Patents

Literature

291 results about "Depth of cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

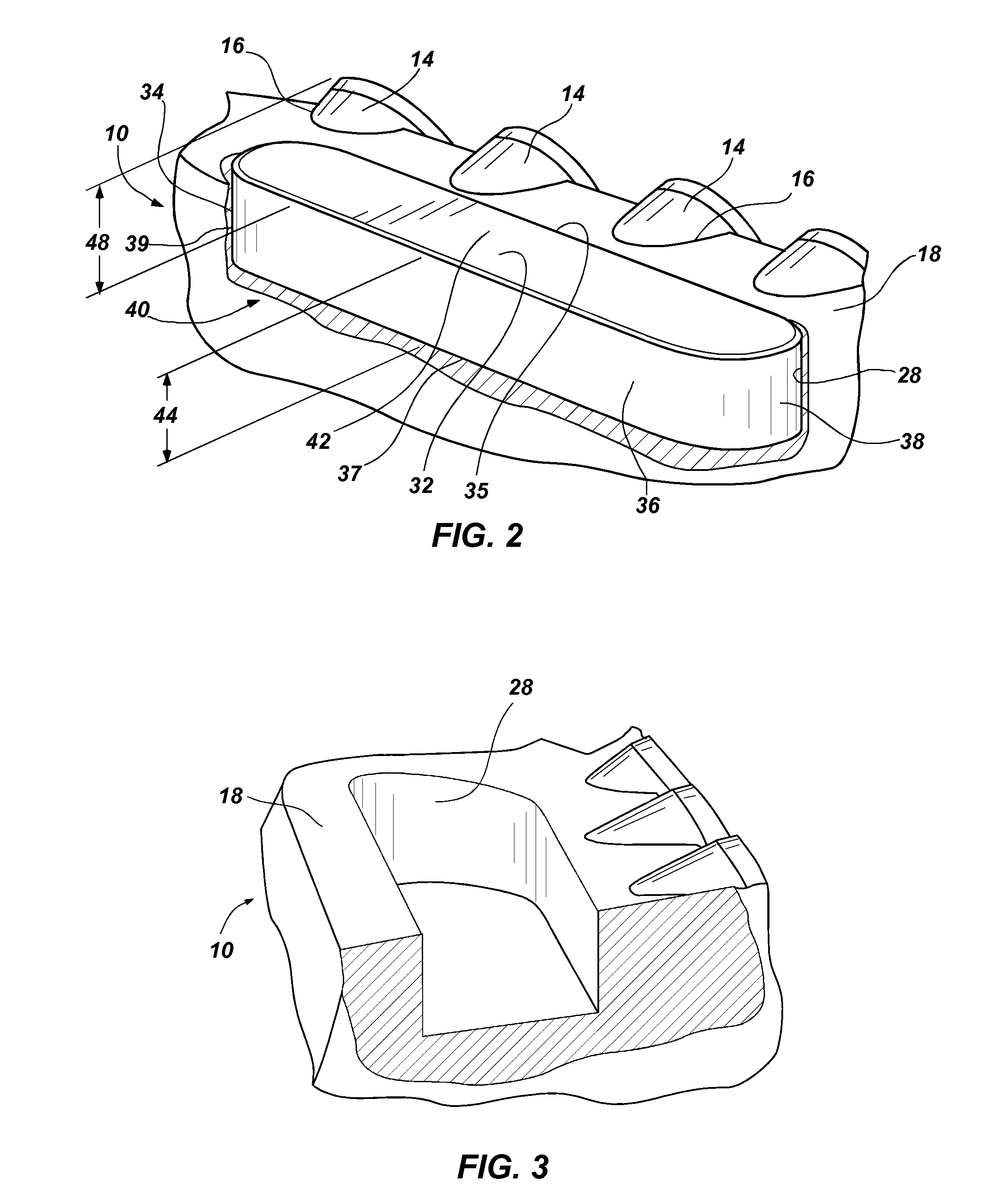

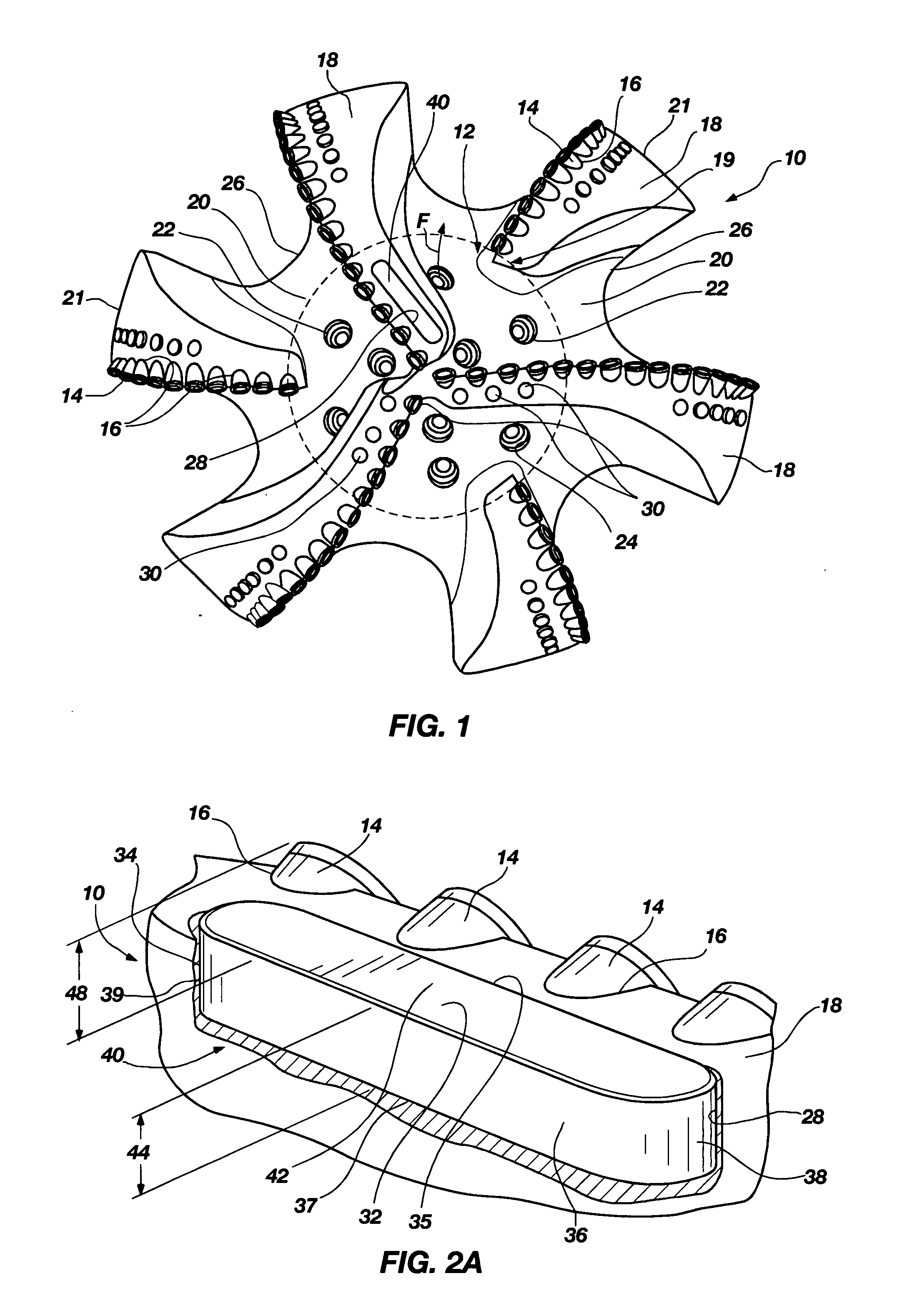

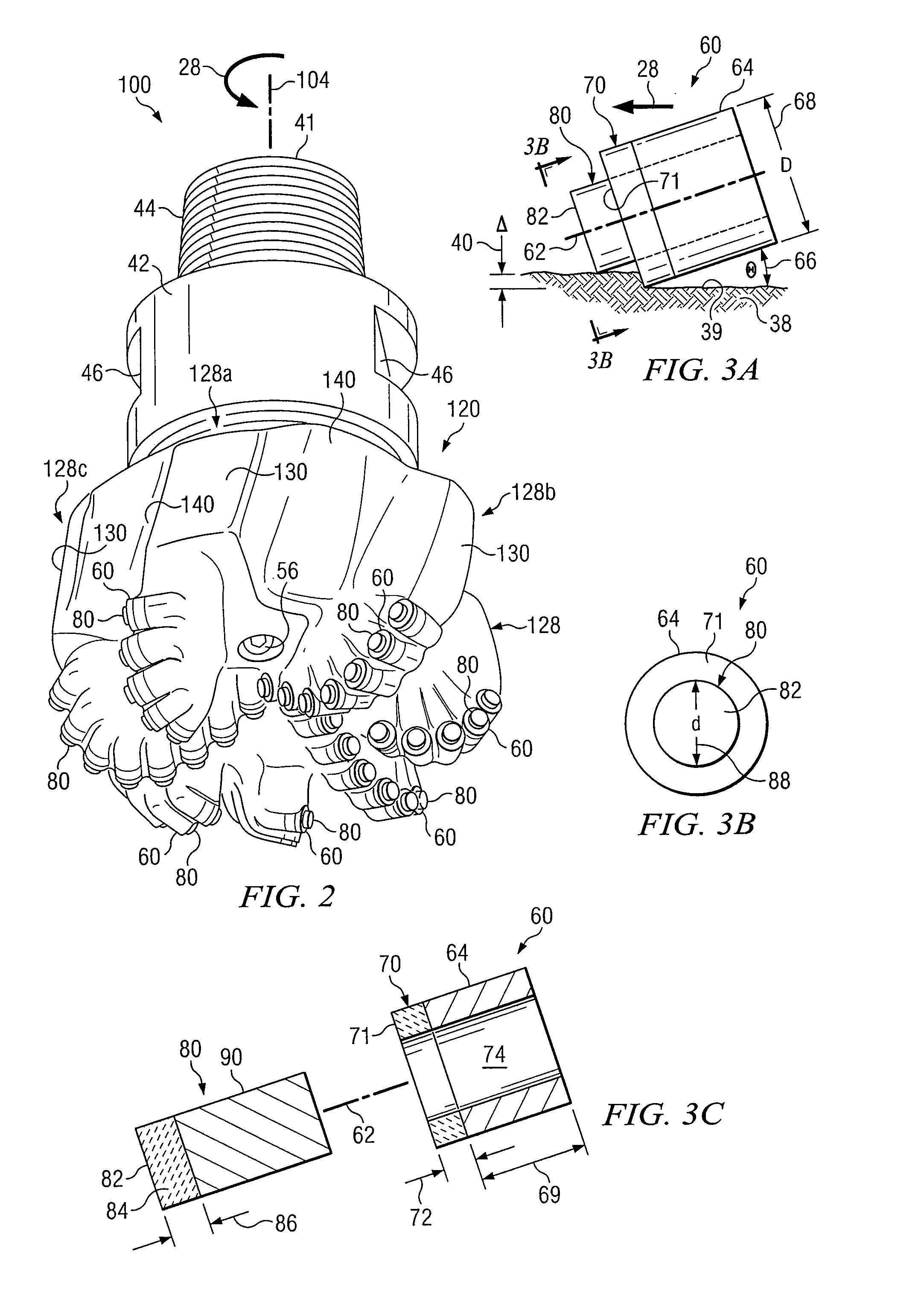

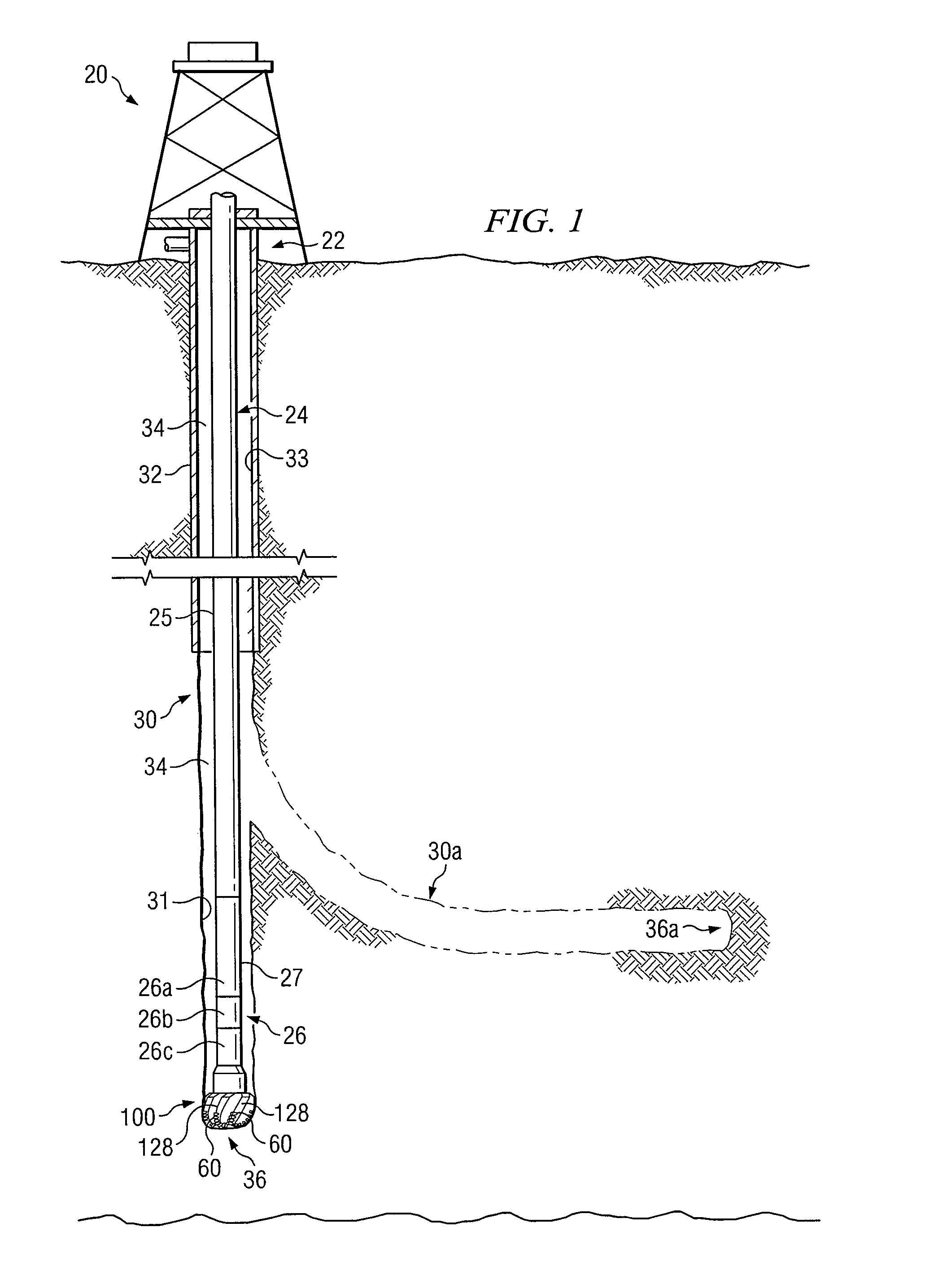

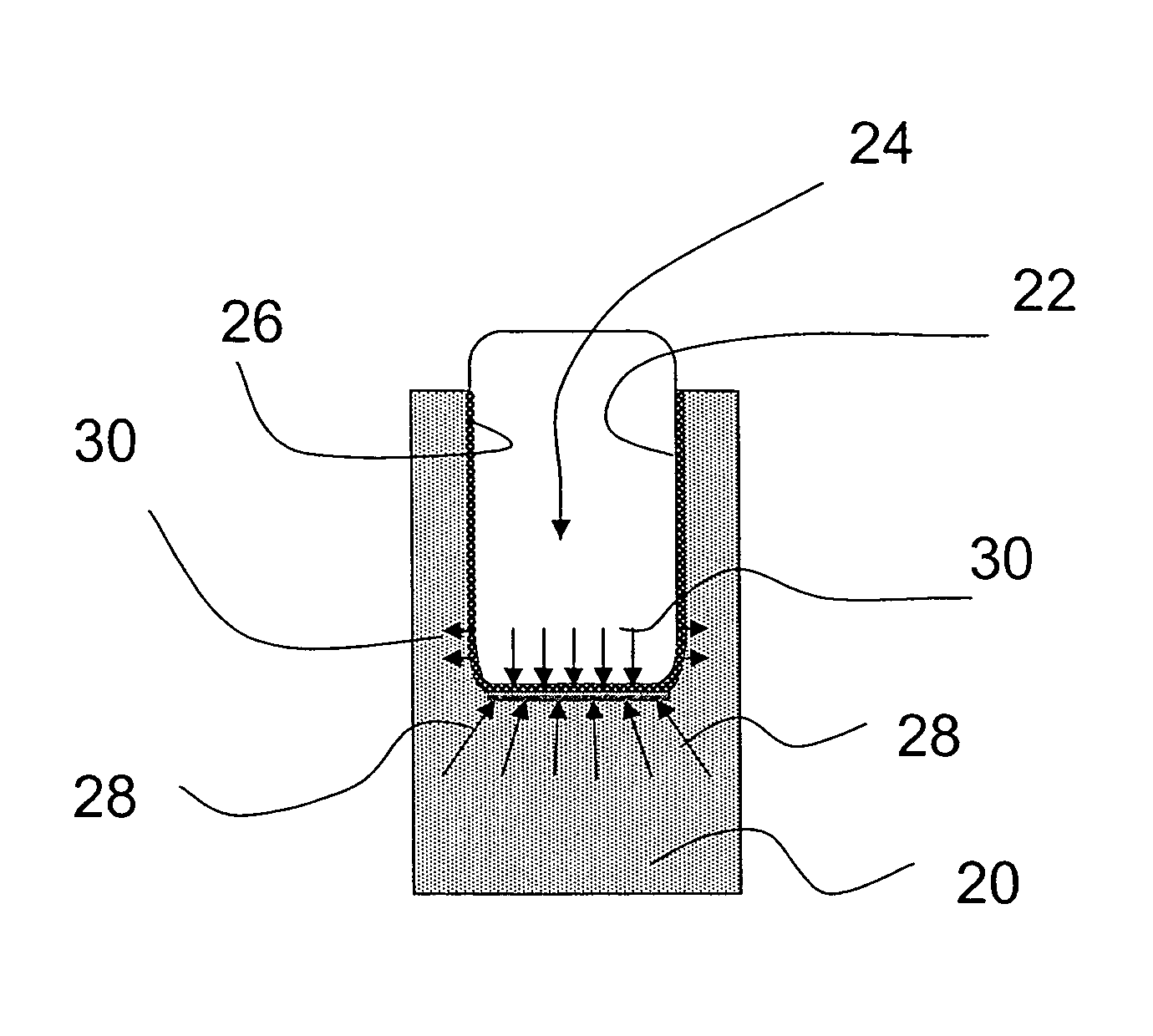

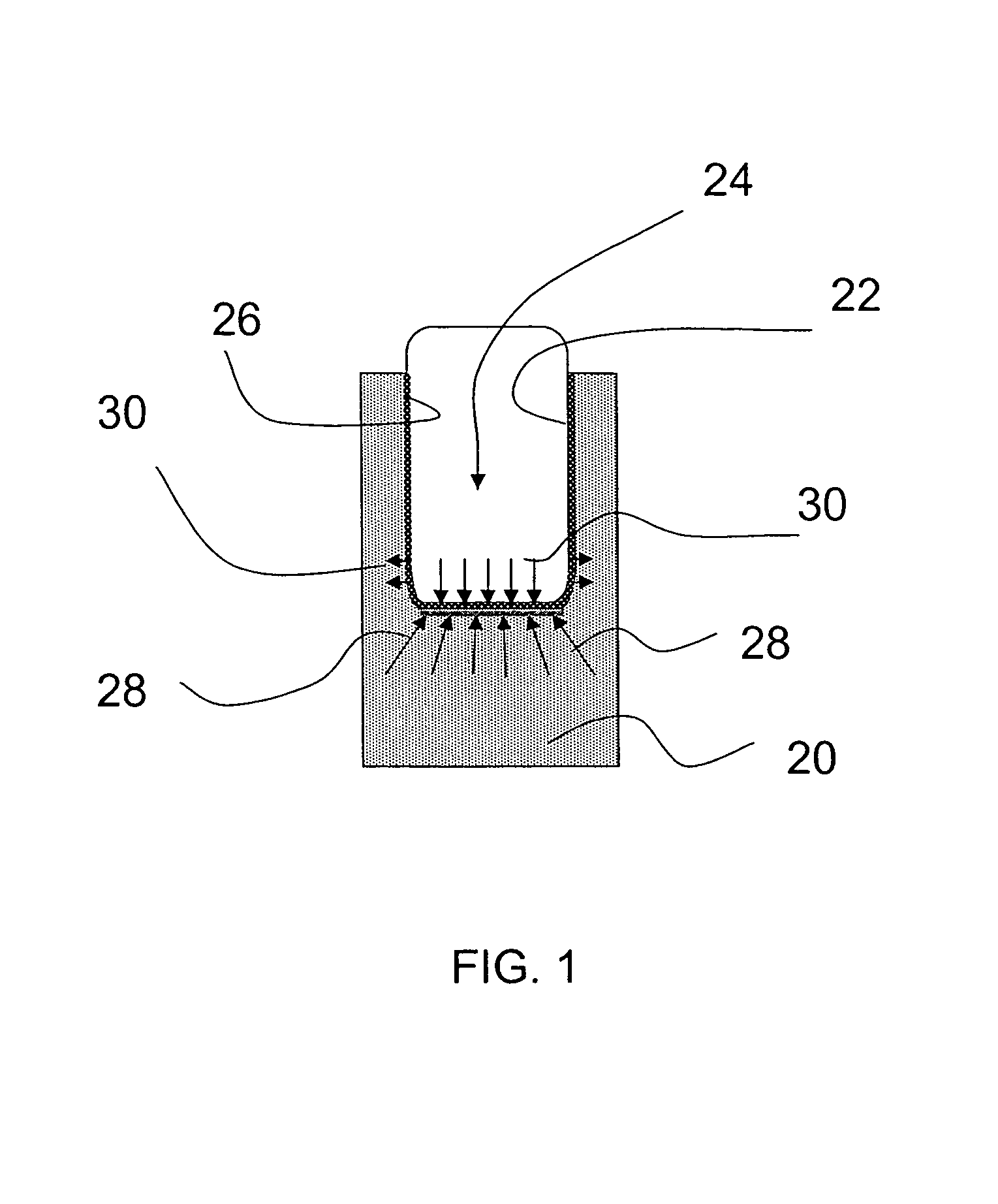

Bearing blocks for drill bits, drill bit assemblies including bearing blocks and related methods

InactiveUS20100276200A1Reduce thicknessExpand the cutting rangeDrill bitsConstructionsDistal portionDrill bit

Methods of drilling subterranean formations include coupling at least one bearing block having an initial thickness to a drill bit, engaging a formation with the drill bit within an initial depth of cut range, and reducing the initial thickness of the bearing block by contacting the formation to cause the initial depth of cut range to be at least partially increased. Methods of forming drill bits for drilling subterranean formations include forming at least one rubbing surface of at least one bearing block from at least one material exhibiting a reduced coefficient of friction and coupling the at least one bearing block to the drill bit. Drill bit assemblies include at least one bearing block having a distal portion configured to provide an initial depth of cut range and a base portion configured to provide an increased depth of cut range greater than the initial depth of cut range.

