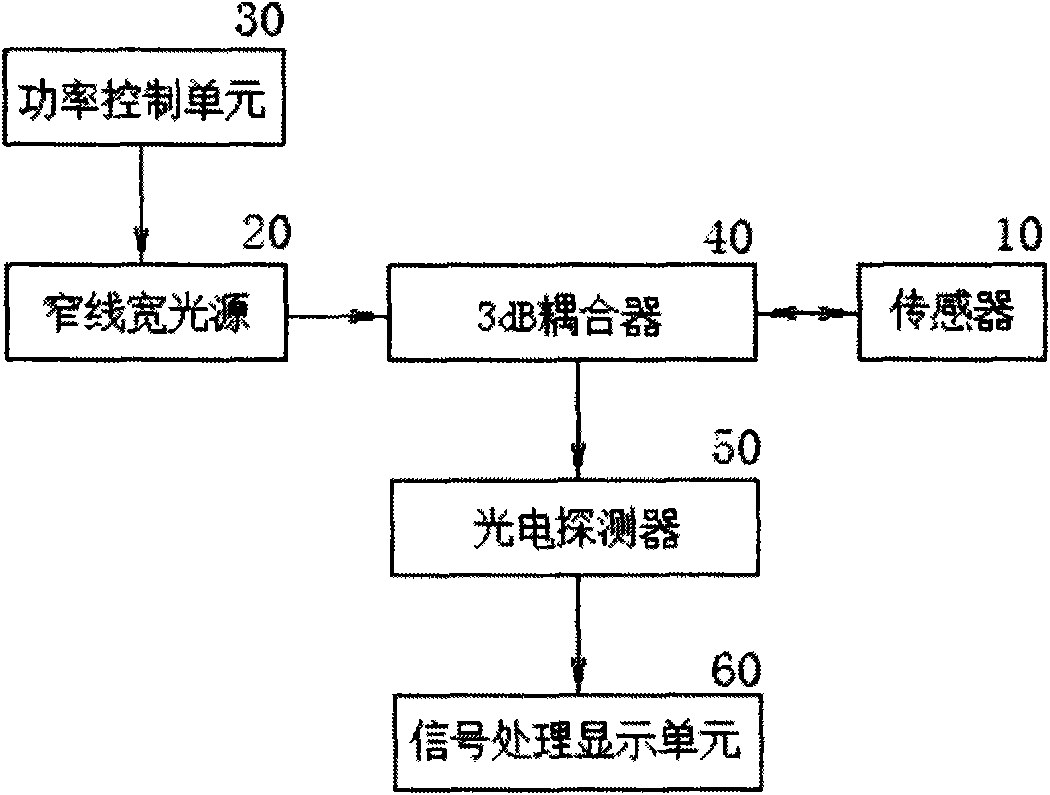

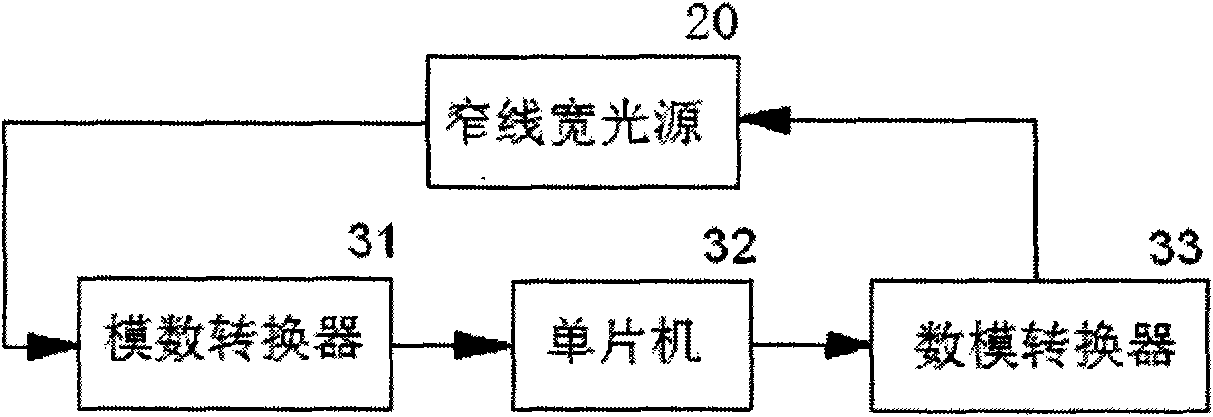

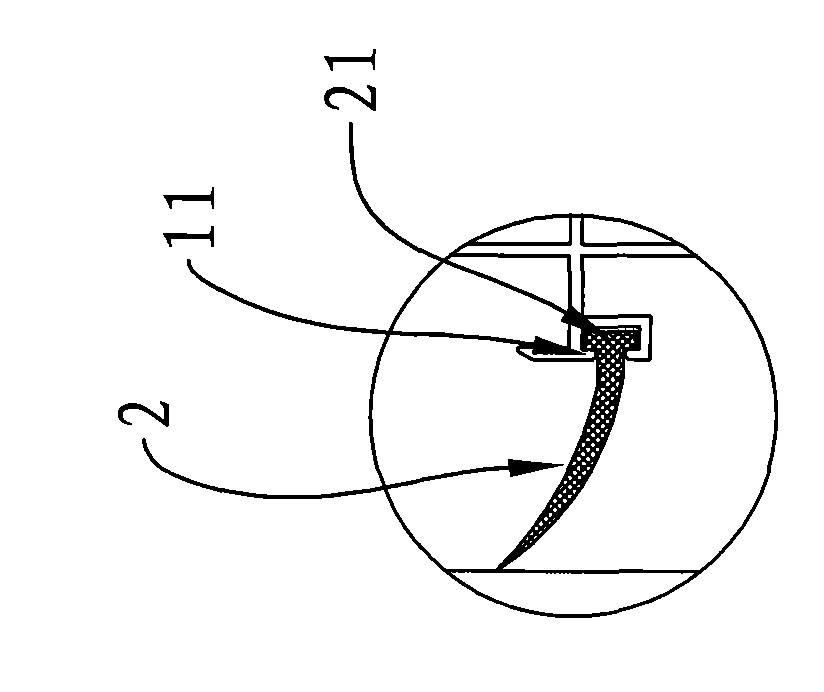

Optical fiber F-P pressure sensor and pressure liquid level sensing device thereof

InactiveCN101614607AOvercoming elastic rangeOvercoming craftFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by optical meansEngineeringHigh pressure

The invention discloses an optical fiber F-P pressure sensor and a pressure liquid level sensing device thereof, relating to a type of pressure sensor. The structure of the sensor is that: a pressure film box / plate provided with pressure injection holes is arranged at the center and connected with the periphery of the opening of a supporting member in a sealing way; the center of the bottom of the supporting member is provided with optical fixing holes and pressure balancing holes, and the optical fixing holes are connected with conductive optical fiber; and an extrinsic F-P cavity is arranged between the end face of the conductive optical fiber and the central plane of the pressure film box / plate. The sensor features simple structure, small volume, convenient mounting, high pressure resolution and is very suitable for measuring requirement of small range and high precision; sensitive elements can be replaced conveniently to adapt to the different measuring requirements; the cost is lower and no special demands for light source wavelength exists; the invention is applicable to computation of storage quantity of small chemical liquid and oil stock tank, chemical / oil stock and transportation tank vehicle and other various types of liquid / gas stock and transportation equipment.

Owner:武汉精昱光传感系统研究院有限公司

Coaxial low pressure injection method and a gas collimator for a kinetic spray nozzle

Owner:F W GARTNER THERMAL SPRAYING

High heat conductivity and high strength dense heterogeneous foamed SiC/Cu material and its preparing method

The present invention relates to heterogeneous foamed ceramic / metal material, and is especially a kind of high strength, high density and high heat conductivity heterogeneous foamed SiC / Cu material and its preparation process. The foamed SiC / Cu material has basic units of closed polygonal ring to form connected 3D network structure, and each of the closed polygonal ring units is heterogeneous foamed ribs comprising SiC in 50-95 vol% and metal Cu in 5-50 vol% and with the relative density not lower than 99 %. The foamed SiC / Cu material is prepared through organic foam soaking, hot pressing to densify, pressure injection filling, thermal decomposition and reaction sintering. The preparation process is simple and low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

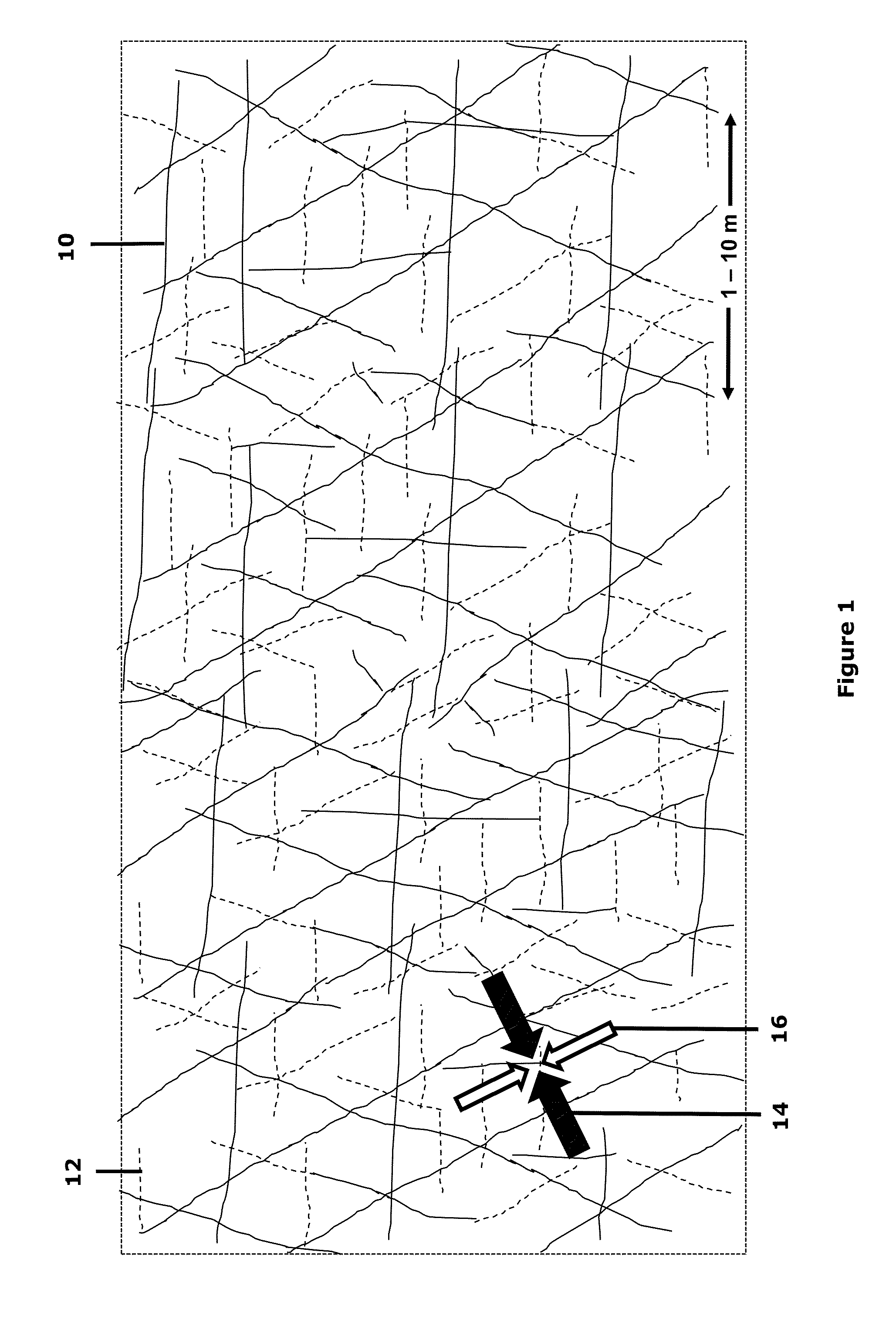

Multi-stage fracture injection process for enhanced resource production from shales

ActiveUS20150129211A1Speed up the extraction processImprove breathabilityFluid removalSlurryAqueous solution

The invention relates to a method of generating an enhanced fracture network in a rock formation by the sequential stages of: i) injecting a non-slurry aqueous solution into a well extending into the formation at a rate and pressure which is close to the minimum hydraulic fracture initiation pressure and rate of the formation, until the maximum possible stimulated volume of the formation has been substantially attained to generate an outer zone of self-propping fractures; ii) injecting a first slurry of relatively fine grains of proppant to prop fractures generated in stage i within an intermediate zone located within and surrounded by the outer zone generated in stage i; and iii) injecting a second slurry comprising relatively coarse grains of to generate large fractures within an inner zone surrounded by and within the intermediate zone, in communication with the fractures generated in stages i and ii.

