Patents

Literature

543results about How to "Realize stepless adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

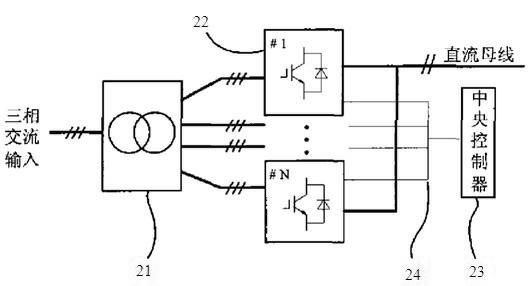

An energy-feedback type traction power supply device and its control method

ActiveCN102267405ARealize stepless adjustmentInjected harmonics are smallPower supply linesSingle network parallel feeding arrangementsTransformerLow voltage

The invention discloses an energy feeding type dragging power supply device and a control method thereof. The energy feeding type dragging power supply device comprises a multiple transformer and at least two four-quadrant converter modules. The energy feeding type dragging power supply device and a diode rectification dragging unit are arranged in parallel form. A primary side of the multiple transformer of the energy feeding type dragging power supply device is connected to an alternated current medium-voltage power grid through a high-voltage switch cabinet; each set of windings at a low-voltage side of the multiple transformer is connected to an alternated current side of one four-quadrant converter module; and the direct current sides of the four-quadrant converter modules are in parallel connection after being connected to a direct current side isolation switch and are connected to a direct current bus through a direct current switch cabinet and a cathode cabinet. The energy feeding type dragging power supply device can work at three different modes of dragging, feedback or SVG (Scalable Vector Graphics) according to the requirements. The energy feeding type dragging power supply device is compatible with an existing dragging power supply system under the condition of meeting a power grid compatibility demand. The energy feeding type dragging power supply device has the advantages of moderate cost, capability of solving the technical problems of feeding back a regenerated braking energy and stabilizing a dragging network voltage, and real-time static reactive power compensation capacity.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

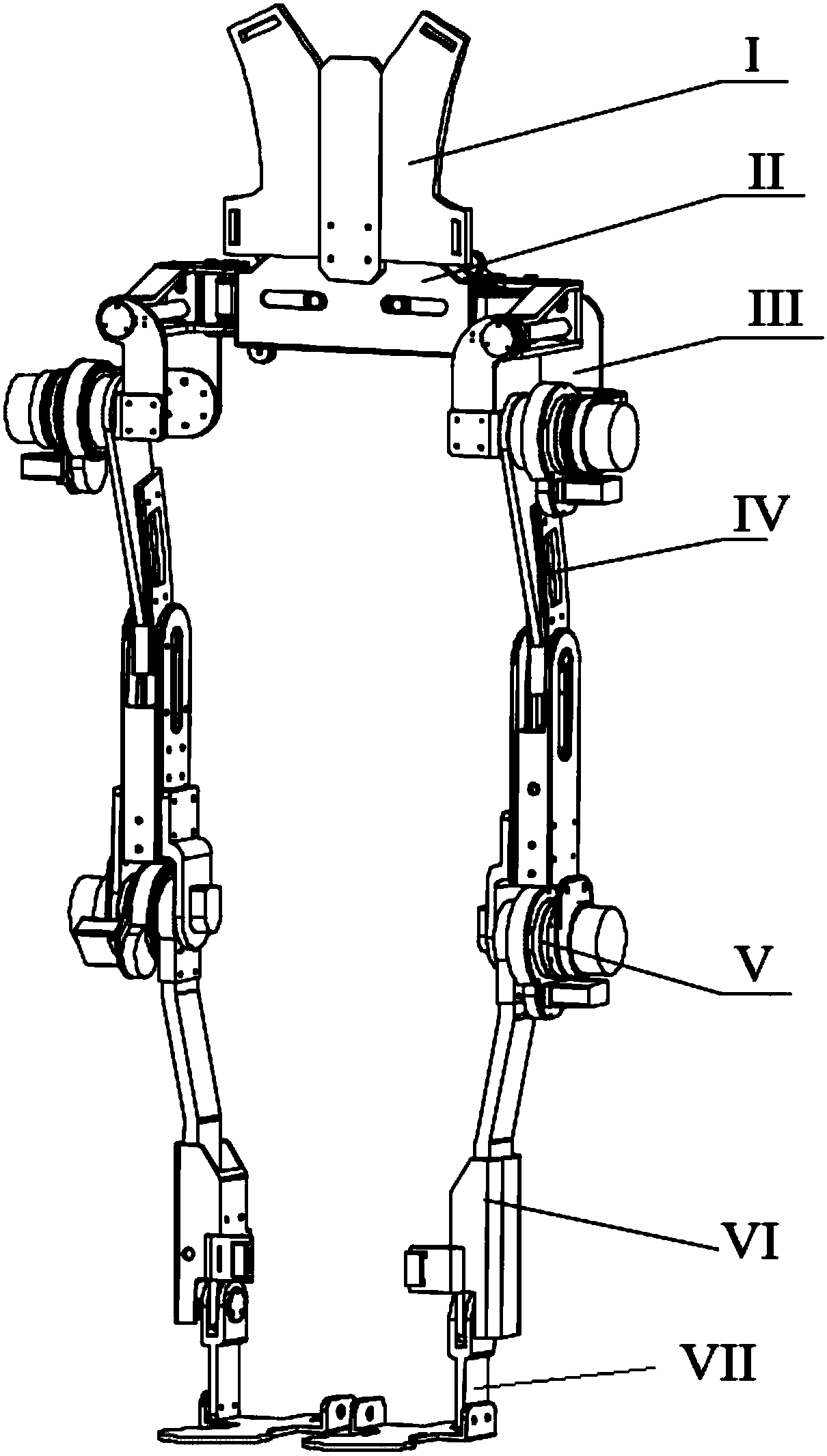

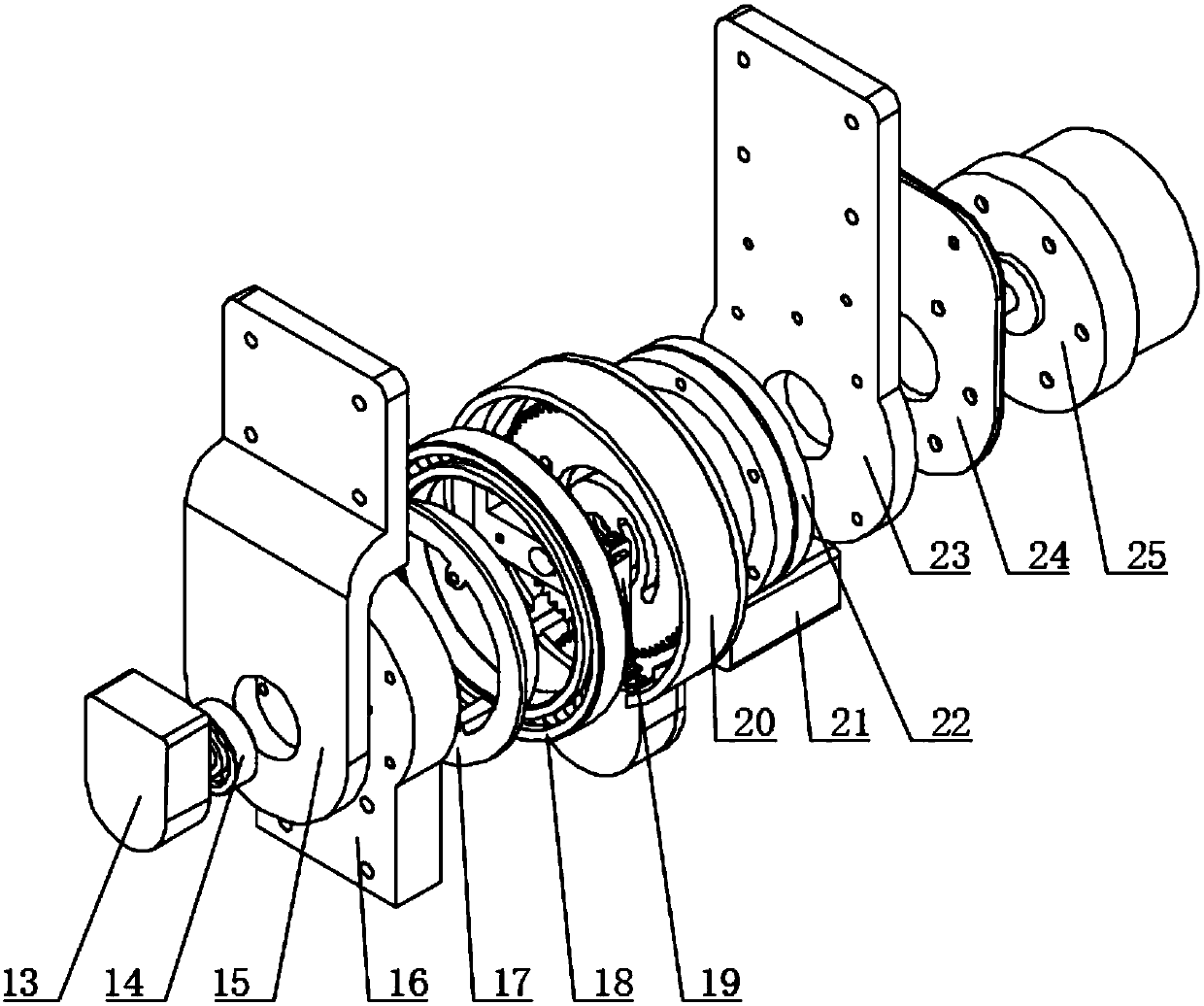

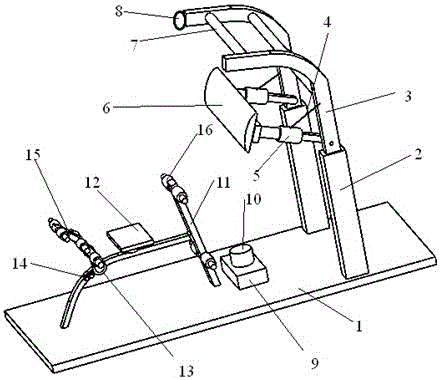

Variable stiffness lower limb external skeleton robot

ActiveCN107773384ASmooth movementAdaptableProgramme-controlled manipulatorChiropractic devicesVariable stiffnessThigh

The invention discloses a variable stiffness lower limb external skeleton robot which comprised a back plate, a flexible waist adjusting mechanism, hip joint mechanisms, thighs, knee joint mechanisms,shanks, ankle joint mechanisms, two driving degrees of freedom and three driven degrees of freedom. A driving control system is arranged on the back plate, the flexible waist adjusting mechanism is fixed with the back plate and connected with the thighs through the hip joint mechanisms, and the thighs are connected with the shanks and the ankle joint mechanisms through the knee joint mechanisms.According to the variable stiffness lower limb external skeleton robot, driving is performed by the aid of a variable stiffness driver, so that the robot is smooth in movement and high in safety, physical structures of lower limbs of human bodies can be effectively fitted by the aid of the two driving degrees of freedom and the three driven degrees of freedom, length adjusting mechanisms are arranged at the waists, the thighs and the shanks, so that the robot can adapt to physical sizes of different users, and the robot is wearable and has flexibility in the movement by the aid of the flexiblewaist adjusting mechanism. The robot can be applied and popularized in aspects of rehabilitation training, boosting and the like.

Owner:WUHAN UNIV

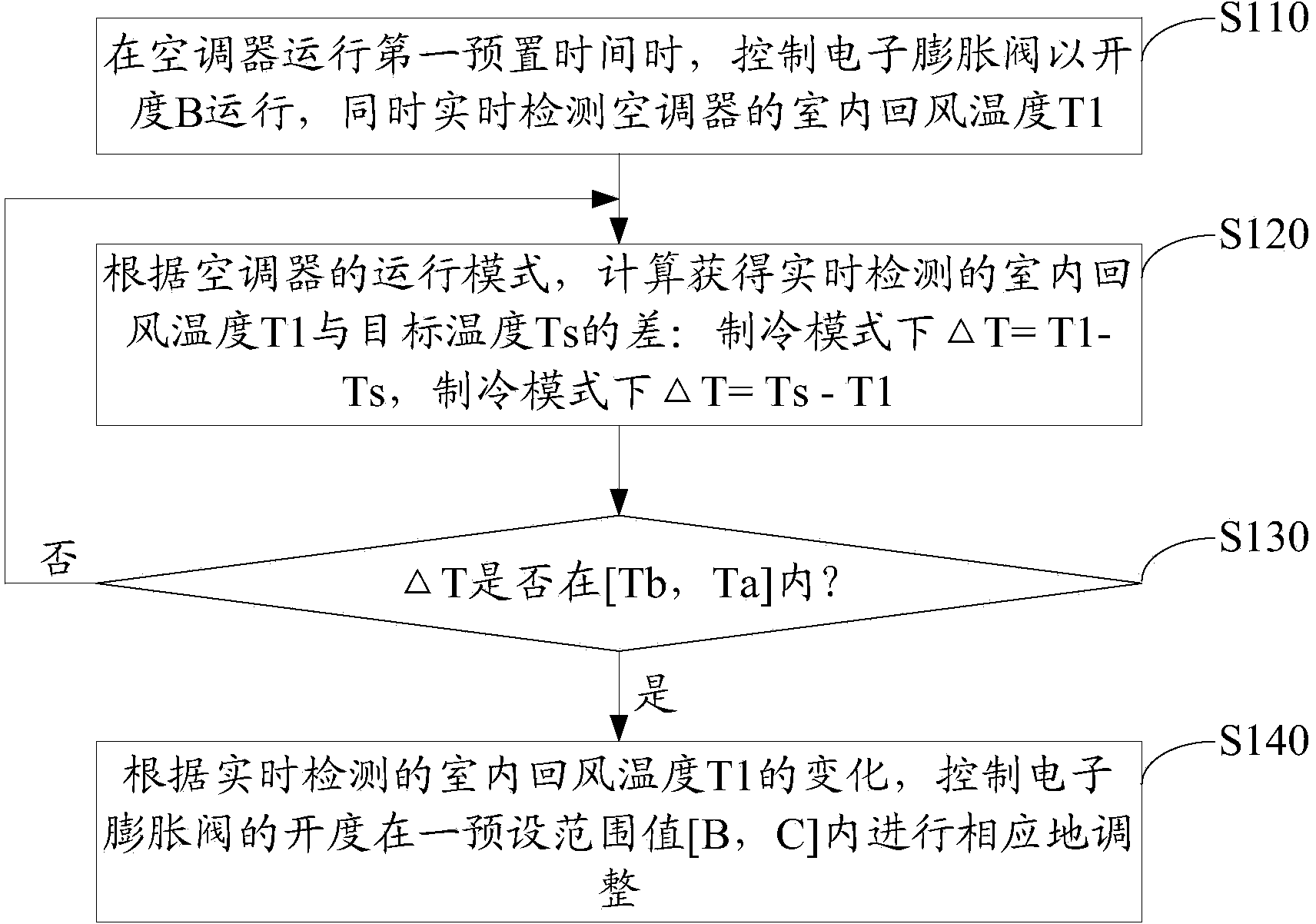

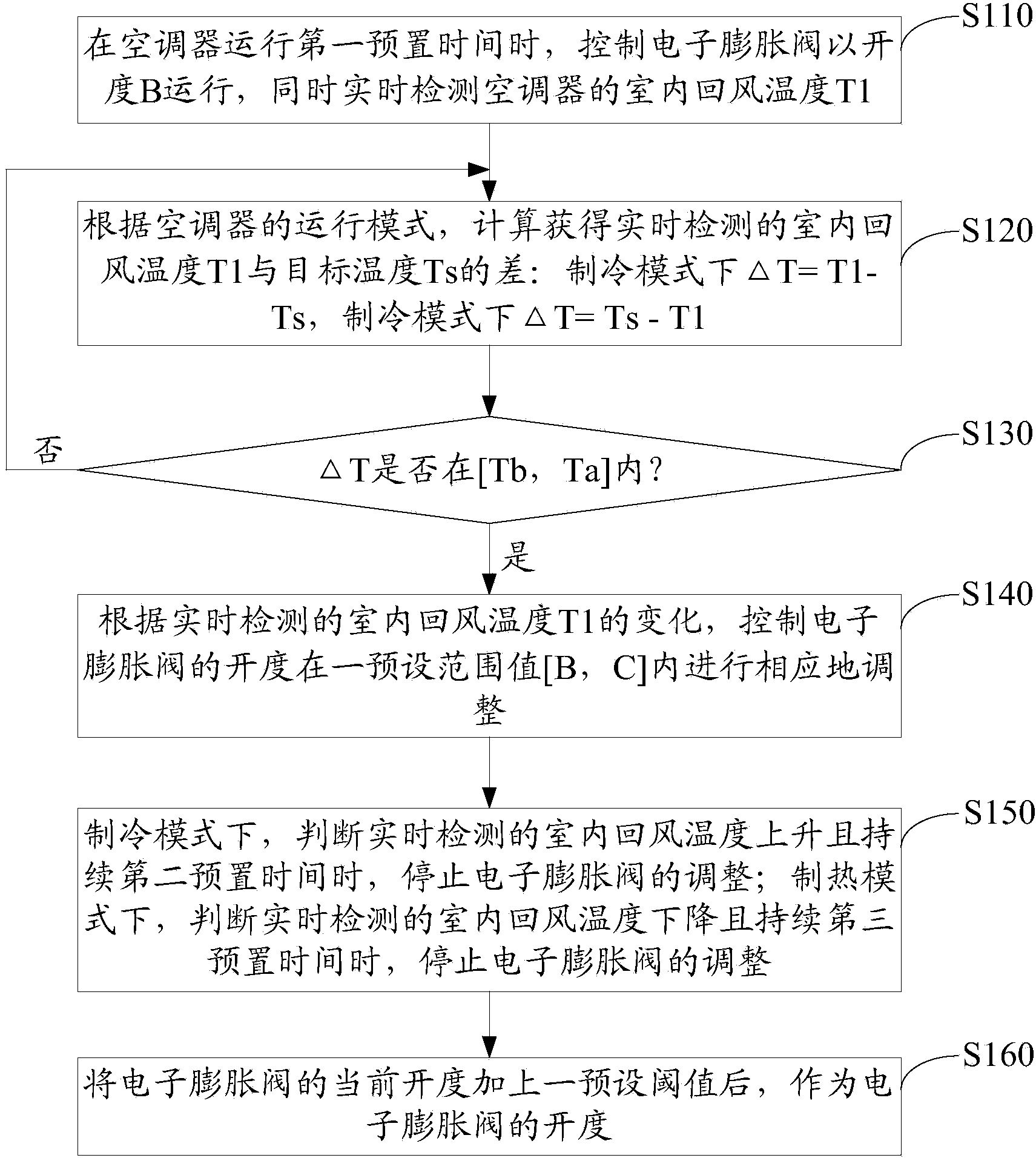

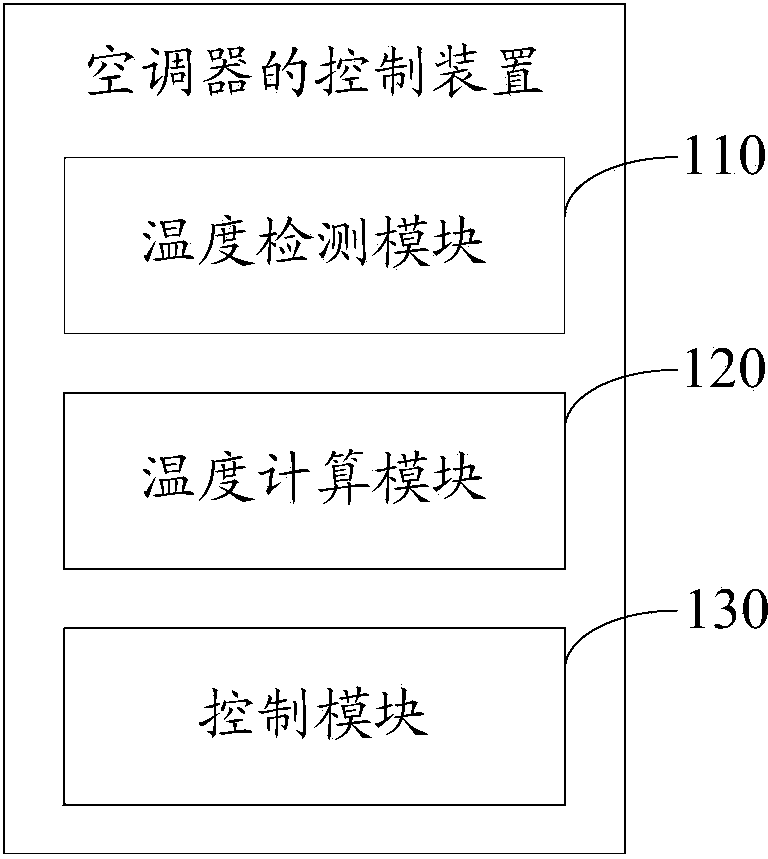

Air conditioner control method and device

ActiveCN103486689ASolve the phenomenon of frequent start and stopSmall temperature fluctuationsSpace heating and ventilation safety systemsLighting and heating apparatusOperation modeRefrigeration

The invention discloses an air conditioner control method. The method includes the steps: when an air conditioner operates for a first preset time, controlling an electronic expansion valve to operate with opening B, and starting to detect indoor return air temperature T1 of the air conditioner in real time; according to an operation mode of the air conditioner, calculating a difference between the indoor return air temperature T1 detected in real time and target temperature Ts; in a refrigeration mode, enabling Delta T=T1-TS, and in a heating mode, enabling Delta T=Ts-T1; judging when the Delta T is within a range of [Tb, Ta], controlling the opening of the electronic expansion valve to be correspondingly regulated within a preset range value [B, C] according to changes of the indoor return air temperature detected in real time. The invention further discloses an air conditioner control device. By the method and device, the problem that a compressor of a fixed frequency air conditioner starts and stops frequently is solved, stepless regulation of refrigerating capacity or heating capacity is solved, and temperature fluctuation of a room with a variable frequency air conditioner is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

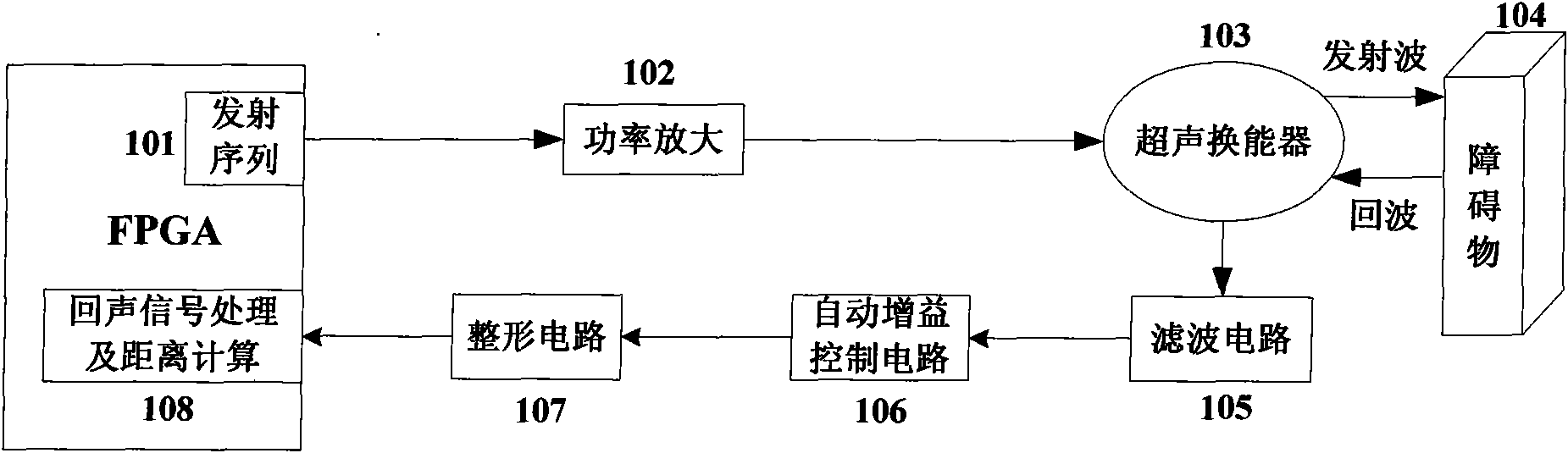

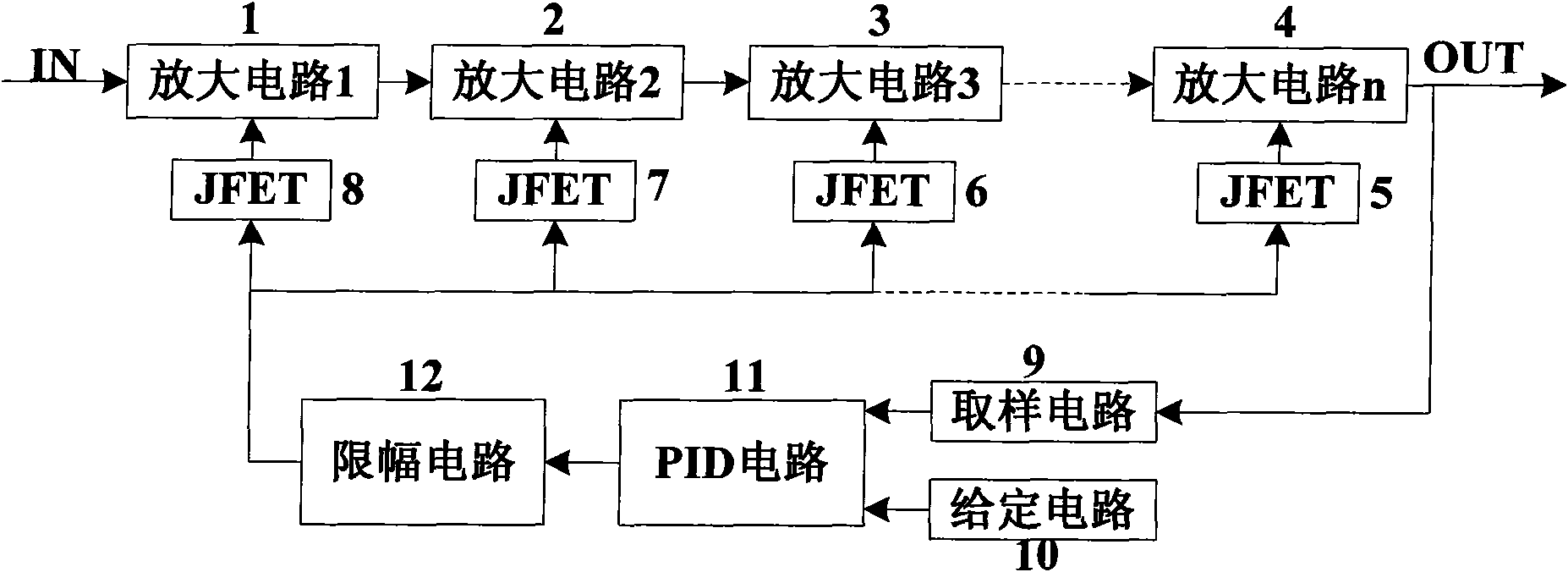

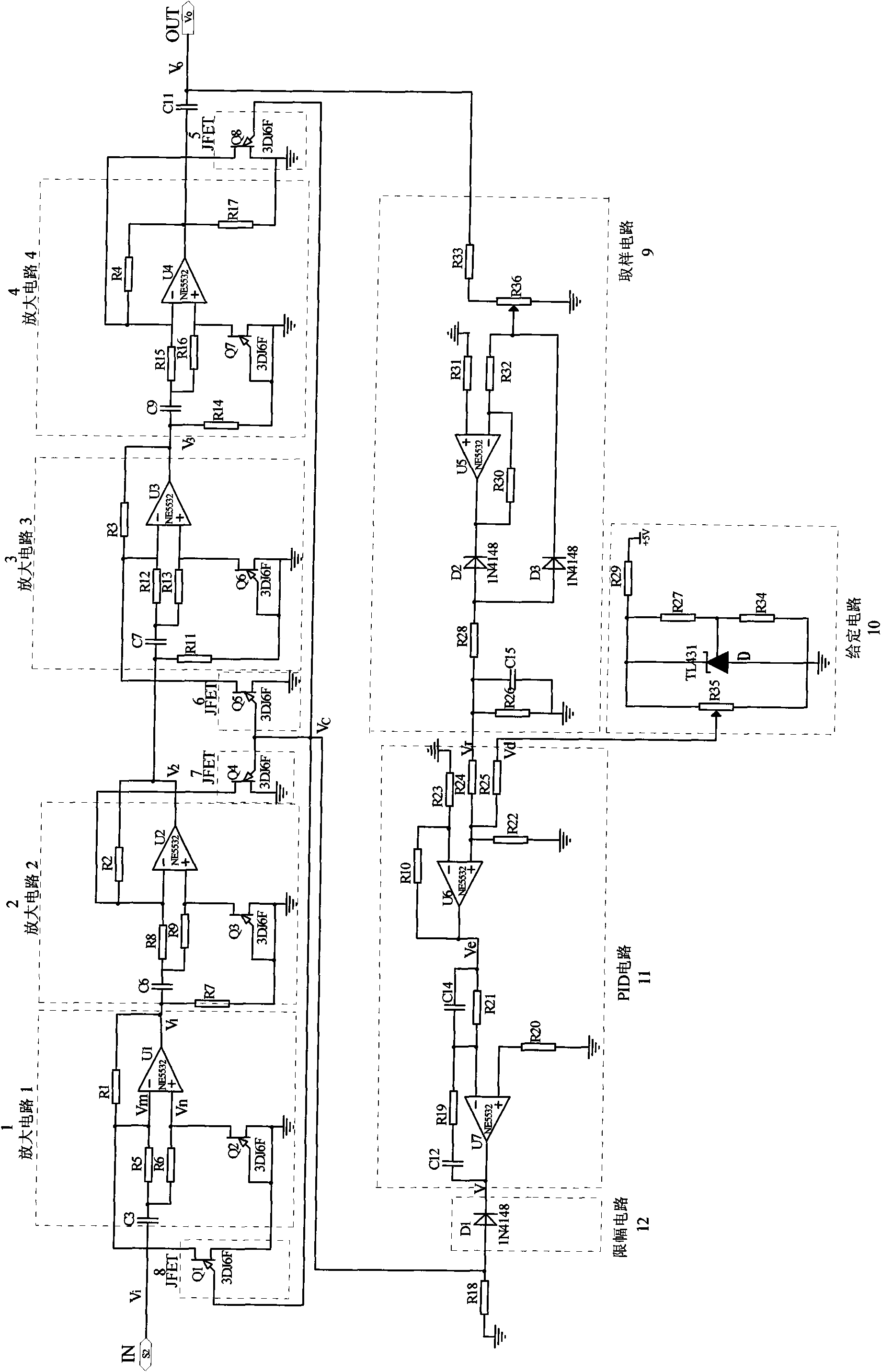

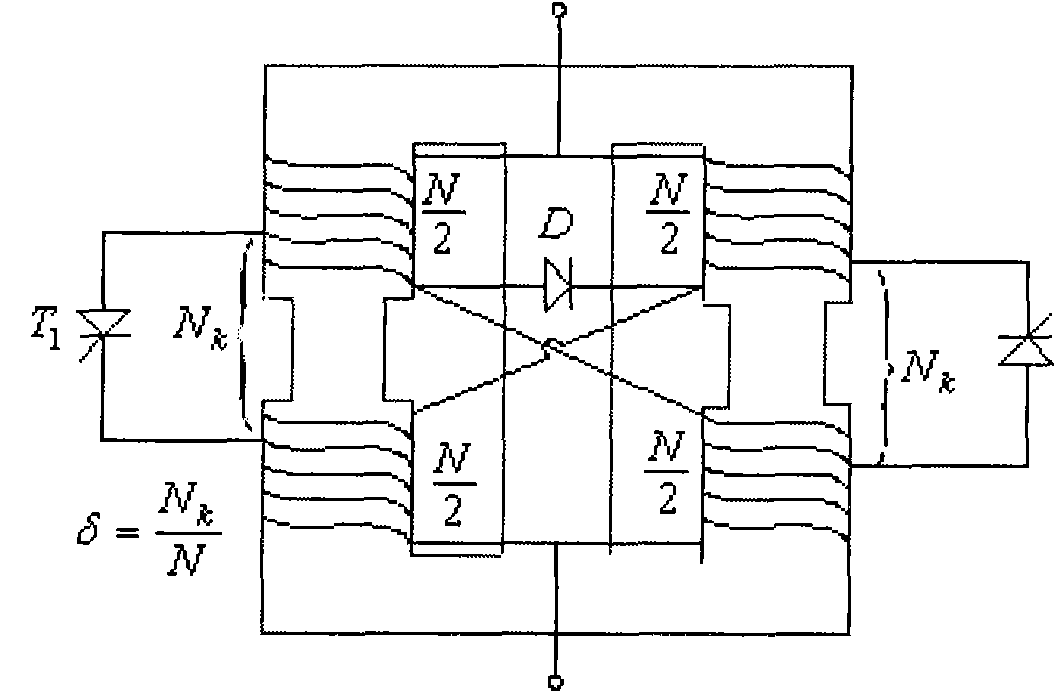

Automatic gain control circuit of multistage high dynamic range used in ultrasonic distance measurement

