Patents

Literature

100results about How to "Overcome water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

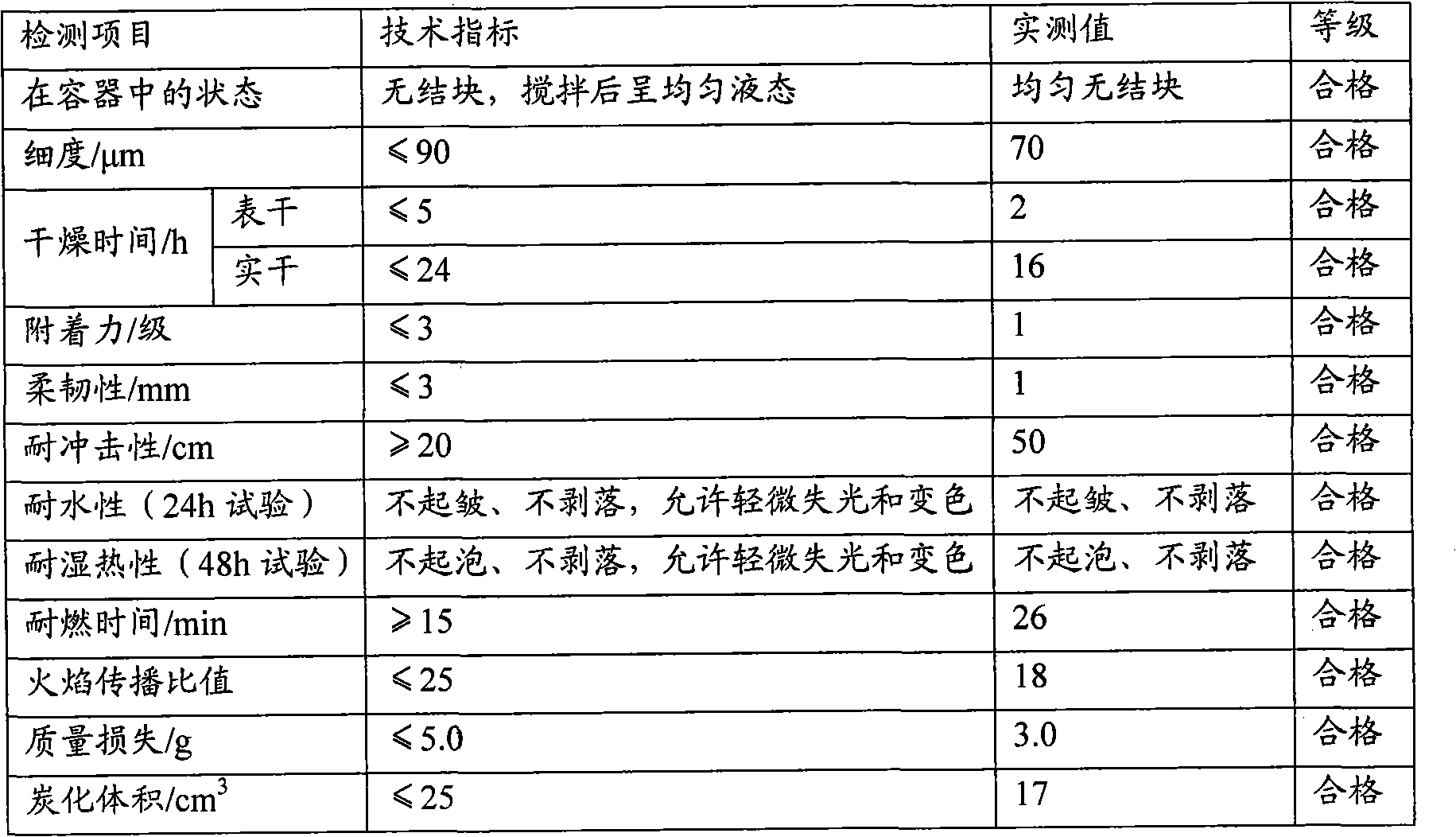

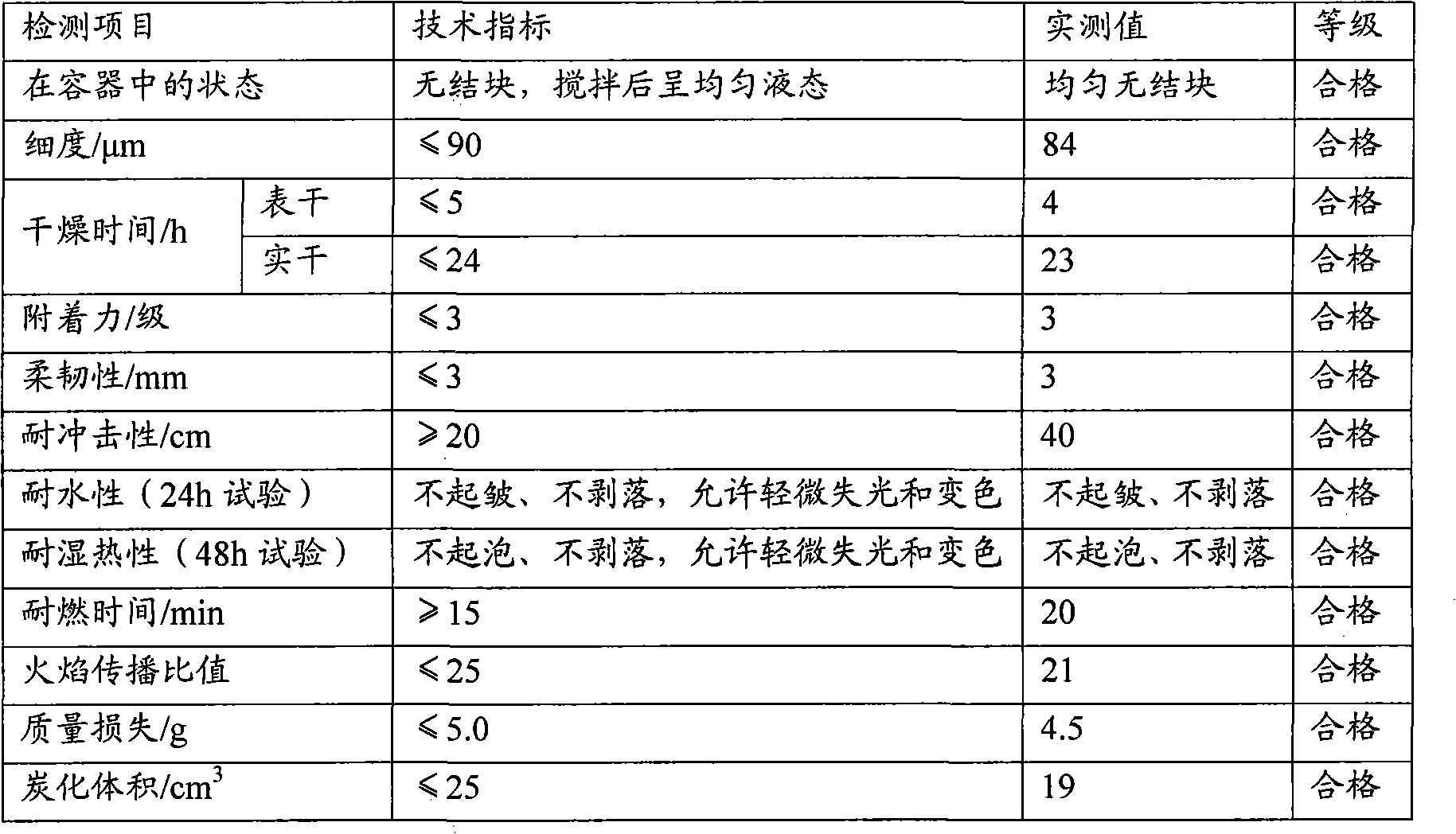

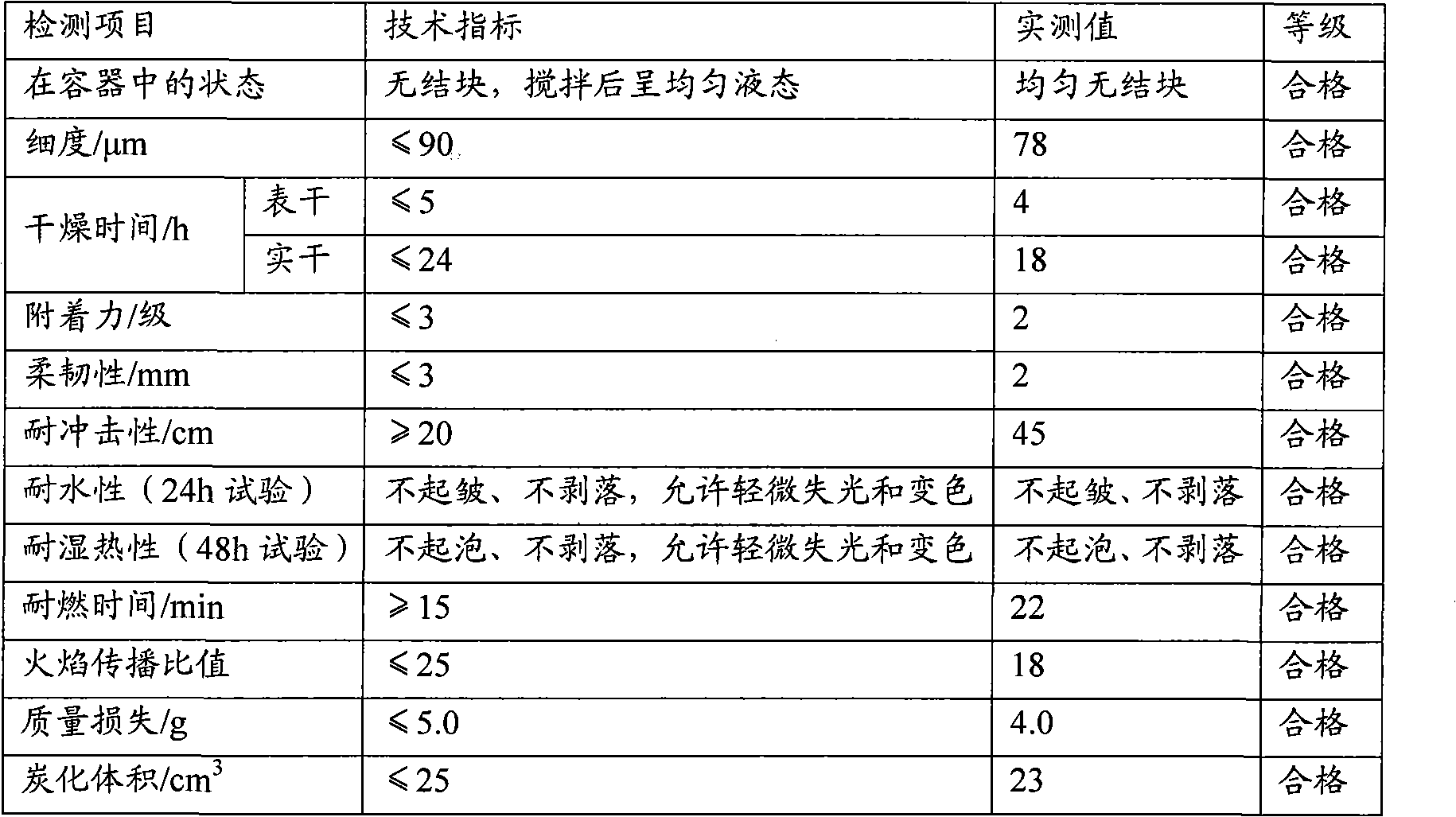

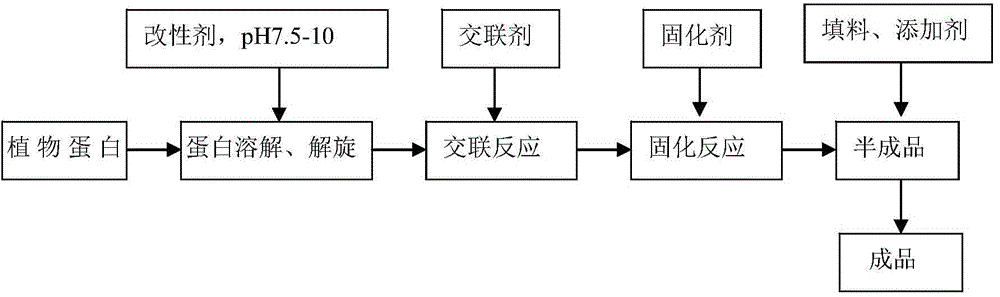

Aldehyde-free vegetable protein-based wood adhesive as well as preparation and application methods thereof

InactiveCN104610909AOvercome water resistanceOvercome strengthNon-macromolecular adhesive additivesProtein adhesivesCross-linkAdhesive

The invention belongs to the technical field of design, research and development of environment-friendly chemical materials and specifically relates to an aldehyde-free vegetable protein-based wood adhesive as well as preparation and application methods thereof. The aldehyde-free vegetable protein-based wood adhesive is prepared from the following components in parts by mass: 100 parts of water, 20-40 parts of vegetable protein, 0.1-5 parts of modifier, 20-40 parts of cross-linking agent, 2-20 parts of curing agent, 1-5 parts of packing and 0-3 parts of additive. The finished product is formed by virtue of vegetation protein dissolution, a cross-linking reaction and a curing reaction. The adhesive is mainly applied to a wood material in such a manner of roll coating, scraper coating, curtain coating or spraying, and then a composite wood artificial board can be obtained by virtue of aging, cold pressing and hot pressing.

Owner:乌鲁木齐奥森碳环生物能源有限公司

Radiation cross-linking waterproof flame retardant polyolefin nano-composite material and preparation method thereof

ActiveCN101899183AOvercoming poor water resistance and weather resistanceOvercome agglomeration or uneven dispersionInsulated cablesInsulated conductorsChemistryAntioxidant

The invention discloses a radiation cross-linking waterproof flame retardant polyolefin nano-composite material and a preparation method thereof and is characterized in that 0.5-5 parts of inflaming retardant synergist is added to 75-80 parts of polyolefin according to the mass ratio, mixed fully at 140-200DEG C, then 20-25 parts of nitrogen and phosphorous mixed expandable flame retardant, 0.5-5 parts of multi-functional group cross-linking agent and 0.1-1 part of antioxidant are added, after being fully mixed, a radiation cross-linking material is extruded and granulated, then the material is extruded and coated on a conductor wire core of a wire or a cable, or is pressed into plates in a forming machine, and finally, a high energy electron beam or a cobalt source is used for radiation cross-linking in 80-240KGy; and the prepared cross-linking polyolefin nano-composite material has good flame retardant property, excellent mechanical property, good waterproof property and good processing property, can be widely applied to wires and cables and transmission belts and can be applied as insulation, sealing and mechanical protection layers of electronic components and metal pipelines, and has good application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

