Patents

Literature

364 results about "Magnesium borate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium borate. 3MgO·B2O3 Crystals that are white or colorless and transparent; soluble in alcohol and acids, slightly soluble in water; used as a fungicide, antiseptic, and preservative.

Magnesium borate whisker hydrothermal synthesis preparation method

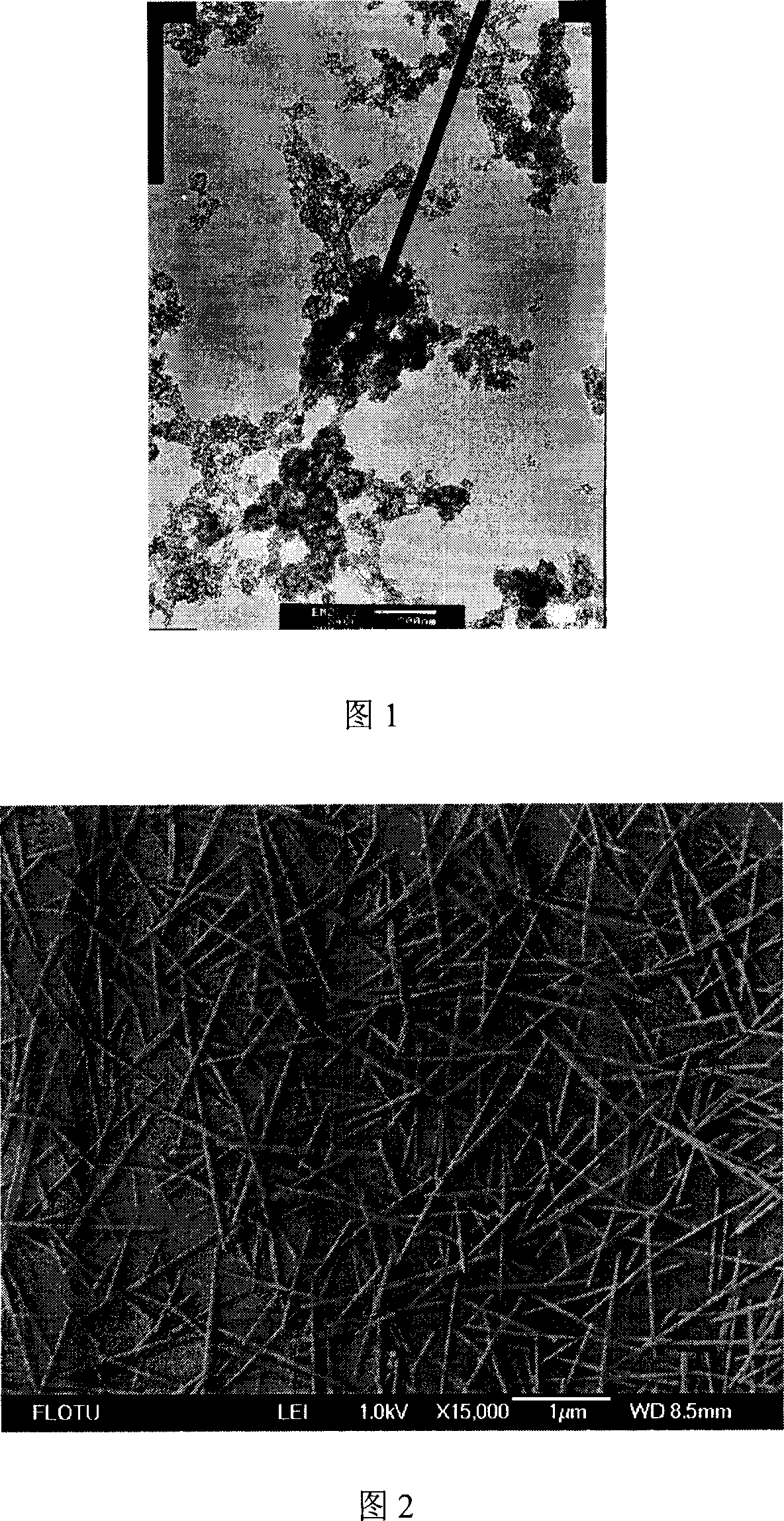

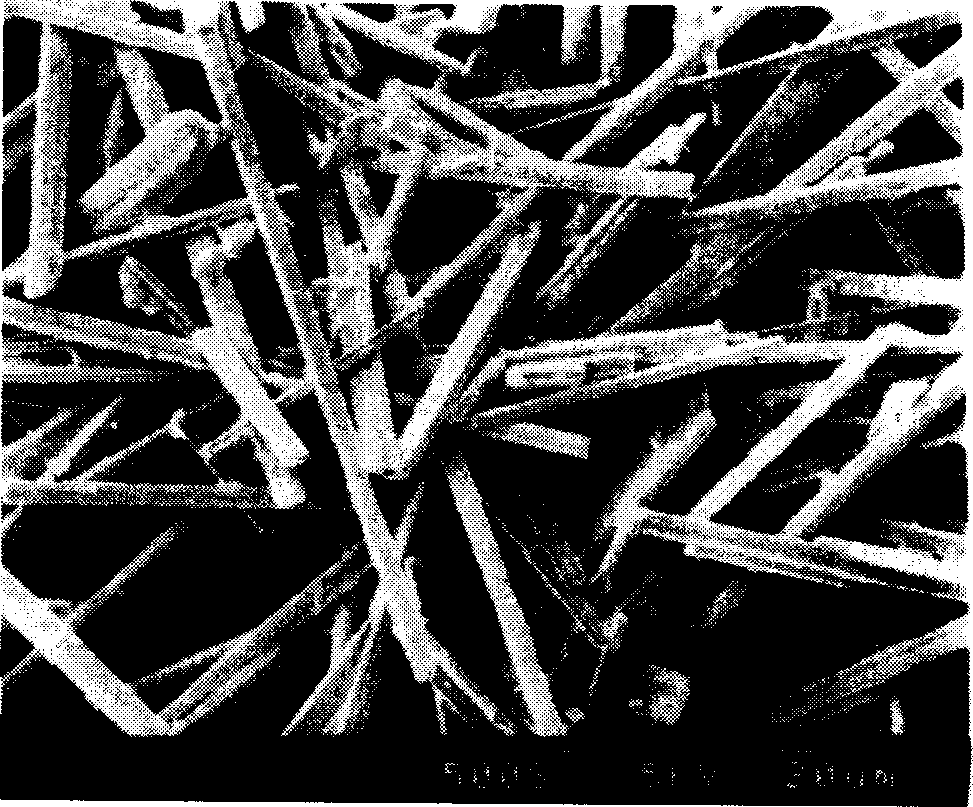

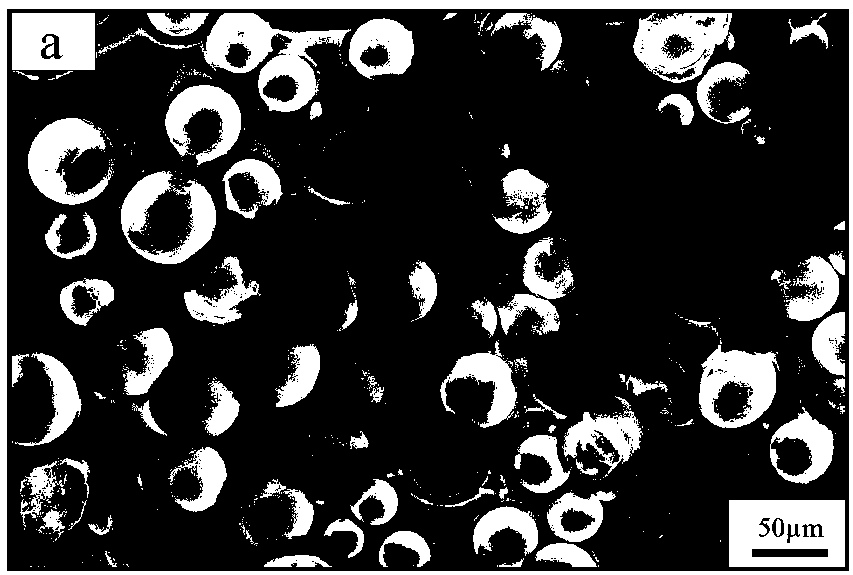

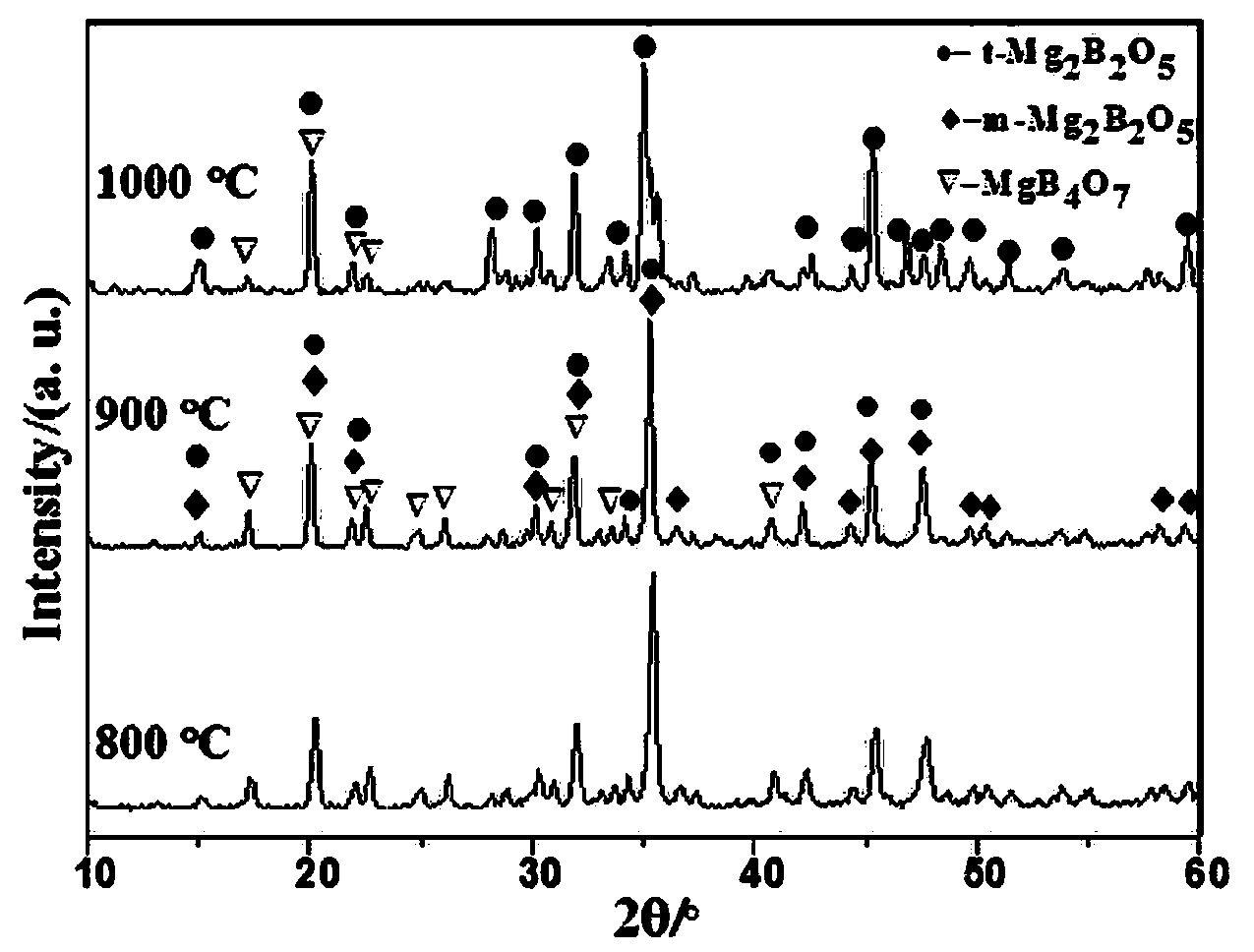

InactiveCN1936104AStable structureSmall particle sizePolycrystalline material growthFrom normal temperature solutionsMagnesium saltWhiskers

The invention relates to a hydrothermal synthesis manufacturing method for magnesium borate crystal whisker that adopts inorganic magnesium salt, magnesium borate and inorganic alkali as main raw material, adding inorganic alkali into mixture solution of magnesium salt and borate at 10-90 degree centigrade, taking hydrothermal treatment to normal temperature product at 100-300 degree centigrade, realizing directional growth through controlling hydrothermal rocks constituents and technology condition to gain one dimension appearance feather alkali magnesium borate crystal whisker, washing, drying the hydrothermal product, and baking under the existence of crystallographic form transforming agent at 600-800 degree centigrade to realize structure reconstruction and phase converting to gain regular appearance and equal size magnesium borate crystal whisker. The invention has the advantages of simple technology, mild condition, cheap raw material, and easy to be manufactured.

Owner:TSINGHUA UNIV

Fire resistant water-based self-adhesion coating

The invention discloses a high-temperature resistance water-based self-adhering paint, which comprises the following parts: 10-80% main agent, which contains alkaline metal silicate from one of quaternary amine, tertiary amine and silicate of guanidine (23.5- 46.3% silicate or 67.8-83.9% phosphate); 26.8-45.1% solidifier, which concludes metal oxide, aluminium hydroxide, magnesium fluosilicate, magnesium borate, zinc borate, magnesium phosphate or potassium phosphate; 16.1-32.2% filler, which contains silica, alumina, mullite, boron nitride or mica.