Owner:DUSSEAULT MAURICE B +1

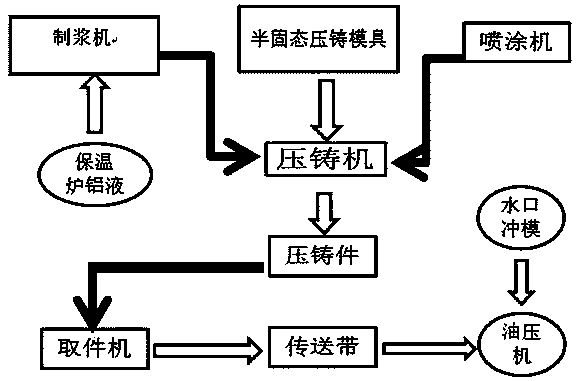

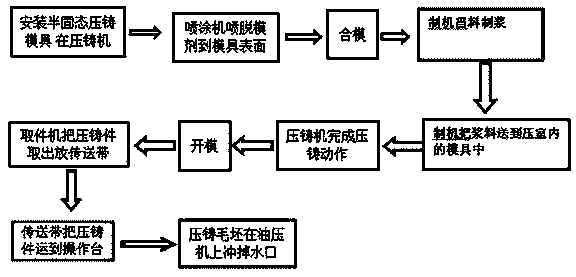

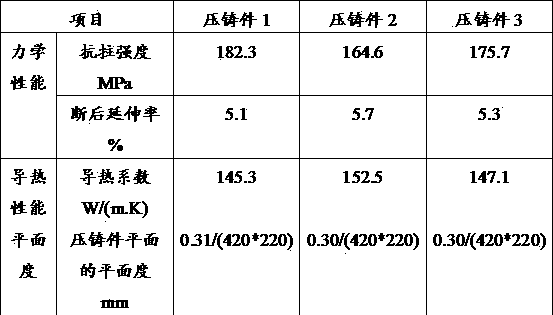

Die-casting process method for semi-solid state metal die-cast formation

The invention discloses a die-casting process method for semi-solid state metal die-cast formation. The die-casting process method includes using a semi-solid state die-casting machine as a processing device and using a pulper as a device for preparing and delivering a semi-solid state slurry; adding a metal modificator to a liquid metal raw material during preparation of the semi-solid state slurry so that the liquid metal raw material generates more crystal nucleuses, and die-cast member products have better mechanical properties. According to the die-casting process method, by means of a die-cast manner of the semi-solid state slurry, the die-cast member products are compact interiorly or do not produce air holes during a die-casting process, the best interior structure and mechanical properties of the die-cast member products and product qualities are guaranteed; by means of semi-solid state slurry die-casting, compared with traditional high-speed high-pressure injection formation processes, the die-casting process method has the advantages that during mold stripping, die-cast members are low in temperature and extremely small in deformation amount and need not complicated surface processing, and the best shapes and surface smoothness of products can be guaranteed.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

