Patents

Literature

5030 results about "Medium pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The medium pressure range of industrial air compressors from the technology leader in high pressure features continuous duty rated, 3-stage, air cooled, pressure lubricated compressors for the most demanding requirements. The full-featured control system allows for unattended, automatic operation.

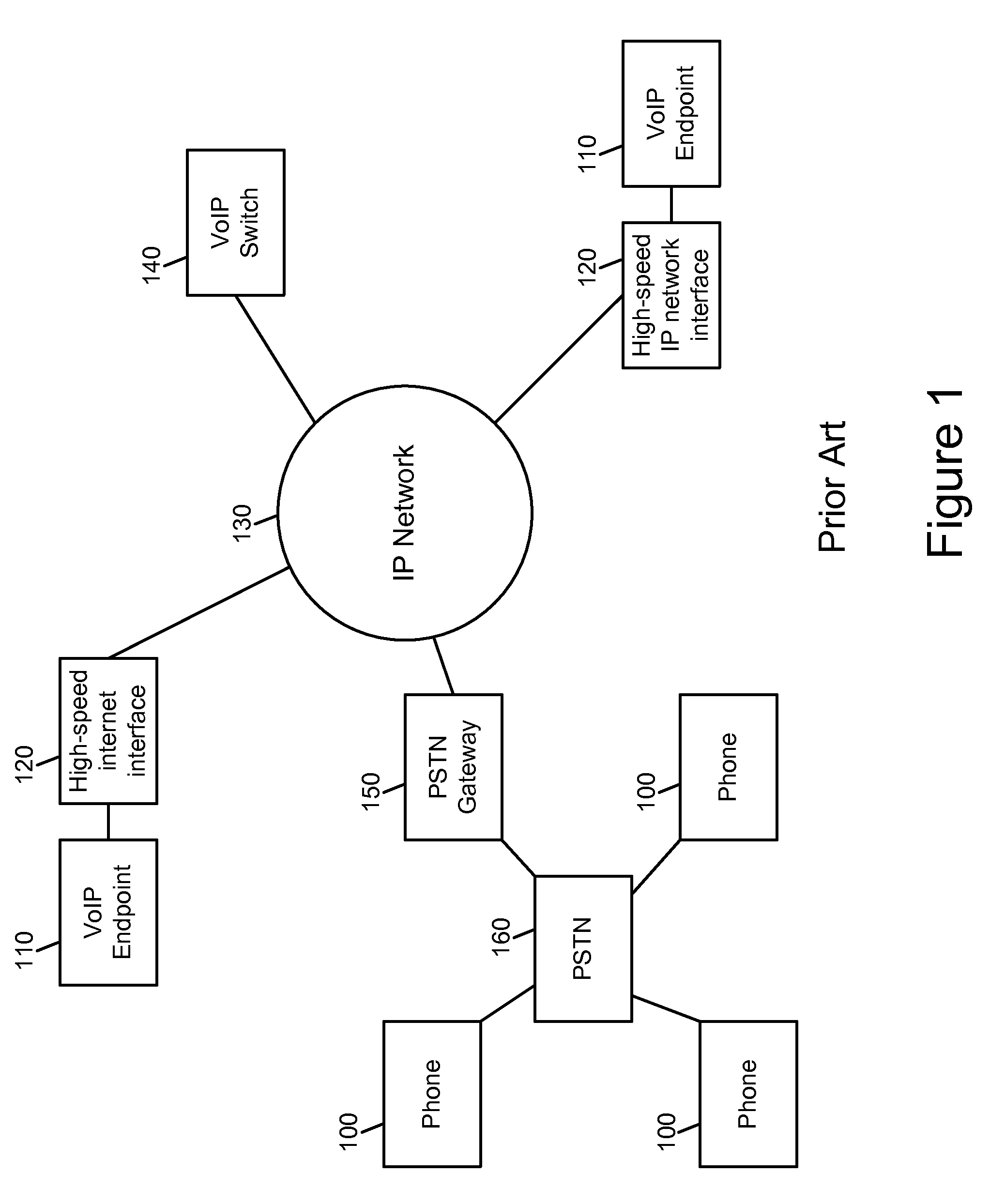

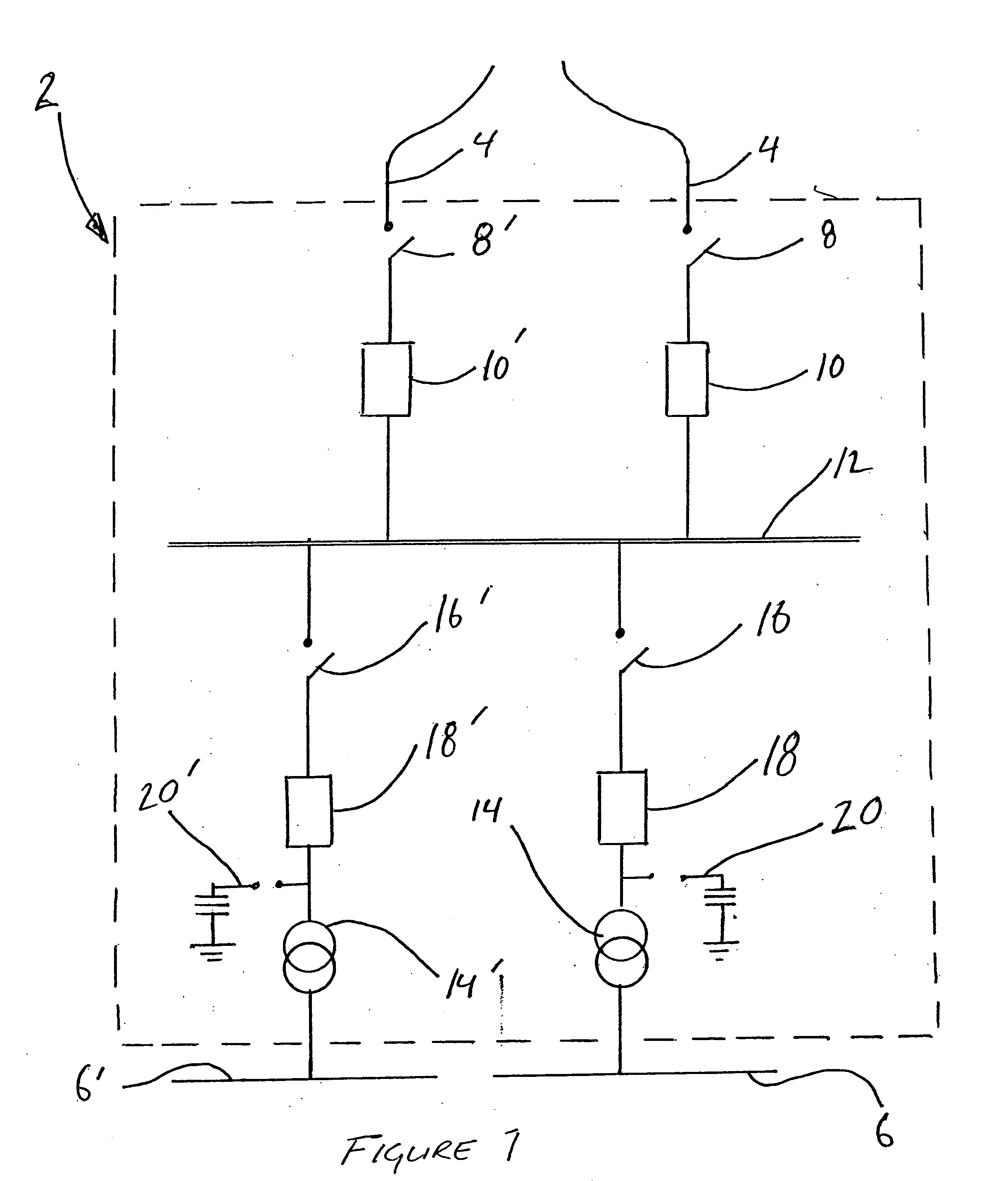

Power line communications device and method

InactiveUS20060192672A1Modulated-carrier systemsFrequency-division multiplex detailsFiberElectricity

A device and method for providing power line communications via an underground residential distribution power system is provided. One embodiment of the present invention includes a medium voltage interface device that may include a first port configured to communicate over the power line and a network interface. A first amplifier may form part of a first communication path between the first port and the network interface and be configured to amplify data signals transmitted via the first port. In addition, a second amplifier may form part of a second communication path between the first port and the network interface and be configured to amplify data signals received via the first port. In addition, the embodiment may include a diplexer forming part of the first communication path between the first amplifier and the first port and forming part of the second communication path between the second amplifier and the first port. The device may include an electro-optic converter coupled to the network interface to convert between electrical and optic data signals, wherein the network interface is configured to communicate via one or more fiber optic conductors.

Owner:CURRENT TECH

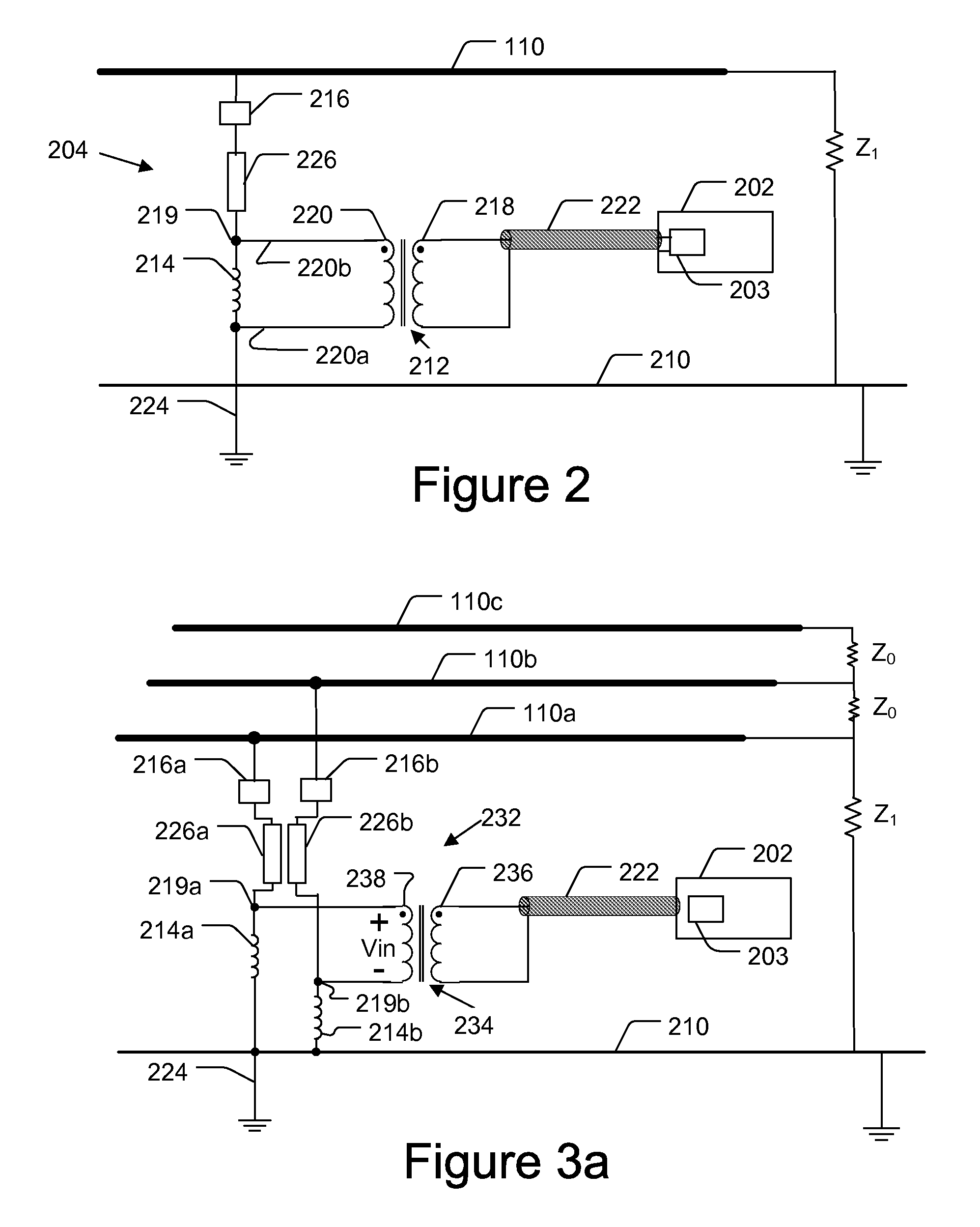

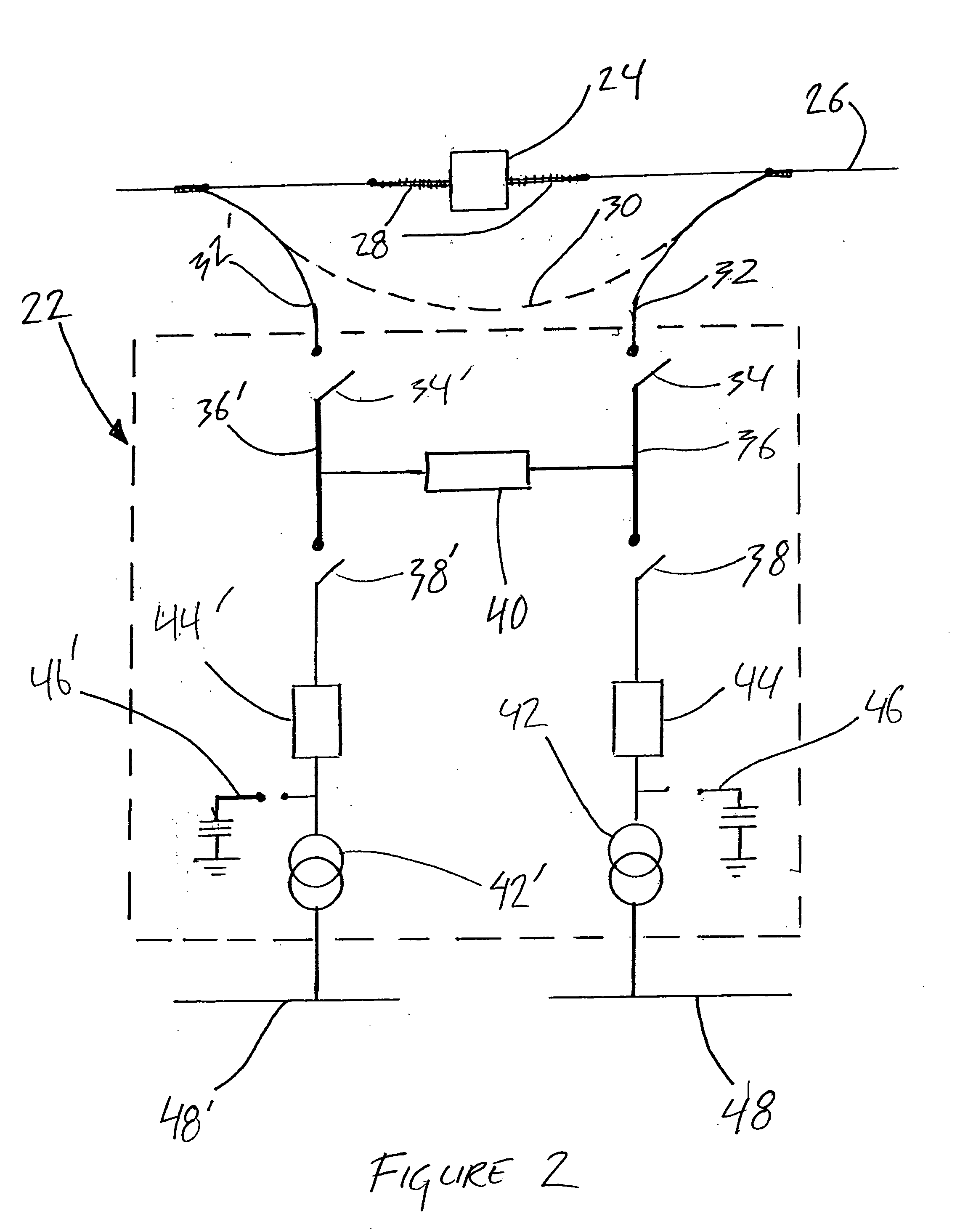

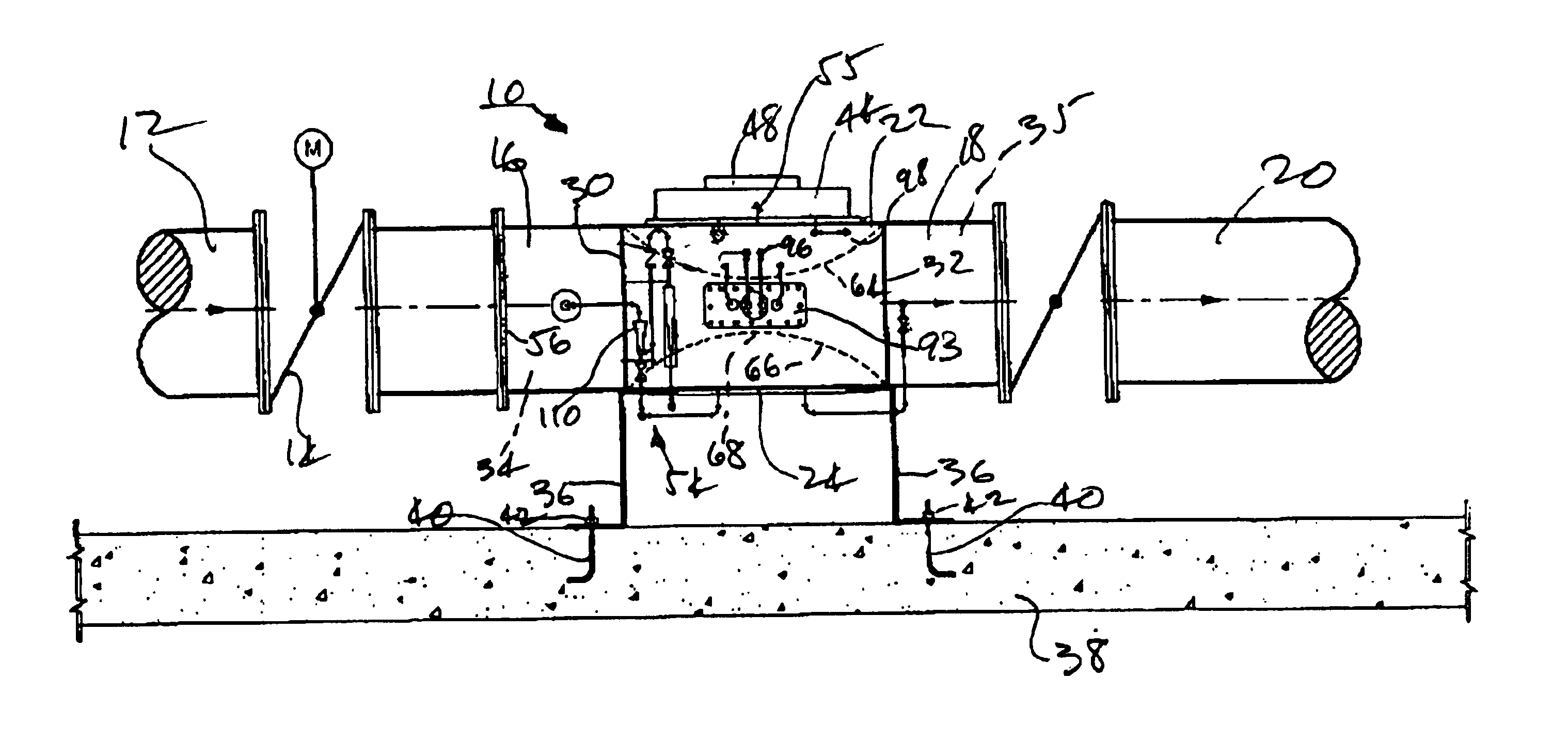

Power line coupling device and method

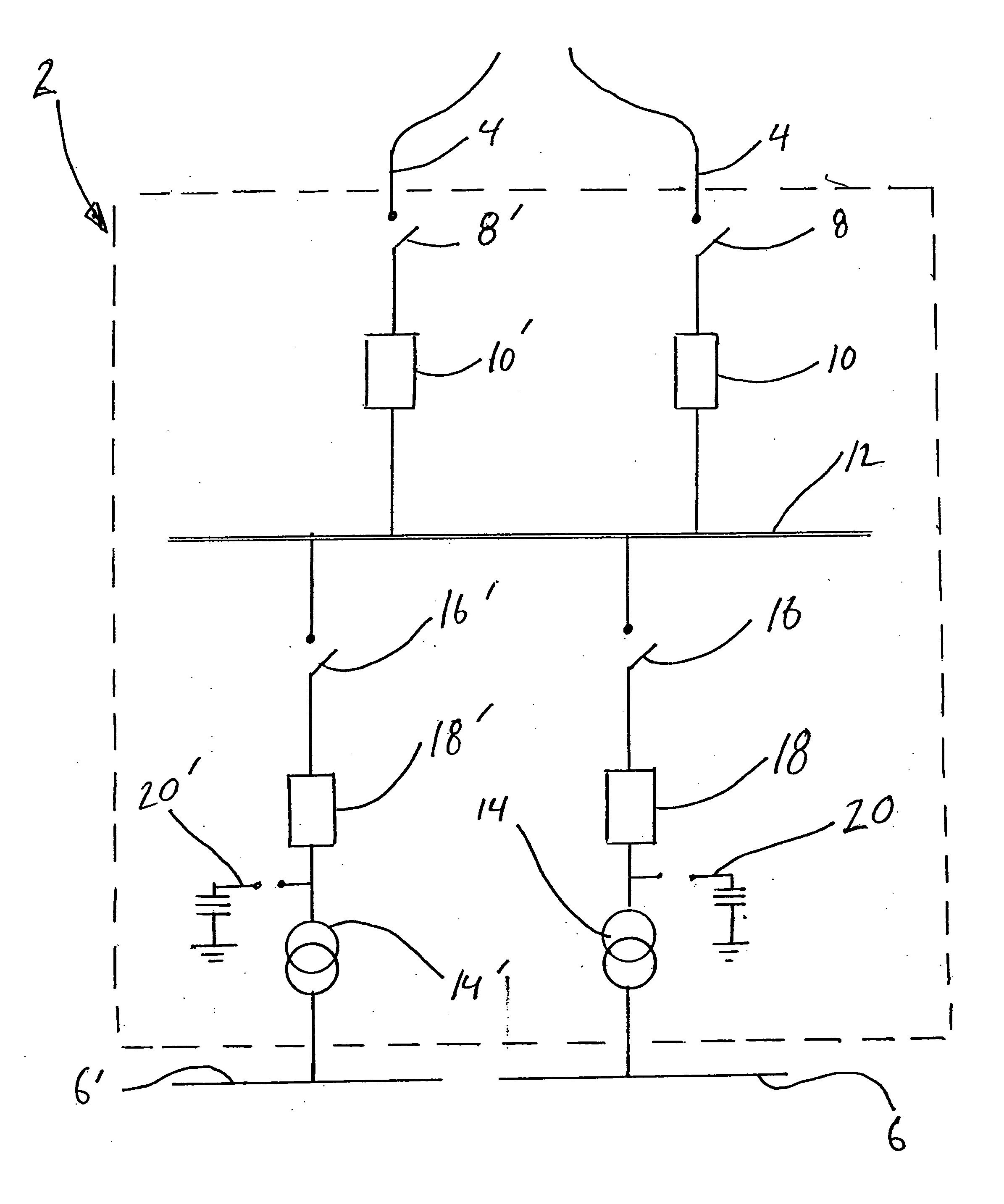

ActiveUS7795994B2Multiple-port networksElectric signal transmission systemsDistribution power systemConductor Coil

A power line coupler for communicating data signals over a power distribution system having a first and second overhead energized medium voltage power line conductors is provided. In one embodiment, the coupler includes a first lightening arrestor having a first end and a second end, wherein the first end of the first arrestor is connected to the first power line conductor. The coupler further includes a first high frequency impedance having a first end connected to the second end of the first lightening arrestor and the first impedance having a second end connected to a neutral conductor of the power line distribution system. The coupler may further include a second lightening arrestor having a first end and a second end, wherein the first end of the second arrestor is connected to the second power line conductor. The coupler further including a second high frequency impedance having a first end connected to the second end of the second lightening arrestor and a second end connected to the neutral conductor. The first high frequency impedance and the second high frequency impedance may each comprise an air core coil that forms an inductor. The coupler may further include a balun having a first winding and a second winding, wherein the first winding is coupled to a communication device, and wherein the second winding has a first end connected to the first end of the first high frequency impedance and a second end connected to the first end of the second high frequency impedance.

Owner:CHEMTRON RES

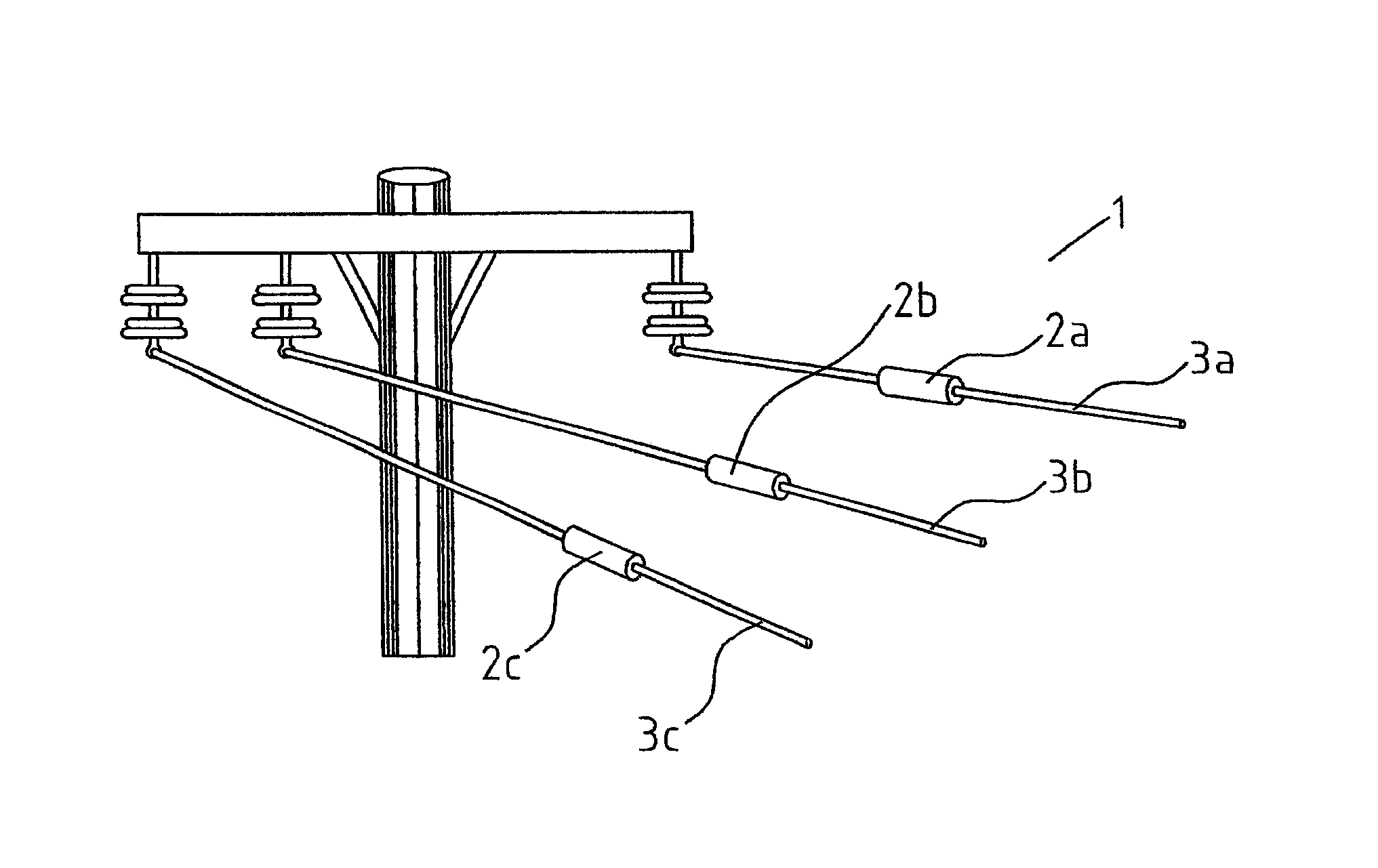

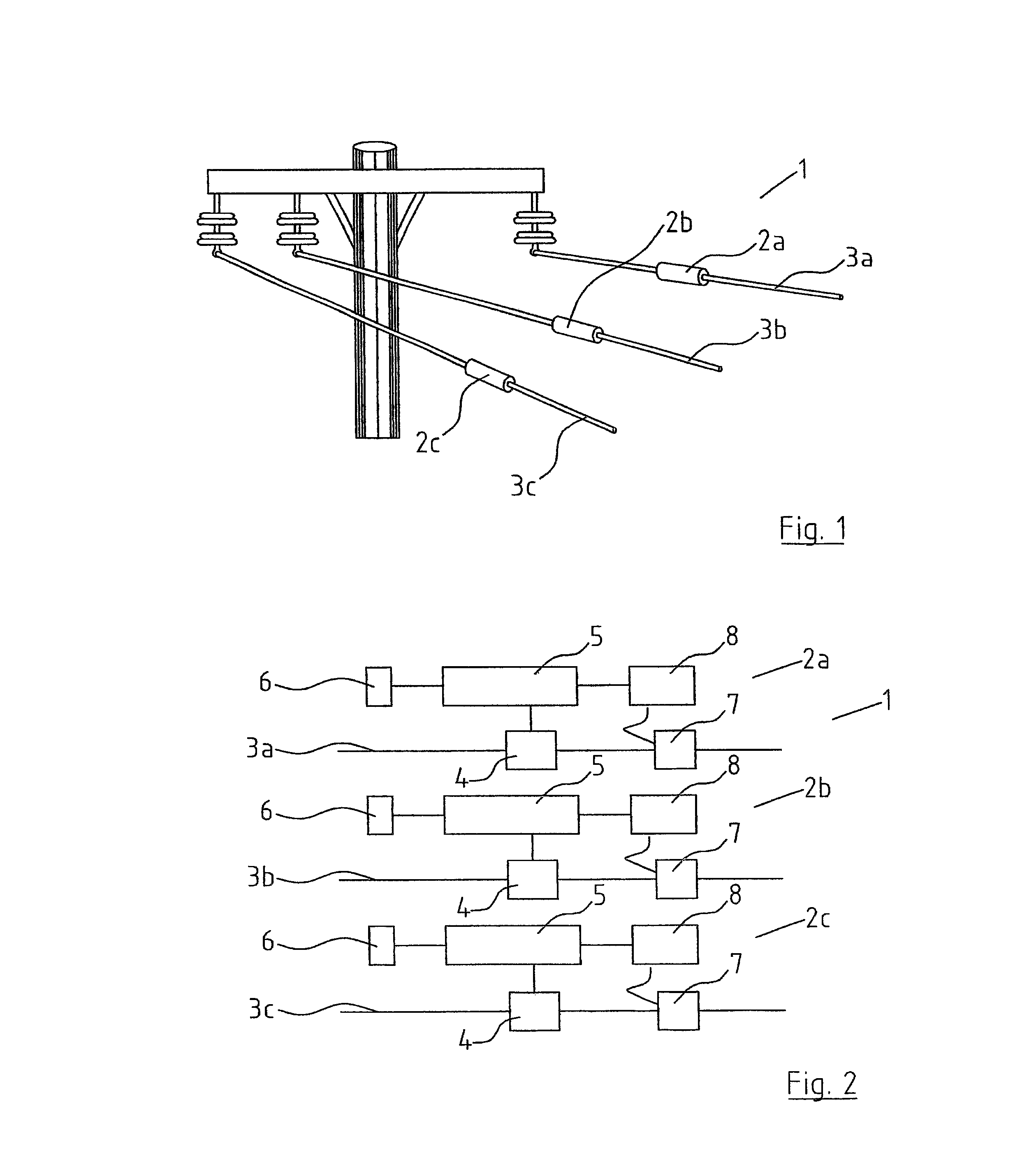

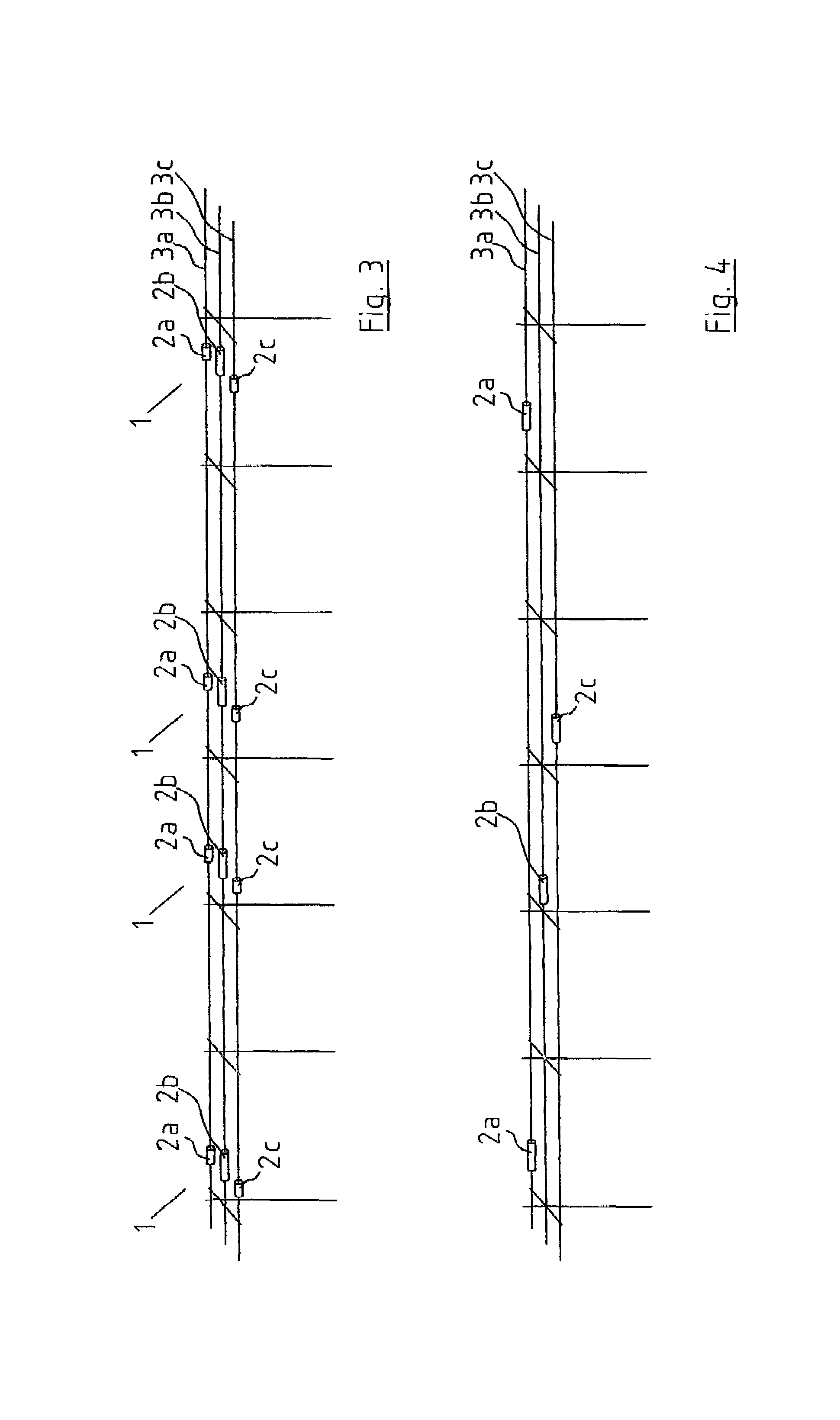

Monitoring device for a medium voltage overhead line

InactiveUS7518529B2Reduce the amount requiredConserve costTelemetry/telecontrol selection arrangementsResistance/reactance/impedenceEngineeringOverhead line

A monitoring device (1) for monitoring the electrical properties of a medium voltage overhead line (3) in a medium voltage network comprises three separate measurement sensors (2a, 2b, 2c), each being adapted for direct connection onto a medium voltage overhead line. Each of the measurement sensors has means to draw operating power from the medium voltage overhead line. The measurement sensors measured results may be combined for accurate measurement analysis.

Owner:FMC TECH LTD

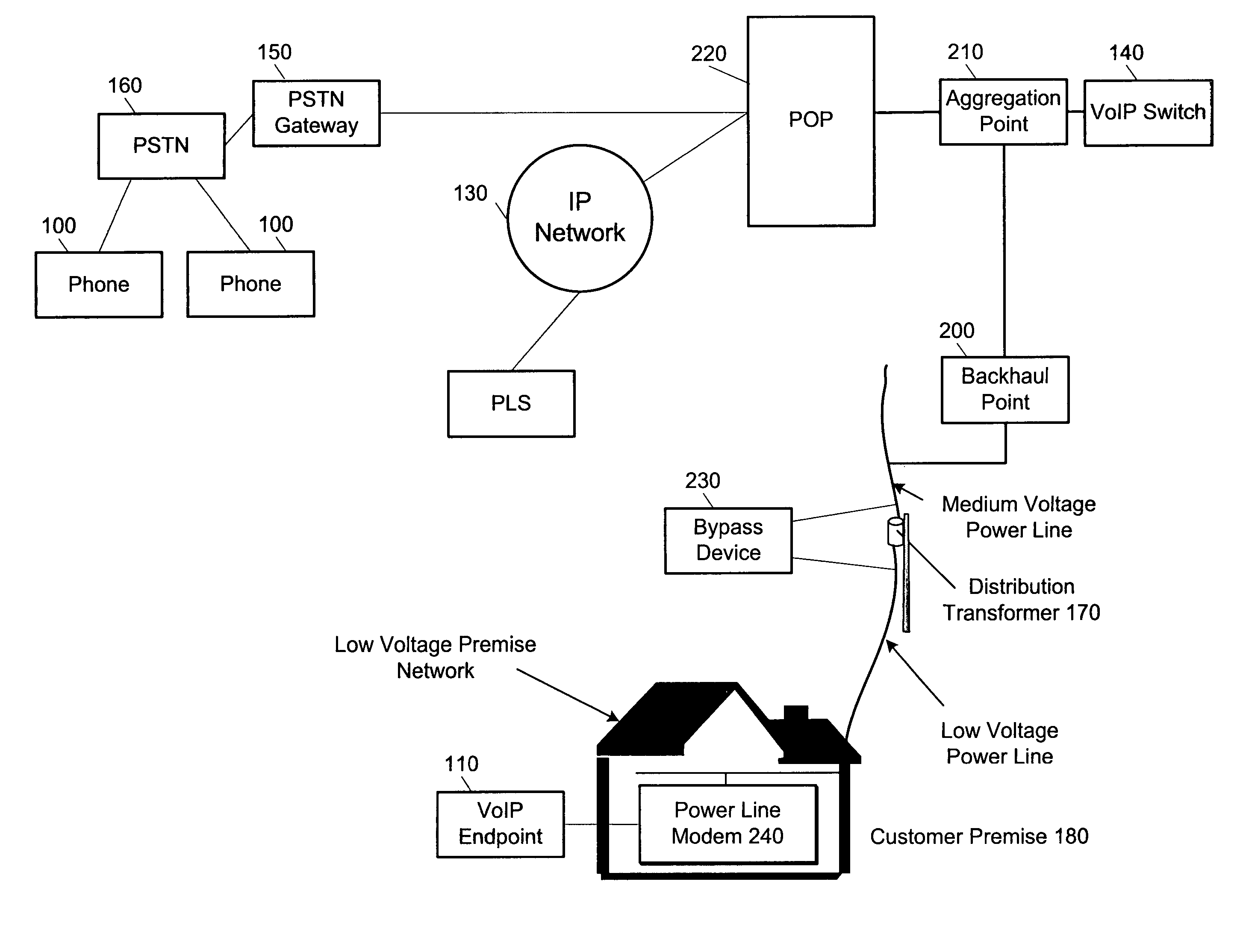

Power line communication voice over IP system and method

A power line communication system communicating over a medium voltage power line including a VoIP endpoint that transmits voice data and requests to establish a voice connection to a medium voltage (MV) access device is provided. The medium voltage access device may determine a response to the request, allocate voice data packets a higher priority than general data packets, and transmit the data packets over the MV power line according to their priority. The MV access device may provide one or more voice over internet protocol (VoIP) switch functions and, in response to the requests, grant or deny the requests based, for example, on the number of established voice connections.