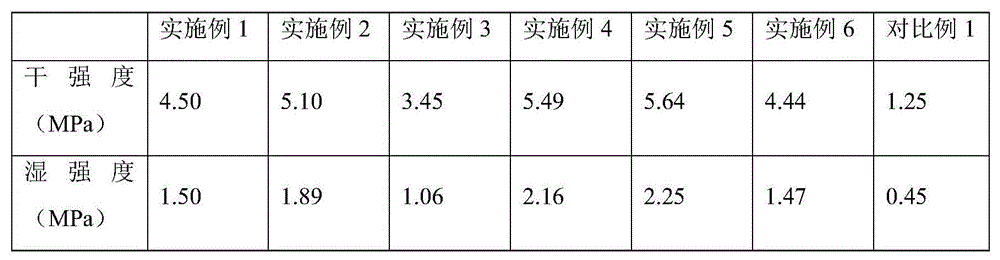

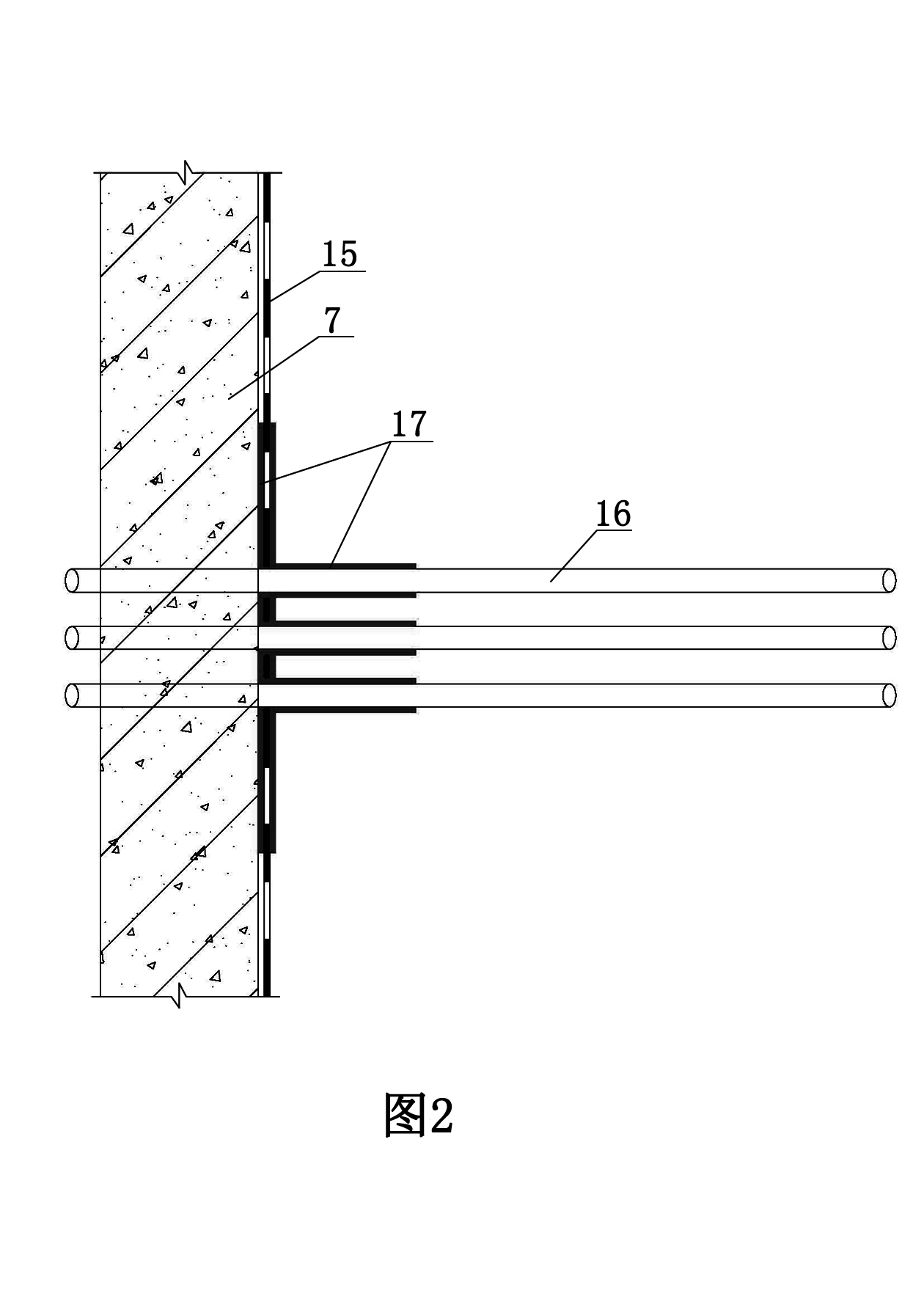

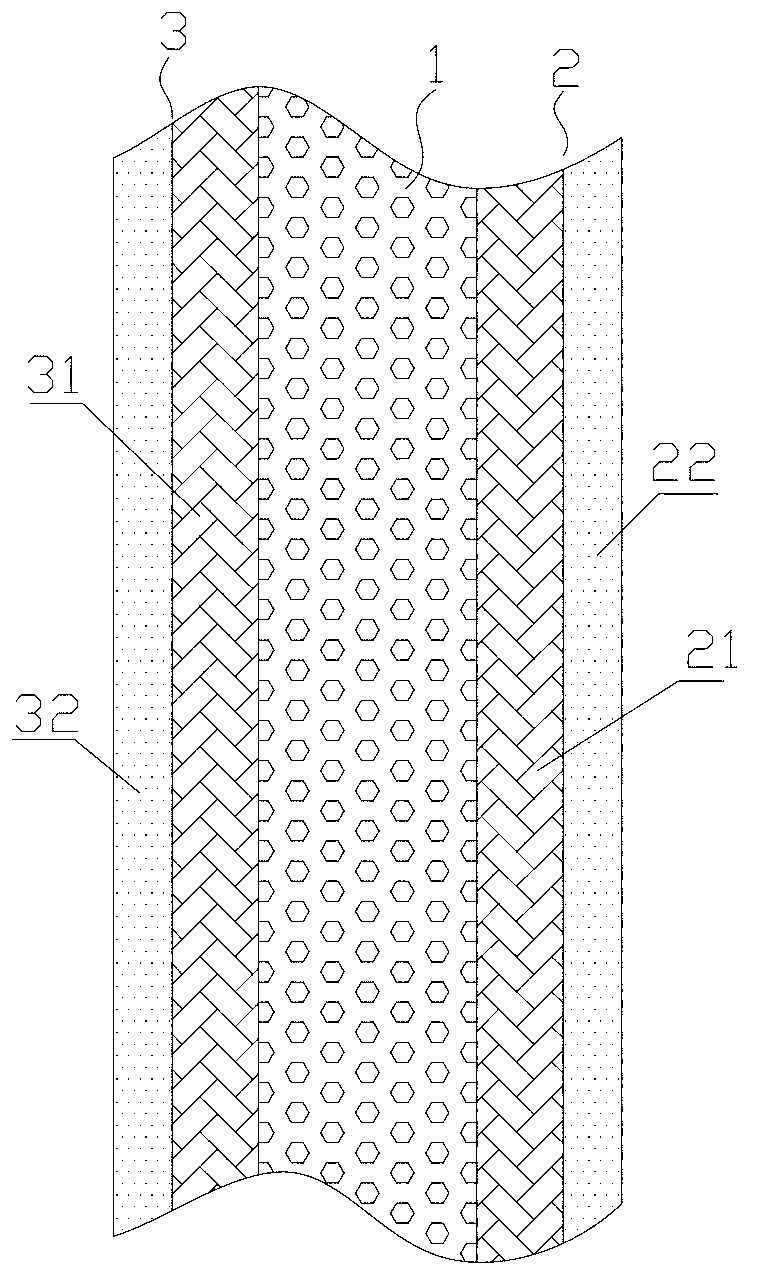

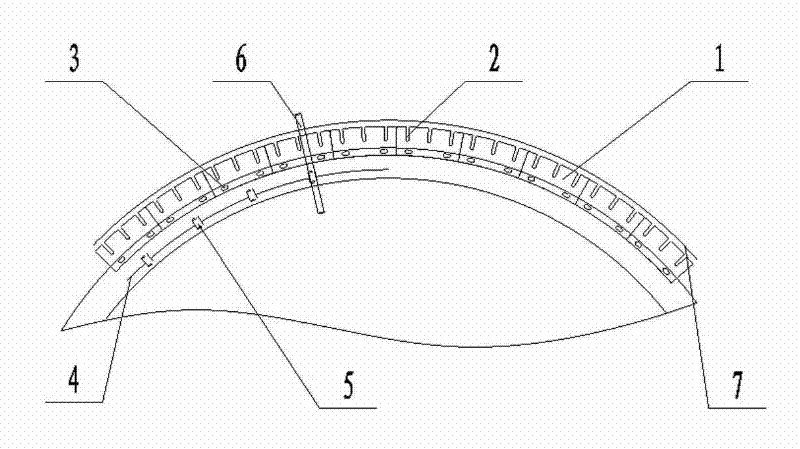

Waterproof system for basement bottom board and wall surface and construction method thereof

InactiveCN101914927AReduce weightHigh tensile strengthArtificial islandsBuild-up roofsBasementBituminous waterproofing

The invention relates to a waterproof system for a basement bottom board and a wall surface and a construction method thereof. The construction method comprises the steps of: horizontally spreading and pasting a self-adhesive rubber bituminous waterproof sheet material on a concrete base layer, and building up a brick permanent protection wall outside a preset position of a basement wall surface, wherein the bottom of the brick permanent protection wall is vertically connected with the concrete base layer, the self-adhesive rubber bituminous waterproof sheet material spreads over corners of the basement wall surface and then is upward folded to be spread and pasted on the water attaining surface of the brick permanent protection wall, then the self-adhesive rubber bituminous waterproof sheet material is lapped with another self-adhesive rubber bituminous waterproof sheet material pasted above the brick permanent protection wall, a self-adhesive rubber bituminous waterproof sheet material is pasted on an outer vertical surface of the basement wall surface. The construction method has the advantages of strong construction continuity, fast speed, good construction environment, low cost and the like, eliminates the hidden danger of fire since the heating is avoided in the construction process, is safe and reliable, completely changes and improves the traditional waterproof construction environments and the waterproof construction technology. The waterproof system can be widely applied in basements, underground structures and roofs.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

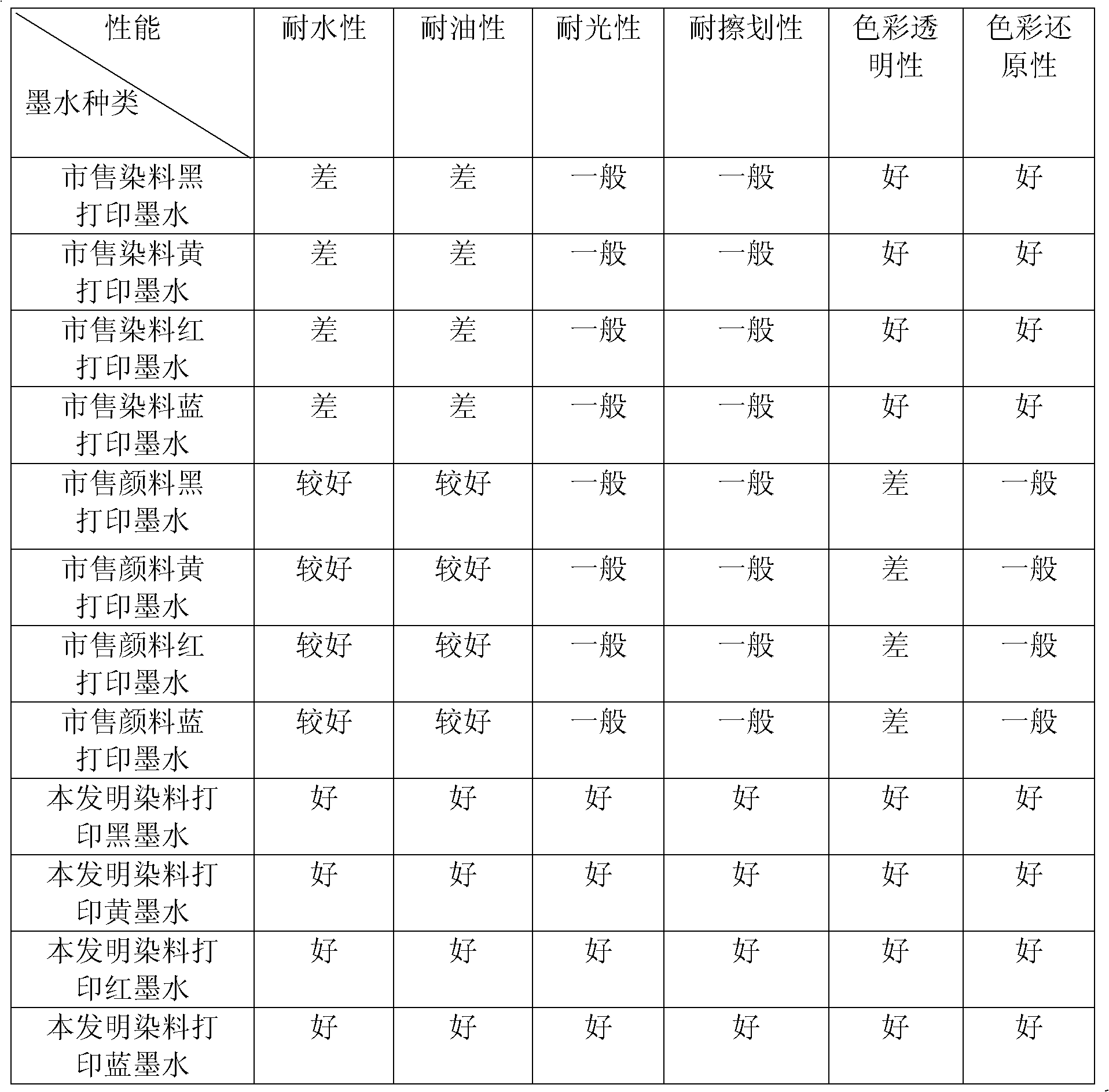

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

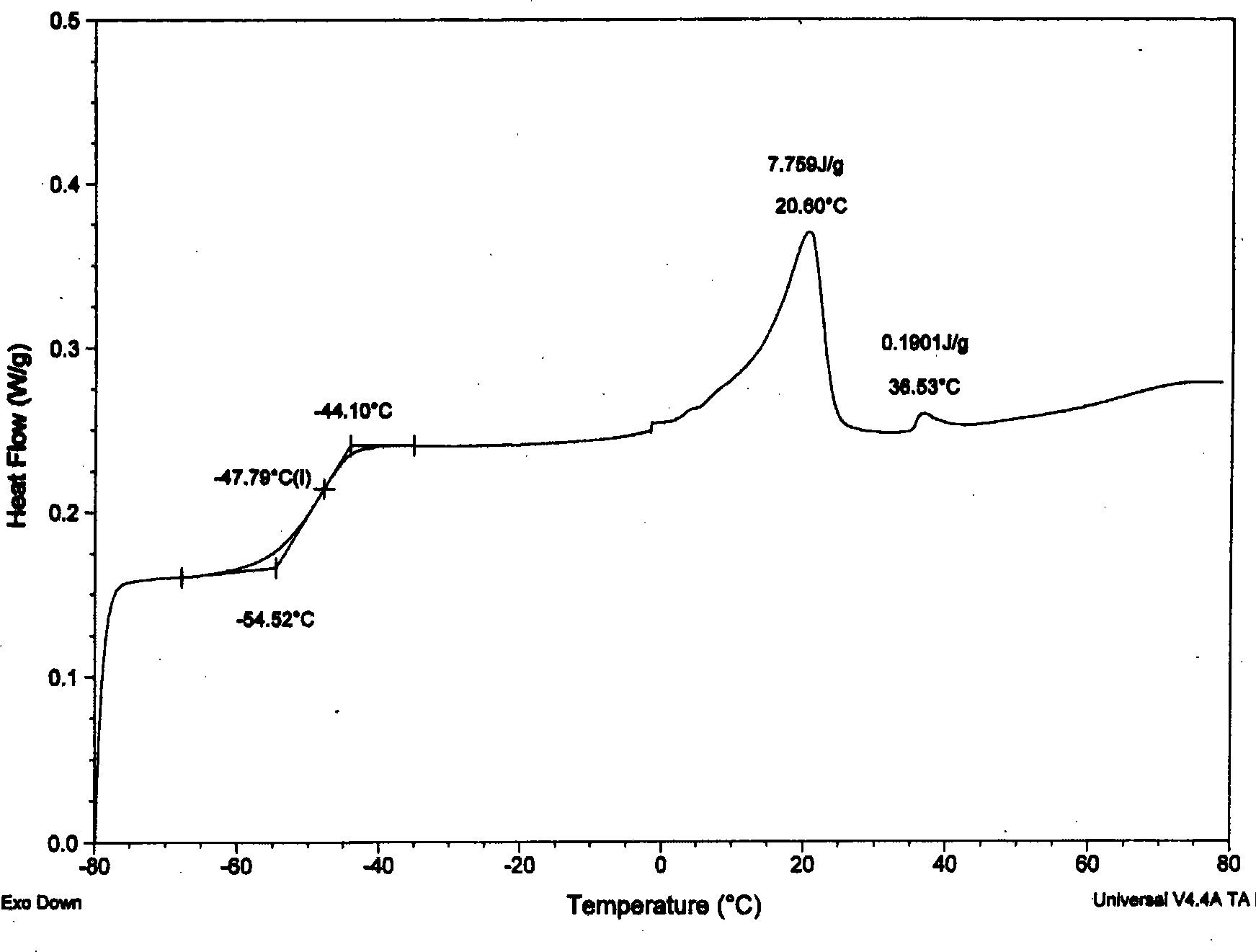

Method for preparing polyurethane loomage water proof and moisture permeable dressing agent

InactiveCN101424045AConsider crystallinityThe synthesis reaction is easy to controlFibre treatmentPolyolMoisture permeability

The invention relates to a method for preparing a waterproof and moisture permeable finishing agent of a polyurethane fabric. Raw materials for the preparation method comprise polyether polyol, vulcabond, and a chain extender, wherein the polyether polyol comprises polyether diol with a molecular weight of between 2,000 and 3,000 and polyether triol with a molecular weight of between 3,000 and 4,000; and the chain extender comprises an ion chain extendor. In the raw materials for the preparation method, the hydrophilic polyether triol with larger molecular weight substitutes the prior small molecular polylol, polyamine or polycarboxylic acid to introduce the internal crosslinking into a polyurethane soft segment phase so as to ensure that a synthesis reaction is easy to control and simultaneously consider the crystallinity, the moisture permeability and the waterproofness of polyurethane. The method overcomes the contradiction of crystallization / crosslinking and waterproofness / moisture permeability caused by adopting the small molecular polylol, polyamine or polycarboxylic acid as a crosslinking agent.

