Patents

Literature

989 results about "Rock cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

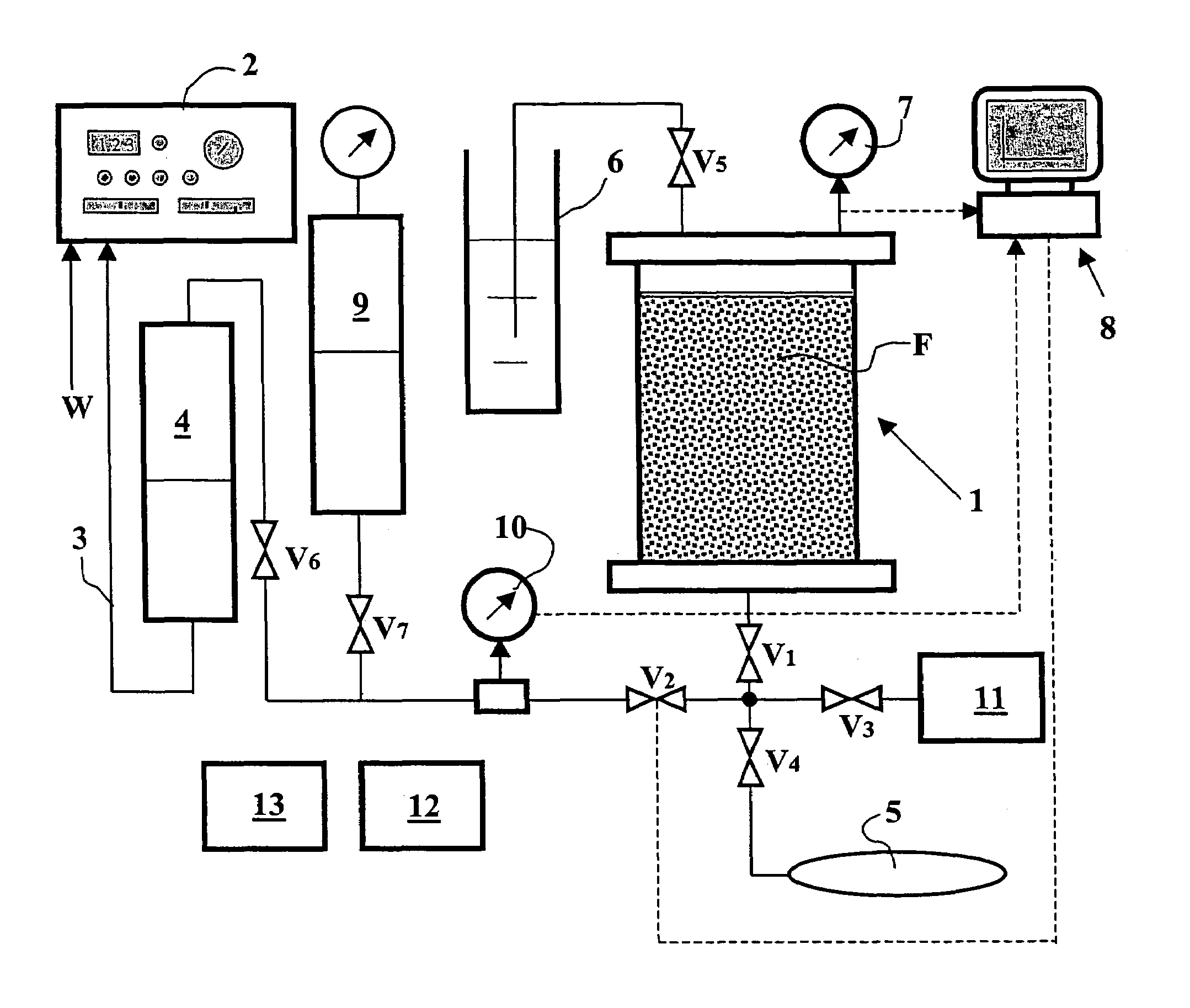

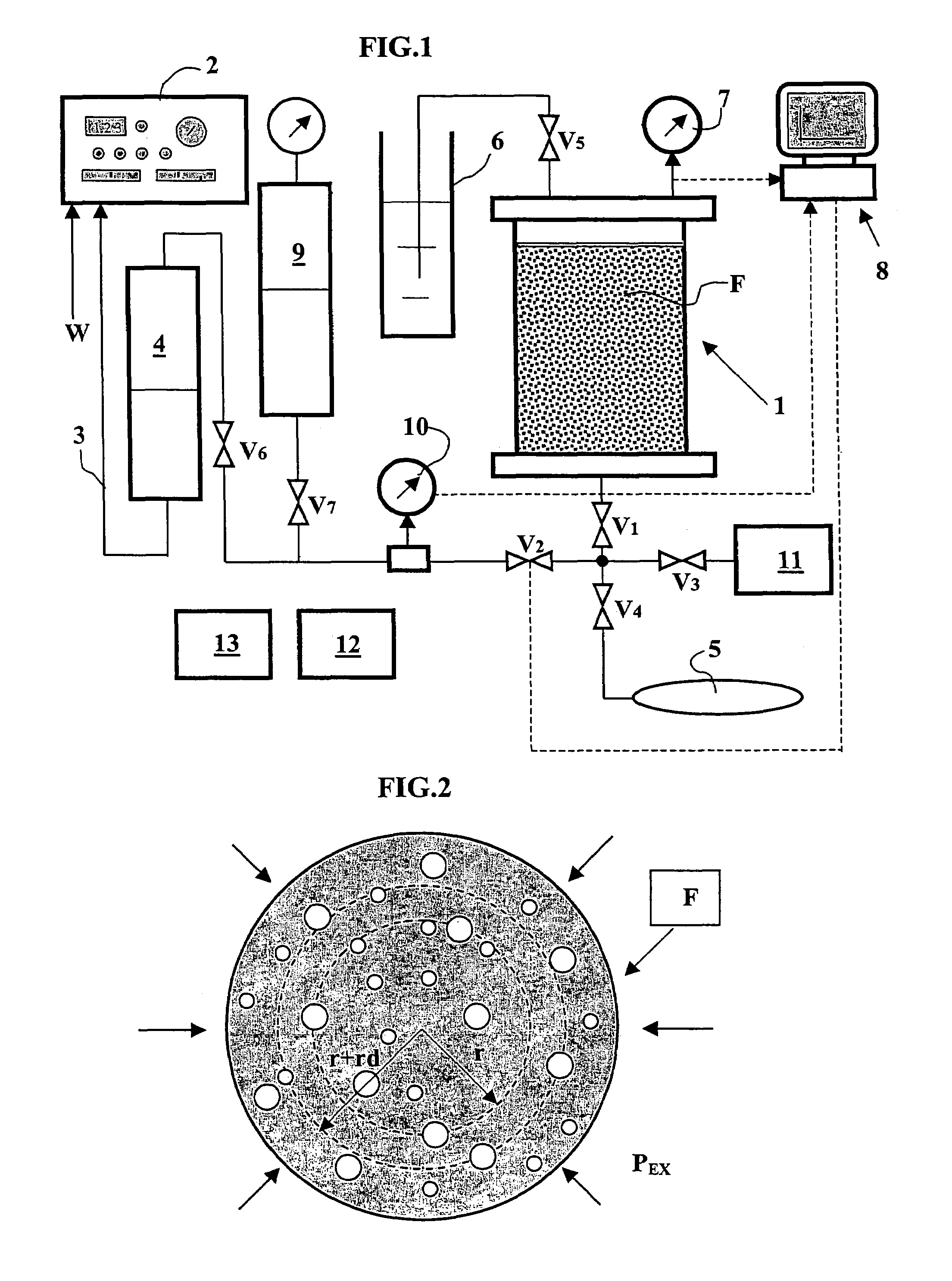

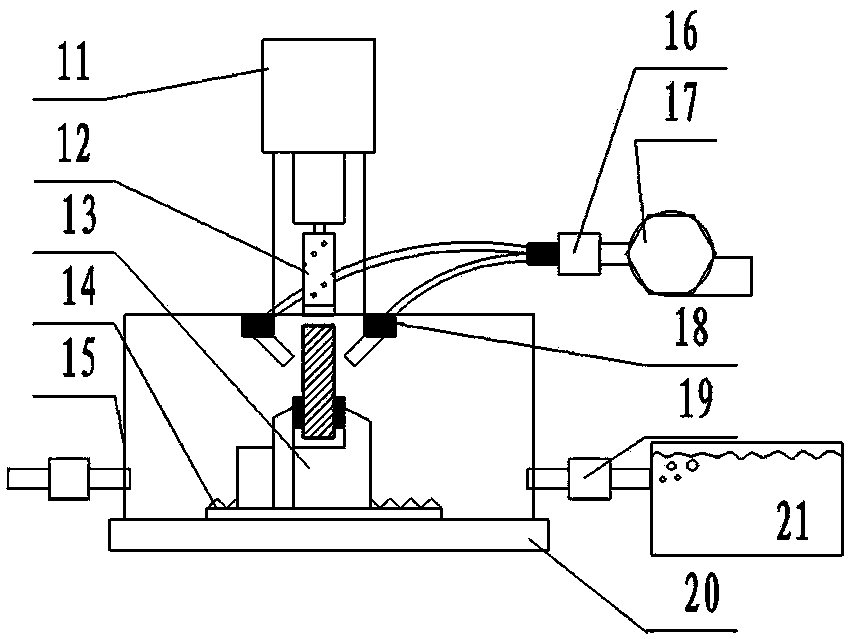

Method and device for evaluating physical parameters of an underground deposit from rock cuttings sampled therein

InactiveUS20050178189A1Short timeLimited spaceElectric/magnetic detection for well-loggingPermeability/surface area analysisMedicinePorous medium