Owner:CURRENT TECH

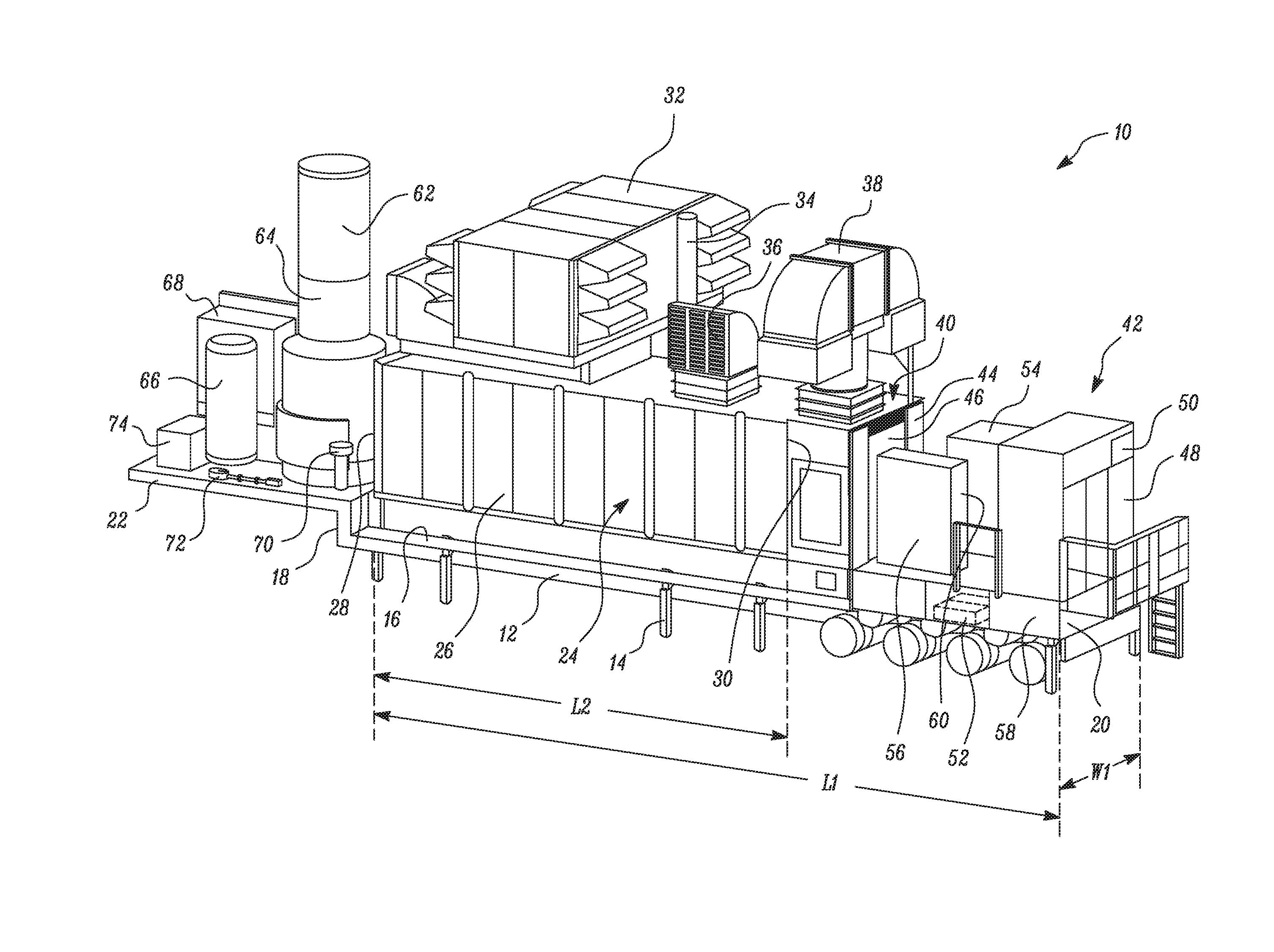

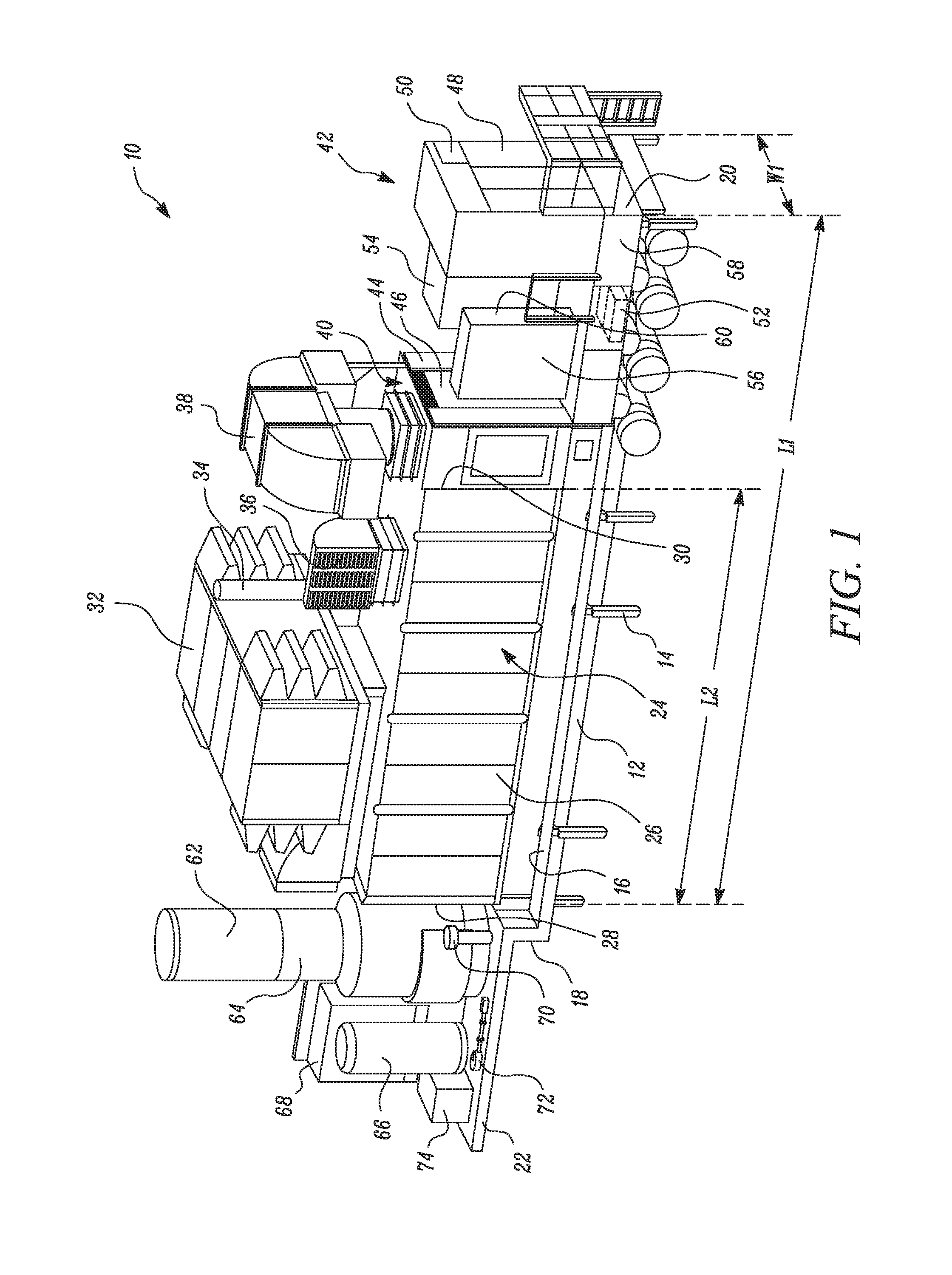

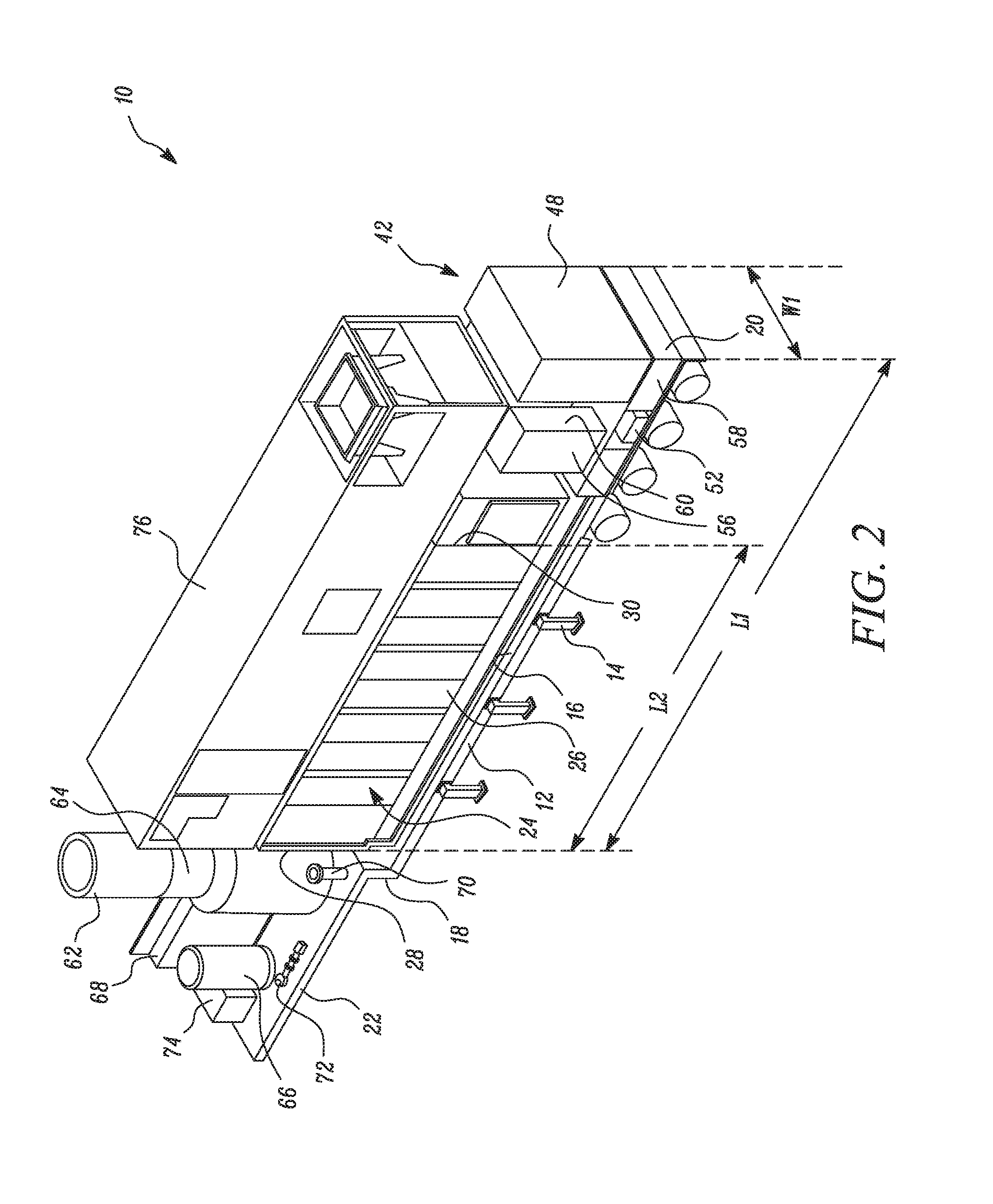

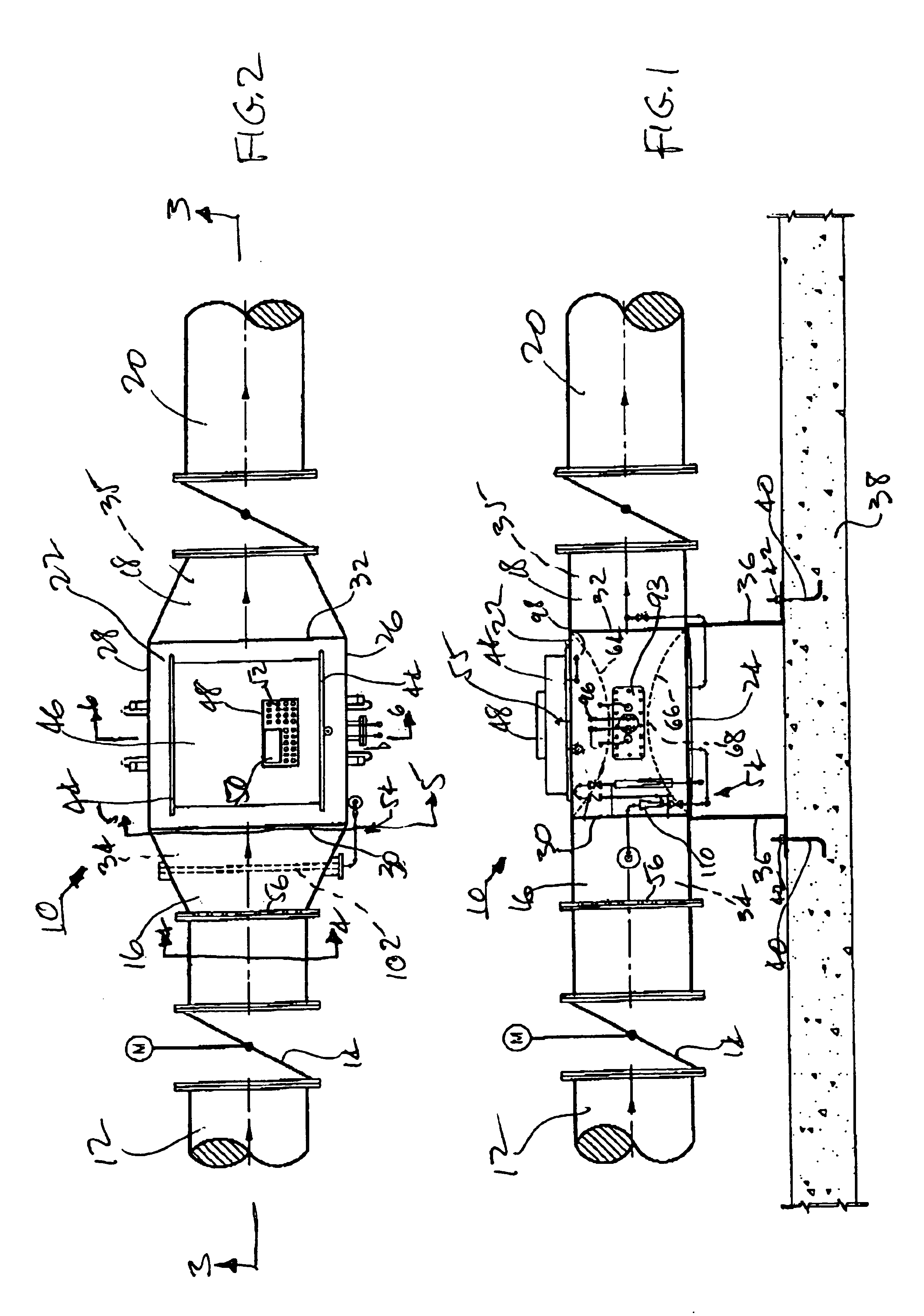

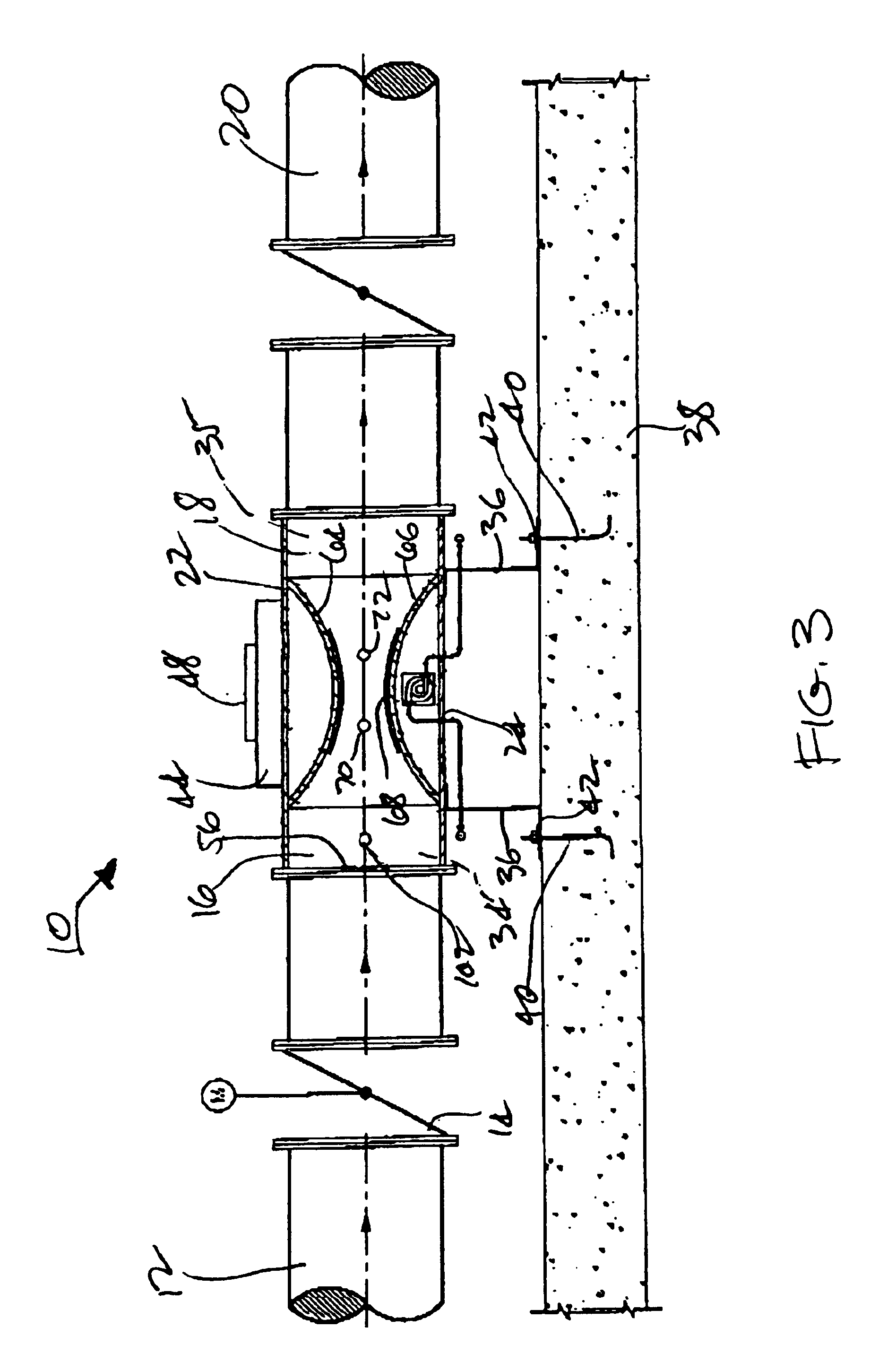

Modular power plant assembly

A modular power plant assembly for distributed power generation includes a power generator assembly, to generate electrical power, mounted on a trailer. An AC / DC distribution panel electrically coupled to the power generator assembly is mounted on the power generator assembly. A Medium Voltage module electrically coupled to the power generator assembly is mounted on the trailer. The AC / DC distribution panel and the Medium Voltage module together control and distribute the electrical power generated by the power generator assembly. A plurality of auxiliary components to supply fuel and air to the power generator assembly are mounted adjacent to the power generator assembly on a skid attached to the trailer.

Owner:SOLAR TURBINES

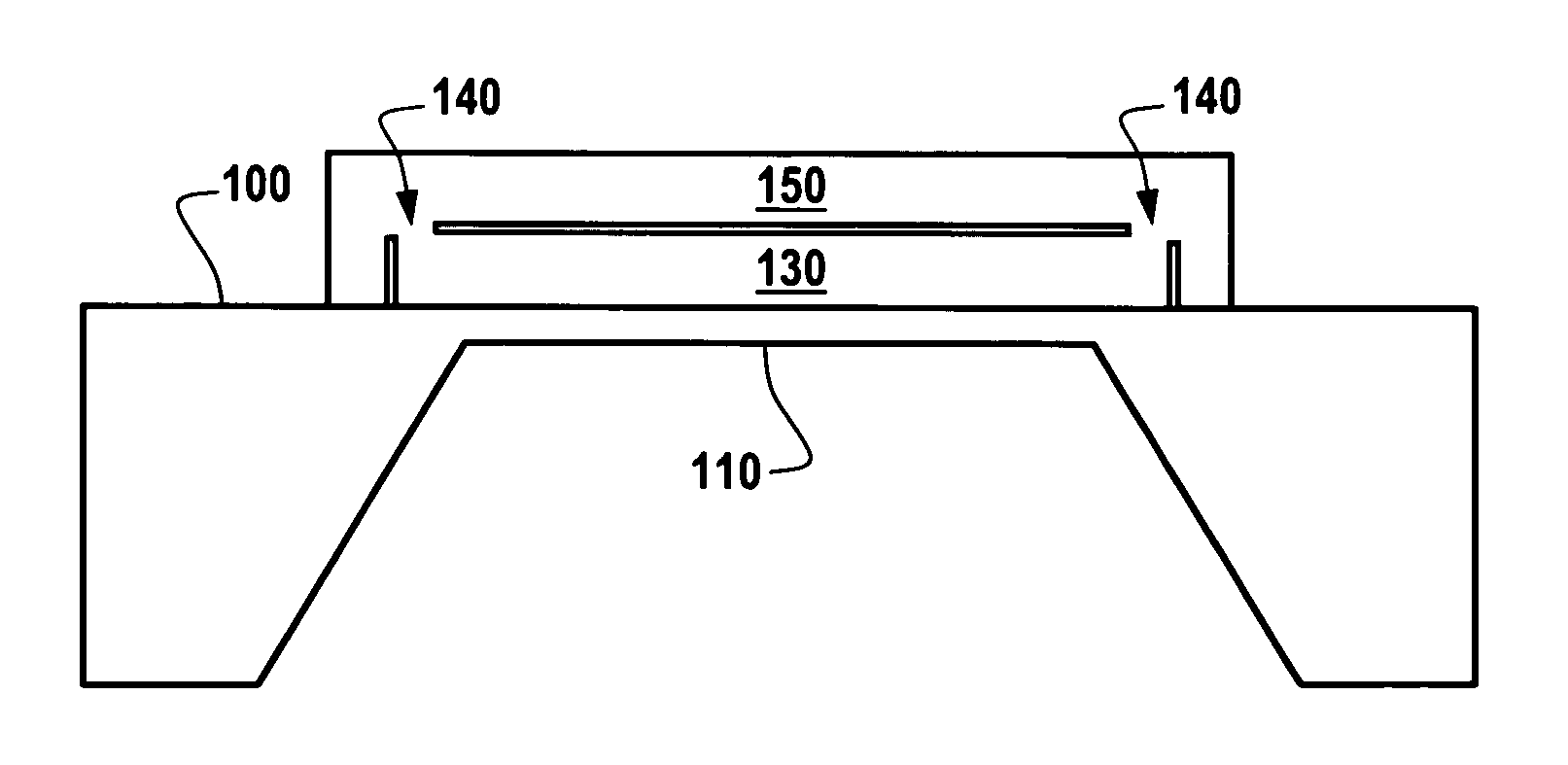

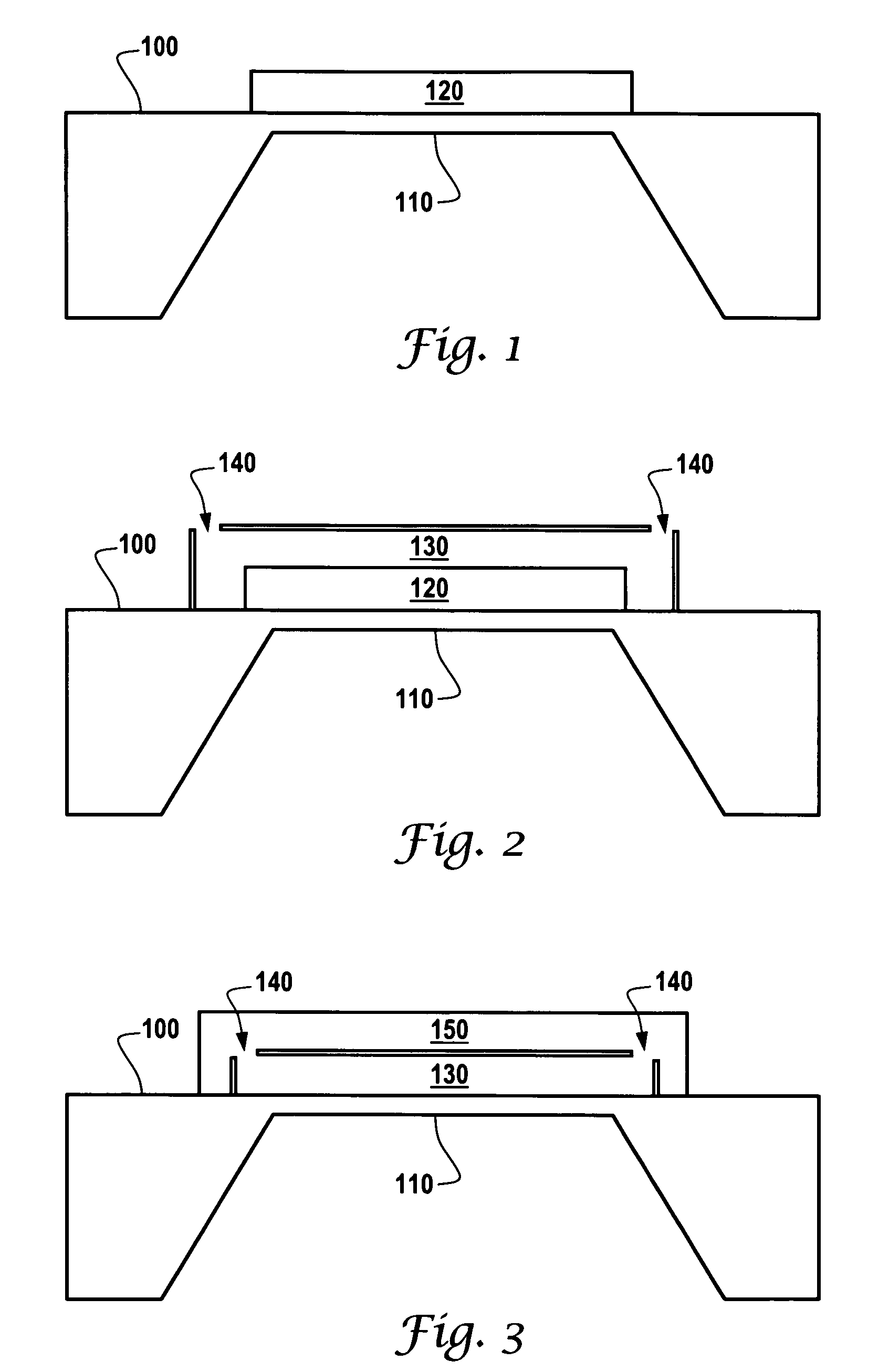

Top side reference cavity for absolute pressure sensor

A pressure sensor includes a silicon diaphragm having bottom and topside surfaces. The bottom surface has been formed using methods known to those skilled in the art. A first layer is formed and patterned on the topside surface of the diaphragm having an area larger than the diaphragm. A second layer is formed and patterned over the first layer, the second layer being larger in area than the first layer. Holes formed in the second layer are used to remove the first layer using methods known to those skilled in the art. A third layer is formed and patterned over the second layer. The third layer seals the holes in the second layer creating a sealed cavity with a reference pressure on the topside surface of the diaphragm. During operation, media is applied to the bottom surface of the diaphragm wherein the media pressure can be sensed by the pressure sensor in relation to the reference pressure sealed on the topside of the diaphragm.

Owner:HONEYWELL INT INC

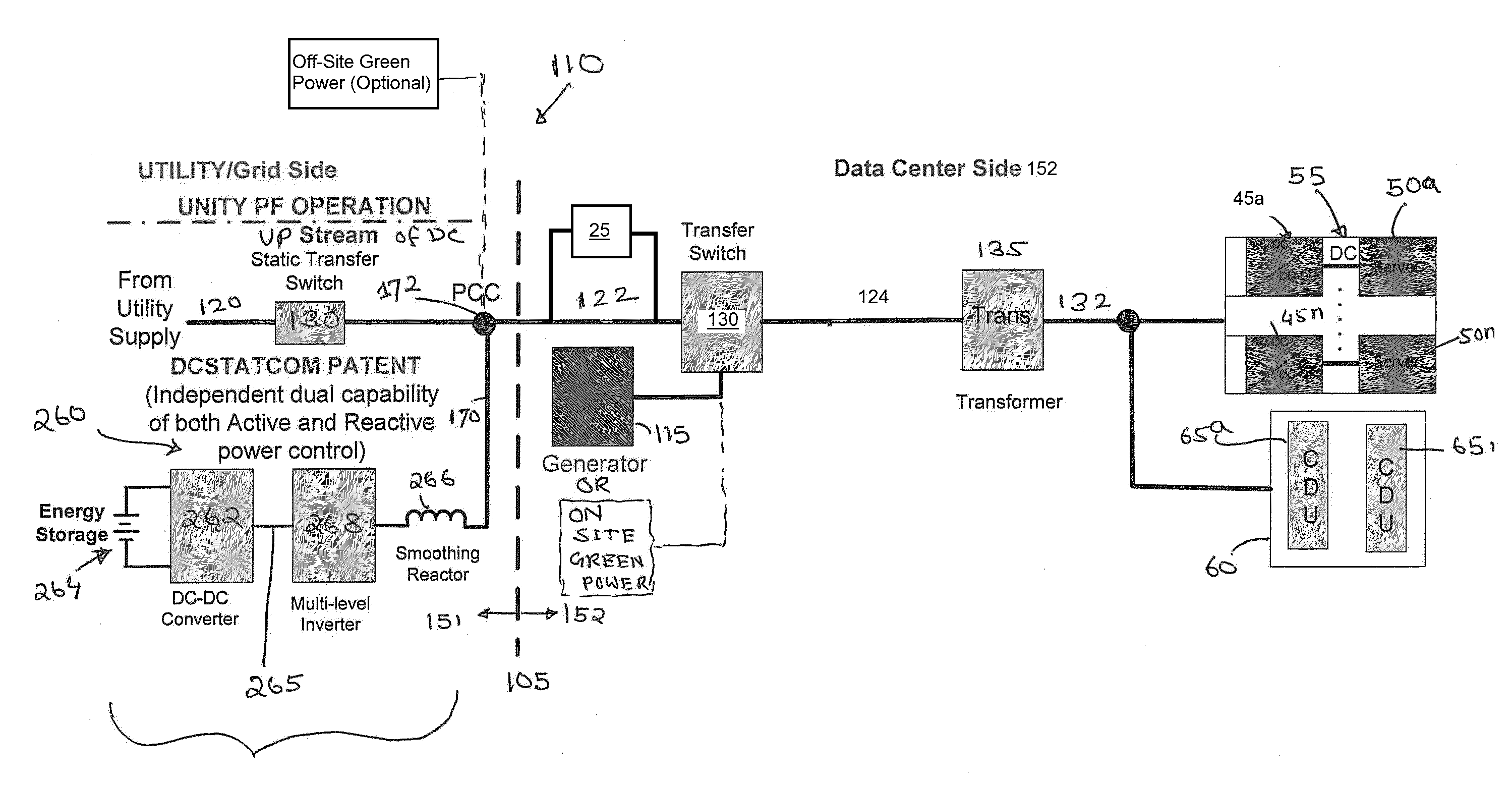

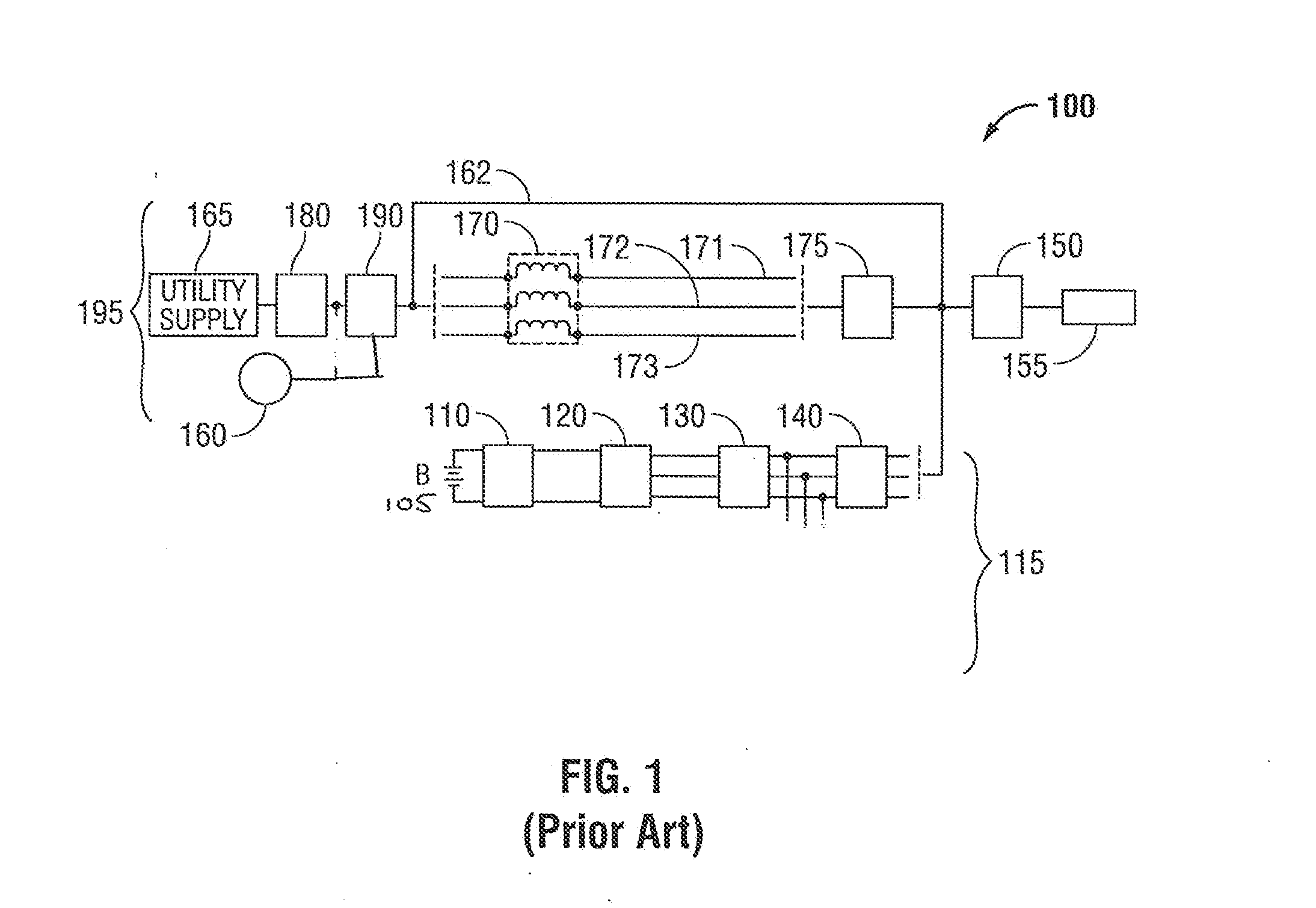

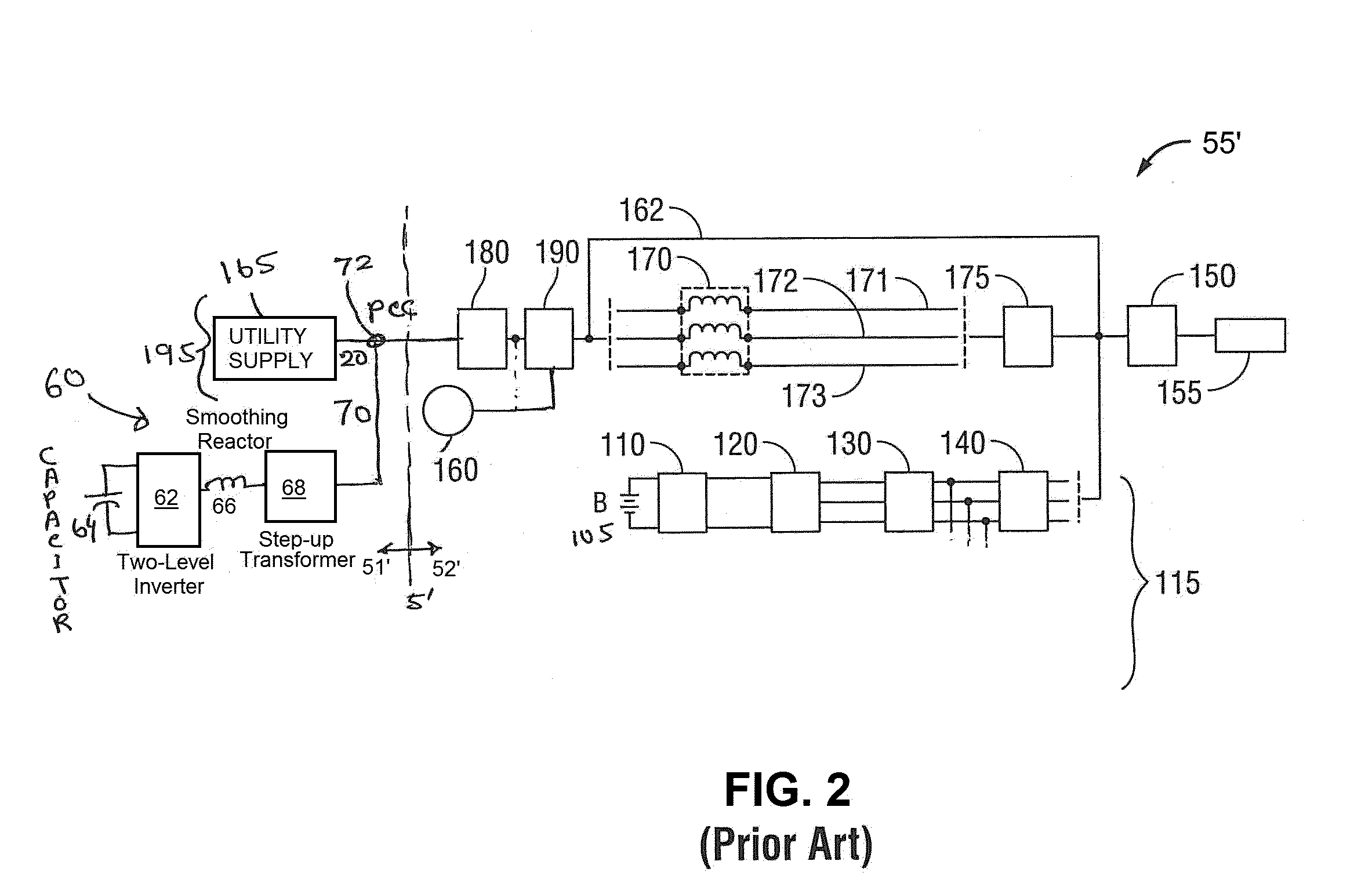

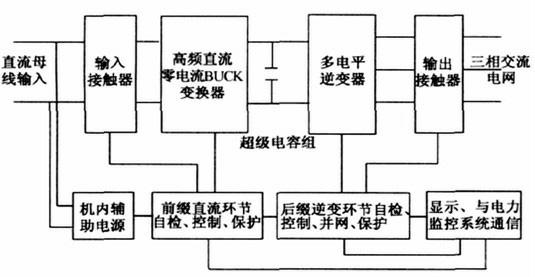

Multi-level medium voltage data center static synchronous compensator (dcstatcom) for active and reactive power control of data centers connected with grid energy storage and smart green distributed energy sources

Systems and methods for supplying power (both active and reactive) at a medium voltage from a DCSTATCOM to an IT load without using a transformer are disclosed. The DCSTATCOM includes an energy storage device, a two-stage DC-DC converter, and a multi-level inverter, each of which are electrically coupled to a common negative bus. The DC-DC converter may include two stages in a bidirectional configuration. One stage of the DC-DC converter uses a flying capacitor topology. The voltages across the capacitors of the flying capacitor topology are balanced and switching losses are minimized by fixed duty cycle operation. The DC-DC converter generates a high DC voltage from a low or high voltage energy storage device such as batteries and / or ultra-capacitors. The multi-level, neutral point, diode-clamped inverter converts the high DC voltage into a medium AC voltage using a space vector pulse width modulation (SVPWM) technique.

