Patents

Literature

110results about How to "Improve cutting life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

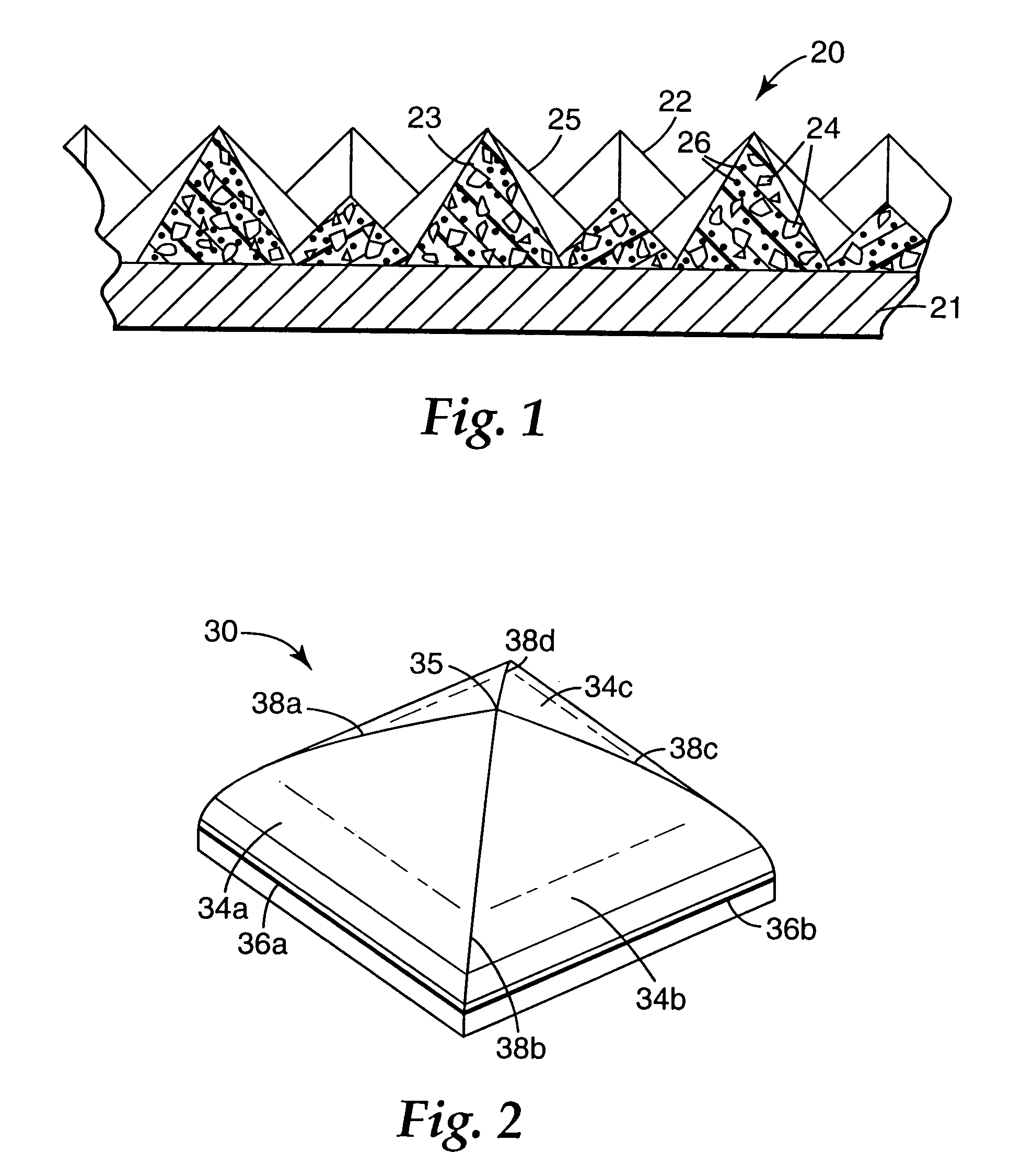

Compositions for abrasive articles

ActiveUS20050060947A1Attenuation consistentImprove cutting lifePigmenting treatmentOther chemical processesSurface finishMicrometer

A structured abrasive article, methods of making an abrasive article, and methods of using an abrasive article. The abrasive composites forming the abrasive article have a height of at least 500 micrometers, and the abrasive particles in the composites have an average particle size of at least 40 micrometers, in some embodiments, at least about 85 micrometers. The large topography composites, together with the large ceramic abrasive particles, provides an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than conventional make / coat abrasive articles with the same size and type of abrasive particles. Additionally, the large topography composites, together with the large ceramic abrasive particles, provide an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than structured abrasive articles having a smaller topography, even with the same abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

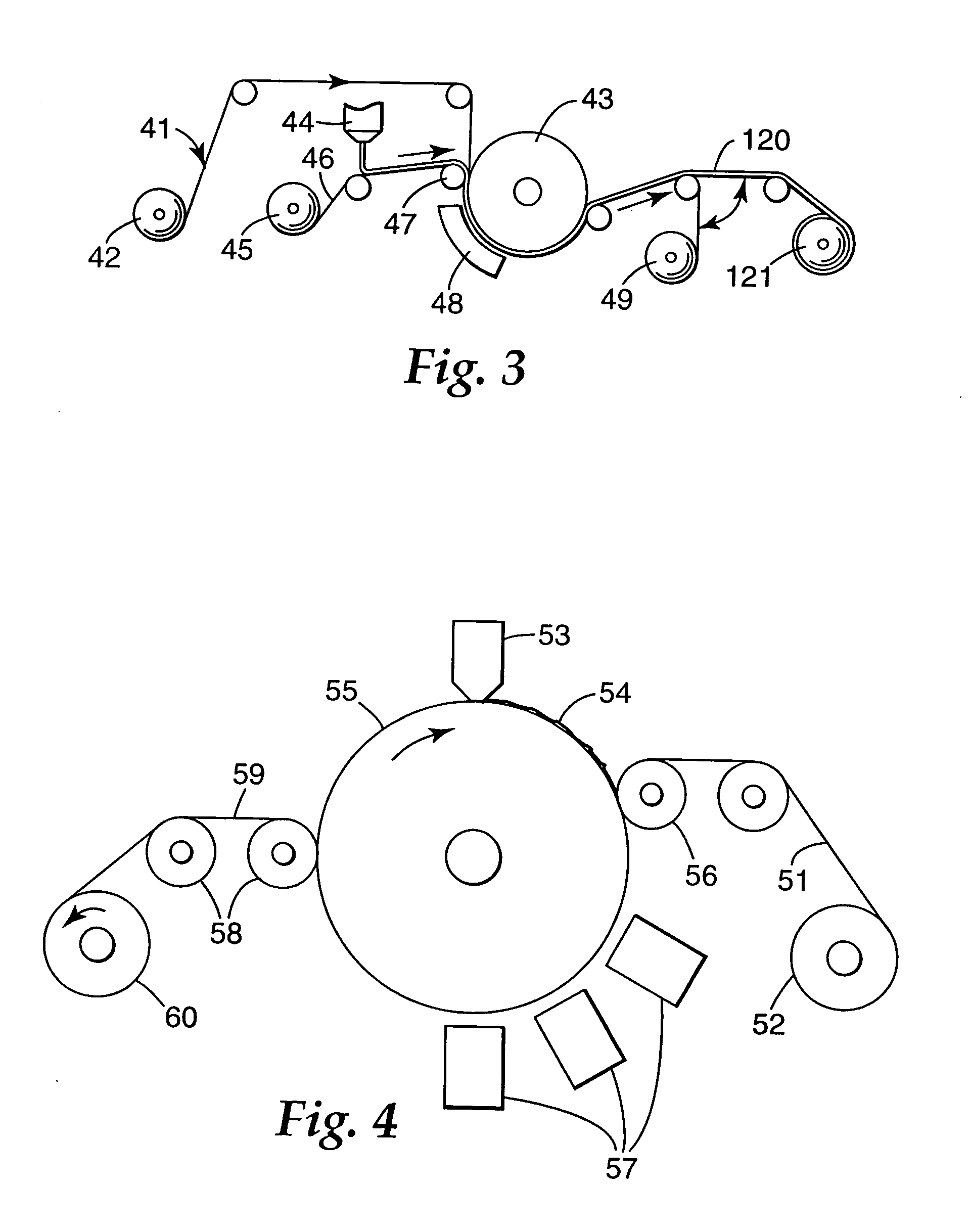

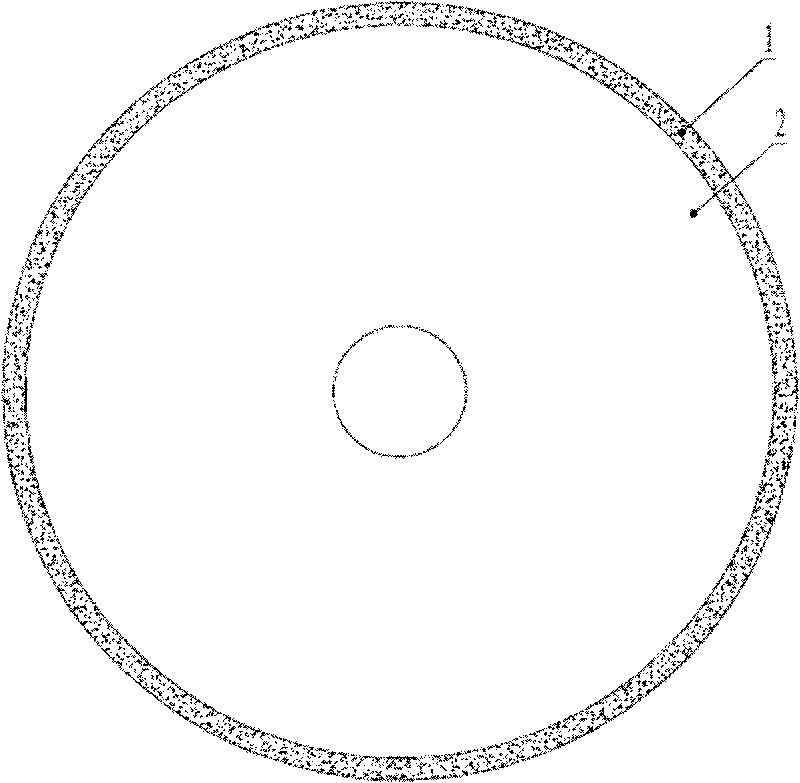

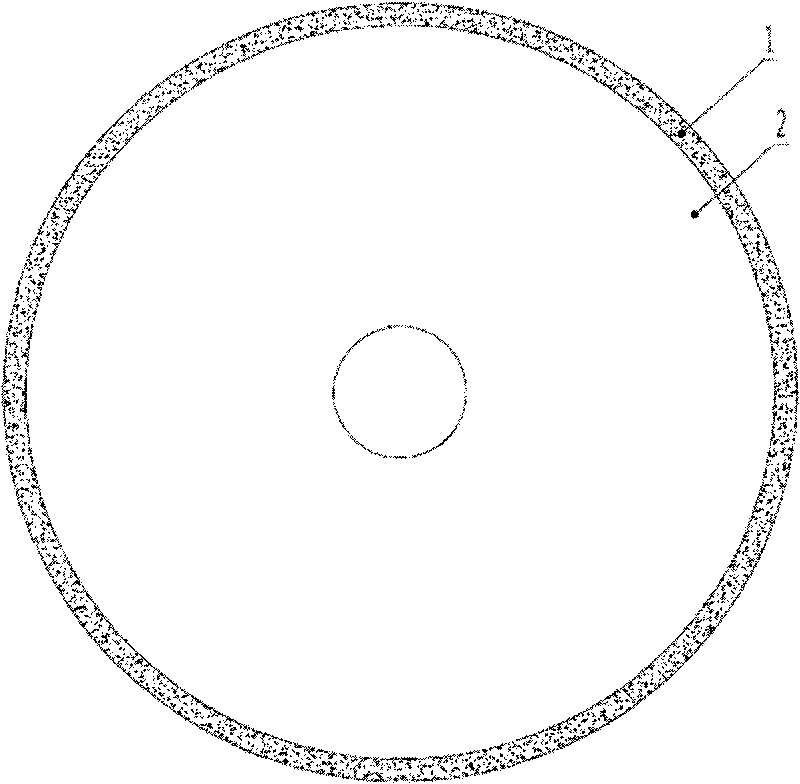

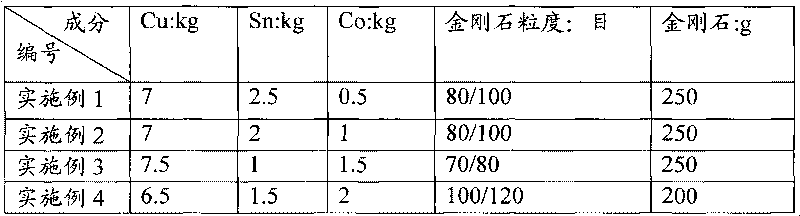

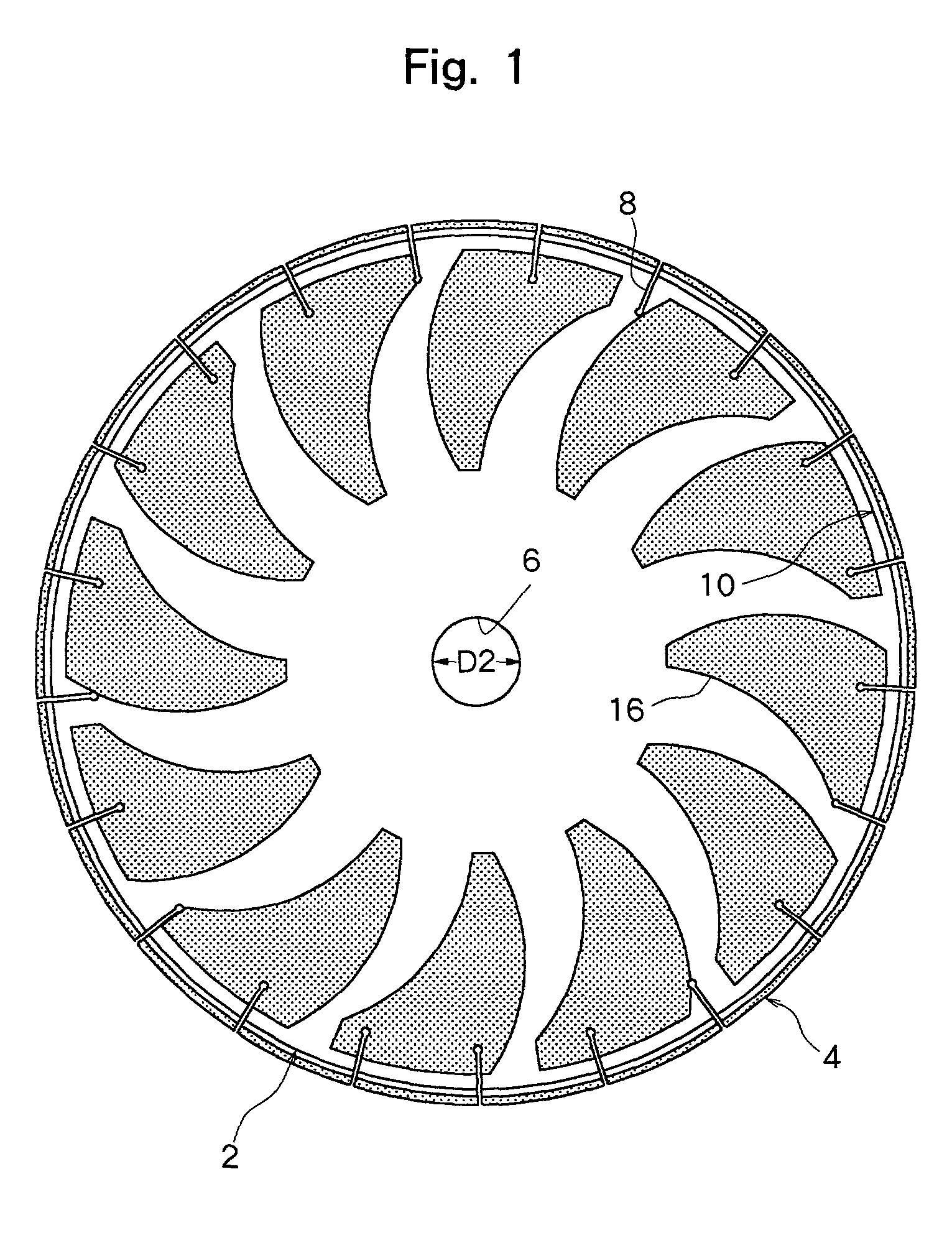

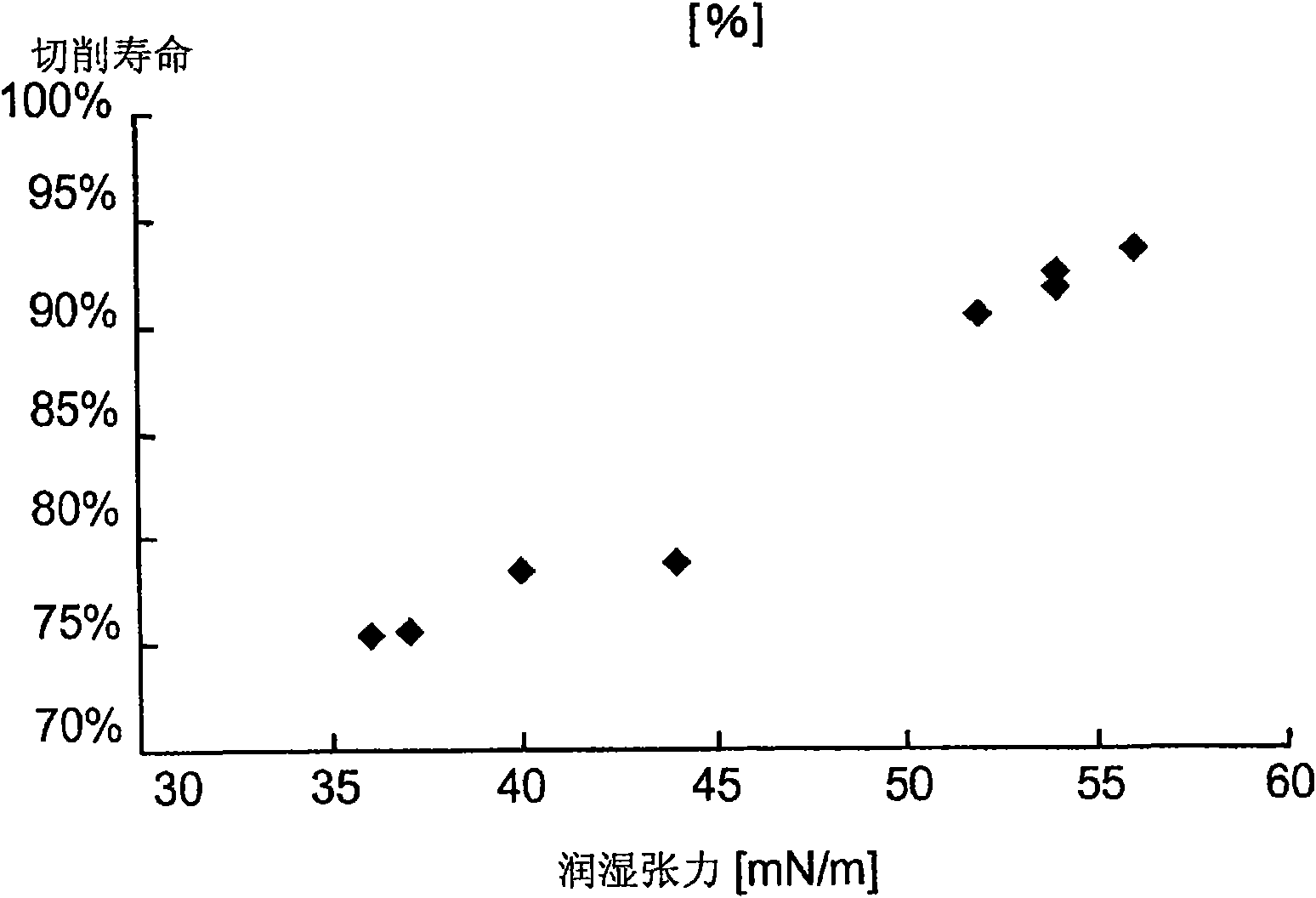

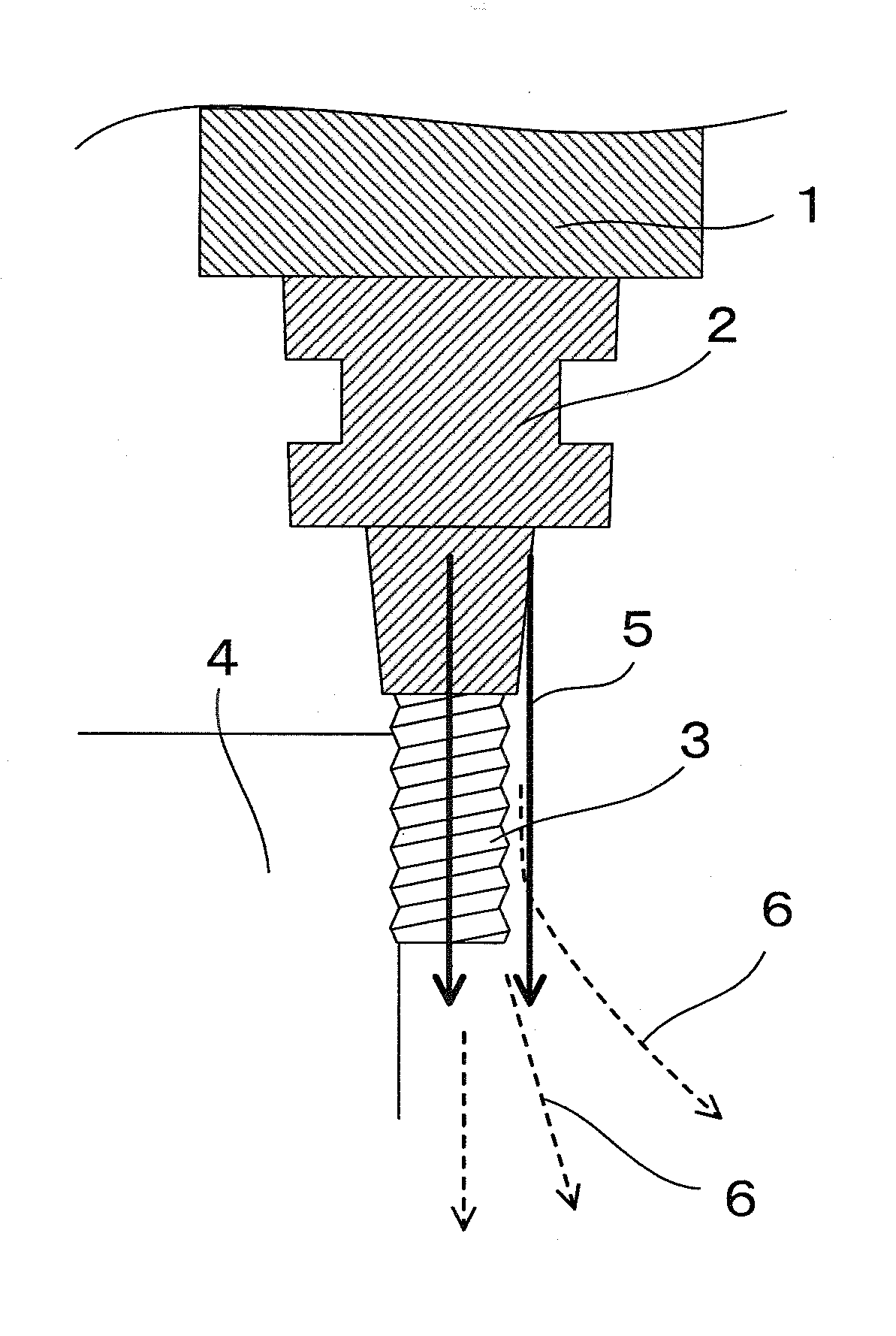

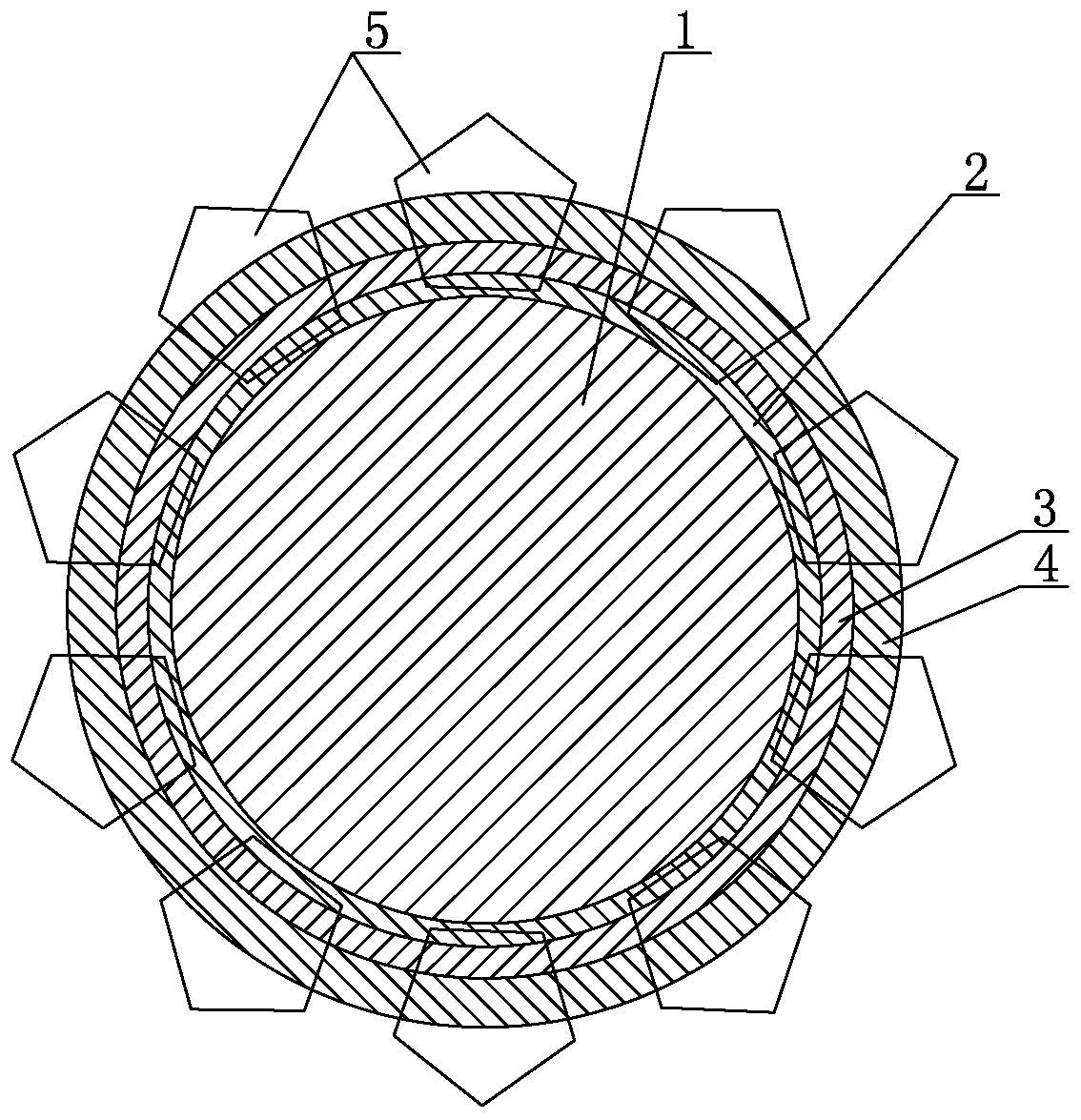

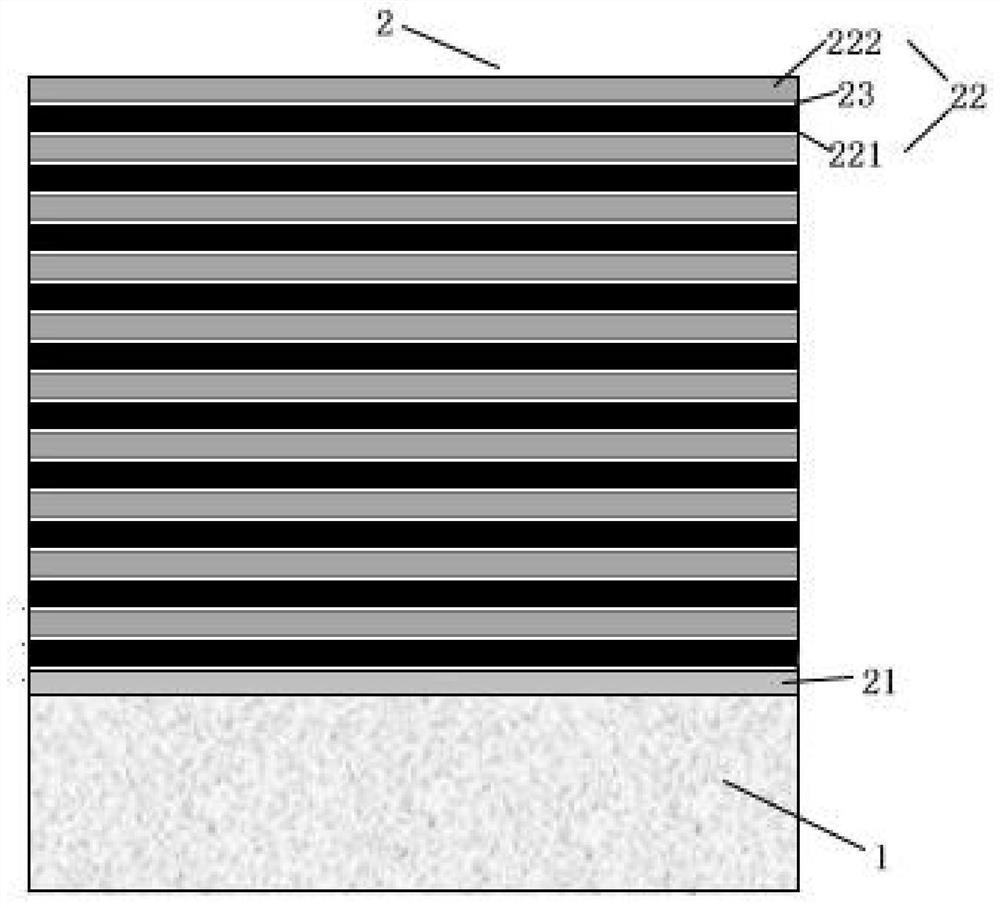

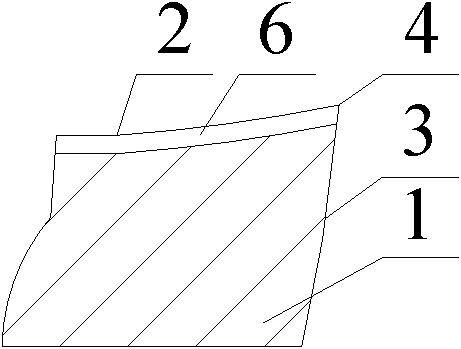

Marble cutting saw blade and preparation method thereof

ActiveCN101758560AFast cutting speedPromote infiltrationStone-like material working toolsAlloyPowder metallurgy

