Furniture production and machining equipment

A technology for processing equipment and furniture, which is applied in metal processing equipment, lighting and heating equipment, wood processing equipment, etc. It can solve the problems of not having the flexible cutting ability of wood raw materials, and can not realize fixed and long grinding, so as to achieve reliable connection, inspection and maintenance Convenience and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be described in detail below in conjunction with the drawings:

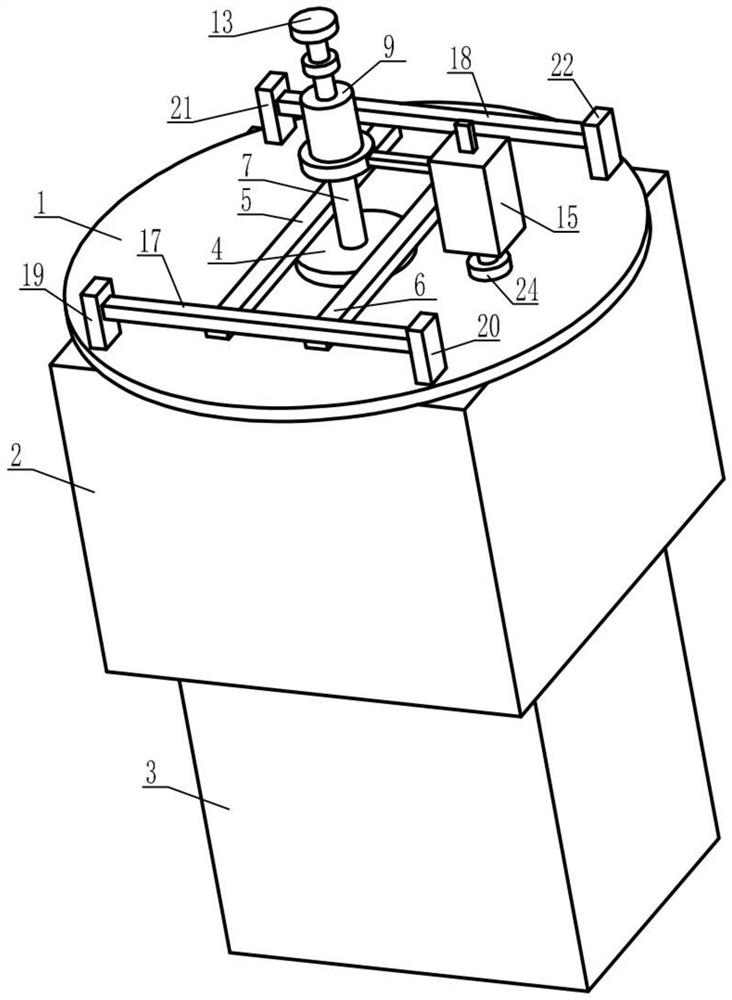

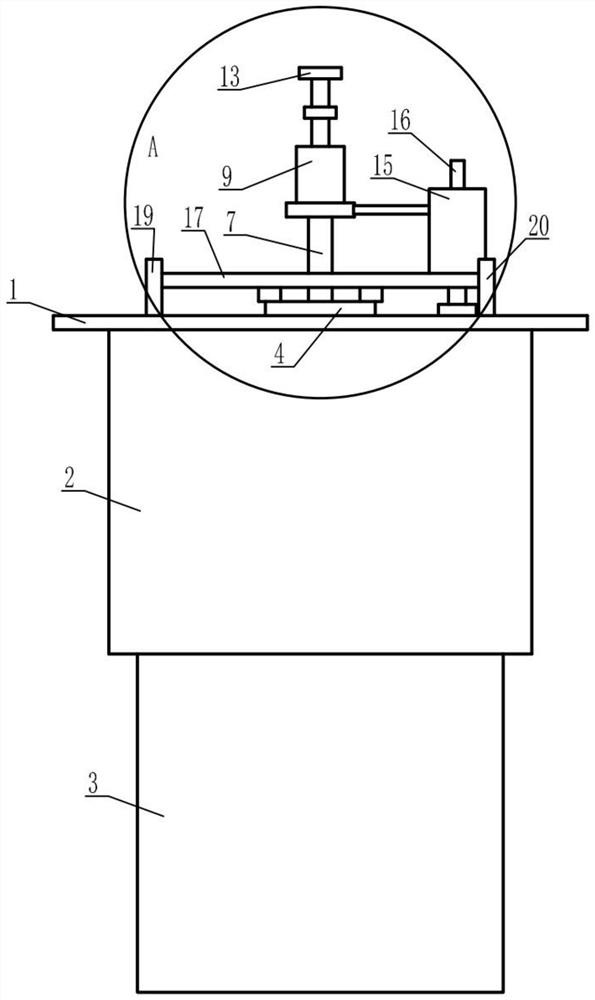

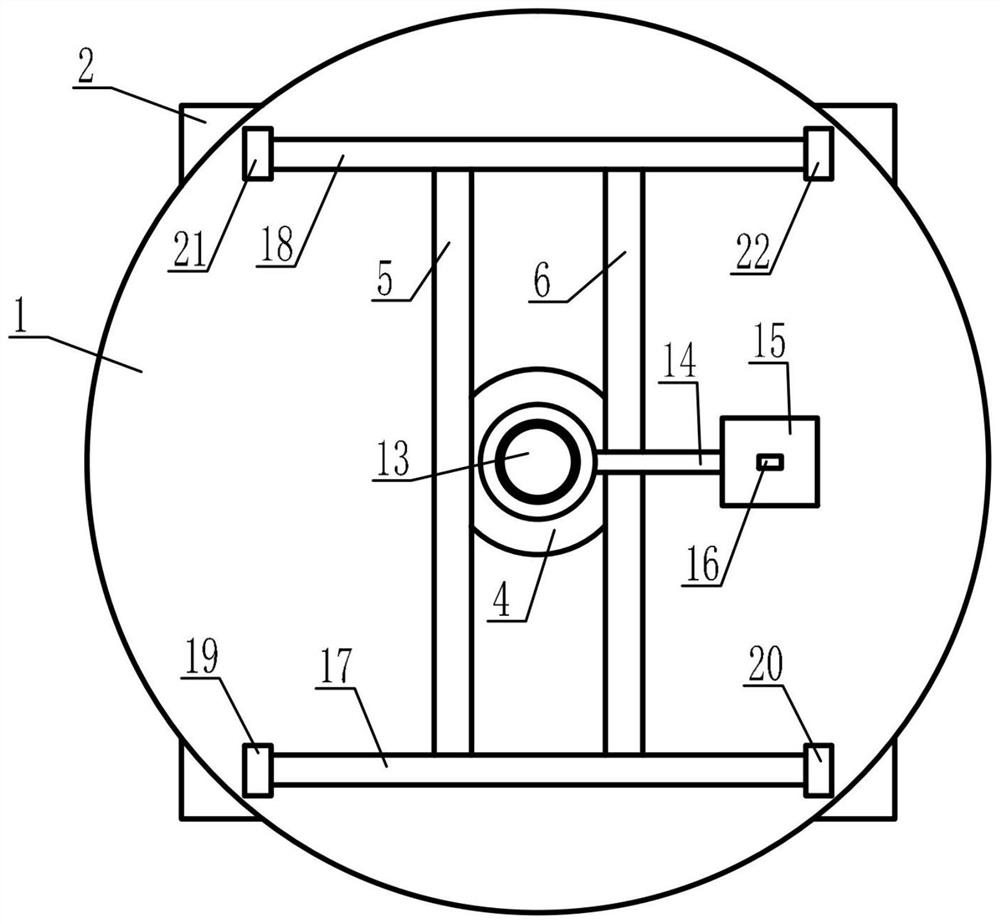

[0031]Refer toFigure 1 to Figure 9, The furniture production and processing equipment provided by the present invention includes a grinding box 2, a circular substrate 1 is arranged on the top of the grinding box 2, and a drying box 3 is arranged at the bottom of the grinding box 2, and The top surface of the circular substrate 1 is fixed with a left front fixed rod 19, a right front fixed rod 20, a left front fixed rod 21, and a left rear fixed rod 22. A front position is fixed between the left front fixed rod 19 and the right front fixed rod 20. Long strip 17, a rear strip 18 is fixed between the left front fixed rod 21 and the left rear fixed rod 22, and the bottom surface of the front strip 17 is connected to the left strip 5 and the right strip 6 The upper surface of the front end is in contact, and the bottom surface of the rear strip 18 is in contact with the upper surface of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com