Owner:INERTECH IP

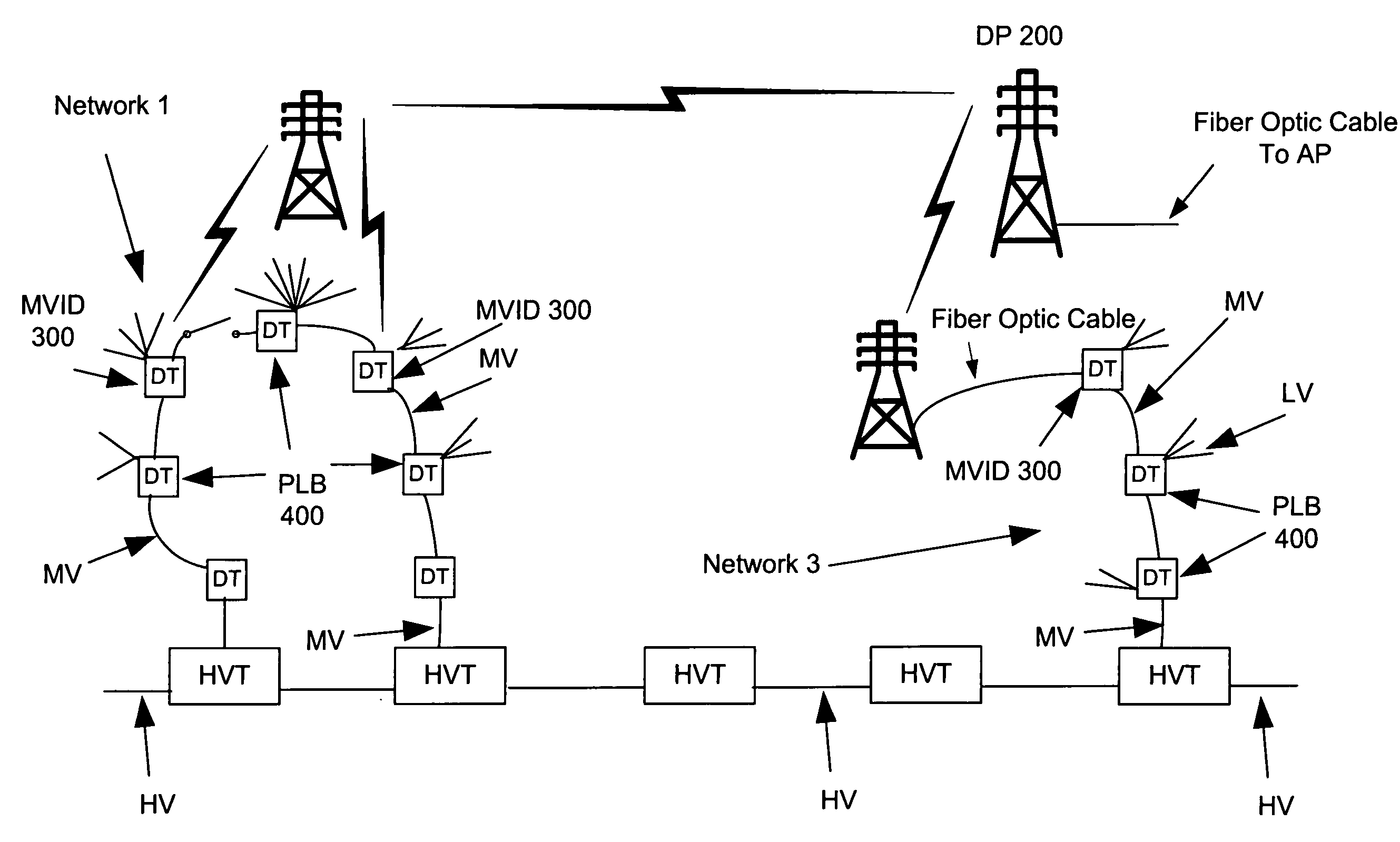

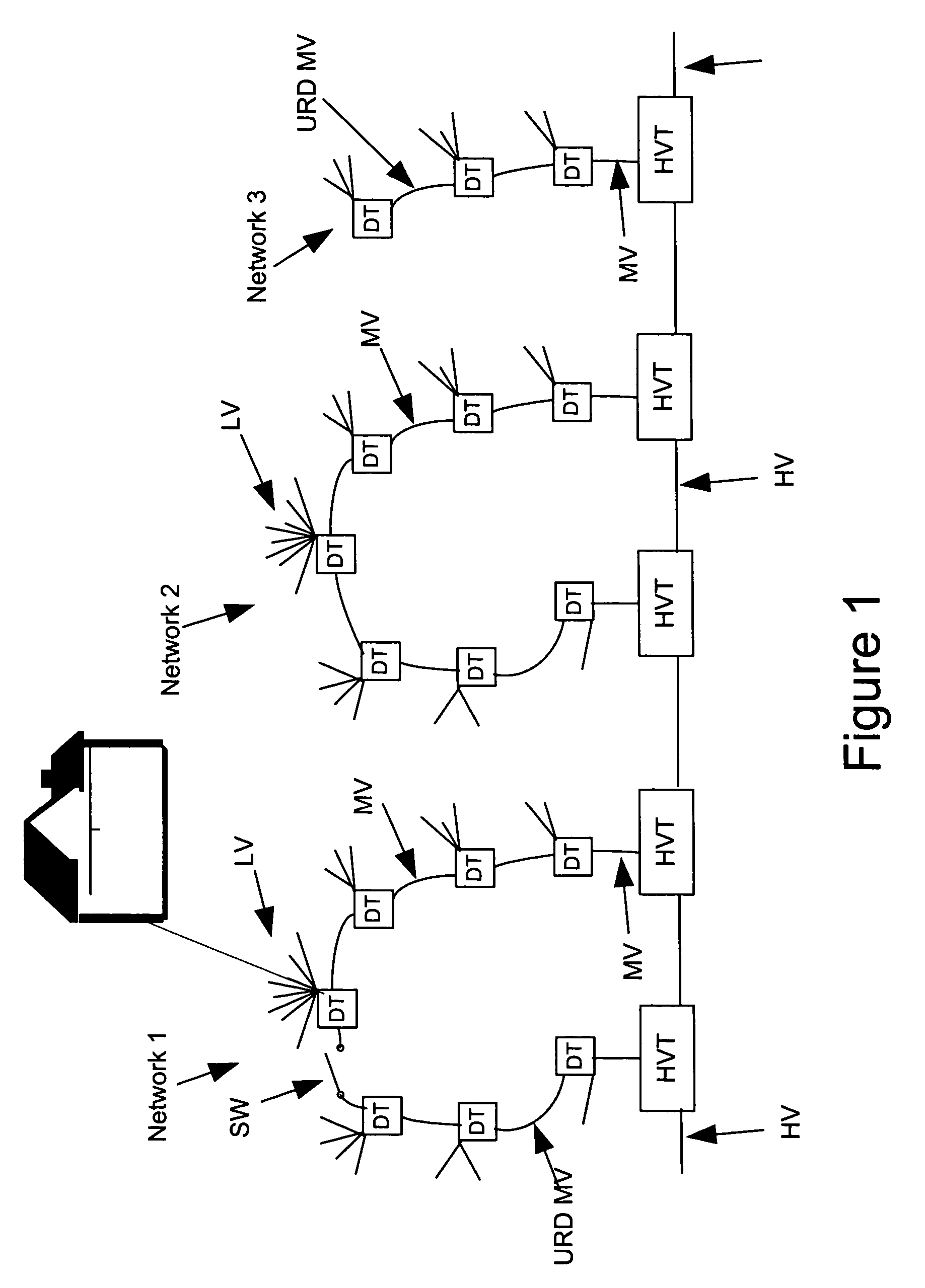

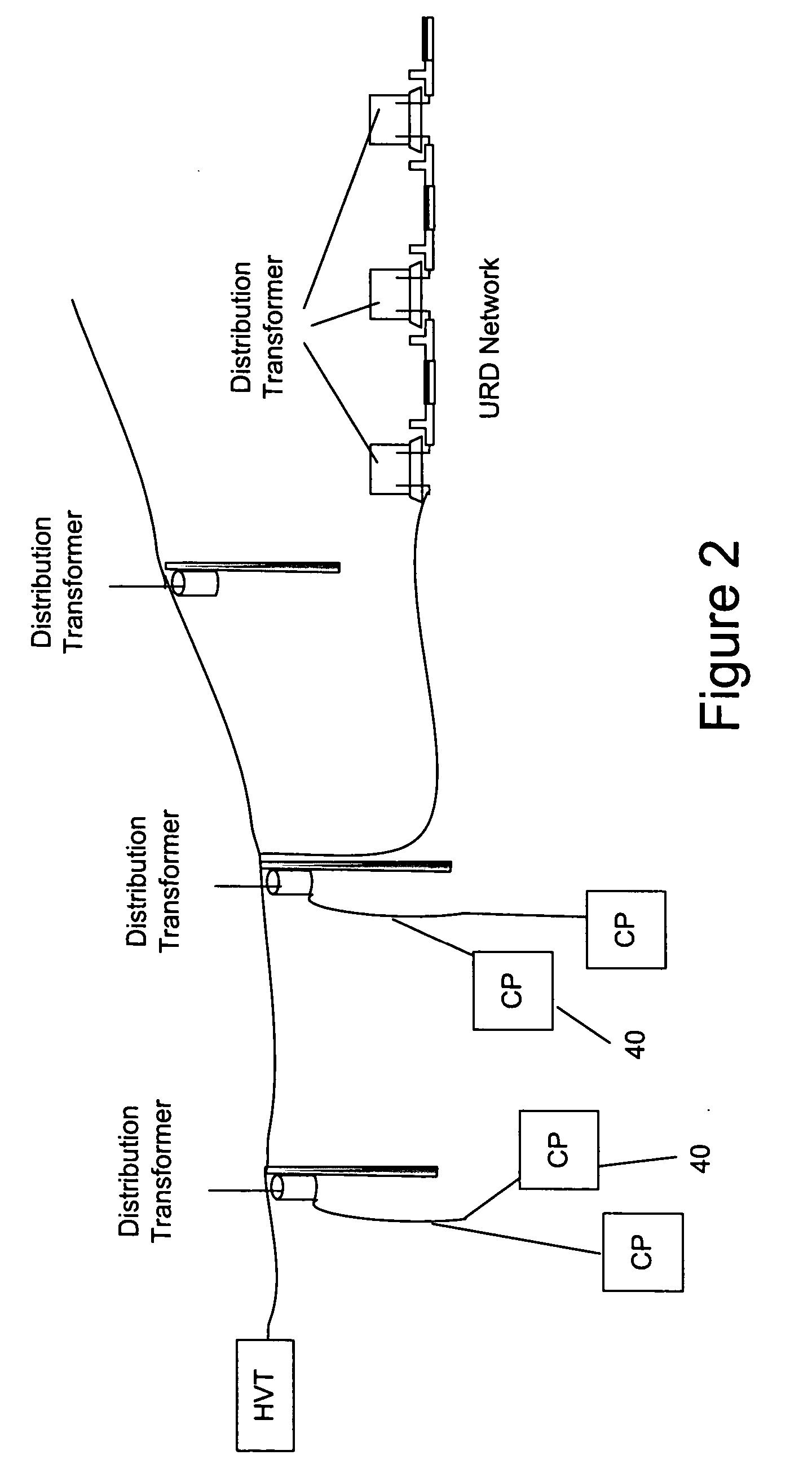

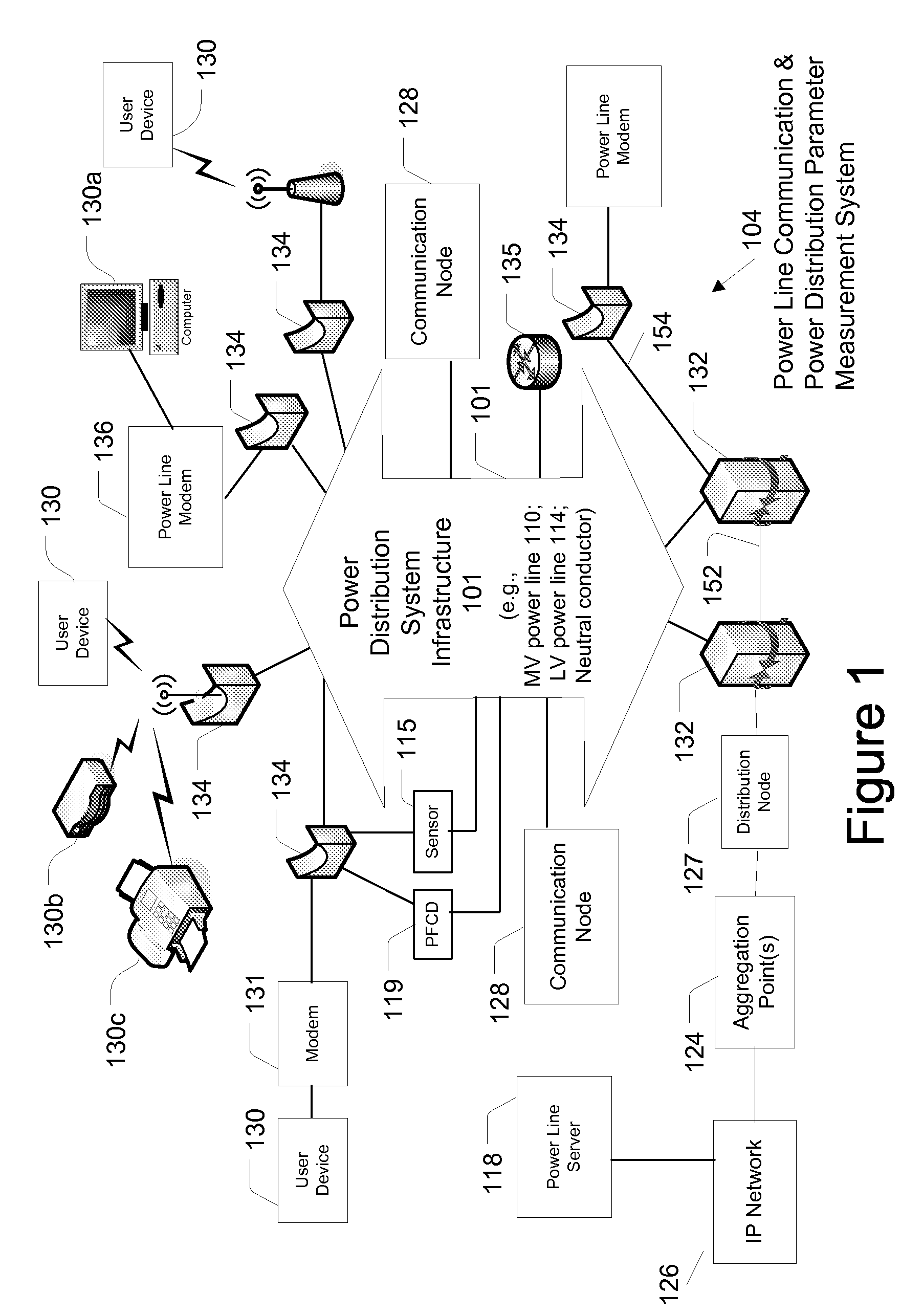

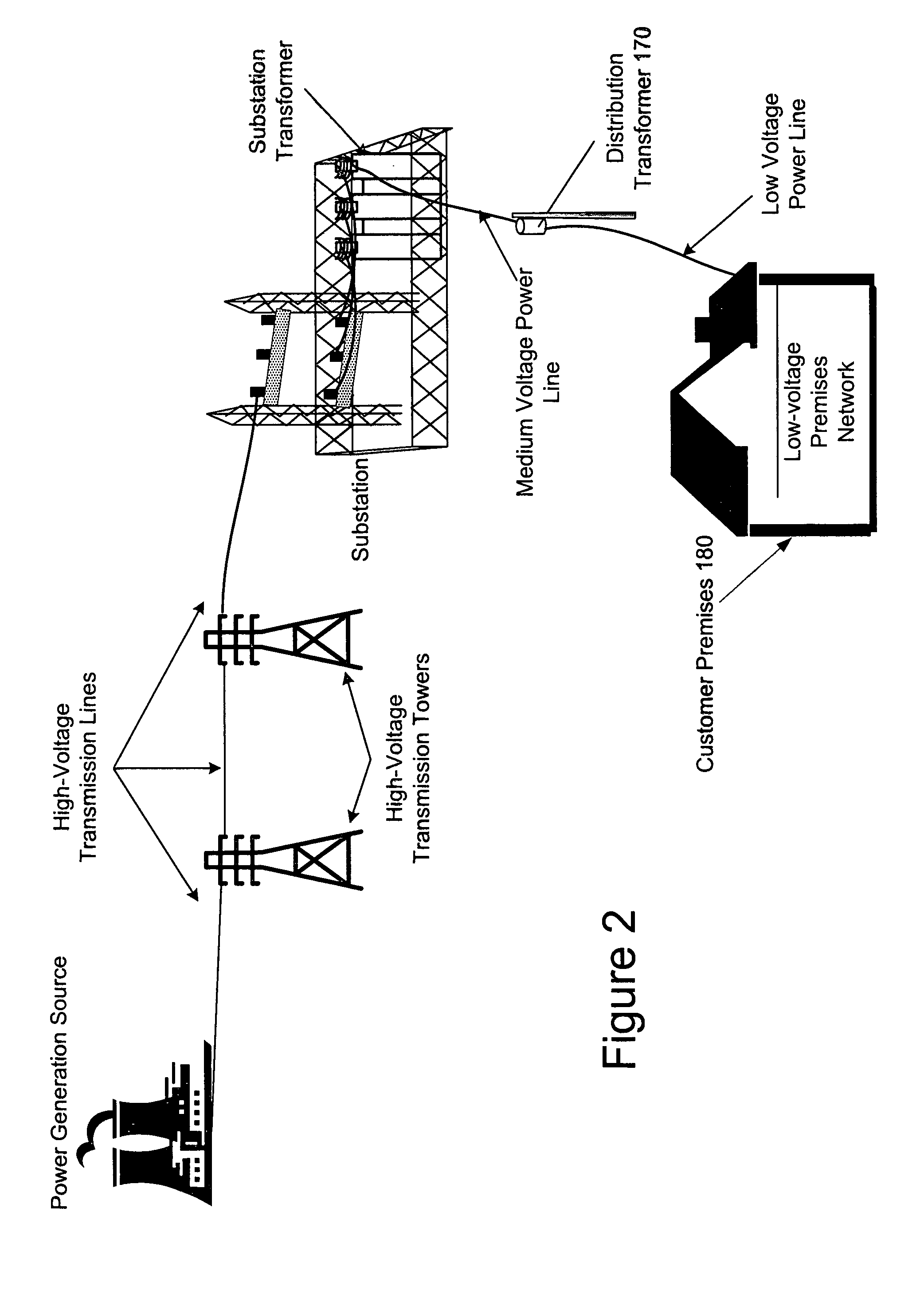

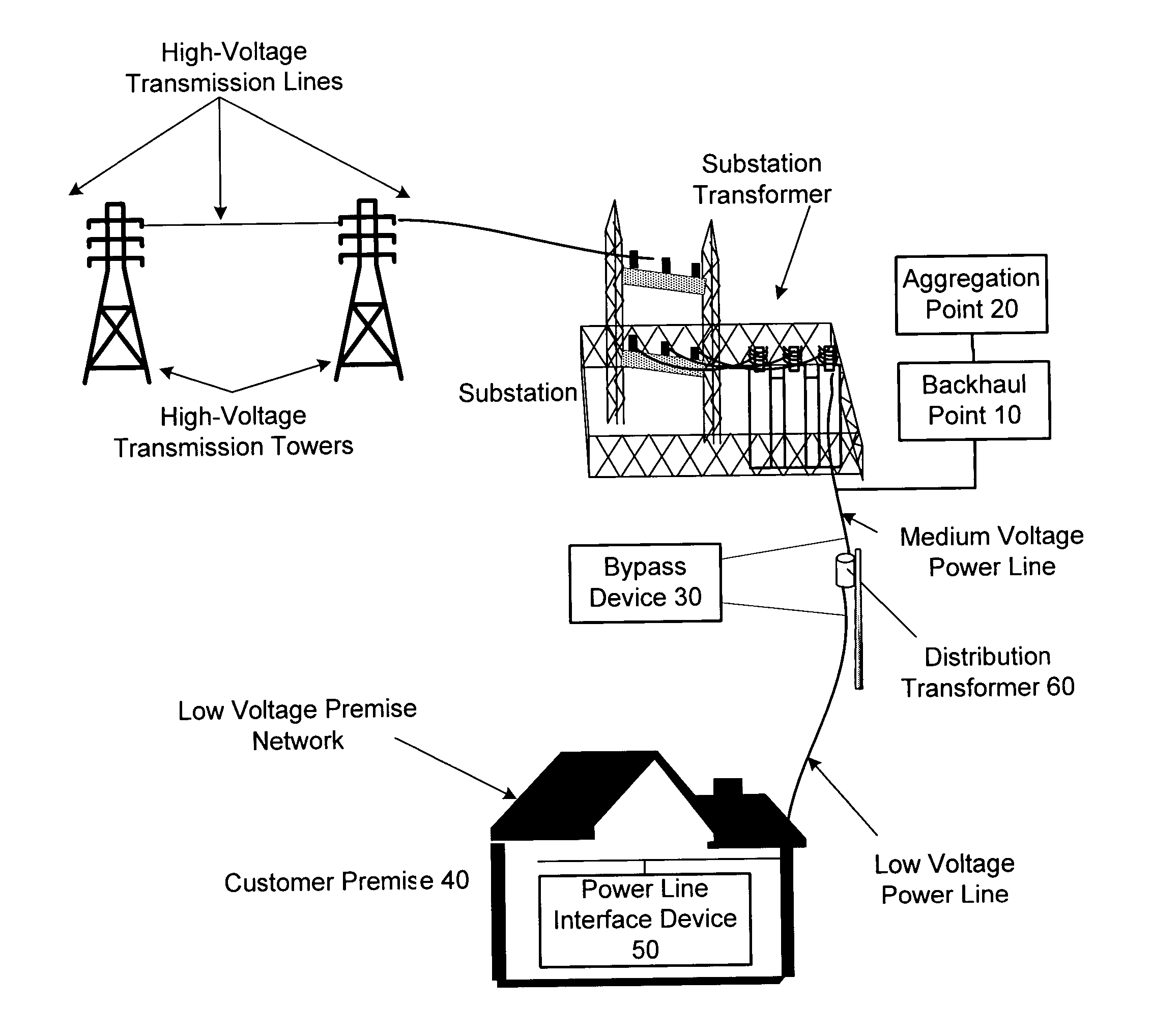

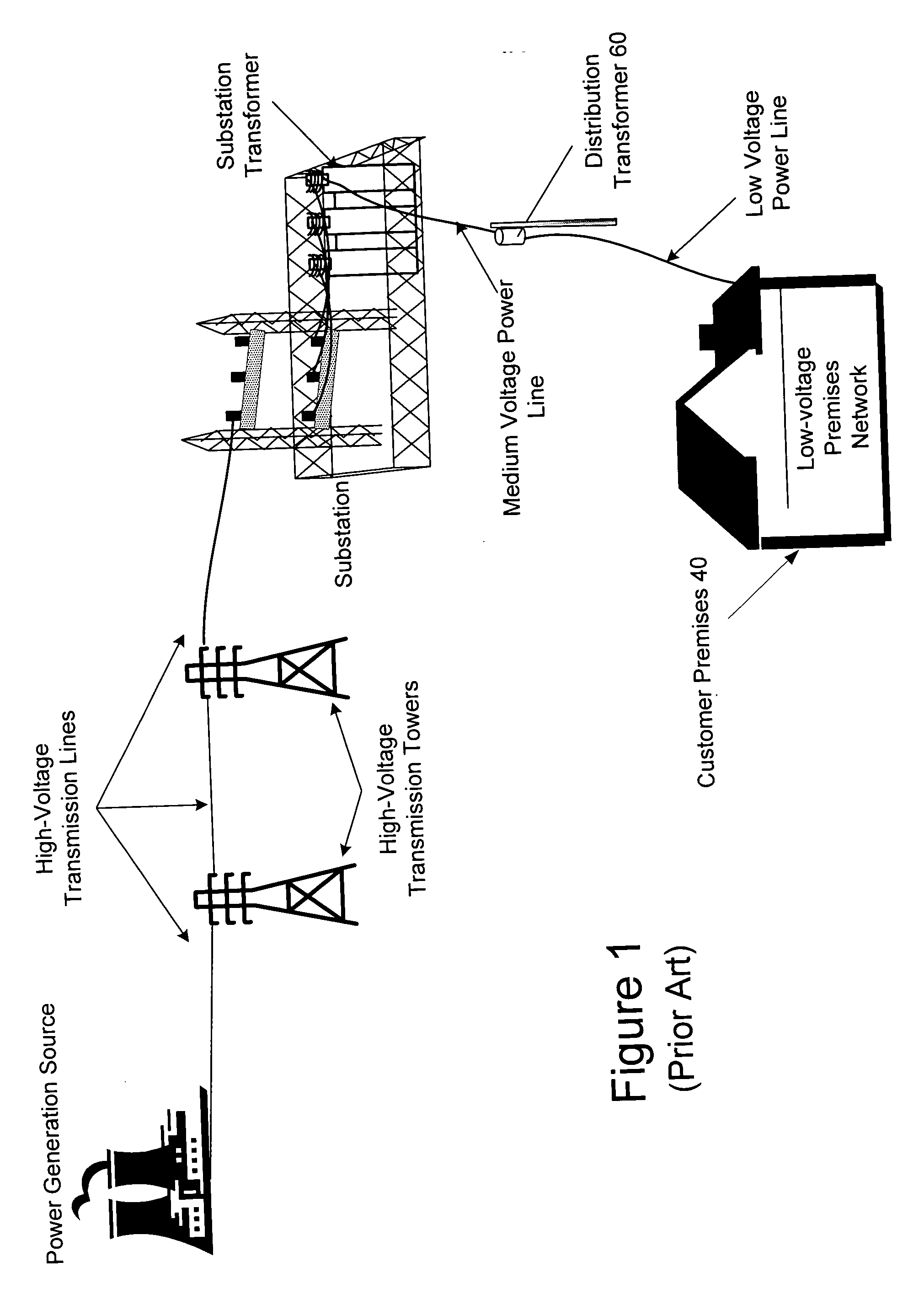

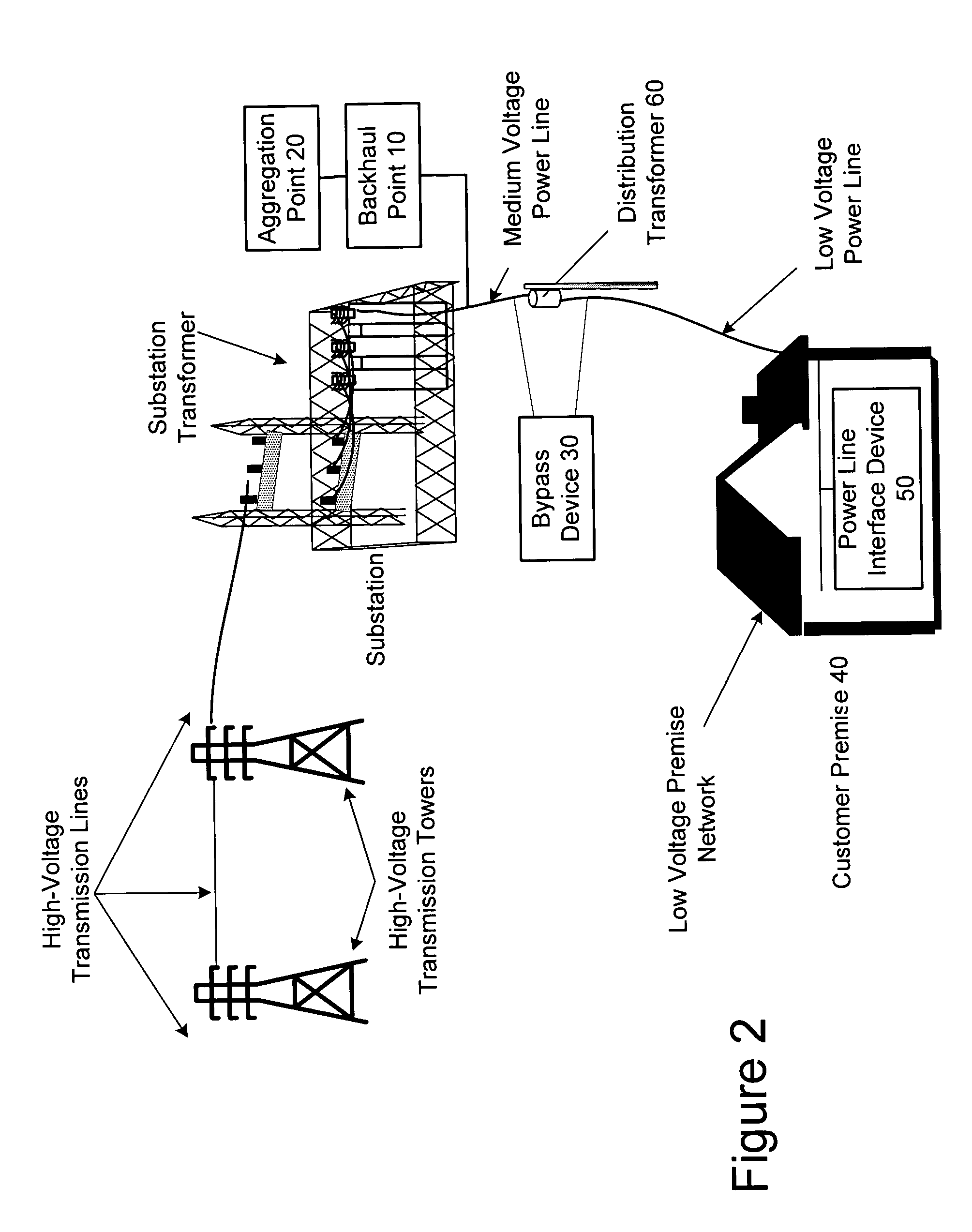

Power line communications system and method of operating the same

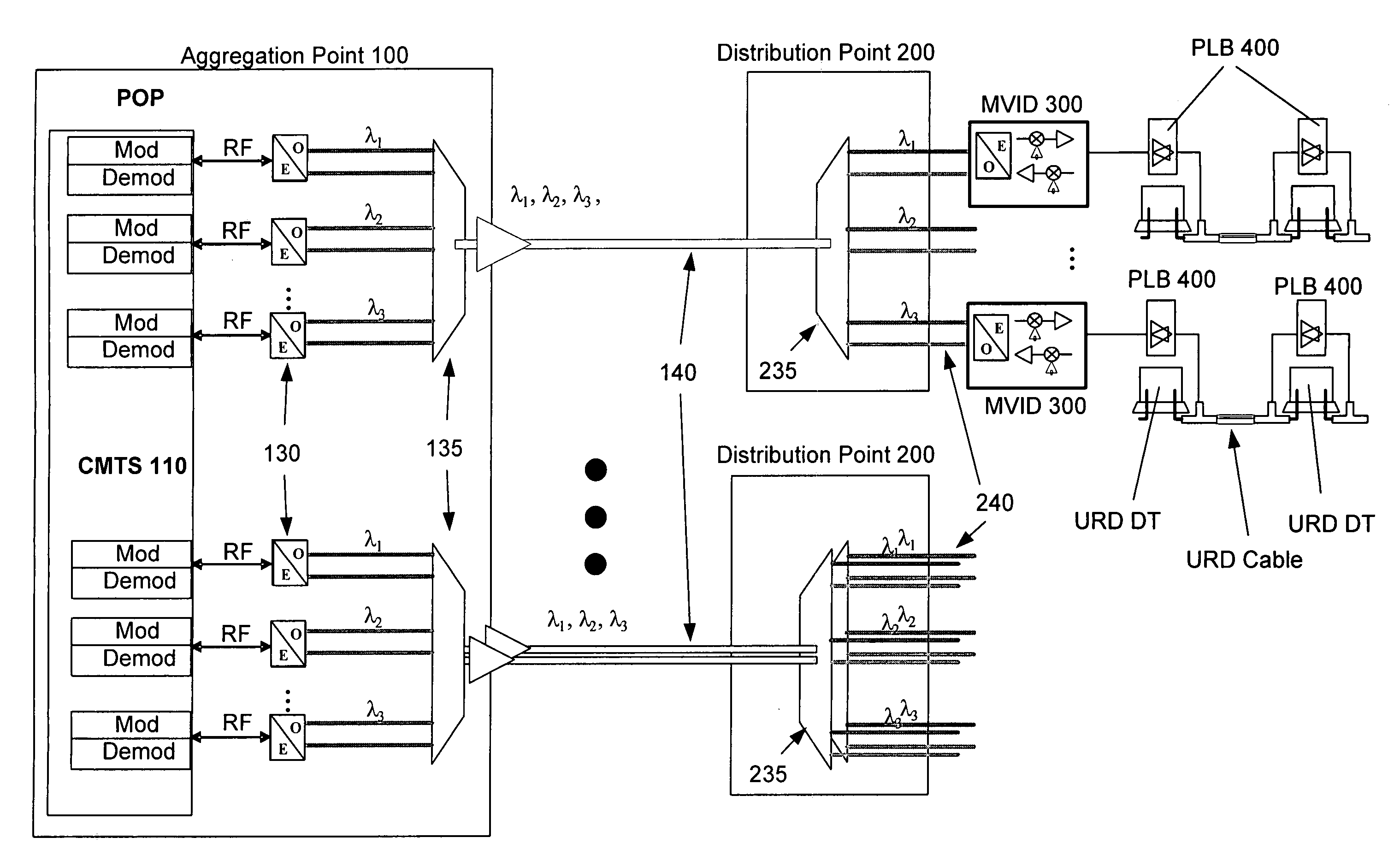

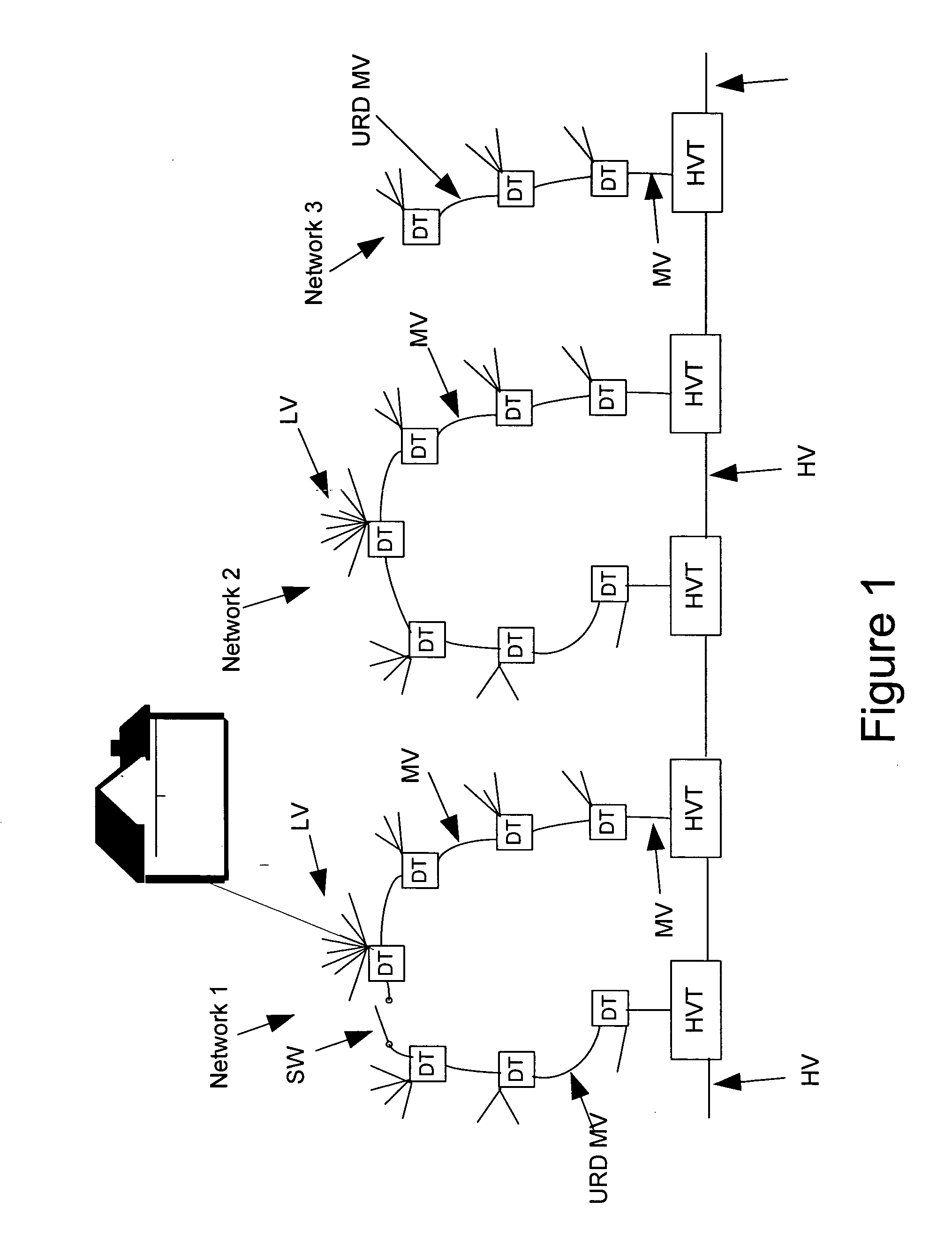

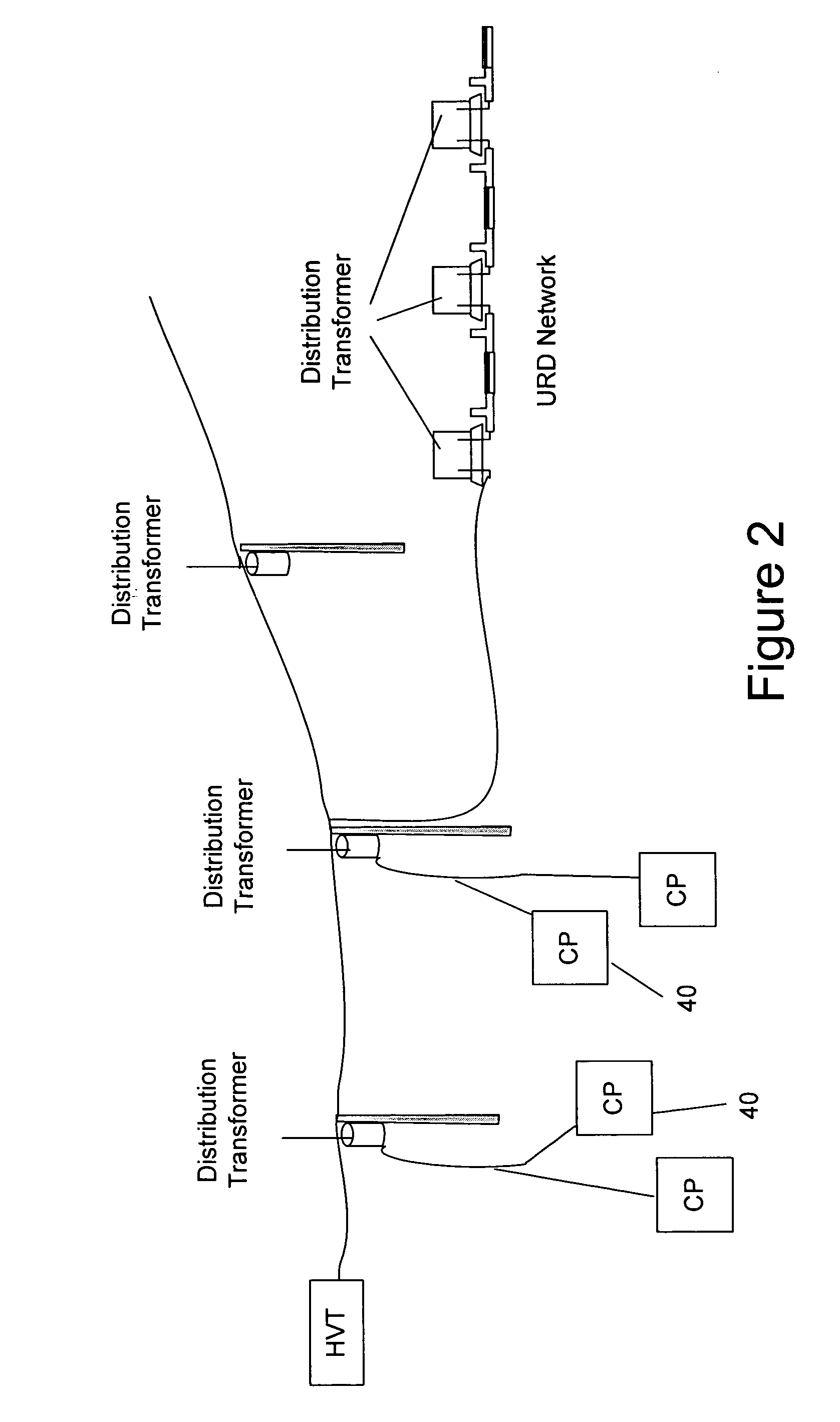

InactiveUS20060097573A1Electric signal transmission systemsFrequency-division multiplex detailsUser deviceDistribution transformer

The present invention provides a system and method for operating a power line communications system for communicating via an underground residential distribution power system. One embodiment of the present invention includes an aggregation point, which may be co-located with a point of presence, communicatively coupled to one or distribution points. The distribution points are communicatively coupled to one or more medium voltage interface devices. The medium voltage interface devices are communicatively coupled to one or more power line bridges via URD medium voltage power lines. The power line bridges may be co-located with a URD distribution transformer and provide communications to the user devices communicatively coupled to the LV power lines of the distribution transformer.