The invention relates to a super-hard tool and a preparation method thereof in the field of powder metallurgy, in particular to a marble cutting saw blade and a preparation method thereof. The saw blade comprises a matrix (1) and a tool bit (2), wherein the tool bit (2) is formed by mixing, thermally pressing and then sintering the matrix powder and the diamond particle; the component of the matrix powder includes 65 to 75 wt% of Cu, 10 to 20 wt% of Sn and 5 to 20 wt% of Co; and the weight of the diamond particle is 2 to 2.5 wt% of that of the matrix powder. The diamond saw blade is prepared after the steps of batching materials, mixing materials, cold press moulding, hot press moulding and subsequent treatment. Compared with the similar products, the Cu-base alloy diamond saw blade of the invention prolongs 1 to 3 times of the service life and reduces 30 to 50% of the cost on the premise of ensuring the constant sharpness and saw-cutting flatness.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

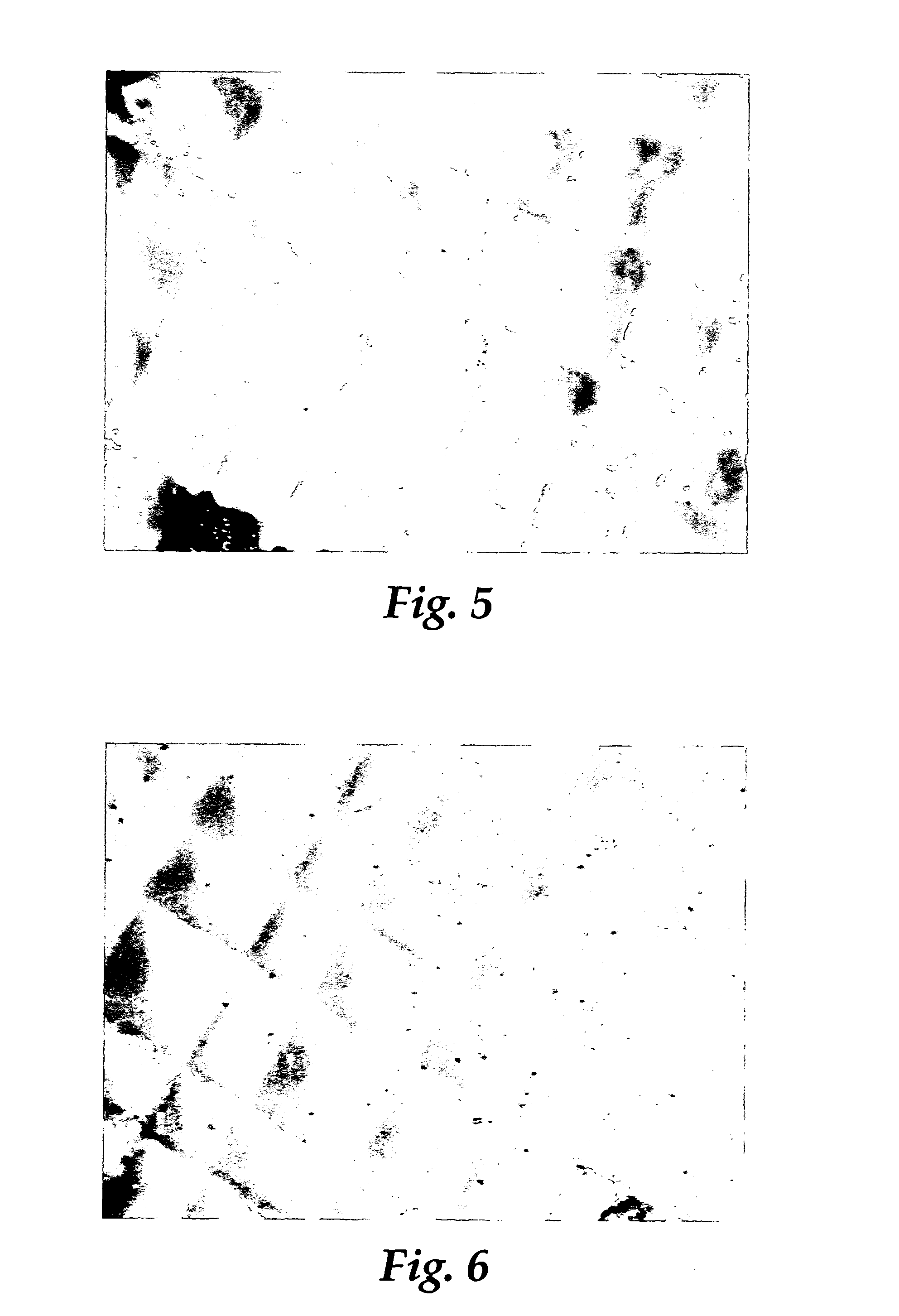

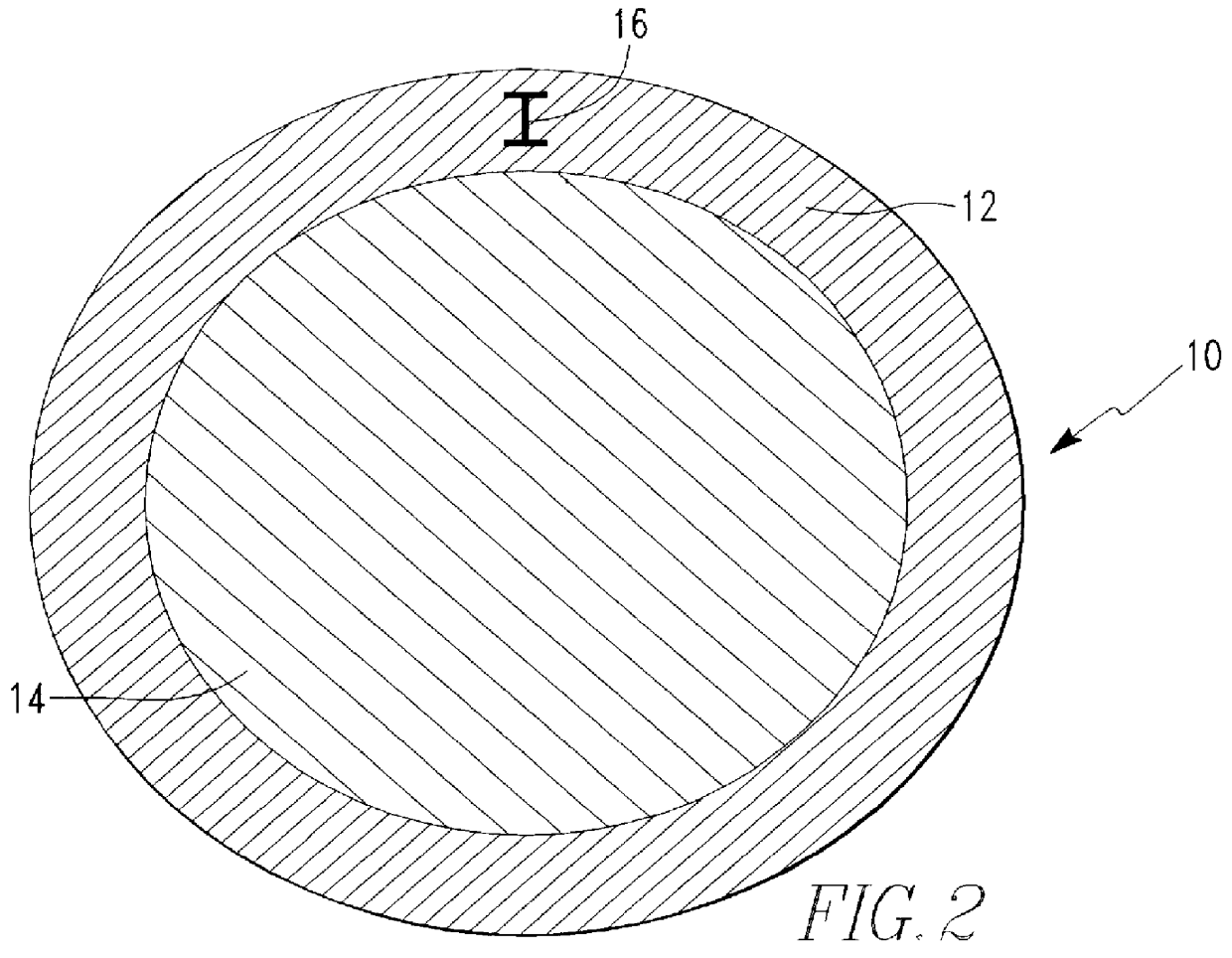

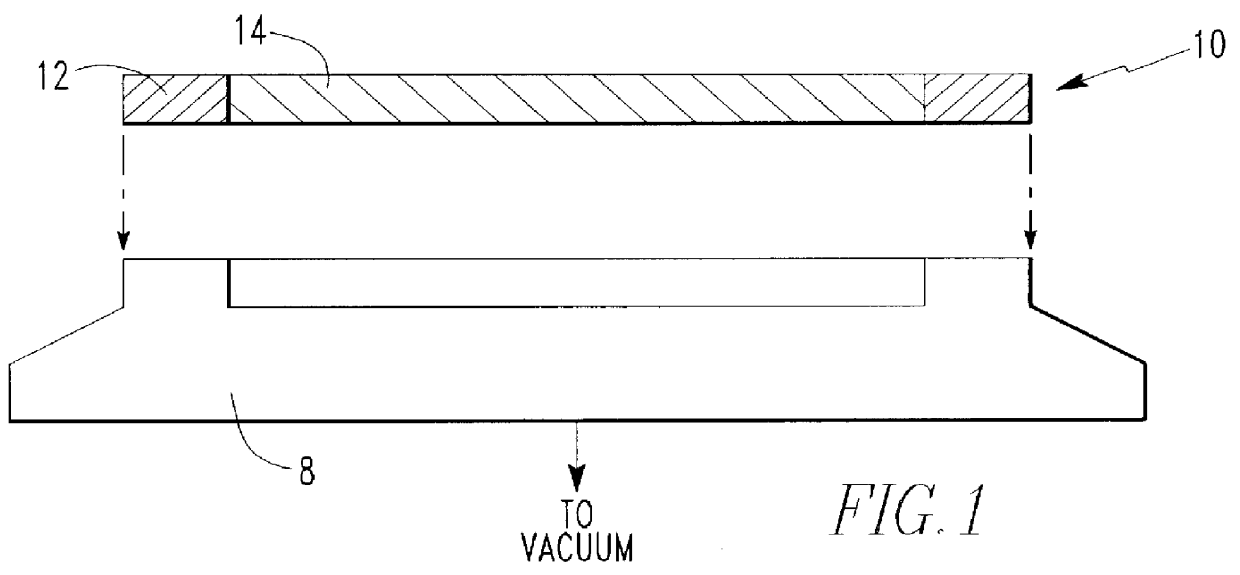

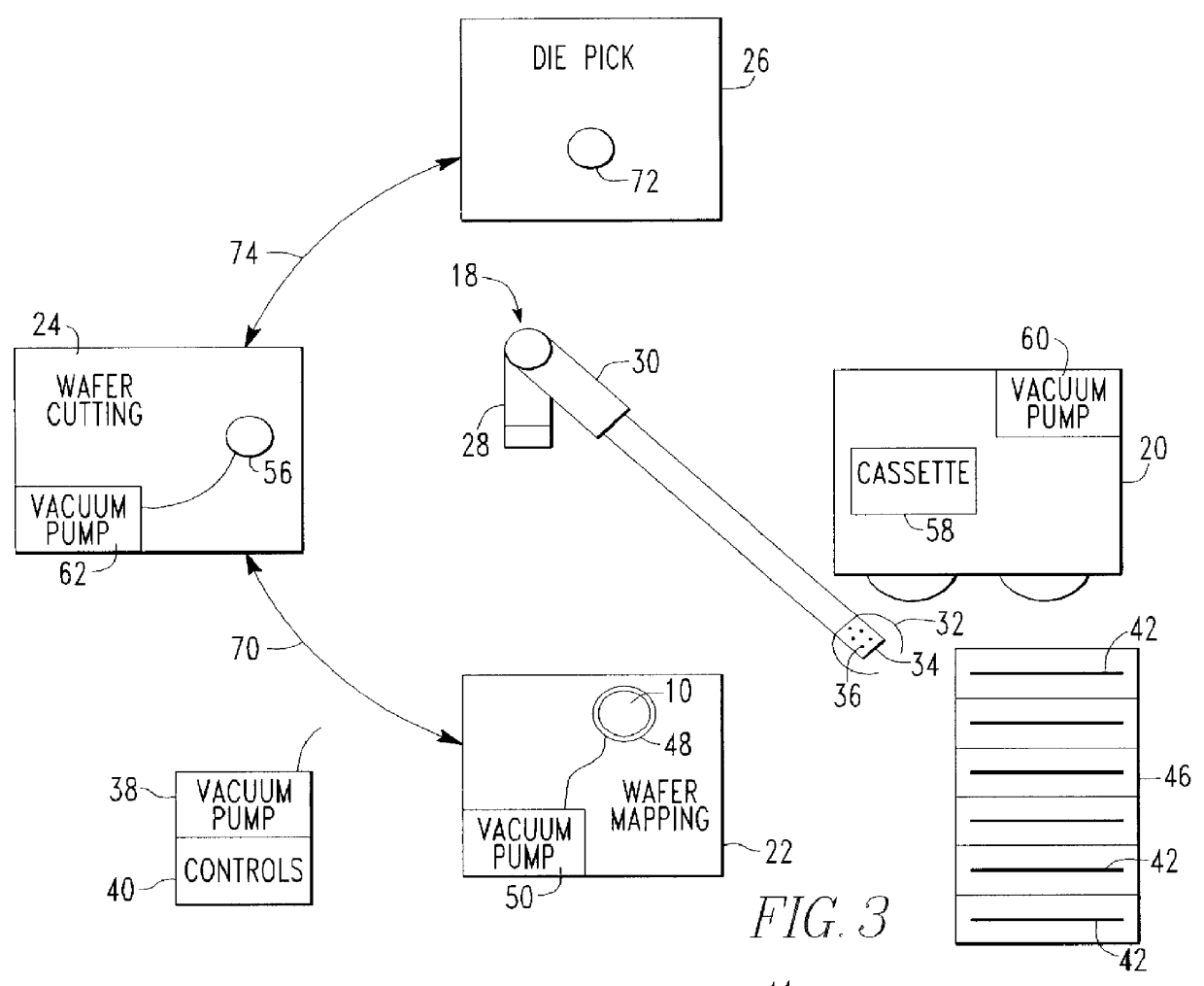

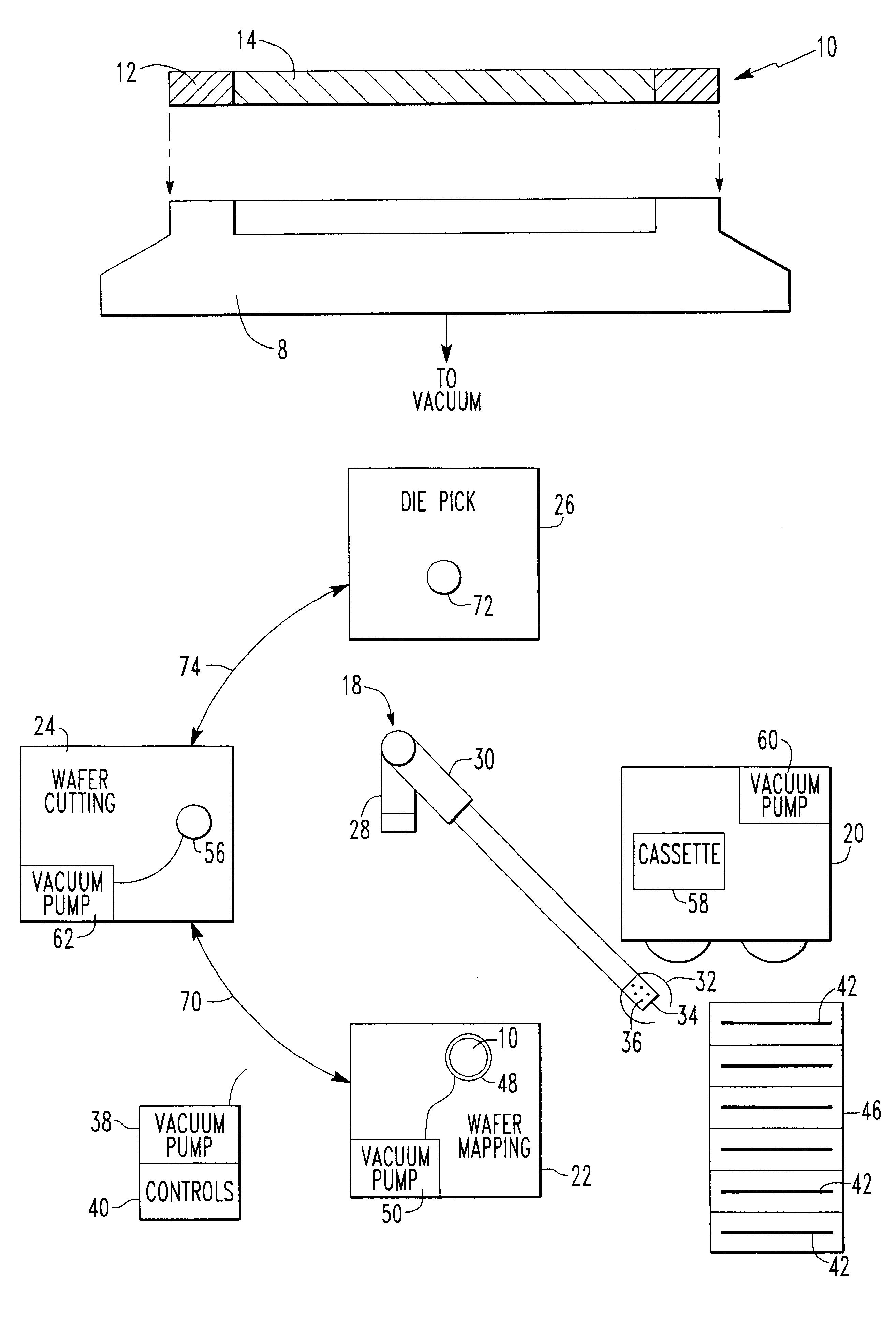

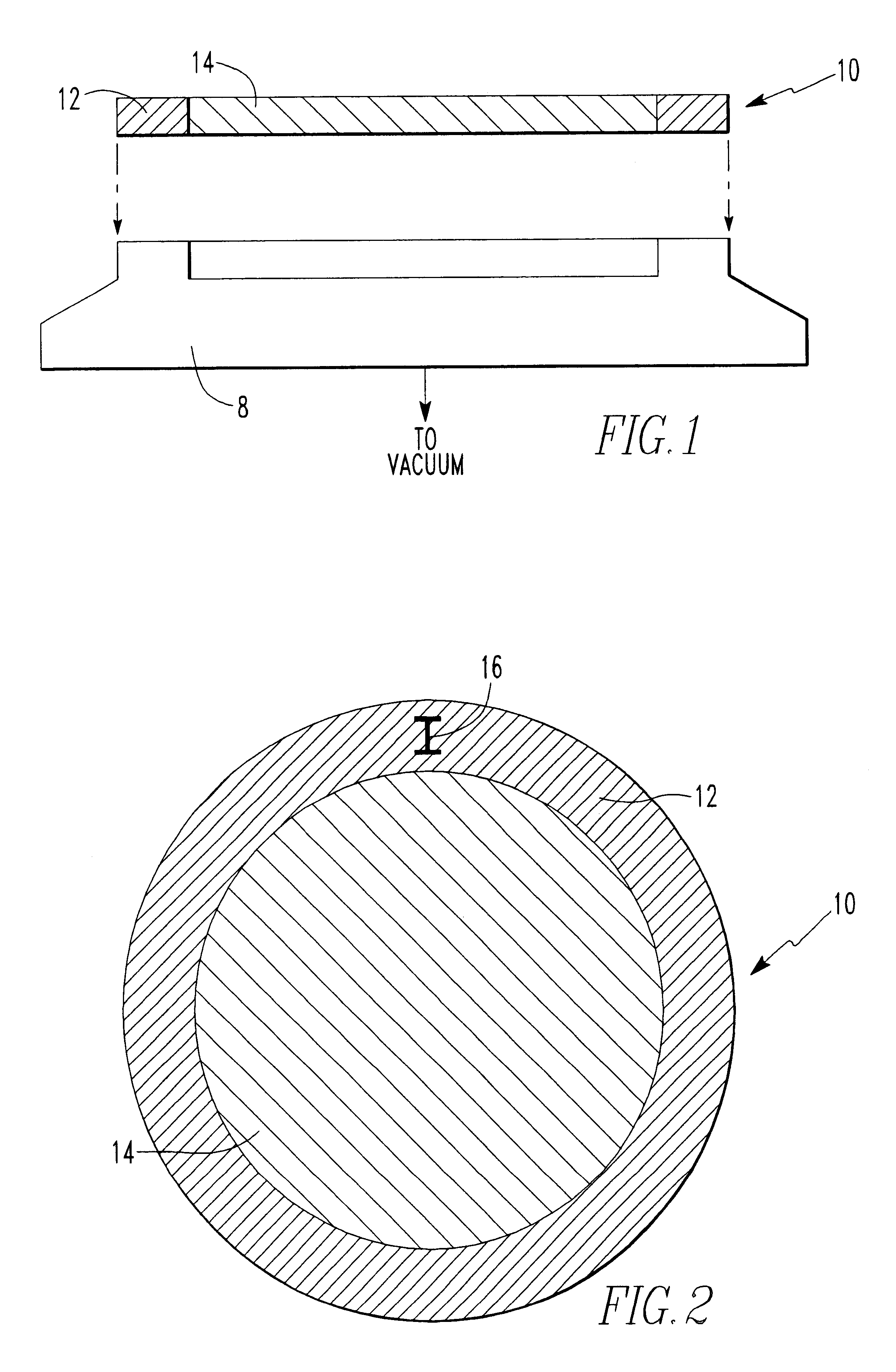

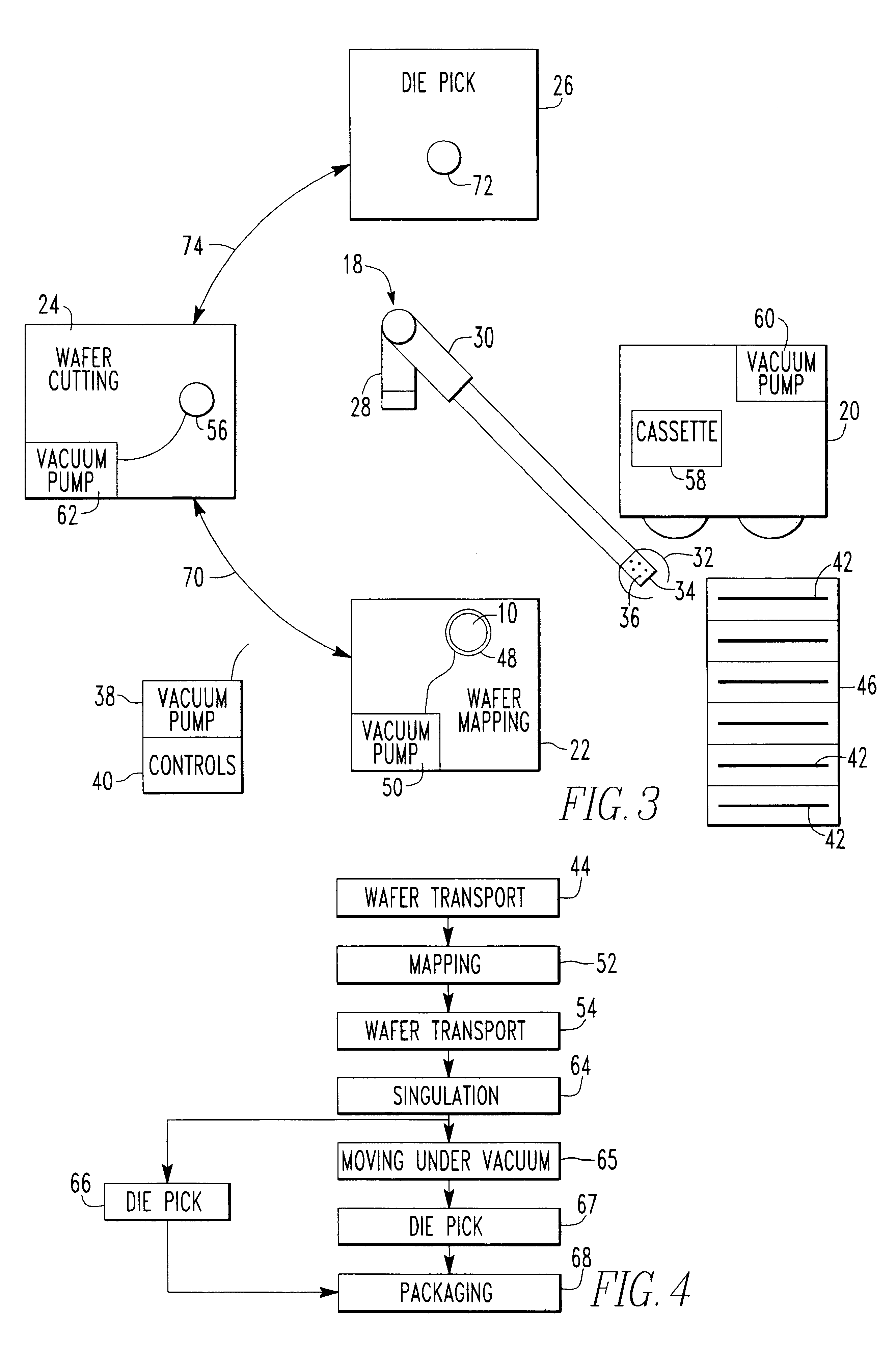

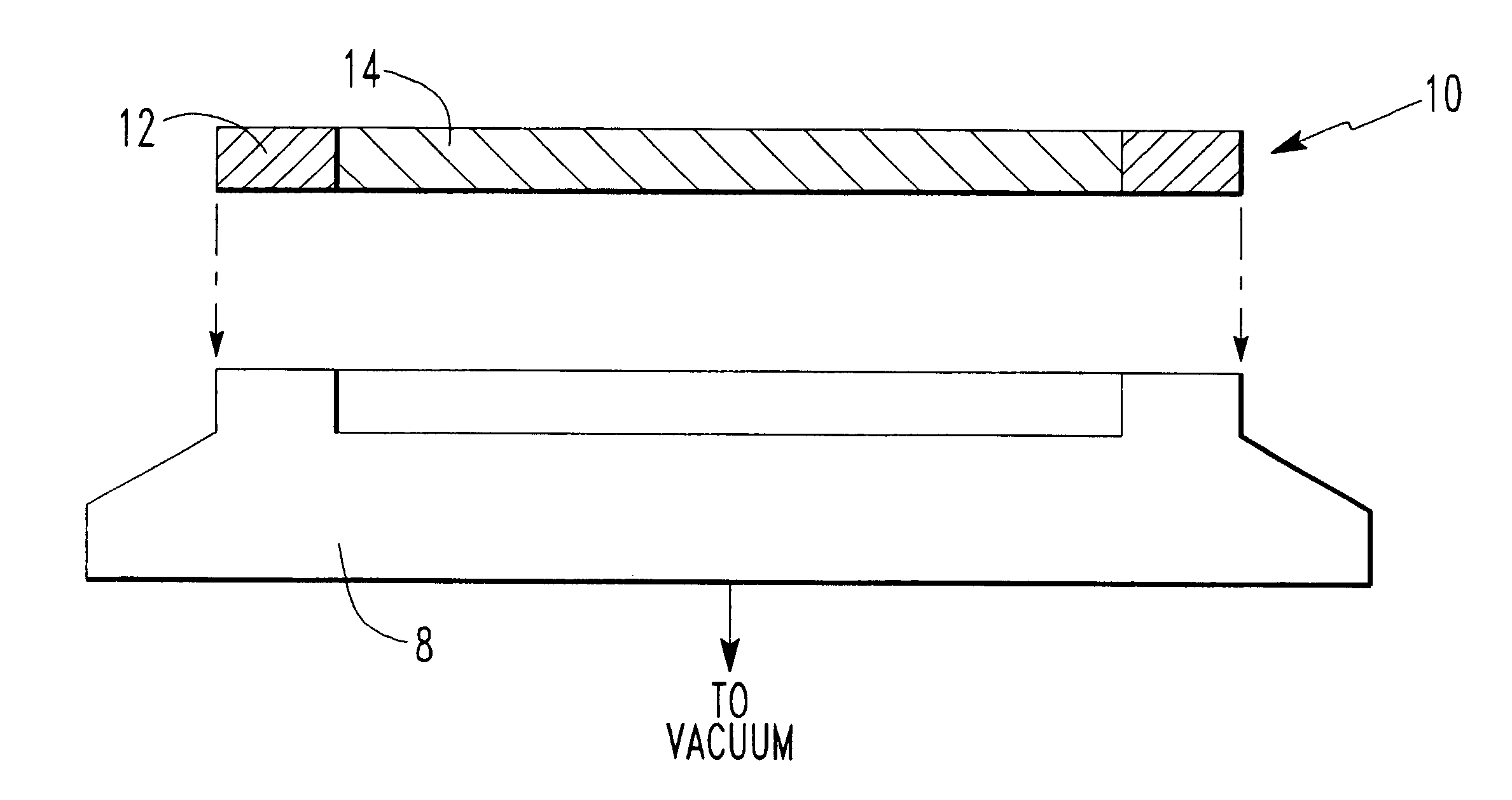

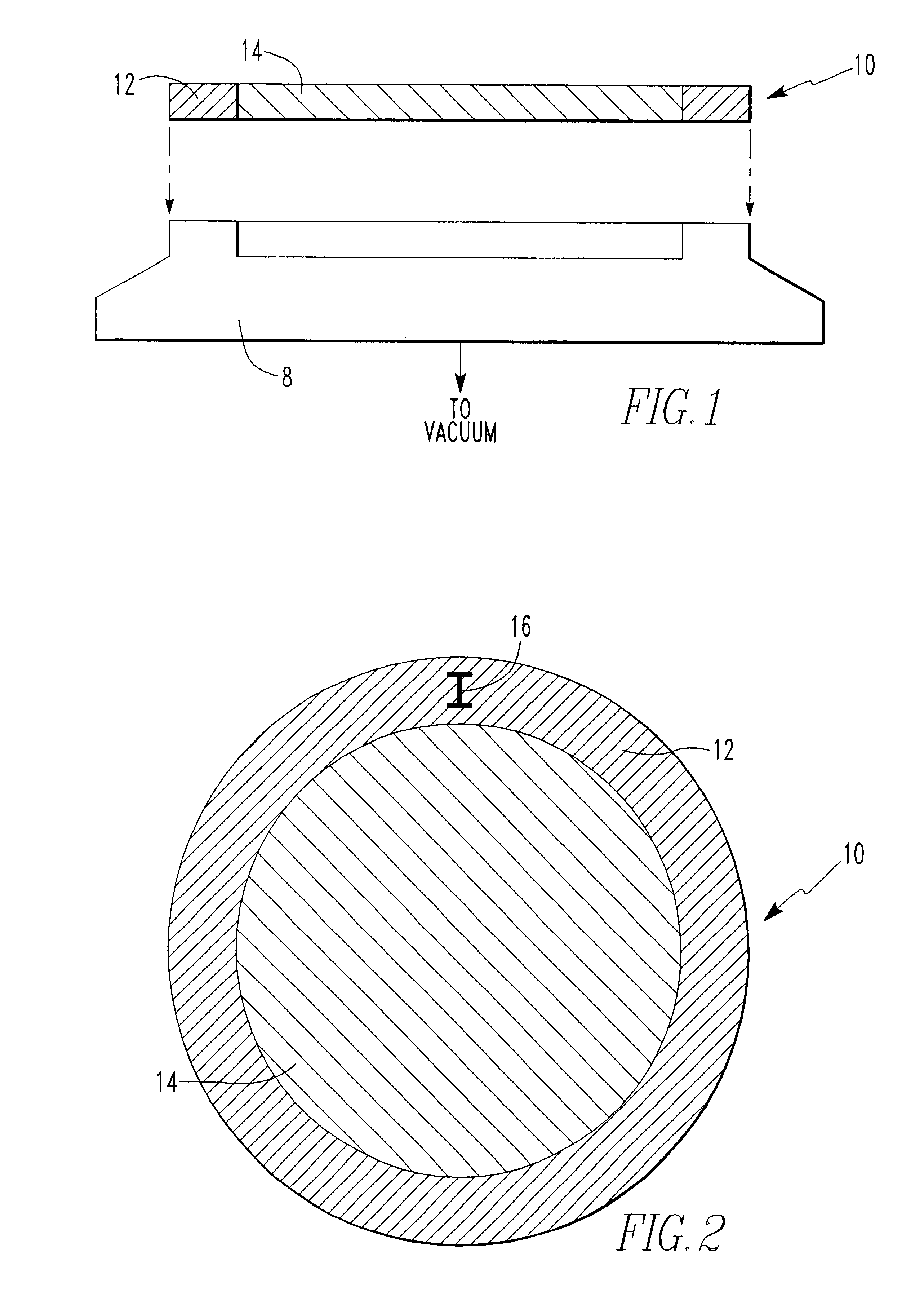

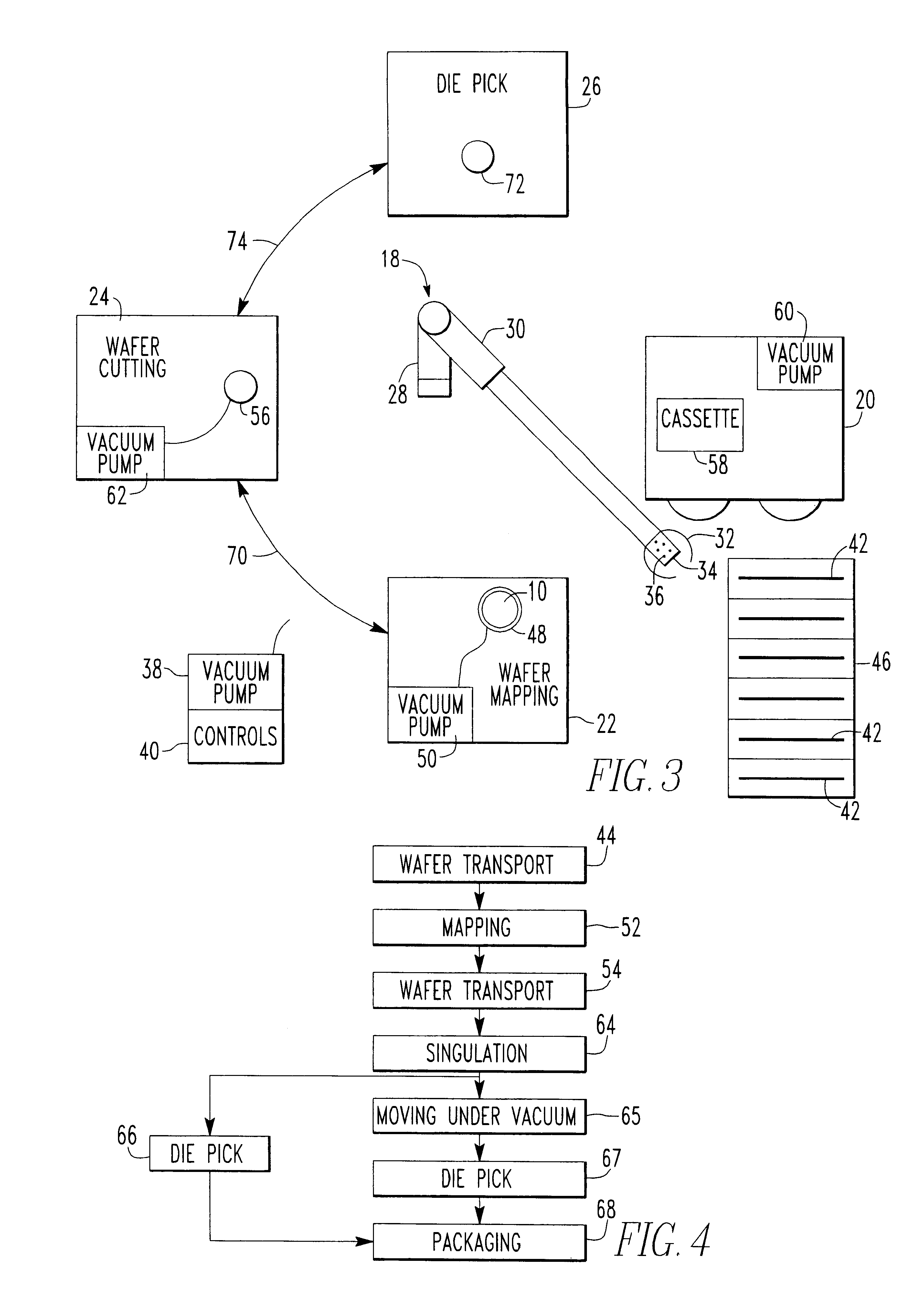

Complete blade and wafer handling and support system without tape

