Gadolinium-containing sintered rare earth permanent magnet alloy and preparation method thereof

A technology of rare earth permanent magnets and alloys, which is applied in the field of magnetic materials, can solve the problems of increasing coercive force and limited temperature coefficient, narrow application range, and reducing costs, etc., and achieves the effect of simple and practical preparation method, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

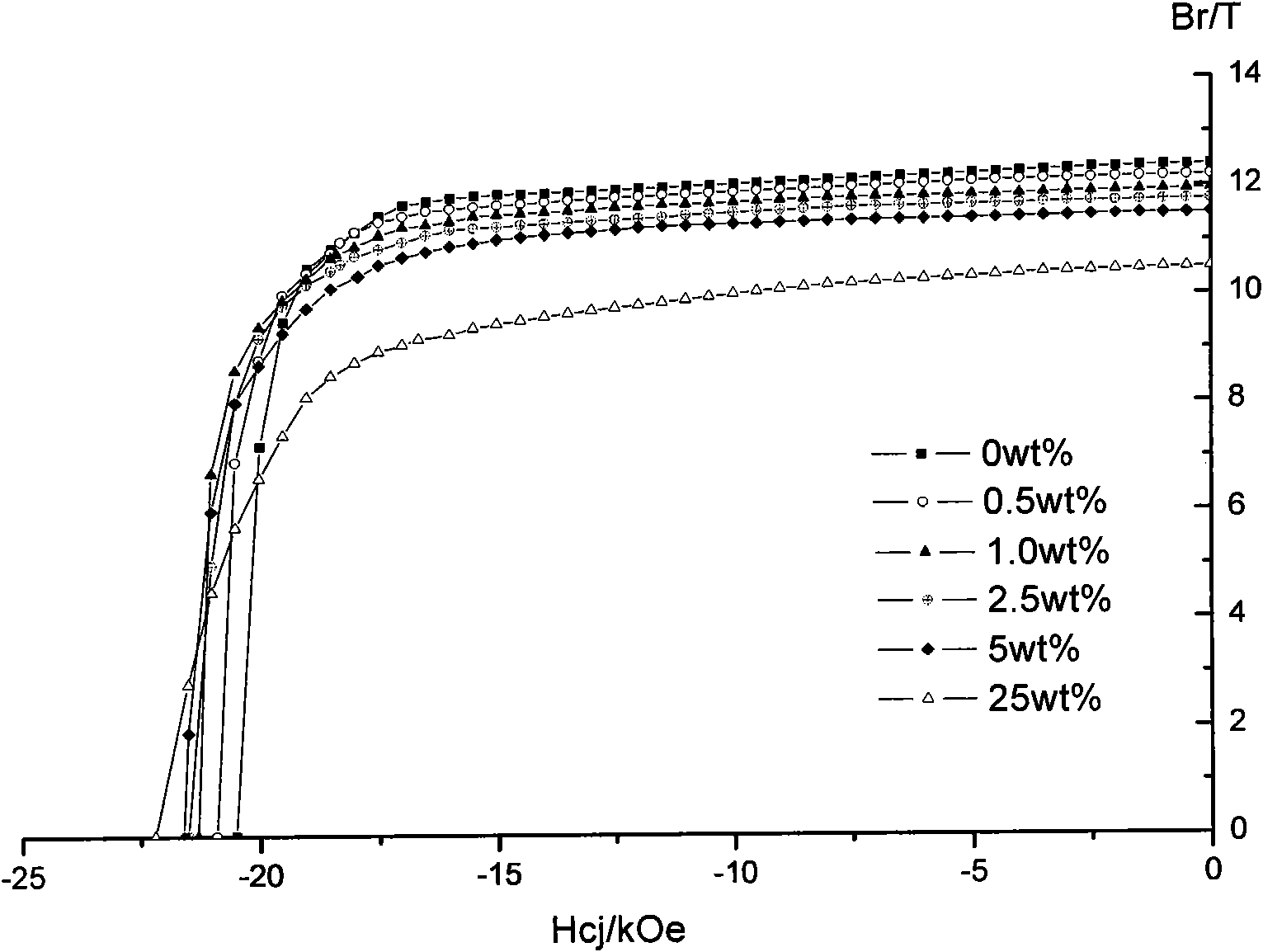

[0034] By composition is (1)Nd 24.5 PR 5 Dy 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 Smelting ingots. Jet milling after hydrogen crushing, the prepared fine powder is oriented and formed in a magnetic field of 1.8-2T, and then isostatically pressed at 200MPa, and finally sintered at 1000-1200°C in a vacuum state to obtain a magnet at 480- Annealed at 600° C. for 5 hours to prepare a Gd-free NdFeB magnet as a control, see Example 1 in Table 1.

[0035] Using the method of the above-mentioned Example 1 to prepare different Gd contents between 0.5wt.% and 25wt.%, the components are (2) Nd respectively 24 PR 5 Dy 2.5 Gd 0.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(3)Nd 23.5 PR 5 Dy 2.5 Gd 1.0 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(4)Nd 22 PR 5 Dy 2.5 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(5)Nd 19.5 PR 5 Dy 2.5 Gd 5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(6)Nd 4.5 Dy 2.5 Gd 25 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 See Table 1 for the room t...

Embodiment 7~9

[0048] The components are respectively (7)Nd 27 Dy 2.5 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(8)Nd 27 Tb 2.5 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(9)Nd 22 PR 5 Tb 1.25 Dy 1.25 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 The ingots were prepared according to the methods of Examples 1-6, and the results are shown in Table 3.

[0049] table 3

[0050] Reality

Embodiment 10~13

[0052] The components are respectively (10)Nd 27 Dy 2.5 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(11)Nd 24.5 Dy 5 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(12)Nd 27 Tb 2.5 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 、(13)Nd 24.5 Tb 5 Gd 2.5 Fe 65.05 co 1.5 Cu 0.15 al 0.3 B 1 The ingots were prepared according to the methods of Examples 1-6, and the results are shown in Table 4.

[0053] Table 4

[0054] Reality

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com