InactiveCN101557204AImprove dynamic rangeRealize stepless adjustmentGain controlAcoustic wave reradiationSonificationAudio power amplifier

The invention relates to an automatic gain control circuit of multistage high dynamic range used in an ultrasonic distance measurement, which comprises n stages of sequentially and serially connected amplifying circuits; the input terminal of a first stage is connected with an input signal; the nth output forms an output signal which goes through sequentially a serially connected sampling circuit, a PID circuit and an amplitude limiter circuit, and then is respectively connected with each technotron; and the signal input terminal of the PID circuit is also connected with a given circuit. Each stage of amplifying circuit comprises an operational amplifier, non-inverting input terminals and inverting input terminals of all the operational amplifiers are respectively connected with the drain electrode of one technotron, the source electrode of each technotron is grounded, the grid electrode of the technotron connected with the inverting input terminal of the operational amplifier is connected with the output terminal of the amplitude limiter circuit, and the grid electrode of the technotron connected with the non-inverting input terminal of the operational amplifier is grounded. The control circuit can lead the amplification times to be stabilized in a given value. Simultaneously, the dynamic range is improved by adopting multistage amplification, and the gain is controlled by adopting a voltage controlled resistor so as to lead the gain to be stepless adjustable.

Owner:TIANJIN UNIV

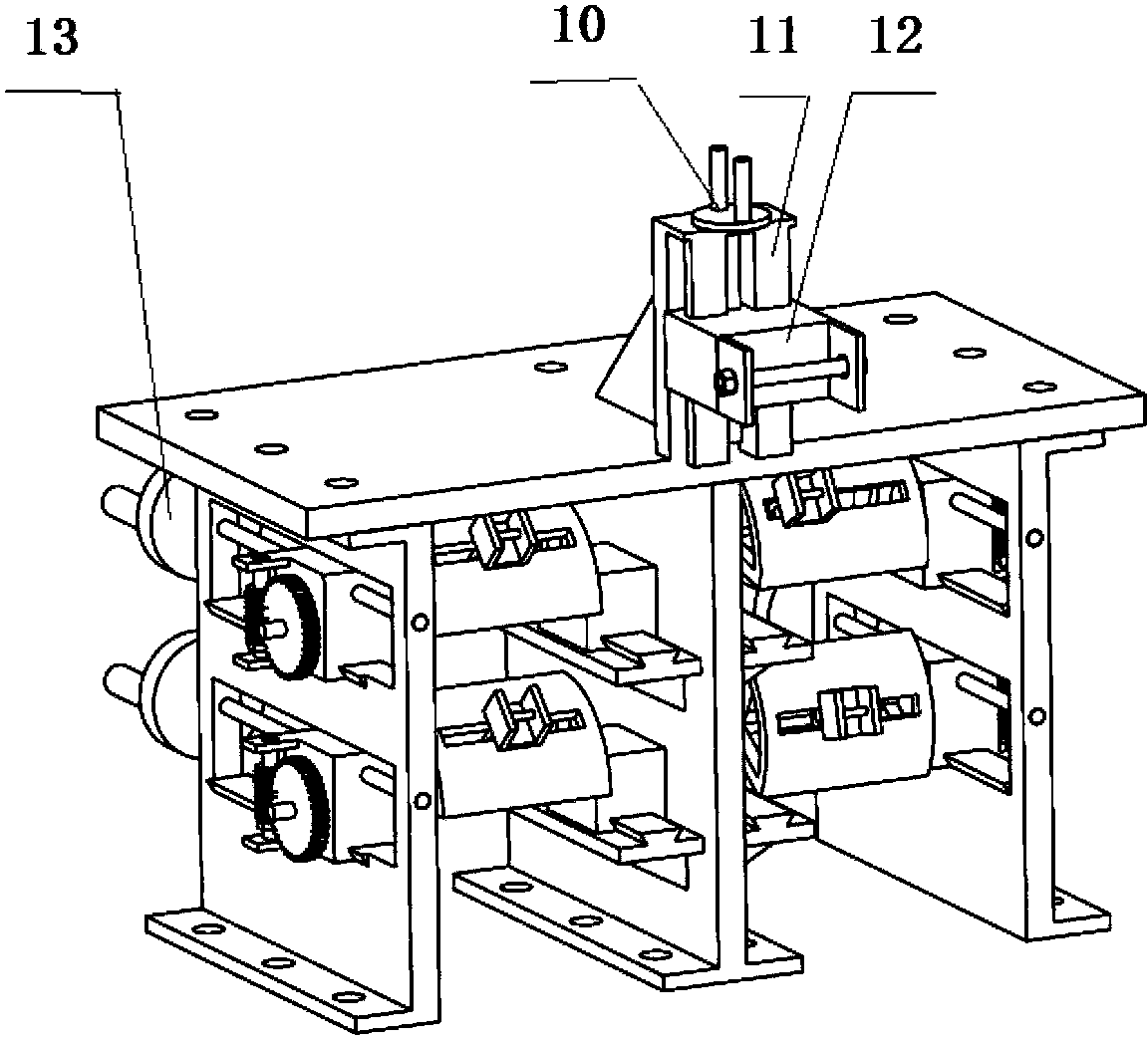

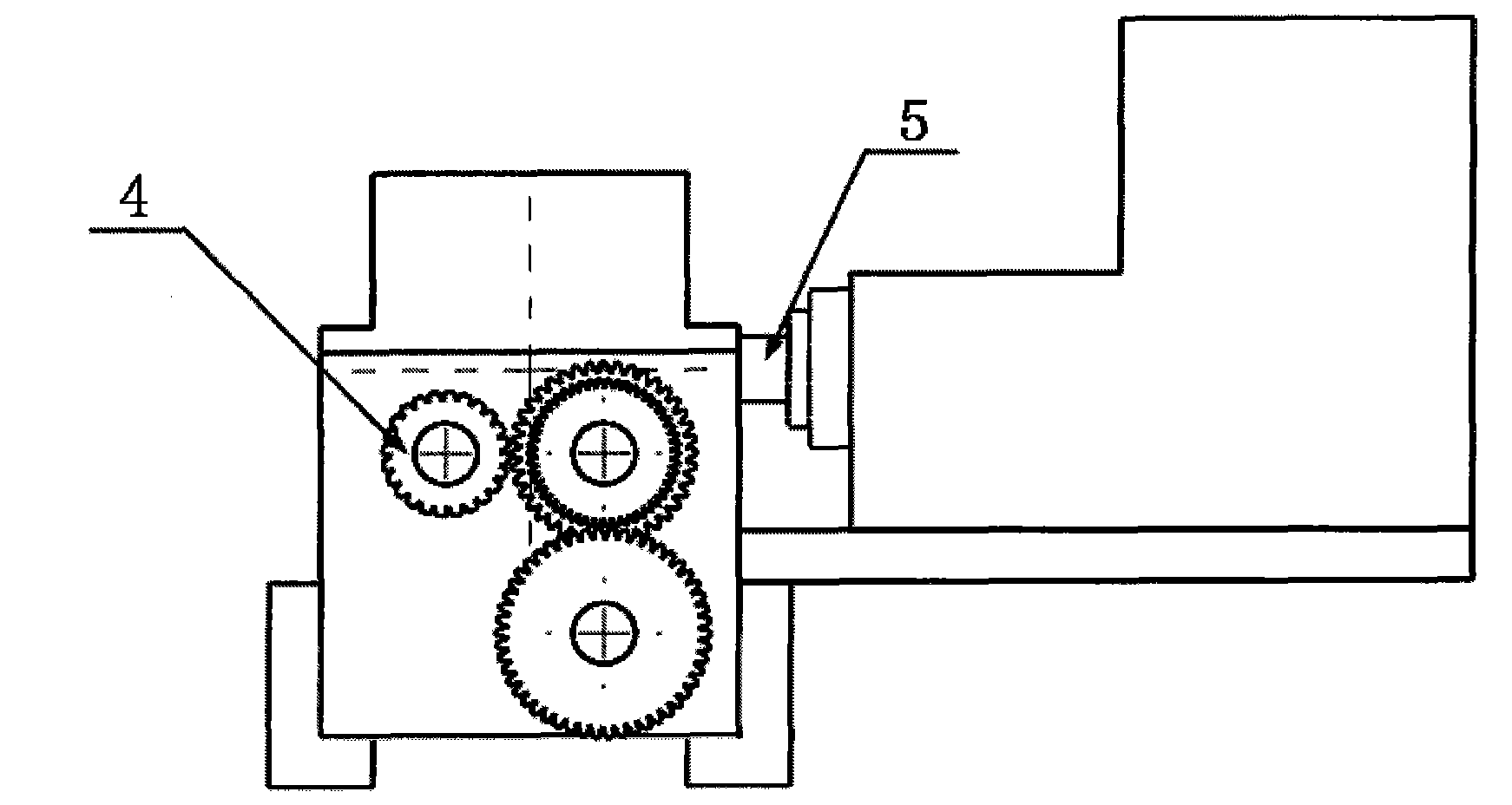

Sine driving mechanism with adjustable amplitude of oscillation for mechanical dolphin

InactiveCN1915742AAvoid repeated startupAvoid brakingPropulsive elements of non-rotary typeStub axleEngineering

A sine propulsion mechanism with adjustable swinging amplitude for robot dolphin is composed of machine frame, main motor, amplitude regulating motor, mainshaft with slide sleeve having ring slot, a conversion box with internal gear and external horizontal U-shaped and curved rack bars, a drive fork screwed on leading screw, a short axle inserted in vertical guide track, a horizontal slide way, and a rockerarm for controlling the tail swinging.

Owner:PEKING UNIV

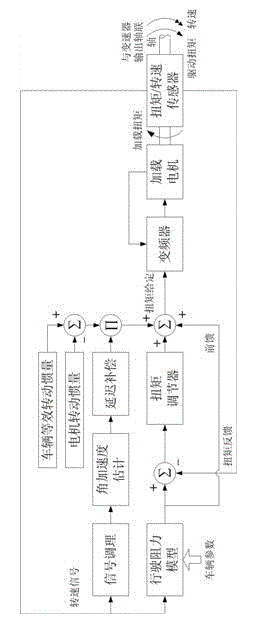

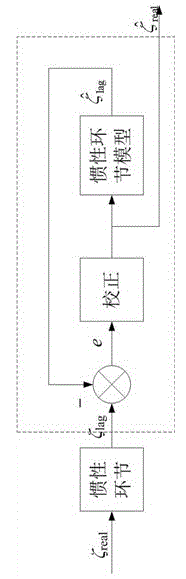

Method for electrically simulating mechanical inertia

InactiveCN102914433AMeet the requirements of the simulationRealize stepless adjustmentMachine gearing/transmission testingElectricityBench test

The invention discloses a method for electrically simulating mechanical inertia. The method comprises the steps of: estimating an angular acceleration by applying Kalman filtering based on a measured angular speed; performing delay compensation on the estimated angular acceleration to obtain an exact real-time angular acceleration; and forming an electric inertia torque given value by the exact real-time angular acceleration based on the value of the simulated inertia, transmitting the electric inertia torque given value to a frequency converter, and controlling an electromagnetic torque of a loading motor by the frequency converter to realize electric simulation of the mechanical inertia. Through the way, the method for electrically simulating the mechanical inertia, provided by the invention, has the advantages of satisfying requirements of a speed changer test to the inertia simulation, simplifying mechanical structure of a speed changer test-bed, improving inertia simulation precision, realizing stepless adjustment of the inertia, removing level difference existing during the simulation of the inertia of a mechanical flywheel, guaranteeing credibility of the test, improving automatic degree of the speed changer test-bed and getting wide attention from car bench test equipment manufacturers.

Owner:SOUTHEAST UNIV

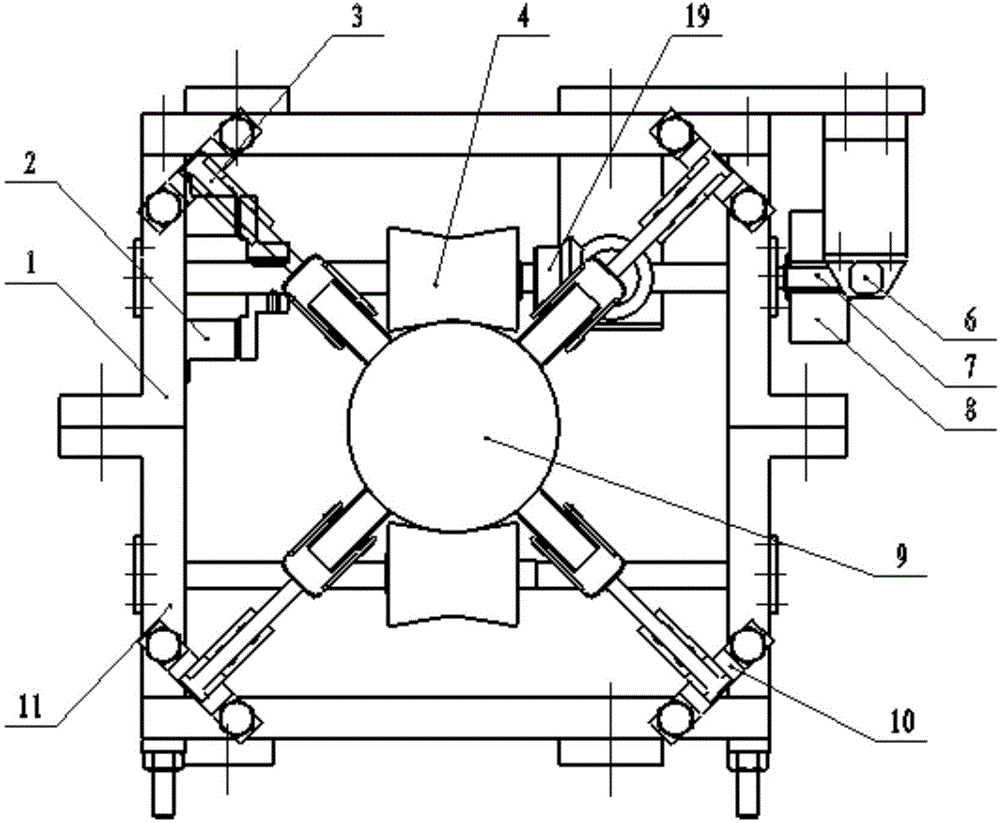

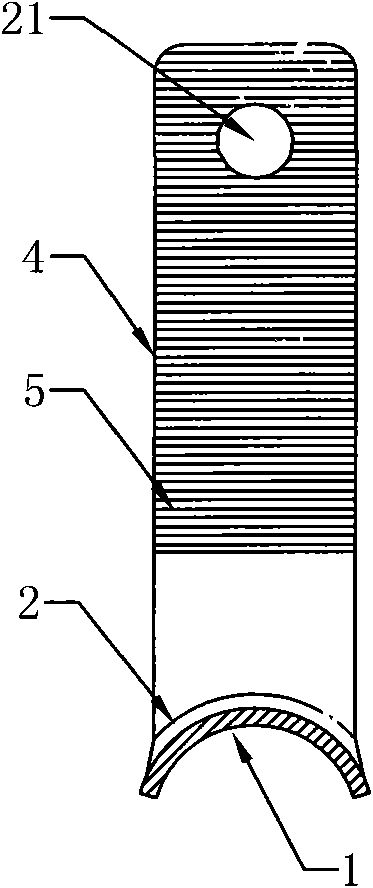

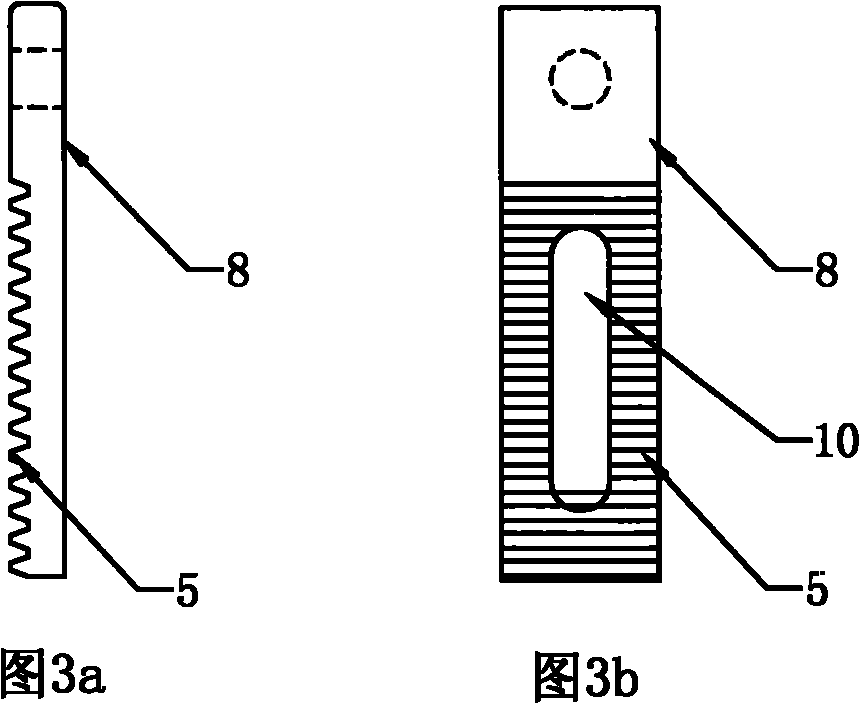

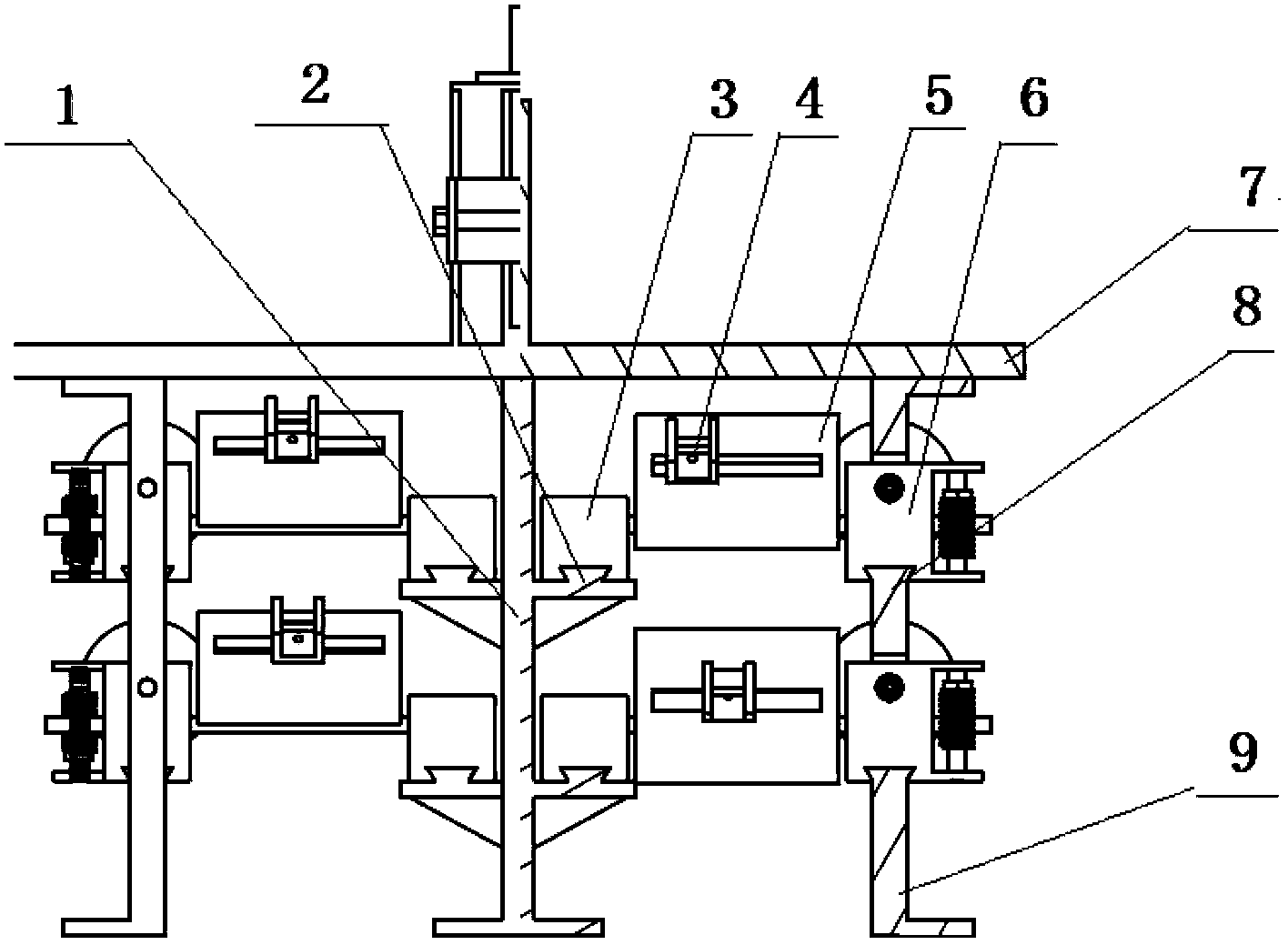

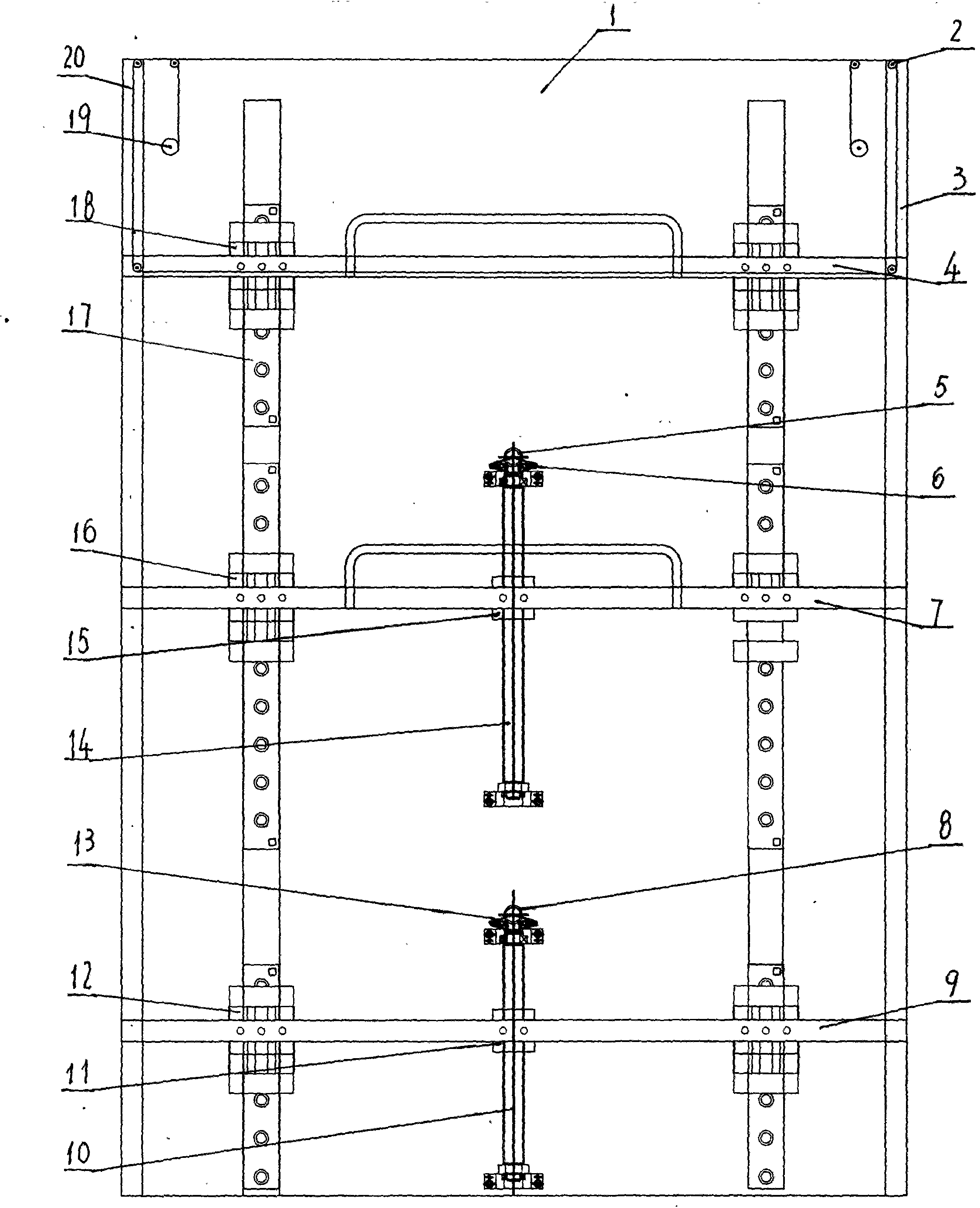

Regulable climbing device with deviation prevention function for detecting defect of bridge guy cable

InactiveCN104894957AImprove stabilityImprove reliabilityBridge structural detailsBridge erection/assemblyEngineeringGravitational potential

The invention relates to a regulable climbing device with a deviation prevention function for detecting a defect of a bridge guy cable. The regulable climbing device comprises a body frame, a regulable pressing component, a regulable deviation prevention component, a gravitational potential energy consumption component and a driving and braking component, wherein the body frame is a cuboid and consists of a fixing frame and a regulable frame, and the fixing frame and the regulable frame which are connected through bolts; the regulable pressing component comprises the regulable frame, sliding blocks, regulating screw rods, compression springs and pressing nuts; the regulable deviation prevention component comprises deviation prevention rods, deviation prevention frames, deviation prevention wheels, stretching springs and extension springs; the gravitational potential energy depletion component comprises a one-way clutch, a crank, a connecting rod and an air cylinder; the driving and braking component comprises a direct current motor, a bevel gear pair and an electromagnetic brake. The regulable climbing device disclosed by the invention can climb along the bridge guy cable and detect the defect, the regulable climbing device with the deviation prevention function can be suitable for bridge guy cables with different diameters and provide accurate information of the quality and the defects of the guy cable for maintaining a bridge, so that the safe operation of the bridge is ensured, and larger social and economic benefits can be created.