Owner:BAOSHAN IRON & STEEL CO LTD

Organic synthetic plugging granules for well drilling, and preparation method and application thereof

ActiveCN104531109AGood dispersionStrong high pressure resistanceDrilling compositionSealing/packingDispersityFiber

The invention discloses organic synthetic plugging granules for well drilling, and a preparation method and application thereof, belonging to the field of organic synthetic granular plugging agents in the technical field of well drilling. The plugging granules are prepared by blending one or more of calcium carbonate whisker, magnesium borate whisker and calcium sulfate whisker with polyetheretherketone and polyetherimide. The preparation method comprises the following steps: adding one or more of calcium carbonate whisker, magnesium borate whisker and calcium sulfate, polyetheretherketone and polyetherimide into a high-speed mixer, mixing at 380 DEG C at the shear velocity of 2.5 / s for 10-30 minutes, extruding at 300 DEG C, cooling, and granulating. The organic synthetic plugging granules can be used as plugging granules and matched with plugging fibers and plugging flexible fragments for bridging plugging. The method solves the problems of poor dispersity, improper density, high water absorptivity, high degradation tendency, high brittleness, high breaking tendency, high sedimentation tendency and the like, and enhances the compression resistance and temperature resistance of the plugging bridging granules.

Owner:CHENGDU DEDAO IND

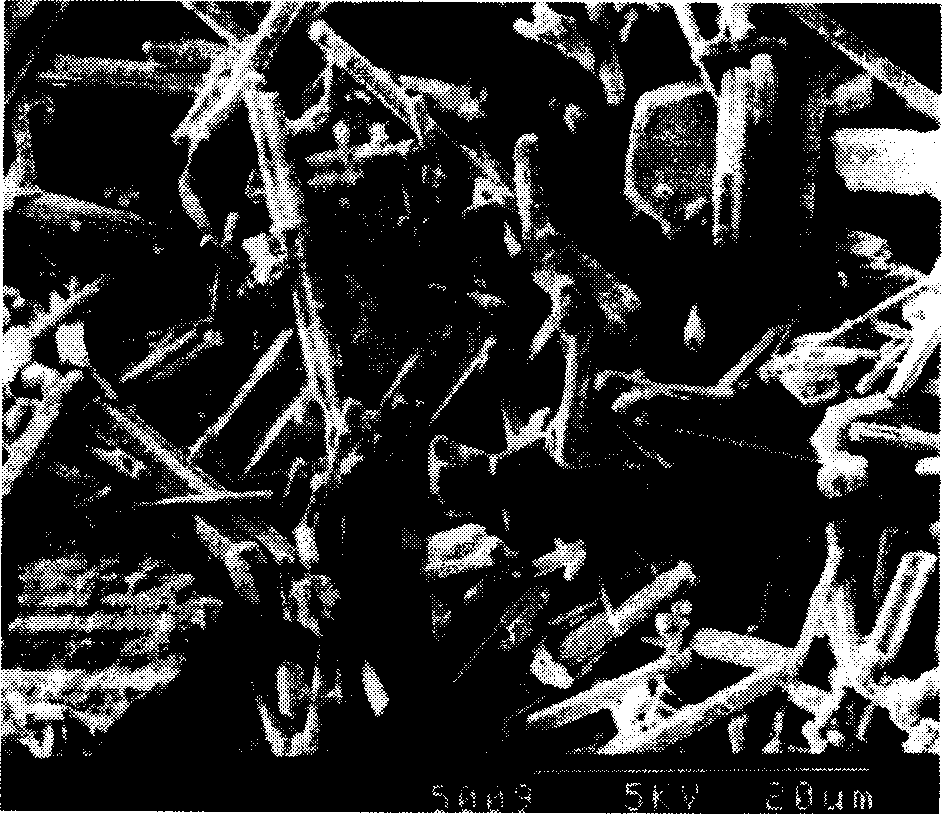

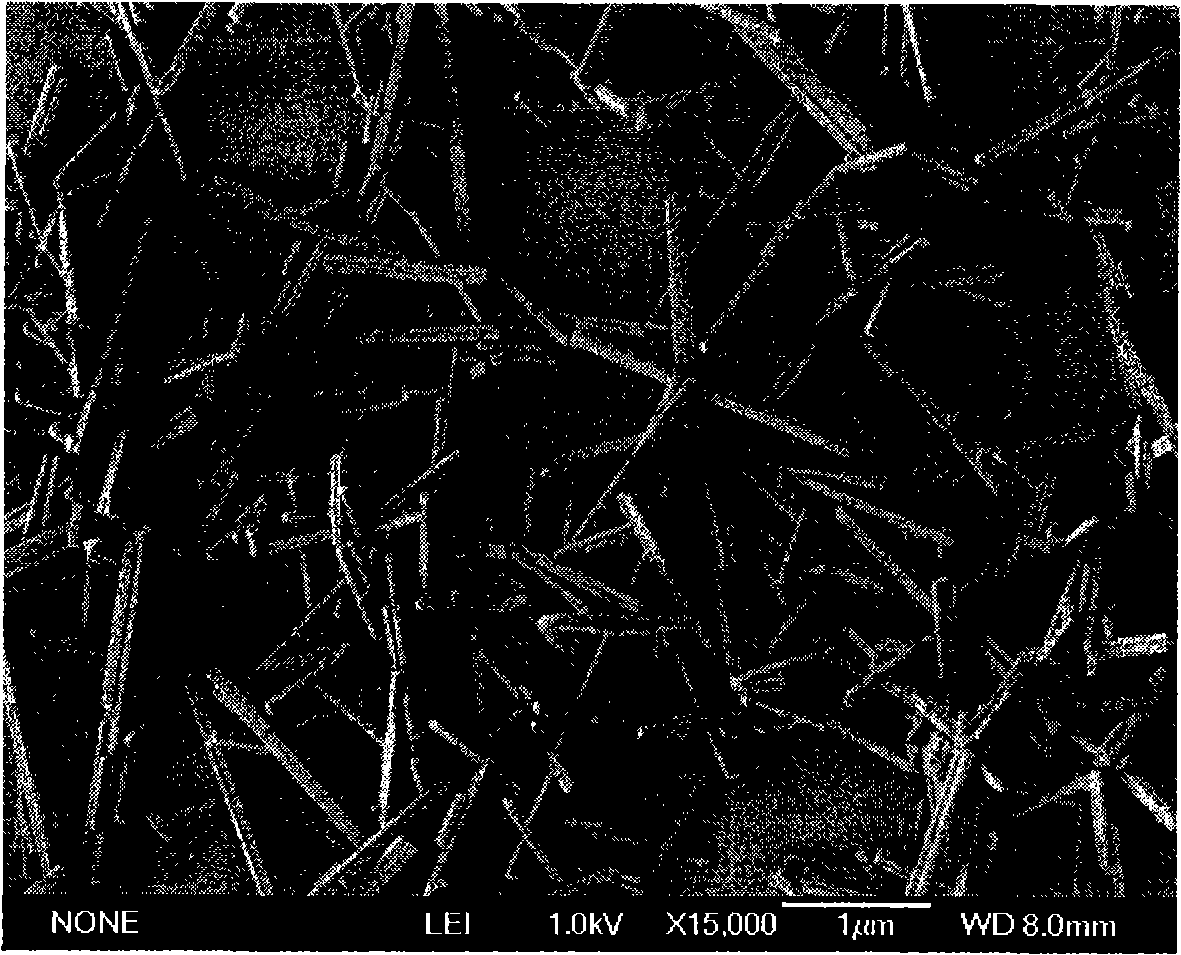

High length-diameter ratio antifungin whisker synthesis method

ActiveCN1807242AImprove qualityAvoid pollutionPolycrystalline material growthBoratesSynthesis methodsHigh-temperature corrosion

The invention relates to a process for synthesizing magnesium borate crystal whisker with high length-diameter ratio, which consists of reacting boric acid, magnesium chloride and caustic soda in water solution by right proportion to obtain boracic magnesium compound precipitate, filtering to obtain precursor for magnesium borate crystal whisker production, then mixing fluxing agent comprising NaCl or NaCl and KCl with the precursor, charging menthol, ethanol, water or their mixed solution, immersing, agitating and mixing, subjecting the mixture to high temperature reaction at 500-900 deg C for 5-10 hours, cooling down, washing with water, and finally drying.

Owner:青海中信国安科技发展有限公司 +1

Low-temperature molten salt thermal inversion preparation method of aporate-crystal antifungin whiskers