Owner:BAKER HUGHES INC

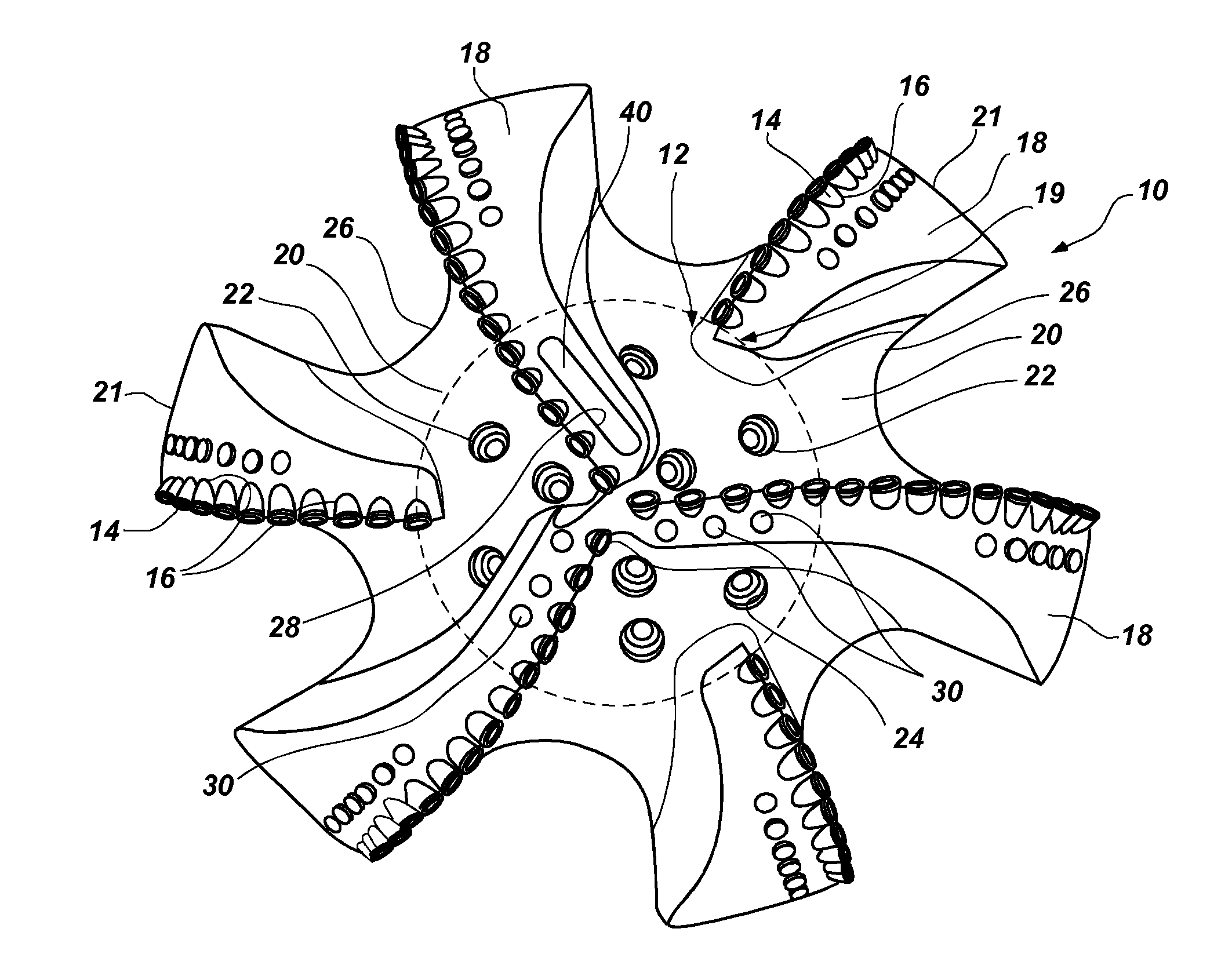

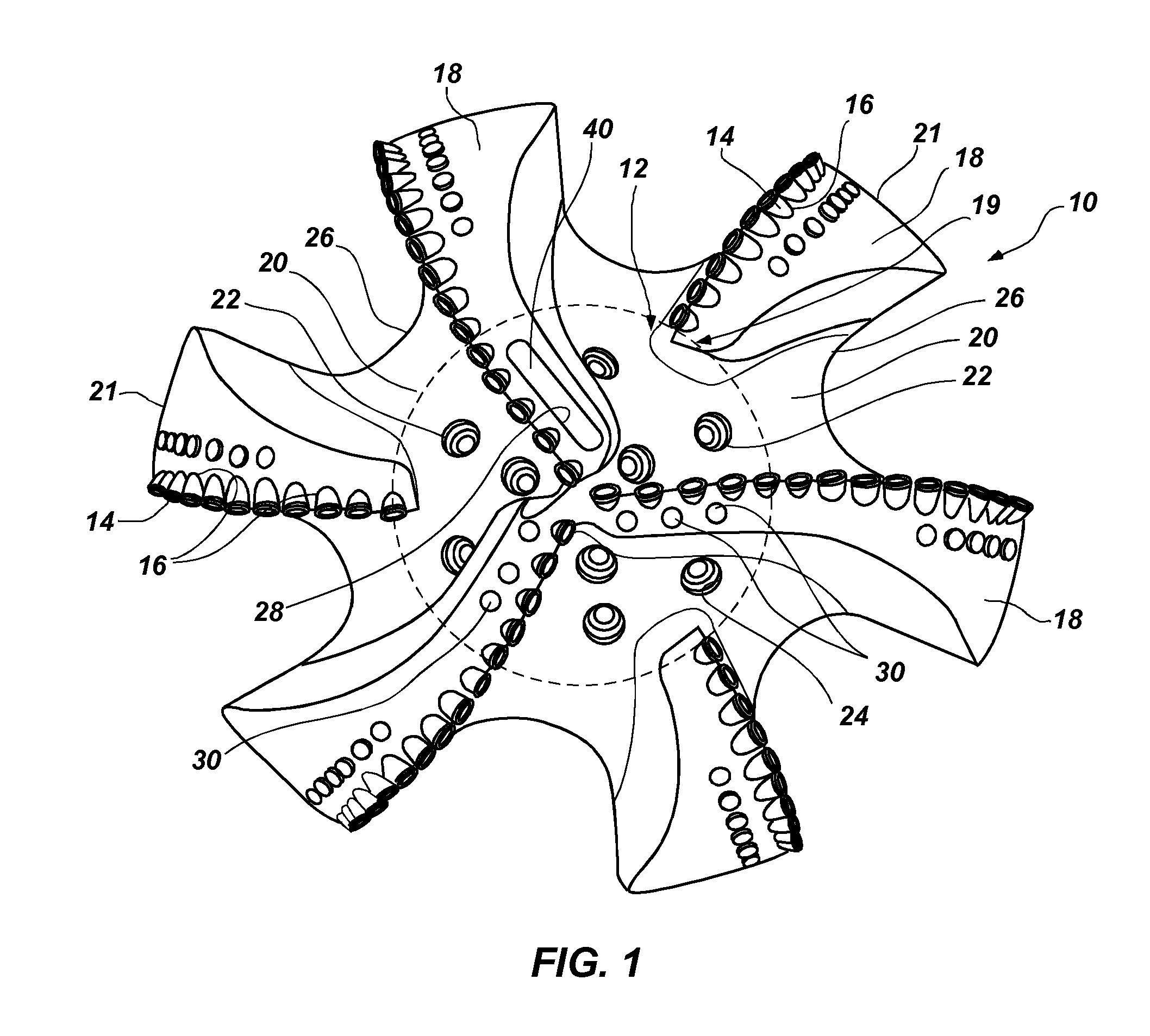

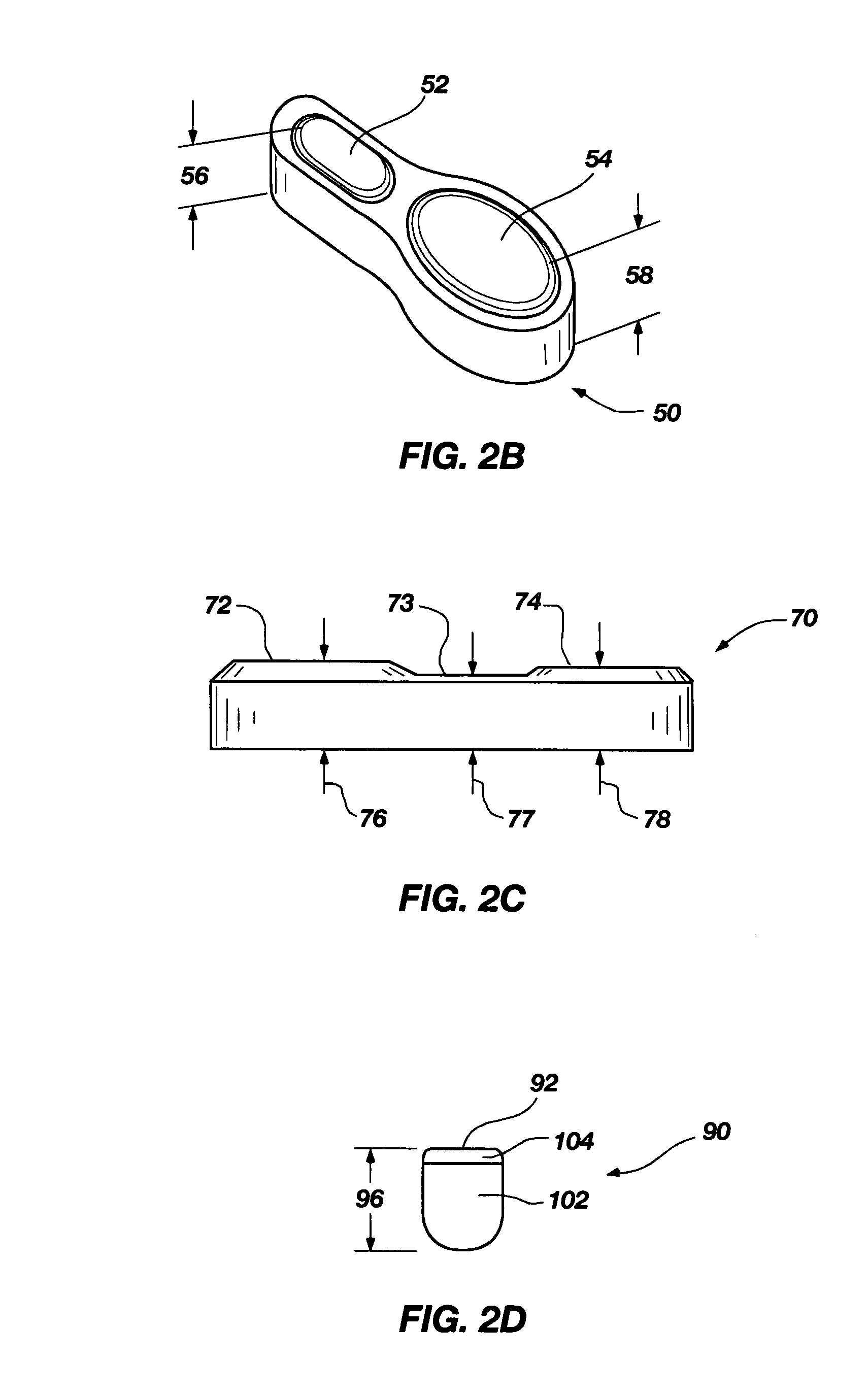

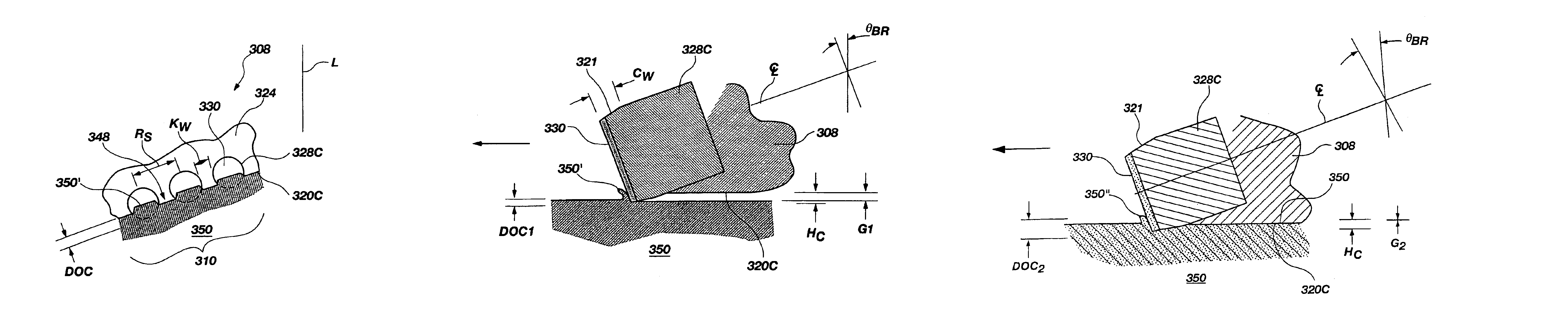

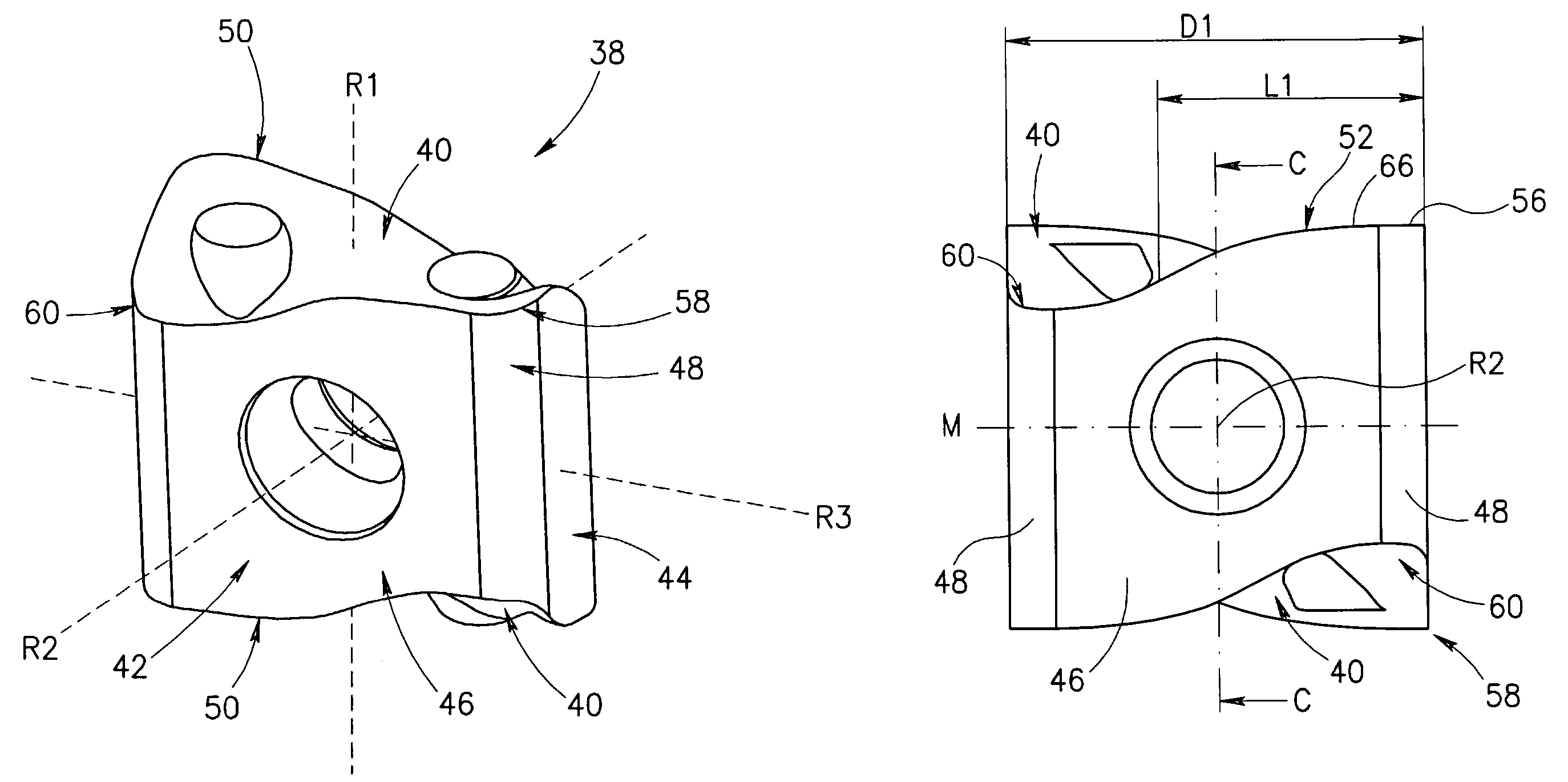

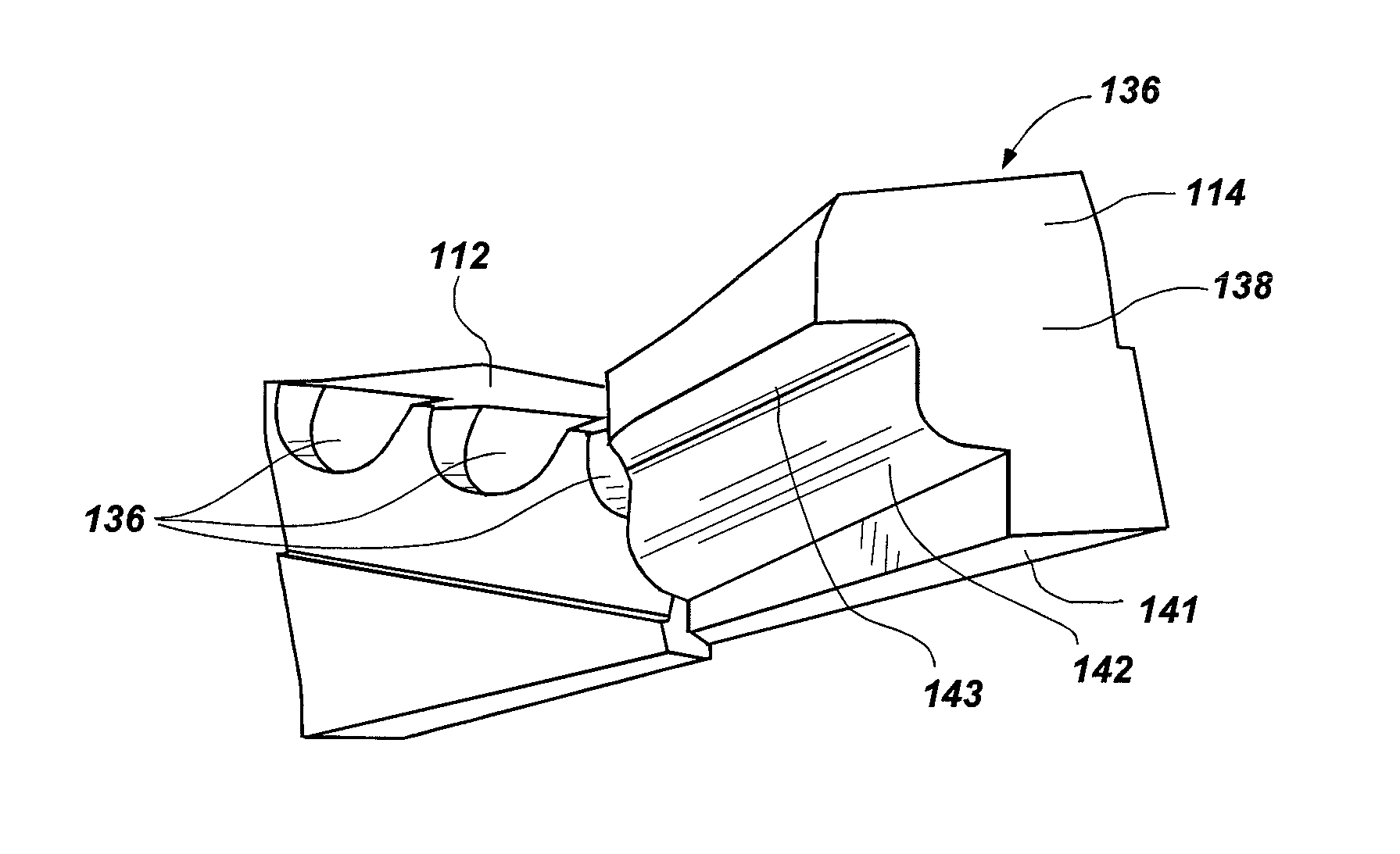

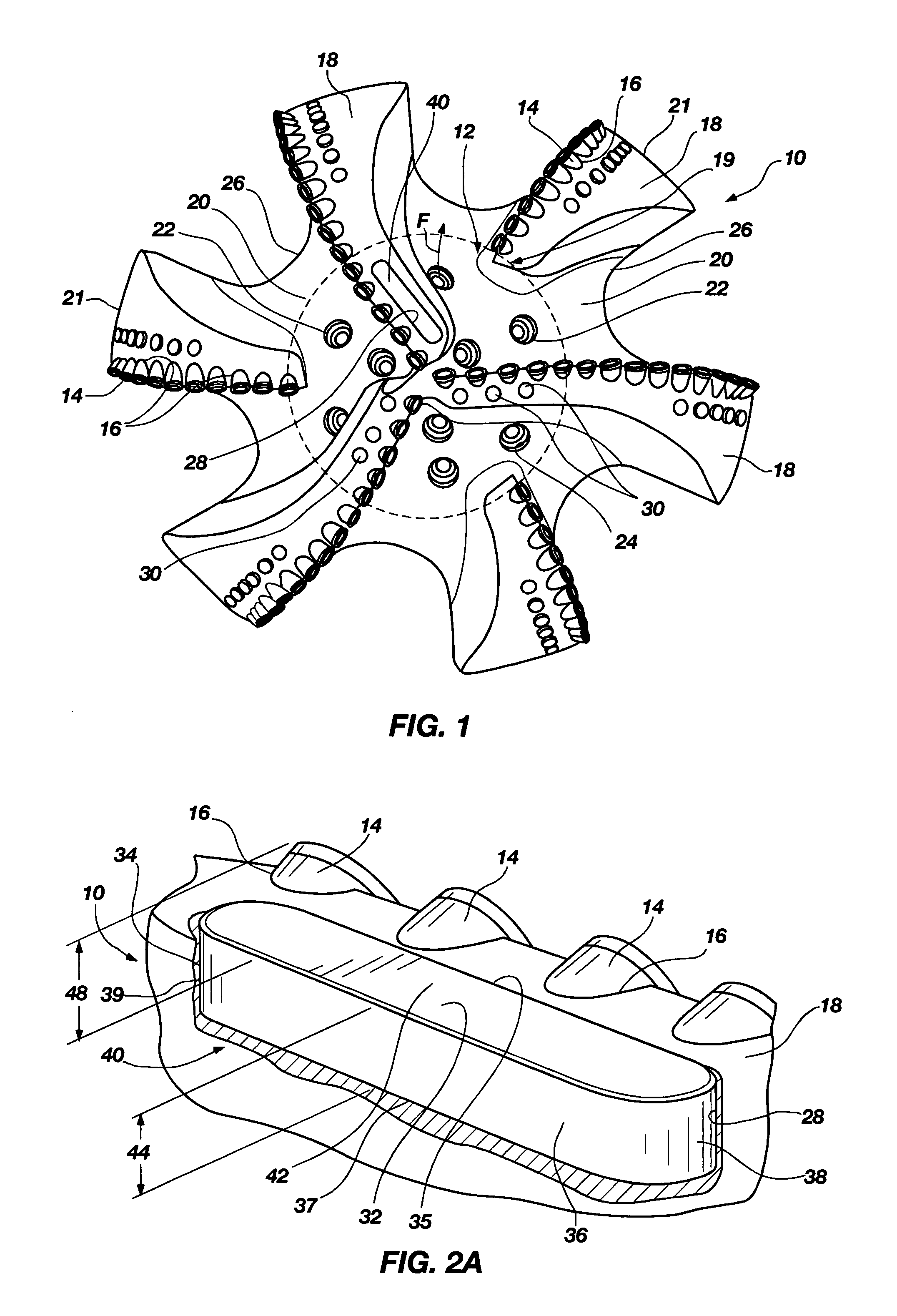

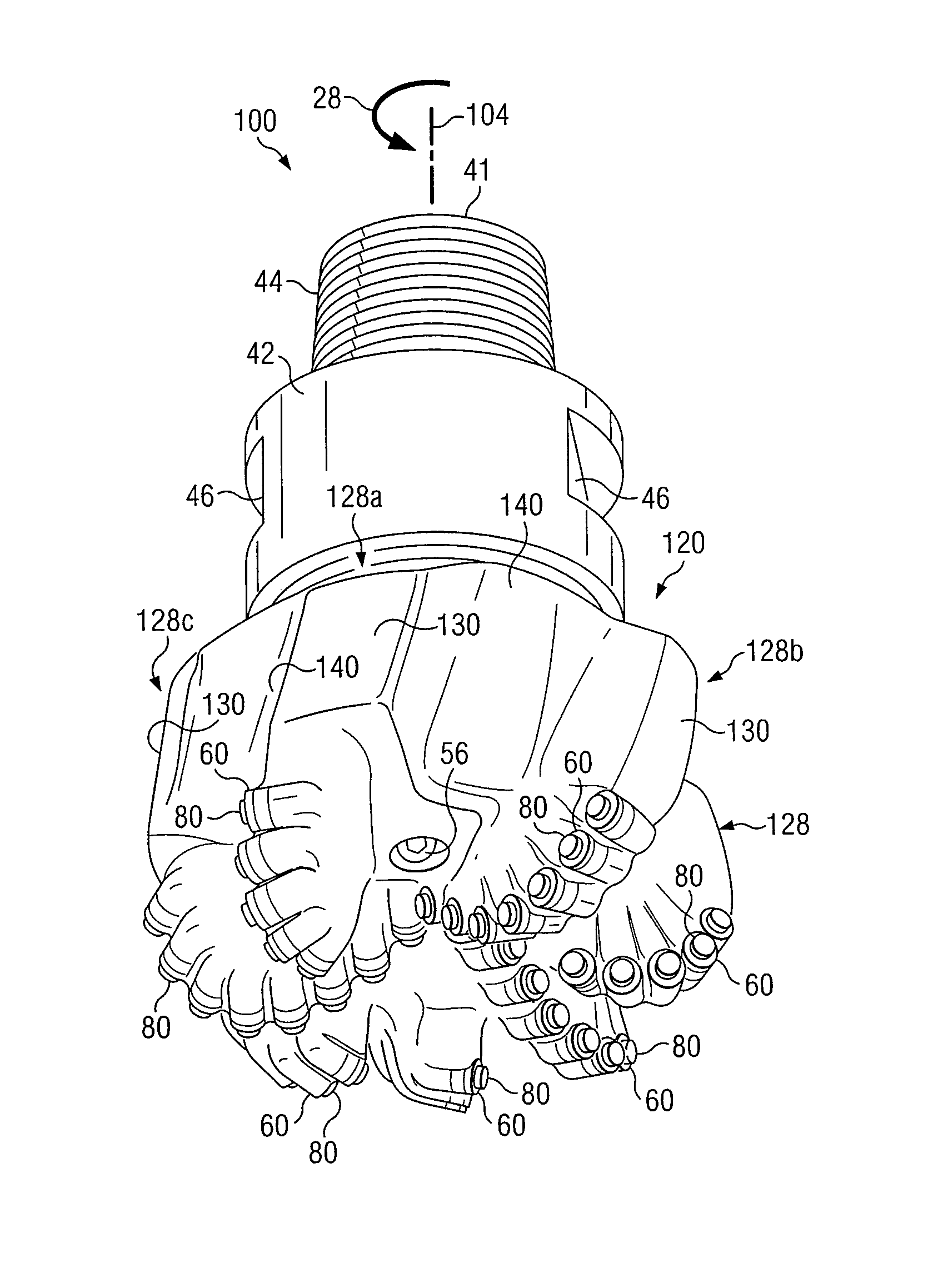

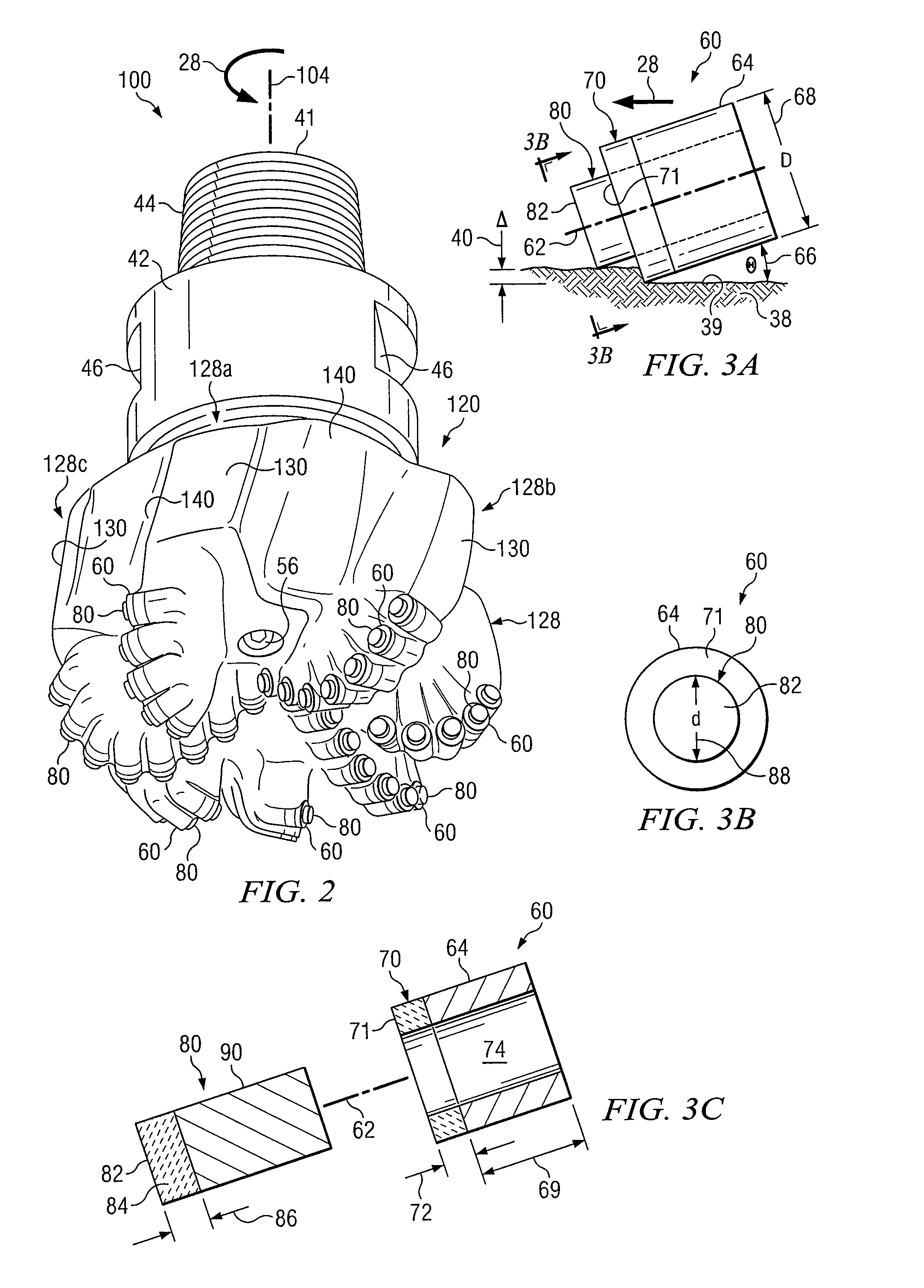

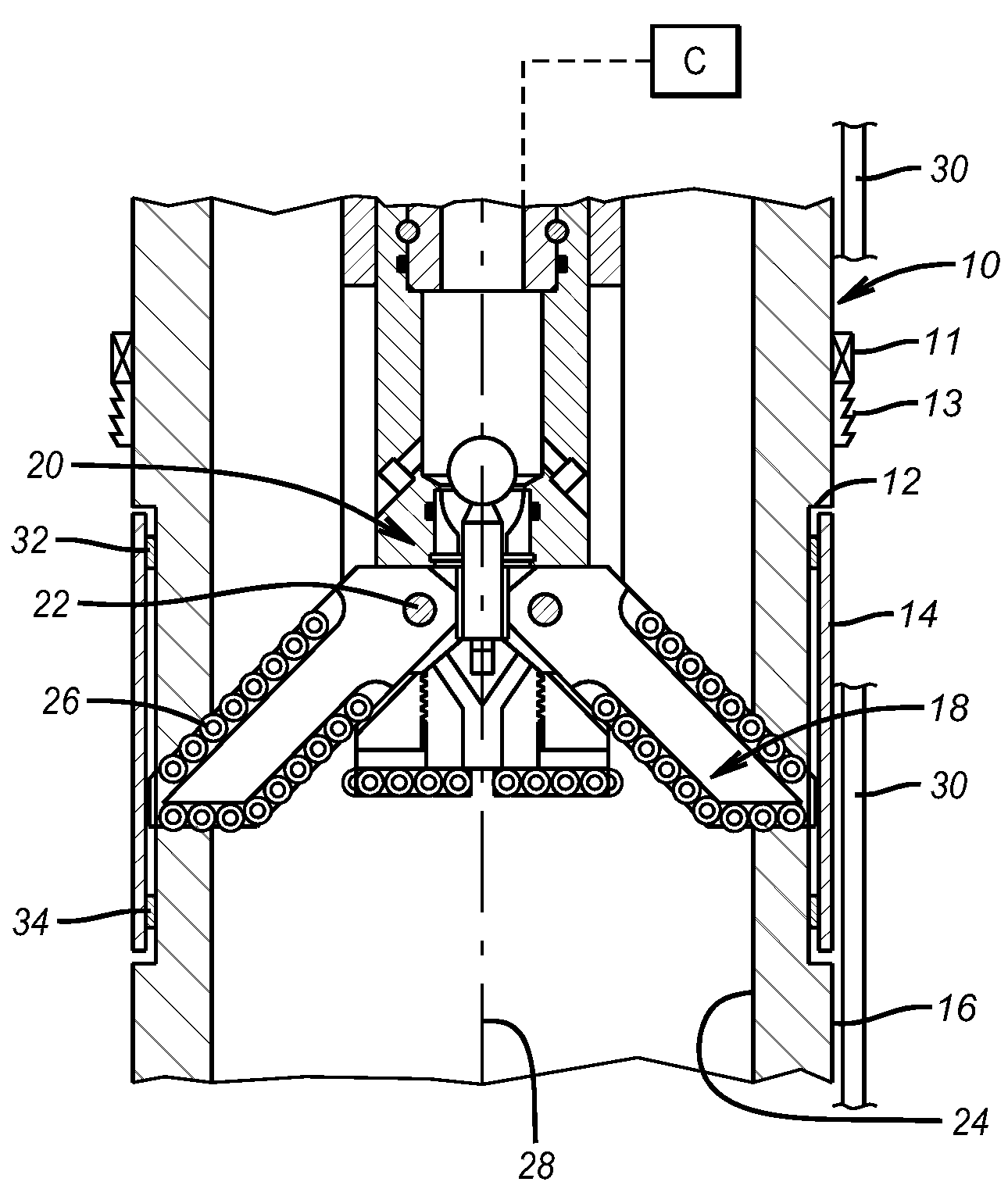

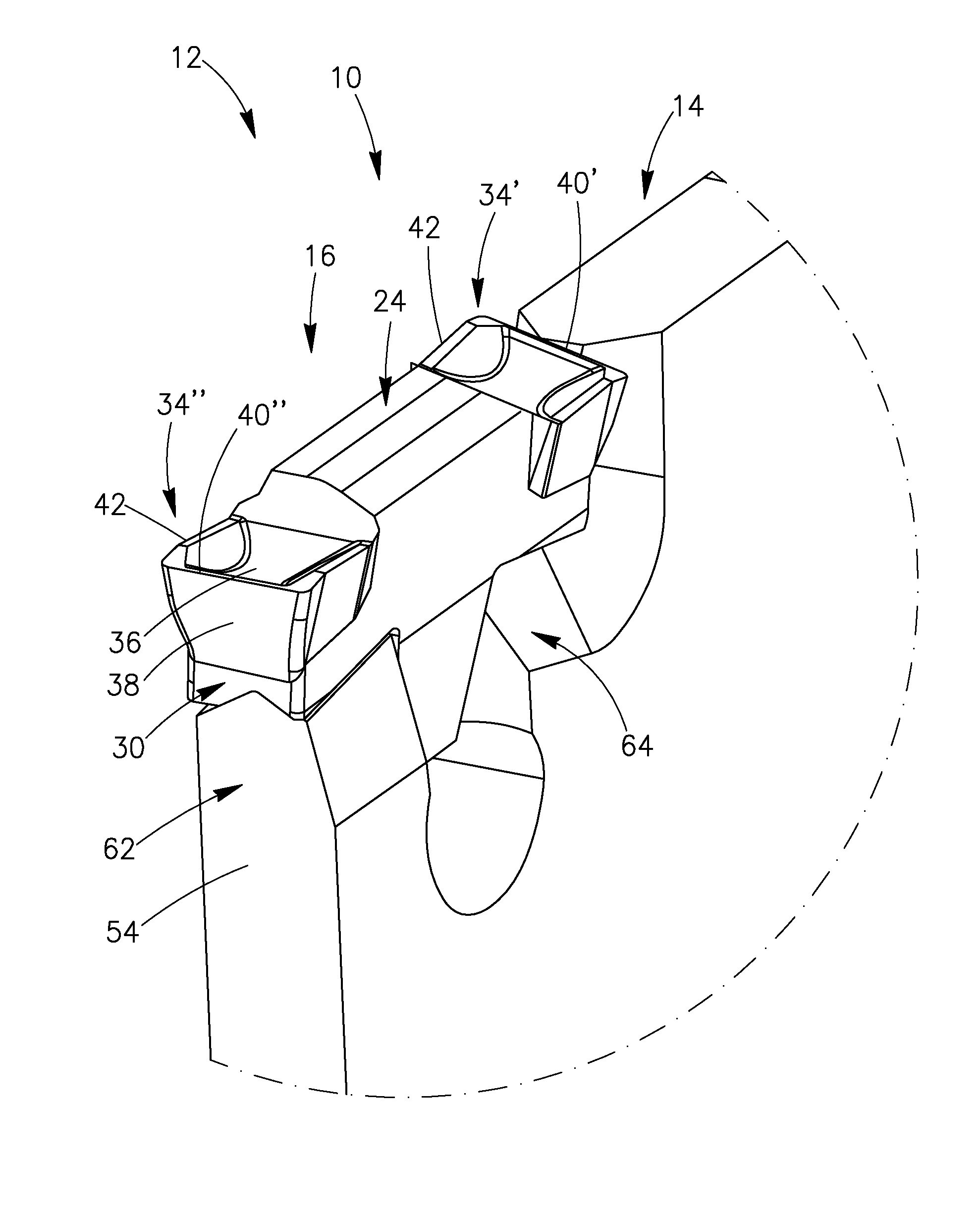

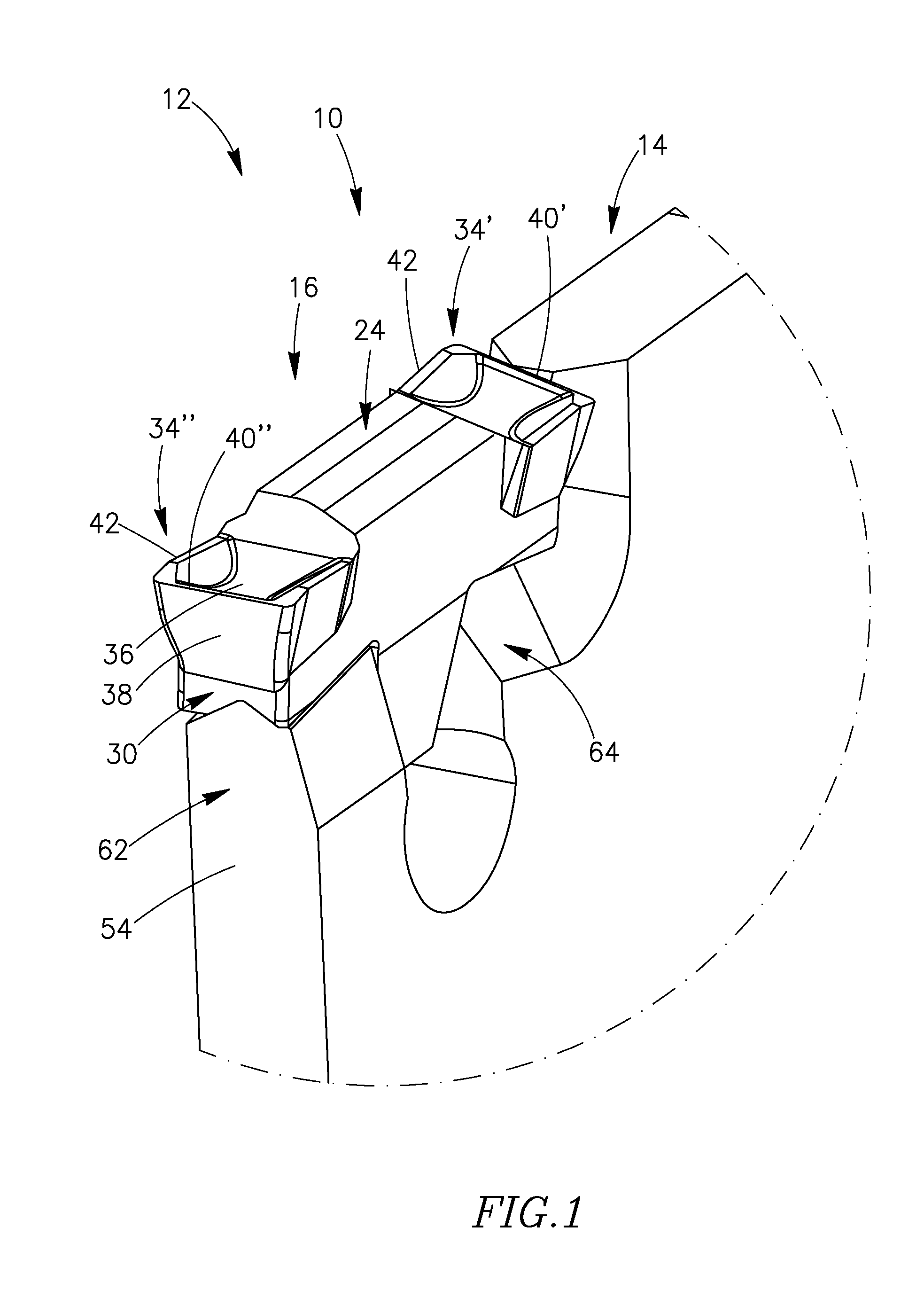

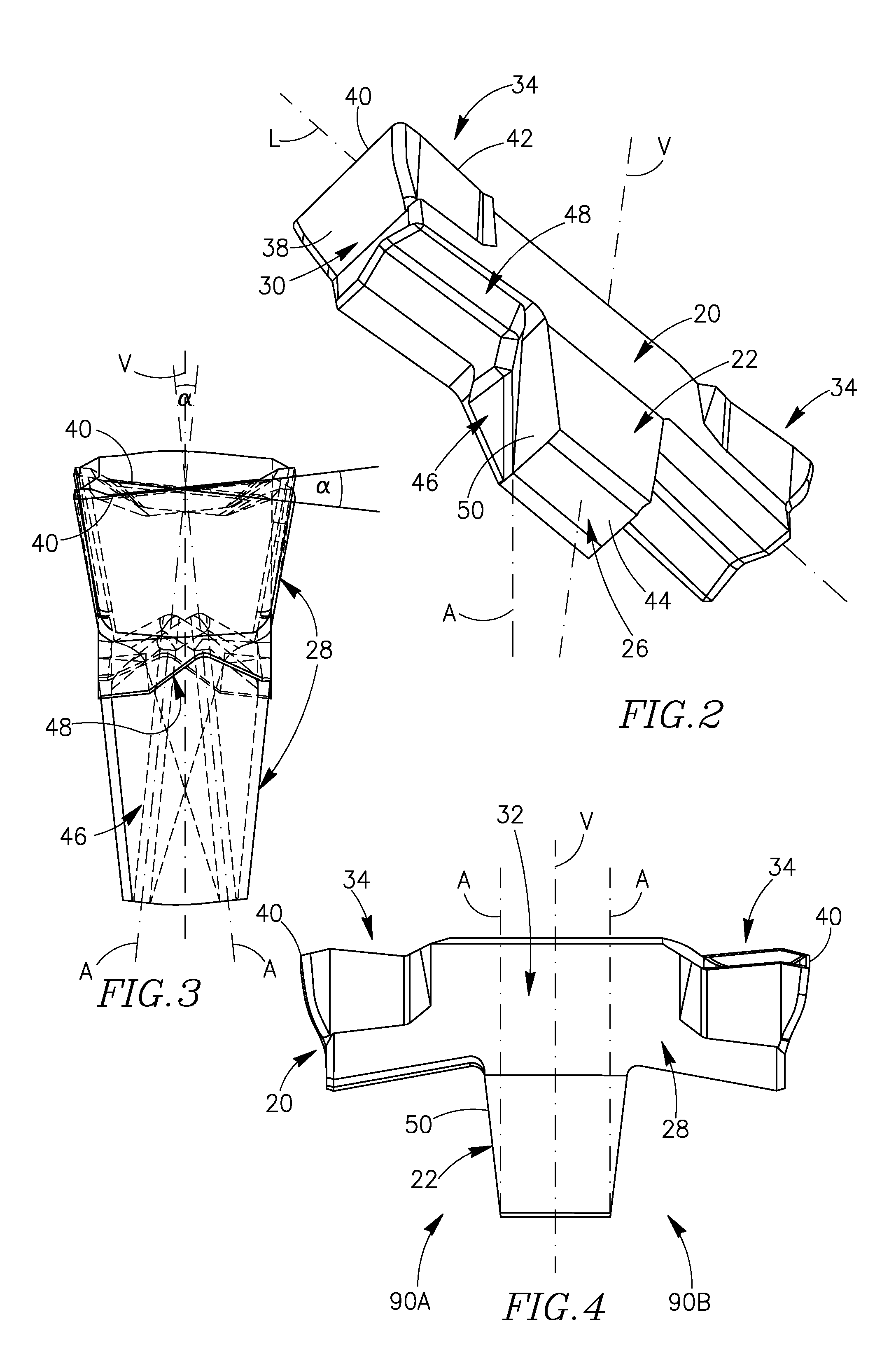

Interchangeable bearing blocks for drill bits, and drill bits including same

ActiveUS20080308321A1Minimize manufacturing tolerance uncertaintyReduce complexityEarth drilling toolsDrill bitsEngineeringRubbing

A bearing block is provided that may be used with a drag bit body or frame to limit depth of cut of cutters on a bit. The bearing block is designed so that it may be interchangeably replaced or repaired without necessitating alteration to a standardized bit frame. The interchangeable bearing block may be used to provide a target depth of cut (TDOC) and / or a selected contact or rubbing area to support weight on bit and limit depth of cut (DOC) for improving drilling performance of a bit. The interchangeable bearing block brings manufacturing selectability by providing a customizable product in terms of depth of cut selection and cutter penetration control for different formations, which is suitable for use with a common bit frame. A rotary drill bit assembly, a unitary cone insert bearing block for a drill bit, and a bit frame are also provided.