InactiveUS6112735AReduce downtimeIncrease productionFine working devicesStone-like material working toolsSupporting systemRobotic arm

The wafer handling and support system disclosed herein does not use tape and is adapted for use in conjunction with a number of work stations. The wafer handling and support system includes a chuck plate comprised of a non-porous section surrounding a porous section and a robotic arm for transporting a chuck plate / wafer combination under vacuum. The chuck plate is sized to be carried by a wafer chuck and the porous section of the chuck plate is configured to support a wafer. The wafer may be held in place on the chuck plate by the application of a vacuum.

Owner:MICRON TECH INC

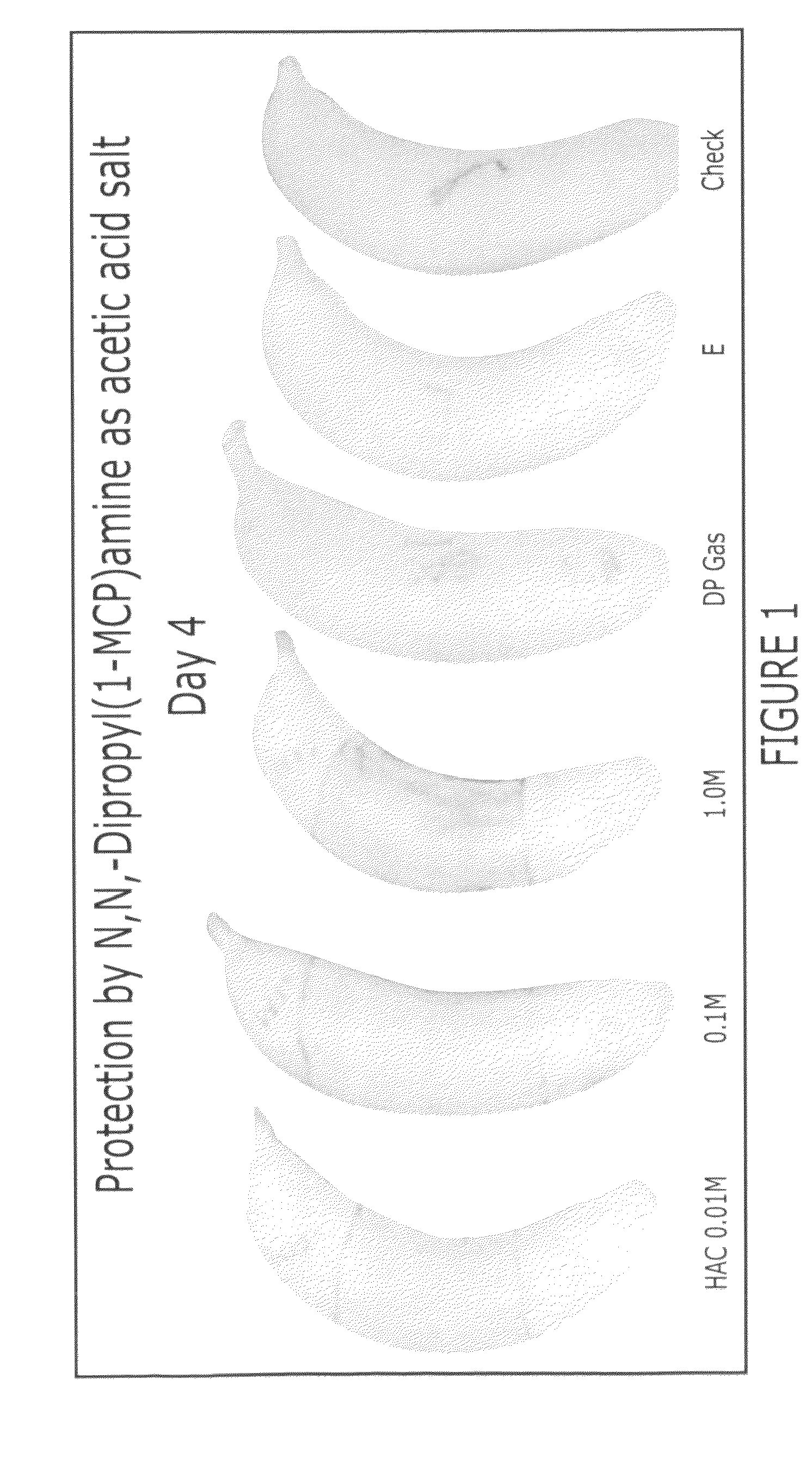

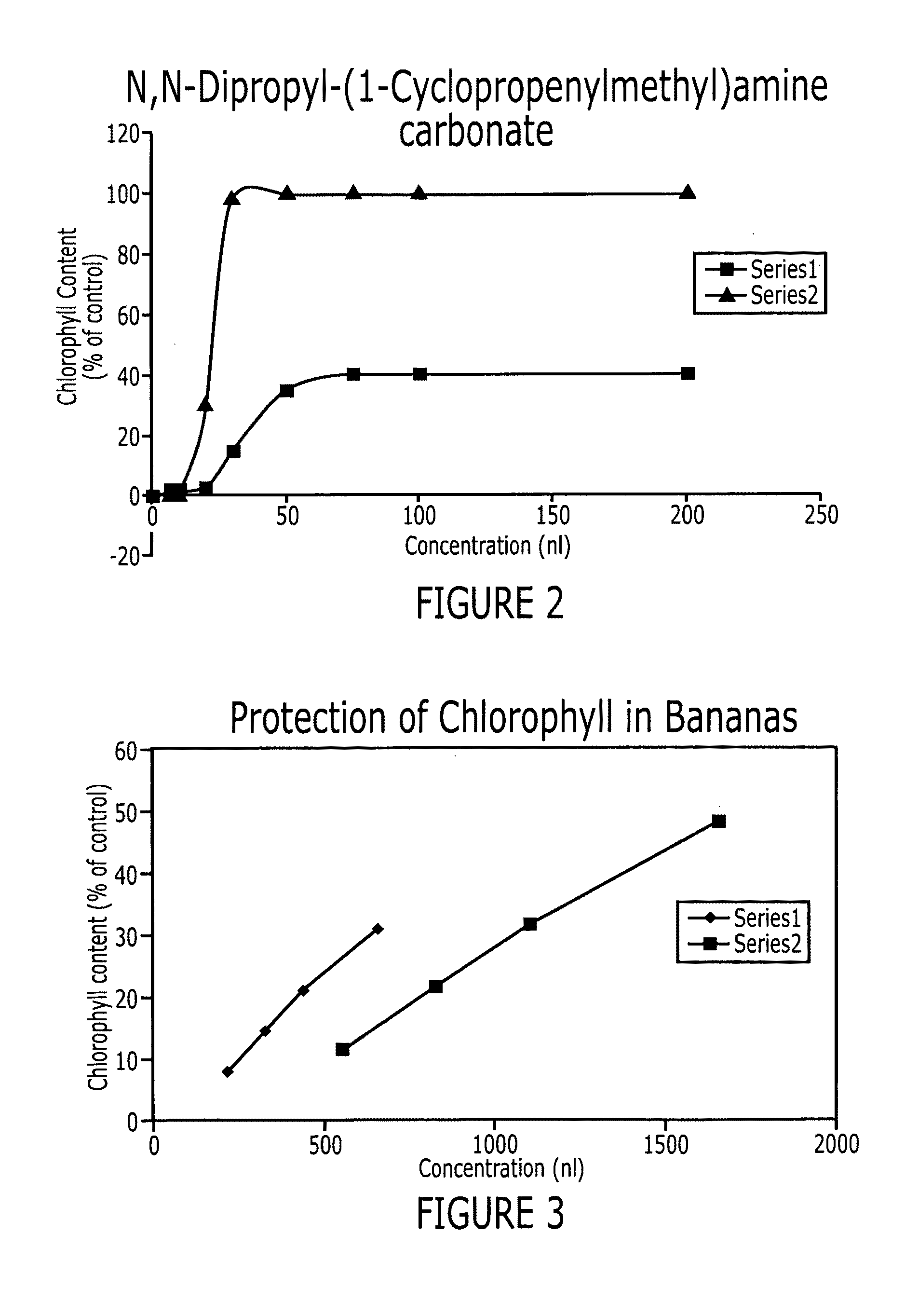

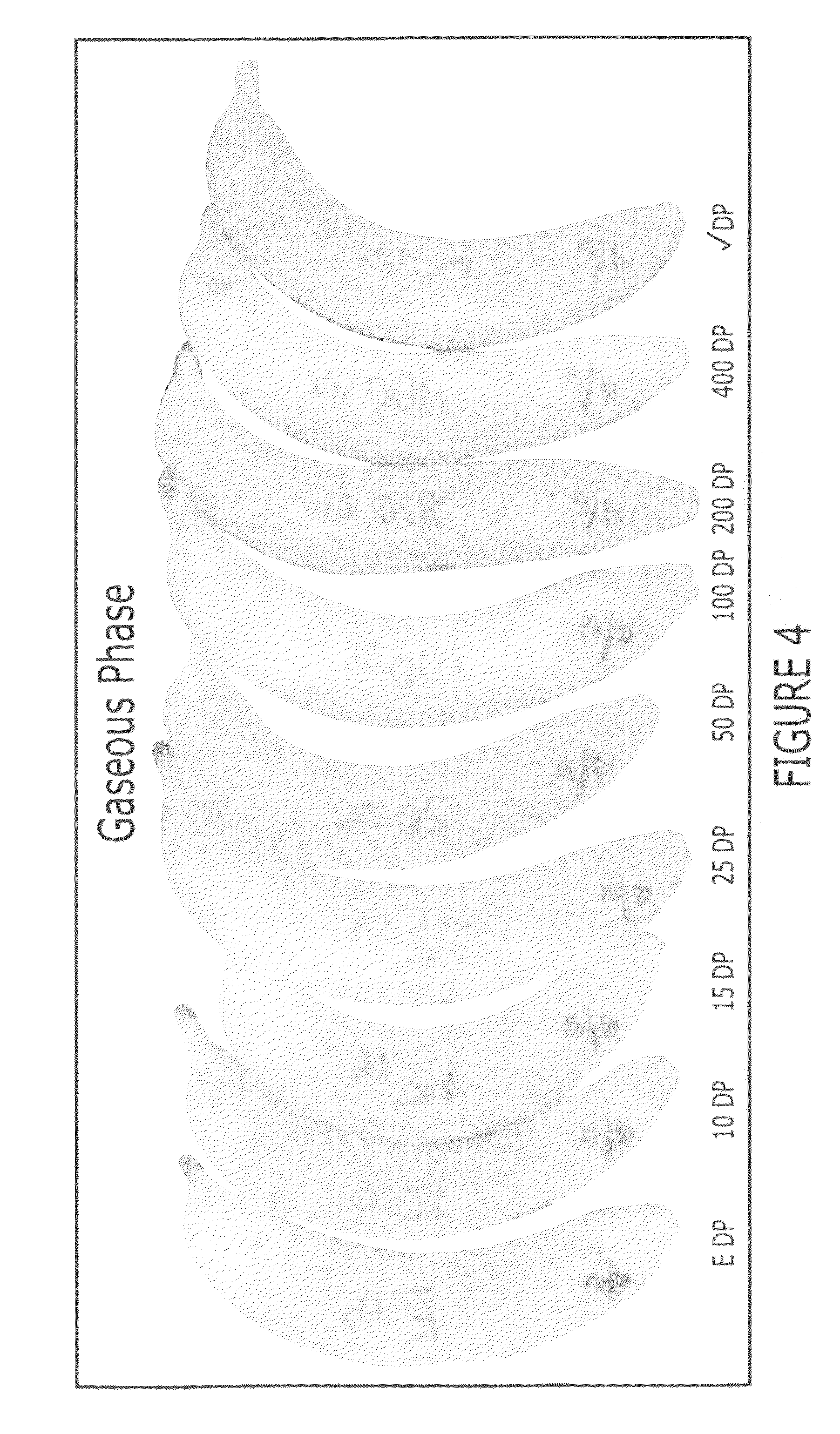

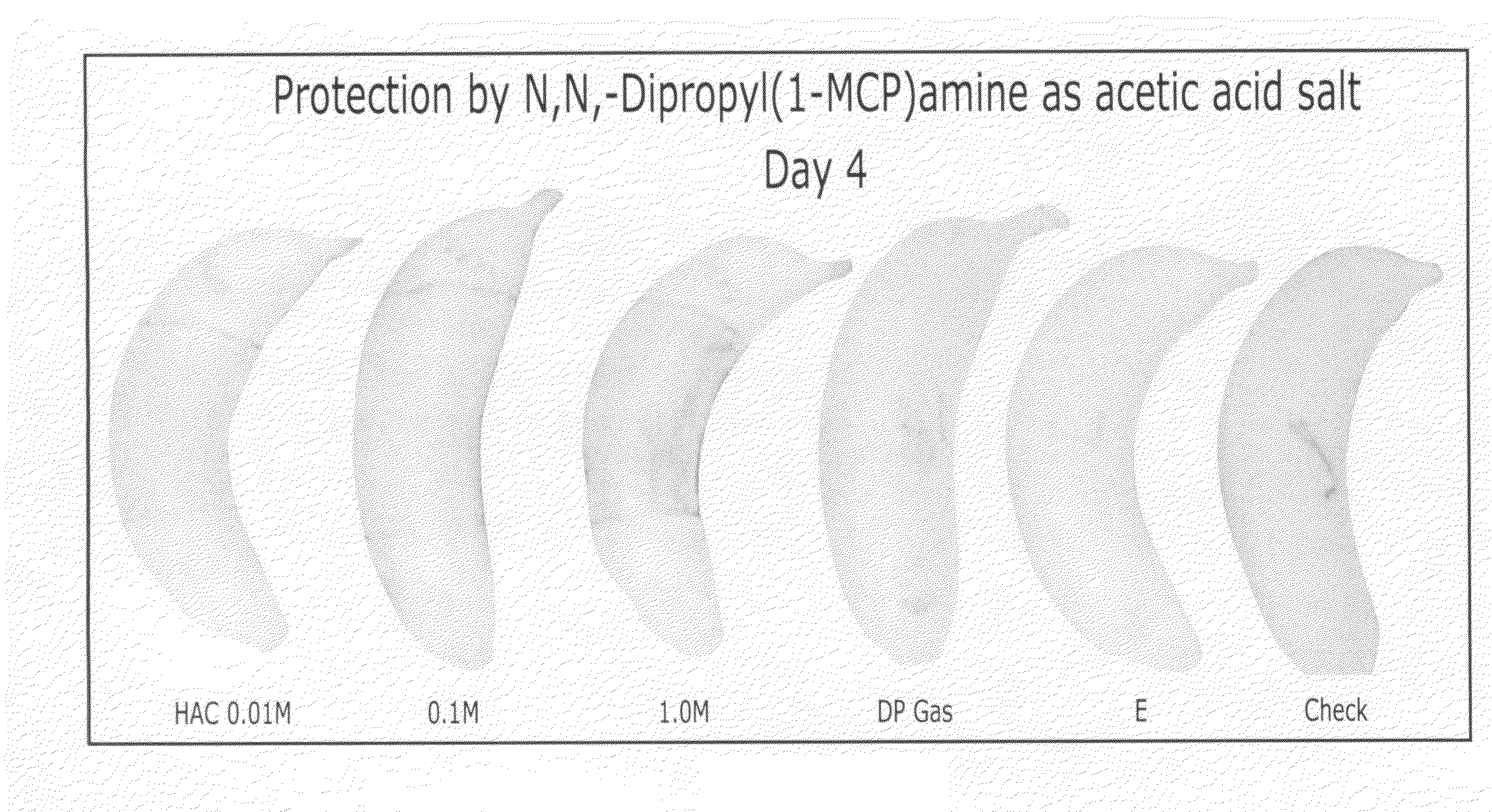

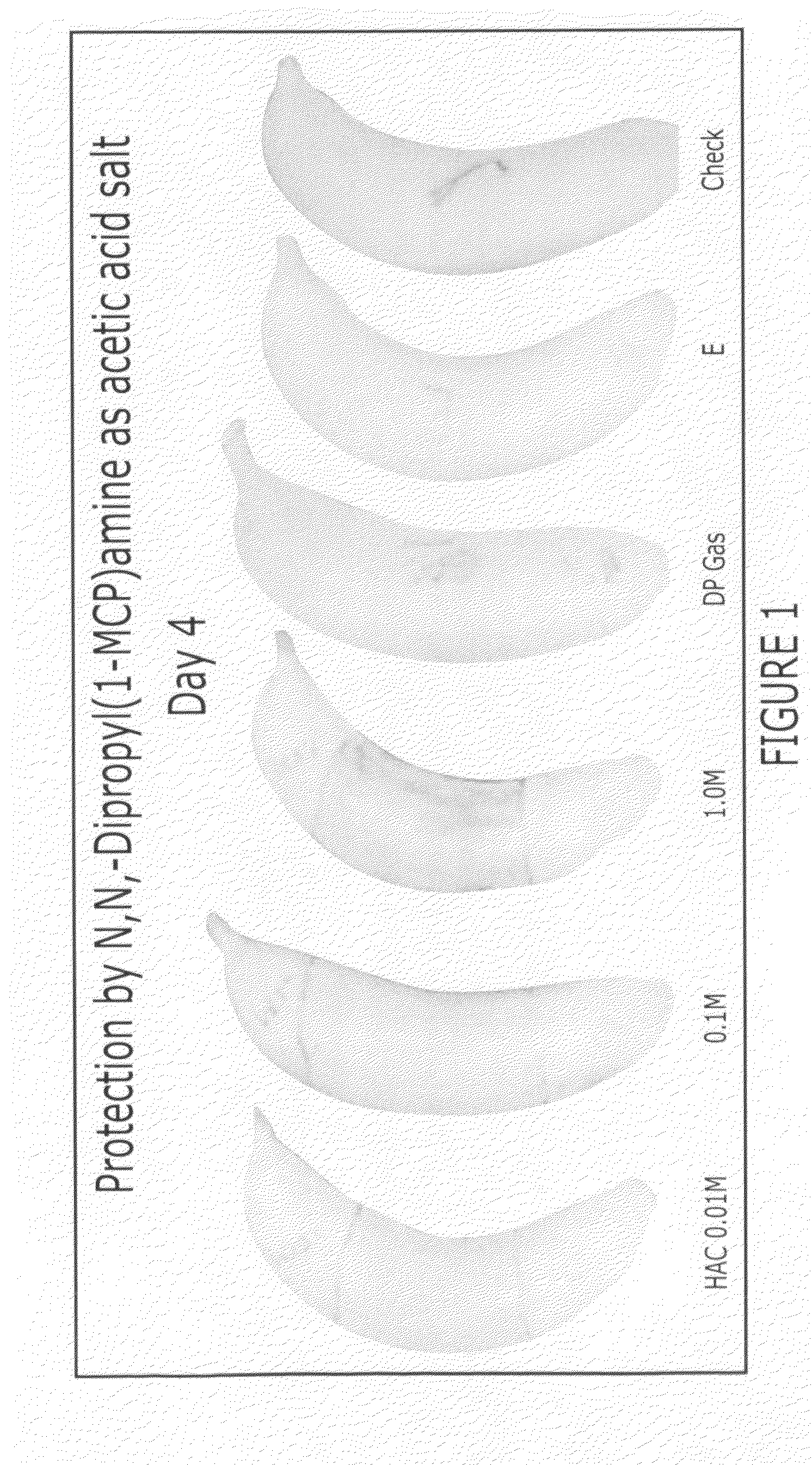

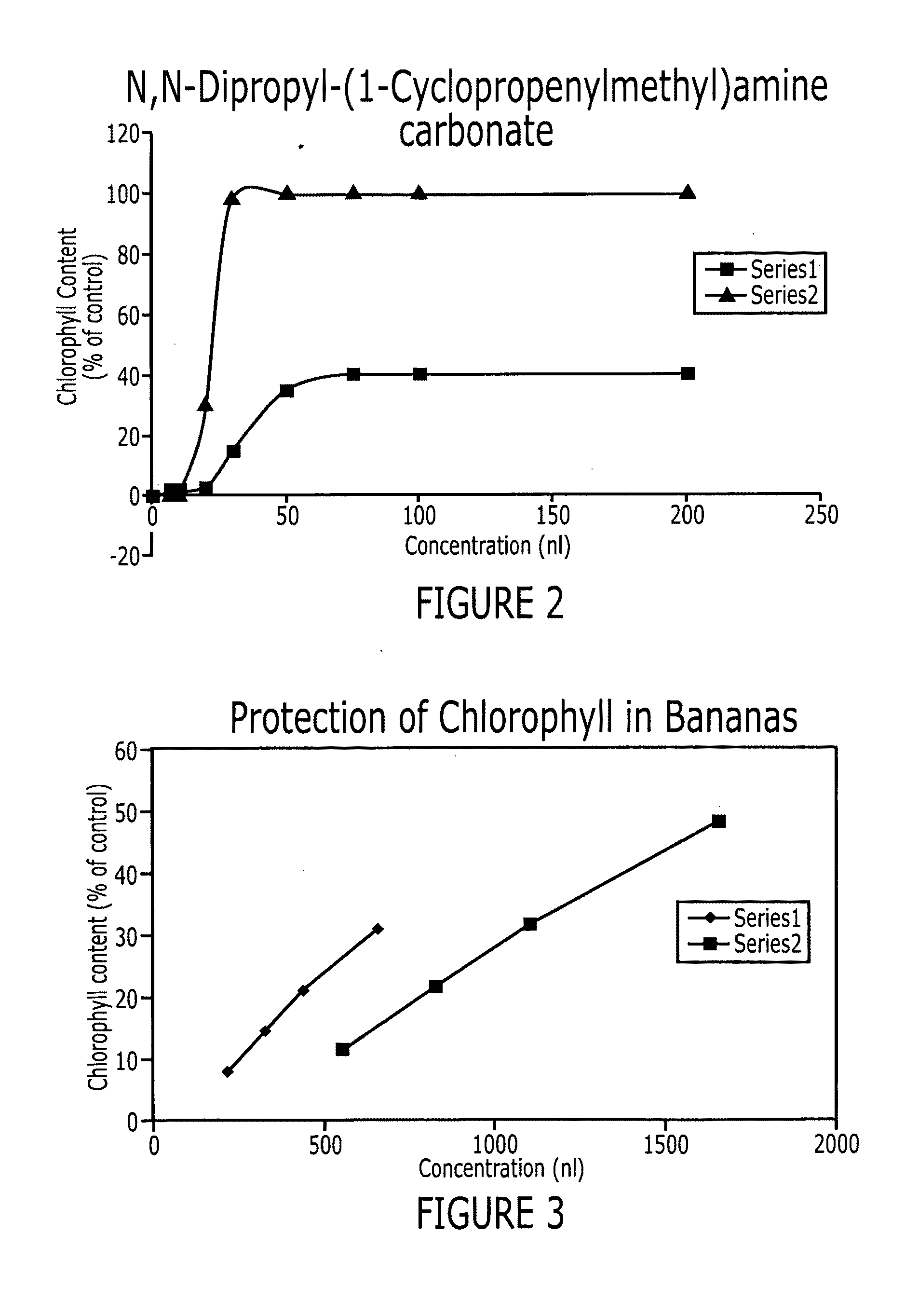

Methods of inhibiting ethylene responses in plants using cyclopropene amine compounds

InactiveUS8093430B2Improve cutting lifeEffective life-prolonging amountBiocideDead plant preservationEnantiomerAmine derivatives

Methods of applying cyclopropene amine derivatives and compositions thereof to inhibit ethylene receptors in plants and plant material are disclosed. Methods include applying to the plant an effective ethylene response-inhibiting amount of at least one cyclopropene amine compound or composition thereof. Cyclopropene amine compounds, enantiomers, stereoisomers or salts thereof are also provided.