Owner:CURRENT TECH

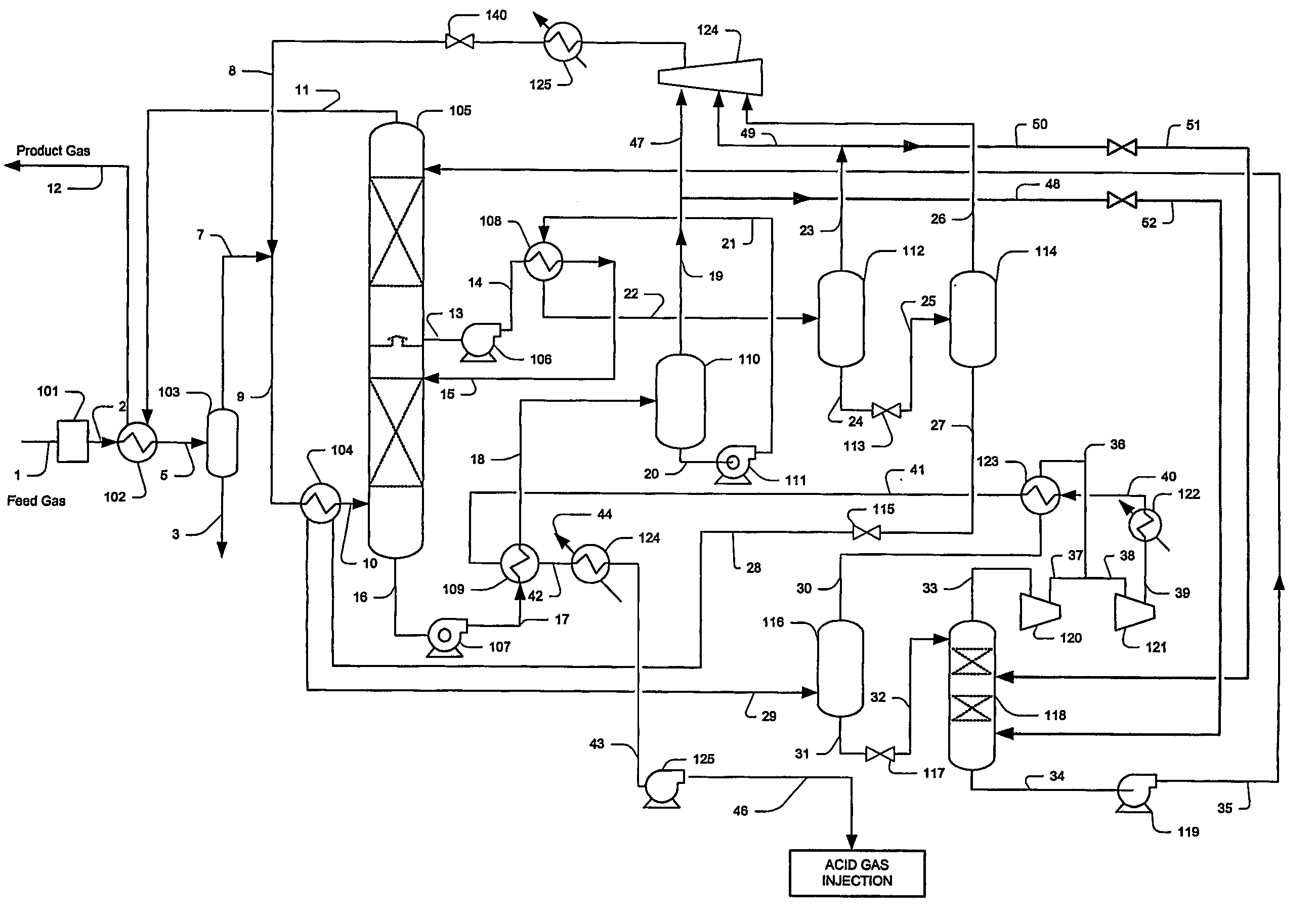

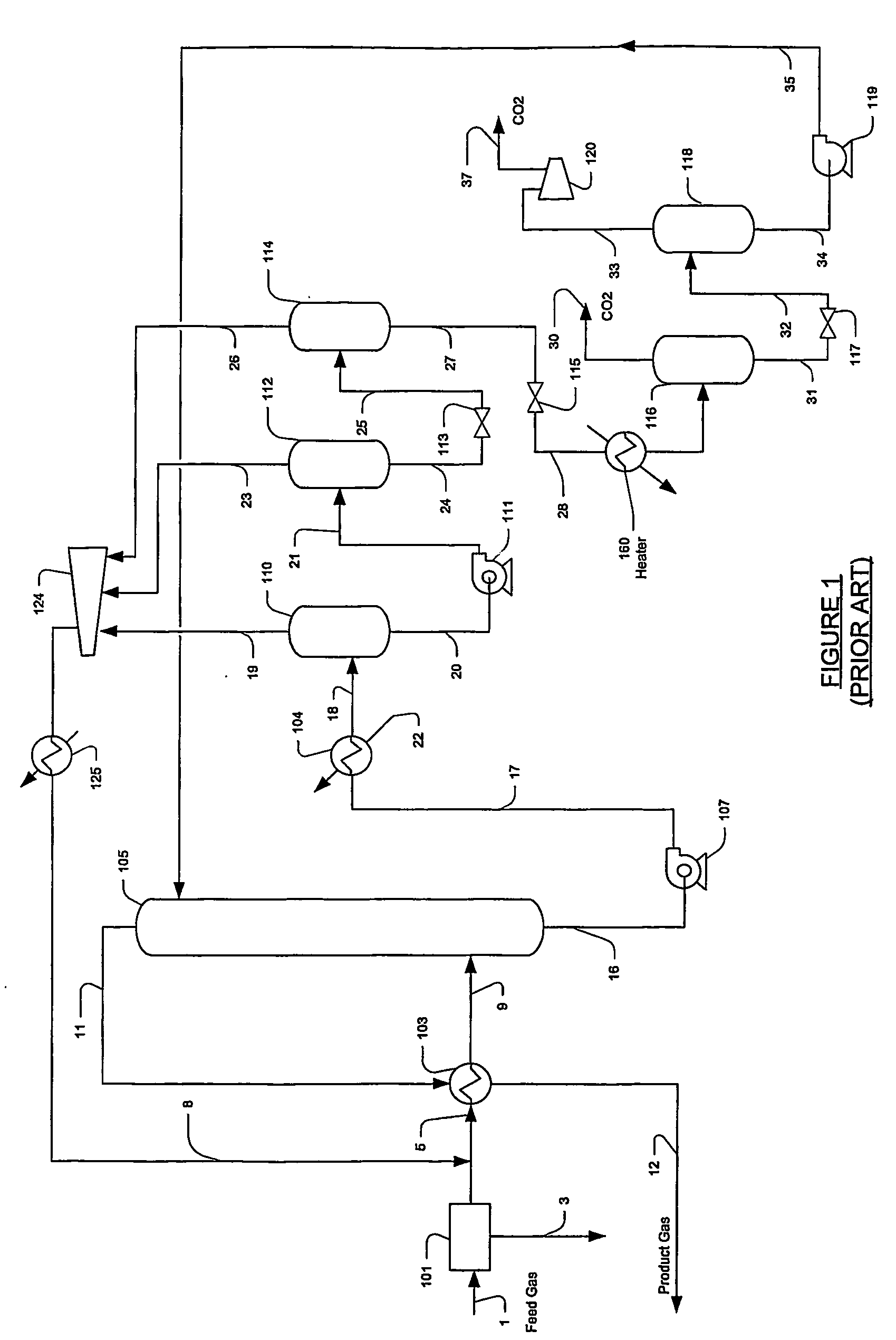

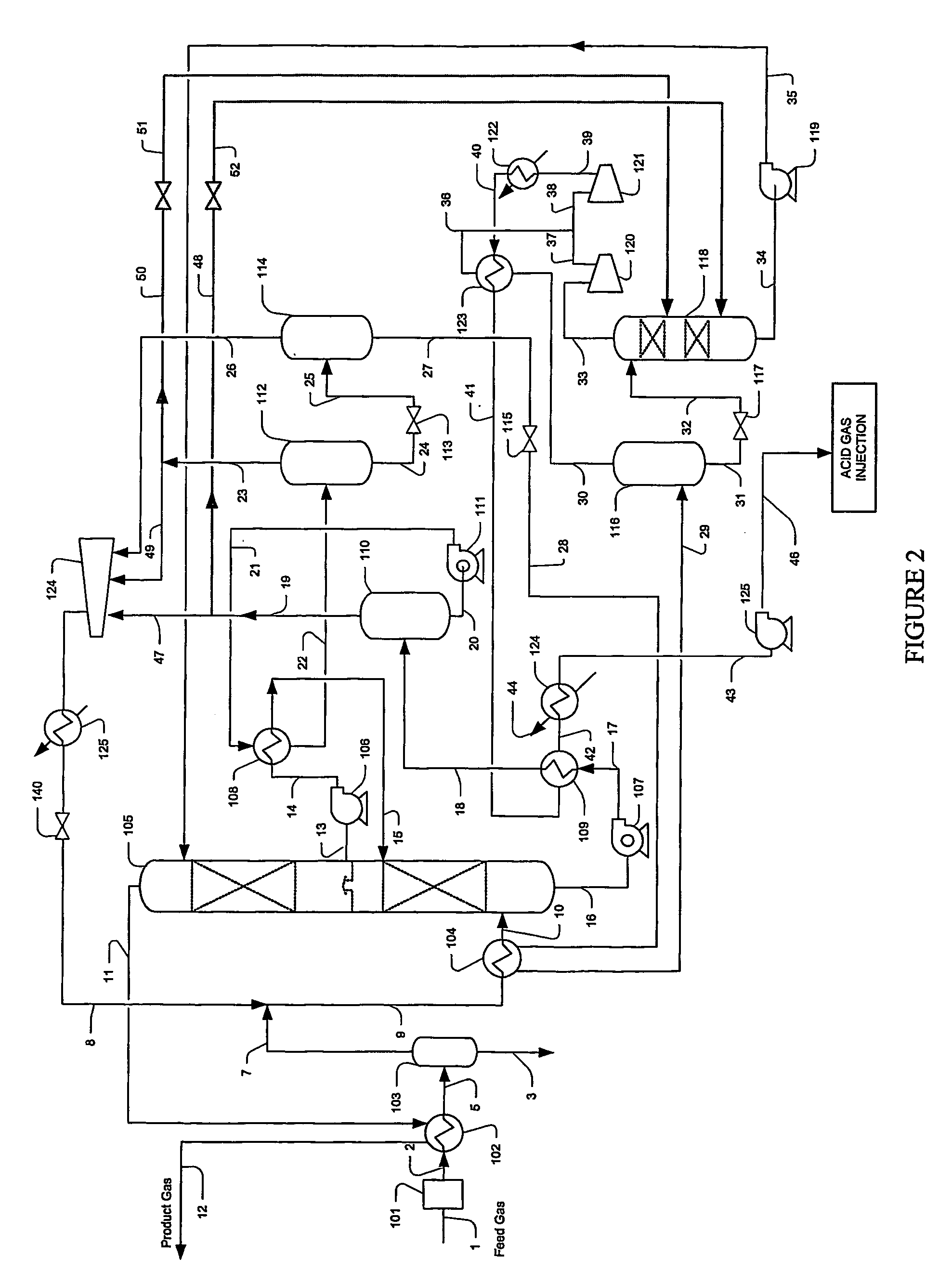

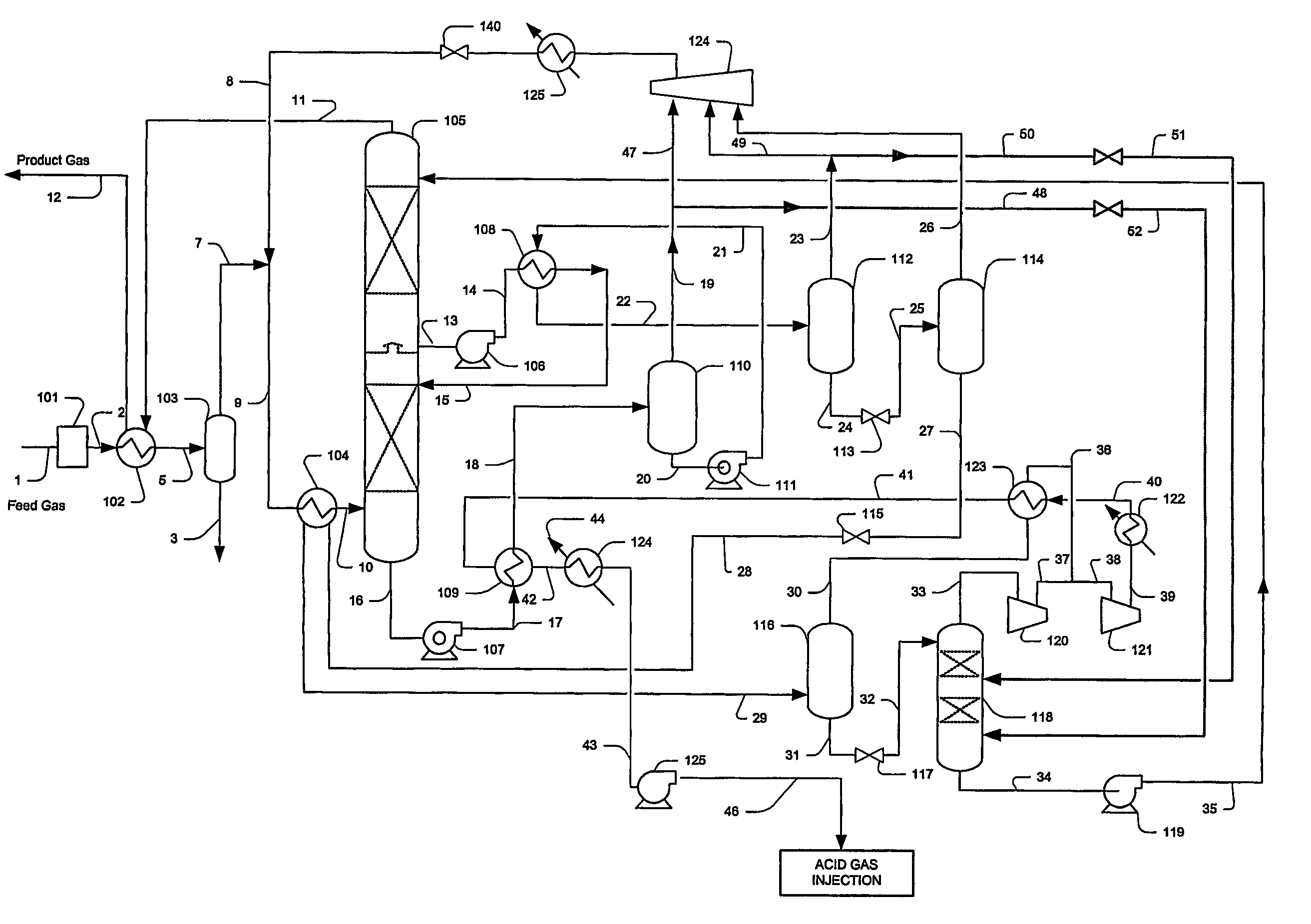

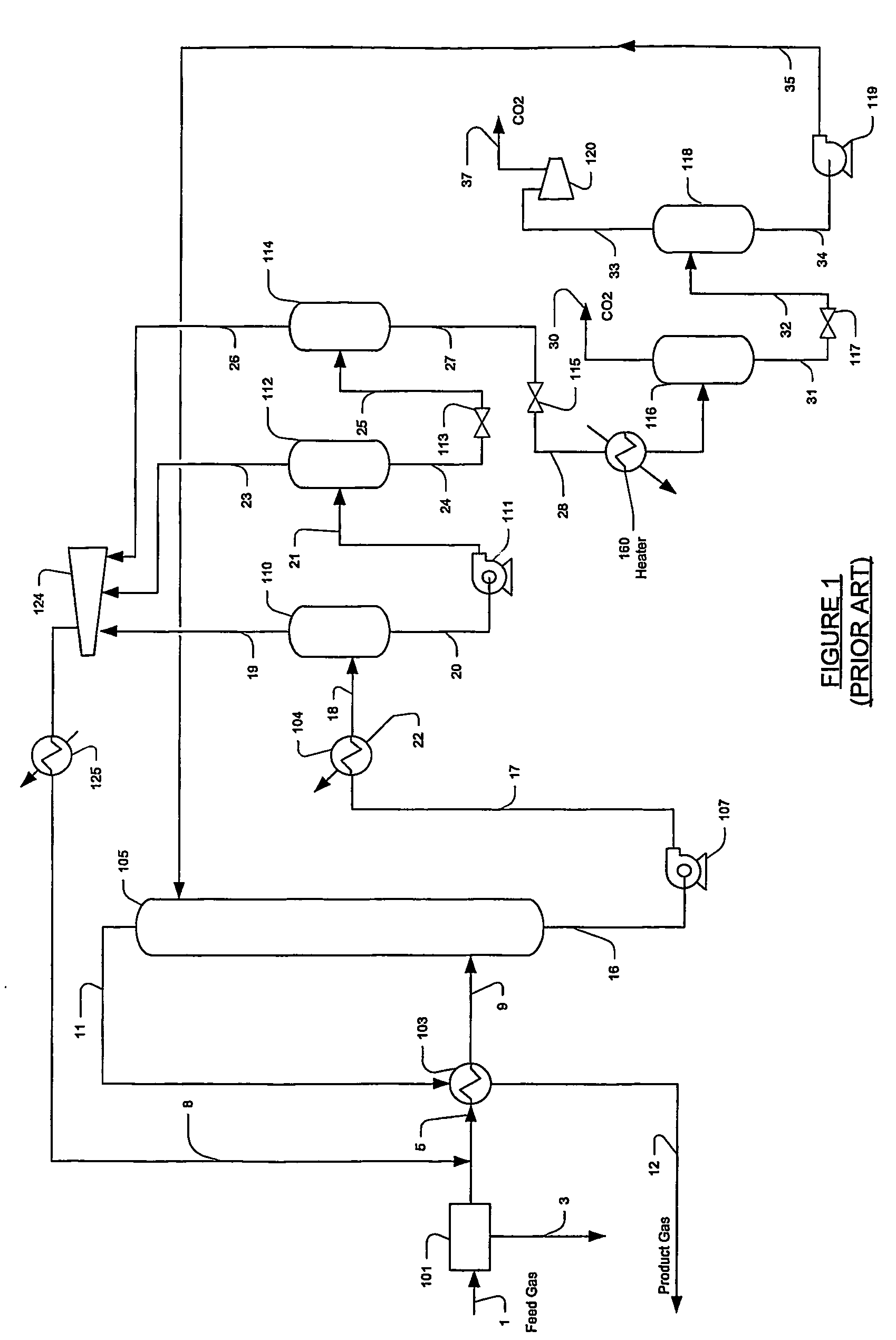

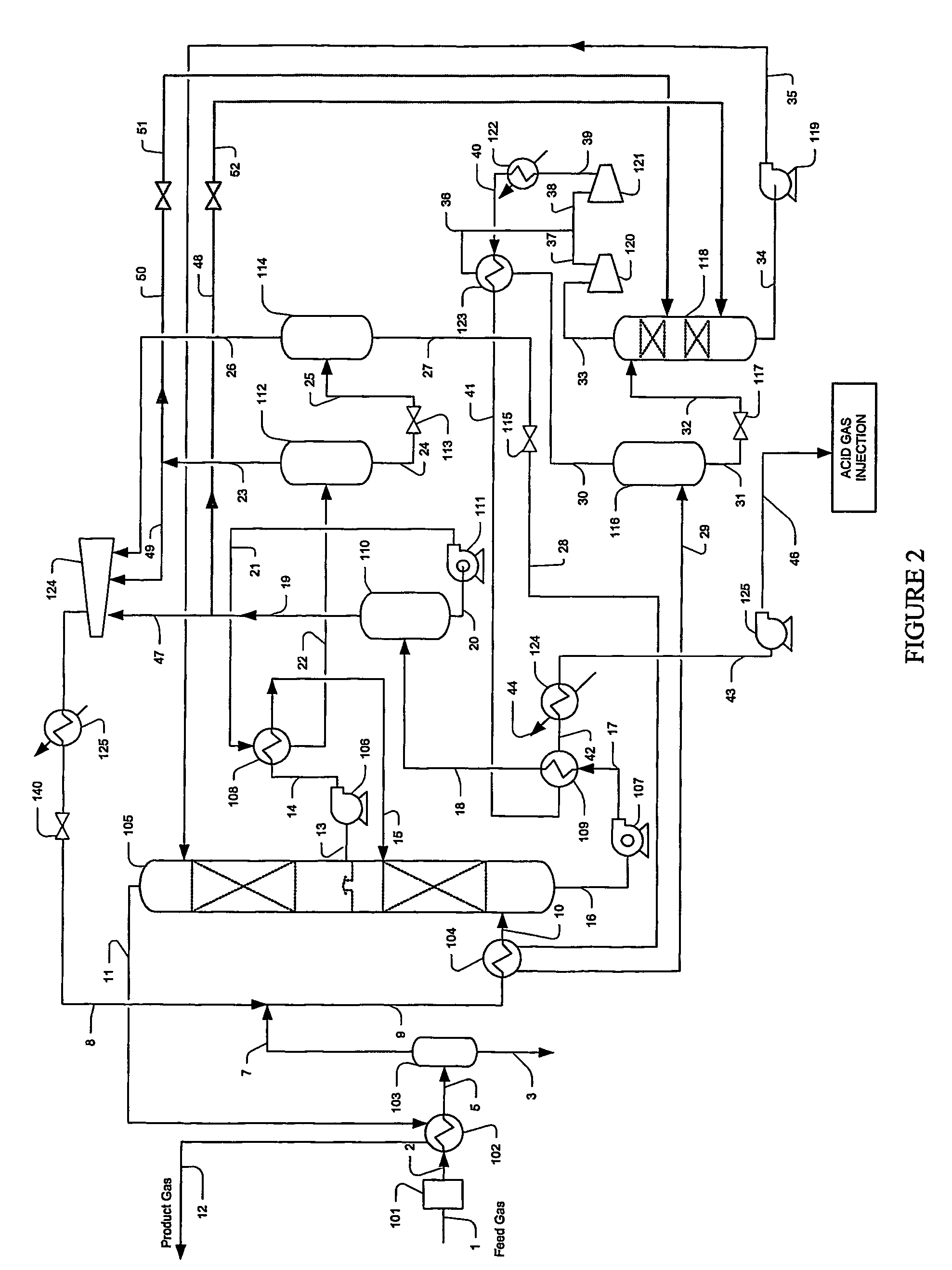

Configurations and methods of acid gas removal

A plant includes a vacuum stripper (118) that receives a lean hydrogen sulfide-containing physical solvent (32) and in which substantially hydrogen sulfide-free stripping gas (51,52) is provided by at least one of a high-pressure flash vessel (110) and a medium pressure flash vessel (112). Contemplated configurations advantageously extend the range of use for physical solvents to treat sour gas comprising carbon dioxide and hydrogen sulfide, and can be used to meet most pipeline specification of 4 ppm hydrogen sulfide.

Owner:FLUOR TECH CORP

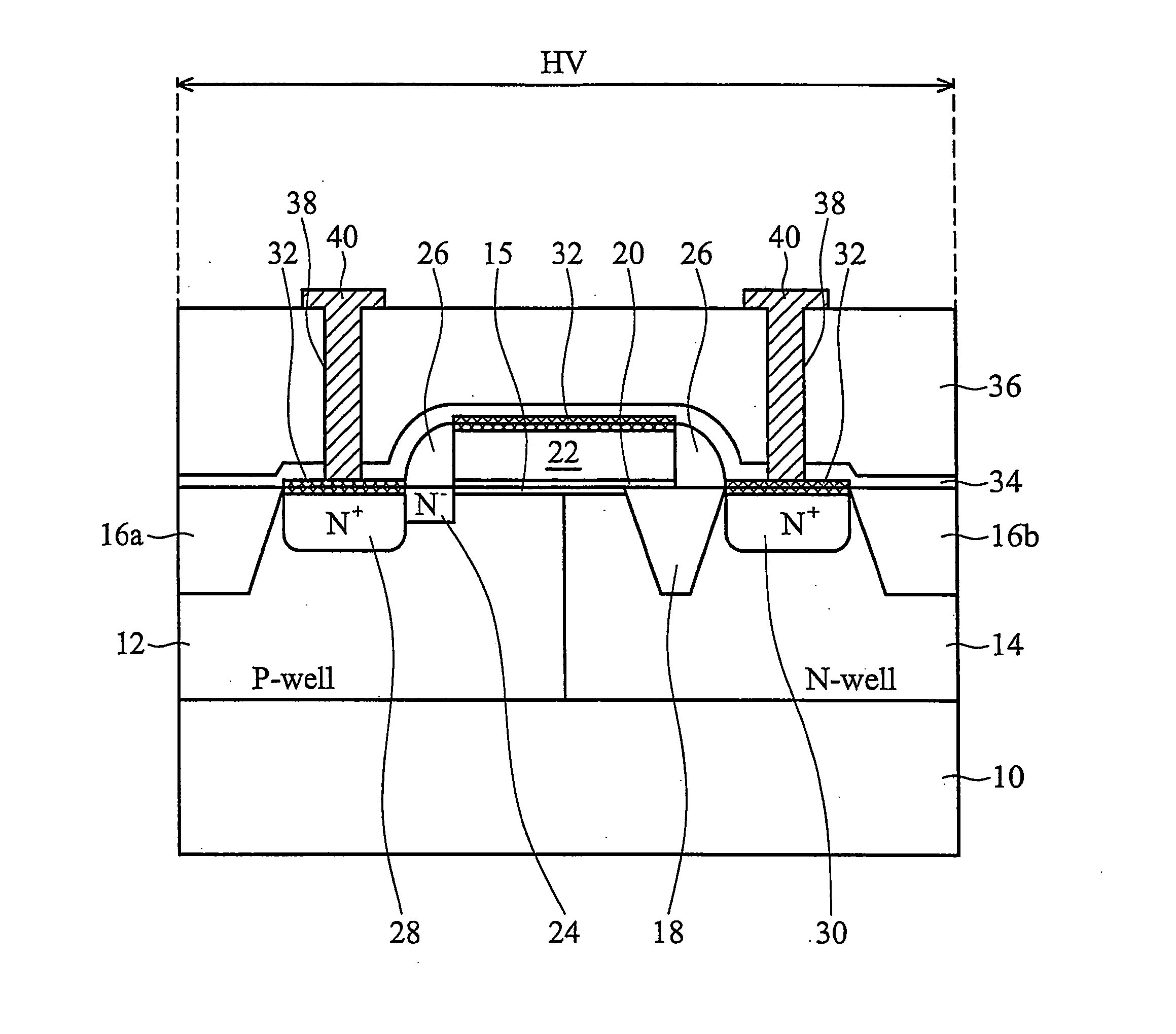

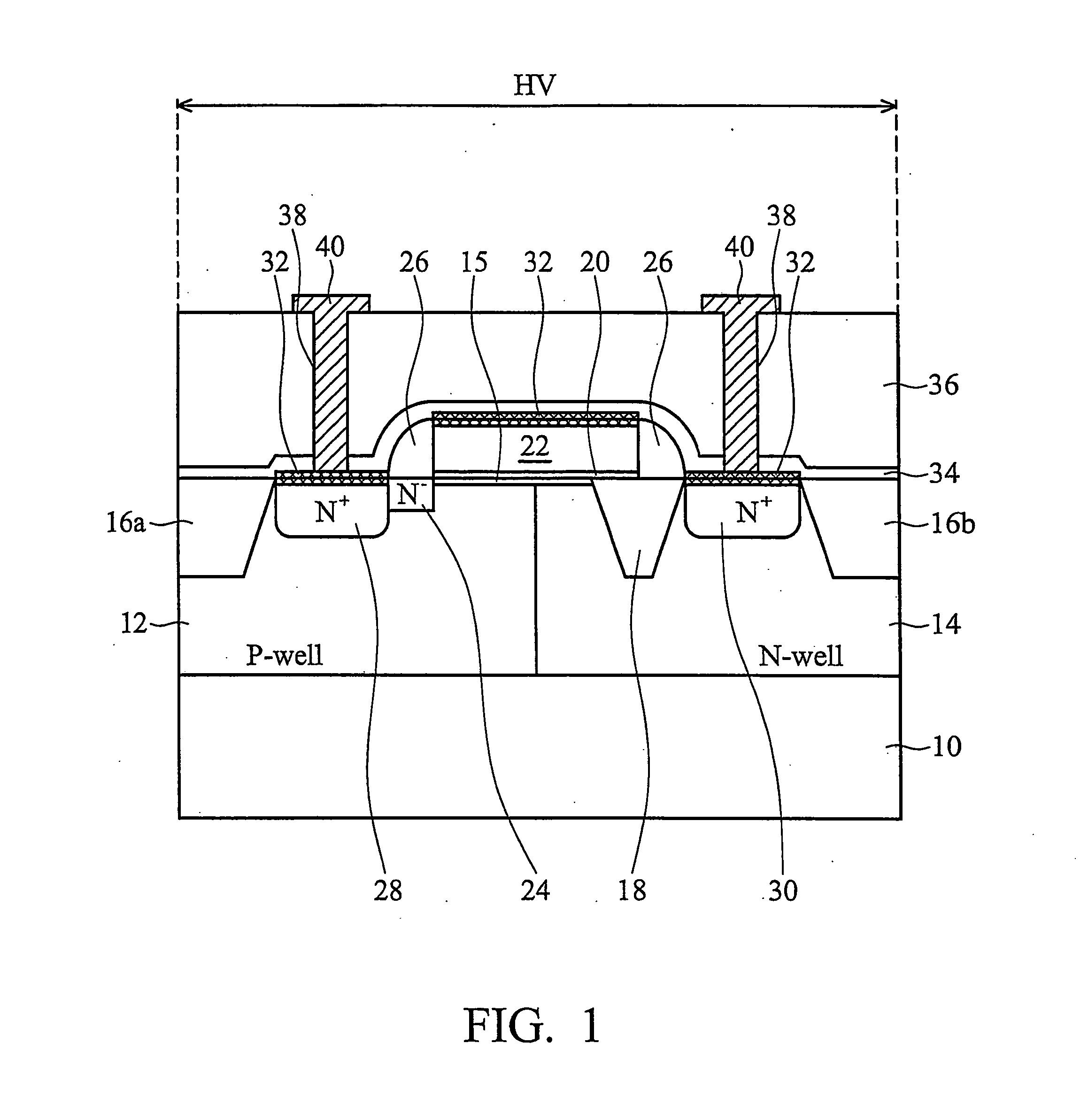

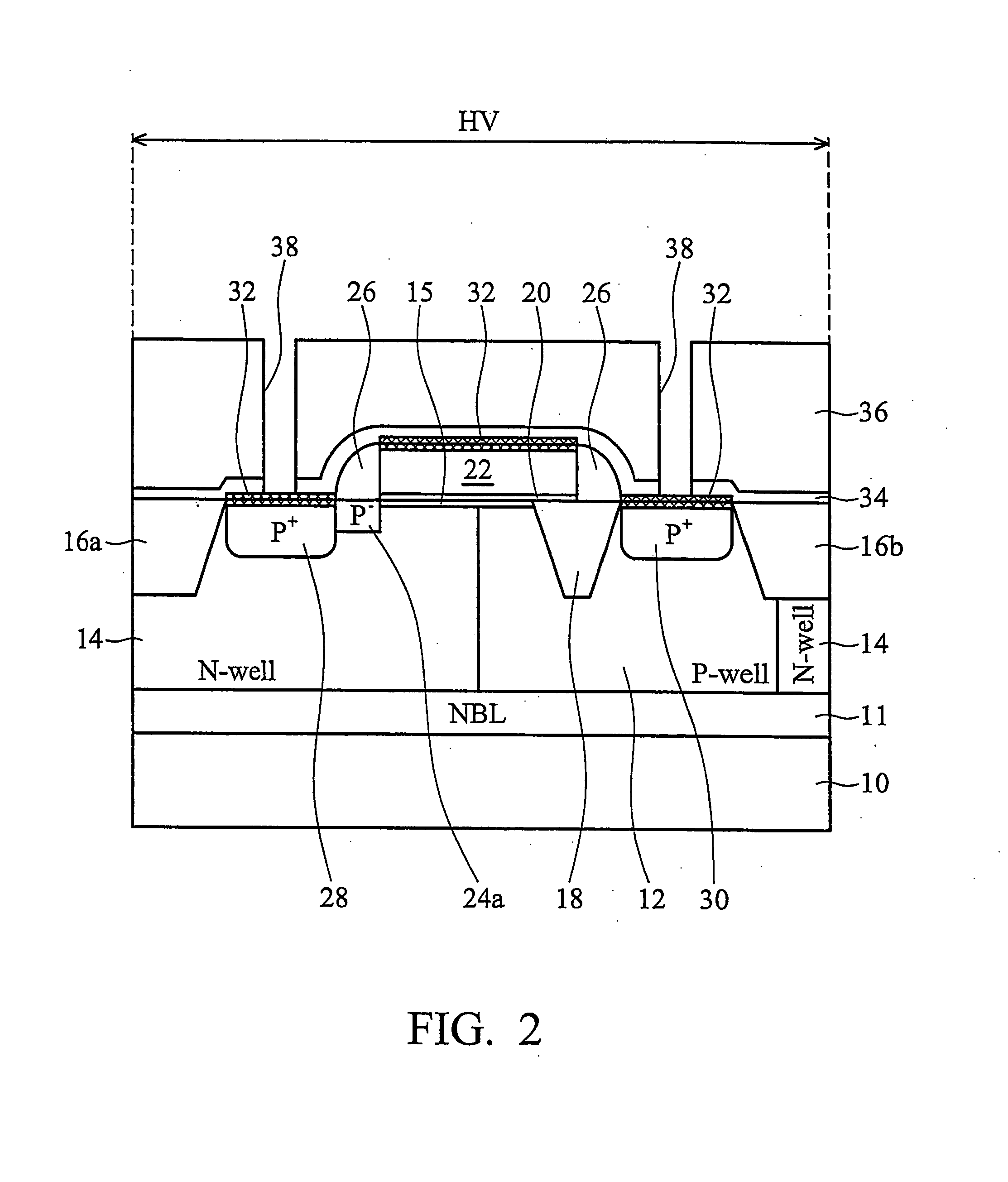

High-voltage transistor device having an interlayer dielectric etch stop layer for preventing leakage and improving breakdown voltage

ActiveUS20060113627A1Prevent leakageImprove breakdown voltageTransistorSolid-state devicesDielectricHigh voltage transistors

A high-voltage transistor device with an interlayer dielectric (ILD) etch stop layer for use in a subsequent contact hole process is provided. The etch stop layer is a high-resistivity film having a resistivity greater than 10 ohm-cm, thus leakage is prevented and breakdown voltage is improved when driving a high voltage greater than 5V at the gate site. A method for fabricating the high-voltage device is compatible with current low-voltage device processes and middle-voltage device processes.

Owner:TAIWAN SEMICON MFG CO LTD

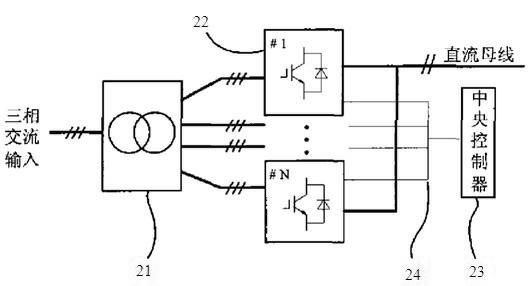

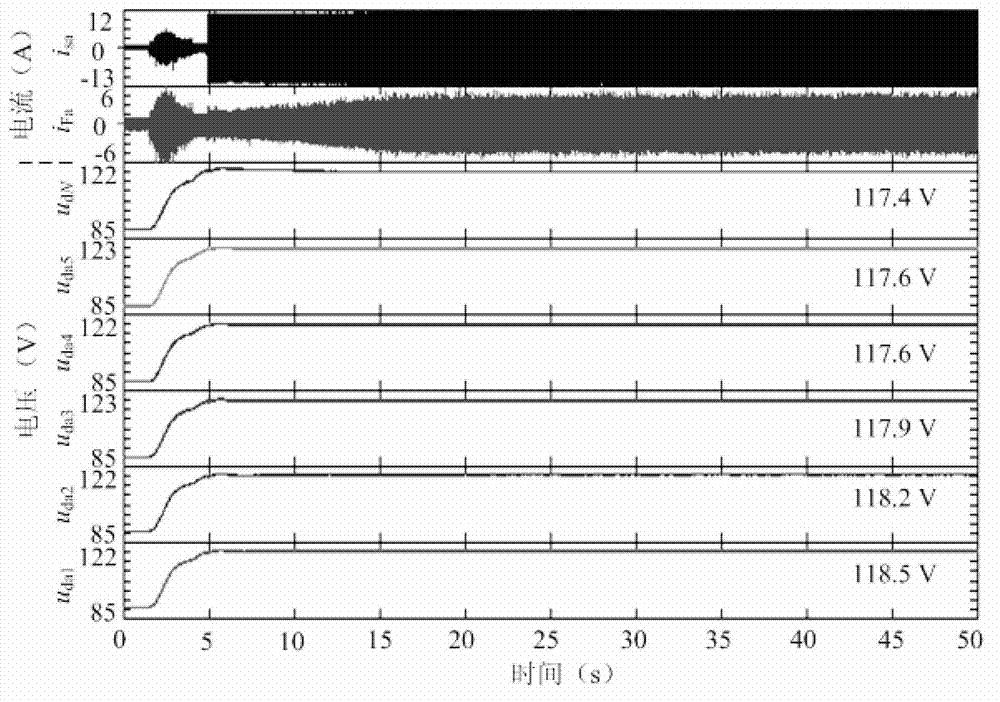

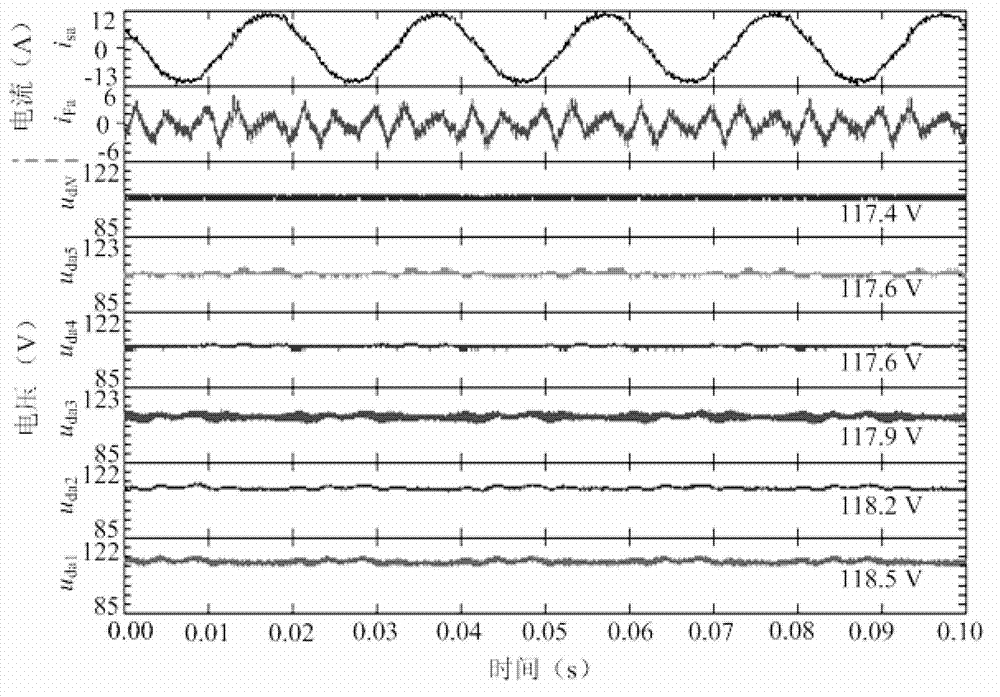

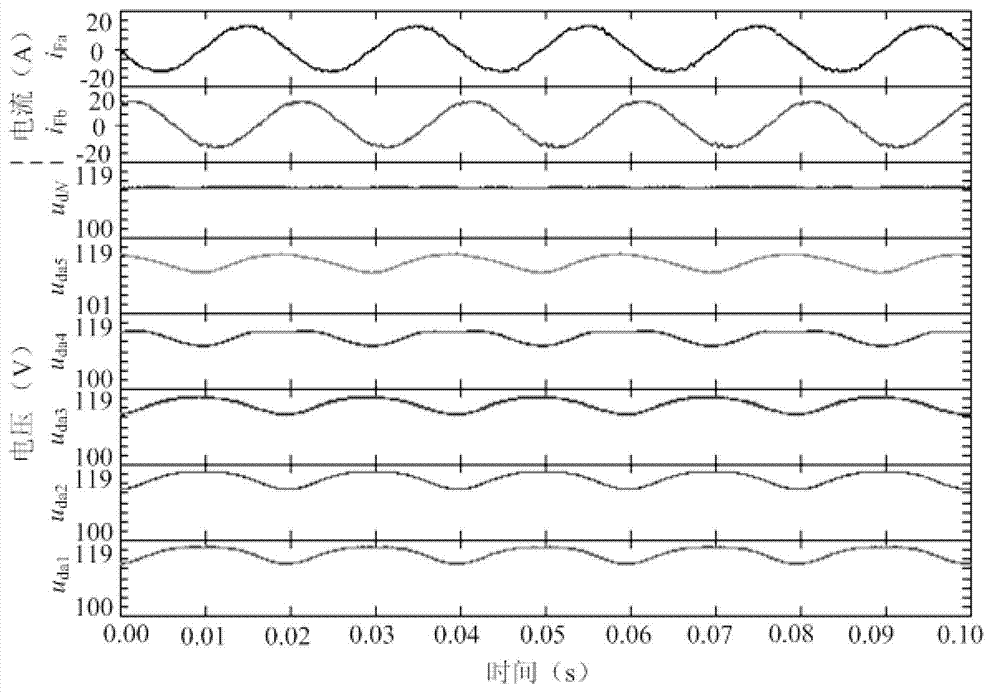

An energy-feedback type traction power supply device and its control method

ActiveCN102267405ARealize stepless adjustmentInjected harmonics are smallPower supply linesSingle network parallel feeding arrangementsTransformerLow voltage

The invention discloses an energy feeding type dragging power supply device and a control method thereof. The energy feeding type dragging power supply device comprises a multiple transformer and at least two four-quadrant converter modules. The energy feeding type dragging power supply device and a diode rectification dragging unit are arranged in parallel form. A primary side of the multiple transformer of the energy feeding type dragging power supply device is connected to an alternated current medium-voltage power grid through a high-voltage switch cabinet; each set of windings at a low-voltage side of the multiple transformer is connected to an alternated current side of one four-quadrant converter module; and the direct current sides of the four-quadrant converter modules are in parallel connection after being connected to a direct current side isolation switch and are connected to a direct current bus through a direct current switch cabinet and a cathode cabinet. The energy feeding type dragging power supply device can work at three different modes of dragging, feedback or SVG (Scalable Vector Graphics) according to the requirements. The energy feeding type dragging power supply device is compatible with an existing dragging power supply system under the condition of meeting a power grid compatibility demand. The energy feeding type dragging power supply device has the advantages of moderate cost, capability of solving the technical problems of feeding back a regenerated braking energy and stabilizing a dragging network voltage, and real-time static reactive power compensation capacity.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

