Modular polar coordinate cutting method with variable functions and digital controlled cutting apparatus

A cutting machine and polar coordinate technology, applied in the direction of digital control, electrical program control, metal processing machinery parts, etc., can solve the problems of fixed processing range, single function, slow cutting speed, etc., and achieve the effect of expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

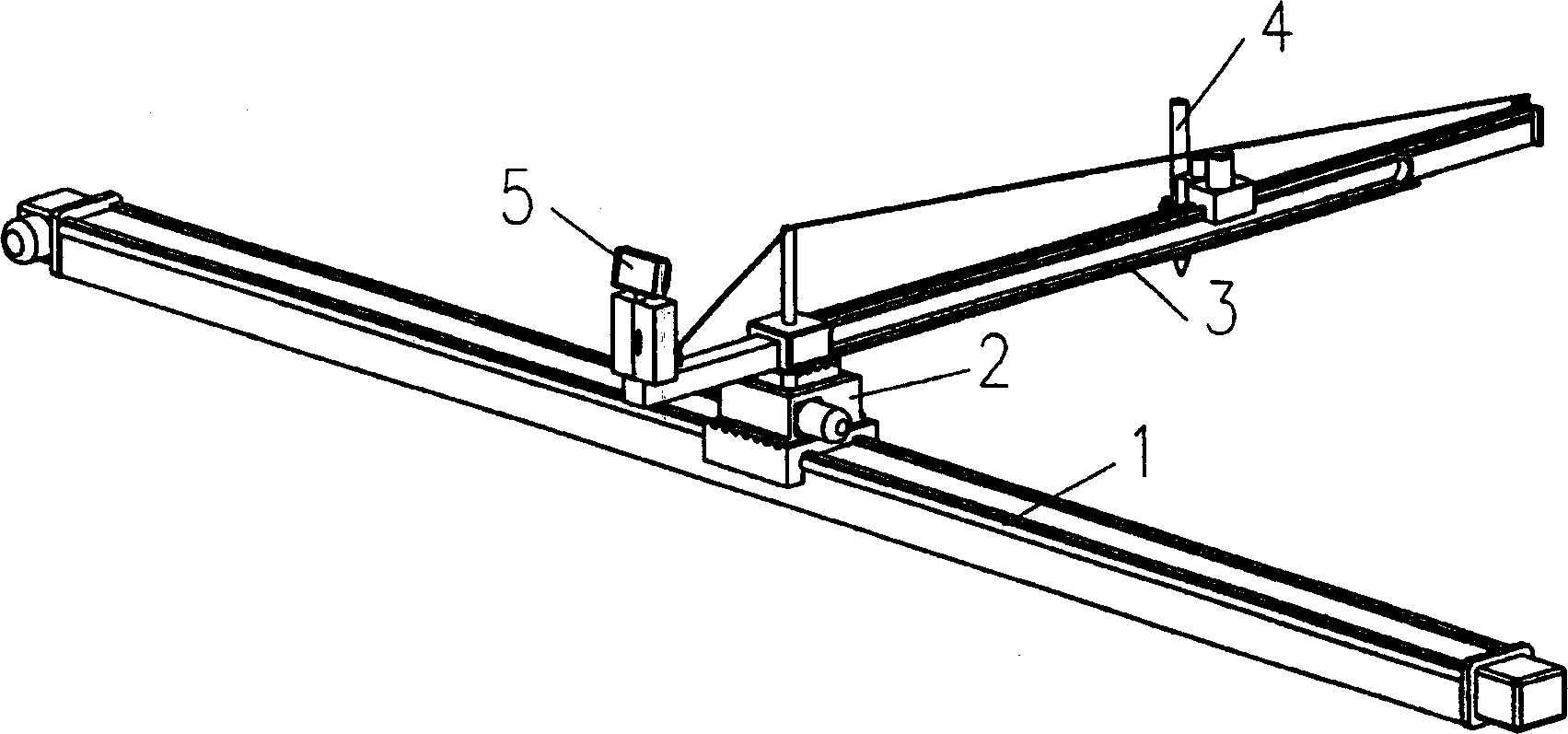

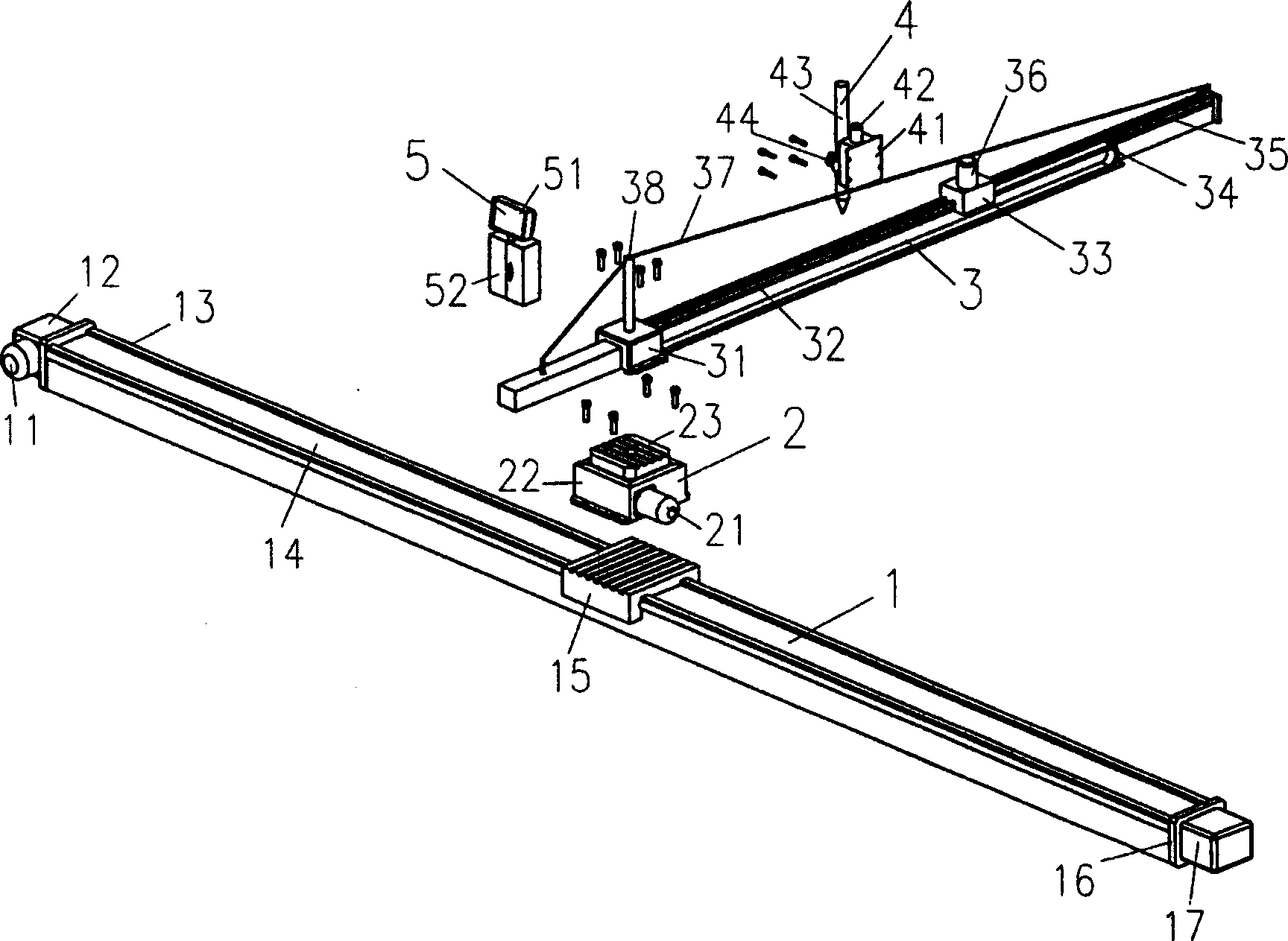