Owner:BAKER HUGHES INC

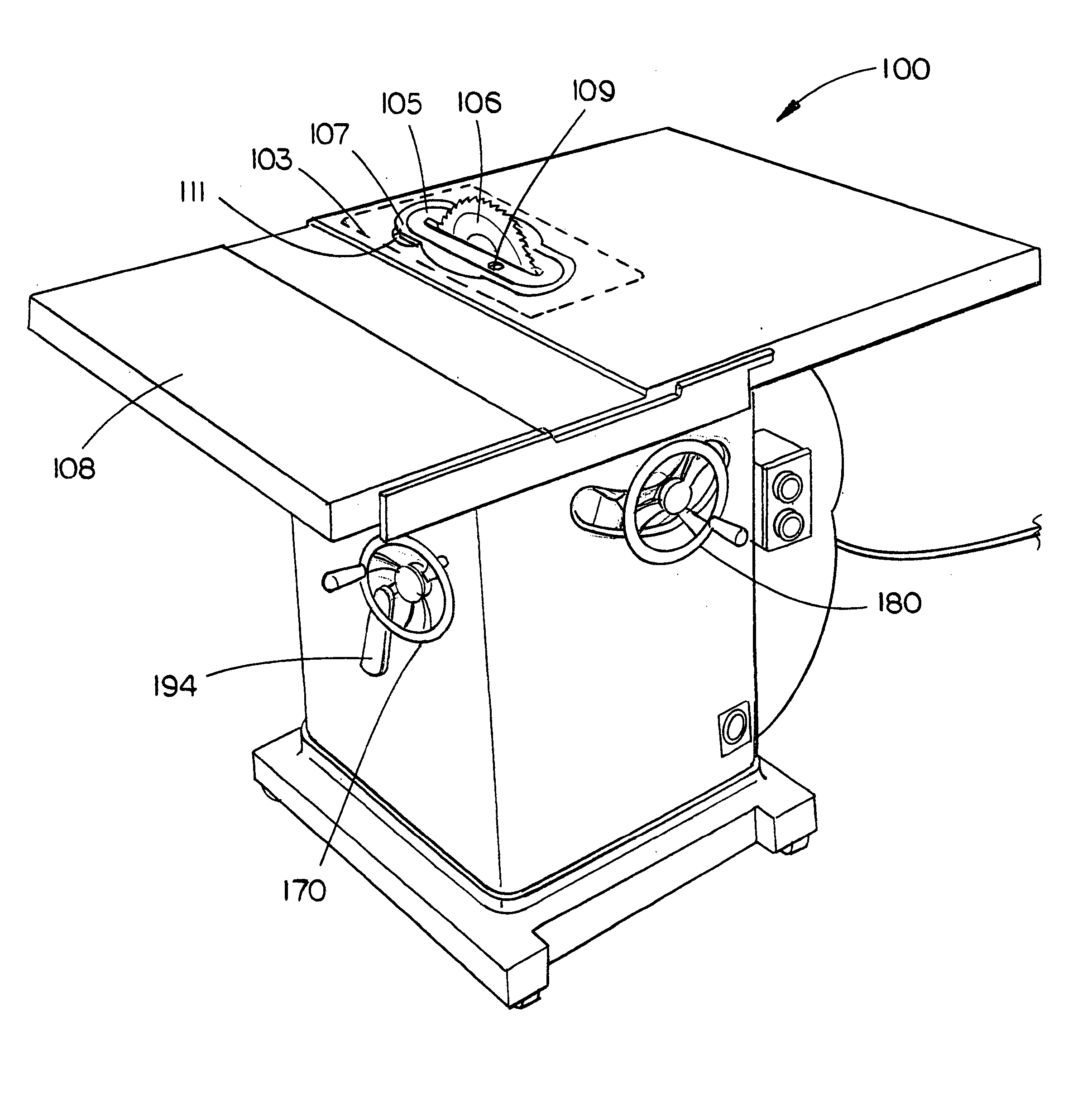

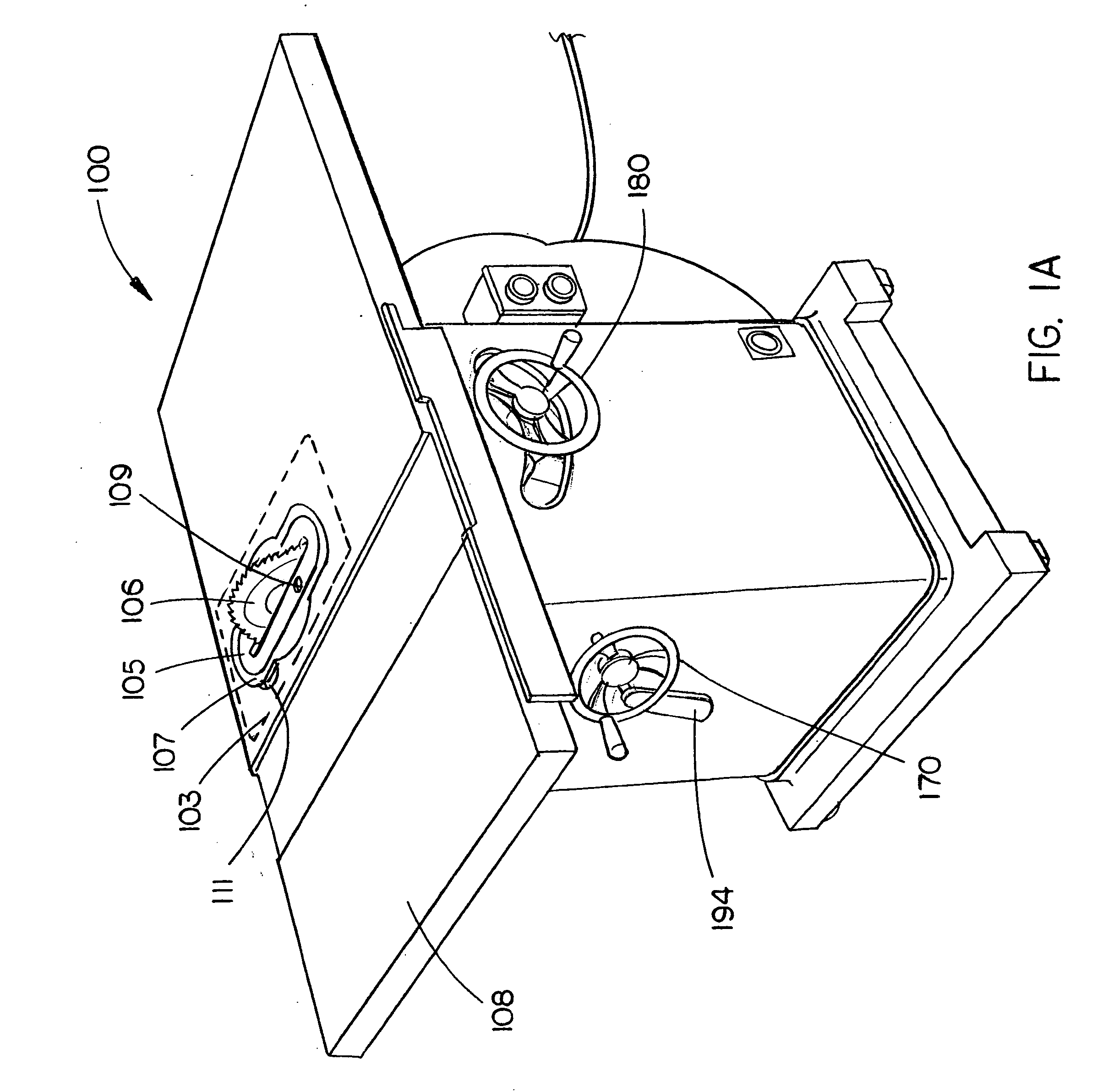

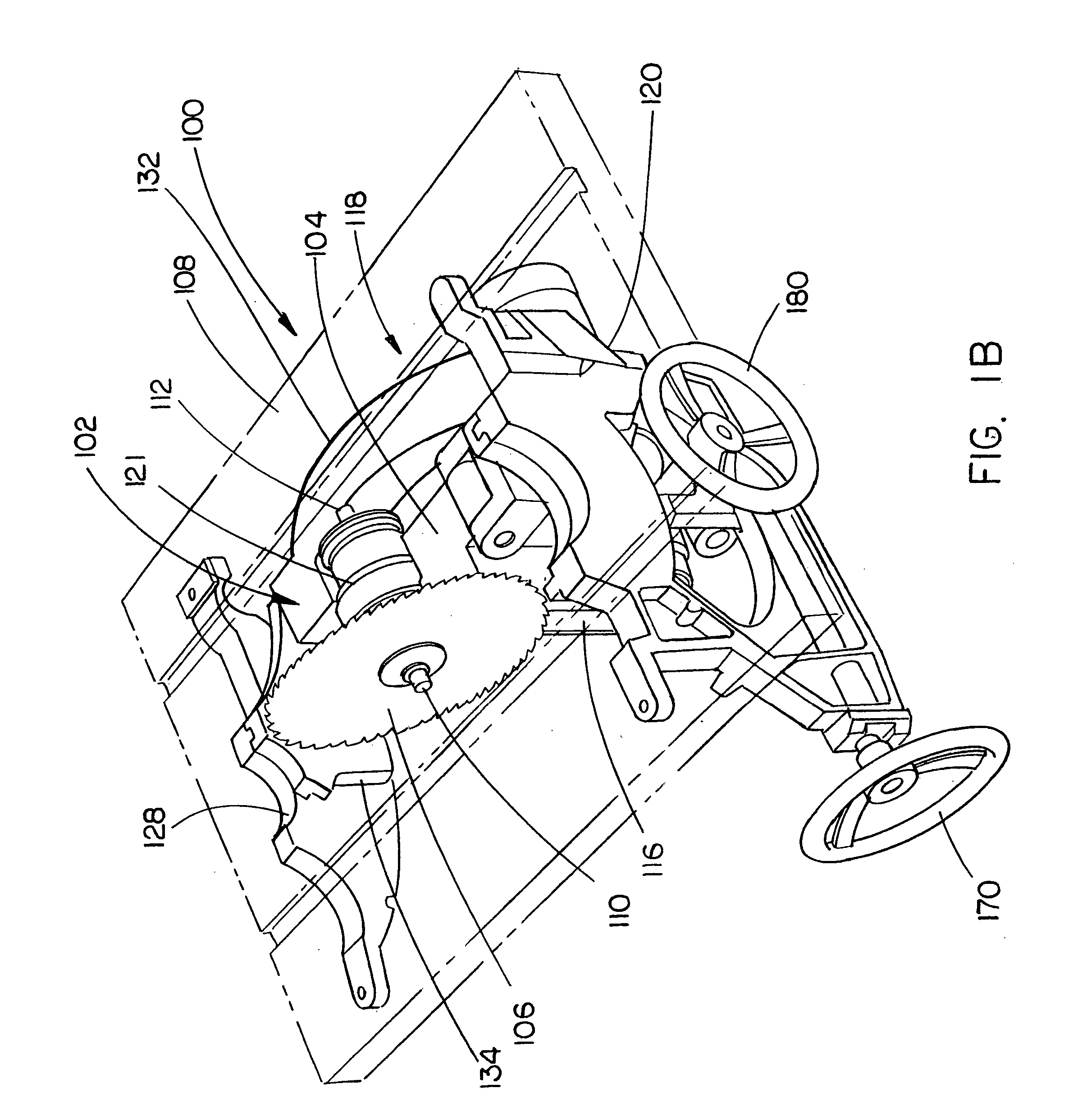

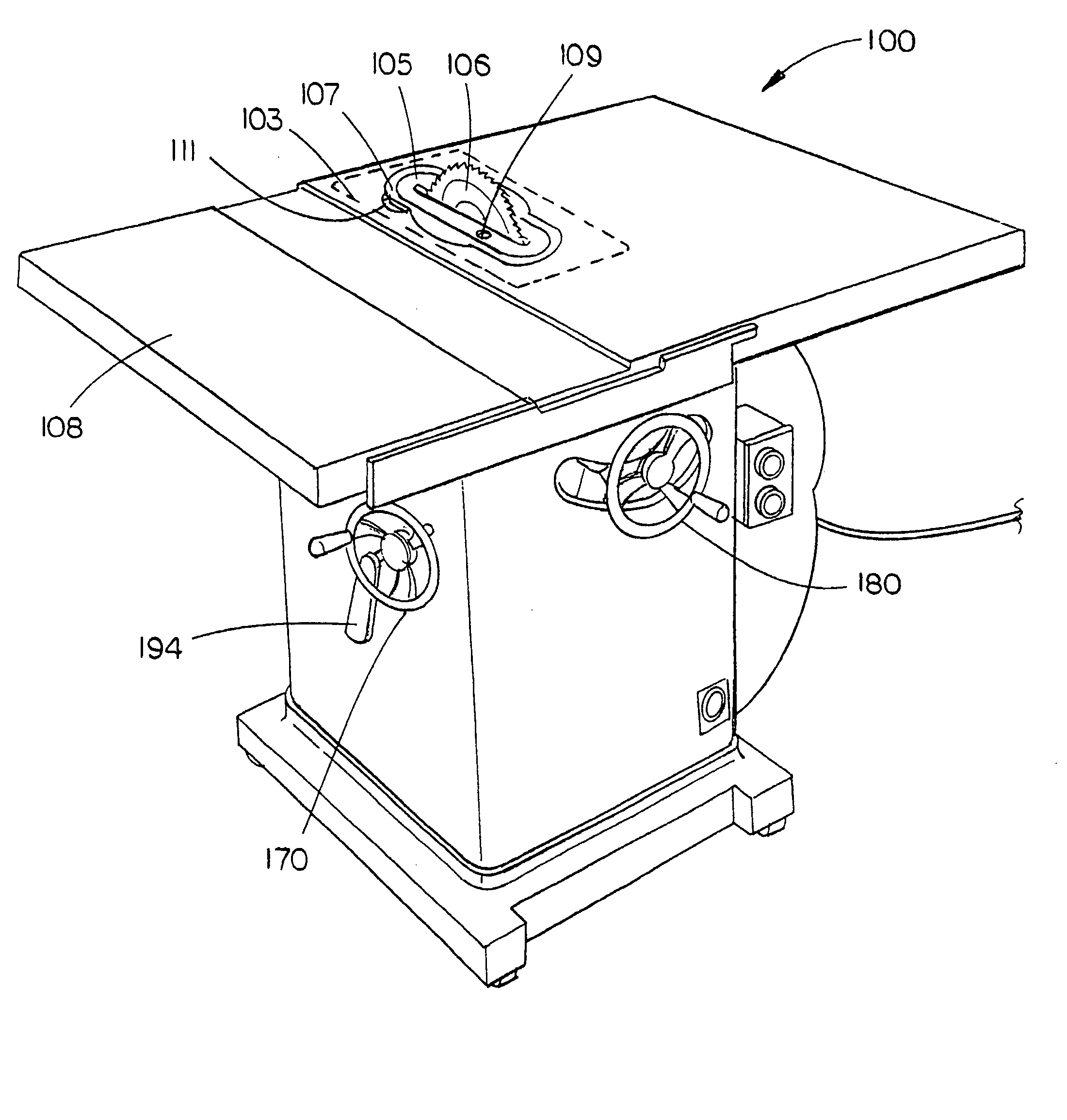

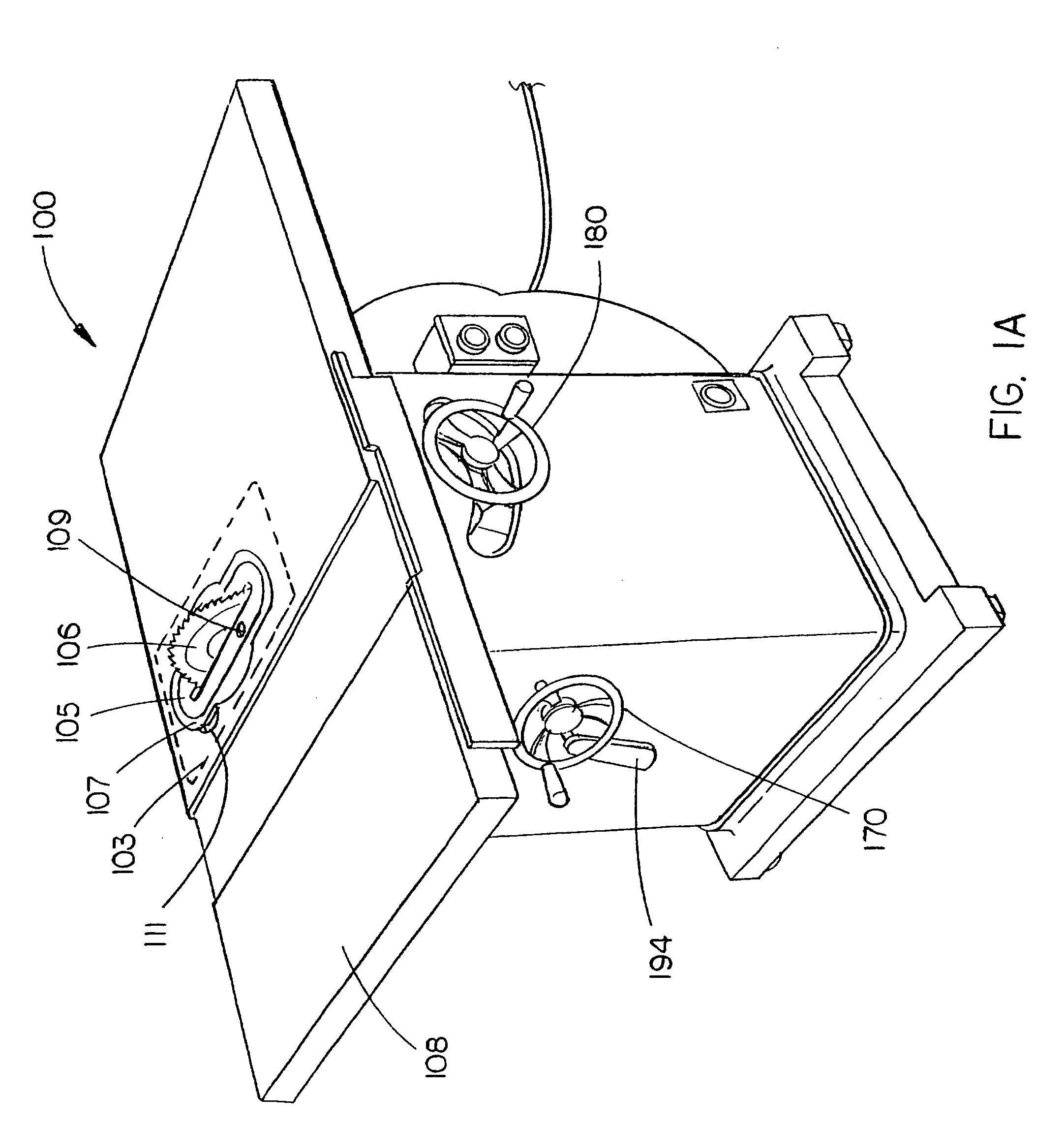

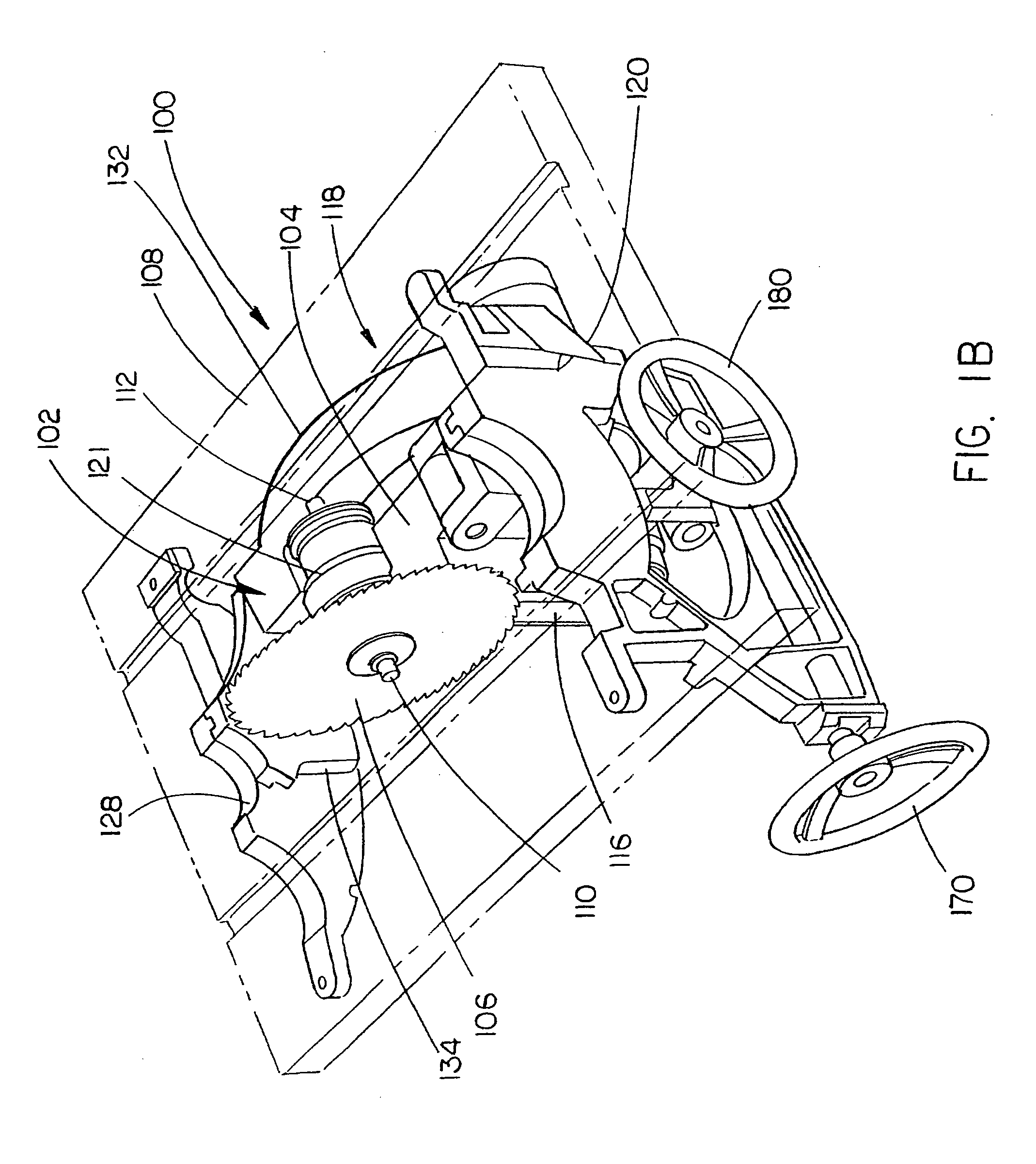

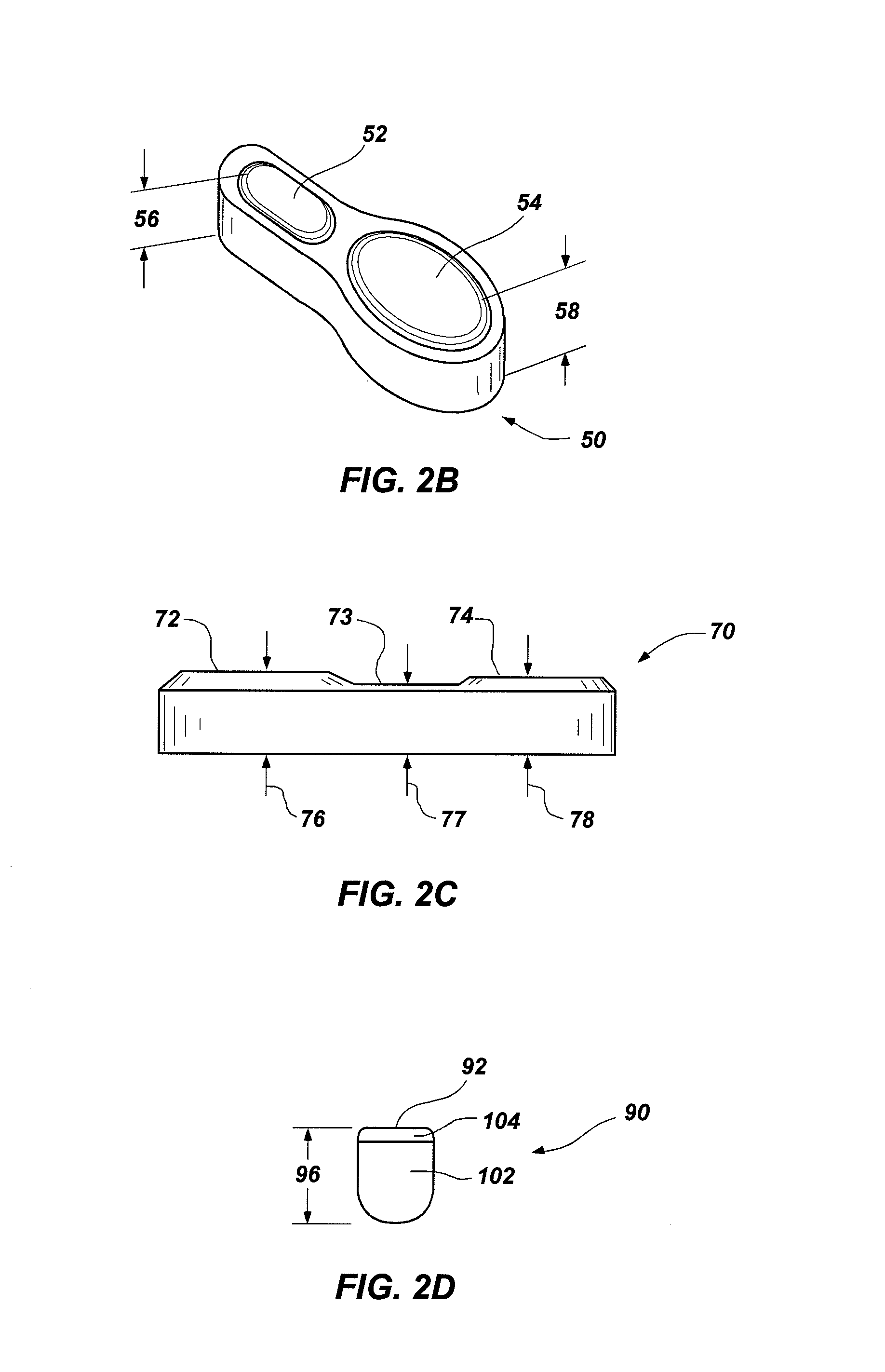

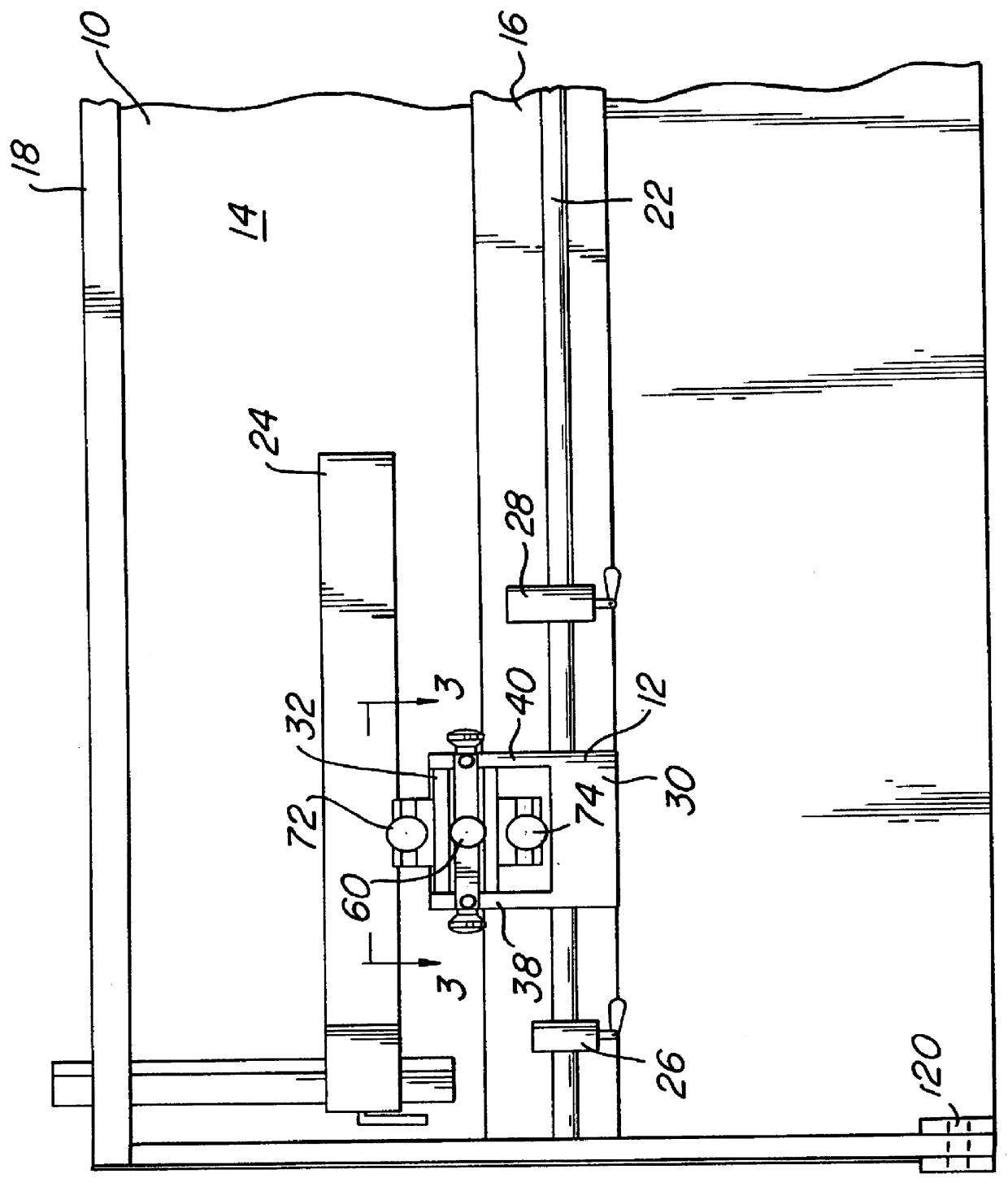

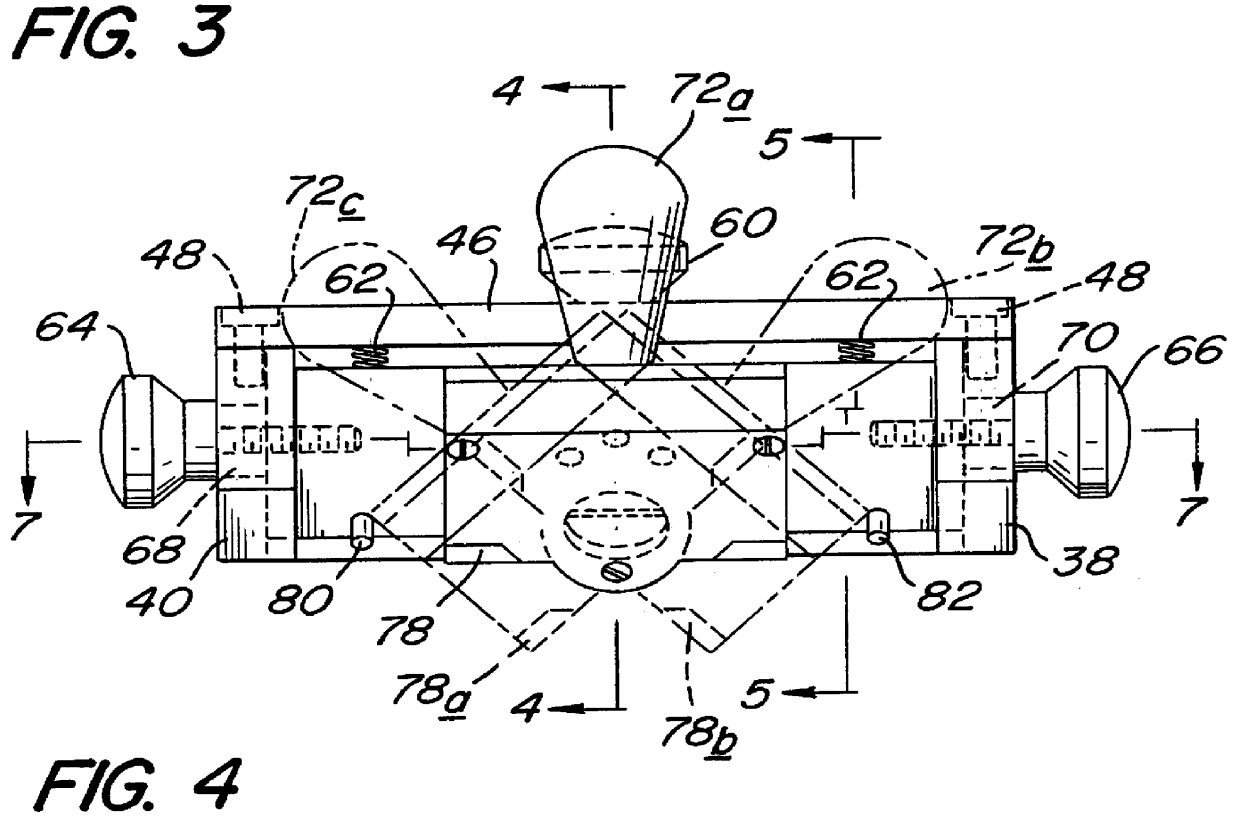

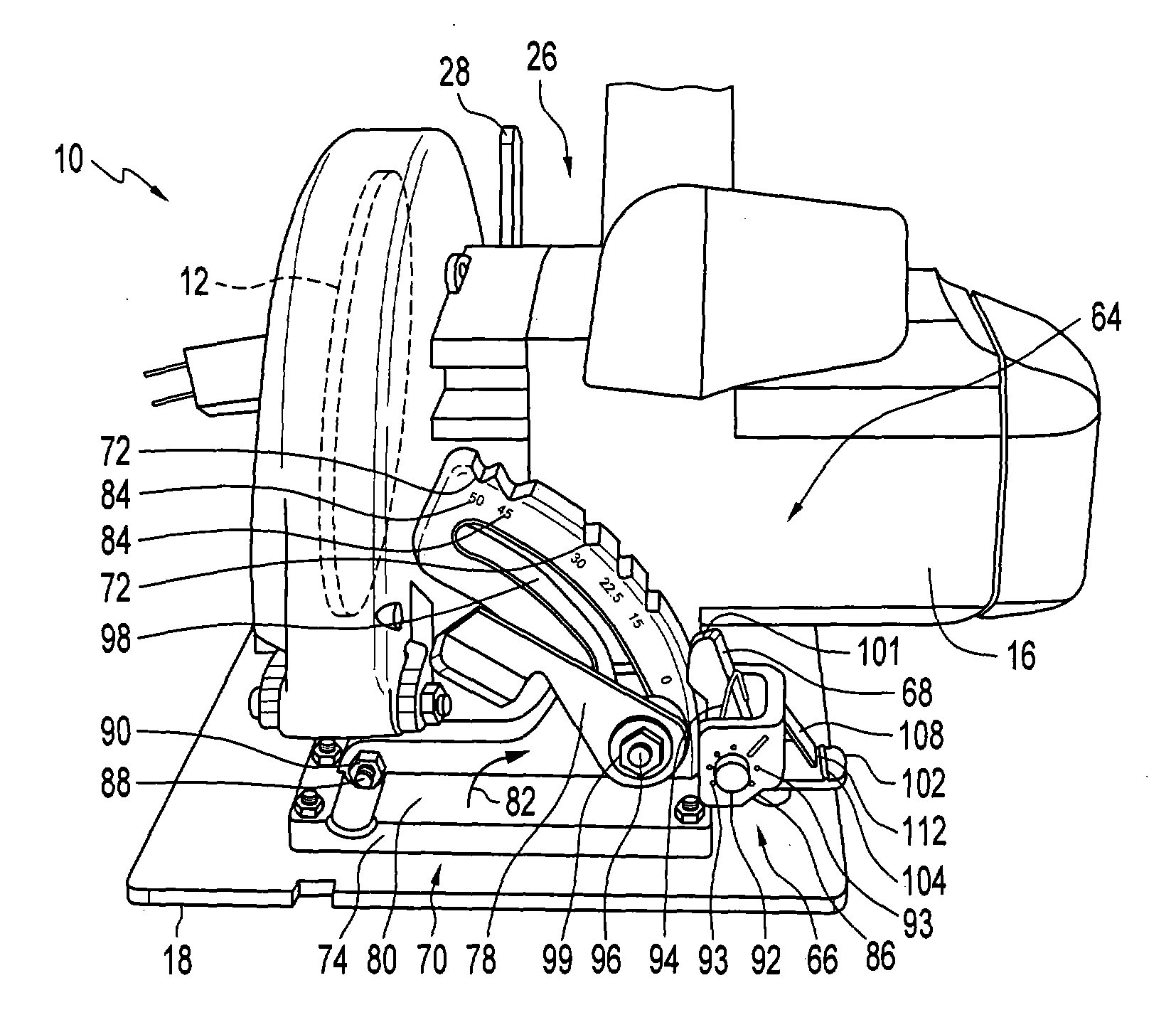

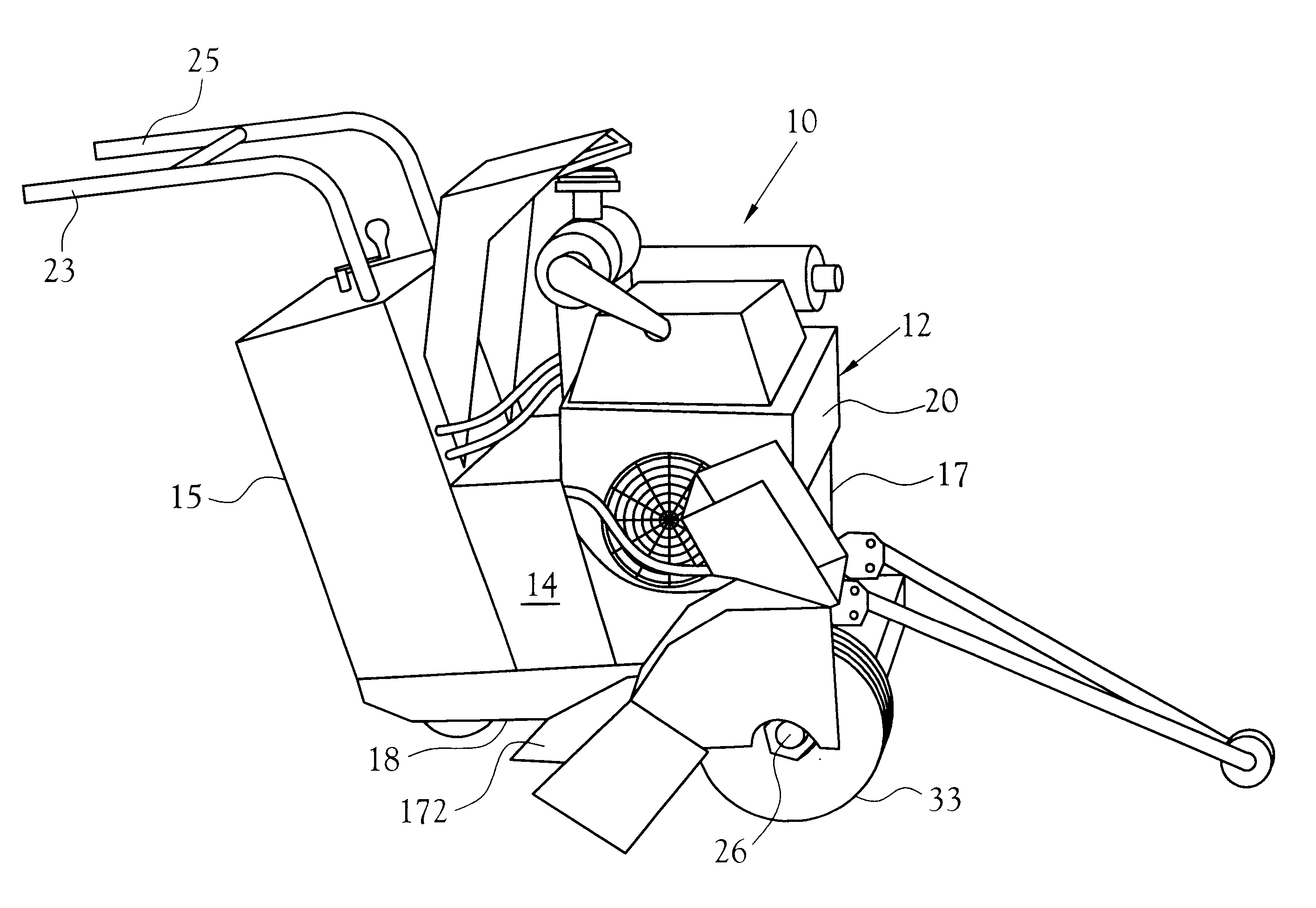

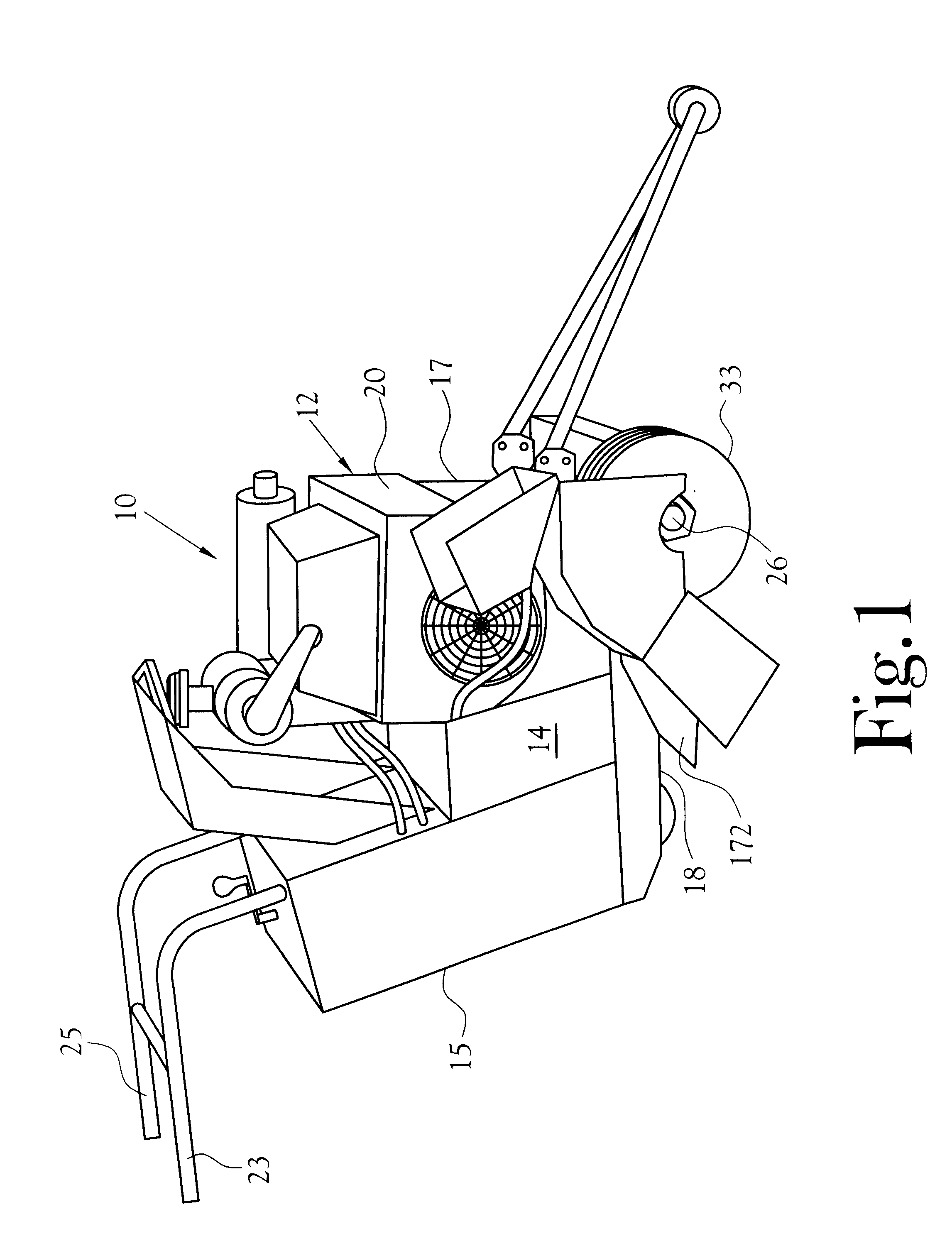

Dual bevel table saw

InactiveUS20040118261A1Efficient use ofMaximizing functional capabilityMetal sawing devicesGuide fencesEngineeringMechanical engineering

A dual bevel table saw provides a table saw enabled with a dual sided arbor assembly and a bi-directional bevel assembly. The dual sided arbor assembly coupled with the bevel assembly further provides for the positioning of a motor and a saw blade to allow for the full range of angular adjustment to be enabled without having to sacrifice any of the cutting features of the saw blade such as depth of cut. The dual bevel table saw may further include a companion saw assembly to provide increased functionality provided by the dual bevel table saw.

Owner:BLACK & DECKER INC

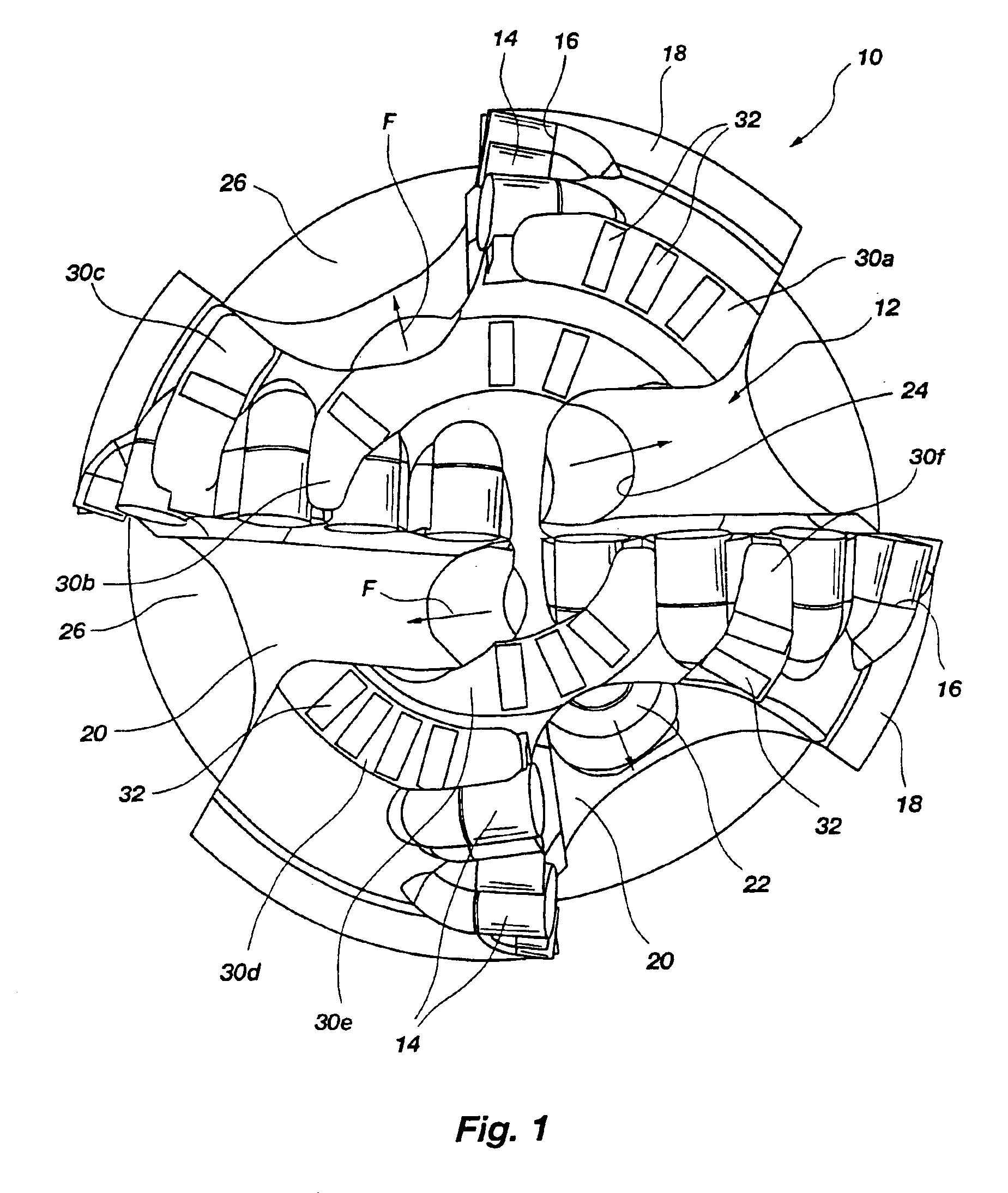

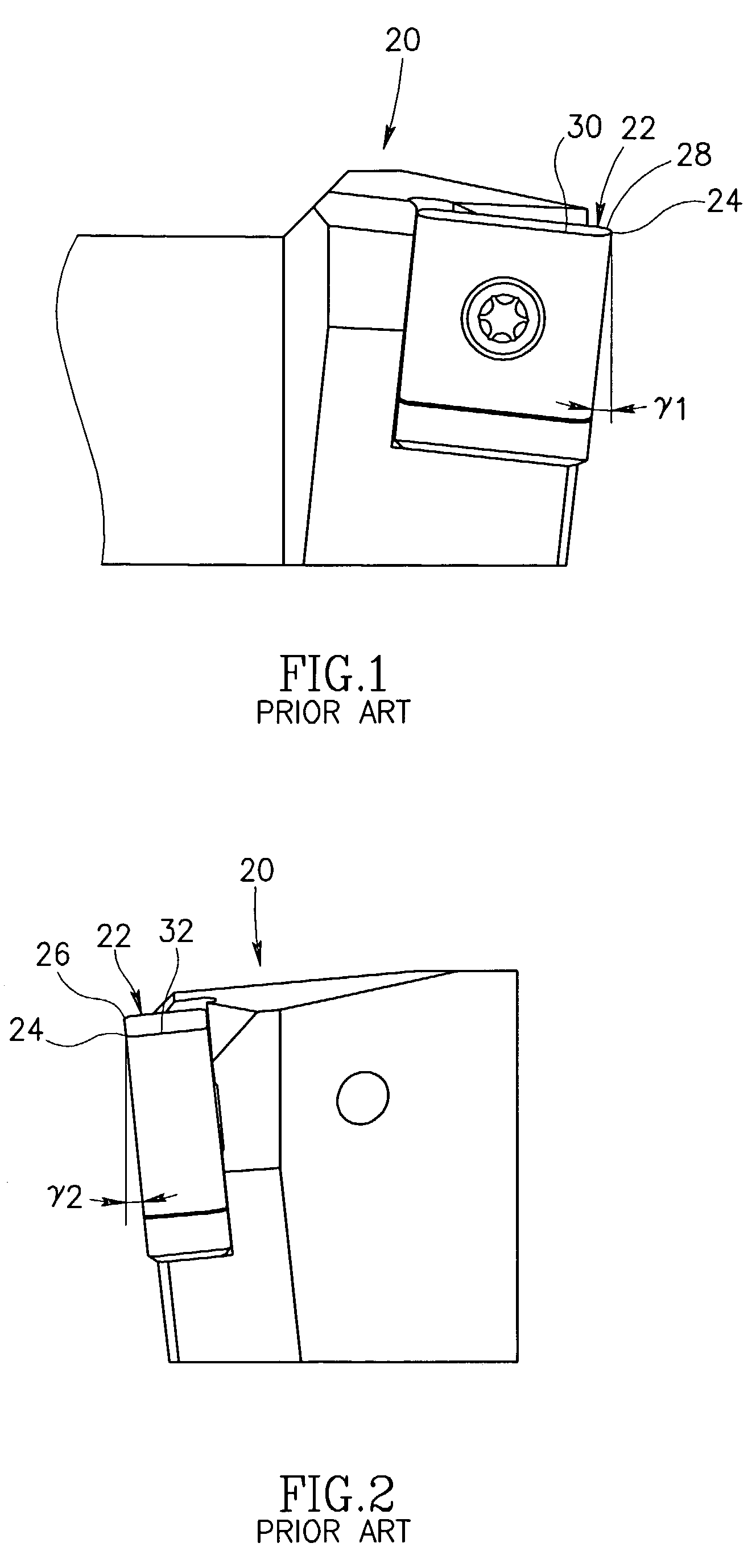

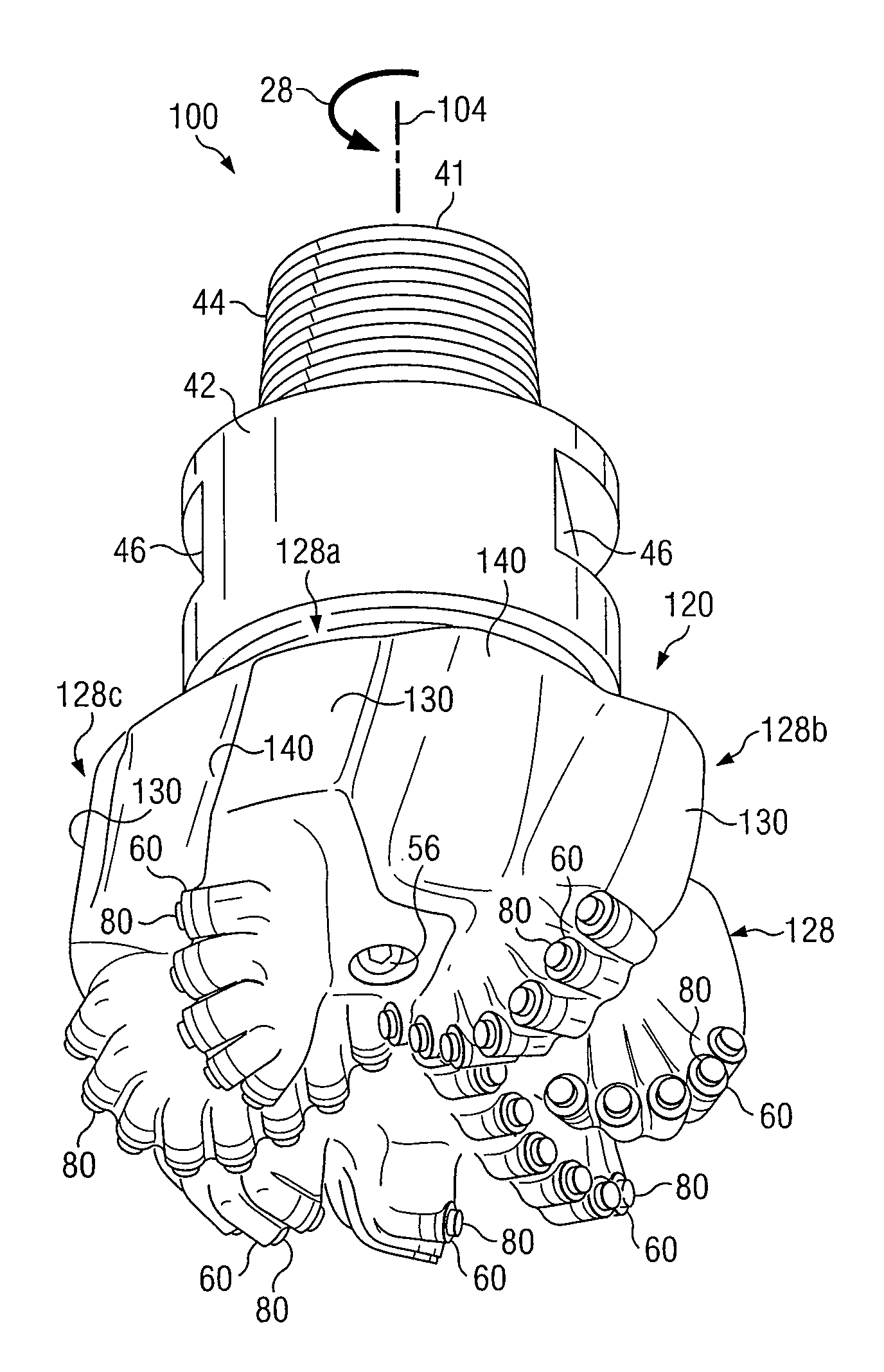

Drill bits with reduced exposure of cutters

InactiveUS6935441B2Easy to implementTorque is limitedEarth drilling toolsDrill bitsEngineeringCompressive strength

A rotary drag bit and method for drilling subterranean formations, including a bit body being provided with at least one cutter thereon exhibiting reduced, or limited, exposure to the formation, so as to control the depth-of-cut of the at least one cutter, so as to control the volume of formation material cut per bit rotation, as well as to control the amount of torque experienced by the bit and an optionally associated bottomhole assembly regardless of the effective weight-on-bit are all disclosed. The exterior of the bit preferably includes a plurality of blade structures carrying at least one such cutter thereon and including a sufficient amount of bearing surface area to contact the formation so as to generally distribute an additional weight applied to the bit against the bottom of the borehole without exceeding the compressive strength of the formation rock.

Owner:BAKER HUGHES INC

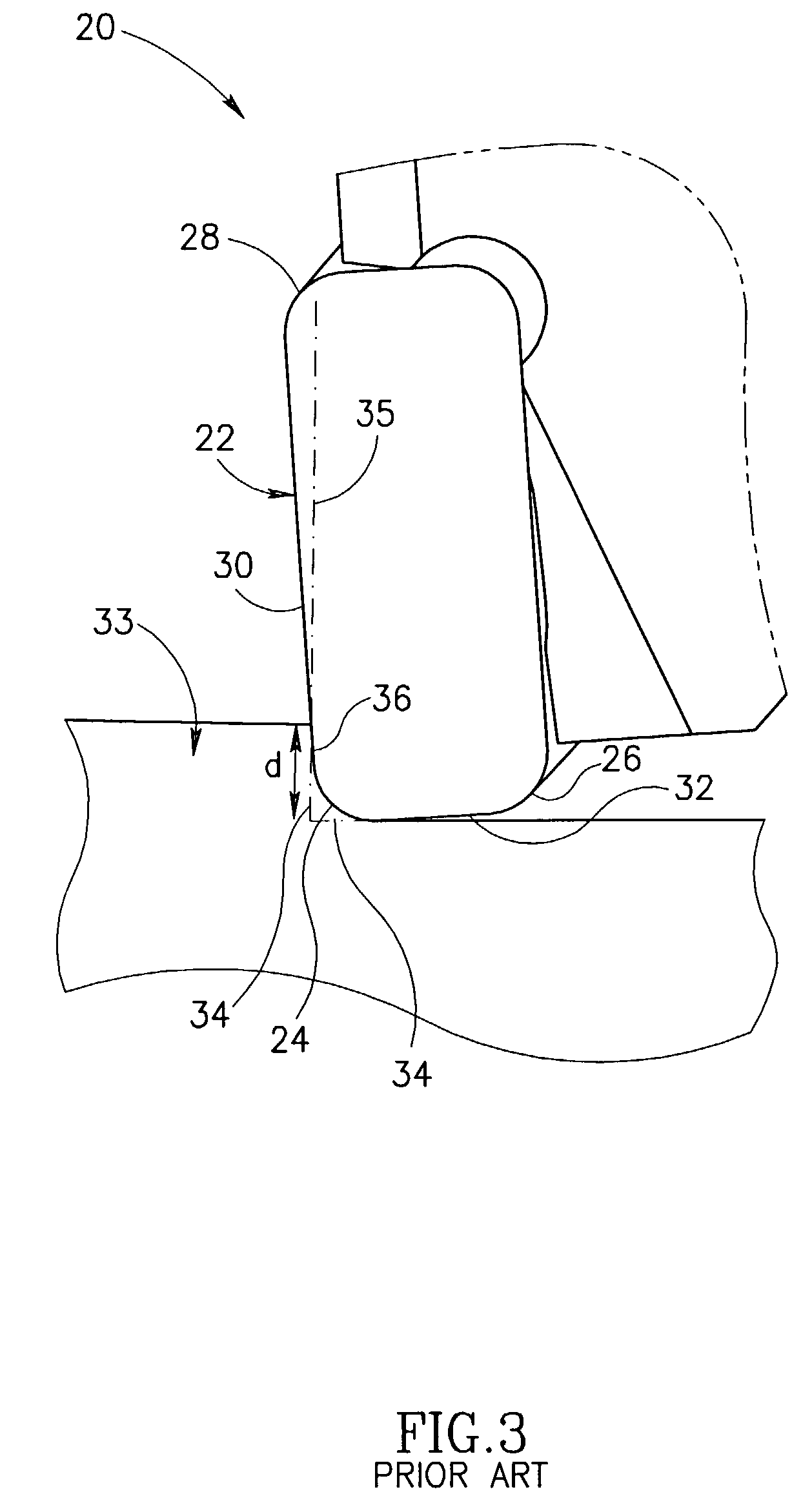

Tangential cutting insert and insert holder

A tangential indexable cutting insert can be used for metal cutting processes in general and for radial and axial turning of a stepped square shoulder in particular. The cutting insert exhibits 180° rotational symmetry about three mutually perpendicular axes. The cutting insert has generally “S”-shaped cutting edges extending between raised and lowered corners. The cutting edges and side surfaces are concave in an end view of the cutting insert. The cutting insert enables radial and axial turning operations of a square shoulder with unlimited depth of cut.