Owner:CHANGSHA DAFANG PRECISION ELECTROMECHANICAL

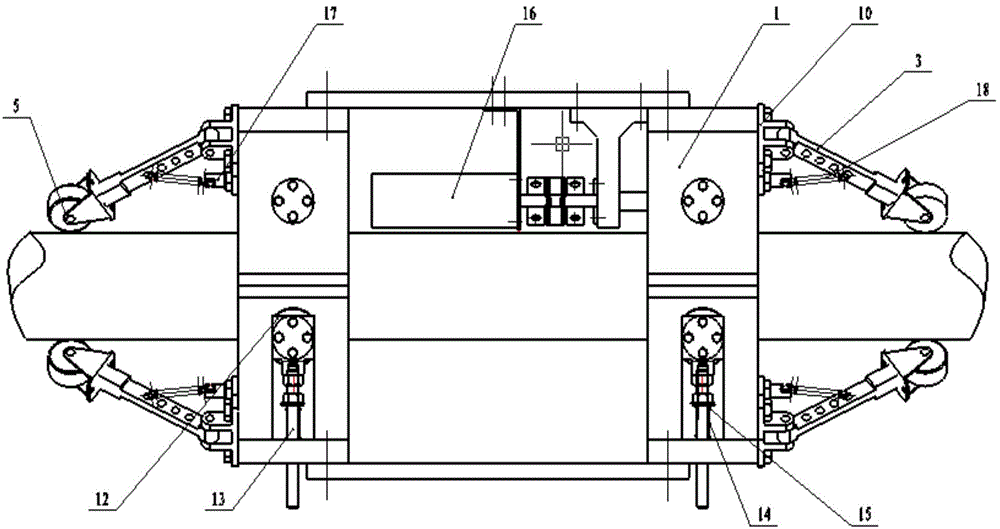

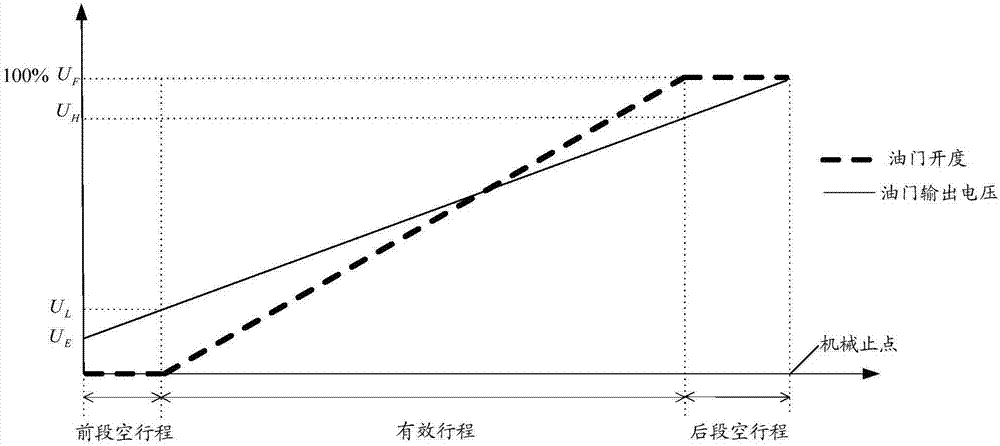

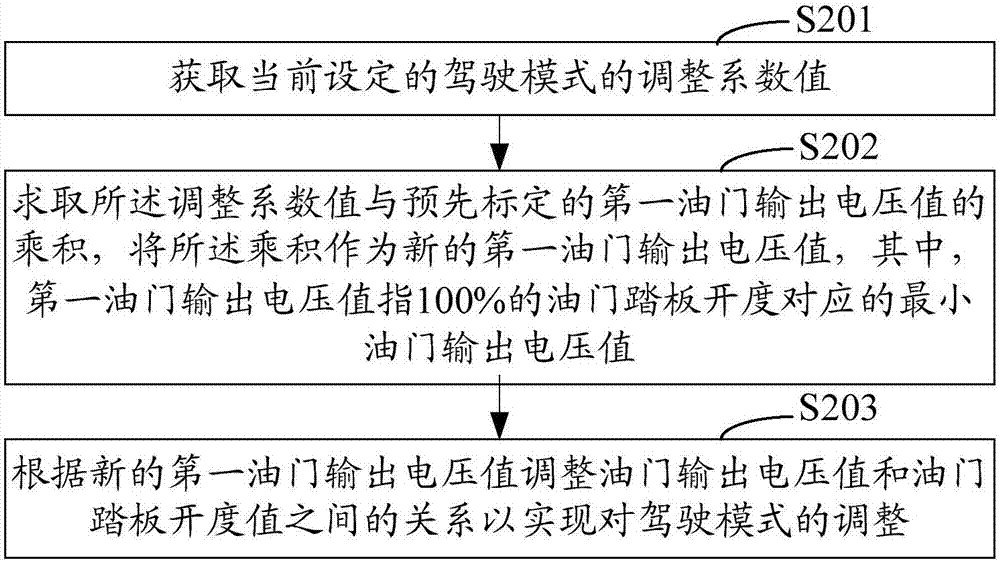

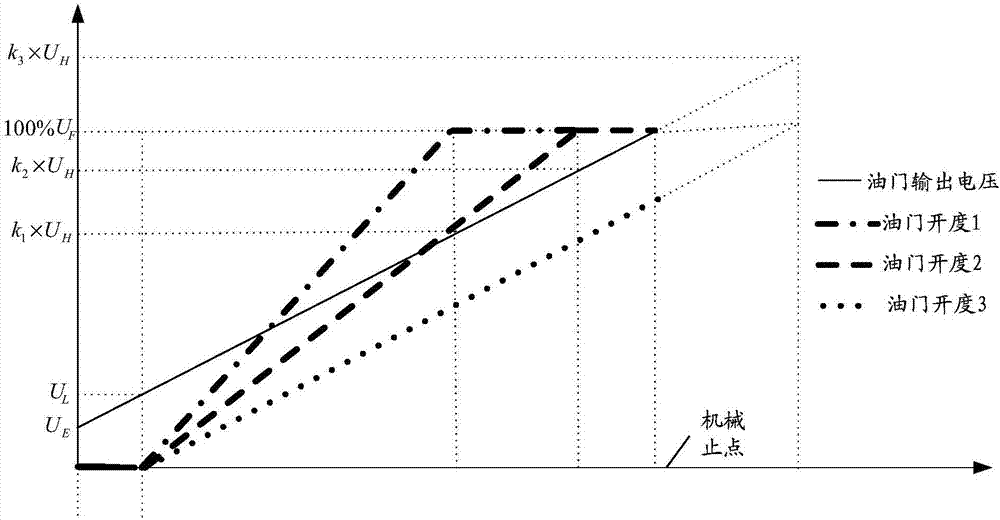

Driving mode adjusting method and device

The invention relates a driving mode adjusting method and device. The driving mode adjusting method comprises the steps that an adjustment coefficient value of the currently set driving mode is obtained; a product of the adjustment coefficient value and a pre-calibrated first throttle output voltage value is obtained, and the product serves as a novel first throttle output voltage value, wherein the first throttle output voltage value is a minimum throttle output voltage value corresponding to 100% throttle pedal opening; and the relationship between the throttle output voltage value and the throttle pedal opening value is adjusted according to the novel first throttle output voltage value to realize adjustment of the driving mode. The invention further relates to a throttle pedal opening degree control method, and the method further comprises the steps that the throttle output voltage is obtained in real time; and the throttle pedal opening degree is controlled according to the relationship between the obtained throttle output voltage value and the adjusted throttle output voltage value and the throttle pedal opening degree value. According to the driving mode adjusting method and device, the number of optional driving modes can be increased, and the driving mode adjusting can be flexibly conducted to meet needs of more users.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

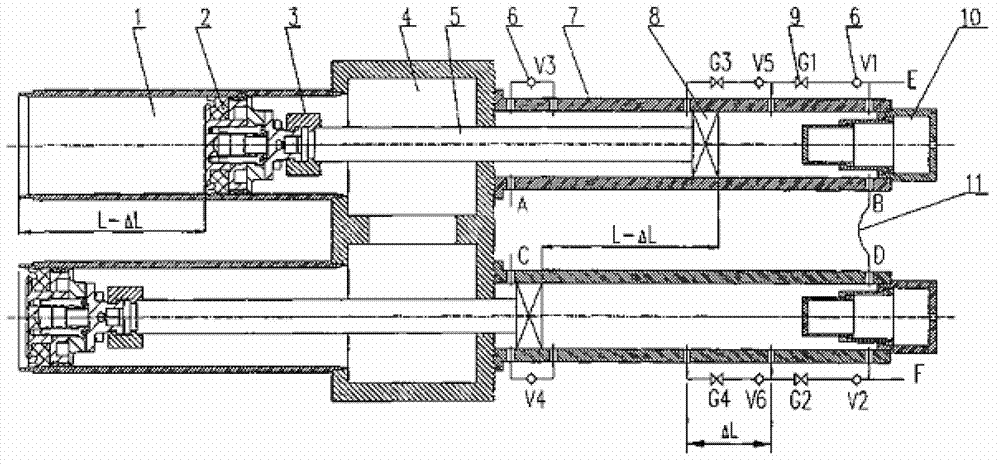

Pumping stroke control method for viscous material double-cylinder pump and pumping equipment for viscous material

ActiveCN103114983AAvoid insufficient suctionImprove pumping and suction efficiencyTelemotorsPump controlPistonEngineering

A pumping stroke control method for a viscous material double-cylinder pump includes the following steps: step 1 according to material condition parameters of predetermined type of to-be-conveyed viscous material, determining a target pumping stroke of the viscous material double-cylinder pump corresponding to the material condition parameters; and step 2 adjusting the current actual pumping stroke (L) of the viscous material double-cylinder pump to be the target pumping stroke by adjusting the volume of hydraulic oil contained in a communication cavity (5) of viscous material double-cylinder pump. In addition, the invention further provides pumping equipment for viscous material. The pumping equipment for viscous material is capable of achieving stepless regulation of pumping stroke of the viscous material double-cylinder pump, and enables a viscous material conveying cylinder to effectively avoid shortage of absorbed material, thereby improving pumping material absorbing efficiency and saving energy. The pumping equipment for viscous material is simple in structure, convenient to operate, and capable of remarkably prolonging service life of a conveying piston due to the fact that invalid stroke of the conveying piston is effectively reduced.

Owner:ZOOMLION HEAVY IND CO LTD

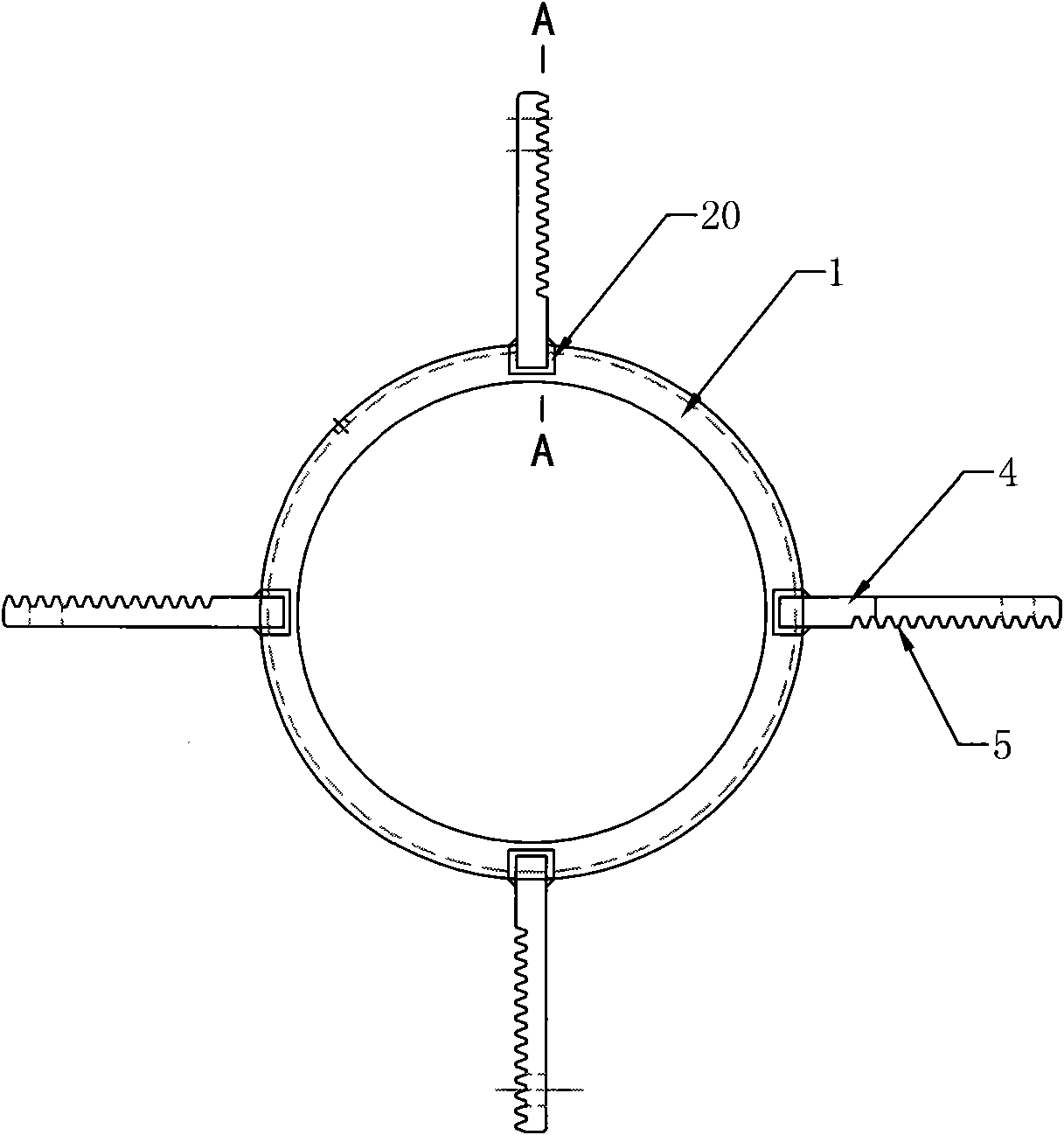

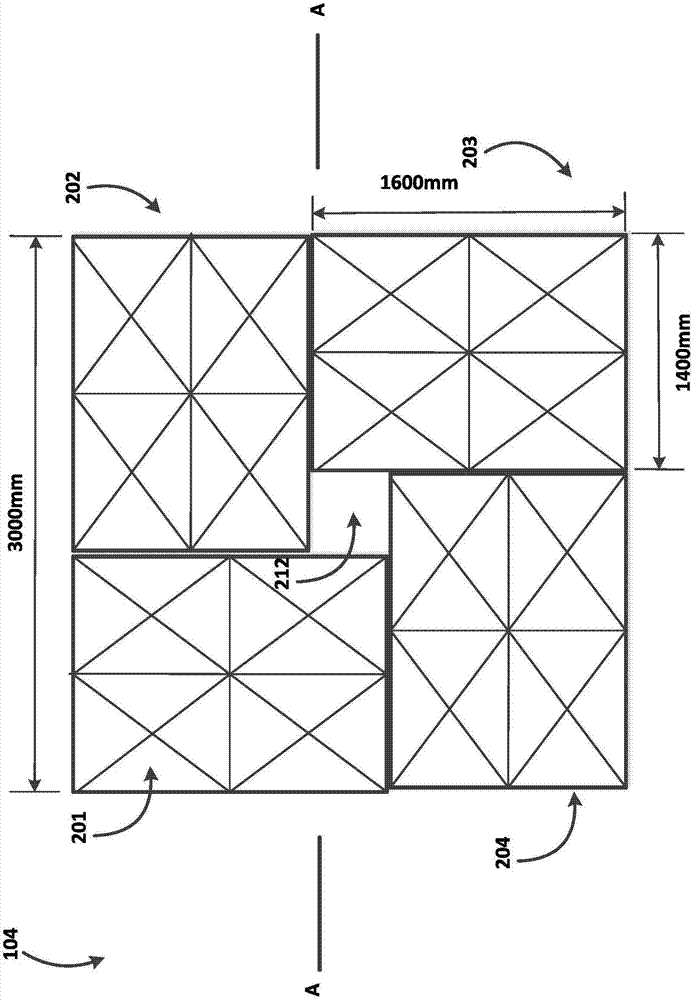

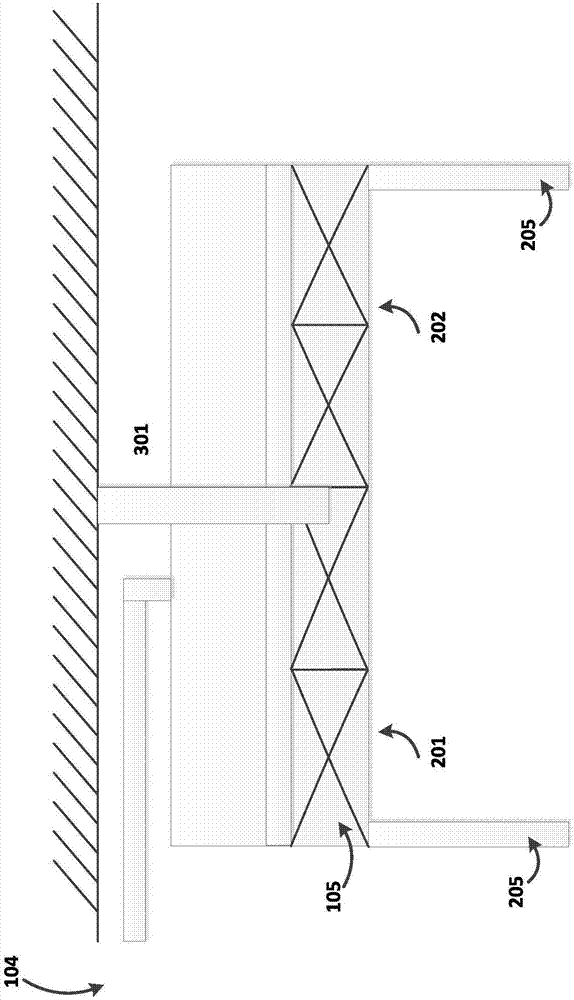

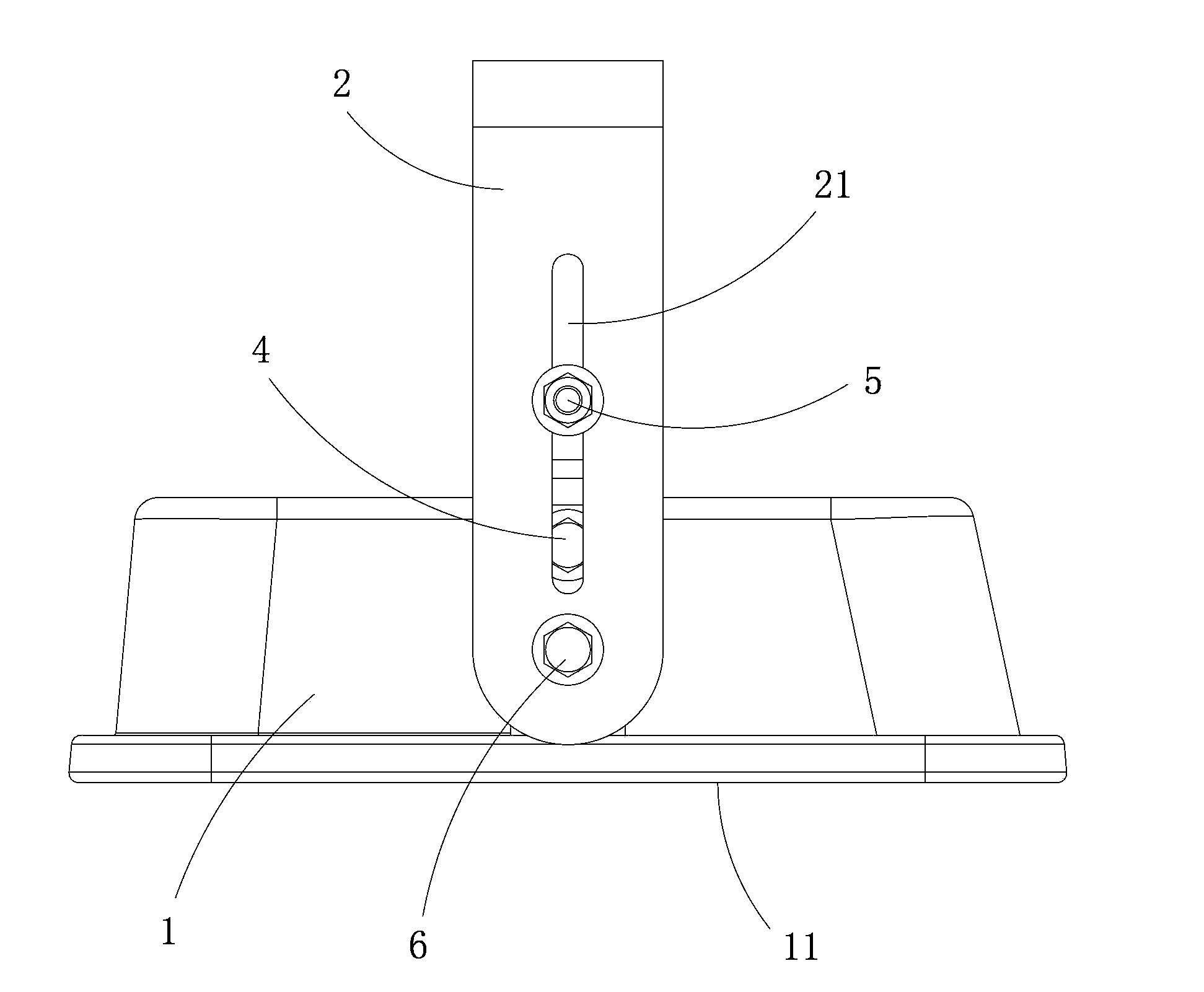

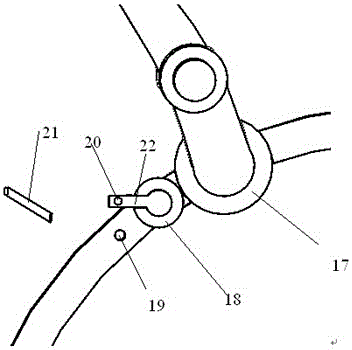

Adjustable sub-lead spacer

ActiveCN101931193ACompact structureEasy to installMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsEngineeringInstallation Error

The invention relates to a spacer for transmission line in the air, in particular to an adjustable sub-lead spacer, comprising a frame, wire clamp bodies and wire clamp cover boards; the frame is ring-shaped, binding plates are uniformly distributed on the outer circumference of the frame; the front part of the wire clamp body and the front part of the wire clamp cover plate are connected together through a connecting piece to form a hollow cavity for clamping the sub-lead; an adjusting plate is connected between two convex lugs at the rear end of the wire clamp body; the binding plate and the adjusting plate are provided with the racks on the sides opposite to each other; and the distance between the sub-leads is adjusted by changing the engaging position of the racks on the binding plate and the adjusting plate. The spacer has the advantages of compact structure, convenient installation, wide application range, and the like, thereby being capable of conveniently compensating the lead arc vertical installation error, and also being capable of adjusting the distance between the sub-leads in fine tuning mode or coarse tuning mode; and the distance is adjusted without blind region to realize stepless adjustment of the distance between the sub-leads.

Owner:CHINA ELECTRIC POWER RES INST +1

Multifunctional massage bed for caring patient through manually lifting back and bending legs

ActiveCN104146841ARelieve muscle fatigueReduce manufacturing costChiropractic devicesVibration massageLocking mechanismMassage

The invention discloses a multifunctional massage bed for caring a patient through manually lifting the back and bending the legs, and belongs to the field of massage beds. The massage bed comprises a bed body frame, a bed board, a back lifting device, a leg bending device, a front massage device and a back massage device. A back lifting traction rope is controlled by a manual back lifting traction and locking mechanism to retract or extend to drive a back lifting bracket to lift and fall, a leg bending traction rope is controlled by a manual leg bending traction and locking mechanism to move forward and backward to drive a leg bending sliding bracket to move forward and backward, the front massage device and the back massage device are utilized to realize the rolling type massage and the vibrating type massage for the patient, the structure which is simpler than the conventional massage bed is utilized to realize the functions of back lifting and leg bending, the operation is simple, the action is fluent, the manufacturing cost of the massage bed is greatly reduced, and the application is convenient; meanwhile, the massage with multiple modes to the patients is realized, the massage comfort is high, so that the massage bed is particularly suitable for the paralytic patients who cannot care themselves, and the labor intensity of medical care personnel and patient families is reduced.

