Height position regulating mechanism for bed boards of berth in train

An adjustment mechanism and plank technology, which is applied to sleeper appliances, railway car body parts, transportation and packaging, etc., can solve the problems of poor convenience and comfort, inability to implement adjustments, inconvenience for passengers, etc., and achieve simple and convenient adjustment operations, structural Novel and reasonable, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

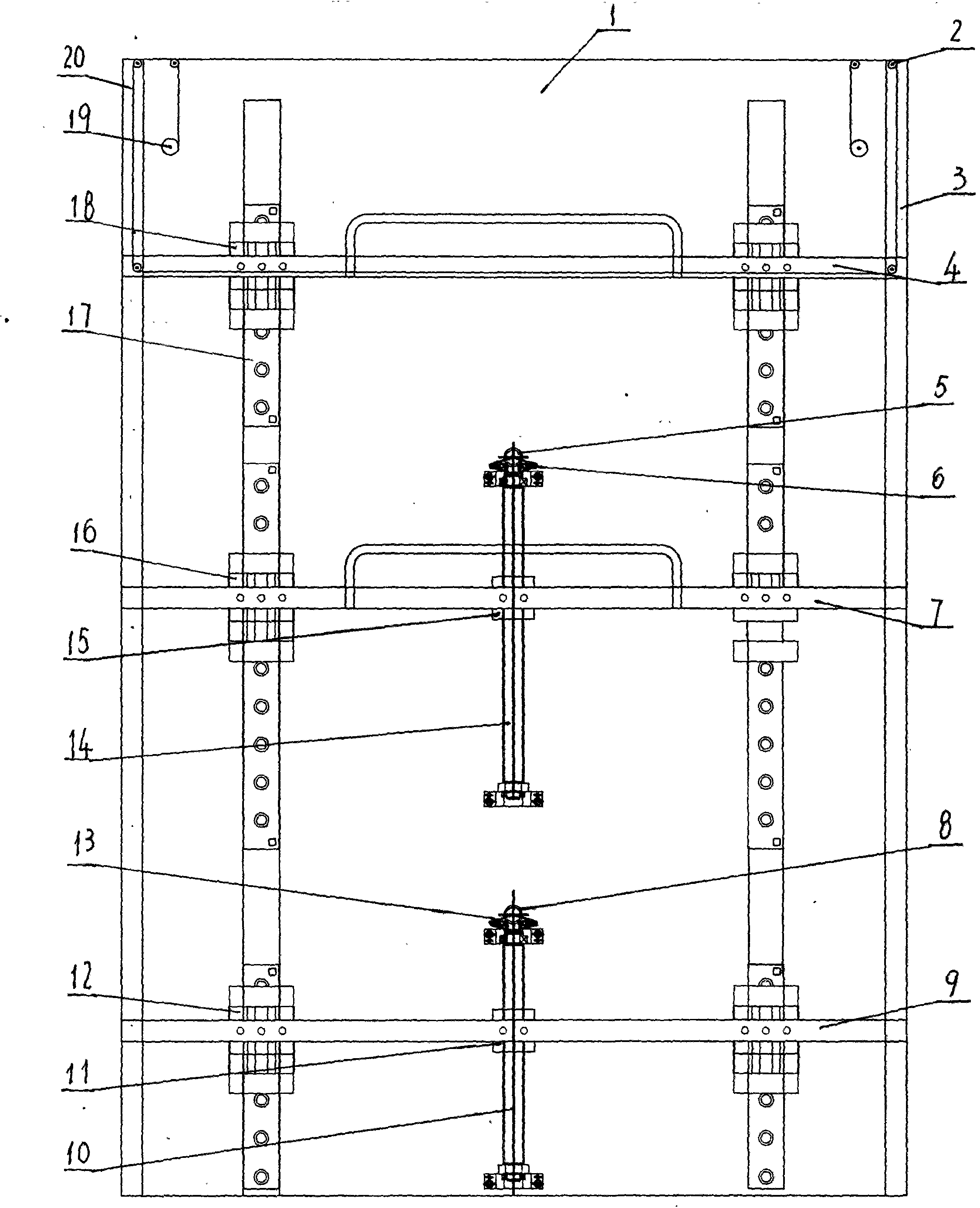

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A mechanism for adjusting the height position of sleeper decks in trains, comprising upper decks 4, middle decks 7, lower decks 9, and inner partitions 1 and end stops arranged on the inner sides and outer ends of the upper, middle, and lower decks 4, 7, and 9 Plate 3, on the left and right sides of the inner partition 1, respectively stand on the fixed guide rails 17, on the guide rails 17 on both sides, the upper slider 18 and the middle slider can be moved up and down sequentially from top to bottom. 16 and the lower slider 12, the upper deck 4, the middle deck 7 and the lower deck 9 are respectively fixed on the upper slider 18, the middle slider 16 and the lower slider 12 in turn; 1. The upper lead screw 14 and the lower lead screw 10 are rotatably installed vertically from top to bottom between the right side guide rails 17, and the upper screw nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com