Owner:NORTH CAROLINA STATE UNIV

Heat apparatus for extending the life of blade cutting edges

InactiveUS20050189338A1Prolong lifeSimple and inexpensiveOhmic-resistance heatingMetal working apparatusWater vaporEvaporation

A method and apparatus for extending the useful life of blade cutting edges, especially shaving razors, comprising a unit having a configuration to support and store the blade or razor and a heat source to raise the temperature of the blade or razor and eliminate contact water through evaporation and further inhibit condensation by maintaining the proximate water vapor above its saturation temperature. Inhibiting the formation of iron oxide and hydrated iron oxide (Rust) extends the life of the blade.

Owner:SUKEFORTH CARL JAMES

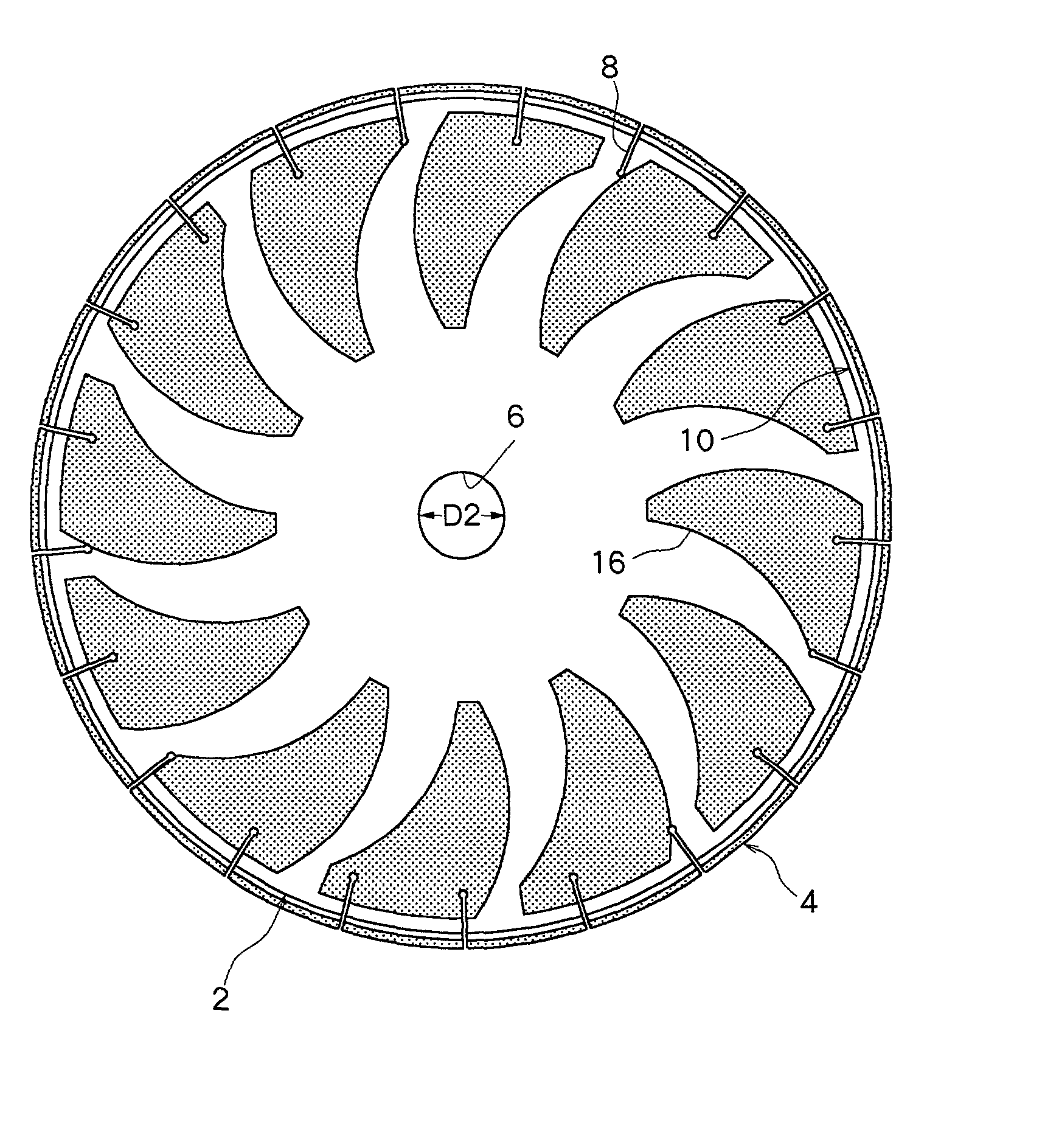

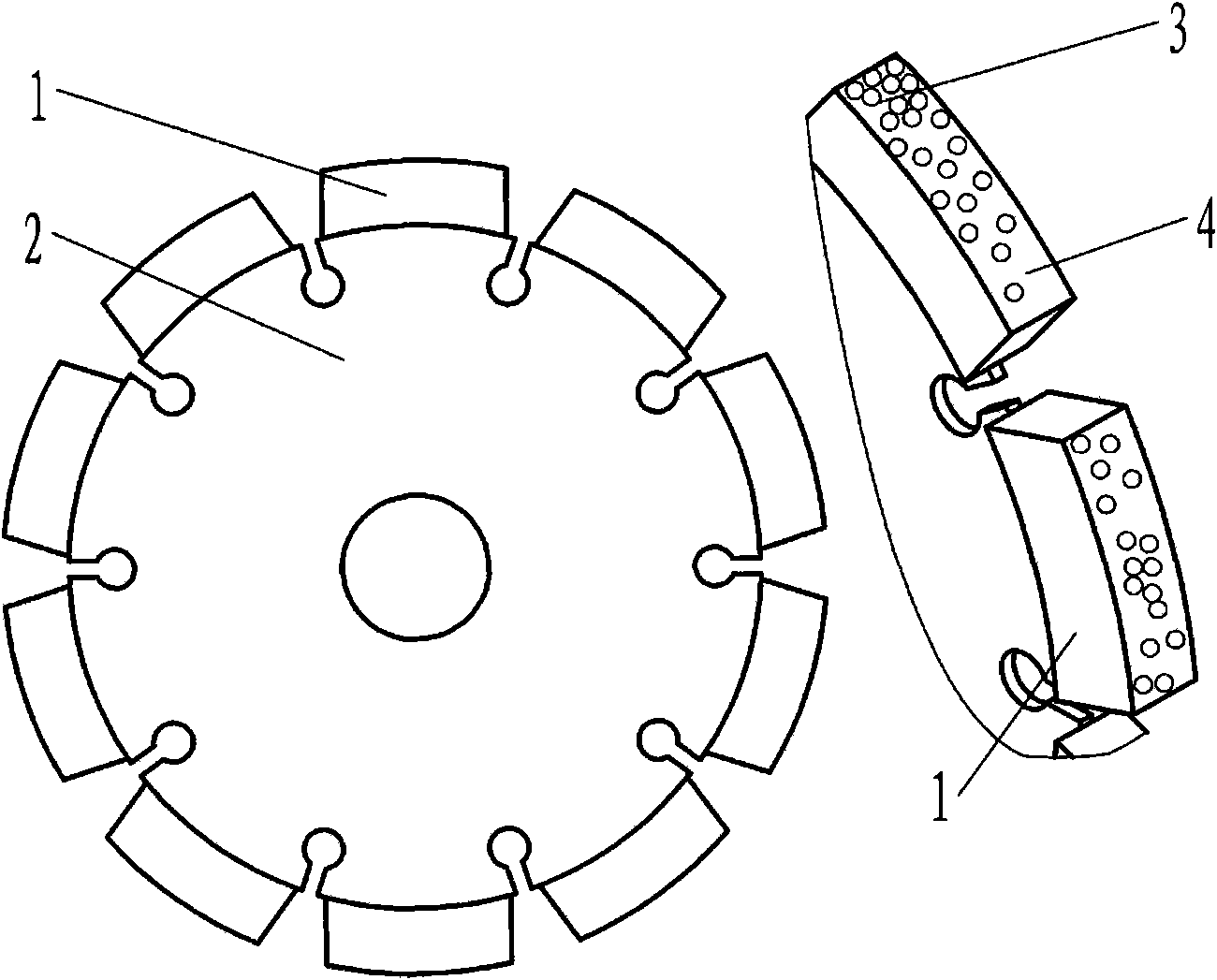

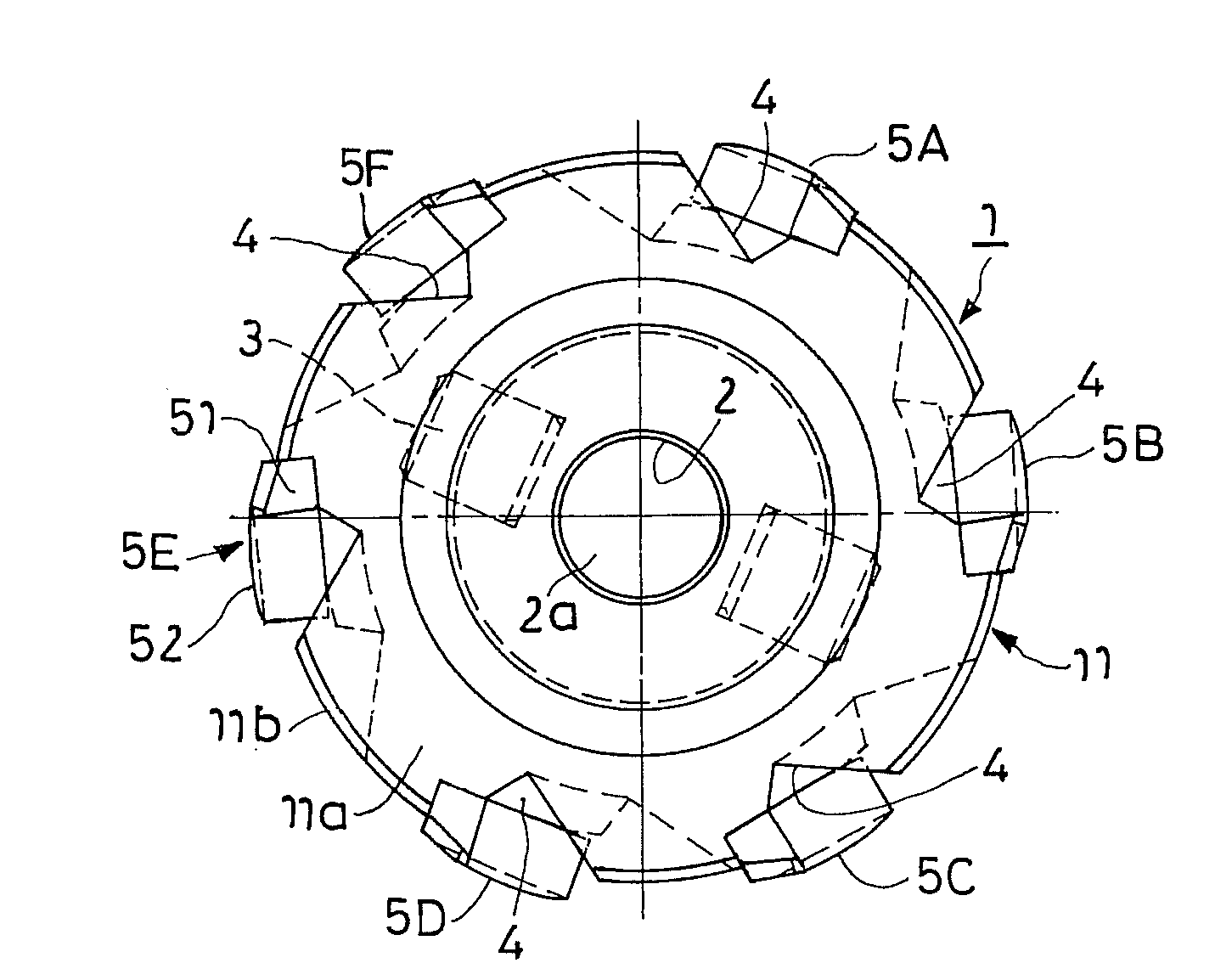

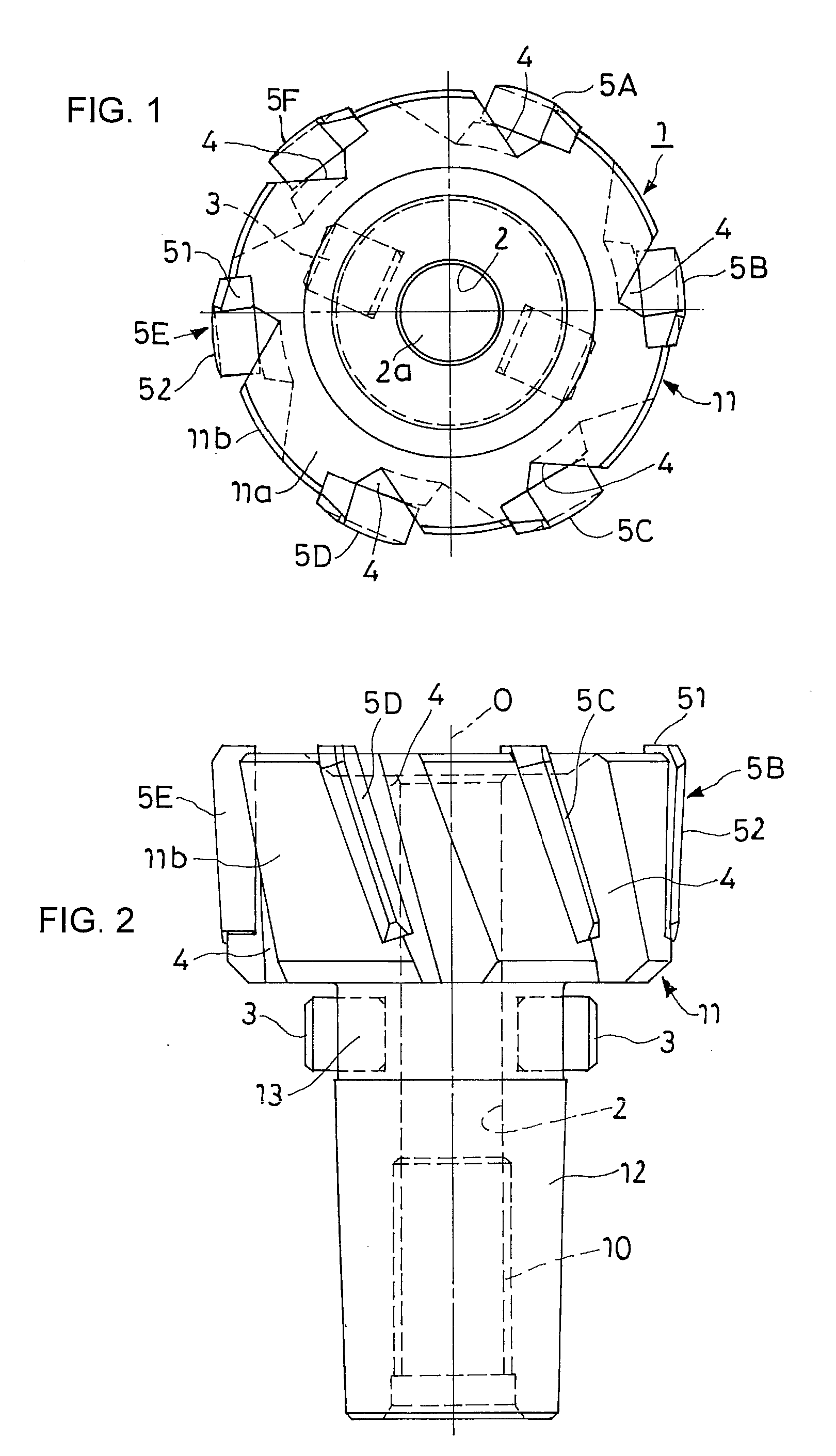

Cutting tool

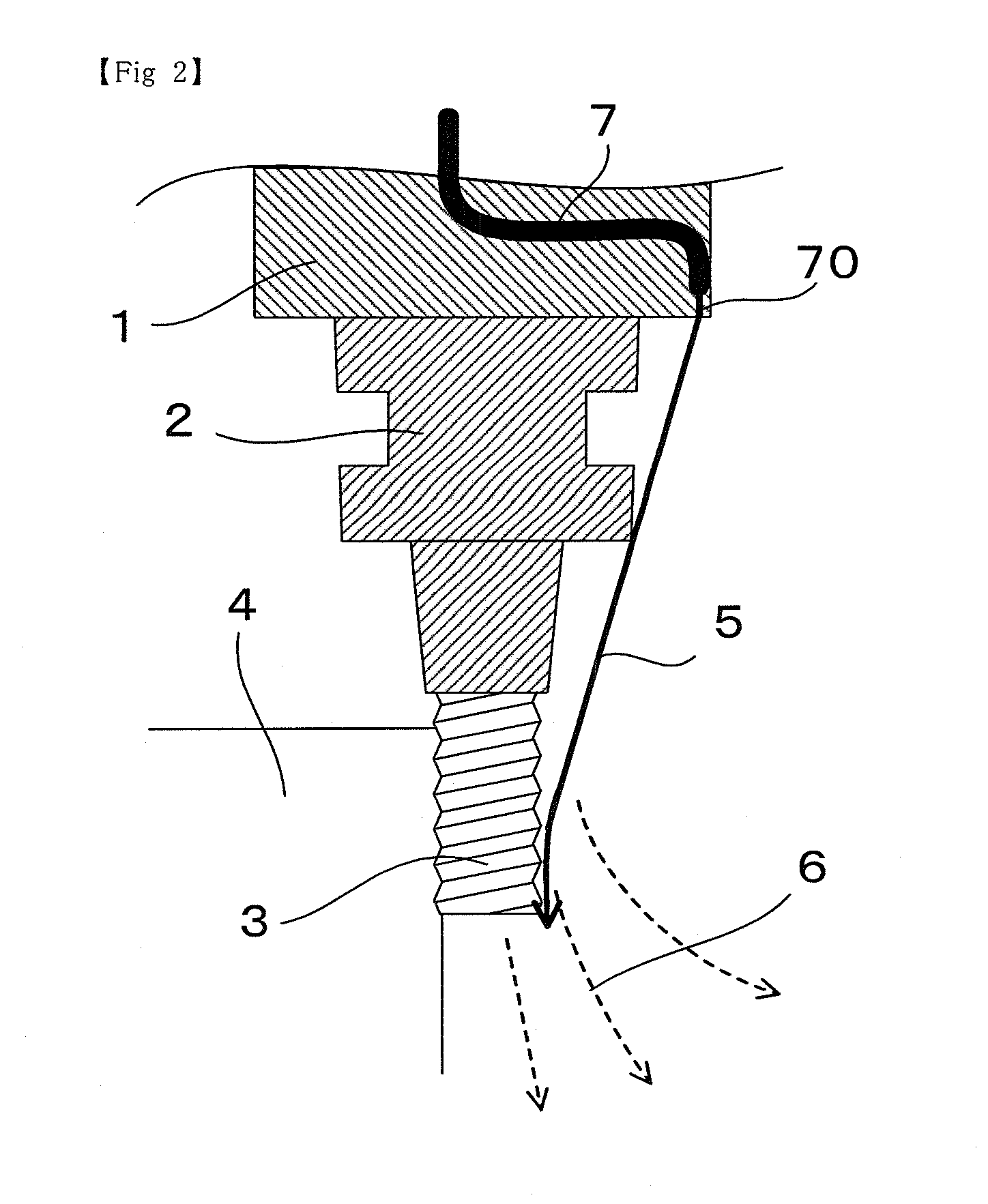

InactiveUS20020178890A1Improve toughnessHigh hardnessMetal sawing devicesMetal sawing toolsEngineeringMechanical engineering

A cutting tool is composed of a circular base plate, and a plurality of arc-shaped cutting tips fixed to the outer peripheral surface of the base plate and spaced from each other in a circumferential direction. The base plate is formed from stainless steel.