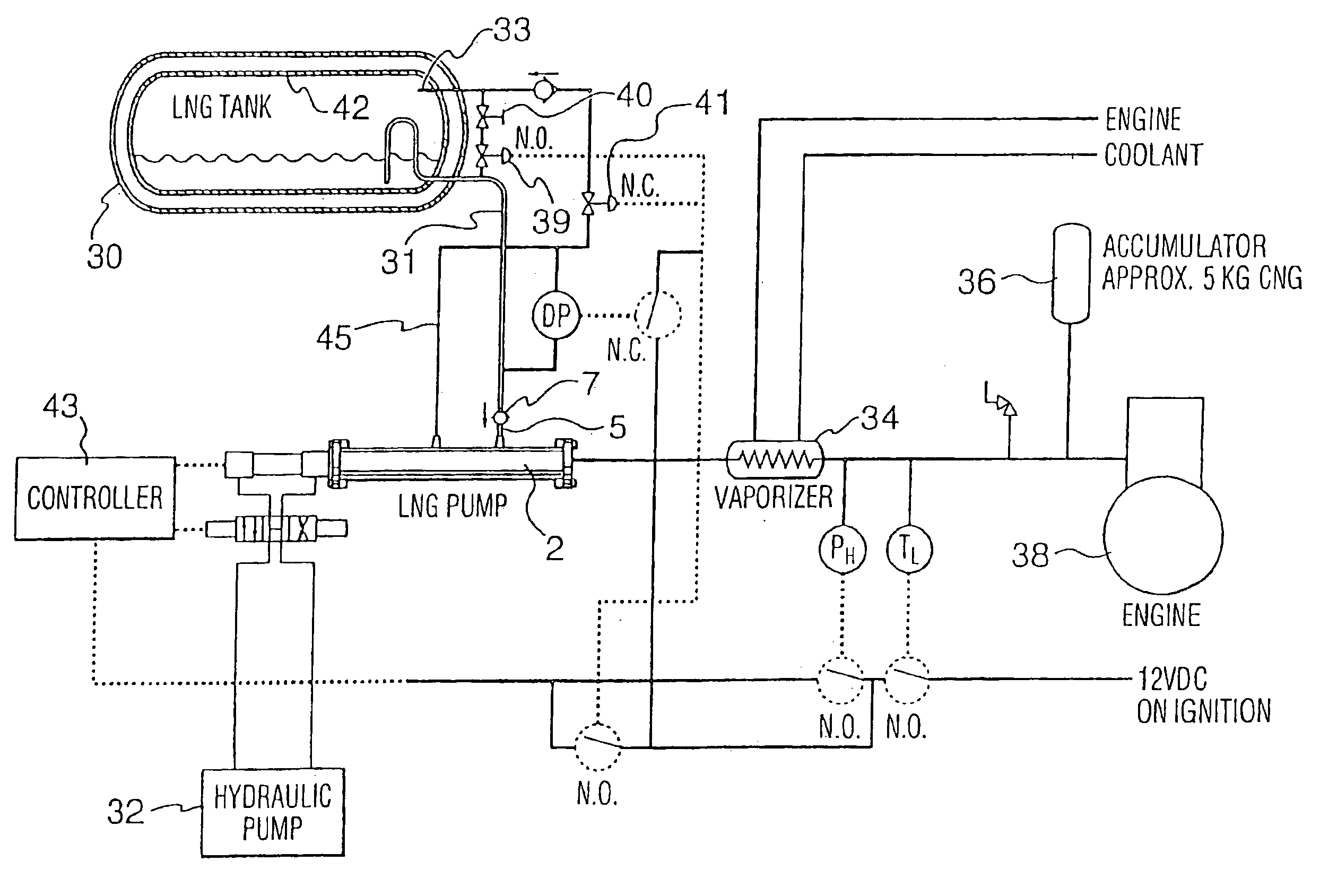

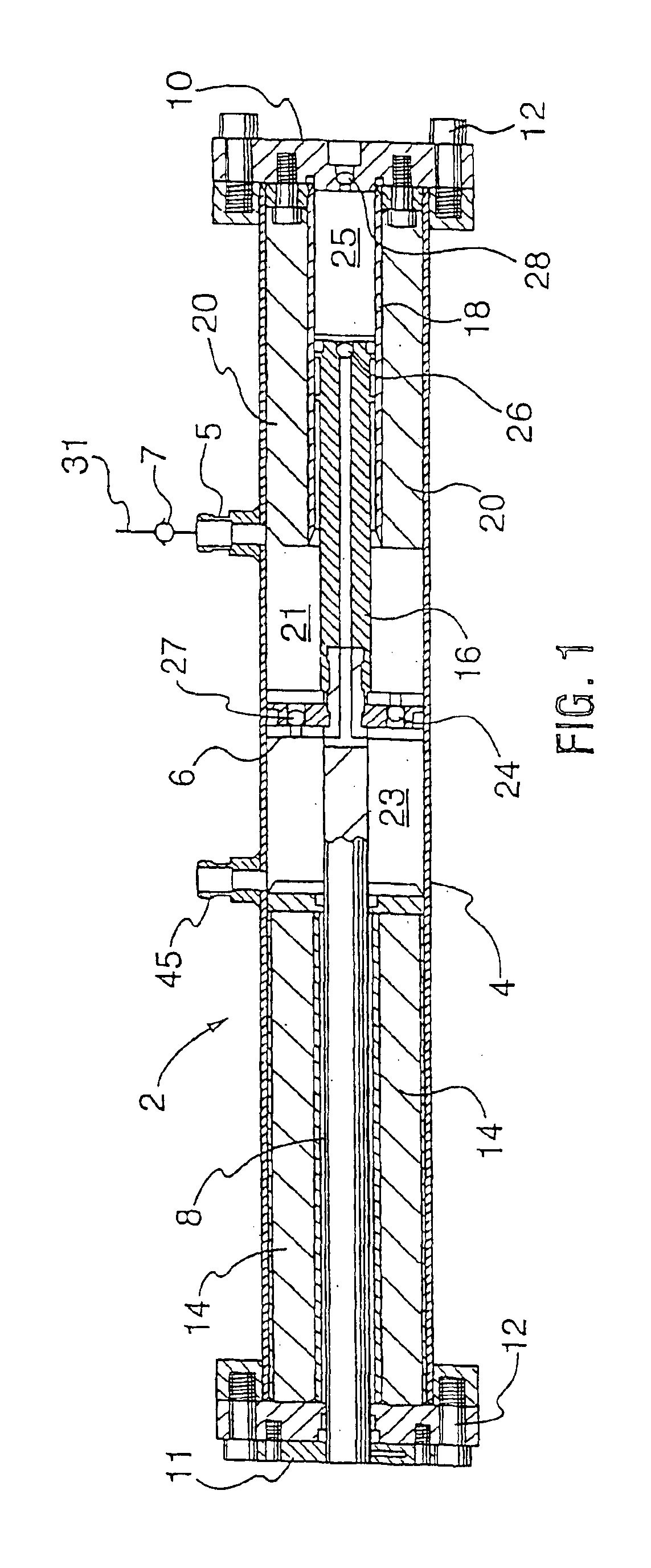

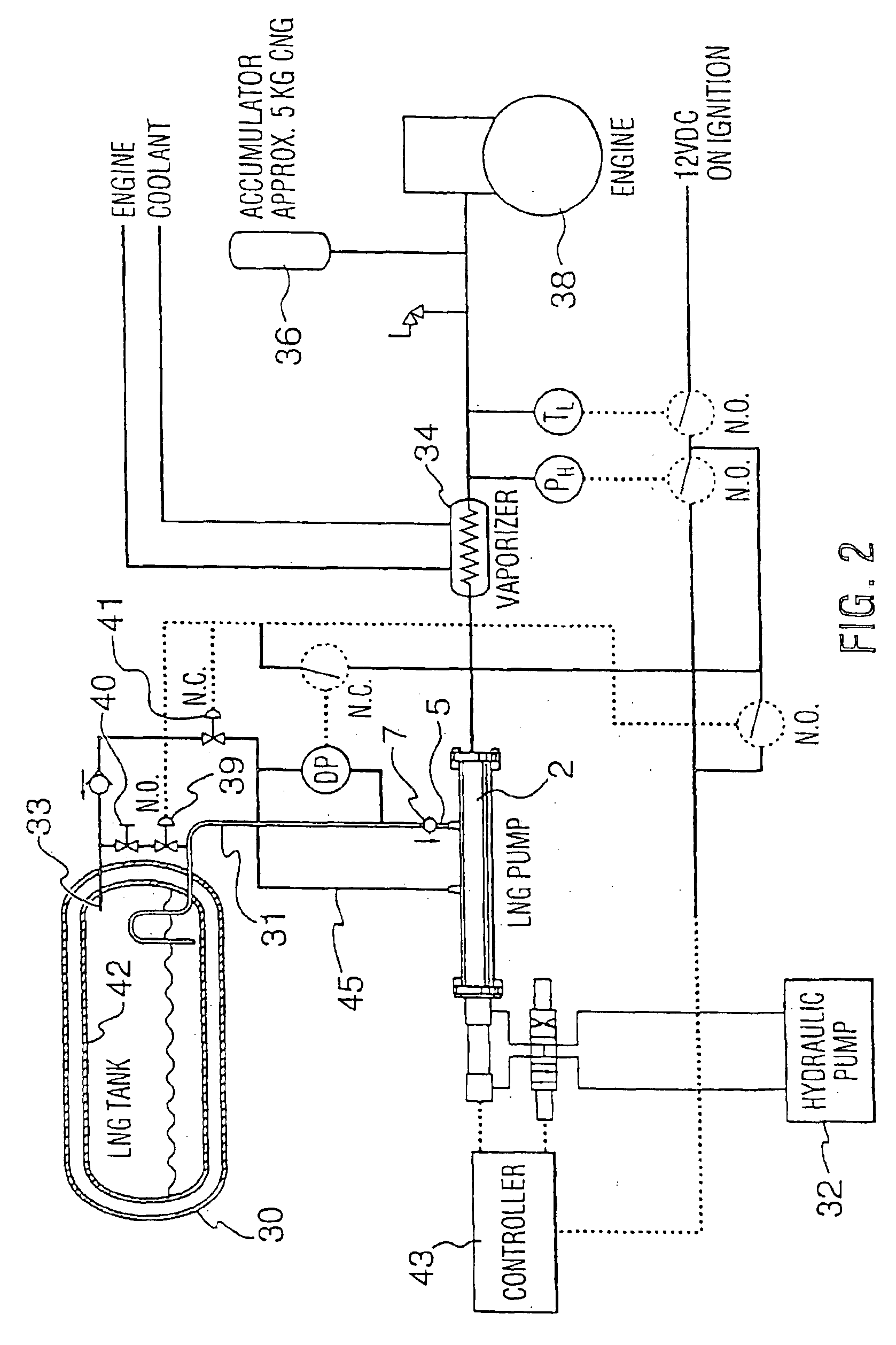

High pressure pump system for supplying a cryogenic fluid from a storage tank

InactiveUS6898940B2Inhibit transferOptimization rangeInternal combustion piston enginesContainer filling methodsProcess engineeringInducer

A medium and high pressure pump systems supplies a cryogenic fluid from a storage tank. The system comprises a pump that is operable to pump cryogenic liquid or a mixture of cryogenic liquid and vapor. The pump preferably comprises an inducer with at least two chambers and means for recycling excess fluid within the inducer instead of returning excess fluid to the storage tank. The reciprocating pump is preferably double acting such that fluid is discharged from the pump during both extension and retraction strokes.

Owner:WESTPORT POWER

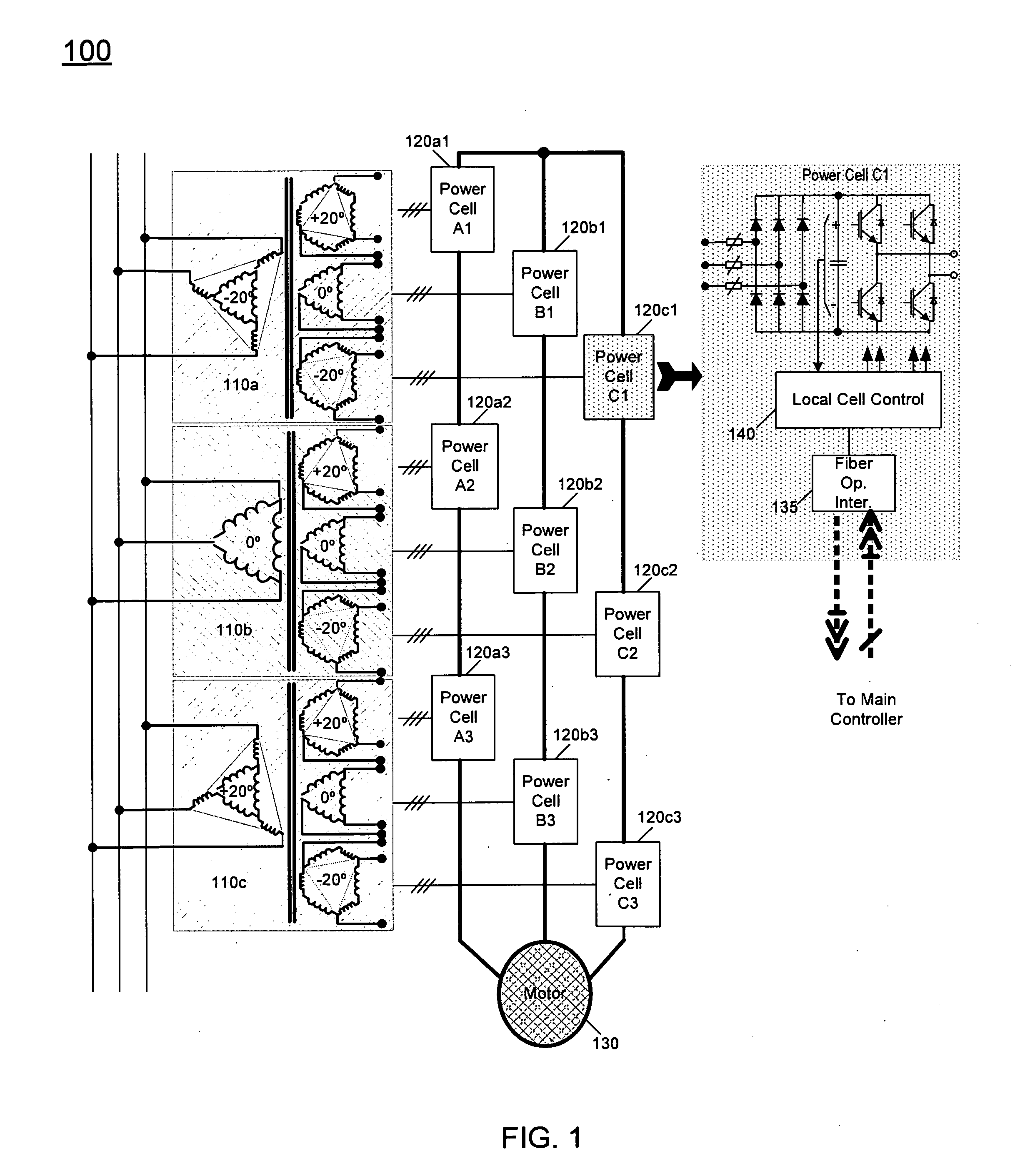

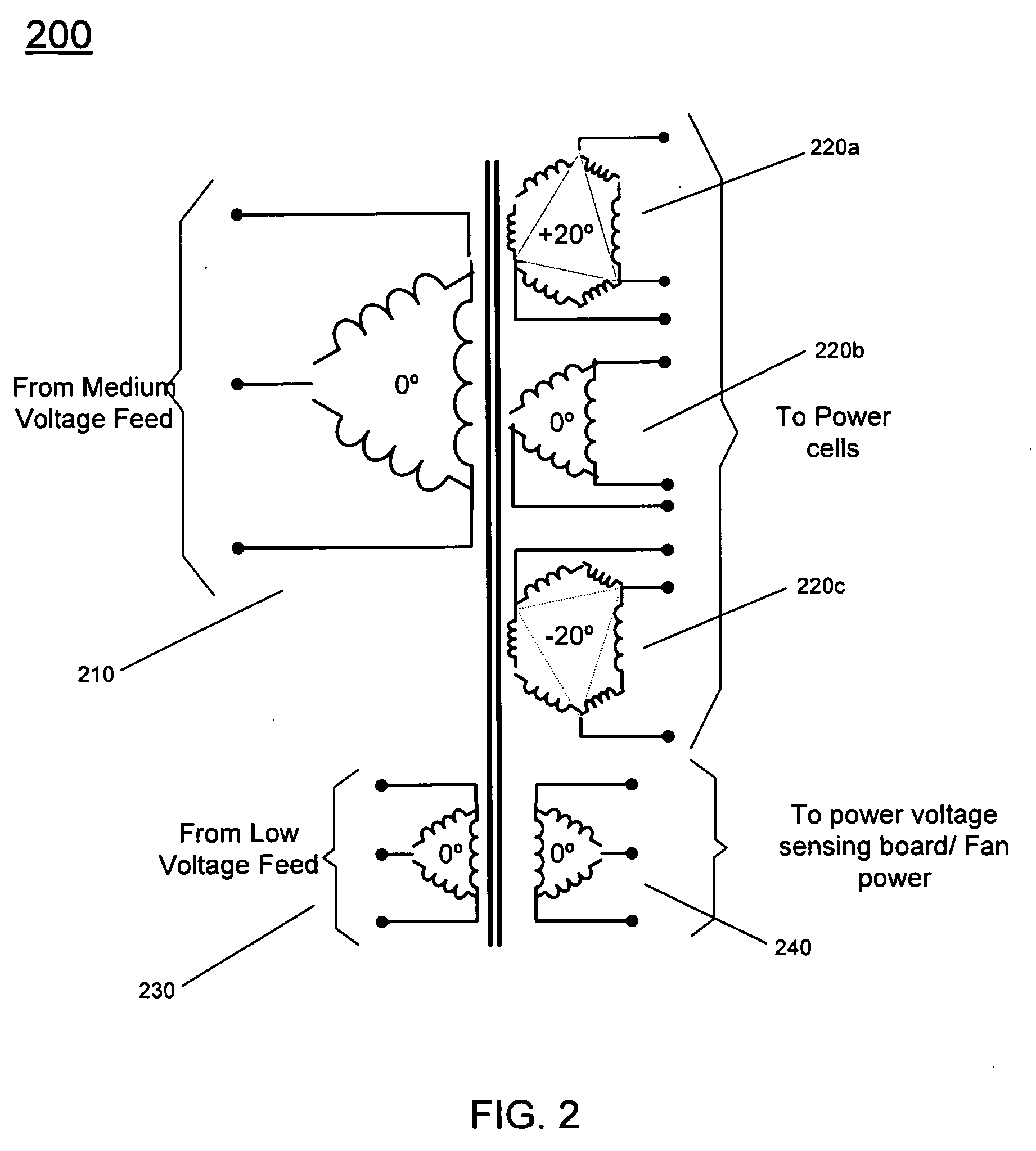

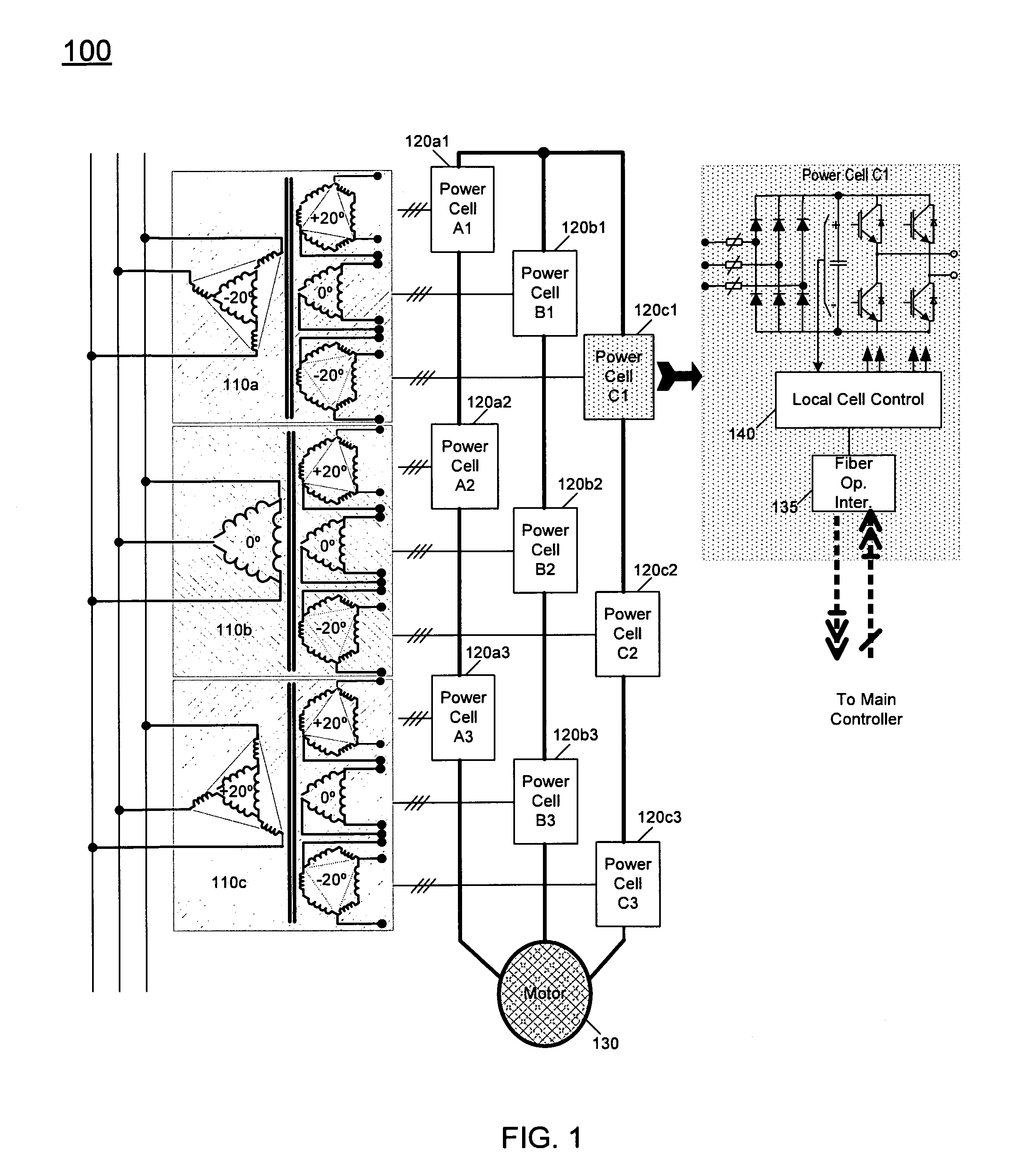

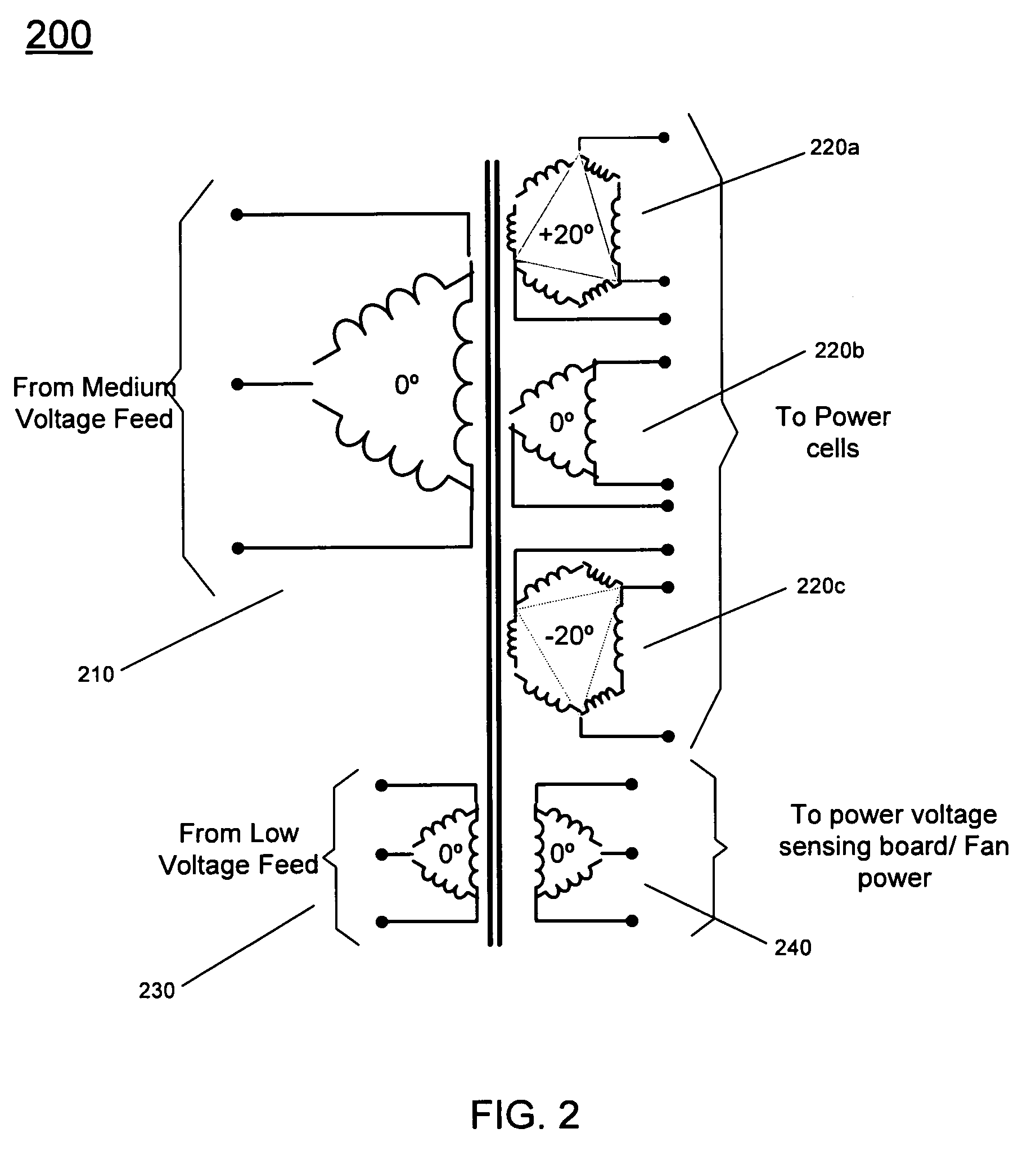

Pre-Charging An Inverter Using An Auxiliary Winding

A transformer module includes a main primary winding coupled to a first input power source to receive a medium voltage signal, multiple main secondary windings each to couple to a power cell of a drive system, and an auxiliary primary winding coupled to a second input power source to receive a low voltage signal. The auxiliary primary winding can be spatially separated from the main windings to increase leakage inductance. The auxiliary primary winding can be active during a pre-charge operation to pre-charge the power cells.

Owner:TECO WESTINGHOUSE MOTOR

Modularized multi-level converter with auxiliary diode

InactiveCN102832841ASimple structureSimplify the control problemActive power filteringAc-dc conversionCapacitor voltageHigh pressure

The invention relates to a modularized multi-level converter with an auxiliary diode. The modularized multi-level converter comprises a three-phase valve body, and three active energy feedback circuits respectively connected to the three-phase valve body, wherein each phase of valve body comprises 2M half-bridge inversion units and 2M-1 auxiliary diodes; direct current capacitors of the 1-(2M-1)th serially connected half-bridge inversion units are respectively connected with one auxiliary diode, and the final (2M)th half-bridge inversion unit is serially connected to form the valve body; the 1-Mth half-bridge inversion units form the upper-half part of the valve body to output a negative polarity voltage; and the (M+1)th to 2Mth half-bridge inversion units form the lower-half part of the valve body to output a positive polarity voltage. The auxiliary diodes and the active energy feedback circuits form a capacitor voltage sharing loop, the modularized multi-level converter realizes capacitance self voltage sharing effect, and realizes that the unit capacitance voltage is measured by using less direct current voltage sensors, thus the detection and the control of multi-level topology are greatly simplified. The modularized multi-level converter can be used in occasions such as reaction compensation and harmonic treatment of a medium-voltage or high-voltage power grid.

Owner:TSINGHUA UNIV

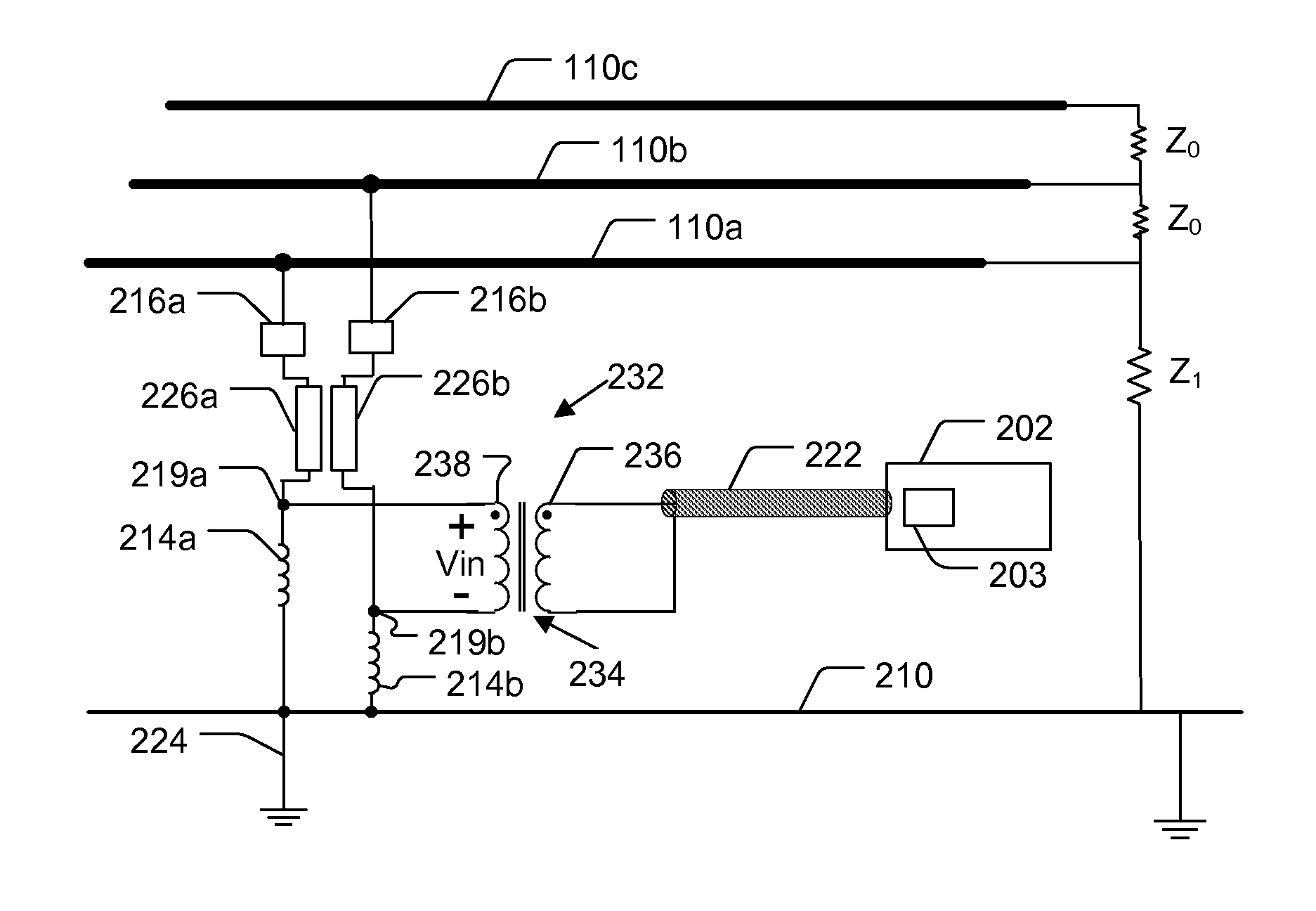

Power line communication apparatus and method of using the same

InactiveUS20050200459A1Electric signal transmission systemsImproving S/N for transmission/receivingElectric forceModem device

The present invention provides a communication device for use with a power line communication system. One embodiment of the present invention forms a bypass device and comprises a LV coupler, a LV signal conditioner, a controller, a MV modem, a first MV signal conditioner, an isolator, a second MV signal conditioner, and a MV coupler. The controller may provide routing functions to give priority to certain types of data, control access to the network, filter data packets, process software upgrades, and provision new subscriber devices. In addition, the controller may monitor, process, and transmit traffic data, measured power data, errors, and other collected data.

Owner:CURRENT TECH

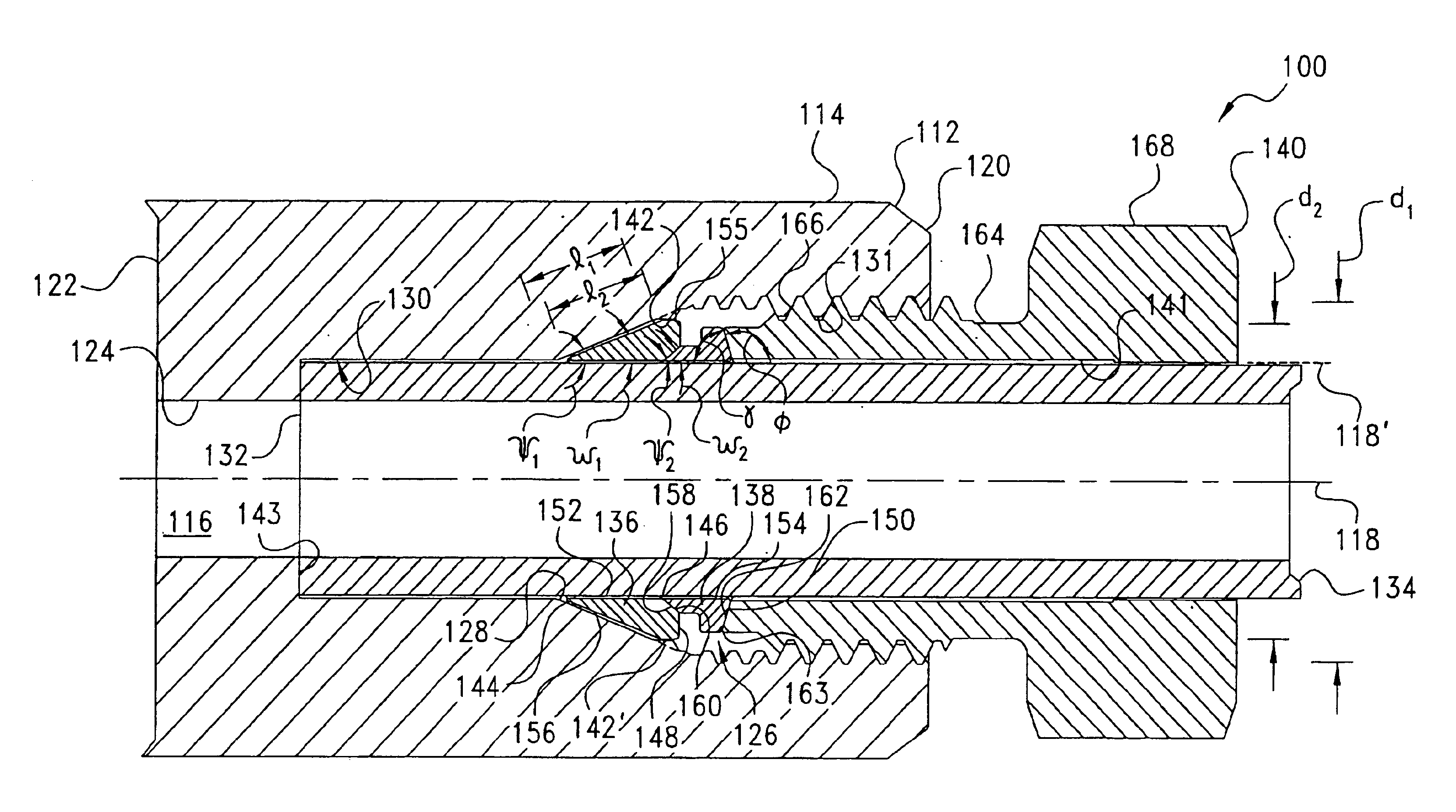

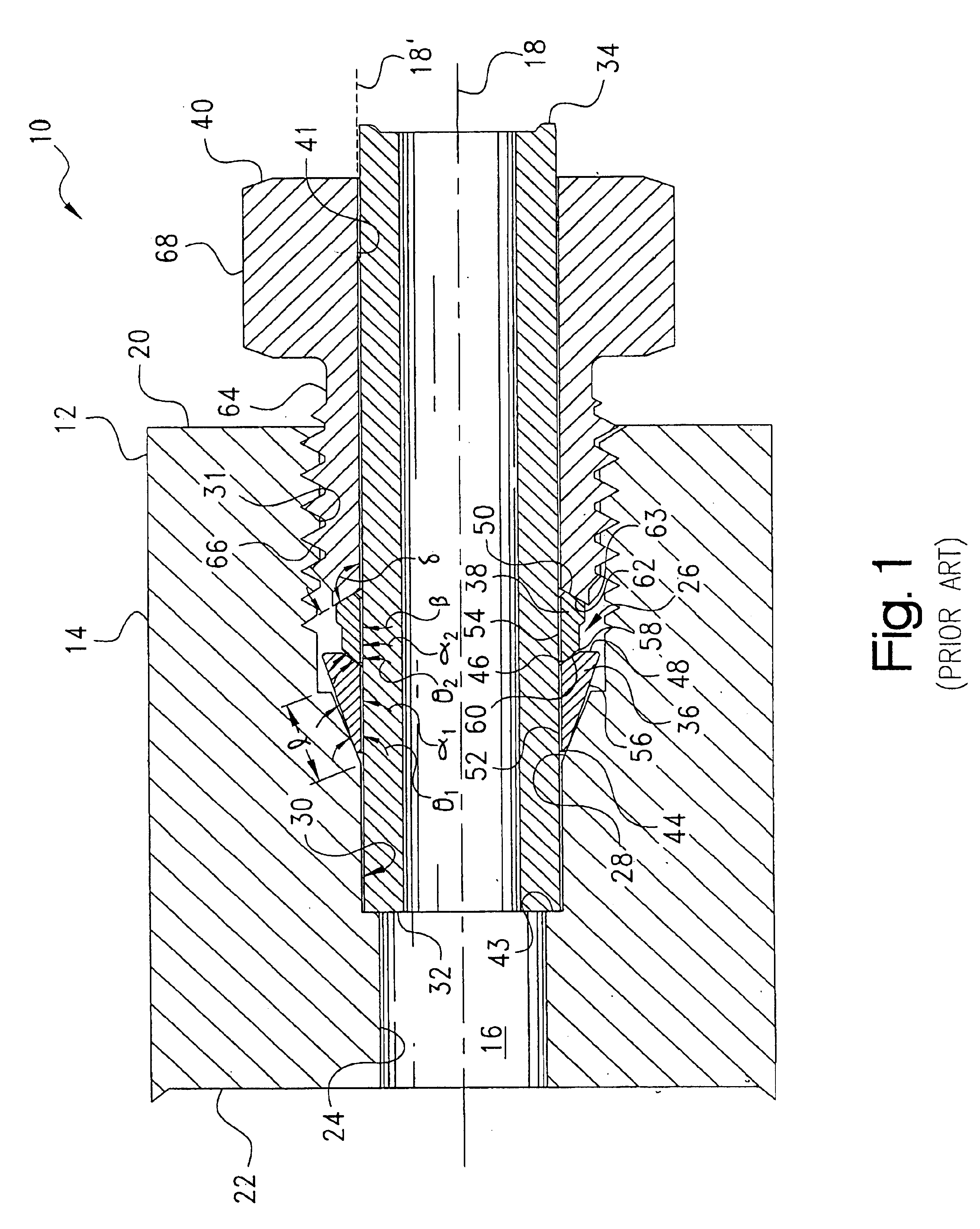

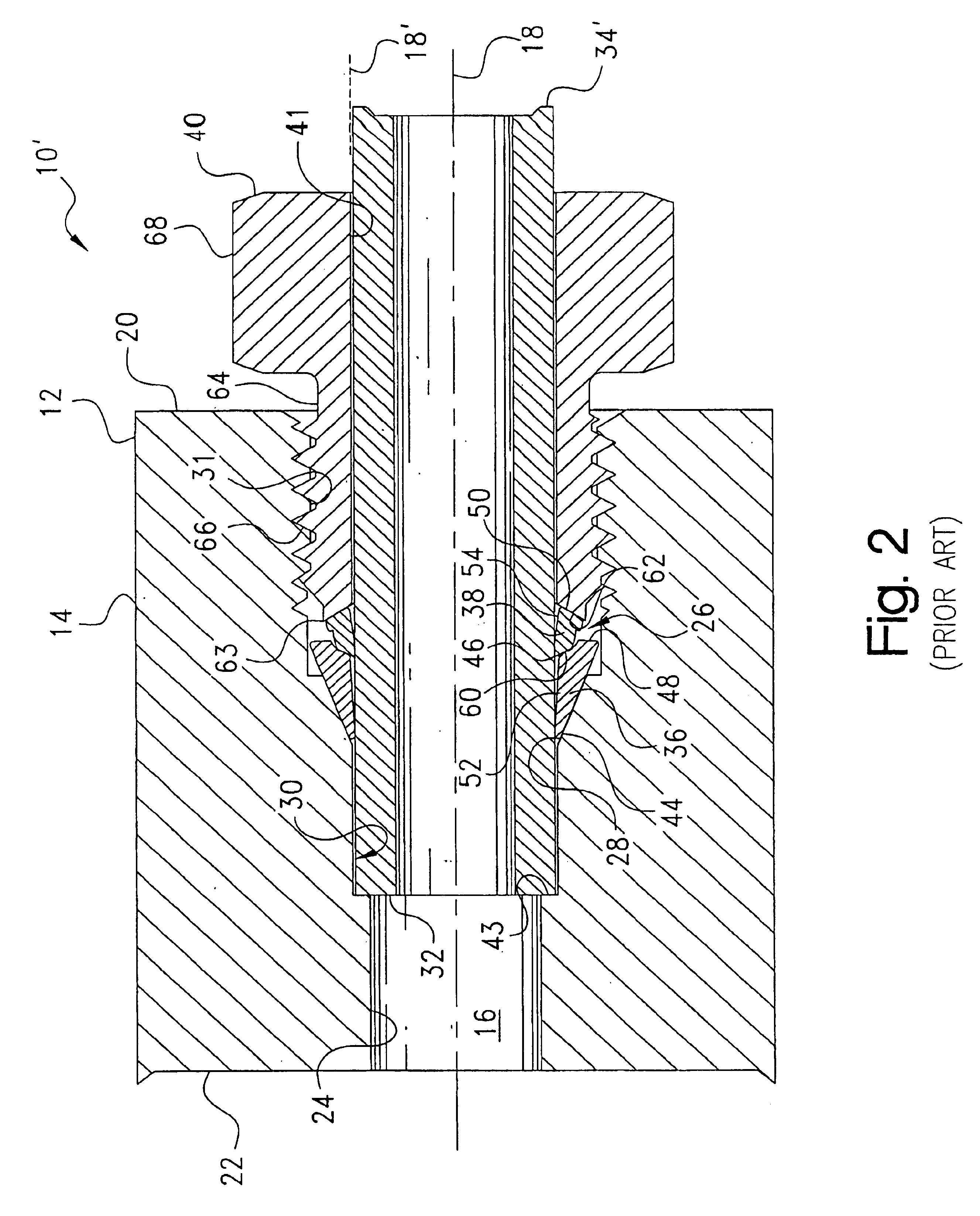

Tube fitting for medium pressure applications

InactiveUS6851729B2Constrainment of the ferruleSleeve/socket jointsFluid pressure sealed jointsScrew threadMedium pressure

A fitting for the connection of a tubing end. The fitting includes a body having a bore with an internally-threaded opening which extends to a seating surface, and a front ferrule which is receivable coaxially over the tubing end. An externally-threaded nut is receivable coaxially over the outer diameter of the tubing end to be positionable thereon rearwardly of the front ferrule such that, with the tubing end and front ferrule being inserted through the bore opening, the nut is threadably engageable with the body urging an outer surface of the ferrule into a canning engagement against the body seating surface. The axial length of the seating surface is provided to extend substantially the entire length of the ferrule outer surface so as to constrain the radial outward expansion of the ferrule rearward end.