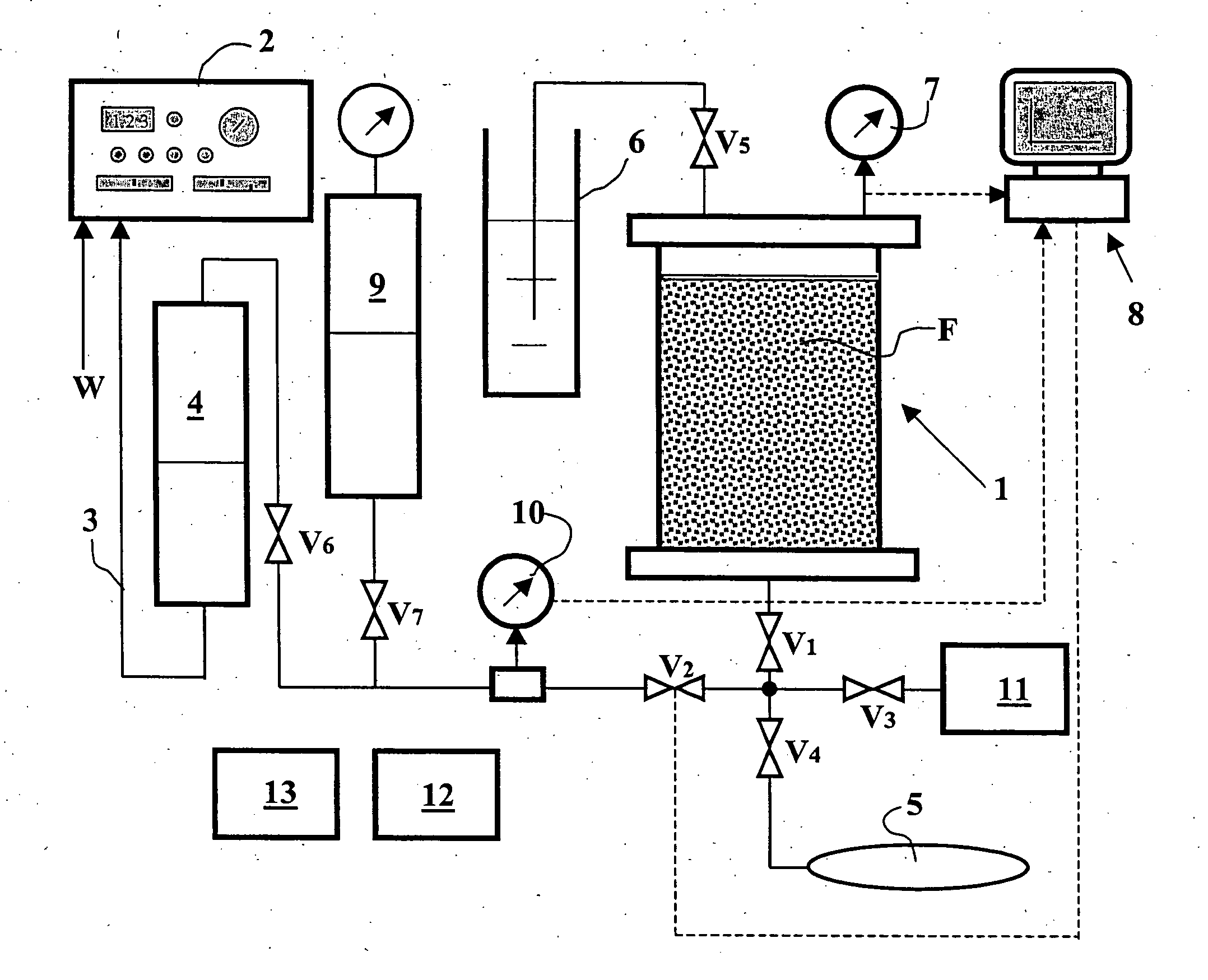

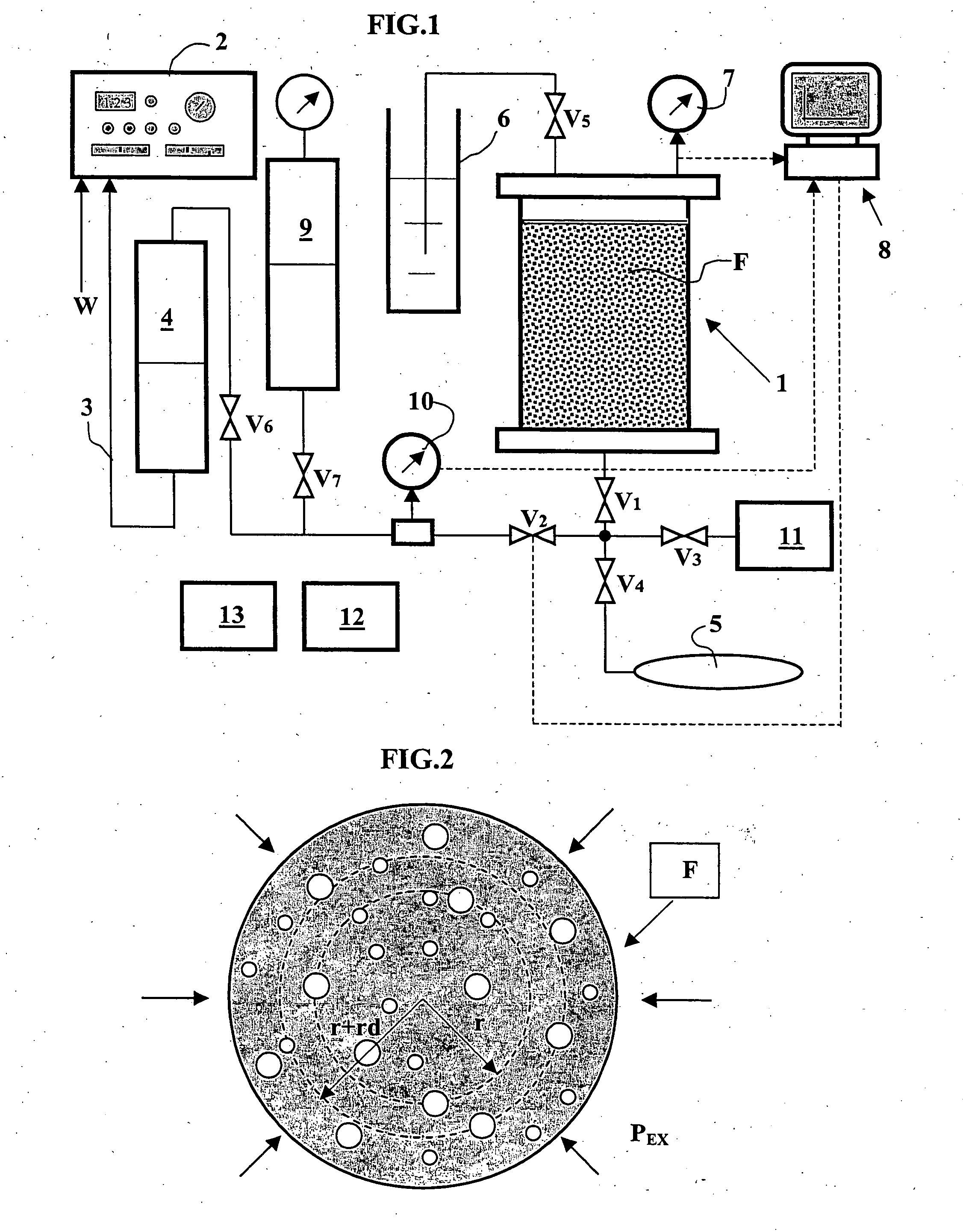

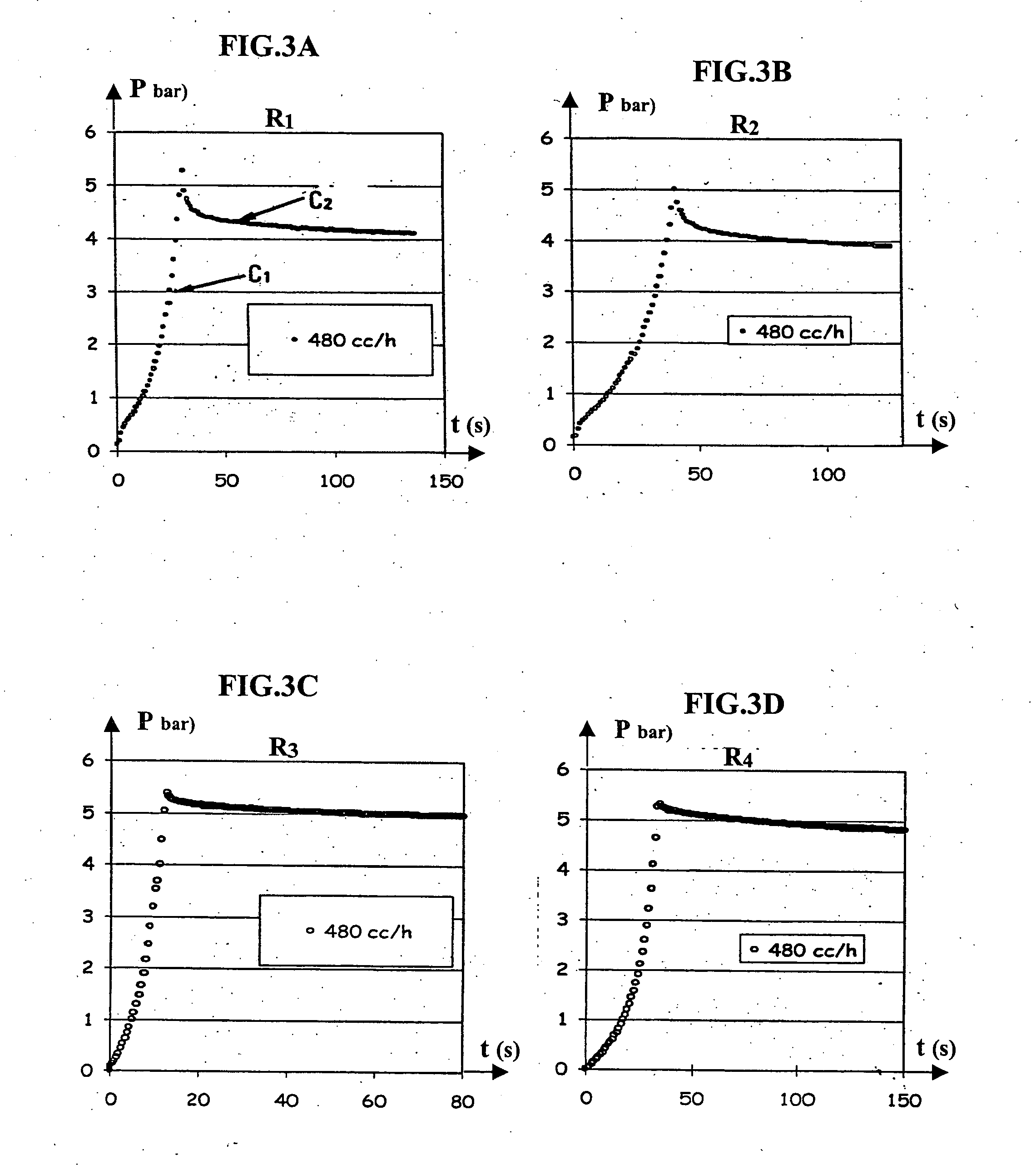

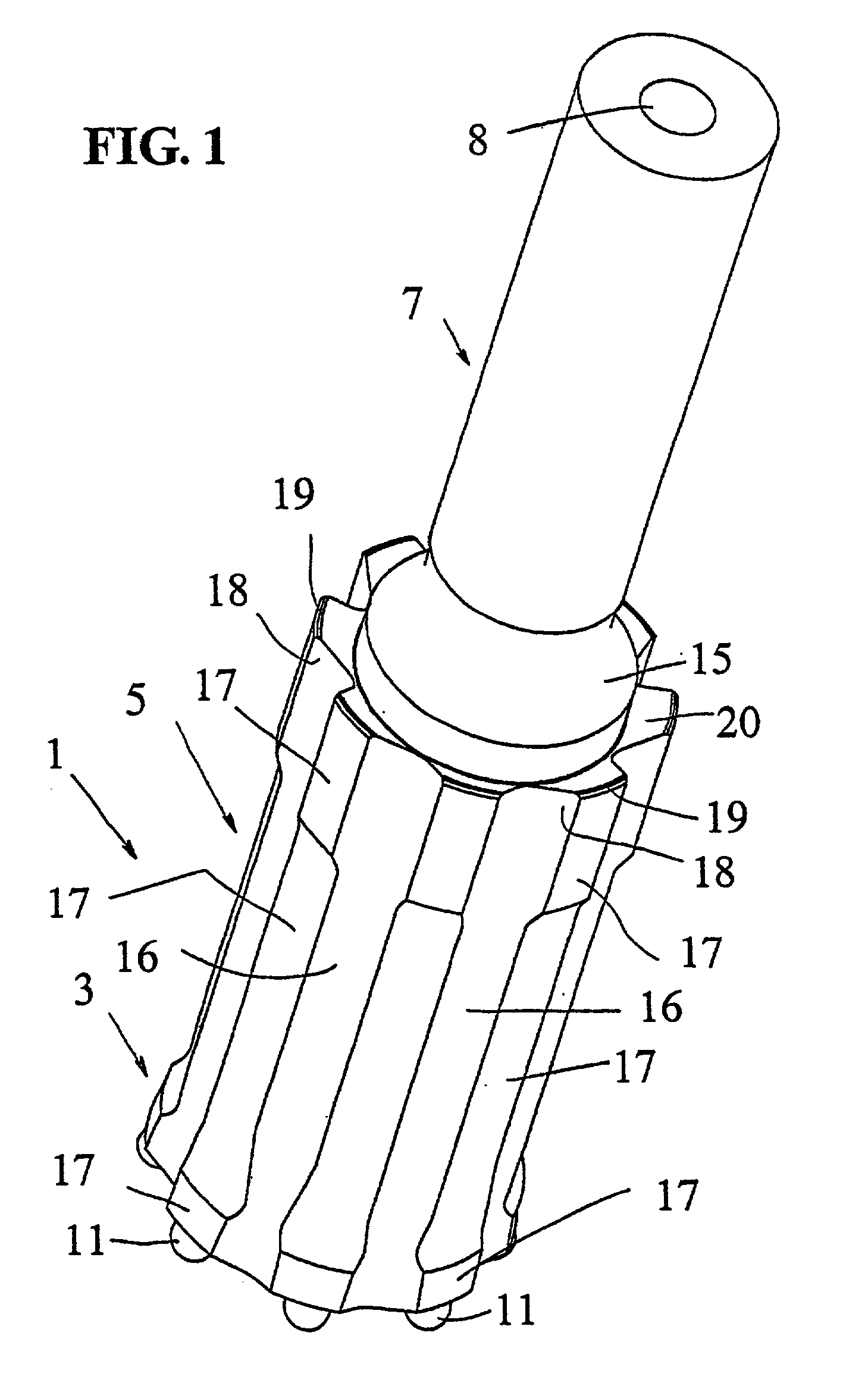

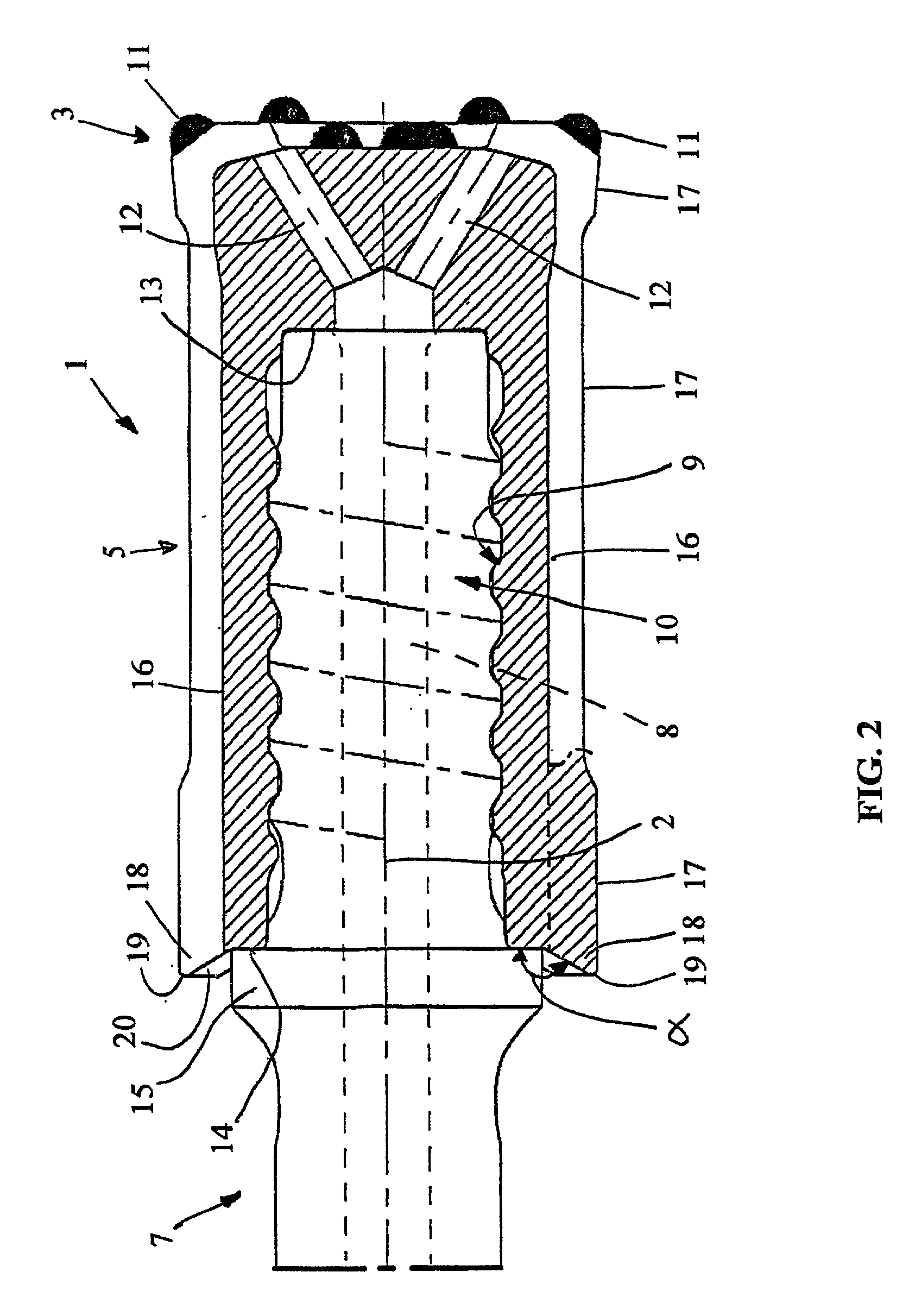

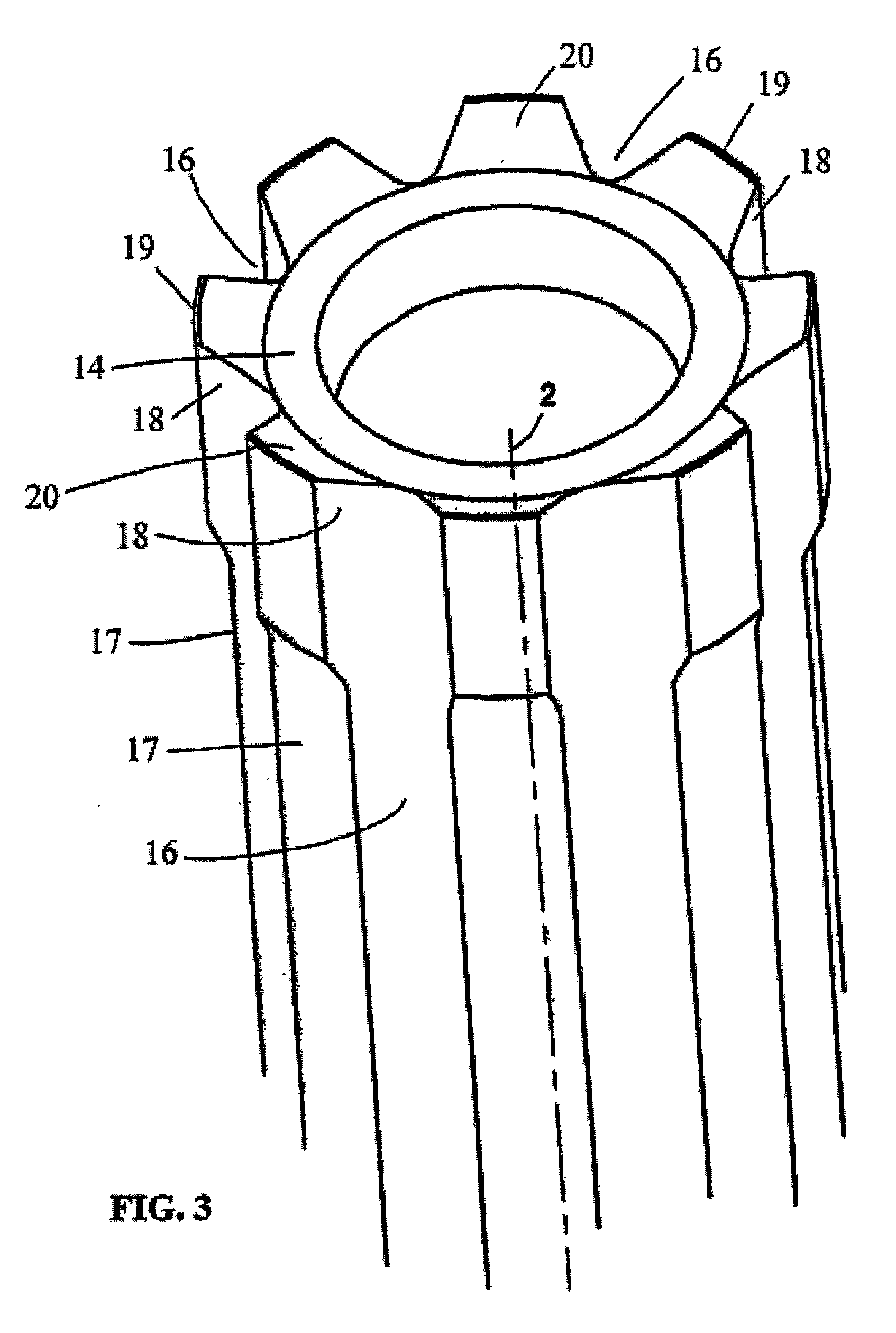

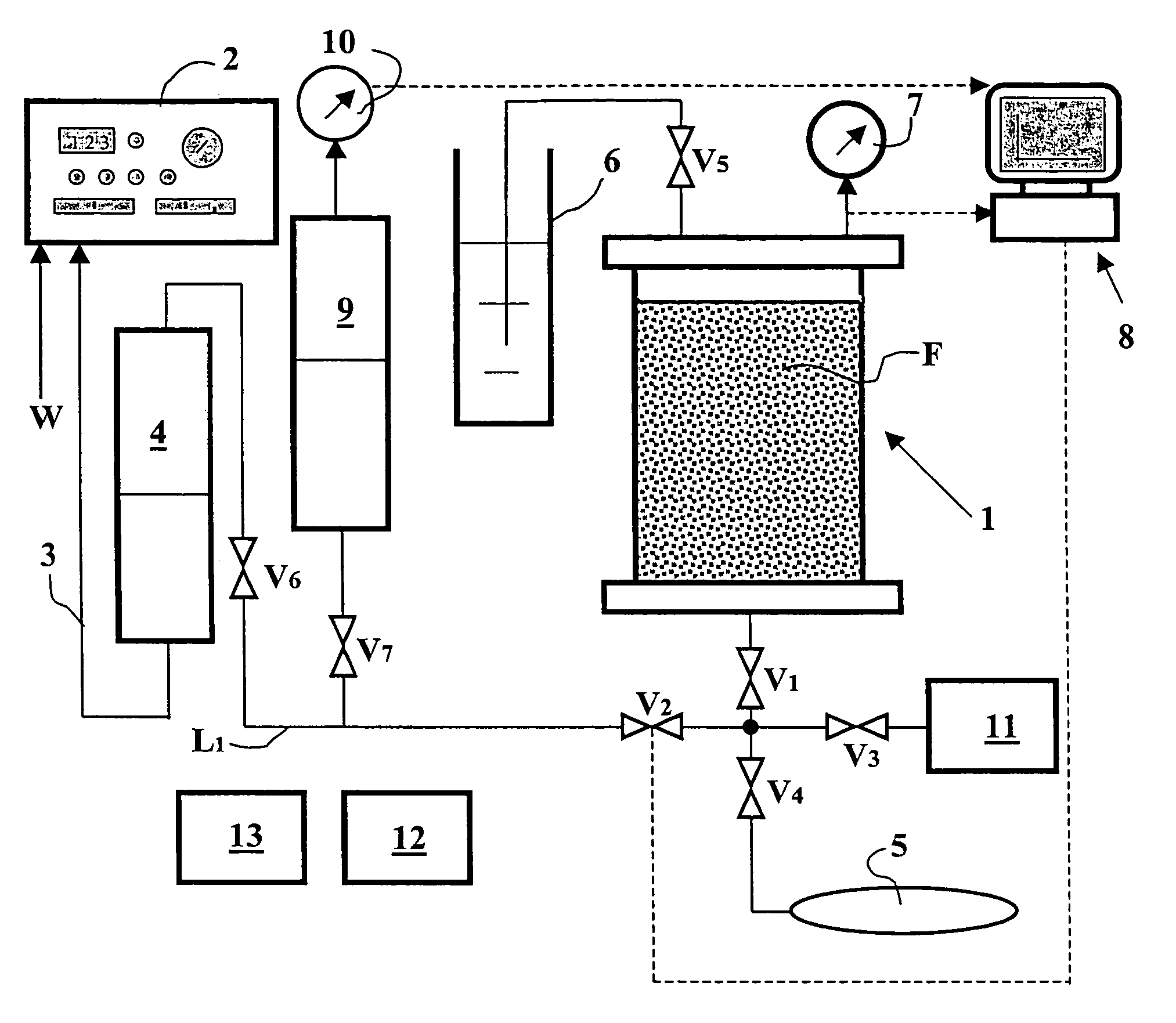

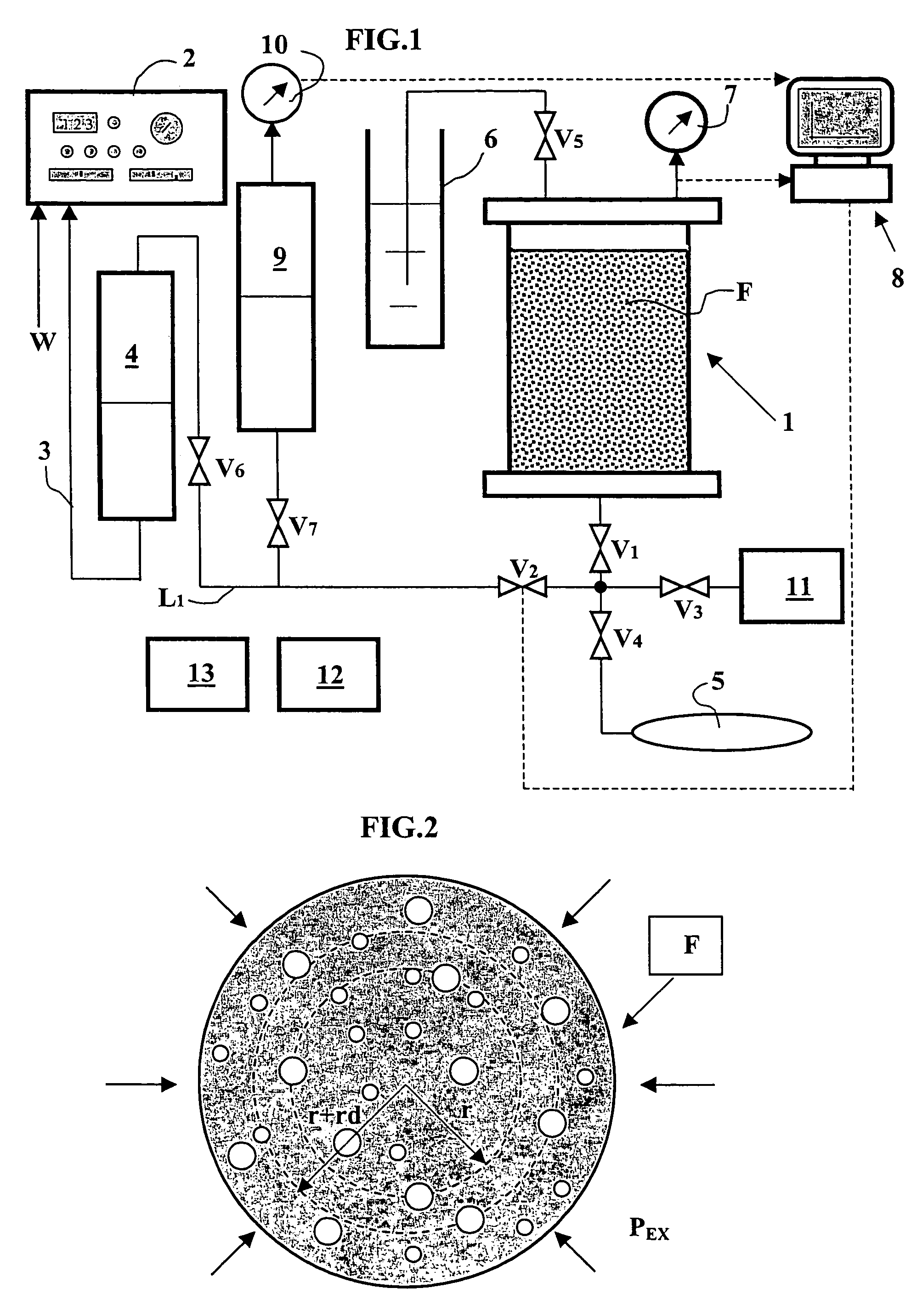

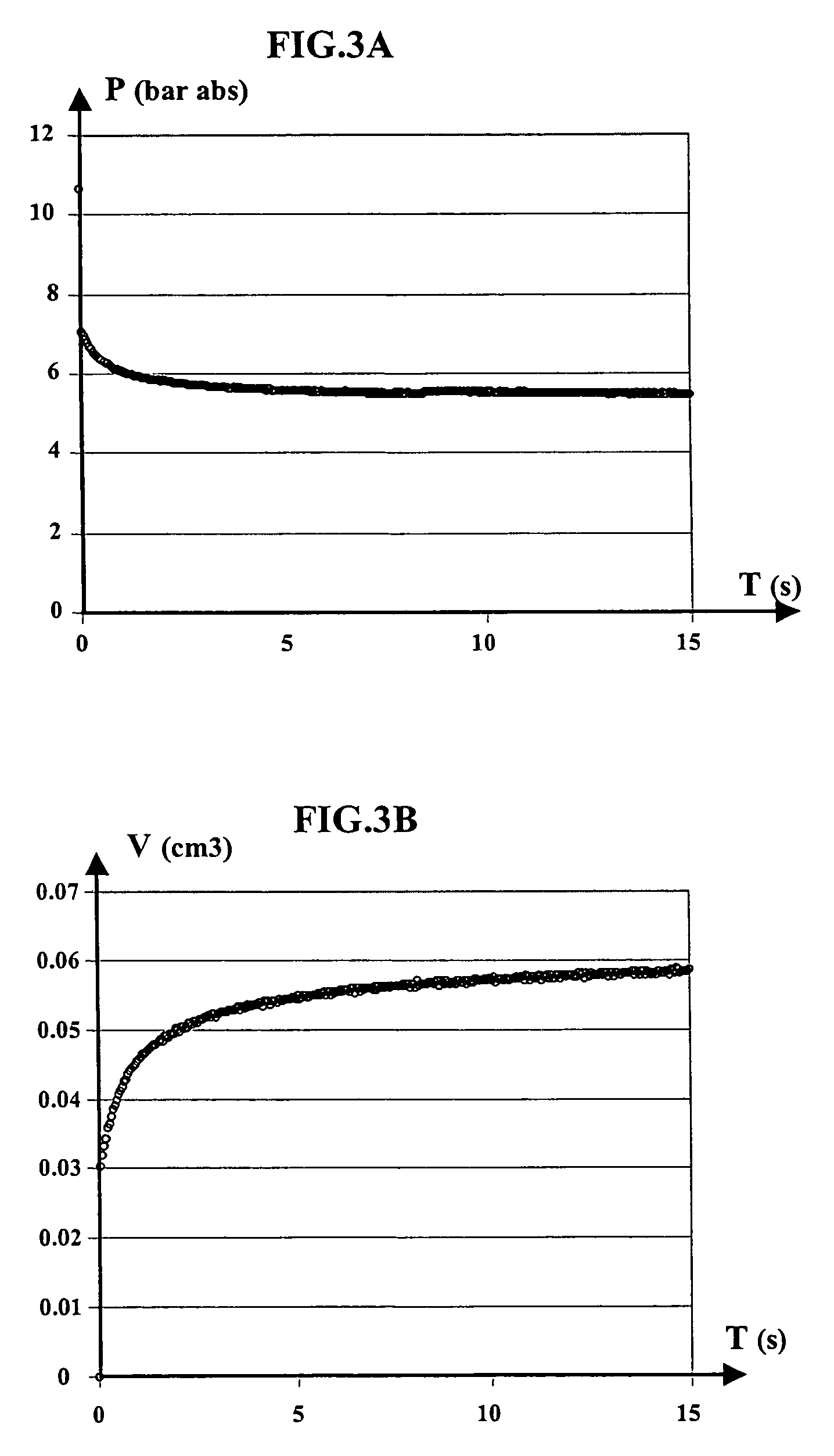

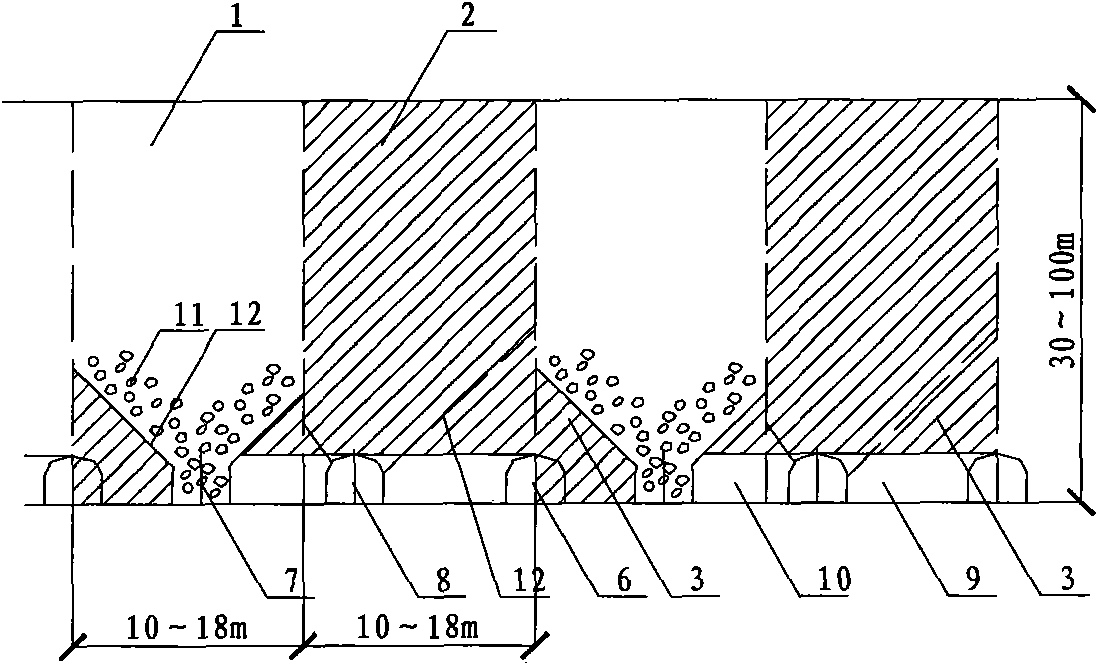

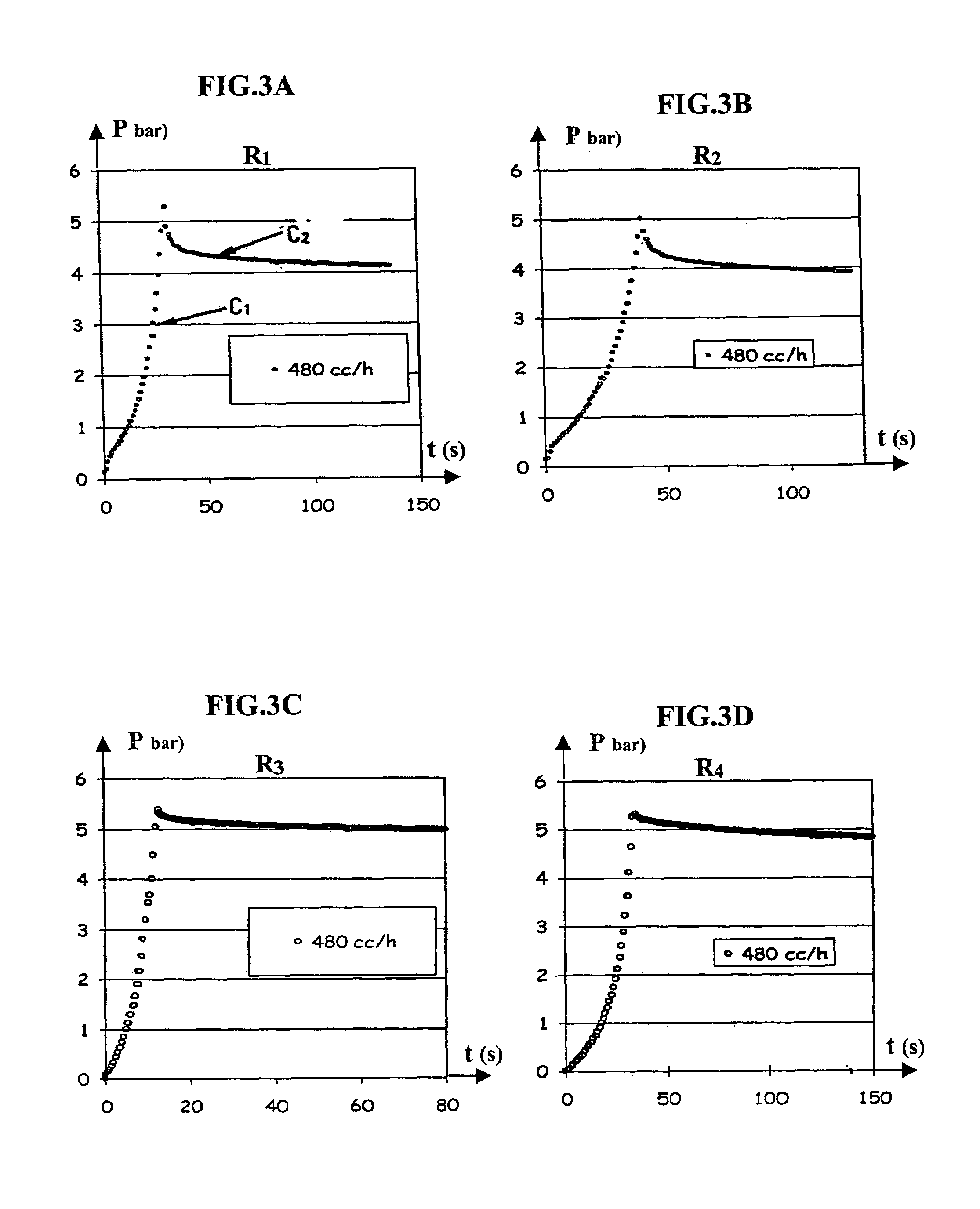

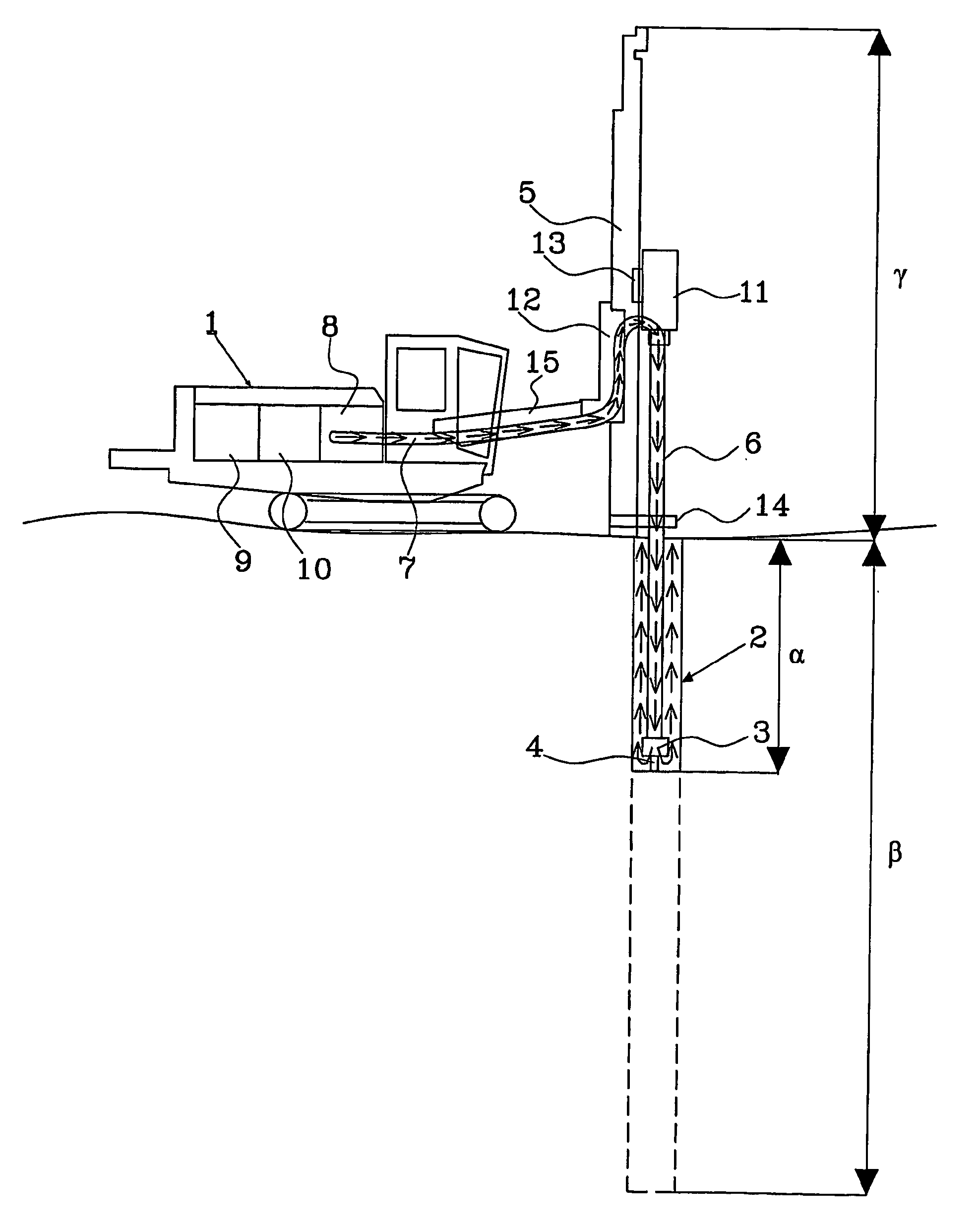

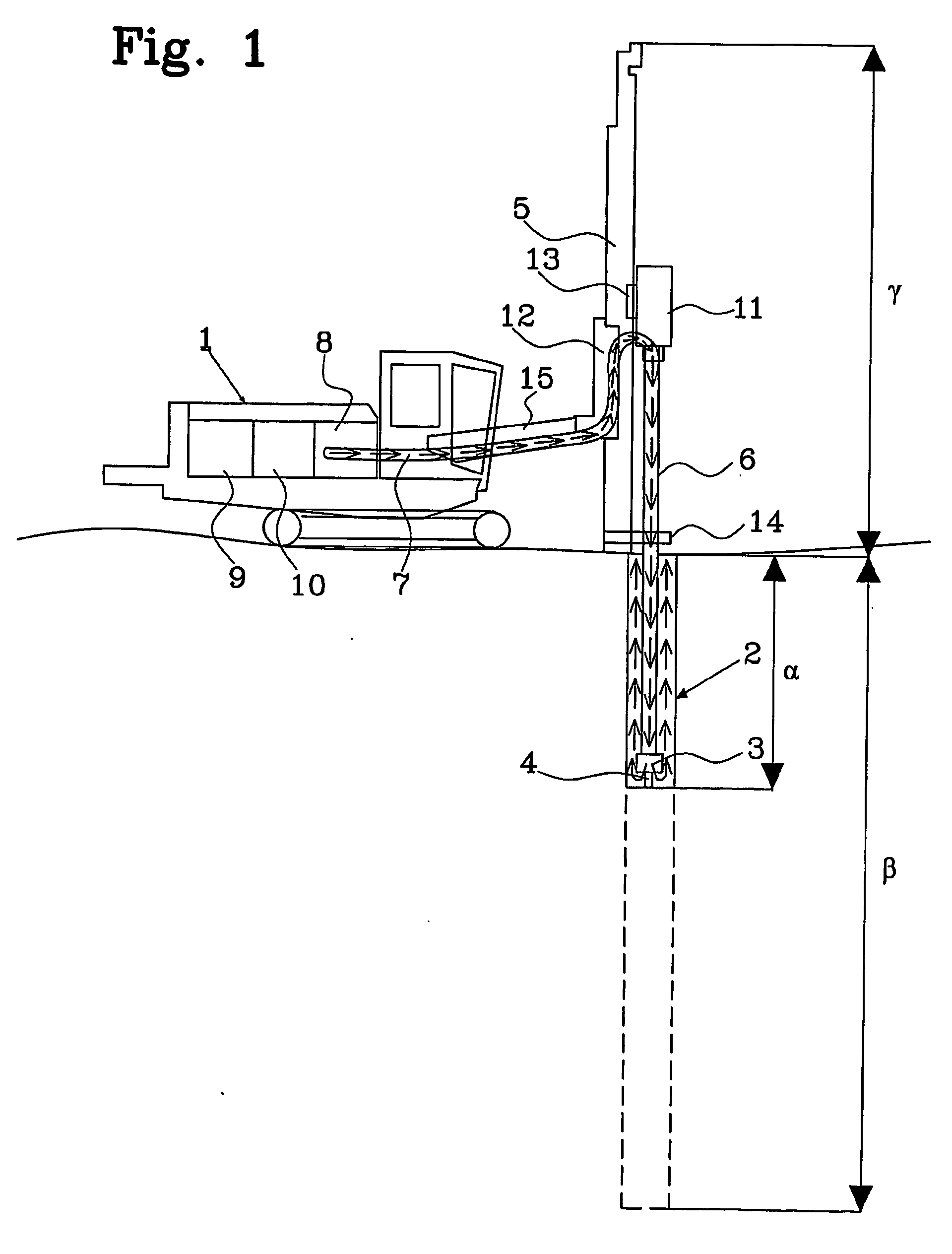

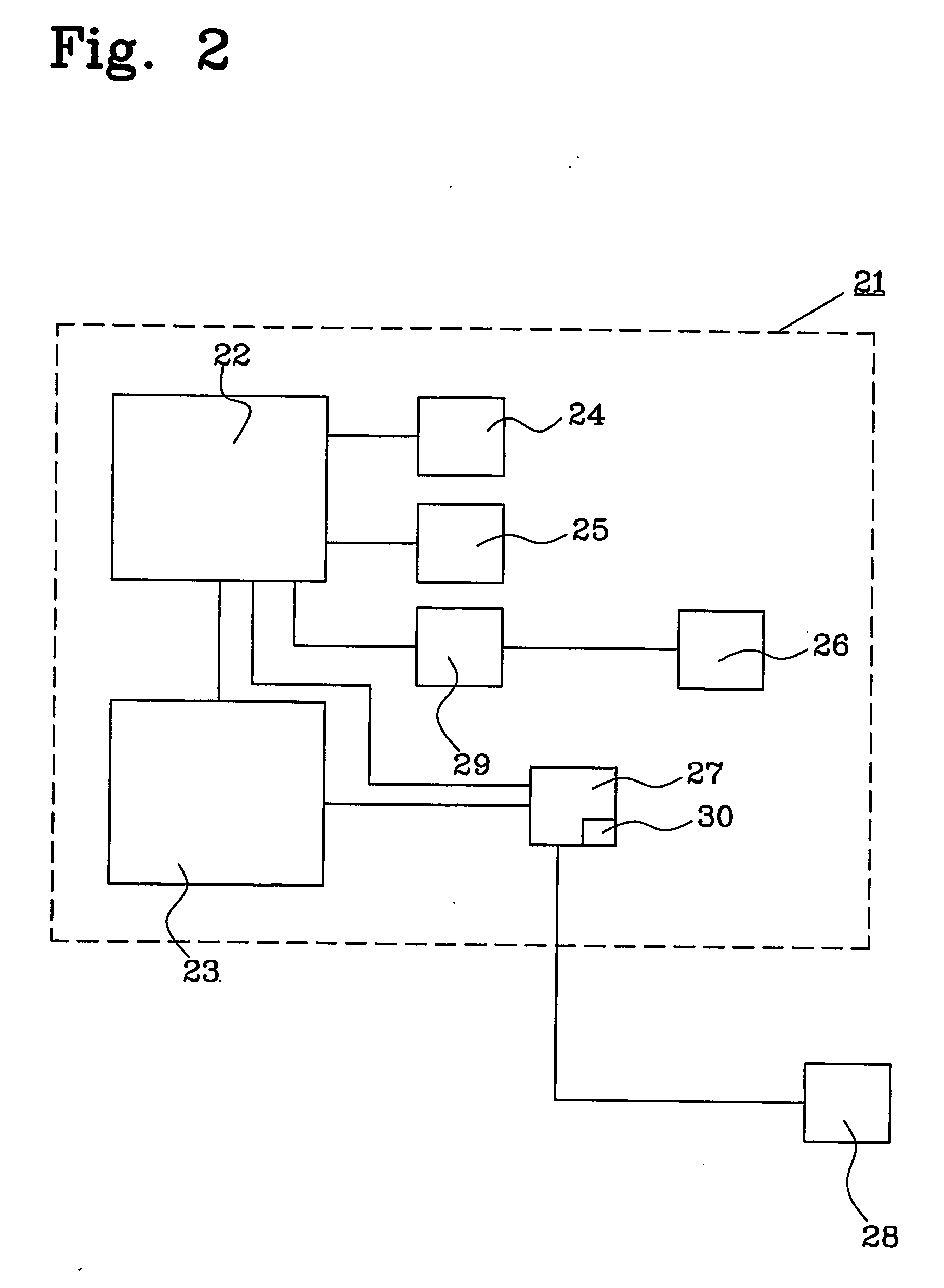

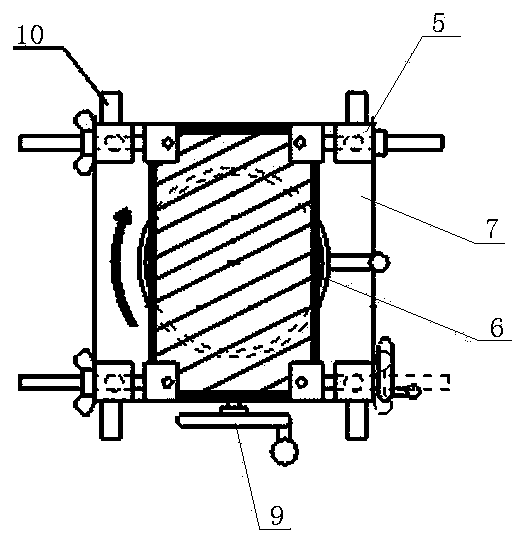

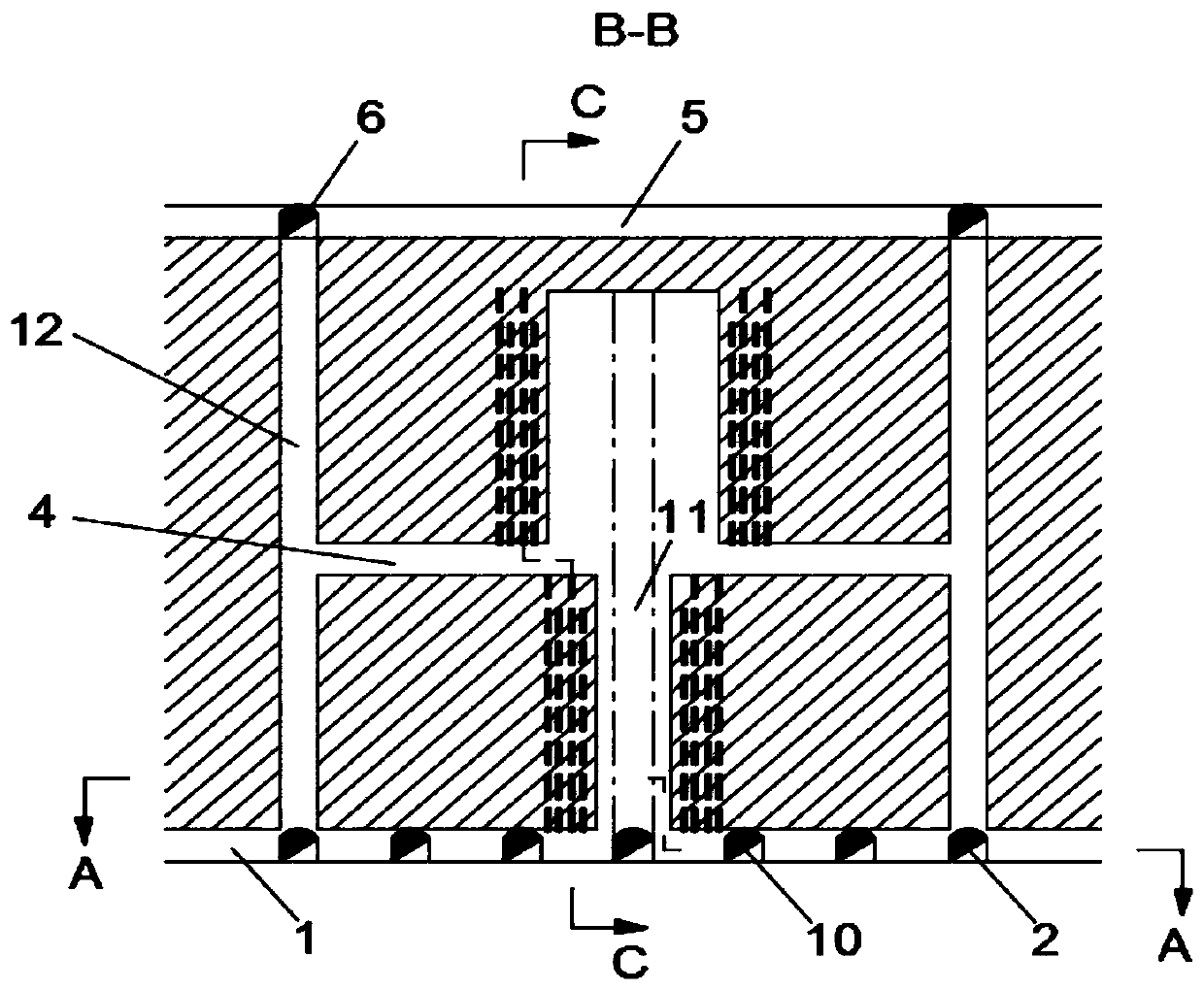

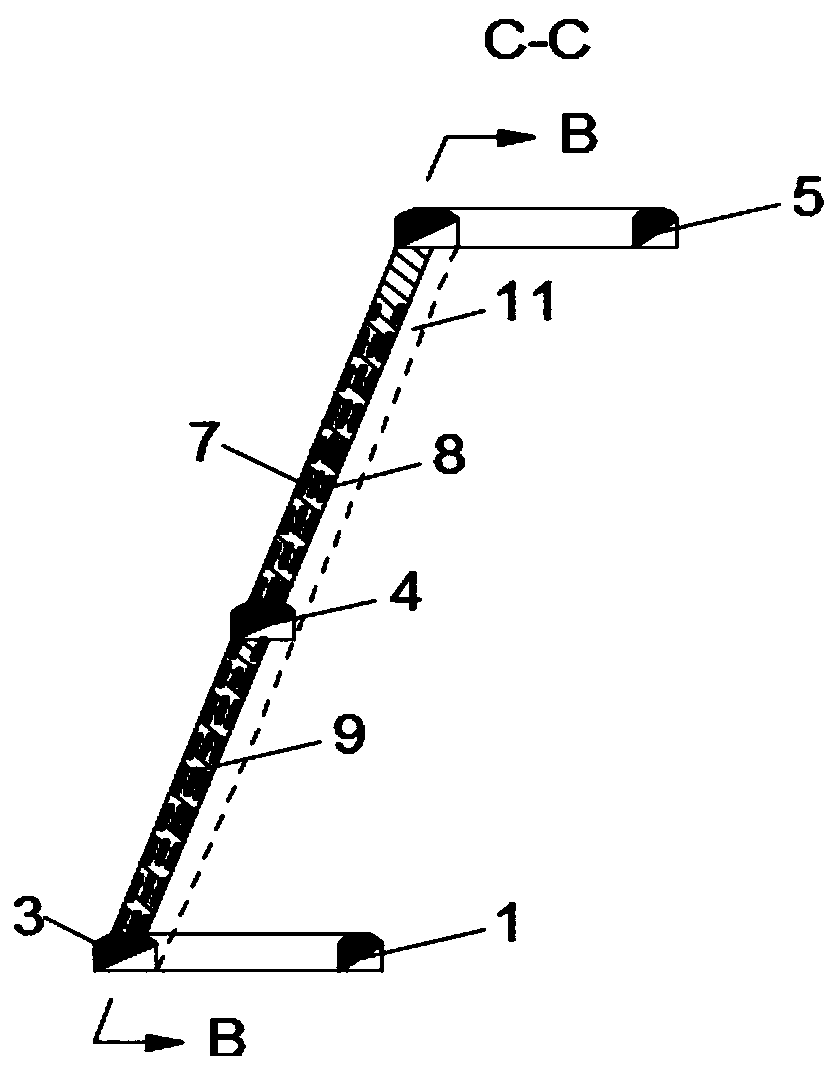

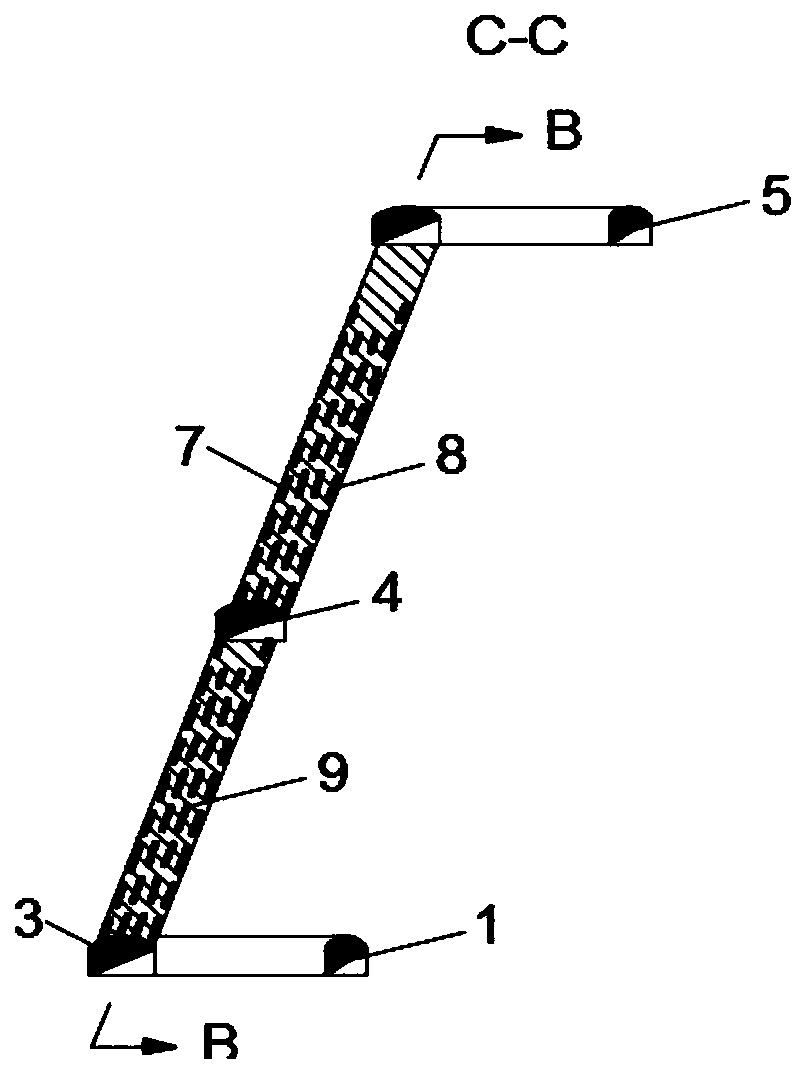

Method and device for evaluating simultaneously, with the same equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented natural or artificial porous medium The porosity of the fragments is measured by means of helium pressure tests according to a protocol known in the art. The chamber (1) containing the fragments is communicated with a tank (11) whose volume is also known and containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the fragments mass are also measured. Combining these