Owner:WUHAN TEXTILE UNIV

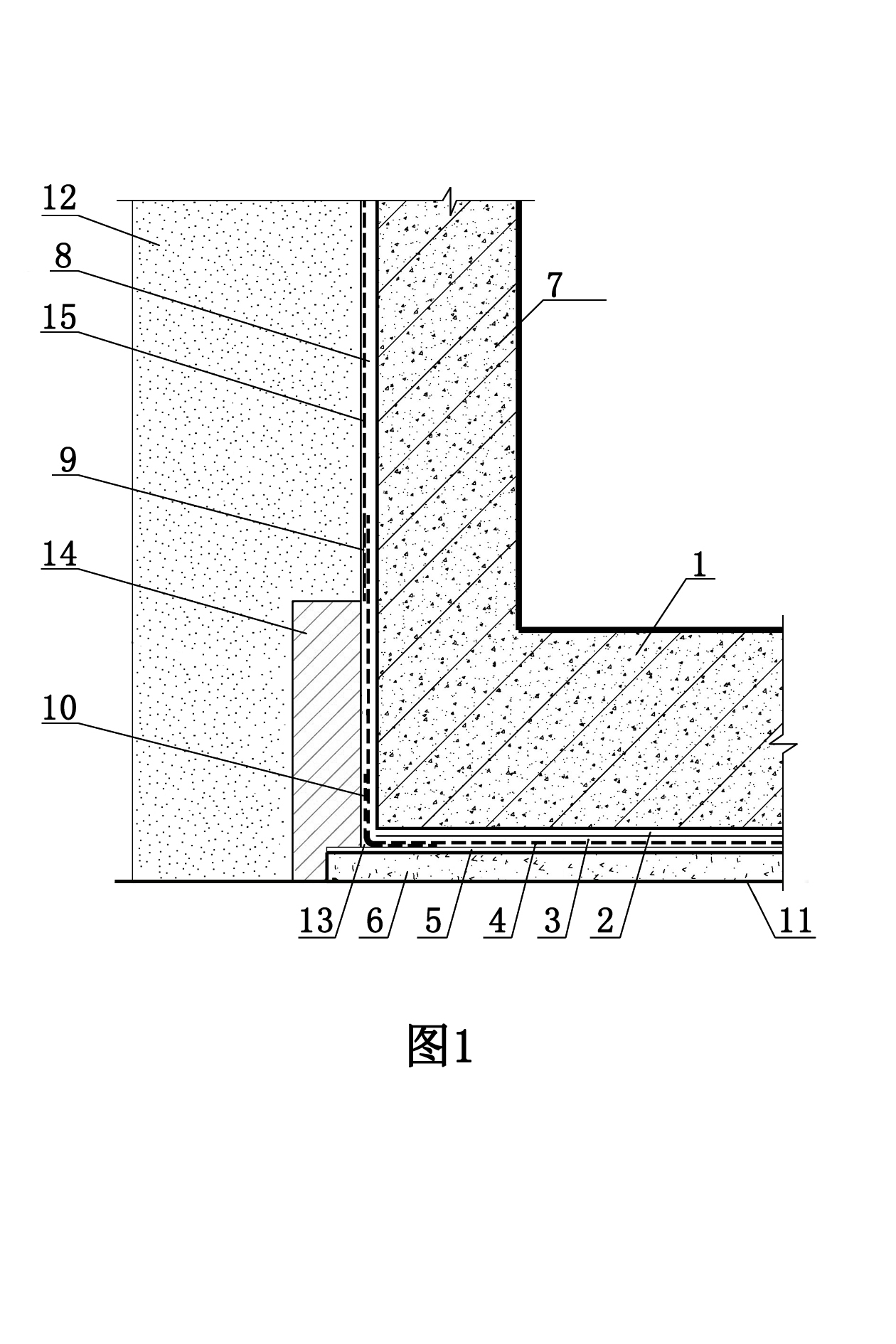

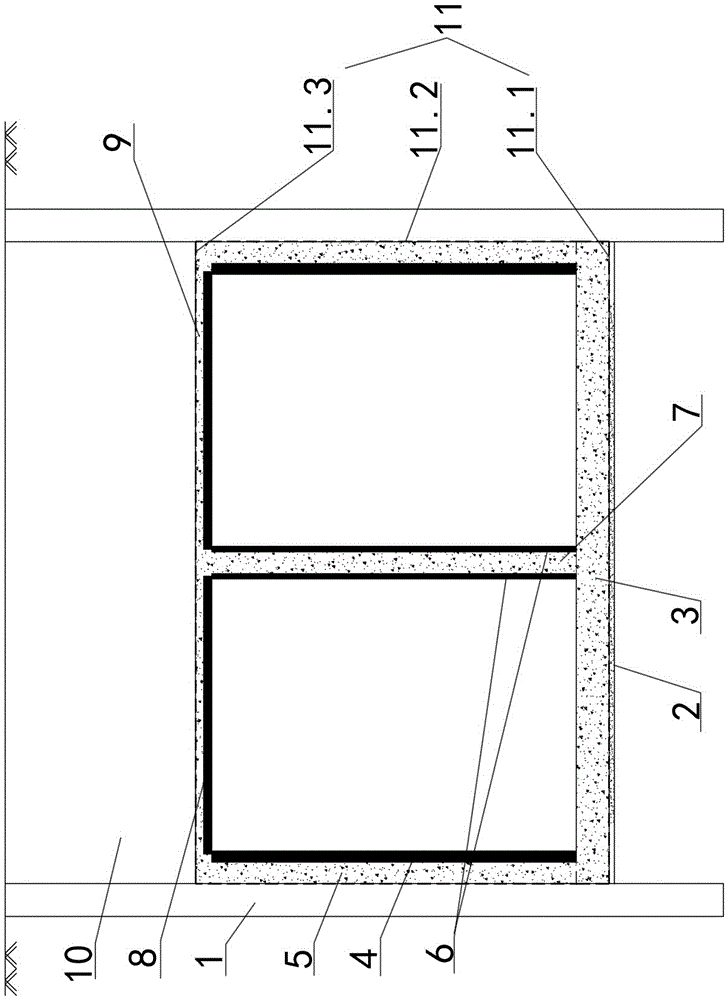

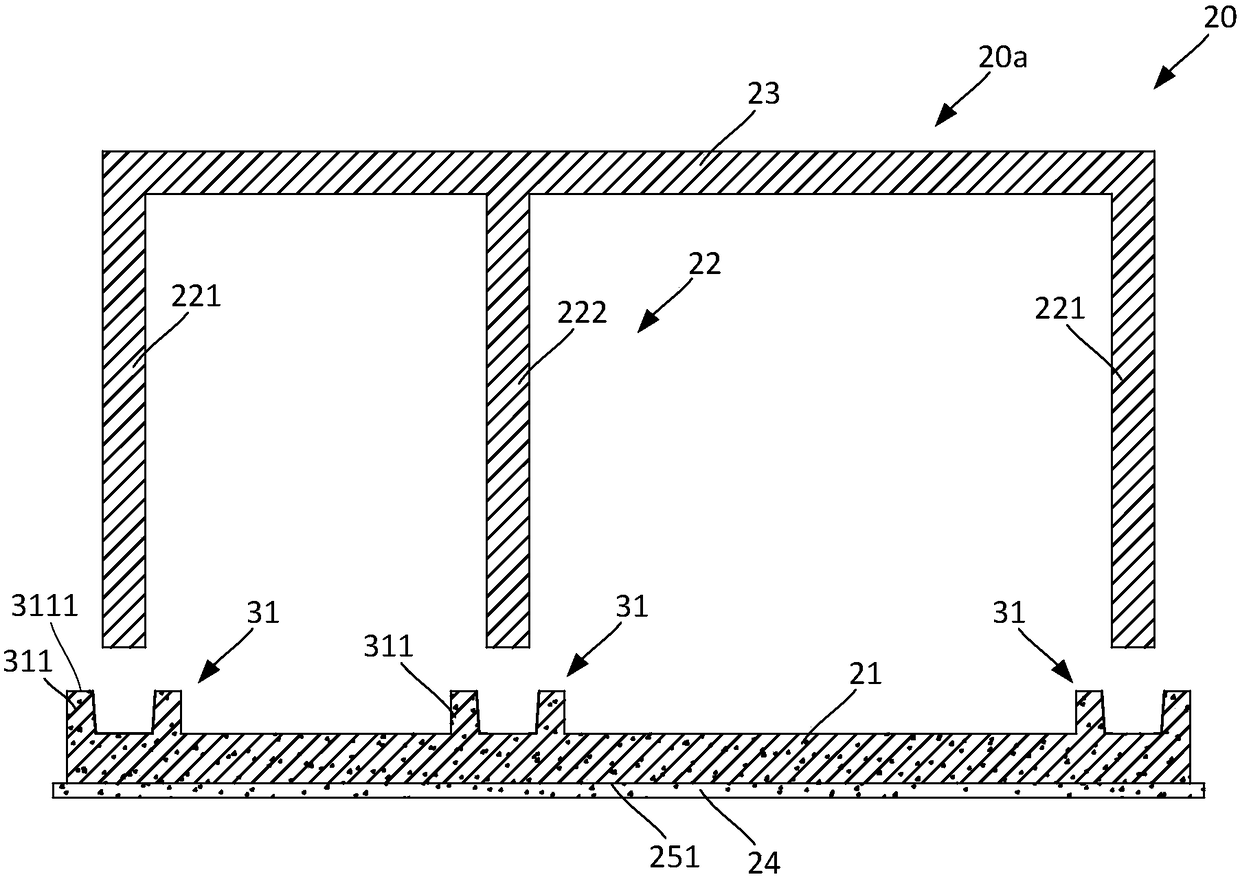

Overlapping integral type prefabricated assembly structure for comprehensive pipe gallery and construction method thereof

ActiveCN106013228ALarge working spaceActive connectionArtificial islandsUnderwater structuresEngineeringAssembly structure

The invention discloses an overlapping integral type prefabricated assembly structure for a comprehensive pipe gallery and a construction method thereof. The overlapping integral type prefabricated assembly structure comprises envelop enclosures, a pipe gallery prefabricated assembly structure body, a bottom plate cushion course and a completely outer-cladding waterproof layer, wherein the envelop enclosures are located in a foundation pit; the pipe gallery prefabricated assembly structure body is arranged between the envelop enclosures; the bottom plate cushion course is arranged under the pipe gallery prefabricated assembly structure body; and the completely outer-cladding waterproof layer is arranged on the outer side surface of the pipe gallery prefabricated assembly structure body in a cladding mode. The upper portion of the pipe gallery prefabricated assembly structure body is filled with backfill earth, and the completely outer-cladding waterproof layer is arranged on the outer side surface of an outer side cast-in-situ part of the pipe gallery prefabricated assembly structure body in a cladding mode. The construction method of the overlapping integral type prefabricated assembly structure comprises the steps of prefabricated component machining, foundation pit excavation, bottom plate pouring, side wall construction, mid-partition construction, top plate construction, earth backfilling and the like. According to the overlapping integral type prefabricated assembly structure for the comprehensive pipe gallery and the construction method thereof, the prominent problems of force bearing of joints, water seepage of connection seams and the like in the underground engineering prefabrication process are solved; and the structural modes of bottom plate casting in situ, side wall single-layer overlapping, mid-partition double-layer overlapping, top plate overlapping, all-joint casting in situ and completely outer-side waterproof layer cladding are adopted, so that effective connection and the waterproof function of the joints are ensured.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

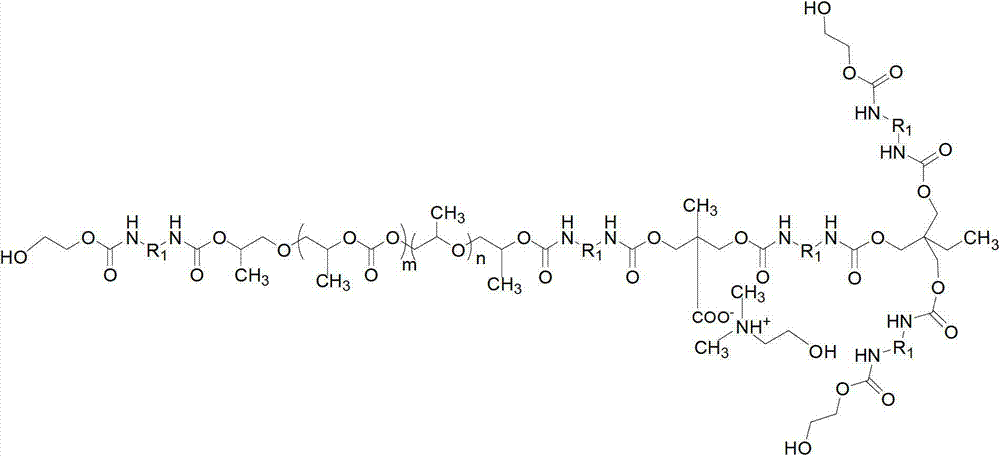

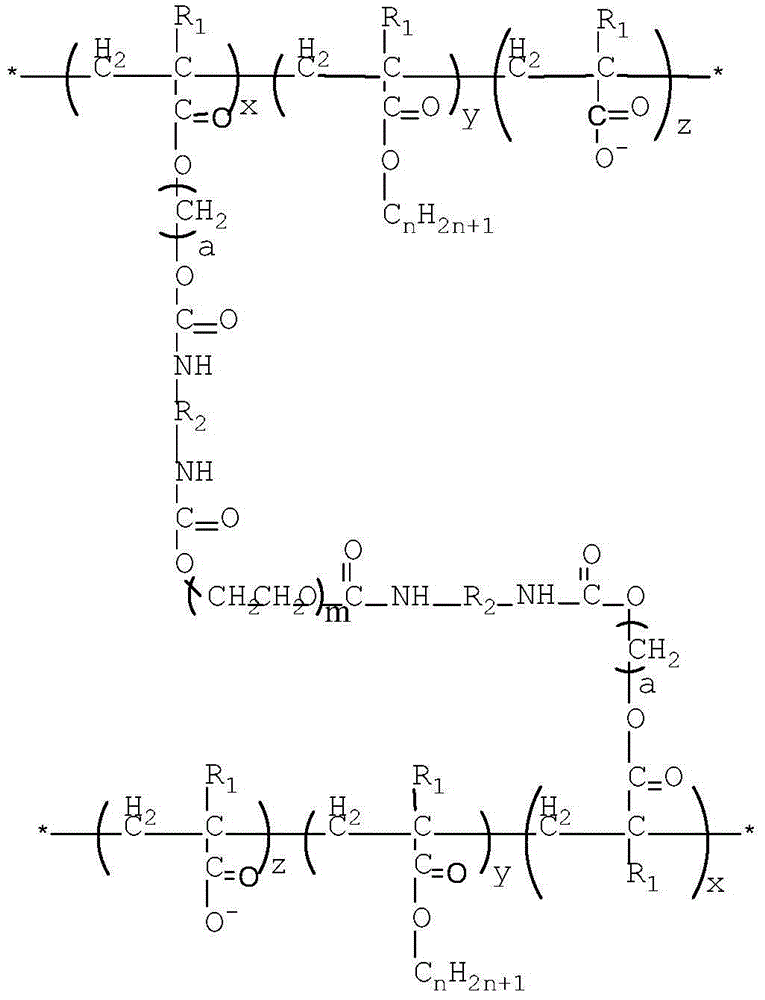

Waterborne polyurethane adhesive and preparation method thereof

ActiveCN103045150AOvercome water resistanceOvercome mechanical propertiesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention provides a waterborne polyurethane adhesive which comprises polyurethane with a structure of a formula (I). The invention also provides a method for preparing the waterborne polyurethane adhesive. The polyurethane provided by the invention is prepared by reacting poly (carbonate ester-ether) with a structure of a formula (II) with trimethylolpropane, diisocyanate, dyhydroxy methyl acrylic acid, ethylene glycol and dimethyl ethanolamine. The poly (carbonate ester-ether) dihydric alcohol has a polyester structure and a polyether structure, the defects that the polyester is poor in water resistance and the polyether is poor in mechanical performance are overcome, a prepared polyurethane main chain is provided with a polyester unit and a polyether unit through a copolymerization reaction, and the adhesion performance is improved.

