Conductive composition containing poly(3,4-ethylenedioxythiophene)/lignosulfonic acid and preparation method thereof

A technology of ethylenedioxythiophene and lignosulfonic acid, which is applied in lignin coatings, conductive coatings, coatings and other directions, can solve the problems of decreased conductivity, falling off, and expensive products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

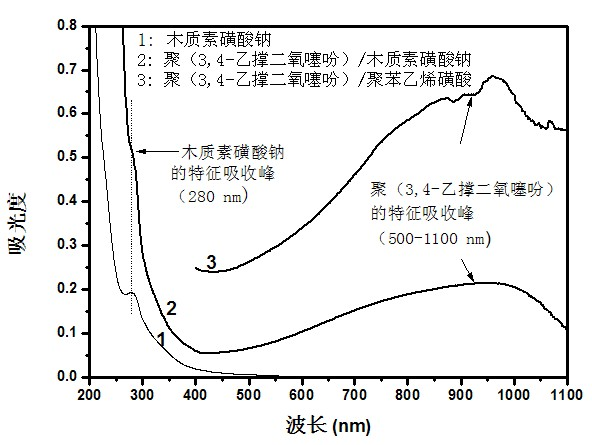

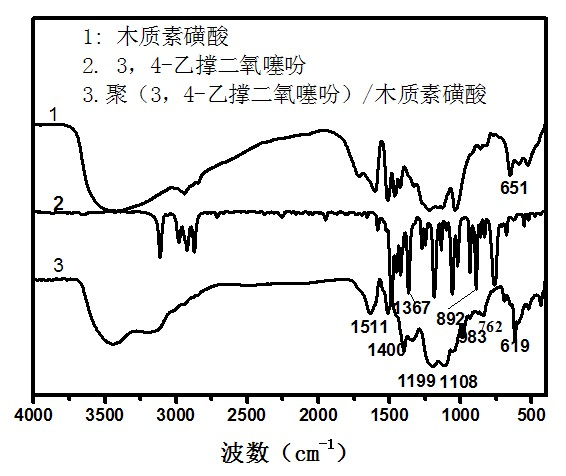

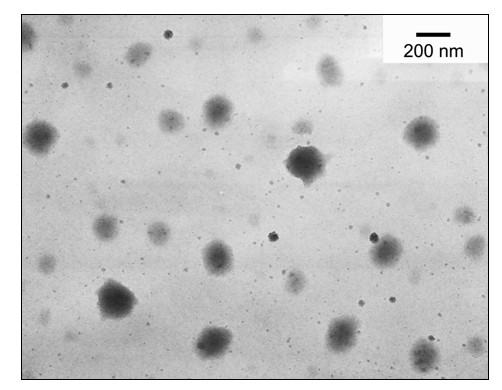

Method used

Image

Examples

Embodiment 1

[0046] Step 1: Polymerization process

[0047] Sodium lignosulfonate is firstly dissolved in water to form a 5wt% (mass percent) aqueous solution. The lignin sulfonate solution is classified by an ultrafiltration machine, and components with a molecular weight cutoff greater than 5000 Da are cut off by an ultrafiltration membrane. Concentrate the lignosulfonate ultrafiltrate with a molecular weight greater than 5000Da, and then flow through a cation exchange resin to exchange hydrogen ions and metal ions. Collect the washing solution that has passed through the cation exchange resin, concentrate, and dry to obtain lignosulfonic acid.

[0048] 300 parts by weight of lignosulfonic acid are dissolved in 5000 parts by weight of water to prepare an aqueous solution with a mass concentration of 6.0%. Add 100 parts by weight of the monomer (3,4-ethylenedioxythiophene) to the aqueous ligninsulfonic acid solution at room temperature, and stir for 30 minutes at a stirring speed of 500...

Embodiment 2

[0053] Step 1: Polymerization process

[0054] Dissolve magnesium lignosulfonate in water to prepare a 10 wt% aqueous solution. The lignin sulfonate solution is classified by an ultrafiltration machine, and components with a molecular weight cutoff greater than 5000 Da are cut off by an ultrafiltration membrane. Concentrate the lignosulfonate ultrafiltrate with a molecular weight greater than 5000Da, and then flow through a cation exchange resin to exchange hydrogen ions and metal ions. Collect the washing solution that has passed through the cation exchange resin, concentrate, and dry to obtain lignosulfonic acid.

[0055] 1000 parts by weight of lignosulfonic acid is dissolved in 10000 parts by weight of water to prepare an aqueous solution with a mass concentration of 10.0%. Add 100 parts by weight of the monomer (3,4-ethylenedioxythiophene) into the aqueous ligninsulfonic acid solution at room temperature, and stir for 10 minutes at a stirring speed of 2000 rpm to make t...

Embodiment 3

[0060] Step 1: Polymerization process

[0061] Dissolve magnesium lignosulfonate in water to prepare a 6wt% aqueous solution. The lignin sulfonate solution is classified by an ultrafiltration machine, and components with a molecular weight cutoff greater than 5000 Da are cut off by an ultrafiltration membrane. Concentrate the lignosulfonate ultrafiltrate with a molecular weight greater than 5000Da, and then flow through a cation exchange resin to exchange hydrogen ions and metal ions. Collect the washing solution that has passed through the cation exchange resin, concentrate, and dry to obtain lignosulfonic acid.

[0062] 500 parts by weight of lignosulfonic acid are dissolved in 5000 parts by weight of water to prepare an aqueous solution with a mass concentration of 10.0%. At room temperature, 100 parts by weight of monomer (3,4-ethylenedioxythiophene) was added to the aqueous ligninsulfonic acid solution, and stirred at a stirring speed of 1000 rpm for 20 minutes to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com