Patents

Literature

367results about How to "Low purity requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

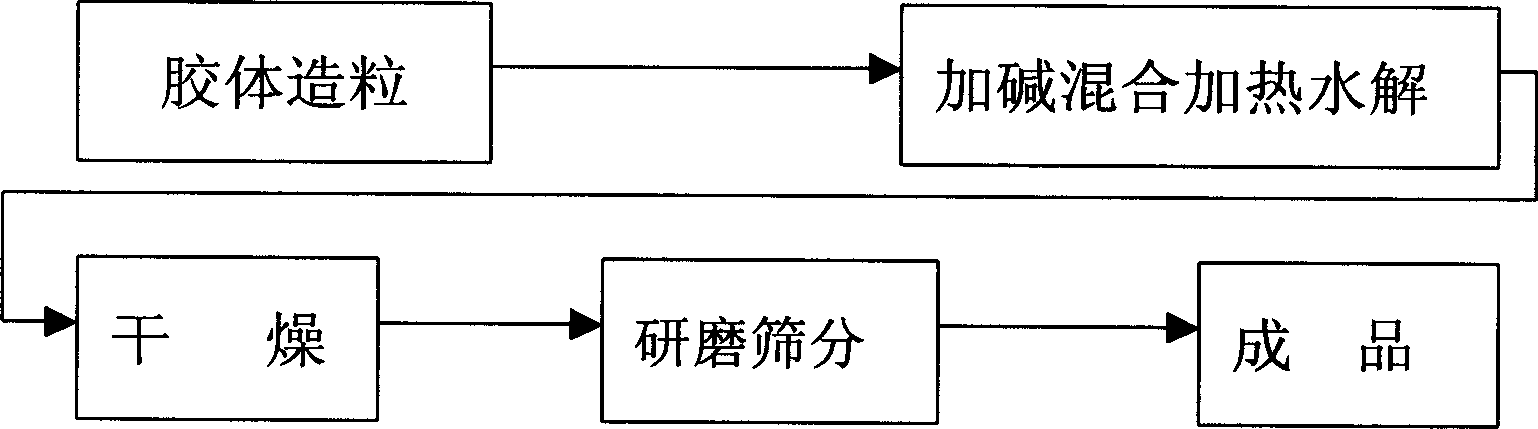

Hydrolysis method in technique for synthesizing polyacrylamide with super molecular weight

A hydraulic process for synthesizing the ultrahigh-molecular polyacrylamide used to treat the sewage in oil field includes polymerizing reaction of the acquous solution of acrylamide to become colloid, granulating, proportionally mixing it with solid alkali, and stirring in stirrer while heatinb by the hot water jacket of stirrer. Its molecular weight can reach 28,000,000.

Owner:PETROCHINA CO LTD

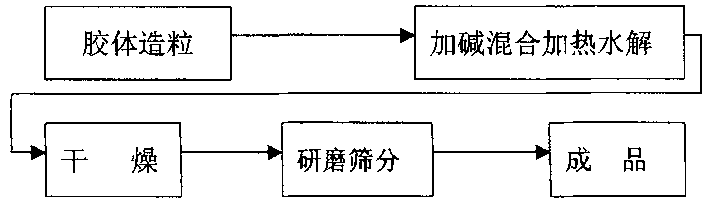

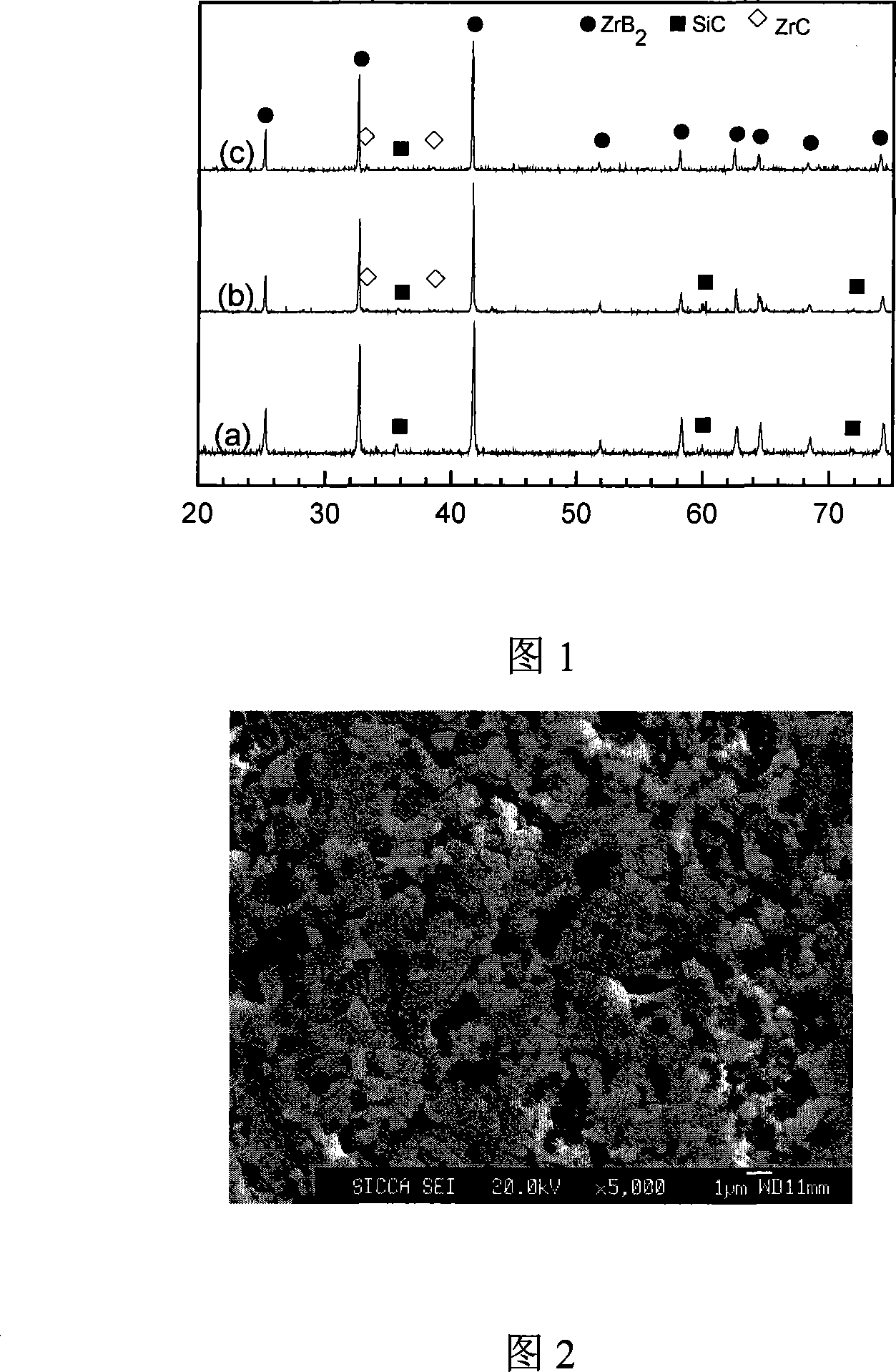

Method for preparing ZrB2-SiC-ZrC diphase ceramic material

The invention relates to a process for preparing ZrB2-SiC-ZrC complex phase ceramic materials, which is characterized in that purity of zirconium powder is not less than 98%, silicon powder and boron carbide powder are used as raw materials, batching according to reaction equation (2+x)Zr+(1-x)Si+B4C=2ZrB2+(1-x)SiC+ZrC, 0<=x<=0.5 of generating ZrB2-SiC-ZrC, then, materials containing different components are obtained. The raw materials after being ball ground and dried are sintered with heat pressing between 1500-1700DEG C by adjusting sintering technique parameter and employing self-propagating reaction of the raw materials generated in the process of heating up, thereby obtaining the ZrB2-SiC-ZrC complex phase ceramic materials of different components. Relative density of the materials prepared by the invention is larger than 97%, bending strength is 600-900MPa, fracture toughness property is 4.5-6MPa,m1 / 2, and hardness is 16-19GPa.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