Owner:PARKER INTANGIBLES LLC

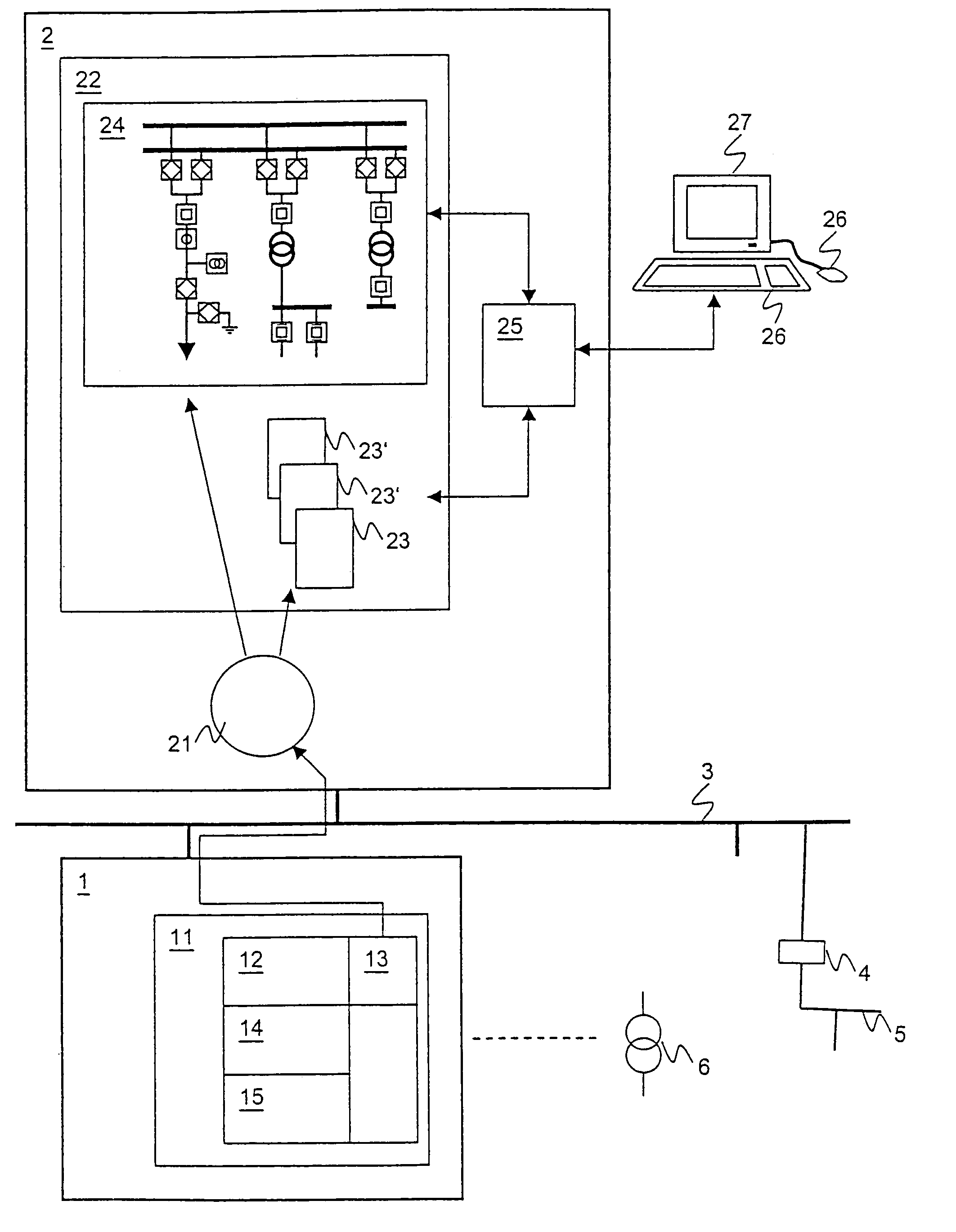

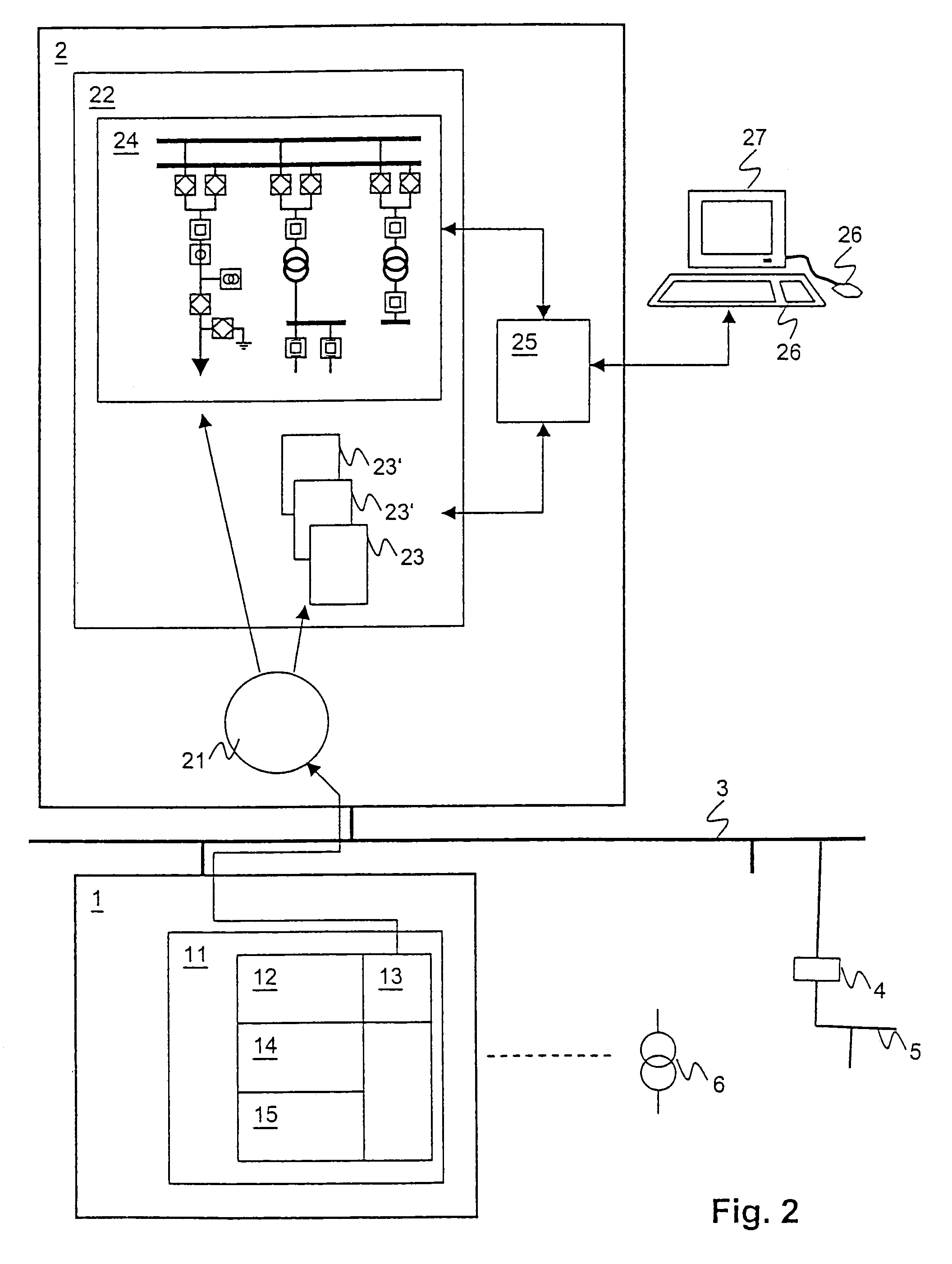

Integration of a field device in an installation control system

InactiveUS6970771B1Save effortReduce effortLevel controlCircuit arrangementsTelecommunications linkControl system

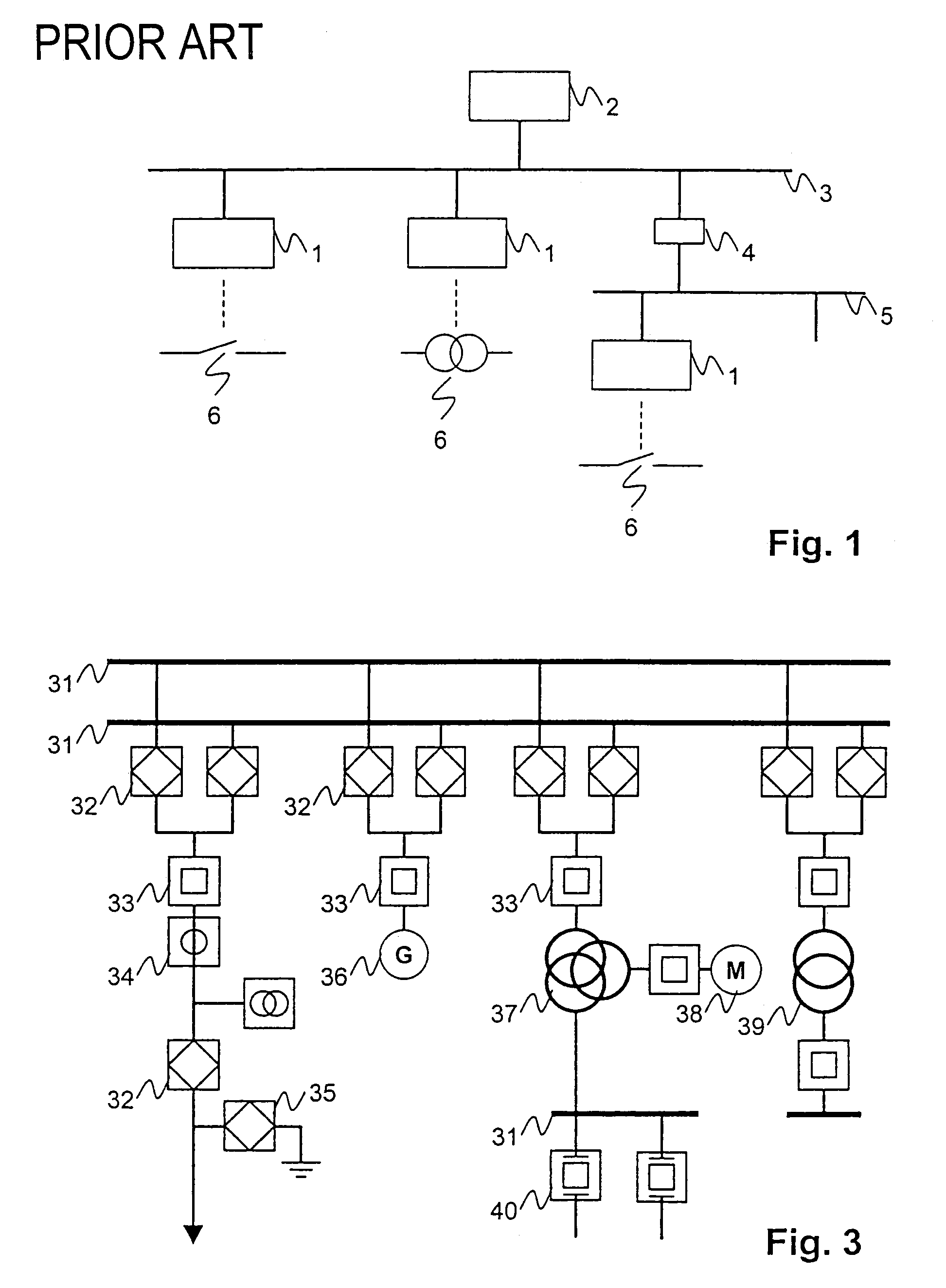

A method and a system for integration of a field device in an installation control system having a communications network and a control station functions in that a field device transmits a functional description of device functions to the control station in a standardized form, whereupon functions associated with the field device are installed on the control station, and communications links are set up between the device functions of the field device and the functions of the control station. In one preferred version of the invention, device functions are automatically or manually combined with an installation structure. The invention is preferably used with high voltage or medium voltage switchgear assemblies and leads to a considerable reduction in the complexity for specification and commissioning of installation internal communications links and to higher quality of a resulting installation control system.

Owner:ABB RES LTD

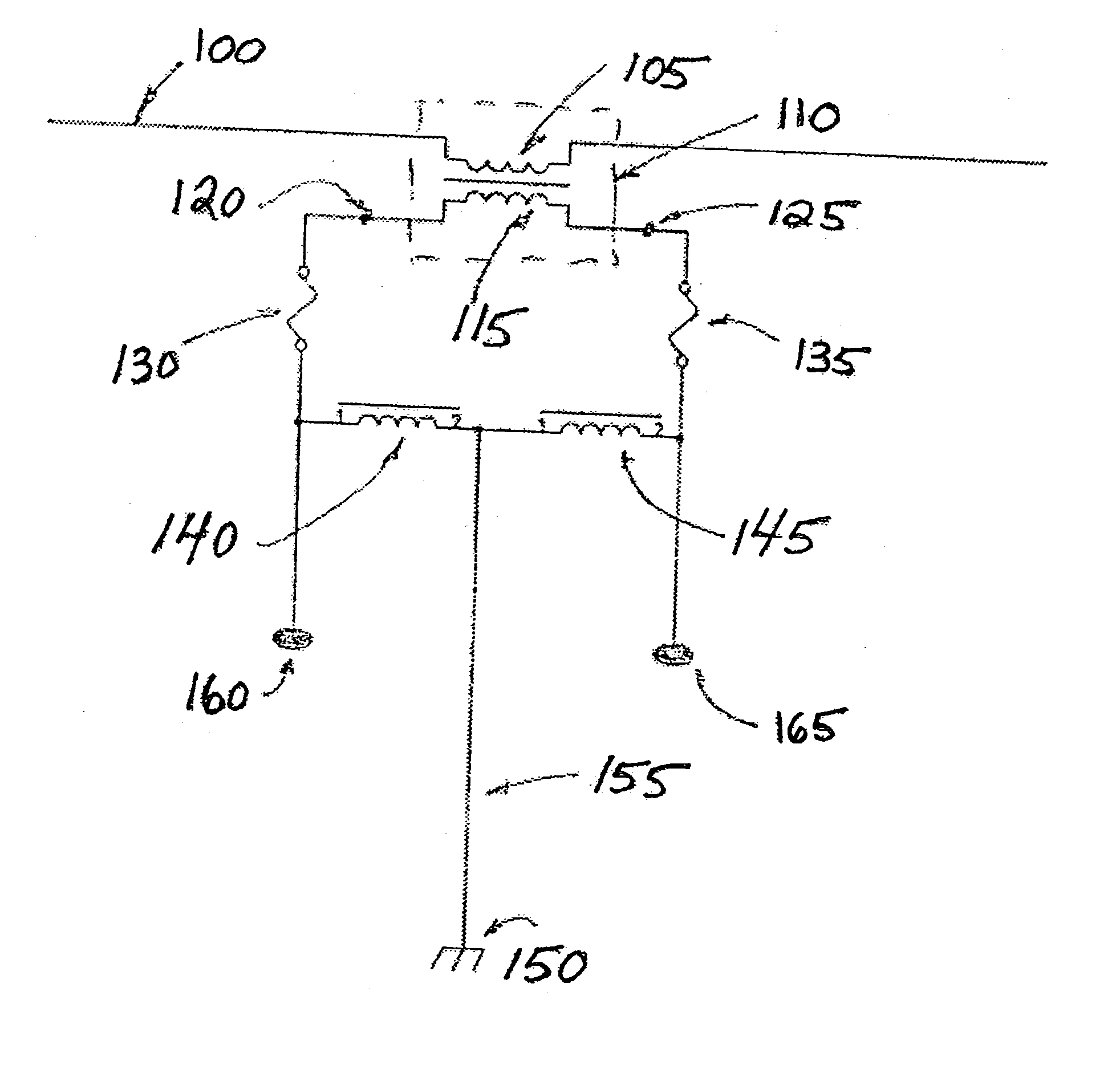

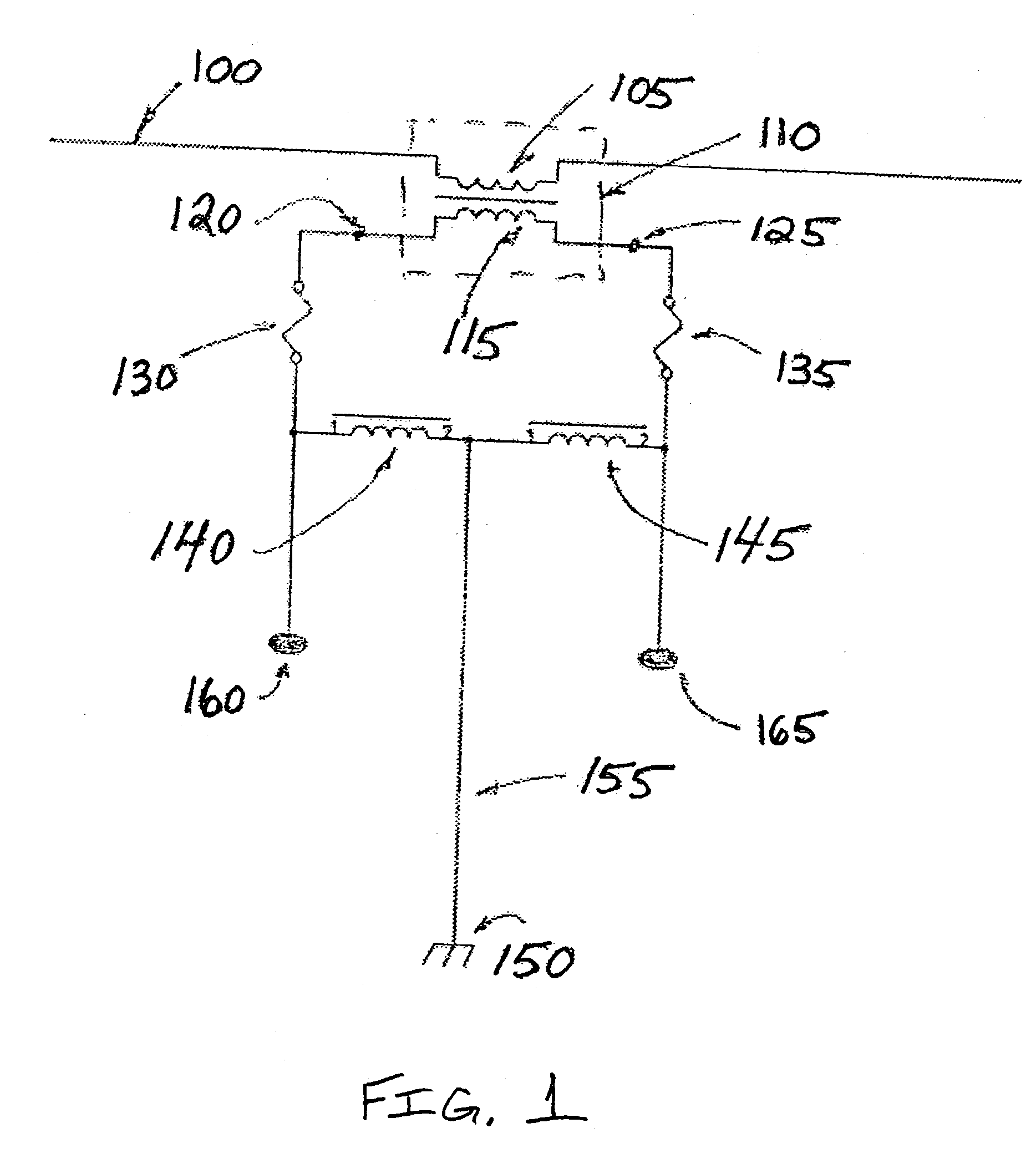

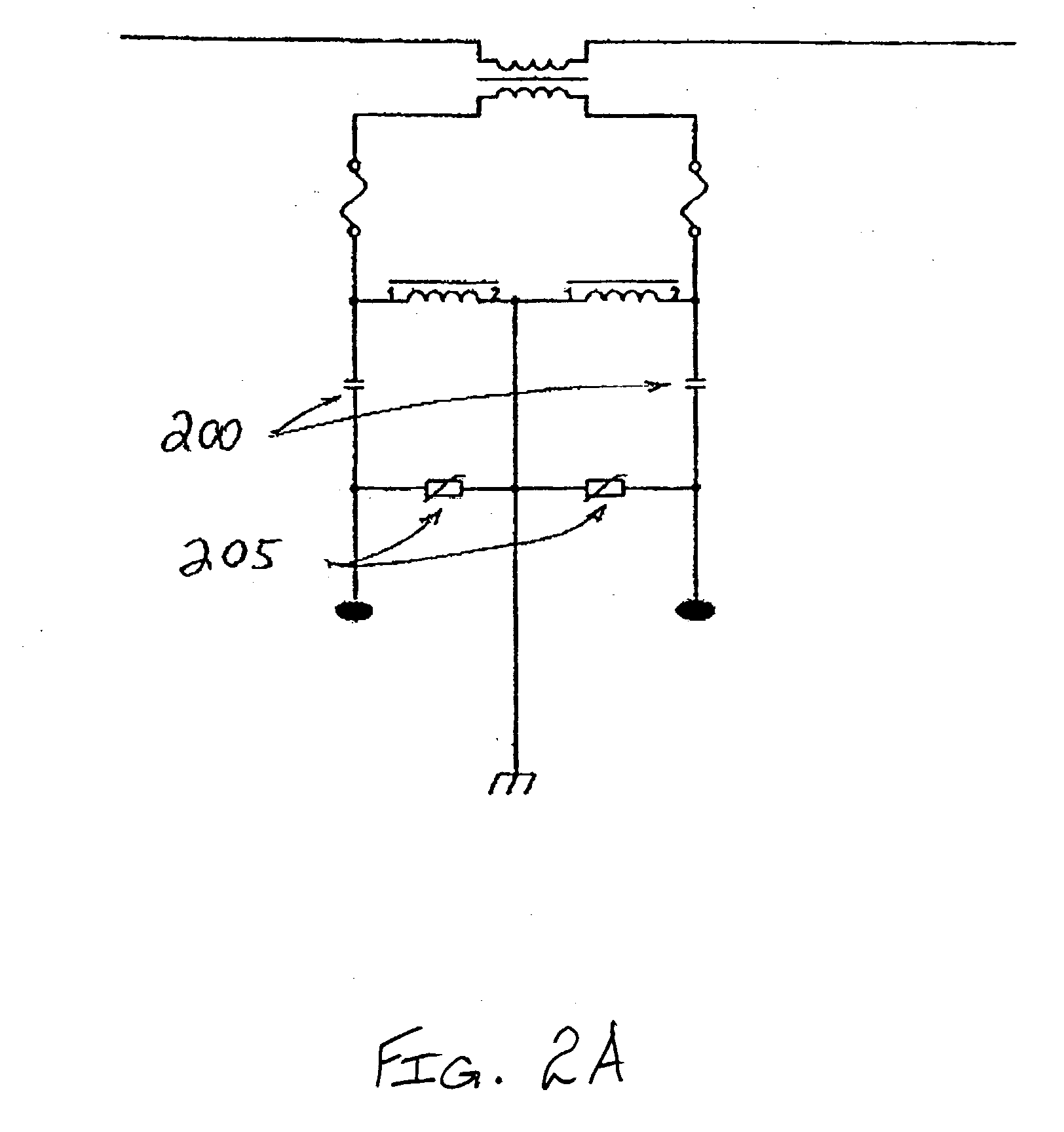

Protecting medium voltage inductive coupled device from electrical transients

ActiveUS20030210135A1TransformersPower distribution line transmissionElectrical conductorDistribution system

There is provided a method for protecting loads associated with power distribution system inductive signal couplers. The method includes (a) providing an inductive signal coupler having a first winding in series with a line conductor of a power distribution system, and a second winding having first and second connection terminals, (b) connecting a first terminal of a first fuse to the first connection terminal, and a first terminal of a second fuse to the second connection terminal, a second terminal of each fuse being connected to a communication device, and (c) connecting a first terminal of a first choke to the second terminal of the first fuse, and a first terminal of a second choke to the second of the second fuse, a second terminal of each choke being connected to an electrical ground.

Owner:ERICSSON INC

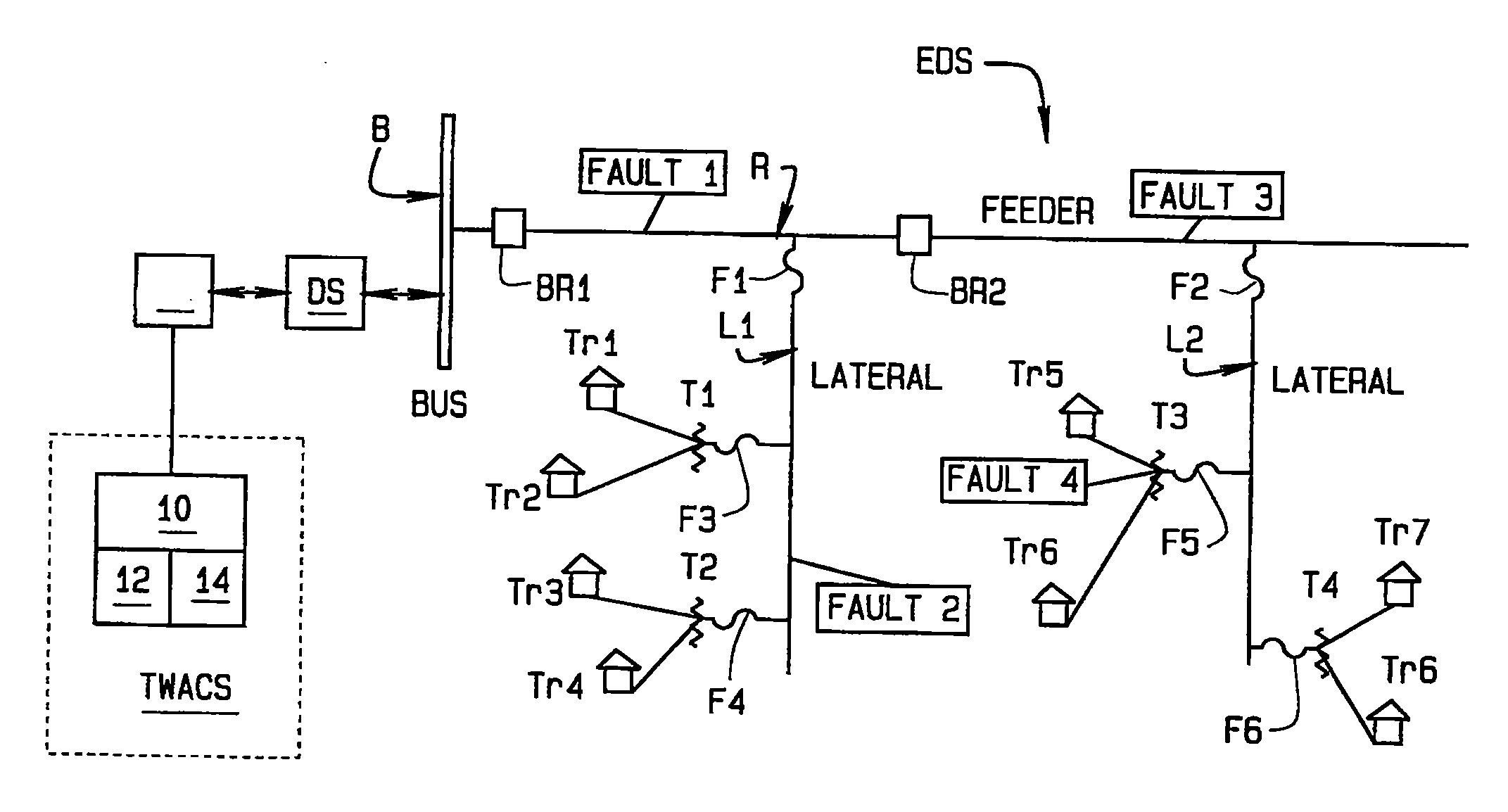

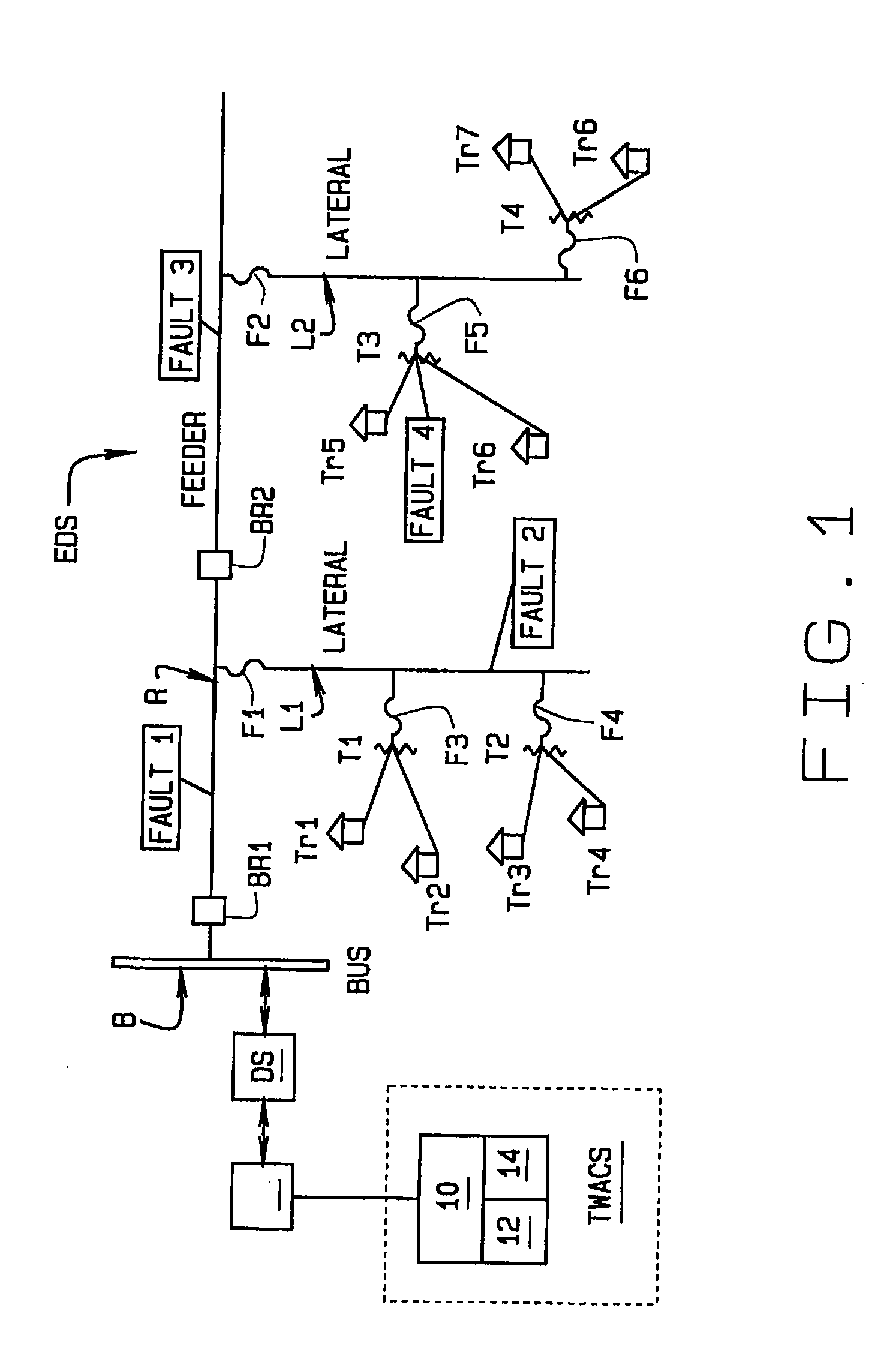

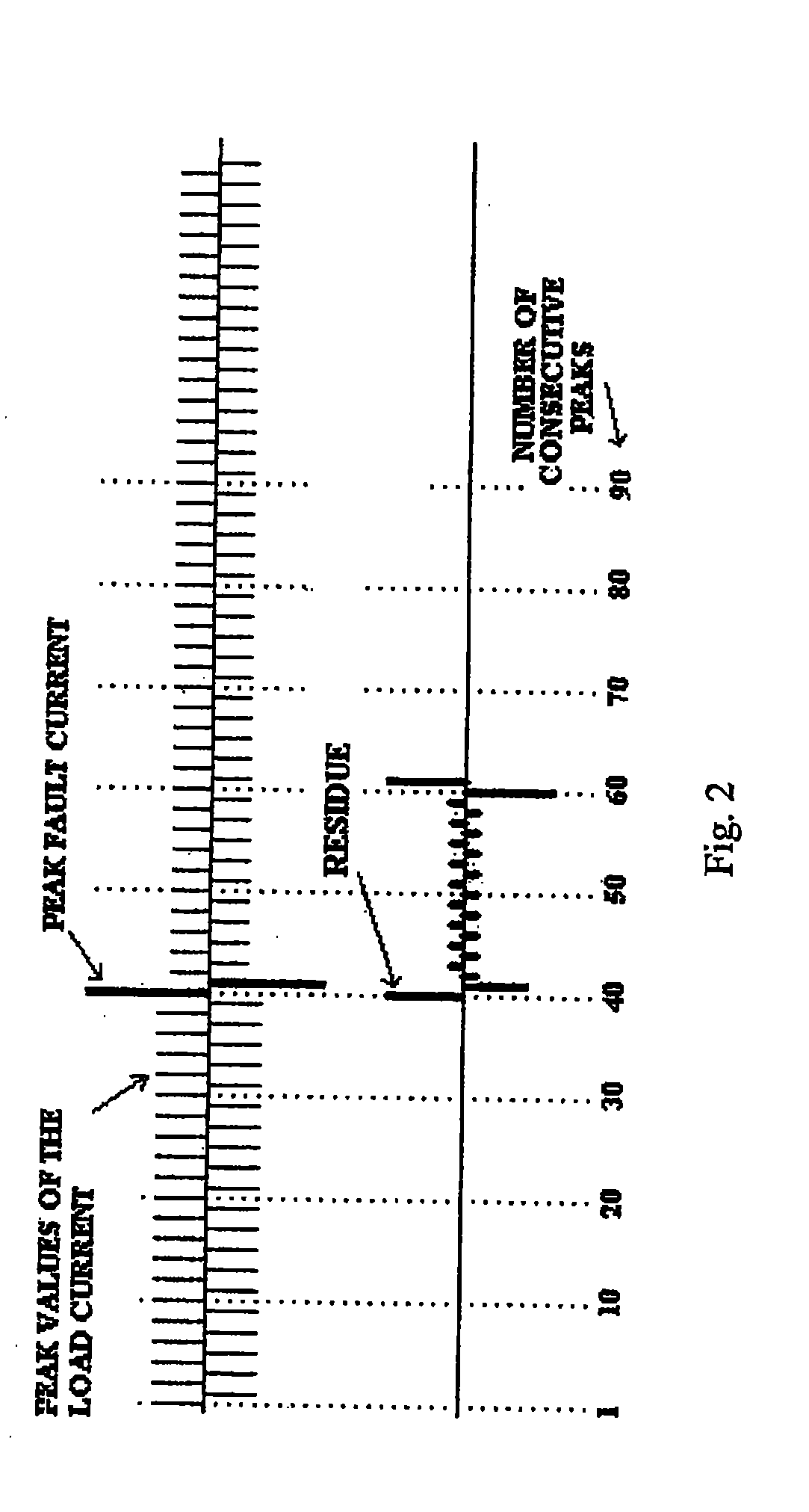

Intelligent fault detector system and method

ActiveUS20070211401A1Time to respondSure easyElectric signal transmission systemsLevel controlLow voltageDistribution system

A quick response system incorporated in a TWACS for mapping an outage in an electrical distribution system without having to continuously poll the electrical meters connected to the system. In a primary embodiment of the invention when a fault is sensed to have occurred, the amplitude of the fault is measured to determine if the fault is a medium voltage fault, or a low voltage fault. The pattern of the fault signature and change in load, both before and after the fault, are examined to determine what protective device was triggered by the fault. Using this information, and knowledge of the number and location of electrical meters connected in the distribution system, a population of meters to be polled is determined. By polling the identified population, a map of the extent of the outage is readily determined, and the time to respond to the fault and restore service is reduced.

