Low-pressure injection molding encapsulation method of polymer battery and low-pressure injection molding polymer battery

A technology of low-pressure injection molding and packaging methods, which is applied in the manufacture of lithium batteries, non-aqueous electrolyte batteries, and electrolyte batteries. Unstable dimensions, guaranteed consistency of dimensions, and simple packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

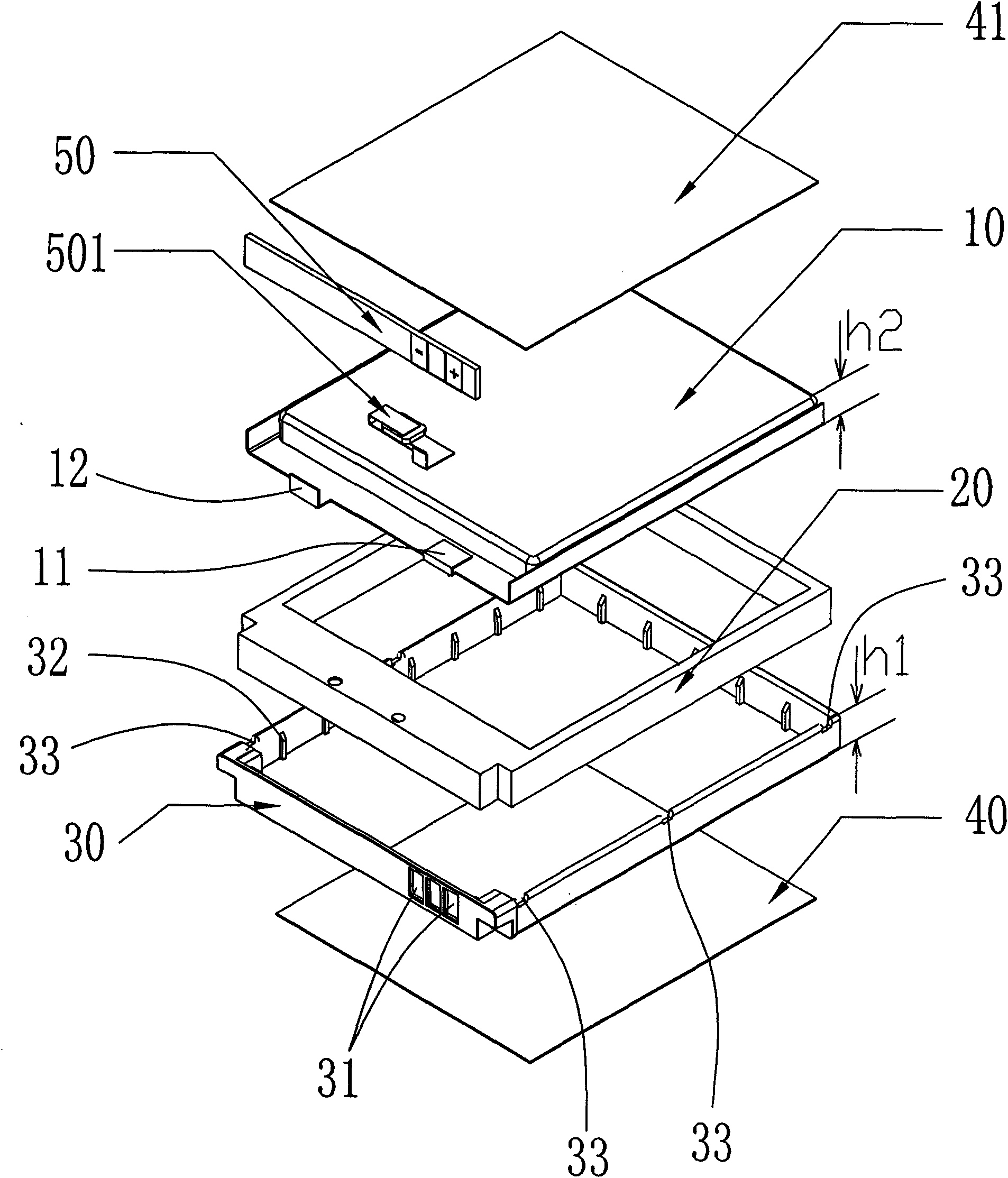

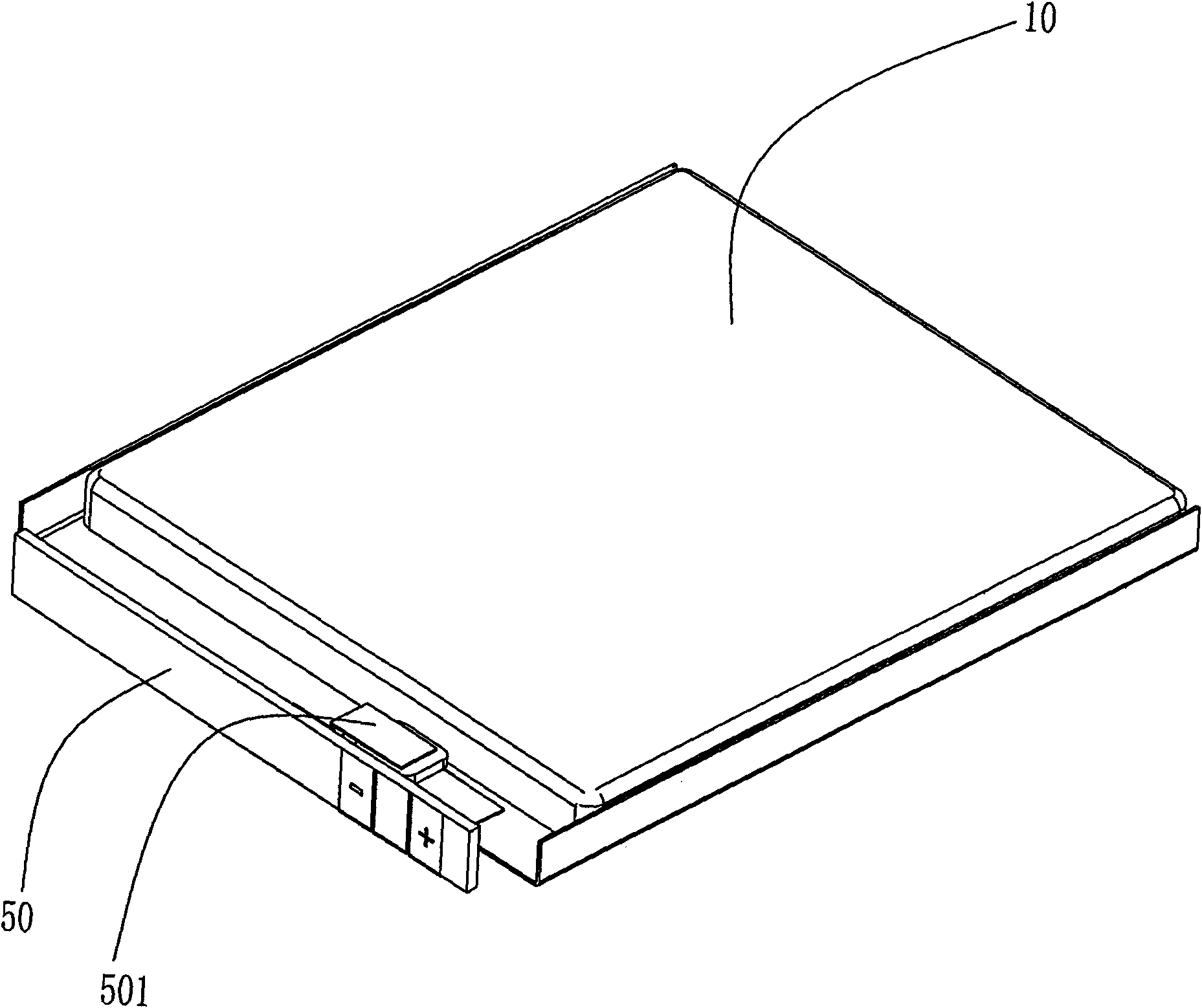