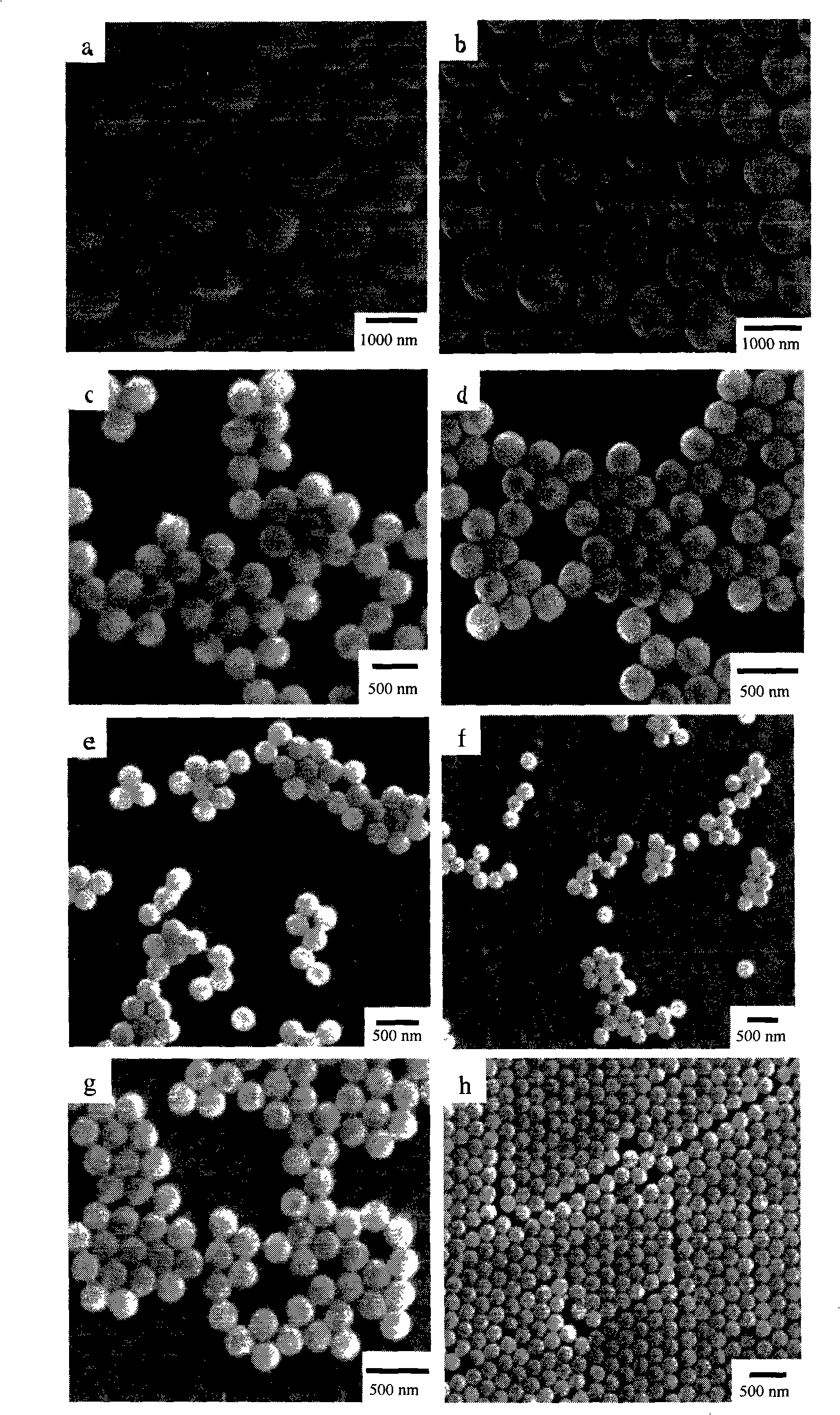

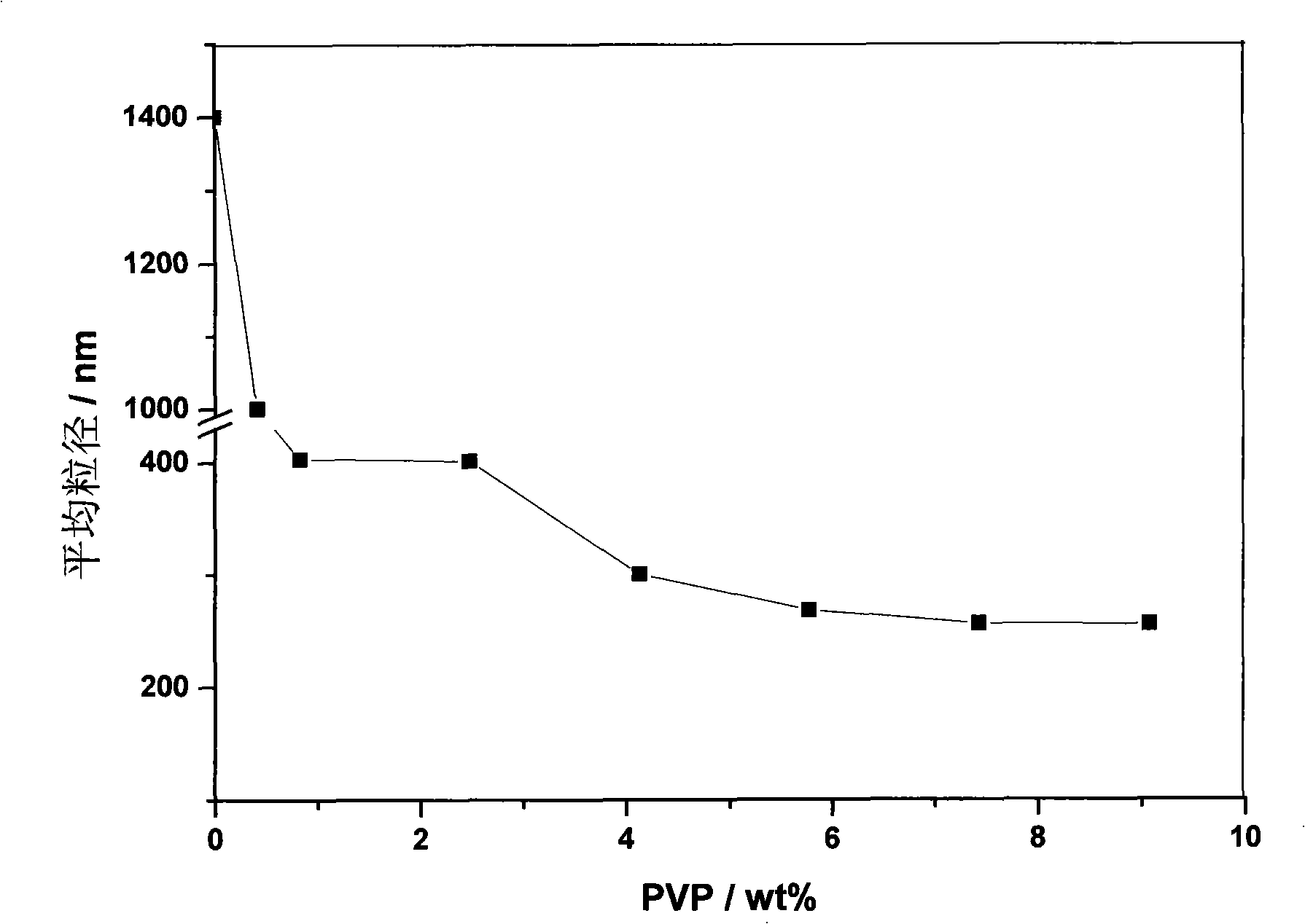

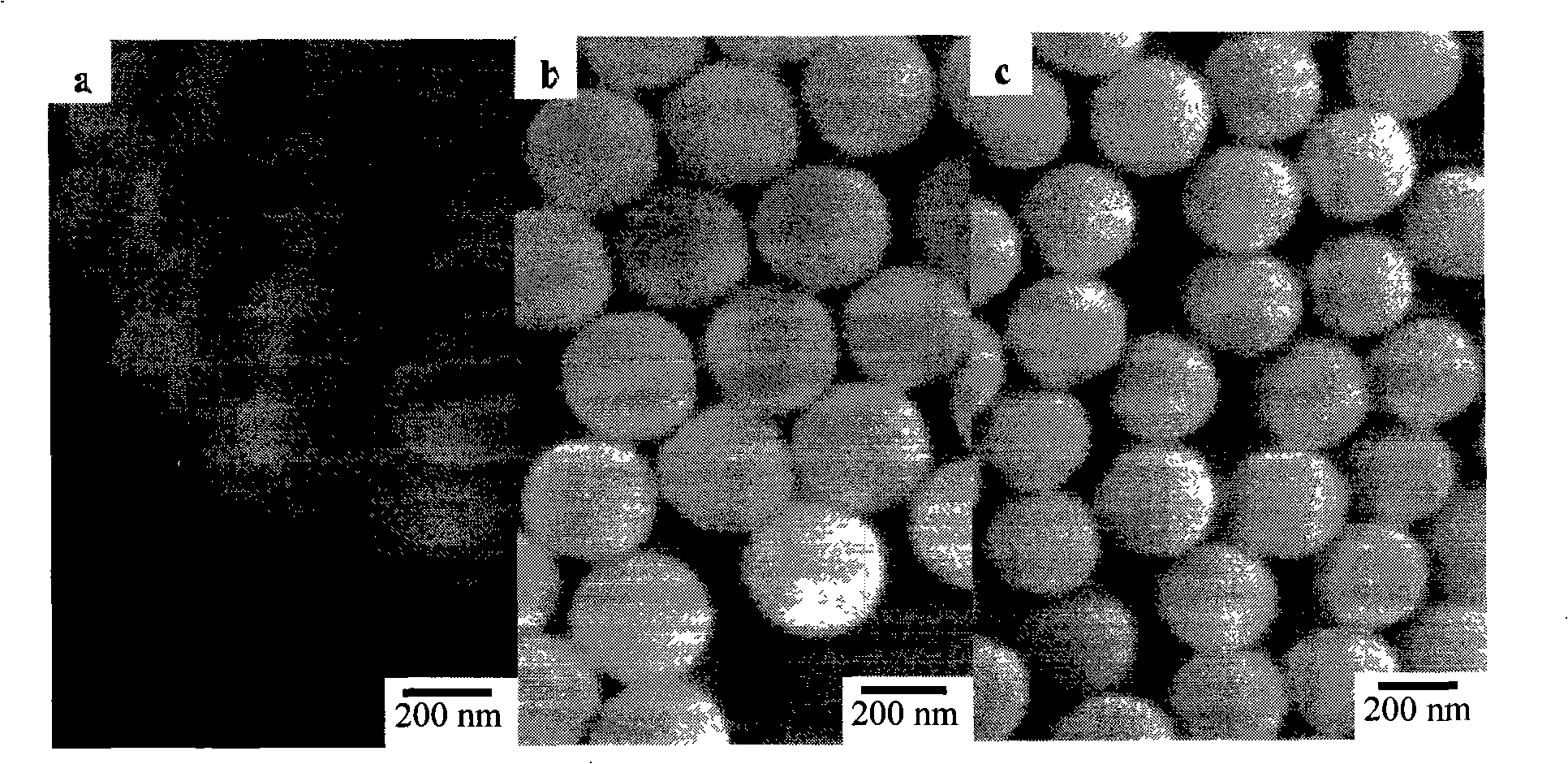

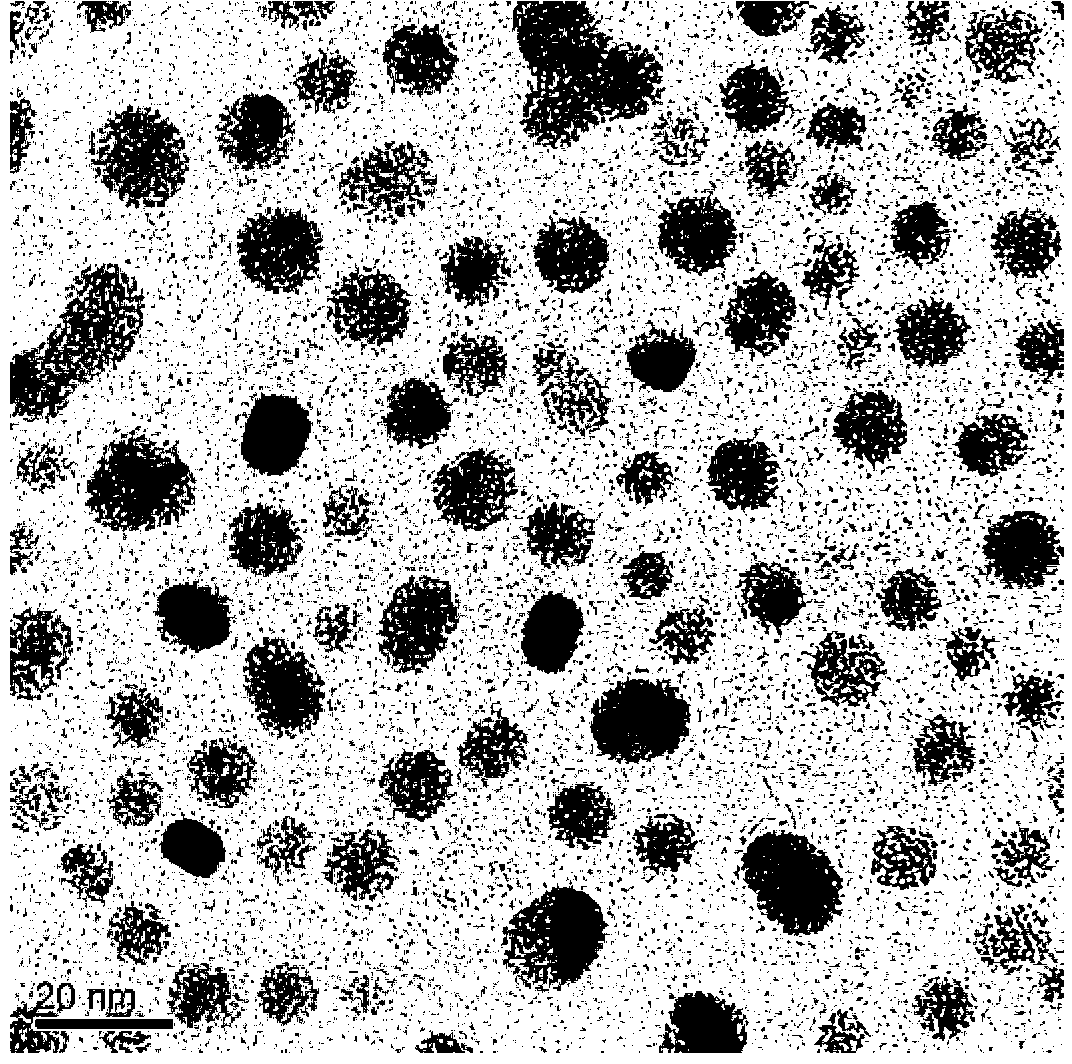

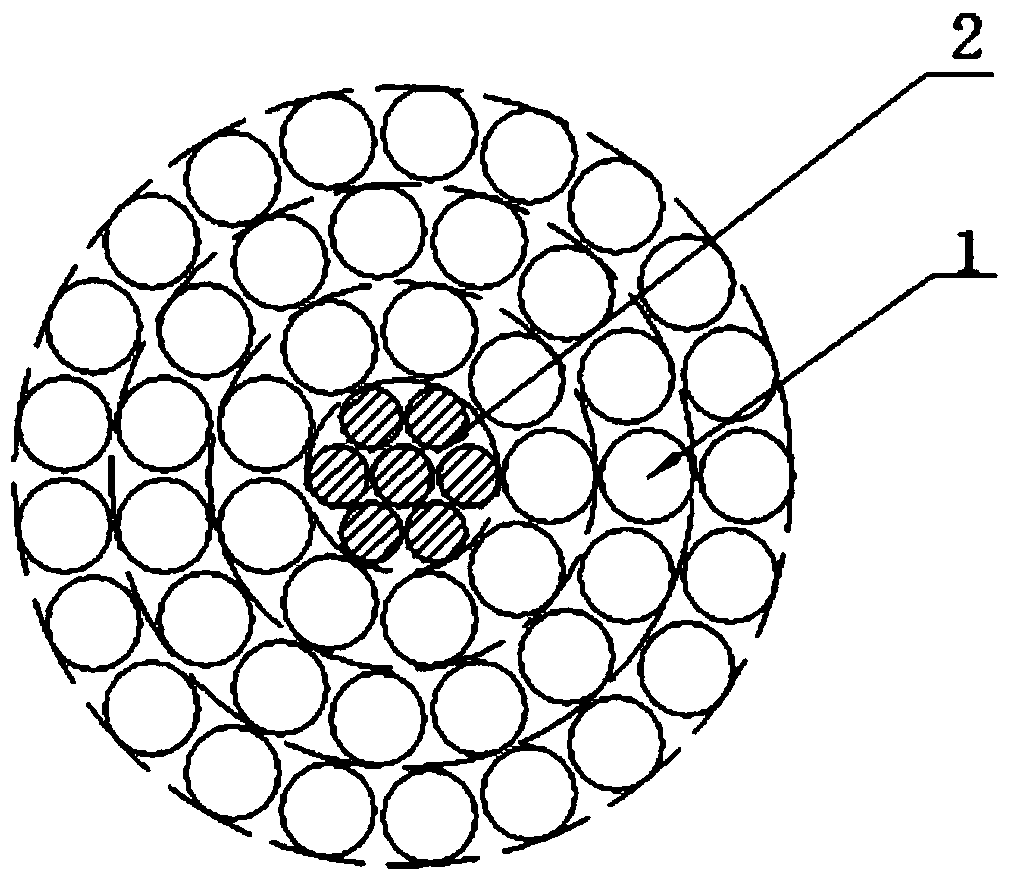

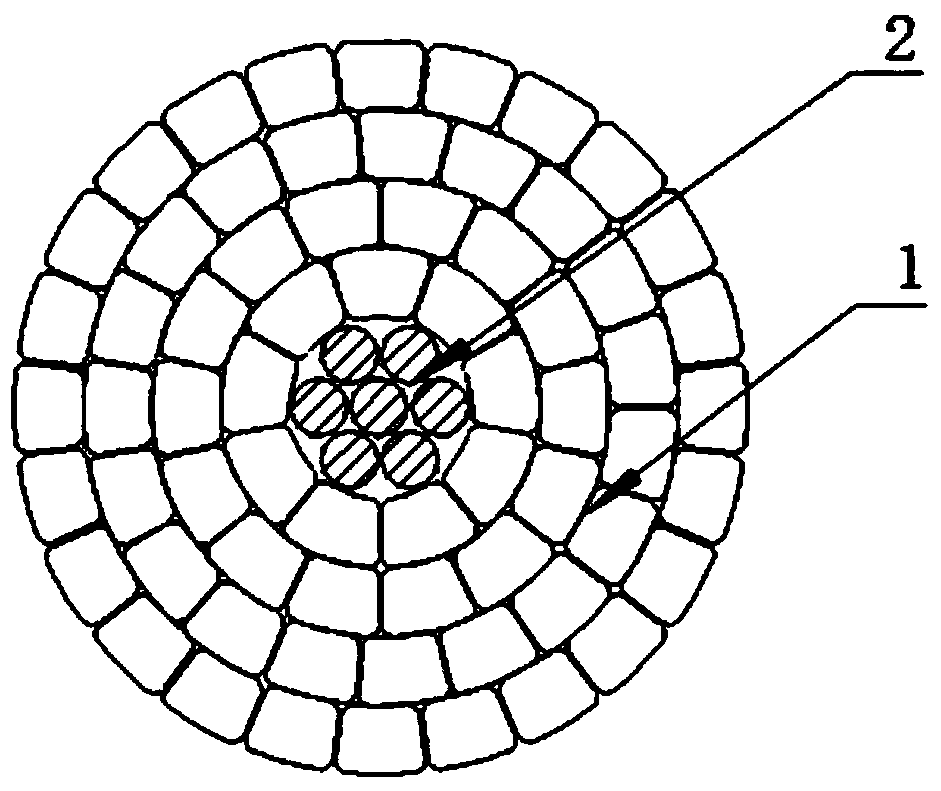

Method for preparing monodisperse polystyrene microsphere with controllable grain diameter

InactiveCN101293936ALow purity requirementGood monodispersityHydrocarbon purification/separationHydrocarbonsPotassium persulfateMicrosphere

The invention belongs to the technology field of nanometer materials preparation, particularly relates to a preparation method of monodisperse polystyrene microspheres capable of controlling the particle size of the polystyrene microspheres within a certain range by changing the use amount of a stabilizer. The invention prepares polystyrene microspheres with simply purified styrene as a monomer, potassium persulfate as an initiator, water as a reaction medium and polyvinylpyrrolidone as a stabilizer by using soap-free emulsion polymerization. The preparation method uses electromagnetic stirring instead of electric stirring; and has the advantages of relatively low requirements for the uniformity of stirring speed, no need of surfactant, simple process, and low cost. The obtained polystyrene microspheres have good monodispersity, and the particle size thereof can be controlled within the range of 250-1,400nm by changing the use amount of the stabilizer. The monodispersed polystyrene microspheres have important application value as a module or template in construction of photonic crystals, inorganic / organic nanometer composite materials and hollow micrometer / nanometer spheres.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

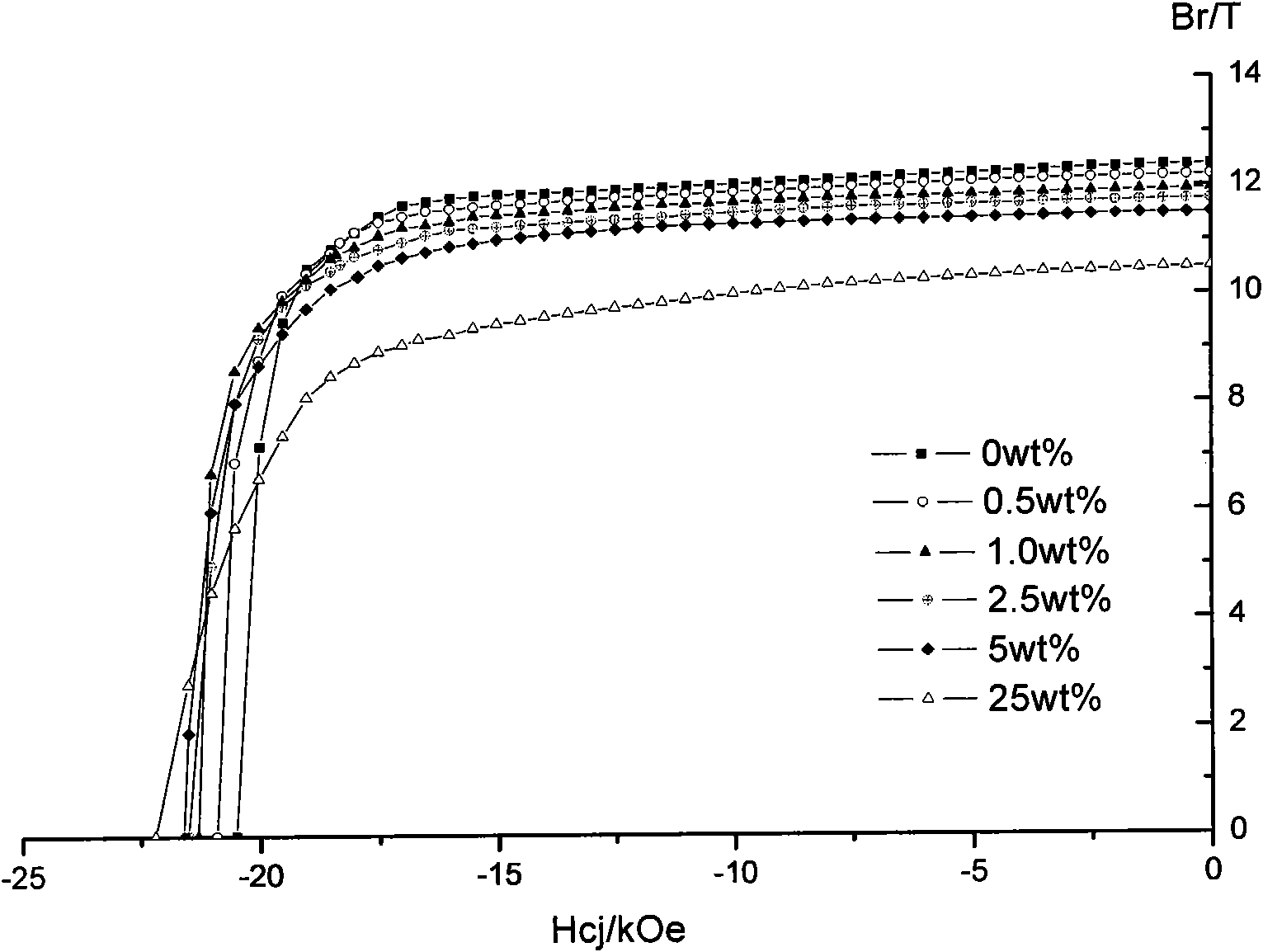

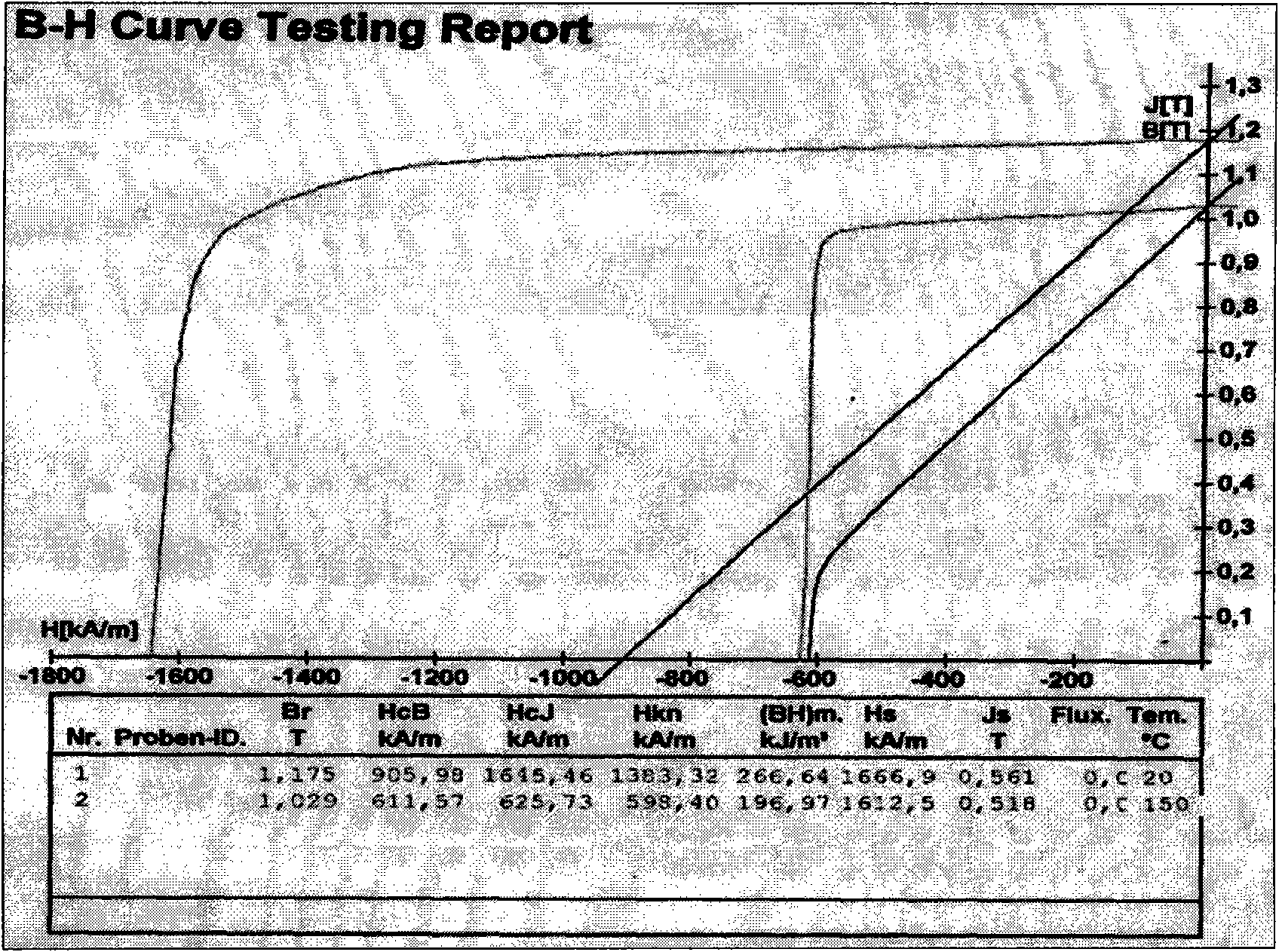

Gadolinium-containing sintered rare earth permanent magnet alloy and preparation method thereof

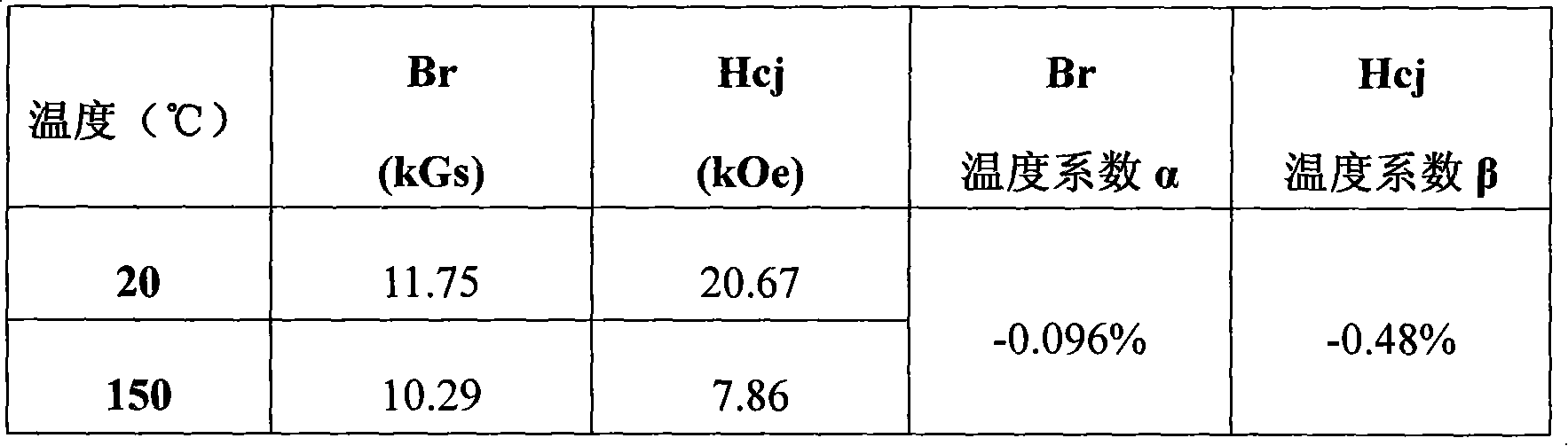

InactiveCN101630557AThe temperature coefficient of coercive force decreasesCoercive force temperature coefficient β decreasesMagnetic materialsGadoliniumRare earth

The invention relates to a gadolinium-containing sintered neodymium-iron-boron rare earth permanent magnet alloy and a preparation method thereof. The permanent magnet alloy comprises components in the following formula: Re[alpha]Gd[beta]B[gamma]MxNyFe[100-alpha-beta-gamma-x-y], wherein the weight percentage beta of the gadolinium element is more than 0.50 and less than or equal to 25. Through the method for adding the Gd element into a sintered Nd-Fe-B magnet, a sintered Nd-Fe-B permanent magnet with high coercive force and high temperature resistance is prepared. The coercive force temperature coefficient beta of the prepared magnet is reduced, so the coercive force of the magnet at high temperature is improved and the magnet has the high temperature resistance.