measurements allows to determine the porosity of the samples and the density of the rock. Their permeability is then measured by immersing them in a viscous fluid and by communicating the chamber with viscous fluid at a determined pressure contained in a vessel (9) so as to compress the gas trapped in the pores of the rock, according to two different protocols. The values of the physical parameters are determined by modelling the evolution of the pressure or of the volume in the chamber and by means of an iterative adjustment. Applications: petrophysical measurements from drilling cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

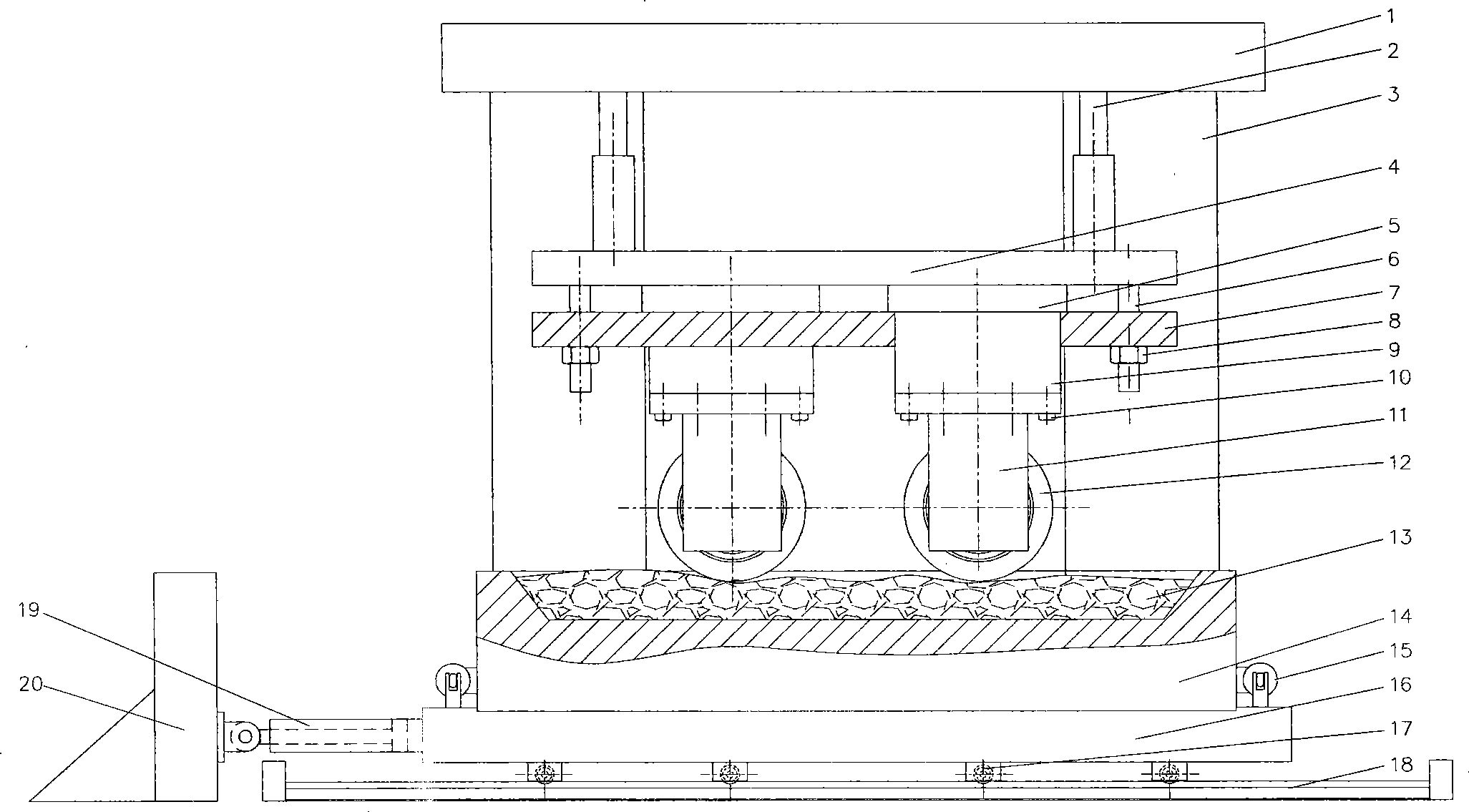

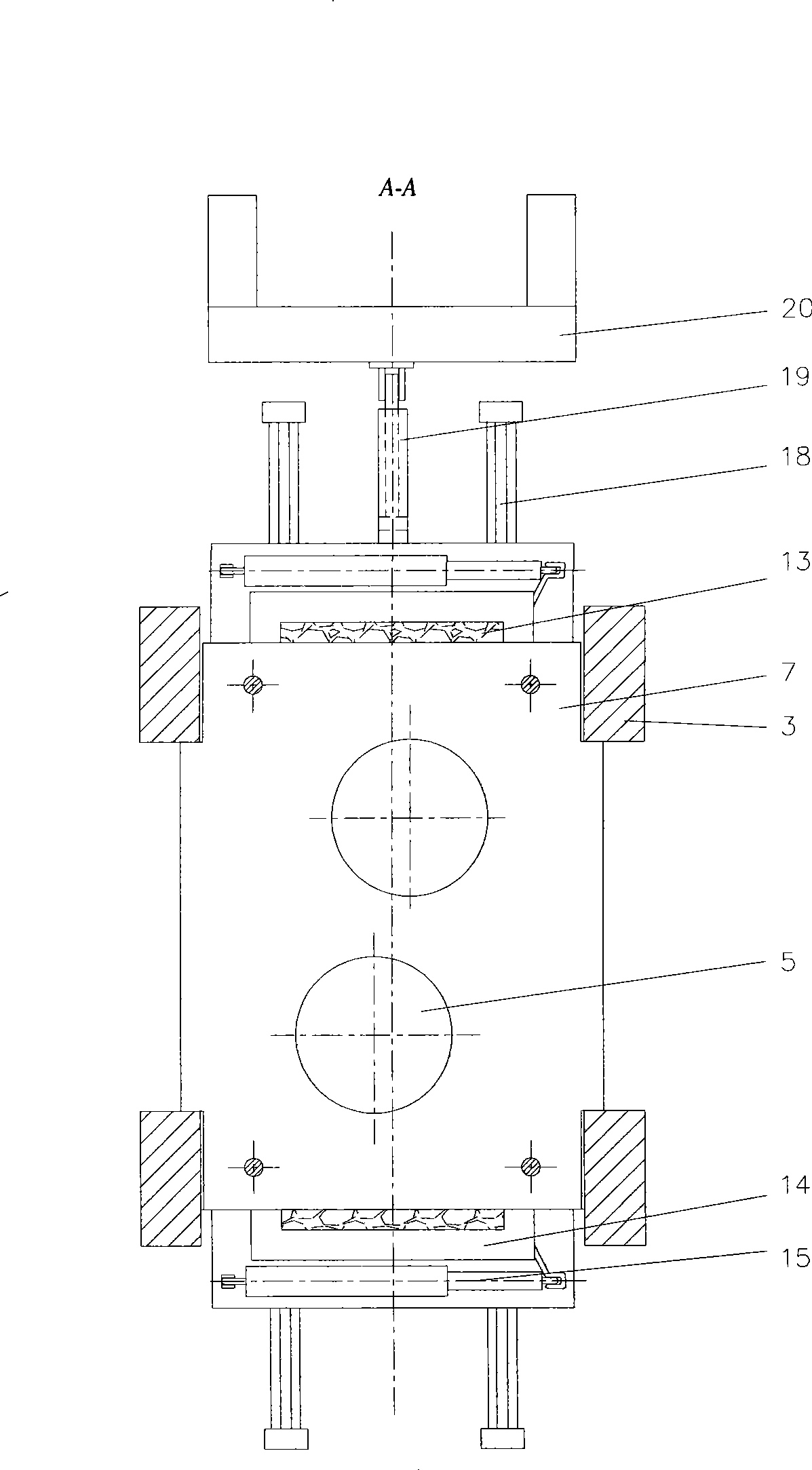

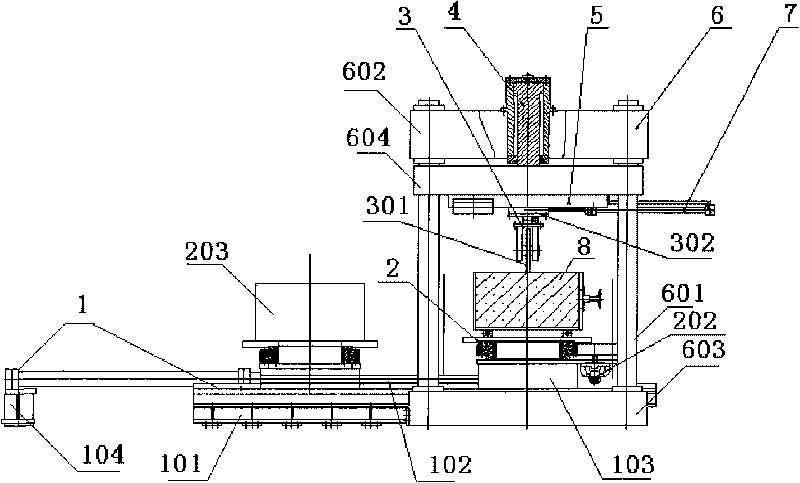

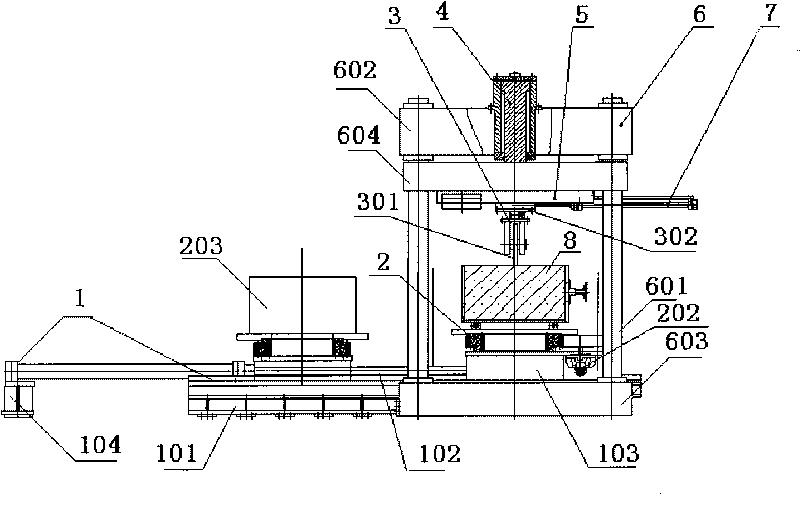

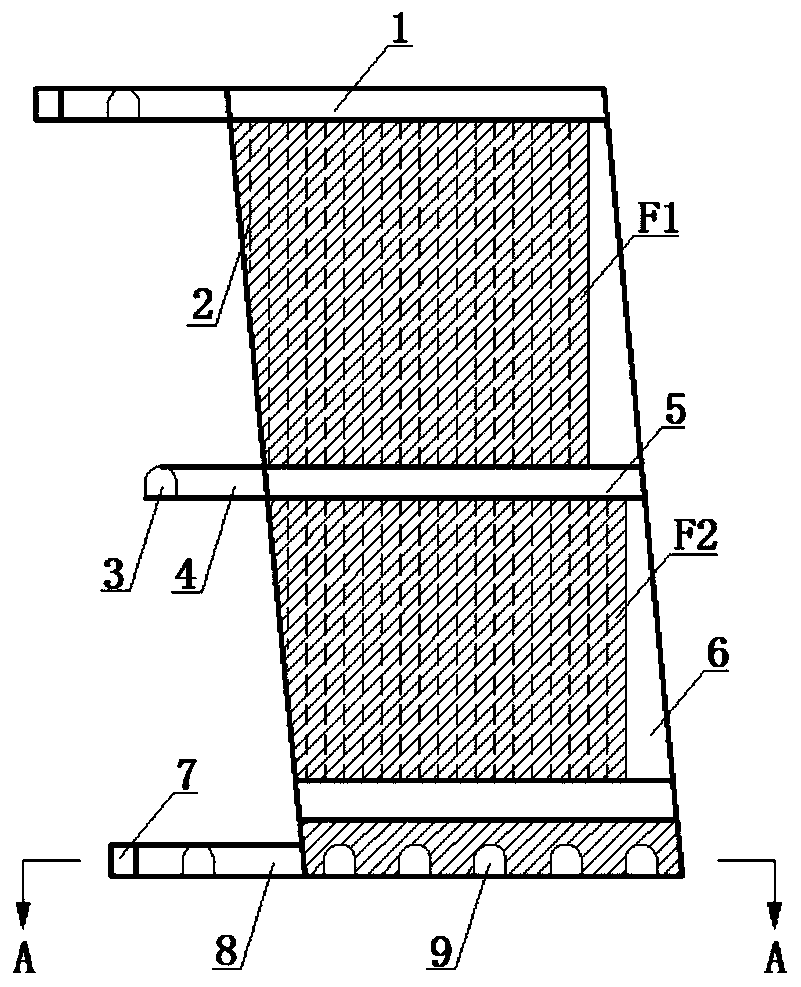

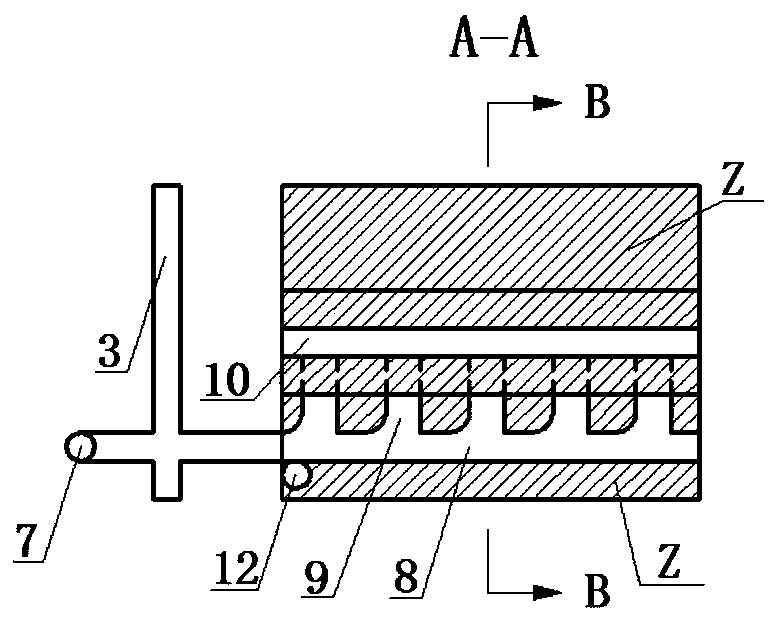

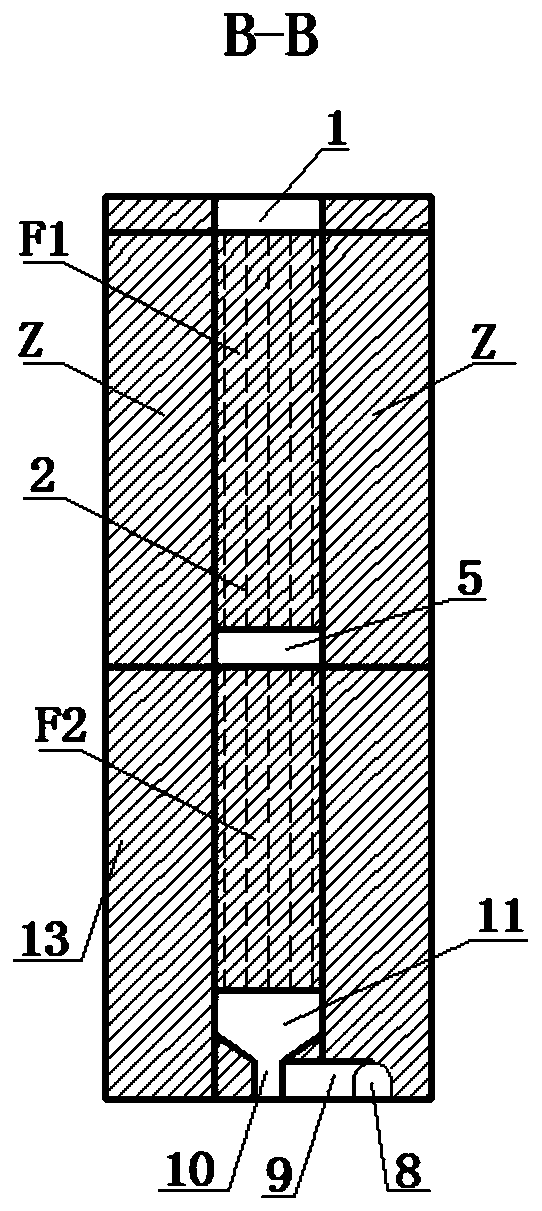

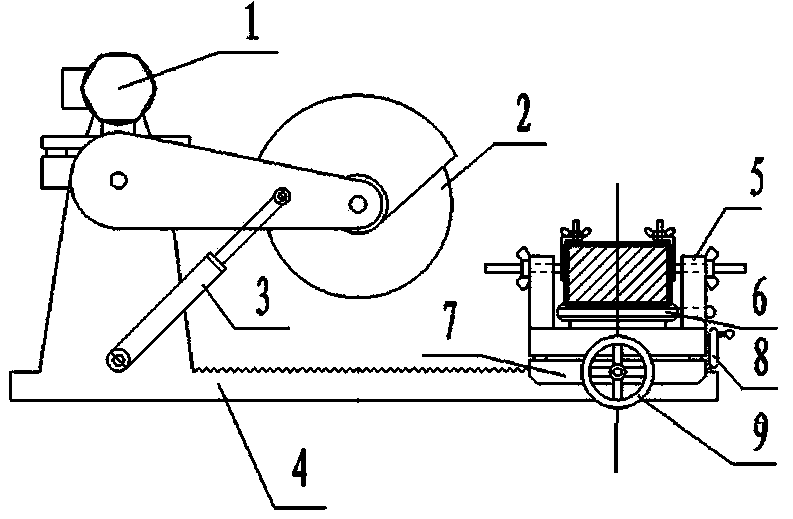

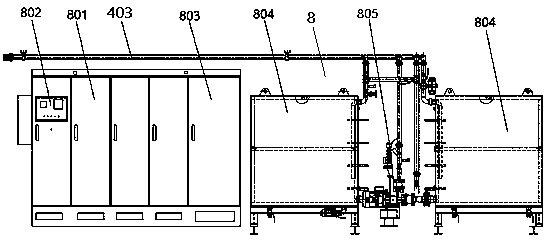

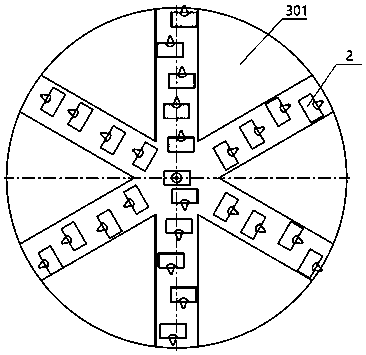

Adjustable multi-hob rock cutting fragmentation test means

InactiveCN101446537AImprove cutting lifeExperimental accuracyInvestigating machinabilityHydraulic cylinderSoil characteristics

