Winch brake pad and manufacture method thereof

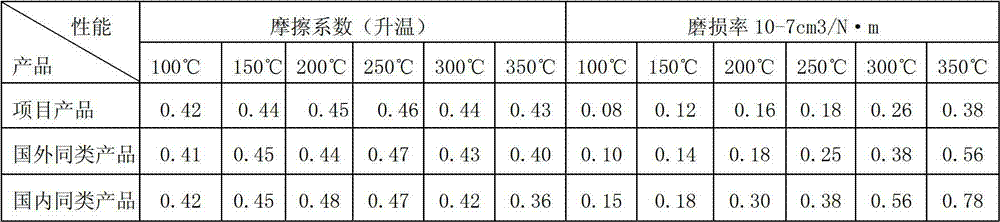

A technology for brake pads and hoisting machines, which is applied in the direction of hoisting devices, mechanical equipment, friction linings, etc., can solve the problems of low application rate of brake friction materials for large-tonnage hoisting machines, and achieve low cost, simple manufacturing, and broad market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

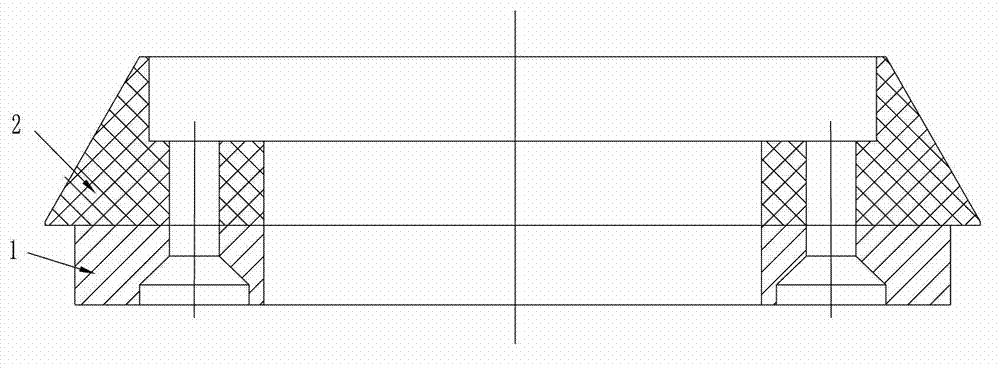

[0027] The hoist brake pad includes an iron-based framework and a friction material layer bonded to the bonding surface of the iron-based framework; wherein the friction material layer is composed of the following raw materials: 10 parts of melamine modified phenolic resin, 8.6 parts of nitrile rubber, ceramic 10 parts of fiber, 4 parts of carbon fiber, 6 parts of aramid fiber, 10 parts of calcium carbonate whisker, 1 part of bauxite, 5 parts of vulcanized ladder, 5 parts of aluminum hydroxide, 6 parts of silicon bath soil, 5 parts of potassium feldspar, 0.5 parts of stearic acid, 0.7 parts of accelerator DM, 1 part of anti-aging agent BLE-W, 1.2 parts of sulfur, 5 parts of cashew nut shell oil friction powder, 3 parts of artificial graphite, 3 parts of foam iron powder, 5 parts of petroleum coke, magnesium borate 6 parts of whiskers, 4 parts of cuprous oxide.

[0028] Preparation:

[0029] 1. Weigh various raw materials according to the formula for use;

[0030] 2. Mixing: ...

Embodiment 2

[0035] The hoist brake pad includes an iron-based framework and a friction material layer bonded to the bonding surface of the iron-based framework; wherein the friction material layer is composed of the following raw materials: 12 parts of melamine modified phenolic resin, 9 parts of nitrile rubber, ceramic 9 parts of fiber, 4 parts of carbon fiber, 5 parts of aramid fiber, 12 parts of calcium carbonate whisker, 1 part of bauxite, 4 parts of vulcanized ladder, 5 parts of aluminum hydroxide, 3 parts of silicon bath soil, 6 parts of potassium feldspar , 0.5 parts of stearic acid, 0.7 parts of accelerator DM, 1 part of anti-aging agent BLE-W, 1.2 parts of sulfur, 6 parts of cashew nut shell oil friction powder, 4 parts of artificial graphite, 3 parts of foam iron powder, 5 parts of petroleum coke, boric acid 5.6 parts of magnesium whiskers, 3 parts of cuprous oxide.

[0036] Preparation:

[0037] 1. Weigh various raw materials according to the formula for use;

[0038] 2. Mixi...

Embodiment 3

[0043] The hoist brake pad includes an iron-based framework and a friction material layer bonded to the bonding surface of the iron-based framework; wherein the friction material layer is composed of the following raw materials: 11 parts of melamine modified phenolic resin, 10 parts of nitrile rubber, ceramic 12 parts of fiber, 4 parts of carbon fiber, 4 parts of aramid fiber, 10 parts of calcium carbonate whisker, 1 part of bauxite, 4 parts of vulcanized ladder, 4 parts of aluminum hydroxide, 3 parts of silicon bath soil, 5 parts of potassium feldspar , 0.5 parts of stearic acid, 0.7 parts of accelerator DM, 1 part of anti-aging agent BLE-W, 1.5 parts of sulfur, 3 parts of cashew nut shell oil friction powder, 5 parts of artificial graphite, 3 parts of foam iron powder, 5 parts of petroleum coke, boric acid 9 parts of magnesium whiskers, 3.3 parts of cuprous oxide.

[0044] Preparation:

[0045] 1. Weigh various raw materials according to the formula for use;

[0046] 2. Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com