Extraction and purification method of ergothioneine

A technology of ergothioneine and purification method, which is applied in the fields of biochemical products, food and medicine, and achieves the effects of few steps, simple operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Preparation of Pleurotus otreatus CGMCC No.6232 mycelium fermentation broth

[0042] Slant medium: PDA medium (Becton, Dickinson and Company).

[0043] Liquid seed medium: corn flour 30g / L, soybean meal 15g / L, α-amylase 54U / L, KH 2 PO 4 3g / L, MgSO 4 ·7H 2 O1.5g / L, the rest is water, sterilized at 121°C for 20 minutes, and the liquid volume in a 500mL Erlenmeyer flask is 150mL.

[0044] Liquid fermentation medium: glycerol 50g / L, casein peptone 35g / L, KH 2 PO 4 3g / L, MgSO 4 ·7H 2 O1.5g / L, the rest is water, sterilized at 121°C for 20 minutes, and the liquid volume in a 500mL Erlenmeyer flask is 150mL.

[0045] The bacterial lawn of strain CGMCC No.6232 from the slant medium was picked and inserted into the seed medium, and cultured on a shaker at 25° C. at 150 rpm for 4 days to obtain a seed solution. The seed liquid was inserted into the fermentation medium with an inoculation amount of 5% by volume, and cultured on a shaker at 25° C. at 150 rpm f...

Embodiment 2

[0046] Embodiment 2: Extraction and purification of ergothioneine

[0047] The mycelium fermented liquid of Pleurotus otreatus CGMCC No.6232 is centrifuged, and 50 g of mycelium is collected, and water of 1:40 is added according to wet mycelium weight: water (g: mL) to make mycelium aqueous suspension. The mycelia suspension was placed in a water bath at 100°C, and leached for 5 minutes without stirring, and the ergothioneine was leached into the aqueous solution. Collect mycelia and filtrate respectively after filtration to obtain 1700 mL of ergothioneine aqueous solution.