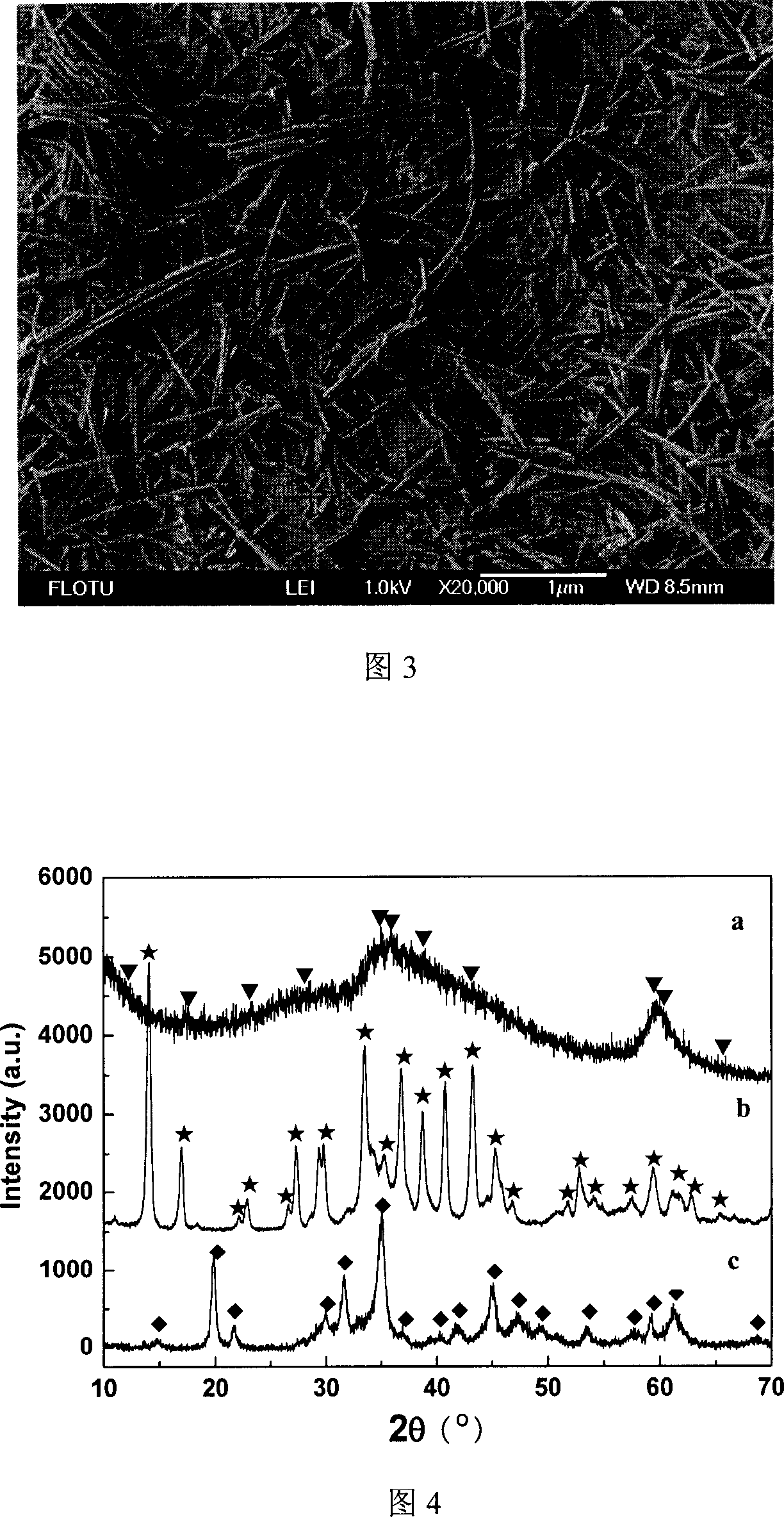

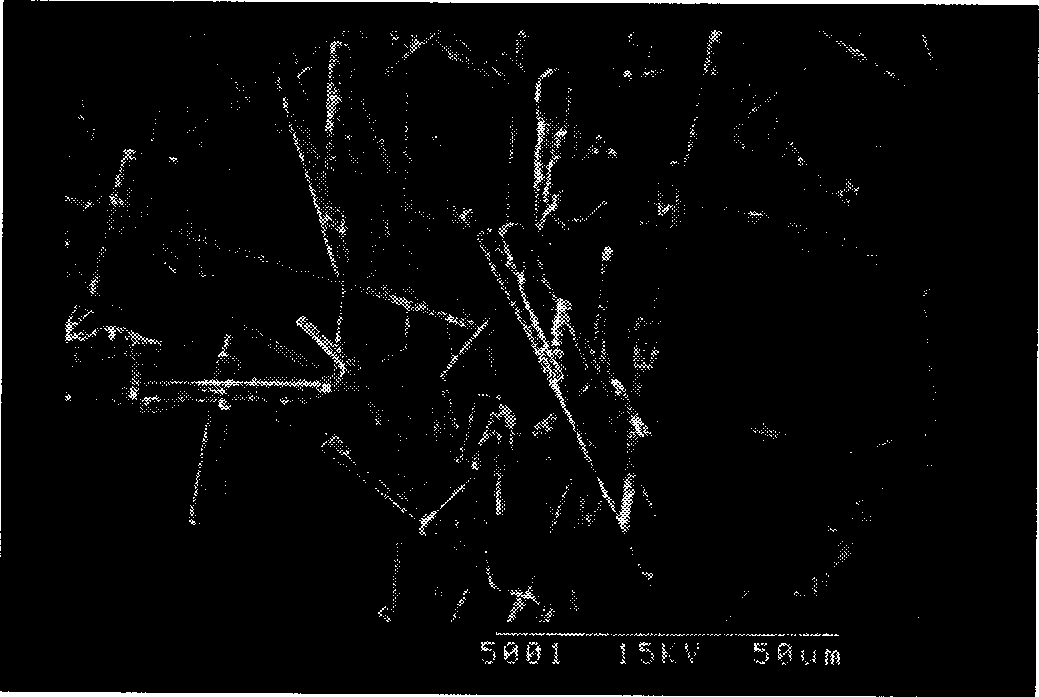

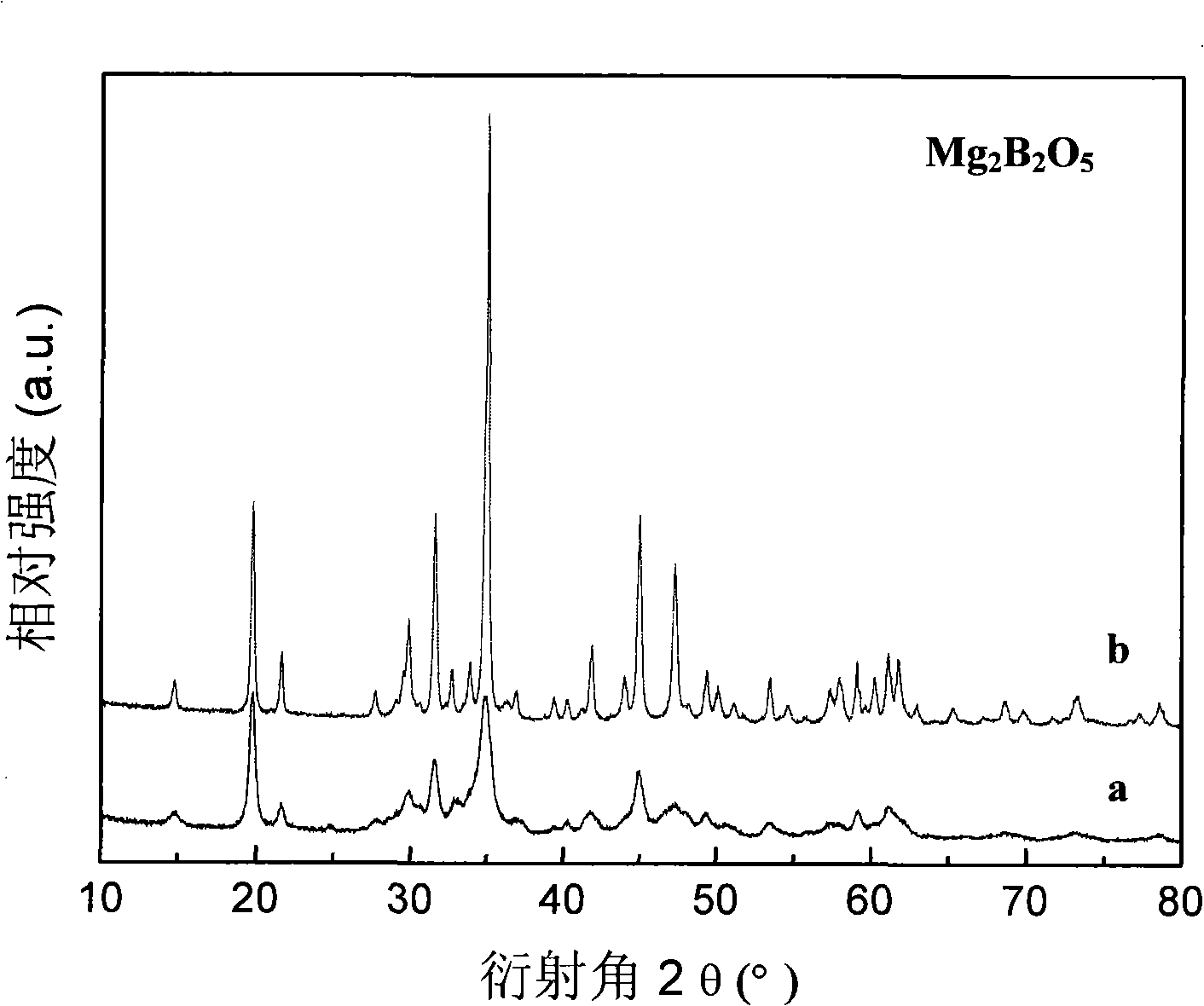

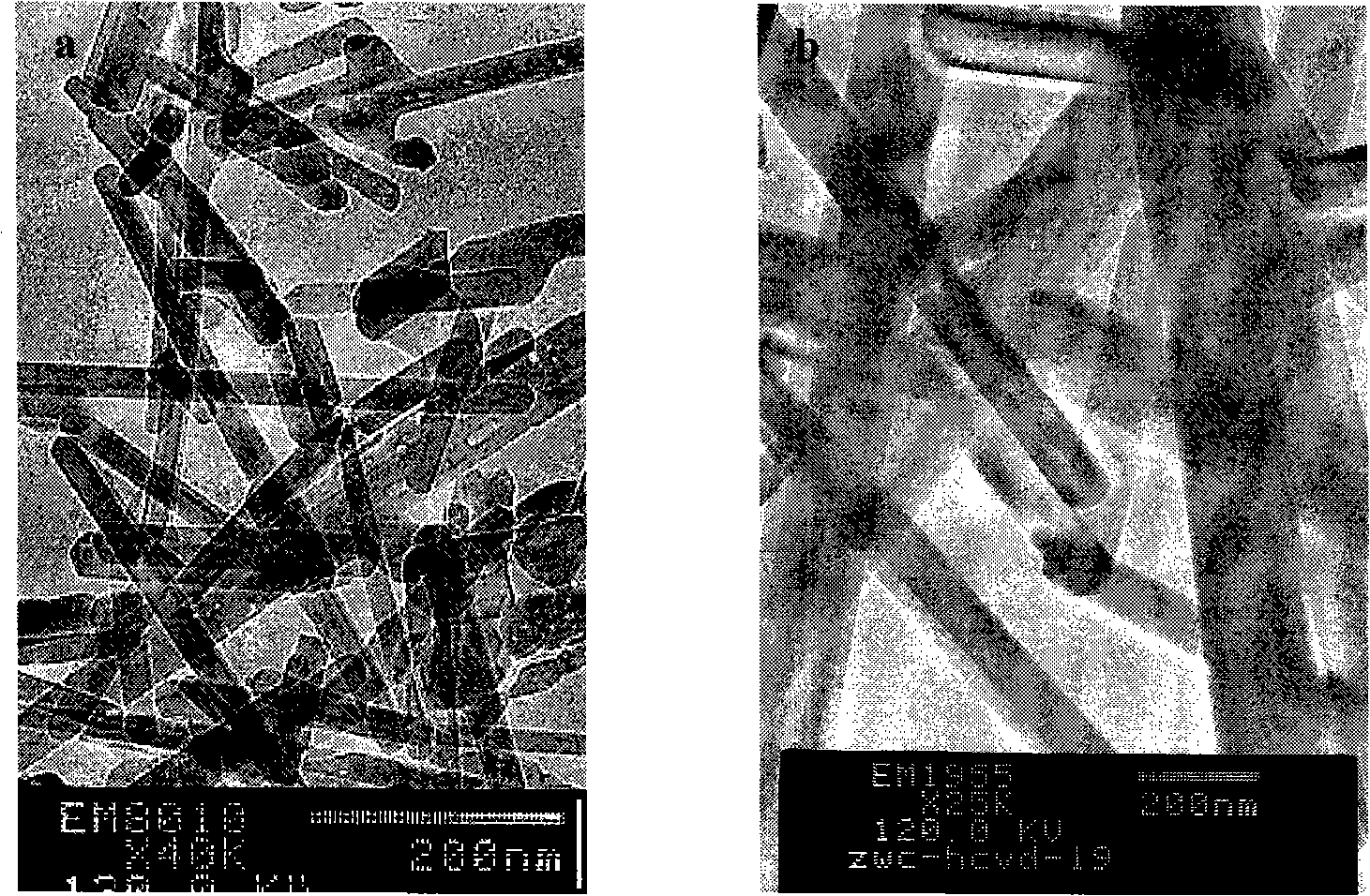

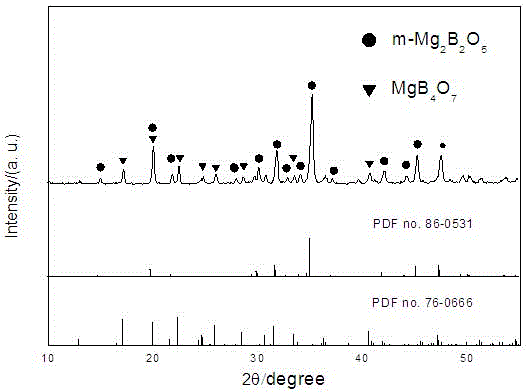

InactiveCN101311372AHigh purityUniform shapePolycrystalline material growthBoratesAir atmosphereThermal transition

The invention discloses a method for preparing a low temperature fused salt of an aporate high crystallization magnesium borate crystal whisker by means of a thermal transition, which belongs to the field of inorganic chemical engineering technology. A hydrothermal product alkali magnesium borate crystal whisker is used by the method as a precursor, roasted for 1-5 hours in an air atmosphere of 600-750<DEG C> with an assistance of minim inorganic fused salt, washed, filtered, and dried, thus obtaining the aporate high crystallization magnesium borate crystal whisker with a length of 0.5-20mum, a diameter of 10-100nm, a slenderness ratio of 10-200, and the main content of the aporate high crystallization magnesium borate crystal whisker is bigger than 98 percent. The method has the advantages that raw materials of the invention are cheap and easy to get; the craftwork is simple; the condition is mild; added value of the product is high; an industrialized popularization is easy; the feature of the prepared magnesium borate crystal whisker is regular; the dispersion is good, no holes exists; the crystallization degree is high; an application to industries of magnesium / aluminium alloy, plastics, rubber, and pottery, and the like, as reinforcing material is hopeful.

Owner:TSINGHUA UNIV

Preparing process for antifungin crystal whisker

InactiveCN1552958AIncrease profitLow costPolycrystalline material growthSingle crystal growth detailsLithiumChloride

Whiskers of magnesium borate are prepared from magnesium chloride by: proportioning materials, sintering, dissolving and immersing, and drying. The products thereby are of high quality with large ratio of length-diameter, purity of 99.55%, yield percentage of 90%, and low cost due to rich resources in the Salt Lake. Its byproduct can be used to recover lithium salts so as to increase use ratio of resources and benefits.

Owner:青海海兴科技开发有限公司

Mixed-phase reinforced magnesium-based composite material and preparation method thereof

InactiveCN107761022ARefine the grain sizeImprove mechanical propertiesMagnesium matrix compositeTension compression

The invention discloses a mixed-phase reinforced magnesium-based composite material and a preparation method thereof. The preparation method comprises the following steps: pretreating magnesium alloypowder, nano-diamond particles and magnesium borate whiskers to obtain mixed powder; performing mixed ball milling on the mixed powder and milling steel balls to obtain ball-milled mixed powder; thenperforming hot pressing in vacuum to obtain a blank, and performing hot extrusion. The mixed-phase reinforced magnesium-based composite material prepared by the preparation method provided by the invention has significantly improved frictional wear and tension-compression symmetry.