Owner:DISCO CORP

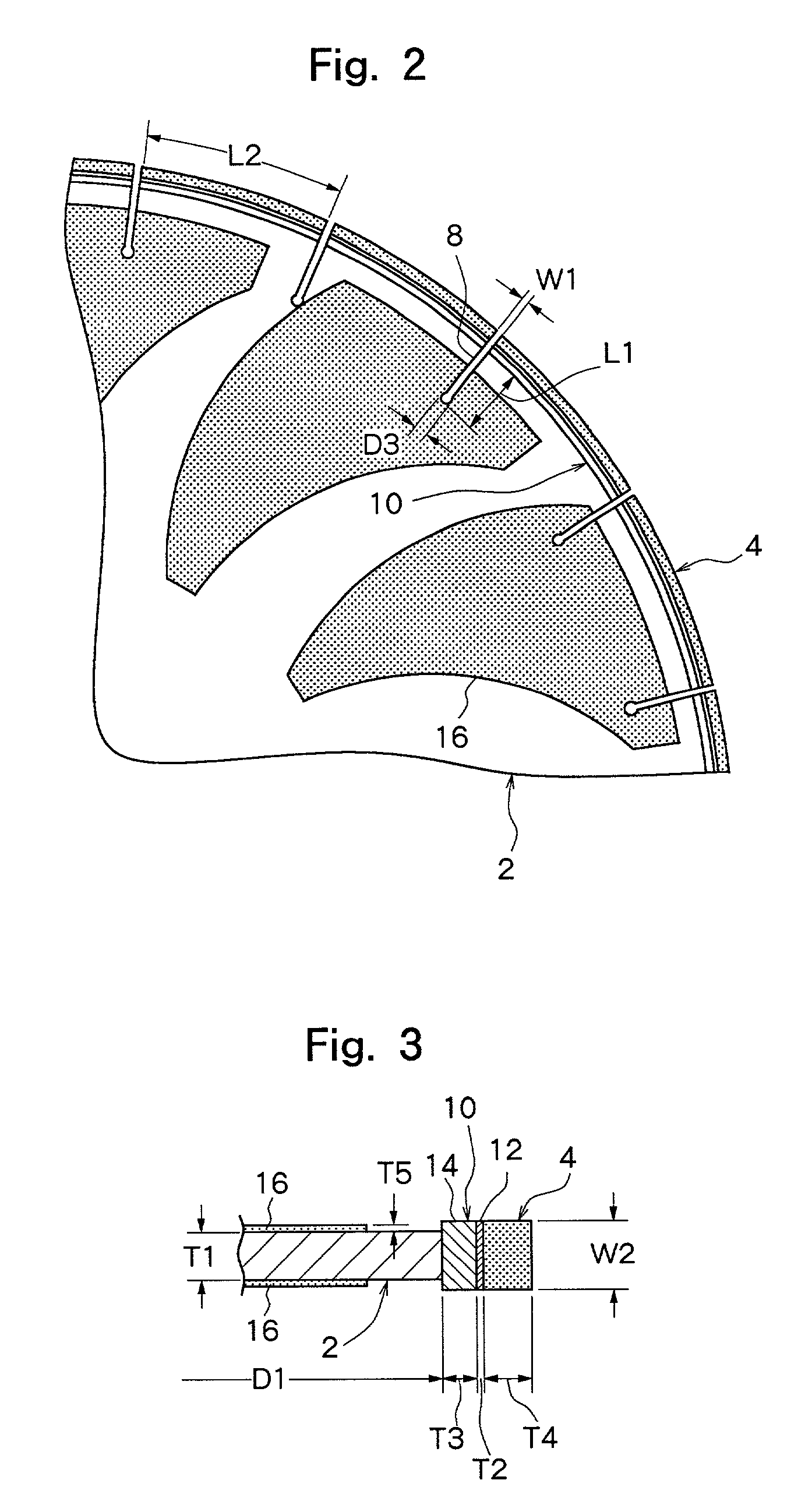

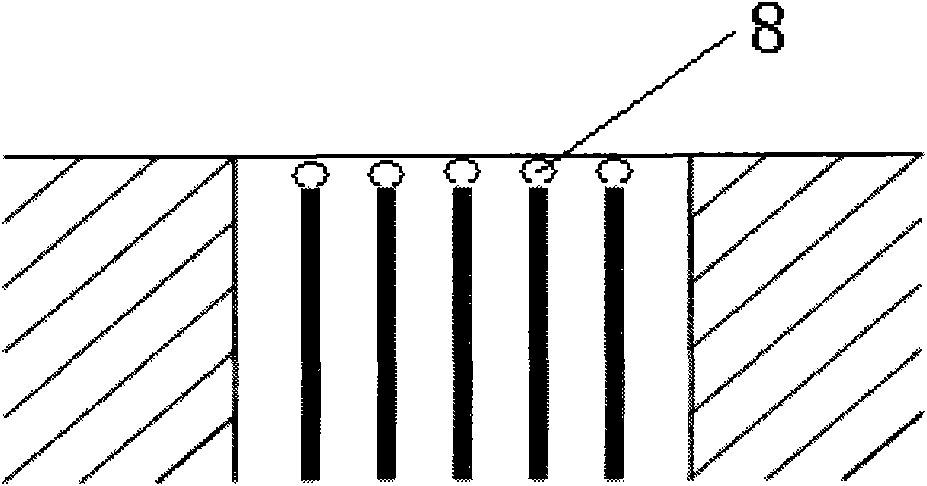

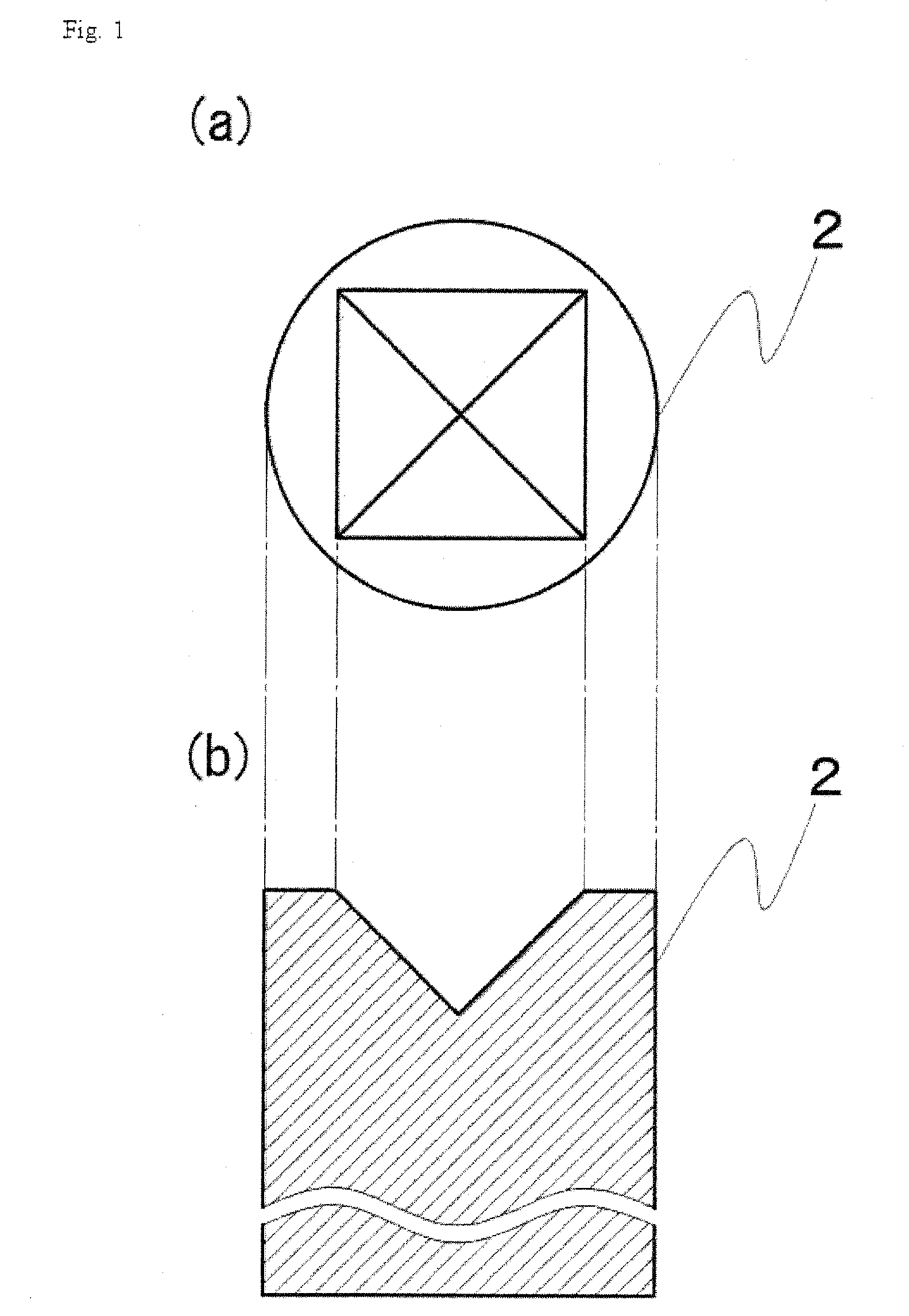

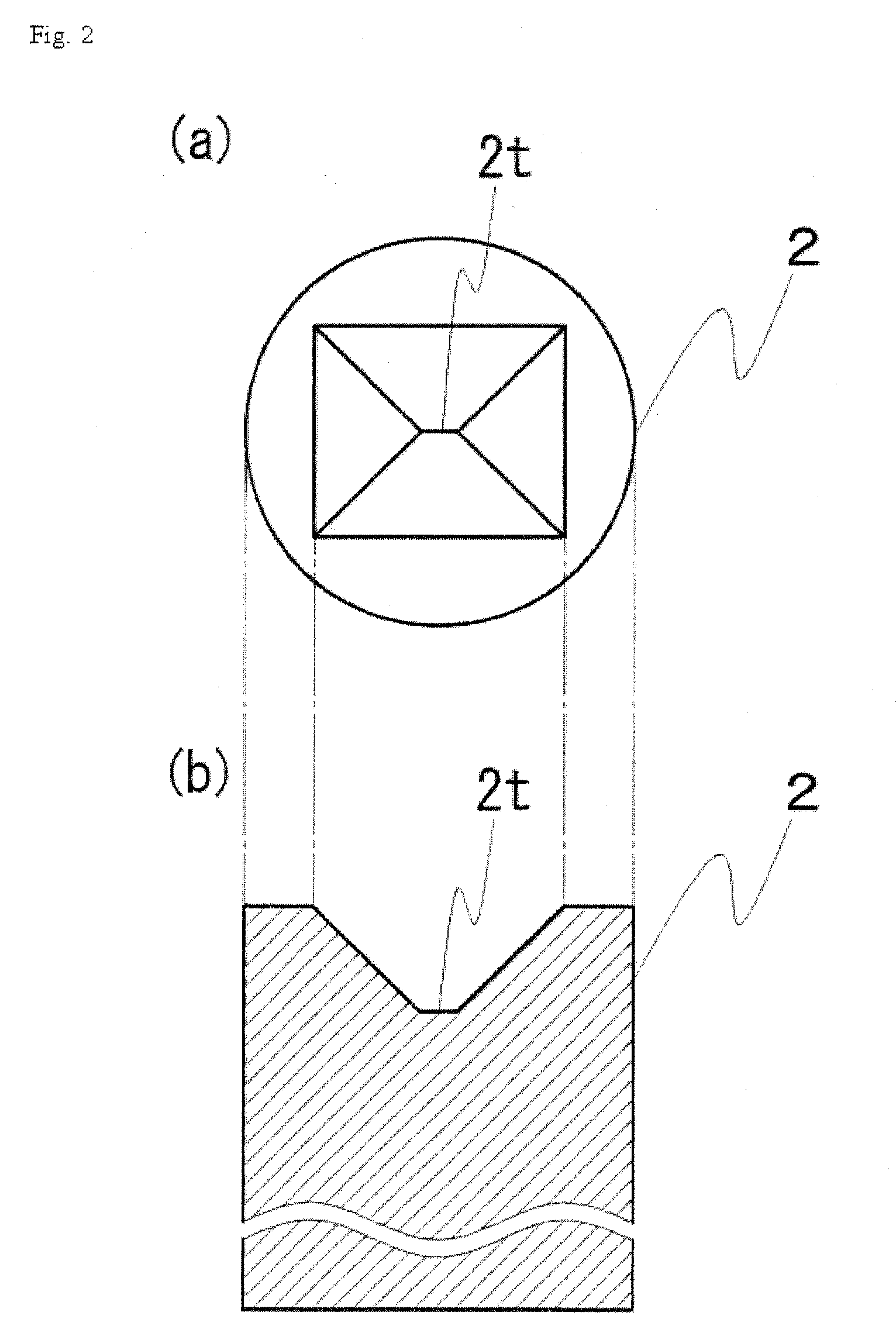

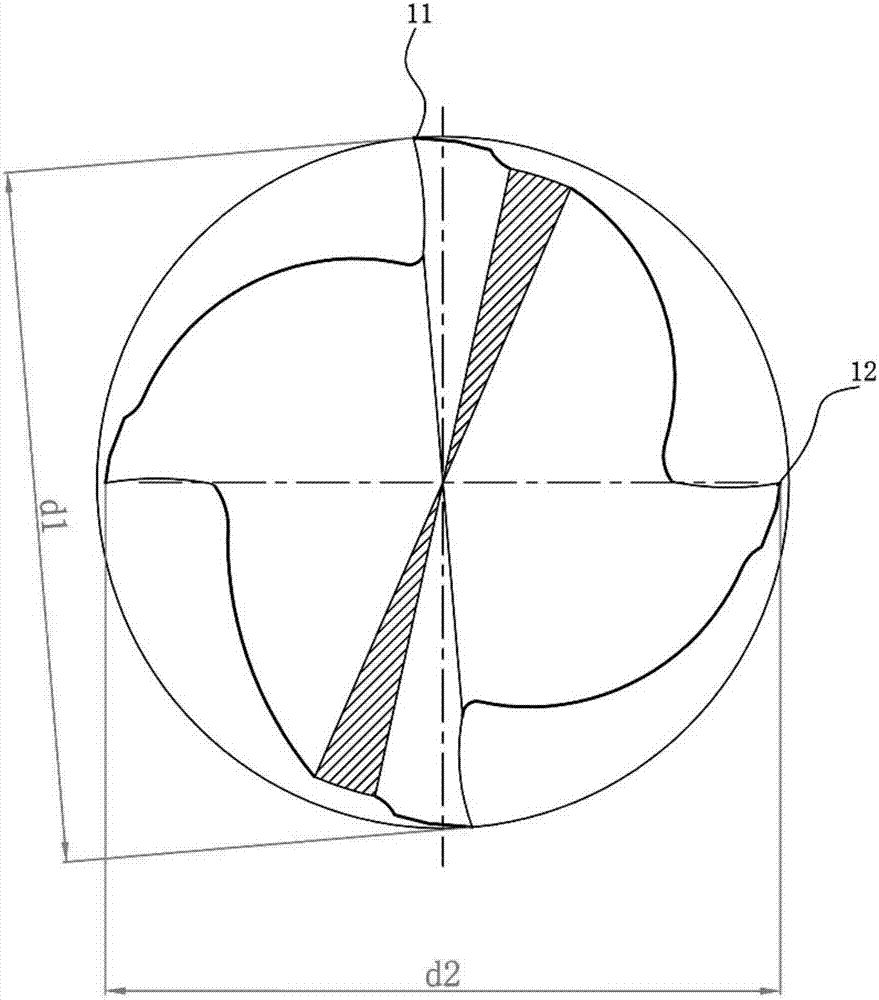

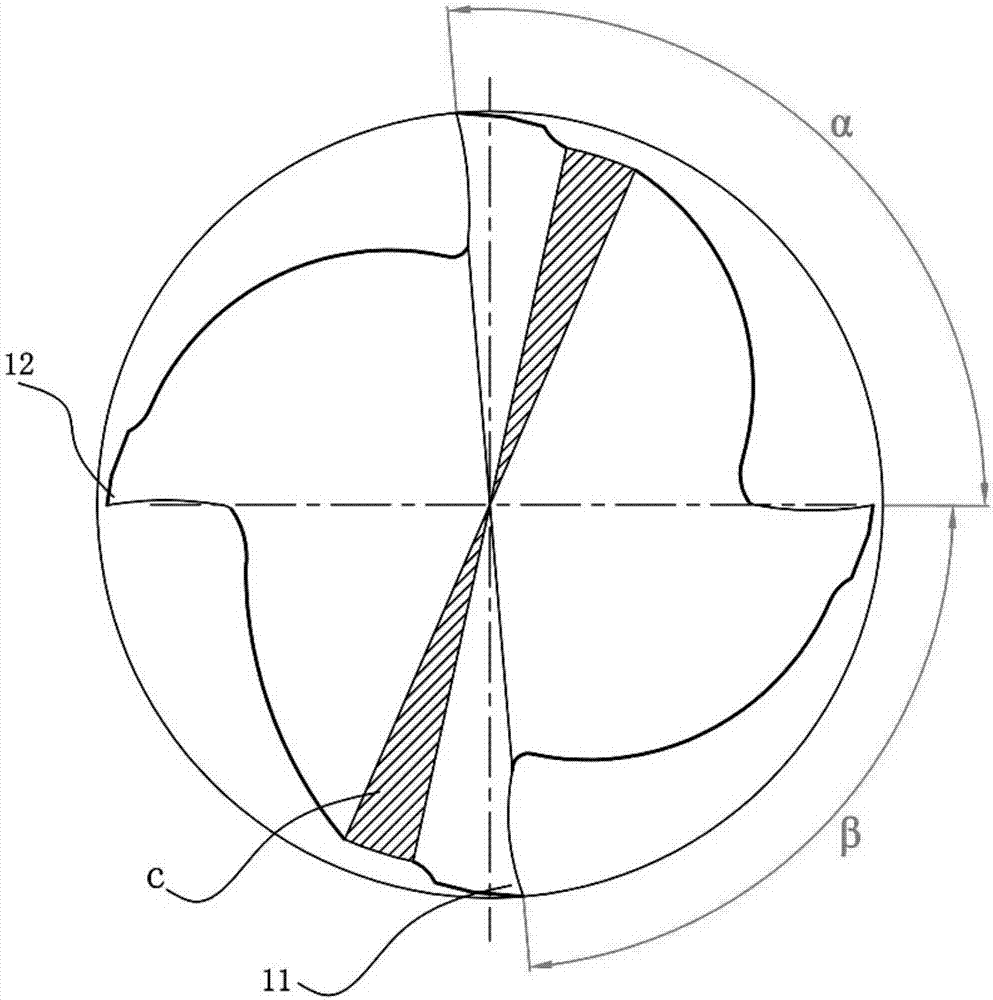

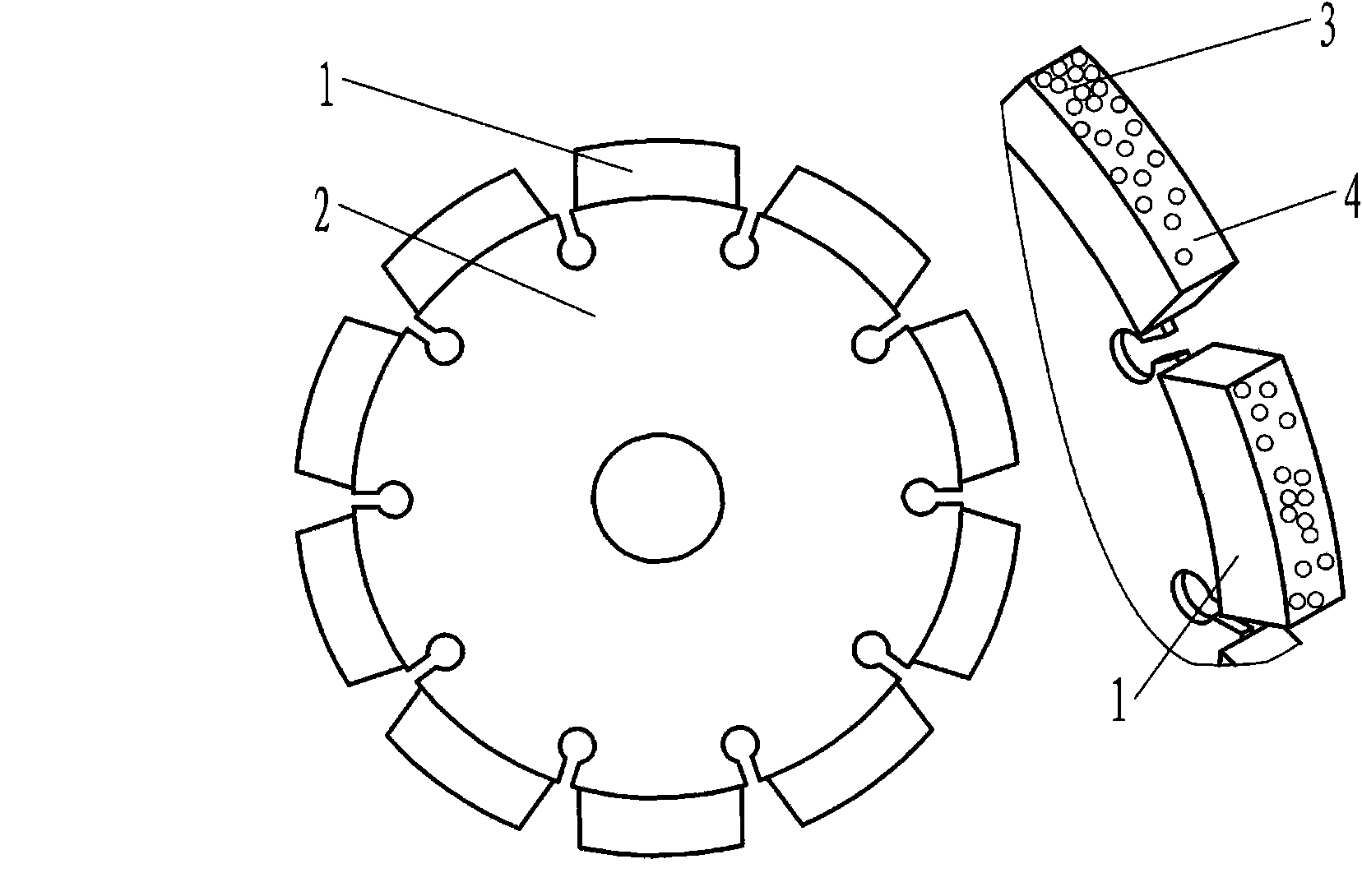

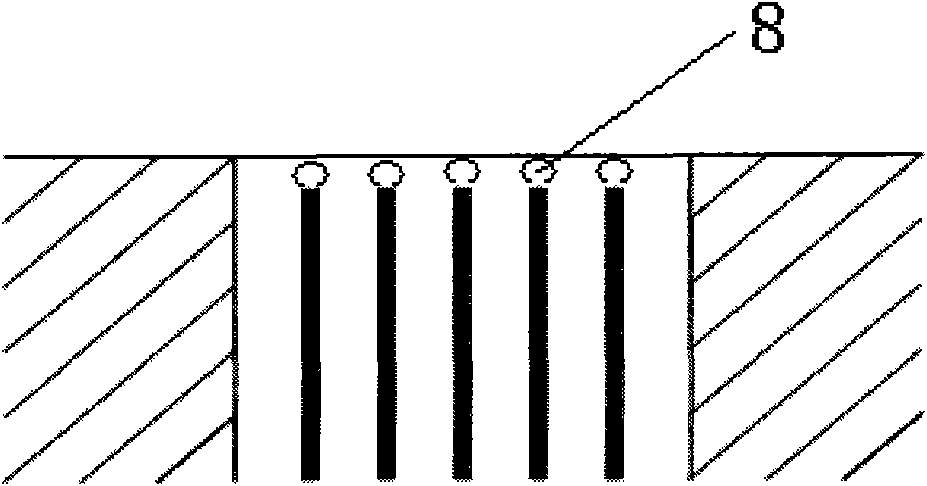

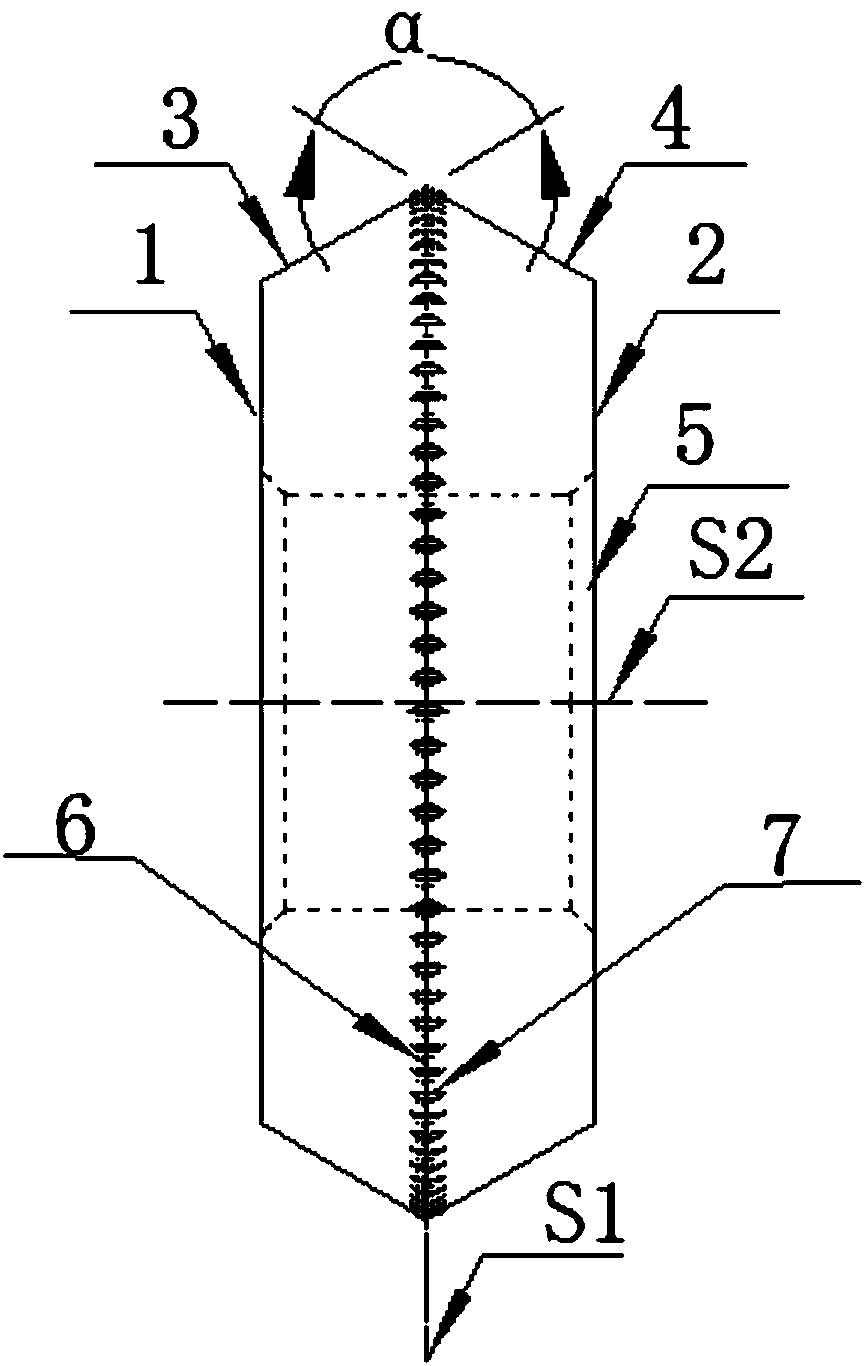

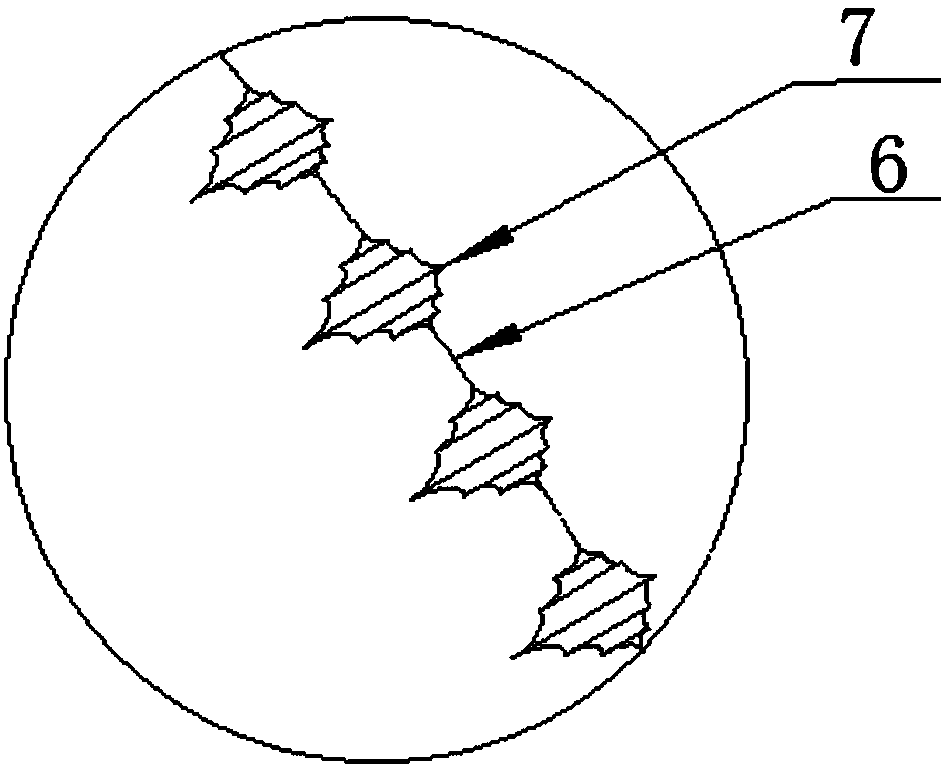

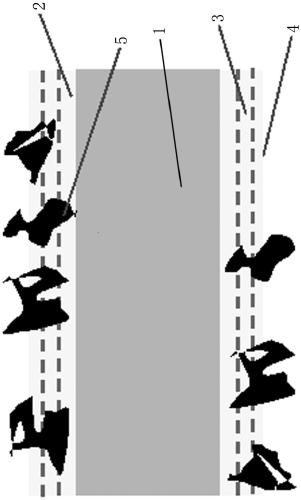

Orientation order distribution of diamond in tool bit realization method

ActiveCN101569903AArranged in an orderly mannerEfficient layoutThree-dimensional spaceThermal compression

The invention relates to an orientation order distribution of diamond in a tool bit realization method. A dip mold with round orifice structure is adopted, a needle rod coordinated with the round orifice is arranged in the round orifice, the needle rod firstly descends the height of one diamond when beginning cold pressing, then a skip car equipped with diamonds streaks the dip mold and then streaks out, thus realizing putting one diamond in each needle hole, the dip mold containing the diamond descends to form a powder-loaded die cavity, the die cavity is filled with matrix powder and the needle rod pushes the diamond into the matrix powder, and then a top mold descends for pressing and forming on the matrix powder, thus obtaining single layer tool bit blank with orientation order distribution of diamond. One or a plurality of orientation order distribution of diamond tool bit blanks in different needle hole distribution modes which are pressed by different molds are assembled, pressed and sintered in certain way, thus realizing orientation order distribution of diamond in tool bit three dimensional space. The method utilizes popular cold and hot press device applied in the industry and has the characteristics of high preparation efficiency and low cost.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

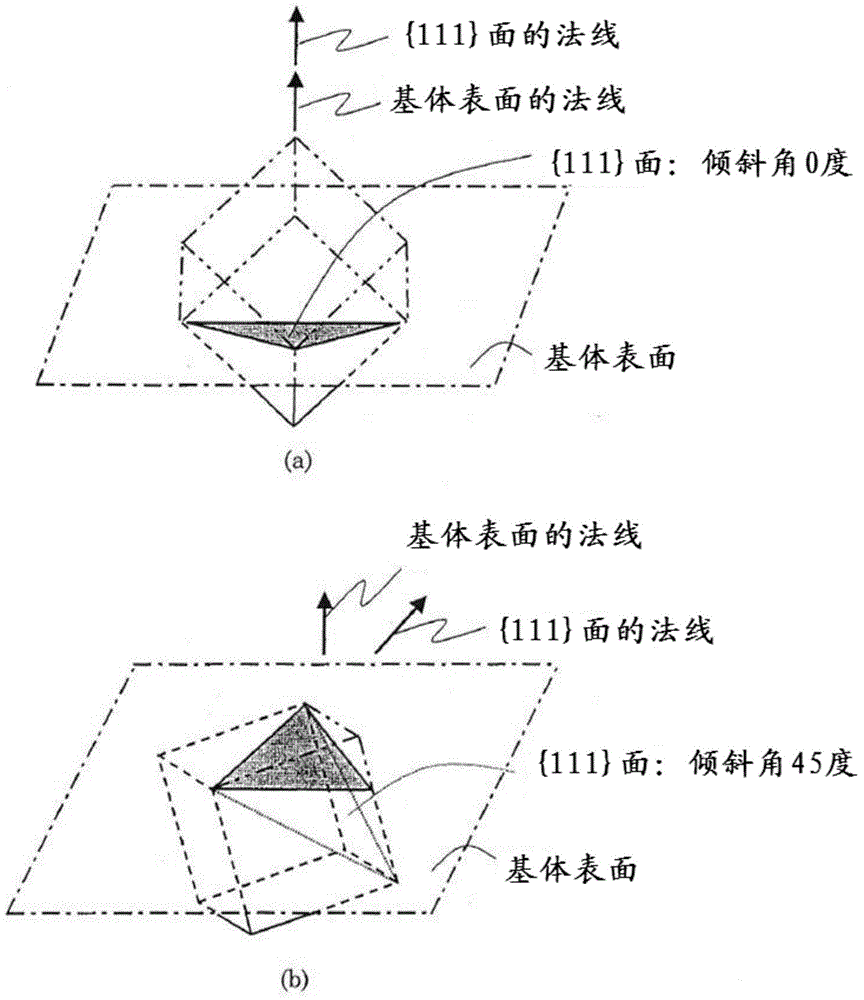

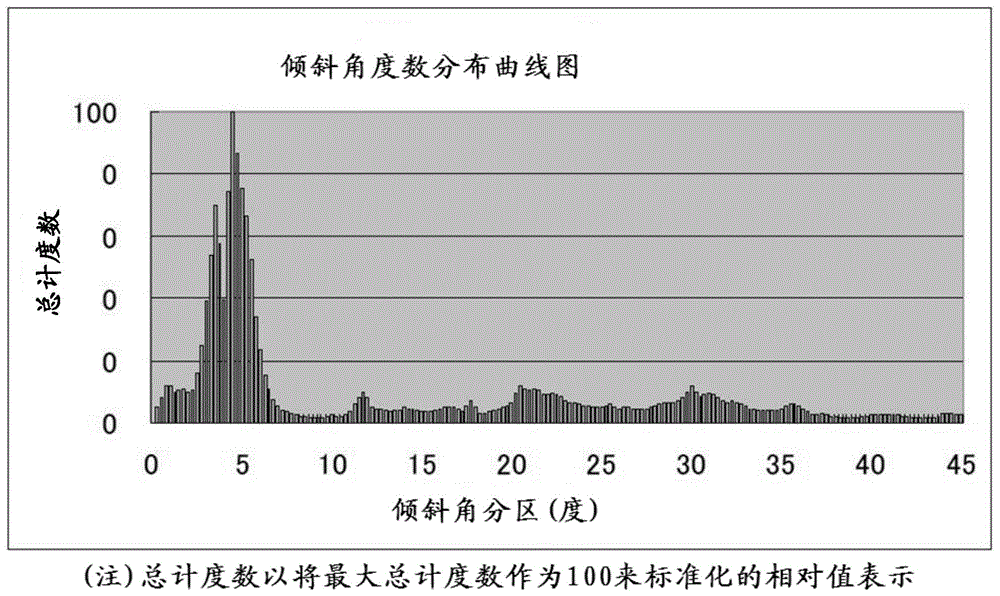

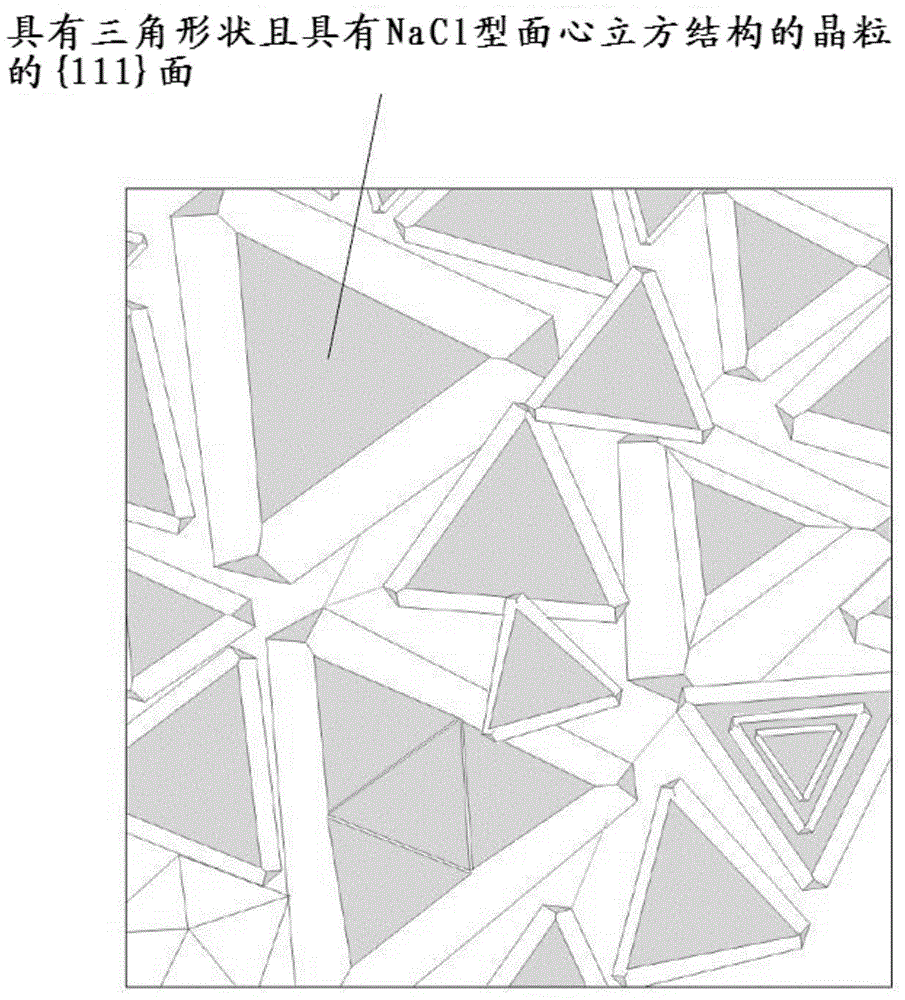

A surface coating cutting tool

ActiveCN104816141ASuppresses chippingSuppression defectChemical vapor deposition coatingEvaporationScanning electron microscope

The invention provides a surface coating cutting tool. An average proportion X[avg] of A1 and an average proportion Y[avg] of C of a (Ti[1-X]A1[X])(C[Y]N[1-Y]) layer, of which film formation is realized through chemical evaporation with A1(CH3) as reaction gases on the surface of a substrate, wherein (Xavg and Yavg are both atomic ratios), satisfy 0.60<= X[avg]<=0.95 and 0<= Y[avg]<=0.005. Crystalline grains having cubic crystalline structures exist in crystalline grains forming complex nitrides or a layer of the complex nitrides. In measurement of distribution of degrees of inclination angles of an inclination angle between a normal of surfaces of crystalline grains (111) and the surface of the substrate, a degree ratio in a scope of 0-12 degrees is more than 45% of all the degrees. When a scanning electron microscope is used to observe organizations from the surface sides of the complex nitrides or the layer of the complex nitrides, the crystalline grains having the c cubic crystalline structures have triangular shapes in surfaces perpendicular to a layer thickness direction. A facet formed by an equivalent crystalline plane expressed by (111) of the crystalline grains accounts for an area proportion of more than 35% in the surface perpendicular to the layer thickness direction.

