Patents

Literature

127results about How to "Expand the cutting range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

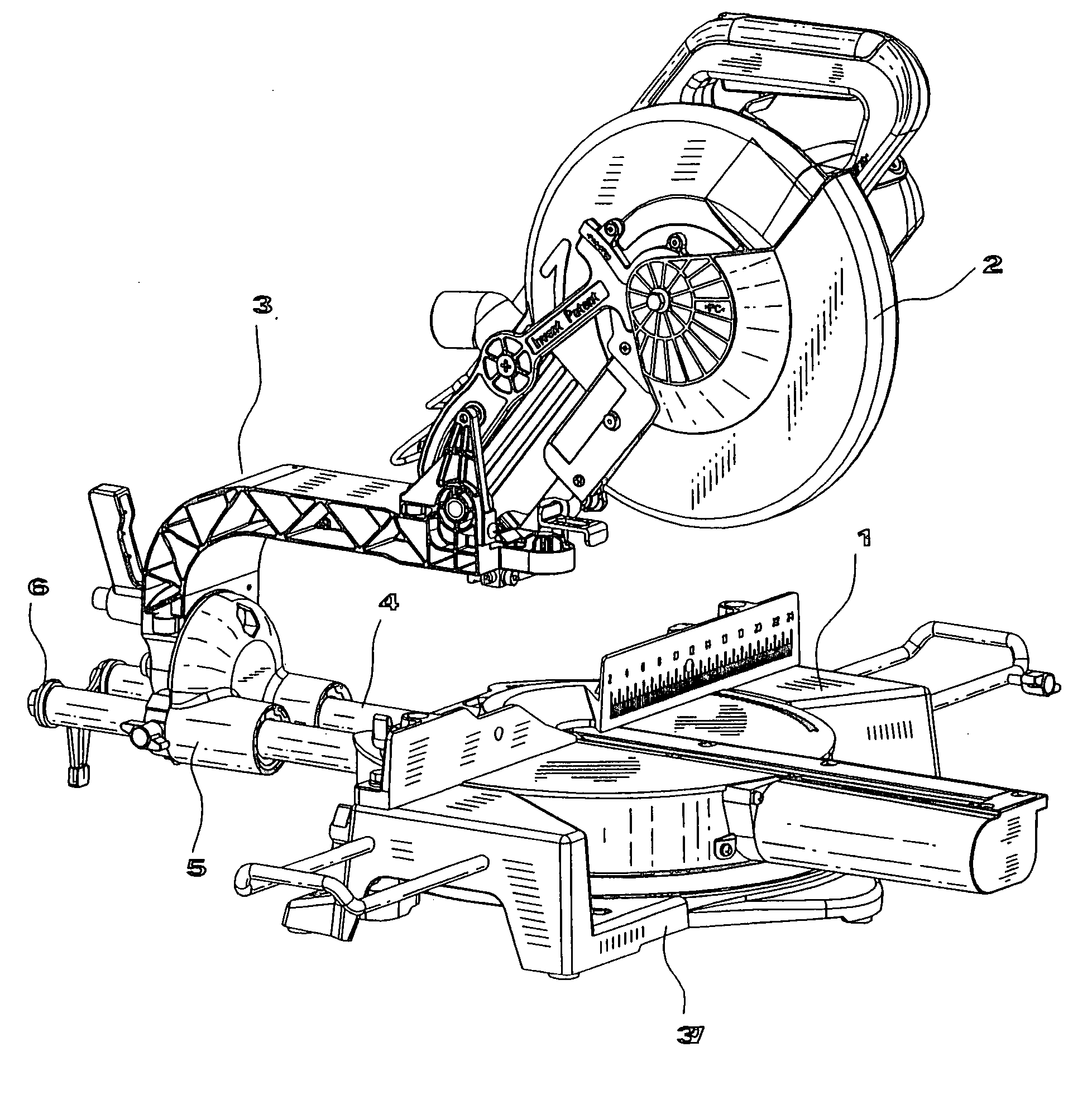

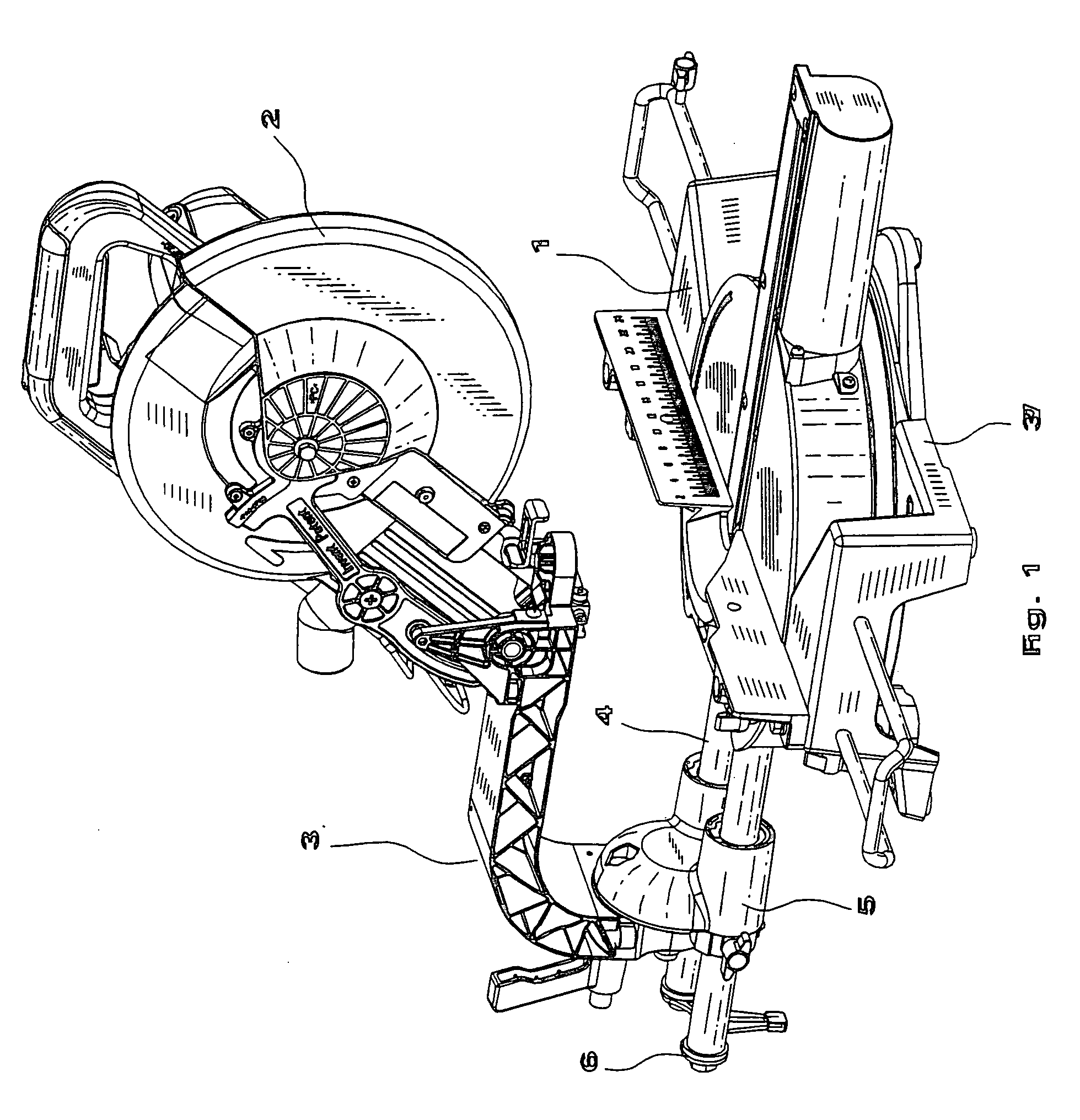

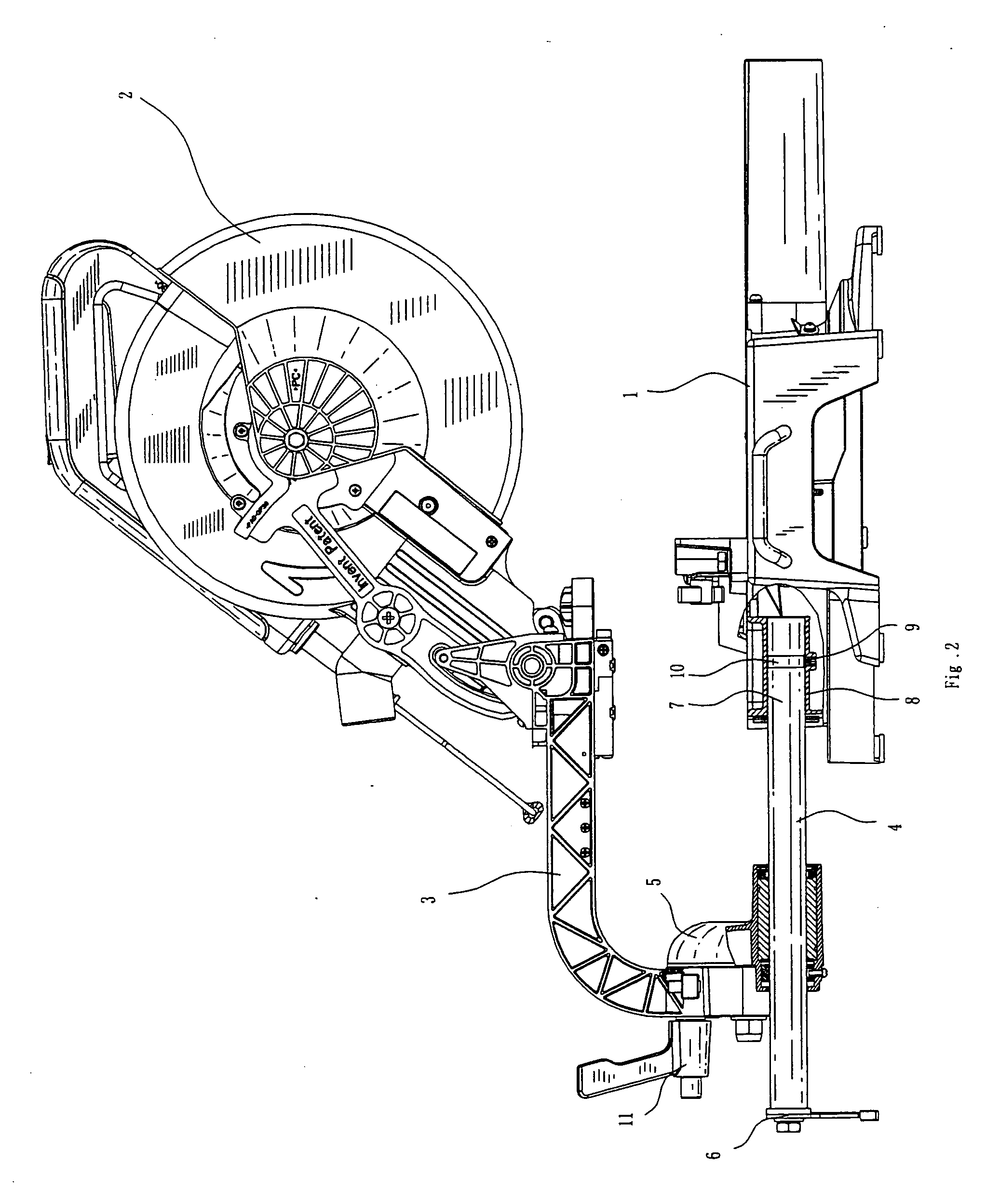

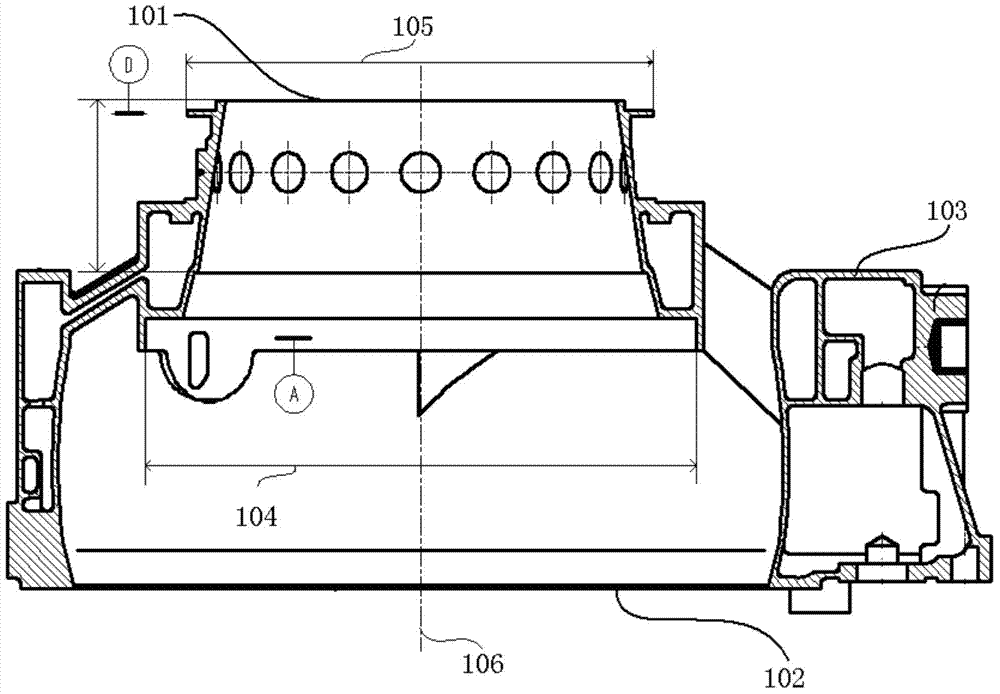

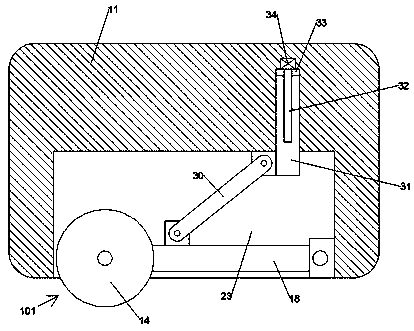

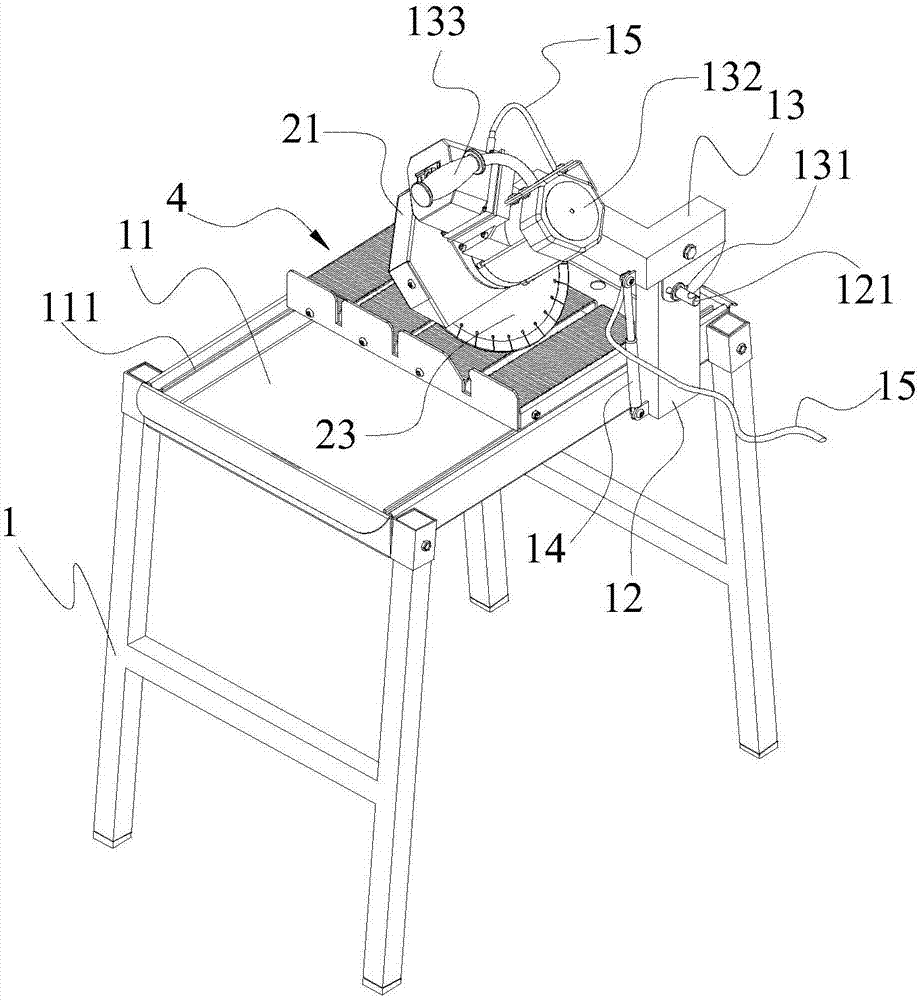

Electric miter saw

InactiveUS20070074611A1Efficient use ofExpand the cutting rangeMetal sawing devicesGuide fencesBall bearingEngineering

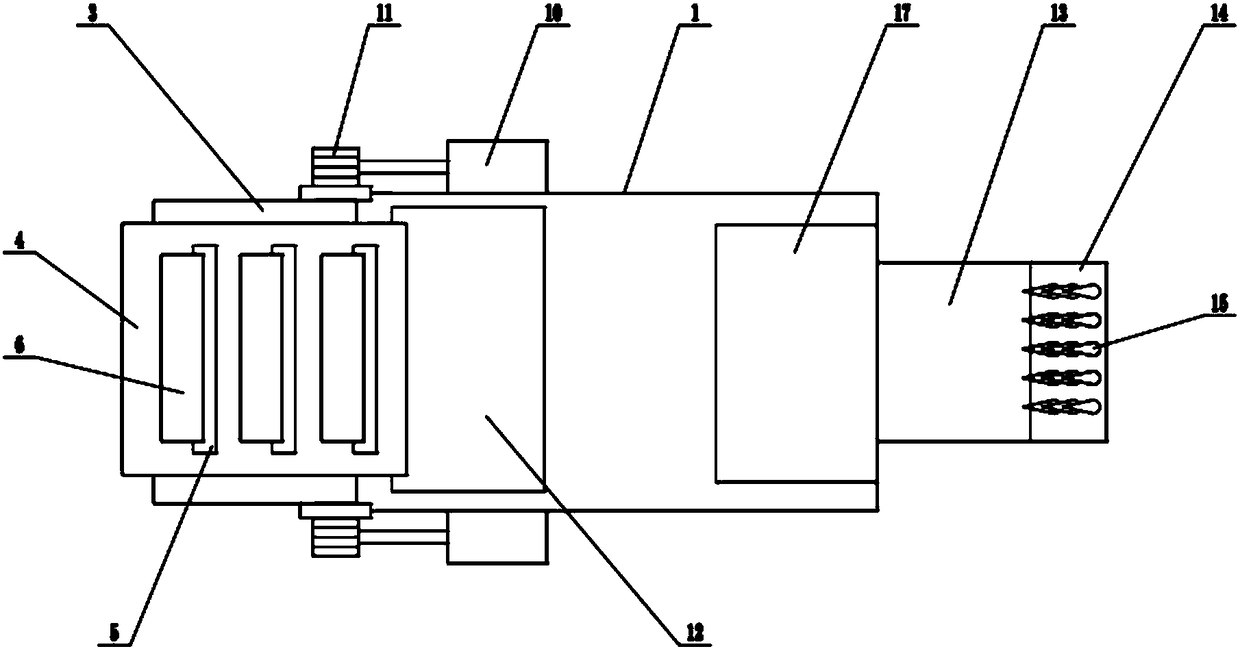

An electric miter saw includes a base, a cutting table, a cutting member and a link arm. The cutting table is mounted on the base. The upper portion of the link arm is connected to a cutting member with the cutting saw blade driven by a motor. The lower portion of the link arm is connected to the upper portion of a supporting member and secured by a threaded central bolt. The linear ball bearing is mounted in the inner aperture of the supporting member, which is slidably connected to the slide rod by a linear ball bearing. At the outer end of the slide rod is mounted a position limit socket. The inner end of the slide rod is connected and secured beneath the cutting table via a releasable securing configuration mentioned above. A flexible blade guard is also provided.

Owner:NIG BO YANG MING ELECTRIC TOOLS

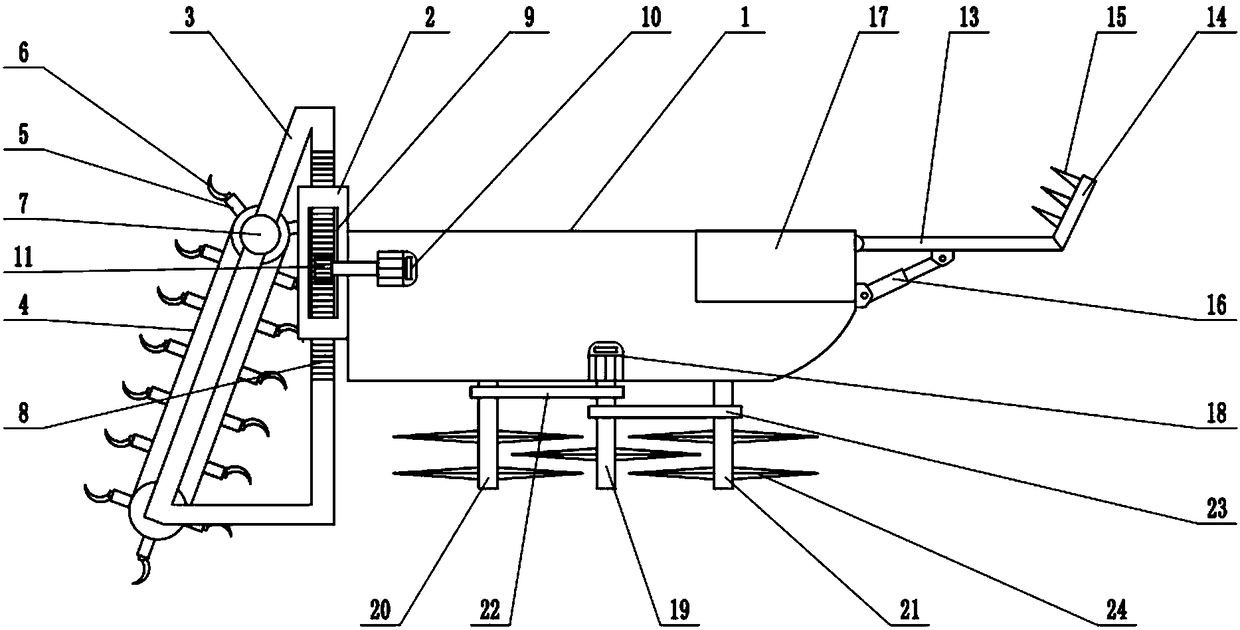

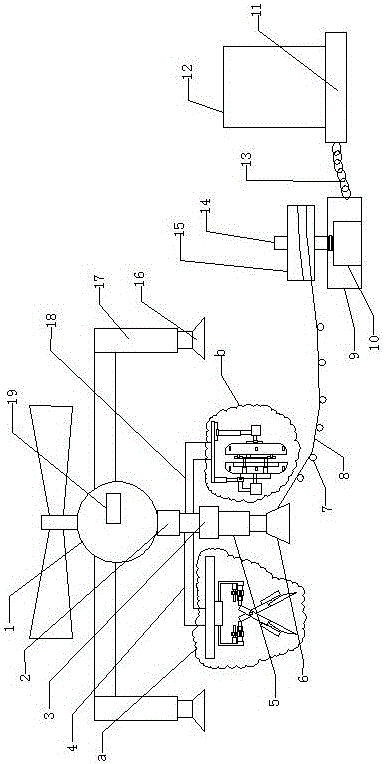

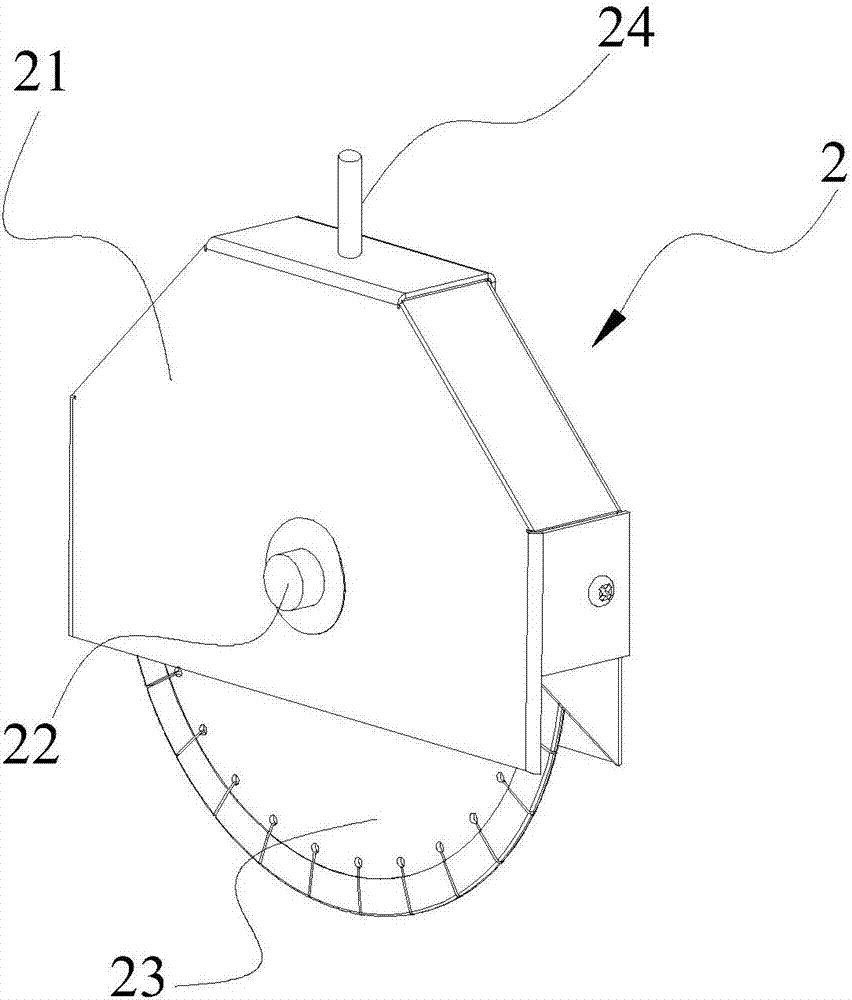

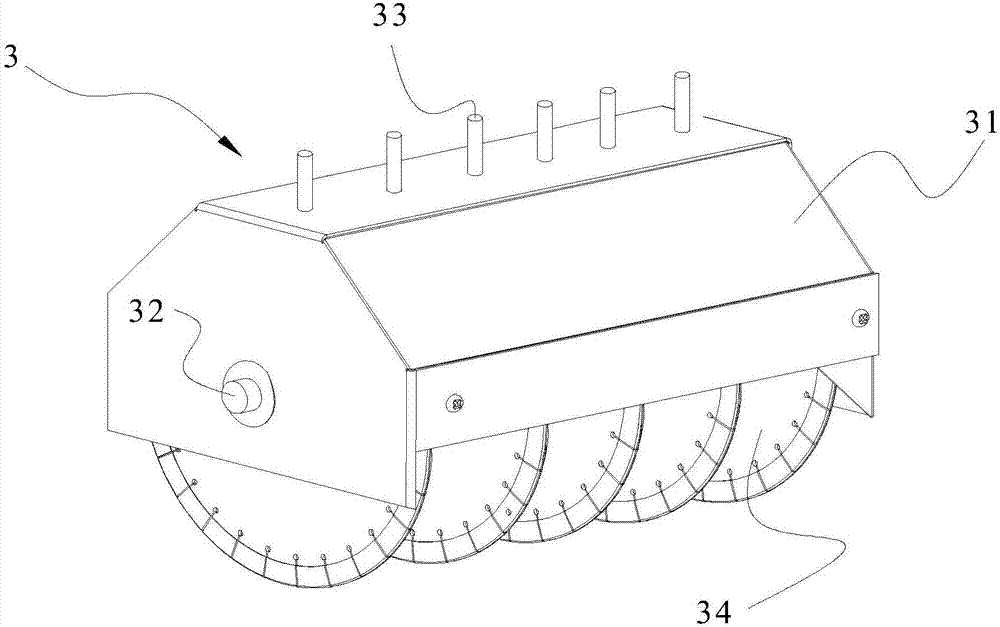

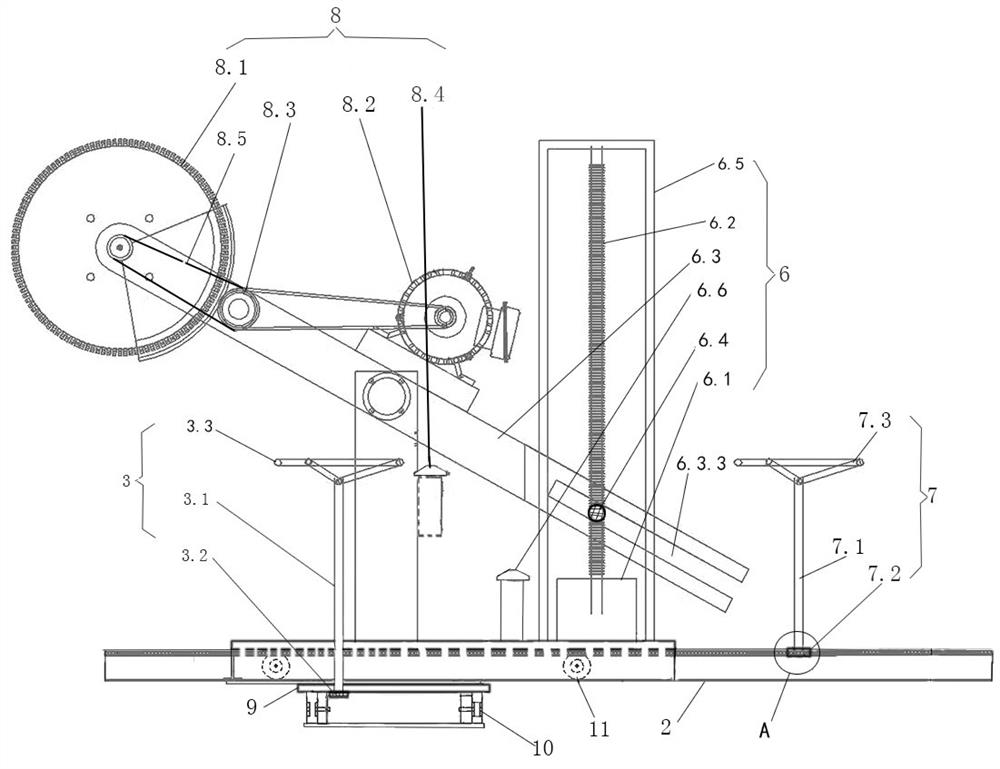

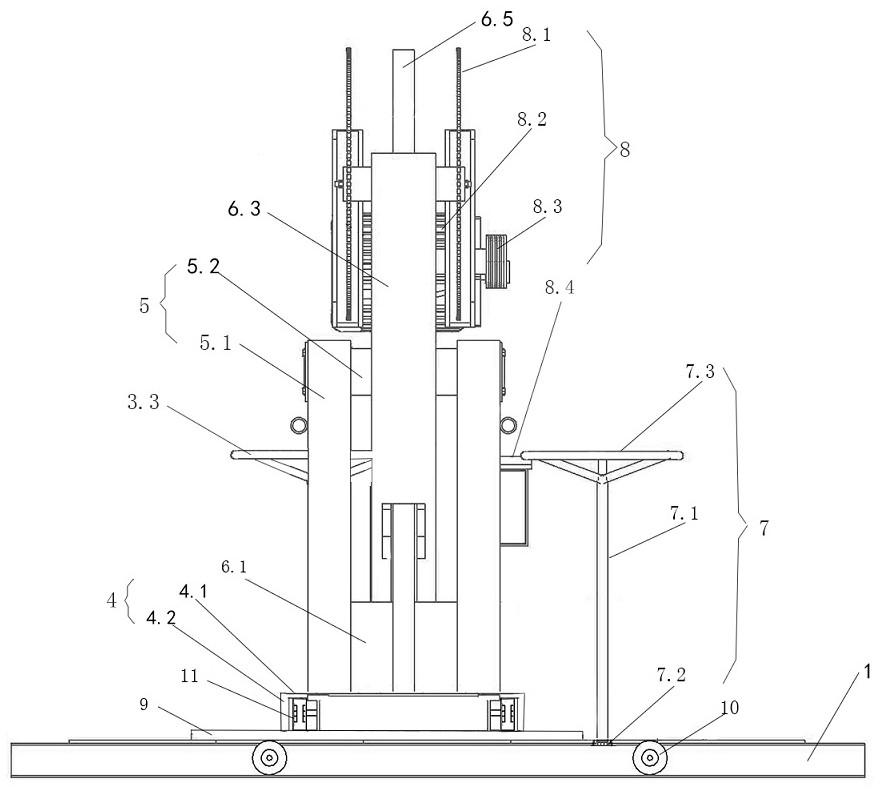

River dredger convenient for clearing weed

InactiveCN108082403AShorten the timeImprove dredging efficiencyWater cleaningWaterborne vesselsLitterEngineering

The invention discloses a river dredger convenient for clearing weed. The river dredger comprises a hull, sliding rails, a support frame, a silt groove, a collection groove and a cutter head, whereinthe sliding rails are fixedly connected to the rear part of the hull; the support frame is embedded between the sliding rails; a conveyor belt is mounted on the oblique side of the support frame; a plurality of fixing plates are distributed on the surface of the conveyor belt; curved plates are fixedly connected to the fixing plates; positive inversion motors are fixedly connected to the two sidesof the hull; gears are fixedly connected to the shaft-extension ends of the positive inversion motors; a guide plate is hinged to the bow section of the hull; a dredging plate is fixedly connected tothe right end of the guide plate; and a weeding motor is fixedly connected to the bottom of the hull. The curved plates are used for scraping silt from the bottom of a river and convey the silt to the silt groove for storage. The underwater depth of the left end of the conveyor belt can be adjusted according to the water depth so that the curved plates can be always in contact with the silt on the bottom of the water, so as to improve the dredging efficiency. The dredging plate and salvaging nails are used for hooking litter from the water surface and putting the litter in the collection groove. The cutter head is used for cutting off the weed in the water.