Owner:上海稼多医疗器械有限公司

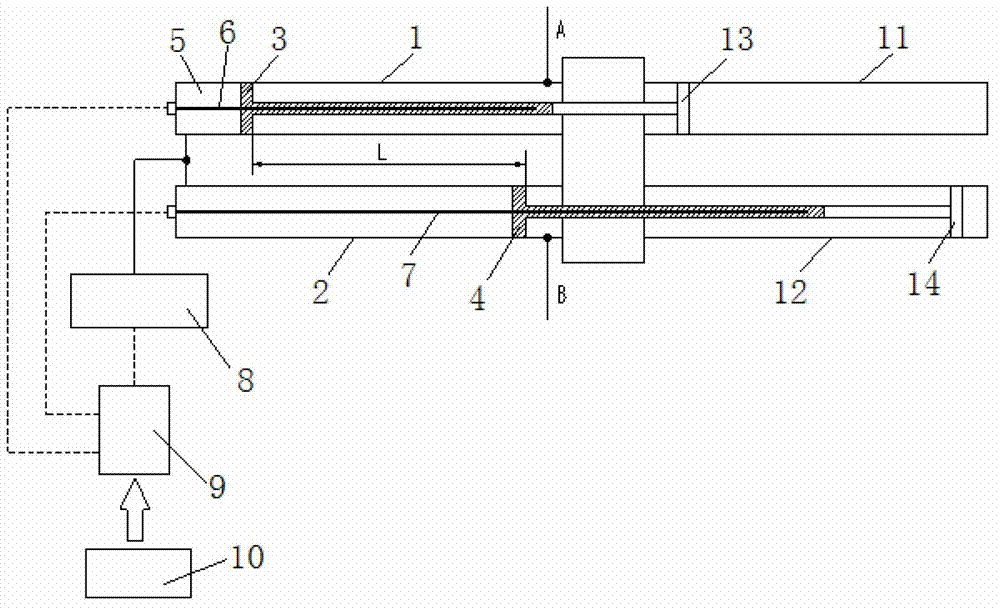

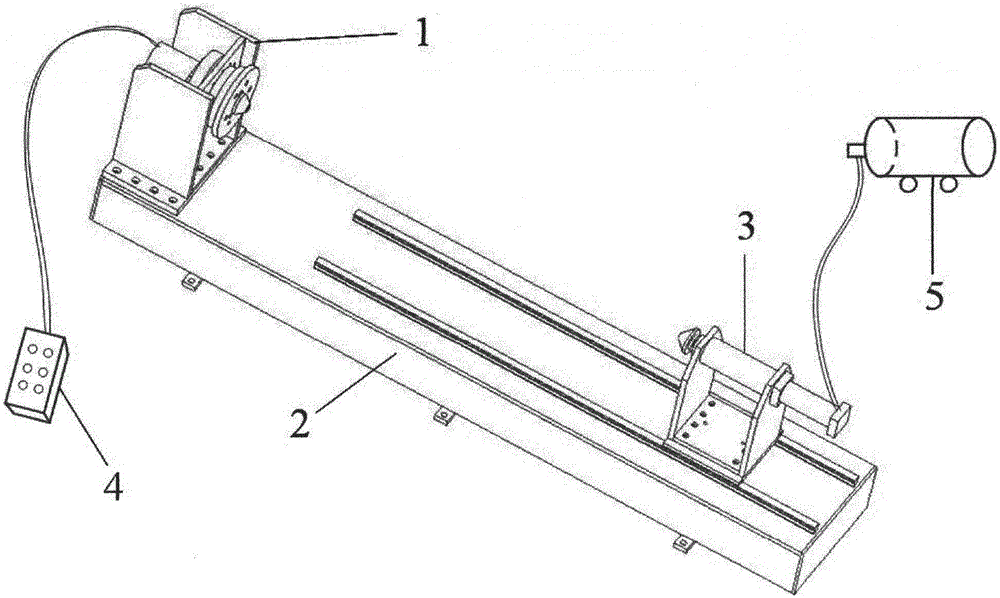

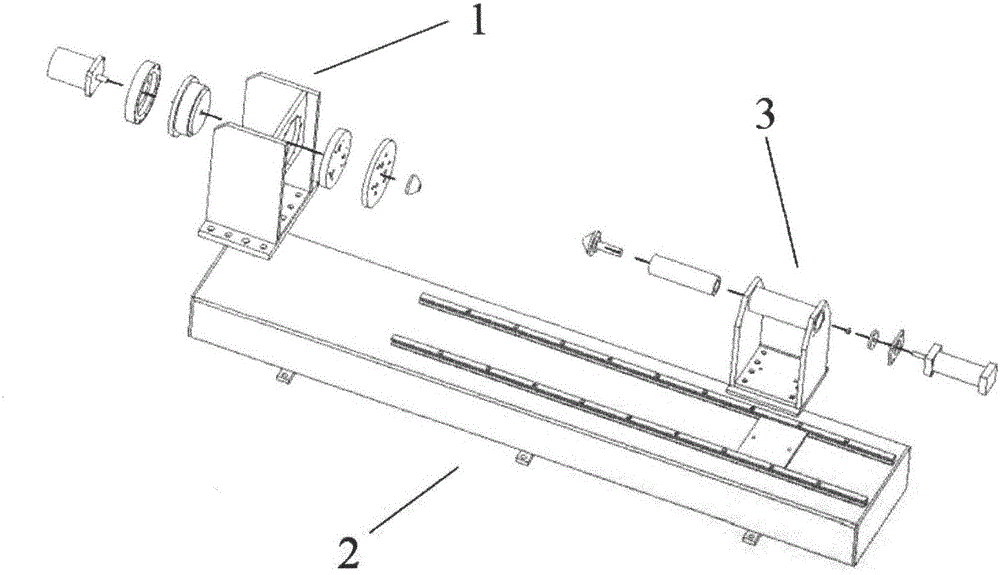

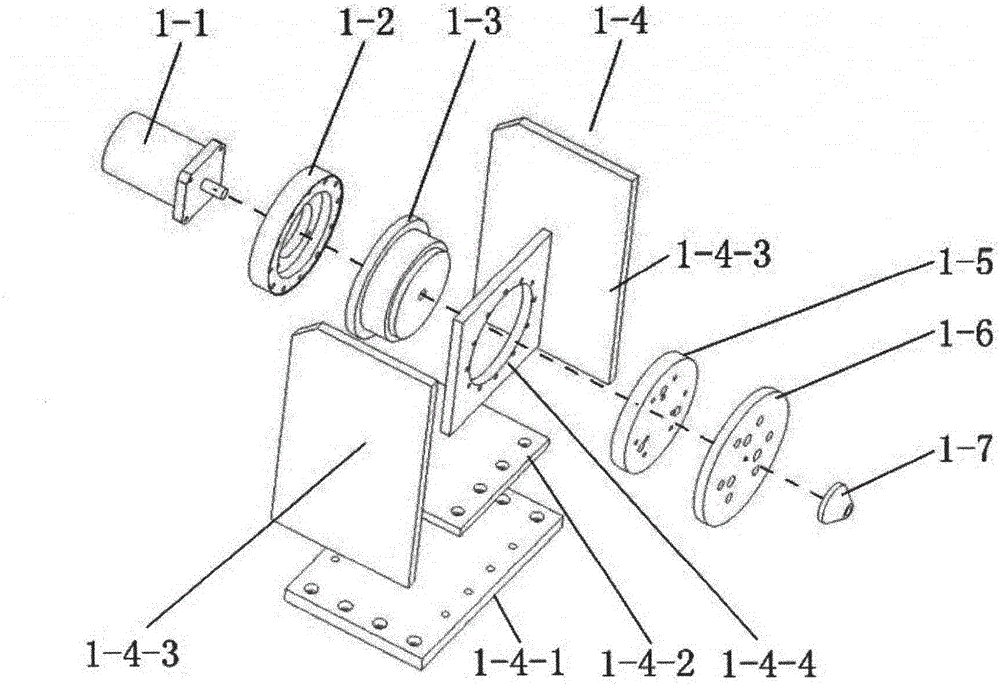

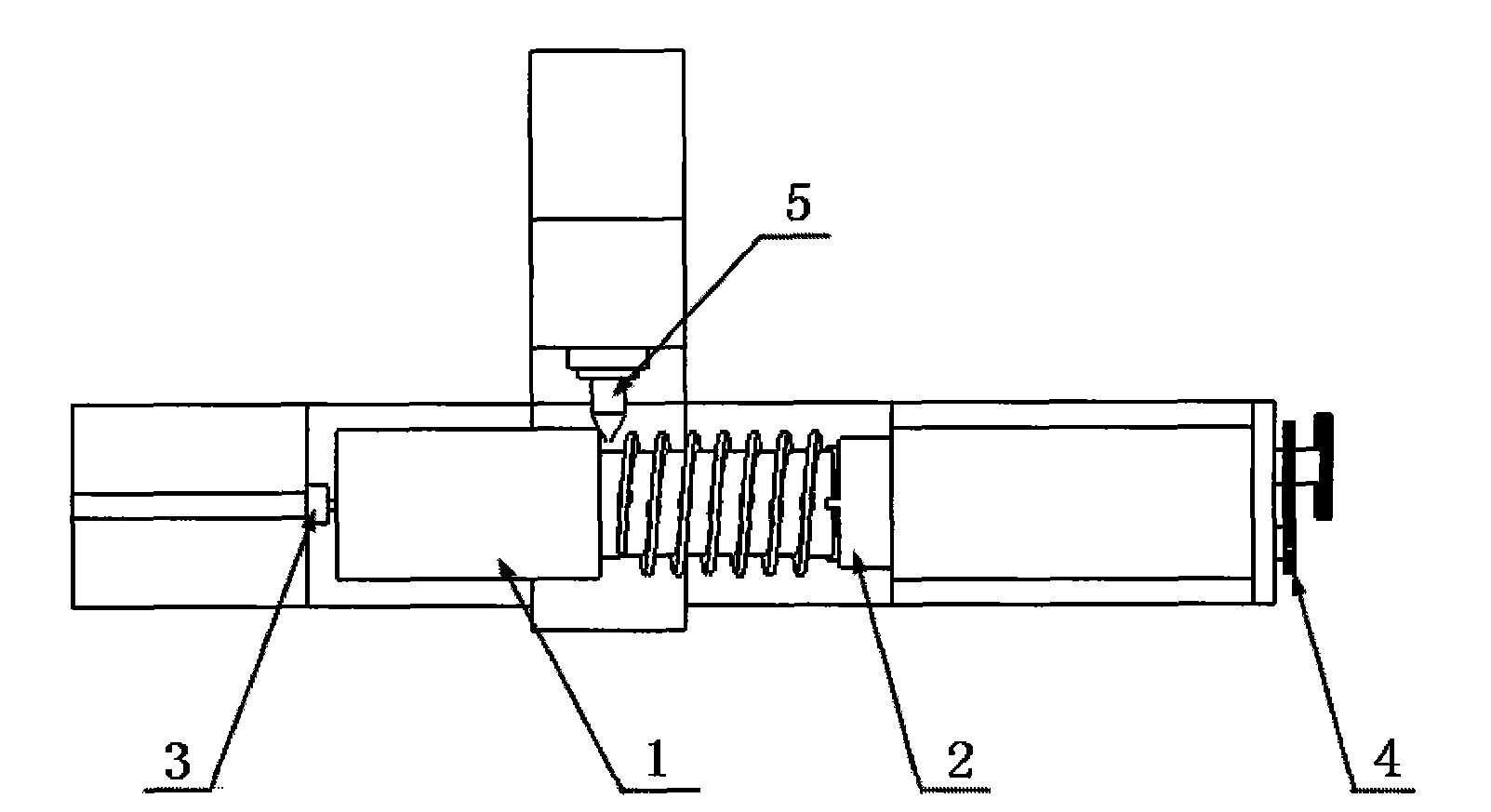

Horizontally flipping welding positioner and use method thereof

InactiveCN105127652ARealize stepless adjustmentImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringReducer

The invention discloses a horizontally flipping welding positioner. The horizontally flipping welding positioner comprises a base, a machine head, a tailstock, an air pump and a control box. The control box is connected to a motor arranged on the machine head which is installed on the left side of the base, a guide rail is installed on the base, the tailstock is installed on the portion, on the right side of the base, of the guide rail, and a cylinder arranged on the tailstock is connected with the air pump which provides power for the cylinder. The machine head comprises the motor, a speed reducer, a flange, a left ejector pin or a chuck and a speed reducer support; the tailstock comprises a sliding block, a cylinder support, a sleeve and an ejector pin, the tailstock can slide left and right on the guide rail, and stepless adjustment of the distance between the tailstock and the machine head is achieved. When the horizontally flipping welding positioner works, after the tailstock is fixed on a proper position on the guide rail, under the action of the air pump, a piston of the cylinder pushes the tailstock ejector pin to be matched with the machine head ejector pin or the chuck to abut against a workpiece, and then the motor rotates the workpiece according to needs. The horizontally flipping welding positioner is easy to operate, convenient to use and capable of flexibly replacing the ejector pin or the chuck according to needs, being controlled independently through the control box, achieving linkage with a welding robot and specially being suitable for welding of a circular weld of the workpiece which is provided with a tubular rotation center.

Owner:青岛艾斯达特智能焊接设备有限公司

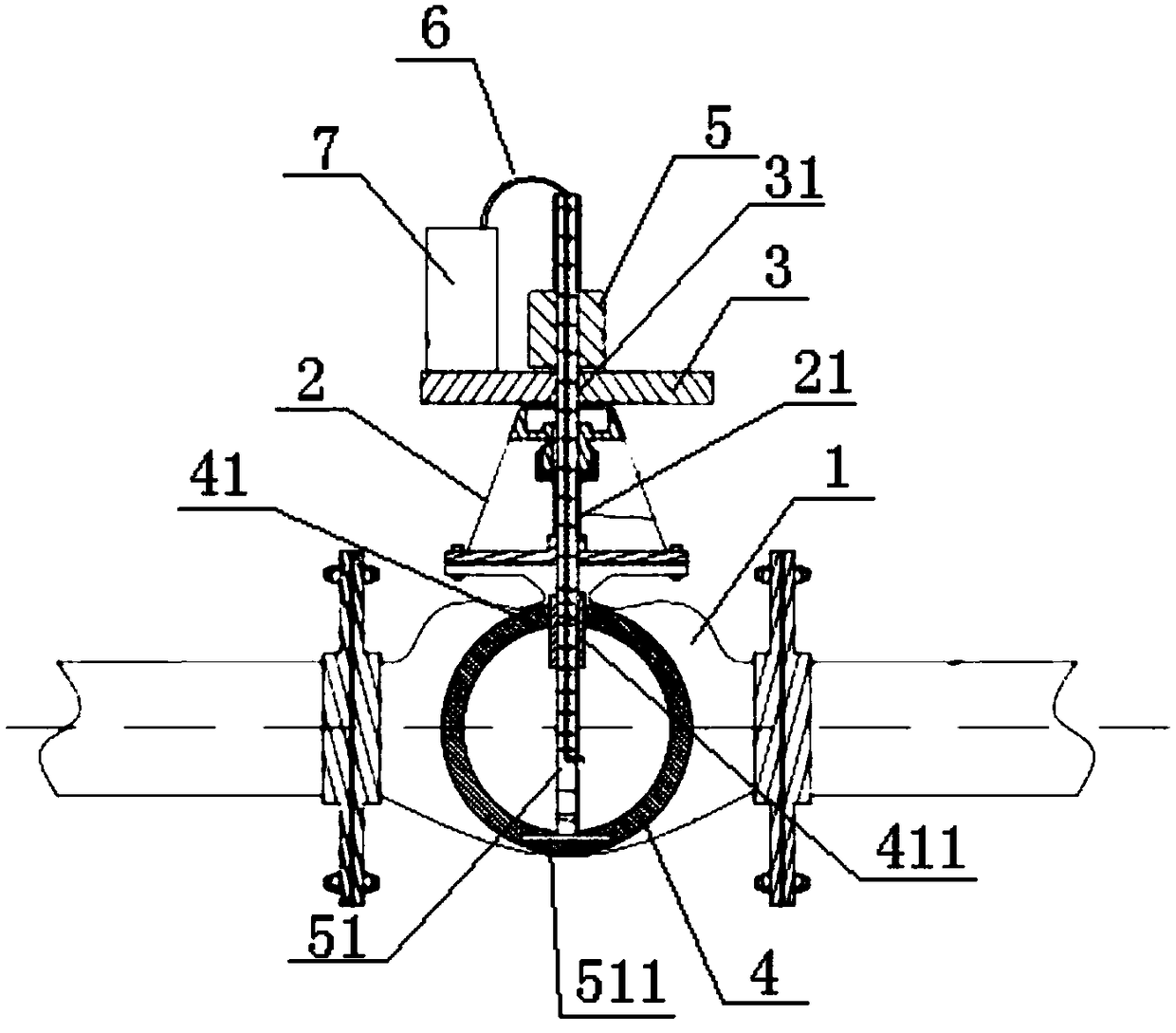

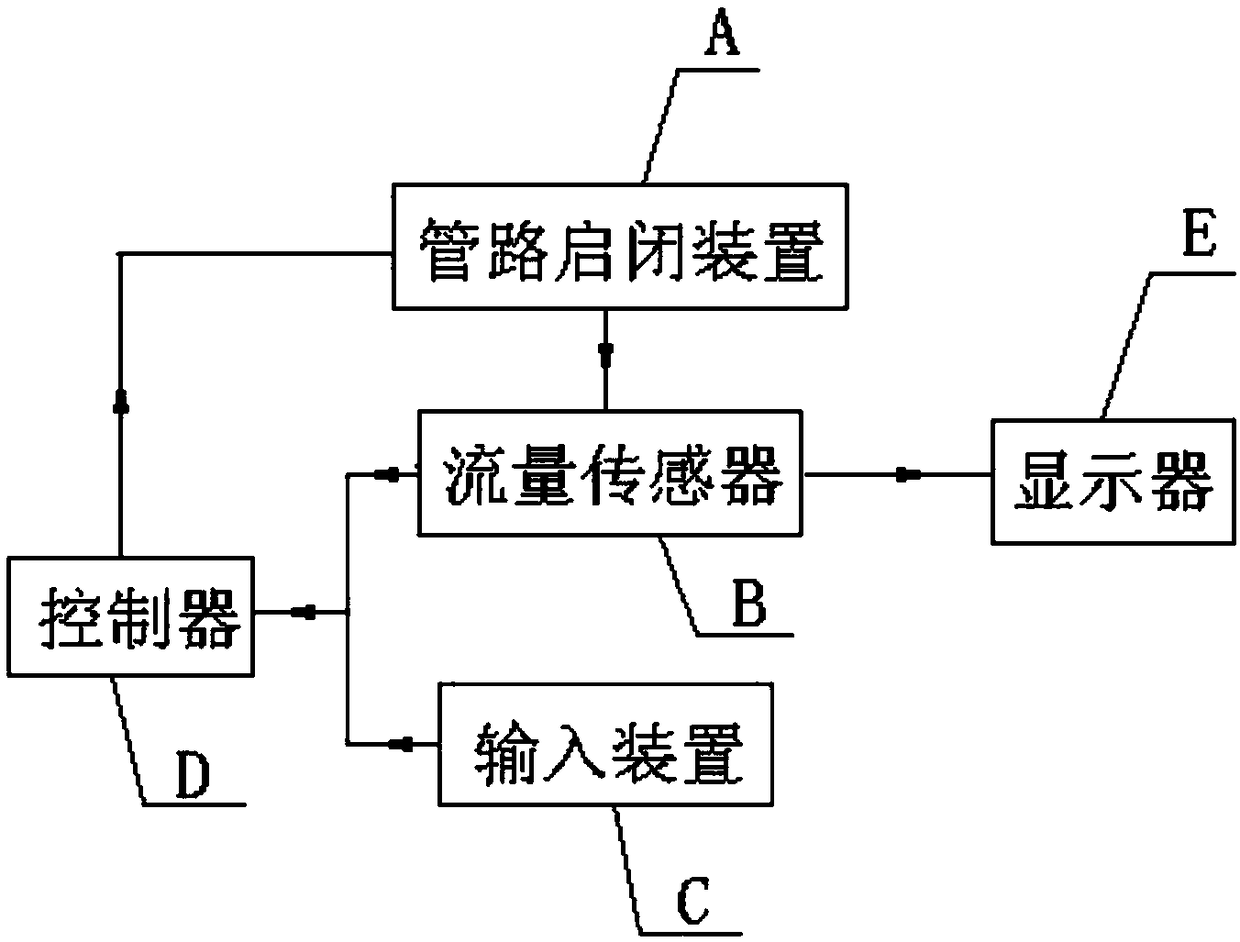

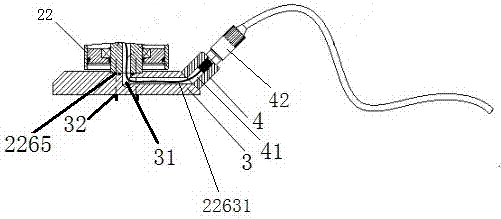

Pipeline switching-on and switching-off device and system

ActiveCN108591528AOpen and closeAchieve closureDiaphragm valvesOperating means/releasing devices for valvesEngineeringAir compressor

The invention discloses a pipeline switching-on and switching-off device and system. According to the switching-on and switching-off device, a valve is switched on and switched off in the manner thatan air bag driven by a lead screw and a hose serves as a valve element of the traditional valve, and the purpose of switching on and switching off a pipeline is achieved. Specifically, an air compressor serves as an air source, the air bag is inflated or the air in the air bag is discharged by controlling air discharging and air feeding of the air compressor, and then switching-off, switching-on and flow adjustment of the pipeline are achieved. To facilitate air inflation and air discharging of the air bag, the pipeline switching-on and switching-off device is further internally provided witha lead screw stepping motor, rapid air inflation and rapid air discharging of the air bag can be realized through match between the lead screw stepping motor and the air compressor, and rapid adjustment of the flow is realized. The air bag serves as the valve element of the valve for the first time, and compared with a previous metal valve element, the air bag valve element has the advantages of being resistant to impurities, capable of realizing stepless adjustment of the flow, long in service life, precise in flow adjustment and the like.