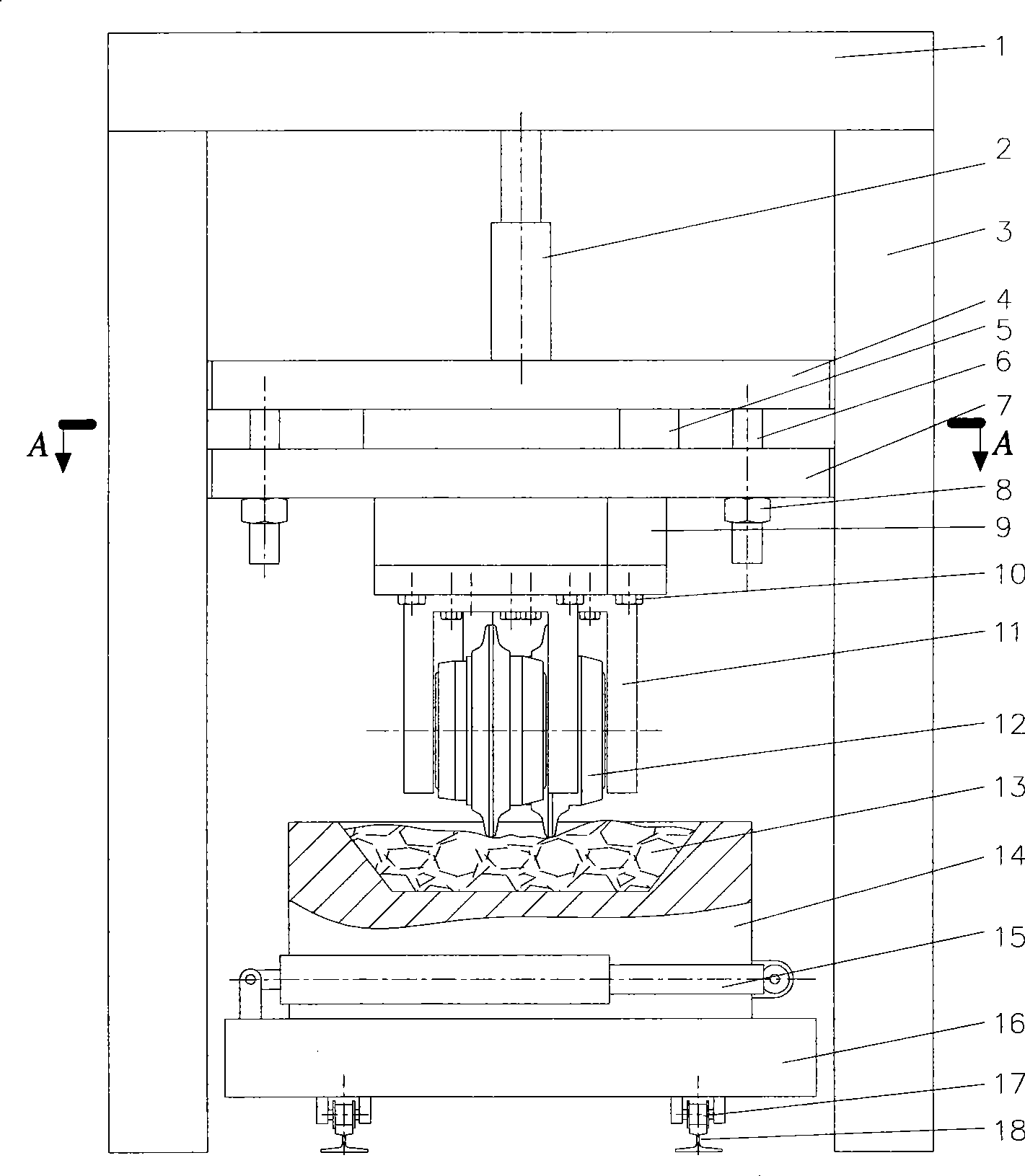

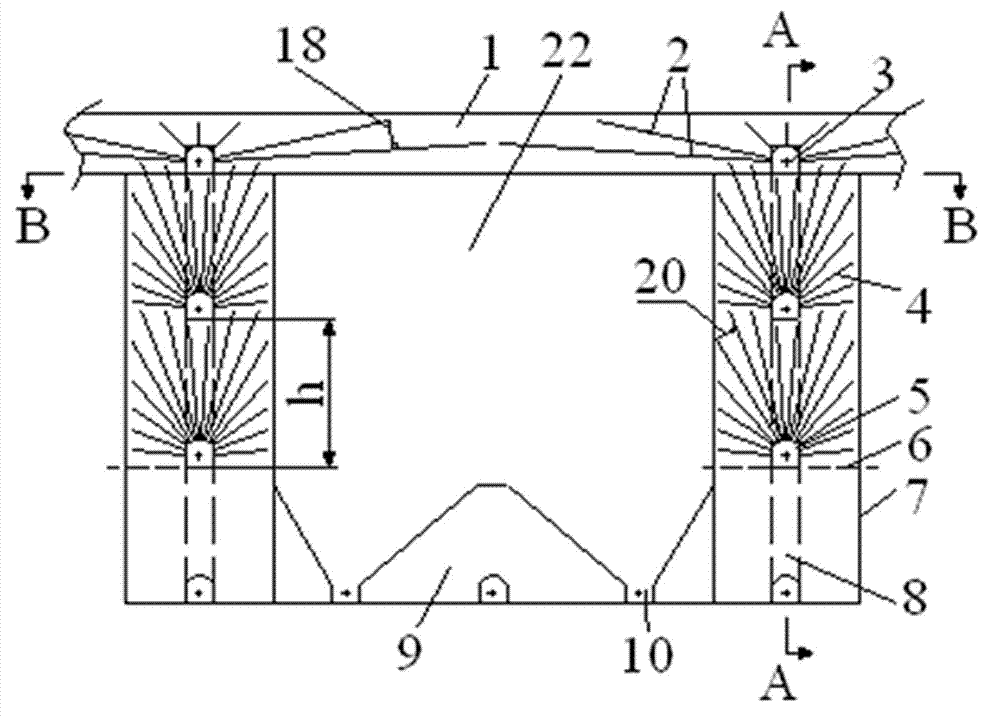

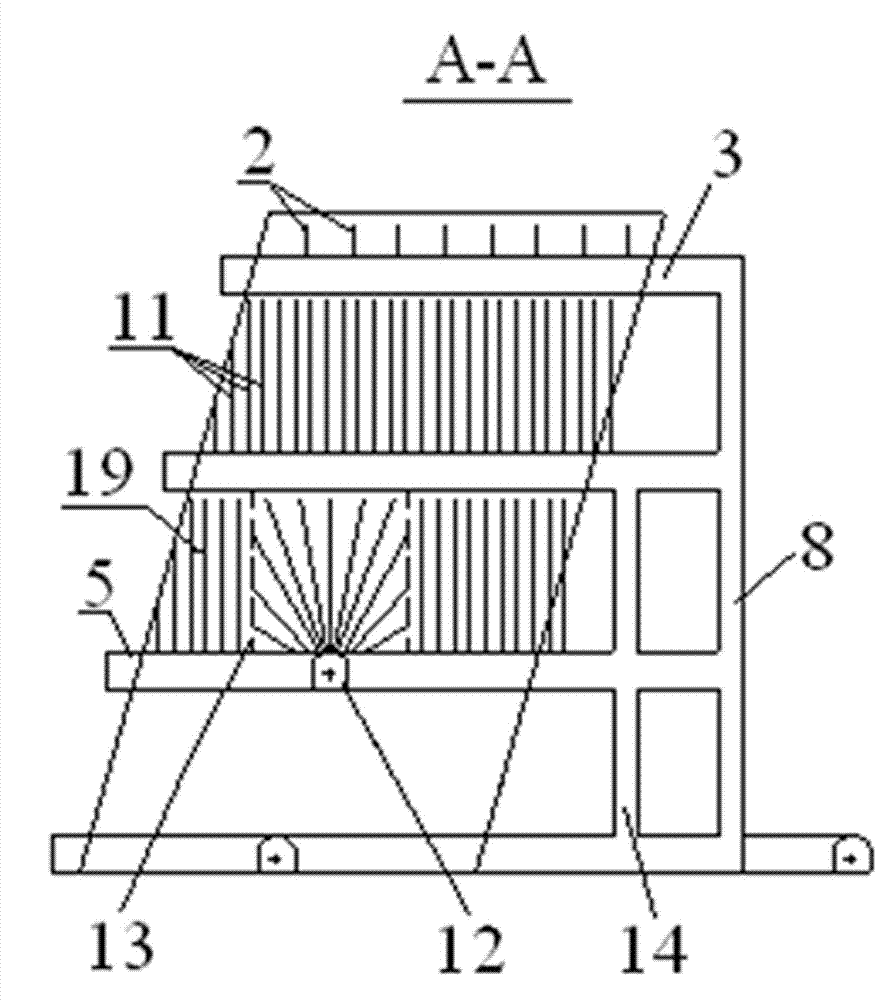

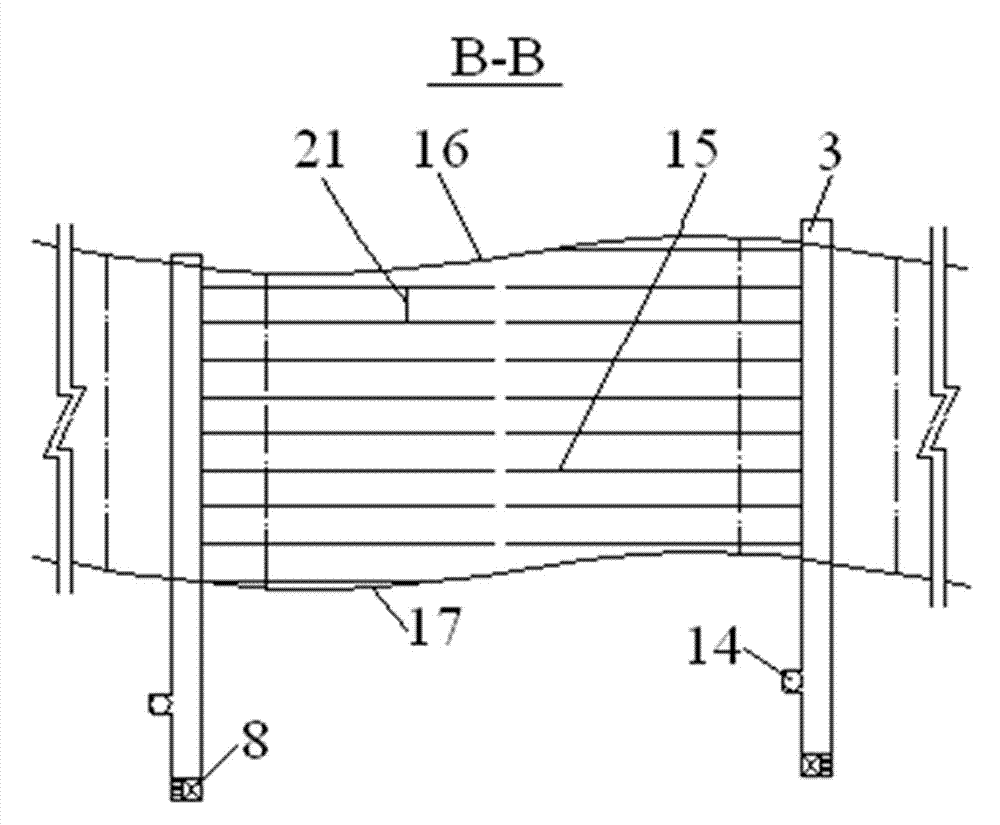

The invention relates to an adjustable multi-hob rock cutting fragmentation test device for the field of tunnel project. Being characterized in that the soil warehouse is provided on a guiding track achieving the vertical movement by the vertically-moving hydraulic cylinder; the soil warehouse is provided on the soil warehouse supporting base for achieving the transverse movement by the transverse hydraulic cylinder fixed on the soil warehouse base; the soil warehouse has the rock soil samples; two sides of the soil warehouse are provided with four pillars leaning against the beams and forming a rectangular frame structure. The lower position of the fixed beams of the vertical movement of two synchronized hydraulic cylinders for the realization of the vertical plate hob feed, vertical hydraulic cylinder mounting bracket for the following connection hob, for the realization of more than the fixed plate hob; mounting bracket Three-axis with the following sensors, hob plate connected to the force sensor in the bottom three of the hob seat, using industrial computer, data acquisition cards, the pressure of traffic and other sensors, such as high-speed digital camera system to test the disk-shaped roll knife load rock, broken rock and soil characteristics.

Owner:CENT SOUTH UNIV

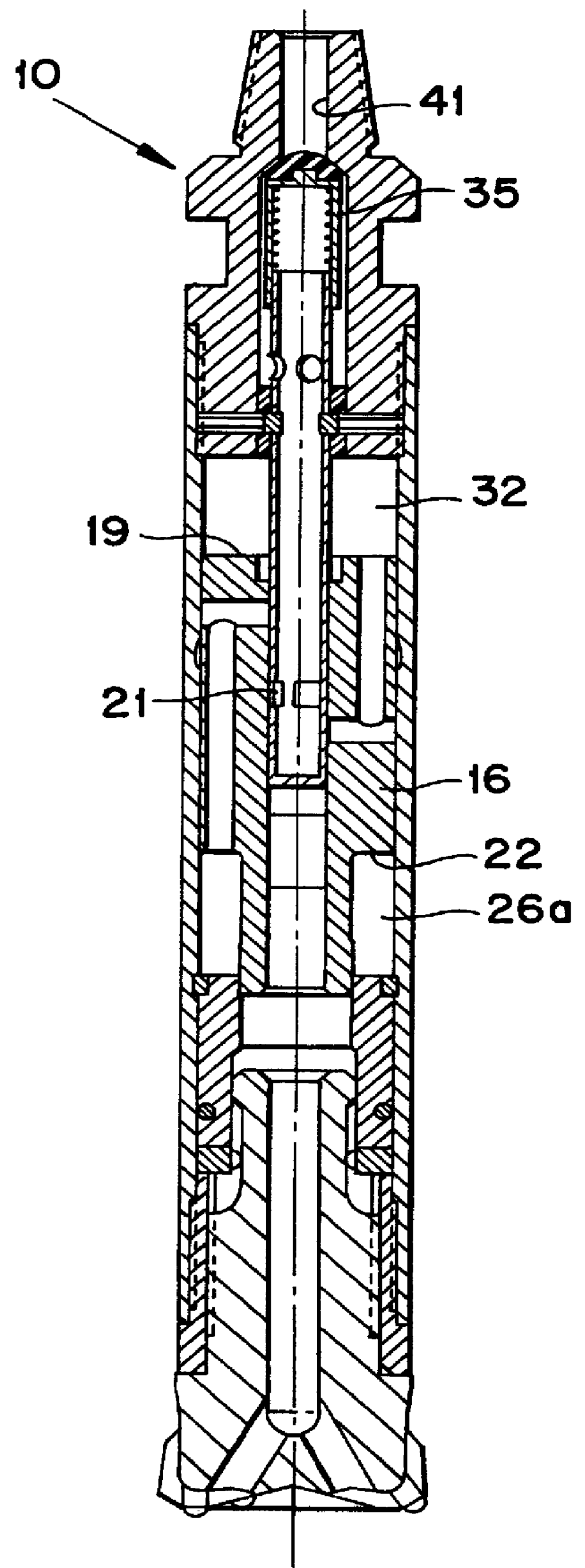

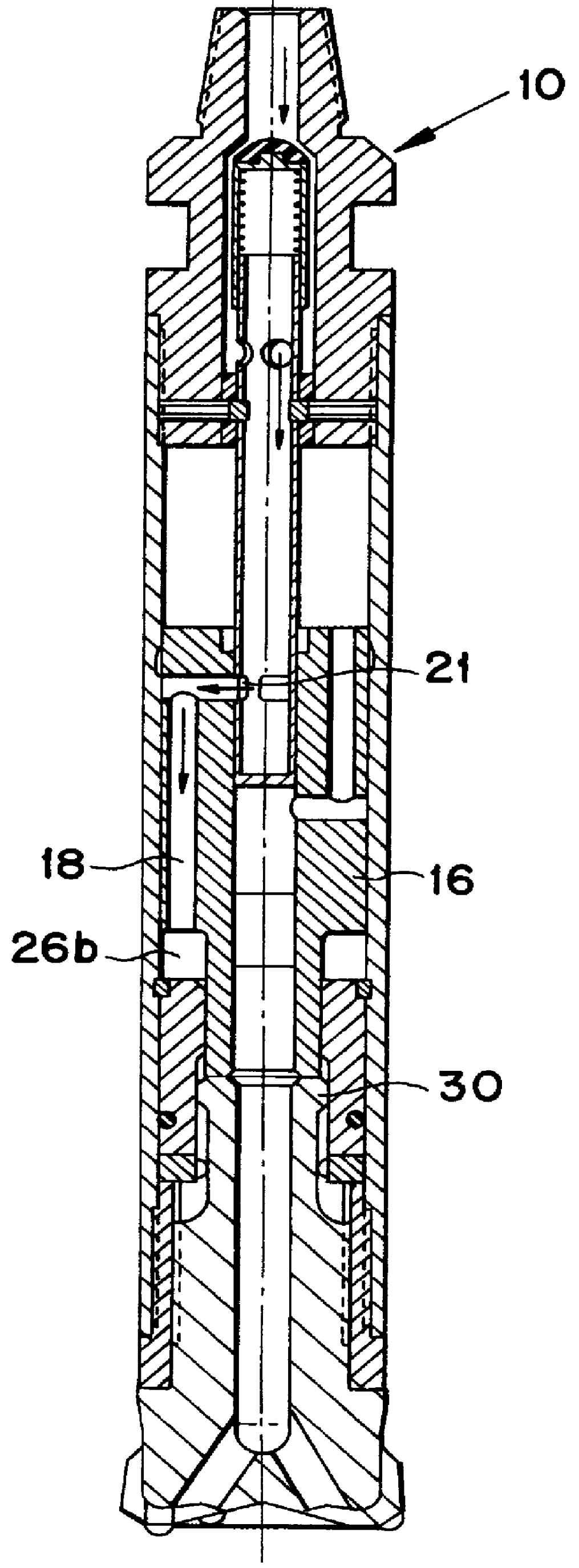

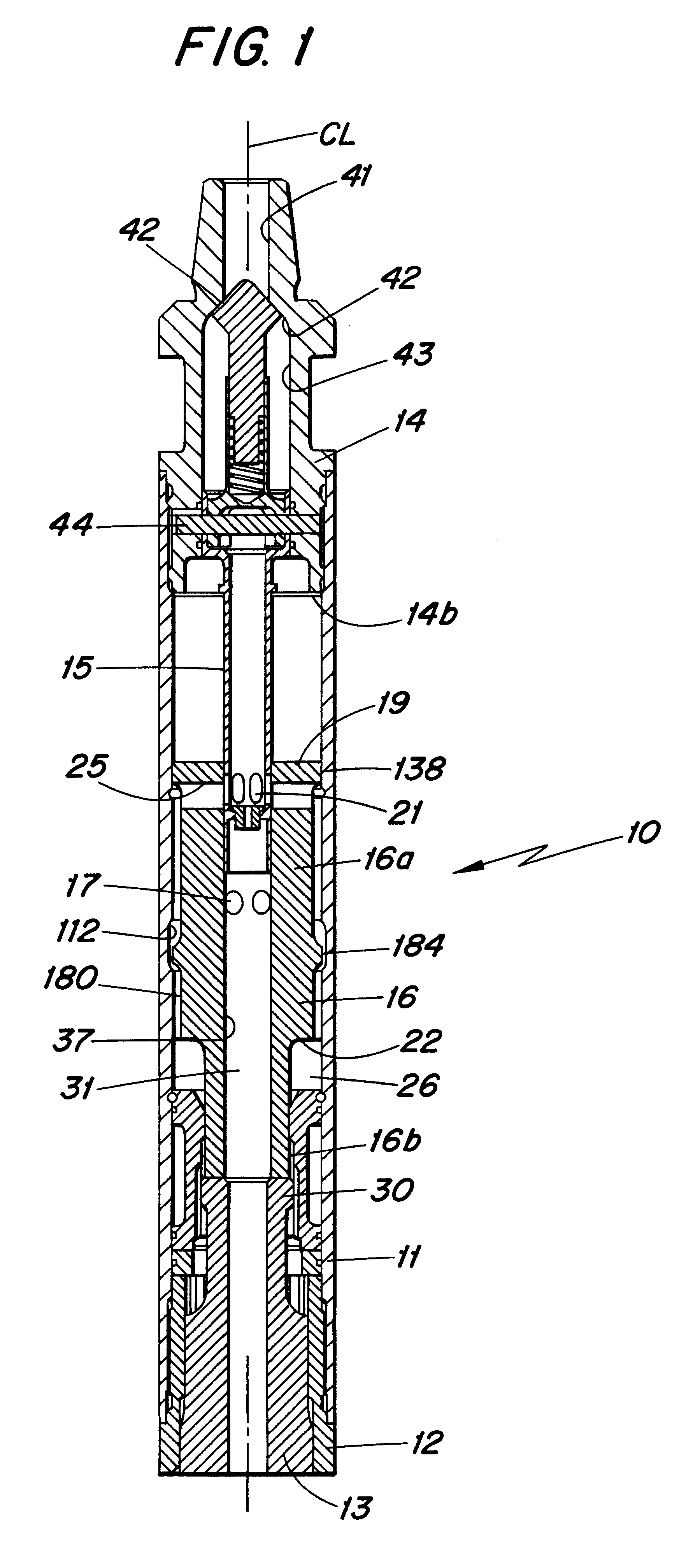

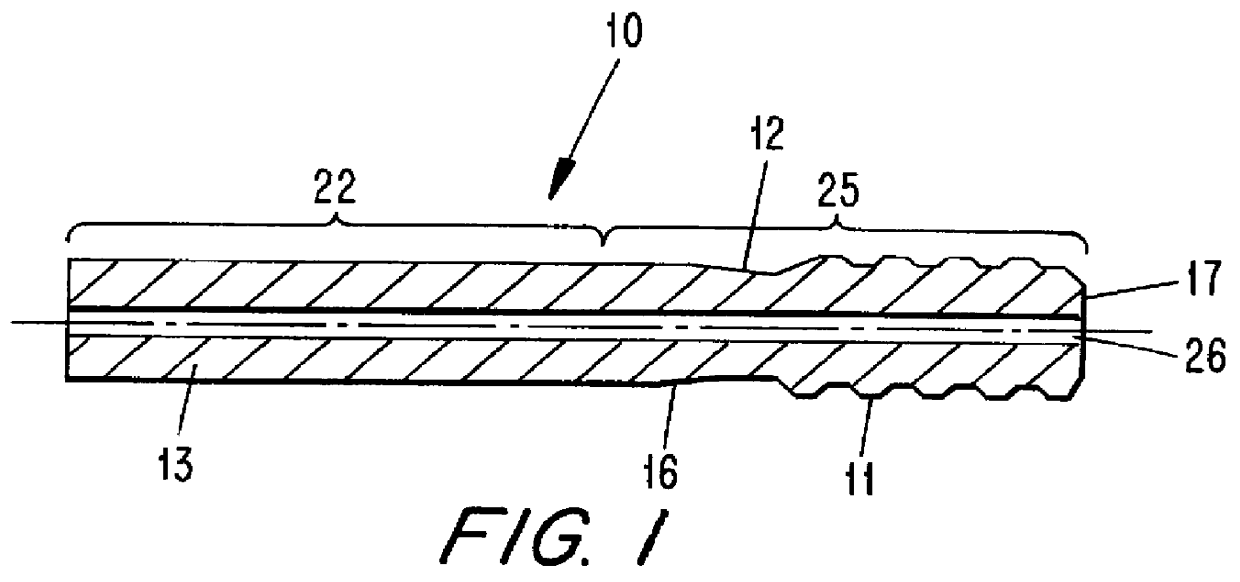

Percussive down-the-hole rock drilling hammer and piston therefor

A down-the-hole percussive drill comprises a casing, a drill bit mounted at a lower end of the casing, a hollow feed tube fixed within the casing and extending along a center axis thereof, and a piston mounted for axial reciprocation within the casing for transmitting impacts to the drill bit. The upper portion forms a downwardly facing surface at the junction between the upper and lower portions. Passages for conducting lubricant-containing pressurized air are formed in the piston. At least one of those passages constitutes a vertical recess formed in the outer periphery of the piston. The piston includes a radially outwardly projecting rib disposed between upper and lower ends of the recess. Air is blocked from traveling past the rib until the rib becomes located opposite an annular groove formed in an inner surface of the casing.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

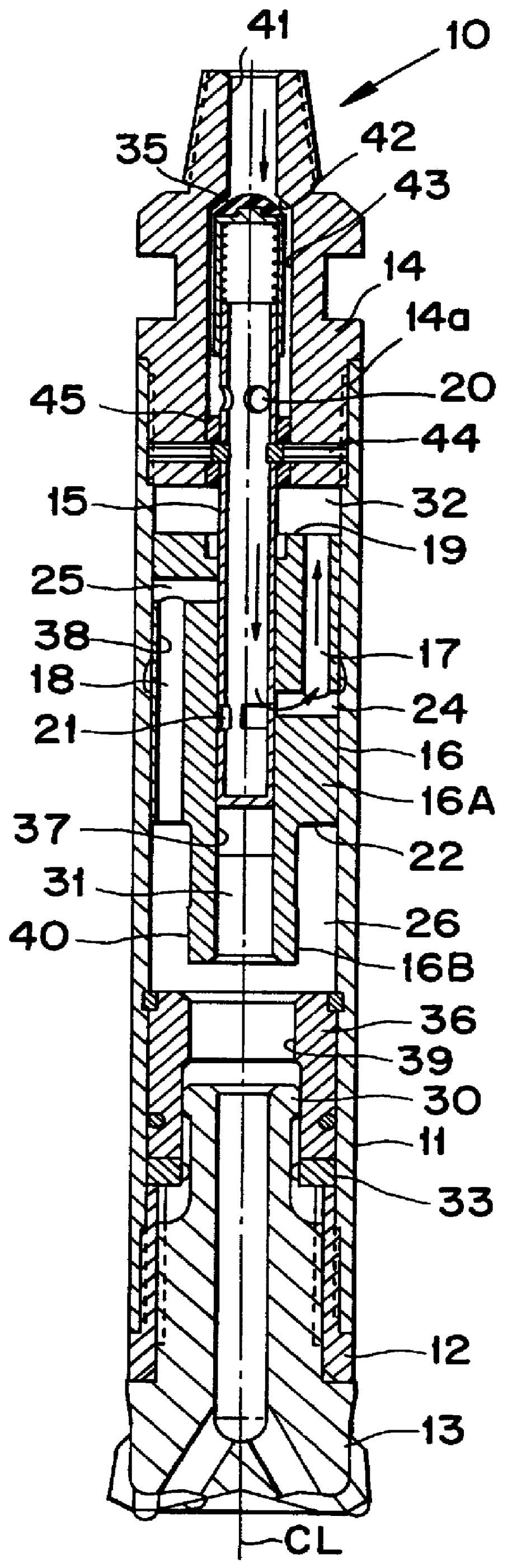

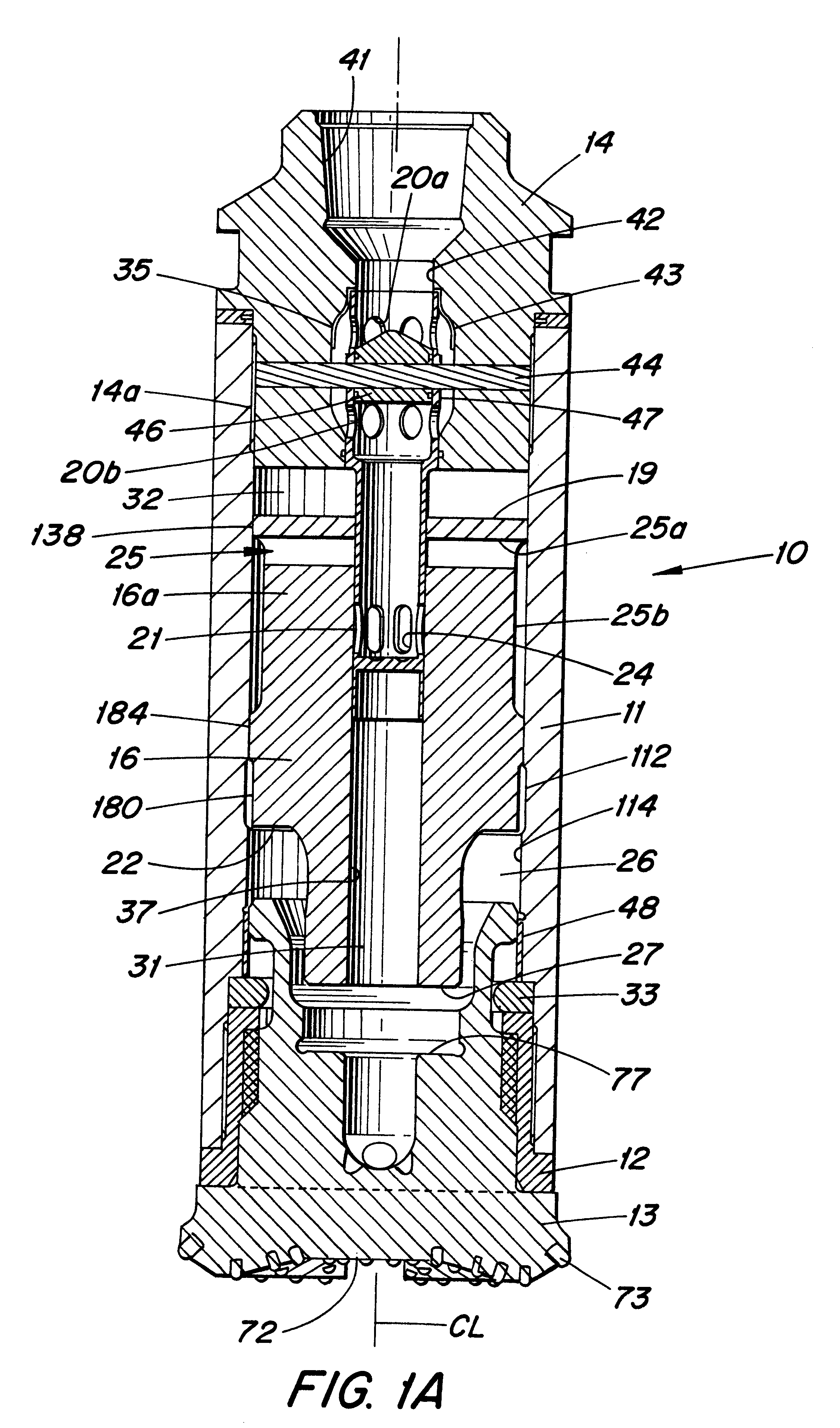

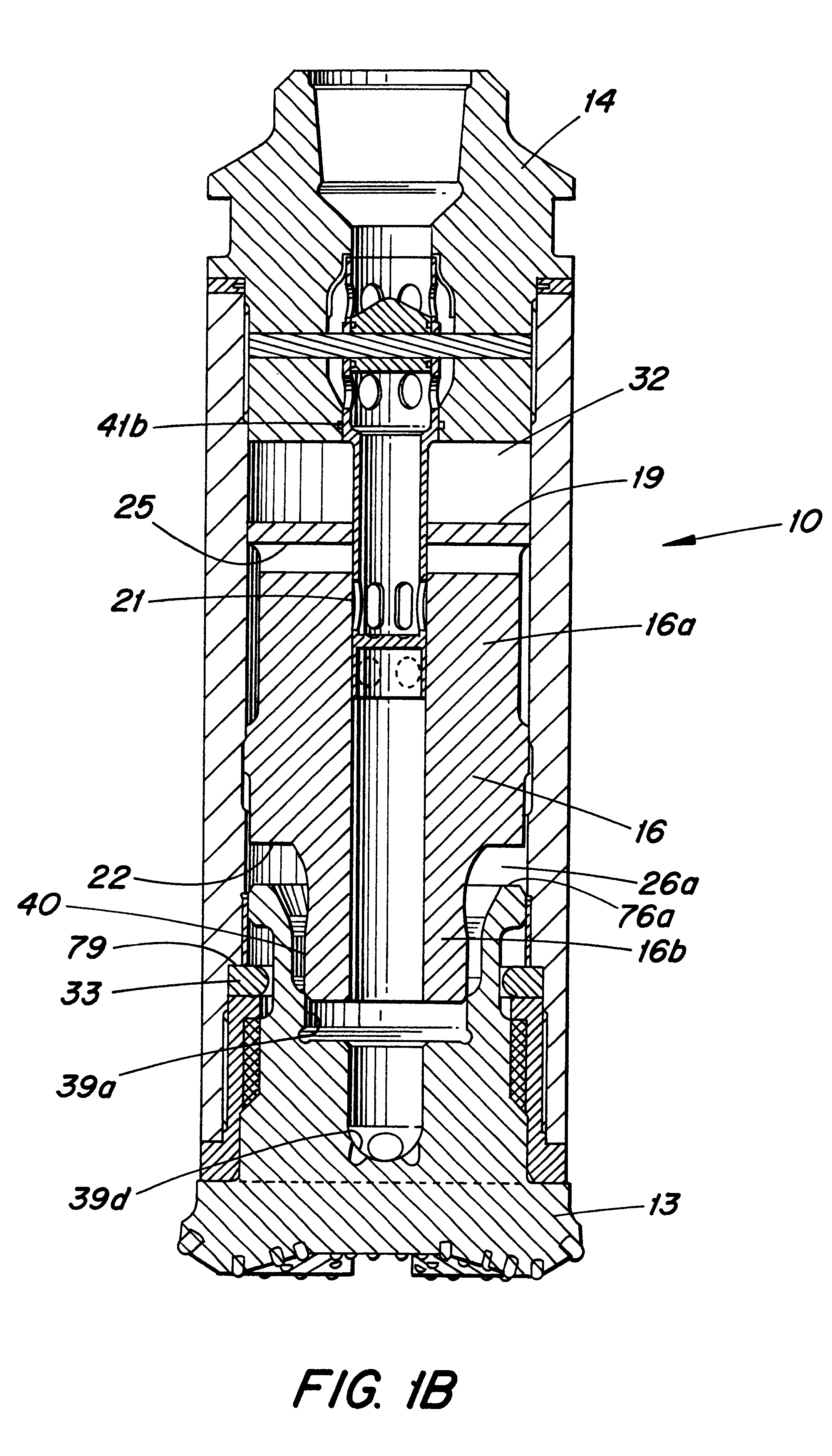

Percussive down-the-hole hammer for rock drilling, and a drill bit used therein

InactiveUS6502650B1Easy to manufactureLow production costDrill bitsBorehole drivesPortion sizeReciprocating motion

A down-the-hole percussive hammer for rock drilling includes a cylindrical casing and a drill bit disposed at a front end of the casing. The drill bit includes a forwardly facing cutting surface and a center longitudinal passage extending forwardly through a rearwardly facing rearwardmost end surface of the drill bit. The passage includes a rearwardly facing impact surface. A piston is mounted in the casing longitudinally behind the drill bit for reciprocation in a longitudinal direction. The piston includes a front portion sized to enter the center passage of the drill bit and strike the impact surface of the drill bit during each forward stroke of the piston. The impact surface of the drill bit is spaced forwardly from the rearwardmost end surface of the drill bit by a distance of at least ten percent of a total longitudinal length of the drill bit.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Rock drill bit having retrac teeth and method for its manufacturing

InactiveUS20010018990A1Inhibits the formation of cracksDrill bitsDrilling rodsStructural engineeringDrill bit

A rock drill bit for percussive drilling, especially top hammer drilling, includes a bit head provided with front rock crushing buttons and a skirt. The bit head is provided with a number of grooves formed in the outside of the skirt and extending in the axial direction of the drill bit. Protruding lands are defined between the grooves, which likewise extend in the axial direction. Axially rearward ends of at least some of the lands are formed with retrac teeth. Each retrac tooth has a cutting edge extending along an outer circumference of the skirt.