Owner:ISCAR LTD

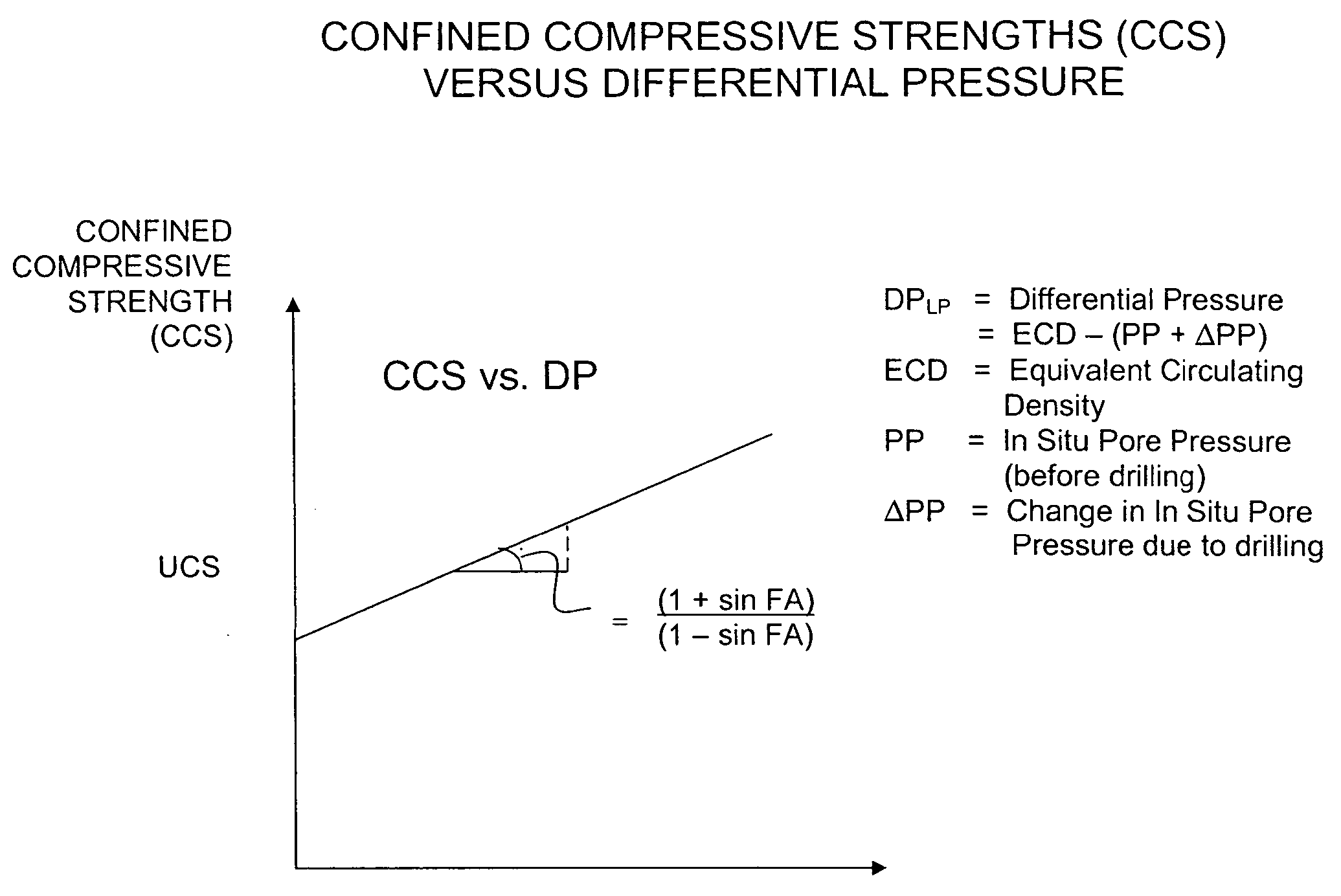

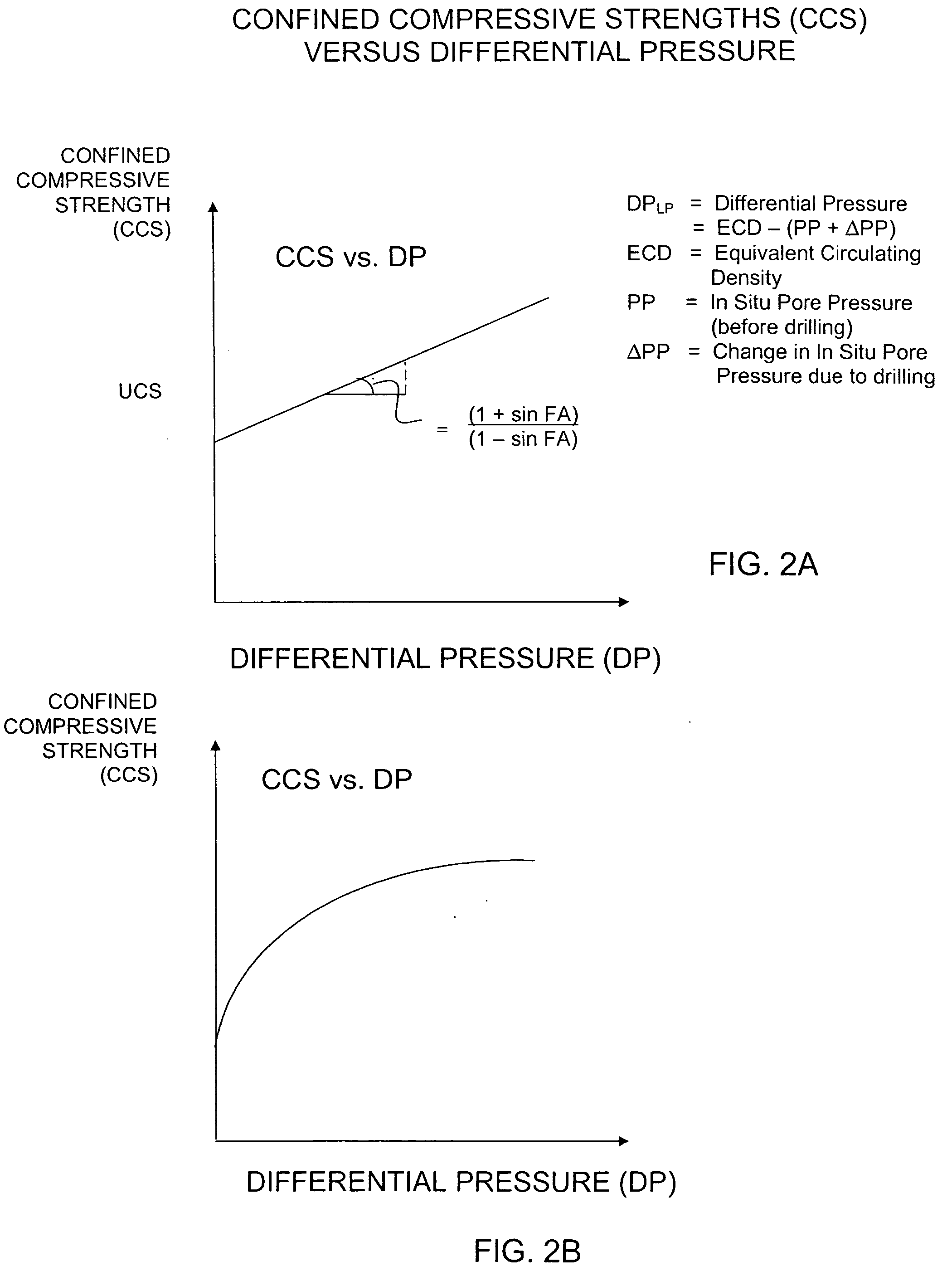

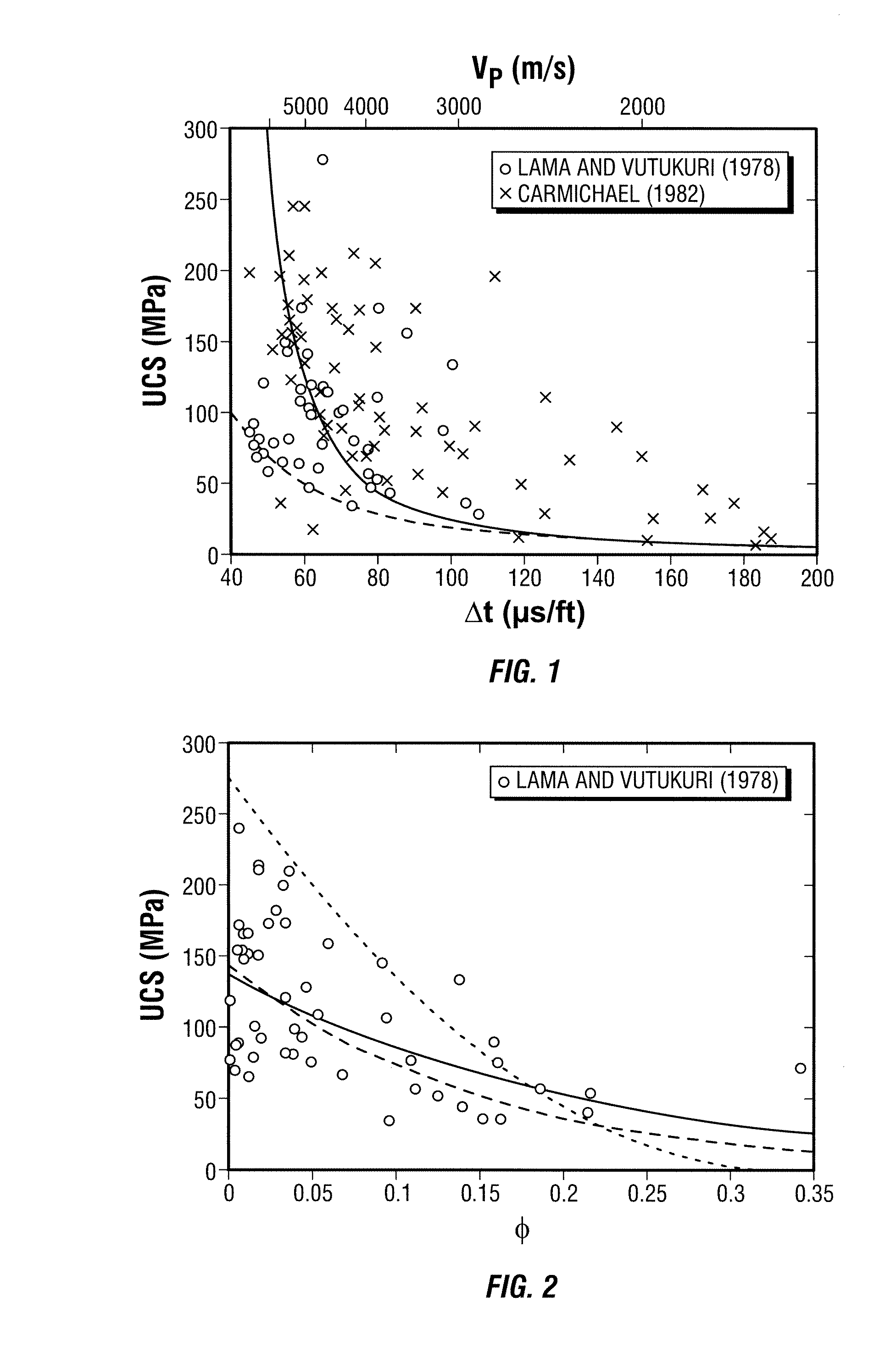

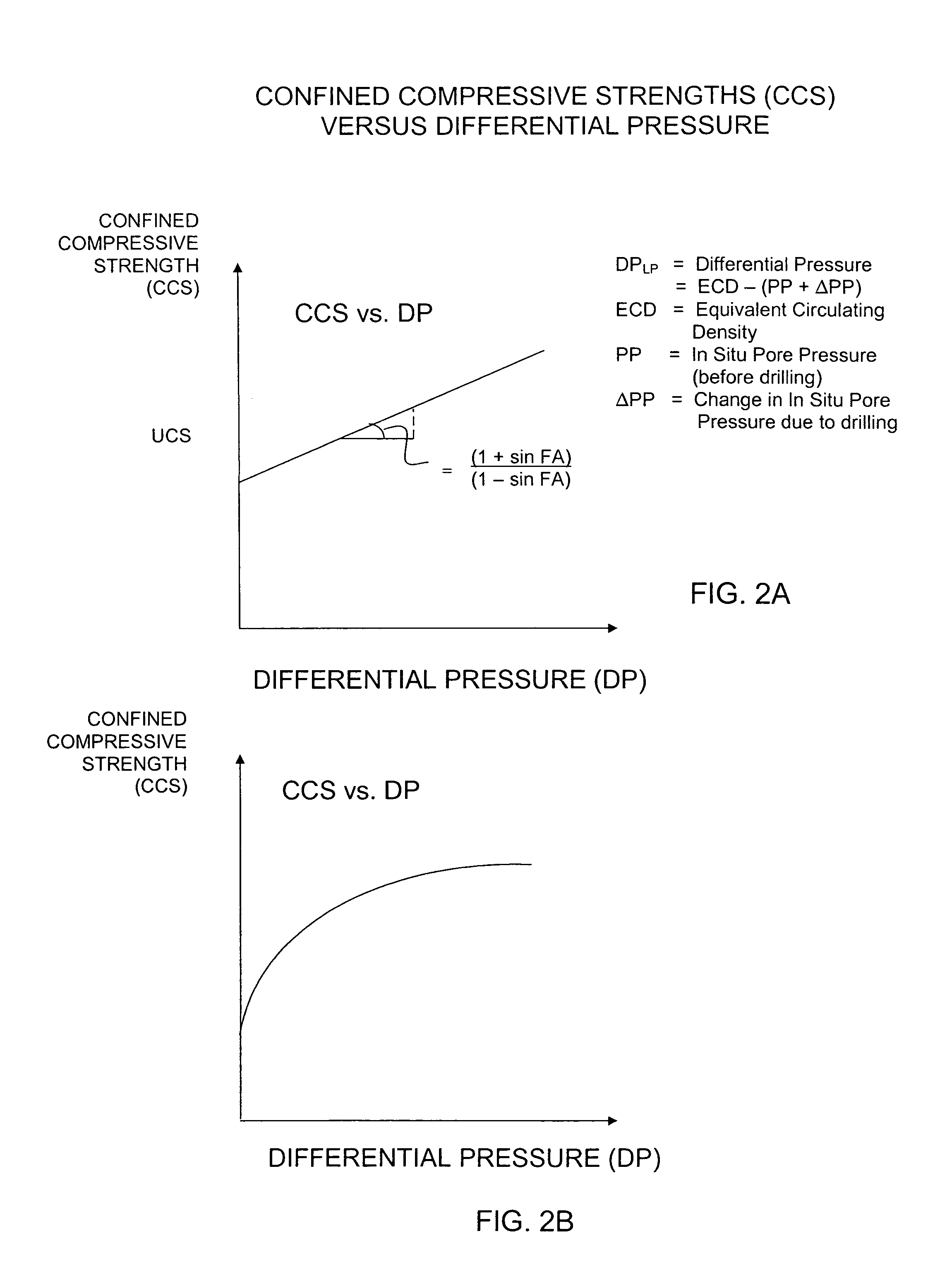

Method for estimating confined compressive strength for rock formations utilizing skempton theory

InactiveUS20060131074A1Improve accuracyElectric/magnetic detection for well-loggingSurveyCompressive strengthUltimate tensile strength

A method for estimating the CCS for a rock in the depth of cut zone of a subterranean formation which is to be drilled using a drilling fluid is disclosed. An UCS is determined for a rock in the depth of cut zone. A change in the strength of the rock due to applied stresses imposed on the rock during drilling is calculated which includes estimating the ΔPP. The CCS for the rock in the depth of cut zone is calculated by adding the estimated change in strength to the UCS. The present invention calculates the ΔPP in accordance with Skempton theory where impermeable rock or soil has a change in pore volume due to applied loads or stresses while fluid flow into and out of the rock or soil is substantially non-existent. CCS may be calculated for deviated wellbores and to account for factors such as wellbore profile, stress raisers, bore diameter, and mud weight utilizing correction factors derived using computer modeling and using a baseline formula for determining an uncorrected value for CCS.

Owner:CHEVROU USA INC

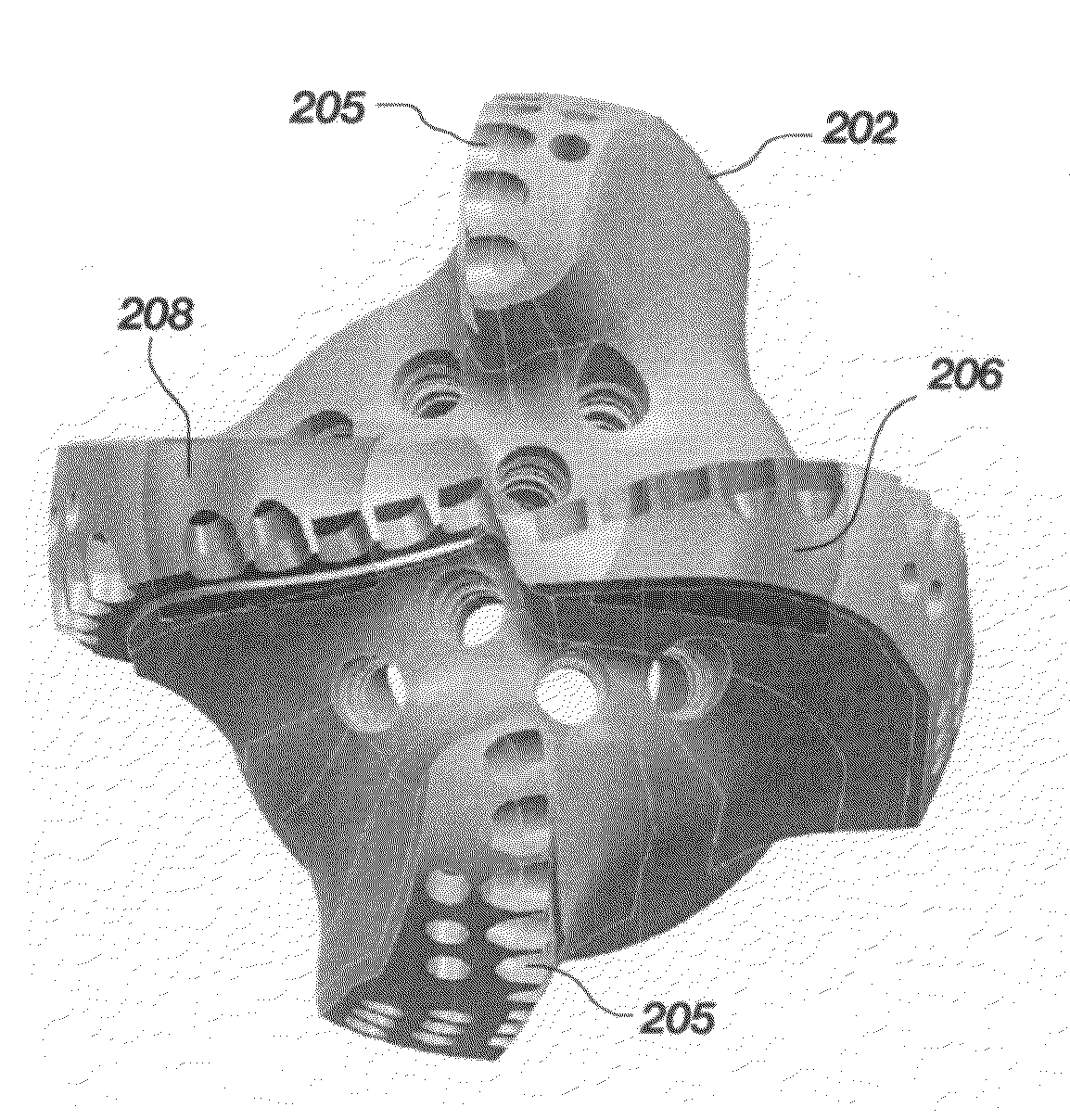

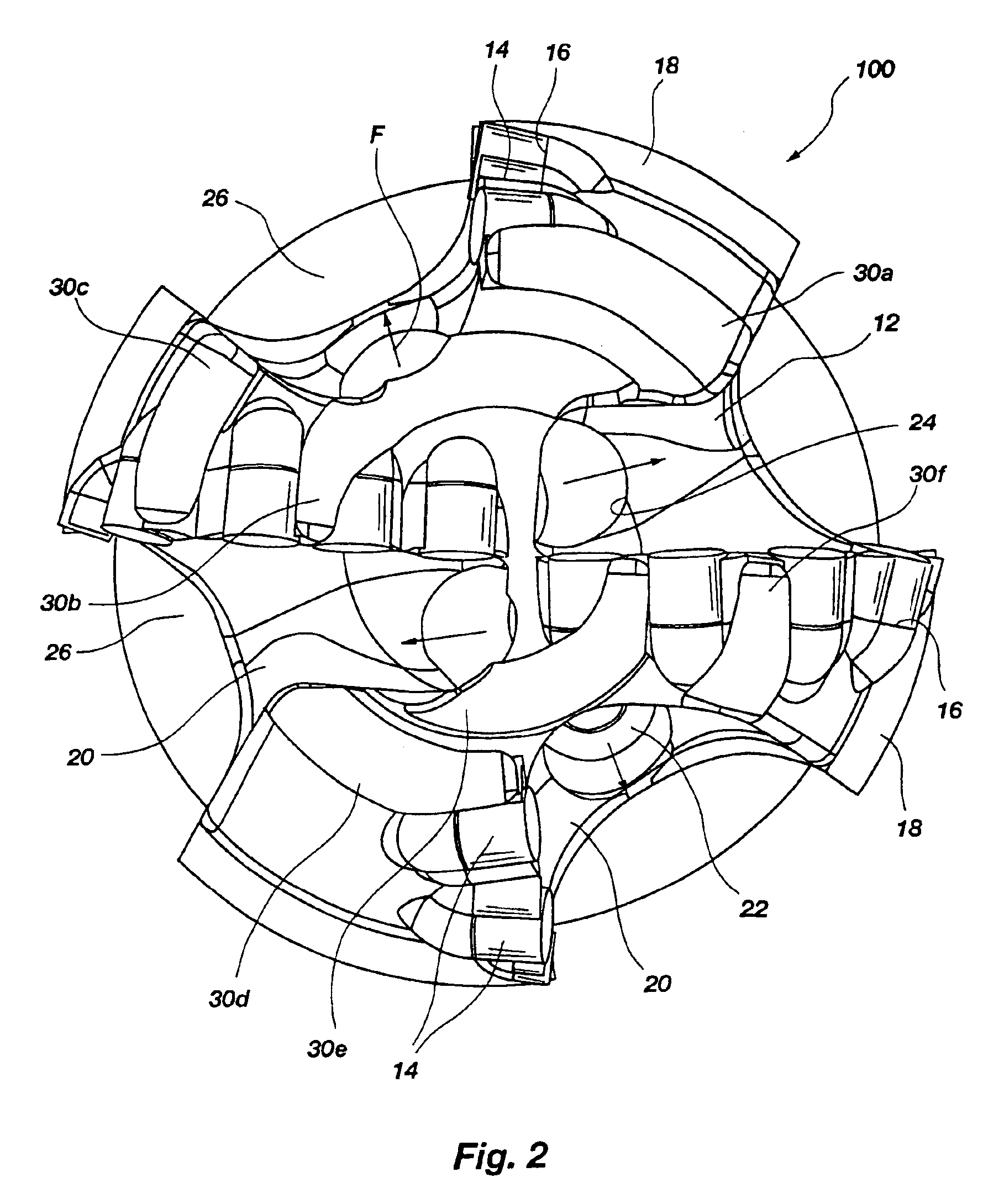

Rotary Drill Bits with Protected Cutting Elements and Methods

ActiveUS20100000800A1Prolong lifeReducing and eliminating damageDrill bitsConstructionsRate of penetrationEngineering

A rotary drill bit with cutting elements operable to control depth of cut and rate of penetration during formation of a wellbore are provided. Respective sets of secondary cutting elements and primary cutting elements may also be disposed on exterior portions of a rotary drill bit. A number of blades may extend from exterior portions of the drill bit with a number of cutting elements disposed on exterior portions of each blade. Each cutting element may include a substrate with a cutting surface disposed thereon. A respective protector may extend from the cutting surface of one or more cutting elements to limit depth of penetration of the associated cutting element into adjacent portions of a downhole formation and / or to control rate of penetration of an associated rotary drill bit.

Owner:HALLIBURTON ENERGY SERVICES INC

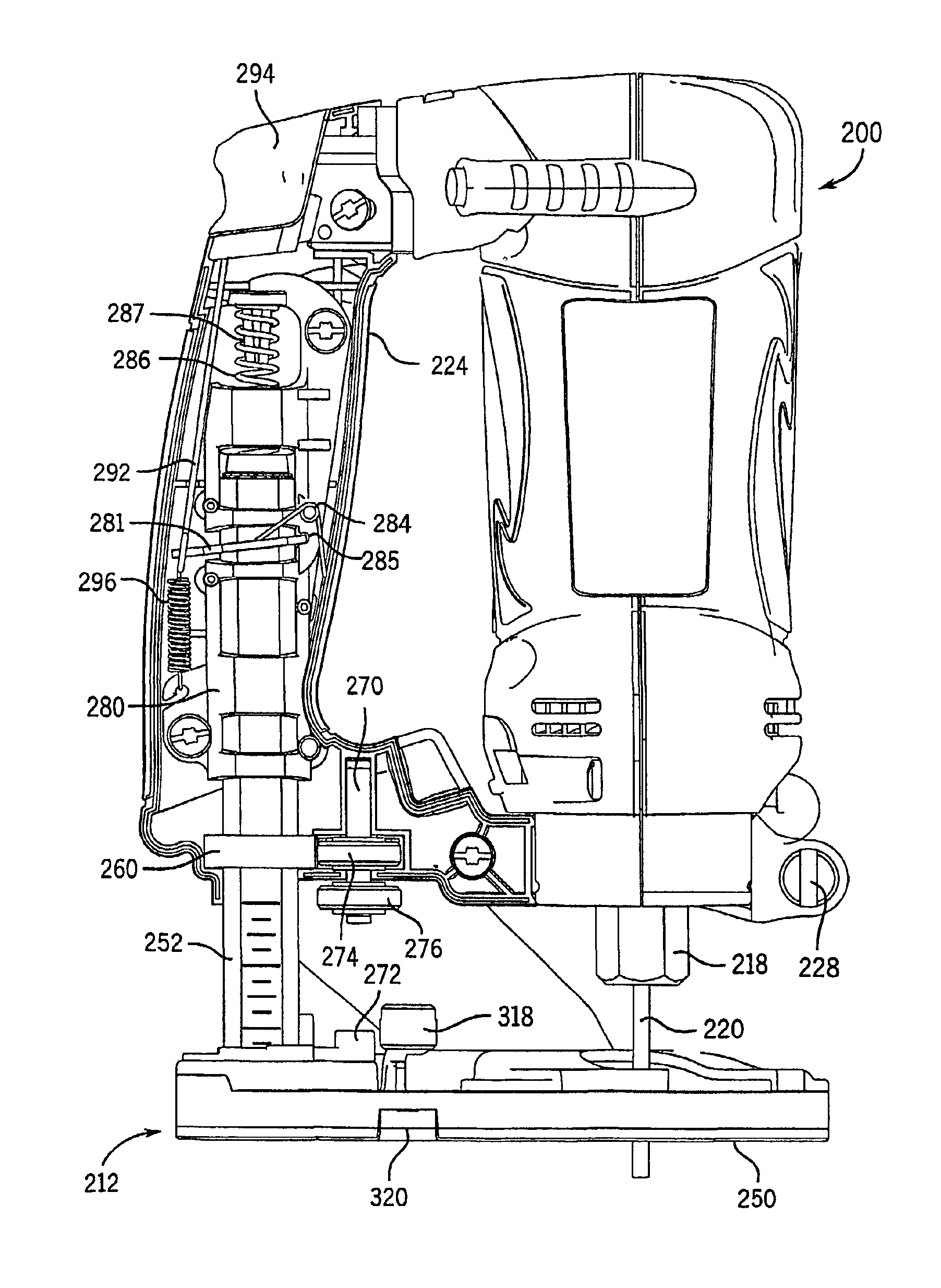

Dual bevel table saw

InactiveUS20050160895A1Efficient use ofMaximizing functional capabilityMetal sawing devicesShearing machinesEngineeringMechanical engineering

A dual bevel table saw provides a table saw enabled with a dual sided arbor assembly and a bi-directional bevel assembly. The dual sided arbor assembly coupled with the bevel assembly further provides for the positioning of a motor and a saw blade to allow for the full range of angular adjustment to be enabled without having to sacrifice any of the cutting features of the saw blade such as depth of cut. The dual bevel table saw may further include a companion saw assembly to provide increased functionality provided by the dual bevel table saw.

Owner:BLACK & DECKER INC

Interchangeable bearing blocks for drill bits, and drill bits including same

ActiveUS7814997B2Reduce complexityReduce inventory quantityDrill bitsDrilling rodsEngineeringRubbing

A bearing block is provided that may be used with a drag bit body or frame to limit depth of cut of cutters on a bit. The bearing block is designed so that it may be interchangeably replaced or repaired without necessitating alteration to a standardized bit frame. The interchangeable bearing block may be used to provide a target depth of cut (TDOC) and / or a selected contact or rubbing area to support weight on bit and limit depth of cut (DOC) for improving drilling performance of a bit. The interchangeable bearing block brings manufacturing selectability by providing a customizable product in terms of depth of cut selection and cutter penetration control for different formations, which is suitable for use with a common bit frame. A rotary drill bit assembly, a unitary cone insert bearing block for a drill bit, and a bit frame are also provided.

Owner:BAKER HUGHES HLDG LLC

Hand-operated cutter for a sheet-like workpiece and a method of cutting

InactiveUS6138546AEasy to doReadily interchangeable partShaping toolsShearing machinesMechanical engineeringDepth of cut

A hand operated cutting apparatus and method of cutting mat board, glass, and other related sheet-like framing material. The apparatus has a cutting head assembly which includes a plurality of interchangeable and adjustable blade holding units. Each blade holding unit provides a different type of cut, such as a beveled, straight edge, or V-groove cut. Most of the blade holding units are intended for use with mat board, but some can be used to cut and trim sheet-like glass or plastic framing material. Each blade holding unit is also capable of vertical adjustment relative to the workpiece so that various depths of cut can be provided. The method of cutting a mat board permits the mat board to be positioned face up on the base board of the cutting apparatus and does not require flipping or taping of the mat board during V-groove cutting operations.

Owner:CUSTOM CRAFT ACQUISITION CORP

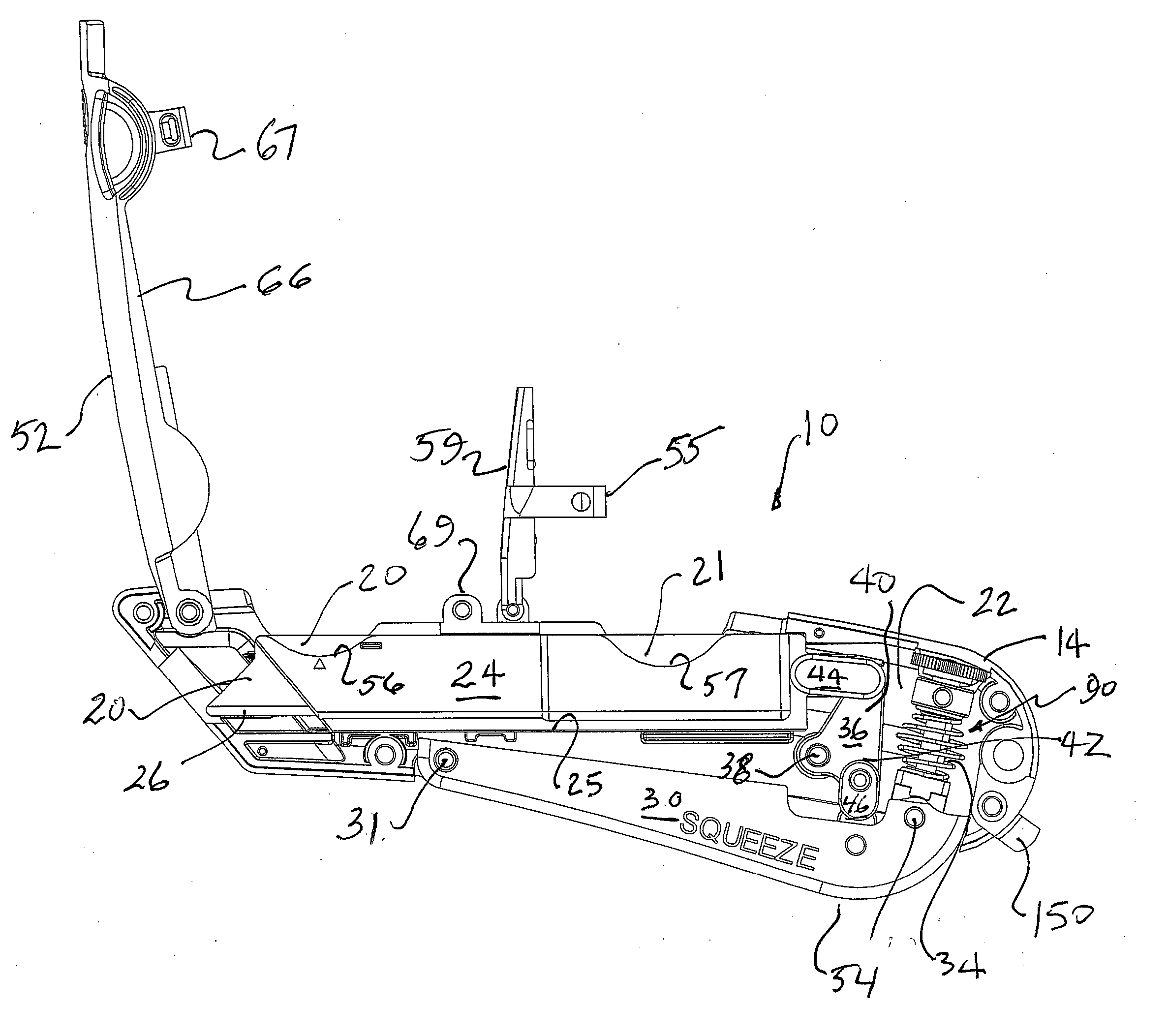

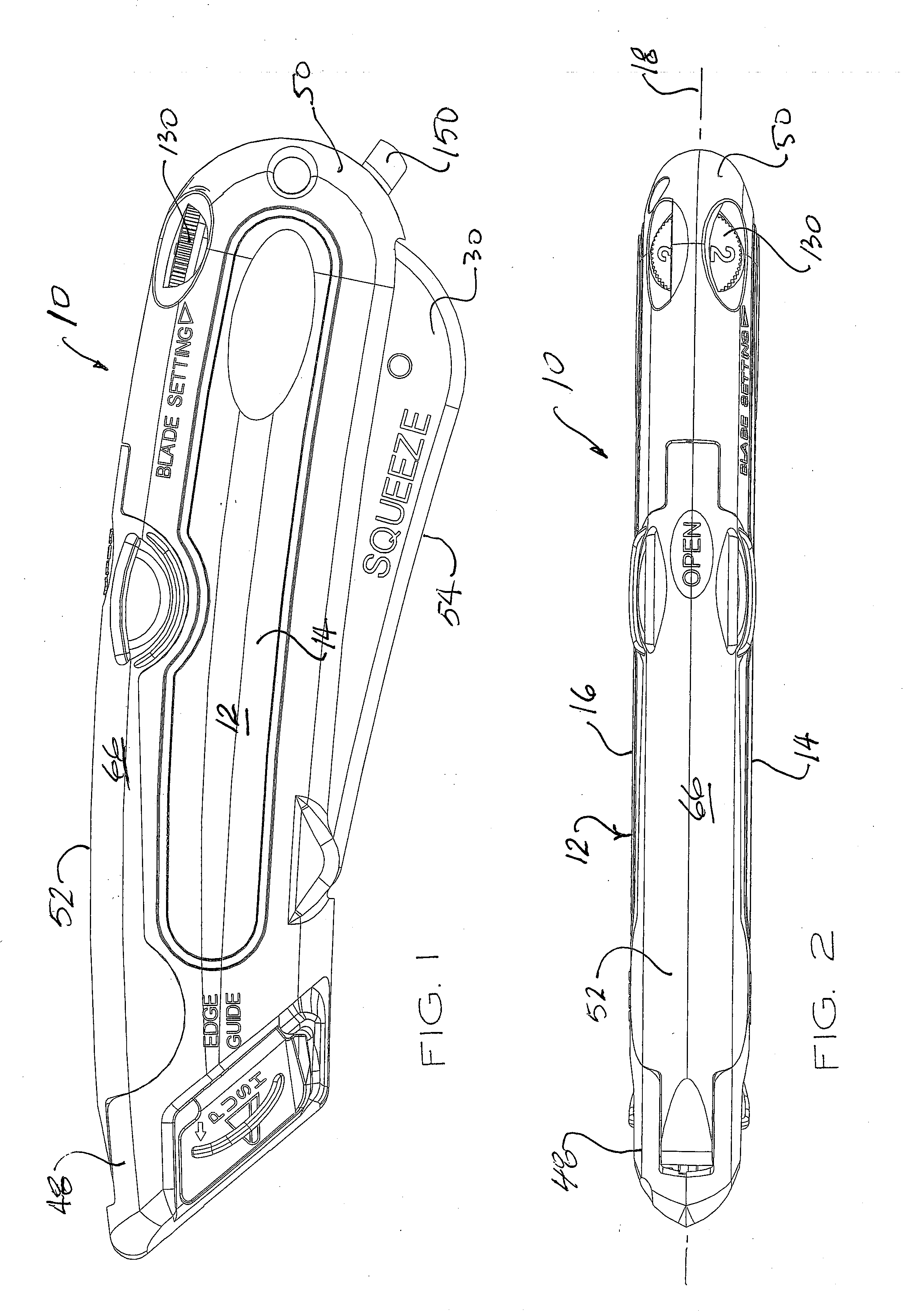

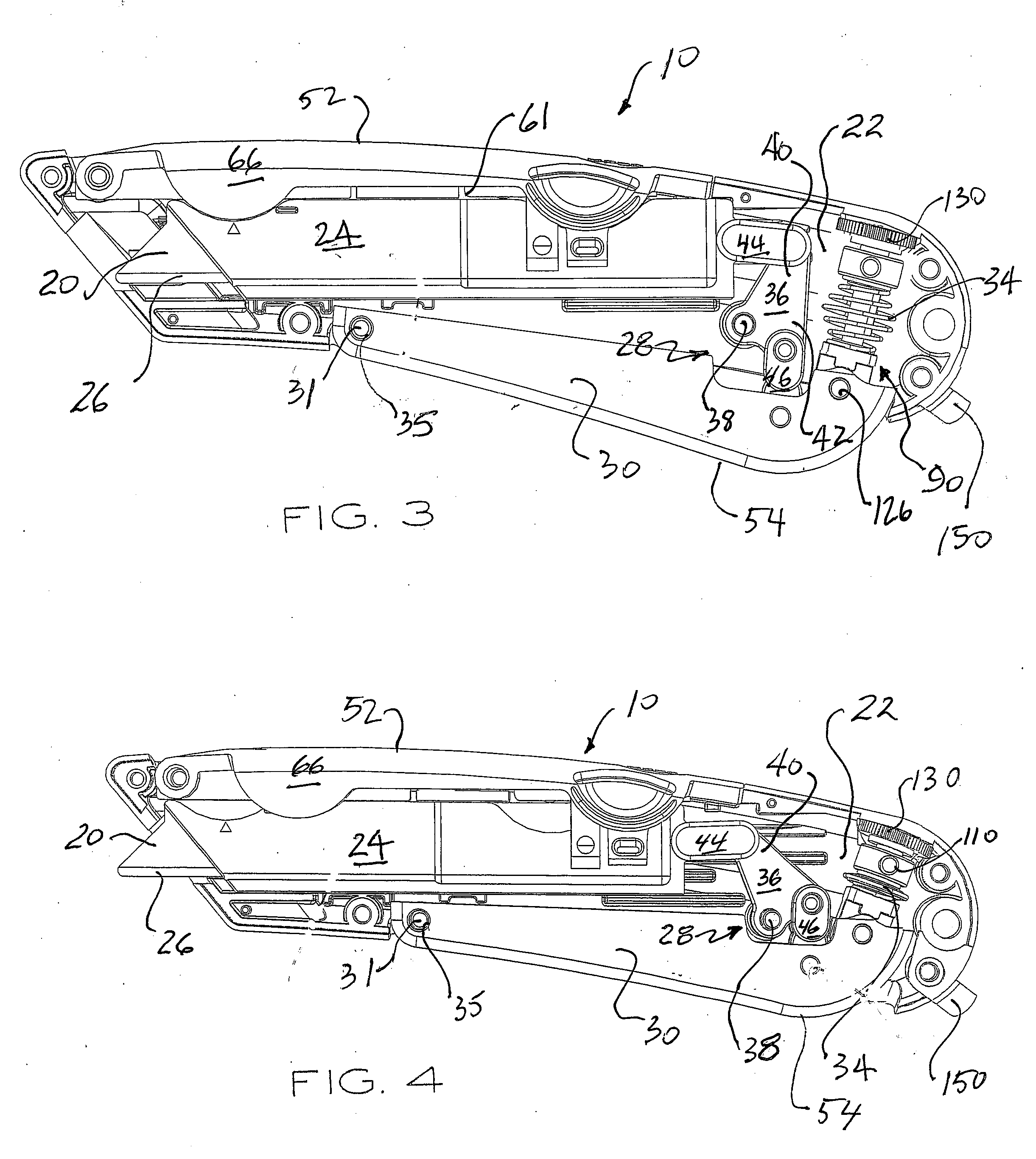

Box cutter with grip-actuated blade extension

InactiveUS20070209209A1Improved operator safetyComfortable gripping and handlingTravelling carriersHoldersReciprocating motionEngineering

An automatic blade-retracting box cutter utility knife has a handle with ergonomic hand grip proportions for comfortable gripping and handling during repetitive cutting operations. A blade-actuating hand-grip lever is mounted on the housing for movement about a pivotal axis. A blade shuffle is mounted for longitudinal sliding reciprocal movement in the housing from a rear retracted end position in which the blade is wholly received in the housing, to a front extended end position in which the blade is extended forward from the housing. The blade shuttle is extended in response to gripping actuation of the hand-grip lever. Extension and retraction forces are transferred from the hand-grip lever to a compression spring and to the blade shuttle via a power transmission assembly that includes a torque plate that is mounted for clockwise and counterclockwise rotation on the housing. Top access to a working blade and a replacement blade stored on the shuttle is provided for blade loading and security. Dual edge guide members are mounted for independent extension and retraction movement. A depth of cut adjustment dial is integrated with the power transmission assembly. Depth of cut, or blade extension, is set by limiting pivoting travel of the gripping lever during hand grip actuation.