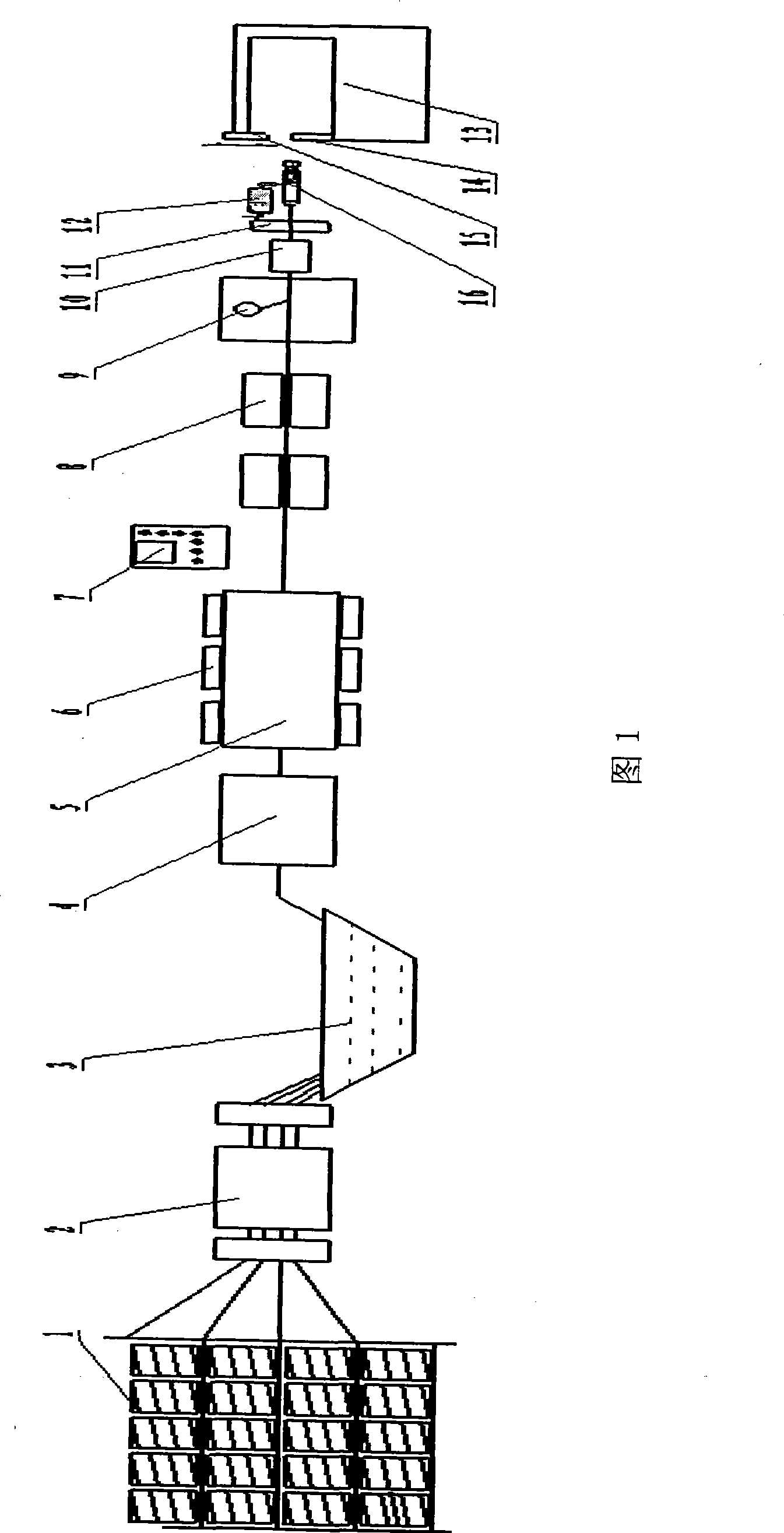

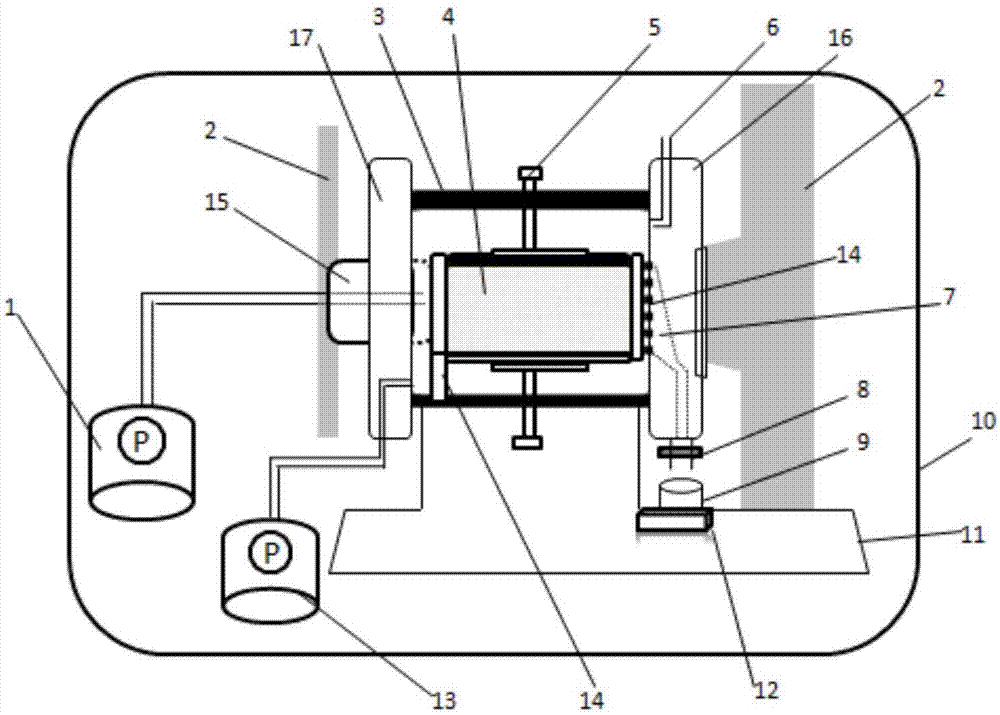

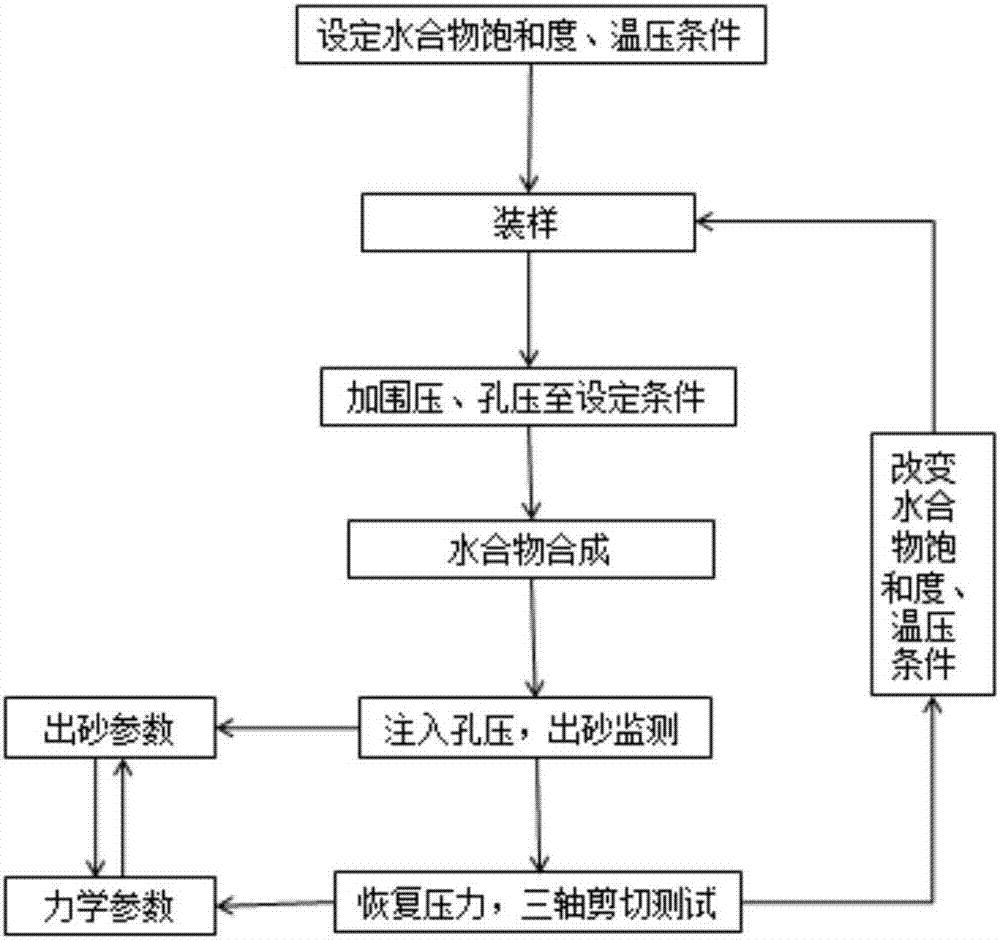

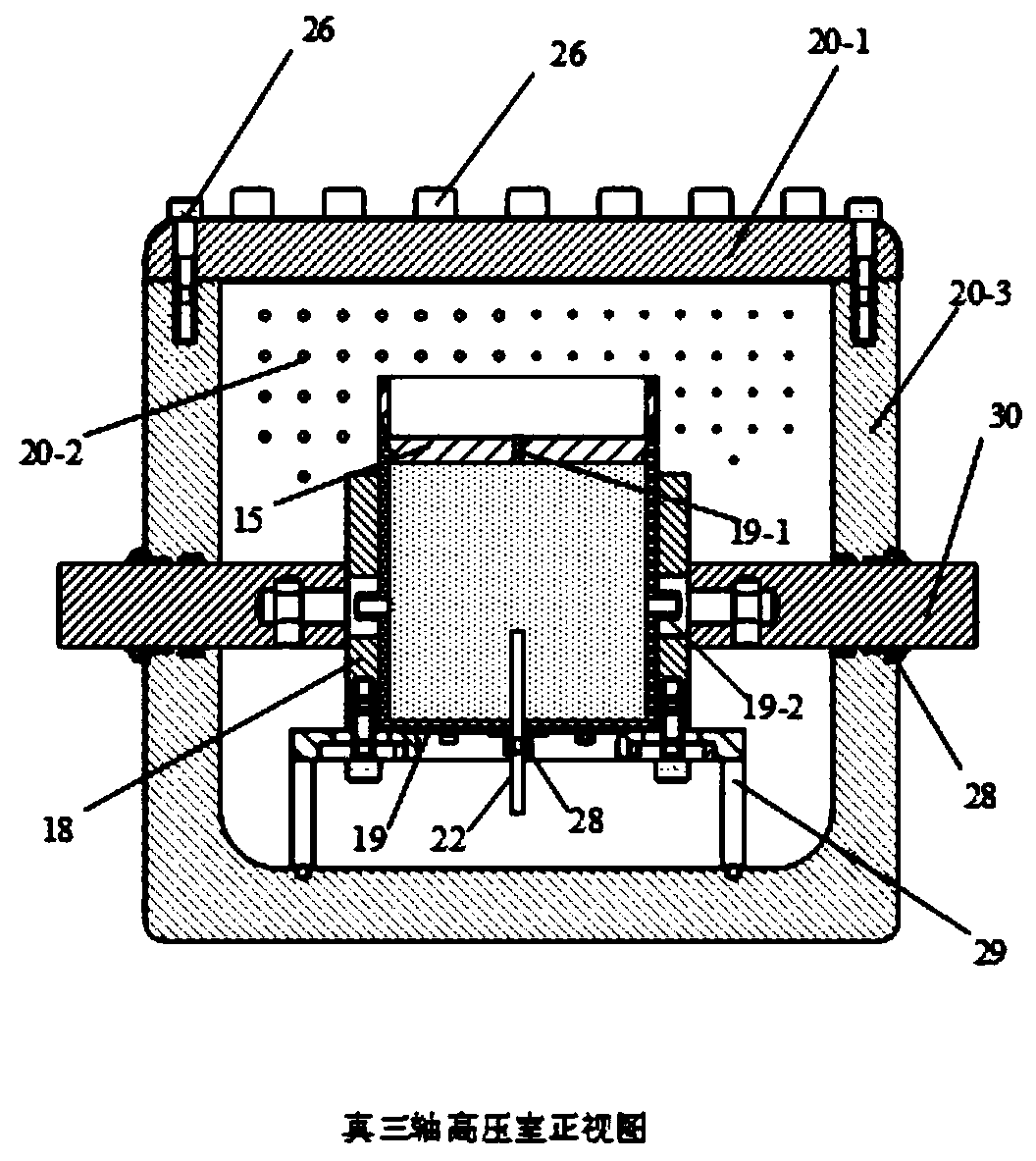

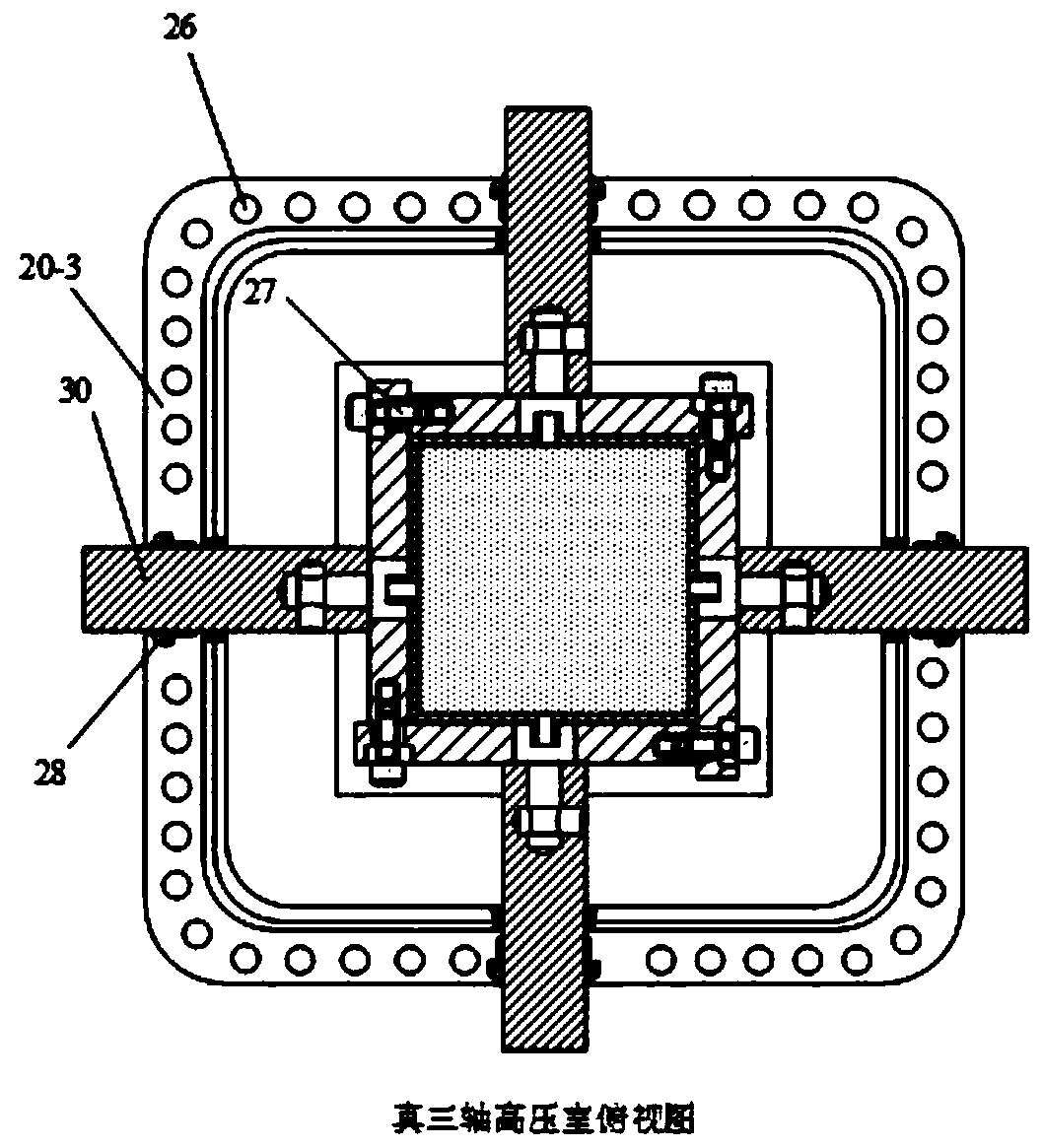

Hydrate-containing sediment shakeout-mechanical parameter coupling process simulation device and method

ActiveCN107121359AEnhance the meaning of engineering guidanceFlow propertiesMaterial strength using tensile/compressive forcesResource developmentStress–strain curve

The invention relates to the technical field of marine gas hydrate resource development engineering, in particular to an indoor experimental device and method for evaluating the mutual coupling relationship between the shakeout process and mechanical parameters of hydrate-containing loose sediments. The device comprises a high-pressure reaction kettle, a thermostatic control system, a triaxial pressurizing system, a confining pressure control system, a pore pressure injection system and a shakeout parameter test system, wherein the confining pressure control system, the pore pressure injection system and the triaxial pressurizing system are connected with the high-pressure reaction kettle; and the shakeout parameter test system is connected with the outlet end of the high-pressure reaction kettle. Through measurement of the mutual coupling relationship between shakeout parameters, such as the shakeout amount, the shakeout grain size and the shakeout speed of the hydrate sediments, under the actual temperature, pressure and stress conditions, and triaxial mechanical parameters, such as the stress-strain curve, the shear strength, the Yong modulus and the cohesion, a support is provided for forecasting the related relationship between the shakeout parameters and the mechanical parameters of a hydrate-containing reservoir, and a new concept is provided for probing into the shakeout mechanism of the natural gas hydrate reservoir.