Owner:MITSUBISHI MATERIALS CORP

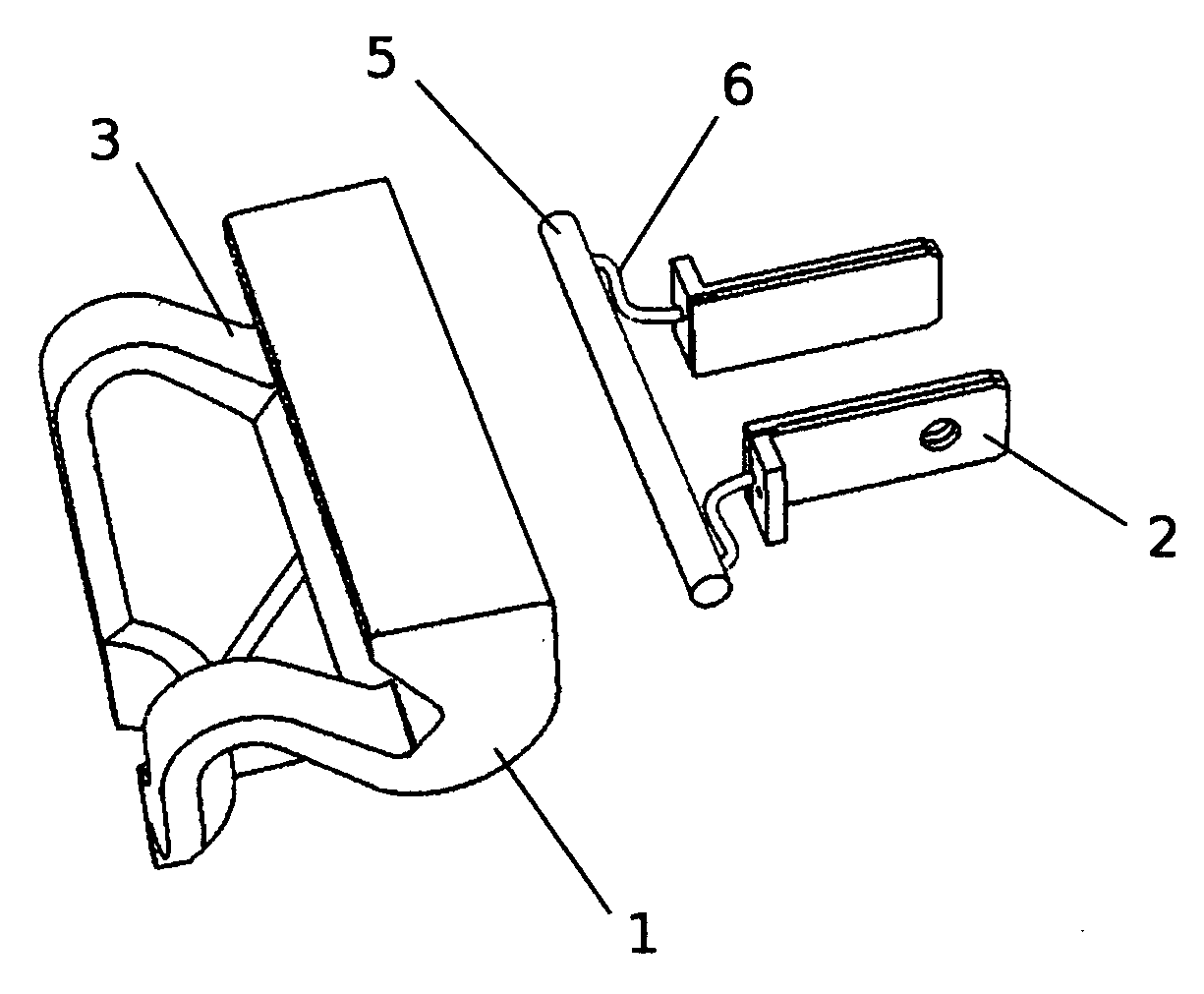

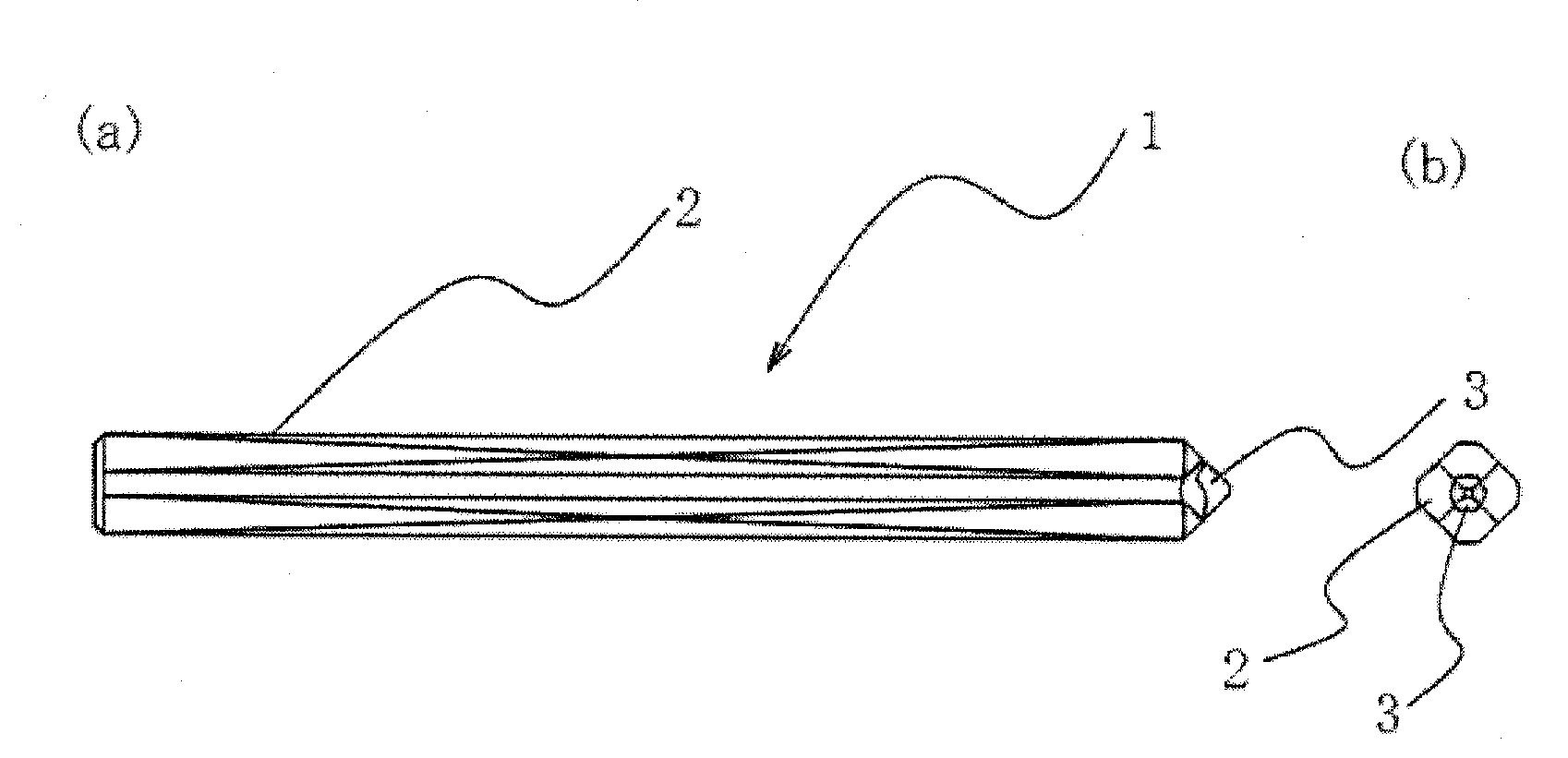

Shank and diamond scriber assembled therewith

InactiveUS20090183617A1Improve wear resistanceHighly preferable fixationWing handlesWing knobsSingle crystalScriber

A shank of a diamond scriber suitable for substantially flat-surfaced materials that is to be scribed with particularly high loads. The shank includes a blind hole for retaining a diamond single crystal. The blind hole includes a rectangular mouth and four triangular sidewalls, each of which includes one edge of the rectangular mouth and meets the other three.

Owner:NAMIKI PRECISION JEWEL CO LTD

Complete blade and wafer handling and support system

InactiveUS6325057B1Reduce downtimeIncrease productionPolishing machinesRevolution surface grinding machinesSupporting systemRobotic arm

The wafer handling and support system disclosed herein does not use tape and is adapted for use in conjunction with a number of work stations. The wafer handling and support system includes a chuck plate comprised of a non-porous section surrounding a porous section and a robotic arm for transporting a chuck plate / wafer combination under vacuum. The chuck plate is sized to be carried by a wafer chuck and the porous section of the chuck plate is configured to support a wafer. The wafer may be held in place on the chuck plate by the application of a vacuum.

Owner:MICRON TECH INC

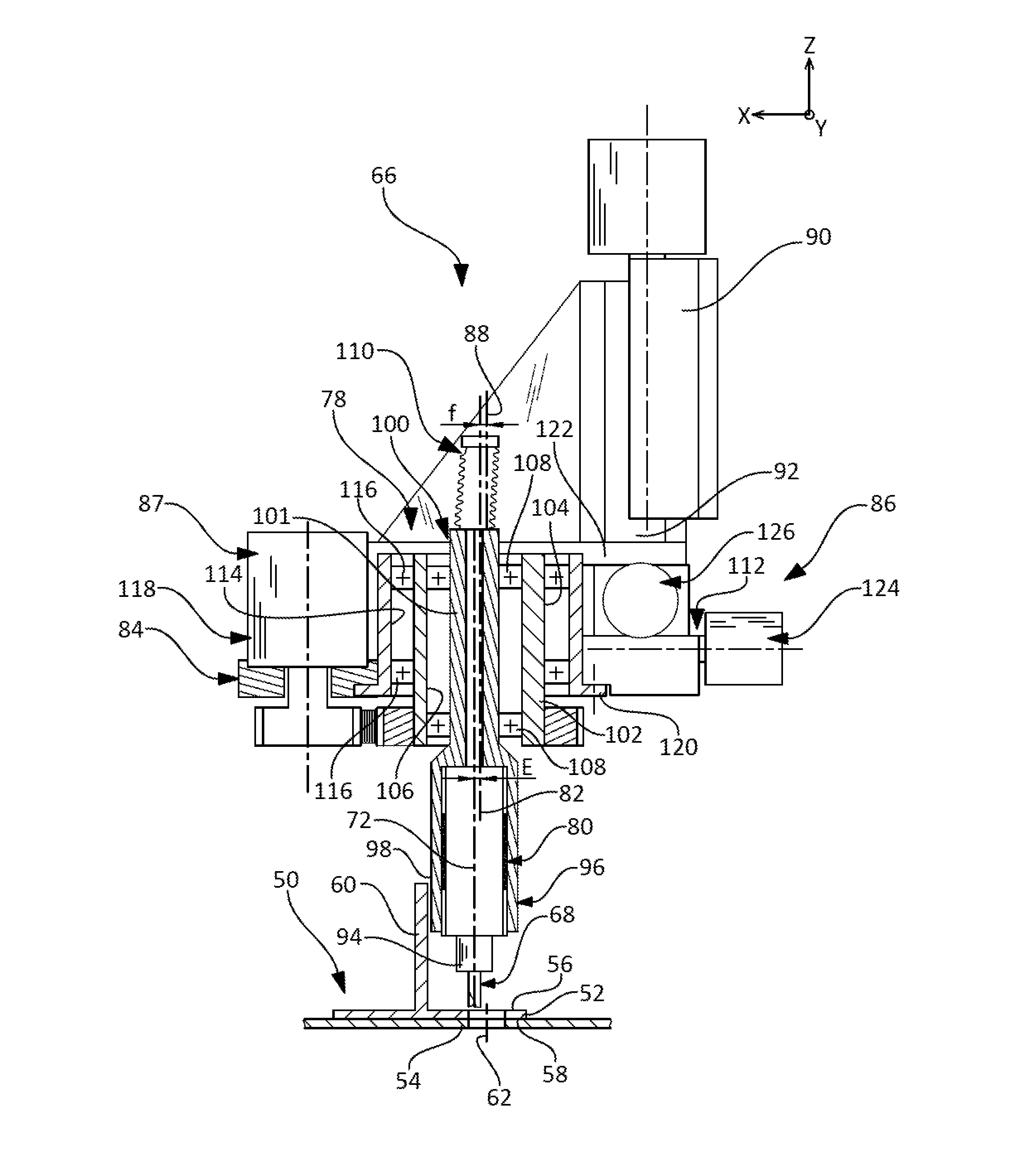

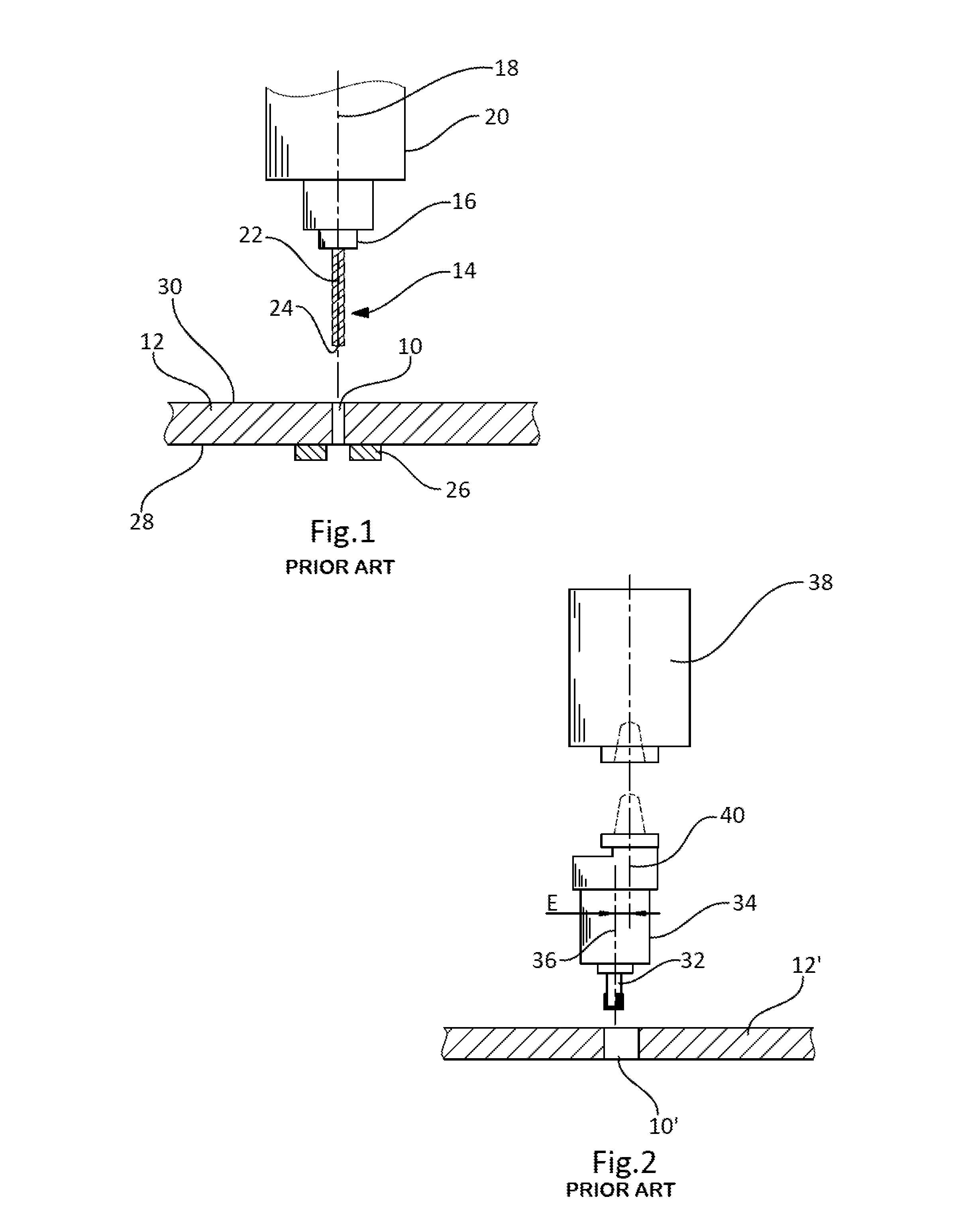

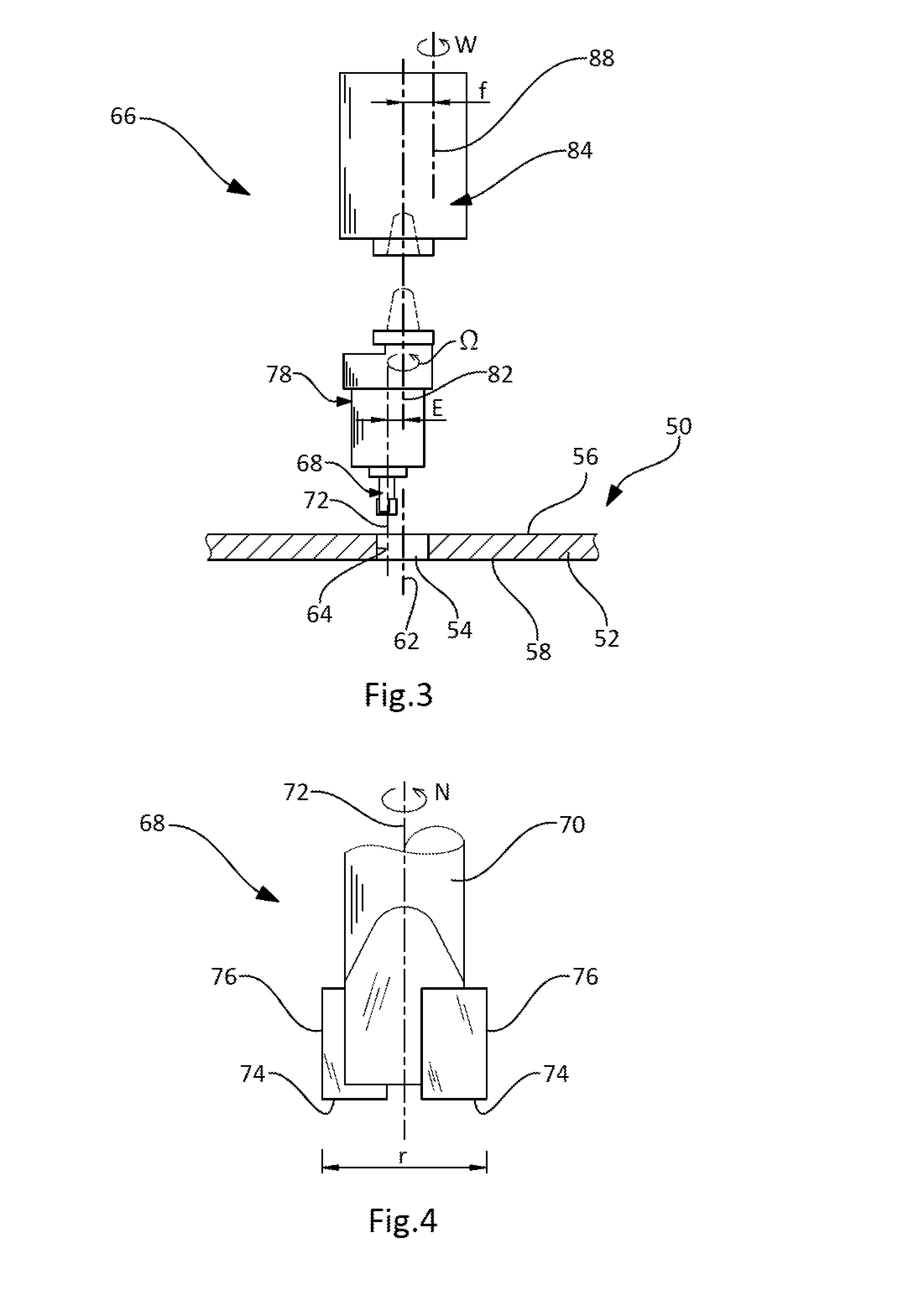

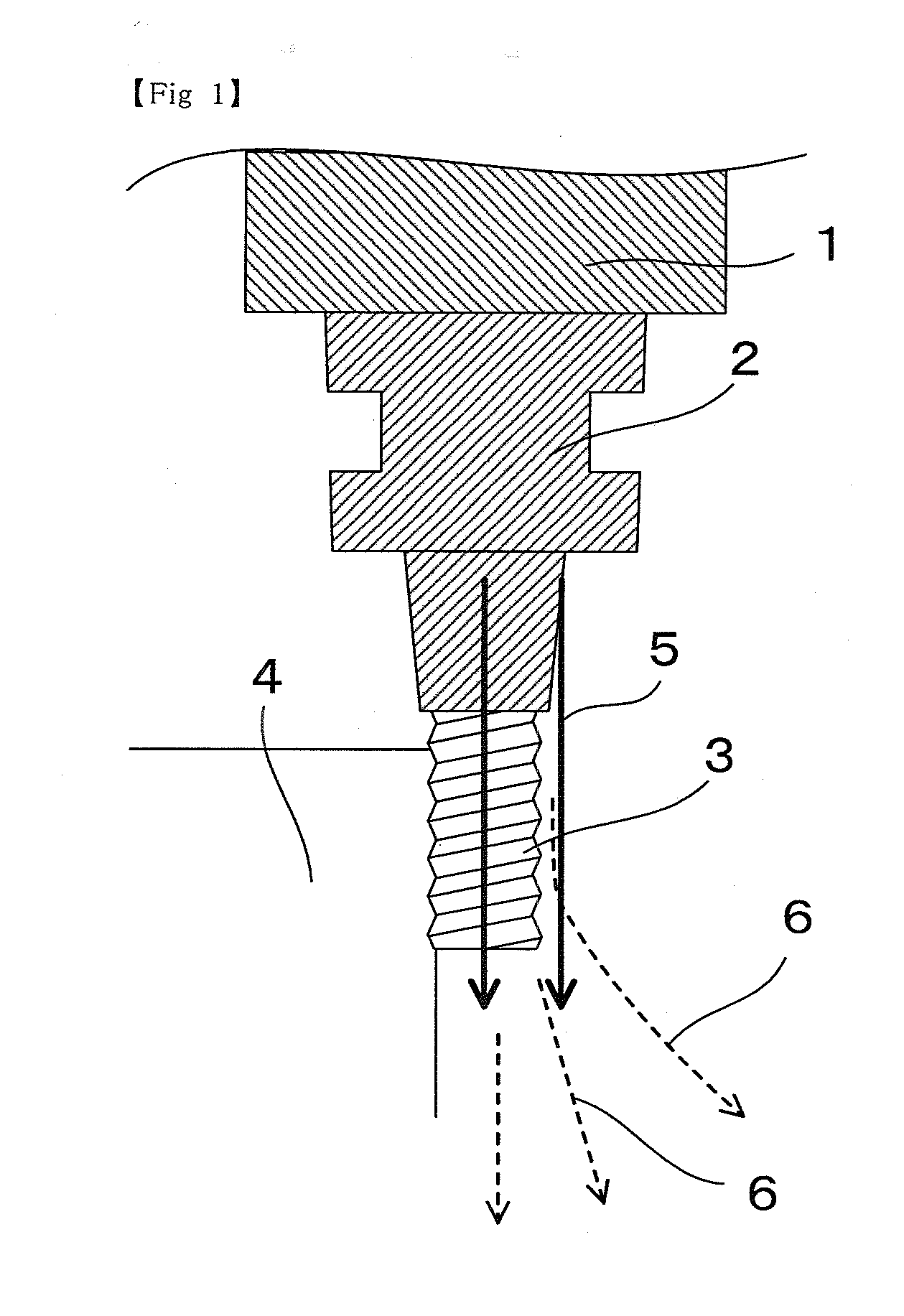

Method For Machining A Through-Hole In A Component And Machining Device For Implementing The Said Method

ActiveUS20140227055A1High surface finishIncrease speedThread cutting auxillary apparatusWorkpiecesProduction rateEngineering

A method for machining a through-hole in a wall of a component, includes setting in rotation on itself a cutting tool about a rotation axis and setting the rotation axis of the tool in rotation about a first orbital rotation axis parallel to, and eccentric by an eccentricity E with respect to, the rotation axis of the tool. The method further includes setting the first orbital rotation axis in rotation, over at least one revolution, about a second orbital rotation axis parallel to, and eccentric by an amount f with respect to, the first orbital rotation axis, the eccentricity being fixed. This configuration makes it possible to balance the elements located between the rotation axis of the tool and the first orbital rotation axis, so that the rotation axis can thus be set in rotation about the first orbital rotation axis at high rotational speeds that contribute toward increasing productivity.

Owner:AIRBUS OPERATIONS (SAS)

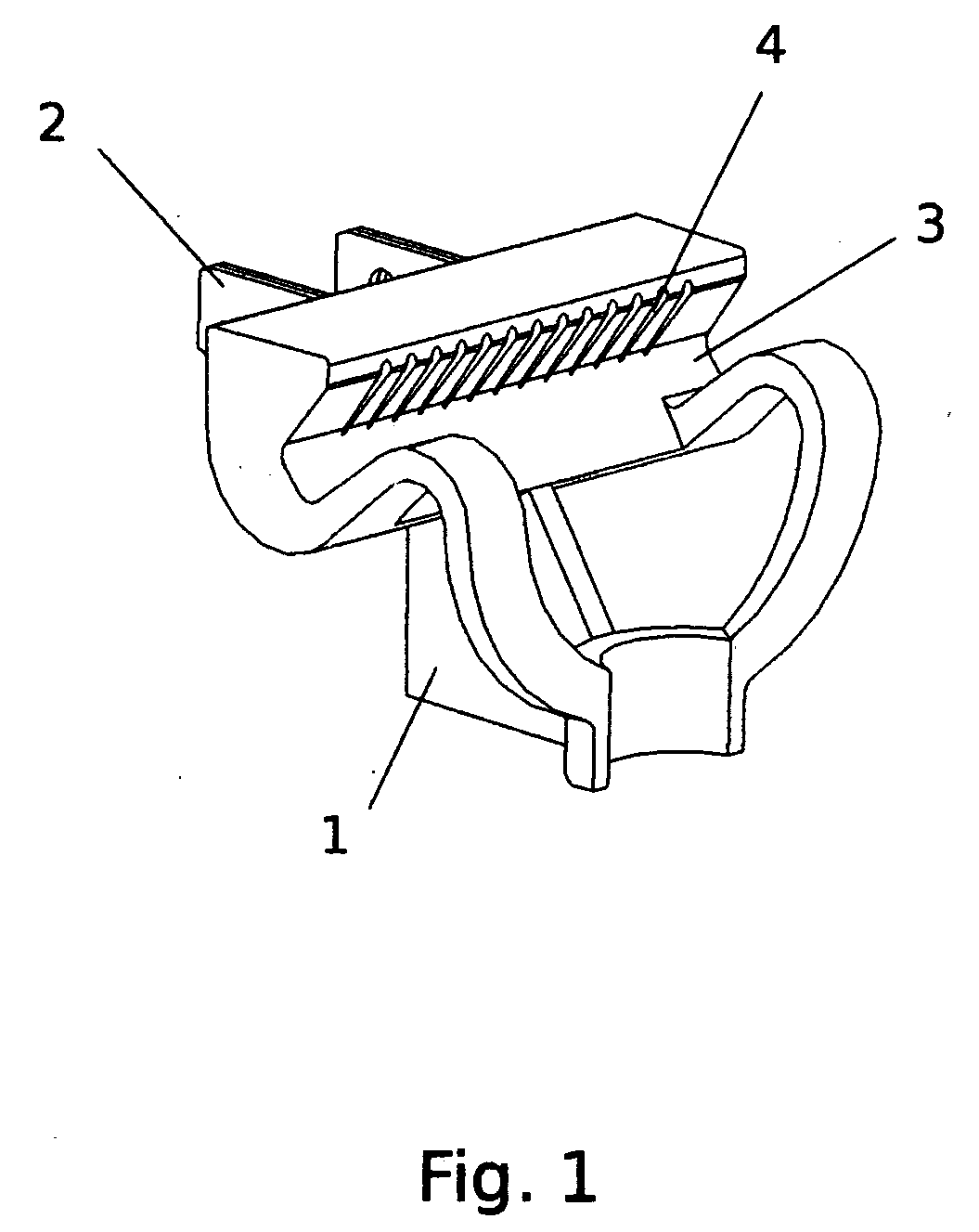

Machine reamer

ActiveUS20070237593A1Increased durabilityImprove machine performanceWood turning toolsTransportation and packagingEngineeringReamer

A machine reamer has blades to which a work material is not easily adhered by heat even if a cutting speed is increased, and hence high processing efficiency can be obtained. Additionally, the cutting edge of the blade is only slightly worn down even if heavy cutting is performed, and hence excellent durability and an extremely long machine life can be obtained. A plurality of slender blades is erected on the outer peripheral part of a reamer head body. Different kinds of materials are used to make the blades.