Owner:吉林天泽二氧化碳科技有限公司

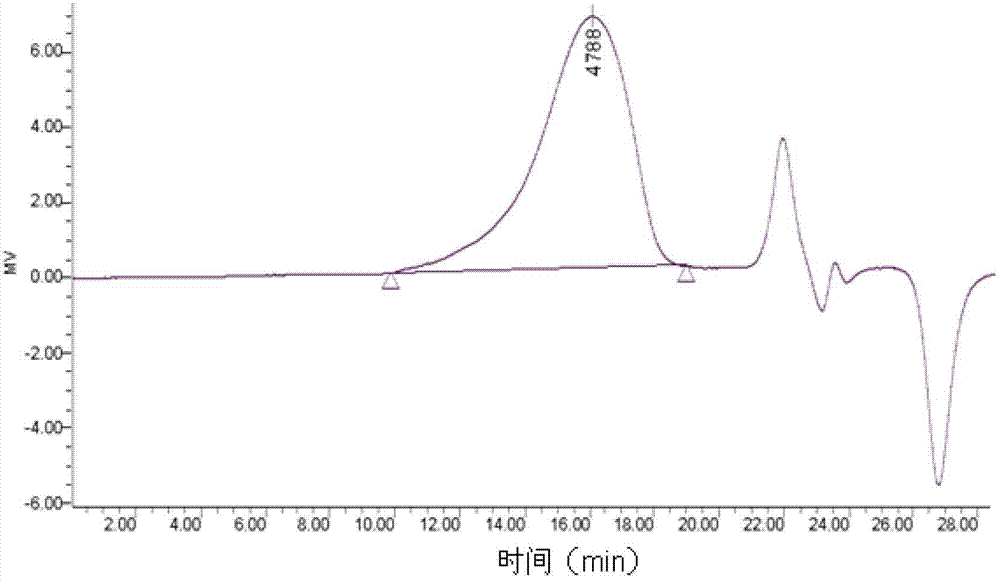

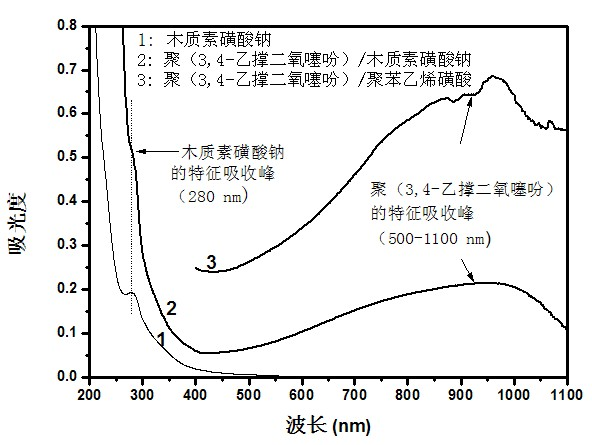

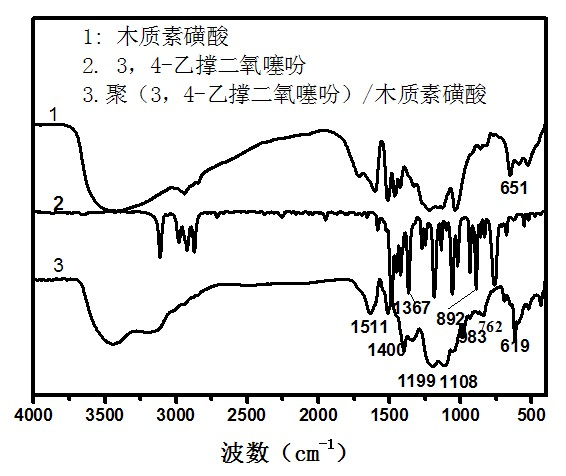

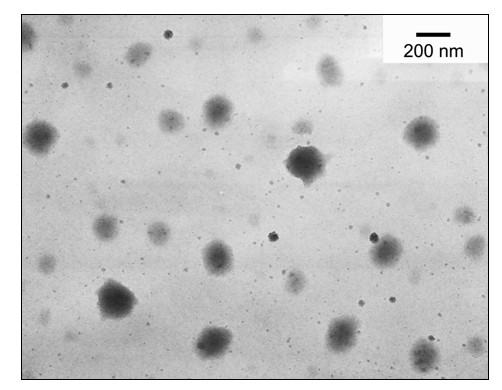

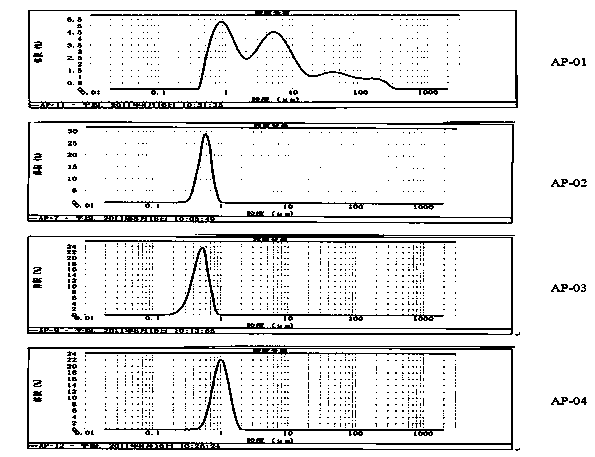

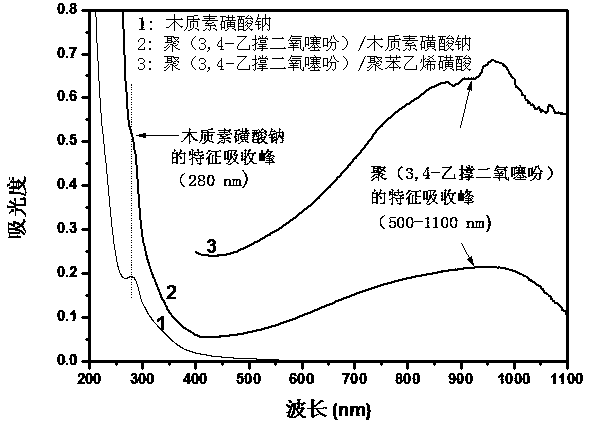

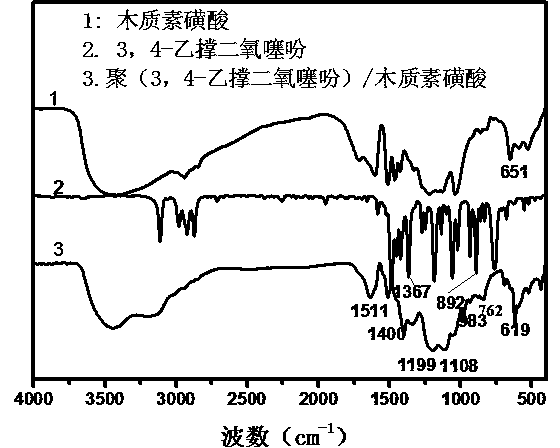

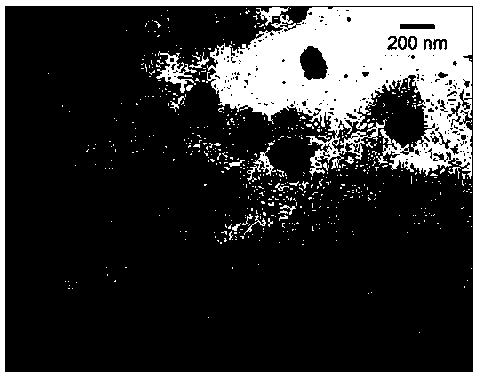

Conductive composition containing poly(3,4-ethylenedioxythiophene)/lignosulfonic acid and preparation method thereof

ActiveCN102516784AIncrease dosageImprove economyLignin material coatingsElectrically-conductive paintsDispersion stabilityAntistatic agent

The invention relates to a conductive composition containing poly(3,4-ethylenedioxythiophene) / lignosulfonic acid and a preparation method thereof. The method comprises the following steps of: chemically oxidizing and polymerizing 100 parts by weight of monomer (3,4-ethylenedioxythiophene) and 170-300 parts by weight of an oxidant in 100-1,000 parts by weight of an aqueous solution in which lignosulfonic acid is taken as a carrier; and adding 200-500 parts by weight of a non-aqueous solvent, 10-100 parts by weight of a polyhydroxy aromatic compound and 50-200 parts by weight of a bonding agent to obtain the conductive composition containing poly(3,4-ethylenedioxythiophene) / lignosulfonic acid. A product prepared with the method meets the requirements of low production cost, transparency, high conducting performance, high adhesion and high hardness in an efficient antistatic agent, and has the characteristics of high dispersion stability, heat stability, temperature stability and water washing resistance. The conductive composition has economic and environmental protection effects as well as a good industrial prospect.

Owner:SOUTH CHINA UNIV OF TECH

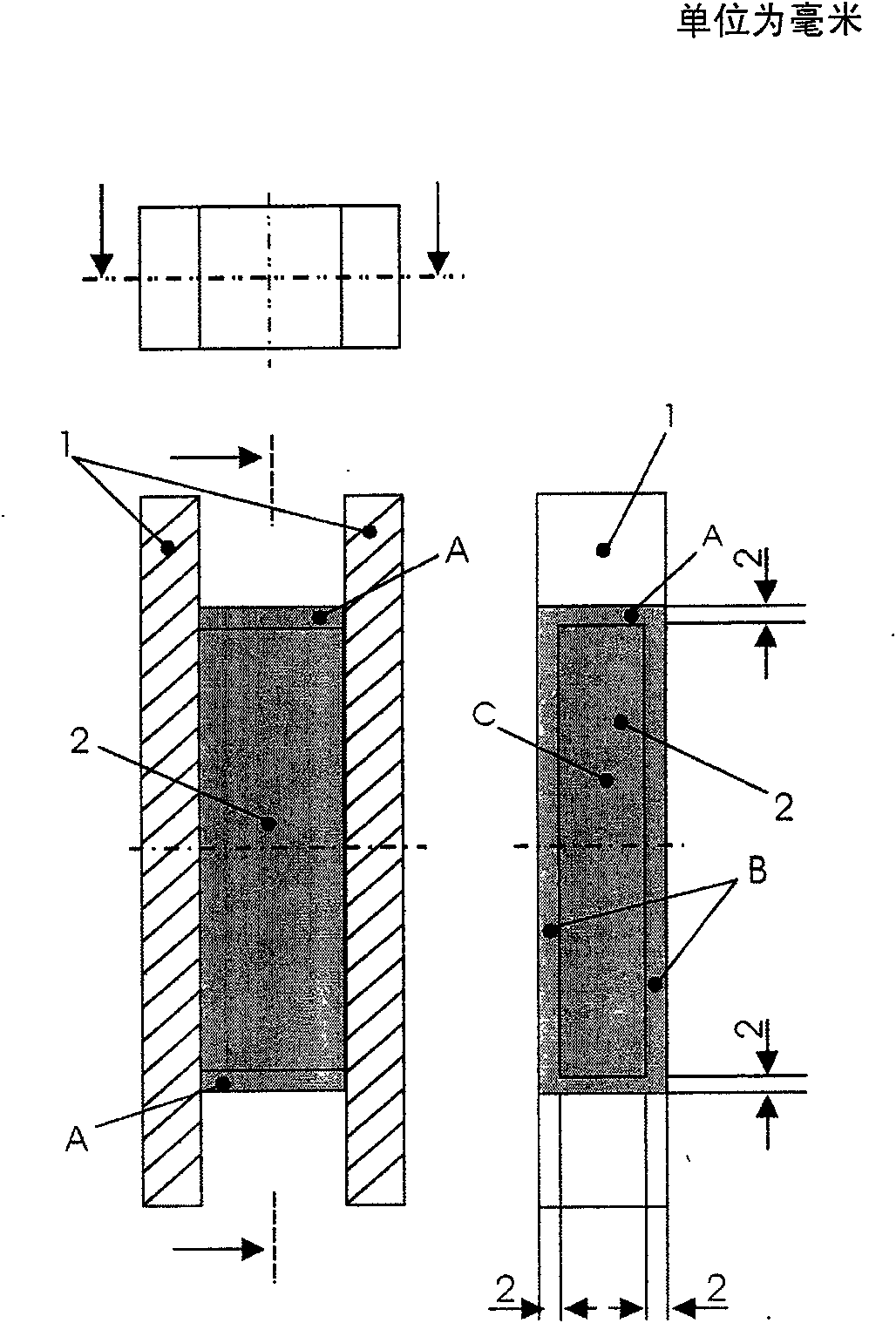

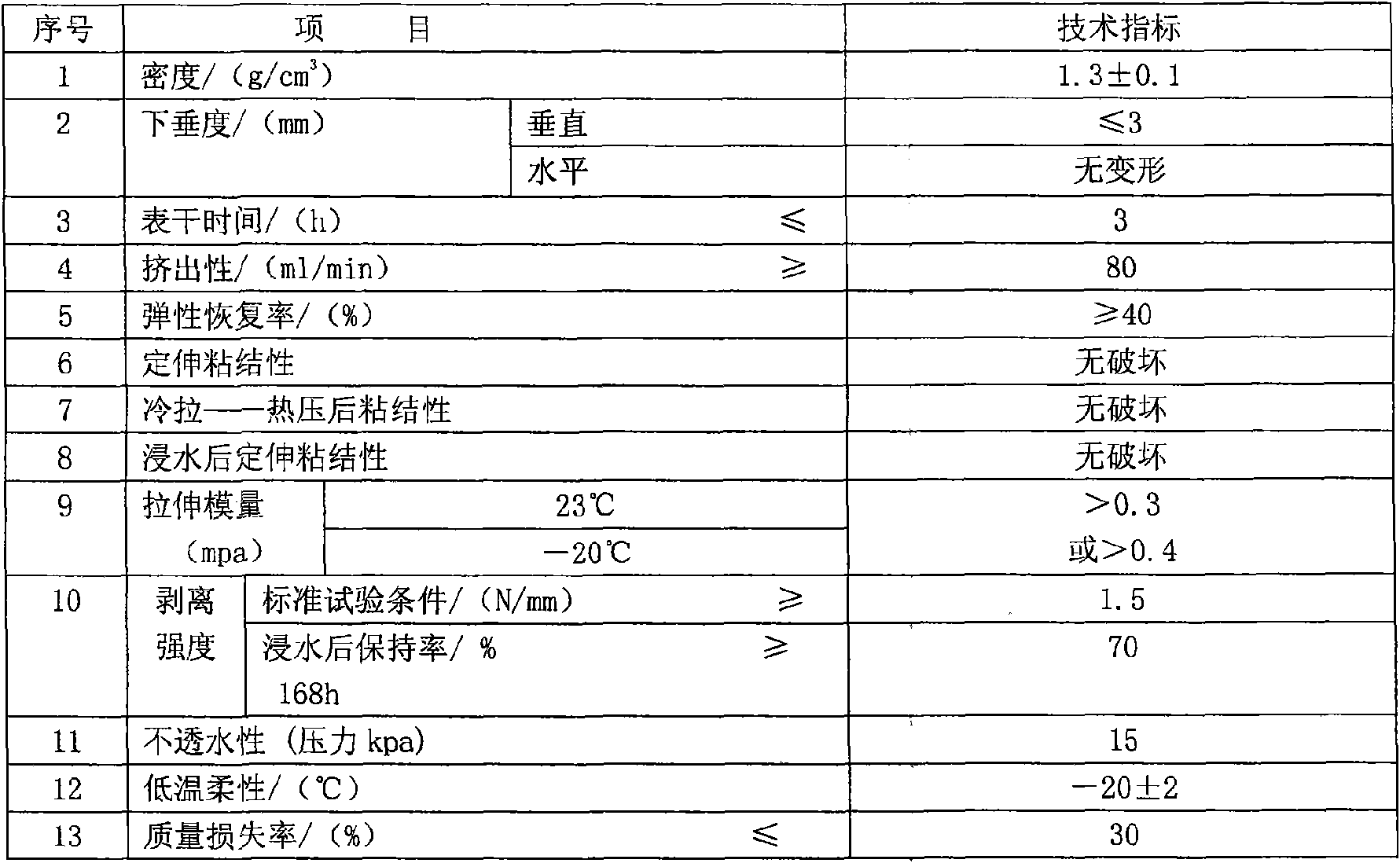

Acrylic ester waterproof gasket cement

InactiveCN101525525AOvercome water resistanceOvercoming AdhesionEster polymer adhesivesEmulsionOrganic solvent

The invention relates to acrylic ester waterproof gasket cement and a preparation method thereof. The acrylic ester waterproof gasket cement includes a technology of environmental-friendly universal glass cement (the patent serial number is 200810083601.8) and comprises the following composition by weight: 30 parts of acrylic ester emulsion, 0.5-3 parts of dispersant, 2-10 parts of silica solution, 0.2-5 parts of coupling agent, 30-80 parts of filling, 0.1-2 parts of pH modifying agent and 0.5-2 parts of coalescing agent. The preparation method of the acrylic ester waterproof gasket cement comprises the following steps: adding one of a plasticizer, the coalescing agent and the coupling agent in a container to be mixed into liquid A, one of the silica solution, the coupling agent is added in another container to be mixed into liquid B, the acrylic ester emulsion is added in the containers, and the dispersant, the liquid A, the liquid B, the filing and the pH modifying agent are added in sequence during stirring the acrylic ester emulsion and the acrylic ester waterproof gasket cement is obtained after the mixture is evenly stirred. The invention overcomes the deficiencies that the aqueous gasket cement is not waterproof and has poor adhesiveness, the solvent-borne type gasket cement has good waterproof performance, but contains over 30 percent of VOC and pollutes the environment seriously, and most of organic solvent belongs to a petrochemical product and causes the waste of energy. The waterproof gasket cement is environmental-friendly and has good waterproof performance and adhesiveness.

Owner:金朝绪

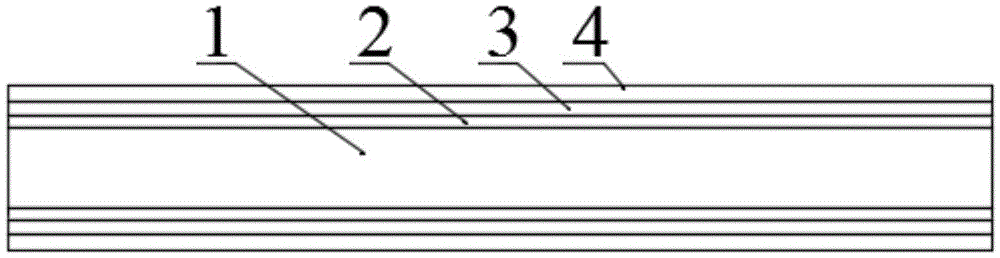

Inorganic composite A-class non-combustible insulation board and preparation method thereof

ActiveCN103276826ASolve thermal insulationSolve fire resistanceHeat proofingFire proofingInsulation systemUltimate tensile strength

The invention discloses an inorganic composite A-class non-combustible insulation board. The insulation board comprises an insulation core material layer. An interface reinforcement layer is arranged on the outer surface and the inner surface of the insulation core material layer respectively, and each of the interface reinforcement layers comprises an alkali resistant screen cloth layer on the inner layer and a polymer water-proof anti-crack mortar layer on the outer layer. Meanwhile, the ratio of components of the insulation core material layer and the polymer water-proof anti-crack mortar layer is disclosed. The invention further discloses a preparation method of the inorganic composite A-class non-combustible insulation board. The inorganic composite A-class non-combustible insulation board has the advantages that both excellent heat insulation performances and good fire-proof performances are provided. The insulation core material layer and the interface reinforcement layers form an organic whole, so that defects of poor water-proof performances and low surface strength of common inorganic insulation boards are overcome. The insulation board can be pasted through polymer mortar directly when being installed on the wall, tedious interface treatment is not required, construction operations are convenient and rapid, and the bonding between the insulation board and a wall base layer is safe and firm. The wire-proof performance reaches the A class, and the whole fire-proof performance of a wall insulation system is greatly improved.