Owner:NINGBO KONIT IND +1

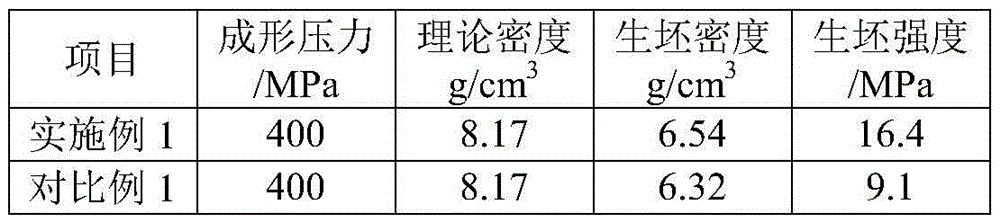

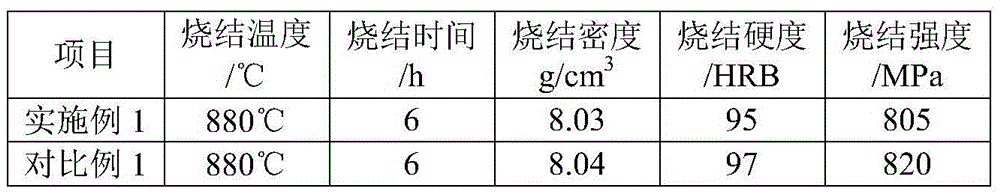

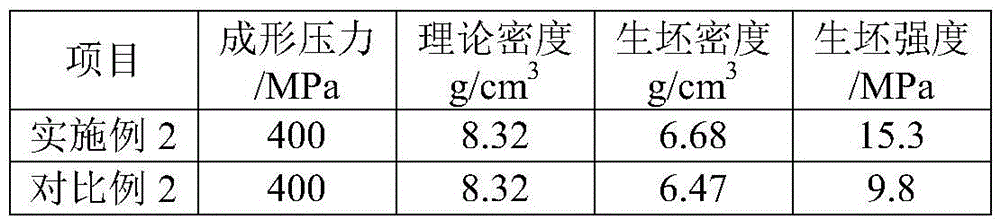

Fully-prealloyed powder and preparation method thereof

ActiveCN105463291AImprove control abilityImprove wear resistanceTransportation and packagingMetal-working apparatusUltimate tensile strengthImpurity

The invention discloses fully-prealloyed powder. The fully-prealloyed powder is prepared from, by weight percentage, 30%-65% of Fe, 15%-45% of Cu, 1%-15% of Sn, 0%-15% of Ni, 1%-30% of Co, 0%-5% of Qt and the balance inevitable impurities, wherein Qt is selected from one or more of Mn, Cr, Ti, P and W. The invention further discloses a preparation method of the fully-prealloyed powder. The formability and sintering strength of the fully-prealloyed powder are improved, and the sintering density of the fully-prealloyed power is increased; in the whole process, only the fully-prealloyed powder is used as a bonding agent in a diamond tool bit; and the advantages that the fully-prealloyed powder is low in sintering temperature, wide in process range and good in pullout strength on diamond are brought into full play.

Owner:BOSUN TOOLS CO LTD

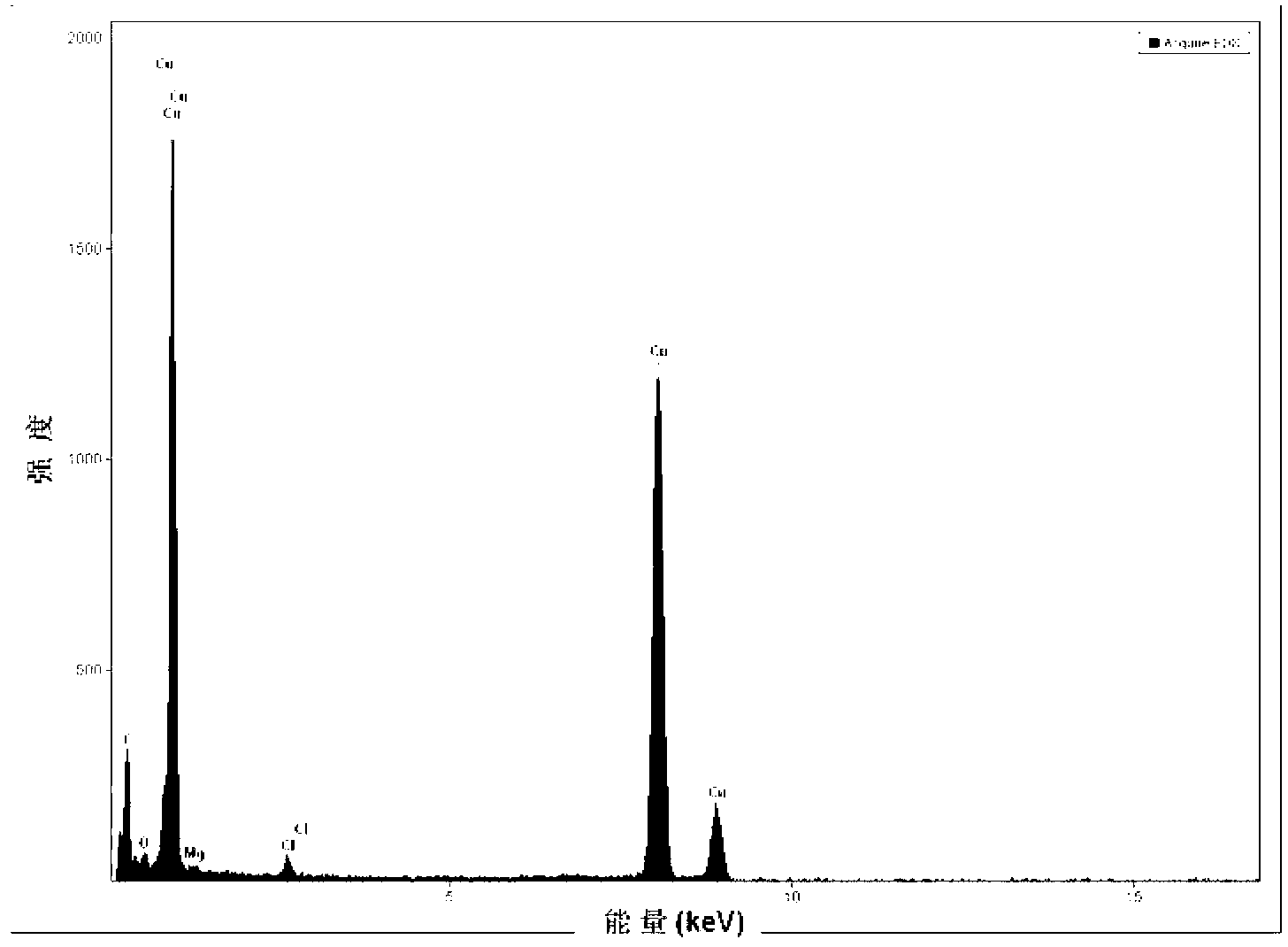

Method for preparing metal nanoparticles

The invention provides a method for preparing metal nanoparticles. By a dealloying method, firstly, precursor alloy solid fine materials containing target metal elements are prepared, secondly, the precursor alloy solid fine materials and acid solution containing hydrogen ions are in dealloying reaction under the condition of violent oscillation, the concentration of the hydrogen ions in the acid solution is controlled in the reaction process, magnesium, rare earth and other relatively active atoms preferentially react with the hydrogen ions and change into ions entering the solution, target metal atoms are freed out, and porous self-assembly and conglobation trend of the target metal atoms is effectively restrained under the condition of violent oscillation, so that uniformly scattered target metal nanoparticles are obtained. Compared with an existing method, the method is low in cost, simple in operation, green, environmentally friendly, high in preparation efficiency, high in by-product value and suitable for large-scale production, and accordingly has a fine application prospect.

Owner:赵远云

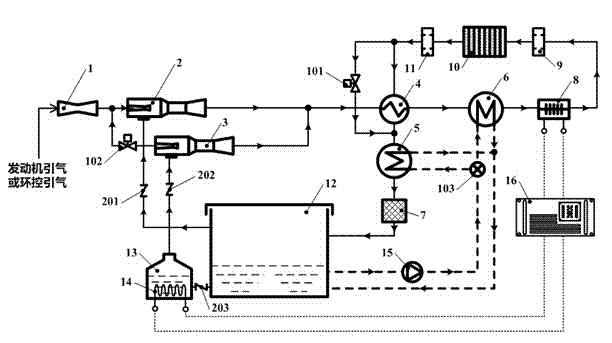

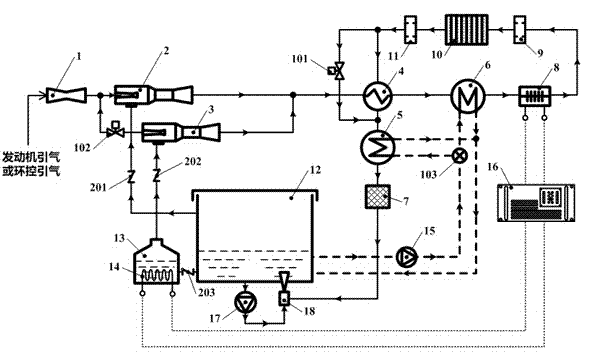

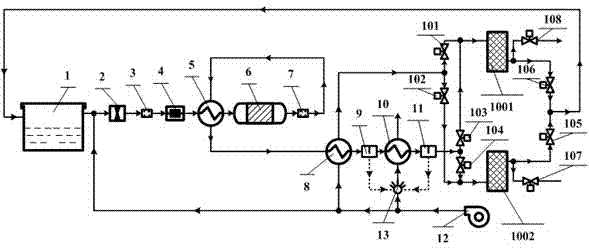

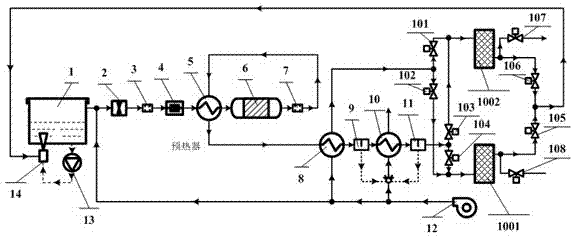

Aircraft oil tank inerting device based on catalytic oxidation technology

InactiveCN104843188ALow purity requirement of gas sourceFast startupFuel tank safety measuresFlight vehicleInjector

The invention discloses an aircraft oil tank inerting device based on a catalytic oxidation technology. High-pressure gas is imported into the device through an engine or an environmental control system, fuel oil steam and mixture other gas in gaseous phase space of the upper portion of an oil tank or fuel oil steam generated by fuel oil electric heater heating in an oil storage tank are / is pumped by two gas ejectors respectively, mixture flammable gas ejected from the gas ejectors is regulated to appropriate temperature through a regenerator, coolers and a gas electric heater then an oxidizing reaction is generated in a catalytic reactor, the fuel oil steam is converted into carbon dioxide and water steam, inert gas which is departed from the water steam is sent to the gaseous phase space of the upper portion of the oil tank or fuel oil of the lower portion of the oil tank, and an inerting aim is achieved. By adopting the technical scheme, the aircraft oil tank inerting device has the advantages that flowing and the mixture of the gas are completed by the gas ejectors, moving parts such as a draught fan are not needed, meanwhile the requirements of dive lowering and air filling increasing can be met, the structure is simple, and the operation is reliable.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

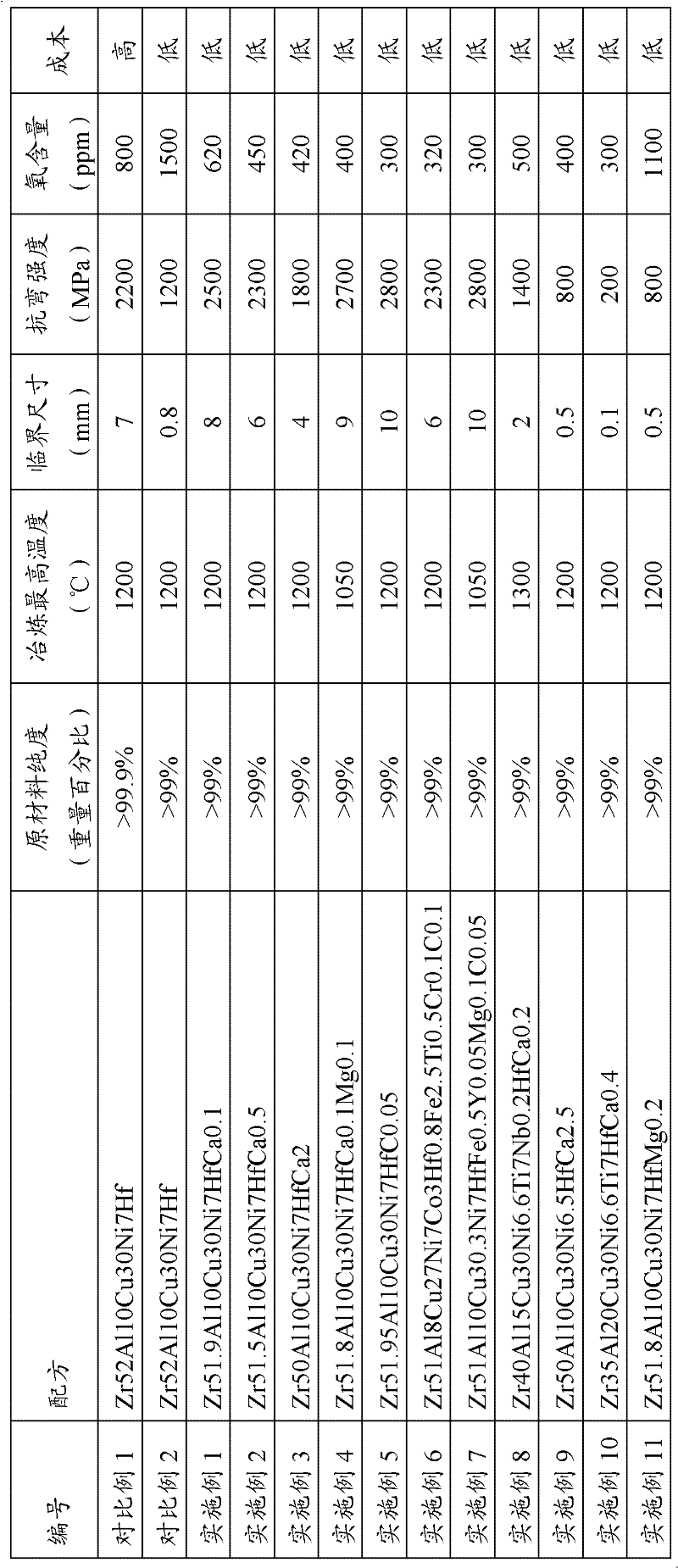

Amorphous alloy and method for preparing same

The invention discloses an amorphous alloy and a method for preparing the amorphous alloy. The amorphous alloy has a chemical formula of ZraCubAlcMdNe; M is one or more of Ni, Fe, Co, Mn, Cr, Ti, Hf, Ta, Nb and rare-earth element; N is one or more of Ca, Mg and C; a, b, c, d and e represent the atomic percentage respectively, wherein 40<=a<=70, 15<=b<=35, 5<=c<=15, 5<=d<=15 and 0<=e<=2, and a+b+c+d+e=100. Because the amorphous alloy contains the elements of calcium, magnesium and carbon, the used amount of the noble metal is effectively decreased or eliminated, the content of oxygen, nitrogen and other non-metallic elements in the amorphous alloy is effectively inhibited, the critical dimension and the mechanical properties of the amorphous alloys are improved, and hereby the amorphous alloy is more suitable for industrial production and promotion. In addition, due to the addition of the elements of calcium, magnesium and carbon, the requirement for the purity of the raw materials of the amorphous alloy is lowered, and hereby the production cost is reduced.

Owner:BYD CO LTD

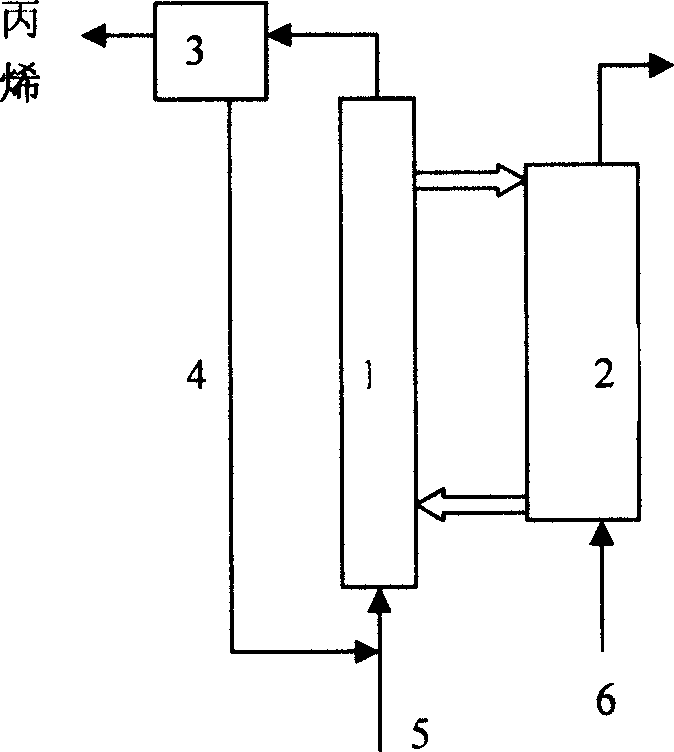

Method for producing propene using silicoaluminophosphate molecular sieve catalytic cracking

ActiveCN1762931ALow purity requirementLow aromatic contentMolecular sieve catalystsBulk chemical productionMolecular sieveHydrocarbon mixtures

The present invention relates to propylene producing catalytically cracking process, and is especially propylene producing process with catalytically cracking aluminum silicophosphate. In fixed bed or fluidized bed reactor and at the conditions of temperature 350-550 deg.c, pressure 0.1-0.3 MPa and space velocity 0.1-300 / hr, dry gas, C4 component and other material are cracked in catalyst containing aluminum silicophosphate molecular sieve SAPO-34. The output hydrocarbon mixture is separated to obtain destination product propylene before the other components are returned to the reactor for circular use. The process of the present invention has low reaction temperature, pressure near normal pressure, simple technological process and high propylene selectivity. The present invention can utilizes dry gas and C4 component effectively.