Owner:YUNITAKKU

Stepped milling cutter

ActiveCN107350531AExtended service lifeGuaranteed strict requirementsMilling cuttersWorkpiecesForming faceStress concentration

The invention discloses a stepped milling cutter. The stepped milling cutter comprises a cutter handle and a cutting part. The cutting part comprises four main cutting edges and four spiral chip removal grooves, each main cutting edge is provided with a steeped cutting edge, the diameter of the two of the four main cutting edges is larger than that of the other two main cutting edges, the large-diameter main cutting edges serve as first circumferential cutting edges, the small-diameter main cutting edges serve as second circumferential cutting edges, and the length of the first circumferential cutting edges is larger than that of the second circumferential cutting edges. According to the stepped milling cutter, the first circumferential cutting edges and the second circumferential cutting edges are different in the outer diameter and are arranged in a staggered mode, so that cutting faces are crossed to form a right-angle step forming face, and the effect that the step root of an IO interface groove of a mobile phone meets the strict rounded corner requirement can be ensured; and by setting the different circumferential cutting edge lengths, the problem of stress concentration of the step root of a small-diameter stepped milling cutter is effectively avoided, the cutter breaking problem is solved, the service life of the stepped milling cutter is greatly prolonged, and compared with existing stepped milling cutters, the cutting edge breaking risk is reduced.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Antiloading composition for an abrasive article and abrasive article having an antiloading coating

InactiveCN101668611AImprove cutting lifeExtended service lifeOther chemical processesAbrasion apparatusPolymer scienceFatty acid

Owner:3M INNOVATIVE PROPERTIES CO

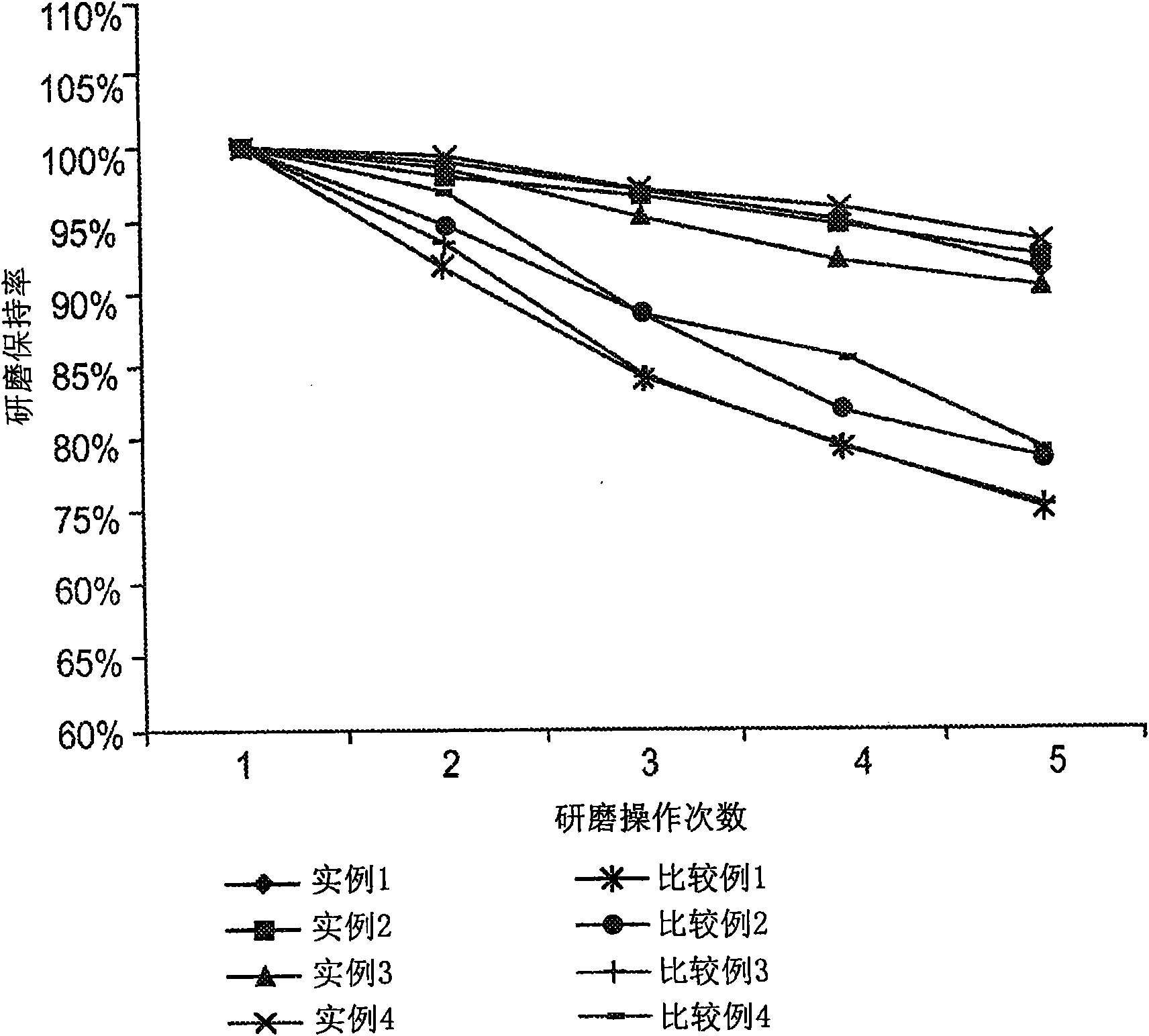

Method for coating membranes on artificial diamond particles

InactiveCN102392231AImprove cutting lifeReduce manufacturing costLiquid/solution decomposition chemical coatingNickelPhosphorus

The invention relates to a method for coating membranes on artificial diamond particles, in particular to a method for coating nickel-phosphorus alloy membranes on artificial diamond particles for a cutter head of a diamond circular cutting saw blade through chemical deposition. The method comprises the following steps of: deoiling, sensitizing and activating the diamond particles, and plating nickel-phosphorus alloy by using a chemical method to obtain the diamond particles of which the surfaces are coated with the nickel-phosphorus alloy membranes. By the method for coating the membranes on the artificial diamond particles, the cutting life of the cutter head of the diamond circular cutting saw blade is prolonged greatly, and the production cost is reduced; and the artificial diamond particles are coated with the membranes, the cost is low, the pollution is light, and the method is easy to operate and master.

Owner:许鹤鸣

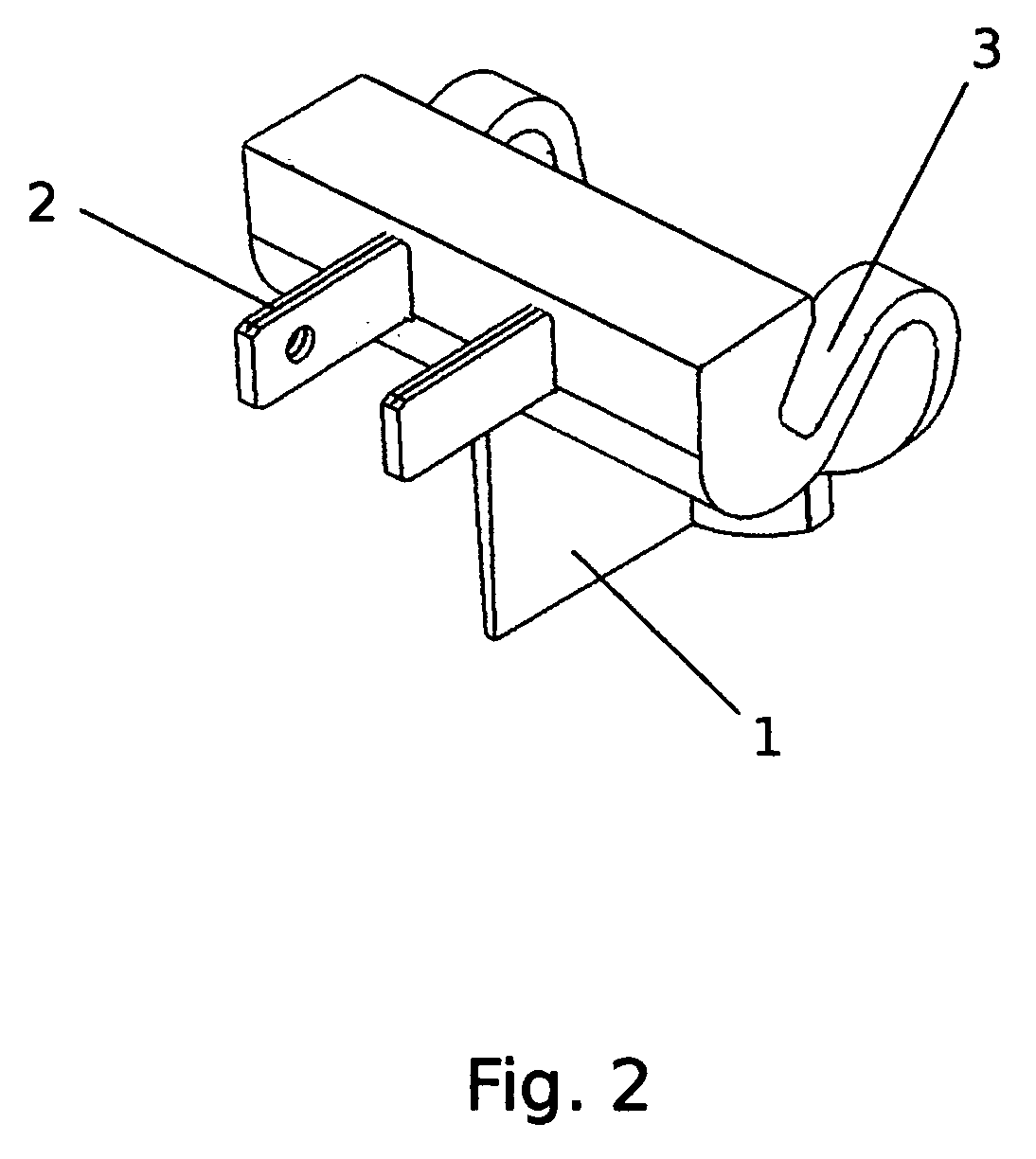

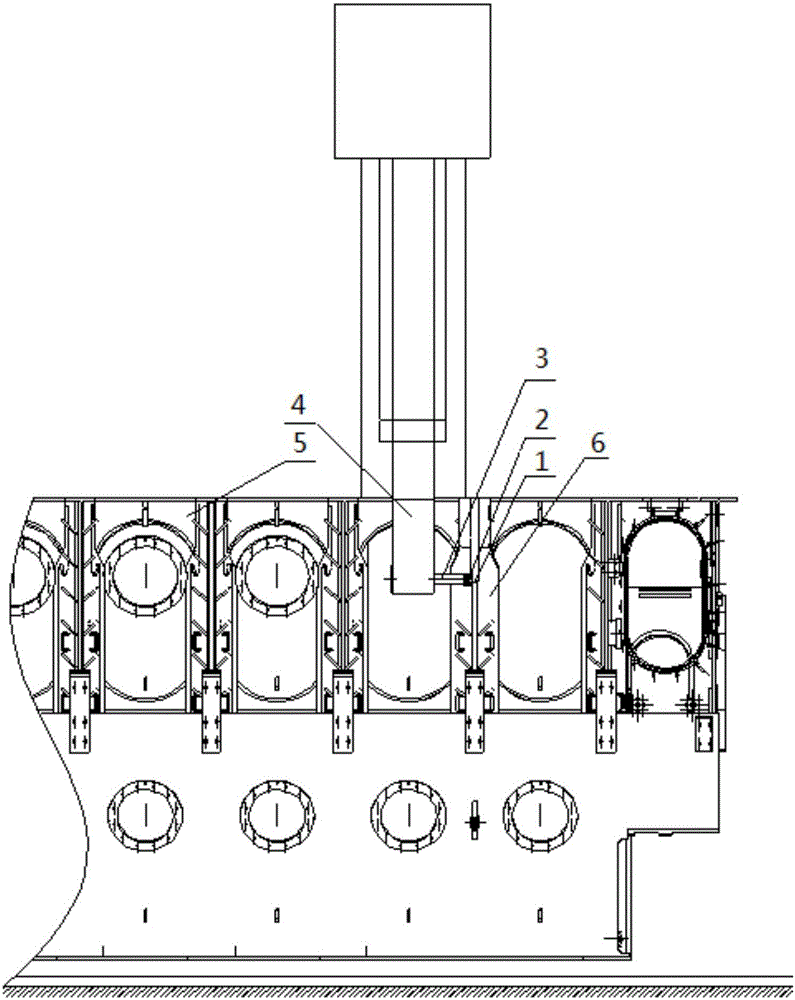

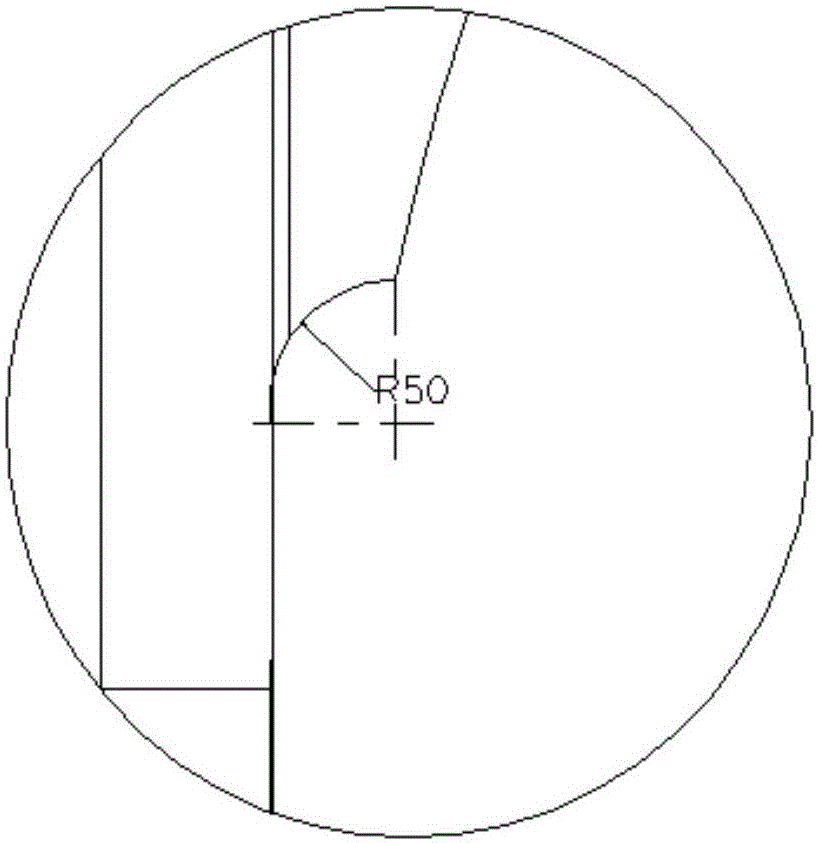

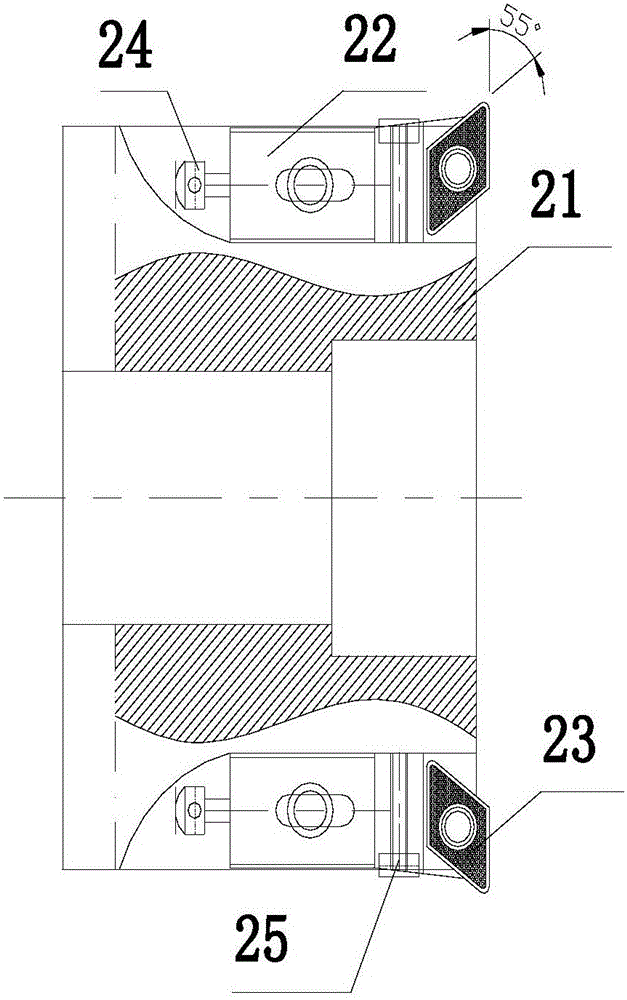

Machining method and tool for R groove in guide plate of marine diesel frame

ActiveCN105149667AReduce tremorImprove cutting lifeMilling cuttersTurning toolsProgram instructionEngineering

The invention discloses a machining method for an R groove in a guide plate of a marine diesel frame. On a numerically controlled planer-type milling machine, a compound boring-milling tool is mounted on a shock-proof tool holder connected to a power spindle accessory, and is controlled to move radially or axially through a numerically controlled program instruction, so as to fulfill automatic cutting of the R groove. The compound boring-milling tool comprises a tool body, a plurality of tool holders and a plurality of blades, wherein the tool holders and the blades are fixed at the periphery of the tool body and uniformly distributed; the blades are mounted on the tool body through the tool holders, and are rhombus-shaped; the angle of the tool noses of the blades are 55 degrees; the pointcut of each tool nose in the R groove for cutting is small, so as to realize overcutting prevention of the blades, low tremble of the tool and high degree of finish of a machined surface. The machining method has the advantages that efficient continuous automatic machining is realized; tremble during machining is reduced effectively; no machined trace is formed; the degree of finish of the machined surface is improved; the service life of the tool is prolonged; the machining cost as well as the labor intensity is reduced.

Owner:CSSC MES DIESEL

Methods of inhibiting ethylene responses in plants using cyclopropene amine compounds

InactiveUS20090124504A1Prolonged lifeImprove cutting lifeBiocidePlant growth regulatorsCyclopropeneStereoisomerism

Methods of applying cyclopropene amine derivatives and compositions thereof to inhibit ethylene receptors in plants and plant material are disclosed. Methods include applying to the plant an effective ethylene response-inhibiting amount of at least one cyclopropene amine compound or composition thereof. Cyclopropene amine compounds, enantiomers, stereoisomers or salts thereof are also provided.

Owner:NORTH CAROLINA STATE UNIV

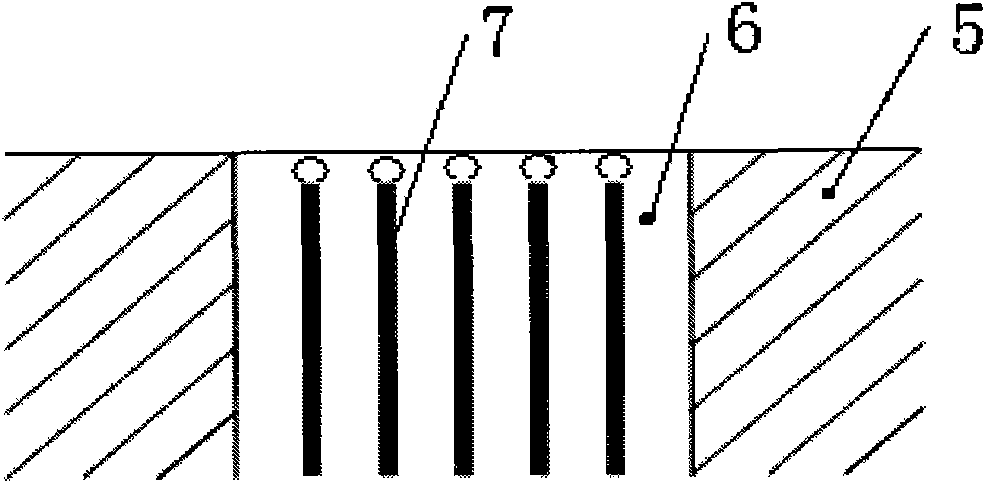

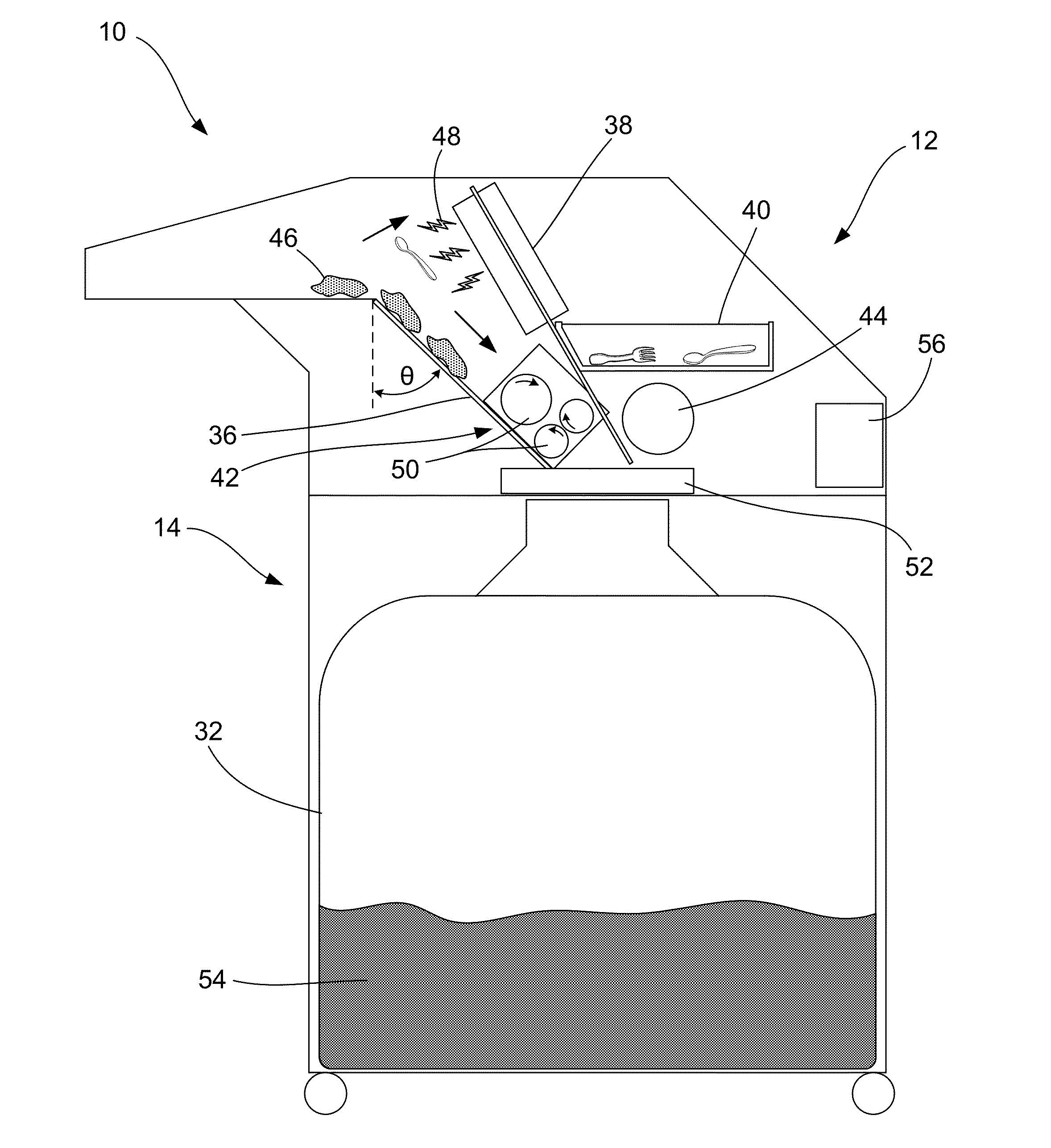

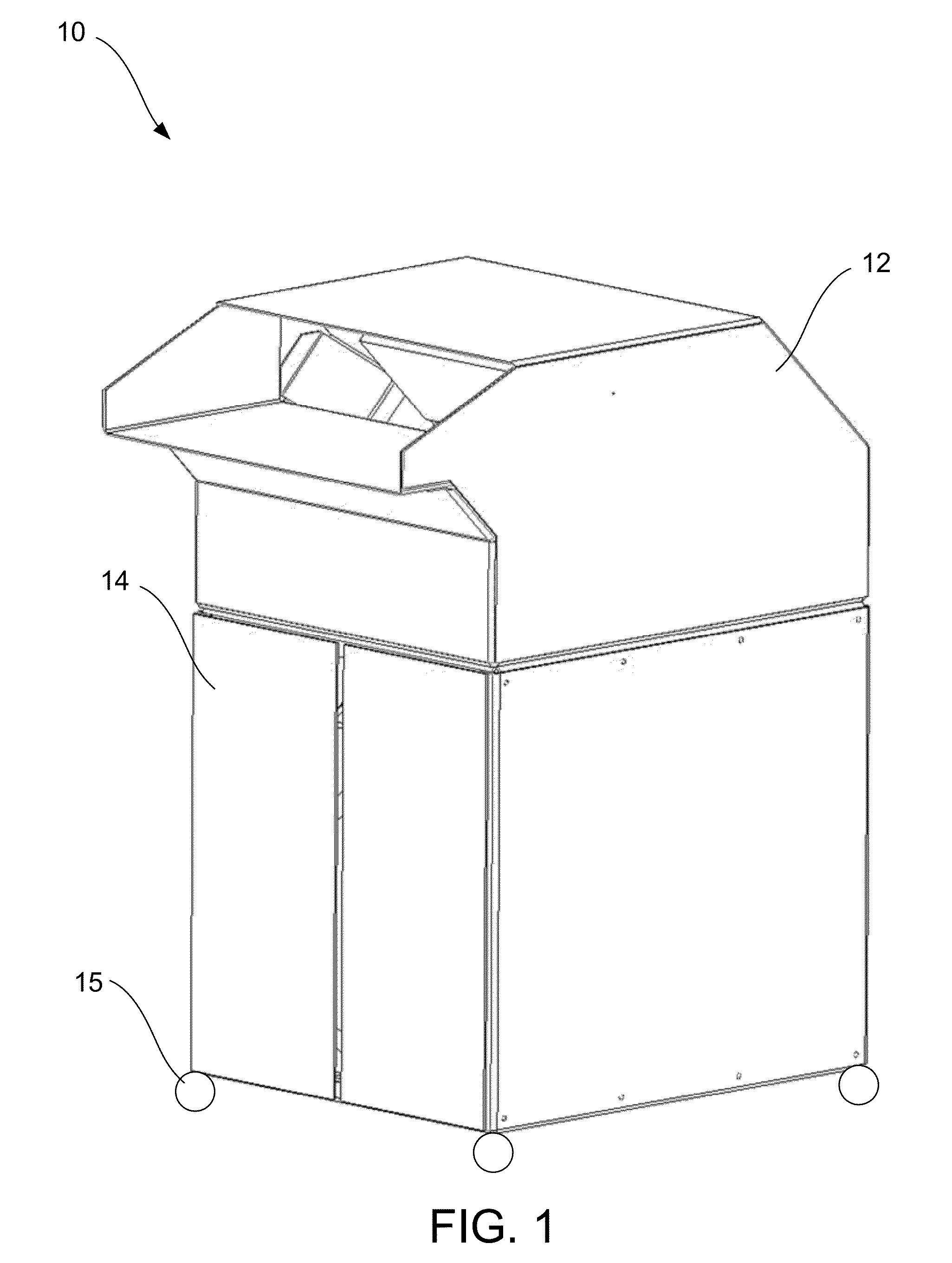

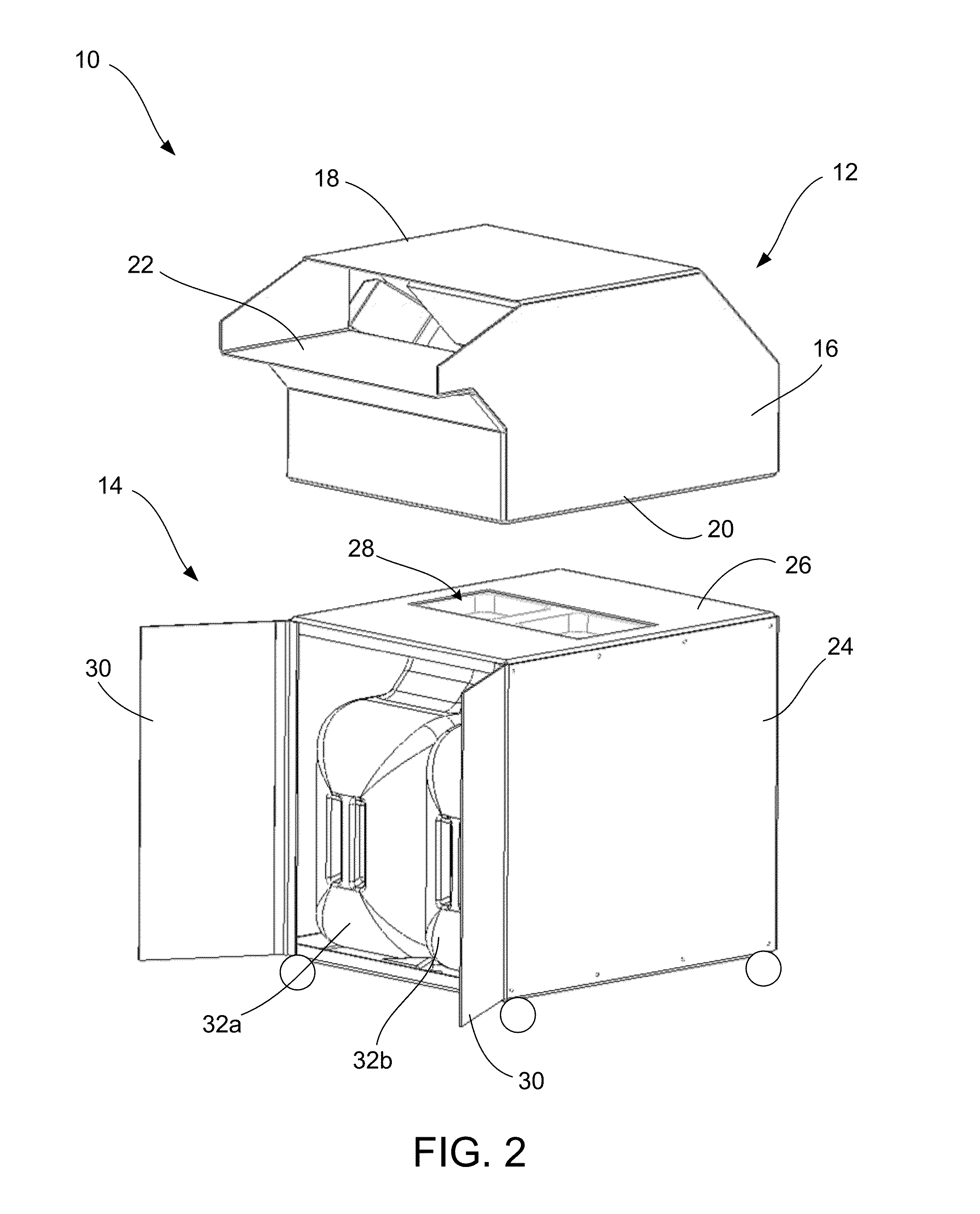

Metal Powder Processing Equipment

ActiveUS20150283649A1Improve cutting lifeHigh cutting surface qualityAdditive manufacturing apparatusArc welding apparatusMetallurgyMetal powder

In metal powder processing equipment where metal powder is sequentially laminated on a table inside a chamber and laser beam melting or electron beam melting, and shaping by a cutting tool subsequent to the melting are performed, unmolded powder remaining at the time of the melting and cut powder generated by the cutting can be scattered by generating air flow with respect to the cutting tool from either side of a main shaft or a tool holder. As a result, life of the cutting tool is prolonged and quality of a cut surface can be improved.

Owner:MATSUURA MACHINERY

Realization method of oriented and orderly assignment of diamond in tool bit

ActiveCN101569903BArranged in an orderly mannerEfficient layoutThree-dimensional spaceThermal compression

The invention relates to an orientation order distribution of diamond in a tool bit realization method. A dip mold with round orifice structure is adopted, a needle rod coordinated with the round orifice is arranged in the round orifice, the needle rod firstly descends the height of one diamond when beginning cold pressing, then a skip car equipped with diamonds streaks the dip mold and then streaks out, thus realizing putting one diamond in each needle hole, the dip mold containing the diamond descends to form a powder-loaded die cavity, the die cavity is filled with matrix powder and the needle rod pushes the diamond into the matrix powder, and then a top mold descends for pressing and forming on the matrix powder, thus obtaining single layer tool bit blank with orientation order distribution of diamond. One or a plurality of orientation order distribution of diamond tool bit blanks in different needle hole distribution modes which are pressed by different molds are assembled, pressed and sintered in certain way, thus realizing orientation order distribution of diamond in tool bit three dimensional space. The method utilizes popular cold and hot press device applied in the industry and has the characteristics of high preparation efficiency and low cost.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Garbage shredding process and products

The invention relates generally to systems for waste management, and, more particularly, to systems and methods for processing and storing waste for subsequent use in biofuel conversion processes.