Owner:安徽华举建材科技股份有限公司

Method for constructing large raft foundation under high temperature

ActiveCN103205979AImprove efficiencyOvercome water resistanceProtective foundationPolyvinyl chlorideEngineering

Provided is a method for constructing a large raft foundation under high temperature. The method includes: dividing the raft foundation into a plurality of small blocks to form 'separated cabins'; arranging a groove type construction seam in the middle of the thickness direction of a construction seam of the raft foundation; overlaying a layer of geotechnical cloth on a plain concrete cushion layer; overlaying a layer of polyvinyl chloride (PVC) waterproof roll materials on the geotechnical cloth; smearing a mortar leveling layer on the PVC waterproof roll materials; arranging a rubber waterstop on the construction seam; overlaying a horizontal grouting tube and a vertical grouting tube on the rubber waterstop; after construction of the groove and waterproof design of the construction seam is finished, pouring small blocks of concrete, maintaining for 7 days, and constructing on one side or the periphery of the poured raft foundation with the cabin divided into small blocks in a comprehensively forwarding mode. By means of the method, no seam can be generated, the contradiction on waterproof construction and raft foundation concrete pouring caused by the construction method of 'blocked pouring' which means pouring a block and reserving a block can be overcome, the using efficiency of machines is improved, and the working period is shortened.

Owner:CHINA MCC17 GRP

Graphene-enhanced water-based anti-oxidative heat-resistant coating as well as preparation method and use method thereof

ActiveCN105440939AOvercome water resistanceOvercome CorrosivityPolyester coatingsWater basedOxidation resistant

The invention belongs to surface treatment technologies, and relates to graphene-enhanced water-based anti-oxidative heat resistant coating which is characterized by being a mixture of a film-forming material, graphene dispersion liquid and a filler, wherein the film-forming material is 50 percent of the mixture by weight; the graphene dispersion liquid is 20 to 40 percent of the mixture by weight; the filler is the balance percent of the mixture. The graphene-enhanced water-based anti-oxidative heat resistant coating is prepared according to the following steps: preparation of the graphene dispersion liquid; mixing; grinding. The invention further provides a formula, a preparation method and a use method of the graphene-enhanced water-based anti-oxidative heat resistant coating; the graphene-enhanced water-based anti-oxidative heat resistant coating can solve the problems of poor water resistance and corrosion resistance of the conventional heat resistant coating.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Self-emulsified epoxy curing agent and reinforced varnish, and preparation method of self-emulsified epoxy curing agent and reinforced varnish

InactiveCN106188502AImprove water resistanceStrong adhesionEpoxy resin coatingsGlycidyl ethersRoom temperature

The invention relates to a preparation method of a self-emulsified epoxy curing agent, wherein the preparation method comprises the following steps: a first step, adding an amine component and single epoxy functionality glycidyl ether to a container having nitrogen protection, and carrying out a reaction for 2-8 h at the temperature of 50-105 DEG C, to obtain an end-capped amine epoxy addition product; a second step, dropwise adding epoxy resin into the end-capped amine epoxy addition product, and carrying out a reaction for 1-8 h at the temperature of 20-100 DEG C, to obtain an intermediate product; and a third step, dropwise adding small molecular diglycidyl ether into the intermediate product, and carrying out an addition reaction for 2-8 h at the temperature of 20-100 DEG C, to obtain the self-emulsified epoxy curing agent. The self-emulsified epoxy curing agent has more excellent application period and physical properties, has shorter surface drying time, and can make epoxy resin cured at room temperature to form a hard paint film.

Owner:江苏丰彩建材(集团)有限公司

Self-dispersing UV photo-curing urethane acrylate aqueous copolymer, preparation method of aqueous copolymer and aqueous emulsion prepared from aqueous copolymer

ActiveCN104650311AImprove aging resistanceImprove antioxidant capacityPolyurea/polyurethane coatingsEmulsionUrethane acrylate

The invention belongs to the technical field of aqueous coatings and discloses a self-dispersing UV photo-curing urethane acrylate aqueous copolymer, a preparation method of the aqueous copolymer and an aqueous emulsion prepared from the aqueous copolymer. The preparation method of the self-dispersing UV photo-curing urethane acrylate aqueous copolymer comprises the following steps: (1) preparing a polyurethane prepolymer; (2) preparing an acrylic ester prepolymer solution; and (3) preparing the self-dispersing UV photo-curing urethane acrylate aqueous copolymer. A preparation method of the aqueous emulsion comprises the following steps: adding alkali into the self-dispersing UV photo-curing urethane acrylate aqueous copolymer under the conditions with normal temperature and high-speed dispersion and neutralizing the aqueous copolymer until the aqueous copolymer is neutral, adding deionized water and subsequently dispersing for 15 minutes at a high speed to prepare the aqueous emulsion. The aqueous emulsion can be automatically dispersed in the water in the absence of extra emulgators, so that the reduction of the coating performance caused by the extra emulgators can be avoided.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

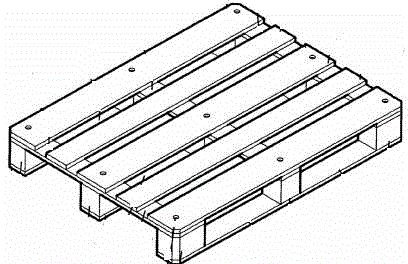

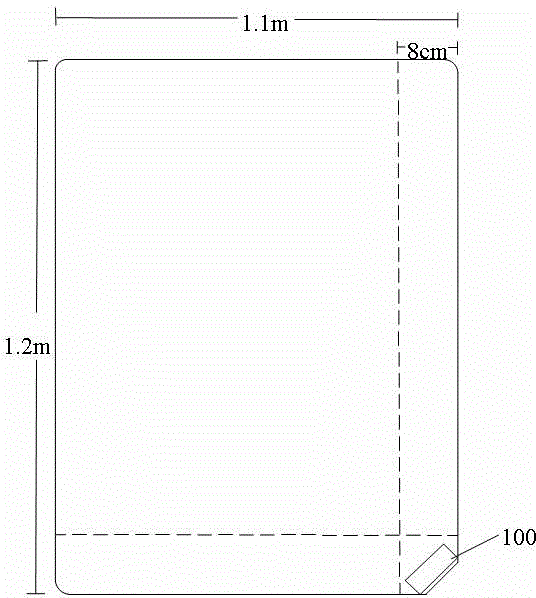

Plastic slip sheet based on RFID and picking-up, placing and information reading method thereof

ActiveCN104129550ATake and place smoothlyHigh tensile strengthContainer decorationsLevel indicationsElectromagnetic interferenceEngineering

The invention discloses a plastic slip sheet based on RFID and a picking-up, placing and information reading method thereof. The plastic slip sheet is a rectangular thin plate made of high density polyethylene materials, and two adjacent side edges of the rectangular thin plate are provided with folded edges respectively. The plastic slip sheet is made of the high polymer materials, has the advantages of being thin, high in tensile strength and free of electromagnetic interference, solves the problems that an existing plastic pallet is thick and heavy and occupies large space, and a paper pallet is not water-proof, and can be widely applied to transfer of various goods. In addition, a special pull-and-push device is designed to match with the plastic slip sheet, and the plastic slip sheet is smoothly picked up and placed, so that a guarantee is provided for application of the plastic slip sheet.

Owner:RICE BRANCH SHENZHEN CEREALS GRP

Water-based printing ink for printing PET (polyethylene terephthalate) films and method for manufacturing water-based printing ink

The invention relates to water-based printing ink for printing PET (polyethylene terephthalate) films. The water-based printing ink comprises, by weight, acrylic hard resin emulsion, acrylic self-crosslinked soft resin emulsion, polyether-modified organic silicon leveling agents, organic siloxane adhesion promoters, organic silicon defoaming agents, polyethylene wax emulsion and water-based color paste. The invention further discloses a method for manufacturing the water-based printing ink. The water-based printing ink and the method have the advantages that the water-based printing ink for printing the PET films is excellent in water resistance and adhesion and free of fading.

Owner:HUIZHOU CITY SHUNFENG PRINTING MATERIAL TECH CO LTD

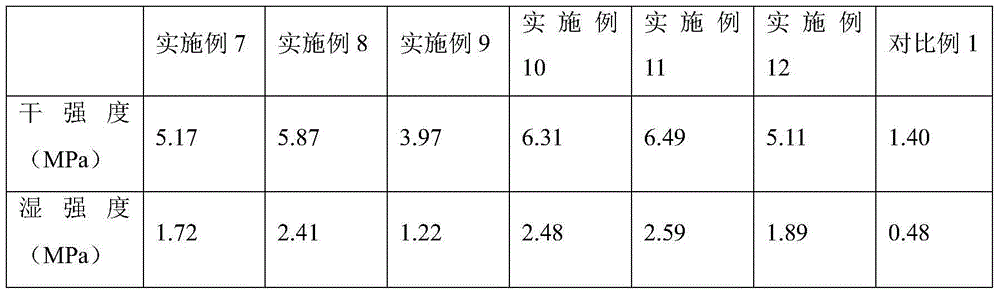

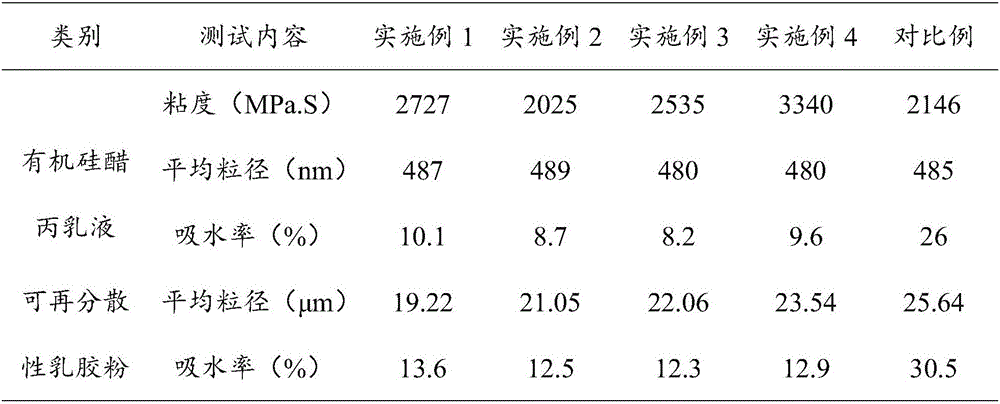

Organosilicon vinyl acetate-acrylic emulsion and preparation method thereof and redispersible emulsion powder prepared from organosilicon vinyl acetate-acrylic emulsion

The invention discloses organosilicon vinyl acetate-acrylic emulsion and a preparation method thereof and redispersible emulsion powder prepared from the organosilicon vinyl acetate-acrylic emulsion. The emulsion is prepared from, by mass, 60-80 parts of vinyl acetate, 12-30 parts of butyl acrylate, 5-15 parts of a functional monomer, 1-6 parts of a crosslinking monomer, 0.2-3 parts of a silane coupling agent, 3-10 parts of protective colloid, 0.2-5 parts of an emulsifying agent, 0.2-0.6 part of a buffering agent, 0.2-0.6 part of a redox initiator and 90-120 parts of water. According to the organosilicon vinyl acetate-acrylic emulsion, by adopting a pre-emulsification method, the emulsion stability is greatly improved, the gelation phenomenon caused by instability of the emulsion in the polymerization process is effectively reduced, and the emulsion preparation success rate is increased; by introducing the crosslinking monomer, the functional monomer and the silane coupling agent into macromolecular chains of a polymer, crosslinking points on the polymer are increased, and a dense three-dimensional net is formed during the film forming process, so that the water resistance is improved, and then the application property of the redispersible emulsion powder in the application fields of building mortar, building waterproof paint and the like is promoted.

Owner:YOUNGWOO CHEMTECH

Acrylic emulsion and preparation method thereof

The invention relates to an acrylic emulsion and a preparation method thereof. The preparation method comprises the following steps: dissolving an alkali-soluble solid acrylic resin and an alkaline substance in water to obtain an alkali-soluble solid acrylic resin solution with the mass concentration of 30%; then adding deionized water, adding a mixed monomer accounting for 5-10% of the total weight in the stirring process, heating to 70 DEG C, adding NaHCO3 and an initiator accounting for 30% of the total weight, and preserving heat at 80-85 DEG C 30-40 minutes; completing dropwise addition of the remaining mixed monomer and the initiator accounting for 60% of the total weight into a reaction kettle within 3-4 hours at 80-85 DEG C; then adding the remaining initiator, and performing a heat preservation reaction at 80-85 DEG C for 1-1.2 hours; naturally cooling to 40-60 DEG C, adjusting the pH to 7-8 by using ammonia water, and filtering to obtain the acrylic emulsion. The obtained acrylic emulsion has relatively high ethanol stability and can overcome the application problems of coating such as poor water resistance and sensitivity to high and low temperatures.

Owner:山西省应用化学研究所(有限公司) +1

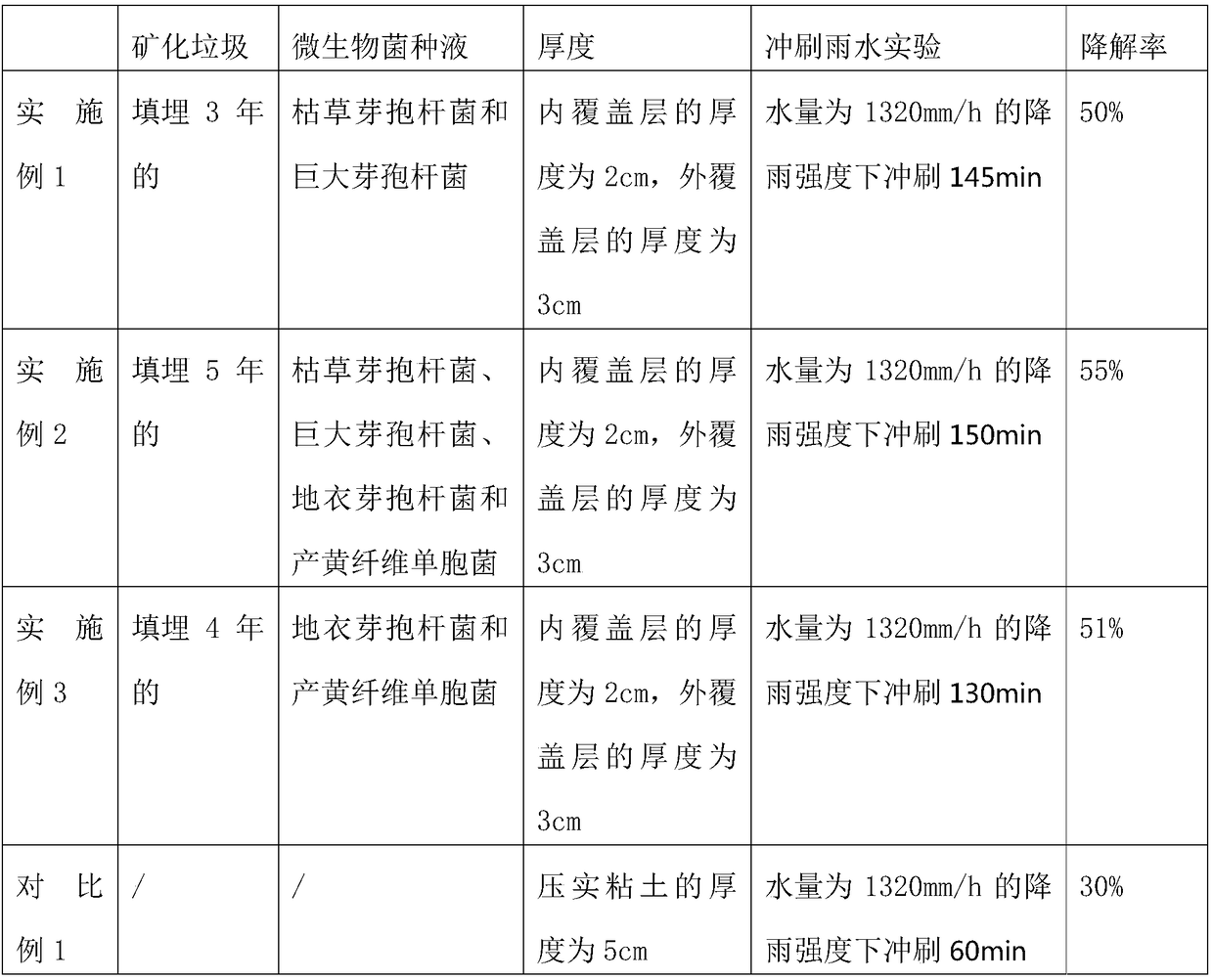

Garbage landfill covering material and preparation method thereof

ActiveCN109465274AImprove CODBig ammonia nitrogenLandfill technologiesSolid waste disposalSodium BentoniteSlag

The invention discloses a garbage landfill covering material in the field of environmental treatment materials, comprising the following raw materials in parts by weight: 50-60 parts of reverse flotation phosphate tailing, 20-30 parts of mineralized garbage, 10-20 parts of modified cement-bentonite material and 3-5 parts of microbial strain liquid, wherein the modified cement-bentonite material iscomposed of four materials: ordinary portland cement, bentonite, blast furnace slag and fly ash, and the mineralized garbage is the mineralized garbage buried in a landfill for 3 years at least, andthe microbial strain liquid is the microbial solution cultured by garbage leachate. In this invention, the reverse flotation phosphate tailing and modified cement-bentonite materials are used as adhesion agents, and are used as waterproof and breathable materials in soilless spraying covering materials; the mineralized garbage is used as a framework while providing microorganisms; after spraying,the covering materials have triple effects of ventilation, waterproof and rain wash resistance; and a core microbial technology for culturing the microbial liquid by adding garbage leachate uniquely and with a rapid degradation effect can effectively deodorize and kill flies for a long time.

