Bearing blocks for drill bits, drill bit assemblies including bearing blocks and related methods

a technology of bearing blocks and drill bits, which is applied in the direction of drilling machines and methods, metal-working drilling tools, constructions, etc., can solve the problems of pdc cutters still suffering from what might simply be termed “overloading, excessive bit aggressiveness, and the like, and achieve the effect of reducing the initial thickness of the bearing block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The illustrations presented herein are not actual views of any particular drilling system, assembly, or device, but are merely idealized representations which are employed to describe embodiments of the present invention.

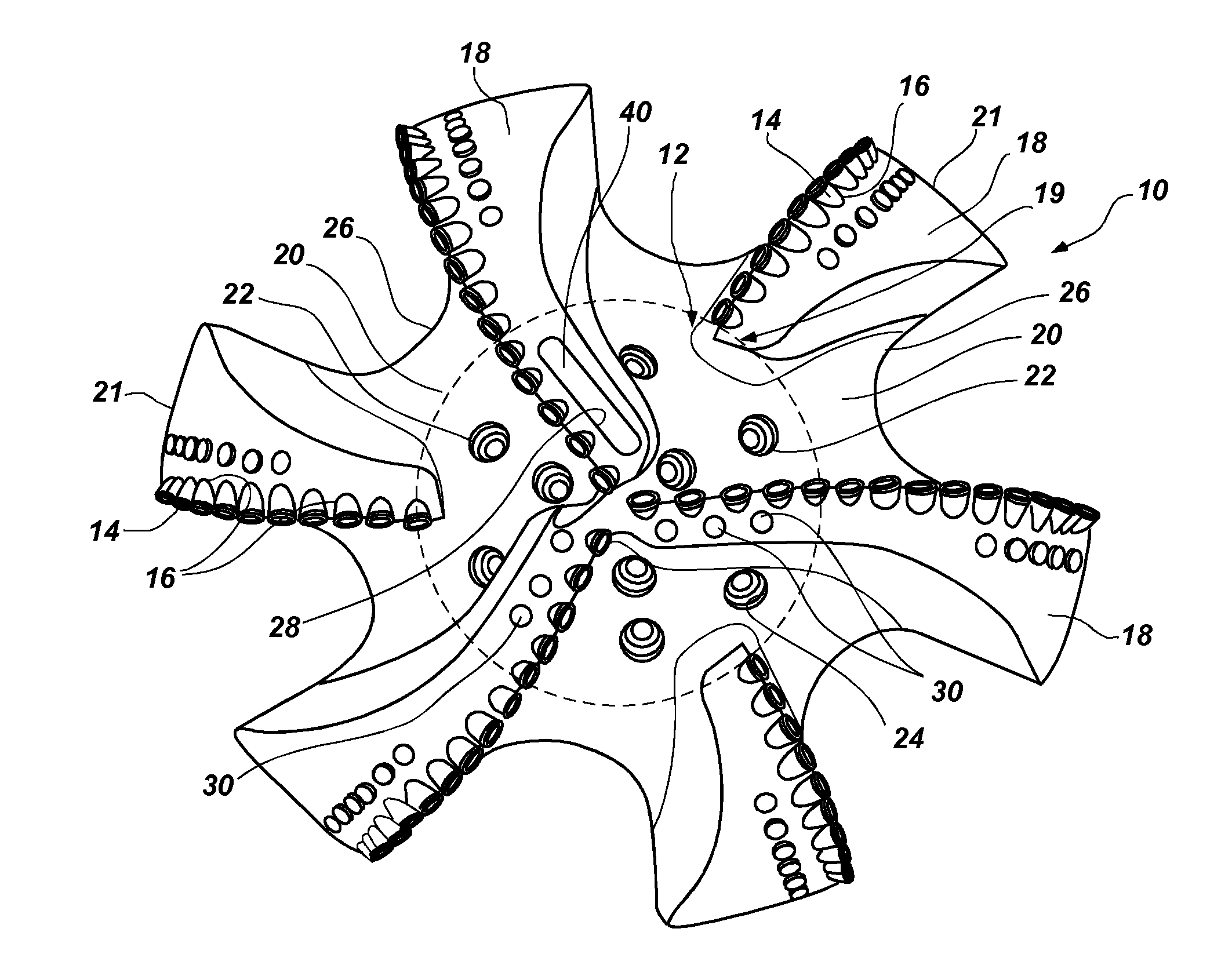

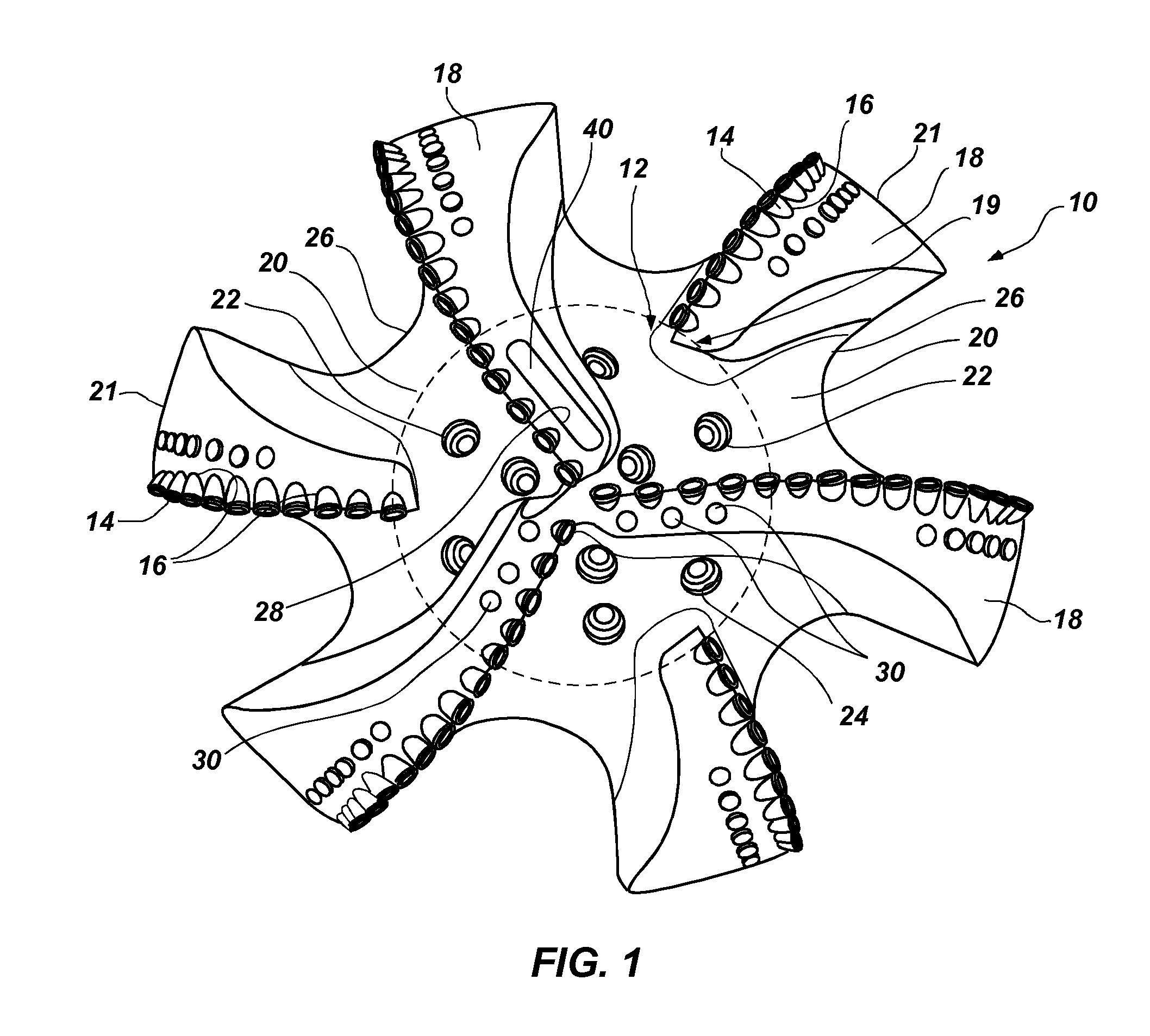

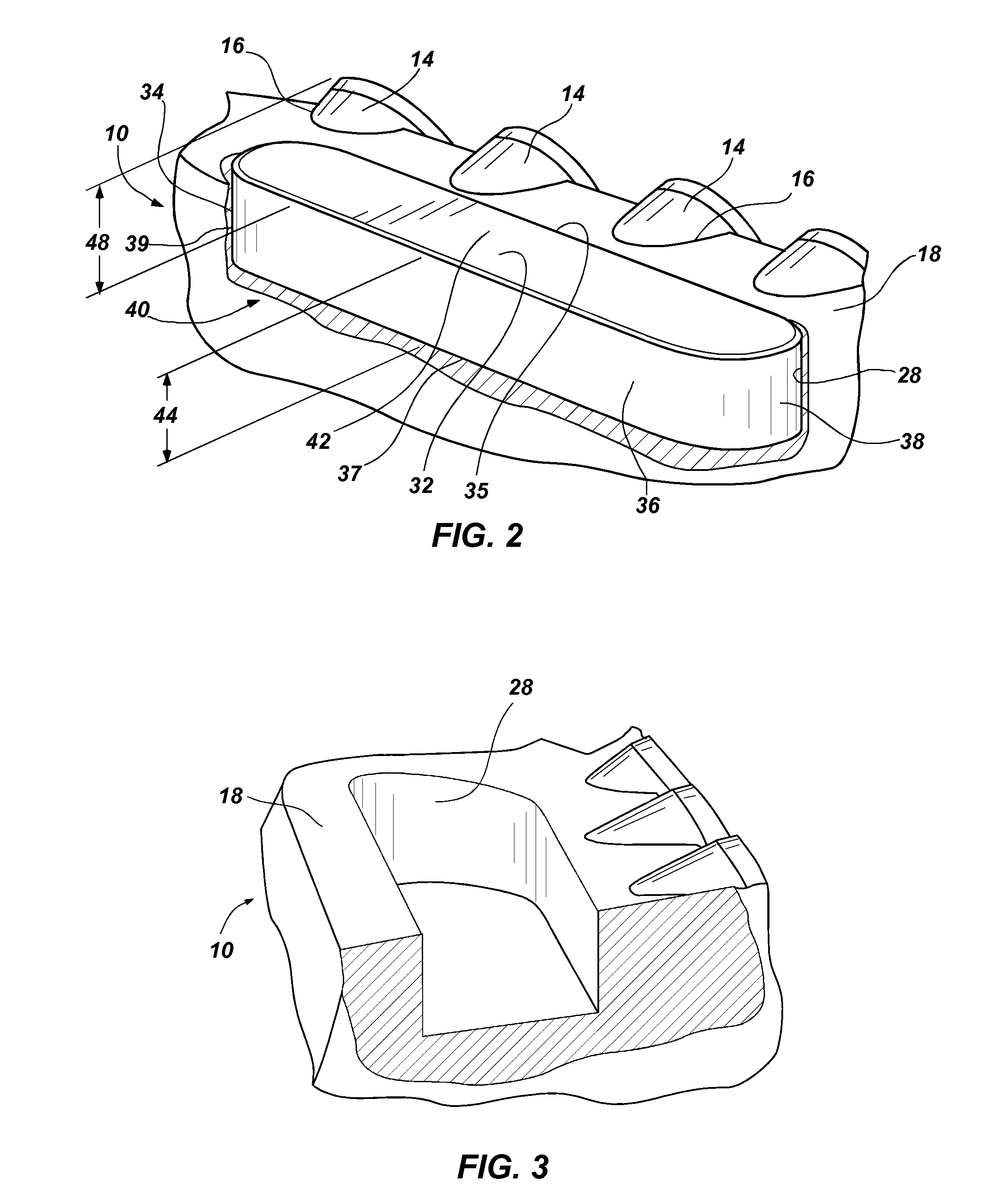

[0036]An embodiment of the current invention is shown in FIGS. 1, 2, 3, and 6. FIG. 1 shows an earth-boring rotary drill bit 10, depicted as a fixed cutter or drag bit employing PDC cutting elements, although of course the invention is not so limited. The bit 10 includes an attached bearing block 40 as viewed by looking upwardly at its face or leading end 12 as if the viewer was positioned at the bottom of a borehole. Bit 10 includes a plurality of PDC cutters 14 bonded by their substrates (diamond tables and substrates not shown separately for clarity), as by brazing, into pockets 16 in blades 18 extending above the face 12 of the bit 10. While the bit 10 depicted in FIG. 1 is a steel body bit, the bit 10 may be fabricated to comprise a particle-matrix compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com