Owner:宁波市江北义盈工贸有限公司

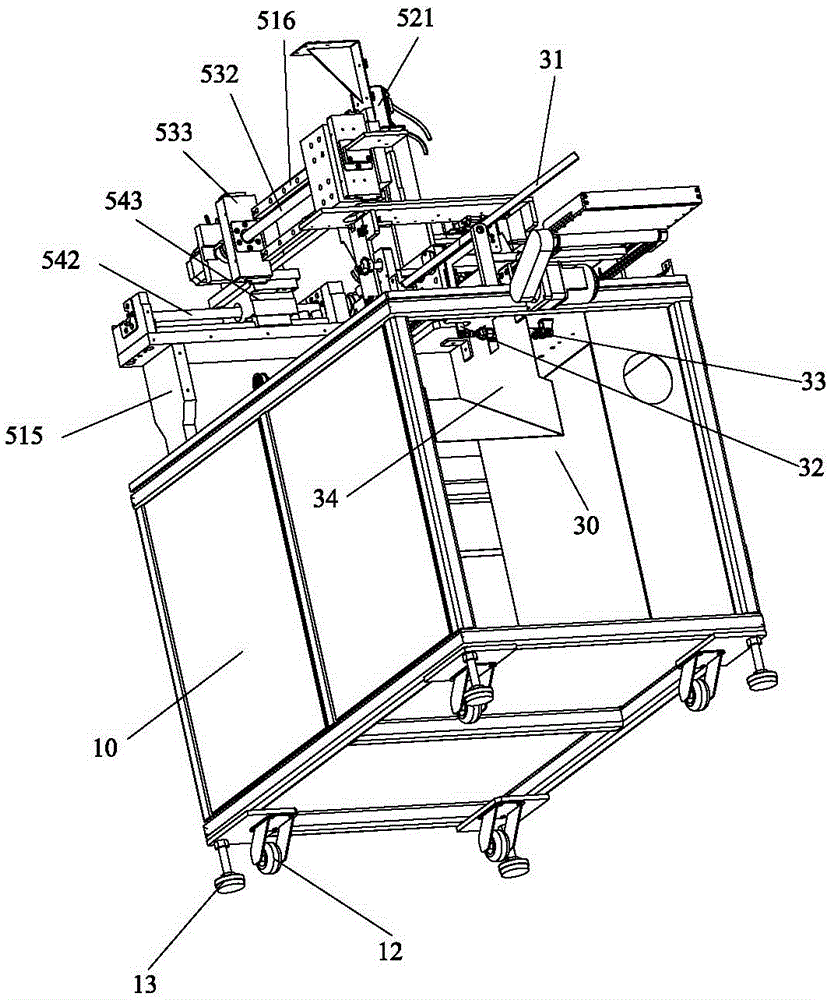

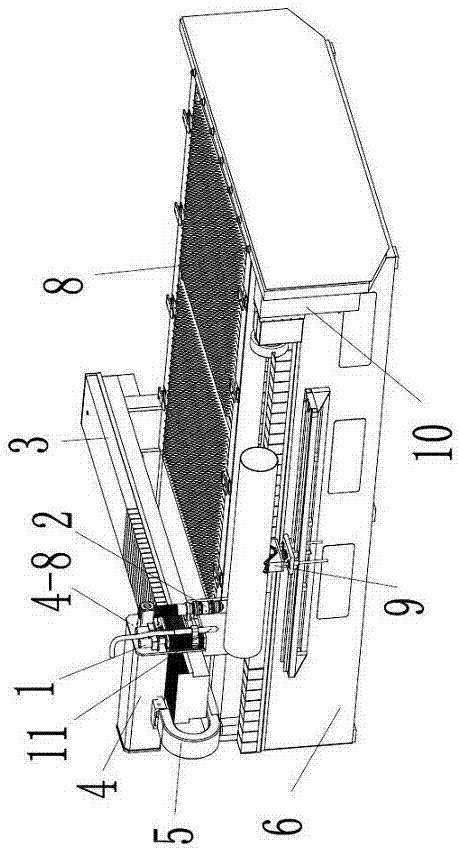

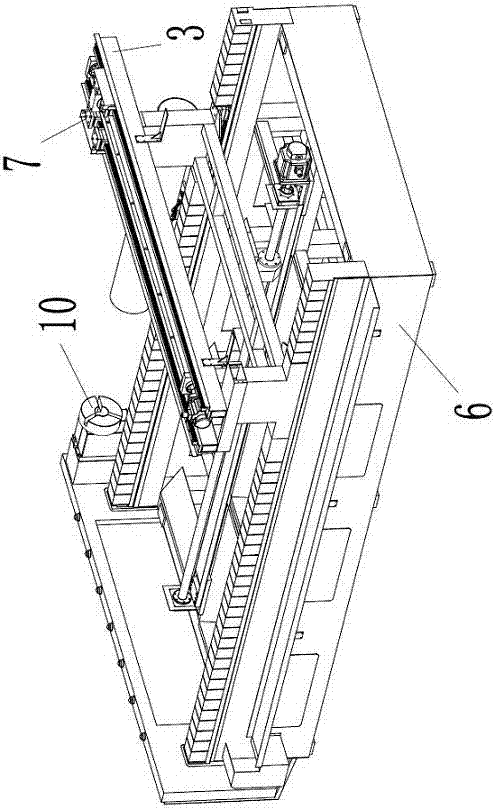

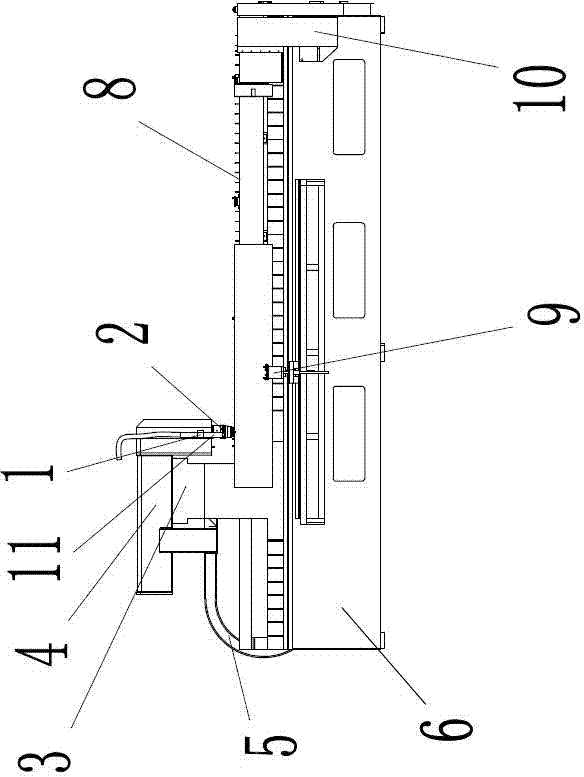

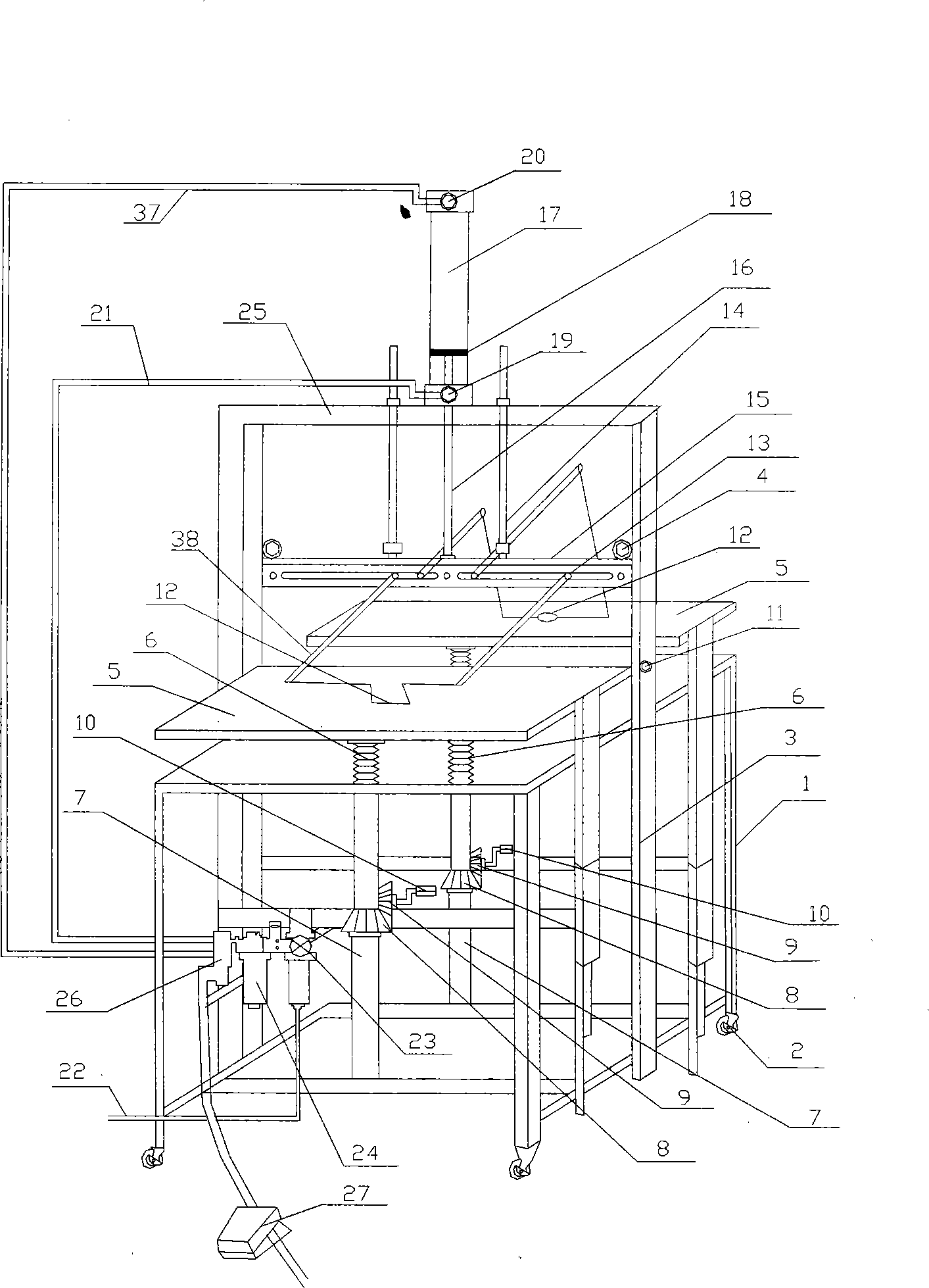

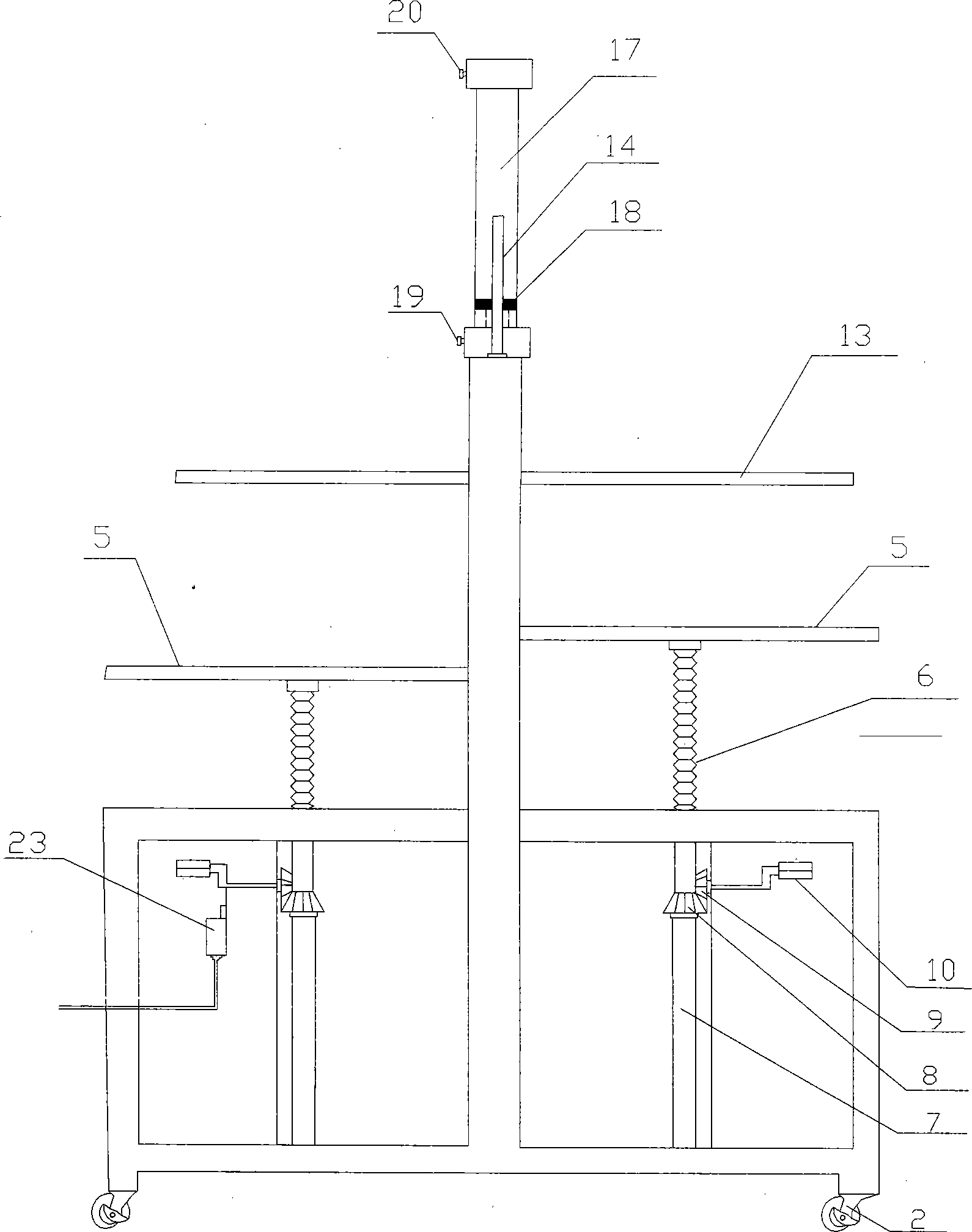

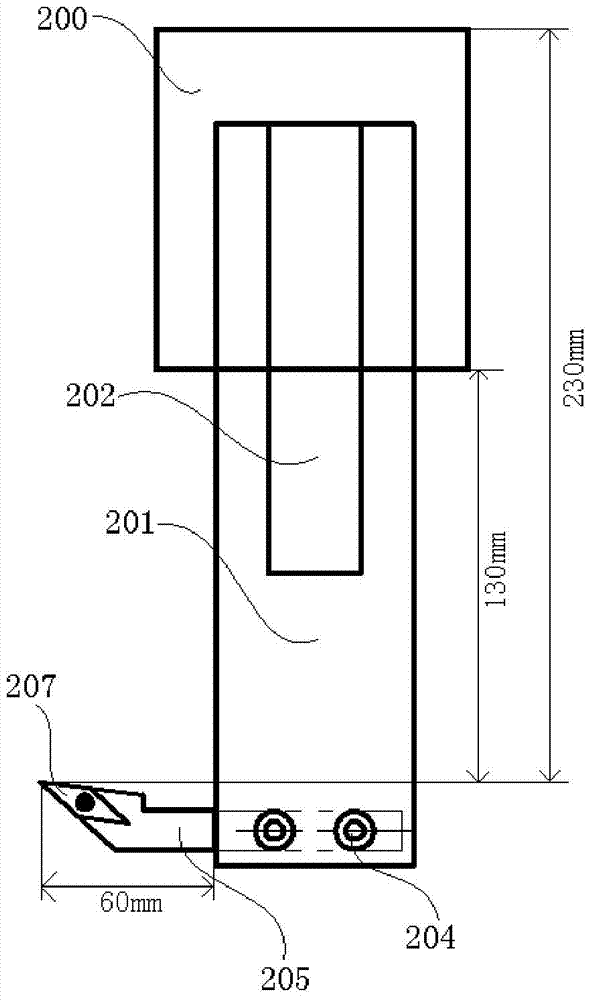

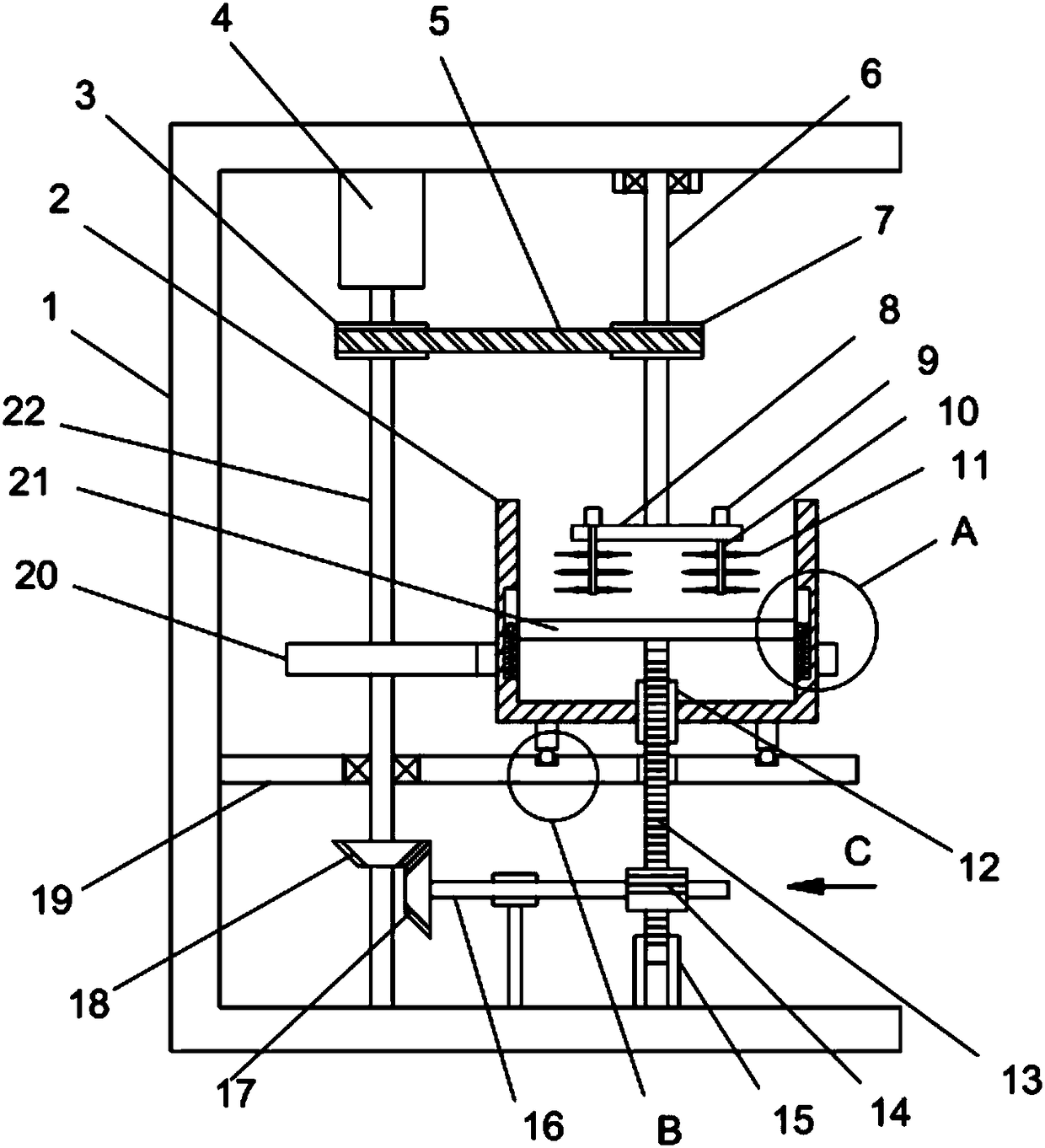

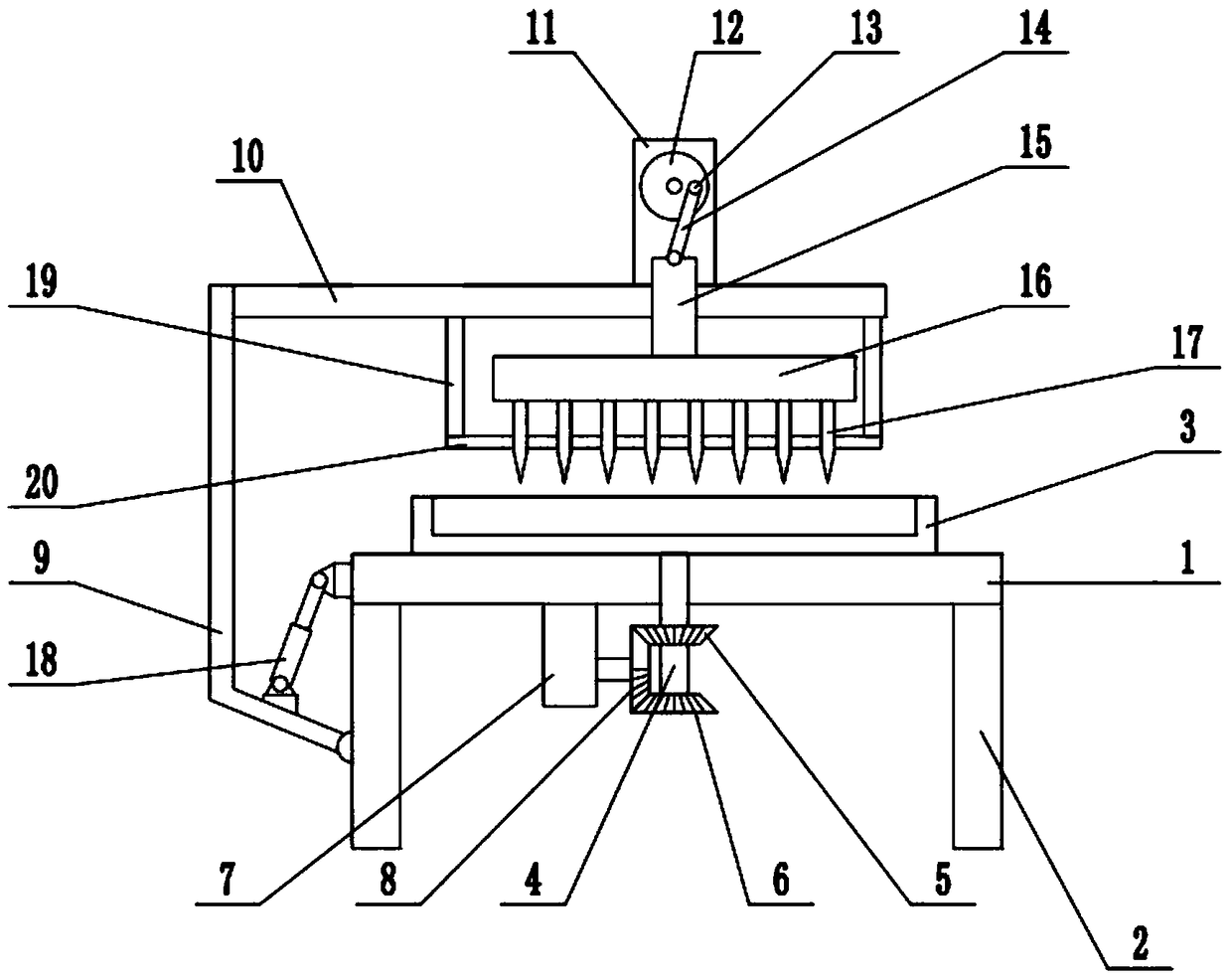

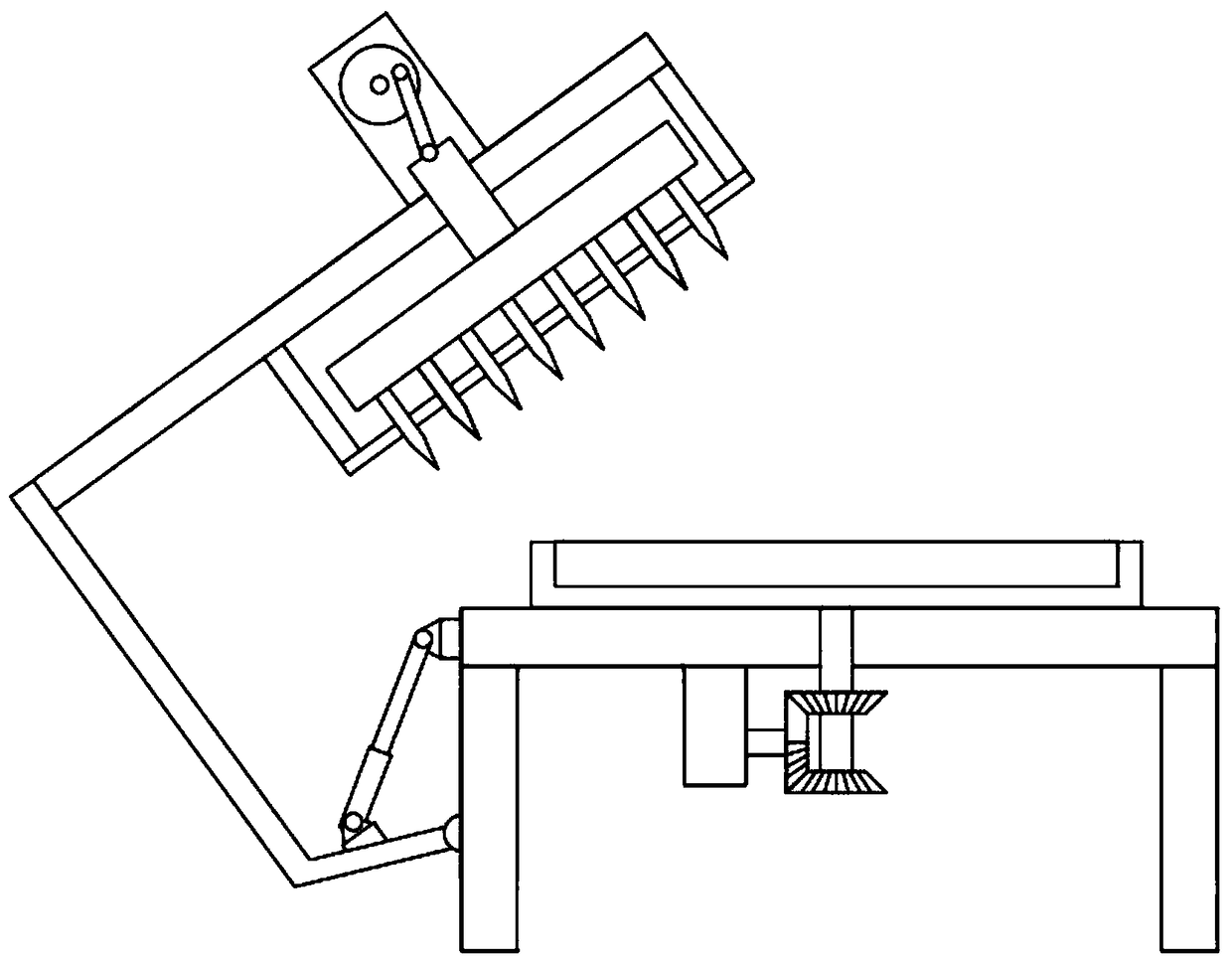

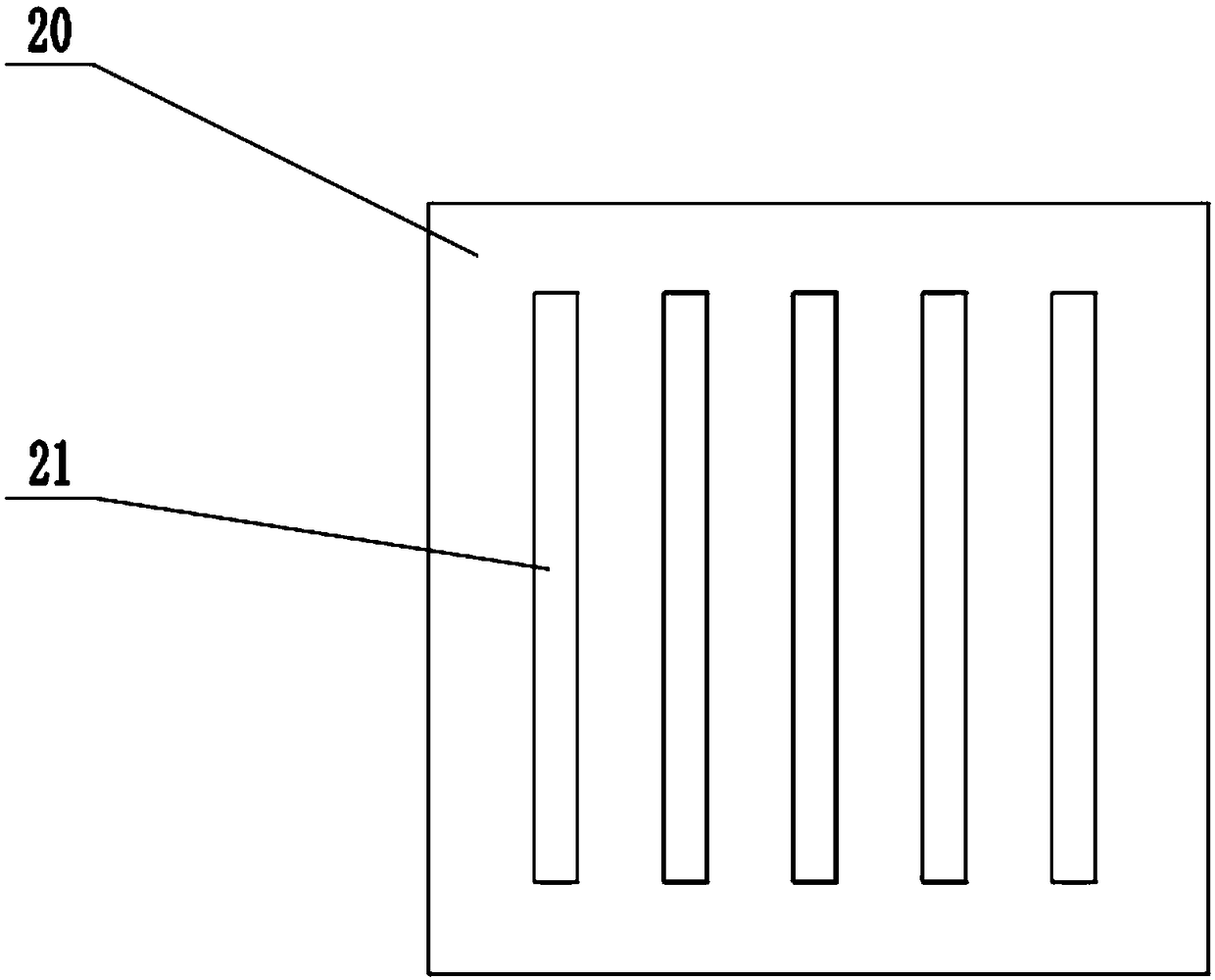

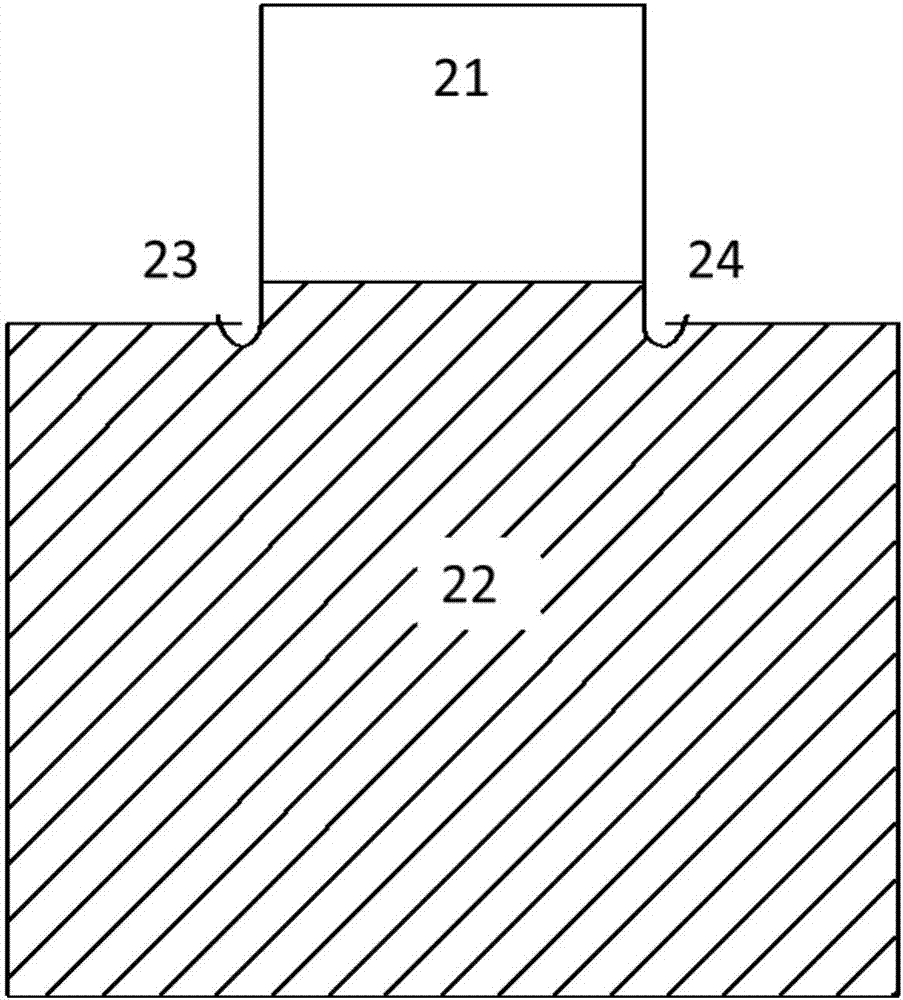

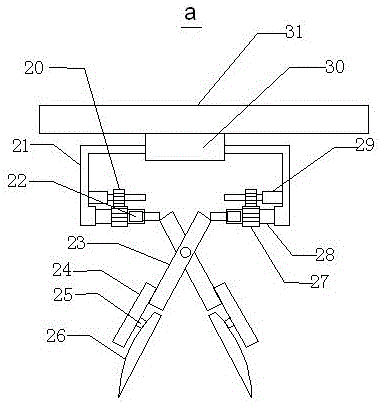

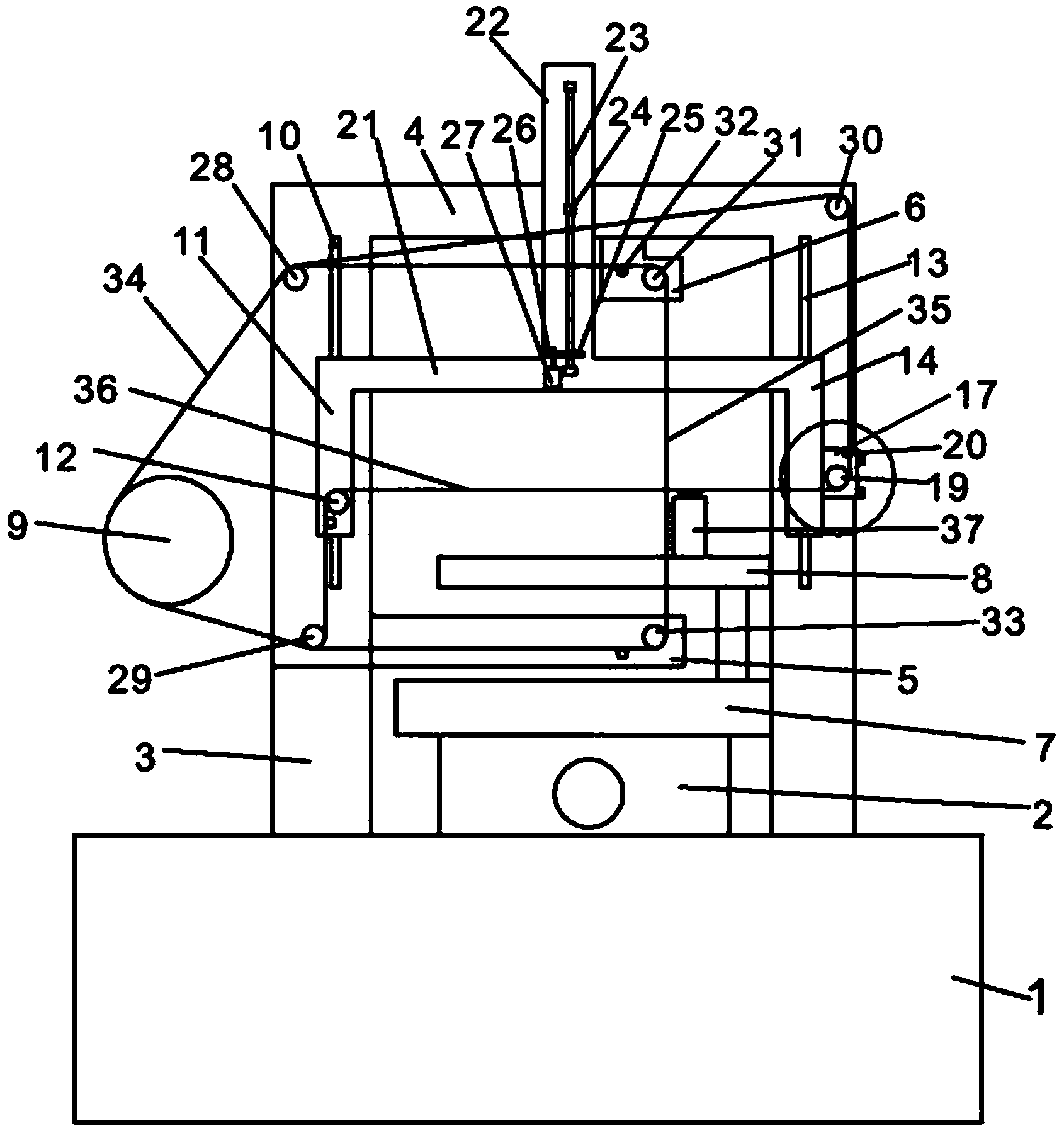

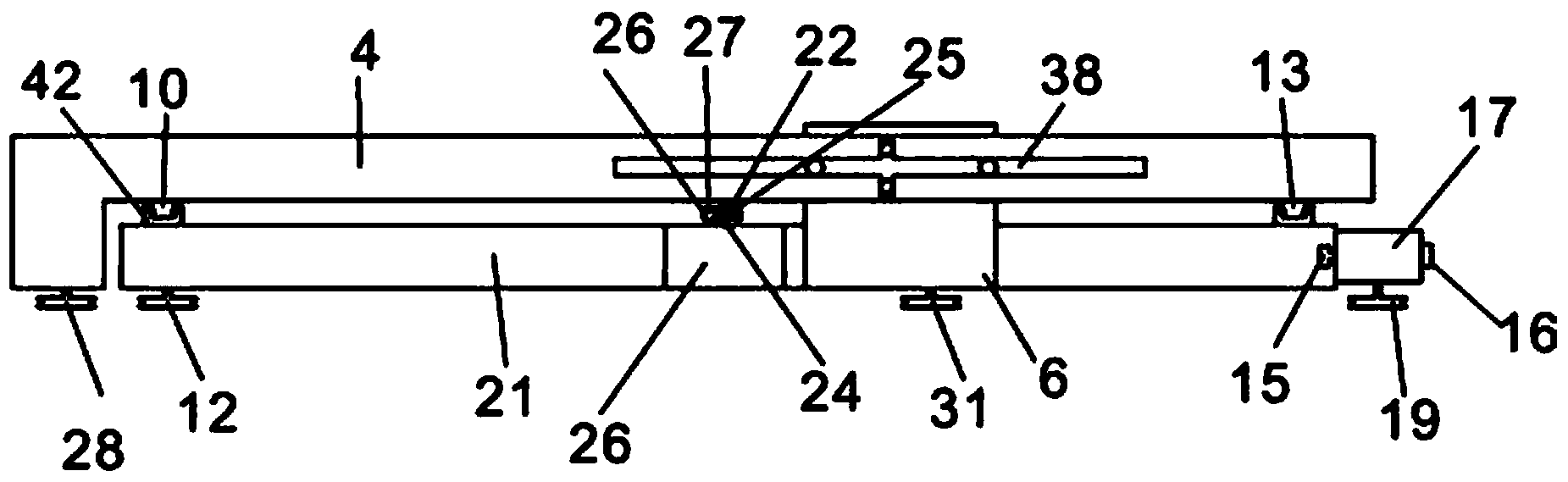

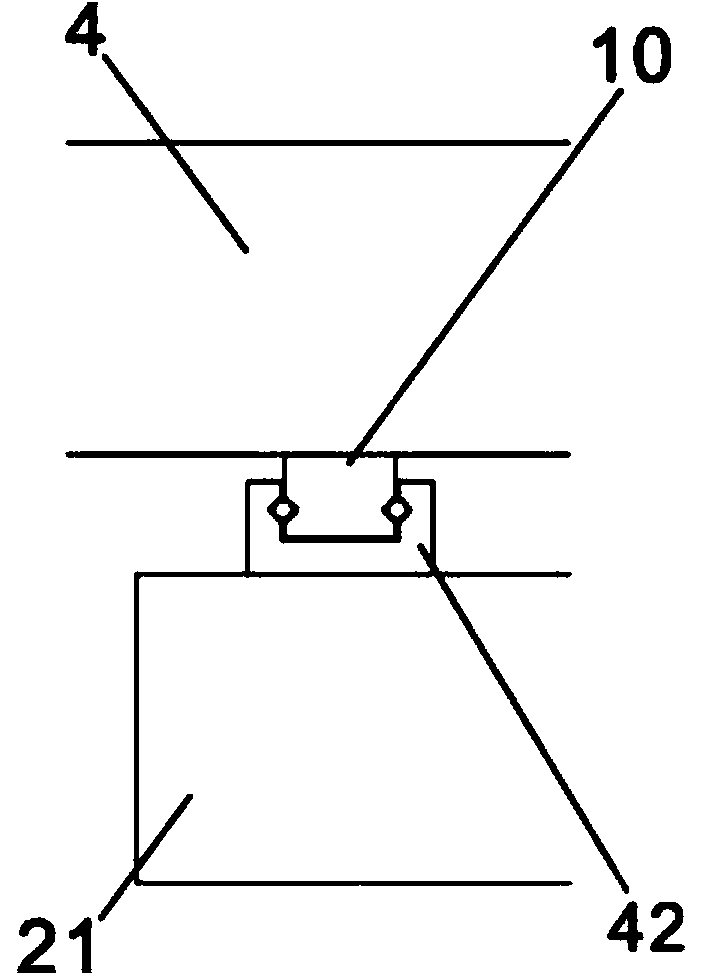

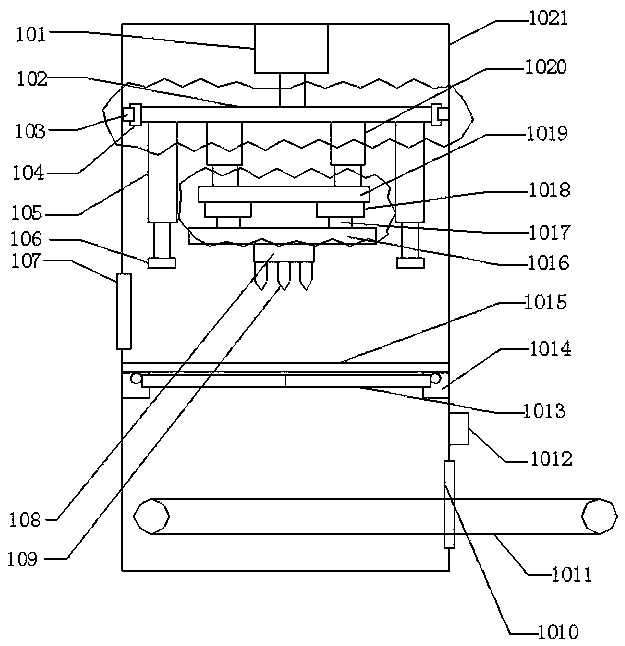

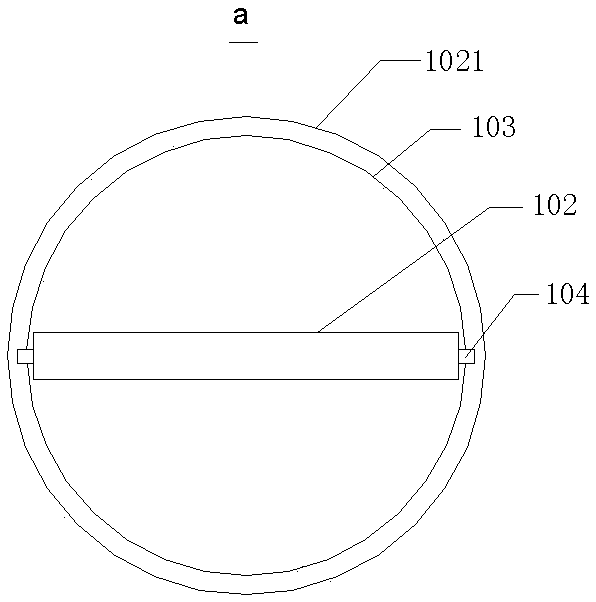

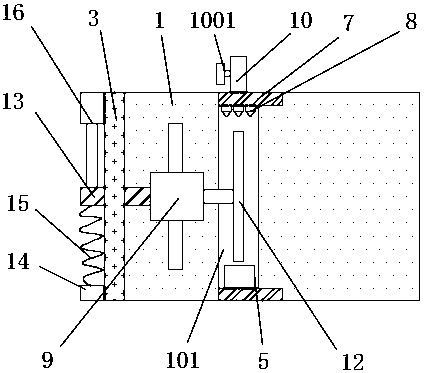

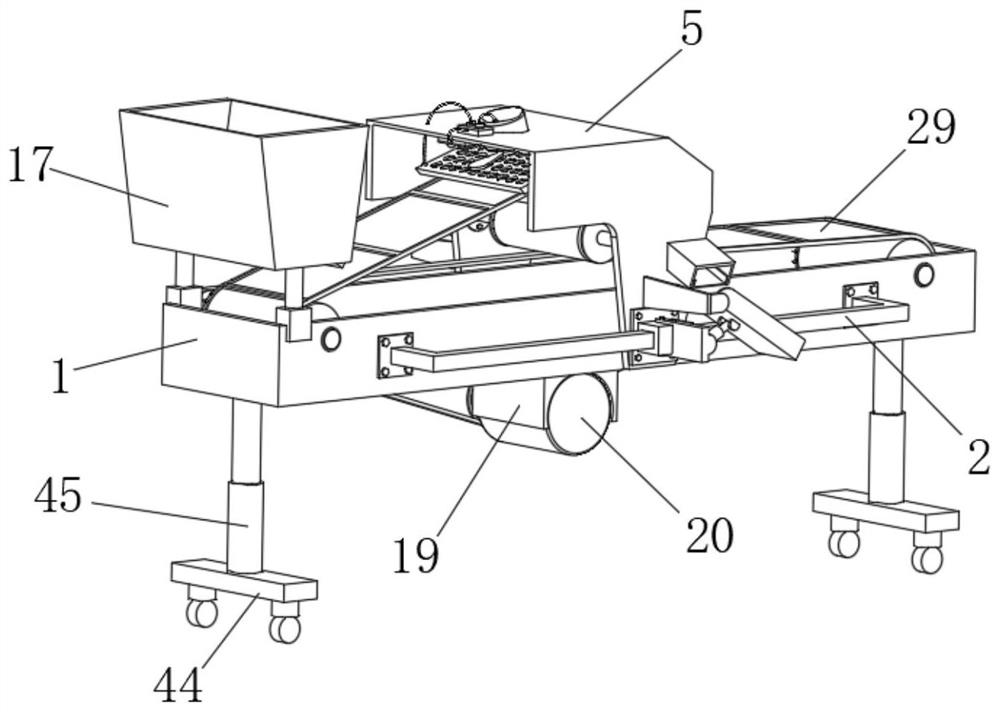

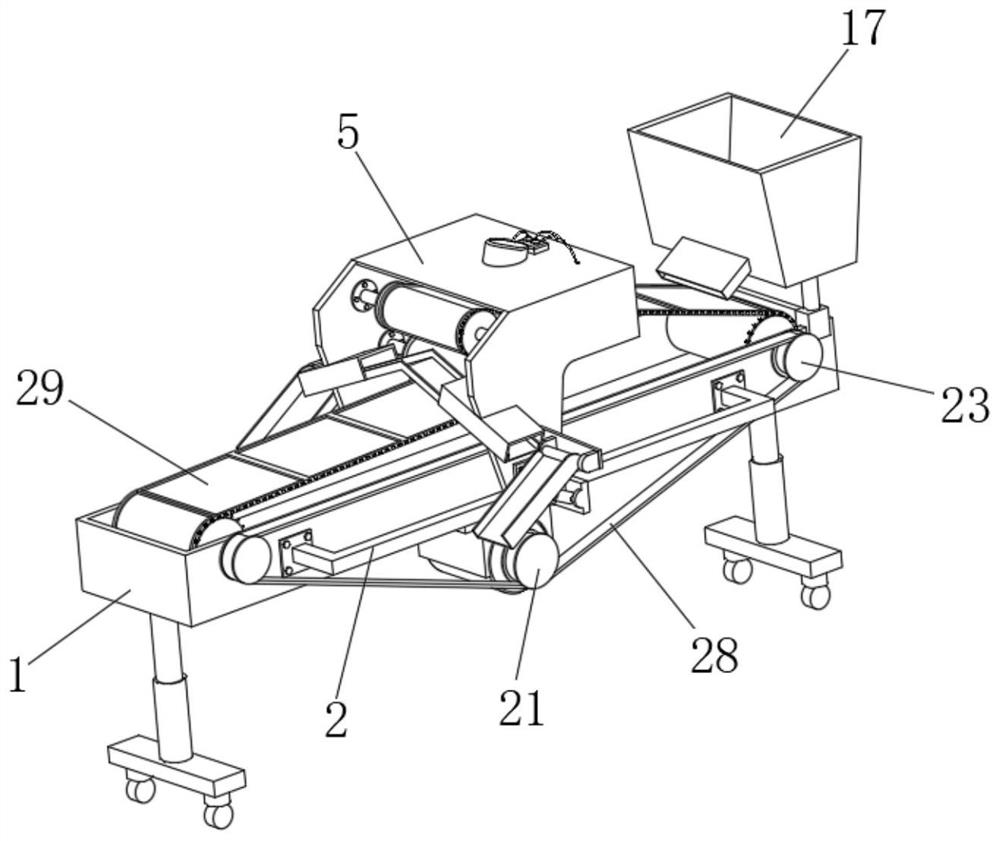

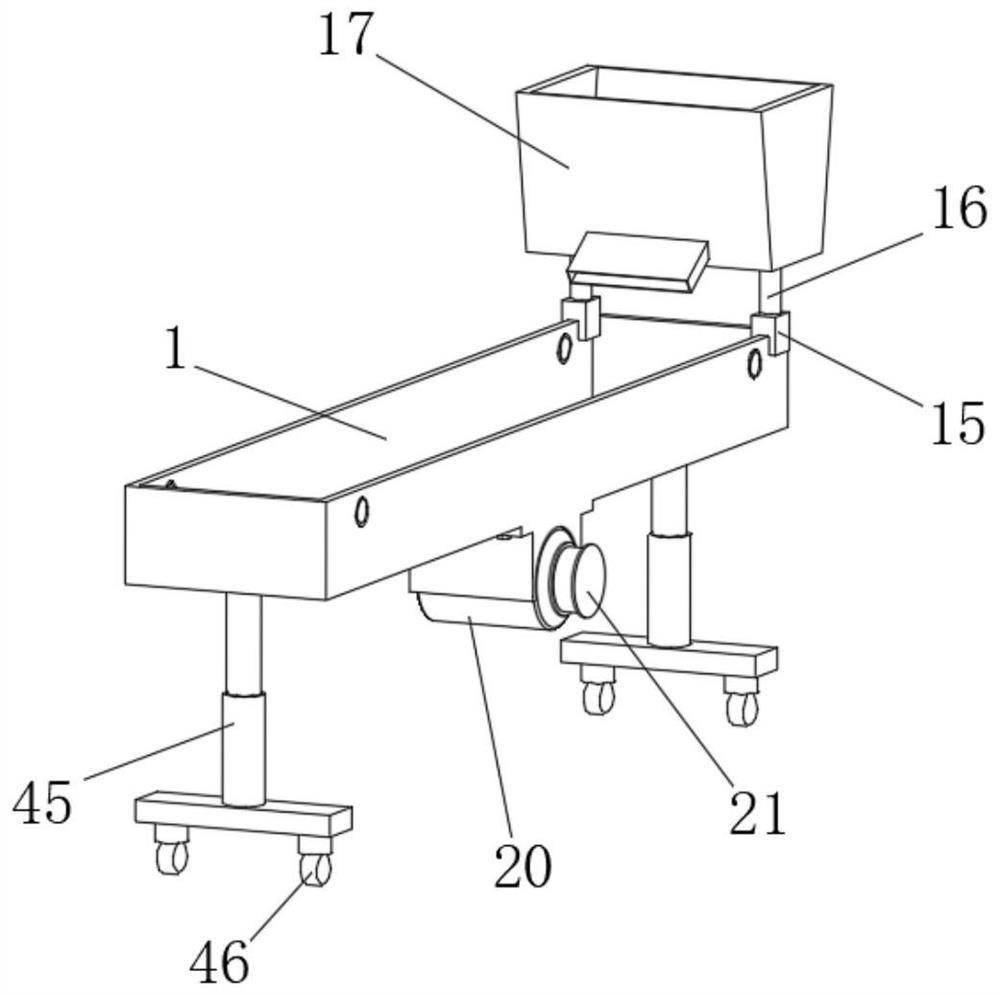