Owner:GUIZHOU OURUIXIN ENVIRONMENTAL PROTECTION TECH

Chromium-aluminum tanning agent for tanning leather

InactiveCN104032047AReduce manufacturing costOvercome water resistanceTanning treatmentAluminium hydroxideSodium bisulfate

The invention discloses a chromium-aluminum tanning agent for tanning leather. The chromium-aluminum tanning agent comprises, by mass ratio, 19.8 parts of sodium chromate, 19.8 parts of aluminum hydroxide, one part of sodium hydroxide, 45 parts to 55 parts of sulfuric acid, 8.1 parts to 10 parts of sulfur dioxide, 1.6 parts of sodium sulfate, one part of sodium carboxymethylcellulose, one part of sodium bisulfate, 0.3 part to 0.5 part of silicon dioxide, 0.6 part of ammonium persulfate and 110 parts of water. The chromium-aluminum tanning agent for tanning leather has the advantages that leather made through the agent can overcome the defects that a single metal aluminum tanning agent is not resistant to water and a single metal chrome tanning agent is dark in hue; leather made though the agent has the advantages of being high in water resistance, high in tension resistance, high in wear resistance and heat resistance, soft in hand feeling and the like; the agent is mainly used for tanning light leather, and can make leather light and thin in quality and make leather surface fine and plump.

Owner:杨帆

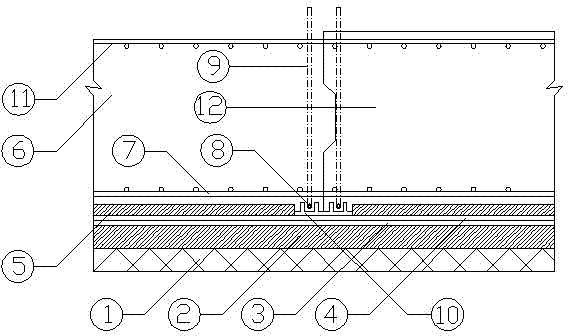

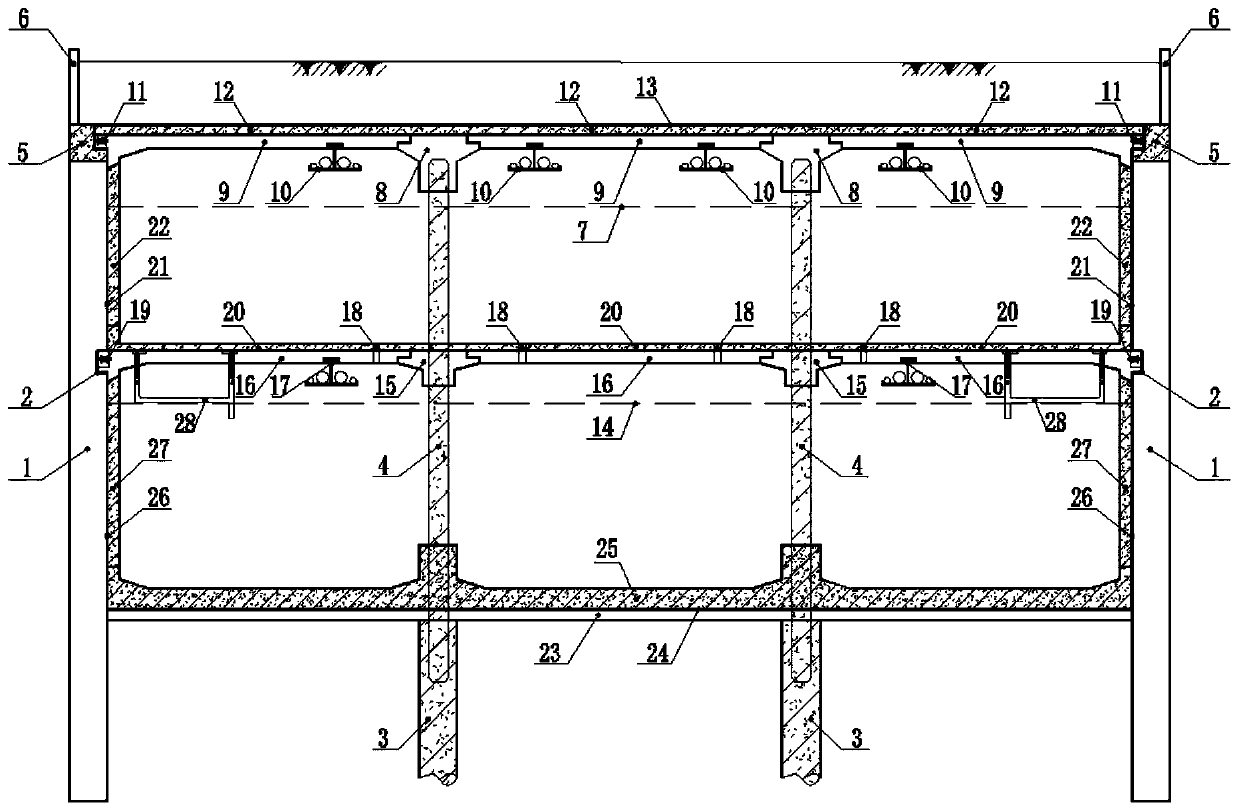

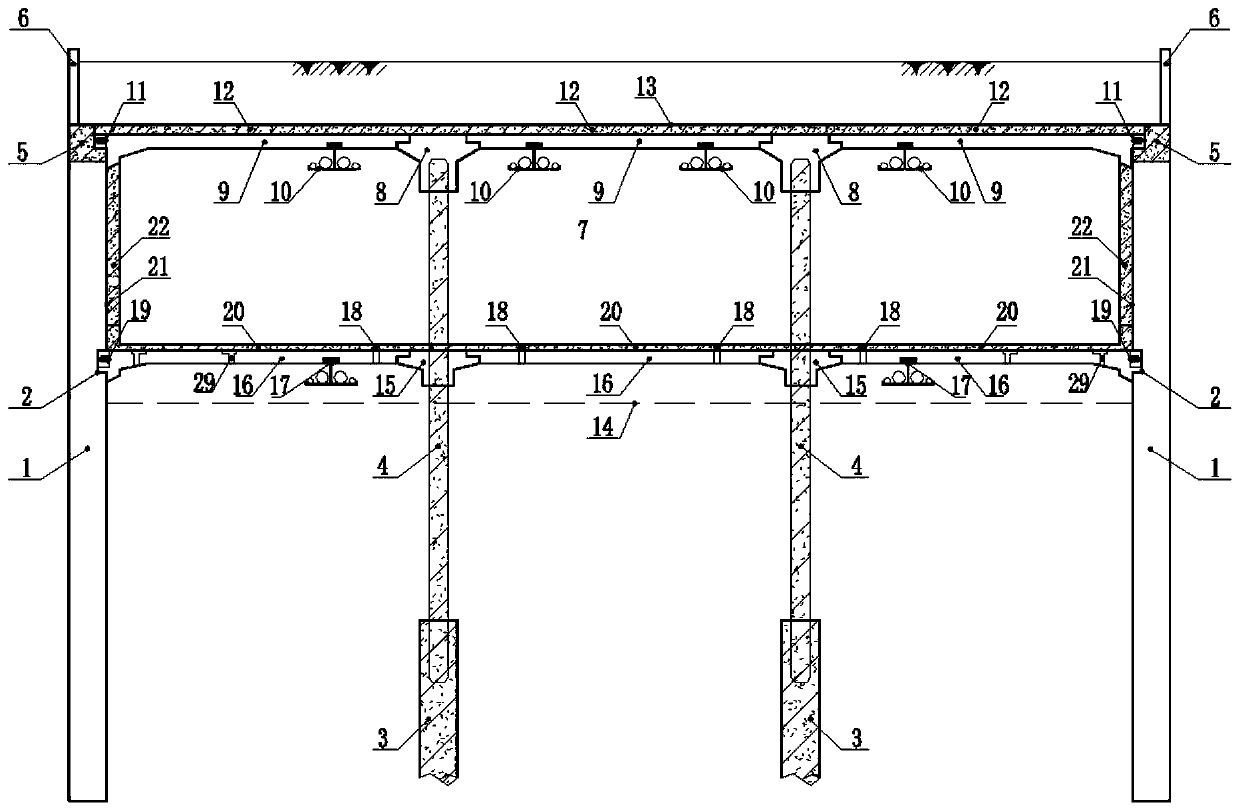

Composite fabricated underground structure and reverse construction method thereof

PendingCN110004981AQuality improvementImprove qualityArtificial islandsProtective foundationWater leakagePre stress

The invention discloses a composite fabricated underground structure. The composite fabricated underground structure comprises underground walls, steel structure clamping grooves, prestressed jacks, and main structure standing columns; prefabricated top longitudinal beams, prefabricated top plates, top plate cast-in-place layers, and top plate waterproof layers jointly form composite waterproof prestressed top plates; prefabricated middle longitudinal beams, prefabricated middle plates, and middle plate cast-in-place layers jointly form composite middle plates; prefabricated cushion layers, bottom plate waterproof layers and cast-in-place bottom plates jointly form composite waterproof bottom plates; the underground walls, side wall waterproof layers, and side wall cast-in-place layers jointly form composite waterproof walls; the composite waterproof prestressed top plates, the composite prestressed middle plates, the composite waterproof bottom plates and the composite waterproof walls are all effectively connected, and the full-package waterproof full-composite fabricated underground structure is formed; thus the problem of water leakage of the fully fabricated underground structure is solved, the limitation of the application range of the fabricated underground structure is broken, the composite fabricated underground structure can be applied to the areas with water-rich stratums, complicated surrounding environment and high deformation control, and the extensive application of the prefabricated structure in underground engineering can be effectively promoted.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