Owner:TSINGHUA UNIV

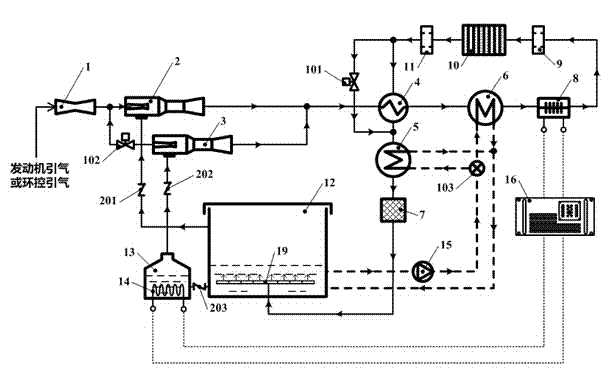

Catalytic combustion inerting oil tank device and method thereof

InactiveCN104843189ALow purity requirementImprove reliabilityPower plant fuel tanksPropulsion power plantsHydrogenWater vapor

The invention discloses a catalytic combustion inerting oil tank device and a method thereof. According to the method, a mixture composed of fuel steam and gas on the upper portion of an oil tank is pumped out and then mixed with the outside air, the mixture enters a catalytic reactor to conduct flameless combustion after being subjected to electric heating and temperature rising through a preheater, carbureted hydrogen in the fuel steam is oxidized to be carbon dioxide and water, gas flowing out of a catalytic reactor outlet is firstly cooled, most water is removed, then the gaseous water vapor is removed out of the gas through two adsorbers working in an intermittent mode, then the gas returns to the upper portion of the oil tank to conduct flushing and inerting, or the gas enters a washing injector to be mixed with fuel to enter the bottom of the oil tank to conduct washing and inerting on the fuel. By the adoption of the technical scheme, fuel steam is converted to be carbon dioxide through a catalytic combustion technology to inert the oil tank, so that the requirement for the gas source purity is low, high-pressure gas guide is not needed, preheating of a film separation device is not needed, and the catalytic combustion inerting oil tank device is high in starting speed, short in inerting time, simple in device structure and and high in reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Titanium dioxide perforated micro-pipe photocatalyst modified by silver and its prodn. method

InactiveCN101015792AHigh catalytic activityImprove degradation rateMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic reactionChloride

The invention relates to a titania porous micro tube optical catalyst modified by silver for degrading fenol in water and relative preparation. The inventive catalyst is TiO2 porous micro tube modified by silver with specific structure composed from direct deposit method, that using titanic chloride as titanium source, directly hydrolyzing and depositing, in the condition with some dispersers, to be filtered, washed, dried, baked and activated to obtain final TiO2 optical catalyst modified by silver. The inventive catalyst has specific structure, integral appearance, and uniform aperture, thereby improving the ability for degrading fenol, with high activity in optical catalysis, the ability for degrading fenol into water and carbon dioxide, and wide application.

Owner:FUDAN UNIV

Method for preparing ball shape mixed lithium cobaltate and it prepared ball shape mixed lithium cobaltate

InactiveCN1588675ALow purity requirementReduce manufacturing costElectrode manufacturing processesCobalt compoundsElectrolysisCobalt(II,III) oxide

The invention provides spheral doping lithium cobaltate prepn. method, high-activity doping colbalt hydroxide is prepared by electrolyzing metal cobalt, then to be fired in oxidating atmosphere to produce sphere cobalt orthoplumbate, finally, the spheral cobalt orthoplumbate and lithium carbonate are mixed first to produce high-activity doping lithium cobalate. By the invention, requirement of purity for raw material used to produce doping lithium cobalate is lower to reduce prodn. costs and increase electrochemistry performance of products.

Owner:BEIJING GREEN POWER TECH +1

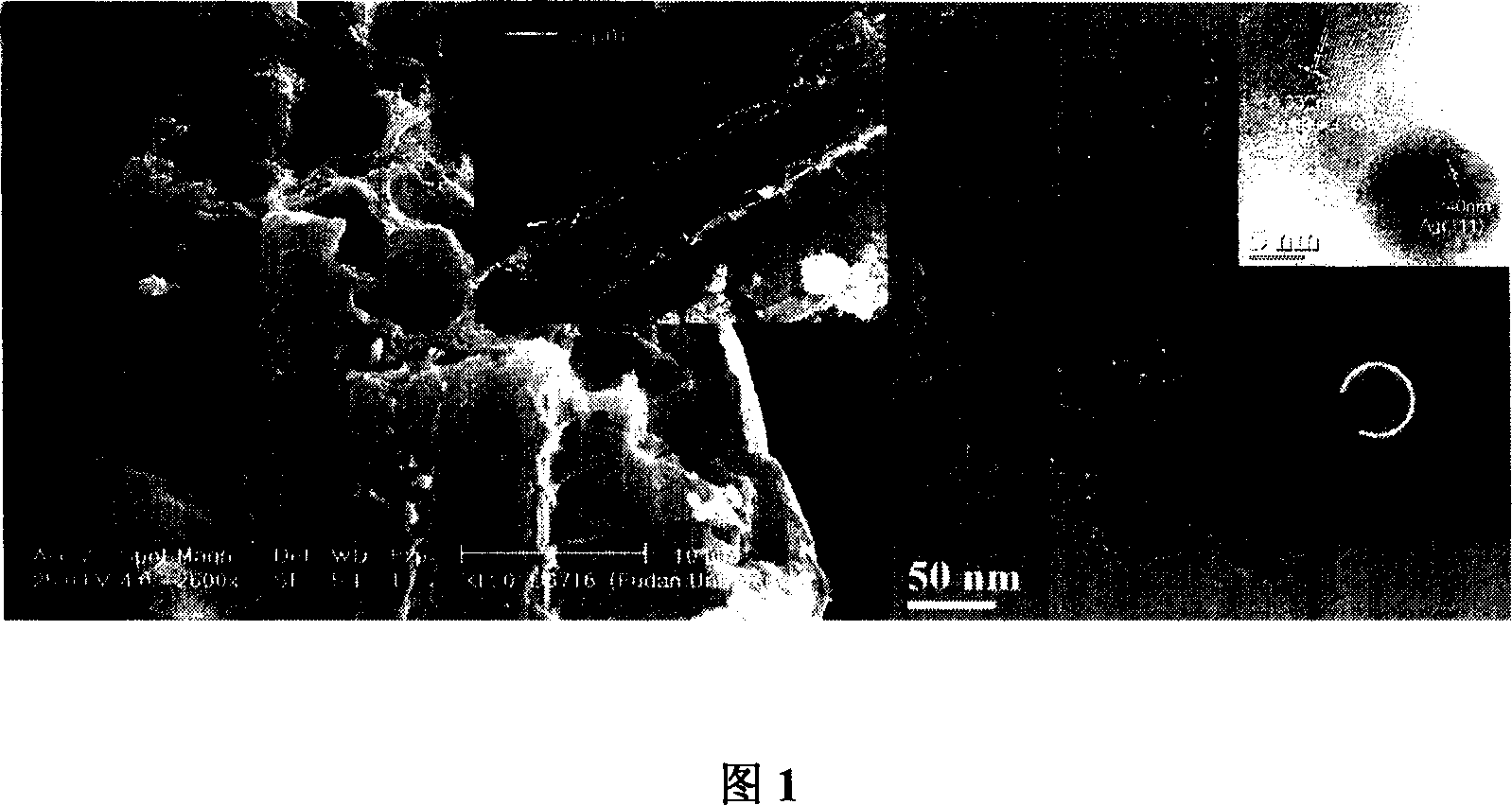

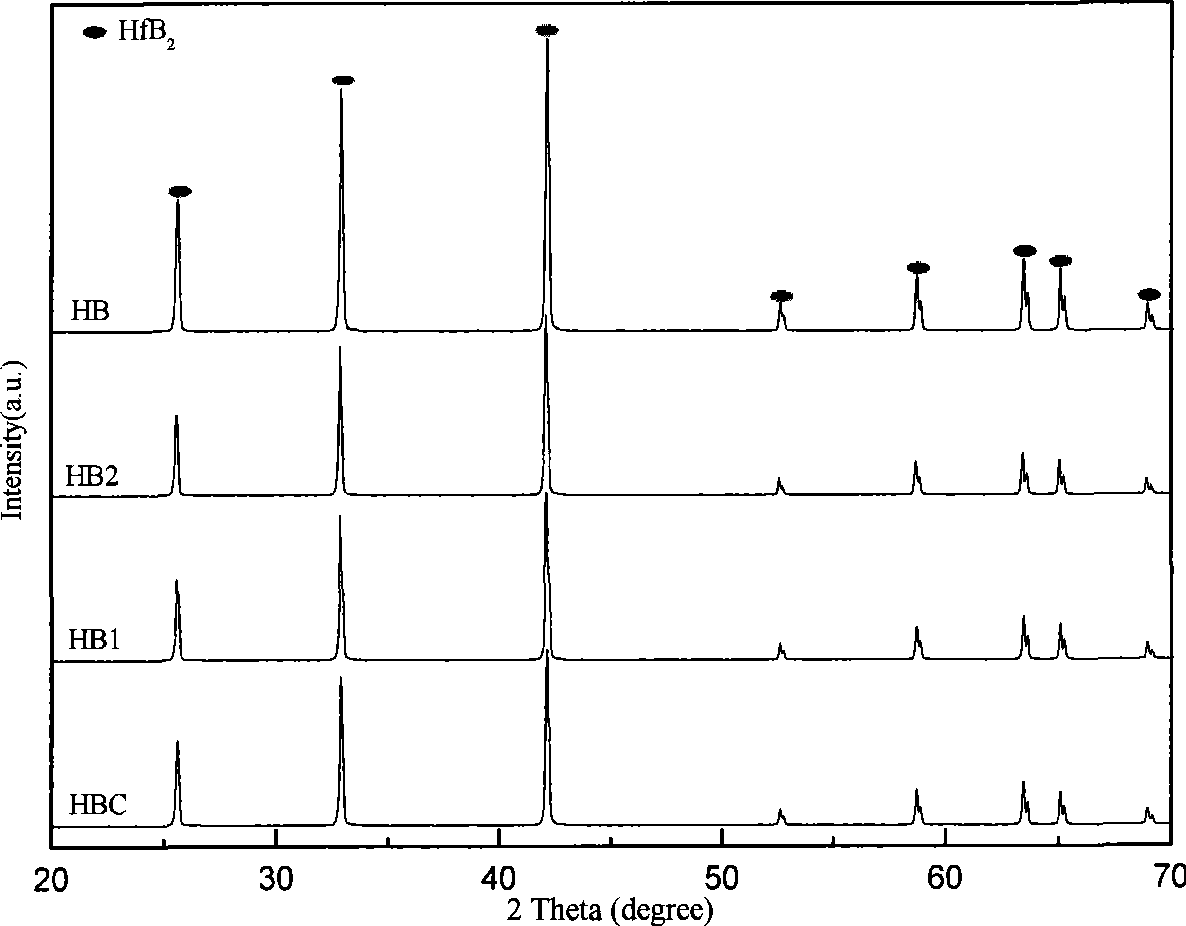

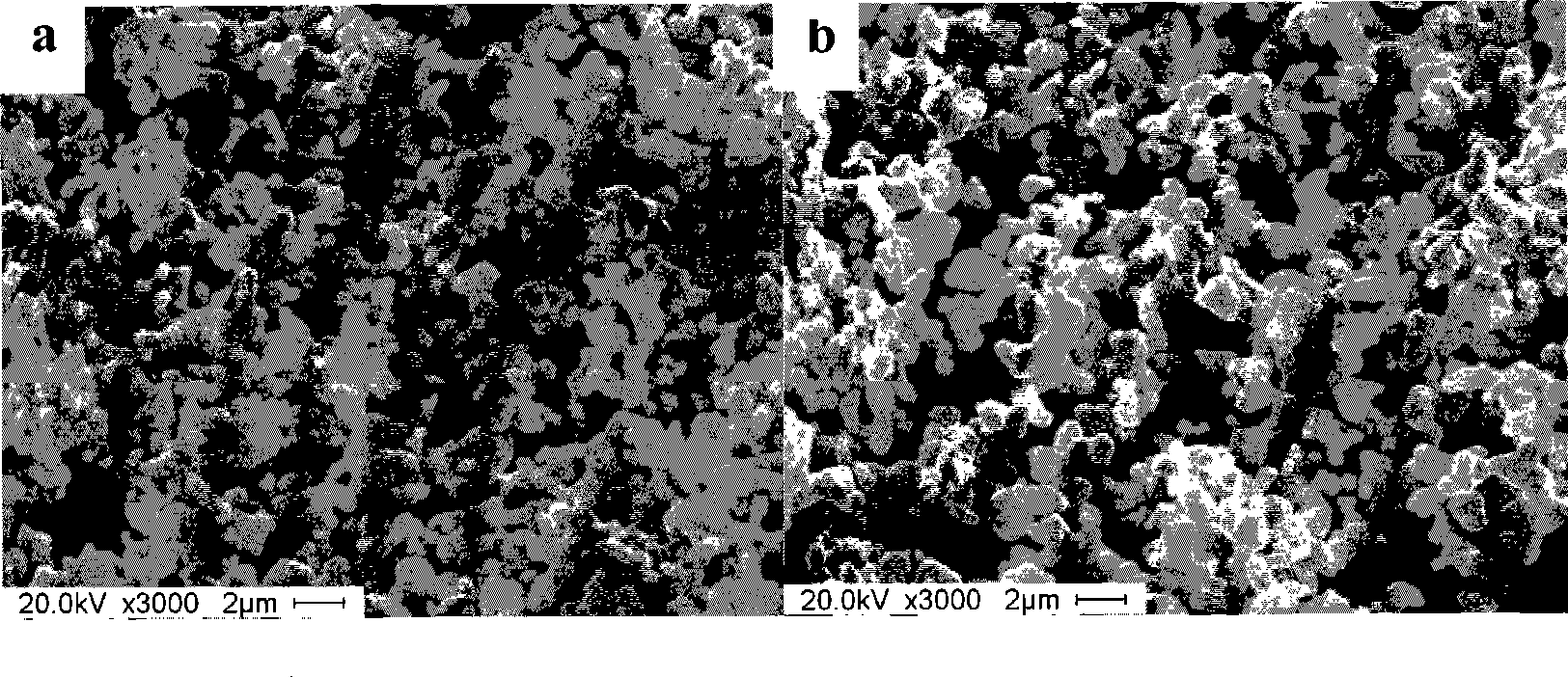

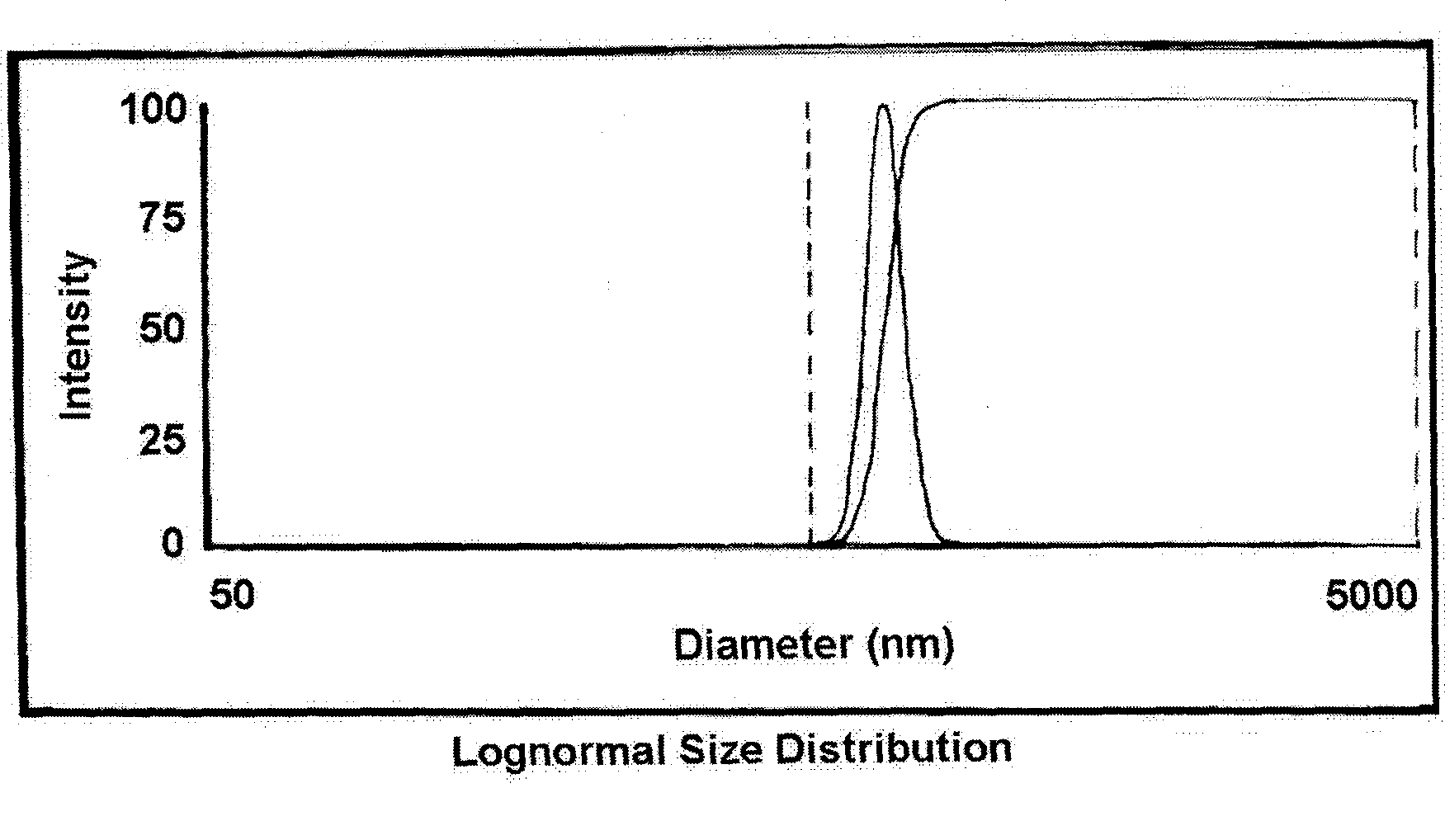

Synthesis of high-purity hafnium boride powder

The invention relates to hafnium boride powder with advantages of high purity, good dispersibility, small grain size and narrow distribution range, and a process for synthesizing the powder. The invention is characterized in that the process adopts hafnium oxide, boron carbide, graphite and amorphous boron as raw materials and is based on carbothermic / borothermic reduction reaction, wherein, in the carbothermic reduction, the mass ratio of HfO 2, B4C and C ranges from (1-5 / 4):(5 / 7-6 / 7):(0-3 / 2); and in the borothermic reduction, the mass ratio of HfO2 and B is 1:(10 / 3-4). Through adjusting the proportion of the raw materials, controlling the synthesizing process, adopting relatively cheap HfO2 raw material, the invention can synthesize the HfB2 powder with oxygen content less than 0.2wt% under the conditions that the temperature is 1500-1600 DEG C, an Ar atmosphere is adopted, or the vacuum degree is smaller than 1 Pa. SEM and laser grading analysis show that the distribution range of powder grain diameter is narrow (the polydispersity coefficient is 0.005), and the average grain diameter is around 1Mum. All of the parameters are superior to the ordinary commercial HfB2 powder, the preparation process and the required equipment are simple, the cost is low and the yield is high.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation technology for recrystallizing carborundum product

The invention discloses a making technique of recrystallizing carborundum product, which comprises the following steps: blending carborundum powder with certain grain grade with purity over 96% and silicon powder and carbon powder evenly; adding a little of adhesive; moulding according to normal technique; placing green compact in the sintering stove; connecting graphite electrode on two ends; filling the composite powder of carborundum powder and carbon powder around two ends; supplying power for graphite electrode; utilizing the conductivity of mould to realize itself heating sintering; insulating 1-4h after the temperature reaches to 1400-1700 deg. c; heating continuously to 2500 deg. c; insulating 3-10h; cooling the stove to indoor temperature naturally; obtaining the high-purity recrystallizing carborundum product.