Owner:SANDVIK AB

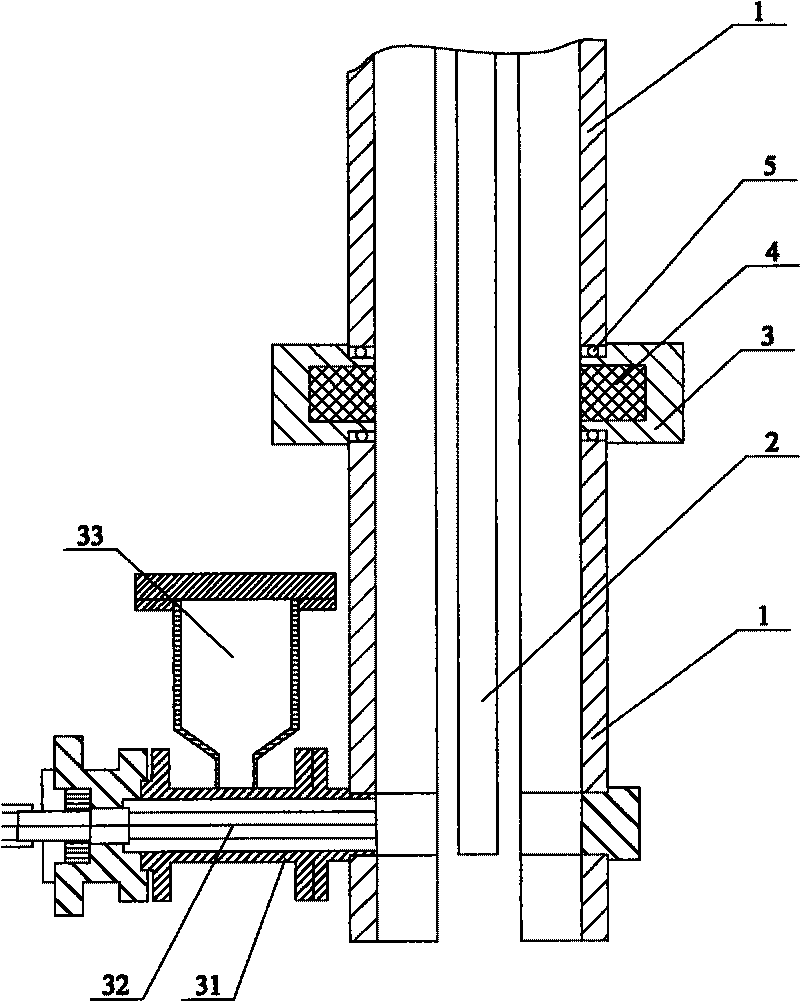

Method and device for evaluating physical parameters of an underground reservoir from rock cuttings taken therefrom

Method and device for evaluating, simultaneously and with a single equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented artificial or natural porous medium.The porosity of the fragments is measured by means of pressure tests using helium or any other gas, according to a protocol known in the art. Chamber (1) in which they are contained is communicated with a tank (11) of known volume containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the mass in fragments are also measured. The porosity of the samples and the density of the rock are determined by combining these measurements. Their permeability is then measured by immersing them in a liquid and by communicating the chamber with a liquid initially at a predetermined pressure contained in an accumulator (9) so as to compress the gas trapped in the pores of the rock. The values of the physical parameters are determined by modelling the evolution of the volume of liquid injected in the chamber and by means of an iterative adjustment.Applications: petrophysical measurements from drill cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

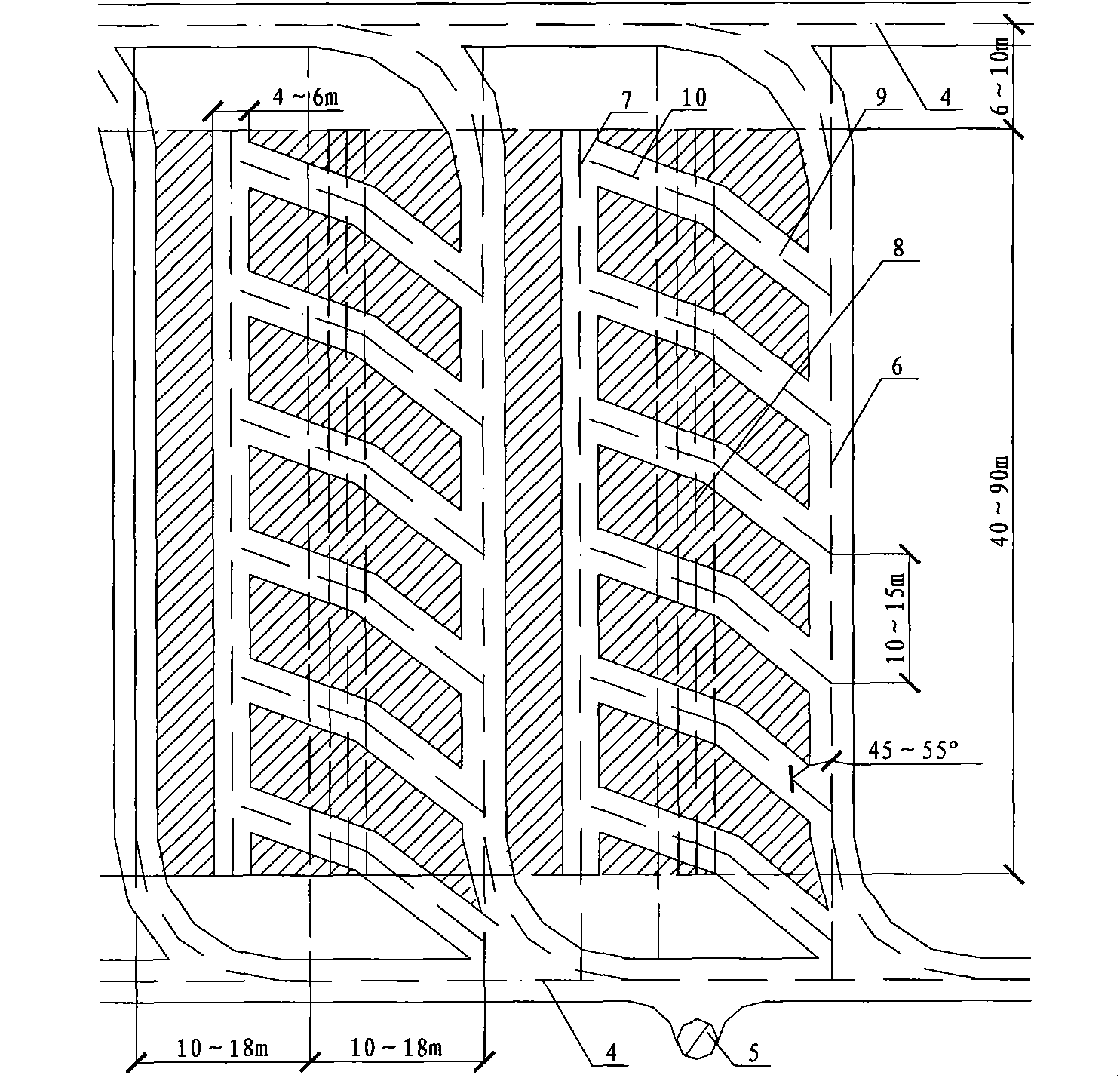

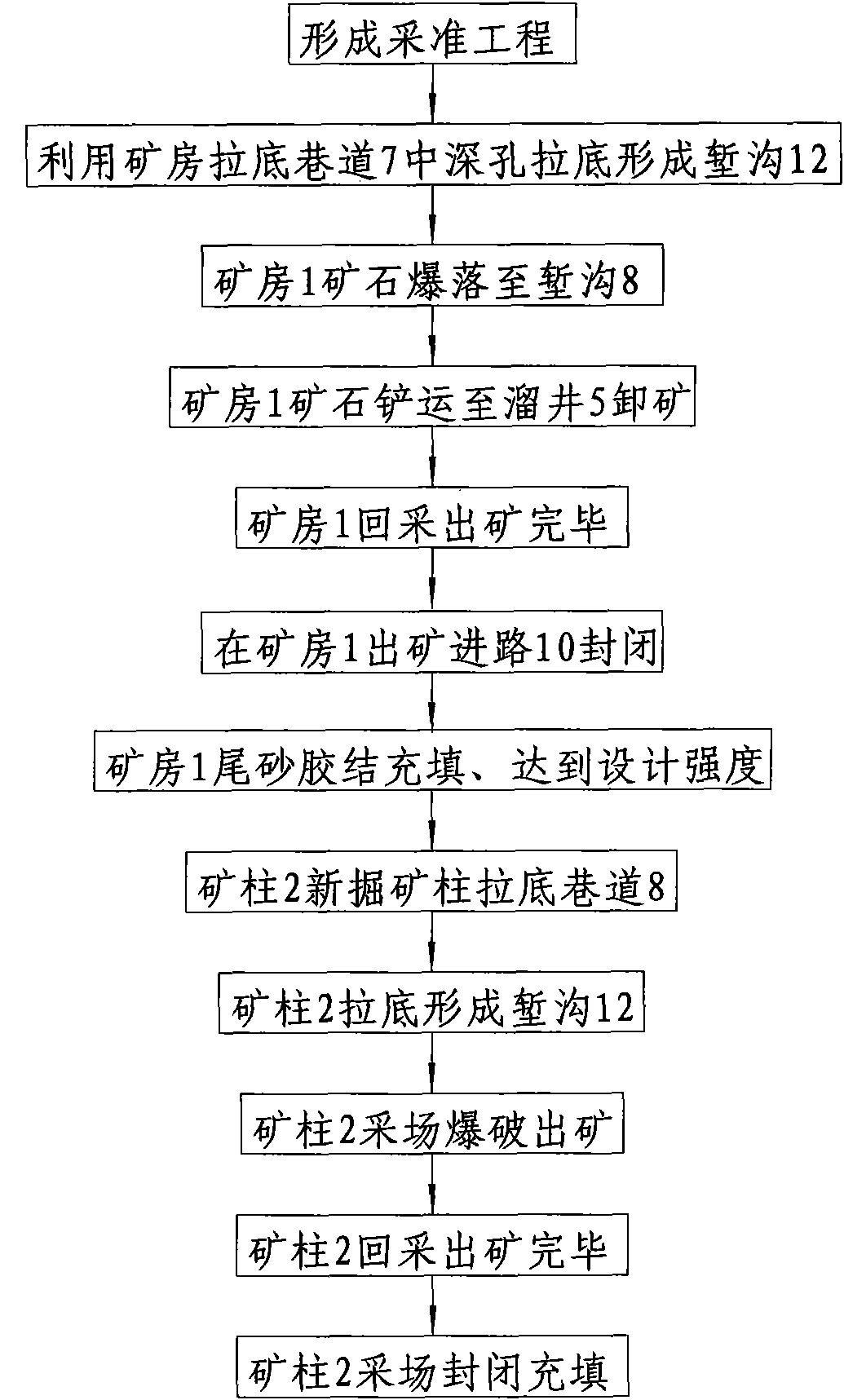

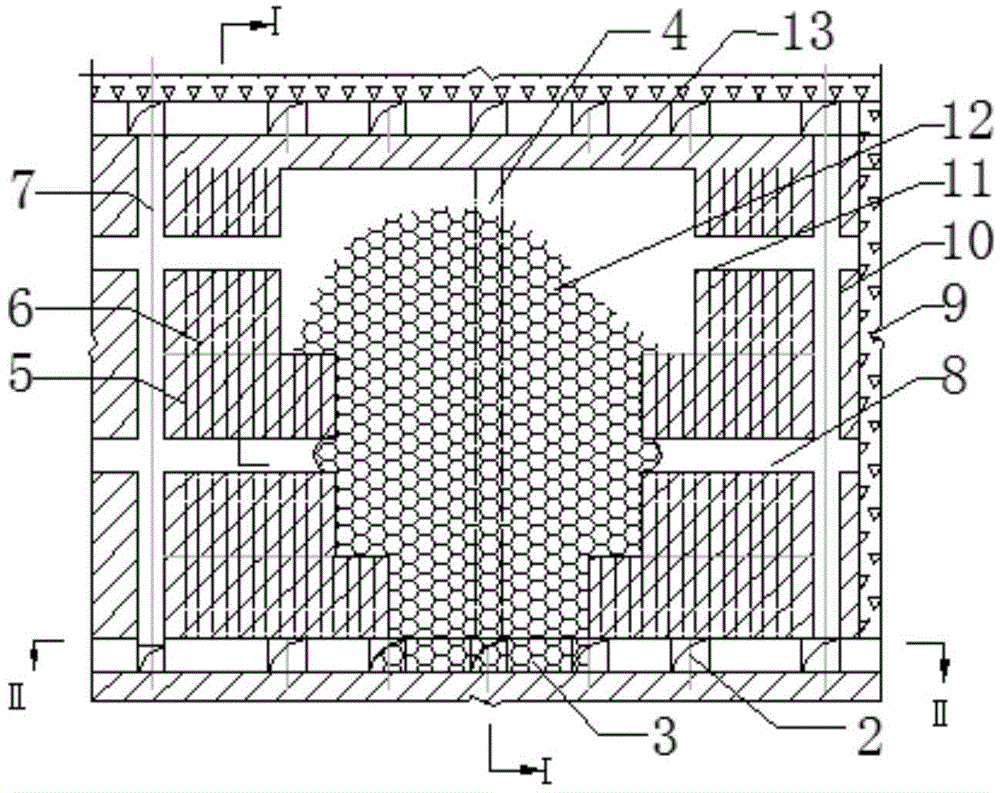

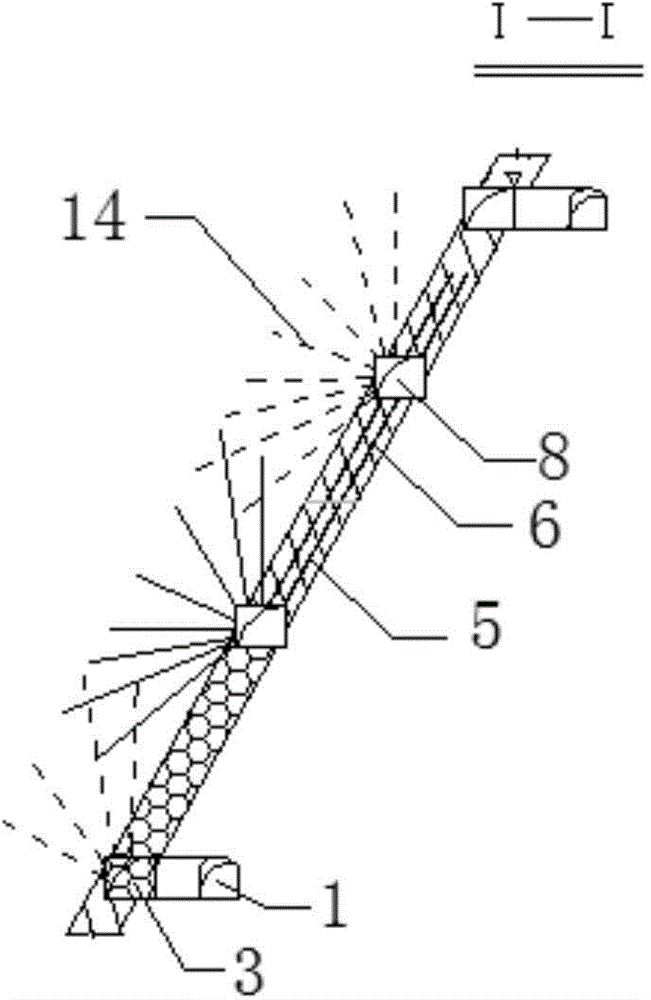

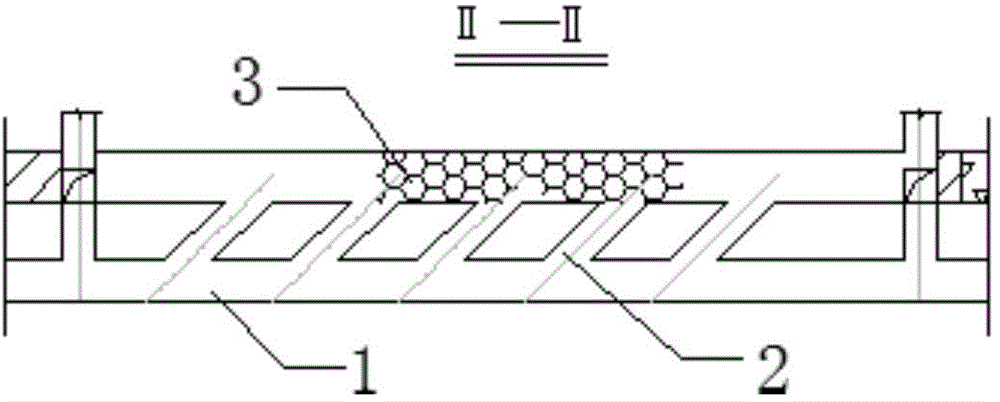

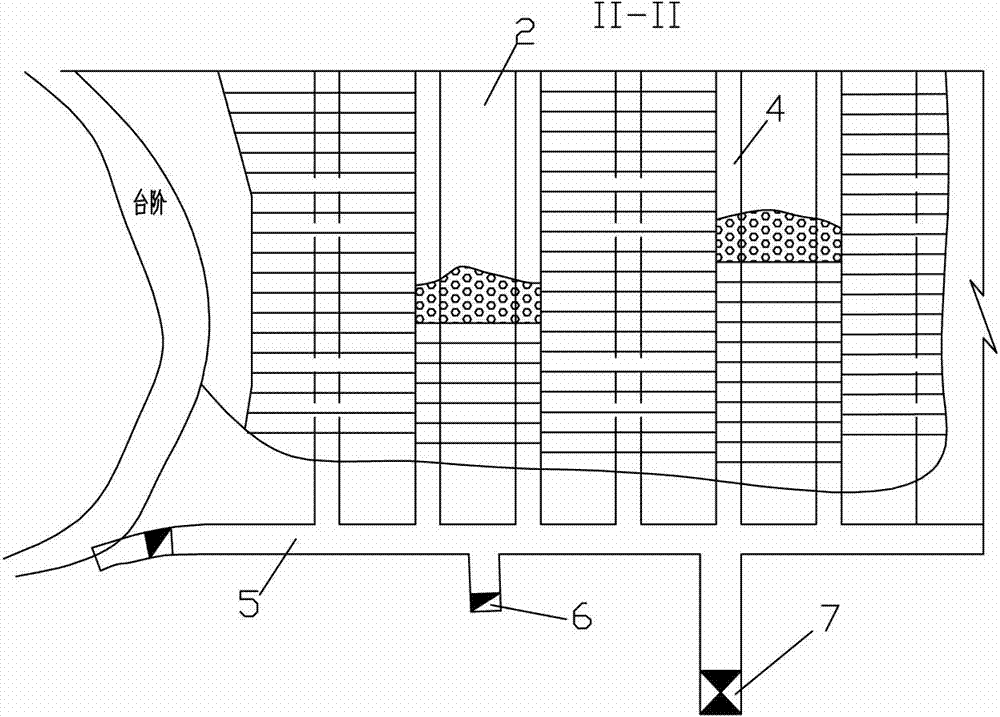

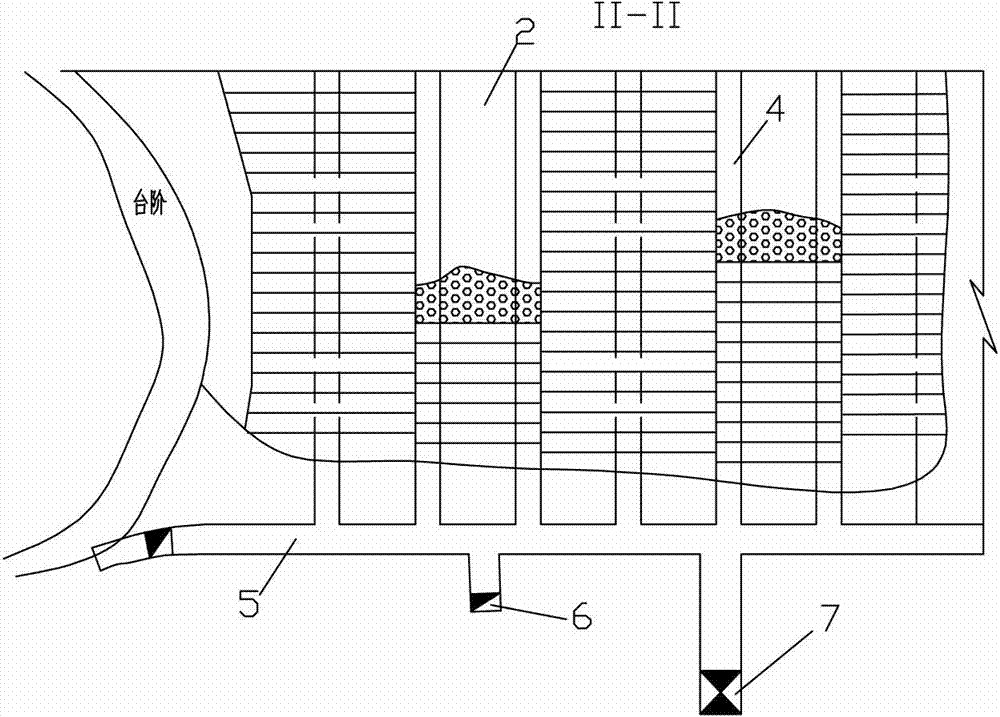

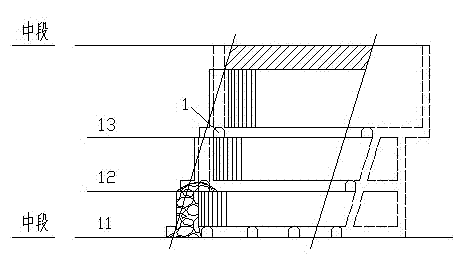

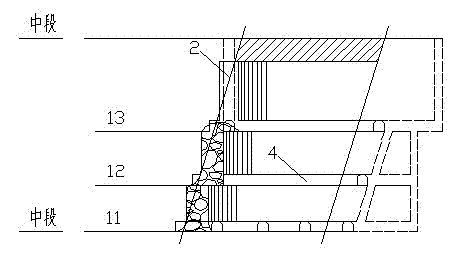

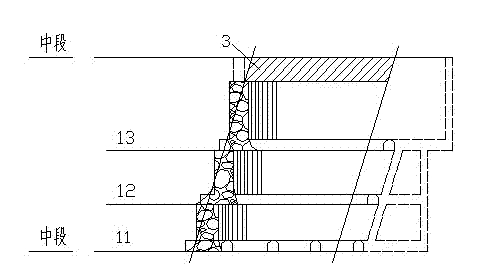

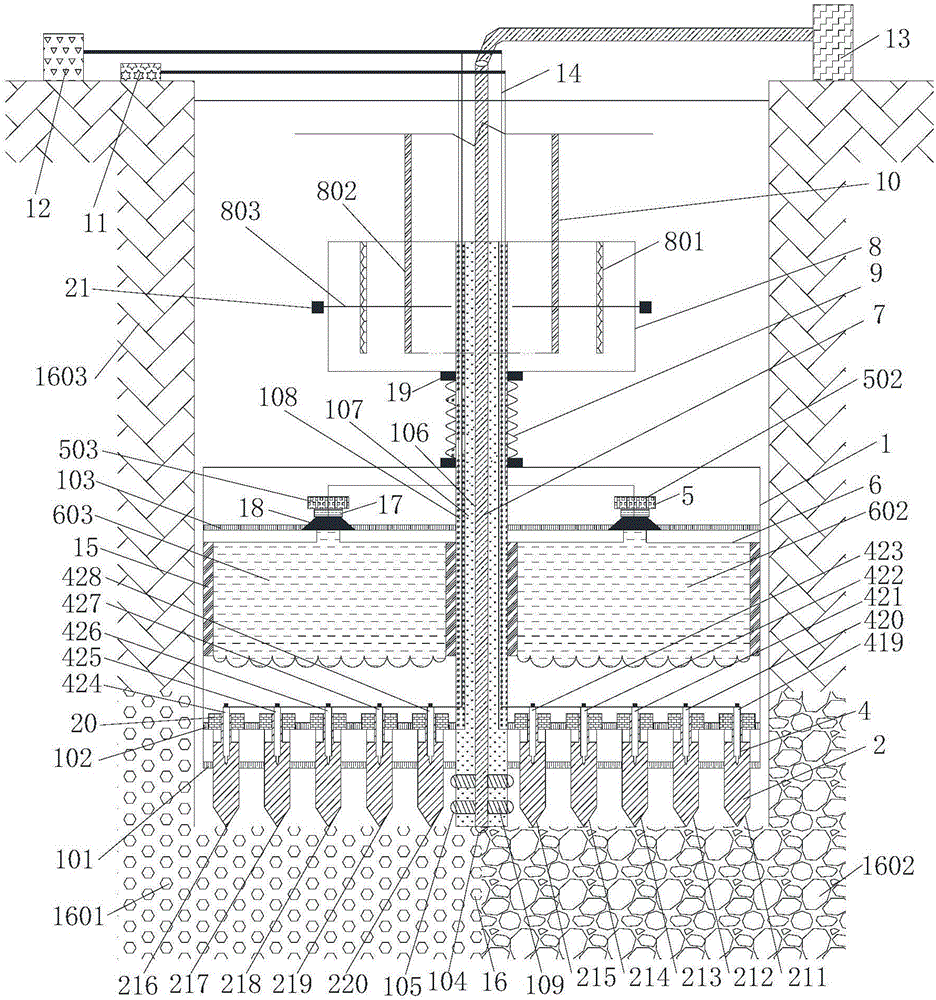

Stope bottom structure suitable for underground two-step mining and production process thereof

ActiveCN102011589ASmall amount of workAvoid secondary excavationUnderground miningSurface miningStructure of the EarthEngineering

The invention discloses a stope bottom structure suitable for underground two-step mining and a production process thereof. An underground stope is divided into a room stope and a pillar stope. Bottom pillars are reserved according to the bottom structure forms. Along-vein travelling roadways (4) and across-vein ore-drawing roadways (6) are utilized to handle the ores. The blasting ores (11) in the stope are blasted and fall in trenches (12). A scraper pours the ores into an ore pass (5) via a common ore-drawing drift (9) and a room ore-drawing drift (10). After tailing-cemented filling of the room of the stope, new pillar undercutting roadways (8) are driven in the bottom pillars (3) during mining the pillar stope. The trenches (12) for room mining are formed through drilling and blasting and undercutting. The goafs formed after mining and ore-drawing of pillars (2) are filled. The stope bottom structure can serve two stopes, reduce the quantities and support quantity, reduce the mining and development ratio of mining, improve the stability and save the mining cost and preparation time of two-step mining.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Sublevel open-stoping mining method with subsequent backfilling for long-hole caving in thin ore bodies

InactiveCN104453901APlay the role of supplementary prospectingFlexibilityUnderground miningSurface miningMaterials scienceDeep hole

The invention discloses a sublevel open-stoping mining method with subsequent backfilling for long-hole caving in thin ore bodies. The sublevel open-stoping mining method with subsequent backfilling is characterized by comprising the following steps: arranging ore blocks along the orientation of the ore bodies, and dividing the ore block into ore chambers and ore pillars; dividing the ore blocks into segments in a vertical direction by sublevel drilling gate ways with an interval of 15-20m; drilling upward parallel or fan-shaped and downward parallel or fan-shaped medium-depth holes in the sublevel drilling gate ways to recover, wherein different sublevel caving sequences can be adopted according to the stabilization condition of the hanging wall surrounding rocks of the ore bodies; laterally loading ores by using a carry scraper from a bottom trench; locally anchoring the unstable areas of the hanging walls of the ore bodies, and drilling the anchored holes along with the caved holes; after the ores are recovered from the ore chambers, recovering the ore pillars according to the condition of the adjacent ore blocks, and finally filling goaf with waste rocks. The method has the prominent effects of good labour conditions, safety in working, high operation efficiency and high production capacity, and can realize intensified mining and ore mucking, and effectively control ore losses and dilution rate.