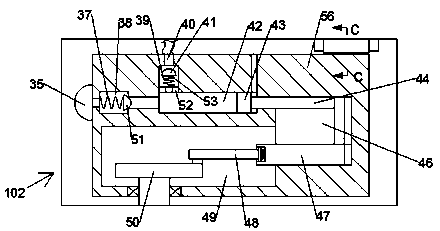

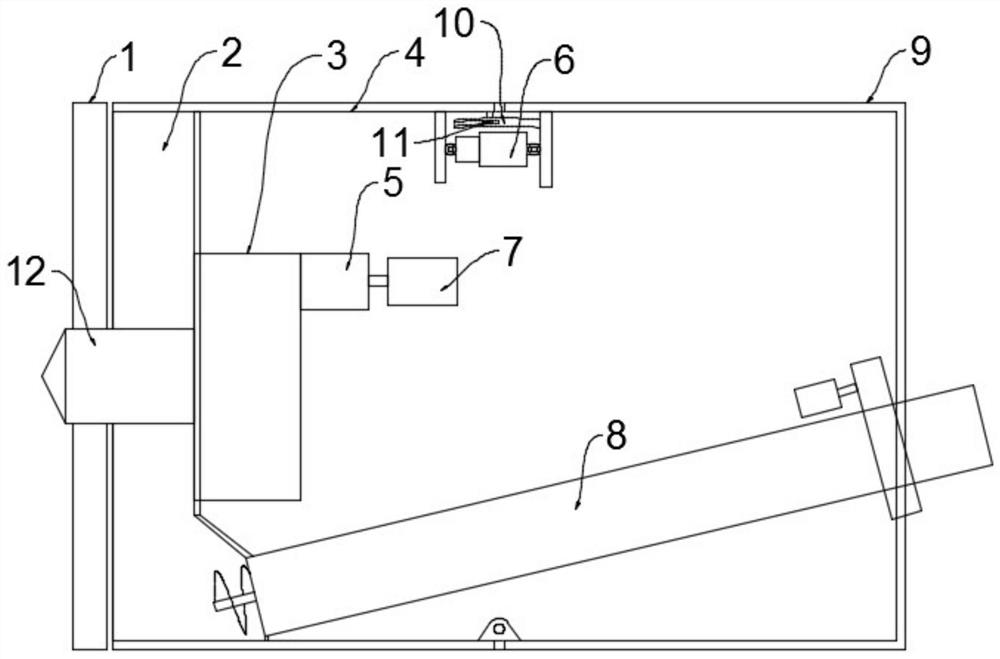

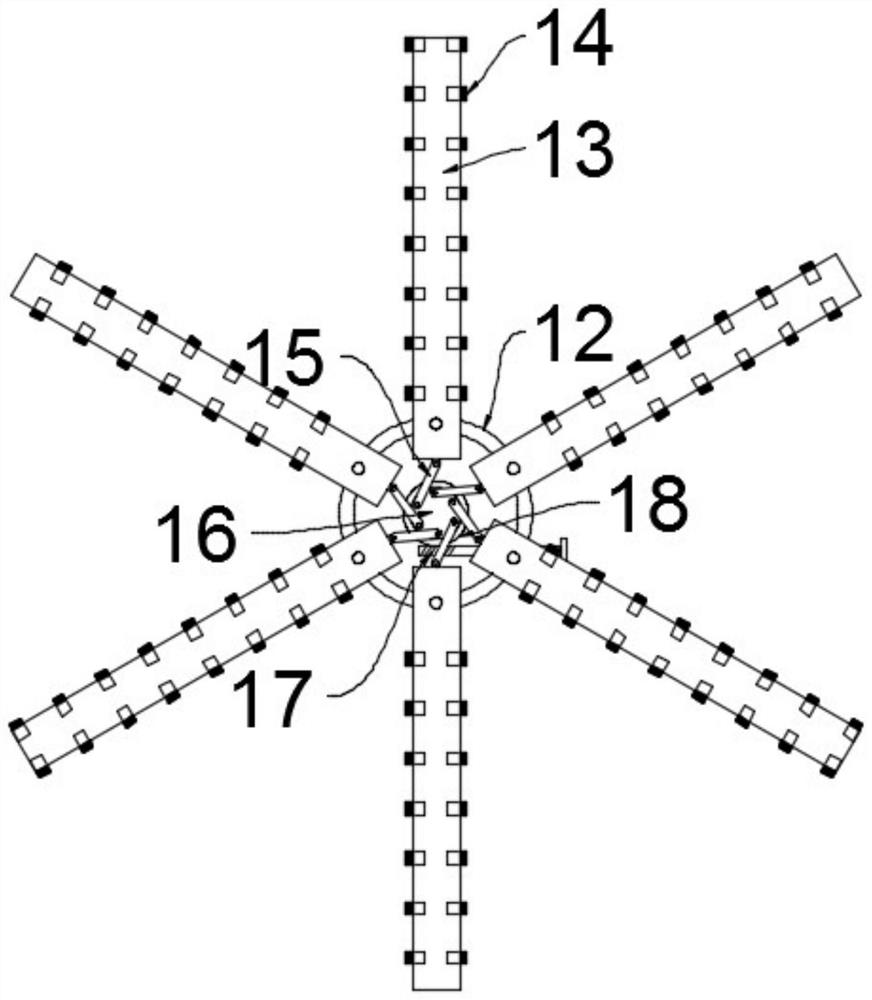

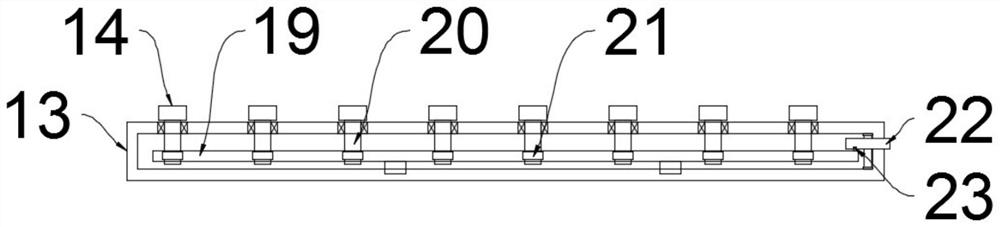

Full-automatic board separating machine

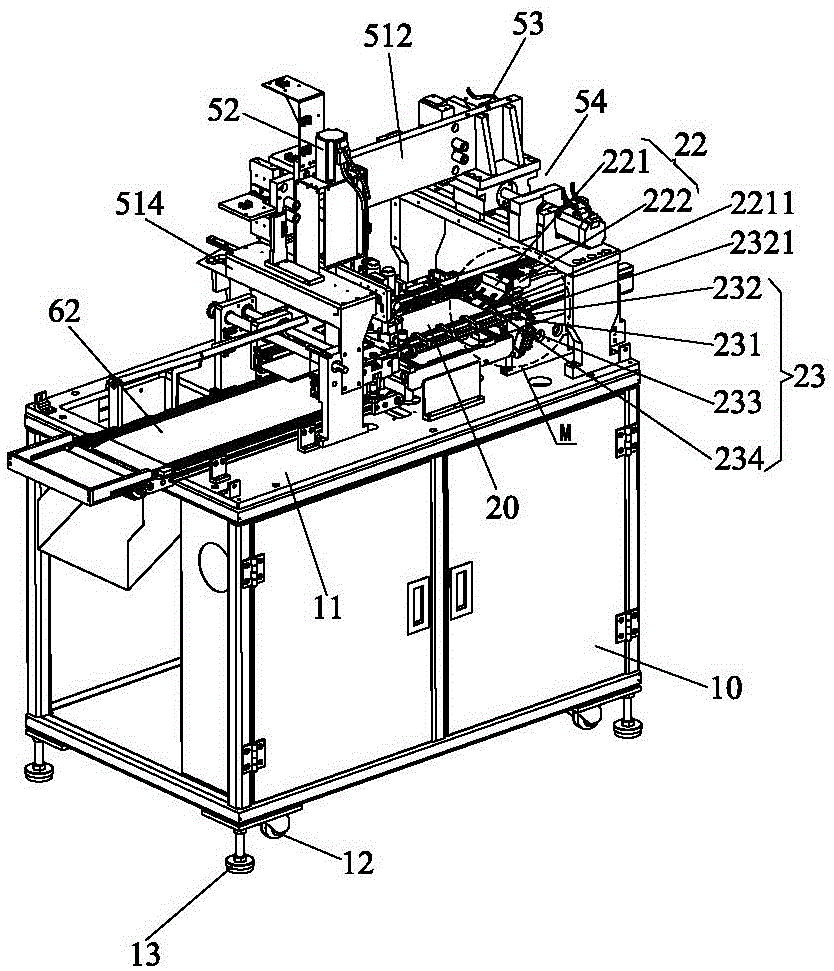

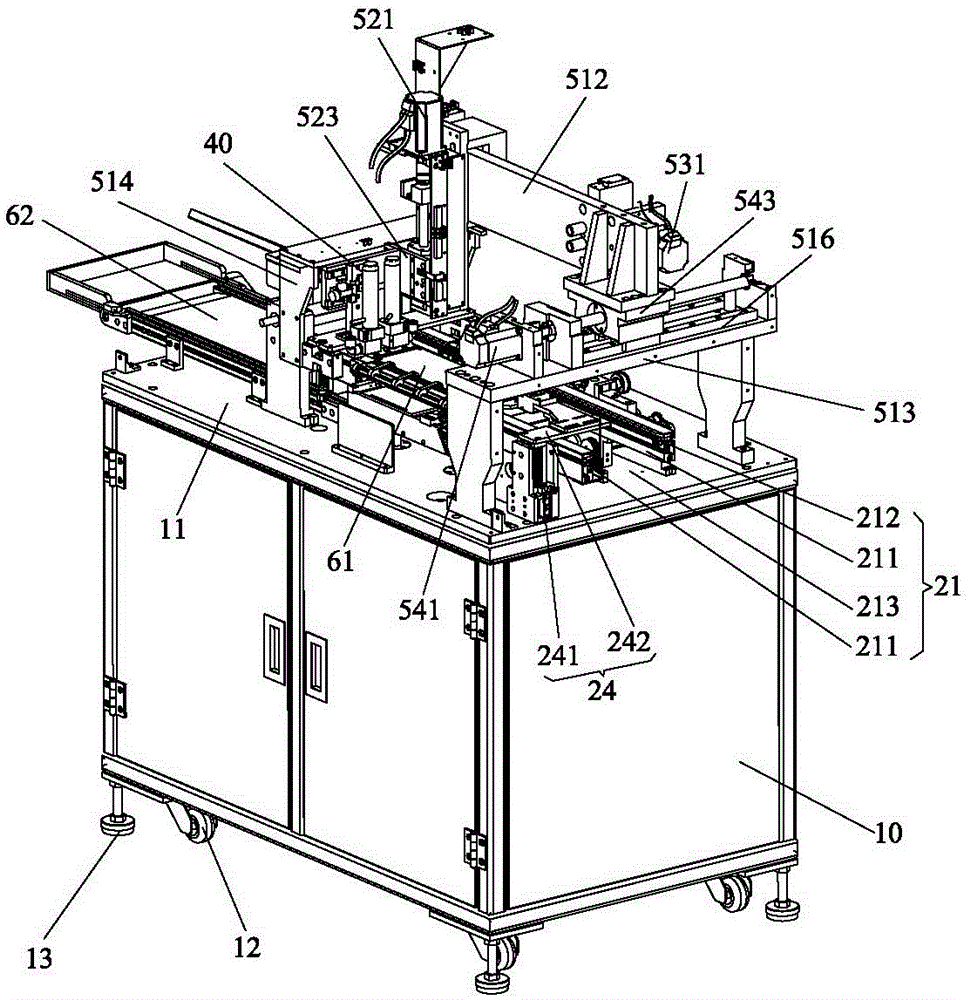

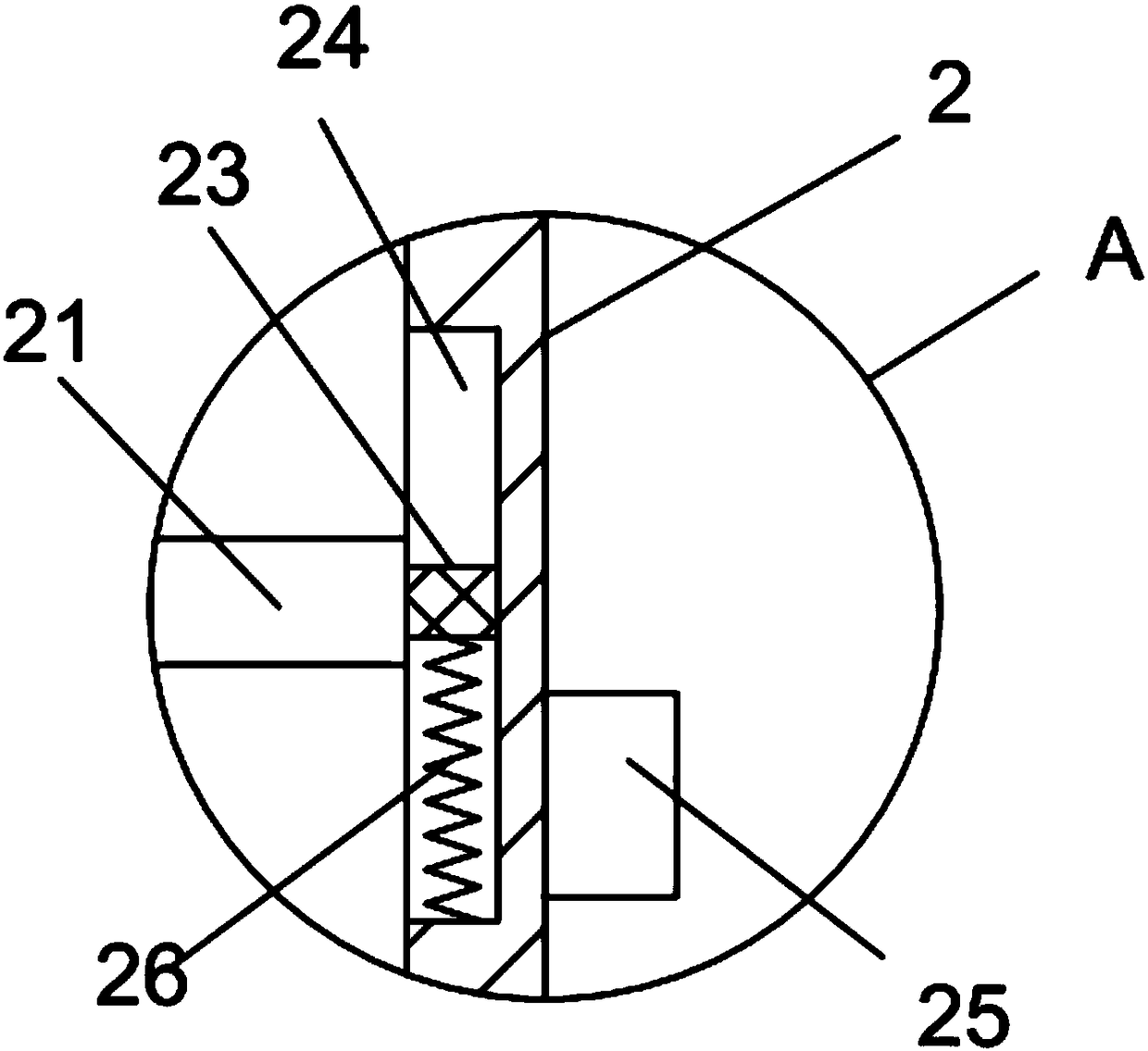

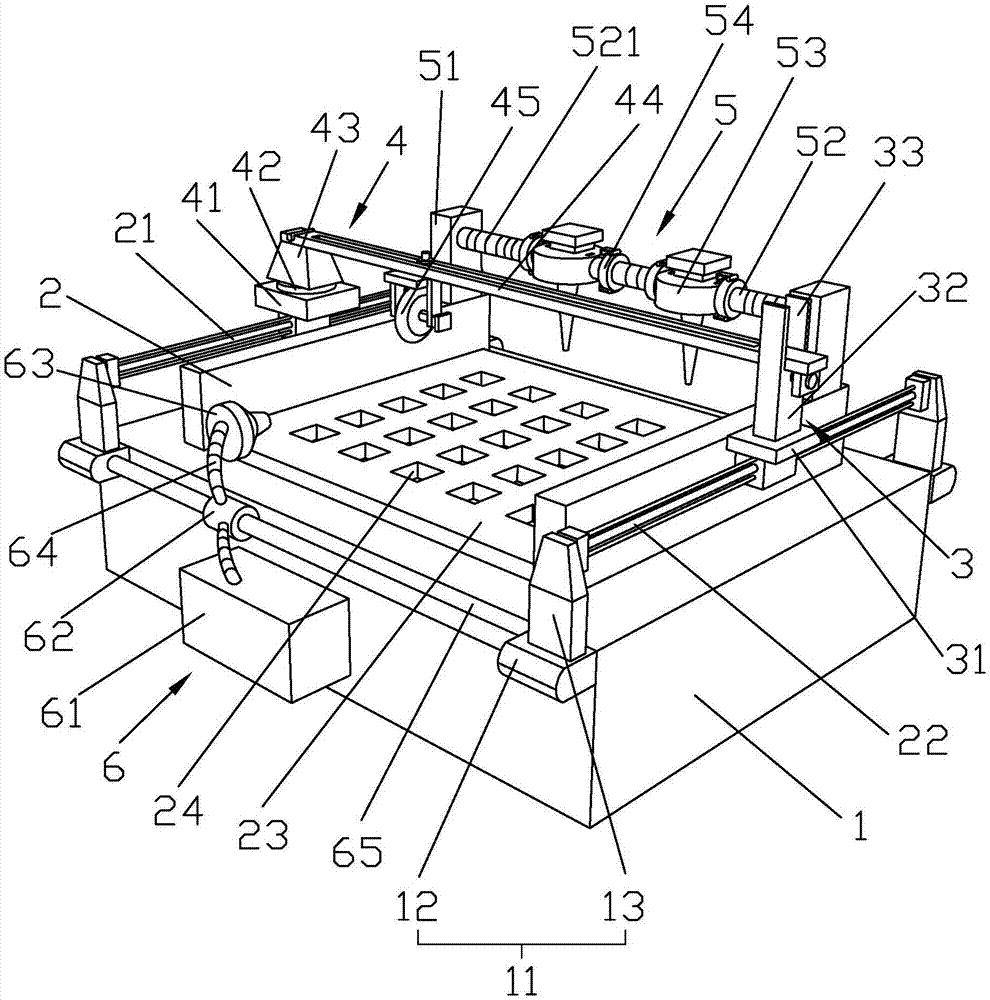

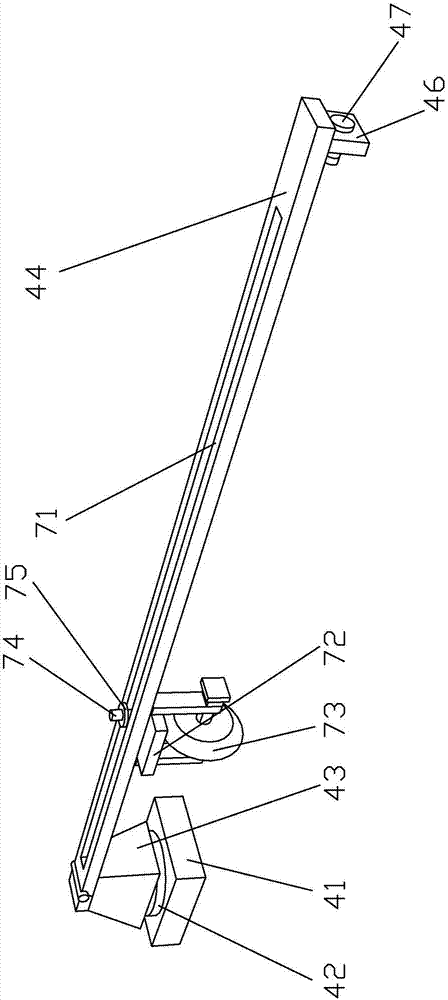

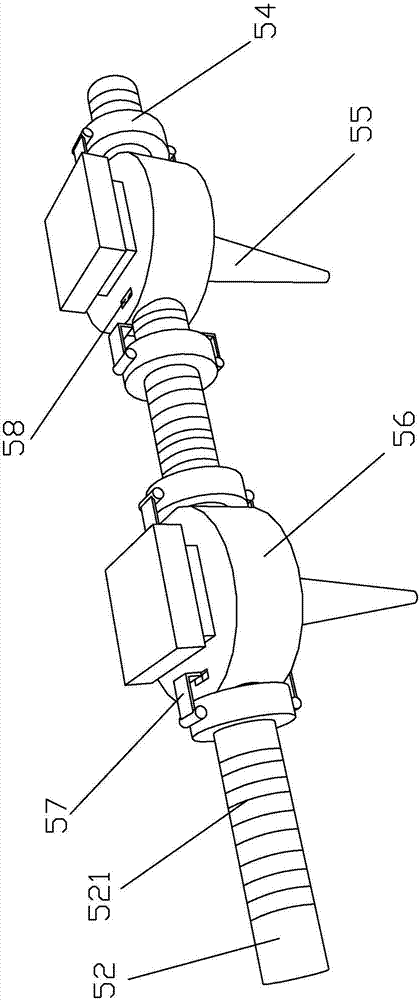

InactiveCN105150251AReduce the amount of manual laborHigh split efficiencyMetal working apparatusProcess engineeringWaste material

The invention discloses a full-automatic board separating machine. The full-automatic board separating machine comprises a machine base, a feeding device, a waste material collecting mechanism, cutting tools, a moving device and a conveying device. The feeding device is used for conveying circuit boards to be cut, the waste material collecting mechanism is used for collecting cutting waste materials, the moving device is used for driving the cutting tools to move, and the conveying device is used for conveying the cut circuit boards. In this way, the feeding device, the waste material collecting mechanism for collecting the cutting waste materials, the cutting tools, the moving device driving the cutting tool to move and the conveying device for conveying the cut circuit boards are combined to form the board separating machine, the board separating machine achieves feeding, cutting, waste material collecting and circuit board conveying automation, and the sum of labor is reduced; the two cutting tools are used for cutting at the same time, and therefore the board separating efficiency is improved effectively; in addition, the driving mode of moving the cutting tools in multiple directions enlarges the cutting range, and the board separating machine can cut the large circuit boards and is wider in application range.