Owner:DALLCO MARKETING SERVICES +1

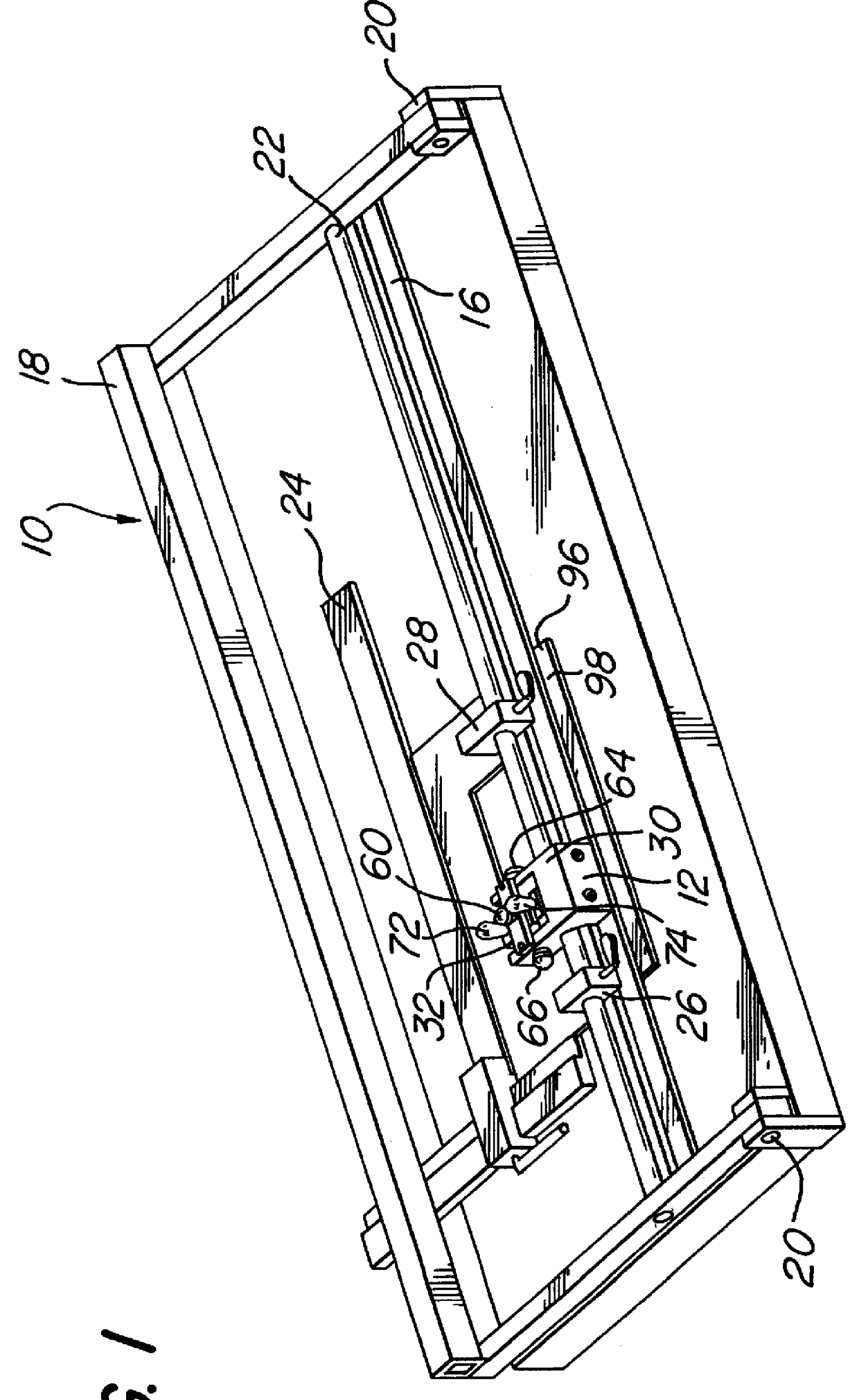

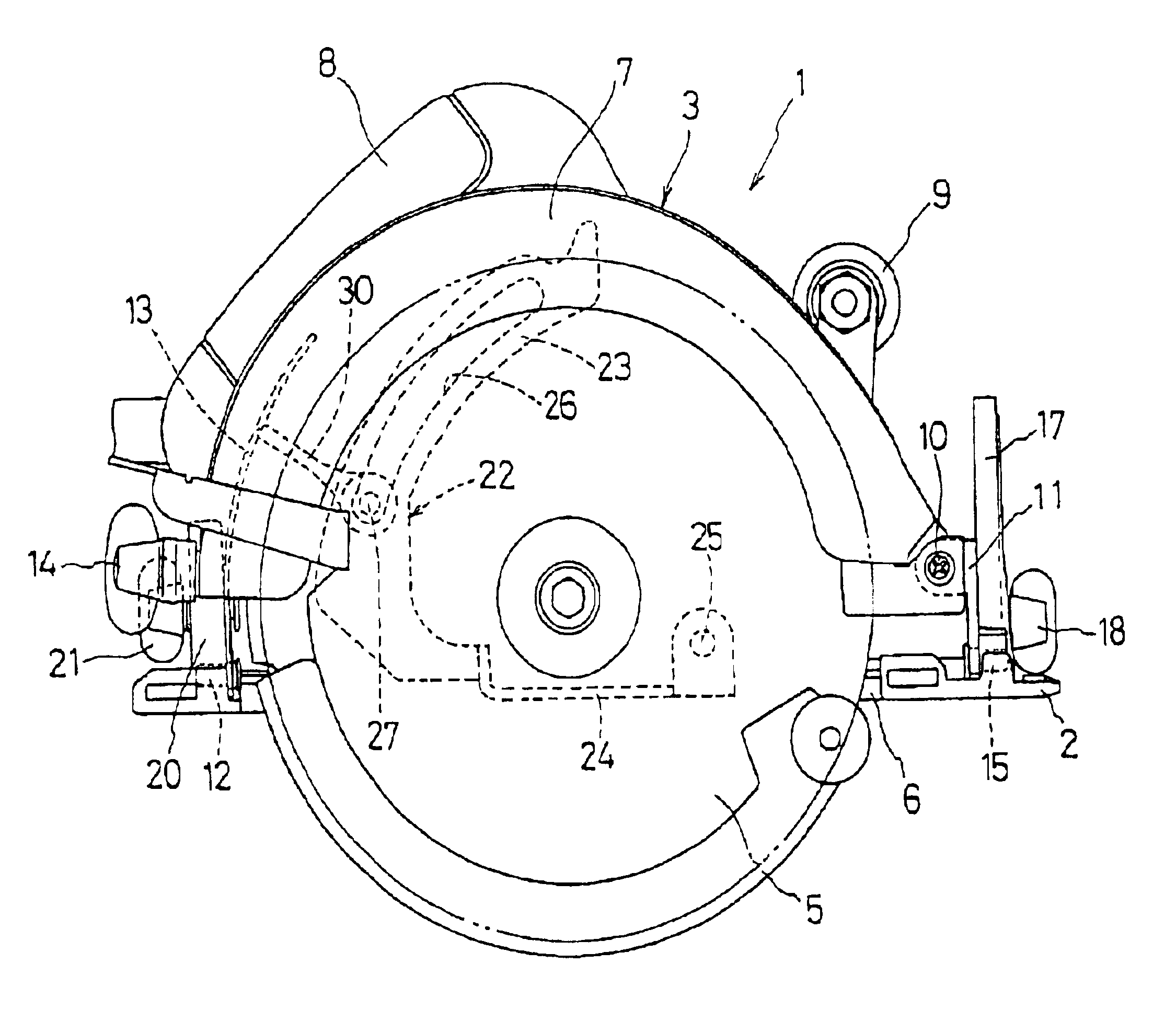

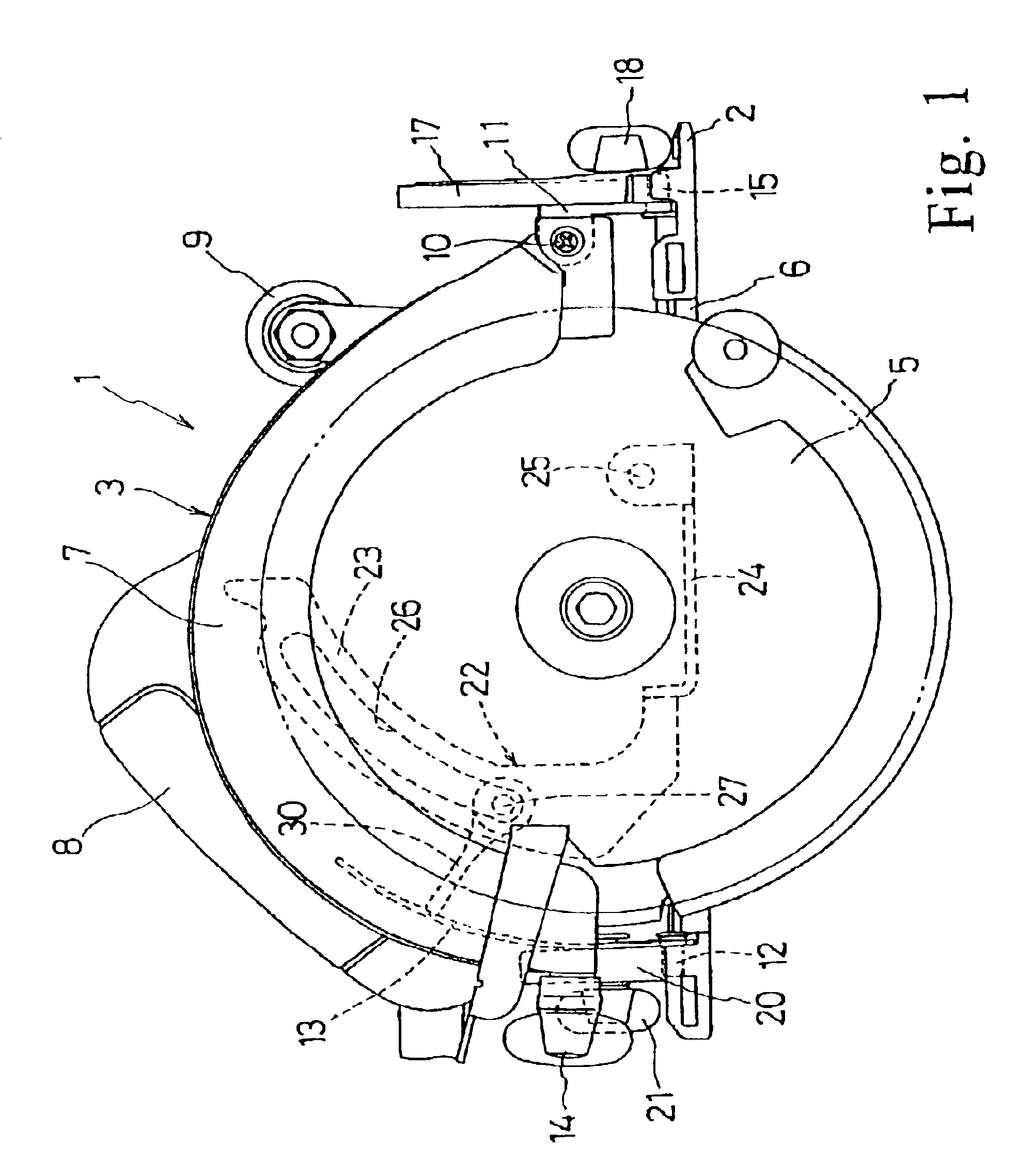

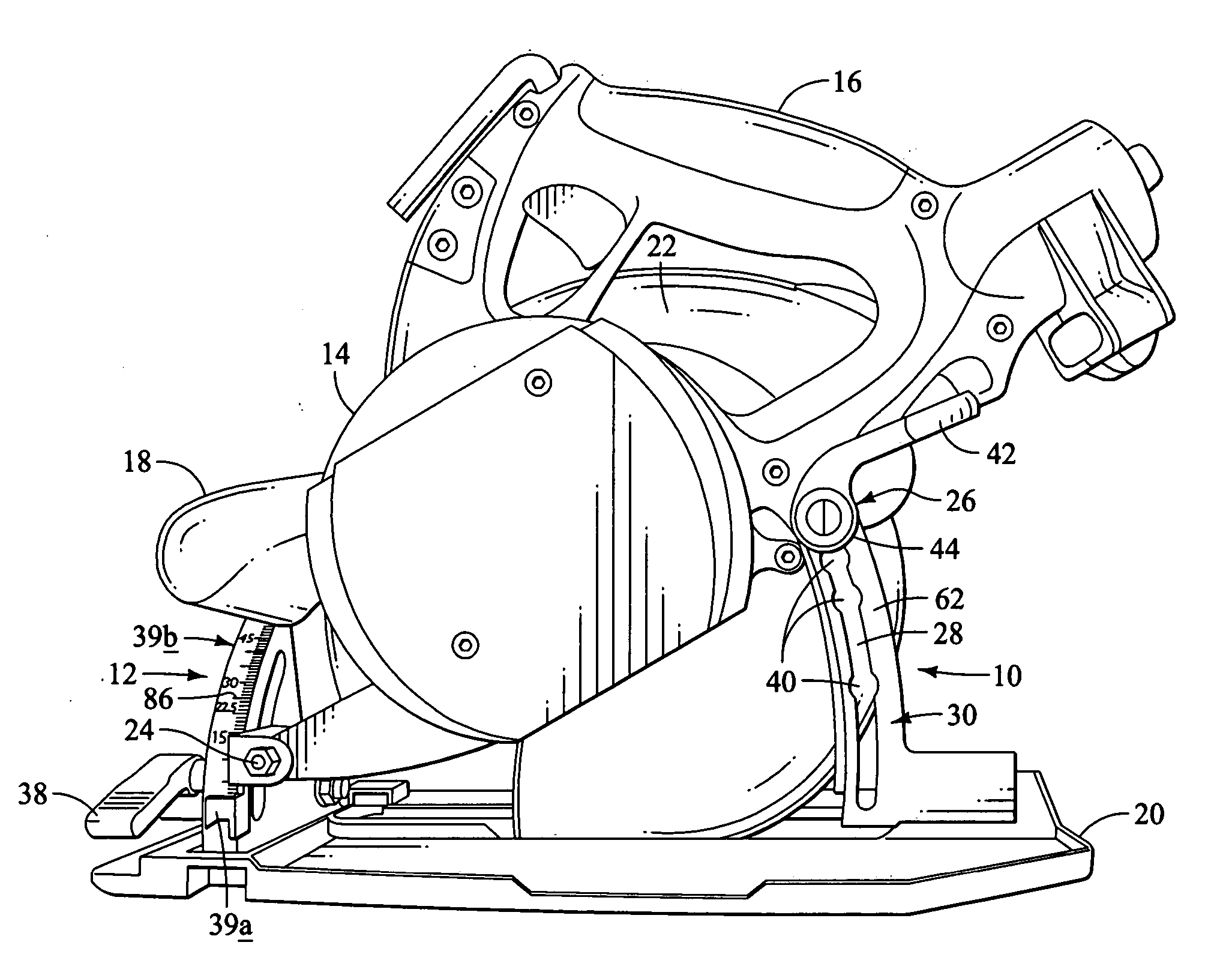

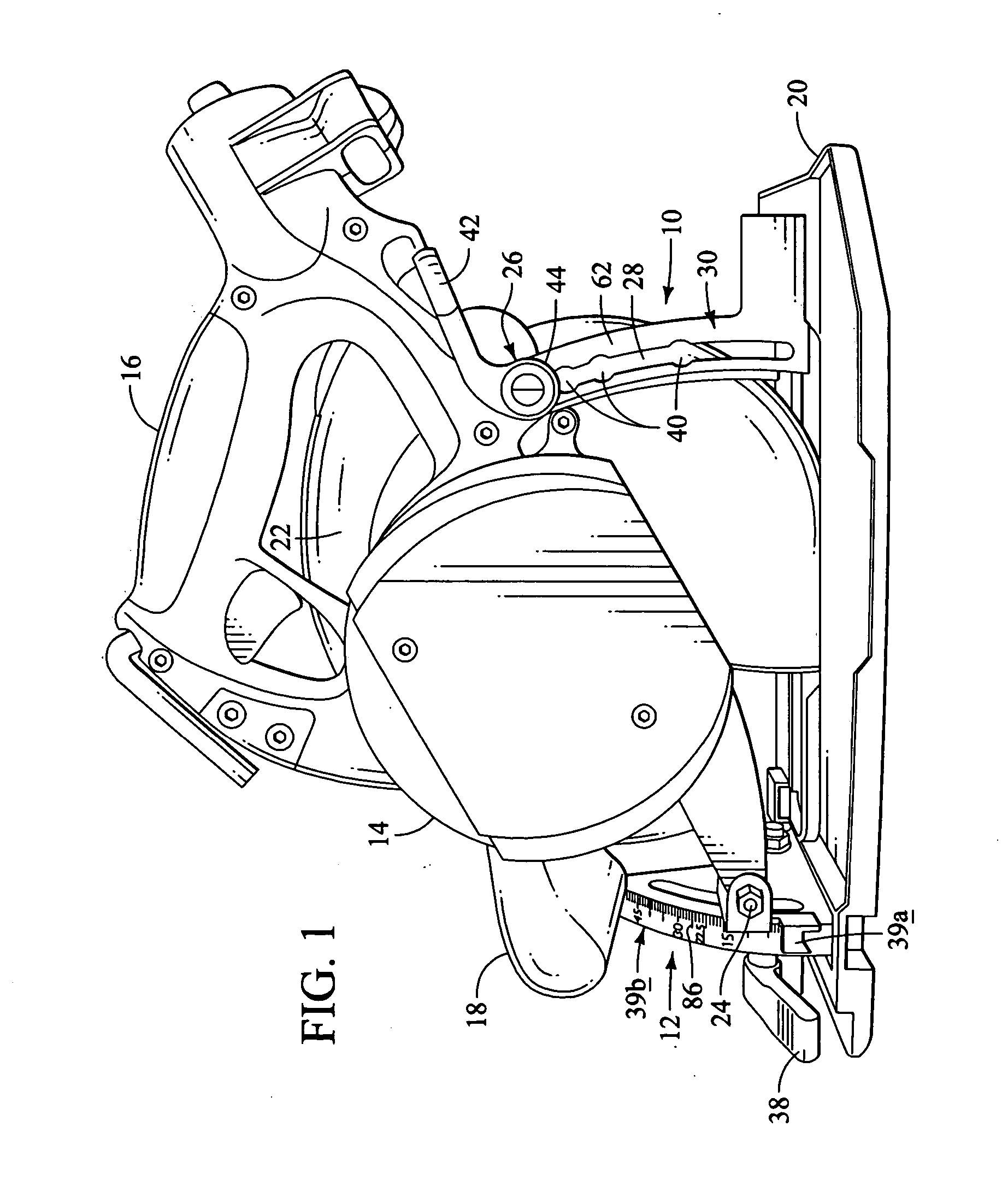

Circular saw having bevel and depth of cut detent system

A circular saw having a saw blade depth adjustment detent mechanism for facilitating rapid positioning of a saw blade at predetermined depth positions includes a housing enclosing a motor disposed therein that rotates a circular saw blade. The circular saw includes a foot which rides on a workpiece to guide the saw blade during cutting operations. The saw blade depth adjustment detent mechanism pivotally interconnects the foot to said housing such that the circular saw blade is adjustable to the foot through a number of saw blade depth settings within a range of saw blade depth of cuts relative to the foot. The saw blade depth adjustment detent mechanism includes a saw blade depth detent and a second member having a plurality of spaced saw blade depth recesses that are each matingly engageable with the saw blade depth detent to provide the range of saw blade depths.

Owner:CREDO TECH CORP

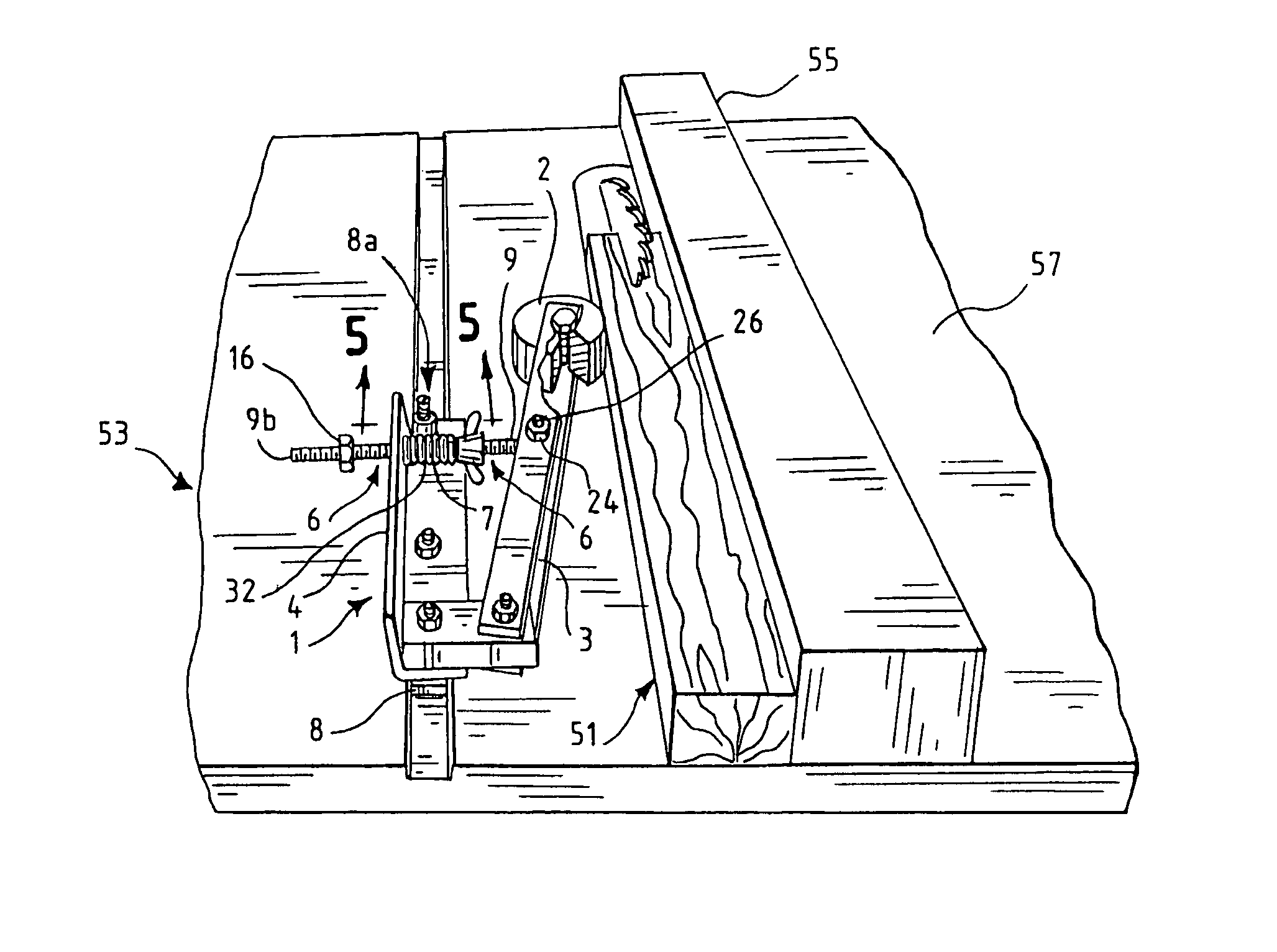

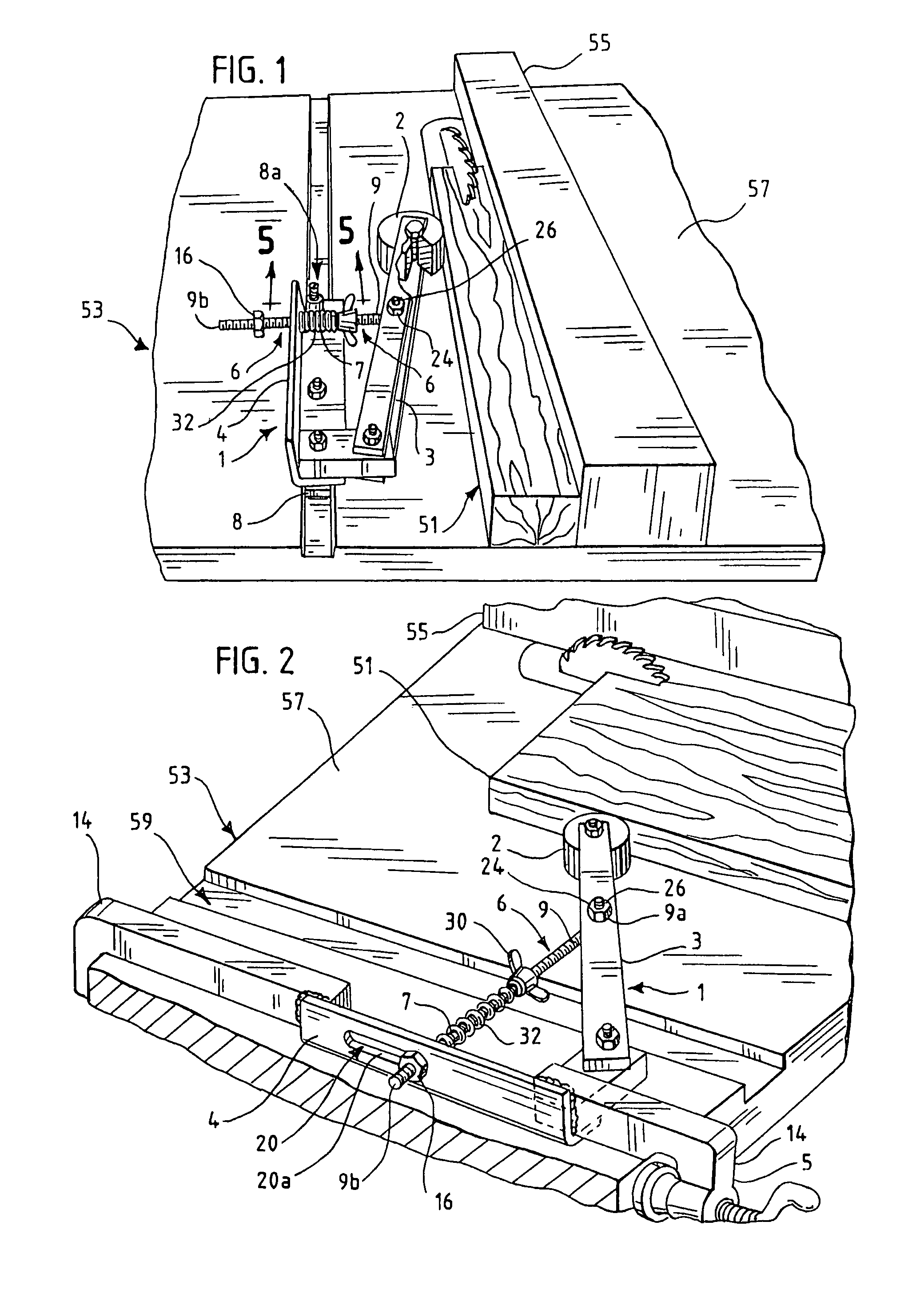

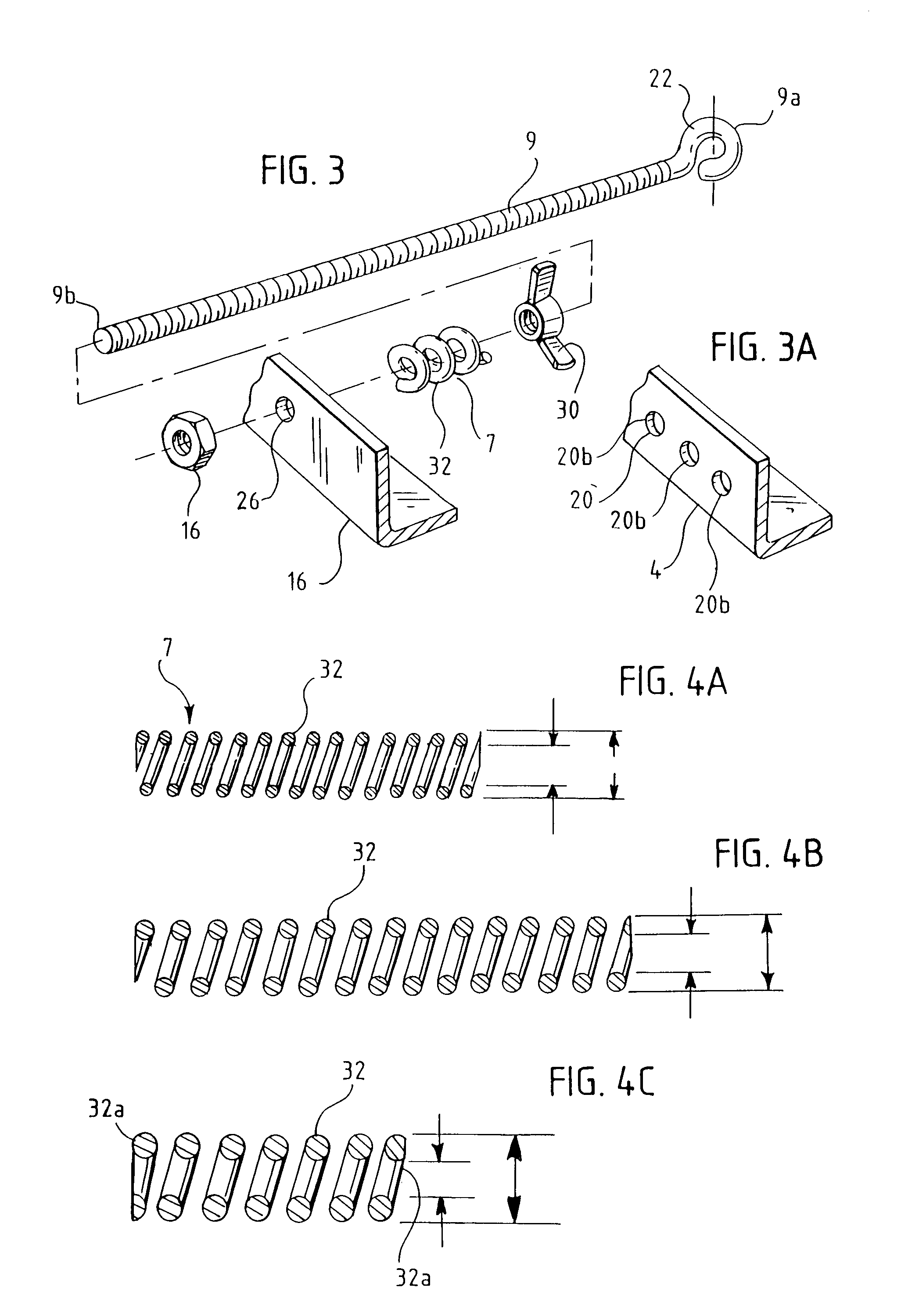

Horizontal hold down jig

InactiveUS7341081B1Uniform pressureEasy to useWood feeding arangementsFeeding devicesCompressive strengthMechanical engineering

A horizontal rotary hold down jig for use in horizontally guiding a piece of wood to be cut on one of a portable table saw and a portable router table comprising a spring biased rotatable wheel that can be secured to the table. The spring biasing can be adjusted to provide uniform or enhanced pressure through use of a plurality of substitutable compression springs of varying compressive strength characteristics to laterally stabilize a piece of wood of varying consistency, wood grain angle, feed cutting speed, width, and thickness or depth of cut.

Owner:VILLIGER ERIC J

Rotary drill bits with protected cutting elements and methods

ActiveUS8210288B2Prolong lifeReducing and eliminating damageDrill bitsConstructionsRate of penetrationEngineering

Owner:HALLIBURTON ENERGY SERVICES INC

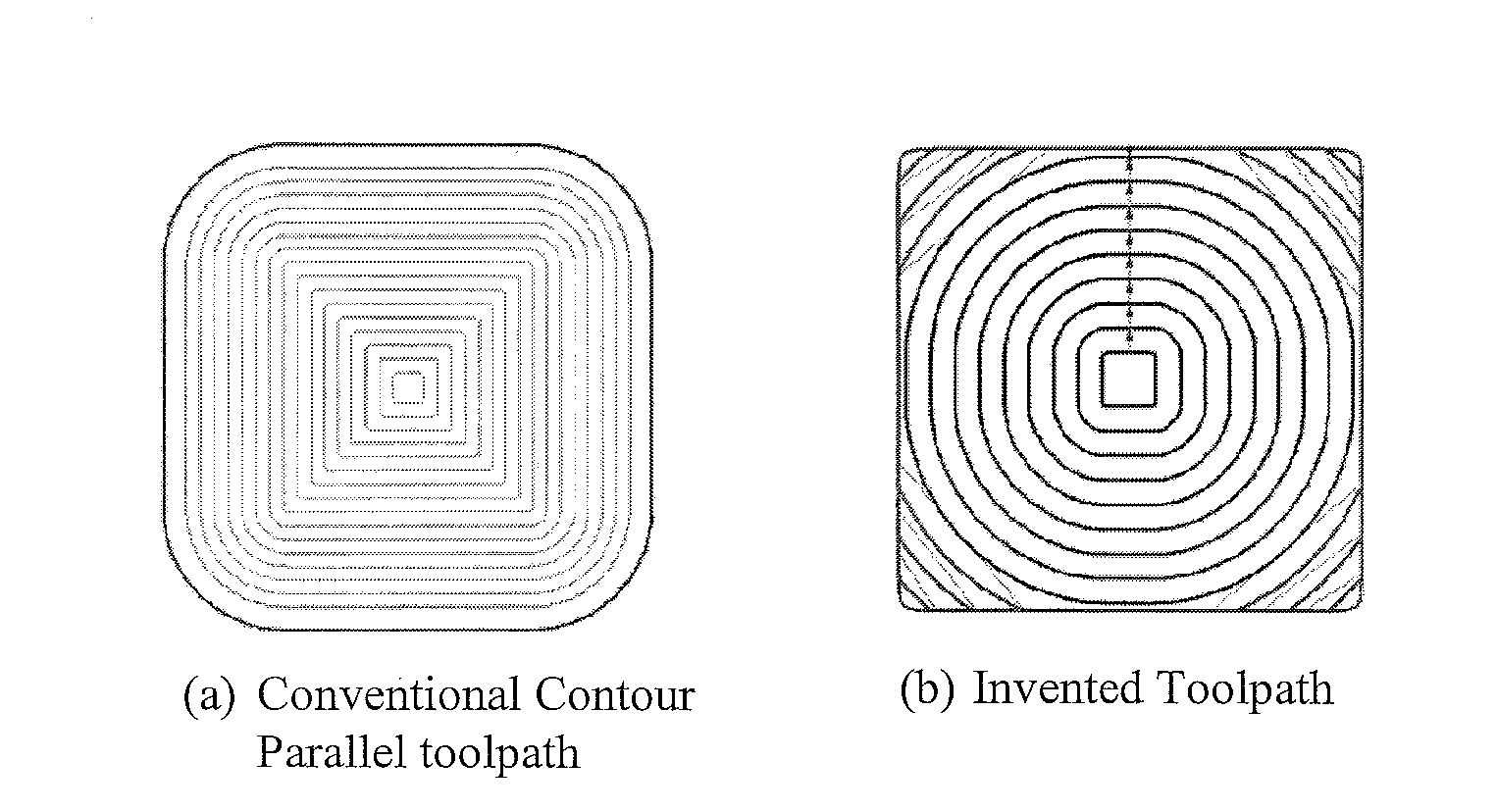

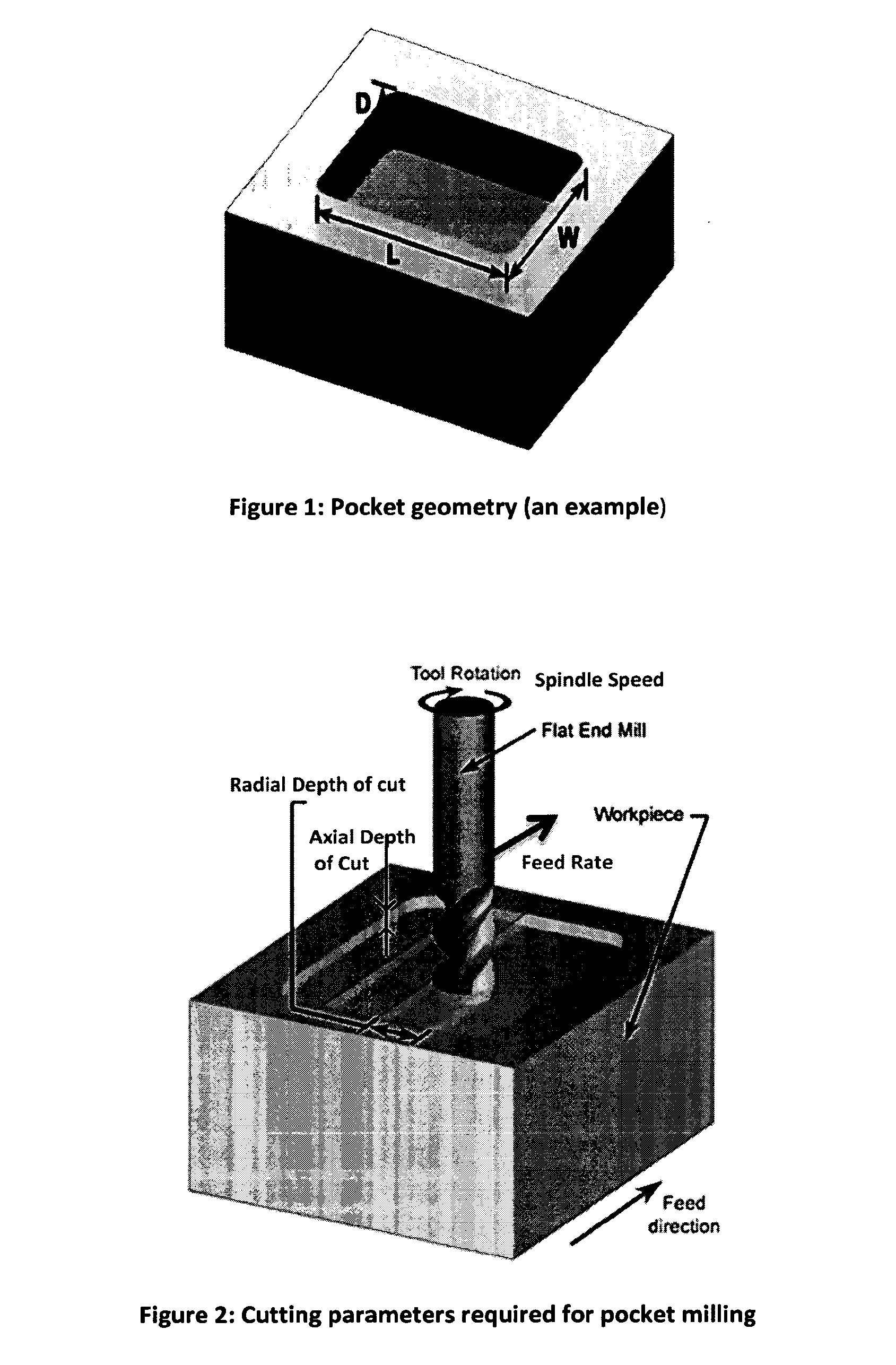

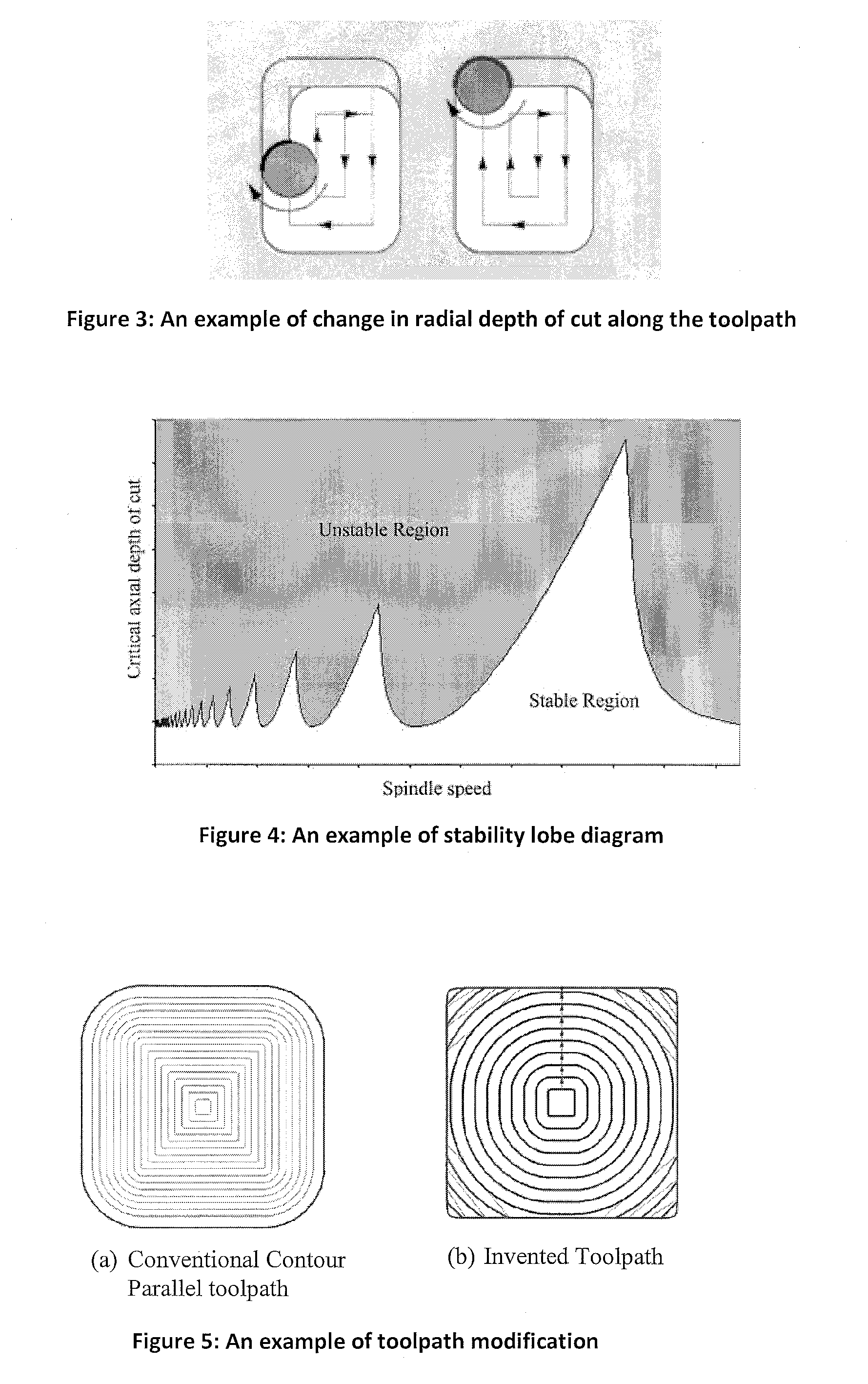

High speed pocket milling optimisation

The invention relates to a method of toolpath generation and cutting parameters optimization for high speed milling of a convex pocket, wherein said method comprises a first sub-method of generating a toolpath and a second sub-method of generating optimized chatfree cutting parameters using a genetic algorithm wherein the first sub-method generates milling toolpaths that minimize the radial depth of cut variations as well as the curvature change variations while avoiding leftover material at the corners, wherein said toolpaths automatically avoid self-intersecting features encountered during the offsetting of pocket boundary such that the said toolpaths result in reduction in milling time for a given maximum acceptable radial depth of cut and wherein said second sub-method allows the free choice of cutting parameters and optimizes the milling time and wherein the optimization method incorporates relevant milling constraints as milling stability constraint, cutting forces, machine-tool and cutting tool capabilities.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

