Turning-milling linkage machining method of large-pitch worm

A processing method and large pitch technology, applied in the direction of worms, toothed components, belts/chains/gears, etc., can solve the problems of low efficiency, long processing cycle, high manufacturing cost, etc., and achieve improved processing efficiency and accurate processing pitch , The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The workpiece to be processed is: the modulus is 20mm; the number of worm heads is 1; the normal pressure angle is 20; the helix angle is 5°30';

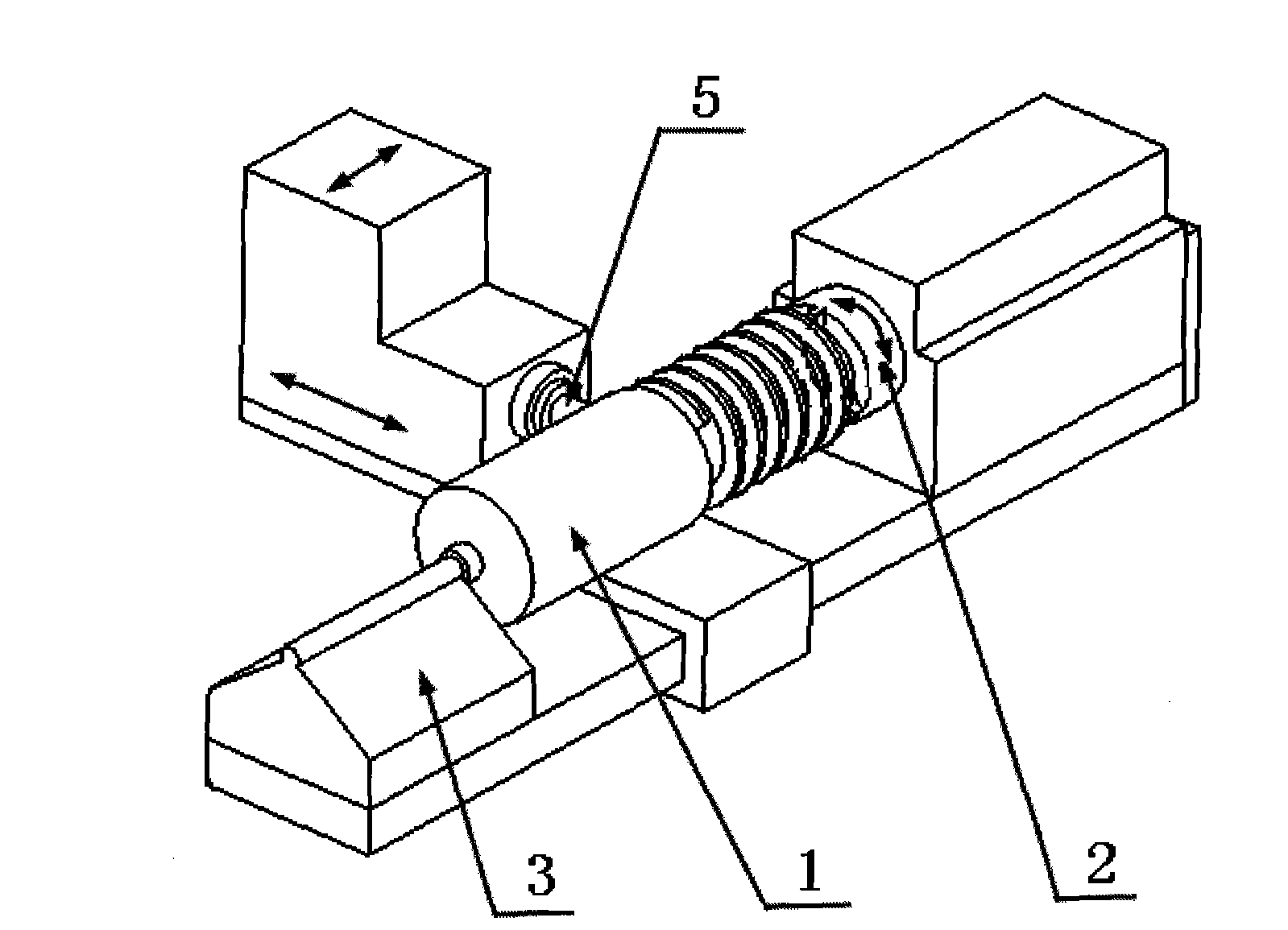

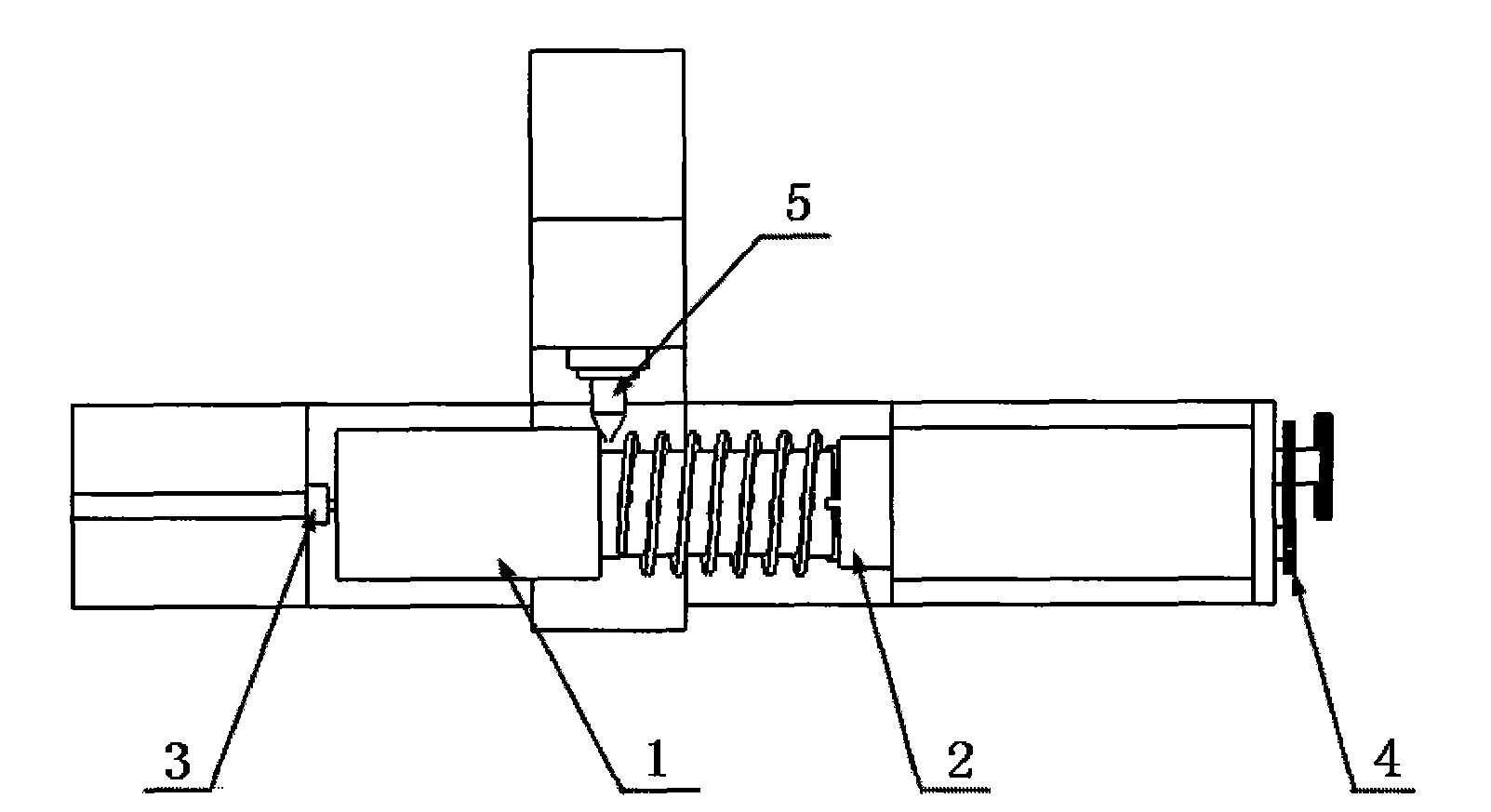

[0027] On the shovel lathe, the worm part 1 to be processed is fixed on the workpiece spindle of the shovel lathe through the three-jaw chuck 2 and the bed end tip 3. The shovel lathe replaces the hanging wheel according to the pitch of the worm to be processed, and adopts a vertical axis that is perpendicular to the part to be processed. The finger-shaped milling cutter 5 installed on the main axis mills the surface of the shaft worm part to be machined through axial and tangential feeds, and the to-be-machined part fixed on the lathe only rotates axially along the main shaft, and the rotational speed of the main shaft of the lathe is 0.2 r / min, the cutting speed of the finger milling cutter is 60r / min, the axial feed is 2mm / min, and the depth of cut is 15mm. noodle.

[0028] The main parameters of the milling cutter: the m...