Owner:ACBEL ELECTRONICS DONG GUAN

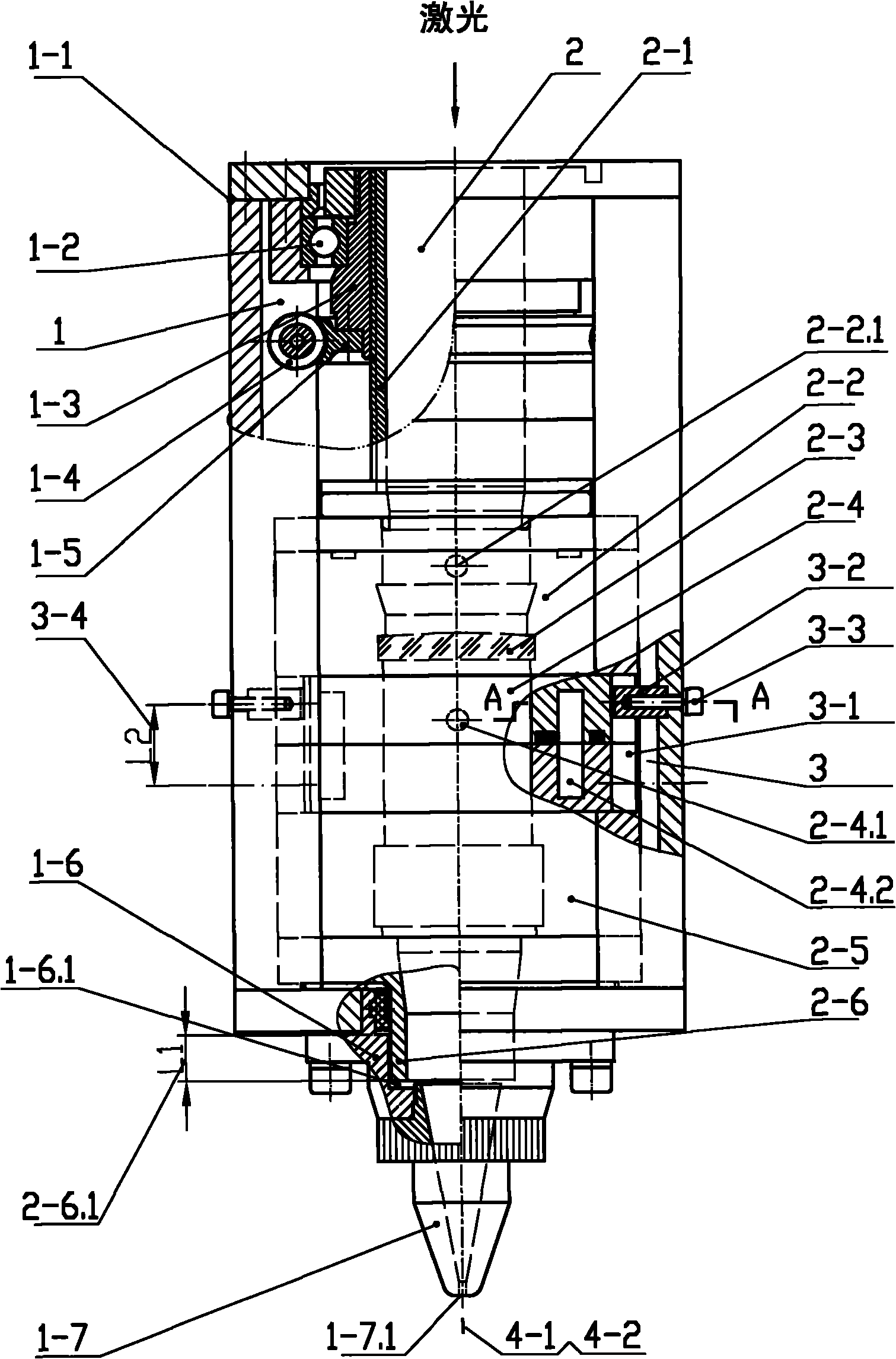

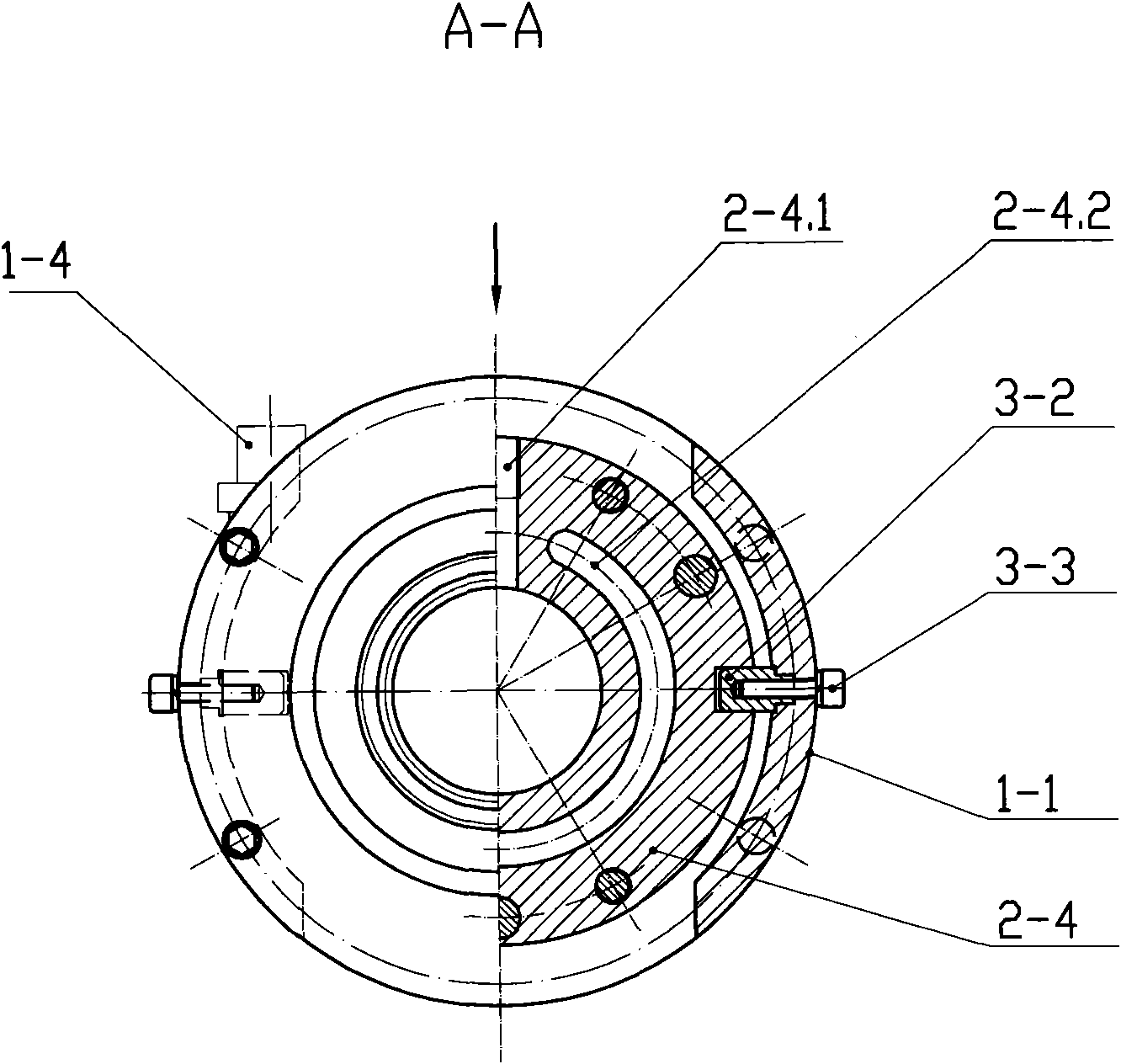

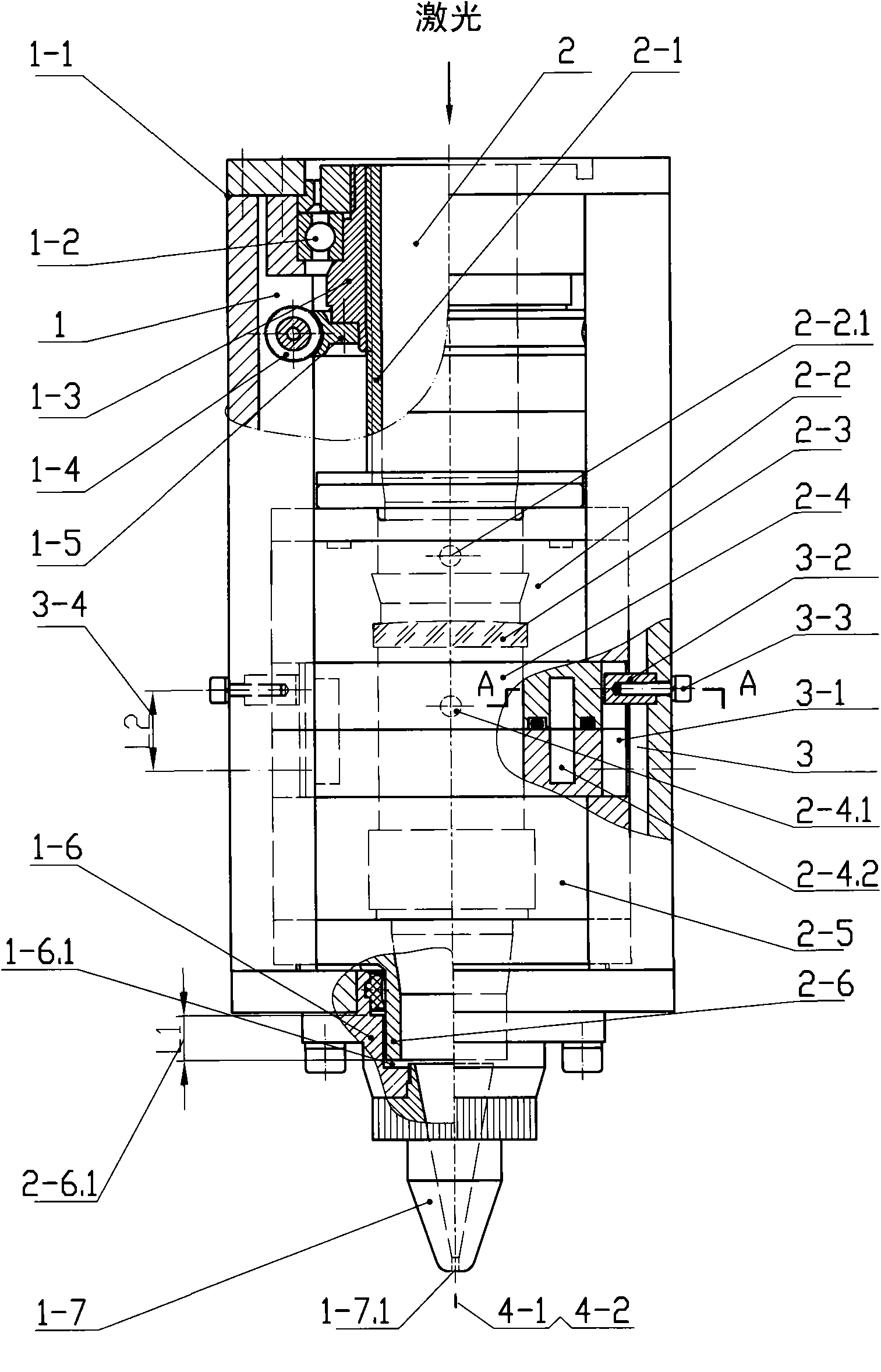

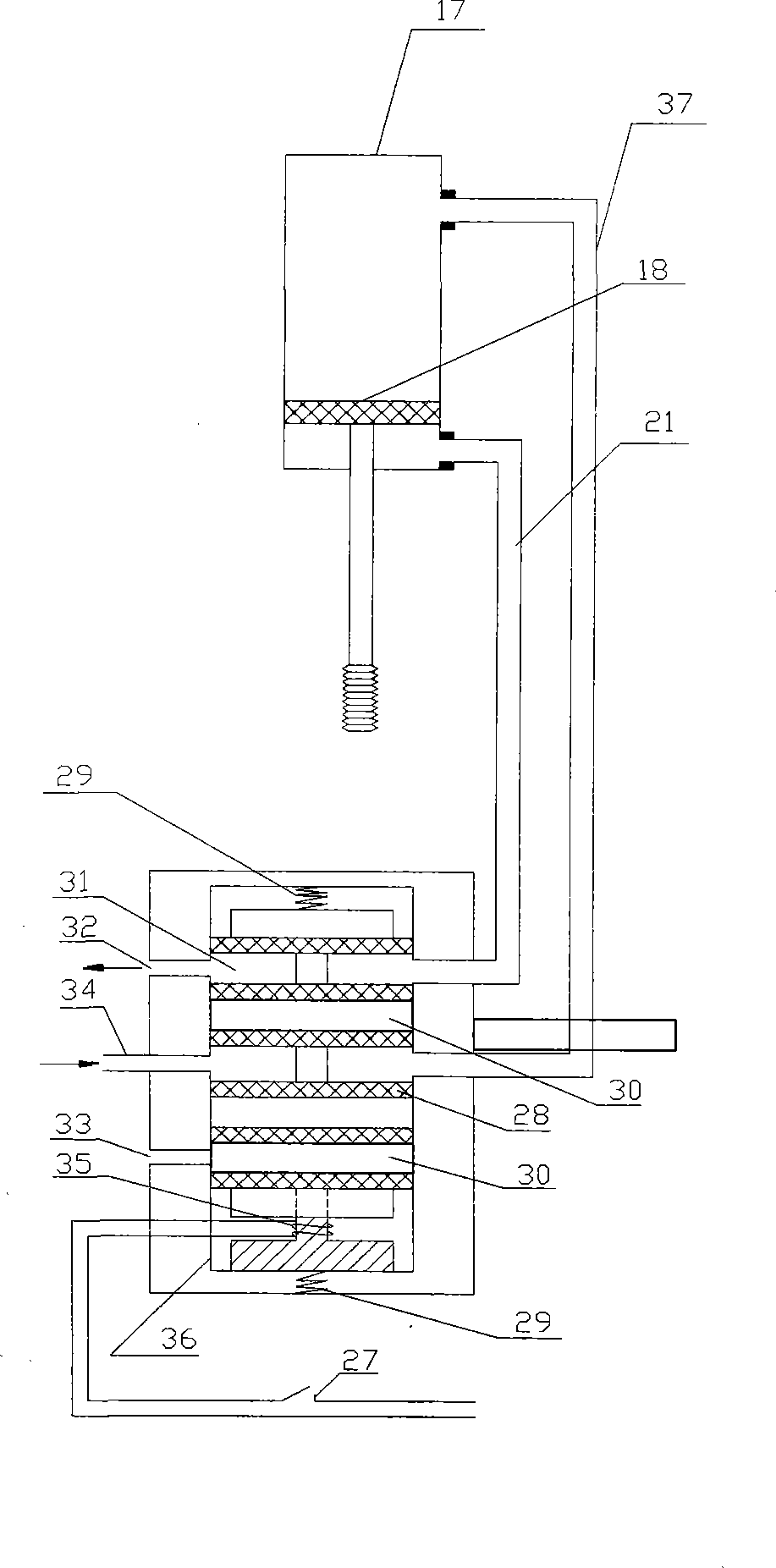

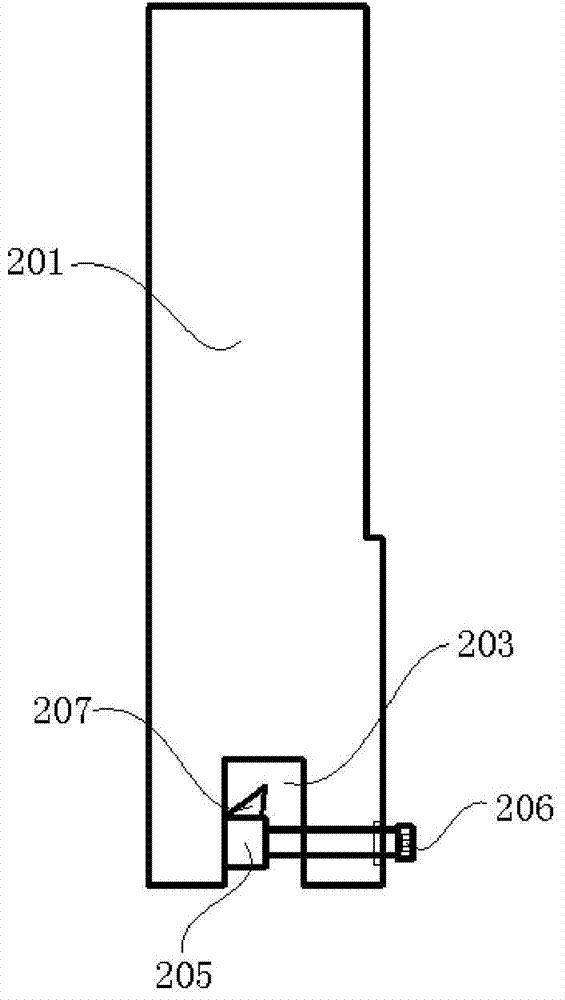

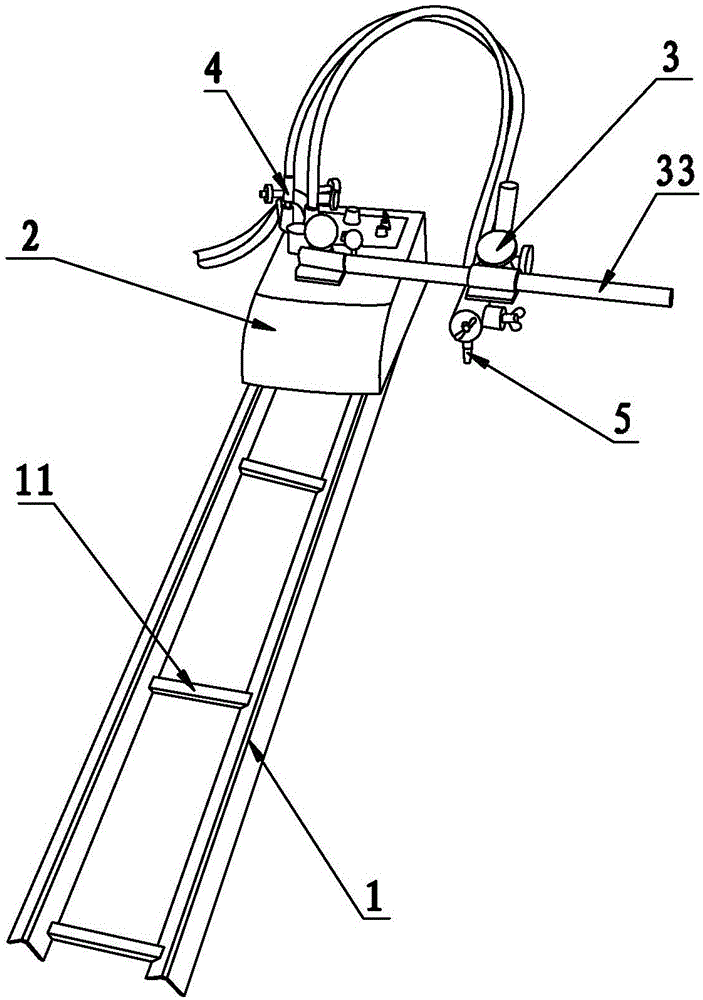

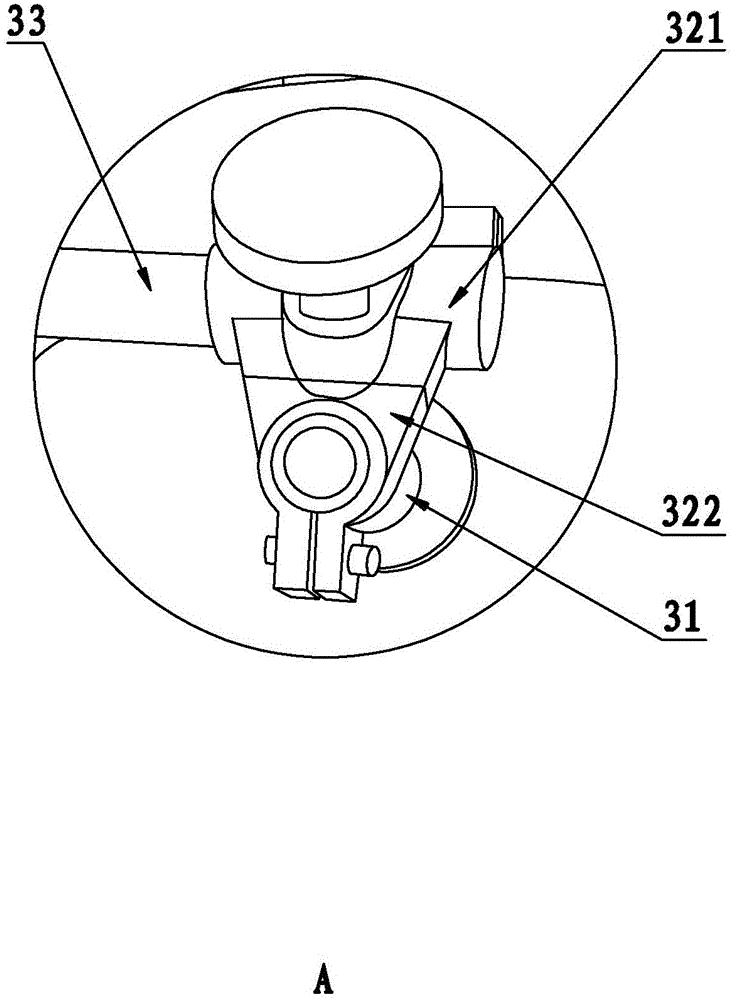

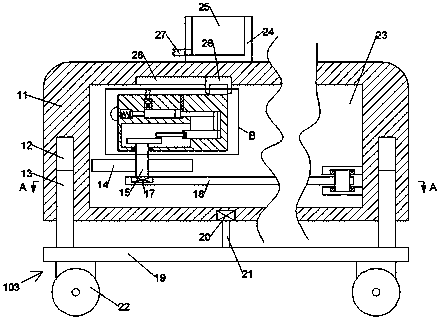

Automatic focus numerical control laser cutter

InactiveCN101837517AExpand the cutting rangeImprove stability and precisionLaser beam welding apparatusEngineeringWater tanks

The invention discloses an automatic focus numerical control laser cutter, which comprises a framework mechanism (1), a focusing mechanism (2), a lens seat mechanism and guide mechanisms (3) consisting of guide slots (3-1), guide keys (3-2) and locking screws (3-3). The framework mechanism comprises a fixed sleeve (1-1), a connecting seat (1-6) and a nozzle (1-7); the focusing mechanism comprises a worm (1-4), a worm gear (1-5), a bearing (1-2), a nut (1-3) and a trapezoidal thread sleeve (2-1); the lens seat mechanism comprises an upper lens seat (2-2) of a blow hole (2-2.1), a focusing lens (2-3) and an aqueous vapor seat (2-4) which consists of an upper part and a lower part and is provided with a blow hole (2-4.1) and an annular cooling water tank (2-4.2), a lower lens seat (2-5) and a ventilation seat (2-6); and the guide mechanisms are arranged in the aqueous vapor seat and bilaterally and symmetrically distributed by taking an axis of the cutter as a center. The cutter with the structure can realize high-precision, high-efficiency and smooth automatic focusing and has large focusing range and good focusing effects so as to expand the thickness range of plates to be cut.

Owner:LONGYAN LISHANG PRECISION MACHINERY

Laser plasma dual-use cutting machine

ActiveCN103157912AQuality improvementImprove dustproof effectWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlTorch

The invention discloses a laser plasma dual-use cutting machine which comprises a beam which is connected with a lathe bed in a transmission mode. A drag plate is connected with the beam in the transmission mode. A working table and a drag chain are fixedly connected with the lathe bed. An yttrium aluminum garnet (YAG) solid laser generator is arranged on the drag plate. The YAG solid laser generator is provided with a light dipping supporting plate. Two sets of lifting mechanisms are connected with the light dipping supporting plate in an installing mode, one set of lifting mechanisms is connected with a double-focal-distance cutting head in the installing mode, and the other set of lifting mechanisms is connected with a plasma cutting torch in the installing mode. The lathe bed is further provided with a rotary cutting pipe chuck and a rotary cutting pipe supporting frame. A laser cutting head and a numerical control plasma cutting head are both arranged on a numerical control cutting machine, and the laser cutting head and the numerical control plasma cutting head are reasonable in structure. Different processing requirements of workpieces can be met by the solid laser generator and the double-focal-distance cutting head, wherein the mirror spacing of the solid laser generator is convenient to adjust, the solid laser generator is good in dust-proof effect, and the double-focal-distance cutting head is capable of changing focal distances rapidly and high in processing precision. The laser plasma dual-use cutting machine particularly conducts cutting on metal tubular products.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

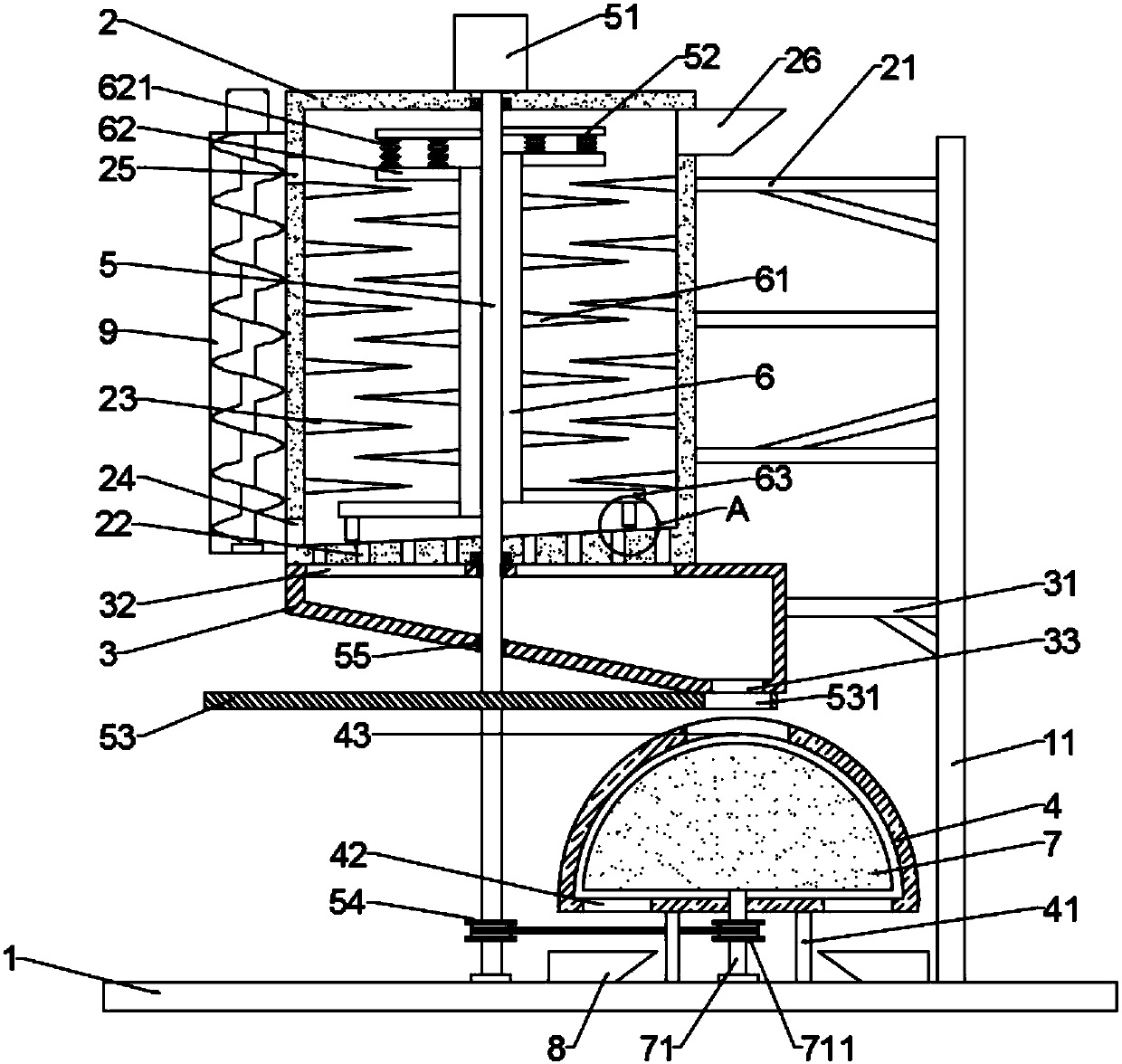

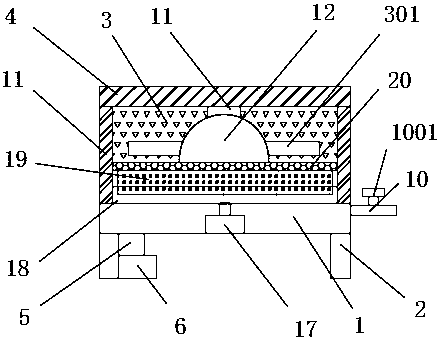

Pulverizing and grinding all-in-one machine for preparing Chinese herbs

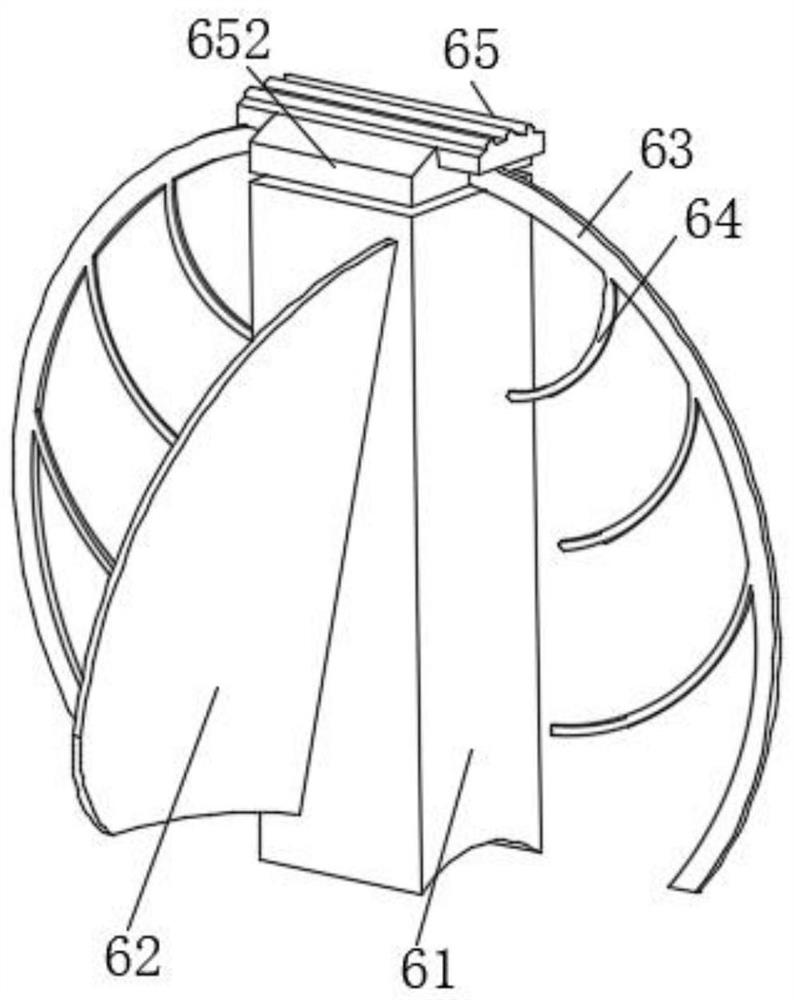

ActiveCN107755050ARealize circular crushingGuaranteed uniformityGrain treatmentsDrive shaftMaterial transfer

The invention discloses a pulverizing and grinding all-in-one machine for preparing Chinese herbs. The pulverizing and grinding all-in-one machine comprises a pulverizing box, a material transfer boxand a grinding shell which are arranged on a base from top to bottom as well as a transmission shaft connected with the base in a rotating manner; the transmission shaft is disposed on the center of the pulverizing box, the transmission shaft is connected with a plurality of tool posts in a sliding manner, and the tool posts are provided with movable cutter blades; the material transfer box is fixed on the bottom of the pulverizing box, and the periphery of a shaft body, disposed below the material transfer box, of the transmission shaft is fixedly provided with a rotating baffle plate; the grinding shell is disposed below the right of the material transfer box; a grinding block is arranged in the grinding shell. By integrating a pulverizing step and a grinding step of the Chinese herbs, the working efficiency is increased; moreover, the Chinese herbs can be efficiently and thoroughly pulverized; the ground Chinese herb particles are high in uniformity.

Owner:武汉钧安制药有限公司

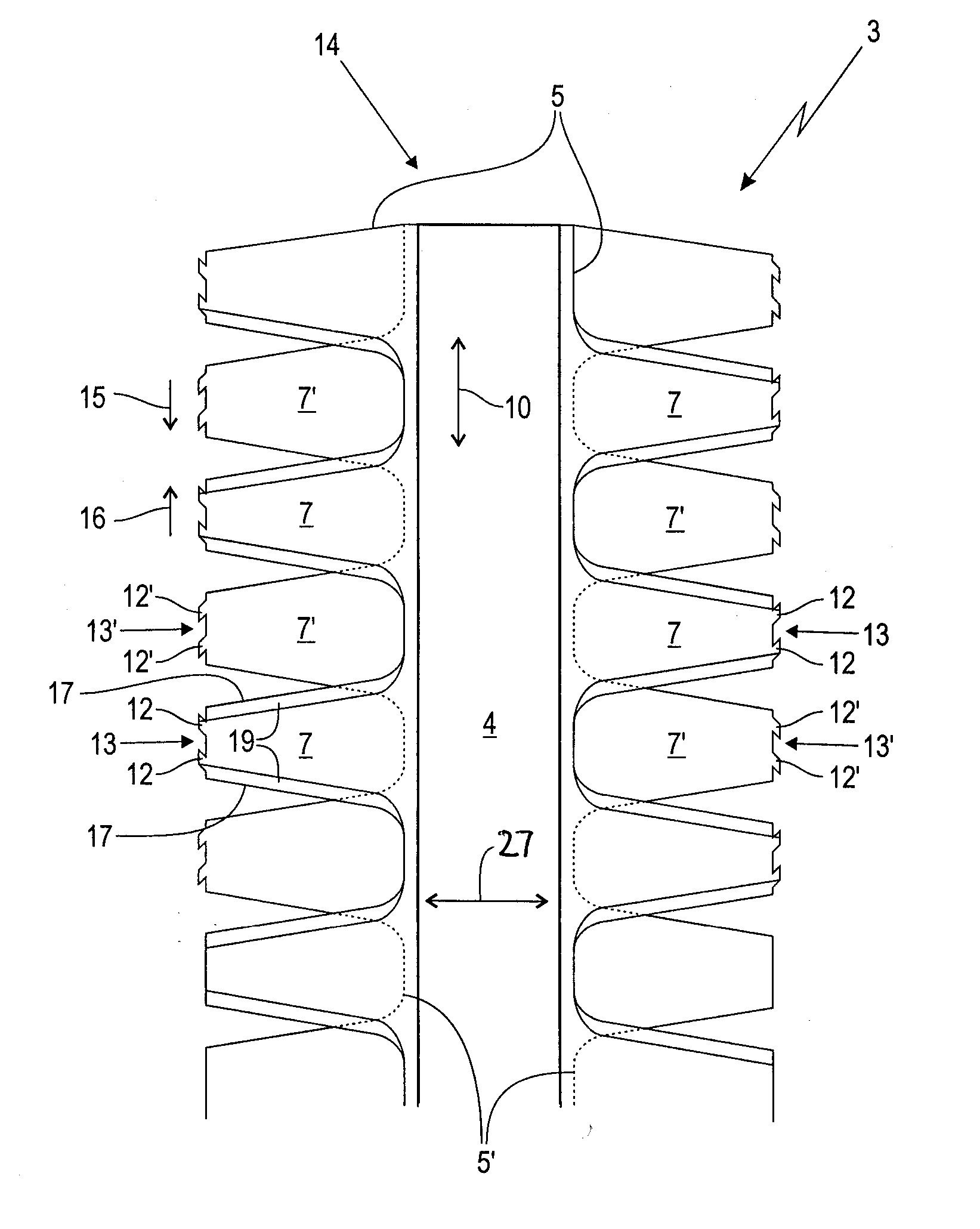

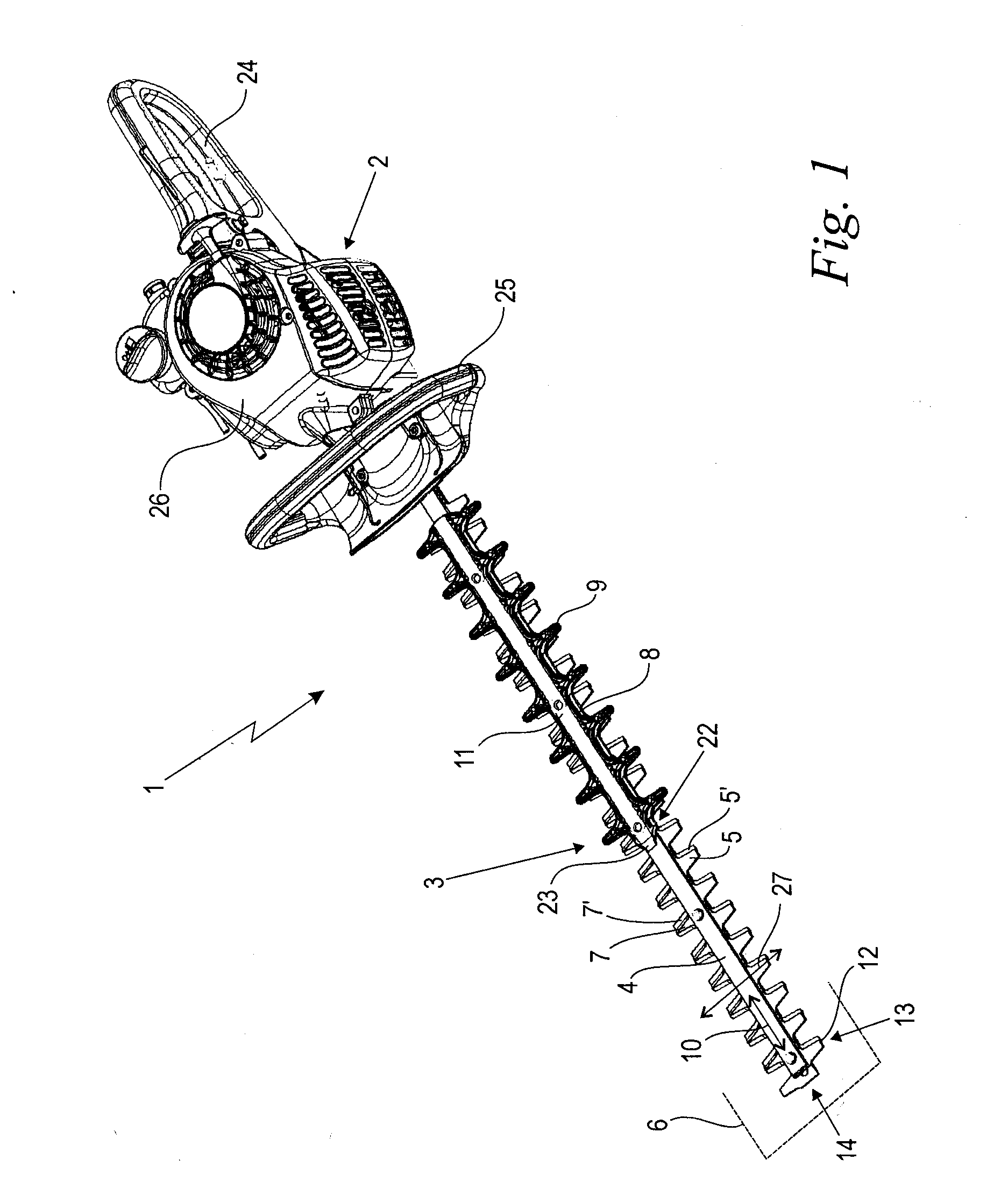

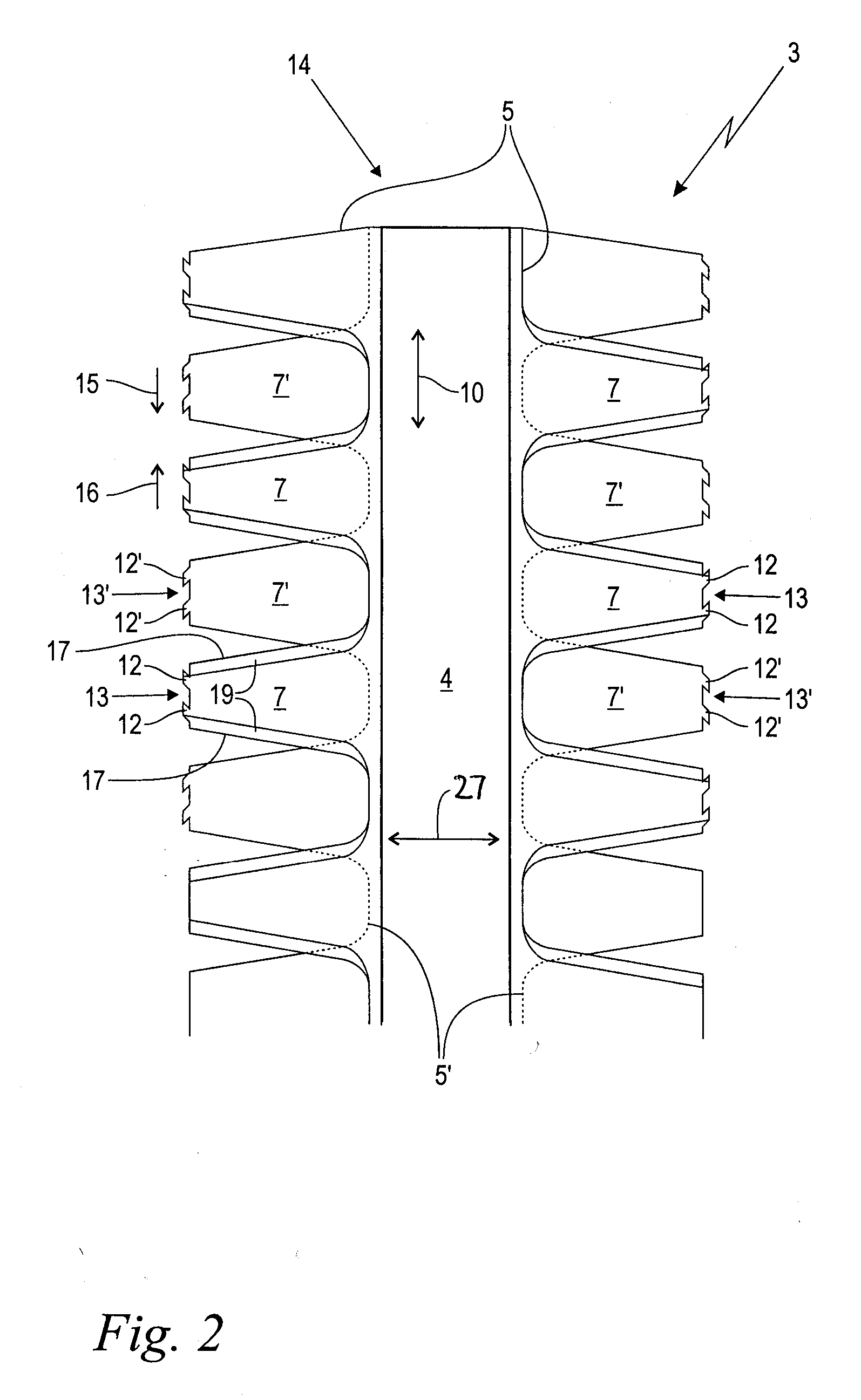

Cutter Bar of a Motor-Operated Hedge Trimmer

InactiveUS20070101581A1Reduce reaction forceImprove precisionCuttersCutting implementsKnife bladesEngineering

A cutter bar for a motor-operated hedge trimmer has a support bar and a shearing blade arranged on the support bar so as to be movable oscillatingly in a longitudinal direction of the support bar. The shearing blade has cutting teeth that project away from the support bar in a lateral direction that is perpendicular to the longitudinal direction. The cutting teeth each have an outer end remote from the support bar. At least one of the cutting teeth has at least one saw tooth that is arranged at the outer end and projects in the lateral direction away from the support bar.