Owner:JACKSON DONNA K

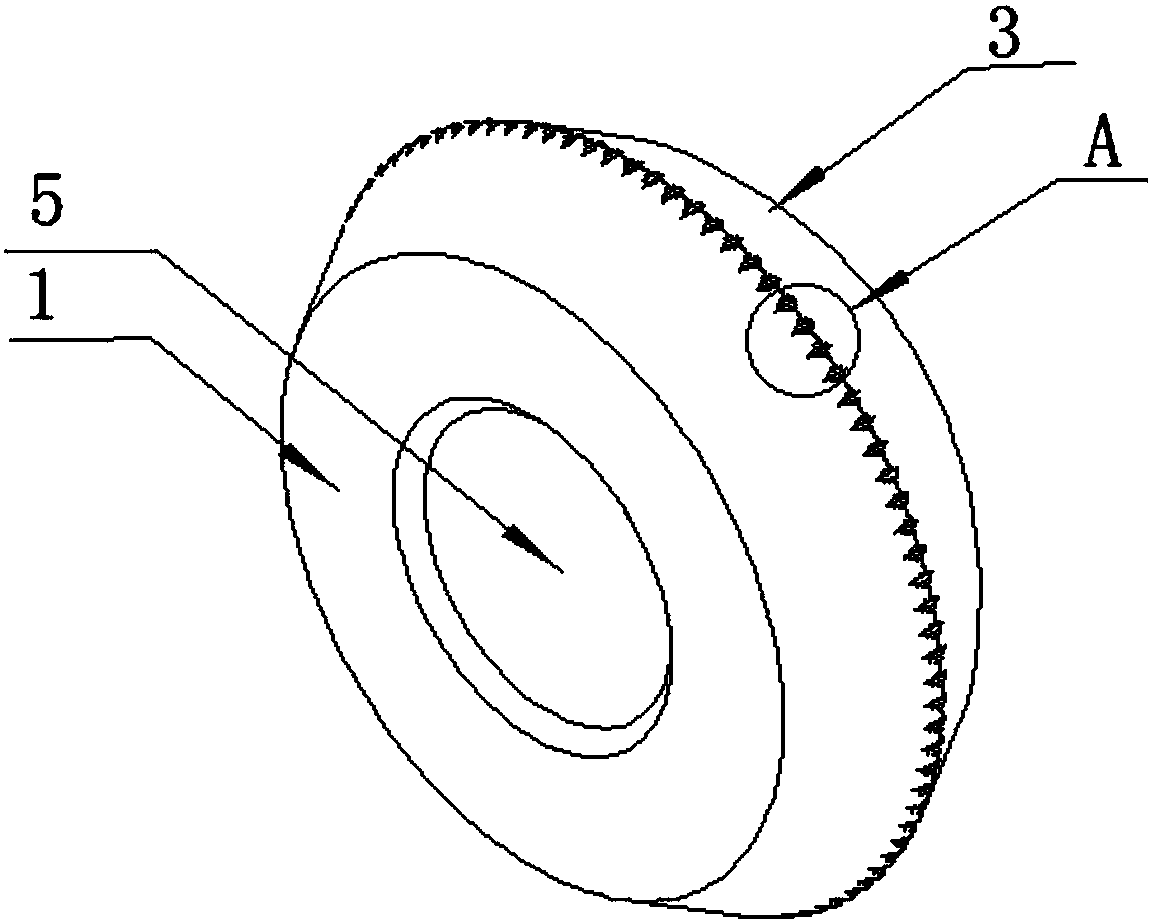

Knife wheel with platforms

PendingCN108341589AReduce wearExtended cutting lifeGlass severing apparatusMechanical engineeringEngineering

The invention discloses a knife wheel with platforms. The knife wheel comprises two symmetrical disk faces and a shaft hole for mounting a knife shaft, wherein the shaft hole is positioned in the center of the knife wheel and transversely extends to the disk faces; the disk faces extend to a longitudinal center cross section of the knife wheel along the outer edge and are intersected to form two symmetrical tapered faces; an intersection line of the tapered faces forms a peripheral edge; grooves are uniformly formed in the peripheral edge; cross sections of openings of the grooves are V-shaped; the openings of the grooves extend to a transverse center cross section of the knife wheel along the peripheral edge and are intersected to form first groove walls and second groove walls; the firstgroove walls and the second groove walls bulge outwards to form at least two platforms; and the platforms transversely extend to the tapered faces to form inner edges. According to the knife wheel with the platforms, a wear degree of the edges is reduced in a cutting process by dispersing cutting pressure at the edges; a cutting life is prolonged; at the same time, the platforms serve as the facial inner edges and can assist in cutting; a cutting scope is enlarged; and the inner edges formed by the platforms can allow a cutting pressure scope and an application scope of the knife wheel to bewider.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

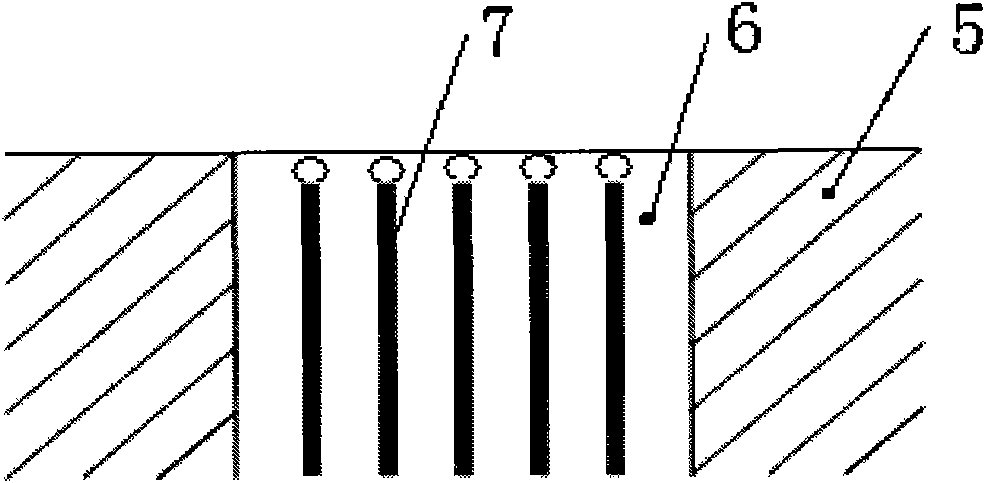

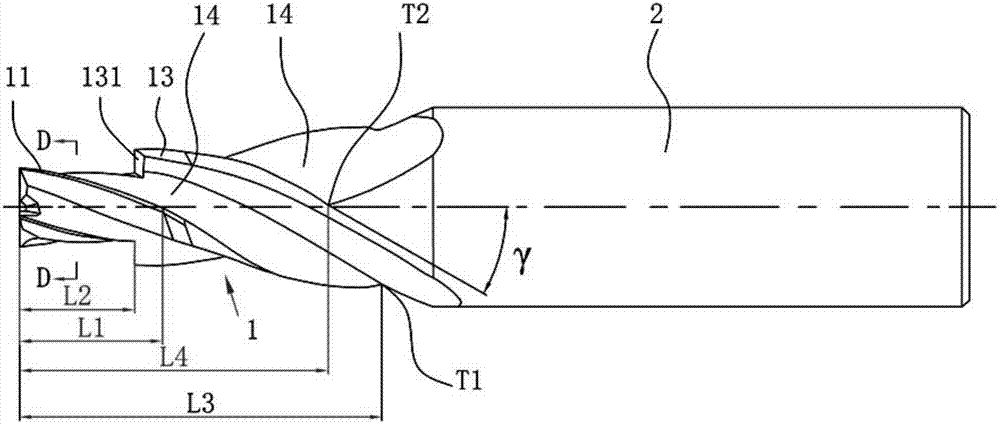

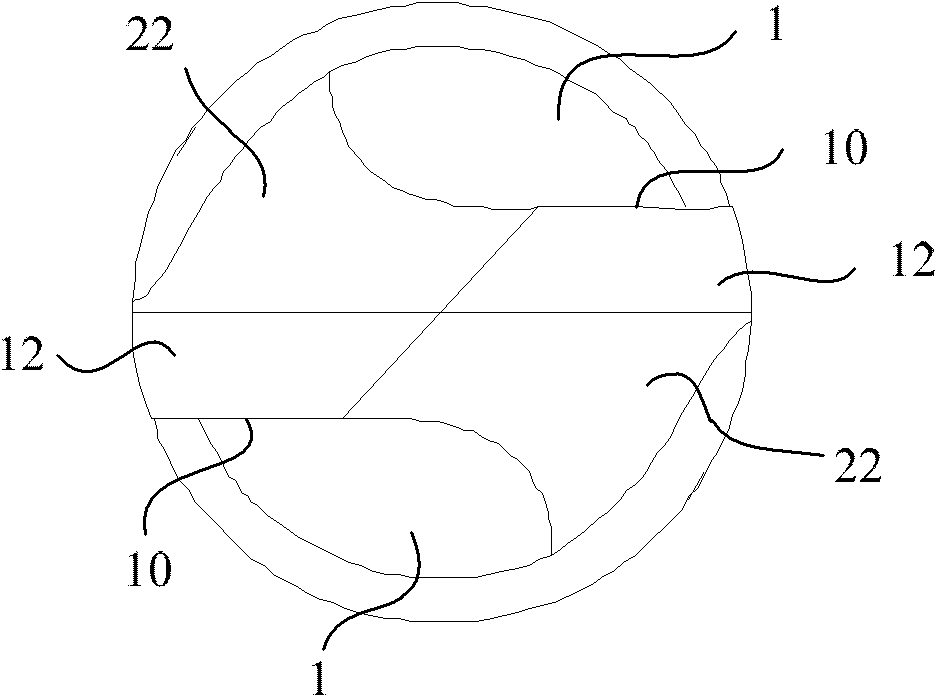

Micro drill and processing method thereof

ActiveCN102416494BImprove cutting lifeSmall cutting entryTransportation and packagingTrepanning drillsChiselSurface roughness

The invention discloses a micro drill and a processing method thereof. The micro drill comprises a chisel edge, two first cutting edges, two first rear knife faces corresponding to the two first cutting edges, two second cutting edges, and two second front knife faces and two second rear knife faces corresponding to the two second cutting edges, wherein two chip removal grooves which are spiral along a drill body correspond to the two first cutting edges; the second front knife faces are formed between the first rear knife faces and the second rear knife faces; the second cutting edges are formed at junctions of the second front knife faces and the second rear knife faces; and the included angle of the second cutting edges relative to a cutting plane is smaller than that of the first cutting edges relative to the cutting plane. Two cutting edges are formed at the drill tip of the drill additionally, and the included angle of the cutting edges relative to the cutting plane is smaller than that of the first cutting edges relative to the cutting plane, so that the cutting service life of the drill is prolonged; in addition, the formed cutting edges are relatively thin, so that the chip removal unobstructed property is improved, and the surface roughness of a hole wall is improved.

Owner:SHENZHEN JINZHOU PRECISION TECH

Low-cost high-speed tool steel for cutting drill bit and preparation process of low-cost high-speed tool steel

InactiveCN104195440AEvenly distributedFine particle sizeIncreasing energy efficiencyCeriumElectro-slag remelting

The invention discloses low-cost high-speed tool steel for a cutting drill bit and a preparation process of the low-cost high-speed tool steel. The low-cost high-speed tool steel for the cutting drill bit is characterized by comprising the following components in percentage by weight: 0.88-0.99% of C, 4.80-5.60% of W, 3.8-4.50% of Mo, 3.80-4.80% of Cr, 1.80-2.25% of V, 0.25-0.45% of Mn, 0.20-0.40% of Si, 0.70-1.30% of Al, 0.10-0.30% of Nb, 0.03-0.06% of La, 0.03-0.06% of Ce, 0.10-0.20% of Ti, 0-0.03% of P, 0-0.03% of S, the balance of Fe and inevitable trace impurities. High-speed steel bars are prepared by a medium frequency induction furnace and an electroslag remelting process. Compared with the prior art, the low-cost high-speed tool steel for the cutting drill bit has the advantages as follows: the using amount of tungsten, molybdenum and other valuable alloys is reduced, aluminum is added and titanium-niobium-lanthanum-cerium mixed rare earth is used for inoculation, so that austenite grains and an eutectic structure of the high-speed steel are obviously refined, most of eutectic carbides are spheroidized and uniformly distributed, the hardness, the red hardness, the impact toughness and the stickness resistance are improved, the cutting service life is prolonged, and the cost is reduced.

Owner:丹阳惠达模具材料科技有限公司

Complete blade and wafer handling and support system without tape

InactiveUS6325058B1Reduce downtimeIncrease productionPolishing machinesRevolution surface grinding machinesSupporting systemRobotic arm

The wafer handling and support system disclosed herein does not use tape and is adapted for use in conjunction with a number of work stations. The wafer handling and support system includes a chuck plate comprised of a non-porous section surrounding a porous section and a robotic arm for transporting a chuck plate / wafer combination under vacuum. The chuck plate is sized to be carried by a wafer chuck and the porous section of the chuck plate is configured to support a wafer. The wafer may be held in place on the chuck plate by the application of a vacuum.

Owner:MICRON TECH INC

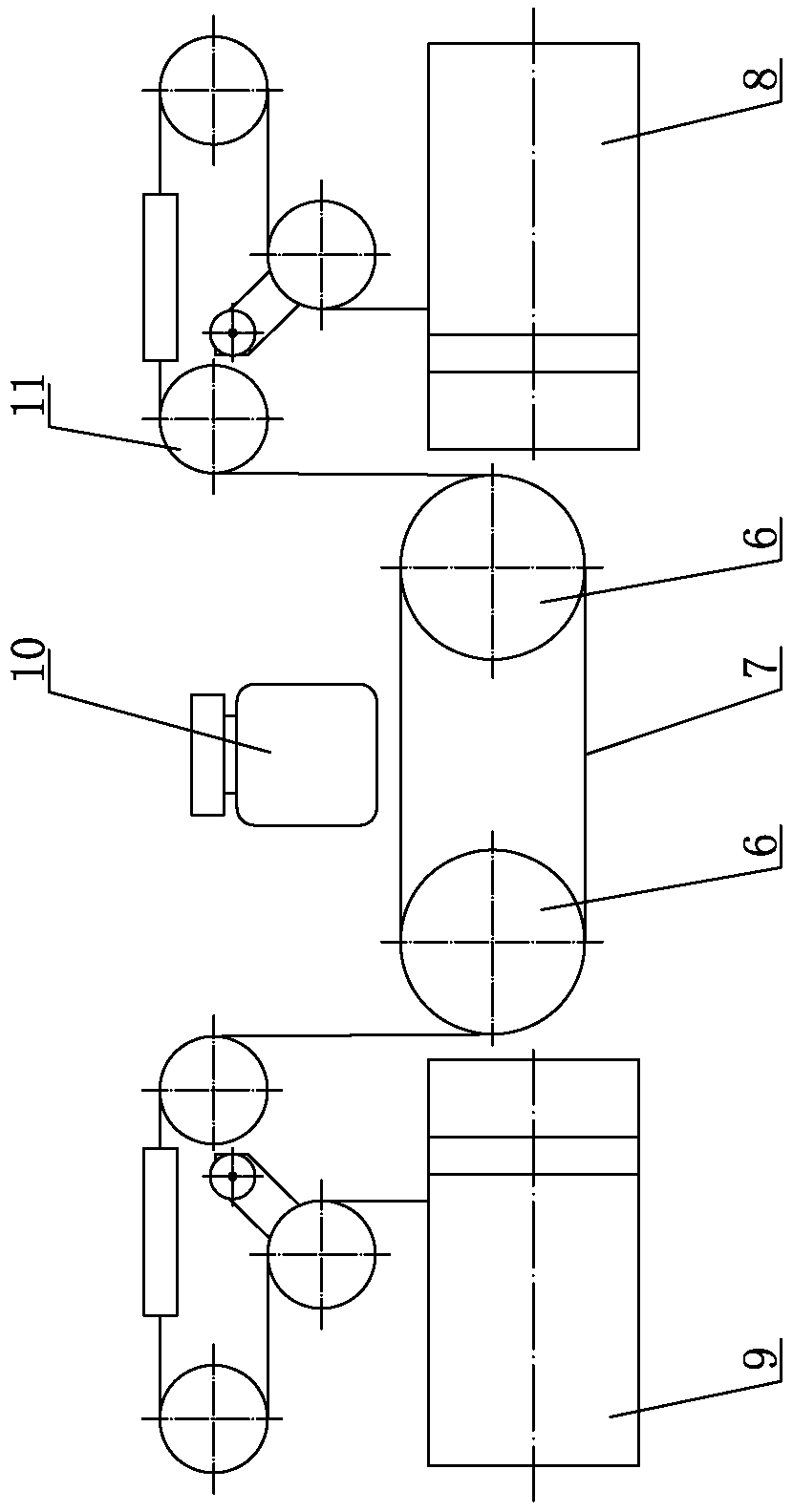

Self-sharpening diamond wire for silicon wafer cutting and manufacturing method and using method thereof

ActiveCN110480530AEffectively fixedReduce risk of sheddingElectrolytic coatingsGrinding devicesCutting forceSilicon

The invention discloses a self-sharpening diamond wire for silicon wafer cutting and a manufacturing method and using method thereof, and belongs to the field of diamond wires for photovoltaic products. The diamond wire comprises a steel bus, the outer surface of the steel bus is plated with a first pre-growing layer, a second composite positioning layer and a third reinforcing layer, and diamondparticles are fixed by all the plated layers. The manufacturing method comprises the steps: surface pretreatment, nickel pre-plating, first-time nickel plating, second-time nickel plating, third-timenickel plating and treatment after plating. The using method comprises the following steps: the diamond wire after use for cutting is immersed into the lower part of etching liquid, a NaOH solution with the mass concentration being 15%-20% is adopted as the etching liquid, the third reinforcing layer is corroded by the etching liquid, and thus the diamond particles are exposed out of the second composite positioning layer to from a cutting blade. The diamond particles are fixed through the three plated layers, the risk of falling-off of the diamond particles is lowered, and the diamond wire maintains cutting force through treatment.

Owner:扬州六如新能源科技有限公司

Cutting edge processing method, component with cutting edge and tool with cutting edge

ActiveCN110373531AImprove cutting lifeHigh strengthFurnace typesHeat treatment furnacesLaser quenchingHardness

The invention discloses a cutting edge processing method, a component with a cutting edge and a tool with the cutting edge, and belongs to a cutting edge processing technology. An existing blade and astainless steel cutter cannot enable a cutting edge to have higher hardness and higher wear resistance on the basis that a base body has relatively low hardness and relatively high toughness. The method comprises the steps of alternately carrying out laser quenching and grinding on the cutting edge, so that a hardened layer is formed on the surface layer of the cutting edge, and the hardness of the hardened layer is improved by 4-5 HRC compared with the hardness of the base body. Compared with a blade with a conventional cutting edge, the cutting life of a blade subjected to laser quenching is improved by 2-3 times. In the case of the grain diameter of a steel and iron material at the cutting edge part which is subjected to refined through laser quenching, the grain size grade reaches 10-11 grade, and the strength of the cutting edge part is improved.

Owner:HANGZHOU GREAT STAR IND CO LTD

Cutting tool with coating

PendingCN113957413AImprove bindingTightly boundChemical vapor deposition coatingSuperimposed coating processTotal thicknessTitanium

The invention discloses a cutting tool with a coating. The cutting tool comprises a substrate and a plurality of wear-resistant coatings which are deposited by adopting a chemical vapor deposition method and have the total thickness of 0.5 microns-20 microns. The plurality wear-resistant coatings sequentially comprise at least one titanium compound layer and at least one periodic coating from inside to outside, the periodic coating is formed by alternately depositing AlTiN layers and AlTiSiN layers, and a transition layer is arranged between each AlTiN layer and the adjacent AlTiSiN layer. The transition layers are composed of AlTiN or AlTiSiN, and the Si content of the transition layers is gradually increased in a gradient mode from the AlTiN layers to the AlTiSiN layers. The cutting tool aims to solve the problem of weak binding force between the AlTiN layers and the AlTiSiN layers in the cutting tool with the coating.

Owner:GANZHOU ACHTECK TOOL TECH

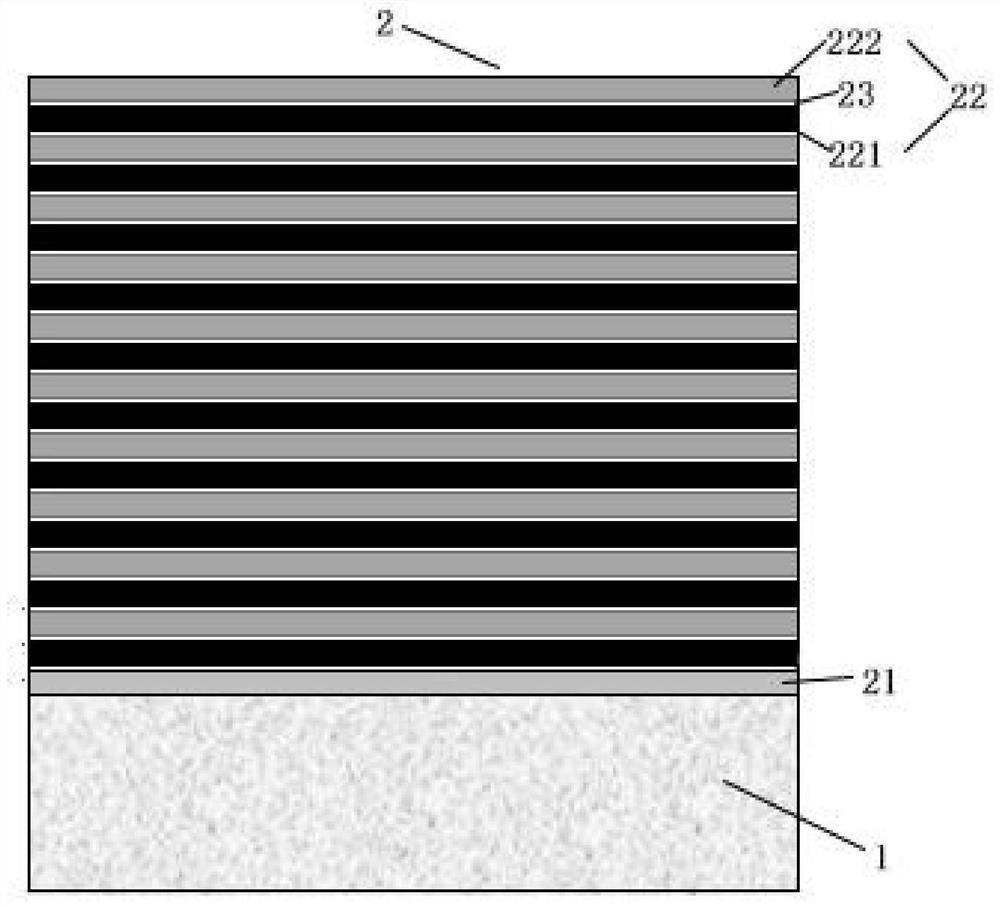

High-strength saw blade production technology

InactiveCN108817545AImprove machining accuracyNarrow kerfMetal sawing tool makingCarbon steelSurface finishing

The invention discloses a high-strength saw blade production technology. The high-strength saw blade production technology sequentially comprises the steps of material selecting, primary processing, heat treatment and surface finishing. Surface finishing comprises the step of sand blasting treatment, specifically, a dry blasting technology is adopted for sand blasting treatment, after sand blasting treatment, smooth tooth tips are formed, grinding is not needed in the sawing process, and the tooth breakage probability of tooth parts is decreased; impact force of cutting and vibrating can be borne, uniform force bearing of a cutting tool is ensured, and the cutting life of the tooth parts of the cutting tool is prolonged; and after sand blasting, the fatigue life of a backing material is prolonged, the fatigue performance of the back of a saw blade in the working condition of cutting ordinary carbon steel is greatly exerted, and the service life of the saw blade is prolonged.

Owner:多棱新材料股份有限公司

Preparation method of diamond coating layer, prepared diamond coating layer and cutter

ActiveCN110885968AStrong adhesionExtended service lifeChemical vapor deposition coatingNanodiamondHot filament

The invention discloses a preparation method of a diamond coating layer, the prepared diamond coating layer and a cutter, and relates to the technical field of diamond films. The preparation method ofthe diamond coating layer comprises the steps that nanometer diamond suspension is used for planting crystals on a basal body with positive / negative charges on the surface, and a heater chemical vapor deposition method is used for growing diamonds to obtain the diamond coating layer; and the electricity of nanometer diamond particles in the nanometer diamond suspension is opposite to the chargeson the surface of the basal body. Through the electrostatic absorption crystal planting mode, the nanometer diamond particles dispersed in the solution are absorbed on a basal body structural part; through the mode, the absorption density of the nanometer diamond particles on the basal body can be greatly increased; the high-density nucleation is realized on the surface of the basal body; and thegrown diamond coating layer is high in adhesion, long in service life, low in roughness and high in precision. The cutter deposited with the coating layer is long in cutting life and high in machiningprecision.

Owner:SHENZHEN INST OF ADVANCED TECH

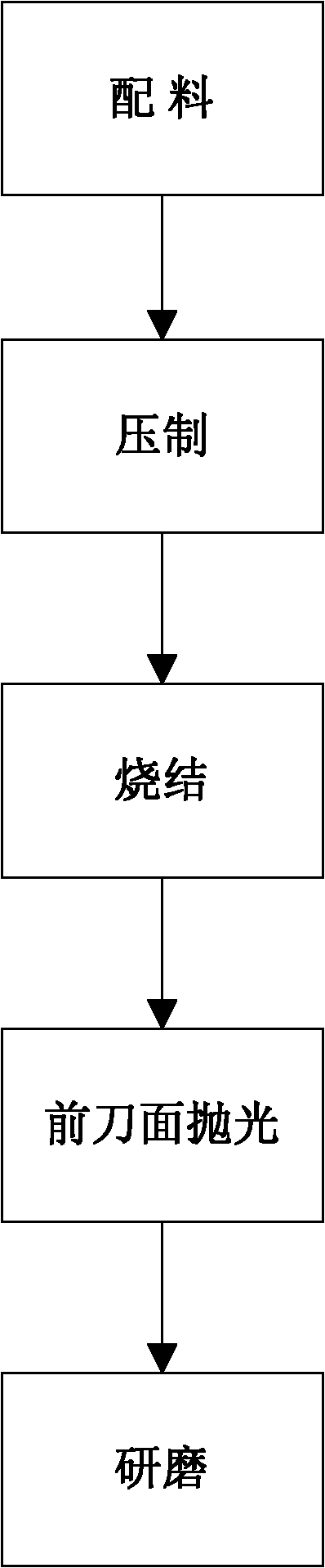

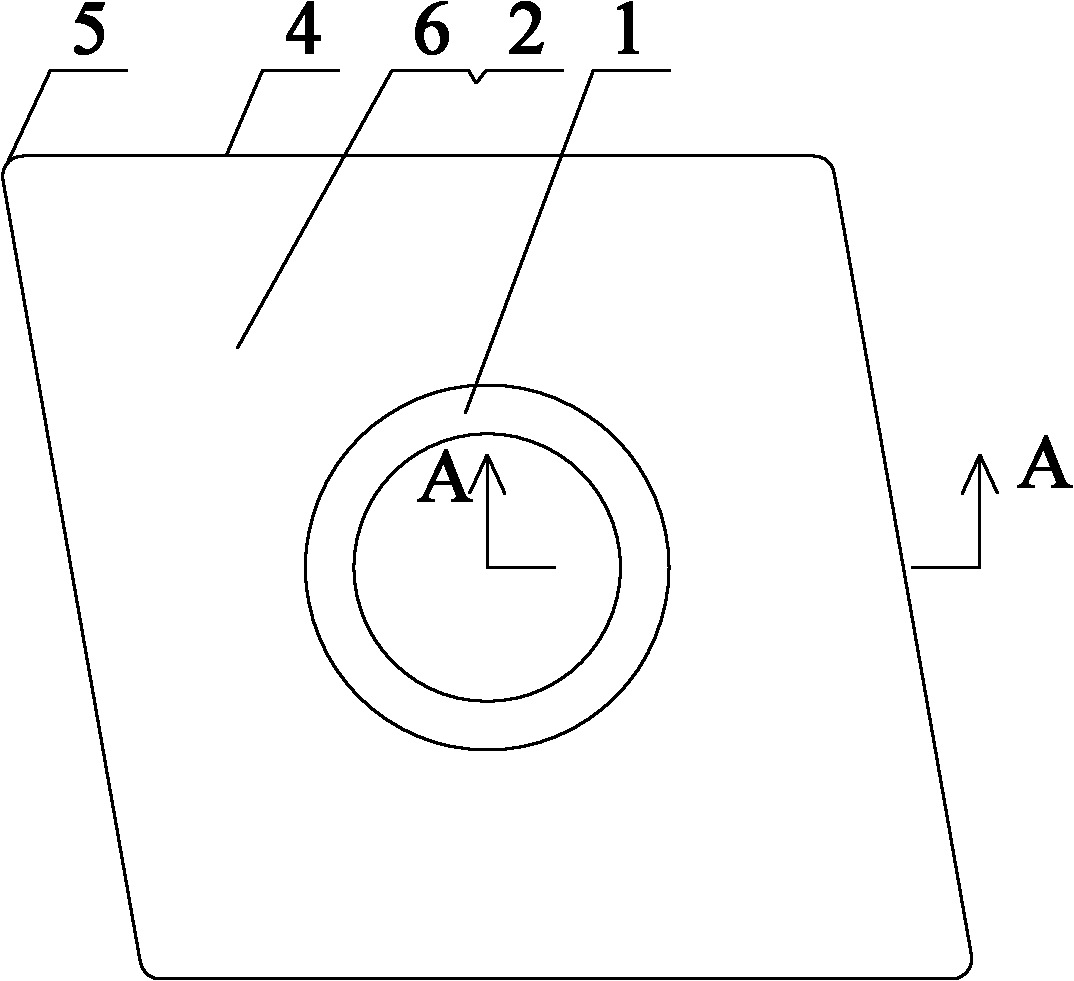

Coated tip for processing aluminum materials and preparation method thereof

The invention belongs to the field of cutting tips and preparation methods thereof, in particular to a coated tip for processing aluminum materials and a preparation method thereof, the coated tip comprises a hard alloy matrix which is provided with a front tool face positioned at the top part and rear tool faces positioned at side parts, the front tool face and the rear tool faces are intersected for forming a cutting edge, the front tool face and any adjacent two rear tool faces are intersected for forming a tool nose, a coating which is polished and has low affinity to the aluminum materials is coated on the front tool face, and the rear tool faces are hard alloy ground surfaces after grinding; and the cutting edge is a sharp cutting edge which is not passivated and extends linearly. The preparation method comprises a plurality of steps of preparing the materials, pressing, sintering, forming, carrying out surface treatment and coating a coating, as well as polishing the front tool face of the tip obtained after the step of coating the coating, further grinding the rear tool faces for forming the sharp cutting edge and finally obtaining the coated tip for processing the aluminum materials. The cutting tip has the advantages of strong anti-adhesion and anti-abrasion capability, high processing efficiency, small processing cost, long service life and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com