Owner:DALIAN COSCO KHI SHIP ENG

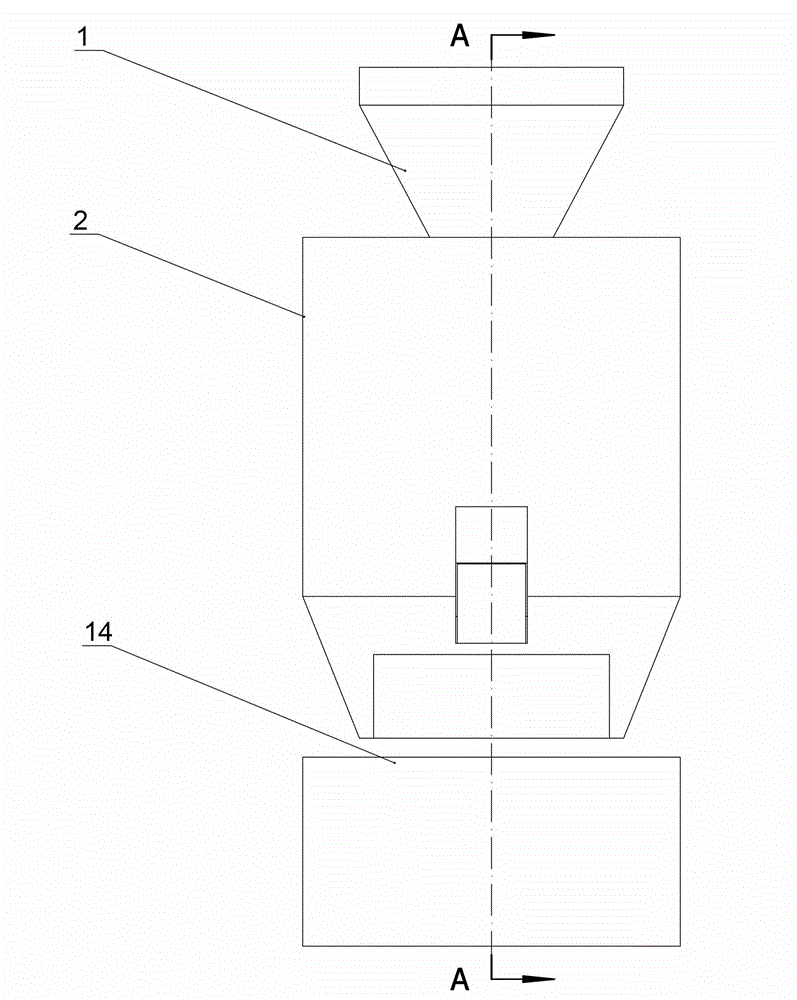

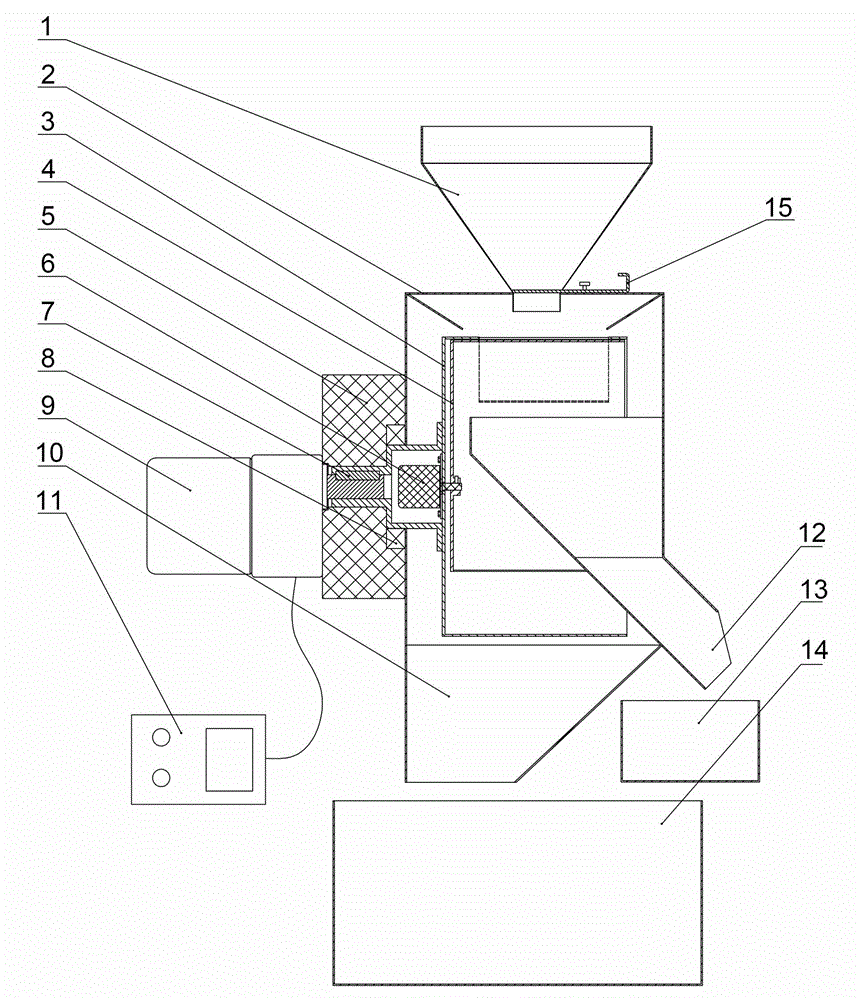

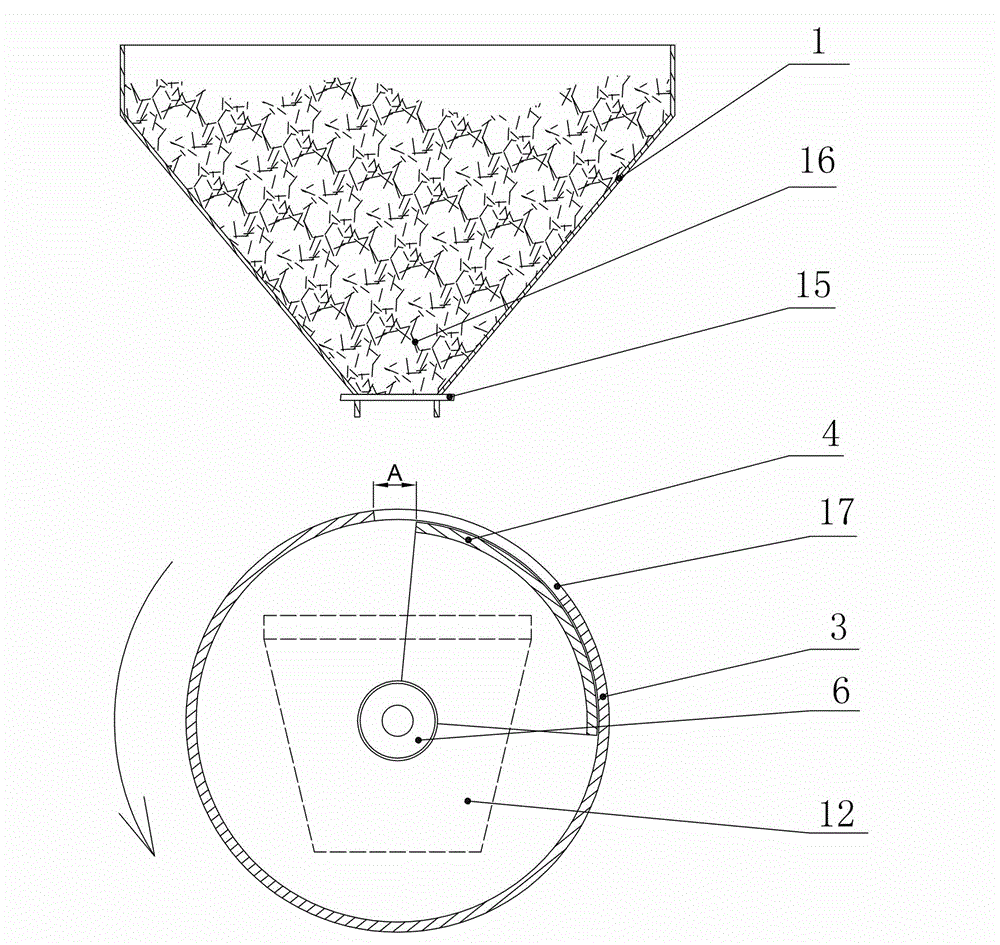

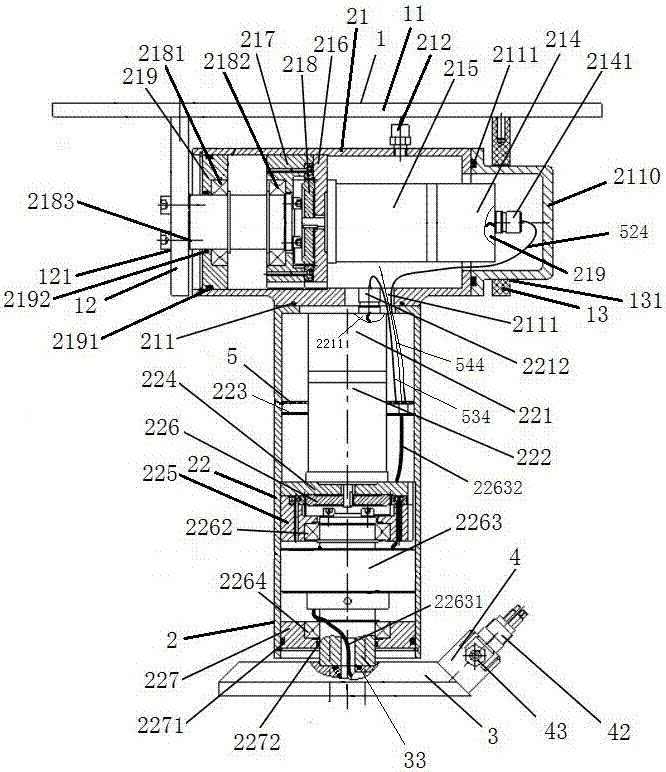

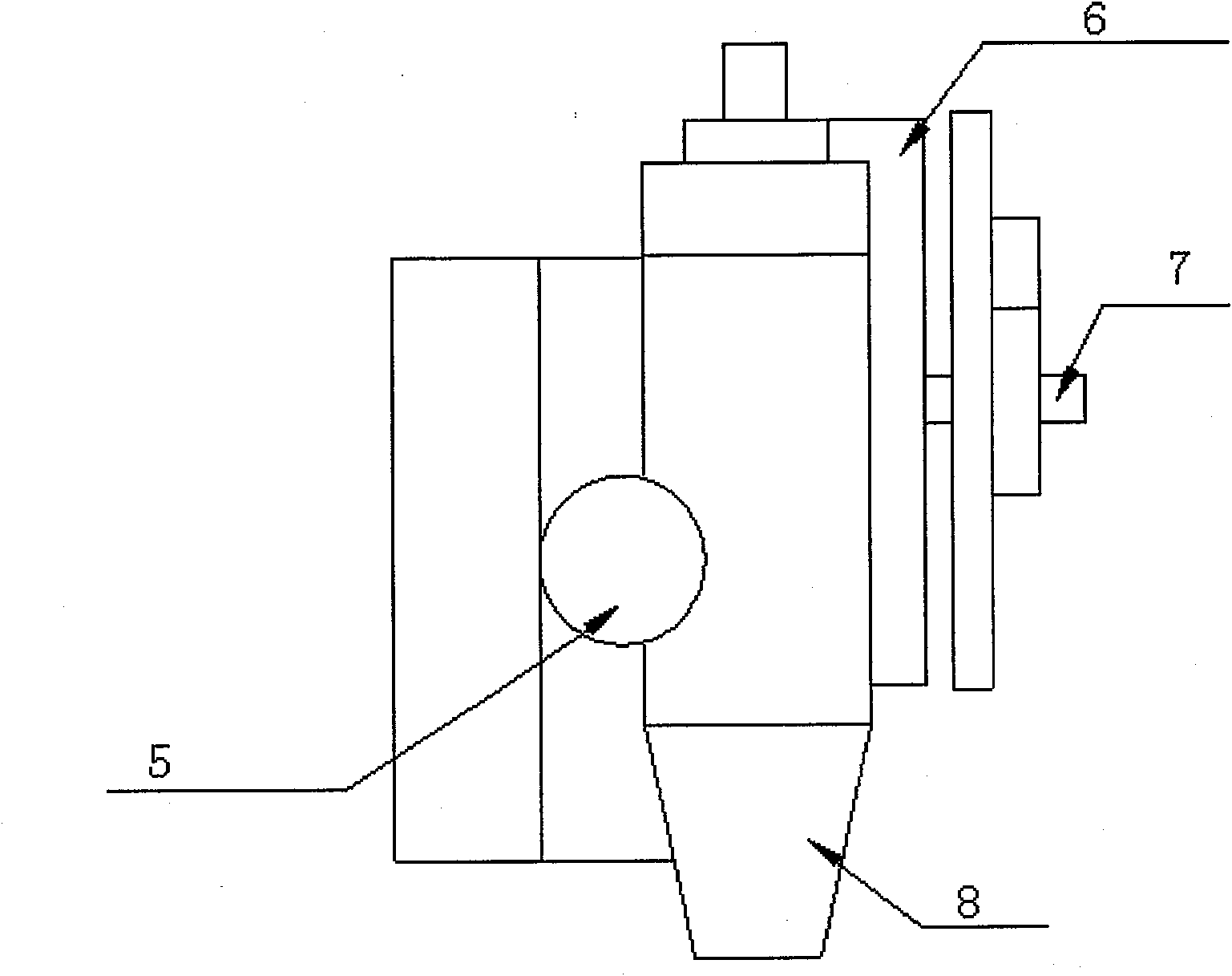

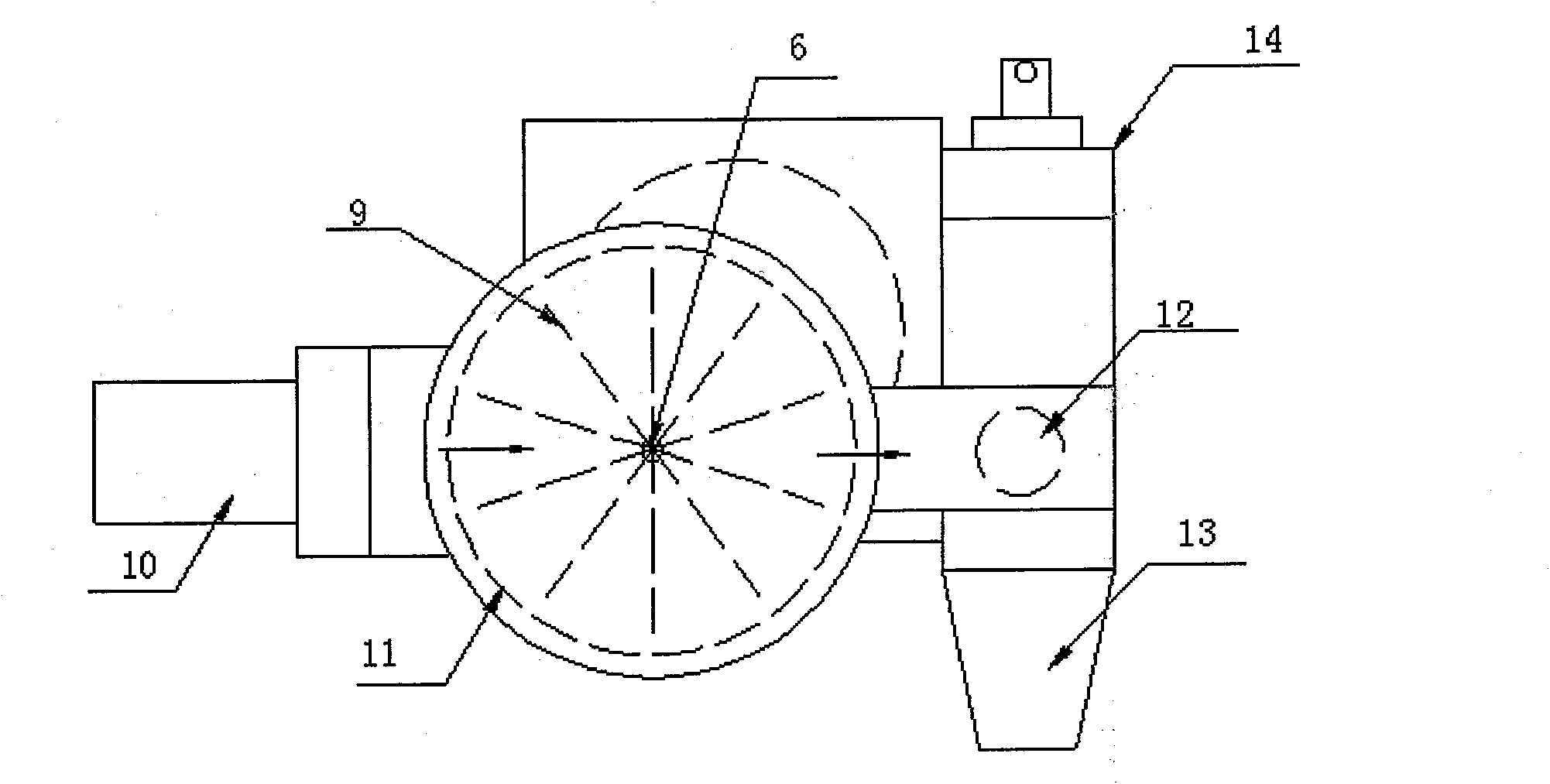

Intelligent divider capable of conducting division with constant mass

InactiveCN102749241ASimple and compact structureSimple and efficient operationWithdrawing sample devicesPreparing sample for investigationEngineeringMechanical engineering

The invention discloses an intelligent divider capable of conducting division with constant mass. The intelligent divider comprises a control unit, a material feeding hopper and a division assembly located at the material discharging end of the material feeding hopper. The division assembly comprises a division rotary drum and a main driving piece used for driving the division rotary drum. More than one material cutting opening is arranged on the outer circle of the division rotary drum, and more than one opening adjusting plate used for being matched with the material cutting opening is arranged in the division rotary drum. The opening adjusting plate is connected with an opening adjusting driving piece and rotates under drive of the opening adjusting driving piece to be matched with the material cutting opening to form material dropping openings with different sizes. The intelligent divider has the advantages of being simple and compact in structure, convenient to operate, high in intelligentization degree, wide in adjusting range, capable of achieving stepless adjustment and the like.

Owner:HUNAN SUNDY SCI & TECH DEV

Full-sea-depth digitized electric pan-tilt

PendingCN107202232AAvoid entanglement damageEasy to controlStands/trestlesFlexible/turnable line connectorsMarine engineeringElectric machine

A full-sea-depth digitized electric pan-tilt comprises an electric pan-tilt body and is characterized in that the electric pan-tilt body is formed by a device installation support, an outer shell body and a base; the device installation support is in a right-angle-n shape and is composed of a left arm, a right arm and an upper plate; the outer shell body is in a T shape and is composed of an upper shell body and a lower shell body; openings are formed in the left end and the right end of the upper shell body, a left end cover is arranged at the position of the opening in the left end, and a right housing is arranged at the position of the opening in the right end; a pitching mechanism composed of a pitching motor, an installation flange and a pitching speed reduction mechanism is arranged in the upper shell body, the pitching motor comprises a pitching pressure-proof air cabin, and the pitching speed reduction mechanism is in a base of a pitching speed reducer; openings are formed in the upper end and the lower end of the lower shell body, and a lower end cover is arranged at the position of the opening in the lower end; a rotation mechanism composed of a rotation motor, a lower flange and a rotation speed reduction mechanism is arranged in the lower shell body, the rotation motor comprises a pressure-proof air cabin, and the rotation speed reduction mechanism is in a base of a rotation speed reducer; the position of the opening in the upper end of the lower shell body and the position of a cabling hole in the middle portion of the lower end face of the upper shell body are connected in a sealed manner; and the position of the lower end cover of the lower shell body and the base are fixedly connected in a sealed manner. The full-sea-depth digitized electric pan-tilt is suitable for being applied to the position with the maximum seawater depth being 11,000 m.