Owner:QINGDAO INST OF MARINE GEOLOGY

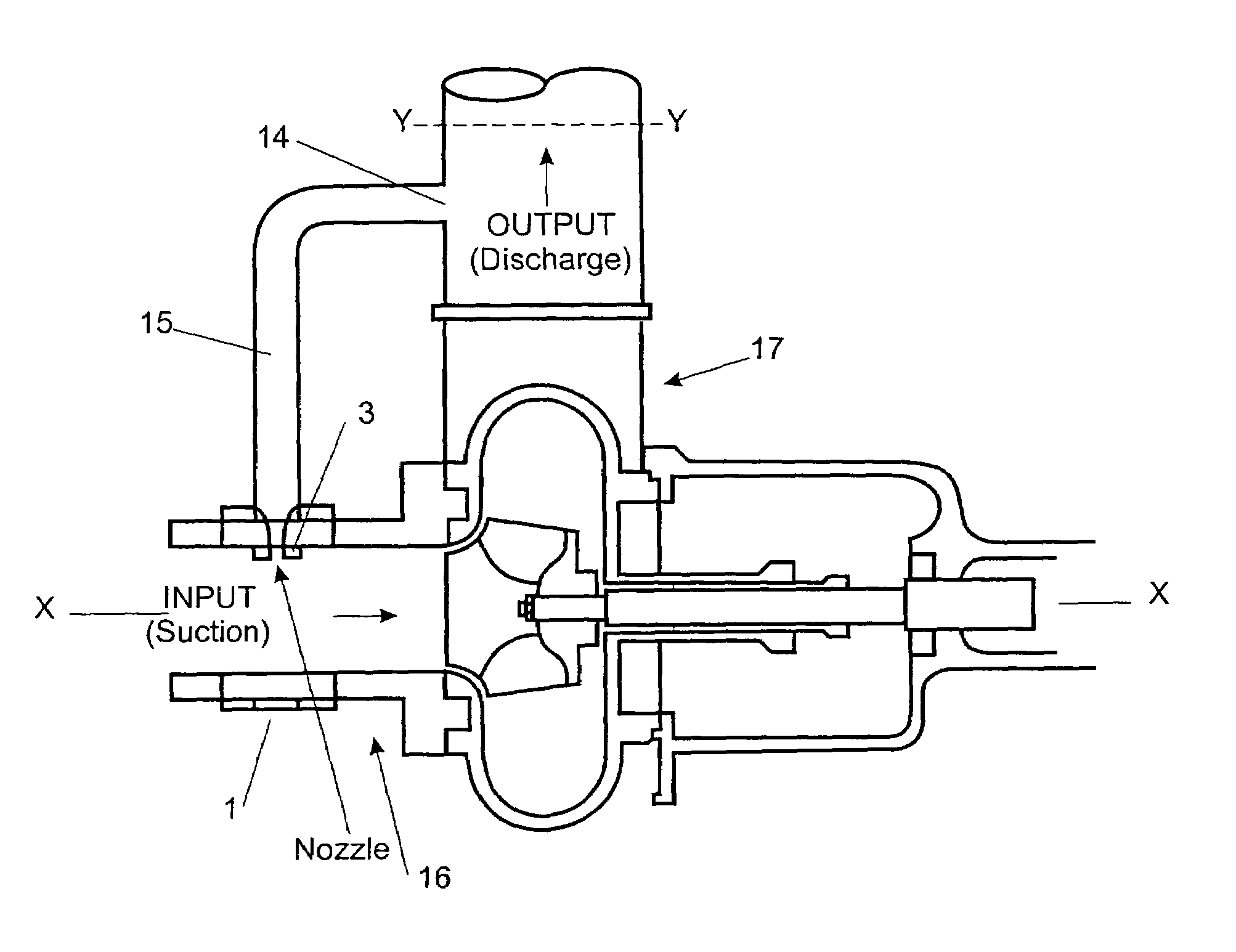

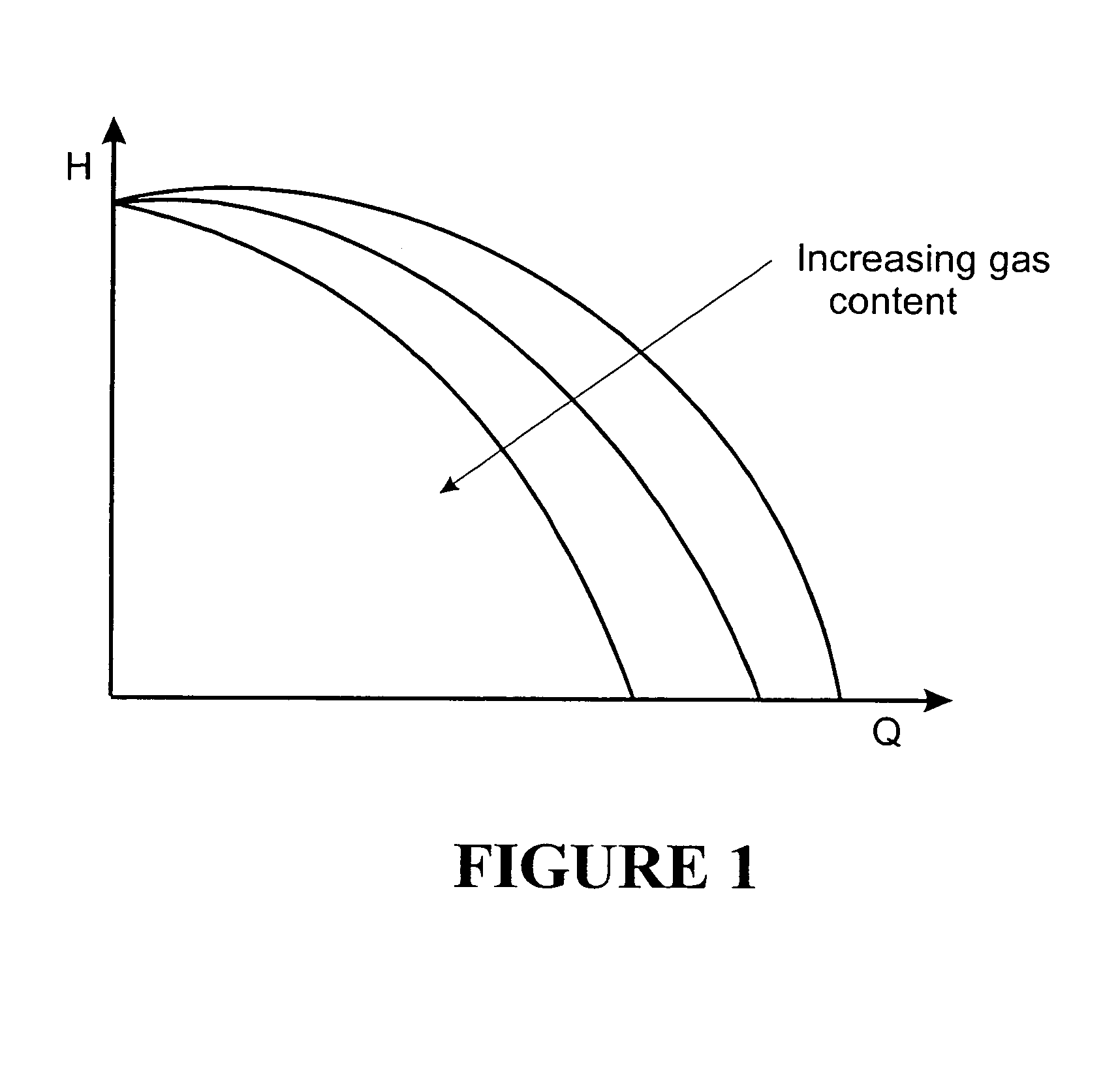

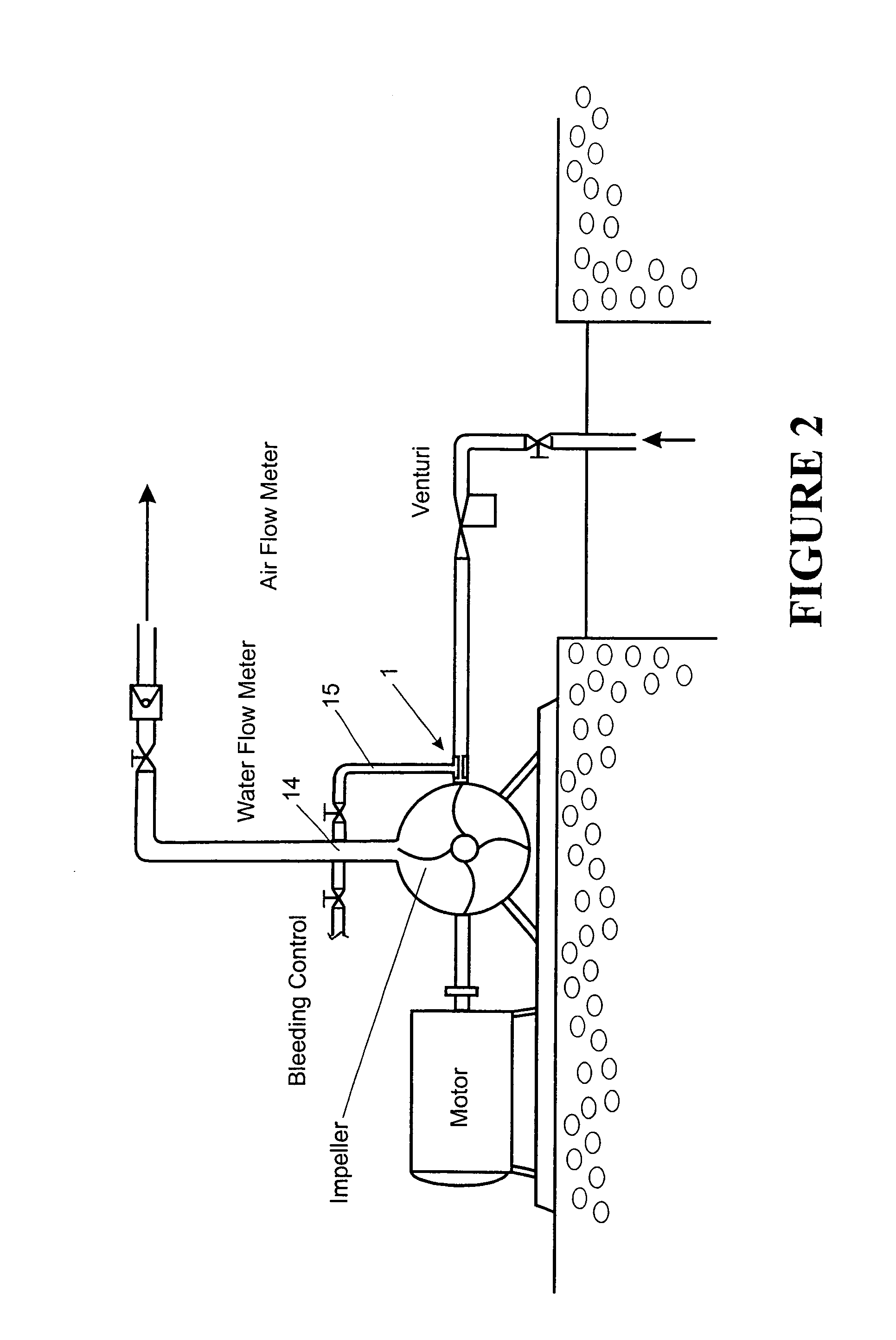

Multi-phase flow pumping means and related methods

InactiveUS7094016B1Reduce disadvantagesReduce problemsPump componentsPump controlEngineeringHigh pressure

A method of pumping and related arrangement for multi-phase fluid flow wherein a centrifugal pump is used for the suction and delivery of the multi-phase fluid which has a fluid communication providing portion to provide a communication of fluid bled from the outlet at a higher pressure to be injected into the inlet conduit of the centrifugal pump in operation. The centrifugal pump is provided with an impeller which has a plurality of vanes configured to define there between larger passageways when compared to a conventional centrifugal pump which would operate in or near optimum conditions when pumping liquid only.