Owner:QINGHAI UNIVERSITY

Modified high-density-polyethylene composite

A modified high-density-polyethylane composite comprises the following raw materials: by weight, 75-90 parts of a high density polyethylene, 5-10 parts of magnesium borate whisker, 5-10 parts of talcum powder, 0.2-1 part of calcium stearate, 0.5-1 part of antioxidant 1076, 1-5 parts of maleic anhydride grafted ethylene-propylene-diene rubber, 2-5 parts of a coupling agent, 0.1-0.5 part of ultraviolet absorbent UV-531 and 0.5-1 part of light stabilizer 744. In the modified high-density-polyethylane composite, the high density polyethylene is HDPE310M, the coupling agent is isopropyl tri-(dioctylpyrophosphato) titanate, the magnesium borate whisker is adopted in the composite, and the coupling agent isopropyl tri-(dioctylpyrophosphato) titanate is compounded into the composite, so that the strength and toughness of the composite can be effectively improved, and the composite has good fluidity and is easy to process. Through addition of the ultraviolet absorbent UV-531 and the light stabilizer 744, the outdoor weather resistance of the composite is effectively improved.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Energy-saving and environment-friendly building material and preparation method thereof

The invention provides an energy-saving and environment-friendly building material and a preparation method thereof and relates to the field of building materials. The energy-saving and environment-friendly building material comprises expanded perlite, pottery clay, magnesium borate whiskers, floating beads, calcium sulfate, barium phosphate, methoxy polyethylene glycol, a polyacrylate emulsion, urea resin, chlorosulfonated polyethylene, phenolic resin, waste polyethylene foam plastics, diatomite, aluminum silicate, activated carbon, bamboo carbon, glass wool, a foaming agent, flame retardant, a thermal stabilizer, a light stabilizer and compatibilizer. The preparation method includes the steps of firstly, weighing the raw materials; secondly, performing ball milling; thirdly, crushing; fourthly, mixing; fifthly, adding into a reaction kettle; sixthly, performing hot compression and cooling. By the energy-saving and environment-friendly building material, the problem that existing building materials used for indoor decoration have defects in fireproof, energy-saving and environment protection performance is solved.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

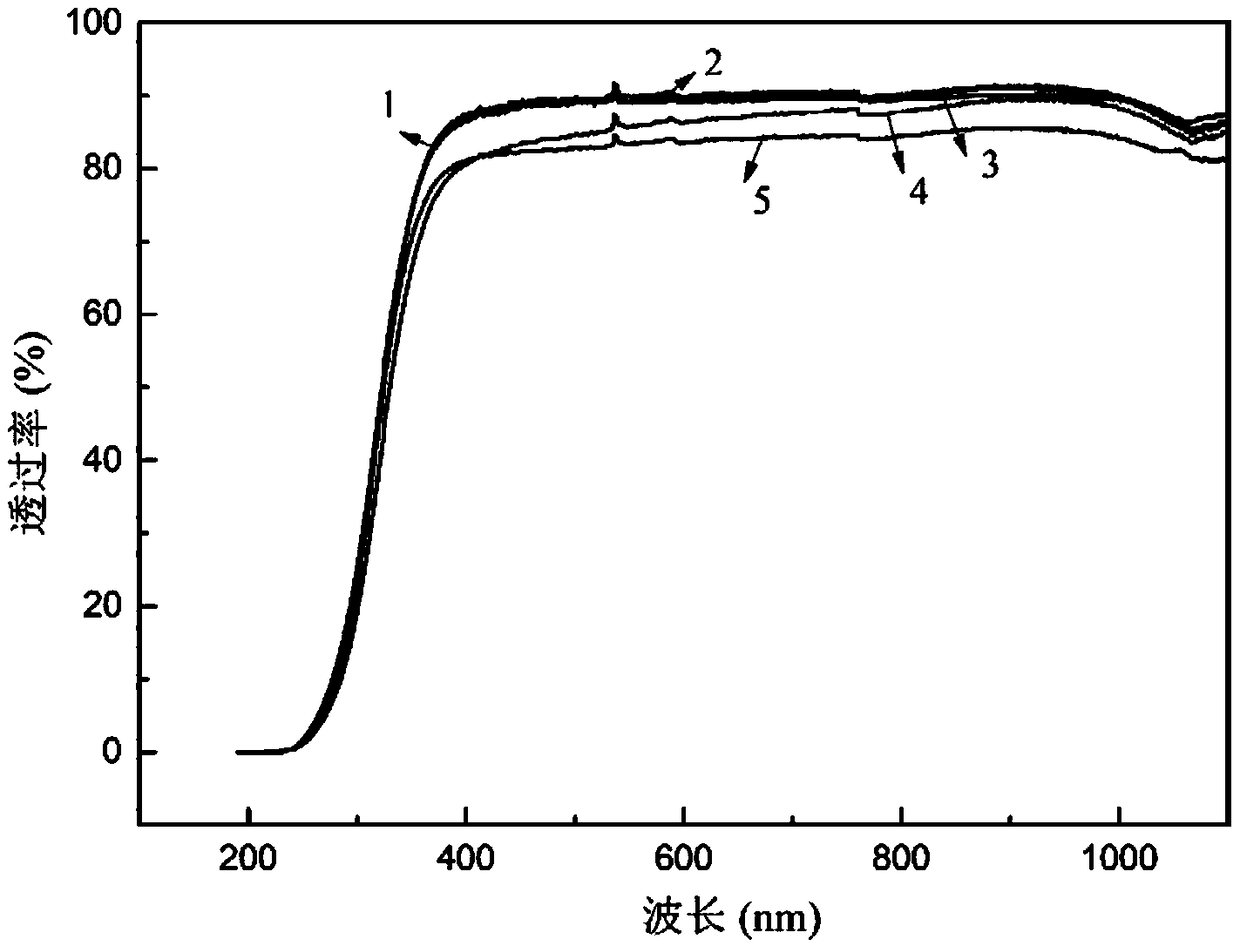

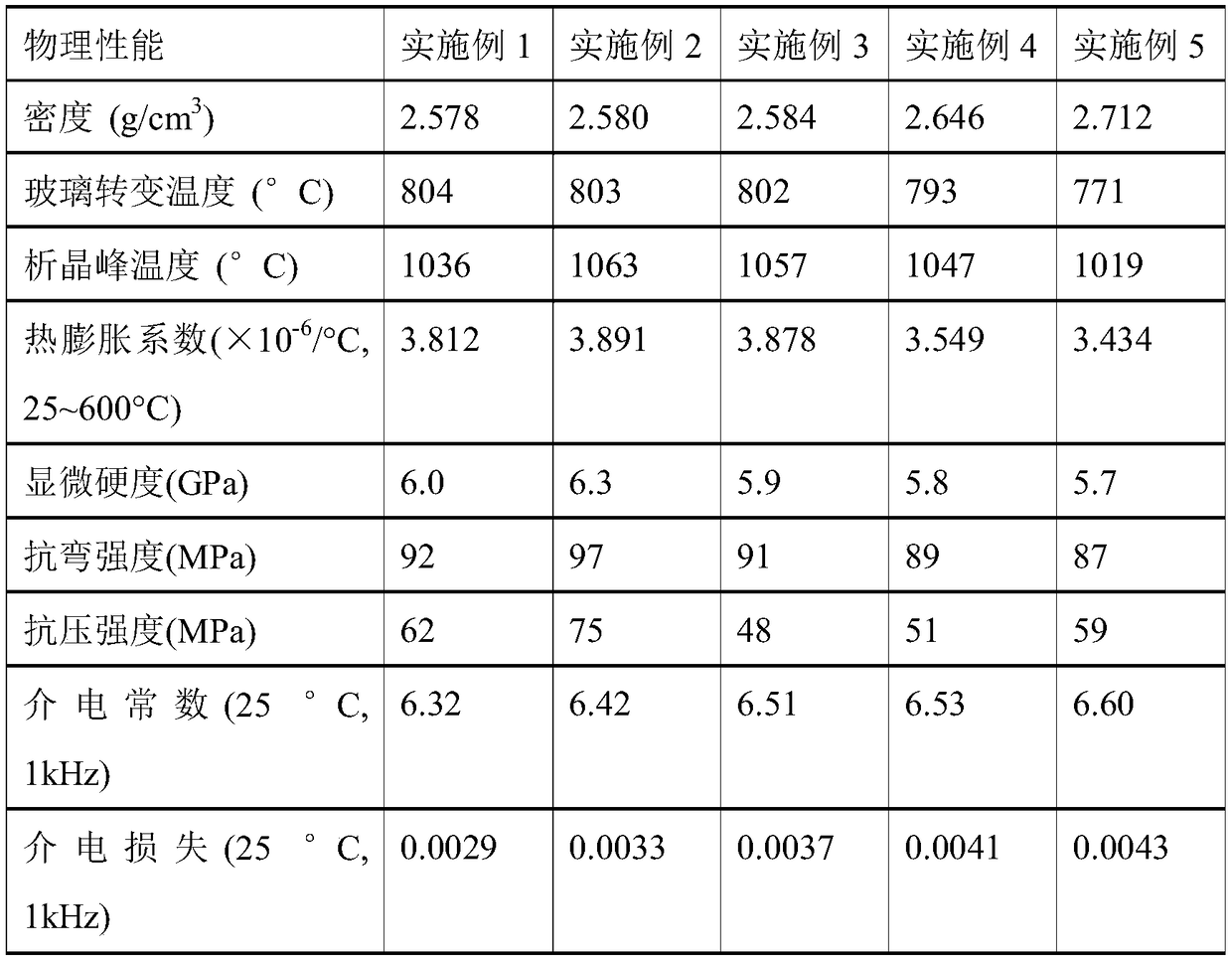

Alkali-free and high-alumina borosilicate glass with low thermal expansion coefficient and preparation method of alkali-free and high-alumina borosilicate glass

PendingCN108658454AIncrease the difficultyIncrease costGlass shaping apparatusAlkali freeThermal expansion

The invention discloses alkali-free and high-alumina borosilicate glass with a low thermal expansion coefficient and a preparation method of the alkali-free and high-alumina borosilicate glass. MgO ispartially replaced with high Al2O3, low SiO2 and ZnO, MgO, ZnO, Al2O3, SiO2 and borate are taken as raw materials, B2O3 is introduced by boric acid, zinc borate, magnesium borate or aluminum borate,the glass comprises oxides as follows: 5.85%-12.37% of MgO, 0.13%-11.81% of ZnO, 29.60%-31.45% of Al2O3, 49.71%-52.83% of SiO2 and 3.03%-3.22% of B2O3, and total mass of MgO and ZnO is 12.50%-17.66%.The preparation process is simple, the melting temperature is low, and the prepared glass has low density, low thermal expansion coefficient, low dielectric loss and moderate dielectric constant and is applied to a hybrid circuit substrate, an encapsulating material or a flat-panel display.

Owner:CENT SOUTH UNIV

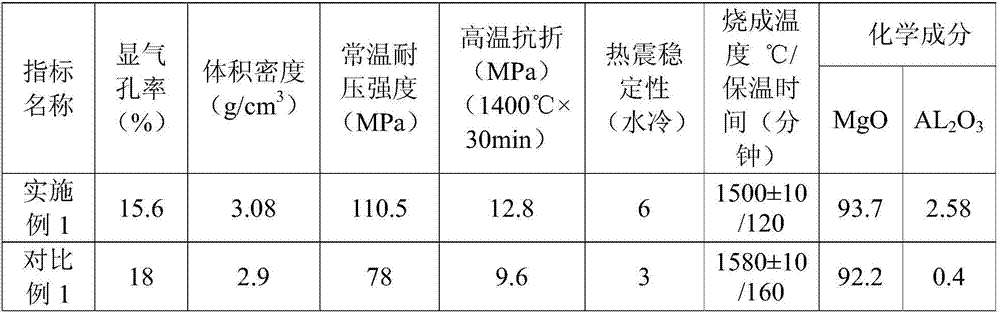

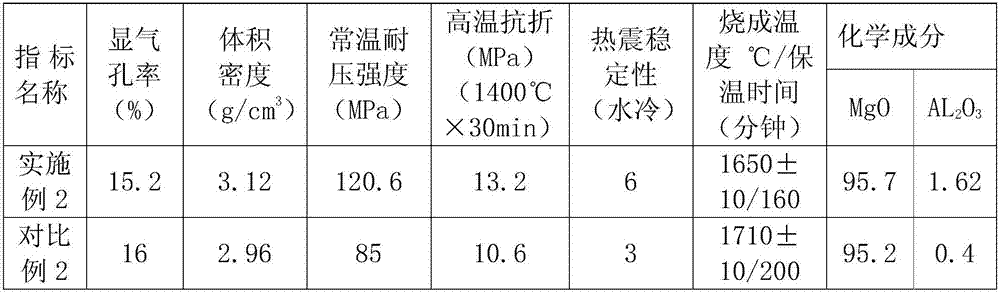

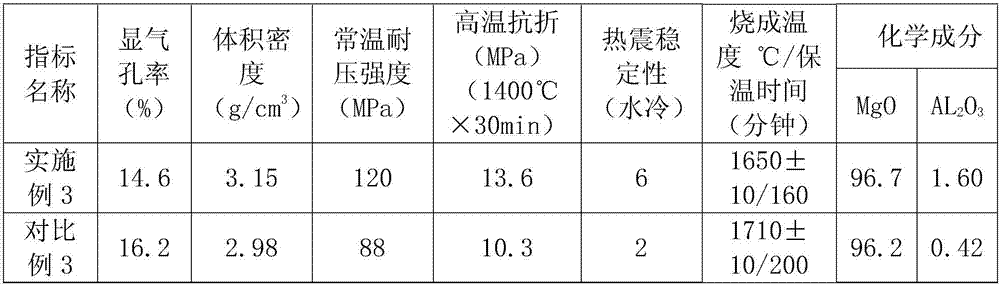

Whisker composite high performance magnesia brick and manufacturing method thereof