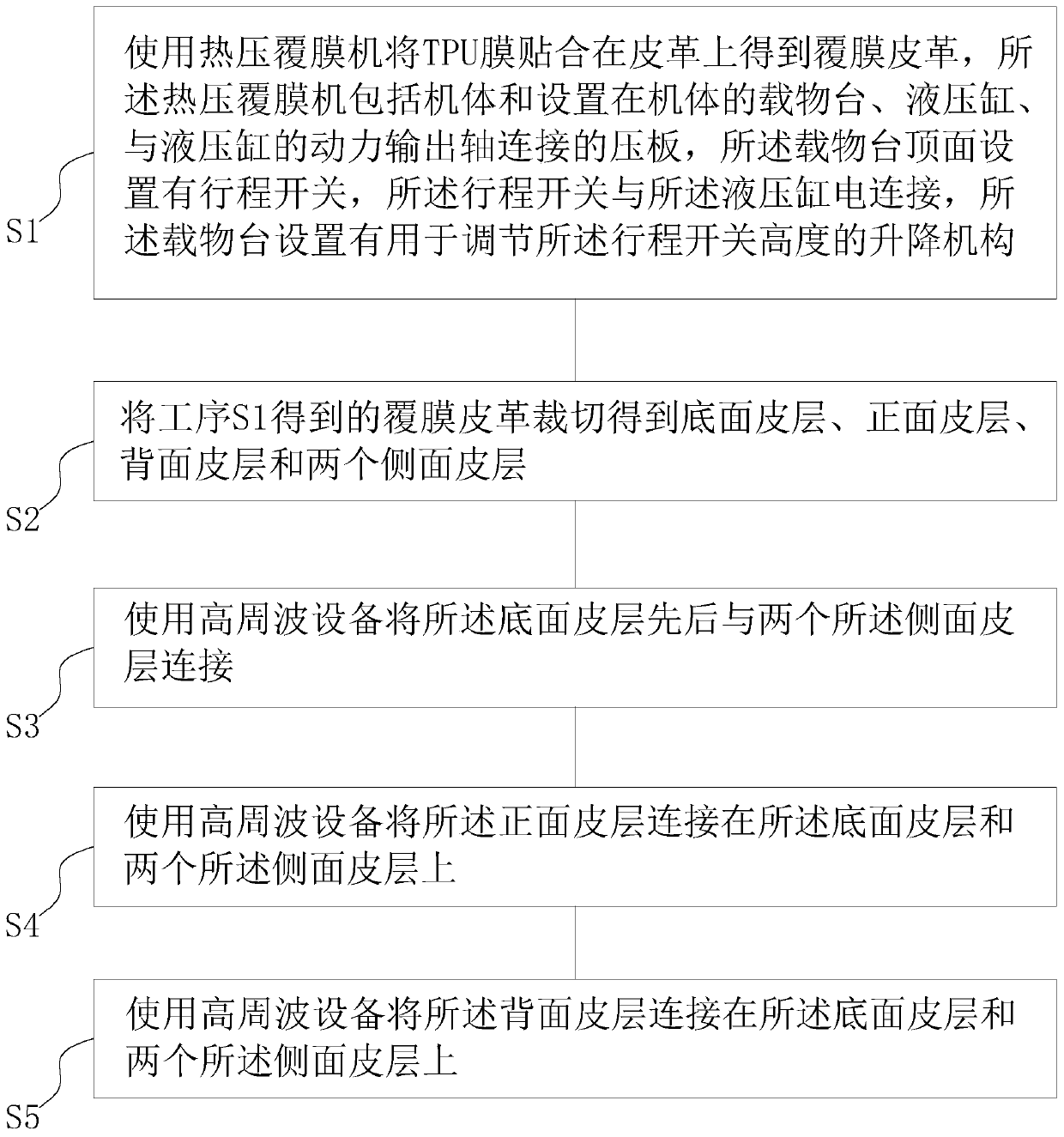

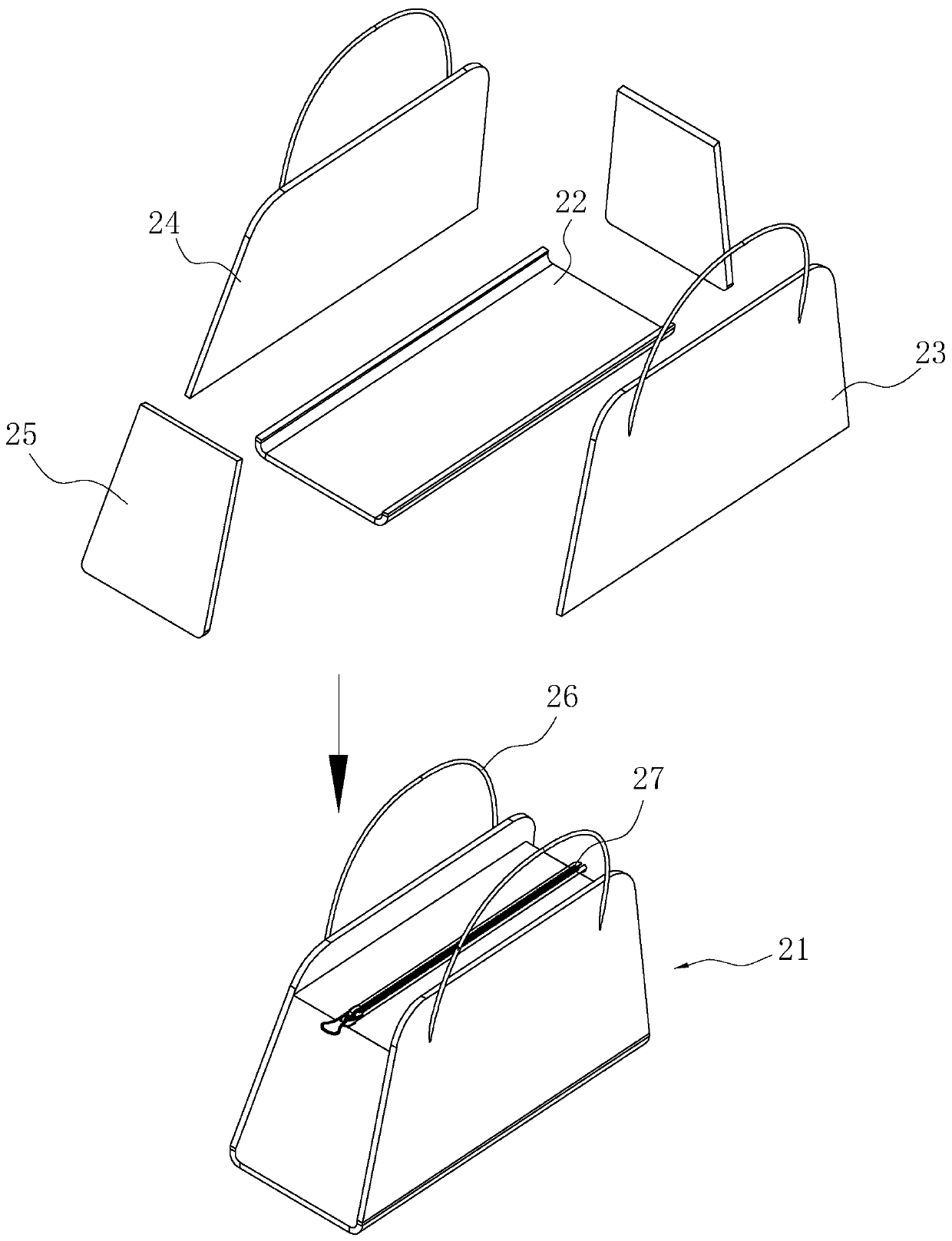

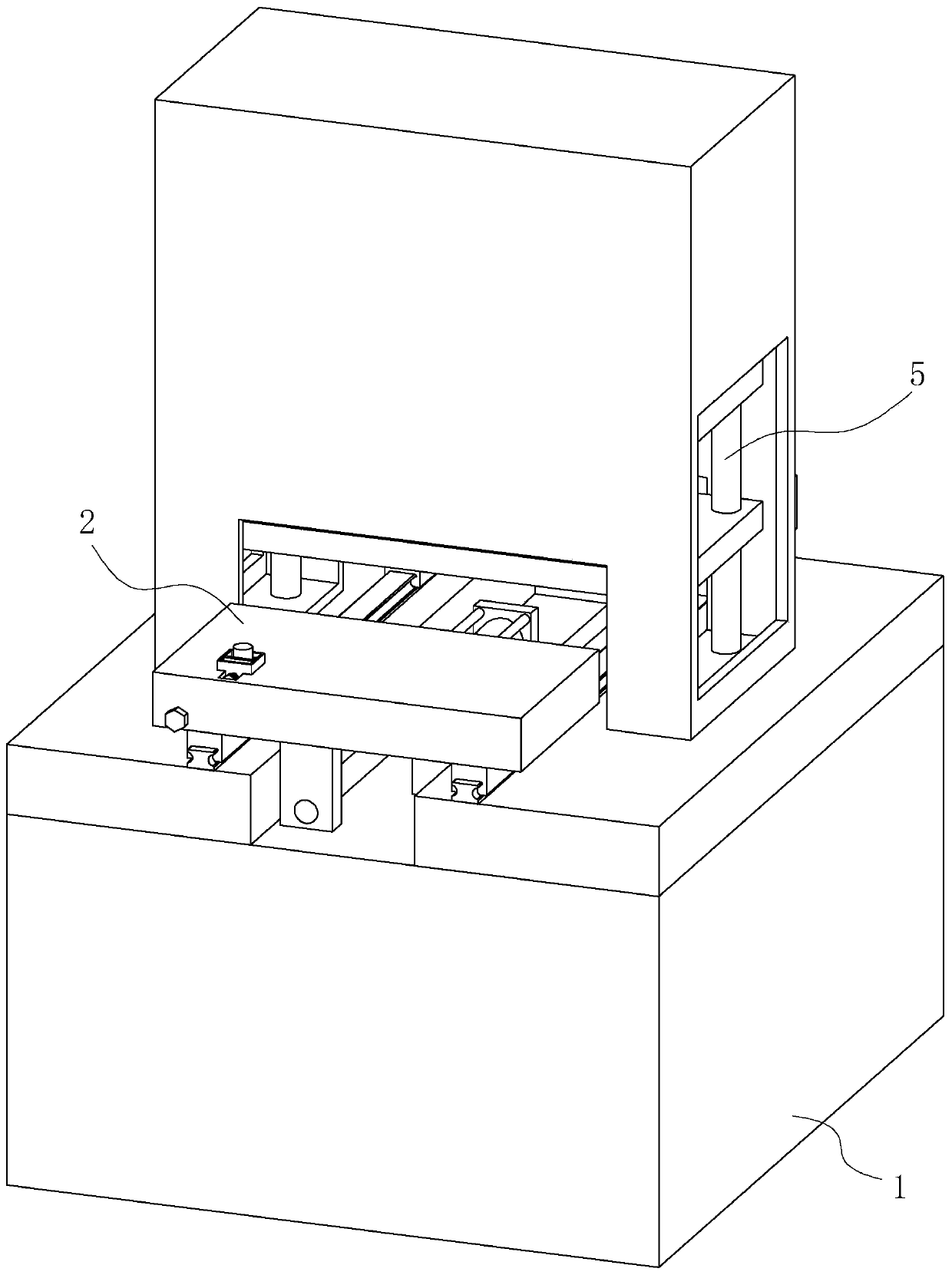

Leather bag processing technology and leather bag processed through technology

InactiveCN110123002AOvercome water resistanceOvercome wear resistanceSynthetic resin layered productsHandbagsHydraulic cylinderEngineering

The invention relates to a leather bag processing technology. The technology comprises the following steps that S1, a TPU film is attached to leather by using a hot-pressing film laminating machine toobtain the coated leather, wherein the hot-pressure laminating machine comprises a machine body, a carrying table arranged on the machine body, a hydraulic cylinder and a pressing plate connected with a power output shaft of the hydraulic cylinder, a travel switch is arranged on the top surface of the carrying table, the travel switch is electrically connected with the hydraulic cylinder, and thecarrying table is provided with a lifting mechanism used for adjusting the height of the travel switch; S2, the coated leather obtained in S1 is cut to obtain a bottom leather layer, a front leatherlayer, a back leather layer and two side leather layers; S3, the bottom leather layer is sequentially connected with the two side leather layers by using high-frequency equipment; S4, the high-frequency equipment is used for making the front leather layer connected to the bottom leather layer and the two side leather layers; S5,the back leather layer is connected to the bottom leather layer and the two side leather layers by using high-frequency equipment. Meanwhile, the invention provides a leather bag processed through the technology. The leather bag has the advantage of improving the strength and attractiveness.

Owner:上海全邯电子科技有限公司

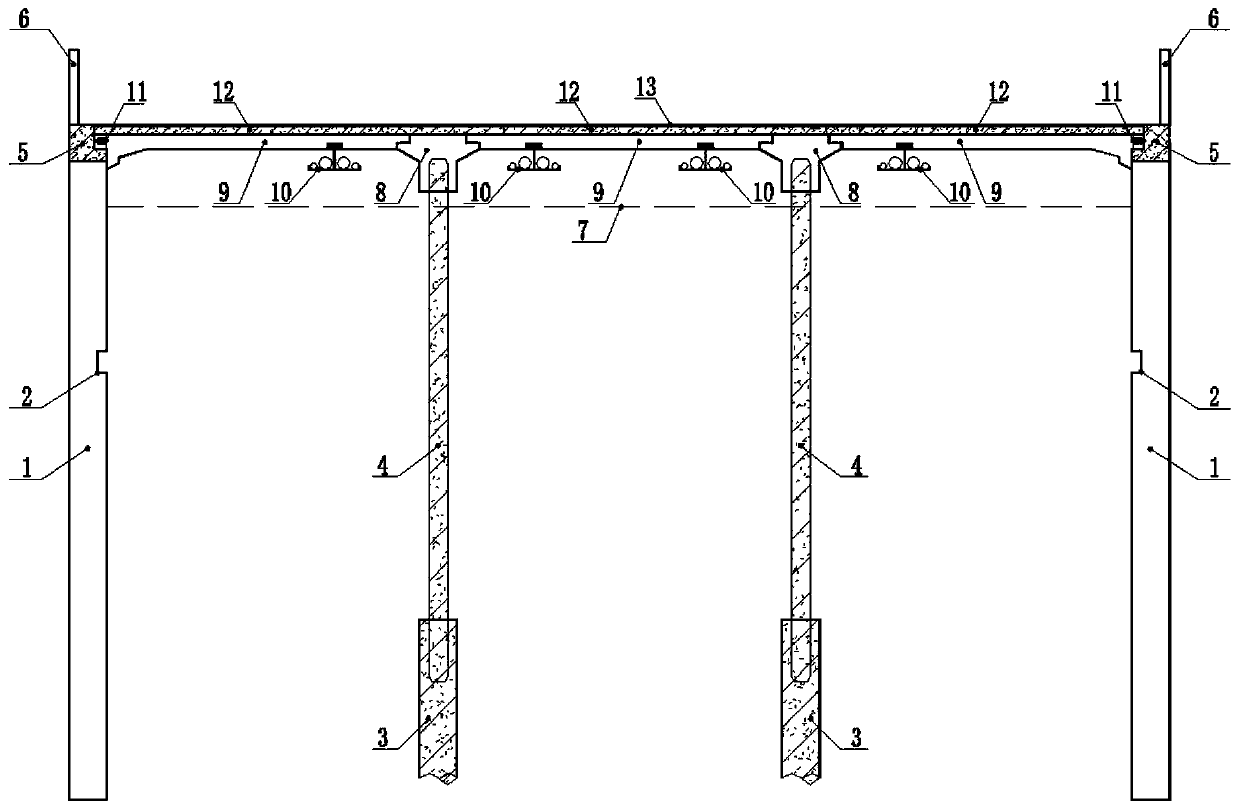

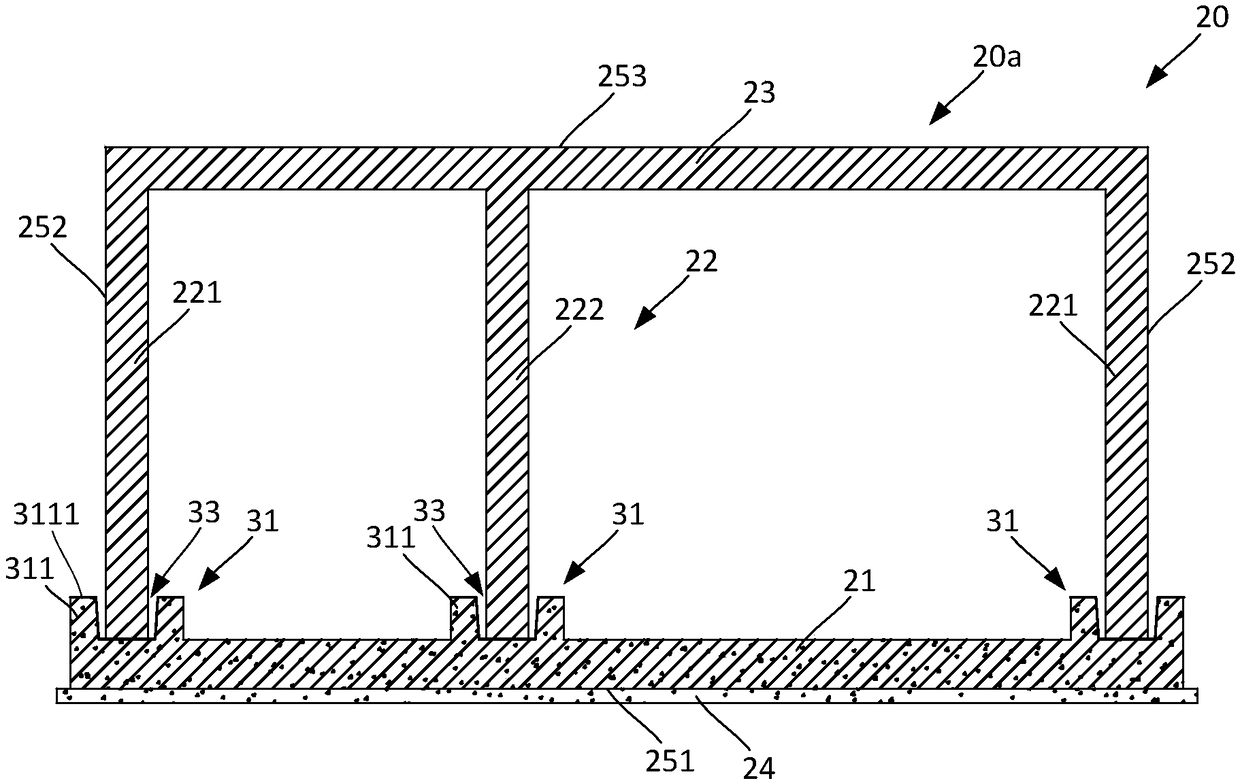

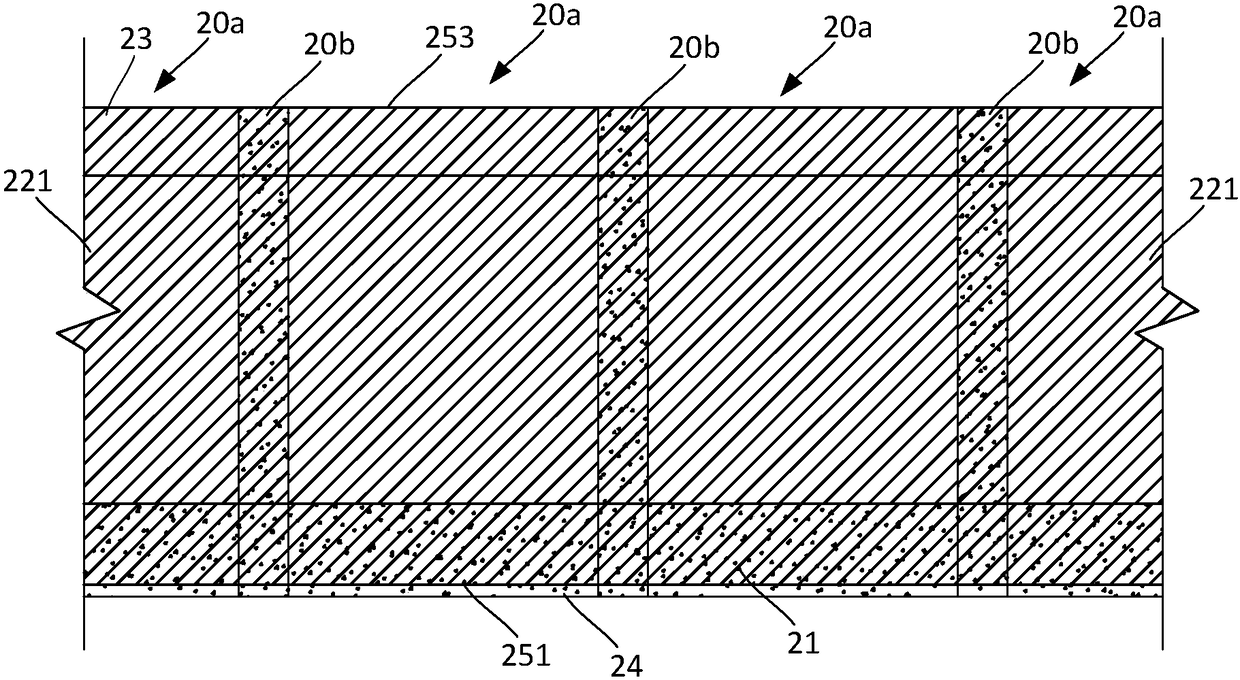

Semi-prefabricated comprehensive pipe rack and construction method thereof

PendingCN108560586AOvercome costsOvercome water resistanceArtificial islandsProtective foundationAsphalt masticRebar

The invention relates to a semi-prefabricated comprehensive pipe rack and a method. The comprehensive pipe rack comprises a cast-in-situ bottom plate, prefabricated pipe rack segments, asphalt masticlayers and waterproof concrete structures, annular grooves are formed in the bottom plate and corresponds to wall plates, each prefabricated pipe rack segment comprises an integrally formed top plateand a plurality of wall plates vertically connected with the top plate, the wall plates are inserted into the corresponding annular grooves, two adjacent pipe rack segments are fixedly connected by acast-in-situ connection section, the annular grooves are filled with the asphalt mastic layers, a set distance is reserved between the top of each asphalt mastic layer and a notch of each annular groove, the waterproof concrete structures are poured in the annular grooves and positioned on the asphalt mastic layers, and the notches of the annular grooves are sealed by the waterproof concrete structures. The cast-in-situ bottom plate is connected with the prefabricated wall plates by cup groove joint structures, reinforcement lapping and binding construction of prefabricated parts and cast-in-situ parts are avoided, construction is simple, and construction efficiency is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

High strength flame retardant waterproof nylon pipe

The invention discloses a high strength flame retardant waterproof nylon pipe, which comprises the following raw materials: nylon 12, nylon 66, polyphenyl ether, polylactic acid, epoxy resin, ethylene-acrylate-maleic anhydride terpolymer, nano calcium carbonate, nano zinc oxide, nano titanium dioxide, talcum powder, boron nitride, nano montmorillonite, modified carbon nanotube, magnesium borate whisker, calcium chloride, basalt fiber powder, ethylene bisstearamide, silane coupling agent, tri(2,4-di-tert-butylphenyl)phosphite, fire retardant, and succinylated monoglyceride, wherein the fire retardant comprises the following raw materials: brominated polystyrene, hydrotalcite, melamine cyanurate, melamine polyphosphate, polyurethane, magnesium hydroxide, phenolic resin, and bis(4-carboxyphenyl)phenyl phosphine oxide. The provided high strength flame retardant waterproof nylon pipe has the advantages of high strength, good heatproof and flame retardant properties, and excellent waterproof performance.