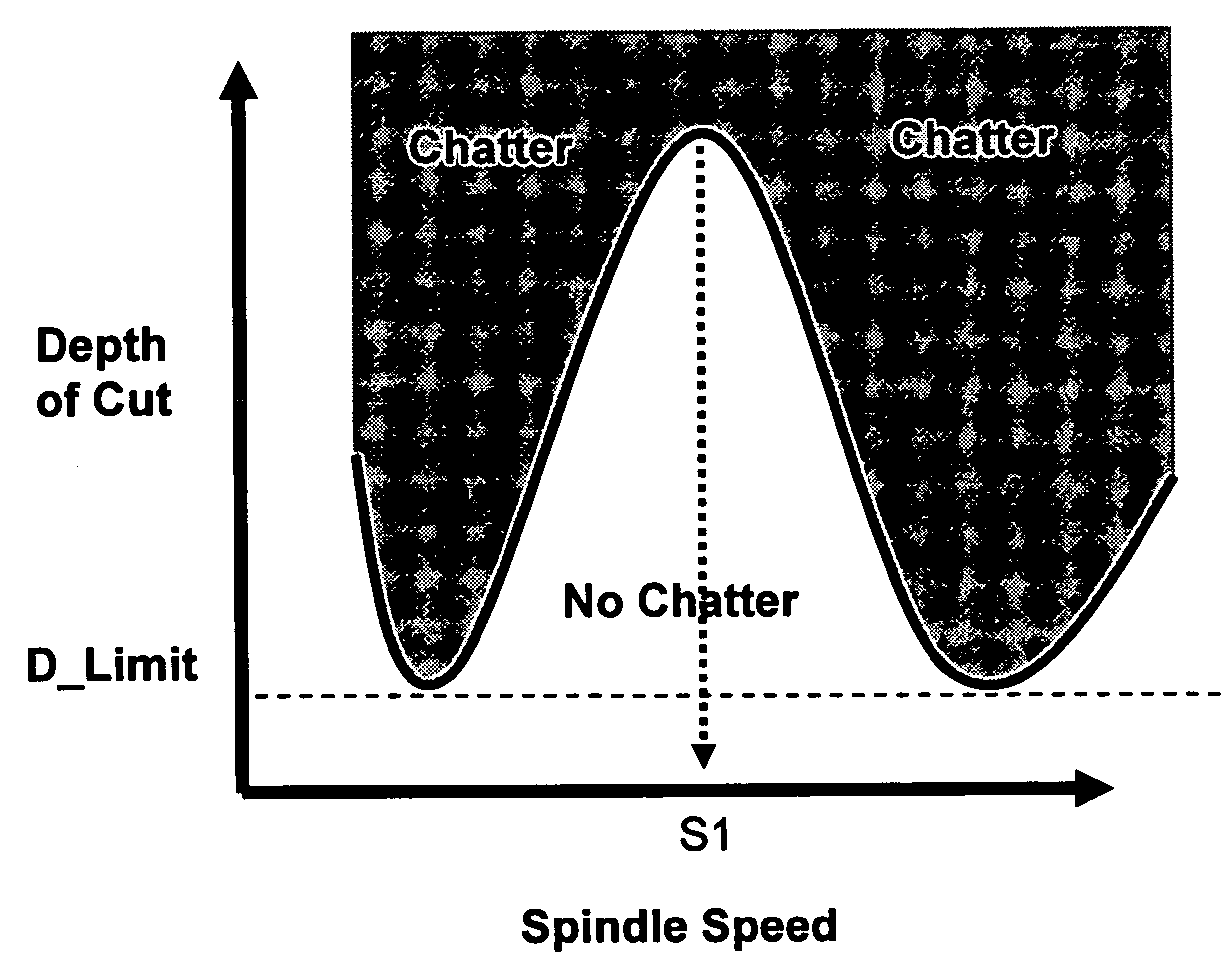

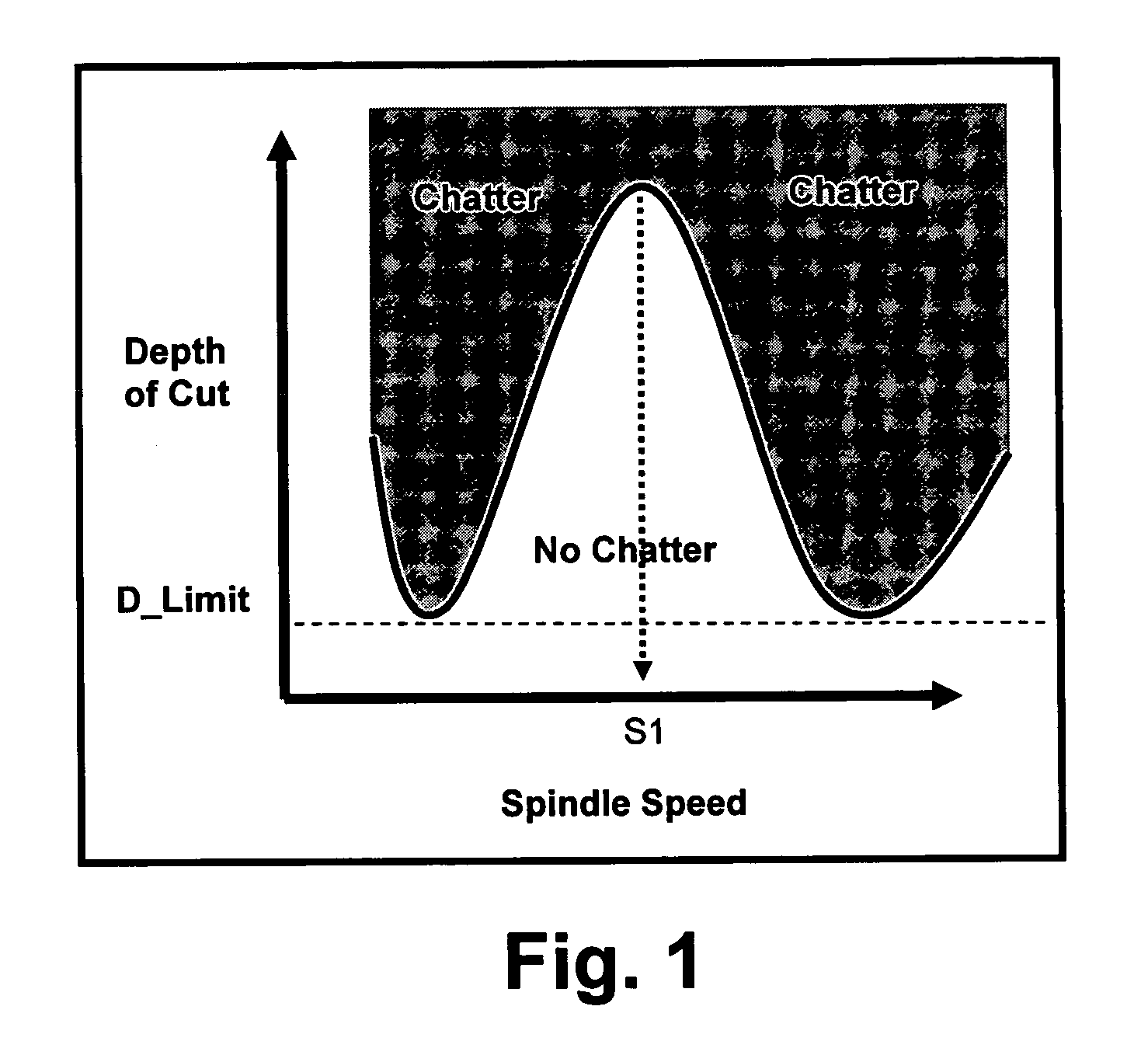

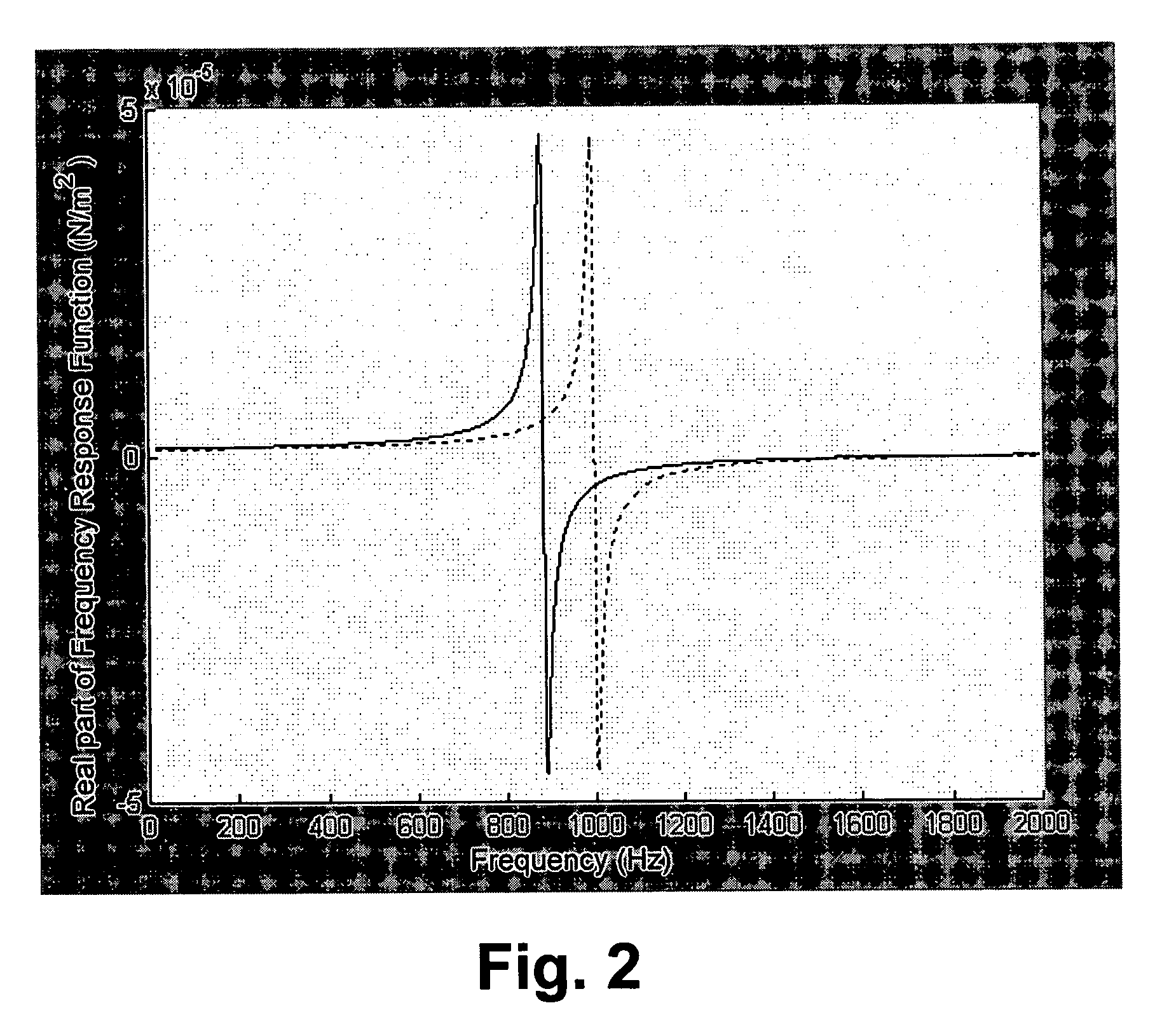

Method for reducing the measurement requirements for the dynamic response of tools in a CNC machine

InactiveUS20050021265A1Simpler, non-contactEasy to measureSpectral/fourier analysisProgramme controlCouplingAnalytical expressions

The present invention provides a method for determining the Frequency Response Function for a collection of tools in a CNC machine by taking four measurements (three of which are independent) on a single tool, held in the same or similar tool holder, spindle and CNC machine. The method uses inverse Receptance Coupling Substructure Analysis (RCSA) to obtain the receptances of the system, exclusive of the single tool. Standard (forward) RCSA is then used with these receptances and certain analytic expressions for the receptances of a freely supported tool to obtain the FRF for each tool in the collection of tools. This information can be used to predict stable, chatter-free depths of cut over a range of spindle speeds in CNC machining, identifying both the limiting depth of cut at any speed as well as special spindle speeds where unusually large, chatter-free depths of cut are available.

Owner:ESTERLING DONALD M

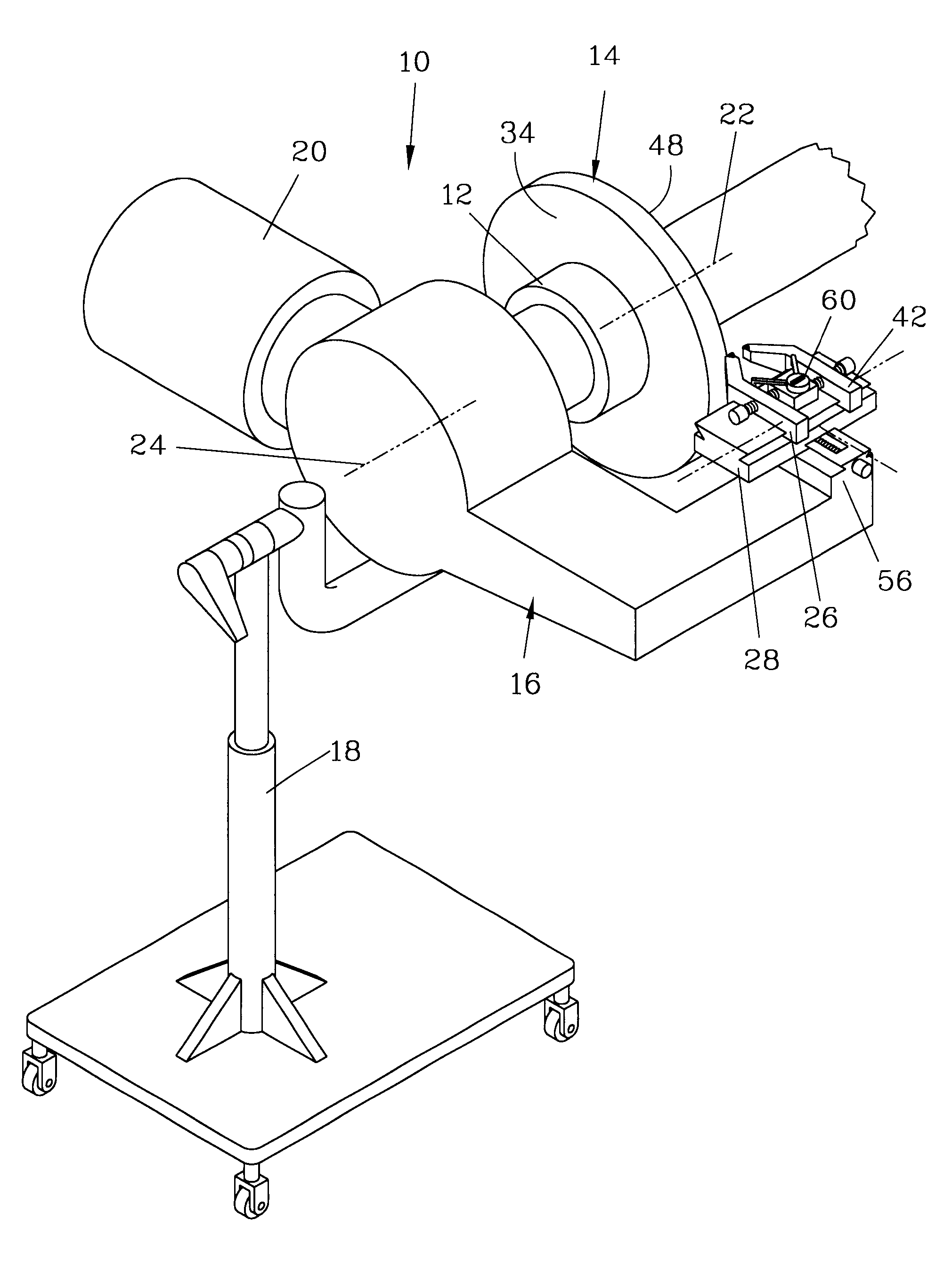

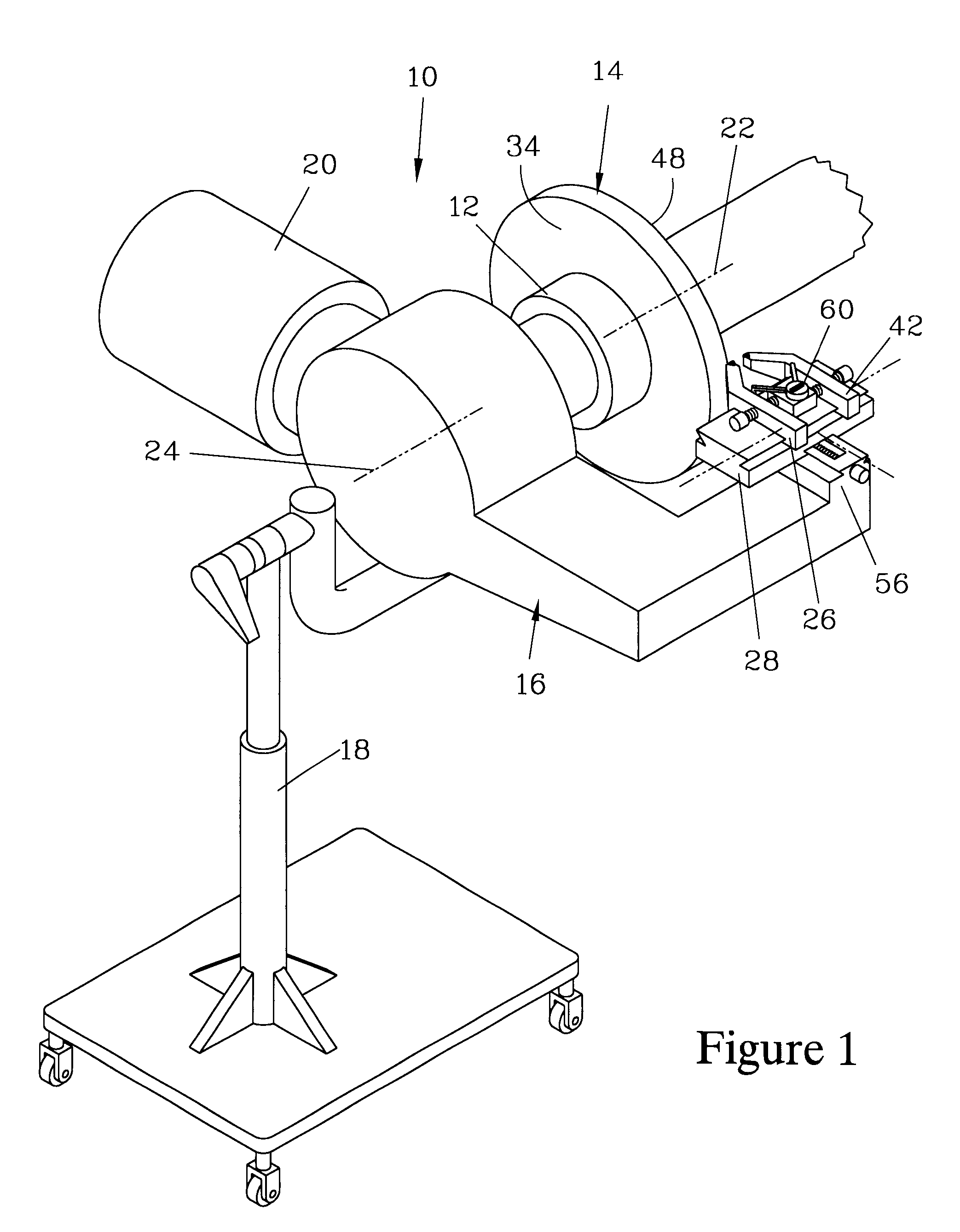

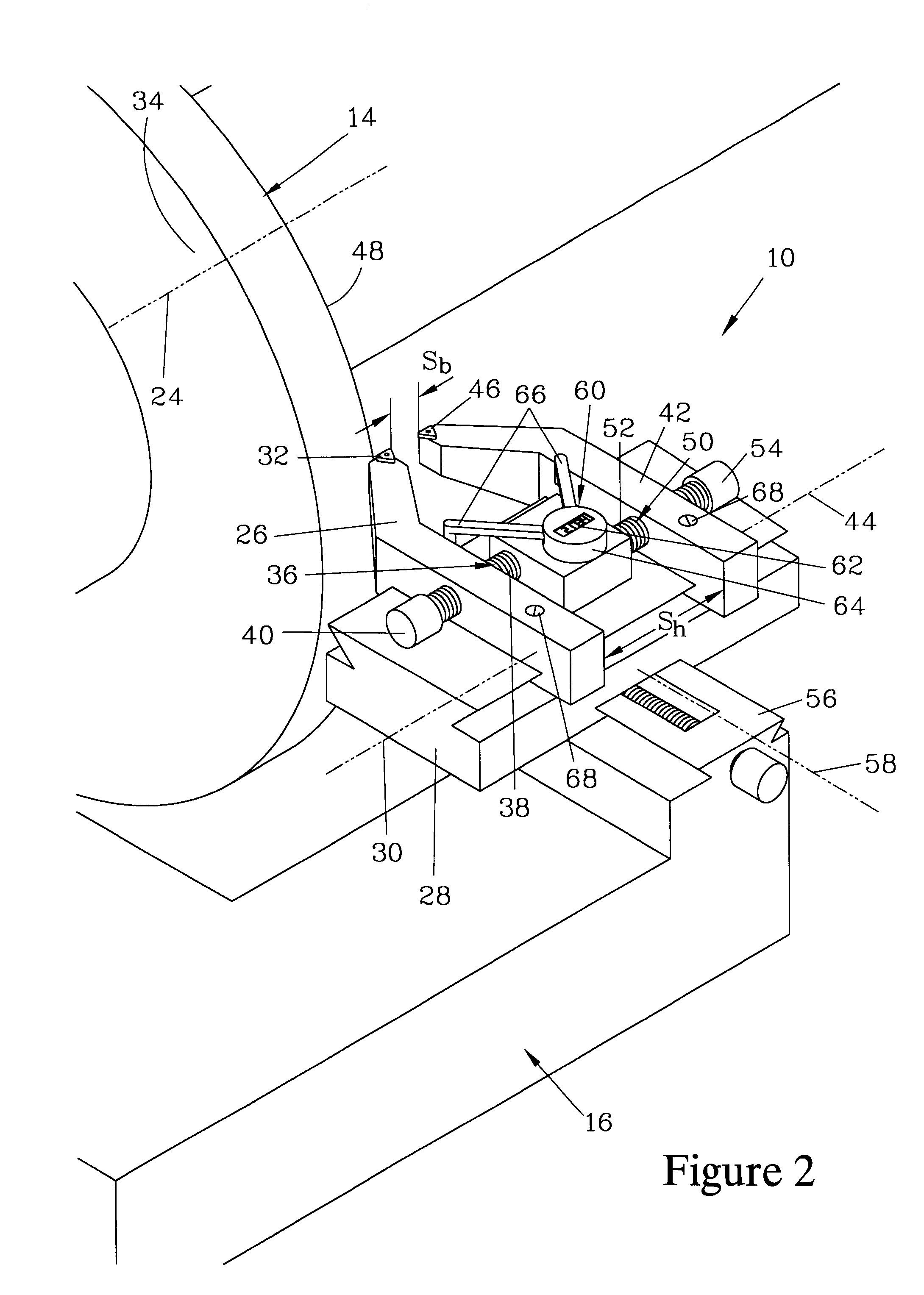

On-vehicle disk brake lathe

InactiveUS6363821B1Easy to adjustEasy to measureTurning machine accessoriesMeasurement/indication equipmentsTool bitEngineering

A disk brake lathe has a pair of tool bits mounted to tool holders which are translatable parallel to a lathe axis to adjust the separation of the tool bits from a brake disk. A displacement gauge responds to changes in the separation between the tool holders. When the tool bits are in continuous contact with the disk, the separation indicates the thickness which would result from machining the disk. This separation can be compared to a specification to determine whether to machine or discard the disk. A method for machining a disk starts by mounting and aligning the lathe to a wheel hub on which the disk is mounted. The tool bits are each advanced until they are in continuous contact the disk surfaces, when the separation of the tool bits is measured and preferably compared to a specification. When the tool bits are sequentially advanced, variation in the separation can be used to determine depth of cut for each tool bit. A system employing a brake lathe has a microprocessor which receives signals responsive to the separation between the tool bits of the lathe. One or more contact sensors indicate contact of the tool bits with the other tool bit or the brake disk, and the microprocessor can implement instructions to practice the above method. A surface displacement gauge can be employed to allow the system to measure the thickness and lateral run-out of the disk prior to machining.

Owner:BONITA IP

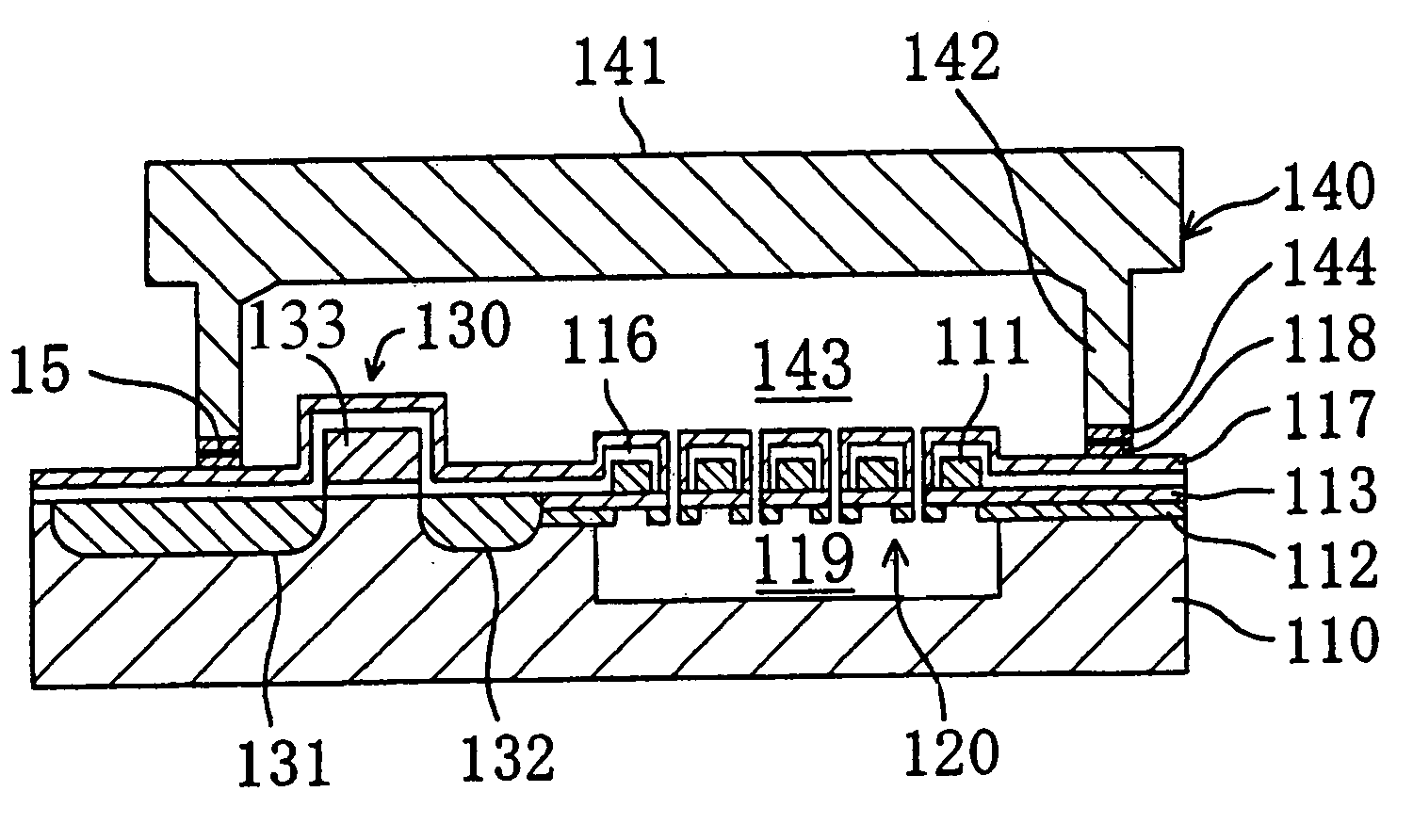

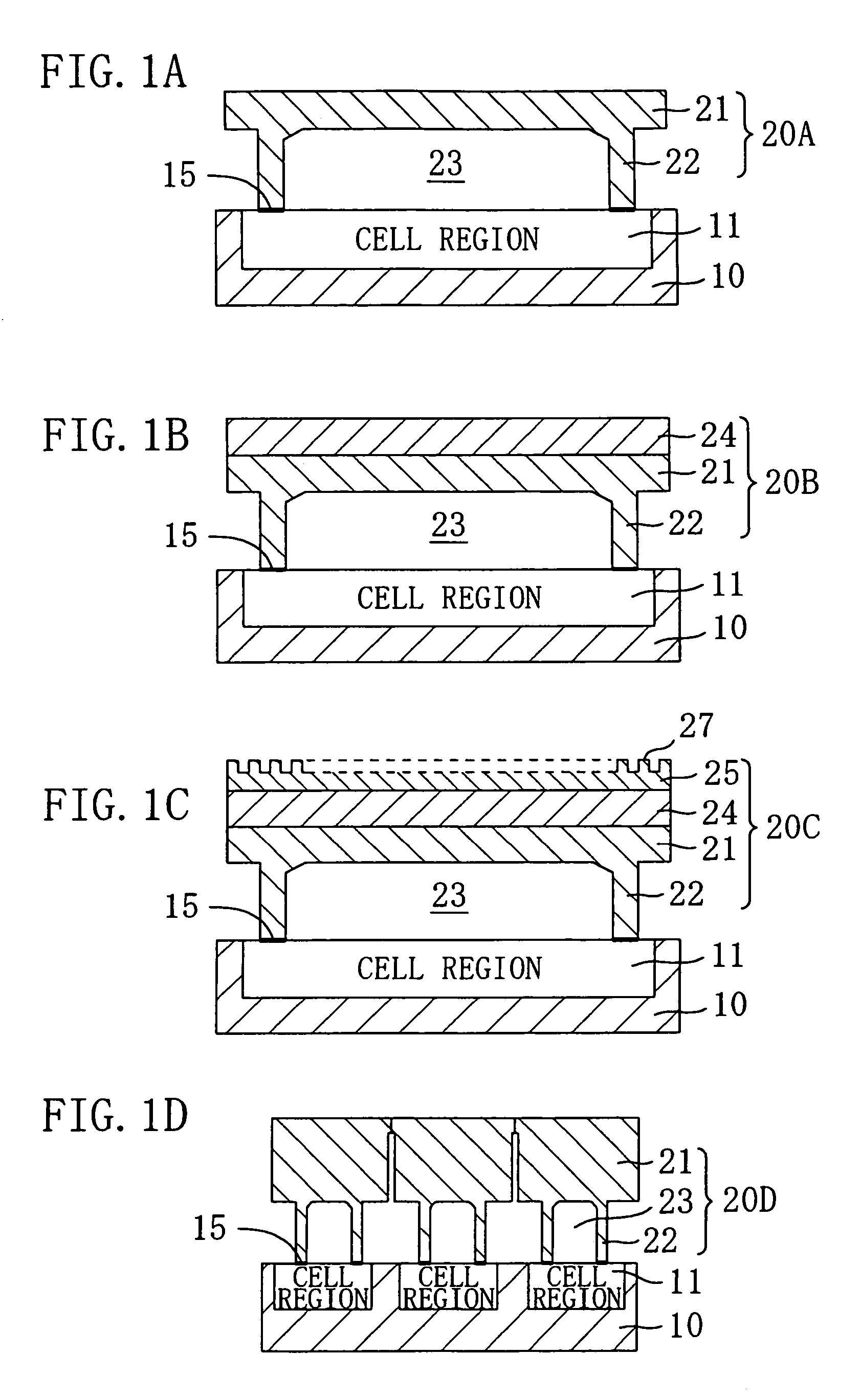

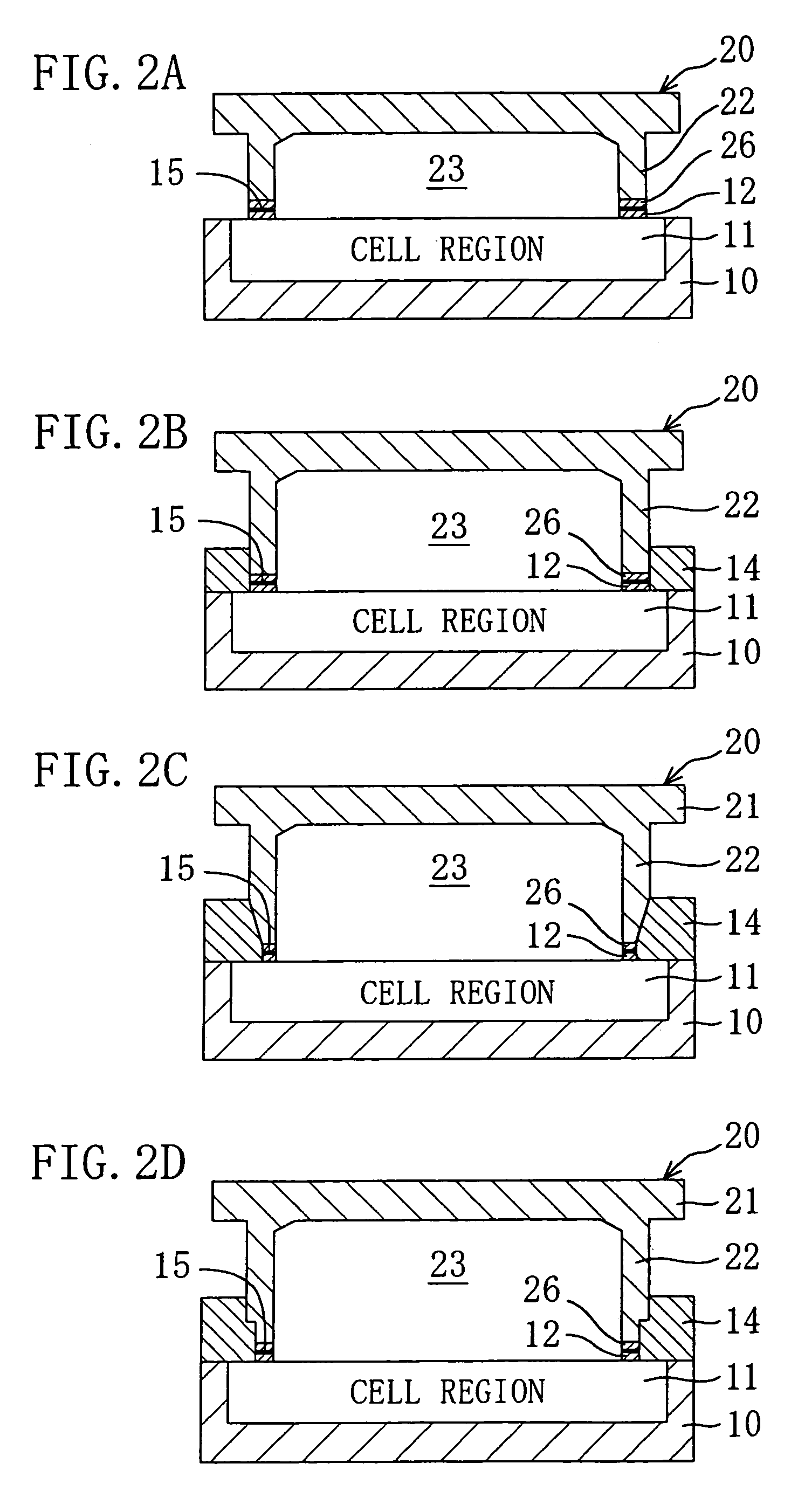

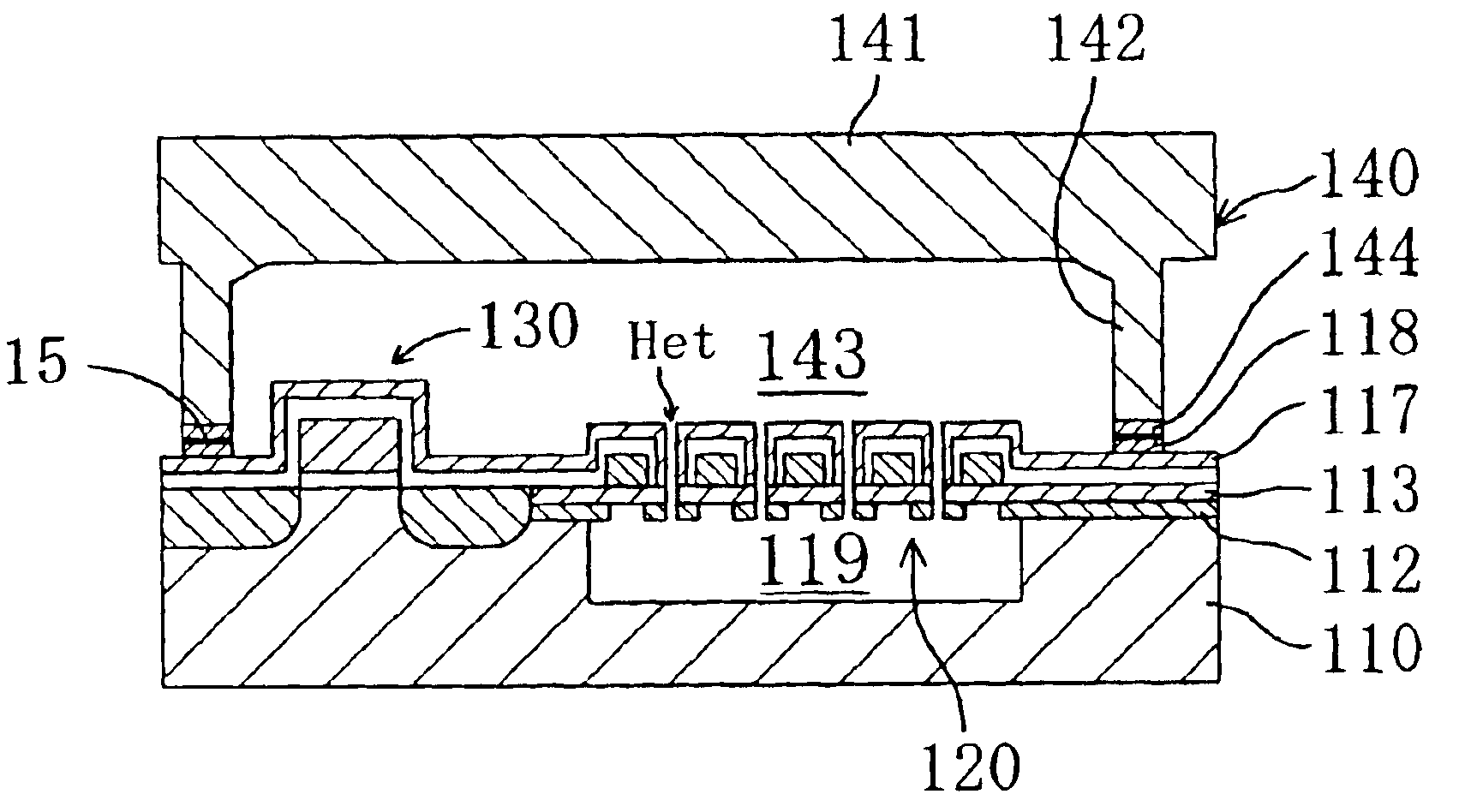

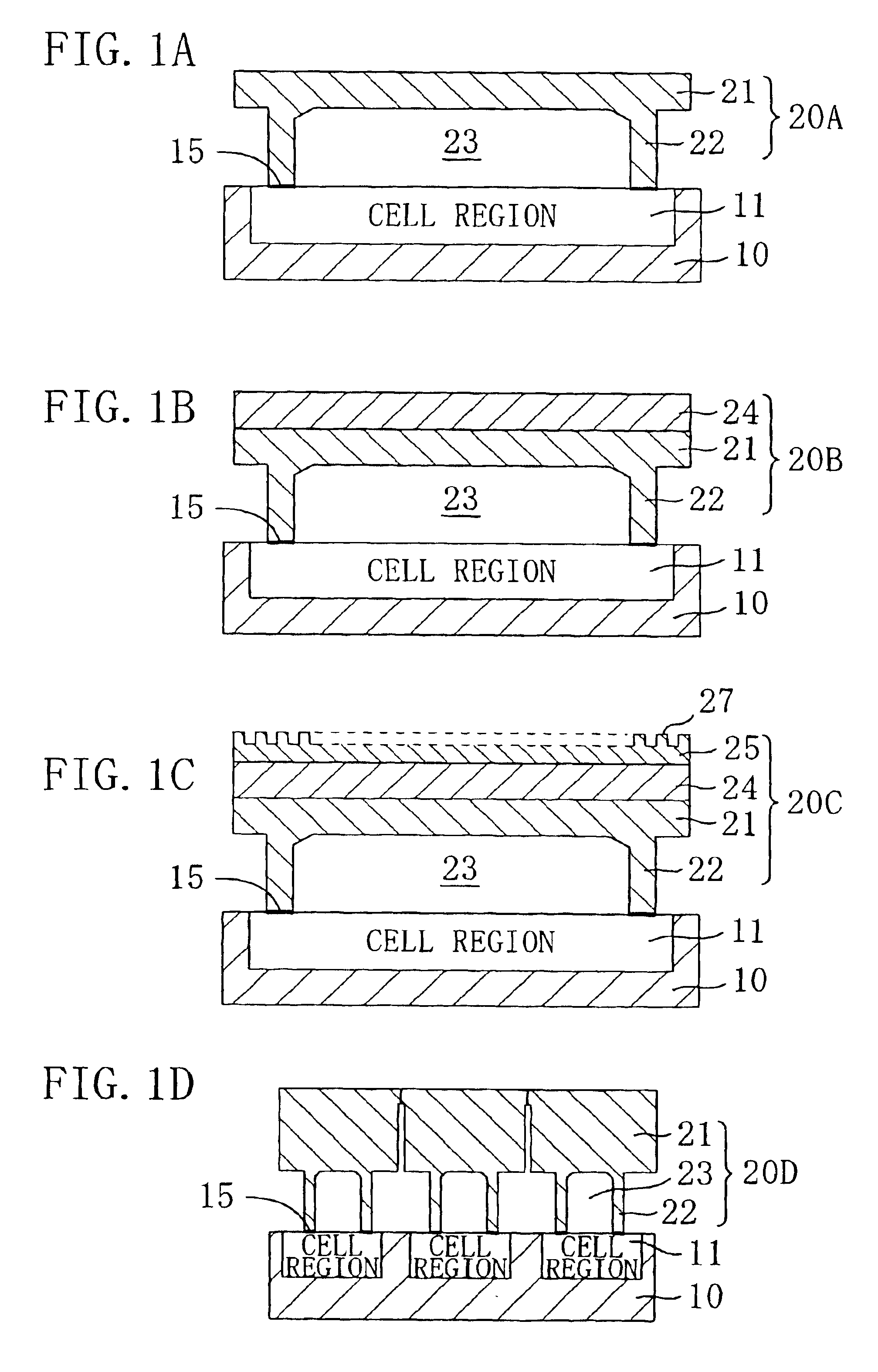

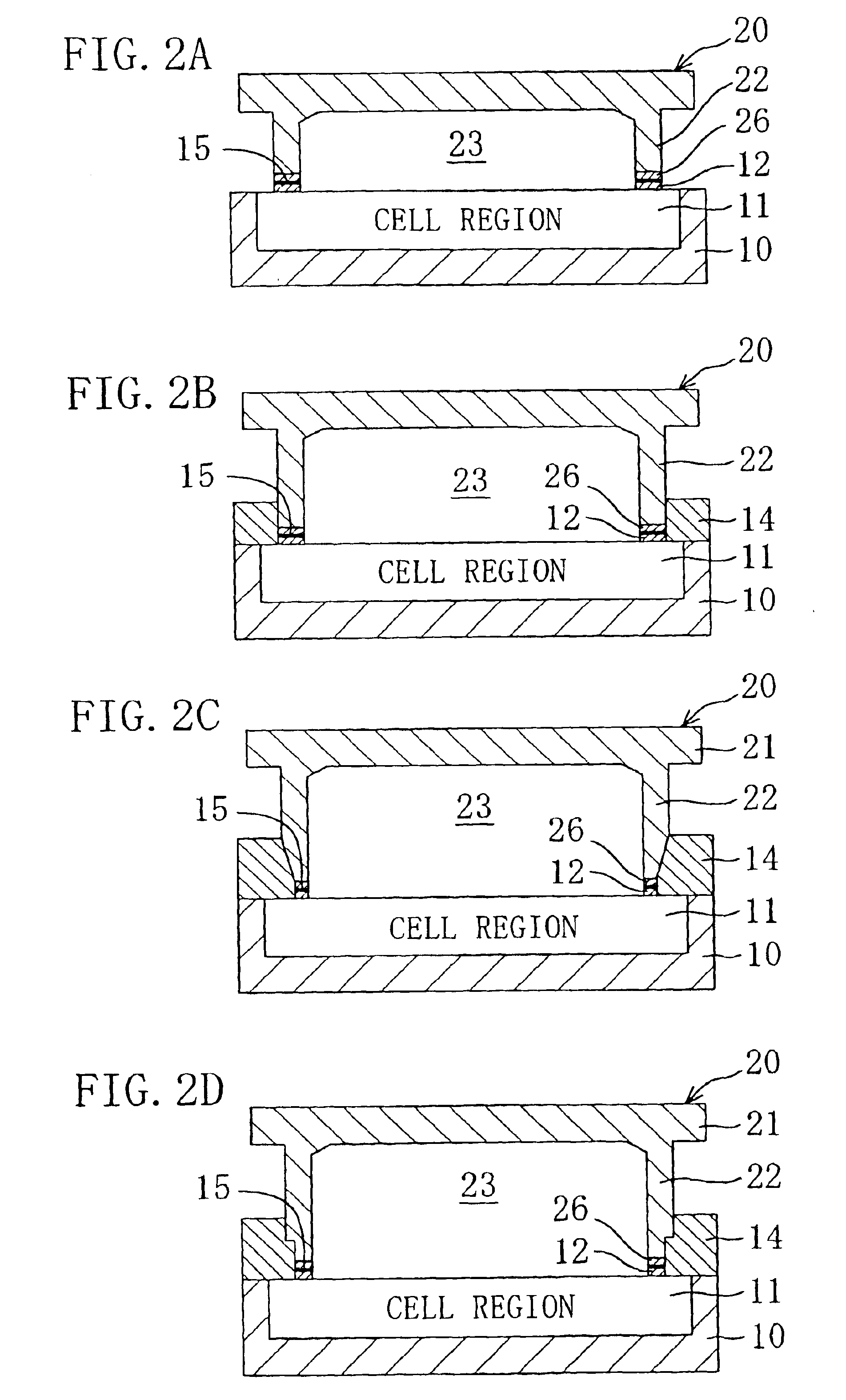

Semiconductor-based encapsulated infrared sensor and electronic device

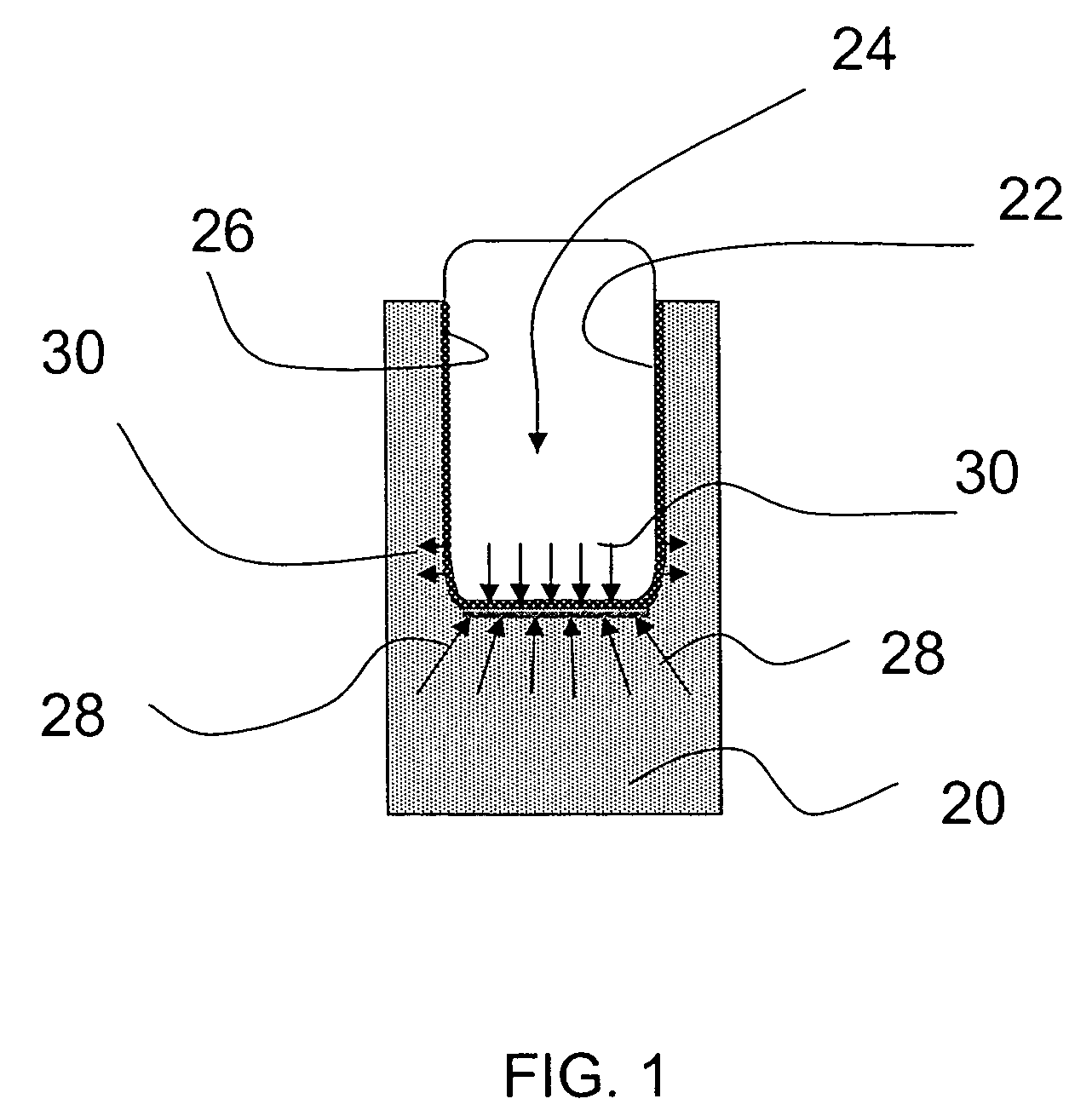

InactiveUS6965107B2Function increaseIncrease vacuumSemiconductor/solid-state device detailsSolid-state devicesEngineeringDry etching

An Al film is formed on a cap wafer and the Al film is patterned into a ring-shaped film. Dry etching is performed by using the ring-shaped film as a mask to form a drum portion enclosing a recess portion to provide a vacuum dome. After forming a depth of cut into the substrate portion of the cap wafer, the cap wafer is placed on a main body wafer having an infrared area sensor formed thereon. Then, the ring-shaped film of the cap wafer and the ring-shaped film of the main body wafer are joined to each other by pressure bonding to form a ring-shaped joining portion.