Owner:HUNAN UNIV

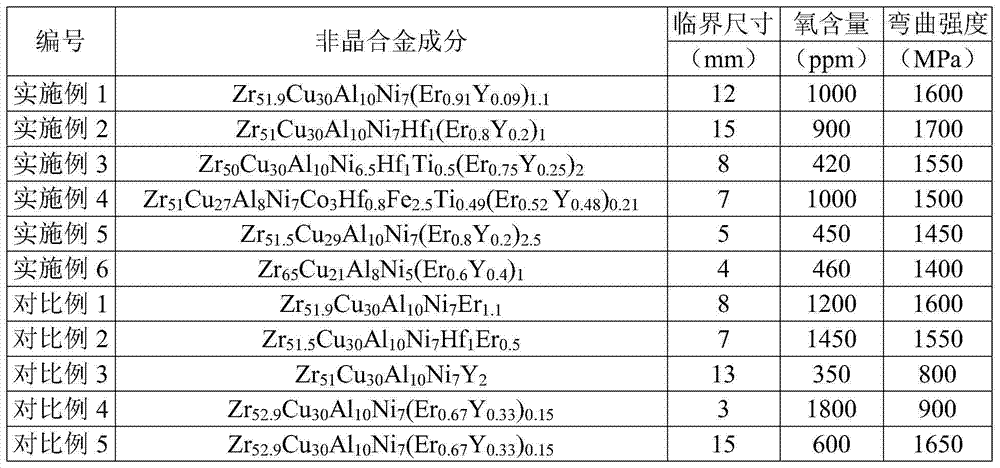

Zr-based amorphous alloy and manufacturing method thereof

InactiveCN104745973ALittle impact on mechanical propertiesEnhanced Amorphous Formation AbilityAlloyZirconium

A zirconium-based amorphous alloy and a preparation method therefor. The composition of the amorphous alloy is ZraCubAlcMd(Er1-xYx)e, wherein M is at least one selected from Ni, Fe, Co, Mn, Cr, Ti, Hf and Ta, 40≤a≤70, 15≤b≤35, 5≤c≤15, 3≤d≤15, 0.2<e≤2.5, and 0<x<0.5, and the amorphous alloy is obtained by smelting and cooling molding under the protection of an inert gas or a vacuum condition.

Owner:BYD CO LTD

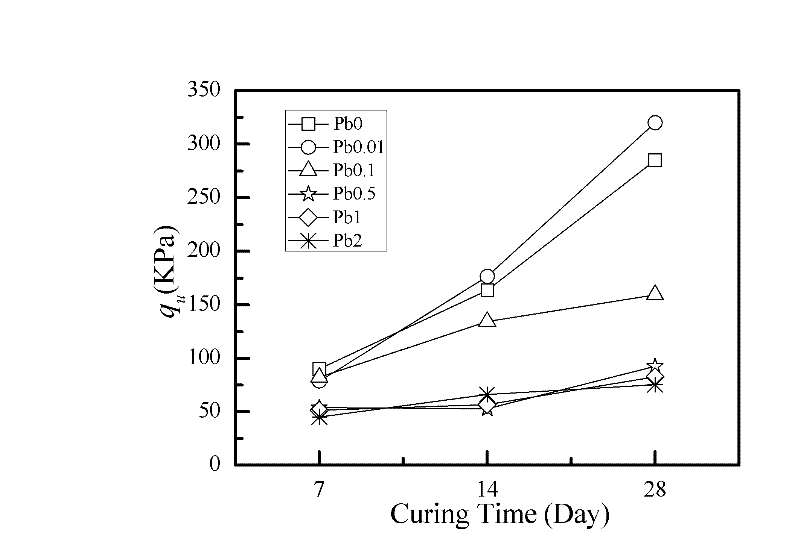

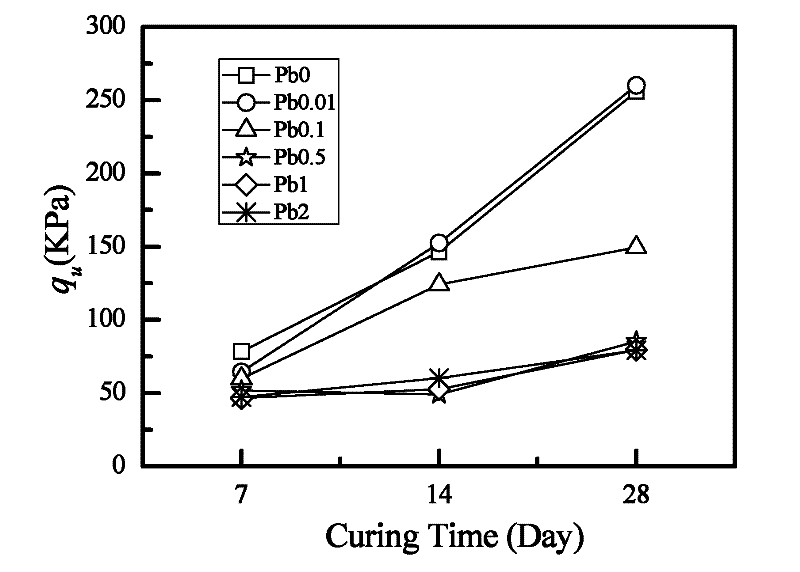

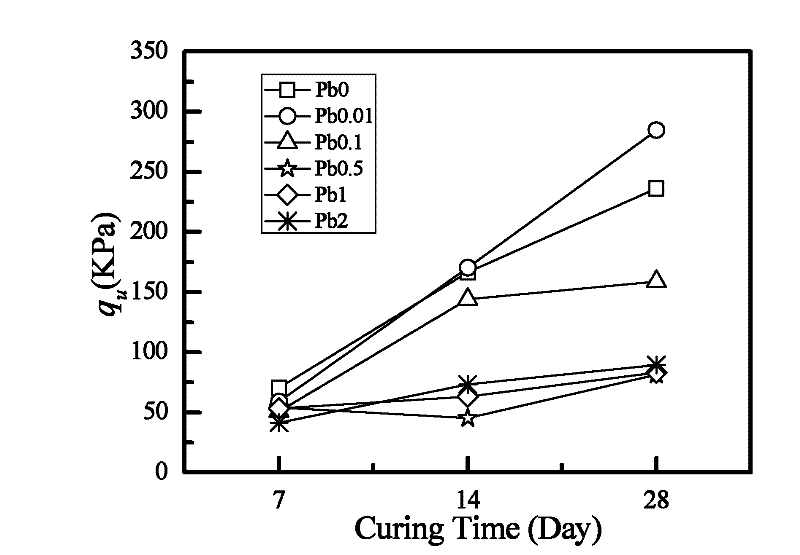

Curing agent for stabilizing heavy metal lead pollution area containing organic matter

ActiveCN102517026APromote repairImprove curing effectAgriculture tools and machinesOther chemical processesAfter treatmentPhosphate

The invention discloses a curing agent for stabilizing a heavy metal lead pollution area containing organic matter. The curing agent is composed of the following components including, by weight, 33%-40% of phosphate, 33%-40% of graining blast furnace slag and 20%-34% of magnesium oxide. The curing agent can be used during in-situ processing of the heavy metal pollution area containing organic matter pollution and is remarkable in curing effects, pH value of the pollution area is low after treatment by the curing agent, and corrosivity is small. Besides, the pollution area has high strength after treatment and can be directly used as a shallow-layer foundation, and the curing agent is environment-friendly and low in cost simultaneously.

Owner:SOUTHEAST UNIV

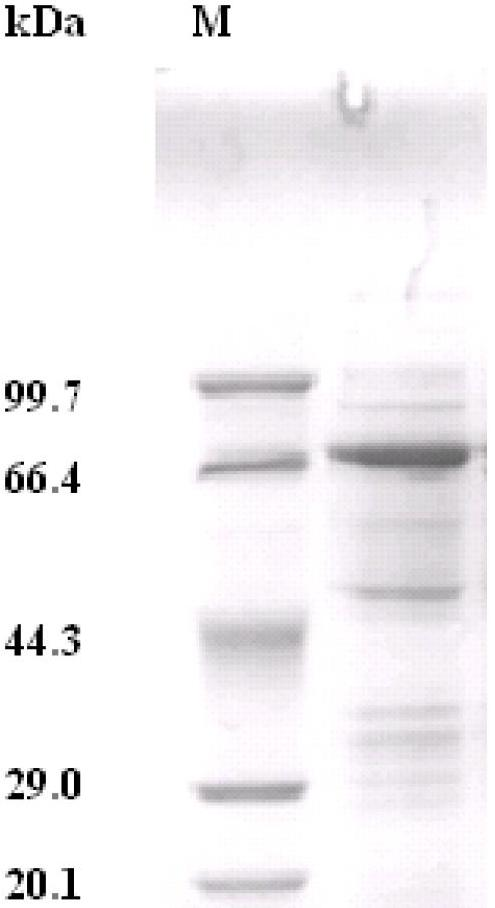

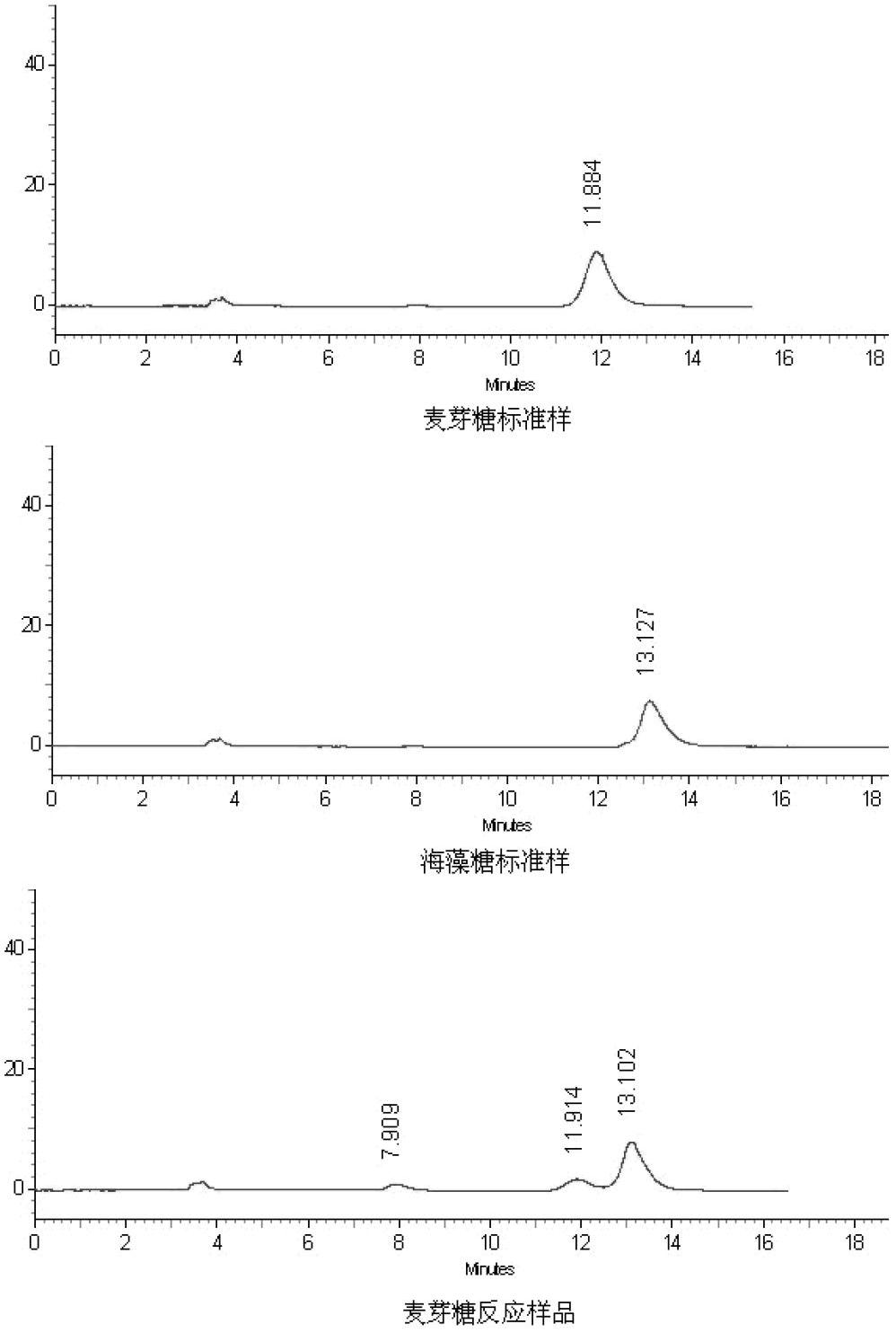

Trehalose synthase of streptomyces griseochromogenes and coding gene and application of trehalose synthase

ActiveCN102690795AReduce occupancyReduce energy consumptionBacteriaTransferasesHydrogenStreptomyces griseochromogenes

The invention discloses trehalose synthase of streptomyces griseochromogenes and a coding gene and application of the trehalose synthase. The trehalose synthase gene is cloned from the streptomyces griseochromogenes. The trehalose synthase can convert maltose to generate trehalose, the proper reaction temperature of the trehalose synthase is 15-35 DEG C and is 20-25 DEG C preferably, and the proper pH (potential of hydrogen) of the trehalose synthase ranges from 6.0 to 8.0 and ranges from 7.0 to 7.5 preferably. The conversion efficiency of the trehalose synthase is high, the maltose is used as a substrate, conversion rate of the maltose is about 80% at the reaction temperature of 25 DEG C, and less than 5% of glucose is generated to be beneficial to increase of the conversion rate of the substrate. The trehalose synthase can be used for converting commercial ultrahigh malt syrup to prepare the trehalose, and a novel method using an enzymic method to produce the trehalose industrially can be provided.