Owner:UNITEC INST OF TECH +1

Adaptive engine injection for emissions reduction

ActiveUS7464690B1Avoiding potentially damaging rapid chamber pressure increasesHigh power outputElectrical controlInternal combustion piston enginesInjection pressureTop dead center

Owner:WISCONSIN ALUMNI RES FOUND

Internal gear manufacturing method and metallic glass internal gear manufactured thereby

InactiveUS8418366B2Shorten production timeImprove productivityMetal rolling stand detailsGearingMetallic materialsDissolution

Owner:NAMIKI PRECISION JEWEL CO LTD +1

Drilling power tool, drilling tool and drilling method for forming boreholes

ActiveCN102705140AImprove rock breaking efficiencyReduce wearDrilling rodsMachines/enginesEngineeringHigh pressure

The invention discloses a drilling power tool, a drilling tool and a drilling method for forming boreholes. The drilling power tool comprises an energy conversion mechanism and a valve shaft system. The energy conversion mechanism is a rotary generator. The valve shaft system comprises a stator, a rotor, a movable valve sheet assembly, a fixed valve sheet assembly and a shaft assembly, wherein the rotor makes a reciprocating motion right and left and drives the movable valve sheet assembly directly connected with the rotor. The energy conversion mechanism is a screw rod or a turbine or an impeller. According to the invention, when a drilling bit is rotated, the drilling pressure at the drilling bit and the drilling pressure at the bottom of a drilling well are similar to the continuous gentle change of the sine law, which is favorable for the strength reduction of surrounding rocks and the development of fractures, so that the rock breaking efficiency can be improved obviously. In addition, because the pressure at the drilling bit and at the bottom of the drilling well is changed periodically, the negative-pressure injection and the high-pressure injection are generated alternately; and when the pressure becomes lower, the well drilling in an underbalance manner or by using the gas drilling fluid is carried out, so that the surrounding rock environment is changed, and the mechanical drilling rate is improved obviously.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Optical sensor

InactiveUS20050199792A1Excellent mechanical propertiesProduced economicallyMeasurement apparatus componentsMaterial analysis by optical meansElectronic componentPressure injection

An optical sensor for detecting objects within an area to be monitored comprises at least one casing to accommodate optical and electronic components. The at least one casing comprises casing parts. The casing parts are composed of a low-pressure injection molding compound and are formed by a low-pressure injection molding operation.