Owner:SHANGHAI OCEAN UNIV

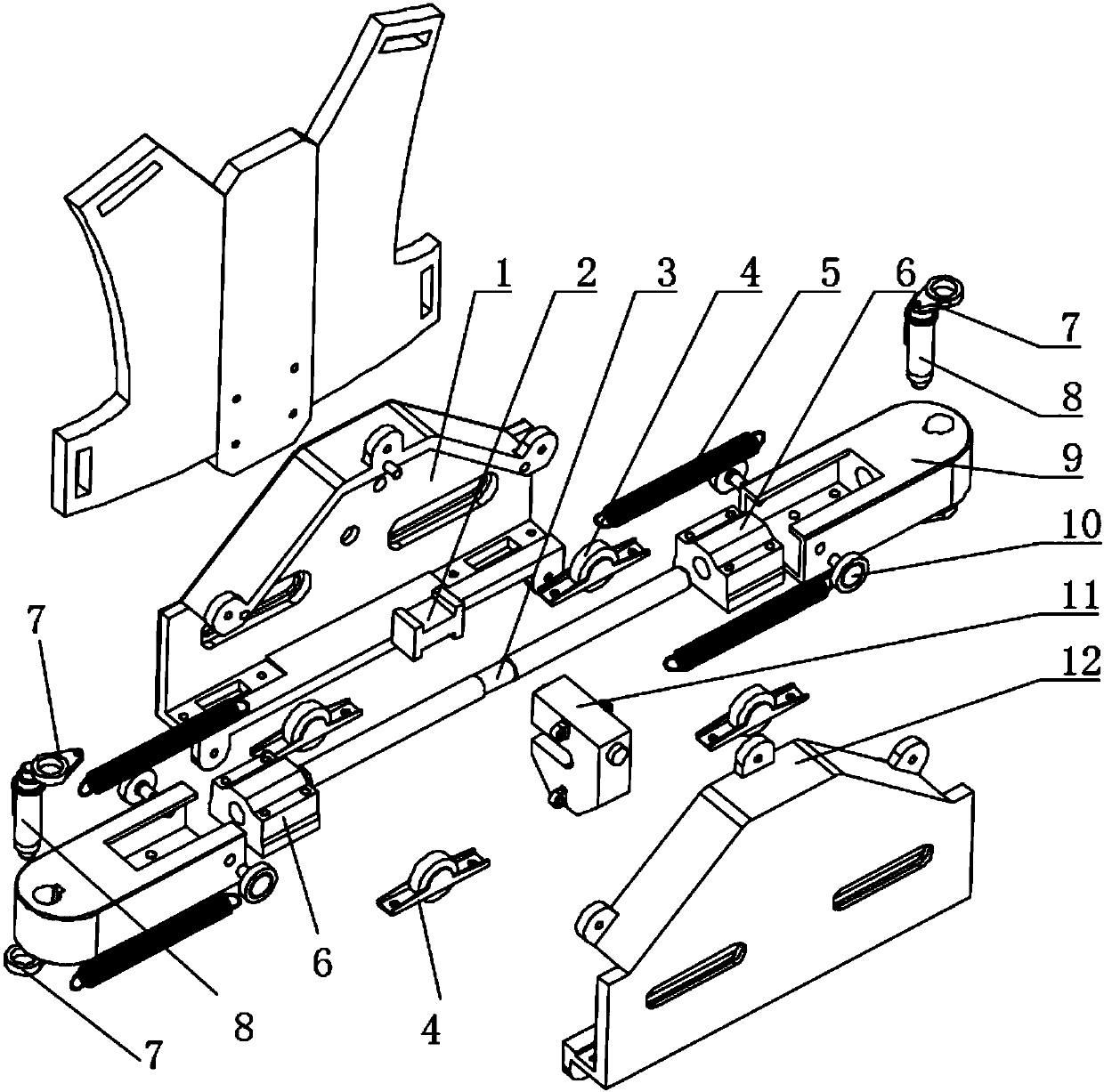

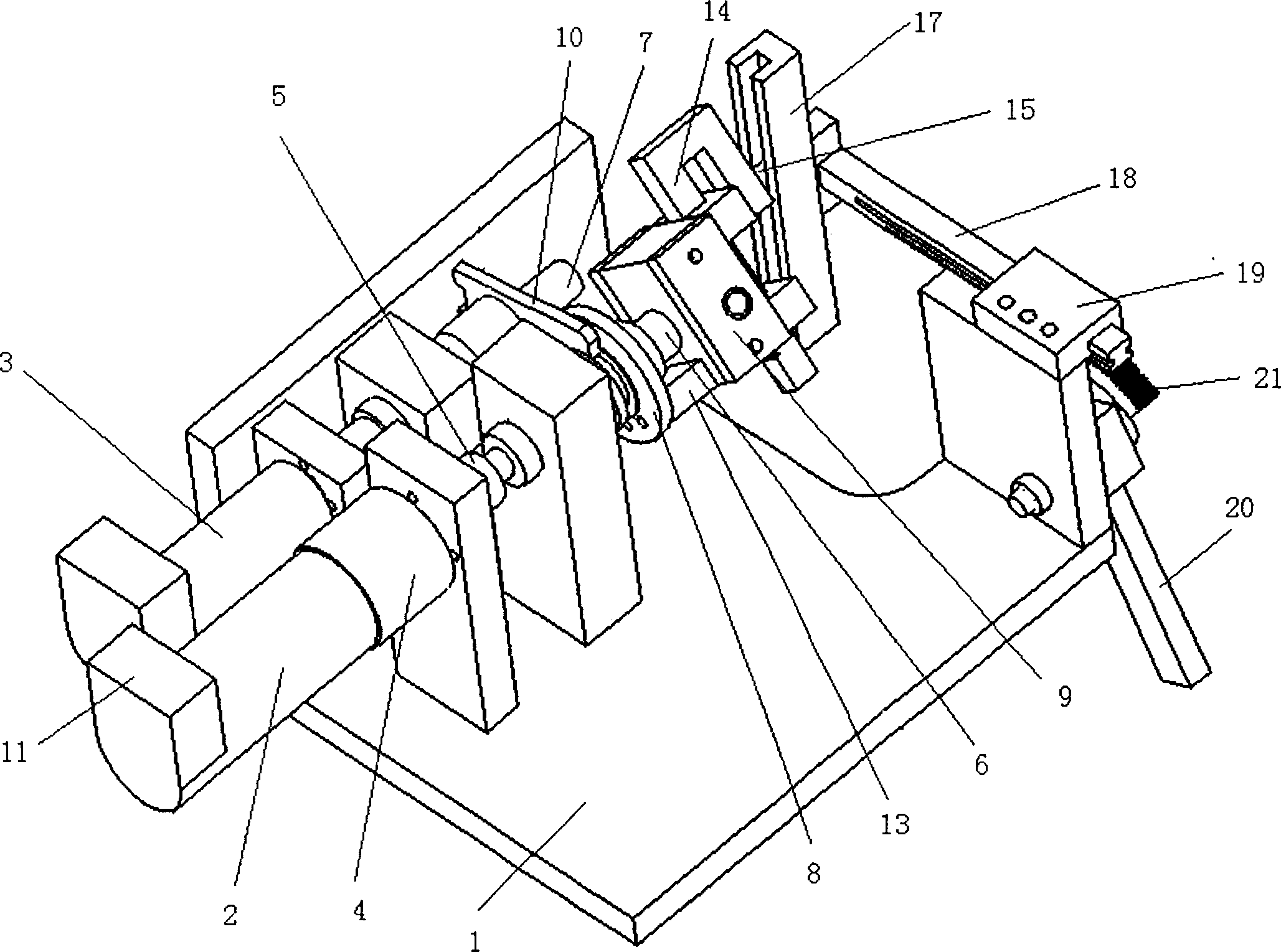

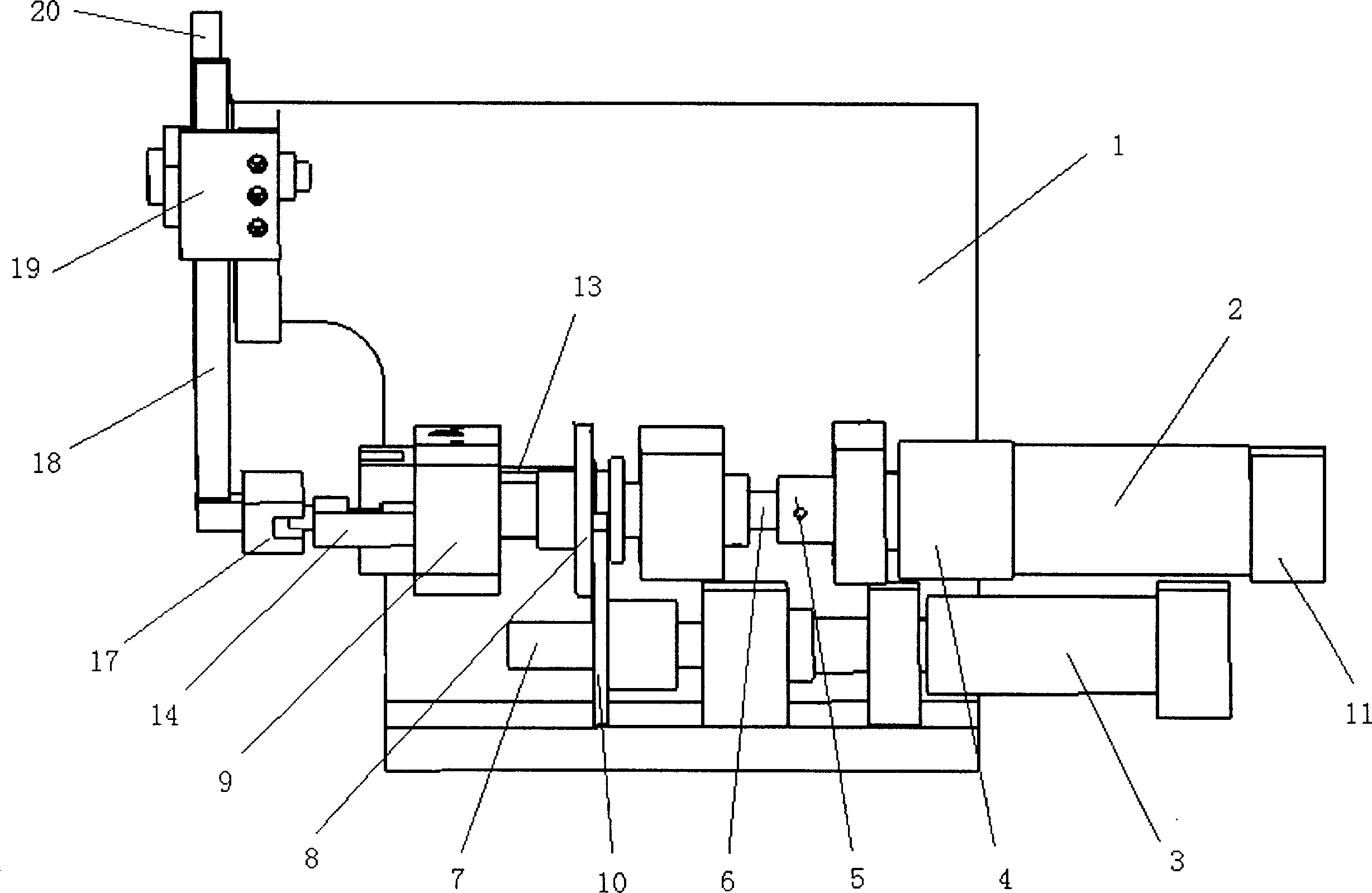

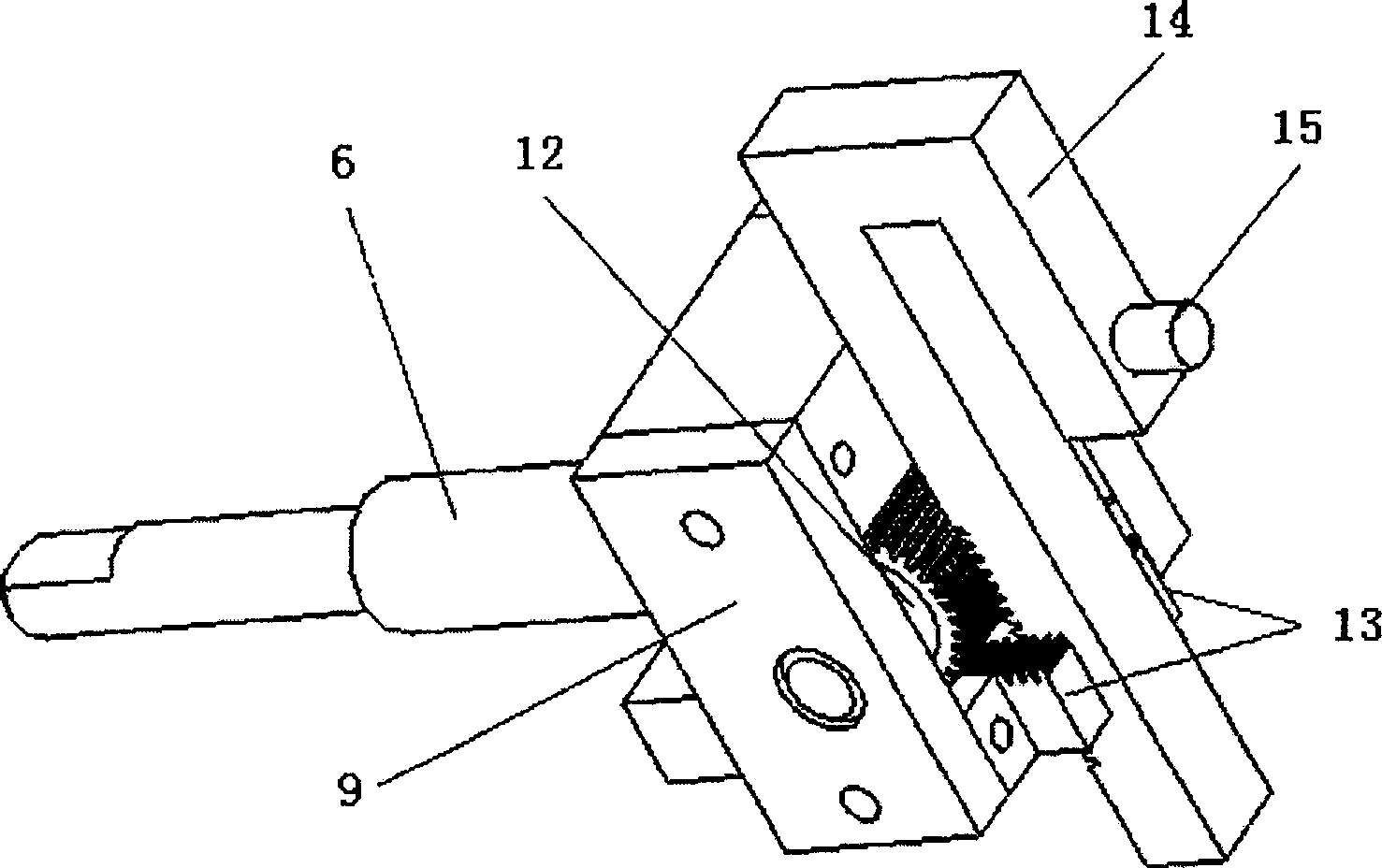

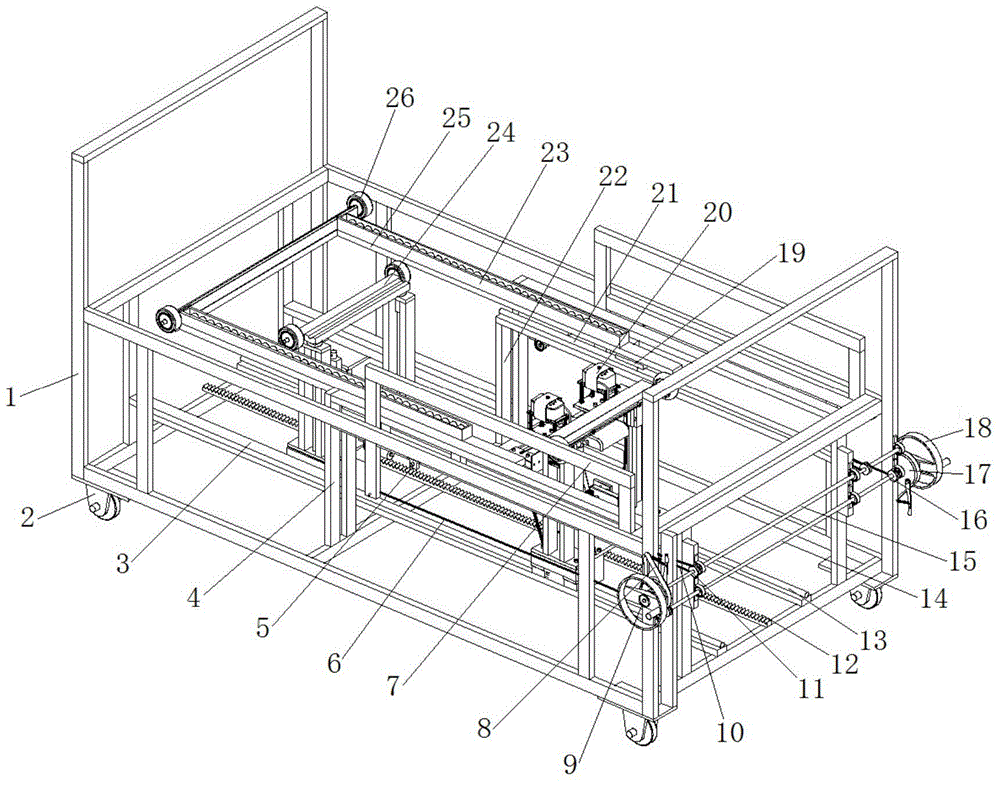

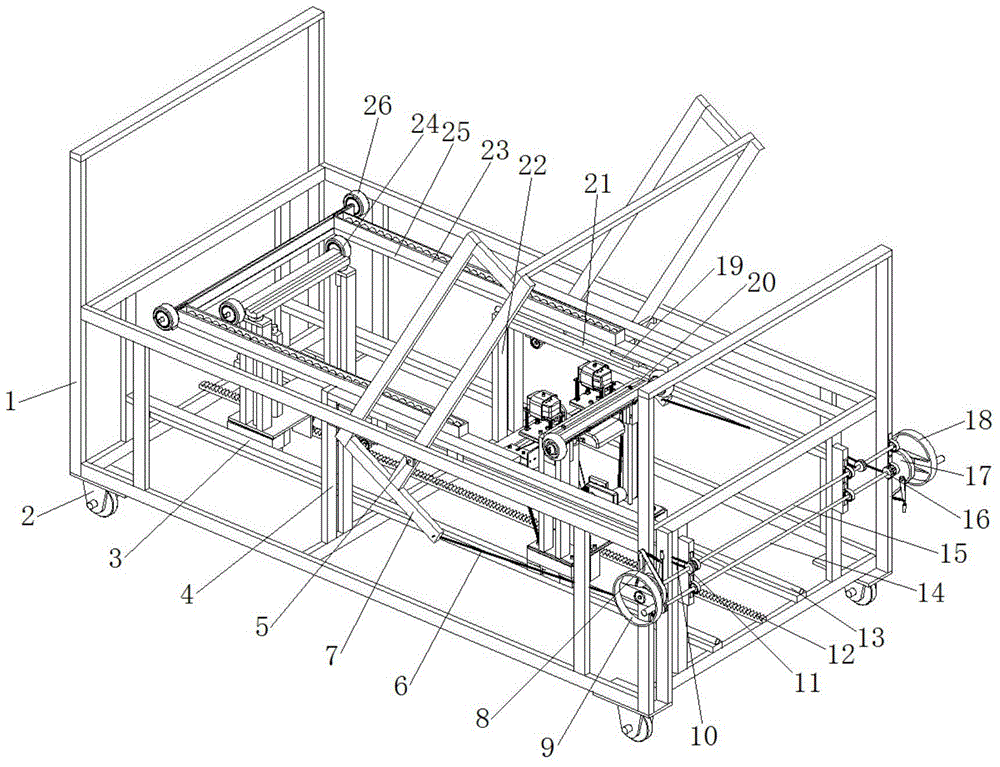

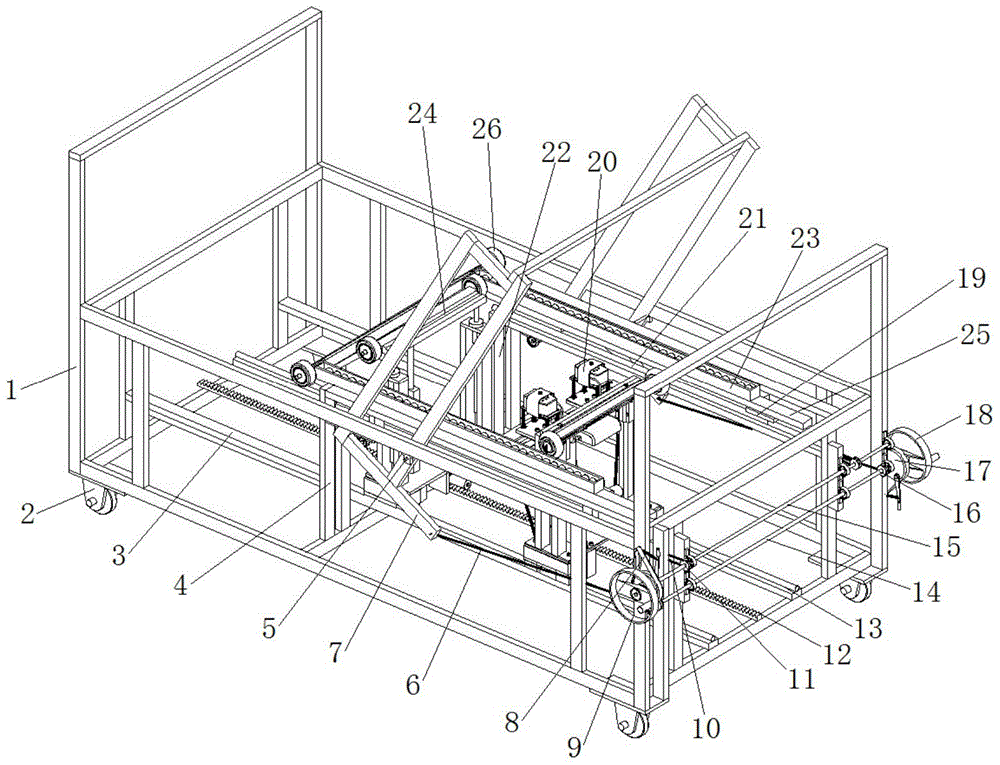

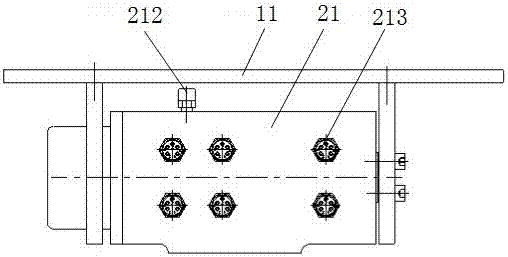

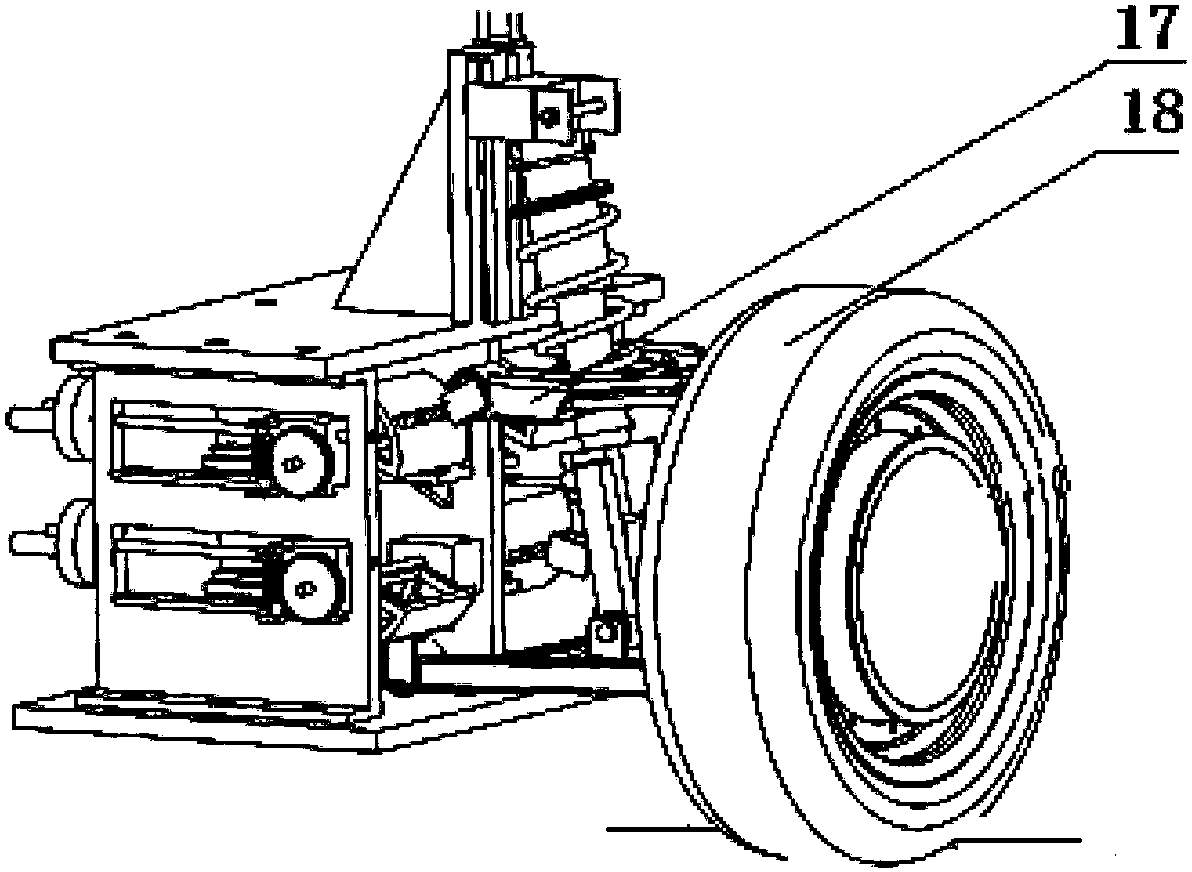

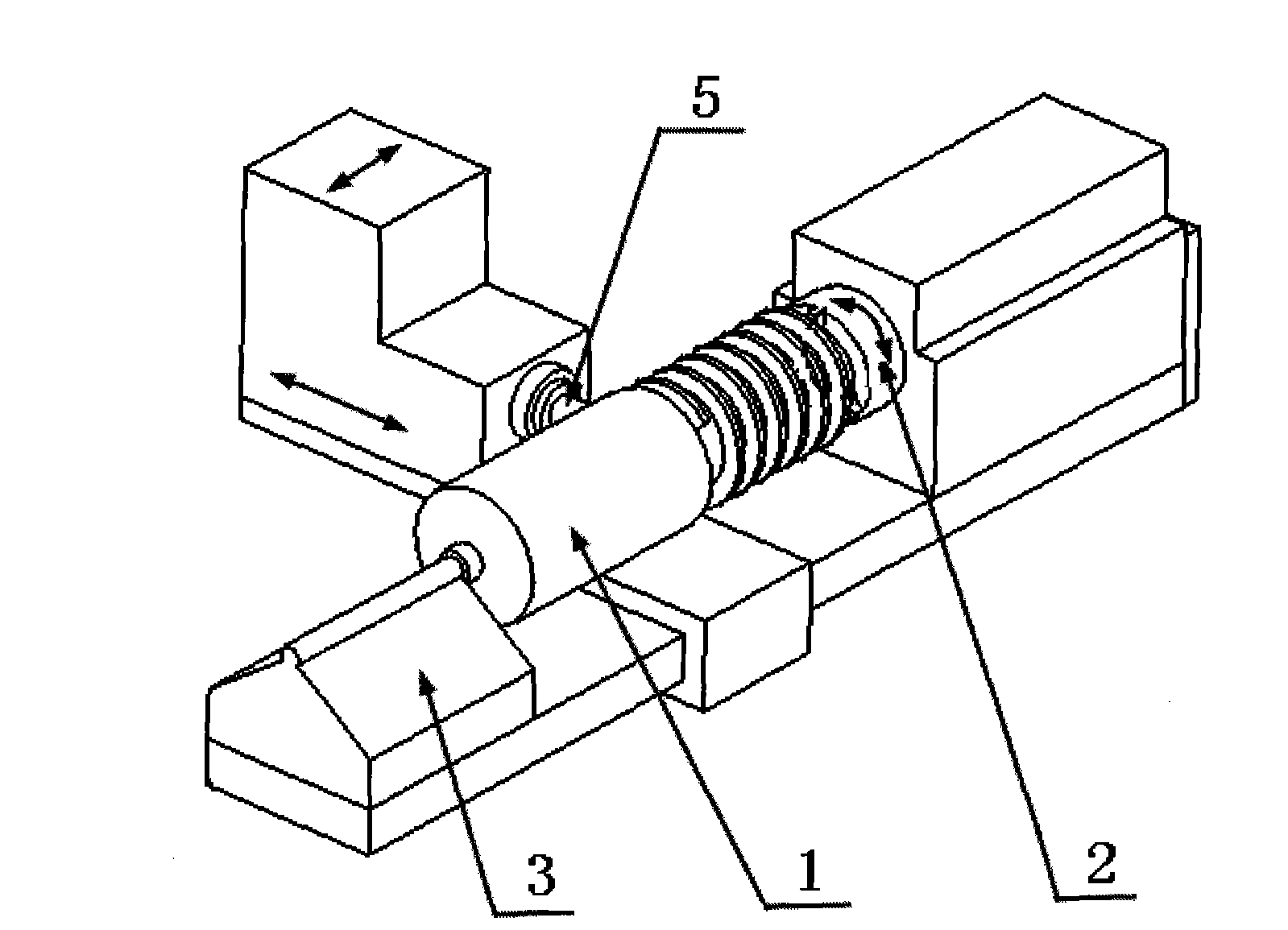

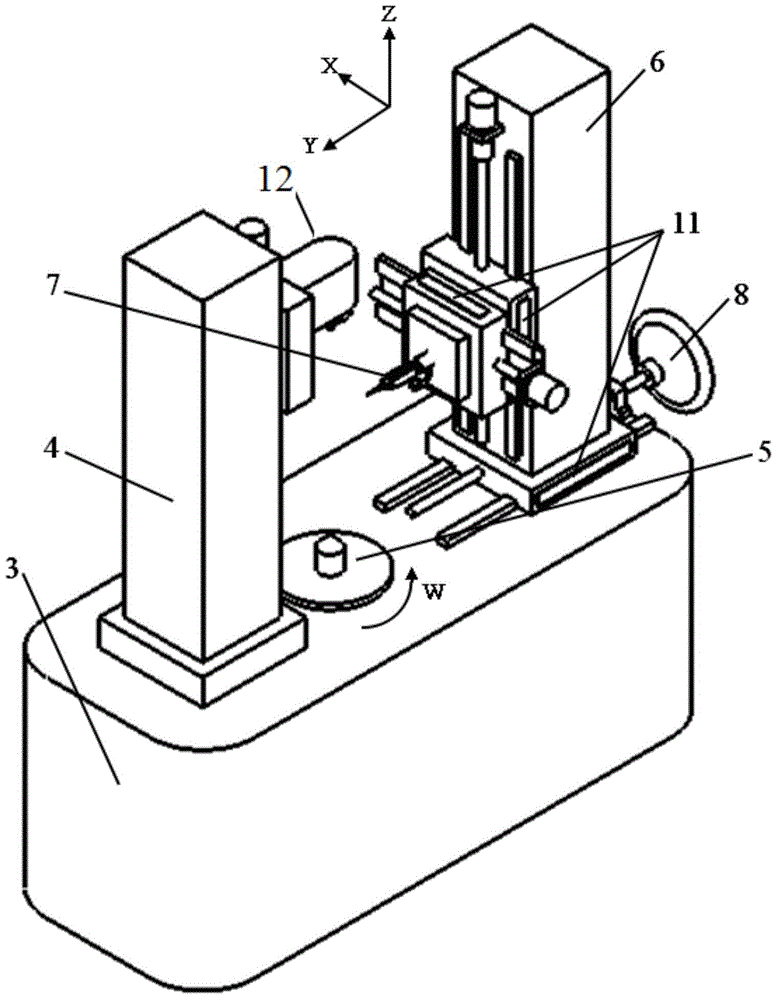

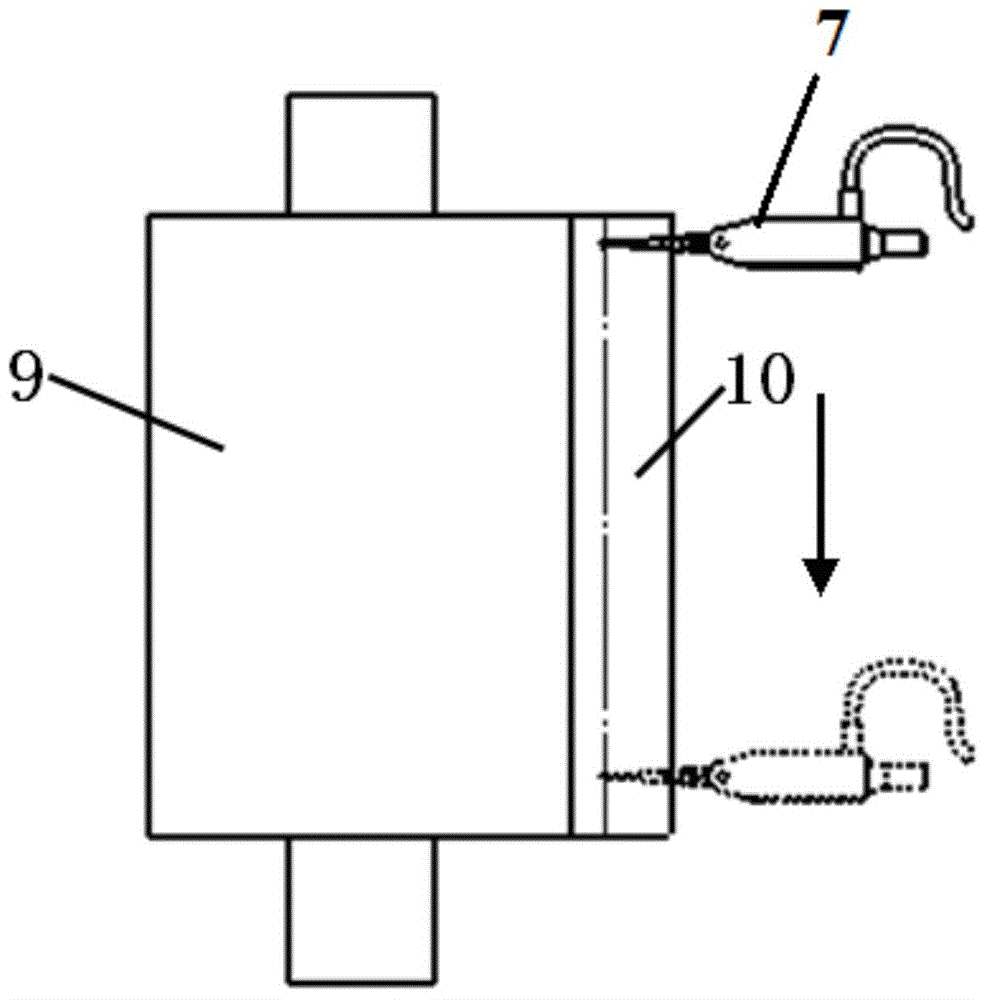

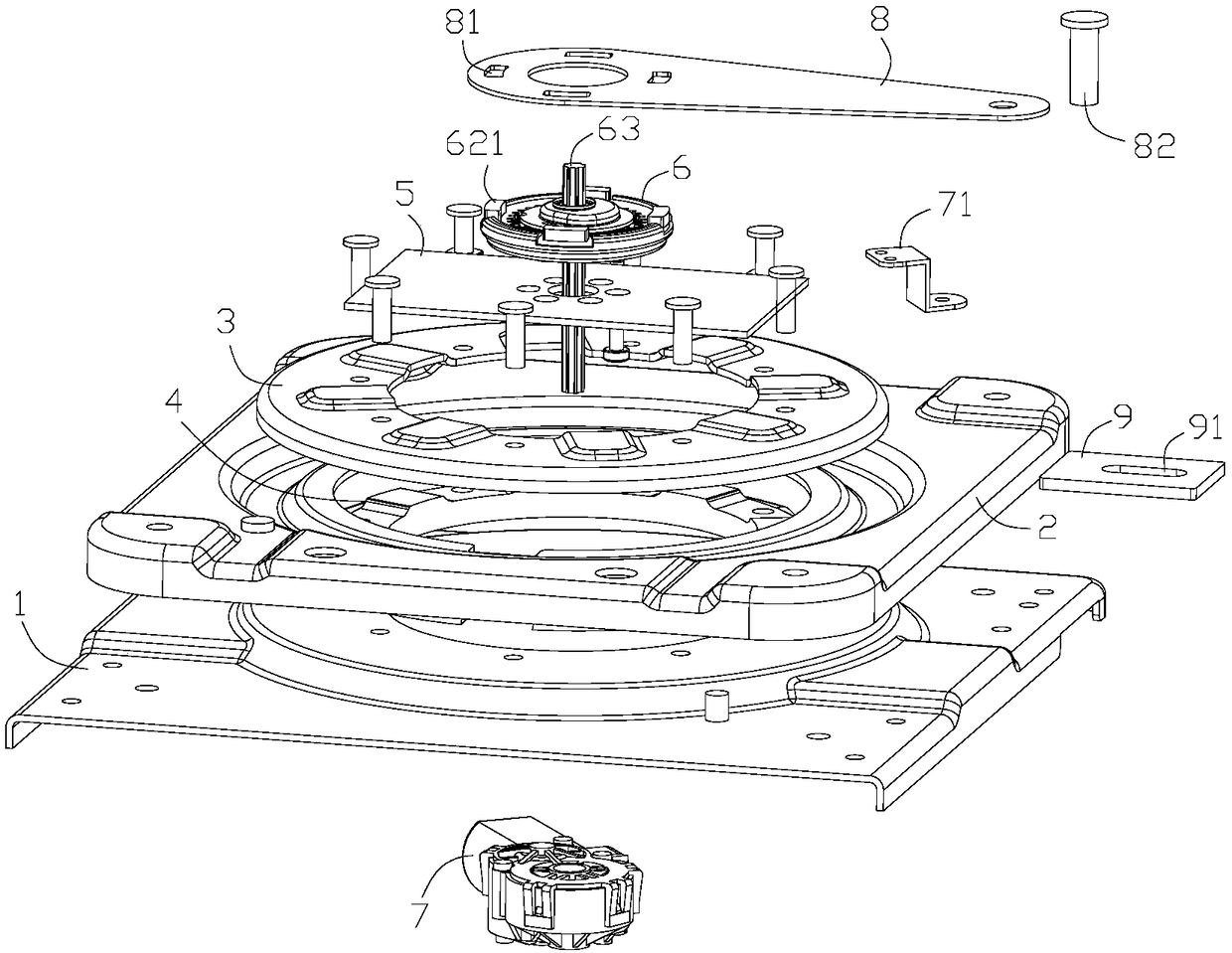

Hard point position stepless adjusting type test rig satisfying multiple suspension fork types

InactiveCN103424268ASimple designEasy to optimizeVehicle suspension/damping testingControl theoryTest rig

The invention relates to a hard point position stepless adjusting type test rig satisfying multiple suspension fork types. The test rig comprises a suspension fork hard point position adjusting mechanism, a supporting frame (9) and a tire suspension fork system loading mechanism. The suspension fork hard point position adjusting mechanism is arranged in the supporting frame, and a cover plate (7) is arranged on the supporting frame (9). The tire suspension fork system loading mechanism is arranged on the cover plate (7). Compared with the prior art, the test rig has the advantages of being simple in structure, compact in layout, suitable for multiple suspension fork types, capable of satisfying the test of the multiple suspension fork types with the hard points smaller than four in number, and also capable of being applied to the suspension fork test with different hard point positions.

Owner:TONGJI UNIV

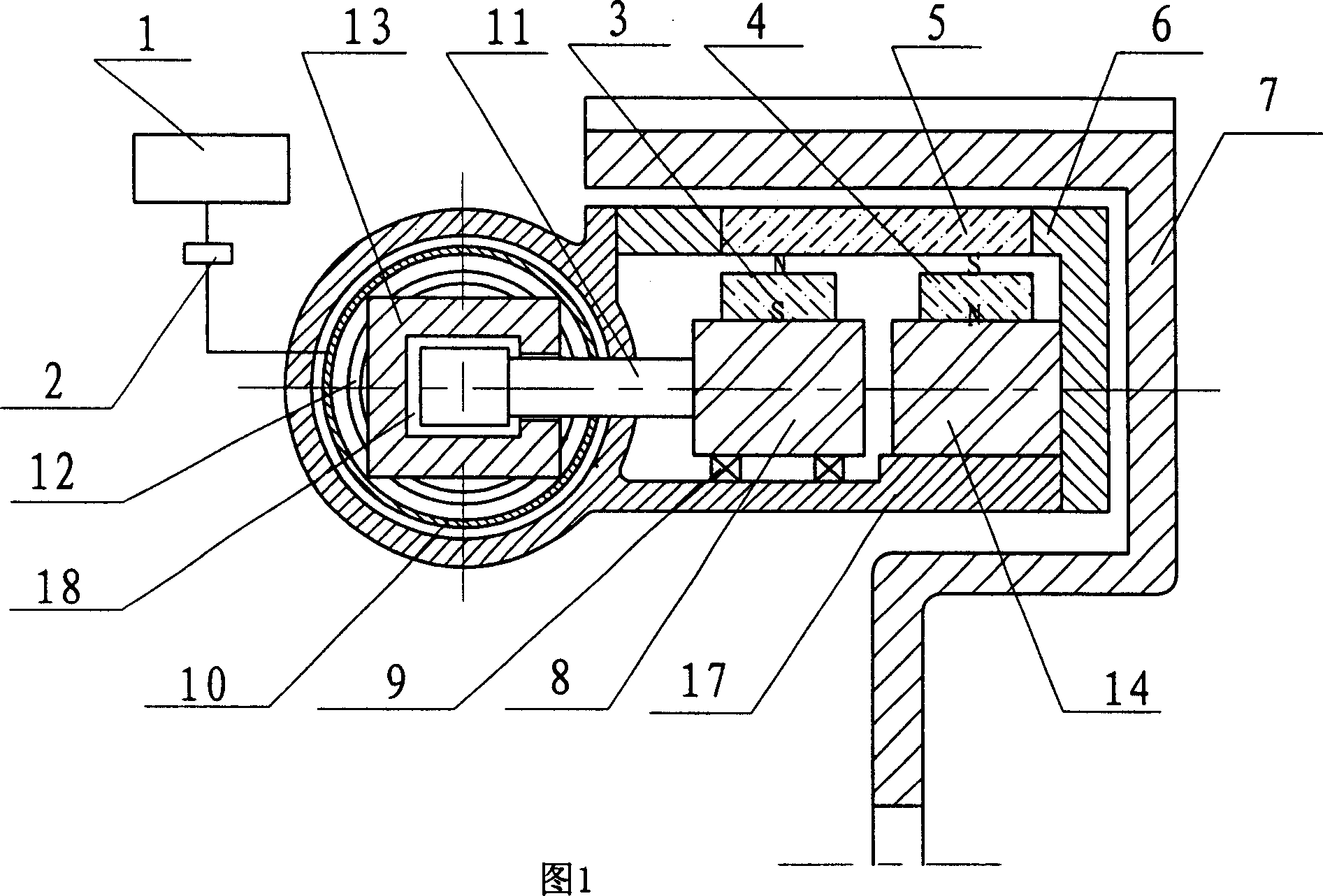

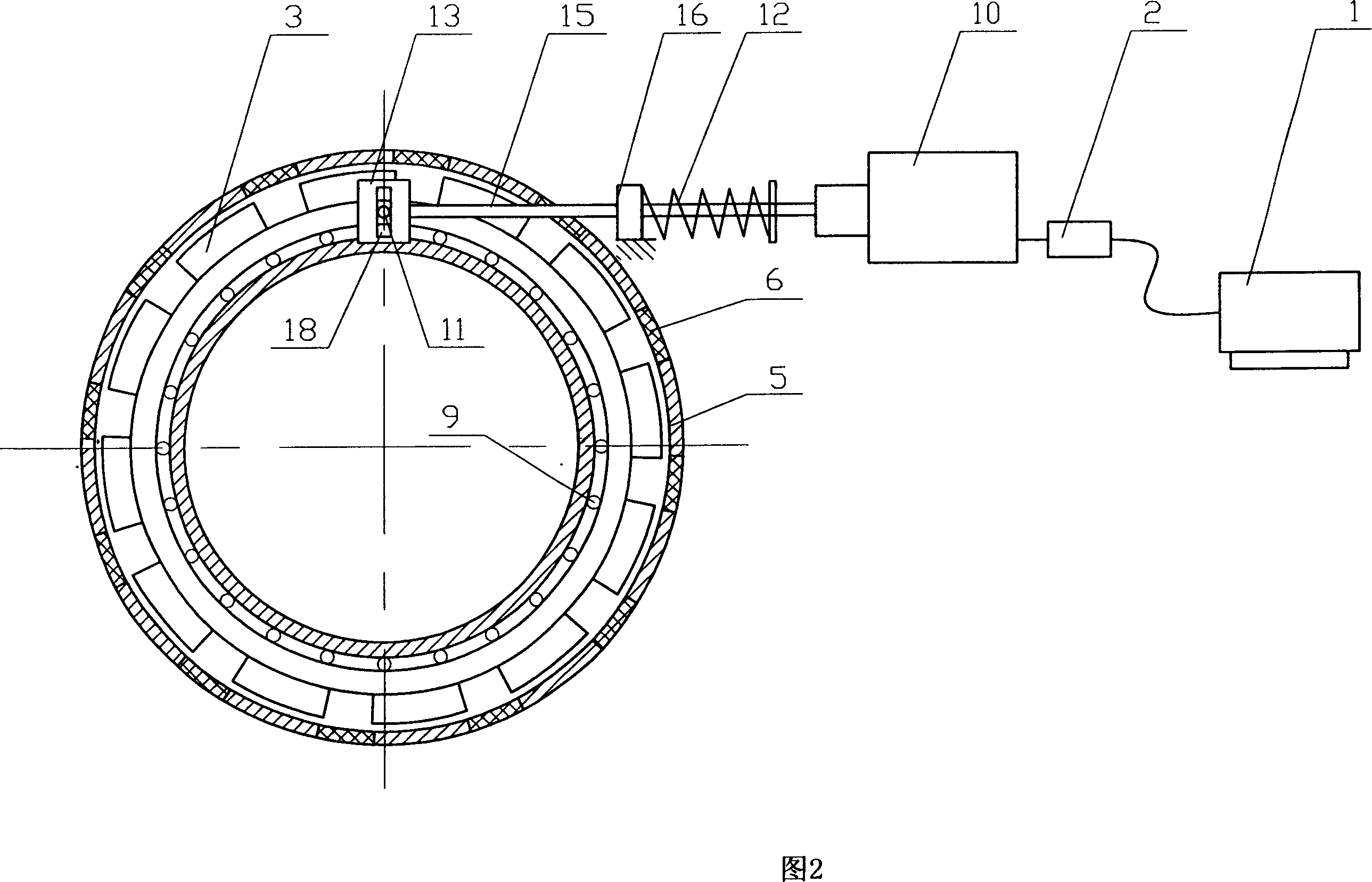

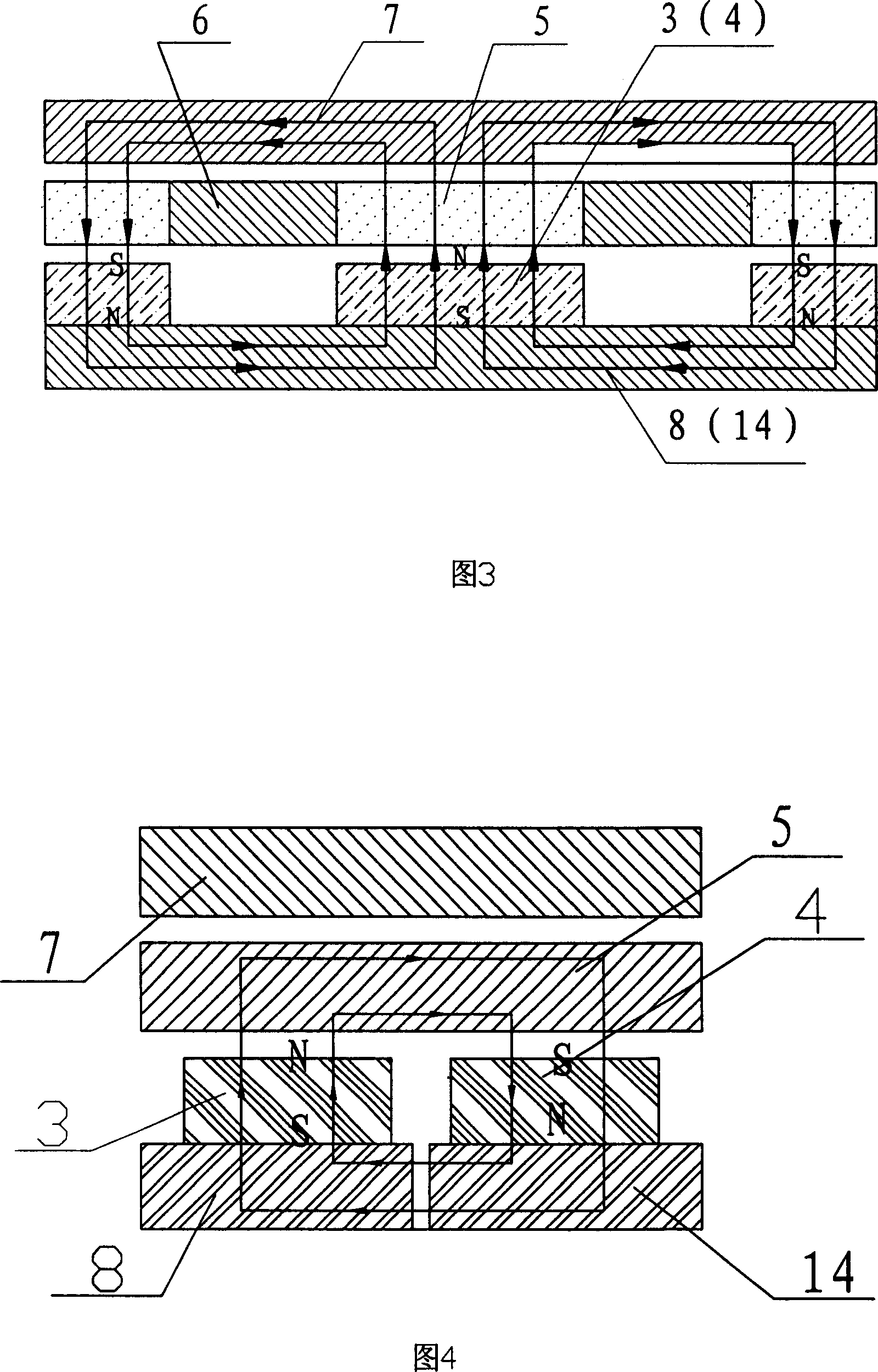

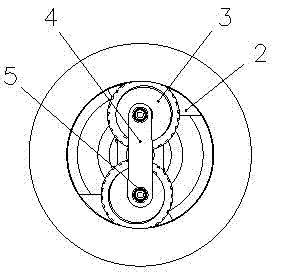

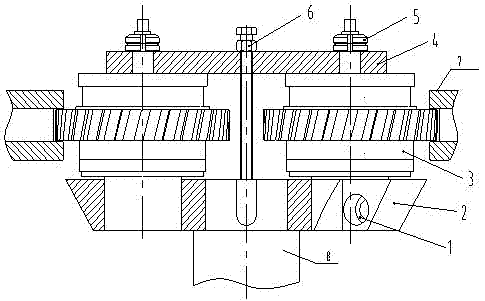

Braking moment stepless regulation permanent-magnet buffer

InactiveCN101009456AChange the strength of the magnetic fieldRealize stepless adjustmentPermanent-magnet clutches/brakesPhysicsStator

The invention relates to trig moment stepless adjusting permanent-magnet slack adjuster. It includes stator and rotor, and at least one elastic device, the rotor is at the out side of the stator, the stator composes magnet retainer, magnet holder, stator casting body, cylinder and several quantity equality fixed permanent magnet and rotating permanent magnet, the active magnet holder can be set in the magnet retainer, the fixed permanent magnet and rotating permanent magnet are separately orientation arranged on the active and fixed magnet holder, the elastic device is connected with active magnet holder and cylinder. The advantages are: the elastic device and magnetic valve are combined to make the rotating permanent magnet rotate any degree based on the demand, so the braking moment can changes one-way continuously for driver to realize the stepless control of braking moment; it adopts ratio magnetic valve to control the operating stroke and pressure of cylinder, the work response of the permanent-magnet slack adjuster is quick, the pressure range of air supply is wide.