Owner:NANJING UNIV OF TECH

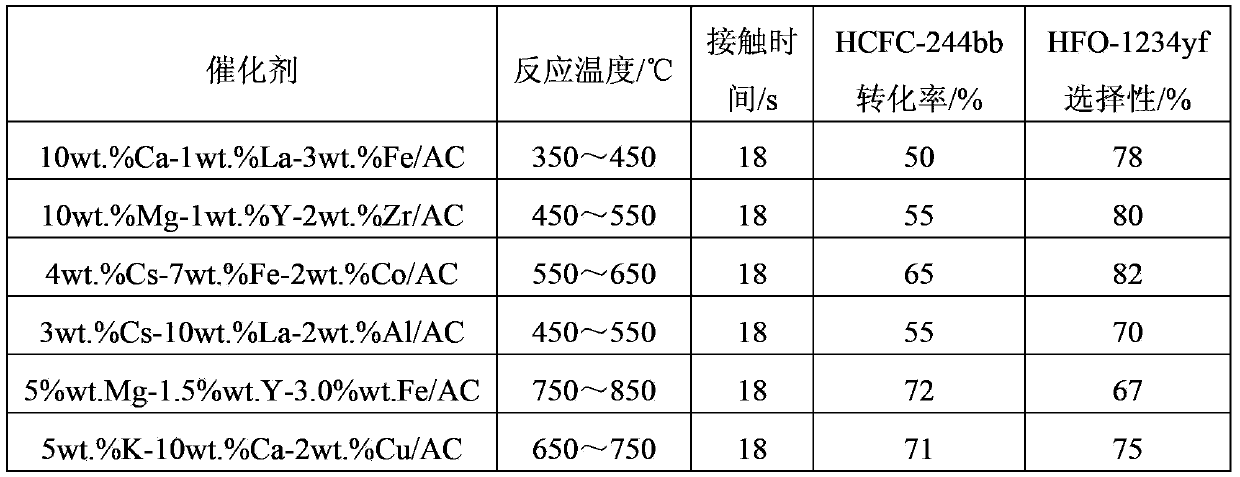

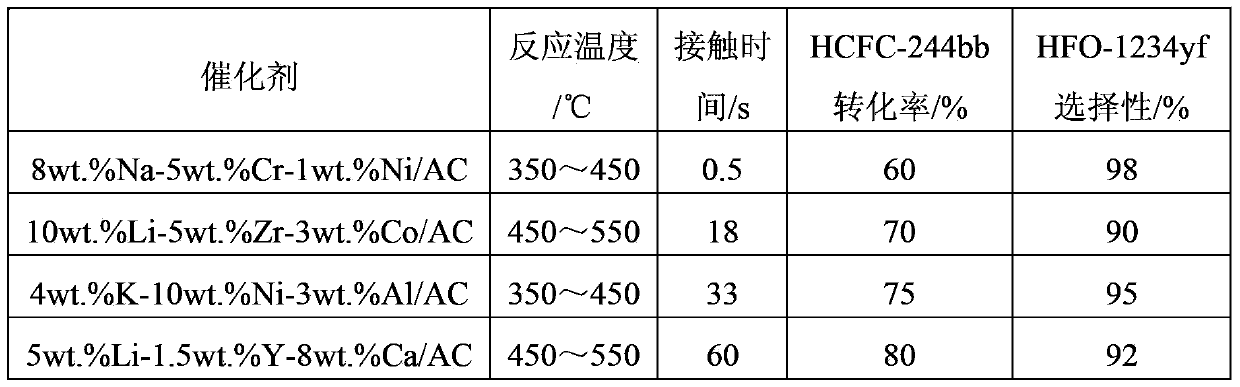

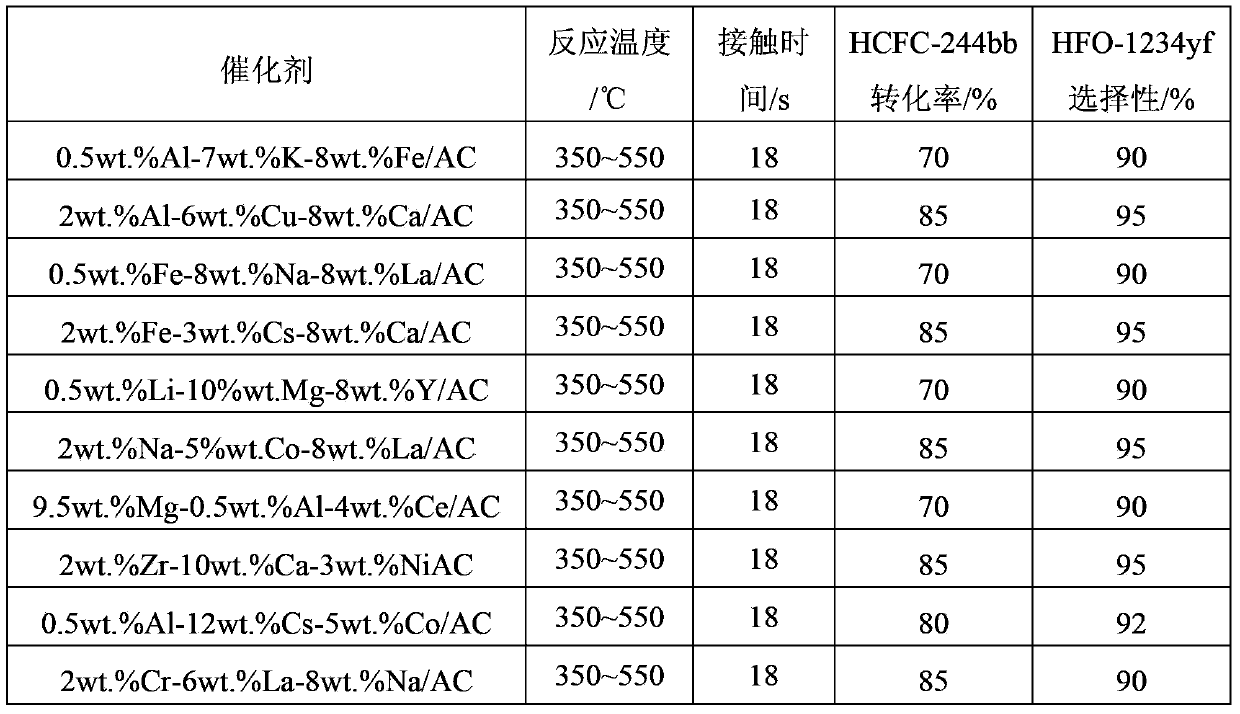

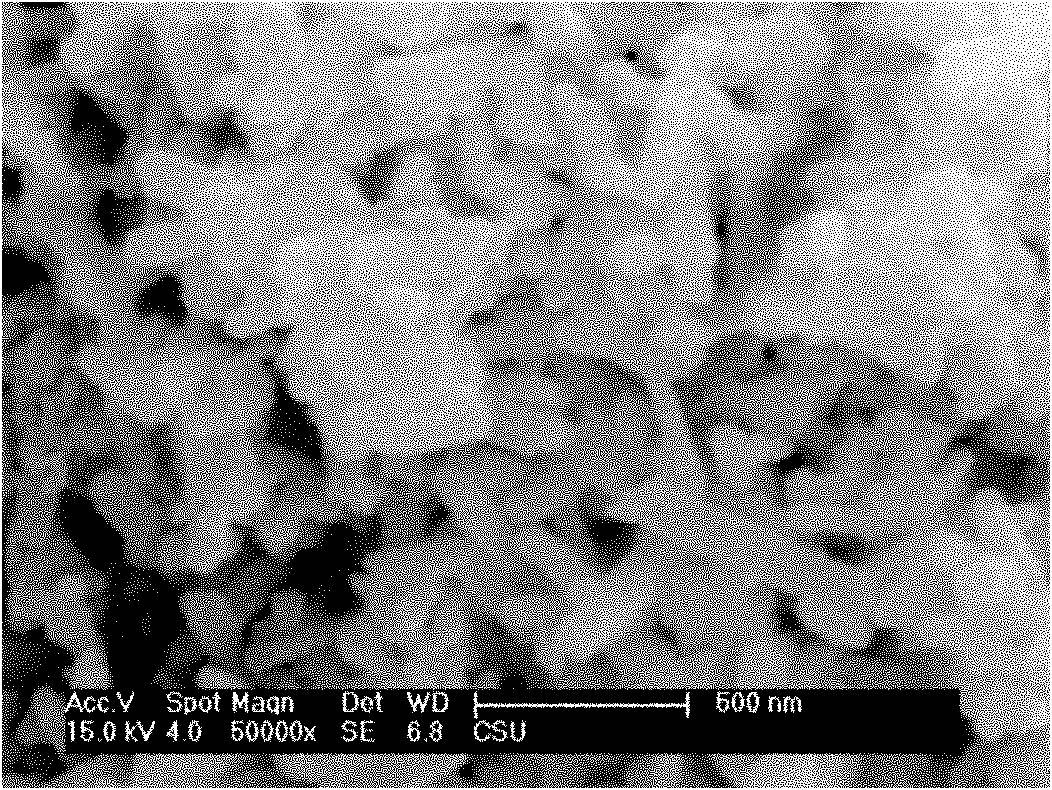

Method for preparing fluorinated alkene by performing dehydrochlorination on chlorofluorocarbon under action of catalyst

ActiveCN103420782ALower specification requirementsLow running costPreparation by hydrogen halide split-offMetal/metal-oxides/metal-hydroxide catalystsRefrigerant2,3,3,3-Tetrafluoropropene

The invention belongs to the field of refrigerant, and provides a method for preparing fluorinated alkene by performing dehydrochlorination on chlorofluorocarbon under the action of a catalyst.According to the invention, the novel catalyst is prepared through an impregnation method, reaction of the catalyst and 2-chloro-l, 1, 2-tetrafluoro propane (HCFC-244bb) with lower purity is performed, and then high-temperature gas phase dehydrochlorination reaction is performed to prepare a fluorinated alkene product 2, 3, 3, 3-tetrafluoro propene. Through the adoption of the novel catalyst, the purity requirement on chlorofluoropropane is reduced, so that HCFC-244bb with the purity of 80 percent can be as a raw material, thereby effectively reducing the operating cost of the process; the halohydrocarbon conversion rate is high, and reach up to 60 percent, and the selectivity of the target fluorinated alkene is greater than 90 percent.

Owner:山东华安近代环保科技有限公司

Preparation method of isocyanate-based polyimide foam

ActiveCN104829835AImprove heat resistanceImprove thermal stabilityMaterials preparationHeat resistance

The invention provides a preparation method of isocyanate-based polyimide foam. The preparation method comprises that 1, polybasic aromatic anhydride is heated and dissolved in a polar solvent and undergoes a reaction with fatty alcohol to produce a polybasic aromatic anhydride derivative solution, 2, the polybasic aromatic anhydride derivative solution and a foam stabilizer are blended to form a white material, 3, polybasic aromatic anhydride and isocyanate undergo a reaction to produce a black material, 4, the foaming white material is immediately poured into the foaming black material at a room temperature under normal pressure, and the mixture is uniformly stirred, then is fast poured into a mold and is subjected to free foaming molding to form a foam intermediate and 5, the foam intermediate is heated and cured to form the isocyanate-based polyimide foam. The preparation method inhibits production of an amino group and an isocyanate group in foam material preparation, reduces a polyurea generation amount and improves isocyanate-based polyimide foam heat resistance, heat stability and flame resistance. The preparation method has the advantages of simple processes, excellent product comprehensive properties, and industrial production and wide application feasibility.

Owner:HARBIN ENG UNIV

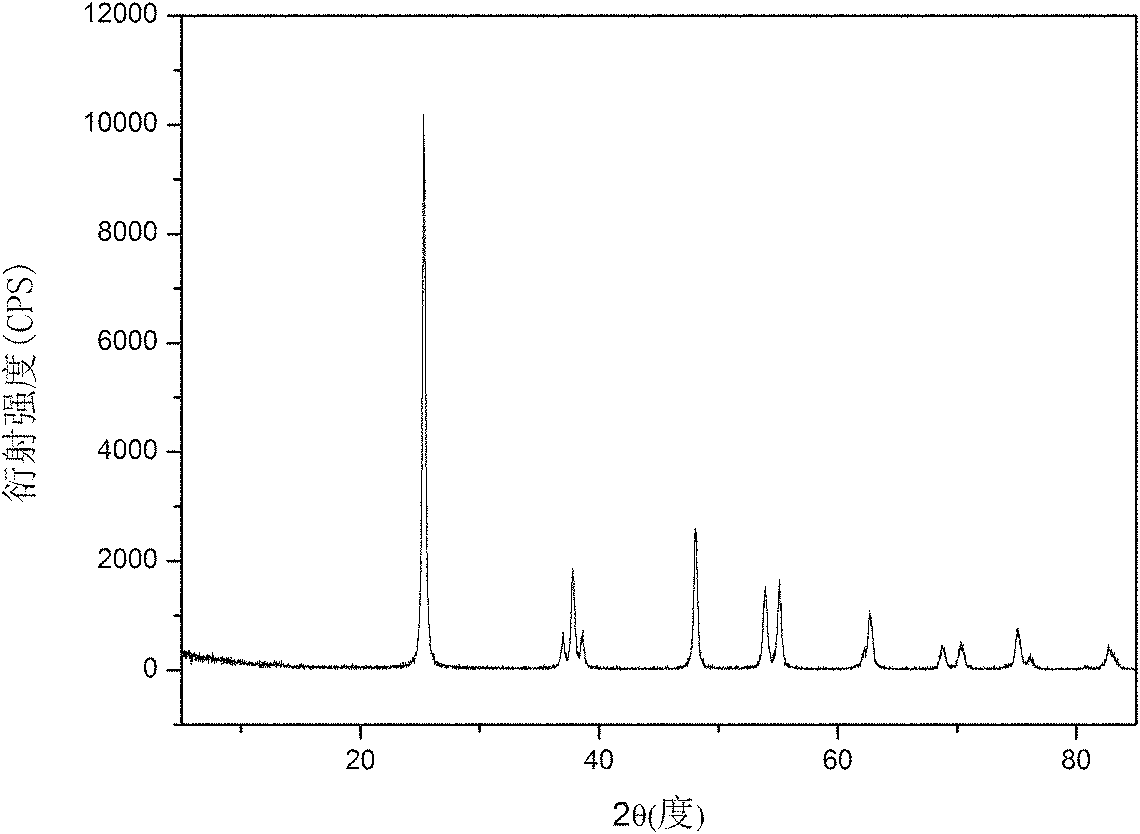

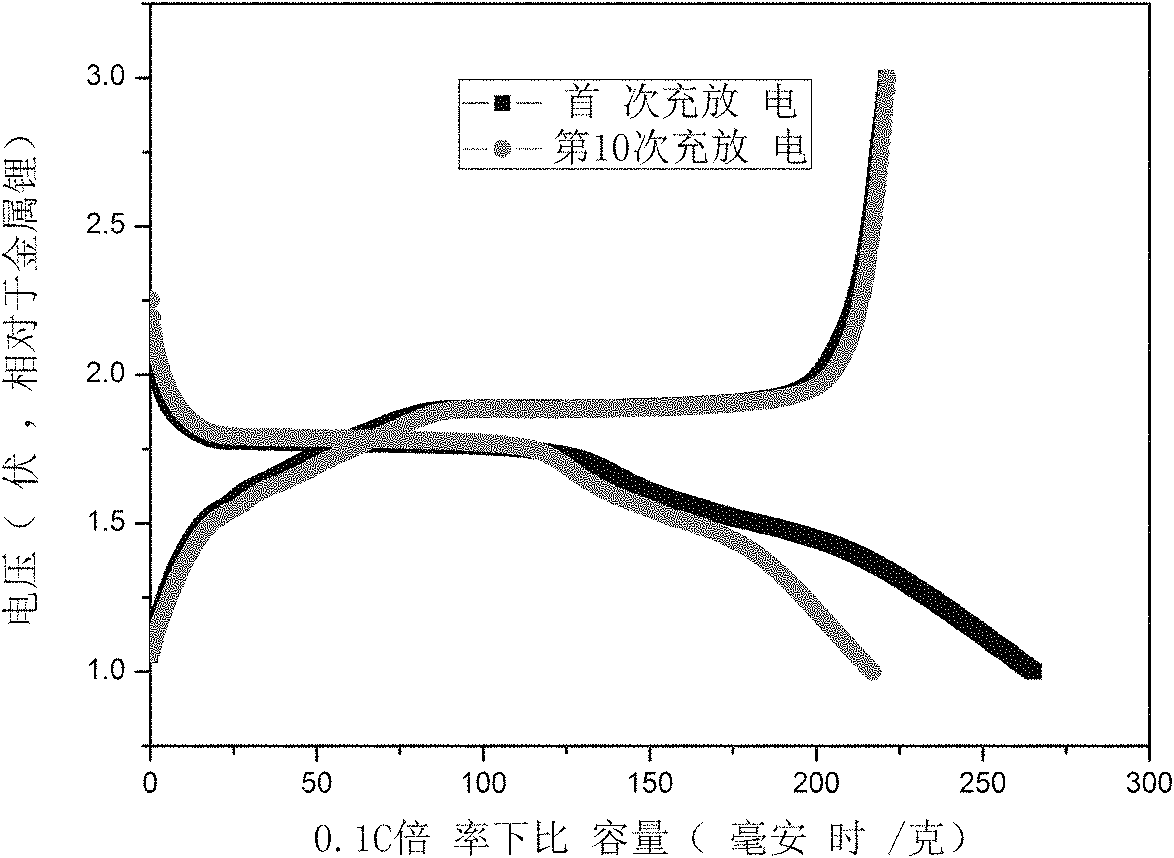

Method for preparing nano-TiO2 serving as cathode material of lithium ion battery

The invention discloses a method for preparing nano-TiO2 serving as a cathode material of a lithium ion battery. The method comprises the following steps of: beating precipitates of titanium prepared from metatitanic acid or various titanium sources by using water, adding a coordinating agent into thick liquid according to a molar ratio of the coordinating agent to the titanium of 1.0:1-10:1, regulating the pH value to be between 7 and 14 by using alkali, reacting in a stirring reactor at the temperature of between 20 and 80 DEG C for 10 to 720 minutes, and filtering to obtain solution of the titanium; and adding the alkali into the solution according to a molar ratio of the alkali to the titanium of 1.0:1-50:1, heating the solution to between 80 and 200 DEG C for 10 to 600 minutes, filtering and washing to obtain a precursor of nano-TiO2, and calcining the precursor at the temperature of 120 and 850 DEG C for 0.5 to 20 hours to obtain the nano-TiO2 serving as the cathode material of the lithium ion battery. The method has the characteristics of wide range of raw materials, simple process flow, low energy consumption, low cost, good appearance of product granularity and excellent electrochemical properties.

Owner:CENT SOUTH UNIV

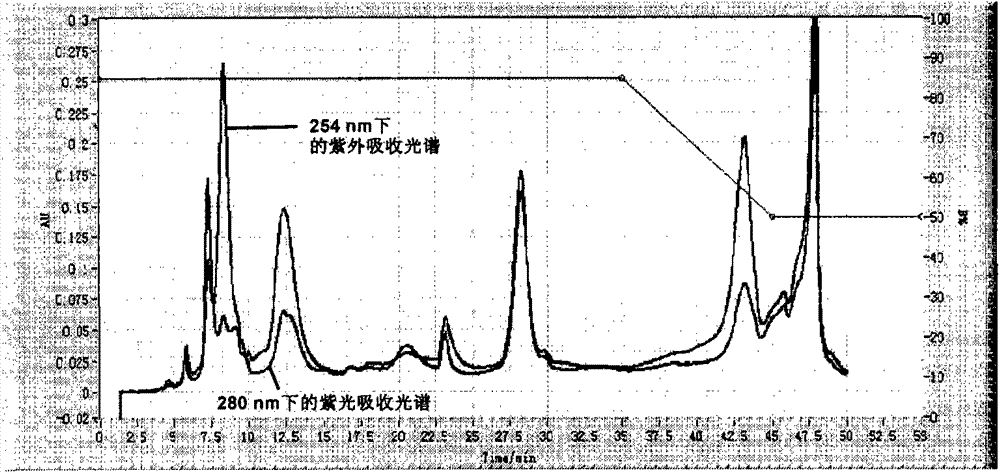

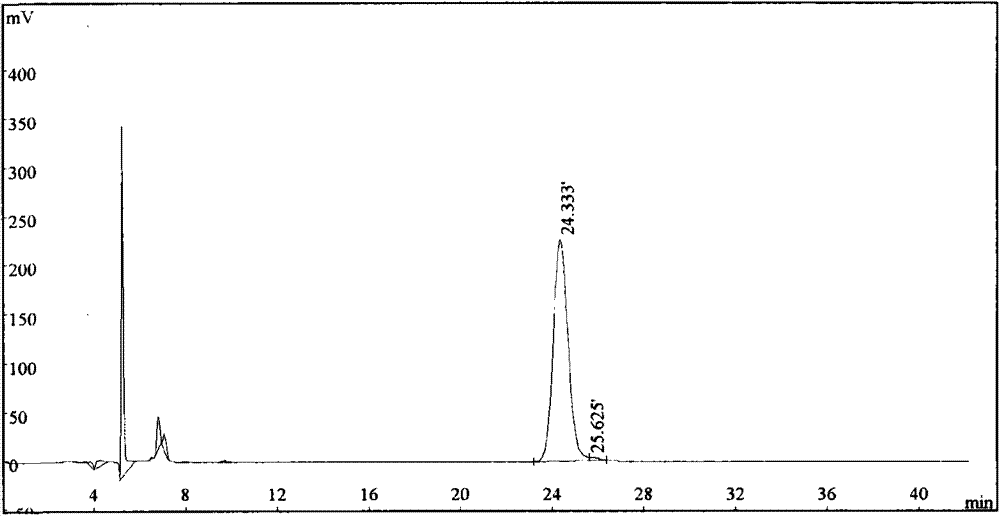

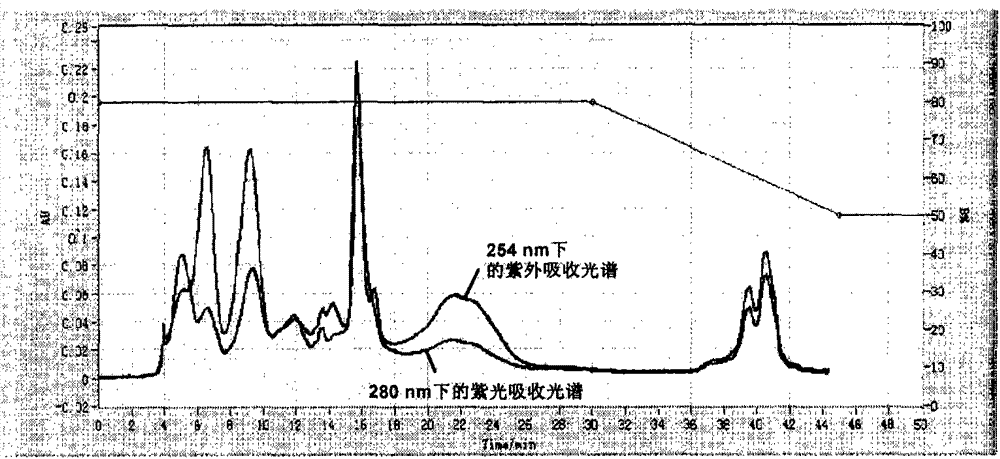

Extraction and purification method of ergothioneine

ActiveCN104774182AFew stepsShort timeOrganic chemistryMicroorganism based processesPurification methodsSulfur