Owner:LEUZE ELECTRONICSLEUZE ELECTRONICS GMBH & CO KG

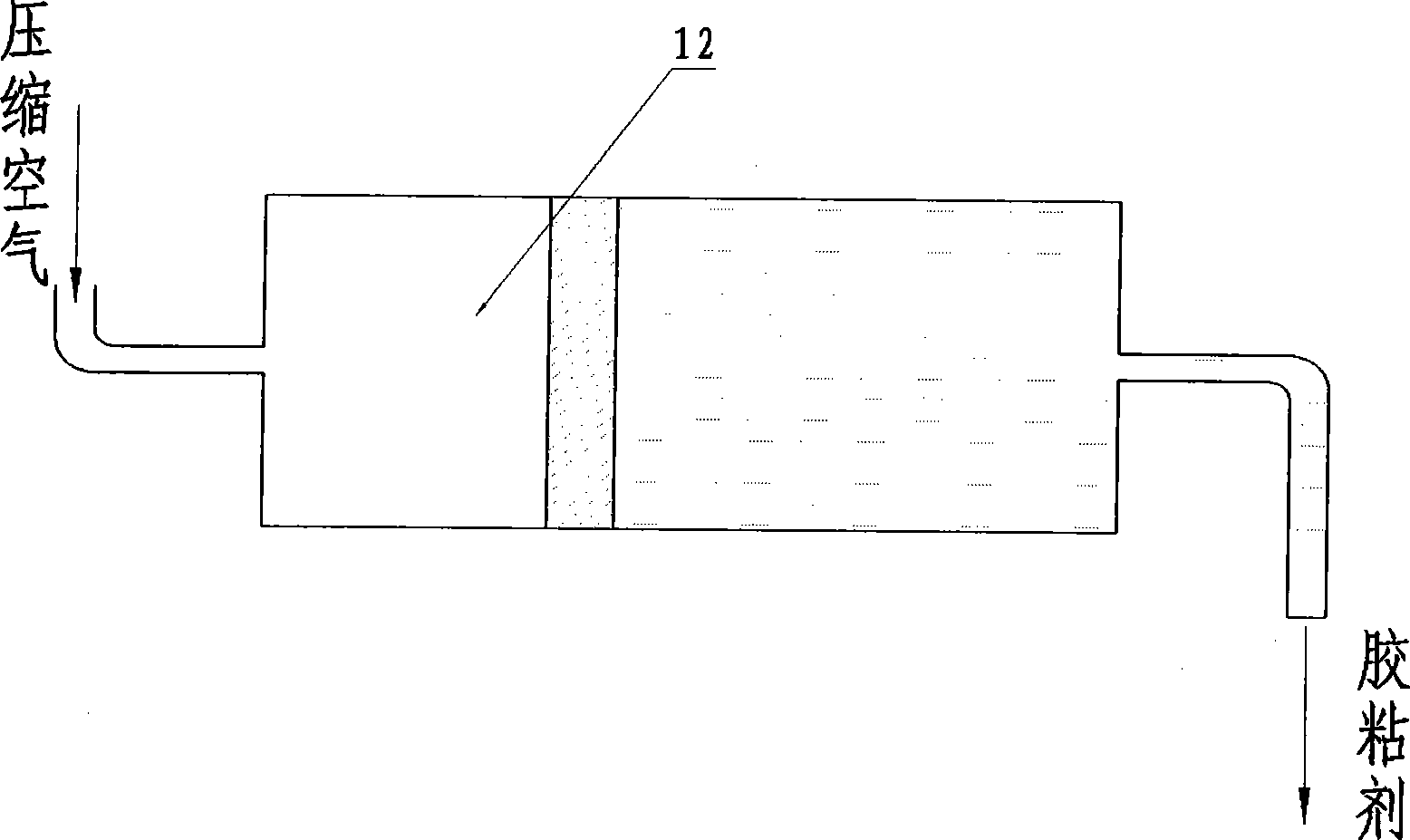

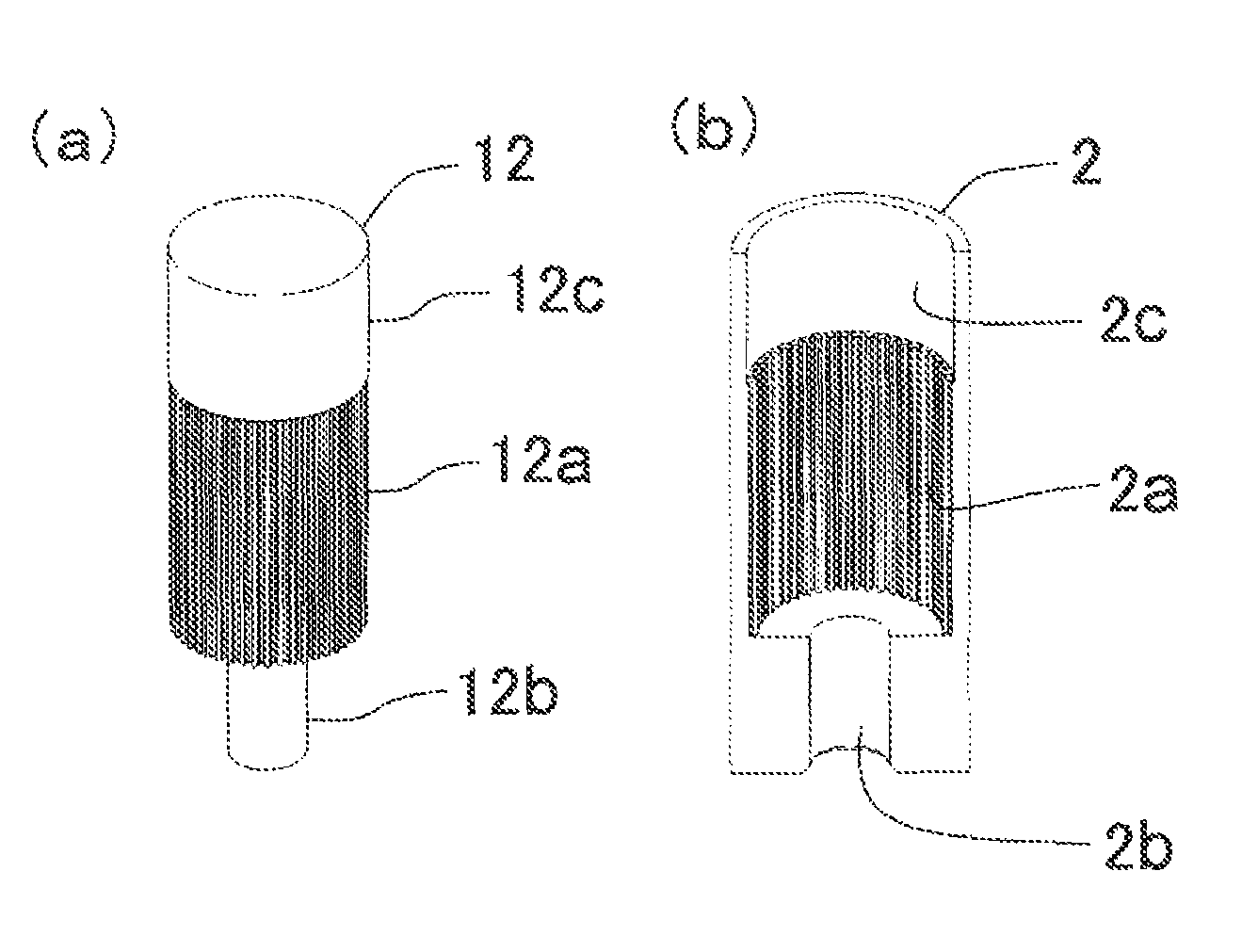

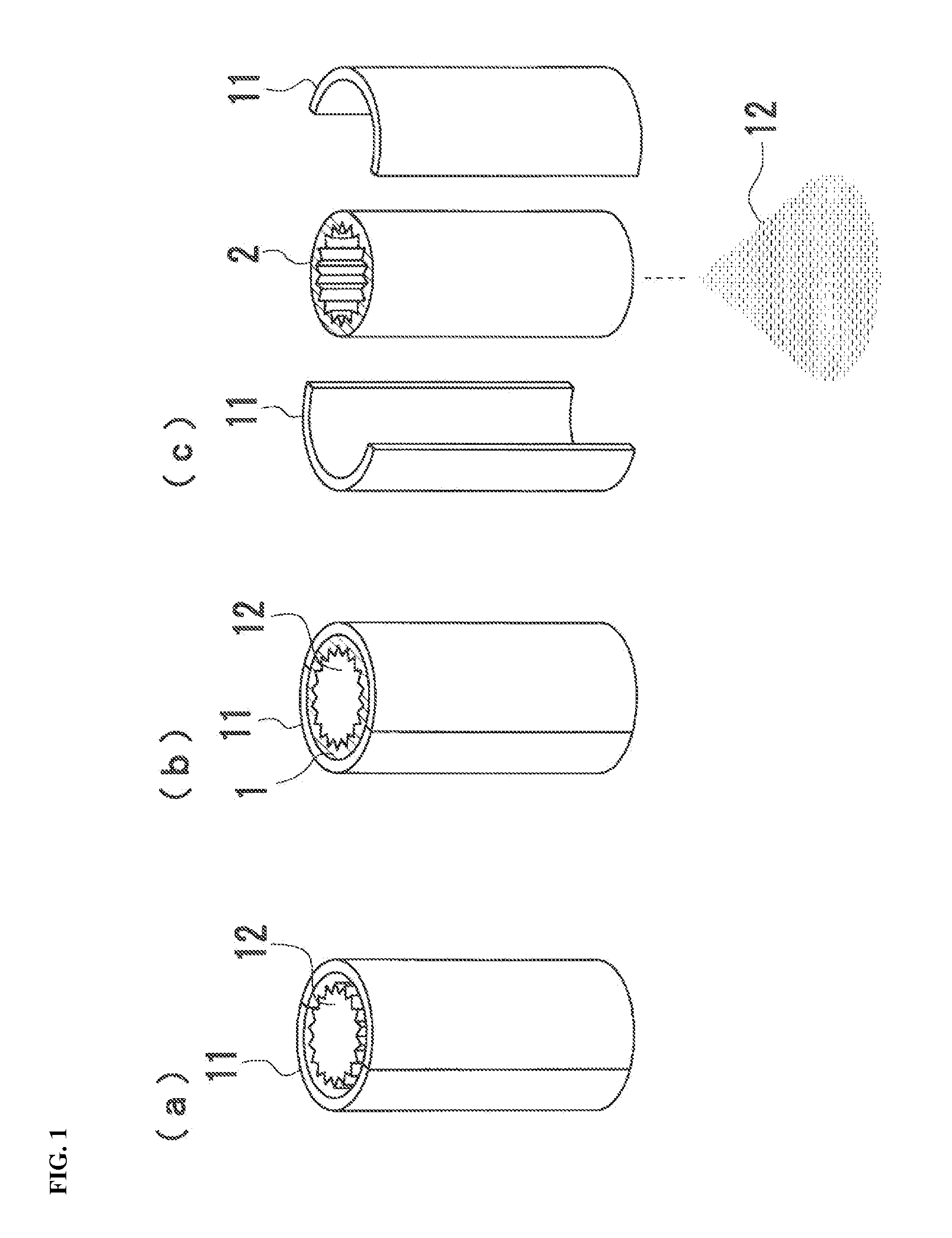

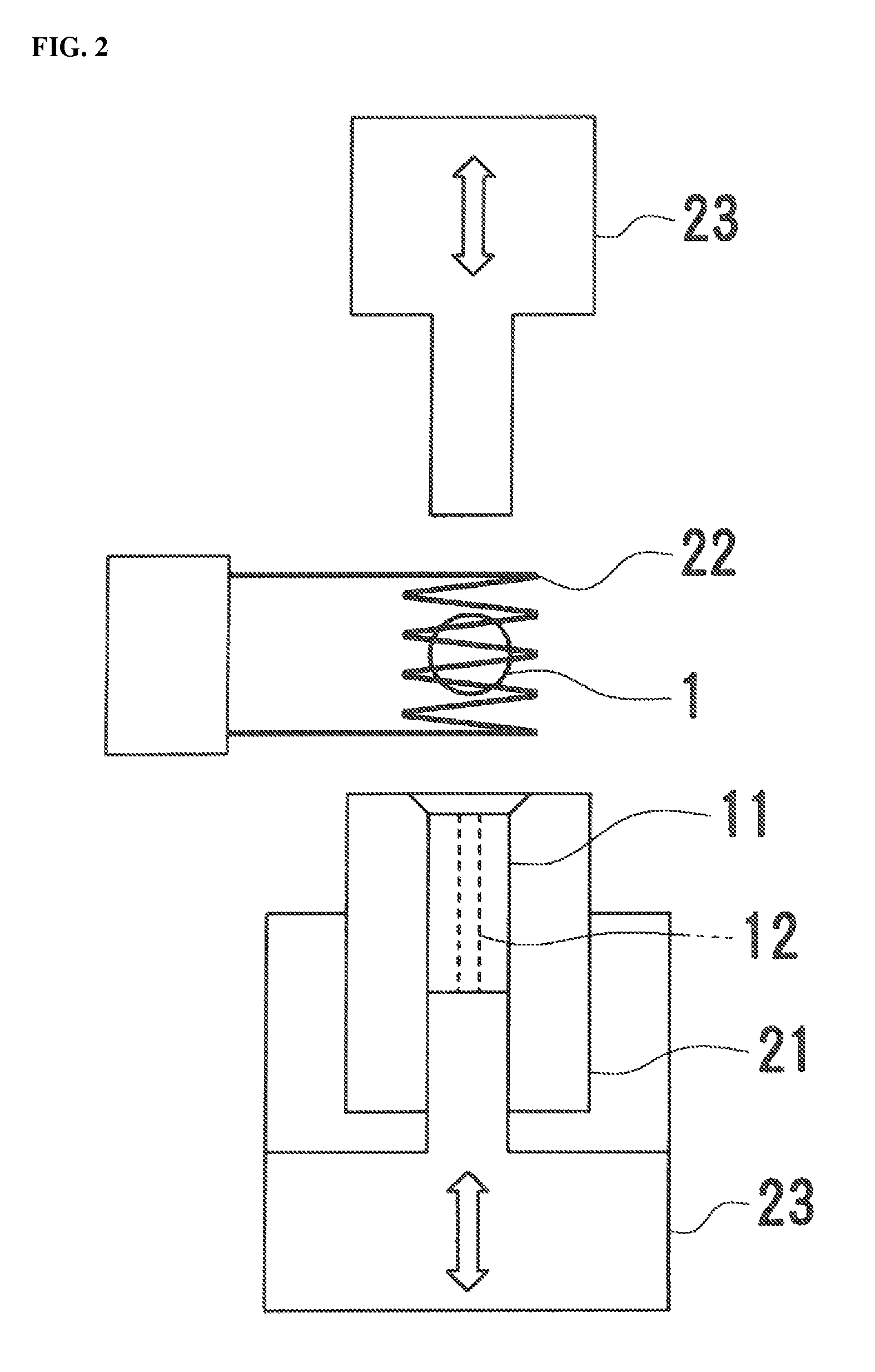

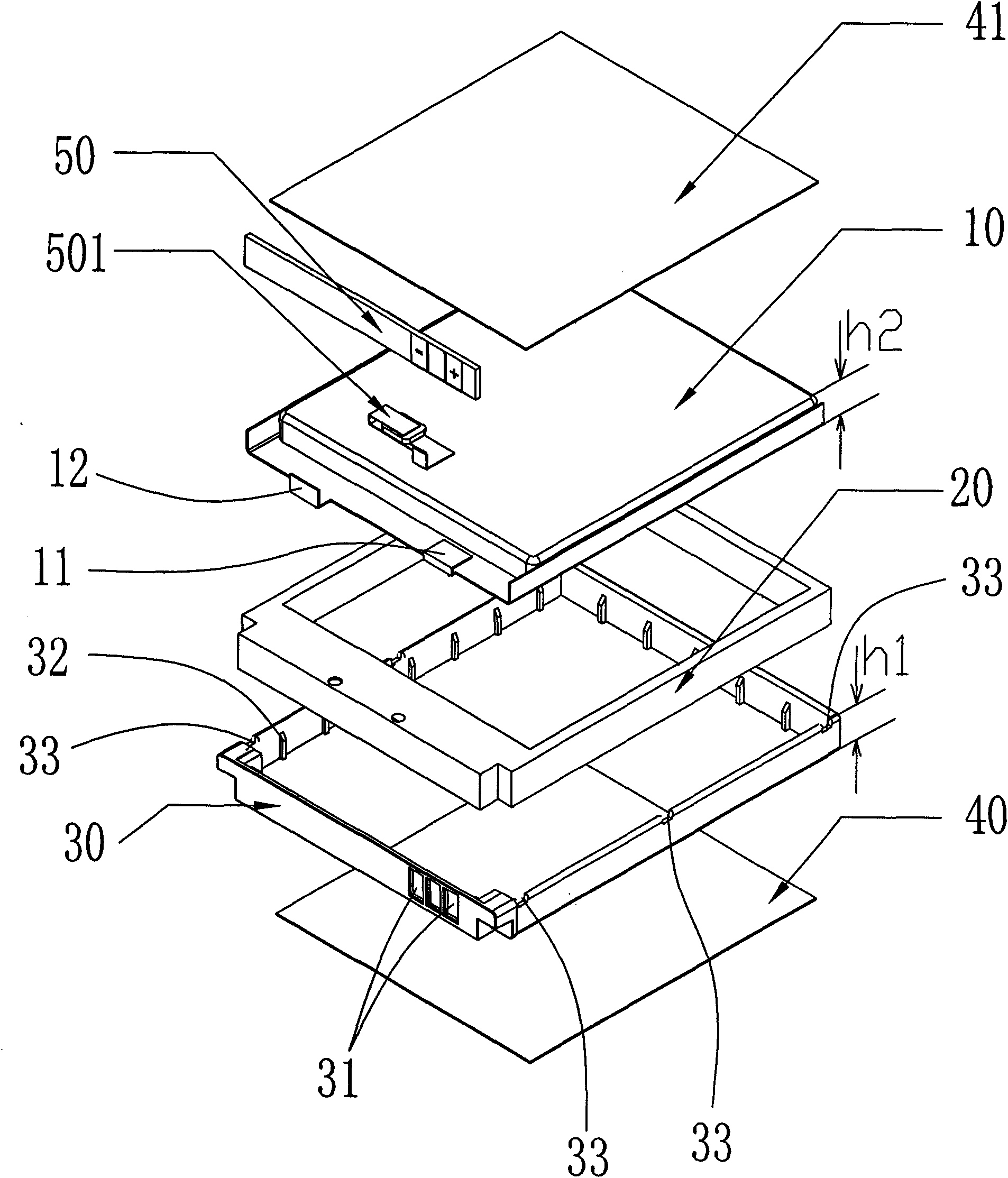

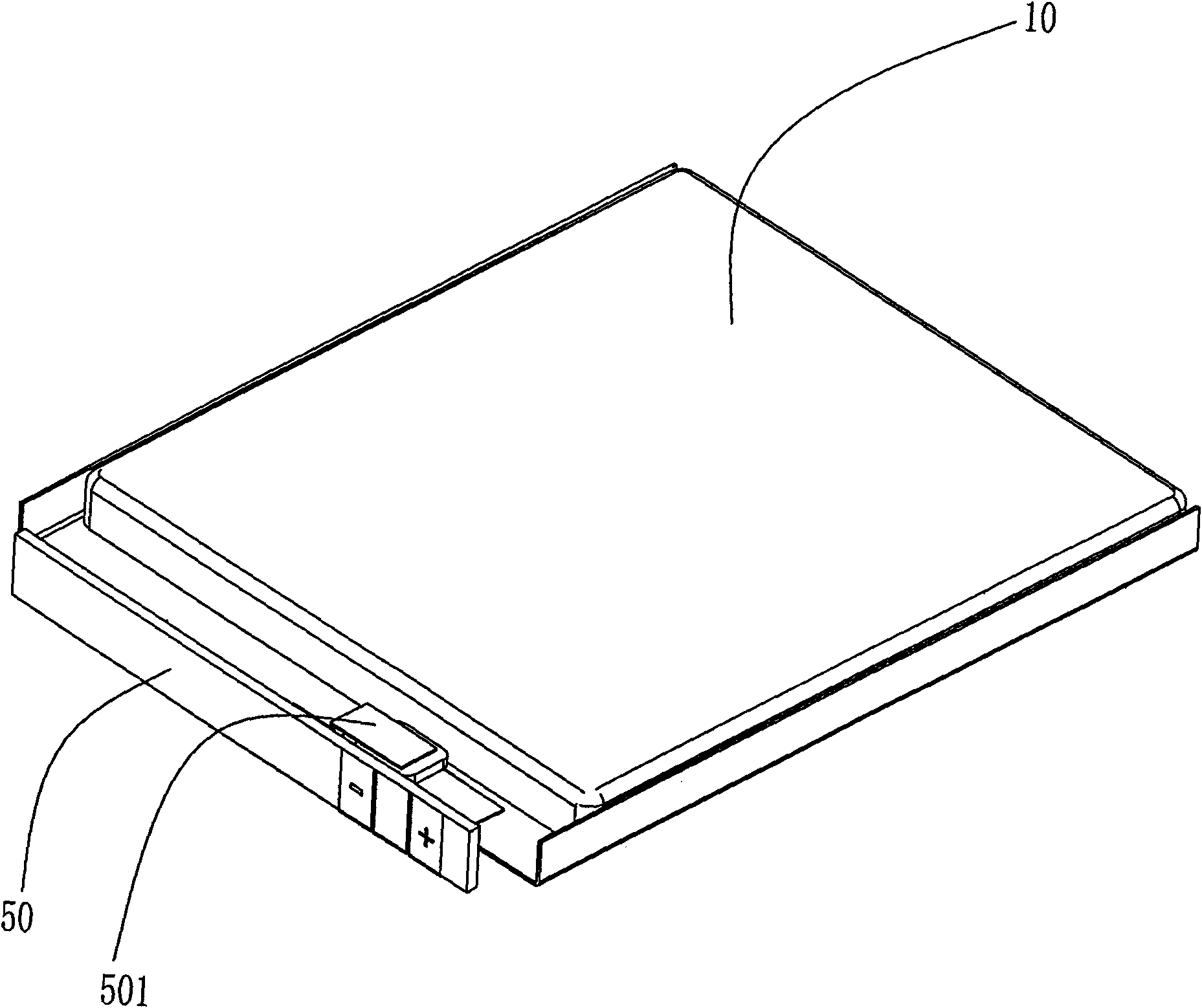

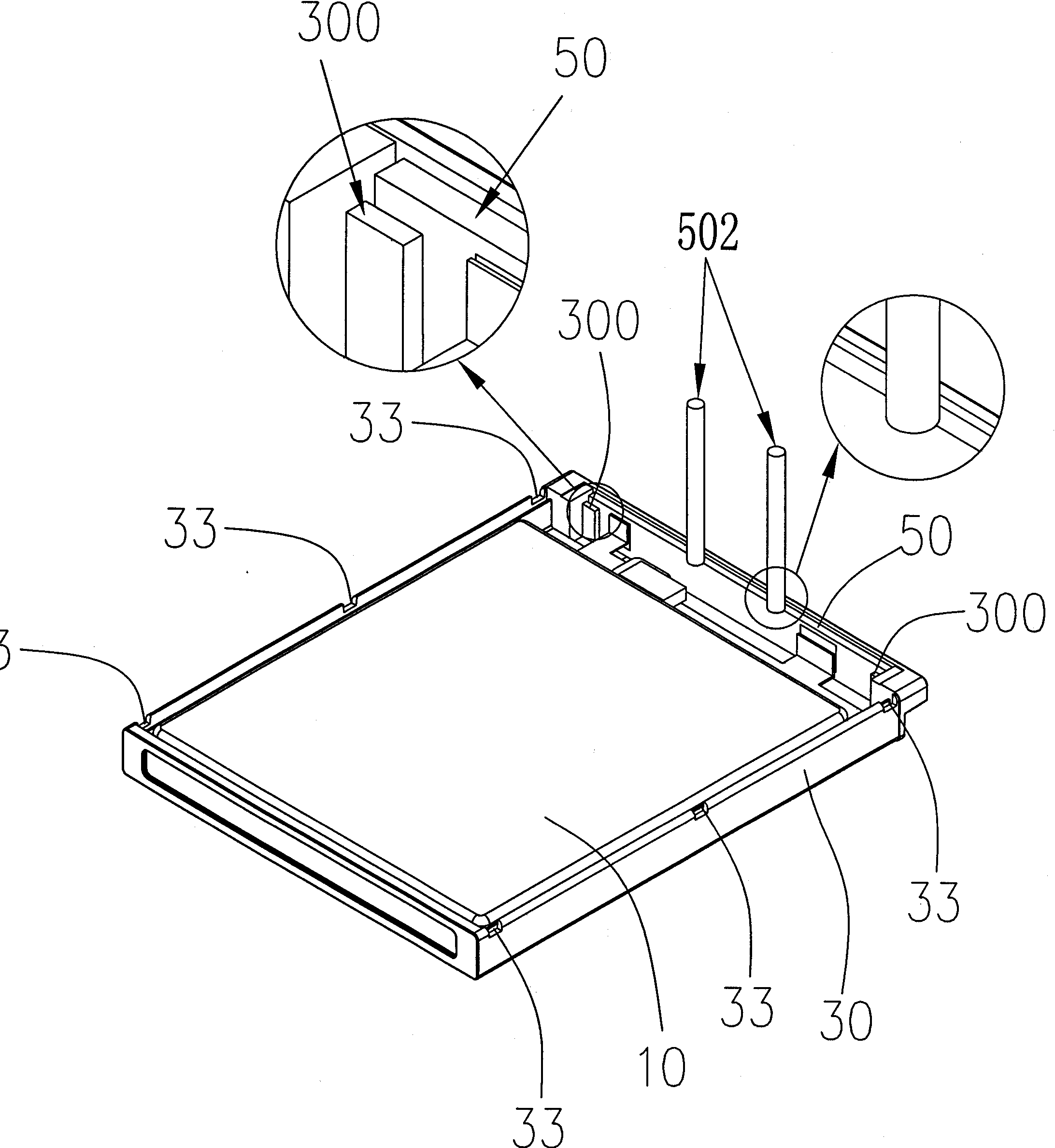

Low-pressure injection molding encapsulation method of polymer battery and low-pressure injection molding polymer battery

InactiveCN101783417AOvercoming Dimensional InstabilityOvercome stabilityFinal product manufactureLi-accumulatorsEngineeringMechanical property

The invention relates to a low-pressure injection molding encapsulation method of a polymer battery and a low-pressure injection molding polymer battery. The battery of the invention comprises a battery protecting board, a battery cell and an adhesive wherein the battery protecting board is welded with the positive pole and the negative pole of the battery cell; the adhesive frame is composed of a front side, a back side, a left side and a right side; the height of the adhesive frame is equivalent to the thickness of the battery cell; the battery protecting board is clamped on one side, which is provided with an electrode hole, of the adhesive frame; a plurality of convex ribs are arranged on the inner sides of the other three sides of the adhesive frame; the convex ribs abut against the corresponding side of the battery cell, so a gap is formed between the battery cell and the adhesive frame; and hot melt adhesive molded by low-pressure injection molding is filled in the residual space in the adhesive frame. The invention has the advantages of simple structure, low manufacturing cost, good mechanical property, low height of the battery, precise dimension and high realizability.