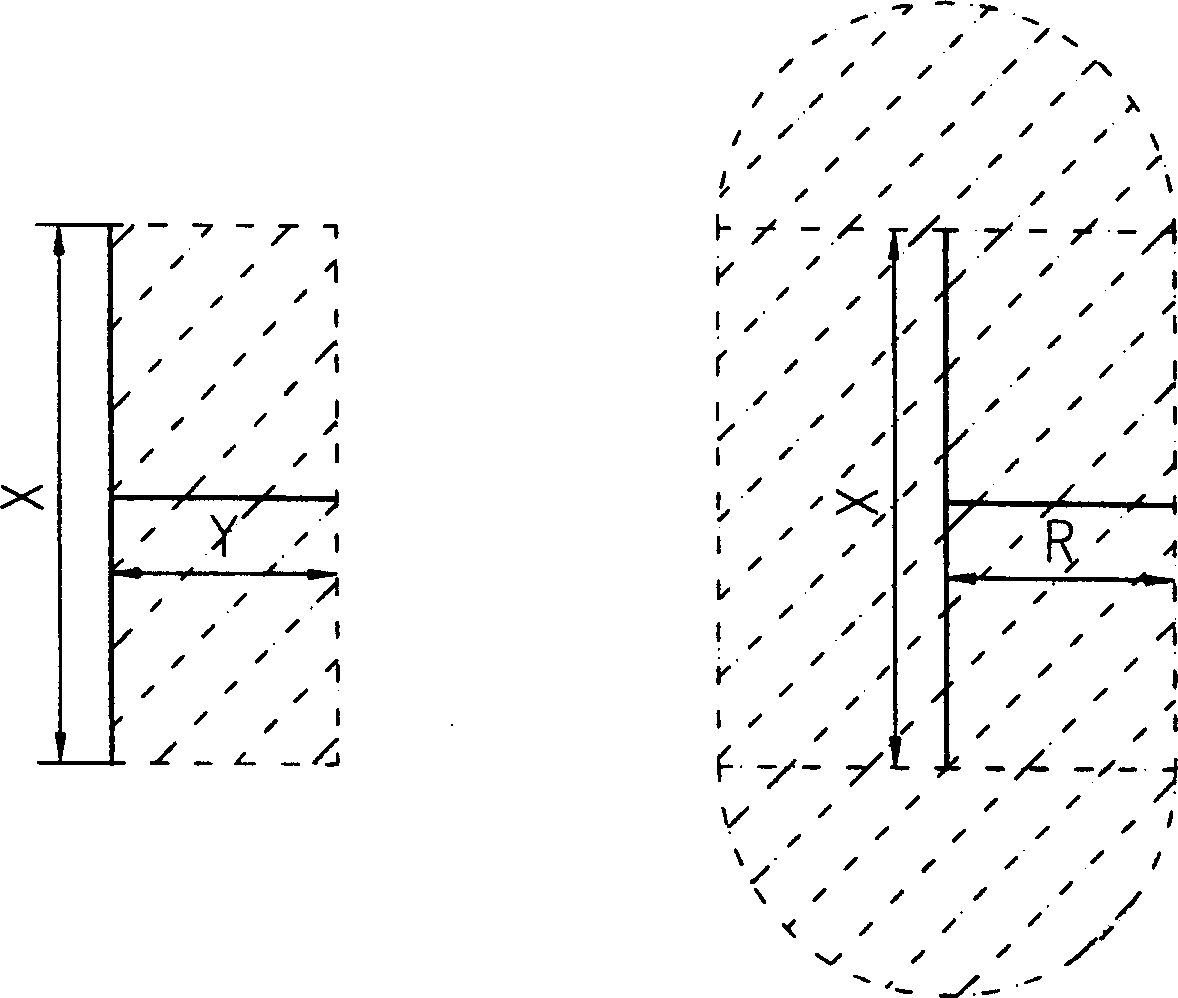

[0023] A module is a group of interchangeable units that have the same function and combined elements but differ in performance, specification or structure. On the basis of market forecast and functional analysis of products, a series of functional modules are divided and designed, and different products are formed through the selection and combination of modules to meet the different needs of the market. Modular technology is the interchangeability of components. Base. The present invention applies the modular design concept to the cutting machine. It decomposes the various components of the cutting machine into modules according to different processing needs. By replacing the corresponding modules, the cutting range of the cutting machine tool is increased or the cutting function of the machine tool is improved. At the same time, each module is designed as a polar coordinate structure, which makes the cutting of arcs, rings, sectors, etc. very simple, so as to improve produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com