Method for preparing magnesium borate whisker porous ceramic by employing in-situ growth

A technology of magnesium borate whiskers and porous ceramics, which is applied in the field of in-situ growth and preparation of magnesium borate whiskers porous ceramics, can solve the problems of whisker adhesion and high-temperature sintering of porous ceramics, and achieve increased strength, reduced material cracking, high The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing magnesium borate whisker porous ceramics by in-situ growth. The preparation method uses inorganic magnesium salt and boric acid as raw materials, uses inorganic nitrate as catalyst, mixes materials through low-temperature ball milling, and then presses the mixed powder into blanks. Roasting carries out phase conversion, washing, drying, and makes magnesium borate whisker porous ceramics, the specific steps are as follows:

[0044] In step 1, the inorganic magnesium salt and boric acid are mixed according to the Mg:B molar ratio of 1:0.5-1:3 and 1%-10% mass fraction of nitrate mixed powder to obtain prefabricated powder. In this process, the mixed powder of inorganic magnesium salt, boric acid and nitrate is put into an agate ball mill jar and milled using a planetary ball mill with a rotational speed of 250-350r / min and a milling time of 6-10 hours.

[0045] In step 2, the above-mentioned prefabricated powder is compressed into a billet with a dia...

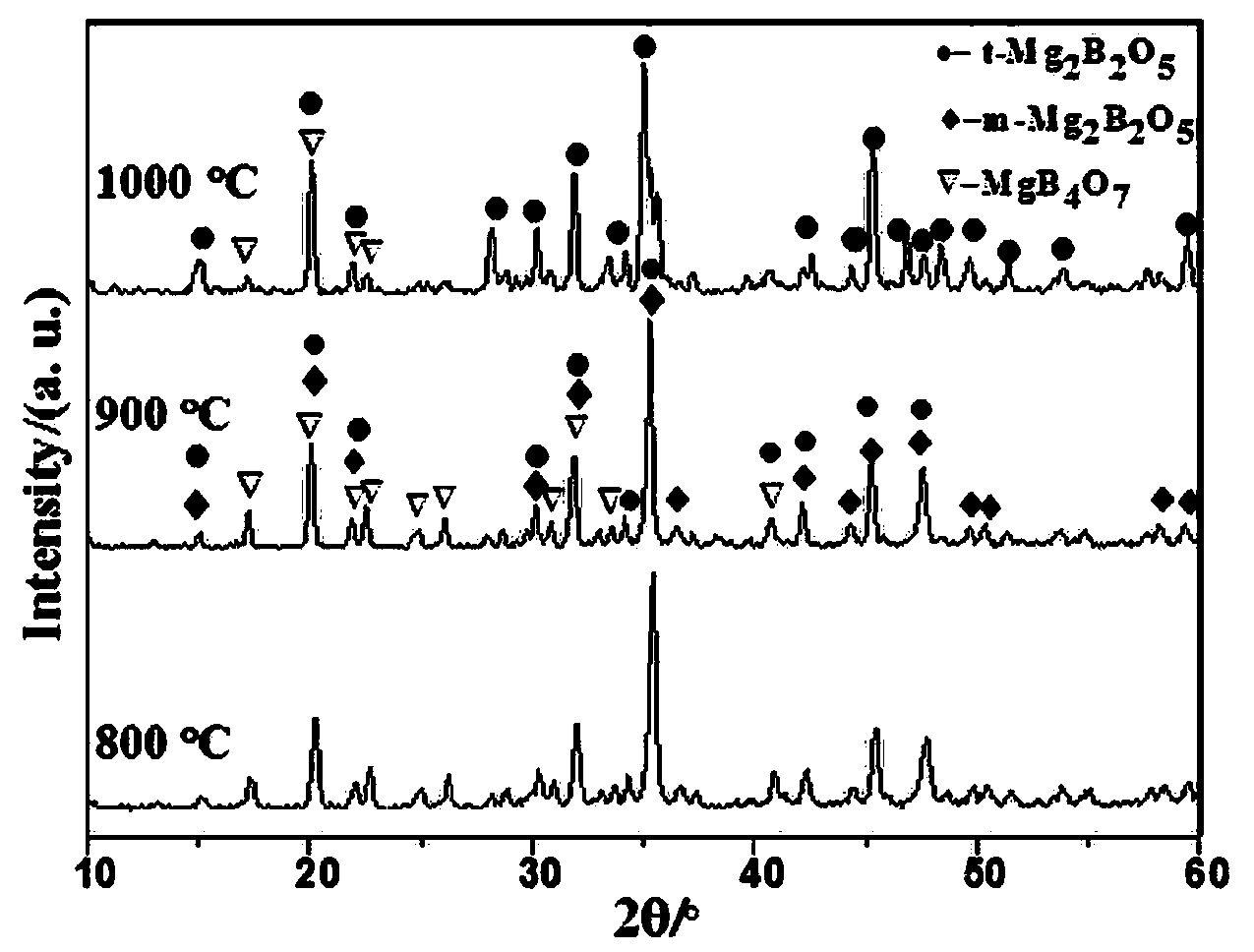

Embodiment 1

[0049] Put 9g of boric acid, 11g of basic magnesium carbonate and nickel nitrate of 5% mass fraction in a ball mill jar for ball milling for 10 hours, then press it into a sheet-shaped billet with a diameter of 10mm, place the billet in a quartz crucible, and place the quartz The crucible was placed in a box-type high-temperature furnace. First, it was raised to 700°C at a constant temperature of 5°C / min for 1 hour, then raised to 800°C for 4 hours to grow whiskers, and then allowed to cool naturally to room temperature to obtain crystals. Magnesium borate whisker porous ceramics with a whisker diameter of 0.5 μm, an average length of 1-2 μm, a compressive strength of 5 MPa, and a porosity of 40%.

Embodiment 2

[0051] Put 10g boric acid, 10g basic magnesium carbonate and 5% ferric nitrate in a ball mill jar for ball milling for 10 hours, then press it into a sheet-shaped billet with a diameter of 10mm, place the billet in a quartz crucible, and place the quartz The crucible was placed in a box-type high-temperature furnace, first raised to 700 °C at a constant temperature of 5 °C / min for 1 hour, then raised to 900 °C for 4 hours to grow whiskers, and then allowed to cool naturally to room temperature to obtain crystals. Magnesium borate whisker porous ceramics with a whisker diameter of 0.4 μm, an average length of 2-5 μm, a porosity of 45%, and a compressive strength of 10 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com