The invention relates to the technical field of refractory materials, particularly relates to the technical field of refractory materials for a refractory furnace permanent lining, an alloy metallurgical smelting furnace, a glass kiln regenerative chamber and a cement rotary kiln and particularly relates to a whisker composite high performance magnesia brick and a manufacturing method thereof. The whisker composite high performance magnesia brick comprises, by weight, 5-10% of fused magnesite of 5-8mm, 10-20% of fused magnesite of 3-5mm, 10-20% of fused magnesite of 3-0.074mm, 5-10% of fused magnesite of less than 0.074mm, 5-10% of high purity magnesite of 5-8mm, 5-15% of high purity magnesite of 3-5mm, 0-10% of high purity magnesite of 3-0.074mm, 5-10% of high purity magnesite of less than 0.074mm, 5-15% of recycled waste magnesium brick of 3-5mm, 5-15% of recycled waste magnesium brick of 0-3mm, 5-15% of magnesium oxide whiskers, 1-15% of magnesium borate whiskers, 2-5% of nano-magnesium aluminate adhesive dry powder and 2-5% of paper pulp.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

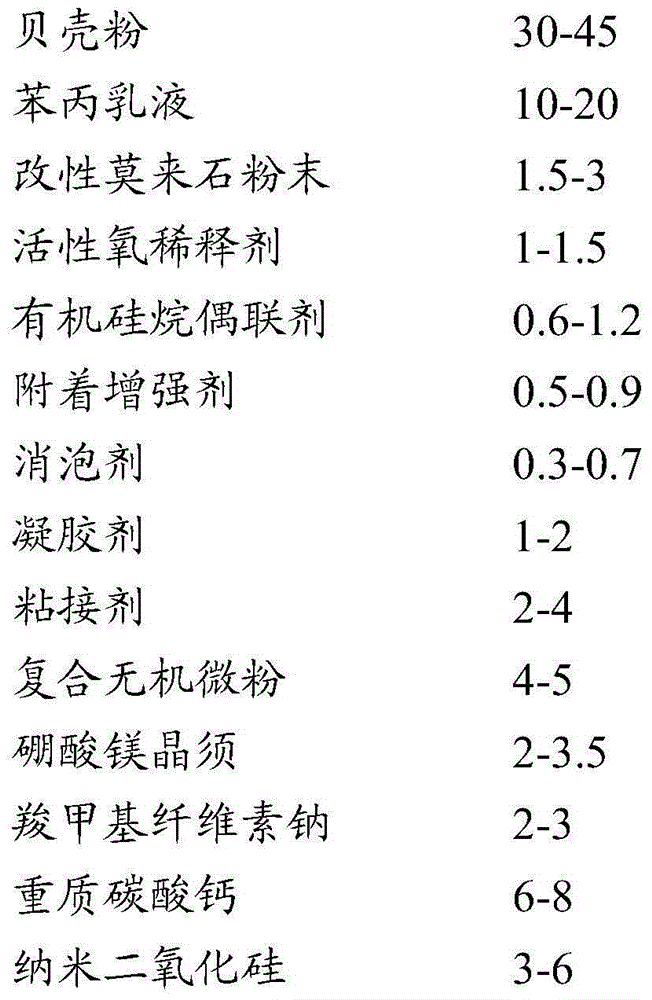

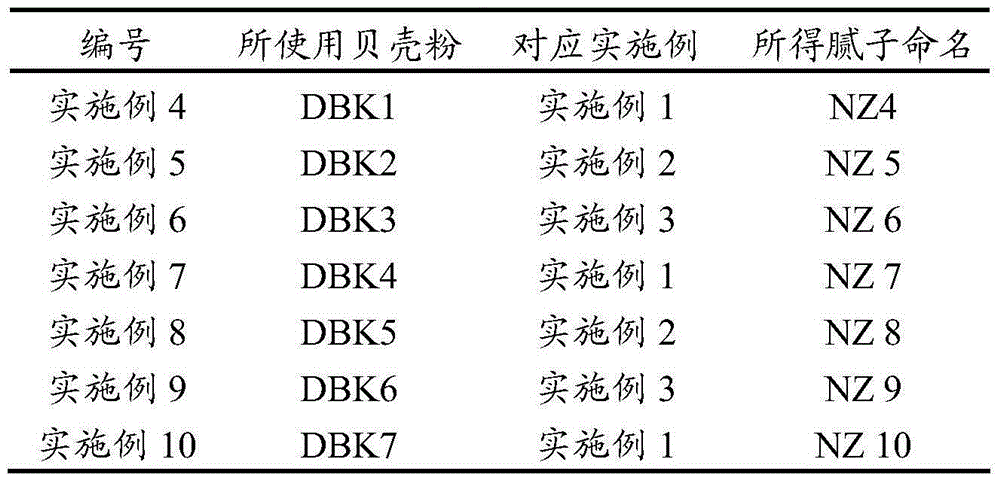

Shell powder putty and preparation method and application thereof

ActiveCN105131692AImprove stabilityImprove adhesion strengthFilling pastesAdhesion strengthSilicon dioxide

The invention provides shell powder putty and a preparation method and application thereof. The shell powder putty is prepared from shell powder, styrene-acrylic emulsion, modified mullite powder, active oxygen diluting agents, organic silane coupling agents, adhesion reinforcing agents, defoaming agents, gel agents, adhesives, composite inorganic micro powder, magnesium borate whiskers, sodium carboxymethylcellulose, heavy calcium carbonate and nano silicon dioxide. According to the shell powder putty, the good stability, adhesion strength, formaldehyde removing capacity, harmful gas removing capacity and appearance quality are achieved through selection and synergy of specific components, usage of the specific preparation method and the like, and therefore the very wide actual application value is achieved in the fields such as building, decorating and coating.

Owner:天津蓝海优贝科技有限公司

Degradable medical film and preparation method thereof

The invention relates to a degradable medical film and a preparation method thereof, and belongs to the field of medical composite materials. The degradable medical film comprises the following components in parts by weight: 18-24 parts of PE, 8-16 parts of PP, 4-9 parts of cellulose acetate butyrate, 6-14 parts of cocoanut oil monoethanolamide, 1-4 parts of sodium hexametaphosphate, 12-17 parts of nanometer magnesia, 2-5 parts of maleic anhydride-grafted ethylene-propylene-diene monomer rubber, 2-7 parts of magnesium borate whiskers, 2-8 parts of polyoxyethylene aliphatic alcohol ether and 3-7 parts of chitosan. The medical film disclosed by the invention is good in heat resistance, capable of being naturally degraded, and capable of achieving a degradation rate of more than 80% in 30 days; the medical film disclosed by the invention is friendly to human body and environment, and capable of being used for a long time; the preparation method disclosed by the invention is simple and practicable, and suitable for large-range popularization and application.

Owner:SUZHOU BEC BIOLOGICAL TECH

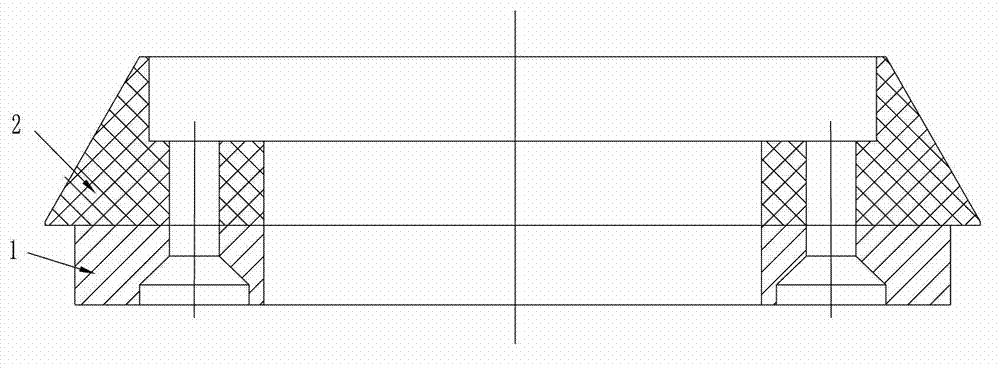

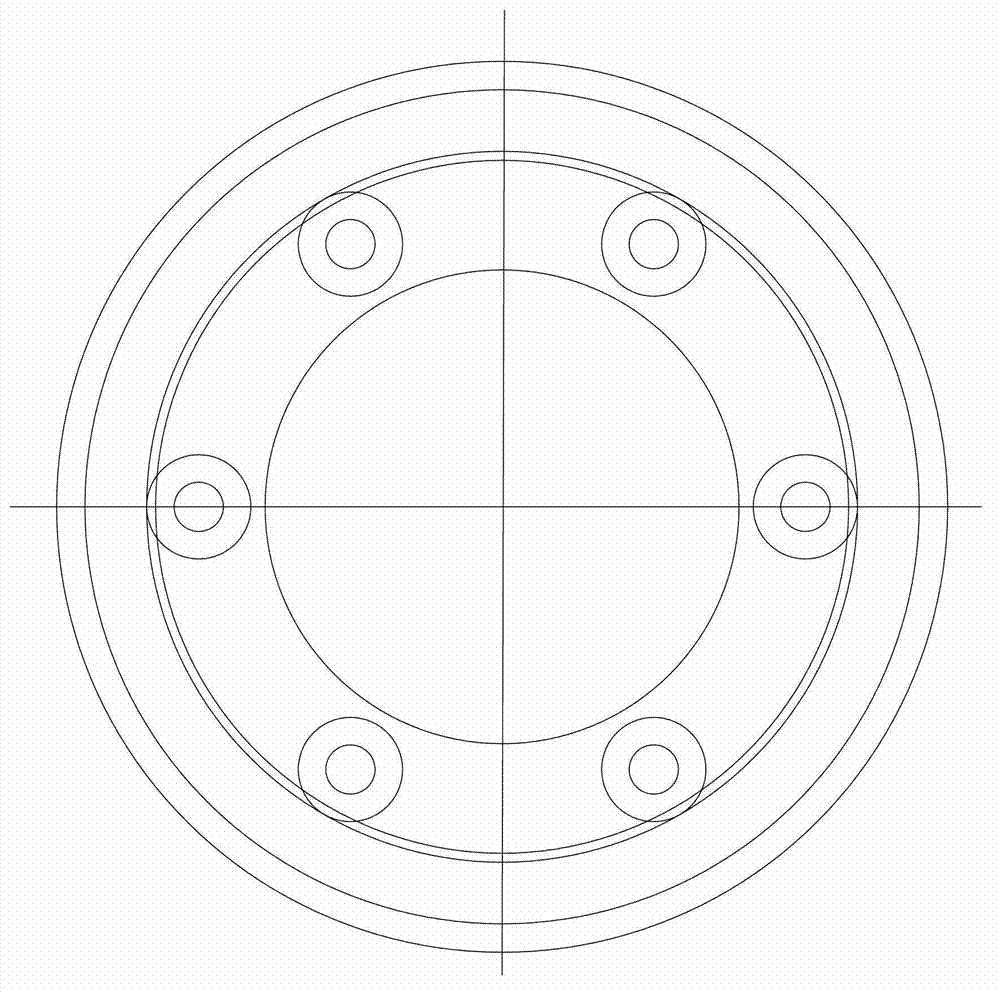

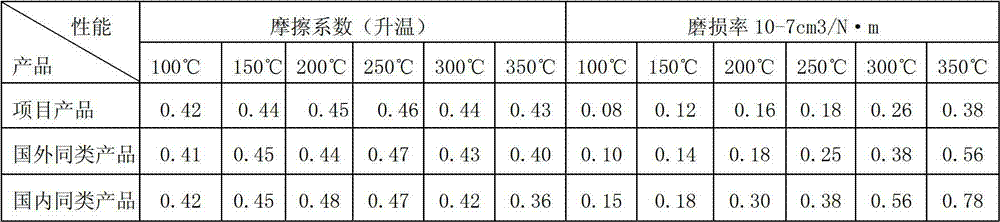

Winch brake pad and manufacture method thereof

InactiveCN102900795AHigh temperature resistantWear-resistantFriction liningHoisting equipmentsWinchPetroleum coke

The invention relates to a winch brake pad and a manufacture method thereof and aims at providing a winch brake pad large in braking torque and high in bonding strength and providing a method which is simple in process, enables manufacture to be convenient and is low in cost. The technical scheme is that the winch brake pad comprises a ferrous metal framework and a friction material layer. The friction material layer comprises melamine modified phenolic resin, nitrile rubber, ceramic fiber, carbon fiber, aramid fiber, calcium carbonate whisker, alumina, antimony sulfide, aluminum hydroxide, diatomaceous earth, potash feldspar, stearic acid, accelerant DM, an anti-aging agent BLE-W, sulphur, cashew nut shell oil frictional powder, synthetic graphite, foam iron, petroleum coke, magnesium borate whisker and cuprous oxide. The manufacture method of the friction material layer of the winch brake pad includes: (1) weighing raw materials according to a formula; (2) mixing and stirring a part of raw materials; (3) mixing another part of the raw materials, adding the mixed raw materials in the step (2) for mixing; (4) compression molding; and (5) thermocuring.