Owner:PANASONIC HLDG CORP

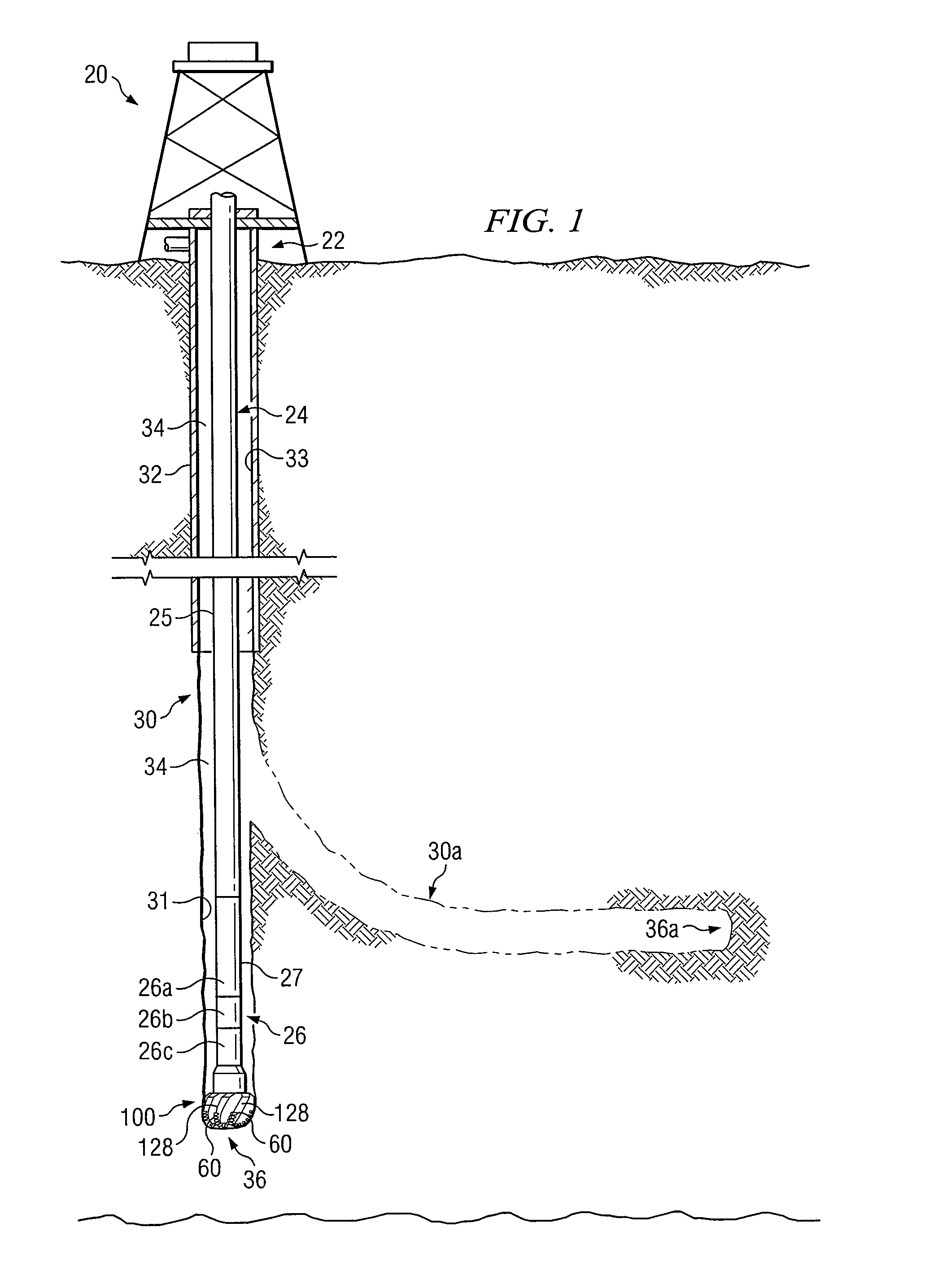

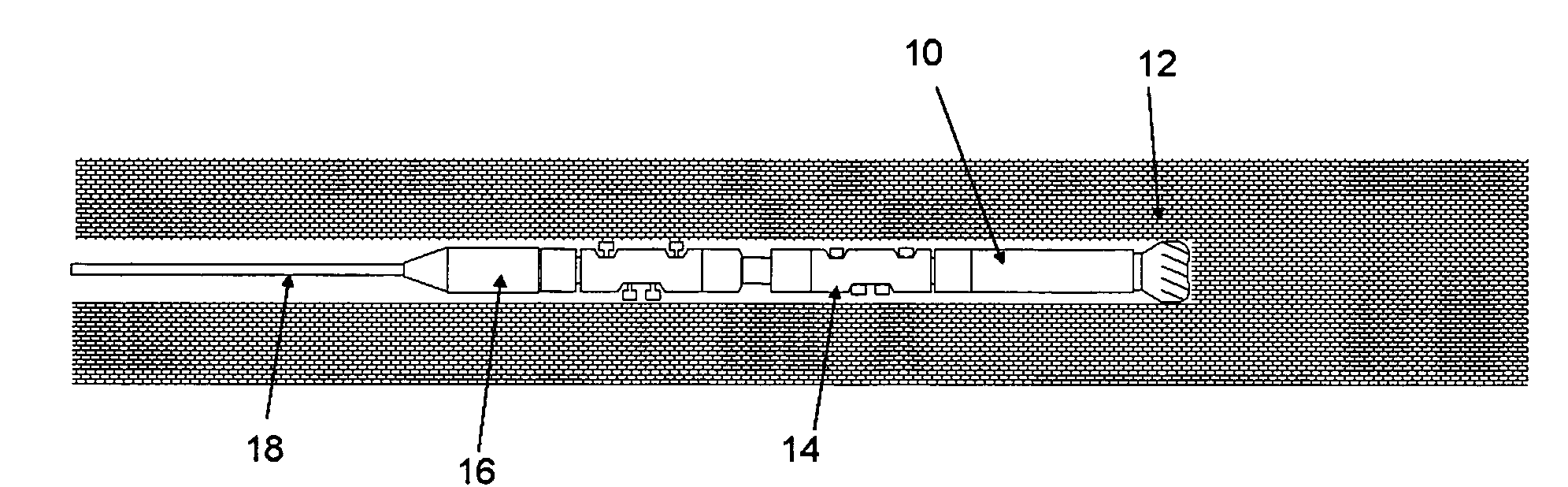

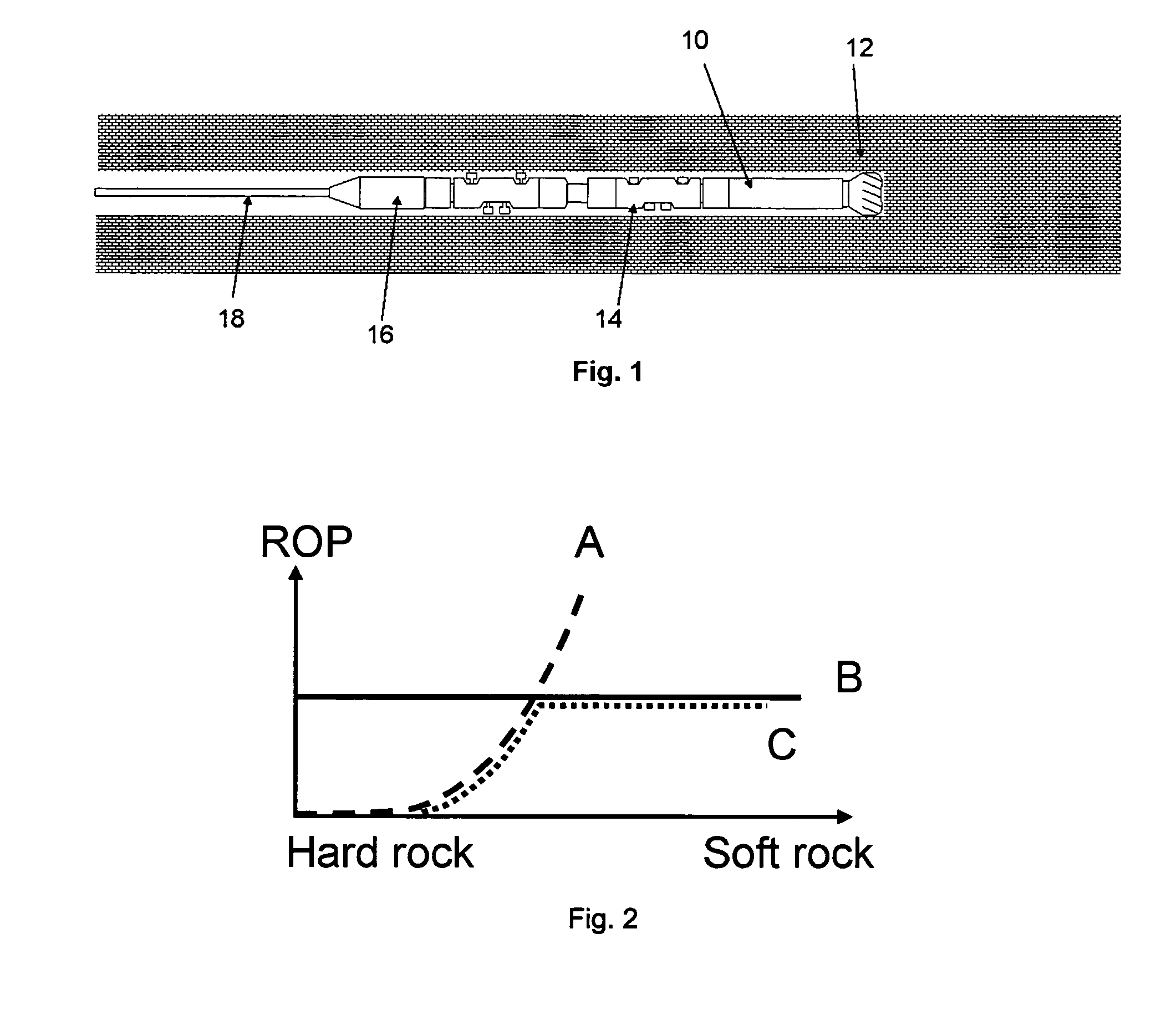

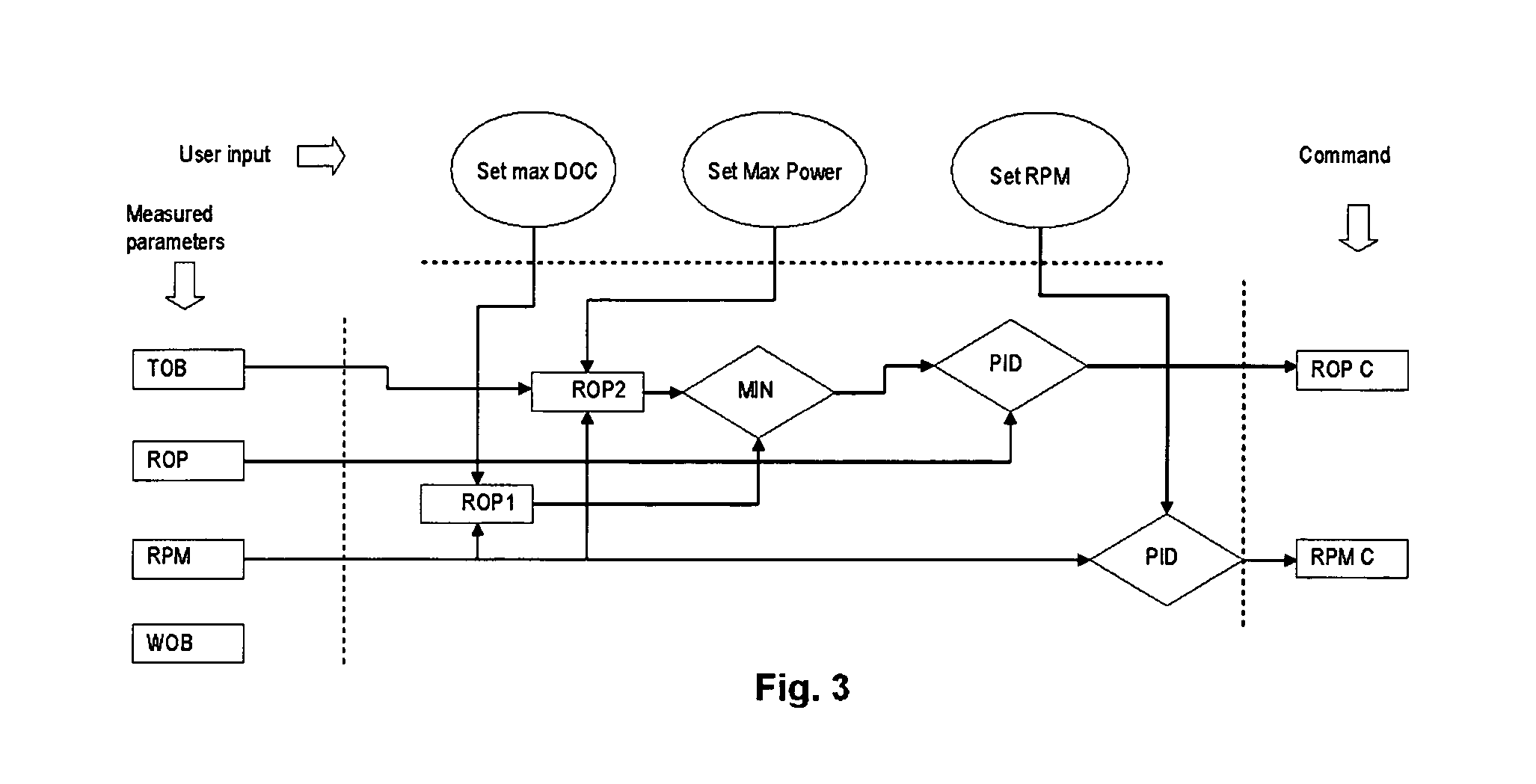

Drilling System

A drilling system for drilling a borehole in an underground formation, comprises a rotary drill bit, a drilling drive mechanism that is capable of applying both rotating the drill bit and applying an axial force to the drill bit, and a control system that is capable of controlling the drive mechanism so as to control rotation of the drill bit and the axial force applied to the drill bit in order to control the depth of cut created by the drill bit when drilling through the formation. A method of drilling a borehole in an underground formation with a rotary drill bit, comprises applying rotation and an axial force to the drill bit and controlling the rotation and axial force so as to control the depth of cut created by the drill bit when drilling through the formation.

Owner:SCHLUMBERGER TECH CORP

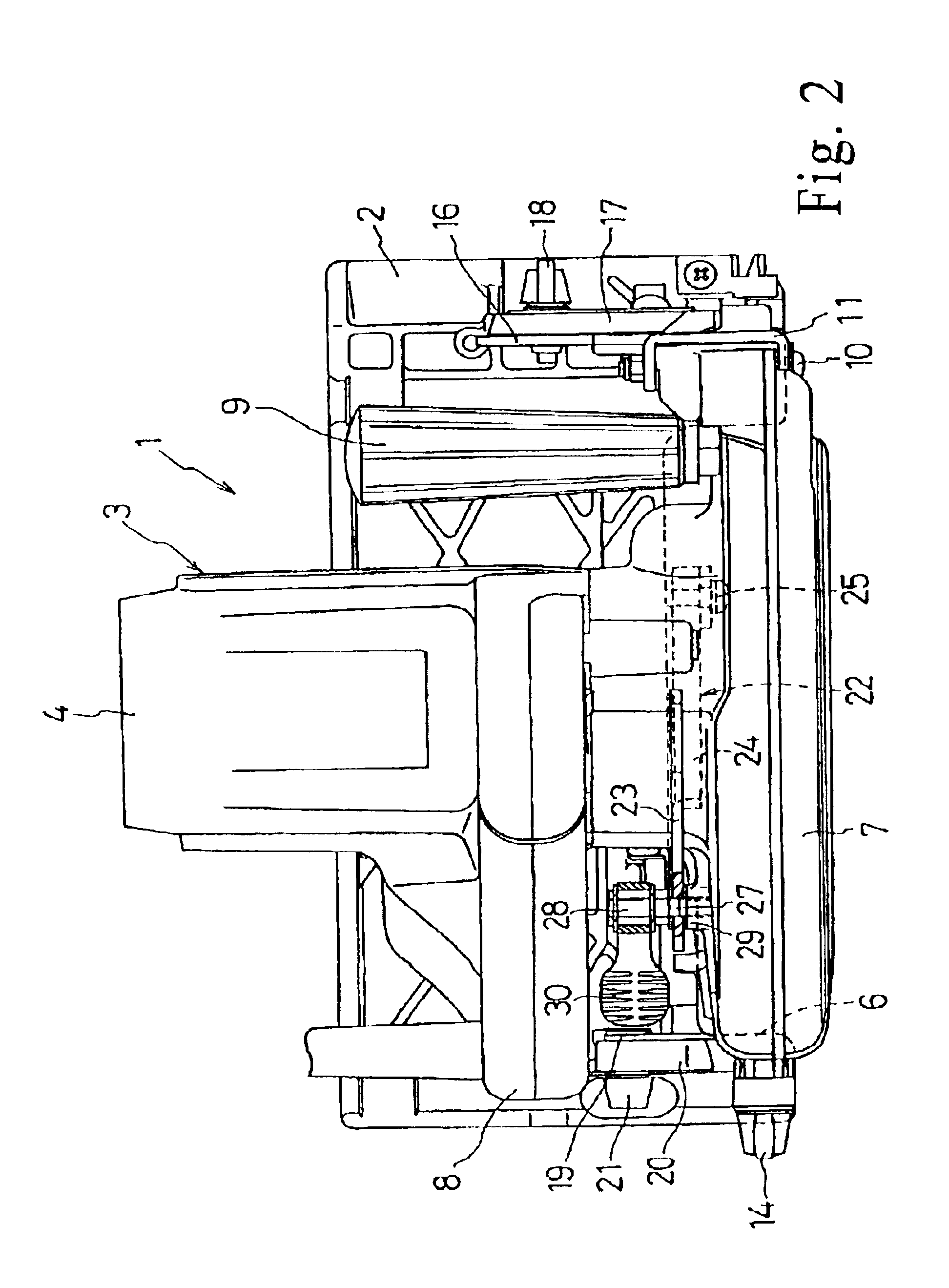

Circular saw with improved cutting depth adjustment

InactiveUS6886259B2Easy to adjustSimple structureMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

A circular saw (1) includes a base (2) and a main body (3) mounted on the base and provided with an upper blade guard (7). Disposed behind the upper blade guard (7) is a stopper (22) which includes an upper curved portion (23) and an lower portion (24) coupled to the curved portion (23). One end of the lower portion (24) is attached to the main body (3) with a pivot screw (25) behind the blade guard (7) so as to permit the stopper to pivot on the screw (25) in parallel with a circular blade (5). Additionally, the curved portion (23) includes an arcuate guide slot (26). The stopper (22) further includes a fixing bolt (27) screwed in a boss (29) formed on the rear surface of the blade guard. The bolt (27) includes a lever (30) to be manually operated to selectively secure the curved portion to the bolt and release the curved portion therefrom. When the curved portion (23) is released, its pivotal position relative to the main body towards the base can be manually changed. Provided on the base is a projection (32) which is abutted by the stopper (22) when the main body (3) is lowered toward the base (2). When the curved portion (23) abuts the projection's upper surface (33), the amount of the blade (5) projecting below the base (i.e., the depth of cut) corresponds to the aforementioned relative position of the curved portion (23) with respect to the base (2).

Owner:MAKITA CORP

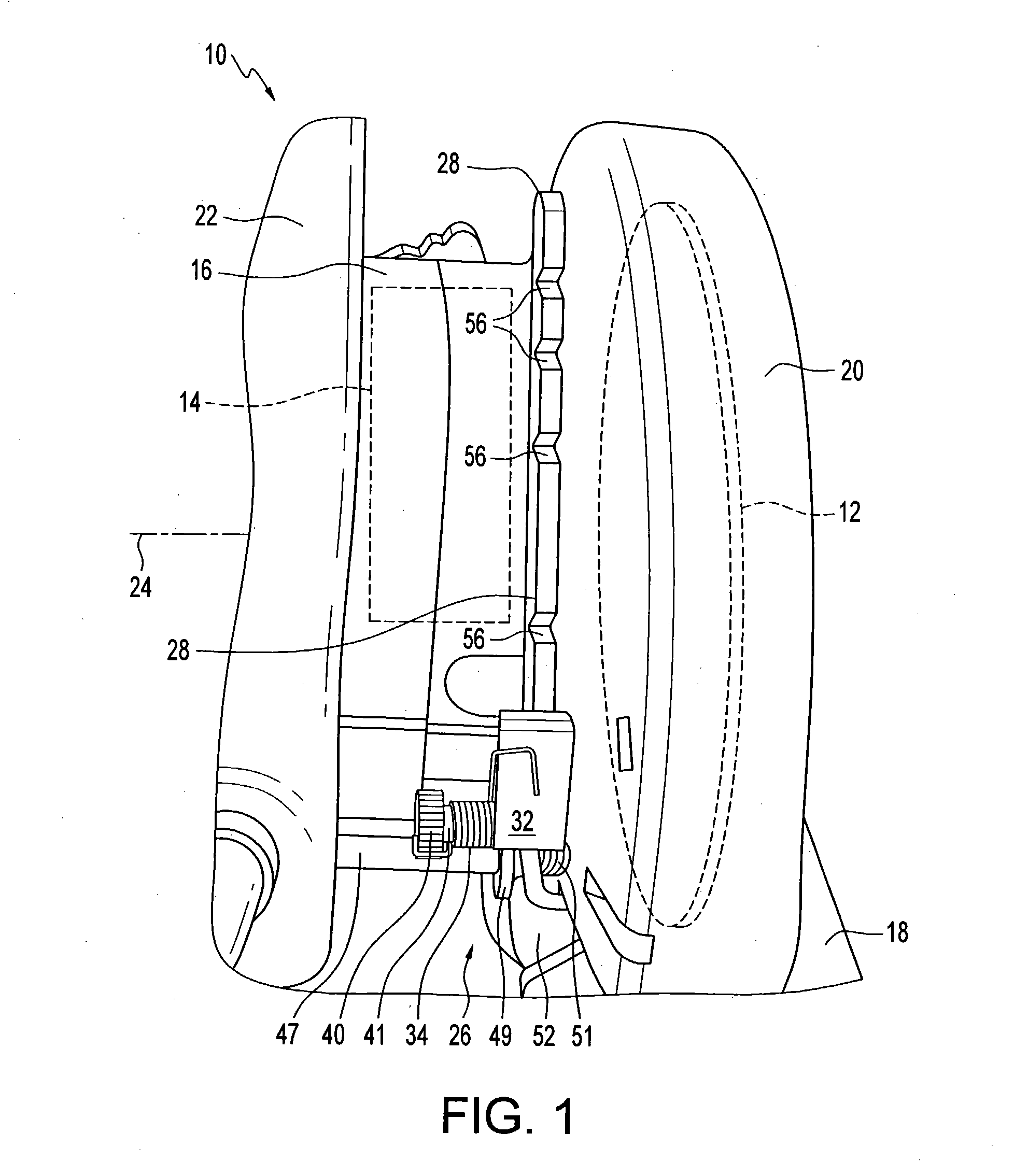

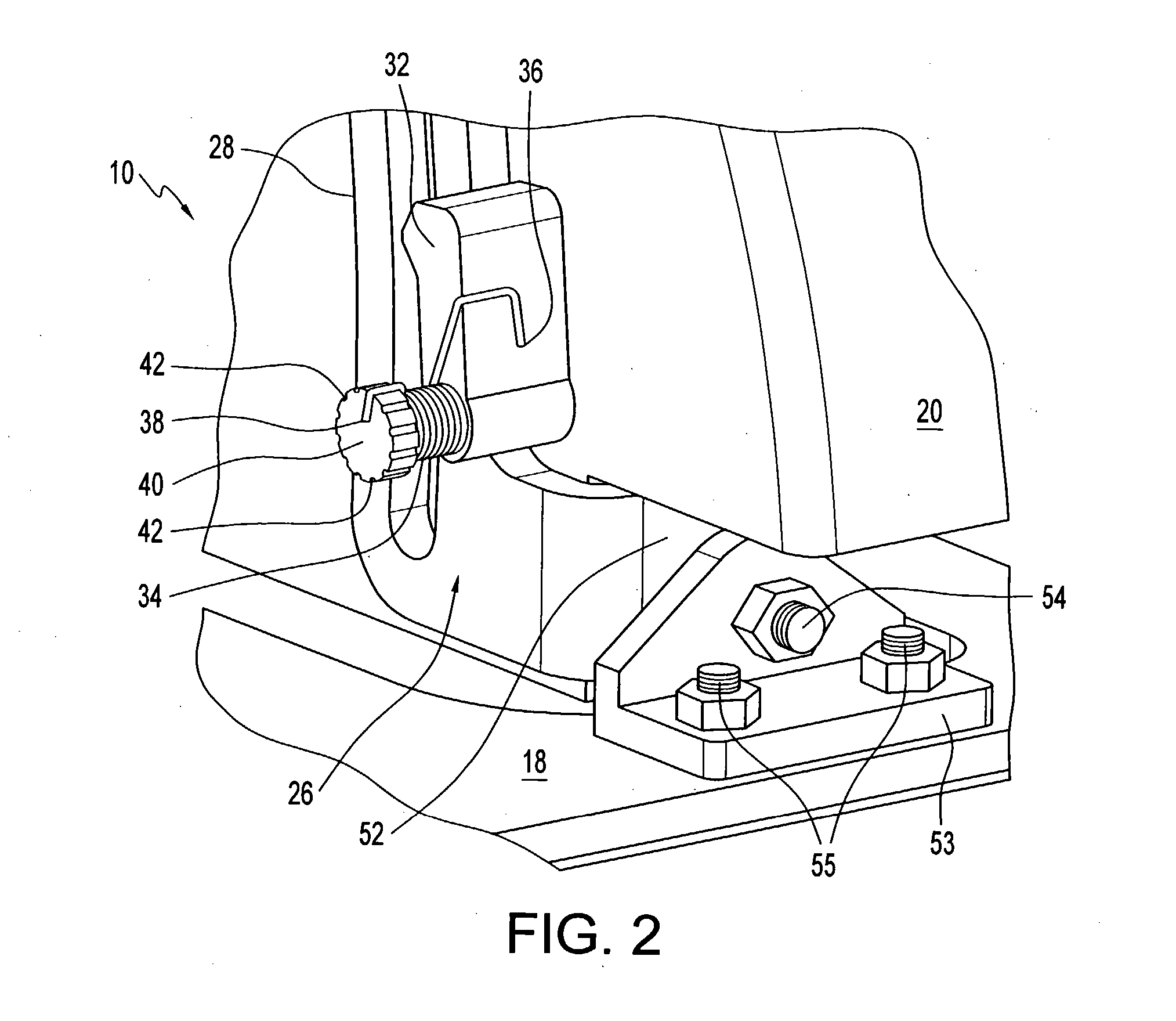

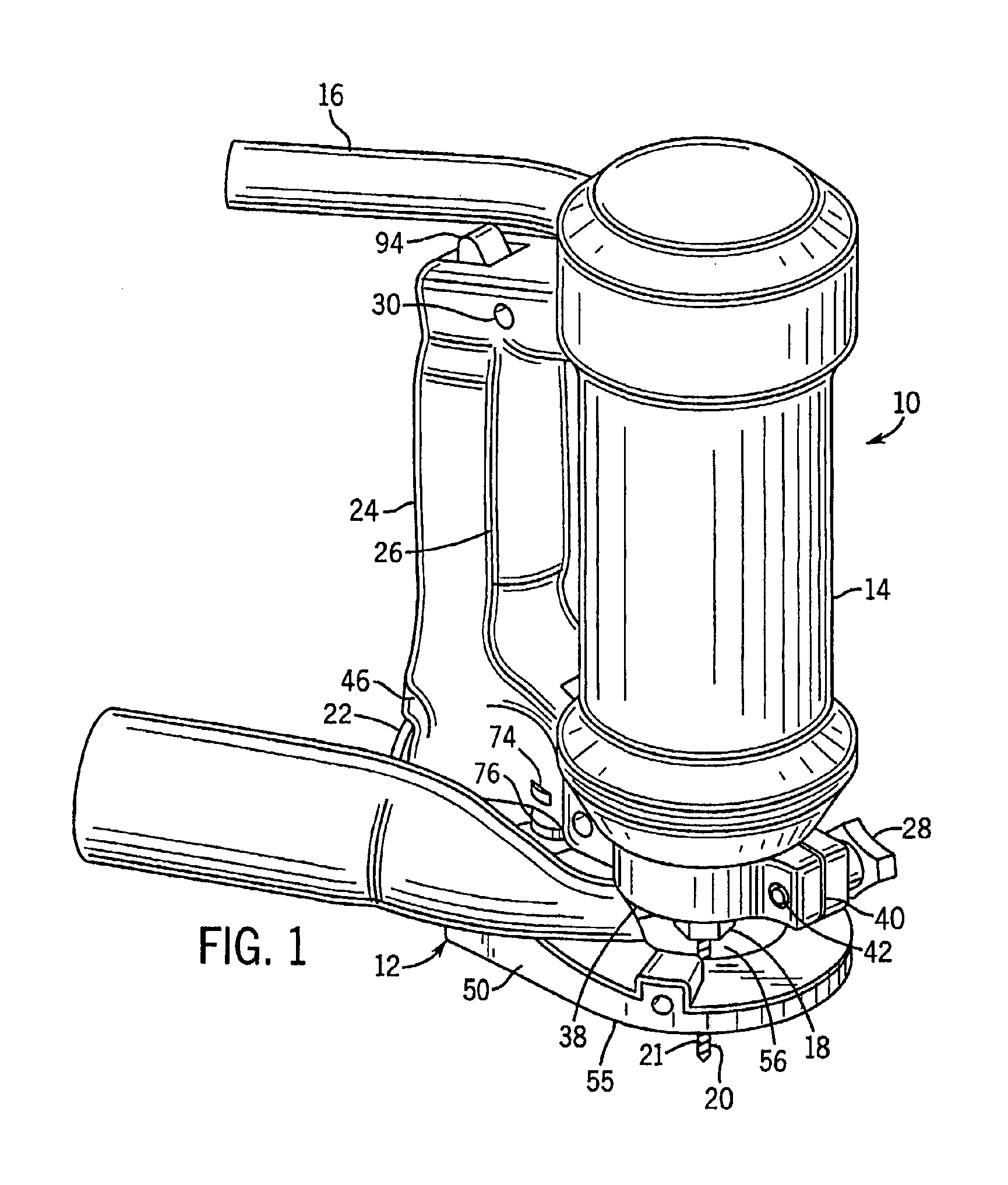

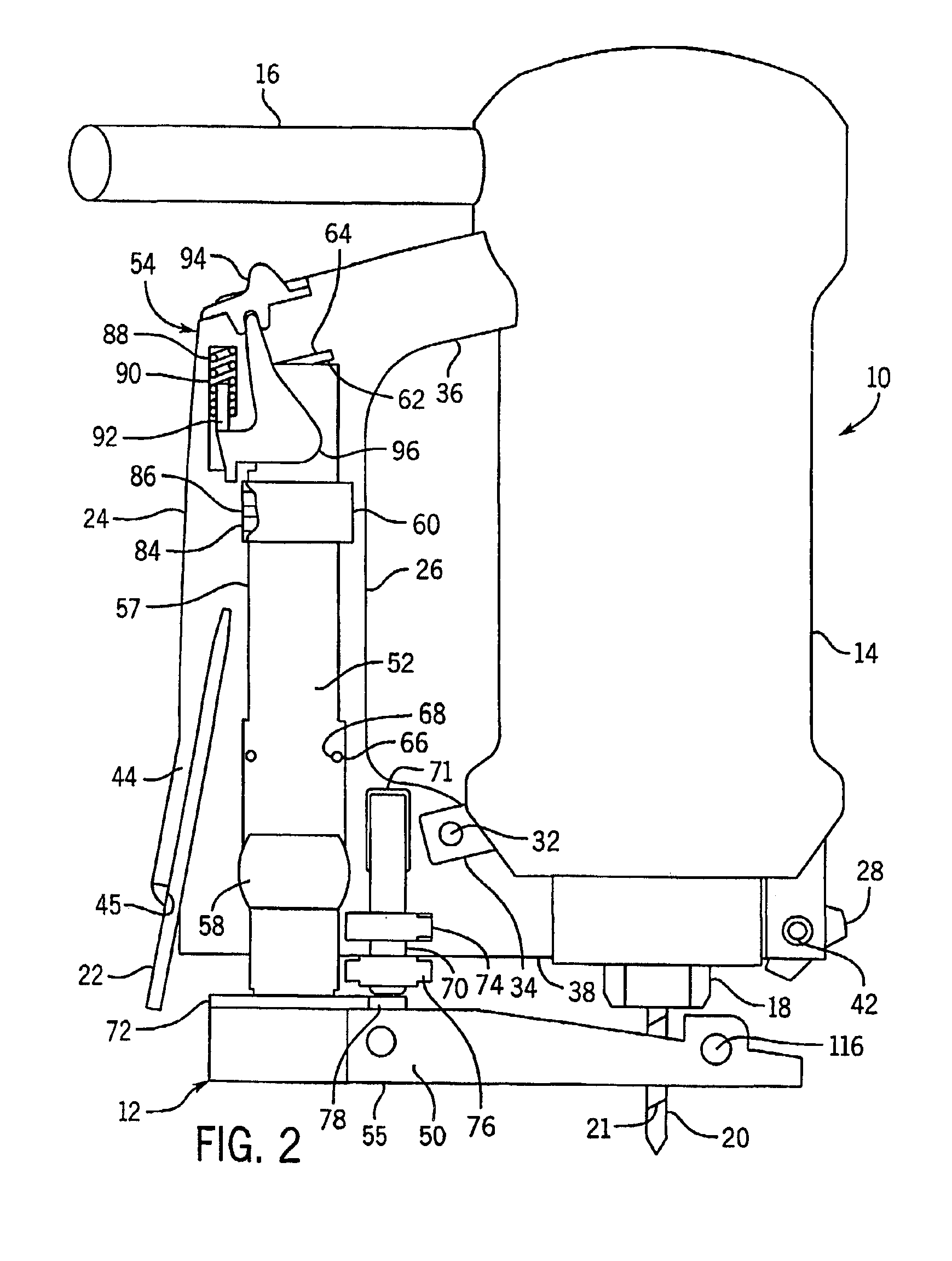

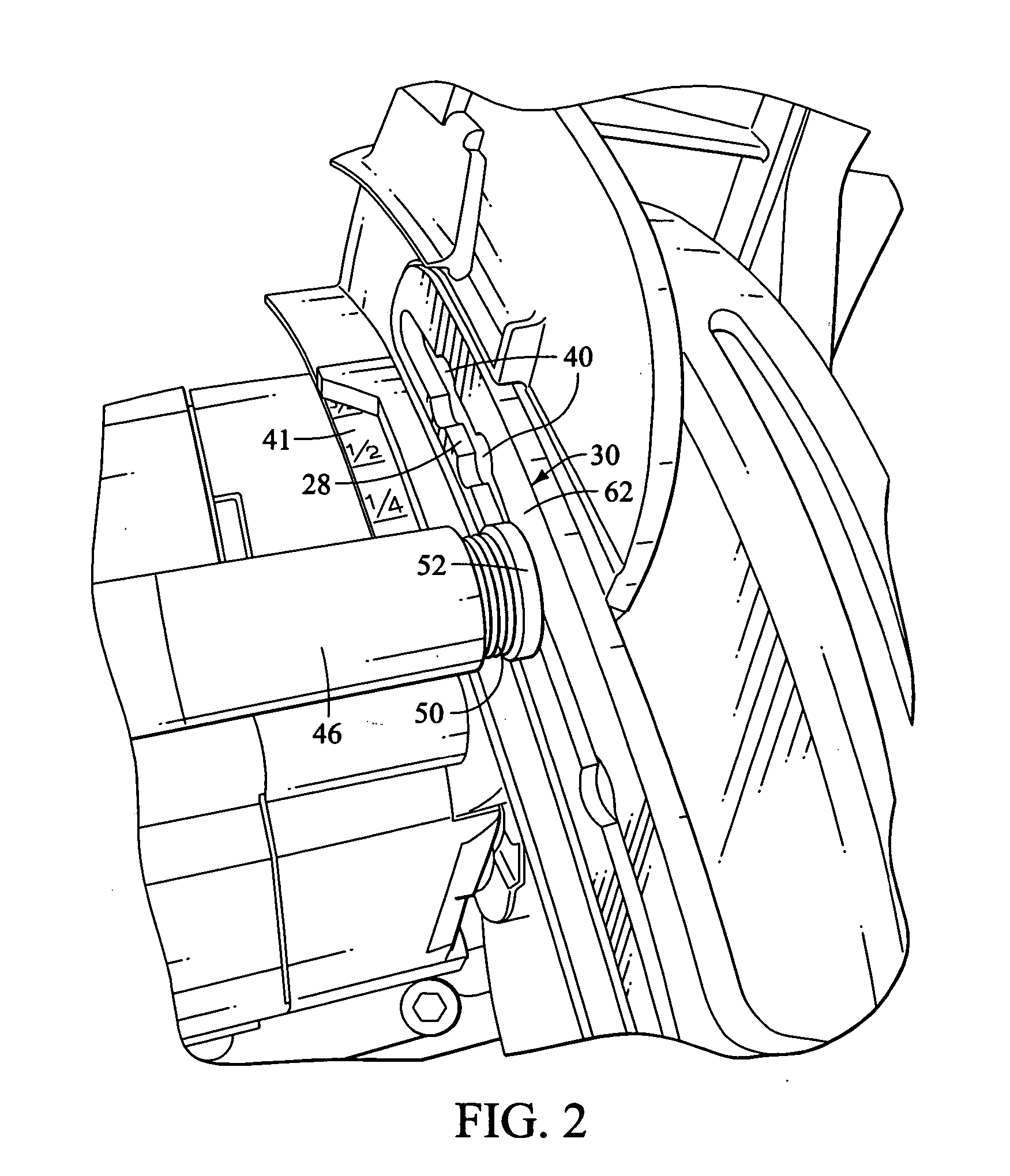

Automatic locking depth guide for cutting tools and the like

A guide (12) for setting the depth of cut of a rotary cutting tool, or other hand-held power tool, which automatically locks into a desired position to set the depth of a cut without requiring manual operation of a locking knob or similar structure. The depth guide is released from the locked position by actuation of a release switch (94). The depth guide includes a depth guide base (50), a depth guide shaft (52) attached to the depth guide base, and an automatic locking and release mechanism (54) coupled to the depth guide shaft. The automatic locking and release mechanism and depth guide shaft may be mounted in a handle (24) of the hand-held power tool, such as a detachable handle, for mounting the depth guide to the tool.