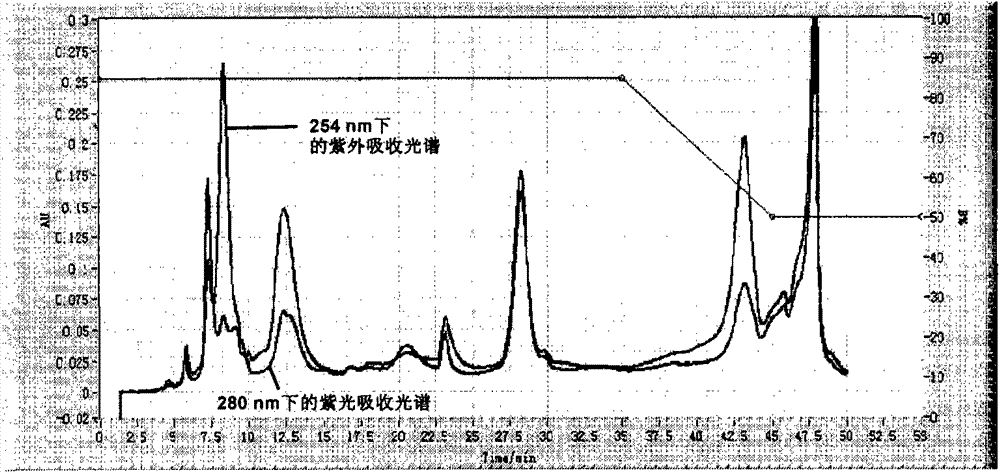

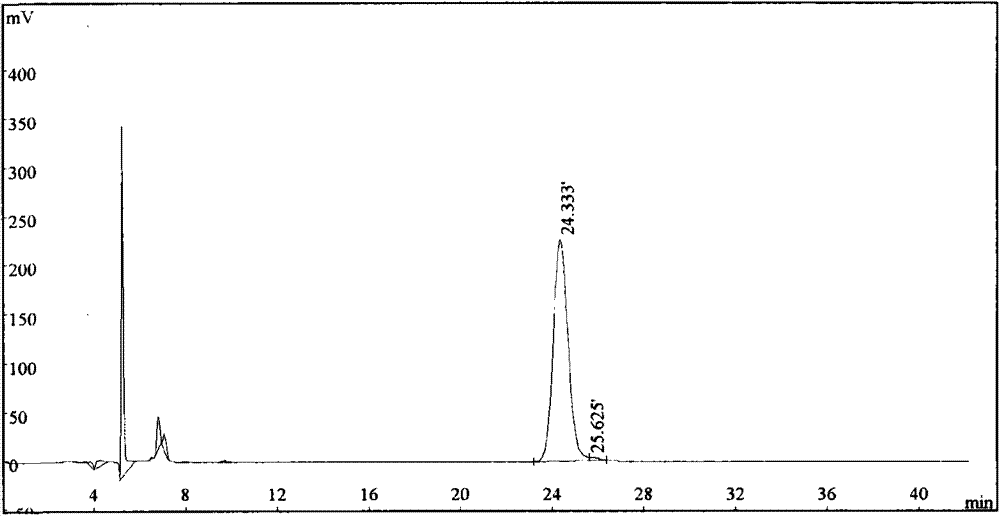

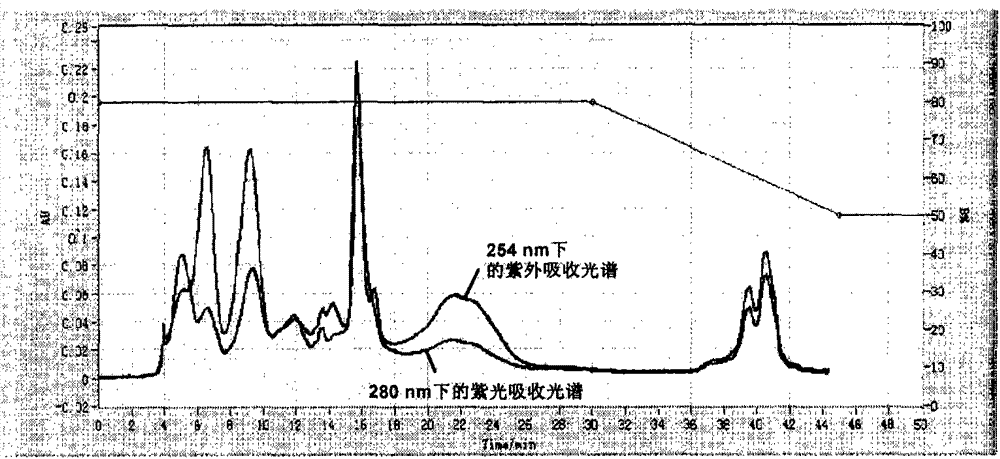

[0048] The above-mentioned aqueous solution of ergothioneine is ultrafiltered by a hollow fiber ultrafiltration membrane with a pore size of 4kDa to obtain 1000mL of permeate, and the purity of ergothioneine measured by high pressure liquid phase reaches 31.6%. The permeated liquid was rotary evaporated at 50° C. to a concentrated solution with an ergothioneine concentration of 1.72 g / L or spray-dried t...

Embodiment 3

[0052] Embodiment 3: Extraction and purification of ergothioneine

[0053] Pleurotus otreatus (Pleurotus otreatus) CGMCC No.6232 mycelia after submerged fermentation, the mycelium fermentation liquid is centrifuged, 600g mycelium is collected, and water of 1:0.5 is added according to wet mycelium weight:water (g:mL) , to make an aqueous suspension of mycelium. The mycelia aqueous suspension is placed in a 70°C water bath, stirred and leached at 600rpm for 60min, and the ergothioneine is leached into the aqueous solution. Mycelia and filtrate were collected respectively after filtration, and mycelium was repeatedly leached 5 times by the above-mentioned method, and the filtrate after merging and leaching was obtained to obtain 1100mL ergothioneine aqueous solution.

[0054] The above-mentioned aqueous solution of ergothioneine is ultrafiltered by a hollow fiber ultrafiltration membrane with a pore size of 6kDa to obtain 600mL of permeate, and the purity of ergothioneine measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com