Embodiment 2

[0031] A turning-milling linkage machining method of a large-pitch worm

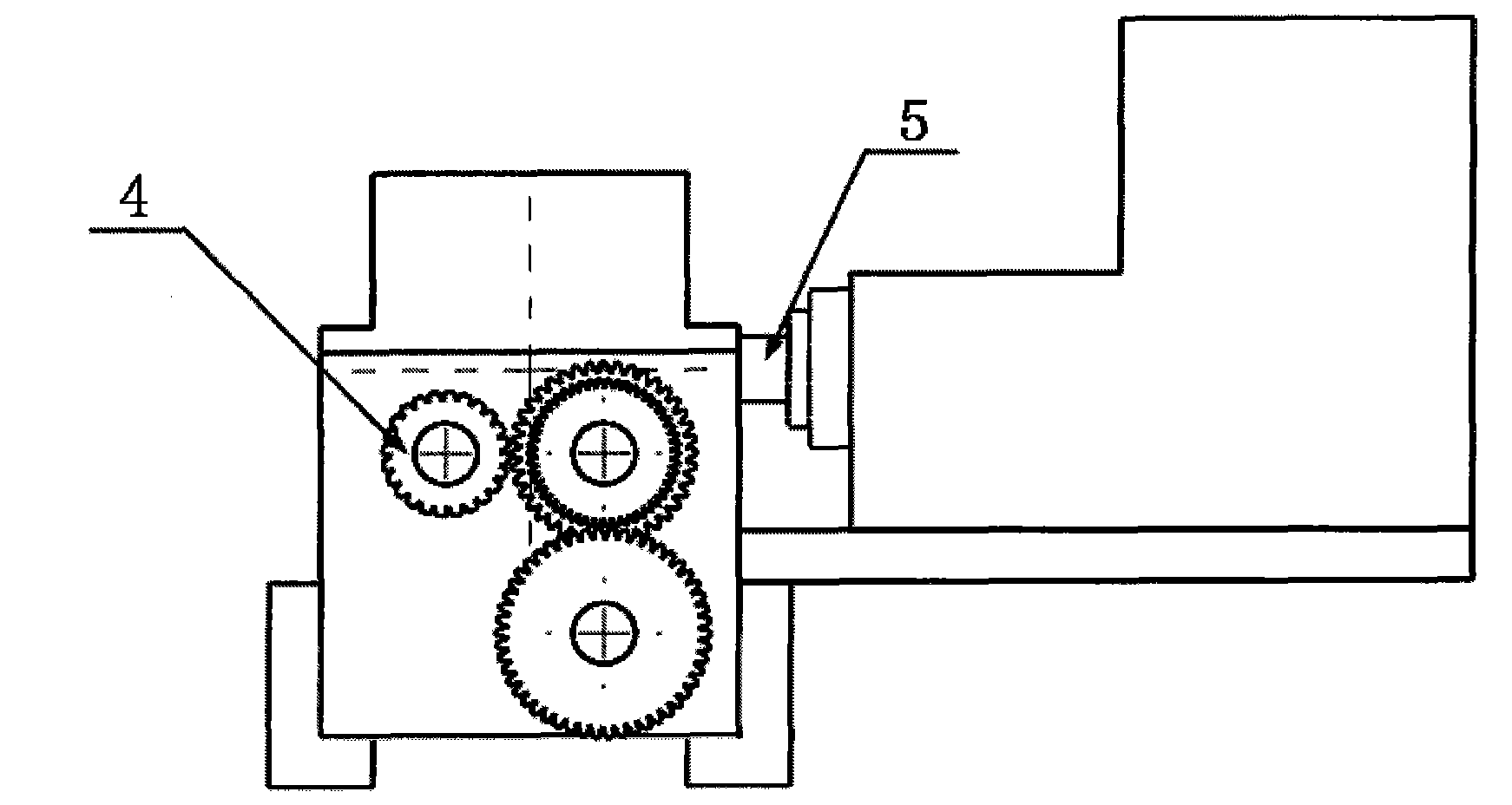

[0032] For shaft worm parts, on the shovel lathe, fix the worm part 1 to be processed on the workpiece spindle of the shovel lathe through the three-jaw chuck 2 and the bed end tip 3, and replace the shovel lathe's hanging wheel 4 to get the appropriate hanger. The wheel ratio meets the requirements of the thread pitch of the worm to be processed, and a finger-shaped milling cutter 5 installed perpendicular to the main axis of the part to be processed is used to mill the surface of the shaft worm part to be processed through axial and tangential feed, and is fixed on the lathe. The parts to be machined only rotate axially along the spindle, the spindle speed of the lathe is 0.2r / min, the speed of the finger milling cutter is 60r / min, the axial feed is 1-12mm / min, and the depth of cut is 15mm. Turning and milling are linked together, and pressure coolant is used to flush the surface of the machined parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com