Owner:杭州汉乐科新材料科技有限公司

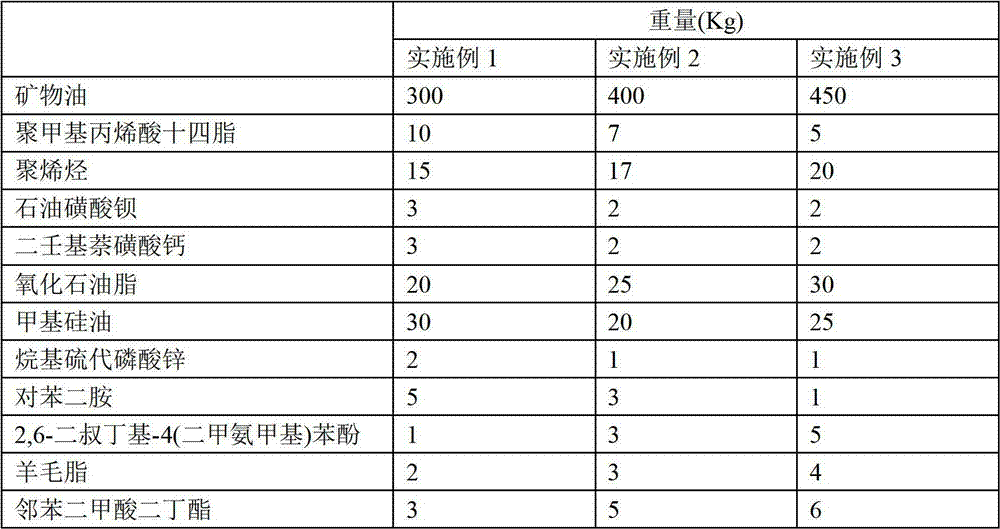

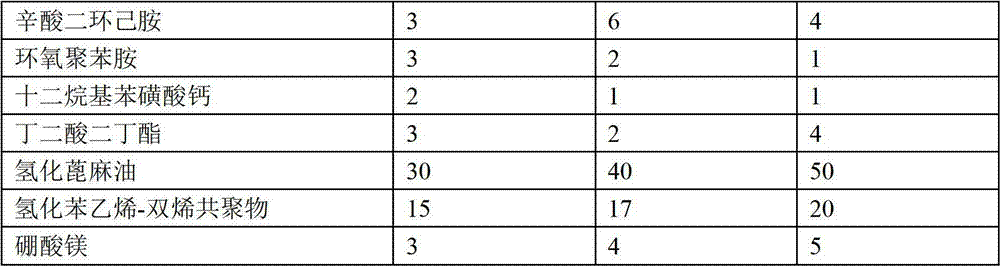

Corrosion-resistant anti-rust oil

The invention provides anti-rust oil capable of resisting corrosion and salt mist and belongs to the technical field of lubricating oil. The anti-rust oil comprises the following components in part by weight: 300 to 450 parts of mineral oil, 5 to 10 parts of polymethylacrylic acid tetradecyl ester, 15 to 20 parts of polyolefin, 2 to 3 parts of barium petroleum sulfonate, 2 to 3 parts of calcium dinonylnaphthalenesulfonate, 20 to 30 parts of oxidation petrolatum, 20 to 30 parts of methyl silicone oil, 1 to 2 parts of zinc alkyl thiophosphate, 1 to 5 parts of p-phenylenediamine, 1 to 5 parts of 2,6-di-tert-butyl-4(dimethylamine methyl)phenol, 2 to 4 parts of wool grease, 3 to 6 parts of dibutyl phthalate, 3 to 6 parts of octanoic acid dicyclohexylamine, 1 to 3 parts of epoxy polyaniline, 1 to 2 parts of calcium dodecyl benzene sulfonate, 2 to 4 parts of dibutyl succinate, 30 to 50 parts of hydrogenated castor oil, 15 to 20 parts of hydrogenated styrene-diene copolymer and 3 to 5 parts of magnesium borate. The anti-rust oil has high lubricating performance, wherein the durability in a salt mist test can reach 108 days and the durability in a warm test can reach 30 days.

Owner:SUZHOU XIELU NETWORK TECH

High-strength building material and preparation method thereof

InactiveCN107151120ATo achieve respiratory humidityImprove insulation effectCeramicwareThermal insulationPhosphate

The invention provides a high-strength building material and a preparation method thereof and relates to the field of building materials. The high-strength building material is prepared from the following raw materials in parts by weight: 6 to 13 parts of expanded perlite powder, 12 to 18 parts of argil, 5 to 9 parts of magnesium borate whisker, 4 to 10 parts of glass bead, 3 to 7 parts of calcium sulfate, 5 to 8 parts of barium phosphate, 6 to 11 parts of methoxy polyethylene glycol, 7 to 15 parts of polyacrylate emulsion, 5 to 10 parts of urea resin, 4 to 7 parts of chlorosulfonated polyethylene, 15 to 21 parts of synthetic fiber, 12 to 16 parts of kieselguhr, 17 to 25 parts of foam cement, 11 to 17 parts of activated carbon and 13 to 21 parts of sea-foam stone powder. The preparation method comprises the following steps: (1) weighing the raw materials; (2) ball milling; (3) mixing; (4) adding into a reaction kettle; (5) hot pressing and cooling. The high-strength building material disclosed by the invention solves the problem that an existing high-strength building material still has insufficiency when being applied to buildings having high requirements for strength, thermal insulation and environmental friendliness.

Owner:温州月煌科技有限公司

Preparation process of modified magnesium borate crystal whisker reinforced magnesium-matrix composite material

InactiveCN101705458AImprove interface binding stateImprove plastic forming abilityMagnesium matrix compositeVacuum pressure

The invention belongs to the technical field of new materials, in particular to a preparation process for modifying and optimizing magnesium alloy matrix and reinforcing the interphase contact surface and interface aiming at the magnesium borate crystal whisker reinforced magnesium-matrix composite material. The study proves that no obvious interface reaction occurs at the interface of the magnesium borate crystal whisker and the magnesium matrix, and the bonding strength of the interface is not high. By adopting the invention, the interface of the crystal whisker reinforced magnesium-matrix composite material reaches a better bonding state, and the performance of the magnesium borate crystal whisker reinforced magnesium-matrix composite material is improved. The preparation process comprises steps of coating the magnesium borate crystal whisker, preparing the modified magnesium borate crystal whisker prefabricated block, preparing cast composite ingot blank by a vacuum pressure infiltration method; and thermally extruding the ingot blank. The composite material comprises components of aluminium isopropoxide Al(OC3H7)3, distilled water, muriatic acid, magnesium borate crystal whisker, magnesium and the balance of magnesium alloy.

Owner:QINGHAI UNIVERSITY

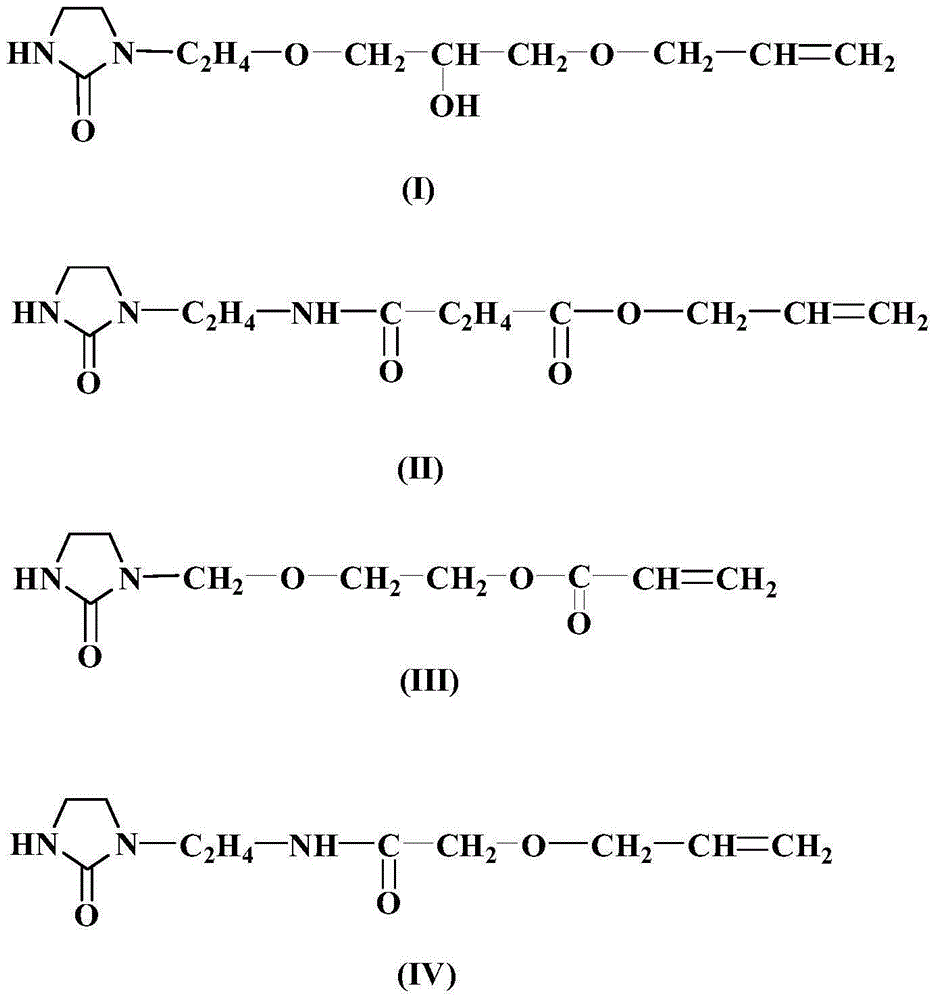

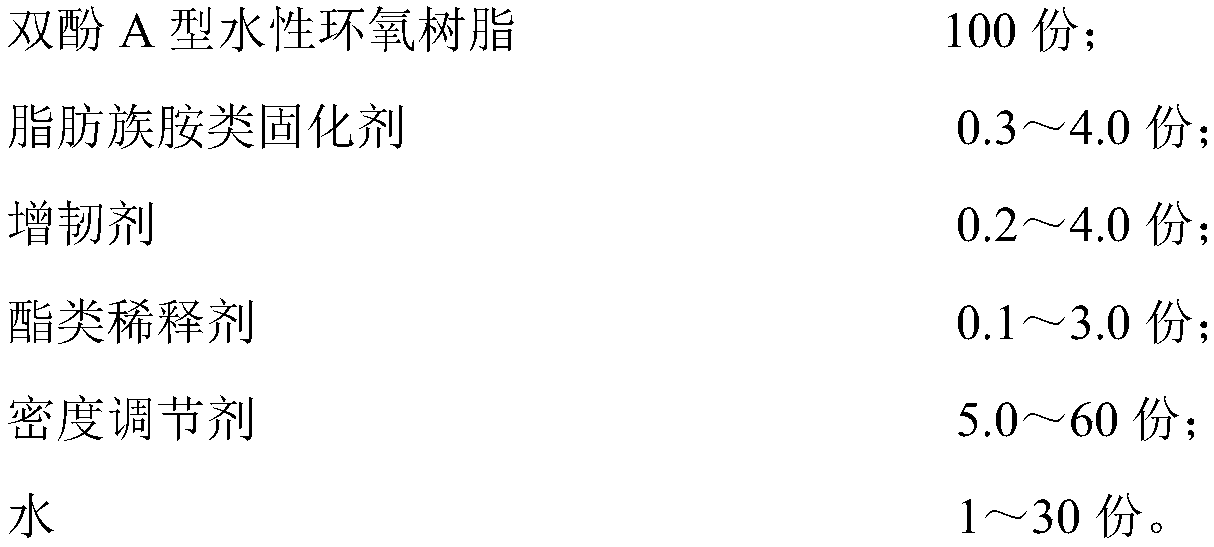

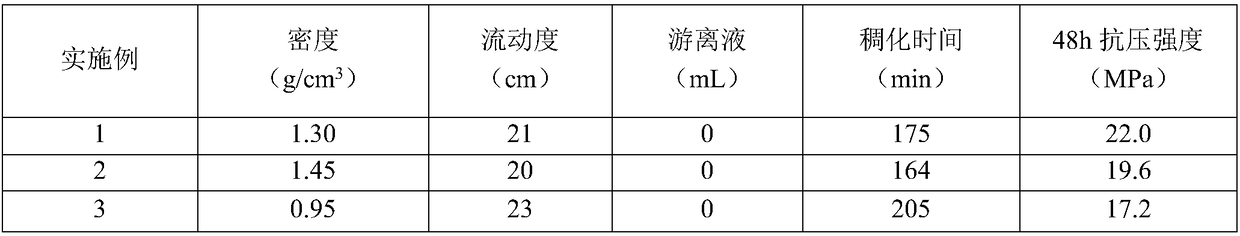

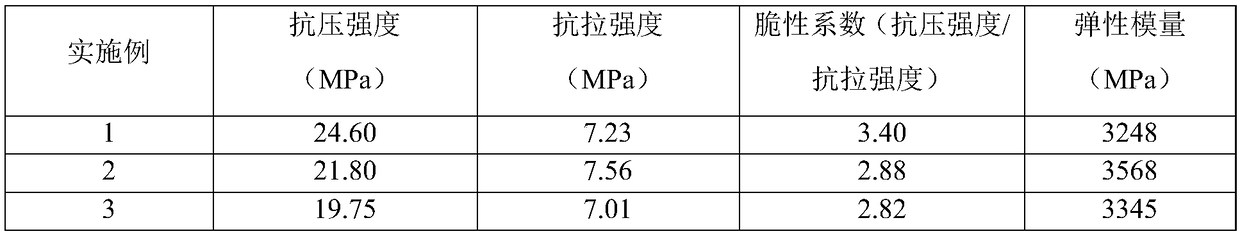

Thermosetting epoxy resin well cementation working solution

The invention discloses a thermosetting epoxy resin well cementation working solution which is prepared from the following ingredients in parts by weight: 100 parts of bisphenol A type waterborne epoxy resin, 0.3 to 4.0 parts of an aliphatic amine curing agent, 0.2 to 4.0 parts of a flexibilizer, 0.1 to 3.0 parts of an ester diluent, 5.0 to 60 parts of a density modifier and 1 to 30 parts of water, wherein the flexibilizer is a mixture of modified carbon nanotube and modified magnesium borate crystal whisker according to a part-by-weight proportion of 0.2 to 3.0; the modified nanotube is prepared by a carbon nanotube surface modifying method, the carbon nano tube is oxidized at first, and the carbon nano tube is treated by sodium hypochlorite; the modified magnesium borate crystal whiskeris prepared by a magnesium borate crystal whisker coupling treatment method. The thermosetting epoxy resin well cementation working solution disclosed by the invention has the characteristics of hightensile strength, high rupture strength and good toughness, can be directly applied to oil gas well cementation, also can be applied to repairing of damaged cement sheaths on which micro cracks arre generated and has a wide market application prospect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