Owner:GUANGXI UNIV

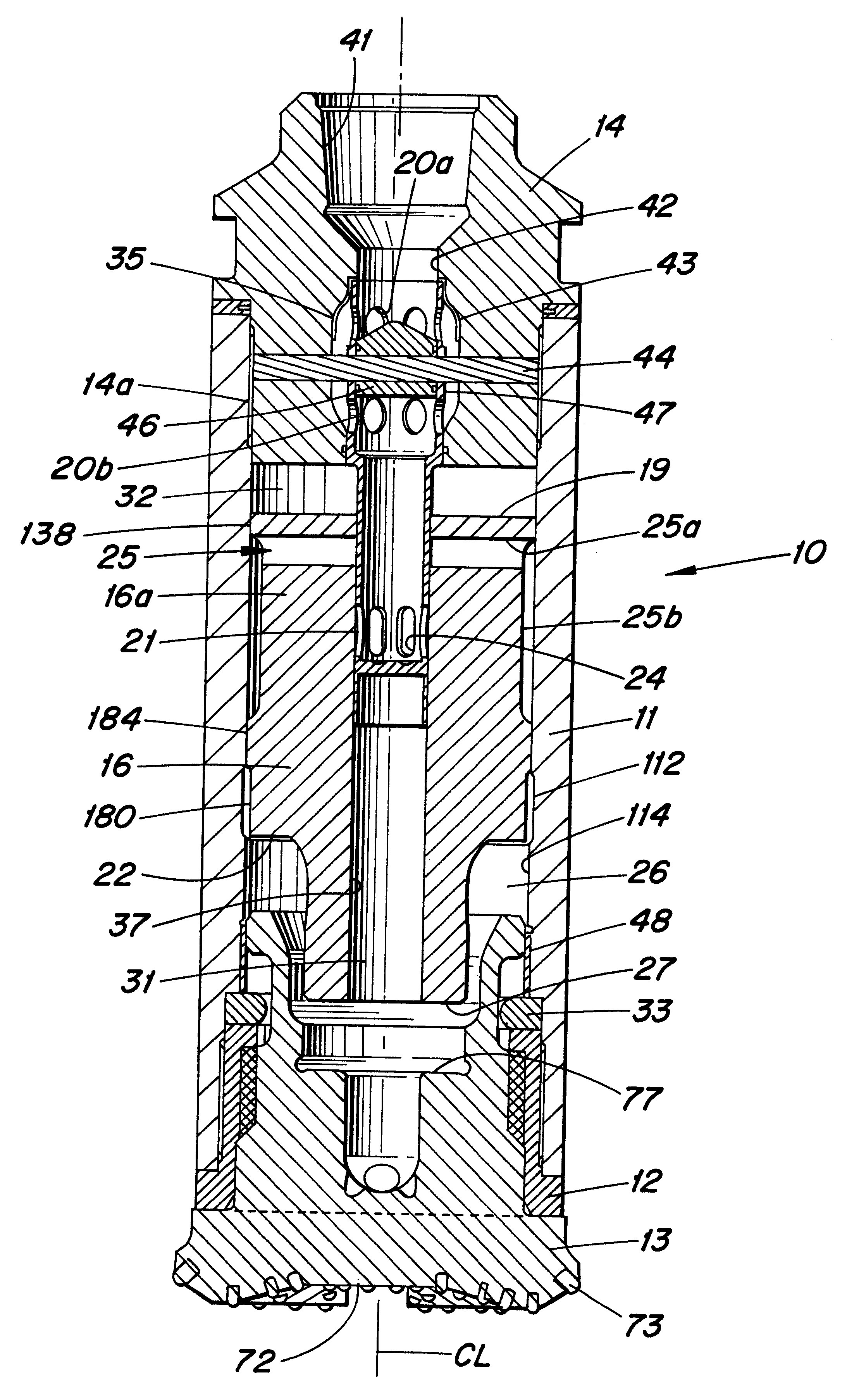

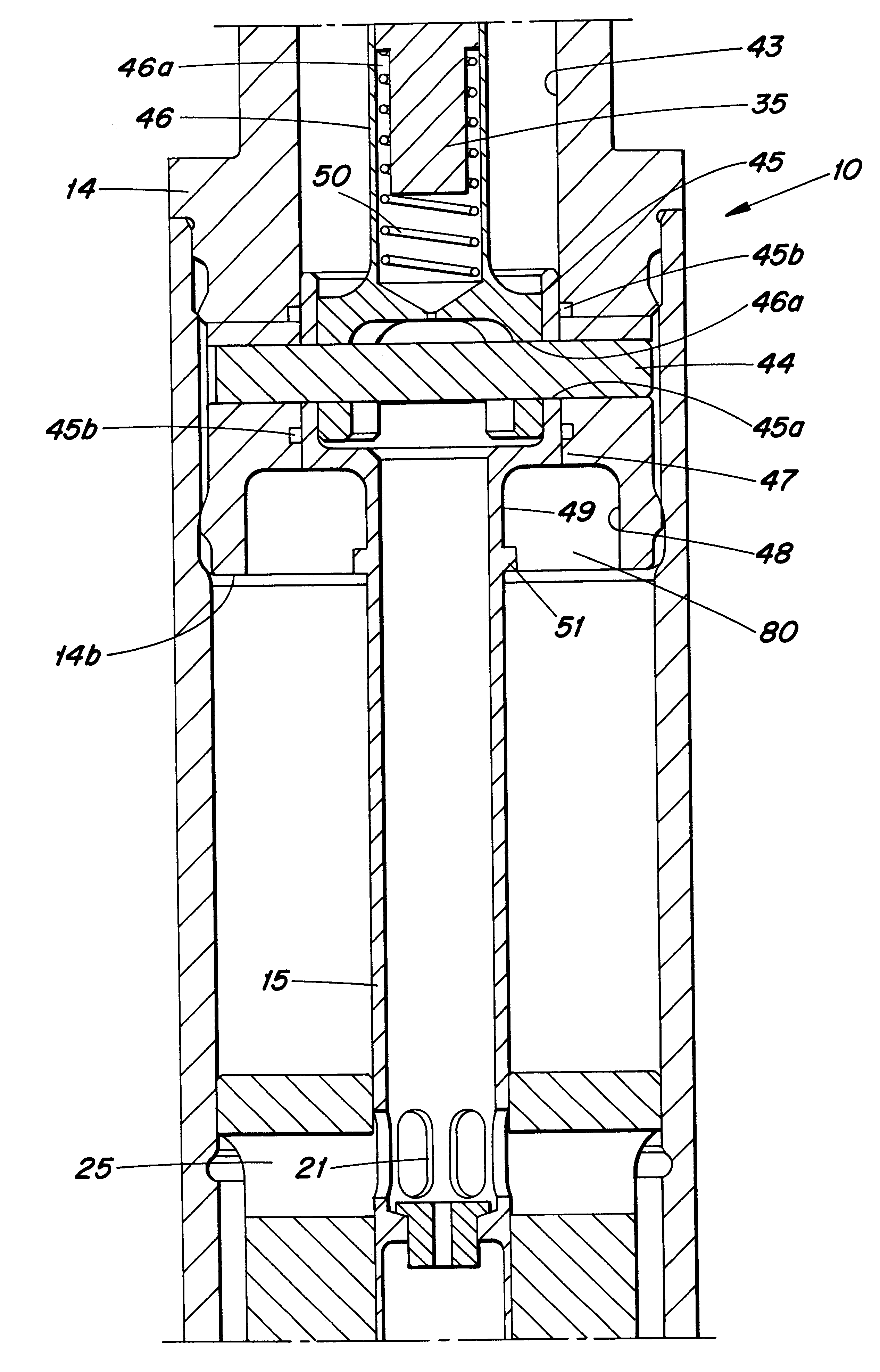

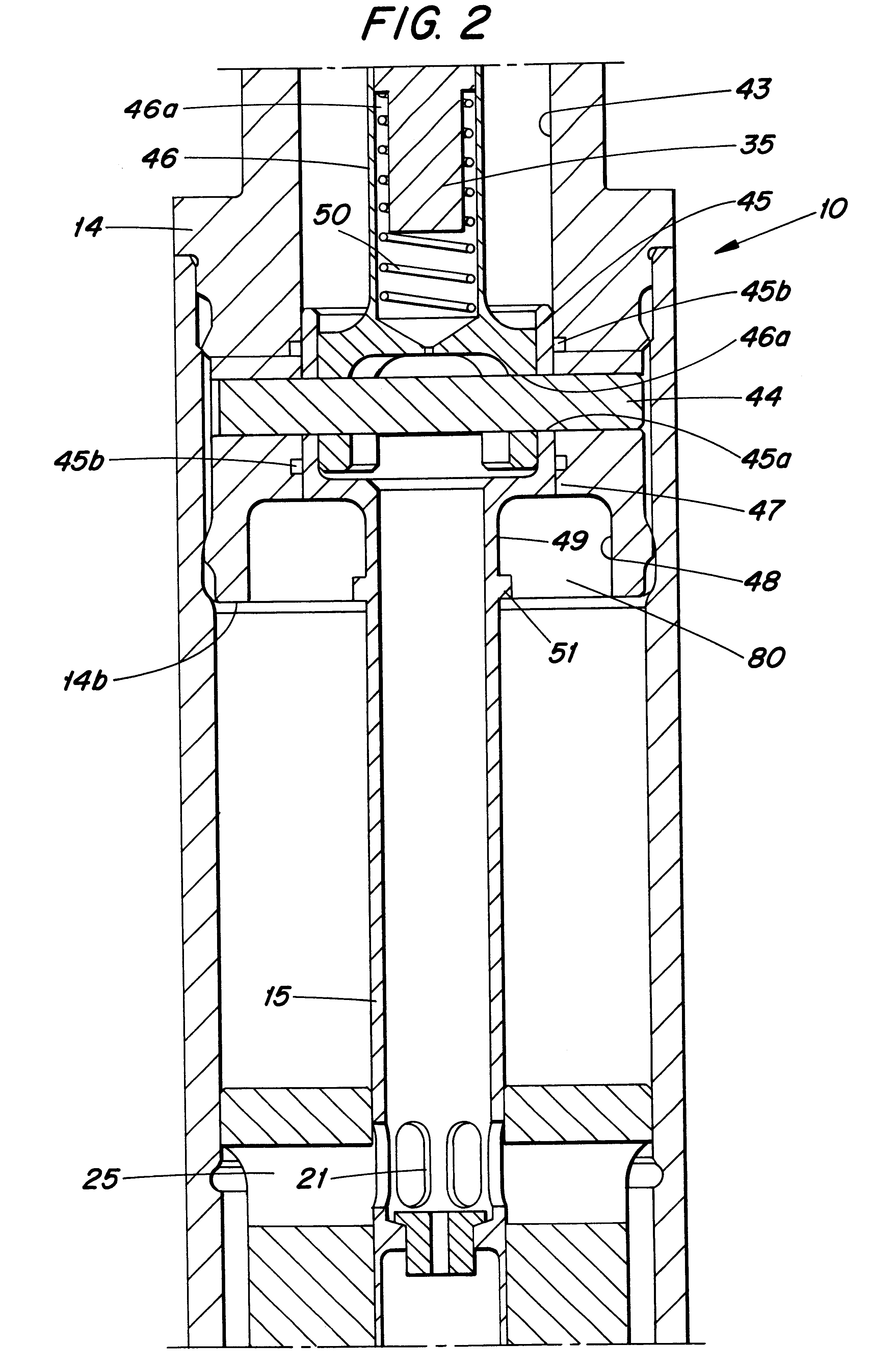

Percussive down-the-hole hammer for rock drilling, a top sub used therein and a method for adjusting air pressure

InactiveUS6454026B1Simple and inexpensive adjustabilityEasy to adjustDrill bitsReciprocating drilling machinesReciprocating motionEngineering

A down-the-hole percussive hammer includes a cylindrical casing adapted to carry a drill bit, and a piston mounted in the casing for reciprocal movement to repeatedly strike the drill bit. A top sub is mounted at a rear portion of the casing, the top sub including a front face facing the piston. A feed tube is mounted to the top sub and extends forwardly along a center axis of the casing and defines an air-conducting passage. The piston includes an axial through-hole which slidably receives the feed tube. The front face and the feed tube together define a recess opening toward the piston. A removable volume-changer is insertable into the recess to vary a volume of a space in which the piston slides, and thus control a pressure at which the piston operates.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

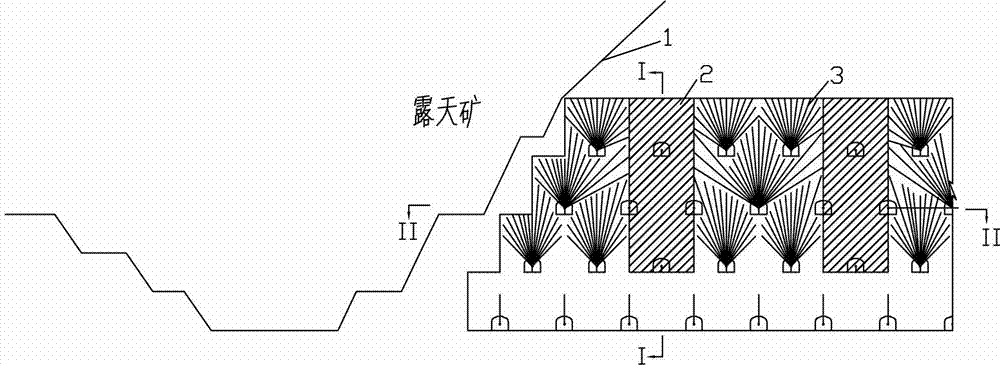

Drift-pillar-free sublevel barnyard caving mining method of open pit transferred underground transitional period

ActiveCN103089266ADecrease the sampling factorReduce the amount of quasi-engineeringUnderground miningBlastingOpen-pit miningRock cutting

The invention relates to a drift-pillar-free sublevel barnyard caving mining method of an open pit transferred underground transitional period. The drift-pillar-free sublevel caving mining method comprises the following steps of: carrying out sublevel recovering; and finishing rock drilling, blasting and ore removing in a feeding path. The drift-pillar-free sublevel caving mining method is characterized in that at an open pit transferred underground recovering transitional period, open pit mining and underground hanging wall ore recovering are carried out at the same time; a barnyard method and a drift-pillar-free sublevel caving method are combined to recover hanging wall ore; when open pit ore is mined, a drift-pillar-free sublevel barnyard method is used for recovering a hanging wall ore sublevel feeding path; and after the open pit mining is finished, a drift-pillar-free sublevel caving method is used for carrying out large-scale blasting and ore removing on safety pillars, other sublevel ores and barnyard-method residual ores. The drift-pillar-free sublevel barnyard caving mining method disclosed by the invention has the advantages of effectively reducing accurate mining coefficient and saving economic cost. The accurate mining engineering amount is greatly reduced and the accurate mining invest is reduced at the same time; and the extracted ore amount and the production capability of unit accurate mining engineering are increased and the economic benefit is effectively improved.

Owner:ANSTEEL GRP MINING CO LTD

Method and device for evaluating physical parameters of an underground deposit from rock cuttings sampled therein

InactiveUS7131317B2Rapid pressure increaseShorten communication timeElectric/magnetic detection for well-loggingPermeability/surface area analysisPorous mediumMedicine

A method and device evaluate simultaneously, with the same equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented natural or artificial porous medium. The porosity of the fragments is measured by means of helium pressure tests according to a protocol known in the art. The chamber (1) containing the fragments is communicated with a tank (11) whose volume is also known and containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the fragments mass are also measured. Combining these measurements allows to determine the porosity of the samples and the density of the rock. Their permeability is then measured by immersing them in a viscous fluid and by communicating the chamber with viscous fluid at a determined pressure contained in a vessel (9) so as to compress the gas trapped in the pores of the rock, according to two different protocols. The values of the physical parameters are determined by modelling the evolution of the pressure or of the volume in the chamber and by means of an iterative adjustment.

Owner:INST FR DU PETROLE

Method for recycling ore pillars by middle-deep hole and deep hole united blasting technique

ActiveCN102808622AImprove safety and reliabilityEasy to operateUnderground miningBlastingDetonatorDetonation

The invention discloses a method for recycling ore pillars by a middle-deep hole and deep hole united blasting technique. The method comprises the following steps: arranging middle-deep hole drilling drifts on barrier pillars of a worked-out chamber; arranging a plurality of rows of middle-deep hole blast-hole sets on the walls of the middle-deep hole drilling drifts; arranging a cutting slot gate way in each middle-deep hole drilling drift, and arraying a plurality of groups of blast-hole sets in the cutting slot gate way; excavating a deep hole drilling drifts in top pillars and arranging a plurality of rows of deep hole blast-hole sets on the walls of the deep hole drilling drifts; arranging nonel detonators on the bottoms of the middle-deep hole blast holes and the middle parts of the deep hole blast holes; using a complex network structure to be connected with the blast holes; using non-electric nonel detonators to detonate the main detonating cord for detonation, and detonating branch detonating cords by the main detonating cord; transmitting detonation wave to each non-electric millisecond detonator section by the connected detonators, and controlling each row of blast holes to detonate in sequence to complete ore pillar detonation; and recycling the detonated ore pillars after ventilation. With the adoption of the method, the barrier pillars and top pillars above the bottom pillars can be once detonated, thereby rate of ore dilution is reduced and the recovery rate is improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method and system for controlling power consumption during a rock drilling process and a rock drilling apparatus therefore

InactiveUS20070089907A1Increase powerAdd depthDrilling rodsConstructionsEngineeringPower consumption

Method for controlling power consumption during a rock drilling process with a rock drilling apparatus, wherein the rock drilling apparatus includes main power supply means for supplying power for the rock drilling process, which includes at least the sub-processes of percussion and / or rotation and flushing, the method comprising the steps of:—adjusting the flush power at least partly as a function of hole depth, and controlling at least the percussion power and / or rotational power and the flush power such that the total power consumption of each sub-process is controlled.

Owner:ATLAS COPCO ROCK DRILLS

Drill rod and method for its manufacturer

InactiveUS6095266AUnique resistance against corrosion fatigueAbility to withstand high impact loadDrill bitsDrilling rodsFriction weldingAbutment

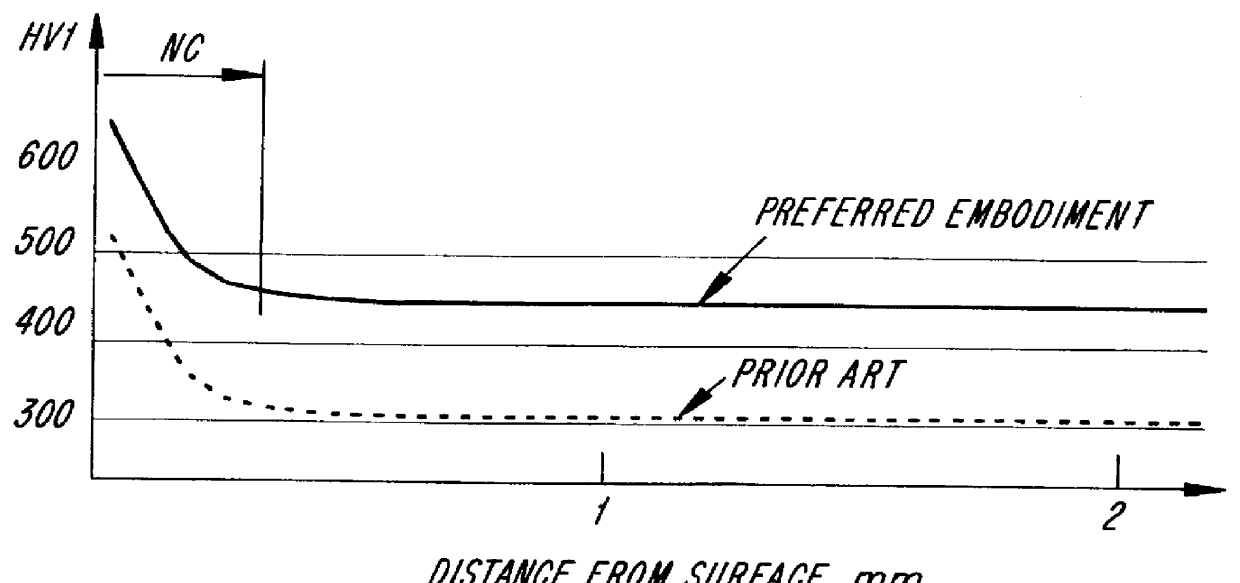

A rock drilling rod is manufactured by placing free ends of first and second hollow rod components in abutment, and establishing relative rotation between the free ends to friction weld those free ends together. The first component comprises a thread and a clearance portion disposed adjacent the thread. The first component has a hot hardness value of at least about 170 HV1 at 600 DEG C. Prior to friction welding the components together, the thread, clearance portion and central passage of the first component are heat treated against corrosion fatigue. Then, the thread is high frequency hardened to a depth at least as great as the heat treated layer. Following the welding, the weld is cooled while keeping a core hardness of the respective portions of the first and second components disposed immediately adjacent the weld no lower than 390 HV1.

Owner:SANDVIK AB

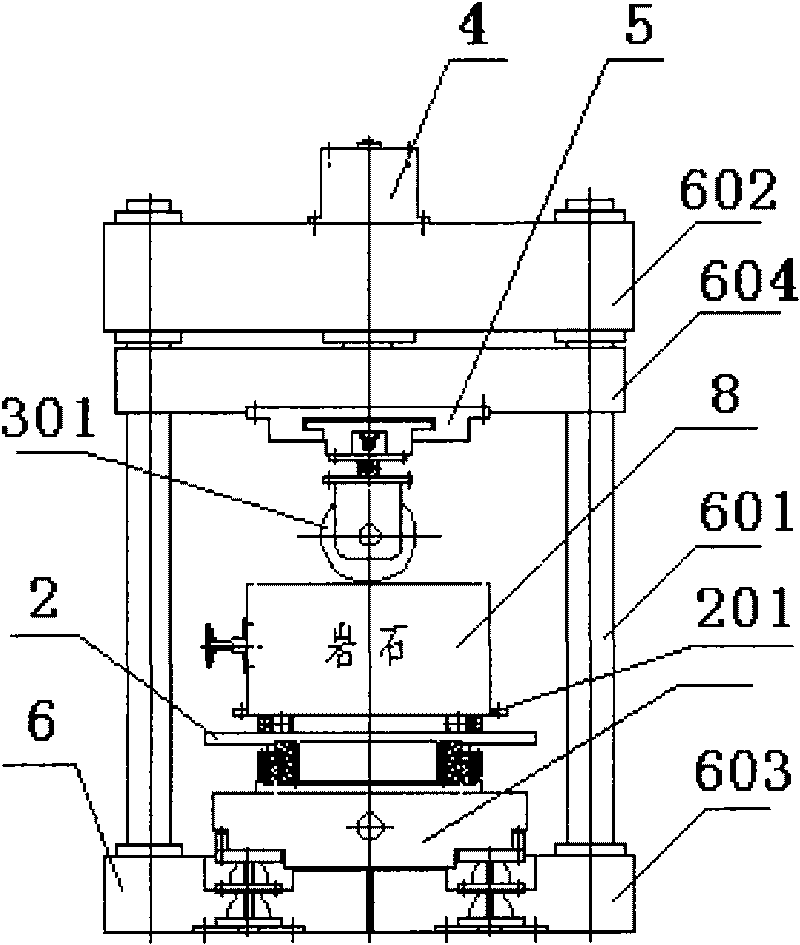

Cutting test method for rock-cutting tool

InactiveCN101713719AAffect the normal service lifeImprove stabilityInvestigating machinabilityHydraulic cylinderPresent method

The invention belongs to the field of hardware tools or tunnel boring machines, and in particular to a cutting test method for a rock-cutting tool. The cutting test method for the rock-cutting tool is characterized in that: a cutting test device for the rock-cutting tool comprises a storage box moving device, a storage box turning device, a cutting tool device, a screw-down oil cylinder device, a cutting tool moving device, a whole frame and a cutting tool locking device; the whole frame is formed by connecting an upper crossbeam, a lower crossbeam and a middle crossbeam by four prestressed pull rods; the whole frame is in rigid connection with the storage box moving device which is connected with a foundation; the storage box moving device at least comprises a pedestal, a guide rail, an operating platform and a hydraulic cylinder; the storage box turning device is arranged on the operating platform which is fixed on the guide rail on the pedestal; and the storage box turning device is moved to a working area to work by pushing the operating platform by the hydraulic cylinder. The cutting test method for the rock-cutting tool can really simulate the actual working condition of a tunnel boring machine (TBM) so as to systematically analyze the rock breaking and wearing processes of the rock-cutting tool.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

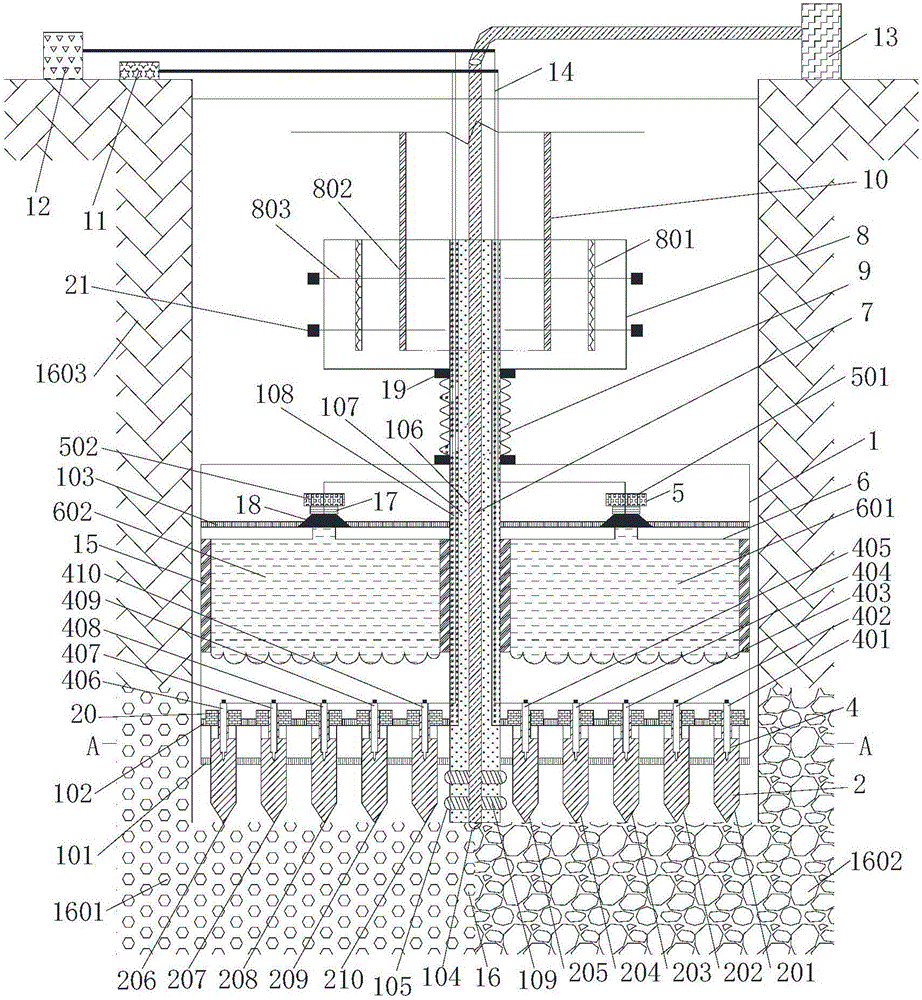

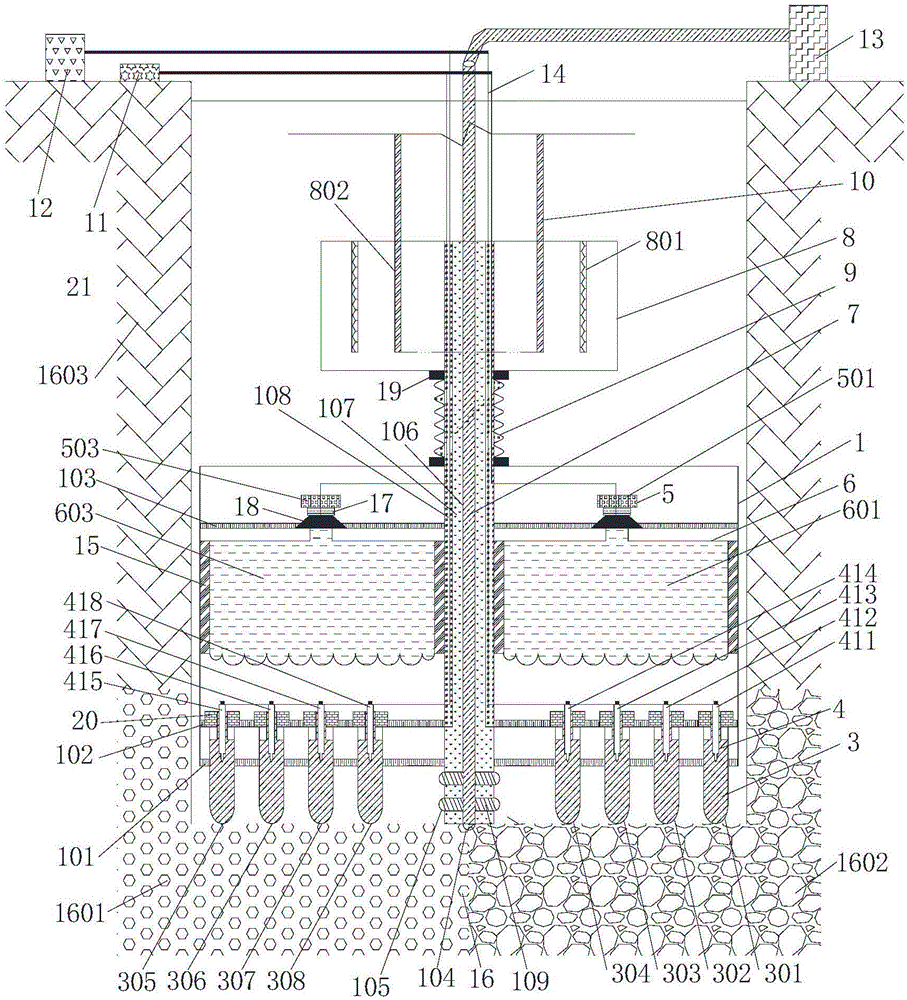

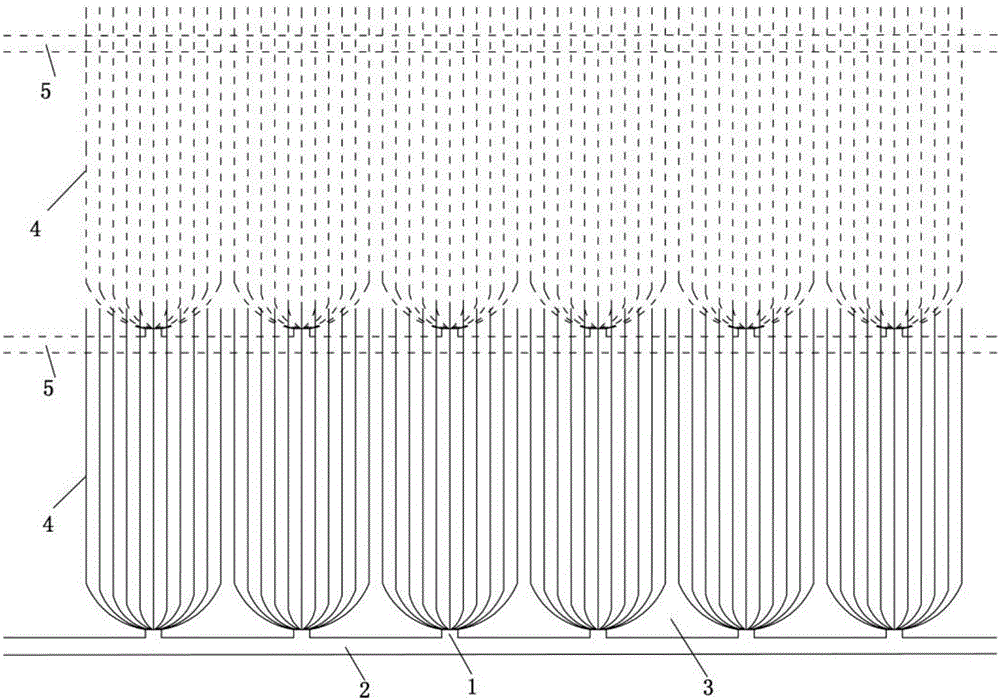

Staged rock drilling and staged mining and subsequent filling mining method

ActiveCN110644997AImprove recovery rateImprove filling efficiencyUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a staged rock drilling and staged mining and subsequent filling mining method. A last-stage ore room and a next-stage ore room share a bottom ore drawing structure of the next-stage ore room, and no top pillar or bottom pillar needs to be arranged between the last-stage ore room and the next-stage ore room; vertical deep holes are drilled in parallel in a rock drilling chamber of the last-stage ore room and a rock drilling chamber of the next-stage ore room; firstly the next-stage ore room is caved row by row, caved ore is shoveled and loaded in a loading roadway, thendischarged into an extra-vein ore pass or an intra-vein ore pass through a loading connecting roadway, a part of ore is reserved as a buffer cushion layer for caving the last-stage ore room; after caved ore of the last-stage ore room and the next-stage ore rooms is completely discharged, a sealing retaining wall is adopted to seal a rock drilling connecting roadway and an ore drawing connecting roadway, a goaf is filled, and the same method is adopted to carry out two-step ore pillar mining after the filling body reaches the specified maintenance strength. Continuous large-scale mining is realized, the workload of pre-mining cutting is reduced, the ore recovery rate and the production efficiency of a stope are improved, and the mining production cost is reduced.