Owner:ANDREAS STIHL AG & CO KG

Air controlled multi-plane special-shaped foam no-die cutting mahcine

InactiveCN101380742AExpand the cutting rangeSimple structureMetal working apparatusAbnormal shapedThree dimensional shape

Owner:李视广

Machining tool and machining method for precise step holes of aluminum alloy thin-wall casing

InactiveCN104759648AExpand the cutting rangeIncrease freedomCutting insertsTurning toolsDegrees of freedomMachine tool

The invention discloses a machining tool and a machining method for precise step holes of an aluminum alloy thin-wall casing. The processing tool is characterized in that a turning tool rod base is used for connecting a turning tool with a tool base part of a machine tool, so that the cutting range of the turning tool is widened, the degree of freedom of the turning tool is improved, and in particular, the turning tool can conveniently extend into the thin-wall casing when the precise step holes of the aluminum alloy thin-wall casing are machined. In the processing method, firstly, the thin-wall casing is placed on a fixture with the large end facing downwards and the small end facing upwards; then, screw holes in a clamping fixing surface at the large end of the thin-wall casing are aligned to screw holes in a clamping fixing surface of the fixture, and the thin-wall casing is clamped and fixed on the fixture through screws; and finally, the step holes are machined. The machining method can finish the machining of the whole step holes by clamping the casing once, and the deformation of the aluminum alloy thin-wall casing caused by clamping external force is prevented, so that the machining quality is guaranteed, and the machining efficiency is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

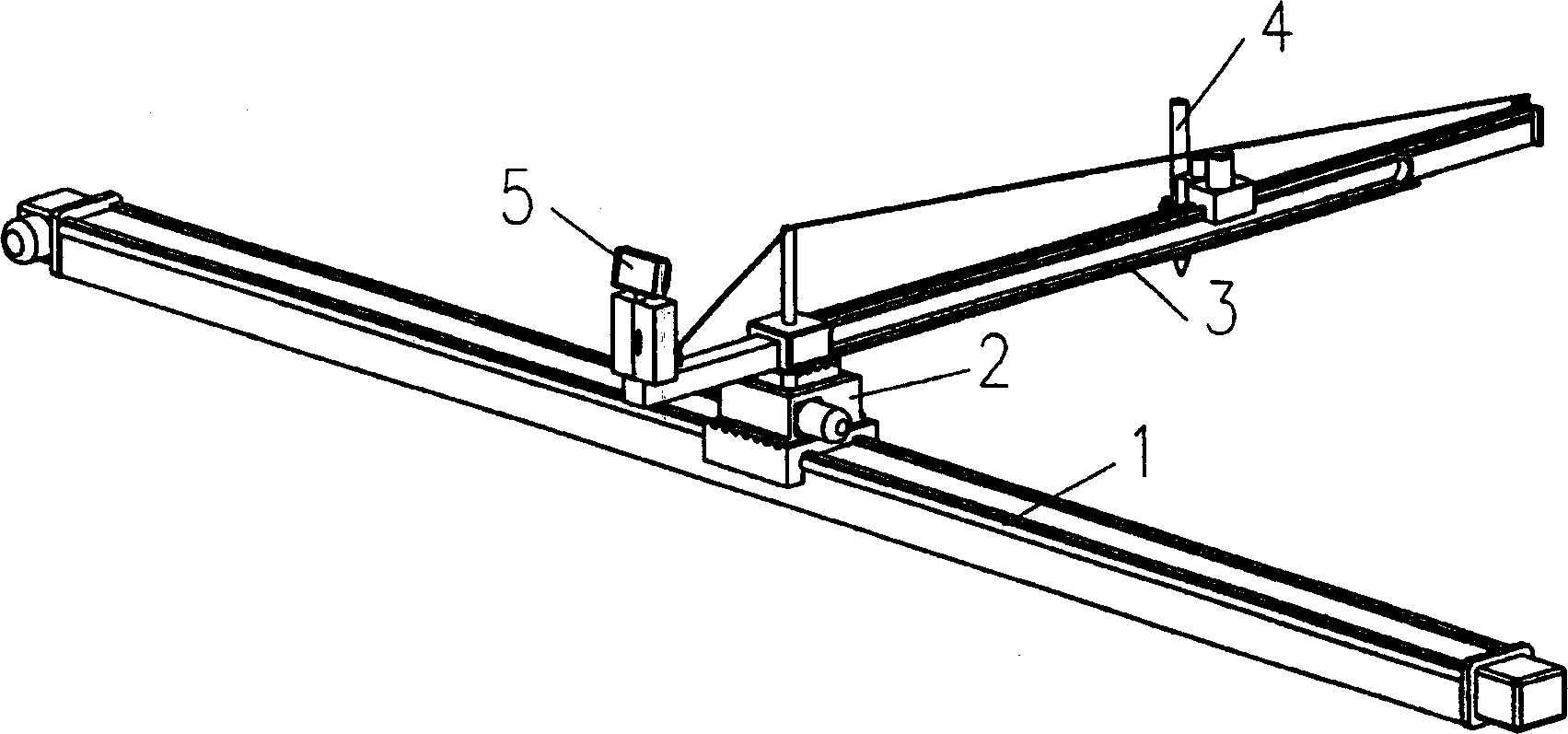

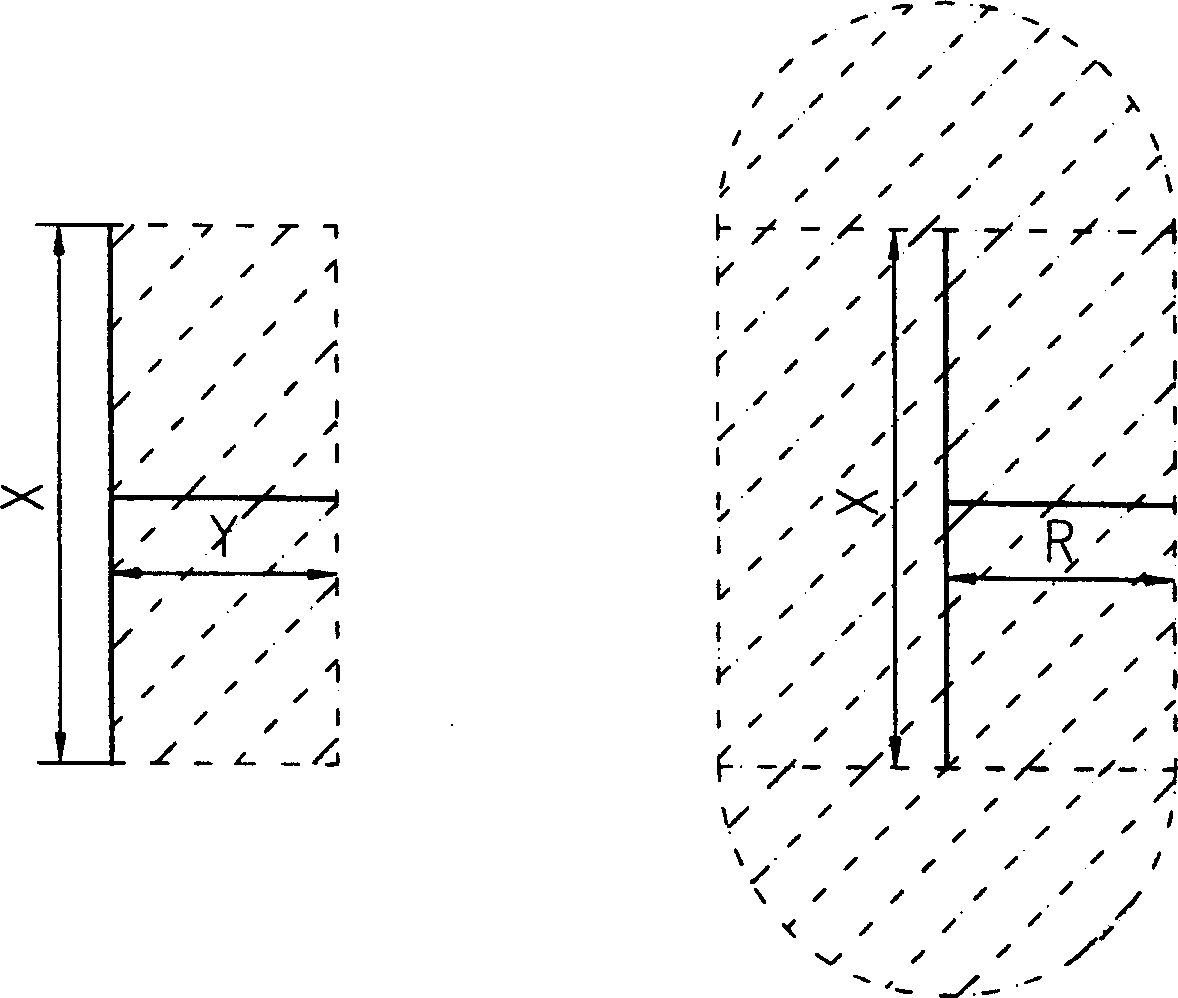

Modular polar coordinate cutting method with variable functions and digital controlled cutting apparatus

InactiveCN1439483AFlexible cutting functionExpand the cutting rangeLarge fixed membersNumerical controlComputer moduleEngineering

A modular polar-coordinate cutting method able to realize function exchange features that the cutting machine can be splitted into modules as required, all modules are mutually connected in polar coordinate mode, the module connected to cutting head can rotate, and exchanging relative module can change its function. A numeral controlled cutting machine based on said method features that its straight moving module has a moving platform connected to polaxis module, its pole radius module is connected to polaxis module and can revolve around it, the control-display module and cutting head module are fixed to pole radius module, and the cutting head module can move in axis direction of pole radius module.

Owner:NAT UNIV OF DEFENSE TECH

Livestock forage cutting device for livestock breeding

The invention discloses a livestock forage cutting device for livestock breeding. The device comprises a bearing frame, a driving motor is fixedly installed on the top in the bearing frame upside down, a driving shaft is coaxially and fixedly installed on an output shaft of the driving motor, a driving pulley sleeves and is fixedly installed on the surface of the driving shaft, a rotating shaft penetrating through a rotary table is coaxially and fixedly installed on an output shaft of a rotating motor, and multiple cutting blades are fixedly installed on the surface of the rotating shaft; a driven bevel gear meshed with a driving bevel gear is coaxially and fixedly installed at the left end of a transmission shaft, and an incomplete gear meshed with a spur rack sleeves and is fixedly installed on the surface of the transmission shaft. Accordingly, the cutting blades are driven by the rotating shaft to cut and crush forage in a crushing groove, at the same time, the rotary table rotatesalong with the rotating shaft, the cutting range of the cutting blades is increased, vertical reciprocating motion of a lifting plate promotes uniform dispersion of the forage, full contact of the cutting blades and the forage is guaranteed, and the crushing efficiency of the forage is greatly improved.

Owner:姜志祥

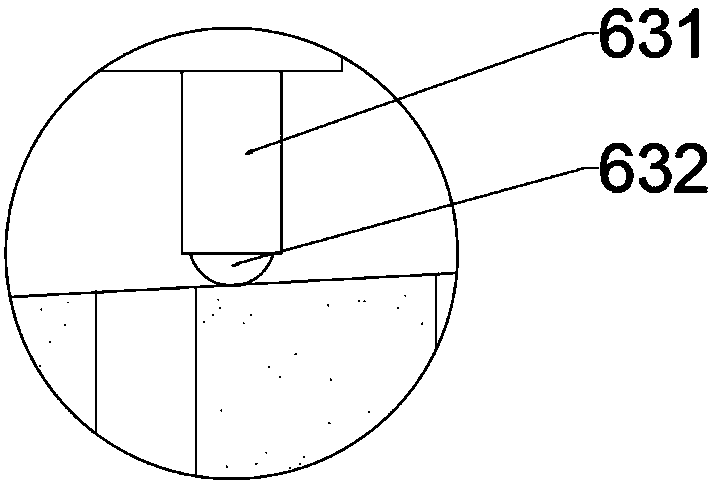

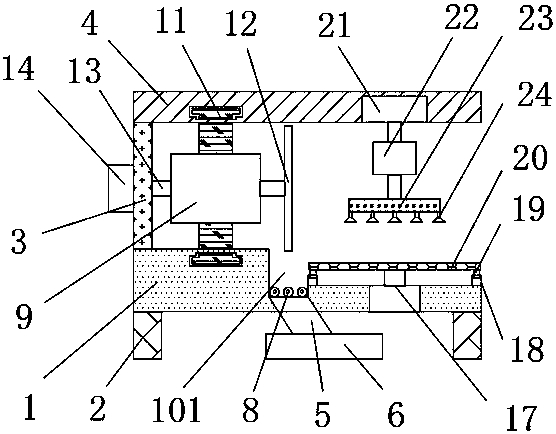

Multifunctional processing equipment for hollow glass

InactiveCN106986531AAchieve replacementShorten fixed timeGlass severing apparatusStone-like material working toolsSlide plateDrill

The invention mainly discloses a multifunctional processing equipment for insulating glass, including a machine base, a machine table, a first rodless cylinder, a second rodless cylinder, a cutting device and a drilling device, the first rodless cylinder and the second rodless cylinder The two rodless cylinders are respectively installed on the left and right sides of the machine base through the mounting bracket. The first rodless cylinder is equipped with a cutting device, and the second rodless cylinder is provided with a fixing device. The cutting device includes a base, a rotating disk, a support and Skateboard, one end of the slideboard is connected with the rotating disk through the support, the other end of the slideboard is connected with the fixing device, the cutter is slidably connected on the slideboard, and the drilling device includes a connecting rod and at least two drilling machines, and the ring of the drilling machine is in the On the connecting rod, the left and right sides of the drilling machine are all provided with limit rings on the connecting rod. The invention can freely switch between cutting and drilling processes on one workbench, saves time for glass processing, and can adjust the positions of cutters and drilling machines at will, expands the processing range, and improves processing efficiency.

Owner:嵊州市赫利玻璃制品有限公司

Rotary meat chopping machine convenient to clean

InactiveCN108703195AReduce difficultyImprove chopping efficiencyMeat processing devicesEngineeringRotating disc

The invention discloses a rotary meat chopping machine convenient to clean. The rotary meat chopping machine comprises a workbench, support plates, a rotating disc, a cutterhead and blades, wherein the supporting plates are fixedly connected to the left end and the right end of the lower surface of the workbench respectively, the rotating disc is arranged on the upper surface of the workbench, andis connected with the upper surface of the workbench rotatably, a support is hinged to the side wall of one support plate, a telescopic mechanism is hinged to the middle of the support, the extensionend of the telescopic mechanism is hinged to the left side wall of the workbench, a mounting plate is connected with the top end of the support fixedly, a meat chopping motor is fixedly connected with the upper surface of the mounting plate, and the rotating disc is connected to the shaft extension end of the meat chopping motor fixedly. During meat chopping, chopped meat adhered to the blades are scraped off by a scraping plate to be prevented from adhering to the blades, and accordingly, difficulty in manual blade cleaning is reduced greatly; during meat chopping, the rotating disc rotatesback and forth, and accordingly, the cutting range is widened; after processing of the chopped meat, the telescopic mechanism drives the mounting plate to rotate, and accordingly, the chopped meat inthe rotating disc is taken out conveniently.

Owner:临泉县生产力促进中心

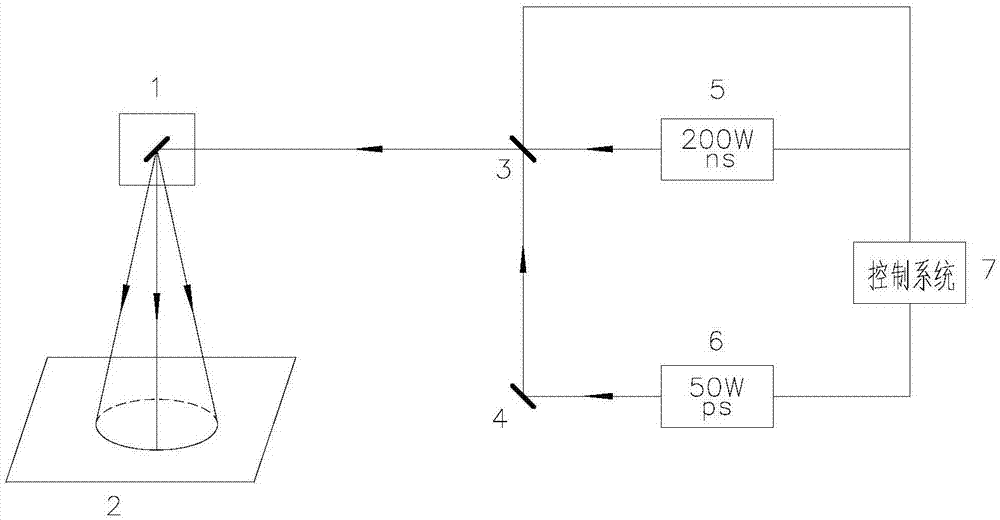

Laser cutting system and cutting method thereof

ActiveCN107234345AFast cutting speedExpand the cutting rangeLaser beam welding apparatusGalvanometerLaser power density

The invention provides a laser cutting system and a laser cutting method thereof. The laser cutting system comprises a galvanometer system, a variable reflector, a fixed reflector, a first laser, a second laser and a control system. The control system is connected with the first laser, the second laser and the variable reflector. The cutting mode is the front focusing cutting mode. According to a rear focusing cutting mode adopted by existing pole piece cutting, the focusing spot of front focusing is smaller than that of rear focusing, the laser power density at the focusing spot is larger, cutting speed can be increased, through matching with a three-axis galvanometer, the cutting range is large, large-breadth cutting and small-breadth batch cutting can be conducted, cutting efficiency is improved, and cost is reduced.

Owner:HANS LASER TECH IND GRP CO LTD

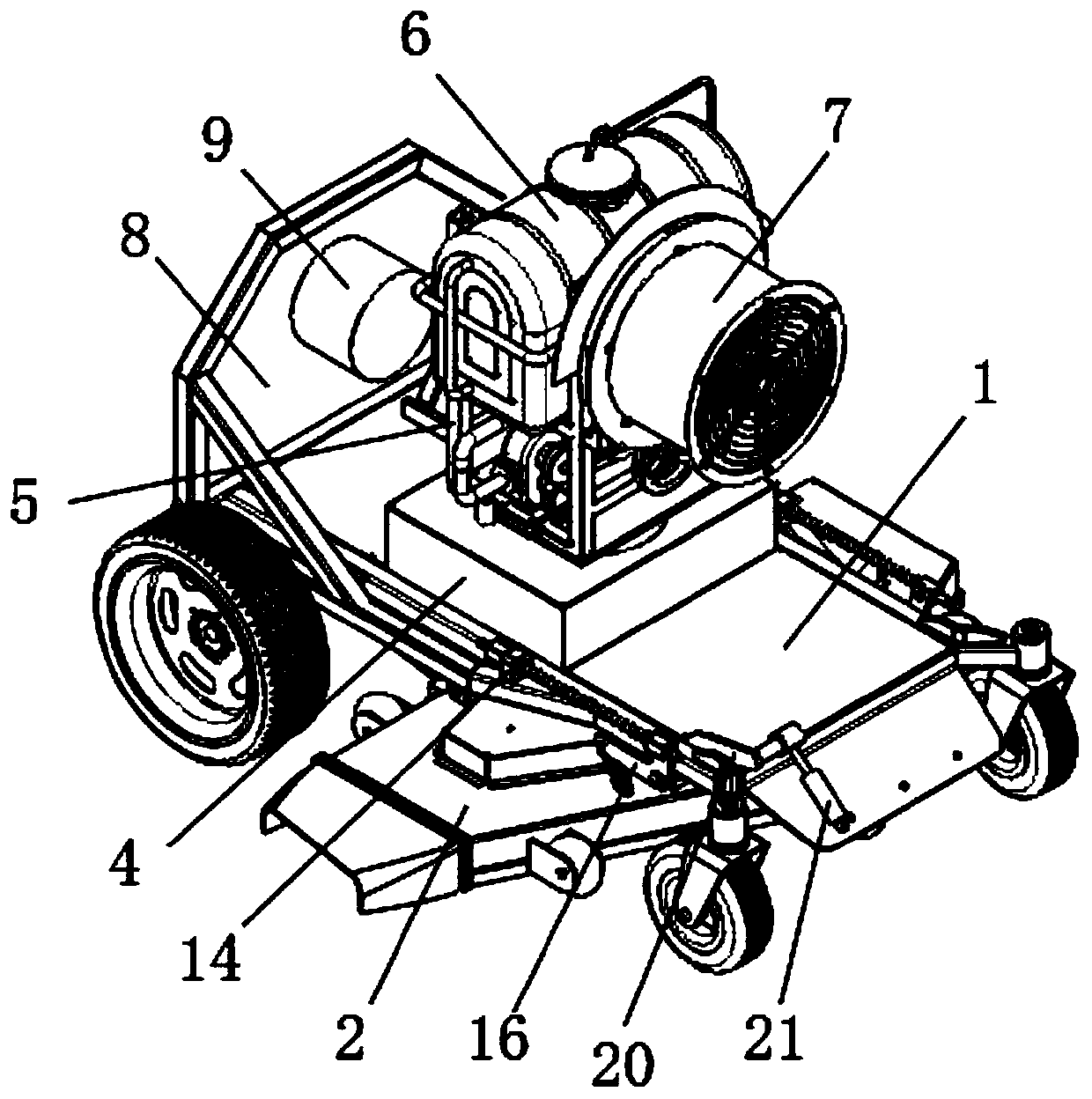

Alga removing device

ActiveCN105887785AExpand the scope of absorptionExpand the cutting rangeWater cleaningEngineeringLinear motor

An alga removing device comprises an unmanned aerial vehicle, a bearing, a first motor, a first support, a fourth air cylinder, a dust collector, floating balls, a rope, a floating plate, a second motor, a floating table, a waste storage tank, a chain, a roll shaft, a coiling block, bottom discs, lifting landing legs, a second support, a controller, second gears, a supporting frame, a first air cylinder, rotating rods, a second linear motor, second movable blocks, blades, first gears, rotating shafts, a third motor, a first movable block, a first linear motor, a first cutter, heating pieces, a second air cylinder, a third movable block, a second sliding block, a frame, a third linear motor, a fourth motor, a second sliding rail, electric push rods, a groove, a first sliding rail, first sliding blocks, a fifth sliding rail, a fifth sliding block, a fifth motor, a second cutter, a third air cylinder, a third sliding block, a third sliding rail and a supporting plate. The lifting landing legs are arranged on the left side and the right side of the unmanned aerial vehicle. The bottom discs are arranged below the lifting landing legs. The alga removing device has the beneficial effect of being capable of automatically removing algae.