Owner:SHENZHEN RUIDE ELECTRONICS IND

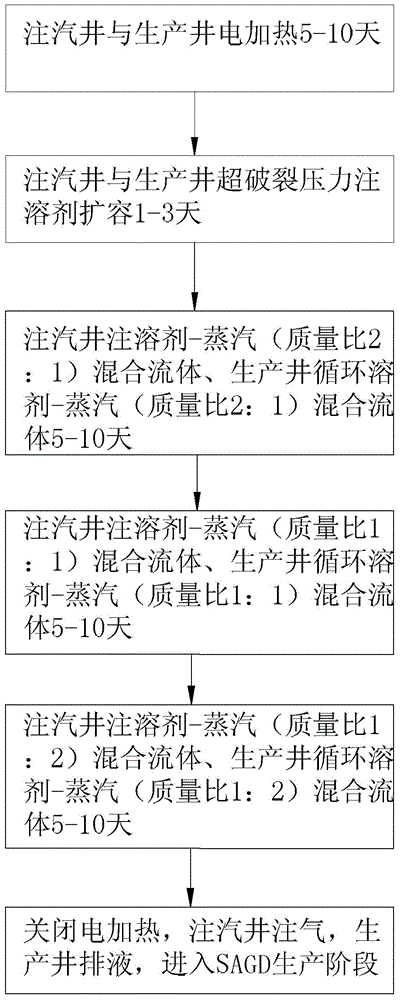

Rapid start method for heavy oil reservoir steam assisted gravity drainage

ActiveCN104453805ABuild pressure connectionIncrease the range of viscosity reductionFluid removalSolventInjection well

The invention discloses a rapid start method for heavy oil reservoir steam assisted gravity drainage. The rapid start method for heavy oil reservoir steam assisted gravity drainage comprises the following steps that (1) a steam injection well and a producing well are electrically heated at a large power; (2) a solvent is injected into a long oil pipe and a short oil pipe of the steam injection well and a long oil pipe and a short oil pipe of the producing well at the same time; (3) a solvent and steam liquid mixture is injected into the long oil pipe and the short oil pipe of the steam injection well at the same time, the solvent and steam liquid mixture is injected into the long oil pipe of the producing well, and the short oil pipe of the producing well discharges liquid; (4) electric heating is stopped, pure steam is injected into the long oil pipe of the steam injection well and the short oil pipe of the seam injection well at the same time, and the long oil pipe and the short oil pipe of the producing well discharge liquid at the same time. Compared with a conventional preheating start method, time is shortened by over two thirds, so that the heat energy utilization rate is greatly increased, rapid preheating start of SAGD can be achieved, and the production speed of SAGD is increased. In addition, through rapid solvent volume expansion and super fracture pressure injection, an even oil drainage channel can be established, and the purposes of increasing the yield and the recovery rate are achieved.