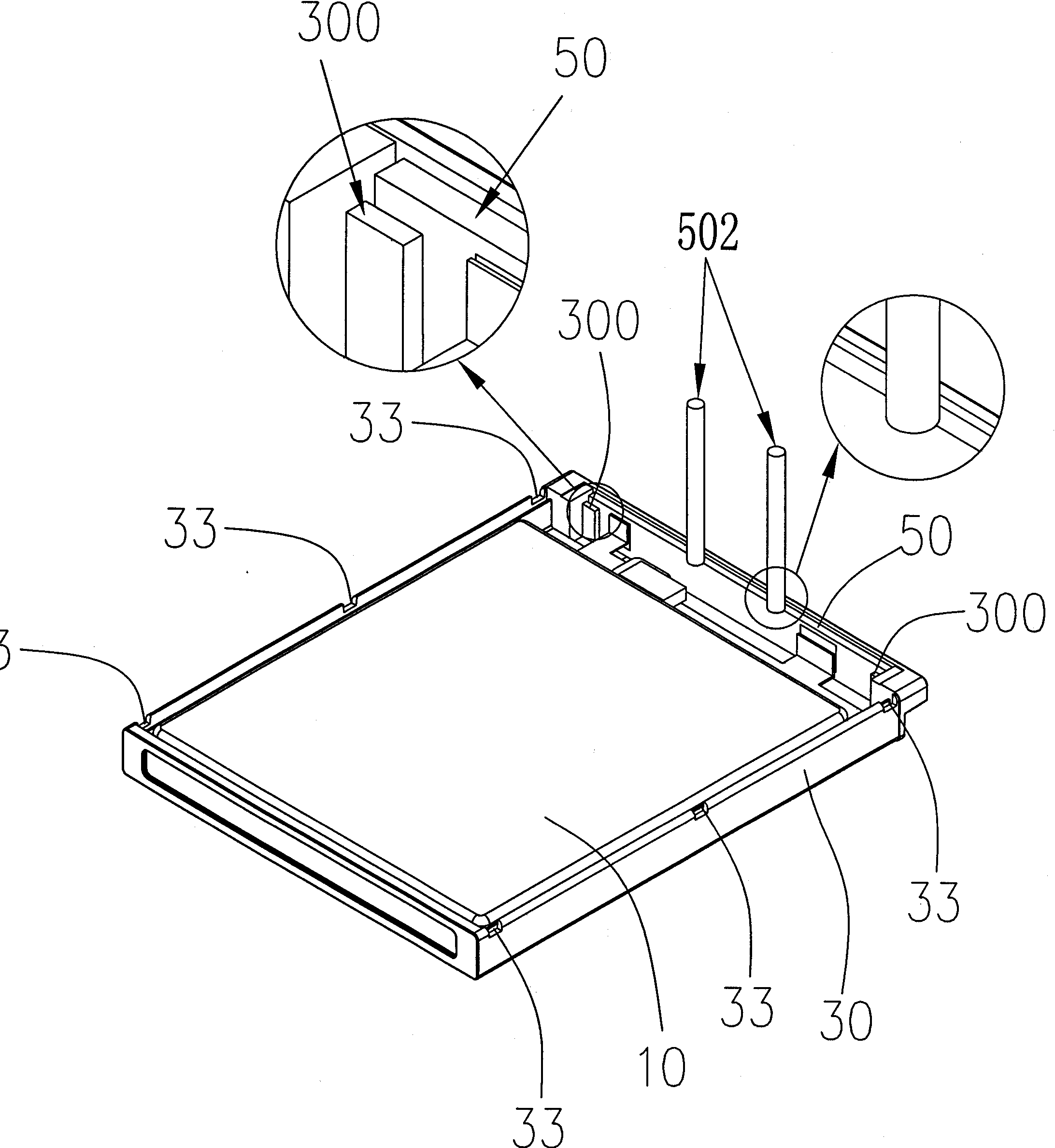

[0031] See figure 1 , the present invention discloses a low-voltage injection-molded polymer battery, including a battery protection plate 50 and an electric core 10, and a protection circuit composed of many independent components is arranged on the battery protection plate 50, and the battery protection plate 50 The positive and negative poles of the protection circuit on the battery are welded to the positive pole 11 and the negative pole 12 of the battery core 10. If necessary, a PTC501 for providing temperature protection can also be connected in series with the positive pole 11 or the negative pole 12 of the battery core 10. The plastic frame 30 is composed of front, rear, left and right sides. The height h1 of the plastic frame 30 is greater than or equal to the thickness h2 of the battery cell. The height h1 is designed to be equal to the thickness h2 of the cell; the battery protection plate 50 is stuck on the side (generally the front side) with the electrode hole 31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com