Owner:平邑经济开发区投资发展有限公司

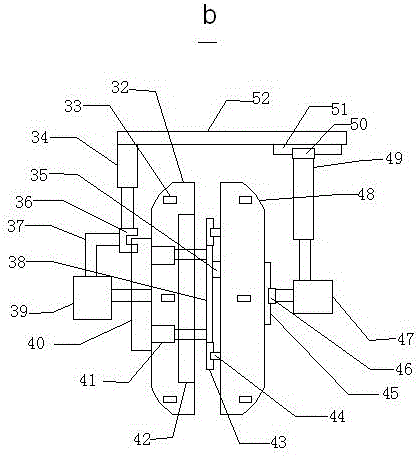

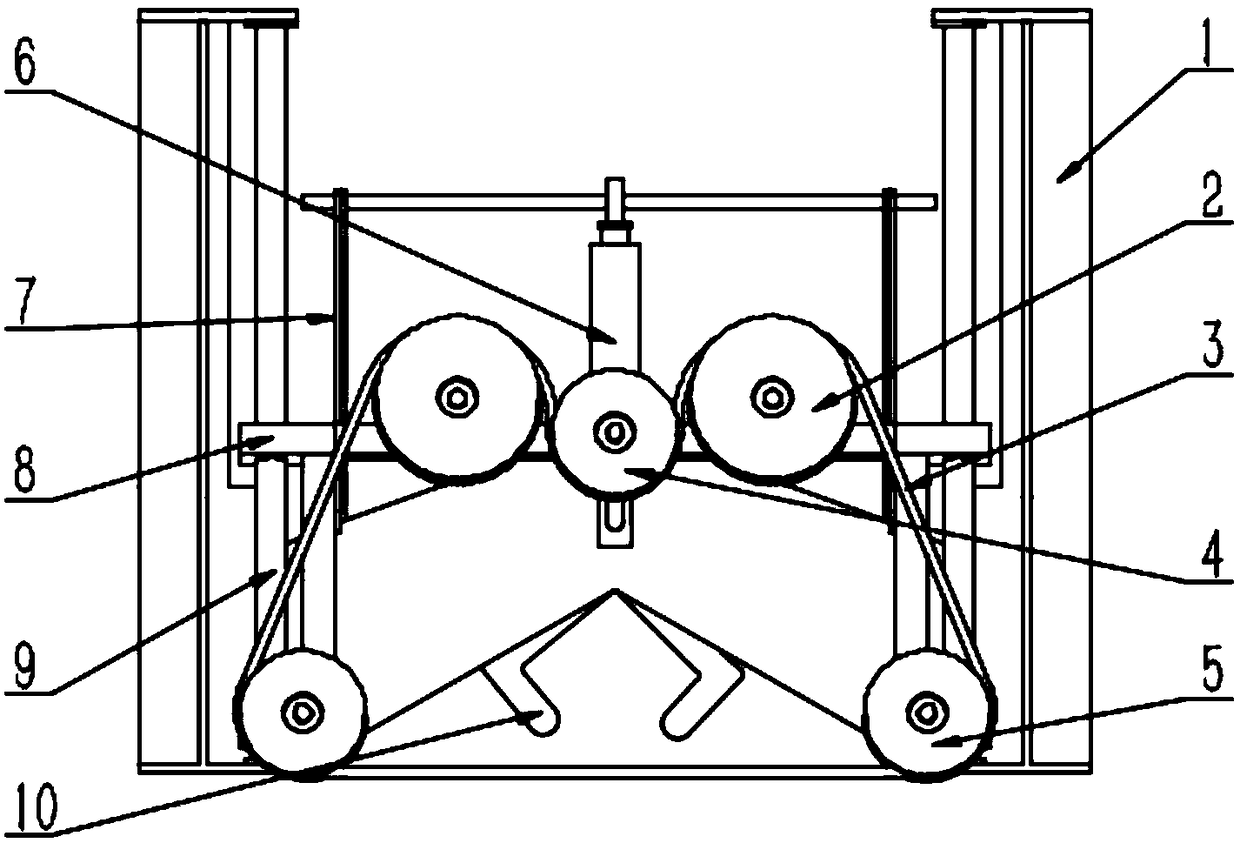

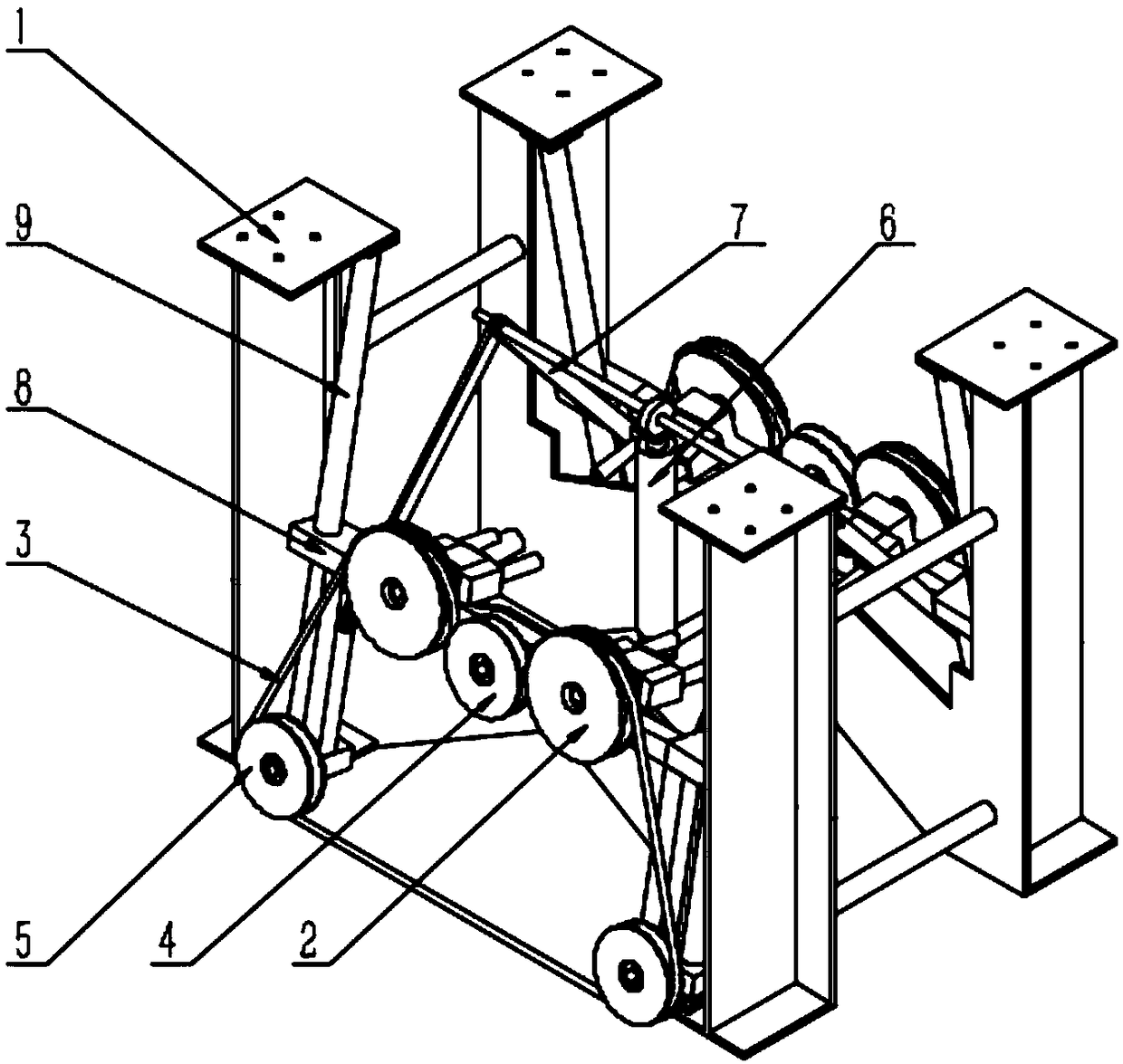

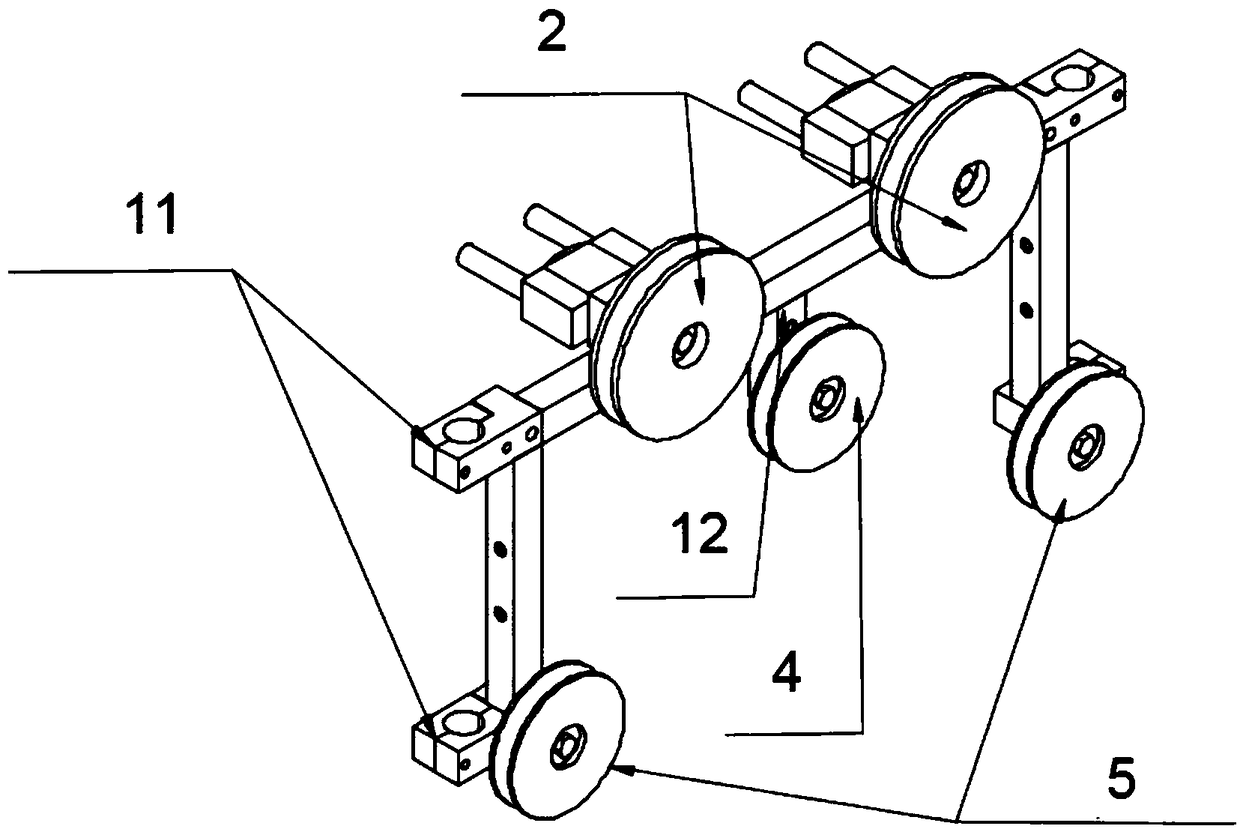

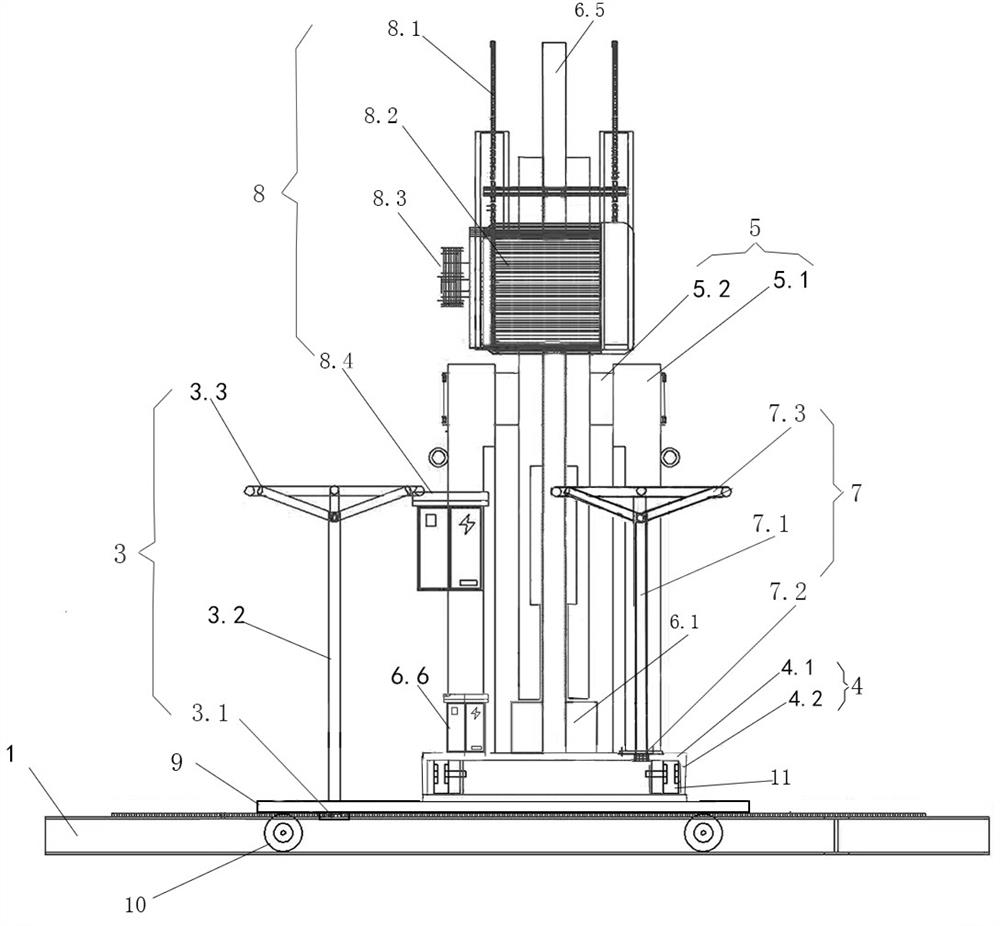

Three-dimensional numerical control electric spark linear cutting machine tool

The invention discloses a three-dimensional numerical control electric spark linear cutting machine tool comprising a machine tool body, a cross saddle which is arranged on the machine tool body, and vertical columns which are fixedly arranged on the left side and the right side of the machine tool body; crossbeams which are connected with the vertical columns on the left side and the right side are arranged at the upper parts of the vertical columns; a left linear arm guide rail is arranged on the vertical column on the left side; a left linear arm is arranged on the left linear arm guide rail; the lower end of the left linear arm is provided with a left guide pulley; a right linear arm guide rail is arranged on the vertical column on the right side; a right linear arm is arranged on the right linear arm guide rail; the lower end of the right linear arm is provided with a right guide pulley; the upper end of the left linear arm is connected with the upper end of the right linear arm through a cross arm; the cross arm is provided with a z-axis lead screw; the z-axis lead screw is movably connected onto a lead screw pair. According to the three-dimensional numerical control electric spark linear cutting machine tool, the structure is simple, three guide pulleys and a group of z saddle are added based on an original common linear cutting machine tool, the winding path of an electrode wire is changed, i.e. the one-time clamping of a work piece is realized, the cutting of a three-dimensional surface is realized, and the machine tool is low in cost, easily used and easily promoted.

Owner:徐州博创建设发展集团有限公司

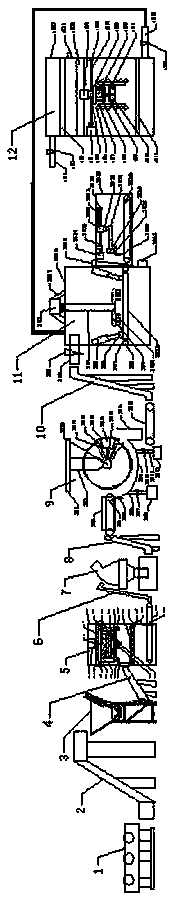

Pollution-free recycling production line for iron waste packages

ActiveCN105363757AExpand the cutting rangeSpeed up the fallDispersed particle filtrationSolid waste disposalProduction lineActivated carbon filtration

A pollution-free recycling production line for iron waste packages comprises a roller conveyor, a first conveyor, a four-axis shredder, a second conveyor, an iron waste package shredder, a third conveyor, a hammer crusher, a fourth conveyor, an iron waste separation device, a fifth conveyor, an iron waste stirring and cleaning device and an activated carbon filtration device. The first conveyor is installed on the right side of the roller conveyor and connected with the left end of the roller conveyor. The fourth-axis shredder is installed on the right side of the first conveyor and connected with the right end of the first conveyor. The second conveyor is installed on the right side of the fourth-axis shredder connected with the left end of the second conveyor. The pollution-free recycling production line for the iron waste packages has the beneficial effect that oil paint residues can be thoroughly separated from waste metal.

Owner:ZHOUSHAN NAHAI SOLID WASTE CENT DISPOSAL

Novel computer glass screen cutting device

InactiveCN108249747ASimple structureInnovative designGlass severing apparatusInlet valveMaterial storage

The invention discloses a novel computer glass screen cutting device. The novel computer glass screen cutting device comprises a working plate, a cutting groove, supporting legs, a supporting plate, asliding groove, a top plate, a material discharging pipe, a material storage box, baffle plates, a spraying head, a first electric motor, an air inlet pipe, an air inlet valve, a sliding column, a cutting knife, a sliding rod, a fixing plate, a spring, a first electric push rod, a second electric push rod, a first retractable plate, a second retractable plate, a placement plate, a third electricpush rod, a second electric motor, a pressing plate and rubber suction discs. The novel computer glass screen cutting device disclosed by the invention is simple in structure and novel in design; eachside surface of a glass screen is cut and a cutting range is improved; meanwhile, the cutting knife moves stably in a cutting process; the cutting precision of the cutting knife is improved and the cutting efficiency is improved; operators can operate conveniently; when the novel computer glass screen cutting device is used, the glass screen is placed stably and the placement height of the placement plate is convenient to adjust according to the thickness of the glass screen; the cutting knife is convenient to cut and is convenient to use.

Owner:戴志威

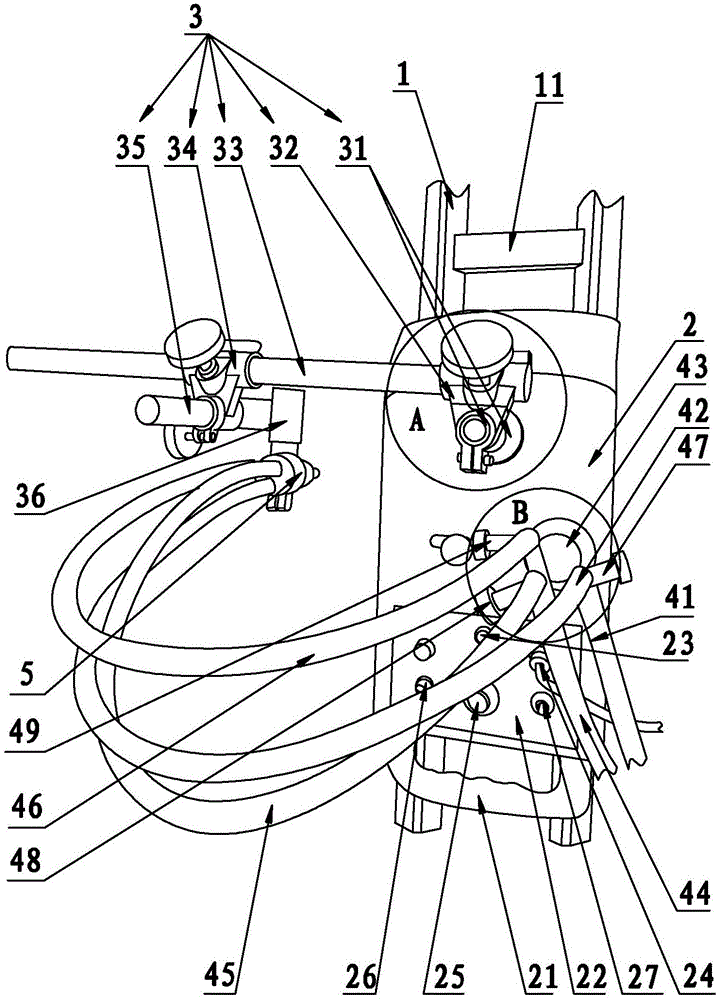

Multifunctional tea planting land weeding device and operation method thereof

InactiveCN110612808ASolve technical problems of growing environmentFunction increaseMowersWeed killersSurface mountingEngineering

The invention discloses a multifunctional tea planting land weeding device and an operation method thereof. The weeding device comprises a mounting bottom plate, a cutting cover plate is arranged on the lower portion of the mounting bottom plate, three cutting blades are mounted at the bottom of the cutting cover plate, a supporting seat is mounted on the upper surface of the mounting bottom plate, a supporting frame is rotatably connected at the top of the supporting seat, a liquid medicine box is fixedly mounted on the supporting frame, and an air supply cylinder is mounted on one side of the liquid medicine box and connected with the supporting frame. The cutting range of the weeding device is wide, large-area weeds can be rapidly cleaned, working efficiency is high, the height of the cutting cover plate is conveniently adjusted, and cutting requirements of different heights of weeds are met. The weeding device is simple in structure, liquid medicine is blown by fan blades, sprayingarea can be increased, spraying distance can be increased, and weeding effects are good. According to the weeding device, weed cutting and weed removal by pesticides are integrated, functions are diverse, and weeding requirements under different conditions can be met.

Owner:金寨县益农农业科技开发有限公司

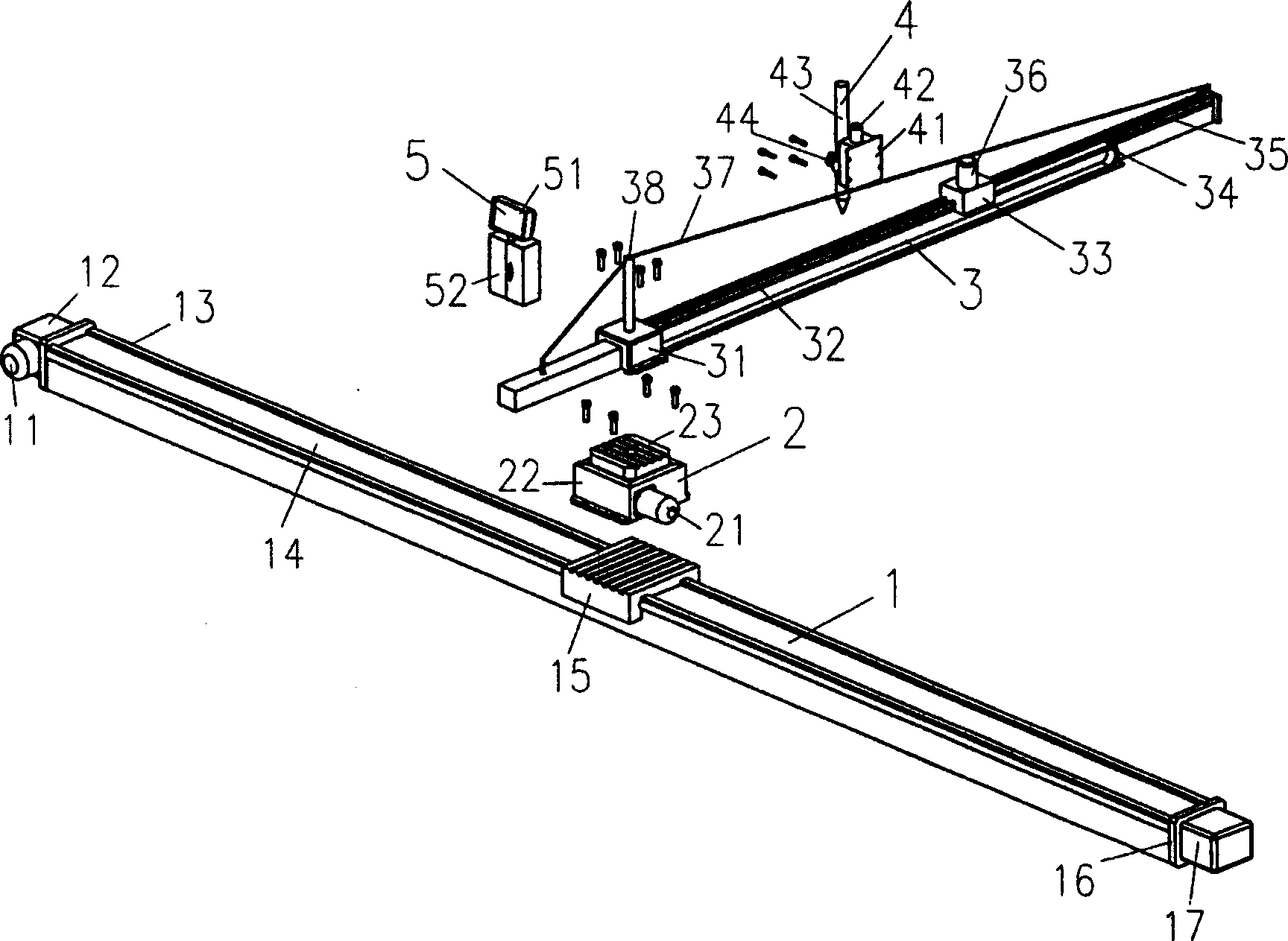

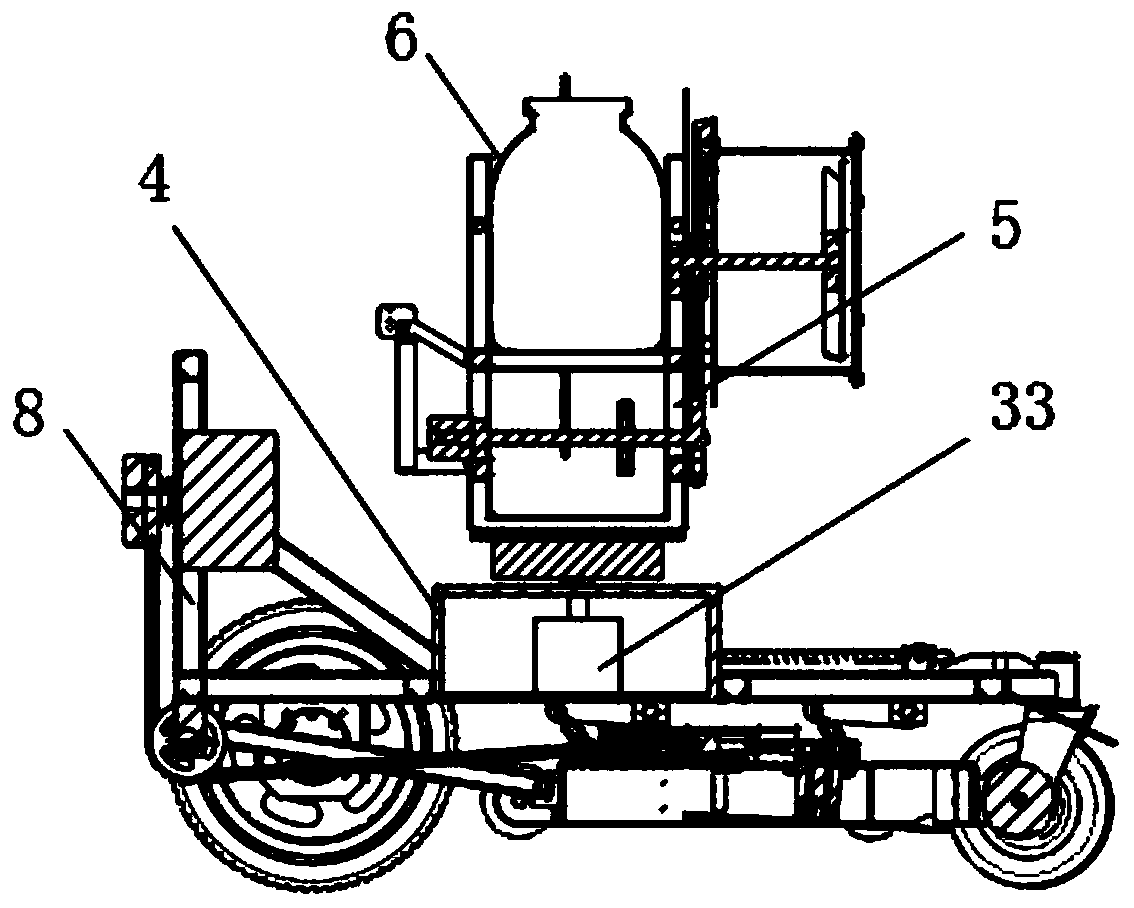

Adjustable track automatic gas cutting machine

InactiveCN105171184ARealize automatic stable feedSolve the flatnessGas flame welding apparatusSlagDrive shaft

The invention discloses an adjustable track automatic gas cutting machine. The adjustable track automatic gas cutting machine comprises guide rails, a gas cutting machine body, an adjusting mechanism, a gas feeding control mechanism and a gas cutting nozzle. The two guide rails are arranged side by side in a left and right manner. A connecting piece is fixedly installed between the two guide rails. Rolling wheels matched with the two guide rails are installed at the bottom of the gas cutting machine body. Driving shafts are installed between the left row of rolling wheels and the right row of rolling wheels. A driving device is in transmission connection between the front driving shaft and the rear driving shaft. A handle is fixedly installed at the rear end of the gas cutting machine body. A controller is installed at the rear of the top face of the gas cutting machine body. An indication lamp, a power line, a regulator, a first switch and a second switch are installed on a control panel of the controller. The indication lamp and the power line are sequentially installed in front of the control panel of the controller from left to right in sequence. The first switch, the regulator and the second switch are installed behind the control panel of the controller from left to right in sequence. The problems that manual operation of an existing gas cutting machine is poor in stability, cutting notches are not smooth because stability is guaranteed by the technological level of workers, and adhering slag exists are solved.

Owner:合肥市迅立达电梯有限公司

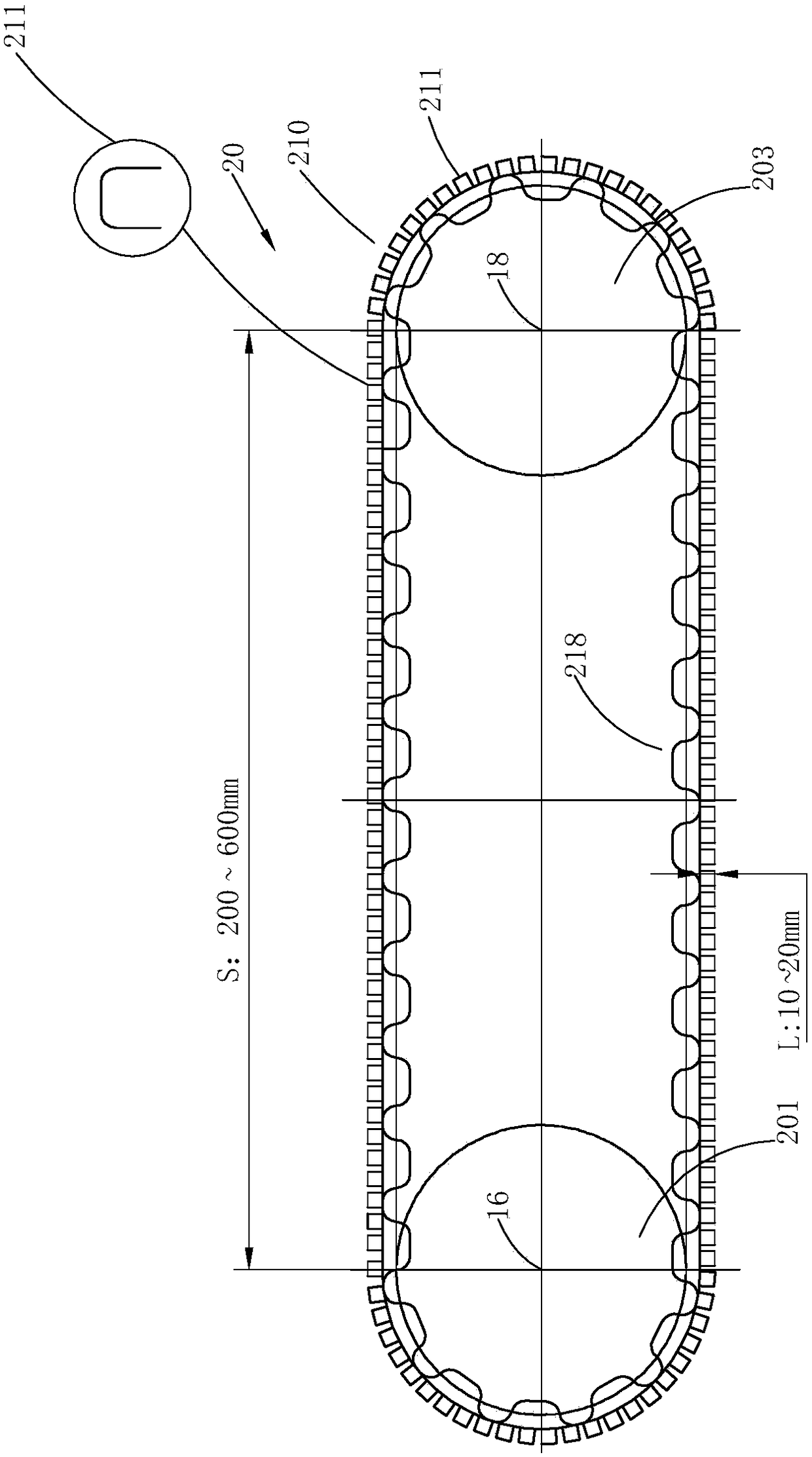

Belt conveyor with variable discharge port

PendingCN112830281AWide range of blankingEnsure storage safety and qualityConveyorsControl devices for conveyorsAir volumeEngineering

The invention relates to the field of belt conveyors, and discloses a belt conveyor with a variable discharge port, which is characterized in that a controller is started, a humidity detector detects the humidity of grains, a detection signal is transmitted into the controller through a data line after detection, the detected humidity is compared with a numerical value set by the controller, an air supply motor and a heating frame are started according to the humidity comparison result, so that the air supply motor enables a fan to rotate to different speeds according to the control of the controller, meanwhile, a heating wire is controlled to heat to different temperatures, the fan rotates to generate a certain amount of air, and the air is blown into the heating frame, heated through the heating wire and then blown into an anti-skid groove, so that the grains can be dried, and meanwhile, the air speed and the heating temperature are controlled through the controller according to the humidity comparison value, and therefore the purpose of saving energy is achieved.

Owner:中粮工程装备无锡有限公司

Forest shrub cutting device capable of achieving dust fall

ActiveCN110421652AExpand the cutting rangeAdjust cutting heightProfiling/shaping machinesBark-zones/chip/dust/waste removalMotor driveDust fall

The invention discloses a forest shrub cutting device capable of achieving dust fall. The forest shrub cutting device comprises a main box. A cutting cavity with an opening being forward is arranged in the main box. A rotating rod is mounted on the inner wall of the right side of the cutting cavity in a hinged manner. A rotating disc enables a sliding block to move left and right through a connecting rod. The sliding block moves left and right to drive a rubber plug to move left and right. A second motor drives a power rod to rotate, and a cutting wheel can rotate to cut shrubs. A threaded rodcan be driven through a first motor to rotate, a threaded block moves front and back, the threaded block drives the rotating rod to rotate through a hinged rod, the cutting position of the cutting wheel is adjusted, and the cutting range of the cutting wheel can be widened. When the cutting wheel carries out cutting, the rubber plug moves left and right. Water in a water cavity is drawn into a cavity through a first hemisphere and a second hemisphere and then is sprayed through a spray head, and wood chip particles generated by the cutting wheel is subjected to dust fall treatment.