Owner:ACLARA TECH LLC

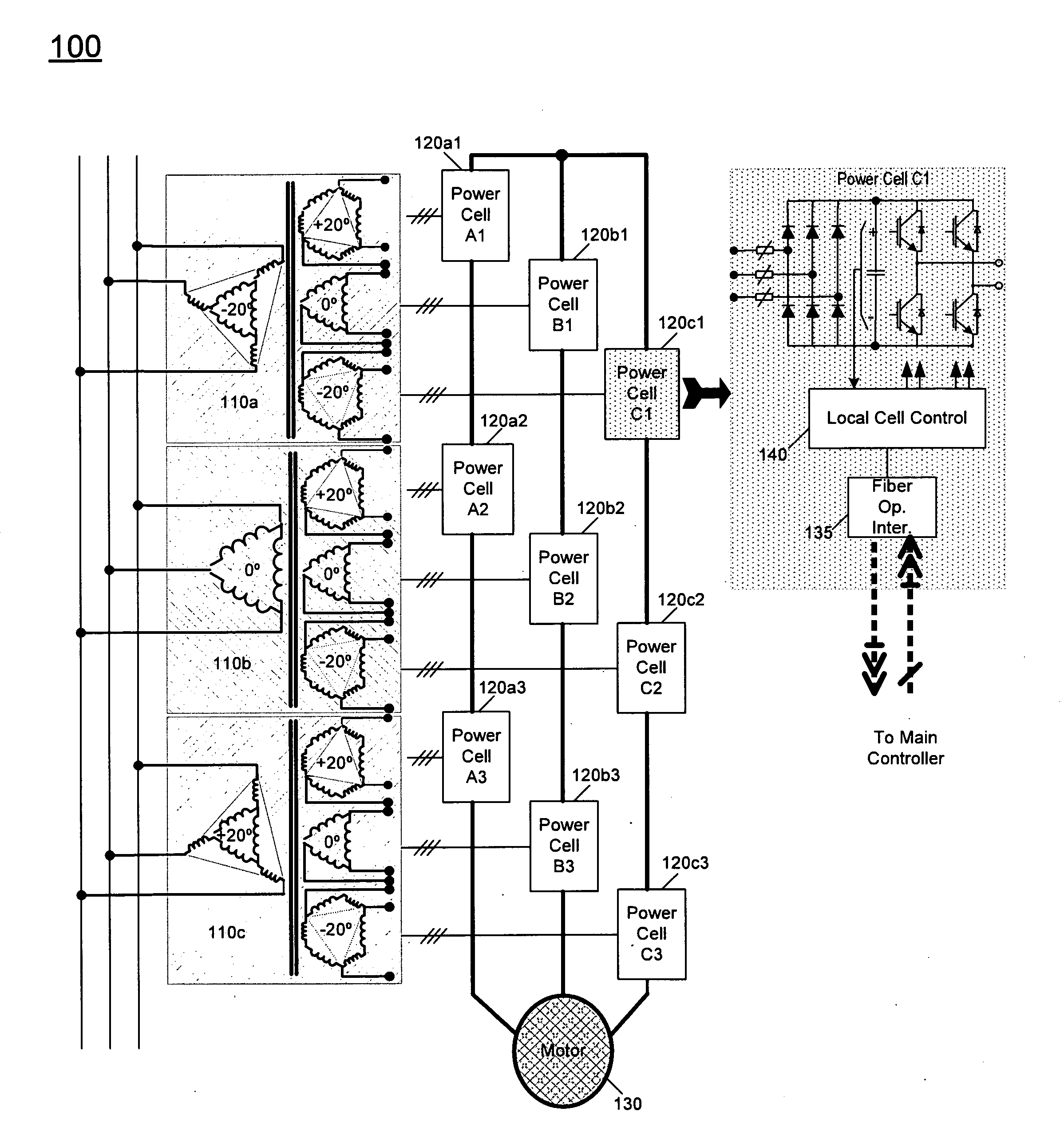

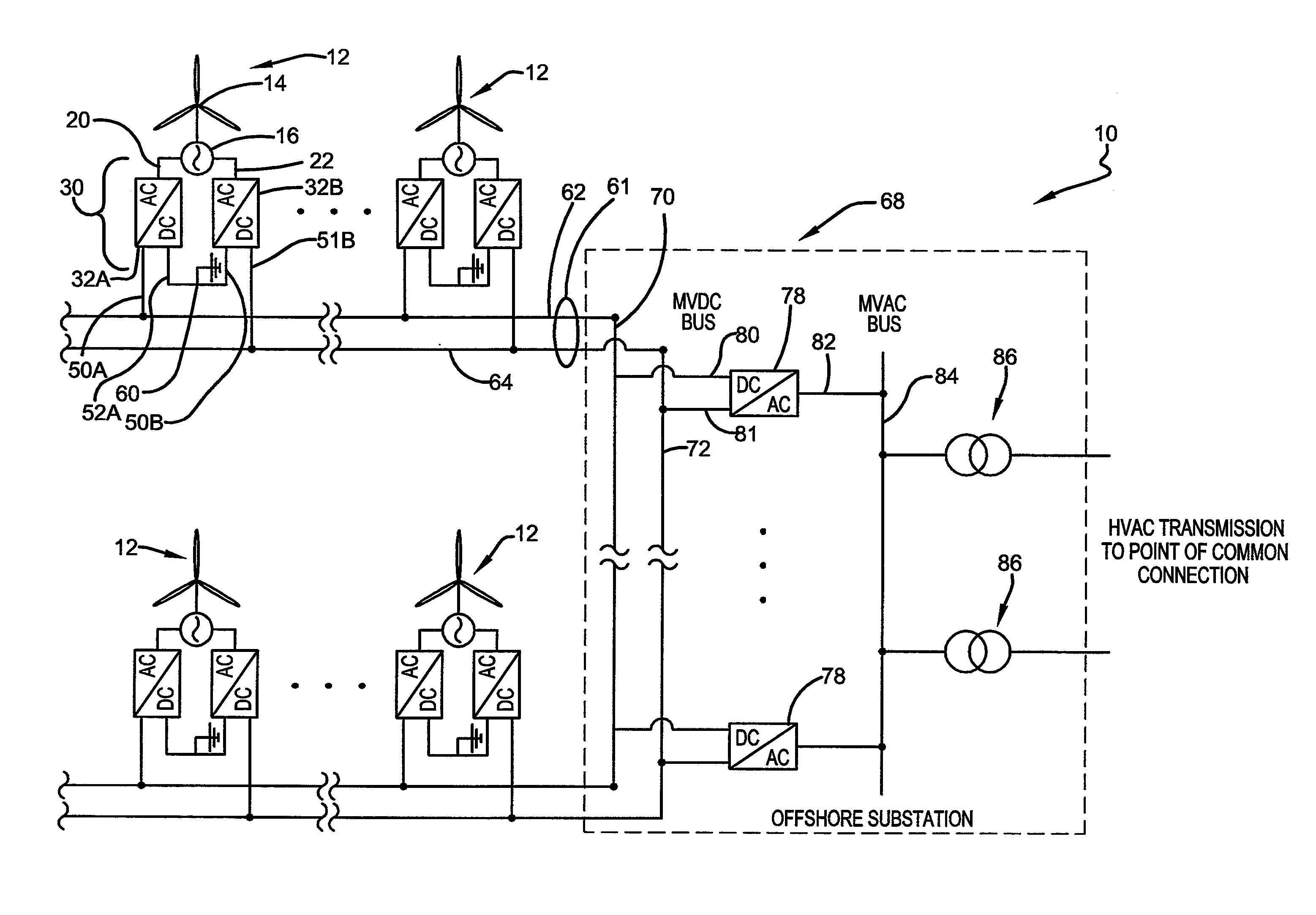

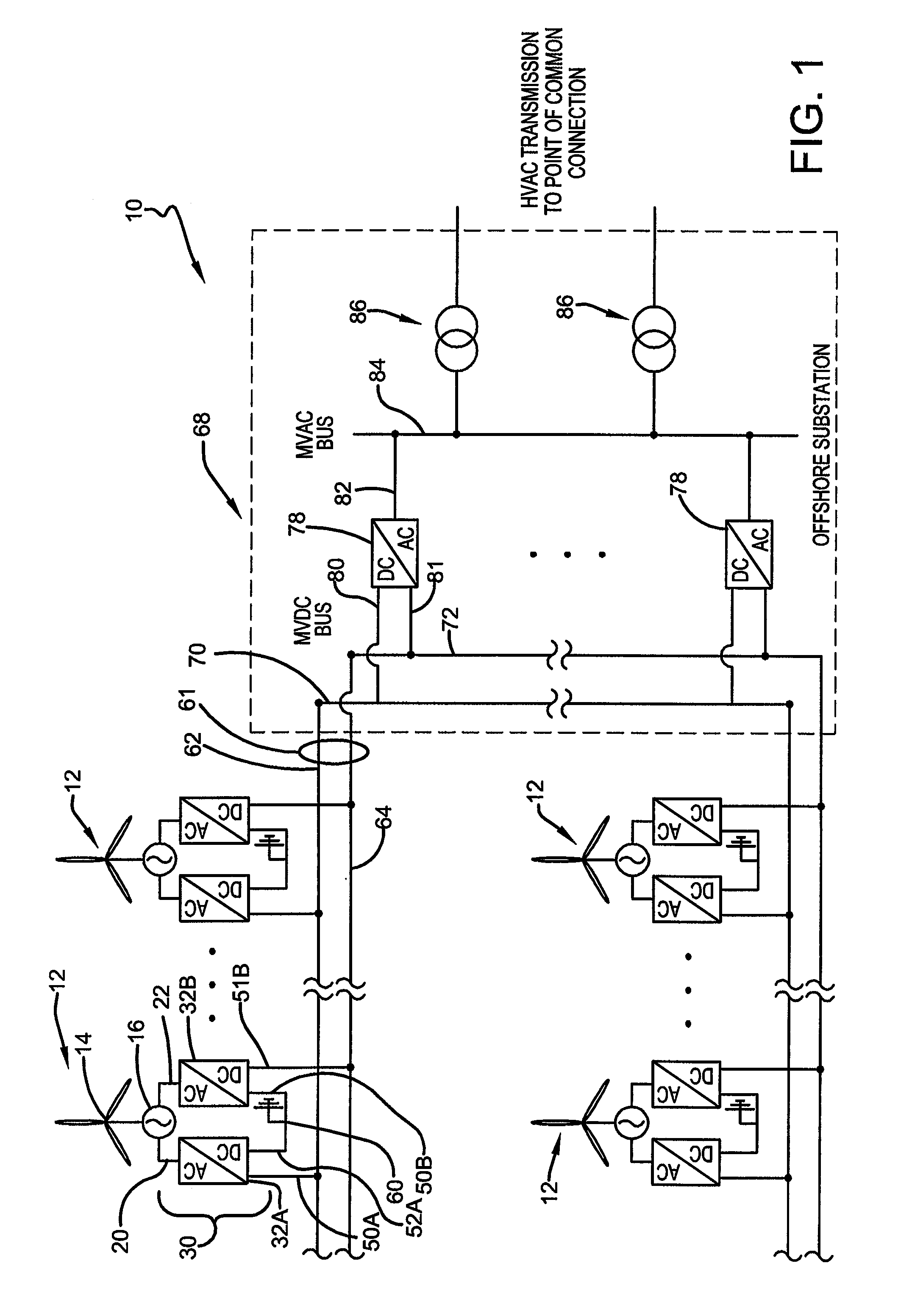

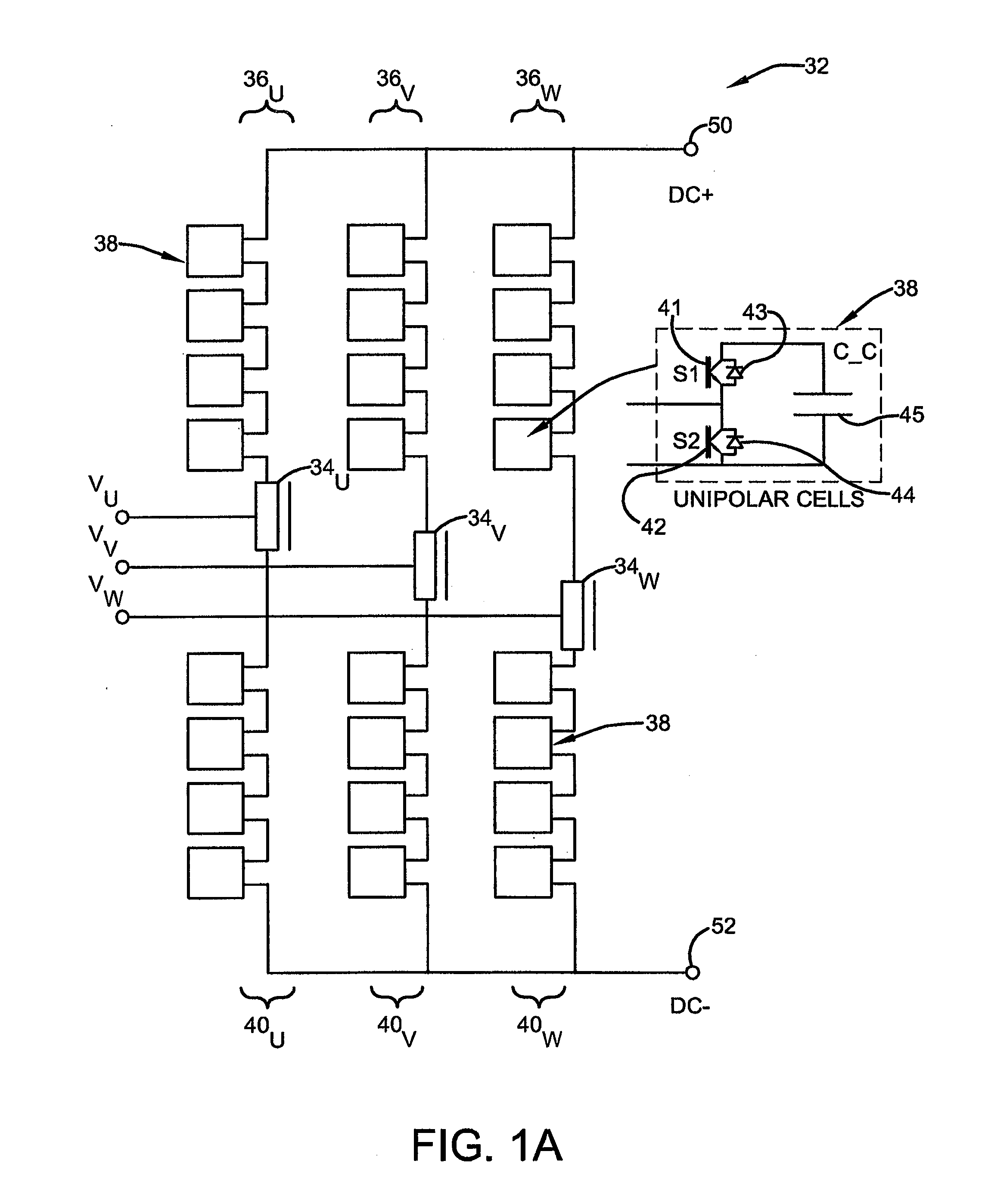

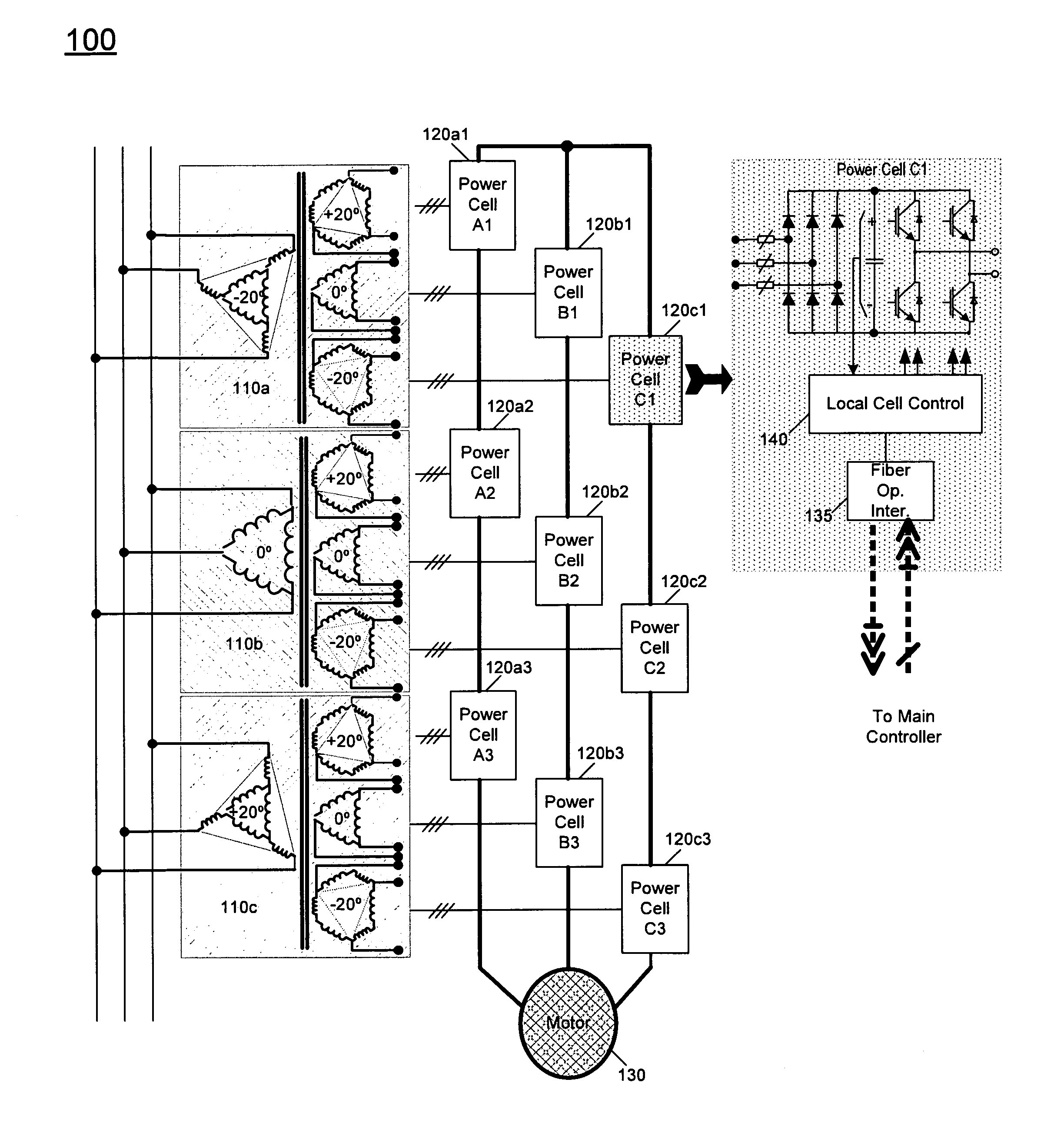

Medium voltage DC collection system

A power generation system includes at least one generator having at least two sets of stator windings, an active rectifier comprising power cell based modular converters associated with each set of generator windings. Each set of windings is connected to an AC voltage side of the associated active rectifier, with each active rectifier having a positive DC voltage output and a negative DC voltage output. The DC voltage outputs of active rectifiers are connected to each other in series. A medium voltage DC (MVDC) collection network comprises positive pole cables and negative pole cables, wherein each positive pole cable is connected to the positive DC voltage output of a first active rectifier and each negative pole cable is connected to the negative DC voltage output of a last active rectifier. A substation receives the negative and positive pole cables of the MVDC collection network for further transformation and transmission.

Owner:ABB (SCHWEIZ) AG

Configurations and methods of acid gas removal

A plant includes a vacuum stripper (118) that receives a lean hydrogen sulfide-containing physical solvent (32) and in which substantially hydrogen sulfide-free stripping gas (51,52) is provided by at least one of a high-pressure flash vessel (110) and a medium pressure flash vessel (112). Contemplated configurations advantageously extend the range of use for physical solvents to treat sour gas comprising carbon dioxide and hydrogen sulfide, and can be used to meet most pipeline specification of 4 ppm hydrogen sulfide.

Owner:FLUOR TECH CORP

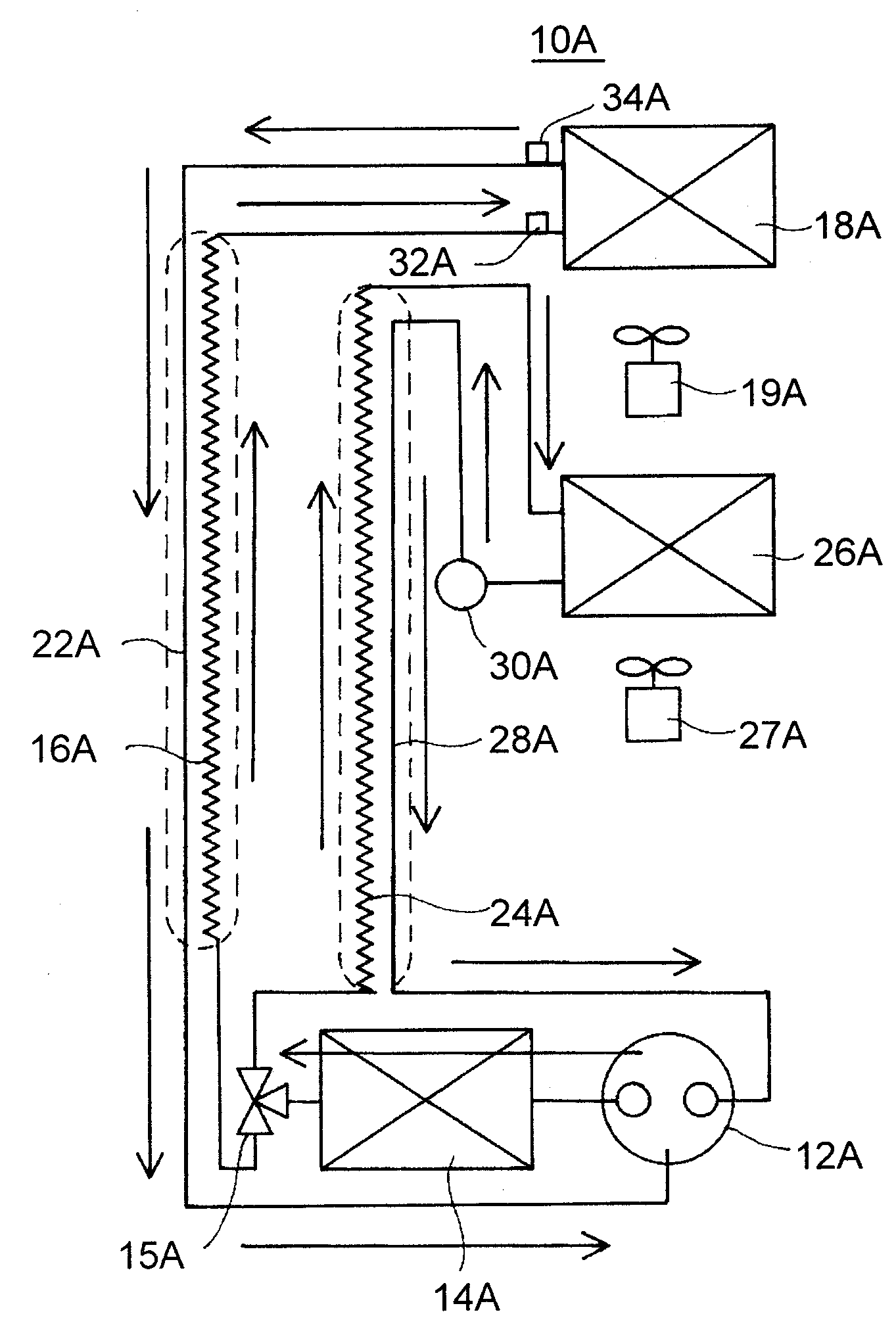

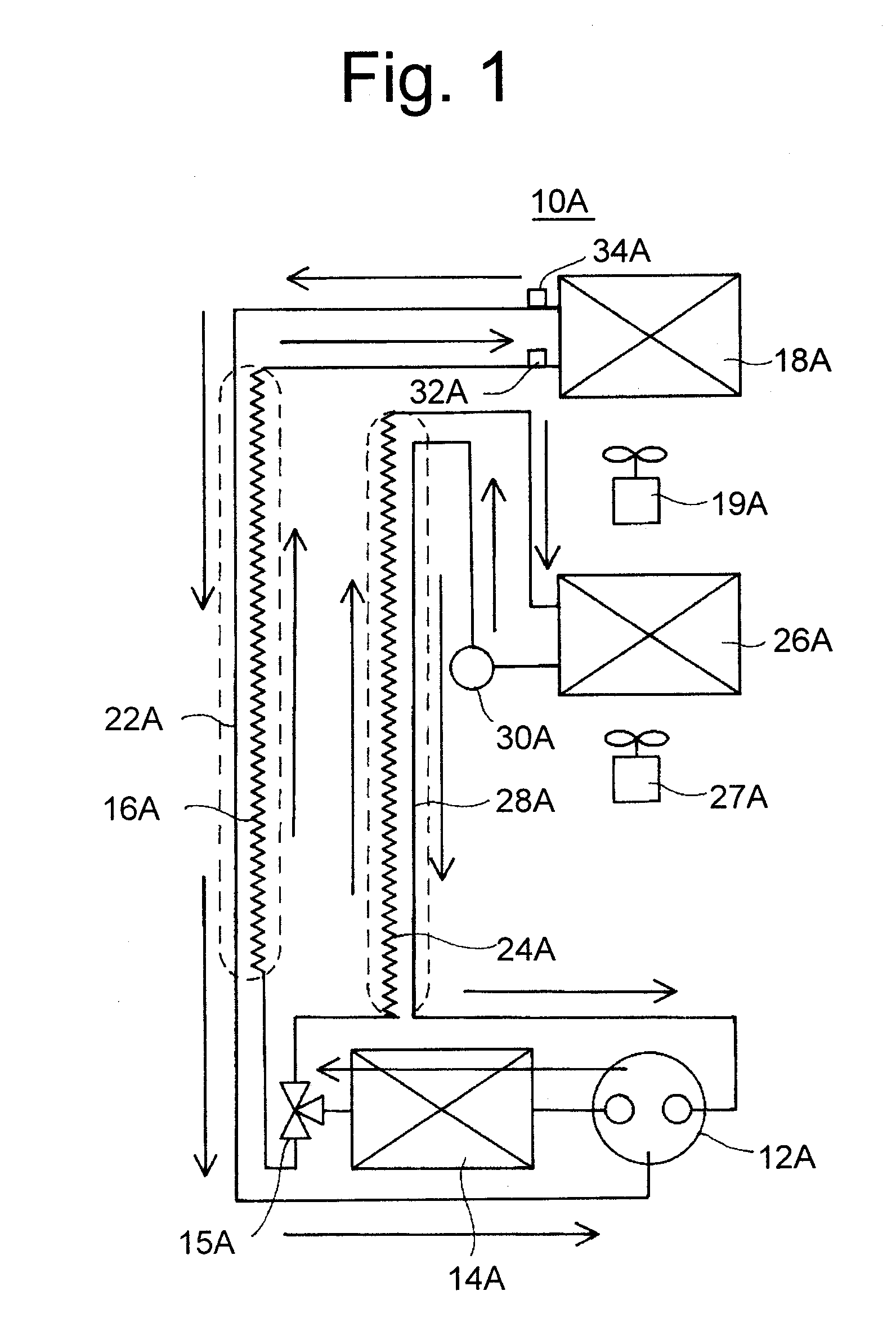

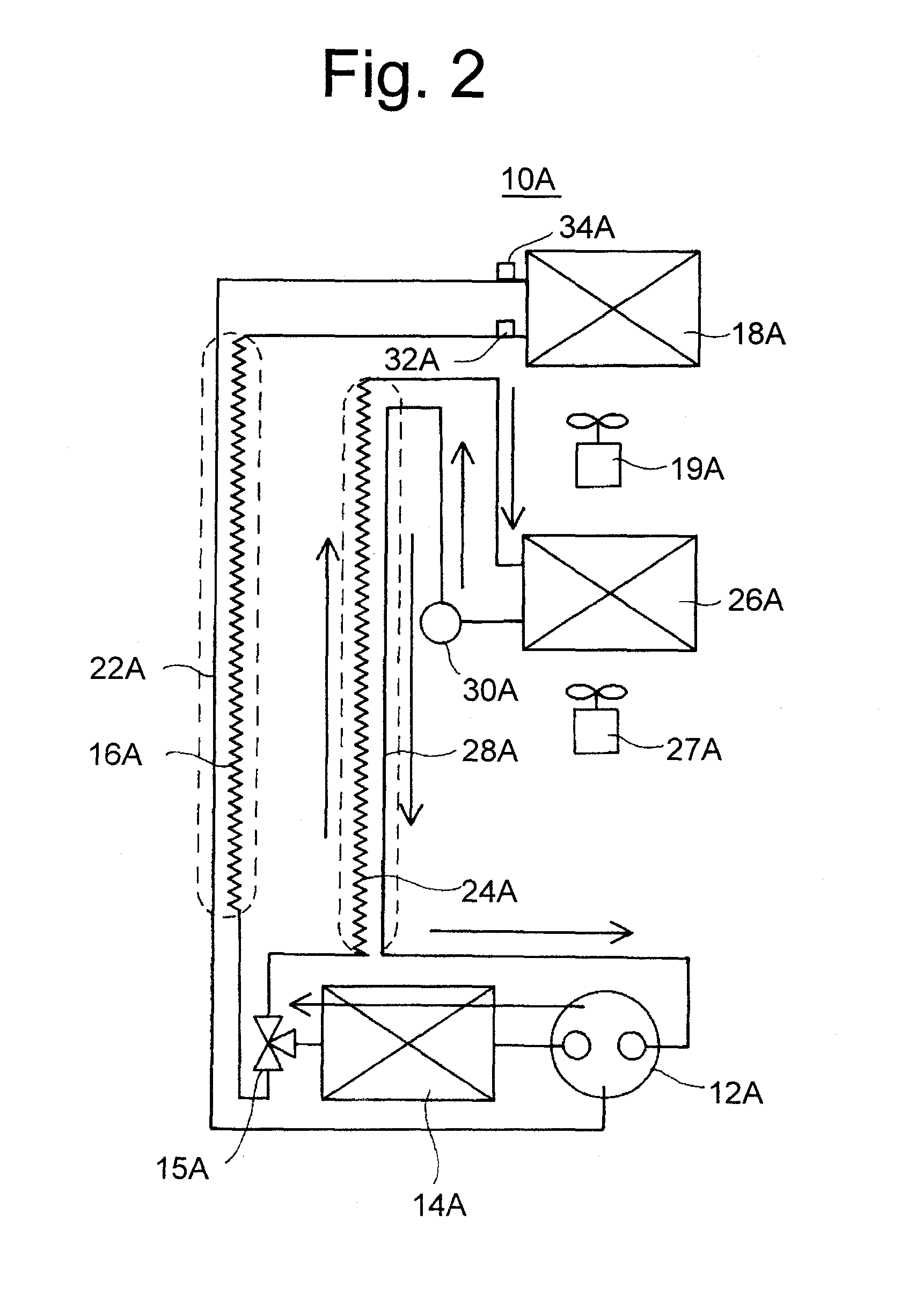

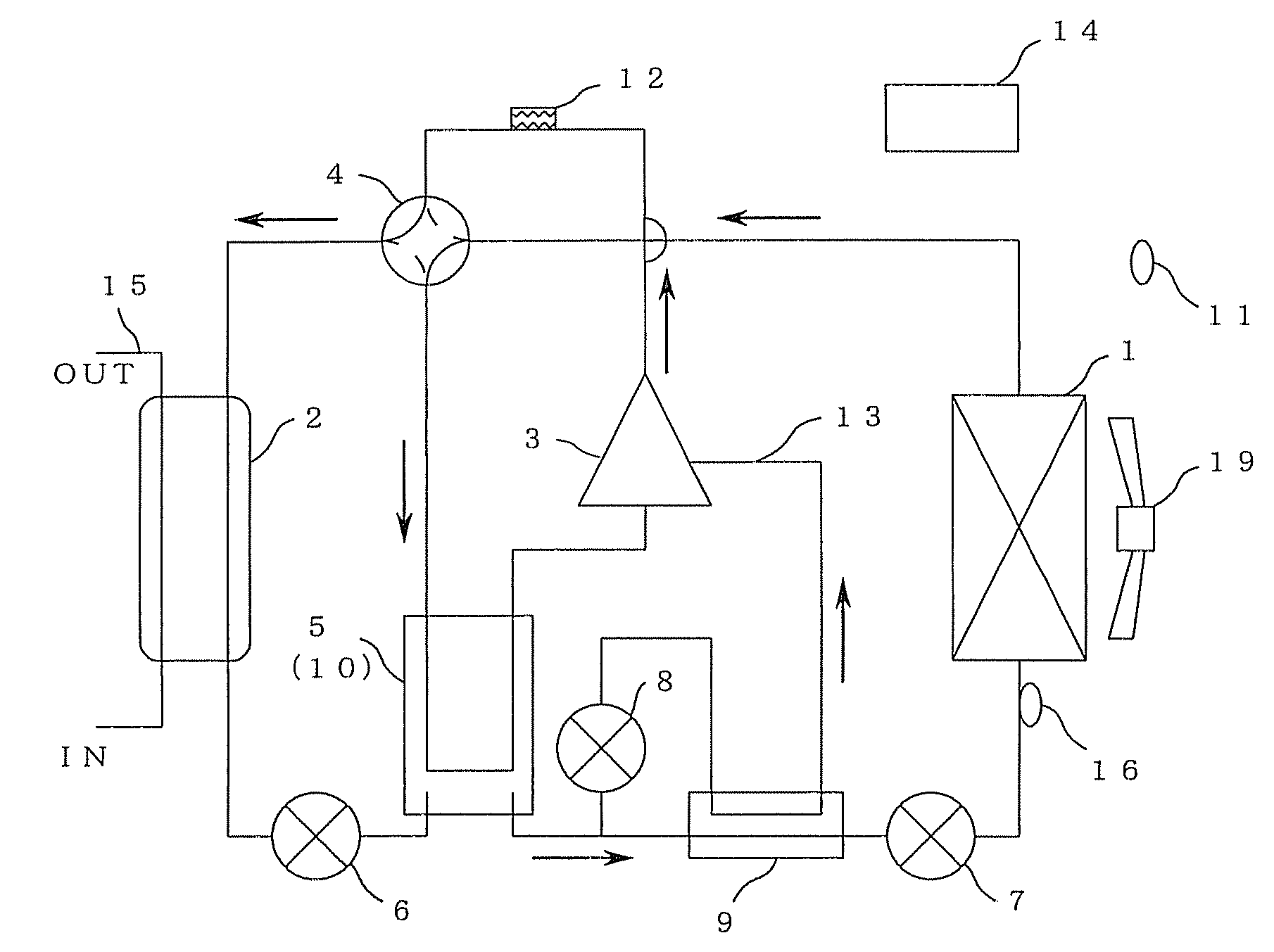

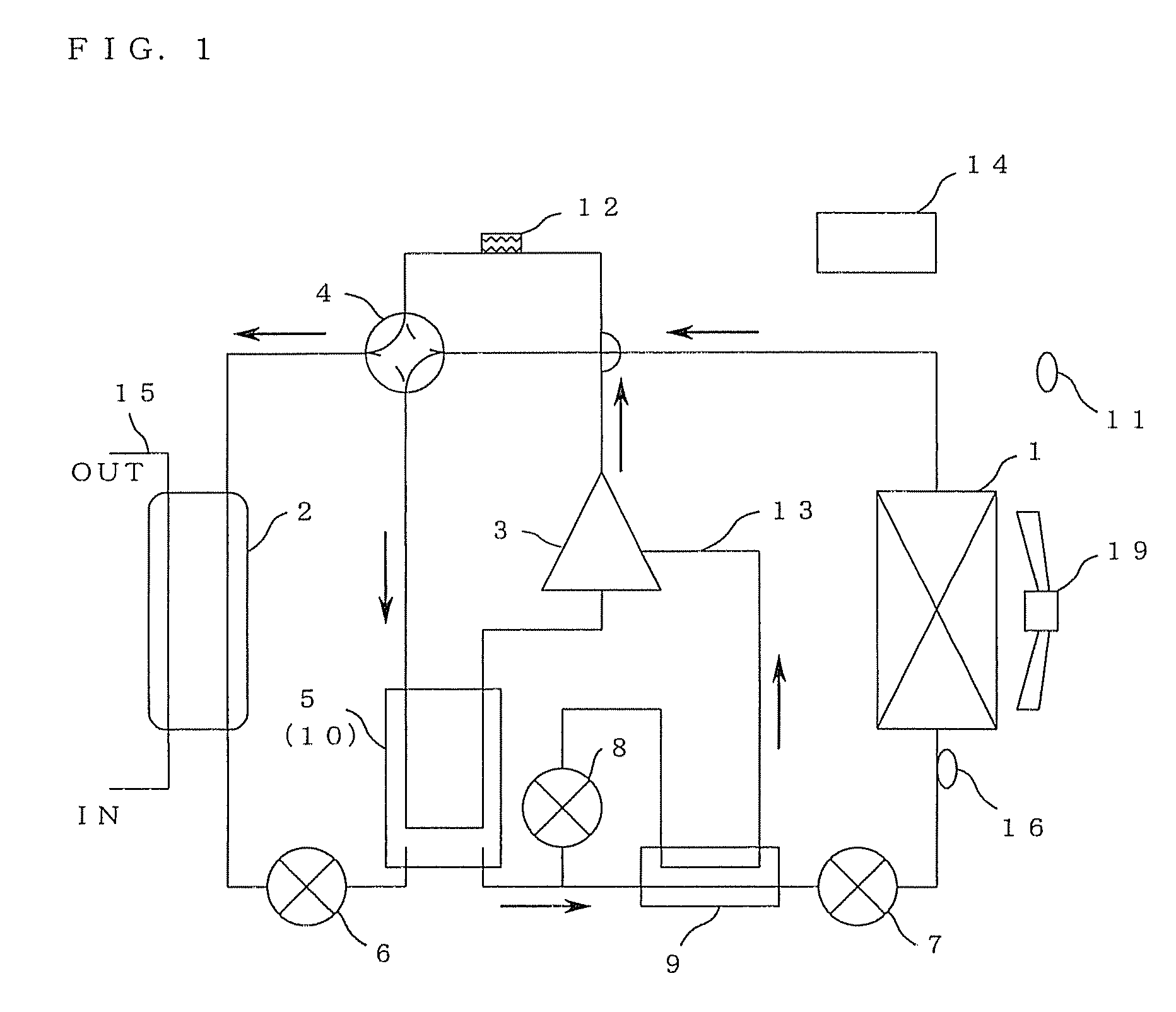

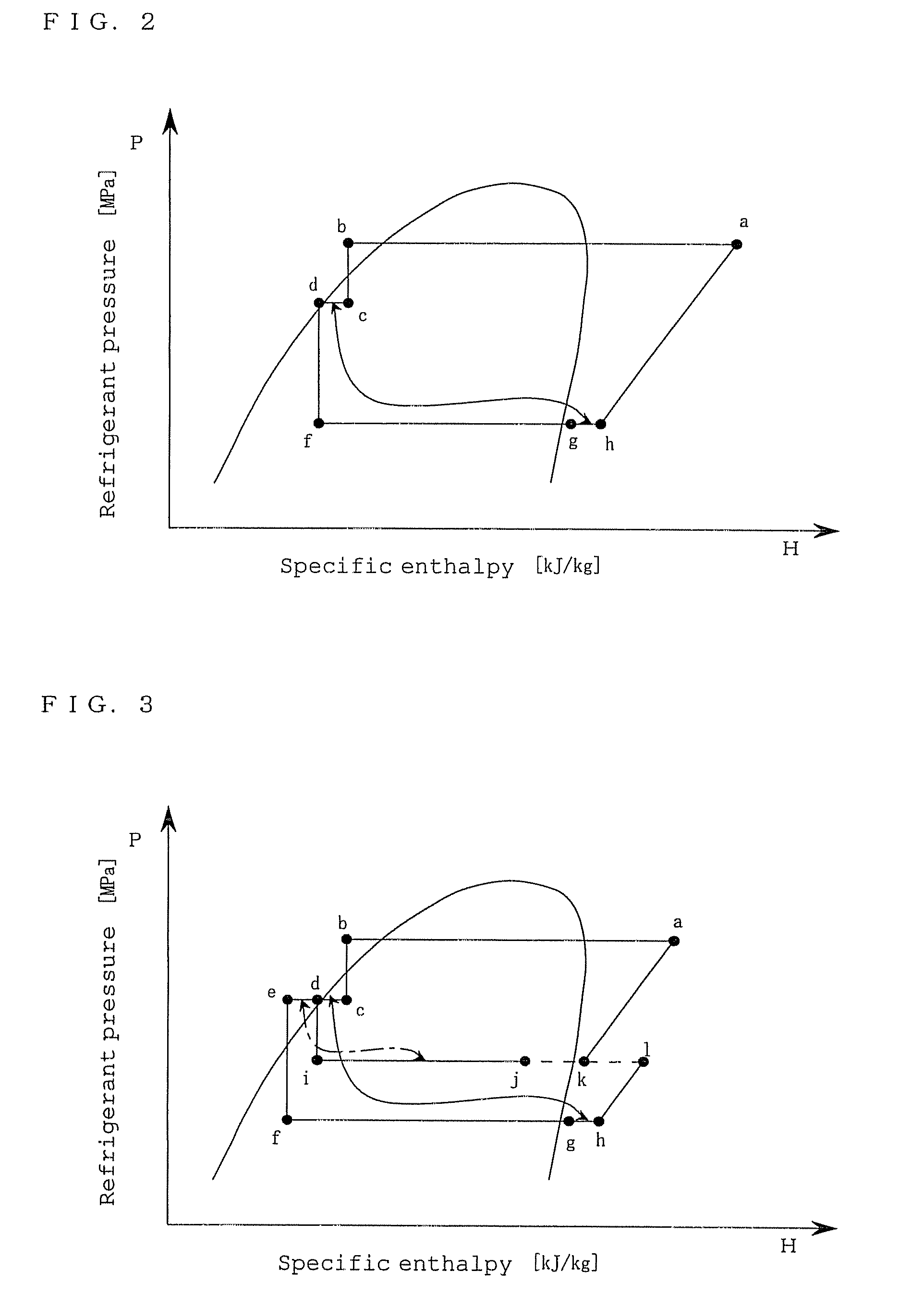

Refrigerator

InactiveUS20080190125A1Easy to controlReduce cooling efficiencyCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringTemperature difference

A high-pressure side discharge port of a two-stage compressor (12A) and a condenser (14A) are connected, condenser (14A) and a PMV (15A) are connected, a refrigerating side exit of PMV (15A) is connected to a medium pressure side suction port of two-stage compressor (12A) via an R capillary tube (16A) and an F evaporator (18A), connected to an F evaporator (26A) via an F capillary tube (24A), F evaporator (26A) is connected to a low-pressure side suction port of two-stage compressor (12A) via a low-pressure suction pipe (28A), PMV (15A) can switch a simultaneous cooling mode and a freezing mode, and in the simultaneous cooling mode, a refrigerant flow rate toward R evaporator (18A) is adjusted by PMV (15A), and thereby a temperature difference control is performed so as to make a difference between an entrance temperature and an exit temperature of R evaporator (18A) equal to a preset temperature difference (for example, 4° C.).A controller (22), on the basis of the detection condition of a temperature sensor (23) for a freezing chamber and a temperature sensor (24) for a refrigerating chamber, controls a freezing cycle device (10). Here, controller (22) controls an opening of a regulating valve (12) so as to make a superheat amount which is a difference between an exit temperature and an entrance temperature of a refrigerating evaporator (5) equal to a target superheat amount, and thereby adjusts a refrigerant flow rate to refrigerating evaporator (5) in a limited state.In this case, when a power is turned on, the entrance temperature and the exit temperature of refrigerating evaporator (5) are the same, so that controller (22), when the power is turned on, calibrates detected temperatures of an entrance temperature sensor (27) and an exit temperature sensor (26) so as to coincide with each other, and thereby can execute surely the subsequent limiting adjustment of regulating valve (12) on the basis of the superheat amount.Further, in this case, when a refrigerant supply to refrigerating evaporator (5) is stopped and the temperature of refrigerating evaporator (5) rises suddenly, controller 22 increases an opening of a valve opening (42) to refrigerating evaporator (5) of regulating valve (12) to a predetermined return value, so that the refrigerant supply amount to refrigerating evaporator (5) is increased at a stretch, and thus the refrigerating evaporator can be cooled quickly.A refrigerator having a two-stage compressor (12A) for cooling efficiently both a refrigerating chamber (2A) and a freezing chamber (5A) will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body so as to make a superheat amount of one evaporator appropriate on the basis of the superheat amount which is a difference between an exit temperature and an entrance temperature of one evaporator, a refrigerator for detecting accurately the entrance temperature and the exit temperature of one evaporator will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body, a refrigerator for causing no delay in a refrigerant supply to one evaporator will be provided.