Owner:NANJING AGRICULTURAL UNIVERSITY

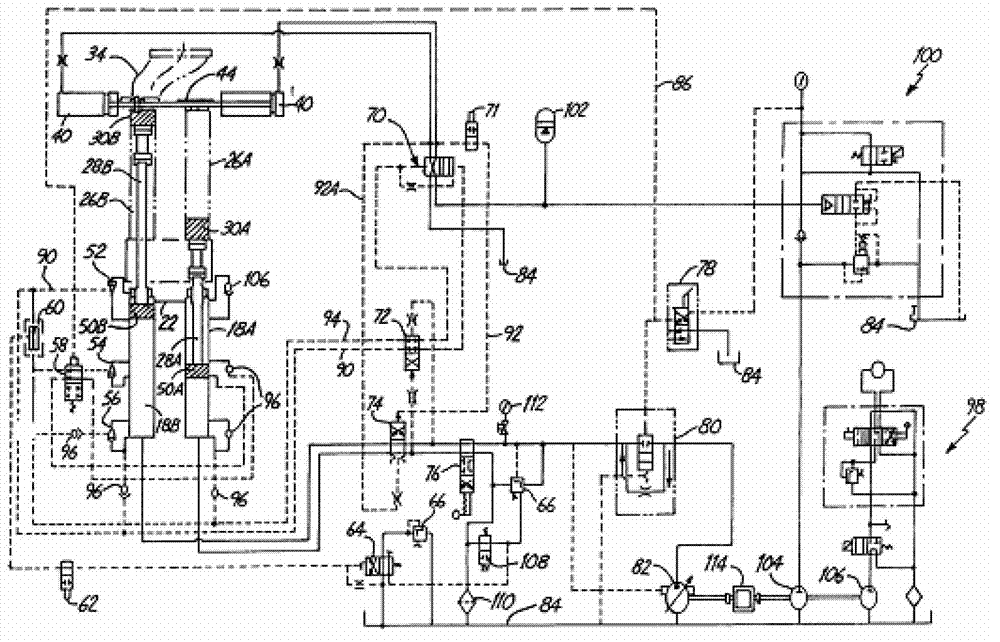

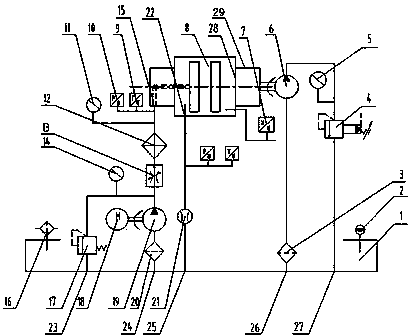

Liquid viscosity transmission tester with hydraulic load device

InactiveCN104047925AEasy to adjustRealize stepless adjustmentFluid-pressure actuator testingLiquid viscosityCoupling

The invention discloses a liquid viscosity transmission tester with a hydraulic load device. The liquid viscosity transmission tester with the hydraulic load device comprises an oil supplying system and a simulation load loading system; an oil supplying system loop is connected with an oil supplying oil path coarse filter, a gear oil pump, an overflow valve, a speed regulating valve, a cooler, a liquid viscosity host, a flowmeter and an oil tank in sequence by a hydraulic pipeline. According to the simulation load loading system, a vane pump is adopted to replace the load device to load; the liquid viscosity host drives the load vane pump to work by the connection of a coupler; a simulation load loading system loop is connected with a load oil path coarse filter, the vane pump, a pilot operated compound relief valve and the oil tank in sequence by a hydraulic pipeline. The liquid viscosity transmission tester with the hydraulic load device is suitable for the test research of a liquid viscosity transmission technology, the system is greatly simplified while the basic demands of the test are met, so the system structure is deeply optimized and the design cost and the manufacturing cost are saved; the load loading system is closer to an actual working condition, so the system is more practical and reliable and has broad use value.

Owner:JIANGSU UNIV

Turning-milling linkage machining method of large-pitch worm

The invention discloses a turning-milling linkage machining method of a large-pitch worm, and relates to the technical field of worm machining methods. The method comprises the following steps of: on a formrelieved tooth lathe, fixing parts to be machined onto the lathe through a three-paw chuck and a centre, wherein the rotation speed of a main shaft of the lathe is 0.1-10r / min, milling the surfaces of the parts by a finger-shaped milling cutter, wherein the rotation speed is 30-80r / min when the finger-shaped milling cutter is used for cutting, the axial feed quantity is 1-12mm / min, the cutting depth is 15mm, the modules of the milling cutter are those of the parts to be machined, the other parameters of teeth of the milling cutter are accordant with the parameters of the worm to be machined, and the installing position of the milling cutter is perpendicular to the principal axis of the parts to be machined, changing a change gear according to the worm machining pitch by the formrelieved tooth lathe to adjust the change gear ratio, and washing the surfaces of the parts to be machined by pressure cooling liquid to form the tooth surface of the worm. The machining method can be used for machining the large-pitch worm, and is high in machining efficiency, and accurate in pitch, and the stepless adjustment on the pitch within a certain range can be realized.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

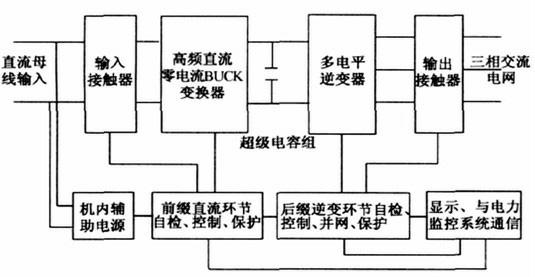

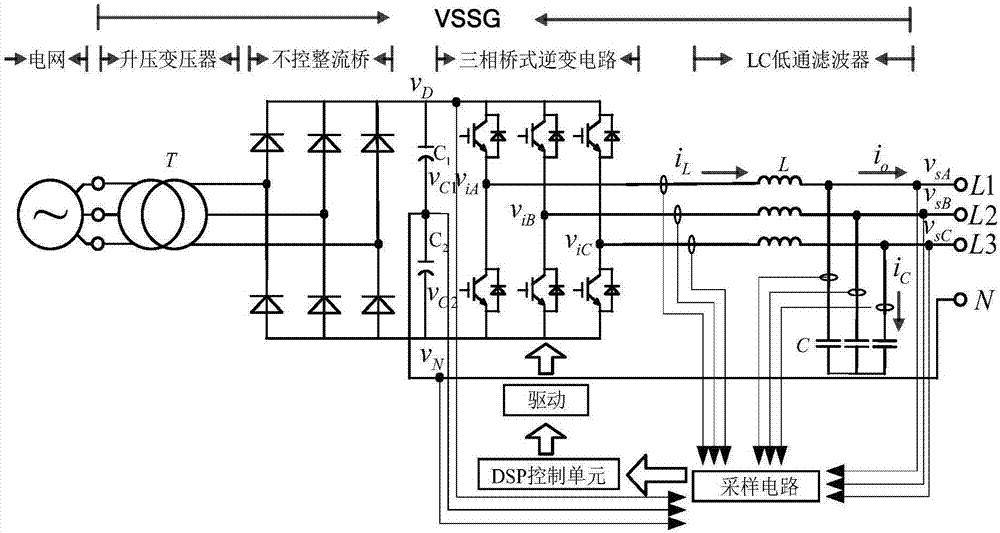

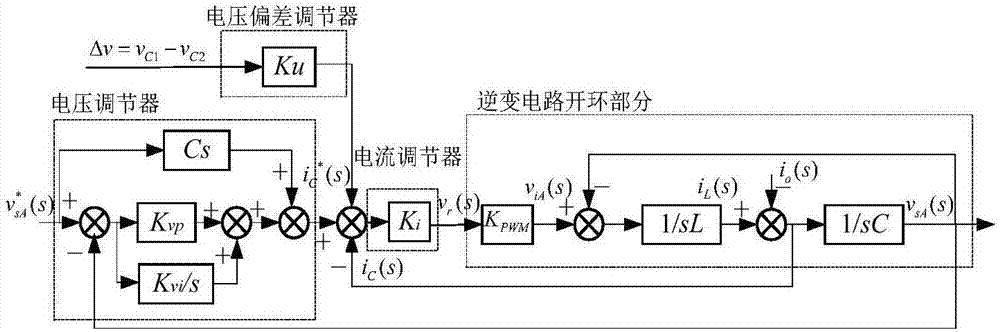

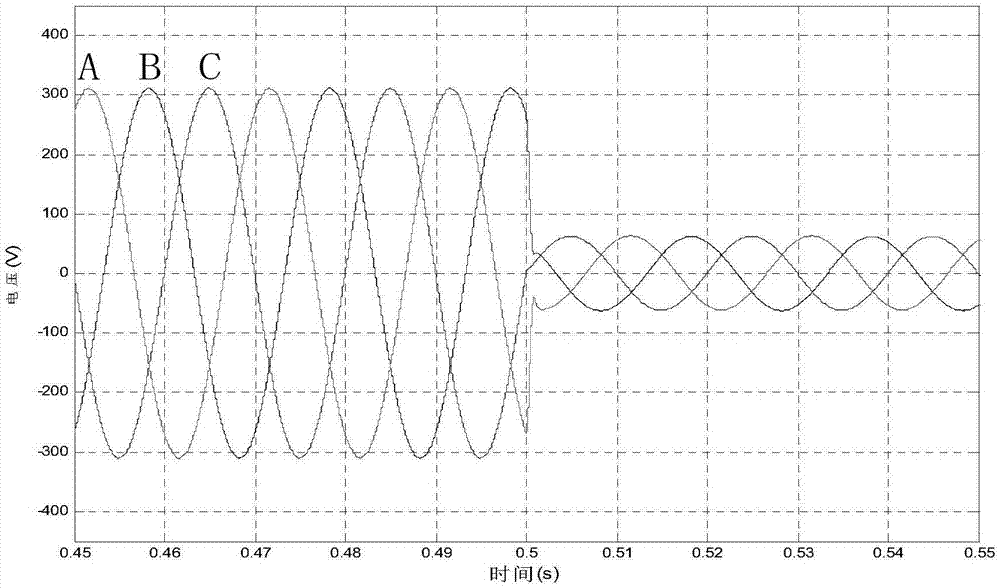

A multi-mode voltage temporary-rise and temporary-drop power supply based on a three-phase inverter

PendingCN107332250ARealize stepless adjustmentOutput voltage continuously regulatedAc-dc conversionAc network voltage adjustmentCapacitanceTransformer

The invention discloses a multi-mode voltage temporary-rise and temporary-drop power supply based on a three-phase inverter. According to the invention, a step-up transformer raises the voltage of the general commercial electric supply to be more than the maximum voltage required for the temporary rise, and rectification is carried out through a three-phase uncontrolled rectifier bridge to provide a DC power supply for the three-phase inverter. A direct current bus split capacitor is connected between the uncontrolled rectifier bridge and a three-phase bridge type inverter circuit. The midpoint of the split capacitor is lead out to be used as an output neutral line to form a three-phase four-wire topological structure to achieve complete decoupling between output phases. Through an inverter SPWM control strategy, each gate signal is generated to control the on / off time of each switch so as to realize the independent control of the voltage of each phase and the control of the voltage deviation of the split capacitor in a DC link; the direct current is converted into an SPWM wave; and finally, an LC sine filter filters out high-frequency harmonics and outputs a sine wave that meets the specified amplitude, phase and frequency to achieve the accurately adjustable duration of the transient voltage and the accurately adjustable voltage phase and amplitude of any phase.

Owner:HANGZHOU DIANZI UNIV

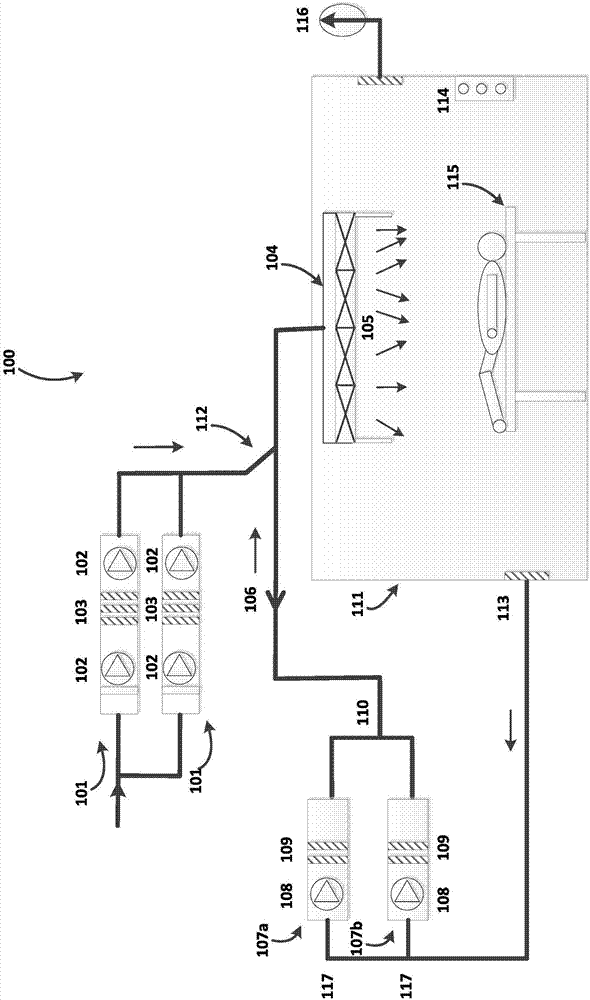

Weak turbulence air purification system capable of regulating cleanliness

PendingCN107883436AReduce the risk of infectionSave electricityMechanical apparatusLighting and heating apparatusAuto regulationAir volume

The invention relates to a weak turbulence air purification system capable of regulating cleanliness. The system is provided with one or more fresh air units, a blowing ceiling, a return air processorand a central controller, wherein the one or more fresh air units is provided with a fan, a fresh air filter layer, a dehumidifying device and an air conditioning device; the blowing ceiling is provided with a filter module which is configured to diffuse input fresh air and return air, so that the fresh air and return air enter a medical room in a form of weak turbulence; the return air processorcomprises a return air filter device for purifying and filtering imported return air; and the central controller is configured to adjust the capacities, for example, blast capacity, cooling capacity,heating capacity, humidification amount and etc.) of various functional units of the air purification system manually or automatically according to the environmental requirements (for example, temperature, humidity, air speed, cleanliness, pressure difference of a filter and etc.) of the medical room (for example, operating rooms of various types). The invention also relates to a corresponding operating room capable of regulating the cleanliness.

Owner:殷晓冬

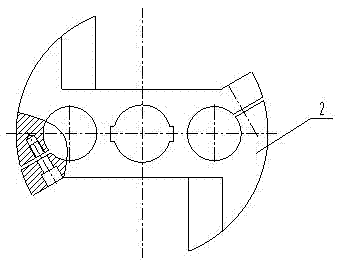

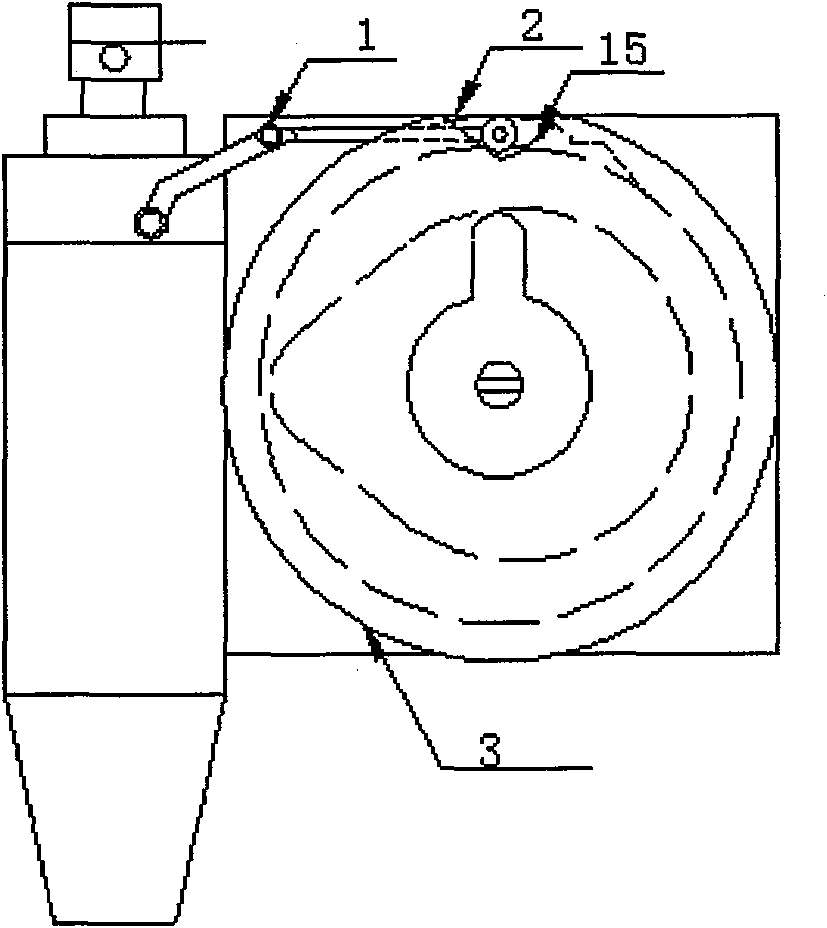

Stepless regulation device for gap between compression roller and ring die

The invention discloses a stepless regulation device for a gap between a compression roller and a ring die, comprising an elastic clamping tumbler fixedly connected to a main shaft, wherein the elastic clamping tumbler is symmetrically provided with two compression roller assemblies; the front ends of the two compression roller assemblies are provided with junction plates fixed by levorotatory round nuts; the middle of each junction plate is provided with a tension stud connected with the elastic clamping tumbler; the middle of the elastic clamping tumbler is rectangular; two sides of the elastic clamping tumbler are in reverse symmetric arc shape; the middle of the elastic clamping tumbler is provided with a center hole matched with a main shaft key; two sides of the center hole are symmetrically provided with two side holes respectively matched with the two compression roller assemblies; one side of the two side holes, which is near the direction of the arc shape, is respectively provided with a gap; and a plane vertical to the gap is provided with an inner hexagon screw. The stepless regulation device has simple structure, can realize the purpose of the stepless regulation of the gap, is convenient to regulate the gap between the compression roller and the ring die and is practical and reliable.

Owner:徐州科融科技园发展有限公司

Mechanical automatic shutoff gate valve

InactiveCN101813199AAccurate calculation of rotational angular velocityPrecisely control the total amount of outflowOperating means/releasing devices for valvesSlide valveImpellerReducer

The invention relates to a mechanical automatic shutoff gate valve, which comprises a turbine, transmission reducer and an automatic shutoff device. The turbine comprises a volute shell, an impeller is arranged in the volute shell, the middle part of the impeller is provided with an impeller shaft, the two ends of the volute shell are respectively provided with an oblique port, the outer sides of the two ends of het volute shell are respectively provided with a diversion net, and the outer sides of the diversion net are respectively provided with an end cover; the transmission reducer comprises a shell, a transmission wheel is arranged in the shell and is engaged with a main wheel, wherein the radius of the transmission wheel is smaller than the radius of the main wheel, the transmission wheel is provided with a transmission wheel shaft, the transmission wheel shaft is fixedly connected with the impeller shaft, the main wheel is provided with a main wheel shaft, and the main wheel shaft is provided with scales; the automatic shutoff device comprises a brake wheel, the brake wheel is provided with a groove, the upper part of the outer side of the brake wheel is provided with a brake lever, the end of the brake lever is provided with an elastic sheet, and the main wheel shaft is fixedly connected with the brake wheel. The invention has a simple structure, and can accurately control the total amount of the effluent completely through the mechanical device, realize the automatic shutoff, and realize the stepless regulation of the total amount of the effluent within the range of the maximum amount of the effluent.

Owner:WUHAN UNIV

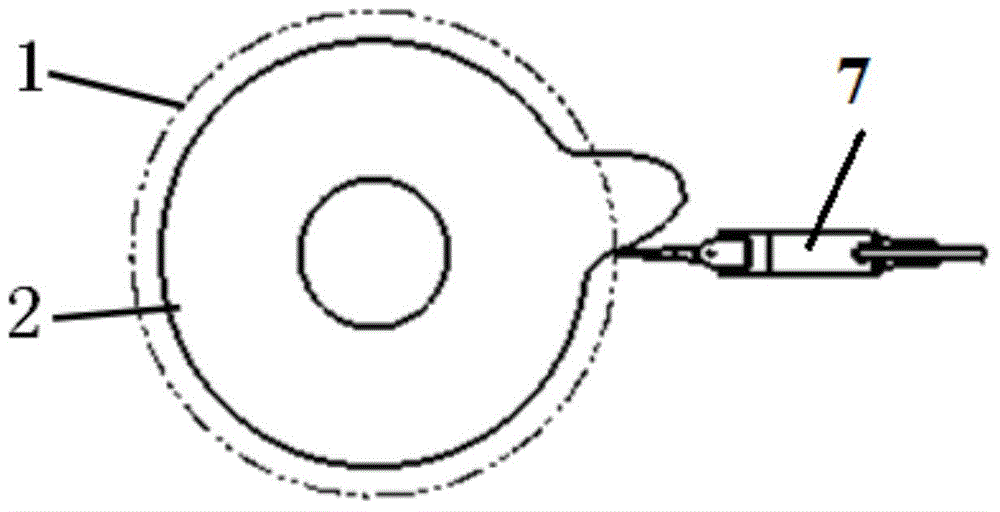

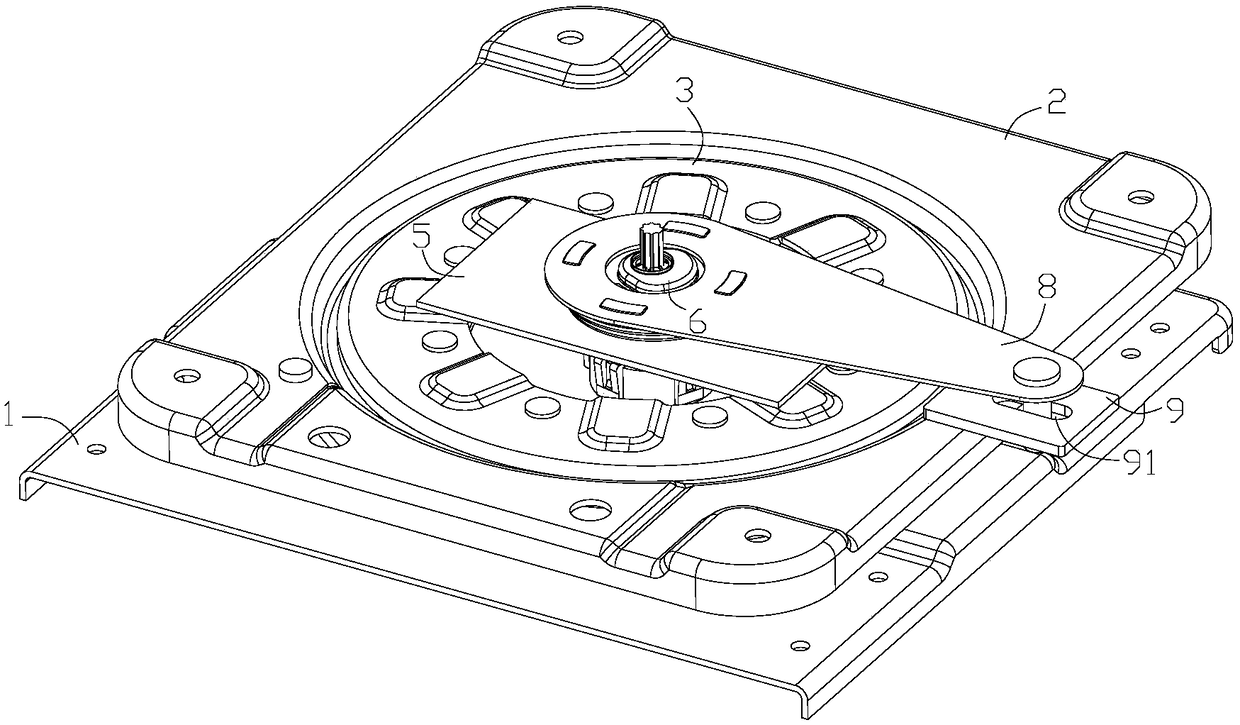

Three-axis linkage-based complicated part accurate measurement central path planning realizing method and device

ActiveCN104154849ARealize stepless adjustmentEasy to detectUsing electrical meansUsing optical meansCircular discElectric sense

The invention provides a three-axis linkage-based complicated part accurate measurement central path planning realizing method and a device. the device comprises a base, a workpiece vertical column, and a measurement vertical column, wherein the measurement vertical column is provided with an electric sensing head capable of moving vertically and horizontally. Horizontal movement of the measurement vertical column is used for contotrlling the distance between the measuring head and the center of a spindle rotating shaft system, stepless adjustment of a basic circle can be realized, a series of basic circle discs do not need to assist measurement of a gear, the detection process is simplified, and detection errors due to wear of the basic circle discs can be solved. Through controlling vertical movement, horizontal movement of the measuring head and linkage of the spindle rotating shaft system, control of the measuring trajectory of the measuring head can be realized respectively, and helix, tooth profile and pitch error of the gear with any base circle radius value within the measuring range can be fully automatically measured. In addition, path planning of an eccentric gear can be realized, and full-automatic measurement on helix, tooth profile and pitch error of the eccentric gear can be realized.