Owner:安徽都邦电器有限公司

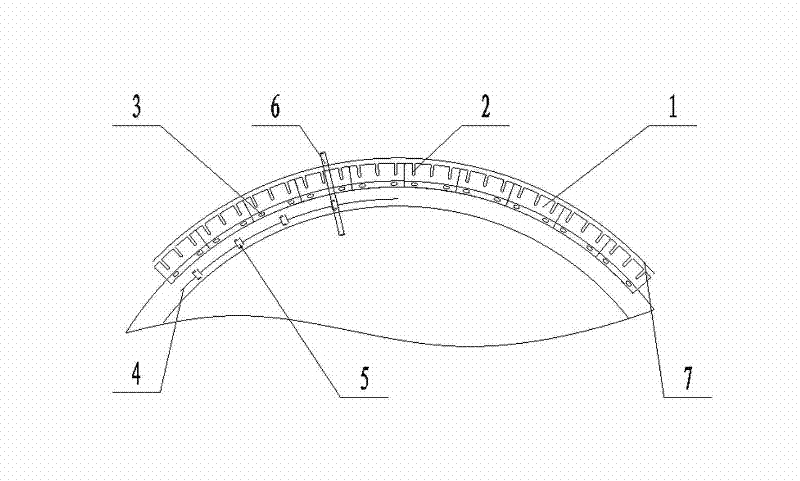

Secondary lining split mounting type blocking head device for metro underground excavation tunnel

ActiveCN102444408AReasonable and reliable structural designOvercoming the easy disconnection of steel barsUnderground chambersTunnel liningRebarSpot welding

The invention particularly relates to a secondary lining split mounting type blocking head device for a metro underground excavation tunnel, which resolves the problems that due to an unreasonable structure of an existing secondary lining blocking head device, reinforced steel bar at construction joints is prone to be broken and waterproof materials cannot be installed in the right positions. The secondary lining split mounting type blocking head device comprises an arc blocking head steel plate which is formed of a plurality of steel plate base bodies, wherein a longitudinal reinforced steel bar clamp groove is arranged at the outer arc edge of each steel plate base body, a key groove shaped bolt hole is arranged on one side of the inner arc of each steel plate base body, a bolt is screwed in the bolt hole, the inner side of the blocking head base body is provided with an arc reinforced steel bar fixed with the section of a secondary lining trolley, radially arranged reinforced sleeves are evenly distributed and fixed on the reinforced steel bar, reinforced steel tubes are arranged in the reinforced sleeves, wood wedges are plugged between the reinforced steel tubes and the blocking head steel plates, and a galvanized water stopping steel plate is welded on an outer arc end face of the blocking head steel plate in point mode. The secondary lining split mounting type blocking head device is reasonable in structural design, can buffer force deformation, is supported and fixed by the reinforced steel tubes, is good in waterproof effect, and has the advantages of being simple in process, convenient in operation and capable of saving cost.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Lightweight and sun-proof heat insulation board for decorating

InactiveCN106739256AImprove fire performanceSolve thermal insulationCovering/liningsCoatingsPolymer scienceCrack resistance

The invention discloses a lightweight and sun-proof heat insulation board for decorating. The lightweight and sun-proof heat insulation board for decorating comprises a core material, and woven fabric surfaces which are arranged on two surfaces of the core material, wherein a polymer mortar layer is arranged on the outer surface of each woven fabric surface; the polymer mortar layers are prepared through the following mortar in parts by weight: 200 to 250 parts of cement, 500 to 550 parts of glass beads, 50 to 80 parts of heavy calcium carbonate powder, 20 to 30 parts of redispersible emulsion powder, 2 to 4 parts of water-retaining agent, 0.5 to 1 part of antifoaming agent, 1 to 2 parts of polypropylene fiber, 2 to 3 parts of water repellent, and 200 to 250 parts of water; the core material is a waterproof rock wool heat insulation board. The lightweight and sun-proof heat insulation board for decorating has the beneficial effects that the heat preservation and insulation performances are outstanding; the fireproofing performance is high; the woven fabric surfaces enable the impact resistance, the fireproofing and anti-penetrability performances and the cracking resistance of the core material, so that the defects that general inorganic heat insulation boards are poor in waterproofing performance and low in surface intensity can be overcome.

Owner:重庆市巴南区添福装饰工程有限公司

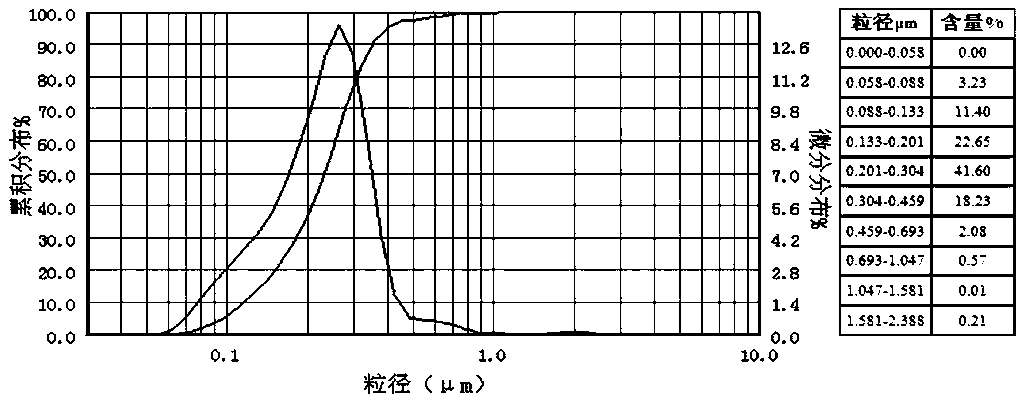

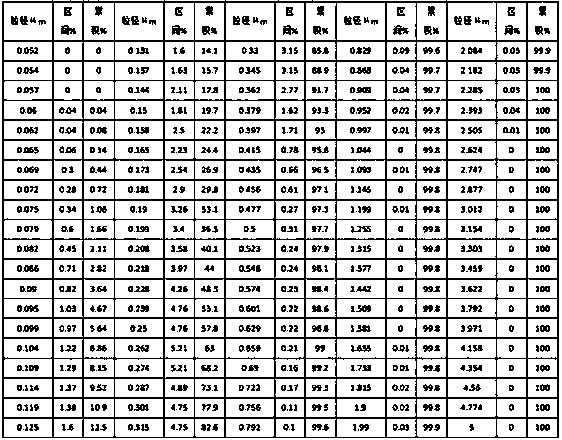

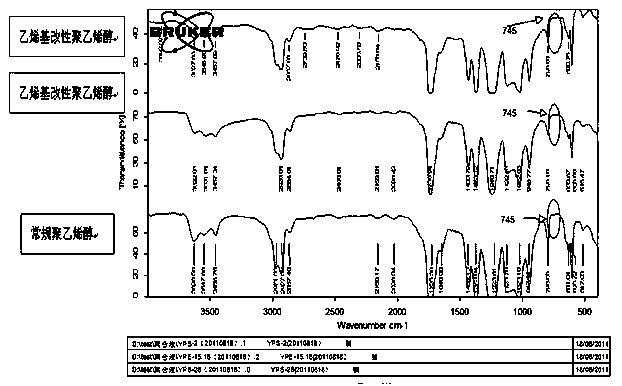

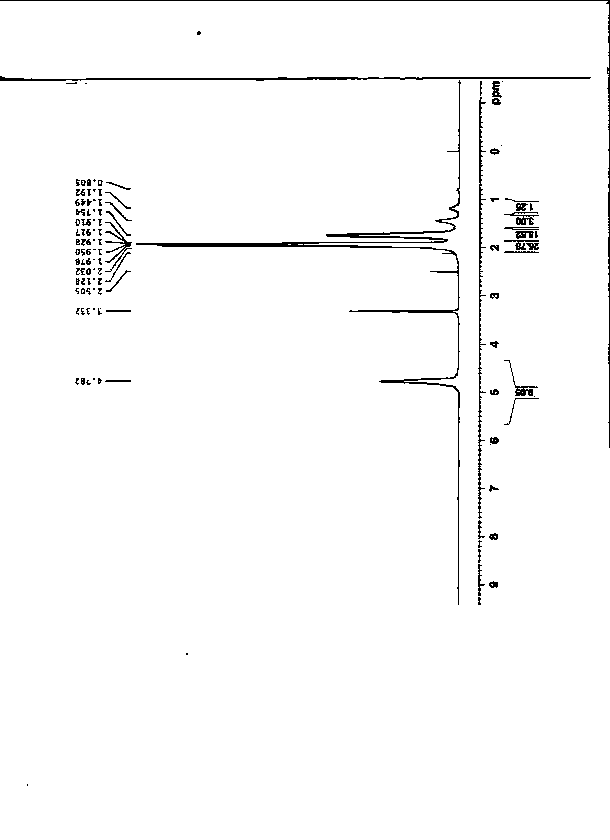

Preparation method for vinyl modified polyvinyl alcohol

The invention relates to a preparation method for vinyl modified polyvinyl alcohol. With 82-88 parts of water, 0.02-0.08 part of a reducing agent, 0.2-0.6 part of an emulsifier, 10-40 parts of a vinyl acetate monomer, 0.045-0.065 part of an oxidizing agent and vinyl monomer as raw materials, the vinyl modified polyvinyl alcohol is prepared by the steps of initial charging, replacement in kettle, polymerization reaction, demulsification purification and saponification. Specifically, the dosage of the vinyl monomer is calculated according to a dosage needed by an introduction reaction time of 3.5-4.5h when introducing the vinyl monomer into the kettle with an internal pressure of 3-20bar. The emulsifier is reactive sulfonate. The prepared vinyl modified polyvinyl alcohol is applied as a polymerization additive into emulsion polymerization, overcomes the disadvantages of poor water resistance, unstable polymerization system and the like in conventional PVA (polyvinyl alcohol), and has significantly enhanced water resistance. With good water solubility, the vinyl modified polyvinyl alcohol can fully satisfy the requirements of being used as a polymerization additive. At the same time, when the vinyl modified polyvinyl alcohol is used as a polymerization additive, the polymerization system has excellent stability, and the particle size distribution is improved significantly.

Owner:CHINA PETROCHEMICAL CORP +1

Conductive composition containing poly(3,4-ethylenedioxythiophene)/lignosulfonic acid and preparation method thereof

ActiveCN102516784BIncrease humidityOvercome stabilityLignin material coatingsElectrically-conductive paintsDispersion stabilityAntistatic agent

Owner:SOUTH CHINA UNIV OF TECH

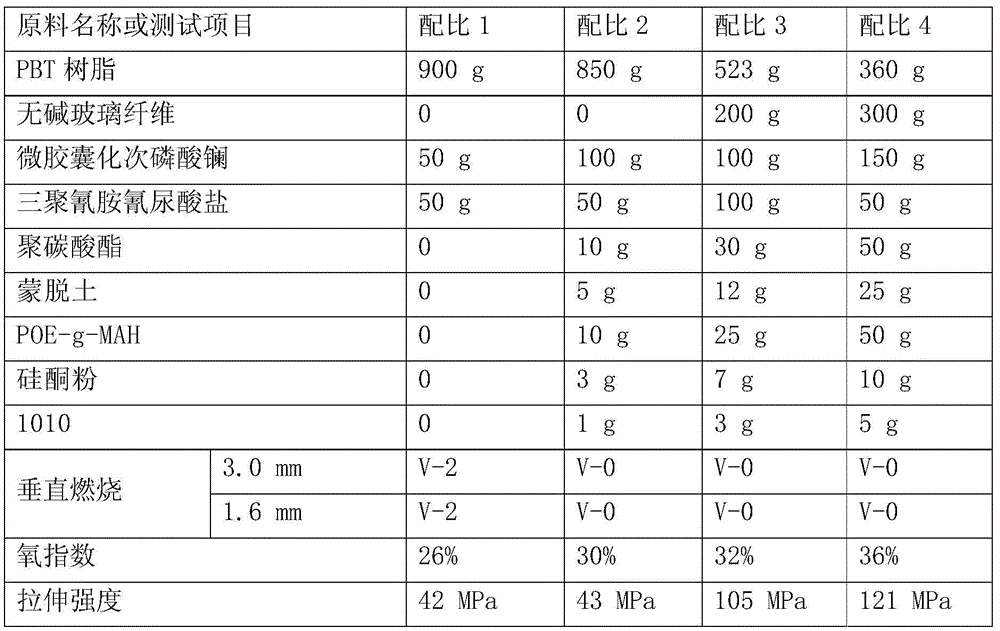

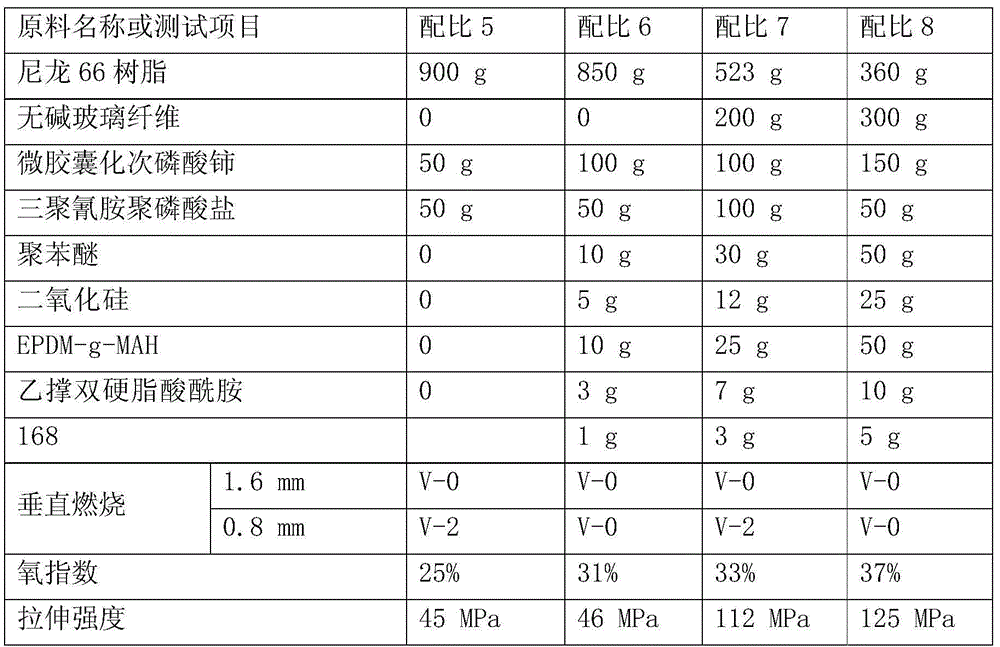

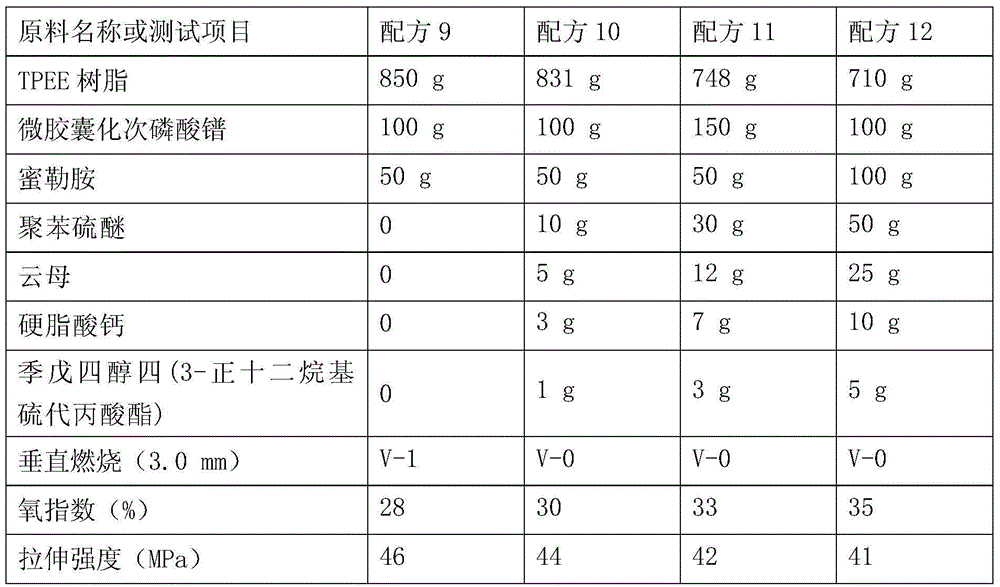

Polymer material containing microencapsulated rare earth metal hypophosphite, and preparation method thereof

InactiveCN104910591AOvercoming poor physical propertiesOvercoming weather resistancePolymer scienceAntioxidant

The invention discloses a polymer material containing microencapsulated rare earth metal hypophosphite, and a preparation method thereof. According to the percentages in the total mass of the composite material, 30-90% of a polymer material, 5-15% of microencapsulated rare earth metal hypophosphite, 5-10% of a nitrogen-series flame retardant, 0-30% of an enhancing agent, 0-6% of a char-forming agent, 0-2.5% of a nano-grade synergist, 0-5% of a compatibilizing agent, 0-1% of a lubricant, and 0-0.5% of an antioxidant are well mixed; the mixture is heated to a temperature of 120-265 DEG C; melt blending, extrusion, drawing, cooling, pelletizing and bake-drying are carried out, such that the polymer material provided by the invention is obtained. The polymer material provided by the invention has good flame retardant property, good mechanical performances, good water precipitation resistance and good weather resistance. With the preparation method, defects of high halogen flame retardant environmental hazard, high inorganic flame retardant addition amount, poor thermal stability, poor water resistance and the like of traditional polymer flame-retardant modification technologies are overcome. The method and the material have good application prospect.

Owner:合肥安聚达新材料科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com