A method for extracting and purifying L-ergothioneine comprises the following steps: (1) soaking and extracting a mushroom mycelium fermentation liquid by using hot water, so as to obtain a mushroom and L-ergothioneine water solution; (2) performing ultrafiltration of the mushroom and L-ergothioneine water solution by using an ultrafiltration membrane with a molecular weight cut-off of 1kDa to 30kDa, and collecting an ultrafiltration liquid; and (3) performing chromatographic purification of the ultrafiltration permeation liquid, the chromatographic purification conditions being: a chromatographic filler being an HILIC filler, a mobile phase forming acetonitrile-water with a volume ratio of 80: 20 to 88: 12, and a quantity of feed of L-ergothioneine being 0.01g to 0.323 per 100g.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Method of producing modified asphalt

ActiveCN102504854AReduce agingImprove ductilityWorking-up pitch/asphalt/bitumen by selective extractionOrganic solventRoom temperature

A method of producing modified asphalt is characterized in that in a temperature range of from room temperature to 100 DEG C, organic solvent and / or mixed solvent oil capable of dispersing or dissolving coal liquefied heavy products and matrix asphalt are used for mixing the coal liquefied heavy products with the matrix asphalt prior to separation and recycling of the solvent so as to obtain the modified asphalt, wherein the coal liquefied heavy products added account for 5-50% of total percentage of the modified asphalt. The method has the advantage that the production temperature is low, and the modified asphalt has good performances.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

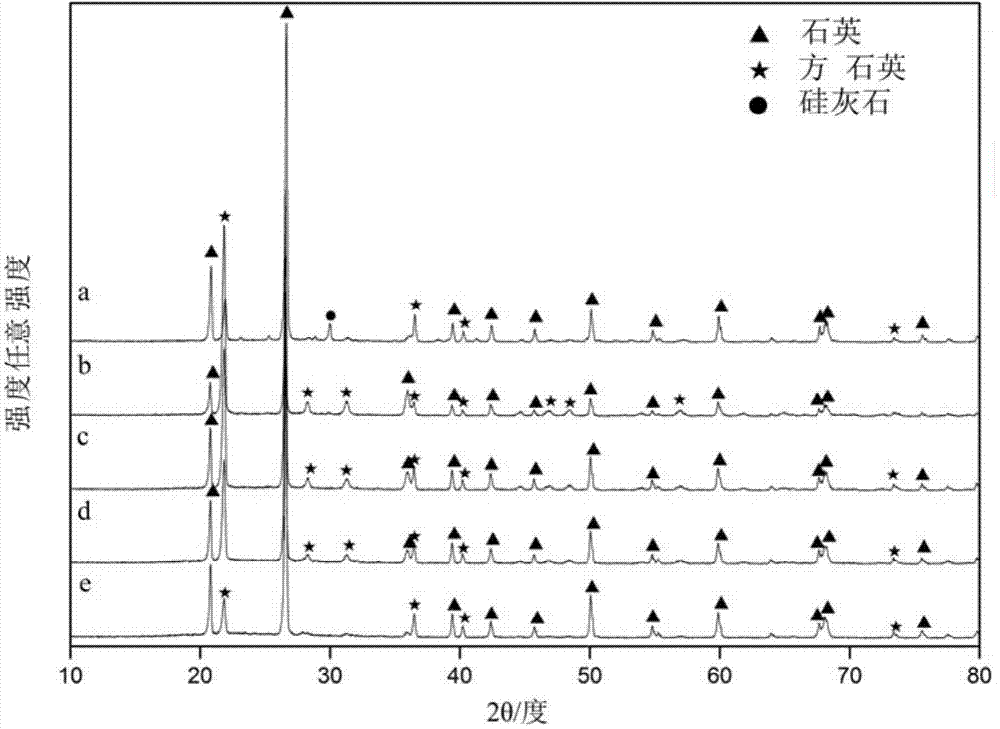

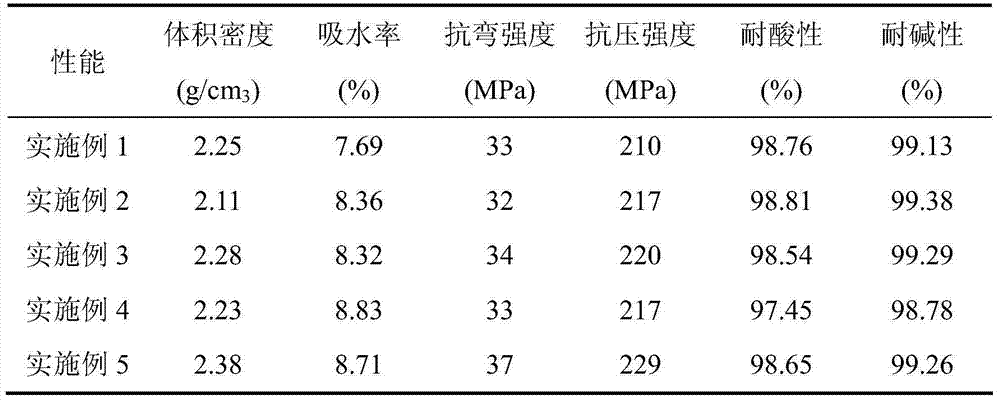

Quartz sand ore tailing or silica sand ore tailing based high-strength ceramic plate and preparation method thereof

ActiveCN104496438AReduce occupancyReduce maintenance costsUltimate tensile strengthChemical stability

The invention discloses a quartz sand ore tailing or silica sand ore tailing based high-strength ceramic plate and a preparation method thereof. The ceramic plate is prepared by carrying out blank making and sintering on quartz sand ore tailing and / or silica sand ore tailing, a ceramic raw material and a sintering assistant. The method has the characteristics of simple preparation technique, mild reaction conditions and low raw material cost. The prepared ceramic plate has the characteristics of high utilization ratio of the quartz sand ore tailing or silica sand ore tailing, high strength, favorable chemical stability, no water accumulation, no secondary pollution and the like. The volume density is 2.11-2.38 g / cm<3>, the water absorptivity is 7.69-8.83%, the bending strength is 32-37 MPa, the compression strength is 210-229 MPa, the acid resistance is 98.45-98.81%, and the alkali resistance is 98.78-99.38%. The ceramic plate is especially suitable to be used as a floor decoration material.

Owner:CENT SOUTH UNIV +1

Production of lithium fluoride

InactiveCN101074103ALow purity requirementHigh purityAlkali metal fluoridesLithiumResource utilization

Owner:BYD CO LTD

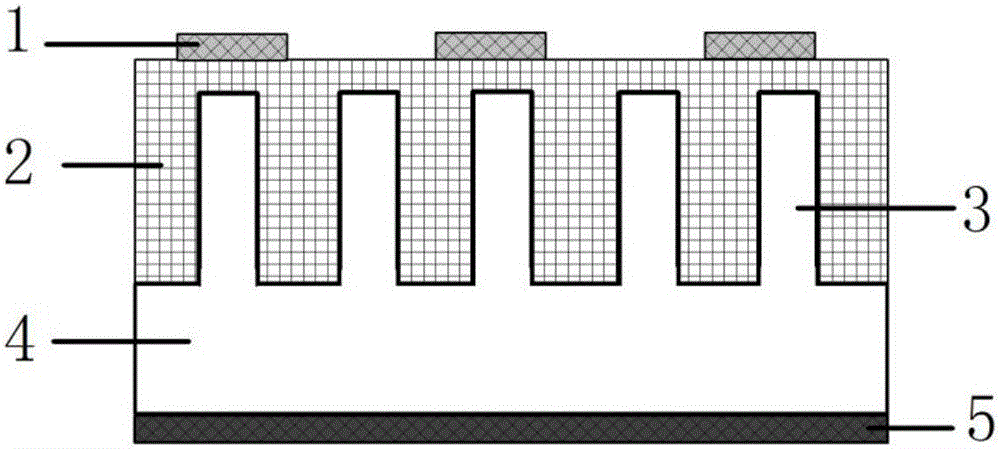

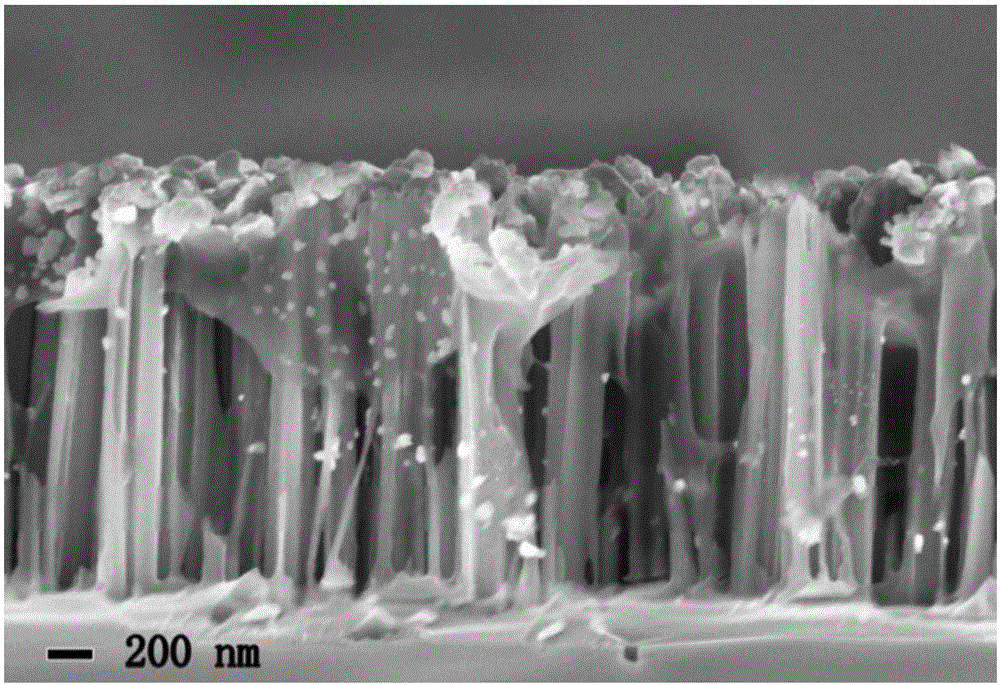

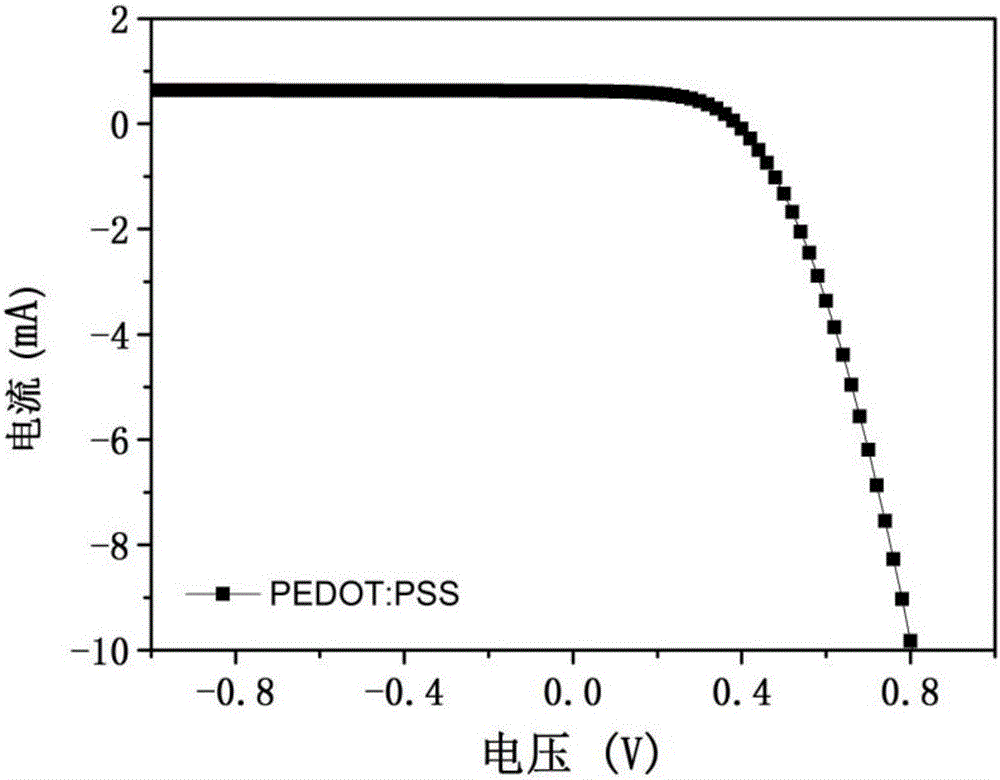

Self-driven wide-spectral-response silicon-based hybrid heterojunction photoelectric sensor and preparation method therefor

ActiveCN105720197AReduce usageReduce manufacturing costFinal product manufactureSolid-state devicesHeterojunctionMicro nano

The invention discloses a self-driven wide-spectral-response silicon-based hybrid heterojunction photoelectric sensor and a preparation method therefor. The photoelectric sensor comprises a metal back electrode, an N type silicon substrate, an N type silicon nanowire array, an organic polymer semiconductor thin film and a sensor positive electrode, wherein the hybrid photoelectric sensor is characterized in that the N type silicon nanowire array and the organic polymer semiconductor thin film form three-dimensional heterojunction contact, so that the transmission path of photo-generated carriers is effectively shortened; the separation efficiency is improved; a surface / interface composite effect is reduced through interface alkylation processing; the silicon-based micro-nano structure is taken as the main light absorption layer and the generation and transmission layers for the photo-generated carriers as well; and a P type organic semiconductor thin film is processed to be used as a hole transport layer. The photoelectric sensor provided by the invention has the characteristics of self powering, wide spectral response, low cost large-area preparation, high photoelectric response speed and the like.

Owner:JINAN UNIVERSITY

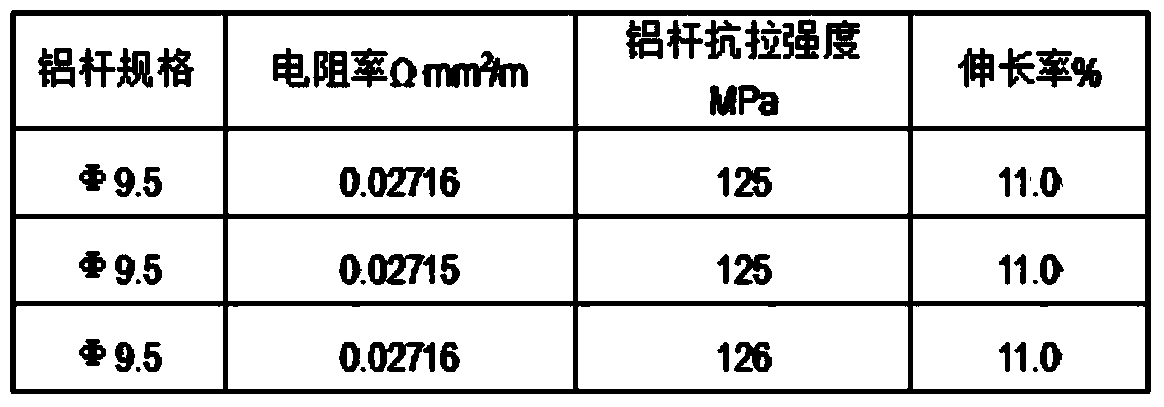

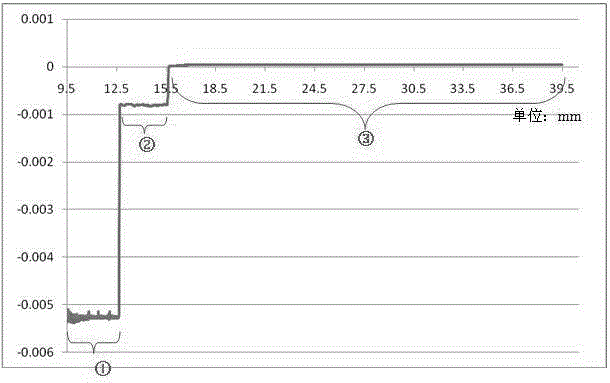

High-conductivity hard aluminum wire and preparing technology thereof

ActiveCN103854807AGuaranteed tensile strengthImprove conductivityNon-insulated conductorsCable/conductor manufactureCarrying capacityAtmospheric pressure

The invention discloses a high-conductivity (63 percent IACS) hard aluminum wire and a preparing technology thereof. The preparing technology of the high-conductivity hard aluminum wire comprises the following steps that firstly, a high-conductivity aluminum rod is prepared in a continuous casting and rolling mode; secondly, the high-conductivity aluminum rod is drawn into high-conductivity aluminum wires which are drawn through various dies, wherein the coefficient of elongation of the last die is controlled within 1.35-1.50, and the coefficients of elongation of the other dies are controlled within 1.30-1.40; thirdly, a plurality of high-conductivity aluminum wires are twisted, the pay-off tension is controlled in the twisting process, the control air pressure is smaller than or equal to 3 kilograms, the tensile strength of the manufactured single hard aluminum wire is larger than or equal to 160 MPa, and the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C. The tensile strength of the manufactured single hard aluminum wire in an overhead conductor is larger than or equal to 160 MPa, the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C, the tensile strength of the hard aluminum wire is kept, the conductivity of the hard aluminum wire is increased to 63 percent IACS, and the conductivity is increased by 3.28 percent compared with the stipulated conductivity of a hard aluminum wire in common GB / T17937-2009. The high-conductivity hard aluminum wire is used in the overhead conductor, the loss of the circuit electric energy can be greatly reduced, the circuit operation cost is reduced, and the carrying capacity of the wire can be obviously improved.