Owner:安徽金安矿业有限公司 +1

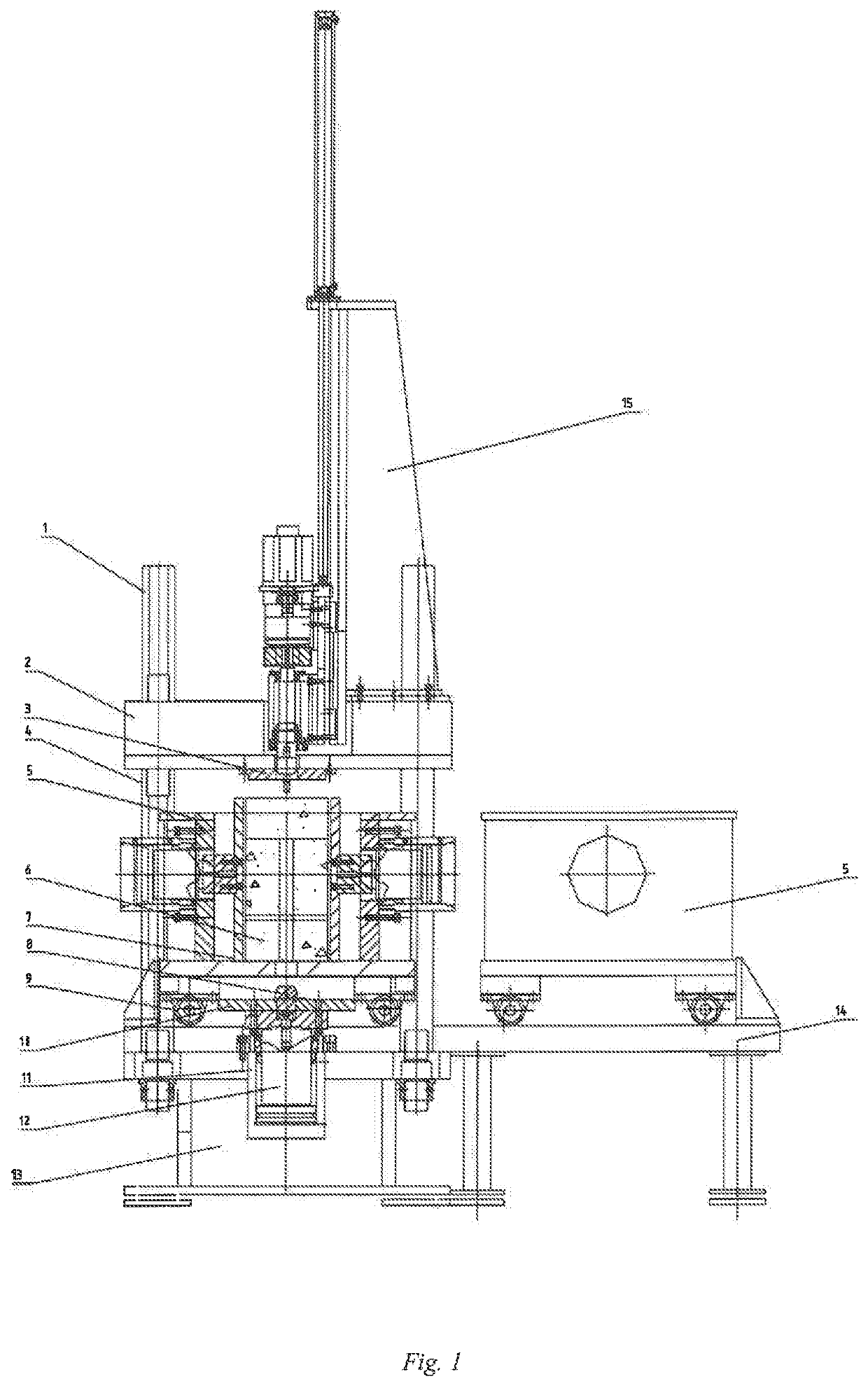

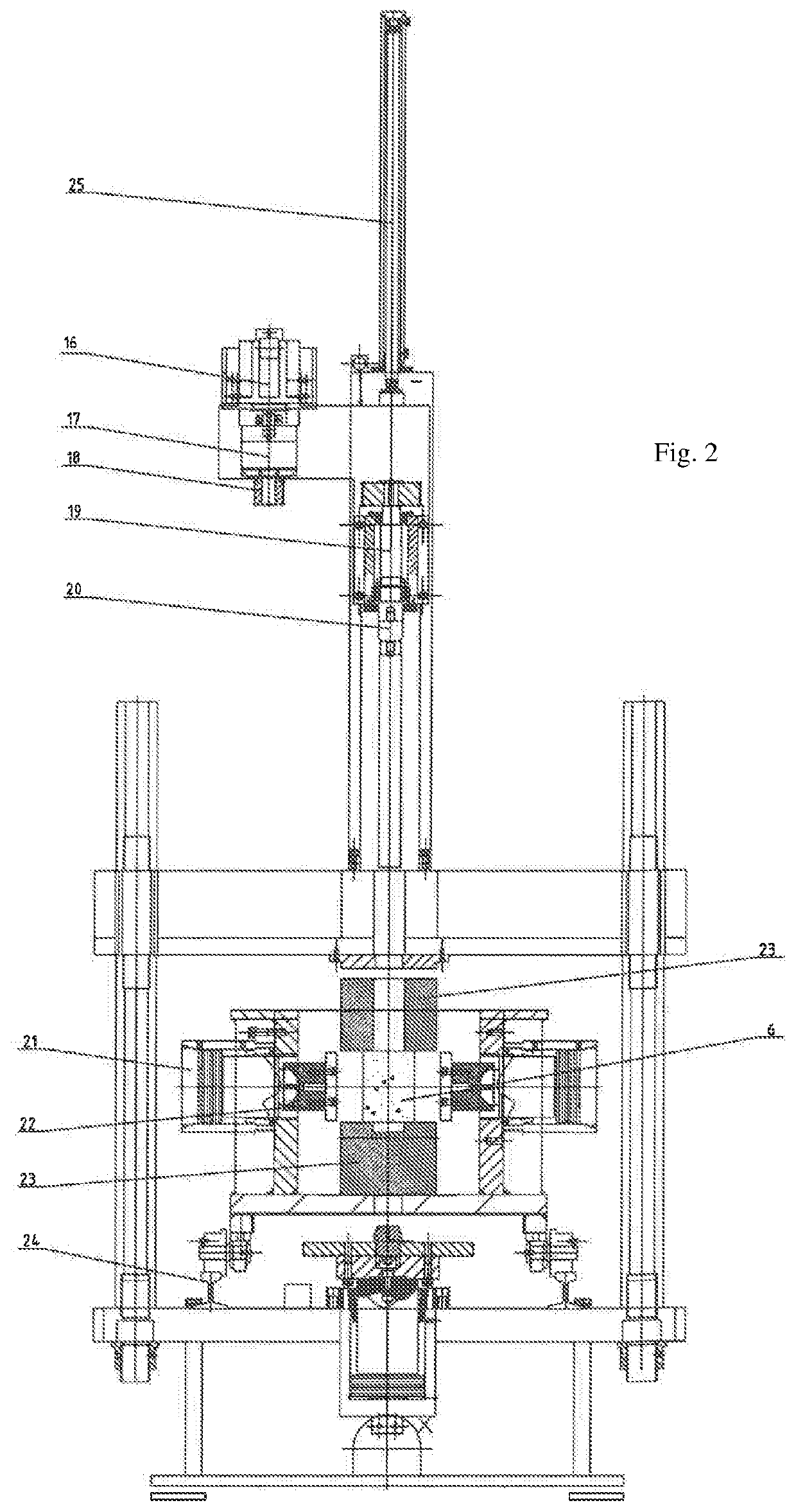

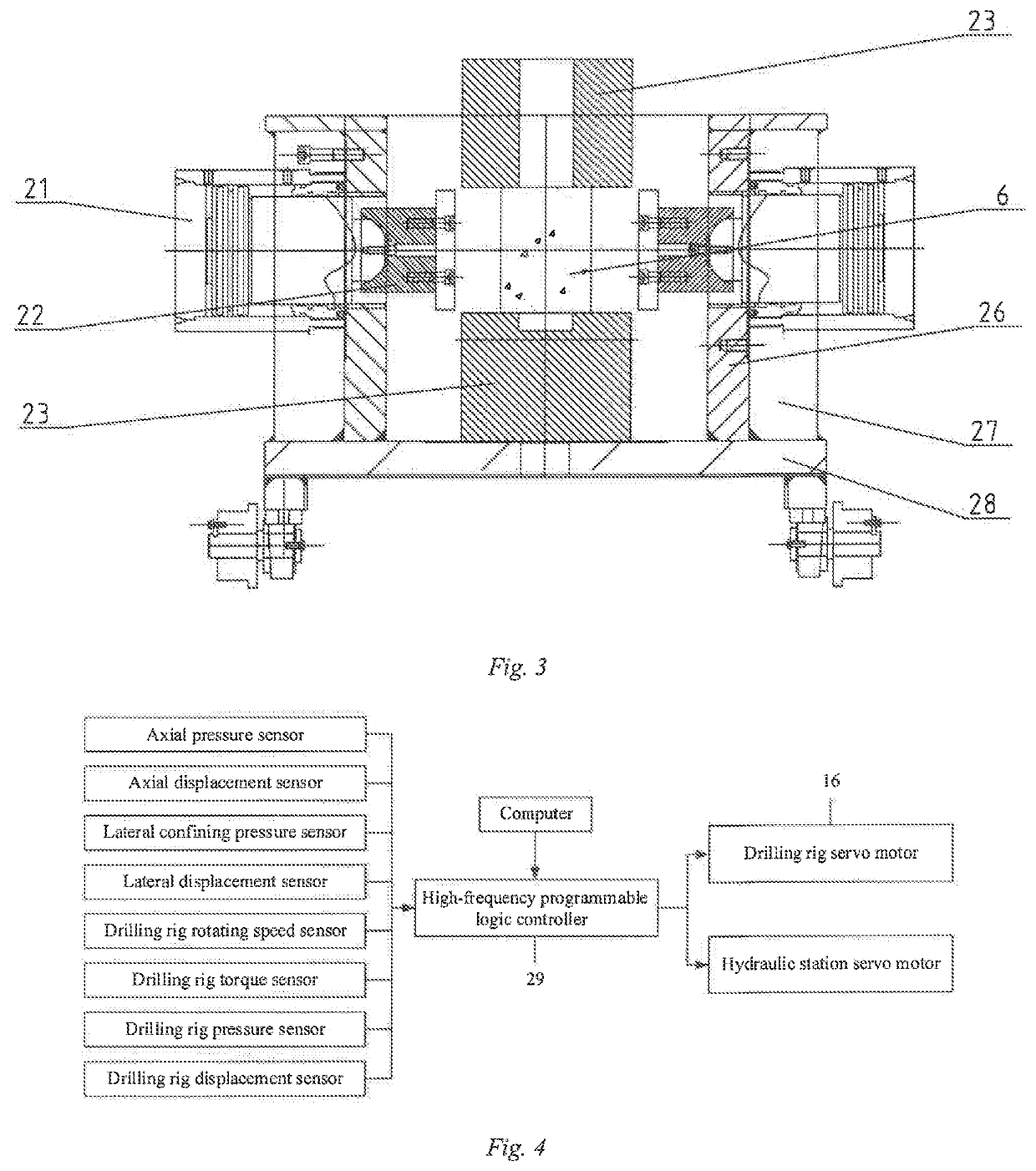

Multifunctional true triaxial rock drilling test system and method

ActiveUS20200386659A1Effective controlMaterial strength using tensile/compressive forcesEarth material testingRock coreTriaxial shear test

A multifunctional true triaxial rock drilling test system and method; rock cores are respectively taken from a plurality of drilling holes on the same test piece, uniaxial test and triaxial test are respectively performed on these rock cores to obtain multiple groups of mechanical property parameters, multiple groups of drilling parameters are obtained according to a multifunctional true triaxial rock drilling tester that can directly measure the drilling parameters, relational expression between mechanical property parameters of rock mass and the drilling parameters is established, and mechanical property parameters of rock mass can be obtained just by detecting the drilling parameters of the rock mass through the relational expression. The multifunctional true triaxial rock drilling tester is preset test device, has function of performing triaxial loading on the test piece, and can simulate drilling process of drilling rig in a three-way confining pressure state in underground engineering of the test piece.

Owner:SHANDONG UNIV +1

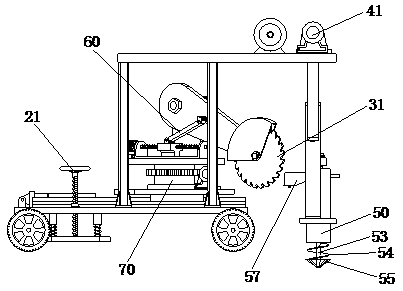

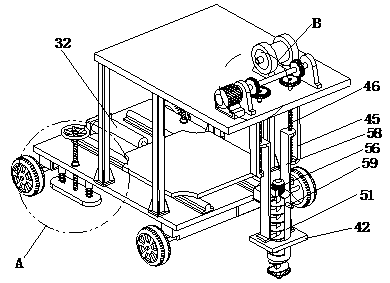

Sampling device for geotechnical exploration

InactiveCN110308010AAutomatic cuttingAutomatic crushing operationWithdrawing sample devicesDrive wheelSpiral blade

The invention discloses a sampling device for geotechnical exploration, and belongs to the technical field of geological exploration equipment. The sampling device comprises a base, a stabilizing mechanism, a rock cutting mechanism and a drilling and sampling mechanism; four driving wheels are arranged at the bottom of the base; a supporting frame is arranged on the top of the base; the drilling and sampling mechanism comprises a lifting assembly, a lifting plate and a drilling and sampling assembly; the drilling and sampling assembly comprises a sampling barrel and a connecting frame; a rotating shaft is arranged on the connecting frame; a spiral blade is arranged on the rotating shaft in a sleeved mode; and a drilling head is arranged at the bottom end of the rotating shaft in a sleevedmode. The sampling device has the beneficial effects that the lifting operation of the drilling and sampling assembly can be realized, and the sample can be conveyed to a material collecting hopper byvirtue of the drilling and sampling mechanism; the automatic cutting assembly can be used for cutting and crushing rock samples; and a rotary assembly can drive the automatic cutting assembly to rotate to a proper position, so that the interference of the automatic cutting assembly on the operation of the drilling and sampling mechanism is avoided.

Owner:胡立宇

Overhand shrinkage spaced-loading split-blasting slot cutting method

ActiveCN103696769AQuality improvementControl chunk rateUnderground miningSurface miningTEX-explosiveMining engineering

The invention discloses an overhand shrinkage spaced-loading split-blasting slot cutting method, which aims at solving the problems that the ore discharging efficiency is low, the consumption of explosive is large, the rate of large ore blocks is high, the construction organization is complicated, a suspended roof is likely to form and the operation safety is poor in a traditional slot cutting process. The method comprises the following steps of step 1, determining geometric parameters of a cutting level; step 2, determining a position of a cutting open yard, to be specific, determining the parameter and height of a cross section, and selecting the position; step 3, determining rock drilling parameters in the slot cutting process, to be specific, determining the parameter of a resisting line, determining the hole-bottom distance parameter and determining side, hole and corner; step 4, forming a cutting slot; and step 5, discharging from the ore in a concentrating manner, wherein after the rearmost rows of blast holes in the uppermost layer of the cutting slot are exploded in an elementary error manner, ores falling into the cutting slot are concentratedly discharged through a first layer. By adopting the method for preserving the ores and finally discharging the ores concentratedly, the slot cutting can be safely and rapidly carried out for a chamber at the high quality.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

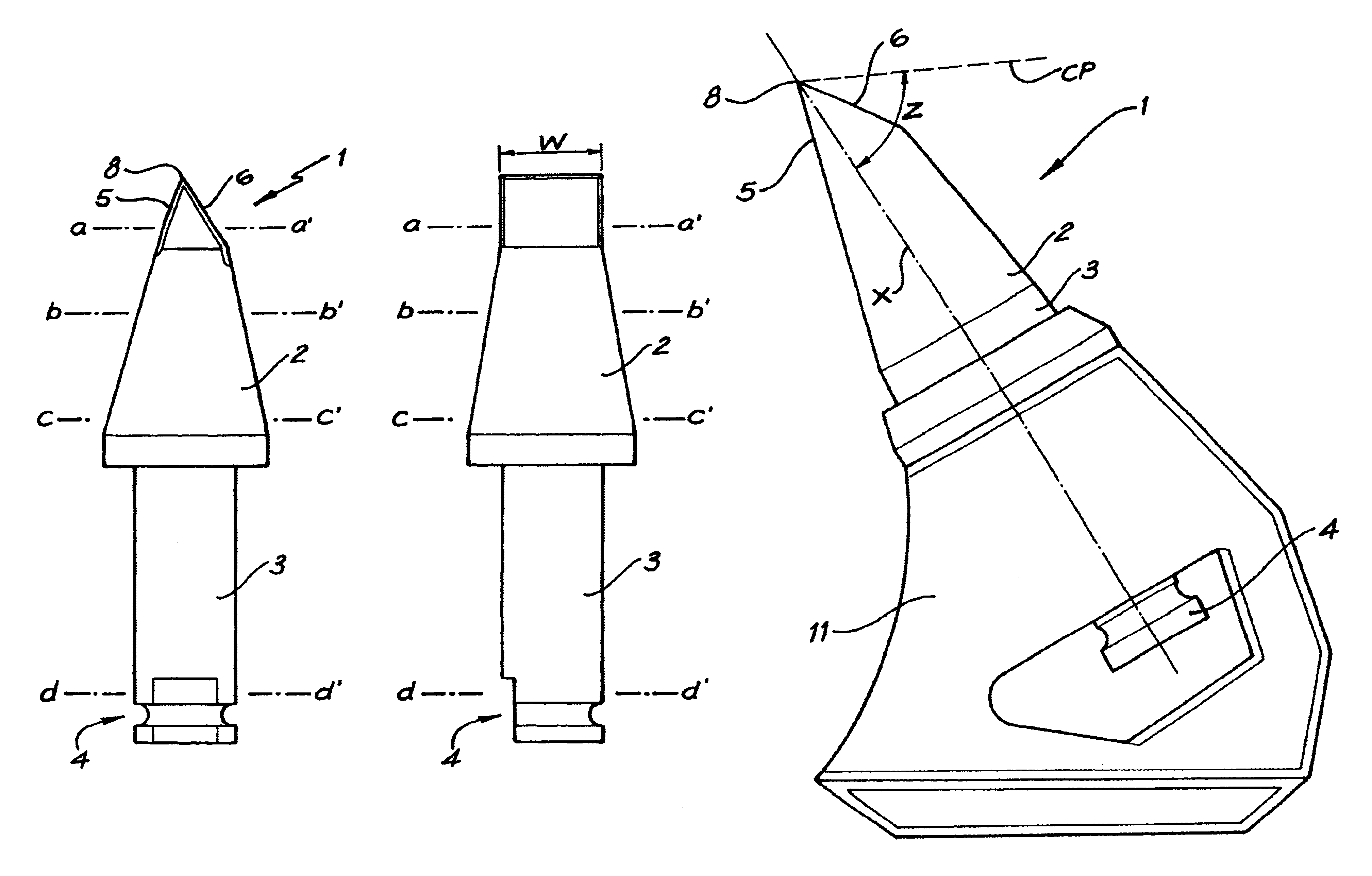

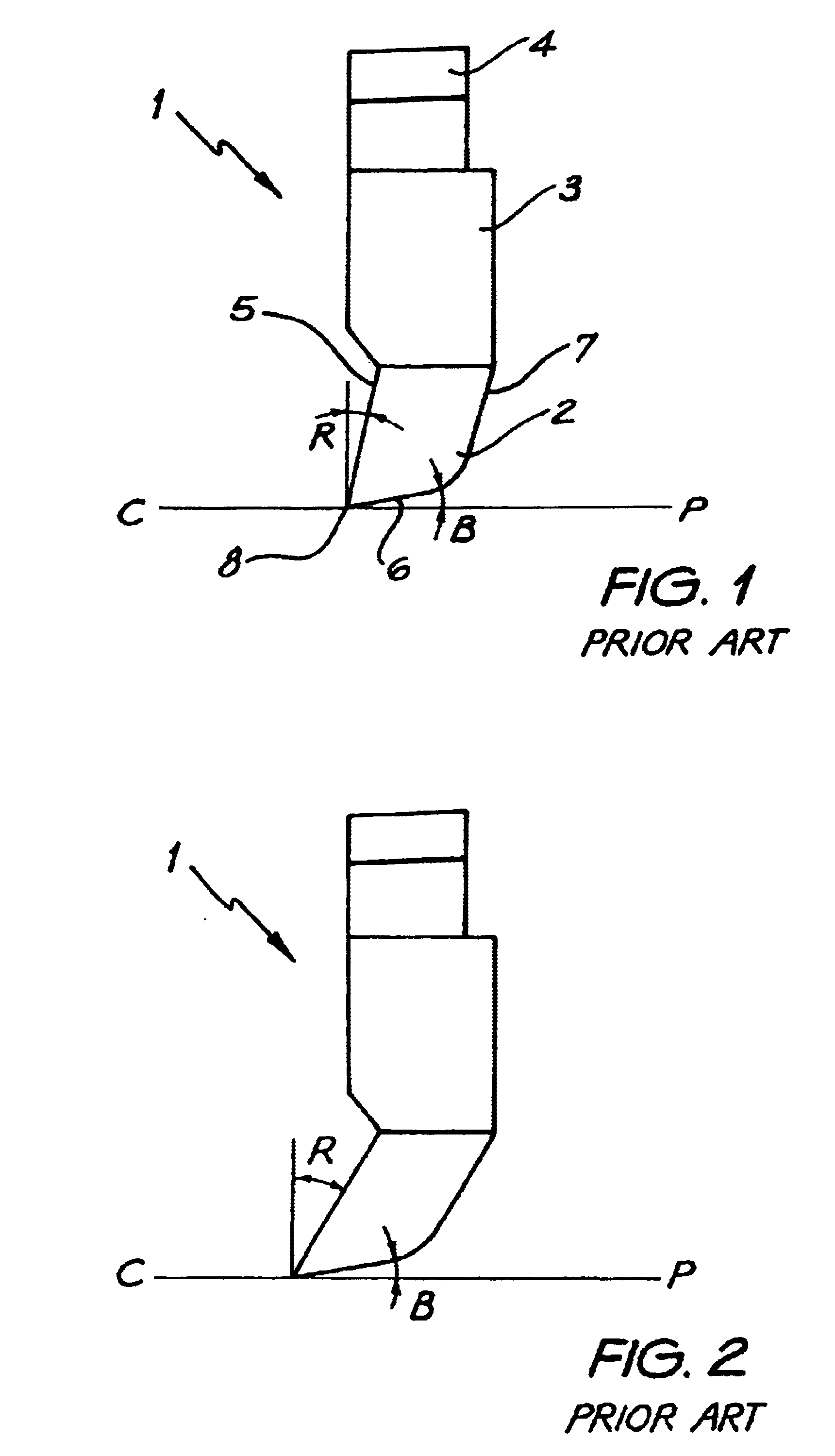

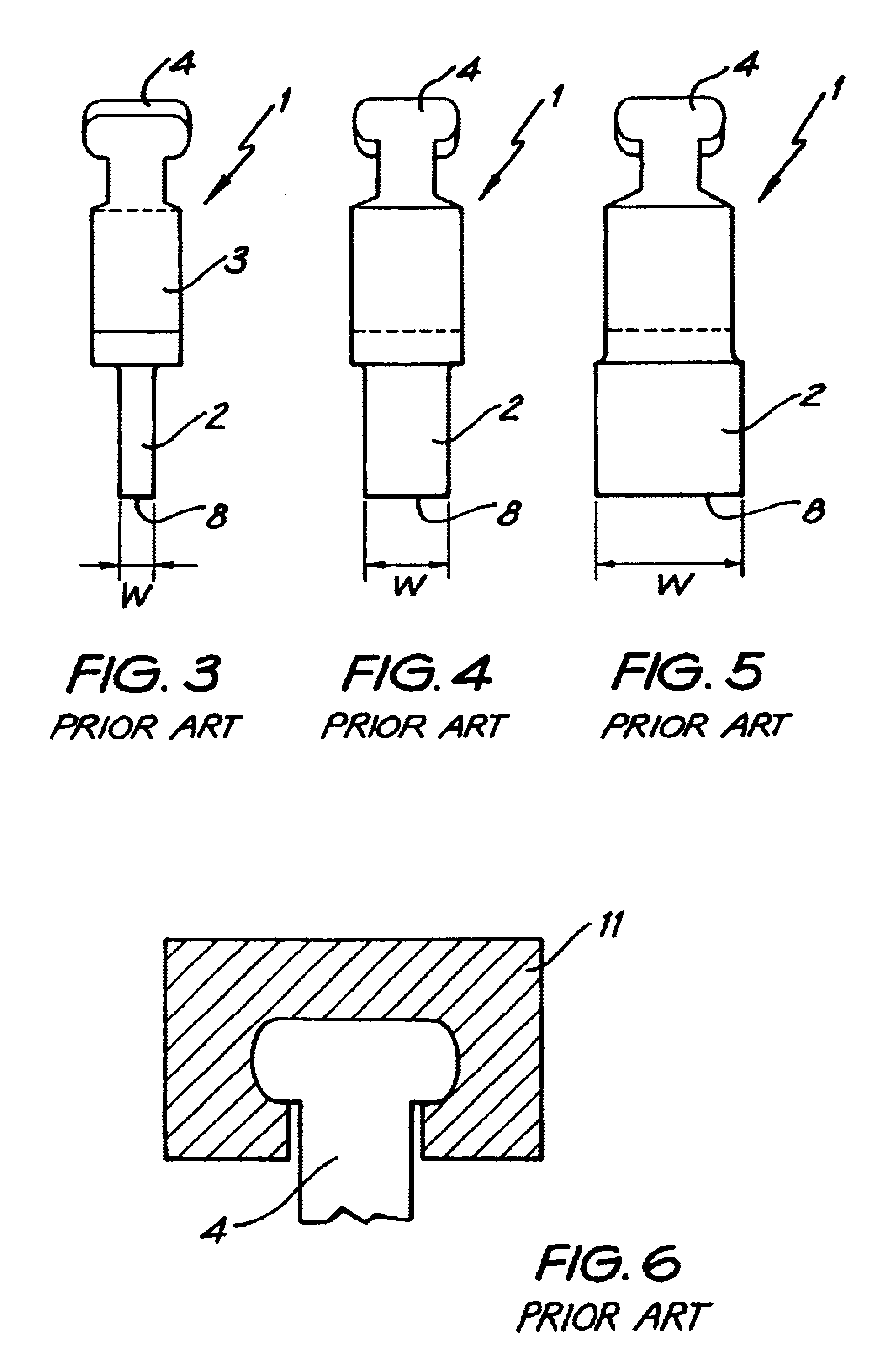

Coal and rock cutting pick

The pick (1) includes a radially inner end (4) and a shank (3) to be fixed to the drum (10) to substantially prevent relative movement between the pick (1) and drum (10). The pick (1) further includes a cutting head (2) having leading (5) and trailing faces (6) intersecting to provide a cutting edge (8) to extend generally parallel to an axis. The leading face (5) in use is inclined by an acute rake angle R to a radius of the axis, with the trailing face (6) being inclined at an acute back clearance angle B to a plane passing through the edge (8) and normal to the radius. The leading face (5) and trailing face (6) being inclined by an acute angle and the shanks when fixed to the drum (10) extends at an acute angle to the radius.

Owner:AGE MINING SERVICES PTY LTD

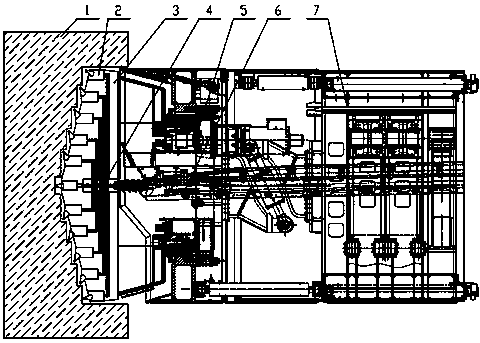

Multi-function tunnel rock drilling and arching all-in-one machine

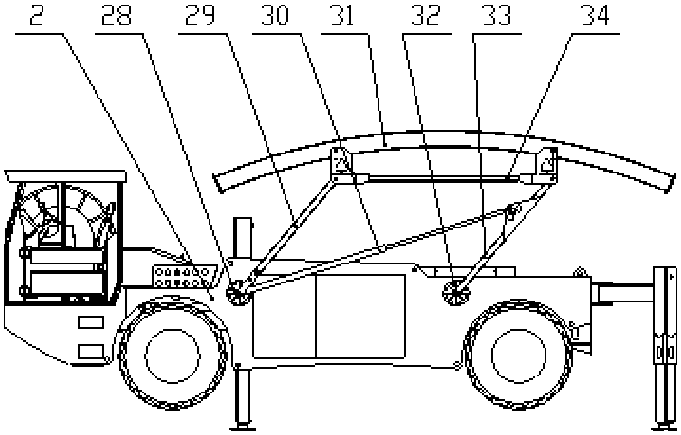

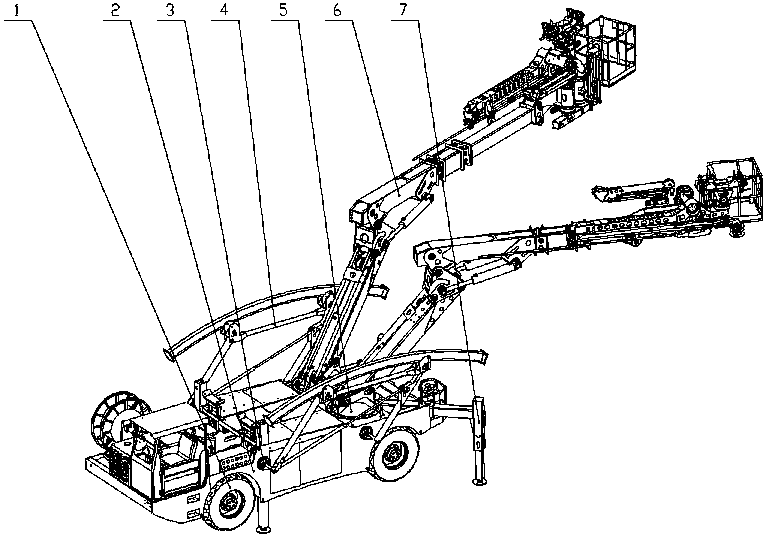

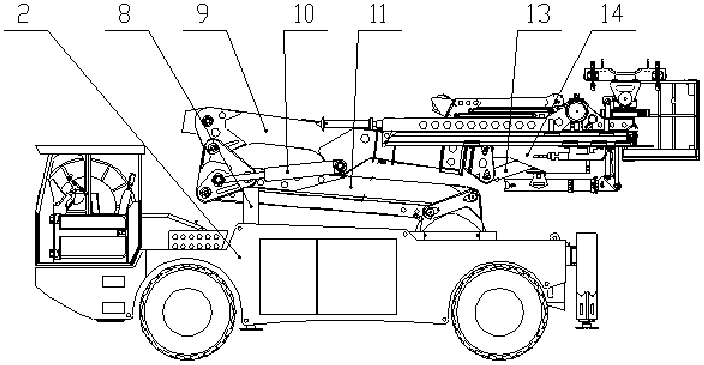

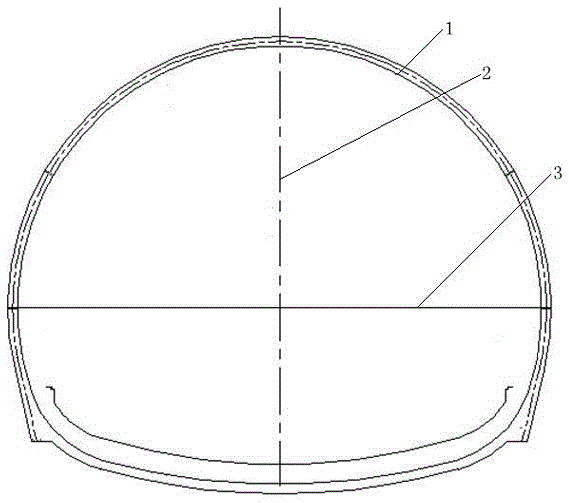

PendingCN107842311AGrow fastSolve the problem that the vehicle cannot be retracted and the vehicle is too long and has a large turning radiusUnderground chambersDerricks/mastsEngineeringDrilling machines

A multi-function tunnel rock drilling and arching all-in-one machine comprises a host platform (2) which is arranged on a basal disc (1); two arm frames (6) are arranged at the rear portion of the host platform by a rotation seat (5), and the arm frames can be folded and stored in a driving or static state; the front end of a forearm is rotationally provided with an arch grabbing device (18), a rock drilling device (19), a manned platform (24), and a truck crane (23). The multi-function tunnel rock drilling and arching all-in-one machine can perform the arch support operation during full section, two-step and three-step excavating of a tunnel. Through the coordination of the two arm frames and the above working devices, the arch frame transported by car, the installation of the arch, the hanging of the reinforcing mesh, the welding of the transverse reinforcement and the installation of a bolt and a drill hole of leading small tube can be realized; the efficiency is far higher than that of the manual operation.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

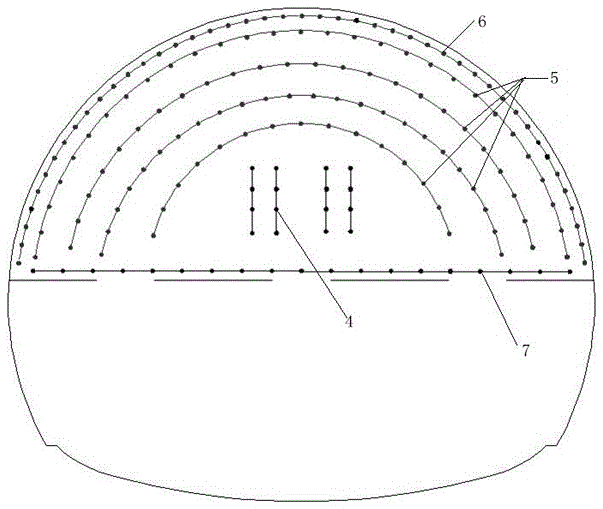

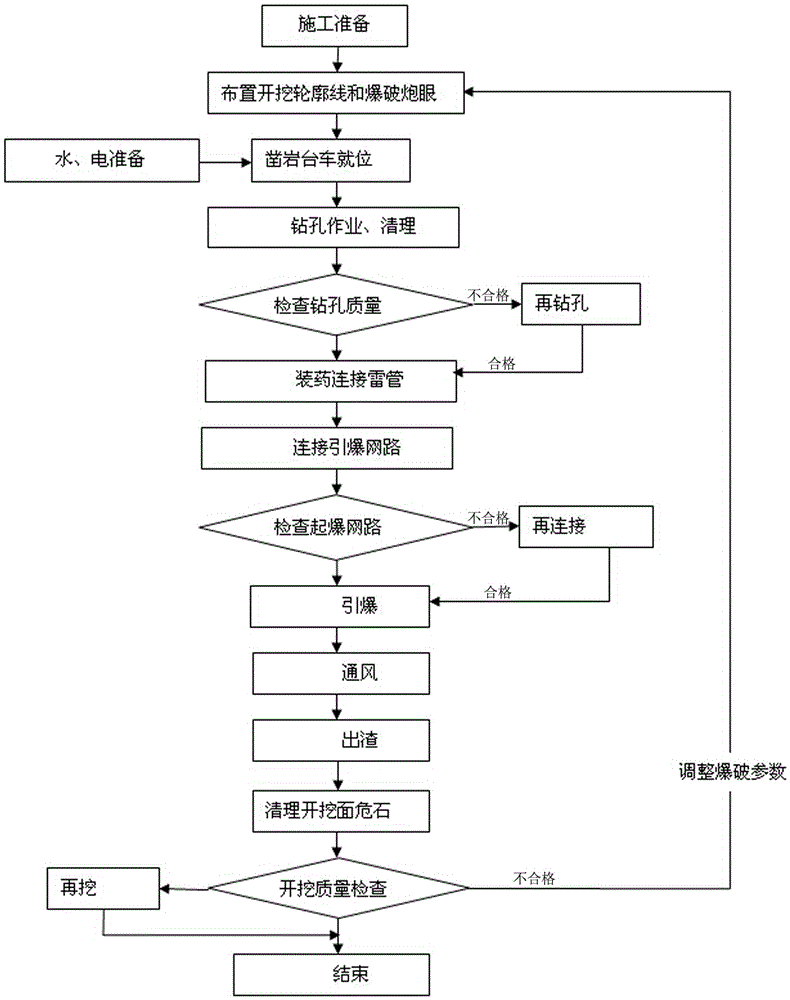

Method for carrying out bench cut method construction in IV-grade surrounding rocks by using three-arm drill jumbo

InactiveCN105605996APrecise positioningDrilling and blasting footage shortenedBlastingRock cuttingDrilling and blasting

The invention belongs to the technical field of tunnel rock mass construction, and particularly relates to a method for carrying out bench cut method construction in IV-grade surrounding rocks by using a three-arm drill jumbo. According to the method for carrying out bench cut method construction in the IV-grade surrounding rocks by using the three-arm drill jumbo, which is disclosed by the invention, a construction section is excavated by adopting smooth blasting; the characteristics of rapidness, positioning accuracy and safety of the three-arm drill jumbo are sufficiently utilized; drilling time is short; an extrapolation angle is easy to control; a drilling and blasting footage of the construction section is shortened; each cycle of drilling and blasting numbers are reduced; and particularly, the three-arm drill jumbo is used for carrying out drilling and blasting for the first time in the excavating process of an upper bench, and manual drilling and blasting are adopted on a lower bench, so that the rapid and accurate drilling operation is achieved, cycle operation time is reduced, and when drilling and blasting quality and operation efficiency are improved, the operation environment is improved, thereby improving integral efficiency of tunnel construction.