Owner:西安秦川思源测量仪器有限公司

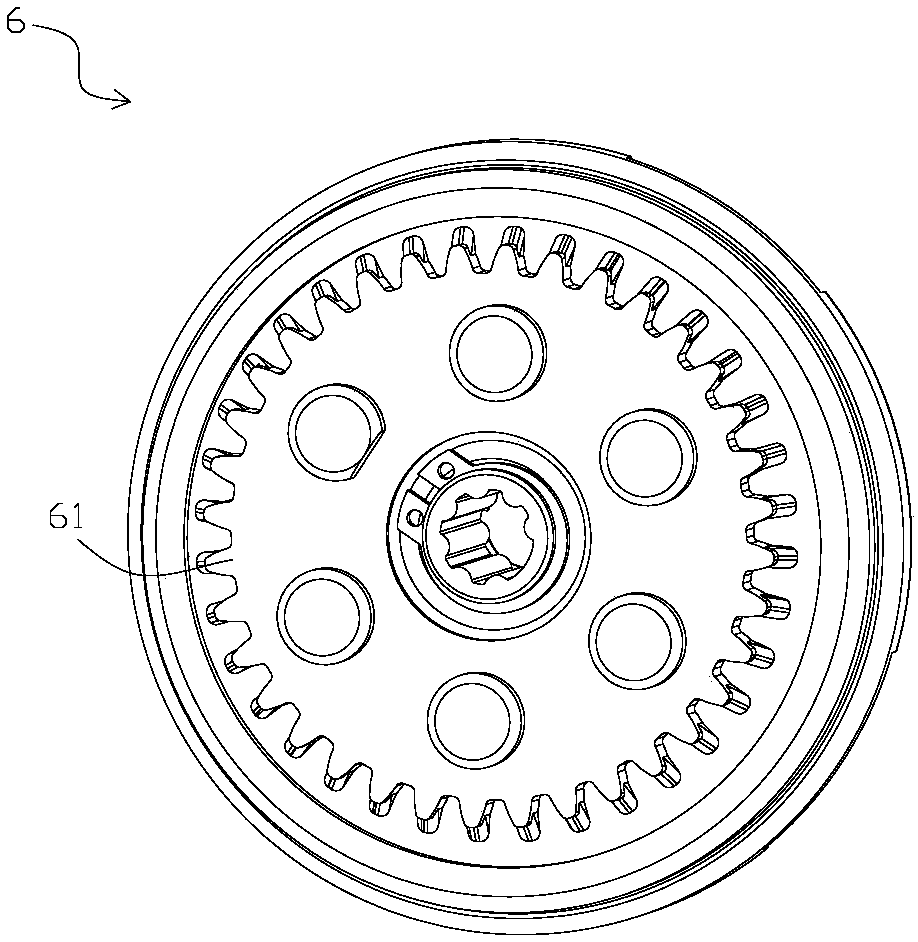

Vehicle seat and electric rotation device thereof

ActiveCN108528280ACompact structureRealize stepless adjustmentMovable seatsDrive wheelElectric machinery

The invention discloses a vehicle seat and an electric rotation device thereof, the electric rotation device comprises a base and a rotary plate and further comprises a driving part, wherein the driving part comprises a motor and an angle adjuster which comprises a rotation shaft, a driving wheel, an inner toothed plate and an outer toothed plate, the inner toothed plate and the outer toothed plate are mutually meshed, and the rotation shaft is connected with the output shaft of the motor and is connected with the outer toothed plate by the driving wheel so that the outer toothed plate can rotate relative to the inner toothed plate; the inner toothed plate is connected with the base, and the outer toothed plate is connected with the rotary table. Accordion to the vehicle seat and an electric rotation device thereof, the motor drives the angle adjuster so that the rotary table can rotate relative to the base, the manpower is saved, the adjustment is convenient, and the vehicle seat hasexcellent comfort. The angle adjuster has the advantage of compact structure on the basis of realizing transmission, stepless regulation of the electric rotation device can be realized, and the rotarytable can rotate to any position relative to the base and is locked when adjusted to the position. The angle adjuster can bear the external force from all direction of the electric rotation device, so that the strength of the electric rotation device can be improved.

Owner:HUBEI HAPM MAGNA SEATING SYST CO LTD

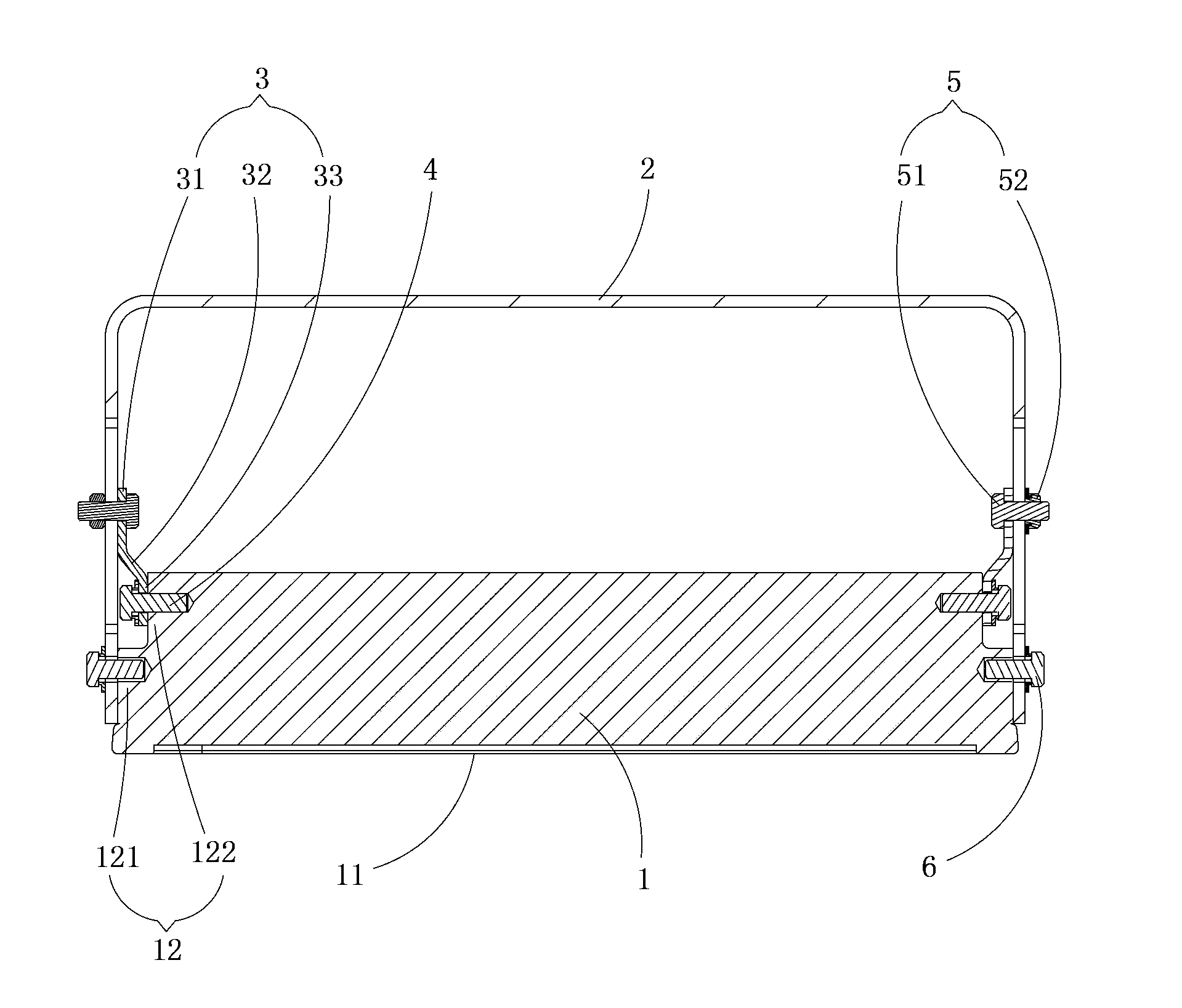

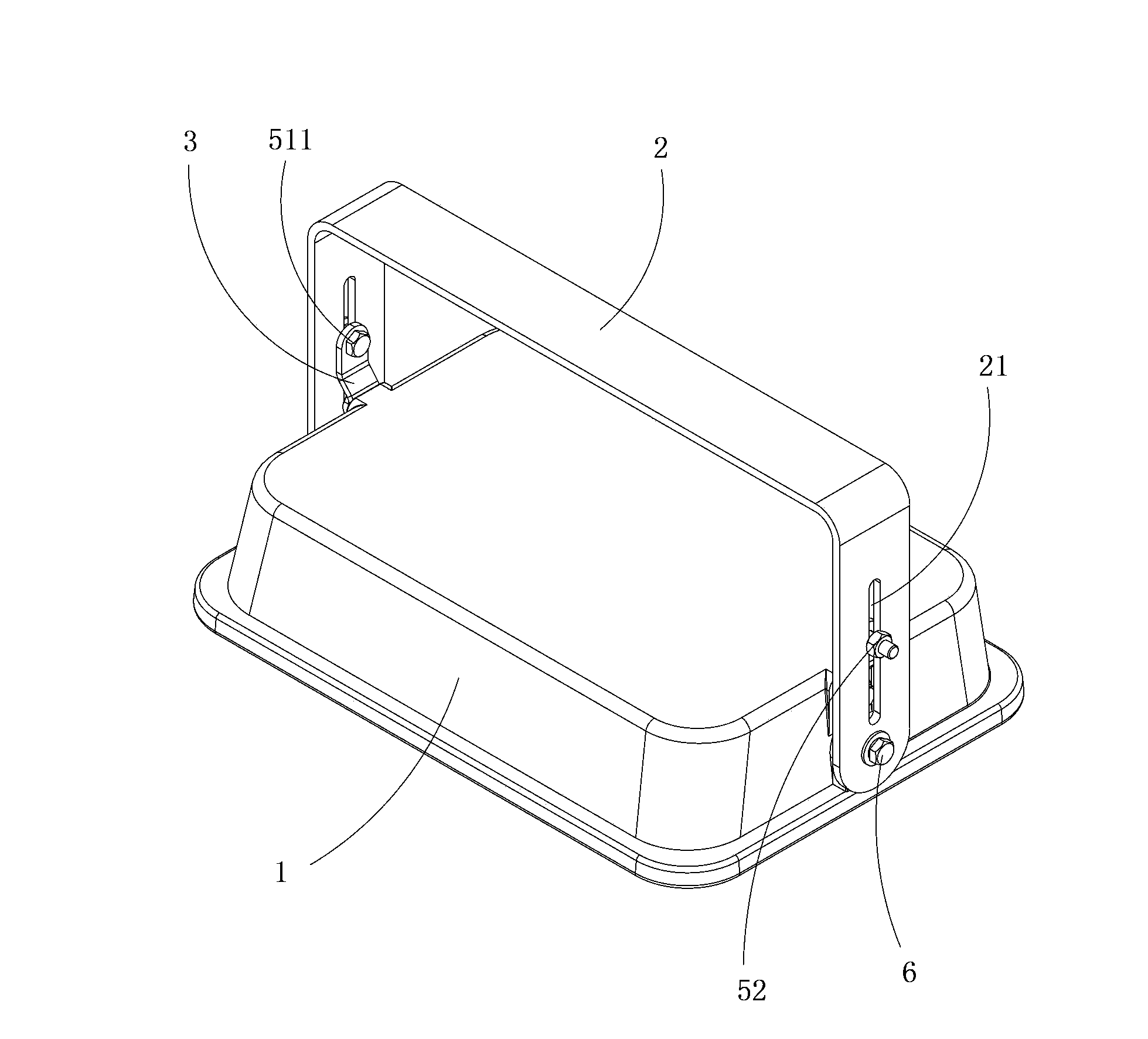

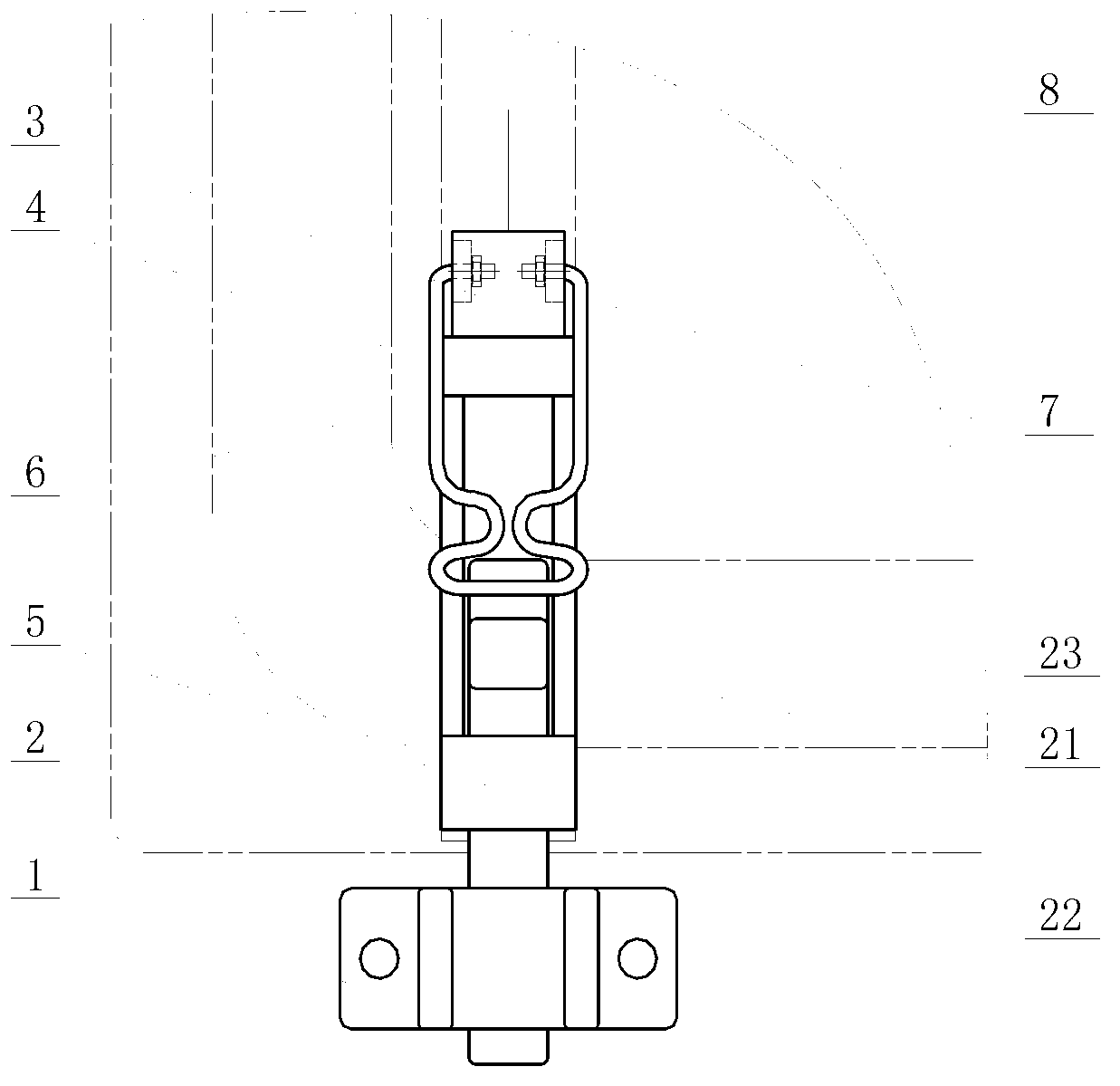

Lamp mounting structure

InactiveCN103791462APrecise positioningIrradiation angle stepless adjustmentLighting support devicesLight fasteningsEngineeringIllumination angle

The invention is applicable to the technical field of lamp installation and discloses a lamp mounting structure. The lamp mounting structure comprises a lamp body and a support, wherein the support is connected with the lamp body in a hanging way, a positioning block capable of preventing the support and the lamp body from rotating relatively is arranged between the support and the lamp body, one end of the positioning block is fixed on the lamp body, while the other end of the positioning block is connected to the support through a locking member, and a sliding groove allowing the locking member to pass therethrough is formed on the support. The lamp mounting structure is characterized in that the positioning block is arranged between the support and the lamp body, one end of the positioning block is fixed on the lamp body, while the other end of the positioning block is connected to the support through the locking member, and the support is further fixedly connected with the lamp body, so that the connection of the lamp body and the support is secured in the three-point positioning way and relative rotation between the lamp body and the support is effectively prevented, and in the meantime, the sliding groove is formed on the support so that the positioning block is slidingly connected to the support and the connection points are continuous, and as a result, the illumination angle of the lamp is accurate and can be adjusted electrodelessly, and the illumination effect of the lamp is improved.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

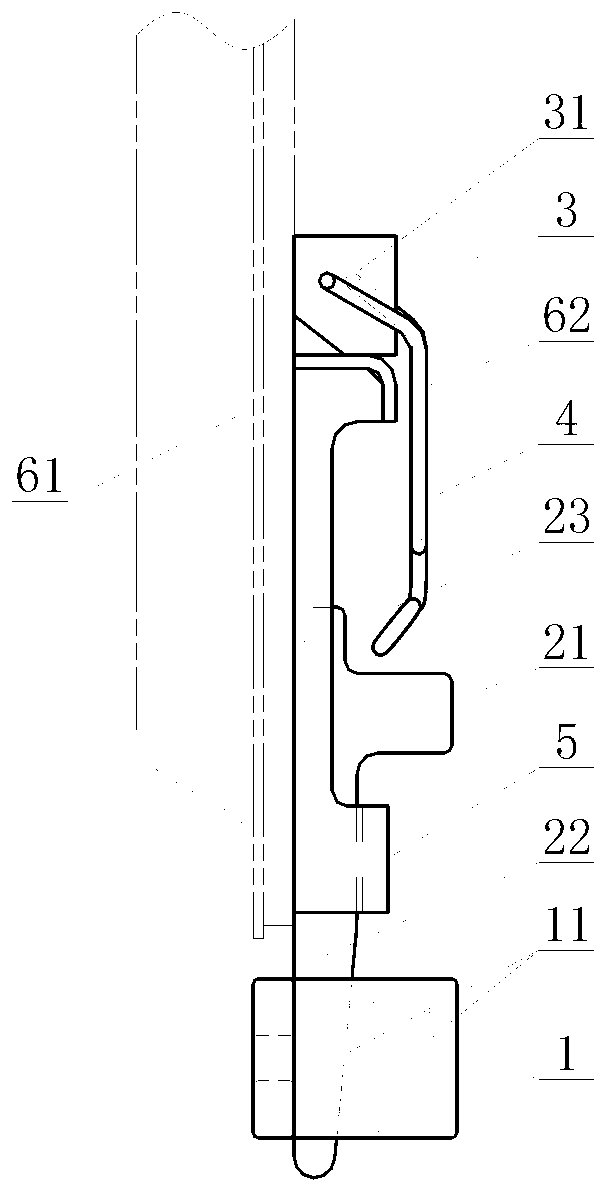

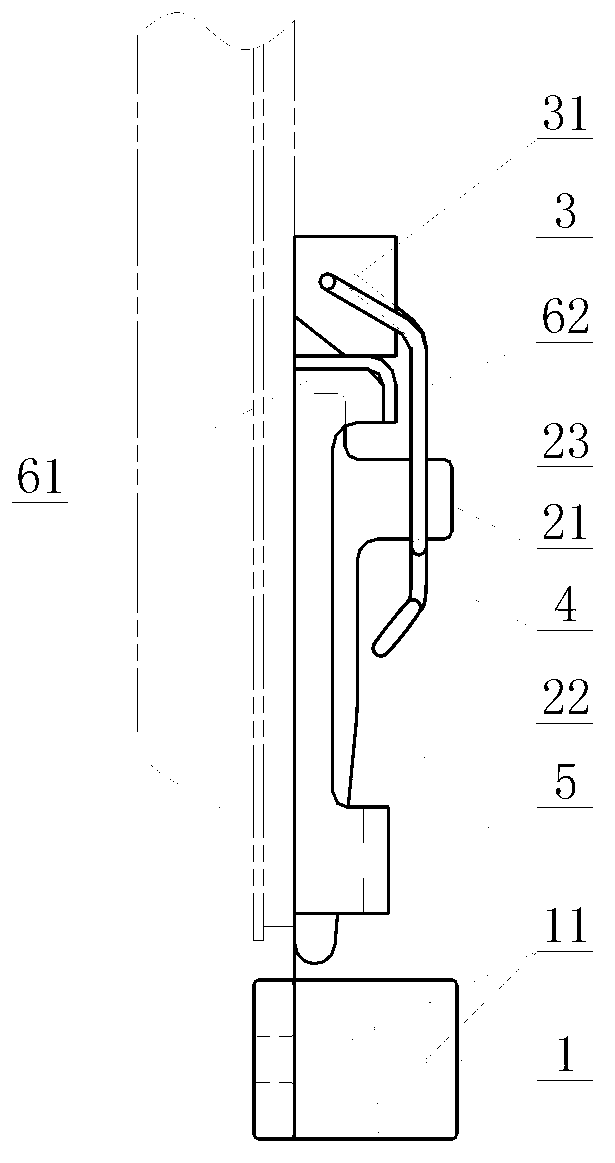

Locking device for bottom side door of railway open wagon

ActiveCN103161362ARealize stepless adjustmentWith self-locking functionVehicle locksEngineeringSelf locking

The invention relates to the technical field of railway transportation equipment, in particular to a locking device for a bottom side door of a railway open wagon. The locking device comprises a plug pin seat, a plug pin, a hanging ring seat and a hanging ring. The plug pin seat is fixed on a wagon body of the open wagon and is provided with a plug pin hole. The plug pin is provided with a transverse protruding plug pin head. The plug pin is in a tapered wedge shape and is matched with the plug pin hole. Matching surfaces between the plug pin and the plug pin hole are oblique surfaces. The inclination angle of the oblique surfaces is a self-locking angle. The hanging ring seat is located over the plug pin and is fixed on a door hinge of the open wagon. Two sides of the hanging ring seat are provided with non-concentric mounting holes. The left end and the right end of the upper portion of the hanging ring are respectively inserted into the non-concentric mounting holes of the hanging ring seat so that a dead point can exist when the hanging ring is turned upwards or downwards. The tapered-wedge-shaped plug pin has a self-locking function. The lower the plug pin is vibrated to be, the tighter the plug pin is. The plug pin is effort-saving in upward unlocking, and stepless adjustment of a door gap can be achieved. According to the locking device, the hanging ring can rotate just after the hanging ring is stressed. Consequently, the plug pin can not be unlocked by accident in the running process of the wagon and can not break away from the plug pin hole when an upper tippler turns over.

Owner:CRRC YANGTZE CO LTD

Height position regulating mechanism for bed boards of berth in train

InactiveCN103818398AAdapt and meet comfortAdapt and meet usabilitySleeping accommodationGear wheelEngineering

The invention discloses a height position regulating mechanism for the bed boards of berths in a train, and belongs to machinery for traffic. guide rails are respectively fixedly arranged on left and right side parts of an inner clapboard; upper, middle and lower slide blocks are arranged on the left and right guide rails; upper, middle and lower bed boards are respectively fixedly arranged on the upper, middle and lower slide blocks in sequence; an upper lead screw with an upper driven bevel gear and an upper nut, and a lower lead screw with a lower driven bevel gear and a lower nut are rotationally arranged on the inner clapboard; an upper driving bevel gear and a lower driving bevel gear assembled on the inner clapboard are respectively meshed with the upper driven bevel gear and the lower driven bevel gear; the upper nut and the lower nut are respectively fixed with the middle and lower bed boards; the upper parts of the left and right sides of the inner clapboard are provided with reversing rolling wheels; a pulling rope is configured on the downside part of the upper bed board in a sliding manner; one end of the pulling rope is connected with a winch drum, while the other end is fixedly connected with the inner clapboard; The mechanism is novel and reasonable in structure, simple and convenient for adjustment, and high in applicability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

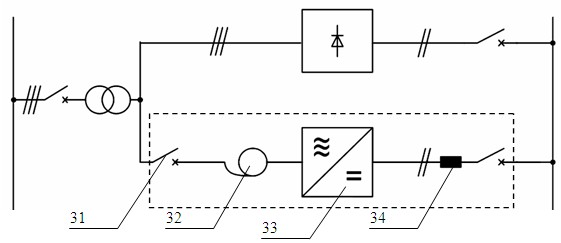

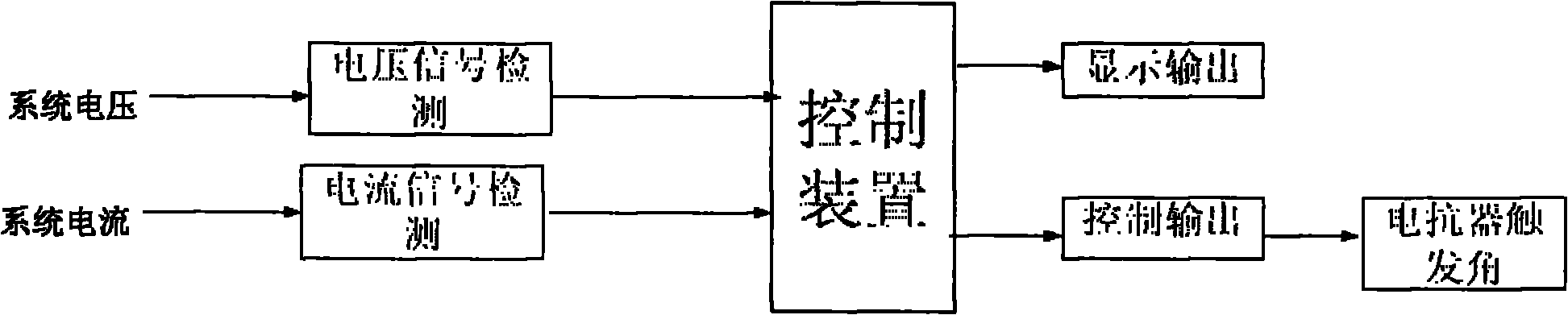

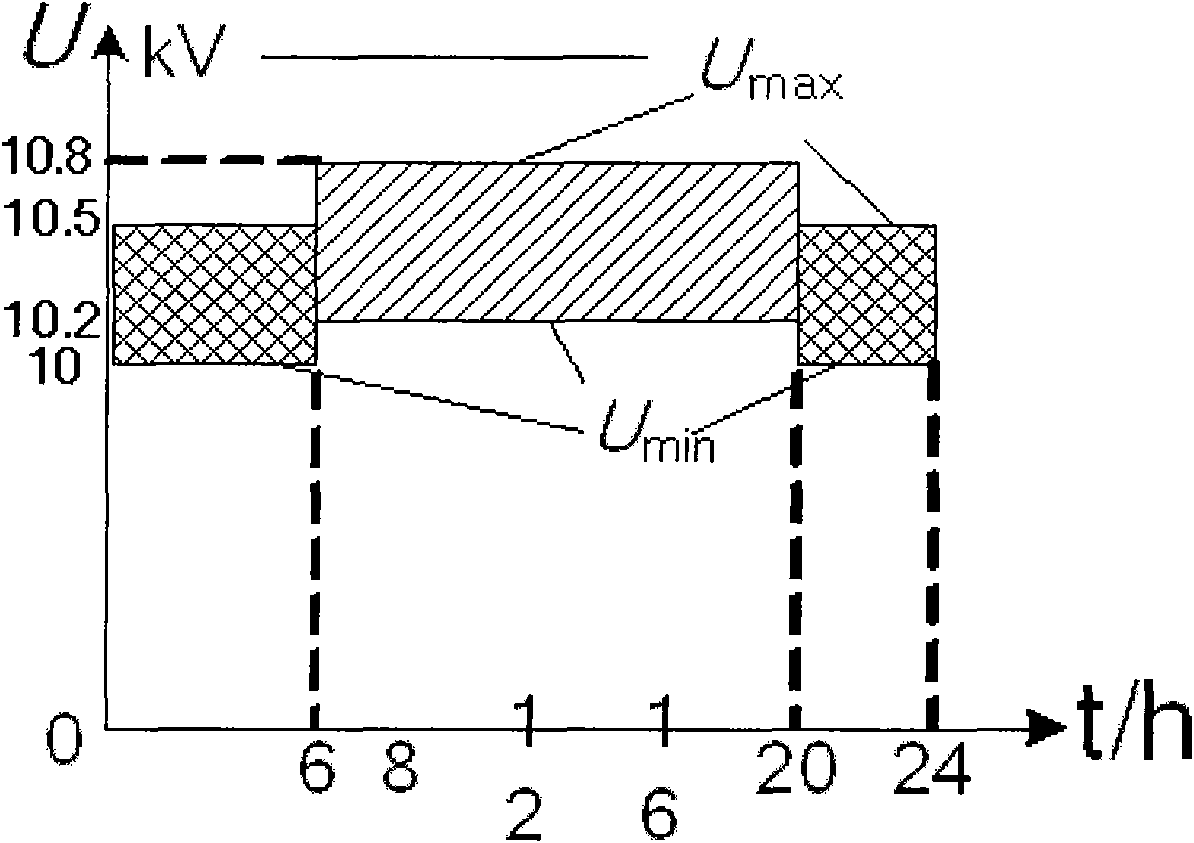

Method for controlling reactive voltages of transformer substation based on magnetic control reactor (MCR)

ActiveCN102055195AReduce capacityLow voltage levelReactive power adjustment/elimination/compensationAc network voltage adjustmentTransformerClosed loop

The invention discloses a method for controlling reactive voltages of a transformer substation based on a magnetic control reactor (MCR). The method comprises the following three steps of: voltage time-shared control, counter-voltage adjustment control and closed loop control. By using the characteristics of the MCR capable of smoothly outputting reactive power, the MCR is matched with the conventional capacitor bank and a loaded high-voltage tap in the transformer substation, and comprehensive control and real-time control of the reactive voltages of the transformer substation and the stepless adjustment of the reactive power are realized.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

Sit-up and abdomen-in appliance for physical exercise

InactiveCN106422186AIncrease exerciseSupine Exercise AchievementGymnastic exercisingEngineeringAbdomen

The invention discloses a sit-up and abdomen-in appliance for physical exercise. The appliance comprises a base, a sit-up exercise assembly and an abdomen-in exercise assembly, wherein the sit-up exercises assembly is disposed on one end of the base; the abdomen-in exercise assembly is disposed on the other end of the base; counters are disposed on the sit-up exercise assembly and the abdomen-in exercise assembly; a display is disposed on the abdomen exercise assembly; and the display is connected to the counter. According to the invention, the sit-up exercise assembly and the abdomen-in exercise assembly are disposed, so that abdomen-in exercise can be also be conducted easily when sit-up exercise is conducted, and exercise effects are enhanced through combination of the two types of exercise; and through an adjustment air cylinder, step-less adjustment of exercise force can be achieved and a person can conduct targeted exercise according to actual demands. In addition, an angle adjustment assembly can be used to adjust angles conveniently and reliably, so that parts such as abdomen, chest, legs, arms and shoulders can be exercised very well.

Owner:宿州学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com