Owner:CREDO TECH CORP

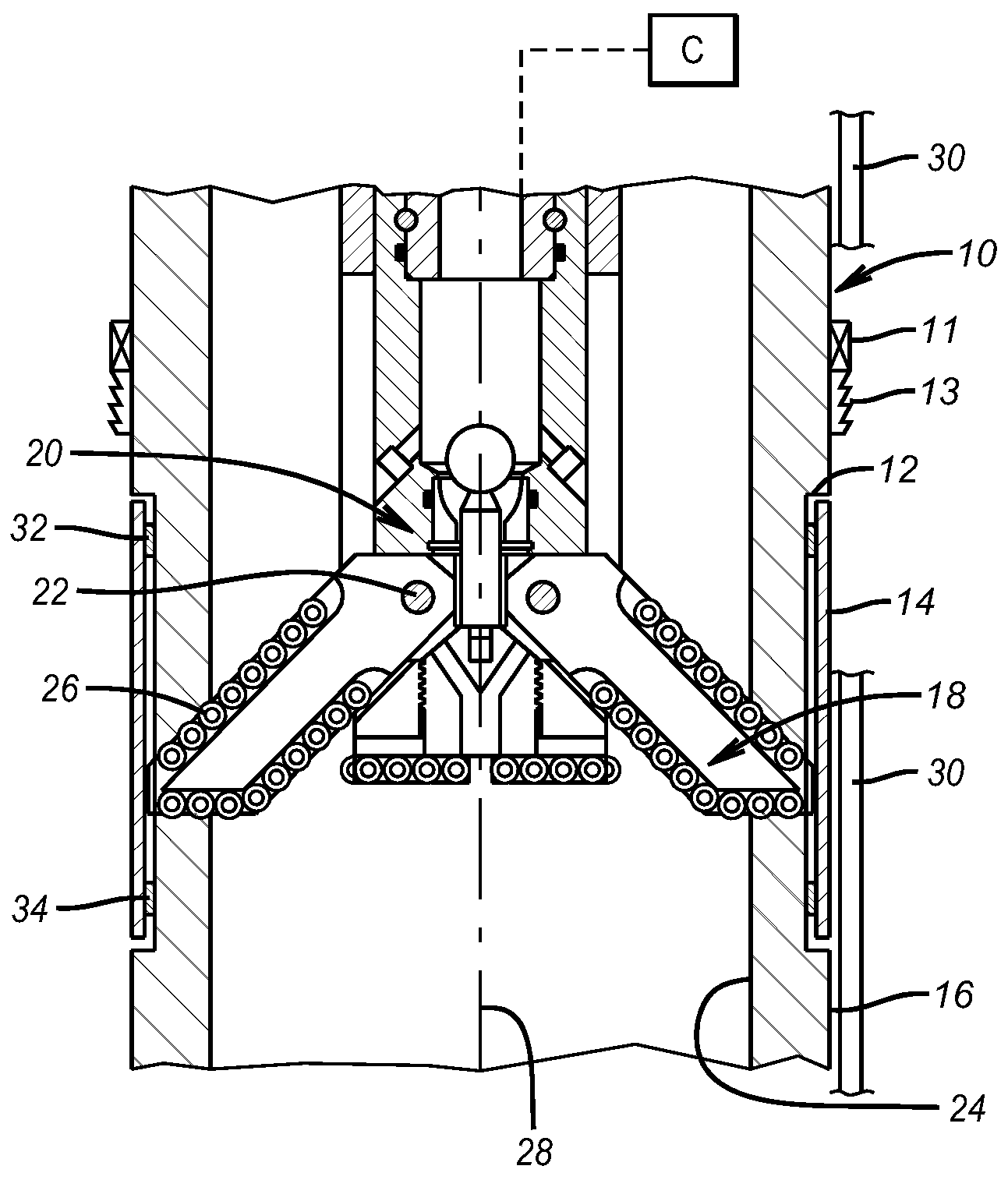

Subterranean Tubular Cutter with Depth of Cut Feature

ActiveUS20100288491A1Preventing further cutting actionTheir depth of cut be limitedSurveyDrill bitsEngineeringKnife blades

A tubular cutter that cuts with extendable and rotating blades has its depth of cut limited upon getting through the tubular to be cut. In a preferred embodiment, the tubular has a loosely mounted member exterior thereto to be engaged by the rotating cutters. When such engagement happens the effect is that the loosely mounted member serves as a cover to the cutters to prevent them from cutting other structures beyond the tubular to be cut. The loosely mounted member is grabbed by the rotating blades for tandem rotation this preventing further cutting action. The load on the mill drops noticeably so that surface personnel have a signal to stop hydraulic pressure to the drive mechanism to allow the blades to retract and the cutter to be removed.

Owner:BAKER HUGHES INC

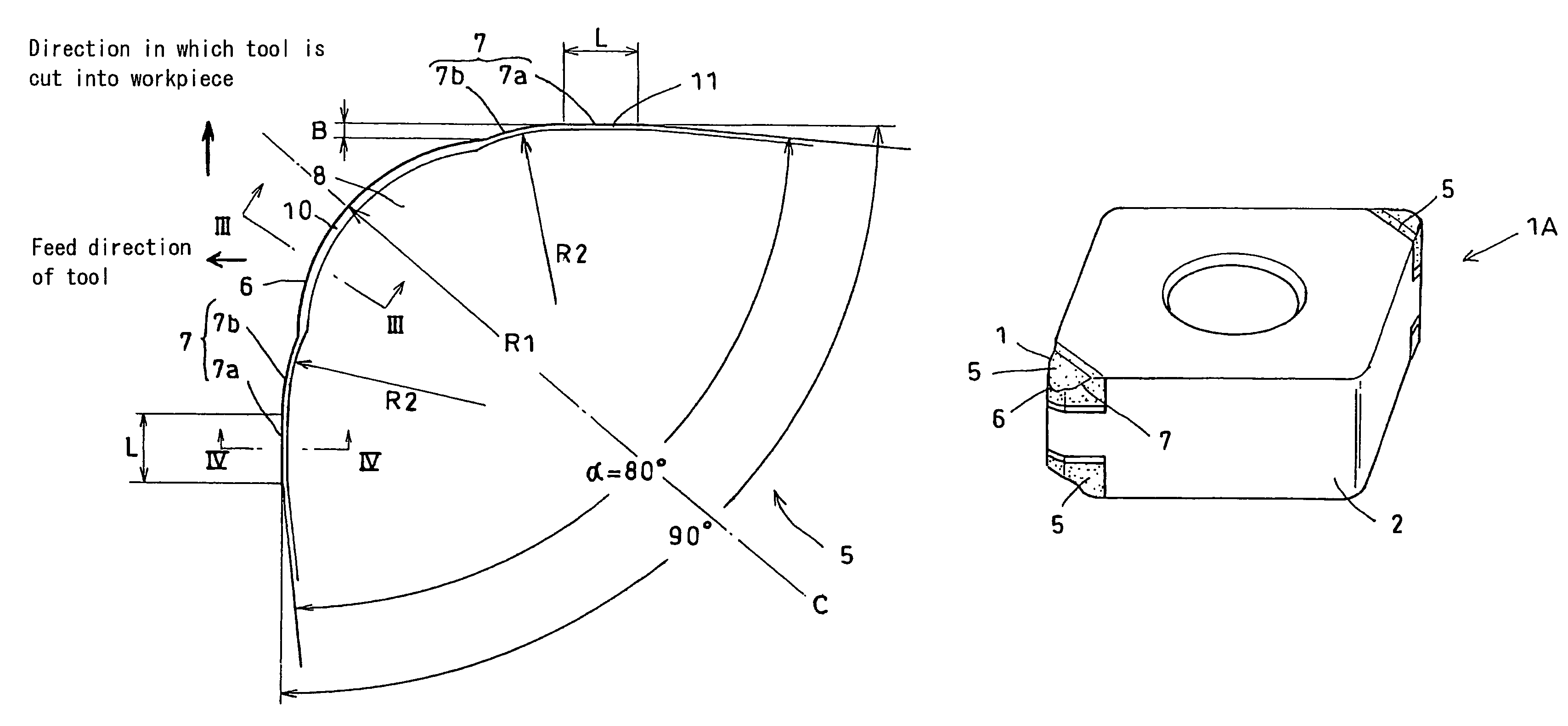

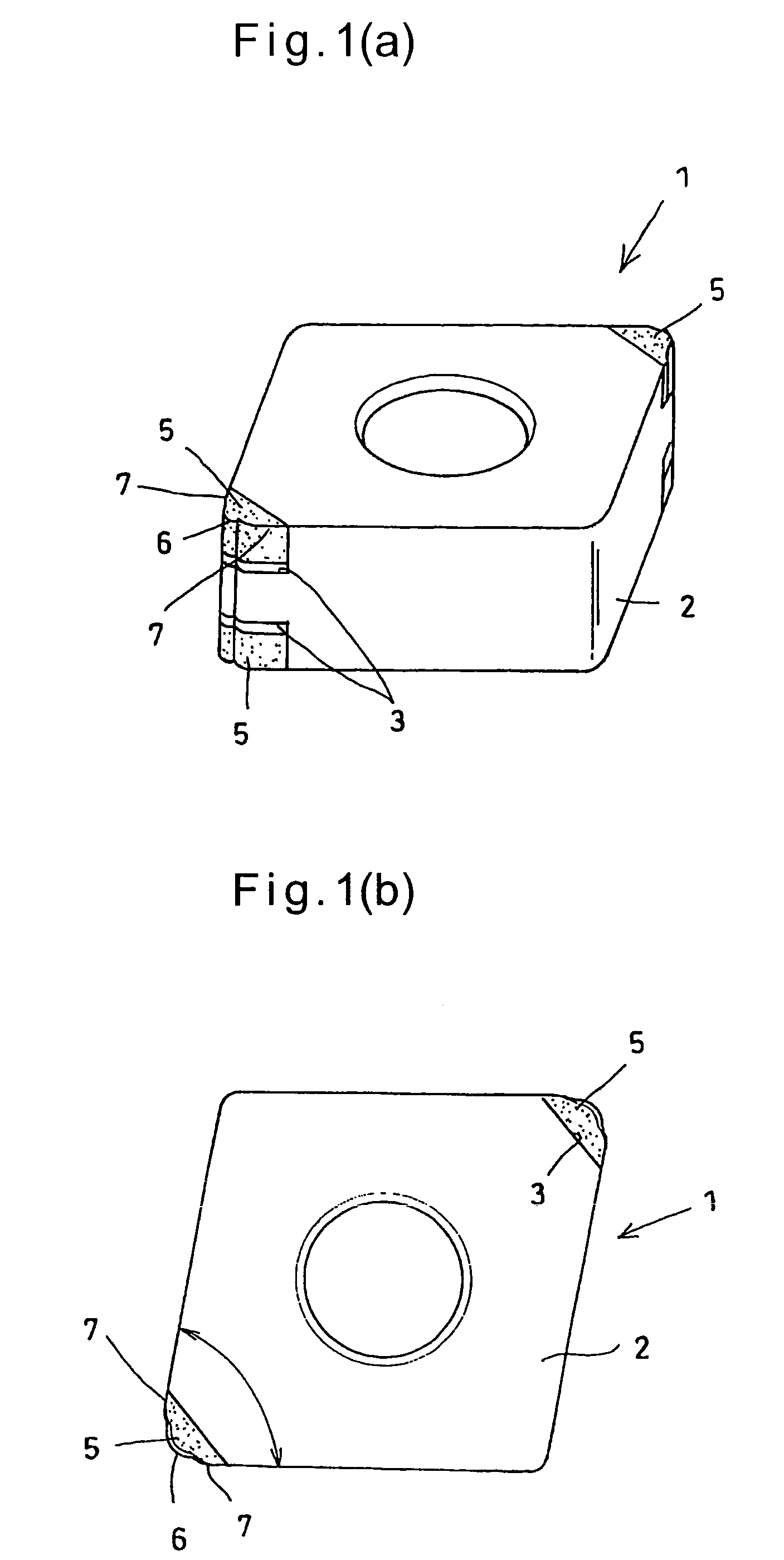

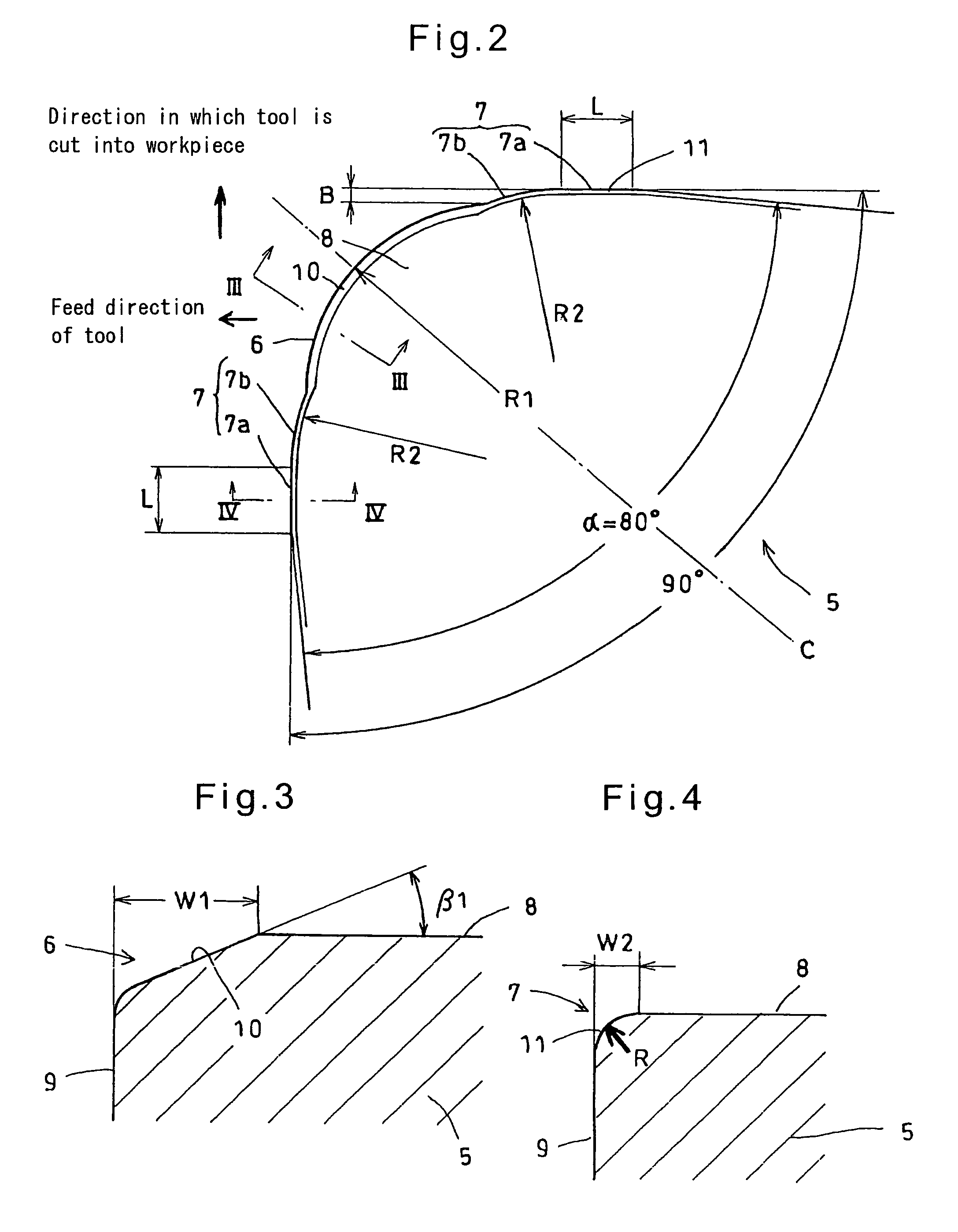

Cutting tool for high-quality high-efficiency machining and cutting method using the same

It is an object to provide a cutting tool which can perform high-quality, high-efficiency machining of a workpiece such as hardened steel.The cutting tool includes a finishing cutting edge 6 which initially cuts into the workpiece, and superfinishing cutting edges 7 for finishing the workpiece cut by the finishing cutting edge. The superfinishing cutting edges 7 project from the finishing cutting edge by a predetermined amount B in such a direction that the depth of cut of the superfinishing cutting edges increases. Each superfinishing cutting edge includes a burnishing portion 7a having a predetermined width L in the feed direction of the tool, and a wiper portion 7b. The superfinishing cutting edges 7 burnish the finished surface formed by the finishing cutting edge, while removing a affected layer formed by the finishing cutting edge.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

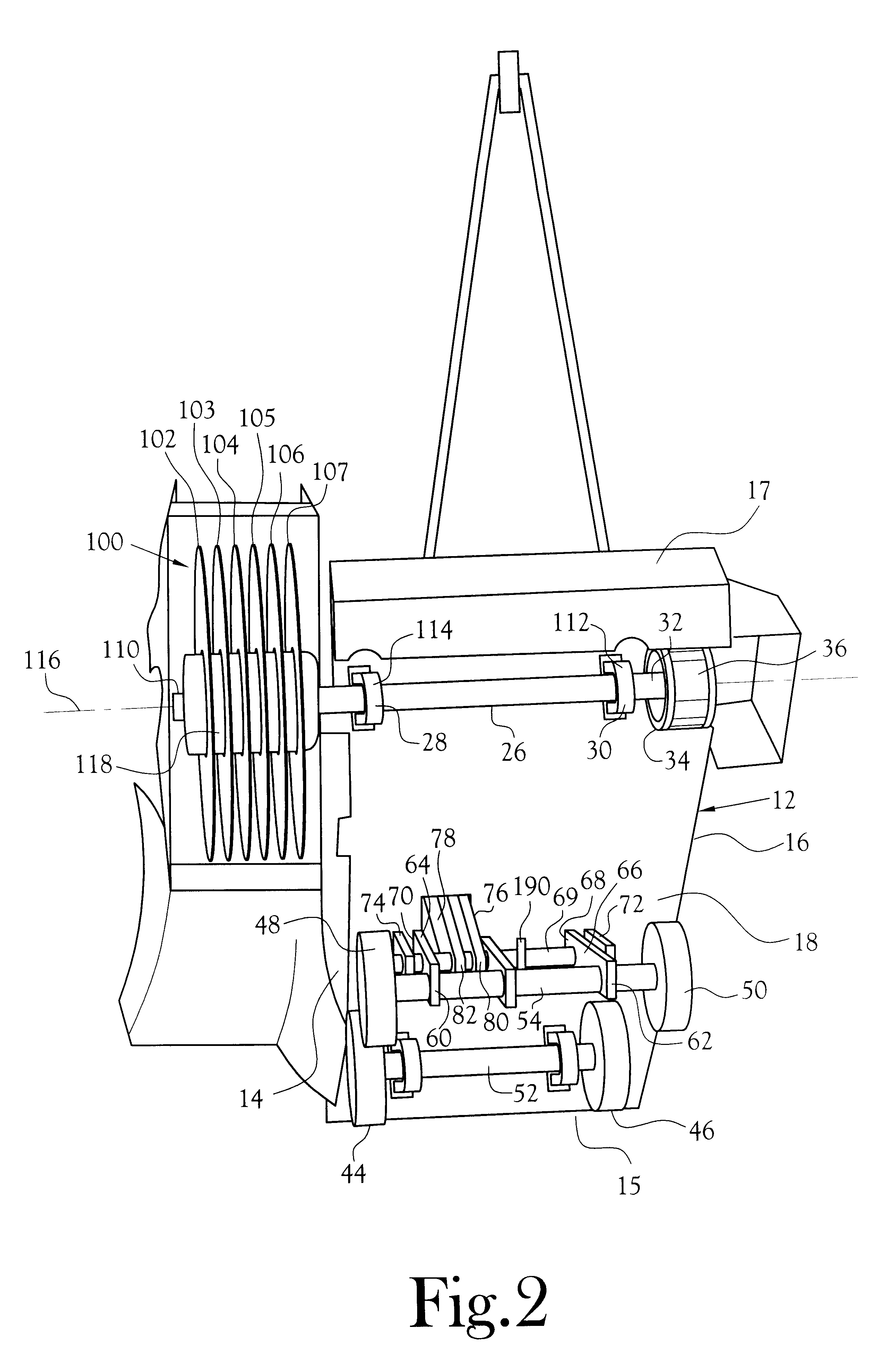

Mobile concrete saw

InactiveUS6390086B1Easy to transportSufficiently mobileMetal sawing devicesRoads maintainenceDrive shaftEngineering

A cured-concrete-cutting saw which is sufficiently mobile as facilitates its transport to a work site located within a building, and between work sites within a building, for example, and which is useful in cutting block-out grooves for expansion joints between adjacent sides of adjacent concrete slabs and / or troughs in the surface of such slabs. The saw includes a housing, a blade assembly comprising a plurality of circular blades disposed in spaced apart parallel relationship to one another on the outboard end of a driven shaft that is mounted on the bottom of the housing. A motor provides power for rotation of the shaft and its blade assembly. Optionally, the motor provides power for propelling the saw over the top surface of a concrete slab. A mechanism is provided for operator adjustment of the depth of cut of the blades of the blade assembly from a position adjacent the aft end of the saw. Through the means of selecting different diameter blades for the blade assembly, the saw may be employed to cut a variety of block-outs or troughs of different cross-sectional geometries, in the top surface of a concrete slab. A method is disclosed for the formation of an elongated block-out or trough in the top surface of a cured concrete slab for the preparation of adjacent side margins of adjacent sides of adjacent concrete slabs and for the installation of an expansion strip in the space between these adjacent sides.

Owner:COLLINS LOUIS M +1

Electronic device and method for manufacturing the same

InactiveUS6890834B2Function increaseIncrease vacuumSemiconductor/solid-state device detailsSolid-state devicesEngineeringDry etching

An Al film is formed on a cap wafer and the Al film is patterned into a ring-shaped film. Dry etching is performed by using the ring-shaped film as a mask to form a drum portion enclosing a recess portion to provide a vacuum dome. After forming a depth of cut into the substrate portion of the cap wafer, the cap wafer is placed on a main body wafer having an infrared area sensor formed thereon. Then, the ring-shaped film of the cap wafer and the ring-shaped film of the main body wafer are joined to each other by pressure bonding to form a ring-shaped joining portion.

Owner:PANASONIC HLDG CORP

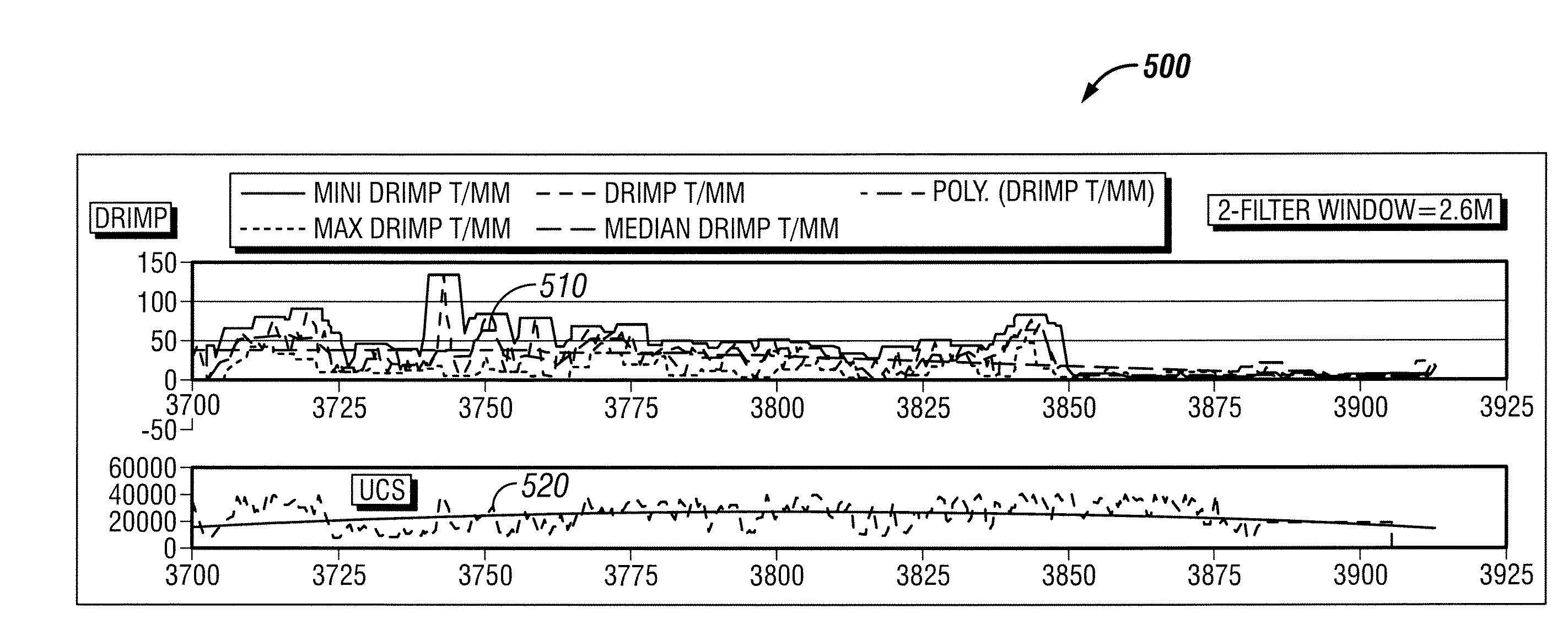

Method to determine rock properties from drilling logs

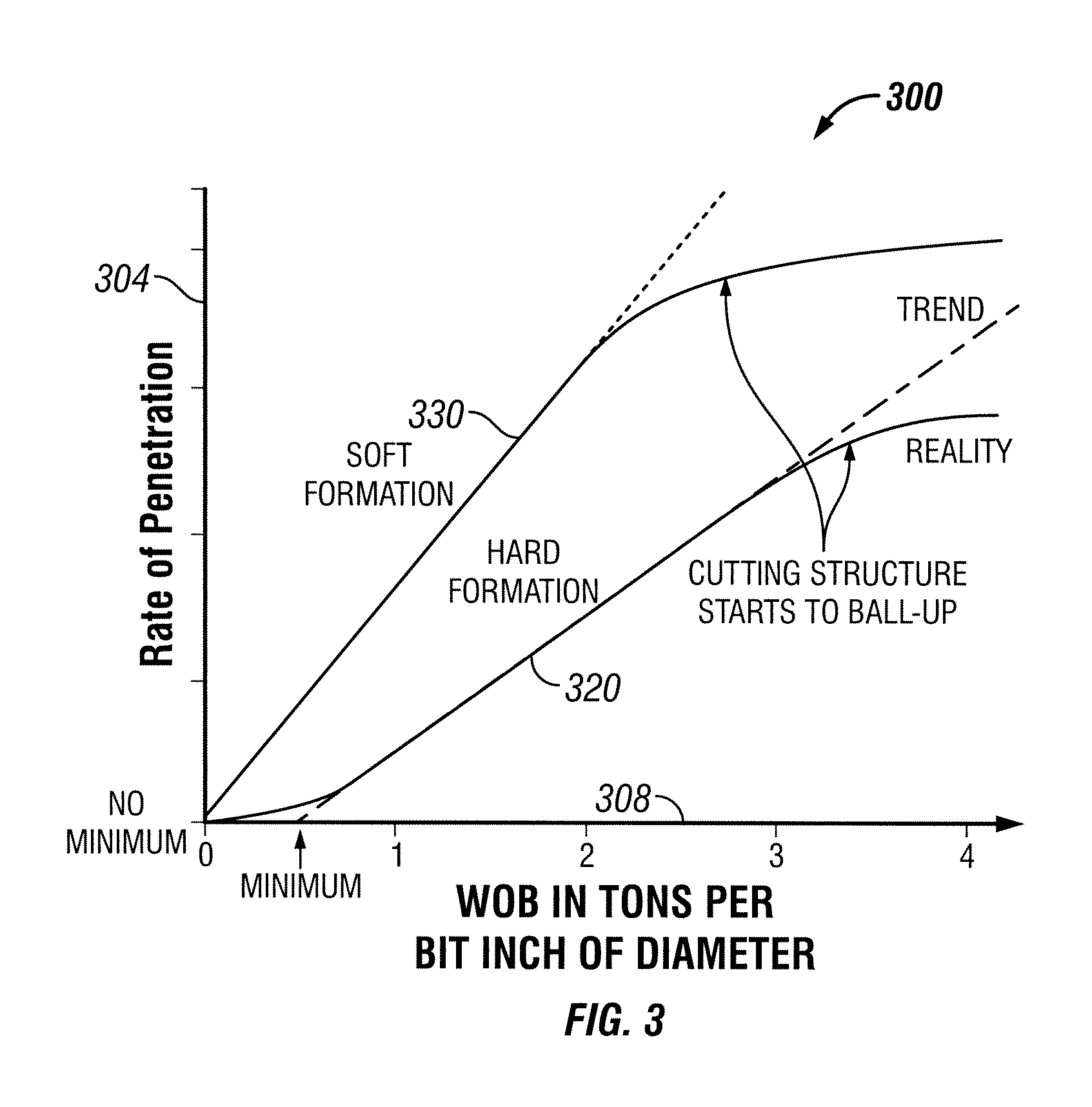

ActiveUS20100191471A1Electric/magnetic detection for well-loggingSeismology for water-loggingPorosityRate of penetration

A method of identifying one or more rock properties and / or one or more abnormalities occurring within a subterranean formation. The method includes obtaining a plurality of drilling parameters, which include at least the rate of penetration, the weight on bit, and the bit revolutions per minute, and then normalizing these plurality of drilling parameters by calculating a depth of cut and an intrinsic drilling impedance. Typically, the intrinsic drilling impedance is specific to the type of bit used to drill the wellbore and includes using a plurality of drill bit constants. From this intrinsic drilling impedance, the porosity and / or the rock strength may be determined which is then compared to the actual values to identify the specific type of the one or more abnormalities occurring. Additionally, the intrinsic drilling impedance may be compared to other logging parameters to also identify the specific type of the one or more abnormalities occurring.

Owner:VAREL INT IND

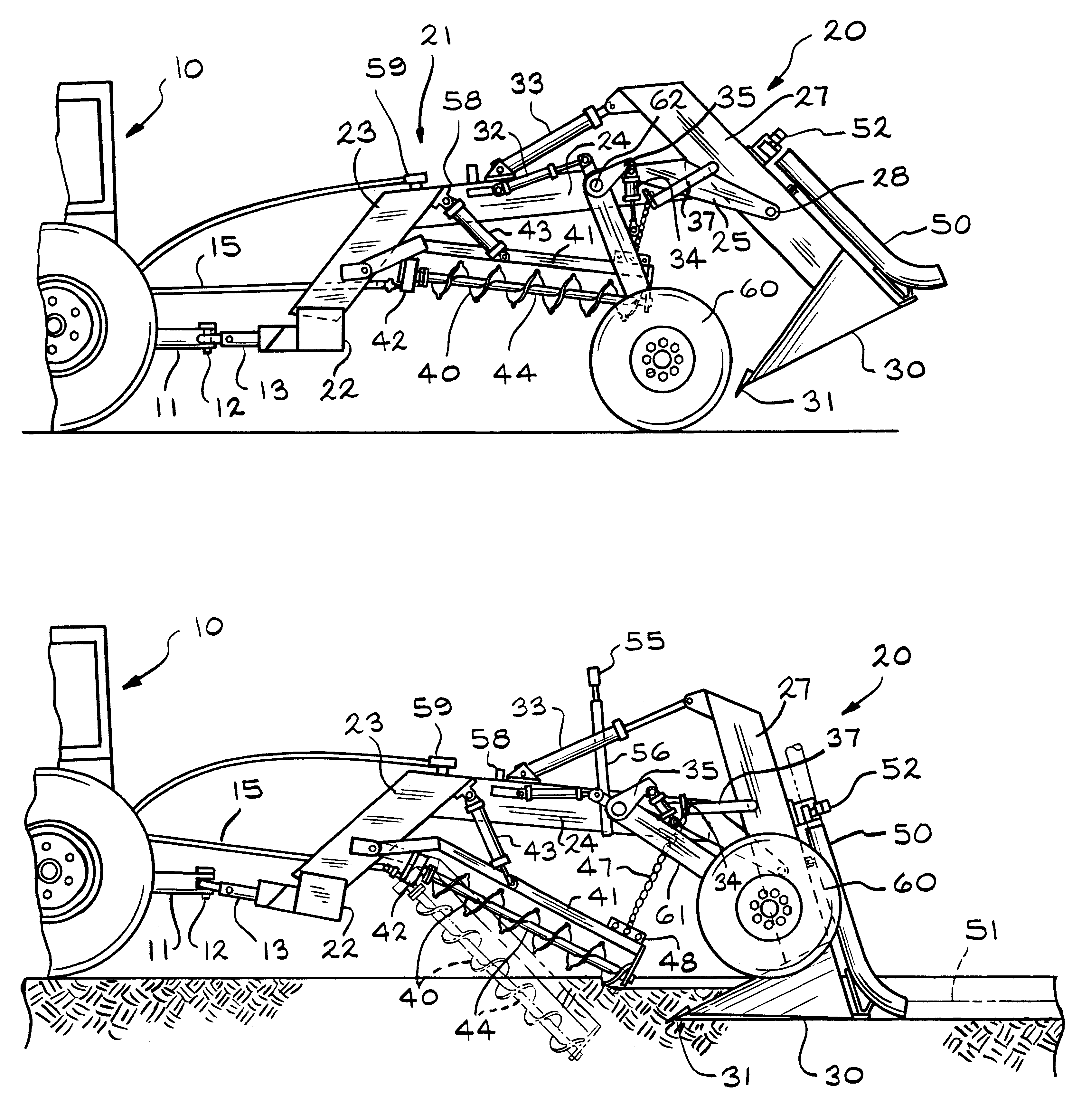

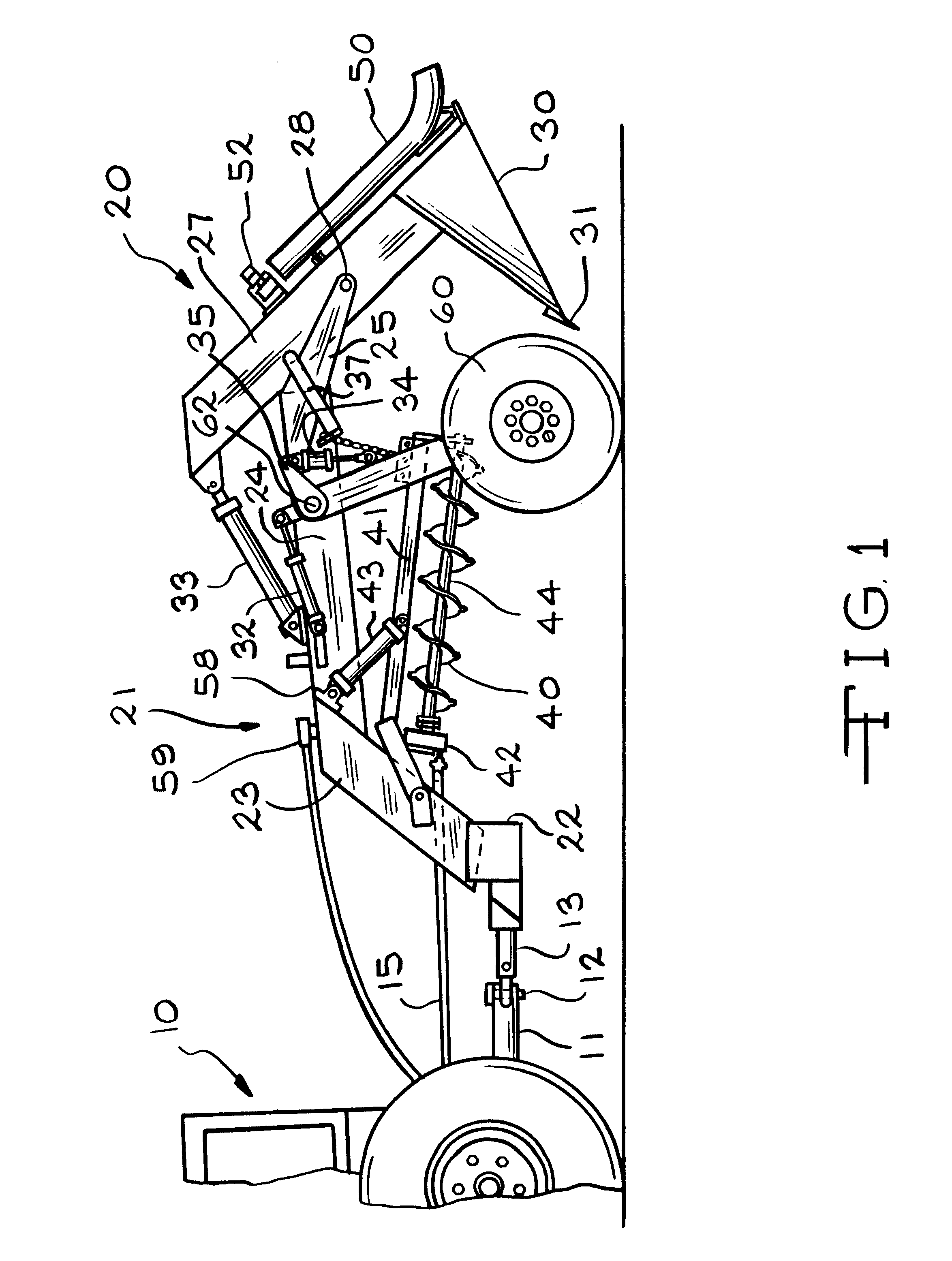

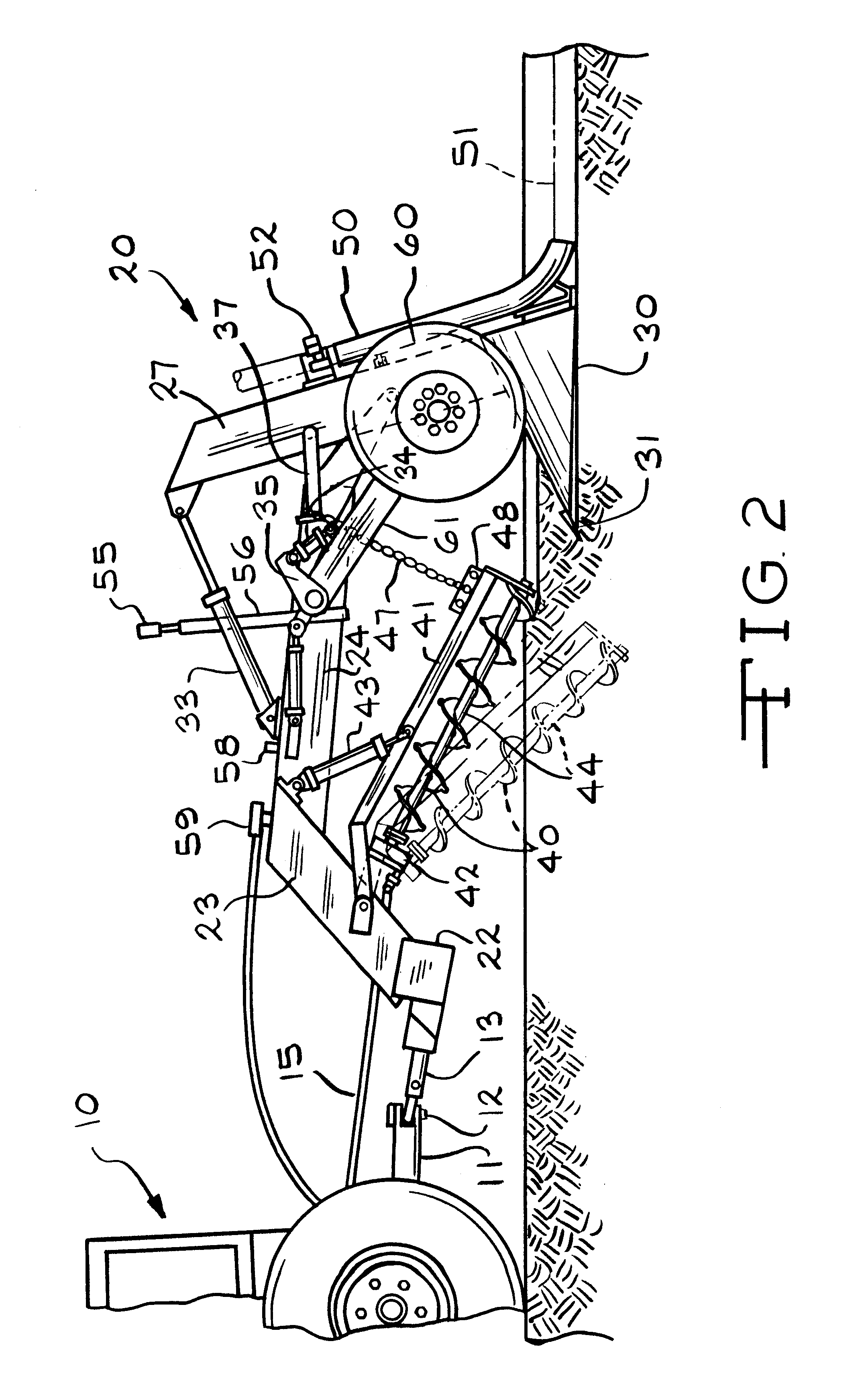

Trencher plow for laying pipe

A trencher plow for laying pipe such as drainage pipe which includes in combination an auger angled downwardly toward a plow which follows, both mounted in a superstructure and being arranged to be cooperatively raised and to set the grade and depth of cut by the plow determinable by sensing the grade setting signal of a laser unit located in the field of cut. The auger is provided with cutting lobes distributed about its teeth which facilitate cutting and throwing soil to the sides of a trench being dug in advance of the plow which finalizes shaping of the trench for deposition of pipe into the trench.

Owner:LIEBRECHT JR SYLVESTER J

Bevel and depth of cut detent system

A circular saw assembly of the type that includes a motor housing, a handle coupled to the motor housing, a generally circular saw blade disposed within a blade housing at a first end of the motor housing, and a foot member through which the blade extends for guiding the saw assembly along a work surface, where the circular saw assembly including a depth of cut locking system and an angle of cut locking system. The depth of cut locking system includes an arcuate bracket with an arcuate slot, and an engagement member extends through the slot and is operatively connected to the motor housing and slideable in the arcuate slot. The angle of cut locking system includes a bracket having an arcuate slot and an engagement member movable in the slot and configured to the bracket. A biasing member is provided to bias the engagement member, and at least one detent recess is provided to retain the engagement member therein.

Owner:CREDO TECH CORP +1

Cutting tool and double-ended cutting insert therefor

A cutting tool for grooving, parting and turning machining operations is capable of grooving to unlimited depths of cut. The cutting tool includes an indexable double-ended cutting insert having a downwardly extending insert clamping portion resiliently clamped in a self-retaining manner in an insert pocket so that chip formation is not hindered during such machining operations.

Owner:ISCAR LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com