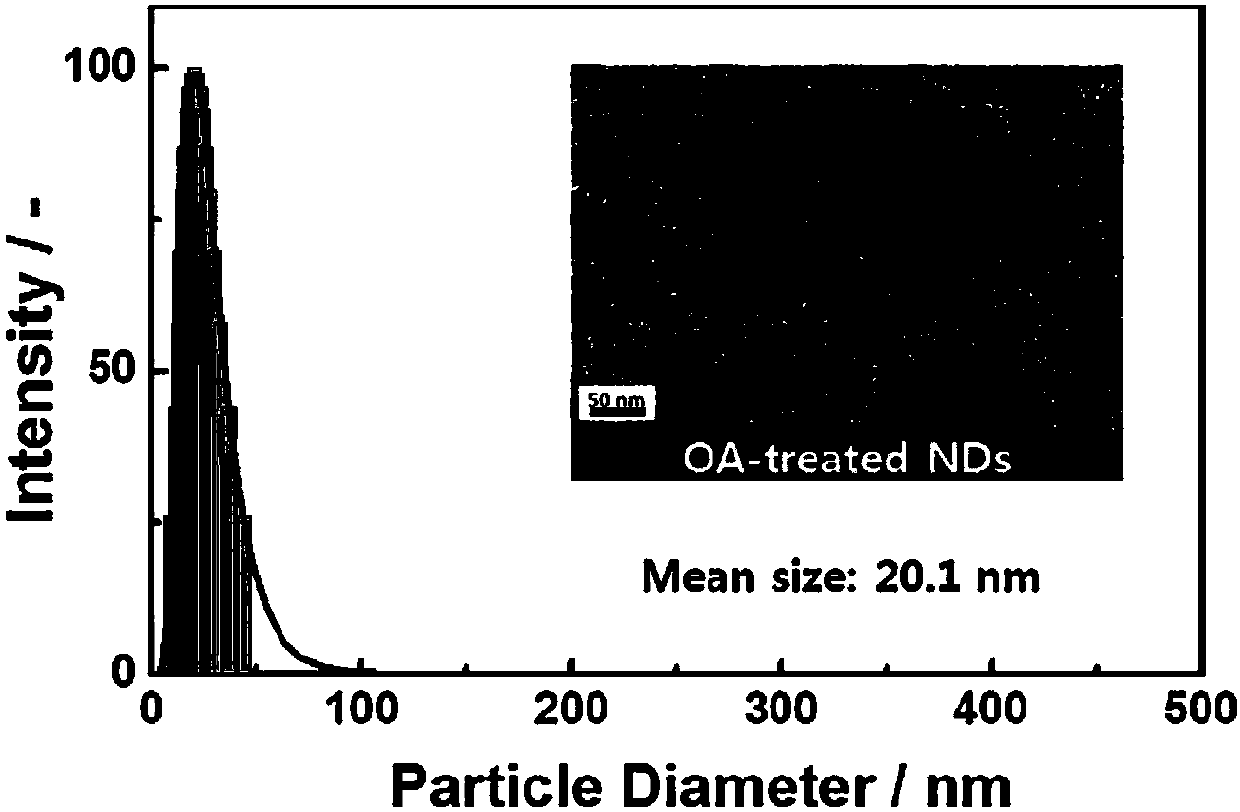

Preparation method of multi-level structure magnesium borate hollow microspheres

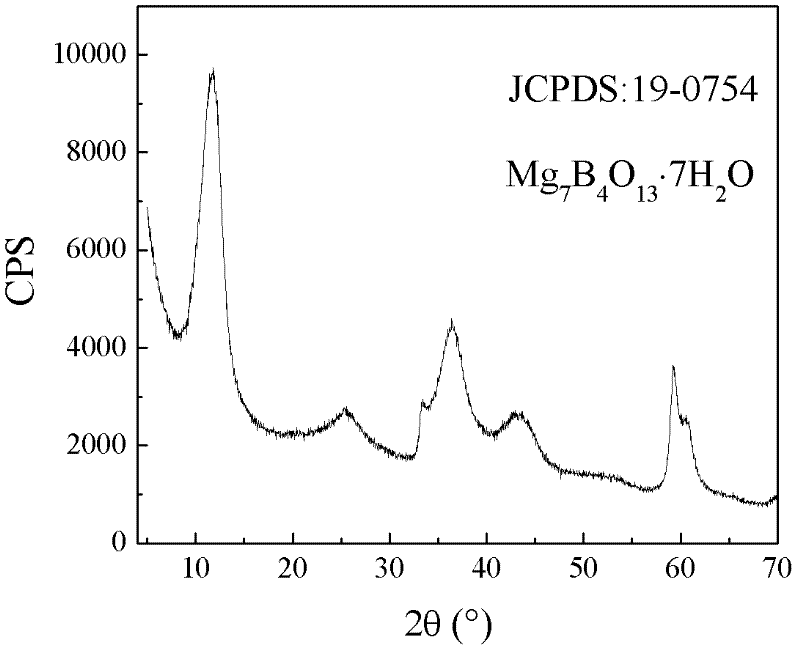

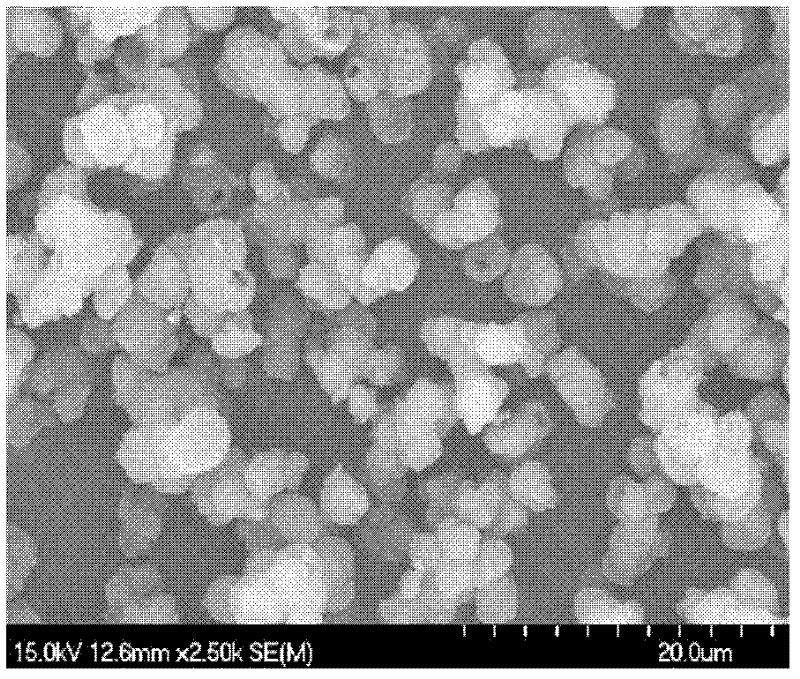

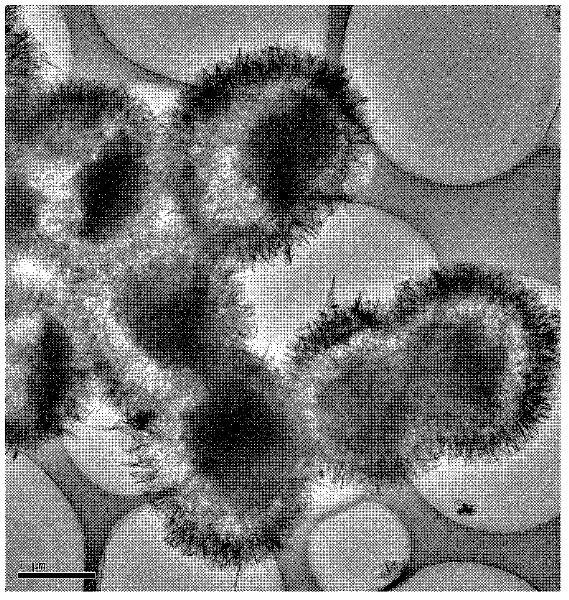

ActiveCN102530976AComplete crystal formSimple processNanotechnologyBoratesAir atmosphereLevel structure

The invention discloses a preparation method of multi-level structure magnesium borate hollow microspheres. The method comprises the following steps of: taking an inorganic magnesium salt water solution in the molar concentration of 0.01-0.20mol / L and a borax water solution in the molar concentration of 0.01-0.20mol / L as raw materials, stirring in ionic liquid at room temperature for 2-5 hours, aging for 2-72 hours at the temperature of 20-120 DEG C to get a precipitate mixture, filtering the precipitate mixture, washing a filter cake, drying and / or calcining at the temperature of 300-900 DEG C in an air atmosphere to get the multi-level structure magnesium borate hollow microspheres. The magnesium borate microspheres with better crystal form and hollow structure can be obtained by the preparation method disclosed by the invention, and the preparation method has the advantages of simple process, easiness in operation, high yield, complete crystal form of products, more uniform size distribution and high purity.

Owner:海宁市黄湾镇资产经营有限公司

Heat-resistant and flame-retardant nylon tube

InactiveCN105482448AImprove the disadvantage of high water absorptionImprove water absorptionPolymer scienceMagnesium borate

The invention discloses a heat-resistant and flame-retardant nylon tube. The heat-resistant and flame-retardant nylon tube is prepared from nylon 66, nylon 6, polymethylhydrosiloxane, epoxy resin, titanate coupling agent modification nano-zinc oxide, modification needle-like wollastonite, an amination carbon nano-tube, nano-silicon dioxide, red phosphorus, melamine cyanurate, organic nano-montmorillonite, glass fibers, magnesium borate whiskers, basic zinc carbonate nanofibers, ethylene-propylene-diene monomer, ethylene-bis-stearamide, calcium pimelate, zinc pimelate, silane coupling agent, aluminum diethylphosphinate and lanthanum stearate. The heat-resistant and flame-retardant nylon tube is good in heat resistance and flame retardancy, high in strength and excellent in impact resistance, and a nylon tube formed by the heat-resistant and flame-retardant nylon tube is good in overall performance and long in service life.

Owner:安徽都邦电器有限公司

Preparation method of ceramic tile with healthcare function

The invention discloses a ceramic tile with a health care function. The raw materials are composed according to the following ratios: 75-92 parts of quartz sand, 33-51 parts of nine-eye stone shale, 21-42 parts of magnetite, and 17-28 parts of white mud 11-17 parts of oil shale ash, 25-40 parts of serpentine, 16-29 parts of olivine, 10-17 parts of waste mortar, 14-25 parts of tuff, 15-22 parts of dry sludge powder, bauxite 12‑23 parts, magnesium borate whiskers 8‑15 parts, red mud 12‑16 parts, steel slag fine powder 19‑25 parts, silicon fine powder 41‑53 parts, zeolite 22‑33 parts, illite 11‑14 parts, jade powder 5-9 parts, Glauber's salt 4-7 parts, Muyu stone 25-29 parts, tuff 13-20 parts, calcium hydrogen phosphate 7-11 parts, waste ceramics 16-22 parts, montmorillonite 12-16 parts, furnace ash 6‑11 parts, andalusite 8‑12 parts. The ceramic brick prepared by the invention has strong positive magnetic field energy, can reconcile the magnetic field of the human body, enhance the blood circulation of the human body, and increase the immunity of the human body.