Owner:TOSHIBA HA PROD +2

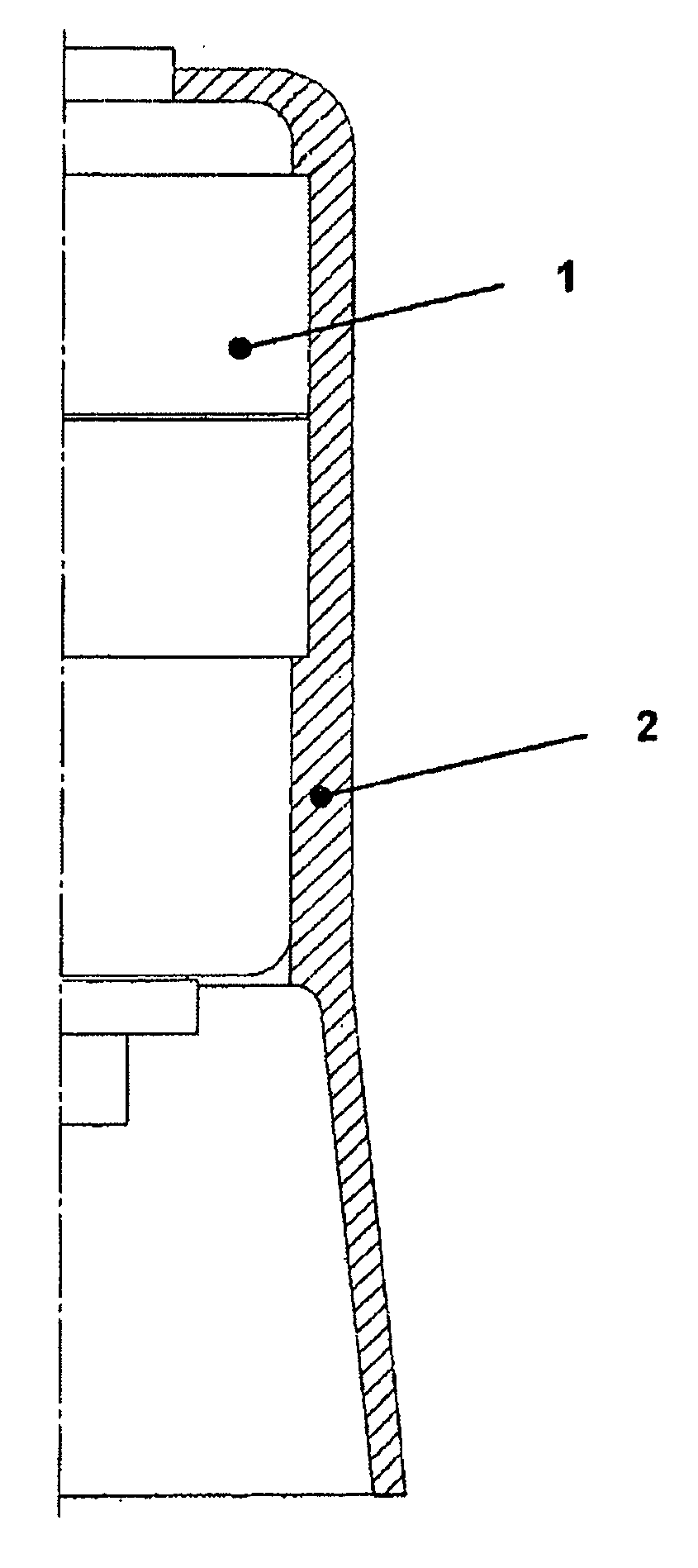

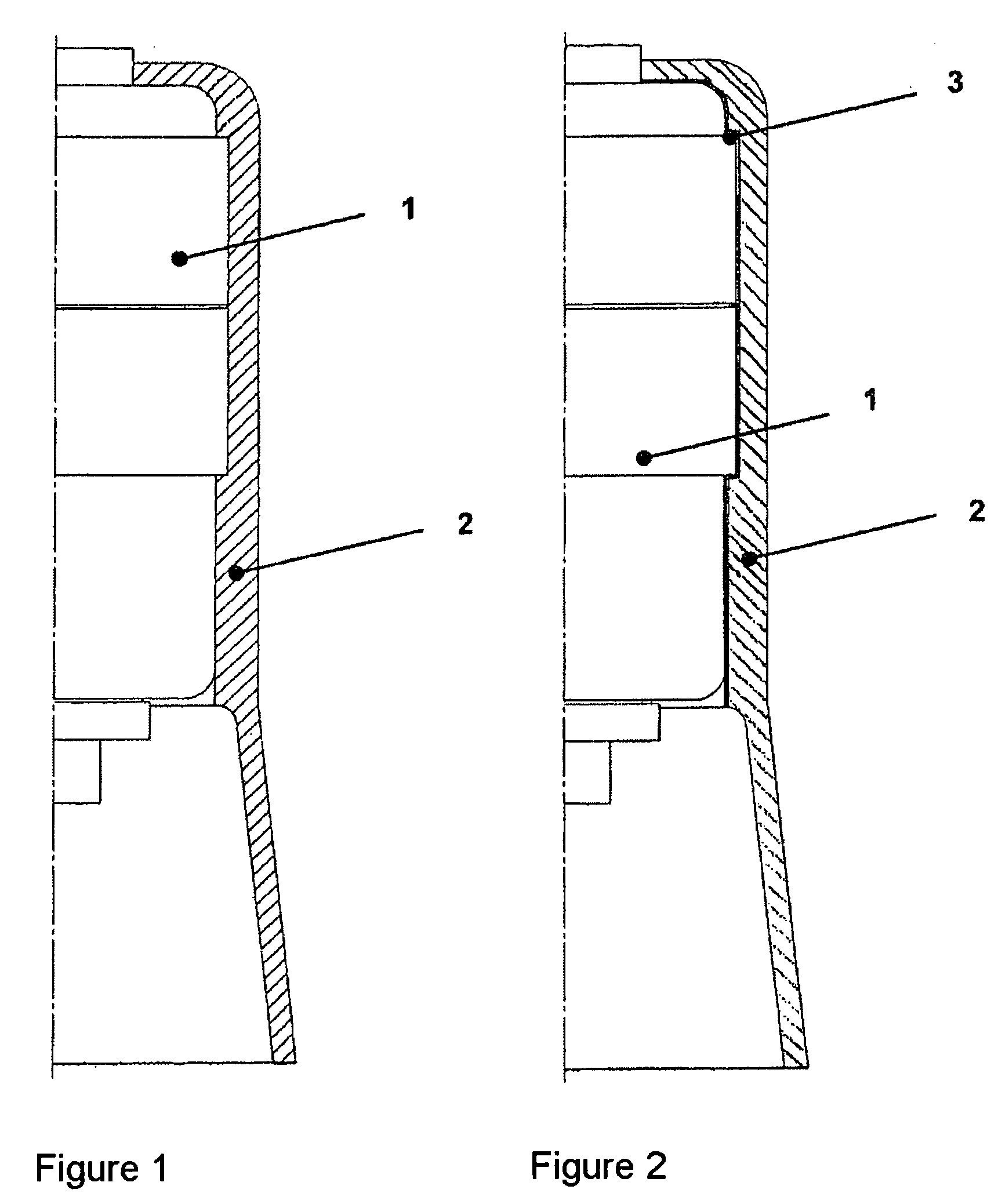

Method for producing breaker pole parts for low-voltage, medium-voltage and high-voltage switchgear assemblies, and breaker pole part itself

ActiveUS20080142485A1Meet the requirementsMouldsHigh-tension/heavy-dress switchesPlastic injection moldingLow voltage

The disclosure relates to a method for producing circuit-breaker parts and plastic components for low, medium and high-voltage switching stations and to a corresponding circuit-breaker part. To obtain a simpler method of production with a higher variance of material characteristics, the outer insulation sleeve is produced in a plastic injection molding method, in which a vacuum interrupter chamber is sheathed in plastic.

Owner:ABB (SCHWEIZ) AG

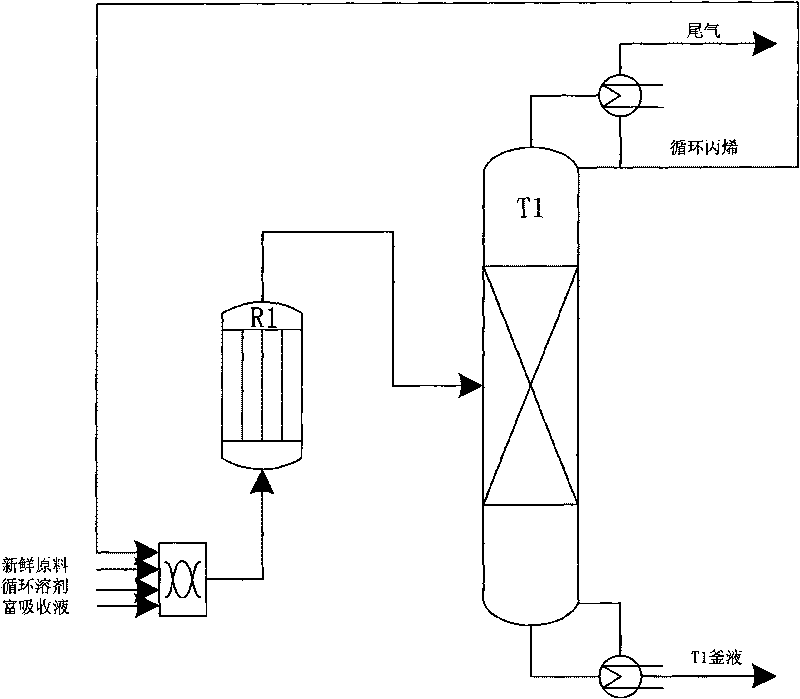

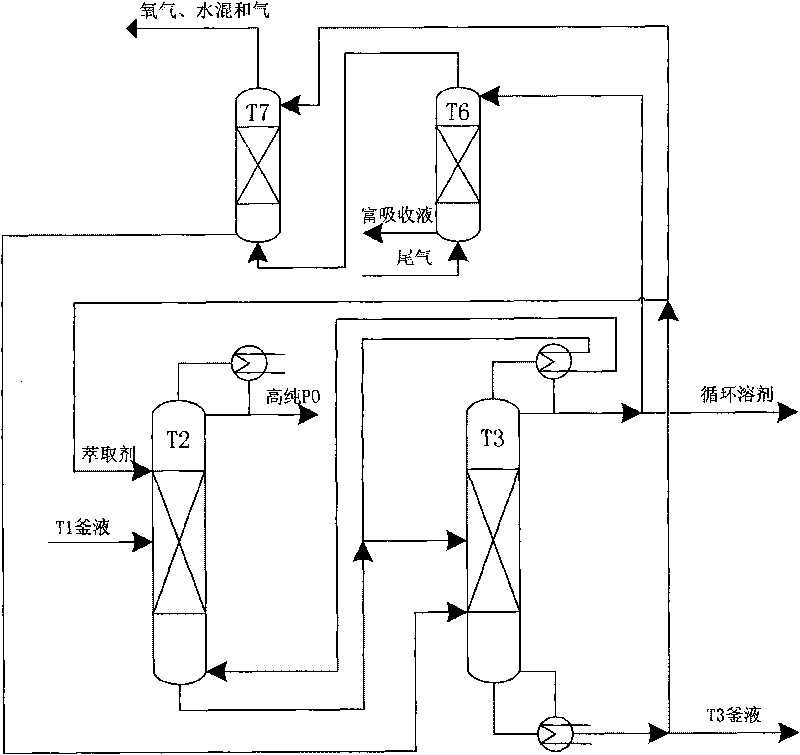

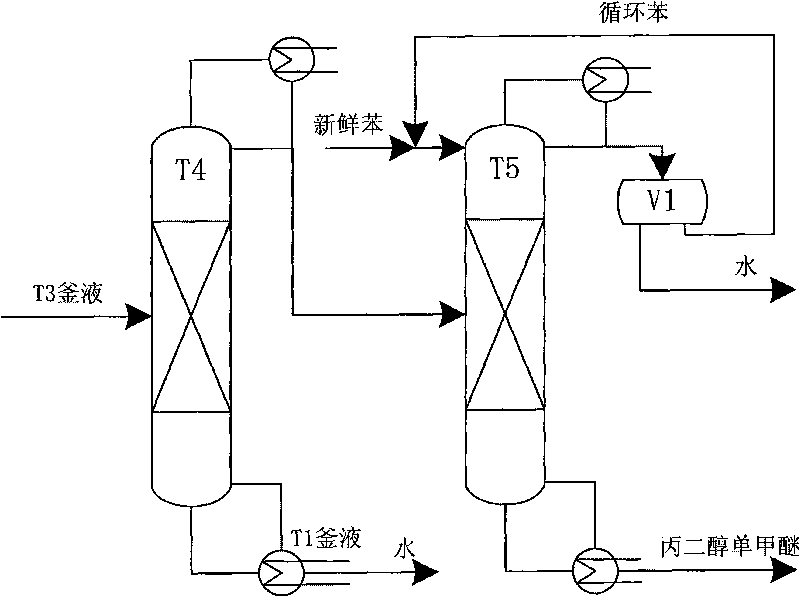

Energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene

InactiveCN101693703ASuitable for industrial productionEther separation/purificationChemical industryThermal energyExtractive distillation

The invention relates to an energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene, belonging to the field of petrochemical technology. The technique comprises a reaction part, a separation part and a tail gas treatment part, and is characterized in that propylene and hydrogen peroxide have an epoxidation reaction through a Ti-Si molecular sieve at medium pressure and low temperature; the propylene and solvent have higher recovery rate, the propane epoxide meeting the requirement of commercial-grade purity can be obtained by extractive distillation, and the joint product of propylene glycol monomethyl ether can be prepared by azeotropic distillation and purification; after part of tail gas is condensed and absorbed and the propylene is recovered, the tail gas reaches the standard and is discharged; extracting agent, absorbing agent and entrainer which are needed by the technique are in closed cycle in the process flow; and medium-pressure operation is adopted by a propylene tower to ensure water-cooling on the top of the tower, and thermal energy can be recovered by multiple-effect rectification and matching of streams. The technique has the effect and the advantage that the new energy-saving and environment-friendly technique for producing the propane epoxide can generate remarkable economic and social benefits.

Owner:DALIAN UNIV OF TECH

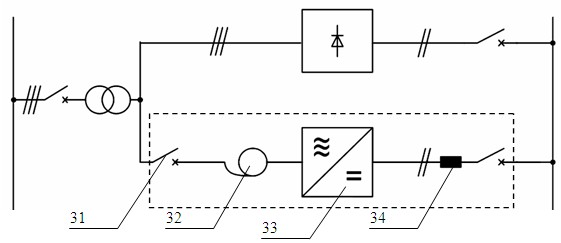

Method for tapping a high voltage transmission line and substation using the same

InactiveUS20050052801A1Non-enclosed substationsBus-bar/wiring layoutsElectricityElectrical conductor

A method of tapping a high voltage transmission line for input into a power distribution substation and system for the conversion of the tapped high voltage electricity to medium voltage electricity are disclosed. The method comprises the steps of dividing the transmission line and attaching the conductors to the primaries of at least two transformers via a series connected first disconnect switch, second disconnect switch and circuit breaker. A bus interconnects the first disconnect switch and the second disconnect switch and the bus of the first transformer bay is connected to the bus of the second transformer bay using a circuit breaker. The system comprises an insulator dividing the transmission line into separate conducting lines and attaching them to the primaries of at least two transformers via a series connected first disconnect switch, second disconnect switch and circuit breaker. A bus interconnects the first disconnect switch and the second disconnect switch and the bus of the first transformer bay is connected to the bus of the second transformer bay using a circuit breaker. The secondaries of said power transformer output the medium voltage electricity.

Owner:GHALI GAMAL A

Heat pump type hot water supply outdoor apparatus

ActiveUS20090241569A1High hot water supply/heating capabilityHighly effective hot water supply/heating operationMechanical apparatusCompression machines with non-reversible cyclePlate heat exchangerCondensation temperature

A heat pump type hot water supply outdoor apparatus, in a compressor, a water heat exchanger, a first expansion valve, a medium pressure receiver, a second expansion valve, and an air heat exchanger are connected circularly, has an injection circuit, which is a bypass for a part of the refrigerant between the medium pressure receiver and the second pressure reduction unit, to inject the part of refrigerant into a compression chamber of the compressor, and has a third expansion valve and an internal heat exchanger for carrying out heat exchange between the refrigerant whose pressure is reduced by the third expansion valve and the refrigerant between the medium pressure receiver and the second expansion valve, a pressure detection sensor for detecting a condensing pressure, and a controller for starting an injection control by the third expansion valve at the time when the condensing pressure detected by the pressure sensor or the condensing temperature calculated from the condensing pressure becomes a first predetermined value or more and stopping the injection control at the time when the condensing pressure or the condensing temperature becomes a second predetermined value which is smaller than the first predetermined value, or less. With this arrangement, an appropriate injection control can be realized and a high hot water supply / heating capability operation can be carried out.

Owner:MITSUBISHI ELECTRIC CORP

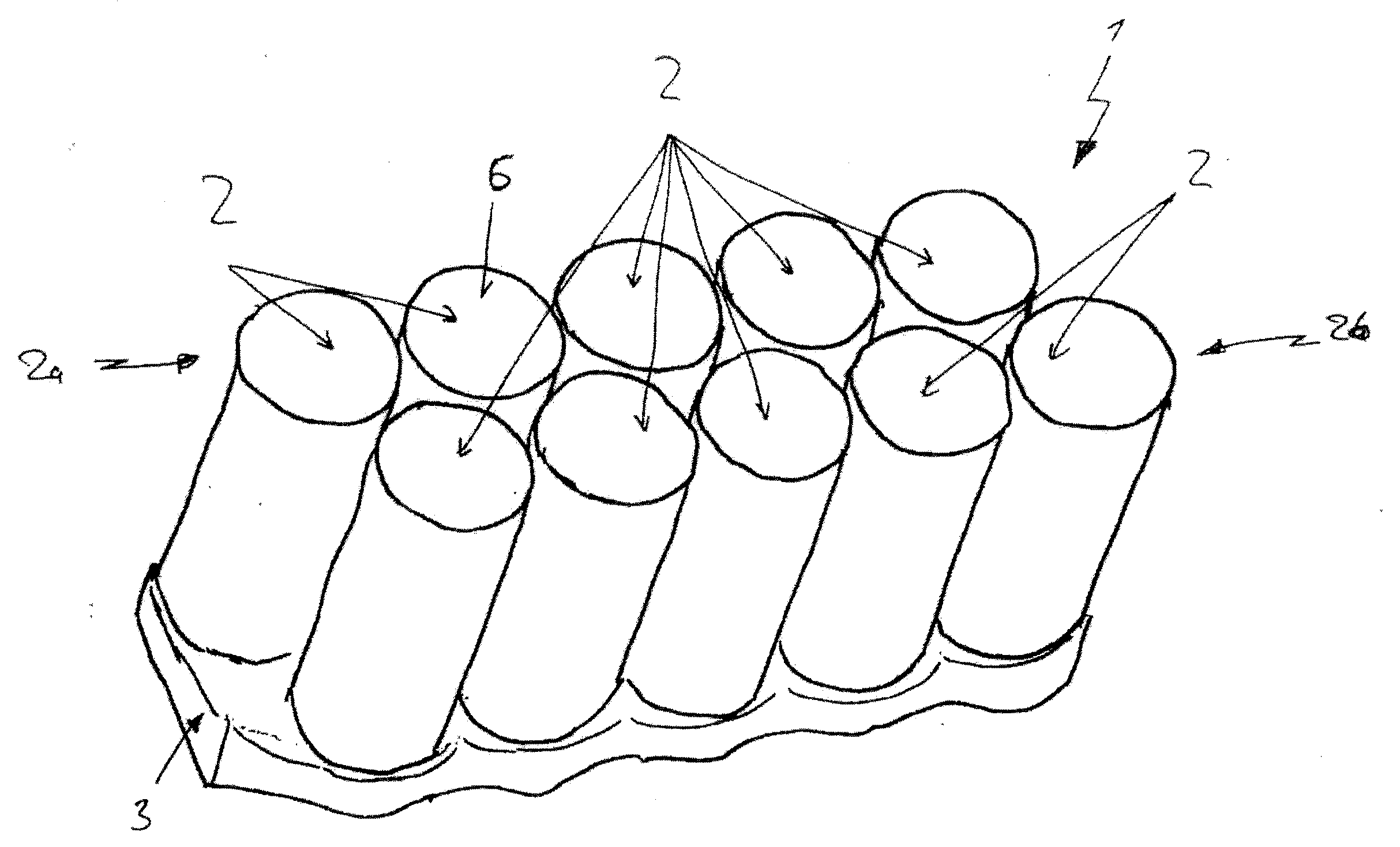

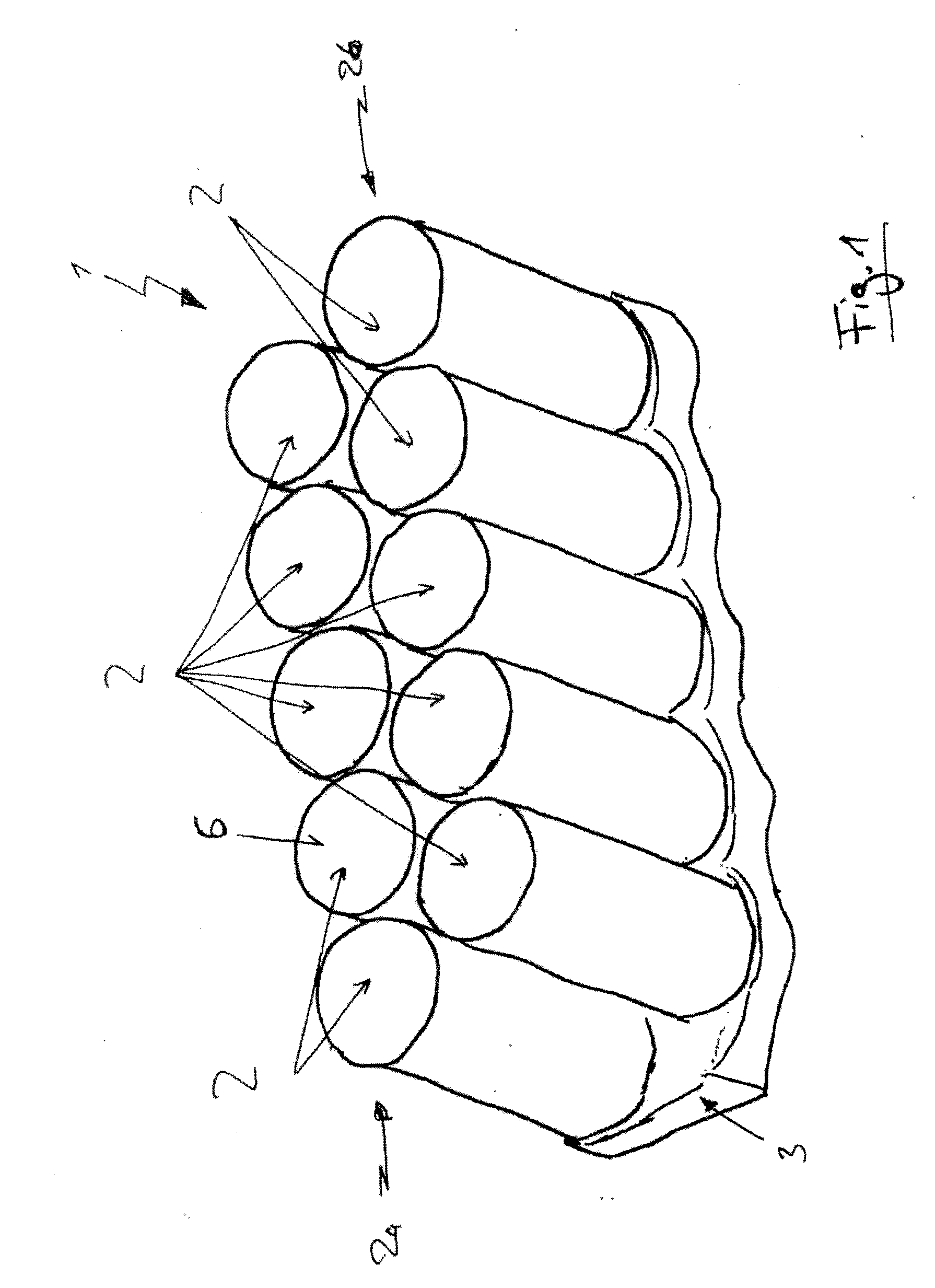

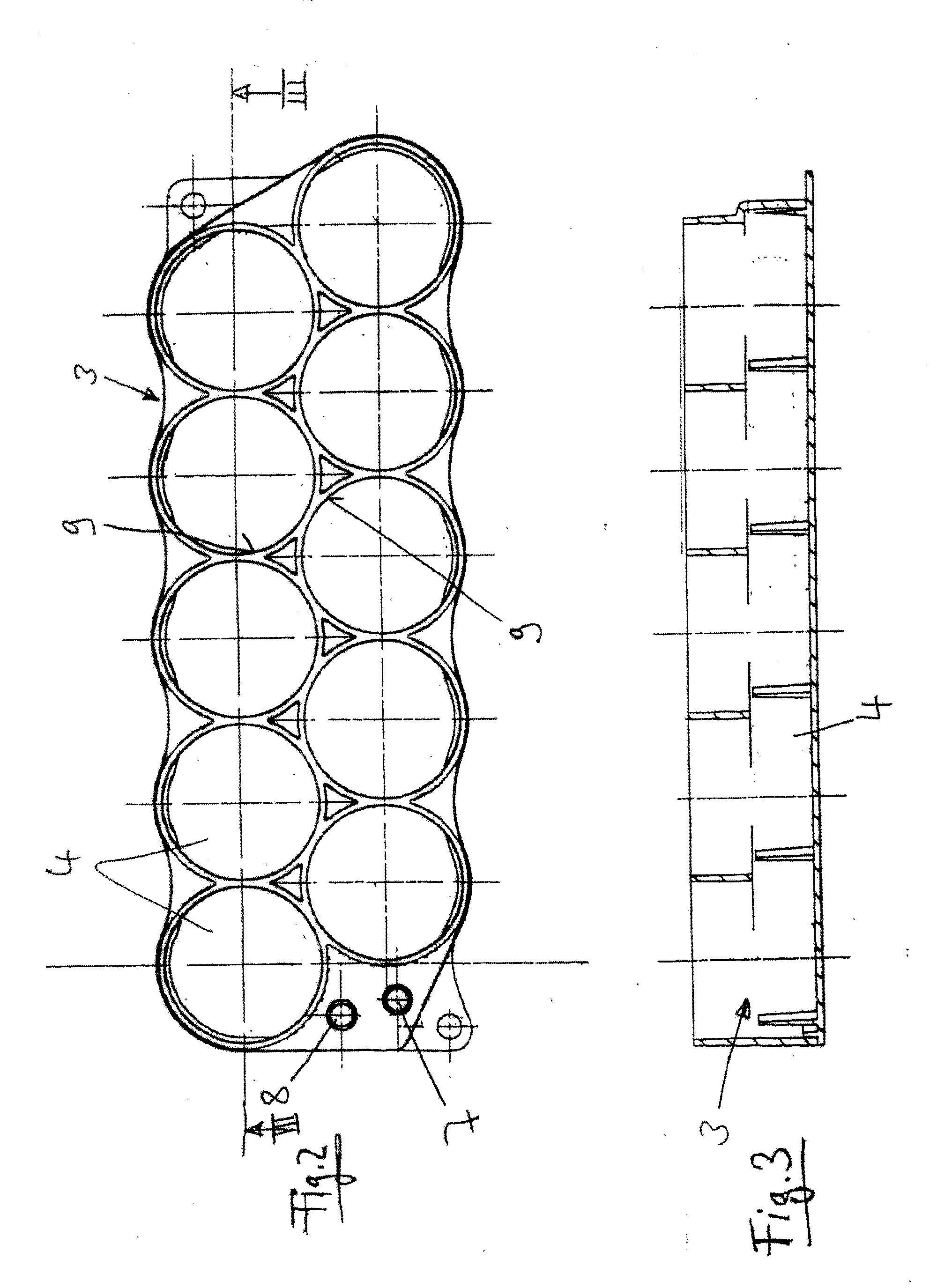

Liquid-Cooled Battery and Method for Operating Such a Battery

InactiveUS20090220850A1Cool down the emerging mediaImprove operating characteristicsSecondary cells charging/dischargingSecondary cell gas removalEngineeringElectrical drive

A liquid-cooled battery, in particular in the form of an energy store for an electrical drive in a motor vehicle is provided. The battery has a plurality of storage cells 2 and at least one volume 4 which makes thermally conductive contact with the storage cells 2 and through which a cooling medium can flow. Each of the storage cells 2 has a safety valve 12 which opens the storage cell when a predetermined media pressure in it is exceeded, and connects the volume of the storage cell to the surrounding area. The safety valve 12 is arranged in the storage cell 2 and the storage cell 2 is arranged with respect to the volume 4 through which the cooling medium can flow such that a connection is produced between the volume 4 through which the cooling medium can flow, and the interior of the storage cell 2 if the safety valve 2 is operated.

Owner:DAIMLER AG

Pre-charging an inverter using an auxiliary winding

A transformer module includes a main primary winding coupled to a first input power source to receive a medium voltage signal, multiple main secondary windings each to couple to a power cell of a drive system, and an auxiliary primary winding coupled to a second input power source to receive a low voltage signal. The auxiliary primary winding can be spatially separated from the main windings to increase leakage inductance. The auxiliary primary winding can be active during a pre-charge operation to pre-charge the power cells.

Owner:TECO WESTINGHOUSE MOTOR

Ultraviolet-light-based disinfection reactor

InactiveUS6940075B2Reduced-area throat sectionWater treatment parameter controlWater/sewage treatment by irradiationFiltrationUltraviolet lights

Owner:CALGON CARBON

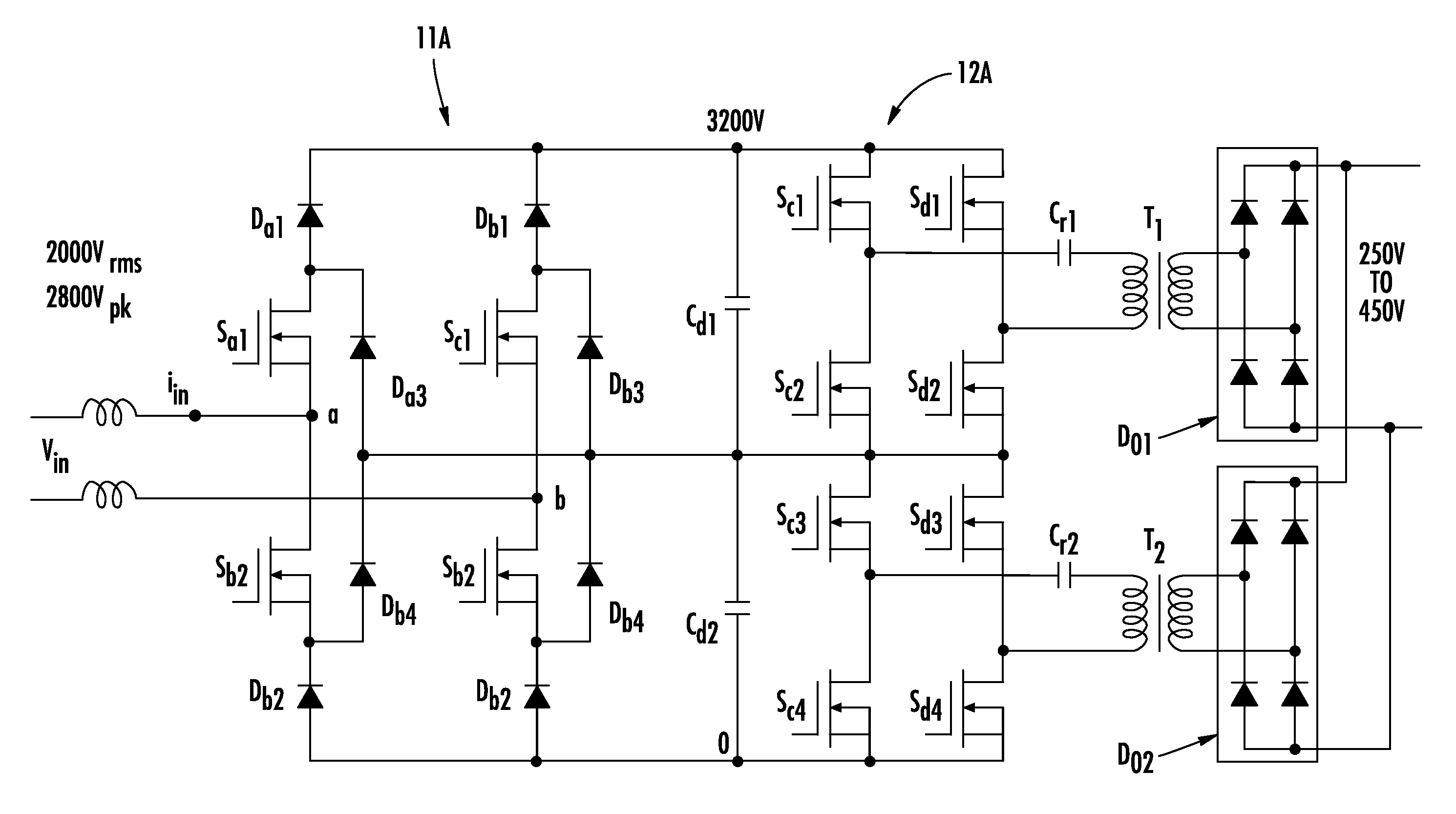

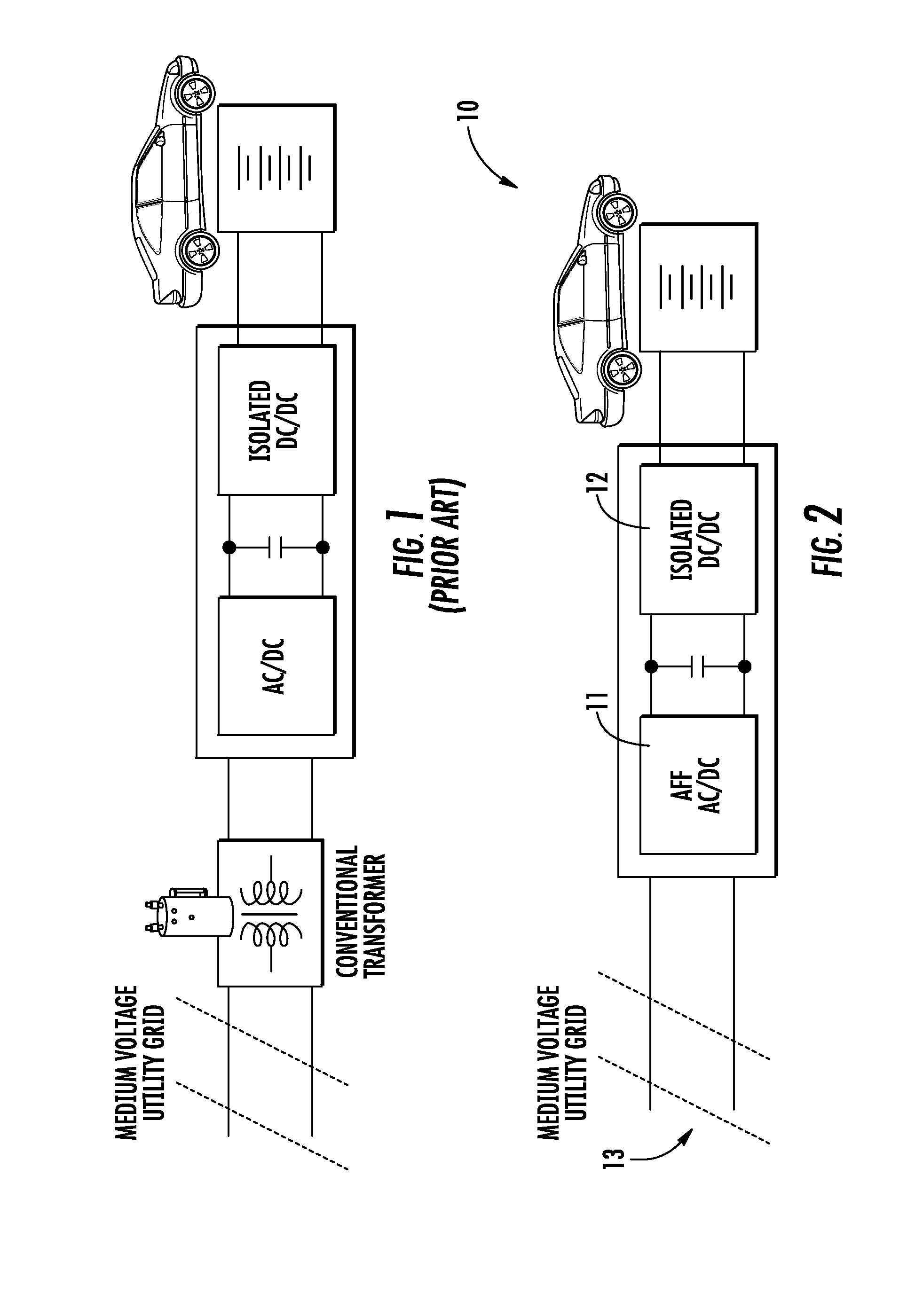

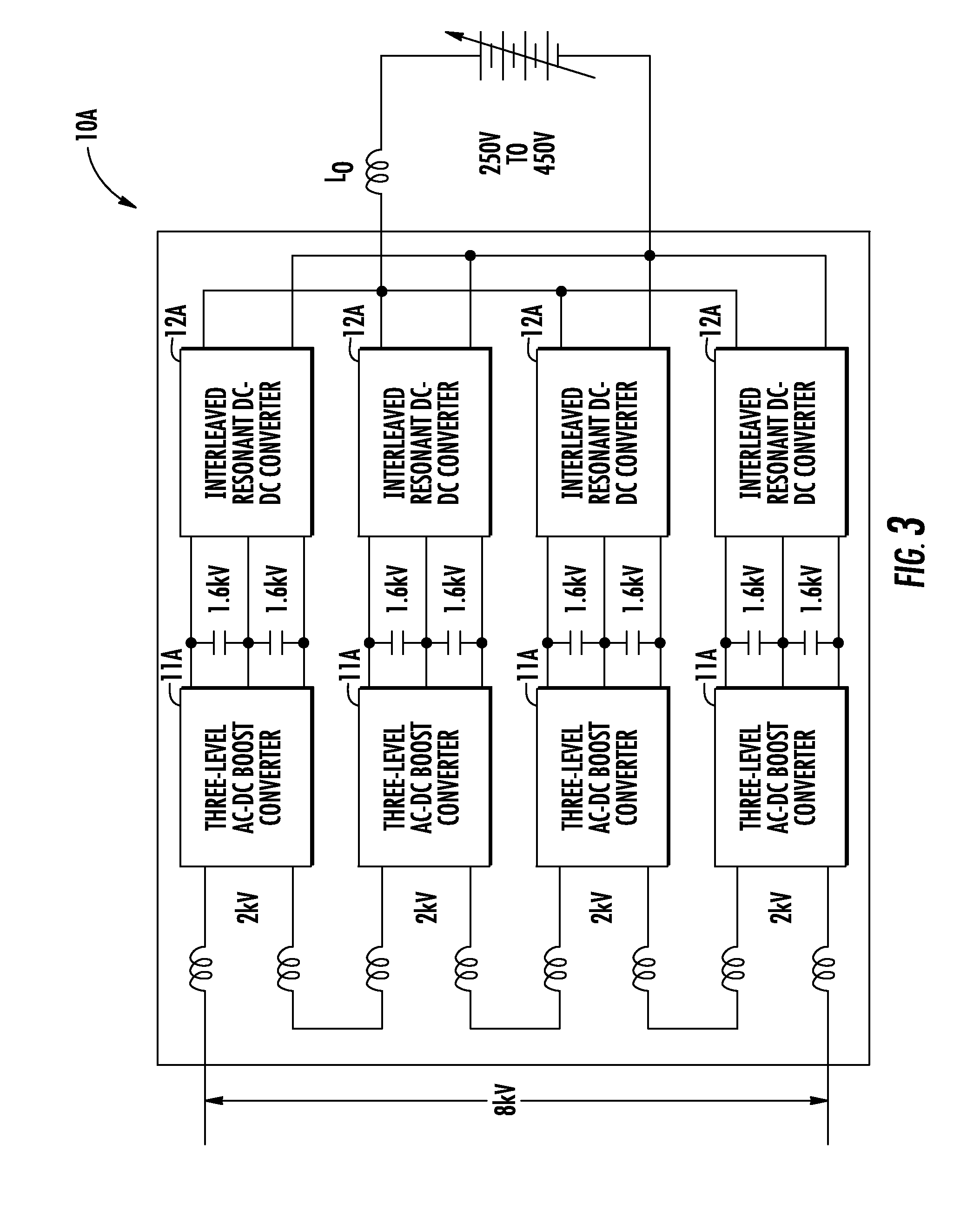

Medium voltage stand alone DC fast charger

InactiveUS20130134935A1Improve efficiencyFast chargingBatteries circuit arrangementsCharging stationsLow voltageFast charging

An apparatus for DC fast charging of an electric vehicle includes an active front end AC-DC converter and an isolated DC-DC converter. The active front end AC-DC converter is adapted to rectify a medium voltage alternating current (AC) from a utility grid to a high voltage direct current (DC). The isolated DC-DC converter is adapted to transform the high voltage DC to a low voltage DC for charging the electric vehicle.

Owner:ELECTRIC POWER RES INST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com