Owner:CCCC TUNNEL ENG

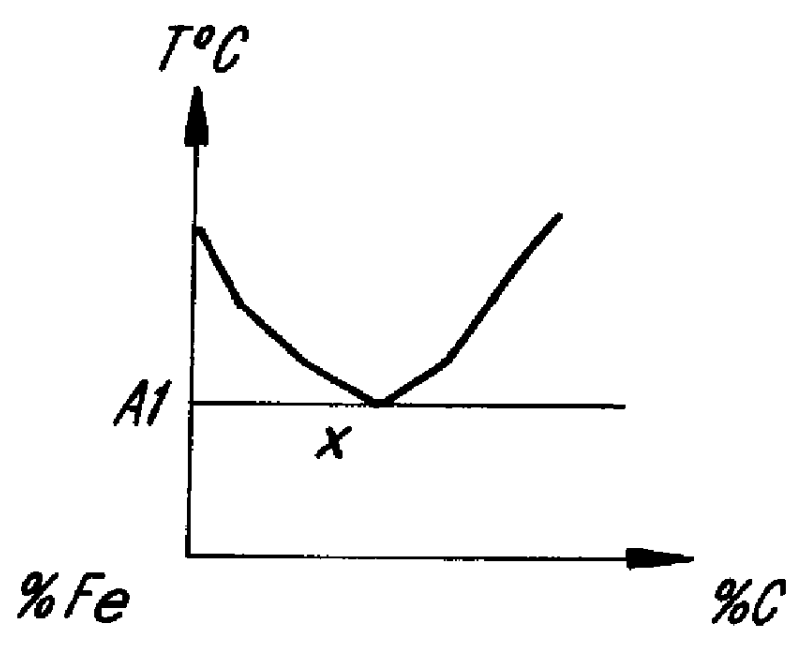

Whisker plasticizing tungsten carbide-cobalt base hard alloy material and its preparation process

The invention discloses a crystal whisker toughened tungsten carbide cobalt-base hard alloy material and the preparing method. It takes powder metallurgy technology, employs tungsten carbide- cobalt as base material, adds titanium carbide crystal whisker and prepares toughened tungsten carbide cobalt-base hard alloy material through a certain process. It is characterized in that: (1) employs powder metallurgy technology and prepares out product with different shapes. (2) the rigidity is high, compression strength and toughness are good, the titanium carbide crystal whisker increases toughness on basis of guranteeing strength of said alloy, and it aslo can be used to replace cobalt and as adhesive phase, to improve material performance. (3) the process is simplea nd cost is low. The hard alloy material can be used in mechanics, metallurgy, mine, first-order instrument and military, and uesd to prepare kinds of blade and drilling button, and new knife tool material.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

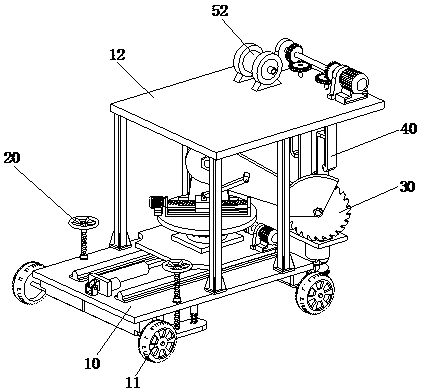

Dry-type joint coal rock sampling device and sampling method thereof

InactiveCN103837368AImprove stabilityAvoid crackingWithdrawing sample devicesCoal briquetteInstability

The invention relates to a dry-type joint coal rock sampling device and a sampling method thereof. The dry-type joint coal rock sampling device comprises a cutting device and a sampling device, wherein the cutting device is provided with a cutting base, one end of a cutting wall is connected with the cutting base, a saw blade is mounted on the other end of the cutting wall, and a height regulating device is mounted between the cutting base and the saw blade; the cutting base further comprises a cutting track; a sliding rail base is connected with the cutting track, the sliding rail base is a two-way sliding rail and capable of moving along the cutting track or in a direction perpendicular to the cutting track, and a base translation control handwheel is mounted on the sliding rail base; a turnplate is mounted at the center of the sliding rail base and is provided with a handwheel, and rock samples are arranged on the turnplate; the sampling device comprises a sampling base, a clamping device, a diamond sampling drill bit, an openable transparent cover, a refrigerating device, an air blowing device and an exhaust fan. The dry-type joint coal rock sampling device is capable of either effectively avoiding coal briquette falling and coal rock cracking due to instability in the coal rock cutting process or accurately controlling the cutting thickness of the coal rock, and therefore, the purpose of accurate cutting is achieved.

Owner:嘉兴骏博精密机械有限公司

Medium deep hole presplitting blasting mining method of steeply inclined thin-to-ultrathin-lode ore body

ActiveCN110952982AImprove securityMine fall avoidanceUnderground miningSurface miningLodeMining engineering

The invention discloses a medium deep hole presplitting blasting mining method of a steeply inclined thin-to-ultrathin-lode ore body. A stope drift along a lode and a layered rock drilling drift in the lode are excavated in the ore body lode along the trend; during ore break down and rock drilling blasting in each time, a pre-splitting blast hole in a hanging side ore and rock boundary surface inan inclination direction of the ore body is drilled along a hanging side ore and rock boundary line in the stope drift or the layered rock drilling drift, and a pre-splitting blast hole in a heading side ore and rock boundary surface in the inclination direction of the ore body is drilled along a heading side ore and rock boundary line in the stope drift or the rock layered drilling drift; and theore rock within about 2 to 4 m along the stope trend at a current layer is enabled to be cut during each time of pre-splitting blasting. The medium deep hole presplitting blasting mining method of the steeply inclined thin-to-ultrathin-lode ore body breaks through the applicable ore body thickness boundary of a stage room mining method, and thereby can be applied to mining of the steeply inclinedthin-to-ultrathin-lode ore body; rock drilling and ore break down on a muck pile under a suspended ceiling when a waste-lifting filling ore mining method or a shrinkage method is used are avoided; the safety of operators is improved; and large-scale and high-efficiency flat-bottom structure ore removal by a method similar to the stage room mining method and by using a carry-scraper or a muck loader can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

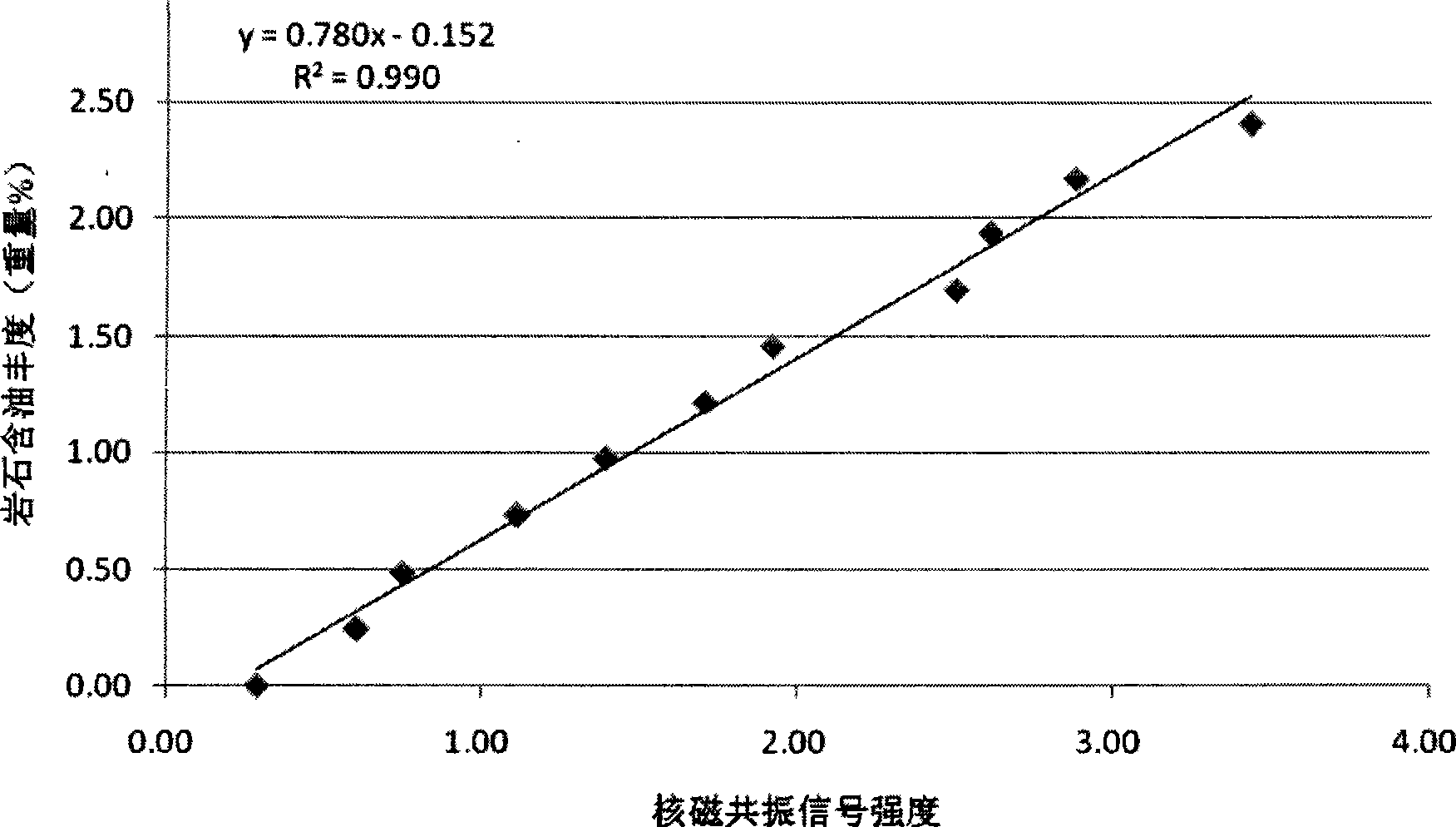

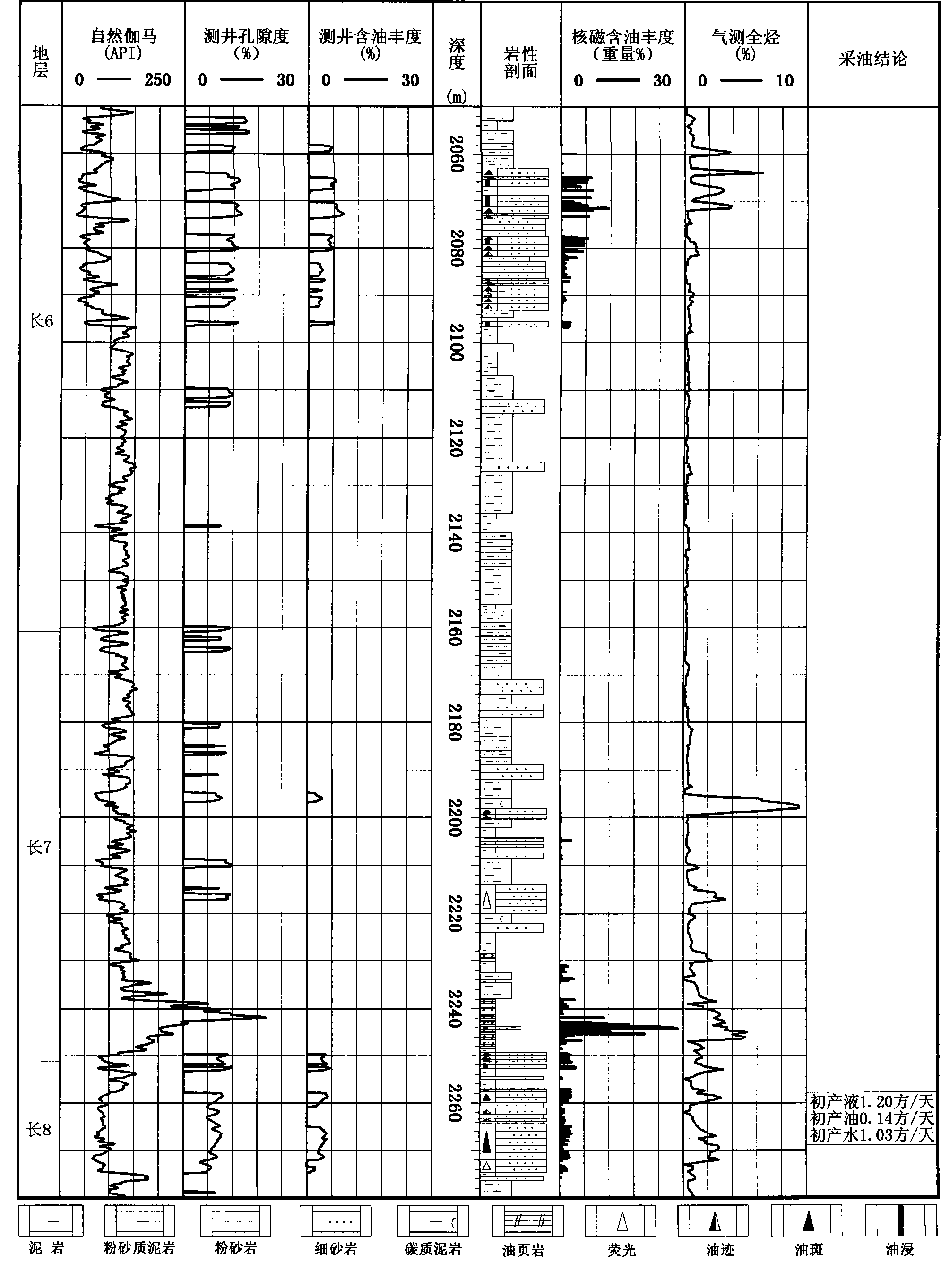

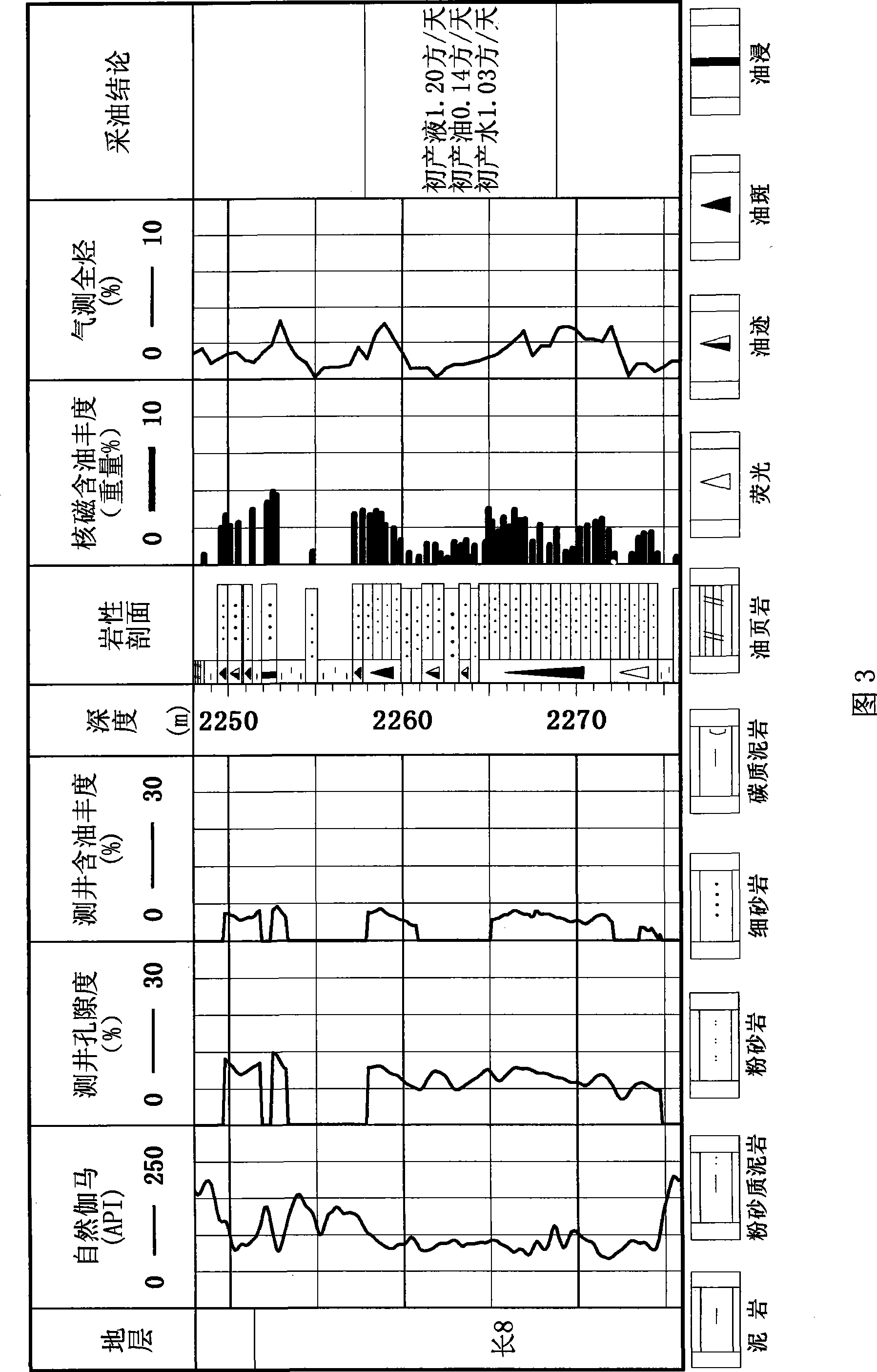

Quantitative analysis method for oil-containing abundance of nuclear magnetic resonance rock in petroleum well drilling

ActiveCN101368481AReal-time analysisObtain oil abundance data in real timeAnalysis using nuclear magnetic resonanceBorehole/well accessoriesHorizonRock cutting

The invention relates to a fine well-drilling cuttings oil-abundance analysis method based on nuclear magnetic resonance technology. The method includes the following steps: debugging and calibrating a nuclear magnetic resonance analytical apparatus; making up a rock oil-abundance working curve at target horizon, getting rock cuttings at a reservoir layer without oil gas at the target horizon within the work area and preparing the rock cuttings into a sample mixture of crude oil and cuttings; soaking the sample mixture in water-soluble paramagnetic ion solution; conducting nuclear magnetic resonance analysis; with the intensity of nuclear magnetic resonance signals as the abscissa and the content of crude oil in the sample as the ordinate, drawing a rock oil-abundance working curve of the target horizon; and then calculating the rock oil-abundance data. The method can analyze well-drilling cuttings real-timely, work out the rock oil-abundance data real-timely and carry out quantitative evaluation to the oil-abundance of the reservoir layer, providing real-time technical support to oil exploration, development and production.

Owner:中石化石油工程技术服务有限公司 +3

Tunneling machine using laser for rock breaking

InactiveCN108561148ASolve the problem of abnormal damage proneImprove rock breaking efficiencyTunnelsElectricitySlag

The invention discloses a tunneling machine using laser for rock breaking. The tunneling machine structurally comprises a tunneling machine host and a water and electricity output system matched withthe tunneling machine host, wherein a cutter head system is arranged at the front part of the tunneling machine host; a plurality of laser generators are uniformly arranged on a cutterhead of the cutterhead system along the movement track; the emitting ends of the laser generators form an inclined angle with the tunnel face rock in the digging position; the laser generators are connected with thewater and electricity output system through a conveying and distribution pipe of a water and electricity conveying and distribution system; the conveying and distribution pipe is a porous pipeline integrating a water pipe and an electric wire pipe; the middle part of the tunneling machine host is provided with a driving system for driving the cutterhead system; a slag discharging system matched with the cutterhead system is arranged inside the tunneling machine host; a step system is arranged on the tunneling machine host. A laser ray system is used for solving the problem that the abnormal damage can easily occur during the rock cutting by a metal cutter; the suspension cutting rock breaking is used, so that the digging efficiency is improved; the digging cost is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Pneumatic control rock cutting device for rock-embedded pile soft-hard interphase layer

ActiveCN106223855AQuality assuranceReduce construction costsConstructionsLiquid/gas jet drillingVibration controlAdhesive

A pneumatic control rock cutting device for a rock-embedded pile soft-hard interphase layer can meet the accurate drilling requirement of the soft-hard interphase layer in the rock-embedded pile construction process, and ensures drilling quality meeting design standards. The pneumatic control rock cutting device comprises a rock cutting retaining cylinder, a conical cutting tool system, a toothed cutting tool system, a vibration sensing system, a pneumatic sensing system, a pneumatic bag system, a high-pressure water pipe, a multi-path connector, an isolation spring, a drill rod, a pneumatic controller, a vibration controller, a high-pressure water pump, a cable, power adhesives, a pneumatic flow controller, a pneumatic stabilization bolt, a rubber shock pad, an isolation fastening bolt and retaining pins. The pneumatic control rock cutting device has the advantages that according to the stress condition of soft-hard rock cutting, constant pressure of a drilled soft rock is kept, pneumatic pressure is applied to incompletely cut hard rocks, and the device solves the common problems that a rock-embedded pile easily deviates in construction in the soft-hard interphase layer and a reinforcement cage cannot descend for installation by the aid of the criterion of 'constant pressure-pressurization'.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

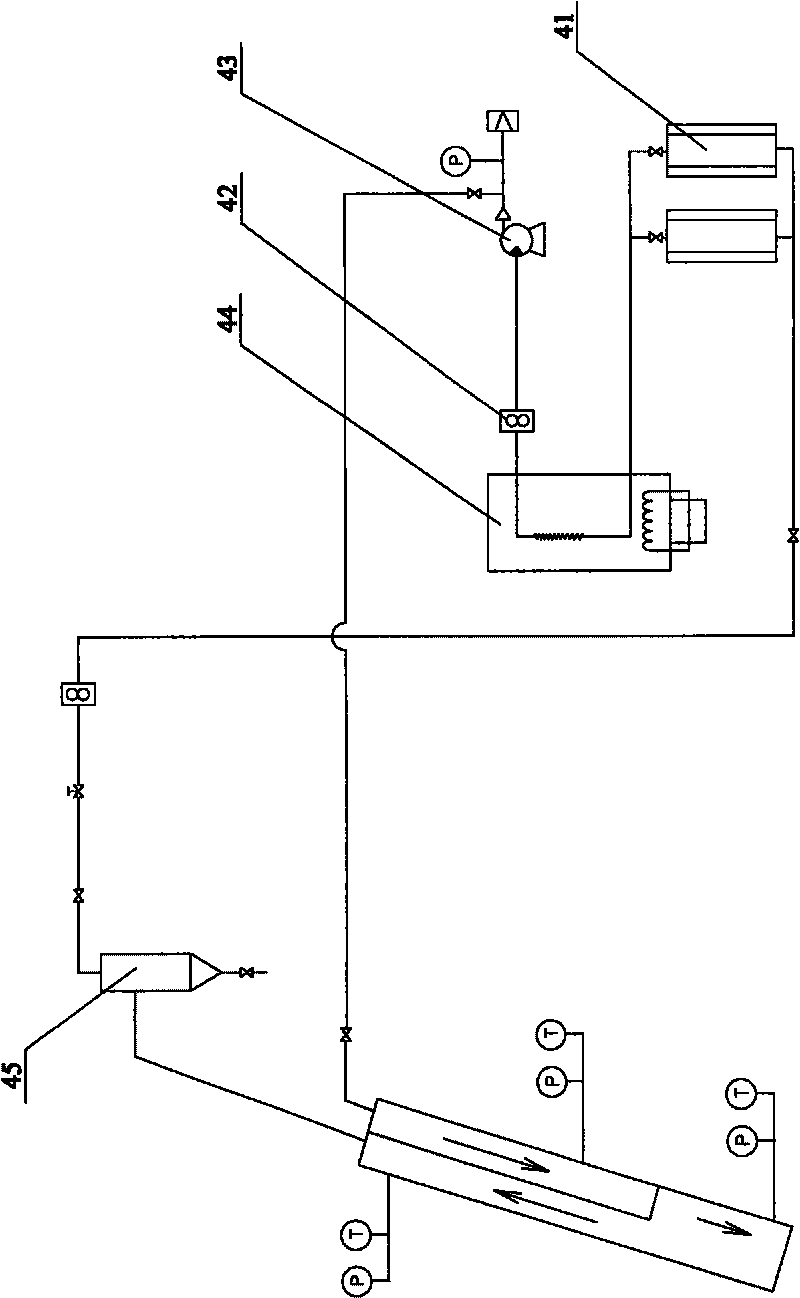

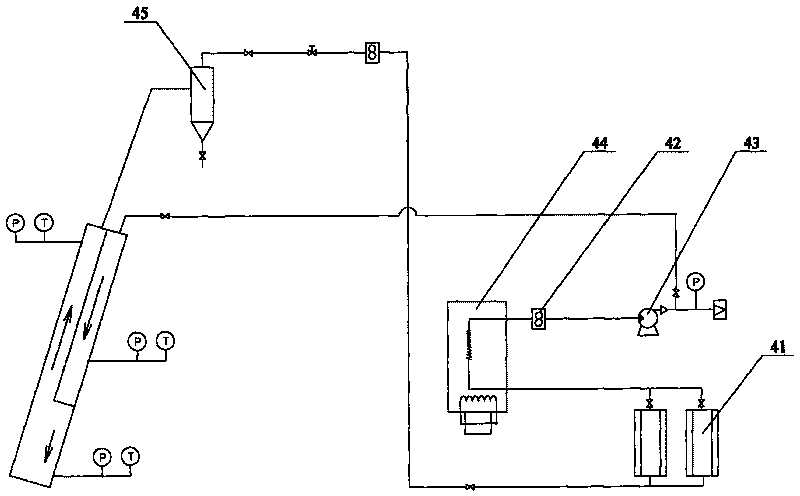

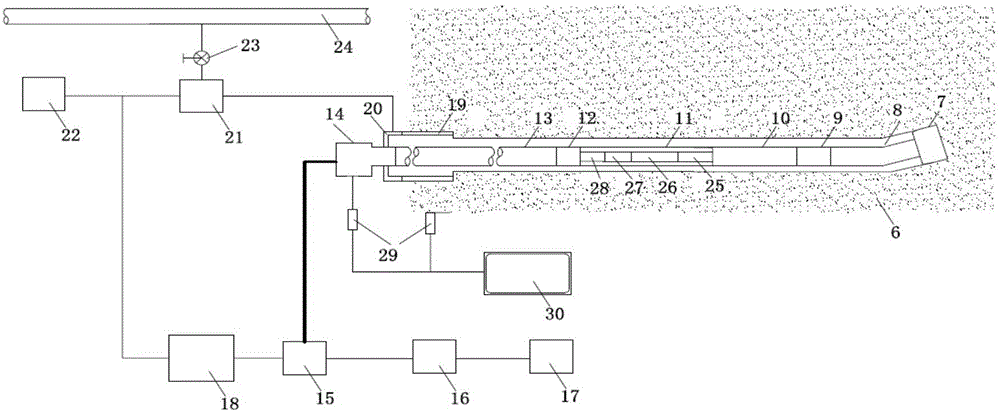

Simulation experiment device for migrating rock cuttings with circulation of deepwater drilling fluid and stabilizing well wall

InactiveCN101701520AAchieve low temperature flow characteristicsAchieve rock-carrying propertiesSurveyConstructionsRock cuttingTemperature and pressure

The invention discloses a simulation experiment device for migrating rock cuttings with circulation of deepwater drilling fluid and stabilizing well wall. The device comprises a plurality of simulation wellholes, simulation drill pipes, and a drilling fluid delivering device; simulation well wall is arranged between an upper simulation wellhole and a lower simulation wellhole; the simulation drill pipes are provided with a drilling fluid inflow passage along axial direction; the drilling fluid circular delivering device comprises a drilling fluid circulation loop formed by sequentially connecting fluid storage tank, cooling device, flowmeter, fluid pump, inlet of the drilling fluid inflow passage, outlet of the drilling fluid inflow passage, liquid-solid separator and again the fluid storage tank by pipelines; and the inner wall of the simulation wellholes is provided with a plurality of temperature and pressure sensors, and transmits the signals to a data processor for processing. The invention can simulate the circulation process of deepwater drilling fluid, can carry out property researches such as low temperature flow, rock cutting migrating and well wall stabilizing, and provide an experimental method and research means for deepwater drilling fluid research.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

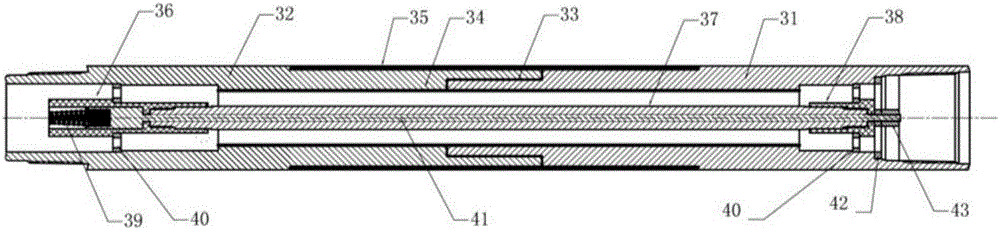

Underground progressive gas pre-extraction and directional hole drilling system and method for broken and soft coal seam

ActiveCN105971517AImprove hole depthHigh hole forming precisionSurveyDrilling rodsRock cuttingEngineering

The invention relates to an underground progressive gas pre-extraction and directional hole drilling system and method for a broken and soft coal seam. An orifice bubble filling system is utilized to provide a continuous bubble flow for a drill hole to drive hole bottom grooving air screw motor to perform rapid drilling, and scouring to the hole wall of the broken and soft coal seam is reduced. A triquetrum auger stem is used for strengthening residue discharge. An orifice bubble-eliminating extraction system is utilized to eliminate bubbles, remove rock cuttings and perform gas extraction, and construction safety is guaranteed. A dual-drive compound directional drilling technology is combined to regulate and control a drilling trajectory and ensure that the drill hole extends along the designed trajectory and penetrates through and covers an unmined working face and a roadway to be excavated. The hole forming depth, the hole forming precision, hole forming efficiency and hole forming rate of the broken and soft coal seam with the Platts hardness coefficient f greater than or equal to 0.5 but smaller than or equal to 0.8 are wholly improved, the formed hole is used for progressive gas pre-extraction in a broken and soft coal seam zone, and a standard-reaching period of the working face of the broken and soft coal seam and coal roadway driving gas extraction is shortened.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com