Owner:GUANGXI UNIV

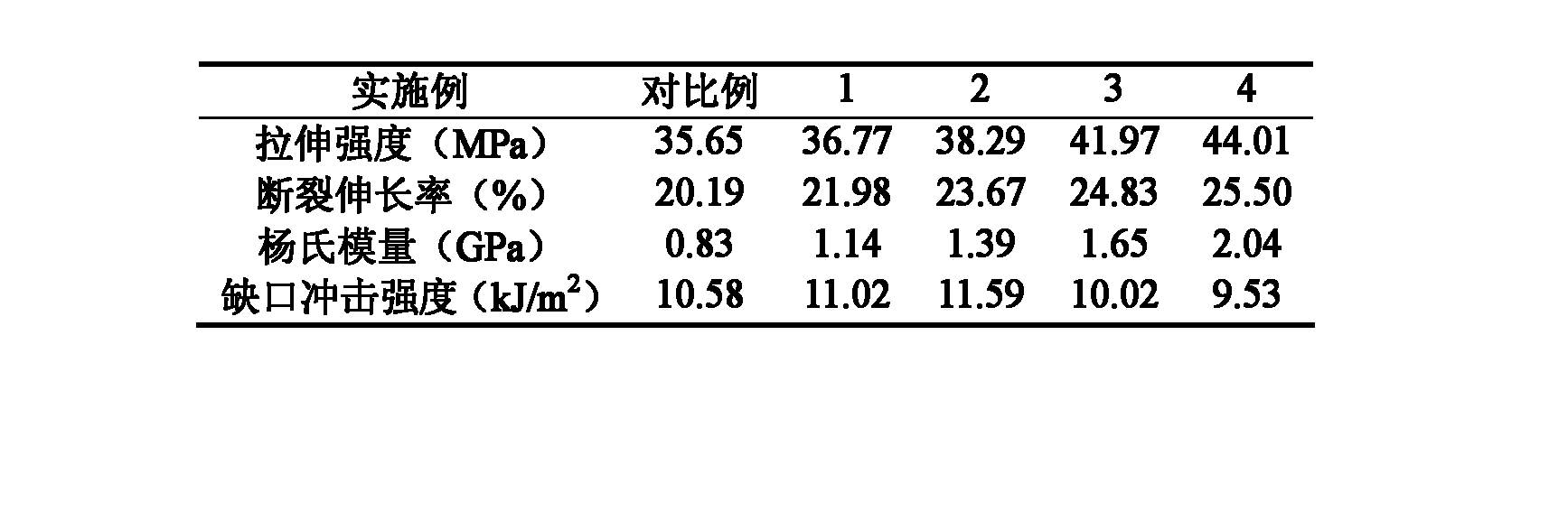

Preparation method of modified magnesium borate whisker/PP (propene polymer) composite material

InactiveCN102504414AImprove mechanical propertiesThe preparation process conditions are simpleMolding machineCoupling

The invention relates to a preparation method of a modified magnesium borate whisker / PP (propene polymer) composite material. In the method, a PP material is used as a matrix, and a borate coupling agent modified magnesium borate whisker is used as reinforcement. The preparation method comprises the following steps of: (1) sufficiently dissolving 1 to 3 parts by mass of borate coupling agent with a proper amount of absolute ethanol at a temperature of between 30 and 50 DEG C, and uniformly mixing for 0.5 to 1 hour with 97 to 99 parts by mass of magnesium borate whisker which is dried for 4 hours at a temperature of between 120 and 140 DEG C, filtering, cleaning, and baking at a temperature of between 90 and 120 DEG C for 4 to 6 hours to obtain a surface modified whisker; (2) preheating a mixing mill to a temperature of between 180 and 200 DEG C, adding a PP base material to melt for 3 to 5 minutes, and adding the borate coupling agent modified magnesium borate whisker which is prepared in the step (1) according to a proportion to mix for 8 to 10 minutes to prepare a semifinished product; and (3) molding the semifinished product prepared in the step (2) for 6 to 8 minutes in a molding machine at a pressure of 10MPa and a temperature of between 180 and 185 DEG C to prepare the modified magnesium borate whisker / PP composite material. The preparation method of the invention has the advantages of simple conditions and low cost; and the mechanical performance of the modified magnesium borate whisker / PP composite material is remarkably improved, and the application prospect is wide.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for preparing magnesium borate whisker porous ceramic by employing in-situ growth

InactiveCN103626510AHigh strengthSolve the problem of high temperature sinteringNitrateMagnesium salt

The invention discloses a method for preparing magnesium borate whisker porous ceramic by employing in-situ growth. The method comprises the following steps: with an inorganic magnesium salt and boric acid as raw materials, and inorganic nitrate as a catalyst, mixing the raw materials in a ball-milling manner, and then pressing the mixed powder to form a blank; carrying out phase transformation by adopting a high-temperature roasting mode; and washing and drying, so as to prepare the magnesium borate whisker porous ceramic. In the procedure of mixing the raw materials in the ball-milling manner, the magnesium salt and the boric acid are mixed according to a molar ratio of Mg to B being 1:0.5 to 1:3, and the mass content of the nitrate is 1-10% of total content of the mixed materials. Compared with the prior art, the method for preparing the magnesium borate whisker porous ceramic by employing in-situ growth, which is disclosed by the invention has the advantages that on one hand, the adhesion problem among whiskers prepared by an existing method for preparing the magnesium borate whisker is solved, and on the other hand, the problem that high-temperature sintering is required in preparation of the porous ceramic is solved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Manufacturing method of polyester fiber with anti-aging function

InactiveCN106400198AImprove anti-agingImproves UV resistanceElectroconductive/antistatic filament manufactureFilament/thread formingFiberProtonation

Owner:RONGSHENG PETROCHEM

High-strength automobile hub and preparation method thereof

InactiveCN108277395AHigh strengthImprove corrosion resistanceFoundry mouldsFoundry coresManganeseAlloy

The invention discloses a high-strength automobile hub and a preparation method thereof. The automobile hub is made of an alloy. The alloy comprises, by mass percent, 3%-12% of silicon, 0.1%-5% of carbon, 0.01%-3% of copper, 1%-10% of manganese, 1.2% or less of calcium, 0.1%-8% of chrome, 3.5% or less of iron, 5%-18% of zinc oxide, 0.001%-0.5% of phosphorus, 0.01%-1% of nickel, 0.001%-0.3% of molybdenum, 0.005%-0.8% of tungsten, 0.0001%-0.5% of lead, 0.001%-0.3% of strontium, 1%-15% of magnesium borate, 0.2%-10% of potassium titanate and the balance aluminum. During smelting, the components are taken and, by weight percent, put into a smelting furnace to be subjected to smelting and deslagging, and then by means of refining, standing, pouring, pressurizing, cooling and demolding, the automobile hub is obtained. According to the high-strength automobile hub and the preparation method thereof, the components are scientific and reasonable, the formula is simple, the preparation process iseasy to implement, and the obtained hub is high in strength, resistant to corrosion, impact and abrasion, good in heat resistance, long in service life and good in casting performance. The preparation process is simple and easy to operate, the energy consumption is low, the production efficiency is high, and the high-strength automobile hub is suitable for being produced on a large scale.

Owner:TIANJIN XUANZE METAL PROD

Novel wear resistant rubber and preparation method thereof

The invention discloses a novel wear resistant rubber, which is composed of the following components in parts by weight: 50 to 70 parts of natural rubber, 30 to 50 parts of fluororubber, 10 to 30 parts of ethylene propylene diene monomer, 10 to 30 parts of kaolin, 3 to 5 parts of phenolic resin, 3 to 5 parts of aramid short fiber, 3 to 5 parts of aromatic hydrocarbon oil, 1 to 3 parts of microcrystalline cellulose, 2 to 6 parts of microcrystalline wax, 6 to 10 parts of sulfur, 2 to 7 parts of titanium dioxide, 0.2 to 0.4 part of vitamin E, 1 to 3 parts of sodium citrate, 1 to 3 parts of limonene, 1 to 3 parts of benzoyl acetone, 2 to 7 parts of tin antimony oxide, 3 to 5 parts of zinc oxide, 3 to 5 parts of magnesium oxide, 3 to 5 parts of petroleum resin, 3 to 5 parts of magnesium borate whisker, 3 to 5 parts of molybdenum disulfide, 2 to 7 parts of rare earth, 5 to 9 parts of silicon carbide, 6 to 8 parts of diamond micropowder, 20 to 30 parts of highly wear resistant carbon black, 1 to 3 parts of stearic acid, 6 to 10 parts of nano calcium carbonate, 2 to 4 parts of crosslinking agent, 1 to 3 parts of antioxidant, and 2 to 4 parts of anti-aging agent. The provided rubber has the advantages of excellent wear resistant performance, corrosion resistant performance, antioxidant property, and anti-aging property.

Owner:NINGGUO NINGKANG SEALING PARTS

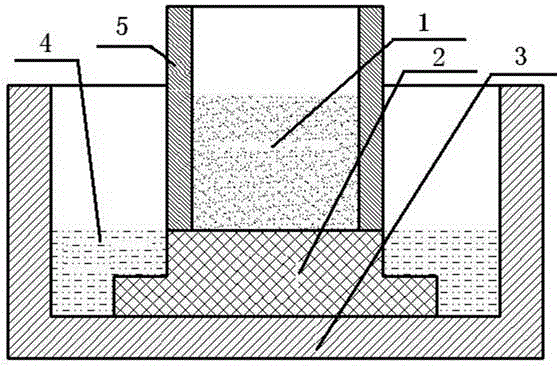

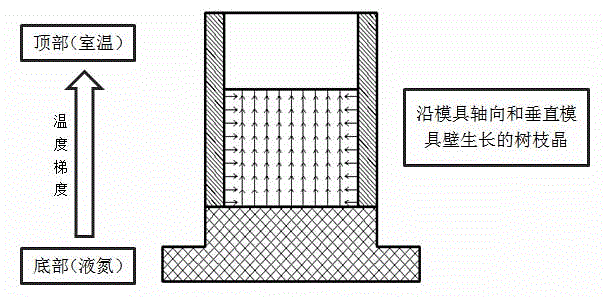

Method for preparing high-porosity in-situ grown magnesium borate whisker porous ceramics

The invention discloses a method for preparing high-porosity in-situ grown magnesium borate whisker porous ceramics. The method is that basic magnesium carbonate and boric acid are used as the raw materials; nitrate is used as a catalyst; sodium methyl cellulose is used as a binder; and polyacrylamide is used as a dispersing agent. The method comprises the steps of (1) mixing the materials through a ball mill; (2) preparing slurry; (3) shaping by injection molding and directionally freezing and curing; (4) freezing and drying in a vacuum condition; (5) sintering at the normal temperature; and (6) washing. Compared with the prior art, the method has the advantages that the in-situ grown magnesium borate whisker porous ceramics with high porosity reaching 85% can be prepared, the problem of relatively low porosity of the in-situ grown magnesium borate whisker porous ceramics prepared by the prior art can be solved, and the problem that non-uniform material mixing leads to non-uniform growing of whiskers in the magnesium borate whisker porous ceramics preparation process can be solved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Enhanced halogen-free flame-retardant PP/PPO alloy and preparation method thereof

The invention relates to enhanced halogen-free flame-retardant PP / PPO alloy and a preparation method thereof, and belongs to the technical field of high molecular material. The enhanced halogen-free flame-retardant PP / PPO alloy comprises, by weight, 70-90 parts of PP, 50-80 parts of PPO, 10-18 parts of magnesium borate crystal whiskers, 8-12 parts of ammonium polyphosphate, 6-10 parts of melamine phosphate, 5-8 parts of magnesium hydrate crystal whiskers, 5-20 parts of compatilizer, 1-2 parts of antioxidants and 0.5-1.4 parts of lubricating agents. The enhanced halogen-free flame-retardant PP / PPO alloy has good mechanical properties and dimensional stability and is easily processed to be formed. Meanwhile, combined flame retarding of an inorganic flame retardant and an organic phosphorus-nitrogen flame retardant is adopted, so that the enhanced halogen-free flame-retardant PP / PPO alloy has good flame retardant performance and is widely applied to the fields of electronic and electric products, automobiles, aviation, petroleum, the chemical industry, precision-machinery components and the like.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

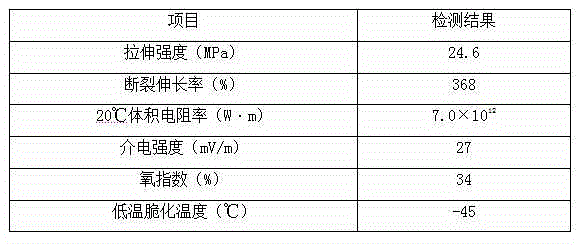

Low-temperature reinforced type heating cable sheathing material and preparation method thereof

InactiveCN104448811AImprove low temperature resistanceHigh mechanical strengthPlastic/resin/waxes insulatorsEpoxyBoride

The invention discloses a low-temperature reinforced type heating cable sheathing material and a preparation method thereof. The low-temperature reinforced type heating cable sheathing material is prepared from the following raw materials in parts by weight: 36-52 parts of nylon 66, 24-48 parts of polytetrafluoroethylene, 18-32 parts of polyamide imide, 10-15 parts of low-molecular-weight polybutylene, 14-18 parts of magnesium borate whiskers, 12-16 parts of illite powder, 10-15 parts of tetraethylene glycol diheptylate, 5-10 parts of nano zirconium boride, 3-5 parts of magnesium oleate, 8-14 parts of diisodecyl adipate, 4-6 parts of aluminum hydroxydistearate, 6-9 parts of caprylic / capric triglyceride, 10-15 parts of dioctyl sebacate, 5-10 parts of epoxy fatty acid methyl ester, 1-2 parts of polyethylene oxide sorbitan monoleate and 3-4 parts of auxiliaries. The low-temperature reinforced type heating cable sheathing material has good low-temperature resistance, a low-temperature brittleness temperature up to -45 DEG C, extremely good mechanical strength and excellent corrosion resistance, ageing resistance and abrasive resistance, and is durable in use and wide in range of application.

Owner:ANBANG ELECTRICAL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com