Owner:PETROCHINA CO LTD

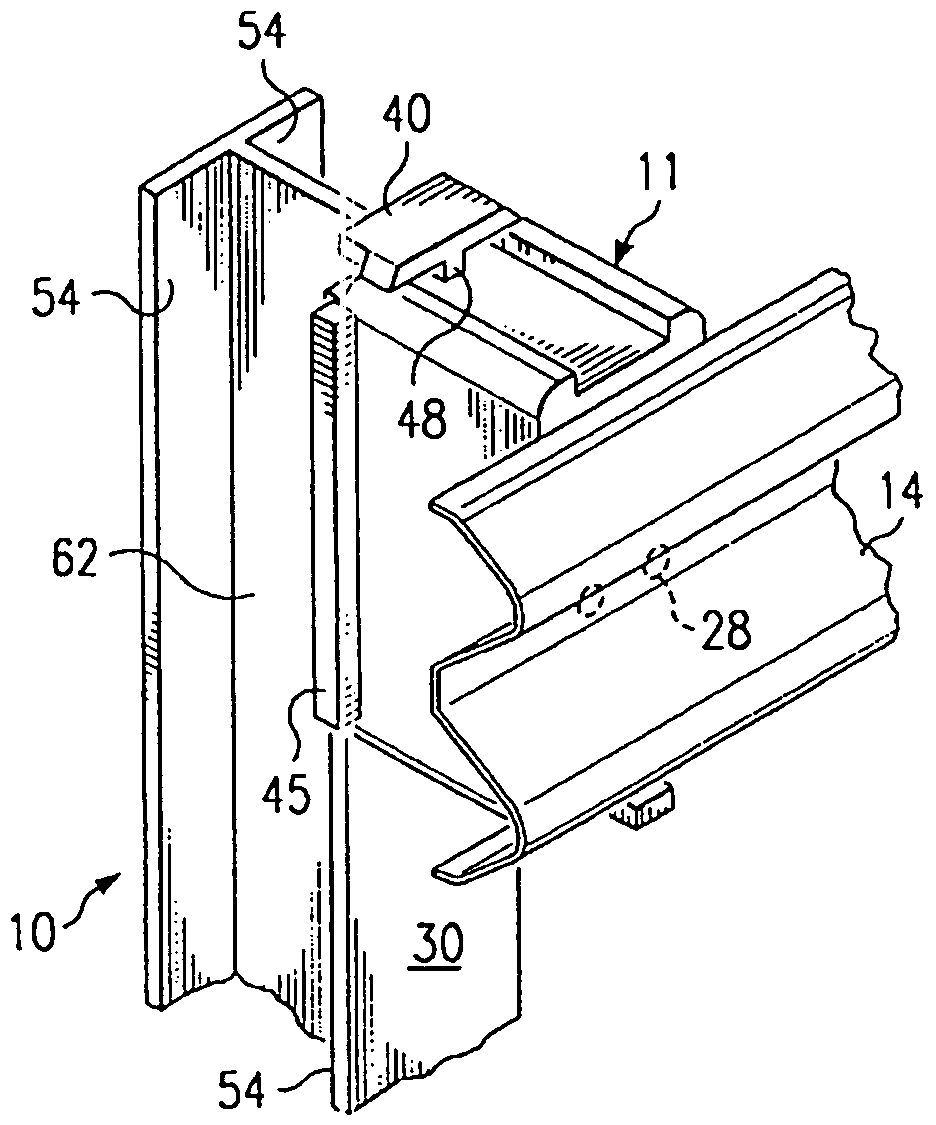

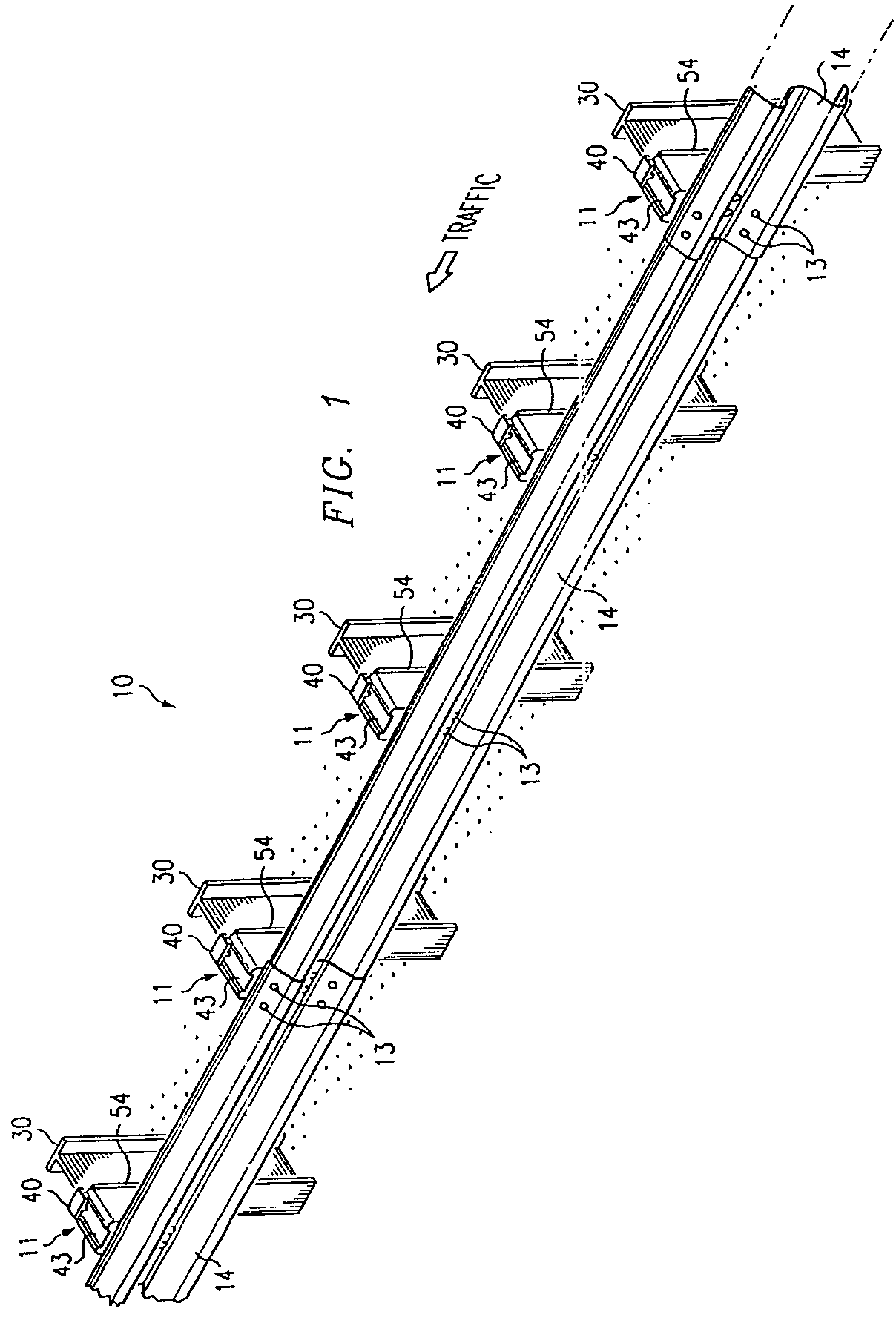

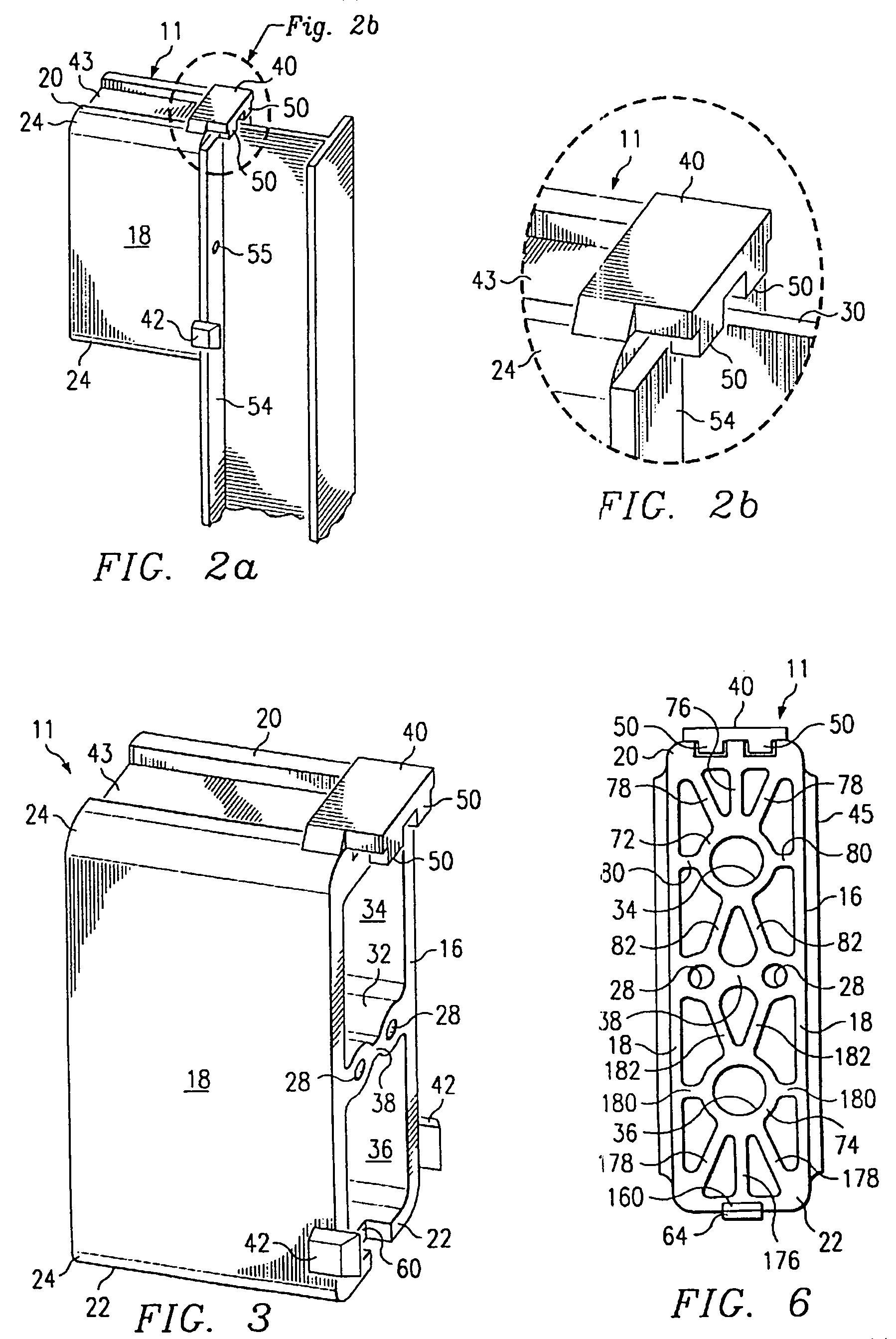

Guardrail support, attachment, and positioning block

InactiveUS7234687B2High strengthReduce weightPasturing equipmentTraffic signalsRubber materialPlastic materials

A block used to space guardrails from support posts. The positioning or spacer block is a generally rectangular block having corded-out cavities to reduce weight and tabs or projections for cooperatively engaging the sides and top of a support post as well as the edges of the guardrail during roadway safety barrier system installation. Webbing within one or more of the cavities is used for additional structural support. The spacer block may be formed by low-pressure injection molding to optimize the strength to weight characteristics of the spacer block. The spacer block is formed from virgin and / or recycled plastic material and / or includes virgin or recycled rubber material, such as that obtained from the regrind of used tires, and / or another elastomeric materials from other sources.

Owner:K E S S

True triaxial fracture seepage continuous test system and method

PendingCN110426286AEnable continuous testingMeet various test requirementsMaterial strength using tensile/compressive forcesPermeability/surface area analysisData acquisitionHydraulic fracturing

The invention discloses a true triaxial fracture seepage continuous test system and method, and belongs to the technical field of rock mass mechanics and engineering. The true triaxial fracture seepage continuous test system comprises a fracture seepage continuous test system, a true triaxial loading system, a confining pressure injection system, an acoustic emission monitoring system, a servo control system and a data acquisition and control system. Fracture seepage continuous testing is achieved by control over a pneumatic steering valve, the actual stress, temperature and seepage conditionof rock in stratum is simulated under effects of a temperature field, a seepage field and a stress field, fracture seepage continuous test is performed on a test piece so as to test a fracture effectof the rock, the crack initiation, expansion and opening and closing characteristic of a gap generated by a crack is completely monitored by the acoustic emission monitoring system, the gap formationand expansion mechanism is observed, analyzed and mastered, and theoretical foundation and experiment basis are provided for hydraulic fracturing of coal bed gas and shale gas.

Owner:中国平煤神马控股集团有限公司 +2

Construction process for filling joints between door and window and universal auxiliary frame and side frame of buildings by pressure injection

InactiveCN101525968AImprove compactnessQuality improvementFrame fasteningJoints tightening/coveringFilling materialsEngineering

The invention provides a construction process for filling joints between door and window and universal auxiliary frame and side frame of buildings by pressure injection, comprising: arranging barrier strips on the peripheries of the auxiliary frame and side frame and near an outward side of the auxiliary frame and side frame, wherein the barrier strips are continuously distributed on the peripheries of the auxiliary frame and side frame; embedding the auxiliary frame and side frame from the outward sides of openings to predetermined positions in the openings, wherein the barrier strips continuously distributed separate the gaps between the auxiliary frame, side frame and openings into outer and inner gaps, injecting filling materials in the outer gaps along the peripheries of the auxiliary frame and side frame by mechanical pressure injection; and after the solidification of the filling materials, injecting filling materials in the inner gaps along the peripheries of the auxiliary frame and side frame by mechanical pressure injection. The invention adopts the creative construction process above, thus improving the compactness of filling joints between door and window and universal auxiliary frame and side frame of building by pressure injection, preventing void filling, and increasing the construction quality and working efficiency of door and window of buildings.

Owner:SHENZHEN FUCHENG TECH DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com