Owner:PUJIANG YIYAN MASCH EQUIP CO LTD

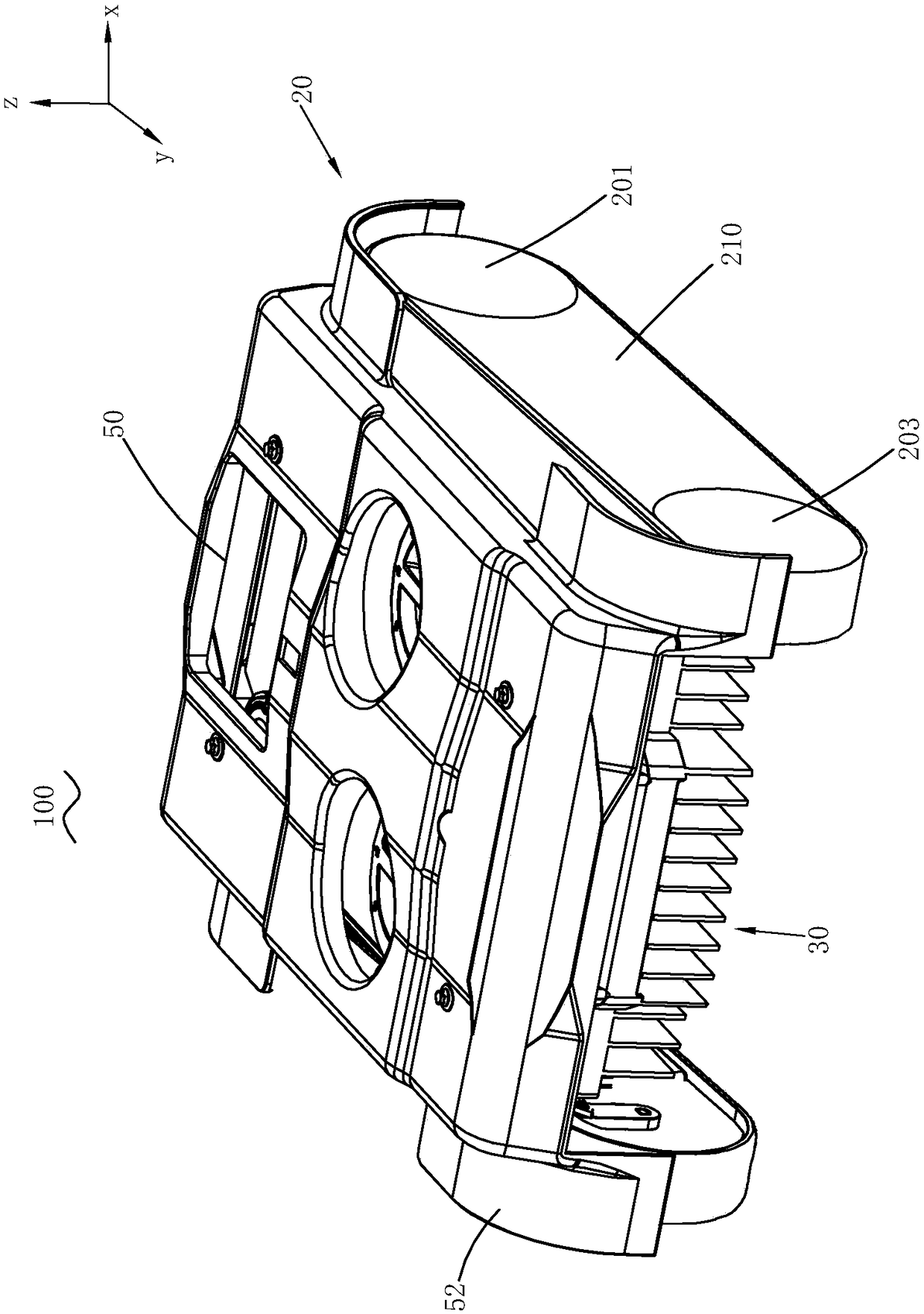

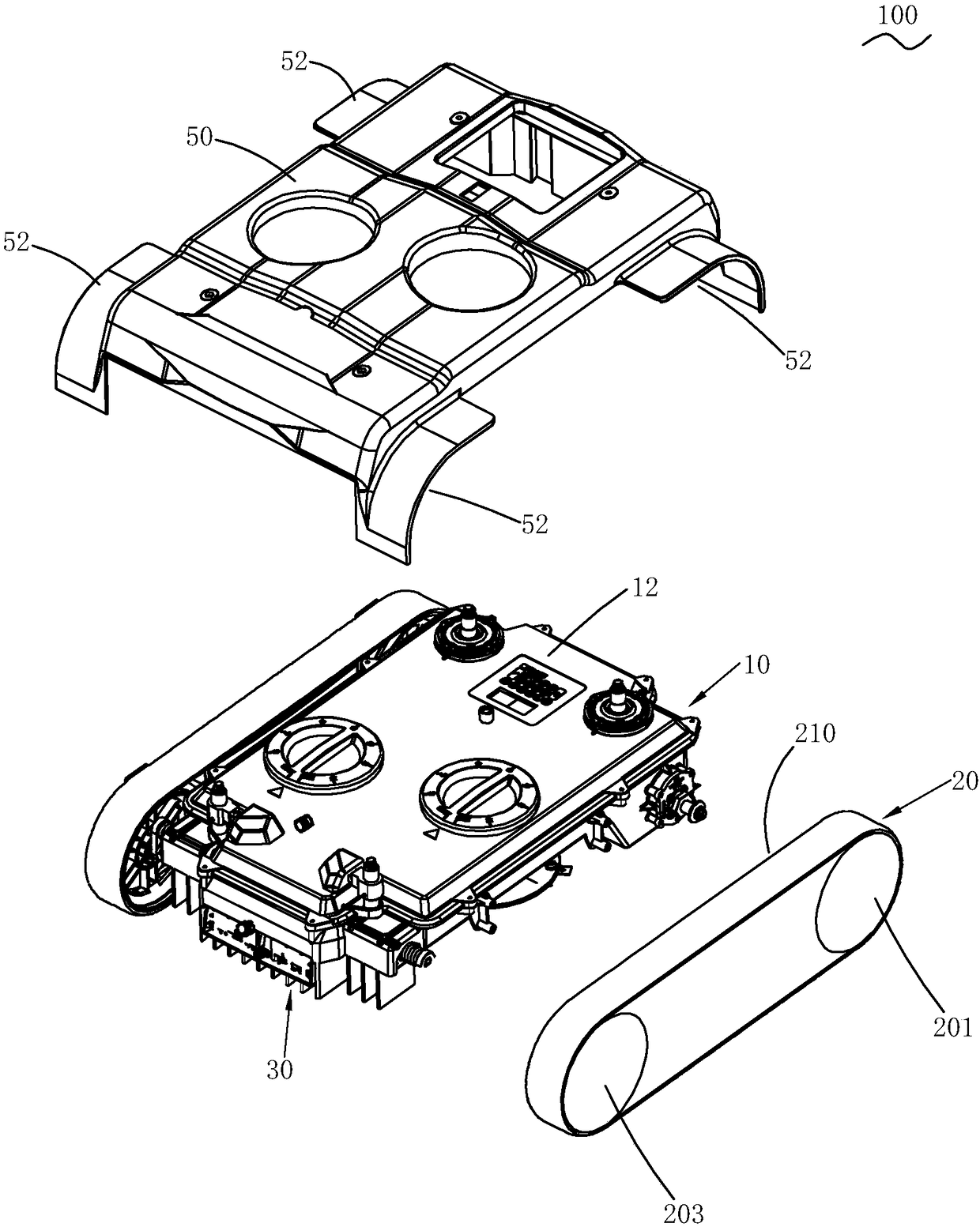

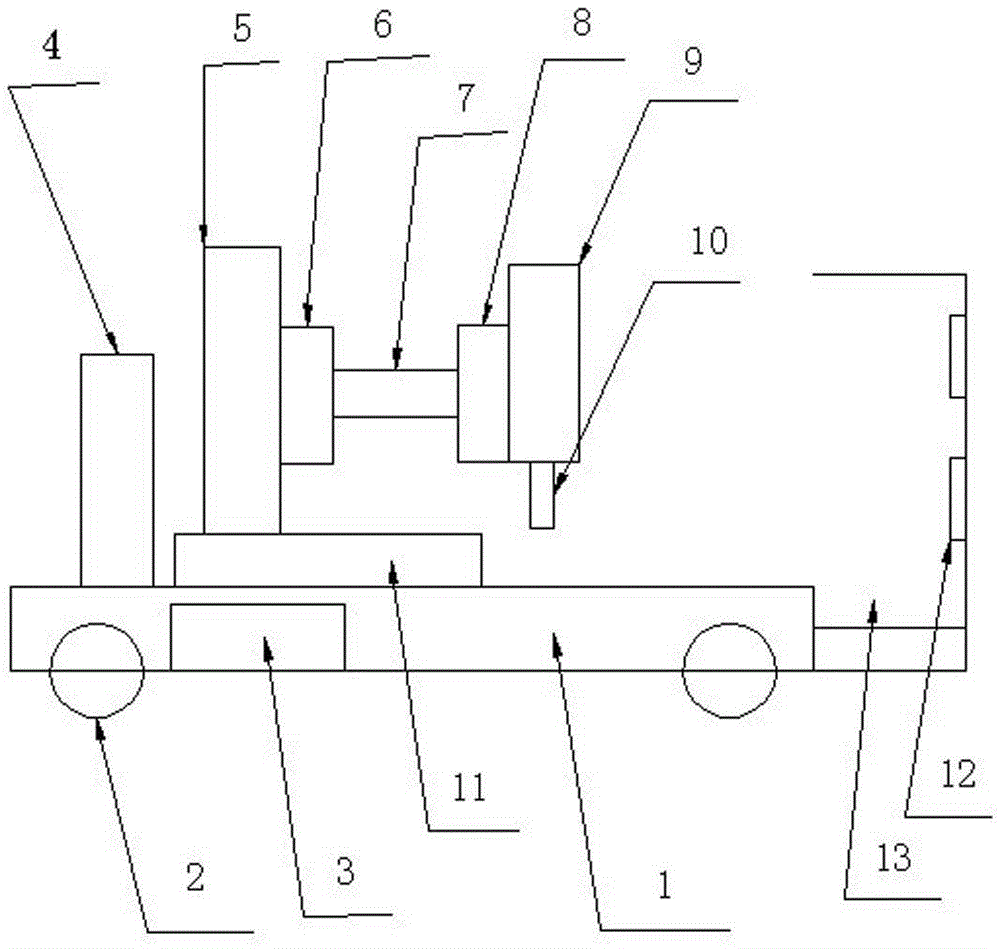

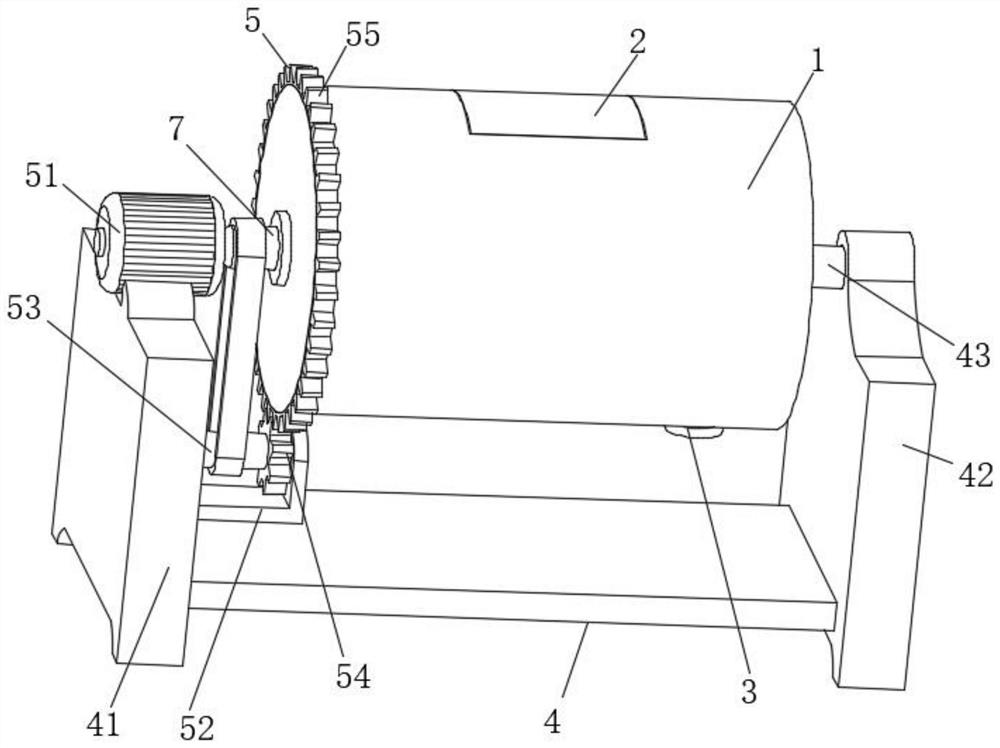

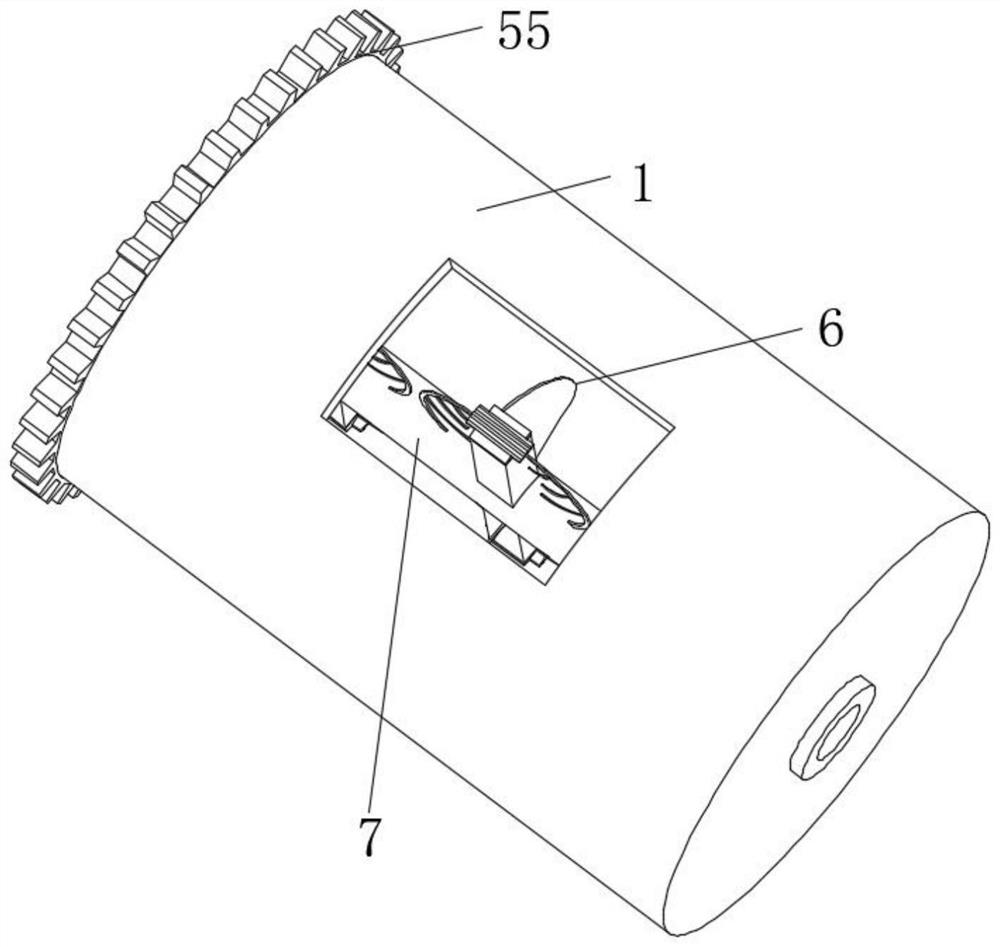

Intelligent robot

PendingCN108693873AAvoid damageNot easy to tearPosition/course control in two dimensionsMotor driveEngineering

The invention provides an intelligent robot. The robot comprises a shell, a work module, walking modules, an energy module, a motor module and caterpillar bands, wherein an accommodation chamber is formed in the shell in a hollow mode; the work module is arranged on the bottom of the shell and is used for executing a work task; the walking modules are arranged on the two sides of the shell, each side of walking module includes a front support wheel, a rear support wheel and the caterpillar band, and the caterpillar band is wound and arranged with the front support wheel and the rear support wheel as two ends; the energy module is arranged in the accommodation chamber; the motor module is arranged in the accommodation chamber and includes a work motor driving the work module and a walking motor driving the walking modules; and the caterpillar bands have inner surfaces which are contacted with the support wheels and outer surfaces which are contacted with ground, the outer surfaces haveembossments, and the surfaces of the embossments are smooth. When the caterpillar-band intelligent robot works, lawn damages are decreased, a lawn is not easy to be torn and cylindrical embossments have a comb grass effect.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Cutting machine

InactiveCN105328271AExpand the cutting rangeAdjust the cutting direction at willPositioning apparatusMaintainance and safety accessoriesWorking environmentElectric machinery

The invention discloses a cutting machine, and relates to the field of machinery. The cutting machine comprises a base, wheels, a motor, a control mechanism, a vertical sliding rail, sliding blocks, a connecting block, a rotating plate, an upper cover, a cutter blade, a horizontal sliding rail, magnets and an accommodating space. The wheels are arranged at the two ends of the base. The motor is arranged inside the base. The upper cover and the cutter blade form a cutting tool which is arranged on the rotating plate. The rotating plate is connected with the sliding blocks through the connecting block. The sliding blocks are connected with the vertical sliding rail and are further arranged below the vertical sliding rail, and the vertical sliding rail is connected with the horizontal sliding rail through the sliding blocks. The horizontal sliding rail and the control mechanism are both arranged on the base. The control mechanism is located at the left end of the vertical sliding rail. The accommodating space is arranged at the right end of the base. The magnets are arranged on the vertical surface of the right end of the accommodating space. The cutting machine has the beneficial effects that the cutting direction can be adjusted freely, comprehensive cutting is convenient, the cutting efficiency is high, and the cut metal debris can be collected in a concentrated mode, so that the working environment for cutting is clean and tidy.

Owner:吕萍华

Preparation method of multicoloured leaf powder

InactiveCN113368970APreparation impactCause wasteHollow article cleaningGrain treatmentsCentrifugationOrganic chemistry

The invention discloses a preparation method of multicoloured leaf powder, and relates to the technical field of multicoloured leaf powder preparation. The preparation method of the multicoloured leaf powder comprises the following steps: S1, taking fresh multicoloured leaves, cleaning, drying, putting the dried leaves into a crushing cylinder, chopping and juicing the same; S2, fully crushing the multicoloured leaves, pouring the multicoloured leaves out of the mixing drum, mixing the multicoloured leaves with a crushed material for cell crushing and deionized water according to a fixed weight ratio, and placing the mixed liquid in a water bath at 50-70 DEG C for 35-50 minutes to obtain a mixed liquid for later use; and S3, putting the mixed liquid into a centrifugal cylinder for centrifugation, and concentrating the centrifugate to control the sugar degree to be 8-15, so as to obtain the multicoloured leaf juice. According to the preparation method of the multicoloured leaf powder, the transmission mechanism is matched with the crushing mechanism, so that waste caused by incomplete crushing of the multicoloured leaves by the crushing barrel due to adhesion of the uncrushed multicoloured leaves on the inner wall of the crushing barrel in the chopping process of the multicoloured leaves is prevented, and the influence of the incompletely crushed multicoloured leaves on preparation of the multicoloured leaf powder is prevented.

Owner:CHINESE ACAD OF TROPICAL AGRI SCI

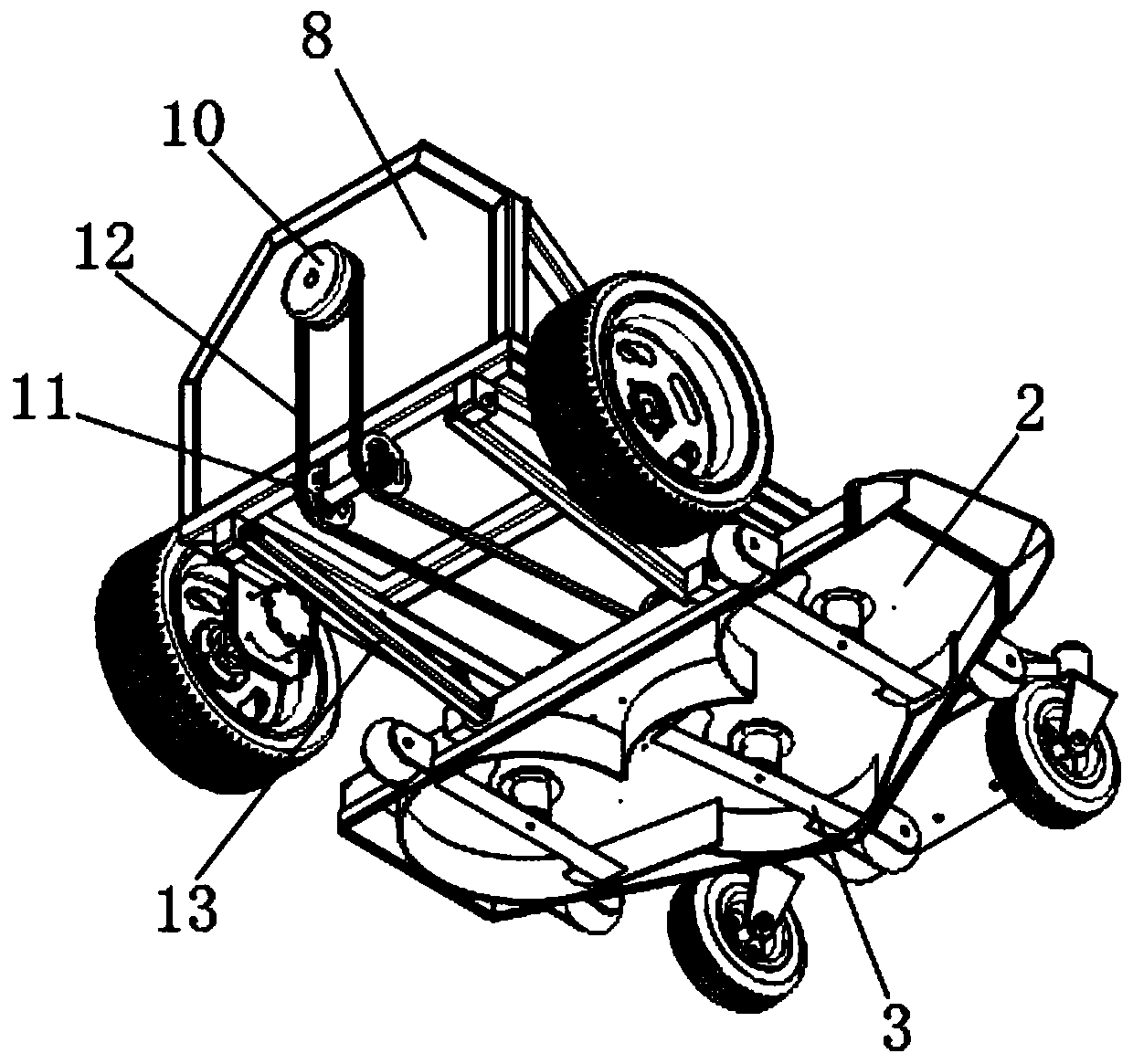

Underwater cutting device and cutting method thereof

PendingCN108788300AIncrease profitReduce energy consumptionMetal sawing devicesDrive wheelEngineering

The invention relates to the technical field of engineering construction, in particular to underwater cutting equipment and a cutting method thereof. A hydraulic power device of the underwater cuttingequipment is connected with a feeding device and cutting devices through hydraulic oil pipes. A piston rod of a hydraulic oil cylinder of the feeding device is connected with one or more transmissionparts. Each transmission part is connected with the corresponding cutting device, wherein one end of a connecting rod of the transmission part is connected with the piston rod of the hydraulic oil cylinder, and the other end of the connecting rod of the transmission part is connected with a cutting frame. Sliding sleeves sleeve sliding rails and are connected with the cutting frames. The slidingrails are obliquely arranged. The sliding sleeves are provided with driving wheels and tensioning wheels. Saw ropes are wound among the driving wheels, the tensioning wheels and driven wheels. The hydraulic power device is arranged on the ground, power is transmitted to an underwater part through hydraulic pipelines, saw rope tensioning and cutting are finished underwater, the executing mechanismpower transmission line is shorter, the energy utilization rate is higher, accordingly, equipment energy consumption is reduced, the equipment price is correspondingly reduced, and installation is more convenient and rapid. Personnel conduct control and monitoring on the ground, and safety is high.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Automatic pushing type soil pressure balance pipe jacking machine

ActiveCN111648778AExpand the cutting rangeImprove work efficiencyTunnelsTunnel engineeringAgricultural engineering

The invention discloses an automatic pushing type soil pressure balance pipe jacking machine, relates to the technical field of tunnel engineering, and mainly aims at solving the problem that the cutting diameter of an existing pipe jacking machine cannot be adjusted. An installing shell, cutter heads, a power unit driving the cutter heads to rotate and a conveying unit for outputting soil are included. The center position of one end of the installing shell is rotationally provided with a main shaft. The shaft section, located at the outer portion of the installing shell, of the main shaft isfixedly provided with the multiple cutter heads in the ring direction at equal interval. Each cutter head comprises an installing plate and two cutters symmetrically arranged on the installing plate at equal interval. An adjusting unit for adjusting the cutting diameter is further included and comprises an adjusting plate, connecting rods and a drive mechanism for driving the adjusting plate to rotate. The adjusting unit is arranged and comprises the adjusting plate, the connecting rods and the drive mechanism for driving the adjusting plate to rotate. The drive mechanism drives the adjustingplate to rotate, the adjusting plate drives the cutter heads to rotate through the connecting rods, the effective cutting length of the cutter heads is adjusted, and the purpose of adjusting the cutting diameter is achieved.

Owner:BEIJING MUNICIPAL CONSTR

Stone cutting equipment

ActiveCN107310056AAdjustable sizeAvoid it happening againWorking accessoriesStone-like material working toolsEngineeringUltimate tensile strength

The invention discloses stone cutting equipment. The stone cutting equipment comprises a base, a first cutting unit and a second cutting unit. The base is provided with a base plate, sliding rails and a workbench. The workbench comprises a support, a push plate and storing plates. The base is provided with a first supporting pillar, and the first supporting pillar is provided with a second supporting pillar. The second supporting pillar is provided with a motor and a main water pipe. The first cutting unit comprises a first mounting cover, a first rotating shaft and a first blade. A first branched water pipe is arranged in the first mounting cover. The second cutting unit comprises a second mounting cover, a second rotating shaft and second blades. The second rotating shaft is provided with first sleeves and second sleeves. Second branched water pipes are arranged in the second mounting cover and are further provided with herringbone sprayers. According to the stone cutting equipment, through combination of the first cutting unit and the second cutting unit, the cutting range is greatly widened and cutting efficiency is greatly improved; and cutting time is greatly shortened, the labor intensity is greatly relieved and the working efficiency is greatly improved.

Owner:达濠市政建设有限公司

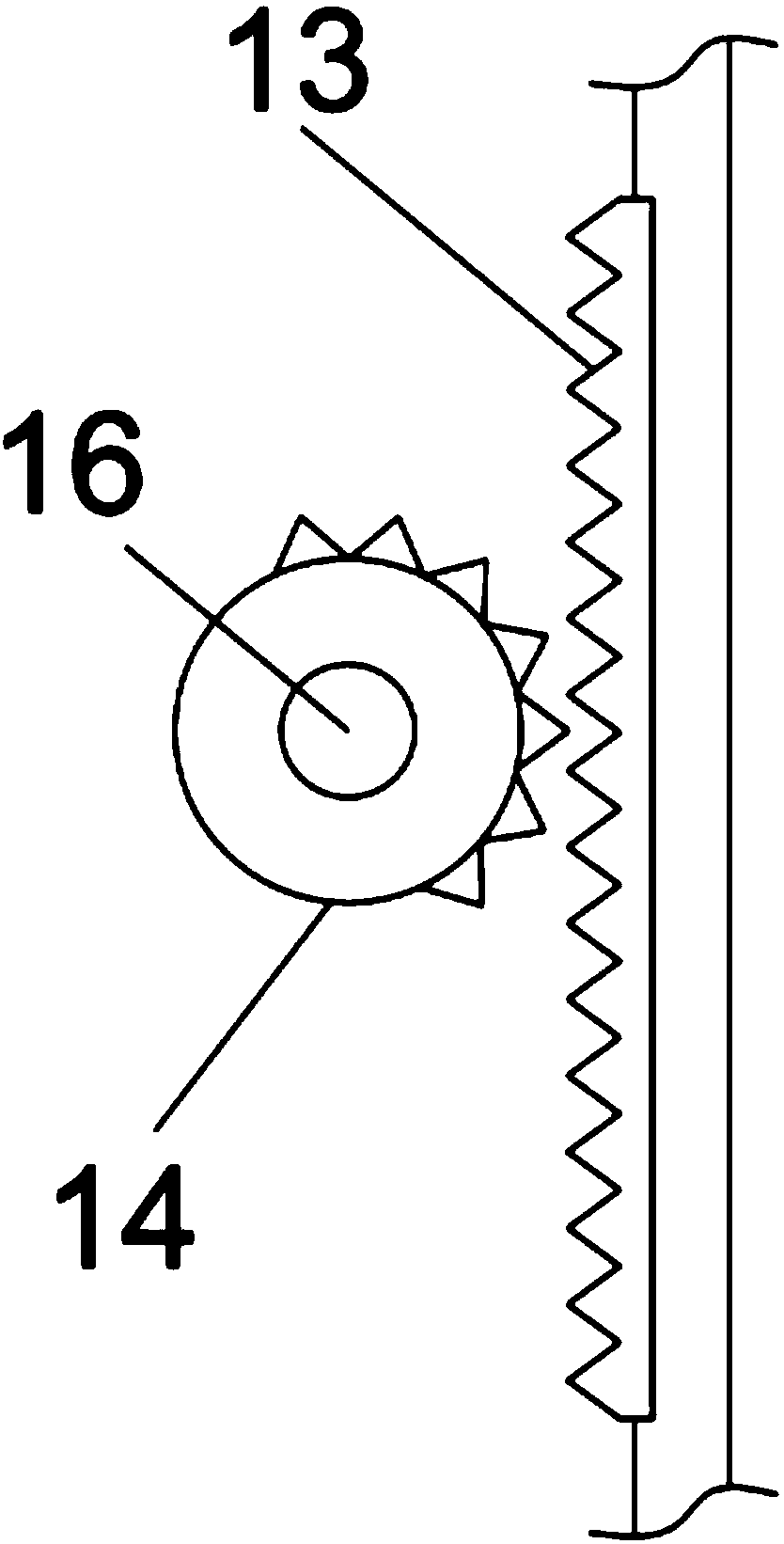

Vertical liftable rock cutting machine and use method thereof

PendingCN114012903AAdjustable widthExpand the cutting rangeWorking accessoriesStone-like material working toolsRock cuttingMachine

The invention discloses a vertical liftable rock cutting device and a use method thereof. The vertical liftable rock cutting device comprises a first sliding rail, a second sliding rail, a first sliding control device, a base, a bracket, an angle control device, a second sliding control device and a cutting device, wherein the first sliding rail is longitudinally arranged on one side of a rock to be cut; first sliding grooves are formed in the two outer longitudinal side faces of the first sliding rail; sawteeth are arranged on one inner longitudinal side face of the first sliding rail in the longitudinal direction in a full-length mode; and the second sliding rail is longitudinally and adjustably connected to the first sliding rail, and a connecting plate is fixed to the bottom of the second sliding rail. The rock cutting machine is particularly suitable for outdoor operation; by arranging the first sliding rail and the second sliding rail, the cutting machine can be transversely and longitudinally adjusted on one side of a rock to be cut, and the width of the rock to be cut can be adjusted according to field requirements. The double-blade type saw blade is adopted and can be vertically lifted, the cutting range is expanded, convenience is provided for the follow-up construction process, the cutting quality is guaranteed, and the construction efficiency is improved.

Owner:中国建筑土木建设有限公司

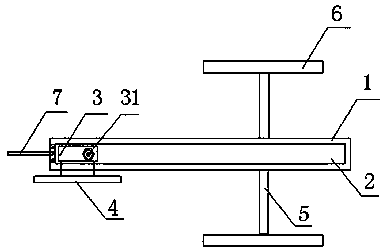

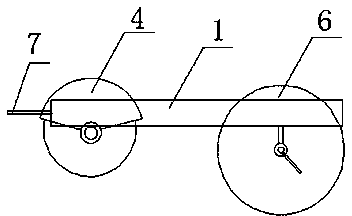

Cutting machine for steel pipe of heat exchanger

InactiveCN104175033AIncrease walking distancePrevent movementWelding/cutting auxillary devicesShearing machinesAgricultural engineeringHeat exchanger

The invention discloses a cutting machine for a steel pipe of a heat exchanger. The cutting machine comprises a rack, a knife wheel is arranged at one end of the rack and connected with a transmission device, one side of the rack is connected with a sliding rail which is connected with a walking linear bearing, the walking linear bearing is connected to the knife wheel, the rack is connected with a wheel shaft, and a wheel is arranged at each of two ends of the wheel shaft. The walking linear bearing can move on the sliding rail, so that parallel moving of the knife wheel on the rack is realized, walking stroke of the cutting machine is increased, and walking process is stable; due to designing of the wheel shaft, the wheels can be adjusted to enable the rack to rotate around the wheel shaft so as to enable the cutting machine to cut within a plane range, so that cutting range is further expanded, and moving of large workpieces is avoided. The cutting machine is practical, convenient, reasonable in structure and suitable for popularization and application.

Owner:WUXI 369 STEEL PIPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com