Owner:FAR EAST CABLE +2

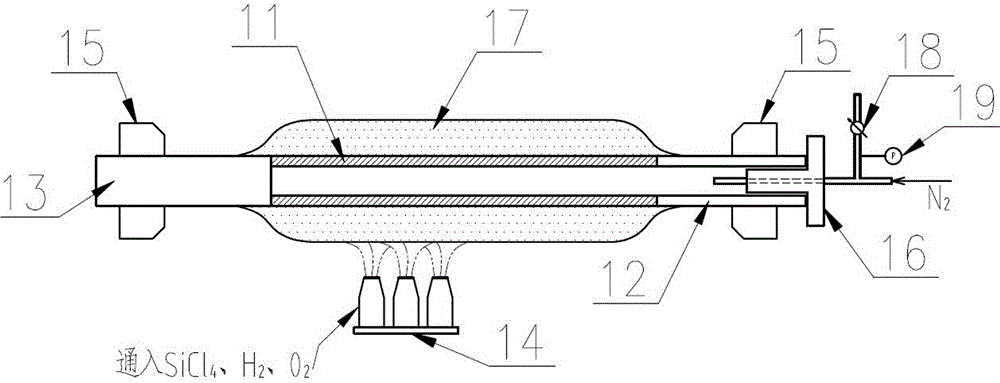

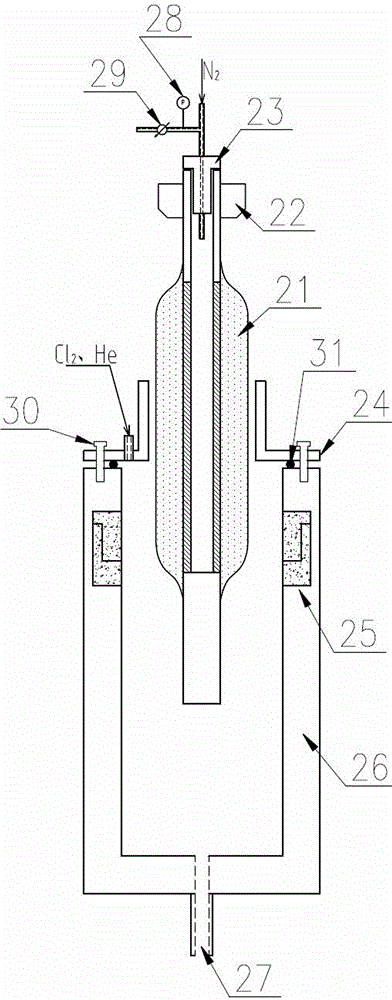

Method and equipment for manufacturing optical fiber perform rod casing pipe with complicated refractive index profile

ActiveCN103951182AReduce lossIncrease flexibilityGlass making apparatusChemical vapor depositionMechanical engineering

The invention relates to a method and equipment for manufacturing an optical fiber perform rod casing pipe with a complicated refractive index profile, and particularly relates to a method and equipment for manufacturing the optical fiber perform rod casing pipe by combination of modified chemical vapor deposition (MCVD) and outside vapor deposition (OVD). The optical fiber perform rod casing pipe manufactured by using the method and the equipment have a deep refractive index sunken zone or the complicated refractive index profile. The equipment comprises a powder casing pipe manufacturing device and a powder casting pipe vitrification device, wherein the powder casing pipe manufacturing device comprises a rotary chuck I, a rotary chuck II, a blow lamp, a sealing rotary joint I, a pressure adjusting valve I and a pressure gauge l, and the powder casting pipe vitrification device comprises a rotary chuck III, a sealing rotary joint II, a sealing cover plate, a fastening bolt, a sealing ring, a furnace body heating zone, a sealing furnace body, an exhaust gas discharge port, a pressure adjusting valve II and a pressure gauge II.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

Method for preparing 1,2-propylene glycol by catalytic hydrogenation of biodiesel base crude glycerine

InactiveCN101362676AHigh activityReduce dosageOrganic compound preparationHydroxy compound preparationBiodieselAsymmetric hydrogenation

The invention relates to a method for directly preparing 1,2-propylene glycol by biological diesel based crude glycerin. The biological diesel based crude glycerin is used as the raw material, and under the action of solid alkali-copper metal catalyst, the reaction is proceeded for 6-20 hours under the temperature of 180-260 DEG C, and the 1,2-propylene glycol is prepared by a batch type one-step reaction. The highest conversion rate of glycerin can reach 91.3 percent, and the yield of 1,2-propylene glycol can reach 85 percent. Compared with the existing method for preparing 1,2-propylene glycol, in the invention, the solid alkali-copper metal catalyst can effectively overcome the influence of alkaline impurity in biological diesel based crude glycerin solution. The method of the invention has the advantages of simple process, high yield, low cost, less environmental pollution and simple separation.

Owner:ZHEJIANG UNIV

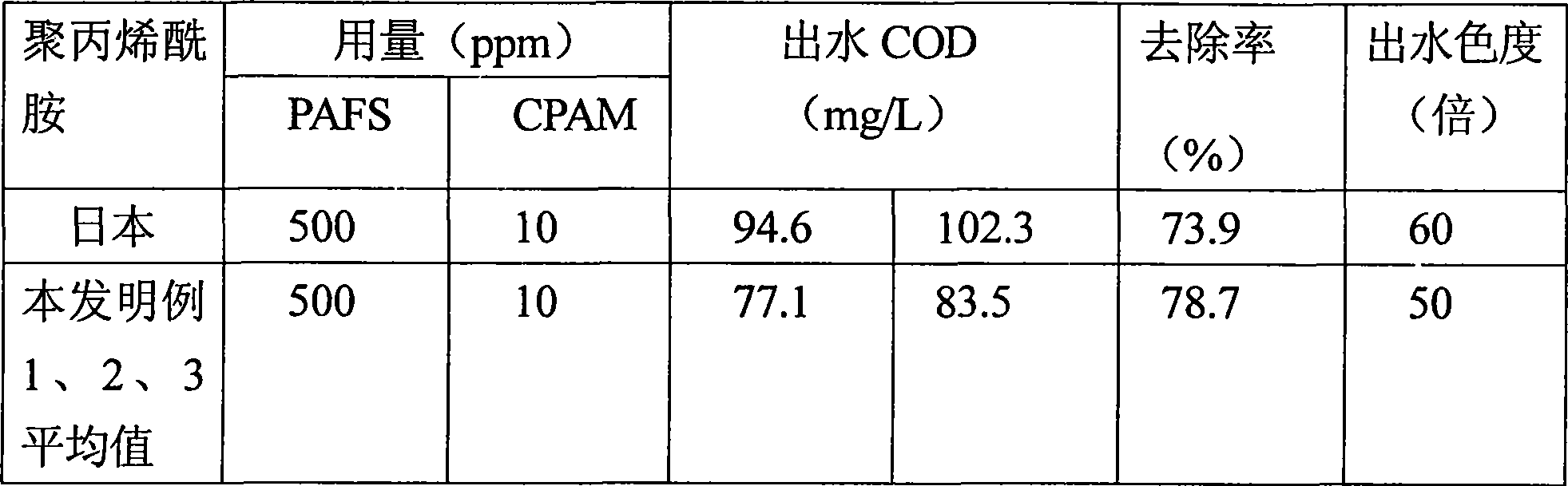

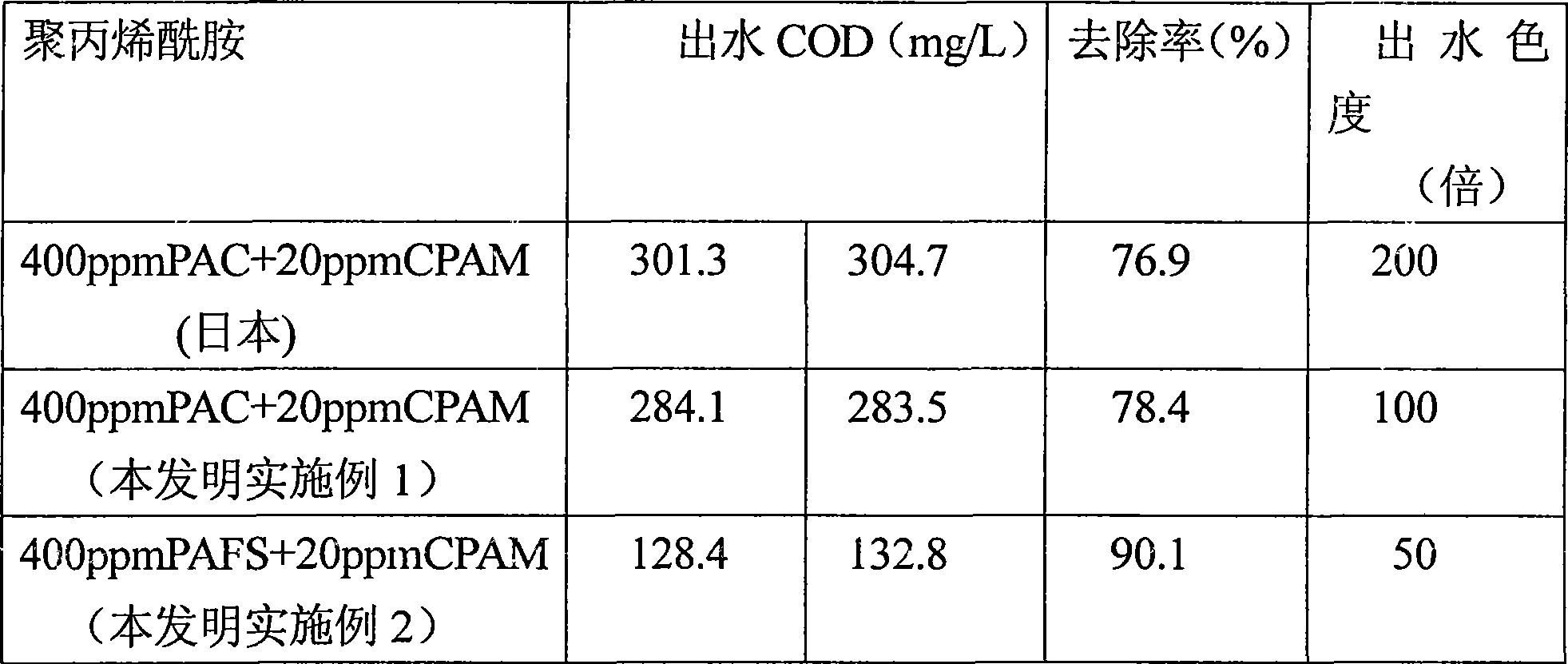

Process for producing cation polyacrylamide

The invention provides a technique for producing cationic polyacrylamide, and comprises the raw materials by mass percent: 10.0 to 25.0% of acrylamide, 5.0 to 10.0% of acryloxyethyl trimethylammonium chloride, 0.02-0.04% of redox, 0.03-0.015% of azo compound, 0.5 to 5.0 of urea, 0.02 to 0.15% of fatty acid salt, and 65.5-84% of deionized water; the raw materials are put into a reactor and added with the redox to have induced polymerization reaction under nitrogen protection at the room temperature, and then added with the azo compound to have secondary induced polymerization reaction; finally, the products of the invention are obtained after granulation and dryness. The technique is stable, slow in induction, even in reaction, mild and ordered, and easy in the control of operation process; the obtained products are rapid in dissolution rate, little in usage, large in water yield, big and dense in floccules, and not easy in fragmentation. The technique is mainly used for various environment-friendly fields such as sewage disposal, sludge dewatering, etc.

Owner:SICHUAN TONGFENG TECH

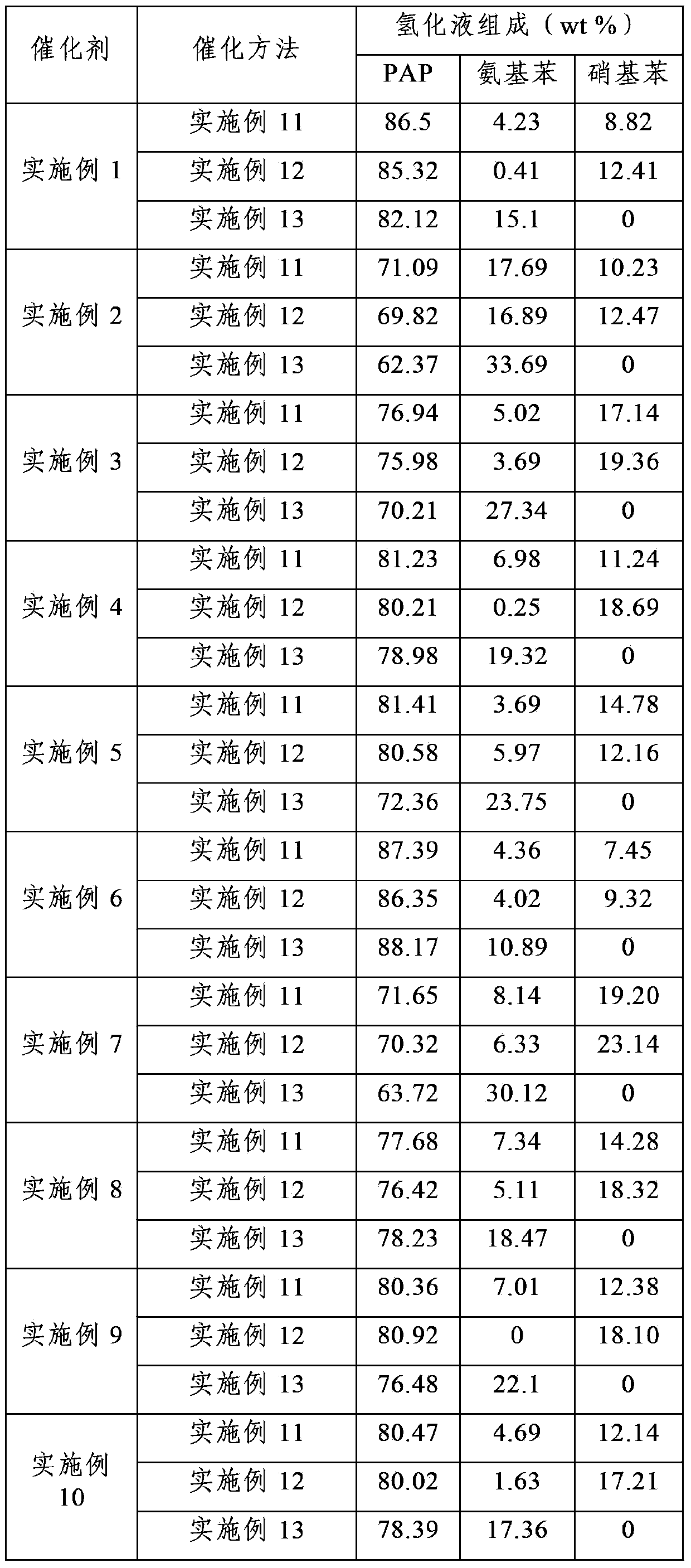

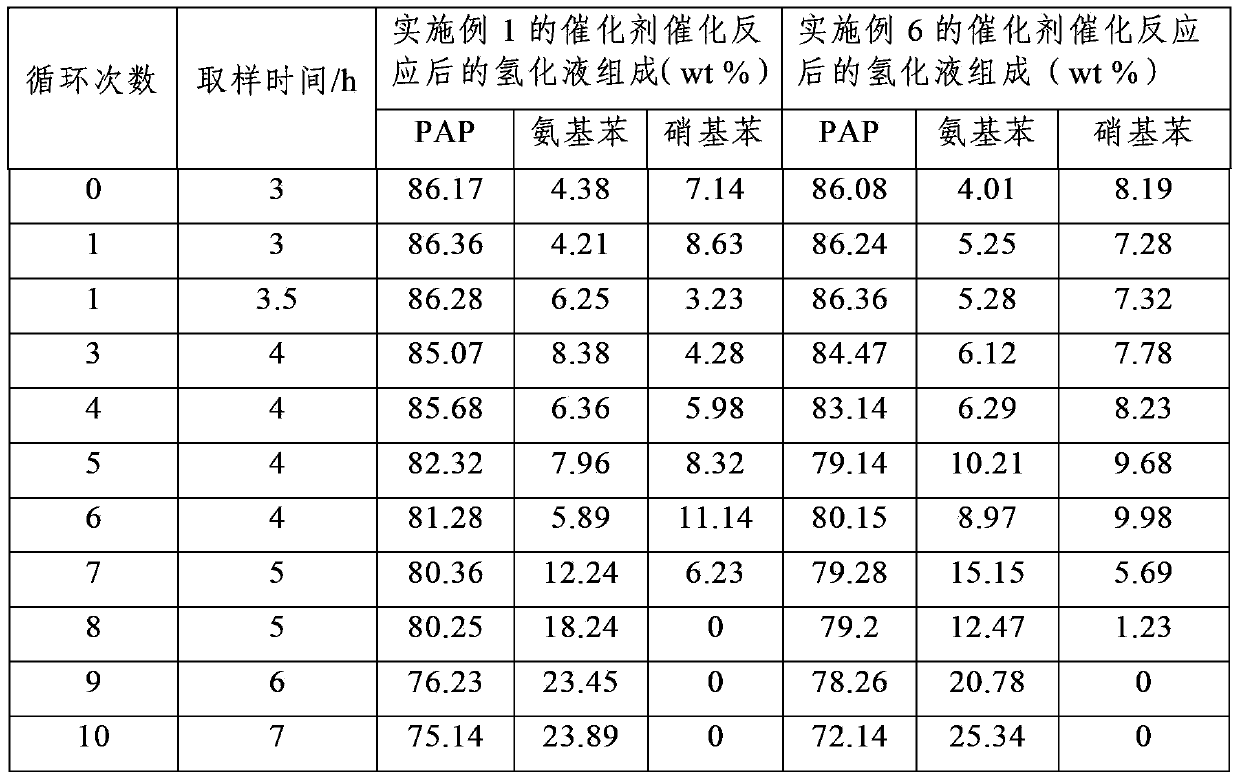

Preparation method and application of catalyst for one-step preparation of p-aminophenol from nitrobenzene

InactiveCN103357407AExtended service lifeHigh catalytic activityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsPlatinum saltsP-Aminophenol

The invention discloses a preparation method of a catalyst for the one-step preparation of p-aminophenol from nitrobenzene. The method comprises the following steps: preprocessing active carbon; loading a platinum salt; loading a vanadate; and reducing a catalyst, wherein the mass percentage contents of platinum and vanadium in the catalyst are 0.5-5% and 0.05-0.2% respectively. The invention also discloses a method for the one-step preparation of p-aminophenol from nitrobenzene through utilizing the catalyst. The addition of a certain amount of metallic vanadium to the Pt / C catalyst reduces the poisoning effect of sulfides in the nitrobenzene raw material to platinum, prolongs the service life of the catalyst and also improves the catalysis activity and selectivity of the catalyst; and the prepared catalyst has stable performances and very good repeatability, can be used for catalyzing the one-step preparation of p-aminophenol from nitrobenzene, reduces the purity requirement of the raw material nitrobenzene and reduces the catalysis cost.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com